Endress+Hauser Proline Promag 50 Operating Instructions Manual

Operating Instructions

Proline Promag 50

HART

Electromagnetic flow measuring system

6

BA00046D/06/EN/14.11

71136623

Valid as of version

V 2.03.XX (device software)

Promag 50 Table of contents

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Notes on safety conventions and icons . . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Nameplate of the transmitter . . . . . . . . . . . . 7

2.1.2 Nameplate of the sensor . . . . . . . . . . . . . . . 8

2.1.3 Nameplate, connections . . . . . . . . . . . . . . . 9

2.2 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

2.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . 10

3 Installation . . . . . . . . . . . . . . . . . . . . . 11

3.1 Incoming acceptance, transport and storage . . . . . . 11

3.1.1 Incoming acceptance . . . . . . . . . . . . . . . . . 11

3.1.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Mounting location . . . . . . . . . . . . . . . . . . . 13

3.2.3 Orientation . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.4 Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.5 Foundations, supports . . . . . . . . . . . . . . . . 17

3.2.6 Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.7 Nominal diameter and flow rate . . . . . . . . 18

3.2.8 Length of connecting cable . . . . . . . . . . . . 20

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . . 21

3.3.1 Installing the Promag D sensor . . . . . . . . . . 21

3.3.2 Installing the Promag L sensor . . . . . . . . . . 24

3.3.3 Installing the Promag W sensor . . . . . . . . . 27

3.3.4 Installing the Promag P sensor . . . . . . . . . . 32

3.3.5 Installing the Promag H sensor . . . . . . . . . . 36

3.3.6 Turning the transmitter housing . . . . . . . . 39

3.3.7 Turning the onsite display . . . . . . . . . . . . . 40

3.3.8 Installing the wall-mount housing . . . . . . . 41

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 43

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 44

4.1 Connecting the remote version . . . . . . . . . . . . . . . 44

4.1.1 Connecting Promag D, L, W, P, H . . . . . . 44

4.1.2 Cable specifications . . . . . . . . . . . . . . . . . . 49

4.2 Connecting the measuring unit . . . . . . . . . . . . . . . 50

4.2.1 Connecting the transmitter . . . . . . . . . . . . 50

4.2.2 Terminal assignment . . . . . . . . . . . . . . . . . 52

4.2.3 HART connection . . . . . . . . . . . . . . . . . . . 52

4.3 Potential equalization . . . . . . . . . . . . . . . . . . . . . . 53

4.3.1 Potential equalization for Promag D . . . . . . 53

4.3.2 Potential equalization for Promag W, P, L . 53

4.3.3 Potential equalization for Promag H . . . . . . 53

4.3.4 Exampels for potential equalization connections

for Promag D . . . . . . . . . . . . . . . . . . . . . . . 54

4.3.5 Exampels for potential equalization connections

for Promag L, W, P . . . . . . . . . . . . . . . . . . 55

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 56

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 57

5 Operation . . . . . . . . . . . . . . . . . . . . . . 58

5.1 Display and operating elements . . . . . . . . . . . . . . . 58

5.2 Brief operating instructions on the function matrix . 59

5.2.1 General notes . . . . . . . . . . . . . . . . . . . . . . 60

5.2.2 Enabling the programming mode . . . . . . . . 60

5.2.3 Disabling the programming mode . . . . . . . . 60

5.3 Displaying error messages . . . . . . . . . . . . . . . . . . . 61

5.3.1 Type of error . . . . . . . . . . . . . . . . . . . . . . . 61

5.3.2 Error message types . . . . . . . . . . . . . . . . . . 61

5.4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4.1 Operating options . . . . . . . . . . . . . . . . . . . 62

5.4.2 Current device description files . . . . . . . . . 63

5.4.3 Device variables . . . . . . . . . . . . . . . . . . . . . 63

5.4.4 Switching HART write protection on/off . . 63

5.4.5 Universal and common practice HART

commands . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.4.6 Device status and error messages . . . . . . . . 68

6 Commissioning . . . . . . . . . . . . . . . . . . 70

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2 Switching on the measuring device . . . . . . . . . . . . 70

6.3 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.3.1 "Commissioning" Quick Setup menu . . . . . 71

6.4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.4.1 Current output: active/passive . . . . . . . . . . 72

6.5 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.5.1 Empty-pipe/full-pipe adjustment . . . . . . . . 73

6.6 Data storage device (HistoROM) . . . . . . . . . . . . . . 74

6.6.1 HistoROM/S-DAT (sensor-DAT) . . . . . . . . 74

7 Maintenance . . . . . . . . . . . . . . . . . . . . 75

7.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.2 Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8 Accessories . . . . . . . . . . . . . . . . . . . . . 76

8.1 Device-specific accessories . . . . . . . . . . . . . . . . . . . 76

8.2 Measuring principle-specific accessories . . . . . . . . . 76

8.3 Communication-specific accessories . . . . . . . . . . . . 77

8.4 Service-specific accessories . . . . . . . . . . . . . . . . . . . 78

9 Troubleshooting . . . . . . . . . . . . . . . . . 79

9.1 Troubleshooting instructions . . . . . . . . . . . . . . . . . 79

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . . 80

9.3 Process error messages . . . . . . . . . . . . . . . . . . . . . . 82

9.4 Process errors without messages . . . . . . . . . . . . . . 83

9.5 Response of outputs to errors . . . . . . . . . . . . . . . . . 84

9.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.6.1 Removing and installing printed circuit boards 87

Endress+Hauser 3

Promag 50 Table of contents

9.6.2 Replacing the device fuse . . . . . . . . . . . . . . 91

9.6.3 Replacing the exchangeable electrode . . . . 92

9.7 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.9 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10 Technical data . . . . . . . . . . . . . . . . . . . 96

10.1 Technical data at a glance . . . . . . . . . . . . . . . . . . . 96

10.1.1 Application . . . . . . . . . . . . . . . . . . . . . . . . 96

10.1.2 Function and system design . . . . . . . . . . . . 96

10.1.3 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.1.4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.1.5 Power supply . . . . . . . . . . . . . . . . . . . . . . . 97

10.1.6 Performance characteristics . . . . . . . . . . . . 98

10.1.7 Operating conditions: Installation . . . . . . . . 98

10.1.8 Operating conditions: Environment . . . . . . 99

10.1.9 Operating conditions: Process . . . . . . . . . 100

10.1.10 Mechanical construction . . . . . . . . . . . . . 105

10.1.11 Human interface . . . . . . . . . . . . . . . . . . . 114

10.1.12 Certificates and approvals . . . . . . . . . . . . 115

10.1.13 Ordering information . . . . . . . . . . . . . . . 116

10.1.14 Accessories . . . . . . . . . . . . . . . . . . . . . . . 116

10.1.15 Documentation . . . . . . . . . . . . . . . . . . . 116

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

4 Endress+Hauser

Promag 50 Safety instructions

1 Safety instructions

1.1 Designated use

The measuring device described in this Operating Manual is to be used only for measuring the flow

rate of conductive fluids in closed pipes.

A minimum conductivity of 20 μS/cm is required for measuring demineralized water. Most liquids

can be measured as of a minimum conductivity of 5 μS/cm.

Examples:

• Acids, alkalis,

• Drinking water, wastewater, sewage sludge,

• Milk, beer, wine, mineral water, etc.

Resulting from incorrect use or from use other than that designated the operational safety of the

measuring devices can be suspended. The manufacturer accepts no liability for damages being

produced from this.

1.2 Installation, commissioning and operation

Please note the following:

• Installation, connection to the electricity supply, commissioning and maintenance of the device

must be carried out by trained, qualified specialists authorized to perform such work by the

facility's owner-operator. The specialist must have read and understood this Operating Manual

and must follow the instructions it contains.

• The device must be operated by persons authorized and trained by the facility's owner-operator.

Strict compliance with the instructions in the Operating Manual is mandatory.

• With regard to special fluids, including fluids used for cleaning, Endress+Hauser will be happy to

assist in clarifying the corrosion-resistant properties of wetted materials.

However, minor changes in temperature, concentration or in the degree of contamination in the

process may result in variations in corrosion resistance. For this reason, Endress+Hauser does not

accept any responsibility with regard to the corrosion resistance of wetted materials in a specific

application.

The user is responsible for the choice of suitable wetted materials in the process.

• If welding work is performed on the piping system, do not ground the welding appliance through

the Promag flowmeter.

• The installer must ensure that the measuring system is correctly wired in accordance with the

wiring diagrams. The transmitter must be grounded apart from when special protective measures

are taken (e.g. galvanically isolated SELV or PELV power supply)

• Invariably, local regulations governing the opening and repair of electrical devices apply.

1.3 Operational safety

Please note the following:

• Measuring systems for use in hazardous environments are accompanied by separate Ex

documentation, which is an integral part of this Operating Manual. Strict compliance with the

installation instructions and ratings as stated in this supplementary

documentation is mandatory. The symbol on the front of this Ex documentation indicates the

approval and the certification body (e.g.

• The measuring device complies with the general safety requirements in accordance with

EN 61010-1, the EMC requirements of IEC/EN 61326 and NAMUR Recommendations NE 21

and NE 43.

• Depending on the application, the seals of the process connections of the Promag H sensor require

periodic replacement.

0 Europe, 2 USA, 1 Canada).

Endress+Hauser 5

Safety instructions Promag 50

• When hot fluid passes through the measuring tube, the surface temperature of the housing

increases. In the case of the sensor, in particular, users should expect temperatures that can be

close to the fluid temperature. If the temperature of the fluid is high, implement sufficient

measures to prevent burning or scalding.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to these

Operating Instructions.

1.4 Return

• Do not return a measuring device if you are not absolutely certain that all traces of hazardous

substances have been removed, e.g. substances which have penetrated crevices or diffused

through plastic.

• Costs incurred for waste disposal and injury (burns, etc.) due to inadequate cleaning will be

charged to the owner-operator.

1.5 Notes on safety conventions and icons

The devices are designed to meet state-of-the-art safety requirements, have been tested, and left the

factory in a condition in which they are safe to operate. The devices comply with the applicable

standards and regulations in accordance with EN 61010-1 "Safety requirements for electrical

equipment for measurement, control and laboratory use".

The devices can, however, be a source of danger if used incorrectly or for anything other than the

designated use. Consequently, always pay particular attention to the safety instructions indicated in

this Operating Manual by the following icons:

#

Warning!

"Warning" indicates an action or procedure which, if not performed correctly, can result in injury

or a safety hazard. Comply strictly with the instructions and proceed with care.

Caution!

"

"Caution" indicates an action or procedure which, if not performed correctly, can result in incorrect

operation or destruction of the device. Comply strictly with the instructions.

!

Note!

"Note" indicates an action or procedure which, if not performed correctly, can have an indirect

effect on operation or trigger an unexpected response on the part of the device.

6 Endress+Hauser

Promag 50 Identification

Promag 50

-20°C (-4°F) <Tamb<+60°C (+140°F)

IP67 / NEMA/Type 4XOrder Code:

Ser.No.:

TAG No.:

50PXX-XXXXXXXXXXXX

12345678901

ABCDEFGHJKLMNPQRST

20-55VAC/16-62VDC

50-60Hz

I-OUT (HART), f-OUT

15VA/W

i

EPD / MSÜ

STATUS-IN

2

3

4

5

9

8

1

N12895

ECC

6

7

2 Identification

2.1 Device designation

The flow measuring system consists of the following components:

• Promag 50 transmitter

• Promag D, Promag L, Promag W, Promag P or Promag H sensor

In the compact version, the transmitter and sensor form a single mechanical unit; in the remote

version they are installed separately.

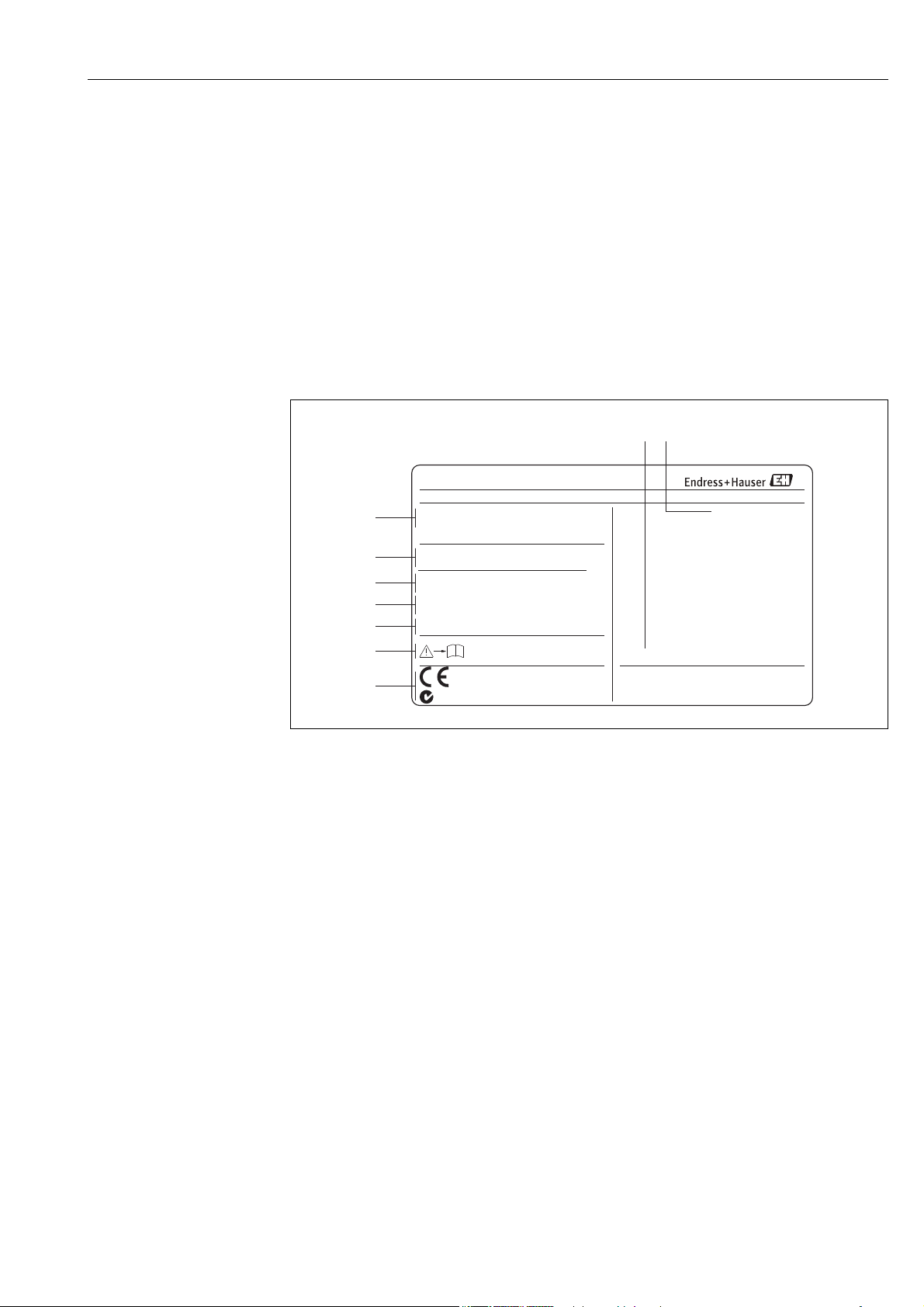

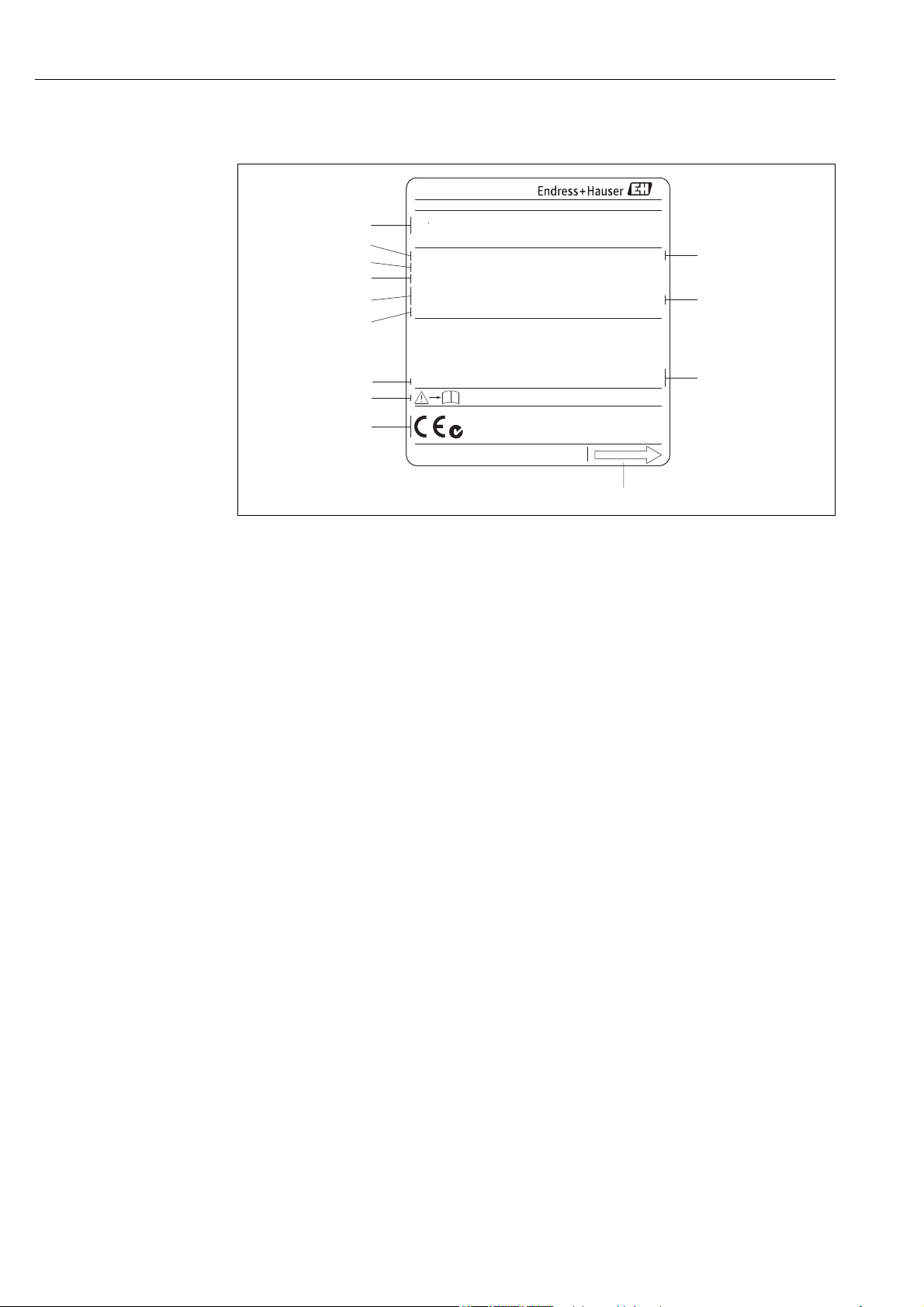

2.1.1 Nameplate of the transmitter

A0005412

Fig. 1: Nameplate specifications for the "Promag 50" transmitter (example)

