Page 1

TI01150G/00/EN/04.18

71421949

2019-02-13

Products Solutions Services

Technical Information

Tankvision Multi Scan

NXA83B

Inventory Management System

with completely integrated software

Valid from SW version 3.4.0 and 4.4.0

Application

Tankvision is a dedicated tank inventory system. It is ideally suited for tank farms with

various protocols used for communicating with the installed field devices and/or

redundancy needs.

Tankvision Multi Scan performs the following tasks:

• scanning of parameters from tank gauges

• provides data to Tankvision Professional NXA85

• provides data to host systems (such as PLC or DCS) via Modbus and/or OPC

Your benefits

• Approved for custody transfer applications according to PTB

• Global system engineering and service support

• A robust industrial operating system with embedded software ensures high stability

and availability.

• Legacy protocol management; allowing gradual upgrades

• No hard disc or fans - no wear out

• Predefined or customized operator screens via the optional touch display for typical

operation of a tank farm.

• Built in web server for basic tank farm operations

• Connects to Tankvision Professional for additional functionality

Page 2

Table of Contents

Tankvision Multi Scan NXA83

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Inventory control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Remote configuration of measuring equipment . . . . . . . . . . . . 3

Application areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Function and system design . . . . . . . . . . . . . . . . . . . . . .3

System design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features with limited functions . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical system architecture. . . . . . . . . . . . . . . . . . . . . . .5

Tankvision Multi Scan in Switch By System redundancy mode 6

Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Supported Input protocols (from the field) . . . . . . . . . . . . . . . . 7

Device support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Supported output/communication (to host system) . . . . . . . . . 8

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . 8

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . 15

MODBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Microsoft,

Windows,

Silverlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HART® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Varec® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . . .8

Wall mounted version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rack mounted version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Embedded human interface with limited functions 10

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LCD display (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Remote desktop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation considerations . . . . . . . . . . . . . . . . . . . . . 13

System requirements

of user PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Network requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shielding and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . 13

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Endress+Hauser

Page 3

Tankvision Multi Scan NXA83

Applications

Inventory control By using Tankvision Multi Scan to scan the parameters of tank gauges together with Tankvision

Professional to monitor the tank level and stored volume of valuable liquids remotely, owners or

operators of tank farms or terminals for petroleum products and chemicals (liquids) can visualize the

volume of the stored medium in real time. The data can be used to plan the inventory and distribution.

The data can also be used to manage tank farm operations like pumping or transferring products.

Tankvision has its unique concept using network technology. Without using proprietary software, the

users can visualize and manage their valuable liquids stored in the tanks by a web browser. Tankvision

Multi Scan is a flexible and cost effective solution due to its scalable architecture. The application

coverage goes from small depots with only a few tanks up to refineries..

Remote configuration of measuring equipment

Application areas • Tank farms in refineries

Some on-site operations can be avoided using remote configuration of measuring equipment during

commissioning or maintenance (the availability of this feature may depend on the system

configuration).

• Ship loading terminals

• Marketing and distribution terminals

• Pipeline terminals

• Logistic terminals for tanks storing products like crude oils, refined white and black products,

chemicals, LPG

Function and system design

System design Tankvision Multi Scan is designed to act as gateway for legacy tank instrumentation into recent Tank

Inventory software (e.g. Tankvision Professional) or control systems (DCS or PLC). Where required also

the redundant collection and distribution of tank parameters is managed by Tankvision Multi Scan.

System configuration Tankvision Multi Scan is configured without any special software only by standard Microsoft Windows

tools (Remote desktop). Network access to the Multi Scan is password protected.

Configuration of connected tank gauges/sensors

Different vendor’s tools can be used to configure gauges by tunneling through the Multi Scan.

Features • Provides data Providing visualization software (e.g. Tankvision Professional) with the scanned

parameters of tank gauges.

• Remote access

Any PC with the specified requirements in the Intranet can be connected to Tankvision.

