Page 1

TI00419G/00/EN/18.18

71425700

2018-12-28

Products

Solutions Services

Technical Information

Tankvision NXA820, NXA821,

NXA822

Tank Gauging

Inventory Management System with completely

integrated software for operation via standard web

browser

Application

Tankvision is a dedicated tank inventory system which is operated by a standard web

browser and does not require proprietary software or licensing costs.

Tankvision is based on a distributed architecture on a Local Area Network (LAN).

Due to its modular structure it can be adjusted to any application. It is ideally suited

for small tank farms with only a couple of tanks, but also for large refineries with

hundreds of tanks.

Tankvision consists of the following components:

• Tankvision Tank Scanner NXA820

scans parameters from tank gauges and performs tank calculations (option)

• Tankvision Data Concentrator NXA821

summarizes data from various Tank Scanners NXA820

• Tankvision Host Link NXA822

provides data to host systems (such as PLC or DCS) via Modbus

Your benefits

• License-free, with access for up to 10 users

• Approved for custody transfer applications according to NMI, PTB and others

• Modular design; easily adjustable to any application; can be upgraded as required

• Configuration, commissioning and operation via web browser; no proprietary

software required

• Common hardware platform for all components; no hard disc or fans to wear out

• Volume calculations and correction included according to international standards

(API/ASTM/IP tables) in Tank Scanner NXA820 (optional)

• Includes OPC Data Access server for Windows PC

Page 2

Table of contents

Tankvision NXA820, NXA821, NXA822

Applications ............................... 3

Inventory control .............................. 3

Inventory calculations (option) .................... 3

Remote configuration of measuring equipment .......... 3

Application areas ............................. 3

Function and system design ................... 3

System design ................................ 3

System configuration ........................... 5

Features ................................... 5

Security .................................... 6

Typical system configuration .................. 7

Wiring example for NXA820/821/822 ............... 7

Wiring example for NXA820 "Interface only" ........... 8

Wiring examples for a wireless connection of NXA820 ..... 8

Function of the components ................... 9

Tankvision Tank Scanner NXA820 .................. 9

System limitations ............................. 9

Tankvision OPC Server ......................... 10

Tankvision Alarm Pop-Up-Agent .................. 10

Tankvision Printer Agent ....................... 10

Tankvision Data Concentrator NXA821 .............. 10

Tankvision Host Link NXA822 .................... 11

NXA820 "Interface only" ........................ 11

Ordering information ....................... 15

Operability ............................... 15

Operating concept ............................ 15

Languages ................................. 15

Certificates and approvals ................... 15

Metrological approvals ......................... 15

Supplementary documentation ............... 16

Operating Instructions ......................... 16

Description of Instrument Functions ................ 16

Registered trademarks ...................... 16

Microsoft Corporation ......................... 16

Schneider Electric ............................ 16

Oracle Corporation ........................... 16

Legal notice concerning trademarks ................ 17

Inputs and outputs ......................... 11

Galvanic isolation ............................ 11

LAN connections ............................ 11

Fieldbus protocols (NXA820) ..................... 12

Host connection (NXA822) ...................... 12

NXA Status Relay ............................ 12

Power supply ............................. 12

Power supply NXA 82x ........................ 12

Installation ............................... 12

Mounting location ............................ 13

Installation instructions ........................ 13

System requirements of user PC ................... 13

Network requirements ......................... 13

Shielding and Grounding ....................... 13

Environment .............................. 14

Ambient temperature range ..................... 14

Storage temperature .......................... 14

Humidity .................................. 14

Operating height ............................. 14

Degree of protection .......................... 14

Electromagnetic compatibility (EMC) ............... 14

Mechanical construction .................... 14

Dimensions ................................ 14

Materials .................................. 14

2 Endress+Hauser

Page 3

Tankvision NXA820, NXA821, NXA822

Applications

Inventory control

Inventory calculations (option)

By using Tankvision to monitor the tank level and stored volume of valuable liquids remotely,

owners or operators of tank farms or terminals for petroleum products and chemicals (liquids) can

visualize the volume of the stored medium in real time. The data can be used to plan the inventory

and distribution. The data can also be used to manage tank farm operations like pumping or

transferring products.

Tankvision has its unique concept using network technology. Without using proprietary software,

the users can visualize and manage their valuable liquids stored in the tanks by a web browser.

Tankvision is a flexible and cost effective solution due to its scalable architecture. The application

coverage goes from small depots with only a few tanks up to refineries.

Choosing the "Interface only" option in Tank Scanner it becomes a fit-for-purpose interface unit to

the tank gauges for Tankvision Professional.