1 Ordering code/serial number: See the specifications on the order confirmation for the meanings of the individual

letters and digits.

2 Power supply, frequency, power consumption

3 Additional information:

EPD/MSÜ: with Empty Pipe Detection

ECC: with electrode cleaning

4 Outputs available:

I-OUT (HART): with current output (HART)

f-OUT (HART): with frequency output

STATUS-IN: with status input (power supply)

5Reserved for information on special products

6 Observe device documentation

7 Reserved for additional information on device version (approvals, certificates)

8 Permitted ambient temperature range

9 Degree of protection

Endress+Hauser 7

Identification Promag 50

-20°C (-4°F)<Tamb<+60°C (+140°F) NEMA/Type4X

50PXX-XXXXXXXXXXXX

1.0000/0000

–10 ...150°C/+14 ...300°F°C °F

PFA

12345678901 RY

ABCDEFGHJKLMNPQRST

DN100 DIN EN PN40/ pnom =PS= 40bar

EPD/MSÜ, R/B

TM:

Order Code:

Materials:

K-factor:

Ser.No.:

TAG No.:

PROMAG P

1

2

3

7

13

12

1.4435/316L

Electrodes:

0.2% CAL

4

5

6

10

11

i

9

8

IP67

2007

N12895

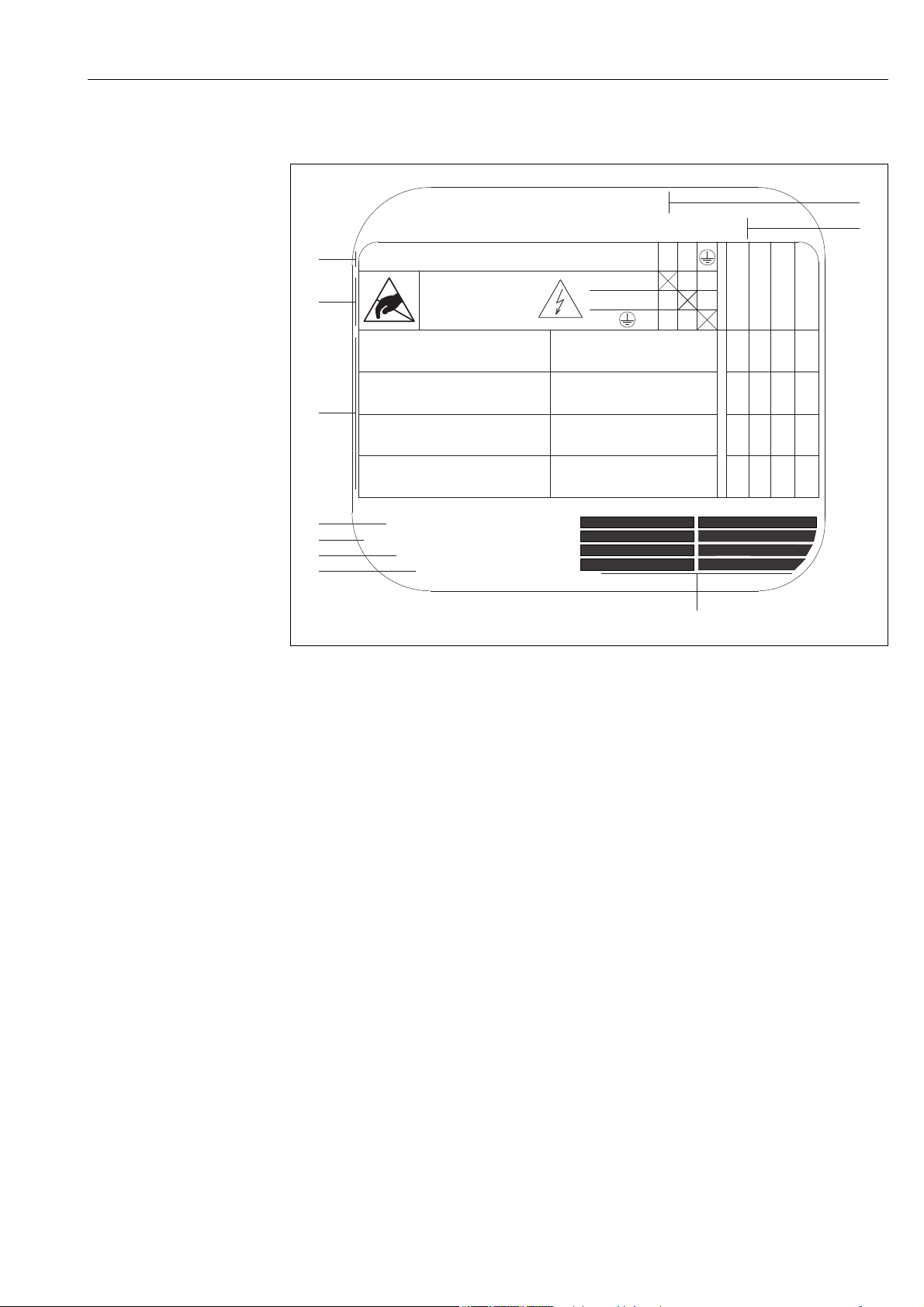

2.1.2 Nameplate of the sensor

A0004374

Fig. 2: Nameplate specifications for the "Promag" sensor (example)

1 Ordering code/serial number: See the specifications on the order confirmation for the meanings of the individual

letters and digits.

2 Calibration factor with zero point

3 Nominal diameter / Pressure rating

4 Fluid temperature range

5 Materials: lining/measuring electrodes

6Reserved for information on special products

7 Permitted ambient temperature range

8 Observe device documentation

9 Reserved for additional information on device version (approvals, certificates)

10 Calibration tolerance

11 Additional information (examples):

– EPD/MSÜ: with Empty Pipe Detection electrode

– R/B: with reference electrode

12 Degree of protection

13 Flow direction

8 Endress+Hauser

Promag 50 Identification

Communication:

Drivers:

Device SW:

ID xxxx (HEX)

XX.XX.XX (WEA)

XXXXXXXXXX

Date: DD.MMM.YYYY

Ex-works / ab-Werk/réglages usine

26(+) / 27(-)

NC:

Versorgung /

Tension d'alimentation

Observer manuel d'instruction

See operating manual

Betriebsanleitung beachten

Active: 0/4...20mA, RL max. = 700 Ohm

Passive: 4...20mA, max. 30VDC

Passive: 30VDC, 250mA

Active: 24VDC/25mA (max. 250mA/20ms)

Passive: 30VDC, 250mA

(HART:RL.min.=250 OHM)

fmax=1kHz

3...30VDC, Ri = 5kOhm

f-OUT

I-

OUT (HART)

12345678912Ser.No.:

Supply /

24(+) / 25(-)

22(+) / 23(-)

20(+) / 21(-)

N/LPE

A:

NO:

P:

L1/L+

12

319475-00XX

A

P

active

passive

normally open contact

normallyclosed contact

X

STATUS-OUT

STATUS-IN

X

Update 1 Update 2

2

3

1

4

5

6

7

8

9

10

2.1.3 Nameplate, connections

A0000963

Fig. 3: Nameplate specifications for transmitter (example)

1 Serial number

2 Possible configuration of current output

3 Possible configuration of relay contacts

4 Terminal assignment, cable for power supply: 85 to 260 V AC, 20 to 55 V AC, 16 to 62 V DC

Terminal No. 1: L1 for AC, L+ for DC

Terminal No. 2: N for AC, L– for DC

5 Signals present at inputs and outputs, possible configuration and terminal assignment (20 to 27),

see also "Electrical values of inputs/outputs"

6 Version of device software currently installed

7 Installed communication type, e.g.: HART, PROFIBUS PA, etc.

8 Information on current communication software (Device Revision and Device Description), e.g.:

Dev. 01 / DD 01 for HART

9 Date of installation

Endress+Hauser 9

10 Current updates to data specified in points 6 to 9

2.2 Certificates and approvals

The devices are designed to meet state-of-the-art safety requirements in accordance with sound

engineering practice. They have been tested and left the factory in a condition in which they are

safe to operate.

The devices comply with the applicable standards and regulations in accordance with EN 61010-1

"Safety requirements for electrical equipment for measurement, control and laboratory use" and

with the EMC requirements of IEC/EN 61326/A1.

The measuring system described in this Operating Manual is therefore in conformity with the

statutory requirements of the EC Directives. Endress+Hauser confirms successful testing of the

device by affixing to it the CE mark.

The measuring system meets the EMC requirements of the Australian Communications and Media

Authority (ACMA)

Identification Promag 50

2.3 Registered trademarks

KALREZ® and VITON

Registered trademarks of E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

®

Registered trademark of Ladish & Co., Inc., Kenosha, USA

®

HART

Registered trademark of the HART Communication Foundation, Austin, USA

HistoROM™, S-DAT®, Field Xpert™, FieldCare

Registered or registration-pending trademarks of Endress+Hauser Flowtec AG, Reinach, CH

®

®

, Fieldcheck®, Applicator

®

10 Endress+Hauser

Promag 50 Installation

3 Installation

3.1 Incoming acceptance, transport and storage

3.1.1 Incoming acceptance

On receipt of the goods, check the following:

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches your

order.

3.1.2 Transport

The following instructions apply to unpacking and to transporting the device to its final location:

• Transport the devices in the containers in which they are delivered.

• Do not remove the protective plates or caps on the process connections until you are ready to

install the device. This is particularly important in the case of sensors with PTFE linings.

Special notes on flanged devices

Caution!

"

• The wooden covers mounted on the flanges from the factory protect the linings on the flanges

during storage and transportation. In case of Promag L they are additionally used to hold the lap

joint flanges in place. Do not remove these covers until immediately before the device in the

pipe.

• Do not lift flanged devices by the transmitter housing, or the connection housing in the case of

the remote version.

#

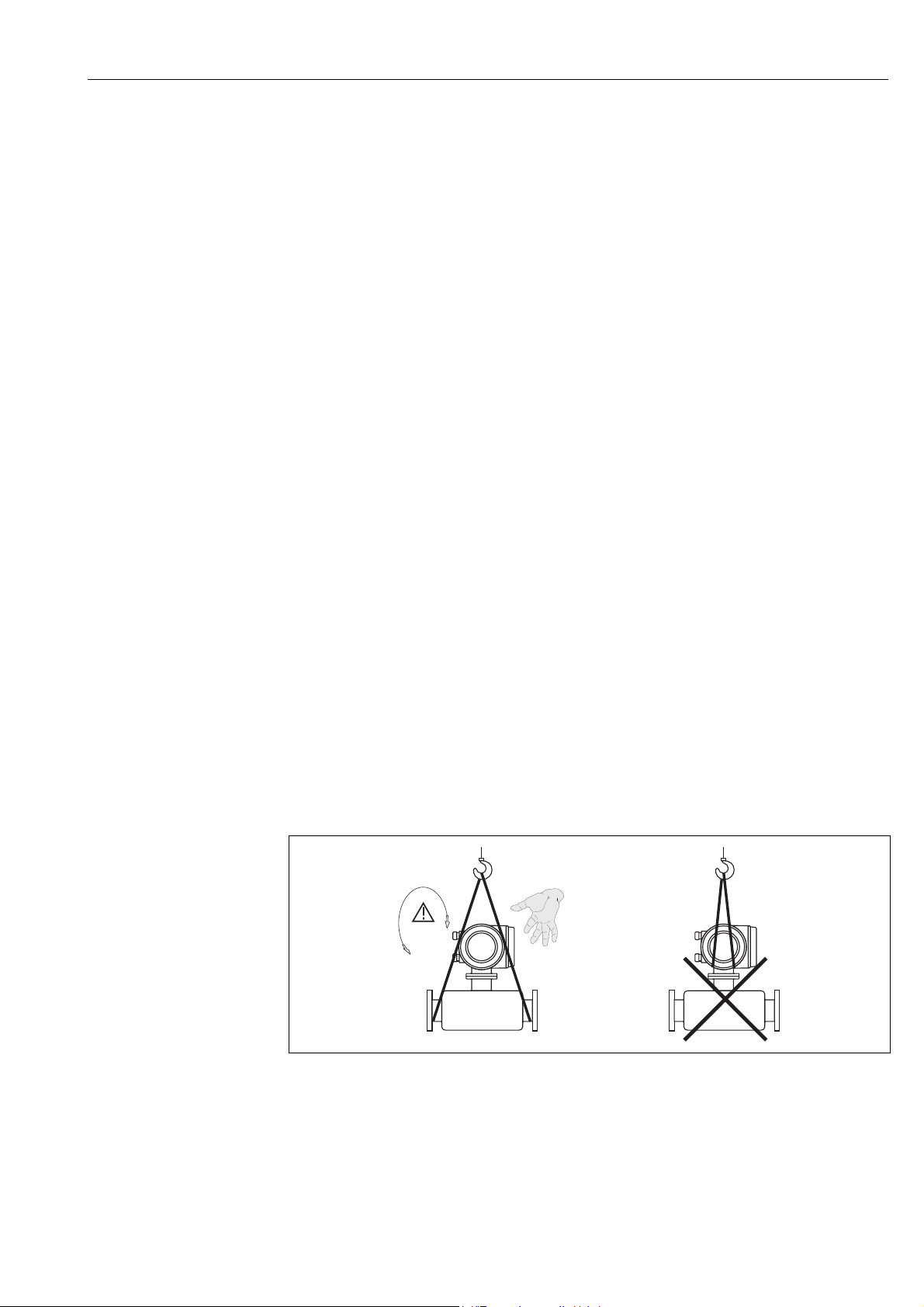

Transporting flanged devices DN 300 (12")

Use webbing slings slung round the two process connections. Do not use chains, as they could

damage the housing.

Warning!

Risk of injury if the measuring device slips. The center of gravity of the assembled measuring device

might be higher than the points around which the slings are slung.