• Redundancy

Hot standby with automatic switchover, various switching rules.

Features with limited functions

• Representation of tank data

Tank data can be represented graphically or in tables.

• Definition and management of products

Product characteristics can be defined.

•Alarms

Limit alarms (high-high, high, low, low-low and other programmable alarms) can be defined for

measured certain tank parameters.

•Reports

Reports can be sent to a printer (network printer or directly connected via USB) at scheduled time

intervals or on demand.

• Volume calculation and correction

Calculation tables according to API, ASTM and IP are integrated.

• Graphical User Interface (GUI)

Tankvision uses an intuitive and optimized user interface.

Endress+Hauser 3

Page 4

Security IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any inadvertent

changes to the device settings.

IT security measures in line with operators' security standards and designed to provide additional

protection for the device and device data transfer must be implemented by the operators themselves.

Endress+Hauser can be contacted to provide support in performing this task.

Tankvision Multi Scan NXA83

4 Endress+Hauser

Page 5

Tankvision Multi Scan NXA83

5

8

8

10

9

4

3

1

2

7

6

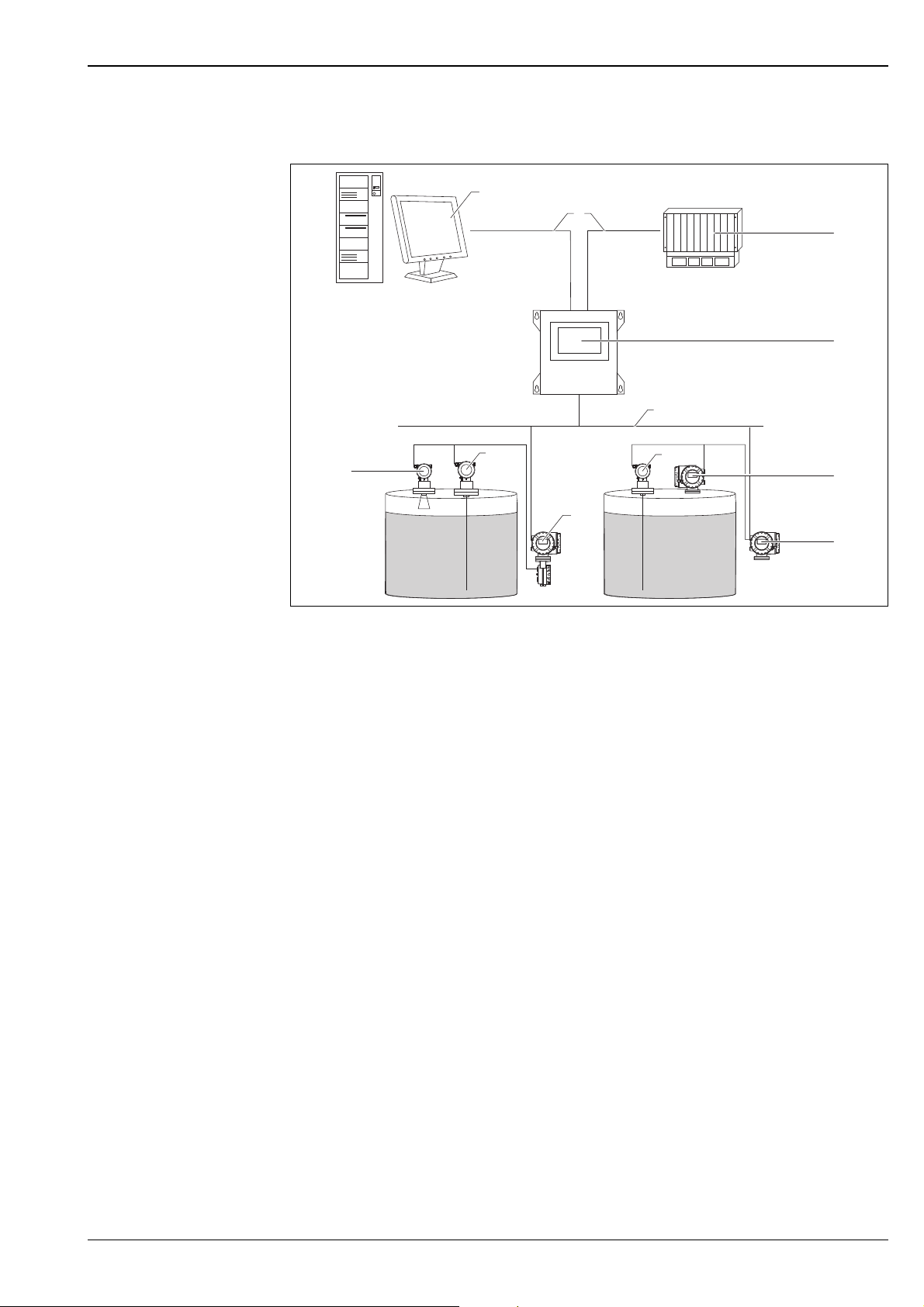

Typical system architecture

NXA83_Typical_system_configu ration

1 Tankvision Professional NXA85 Workstation

2 Ethernet/Serial

3 DCS/PLC (Distributed control system/Programmable logic controlled)

4 Tankvision Multi Scan NXA83B

5 Fieldbus protocol (Modbus, Sakura V1, Whessoe WM550)

6 Proservo

7Promonitor

8Prothermo

9Tank Side Monitor

10 Micropilot

Endress+Hauser 5

Page 6

Tankvision Multi Scan in

5

5

4

4

8

8

10

3

9

3

11

22

7

6

Switch By System redundancy

mode

Tankvision Multi Scan NXA83

NXA83_System-configuration_ Switch-by-system

1 Tankvision Professional NXA85 Workstation

2Ethernet

