Page 1

BA01335G/00/EN/02.15

71310503

Valid as of software version:

1.1.0

Products Solutions Services

Operating Instructions

Tankvision Gauge Link NXA20

Installation, Operation and Maintenance Manual

Page 2

Tankvision Gauge Link

TAG No.: XXX000

Ser. No.: X000X000000

Order code 00X00-XXXX0XX0XXX

www.endress.com/deviceviewer Endress+Hauser Operations App

Serial number

A0023555

2 Endress+Hauser

Page 3

Tankvision Gauge Link

Table of Contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Target audience for this manual . . . . . . . . . . . . . . . 4

1.2 Version history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Basic safety instructions . . . . . . . . . . . . . 6

2.1 Requirements for the personnel . . . . . . . . . . . . . . . 6

2.2 IT security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Identification . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Product identification . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Order code and device version . . . . . . . . . . . . . . . . . 9

3.4 Device documentation . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 9

4 Technical specification . . . . . . . . . . . . . 10

4.1 Environmental conditions . . . . . . . . . . . . . . . . . . 10

4.2 Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Installation . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 Mechanical installation/mounting . . . . . . . . . . . 11

5.2 Electrical installation . . . . . . . . . . . . . . . . . . . . . . 13

6 Controls and indicators . . . . . . . . . . . . . 17

6.1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Weights & measures seal . . . . . . . . . . . . . . . . . . . 17

6.3 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.4 Transmit/receive . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.5 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3 Engineering mode . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 Troubleshooting. . . . . . . . . . . . . . . . . . . 36

8.1 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.2 Fault finding chart . . . . . . . . . . . . . . . . . . . . . . . . 36

9 Maintenance. . . . . . . . . . . . . . . . . . . . . . 38

9.1 Foreign object/liquid ingress . . . . . . . . . . . . . . . . 38

9.2 Insulation/Hi-Pot testing . . . . . . . . . . . . . . . . . . . 38

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Endress+Hauser 3

Page 4

Document information Tankvision Gauge Link

DANGER

WARNING

CAUTION

NOTICE

)

*

1 Document information

1.1 Target audience for this manual

This manual should support during the installation of the NXA20 units. It deals with the

mechenical, electrical and signal line installation. The first commisioning steps are described

as well.

Beside basic PC operating knowledge no special training is needed to perform the Tank

Gauging System operations. Nevertheless it is recommended receiving a training on the

system by Endress+Hauser.

1.2 Version history

Document version Valid for SW version Changes to the previous version

BA01335G/00/EN/01.14 1.1.0 Initial version

1.3 Document function

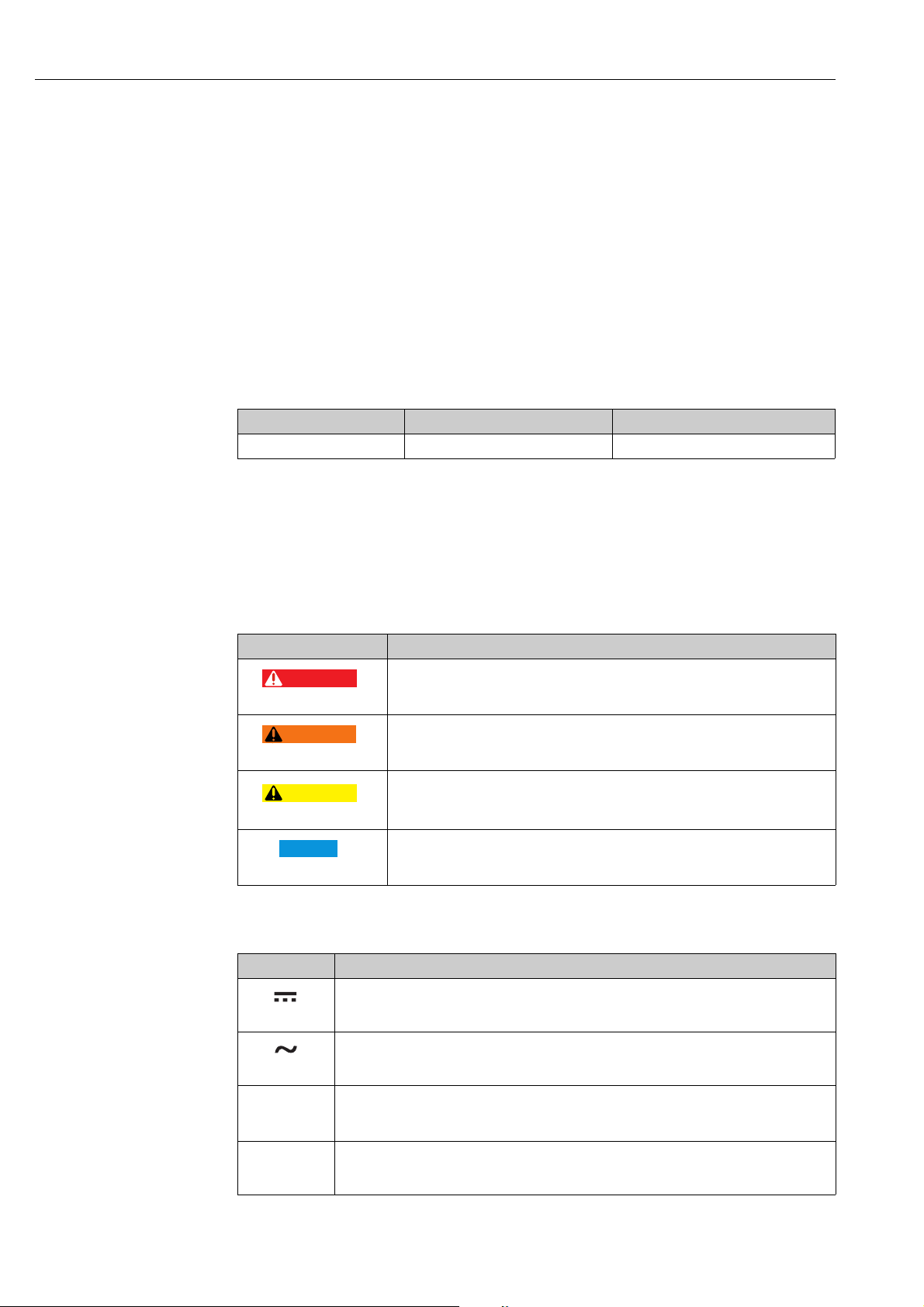

1.3.1 Used symbols

Safety symbols

Symbol Meaning

DANGER!

A0011189-EN

A0011190-EN

A0011191-EN

A0011192-EN

Electrical symbols

Symbol Meaning

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

A0011197

Alternating current

A terminal to which alternating voltage is applied or through which alternating current flows.

A0011198

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

A0011200

system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011199

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result

in personal injury.

4 Endress+Hauser

Page 5

Tankvision Gauge Link Document information

1.

2.

3.

1.

2.

3.

-

.

Symbols for certain types of information

Symbol Meaning

Tip

Indicates additional information.

A0011193

Reference to page

Refers to the corresponding page number.

A0011195

, , ... Series of steps

Result of a sequence of actions

A0018373

Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, , ... Series of steps

A, B, C ... Views

Hazardous area

Indicates a hazardous area.

A0011187

Indicates a non-hazardous location

Safe area (non-hazardous area)

A0011188

1.4 Documentation

1.4.1 Operating instructions

Document number Instrument Type of Document

BA01334G/00 Tankvision NXA20 Gauge Link Modbus Map Protocol

Endress+Hauser 5

Page 6

Basic safety instructions Tankvision Gauge Link

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates

(depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner operator

• Following the instructions in these Operating Instructions

2.2 IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

2.3 Designated use

2.3.1 Application

The Tankvision Gauge Link is a tank gauging protocol converter to allow integration of third

party gauging equipment into the Tankvision system. The Tankvision Gauge Link is available

with a range of different field bus interface options. Most field bus interfaces will support

connection of a number of gauges in a “multi-drop” or bus configuration. The number of

gauges which may be configured in the Tankvision Gauge Link is limited to 32 (limited to 15

when used in combination with NXA820), which should be adequate for most typical tank

gauging field busses, however electrical and / or protocol limitations may reduce this

number. The functionality which obtains will be determined by that offered by the connected

gauge(s) and the interface / protocol.

Connection to the host system is via EIA/TIA-485 (formerly RS-485) Modbus. This is

primarily intended for “one-to-one” connection with the Tankvision Tank Scanner or similar

device.

The Tankvision Gauge Link must only be used in “safe” areas where there is no hazard from

the presence of potentially explosive or flammable atmospheres.

The Tankvision Gauge Link has not been assessed in respect of functional safety.

Accordingly it is not intended to be used as a safety critical component or part of a safety

critical system or in the implementation of any safety function.

6 Endress+Hauser

Page 7

Tankvision Gauge Link Basic safety instructions

2.4 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national

regulations.

• Switch off the supply voltage before connecting the device.

2.5 Operational safety

Risk of injury!

• Operate the device in proper technical condition and fail-safe condition only.

• The operator is responsible for interference-free operation of the device.

• In normal operation the Tankvision Gauge Link contains hazardous voltages. Connectors

on the front panel, accessible behind the front cover / door are “touchproof”, but care

must be exercised when carrying out service work with the door open. The unit must not

be operated with any other cover removed.

• If (or it is suspected that) any liquid or conductive object or debris has entered the

enclosure of the Tankvision Gauge Link, the mains supply to the equipment must

immediately be isolated.

Proper operation of the Tankvision Gauge Link is dependent upon correct installation and

configuration. The equipment must be operated and maintained by suitably trained and

competent personnel who are aware of and fully understand the instructions provided

herein.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers

• If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

• Carry out repairs on the device only if they are expressly permitted.

• Observe federal/national regulations pertaining to repair of an electrical device.

• Use original spare parts and accessories from Endress+Hauser only.

The Tankvision Gauge Link contains no user-serviceable parts. Other than the mains supply

fuse, the Tankvision Gauge Link contains no user replaceable parts. Any modification or

repair work must only be performed by the manufacturer or its authorised agents.

2.6 Product safety

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device complies with the

applicable standards and regulations as listed in the EC declaration of conformity and thus

complies with the statutory requirements of the EG directives. Endress+Hauser confirms the

successful testing of the device by affixing to it the CE mark.

Endress+Hauser 7

Page 8

Identification Tankvision Gauge Link

Baud rate: 9600 Baud

Data bits: 8

Parity: none

Stop bits: 1

Flow control: none

90 ... 250 V AC 50/60 Hz 23 VA

MODBUS

IP20

TRL2

250002972-B

Made in Great Britain

Melsonby, DL10 5NY

Tankvision

Order code: NXA20

Ext. ord. cd.:

Ser.-No.: XXXXXXXXXXX

-XXXX/XXX

NXA20-XXXXXXXX

-40°C (-40°F)

£

T60°C (140°F)£

amb

1 2

345

6

8

9

10

11

12

13

14

7

3 Identification

3.1 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is

displayed.