Based on measured variables and tank capacity tables, Tankvision calculates:

• Gross volumes

• Net volumes

• Mass

Volumes and density of products like the following are processed:

• Hydrocarbons

• LPGs

• Asphalt

• Alcohols

Volumes and density are corrected according to international standards, including API/ASTM tables

5A, 5B/6, 53A, 53B/54, 23/24, LPG according to tables GPA TP-25 Table 24E, GPA TP-27 Table

24E, GPA TP-27 Table 54E, GPA TP-27 Table 60E, M B & Redwood VCF, alcoholometric tables

according to OIML R22 tables I, II, IIIA, IVA, VI, VII. This includes temperature corrections at 15 °C,

60 °F and alternative temperatures. Additionally, available pumpable volumes and water volume are

calculated.

Up to 200000 strapping points in sum over all tanks are supported for vertical, spherical and bullet

tanks.

More standards are added continuously. Please ask Endress+Hauser for an updated list.

Remote configuration of measuring equipment

Application areas

Tankvision does not only acquire the current measured level or volume from the tanks. The

configuration of device settings from the control room is also possible by using FieldCare, the

operating software from Endress+Hauser, for the connected Endress+Hauser devices. Tankvision

passes on the device setting information transparently, so that all device functions for the respective

operating software are available from the control room. Some on-site operations can be avoided

using this feature during commissioning or maintenance. (The availability of this feature may

depend on the system configuration.)

• Tank farms in refineries

• Ship loading terminals

• Marketing and distribution terminals

• Pipeline terminals

• Logistic terminals for tanks storing products like crude oils, refined white and black products,

chemicals, LPGs, fuels, biofuels, alcohols

Function and system design

System design Tank management visualization without proprietary software

Tankvision is the first tank management visualization system providing its functionality without the

need to have proprietary software installed and maintained on a PC. The main functionality is

realized by embedded web pages in the Tankvision components. Tankvision uses an industrial

proven operating system and provides high availability. Tankvision is not based on a PC platform and

runs independent of connected PCs. This eliminates the need to maintain a specialized PC with a

Windows operating system and necessary updates and hot fixes. Tankvision web pages can be

Endress+Hauser 3

Page 4

Tankvision NXA820, NXA821, NXA822

accessed from a standard PC with a web browser and the Java Runtime Environment only. Multiple

users with different roles can simultaneously log in to each Tankvision component. Additional users

can be added as required. There are no multi-user licence fees.

Please check with Endress+Hauser for recommendations on PC, operating system and web browser.

Examples of operating pages

Tank group

1 Alarms and events viewer

2 Main window

3 Navigation tree

4 Internet Explorer menu and symbol bar

Single tank

1 Alarms and events viewer

2 Main window

3 Navigation tree

4 Endress+Hauser

Page 5

Tankvision NXA820, NXA821, NXA822

Distributed architecture and scalability

Tankvision is based on a distributed architecture on a Local Area Network (LAN). Coordinated

components perform all inventory management tasks. The modular design makes it easy to enlarge

the system whenever required and to add further tank areas. Thus, Tankvision is fully scalable and is

ideally suited for applications of any size - from small tank farms to large refineries.

Common hardware platform

Tankvision is based on a distributed architecture on a Local Area Network (LAN). Coordinated

components perform all inventory management tasks. The modular design makes it easy to enlarge

the system whenever required and to add further tank areas. Thus, Tankvision is fully scalable and is

ideally suited for applications of any size - from small tank farms to large refineries.

The Tankvision components have dedicated tasks in a system, but have a common architecture,

based on a 32 Bit processor. The embedded tank management software uses a multi-threaded real

time operating system (RTOS), specifically designed for industrial applications. The hardware is

designed without wear-out components like hard discs or fans. This guarantees high reliability.

System configuration Configuration of the components

Each Tankvision component has its own data base and a web server. The components are connected

and exchange data with time stamp and status information. Data is optionally encrypted and secured

by a CRC checksum.

The Tankvision components are configured with static IP addresses, which are reserved on a DHCP

network.

The configuration pages are embedded in the Tankvision components and allow configuration of

Tankvision via a connected web browser without configuration software. No Internet access is

necessary, as all pages are loaded from the Tankvision system itself.

Features

Configuration of the connected tank gauges/sensors

Tankvision supports connection of the Endress+Hauser configuration tool, FieldCare, via LAN. This

enables configuration of the tank gauges if they support remote configuration (e.g. Proservo, Tank

Side Monitor and the level radars Micropilot S and Micropilot).

The tank gauges must be connected to the Tank Scanner NXA820 in one of the following ways:

• via a field protocol

• via HART to the Tank Side Monitor NRF590 (version 02.04) which in turn is connected via one of

the following protocols to the Tank Scanner NXA820:

– MODBUS

– Sakura V1

• Representation of tank data

Tank data can be represented graphically or in tables. The corresponding HTML pages are

predefined.

