Page 1

TI01251G/00/EN/02.17

71355021

Products Solutions Services

Technical Information

Tankside Monitor NRF81

Tank Gauging

Application

Tankside Monitor NRF81 is a robust gateway for collecting and integrating tank

gauging data in storage and process applications. It fulfills the exacting demands of

tank inventory management, inventory control, custody transfer, loss control, total

cost saving, and safe operation.

Typical areas of application

• Hydrostatic Tank Gauging

• Hybrid Tank Measurement Systems

Your benefits

• SIL2 certified (Min, Max, Continuous level)

• SIL3 (in preparation)

• Up to 6 SIL relay outputs

• Wide range of output signals including V1, Modbus RS 485, and HART protocol

• Integration of e.g. temperature, water level, pressure, overfill prevention sensor

• Robust IP66/68, NEMA Type 4x/6P enclosure

• Operation and display in a wide variety of local languages

Page 2

Table of contents

Tankside Monitor NRF81

Document information ....................... 3

Symbols .................................... 3

Function and system design ................... 5

Integration of tank sensors ....................... 5

Input/output ............................... 6

HART Ex ia/IS active input ....................... 6

I/O modules ................................. 7

Power supply ............................. 13

Terminal assignment .......................... 13

Supply voltage .............................. 13

Cable entries ............................... 14

Cable specification ............................ 14

Overvoltage protection ......................... 14

Installation ............................... 15

Installation conditions ......................... 15

Environment .............................. 17

Ambient temperature range ..................... 17

Classification of environmental conditions according to

DIN EN 60721-3-4 ........................... 17

Storage temperature .......................... 17

Humidity .................................. 17

Degree of protection .......................... 17

Shock resistance ............................. 17

Vibration resistance ........................... 17

Electromagnetic compatibility (EMC) ............... 17

Ordering information ....................... 25

Ordering information .......................... 25

Marking .................................. 25

Application packages ....................... 26

Advanced tank measurement methods .............. 26

Accessories ............................... 31

Device-specific accessories ...................... 31

Communication-specific accessories ................ 32

Service-specific accessories ...................... 32

