Page 1

TI00071D/06/EN/14.17

71385973

Products Solutions Services

Technical Information

Proline Promag 55S

Electromagnetic flowmeter

The flowmeter with outstanding abrasion resistance and integrated solids

content diagnostics

Application

• The bidirectional measuring principle is virtually independent

of pressure, density, temperature and viscosity

• Ideal for the most demanding applications with high solids

content and high abrasion

Device properties

• Intensified coil system

• Large range of liners

• Solids content up to 80% by weight

• 4-line backlit display with touch control

• Two switch outputs

• HART, PROFIBUS PA/DP, FOUNDATION Fieldbus

Your benefits

• Superb signal stability due to unique signal processing

• Maximum safety – industry-optimized measuring electrodes

and linings

• Energy-saving flow measurement – no pressure loss due to

cross-section constriction

• Maintenance-free – no moving parts

• Highest performance – with integrated solids measurement

for demanding fluids

• Highest safety – integrated electrode cleaning

• Automatic recovery of data for servicing

Page 2

Table of contents

Proline Promag 55S

Function and system design . . . . . . . . . . . . . . . . . . . . . .3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operable flow range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Low flow cut off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical connection, remote version . . . . . . . . . . . . . . . . . . . . . 8

Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Remote version cable

specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure tightness (lining) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Limiting flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 27

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Measuring tube

specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Fitted electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Surface roughness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Language groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . 44

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

C-tick symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Sanitary compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pressure equipment directive . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

FOUNDATION Fieldbus certification . . . . . . . . . . . . . . . . . . . . . 44

PROFIBUS DP/PA certification . . . . . . . . . . . . . . . . . . . . . . . . . 44

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 44

Performance characteristics . . . . . . . . . . . . . . . . . . . . 13

Reference operating

conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inlet and outlet runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Length of connecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Foundations, supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Shock and vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . 19

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Medium temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pressure-temperature ratings . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Medium pressure range (nominal pressure) . . . . . . . . . . . . . . 23

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . 45

2 Endress+Hauser

Page 3

Proline Promag 55S

Ue

I

I

B

L

V

r

C

r

S

1

2

r

M

m

V

Function and system design

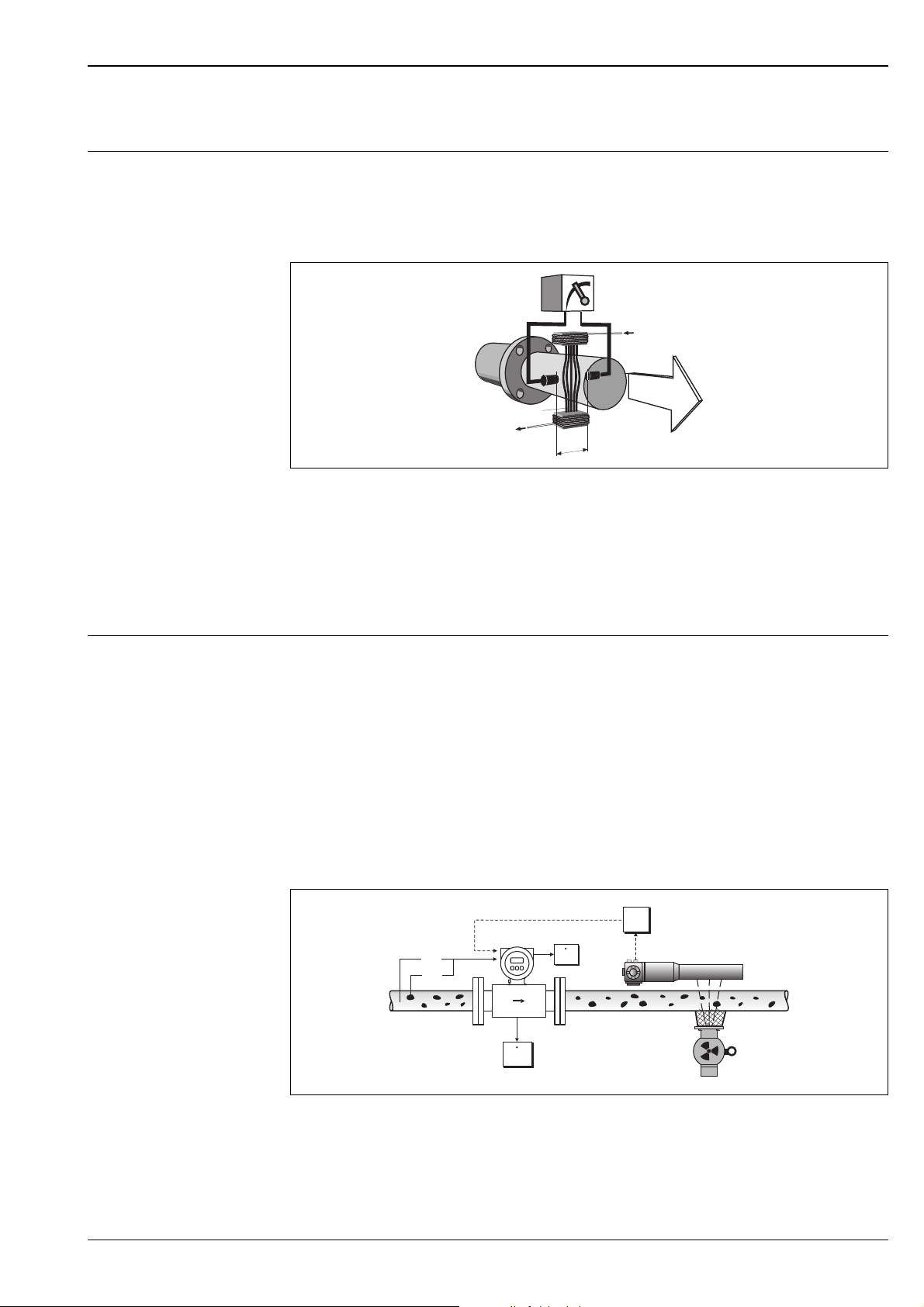

Measuring principle Faraday’s law of induction states that a voltage is induced in a conductor moving in a magnetic field.

In electromagnetic measuring, the flowing medium corresponds to the moving conductor. The induced

voltage is proportional to the flow velocity and is detected by two measuring electrodes and

transmitted to the amplifier. Flow volume is computed on the basis of the pipe’s diameter. The

constant magnetic field is generated by a switched direct current of alternating polarity.

A0003191

Ue = B · L · v

Q = A · v

Ue induced voltage

B magnetic induction (magnetic field)

Lelectrode gap

v flow velocity

Q volume flow

A pipe cross-section

I current strength

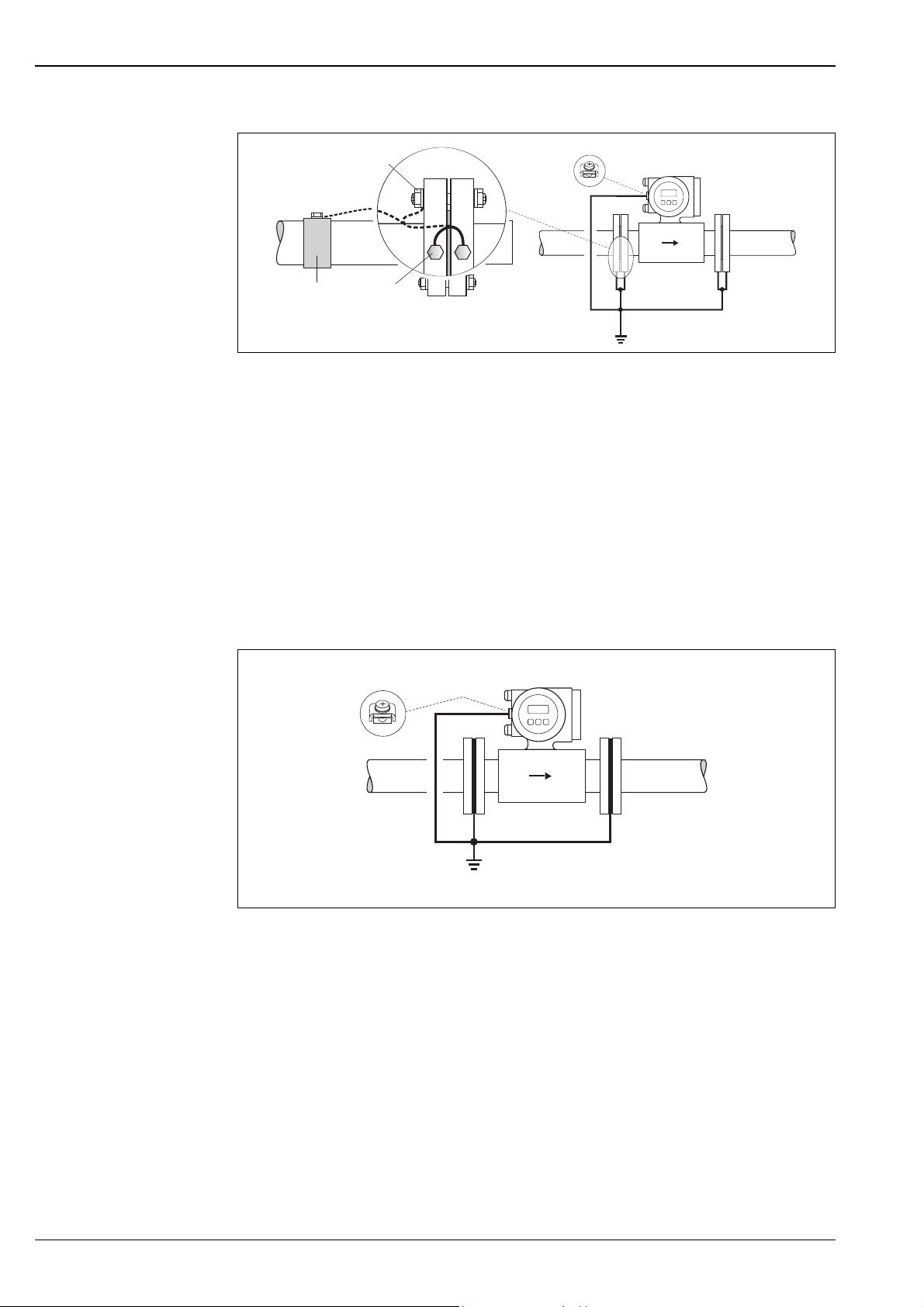

Measuring system The flow measuring system consists of the following components:

• Promag 55 transmitter

• Promag S sensor (DN 15 to 600 / ½ to 24")

Two versions are available:

• Compact version: Transmitter and sensor form a single mechanical unit.

• Remote version: Transmitter and sensor are installed separately.

Measurement of solids flow rates

In combination with a density meter, e.g. with "Gammapilot M" from Endress+Hauser, Promag 55S also

determines the throughput of solids in mass, volume or percentage rates.

The following order specifications are required for this: order option for software function "Solids

content flow" (F-CHIP) and order option for a current input.

A0006118

Solids content flow measurement (m) with the aid of a density and flow measuring device. If the solid density (ρS) and the density of

the carrier liquid (ρ

1 Flow measuring device (Promag 55S) → volume flow (V). The solid density (ρ

must be entered in the transmitter.

2 Density measuring device (e.g. "Gammapilot M") → total fluid density (ρ

) are also known, they can be used to calculate the solids flow.

C

) and the density of the transport liquid (ρC)

S

) (transport liquid and solids)

M

Endress+Hauser 3

Page 4

Proline Promag 55S

Input

Measured variable • Flow rate (proportional to induced voltage)

• Conductivity (without temperature compensation)

Measuring ranges • Flow rate: Typical v = 0.01 to 10 m/s (0.03 to 33 ft/s) with the specified measuring accuracy

• Conductivity s = 5 to 2000 μS/cm

not for sensors without reference electrode (Promag S with brush electrodes)

Operable flow range Over 1000 : 1

Input signal Status input (auxiliary input)

U = 3 to 30 V DC, Ri = 5 kΩ,

Configurable for: totalizer(s) reset, positive zero return, error-message reset

Status input (auxiliary input) with PROFIBUS DP

U = 3 to 30 V DC, R

= 3 kΩ, galvanically isolated.

i

Switch level: ±3…±30 V DC, independent of polarity.

