Page 1

BA00426G/00/EN/17.18

71424924

Valid as of software version:

02.02.00

Products Solutions Services

Operating Instructions

Tankvision

Tank Scanner NXA820,

Data Concentrator NXA821,

Host Link NXA822

System Description

Page 2

Tankvision

Order code:

Ext. ord. cd.:

Ser. no.:

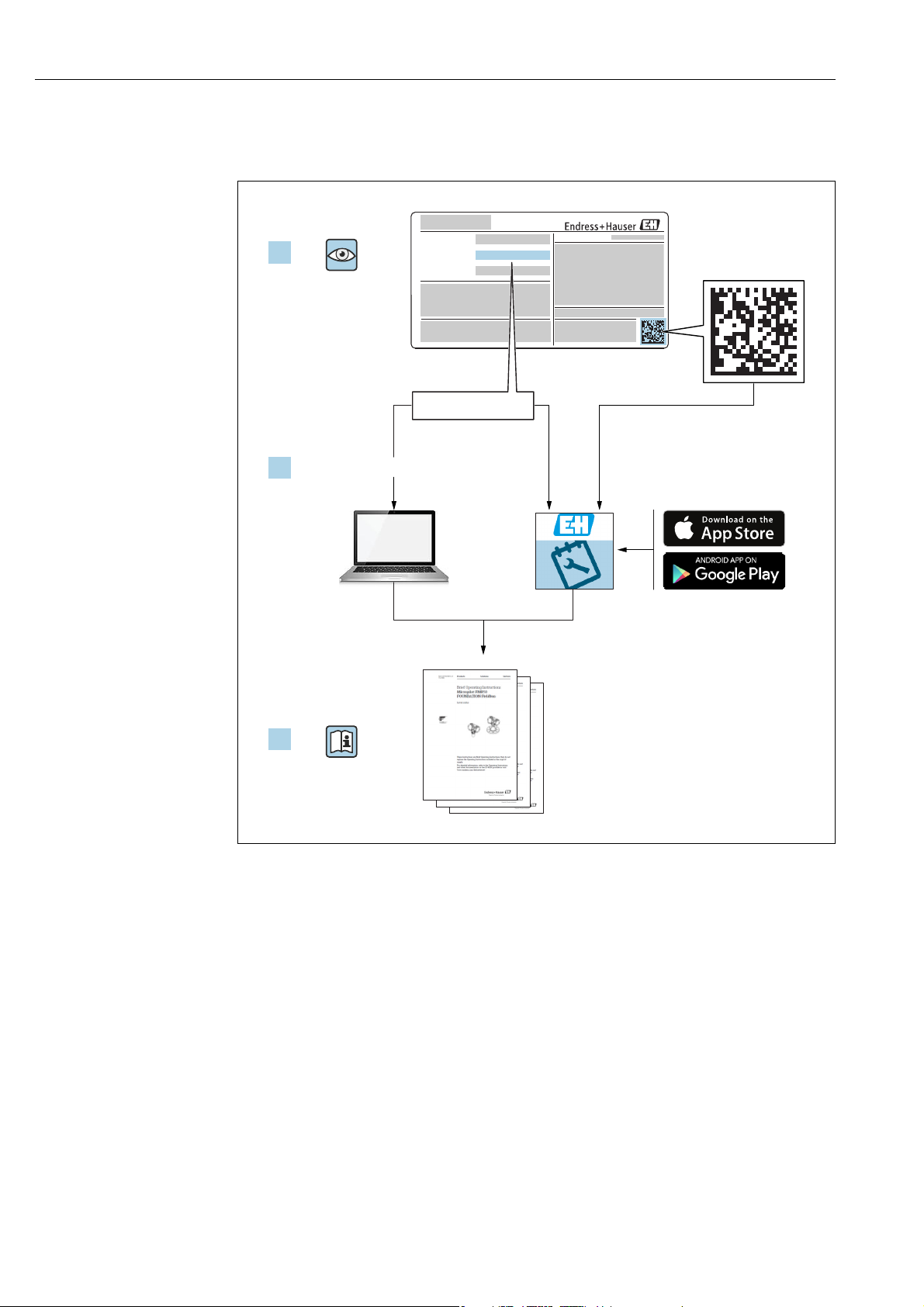

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to

these Instructions.

A0023555

2 Endress+Hauser

Page 3

Tankvision

Table of Contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Version history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 6

2 Basic safety instructions . . . . . . . . . . . . . 7

2.1 Requirements for the personnel . . . . . . . . . . . . . . . 7

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 IT security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Application . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Inventory control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Application areas . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Identifying the components . . . . . . . . .10

4.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Tank Scanner NXA820 . . . . . . . . . . . . . . . . . . . . . 11

4.3 Data Concentrator NXA821 . . . . . . . . . . . . . . . . . 12

4.4 Host Link NXA822 . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Explosion picture . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Tankvision OPC Server . . . . . . . . . . . . . . . . . . . . . 16

4.7 Tankvision Printer Agent . . . . . . . . . . . . . . . . . . . 16

4.8 Tankvision Alarm Agent . . . . . . . . . . . . . . . . . . . 17

8.7 JIS calculation flow charts . . . . . . . . . . . . . . . . . . . 63

8.8 Annex A.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.9 Annex A.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.10 Annex A.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.11 Annex A.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.12 Annex A.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.13 Annex A.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.14 Annex A.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.15 Annex A.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.16 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5 PC recommendations. . . . . . . . . . . . . . . 18

5.1 PC connection for viewing data . . . . . . . . . . . . . . 18

5.2 Recommendations when using OPC Server,

Printer Agent or Alarm Agent . . . . . . . . . . . . . . . 18

5.3 Alternations from the recommendations . . . . . 18

6 Connections to gauges and host systems

19

6.1 Field instruments and slave devices . . . . . . . . . . 19

6.2 Host Systems communication . . . . . . . . . . . . . . . 24

7 Examples . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1 System architecture . . . . . . . . . . . . . . . . . . . . . . . 25

7.2 Screen examples in Browser . . . . . . . . . . . . . . . . 26

8 Calculations. . . . . . . . . . . . . . . . . . . . . . . 28

8.1 API Flow Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2 GBT calculation flow chart . . . . . . . . . . . . . . . . . . 42

8.3 Mass Measurement . . . . . . . . . . . . . . . . . . . . . . . 48

8.4 Calculations for liquefied gases . . . . . . . . . . . . . . 53

8.5 CTSh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.6 Alcohol calculations . . . . . . . . . . . . . . . . . . . . . . . 61

Endress+Hauser 3

Page 4

Document information Tankvision

DANGER

WARNING

CAUTION

NOTICE

1 Document information

1.1 Version history

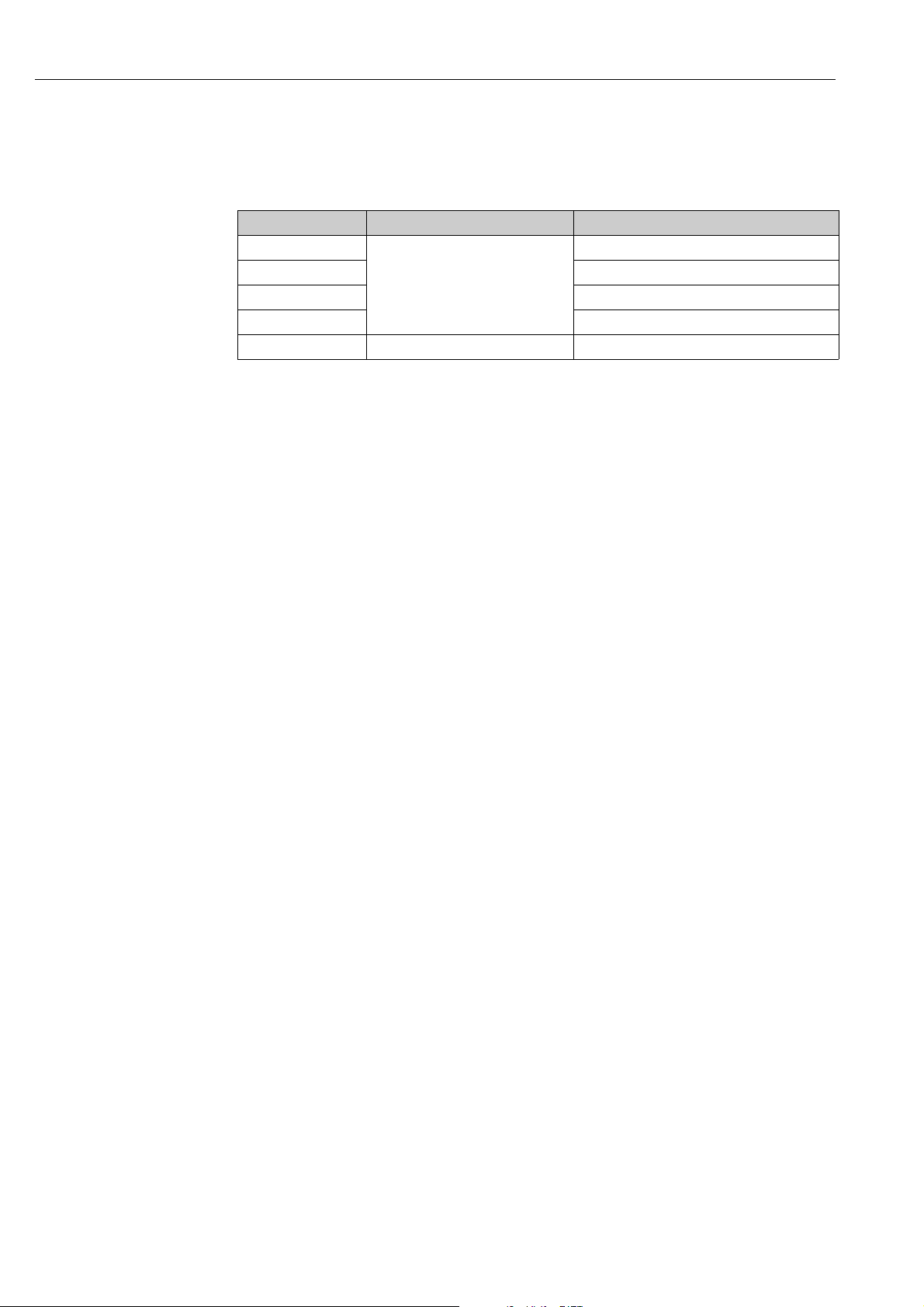

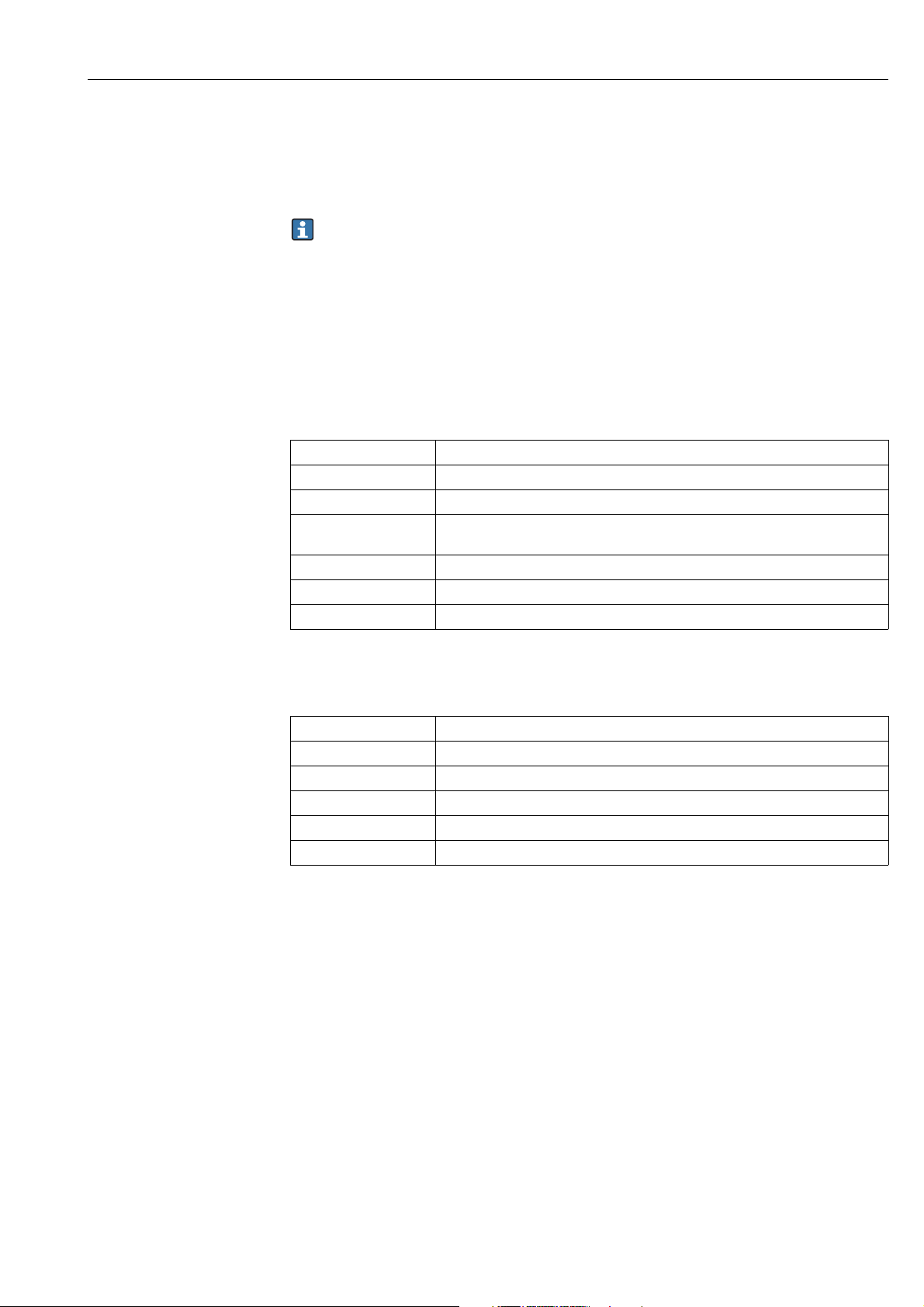

Document version Valid for SW version Changes to the previous version

BA00426G/00/EN/01.12 01.02.02-00xxx/01.04.00 Initial version

BA00426G/00/EN/13.13 01.05.00 Initial version

BA00426G/00/EN/14.15 01.06.00 Java applets replacement, new layout

BA00426G/00/EN/15.17 02.00.00 Introduced Temperature and Density Profile

BA00426G/00/EN/16.17 02.01.00 Introduced Floating Roof Weight Correction,

BA00426G/00/EN/17.18 02.02.00 Introduced Switch by Gauge redundancy mode

1.2 Document function

Redundancy functionality with NXA820

Interface Only, CH alarm for Volume or Mass

for NXA820 Interface Only

This manual is giving detailed information on the system capabilities and architecture. It

supports project and sales engineers in designing the system architecture during acquisition

and execution phase. Furthermore during operation time of the system all servicing

personnel in need of detailed knowledge about the system capabilities.

