Page 1

BA00424G/00/EN/17.18

71424923

Valid as of software version:

02.02.00

Products Solutions Services

Operating Instructions

Tankvision

Tank Scanner NXA820,

Data Concentrator NXA821,

Host Link NXA822

Operator Manual

Page 2

Tankvision

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

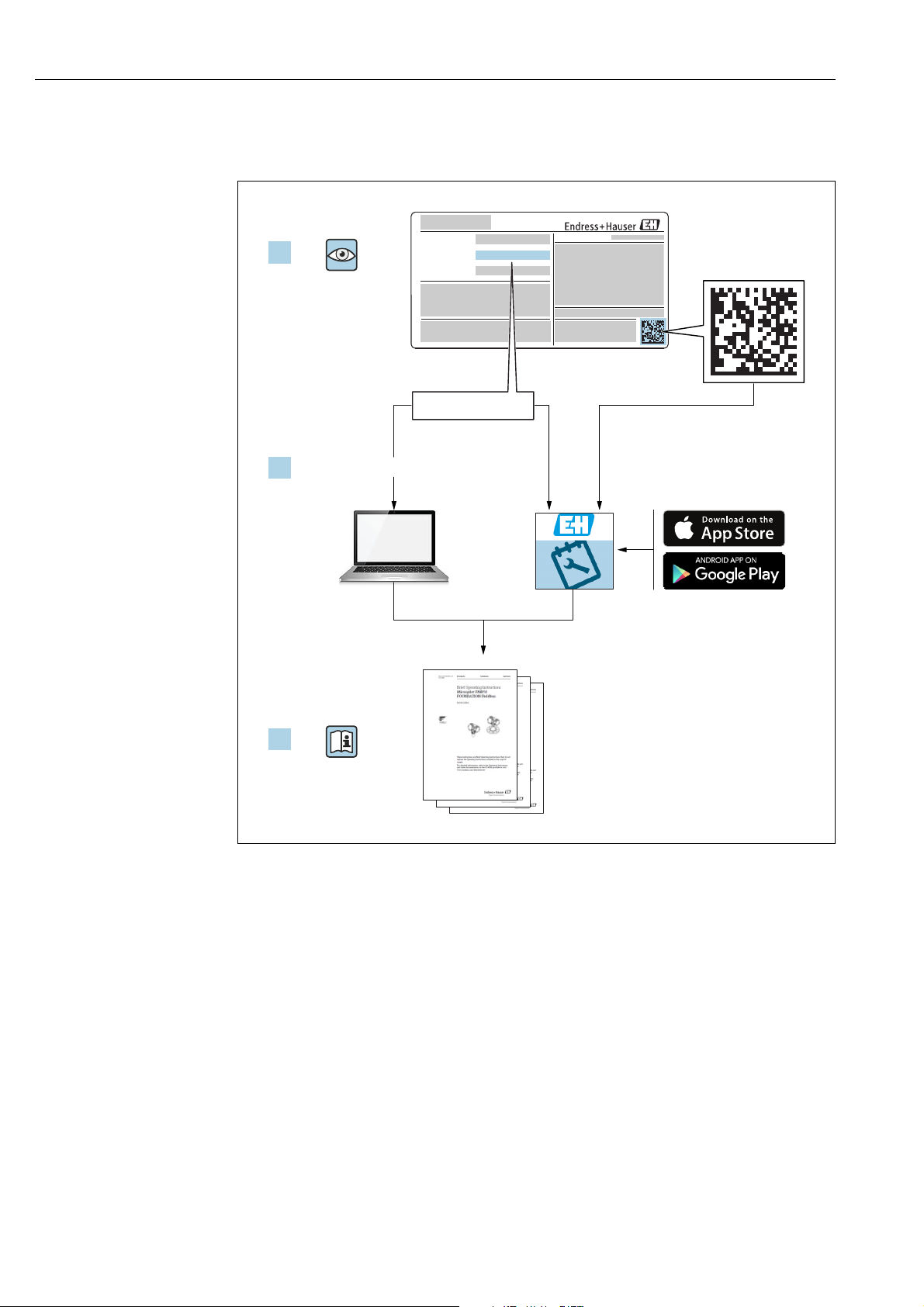

1.

3.

2.

Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to

these Instructions.

A0023555

2 Endress+Hauser

Page 3

Tankvision

Table of Contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 6

2 Basic safety instructions . . . . . . . . . . . . . 7

2.1 Requirements for the personnel . . . . . . . . . . . . . . . 7

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 IT security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Recommendation PC configuration. . . . 9

4 User interface . . . . . . . . . . . . . . . . . . . . .10

5 User access rights. . . . . . . . . . . . . . . . . . 13

6 Operations. . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 How to log on? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 How to view tank details . . . . . . . . . . . . . . . . . . . 17

6.3 How to view Temperature Profiles . . . . . . . . . . . 25

6.4 How to view Density Profiles . . . . . . . . . . . . . . . . 26

6.5 How to view and enter Manual Data . . . . . . . . . 27

6.6 How to enter dipped data . . . . . . . . . . . . . . . . . . . 29

6.7 How to issue gauge commands . . . . . . . . . . . . . . 29

6.8 How to view a real time trend . . . . . . . . . . . . . . . 34

6.9 How to assign/change products at a tank . . . . . 37

6.10 How to do Product transfer . . . . . . . . . . . . . . . . . 38

6.11 How to view a Transfer report . . . . . . . . . . . . . . . 44

6.12 How to view and change Tank Status . . . . . . . . . 45

6.13 How to do tank calculations . . . . . . . . . . . . . . . . . 48

6.14 How to view products groups . . . . . . . . . . . . . . . 49

6.15 How to view customized groups . . . . . . . . . . . . . 52

6.16 How to view transfer groups . . . . . . . . . . . . . . . . 55

6.17 How to issue reports . . . . . . . . . . . . . . . . . . . . . . . 56

6.18 How to view and acknowledge alarms . . . . . . . . 63

6.19 How to select and view historical trends . . . . . . 70

6.20 How to check the sealing status . . . . . . . . . . . . . 72

7 Diagnostics and troubleshooting. . . . . 75

7.1 General troubleshooting . . . . . . . . . . . . . . . . . . . 75

7.2 Firmware history . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8 Maintenance. . . . . . . . . . . . . . . . . . . . . . 76

9 Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Endress+Hauser 3

Page 4

Document information Tankvision

DANGER

WARNING

CAUTION

NOTICE

1 Document information

1.1 Document function

This manual should support the operating personal working on a regular basis with the Tank

Gauging System understanding the possible tasks they have to perform and should serve as

encyclopedia for those tasks.

Beside basic PC operating knowledge no special training is needed to perform the Tank

Gauging System operations. Nevertheless it is recommended receiving a training on the

system by Endress+Hauser.

1.2 Symbols

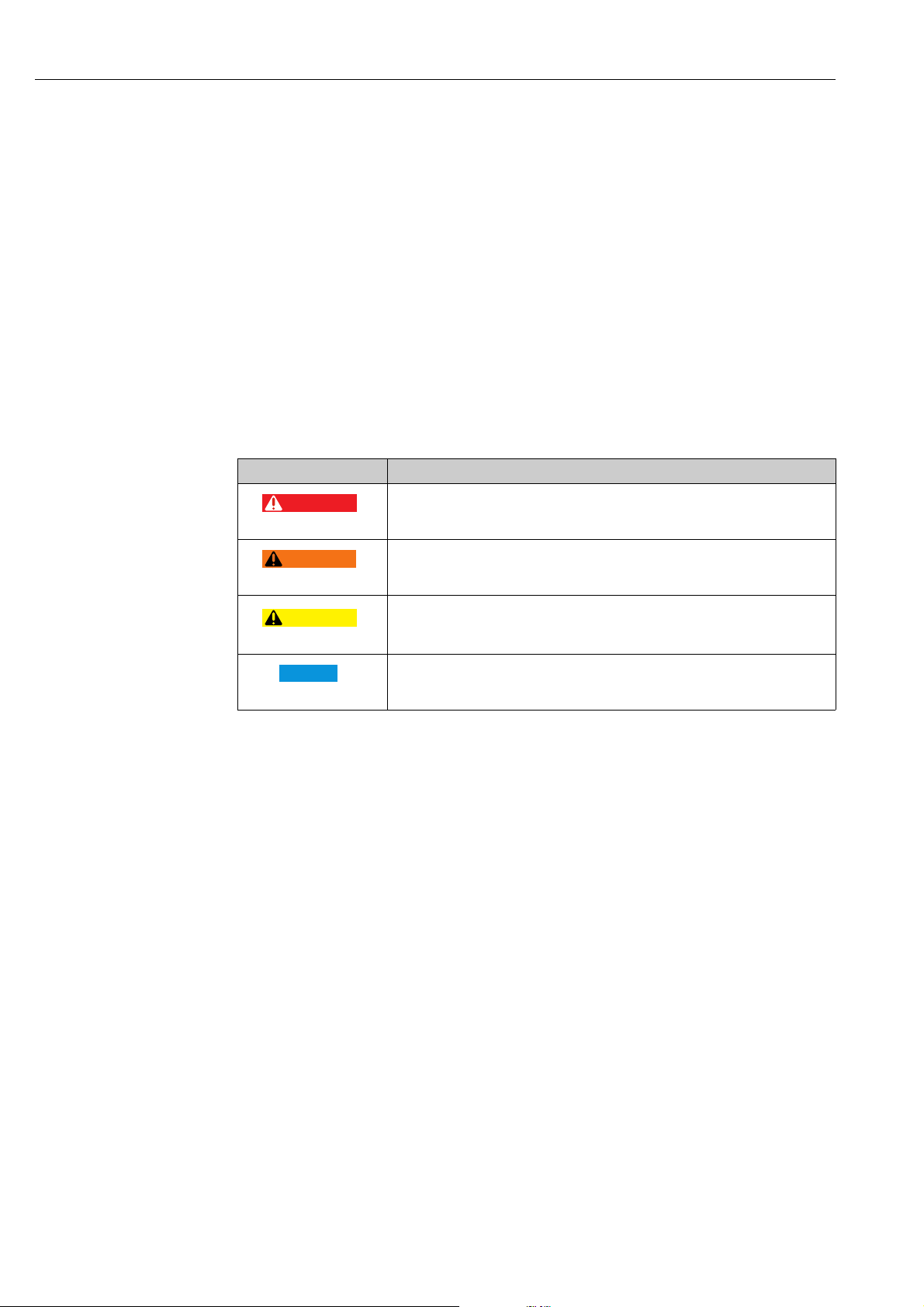

1.2.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-EN

A0011190-EN

A0011191-EN

A0011192-EN

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result

in personal injury.

4 Endress+Hauser

Page 5

Tankvision Document information

)

*

1.

2.

3.

1.

2.

3.

-

.

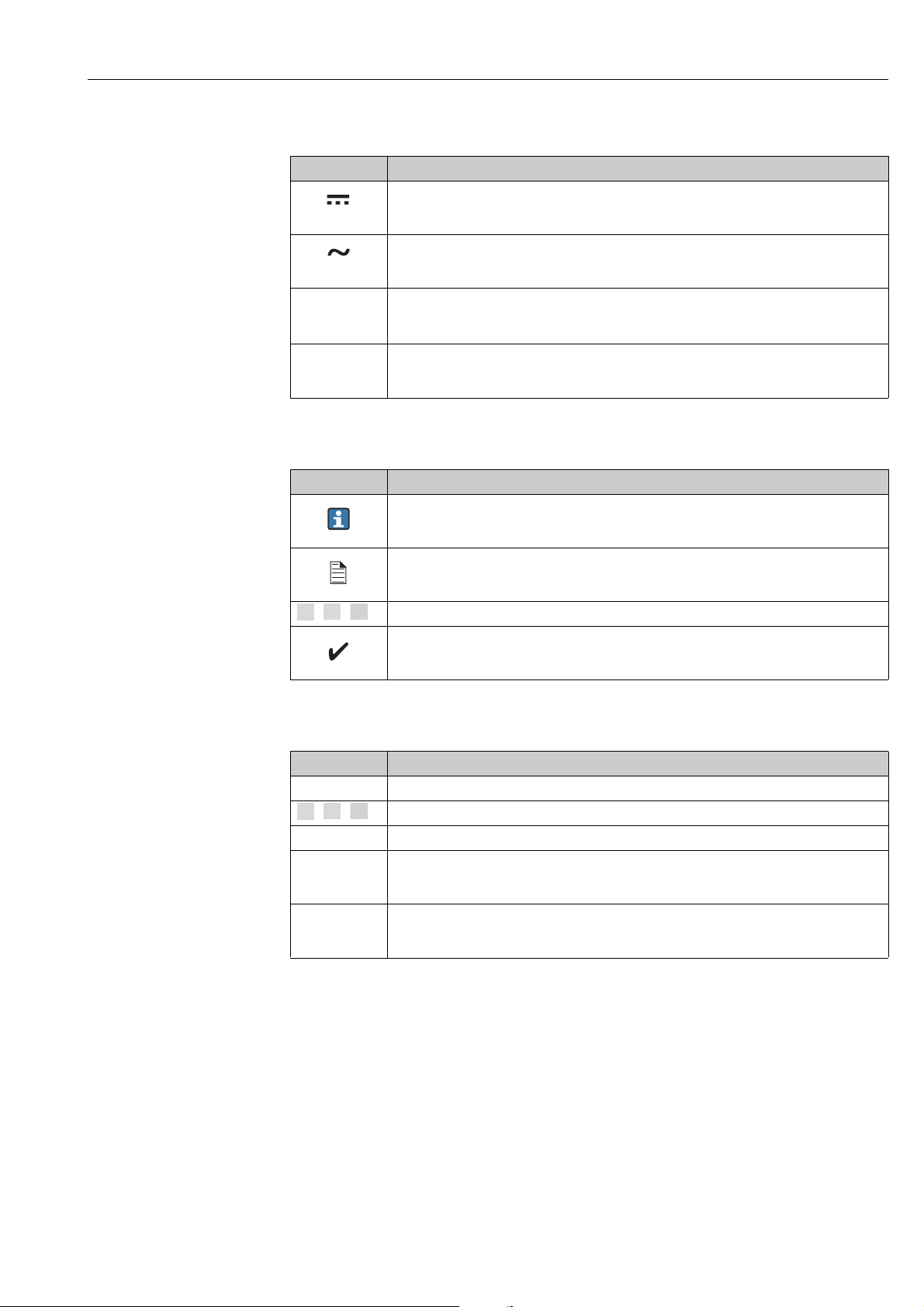

1.2.2 Electrical symbols

Symbol Meaning

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

A0011197

Alternating current

A terminal to which alternating voltage is applied or through which alternating current flows.

A0011198

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

A0011200

system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011199

1.2.3 Symbols for certain types of information

Symbol Meaning

Tip

Indicates additional information.

A0011193

Reference to page

Refers to the corresponding page number.

A0011195

, , ... Series of steps.

Result of a sequence of actions.

A0018373

1.2.4 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, , ... Series of steps

A, B, C ... Views

Hazardous area

Indicates a hazardous area.