3 Tankvision Multi Scan NXA83B

4 Control link RS232

5 Fieldbus protocol

6 Proservo

7Promonitor

8Prothermo

9 Tank Side Monitor

10 Micropilot

6 Endress+Hauser

Page 7

Tankvision Multi Scan NXA83

Inputs and Outputs

Power supply

Supply voltage Frequency Power consumption Current consumption

100 to 240 V

AC

50 to 60 Hz 40 VA max. 0.8 A

The Multi Scan contains a 20 x 5 mm cartridge fuse protecting the mains input. The fuse is rated at

3.15 A, time delay (antisurge/slow blow). The fuse is suitable for use at 240 V

Interfaces The Multi Scan is available in two versions:

• 1 to 8 serial ports

• 1 to 20 serial ports

The ports can be configured to be either inputs (from the field/host ports) or outputs (to host systems/

slave ports). For the version 1 to 20 serial ports, 4 ports are reserved for outputs only.

Multi Scan support the following electrical interfaces:

• RS232

• RS485

•Bi-Phase Mark

•Current Loop

In addition an Ethernet port with up to 5 connections and two USB ports are also provided.

Multi Scan has an LED module, one pair for each of the serial ports, to indicate communication activity.

One LED indicates transmission and the other one indicates the receipt of data.

Non isolated (bus ground = Multi Scan chassis ground):

•RS-232

Optocoupler isolated:

•RS-485

• Current Loop (GPE/Whessoe)

•L&J

•Varec

Transformer isolated:

•Enraf BPM

•"SAAB"/Rosemount TRL/2

.

ac

Supported Input protocols (from the field)

• Modbus RS485/RS232, max. 15 gauges

•Modbus Ethernet

• Sakura V1, max. 10 gauges

• Whessoe WM550, max. 15 gauges

• Protocol compatible to Enraf GPU (Bi-Phase Mark), max. 8 gauges

• Protocol compatible to Saab TRL/2, max. 8 gauges

• Protocol compatible to VAREC Mark/Space, max. 15 gauges

• Protocol compatible to Scientific Instruments (RS485), max. 15 gauges

• Protocol compatible to Tokyo Keiso (FW9000), max. 15 gauges

Additional protocols and variants upon request.