At all times, therefore, make sure that the device does not unexpectedly turn around its axis or slip.

a0004294

Fig. 4: Transporting sensors with DN 300 ( 12")

Endress+Hauser 11

Installation Promag 50

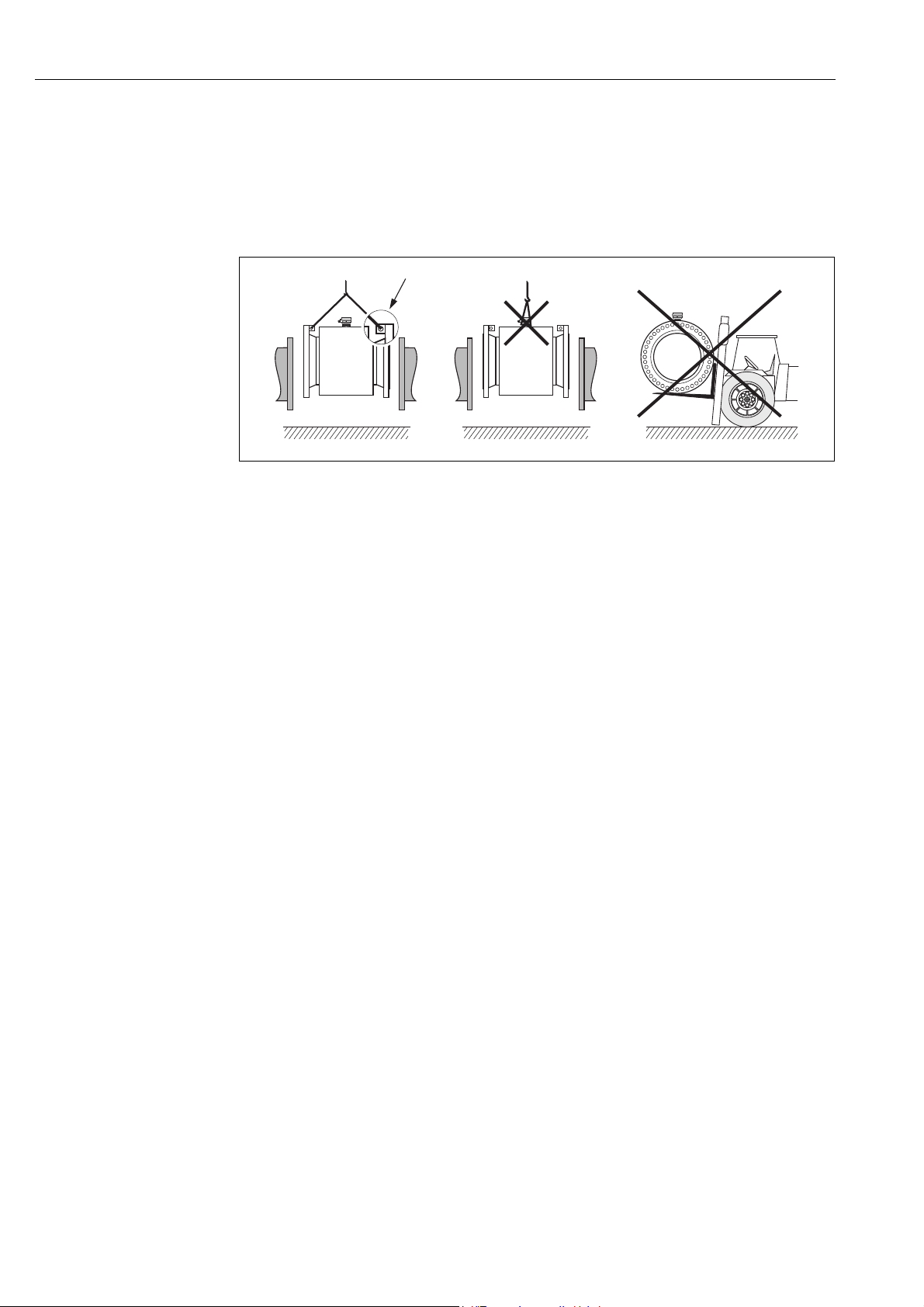

Transporting flangeddevices DN > 300 (> 12")

Use only the metal eyes on the flanges for transporting the device, lifting it and positioning the

sensor in the piping.

Caution!

"

Do not attempt to lift the sensor with the tines of a fork-lift truck beneath the metal casing. This

would buckle the casing and damage the internal magnetic coils.

a0004295

Fig. 5: Transporting sensors with DN > 300 (> 12")

3.1.3 Storage

Please note the following:

• Pack the measuring device in such a way as to protect it reliably against impact for storage

(and transportation). The original packaging provides optimum protection.

• The storage temperature corresponds to the operating temperature range of the measuring

transmitter and the appropriate measuring sensors ä 99.

• Do not remove the protective plates or caps on the process connections until you are ready to

install the device. This is particularly important in the case of sensors with PTFE linings.

• The measuring device must be protected against direct sunlight during storage in order to avoid

unacceptably high surface temperatures.

• Choose a storage location where moisture does not collect in the measuring device. This will help

prevent fungus and bacteria infestation which can damage the liner.

12 Endress+Hauser

Promag 50 Installation

h 2 x DN³

3.2 Installation conditions

3.2.1 Dimensions

The dimensions and installation lengths of the sensor and transmitter can be found in the "Technical

Information" for the device in question. This document can be downloaded as a PDF file from

www.endress.com. A list of the "Technical Information" documents available is provided in the

"Documentation" section on ä 116.

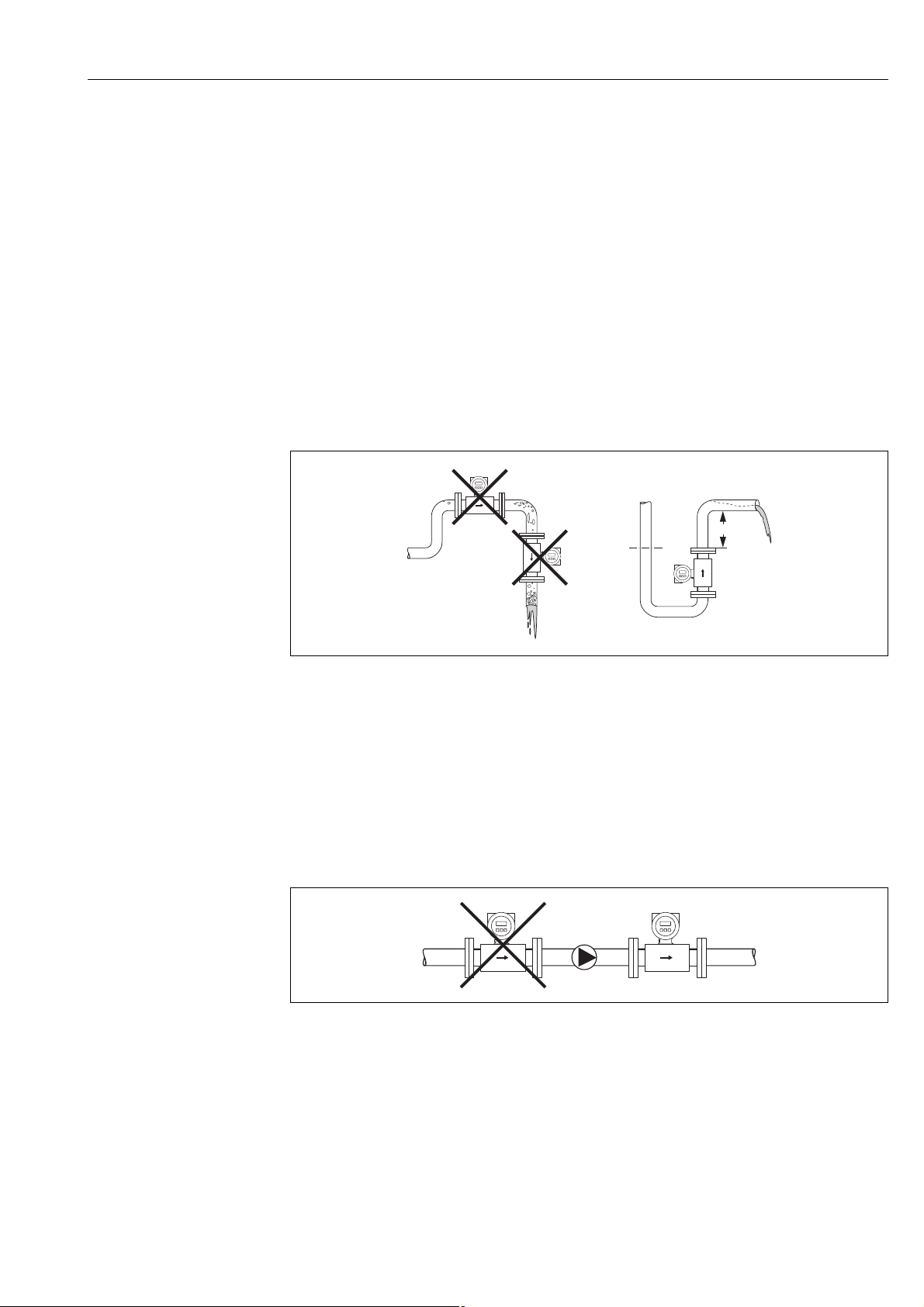

3.2.2 Mounting location

Entrained air or gas bubble formation in the measuring tube can result in an increase in measuring

errors.

Avoid the following locations:

• Highest point of a pipeline. Risk of air accumulating!

• Directly upstream from a free pipe outlet in a vertical pipeline.

A0008154

Fig. 6: Mounting location

Installation of pumps

Do not install the sensor on the intake side of a pump. This precaution is to avoid low pressure and

the consequent risk of damage to the lining of the measuring tube. Information on the lining's

resistance to partial vacuum can be found on ä 103.

It might be necessary to install pulse dampers in systems incorporating reciprocating, diaphragm or

peristaltic pumps. Information on the measuring system's resistance to vibration and shock can be

found on ä 99.

A0003203

Fig. 7: Installation of pumps

Endress+Hauser 13

Installation Promag 50

5 x DN

2 x DN

³

³

h

2

1

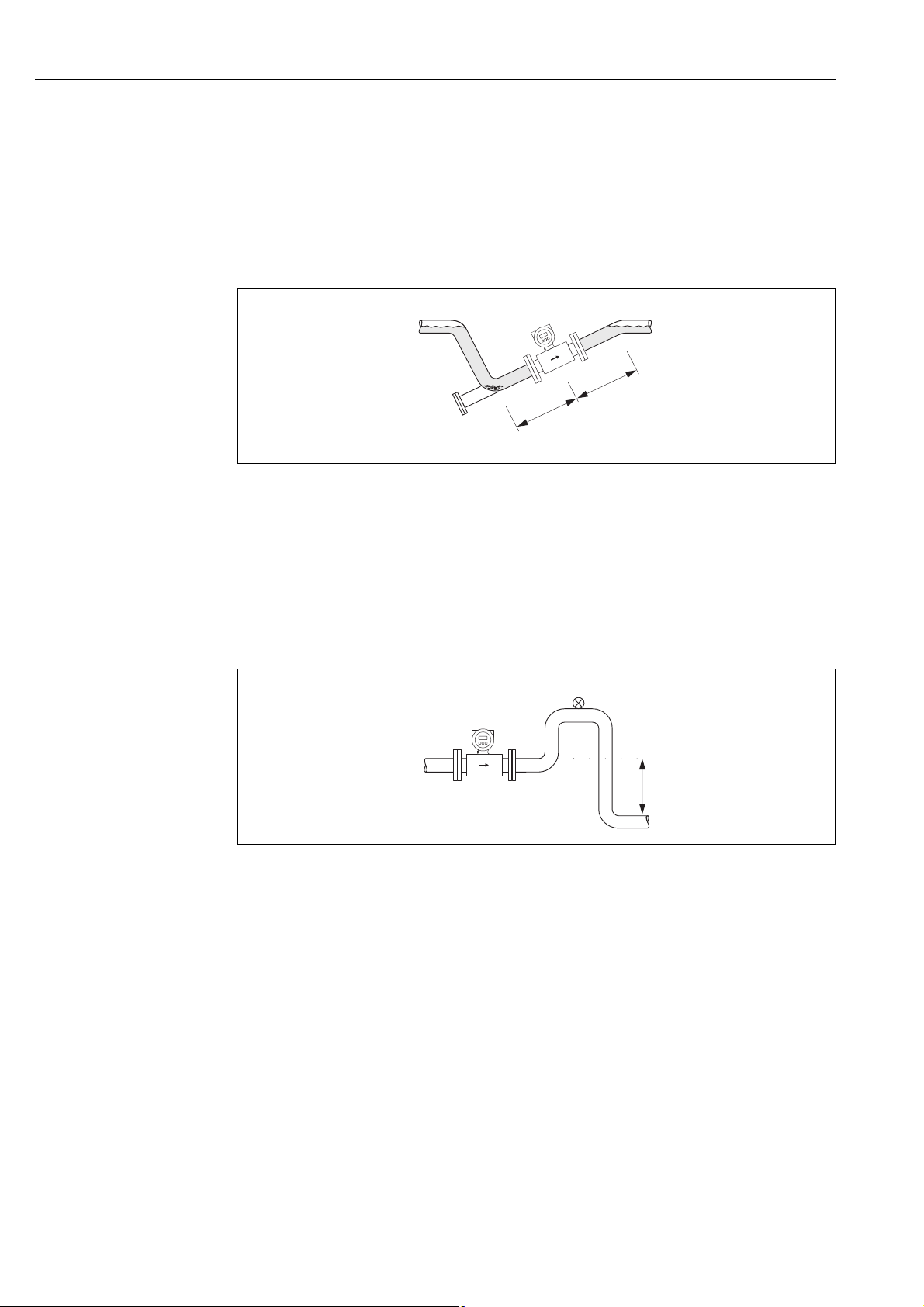

Partially filled pipes

Partially filled pipes with gradients necessitate a drain-type configuration.

The Empty Pipe Detection function (EPD ä 73) offers additional protection by detecting empty

or partially filled pipes.

Caution!

"

Risk of solids accumulating. Do not install the sensor at the lowest point in the drain. It is advisable

to install a cleaning valve.

A0008155

Fig. 8: Installation in a partially filled pipe

Down pipes

Install a siphon or a vent valve downstream of the sensor in down pipes whose length h 5 m

(16.4 ft). This precaution is to avoid low pressure and the consequent risk of damage to the lining

of the measuring tube.

This measure also prevents the system losing prime, which could cause air pockets. Information on

the lining's resistance to partial vacuum can be found on ä 103.