A0011187

Indicates a non-hazardous location

Safe area (non-hazardous area)

A0011188

Endress+Hauser 5

Page 6

Document information Tankvision

1.3 Documentation

1.3.1 Operating instructions

Document number Instrument Type of Document

BA00339G/00

BA00340G/00 Installation Instructions

BA00424G/00 System Description

BA00426G/00 Operator Manual

BA01137G/00 Tankvision NXA820 OPC Server User Manual

• Tank Scanner NXA820

• Data Concentrator NXA821

• Host Link NXA822

Description of Instrument Functions

1.4 Registered trademarks

Microsoft®, Windows® and Internet Explorer

Registered trademarks of the Microsoft Corporation

®

Modbus

TM

Modbus is a registered trademark of Schneider Electric USA, Inc.

®

Java

Registered trademark of Oracle® Corporation

Mozilla

®

Firefox

®

Registered trademark of the Mozilla Foundation

6 Endress+Hauser

Page 7

Tankvision Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner operator

• Following the instructions in these Operating Instructions

2.2 Designated use

2.2.1 Application

Tankvision is a dedicated tank inventory management system.

Components:

• Tankvision Tank Scanner NXA820

scans parameters from tank gauges and performs tank calculations

• Tankvision Data Concentrator NXA821

summarizes data from various Tank Scanners NXA820

• Tankvision Host Link NXA822

provides data to host systems (such as PLC or DCS) via Modbus

The above mentioned components are operated via a standard web browser. It does not

require any proprietary software. Tankvision is based on a distributed architecture on a Local

Area Network (LAN). Due to its modular structure it can be adjusted to any application. It is

ideally suited for small tank farms with only a couple of tanks, but also for large refineries

with hundreds of tanks.

Endress+Hauser 7

Page 8

Basic safety instructions Tankvision

2.3 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national

regulations.

• Switch off the supply voltage before connecting the device.

2.4 Operational safety

Risk of injury!

• Operate the device in proper technical condition and fail-safe condition only.

• The operator is responsible for interference-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers

• If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

• Carry out repairs on the device only if they are expressly permitted.

• Observe federal/national regulations pertaining to repair of an electrical device.

• Use original spare parts and accessories from Endress+Hauser only.

2.5 Product safety

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device complies with the

applicable standards and regulations as listed in the EC declaration of conformity and thus

complies with the statutory requirements of the EG directives. Endress+Hauser confirms the

successful testing of the device by affixing to it the CE mark.

2.6 IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser can be contacted to provide support in performing this task.

8 Endress+Hauser

Page 9

Tankvision Recommendation PC configuration

3 Recommendation PC configuration

With all on the market available web browser entering the Tankvision web server is possible.

Nevertheless the pages are optimized for Microsoft Internet Explorer (supported version IE9,

IE10 and IE11– Compatibility Mode).

The user interface pages are optimized for a screen resolution of 1280x1024 (or higher).

Endress+Hauser 9

Page 10

User interface Tankvision

1

2

34

65

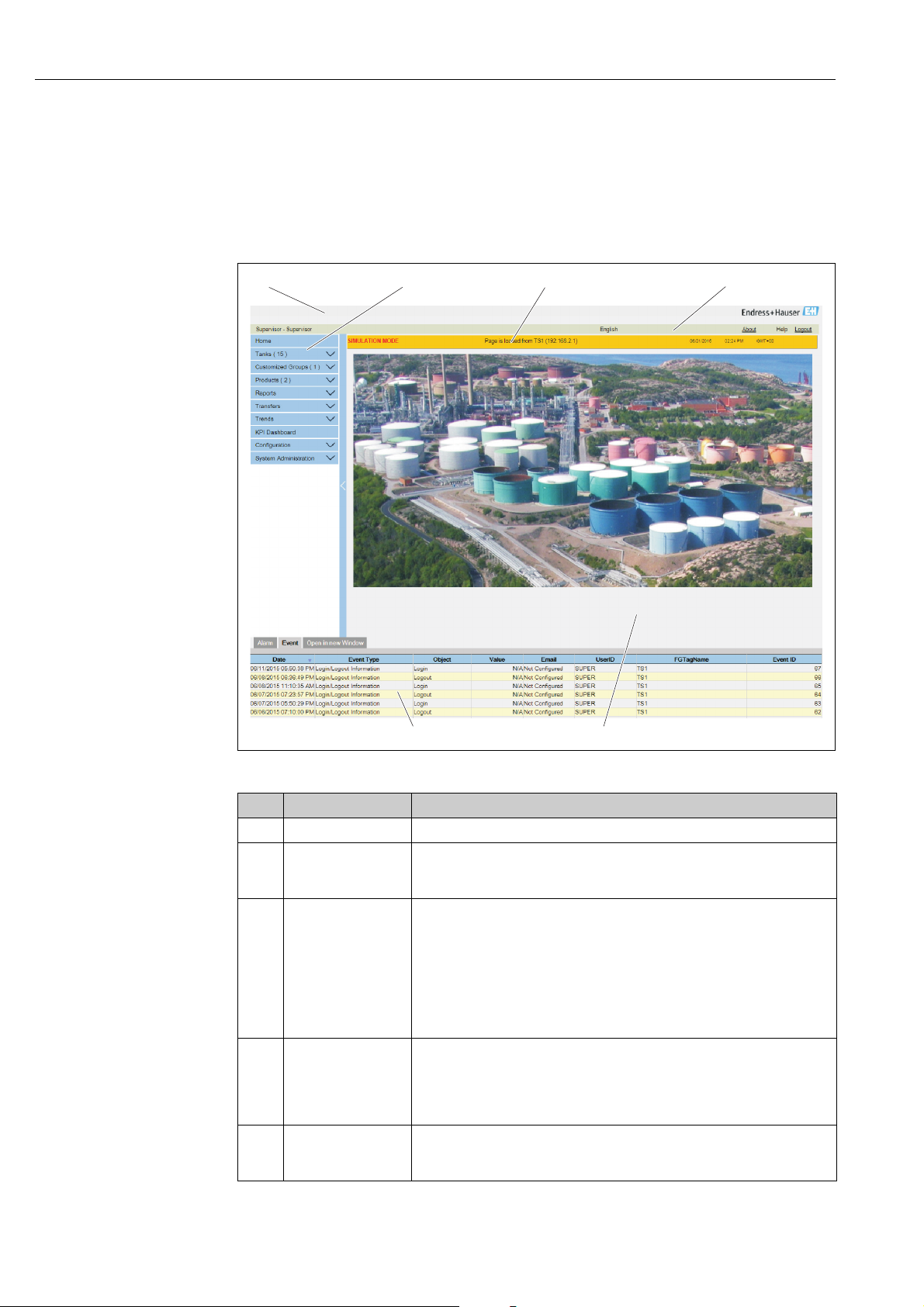

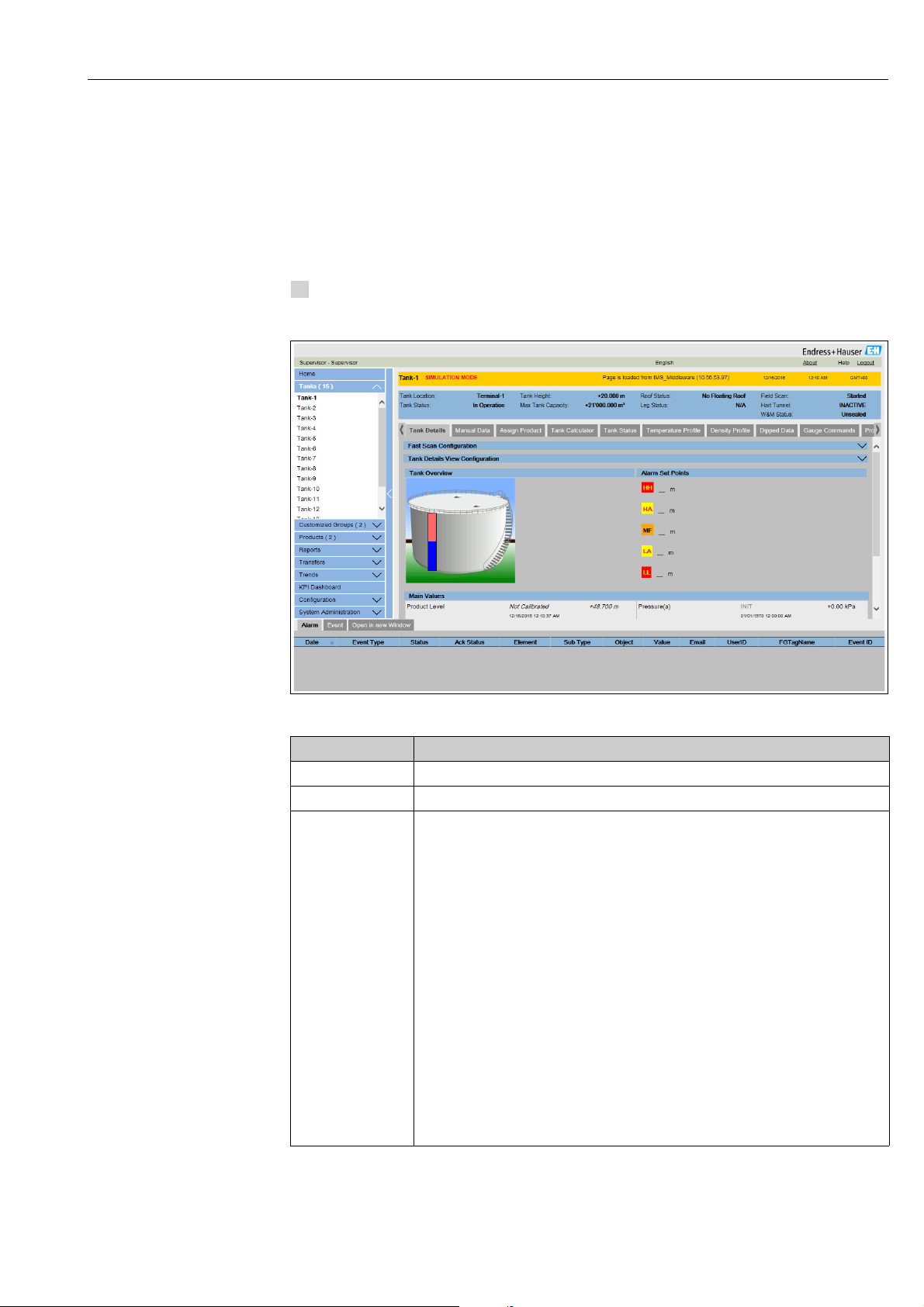

4 User interface

Tankvision provides an intuitive user interface allowing the user to quickly navigate through

the system. The following sections illustrate various parts of the Tankvision user interface

and their usage.

The Home Page

The_Homepage

Pos. Field Description

1 System Header Displays the Customer Logo or Graphic.

2 Navigation Tree Contains header bars corresponding to different functional objects or groups in

3 Main Header Displays the following information:

4 Metadata Header Displays the following information:

5 Main View Displays the screens that the user has selected to configure the settings and

the system.

Refer to "Navigation Tree - detailed description" (→ ä 11) for details.

• The site name, tank name, Tankvision tag name or product name depending on what is displayed in the Main View below the header

• The system date and time

The main header is displayed with a background color depending on the access

rights of the user logged into the system:

• Grey: the user does not have configuration rights and can only view data.

• Orange: the user has configuration rights and can view real time data.

• The user name and the user type

• The language options link

• The help link

• The logout option

view the operational information. Refer to "Main View Section- Colors in Edit

Data" (→ ä 12) for details.

10 Endress+Hauser

Page 11

Tankvision User interface

1

2

3

5

4

Pos. Field Description

6Alarm and Event

Panel

The Alarm and Event Panel displays the real time information about alarms

and events.

Refer to "Alarm and Event Panel Section- Description" (→ ä 12) for details.

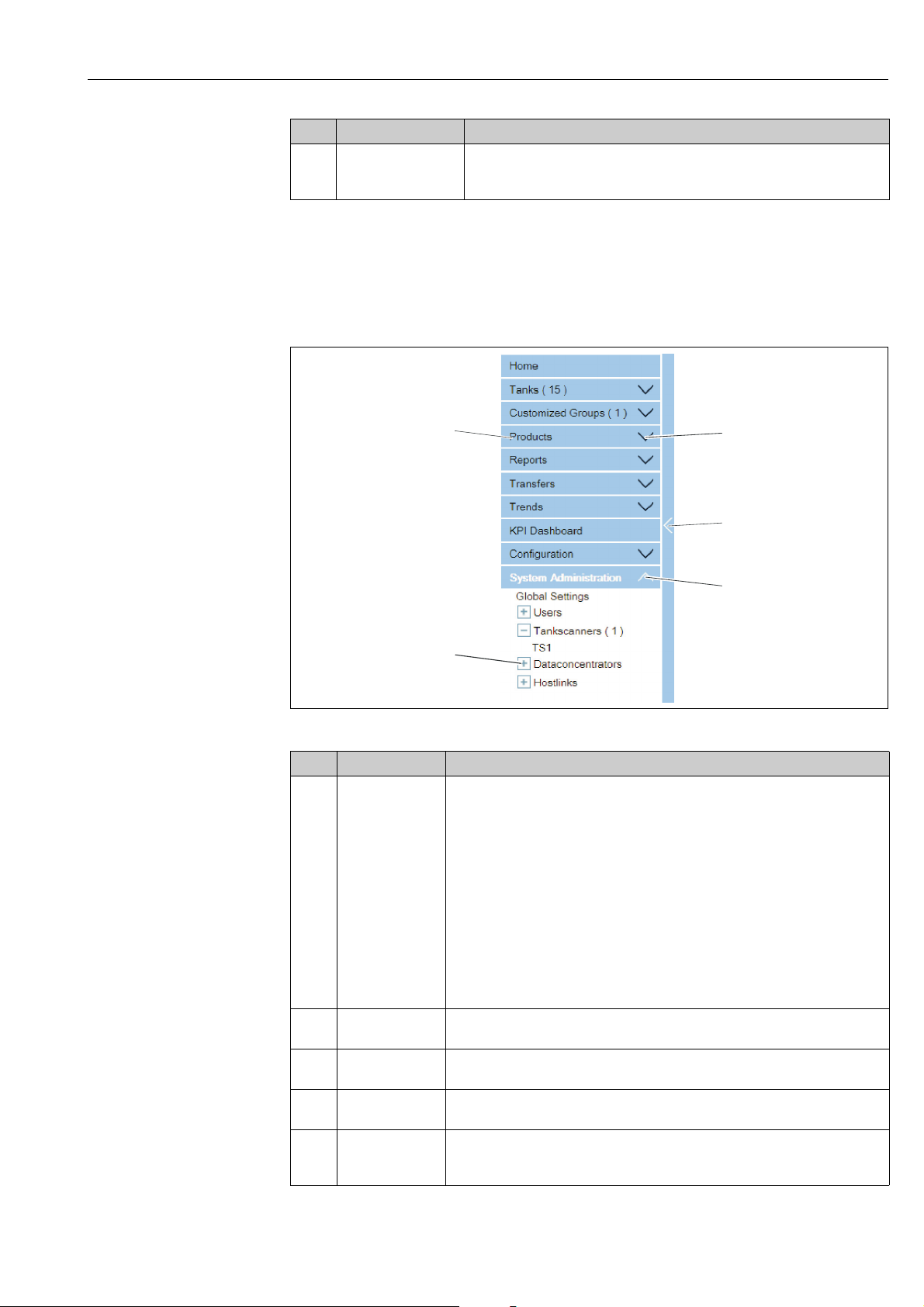

Navigation Tree - Detailed Description

The Navigation Tree is shown on the left side of the screen. Typically, the Navigation Tree

allows the user to navigate down to the tanks. The image of the expanded Navigation Tree

is as follows:

Navigation_Tree _Detailed_EN

Pos. Field Description

1 Header The user can click on the text or the arrow of the Header to expand or collapse the

branch.

