Page 1

BA01026G/00/EN/22.19

71435462

2019-04-26

Products Solutions Services

Operating Instructions

Prothermo NMT539

Average temperature device

Device functions

Page 2

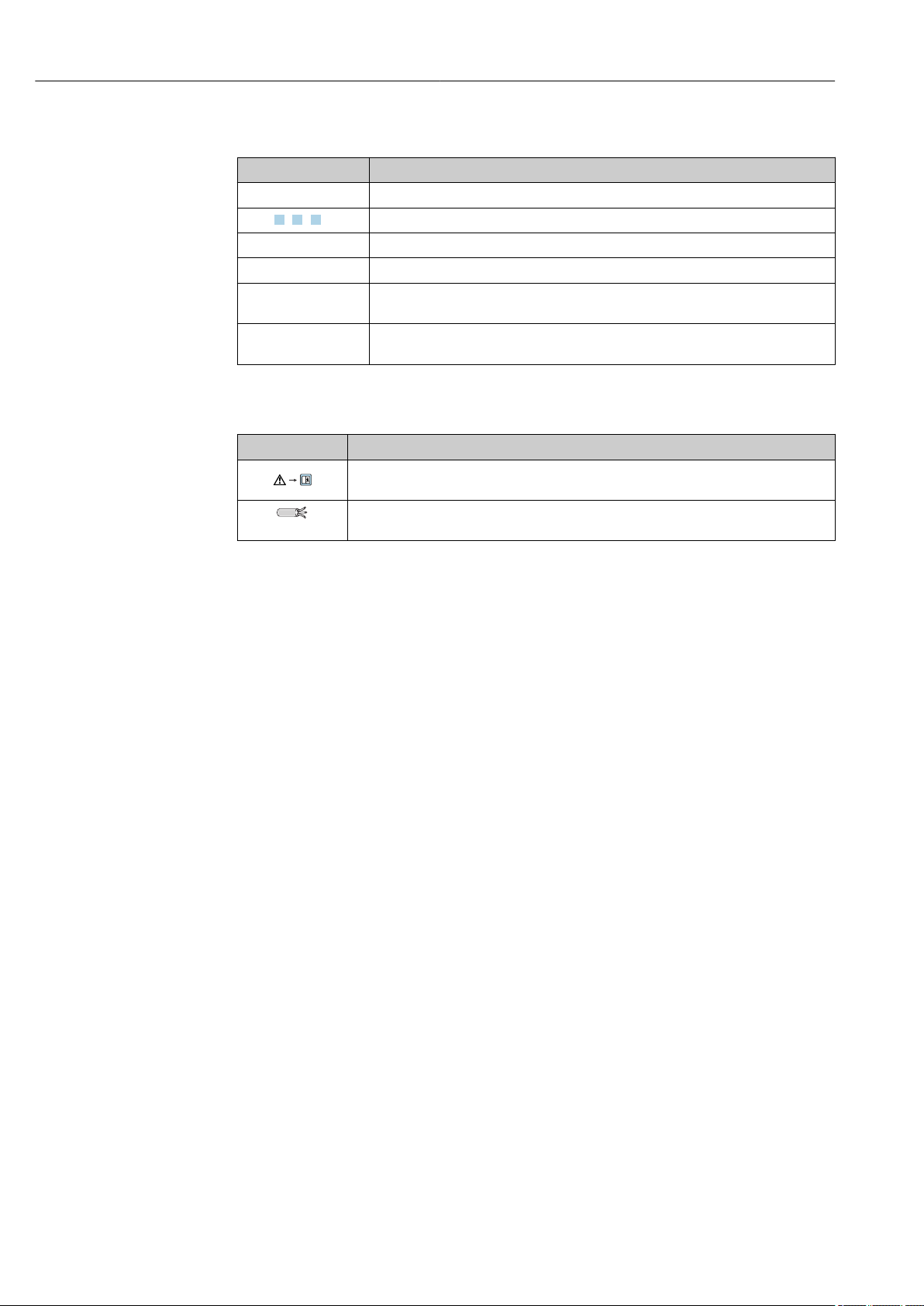

Prothermo NMT539

Order code:

Ext. ord. cd.:

Ser. no.:

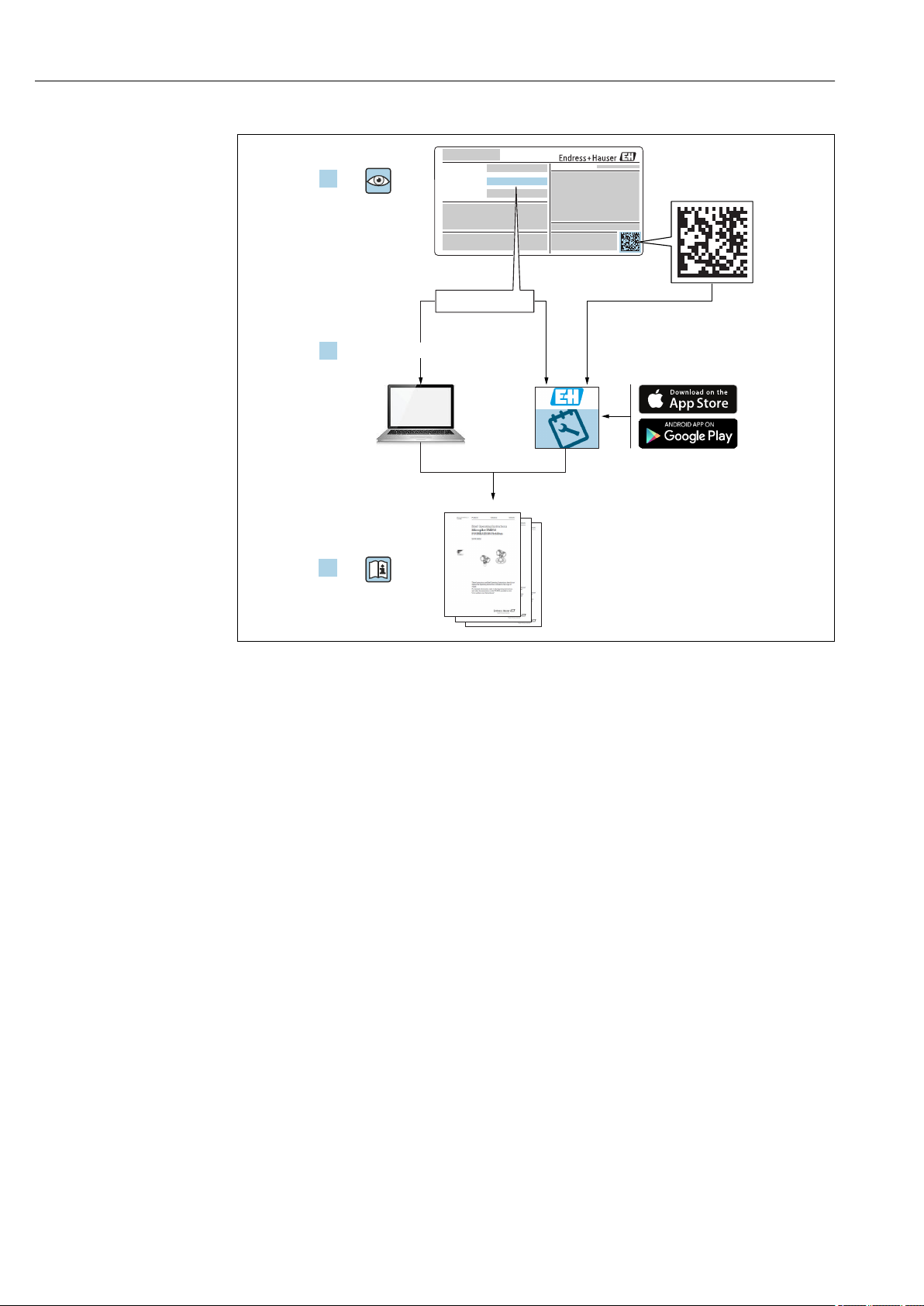

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

2 Endress+Hauser

Page 3

Prothermo NMT539 Table of contents

Table of contents

1 About this document ................ 4

1.1 Document function ..................... 4

1.2 Symbol .............................. 4

1.3 Documentation ........................ 7

1.4 Registered trademarks ................... 7

2 Basic safety instructions ............ 8

2.1 Requirements for personnel ............... 8

2.2 Designated use ........................ 8

2.3 Workplace safety ....................... 8

2.4 Operational safety ...................... 9

2.5 Product safety ......................... 9

3 Product description ................ 10

3.1 Product design ........................ 10

3.2 Technical data ........................ 10

3.3 Description of functions ................. 13

4 Adjustment and settings ........... 18

4.1 Local HART connection ................. 18

4.2 Device configuration: NRF590 ............ 19

4.3 Device configuration: NMS5/NMS7 ........ 19

4.4 Configuring NMT539 with NMS8x/NMR8x/

NRF81 ............................. 21

5 Operation ......................... 28

5.1 HART device codes ..................... 28

5.2 Device data .......................... 28

5.3 Temperature measurement .............. 28

5.4 WB measurement ..................... 42

5.5 Temperature + water bottom measurement .. 47

5.6 Exclusion of WB temperature elements from

average temperature calculation ........... 47

5.7 WB (water bottom) level input from host .... 48

5.8 Temperature element near the tank bottom .. 49

5.9 Write-protection switch (write-protection

plug) ............................... 51

5.10 Module configuration .................. 51

Index .................................. 52

Endress+Hauser 3

Page 4

About this document Prothermo NMT539

DANGER

WARNING

CAUTION

NOTICE

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required during various

phases of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbol

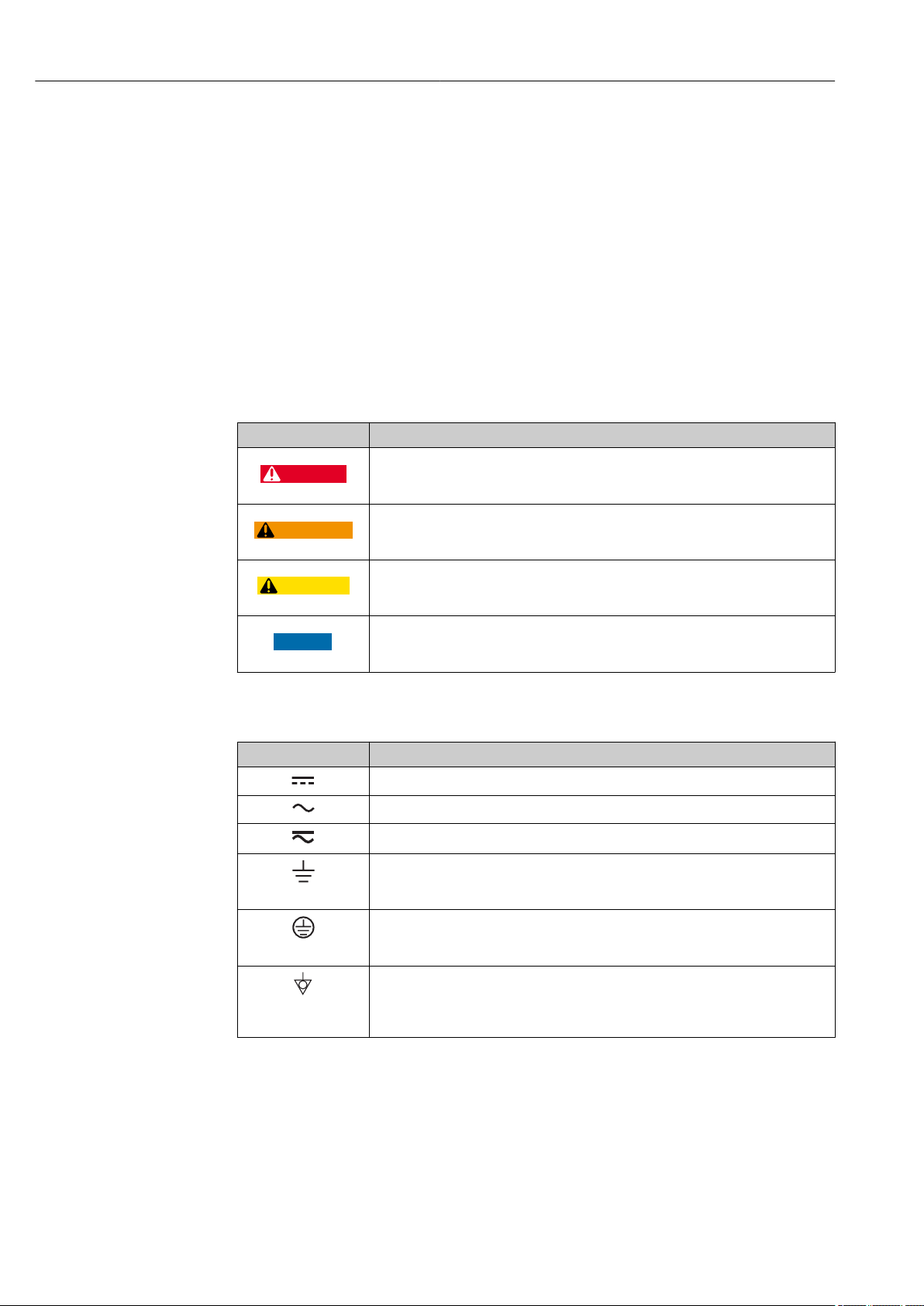

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury, as well as a risk of fire or explosion.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in a risk of serious or fatal injury, fire or explosion.

Note

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in a risk of minor or moderate injury and damages to properties.

NOTE!

This symbol contains information on procedures and other facts that do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal that, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal that must be connected to the ground prior to establishing any other

connections.

Equipotential connection

This connects with the grounding system at the plant. It includes equipotential line

and single point ground systems, depending on the norms of each country or

company.

4 Endress+Hauser

Page 5

Prothermo NMT539 About this document

A

1.

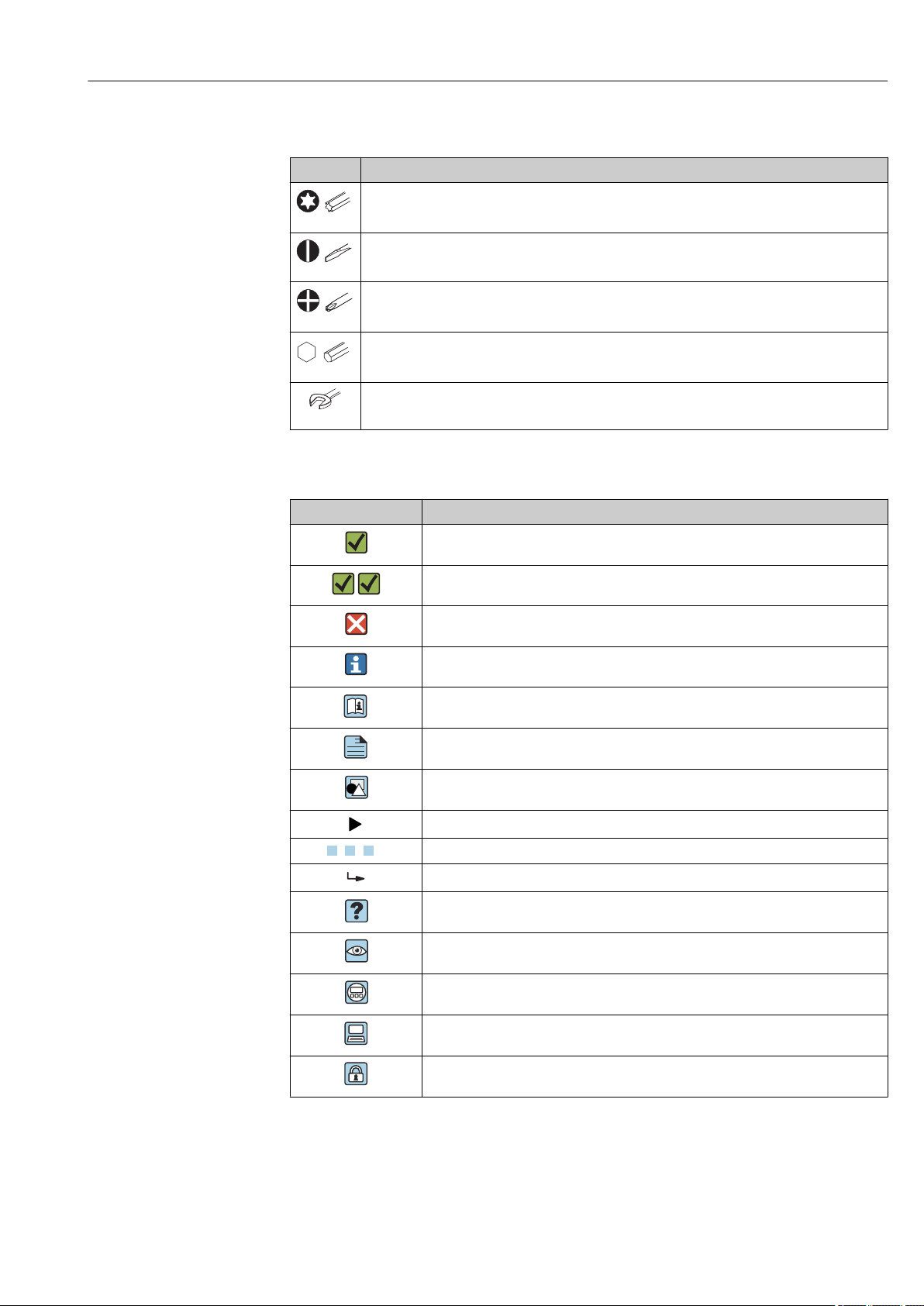

1.2.3 Tool symbols

Symbol Meaning

Torx screwdriver

A0013442

Flat blade screwdriver

A0011220

Phillips screwdriver

A0011219

Allen key

A0011221

Open-ended wrench

A0011222

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted

Preferred

Procedures, processes or actions that are preferred

Forbidden

Procedures, processes or actions that are forbidden

Tip

Indicates additional information

Reference to documentation

Reference to page

Reference to graphic

Notice or individual step to be observed

, 2., 3. … Series of steps

Result of an operation or commissioning

Help in the event of a problem

Visual inspection

Operation via the local display

Operation via operating tool

Write-protected parameter

Endress+Hauser 5

Page 6

About this document Prothermo NMT539

1.

-

.

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3. … Series of steps

A, B, C, ... Graphics

A-A, B-B, C-C, ... Cross-sections

Hazardous area

Indicates the hazardous area

Safe area (non-hazardous area)

Indicates the non-hazardous area

1.2.6 Device symbol

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

6 Endress+Hauser

Page 7

Prothermo NMT539 About this document

1.3 Documentation

For an overview of the scope of the relevant Technical Documentation included with

the product, refer to the following:

• The W@M Device Viewer: Enter the serial number from the nameplate

(www.endress.com/deviceviewer).

• The Endress+Hauser Operations App: Enter the serial number from the nameplate

or scan the 2-D matrix code (QR code) on the nameplate.

1.3.1 Technical information

The Technical Information contains all the technical data on the device and provides an

overview of the accessories and other products that can be ordered for the device.

Device Technical Information

Prothermo NMT539 TI01005G

1.3.2 Operating instructions (BA)

The Operating Instructions contain all the information that is required during various

phases of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

The Operating Instructions also contain detailed descriptions of each parameter in the

operation menu. The description is aimed at those who work with the device over the

entire life cycle and perform specific configurations.

Device Operating Instructions

Prothermo NMT539 BA01025G

BA01026G

1.3.3 Safety instructions (XA)

Feature 010 ("Approval") Meaning Ex / XA

A Ex ia IIB T4 Ex463-820XJ

Ex1060-953XJ

Ex496-826XJ

B ATEX Ex ia IIB T2-T6 XA00585G

C Ex ia IIB T2 Ex495-823XJ

E Ex d[ia] IIB T4 Ex1061-986XJ

F IEC Ex ia IIB T2-T6 XA01790G

G NEPSI Ex ia IIB T2-T6 XA01259G

7 FM C/US IS Ci. I Div.1 Gr. C-D Ex461-851-1

Ex461-850-1

1.4 Registered trademarks

FieldCare

Registered trademark of the Endress+Hauser Process Solutions AG, Reinach, Switzerland.

HART

Registered trademark of the FieldComm Group, Austin, USA.

®

®

Endress+Hauser 7

Page 8

Basic safety instructions Prothermo NMT539

2 Basic safety instructions

2.1 Requirements for personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Be specialists who are trained and have a relevant qualification for this specific

‣

function and task.

Be authorized by the plant owner-operator.

‣

Be familiar with local/national regulations.

‣

Before starting work, read and understand the instructions in the Operating

‣

Instructions and supplementary documentation as well as the certificates (depending

on the application).

Follow instructions and comply with basic conditions.

‣

The operating personnel must fulfill the following requirements:

Be instructed and authorized according to the requirements of the task by the facility's

‣

owner-operator.

Follow the instructions in this manual.

‣

2.2 Designated use

Application and measured materials

Depending on the version ordered, the device can also be used with potentially explosive,

flammable, poisonous or oxidizing materials.

Devices that are used in hazardous areas have corresponding labels on their nameplates.

To ensure that the device remains in proper condition for the operation time:

Only use the device in full compliance with the data on the nameplate and the general

‣

conditions listed in the Operating Instructions and supplementary documentation.

Check the nameplate to verify if the device can be put to its intended use in hazardous

‣

areas.

If the device is not operated at an atmospheric temperature, compliance with the

‣

relevant basic conditions specified in the relevant device documentation is absolutely

essential.

Protect the device permanently against corrosion from environmental influences.

‣

Observe the limit values in the "Technical Information".

‣

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to local/national

‣

regulations.

8 Endress+Hauser

Page 9

Prothermo NMT539 Basic safety instructions

2.4 Operational safety

Risk of injury!