Device support The Multi Scan is designed to interface to the following gauge and transmitter types.

Endress+Hauser:

• Micropilot S + Tank Side Monitor, Micropilot NMR81, Micropilop NMR84, Tank Side Monitor

NRF590, Tank Side Monitor NRF81, Proservo NMS8, Proservo NMS80, Proservo NMS81

Enraf:

• 811 Servo Gauge

• 813 Mechanical Gauge Transmitter

• 854 Servo Gauge

• 872 Radar Gauge

• 873 Radar Gauge

• 865 Temperature Selector

Whessoe:

• 1311 Transmitter/1071 Outstation

Endress+Hauser 7

Page 8

Tankvision Multi Scan NXA83

• 1315 Transmitter/2006 Mechanical float gauge, 1140 Servo gauge

• ITG 50/60/70 Servo gauges

Emerson:

• TRL2, Rex, Raptor, Pro Radar Gauges

Varec:

• 1800/1900 Mark/Space Transmitters

Other devices supported upon request.

A range of gauge commands are supported but the availability of these commands depends on the

gauge types.

The host and field communication parameters are configurable, however, a number of the above

devices operate with fixed parameters.

Supported output/ communication (to host system)

• Native driver to connect to Tankvision Professional (Ethernet, RS485, RS232)

• Modbus (RS485, RS232, Ethernet)

• OPC DA Server to connect to Clients using version 1.0, 2.0, 3.0 (Ethernet)

Additional protocols and variants upon request.

Environment

Mounting location Indoor

Ambient temperature 0 to +40 °C (+32 to +104 °F)

Storage temperature 0 to +70 °C (+32 to +158 °F)

Relative humidity max. 90 % at +25 °C (+77 °F) (non-condensing)

Electromagnetic compatibility (EMC)

EMC according to the requirements of the EN 61326-series and the NAMUR-recommendation EMC

(NE21). Details can be found in the Declaration of Conformity.

Mechanical construction

Wall mounted version The wall mount version is housed in a stainless steel enclosure, suitable for wall mounting via 4 fixing

holes designed to accept M6 bolts.

All connectors for power and signals are located on the bottom face of the enclosure. The unit should

always be mounted with this face at the bottom.

8 Endress+Hauser

Page 9

Tankvision Multi Scan NXA83

300 (11.81)

300 (11.81)

263 (10.35)

110 (4.33)

322 (12.68)

mm (in)

NXA83_WallMount_Measurements

Rack mounted version The rack mount version is housed in an aluminum 4U 19 in case, which has 4 front fixing holes

suitable for M6 bolts.

All power and signal connectors are located on the rear panel of the enclosure.

Endress+Hauser 9

Page 10

Tankvision Multi Scan NXA83

483 (19.00)

465 (18.31)

226 (8.90)

176 (6.93)

140 (5.51)

102 (4.02)

mm (in)

NXA83_RackMount_Measurements

Depth of enclosure: 260 mm (10.24 in)

Embedded human interface with limited functions

Web Server The Web Client can be provided on any Windows station with a network connection to the device.

The installation of Microsoft Silverlight is necessary to operate the web client screens. The webserver

access is limited to 2 concurrent users.

NXA83_Web-Server_Homepage

Home Page

10 Endress+Hauser

Page 11

Tankvision Multi Scan NXA83

NXA83_Web-Server_Tank-Det ail

Single Tank Overview

Alarm Event Viewer

Grid View

NXA83_Web-Server_Alarm-Event-Viewer

NXA83_Web-Server_Grid-View

Endress+Hauser 11

Page 12

Tankvision Multi Scan NXA83

LCD display (optional) The Multi Scan is available with a 7 in Widescreen LCD screen built into the front of the device, with

navigation via a touch screen.