For an overview of the technical documentation provided, enter the serial number from the

nameplates in the W@M Device Viewer (www.endress.com/deviceviewer)

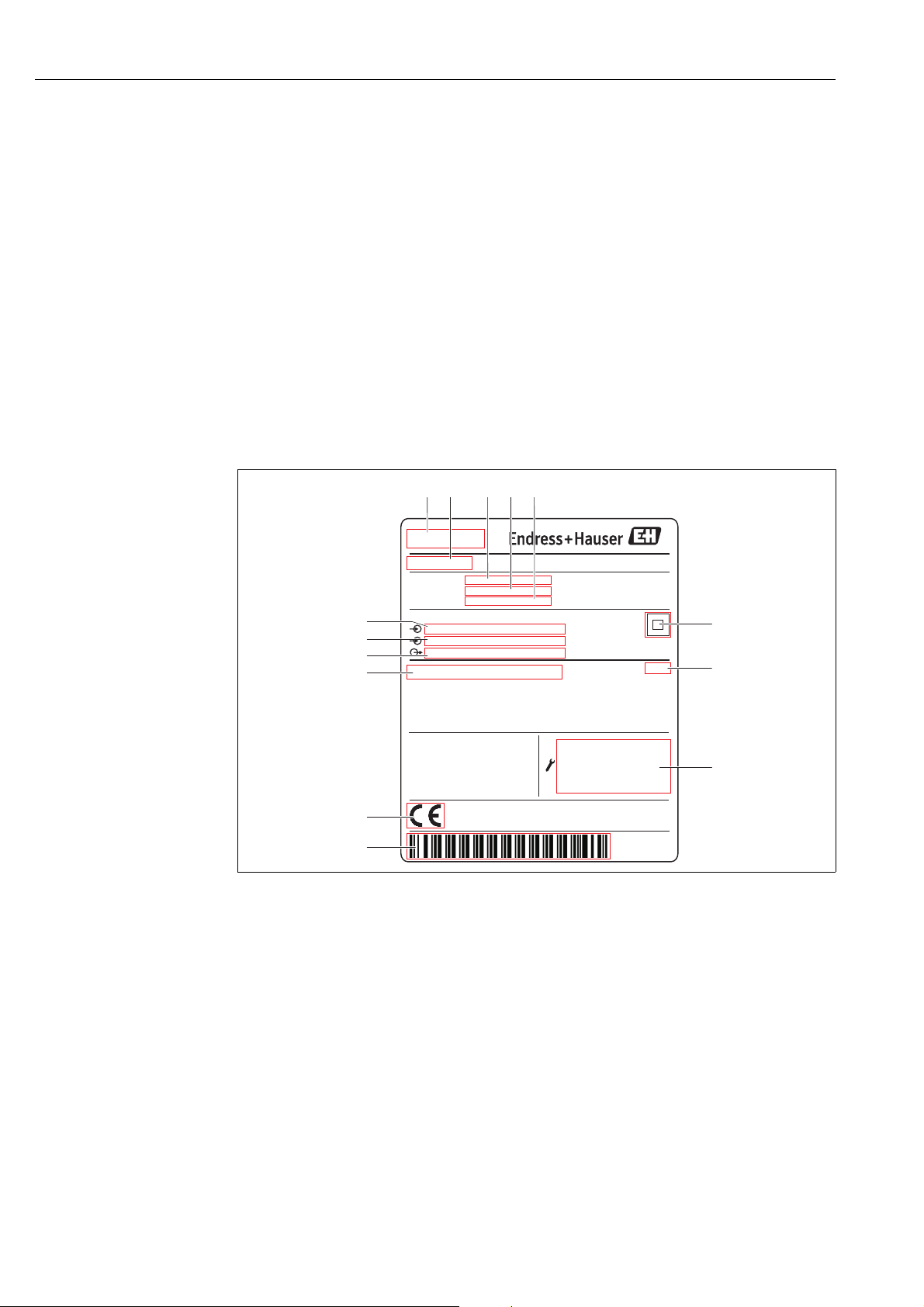

3.2 Nameplate

1 Address of manufacturer

2Device name

3Order code

8 Endress+Hauser

4 Extended order code (Ext. ord. cd.)

5 Serial number (Ser. no.)

6Data Matrix Code

7 Degree of protection

8 Technical data of the Serial Service port

9Barcode

10 CE mark

11 Admissible ambient temperature

12 Type of fieldbus communication (output)

13 Type of fieldbus communication (input)

14 Supply voltage

nameplate_NXA20

Page 9

Tankvision Gauge Link Identification

1.

2.

1.

2.

1.

2.

3.3 Order code and device version

To find out the version of your device, enter the order code indicated on the nameplate

in the search screen at the following address: www.products.endress.com/order-ident

3.4 Device documentation

The information required to retrieve the documentation can be found on the nameplate of

the device.

Technical documentation can also be downloaded from the Download Area of the

Endress+Hauser web site: www.endress.com→ Download. However this technical

documentation applies to a particular instrument family and is not assigned to a

specific device.

3.4.1 W@M Device Viewer

Launch the W@M Device Viewer: www.endress.com/deviceviewer

Enter the serial number (Ser. no.) of the device: see nameplate.

All the associated documentation is displayed.

3.4.2 Endress+Hauser Operations App

The Endress+Hauser Operations App is available both for android smart phones

(Google Play Store) and for iPhones and iPads (App Store).

Via the serial number:

Launch the Endress+Hauser Operations App.

Enter the serial number (Ser. no.) of the device: see nameplate.

All the associated documentation is displayed.

Via the 2-D matrix code (QR code):

Launch the Endress+Hauser Operations App.

Scan the 2-D matrix code (QR code) on the nameplate.

All the associated documentation is displayed.

3.5 Registered trademarks

Microsoft®, Windows® and Internet Explorer

Registered trademarks of the Microsoft Corporation

Modbus

®

Registered trademark of the Modbus-IDA, Hopkinton, MA, USA

®

Java

Registered trademark of Sun Microsystems, Inc.

®

Mozilla

®

Firefox

®

Registered trademark of the Mozilla Foundation

Enraf, Honeywell, Rosemount, Emerson, Saab, L&J, VAREC, GPE are registered trademarks

and trademarks of these organizations and companies.

All other marks are property of their respective owners.

Endress+Hauser 9

Page 10

Technical specification Tankvision Gauge Link

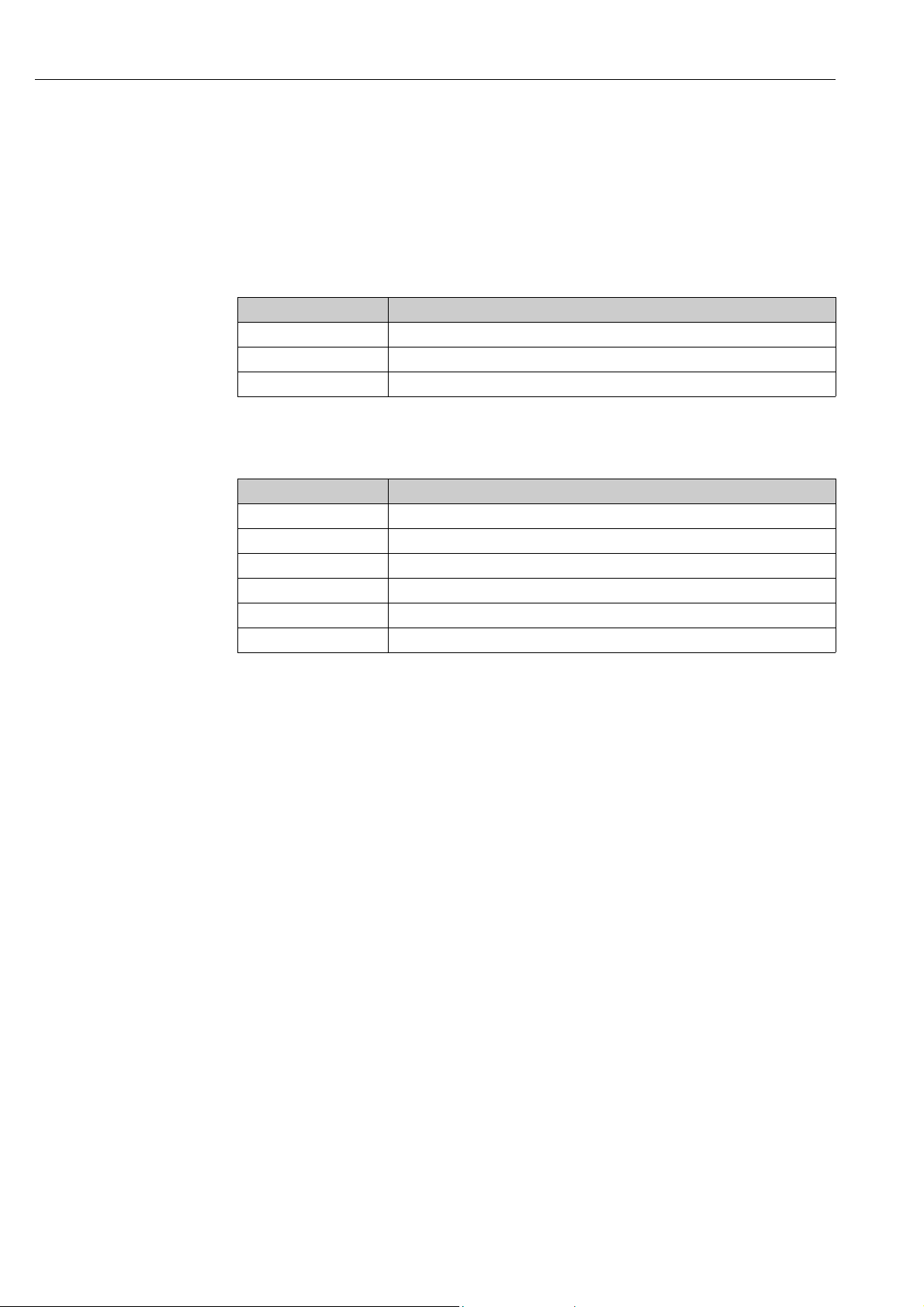

4 Technical specification

4.1 Environmental conditions

The Tankvision Gauge Link enclosure is rated IP20 to BS EN 60529. Further protection

against dust and water/moisture ingress must be provided by the location in which the

Tankvision Gauge Link is installed.

Property Specification

Operating Temperature -40 to +60 °C (-40 to +140 °F)

Storage Temperature -40 to +85 °C (-40 to +185 °F)

Relative humidity max 90 % at +25 °C (+77 °F), non-condensing

4.2 Electrical ratings

Property Specification

Supply voltage 90 to 250 V

Frequency 50 / 60 Hz

Power 23 VA

Overvoltage Category II

AC

Fuse (mains supply) T 400 mA HBC 250V AC, 20 x 5 mm (0,79 x 0,2 in)