• Definition and management of tank groups

The total contents of static or dynamic tank groups (e.g. of tanks containing the same product) can

be displayed.

• Definition and management of products

Product characteristics can be defined. The defined product can be attributed to a number of tanks.

• Trend display

Real time and historical trends of the tank parameters can be displayed. The data is stored in the

internal memory.

• Archive

Tankvision stores measured and calculated data, log files and alarms on the internal flash

memory.

• Alarms

Limit alarms (high-high, high, low, low-low) can be defined for measured and calculated tank

parameters. An alarm bar visualizes alarms in the browser window.

Alarms can be reported by an optional Alarm Popup

1)

window.

• Products

A product database allows definition of 50 products per NXA or shared in the system.

1) available for Windows on the device to upload

Endress+Hauser 5

Page 6

• Monitoring of transfers

Product transfers from and to tanks can be monitored. Pre-alarms can be generated before

completion of the transfer. A report is issued after the transfer.

• Auditing

An auditing table contains all events such as alarms or configuration changes.

• Log-In roles

Log-In roles with different access rights (supervisor, operator, guest) can be assigned to users and

user groups.

• Reports

Reports are predefined as HTML pages. They can be sent to a printer connected to a computer at

scheduled time intervals by an optional Printer Agent

• Volume calculation and correction

Available calculation tables according to API, ASTM and IP can be integrated.

• Graphical User Interface (GUI)

Tankvision uses an intuitive and optimized user interface (e.g. automatic creation of dynamic tank

groups).

• Remote access

Any PC with the specified requirements which is connected to the Intranet can be connected with

Tankvision.

• OPC Server

Data can be transferred to other systems using the open OPC standard (OPC DA 3.0).

Security IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any inadvertent

changes to the device settings.

IT security measures in line with operators' security standards and designed to provide additional

protection for the device and device data transfer must be implemented by the operators themselves.

Endress+Hauser can be contacted to provide support in performing this task.

Tankvision NXA820, NXA821, NXA822

1)

.