System components ........................... 32

Documentation ............................ 33

Technical Information (TI) ...................... 33

Brief Operating Instructions (KA) .................. 33

Operating Instructions (BA) ..................... 33

Description of Device Parameters (GP) ............... 33

Safety instructions (XA) ........................ 34

Registered trademarks ...................... 35

Custody transfer approval ................... 18

Mechanical construction .................... 19

Dimensions ................................ 19

Weight ................................... 19

Materials .................................. 20

Operability ............................... 21

Operating concept ............................ 21

Operating options ............................ 21

Local operation .............................. 21

Remote operation ............................ 22

Operation via service interface .................... 22

Certificates and approvals ................... 23

CE mark ................................... 23

RCM-Tick marking ............................ 23

Ex approval ................................ 23

Single seal according to ANSI/ISA 12.27.01 ........... 23

Functional Safety (SIL) ......................... 23

WHG ..................................... 23

Weight & Measure approval ..................... 23

Non-ionizing radiation protection .................. 23

Other standards and guidelines ................... 23

2 Endress+Hauser

Page 3

Tankside Monitor NRF81

DANGER

WARNING

CAUTION

NOTICE

A

Document information

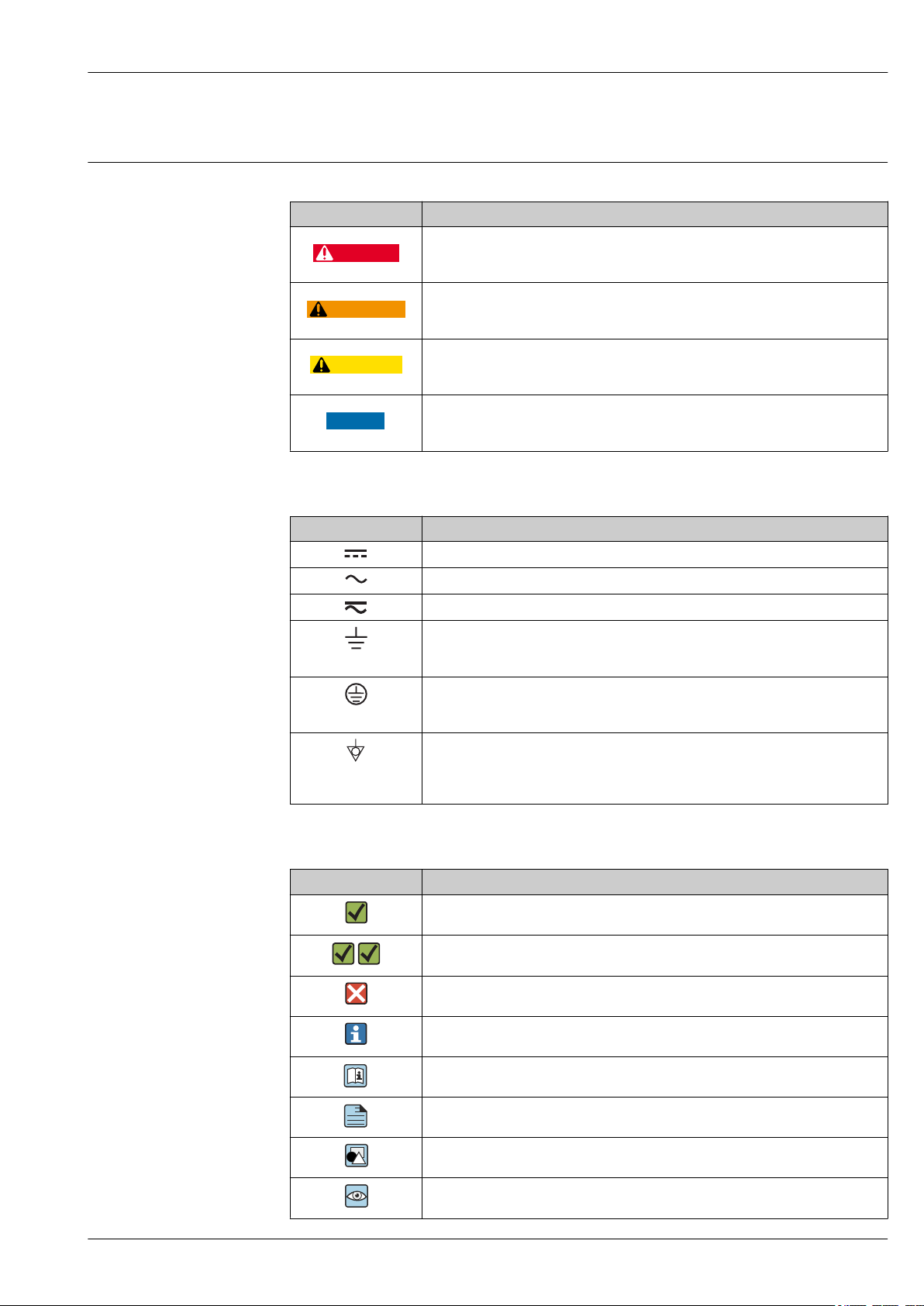

Symbols Safety symbols

Symbol Meaning

Electrical symbols

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or

company codes of practice.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

Endress+Hauser 3

Page 4

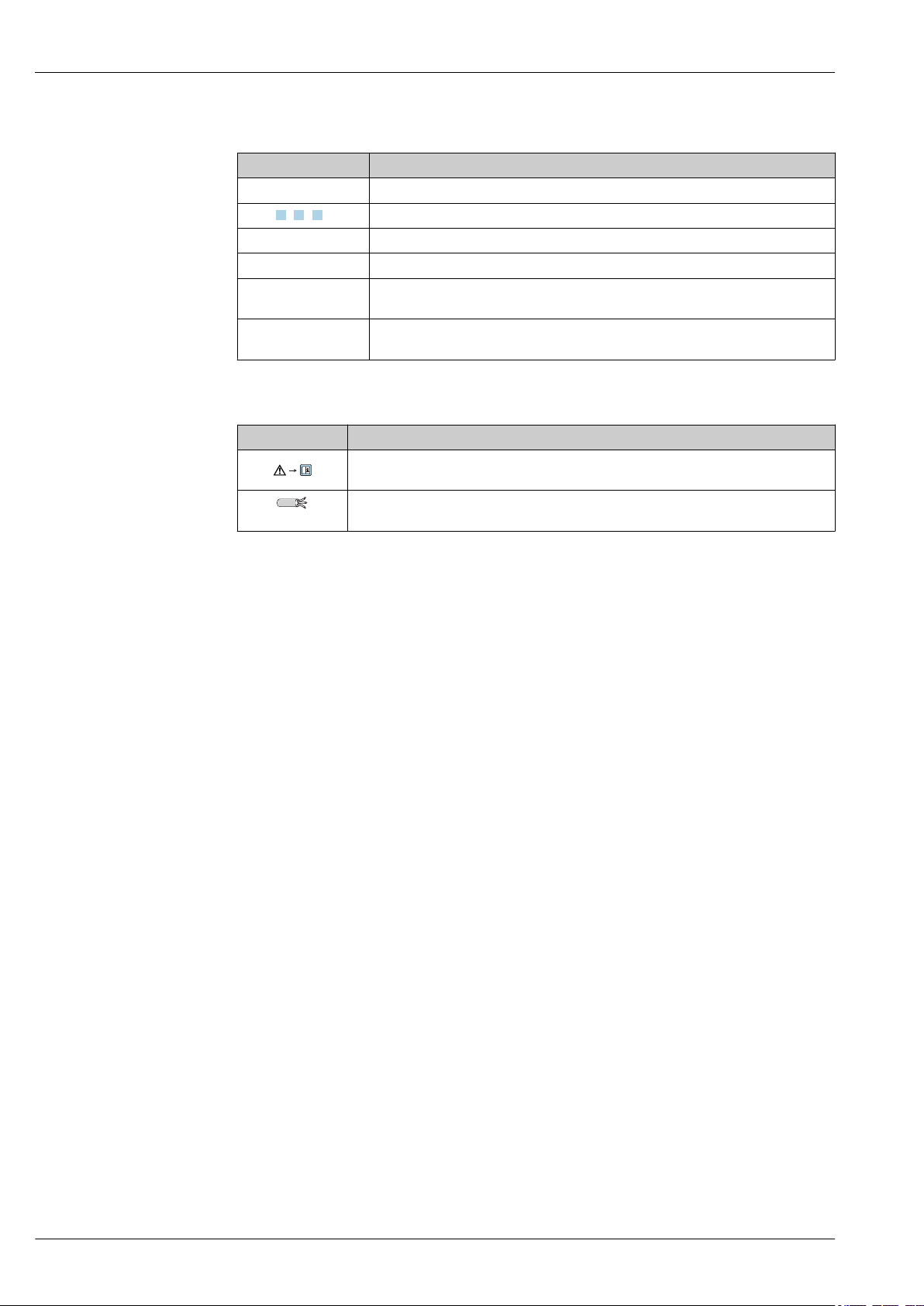

Symbols in graphics

1.

-

.

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

Tankside Monitor NRF81

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

4 Endress+Hauser

Page 5

Tankside Monitor NRF81

2 2

3

3

1 1

HART

4-20 mA

A

B

HART

4-20 mA

HART

HART

4

55

6 6

4

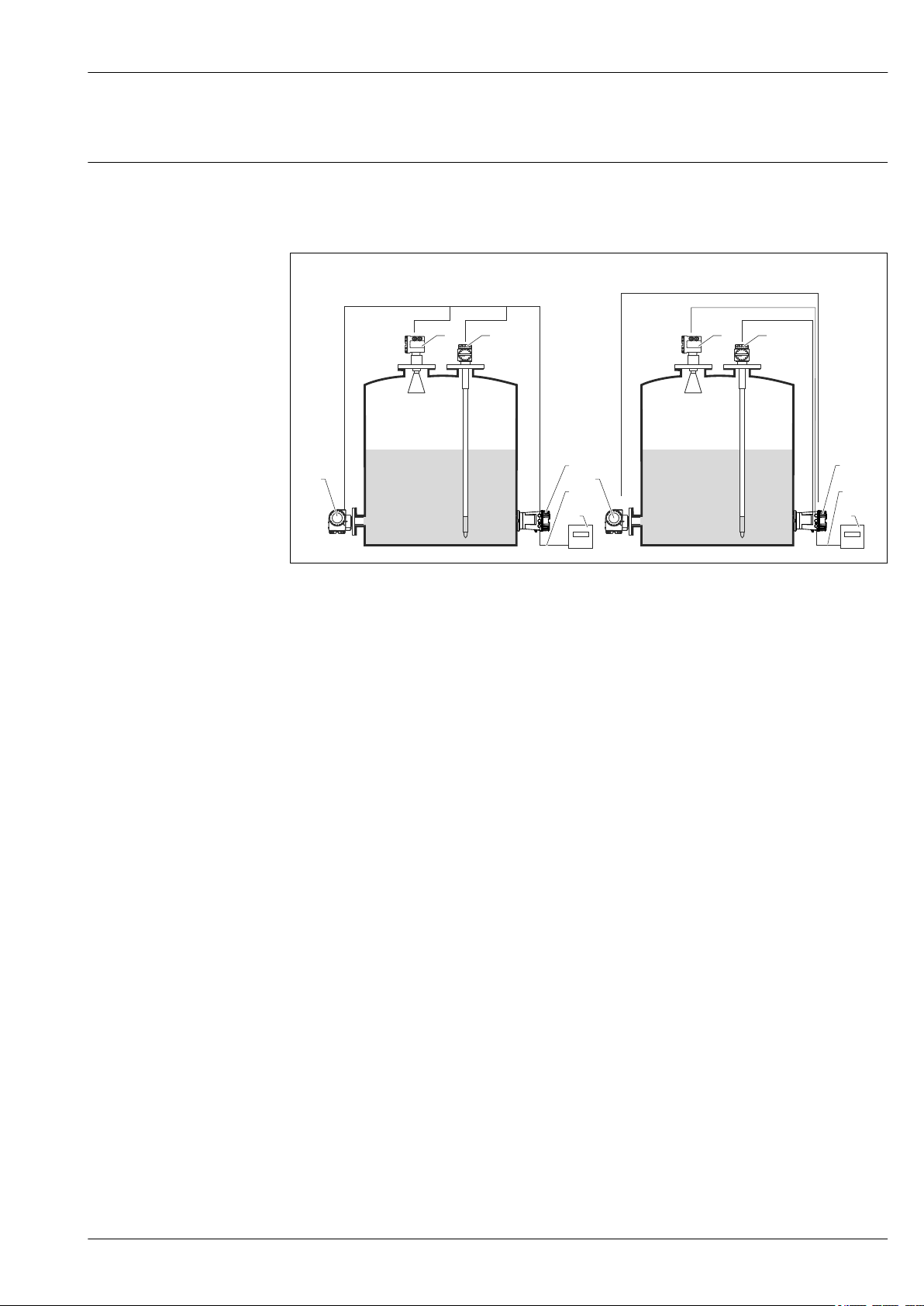

Function and system design

Integration of tank sensors

The Tankside Monitor is a field device for the integration of tank sensors into tank inventory

systems. It is typically installed at the bottom of the tank and allows access to all connected tank

sensors. All measured and calculated values can be displayed at the on-site display. Via a field

communication protocol, they can be transferred to an inventory control system.