Operate the device in proper technical conditions and fail-safe conditions only.

‣

The plant owner-operator is responsible for interference-free operation of the device.

‣

Modifications to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers:

If modifications are nevertheless required, contact your Endress+Hauser Sales Center.

‣

Repair

To ensure continued operational safety and reliability:

Carry out repairs on the device only if they are expressly permitted.

‣

Observe local/national regulations pertaining to repair of an electrical device.

‣

Use only original spare parts and accessories from Endress+Hauser.

‣

Ex-area

Observe the following notes to eliminate the risk of danger to persons or the facility when

the device is used in Ex-areas (e.g. explosion protection, pressure equipment safety):

Check the model nameplate to ensure that the ordered device is explosion proof.

‣

Observe the specifications in the separate supplementary documentation attached to

‣

these Instructions.

2.5 Product safety

This device was designed in accordance with GEP (Good Engineering Practice) to meet

state-of-the-art safety requirements, has been tested and left the factory in a condition in

which it is safe to operate. It meets the general safety standards and legal requirements.

Endress+Hauser 9

Page 10

Product description Prothermo NMT539

3 Product description

3.1 Product design

NMT539 performs precise liquid and gas phase average temperature measurement, which

makes it ideal for inventory management of large-scale tanks.

It is equipped with a capacitance WB device in crude oil and two-phase liquids, and it

performs accurate average temperature and WB measurements.

The position of the flange cannot be adjusted in a welding flange type.

3.2 Technical data

Item Details

Application • Flange installation: Standard 50.8 mm (2 in)

• Temperature measuring range: Maximum length 99.999 m (3.94 in) (ATEX, IECEx, NEPSI, FM C/US), maximum length

40.000 m (1.57 in) (TIIS)

• WB measuring range: 1 m (3.28 ft) or 2 m (6.56 ft)

Measuring principle • Temperature measurement

NMT539 consists of up to 16 platinum resistance elements (Pt100) in a SUS316 protection tube. Pt100 has a unique

characteristic of linear resistance change with respect to the surrounding ambient temperature change. A module in the

NMT539 converter receives this resistance signal change as an input variable and converts it to temperature data. The

converted and calculated data are then transmitted to the host device as a local HART signal.

• Water bottom (water interface level) measurement

An attached capacitance level measurement probe detects the presence of water.The WB is converted into a given frequency

variable (default setting) and its data is transmitted via local HART converter to the connected host device.

Minimum element

interval (distance)

Device structure RTD average temperature signal for local HART conversion

Measuring range • Temperature measurement

• Standard specifications: 150 mm (5.9 in) (Order Code: 030 Option 1, 4, 5)

• High temperature / Low temperature: 400 mm (15.75 in) (Order Code: 030 Option 2, 3, 6)

If NMT539 comes with a WB (water bottom) probe option, the maximum number of WB internal elements is two,

because of the restriction posed by the internal diameter.

RTD average temperature measurement + local HART converter

Average temperature + WB measurement + local HART converter

• Temperature conversion: –200 to 235 °C (–328 to 455 °F) (–170 to 235 °C (–274 to 455 °F) TIIS)

• Standard: –40 to 100 °C (–40 to 212 °F) (–20 to 100 °C (–4 to 212 °F) TIIS)

• Wide range: –55 to 235 °C (–67 to 435 °F) (–20 to 235 °C (–4 to 455 °F) TIIS)

• Cryogenic: –170 to 60 °C (–274 to 140 °F)

• Probe length: Maximum length 99.999 m (328.08 ft) (ATEX, IECEx, NEPSI, INMETRO, FM C/US)

Maximum length 40.000 m (131.23 ft) (TIIS)

• WB measurement

Standard probe range: 1 m (3.28 ft) or 2 m (6.56 ft)

–200 to 100 °C (–328 to 212 °F), which is below cryogenic temperature, can be accommodated upon request.

Output signal Local HART protocol, exclusively for the local host device

Alarm signal Error information can be accessed via the following interfaces and transmitted digital protocol (refer to "Prothermo NMT539

Operating Instructions and Description of Instrument Function" for the following instruments):

• NRF590 (BA00256F, BA00257F)

• NMS5 (BA00401G)

• NMS8x (BA1456G, BA1459G, BA1462G)

• NMR8x (BA01450G, BA01453G)

• NRF81 (BA01465G)

Local HART load Minimum loading for local HART circuit: 250 Ω

Cable glands Thread G1/2, Thread NPT1/2, Thread M20

Supply voltage • DC 16 to 30 V: Ex ia

• DC 20 to 24 V: Ex d [ia]

10 Endress+Hauser

Page 11

Prothermo NMT539 Product description

Item Details

Power consumption Ex ia: 6 mA (temperature measurement), 12 mA (WB measurement), Ex d [ia]: 8 mA (temperature measurement), 14 mA

(WB measurement)

Reference operating

conditions

Measured value

resolution

Maximum

measurement error

Ambient

temperature

Storage temperature –40 to 85 (–40 to 185)

Climate class DIN EN 60068-2-38 (test Z/AD)

Protection class • IP66/68 NEMA4X/6P: Converter set equipped with a temperature device or a WB device

Electromagnetic

compatibility

Process temperature

range

Process pressure Atmospheric pressure (absolute pressure 1 bar, 100 kPa, 14.5 psi)

Data transmission • Minimum cable diameter: #24 AWG

• Temperature: 25 °C (77 °F) ± 5 °C (9 °F)

• Pressure: 1 013 mbar abs. ± 20 mbar abs. (1 013 hPa abs. ± 20 hPa abs. , 14.7 psi abs. ± 0.3 psi abs.)

• Relative humidity (air): 65 % ± 20 % (linearity)

• Converter and precision resistor combination or converter and probe combination

• WB measurement range: 80 % (100 to 900 mm (3.94 to 35.43 in))

• The factory default is adjusted based on DC (er) = 2.1. Adjustment should be made on-site when necessary

• Temperature: ≤ 0.1 °C (0.18 °F)

• WB: ≤ 0.1 mm (0.004 in)

The values below represent performances under the reference conditions (including linearity, repeatability, hysteresis).

Conversion accuracy

Temperature Standard /PTB spec. ± 0.1 °C (0.18 °F)

WB 1 m (3.28 ft) spec. ± 2 mm (0.08 in)

2 m (6.56 ft) spec. ± 4 mm (0.16 in)

Probe system

Temperature Standard spec. ± 0.15 °C + 0.002 °C x |t| (0.27 °F + 0.0036 °F |t|)

IEC 60751 / DIN EN 60751 / JIS C1604 Class A temperature element

PTB spec. ± (0.3 °C + 0.005 °C x |t|) / 10 ((0.54 °F + 0.009 °F x |t|) / 10)

Class 1/10B temperature element

WB 1 m (3.28 ft) spec. ± 2 mm (0.08 in)

2 m (6.56 ft) spec. ± 5 mm (0.2 in)

Overall accuracy

Temperature Standard spec. Conversion accuracy ± 0.1 °C (0.18 °F) + Environmental effect ± 0.05 °C (0.09 °F) +

Class A temperature element ± 0.15 °C + 0.002 °C x |t| (0.27 °F + 0.0036 °F x |t|)

PTB spec. Conversion accuracy ± 0.1 °C (0.18 °F) + Environmental effect ± 0.05 °C (0.09 °F) +

Class 1/10B temperature element ± (0.3 °C + 0.005 °C x |t|) / 10 (0.54 °F +

0.009 °F x |t| / 10)

WB 1 m (3.28 ft) spec. Conversion accuracy ± 2 mm (0.08 in) + Probe accuracy ± 2 mm (0.08 in)

2 m (6.56 ft) spec. Conversion accuracy ± 5 mm (0.2 in) + Probe accuracy ± 5 mm (0.2 in)

• Accuracy can be improved for each application by making adjustments on-site, such as adjusting the offset.

• |t| represents the temperature of the measured item.

• –40 to 85 (–40 to 185)

• –20 to 60 °C (–4 to 140 °F): TIIS

• IP65 NEMA4X: Converter only (open housing: IP20)

When installing the probes to metal or concrete tanks and when using a coax probe:

• Interference emission according to EN 61326, Electrical Equipment Class B

• Interference immunity according to EN 61326, Annex A (Industrial)

Temperature probe: –175 to 235 °C (–274 to 455 °F)

WB probe: –0 to 100 °C (32 to 212 °F)

• Pressure tank: If the pressure inside the tank exceeds the process pressure shown above, install a stilling well

(protective tube) without holes or slits in the NMT539 to protect the probe from the pressure.

• Static pressure: Because NMT539 has undergone an airtightness test at an absolute pressure of 7 bar, it can withstand

static pressure head in the 50 m (164 ft) range in petroleum/chemical product applications.

• Cable type: Twist pair with a shield

Endress+Hauser 11

Page 12

Product description Prothermo NMT539

Item Details

Weight Approx. 13 kg

Conditions

• Number of elements: 16 points

• Temperature probe: 10 m (32.8 ft)

• WB probe: 1 m (3.28 ft)

• Flange: 2" 150 lbs RF, SUS316

Material • Temperature measurement elements: Class A Pt100, IEC60751/DIN EN60751/JISC1604

• Housing: Aluminum die cast

• Temperature probe: SUS316, SUS316L (refer to the "Dimension")

• WB probe: SUS316 (center rod SUS 304 / PFA protected)

Flange specifications • 10K 50A RF, SUS316, flange JIS B2220

• NPS 2" Cl.150 RF, SUS316 flange ASME B16.5

• DN50 PN10 B1, SUS316, flange EN1092-1 (DIN2527 B)

• 50A 150 lbs RF, SUS316, flange JPI 7S-15

• Universal coupling, G3/4, (converter only)

• M20 threaded (converter only)

CE approval By attaching the CE mark, Endress+Hauser confirms that the instruments have passed the required tests.

External standards

and guidelines

Ex approvals ATEX

• EN 60529

• Protection class of housing (IP-code)

• EN 61326

• Emissions (equipment class B), compatibility (appendix A – industrial area)

• II 1/2 G Ex ia IIB T2-T6 Ga/Gb (converter with temperature device and/or WB device)

• II 2G Ex ia IIB T2-T6 Gb (converter only)

IEC

• Ex ia IIB T2-T6 Ga/Gb (converter with temperature device and/or WB device)

• Ex ia IIB T2-T6 Ga (converter only)

FM C/US

Converter with temperature device and/or WB device

• IS Cl. I, Div. 1, Gr. C, D T2-T6

• IS Cl. I, Zone 0, AEx ia IIB Ga T2-T6

• NI Cl. I, Div. 2, Gr. C, D T2-T6

Converter only

• IS Cl. I, Div. 1, Gr. C, D T4

• IS Cl. I, Zone 0, AEx ia IIB Ga T4

• NI Cl. I, Div. 2, Gr. C, D T4

TIIS

• Ex ia IIB T4 (converter with temperature device and/or WB device) (converter only)

• Ex ia IIB T2 (converter with temperature device)

• Ex d[ia] IIB T4 (converter with temperature device and/or WB device)

NEPSI

• Ex ia IIB T2-T6 (converter with temperature device and/or WB device)

• Ex ia IIB T2-T6 Ga (converter only)

12 Endress+Hauser

Page 13

Prothermo NMT539 Product description

b c

a

e

d

f

3

2

1

3.3 Description of functions

Detailed descriptions of the function groups, functions and parameters are given in

"NMT539 Operating Instructions and Description of Instrument Functions. "When

NMT539 with WB probe and NRF590 are used together, confirm that the supply voltage

to TMD1/NMS/TGM/NRF590 is stable at a voltage of 100 VAC or higher.