The Header name shows a number, which is dynamically appended. The number

states the following:

• Tanks: The number of tanks in the NXA820

• Products: The number of products defined in the system

• Customized Groups: The number of tank groups defined in the system

• Transfers: The number of product transfer stages (Waiting, In Progress,

Finished, and Aborted) defined in the system

• Reports: The list of available system reports

• Users: The number of users defined in the system

• Historical Trend: Direct line to the historical Historical Data and Trend

functionality

The text will appear in bold and black when the header is in the expanded form.

2 Collapsed Arrow This type of arrow is displayed when the Header is in the collapsed position. Click

3Collapse/Expand

Navigation Tree

4 Expanded Arrow This type of arrow is displayed when the Header is in the expanded position. Click

5 Node The user can click on the Node to view the operational information on the Main

on the collapsed arrow to expand the Header.

The user can click on this arrow to collapse or expand the Navigation Tree.

on the expanded arrow to collapse the Header.

View section. If a Node is selected, it will appear in red color.

The number of tanks in the group is appended to the Node name.

Endress+Hauser 11

Page 12

User interface Tankvision

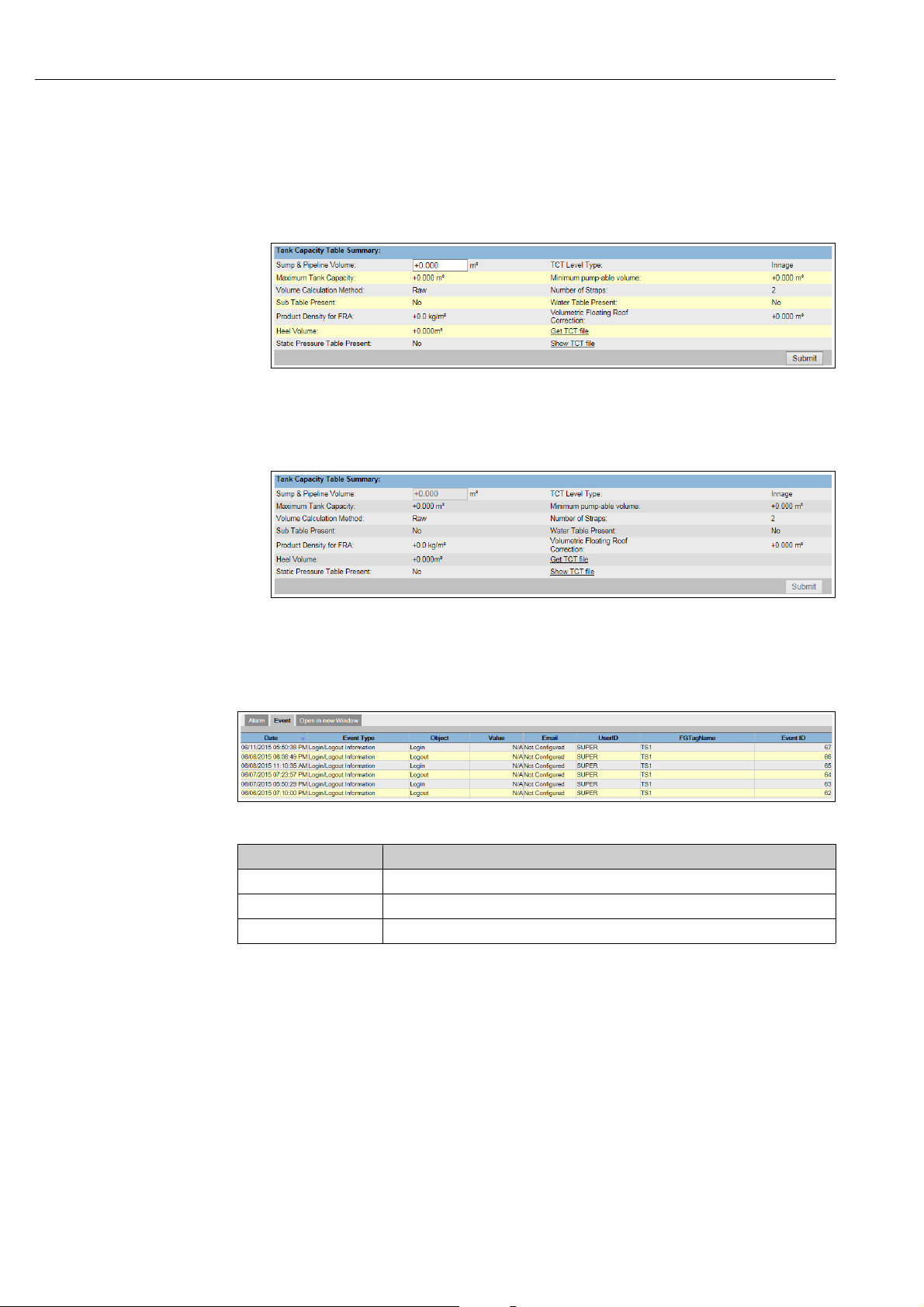

Main View Section - Colors in the Edit Data Area

The system displays different colors in the Edit Data area, based on the access rights of the

user:

1. If the user has access rights, then the edit data area has a light grey and light yellow

background on alternate rows. The Submit button to save the settings is enabled.

NXA82x_Tank-Capacity-Table-Summary

2. If the user does not have access rights, then the edit data area has a light grey and dark

grey background on alternate rows. The Submit button to save the settings is disabled.

NXA82x_Tank-Capacity-Table-Summary_Inactive

Alarm and Event Panel - Description

The Alarm and Event Panel displays the alarm and event information, which is dynamically

generated by the system. 200 events are shown.

Events (Overview)

Tab Description

Alarm Displays details of the alarms generated by the system.

Events Displays details of the events generated by the system.

Open in new Window Opens the Alarm and Event Panel in a new window.

12 Endress+Hauser

Page 13

Tankvision User access rights

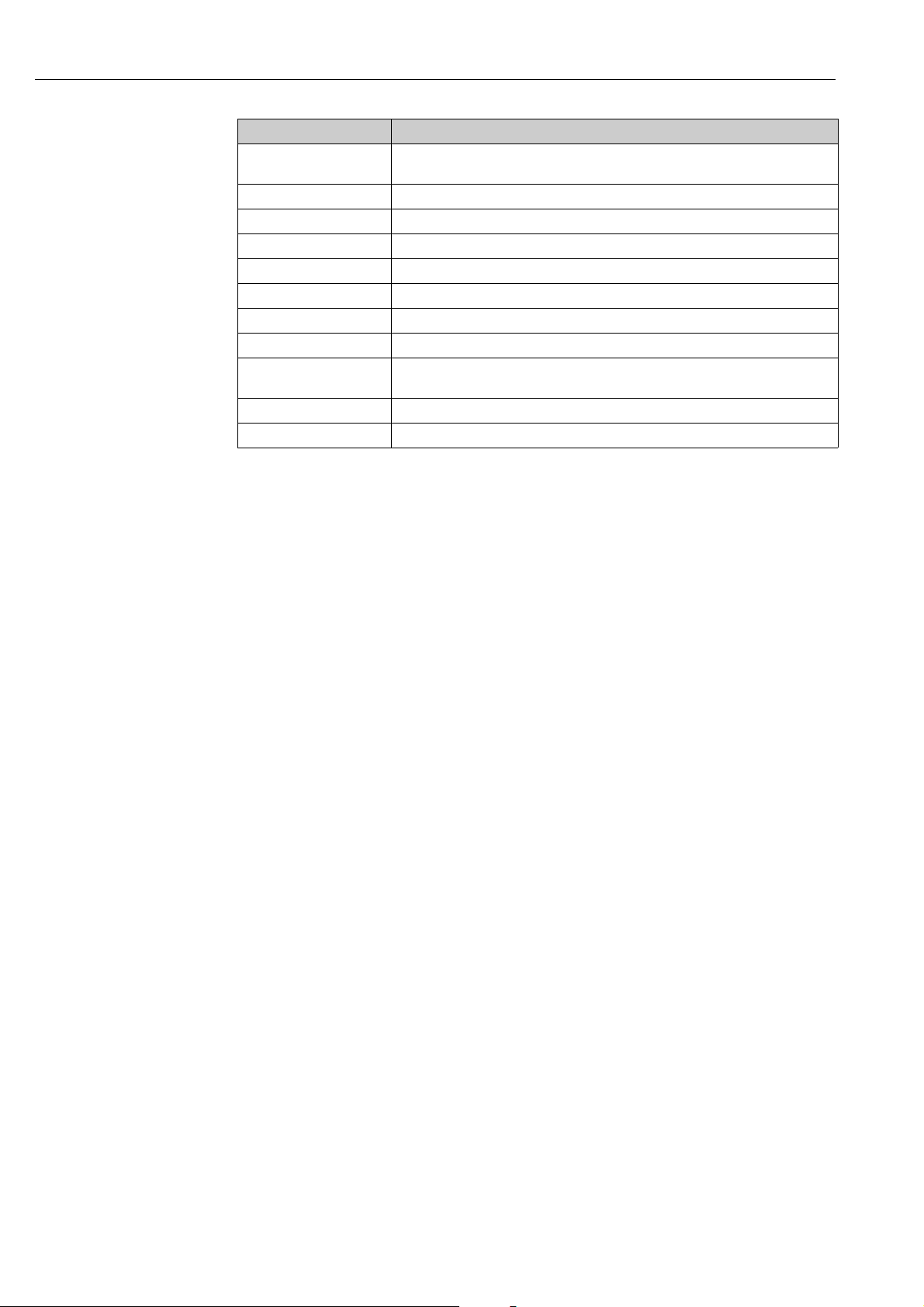

5 User access rights

The Tankvision system has an inbuilt authentication mechanism to prevent unauthorized

access. The system identifies the user by a unique logon name and password. The system

records all the activities performed by each user and allows only a specific number of users

from each user type to be logged in at the same time. This can be configured in system

settings by an authorized entity. Each Tankvision unit has an option to confine user access

rights data for local use within the unit or enable user access rights data for the central

Tankvision unit thereby allowing the user to access all the units that are configured to the

central Tankvision unit.

All in this manual described functionality is based on the default settings for the role

of the "Operator". The operator is not allowed to perform any changes in the user access

rights.

In case the "Operator" is allowed to perform other operations than the ones specified

with the default settings refer to the "Description of Instrument Functions" BA00339F/00/EN.

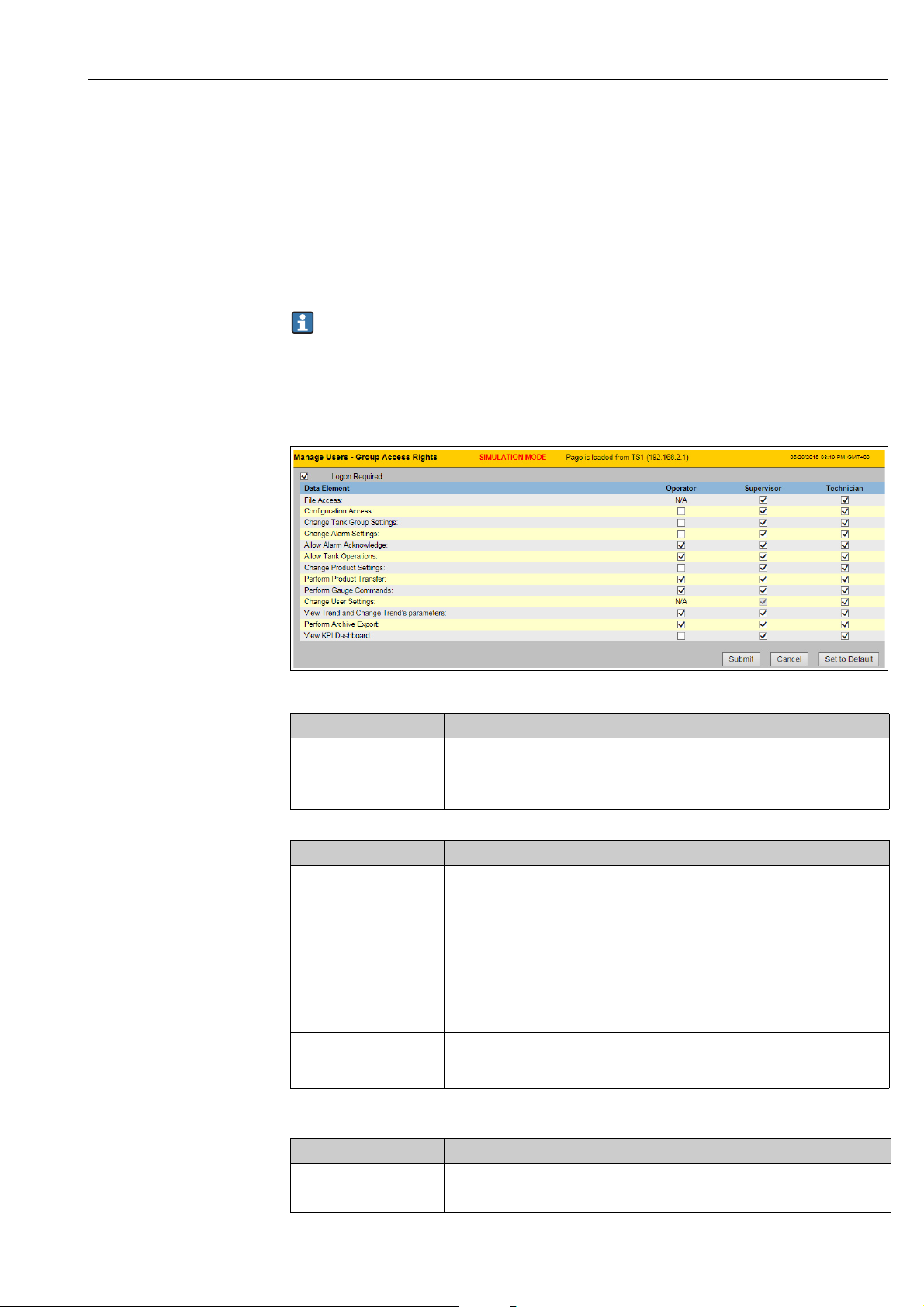

NXA82x_Manage-User-Group-Access -Rights

Field Description

Logon Required Select the check box to prompt the user to log on to access the Tankvision system.

Clear the check box to allow the user to access any feature of the Tankvision system

without logging in to the system. This Field indicates whether the user needs to

logon to the system to access the Tankvision functionality.