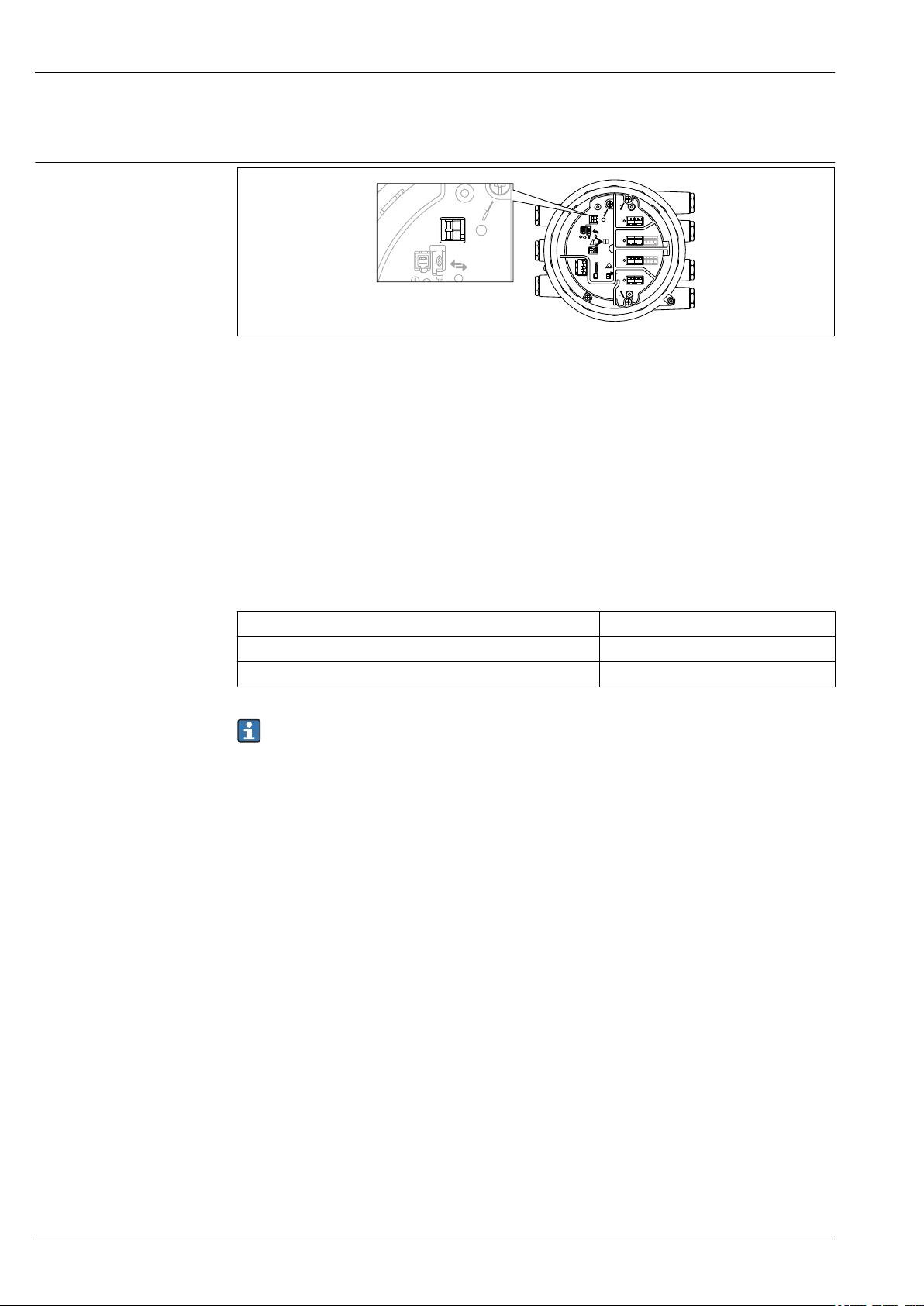

A0023766

1 Integration of tank sensors with Tankside Monitor (Example)

A HART multidrop mode

B HART and analog mode

1 Pressure transmitter

2 Level radar

3 Average temperature transmitter

4 Tankside Monitor

5 Field protocol transmits data to an inventory control system

6 Inventory control system (e.g. Tankvision NXA820 or Tankvision Professional NXA85)

Typical values measured by the sensors are:

• Level

• Spot temperature

• Average temperature

• Water level

• Pressure

• Secondary level value (for critical applications)

Endress+Hauser 5

Page 6

HART Ex ia/IS active input

D

E

G

F

C

B

A

1

1

1

1

1 3

2

3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

POWER

i

E

1

1

2

CDI

D

C

1 2 3 4

1 2 3 4

Tankside Monitor NRF81

Input/output

A0027364

2 HART Ex ia/IS active input

E1 HART +

E2 HART -

The device has a HART Ex ia/IS active input. Additional features are provided if the following

Endress+Hauser devices are connected:

• Prothermo NMT

The measured level is transmitted to the Prothermo. Prothermo uses this level to calculate the

average temperature of the product.

• Micropilot S FMR53x

The calculated distance correction factor or distance correction value is sent to the Micropilot.

Micropilot uses this value to indicate the corrected level at its local display.

Technical data

Transmitter power supply voltage 23.0 V - 380 Ω ⋅ I

Maximum load 500 Ω including signal line

Maximum current of all connected devices 24 mA

load

The HART Ex ia/IS active input is available by default. It needs not to be chosen explicitly when

ordering a device.

6 Endress+Hauser

Page 7

Tankside Monitor NRF81

E

G

F

1

1

1

1 3

2

2

2 4

HR

CDI

WP

on

SIM

POWER

i

D

C

B

A

1122334

4

112233445566778

8

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

NRF81 - XX xx xxxxxx ...

040

NRF81 - xx XX xxxxxx ...