This manual is not suitable for the Interface only version of NXA820.

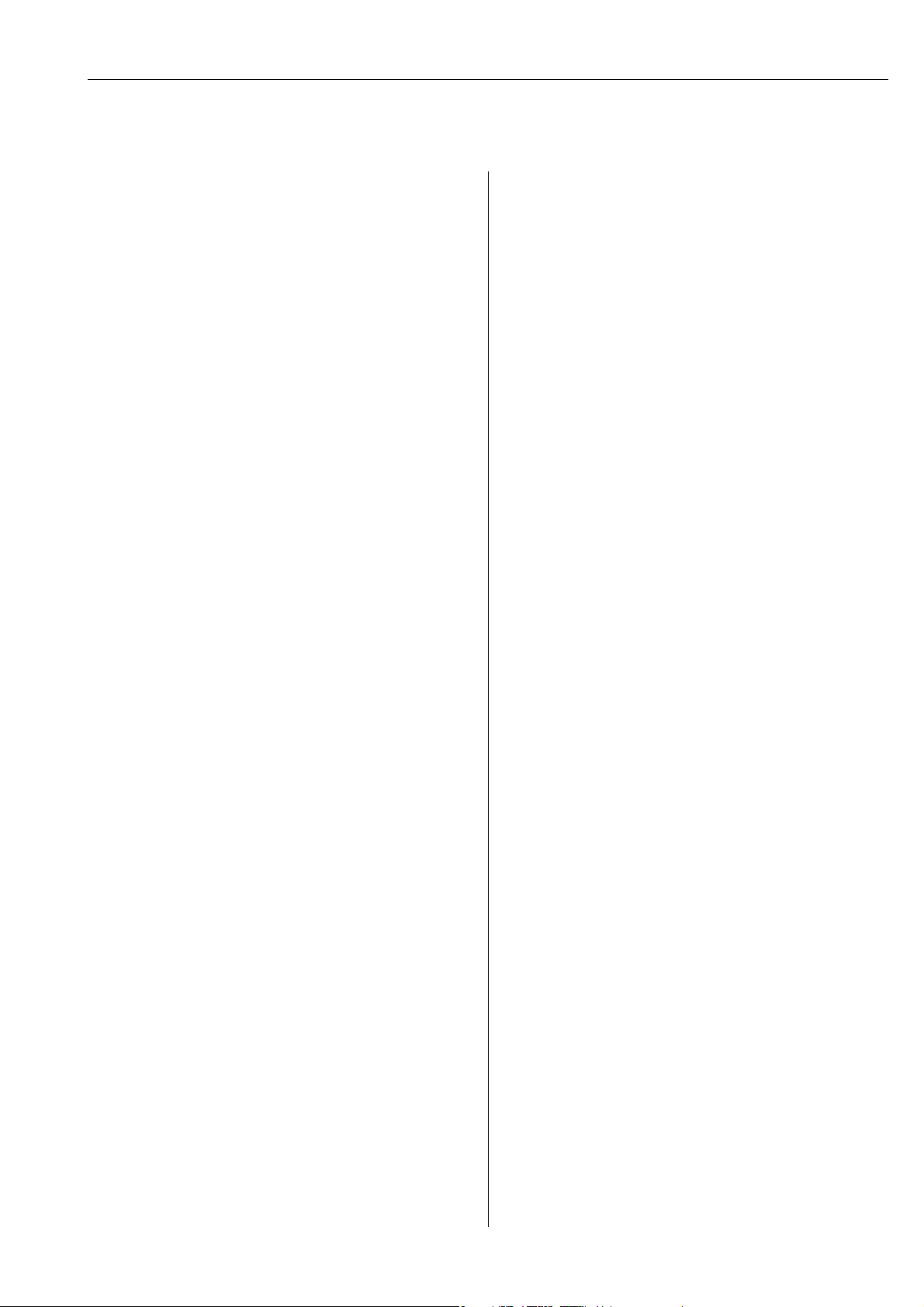

1.3 Symbols

1.3.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-EN

A0011190-EN

A0011191-EN

A0011192-EN

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result

in personal injury.

4 Endress+Hauser

Page 5

Tankvision Document information

)

*

1.

2.

3.

1.

2.

3.

-

.

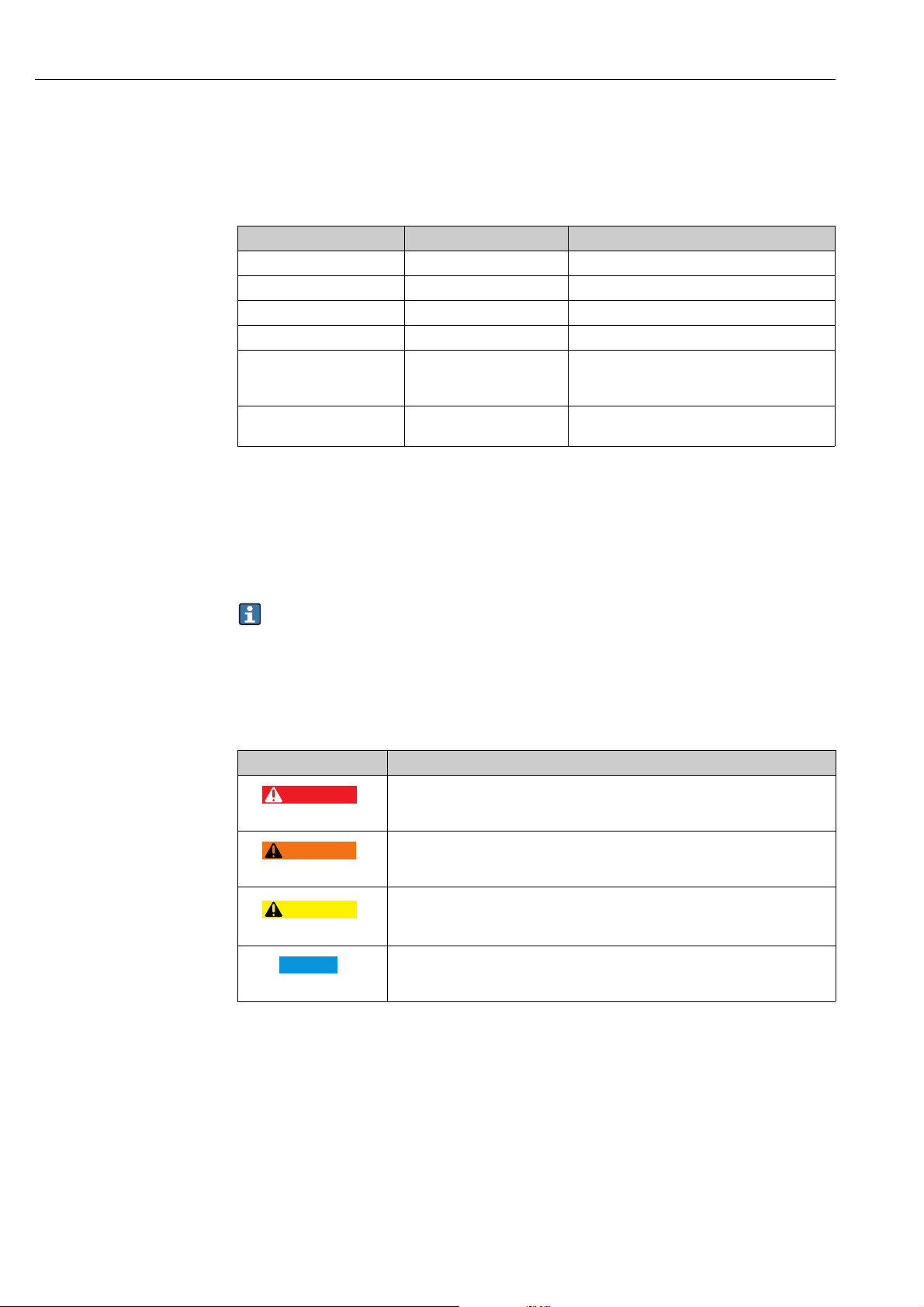

1.3.2 Electrical symbols

Symbol Meaning

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

A0011197

Alternating current

A terminal to which alternating voltage is applied or through which alternating current flows.

A0011198

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

A0011200

system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011199

1.3.3 Symbols for certain types of information

Symbol Meaning

Tip

Indicates additional information.

A0011193

Reference to page

Refers to the corresponding page number.

A0011195

, , ... Series of steps

Result of a sequence of actions

A0018373

1.3.4 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, , ... Series of steps

A, B, C ... Views

Hazardous area

Indicates a hazardous area.

A0011187

Indicates a non-hazardous location

Safe area (non-hazardous area)

A0011188

Endress+Hauser 5

Page 6

Document information Tankvision

1.4 Documentation

1.4.1 Operating instructions

Document number Instrument Type of Document

BA00339G/00

BA00340G/00 Installation Instructions

BA00424G/00 System Description

BA00426G/00 Operator Manual

BA01137G/00 Tankvision NXA820 OPC Server User Manual

• Tank Scanner NXA820

• Data Concentrator NXA821

• Host Link NXA822

Description of Instrument Functions

1.5 Registered trademarks

Microsoft®, Windows® and Internet Explorer

Registered trademarks of the Microsoft Corporation

®

Modbus

TM

Modbus is a registered trademark of Schneider Electric USA, Inc.

®

Java

Registered trademark of Oracle® Corporation

6 Endress+Hauser

Page 7

Tankvision Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner operator

• Following the instructions in these Operating Instructions

2.2 Designated use

2.2.1 Application

Tankvision is a dedicated tank inventory management system.

Components:

• Tankvision Tank Scanner NXA820

scans parameters from tank gauges and performs tank calculations

• Tankvision Data Concentrator NXA821

summarizes data from various Tank Scanners NXA820

• Tankvision Host Link NXA822

provides data to host systems (such as PLC or DCS) via Modbus

The above mentioned components are operated via a standard web browser. It does not

require any proprietary software. Tankvision is based on a distributed architecture on a Local

Area Network (LAN). Due to its modular structure it can be adjusted to any application. It is

ideally suited for small tank farms with only a couple of tanks, but also for large refineries

with hundreds of tanks.

Endress+Hauser 7

Page 8

Basic safety instructions Tankvision

2.3 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national

regulations.

• Switch off the supply voltage before connecting the device.

2.4 Operational safety

Risk of injury!

• Operate the device in proper technical condition and fail-safe condition only.

• The operator is responsible for interference-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers

• If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

• Carry out repairs on the device only if they are expressly permitted.

• Observe federal/national regulations pertaining to repair of an electrical device.

• Use original spare parts and accessories from Endress+Hauser only.

2.5 Product safety

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device complies with the

applicable standards and regulations as listed in the EC declaration of conformity and thus

complies with the statutory requirements of the EG directives. Endress+Hauser confirms the

successful testing of the device by affixing to it the CE mark.

2.6 IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser can be contacted to provide support in performing this task.

8 Endress+Hauser

Page 9

Tankvision Application

3Application

3.1 Inventory control

By using Tankvision to monitor the tank level and stored volume of valuable liquids

remotely, owners or operators of tank farms or terminals for petroleum products and

chemicals (liquids) can visualize the volumes or mass of the stored medium in real time. The

data can be used to plan the inventory and distribution. The data can also be used to manage

tank farm operations like pumping or transferring products.

Tankvision has its unique concept using network technology. Without using proprietary

software, the users can visualize and manage their valuable liquids stored in the tanks by a

web browser.

Tankvision is a flexible and cost effective solution due to its scalable architecture. The

application coverage goes from small depots with only a few tanks up to refineries.