Column Description

Data Element This column displays a list of Data Elements, which are accessible only to specific

Operator An operator performs day-to-day operations at the tank farm and can view

Supervisor A supervisor configures and maintains the Tankvision system. He can view

Technician A technician is a service person from Endress+Hauser who performs the initial

user groups. To obtain access to these elements, the user with valid access rights

(for example, supervisor/ technician) needs to allot access rights to the user group.

refreshed data and alarm notifications. Select the appropriate check box to allow

the operator group to access the relevant Data Element.

refreshed data and alarm notifications. Select the appropriate check box to allow

the supervisor group to access the relevant Data Element.

setup and configuration of the Tankvision system. Select the appropriate check box

to allow the technician group to access a particular Data Element.

Data Elements Description

File Access Access to allow file upload or download e.g. Firmware or web page templates

Configuration Access Access to change configuration

Endress+Hauser 13

Page 14

User access rights Tankvision

Data Elements Description

Change Tank Group

Settings

Change Alarm Settings Allows to create, modify and delete alarm configurations

Allow Alarm Acknowledge Allows to acknowledge active alarms

Allow Tank Operations Allows to change tank status, product contents and enter manual data operations

Change Product Settings Allows to create, modify and delete products

Perform Product Transfer Allows to arm, start and stop product movements

Perform Gauge Commands Allows to issue, kill and schedule gauge commands

Change User Settings Allows to add, modify and delete users, and modify user access rights

View Trend and Change

Trend’s parameters

Perform Archive Export Allows the export of the archive.

View KPI Dashboard Allows to view the KPI Dashboard.

Allows to add, modify and delete tank group settings for static and dynamic tank

groups

Allows to configure real time and historical trend, and start or stop the real time

and historical trends

14 Endress+Hauser

Page 15

Tankvision Operations

1.

2.

3.

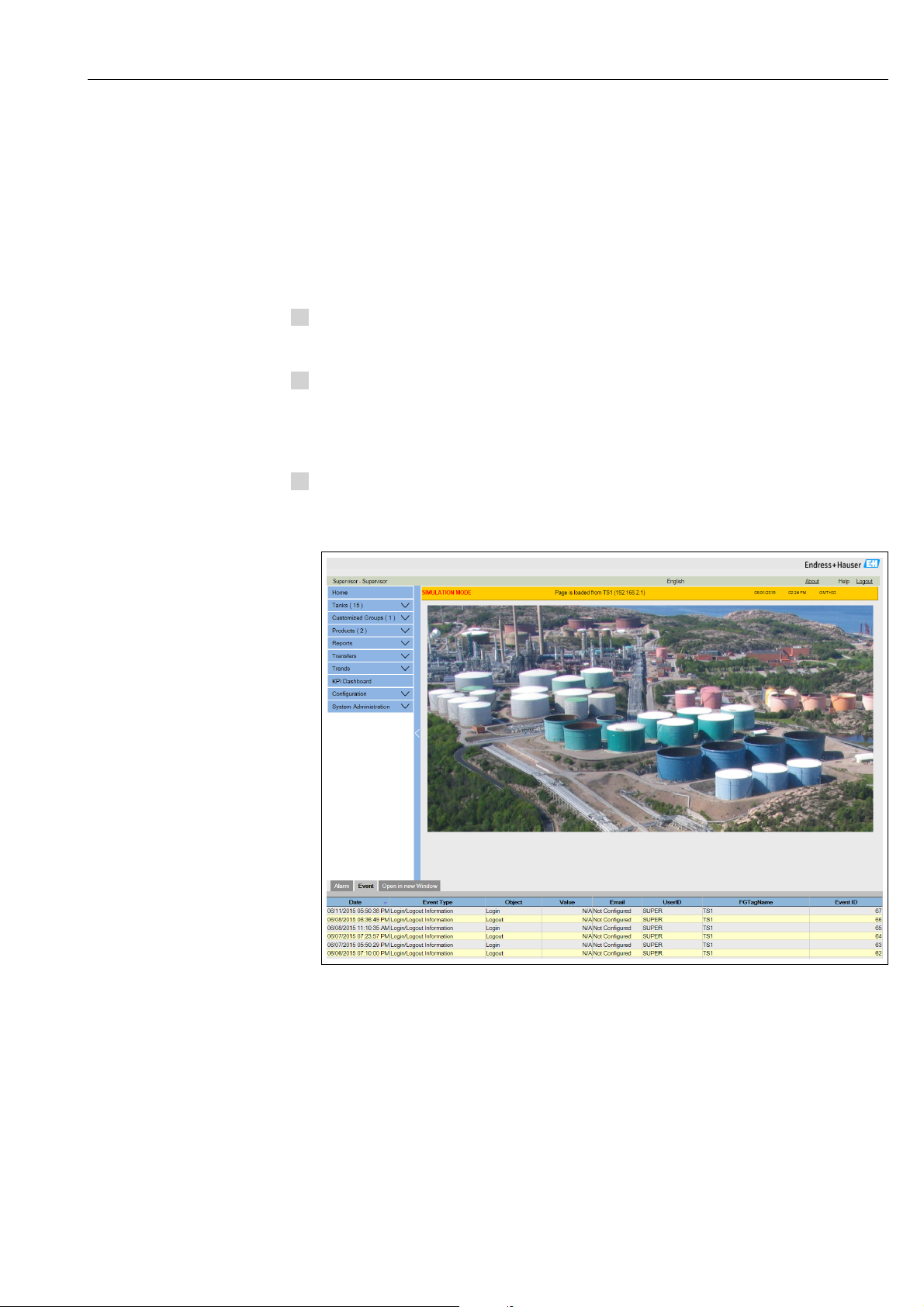

6Operations

6.1 How to log on?

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The user interface is reached via standard web browsers whereas the recommended web

browser is Microsoft Internet Explorer.

Open a browser window (depending on the PC configuration this point might be skipped

as opening a browser window is configured to be in the auto start and can’t be closed

without the necessary PC access rights.

Type in the IP address

IP addresses are specific for every single Tankvision units in the system (example IP

address 192.168.2.1). Depending on the browser configuration this point might be

skipped as it is recommended to select the Tankvision IP address as home page which is

automatically opened the browser starts up.

The user interface opens and is ready for operation. Per default Tankvision is delivered

without a logon required. In this case the default user access rights are set to Operator.

The following screens opens:

Endress+Hauser 15

Page 16

Operations Tankvision

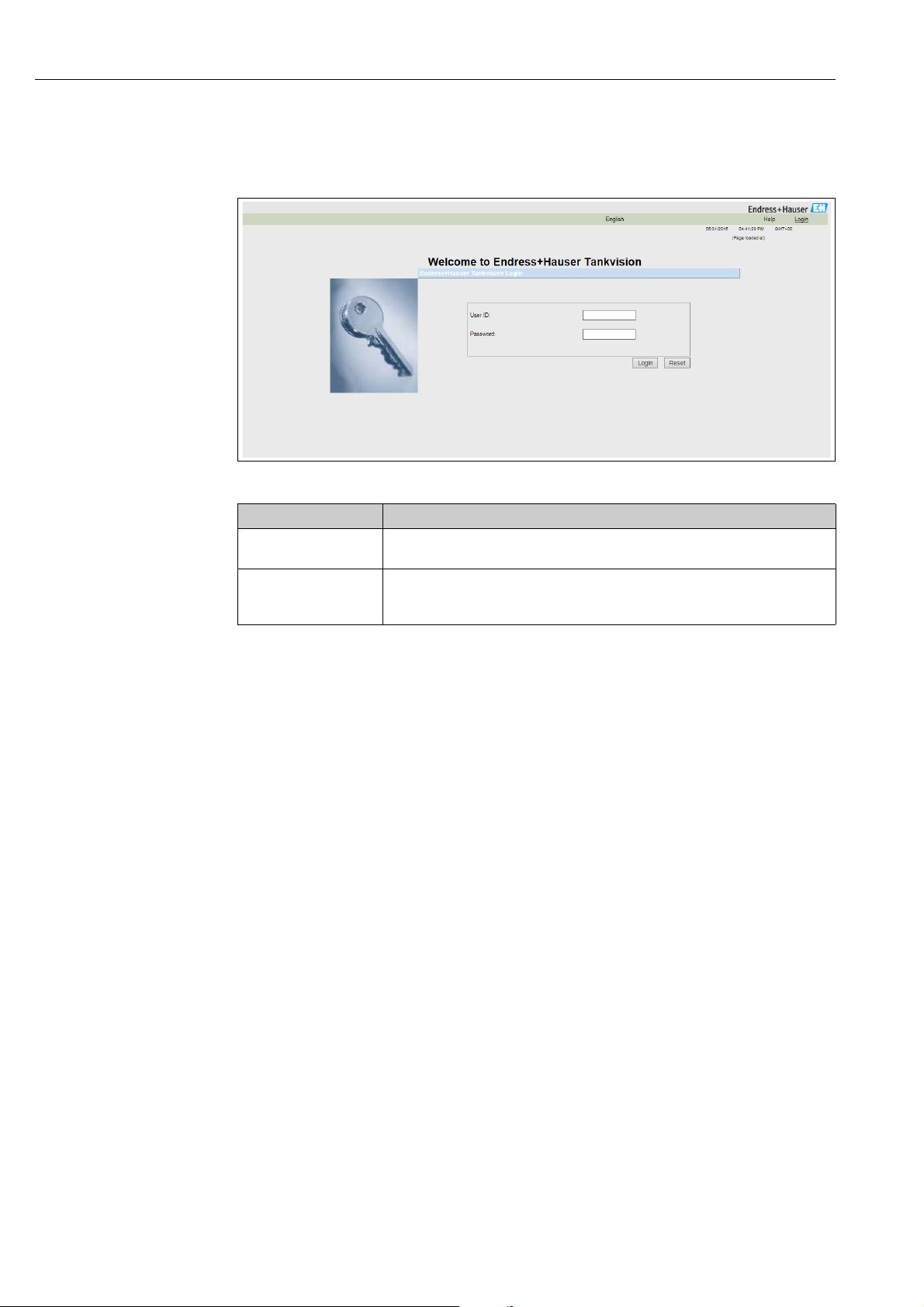

If Logon required is selected in the user access rights (done during commissioning by the

supervisor) the following screen opens before the above:

NXA82x_Login-Screen

Field Description

User ID Enter the appropriate user login name .

The user login name is alphanumeric and case sensitive.

Password Enter the appropriate password.

The user password is alphanumeric and case sensitive. It consists of 3 to 8

characters.

User ID and the according Password are created during commissioning. Factory default:

•User ID: Oper

• Password: Oper

16 Endress+Hauser

Page 17

Tankvision Operations

1.

6.2 How to view tank details

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The General Details tab displays the most important tank data dynamically.

To view the General Details tab

On the Tank Details screen, click the Tank Details tab. Tankvision displays the screen

as follows:

NXA82x_Tank_ General-Details-Tab

Column Description

Tank Overview This area displays the picture of the tank.

Alarm Set Points This area displays the corresponding Alarm Set Points for that particular tank.

Main Values This area displays the measured and calculated values of the product or tank parameters

in terms of temperature, pressure, density and water level along with their respective

units of measurement, depending on the configuration made in Tank Details View

Configuration (see BA00339G). The date and time at which the value of each parameter

has changed is also displayed along with the measured value status:

•OK

Ok Status

•INIT

Field Scan started, value not yet received and processed

•MANUAL

Value set to manual

• NODATA

Calculation not configured, Field Scan is off

• INVALIDDATA

Calculation is out of boundaries

• LASTVALIDVALUE

Value is set on HOLD, need additional servo configuration

•FAIL

Communication error on field protocol of device configuration

• NOT CALIBRATED

Value is not calibrated

Endress+Hauser 17

Page 18

Operations Tankvision

Column Description

Secondary Values This area displays the measured and calculated values of the product parameters in terms

of volume, tank capacity, reference density, floating roof adjustment, product and vapor

mass along with their respective units of measurement and status. Which values are

displayed, depends on the configuration made in Tank Details View Configuration (see

BA00339G).

Tank & Product

Configuration

This area displays the tank and product configuration data used for calculation.