6 Endress+Hauser

Page 7

Tankvision NXA820, NXA821, NXA822

1

7

3

4

5

6

2

88

7

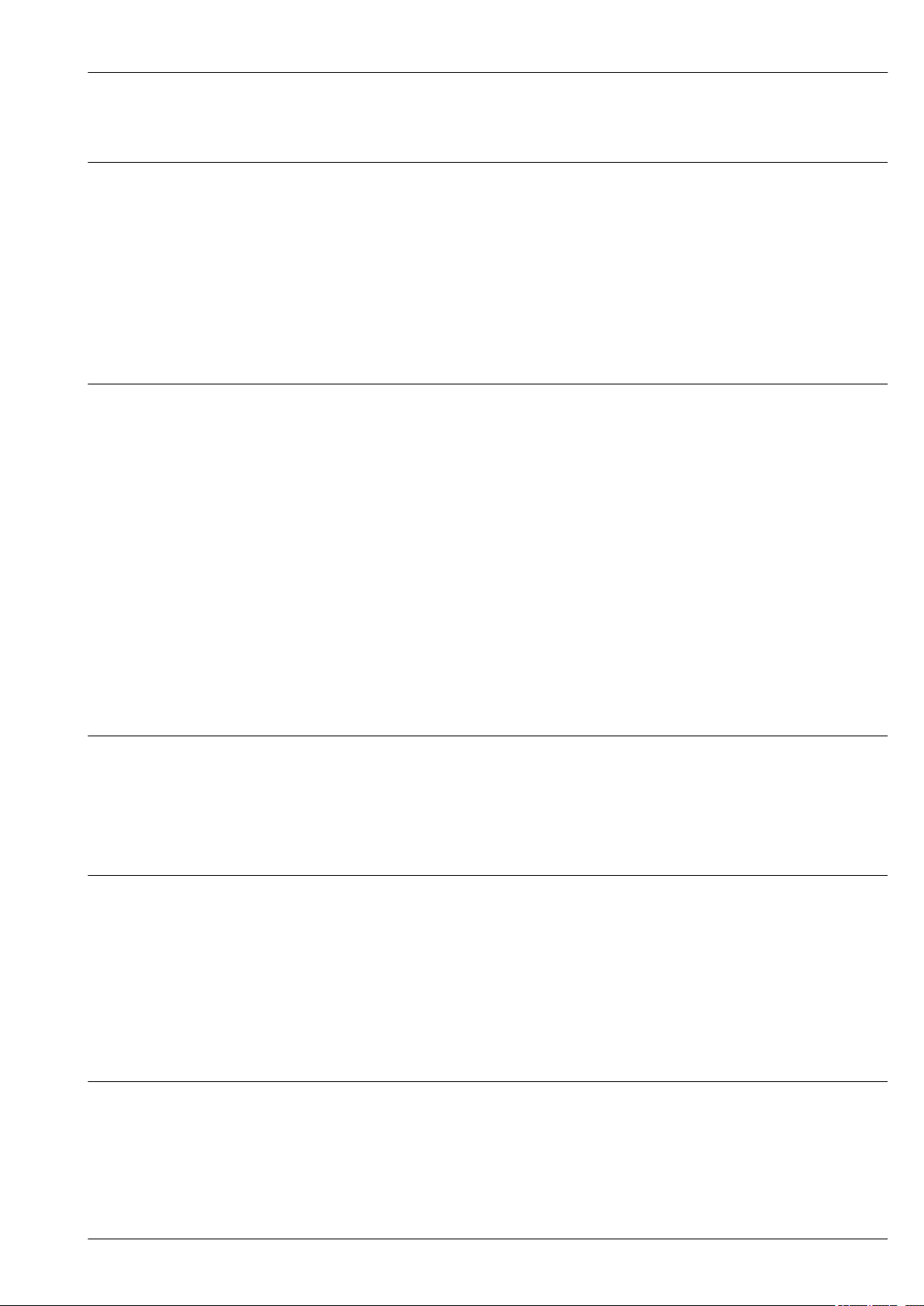

Typical system configuration

Wiring example for NXA820/821/822

A0034276

1 DCS /PLC (Distributed control system/Programmable logic controller)

2 Modbus

3 Host Link NXA822

4 Data Concentrator NXA821

5 Switch

6 Operator with Browser/SupplyCare Enterprise (Server)

7 Tank Scanner NXA820

8 Fieldbus protocol

Endress+Hauser 7

Page 8

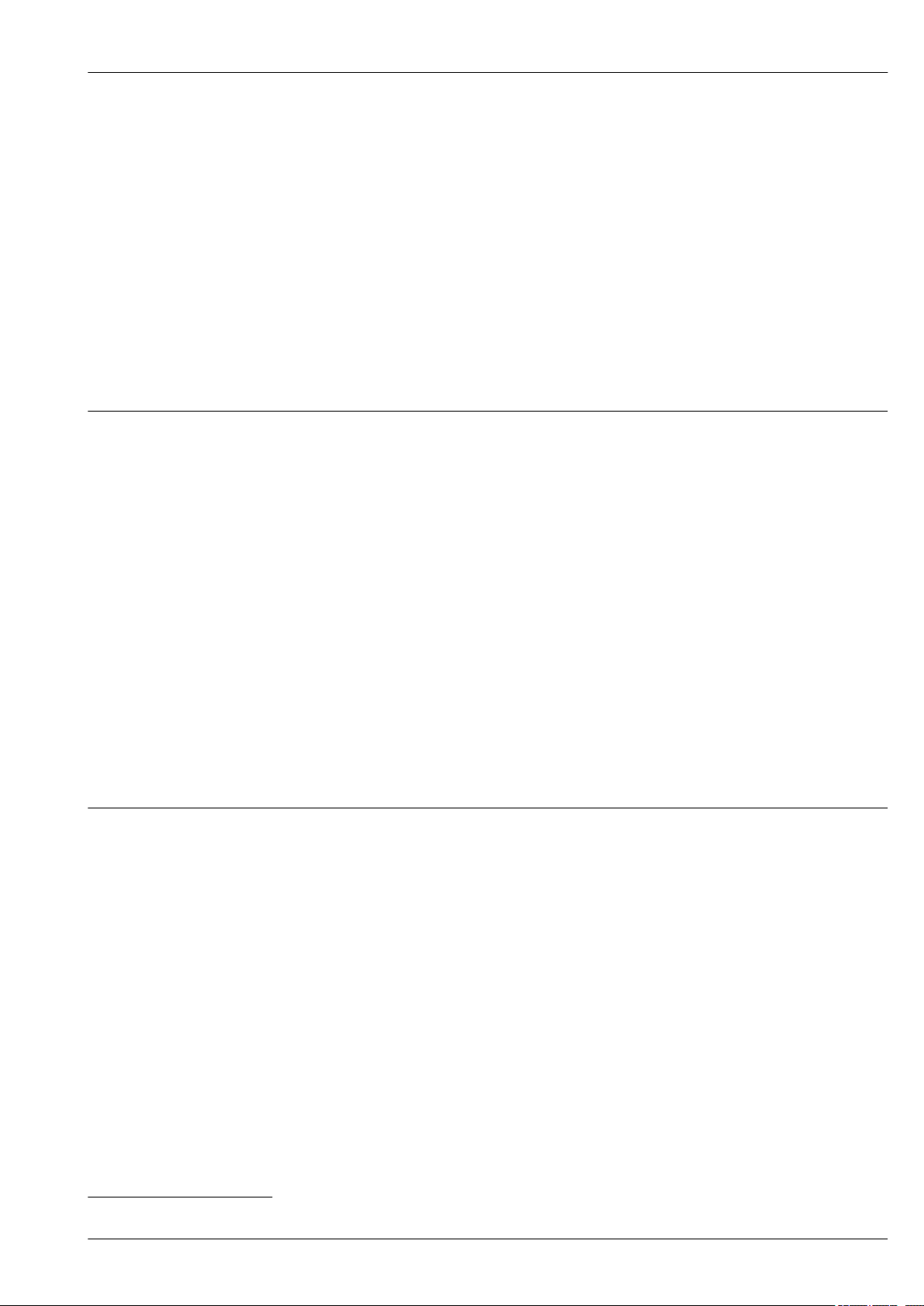

Wiring example for NXA820

1

2

6

7

8

999

10

88

5

1

4

3

3

NXA820

2

1

4

5

6

"Interface only"

Tankvision NXA820, NXA821, NXA822

Wiring examples for a wireless connection of NXA820

1 DCS / PLC (Distributed control system / Programmable logic controller)

2 Host Link NXA822

3 OPC Server (Open Platform Communications)

4 FieldCare

5 Tankvision Professional NXA85 Workstation/SupplyCare Enterprise (Server)

6 Switch

7 Ethernet

8 Tank Scanner NXA820

9 Fieldbus protocol (Modbus, Sakura V1, Whessoe WM550)

10 Modbus RTU RS 232/485 or Modbus TCP

A0034277

1 Operator with Browser

2 Tank Scanner NXA820

3 MODBUS RTU communication RS-485 serial interface

4 Endress+Hauser WirelessHART Fieldgate SWG70

5 Endress+Hauser WirelessHART Adapter SWA70

6 WirelessHART communication interface (IEC 62591)

A0034274

8 Endress+Hauser

Page 9

Tankvision NXA820, NXA821, NXA822

NXA820

2

1

3

3

4

1 Operator with Browser

2 Tank Scanner NXA820

3 Banner DX80DR2M-H-13680 or Banner DX80DR2M-H or Banner DX80DR9M-H

4 Wireless Modbus RTU RS 232/485 or Modbus TCP

A0034275

Tankvision Tank Scanner NXA820

The field instruments can also be connected to Tankvision Tank Scanner with appropriate wireless

components.

For custody transfer applications the following components can be applied:

• Banner DX80DR2M-H-13680

• Banner DX80DR2M-H

• Banner DX80DR9M-H

Certificates and approvals → 15

For distributed systems special requirements apply. Please contact your local Endress+Hauser