Configurable for: positive zero return, error message reset, zero point adjustment start

galvanically isolated

Current input

Active/passive selectable, galvanically isolated, full scale value adjustable, resolution: 3 μA,

temperature coefficient: typically 0.005% o.f.s./°C (0.003% o.f.s./°F)

• Active: 4 to 20 mA, R

• Passive: 0/4 to 20 mA, Ri ≤ 150 Ω, U

Output

Output signal Current output

Active/passive selectable, galvanically isolated, time constant selectable (0.01 to 100 s),

full scale value adjustable, temperature coefficient: typically 0.005% o.f.s./°C (0.003 % o.f.s./°F),

resolution: 0.5 μA

• Active: 0/4 to 20 mA, RL < 700 Ω (for HART: RL ≥ 250 Ω)

• Passive: 4 to 20 mA; supply voltage VS: 18 to 30 V DC; Ri ≥ 150 Ω

Pulse/frequency output

Active/passive selectable (Ex i version passive only), galvanically isolated

• Active: 24 V DC, 25 mA (max. 250 mA over 20 ms), RL > 100 Ω

• Passive: open collector, 30 V DC, 250 mA

• Frequency output: end frequency 2 to 10000 Hz (f

pulse width max. 10 s

• Pulse output: pulse value and pulse polarity selectable, pulse width configurable (0.05 to 2000 ms)

≤ 150 Ω, U

i

= 24 V DC, short-circuit proof

out

= 30 V DC

max

= 12500 Hz), on/off ratio 1:1,

max

PROFIBUS DP interface

• Transmission technology (Physical Layer): RS485 according to ASME/TIA/EIA-485-A: 1998,

galvanically isolated

• Profile Version 3.0

• Data transmission rate: 9.6 kBaud to 12 MBaud

• Automatic identification of data transmission rate

• Function blocks: 2 × analog input, 3 × totalizer

• Output data: volume flow, calculated mass flow, totalizer 1 to 3

• Input data: positive zero return (ON/OFF), totalizer control, value for local display

• Cyclic data transmission compatible with previous model Promag 35S

• Bus address adjustable via miniature switches or local display (optional) at the measuring device

• Available output combination → 6

4 Endress+Hauser

Page 5

Proline Promag 55S

PROFIBUS PA interface

• Transmission technology (Physical Layer): IEC 61158-2 (MBP), galvanically isolated

• Profile version 3.0

• Current consumption: 11 mA

• Permissible supply voltage: 9 to 32 V

• Bus connection with integrated reverse polarity protection

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Function blocks: 2 × analog input, 3 × totalizer

• Output data: volume flow, calculated mass flow, totalizer 1 to 3

• Input data: positive zero return (ON/OFF), totalizer control, value for local display

• Cyclic data transmission compatible with previous model Promag 35S

• Bus address adjustable via miniature switches or local display (optional) at the measuring device

FOUNDATION Fieldbus interface

• FOUNDATION Fieldbus H1

• Transmission technology (Physical Layer): IEC 61158-2 (MBP), galvanically isolated

•ITK version 5.01

• Current consumption: 12 mA

•Inrush current: < 12 mA

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Permissible supply voltage: 9 to 32 V

• Bus connection with integrated reverse polarity protection

•Function blocks:

– 5 × Analog Input (execution time: 18 ms each)

– 1 × PID (25 ms)

– 1 × Digital Output (18 ms)

– 1 × Signal Characterizer (20 ms)

– 1 × Input Selector (20 ms)

– 1 × Arithmetic (20 ms)

–1 × Integrator (18 ms)

•Total VCRs: 48

• Total link objects in VFD: 40

• Output data: volume flow, calculated mass flow, temperature, totalizer 1 to 3

• Input data: positive zero return (ON/OFF), reset totalizer

• Link Master (LM) functionality is supported

Signal on alarm Current output

Failsafe mode selectable (e.g. according to NAMUR recommendation NE 43)

Pulse/frequency output

Failsafe mode selectable

Relay output

"de-energized" in the event of a fault or power supply failure

PROFIBUS DP/PA

Status and alarm messages in accordance with PROFIBUS Profile Version 3.0

Load See "output signal"

Low flow cut off Switch points for low flow freely selectable.

Galvanic isolation All circuits for inputs, outputs, and power supply are galvanically isolated from each other.

Switching output Relay output

Normally closed (NC or break) or normally open (NO or make) contacts available

(default: relay 1 = NO, relay 2 = NC),

max. 30 V / 0.5 A AC; 60 V / 0.1 A DC, galvanically isolated. Configurable for: error messages, empty

pipe detection (EPD), direction of flow, limit values.

Endress+Hauser 5

Page 6

Power supply

Proline Promag 55S

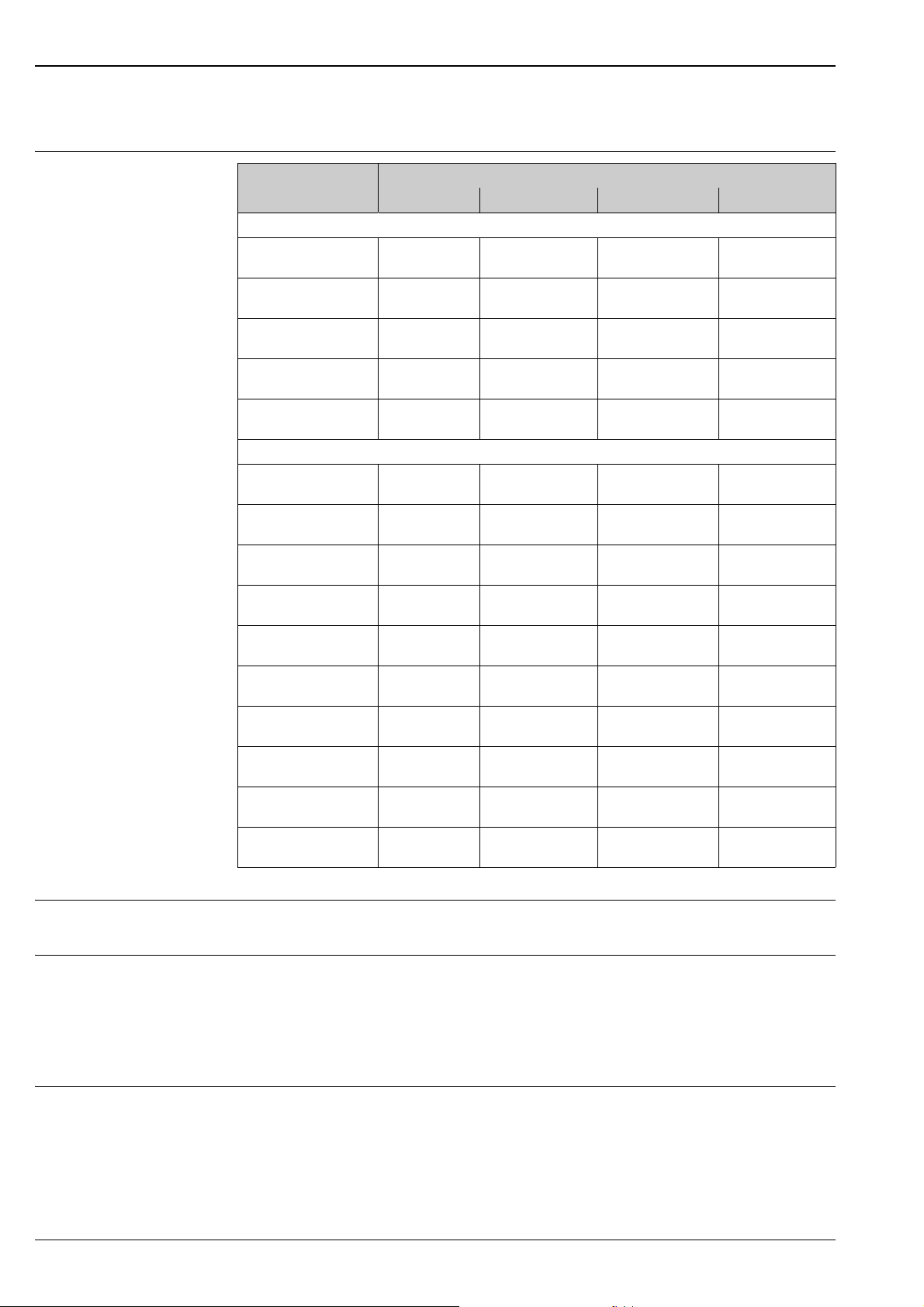

Terminal assignment

Order code for

"Input / Output"

Fixed communication boards (fixed assignment)

A – – Frequency output

B Relay output 2 Relay output 1 Frequency output

H–––

J––

K–––

Flexible communication boards

C Relay output 2 Relay output 1 Frequency output

D Status input Relay output Frequency output

L Status input Relay output 2 Relay output 1

M Status input Frequency output 2 Frequency output 1

P Current output Frequency output Status input

20 (+) / 21 (–) 22 (+) / 23 (–) 24 (+) / 25 (–) 26 (+) / 27 (–)

Terminal No.

termination)

+5V (ext.

Current output

HART

Current output

HART

PROFIBUS PA

PROFIBUS DP

FOUNDATION

Fieldbus

Current output

HART

Current output

HART

Current output

HART

Current output

HART

PROFIBUS DP

V Relay output 2 Relay output 1 Status input

2 Relay output Current output 2 Frequency output

3

4 Current input Relay output Frequency output Current output

5 Status input Current input Frequency output Current output

Current input

Current output 2 Frequency output

Supply voltage 20 to 260 V AC, 45 to 65 Hz

20 to 64 V DC

Power consumption AC: < 45 VA at 260 V AC; < 32 VA at 110 V AC (incl. sensor)

DC: < 19 W (including sensor)

Switch-on current:

• Max. 2.5 A (< 200 ms) at 24 V DC

• Max. 2.5 A (< 5 ms) at 110 V AC

• Max. 5.5 A (< 5 ms) at 260 V AC

Power supply failure Lasting min. 1 power cycle:

• EEPROM or HistoROM/T-DAT saves measuring system data if power supply fails

• HistoROM/S-DAT: exchangeable data storage device which stores sensor characteristic data

(nominal diameter, serial number, calibration factor, zero point etc.)

PROFIBUS DP

Current output 1

HART

Current output 1

HART

HART

HART

6 Endress+Hauser

Page 7

Proline Promag 55S

HART

PROFIBUS DP**

27

25

23

21

2

1

26

24

22

20

L1 (L+)

N (L-)

–

–

–

+

+

+

PROFIBUS PA*

FOUNDATION Fieldbus*

PA(–)/FF(–)

27

25

23

21

2

1

26

24

22

20

L1 (L+)

N (L-)

–

–

–

+

+

+

A (RxD/TxD-N)

B (RxD/TxD-P)

PA(+)/FF(+)

d

c

e

b

–27

–25

–23

–21

+ 26

+ 24

+ 22

+ 20

N (L-) 2

L1 (L+)1

25

23

21

2

1

24

22

20

L1 (L+)

N (L-)

–

–

–

+

+

+

27

26

A (RxD/TxD-N)

B (RxD/TxD-P)

a

A

d

b

g

d

c

e

b

d

c

e

b

g

d

c

e

b

g

PROFIBUS DP*

f f

f f

a

B

(d)

b

d/(g)

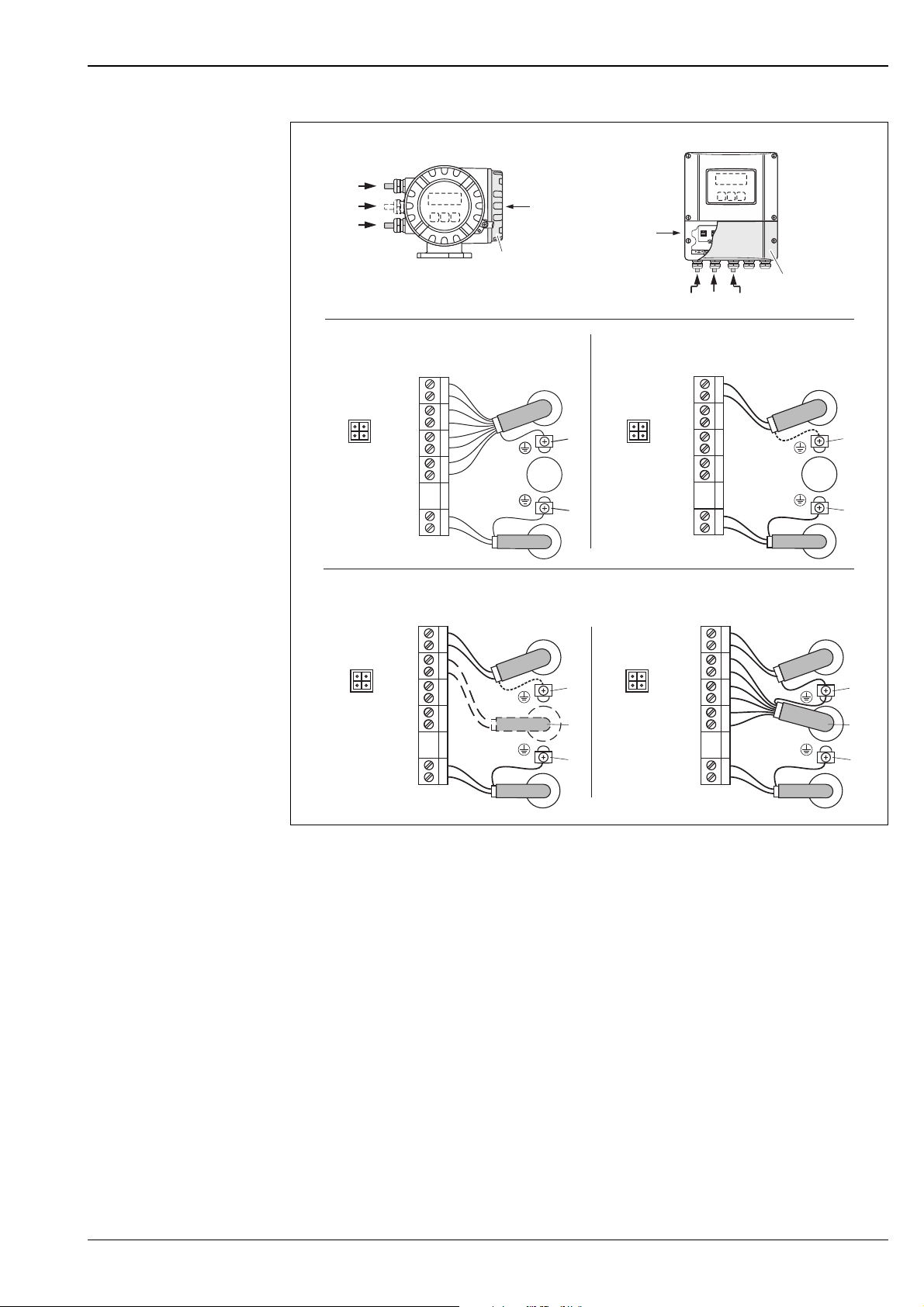

Electrical connection

Connecting the transmitter, cable cross-section max. 2.5 mm2 (14 AWG)

A View A (field housing)

B View B (wall-mount housing)

*) Fixed communication boards

**) Flexible communication boards

a Connection compartment cover

b Cable for power supply: 20 to 260 V AC / 20 to 64 V DC

c Ground terminal for protective conductor

d Electrode cable: see Terminal assignment → 6

e Ground terminal for electrode cable shield / Fieldbus cable

f Service adapter for connecting service interface FXA193 (Fieldcheck, FieldCare)

g Electrode cable: see Terminal assignment → 6

- Terminal No. 1: L1 for AC, L+ for DC

- Terminal No. 2: N for AC, L– for DC

Fieldbus cable:

- Terminal No. 26: DP (B) / PA (+) / FF (+): with polarity protection

- Terminal No. 27: DP (A) / PA (–) / FF (–): with polarity protection

Cable for external termination (only for PROFIBUS DP with permanent assignment communication board):

- Terminal No. 24: +5 V

- Terminal No. 25: DGND

A0015195

Endress+Hauser 7

Page 8

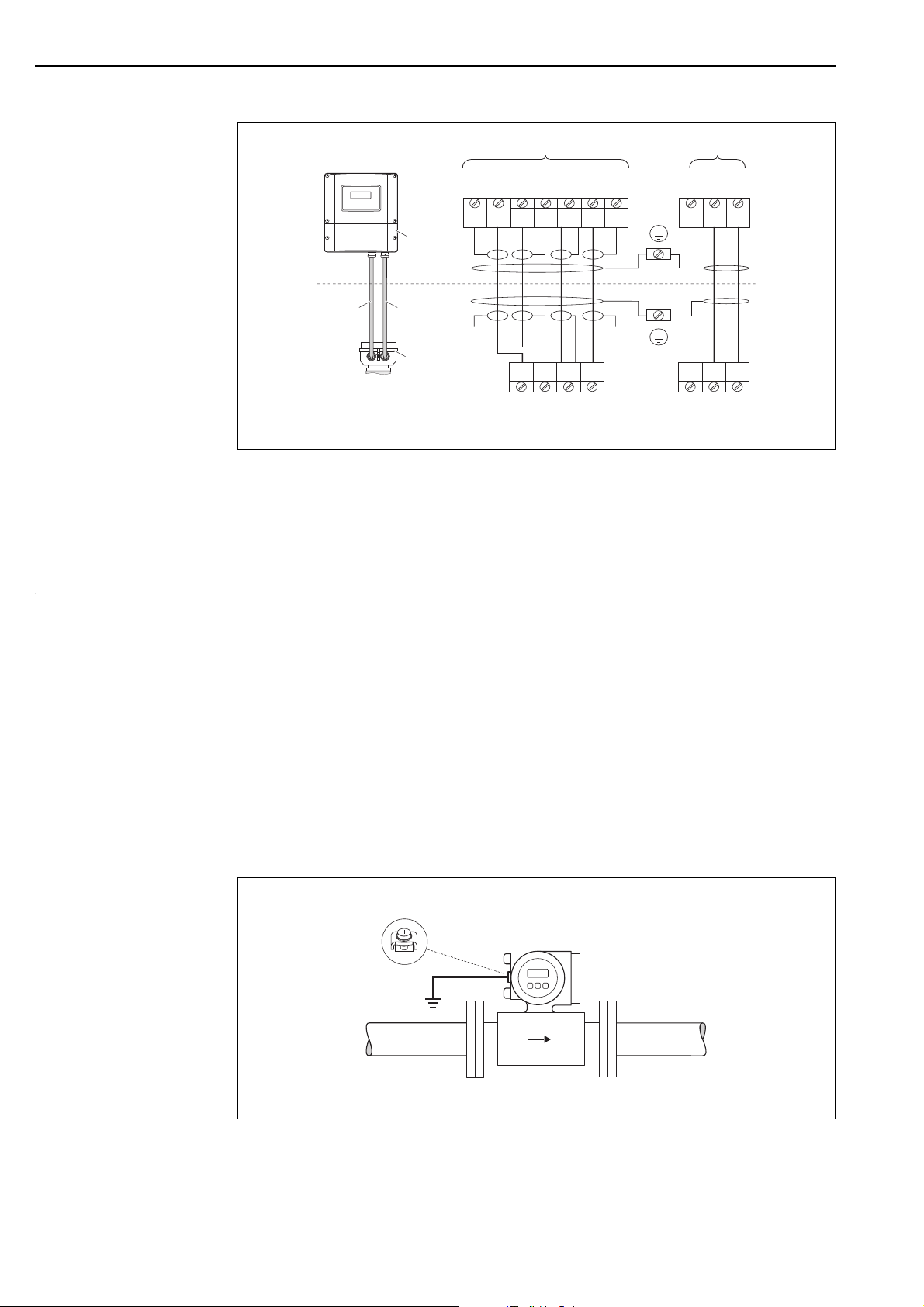

Electrical connection,

E1

E2

GND

E

S1

E1

E2

S2

GND

E

S

5

7

4

37

42 41

42 41

6

5

7

8

4

37 36

n.c. n.c.

dc

c

d

a

b

n.c.

remote version

Connecting the remote version

a Connection compartment, wall-mount housing

b Cover of connection housing, sensor

c Electrode cable

d Coil current cable

n.c. unconnected, insulated cable shields

Terminal no. and cable colors: 6/5 = brown; 7/8 = white; 4 = green; 36/37 = yellow

Proline Promag 55S

A0011722

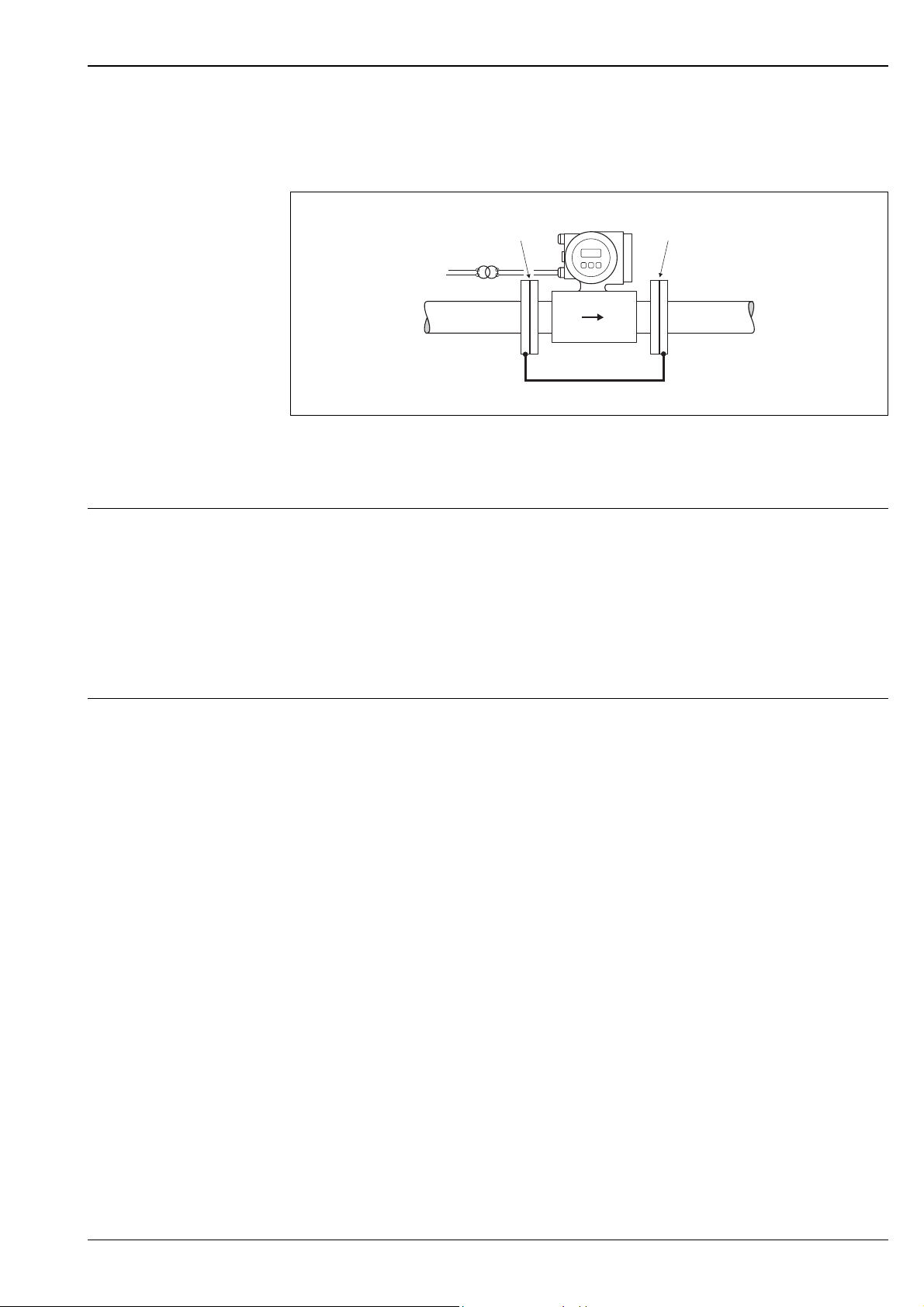

Potential equalization Standard case

Perfect measurement is only ensured when the medium and the sensor have the same electrical

potential. Most Promag sensors have a reference electrode installed as standard, which guarantees the

required potential equalization. This usually means that additional potential equalization measures

are unnecessary.

Promag S:

• Reference electrode is standard for electrode materials 1.4435/316L, Alloy C-22, tantalum,

titanium Gr. 2, Duplex 1.4462, tungsten carbide coating (for electrodes made of 1.4435)

• Reference electrode is optional for electrode material platinum

• Reference electrode not present in measuring tubes with a natural rubber lining in conjunction with

brush electrodes

!

Note!

For installation in metal pipes, it is advisable to connect the ground terminal of the transmitter housing

to the piping. Also, observe company-internal grounding guidelines.

Potential equalization by means of the transmitter's ground terminal

A0004375

8 Endress+Hauser

Page 9

Proline Promag 55S

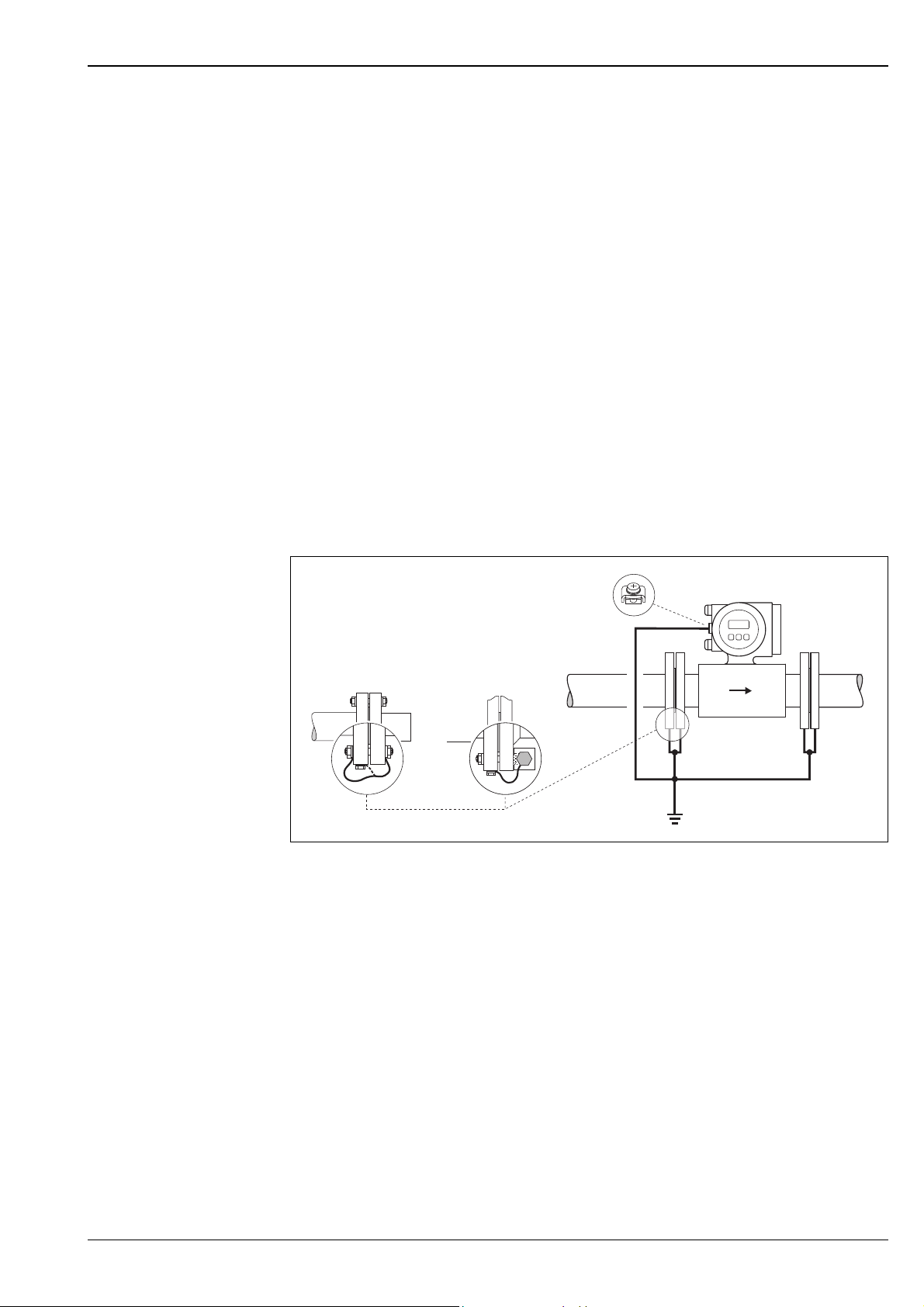

AB

!

!

Note!

• For sensors without reference electrodes or without metal process connections, carry out potential

equalization as per the instructions for special cases described below. These special measures are

particularly important when standard grounding practice cannot be ensured or extremely strong

matching currents are expected.

• Sensors with brush electrodes do not have a reference electrode. For this reason, ground disks must

be installed if necessary to ensure sufficient potential equalization to the fluid. This applies in

particular to isolating lined pipes which are not grounded → 9.

Special cases

Metal, ungrounded piping

In order to prevent outside influences on measurement, it is necessary to use ground cables to connect

each sensor flange to its corresponding pipe flange and ground the flanges. Connect the transmitter or

sensor connection housing, as applicable, to ground potential by means of the ground terminal

provided for the purpose (see diagram).

The ground cable for flange-to-flange connections can be ordered separately as an accessory from

Endress+Hauser → 45.