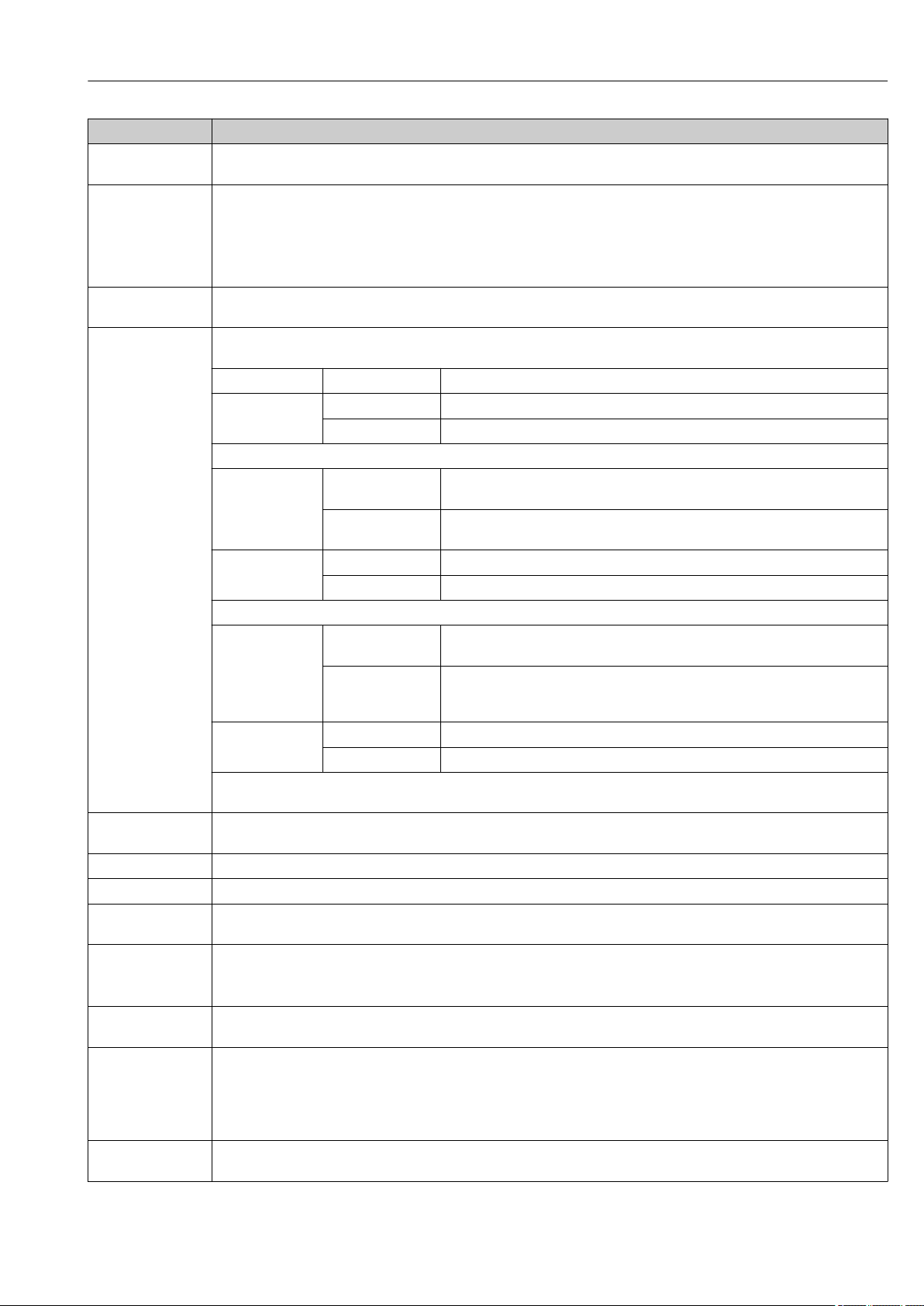

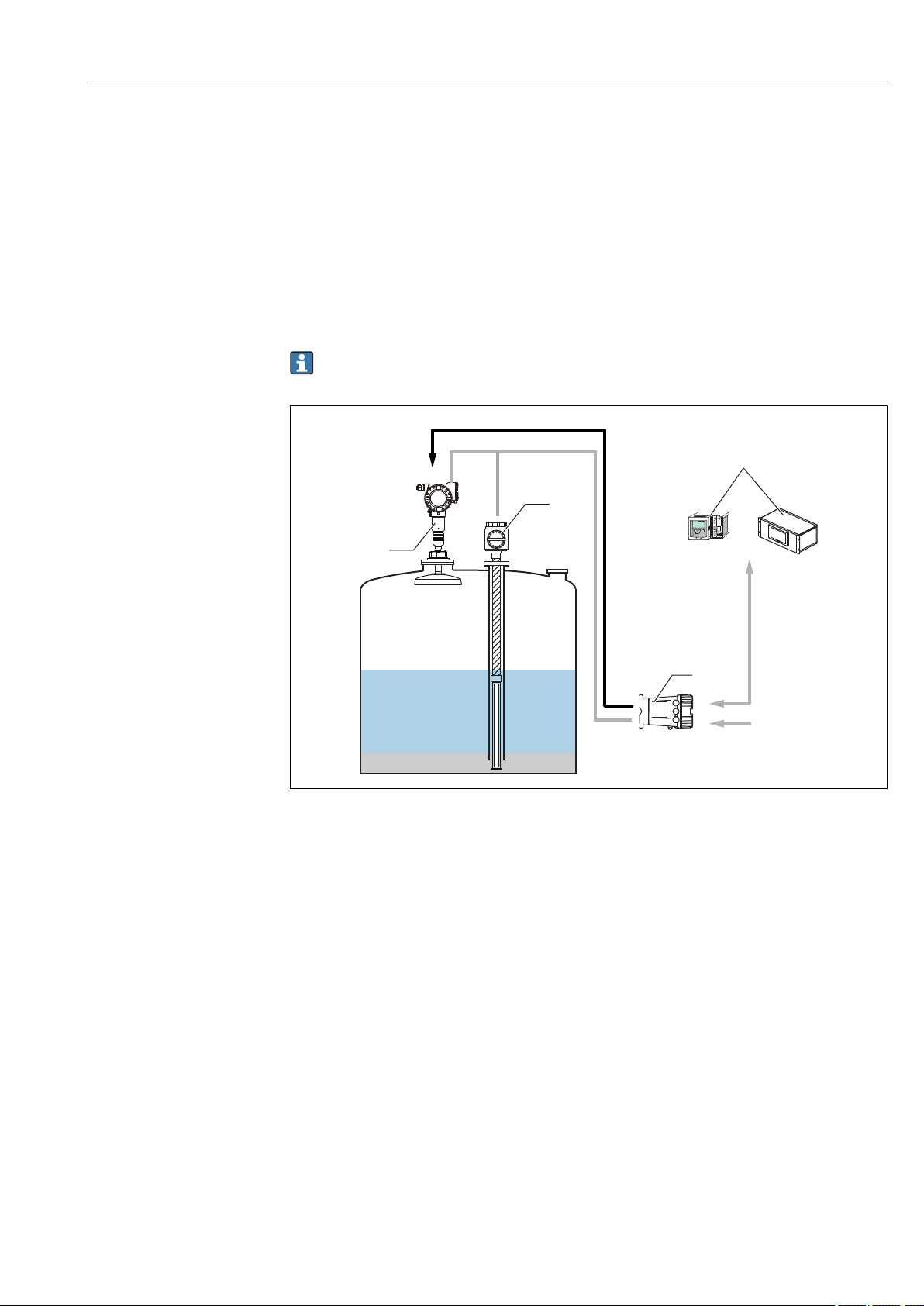

3.3.1 NMT539 Ex ia and NMS8x Exd [ia] combination

he connection of NMT539 shown below is only available for connection with NMS5 or

NMS8x.

A0038539

1 NMS8x and NMS539 system design

a Fieldbus protocol

b Power supply

c Local HART (Ex i) loop (data transmission)

d Level

e Gas temperature

f Liquid temperature

1 Tankvision

2 NMS8x

3 NMT539

Typical application of NMT539 converter + temperature probe version

NMT539 is the successor of the former NMT535. For proper migration, NMT539 has

inherited all the functionality and specifications of NMT535, including connection flange

specifications, cable entries and wiring method. Since NMS5 or NMS8x is provided with

WB measurement function, they can be combined with the converter + average

temperature probe version of NMT539. When the converter + average temperature probe

+ WB probe version is combined with NMS5 or NMS8, the product in the tank will

simultaneously be managed with level, continuous temperature and WB measurements.

Most changes and parameter settings for NMT539 can be performed by NMS5 or NMS8x.

NMT539 receives liquid level data from NMS5 or NMS8x and then calculates the average

temperature of the liquid and gas phases. The calculated average temperature data of the

Endress+Hauser 13

Page 14

Product description Prothermo NMT539

b

a

c

e

d

f

3

2

1

liquid and gas phases are transmitted to NMS8x or NMS5 along with the measured

temperature of each element and the NMT539 device status.

All gathered data in the field interface unit are sent to inventory management

software (Tankvision) or to NMS8x, NMS5x, NMS7, NMR8x, NRF8x or NRF590.