18 Endress+Hauser

Page 19

Tankvision Operations

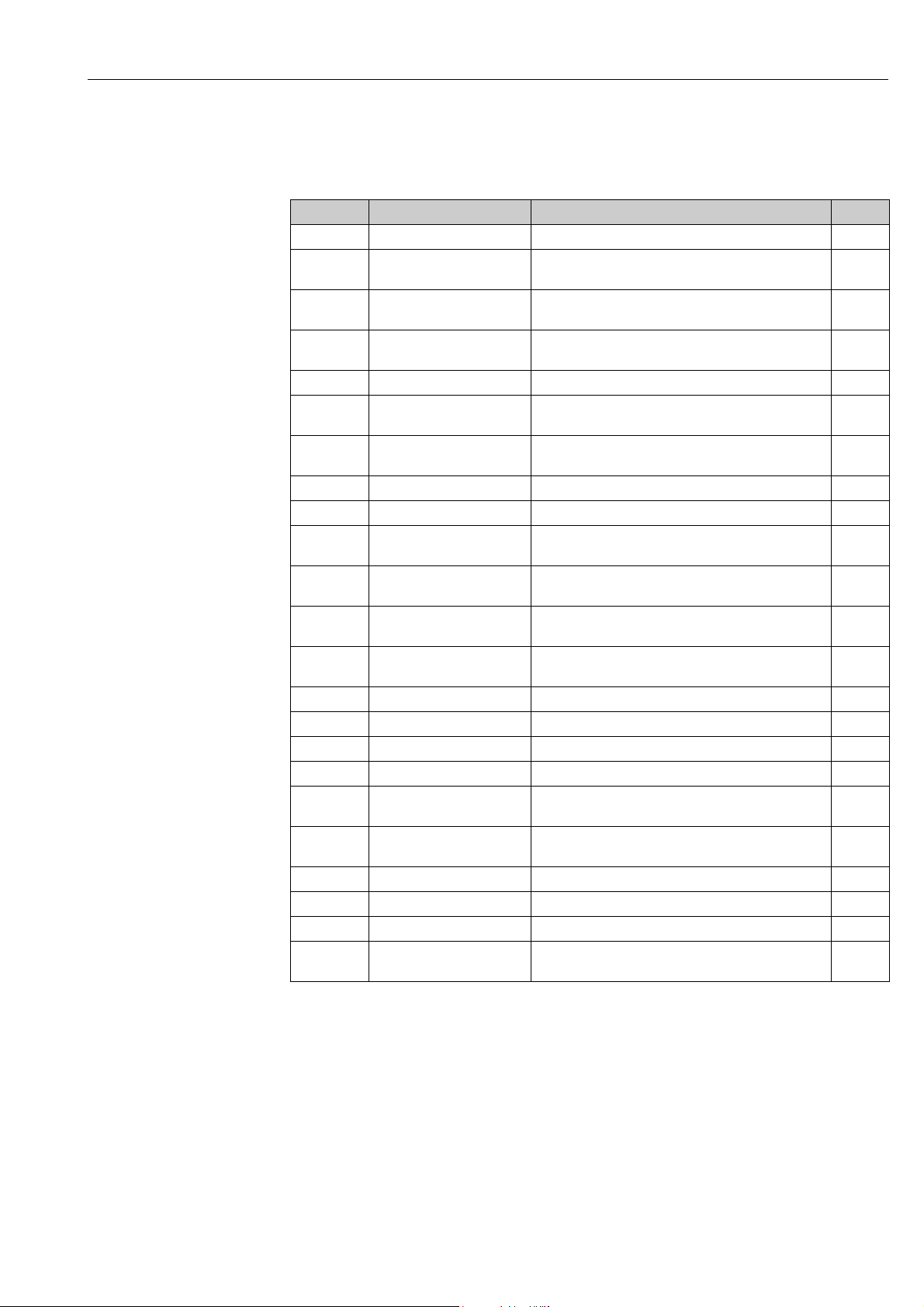

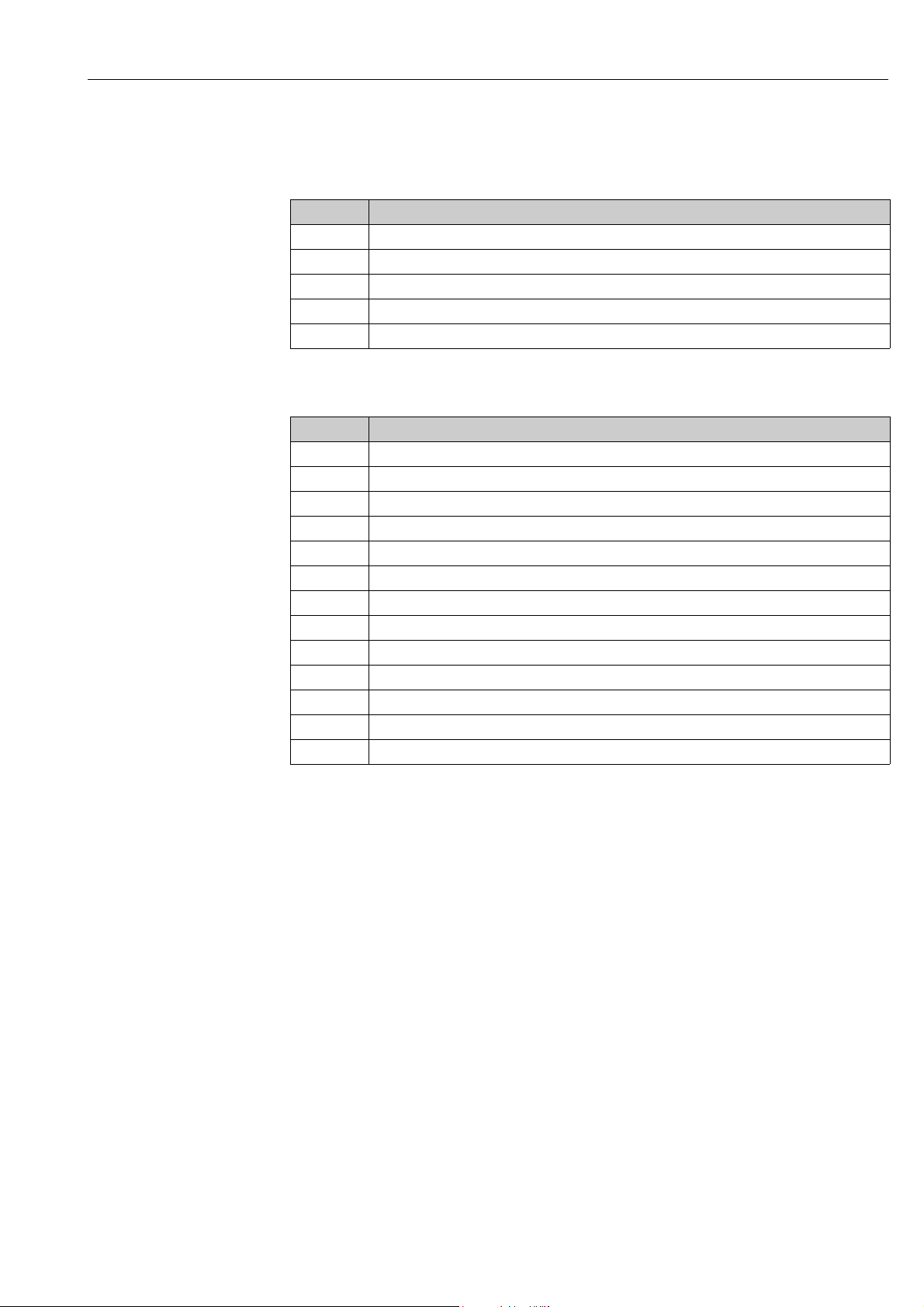

6.2.1 Error and Status codes Modbus communication

Gauge Error NMS5

Error Code Description Definition Remarks

0 No error No error present

101 OVER TENSION Measured displacer weight exceeds the Over Tension

set value at GVH 162

102 UNDER TENSION Measured displacer weight reduced below the Under

106 Z PHASE NO INPUT (2nd) Unable to recognize Z phase pulse (1 complete rotation

107 ADC/SENSOR ERROR Signal from AD converter out of the range

111 LOCAL ERROR NMT Recognize device error at the Prothermo NMT 53x

112 Z PHASE NO INPUT (1st) Unable to recognize Z phase pulse (1 complete rotation

113 LOCAL ERROR NRF Recognized device error at the Promonitor NRF560 *3

114 SIFA ERROR Local HART master IC failure on the Proservo

115 WIRE CALIB. ERROR Excess auto wire calibration range (e.g. build up on the

120 DISPLACER CALIB. ERROR Excess auto weight calibration range (e.g. deposit and

121 LCD CHECK Recognized error between display panel 3 keys control

122 A PHASE NO INPUT Unable to recognize a phase pulse (20 pulse / 1

124 POWER FAILURE Supply voltage drop below allowable value

201 MEMORY ERROR Memory defect in W&M parameters

232 LOCAL ERROR DEVICE1 Recognized device error at connected HART device 1 *3

233 LOCAL ERROR DEVICE 2 Recognized device error at connected HART device 2 *3

240 DEVICE ERROR NRF Local HART communication error to the Promonitor

250 DEVICE ERROR NMT Local HART communication error to the Prothermo

130 DEVICE ERROR: DEVICE1 Local HART communication error to the HART device 1 *3

131 DEVICE ERROR: DEVICE2 Local HART communication error to the HART device 2 *3

132 ROM ERROR Failure in the EEPROM data

133 ECONOUCE CONTACT ON Status input activated via connected switch (e.g. Leak

Tension set value at GVH 163

of encoder) to CPU after retry

*2

(Average Temperature)

of encoder) to CPU

wire)

build up on the displacer)

input to CPU

rotation of encoder) to CPU

*3

NRF560

*2

NMT53x

detector, level alarm switch)

Remarks

*2 Error code available only when the Prothermo NMT53x or 3 wire RTD SPOT

temperature bulb is connected.

*3 Error code available only when the Promonitor NRF560 or HART device 1/2 is

connected.

Endress+Hauser 19

Page 20

Operations Tankvision

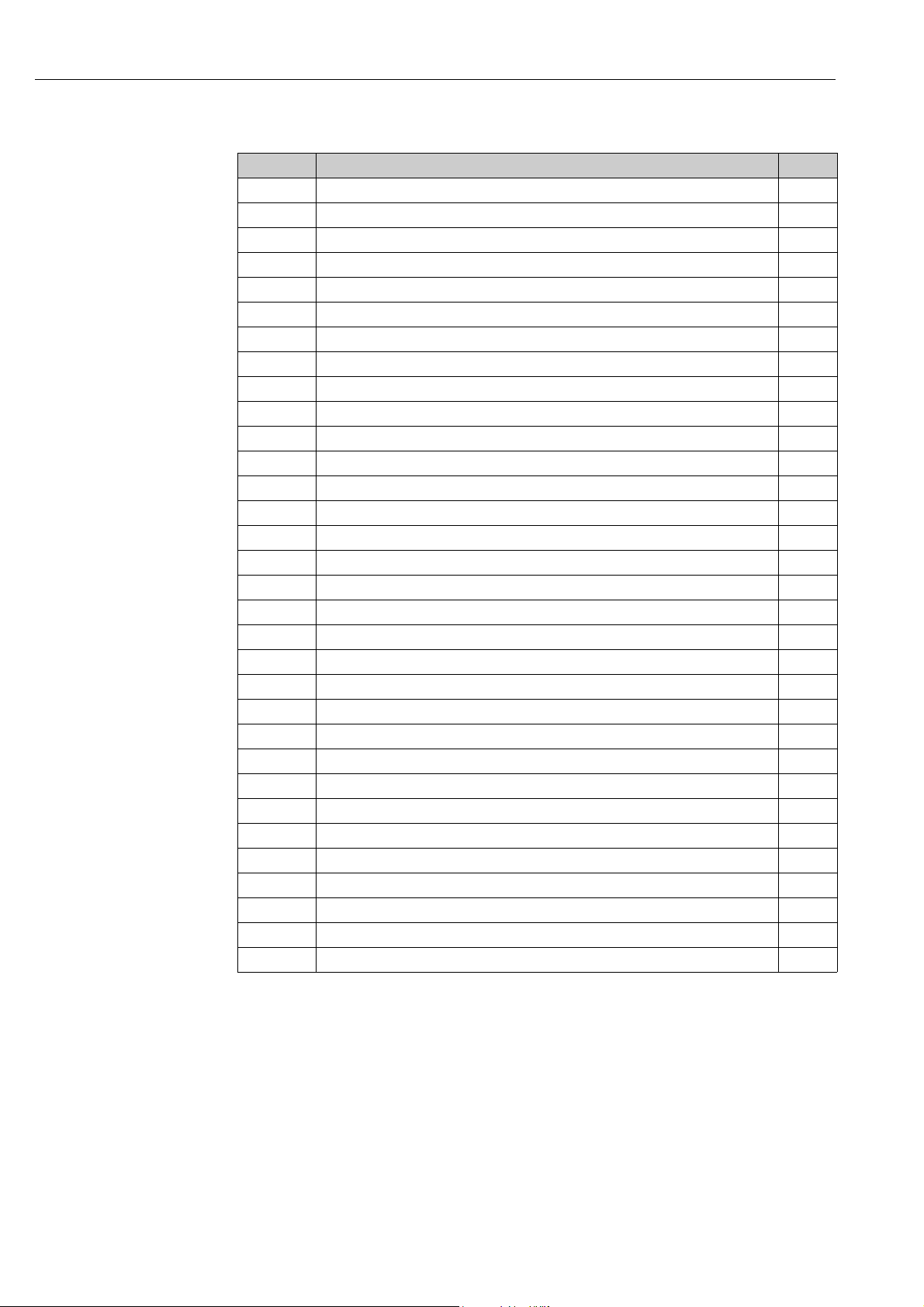

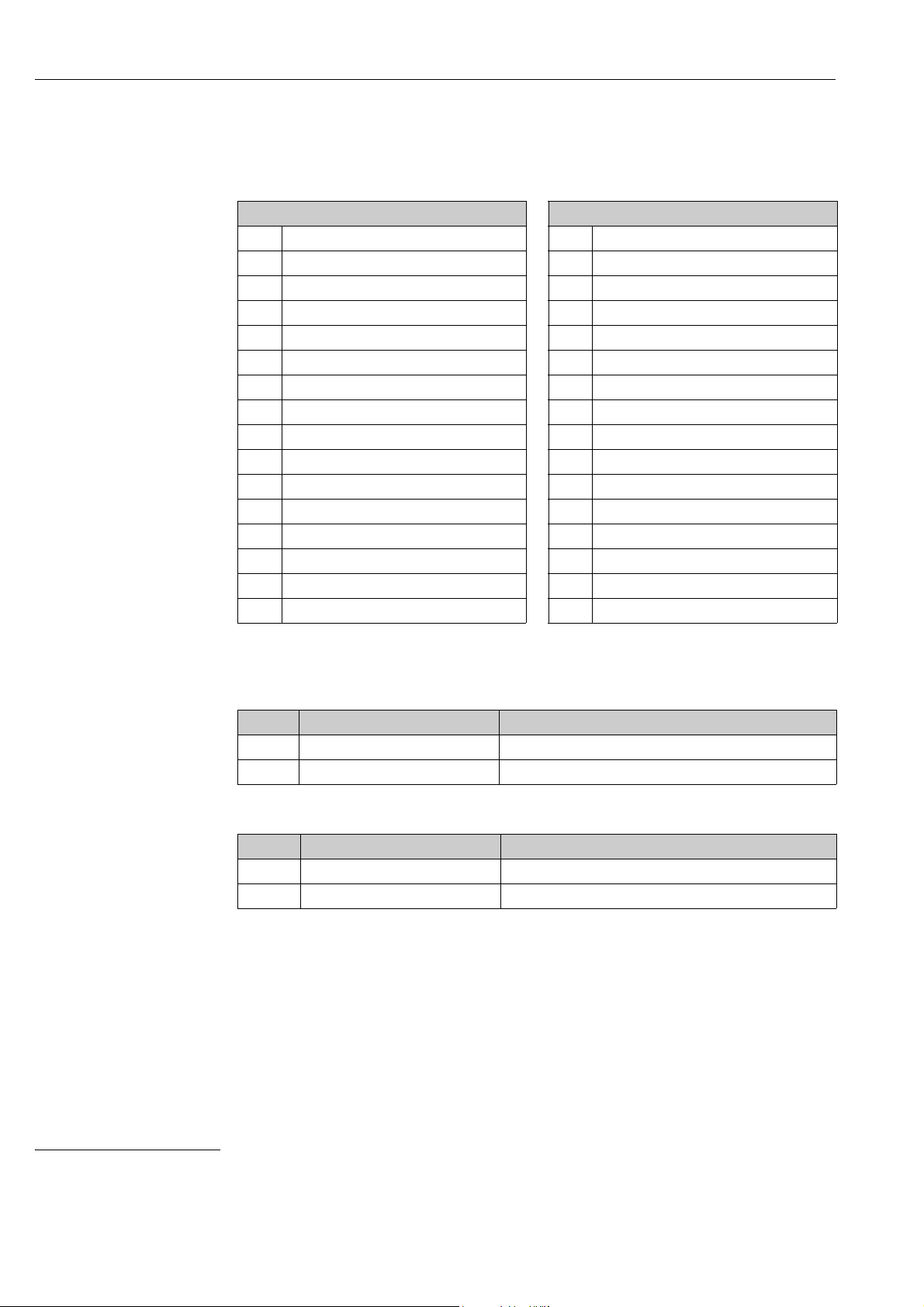

Gauge Status NMS5

Error Code Description Remarks

0 No definition

1 Displacer at reference position

2 Displacer hoisting up

3None

4Displacer stop

5 Level measurement, balanced

6 Up. I/F level, balanced *1

7 Mid. I/F level, balanced *1

8 Bottom meas. balanced *1

9 Upper Dens, finished *1

10 Middle Dens, finished *1

11 Bottom Dens, finished *1

12 Release over tension

13 Calibration activated

14 Seek level

15 Follow level

16 Seek Upper Density *1

17 Seek Middle Density *1

18 Seek Density Bottom *1

19 Seek Upper I/F level *1

20 Follow up. I/F level *1

21 Seek Mid. I/F level *1

22 Follow Mid. I/F level *1

23 Seek Bottom Level

24 Not initialised

25 Stopped at High Stop.

26 Stopped at Low Stop

27 Repeatability testing

28 Seeking water level *1

29 Water level, balanced *1

30 Follow water level *1

31 Over/Under Tension

Remarks

*1 Status available when the Proservo NMS53x is implemented with Interface and Density

measurement functionality.