10 Endress+Hauser

Page 11

Tankvision Gauge Link Installation

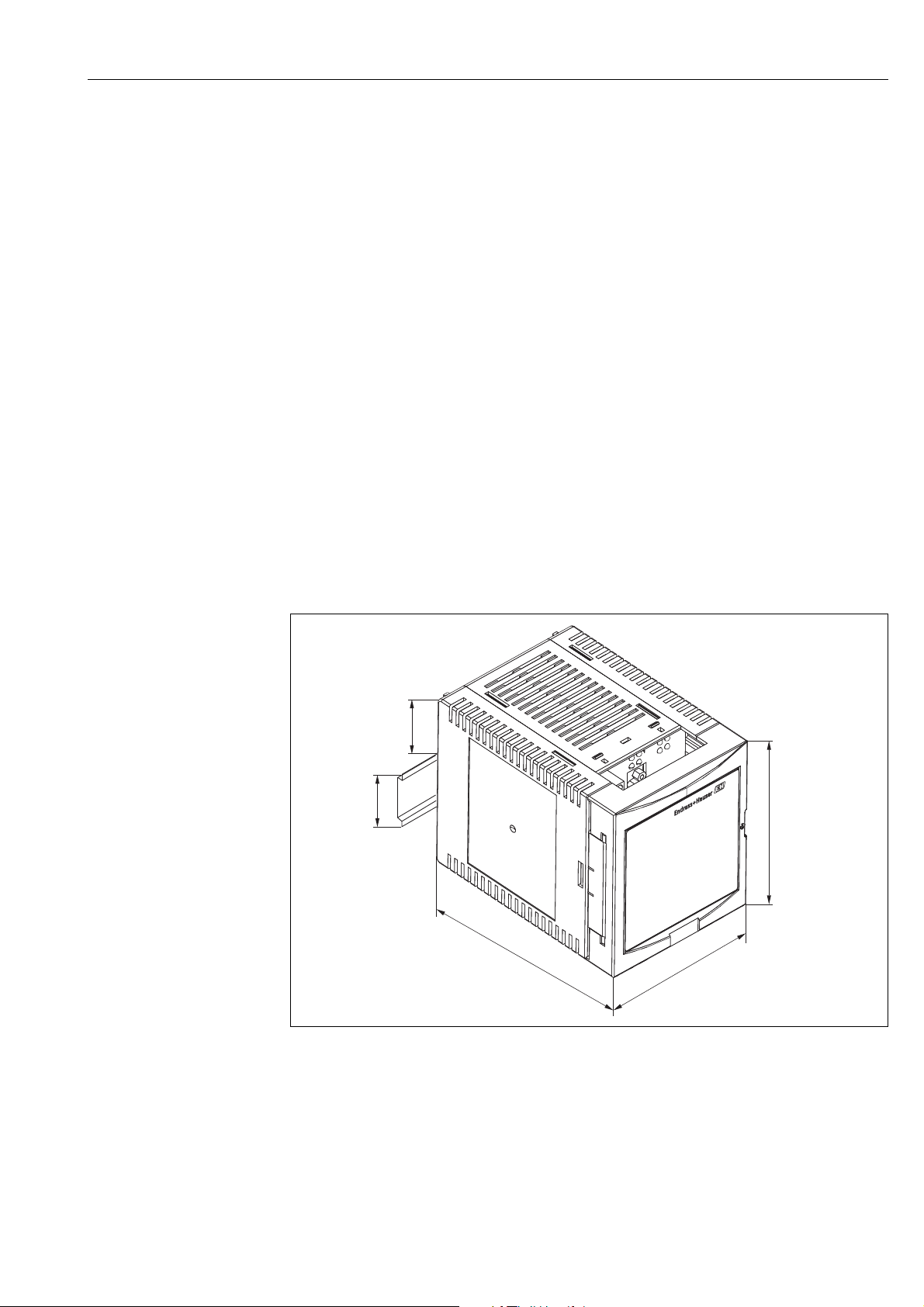

43 (1.7)

35 (1.4)

104 (4.1)

91 (3.6)

140 (5.5)

mm (in)

5Installation

5.1 Mechanical installation/mounting

Prior to installation, visually inspect the Tankvision Gauge Link for any signs of damage.

Confirm that the type label shows the correct field bus interface for the intended application.

The Tankvision Gauge Link must only be installed in a “safe” area where there is no hazard

from the presence of potentially explosive or flammable atmospheres.

The Tankvision Gauge Link must be installed in a cabinet or similar enclosure which provides

protection against dust and water ingress. The location must also provide protection against

moisture or the formation of condensation.

Ensure that the temperatures likely to be encountered at the installation location lie within

the relevant minimum /maximum operating and storage temperature ratings of the

Tankvision Gauge Link.

The Tankvision Gauge Link should not be installed near to high voltage circuits or to cables

feeding motors or other high current loads, or near to contactors, variable frequency drives,

inverters or frequency converters or other switchgear / controlgear which may emit

significant electromagnetic interference.

A clear space of about 50 mm (1.97 in) above and below the Tankvision Gauge Link

enclosure should be allowed for ventilation. A gap of 10 mm (0.39 in) to either side of the

Tankvision Gauge Link will ease mounting and opening of the front cover of the enclosure.

The enclosure of the Tankvision Gauge Link is intended to be mounted onto “top hat” DIN

rail, T35 to BS EN 60715 (or BS 5584 / EN 50022 / DIN 46277-3). The rail should be

mounted on a vertical surface, with the rail running horizontally, so that the Tankvision

Gauge Link connection plate / access cover is to the front and in a readily accessible location.

To attach the Tankvision Gauge Link to the mounting rail, first hook the enclosure over the

top of the rail, then turn downwards until the spring clip on the back of the enclosure latches

onto the lower edge of the mounting rail (fig. A below).

Endress+Hauser 11

GaugeLink_Dimensions

Page 12

Installation Tankvision Gauge Link

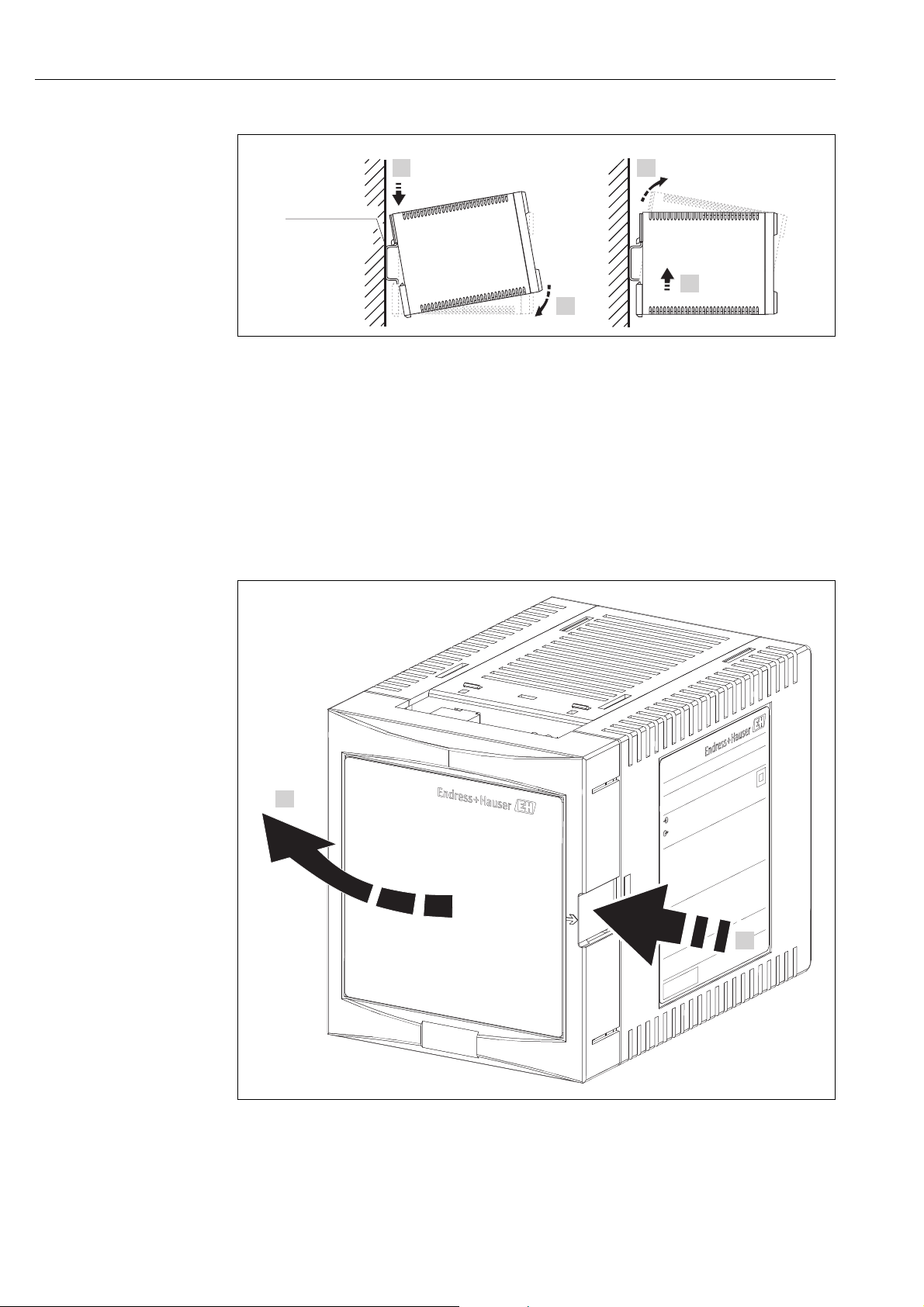

A

B

1.

2.

1.

2.

EN 60715

TH 35x7.5/15

(1.4x0.3/0.6)

mm (in)

2.

1.

L00-FMU90xxx-17-00-00-xx-002

A Attaching the instrument to the rail

B Detaching the instrument from the rail

To remove the Tankvision Gauge Link from the mounting rail (fig. B above), first push the

enclosure upwards against the spring clip until the body of the enclosure is released from the

top of the rail, then turn the enclosure forwards, away from the mounting rail.

All electrical connections and controls are available on the front panel of the Tankvision

Gauge Link in the terminal compartment, accessed by opening the front cover / door. This is

hinged at the left and clicks shut. Press on the arrowed area at the right side of the door to

release and open.

12 Endress+Hauser

GaugeLink_Open-Door

Page 13

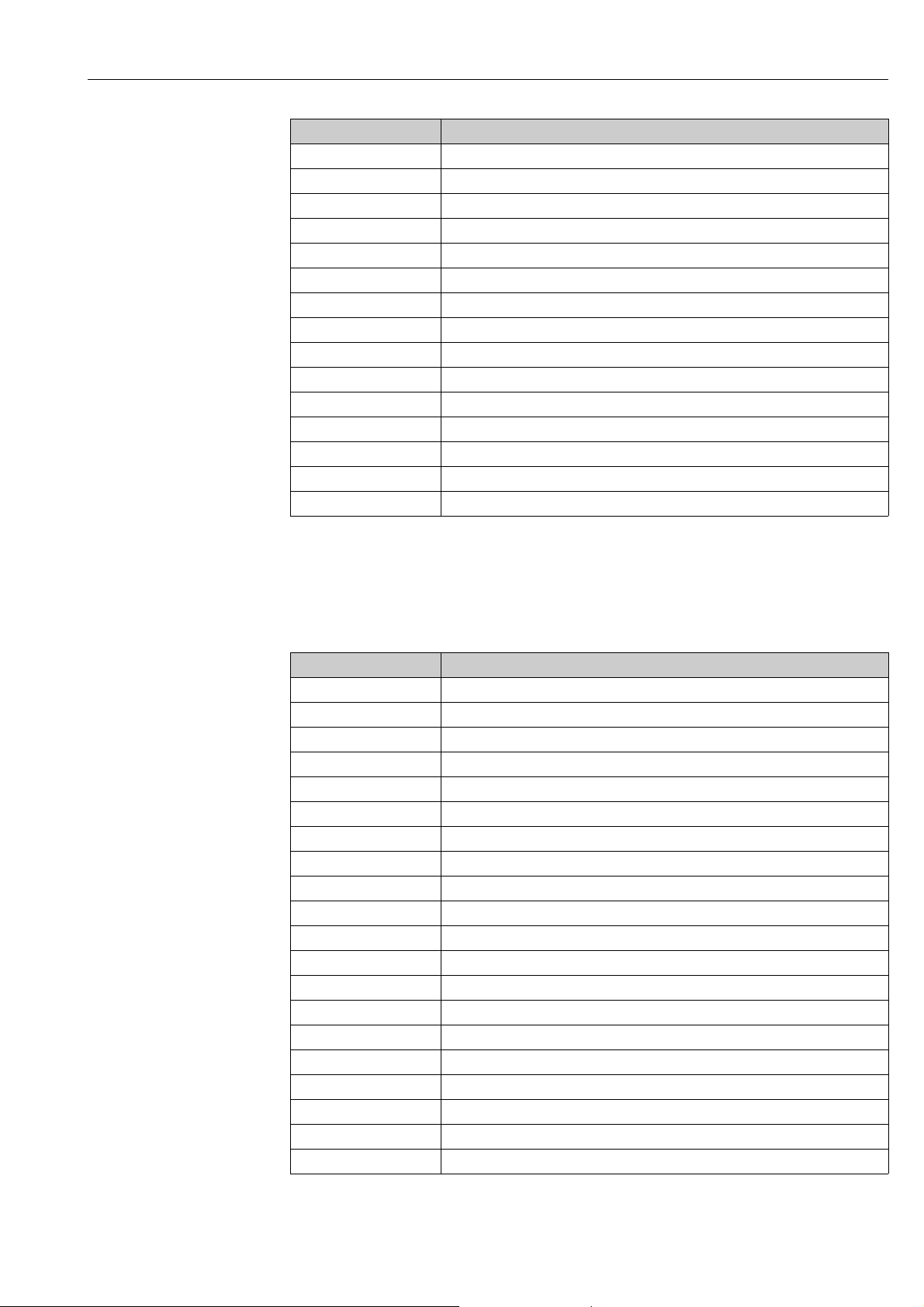

Tankvision Gauge Link Installation

AB

C

D

E

F

G

H

I

J

GaugeLink_Connections

A Mains supply connector

B Host port status LEDs

C Field port status LEDs

D Diagnostic/Service port connector

E Field port connector

F Host port connector

G Functional earthing terminal

H Weights & Measures sealing switch

I Status relay connector (Not used)