•DN 300 (12"): The ground cable is in direct connection with the conductive flange coating and is

secured by the flange screws (A).

•DN 350 (14"): The ground cable connects directly to the metal transport bracket (B).

Note!

Also, observe company-internal grounding guidelines.

Potential equalization with equalizing currents in ungrounded, metal pipes

(ground cable: copper wire, at least 6 mm

A Installing ground cable at DN ≤ 300 (12")

B Installing ground cable at DN ≥ 350 (14")

Pre-installed ground cable for DN ≤ 300 (12") (order option)

Ground cables which are preinstalled on the sensor flange, are also available. These ground cables can

be mounted and connected electrically to the piping in different ways:

• Using a screw on the side of the pipe flange (a)

• Using the flange screws (b)

• Using a pipe clip installed around the pipe (c)

2

/10 AWG)

Endress+Hauser 9

A0004376

Page 10

!

a

b

c

Proline Promag 55S

A006117

Possibilities for connecting and mounting pre-installed ground cables

(ground cable: copper wire at least 6 mm

2

/10 AWG)

Plastic pipes and isolating lined pipes

Normally, potential is matched using the reference electrodes in the measuring tube. However, in

exceptional cases it is possible that, due to the grounding plan of a system, matching currents flow over

the reference electrodes. This can lead to destruction of the sensor, e.g. through electro-chemical

decomposition of the electrodes. In such cases, e.g. for fiberglass or PVC pipings, it is therefore

essential that you use additional ground disks for potential equalization. This applies also to twophase or two-component flow, where the fluid is not well mixed or its constituents are not mixable.

Note!

• Risk of damage by electrochemical corrosion. Note the electrochemical insulation rating, if the

ground disks and measuring electrodes are made of different materials.

• Also, observe company-internal grounding guidelines.

A0004377

Potential equalization/ground disks in the case of plastic pipes or isolating lined pipes

(ground cable: copper wire at least 6 mm

2

/ 10 AWG)

Plastic pipes and isolating lined pipes

In such cases, install the measuring instrument without potential in the piping:

• When installing the measuring device, make sure that there is a terminal assignment between the

two piping runs (copper wire, at least 6 mm2 / 10 AWG).

• When using ground disks in plastic or isolating lined pipes, ensure that they are electrically

connected with each other (copper wire at least 6 mm

2

/ 10 AWG).

• Make sure that the mounting material used does not establish a conductive connection between the

pipe and the measuring device and that the mounting material withstands the torques applied when

the threaded fasteners are tightened during installation.

• Check the galvanic isolation using an insulation tester (protection against contact).

• Also comply with the regulations applicable to potential-free installation.

10 Endress+Hauser

Page 11

Proline Promag 55S

1

22

!

Cable entries Power-supply and electrode cables (inputs/outputs):

Note!

For the remote version, both the sensor and the transmitter must be installed so that they are

potential-free.

Potential equalization and cathodic protection (connecting cable: copper wire at least 6 mm2 / 10 AWG)

1 Isolation transformer power supply

2 Electrically insulated

• Cable gland M20 × 1.5 (8 to 12 mm / 0.31 to 0.47")

• Cable entries for thread ½" NPT, G ½"

Fieldbus cable:

• Fieldbus connector for PROFIBUS PA, M12 × 1 / PG 13.5 plus adapter PG 13.5 / M20.5

• Fieldbus connector for FOUNDATION Fieldbus, 7/8-16 UNC × M20

Connecting cable for remote version:

• Cable gland M20 × 1.5 (8 to 12 mm / 0.31 to 0.47")

• Cable entries for thread ½" NPT, G ½"

A0004378

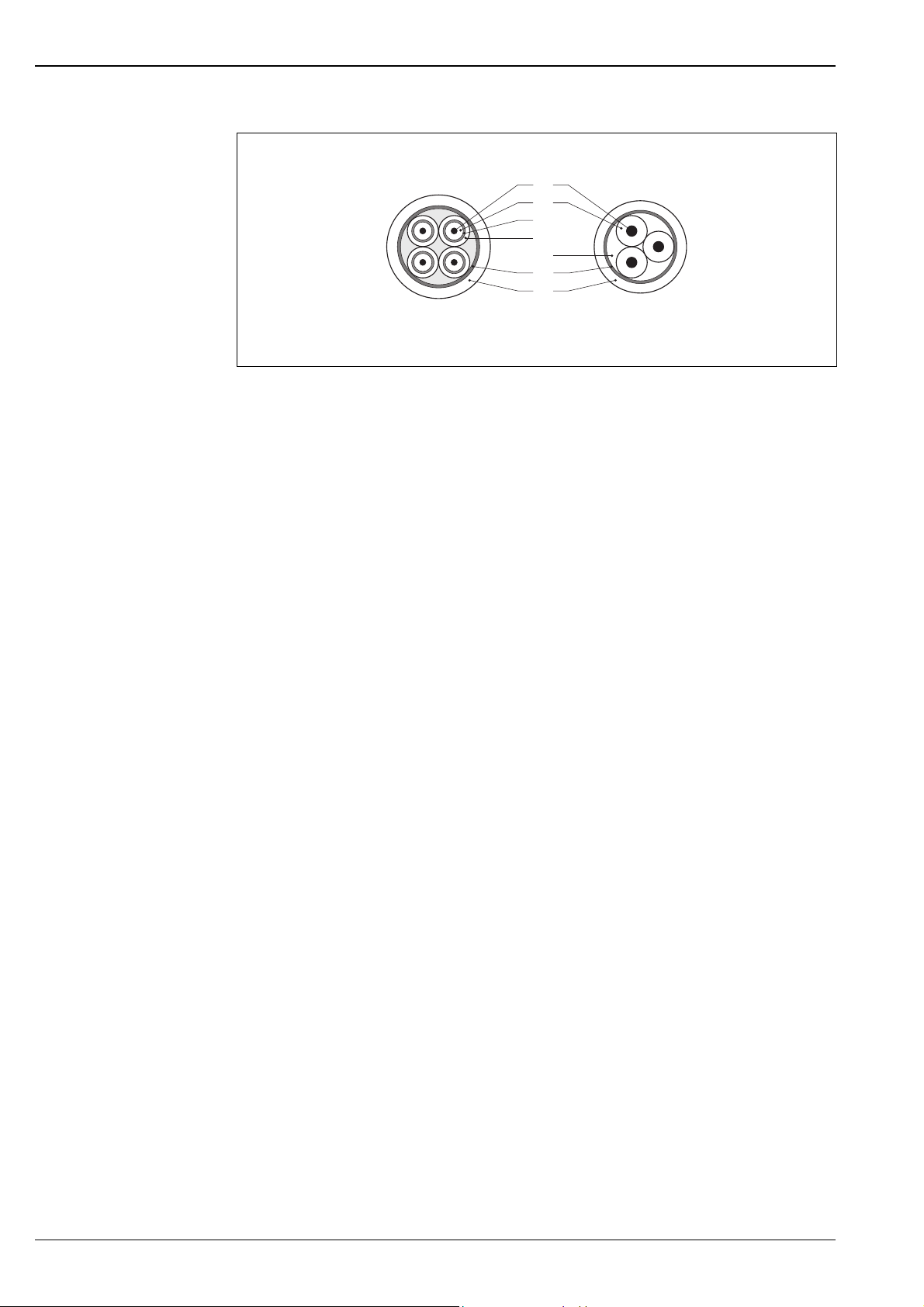

Remote version cable specifications

Coil current cable

• 2 × 0.75 mm² (18 AWG) PVC cable with common, braided copper shield (⌀ ~ 7 mm / 0.28")

• Conductor resistance: ≤37 Ω/km (≤0.011 Ω/ft)

• Capacitance: core/core, shield grounded: ≤120 pF/m (≤37 pF/ft)

• Operating temperature:

– Cable not permanently routed: –20 to +80 °C (–4 to +176 °F)

– Cable permanently routed: –40 to +80 °C (–40 to +176 °F)

• Cable cross-section: max. 2.5 mm² (14 AWG)

Electrode cable

• 3 × 0.38 mm² (20 AWG) PVC cable with common, braided copper shield (⌀ ~ 7 mm / 0.28") and

individually shielded cores

• With Empty Pipe Detection (EPD): 4 × 0.38 mm² (20 AWG) PVC cable with common, braided copper

shield (⌀ ~ 7 mm / 0.28") and individually shielded cores

• Conductor resistance: ≤ 50 Ω/km (≤ 0.015 Ω/ft)

• Capacitance: core/shield: ≤ 420 pF/m (≤ 128 pF/ft)

• Operating temperature:

– Cable not permanently routed: –20 to +80 °C (–4 to +176 °F)

– Cable permanently routed: –40 to +80 °C (–40 to +176 °F)

• Cable cross-section: max. 2.5 mm² (14 AWG)

Endress+Hauser 11

Page 12

a Electrode cable

1

2

3

4

5

6

7

a

b

b Coil current cable

1Core

2 Core insulation

3 Core shield

4 Core jacket

5 Core reinforcement

6 Cable shield

7 Outer jacket

Proline Promag 55S

A0003194

!

As an option, Endress+Hauser can also deliver reinforced connecting cables with an additional,

reinforcing metal braid. We recommend such cables for the following cases:

• Directly buried cable

• Cables endangered by rodents

• Device operation which should comply with the IP 68 (NEMA 6P) standard of protection

Operation in zones of severe electrical interference

The measuring device complies with the general safety requirements in accordance with EN 61010-1,

the EMC requirements of IEC/EN 61326 and NAMUR recommendation NE 21.

Note!

Grounding of the shield is by means of the ground terminals provided for the purpose inside the

connection housing. Keep the stripped and twisted lengths of cable shield to the terminals as short as

possible.

12 Endress+Hauser

Page 13

Proline Promag 55S

0

1

2.5

[%]

2.0

1.5

1.0

0.5

0

246810 [m/s]

v

5 10 15 20 25 30 32 [ft]0

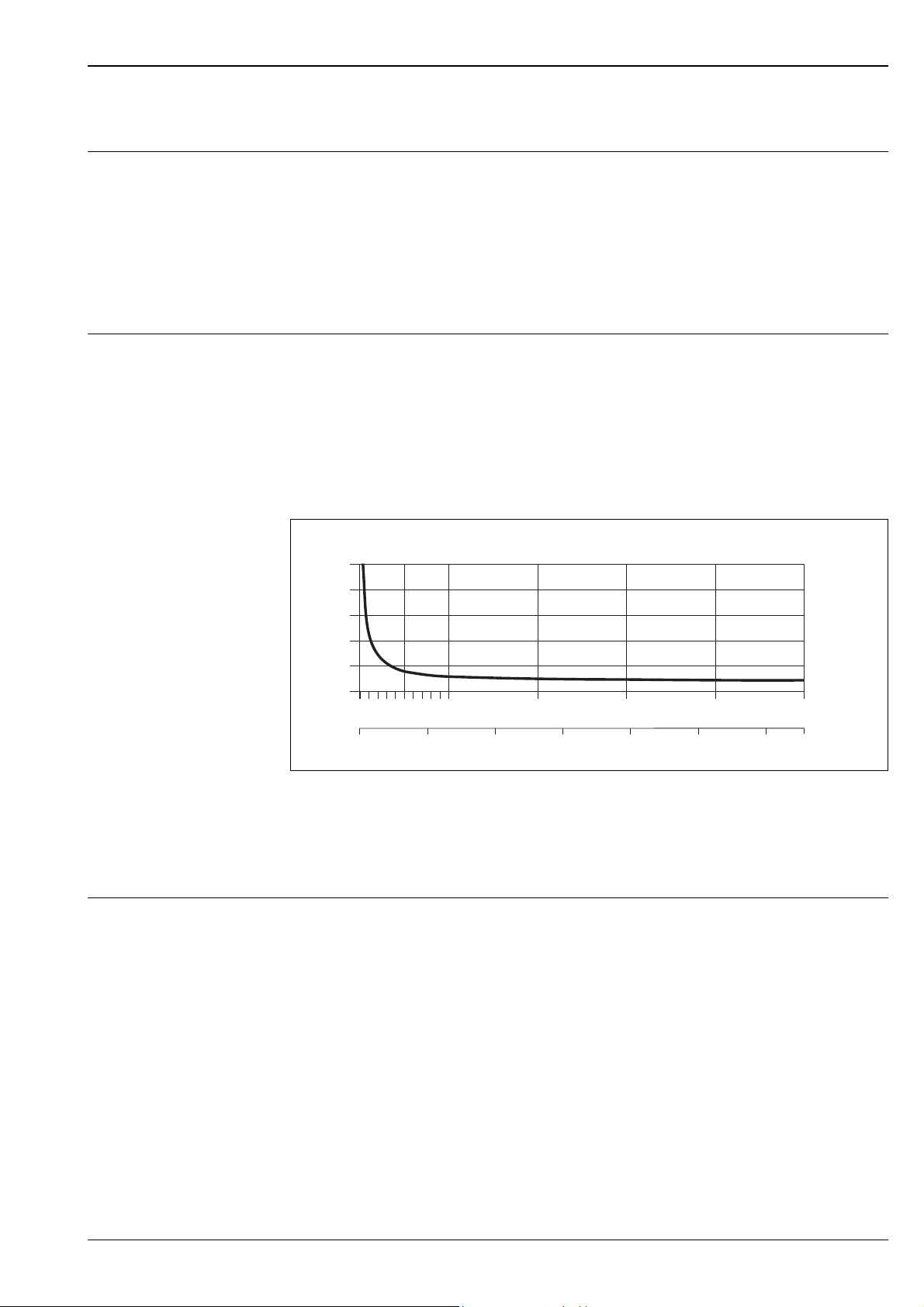

Performance characteristics

Reference operating conditions

Maximum measured error Pulse output:

!

To DIN EN 29104 and VDI/VDE 2641:

• Fluid temperature: +28 °C ± 2 K (+82 °F ± 2 K)

• Ambient temperature: +22 °C ± 2 K (+72 °F ± 2 K)

• Warm-up time: 30 minutes

Installation:

• Inlet run > 10 × DN

• Outlet run > 5 × DN

• Sensor and transmitter grounded.