A0008157

Fig. 9: Measures for installation in a down pipe

1 Vent valve

2Pipe siphon

h Length of down pipe

14 Endress+Hauser

Promag 50 Installation

A

1

22

A

3

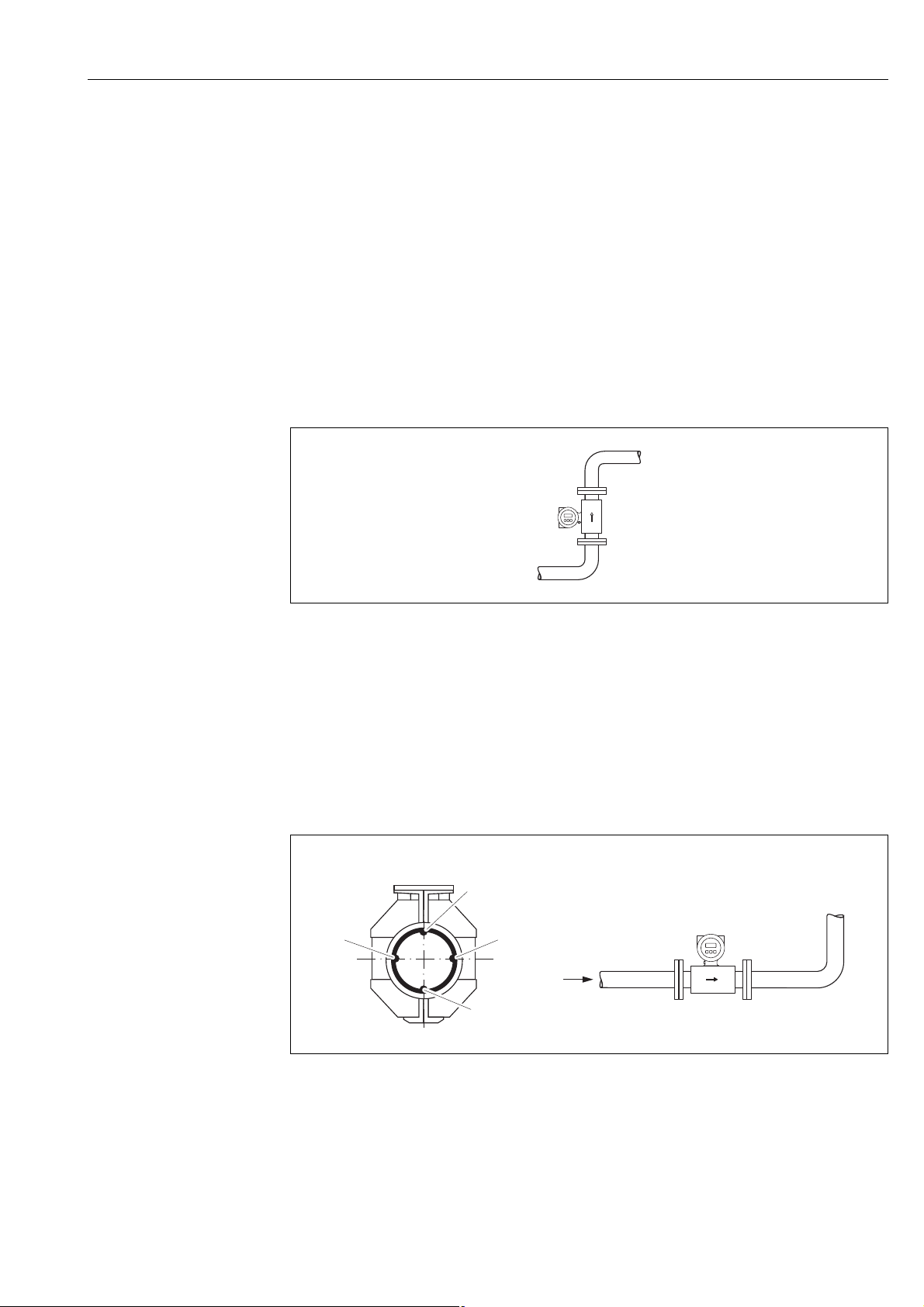

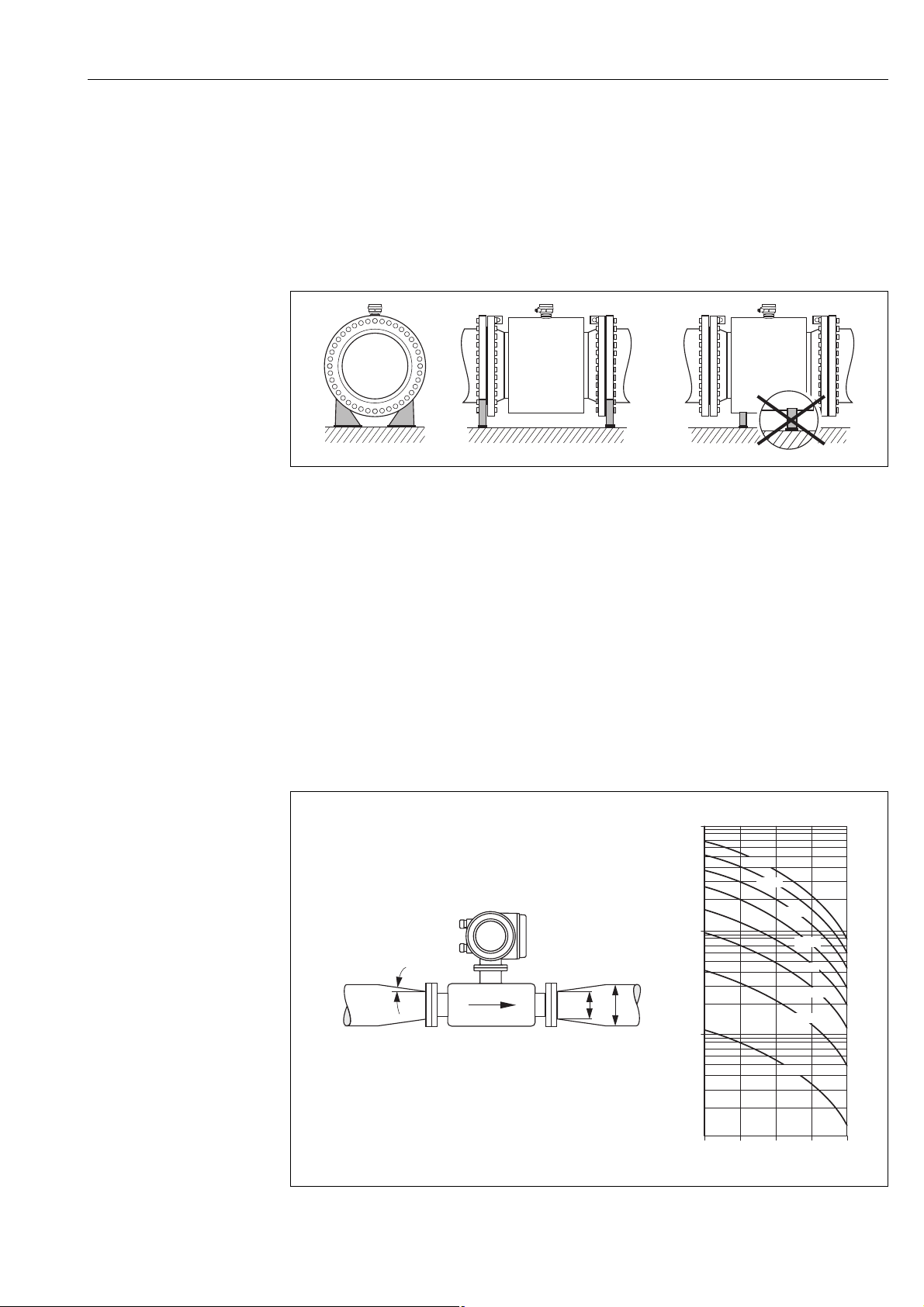

3.2.3 Orientation

An optimum orientation position helps avoid gas and air accumulations and deposits in the

measuring tube. However, Promag offers the additional Empty Pipe Detection (EPD) function to

ensure the detection of partially filled measuring tubes, e.g. in the case of degassing fluids or varying

process pressure:

• Electrode Cleaning Circuit (ECC) for applications with accretive fluids, e.g. electrically

conductive deposits ( "Description of Device Functions" manual).

• Empty Pipe Detection (EPD) ensures the detection of partially filled measuring tubes, e.g. in the

case of degassing fluids ( ä 73)

• Exchangeable Measuring Electrodes for abrasive fluids ( ä 92)

Vertical orientation

This is the ideal orientation for self-emptying piping systems and for use in conjunction with Empty

Pipe Detection.

Fig. 10: Vertical orientation

Horizontal orientation

The measuring electrode plane should be horizontal. This prevents brief insulation of the two

measuring electrodes by entrained air bubbles.

Caution!

"

Empty Pipe Detection functions correctly only when the measuring device is installed horizontally

and the transmitter housing is facing upward ( å 10). Otherwise there is no guarantee that

Empty Pipe Detection will respond if the measuring tube is only partially filled or empty.

A0008158

Fig. 11: Horizontal orientation

1 EPD electrode for the detection of empty pipes (not with Promag D and Promag H (DN 2 to 15; 1/12" to ½"))

2 Measuring electrodes for signal detection

3 Reference electrode for the potential equalization (not with Promag D and H)

Endress+Hauser 15

A0003207

Installation Promag 50

5 x DN³

³ 2 x DN

L

Inlet and outlet run

If possible, install the sensor upstream from fittings such as valves, T-pieces, elbows, etc. The

following inlet and outlet runs must be observed in order to meet accuracy specifications:

• Inlet run: 5 × DN

•Outlet run: 2 × DN

A0003210

Fig. 12: Inlet and outlet runs

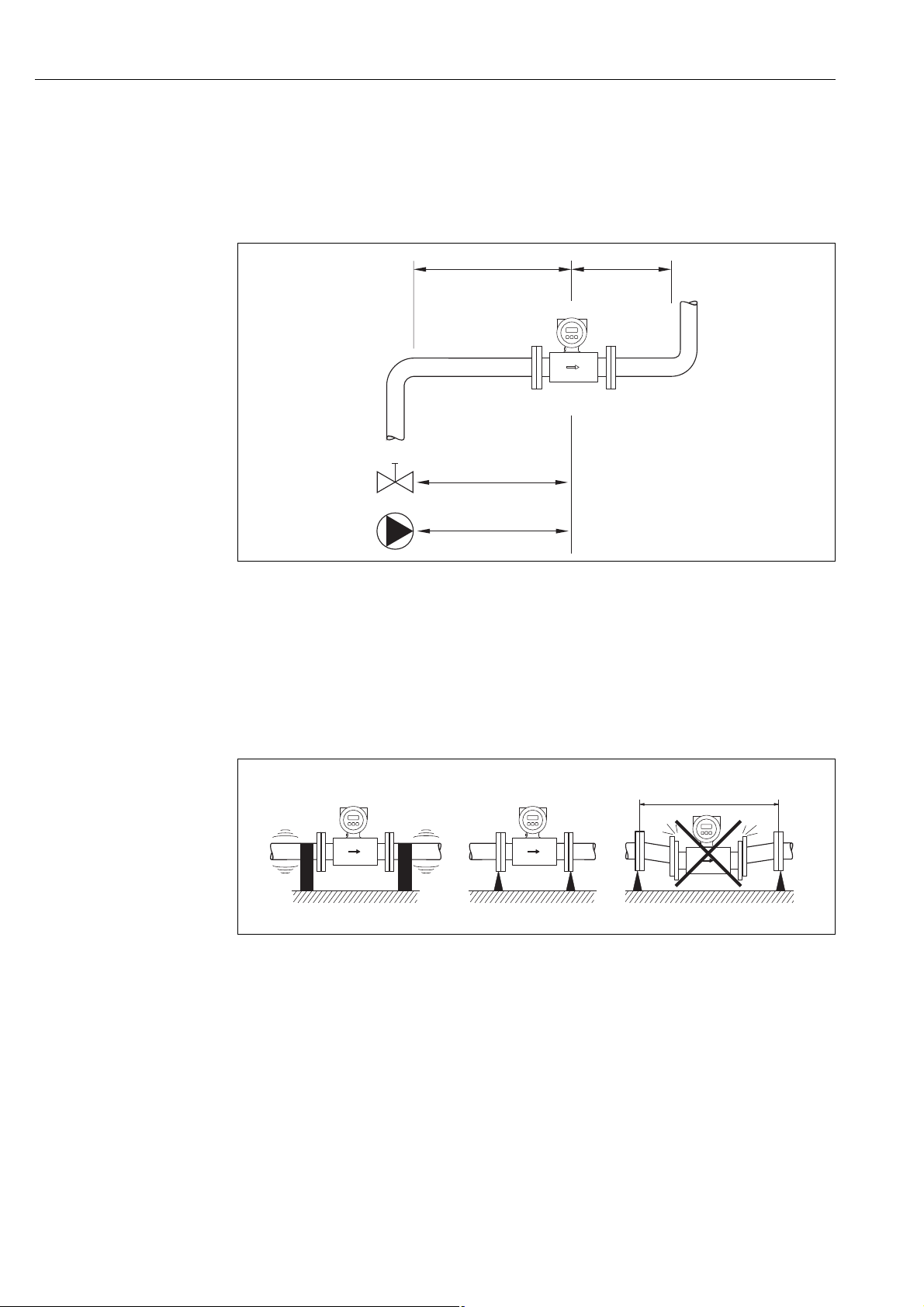

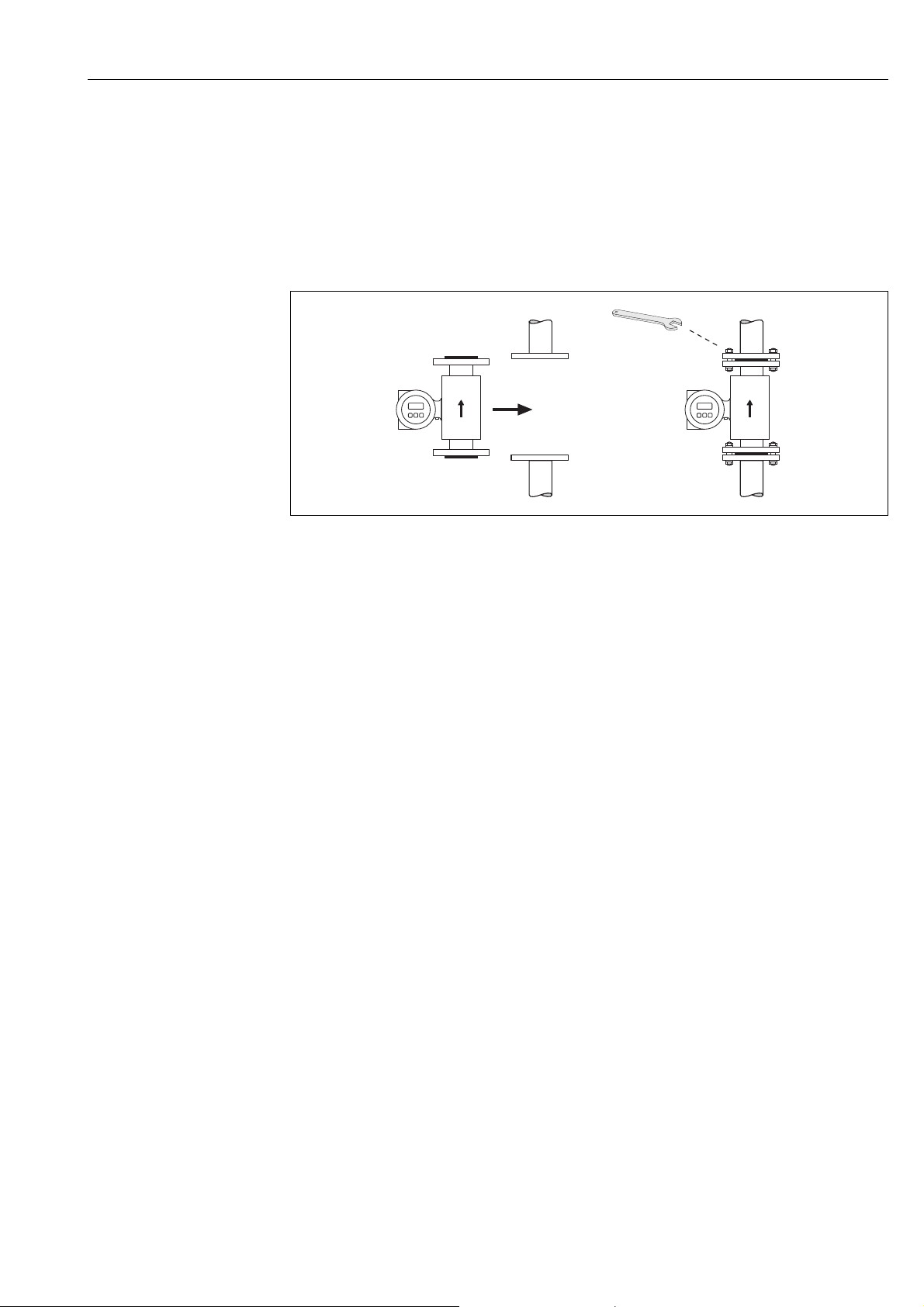

3.2.4 Vibrations

Secure the piping and the sensor if vibration is severe.

Caution!

"

If vibrations are too severe, we recommend the sensor and transmitter be mounted separately.

Information on resistance to vibration and shock can be found on ä 99.

A0003208

Fig. 13: Measures to prevent vibration of the device (L > 10 m (32.8 ft))

16 Endress+Hauser

Promag 50 Installation

100

10

0.5

d / D

[mbar]

0.60.70.80.9

1m/s

2m/s

3m/s

4 m/s

5m/s

6m/s

7m/s

8m/s

1

D

d

max. 8°

3.2.5 Foundations, supports

If the nominal diameter is DN 350, mount the sensor on a foundation of adequate load-bearing

strength.

Caution!

"

Risk of damage.

Do not support the weight of the sensor on the metal casing: the casing would buckle and damage

the internal magnetic coils.

A0003209

Fig. 14: Correct support for large nominal diameters (DN 350)

!

3.2.6 Adapters

Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor in largerdiameter pipes.

The resultant increase in the rate of flow improves measuring accuracy with very slow-moving

fluids. The nomogram shown here can be used to calculate the pressure loss caused by reducers and

expanders.

Note!

The nomogram only applies to liquids of viscosity similar to water.

1. Calculate the ratio of the diameters d/D.

2. From the nomogram read off the pressure loss as a function of flow velocity (downstream from

the reduction) and the d/D ratio.

