Endress+Hauser Proline Promass 83 Brief Operating Instructions

KA00024D/06/EN/15.12

71197503

Brief Operating Instructions

Proline Promass 83

Coriolis Mass Flow Measuring System

These Brief Operating Instructions are not intended to replace the

Operating Instructions provided in the scope of supply.

Detailed information is provided in the Operating Instructions and

the additional documentation on the CD-ROM supplied.

The complete device documentation consists of:

• These Brief Operating Instructions

• Depending on the device version:

– Operating Instructions and the Description of Device Functions

– Approvals and safety certificates

– Safety instructions in accordance with the approvals for

the device (e.g. explosion protection, pressure equipment

directive, etc.)

– Additional device-specific information

Proline Promass 83

2 Endress+Hauser

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Installation, commissioning and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Safety conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Transporting to the measuring point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Post-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Connecting the various housing types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Post-connection check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Hardware settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Device address PROFIBUS DP/PA, Modbus RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Device address EtherNet/IP network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Terminating resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Switching on the measuring device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Navigating within the function matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Calling the Commissioning Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5 Software settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Proline Promass 83 Safety instructions

Endress+Hauser

3

1 Safety instructions

1.1 Designated use

• The measuring device should only be used to measure the mass flow rate of liquids and gases.

At the same time, the measuring device also measures the density and fluid temperature.

These parameters are then used to calculate other process variables such as volume flow.

• Any use other than that described here compromises the safety of persons and the entire

measuring system and is, therefore, not permitted.

• The manufacturer is not liable for damage caused by improper or non-designated use.

1.2 Installation, commissioning and operation

• The measuring device must only be installed, connected, commissioned and maintained by

qualified and authorized specialists (e.g. electrical technicians) in full compliance with the

instructions in these Brief Operating Instructions, the applicable norms, legal regulations and

certificates (depending on the application).

• The specialists must have read and understood these Brief Operating Instructions and must

follow the instructions they contain. If you are unclear on anything in these Brief Operating

Instructions, you must read the Operating Instructions (on the CD-ROM). The Operating

Instructions provide detailed information on the measuring device.

• The measuring device should only be installed in the pipe in a de-energized state free from

outside loads or strain.

• The measuring device may only be modified or repaired if such work is expressly permitted

in the Operating Instructions (on the CD-ROM).

• Repairs may only be performed if a genuine spare parts kit is available and this repair work is

expressly permitted.

• If performing welding work on the piping, the welding unit may not be grounded by means

of the measuring device.

1.3 Operational safety

• The measuring device is designed to meet state-of-the-art safety requirements, has been

tested, and left the factory in a condition in which it is safe to operate. Relevant regulations

and European standards have been observed.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to these

Operating Instructions.

• The information specified on the warning notices, nameplates and connection labels fitted on

the measuring device must be observed. These contain important data, including information

on the permitted operating conditions, the application of the measuring device and data on

materials.

If the measuring device is not operated at atmospheric temperatures, compliance with the

relevant basic conditions specified in the device documentation provided (on the CD-ROM)

is absolutely essential.

Safety instructions Proline Promass 83

4 Endress+Hauser

• The measuring device must be wired in accordance with the wiring diagrams and connection

labels. Interconnecting must be permitted.

• All parts of the measuring device must be integrated into the potential matching system of the

plant.

• The cables, tested cable glands and tested dummy plugs must suit the prevailing operating

conditions, e.g. the temperature range of the process. Housing openings that are not used

need to be sealed with dummy plugs.

• The measuring device can only be used in conjunction with fluids to which all the wetted

parts of the measuring device are adequately resistant. With regard to special fluids, including

fluids used for cleaning, Endress+Hauser will be happy to assist in clarifying the

corrosion-resistant properties of wetted materials. However, minor changes in temperature,

concentration or in the degree of contamination in the process may result in variations in

corrosion resistance. For this reason, Endress+Hauser does not accept any responsibility with

regard to the corrosion resistance of wetted materials in a specific application. The user is

responsible for the choice of suitable wetted materials in the process.

• When hot fluid passes through the measuring tube, the surface temperature of the housing

increases. In the case of the sensor, in particular, users should expect temperatures that can

be close to the fluid temperature. If the temperature of the fluid is high, implement sufficient

measures to prevent burning or scalding.

• Hazardous areas

Measuring devices for use in hazardous areas are labeled accordingly on the nameplate.