J Mains supply fuse

5.2 Electrical installation

Two-part connectors are used for permanently connected wiring. The free (or cable end)

connector may be unplugged from the panel to assist wiring. Terminals are of the cage clamp

quick connect type; use a screwdriver or similar implement to press down on the orange tab

to open the clamp and allow the stripped wire end to be inserted. The terminals will accept

0.2 to 2.5 mm

insertion of the wire, ensure that no bare conductor is visible, no strands of the conductor

are protruding from the wire entry of the terminal and that the conductor is held securely in

the terminal.

Cables should be routed to pass out through the slot at the bottom of the door. Ensure cables

are not trapped when closing the door.

5.2.1 Mains power supply connections

Mains power supply connection is at the upper left of the front panel.

The Tankvision Gauge Link is double insulated, and thus does not require connection of a

protective earth for safety reasons. An earth terminal is included in the mains supply

connector for EMC purposes. This should be connected to the earth/equipotential conductor

of the supply.

2

(24 to 14 AWG) insulated wires, which should be stripped 10 mm. After

Endress+Hauser 13

Page 14

Installation Tankvision Gauge Link

The Tankvision Gauge Link is regarded as permanently connected equipment. An integral

fuse is provided for overcurrent protection. Protection against electric shock is by double

insulation. It is recommended that the mains supply terminals be connected to the source of

supply by means of an approved flexible cord/cable.

The supply for the Tankvision Gauge Link should be taken from a circuit breaker or switch/

fuse combination to provide electrical isolation external to the Tankvision Gauge Link and

overcurrent protection for the supply cable. This means of isolation should be clearly labelled

as to its function and should be located within easy reach of the Tankvision Gauge Link and

be easy to operate.

5.2.2 Functional earthing terminal

A functional earthing terminal is provided at the lower right of the front panel. This terminal

is used for non-safety earthing of the electronic interface circuits of the Tankvision Gauge

Link, e.g. for EMC purposes.

The functional earthing terminal is electrically separate from and not connected to the earth

terminal of the mains power supply connector.

The functional earthing terminal should be connected to the plant equipotential “ground”

using wire of 4mm

2

(12 AWG) or larger section, with a resistance less than one Ohm.

5.2.3 Status relay connections

The status relay connection at the lower left of the front panel is not used by the Tankvision

Gauge Link. No connection should be made to these terminals.

5.2.4 Host port connections

Host port connection is towards the centre of the front panel. The Modbus host port uses

EIA/TIA-485 (RS-485) “two wire” interface. This provides the “A” / “B” data signal lines and

the “C” common connection.

Note that the polarity of the “A” / “B” data signals is in accordance with the EIA/TIA-485

standard. Many third party devices with “RS-485” interfaces have the sense of the “A” / “B”

lines reversed. When connecting to such devices, it may be necessary to “cross” the “A” and

“B” connections between the devices to obtain the correct signal polarity.

The “S” terminal is provided for connection of the cable screen. This terminal is internally

connected to the functional earthing terminal of the Tankvision Gauge Link (at lower right

of front panel).

Bus termination and biasing are controlled by software selectable settings in the Tankvision

Gauge Link. By default, these are enabled for point-to-point links or the devices in a multidrop network that are at the outer “ends” of the cable. If the Tankvision Gauge Link is part

of a multi-drop network and is not the “end” device on the cable, the termination and biasing

may be disabled. For details of these settings, → ä 18.

The host RS485 connection offers transient overvoltage protection compatible with RS485

signal level.

5.2.5 Field port connections

Field port connection is towards the right of the front panel. The connections will depend

upon the interface.

For Enraf Bi-Phase Mark and “SAAB” Rosemount TRL/2, the fieldbus uses a two wire

connection. The polarity of the connection is not important.

The “S” terminal is provided for connection of the cable screen. This terminal is internally

connected to the functional earthing terminal of the Tankvision Gauge Link (at lower right

of front panel).

Both the Enraf Bi-Phase Mark and SAAB Rosemount TRL/2 fieldbuses are galvanically

isolated and offer over voltage protection commensurate with the original gauge

manufacturers’ equipment.

The Tankvision Gauge Link will be supplied as two different versions, one supporting the

Enraf Protocol and the other supporting the SAAB Rosemount TRL/2 protocol.

14 Endress+Hauser

Page 15

Tankvision Gauge Link Installation

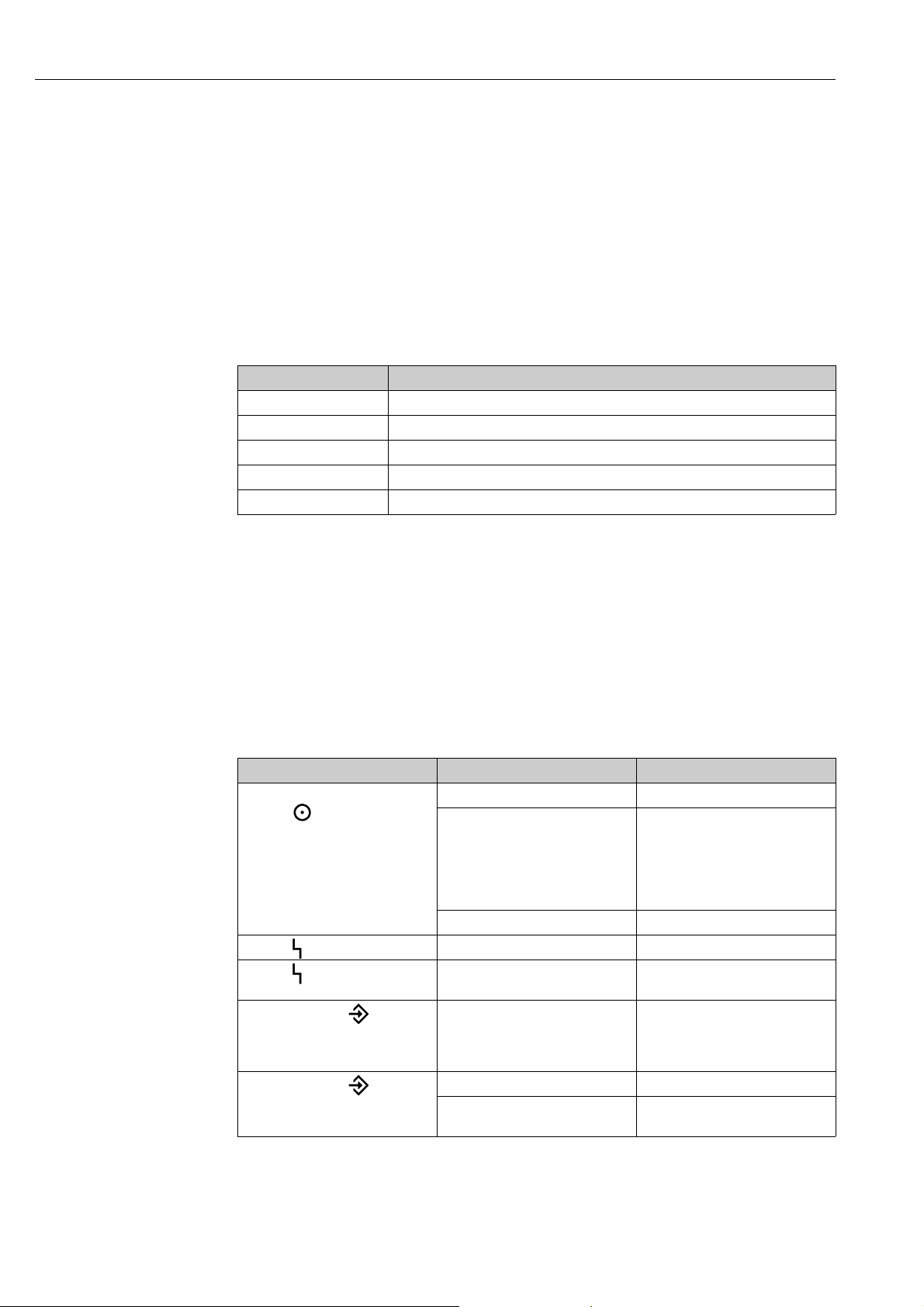

PC

TVGL

= R

= O

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

5.2.6 Diagnostic/service port connections

The diagnostic / service port generally remains unconnected during normal operation of the

Tankvision Gauge Link. The port has a 9 way “D” type socket connector. A suitable cable with

mating plug will be required for local connection of a service laptop PC or similar.

A “standard” serial port, a 9 way fully wired plug – socket cable will be required. The cable

should be wired pin-to-pin, i.e. 1-1, 2-2, 3-3, … 9-9. Proprietary cables will generally have

all pins wired, though only pins 2, 3, 4, 5 and 7 are actually used. Cable length should not

exceed 2 metres (6,6 ft).

Diagnostic-service_po rt_connections

PC Service laptop PC or similar

TVGL Tanvision Gauge Link

RRequired connection

O Optional connection

Note that in the case of Tankvision Gauge Links on a multi-dropped network, the

service port provides local access to the individual Tankvision Gauge Link only. It is not

possible to communicate with other Tankvision Gauge Links on the network through

this service port.

5.2.7 Internal jumper links

The Print circuit boards within the plastic enclosure of the Tankvision Gauge Link are fitted

with Jumper links, all the jumpers don’t need to be accessed apart from one jumper link.

LK_TS on the BPM module which only needs to be fitted if the field bus baud rate is 2400.

Module Jumper link Use

TRL/2 module LK_P link Used to feed 5vdc supply to board. (default:- open)

Endress+Hauser 15

Page 16

Installation Tankvision Gauge Link

Module Jumper link Use

LK_P link Used to feed 5vdc supply to board. (default:- open)

LK_TS link Fitted for 2400 baud rate. (default:- open)

BPM module

Main Processor

module

Gain can be achieved using LK_G links (gain is described in detail further in the manual)

A link Gain control (bit 0) (default:- open)

B link Gain control (bit 1) (default:- open)

C link Gain control (bit 2) (default:- open)

LK_SG RS485 signal ground. (default:- closed)

ISP Firmware update control (default:- open)

RST Firmware update control (default:- open)

JTAG Debug control (default:- open)

16 Endress+Hauser

Page 17

Tankvision Gauge Link Controls and indicators

6 Controls and indicators

6.1 Reset

A small pushbutton switch is provided to allow the user to reset the Tankvision Gauge Link

without the need to cycle the power. The switch is recessed to prevent inadvertent operation.