050

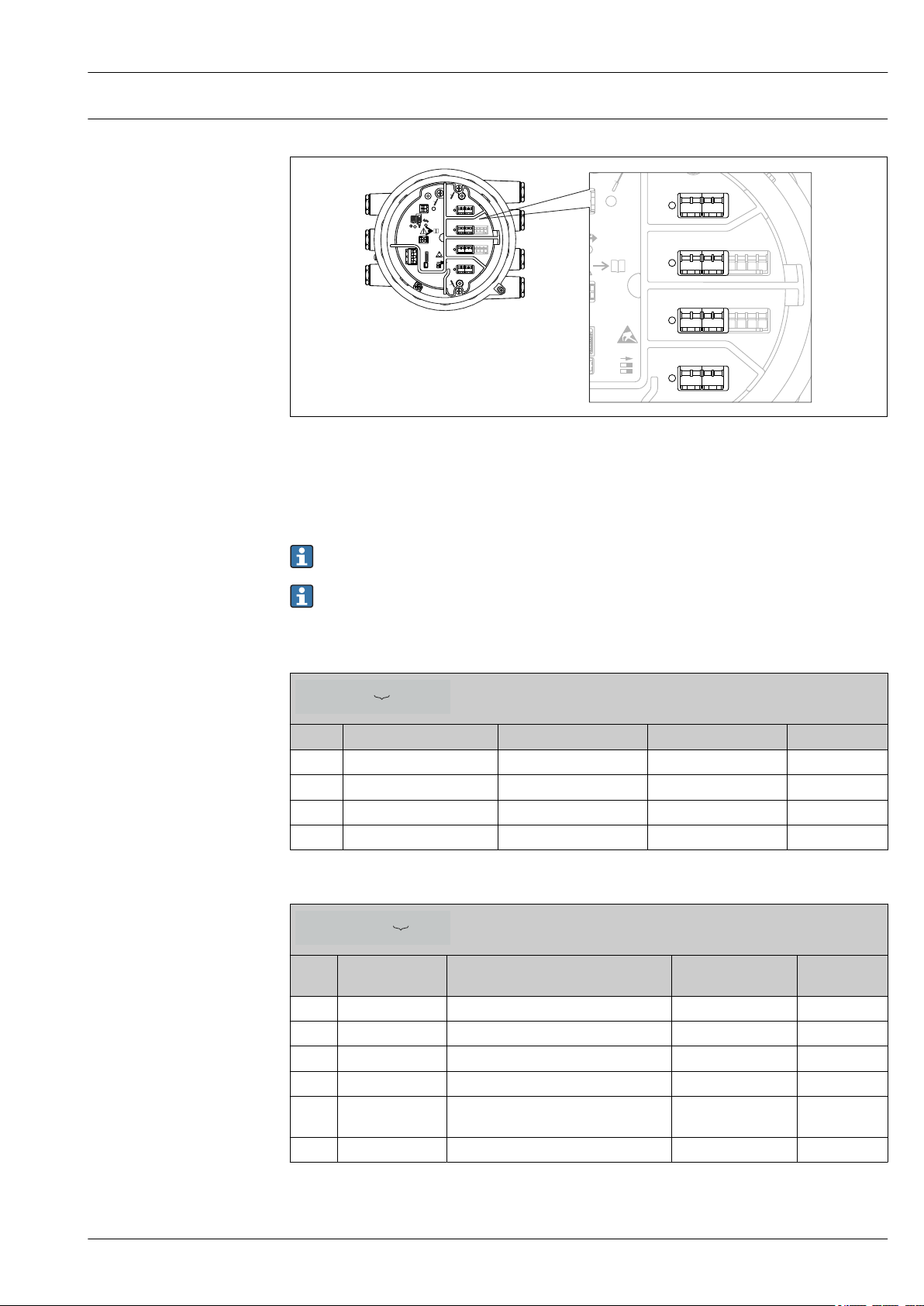

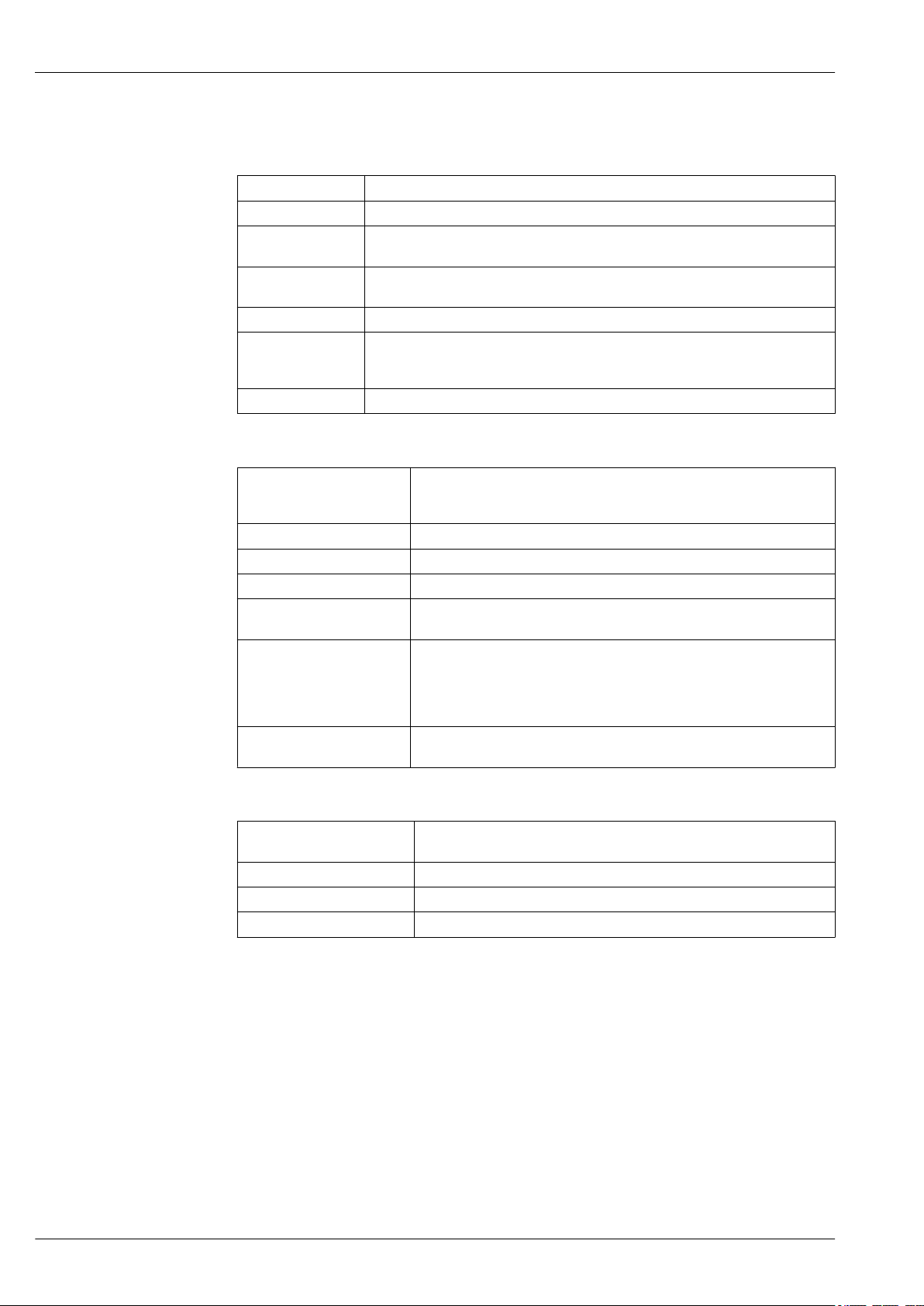

I/O modules Overview

3 Position of the I/O modules in the terminal compartment

The terminal compartment contains up to four I/O modules, depending on the order code.

• Modules with four terminals can be in any of these slots.

• Modules with eight terminals can be in slot B or C.

The exact assignment of the modules to the slots is dependent on the device version. For a

detailed description refer to the Operating Instructions of the device in question.

The following restrictions apply when selecting the modules:

• The device may contain a maximum of four I/O modules.

• A maximum of two I/O modules with 8 terminals is possible.

A0027363

Ordering feature 040: "Primary Output"

Option Number of I/O modules Type of I/O module Number of terminals Technical data

A1 1 Modbus RS485 4 → 8

B1 1 V1 4 → 9

E1 1 4-20mA HART Ex d/XP 8 → 10

H1 1 4-20mA HART Ex i/IS 8 → 10

Ordering feature 050: "Secondary IO Analogue"

Option Number of I/O

modules

A1 1 1 x "Ex d/XP 4-20mA HART + RTD input" 1 x 8 → 10

A2 2 2 x "Ex d/XP 4-20mA HART + RTD input" 2 x 8 → 10

B1 1 1 x "Ex i/IS 4-20mA HART+ RTD input" 1 x 8 → 10

B2 2 2 x "Ex i/IS 4-20mA HART+ RTD input" 2 x 8 → 10

C2 2 1 x "Ex i/IS 4-20mA HART + RTD input"

X0 0 none 0 -

Type of I/O module Number of terminals Technical data

2 x 8 → 10

1 x "Ex d/XP 4-20mA HART + RTD input"

Endress+Hauser 7

Page 8

Tankside Monitor NRF81

NRF81 - xx xx XXxxxx ...

060

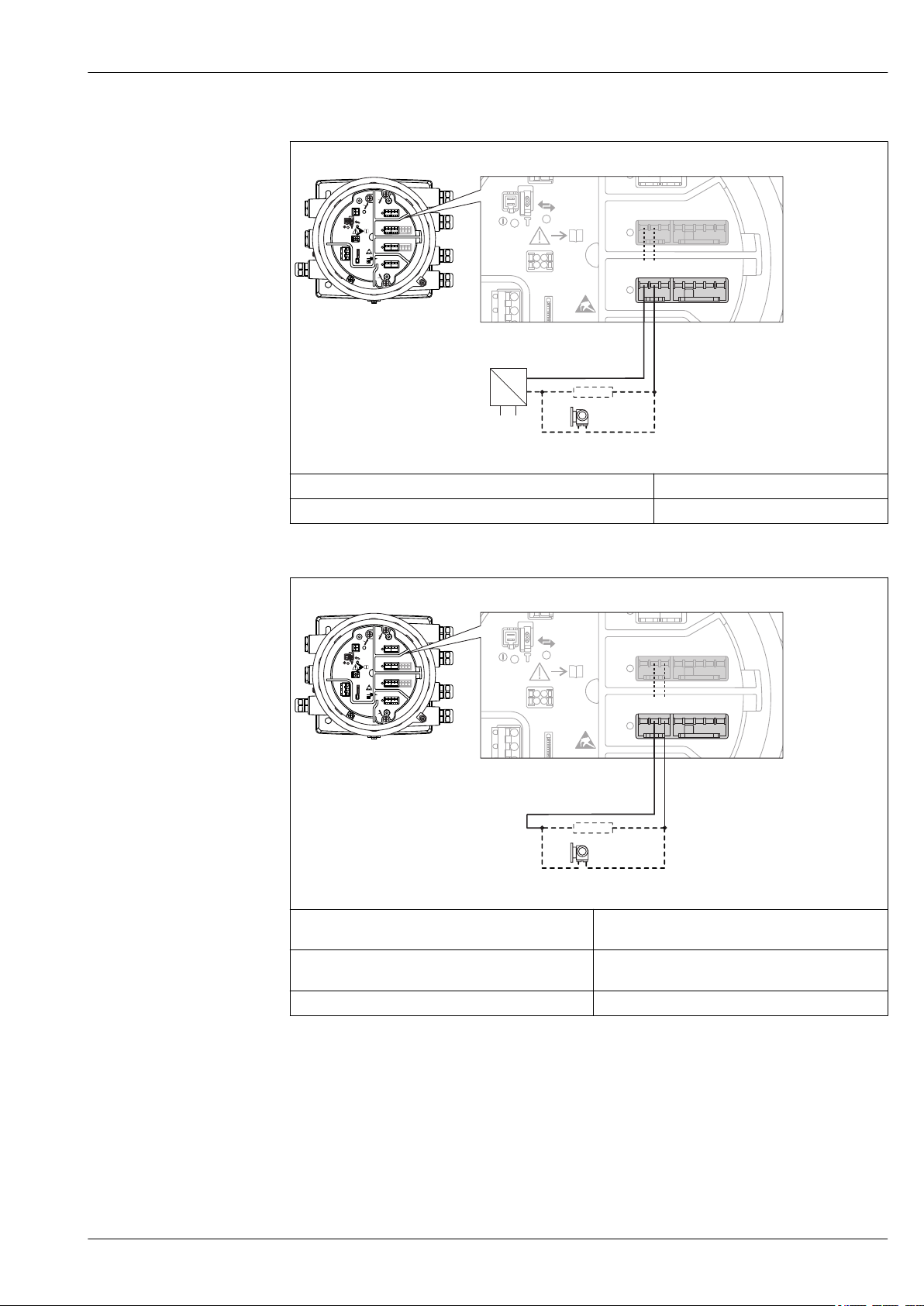

Ordering feature 060: "Secondary IO Digital Exd"

Option Number of I/O modules Type of I/O module Number of terminals Technical data

A1 1 1 x "2x relay + 2x discrete I/O" 1 x 4 → 12

A2 2 2 x "2x relay + 2x discrete I/O" 2 x 4 → 12

A3 3 3 x "2x relay + 2x discrete I/O" 3 x 4 → 12

B1 1 1x "Modbus RS485" 1 x 4 → 8

B2 2 1x "Modbus RS485"

1 x "2x relay + 2x discrete I/O"

B3 3 1x "Modbus RS485"

2 x "2x relay + 2x discrete I/O"

X0 0 none 0 -

"Modbus RS485": Technical data

No. of units Maximum 15 instruments per loop

Baud rate Selectable:

• 600 bit/s

• 1 200 bit/s

• 2 400 bit/s

• 4 800 bit/s

• 9 600 bit/s

• 19 200 bit/s

Parity Selectable:

• Odd

• Even

• None

Cable Three-wire cable with screening. The screening must be connected inside the housing.

Termination resistors To be set as required in specific environments

Topology • Serial bus

• Tree structure

Transmission distance Maximum 1 200 m (3 900 ft) including limbs or branches;

branches under 3 m (9.8 ft) are negligible

Instrument address Each transmitter has an individual bus address configured in the software of the

transmitter.

Isolation Bus inputs are electrically isolated from the other electronics.