Relevant national regulations must be observed when operating the device in hazardous areas.

• Hygienic applications

Measuring devices for hygienic applications have their own special labeling. Relevant national

regulations must be observed when using these devices.

• Pressure instruments

With the identification PED/G1/III on the sensor nameplate, Endress+Hauser confirms

conformity with the "Basic safety requirements" of Appendix I of the Pressure Equipment

Directive 97/23/EC. Devices without this identification (without PED) are designed and

manufactured according to good engineering practice.

• Endress+Hauser will be happy to assist in clarifying any questions on approvals, their

application and implementation.

Proline Promass 83 Safety instructions

Endress+Hauser

5

1.4 Safety conventions

#

Warning!

"Warning" indicates an action or procedure which, if not performed correctly, can result in injury

or a safety hazard. Comply strictly with the instructions and proceed with care.

"

Caution!

"Caution" indicates an action or procedure which, if not performed correctly, can result in

incorrect operation or destruction of the device. Comply strictly with the instructions.

!

Note!

"Note" indicates an action or procedure which, if not performed correctly, can have an indirect

effect on operation or trigger an unexpected response on the part of the device.

Installation Proline Promass 83

6 Endress+Hauser

2 Installation

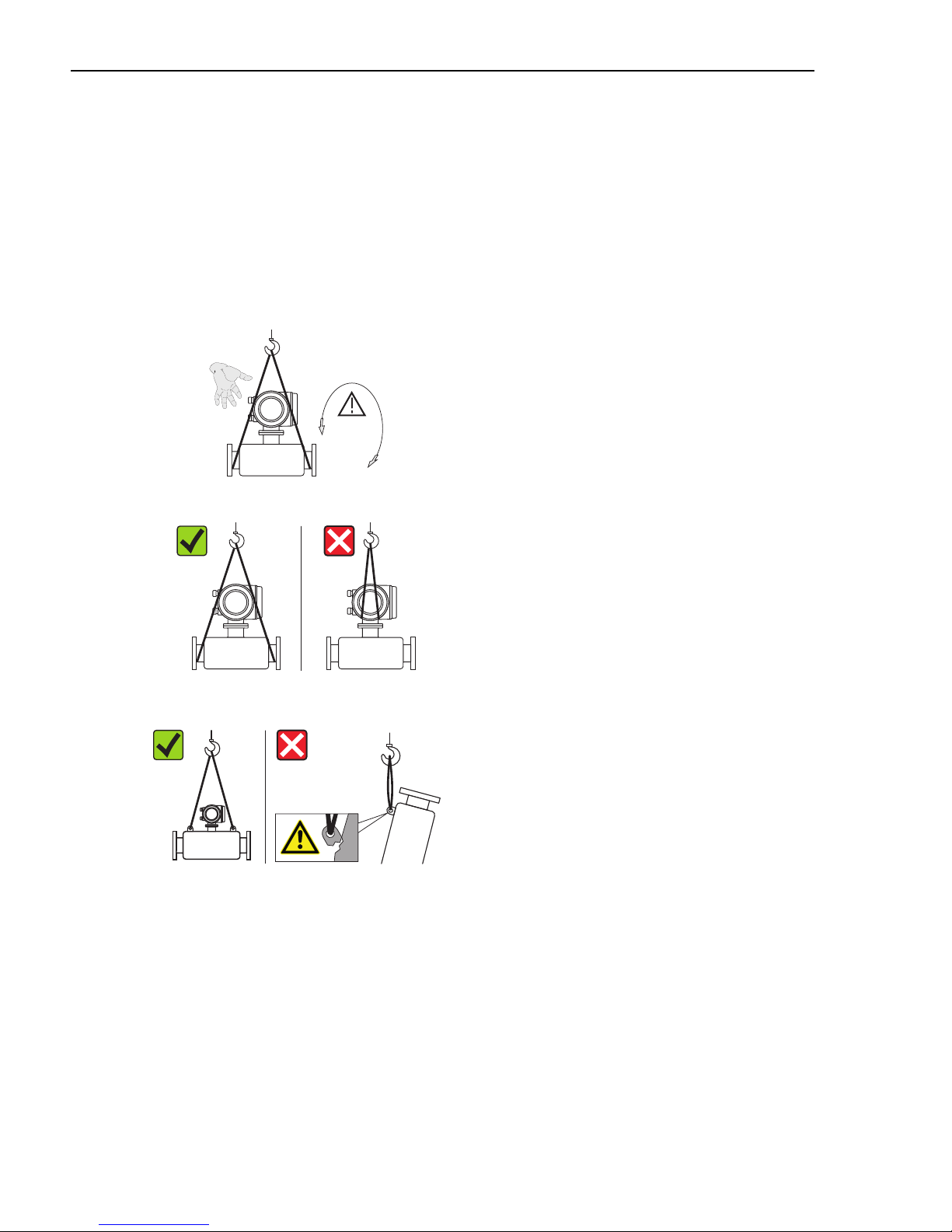

2.1 Transporting to the measuring point

• Transport the measuring device to the measuring point in the original packaging.