A pointed object such as a pen may be used to operate the reset switch.

When the Tankvision Gauge Link is reset, the red FAULT ( ) LED will flash once while the

unit carries out software initialisation. If this LED flashes repeatedly after power up then this

indicates a fault and will need to be investigated.

This reset button behaves the same as turning the Tankvision Gauge Link off and back on

again.

6.2 Weights & measures seal

This switch is used to disable any configuration through the Modbus port and the

engineering port, such as hyper-terminal. When this switch is set, any attempted

configuration changes via Modbus will result in timeouts for the host via hyper-terminal and

the following message will appear: ’config disabled’.

6.3 Power

The Tankvision Gauge Link has two POWER ( ) LEDs, one for the main processor and one

for the field bus interface. The main processor LED is green and the field bus LED is yellow.

These should both be lit during normal operation. A flashing or unlit POWER LED indicates

the presence of a power supply fault.

6.4 Transmit/receive

The host port and field bus interface port both have yellow TRANSMIT ( ) and RECEIVE

( ) LEDs. These flash to indicate activity on the respective communication port data lines.

Note that the TRANSMIT / RECEIVE LEDs indicate only electrical activity on the data

lines, but do not give any indication as to the validity of the data.

6.5 Communications

A yellow COMMUNICATIONS ( ) LED is provided for the field bus interface port. This

flashes to indicate that a valid query – response cycle has been performed by the Tankvision

Gauge Link and that the response from the gauge / field device has been understood by the

Tankvision Gauge Link.

Note that the COMMUNICATIONS LED indicates that the response received was

correctly framed according to the field bus protocol and was thus able to be accepted

and decoded by the Tankvision Gauge Link. It does not give any indication as to the

meaning of the data contained within the response. This yellow LED does not flash

when an engineering software tool is connected to the Tankvision Gauge Link, such as

Ensite.

Endress+Hauser 17

Page 18

Operation Tankvision Gauge Link

7Operation

7.1 Configuration

7.1.1 Connecting to the diagnostic/service port

Connect a laptop PC with a terminal emulation program (e.g. Hyperterminal) to the service

port using a straight-through “null modem” cable.

Set the terminal emulation program to the following communications settings:

Parameter Setting

Baud rate 9600 Baud

Data bits 8

Parity none

Stop bits 1

Flow control none

When the ‘hyper-terminal’ terminal emulation programs are not available, for example

windows 7 is being used, a program such as Tera Term can be used. This program has been

tested, free and is open source.

If the PC doesn’t have a serial port and USB-RS232 can be used. A recommend USB-RS232

is the ULinx USO9ML2DR-2 converter.

7.1.2 Configuration using a terminal emulation program

Using this configuration only allows the Tankvision Gauge Link to be configured,

configuration of Honeywell Enraf and Emerson SAAB gauges must be done separately by a

competent engineer.

Once the Tankvision Gauge Link has been connected the diagnostic port and the terminal

emulation program has been set up, the Tankvision Gauge Link can be powered up. When

the Tankvision Gauge Link is powered up a message is printed and is similar to the message

shown below.

NVRAM STATUS- GOOD

P0264

VERSION – V1-0-0

CHECKSUM – 726E9AE7

FIELD - GPU

MODE - TERMINAL

HTS - 9600

FTS - 1200

HPA - NONE

GPU GAIN – 0

RS485 +VE BIAS - OFF

RS485 -VE BIAS – OFF

RS485 TERM - OFF

The data shown above gives general status and information on the basic configuration, such

as the status of none volatile (flash) memory, the project number of this model and the

firmware version number.

A checksum is also created when the Tankvision Gauge Link is powered up, this number can

be used to confirm the validity of the firmware.

The mode is the terminal emulation mode on the RS232 port.

18 Endress+Hauser

Page 19

Tankvision Gauge Link Operation

The type of Field driver is also displayed which will be either GPU (Honeywell Enraf protocol)

or TRL (Emerson protocol). The Host baud rate (HTS), Field baud rate (FTS) and Host parity

(HPA) are also displayed.

The GPU gain is displayed, this gain will only take affect if the fieldbus is GPU. The

termination and bias resistors are also shown if they are enabled or not.

The above information can be displayed by typing in the INFO(return) command.

7.1.3 Typing and entering a command

Entering a configuration command into Tankvision Gauge Link is done by simply typing the

text into the terminal emulation software and pressing return at the end of the command.

E.g. to print general status and information type: "INFO(return)".

This command will print the information shown in the above section.

After most valid commands an ‘OK’ message will be printed. If an ‘INVALID COMMAND’ or

‘OUT OF RANGE’ message is printed, then re-type the command or investigate the ‘out of

range’ message.

All valid commands are saved in Tankvision Gauge Link flash memory, so when the unit is

powered down and back up the configuration will remain.

7.1.4 Commands

INFO(return)

This command prints the information shown in the above section.

FTS=XXXX(return)

Where XXXX is a 4 digit number.

This command sets the field bus baud rate. If the field driver selected was a TRL driver, then

this command will not have any effect on the Field bus baud rate, because the TRL/2 field

bus is always set to 4800 baud. If the Field driver selected is a GPU driver then there is a

choice of 2 baud rates, 1200 and 2400 baud.

When setting the BPM baud rate to 2400 the jumper link (LK_TS) on the BPM

communication needs to be fitted.

To configure the GPU field bus with a 1200 baud rate, type: FTS=1200(return)

To configure the GPU field bus with a 2400 baud rate, type: FTS=2400(return)

Any other baud rate and an ‘INVALID COMMAND’ message will be printed.

HTS=XXXX(return)

Where XXXX is a 4 digit number.

This command sets the host RS485 field bus baud rate. There are a range of different baud

rates which this command supports, see below the baud rates with the command to set the

baud rate.

Baud rate Command

1200 HTS=1200(return)

2400 HTS=2400(return)

4800 HTS=4800(return)

9600 HTS=9600(return)

Endress+Hauser 19

Page 20

Operation Tankvision Gauge Link

Baud rate Command

19200 HTS=1920(return)

Any other baud rate and an ‘INVALID COMMAND’ message will be printed.

HPA=X(return)

Where X is represents the parity.

The Host field bus can be configured to support 3 different parities. To configure the parities

is shown below:

Parity Command

None HPA=N(return)

Even HPA=E(return)

Odd HPA=O(return)

Any other letter typed and an ‘INVALID COMMAND’ message will be printed.

GPUGAIN=X(return)

This command is only used for Enraf Gauges. This command increases the received data

sensitivity. If the communication is poor and the BPM cabling is long, by increasing this value

the communication should improve.

Where X represents a number between 0 and 7.

0 is the lowest gain and 7 is the highest gain.

For example for the GPU BPM field bus to have a gain of 7, type in the following command:

GPUGAIN=7(return)

RS485+=X(return)

RS485-=X(return)

Where X is represents Y (yes) or N (no).

These commands allow the user to enable the 910R bias resistors to pull the A and B lines

to +5V and 0 volts. This is sometimes referred to as “fail-safe” biassing mode.

Generally these are set to ON when the RS485 comms is point to point and OFF when devices

are multi-dropped on the RS485 comms.

To enable the bias resistors type:

RS485+=Y(return) and RS485-=Y(return)

To disable the bias resistors type:

RS485+=N(return) and RS485-=N(return)

Any other letter typed and an ‘INVALID COMMAND’ message will be printed.

RS485T=X(return)

Where X is represents Y (yes) or N (no).

This command allows the user to enable the 120R terminator resistor between the A and B

lines.

To enable the terminator resistor type: RS485T=Y(return)

To disable the terminator resistor type: RS485T=N(return)

20 Endress+Hauser

Page 21

Tankvision Gauge Link Operation

Generally this is set to ON when Tankvision Gauge Link is at the end of a RS485 multi-drop

line.

Any other letter typed and an ‘INVALID COMMAND’ message will be printed.

CONFIG(return)

This command enables gauge address’s / registers / functions to be written directly to the

modbus holding registers which hold the gauge parameter address’s/registers. Please refer

to document TankVisionFieldLinkModbusMapV1-3-1.

Once this command has been entered values can then be written directly to the holding

registers, using the below command.

Z=X(return) or

Z=XX(return) or

Z=XXX(return) or

ZZ=X(return) or

ZZ=XX(return) or

ZZ=XXX(return) or

ZZZ=X(return) or

ZZZ=XX(return) or

ZZZ=XXX(return) or

ZZZZ=X(return) or

ZZZZ=XX(return) or

ZZZZ=XXX(return)

Where Z represents the modbus holding register and X represents the value to be put into

this holding register.

After every command, enter the value into the holding register, the cursor in the terminal

emulation program will go to the start of the next line and wait for another value to be

entered into the holding register. If no more values are to be entered press (return) and the

message ‘DOWNLOAD COMPLETE’ message will be printed.

For example:

Two gauges are required to be polled by the Tankvision Gauge Link, these gauges are an 873

radar gauge and an 854 servo gauge. Level, temperature and temperature elements are

required from both of the gauges. The 873 gauge also requires a live water value to be read

from it. The 873 gauge has an address of 1 and the 854 gauge has an address of 15.

Type the following bold letters to enter values into the modbus holding registers to poll for

the above parameters.

Enter Result

CONFIG(return) Enable configuration

0=1(return) Level address = 1

100=1(return) Temp address = 1

200=1(return) Element temps address = 1

300=1(return) Water address = 1

1100=82(return) Gauge type is a radar (82)

1=15(return) Level address = 15

101=15(return) Temp address = 15

201=15(return) Temp elements address = 15

1101=83(return) Gauge type is a servo (83)

(return)

Endress+Hauser 21

Page 22

Operation Tankvision Gauge Link

The numbers 78, 82 and 83 in Modbus holding register 1100 – 1131 represent:

78 = decimal value for ascii ‘N’ (Where N = NRF590)

82 = decimal value for ascii ‘R’ (Where N = RADAR)

83 = decimal value for ascii ‘S’ (Where N = SERVO)

When setting a value of 82 in holding registers 1100 – 1131 causes the Tankvision Gauge

Link to poll for the ZQR command, which is the radar status register.

When setting a value of 83 in holding registers 1100 – 1131 causes the Tankvision Gauge

Link to poll for the ZQS command, which is the servo status register.

When setting a value of 78 in holding registers 1100 – 1131 causes the Tankvision Gauge

Link to not poll for any status registers and it will pick its status value from the ‘B’ record.

If holding registers 1100 – 1131 are set to anything other than 78, 82 and 83 then the

status of the gauge will be picked up from the ‘B’ record and ZQR and ZQS will NOT be polled

for.

DEVICES(return)

The devices and configuration parameters for the gauges which have been configured can be

viewed at any time. This command allows you to look at the Modbus holding registers.

The data displayed lists the Modbus holding registers in columns of 100 registers. The first

block to the left lists all the level addresses configured, the second block lists the temperature

addresses configured, these blocks are the blocks of registers detailed in the Tankvision

Gauge Link Modbus Map document. It can be seen at the top of each column shows which

block of 100 registers is detailed. Down the left side the block register is incremented.

The example print out shows the configuration done in the above example:

DEVICES

0000 0100 0200 0300 0400 0500 0600 0700 0800 0900 1000 1100

+ 00 001 001 001 001 255 255 255 255 255 255 255 082

+ 01 015 015 015 255 255 255 255 255 255 255 255 083

As it can be seen the registers configured in the above example marry up with the data

shown above.