representative.

Function of the components

• The Tank Scanner NXA820 connects multiple tank gauges from up to 15 tanks via one field-loop.

The Tank Scanner NXA820 supports different field protocols (Modbus EIA485, Sakura V1,

Whessoematic WM550).

• The measured values are transmitted by the network and visualized on HTML pages.

• The Tank Scanner NXA820 can be used stand-alone for small tank farms, but also be integrated

into a large system for use in refineries.

• The Tank Scanner NXA820 is optionally equipped with a full set of tank inventory calculations.

The calculations are based on various international standards such as API, ASTM, IP and many

others. Measured values are used to calculate volume and mass.

System limitations

In order to ensure the best performance and system stability we recommend following limitations:

• Maximum 2000 parameters can be scanned from the field (all tanks counted together)

• Maximum 100 000 straps can be used for the strapping tables (all tanks counted together)

• Maximum 1 500 points for the TPD tables (all products counted together)

• Maximum 20 parameters can be archived per tank per 5 minutes

• Maximum 20 parameters can be archived per group per 5 minutes

• Maximum 10 groups (Static Group or Dynamic Group) can be defined

Endress+Hauser 9

Page 10

Tankvision NXA820, NXA821, NXA822

• Minimum 1 h between each archive export

• Maximum 10 scheduled reports via the Printer Agent per hour

• Maximum 3 Internet explorer browser pages open

By reducing the one or the other limit other can be augmented. In order to prevent unstable

system it is recommended to configure automated reports or archive exports sequentially, in

order to distribute the load.

Tankvision OPC Server

Tankvision Alarm Pop-UpAgent

• The OPC Server is a Windows program installed on a PC connecting to NXA820 and allows access

to measured and calculated tank parameters.