• The covers or caps fitted on the process connections prevent mechanical damage to the

sensors during transport and storage. For this reason, do not remove the covers or caps until

immediately before installation.

A0007408

To transport the unit, use slings slung around the process

connections or use lugs (if available).

#

Warning!

Risk of injury! The device can slip.

The center of gravity of the measuring device may be

higher than the holding points of the slings.

Always ensure that the device cannot slip or turn around

its axis.

A0007409

Do not lift measuring devices by the transmitter housing

or the connection housing in the case of the remote

version. Do not use chains as they could damage the

housing.

A0007409

The assembly must always be attached to at least two

lifting eyes.

Proline Promass 83 Installation

Endress+Hauser

7

2.2 Installation conditions

For mechanical reasons, and in order to protect the piping, it is advisable to support heavy

sensors.

2.2.1 Dimensions

For the dimensions of the measuring device see associated Technical Information on the

CD-ROM.

2.2.2 Mounting location

The following mounting locations are recommended:

• Upstream from assemblies such as valves, T-pieces, elbows, etc.

• On the pressure side of pumps (for high system pressure)

• At the lowest point in an ascending pipe (for high system pressure)

The following mounting locations should be avoided:

• At the highest point in a pipe (risk of air accumulating)

• In an open down pipe directly upstream from a free pipe outlet. For ways of using the

measuring device in down pipes, see the related Operating Instructions on the CD-ROM.