Error on alarm Error message classified according to NAMUR NE 107

2 x 4 → 8

→ 12

3 x 4 → 8

→ 12

8 Endress+Hauser

Page 9

Tankside Monitor NRF81

"V1": Technical data

No. of units Maximum 10 instruments per loop

Baud rate 3 300 bit/s

Parity Selectable:

• Odd

• Even

• None

Cable • Two-wire twisted pair; screening recommended

• Two-wire unscreened

Termination resistors Not required

Topology • Serial bus

• Tree structure

Transmission distance Maximum 6 000 m (19 700 ft)

Instrument address Each transmitter has an individual bus address configured in the software of the

transmitter.

Isolation Serial communication circuit isolated from other circuits

Error on alarm Error message classified according to NAMUR NE 107

Endress+Hauser 9

Page 10

Tankside Monitor NRF81

"4-20mA HART" I/O module (Ex d/XP or Ex i/IS): Technical data

General data

No. of units Max. 6 instruments per loop

Baud rate 1 200 bit/s

Cable Two-wire, twisted pair screened cable;

Core cross section: 0.2 to 2.5 mm2 (24 to 13 AWG)

Topology • Serial bus

• Tree structure

Transmission distance Maximum 1 200 m (3 900 ft)

Instrument address Each transmitter on a signal loop has an individual bus address. This is defined within

the transmitter software and / or auxiliary configuration environment such as host

system or Field Communicator 475.

Isolation Bus inputs are electrically isolated from the other electronics

Input data

Input operating modes • 4..20mA input (1 external device)

• HART master+4..20mA input (1 external device)

• HART master (up to 6 external devices)

Internal load (to ground) 400 Ω

Measuring range 0 to 26 mA

Accuracy ±15 µA (after linearization and calibration)

Connection of a Prothermo

NMT

Connection of a Micropilot S

FMR5xx

Connection of a RTD

temperature probe

The measured level is transmitted to the Prothermo. Prothermo uses this level

to calculate the average temperature of the product.

• The auxiliary energy for the Micropilot S can be supplied by the analogue

I/O module

• The calculated distance correction factor or distance correction value is sent

to the Micropilot. Micropilot uses this value to indicate the corrected level at

its local display.

2-, 3- or 4-wire connection

Output data

Output operating modes • 4..20mA output

• HART slave +4..20mA output

Output current 3 to 24 mA

Accuracy ±15 µA (after linearization and calibration)

Error on alarm HART error message classified according to NAMUR NE 107

10 Endress+Hauser

Page 11

Tankside Monitor NRF81

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

-

+

!

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

-

+

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

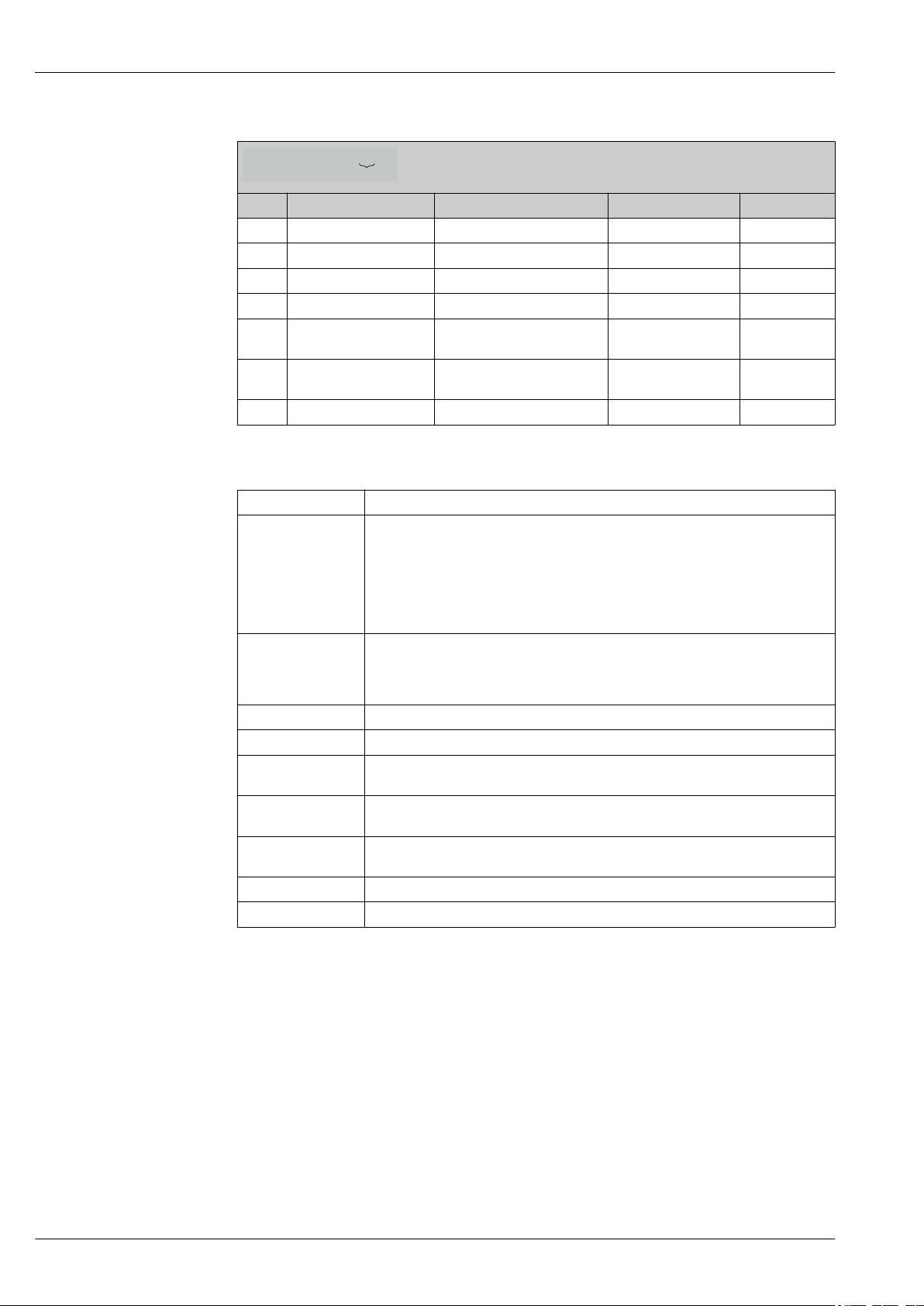

Data for passive usage (input or output)

A0033030

4 Passive input or output: Use terminals 1 and 2

Minimum terminal voltage 10.4 V

Maximum terminal voltage 29 V

Data for active usage (input or output)

5 Active input or output: Use terminals 2 and 3

Transmitter power supply voltage

(Ex d/XP)

Transmitter power supply voltage

(Ex i/IS)

Output load max. 500 Ω including signal line

18.5 V - 360 Ω ⋅ I

20.0 V - 360 Ω ⋅ I

load

load

A0033031

Endress+Hauser 11

Page 12

Tankside Monitor NRF81

"Digital I/O module": Technical data

Output

Relay switching power for resistive load • 30 VDC @ 2 A

• 250 VDC @ 0.1 A

• 250 VAC @ 2 A

Relay type normally open;

can be set to "normally closed" by a software option

Input

Maximum pick-up voltage • 250 V

Minimum pick-up voltage • 25 V

• 250 V

• 5 V

DC

AC

DC

AC

Current consumption at maximum voltage • ≤ 1 mA (DC)

• ≤ 2 mA (AC)

1) In case of a power supply failure, the switching state is always "open", irrespectiv of the selected software

option.

1)