Fig. 15: Pressure loss due to adapters

A0011907

Endress+Hauser 17

Installation Promag 50

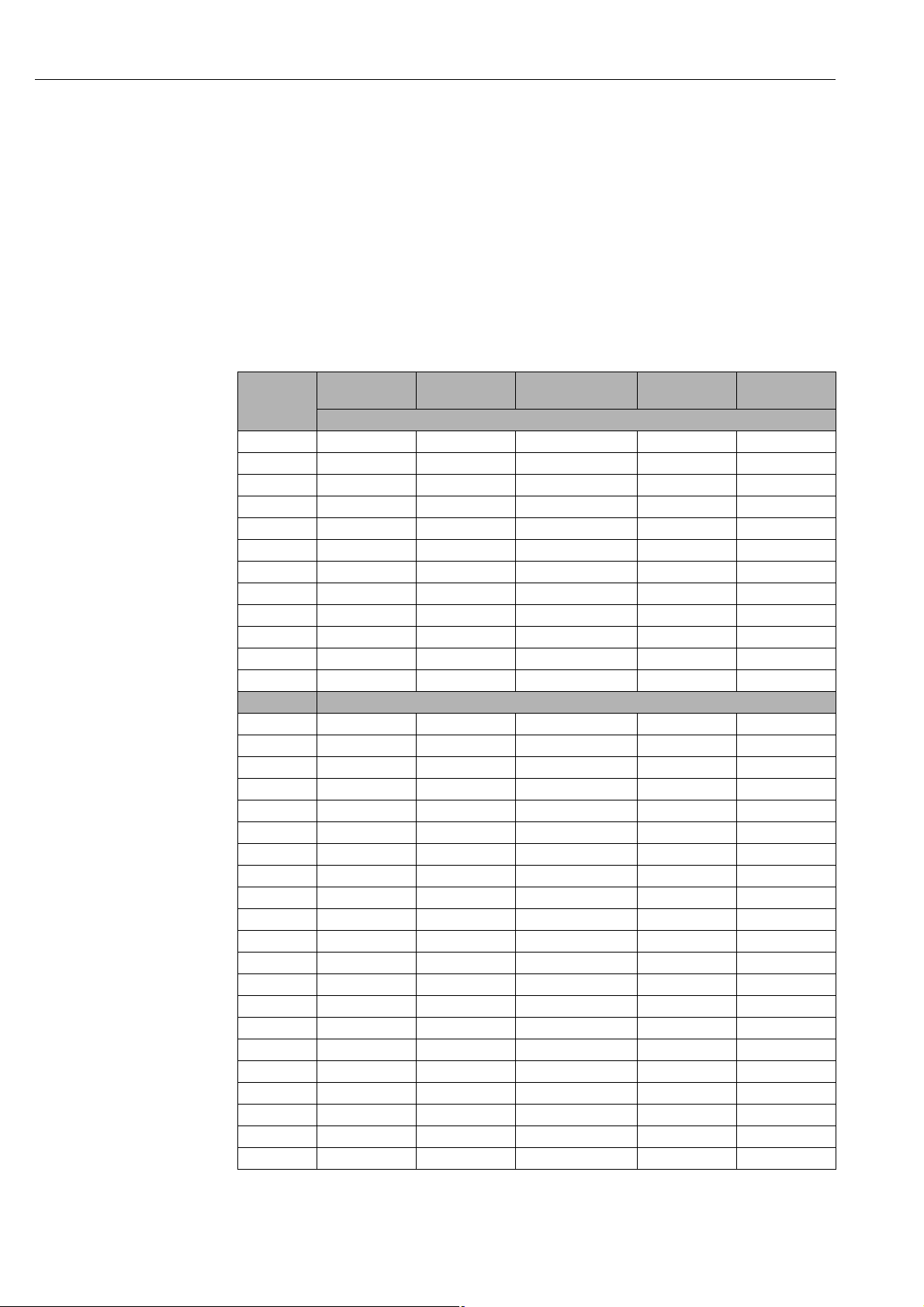

3.2.7 Nominal diameter and flow rate

The diameter of the pipe and the flow rate determine the nominal diameter of the sensor. The

optimum velocity of flow is between 2 and 3 m/s (6.5 to 9.8 ft/s)

The velocity of flow (v), moreover, has to be matched to the physical properties of the fluid:

• v < 2 m/s (v < 6.5 ft/s): for abrasive fluids

• v > 2 m/s (v > 6.5 ft/s): for fluids producing buildup

!

Note!

Flow velocity can be increased, if necessary, by reducing the nominal diameter of the sensor

( ä 17).

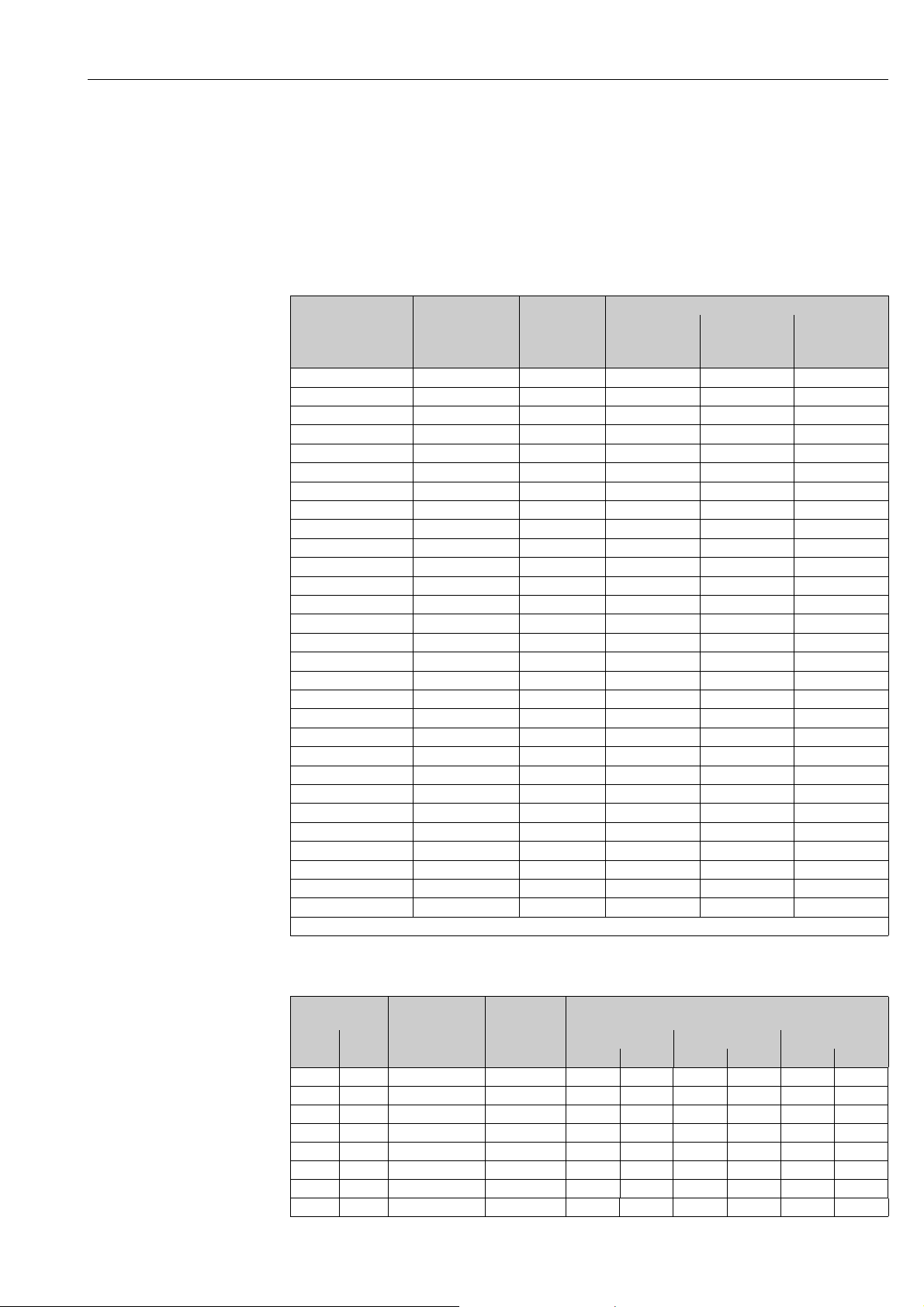

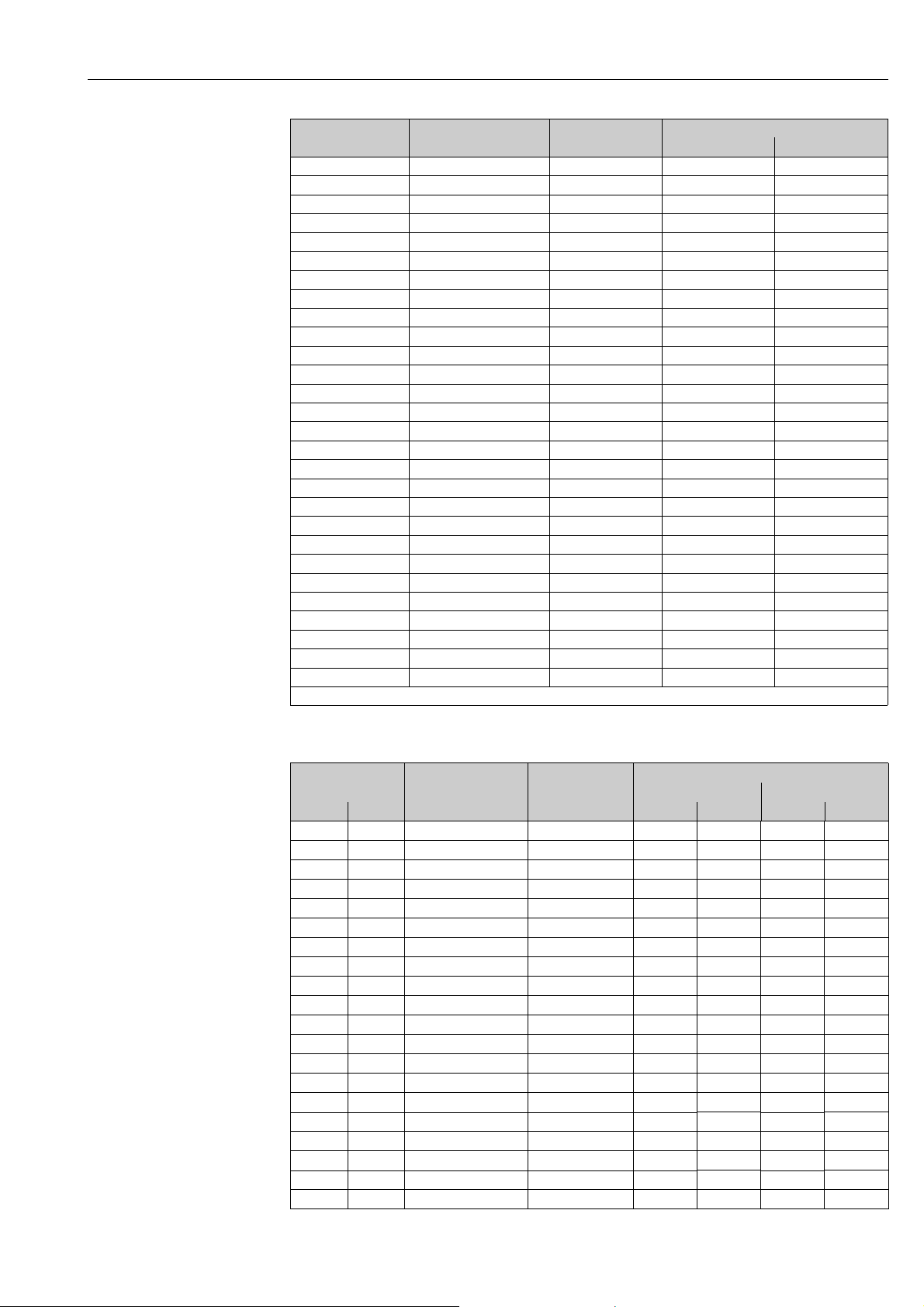

Recommended flow (SI units)

Nominal

diameter

[mm] Min./max. full scale value (v 0.3 or 10 m/s) in [dm³/min]

2 – – – – 0.06 to 1.8

4 – – – – 0.25 to 7

8 – – – – 1 to 30

15 – – – 4 to 100 4 to 100

25 9 to 300 – 9 to 300 9 to 300 9 to 300

32 – – 15 to 500 15 to 500 –

40 25 to 700 – 25 to 700 25 to 700 25 to 700

50 35 to 1100 35 to 1100 35 to 1100 35 to 1100 35 to 1100

65 60 to 2000 60 to 2000 60 to 2000 60 to 2000 60 to 2000

80 90 to 3000 90 to 3000 90 to 3000 90 to 3000 90 to 3000

100 145 to 4700 145 to 4700 145 to 4700 145 to 4700 145 to 4700

125 – 220 to 7500 220 to 7500 220 to 7500 –

[mm] Min./max. full scale value (v 0.3 or 10 m/s) in [m³/h]

150 – 20 to 600 20 to 600 20 to 600 –

200 – 35 to 1100 35 to 1100 35 to 1100 –

250 – 55 to 1700 55 to 1700 55 to 1700 –

300 – 80 to 2400 80 to 2400 80 to 2400 –

350 – 110 to 3300 110 to 3300 110 to 3300 –

375 – 140 to 4200 140 to 4200 – –

400 – 140 to 4200 140 to 4200 140 to 4200 –

450 – 180 to 5400 180 to 5400 180 to 5400 –

500 – 220 to 6600 220 to 6600 220 to 6600 –

600 – 310 to 9600 310 to 9600 310 to 9600 –

700 – 420 to 13500 420 to 13500 – –

750 – 480 to 15200 480 to 15200 – –

800 – 550 to 18000 550 to 18000 – –

900 – 690 to 22500 690 to 22500 – –

1000 – 850 to 28000 850 to 28000 – –

1050 – 950 to 40000 950 to 40000 – –

1200 – 1250 to 40000 1250 to 40000 – –

1400 – – 1700 to 55000 – –

1600 – – 2200 to 70000 – –

1800 – – 2800 to 90000 – –

2000 – – 3400 to 110000 – –

Promag D Promag L Promag W Promag P Promag H

18 Endress+Hauser

Promag 50 Installation

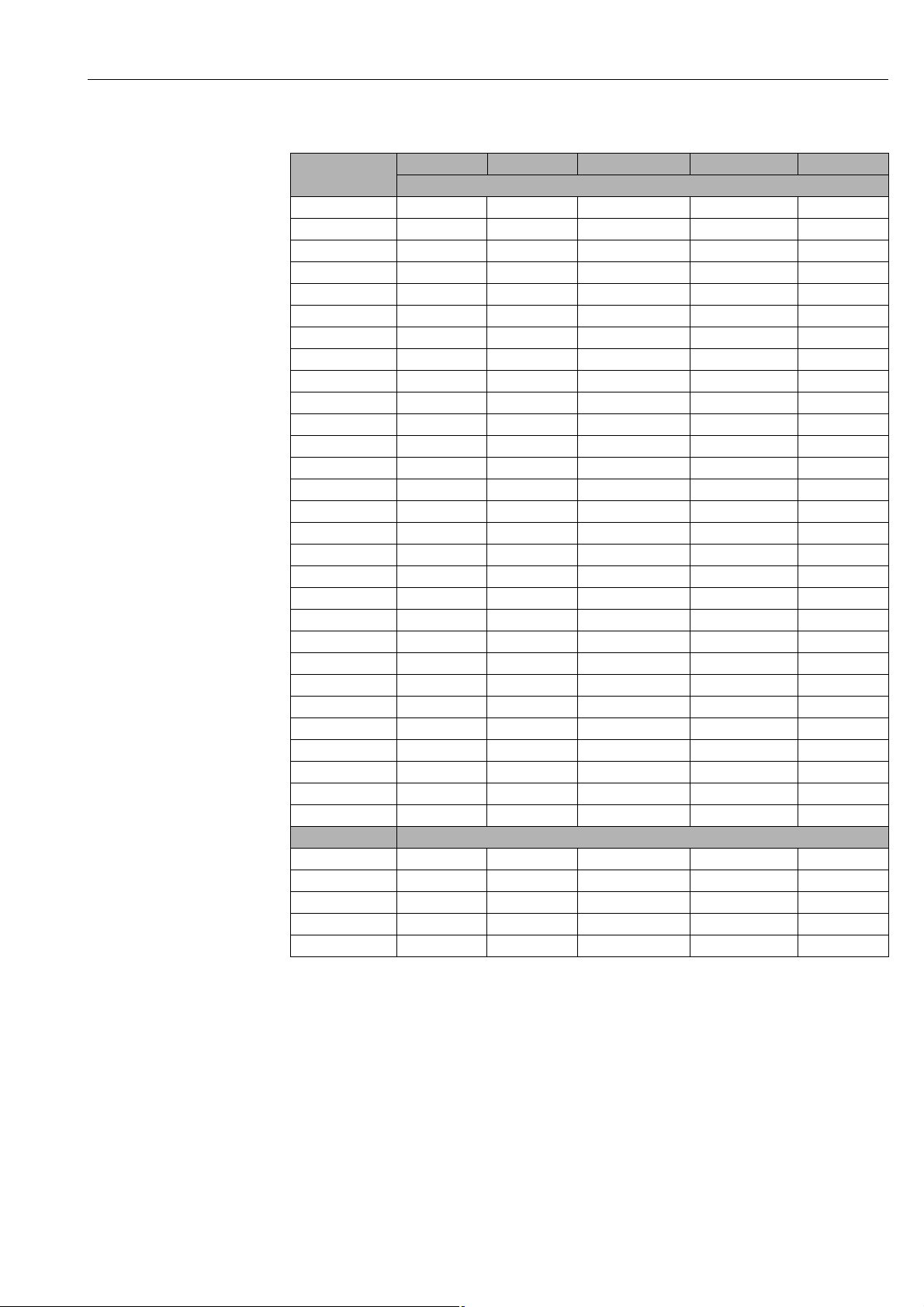

Recommended flow (US units)