3.2 Application areas

• Tank farms in refineries

• Ship loading terminals

• Marketing and distribution terminals

• Pipeline terminals

• Logistic terminals for tanks storing products like crude oils, refined white and black

products, chemicals, LPGs, fuels, biofuels, alcohols

Endress+Hauser 9

Page 10

Identifying the components Tankvision

4 Identifying the components

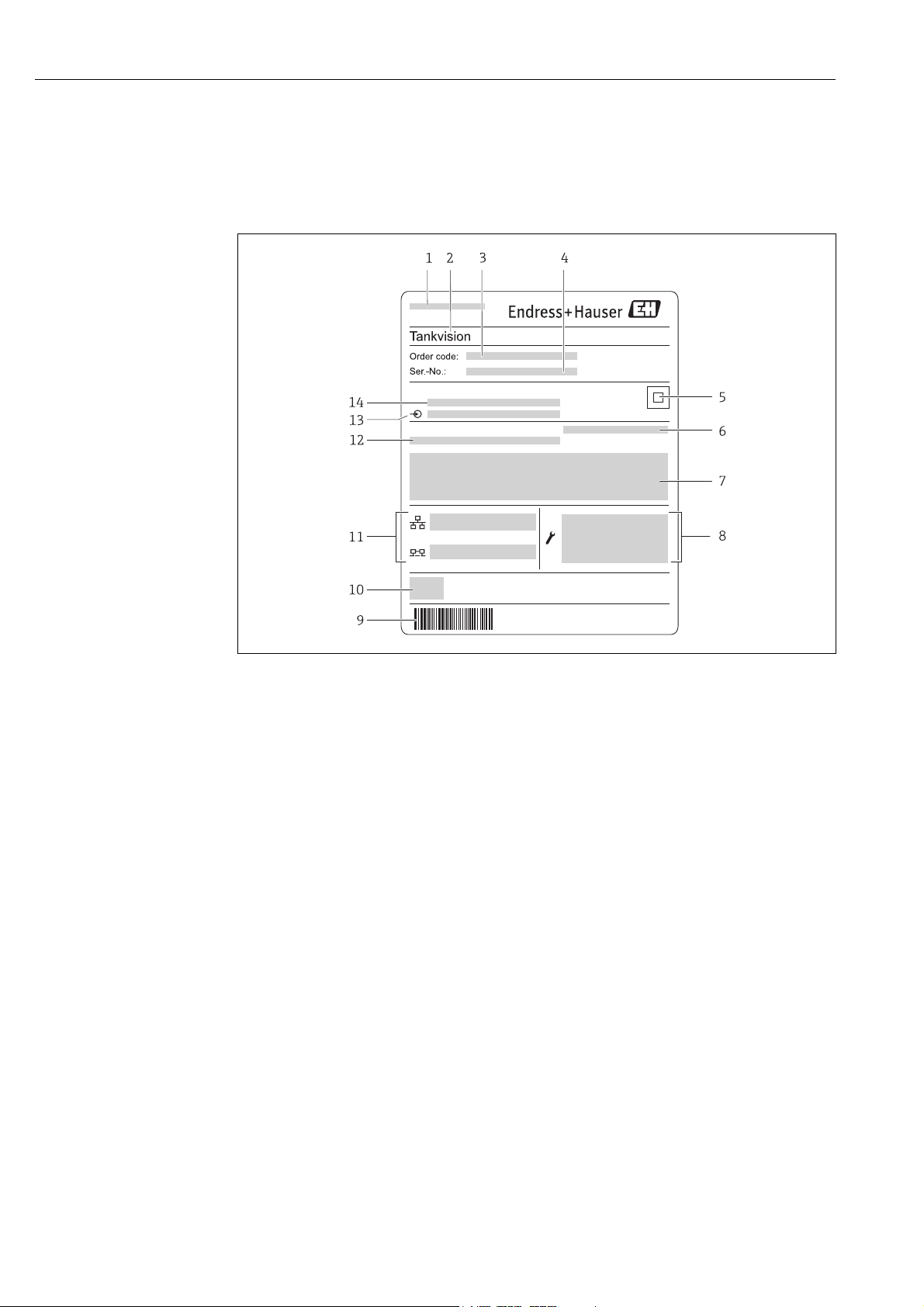

4.1 Nameplate

1 Address of manufacturer

2Device name

3Order code

4 Serial number (Ser. no.)

5Data Matrix Code

6 Degree of protection

7 Certificate and approval relevant data

8 Technical data of the Service LAN port

9Barcode

10 CE mark

11 MAC address of the System LAN port and Sync LAN port

12 Admissible ambient temperature

13 Type of fieldbus communication (only for Tank Scanner NXA820)

14 Supply voltage

nameplate_2

10 Endress+Hauser

Page 11

Tankvision Identifying the components

4.2 Tank Scanner NXA820

• The Tank Scanner NXA820 connects multiple tank gauges:

from up to 15 tanks via one field-loop. The Tank Scanner NXA820 supports different field

protocols (Modbus EIA485, Sakura V1, Whessoe WM550).

• The measured values are transmitted by the network and visualized on HTML pages.

• The Tank Scanner NXA820 can be used stand-alone for small tank farms, but also be

integrated into a large system for use in refineries.

• The Tank Scanner NXA820 is equipped with a full set of tank inventory calculations. The

calculations are based on various international standards such as API, ASTM, IP and many

others. Measured values are used to calculate volume and mass.

4.2.1 Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configuration on the Endress+Hauser website: www.endress.com → Select

country → Instruments → Select device → Product page function: Configure this product

• From your Endress+Hauser Sales Center: www.endress.com/worldwide

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

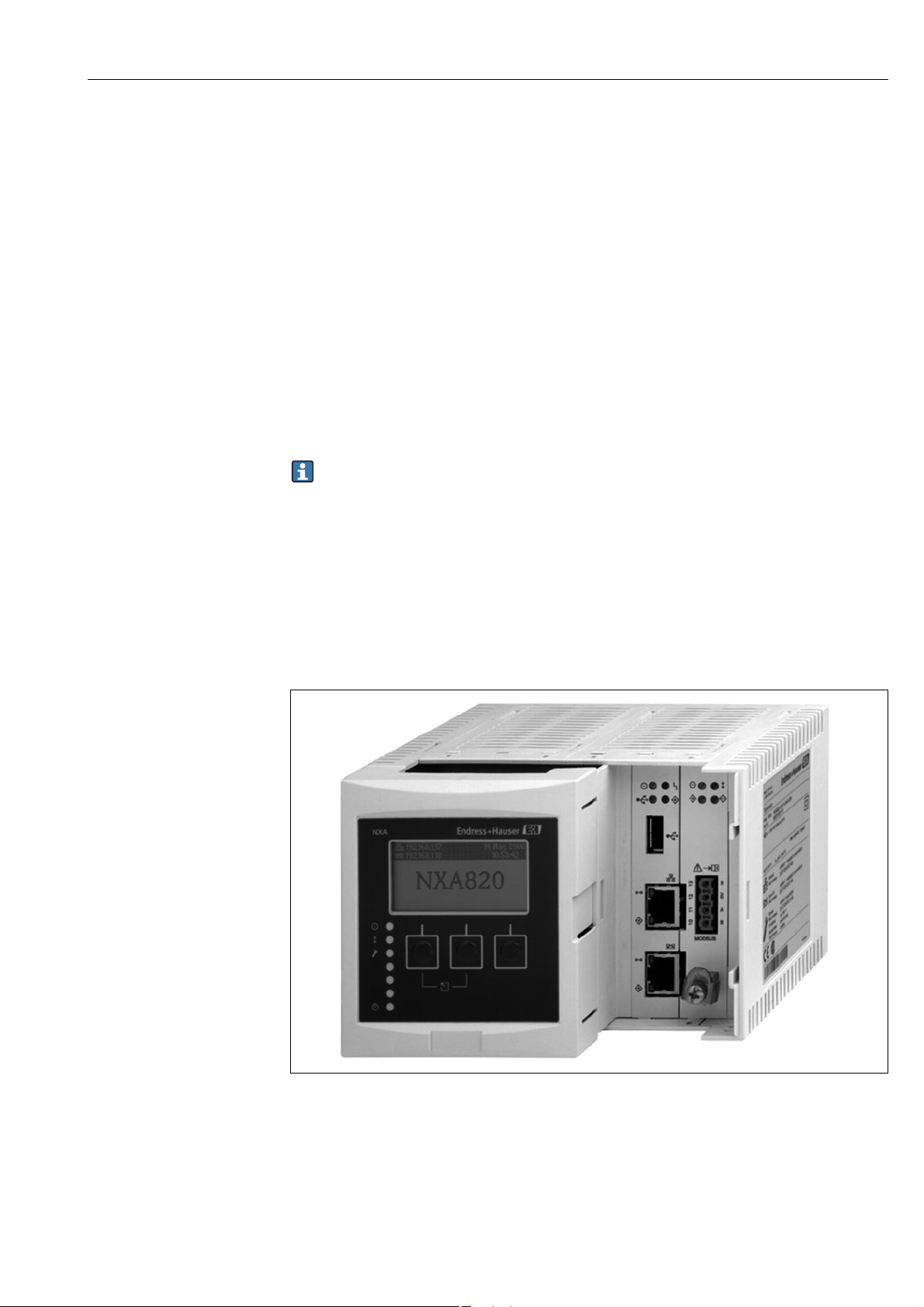

4.2.2 Product picture

L00-NXA8xxxx-10-08-06-xx-002

Endress+Hauser 11

Page 12

Identifying the components Tankvision

4.3 Data Concentrator NXA821

• The NXA821 Tankvision Data Concentrator is the enhanced solution for large tank farms

and refineries. The Data Concentrator is required if:

The plant contains more than one field loop (each of which has its own Tank Scanner

NXA820) and tanks of more than one Tank Scanner NXA820 are to be grouped

• The Data Concentrator collects the data of several Tank Scanner units and enables

reconciliation and totalization of the tank data of many or all tanks in structured groups.

• Alarms and events from all connected Tank Scanners NXA820 can be shown in a common

screen. Any tank of the system can be assigned to any tank group, regardless of the Tank

Scanner it is linked to. This ensures the highest possible flexibility for the plant or tank

farm.

• An alarm pop-up shows alarms of all connected Tank Scanners NXA820 even if the web

browser is closed.

• Direct serial printer connection for report printing (W+M certified acc. PTB)

• 90 tanks (more on request) can be allocated to each Data Concentrator NXA821. Each of

these tanks must have been allocated to a Tank Scanner NXA820 beforehand.

• Tanks from up to 6 different Tank Scanners NXA820 (more on request) can be integrated

in this way.

4.3.1 Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configuration on the Endress+Hauser website: www.endress.com → Select

country → Instruments → Select device → Product page function: Configure this product

• From your Endress+Hauser Sales Center: www.endress.com/worldwide

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

12 Endress+Hauser

Page 13

Tankvision Identifying the components

4.3.2 Product picture

L00-NXA8xxxx-10-08-06-xx-003

Endress+Hauser 13

Page 14

Identifying the components Tankvision

4.4 Host Link NXA822

• The Host Link NXA822 collects data from all Tank Scanners NXA820 on a network and

transfers them to the host system.

• The MODBUS option supports serial EIA-232(RS) and EIA-485(RS) or MODBUS TCP/IP.

The NXA822 is configured as a MODBUS slave. Supported functions are:

– Coil Status (#01)

– Read Input Status(#02)

– Holding Registers (#03)

– Input Registers (#04)

– Force Single Coil (#05)

– Write Modbus Values (#06)

– Force Multiple Coils (#15)

– Preset Multiple Registers (#16)

• The MODBUS register map is described via XML files and can easily be adapted to

individual MODBUS master requirements.

• Gauge commands for Servo Gauges

• 90 tanks (more on request) can be allocated to each Host Link NXA822. Each of these

tanks must have been allocated to a Tank Scanner NXA820 beforehand.

• Tanks from up to 6 different Tank Scanners NXA820 (more on request) can be integrated

in this way.

• Per system 2 NXA822 units can be installed.

4.4.1 Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configuration on the Endress+Hauser website: www.endress.com → Select

country → Instruments → Select device → Product page function: Configure this product

• From your Endress+Hauser Sales Center: www.endress.com/worldwide

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

14 Endress+Hauser

Page 15

Tankvision Identifying the components

4.4.2 Product picture

L00-NXA8xxxx-10-08-06-xx-004

Endress+Hauser 15

Page 16

Identifying the components Tankvision

1

2

3

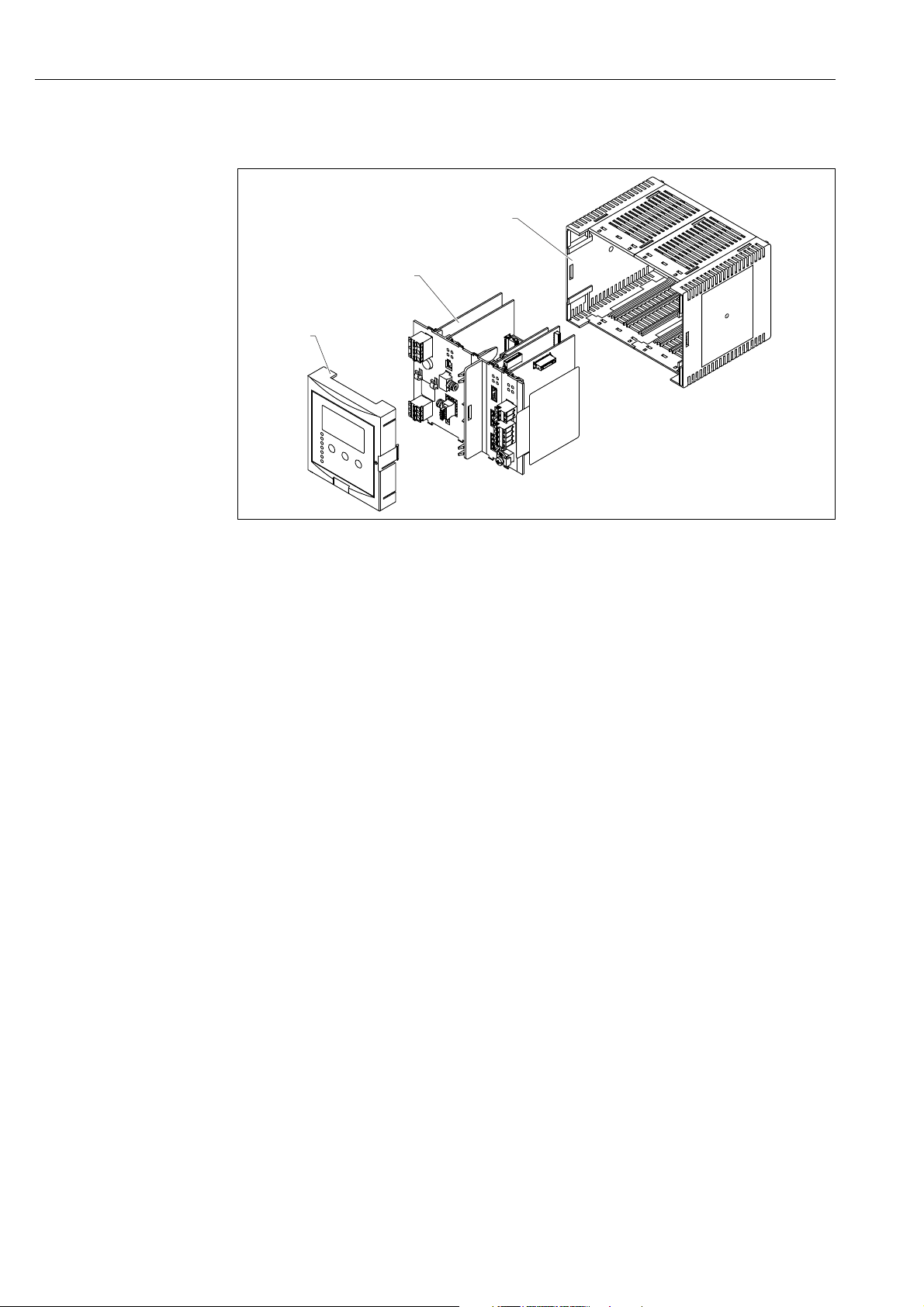

4.5 Explosion picture

L00-NXA82xxx-16-00-00-xx-071

1Cover plate

2 Inner electronics

3Housing

4.6 Tankvision OPC Server

• The OPC Server is a Windows program installed on a PC connecting to NXA820 and allows

access to measured and calculated tank parameters.