The first, left most block of registers, shows the values of 001 and 015. These are the level

addresses. The second block (0100) show the values of 001 (+00) and 015 (+01) these are

the temperature addresses. This pattern is repeated up to block 1100, where it can be seen

block 1100 (+00) contains the value 82 and block 1100 (+01) contains the value 83.

All the unused registers contain the value 255, which represents values which are out of

range.

When connecting to Enraf gauges holding registers 600 – 631 are reserved and not used.

When connecting to SAAB Rosemount gauges holding registers 200 – 231, 400 – 431, 500

– 531, 600 – 631 and 1100 – 1131 are not used.

All holding registers above 31 to the next 100 in the block are un-used.

The diagram below shows in more detail what each column and row represents.

The below is configures to poll for 3 gauges.

st

1

gauge Gauge address 01, Modbus address 01. Radar (82)

Level (Reg 0000)

Temperature (Reg 0100)

Temp elements (Reg 0200)

Live water (Reg 0300)

22 Endress+Hauser

Page 23

Tankvision Gauge Link Operation

2nd gauge Gauge address 15, Modbus address 15, Servo (83)

Level (Reg 0001)

Temperature (Reg 0101)

Temp elements (Reg 0201)

rd

3

gauge Gauge address 16, Modbus address 16, None Enraf gauge (78)

Level (Reg 0002)

Temperature (Reg 0102)

Temp elements (Reg 0202)

The modbus address is always the same as the level address stored in holding registers 0000

– 0031.

So for example the gauge address to read level for the 1st gauge is address 01 in holding

register 0000.

The gauge address to read temperature elements for the 3rd gauge is address 16 in holding

register 202.

FIRST HOLDING REGISTER → 0000 0100 0200 0300 0400 0500 0600 0700 0800 0900 1000 1100

ADDRESSES IN 1ST HOLDING

REGISTER →

ADDRESSES IN 2ND HOLDING

REGISTER →

ADDRESSES IN 3RD HOLDING

REGISTER →

+ 00 001 001 001 001 255 255 255 255 255 255 255 082

+ 01 015 015 015 255 255 255 255 255 255 255 255 083

+ 02 016 016 016 255 255 255 255 255 255 255 255 078

HOLDING REGISTER INDEX →

LEVEL ADDRESS →

TEMPERATURE ADDRESS →

TEMP ELEMENT ADDRESS →

LIVE WATER ADDRESS →

WATER DIP ADDRESS →

DENSITY ADDRESS →

RESERVED ADDRESS →

VAPOUR TEMP ADDRESS →

BASE PRESSURE (P1) ADDRESS →

LIQUID PRESSURE (P2) ADDRESS →

VAPOUR PRESSURE (P3) ADDRESS →

ALLDEVICES(return)

This command basically does the same command as above, but all 32 registers for each block

are displayed.

This command is useful in troubleshooting, to check if there are no random registers

containing values.

GAUGE TYPE →

BLANKXX(return)

Where XX represents a row of gauge parameters between 0 and 32.

XX must be entered as a 2 digit number. E.g. 3 must be entered as 03.

This command blanks all the parameters for a gauge and defaults all the parameters back to

255. This parameter is used if you require to remove a gauge from the system. All gauges

above this gauge will be automatically shuffled down and fill the space which was originally

blanked.

Endress+Hauser 23

Page 24

Operation Tankvision Gauge Link

For example:

It is required that the second gauge needs to be removed from the system, type the following:

BLANK01(return)

FULLBLANK(return)

This command removes all the gauges and parameters from the Tankvision Gauge Link and

defaults the holding register database back to no gauges in the system.

This command is used if you require to start configuration from a fresh.

ENG=ENSITE(return)

This command allows Honeywell Enraf configuration PC tool, Ensite, to be connected to

Tankvision Gauge Link engineering port and support all the features that the Ensite

software require.

Once the above command has been set, a 4 minute timer is set to allow time for the engineer

to disconnect the terminal emulation software and connect the Ensite software. If no data

has been seen after four minutes on the RS232 port of the Tankvision Gauge Link, the port

will then switch back to its normal mode of operation and allow the terminal emulation

software to be used. Once data has been seen on the RS232 port, the timer will reset and if

no data is then seen for 2 minutes the Tankvision Gauge Link will default back to the

terminal emulation mode.

If the Tankvision Gauge Link is powered down and back up when in Ensite mode, it will

power back up in normal, terminal emulation mode, and will need to be set back to Ensite

mode by using the above command.

If Ensite is not polling for data when in this mode, the Tankvision Gauge Link will then

starting poll for normal data as configured in its database, this allows the Tankvision Gauge

Link to keep the data in its database as live as possible, if Ensite then starts polling for data,

the Tankvision Gauge Link will then switch to tunnelling mode and pass the data through

from Ensite to the gauges on the BPM fieldbus.

The CIU address of the Tankvision Gauge Link is always set to 0 (zero). The baud rate of the

Ensite port can run at either 1200 or 2400, this baud rate is determined by what the Field

bus baud rate is set to using the FTS command. Both the Field bus and Ensite baud rates need

to be the same.

The COMMUNICATIONS LED of the fieldbus module will not light up when Ensite is

tunnelling data, but it will light if the Tankvision Gauge Link polls for valid data. This can be

useful to determine what is driving the BPM field bus, Ensite or the Tankvision Gauge Link.

ENG=ENGAUGE(return)

This command offers all the features that the Ensite mode offers, including the Honeywell

Enraf Flexconn configuration tool.

Disabling, CIU address etc are the same as the Ensite mode.

For optimum ENgauge operation with the TVGL, set ENgauge as follows:

•New site

• Enter the units of the parameters

• Add a device to the comms

• Add a field connector

– Choose smartlink and give it a name

• Select the SmartLink and change its comms parameters

– GPU: 1200, 7, O, 1

– Flexconn: 1200, 8, N, 1

• Add a Tank

24 Endress+Hauser

Page 25

Tankvision Gauge Link Operation

• Add a gauge

• Edit gauge properties

– GPU Gauge address (Example 02)

– FlexConn address (Example 0101)

• Once ENG=ENGAUGE in TVGL scan for boards within the actual gauges and use the

ENgauge commands.

ENG=WINSETUP(return)

This is a similar command to the Ensite and Engauge mode, in that it will drop back after 2

or 4 minutes, if the RS232 port sees no data. When Winsetup is NOT polling for data,

Tankvision Gauge Link will start polling for data until the Winsetup then starts polling for

data. The COMMUNICATIONS LED does not light up when Winsetup polls for data. If the

Tankvision Gauge Link is powered down and back up, the unit will default back to normal,

terminal emulation software. The baud rate for this port when in Winsetup mode is always

set to 4800 and no other baud rate can be used.

DEBUG(return)

This command is used to print the data transmitted and received on the Field bus port. This

feature can be useful when commissioning a system. To cancel the debug mode, press the

‘return’ key a few times or power the Tankvision Gauge Link down and back up.

If the Field bus port is a BPM port, then the data printed will be the raw ASCII data, generally

the transmitted and received data will be printed on the same line per gauge, a new line will

be printed for a different gauge.

If the Field port is a TRL/2 port, then the data printed will be the raw decimal data. If a long

message is received, then serial port may not be able to handle all the data so quickly, so the

received data can be shorted, so only the address, function and CRC is viewed, all the rest of

the viewed data will be replaced with a #. To set this command type S(return) when in debug

mode. This feature is only supported for the TRL/2 field bus mode.

7.1.5 Quick list of commands

INFO(return)

FTS=XXXX(return)

HTS=XXXX(return)

HPA=X(return)

GPUGAIN=X(return)

CONFIG(return)

ZZZZ=XXX(return)

DEVICES(return)

ALLDEVICES(return)

BLANKX(return)

FULLBLANK(return)

ENG=ZZZZZ(return)

DEBUG(return)

S(return)

Where X and Z represent letters or numbers.

7.1.6 Configuration practices

Configuring the Tankvision Gauge Link using terminal emulation software is straight

forward to do but a few practices need to be carried out.

When configuring the Tankvision Gauge Link to communicate with Honeywell Enraf, the

type of gauge must be setup in the 1100 block of holding registers, if the type of gauge isn’t

configured, the Tankvision Gauge Link will treat the gauge as a basic Honeywell Enraf 811

gauge.

No type of gauge is required to be configured if connection to Emerson SAAB gauges.

Endress+Hauser 25

Page 26

Operation Tankvision Gauge Link

When adding gauges to the Tankvision Gauge Link it is important that the gauges are added

in consecutive order, otherwise the Tankvision Gauge Link will only poll for the first

addresses until it reaches a level holding register which contains 255, then it will go back

and repeat polling for the first gauges.

For example:

If level and temperature are required from 6 off 854 Honeywell Enraf gauges, having

addresses 01, 02, 03, 04, 05 and 06 respectively, then it is advised that configuration to be

done as follows:

Enter Result

CONFIG(return) Enable configuration

0=1(return) Level address = 1

100=1(return) Temp address = 1

1100=83(return) Gauge type is a servo (83)

1=2(return) Level address = 2

101=2(return) Temp address = 2

1101=83(return) Gauge type is a servo (83)

2=3(return) Level address = 3

102=3(return) Temp address = 3

1102=83(return) Gauge type is a servo (83)

3=4(return) Level address = 4

103=4(return) Temp address = 4

1103=83(return) Gauge type is a servo (83)

4=5(return) Level address = 5

104=5(return) Temp address = 5

1104=83(return) Gauge type is a servo (83)

5=6(return) Level address = 6

105=6(return) Temp address = 6

1105=83(return) Gauge type is a servo (83)

(return)

If the above was configured but the last gauge with address 6 was mapped to as follows:

Enter Result

8=6(return) Level address = 6

108=6(return) Temp address = 6

1108=83(return) Gauge type is a servo (83)

This gauge with address 6 will not be polled for because it is not directly preceeding the

gauge before it.

Each parameter can have a different address within the modbus holding registers. The

reason for this is that different parameters can come from different devices with different

addresses. This allows data from different addresses to be mapped to the group of input

registers, where the address of the input registers is derived from the level address of the

device.

26 Endress+Hauser

Page 27

Tankvision Gauge Link Operation

For example:

If a system requires a level from an Enraf 854 (address 1) and average temperature and

elements from an 864 (address 11) then configuration can be done as shown below:

Enter Result

CONFIG(return) Enable configuration

0=1(return) Level address = 1

100=11(return) Temp address = 11

200=11(return) Temp elements address = 11

1100=83(return) Gauge type is a servo (83)

(return)

All the data will be picked up from input registers with an address of 1.

If a system requires a level from an Emerson REX (address 1) and average temperature and

elements from a DAU (address 101) then configuration can be done as shown below:

Enter Result

CONFIG(return) Enable configuration

0=1(return) Level address = 1

100=101(return) Temp address = 101

(return)

All the data will be picked up from input registers with an address of 1.

As it can be seen, the element temperature is automatically mapped to address 101 because

the elements is associated with average temperature. No gauge type is required for the TRL/

2 fieldbus.

7.1.7 Honeywell Enraf Fieldbus

Configuration of the Tankvision Gauge Link to poll for Honeywell Enraf gauges has been

covered in the above examples and explanations. Configuring the Tankvision Gauge Link to

poll for Emerson SAAB gauges is slightly different.

7.1.8 Emerson SAAB Fieldbus

Configuration of the Tankvision Gauge Link to poll for level and temperature from Emerson

SAAB devices is the same as configuring Honeywell Enraf devices, in that the level address

comes from holding registers 0 – 31 and temperature address comes from holding registers

100 -131.

The temperature elements address automatically comes from the address in holding

registers 100 – 131, so there is no need to configure any addresses in holding registers 200

– 231.