Nominal diameter Promag D Promag L Promag W Promag P Promag H

[inch] Min./max. full scale value (v 0.3 or 10 m/s) in [gal/min]

/" – – – – 0.015 to 0.5

1

/"–– – –0.07 to 2

/"–– – –0.25 to 8

/" – – – 1.0 to 27 1.0 to 27

1" 2.5 to 80 – 2.5 to 80 2.5 to 80 2.5 to 80

1

/" – – 4 to 130 4 to 130 –

/" 7 to 190 7 to 190 7 to 190 7 to 190 7 to 190

1

2" 10 to 300 10 to 300 10 to 300 10 to 300 10 to 300

2

/" 16 to 500 16 to 500 16 to 500 16 to 500 16 to 500

3" 24 to 800 24 to 800 24 to 800 24 to 800 24 to 800

4" 40 to 1250 40 to 1250 40 to 1250 40 to 1250 40 to 1250

5" – 60 to 1950 60 to 1950 60 to 1950 –

6" – 90 to 2650 90 to 2650 90 to 2650 –

8" – 155 to 4850 155 to 4850 155 to 4850 –

10" – 250 to 7500 250 to 7500 250 to 7500 –

12" – 350 to 10600 350 to 10600 350 to 10600 –

14" – 500 to 15000 500 to 15000 500 to 15000 –

15" – 600 to 19000 600 to 19000 – –

16" – 600 to 19000 600 to 19000 600 to 19000 –

18" – 800 to 24000 800 to 24000 800 to 24000 –

20" – 1000 to 30000 1000 to 30000 1000 to 30000 –

24" – 1400 to 44000 1400 to 44000 1400 to 44000 –

28" – 1900 to 60000 1900 to 60000 – –

30" – 2150 to 67000 2150 to 67000 – –

32" – 2450 to 80000 2450 to 80000 – –

36" – 3100 to 100000 3100 to 100000 – –

40" – 3800 to 125000 3800 to 125000 – –

42" – 4200 to 135000 4200 to 135000 – –

48" – 5500 to 175000 5500 to 175000 – –

[inch] Min./max. full scale value (v 0.3 or 10 m/s) in [Mgal/d]

54" – – 9 to 300 – –

60" – – 12 to 380 – –

66" – – 14 to 500 – –

72" – – 16 to 570 – –

78" – – 18 to 650 – –

Endress+Hauser 19

Installation Promag 50

200

100

5

10 100 200

L

max

[m][m]

[µS/cm]

L

max

[ft]

200 6000

400

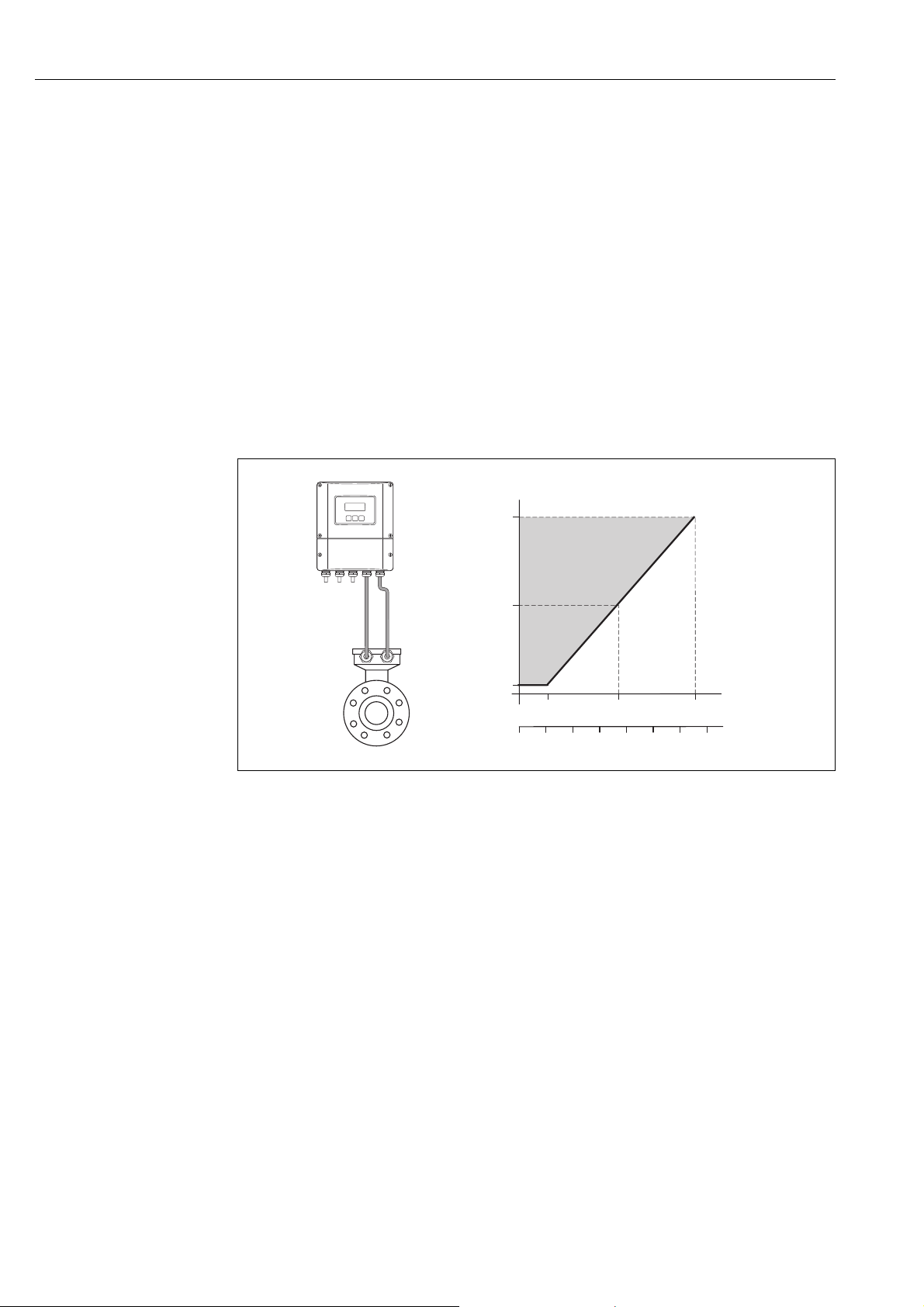

3.2.8 Length of connecting cable

In order to ensure measuring accuracy, comply with the following instructions when installing the

remote version:

• Fix cable run or lay in armored conduit. Cable movements can falsify the measuring signal

especially in the case of low fluid conductivities.

• Route the cable well clear of electrical machines and switching elements.

• Ensure potential equalization between sensor and transmitter, if necessary.

• The permitted connecting cable length L

is determined by the fluid conductivity ( å 16).

max

A minimum conductivity of 20 μS/cm is required for measuring demineralized water. Most

liquids can be measured as of a minimum conductivity of 5 μS/cm.

• The maximum connecting cable length is 10 m (32.8 ft) when empty pipe detection

(EPD ä 73) is switched on.

Fig. 16: Permissible cable length for the remote version

Area shaded gray = permitted range

Lmax = connecting cable length in [m]

Fluid conductivity in [μS/cm]

A0010734

20 Endress+Hauser

Promag 50 Installation

5

1

2

3

4

3.3 Installation instructions

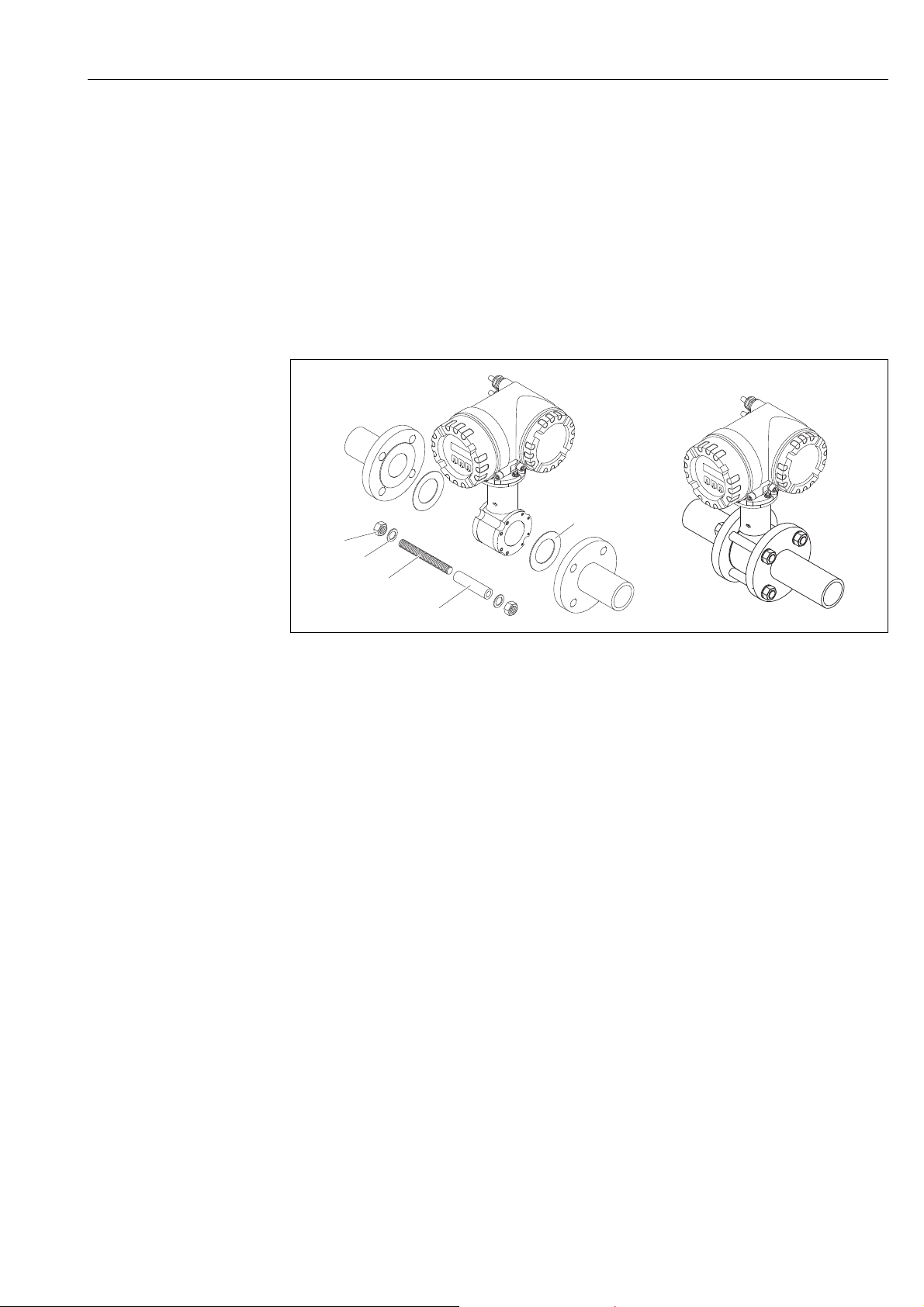

3.3.1 Installing the Promag D sensor

The sensor is installed between the pipe flanges with a mounting kit. The device is centered using

recesses on the sensor ( ä 22).

!

"

Note!

A mounting kit consisting of mounting bolts, seals, nuts and washers can be ordered separately

( ä 76). Centering sleeves are provided with the device if they are required for the installation.

Caution!

When installing the transmitter in the pipe, observe the necessary torques ( ä 23).

a0010776

Fig. 17: Mounting the sensor

1Nut

2Washer

3 Mounting bolt

4 Centering sleeve

5Seal

Seals

When installing the sensor, make sure that the seals used do not project into the pipe cross-section.

Caution!

"

Risk of short circuit! Do not use electrically conductive sealing compounds such as graphite! An

electrically conductive layer could form on the inside of the measuring tube and short-circuit the

measuring signal.

!

Endress+Hauser 21

Note!

Use seals with a hardness rating of 70° Shore.

Installation Promag 50

1

1

1

1

1

1

1

1

1

1

1

1

2

2

22

3

3

3

3

3

3

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

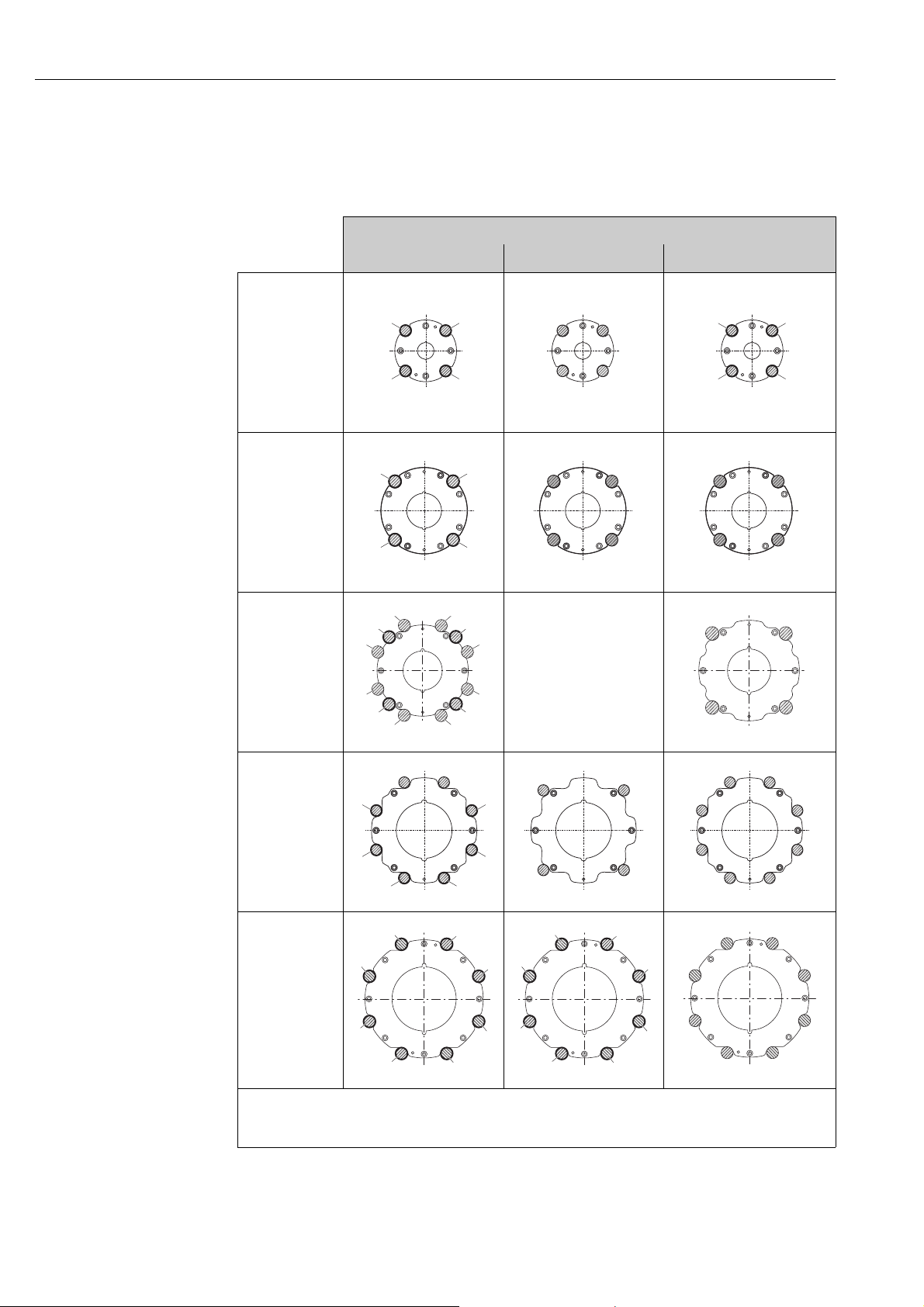

Arrangement of the mounting bolts and centering sleeves

The device is centered using recesses on the sensor. The arrangement of the mounting bolts and the

use of the centering sleeves supplied depend on the nominal diameter, the flange standard und the

pitch circle diameter.