• The OPC Server connects to OPC clients on the same PC or other PCs via LAN.

• The OPC Server supports browsing tanks and tank parameters on NXA820.

• The OPC Server is included in each NXA820 and can be uploaded to the PC.

• The OPC Server is based on OPC DA V3.0

4.7 Tankvision Printer Agent

• The Printer Agent is a Windows program installed on a PC, connecting to NXA820/

NXA821. Supports up to 2 network connection per PC.

• The program is running in the background and enables (scheduled) printing reports on

connected printers.

• Up to 3 printers (directly connected to the PC or network printers) can be assigned to the

Printer Agent.

• If a printout can not be performed, a record is kept within the Printer Agent.

• The printer agent software is included in each NXA820 and can be uploaded to the PC (for

more information, see document BA00339G).

16 Endress+Hauser

Page 17

Tankvision Identifying the components

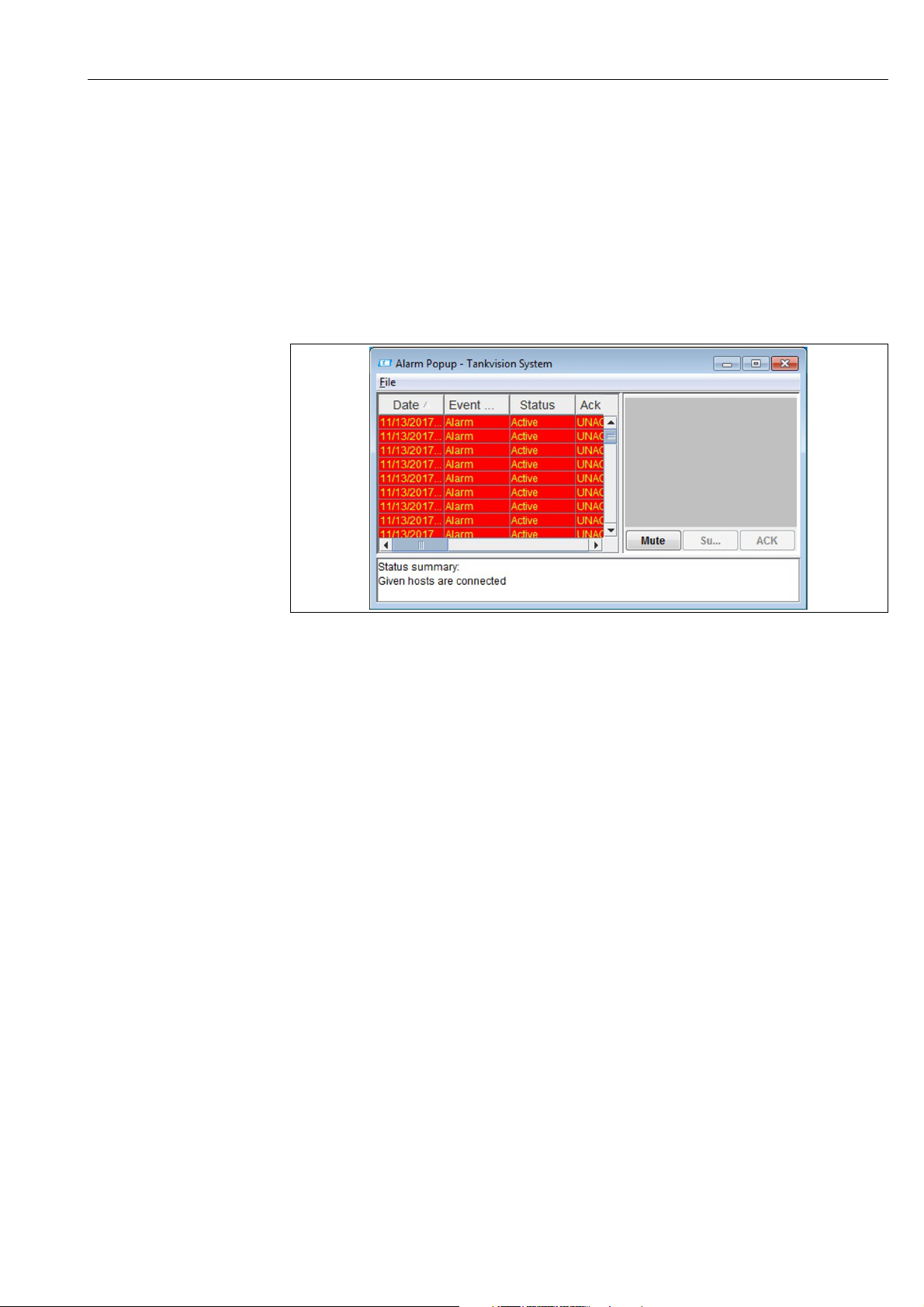

4.8 Tankvision Alarm Agent

• The Alarm Pop-Up-Agent is a Windows program installed on a PC, connecting to

NXA820/NXA821.

• The program is running in the background and scans for alarms generated in NXA820/

NXA821.

• If an alarm is present, a pop-up window opens displaying the alarm.

• The alarm can be acknowledged within this window.

• The window can only be closed if no alarm is active.

• The Alarm Agent can be uploaded from NXA820/821 to the PC.

• A single alarm Agent can support multiple NXA820/NXA821.

For more information, see document BA00339G.

Alarm-Popup-Agent

Endress+Hauser 17

Page 18

PC recommendations Tankvision

5PC recommendations

5.1 PC connection for viewing data

Tankvision Tank Scanner NXA820, Tankvision Data Concentrator NXA821 and Tankvision

Host Link NXA822 are providing a web server to view and enter data or perform

configurations. Viewing the pages requires a web browser and JAVA runtime installed on a

PC.

PC and the Tankvision components must be connected within the same Local Area Network

(LAN) consisting out of Ethernet lines, switches and/or routers.

HUBs shall not be used. In secured systems e.g. for W&M purposes, routers cannot be

used. If company policies allow a remote connection into the LAN also enables a

remote connection to Tankvision components.

5.1.1 Recommendations PC configuration

With all on the market available web browser entering the Tankvision web server is possible.

Nevertheless the pages are optimized for Microsoft Internet Explorer (supported version IE9,

IE10 and IE11 – Compatibility Mode).

The user interface pages are optimized for a screen resolution of 1280x1024 (or higher).

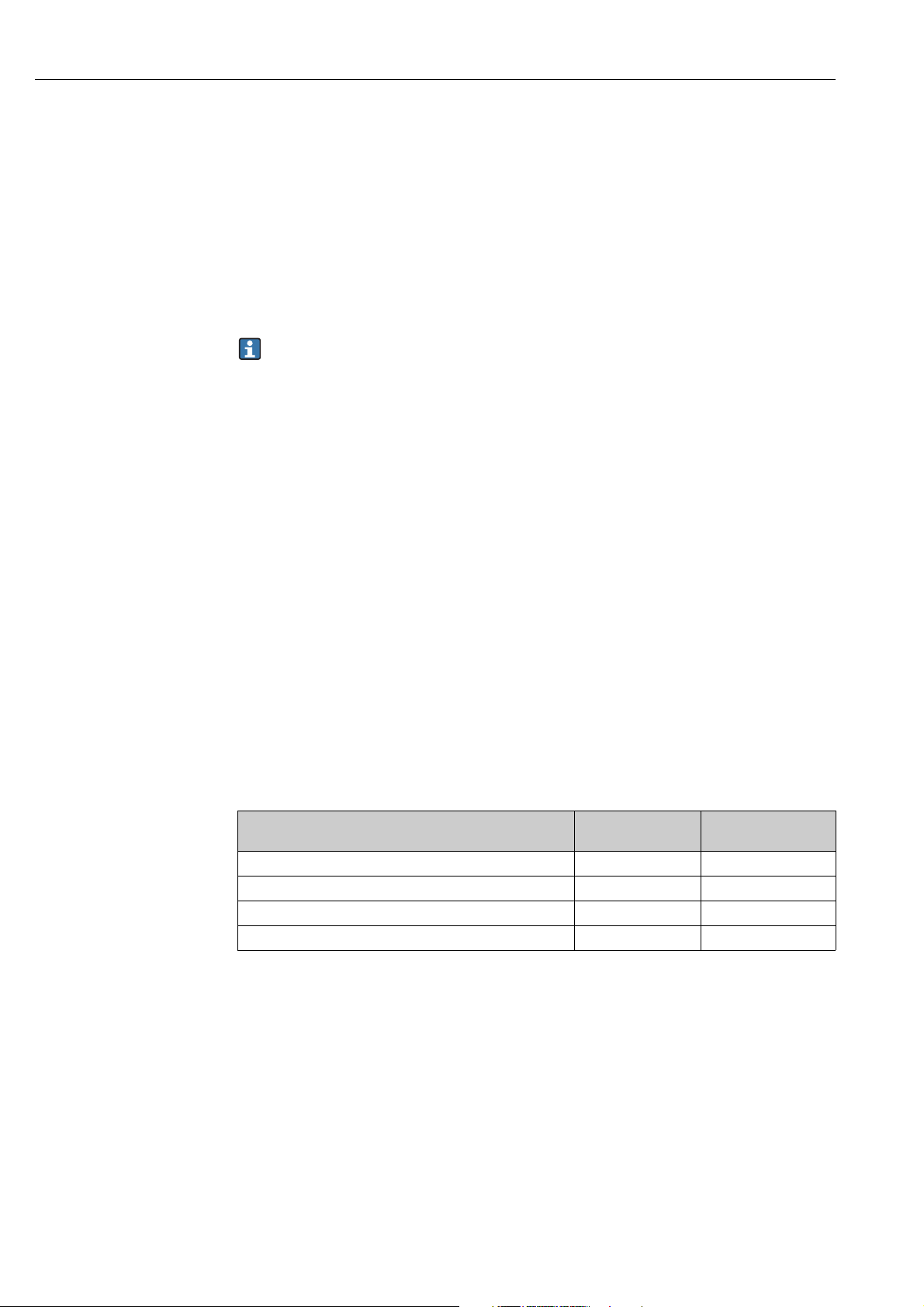

5.2 Recommendations when using OPC Server, Printer Agent or Alarm Agent

• Windows XP 32 Bit Service Pack 3, Windows 7 32 Bit or Windows 7 64 Bit

• Java 8 or higher

5.3 Alternations from the recommendations

Alternations to the recommendations in the previous chapters might have influences on the

proper behaviour of the system especially when communication ports are used by other

programs (e.g. other OPC servers). In case of uncertainty consult Endress+Hauser.

Included Software and Operating System requirements Windows 7

(32/64 bit)

OPC Server X X

Alarm Agent X –

Printer Agent X –

Tankvision Installation and Recovery Tool X –

Windows Server 2008

18 Endress+Hauser

Page 19

Tankvision Connections to gauges and host systems

6 Connections to gauges and host systems

6.1 Field instruments and slave devices

Please take care that the signal and power cables always are separated to prevent noise

and electrical interference between them.

6.1.1 Communication variants

Field instruments or other slave devices are connected to the Tankvision Tank Scanner

NXA820. The unit is available in 3 communication versions.

• Modbus RTU RS485

According to "Modbus over serial line specification and implementation guide V1.02"

published by the Modbus-IDA organization (www.modbus.org) and based upon the EIA/

TIA-485-A physical layer specification.

Characteristic impedance 135 to 165 Ω at measuring frequency of 3 to 20 MHz

Cable capacitance ≤ 30 pF/m

Core cross-section ≥ 0.34 mm² (AWG 22) multi-strand cable is preferred

Cable type Single twisted pair + third conductor (for common) or

Cable resistance ≤ 110 Ω /km

Signal damping Max. 9 dB over the entire length of the cable cross-section

Shielding Copper braided shielding or combined foil and braided shielding

Dual twisted pair (common uses second pair with wire joined together)

• Sakura V1

V1 fieldbus is a voltage mode digital communication using up to ±30 VDC.

Cable capacitance ≤ 50 nF/m

Core cross-section ≥ 0.9 mm² (AWG 17) multi-strand cable is preferred

Cable type Twisted pair

Cable resistance ≤ 30 Ω /km

Shielding Copper braided shielding or combined foil and braided shielding

Insulation ≥ 60 V

DC

• Whessoe WM550

The WM550 communication protocol works using a current loop principle.

Connection

Please take into consideration that the principle of current loop connection works as

follows:

The Tankvision (master) (-) signal point connects to slave 1 (+) signal point. Slave 1 (-)

signal point connects to slave 2 (+) signal point until (the last) slave N (-) signal point

connects back to the Tankvision (master) (+) signal point closing the current loop.

Cable specification

Please ensure to follow the following recommendations for field installation of the

Tankvision with the WM550 protocol variant.