12 Endress+Hauser

Page 13

Tankside Monitor NRF81

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

G

1

3

2

POWER

G1 N

G3 L

AC 85...264 V

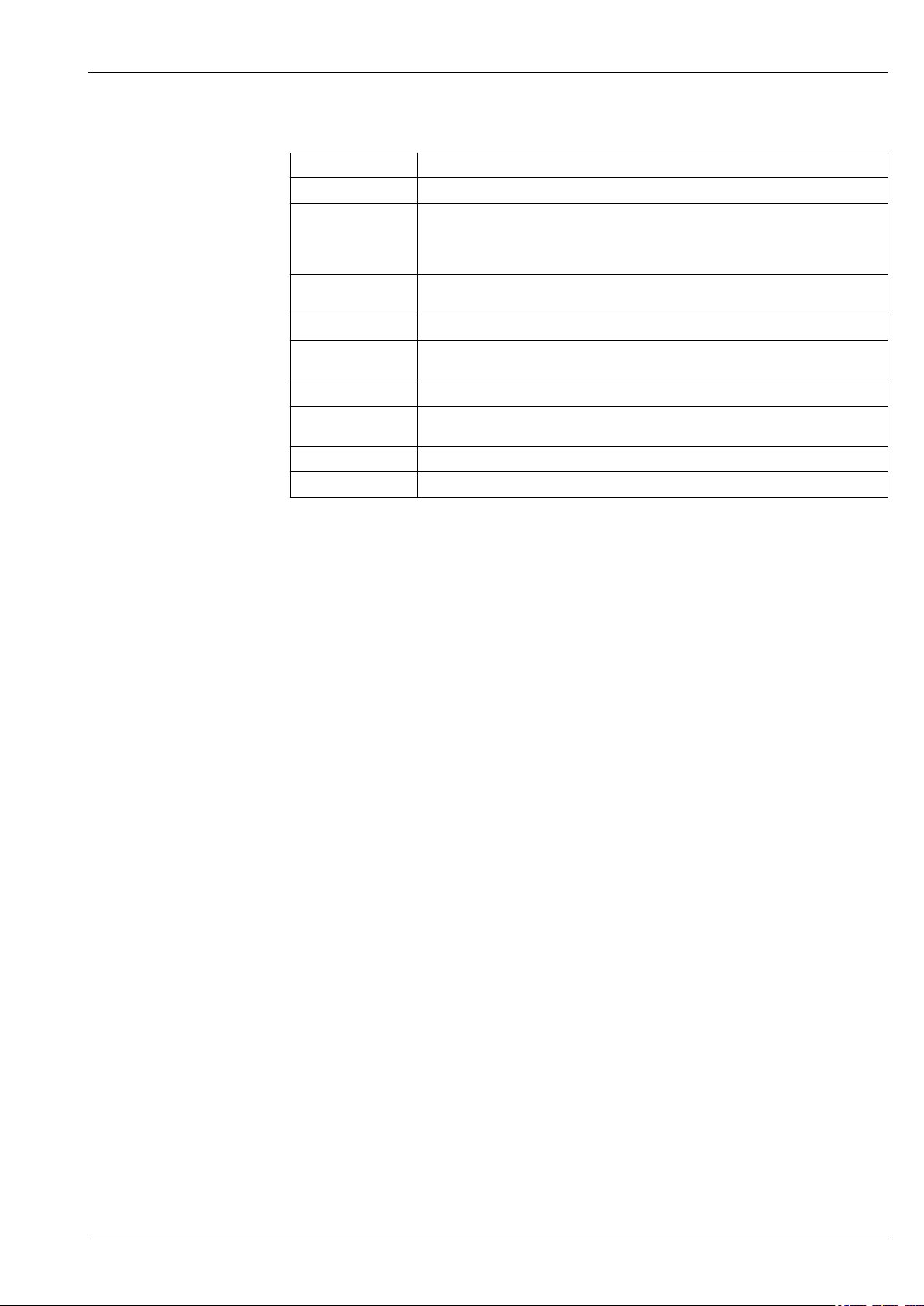

Terminal assignment

Power supply

A0027362

6 Terminal compartment (typical example) and ground terminals

Supply voltage

Terminal area Module

Up to four I/O modules, depending on the order code

• Modules with four terminals can be in any of these slots.

A/B/C/D

(slots for I/O modules)

• Modules with eight terminals can be in slot B or C.

The exact assignment of the modules to the slots is dependent on the device

version. For a detailed description refer to the Operating Instructions of the

device in question.

E HART Ex i/IS interface

• E1: H+

• E2: H-

F Remote display (in preparation)

Power supply: 85 to 264 V

G

• G1: N

• G2: not connected

AC

• G3: L

Protective ground connection

A0018339

85 to 264 VAC, 50/60 Hz, 28.8 VA

1)

1) maximum value; actual value depending on modules installed

Endress+Hauser 13

Page 14

Tankside Monitor NRF81

Cable entries

Ordering feature 090 "Electrical Connection"

A 7 x thread M20

B 7 x thread M25

C 7 x thread G1/2

D 7 x thread G3/4

E 7 x thread NPT1/2

F 7 x thread NPT3/4

1) Position 13 of the order code, e.g. NMx8x-xxxxxxxxxxxxA...

For the following devices with TIIS Ex d approval, cable glands are attached to the device (see

position 1 and 2 of the order code). These cable glands must be used.

Tankside Monitor NRF81-TA...

Cable specification Terminals

Terminal Wire cross section

Signal and power supply

• Spring terminals (NRF81-xx1...)

• Screw terminals (NRF81-xx2...)

Ground terminal in the terminal compartment max. 2.5 mm2 (13 AWG)

Ground terminal at the housing max. 4 mm2 (11 AWG)

1)

Cable entries (with blind plugs)

0.2 to 2.5 mm2 (24 to 13 AWG)

Overvoltage protection

Power supply line

Standard device cable is sufficient for the power line.

HART communication line

• Standard device cable is sufficient if only the analog signal is used.

• Shielded cable is recommended if using the HART protocol. Observe the grounding concept of the

plant.

Modbus communication line

• Observe the cable conditions from the TIA-485-A, Telecommunications Industry Association.

• Additional conditions: Use shielded cable.

V1 communication line

• Two wire (twisted pair) screened or un-screened cable

• Resistance in one cable: ≤ 120 Ω

• Capacitance between lines: ≤ 0.3 µF

On the communication and power lines; according to IEC 60060-1 /DIN 60079-14:

10 kA, 8/20 μs, 10 pulses according to IEC 60060-1 / DIN 60079-14

14 Endress+Hauser

Page 15

Tankside Monitor NRF81

150 (5.9)

150 (5.9)

ø

13.5 (0.53)

M12

≤15 Nm (11.06 lbf ")

≤15 Nm (11.06 lbf ")

Installation

Installation conditions Wall mounting

7 Wall mounting of the Tankside Monitor

A0029901

Pipe mounting

A mounting kit consisting of two brackets and four nuts can be ordered with the device. It can be

used for mounting the Tankside Monitor on horizontal or vertical pipes.

Ordering feature 620 "Accessory enclosed" Mounting kit

PV Mounting kit, pipe, DN32-50 (1-1/4" - 2")

PW Mounting kit, pipe, DN80 (3")

8 Mounting of the Tankside Monitor at a vertical pipe

A0029899

Endress+Hauser 15

Page 16

≤15 Nm (11.06 lbf ")

9 Mounting of the Tankside Monitor at a horizontal pipe

Tankside Monitor NRF81

A0029900

16 Endress+Hauser

Page 17

Tankside Monitor NRF81

Environment

Ambient temperature range

Classification of environmental conditions according to DIN EN 60721-3-4

Storage temperature

Humidity

Degree of protection

Shock resistance

Vibration resistance

Device –40 to +60 °C (–40 to +140 °F)

Display module –20 to +70 °C (–4 to +158 °F)

The readability of the display may be impaired at temperatures outside this

temperature range.

4K5, 4K6, 4B1, 4M7, 4Z2, 4Z3, 4Z8

–50 to +80 °C (–58 to +176 °F)

≤ 95 %

• IP68/66 according to DIN EN 60529

• Type 6P/4x according to NEMA 250

• 30 g (18 ms) according to DIN EN 60068-2-27 (1993)

• Classification according to DIN EN 60721-3-4: 4M7

• 20 to 2 000 Hz, 1 (m/s2)2/Hz according to DIN EN 60068-2-64 (1994)

• This corresponds to an acceleration value of 4.5 g and fulfills class 4M7 of DIN EN 60721-3-4

(1995)

Electromagnetic compatibility (EMC)

• Transient emissions according to DIN EN 61326, class B

• Interference resistance according to DIN EN 61326, Appendix A (Industry use) and NAMUR

recommendation NE21

Endress+Hauser 17

Page 18

Custody transfer approval

Tankside Monitor NRF81

Ordering feature 150 "Weight

+ Measure Approval"

ICR Standard version, without calibration certificate

NTC Custody transfer type approval according to NMi, OIML R85, API 3.1B,

PTC (in preparation) Custody transfer type approval per PTB, factory calibration certificate

1) Position 14 to 16 in the order code (e.g. NRF8x-xxxxxxxxxxxxxICR...)

1)

Accuracy properties (compared to the connected level gauge as defined in

OIML R85)

ISO4622, factory calibration certificate

18 Endress+Hauser

Page 19

Tankside Monitor NRF81

310 (12.2)

215 (8.46)

206 (8.11)

Mechanical construction

Dimensions Housing

Weight

A0023874

10 Dimensions of Tankside Monitor NRF81; unit of measurement: mm(in); adapters for cable entries are not

taken into account in this drawing.