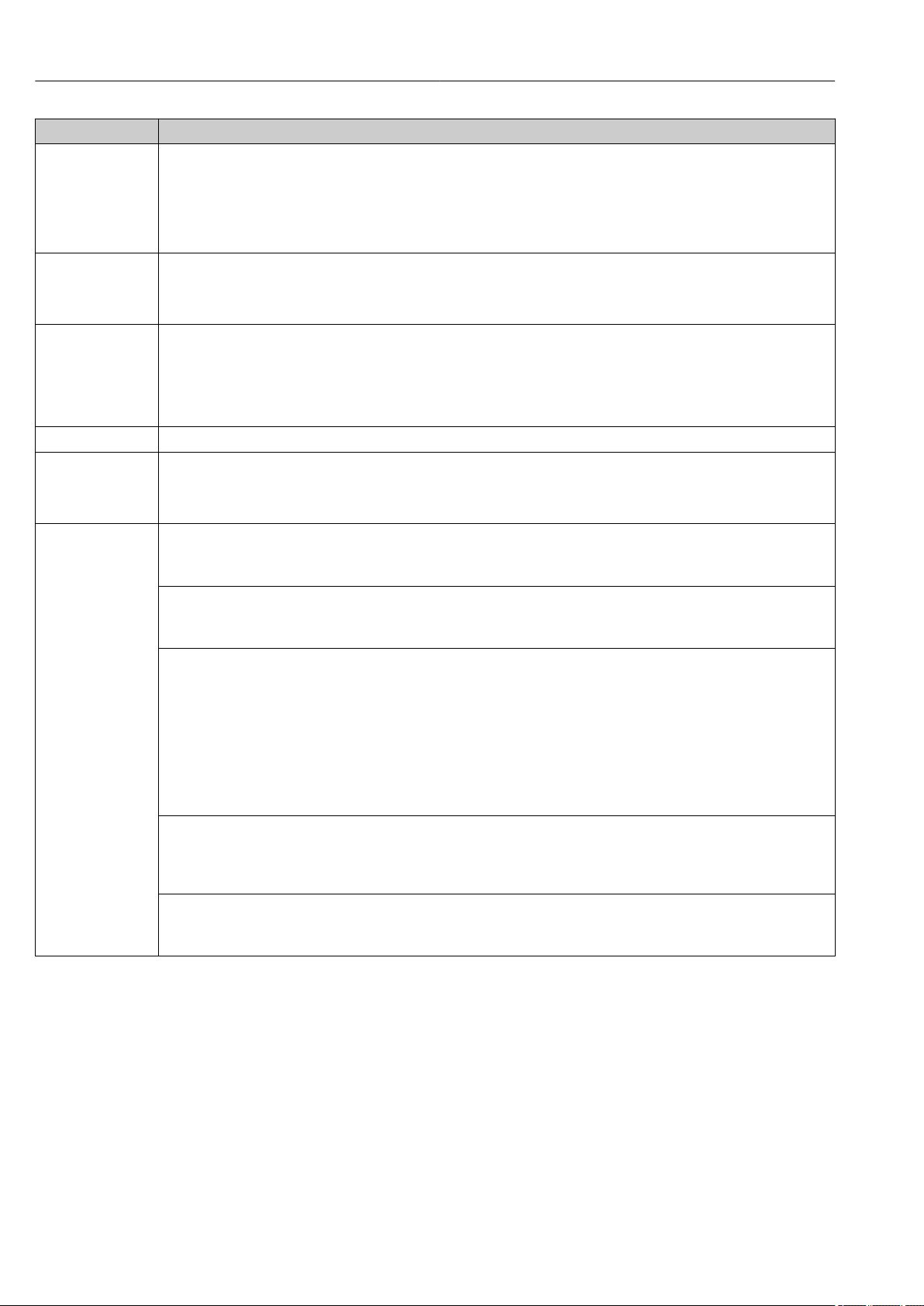

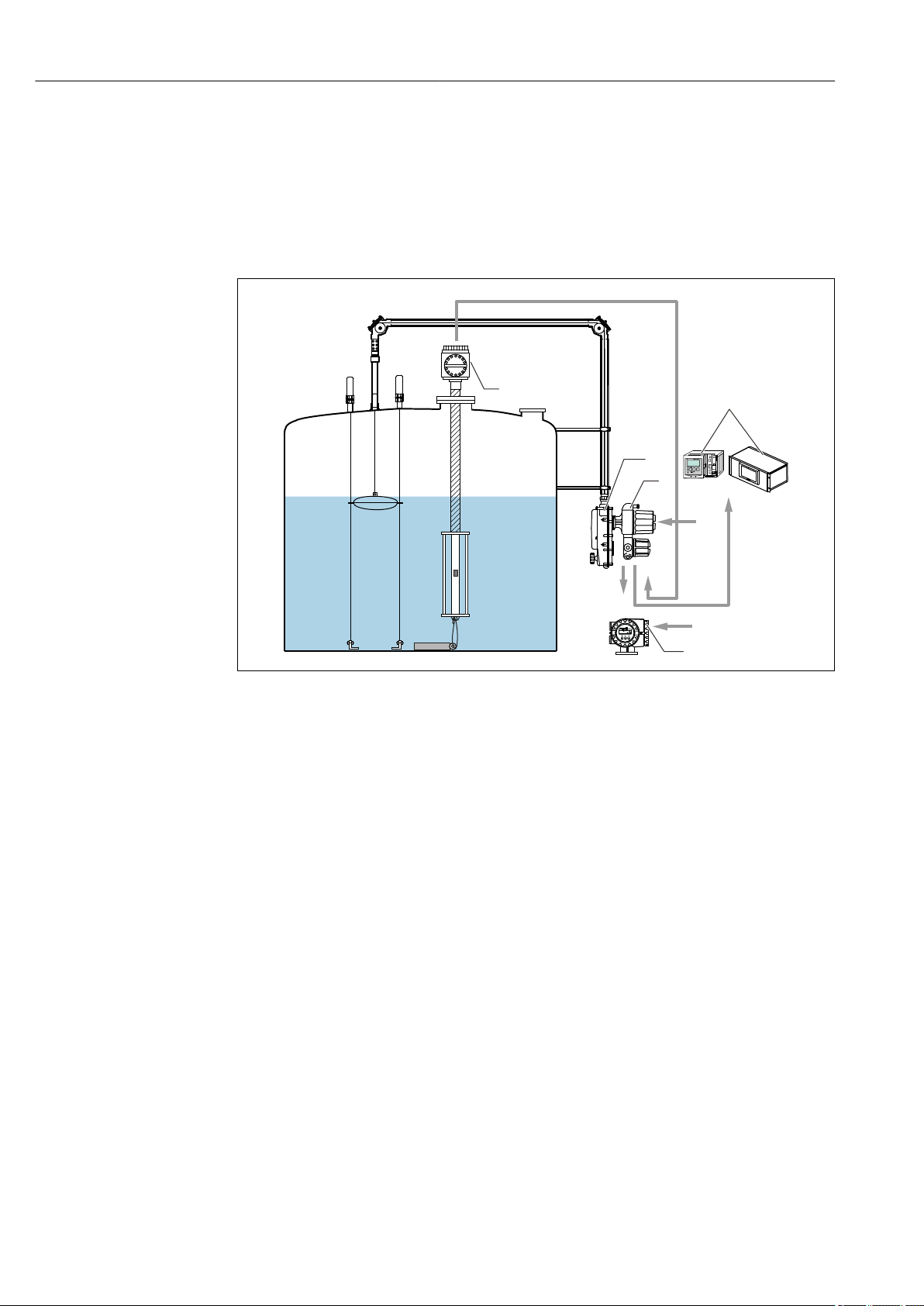

3.3.2 NMT539 Ex ia and NMR8x Ex d [ia] combination

The connection of NMT539 shown below is only available for connection with NMR8x Ex

d [ia].

NRF81 is required as a gateway for FMR5xx and NMT539 Tankvision when using FMR5xx

Ex ia radar.

2 NMT539 Ex ia and NMR8x combination

a Fieldbus protocol

b Power supply

c Local HART (Ex i) loop (data transmission)