– Cable with twisted and non-shielded pairs

– Cable with at least 0.5 mm² (AWG 20) section

– Maximum total cable resistance: 250 Ω

– Cable with low capacitance

Endress+Hauser 19

Page 20

Connections to gauges and host systems Tankvision

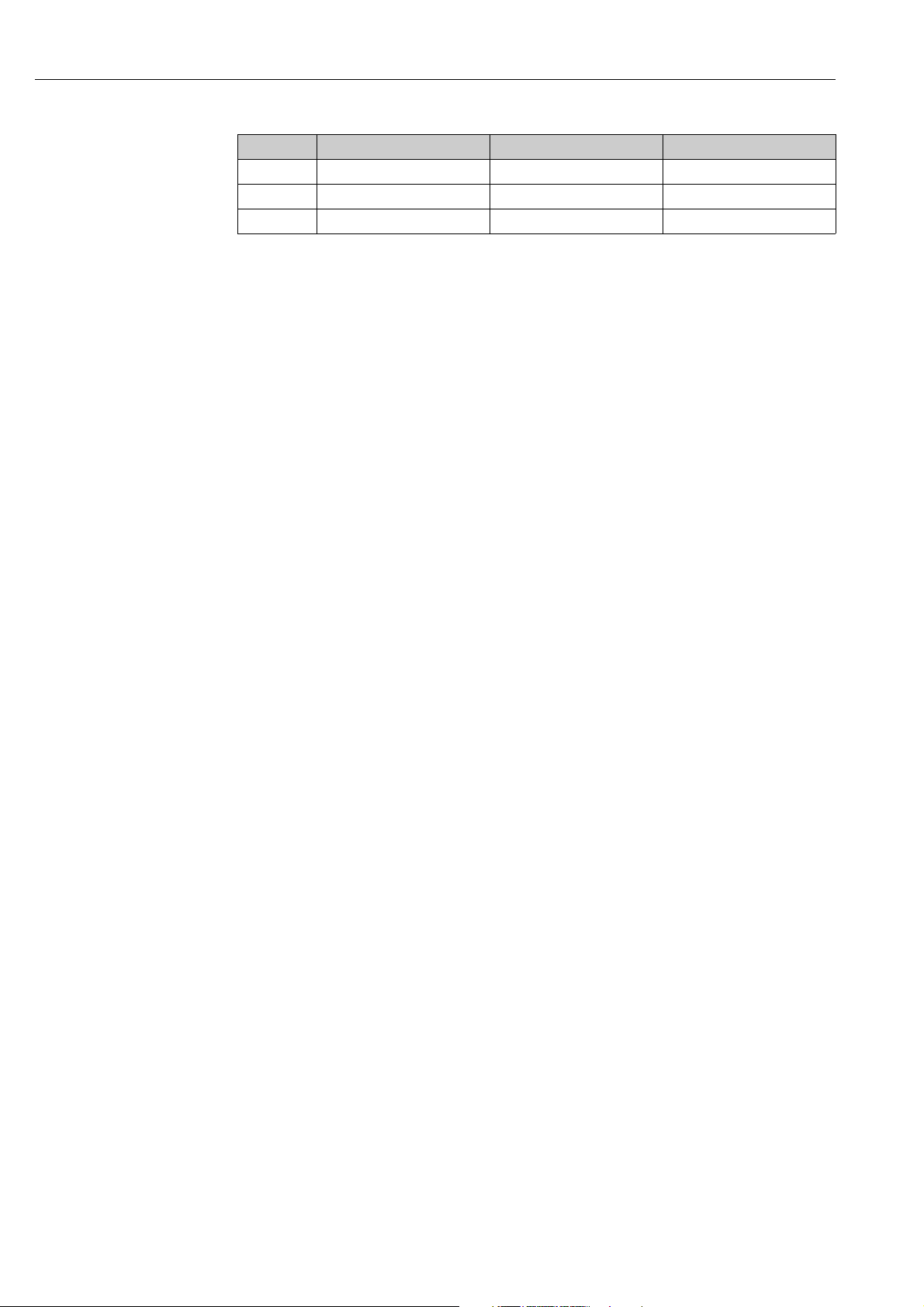

Cross section (mm² (AWG)) Resistance (Ω/km) Capacitance (nF/km)

Cable 1 0.5 (20) 39.2 60

Cable 2 0.75 (18) 24.6 65

Cable 3 1.3 (16) 14.2 75

6.1.2 Field devices

The following list gives an overview on possible field instruments which can be connected

directly or via system components. Nevertheless the connection possibilities are not limited

to these devices.

• Micropilot NMR8x

Micropilot NMR81 is used for custody transfer and inventory control applications with

NMi- and PTB-approvals and meets the requirements according to OIML R85 and API

3.1B. NMR81 is particularly suited for free space applications up to 70 m. The drip-off lens

antenna with 79 GHz transmitting frequency produces a sharply focused beam angle of 3°

and avoids obstacles even close to tank wall.

Micropilot NMR81 is available with Modbus RS485 and Sakura V1 output.

For more information see TI01252G/00/EN.

Micropilot NMR84 is used for custody transfer and inventory control applications with

NMi- and PTB-approvals. It meets the relevant requirements according to OIML R85 and

API 3.1B. The NMR84 free space radar with drip-off planar antenna is specifically suited

for stilling well applications. The superior drip-off antenna design with proven track

record eliminates problems caused by condensation.

Micropilot NMR84 is available with Modbus RS485 and Sakura V1 output.

For more information see TI01253G/00/EN.

• Proservo NMS8x

The intelligent tank gauge Proservo NMS80 is designed for high accuracy liquid level

measurement in custody transfer and inventory control applications with NMi- and PTBapprovals. It meets the relevant requirements according to OIML R85 and API 3.1B. It

fulfills the exact demands of tank inventory management and loss control and is optimized

in regards of total cost saving and safe operation.

Proservo NMS8x is available with Modbus RS485 and Sakura V1 output.

For more information see TI01248G/00/EN, TI01249G/00/EN or TI01250G/00/EN.

• Tank Side Monitor NRF8x

The Tank Side Monitor NRF81 is a sensor integration and monitoring unit for bulk storage

tank gauging applications. It integrates various level, temperature and pressure tank

sensor data into a control host system. Various selectable alarms and outputs.

Tank Side Monitor NRF8x is available with Modbus RS485 and Sakura V1 output.

For more information see TI01251G/00/EN.

• Proservo NMS5/7

The Proservo NMS5/7 intelligent tank gauges are designed for high accuracy liquid level

measurement in storage and process applications. Tank mounted intelligence makes the

Proservo NMS5 ideal for single or multi-task installation, converting a wide of

measurement functions including beside others:

–Liquid level

–Interface level

– Spot density

– Density profile

Proservo NMS5/7 is beside others available with Modbus RTU RS485, Sakura V1,

Whessoe WM550 output. For more information see TI00452G/08/EN.

• Tank Side Monitor NRF590

20 Endress+Hauser

Page 21

Tankvision Connections to gauges and host systems

The Tank Side Monitor NRF590 is a sensor integration and monitoring unit for bulk

storage tank gauging applications. It can be used with Micropilot radar or Proservo level

gauges and can be combined with other HART compatible devices.

Connects up to 6 HART devices via intrinsic safe 2 wire, for example Prothermo for average

temperature measurement and Cerabar/Deltabar for HTMS density applications. Various

industry standard communication protocols, including

–Sakura V1

– EIA-485 Modbus

– Whessoe WM550

For more information see TI00402F/00/EN.

• Micropilot S FMR53x/FMR540

The Micropilot S is used for highly accurate level measurement in storage tanks and can

be applied in custody transfer applications. It meets the relevant requirements according

to OIML R85 and API 3.1B.

The Micropilot S is communicating via the industry standard protocoll HART (Standard 5)

and can be connected to the Tankvision Tank Scanner via the Tank Side Monitor. For more

information see TI00344F/00/EN and TI00412F/00/EN.

• Prothermo NMT539

The Prothermo NMT539 is based on API (American Petroleum Institute) Manual of

Petroleum Measurement Standard, Chapter 7, and enables high accuracy temperature

measurement. At the same time, it is an intelligent average temperature sensor for tank

gauging with an optional WB capacitance sensor at the bottom of the temperature probe.

For average temperature measurement, it consists of precision multi-spot Pt100

elements. The NMT539 is a highly capable solution that provides both contant average

temperature data and water interface data via local HART® communication. For accurate

inventory measurement, it is best suited connected to Endress+Hauser’s Proservo NMS,

Micropilot NMR or Tank Side Monitor NRF with level tankg gauge (e.g. Micropilot). For

more information see TI00042G/08/EN.

• Prothero NMT532

The Prothermo NMT532 consists of an intelligent local HART® signal converter and

average temperature sensor. For average temperature measurement, it consists of

precision multi-spot Pt100 (max. 6) elements which have fixed interval (2 m (6.6 ft) or

3 m (9.8 ft)). The NMT532 is a highly capable solution for a variety of tank gauging

applications and provides constant average temperature data via local HART®

communication. For accurate inventory measurement, it is best suited connected to

Endress+Hauser’s Proservo NMS, Micropilot NMR or Tank Side Monitor NRF with level

tank gauge (e.g. Micropilot). For more information see TI00049G/08/EN.

• Micropilot M FMR2xx

The Micropilot M is used for continuous, non-contact level measurement of liquids, pastes,

slurries and solids. The measurement is not affected by changing media, temperature

changes.

– The FMR230 is especially suited for measurement in buffer and process tanks.

– The FMR231 has its strengths wherever high chemical compatibility is required.

– The FMR240 with the small 40 mm (1½") horn antenna is ideally suited for small

vessels. Additionally, it provides an accuracy of ±3 mm (0.12 in).

– The FMR244 combines the advantages of the horn antenna with high chemical

resistance.

The 80 mm (3") horn antenna is used additionally in solids.

– The FMR245 - highly resistance up to 200 °C (392 °F) and easy to clean.

The Micropilot M is communicating via the industry standard protocol HART and can be

connected to the Tankvision Tank Scanner via the Tank Side Monitor or an HART to

Modbus converter e.g. by Moore Industries. For more information see TI000345F/00/EN.

• Levelflex M FMP4x

Endress+Hauser 21

Page 22

Connections to gauges and host systems Tankvision

Level Measurement - Continuous level measurement of powdery to granular bulk solids

e.g. plastic granulate and liquids.

– Measurement independent of density or bulk weight, conductivity, dielectric constant,

temperature and dust e.g. during pneumatic filling.

– Measurement is also possible in the event of foam or if the surface is very turbulent.

Interface measurement

Continuous measurement of interfaces between two liquids with very different dielectric

constants, such as in the case of oil and water for example.

The Levelflex M is communicating via the industry standard protocol HART and can be

connected to the Tankvision Tank Scanner via the Tank Side Monitor or an HART to

Modbus converter e.g. by Moore Industries. For more information see TI00358F/00/EN.

• Levelflex FMP5x

–FMP51

Premium device for level and interface measurement in liquids.

–FMP52

Premium device with coated probe for the use in aggressive liquids. Material of wetted

parts FDA listed and USP Class VI compliant.

–FMP54

Premium device for high-temperature and high-pressure applications, mainly in liquids.

Levelflex is communicating via the industry standard protocol HART and can be connected

to the Tankvision Tank Scanner via the Tank Side Monitor or an HART to Modbus

converter e.g. by Moore Industries. For more information see TI01001F/00/EN.

•Cerabar M

The Cerabar M pressure transmitter is used for the following measuring tasks:

– Absolute pressure and gauge pressure in gases, steams or liquids in all areas of process

engineering and process measurement technology.

– High reference accuracy: up to ±0.15%, as PLATINUM version: ±0.075%

Cerabar M is communicating via the industry standard protocol HART and can be

connected to the Tankvision Tank Scanner via the Tank Side Monitor or Proservo.

For more information see TI000436P/00/EN.

•Cerabar S

The Cerabar S pressure transmitter is used for the following measuring tasks:

– Absolute pressure and gauge pressure in gases, steams or liquids in all areas of process

engineering and process measurement technology.

– High reference accuracy: up to ±0.075%, as PLATINUM version: ±0.05%

Cerabar S is communicating via the industry standard protocol HART and can be connected

to the Tankvision Tank Scanner via the Tank Side Monitor or Proservo.

For more information see TI000383P/00/EN.

•Deltabar M

The Deltabar M differential pressure transmitter is used for the following measuring tasks:

– Flow measurement (volume or mass flow) in conjunction with primary elements in

gases, vapors and liquids

– Level, volume or mass measurement in liquids

– Differential pressure monitoring, e.g. of filters and pumps

– High reference accuracy: up to ±0.1%, as PLATINUM version: ±0.075%

Deltabar M is communicating via the industry standard protocol HART and can be

connected to the Tankvision Tank Scanner via the Tank Side Monitor or Proservo.

For more information see TI000434P/00/EN.

•Deltabar S

The Deltabar S differential pressure transmitter is used for the following measuring tasks:

– Flow measurement (volume or mass flow) in conjunction with primary devices in gases,

vapors and liquids

– Level, volume or mass measurement in liquids

– Differential pressure monitoring, e.g. of filters and pumps

22 Endress+Hauser

Page 23

Tankvision Connections to gauges and host systems

– High reference accuracy: up to ±0.075%, as PLATINUM version: ±0.05%

Deltabar S is communicating via the industry standard protocol HART and can be

connected to the Tankvision Tank Scanner via the Tank Side Monitor or an HART to

Modbus converter e.g. by Moore Industries. For more information see TI000382P/00/EN.

•Liquicap M

The Liquicap M FMI5x compact transmitter is used for the continuous level measurement

of liquids.

– Suitable for interface measurement

Liquicap M is communicating via the industry standard protocol HART and can be

connected to the Tankvision Tank Scanner via the Tank Side Monitor or an HART to

Modbus converter e.g. by Moore Industries. For more information see TI00401F/00/EN.

• Whessoe ITGs

• Sakura Endress Float&Tape Transmitter TMD

• Sakura Endress TGM5000

• Sakura Endress TGM4000

• SWG70: Wireless HART gateway

• Modbus slave devices

As Modbus is an open protocol there are various system components available which can

be connected to Tankvision Tank Scanner. To do so the so called gauge definition file and

the Modbus map file need to be adapted to the needs. This is a standard procedure and

described in BA00339G/00/EN. Examples for such devices are HART to Modbus

converters, PLCs or other protocol converters e.g. Gauge Emulator by MHT.