Installation Proline Promass 83

8 Endress+Hauser

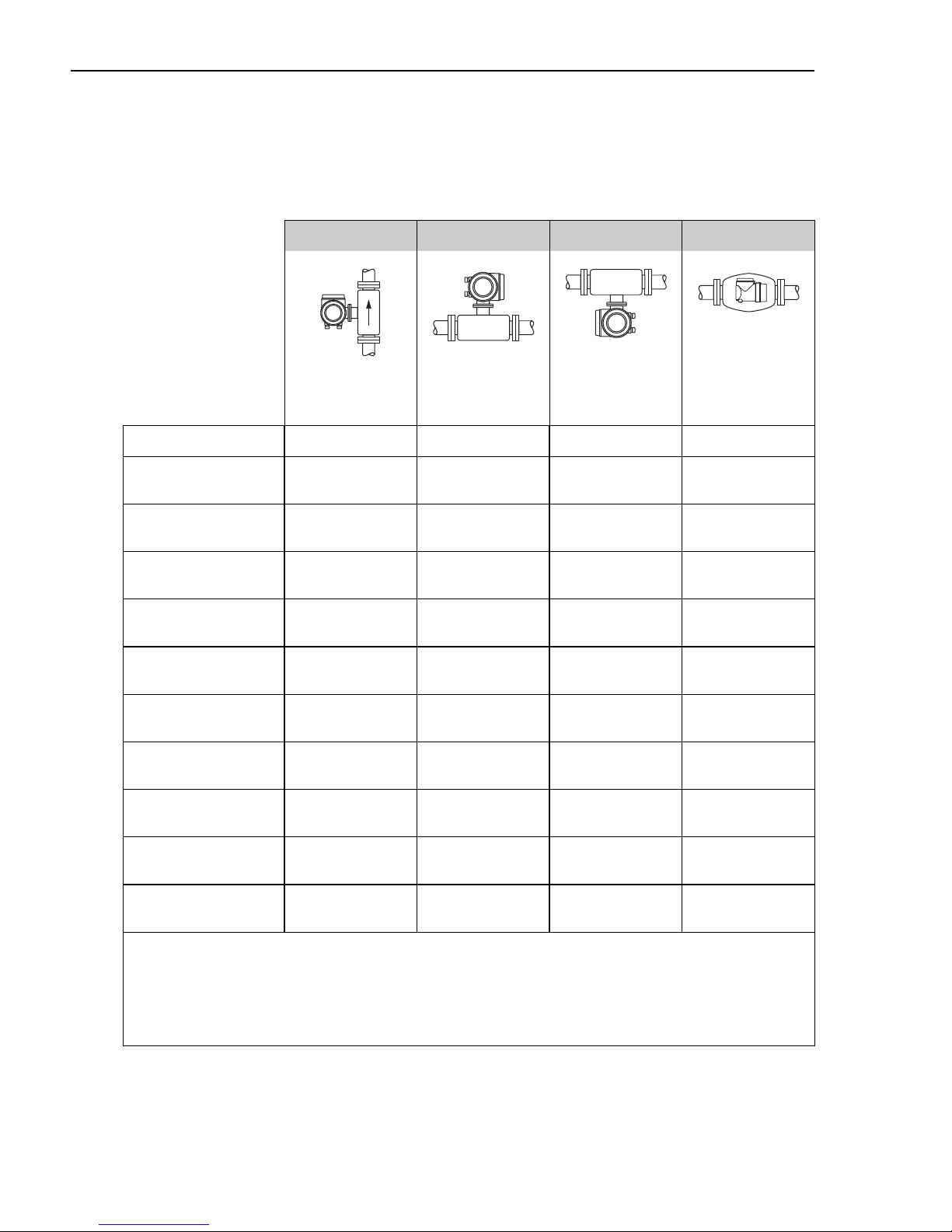

2.2.3 Orientation

• The direction of the arrow on the nameplate of the measuring device must match the flow

direction of the fluid.

• The following table lists the possible orientations of the measuring devices:

Vertical Horizontal Horizontal Horizontal

A0004572

A0004576

A0004580

A0015445

Transmitter at the

side

Transmitter at the

top

Transmitter at the

bottom

Transmitter at the

side

Promass A Recommended Possible (

m

) Possible (m, p) Not suitable

Promass E

Recommended

Recommended

(

n

)

Recommended

(o, p)

Not suitable

Promass F

Recommended

Recommended

(

n

)

Recommended

(o, p)

Not suitable

Promass F HT*

Compact version

Recommended Not suitable

Recommended

(

o, p

)

Not suitable

Promass F HT*

Remote version

Recommended Possible (

n

)

Recommended

(

o, p

)

Not suitable

Promass H

Recommended Recommended

Recommended

(

p

)

Recommended

Promass I

Recommended Recommended

Recommended

(

p

)

Recommended

Promass P

Recommended Recommended

Recommended

(

p

)

Recommended

Promass S

Recommended Recommended

Recommended

(

p

)

Recommended

Promass O

Recommended

Recommended

(

n

)

Recommended

(o, p)

Not suitable

Promass X

Recommended Recommended

Recommended

(

p

)

Possible

*HT = high temperature version for medium temperatures (TM) > 200 °C (392 °F)

m

Do not install the measuring device in such a way that is suspended without any support or securing unit.

n

This orientation is not suitable for fluids with entrained solids.

o

This orientation is not suitable for outgassing fluids.

p

This orientation is not suitable for low fluid temperatures.