Live water, Vapour temperature, Base pressure, Liquid pressure and vapour temperature can

be mapped back to the input registers with an address of the level address. The TRL/2

protocol doesn’t specifically have a register for the above parameters, but the Emerson REX

gauge has analogue and HART inputs which can be mapped and scaled within the Emerson

REX gauge. These inputs can then be picked up on the TRL/2 protocol and mapped within

the Tankvision Gauge Link.

The Tankvision Gauge Link will not scale the above parameters which come back on the TRL/

2 protocol, this must be done in the gauge and this is the usual practice when working with

Emerson equipment.

Endress+Hauser 27

Page 28

Operation Tankvision Gauge Link

The below inputs to the Emerson REX gauge are mapped to the TRL/2 registers. These will

only be picked up from the gauge with the address in holding registers 0 -31. These will not

be picked up from a DAU.

Emerson REX input TRL/2 Register

Analogue input current 1 06

Analogue input current 2 07

Analogue input current 3 08

Analogue input 1 30

Analogue input 2 32

HART Input 3 36

HART Input 2 38

HART Input 1 40

For example:

A system has a REX gauge with an address of 2 and a DAU for temperature of 102. Live

water and vapour temperature is also required, these will be mapped to Analogue input

current 1 and HART input 1 respectively in the REX gauge. Configure the Tankvision Gauge

Link as follows:

Enter Result

CONFIG(return) Enable configuration

0=2(return) Level address = 2

100=102(return) Temp address = 102

300=06(return) Water from register 06 with address 2

700=40(return) Vapour temp from register 40 with address 2

(return)

7.1.9 Worked examples

Example 1

A system requires to be connected to 5 off Honeywell Enraf gauges. GPU baud rate is 1200.

The modbus interface is 9600, None, 8, 1.

• Gauge address = 1, needs level and temp. Gauge type 854.

• Gauge address = 2, needs level and temp. Gauge type 873.

• Gauge address = 5, needs level, temp, temp elements, water dip and density. Gauge type

854.

• Gauge address = 9, needs level. Temp and its elements are from an 864 with address 19.

Gauge type 873.

• Gauge address = 20, needs level and temp. Gauge type is an Enraf emulation coming from

a none Enraf gauge.

Ensure the Tankvision Gauge Link is the Enraf version.

Enter Result

FTS=1200(return) Enable

HTS=9600(return) Enable

HPA=N(return) Enable

28 Endress+Hauser

Page 29

Tankvision Gauge Link Operation

Enter Result

CONFIG(return) Enable configuration

0=1(return) Level address = 1 (modbus address = 1)

100=1(return) Temp address = 1

1100=83(return) Gauge type is a servo (83)

1=2(return) Level address = 2 (modbus address = 2)

101=2(return) Temp address = 2

1101=82(return) Gauge type is a radar (82)

2=5(return) Level address = 5 (modbus address = 5)

102=5(return) Temp address = 5

202=5(return) Element temp address = 5

402=5(return) Water dip address = 5

502=5(return) Density = 5

1102=83(return) Gauge type is a servo (83)

3=9(return) Level address = 9 (modbus address = 9)

103=19(return) Temp address = 19

203=19(return) Temp address = 19

1103=82(return) Gauge type is a servo (82)

4=20(return) Level address = 20 (modbus address = 20)

104=20(return) Temp address = 20

1104=78(return) Gauge type is basic (78)

(return)

Once the above has been done type in DEVICES(return) to confirm your configuration is

correct.

Example 2

A system requires to be connected to 5 off Emerson gauges. The modbus interface is 19200,

None, 8, 1.

• Gauge address = 1, needs level and temp.

• Gauge address = 2, needs level and temp.

• Gauge address = 7, needs level, temp, temp elements, live water from gauge register

analogue input current 2 and product pressure from gauge register HART input 2.

• Gauge address = 8, needs level. Temp and its elements is from a DAU with address 108.

• Gauge address = 21, needs level and temp. Gauge type is an TRL emulation coming from

a none Emerson gauge.

Ensure the Tankvision Gauge Link is the TRL/2 version.

Enter Result

HTS=1920(return)

HPA=N(return)

CONFIG(return) Enable configuration

Endress+Hauser 29

Page 30

Operation Tankvision Gauge Link

Enter Result

0=1(return) Level address = 1 (modbus address = 1)

100=1(return) Temp address = 1

1=2(return) Level address = 2 (modbus address = 2)

101=2(return) Temp address = 2

2=7(return) Level address = 7 (modbus address = 7)

102=7(return) Temp address = 7

302=7(return) Water register 07 from address 7

902=38(return) Product pressure register 38 from address 7

3=8(return) Level address = 8 (modbus address = 8)

103=108(return) Temp address = 108

4=21(return) Level address = 21 (modbus address = 21)

104=21(return) Temp address = 21

(return)

Once the above has been done type in DEVICES(return) to confirm your configuration is

correct.

Example 3

A system requires to be connected to 6 of NRF590 gauges (emulating Enraf GPU) with

address 01 – 06.

Level and temperature are required from all gauges.

Host baud rate is 9600, with a parity of none. BPM baud rate is 1200.

Enter Result

FTS=1200(return)

HTS=9600(return)

HPA=N(return)

CONFIG(return) Enable configuration

0=1(return) Level address = 1 (modbus address = 1)

100=1(return) Temp address = 1

1100=78(return) Gauge type is a NRF590 (78)

1=2(return) Level address = 2 (modbus address = 2)

101=2(return) Temp address = 2

1101=78(return) Gauge type is a NRF590 (78)

2=3(return) Level address = 3 (modbus address = 3)

102=3(return) Temp address = 3

1102=78(return) Gauge type is a NRF590 (78)

30 Endress+Hauser

Page 31

Tankvision Gauge Link Operation

Enter Result

3=4(return) Level address = 4 (modbus address = 4)

103=4(return) Temp address = 4

1103=78(return) Gauge type is a NRF590 (78)

4=5(return) Level address = 5 (modbus address = 5)

104=5(return) Temp address = 5

1104=78(return) Gauge type is a NRF590 (78)

5=6(return) Level address = 6 (modbus address = 6)

105=6(return) Temp address = 6

1105=78(return) Gauge type is a NRF590 (78)

(return)

Example 4

A system requires to be connected to 4 of NRF590 gauges (emulating Enraf GPU) with

address 01 – 04.

Level Only is required.

Host baud rate is 9600, with a parity of none. BPM baud rate is 1200.

Enter Result

FTS=1200(return)

HTS=9600(return)

HPA=N(return)

CONFIG(return) Enable configuration

0=1(return) Level address = 1 (modbus address = 1)

1100=78(return) Gauge type is a NRF590 (78)

1=2(return) Level address = 2 (modbus address = 2)

1101=78(return) Gauge type is a NRF590 (78)

2=3(return) Level address = 3 (modbus address = 3)

1102=78(return) Gauge type is a NRF590 (78)

3=4(return) Level address = 4 (modbus address = 4)

1103=78(return) Gauge type is a NRF590 (78)

(return)

Example 5

A system requires to be connected to 4 of 873 gauges and 2 off 854 gauges with address 01

– 06.

Endress+Hauser 31

Page 32

Operation Tankvision Gauge Link

Level and temperature are required from all gauges.

Host baud rate is 9600, with a parity of none. BPM baud rate is 1200.

Enter Result

FTS=1200(return)

HTS=9600(return)

HPA=N(return)

CONFIG(return) Enable configuration

0=1(return) Level address = 1 (modbus address = 1)

100=1(return) Temp address = 1

1100=82(return) Gauge type is a RADAR (82)

1=2(return) Level address = 2 (modbus address = 2)

101=2(return) Temp address = 2

1101=82(return) Gauge type is a RADAR (82)

2=3(return) Level address = 3 (modbus address = 3)

102=3(return) Temp address = 3

1102=82(return) Gauge type is a RADAR (82)

3=4(return) Level address = 4 (modbus address = 4)

103=4(return) Temp address = 4

1103=82(return) Gauge type is a RADAR (82)

4=5(return) Level address = 5 (modbus address = 5)

104=5(return) Temp address = 5

1104=83(return) Gauge type is a SERVO (83)

5=6(return) Level address = 6 (modbus address = 6)

105=6(return) Temp address = 6

1105=83(return) Gauge type is a SERVO (83)

(return)

Example 6

A system requires to be connected to 2 of 873 gauges and 2 off 854 gauges with address 01

– 04.

Level only is requires.

Host baud rate is 9600, with a parity of none. BPM baud rate is 1200.

Enter Result

FTS=1200(return)

HTS=9600(return)

HPA=N(return)

32 Endress+Hauser

Page 33

Tankvision Gauge Link Operation

Enter Result

CONFIG(return) Enable configuration

0=1(return) Level address = 1 (modbus address = 1)

1100=82(return) Gauge type is a RADAR (82)

1=2(return) Level address = 2 (modbus address = 2)

1101=82(return) Gauge type is a RADAR (82)

2=3(return) Level address = 3 (modbus address = 3)

1102=83(return) Gauge type is a SERVO (83)

3=4(return) Level address = 4 (modbus address = 4)

1103=83(return) Gauge type is a SERVO (83)

(return)

Example 7

A system requires to be connected to 5 of SAAB rosemount gauges address 01 - 05.

Level and temperature are required.

Host baud rate is 9600, with a parity of none.

Enter Result

HTS=9600(return)

HPA=N(return)

CONFIG(return) Enable configuration

0=1(return) Level address = 1 (modbus address = 1)

100=1(return) Temp address = 1

1=2(return) Level address = 2 (modbus address = 2)

101=2(return) Temp address = 2

2=3(return) Level address = 3 (modbus address = 3)

102=3(return) Temp address = 3

3=4(return) Level address = 4 (modbus address = 4)

103=4(return) Temp address = 4

4=5(return) Level address = 5 (modbus address = 5)

104=5(return) Temp address = 5

(return)

Endress+Hauser 33

Page 34

Operation Tankvision Gauge Link

Example 8

A system requires to be connected to 4 of SAAB rosemount gauges address 01 - 04

Level only is required.

Host baud rate is 9600, with a parity of none.

Enter Result

HTS=9600(return)

HPA=N(return)

CONFIG(return) Enable configuration

0=1(return) Level address = 1 (modbus address = 1)

1=2(return) Level address = 2 (modbus address = 2)

2=3(return) Level address = 3 (modbus address = 3)

3=4(return) Level address = 4 (modbus address = 4)

(return)

7.1.10 Configuring through the Modbus Map

The holding registers which contain the gauge addresses etc can also be configured through

the RS485 Modbus host port using function code 3 of the Modbus protocol. Writing into

these registers is done using function code 6 or 16.

The purpose of this feature allows gauges to be added or deleted from a system remotely,

which allows host packages which have a configuration tool as part of it’s software suit to do

the configuration. This feature also allows its configuration to be stored remotely and the

configuration to be downloaded to the Tankvision Gauge Link on power up of a whole system

if required.

Refer to the Tankvision Gauge Link Modbus Map document for configuring the Tankvision

Gauge Link through the Modbus interface. The same principles apply when configuration is

done through the terminal emulation program, such as the gauges much be configured in

consecutive order (→ ä 25).

The address when configuring the Tankvision Gauge Link is default 247 or any of the

addresses configured in holding registers 0 -31.

The only parameters which can not be configured through the modbus link are parameters,

such as the engineering mode, field mode, baud rates, parity, GPU gain.

7.2 Operation

The operation of the Tankvision Gauge Link is straight forward, the Modbus interface

complies with the Modbus specification. Refer to the document Tankvision Gauge Link

Modbus Map. In general data from each gauge and auxiliary device is mapped to an address

which is assigned in holding registers 0 – 31. The data will be picked up from the input

registers using function code 4. The Tankvision Gauge Link can support up to 32 Modbus

addresses, so in theory 32 gauges and auxiliary devices can be connected, but in practice the

electrical limitations of the BPM and TRL/2 field bus wouldn’t allow for this.