Remote service access via the Endress+Hauser device configuration tool FieldCare is

supported for the following device combination:

• Tankvision Tank Scanner with Modbus or Sakura V1 communication

• Tank Side Monitor Modbus or Sakura V1 communication and SW version 02.04.00 or

later

• HART devices connected to Tank Side Monitor intrinsic safe HART bus and supporting

FDT/DTM

or

• Tankvision Tank Scanner with Modbus or Sakura V1 communication

• Proservo NMS5/7 (Modbus or Sakura V1 communication) with

– TCB-6 version 4.27E

– Graphical display operation module

– Modbus communication module COM-5, version 2.0 or

– V1 communication module COM-1 (SRAM-mounted), version 5.01

– HART devices connected to Proservo cannot be reached by FieldCare

Endress+Hauser 23

Page 24

Connections to gauges and host systems Tankvision

6.2 Host Systems communication

To transfer and receive data to/from host system the communication variants OPC DA

(version 3.0) and Modbus RS232, Modbus RS485 and Modbus TCP are available.

6.2.1 OPC DA server

See "Tankvision OPC Server", → ä 16.

For available parameters see A.1 Parameter list.

6.2.2 Modbus slave via Host Link NXA822

See "Host Link NXA822", → ä 14.

For available parameters see A.1 Parameter list.

6.2.3 Connection to Tankvision Professional

To connect to Tankvision Professional a dedicated communication is available. In this case

measured data are transferred as the calculations are performed in Tankvision Professional.

24 Endress+Hauser

Page 25

Tankvision Examples

NXA820

Tank Scanner

NXA820

Tank Scanner

Switch

NXA820

Tank Scanner

NXA821

Data Concentrator

NXA820

NXA820

NXA822

Host Link

NXA820 NXA820 NXA820

Ethernet

DCS

OPC Server FieldCareSeveral Printer

for W+M reports

Printer

Browser

Browser

Browser

DCS

Modbus RTU RS232/485,

Modbus TCP

Fieldbus protocol

Fieldbus protocol

Operator 1

Operator 2

Operator 3

Fieldbus protocol

(e.g. Modbus, V1, WM550)

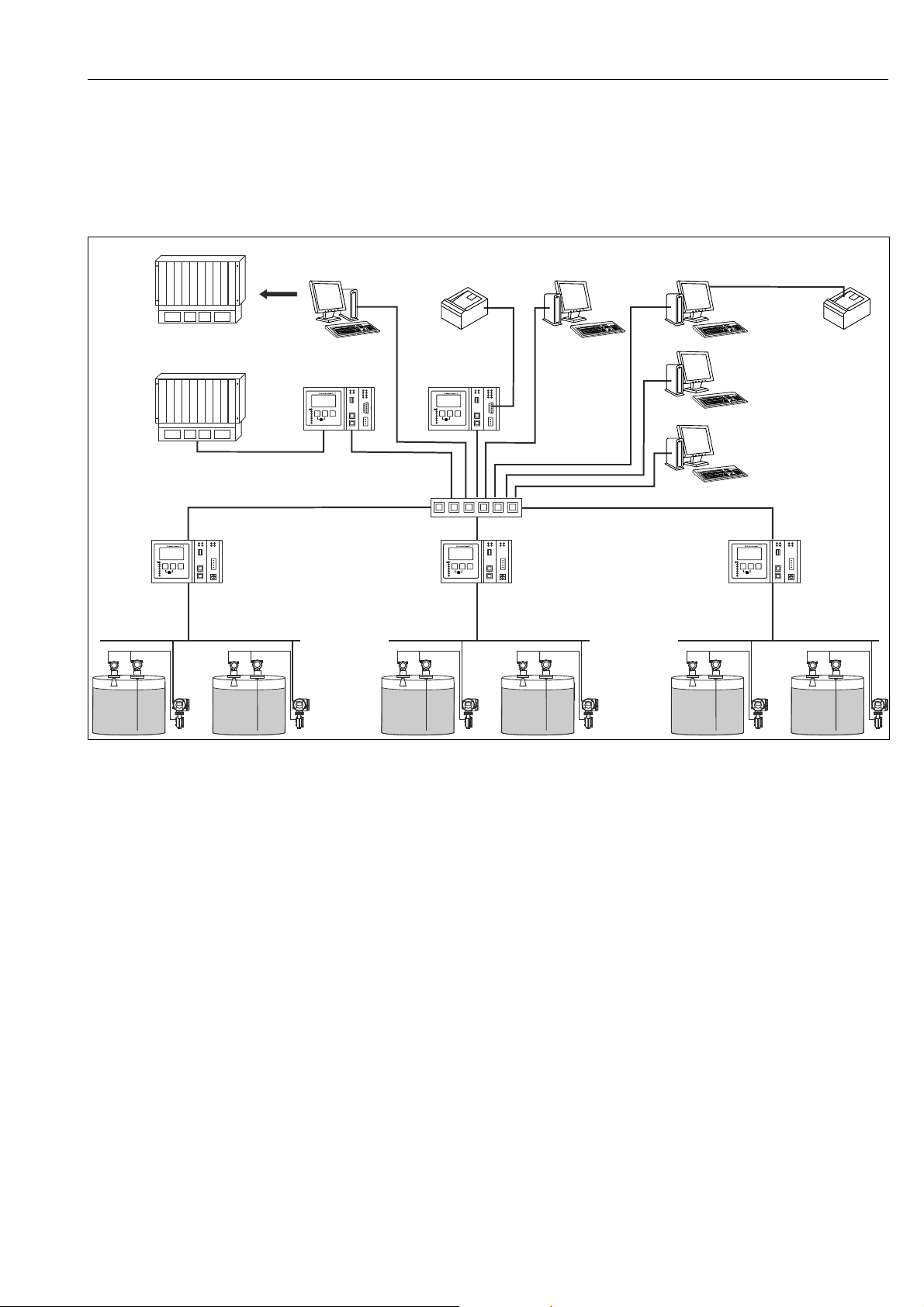

7Examples

7.1 System architecture

L00-NXA82xxx-02-00-00-en-006

Endress+Hauser 25

Page 26

Examples Tankvision

7.2 Screen examples in Browser

Tank tabular view

Tank details

Tabular view

NXA82x_Tank_General-Details-Tab

26 Endress+Hauser

Page 27

Tankvision Examples

Trend view

Trend

Endress+Hauser 27

Page 28

Calculations Tankvision

Level

Level

Flow

S&WV

FWL

Base Temp.

Ambient temp.

Air density

air density

Product temp.

Hydrom. corr.

Product Code

S&W

Table & Product

Code

Obs. density &

Obs. temp.

Ref. density

FWV

CTSh

Sump/Heel

volume

RemCap AvailVol

TOV

GOV

VCF

WAC

Ref. Density

CSW

GSV

NSV

NSW in air

Liquid Mass/

NSW in VacuumAir

If Ullage

NoGo

Zones

convert to

Innage

calculate

FWV

Floating

API/ASTM

Obs-Ref

density

conversion

S&W

calculation

Roof

Air corr.

calc.

corrections

Calculate

Remain cap.

Calculate

AvailVol

Calculate

TOV

Calculate

EquivArea

Calculate

EquivArea

TankTop

P-TCT

W-TCT

Tank Shell

details

Roof

Details

+

-

1.

Ullage Conversion

2.

Volume calculation

3.

Free Water Volume

calculation

4.

Tank Shell correction

5.

Floating Roof

corrections

7.

Volume Correction

Factor calculation

8.

Sediment & Water

calculations

12.

Flow calculation

6.

Sump/Heel Volume

11.

Net Standard Weight

calculation

9.

Reference Density

Calculation

10.

Net weight in Air

Calculation

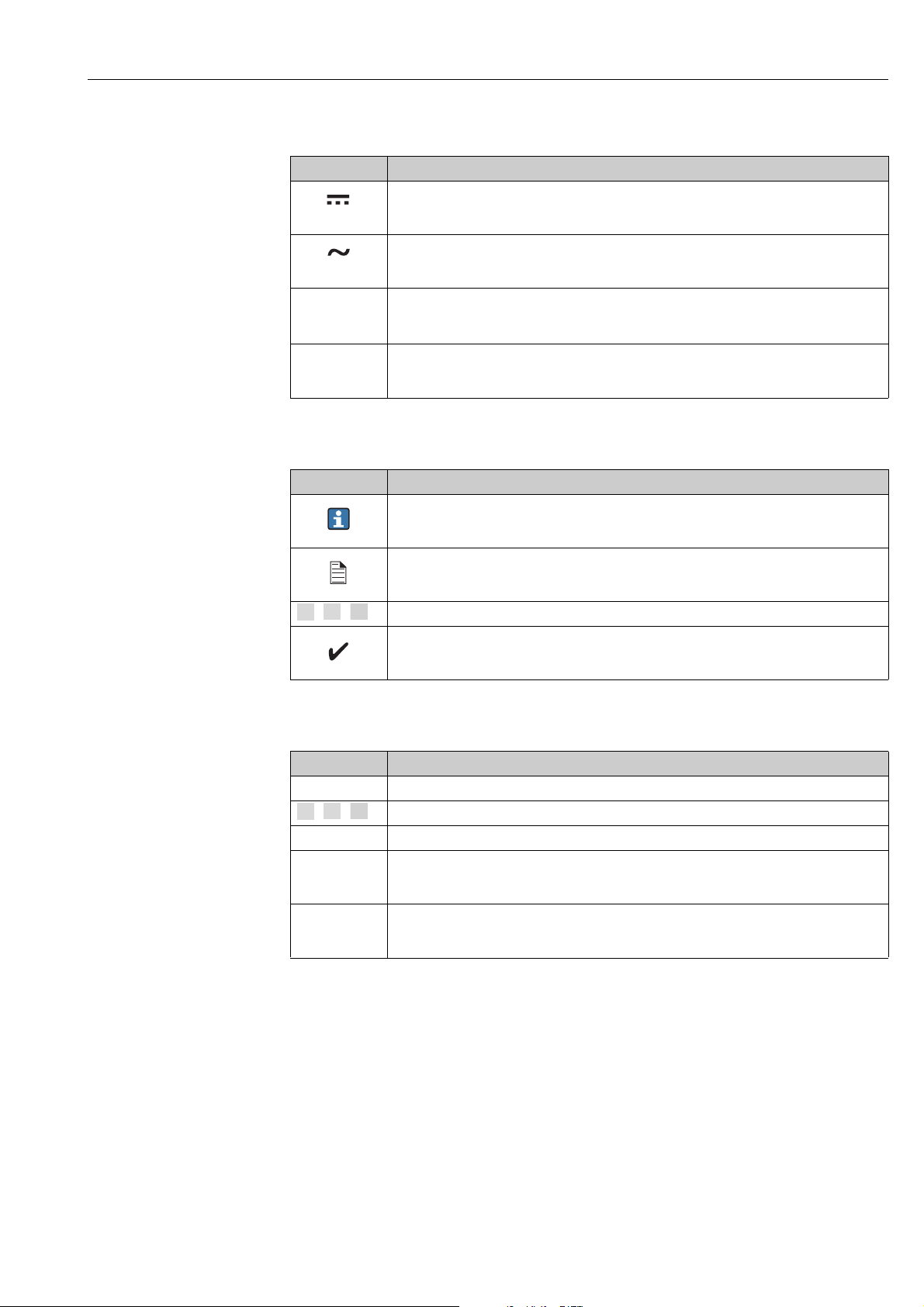

8Calculations

Tankvision Tank Scanner can perform various kinds of calculations which are described in

the following chapters. The inventory calculations allow the conversion from measured data

like level and temperature to standard data (e.g. Net standard volume or mass). There are

various standards for these calculations available differing in the sequence of the calculation

or the way compensation factors are determined (from tables or formula). Today

calculations from API (see Text → ä 29) and GB/T (see Text → ä 29) are implemented in

Tankvision Tank Scanner.

8.1 API Flow Charts

The chart shows the sequence calculations are done according to the API. The different steps

are explained in the following chapters.

L00-NXA82xxx-16-00-00-xx-034

28 Endress+Hauser

Page 29

Tankvision Calculations

API (American Petroleum Institute)

The American Petroleum Institute, commonly referred to as API, is the largest U.S trade

association for the oil and natural gas industry. It claims to represent about 400 corporations

involved in production, refinement, distribution and many other aspects of the petroleum

industry.

The association’s chief functions on behalf of the industry include advocacy and negotiation

with governmental, legal and regulatory agencies; research into economic, toxicological and

environmental effects; establishment and certification of industry standards; and education

outreach. API both funds and conducts research related to many aspects of the petroleum

industry.

GB (Chinese national standards)

GB standards are the Chinese national standards issued by the Standardization

Administration of China (SAC), the Chinese National Committee of the ISO and IEC. GB

stand for Guobiao, Chinese for national standard. Mandatory standards are prefixed "GB".

Recommended standards are prefixed "GB/T". A standard number follows "GB" or "GB/T".

Endress+Hauser 29

Page 30

Calculations Tankvision

Level

RemCap AvailVol

TOV

If Ullage

convert to

Innage

Calculate

Remain. cap.

Calculate

AvailVol

Calculate

TOV

TankTop

P-TCT

1.

Ullage Conversion

2.

TOV calculation

FWLFWV

TOV

calculate

FWV

W-TCT

-

3.

Free Water Volume

calculation

8.1.1 Total Observed Volume - TOV

L00-NXA82xxx-16-00-00-xx-035

The Total Observed Volume (TOV) is determined with the level information and the Tank

Capacity Table (TCT). The TOV is the volume observed at the present (temperature)

conditions.

The TCT is a tank specific table created by calibration holding the level to volume transfer

information. To differentiate the TCT for the Product and for the Water the TCT gets marked

with a P (P-TCT).

The level information needed for this step is in innage which is the normal way the level is

transferred from the gauge. In case the gauge inputs ullage to the system a calculation into

innage is necessary beforehand (Ullage substracted from Mounting position).