Housing with electronics: approx. 12 kg (26 lb)

Endress+Hauser 19

Page 20

Materials Materials of housing

1

2

4

3

5

6

7

9

10

8

Tankside Monitor NRF81

A0026339

Pos. Part Materials for Aluminum version

1 Housing AC 43000 T6 316L (1.4404)

2 Cover • Cover: AC 43000 T6

• Window: Glass

• Seal: FVMQ

• Thread-coating: Graphite-based

lubricant varnish

3 Cover lock • Capstan screw: 316L (1.4404)

• Clamp: 316L (1.4435)

4 Tag for measuring

point label

5 Pressure release

stopper

6 Nameplate • Sticker: Plastic

7 Mounting plate AC 43000 T6 316L (1.4404)

8 Dummy screws for

weather protection

cover

9 Dummy plug, cable

gland or adapter

10 Ground terminal • Screw: A4-70

316L (1.4404) 316L (1.4404)

• Stopper: 316L (1.4404)

• O-ring: EPDM

• Sealing screw: A4

• O-ring: FKM

• Screw: A4-70

• O-ring: EPDM

• Dummy plug

3)

– 1.4435

– LD-PE

• Adapter:

– Ms/Ni (TIIS)

– 1.4404 (other versions)

• Seal:

– EPDM

– NBR

– PTFE tape

• Spring washer: A4

• Clamp and holder: 316L (1.4404)

1)

Materials for stainless steel version

• Cover: 316L (1.4404)

• Window: Glass

• Seal: FVMQ

• Thread-coating: Graphite-based

lubricant varnish

• Capstan screw: 316L (1.4404)

• Clamp: 316L (1.4435)

• Stopper: 316L (1.4404)

• O-Ring: EPDM

• Nameplate: 316L (1.4404)

• Groove pins: 316Ti (1.4571)

• Sealing screw: A4

• O-ring: FKM

• Screw: A4-70

• O-ring: EPDM

• Dum my plug

– 1.4435

– LD-PE

• Adapter:

– Ms/Ni (TIIS)

– 1.4404 (other versions)

• Seal:

– EPDM

– NBR

– PTFE tape

• Screw: A4-70

• Spring washer: A4

• Clamp and holder: 316L (1.4404)

2)

1) Ordering feature 070 "Housing", Option "AA"; position 11/12 of the order code: NXXXX-xxxxxxxxxxAA...

2) Ordering feature 070 "Housing", Option "BA"; position 11/12 of the order code: NXXXX-xxxxxxxxxxBA...

3) Depending on device version

20 Endress+Hauser

Page 21

Tankside Monitor NRF81

1

E

Operability

Operating concept

Operating options

Operator-oriented menu structure for user-specific tasks

• Commissioning

• Operation

• Diagnostics

• Expert level

Operating languages

• English

• German

• Japanese

Feature 500 of the product structure determines which of these languages is preset on delivery.

Quick and safe commissioning

• Guided menus ("Make-it-run" wizards) for applications

• Menu guidance with brief explanations of the individual parameter functions

Reliable operation

Standardized operation at the device and in the operating tools

Efficient diagnostics increase measurement reliability

• Remedy information is integrated in plain text

• Diverse simulation options

• Local display; operation via the local display is possible without opening the device.

• Tank Gauging system

• Plant Asset Management tool (e.g. FieldCare); connected via

– HART

– Service port (CDI)

Local operation

11 Local operation of the Tankside Monitor NRF81

1 Display and operating module

Display elements

• 4-line display

• White background lighting; switches to red in event of device errors

• Format for displaying measured variables and status variables can be individually configured

• Permitted ambient temperature for the display: –20 to +70 °C (–4 to +158 °F)

The readability of the display may be impaired at temperatures outside the temperature range.

Operating elements

• External operation via touch control; 3 optical keys:

, ,

• Operating elements also accessible in various hazardous areas

A0025574

Endress+Hauser 21

Page 22

Remote operation

NXA820

5

6

4

1 2 3

7

CDI

1

2

3

Tankside Monitor NRF81

A0025621

12 Remote operation of Tank Gauging devices

1 Proservo NMS8x

2 Tankside Monitor NRF81

3 Micropilot NMR8x

4 Field protocol (e.g. Modbus, V1)

5 Tankvision Tank Scanner NXA820

6 Ethernet

7 Computer with operating tool (e.g. FieldCare)

Operation via service interface

A0025572

13 Operation via service interface

1 Service interface (CDI = Endress+Hauser Common Data Interface)

2 Commubox FXA291

3 Computer with "FieldCare" operating tool and "CDI Communication FXA291" COM DTM

22 Endress+Hauser

Page 23

Tankside Monitor NRF81

Certificates and approvals

CE mark

RCM-Tick marking

Ex approval

Single seal according to ANSI/ISA 12.27.01

The measuring system meets the legal requirements of the applicable EC guidelines. These are listed

in the corresponding EC Declaration of Conformity together with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

The supplied product or measuring system meets the ACMA (Australian Communications and Media

Authority) requirements for network integrity, interoperability, performance characteristics as well

as health and safety regulations. Here, especially the regulatory arrangements for electromagnetic

compatibility are met. The products are labelled with the RCM- Tick marking on the name plate.

A0029561

The devices are certified for use in hazardous areas and the relevant safety instructions are provided

in the separate "Safety Instructions" (XA) document. Reference is made to this document on the

nameplate.

The devices have been designed according to ANSI/ISA 12.27.01 as single seal devices, allowing the

user to waive the use and save the cost of installing external secondary process seals in the conduit

as required by the process sealing sections of ANSI/NFPA 70 (NEC) and CSA 22.1 (CEC) These

instruments comply with the North-American installation practice and provide a very safe and costsaving installation for pressurized applications with hazardous fluids.

Further information can be found in the Safety Instructions (XA) of the relevant devices.

Functional Safety (SIL)

WHG

Weight & Measure approval

Non-ionizing radiation protection

Other standards and guidelines

Use for level monitoring (MIN, MAX, range) up to SIL 2 according to IEC 61508:2010.

For details refer to the "Functional Safety Manual":

SD01929G (NRF81)

in preparation

• OIML R85 (2008)

• NMi

• PTB (in preparation)

• PAC

• LNE (in preparation)

• WELMEC

• GOST (in preparation)

The device has a sealable locking switch according to the Weight & Measure requirements. This

switch locks all software parameters related to the measurement. The switching status is

indicated on the display and via the communication protocol.

According to guideline 2004/40/EG-ICNIRP Guidelines EN50371

Industry standards

• Directive 2002/95/EC: "Restriction of Hazardous Substances Directive" (RoHS)

• Directive 2004/22/EC: "Measuring Instruments Directive" (MID)

• IEC61508: "Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related

Systems" (SIL)

• NACE MR 0175, NACE MR 0103: "Sulfide stress cracking resistant metallic materials for oilfield

equipment"

• API Recommended Practice 2350: "Overfill Protection for Storage Tanks in Petroleum Facilities"

• API MPMS: "Manual of Petroleum Measurement Standards"

• EN 1127: "Explosive atmospehres - Explosion prevention and protection"

• IEC 60079: "Equipment protection"

Endress+Hauser 23

Page 24

Tankside Monitor NRF81

• EN 1092: "Flanges and their joints"

• EN 13463: "Non-electrical equipment for use in potentially explosive atmospheres"

• TIA-485-A: "Electrical Characteristics of Generators and Receivers for Use in Balanced Digital

Multipoint Systems "

• IEC61511: "Functional safety - Safety instrumented systems for the process industry sector"

• IEEE 754: "Standard for Binary Floating-Point Arithmetic for microprocessor systems "

• ISO4266: "Petroleum and liquid petroleum products - measurement of level and temperature in

storage tanks by automatic methods"

• ISO6578: "Refrigerated hydrocarbon liquids - Static measurement - Calculation procedure"

• ISO 11223: "Petroleum and liquid petroleum products - Determination of volume, density and

mass of the contents of verical cylindrical tanks by Hybrid Tank Measurement Systems"

• ISO15169: "Petroleum and liquid petroleum products - Direct static measurement - Measurement

of content of vertical storage tanks by hydrostatic tank gauging"

• JIS K2250: "Petroleum Measurement Tables"

• JIS B 8273: "Bolted flange for pressure vessels"

• G.I.I.G.N.L.: "LNG Custody transfer handbook"

• NAMUR NE043: "Standardization of the Signal Level for the Failure Information of Digital

Transmitters"

• NAMUR NE107: "Self-Monitoring and Diagnosis of Field Devices"

• PTBA-A-4.2: "Volume measuring devices for liquids in a stationary condition - Storage containers

and their measuring devices"ur

Metrological standards

• OIML R85 (2008) "Requirements for ambient temperature low –25 °C (–13 °F) and ambient

temperature high +55 °C (+131 °F)

• "Mess- und Eichverordnung" (Calibration regulations for the Federal Republic of Germany)

• Directive 2004/22/EC of the European Parliament and of the Council of 31 March 2004 on

measuring instruments

24 Endress+Hauser

Page 25

Tankside Monitor NRF81

Ordering information

Ordering information

Marking

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Option of ordering feature 895

"Marking"

Z1 Tagging (TAG)

Z2 Bus address

Optionally, the device can be ordered with a specific tagging and/or bus address according to the

table above. When the respective option is selected, the tag or bus address must be defined in an

additional specification.

Meaning

Endress+Hauser 25

Page 26

Application packages

1

2 3

2

4 1

3

Tankside Monitor NRF81

Advanced tank measurement methods

Direct level measurement modes

Measuring mode

Level only

1 Level transmitter (e.g. typically FMR540, FMR51,.. but not NMR8x or NMS8x)

2 Tankside Monitor

3 To inventory management system

Level + temperature

The device software provides the following tank measurement methods:

• Direct level measurement → 26

• Hybrid tank measurement system (HTMS) → 27

• Hydrostatic tank gauging (HTG) → 28

• Hydrostatic tank shell correction (HyTD) → 30

• Thermal tank shell correction (CTSh) → 30

Direct level measurement

If no advanced tank measurement methods have been selected, level and temperature are measured

directly.