• Sensor centered relative to the pipe.

• Standard: ±0.2% o.r. ± 2 mm/s (±0.2% o.r. ± 0.08 in/s)

• With brush electrodes (Option): ±0.5% o.r. ± 2 mm/s (±0.5% o.r. ± 0.08 in/s)

(o.r. = of reading)

Current output:

In addition typically ±5 μA

Note!

Supply-voltage fluctuations have no effect within the specified range.

A0004456

Max. measured error in % of reading

Conductivity

• Max. measuring error not specified

• Without temperature compensation (cell constant is a factory setting)

Repeatability Volume flow

• Standard: max. ±0.1% o.r. ± 0.5 mm/s (±0.1% o.r. ± 0.02 in/s)

• With brush electrodes (Option): max. ±0.2% o.r. ± 0.5 mm/s (±0.2% o.r. ± 0.02 in/s)

(o.r. = of reading)

Conductivity

•Max. ±5% o.r.

(o.r. = of reading)

Endress+Hauser 13

Page 14

Proline Promag 55S

h2DN³´

Installation

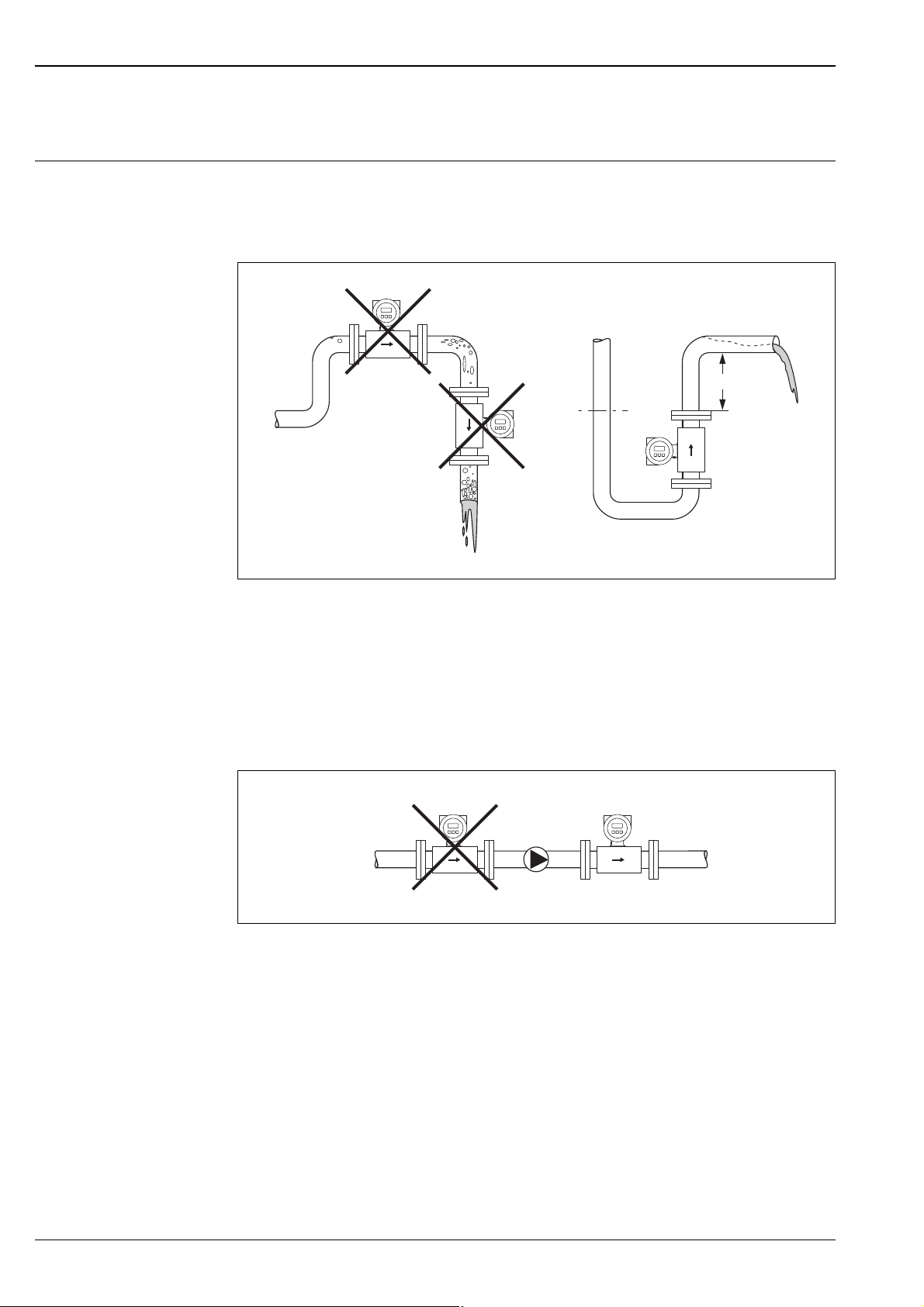

Mounting location The accumulation of air or gas bubbles in the measuring tube could result in an increase in measuring

errors. Avoid the following locations:

• At the highest point of a pipeline. Risk of air accumulating.

• Directly upstream from a free pipe outlet in a vertical pipeline.

A0003202

Mounting location

Installation of pumps

Do not install the sensor on the intake side of a pump. This precaution is to avoid low pressure and the

consequent risk of damage to the lining of the measuring tube. Information on the lining's resistance

to partial vacuum → 23.

It might be necessary to install pulse dampers in systems incorporating reciprocating, diaphragm or

peristaltic pumps. Information on the measuring system's resistance to vibration and shock → 19.

A0003203

Installation of pumps

14 Endress+Hauser

Page 15

Proline Promag 55S

³´5DN

³ 2

´ DN

h

2

1

!

Partially filled pipes

Partially filled pipes with gradients necessitate a drain-type configuration. The Empty Pipe Detection

function offers additional protection by detecting empty or partially filled pipes.

Note!

Risk of solids accumulating. Do not install the sensor at the lowest point in the drain. It is advisable to

install a cleaning valve.

A0003204

Installation with partially filled pipes

Down pipes

Install a siphon or a vent valve downstream of the sensor in down pipes h ≥ 5 m (16.4 ft). This

precaution is to avoid low pressure and the consequent risk of damage to the lining of the measuring

tube. This measure also prevents the system losing prime, which could cause air inclusions.

Information on the lining's resistance to partial vacuum → 23.

A0008157

Installation measures for vertical pipes

1Vent valve

2Siphon

h Vertical height of the down pipe regarding the sensor

Endress+Hauser 15

Page 16

Proline Promag 55S

A

1

22

A

3

Orientation An optimum orientation position helps avoid gas and air accumulations and deposits in the measuring

tube. Promag, nevertheless, supplies a range of functions and accessories for correct measuring of

problematic fluids:

• Electrode Cleaning Circuit (ECC) for applications with fluids producing build-up, e.g. electrically

conductive deposits → "Description of Device Functions" manual.

• Empty Pipe Detection (EPD) ensures the detection of partially filled measuring tubes, e.g. in the case

of degassing fluids.

Vertical orientation

A vertical orientation is ideal in the following cases:

• For self-emptying piping systems and when using empty pipe detection.

• For sludge containing sand or stones and where the solids cause sedimentation.

!

A0008158

Horizontal orientation

The measuring electrode plane should be horizontal. This prevents brief insulation of the two

electrodes by entrained air bubbles.

Note!

Empty Pipe Detection functions correctly with the measuring device installed horizontally only when

the transmitter housing is facing upward (see diagram). Otherwise there is no guarantee that Empty

Pipe Detection will respond if the measuring tube is only partially filled or empty.

A0003207

1 EPD electrode for empty pipe detection (not available for "measuring electrode only" option)

2 Measuring electrodes for signal detection

3 Reference electrode for potential equalization (not available for "measuring electrode only" option)

16 Endress+Hauser

Page 17

Proline Promag 55S

³ 5DNx

³ 2DNx

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

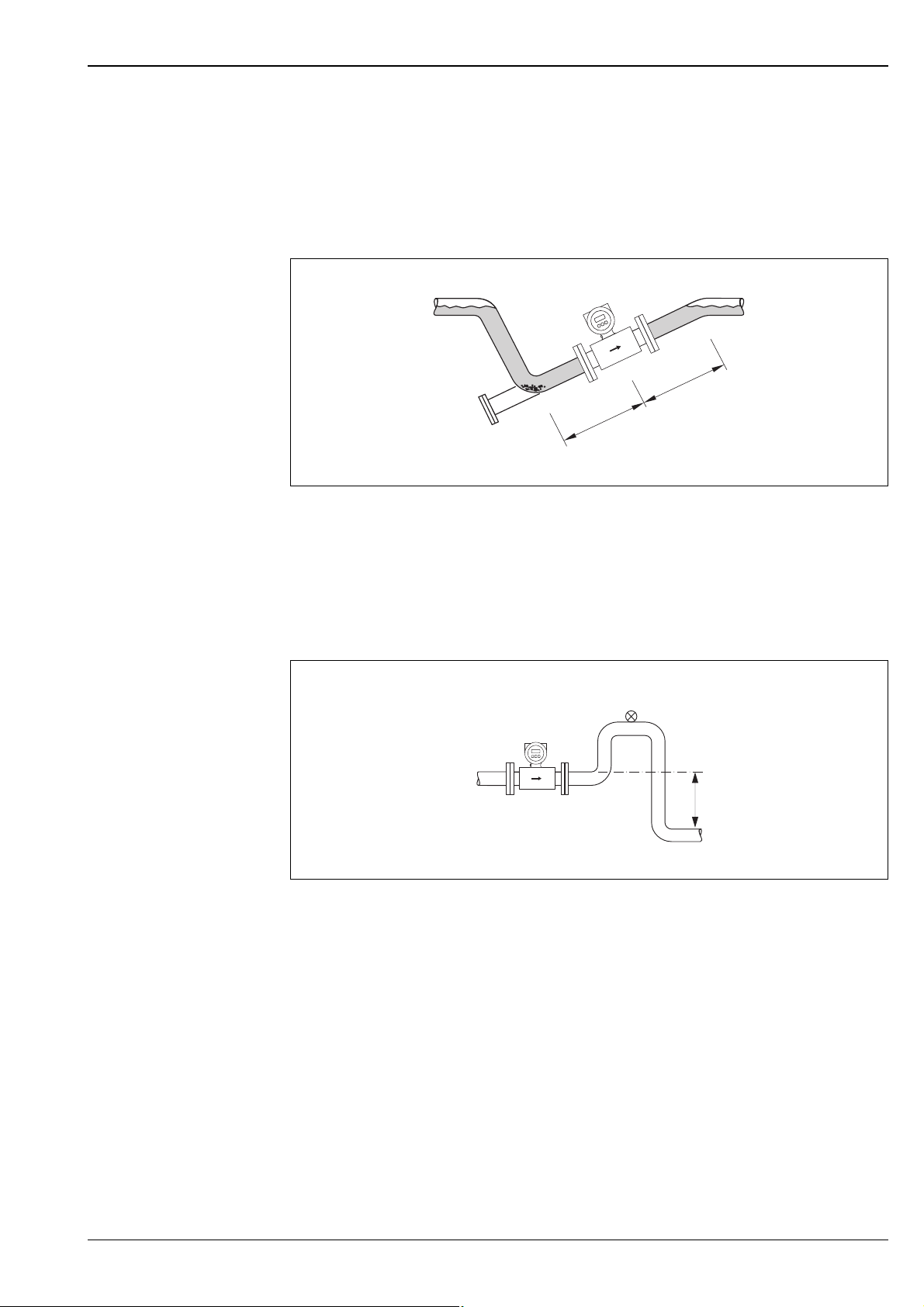

Inlet and outlet runs If possible, install the sensor well clear of fittings such as valves, T-pieces, elbows etc.

Compliance with the following requirements for the inlet and outlet runs is necessary in order to

ensure measuring accuracy.

• Inlet run ≥ 5 × DN

•Outlet run ≥ 2 × DN

A0003210

Adapters Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor in larger-

diameter pipes. The resultant increase in the rate of flow improves measuring accuracy with very slowmoving fluids. The nomogram shown here can be used to calculate the pressure loss caused by crosssection reduction.

!

Note!

The nomogram applies to fluids of viscosity similar to water.

1. Calculate the ratio of the diameters d/D.

2. From the nomogram, read off the pressure loss as a function of fluid velocity (downstream from

the reduction) and the d/D ratio.

Pressure loss due to adapters (for pressure losses in US units, please contact Endress+Hauser)

A0003213

Endress+Hauser 17

Page 18

Proline Promag 55S

[µS/cm]

50

40

30

20

10

5

0

10020304050

[m]

L

max

L

max

50 100 1500

[ft]

Length of connecting cable In order to ensure measuring accuracy, comply with the following instructions when installing the

remote version:

• Secure the cable run or route the cable in an armored conduit. Movement of the cable can falsify the

measuring signal, particularly if the fluid conductivity is low.

• Route the cable well clear of electrical machines and switching elements.

• Ensure potential equalization between sensor and transmitter, if necessary.

• The permissible cable length L

• The maximum connecting cable length is 10 m (32.8 ft) when empty pipe detection (EPD) is

switched on.

depends on the fluid conductivity (see Figure).

max

A0006116

Permitted lengths for connecting cable in remote version, as a function of the conductivity of the fluid

Gray shaded area = permissible area

= Length of connecting cable

L

max

Foundations, supports If the nominal diameter is DN ≥ 350 (14"), mount the sensor on a foundation of adequate load-bearing

strength.

!

Note!

Risk of damage.

Do not support the weight of the sensor on the metal casing: the casing would buckle and damage the

internal magnetic coils.

18 Endress+Hauser

Correct support for large nominal diameters (DN ≥ 350 / 14")

A0003209

Page 19

Proline Promag 55S

Environment

Ambient temperature range Transmitter:

• Standard:

– Compact version: –20 to +50 °C (–4 to +122 °F)

– Remote version: –20 to +60 °C (–4 to +140 °F)

• Optional:

– Compact version: –40 to +50 °C (–40 to +122 °F)

– Remote version: –40 to +60 °C (–40 to +140 °F)

!