The Tankvision Gauge Link supports a range of different units, which are detailed in the

Tankvision Gauge Link Modbus Map. The Tankvision Gauge Link reads the units on power

34 Endress+Hauser

Page 35

Tankvision Gauge Link Operation

up from the gauges, it is important that the Modbus host has been configured to calculate

the different units. The Tankvision Gauge Link can support gauges on the same field bus

with different units, but in practice, all the gauges on the field bus would typically have the

same units.

The scan cycle is the level is polled on a frequent basis, temperature is polled for

approximately half to a quarter the level depending on the gauge type. Other parameters are

polled once every cycle. The cycle time is dependent on the number of gauges and

parameters configured.

If a gauge was lost the Tankvision Gauge Link would do a number of polls for that gauge, if

still no gauge was detected, it would set all the registers associated with that gauge to

0xFFFF hex. It would then move on and poll for the rest of the gauges. Depending on the

gauge setup, if an auxiliary device was connected such as a DAU and comms was lost to the

gauge but not DAU, the data from the DAU would still be returned, this would also apply if

comms was lost from the DAU but not the gauge.

If a parameter from the gauge had an error, the last valid reading would be returned to the

Modbus map, but the status bit(s) would be set to indicate an error, the last valid reading can

be useful to know when troubleshooting.

Commands can be issued from the Tankvision Gauge Link, if the gauge supports it, such as

stow, density dip etc.

A range of other data can be read from the gauges as detailed in the Modbus specification

document. These parameters must be setup in the appropriate gauge, such as the high and

low alarms.

The Tankvision Gauge Link has a heartbeat and various information registers, these are

detailed in the Modbus map manual.

Generally the status register offset 21 is used to read the status of the gauge such as ‘is the

gauge doing a water dip?’ etc. The status register for each parameter is generally used to test

whether the parameter is healthy or not.

7.3 Engineering mode

This mode allows, Ensite, Engauge or Winsetup to be connected to the RS232 port and used

to interface directly to the gauges.

When using these tools a trained engineer much be familiar with the tools.

Data, such as level, temp etc, can still be read from the gauges when using the tunnelling

engineering tools, but if the tools are running for long periods of time an update of new date

to the Tankvision Gauge Link may take some time. It is important that the control room must

be made aware that the data from the modbus link may not be live. It is the responsibility of

the engineer to ensure that the data read from the Tankvision Gauge Link may not be live

when using the engineering tools and advise the control room of this.

If the engineering tool stops communicating through the Tankvision Gauge Link for 1

second, then the Tankvision Gauge Link will then start polling for data. As soon as the

engineering tool starts sending data to the gauges, the Tankvision Gauge Link then stops

polling for live data.

The COMMUNICATIONS understood LED will not flash when the engineering tool is passing

data through the Tankvision Gauge Link. This can be useful to determine which device is

polling for data.

Endress+Hauser 35

Page 36

Troubleshooting Tankvision Gauge Link

8Troubleshooting

8.1 Diagnostics

8.1.1 Use of fully wired serial cables

Use the cable as described in previous section and connect to the RS232 port of the

Tankvision Gauge Link and connect the other end to a laptop PC with a terminal emulation

program (e.g. Hyperterminal).

Set the terminal emulation program to the following communications settings:

Parameter Setting

Baud rate 9600 Baud

Data bits 8

Parity none

Stop bits 1

Flow control none

Use the command DEBUG(return) to print the raw GPU (Enraf) or TRL/2 (SAAB) data on

the fieldbus. If the fieldbus is TRL/2 then the command S(return) may be required as the

TRL/2 messages maybe too long so the S Command will Shorten the data printed to hyperterminal.

If for any reason a firmware update is required, links (ISP and RST) within the Tankvision

Gauge Link need to be fitted and the use of flash magic to update the firmware. Details of

firmware updates will be supplied if firmware updates are required in the future.

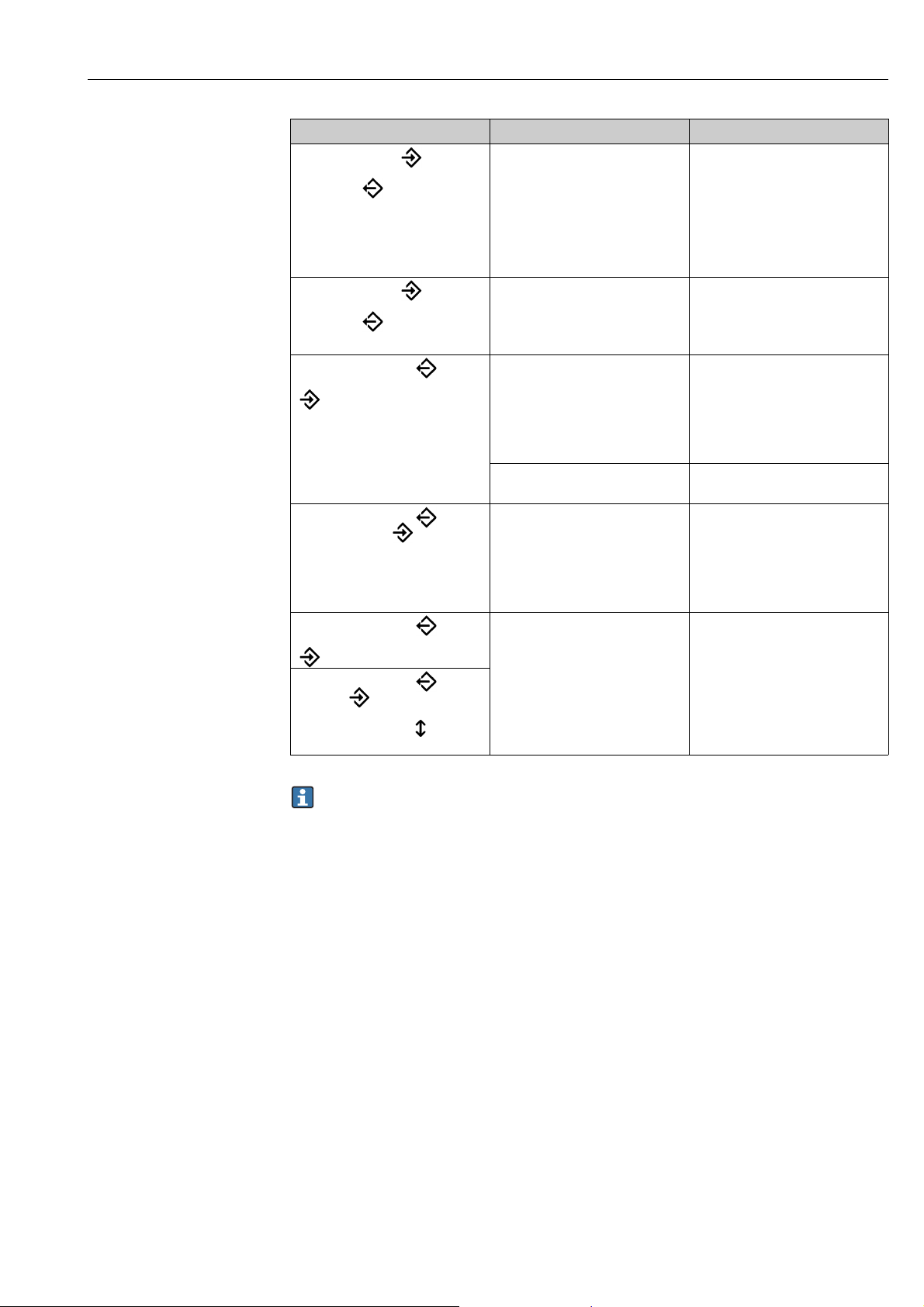

8.2 Fault finding chart

Symptom Possible cause Remedy

No LED indications:

POWER ( ) LEDs not lit

FAULT ( ) LED lit Internal fault Return unit for repair.

FAULT ( ) LED flashes

repeatedly

Host port RECEIVE ( ) LED

appears to be “permanently” lit,

possibly flickers off for very short

time

Host port RECEIVE ( ) LED does

not flicker / no activity

Mains power failure Investigate and rectify.

Mains supply fuse ruptured Investigate. If no fault evident,

Internal fault Return unit for repair.

Internal fault Return unit for repair.

EIA-485 “A” / “B” data signal lines

“crossed”

No requests from host Investigate and rectify.

Wiring fault between host and

Tankvision Gauge Link

replace fuse with new one of same

rating. If fuse immediately ruptures

or Tankvision Gauge Link does not

operate normally, return unit for

repair.

Swap “A” / “B” connections at host

port connector.

Investigate and rectify.

36 Endress+Hauser

Page 37

Tankvision Gauge Link Troubleshooting

Symptom Possible cause Remedy

Host port RECEIVE ( ) LED

flickers but no activity on

TRANSMIT ( ) LED

Host port RECEIVE ( ) LED

flickers, intermittent or no

TRANSMIT ( ) LED activity

Field port TRANSMIT ( ) LED

flickers but no activity on RECEIVE

() LED

Field port TRANSMIT ( ) LED

flickers, RECEIVE ( ) LED flickers

normally except periodic gaps in

activity at evenly spaced regular

intervals

Field port TRANSMIT ( ) LED

flickers, intermittent or no RECEIVE

( ) LED activity

Field port TRANSMIT ( ) and

RECEIVE ( ) LEDs flicker,

intermittent or no

COMMUNICATIONS ( ) LED

activity

Incorrect configuration:

• wrong communications

parameters (Baud rate, etc.)

• wrong protocol

• wrong Modbus slave address

Garbled communications:

• loose connection

• noise/interference

• Baud rate too high

Incorrect configuration:

•wrong field bus interface

• wrong communications

parameters (Baud rate, etc.)

• wrong protocol

•wrong gauge addresses

Wiring fault between Tankvision

Gauge Link and gauges

Incorrect configuration:

• wrong data parameters

• requesting parameters that are

not supported by the gauge

• one or more wrong gauge

addresses

Garbled communications:

• loose connection

• noise/interference

• Baud rate too high

• excessive bus loading

Investigate and rectify.

Host and Tankvision Gauge Link

must be set to same comms

parameters.

Protocol is Modbus RTU.

Modbus requires 8 data bits for

RTU. Parity is usually “none” (not

needed for RTU)

Check wiring.

Check for sources of noise/

interference.

Try slower Baud rate.

Investigate and rectify.

Tankvision Gauge Link must be set

to same comms parameters as

gauges.

Protocol must suit field bus

interface option.

Investigate and rectify.

Check wiring.

Investigate and rectify.

Tankvision Gauge Link must be set

to only request parameters that are

available from the gauges.

Check for incorrect or conflicting

gauge address.

Check wiring.

Check for sources of noise/

interference.

Try slower Baud rate (subject to

protocol limitations).

Reduce number of gauges on field

bus. (see note)

If the Tankvision Gauge Link is being installed to replace an existing tank gauging host,

it may be possible to verify the prevailing field bus communications conditions before

attempting to install the Tankvision Gauge Link. This will assist in tracing subsequent

communications problems if they relate to incorrect configuration, or poor

communications/intermittent comms failures resulting from field conditions (bus

loading, noise/interference, etc.).

Endress+Hauser 37

Page 38

Maintenance Tankvision Gauge Link

9 Maintenance

The Tankvision Gauge Link normally requires no routine / preventive maintenance other

than periodically checking for signs of the enclosure ventilation slots becoming blocked with

dust, etc.

9.1 Foreign object/liquid ingress