d Level

e Gas temperature

f Liquid temperature

1 Tankvision

2 NMR8x

3 NMT539

A0038540

14 Endress+Hauser

Page 15

Prothermo NMT539 Product description

2

3

1

a

b

c

d

f

e

4

g

h

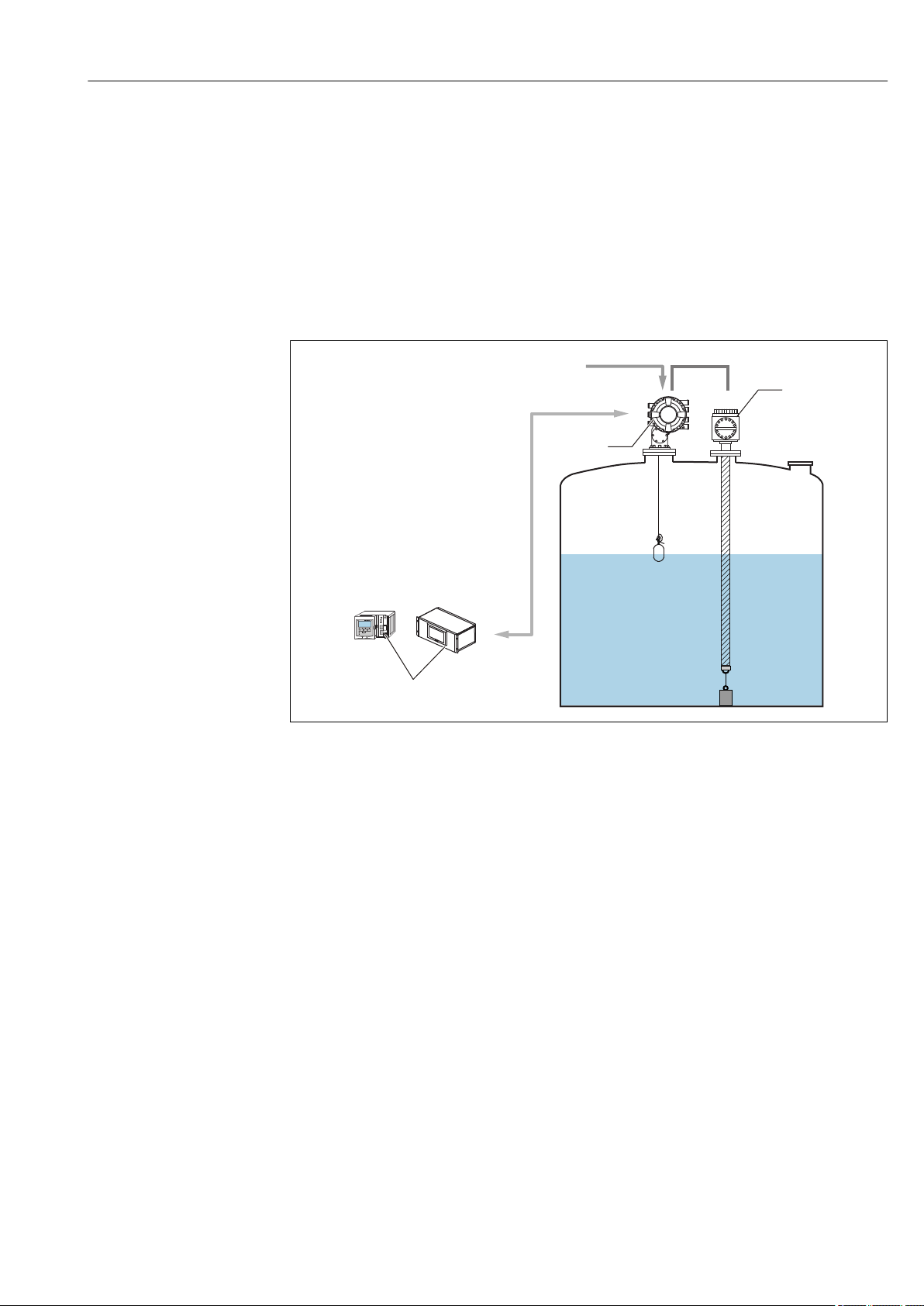

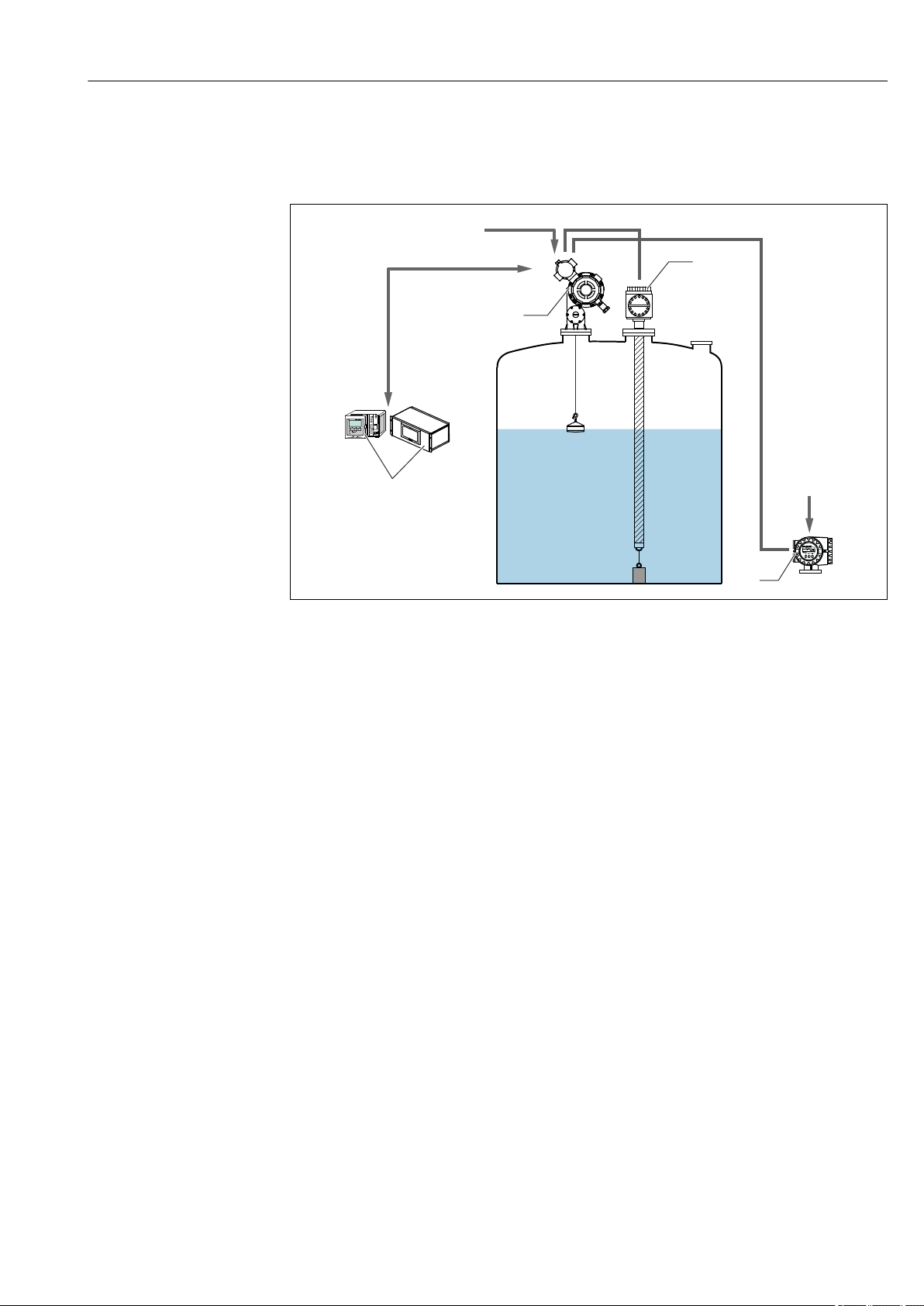

3.3.3 NMT539 Ex ia and NRF590 Ex d [ia] combination

Typical application of NMT539 converter + temperature probe + WB probe version

The NMT539 converter + temperature probe + WB probe version is utilized most

effectively in combination with radar level gauging. Water interface, temperature and

liquid level measurement, with data collection and calculations via the NRF590 or NRF81,

allow for optimal inventory control.Details on NMT539 functions and data can be accessed

from NRF81 or NRF590. NMT539 receives radar level data from NRF590 or NRF81 and

then calculates the average temperature of the liquid and gas phases. The calculated

average temperature data of the liquid and gas phases are transmitted to NRF81 or

NRF590 along with the measured temperature of each element and the NMT539 device

status.

All gathered data in the field interface unit are sent to inventory management

software (Tankvision) or to NMS8x, NMS5x, NMS7, NMR8x, NRF8x or NRF590.

A0038541

3 NMT539 Ex ia and NRF590 Ex d [ia] combination

a FMR power supply (DC/Ex i)

b Local HART (Ex i) loop (data transmission)

c Gas temperature

d Level

e Liquid level temperature

f Water

g Fieldbus protocol

h Power supply

1 FMR540

2 NMT539

3 NRF81/NRF590

4 Tankvision

Endress+Hauser 15

Page 16

Product description Prothermo NMT539

a

b

c

d

1

3

4

2

5

b

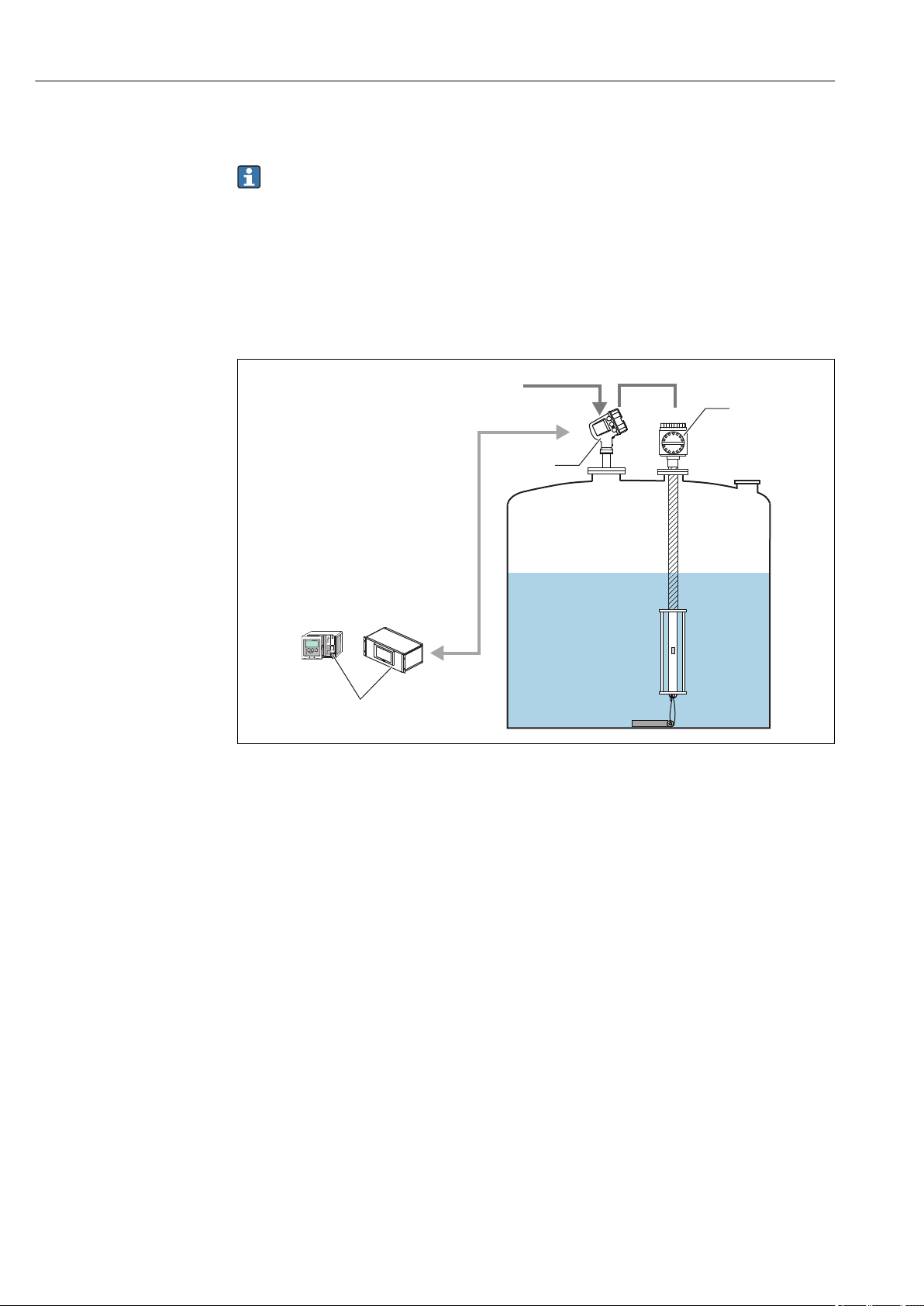

3.3.4 NMT539 Ex d [ia] and TMD1 Ex d combination

Average temperature device NMT539 can be connected to Transmitter TMD1 or Servo

Level Gauge TGM5 via local HART (Ex d) communication. Because local HART

communication is digital, it is able to send a larger volume of information compared to the

conventional RTD method. This means that NMT539 can work with not just DRM9700 but

also with NRF560. If NMT539 WB probe and NRF560 are used together, confirm that the

supply voltage to TMD1 is stable at 100 VAC or higher.

4 NMT539 Ex d [ia] and TMD1 combination

a Local HART (Ex d) loop (data transmission)

b Power supply

c Fieldbus protocol

d HART (Ex d) loop (data transmission)

1 NMT539

2 Tankvision

3 LT5

4 TMD1

5 NRF560

A0038542

16 Endress+Hauser

Page 17

Prothermo NMT539 Product description

2

3

b

a

c

d

b

4

5

6

7

1

3.3.5 NMT539 Ex d [ia] and TGM5 combination

When NMT539 with WB probe and NRF560 are used together, confirm that the supply

voltage to TGM5 is stable at 100 VAC or higher.

A0038543

5 NMT539 Ex d [ia] and TGM5 combination

a Fieldbus protocol

b Power supply

c Local HART (Ex d) loop (NMT539 and TGM5)

d Local HART (Ex d) loop (TGM5 and NRF560)

1 Tankvision

2 TGM5

3 NMT539

4 NRF560

5 Level

6 Gas temperature

7 Liquid temperature

Endress+Hauser 17

Page 18

Adjustment and settings Prothermo NMT539

4 Adjustment and settings

4.1 Local HART connection

4.1.1 Endress+Hauser tank gauging instrument

NMT539 is designated to work with Endress+Hauser tank instruments tank side monitors

NRF590, NRF81 or Proservo NMS5, NMS7, NMS8x or NMR8x to build a comprehensive

instrumentation system. Both temperature and/or WB information is transmitted via

HART loop. NRF590, NRF81 and NMS5, NMS, NMS8x and NMR8x have a settings menu

for the NMT Series by default, which means that they can configure NMT539 default

settings.