!

Note!

At ambient temperatures below –20 °C (–4 °F), the readability of the display may be impaired.

Sensor:

• Flange material carbon steel: –10 to +60 °C (+14 to +140 °F)

• Flange material stainless steel: –40 to +60 °C (–40 to +140 °F)

Note!

Do not exceed the min. and max. temperatures for the lining of the measuring tube

(→ "Medium temperature range").

Note the following points:

• Install the device at a shady location. Avoid direct sunlight, particularly in warm climatic regions.

• If both fluid and ambient temperatures are high, install the transmitter at a remote location from the

sensor (→ "Medium temperature range").

Storage temperature The storage temperature corresponds to the operating temperature range of the transmitter and

sensor.

Degree of protection • Standard: IP 67 (NEMA 4X) for transmitter and sensor

• Optional: IP 68 (NEMA 6P) for remote version of Promag S sensor

• For information regarding applications where the device is buried directly in the soil or is installed

in a flooded wastewater basin please contact your local Endress+Hauser Sales Center.

Shock and vibration resistance

Electromagnetic compatibility (EMC)

Acceleration up to 2 g by analogy with IEC 600 68-2-6

(High temperature version: no data available)

According to IEC/EN 61326 and NAMUR recommendation NE 21

Endress+Hauser 19

Page 20

Process

PTFE

HT

PFA

2

0

0

0

0

-20-40

-40

20

20

40

100

60

140

[°F] [°C]

T

A

40 60 80

T

F

100

100

120 140 160

200 300

180 [°C]

360 [°F]

-20

-40

-40

1

HT

PTFE

PFA

0

0

0

0

-20-40

-40

20

20

40

100

60

140

[°F] [°C]

T

A

40 60 80

T

F

100

100

120 140 160

200 300

180 [°C]

360 [°F]

-20

-40

-40

2

1

Medium temperature range The permitted temperature depends on the lining of the measuring tube:

• 0 to +60 °C (+32 to +140 °F) for natural rubber (DN 65 to 600 / 2½ to 24")

• 0 to +80 °C (+32 to +176 °F) for hard rubber (DN 65 to 600 / 2½ to 24")

• –20 to +50 °C (–4 to +122 °F) for polyurethane (DN 25 to 600 / 1 to 24")

• –20 to +180 °C (–4 to +356 °F) for PFA (DN 25 to 200 / 1 to 8"), restrictions → see diagrams

• –40 to +130 °C (–40 to +266 °F) for PTFE (DN 15 to 600 / ½ to 24"), restrictions → see diagrams

Proline Promag 55S

Promag S compact versions (with PFA or PTFE lining)

T

Ambient temperature

A

Fluid temperature

T

F

HT High temperature version with insulation

1 Gray shaded area → temperature range from –10 to –40 °C (–14 to –40 °F) applies only to stainless steel flanges

2 HE + IP 68 to 130 °C (266 °F) only

20 Endress+Hauser

Promag S remote versions (with PFA or PTFE lining)

Ambient temperature

T

A

Fluid temperature

T

F

HT High temperature version with insulation

1 Gray shaded area → temperature range from –10 to –40 °C (–14 to –40 °F) applies only to stainless steel flanges

2 HE + IP 68 to 130 °C (266 °F) only

A0006119

A0002671

Page 21

Proline Promag 55S

0

5

10

15

20

25

35

30

40

[bar][psi]

-40

-20

020

40 60 80 100120140160180 [°C]

360 [°F]

0-40 100 200 300

200

100

400

300

500

600

0

PN 25

PN 16

PN 10

PN 6

PN 40

PN 16

PN 10

PN 40

PN 6

0

5

10

15

20

25

35

30

40

[bar][psi]

-60

-40

-20

020

40 60 80 100120140 160180 [°C]

360 [°F]

0-40 100 200 300

200

100

400

300

500

600

0

PN 25

Conductivity Minimum conductivity:

• ≥ 5 μS/cm for all liquids (incl. demineralized water)

!

Note!

In the remote version, the required minimum conductivity is also influenced by the length of the cable

→ 18.

Pressure-temperature ratings

The following diagrams contain material load curves (reference curves) for various process connections

relating to the fluid temperature. But the maximal permissible fluid temperature always depends on

the lining material of the sensor and/or the sealing material.

Process connection: flange according to EN 1092-1 (DIN 2501)

Process connection material: S235JRG2, S235JR+N, P250GH, P245GH, E250C, A105

A0021188-EN

Process connection: flange according to EN 1092-1 (DIN 2501)

Process connection material: 1.4571, F316L

Endress+Hauser 21

A0021184-EN

Page 22

Process connection: flange according to ASME B16.5

Class 300

Class 150

0

10

20

30

40

50

[bar][psi]

-40

-20

020

40 60 80 100120140 160180 [°C]

360 [°F]

0-40 100 200 300

200

100

400

300

500

600

700

800

900

60

0

Class 300

Class 150

0

10

20

30

40

50

[bar][psi]

-40

-20

020

40 60 80 100120140 160180 [°C]

360 [°F]

0-40 100 200 300

200

100

400

300

500

600

700

800

900

0

60

10K

20K

-40

-20

020

40 60 80 100120140 160180 [°C]

0

10

20

30

[bar]

360 [°F]

0-40 100 200 300

[psi]

200

100

400

300

0

Process connection material: A105

Process connection: flange according to ASME B16.5

Process connection material: F316L

Proline Promag 55S

A0021182-EN

Process connection: flange according to JIS B2220

Process connection material: A105, A350 LF2, F316L

22 Endress+Hauser

A0021185-EN

A0021183-EN

Page 23

Proline Promag 55S

-40

-20

020

40 60 80 100120140 160 [°C]

0

10

5

20

15

[bar]

0-40 100 200

300 [°F]

[psi]

200

100

300

0

TableE

-40

-20

020

40 60 80 100120140 160 [°C]

0

10

5

20

15

[bar]

0-40 100 200

300 [°F]

[psi]

200

100

300

0

PN 16

Process connection: flange according to AS 2129 Table E or AS 4087 PN 16

Process connection material: A105, P235GH, P265GH, S235JRG2

A0021189-EN

Process connection: flange according to AS 2129 Table E or AS 4087 PN 16

Process connection material: A105, P265GH, S275JR

Medium pressure range (nominal pressure)

• EN 1092-1 (DIN 2501): PN 10 (DN 200 to 600 / 8 to 24"), PN 16 (DN 65 to 600 / 2½ to 24"),

PN 25 (DN 200 to 600 / 8 to 24"), PN 40 (DN 15 to 150 / ½ to 6")

• ASME B16.5: Class 150 (DN ½ to 24"), Class 300 (DN ½ to 6")

• JIS B2220: 10K (DN 50 to 600 / 2 to 24"), 20K (DN 15 to 600 / ½ to 24")

• AS 2129: Table E (DN 25 / 1", DN 50 / 2")

• AS 4087: PN 16 (DN 50 / 2")

Pressure tightness (lining) Pressure tightness in SI units [mbar]

Promag S

Nominal

diameter

[mm] 25 °C 50 °C 80 °C 100 °C 130 °C 150 °C 180 °C

25 to 600 Polyurethane 0 0 - - - - -

65 to 600 Natural rubber 0 0 - - - - -

65 to 600 Hard rubber 0 0 0 - - - -

Promag S

Nominal

diameter

Endress+Hauser 23

[mm] 25 °C 80 °C 100 °C 130 °C 150 °C 180 °C

15 PTFE 0 0 0 100 – –

25 PTFE / PFA 0/0 0/0 0/0 100/0 –/0 –/0

Measuring tube

lining

Measuring tube

lining

Resistance of measuring tube lining to partial vacuum (SI units)

Limit values for abs. pressure [mbar] at various fluid temperatures

Resistance of measuring tube lining to partial vacuum (SI units)

Limit values for abs. pressure [mbar] at various fluid temperatures

A0023077-EN

Page 24

Proline Promag 55S

32 PTFE / PFA 0/0 0/0 0/0 100/0 –/0 –/0

40 PTFE / PFA 0/0 0/0 0/0 100/0 –/0 –/0

50 PTFE / PFA 0/0 0/0 0/0 100/0 –/0 –/0

65 PTFE / PFA 0/0 * 40/0 130/0 –/0 –/0

80 PTFE / PFA 0/0 * 40/0 130/0 –/0 –/0

100 PTFE / PFA 0/0 * 135/0 170/0 –/0 –/0

125 PTFE / PFA 135/0 * 240/0 385/0 –/0 –/0

150 PTFE / PFA 135/0 * 240/0 385/0 –/0 –/0

200 PTFE / PFA 200/0 * 290/0 410/0 –/0 –/0

250 PTFE 330 * 400 530 – –

300 PTFE 400 * 500 630 – –

350 PTFE 470 * 600 730 – –

400 PTFE 540 * 670 800 – –

450 PTFE

Partial vacuum is impermissible!500 PTFE

600 PTFE

* No value can be quoted.

Pressure tightness in US units [psi = pounds/inch2]

Promag S

Nominal

diameter

[inch] 77 °F 122 °F 176 °F 212 °F 266 °F 302 °F 356 °F

1 to 24" Polyurethane 0 0 - - - - -

3 to 24" Natural rubber 0 0 - - - - -

3 to 24" Hard rubber 0 0 0 - - - -

Promag S

Nominal

diameter

[inch] 77 °F 176 °F 212 °F 266 °F 302 °F 356 °F

½" PTFE 0 0 0 1.5 – –

1" PTFE / PFA 0/0 0/0 0/0 1.5/0 –/0 –/0

– PTFE / PFA 0/0 0/0 0/0 1.5/0 –/0 –/0

1½" PTFE / PFA 0/0 0/0 0/0 1.5/0 –/0 –/0

2" PTFE / PFA 0/0 0/0 0/0 1.5/0 –/0 –/0

– PTFE / PFA 0/0 * 0.6/0 1.9/0 –/0 –/0

3" PTFE / PFA 0/0 * 0.6/0 1.9/0 –/0 –/0

4" PTFE / PFA 0/0 * 2.0/0 2.5/0 –/0 –/0

– PTFE / PFA 2.0/0 * 3.5/0 5.6/0 –/0 –/0

6" PTFE / PFA 2.0/0 * 3.5/0 5.6/0 –/0 –/0

8" PTFE / PFA 2.9/0 * 4.2/0 5.9/0 –/0 –/0

10" PTFE 4.8 * 5.8 7.7 – –

12" PTFE 5.8 * 7.3 9.1 – –

14" PTFE 6.8 * 8.7 10.6 – –

16" PTFE 7.8 * 9.7 11.6 – –

18" PTFE

24" PTFE

* No value can be quoted.

Measuring tube

lining

Measuring tube

lining

Resistance of measuring tube lining to partial vacuum (US units)

Limit values for abs. pressure [psi] at various fluid temperatures

Resistance of measuring tube lining to partial vacuum (US units)

Limit values for abs. pressure [psi] at various fluid temperatures

Partial vacuum is impermissible!20" PTFE

24 Endress+Hauser

Page 25

Proline Promag 55S

Limiting flow The diameter of the pipe and the flow rate determine the nominal diameter of the sensor. The

optimum flow velocity is between 2 and 3 m/s (6 to 10 ft/s). The flow velocity (v), moreover, has to be

matched to the physical properties of the fluid:

• v < 2 m/s (6 ft/s): for abrasive fluids where solids do not cause sedimentation (e.g. lime milk)

• v > 2 m/s (6 ft/s): for fluids producing build-up (e.g. wastewater sludge)

• v > 2 m/s (6 ft/s): for abrasive sludge with a high sand or stone content and where the solids easily

cause sedimentation (e.g. ore slurry)

!

Note!

Flow velocity can be increased, if necessary, by reducing the nominal diameter of the sensor through

the use of adapters → 17.