• The OPC Server connects to OPC clients on the same PC or other PCs via LAN.

• The OPC Server supports browsing tanks and tank parameters on NXA820.

• The OPC Server is included in each NXA820 and can be downloaded.

• The OPC Server is based on OPC DA V3.0

• The Alarm Pop-Up-Agent is a Windows program installed on a PC, connecting to NXA820/

NXA821.

• The program is running in the background and scans for alarms generated in NXA820/NXA821.

• If an alarm is present, a pop-up window opens displaying the alarm.

• The alarm can be acknowledged within this window.

• The window can only be closed if no alarm is active.

Tankvision Printer Agent

Tankvision Data Concentrator NXA821

• The Printer Agent is a Windows program installed on a PC, connecting to NXA820/NXA821.

• The program is running in the background and enables printing reports on connected printers.

• Up to 3 printers (directly connected to the PC or network printers) can be assigned to the Printer

Agent.

• If a printout can not be performed, a record is kept within the Printer Agent.

• The NXA821 Tankvision Data Concentrator is the enhanced solution for large tank farms and

refineries. The Data Concentrator is required if:

– the plant contains more than one field loop (each of which has its own Tank Scanner NXA820)

– tanks of more than one Tank Scanner NXA820 are to be grouped

• The Data Concentrator collects the data of several Tank Scanner units and enables reconciliation

and totalization of the tank data of many or all tanks in structured groups.

• Alarms and events from all connected Tank Scanners NXA820 can be shown in a common screen.

Any tank of the system can be assigned to any tank group, regardless of the Tank Scanner it is

linked to. This ensures the highest possible flexibility for the plant or tank farm.

• An alarm pop-up shows alarms of all connected Tank Scanners NXA820 even if the web browser is

closed.

• 90 tanks (more on request) can be allocated to each Data Concentrator NXA821. Each of these

tanks must have been allocated to a Tank Scanner NXA820 beforehand.

• Tanks from up to 6 different Tank Scanners NXA820 (more on request) can be integrated in this

way.

10 Endress+Hauser

Page 11

Tankvision NXA820, NXA821, NXA822

Tankvision Host Link NXA822

NXA820 "Interface only" Operation

• The Host Link NXA822 collects data from all Tank Scanners NXA820 on a network and transfers

them to the host system.

• The MODBUS option supports serial EIA-232(RS) and EIA-485(RS) or MODBUS TCP/IP. The

NXA822 is configured as a MODBUS slave. Supported functions are:

– Coil Status (#01)

– Holding Registers (#03)

– Input Registers (#04)

– Write Modbus Values (#06)

– Write Multiple Value (#16)

• The MODBUS register map is described via XML files and can easily be adapted to individual

MODBUS master requirements.

• Gauge commands for Servo Gauges

• 90 tanks (more on request) can be allocated to each Host Link NXA822. Each of these tanks must

have been allocated to a Tank Scanner NXA820 beforehand.

• Tanks from up to 6 different Tank Scanners NXA820 (more on request) can be integrated in this

way.

• Scans for the tank parameters and their status via Modbus, Sakura V1 or Whessoe WM550

protocol

• Forwards the tank parameters to Tankvision Professional and/or Tankvision OPC Server and/or

Tankvision Host Link

• Forwards Gauge commands from the Inventory systems to the tank gauges

• Redundancy capable device, exchanging data between primary and secondary units

Configuration

The configuration is done via a comprehensive web page which can be accessed by standard web

browser.

The setup consist of only 3 steps:

• Date and Time setting

• Network settings

• Protocol settings

A variety of scanning routines can be selected which cover most of the typical application needs. In

addition those scanning routines can be easily tuned for more specialized application

requirements.

Applying the Field Link in Weight & Measure approved systems needs an additional configuration

step.

Remote configuration of measuring equipment

Tankvision Field Link does not only acquire the current measured values from the tanks. The

configuration of device settings from the control room is also possible by using FieldCare, the Plant

Asset Management tool from Endress+Hauser, for the connected Endress+Hauser devices.

Tankvision Field Link passes on the device setting information transparently, so that all device

functions for the respective operating software are available from the control room. Some on-site

operations can be avoided using this feature during commissioning or maintenance. The availability

of this feature may depend on the system configuration.

Inputs and outputs

Galvanic isolation

LAN connections System LAN port

The following terminals are galvanically isolated from each other:

• Alarm relay output

• LAN interfaces

• Fieldbus interface

100 BASE-TX, Full/Half Duplex, 100 Mbit, Shielded RJ45 connector

Connects the NXA82x to the Local Area Network (LAN)

Endress+Hauser 11

Page 12

Tankvision NXA820, NXA821, NXA822

Service LAN port

100 BASE-TX, Full/Half Duplex, 100 Mbit, Shielded RJ45 connector

Connects the NXA82x to a local computer only for local commissioning and service operations. The

computer does not become part of the local area network the NXA82x is connected to through the

System LAN port.