For NRF590 neither status codes nor error codes are available the Gauge Error/Gauge Status

are set to 0 with the status INIT to show that the data are invalid.

20 Endress+Hauser

Page 21

Tankvision Operations

6.2.2 Error and Status codes V1

Error codes NMS5

Error Code Description

0No Error

1Over Tension

2 Under Tension

3Encoder Error

4Hall Sensor Error

Status codes NMS5

Status Code Operation Status

01 Up

02 Stop

03 Bottom

04 Upper Density

05 Level

08 Upper Interface Level

09 Release Over Tension

10 Middle Density

11 Density Bottom

12 Middle Interface Level

13 Calibration Active

27 Repeatability Testing

28 Water Dipping

Endress+Hauser 21

Page 22

Operations Tankvision

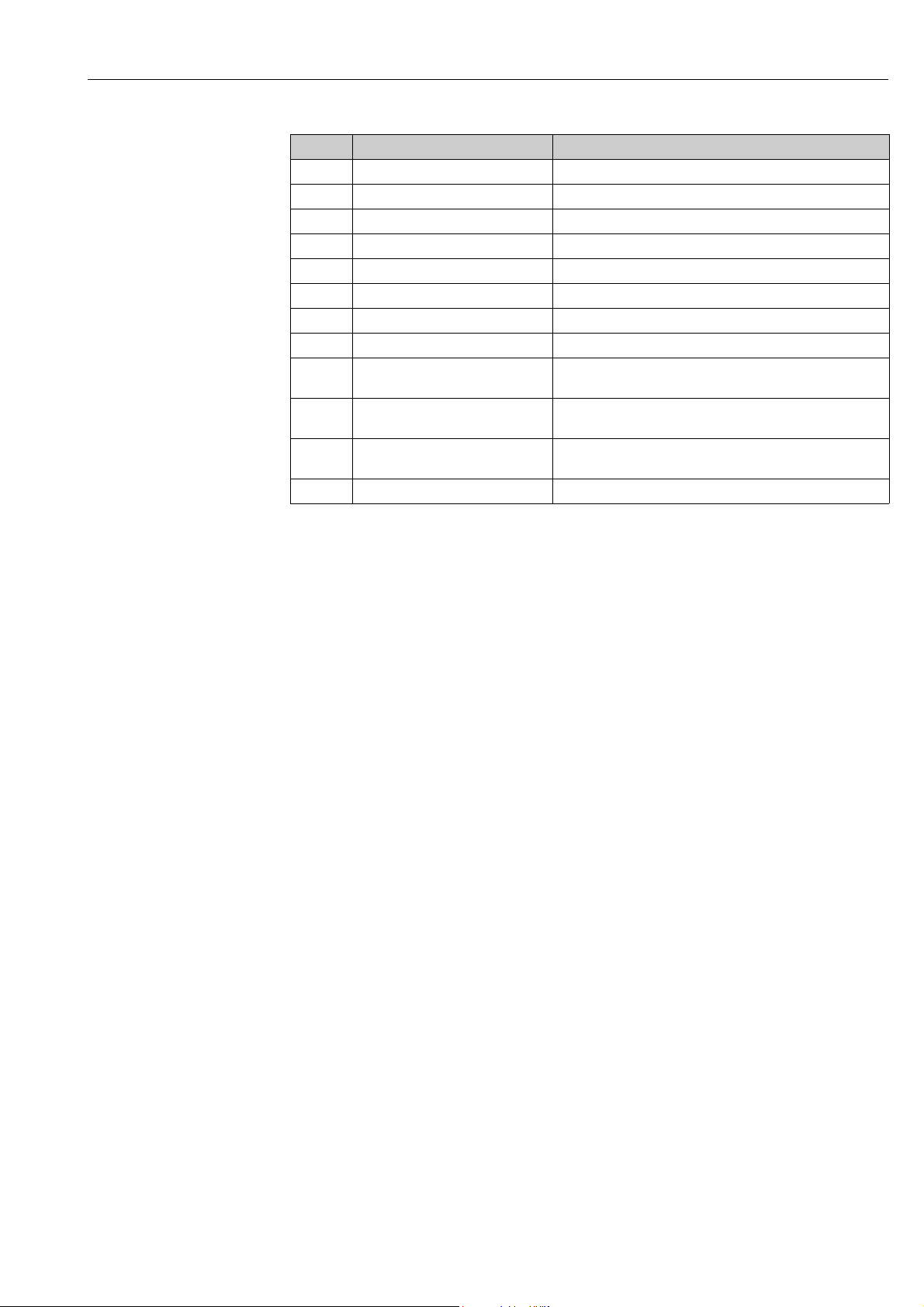

6.2.3 Status Codes WM550

With WM550 the status are transferred bit coded. In Tankvision this bit sequence is shown

as decimal number which needs to be transferred into bits to be interpreted.

Gauge Error Bits Gauge Status Bits

0 Servo Check 0Gauge Servoing

1Seeking Level

2 Doing Profile

3Doing Dip 3 Stow received on port 2

4Finding BSW

5Following BSW

6Finding Datum

7Following Level

8Density Sensor

9Temp. Sensor

10 BSW Sensor

11 Datum Sensor

12 Conf. Warning

13 Liquid State 13 -

14 Liquid State Unknown

15 ISH Fitted

1Gauge Stowed

2 Stow received on port 1

4NOVRAM corrupted

5 Multielement therm. Fitted

6 Ref. Voltage is DN

7Calibration bit 0

8Calibration bit 1

9Calibration bit 2

10 -

11 -

12 -

14 -

15 -

1)

Gauge Error from NRF590 and NMS5

Tank Side Monitor NRF590 (Task 2, 3, 4, 5, 9, 11, 27, 28, 30, 31, 36, 37, 38)

Decimal Bit Coded Description

0 0000’0000’0000’0000 Level

1 0000’0000’0000’0001 Stop

Proservo NMS5 (Task 2, 3, 4, 5, 9, 11, 27, 28, 30, 31)

Decimal Bit Coded Description

0 0000’0000’0000’0000 Level

1 0000’0000’0000’0001 Stop

1) To translate the decimal number in the gauge staus/gauge error field into binary number you can use the following formular in Excel (change A1

to the field the decimal number is written):

=RIGHT(SUMPRODUCT(INT(MOD(A1/2^(ROW(16:30)-1),2))*10^(ROW(1:15)-1))&TEXT(SUMPRODUCT(INT(MOD(A1/2^(ROW(1:15)-

1),2))*10^(ROW(1:15)-1)),REPT("0",15)),INT(LN(A1)/LN(2))+1)

22 Endress+Hauser

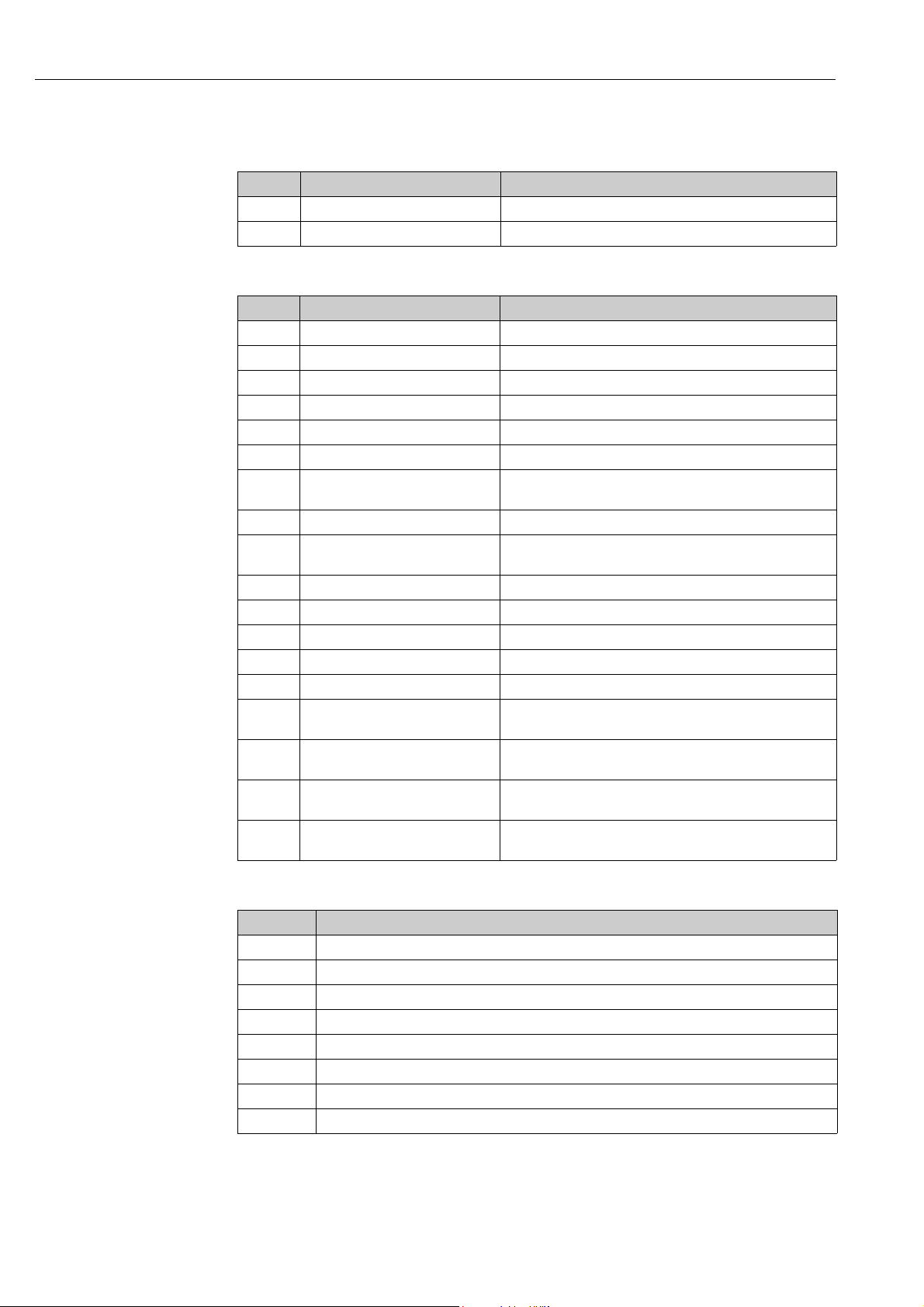

Page 23

Tankvision Operations

Proservo NMS5 (Task 36, 37, 38)

Decimal Bit Coded Description

16386 0100’0000’0000’0010 Level unbalanced or seeking level

16388 0100’0000’0000’0100 Upper density or density seeking

16400 0100’0000’0001’0000 Upper interface level (unbalanced) or upper interface seeking

16416 0100’0000’0010’0000 Upper interface level (balanced) or upper interface following

16448 0100’0000’0100’0000 Bottom level, Bottom Density seeking or Bottom seeking

16512 0100’0000’1000’0000 Level or Level following

49154 1100’0000’0000’0010 Level unbalanced or seeking level, compatibility mode

49156 1100’0000’0000’0100 Upper density or density seeking, compatibility mode

49168 1100’0000’0001’0000 Upper interface level (unbalanced) or upper interface seeking,

compatibility mode

49184 1100’0000’0010’0000 Upper interface level (balanced) or upper interface following,

compatibility mode

49216 1100’0000’0100’0000 Bottom level, Bottom Density seeking or Bottom seeking,

49280 1100’0000’1000’0000 Level or Level following, compatibilty mode

compatibility mode

Endress+Hauser 23

Page 24

Operations Tankvision

Gauge Error from NRF590 and NMS5

Status report (Task 1) NRF590

Decimal Bit Coded Description

0 0000’0000’0000’0000 No multi element temperature fitted

32 0000’0000’0010’0000 Multe element temperature fitted

Status report (Task 1) NMS5

Decimal Bit Coded Description

1 0000’0000’0000’0001 Gauge Servoing

5 0000’0000’0000’0101 Stow received on port 1

7 0000’0000’0000’0111 Stow received on port 1, Gauge Stowed

9 0000’0000’0000’1001 Stow received on port 2

11 0000’0000’0000’1011 Stow received on port 2, Gauge Stowed

21 0000’0000’0001’0101 NMS Error Code present (see below), Stow received on port 1

23 0000’0000’0001’0111 NMS Error Code present (see below), Stow received on port 1,

Gauge Stowed

25 0000’0000’0001’1001 NMS Error Code present (see below), Stow received on port 2

27 0000’0000’0001’1011 NMS Error Code present (see below), Stow received on port 2,

Gauge Stowed

33 0000’0000’0010’0001 NMT connected, Gauge Servoing

37 0000’0000’0010’0101 NMT connected, Stow received on port 1

39 0000’0000’0010’0111 NMT connected, Stow received on port 1, Gauge Stowed

41 0000’0000’0010’1001 NMT connected, Stow received on port 2

43 0000’0000’0010’1011 NMT connected, Stow received on port 2, Gauge Stowed

53 0000’0000’0011’0101 NMS Error Code present (see below), NMT connected, Stow

received on port 1

55 0000’0000’0011’0111 NMS Error Code present (see below), NMT connected, Stow

received on port 1, Gauge Stowed

57 0000’0000’0011’1001 NMS Error Code present (see below), NMT connected, Stow

59 0000’0000’0011’1011 NMS Error Code present (see below), NMT connected, Stow

received on port 2

received on port 2, Gauge Stowed

NMS Error Codes

Error Code Description

101 Over Tension

102 Under Tension

106 Z Phase no Input (2)

107 ADC Sensor Error

112 Z Phase no Input

115 Wire calibration error

120 Displacer calibration error

122 A Phase no input

24 Endress+Hauser

Page 25

Tankvision Operations

1.

6.2.4 WM550 Task-51

The WM550 protocol offers only a limited value resolution and therefore an additional

Task-51 has been added to the WM550 protocol for the Tank Side Monitor NRF590. This

Task-51 can be added to the foreground task in gauge map file as shown below:

NXA82x_WM550_Task51

The Task-51 delivers a predefined set of information which is described in the table below.

Measured Value Tank Parameter Granularity Units

Level Product Level 1 mm

BSW Water Level 1 mm

Temperature Product Temperature 0.1 °C

Temperature Vapor Temperature 0.1 °C

Pressure P1(Bottom) Pressure 0.01 bar

Pressure P2(Middle) Pressure 0.01 bar

Pressure P3 (Top) Pressure 0.01 bar

Density Observed Density 0.1 kg/m3

6.3 How to view Temperature Profiles

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The Temperature Profile tab displays measured values from the spot elements of an

average temperature probe, if configured.