Flow rate characteristic values - Promag S (SI units)

Nominal

Recommended flow rate Factory settings

diameter

[mm] min./max. full scale value

(v ≈ 0.3 or 10 m/s)

15 4 to 100 dm

25 9 to 300 dm

32 15 to 500 dm

40 25 to 700 dm

50 35 to 1100 dm

65 60 to 2000 dm

80 90 to 3000 dm

100 145 to 4700 dm

125 220 to 7500 dm

150 20 to 600 m

200 35 tof 1100 m

250 55 to 1700 m

300 80 to 2400 m

350 110 to 3300 m

400 140 to 4200 m

450 180 to 5400 m

500 220 to 6600 m

600 310 to 9600 m

3

3

3

3

3

3

3

3

3

Full scale value

(v ≈ 2.5 m/s)

3

/min 25 dm3/min 0.20 dm

3

/min 75 dm3/min 0.50 dm

3

/min 125 dm3/min 1.00 dm

3

/min 200 dm3/min 1.50 dm

3

/min 300 dm3/min 2.50 dm

3

/min 500 dm3/min 5.00 dm

3

/min 750 dm3/min 5.00 dm

3

/min 1200 dm3/min 10.00 dm

3

/min 1850 dm3/min 15.00 dm

Pulse value

(≈ 2 pulse/s)

/h 150 m3/h 0.025 m

/h 300 m3/h 0.05 m

/h 500 m3/h 0.05 m

/h 750 m3/h 0.10 m

/h 1000 m3/h 0.10 m

/h 1200 m3/h 0.15 m

/h 1500 m3/h 0.25 m

/h 2000 m3/h 0.25 m

/h 2500 m3/h 0.30 m

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

Low flow cut off

(v ≈ 0.04 m/s)

0.5 dm3/min

1dm3/min

2dm3/min

3dm3/min

5dm3/min

8dm3/min

12 dm3/min

20 dm3/min

30 dm3/min

2.5 m3/h

5.0 m3/h

7.5 m3/h

10 m3/h

15 m3/h

20 m3/h

25 m3/h

30 m3/h

40 m3/h

Endress+Hauser 25

Page 26

Flow rate characteristic values - Promag S (US units)

L

Proline Promag 55S

Nominal

diameter

[inch] min./max. full scale value

½" 1.0 to 27 gal/min 6 gal/min 0.05 gal 0.10 gal/min

1" 2.5 to 80 gal/min 18 gal/min 0.20 gal 0.25 gal/min

1¼" 4 to 130 gal/min 30 gal/min 0.20 gal 0.50 gal/min

1½" 7 to 190 gal/min 50 gal/min 0.50 gal 0.75 gal/min

2" 10 to 300 gal/min 75 gal/min 0.50 gal 1.25 gal/min

2½" 16 to 500 gal/min 130 gal/min 1 gal 2.0 gal/min

3" 24 to 800 gal/min 200 gal/min 2 gal 2.5 gal/min

4" 40 to 1250 gal/min 300 gal/min 2 gal 4.0 gal/min

5" 60 to 1950 gal/min 450 gal/min 5 gal 7.0 gal/min

6" 90 to 2650 gal/min 600 gal/min 5 gal 12 gal/min

8" 155 to 4850 gal/min 1200 gal/min 10 gal 15 gal/min

10" 250 to 7500 gal/min 1500 gal/min 15 gal 30 gal/min

12" 350 to 10600 gal/min 2400 gal/min 25 gal 45 gal/min

Recommended flow rate Factory settings

(v ≈ 1.0 or 33 ft/s)

Full scale value

(v ≈ 8.2 ft/s)

Pulse value

(≈ 2 pulse/s)

Low flow cut off

(v ≈ 0.1 ft/s)

14" 500 to 15000 gal/min 3600 gal/min 30 gal 60 gal/min

16" 600 to 19000 gal/min 4800 gal/min 50 gal 60 gal/min

18" 800 to 24000 gal/min 6000 gal/min 50 gal 90 gal/min

20" 1000 to 30 000 gal/min 7500 gal/min 75 gal 120 gal/min

24" 1400 to 44 000 gal/min 10500 gal/min 100 gal 180 gal/min

Pressure loss • No pressure loss if the sensor is installed in a pipe of the same nominal diameter.

• Pressure losses for configurations incorporating adapters according to DIN EN 545 → 17.

Vibrations Secure and fix both the piping and the sensor if the vibrations are severe.

!

Note!

It is advisable to install sensor and transmitter separately if vibration is excessively severe. Information

on the permitted resistance to vibration and shock → 19.

Measures to prevent vibration of the measuring device (L > 10 m / 33 ft)

A0003208

26 Endress+Hauser

Page 27

Proline Promag 55S

Esc

E

- +

D

C

B

A

F

E

G

K

J

Q

N

L

O

R

H J

M

PP

SS

T

Mechanical construction

Design, dimensions Transmitter wall-mount housing (non hazardous area and II3G / zone 2)

Dimensions (SI units)

A B C D E F G H J K

215 250 90.5 159.5 135 90 45 > 50 81 53

L M N O P Q R S T

95 53 102 81.5 11.5 192 8 × M5 20 2 × ⌀ 6.5

1)

Securing screw for wall mounting: M6 (screw head max. 10.5 mm)

All dimensions in [mm]

Dimensions (US units)

A B C D E F G H J K

8.46 9.84 3.56 6.27 5.31 3.54 1.77 > 1.97 3.18 2.08

L M N O P Q R S T

3.74 2.08 4.01 3.20 0.45 7.55 8 × M5 0.79 2 × ⌀ 0.26

1)

Securing screw for wall mounting: M6 (screw head max. 0.41")

All dimensions in [inch]

A0001150

1)

1)

Endress+Hauser 27

Page 28

Proline Promag 55S

245 (9.65)

~110 (~4.33)

210 (8.27)

+0.5 (+0.019)

–0.5 (–0.019)

+0.5 (+0.019)

–0.5 (–0.019)

Ø 20…70

(Ø 0.79…2.75)

~~ 6.1)155 (

There is a separate mounting kit for the wall-mounted housing. It can be ordered from Endress+Hauser

as an accessory. The following installation variants are possible:

• Panel-mounted installation

•Pipe mounting

Installation in control panel

Pipe mounting

A0001131

A0001132

28 Endress+Hauser

Page 29

Proline Promag 55S

J

L

E

G

F

H

B

C

A

D

Sensor, remote version DN ≤ 300 (12")

A0012462

Dimensions (SI units)

DN A B C D E F G H J L

EN (DIN) / JIS / AS

15

25 286 202 84 120 94 200

32 286 202 84 120 94 200

40 286 202 84 120 94 200

50 286 202 84 120 94 200

65 336 227 109 180 94 200

80 336 227 109 180 94 200

100 336 227 109 180 94 250

125 417 267 150 260 140 250

150 417 267 150 260 140 300

200 472 292 180 324 156 350

250 522 317 205 400 166 450

300 572 342 230 460 166 500

The fitting length (L) is always the same, regardless of the pressure rating.

1)

Only DN 25 and DN 50 are available for flanges according to AS.

All dimensions in [mm]

1)

286 202 84 120 94 200

129 163 143 102

Endress+Hauser 29

Page 30

Dimensions (US units)

E1

D1

110

(4.33)

DN A B C D E F G H J L

ASME

½"

1" 11.3 7.95 3.31 4.72 3.70 7.87

1½" 11.3 7.95 3.31 4.72 3.70 7.87

2" 11.3 7.95 3.31 4.72 3.70 7.87

3" 13.2 8.94 4.29 7.09 3.70 7.87

4" 13.2 8.94 4.29 7.09 3.70 9.84

6" 16.4 10.5 5.91 10.2 5.51 11.8

8" 18.6 11.5 7.08 12.8 6.14 13.8

10" 20.6 12.5 8.07 15.8 6.54 17.7

12" 22.5 13.5 9.06 18.1 6.54 19.7

The fitting length (L) is always the same, regardless of the pressure rating.

All dimensions in [inch]

5.08 6.42 5.63 4.02

11.3 7.95 3.31 4.72 3.70 7.87

Proline Promag 55S

High temperature version DN ≤ 300 (12")

Measurement D1, E1 = Measurement D, E of the standard remote version plus 110 mm (4.33")

A0005570

30 Endress+Hauser

Page 31

Proline Promag 55S

H

E

G

F

L

J

A

B

C

D

Sensor, remote version DN ≥ 300 (12")

A0003220

Dimensions (SI units)

DN A B C D E F G H J L

EN (DIN)

350

400 735.5 427.5 308.0 616 288 600

450 785.5 452.5 333.0 666 292 650

500 836.5 478.0 358.5 717 292 650

600 940.5 530.0 410.5 821 402 780

The fitting length (L) is always the same, regardless of the pressure rating.

All dimensions in [mm]

129 163 143 102

683.5 401.5 282.0 564 288 550

Dimensions (US units)

DN A B C D E F G H J L

ASME

14"

16" 29.0 16.8 12.1 24.3 11.3 23.6

The fitting length (L) is always the same, regardless of the pressure rating.

All dimensions in [inch]

18" 30.9 17.8 13.1 26.2 11.5 25.6

20" 32.9 18.8 14.1 28.2 11.5 25.6

24" 37.0 20.9 16.2 32.3 15.8 30.7

5.08 6.42 5.63 4.02

26.9 15.8 11.1 22.2 11.3 21.7

Endress+Hauser 31

Page 32

Compact version DN ≤ 300 (12")

Esc

E

-

+

K

H

L

E

G

F

A*

A

B

C

D

Proline Promag 55S

Dimensions (SI units)

DN A A* B C D E F G H K L

EN (DIN) / JIS / AS

15

25 341 257 84 94 120 200

32 341 257 84 94 120 200

40 341 257 84 94 120 200

50 341 257 84 94 120 200

65 391 282 109 94 180 200

80 391 282 109 94 180 200

100 391 282 109 94 180 250

125 472 322 150 140 260 250

150 472 322 150 140 260 300

200 527 347 180 156 324 350

250 577 372 205 166 400 450

300 627 397 230 166 460 500

The fitting length (L) is always the same, regardless of the pressure rating.

1)

Only DN 25 and DN 50 are available for flanges according to AS.

All dimensions in [mm]

1)

341 257 84 94 120 200

227 207 187 168 160

A0005423

32 Endress+Hauser

Page 33

Proline Promag 55S

E1

D1

110

(4.33)

Dimensions (US units)

DN A A* B C D E F G H K L

ASME

½"

1" 13.410.13.313.704.727.87

1½" 13.410.13.313.704.727.87

2" 13.410.13.313.704.727.87

3" 15.411.14.293.707.097.87

4" 15.411.14.293.707.099.84

6" 18.6 12.7 5.91 5.51 10.2 11.8

8" 20.8 13.7 7.09 6.14 12.8 13.8

10" 22.7 14.7 8.07 6.54 15.8 17.7

12" 24.7 15.6 9.06 6.54 18.1 19.7

The fitting length (L) is always the same, regardless of the pressure rating.

All dimensions in [inch]

8.94 8.15 7.36 6.61 6.30

13.410.13.313.704.727.87

High temperature version DN ≤ 300 (12")

Measurement D1, E1 = Measurement D, E of the standard compact version plus 110 mm (4.33")

A0005529

Endress+Hauser 33

Page 34

Compact version DN ≥ 300 (12")

L

H

E

G

F

J

Esc

E

- +

AB

A*

C

D

Proline Promag 55S

Dimensions (SI units)

DN A A* B C D E F G H J L

EN (DIN)

350

400 790.5 482.5 308.0 616 288 600

450 840.5 507.5 333.0 666 292 650

227 207 187 168 160

500 891.5 533.0 358.5 717 292 650

600 995.5 585.0 410.5 821 402 780

The fitting length (L) is always the same, regardless of the pressure rating.

All dimensions in [mm]

Dimensions (US units)

DN A A* B C D E F G H J L

ASME

14"

16" 31.1 19.0 12.1 24.3 11.3 23.6

18" 33.1 20.0 13.1 26.2 11.5 25.6

20" 35.1 21.0 14.1 28.2 11.5 25.6

8.94 8.15 7.36 6.61 6.30

24" 39.2 23.0 16.2 32.3 15.8 30.7

The fitting length (L) is always the same, regardless of the pressure rating.

All dimensions in [inch]

A0005424

738.5 456.5 282.0 564 288 550

29.1 18.0 11.1 22.2 11.3 21.7

34 Endress+Hauser

Page 35

Proline Promag 55S

D

D

DN £ 300 (12")

t

E

Æ

B

Æ

A

Æ

C

Æ

A

Æ

B

Æ

t

³DN 350 (14")

C

Æ

E

Æ

Ground disk for flange connections

A0003221

Dimensions (SI units)

1)

DN

EN (DIN) / JIS / AS4)PTFE, PFA, PU, HR, NR

15 16 – 43 61.5 73

25 26 – 62 77.5 87.5

32 35 – 80 87.5 94.5

40 41 – 82 101 103

50 52 – 101 115.5 108

65 68 53 121 131.5 118

80 80 66 131 154.5 135

100 104 91.5 156 186.5 153

125 130 117 187 206.5 160

150 158 143.5 217 256 184

200 206 192 267 288 205

250 260 245 328 359 240

2)

300

3)

300

2)

350

2)

400

2)

450

2)

500

2)

600

1)

Ground disks at DN 15 to 250 can be used for all flange standards/nominal pressures available as standard.

2)

PN 10/16, Cl 150

3)

PN 25, JIS 10K/20K

4)

Only DN 25 and DN 50 are available for flanges according to AS.

5)

Abbreviations (lining): PU = Polyurethane, HR = Hard rubber, NRa = Natural rubber thin, NRb = Natural rubber

thick

All dimensions in [mm]

A B C D E t

5)

a

NR

5)

b

312 294.5 375 413 273

310 – 375 404 268

343 323.5 433 479 365

393 371 480 542 395

439 420 538 583 417

493 469 592 650 460

593 566 693 766 522

6.5

2

9.0

Endress+Hauser 35

Page 36

Proline Promag 55S

Dimensions (US units)

1)

DN

ASME PTFE, PFA, PU, HR, NR

½" 0.63 – 1.69 2.42 2.87

1" 1.02 – 2.44 3.05 3.44

1½" 1.61 – 3.23 3.98 4.06

2" 2.05 – 3.98 4.55 4.25

3" 3.15 2.60 5.16 6.08 5.31

4" 4.09 3.60 6.14 7.34 6.02

6" 6.22 5.65 8.54 10.08 7.24

8" 8.11 7.56 10.5 11.3 8.07

10" 10.2 9.65 12.9 14.1 9.45

12" 12.3 11.6 14.8 16.3 10.8

14" 13.5 12.7 17.1 18.9 14.4

16" 15.45 14.6 18.9 21.3 15.6

18" 17.3 16.5 21.2 23.0 16.4

20" 19.4 18.5 23.3 25.6 18.1

24" 23.4 22.3 27.3 30.1 20.6

1)

Ground disks can be used for all pressure ratings.