Proline Promass 83 Installation

Endress+Hauser

9

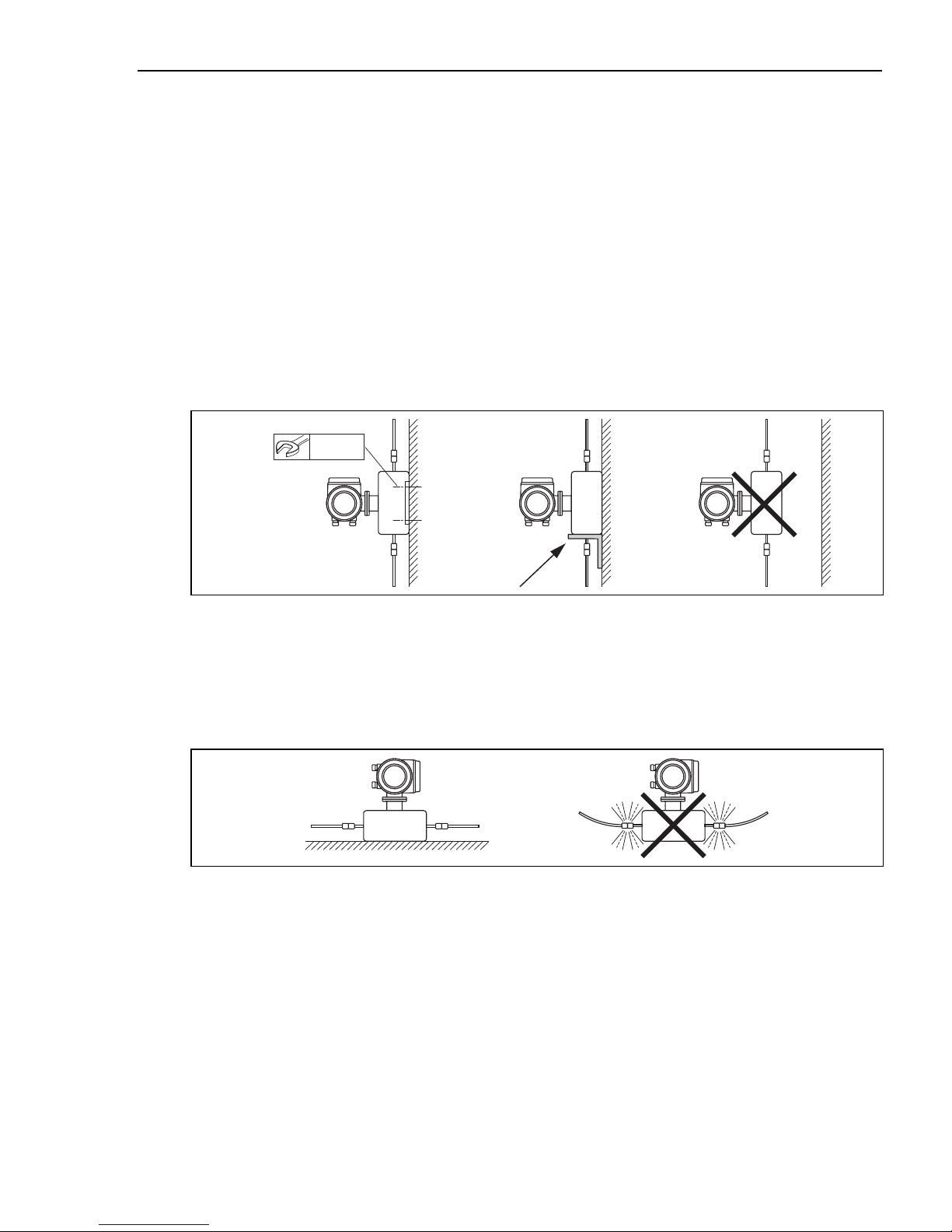

Special installation instructions for Promass A

"

Caution!

Risk of measuring pipe fracture if sensor installed incorrectly!

The sensor may not be installed in a pipe as a freely suspended sensor:

• Using the base plate, mount the sensor directly on the floor, the wall or the ceiling.

• Support the sensor on a firmly mounted support base (e.g. angle bracket).

Vertical

We recommend two installation versions when mounting vertically:

• Mounted directly on a wall using the base plate

• Measuring device supported on an angle bracket mounted on the wall

A0018980

Horizontal

We recommend the following installation version when mounting horizontally:

• Measuring device standing on a firm support base

A0018979

2.2.4 Heating

For information on the heating, please see the Operating Instructions on the CD-ROM.

2.2.5 Thermal insulation

For information on the thermal insulation, please see the Operating Instructions on the

CD-ROM.

10 mm

4 x

Installation Proline Promass 83

10 Endress+Hauser

2.2.6 Inlet and outlet runs

No inlet and outlet runs are required.

2.2.7 Vibrations

No measures are necessary.