Two more information can be derived from TCT and level:

• Remaining Capacity (RemCap) shows how much more product could be pumped into the

tank safely.

• Available Volume (AvailVol) indicates how much product can be pumped out of the tank

to the lowest (defined) possible point e.g. the tank outlet.

8.1.2 Free Water Volume - FWV

L00-NXA82xxx-16-00-00-xx-036

In some cases the tank can also contain water. It can derive from the delivered crude oil, the

processing or by tank breathing. The (innage) water level information together with a Water

Tank Capacity Table (W-TCT) result in the Free Water Volume. It is substracted from the

TOV.

30 Endress+Hauser

Page 31

Tankvision Calculations

Base Temp.

Ambient temp.

CTSh

Tank Shell

details

4.

Tank Shell correction

air density

Ref. density

NoGo

Zones

Floating

Roof

corrections

Roof

Details

5.

Floating Roof

corrections

B AAA BB

1

3

2

3

1

2

8.1.3 Tank Shell Correction - CTSh

• The Tank Shell expands and contracts with temperature changes (compared to TCT

calibration temperature)

• Some countries require CTSh (Correction for Tank Shell temperature effects)

• For heated products the CTSh can be in excess of 0.3% TOV

L00-NXA82xxx-16-00-00-xx-037

For more details see → ä 56, Chapter "CTSh".

The Tank Shell Correction is a factor which is multiplied with the TOV reduced by the

FWV.

8.1.4 Floating Roof Correction - FRC

L00-NXA82xxx-16-00-00-xx-038

A tank can often have a floating roof. A floating roof is called so because it floats on the

product stored in the tank. The roof moves up or down along with product level. Since the

roof is floating on the tank, it displaces some amount of product depending on the weight of

the roof and the density of the product. This displacement in product level results in a

different apparent level, introducing an error into the volume calculations. The product

volume therefore needs to be corrected.

A floating roof often has supporting legs. The roof can be rested on these legs when the level

is too low or the tank is empty. This allows maintenance staff to enter below the roof for

carrying on tank maintenance. Based on the product level, the floating roof can be landed on

the legs or floating on the product. However, in a certain range of product level, the floating

roof can be partially landed. This zone is called "critical zone". In the Tankvision system there

can be two critical zones related to the position of the floating roof legs.

Endress+Hauser 31

L00-NXA82xxx-16-00-00-xx-039

Page 32

Calculations Tankvision

Volume

132

Roof Landed

Height

Roof Take Off Height

Level

RLH

without FRA

with FRA

RTOH

3c

3a

3d

3b

123

FR ’

3

L00-NXA82xxx-16-00-00-xx-040

Inside critical zone:

3a Apply full FRA

3b Do not Apply FRA

3c Do not calculate FRA

3d Use partial FRA (interpolate)

Floating roofs can already be considered in the TCT.

8.1.5 Weight correction of the floating roof

The Floating roof position can be changed due to heavy snowfall, rain, sand or during

unloading which triggers the roof to fluctuate that may cause variations in the stock

inventory calculation. It's required to compensate Floating Roof immersion and also to

compensate changing weight on floating roof.

The floating roof position can be monitored with 3 additional level sensors mounted on top

of the floating roof. The level devices are connected to gauges which will be connected to

Tankvision NXA820.

L00-NXA82xxx-00-00-00-xx-001

1FR Level 1

2FR Level 2

3FR Level 3

To measure the submersion or elevation of a floating roof it is required to monitor the level

of the roof. If the gauges are on the floating roof, then the average of the distances FR1/2/

3 compared to the average of the Reference FR1/2/3 provide:

32 Endress+Hauser

Page 33

Tankvision Calculations

ΔFR = FR ’ − FR

11 1

ΔFR = FR ’ − FR

22 2

ΔFR = FR ’ − FR

33 3

ΔFR =

ΔFR

123

+FR+FRΔΔ

3

Sump/Pipe

volume

TOV

GOV GOV = (TOV - FWV) CTSh FRA + SPV´± {}

FRA

Add Sump/Pipe Volume

Correct for Floating Roof Weight

CTSh Apply CTSh

FWV Subtract Free Water Volume

Floating

Roof

corrections

+

-

L00-NXA82xxx-00-00-00-xx-002

If ΔFR < 0 then we have an elevation

If ΔFR > 0 then we have a submersion

Additional volume and mass of the floating roof calculated as:

ΔV = ΔFR × A

FR

Δm =ΔFR × AFR × ρ

A

: The numerical value of the horizontal cross-sectional area floating roof

FR

Δm : Additional Mass of the floating roof (Mass of snow, sand, rain or others)

ρ : Observer Density

ΔV : Addition Volume displaced in floating roof due to snow/rain/sand or others

Total mass of the roof = Original mass of the Floating roof (m') + Additional Mass of the

floating roof due to snow, rain etc. (Δm)

m = m' + Δm

m = m' + ΔFR *A

* ρ

FR

This equation can be used to calculate the GOV of the tank.

GOV = TOV – (ΔFR * A

+ m / ρ)

FR

8.1.6 Sump/Heel/Pipe volume

Volume of the Sump and Pipes are added.

8.1.7 Gross Observed Volume - GOV

Endress+Hauser 33

L00-NXA82xxx-16-00-00-xx-041

Page 34

Calculations Tankvision

VCF = e

[- t(1.0+0.8t)]aD aD

60 60

a60==

++

K +K p +K p

01 2

**2

K0K

1

K

2

p

*2

p*2p

*

900

800

700

600

500

400

300

a

T

X10 (°F)

5 -1

.81.01.21.4 1.61.82.02.22.4 2.6

(1/p) X 10 [kg/m ]

T

25 32

1

2

3

4

5

8.1.8 Volume Correction Factor - VCF

The VCF corrects for the temperature expansion of the liquid. Especially hydrocarbons have

a large expansion factor. The most common VCF corrections were developed by American

Society for Testing and Materials (ASTM), USA and Institute of Petroleum, UK and updated

regularly. There are more authorities issuing VCF corrections. Most of them are derived from

the ASTM/IP tables.

VCF Implementation

• Calculations are based on "representative samples" ("generalized products")

• The "Tables" are based on specific calculation procedures

• Calculation is complex and rounding and truncating unique. There are many small but

significant differences - exact requirements and needs depend on application, country and

company.

L00-NXA82xxx-16-00-00-xx-044

1 Gasolines

2Crudes

3Jets

4 Fuel oils

5 Lube oils

VCF Tables

• The formulas are too complex for direct use - hence the "Tables" were printed

• There are specific tables for:

– Products (crudes, refined products, lube oils, alcohols, palm oil, chemicals, etc.)

– Different measurement units (kg/m³ vs. °API, °C vs. °F, etc.)

– Different "Reference" or standard temperature (60 °F, vs. 15 °C, 25 °C or 30 °C)

– Each table has range limits

– Tables for VCF and for density correction are available

34 Endress+Hauser

Page 35

Tankvision Calculations

Most known VCF "Tables"

The Tables are normally grouped in pairs:

• Tables 5 and 6 - ODC resp. VCF °API at 60 °F

• Tables 53 and 54 - ODC resp. VCF kg/m³ at 15 °C

• Tables 24 and 25 - ODC resp. VCF RD 60/60 °F at 60 °F

• Tables 50 and 60 - ODC resp. VCF kg/m³ at 20 °C

Most tables have so called Product Codes:

• A = for generalized crude’s

• B = for refined products

•C = for chemicals

• D = for lube oils

• E = liquefied gases

For chemicals normally a "polynomial equation" is used.

Endress+Hauser 35

Page 36

Calculations Tankvision

VCF = EXP [- t(1.0+0.8t)]aD aD

15 15

K = 346.4228

0

K = 0.4388

1

where:+Dt = DEGC - 15.0

a

15

=

K

0

K

1

p

15

p

15

2

VCF = {D - A 10E3 (T -T) - B 10E3 (T - T)

- C 10E3 (T -T) - D 10E3 (T -T)

- E 10E3 (T -T) } / D

Ref Obs Ref obs Ref

Obs Ref Obs Ref

Obs Ref Ref

´´ ´´

´´ ´´

´´

2

3 4

5

TCF = K0 + K1t + K2´ D ´ D ´ D ´ Dt + K3t + K4 t

234

Dt = t - T

Ref

TCF = 1 - TCF (T - T)´

Obs Ref

Typical table example: 54B (1980)

The range of application:

Density, kg/m³ Temperature, °C

653.0 to 778.5 -18.0 to 90.0

779.0 to 824.0 -18.0 to 125.0

824.5 to 1075.0 -18.0 to 150.0

L00-NXA82xxx-16-00-00-xx-046

Special corrections

VCF Chemical 1

with:

•D

= Reference density

Ref

•T

= Actual or observed temperature

Obs

•T

= Reference Temperature

Ref

• A-E = Configurable coefficients

TCF Method

with:

•K

, K1, K2, K3, K4 = Customer coefficients

0

• t = Actual product temperature

•T

= Reference Temperature

Ref

For the VCF we can write:

L00-NXA82xxx-16-00-00-xx-049

L00-NXA82xxx-16-00-00-xx-050

L00-NXA82xxx-16-00-00-xx-051

With the TCF method the p

provided) and an actual p

no actual p

is available.

Obs

can be calculated with p

Ref

can be calculated with p

Obs

/ VCF (when manual p

Obs

x VCF, when p

Ref

is known and

Ref

36 Endress+Hauser

Obs

is

Page 37

Tankvision Calculations

D = K + K T + K (T ) + K (T ) + K (T )

Obs 0 1 Obs 2 Obs 3 Obs 4 Obs

´´´´

234

D = K + K T + K (T ) + K (T ) + K (T )

ref 0 1 ref 2 ref 3 ref 4 ref

´´´´

234

K + K T + K (T ) + K (T ) + K (T )

0 1 Obs 2 Obs 3 Obs 4 Obs

´´´´

234

K + K T + K (T ) + K (T ) + K (T )

0 1 ref 2 ref 3 ref 4 ref

´´´´

234

VCF =

Product temp.

Table & Product

Code

Ref. density

VCF

Obs. Dens.

API/ASTM

7.

Volume Correction

Factor calculation

GOV

VCF

GSV

Palm oil

L00-NXA82xxx-16-00-00-xx-052

For the VCF we can easily derive: VCF= D

Obs/Dref

L00-NXA82xxx-16-00-00-xx-053

VCF Calculation

• The API/ASTM Tables are a "primary" need for any Tank Inventory system

The correct table for the product must be chosen. Together with the Product temperature

and reference density the VCF can be calculated.

In addition to the VCF the observed density can be calculated.

8.1.9 Gross Standard Volume - GSV

The Gross Standard Volume is calculated by applying the VCF to the GOV.

L00-NXA82xxx-16-00-00-xx-048

Endress+Hauser 37

Page 38

Calculations Tankvision

S&WV

S&W

S&W

calculation

8.

Sediment & Water

calculations

CSW

SWF = 1 - (100 - S&W%) / 100

= S&W%/100

S&WV

S&W

CSW

GSV

NSV

S&W

calculation

11.

Net Standard Weight

calculation

8.1.10 Sediment & Water - S&W

L00-NXA82xxx-16-00-00-xx-072

• Some products have entrained (suspended) sediment and water (S&W)

– i.e. crudes

• S&W is determined from sample by laboratory method ("Karl-Fisher"-method). The

Sediment and Water percentage (S&W%) determined with the sample is transferred in the

Sediment and Water Fraction (SWF). A correction factor for the product is determined.

As second result the Sediment and Water Volume can be calculated.

Sediment & Water calculation methods

There are 6 methods to calculate S&W

1. SWV = 0

2. SWV = TOV x SWF

3. SWV = (TOV - FWV) x SWF

4. SWV = {(TOV - FWV) x CTSh} x SWF

5. SWV = GOV x SWF

6. SWV = GSV x SWF ("standard" or "default" method)

Where the sediment and water fraction (SWF) is:

8.1.11 Net Standard Volume - NSV

L00-NXA82xxx-16-00-00-xx-058

L00-NXA82xxx-16-00-00-xx-056

Subtracting the SWV from the GSV result in Net Standard Volume.

38 Endress+Hauser

Page 39

Tankvision Calculations

Hydrom. corr.

Product Code

Obs. density &

Obs. temp.

Ref. Density

Obs-Ref

density

conversion

9.

Reference Density

Calculation

HYC = 1.0 - A (t - T) - B(t - T)

HYC Cal HYC Cal

´´

2

8.1.12 Density calculations

L00-NXA82xxx-16-00-00-xx-073

We have to distinguish between: observed and reference density

• Observed density is the density of the product at actual (observed) temperature

• Reference density is the density the product would have if we heat/cool it until the

reference temperature (usually 15 °C/60 °F)

• Reference density is used to calculate VCF, FR and mass

• If you know the RefDens you can easily geht the ObDens

ObsDens = RefDens x VCF

• If you know the ObsDens you need (API/ATSM) tables and the sample temperature to get

the RDC (reference density correction factor).

• You can also correct for the thermal expansion of the hydrometer glass (HYC)

RefDens = RDC x ObsDens x HYC

Hydrometer Correction - HYC

with:

• HYC = Hydrometer correction

•A

, B

HYC

= Thermal expansion coeff. for glass

HYC

• t = Temperature of sample

•T

= Calibration temperature of glass hydrometer

Cal

T

Cal

15 °C 0.000 0230 0 0.000 000 020

60 °F 0.000 0127 8 0.000 000 062

A

HYC

B

HYC

L00-NXA82xxx-16-00-00-xx-054

Endress+Hauser 39

Page 40

Calculations Tankvision

Ref. Density1.

2.

3.

4.

5.

Servo Density

Product temp.

Ref. Density

VCF

Obs. Density

Obs. Density

Product temp.

Sample Temp.

Pressure

Hydrom. corr.

Obs. Density

HTG or HTMS

density

Table & Product

Code

Ref. Density

NSV

Liquid Mass/

NSW in VacuumAir

11.