2)

Abbreviations (lining): PU = Polyurethane, HR = Hard rubber, NRa = Natural rubber thin, NRb = Natural rubber

thick

All dimensions in [inch]

A B C D E t

2)

a

NR

2)

b

0.26

0.35

0.08

36 Endress+Hauser

Page 37

Proline Promag 55S

Weight Weight in [kg]

Nominal

diameter

Compact version Remote version (without cable)

[mm] EN (DIN) / AS* JIS EN (DIN) / AS* JIS (Wall-mount housing)

15

25 7.3 7.3 5.3 5.3 6.0

32 8.0 7.3 6.0 5.3 6.0

40 9.4 8.3 7.4 6.3 6.0

50 10.6 9.3 8.6 7.3 6.0

65

80 14.0 12.5 12.0 10.5 6.0

100 16.0 14.7 14.0 12.7 6.0

125 21.5 21.0 19.5 19.0 6.0

150 25.5 24.5 23.5 22.5 6.0

200

250 65 69.4 63 67.4 6.0

300 70 72.3 68 70.3 6.0

350 115 79 113 77 6.0

400 135 100 133 98 6.0

450 175 128 173 126 6.0

500 175 142 173 140 6.0

600 235 188 233 186 6.0

Transmitter (compact version): 3.4 kg

High-temperature version: +1.5 kg

* Only DN 25 and 50 are available for flanges according to AS

6.5

PN 40

12.0 11.1

PN 16

45 41.9

PN 10

10K

10K

Weight in kilograms [kg]

6.5

4.5

PN 40

10.0 9.1 6.0

PN 16

43 39.9 6.0

PN 10

Sensor Transmitter

4.5 6.0

10K

Endress+Hauser 37

Page 38

Proline Promag 55S

Weight in [lbs]

Nominal

diameter

Compact version Remote version (without cable)

[inch] ASME ASME (Wall-mount housing)

½"

1" 16 12 13

1 ½" 21 16 13

2" 23 19 13

3" 31 26 13

4" 35 31 13

6" 56 52 13

8" 99 95 13

10" 165 161 13

12" 243 238 13

14" 386 381 13

16" 452 448 13

18" 562 558 13

20" 628 624 13

24" 893 889 13

Transmitter (compact version): 7.5 lbs

High-temperature version: +3.3 lbs

Class 150

14

Weight in pounds [lbs]

Sensor Transmitter

10 13

Class 150

38 Endress+Hauser

Page 39

Proline Promag 55S

Measuring tube specifications

Measuring tube specifications - Promag S (SI units)

Nominal

Pressure rating Inside diameter of measuring tube

diameter

[mm] [inch]

EN

(DIN)

[bar]

AS

2129

AS

4087

ASME

[lbs]

JIS with

PFA

[mm]

with

PTFE

[mm]

PU

[mm]

HR

[mm]

NR

[mm]

NR

a

[mm]

15 ½" PN 40 – – Cl 150 20K – 15 – – – –

25 1" PN 40 Table E – Cl 150 20K 23 26 24 – – –

32 – PN 40 – – – 20K 32 35 32 – – –

40 1½" PN 40 – – Cl 150 20K 36 41 38 – – –

50 2" PN 40 Table E PN 16 Cl 150 10K 48 52 50 50 – –

65 – PN 16 – – – 10K 63 67 66 66 63 52

80 3" PN 16 Table E PN 16 Cl 150 10K 75 80 79 79 76 65

100 4" PN 16 Table E PN 16 Cl 150 10K 101 104 102 102 101 91

125 – PN 16 – – – 10K 126 129 127 127 127 116

150 6" PN 16 Table E PN 16 Cl 150 10K 154 156 156 156 155 142

b

200 8" PN 10 Table E PN 16 Cl 150 10K 201 202 204 204 204 190

250 10" PN 10 Table E PN 16 Cl 150 10K – 256 258 258 258 244

300 12" PN 10 Table E PN 16 Cl 150 10K – 306 309 309 309 292

350 14" PN 10 Table E PN 16 Cl 150 10K – 337 342 342 341 322

400 16" PN 10 Table E PN 16 Cl 150 10K – 387 392 392 391 369

450 18" PN 10 Table E PN 16 Cl 150 10K – 432 437 437 440 417

500 20" PN 10 Table E PN 16 Cl 150 10K – 487 492 492 491 466

600 24" PN 10 Table E PN 16 Cl 150 10K – 593 594 594 593 562

Abbreviations (lining): PU = Polyurethane, HR = Hard rubber, NRa = Natural rubber thin, NRb = Natural rubber

thick

Endress+Hauser 39

Page 40

Measuring tube specifications - Promag S (US units)

Proline Promag 55S

Nominal

Pressure rating Inside diameter of measuring tube

diameter

[inch] [mm]

EN

(DIN)

[bar]

AS

2129

AS

4087

ASME

[lbs]

JIS with

PFA

[inch]

with

PTFE

[inch]

PU

[inch]

HR

[inch]

NR

[inch]

a

½" 15 PN 40 – – Cl 150 20K – 0.59 – – – –

1" 25 PN 40 Table E– Cl 150 20K 0.91 1.02 0.94 – – –

– 32 PN 40 – – – 20K 1.26 1.34 1.26 – – –

1½" 40 PN 40 – – Cl 150 20K 1.42 1.61 1.50 – – –

2" 50 PN 40 Table EPN 16 Cl 150 10K 1.89 2.05 1.97 1.97 – –

– 65 PN 16 – – – 10K 2.48 2.64 2.60 2.60 2.48 2.05

3" 80 PN 16 – – Cl 150 10K 2.95 3.15 3.11 3.11 2.99 2.56

4" 100 PN 16 – – Cl 150 10K 3.98 4.09 4.02 4.02 3.98 3.58

– 125 PN 16 – – – 10K 4.96 5.08 5.00 5.00 5.00 4.57

NR

b

[inch]

6" 150 PN 16 – – Cl 150 10K 6.06 6.14 6.14 6.14 6.10 5.59

8" 200 PN 10 – – Cl 150 10K 7.91 7.92 8.03 8.03 8.03 7.48

10" 250 PN 10 – – Cl 150 10K – 10.08 10.16 10.16 10.16 9.61

12" 300 PN 10 – – Cl 150 10K – 12.05 12.17 12.17 12.17 11.50

14" 350 PN 10 – – Cl 150 10K – 13.27 13.46 13.46 13.43 12.68

16" 400 PN 10 – – Cl 150 10K – 15.24 15.43 15.43 15.39 14.53

18" 450 PN 10 – – Cl 150 10K – 17.01 17.20 17.20 17.32 16.42

20" 500 PN 10 – – Cl 150 10K – 19.17 19.37 19.37 19.33 18.35

24" 600 PN 10 – – Cl 150 10K – 23.35 23.39 23.39 23.35 22.13

Abbreviations (lining): PU = Polyurethane, HR = Hard rubber, NRa = Natural rubber thin, NRb = Natural rubber

thick

40 Endress+Hauser

Page 41

Proline Promag 55S

Nominal diameter

[inch] [mm] [inch] [mm] [inch] [mm]

2½" 65

3" 80 2.56 65 0.39 10

4" 100 3.58 91 0.39 10

5" 125 4.57 116 0.39 10

6" 150 5.59 142 0.47 12

8" 200 6.30 190 0.47 12

10" 250

12" 300 11.50 292 0.51 13

14" 350 12.68 322 0.55 14

16" 400 14.53 369 0.63 16

18" 450 16.42 417 0.55 14

20" 500 18.35 466 0.67 17

24" 600 22.13 562 0.79 20

10" 250

12" 300 11.46 291 0.47 12

14" 350 12.60 320 0.51 13

16" 400 14.49 368 0.55 14

18" 450 16.42 417 0.55 14

20" 500 18.31 465 0.63 16

24" 600 22.17 563 0.63 16

NRb = Natural rubber thick

Inside diameter of measuring tube

with natural rubber NR

2.05 52 0.39 10

PN 16/150 lbs

9.61 244 0.47 12

PN 10

9.57 243 0.47 12

150 lbs

1)

b

Thickness of lining material

natural rubber NR

1)

b

Material Transmitter housing:

• Compact and remote version: Powder-coated die-cast aluminum

Sensor housing:

• DN 15 to 300 (½ to 12"): Powder-coated die-cast aluminum

• DN 350 to 600 (14 to 24"): Painted steel

Measuring tube:

• DN < 350 (14"): Stainless steel 1.4301 (304) or 1.4306 (304L). For flanges of carbon steel with

Al/Zn protective coating.

• DN > 300 (12"): Stainless steel 1.4301 (304). For flanges of carbon steel with protective paint finish.

Flange:

• EN 1092-1 (DIN 2501): S235JRG2, S2345JR+N, P245GH, P250GH, E250C, A105, 1.4571, F316L

(DN < 350 (14"): with Al/Zn protective coating; DN > 300 (12") with protective paint finish)

• ASME B16.5: A105; F316L

(DN < 350 (14") with Al/Zn protective coating; DN > 300 (12") with protective paint finish)

• JIS B2220: A105, A350 LF2, F316L

(DN < 350 (14") with Al/Zn protective coating; DN > 300 (12") with protective paint finish)

• AS 2129: A105, P235GH, P265GH, S235JRG2, with Al/Zn protective coating

• AS 4087: A105, P265GH, S275JR, with Al/Zn protective coating

Ground disks: 1.4435 (316L) or Alloy C-22

Endress+Hauser 41

Page 42

Electrodes:

• 1.4435 (316L), platinum, Alloy C-22, tantalum, titanium Gr. 2, tungsten carbide coating (for

electrodes made from 1.4435)

• 1.4310 (302) (for brush electrodes), Duplex 1.4462, Alloy X750 (for brush electrodes)

Seals: according to DIN EN 1514-1 form IBC

Fitted electrodes Comes as standard:

• 2 measuring electrodes for signal detection

• 1 EPD electrode for empty pipe detection

• 1 Reference electrode for potential equalization

Optionally available for measuring electrodes made of platinum:

• 1 EPD electrode for empty pipe detection

• 1 Reference electrode for potential equalization

For measuring tube with natural rubber lining in combination with brush electrodes:

• 2 brush electrodes for signal detection

Process connections Flange connection:

• EN 1092-1 (DIN 2501)

– DN < 300 (12"): Form A

– DN > 300 (12"): Form B

– DN 65 (2½") PN 16 and DN 600 (24") PN 16 exclusively according to EN 1092-1

•ASME B16.5

• JIS B2220

• AS 2129

• AS 4087

Proline Promag 55S

Surface roughness • Lining with PFA: ≤ 0.4 μm (16 μin)

• Electrodes: 0.3 to 0.5 μm (12 to 20 μin)

All data relate to wetted parts.

42 Endress+Hauser

Page 43

Proline Promag 55S

Operability

Local operation Display elements

• Liquid-crystal display: illuminated, four lines with 16 characters per line

• Custom configurations for presenting different measured values and status variables

• 3 totalizers

• At ambient temperatures below –20 °C (–4 °F), the readability of the display may be impaired.

Operating elements

• Onsite operation with three optical sensor keys (//)

• Application-specific Quick Setup menus for straightforward commissioning

Language groups Language groups available for operation in different countries:

• Western Europe and America (WEA):

English, German, Spanish, Italian, French, Dutch, Portuguese

• Eastern Europe/Scandinavia (EES):

English, Russian, Polish, Norwegian, Finnish, Swedish, Czech

• South and East Asia (SEA):

English, Japanese, Indonesian

•China (CN):

English, Chinese

!

Note!

You can change the language group via the operating program "FieldCare".

Remote operation Remote operation via HART, PROFIBUS DP/PA, FOUNDATION Fieldbus

Endress+Hauser 43

Page 44

Proline Promag 55S

Certificates and approvals

CE mark The measuring system described in these Operating Instructions therefore complies with the legal

requirements of the EU Directives. Endress+Hauser confirms this by affixing the CE mark to it and by

issuing the CE declaration of conformity.

C-tick symbol The measuring system meets the EMC requirements of the "Australian Communications and Media

Authority (ACMA)".

Ex approval Information on the currently available Ex-rated versions (ATEX, FM, CSA etc.) is available on request

from your Endress+Hauser sales outlet. All information relevant to explosion protection is available in

separate documents that you can order as necessary.

Sanitary compatibility No applicable approvals or certification

Pressure equipment directive The measuring devices can be ordered with or without PED (Pressure Equipment Directive). If a device

with PED is required, this must be ordered explicitly. For devices with nominal diameters less than or

equal to DN 25 (1"), this is neither possible nor necessary.

• With the identification PED/G1/III on the sensor nameplate, Endress+Hauser confirms conformity

with the "Basic safety requirements" of Appendix I of the Pressure Equipment Directive 2014/68/EU.

• Devices with this identification (with PED) are suitable for the following types of fluid:

– Fluids of Group 1 and 2 with a steam pressure of greater or less than 0.5 bar (7.3 psi)

–Unstable gases

• Devices without this identification (without PED) are designed and manufactured according to good

engineering practice. They correspond to the requirements of Art.4, Section 3 of the Pressure

Equipment Directive 2014/68/EU. Their application is illustrated in Diagrams 6 to 9 in Appendix II

of the Pressure Equipment Directive 2014/68/EU.

FOUNDATION Fieldbus certification

PROFIBUS DP/PA certification

Other standards and guidelines

The flow device has successfully passed all the test procedures carried out and is certified and

registered by the Fieldbus Foundation. The device thus meets all the requirements of the following

specifications:

• Certified to FOUNDATION Fieldbus Specification

• The device meets all the specifications of the FOUNDATION Fieldbus H1

• Interoperability Test Kit (ITK), revision status 5.1 (device certification number: on request)

• The device can also be operated with certified devices of other manufacturers

• Physical Layer Conformance Test of the Fieldbus Foundation

The flowmeter has successfully passed all the test procedures carried out and is certified and registered

by the PNO (PROFIBUS User Organization). The device thus meets all the requirements of the following

specifications:

• Certified in accordance with PROFIBUS Profile Version 3.0 (device certification number: available on

request)

• The measuring device can also be operated with certified devices of other manufacturers

(interoperability)

• EN 60529

Degrees of protection by housing (IP code)

• EN 61010-1

Protection Measures for Electrical Equipment for Measurement, Control,Regulation and Laboratory

Procedures

• IEC/EN 61326

"Emission in accordance with requirements for class A".

Electromagnetic compatibility (EMC requirements).

• ANSI/ISA-S82.01

Safety Standard for Electrical and Electronic Test, Measuring, Controlling and related Equipment General Requirements. Pollution degree 2, Installation Category II.

• CAN/CSA-C22.2 (No. 1010.1-92)

Safety requirements for Electrical Equipment for Measurement and Control and Laboratory Use.

Pollution degree 2, Installation Category I.

44 Endress+Hauser

Page 45

Proline Promag 55S

!

!

•NAMUR NE 21

Electromagnetic compatibility (EMC) of industrial process and laboratory control equipment.

•NAMUR NE 43

Standardization of the signal level for the breakdown information of digital transmitters with analog

output signal.

•NAMUR NE 53