• The parameters listed in this document are parameters that can be checked when

the instruments are connected to NMT539 with FieldCare. Since the parameters

that can be checked from the HMI of the connected HART Master, such as NMS8x

and NMS5, differ depending on which HART Master is being used, refer to the

respective operating instructions.

• Before starting up NMT539, refer to "Prothermo NMT539 Operating Instructions"

and check the installation procedure.

• There are four types of standard basic data depending on the NMT539

measurement function.

4.1.2 Measuring functions

Temperature measurement

0 Converter only

1 Temperature + converter

These four types of basic data are available as standard.

• Average liquid temperature

• Average gas temperature

• Level (VH02 measured distance)

• Device status

Water bottom measurement

2 WB probe + converter

These four types of basic data are available as standard.

• WB level

• WB probe capacitance

• WB probe frequency

• Device status

Temperature + WB + converter

3 Temperature + WB + converter

These four types of basic data are available as standard.

18 Endress+Hauser

Page 19

Prothermo NMT539 Adjustment and settings

• Average liquid temperature

• WB level

• Average gas temperature

• Device status

4.2 Device configuration: NRF590

Connect the loop-powered local HART communication cable from NRF590 (intrinsically

safe side compartment) to NMT539 according to "Prothermo NMT539 Operating

Instructions. " NRF590 has been designed to recognize NMT539 as a specific Endress

+Hauser local HART device.

4.2.1 HART scanner

Once NMT539 and NRF590 have been wired together, all HART devices will be scanned

automatically when NRF590 is turned on.

Not all NRF590 are fully compatible for recognizing NMT539. Contact your Endress

+Hauser Sales Center for information on NRF590 software and hardware version

compatibility.

4.2.2 NMT539 specific parameter setup for NRF590

The configuration of NMT539 parameters displayed on NRF590 depends on the installed

software and hardware versions of NRF590. Refer to the NRF590 operating manual to

determine accessible parameters. All default settings and parameter configurations can be

carried out using FieldCare. Detailed information will be provided in the following sections.

4.3 Device configuration: NMS5/NMS7

NMS5/NMS7 are specifically designed to recognize NMT539 as HART Master. Terminals

24 and 25 of NMT539 and NMS5/NMS7 are connected with a local HART cable.

Connection between NMS5/NMS7 and NMT539 is required for Ex Approval. Follow

the separate BA01025G operating instructions, "4.4.Terminal connection."

4.3.1 Preparation for NMS5/NMS7 configuration

NMS5/NMS7 must be set to default before connecting to NMT539.

Code Display Details

GVH362 NMT Connection Select "NMT Connection" and "Average" and configure the NMT.

To change this parameter, an access code is required. For

details, see "Prothermo NMT539 Operating Instructions."

4.3.2 Configuring NMT539 with NMS5/NMS7

NMT539 parameters can be configured using the NMS5/NMS7 programming matrix G4

"Temperature Device."

Typical NMT539 parameters (same as NMT535) are displayed in the NMS5/NMS7

matrix.

WB probe information is not available on NMS5/NMS7 ROM version 4.24 or earlier

versions. Contact your Endress+Hauser Sales Center to update existing NMS5/NMS7

functions.

Endress+Hauser 19

Page 20

Adjustment and settings Prothermo NMT539

G0 Static Matrix

Code Display Details

GVH010 Liquid temp NMT539 displays the average liquid temperature.

GVH013 Gas temp NMT539 displays the average gas temperature.

G4 Temperature Matrix

Code Display Details

GVH440 Liquid temp Displays the same value indicated in GVH010: Liquid temp

GVH441 Gas temp Displays the same value indicated in GVH013: Gas temp

GVH442 Level The liquid level collected from NMS5/NMS7 is selected as either

GVH000: Level (Displacer position) or GVH008: Level data

(Level). NMT539 calculates both liquid and gas phase

temperatures based on this liquid level data.

GVH447 Element No. 0 temp Checks that the measuring temperature resistor temperature

conversion is executed correctly.

The tolerance range is –1.0 to 1.0 °C (–30.2 to 33.8 °F).

GVH449 Element temp 17 temp This temperature is used for checking when shipping from the

factory.

GVH450-459 Element temp No.1-10

temp

GVH460-469 Element No.1-10

position

GVH470 Select point A matrix is selected for GVH471 "Zero Adjust," GVH473 "Element

GVH480 Diagnostic Displays error code messages. Refer to the error code chart in

GVH482 Element number The number of elements installed on the temperature

GVH485 Type of interval Sets measurement element intervals. If the element intervals are

GVH486 Bottom point Sets the height of the lowest element. This is only set when the

GVH487 Element interval The element interval is entered if "Equal interval" was selected in

The measured temperature is the temperature data collected

from each element (maximum 16 points). The temperature

measurement elements 11 to 16 are selected from GVH470

"Select point," and the selected element is displayed in GVH473

"Element temp."

Indicates the position of each element in the probe. Temperature

measurement elements 11 to 16 are selected from GVH470

"Select point," and the selected element is displayed in GVH474

"Element position."

temp" and GVH474 "Element position," and required element

data are input.

this manual.

measurement tube is entered.

equal, select GVH487 "Element interval" to set the interval, and

then select GVH486 "Bottom point" to set the height of the

lowest edge of the elements. If the element intervals are not

equal, manually set the intervals.

This parameter configuration is only used to change the

theoretical element position within NMT539's software for

average temperature calculation. The physical positions of

the elements will not change.

elements have equal intervals.

This parameter configuration is only used to change the

theoretical element position within NMT539's software for

average temperature calculation. The physical positions of

the elements will not change.

GVH485 "Type of interval."

This parameter configuration is only used to change the

theoretical element position within NMT539's software for

average temperature calculation. The physical positions of

the elements will not change.

20 Endress+Hauser

Page 21

Prothermo NMT539 Adjustment and settings

a

4.4 Configuring NMT539 with NMS8x/NMR8x/NRF81

NMS8x, NMR8x and NRF81 are specifically designed to recognize NMT539 as HART

Master. Terminals E1 and E2 or B3 and C3 of NMR8x, NRF81 and NMS8x are connected

to NMT539 with a local HART cable.

Connection from NMS8x, NMR8x and NRF81 to NMT539 is required for Ex Approval.

Follow the connection instructions in the separate BA01025G operating instructions,

"Terminal connection."

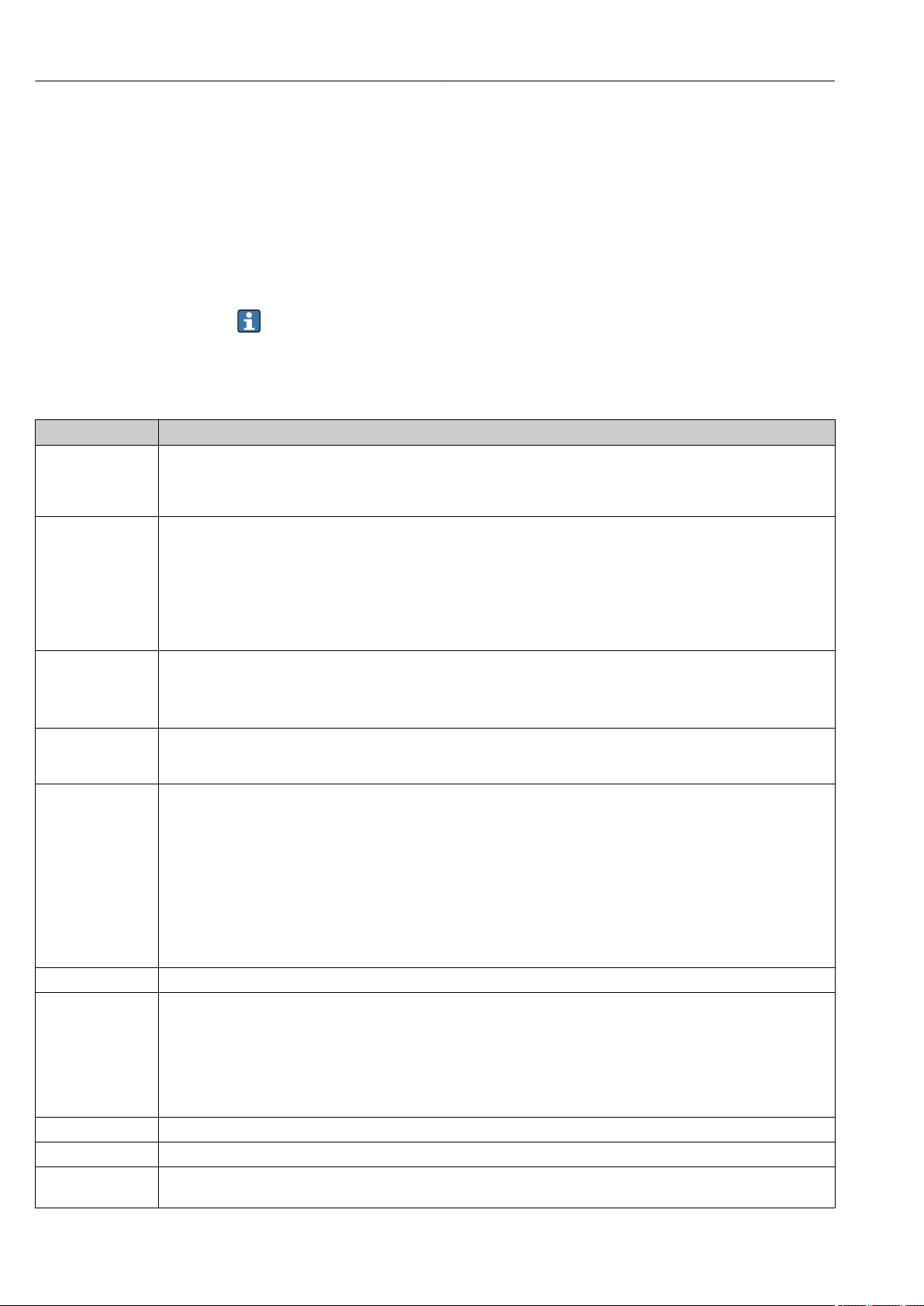

4.4.1 Preparation for configuring NMS8x/NMR8x/NRF81

NMS8x, NMR8x and NRF81 must be set to default before connecting to NMT539.

Setting procedure

1. From the Expert menu, choose Input/Output → HART device → HART device(s) →

NMT device configuration.

2. Select "Yes" for Config. device?

3. Enter the bottom temperature element in Bottom point (see diagram below).

This completes the setting procedure.

A0038544

6 Position of the bottom-point temperature element

a Distance between the bottom-point temperature element to the reference (tank bottom or reference plate)

Default a is 500 mm (19.69 in), but this can be modified as needed.