NXA83_Display_Single-Tank-View

Single Tank View

NXA83_Display_Grid-View

Grid View

Remote desktop The Remote desktop is used for configuration purpose only.

It is offering a standard Windows XP operating user interface.

12 Endress+Hauser

Page 13

Tankvision Multi Scan NXA83

NOTICE

NOTICE

NOTICE

Installation considerations

It is recommended to take the information contained in the Operating Instructions into

consideration when designing the system architecture ( ä 14).

System requirements of user PC

Network requirements Network switches must always be used to interconnect Tankvision components (Network hubs must

Shielding and Grounding When planning the shielding and grounding for a fieldbus system, there are three important points to

Check the latest information on hardware and software requirements.

Please contact your local Endress+Hauser Sales Center.

never be used).

Only use screened cables (Category 5 or higher).

EMC requirements

The legal EMC requirements are fulfilled only when

‣ a screened LAN cable is used and

‣ the cable screen is properly terminated to screened RJ45 connectors.

Harsh environments

Most commercial and IT infrastructure networking switches (and components) are not designed to be

used within harsh environments (e.g. temperatures below +5 ºC, dusty or with high levels of EMC or

electrical noise).

‣ It is therefore recommended that only networking components specifically designed for industrial

control purposes be used within the control room (or control cabinet) environment as part of the

Tankvision system.

consider:

• Electromagnetic compatibility (EMC)

• Explosion protection

• Safety of the personnel

To ensure the optimum electromagnetic compatibility of systems, it is important that the system

components and all cables, which connect the components, are shielded and that no portion of the

system is unshielded. Ideally, the cable shields are connected to the normal metal housings of the

connected field devices. Since these are generally connected to the protective earth, the shield of the

bus cable is grounded many times. Keep the stripped and twisted lengths of cable shield to the

terminals as short as possible.

This approach, which provides the best electromagnetic compatibility and personnel safety, can be

used without restriction in systems with good potential equalization.

In the case of systems without potential equalization, a power supply frequency (50/60 Hz) equalizing

current can flow between two grounding points which, in unfavourable cases, e.g. when it exceeds the

permissible shield current, may destroy the cable.

To suppress the low frequency equalizing currents on systems without potential equalization, it is

therefore recommended to connect the cable shield directly to the building ground (or protective earth)

at one end only and to use capacitive coupling to connect all other grounding points.

EMC requirements

The legal EMC requirements are fulfilled only when

‣ the cable shield is grounded on both sides!

Certificates and approvals

CE mark The measuring system meets the legal requirements of the EC-guidelines.

Endress+Hauser confirms the instrument passing the required tests by attaching the CE-mark.

Endress+Hauser 13

Page 14

Tankvision Multi Scan NXA83

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com Select country

Instruments Select device Product page function: Configure this product

• From your Endress+Hauser Sales Center: www.endress.com/worldwide

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as measuring

range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Documentation

Operating Instructions BA01288G

Operation manual

BA01290G

Installation and Maintenance manual

BA01291G

Configuration manual

BA01292G

DCC Communications Configuration

BA01289G

OPC Tank Data Server

BA01287G

Weights and Measures Additions

BA01297G

Web Client System Operation

BA01296G

Redundancy manual

14 Endress+Hauser

Page 15

Tankvision Multi Scan NXA83

Registered trademarks

Modbus

Microsoft, Windows, Silverlight

HART® Registered trademark of HART Communication Foundation, Austin, USA

Varec® Registered trademark of Varec, Inc. Copyright 2003

Others Enraf, Honeywell, Rosemount, Emerson, Saab, L&J, GPE are registered trademarks and trademarks of

TM

Modbus is a registered trademark of Schneider Electric USA, Inc.

Microsoft, Windows and Silverlight are registered trademarks of the Microsoft Corporation

these organizations and companies.

All other marks are property of their respective owners.

Endress+Hauser 15

Page 16

www.addresses.endress.com

71421949

Loading...

Loading...