Depending on the system architecture this parameters might be used for displaying

other values than temperatures.

To view the Temperature Profile tab

On the Tank Details screen, click the Temperature Profile tab. Tankvision displays the

screen as follows:

Temperature_Profile

Endress+Hauser 25

Page 26

Operations Tankvision

1.

The table presents the temperature profile data according to the corresponding

Temperature Index (element number, where the lowest element is the element number 1).

This information is also presented graphically next to this table in the Temperature Graph.

The amount of elements to be displayed (according to the average temperature probe which

is in use) can be selected in the Temperature Profile Configuration section.

6.4 How to view Density Profiles

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The Density Profile tab displays measured values from the spot elements of an average

density probe, if configured.

Depending on the system architecture this parameters might be used for displaying

other values than densities.

To view the Density Profile tab

On the Tank Details screen, click the Density Profile tab. Tankvision displays the

screen as follows:

NXA82x_Density_Profile

The table presents the density profile data according to the corresponding Density

Positions. This information is also presented graphically next to this table in the Density

Graph.

The amount of elements to be displayed (according to the average density probe which is in

use) can be selected in the Density Profile Configuration section.

26 Endress+Hauser

Page 27

Tankvision Operations

1.

2.

6.5 How to view and enter Manual Data

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13). The Manual Data tab gives you the option of

entering values for the product level, temperature, density and pressure manually.

Functionality is depending on the user right settings.

Selection of Parameters for manual data entry

Click the Manual Data tab. With opening the Set/Configure Manual Parameters the

following screen for selecting parameters for manual data entry is shown.

NXA82x_Manual-Data_Set-Confi gure-Manual-Parameters

The user can select one or several parameter from the available parameter list and move

them to the selected parameter list by using > button and clicking Submit. Using >>

moves all available parameters in the selected Parameters (deselecting works in

accordance by using the < or << buttons). From the following list the parameters can be

chosen (see below):

Field Description

Product level Enter the appropriate value for the product level in the according text box.

Water level Enter the appropriate value for the water level in the according text box.

Product Temperature Enter the appropriate value for the product temperature in the according text box. This

Vapor Temperature Enter the appropriate value for the vapor temperature in the according text box. This

Ambient

Temperature

Observed Density Enter the appropriate value for the observed density in the according text box. This field

Sample Temperature Enter the temperature at which the density of the sample was measured in the according

Reference Density Enter the appropriate value for the reference density in the according text box. This field

The data type for this field is numeric.

The data type for this field is numeric.

field displays the temperature of the product in the tank. The data type for this field is

numeric.

field displays the temperature of the vapor in the tank. The data type for this field is

numeric.

Enter the appropriate value for the ambient temperature in the according text box. This

field displays the ambient temperature outside the tank. The data type for this field is

numeric.

displays the observed density of the product in the tank. The data type for this field is

numeric.

text box. This field displays the temperature of the density sample. The data type for this

field is numeric.

displays the reference density of the product in the tank. The data type for this field is

numeric.

Endress+Hauser 27

Page 28

Operations Tankvision

3.

1.

2.

3.

4.

Field Description

Vapor Pressure Enter the appropriate value for the vapor pressure in the according text box. This field

displays the vapor pressure of the product in the tank. The data type for this field is

numeric.

In the radio buttons below mark the pressure measurement method: absolute or

relative.

Pressure Enter the appropriate value for the pressure in the according text box. This field displays

the pressure of the product in the tank. The data type for this field is numeric.

In the radio buttons below mark the pressure measurement method: absolute or

relative.

Tankvision will show a confirmation message and the parameters are now available to

enter manual values.

To enter manual data

Click the Manual Data tab. Tankvision displays the screen as follows:

NXA82x_Manual-Data_Enter-Manual-Parameters

Column Description

Parameter Name This column displays a list of the tank parameters that can be configured manually.

Manual Gauge Value This column displays the text boxes that allow the user to enter the data for the relevant

parameter.

Enter the appropriate information in the relevant fields.

Click the Submit button.

After saving the settings, Tankvision displays a confirmation message.

An event is generated after manually entering a value for a tank parameter. The event

details can be viewed in the Event overview.

28 Endress+Hauser

Page 29

Tankvision Operations

6.6 How to enter dipped data

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The Dipped Data tap gives you the option of entering dipped values for the product level,

water level, product temperature, observed density with acc. sample temperature and the

reference density.

Dipped Data

Field Description

Product level Enter dipped values for the product level. Activate the field by enabling the check box in

the beginning of the column.

Water level Enter dipped values for the water level. Activate the field by enabling the check box in the

Product temperature Enter dipped values for the product temperature. Activate the field by enabling the check

Date and Time Enter the appropriate Date and Time in the text box / drop down list. This time will be

beginning of the column.

box in the beginning of the column.

used as time stamp for the manually entered value. The data type for this field is time.

6.7 How to issue gauge commands

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

Every gauge supports a specific set of commands. The Tankvision system supports these

gauges and stores their data and corresponding gauge commands in "gauge definition files".

The functionality of gauge commands is dependent on the gauge type assigned to the tank,

whereas completion of a gauge command is based on the gauge status or gauge commands

status. The Tankvision system retrieves these commands from the "gauge definition files"

during the configuration of gauge commands. Gauge commands can be scheduled and sent

only by an authorized user. Most of these commands are unique for servo gauges. You can

send a gauge command to a gauge installed on a tank manually or even schedule a gauge

command to be sent automatically.

Tankvision Tank Scanner prevents the user to send the same gauge command multiple times

to a servo gauge (i.e. the Tank Scanner only sends gauge command once to the servo gauge

and ignores the gauge command until a new command is requested). This applies for gauge

command requests via the Host Link, OPC DA or the web interface.

In case a gauge command has been given to the servo gauge via a separate way (e.g. directly

from the display), then the Tank Scanner will not get this information. In this case simply by

sending a different gauge command and switching back to the gauge command will solve the

issue.

6.7.1 Schedule Gauge Command

The Tankvision system allows the user to schedule gauge commands, such that they can be

executed either immediately or at a certain time. An operator can schedule a gauge

command only if that particular gauge command is enabled in the Gauge Command

configuration screen.

Endress+Hauser 29

Page 30

Operations Tankvision

1.

2.

3.

To schedule a gauge command

Click the Gauge Commands tab. Tankvision displays the screen as follows:

Gauge_Commands

Click on Schedule Gauge Command. Tankvision displays the screen as follows:

NXA82x_Tank_Gauge-Commands-Tab

Field Description

Gauge Type This field displays the Gauge Type.

Gauge Command Select the appropriate gauge command from the drop down list.

Schedule Type Select the appropriate Schedule type from the drop down list. The gauge command can be

Interval Enter the appropriate interval in the text box. This field is enabled if the Schedule Type

Date Enter or select the appropriate date from the drop down calendar. The Tankvision system

Status Select the appropriate option. This field indicates the status of the gauge command. This

The data type for this field is "character".

scheduled to be sent once or scheduled for automatic repetition.

Sent Once: Select sent once to enable the gauge command to be sent only once.

Automatic Repetition: Select automatic repetition to enable the Interval field.

This field allows you to schedule the system to send a particular gauge command

periodically. The data type for this field is "character".

for the gauge command is selected as Automatic Repetition. The data type for this field

is "numeric".

Also, in the adjacent text box:

Select the appropriate unit for the interval from the drop down list. The system allows

you to schedule the interval for the gauge commands in terms of hours or minutes.

The data type for this field is character.

allows you to select the date on which the gauge command is to be sent. The data type for

this field is alphanumeric. Also, enter or select the appropriate time in terms of hours and

minutes from the respective drop down lists. The Tankvision system allows you to select

the exact time at which the gauge command is to be sent. If the Schedule Type for a

gauge command is "automatic repetition", then the time entered in the text boxes

indicates the first time the gauge command is to be sent. The data type for this field is

numeric.

field allows you to enable or disable a gauge command.

Enter the appropriate information in the relevant fields.

30 Endress+Hauser

Page 31

Tankvision Operations

4.

5.

Click the "Submit button to send a gauge command, or click the Reset button to exit.

After saving the settings, Tankvision displays a confirmation message.

The system generates an event, when the Gauge Command is sent. This information

can be viewed in the Event tab.

Error Messages

1. "Cannot send gauge command while tank status is Manual, In Maintenance, or Locked."

This message appears when the user sends a gauge command while tank status is

Manual, In Maintenance or Locked.

Endress+Hauser 31

Page 32

Operations Tankvision

1.

2.

3.

4.

5.

6.7.2 Send Gauge Command

The Tankvision system allows you to send commands to a gauge installed on a tank. A gauge

command can be sent only if that particular command is enabled for the tank in the Gauge

Command configuration screen. Once a gauge command is sent, it remains active till the

system receives an appropriate response from the gauge. The response for a gauge

command depends on the gauge and communication protocol.

The Tankvision system allows the user to send gauge commands via following interfaces:

1. Via Tankvision Tankscanner web interface

2. Via connected Host application with NXA822

3. Via OPC Server

To send a gauge command

Click the Gauge Commands tab. Tankvision displays the screen as follows:

Gauge_Commands

Click on Send Gauge Command. Tankvision displays the screen as follows:

NXA82x_Gauge-Commands_Send-Gauge-Co mmand

Field Description

Product level

Product temperature

Status

Date and Time

Column Description

Select Select the appropriate gauge command option corresponding to the gauge command

Gauge Command This column displays a list of gauge commands in abbreviated form.

Description This column displays a short description corresponding to each gauge command.

Displaying Product Level and Product Temperature incl. Status

Displaying Active Gauge Command and issuing Date and Time

name.

The radio buttons are highlighted only if the corresponding gauge commands are

configured in the Gauge Command screen.

Select the appropriate gauge command option.

Click the Send button to activate the gauge command.

After saving the settings, Tankvision displays a confirmation message as follows:

32 Endress+Hauser

Page 33

Tankvision Operations

6.

NXA82x_Gauge-Commands_Send-Gauge-Command_Successfully

In the above figure, all options in the Select column are disabled, except the Stop option.

If the gauge command has to be stopped, then select the stop option, and click the Send

button.

If another gauge command needs to be sent, it might be necessary to cancel the active

command by sending the STOP command prior issuing the new command.

The system generates an event, when a Gauge Command is activated. This information

can be viewed in the Event tab.

Error Messages

1. "Cannot send gauge command while tank status is Manual, In Maintenance, or Locked."

This message appears when the user sends a gauge command while the tank status is

Manual, In Maintenance or Locked.

Endress+Hauser 33

Page 34

Operations Tankvision

1.

2.

6.8 How to view a real time trend

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The Tankvision system collects data from the tanks and monitors these values using a trend.

A trend is a line graph which gives a pictorial representation of the recent changes of the

measured values over time. The Real Time Trend is hosted in the Tankvision unit. It depicts

the real-time measured or calculated values of a selected tank as a function of time in the

form of a line chart.

The system has default settings which can be customized as required for each tank element

and will eventually be plotted on the trend. Up to 4 values can be plotted in one chart.

To view a real time trend

In the navigation tree, click the Trends header. Click Real Time trend. Tankvision

displays the screen as follows:

NXA82x_Trends_Real-Time-Tren ds_Trend-Configuration

Section Description

Pen settings This section displays a list of pens (Pen 0, Pen 1, Pen 2 and Pen 3) that are used to

identify the parameters selected. Select the appropriate tanks, parameters, pen colors

and pen style from the respective drop down lists.

Global trend settings Select the Background color, Grid color and Plot Cursor color from the respective drop

down lists.

Trend preview See a preview of the real time trend plot with the currently selected settings.

Select the appropriate settings and click the apply button. Tankvision displays the

screen as follows:

34 Endress+Hauser

Page 35

Tankvision Operations

NXA82x_Trends_Real-Time-Trends_T rend-Configuration

The line graphs are displayed based on the selection of tank parameters in the Trend

Configuration area.

A plotter can be moved through the graphic area. According to the position of the plotter

values are displayed in a field next to it. For example:

NXA82x_Trends_Real-Time-Trends _Trend-Configuration_Plotter

Click and drag with the mouse to zoom into the graph.

Field Description

Period The Period icons allow you to make changes to the current time window. The selected

period (last 6 hours, 3 hours, 90, 60, 30, 15, 10, 5 minutes or the last minute) is

displayed in the plotting area.

print chart The print chart icon lets you print the current real time trend chart with a connected

printer.

Endress+Hauser 35

Page 36

Operations Tankvision

Field Description

Pan The Pan icons allow you to make changes in the current time window displayed in trend.

The Go First button rewinds the trend to the oldest available values in the rolling

data buffer of the trend.

The Go Previous button shows the previous time window.

The Go Next button shows the next time window.

The Go Last button shows current or latest values in the trend.

run/stop The run/stop icon lets you run or stop the real time trend. When the trend is running,

run is displayed. When the trend is stopped, stop is displayed.

36 Endress+Hauser

Page 37

Tankvision Operations

1.

2.

3.

4.

6.9 How to assign/change products at a tank

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

After configuring a product, it has to be assigned to a tank. The user can assign only one

product to a tank. A product which is currently assigned to a tank can not be deleted from

the system.

To assign a product to a tank

Click the Assign Product tab. Tankvision displays the screen as follows:

Assign Product

Field Description

Product Select the appropriate product from the drop down list.

This field enables the system to assign a product to a specific tank.

Sediment and Water

Percentage

Enter the appropriate sediment and water percentage for the selected product. The

Tankvision system uses the sediment and water percentage in tank inventory

calculations and corrects the product volume according to the sediment and water

content.

The data type for this field is numeric.

Enter the appropriate information in the relevant fields.

Click the Submit button to assign the product to the tank.

After saving the settings, Tankvision displays a confirmation message.

Once the product is assigned to the tank, the tank is automatically added to the builtin product group, and the tank can be seen in the navigation tree of the screen under

the Products Header.

An event is generated after a product is assigned to a tank. The event details can be

viewed in the Event overview.

Endress+Hauser 37

Page 38

Operations Tankvision

1.

6.10 How to do Product transfer

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The product transfer is a day-to-day tank farm operation. During the tank farm operation, a

product is pumped into or out of a tank. A tank may receive product from a pipeline, tanker,

ship or another tank. When the product is to be filled into a tank, it is necessary to check the

available tank capacity. Similarly, when the product is to be pumped out of a tank, it is

necessary to check the product volume in the tank. Tankvision allows an operator to create

a new product transfer.

Tankvision does not control the product transfer, but it monitors product transfers and

generates product transfer data and reports. When a company sells the product stored in

tanks to another company, it is important that the tank is W&M (weights and measurement)

certified for correct measurements. The Tankvision system provides this facility by

calibrating the system and then gets it W&M approved. All tanks which are W&M certified

can be used for custody transfers.

In this case the product transfer report (→ ä 44) will mention the W&M approved status,

which can be used to prove that the correct amount of product has been transferred.

6.10.1 Product Transfer Life Cycle

The Tankvision system allows the user to create, finish or abort a product transfer. Once a

product transfer is created, the system monitors the product transfer to detect "start of

transfer (active)", "product transfer paused" or "product transfer completed".