This port has a fixed IP address and can also provide the connected computer automatically with a

compatible IP address using a DHCP server built into the NXA82x. For this automatic IP function to

work the computer must be set to obtain its IP address using a DHCP server.

All LAN ports support Auto-MDIX, this system automatically detects the type of cable

connected (either straight or crossed) and adjusts itself to match. With this feature you do not

need to obtain special crossed cables to interconnect Tankvision components.

Fieldbus protocols (NXA820)

Host connection (NXA822)

NXA Status Relay

Power supply NXA 82x

The Tank Scanner NXA820 is available with the following field protocols:

• MODBUS EIA-master, max. 15 gauges

2)

• Sakura V1, max. 10 gauges

• Whessoe 550, max. 15 gauges

Modbus

3)

• EIA-232(RS)

• EIA-485(RS)

• TCP-IP on system LAN port

• Potential free relay, SPDT

• Normally-closed when NXA is operating normally, open when NXA is powered off or fault status

exists

• Switching power:

– 25 VDC, 100 W

– 250 VAC, 4 A, 1 000 VA

Power supply

Instrument version Supply voltage Power

consumption

AC voltage

NXA82# #1#######

DC voltage

NXA82# #2#######

90 to 250 VAC,

(50 to 60 Hz)

10.5 to 32 V

max. 23 VA max. 100 mA at

DC

max. 14 W max. 580 mA at

Current

consumption

230 V

AC

24 V

DC

Fuse

400 mA T

2 A T

The versions are selectable via order code. → 15

Installation

It is recommended to take the information contained in the Operating Instructions into

consideration when designing the system architecture.→ 16

2) Consider the "MODBUS over Serial Line Specification and Implementation Guide V1.02" (Dec. 2006)

3) Consider the "MODBUS over Serial Line Specification and Implementation Guide V1.02" (Dec. 2006) and the "MODBUS Messaging on TCP/IP

Implementation Guide V1.0b" (Oct. 2006)

12 Endress+Hauser

Page 13

Tankvision NXA820, NXA821, NXA822

Mounting location

Installation instructions

System requirements of user PC

Network requirements

Cabinet or protective housing

When installed in wet locations, cabinet should be at least IP67.

When installed in wet locations, cabinet should only be opened when temperature is

5 to 40 °C (41 to 104 °F) and maximum relative humidity is 80 % for temperatures up to

31 °C (88 °F) decreasing linearly to 50 % relative humidity at 40 °C (104 °F).

Tankvision Tank Scanner NXA820, Data Concentrator NXA821 and Host Link NXA822 are designed

to be installed in a cabinet, using a standard 35 mm (1.38 in) DIN (top-hat) rail conforming to

EN50022 (BS5584) (IEC 60715).

Check the latest information on hardware and software requirements. Please contact your local

Endress+Hauser Sales Center.

• Network switches must always be used to interconnect Tankvision components. Network hubs

must never be used.

• Only use screened cables (Category 5 or higher).

Network settings

The address range 192.168.1.xxx cannot be configured for the NXA82x devices as it is reserved

for the service (ethernet) port.

NOTICE

EMC requirements

The legal EMC requirements are fulfilled only when

a screened LAN cable is used and

‣

the cable screen is properly terminated to screened RJ45 connectors.

‣

Shielding and Grounding

NOTICE

Harsh environments

Most commercial and IT infrastructure networking switches (and components) are not designed to

be used within harsh environments (e.g. temperatures below +5 ºC (+41 °F), dusty or with high

levels of EMC or electrical noise).

It is therefore recommended that only networking components specifically designed for

‣

industrial control purposes be used within the control room (or control cabinet) environment as

part of the Tankvision system.

When planning the shielding and grounding for a fieldbus system, there are three important points

to consider:

• Electromagnetic compatibility (EMC)

• Explosion protection

• Safety of the personnel

To ensure the optimum electromagnetic compatibility of systems, it is important that the system

components and above all cables, which connect the components, are shielded and that no portion of

the system is unshielded. Ideally, the cable shields are connected to the normally metal housings of

the connected field devices. Since these are generally connected to the protective earth, the shield of

the bus cable is grounded many times. Keep the stripped and twisted lengths of cable shield to the

terminals as short as possible.

This approach, which provides the best electromagnetic compatibility and personnel safety, can be

used without restriction in systems with good potential equalization.