Process connection

EN (DIN) ANSI JIS

DN 25 to 40

(DN 1" to 1 ½")

A0010896 A0010824 A0010896

DN 50

(DN 2")

DN 65

DN 80

(DN 3")

DN 100

(DN 4")

A0010897 A0010825 A0010825

–––––––––––––––––

A0012170

A0010898 A0010827 A0010826

A0012171

A0012168 A0012168 A0012169

1 = Mounting bolts with centering sleeves

2 = EN (DIN) flanges: 4-hole with centering sleeves

3 = EN (DIN) flanges: 8-hole without centering sleeves

22 Endress+Hauser

Promag 50 Installation

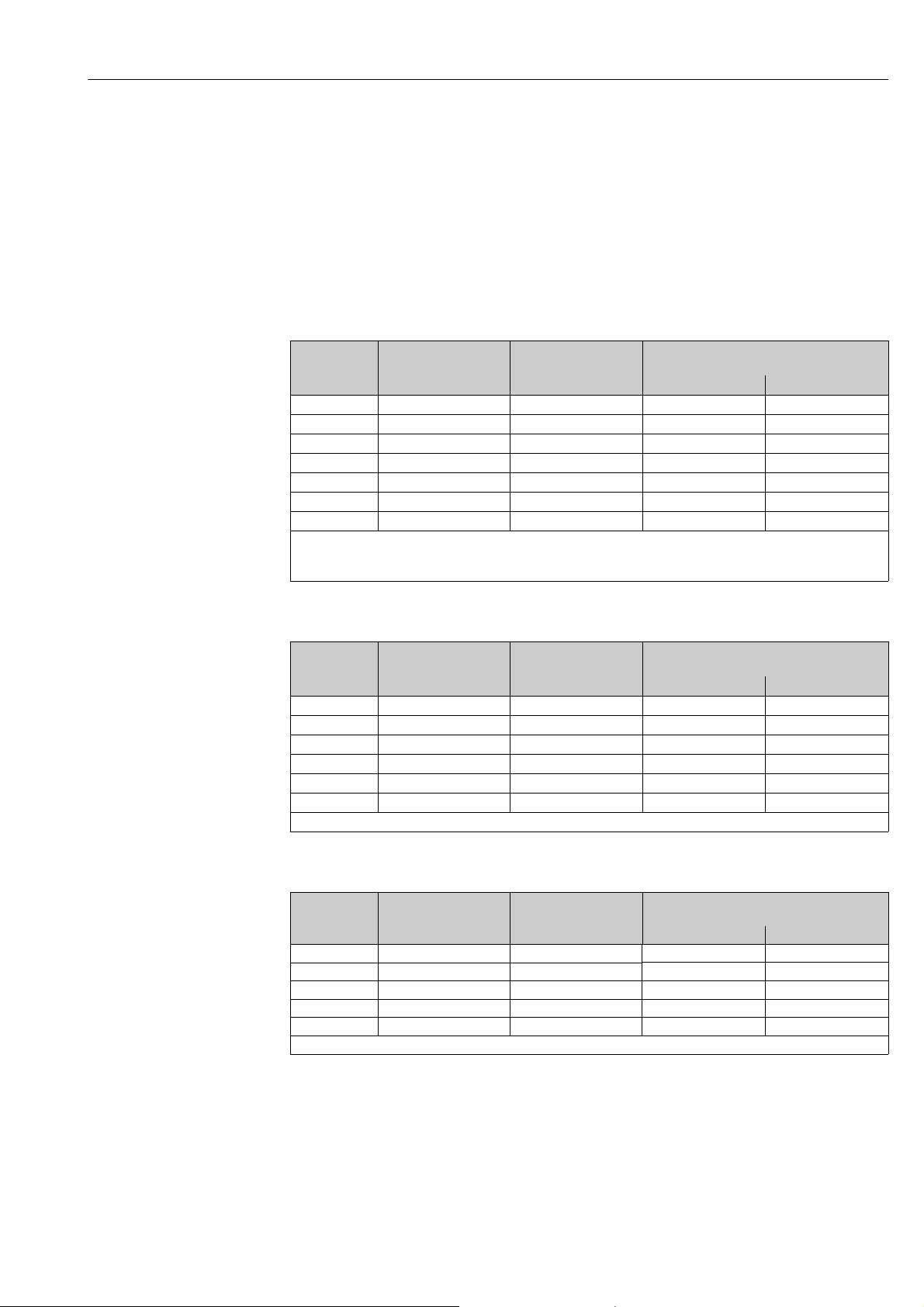

Screw tightening torques (Promag D)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

The tightening torques apply to situations where an EPDM soft material flat seal (e.g. 70 Shore) is

used.

Tightening torques, mounting bolts and centering sleeves for EN (DIN) PN 16

Nominal

diameter

[mm] [mm] [mm] smooth seal face raised face

25 4 × M12 × 145 54 19 19

40 4 × M16 × 170 68 33 33

50 4 × M16 × 185 82 41 41

65

65

80 8 × M16 × 225 116 36 36

100 8 × M16 × 260 147 40 40

EN (DIN) flanges: 4-hole with centering sleeves

EN (DIN) flanges: 8-hole without centering sleeves

A centering sleeve is not required. The device is centered directly via the sensor housing.

Mounting bolts

4 × M16 × 200 92 44 44

8 × M16 × 200 –

Centering sleeve

length

Tightening torque [Nm]

with a process flange with a

29 29

Tightening torques, mounting bolts and centering sleeves for JIS 10 K

Nominal

diameter

[mm] [mm] [mm] smooth seal face raised face

25 4 × M16 × 170 54 24 24

40 4 × M16 × 170 68 32 25

50 4 × M16 × 185 – * 38 30

65 4 × M16 × 200 – * 42 42

80 8 × M16 × 225 – * 36 28

100 8 × M16 × 260 – * 39 37

* A centering sleeve is not required. The device is centered directly via the sensor housing.

Mounting bolts

Centering sleeve

length

Tightening torque [Nm]

with a process flange with a

Tightening torques, mounting bolts and centering sleeves for ANSI Class 150

Nominal

diameter

[inch] [inch] [inch] smooth seal face raised face

1" 4 × UNC 1/2" × 5.70" – * 14 7

1 ½" 4 × UNC 1/2" × 6.50" – * 21 14

2" 4 × UNC 5/8" × 7.50" – * 30 27

3" 4 × UNC 5/8" × 9.25" – * 31 31

4" 8 × UNC 5/8" × 10,4" 5,79 28 28

* A centering sleeve is not required. The device is centered directly via the sensor housing.

Mounting bolts

Centering sleeve

length

Tightening torque [lbf · ft]

with a process flange with a

Endress+Hauser 23

Installation Promag 50

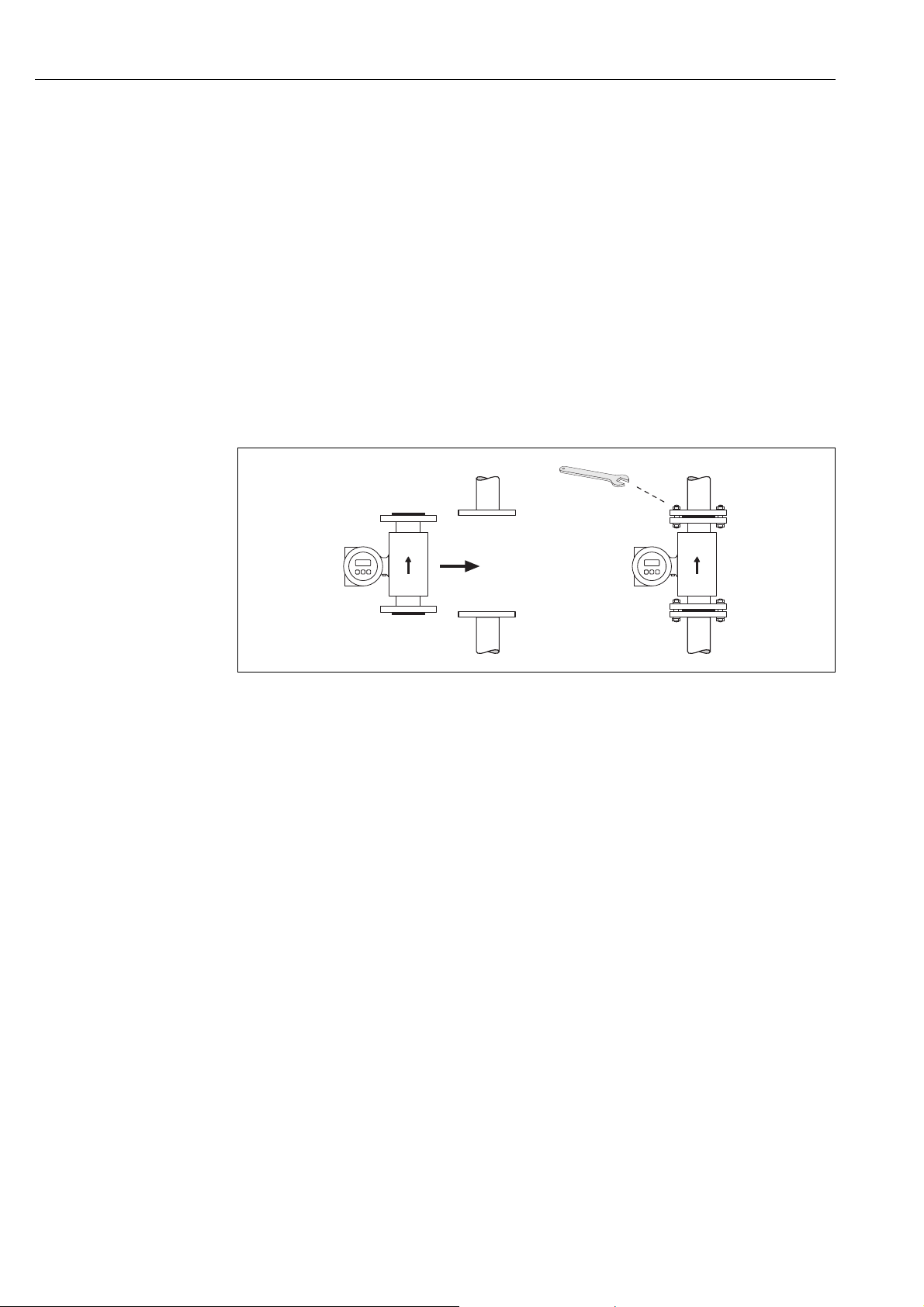

3.3.2 Installing the Promag L sensor

Caution!

"

• The protective covers mounted on the two sensor flanges (DN 50…300) are used to hold the lap

joint flanges in place and to protect the PTFE liner during transportation. Consequently, do not

remove these covers until immediately before the sensor is installed in the pipe.

• The covers must remain in place while the device is in storage.

• Make sure that the lining is not damaged or removed from the flanges.

!

Note!

Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the customer.

The sensor is designed for installation between the two piping flanges.

• Observe in any case the necessary screw tightening torques on ä 25

• If grounding disks are used, follow the mounting instructions which will be enclosed with the

shipment

• To comply with the device specification, a concentrical installation in the measuring section is

required

Fig. 18: Installing the Promag L sensor

Seals

Comply with the following instructions when installing seals:

• Hard rubber lining additional seals are always necessary.

• Polyurethane lining no seals are required.

• PTFE lining no seals are required.

• For DIN flanges, use only seals according to EN 1514-1.

• Make sure that the seals do not protrude into the piping cross-section.

Caution!

"

Risk of short circuit!

Do not use electrically conductive sealing compounds such as graphite! An electrically conductive

layer could form on the inside of the measuring tube and short-circuit the measuring signal.

Ground cable

• If necessary, special ground cables for potential equalization can be ordered as an accessory

( ä 76).

• Information on potential equalization and detailed mounting instructions for the use of ground

cables can be found on ä 55.

a0004296

24 Endress+Hauser

Promag 50 Installation

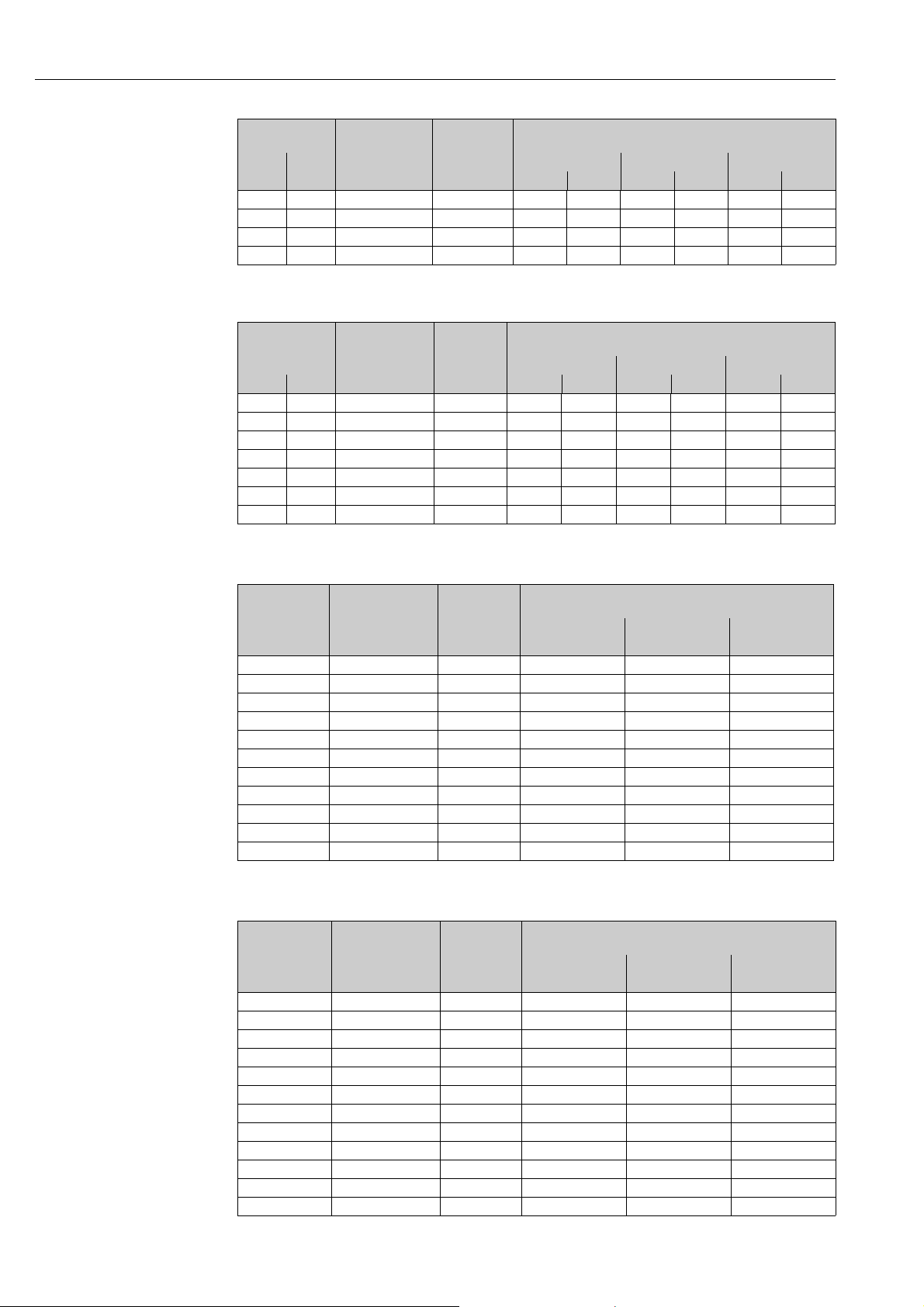

Screw tightening torques (Promag L)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

Promag L tightening torques for EN (DIN)

Nominal diameter EN (DIN) Max. tightening torque

Hard rubber Polyurethane PTFE

[mm] Pressure rating

[bar]

50 PN 10/16 4 × M 16 - 15 40

65* PN 10/16 8 × M 16 - 10 22

80 PN 10/16 8 × M 16 - 15 30

100 PN 10/16 8 × M 16 - 20 42

125 PN 10/16 8 × M 16 - 30 55

150 PN 10/16 8 × M 20 - 50 90

200 PN 10 8 × M 20 - 65 130

250 PN 10 12 × M 20 - 50 90

300 PN 10 12 × M 20 - 55 100

350 PN 6 12 × M 20 111 120 350 PN 10 16 × M 20 112 118 400 PN 6 16 × M 20 90 98 400 PN 10 16 × M 24 151 167 450 PN 6 16 × M 20 112 126 450 PN 10 20 × M 24 153 133 500 PN 6 20 × M 20 119 123 500 PN 10 20 × M 24 155 171 600 PN 6 20 × M 24 139 147 600 PN 10 20 × M 27 206 219 700 PN 6 24 × M 24 148 139 700 PN 10 24 × M 27 246 246 800 PN 6 24 × M 27 206 182 800 PN 10 24 × M 30 331 316 900 PN 6 24 × M 27 230 637 900 PN 10 28 × M 30 316 307 -