2.3 Post-installation

2.3.1 Turning the transmitter housing

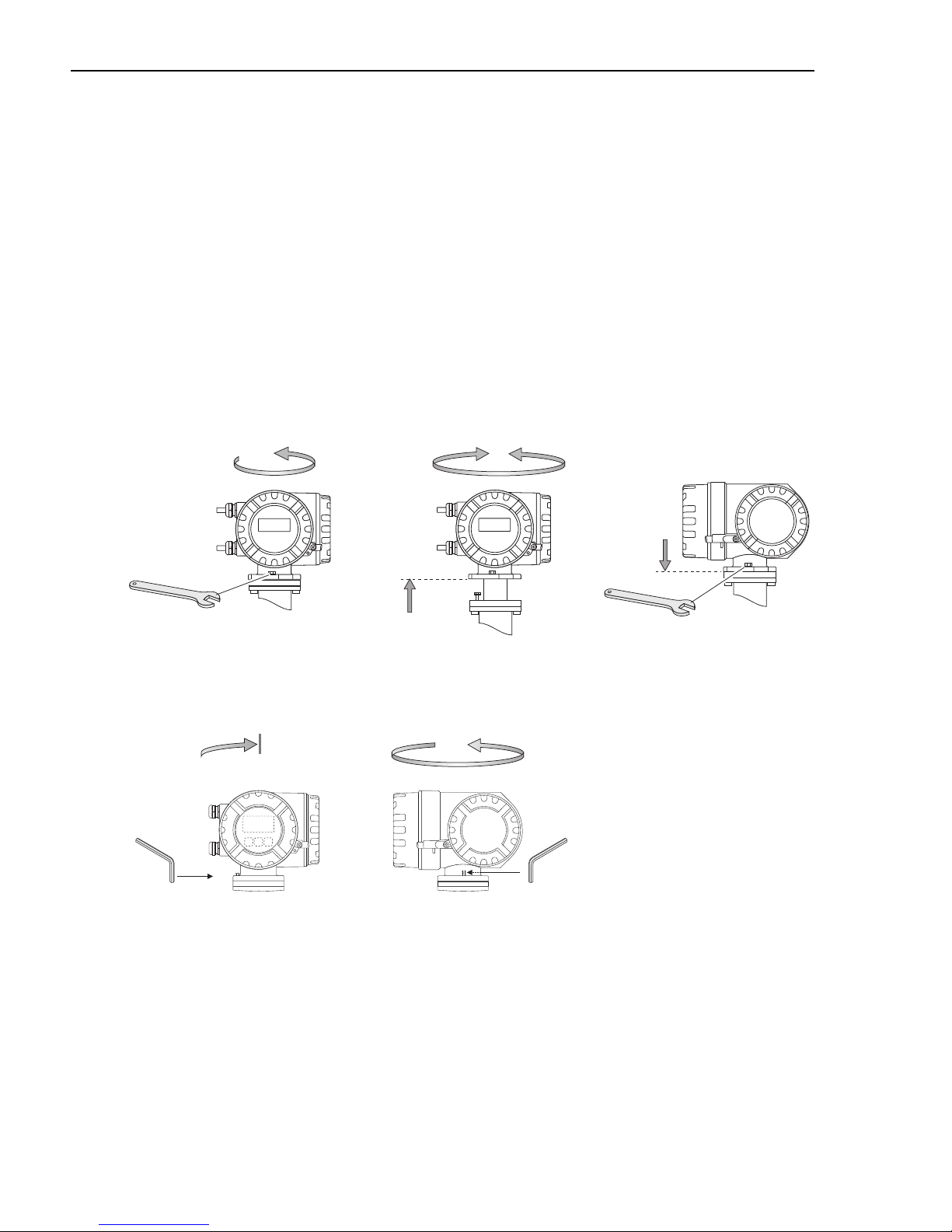

Turning the aluminum field housing

Aluminum field housing for non-Ex area

Aluminum field housing for Zone 1 or Class I Div. 1

A0007540

A0008036

a. Release the setscrew.

b. Turn the transmitter housing

gently clockwise until the stop

(end of the thread).

c. Turn the transmitter

counterclockwise (max. 360°)

to the desired position.

d. Retighten the setscrew.

c

e

f

a

b

d

£ 180° £ 180°

N

i

c

h

t

u

n

t

e

r

S

p

a

n

n

u

n

g

ö

f

f

n

e

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

N

e

p

a

s

o

u

v

r

i

r

l

’

a

p

p

a

r

e

i

l

s

o

u

s

t

e

n

s

i

o

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

max. 360°

Nicht-eigensichere

Stromkreise durch

IP40-Abdeckung geschützt

Non-intrinsically safe

circuits Ip40 protected

Boucles de courant

sans sécurité intrinsèque

protégées par Ip40

c

a

b

d

Loading...

Loading...