In the case of systems without potential equalization, a power supply frequency (50/60 Hz)

equalizing current can flow between two grounding points which, in unfavourable cases, e.g. when it

exceeds the permissible shield current, may destroy the cable.

To suppress the low frequency equalizing currents on systems without potential equalization, it is

therefore recommended to connect the cable shield directly to the building ground (or protective

earth) at one end only and to use capacitive coupling to connect all other grounding points.

The NXA820 provides two grounding points for the shield, close to the fieldbus interface connector:

• The “)” terminal, which should already be connected directly to ground

• The “S” terminal (13), which provides capacitive connection to the “)” terminal

Endress+Hauser 13

Page 14

NOTICE

43 (1.7)

35 (1.4)

104 (4.1)

150 (5.9)

140 (5.5)

1 ( . )12 4 4

EMC requirements

The legal EMC requirements are fulfilled only when

the cable shield is grounded on both sides!

‣

Environment

Tankvision NXA820, NXA821, NXA822

Ambient temperature range

Storage temperature

Humidity

Operating height

Degree of protection

Electromagnetic compatibility (EMC)

Dimensions

–40 to +60 °C (–40 to +140 °F)

–40 to +85 °C (–40 to +185 °F)

Max. 90 % at 25 °C (77 °F) (non-condensing)

Device shall only be operated at maximum altitude of 2 000 m (6 600 ft) above MSL

• IP20 (as per IEC/EN 60529)

• IK06 (as per IEC/EN 62262)

EMC according to the requirements of the EN 61326-series and the NAMUR-recommendation EMC

(NE21). Details can be found in the Declaration of Conformity.

Mechanical construction

1 Dimensions in mm (inch)

Materials Housing

Polycarbonate

14 Endress+Hauser

Colour: light grey

A0034273

Page 15

Tankvision NXA820, NXA821, NXA822

Front cover

Polyamide PA6

Colour: grey

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Operability

Operating concept

Languages

Tankvision is operated by a standard web browser (e.g. Microsoft Internet Explorer).

The Tankvision components contain predefined operating pages. If required, they can be adjusted by

the user.

The operating pages are available in the following languages:

• Chinese

• English

• French

• German

• Japanese

• Polish

• Russian

• Spanish

Check with Endress+Hauser for the latest information on available languages.

Certificates and approvals

Metrological approvals OIML R85 (2008)

Compliance tested by NMi

NMi

Test certificate TC 7445

PTB

Innerstaatliche Bauartzulassung 4.454-08.10

Due to legislational regulations, the connection to other systems (via Host Link NXA822 or

Tankvision OPC Server) is not included in the approvals listed above.

Endress+Hauser 15

Page 16

RCM-Tick marking

The supplied product or measuring system meets the ACMA (Australian Communications and Media

Authority) requirements for network integrity, interoperability, performance characteristics as well

as health and safety regulations. Here, especially the regulatory arrangements for electromagnetic

compatibility are met. The products are labelled with the RCM- Tick marking on the name plate.

Supplementary documentation

Operating Instructions BA00340G

Installation Instructions for NXA820, NXA821 and NXA822.

Describes installation, electrical connection and first setup.

Tankvision NXA820, NXA821, NXA822

A0029561

Description of Instrument Functions

BA00424G

Operator Manual for NXA820, NXA821 and NXA822.

Describes user interface, user access rights and operation.

BA00426G

System Description for NXA820, NXA821 and NXA822.

Describes the connection to gauges and host systems and the calculations the Tank Scanner can

perform.

BA01137G

Operating Instructions for Tankvision NXA820 OPC Server.

Describes installation, configuration and usage.

BA00339G

Description of Instrument Functions for Tank Scanner NXA820, Data Concentrator NXA821 and

Host Link NXA822.

Contains a detailed description of all instrument functions.

Registered trademarks

Microsoft Corporation

Schneider Electric

Oracle Corporation

The following trademarks are either registered trademarks or trademarks of Microsoft Corporation

in the United States and/or other countries:

Microsoft®

Windows®

The following trademark is a registered trademark of Schneider Electric or its affiliates in the United

States and/or other countries:

Modbus

The following trademarks are registered trademarks of Oracle and/or its affiliates:

Oracle®

Java®

TM

16 Endress+Hauser

Page 17

Tankvision NXA820, NXA821, NXA822

Legal notice concerning trademarks

All company/product names and/or all company logos may be trade names, trademarks and/or

registered trademarks of Endress+Hauser, its affiliates or of their respective owners with which they

are associated.

Endress+Hauser 17

Page 18

Page 19

Page 20

*71425700*

71425700

www.addresses.endress.com

Loading...

Loading...