Net Standard Weight

calculation

Density handling in NXA820

L00-NXA82xxx-16-00-00-xx-110

NXA820 offers various possibilities to enter and further process density information:

1. Manual entry of Reference density (from laboratory)

2. Manual entry of Observed density with the according sample temperature (from

laboratory) is required corrected for the hydrometer. With the above information and

the according Product information and ASTM/IP table (for density correction) the

reference density can be calculated.

3. Product pressure, temperature, density table (PTD table): look up table for observed

density with the use of measured product temperature and pressure. With the from the

table derived Observed density, the product temperature and the according Product

information and ASTM/IP table (for density correction) the reference density can be

calculated.

4. Density from HTG or HTMS calculation (→ ä 48). With the from the calculations

derived Observed density, the product temperature and the according Product

information and ASTM/IP table (for density correction) the reference density can be

calculated.

5. Density measured by Servo gauge. With the by the servo gauge measured Observed

density, the product temperature and the according Product information and ASTM/IP

table (for density correction) the reference density can be calculated.

Having the reference density and the according Product information and ASTM/IP table (for

volume correction) the VCF can be determined.

Observed density can be calculated by multiplying reference density with VCF.

8.1.13 Mass/Net Weight in Vacuum

40 Endress+Hauser

L00-NXA82xxx-16-00-00-xx-074

Page 41

Tankvision Calculations

Air density

WAC

NSW in Air

Liquid Mass/

NSW in VacuumAir

Air corr.

calc.

10.

Net Weight in Air

Calculation

WAC =

NWA = WAC Mass´

1 -

1 -

Dens

Air

Dens

Ref

Dens

Vap

Dens

Brass

• Mass in temperature and product property independent

• Mass is needed for "Loss Reconciliation" required for every refinery and terminal

• Mass is calculated out of NSV and the reference density (or GOV and observed density)

8.1.14 Net Weight in Air - NWA

L00-NXA82xxx-16-00-00-xx-075

• The flotation of a body is based on the principle discovered by Archimedes on century 3 BC

"Every submerged body in a liquid experience a vertical upper force that is equal to the

weight of the liquid displaced"

• Considering the liquid displaced is air

• The flotation is related to the liquid density where the body is floating because:

Weight = Vol x Dens.

Calculation formula:

L00-NXA82xxx-16-00-00-xx-057

DensAir Air density

DensRef Product reference density

DensVap vapor density

DensBrass Brass density used to calibrate the weight scale

Net weight in Air methods

WAC Methods Calculated AirDen VapDen BrassDen

Weight in vacuum No 0 0 0

OIML R85 Yes 1.2 1.2 8000

Table 56 Yes 1.22 1.22 8100

Table 57 (short

tons)

Table 57 (long tons) Yes 1.224 1.224 8135.8

Simplified Yes 1.1 0 1

Custom Yes 1.225 1.225 8553

Yes≈ 1.2194 1.2194 8393.437

The Net Standard Weight in Air is in some countries called Mass.

Endress+Hauser 41

Page 42

Calculations Tankvision

Product Temp

Ref. Density

FWL

Amb. Temp

Product Temp

Insulation Type

Steel Expa. coef

FRA Mass(G)

S&W

NWA

WCF

(Ref. Density - 1.1

WCF

(Ref. Density - 1.1

NSW/Product

Mass/Total

Mass

Obs. Density

Product Temp

Ref. Density

VSPAvailVol**

RemCap**

LEVEL

Water Density

at 4°C

TOV

VCF

GOV

NSV

Level

HyDC Vol.

FWV**

CTSh**

CSW**

Ref. Density

Sump/Pipe

Volume

+

+

-

-

Calculate Tank

shell correction**

S&W

Calculation**

«»Table 59 A.b.D

Ref. Density Calc.**

Calculate Gauge

Volume**

«»Table 60 A.B.D

Calculate VCF**

Calculate FWV**

Water TCT

Product TCT

VSP Table

FRA Volume

8.2 GBT calculation flow chart

The GBT standard is the standard for China.

Main difference is the hydrostatic deformation of the tank not being part of the product TCT

but in a separate table. The VCF and density calculations are based on the same ASTM/IP

tables like the API calculations.

L00-NXA82xxx-16-00-00-xx-033

42 Endress+Hauser

Page 43

Tankvision Calculations

Level

Calculate Gauge

Volume**

Product TCT

VSP

LEVEL

VSP Table

8.2.1 Calculated Gauge Volume

L00-NXA82xxx-16-00-00-xx-093

The Calculated Gauge Volume is determined with the level information and the Tank

Capacity Table (TCT). The Calculated Gauge Volume is the volume observed at the present

(temperature) conditions without considering the hydrostatic deformation of the tank.

The TCT is a tank specific table created by calibration holding the level to volume transfer

information. To differentiate the TCT for the Product and for the Water the TCT gets marked

with a P (P-TCT).

The level information needed for this step is in innage which is the normal way the level is

transferred from the gauge. In case the gauge inputs ullage to the system a calculation into

innage is necessary beforehand (Ullage subtracted from Mounting position).

8.2.2 Static Pressure Correction Volume - VSP

L00-NXA82xxx-16-00-00-xx-094

The VSP is determined with the level information and the static pressure correction table

(VSP-table). The VSP is the volume the tank expands at the actual level if it would be filled

with water (wet calibration).

Endress+Hauser 43

Page 44

Calculations Tankvision

Product Temp

Obs. Density

Ref. Density

VSP

Water Density

at 4°C

HyDC Vol.

«»Table 59 A.b.D

Ref. Density Calc.**

HyDC = [Vsp ]´ r

r

rr

rw4

= [ / ]r

20

AvailVol**

RemCap**

TOV

VSP Vol.

+

Calculate Gauge

Volume**

FWL

FWV**

Calculate FWV**

Water TCT

8.2.3 Hydrostatic Deformation Correction Volume - HyDC Vol

L00-NXA82xxx-16-00-00-xx-095

The Hydrostatic Deformation Correction Volume is the real from the product fill level created

hydrostatic volume.

It is calculated by correcting the VSP with the ratio of the density of the product versus the

water density.

ρ

20 Reference Density at 20 °C (68 °F)

ρ

w4 Water Density at 4°C (39°F)

The reference density of the Product can be calculated (if not known) with the Observed

Density, the Product/Sample Temperature and the Reference Density Table for the Product.

8.2.4 Total Observed Volume - TOV

L00-NXA82xxx-16-00-00-xx-097

The Total Observed Volume is calculated from the Calculated Gauge Volume and the

Hydrostatic Deformation Correction Volume.

Two more information can be derived from TCT and level:

• Remaining Capacity (RemCap) shows how much more product could be pumped into the

tank safely

• Available Volume (AvailVol) indicates how much product could be pumped out of the tank

to the lowest (defined) possible point e.g. the tank outlet.

8.2.5 Free Water Volume - FWV

L00-NXA82xxx-16-00-00-xx-098

In some cases the tank can also contain water. It can derive from the delivered crude oil, the

44 Endress+Hauser

processing or by tank breating.

The (innage) water level information together with a Water Tank Capacity Table (W-TCT)

result in the Free Water Volume. It is subtracted from the TOV.

Page 45

Tankvision Calculations

Amb. Temp

Product Temp

Insulation Type

Steel Expa. coef

CTSh**

Calculate Tank

shell correction**

FRA Mass(G)

WCF

(Ref. Density - 1.1

FRA Volume

FRA Volume

TOV

GOV

FWV

**

CTSh**

Sump/Pipe

Volume

+

-

-

8.2.6 Correction for the thermal Expansion of the tank shell - CTSh

L00-NXA82xxx-16-00-00-xx-099

• The Tank Shell expands and contracts with temperature changes (compared to TCT

calibration temperature)

• Some countries require CTSh (Correction for Tank Shell temperature effects)

For more details see → ä 56, Chapter "CTSh".

8.2.7 Floating roof adjustment - FRA

L00-NXA82xxx-16-00-00-xx-100

Additional displacement due to the air is considered, see Net Weight in Air calculation.

8.2.8 Sump/pipe volume

The Volume of the sump and pipes is added.

8.2.9 Gross Observed Volume - GOV

GOV is calculated like follows:

•Starting from the TOV

• Subtract FWV

• Multiply ba the thermal expansion correction factor

• Subtract the floating roof adjustment volume and

• Add the Sump/pipe volume

Endress+Hauser 45

L00-NXA82xxx-16-00-00-xx-101

Page 46

Calculations Tankvision

Ref. Density

Product Temp

VCF

«»Table 60 A.B.D

Calculate VCF**

S&W

CSW**

S&W

Calculation**

SWF = 1 - (100 - S&W%) / 100

= S&W%/100

VCF

GOV

NSV

CSW**

8.2.10 Volume Correction Factor - VCF

L00-NXA82xxx-16-00-00-xx-102

8.2.11 Sediment and Water

L00-NXA82xxx-16-00-00-xx-103

• Some products have entrained (suspended) sediment and water (S&W)

– i. e. crudes

• S&W is determined from sample by laboratory method ("Karl-Fisher"-method). The

Sediment and Water percentage (S&W%) determined with the sample is transferred in the

Sediment and Water Fraction (SWF). A correction factor for the product is determined.

As second result the Sediment and Water Volume can be calculated.

Sediment & Water calculation methods

There are 6 methods to calculate S&W

1. SWV = 0

2. SWV = TOV x SWF

3. SWV = (TOV - FWV) x SWF

4. SWV = {(TOV - FWV) x CTSh} x SWF

5. SWV = GOV x SWF

6. SWV = GSV x SWF ("standard" or "default" method)

Where the sediment and water fraction (SWF) is:

8.2.12 Net Standard Volume - NSV

L00-NXA82xxx-16-00-00-xx-058

L00-NXA82xxx-16-00-00-xx-104

Net Standard Volume is calculated like follows:

• Starting from GOV

• Multiply by the Volume Correction Factor and

• Multiply by the S&W correction factor

46 Endress+Hauser

Page 47

Tankvision Calculations

NSW/Product

Mass/Total

Mass

NSV

Ref. Density

NWA

WCF

(Ref. Density - 1.1

NSV

8.2.13 Net Standard Weight - NSW / Product Mass

L00-NXA82xxx-16-00-00-xx-105

Mass is calculated by multiplying NSV with the Reference density.

8.2.14 Net Standard Weight in air - NWA

L00-NXA82xxx-16-00-00-xx-106

The Net Standard Weight in Air is calculated by multiplying the NSV with the Reference

Density reduced by the influence of the Air buoyancy (Reference density - 1.1).

Endress+Hauser 47

Page 48

Calculations Tankvision

P

3

P

2

P

1

Y

L =

Y

Y

L

P - P

13

P - P

12

P - P

12

D =

obs

8.3 Mass Measurement

Today, most hydrocarbons in the western world are bought and sold using volume

measurement. However, in many eastern countries and in some specialised industries,

product are sold based on mass due to traditions in particular markets, so mass calculation

can be important in those areas of trade. Mass-based measurement offers other advantages,

since mass is independent of product temperature and other parameters.

For custody transfer, high accuracy tank gauging is required, and mass-based calculation is

often used.

8.3.1 Hydrostatic Tank Gauging

The advantage of HTG is that it provides direct mass measurement with only pressure

transmitters to measure hydrostatic pressure in determining density via a fixed distance and

vapor pressure. Therefore, it is a low-cost solution for mass measurement. However, there

are substantial disadvantages:

• Level and volume measurements are less accurate, especially when density stratification

occurs.

• Density is only measured at the between the two pressure sensors.

• Difficult to verify, commission and calibrate

L00-HTGSxxx-05-00-00-xx-001_

The middle or P2 transmitter is unique to Hydrostatic Tank Gauging.

48 Endress+Hauser

Page 49

Tankvision Calculations

P

1

L

Z

D

obs

=

P1 - P

3

L - Z

8.3.2 Hybrid Tank Measurement Systems

A Hybrid Tank Management System (HTMS) is a combination of conventional level gauging,

enhanced with one or two pressure transmitters for continuous measurement of the actual

observed density in a bulk liquid storage tank. Or otherwise stated, it is a combination of

level and hydrostatic pressure measurement. Pressure measurement, combined with level,

provides true average density measurement over the entire product level height. Normally,

the vapor (top) pressure is identified as P

as P

.

1

Advantage of HTMS

• Accurate level measurement

• Continuous density measurement

• Excellent mass and volume measurements

and the hydrostatic (bottom) pressure is identified

3

L00-HTGSxxx-05-00-00-xx-002

Endress+Hauser 49

Page 50

Calculations Tankvision

Level

Calculate

TOV

TOV

AvailVol

RemCap

TCT

FWV

Calculate

FWV

FWL

CtSh

GOV

GSV

S&W

Calculation

FRA

NSV

HTG

Product Pressure

Calculate

Liquid Mass

Liquid Mass/

NSW in Vacuum/Air

Ref. Density

Total Mass

in Vac/Air

Air Density

Mass in Vap

Level

Product Temp

VCF

Tank Shell

Details

Ambient Temp

Roof Details

Air Density

TCV

FWV

API/ASTM

Ref. Density

Product Temp

Obs. Density

S&W

Obs-Ref

Density

conversion

Obs. Density

&

Obs. Temp

Product Code

Hydrom. Cor.

Liquid to

Vapour Ratio

calculation

Vapour Vol

Vapour Density

Obs-Ref

Density

conversion

Vapour Press.

Vapour Temp.

Vapour Details

HTG

Mass of Water

HTG

Mass of

Sediment&Water

Mass of

Water

Mass of

Sediment&Water

Mass of

FRA

HTG

Mass of

FRA

V20

V20

HTG

Gauged Volume

HTG

Mass of

Sediment&Water

S&W

HTG

Mass of

Sediment&Water

HTG

Mass of

Sediment&Water

S&W

HTG

Mass of

Sediment&Water

S&W

HTG

Mass of

Sediment&Water

S&W

S&W

OnTOV

S&W On

TOV - FWV

S&W On

(TOV–FWV)*CtSh

S&W On

(TOV–FWV)*CtSh

+FRA

S&W