The life cycle of a product transfer

The product transfer traverses through its life cycle as follows:

• Create a product transfer for a tank

• Detection of the start of the product transfer

• Detection of a paused transfer

• Detection of a completed transfer

• Transfer finished or aborted

• Product transfer report

To transfer a product for a tank

Click the Product Transfer tab. Tankvision displays the screen as follows:

Field Description

Source/Destination The system displays the status of inflow or outflow of the product. If the transfer type is In,

then this field displays Source. If the transfer type is Out, then this field displays

Destination.

38 Endress+Hauser

Product_Transfer_red

Page 39

Tankvision Operations

Batch [%]

Max.

Min.

100%

0

t

Field Description

Transfer Type Select the appropriate product transfer type from the drop down list. This field enables the

system to allow transfer of the product into or out of the tank depending on the selected

option, viz., In or Out.

In: A product is being filled into a tank.

Out: A product is being pumped out from a tank.

This field is disabled after creating a new product transfer.

Batch Mode Select the appropriate batch mode from the drop down list. This field allows you to select

the mode of product transfer. The batch mode is Volume or Mass.

Volume: The quantity of product to be transferred is specified as Total Observed Volume

(TOV) of product.

Mass: The quantity of product to be transferred is specified as product Mass.

This field is disabled after creating a new product transfer.

Batch Size Enter the appropriate batch size in the text box. This field displays the quantity of the

product that is being transferred. The unit depends on whether the mode of product

transfer is in volume or mass. The data type for this field is numeric.

Batch Deviation

Percentage

Minimum

Enter the minimum batch percentage.This

field is used to determine, whether the

product transfer is complete or not. The

product transfer is considered as completed,

if:

• The quantity of product that has been

transferred so far (calculated as per batch

mode) is equal to or more than the

minimum batch deviation percentage of

the batch size, and ...

• ... the rate of change of volume is less than the minimum rate of change of the volume

The data type for this field is numeric.

Maximum

Enter the maximum batch percentage. This

field is used to determine, whether the

product transfer is complete or not. The

product transfer is considered as completed,

if:

• If the batch exceeds the max. batch

percentage an event is generated.

• The quantity of product that has been

transferred so far (calculated as per batch

mode) is equal to or more than the

minimum batch deviation percentage of

the batch size and is less than the

maximum batch deviation percentage of

the batch size; and ...

Pre Alarm

Percentage

Comments Enter the appropriate comments in the comments field. This field allows the user to enter

E-Mail Addresses Enter the appropriate e-mail addresses. Whenever the product transfer is completed, the

Transfer Status This field displays the status of the product transfer. The product transfer status can be:

Enter the pre-alarm percentage. If the quantity of product transfered (calculated as per the

batch mode) increases above the pre alarm percentage of the batch size for In transfer or

decreases below the pre-alarm percentage for Out transfer, then the system raises a prealarm.

The data type for this field is numeric.

comments related to the product transfer. This information is captured in the product

transfer report. The data type for this field is characters.

system sends a product transfer report by e-mail to the e-mail addresses entered in this

field.

"Armed", "Active", "Paused", "Completed", "Finished" or "Aborted".

• "Armed" (Ready to start)

• "Active" (In progress)

•"Paused" (On hold)

• "Completed" (if min. batch dev. percentage is reached 0 and flow goes to 0)

• "Finished" (tank transfer finished)

• "Aborted" (stop immediately before finishing)

Endress+Hauser 39

Page 40

Operations Tankvision

2.

3.

4.

Below the Product Transfer Configuration, the Product Transfer Overview is displayed.

Enter the appropriate information in the relevant fields.

Click the Submit button to create a new product transfer.

After saving the settings, Tankvision displays a confirmation message.

An event is generated after creating a product transfer. The event details can be viewed

in the Event overview.

6.10.2 Status of a Product Transfer

Create a New Product Transfer

Creating a new product transfer is the first step to be followed after the pre-condition for

product transfer is set in the system. While creating a new product transfer, the transfer

status of the tank should be "None". The product transfer status "None" means that the tank

does not have any product transfer associated with it in the Armed or Active status, and thus

a new product transfer can be created. An image of Tankvision displaying the status as

"None" is as follows:

Product_Transfer

Validate product transfer details

Once the user has created a new product transfer for a tank, this tank is said to be "Armed"

for product transfer. The system starts monitoring a tank (with status) "Armed" to

automatically detect the start of the product transfer. Auto detection of start of Product

transfer defined in. Once a tank is armed for a product transfer, no other product transfer

can be created for the tank, unless the existing transfer is cancelled.

An image of Tankvision displaying the status as "Armed" is as follows:

Product_Transfer_ Status-Armed

The system generates an event when the status is changed from "None" to "Armed". This

information can be viewed in the Event tab.

40 Endress+Hauser

Page 41

Tankvision Operations

Detection of the start of a product transfer

Once the product transfer has been armed, the system detects the start of the product

transfer based on a change in the level and the rate of change of the level. The system treats

the product transfer as started and the product transfer status is changed to "Active" if:

• The change in product level is greater than the minimum level change, and

• The rate of change of level is greater than the minimum rate of change of level configured

under the flow calculation details

Once a tank is in the "Active" status for a product transfer, no other product transfer can be

created for the tank, unless the active transfer is Finished or Aborted.

An image of Tankvision displaying the status as "Active" is as follows:

Product_Transfer_active

Product transfer paused

The system treats an Active product transfer as Paused and the product transfer status is

changed to "Paused" if:

• the flow rate drops below the minimum volume change rate,

• the rate of change of level drops below the minimum rate of change of level configured

under the tank flow calculation details, and

• the quantity of product that has been transferred is less than the minimum batch deviation

percentage of the batch size

An image of Tankvision displaying the status as "Paused" is as follows:

Status- Paused_NXA820

Endress+Hauser 41

Page 42

Operations Tankvision

Product transfer completed

The product transfer is considered as completed, if:

• The quantity of product that has been transferred so far (calculated as per batch mode) is

equal to or more than minimum batch deviation percentage of batch size, and is less than

the maximum batch deviation percentage of the batch size; and

• the rate of change of volume is less than the minimum rate of change of volume

An image of Tankvision displaying the status as "Completed" is as follows:

Status- Completed_NX A820

The system generates an event for a completed product transfer. The event details can

be viewed in the Event tab.

Product transfer finished

The user may choose to finish the product transfer before the product transfer is completed.

The product transfer can be finished, when the tank is in an "Active" transfer stage.

An image of Tankvision displaying the status as "Finished" is as follows:

Status- Finished_NXA820

The system displays a pop up message to confirm about finishing the product transfer.

•When the user manually finishes the product transfer, the system generates and

displays the Product Transfer Report.

•The system generates an event for product transfer finished by user. The information

can be viewed in the Events tab.

•The user cannot manually finish the product transfer, if the product transfer status is

"Completed".

Product transfer aborted

The user may choose to abort the product transfer before the product transfer is completed.

The product transfer can be "Aborted", when the tank is in an "Active" transfer stage. When

the product transfer is aborted, the system does not record the data of starting and ending

of product transfer. In such case, the system maintains different sets of data. The data of a

42 Endress+Hauser

Page 43

Tankvision Operations

previously completed or finished product transfer are preserved, and the data of the aborted

product transfer are discarded.

Status- Aborted_NXA8 20

The system displays a pop up message to confirm about the aborting of the product

transfer.

The system generates an event for an aborted product transfer. The event details can

be viewed in the Event tab.

Error Messages

1. "Tank cannot be armed for product transfer if "No product" has been assigned to tank"

This message appears when the user attempts to create a product transfer when "No

Product" is assigned to the tank.

2. "The Tank status is "Locked", cannot create a new product transfer for a tank that is

locked"

This message appears when the user attempts to create a product transfer when the

tank status is "Locked".

3. "The Tank status is "In Maintenance", cannot create a new product transfer for a tank

that is in maintenance"

This message appears when the user attempts to create a product transfer when the

tank status is "In Maintenance".

4. "Batch size cannot be zero, if you do not wish to specify batch size leave the field empty"

This message appears when the Batch size entered by the user is equal to zero.

5. "Batch size should be greater than zero"

This message appears when the value of the Batch size entered by the user is less than

zero.

6. "Batch size should be smaller than remaining tank capacity"

This message appears when the transfer type is "In" and the batch size entered by the

user is more than the remaining tank capacity.

7. "Batch size should be smaller than available product quantity"

This message appears when the transfer type is "Out" and the batch size entered by the

user is more than the available product quantity.

8. "Minimum batch deviation should be less than maximum batch deviation"

This message appears when the Minimum batch deviation entered by the user is greater

than or equal to maximum batch deviation.

9. "Pre-alarm percentage should be greater than zero"

This message appears when the Pre-alarm percentage entered by the user is less than

or equal to zero.

10. "Pre alarm percentage should be less than minimum batch deviation"

This message appears when the pre-alarm percentage entered by the user is more than

the minimum batch deviation.

Endress+Hauser 43

Page 44

Operations Tankvision

1.

2.

6.11 How to view a Transfer report

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The Tankvision system allows the user to arm a tank for product transfer, and is set up to

detect the start and end of the product transfer details for a tank. The system records the

product transfer data and generates a report for the product transfer with "Completed" and

"Finished" statuses, using an appropriate template. You can view or even edit the product

transfer report for the last product transfer that has been completed by the system.

To generate a product transfer report

In the navigation tree, click the Reports header. Click Product Transfer Report.

Tankvision displays the screen as follows:

Product Transfer Report_NXA820

Field Description

W&M Approved This section displays the status of W&M approval.

Configuration Setting

Details

Product Transfer

Details

Element Name This section displays the result of the product transfer in terms of parameter changes.

This section displays the report of the configuration settings.

This section displays the report of Product Transfer settings.

Refer to "Product Transfer Life Cycle" (→ ä 38) for details.

Refer to "Tank Calculator" (→ ä 48) for details.

Refer to the "View Product Transfer Report" section under the "Reports" chapter for more

information on the product transfer report.

44 Endress+Hauser

Page 45

Tankvision Operations

1.

2.

3.

4.

6.12 How to view and change Tank Status

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The tanks in the Tankvision system are associated with a status which can be changed by the

operator.

To change the tank status for all tanks at once, go to the Configuration → Tank Status

page, → ä 47.

To change the tank status

Click the Tank Status tab. Tankvision displays the screen as follows:

Tank_Status

Field Description

Current Status The system displays the current status of the tank.

Change Status to Select the appropriate status type from the drop down list. This field allows you to select

the status in which the tank is required to function. The statuses are:

• In Operation: The tank is in normal operation.

• In Maintenance: The tank is under maintenance. A tank is always empty under

maintenance, and tank operations such as gauge commands or product transfers

cannot be performed. The field scan is not needed.

• Manual: The tank is in operated manually, which means the system will not measure

the data automatically. All tank parameters are in manual mode and the field scan is in

off mode. A product transfer can occur.

• Locked: The tank is generally filled but locked to disallow product transfer. All other

activities can be performed.

Refer to "Tank Status Change Matrix" (→ ä 45) for the activities that can be performed

under various tank statuses, and to "Tank Status Indicator" (→ ä 46) to learn about the

notification on the tank status graph.

Enter the appropriate information in the relevant fields.

Click the Submit button to change the tank status.

After saving the settings, Tankvision displays a confirmation message.

An event is generated after changing the tank status. The event details can be viewed

in the Event overview.

6.12.1 Tank Status Change Matrix

The activities that can be performed under various tank statuses are as follows:

Activity vs Tank Status In Operation Manual Maintenance Locked

Inventory Calculation Yes Yes No Yes

Product Transfer Yes Yes No No

Gauge Commands Yes No No No

Raise Change in Volume Alarm No No No Yes

Field Scan Yes No No Yes

Raise Alarms Yes No No Yes

Endress+Hauser 45

Page 46

Operations Tankvision

6.12.2 Tank Status Indicator

Tankvision indicates the tank status on the Tank Overview section on the Tank Details tab.

When the tank status is modified to "In Operation", the system indicates the tank status on

the Tank Overview section as follows:

NXA82x_Tank-Status-Indicator_Ope ration

When the tank status is modified to "In Maintenance", the system indicates the tank status

on the Tank Overview section as follows:

NXA82x_Tank-Status-Indicator_M aintenance

When the tank status is modified to "Manual", the system indicates the tank status on the

Tank Overview section as follows:

NXA82x_Tank-Status-Indicator_Man ual

When the tank status is modified to "Locked", the system indicates the tank status on the

Tank Overview section as follows:

46 Endress+Hauser

Page 47

Tankvision Operations

1.

2.

3.

4.

NXA82x_Tank-Status-Indicator_L ocked

6.12.3 Changing the TankStatus for all Tanks at once

To change the tank status for all tanks at once

In the navigation tree, click the Configuration header. Click Tank Status. Tankvision

displays the screen as follows:

NXA82x_Configuration_Tank-Stat us

Set the statuses of the tanks with the Change Status To picklists. To change all tanks to

the same status, select All Tanks.

Click the Submit button to change the tank statuses.

After saving the settings, Tankvision displays a confirmation message.

An event is generated after changing the tank status. The event details can be viewed

in the Event overview.

Endress+Hauser 47

Page 48

Operations Tankvision

1.

2.

6.13 How to do tank calculations

The below described operations can be performed with the default user access rights for an

operator ("User access rights", → ä 13).

The Tankvision system performs inventory calculations based on the measured data scanned

from a gauge or entered manually. The system uses the tank and product configuration

mainly to perform these calculations. Tankvision provides a tank calculator to evaluate

various "what if" scenarios. These scenarios could be:

• What would be the product volume for a certain product level?

• What would be the product level, if a certain quantity of product is pumped into the tank?

• What would be the product volume, if the product level is equal to the high level alarm?

Based on the above mentioned scenarios, the tank calculator would also indicate whether

the resulting tank parameter could cause an alarm.

Thus, prior to an actual product transfer, the tank calculator can be used to verify whether

it is possible to perform an "out" or "in" product transfer without resulting in an alarm. Any

tank parameter that is changed in the tank calculator is used to carry out calculations and

display results to evaluate the what-if scenarios. Changing tank parameters in the tank

calculator does not change the actual tank data.

To use the tank calculator

Click the Tank Calculator tab. Tankvision displays the screen as follows:

NXA82x_Tank_Tank-Calculato r--Tab

Column Description

Parameter This column displays a list of product parameters for which the start and end value can be

entered for the purpose of calculation.

Start Value Enter the appropriate start values for the relevant parameters in the corresponding text

boxes.

The start value is the initial value of the parameter. For example, the initial level of the

product will be the start value for Product Level. The data type for this field is numeric.

End Value Enter the appropriate end values for the relevant parameters in the corresponding text

boxes.

The end value is the current or final value of parameter. For example, the current or final

level of the product will be the end value for Product Level. The data type for this field is

numeric.

Delta Value The delta values are not editable. The delta value is the difference between the start value

and the end value of a parameter. The data type for this field is numeric.

Enter the appropriate information in the relevant fields and click the Calculate button.

48 Endress+Hauser

Page 49

Tankvision Operations

1.

2.

3.

4.