1000 PN 6 28 × M 27 218 208 1000 PN 10 28 × M 33 402 405 1200 PN 6 32 × M 30 319 299 1200 PN 10 32 × M 36 564 568 -

* Designed acc. to EN 1092-1 (not to DIN 2501)

Threaded

fasteners

[Nm] [Nm] [Nm]

Promag L tightening torques for ANSI

Nominal diam-

eter

[mm] [inch] [lbs] [Nm] [lbf · ft] [Nm] [lbf · ft] [Nm] [lbf · ft]

50 2" Class 150 4 × 5/8" - - 15 11 40 29

80 3" Class 150 4 × 5/8" - - 25 18 65 48

100 4" Class 150 8 × 5/8" - - 20 15 44 32

150 6" Class 150 8 × ¾" - - 45 33 90 66

200 8" Class 150 8 × ¾" - - 65 48 125 92

250 10" Class 150 12 × 7/8" - - 55 41 100 74

300 12" Class 150 12 × 7/8" - - 68 56 115 85

350 14" Class 150 12 × 1" 135 100 158 117 - -

ANSI Threaded

fasteners

Pressure rating Hard rubber Polyurethane PTFE

Max. tightening torque

Endress+Hauser 25

Installation Promag 50

Nominal diam-

eter

[mm] [inch] [lbs] [Nm] [lbf · ft] [Nm] [lbf · ft] [Nm] [lbf · ft]

400 16" Class 150 16 × 1" 128 94 150 111 - 450 18" Class 150 16 × 1 1/8" 204 150 234 173 - 500 20" Class 150 20 × 1 1/8" 183 135 217 160 - 600 24" Class 150 20 × 1 ¼" 268 198 307 226 - -

ANSI Threaded

fasteners

Pressure rating Hard rubber Polyurethane PTFE

Max. tightening torque

Promag L tightening torques for AWWA

Nominal diam-

eter

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft] [Nm] [lbf · ft]

700 28" Class D 28 × 1 ¼" 247 182 292 215 - 750 30" Class D 28 × 1 ¼" 287 212 302 223 - 800 32" Class D 28 × 1 ½" 394 291 422 311 - -

900 36" Class D 32 × 1 ½" 419 309 430 317 - 1000 40" Class D 36 × 1 ½" 420 310 477 352 - 1050 42" Class D 36 × 1 ½" 528 389 518 382 - 1200 48" Class D 44 × 1 ½" 552 407 531 392 - -

AWWA Threaded

fasteners

Pressure rating Hartgummi Polyurethane PTFE

Max. tightening torque

Promag L tightening torques for AS 2129

Nominal

diameter

[mm] [Nm] [Nm] [Nm]

350 Table E 12 × M 24 203 - 400 Table E 12 × M 24 226 - 450 Table E 16 × M 24 226 - 500 Table E 16 × M 24 271 - 600 Table E 16 × M 30 439 - 700 Table E 20 × M 30 355 - 750 Table E 20 × M 30 559 - 800 Table E 20 × M 30 631 - -

900 Table E 24 × M 30 627 - 1000 Table E 24 × M 30 634 - 1200 Table E 32 × M 30 727 - -

AS 2129 Threaded

fasteners

Pressure rating Hard rubber Polyurethane PTFE

Max. tightening torque

Promag L tightening torques for AS 4087

Nominal dia-

meter

[mm] [Nm] [Nm] [Nm]

350 PN 16 12 × M 24 203 - -

375 PN 16 12 × M 24 137 - -

400 PN 16 12 × M 24 226 - -

450 PN 16 12 × M 24 301 - -

500 PN 16 16 × M 24 271 - -

600 PN 16 16 × M 27 393 - -

700 PN 16 20 × M 27 330 - -

750 PN 16 20 × M 30 529 - -

800 PN 16 20 × M 33 631 - -

900 PN 16 24 × M 33 627 - -

1000 PN 16 24 × M 33 595 - 1200 PN 16 32 × M 33 703 - -

AS 4087 Threaded

fasteners

Pressure rating Hard rubber Polyurethane PTFE

Max. tightening torque

26 Endress+Hauser

Promag 50 Installation

3.3.3 Installing the Promag W sensor

!

"

Note!

Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the customer.

The sensor is designed for installation between the two piping flanges.

• Observe in any case the necessary screw tightening torques on ä 27

• If grounding disks are used, follow the mounting instructions which will be enclosed with the

shipment

a0004296

Fig. 19: Installing the Promag W sensor

Seals

Comply with the following instructions when installing seals:

• Hard rubber lining additional seals are always necessary.

• Polyurethane lining no seals are required.

• For DIN flanges, use only seals according to EN 1514-1.

• Make sure that the seals do not protrude into the piping cross-section.

Caution!

Risk of short circuit!

Do not use electrically conductive sealing compounds such as graphite! An electrically conductive

layer could form on the inside of the measuring tube and short-circuit the measuring signal.

Ground cable

• If necessary, special ground cables for potential equalization can be ordered as an accessory

( ä 76).

• Information on potential equalization and detailed mounting instructions for the use of ground

cables can be found on ä 55

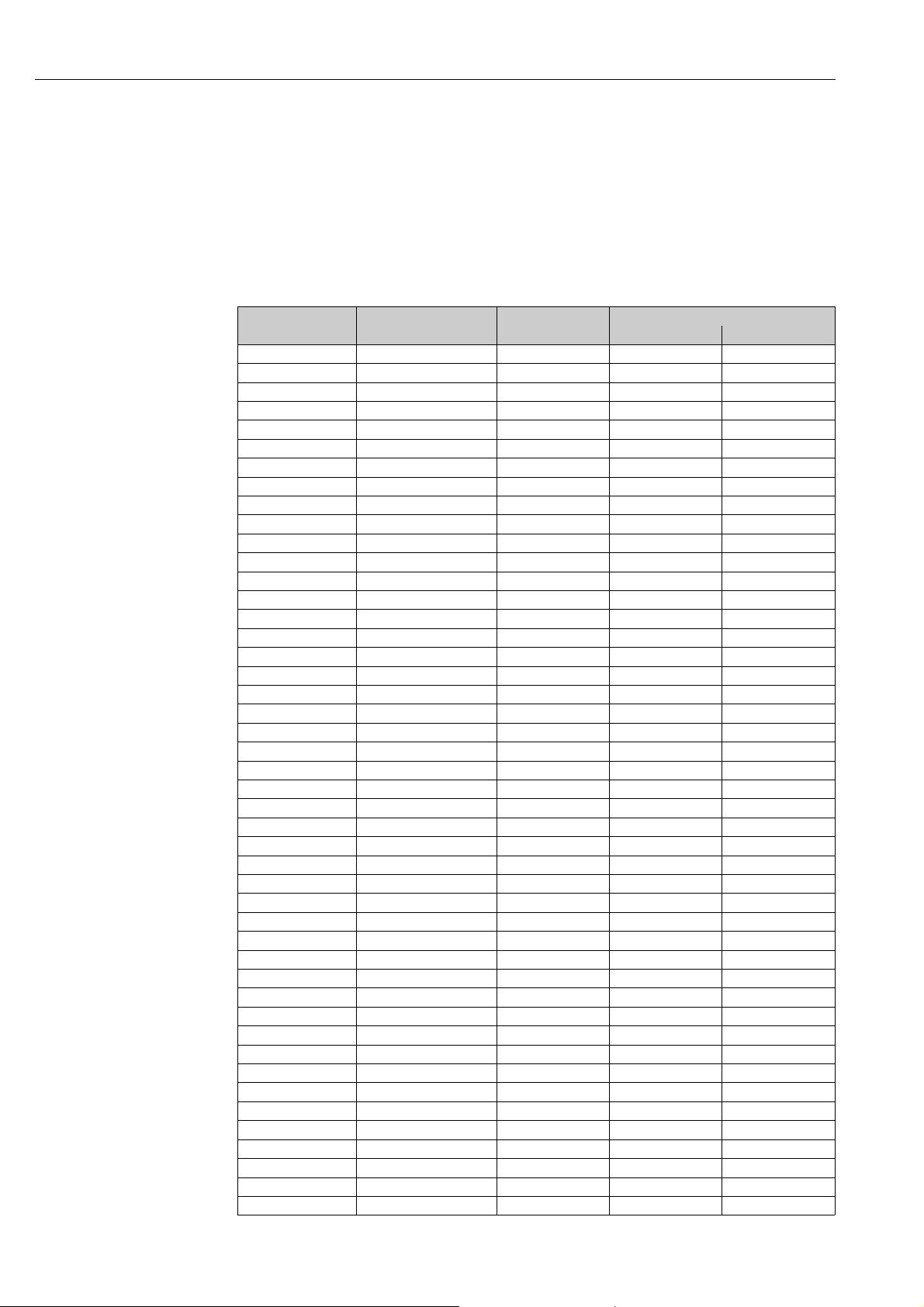

Screw tightening torques (Promag W)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

Endress+Hauser 27

Installation Promag 50

Tightening torques for:

•EN (DIN) ä 28

• JIS ä 30

•ANSI ä 29

• AWWA ä 30

• AS 2129 ä 31

• AS 4087 ä 31

Promag W tightening torques for EN (DIN)

Nominal diameter EN (DIN)

[mm] Pressure rating [bar] Hard rubber Polyurethane

25 PN 40 4 × M 12 - 15

32 PN 40 4 × M 16 - 24

40 PN 40 4 × M 16 - 31

50 PN 40 4 × M 16 48 40

65* PN 16 8 × M 16 32 27

65 PN 40 8 × M 16 32 27

80 PN 16 8 × M 16 40 34

80 PN 40 8 × M 16 40 34

100 PN 16 8 × M 16 43 36

100 PN 40 8 × M 20 59 50

125 PN 16 8 × M 16 56 48

125 PN 40 8 × M 24 83 71

150 PN 16 8 × M 20 74 63

150 PN 40 8 × M 24 104 88

200 PN 10 8 × M 20 106 91

200 PN 16 12 × M 20 70 61

200 PN 25 12 × M 24 104 92

250 PN 10 12 × M 20 82 71

250 PN 16 12 × M 24 98 85

250 PN 25 12 × M 27 150 134

300 PN 10 12 × M 20 94 81

300 PN 16 12 × M 24 134 118

300 PN 25 16 × M 27 153 138

350 PN 6 12 × M 20 111 120

350 PN 10 16 × M 20 112 118

350 PN 16 16 × M 24 152 165

350 PN 25 16 × M 30 227 252

400 PN 6 16 × M 20 90 98

400 PN 10 16 × M 24 151 167

400 PN 16 16 × M 27 193 215

400 PN 25 16 × M 33 289 326

450 PN 6 16 × M 20 112 126

450 PN 10 20 × M 24 153 133

450 PN 16 20 × M 27 198 196

450 PN 25 20 × M 33 256 253

500 PN 6 20 × M 20 119 123

500 PN 10 20 × M 24 155 171

500 PN 16 20 × M 30 275 300

500 PN 25 20 × M 33 317 360

600 PN 6 20 × M 24 139 147

600 PN 10 20 × M 27 206 219

600 * PN 16 20 × M 33 415 443

600 PN 25 20 × M 36 431 516

700 PN 6 24 × M 24 148 139

700 PN 10 24 × M 27 246 246

700 PN 16 24 × M 33 278 318

Threaded

fasteners

Max. tightening torque [Nm]

28 Endress+Hauser

Promag 50 Installation

Nominal diameter EN (DIN)

[mm] Pressure rating [bar] Hard rubber Polyurethane

700 PN 25 24 × M 39 449 507

800 PN 6 24 × M 27 206 182

800 PN 10 24 × M 30 331 316

800 PN 16 24 × M 36 369 385

800 PN 25 24 × M 45 664 721

900 PN 6 24 × M 27 230 637

900 PN 10 28 × M 30 316 307

900 PN 16 28 × M 36 353 398

900 PN 25 28 × M 45 690 716

1000 PN 6 28 × M 27 218 208

1000 PN 10 28 × M 33 402 405

1000 PN 16 28 × M 39 502 518

1000 PN 25 28 × M 52 970 971

1200 PN 6 32 × M 30 319 299

1200 PN 10 32 × M 36 564 568

1200 PN 16 32 × M 45 701 753

1400 PN 6 36 × M 33 430 398

1400 PN 10 36 × M 39 654 618

1400 PN 16 36 × M 45 729 762

1600 PN 6 40 × M 33 440 417

1600 PN 10 40 × M 45 946 893

1600 PN 16 40 × M 52 1007 1100

1800 PN 6 44 × M 36 547 521

1800 PN 10 44 × M 45 961 895

1800 PN 16 44 × M 52 1108 1003

2000 PN 6 48 × M 39 629 605

2000 PN 10 48 × M 45 1047 1092

2000 PN 16 48 × M 56 1324 1261

* Designed acc. to EN 1092-1 (not to DIN 2501)

Threaded

fasteners

Max. tightening torque [Nm]

Promag W tightening torques for ANSI

Nominal

diameter

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft]

25 1" Class 150 4 × ½" - - 7 5

25 1" Class 300 4 × 5/8" - - 8 6

40 1 ½" Class 150 4 × ½" - - 10 7

40 1 ½" Class 300 4 × ¾" - - 15 11

50 2" Class 150 4 × 5/8" 35 26 22 16

50 2" Class 300 8 × 5/8" 18 13 11 8

80 3" Class 150 4 × 5/8" 60 44 43 32

80 3" Class 300 8 × ¾" 38 28 26 19

100 4" Class 150 8 × 5/8" 42 31 31 23

100 4" Class 300 8 × ¾" 58 43 40 30

150 6" Class 150 8 × ¾" 79 58 59 44

150 6" Class 300 12 × ¾" 70 52 51 38

200 8" Class 150 8 × ¾" 107 79 80 59

250 10" Class 150 12 × 7/8" 101 74 75 55

300 12" Class 150 12 × 7/8" 133 98 103 76

350 14" Class 150 12 × 1" 135 100 158 117

400 16" Class 150 16 × 1" 128 94 150 111

450 18" Class 150 16 × 1 1/8" 204 150 234 173

500 20" Class 150 20 × 1 1/8" 183 135 217 160

600 24" Class 150 20 × 1 ¼" 268 198 307 226

ANSI Max. tightening torque

Pressure rating

[lbs]

Threaded

fasteners

Hard rubber Polyurethane

Endress+Hauser 29

Installation Promag 50

Promag W tightening torques for JIS

Nominal diameter JIS Threaded

[mm] Pressure rating Hard rubber Polyurethane

25 10K 4 × M 16 - 19

25 20K 4 × M 16 - 19

32 10K 4 × M 16 - 22

32 20K 4 × M 16 - 22

40 10K 4 × M 16 - 24

40 20K 4 × M 16 - 24

50 10K 4 × M 16 40 33

50 20K 8 × M 16 20 17

65 10K 4 × M 16 55 45

65 20K 8 × M 16 28 23

80 10K 8 × M 16 29 23

80 20K 8 × M 20 42 35

100 10K 8 × M 16 35 29

100 20K 8 × M 20 56 48

125 10K 8 × M 20 60 51

125 20K 8 × M 22 91 79

150 10K 8 × M 20 75 63

150 20K 12 × M 22 81 72

200 10K 12 × M 20 61 52

200 20K 12 × M 22 91 80

250 10K 12 × M 22 100 87

250 20K 12 × M 24 159 144

300 10K 16 × M 22 74 63

300 20K 16 × M 24 138 124

fasteners

Max. tightening torque [Nm]

Promag W tightening torques for AWWA

Nominal diameter AWWA Max. tightening torque

Pressure

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft]

700 28" Class D 28 × 1 ¼" 247 182 292 215

750 30" Class D 28 × 1 ¼" 287 212 302 223

800 32" Class D 28 × 1 ½" 394 291 422 311

900 36" Class D 32 × 1 ½" 419 309 430 317

1000 40" Class D 36 × 1 ½" 420 310 477 352

1050 42" Class D 36 × 1 ½" 528 389 518 382

1200 48" Class D 44 × 1 ½" 552 407 531 392

1350 54" Class D 44 × 1 ¾" 730 538 633 467

1500 60" Class D 52 × 1 ¾" 758 559 832 614

1650 66" Class D 52 × 1 ¾" 946 698 955 704

1800 72" Class D 60 × 1 ¾" 975 719 1087 802

2000 78" Class D 64 × 2" 853 629 786 580

rating

Threaded

fasteners

Hard rubber Polyurethane

30 Endress+Hauser

Loading...

Loading...