Installation example Measured variables Calculated

variables

Level None

A0023756

• Level

• Temperature (point or

average)

None

A0023757

1 Level transmitter (e.g. typically FMR540, FMR51,.. but not NMR8x or NMS8x)

2 Tankside Monitor

3 To inventory management system

4 Temperature transmitter (point or average)

26 Endress+Hauser

Page 27

Tankside Monitor NRF81

2

4

D1

1

3

2

4

5 1

D3

3

HTMS measuring modes

Hybrid tank measurement system (HTMS)

HTMS uses level and pressure measurements to calculate the contents of the tank and (optionally)

the density of the medium.

Measuring mode

HTMS + P1

This mode should be used in

atmospheric (i.e. nonpressurized) tanks

HTMS + P1 + P3

This mode should be used in

non- atmospheric (i.e.

pressurized) tanks

Installation example Measured

A0023758

1 Level transmitter (e.g. typically FMR540, FMR51,.. but not NMR8x

or NMS8x)

2 Tankside Monitor

3 To inventory management system

4 Pressure transmitter (bottom)

variables

• Level

• Bottom pressure

(at position D1)

• Level

• Bottom pressure

(at position D1)

• Top pressure (at

position D3)

Calculated

variables

Density of the

medium

Density of the

medium

A0023759

1 Level transmitter (e.g. typically FMR540, FMR51,.. but not NMR8x

or NMS8x)

2 Tankside Monitor

3 To inventory management system

4 Pressure transmitter (bottom)

5 Pressure transmitter (top)

Endress+Hauser 27

Page 28

HTG measuring modes

1

3

D1

2

1

3

D1

4

D3

2

Measuring mode Installation example Measured variables Calculated

HTG P1

This mode should be used in

atmospheric (i.e. non-pressurized)

tanks

HTG P1 + P3

This mode should be used in non-

atmospehric (i.e. pressurized) tanks

Tankside Monitor NRF81

Hydrostatic tank gauging (HTG)

HTG uses one, two or three pressure measurements at different positions to calculate the tank

contents and (optionally) the density of the medium.

variables

A0023760

1 Tankside Monitor

2 To inventory management system

3 Pressure transmitter (bottom)

Bottom pressure (at position D1)

The density of the medium must

be entered manually.

• Bottom pressure (at position D1)

• Top pressure (at position D3)

The density of the medium must

be entered manually.

Level

Level

A0023761

1 Tankside Monitor

2 To inventory management system

3 Pressure transmitter (bottom)

4 Pressure transmitter (top)

28 Endress+Hauser

Page 29

Tankside Monitor NRF81

1

4

3

D1

D1-2

2

1

4

3

D1

D1-2

5

D3

2

Measuring mode Installation example Measured variables Calculated

HTG P1 + P2

This mode should be used in

atmospheric (i.e. non-pressurized)

tanks

HTG P1 + P2 + P3

This mode should be used in non-

atmospehric (i.e. pressurized) tanks

A0023762

1 Tankside Monitor

2 To inventory management system

3 Pressure transmitter (middle)

4 Pressure transmitter (bottom)

• Bottom pressure (at position D1)

• Middle pressure (at position D2)

• Bottom pressure (at position D1)

• Middle pressure (at position D2)

• Top pressure (at position D3)

variables

• Level

• Density of the

medium

• Level

• Density of the

medium

A0023763

1 Tankside Monitor

2 To inventory management system

3 Pressure transmitter (middle)

4 Pressure transmitter (bottom)

5 Pressure transmitter (top)

Endress+Hauser 29

Page 30

Tankside Monitor NRF81

Δx

Hydrostatic tank shell correction (HyTD)

The hydrostatic tank shell correction can be used to compensate for vertical movement of the Gauge

Reference Height due to bulging of the tank shell caused by the hydrostatic pressure exerted by the

liquid stored in the tank. The compensation is based on a linear approximation obtained from

manual hand dips at several levels distributed over the full range of the tank.

A0023774

14 Movement Δx of the Gauge Reference Height due to the bulging of the tank shell caused by hydrostatic

pressure

Thermal tank shell correction (CTSh)

The thermal tank shell correction can be used to compensate for vertical movement of the Gauge

Reference Height due to temperature effects on the tank shell or stilling well. The calculation is

based on the thermal expansion coefficients of steel and on insulation factors for both the dry and

wetted part of the tank shell.

This correction is recommended for any tank gauge operating at conditions deviating

considerably from the conditions during calibration and for extremely high tanks. For

refrigerated, cryogenic and heated applications this correction is highly recommended.

30 Endress+Hauser

Page 31

Tankside Monitor NRF81

56.1 (2.21)

32.5 (1.28)

319 (12.6)

361.6 (14.2)

Accessories

Device-specific accessories Weather protection cover

15 Weather protection cover; dimensions: mm (in)

Materials

Part Material

Protection cover and mounting brackets 316L (1.4404)

Screws and washers A4

• The weather protection cover can be ordered together with the device:

Ordering feature 620 "Accessory Enclosed", option PA "Weather Protection Cover")

• It can also be ordered as an accessory:

Order code: 71292751 (for NMR8x and NRF8x)

A0028479

Endress+Hauser 31

Page 32

Tankside Monitor NRF81

Communication-specific accessories

Service-specific accessories

Accessory Description

WirelessHART Adapter

SWA70

Accessory Description

Commubox FXA195

HART

Accessory Description

Commubox FXA291 Connects Endress+Hauser field devices with CDI interface (= Endress+Hauser

Accessory Description

FieldCare Endress+Hauser's FDT-based Plant Asset Management tool.

Connects field devices to a WirelessHART network.

The WirelessHART adapter can be mounted directly at a HART device and is easly

integrated into an existing HART network. It ensures safe data transmission and

can be operated in parallel with other wireless networks.

For details refer to Operating Instructions BA00061S

For intrinsically safe HART communication with FieldCare via the USB interface.

For details refer to Technical Information TI00404F

Common Data Interface) to the USB interface of a computer.

For details refer to Technical Information TI00405C

Helps to configure and maintain all field devices of your plant. By supplying status

information it also supports the diagnosis of the devices.

For details refer to Operating Instructions BA00027S and BA00059S.

System components

Accessory Description

RIA15 Compact process display unit with very low voltage drop for universal use to display

4 to 20 mA/HART signals

For details refer to Technical Information TI01043K.

Tankvision

• Tank Scanner NXA820

• Data Concentrator

NXA821

• Host Link NXA822

Inventory Management System with completely integrated software for operation

via standard web browser

For details refer to Technical Information TI00419G.

32 Endress+Hauser

Page 33

Tankside Monitor NRF81

Documentation

Technical Information (TI)

Brief Operating Instructions (KA)

Operating Instructions (BA)

Description of Device Parameters (GP)

The Technical Information contains all the technical data on the device and provides an overview of

the accessories and other products that can be ordered for the device.

Device Technical Information

Tankside Monitor NRF81 TI01251G

The Brief Operating Instructions contain all the essential information from incoming acceptance to

initial commissioning.

Device Brief Operating Instructions

Tankside Monitor NRF81 KA01209G

The Operating Instructions contain all the information that is required in various phases of the life

cycle of the device: from product identification, incoming acceptance and storage, to mounting,

connection, operation and commissioning through to troubleshooting, maintenance and disposal.

It also contains a detailed explanation of each individual parameter in the operating menu (except

the Expert menu). The description is aimed at those who work with the device over the entire life

cycle and perform specific configurations.

Device Operating Instructions

Tankside Monitor NRF81 BA01465G

The Description of Device Parameters provides a detailed explanation of each individual parameter in

the 2nd part of the operating menu: the Expert menu. It contains all the device parameters and

allows direct access to the parameters by entering a specific code. The description is aimed at those

who work with the device over the entire life cycle and perform specific configurations.

Device Description of Device Parameters

Tankside Monitor NRF81 GP01083G (in preparation)

Endress+Hauser 33

Page 34

Tankside Monitor NRF81

Safety instructions (XA)

Ordering feature 010 "Approval" Meaning XA

BA ATEX II 2 (1)G Ex db [ia Ga] IIC T6 Gb XA01531G

FD FM C/US XP-AIS Cl.I Div.1 Gr.BCD T6

AEx d[ia] IIC T6

GA EAC Ex db[ia Ga] IIC T6 Gb in preparation

IA IEC Ex db [ia Ga] IIC T6 Gb XA01531G

KA KC Ex db[ia Ga] IIC T6 Gb in preparation

MA INMETRO Ex db[ia Ga] IIC T6 Gb in preparation

NA NEPSI Ex db[ia Ga] IIC T6 Gb in preparation

TA TIIS Ex d[ia] IIC T6 Ga/Gb in preparation

XA01532G

34 Endress+Hauser

Page 35

Tankside Monitor NRF81

Registered trademarks

FieldCare

Registered trademark of the Endress+Hauser Process Solutions AG, Reinach, Switzerland

MODBUS

Registered trademark of the MODBUS-IDA, Hopkinton, MA, USA

®

®

Endress+Hauser 35

Page 36

*71355021*

71355021

www.addresses.endress.com

Loading...

Loading...