Liquid temperature display

Item Details

Navigation Operation → Temperature → Liquid temp

Description Displays the average or spot temperature of the measured liquid.

Additional information Read access: Operator

Write access: -

Endress+Hauser 21

Page 22

Adjustment and settings Prothermo NMT539

Manual gas phase temperature display

Item Details

Navigation Operation → Temperature → Manual gas phase temperature

Description Displays the temperature of the measured gas.

Additional information Read access: Operator

Write access: -

Display of element temperature 1-24

Item Details

Navigation Operation → Temperature → Manual gas phase temperature

Description Displays the NMT element temperature.

Additional information Read access: Operator

Write access: -

Selection of liquid level

Item Details

Navigation Setting → Advanced settings → Application → Tank settings → Level → Select

liquid level

Description Sets the liquid level source.

Selection No input

HART device, Level 1-15

Level SR (see Note)

Liquid level (see Note)

Displacer position (see Note)

AIO B1-3 value

AIO C1-3 value

AIP B4-8 value

AIP C4-8 value

Factory setting The setting is different depending on the device.

Additional information Read access: Operator

Write access: -

The display will be different depending on the selected options and equipment

settings.

22 Endress+Hauser

Page 23

Prothermo NMT539 Adjustment and settings

HART dev. confg

Config. device?

Access code

Total no element

Bottom point

Temp elem. short

Temp elem. open

Output at error

Gain adjust

Kind of interval

Element interval

Element setup

Select element

Zero adjust

Element temp

Element position

4.4.2 NMS8x/NMR8x/NRF81 configuration

Below are NMT539-related parameters. For details on the operation of NMS8x, NMR8x

and NRF81, see their respective operating instructions.

The following parameters can be checked from the display accessed through the

Main Menu → Expert → Input/Output → HART device → HART device(s) [MenuName].

A0038545-EN

7 Parameter structure

Configure device?

Item Details

Navigation Expert → Input/Output → HART Device → HART device(s) [MenuName] →

HART device configuration → Config. device? (14728)

Description Configures the NMT device.

Selection Yes (The device is recognized as NMT)

No (The device will not be recognized)

Factory setting No

Additional information Read access: Operator

Write access: Maintenance

Endress+Hauser 23

Page 24

Adjustment and settings Prothermo NMT539

Access code

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART Device configuration → Access code (14714)

Conditions Configure device? = Yes

Description Displays the access code.

Input range 0-65535

Factory setting 0

Additional information Read access: Operator

Write access: Maintenance

Total number of elements

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART Device configuration → Total No. elements (14730)

Description Displays the total number of elements that can be configured.

Additional information Read access: Operator

Write access: -

Bottom point

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART Device configuration → Bottom point (14729)

Description Displays the bottom-point temperature element.

Input unit Numerical value (mm)

Factory setting 0 mm

Additional information Read access: Operator

Write access: Maintenance

Temp element short

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART device configuration → Temp elem.short (14731)

Description Configures the error code for when an element short-circuits.

Input unit Numerical value (℃)

Factory setting 0 °C

Additional information Read access: Operator

Write access: Maintenance

24 Endress+Hauser

Page 25

Prothermo NMT539 Adjustment and settings

Temp element open

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART device configuration → Temp elem. open (14732)

Description Configures the error code for when an element is open.

Input unit Numerical value (℃)

Factory setting 0 °C

Additional information Read access: Operator

Write access: Maintenance

Output error

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART device configuration → Output error (14733)

Description Selects the error display for when an element shorts and opens.

Selection OFF

ON

Additional information Read access: Operator

Write access: Maintenance

Gain adjust

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART device configuration → Gain adjust (14736)

Description Adjusts the temperature of all elements and references 0 and 17.

Input unit Numerical value

Factory setting 0

Additional information Read access: Operator

Write access: Maintenance

Kind of interval

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART Device configuration → Adjust interval (14744)

Description Sets the type of element interval.

Selection Equal

Unequal

Factory setting Equal

Additional information • Equal division: Bottom point + Element interval

• Unequal: Set manually

Read access: Operator

Write access: Maintenance

Endress+Hauser 25

Page 26

Adjustment and settings Prothermo NMT539

Element interval

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) [MenuName] →

HART device configuration → Element interval (14743)

Conditions Kind of interval: Equal

Description Sets the interval of each element.

Input unit Numerical value

Factory setting 0 mm

Additional information Read access: Operator

Write access: Maintenance

Select element

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) → NMT device

configuration → Element configuration → Select element (14734)

Description The element to be configured is manually selected.

Input unit 1-16

Factory setting 1

Additional information Read access: Operator

Write access: Maintenance

Zero adjust

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) → NMT device

configuration → Element configuration → Zero adjust (14735)

Description Adjusts the offset of the selected element.

Input unit Numerical value

Factory setting 0 (None)

Additional information Read access: Operator

Write access: Maintenance

Element temperature

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) → NMT device

configuration → Element configuration → Element temp (14737)

Description Displays the element temperature.

Additional information Read access: Operator

Write access: -

26 Endress+Hauser

Page 27

Prothermo NMT539 Adjustment and settings

Element position

Item Details

Navigation Expert → Input/Output → HART device → HART device(s) → NMT device

configuration → Element configuration → Element position (14738)

Description Adjusts the element position.

Input unit Numerical value

Factory setting 0 mm

Additional information Read access: Operator

Write access: Maintenance

Endress+Hauser 27

Page 28

Operation Prothermo NMT539

5 Operation

The following configuration uses FieldCare. NMT539 has different HART device codes

depending on the measurement function. The following four local HART device codes are

preset at the factory based on the jumper setting.

WARNING

L

Modification of modules

Changing the jumper setting by disassembling the internal module of NMT539 may

invalidate the accuracy of the calibration that was performed at the factory. It may also

cause serious accidents.

Do not disassemble a module or change the jumper setting.

‣

5.1 HART device codes

Code Details Descriptions

184 Device code for

temperature

measurement function

185 Device code for NMT539

WB measurement

function

186 Device code for fully-

equipped NMT539

184 is specially designed for the NMT539 converter-only

version and converter + temperature probe version. Code 184 is

used in an NMT539 that is not equipped with a WB probe.

FieldCare does not recognize Code 185.

Code 186 is used for NMT539 that is equipped with converter +

temperature probe + WB probe.

5.2 Device data

Item Details Descriptions

Tag number Read / Write This number is for customer-specified device

identification and control number, tank name, site name

and other ID

production process.

Assembly

number

Default: HART

Read / Write This number is for manufacture control based on

Default: 0

5.3 Temperature measurement

HART device code 184 is designed for the temperature measurement function. Available

parameters and functions are as follows. The description of parameters is based on the

FieldCare display screen.

The HART device code appears in the default header position or on the FieldCare

display screen only when VH99 "Device Type Code" has been selected.

Devices with a temperature measurement function as specified by product order codes are

as follows.

Measuring functions

Setting Details

0 Converter only

1 Converter + temperature probe

4 Converter + temperature probe (W&M certificate)

28 Endress+Hauser

Page 29

Prothermo NMT539 Operation

5.3.1 Primary value: VH00-VH09

Code Display Details

VH00 Liquid Temp

(Average liquid

temperature)

VH01 Gas Temp

(Average gas

temperature)

VH02 Measured Distance

(Liquid level)

VH07 Temperature 0

(Element 0

temperature)

VH09 Temperature 17

(Element 17

temperature)

Item type Read only

Range –200 to 240 °C (–328 to 464 °F)

Display of the average temperature of the liquid phase

The measured liquid levels that are required for calculating the

average temperature of the liquid phase are provided by

Micropilot FMR Series (via NRF590) or NMS5, NMS7 or NMS8x.

Item type Read only

Range –200 to 240 °C (–328 to 464 °F)

Displays the average temperature of the measured gas (vapor) phase

Gas phase measurements that are required for calculating the

average gas phase temperature are provided by Micropilot FMR

series (via NRF590) or NMS5, NMS7 or NMS8x.

Item type Read only

Range 0 to 99 999 mm

Displays the liquid level inside the tank as configured by a level gauge.

If a level gauge is not connected, a directly input liquid level can be

used as a device test.

Item type Read only

Tolerance –1.0 to 1.1 °C (30.2 to 33.8 °F)

Checks that the measuring temperature resistor temperature

conversion is executed correctly.

Item type Read only

This temperature is used for checking when shipping from the factory.

5.3.2 Temperature measurement elements 1: VH10-VH19

Code Display Details

VH10-19 Temperature 1-10

(Temperature of

elements 1 to 10)

Item type Read only

Range –200 to 240 °C (–328 to 464 °F)

Displays individual temperature measurement elements.

5.3.3 Temperature measurement elements 2: VH20-VH29

Code Display Details

VH20-25 Temperature 11-16

(Temperature of

elements 11 to 16)

VH26 Selec. Ave Method

(Average

temperature

calculation method)

Item type Read only

Range –200 to 240 °C (–328 to 464 °F)

Displays individual temperature measurement elements.

Item type Selection

Selection Standard / Advanced

Selects the method of average temperature calculation.

Endress+Hauser 29

Page 30

Operation Prothermo NMT539

1

2

3

4

5

1

2

3

4

5

Standard calculation method

Regardless of the shape of the tank, average temperature is calculated using the following

formula:

Formula: (T1 + T2 + T3) / Number of elements in liquid phase = Average temperature

(3.5 °C (38.3 °F) + 3.0 °C (37.4 °F) + 2.0 °C (35.6 °F)) / 3 = 2.83 °C (37.1 °F)

A0038546

8 Standard calculation method for liquid temperature

1 Element No.5: 4.5 °C (40.1 °F) (T5)

2 Element No.4: 4.0 °C (39.2 °F) (T4)

3 Element No.3: 2.0 °C (35.6 °F) (T3)

4 Element No.2: 3.0 °C (37.4 °F) (T2)

5 Element No.1: 3.5 °C (38.3 °F) (T1)

Advanced calculation method

Average temperature is calculated by adding a corrective factor for unequal volume

distribution.

Formula: (T1*V1 + T2*V2 + T3*V3) / (V1 + V2 + V3) = Average temperature

Parameters that are related to V = additional volume factors are determined in VH53,

54 and 55.

9 Standard calculation method for liquid temperature

1 Element No.5: 4.5 °C (40.1 °F) (T5)

2 Element No.4: 4.0 °C (39.2 °F) (T4)

3 Element No.3: 2.0 °C (35.6 °F) (T3)

4 Element No.2: 3.0 °C (37.4 °F) (T2)

5 Element No.1: 3.5 °C (38.3 °F) (T1)

A0038546

30 Endress+Hauser

Page 31

Prothermo NMT539 Operation

2.0 °C 2.0 °C 2.0 °C 2.0 °C

3.0 °C 3.0 °C 3.0 °C

3.5 °C 3.5 °C

1

2

3

4

5

Advanced calculation method 2

Average temperature is calculated by adding a corrective factor for unequal volume

distribution.

Formula: (3.5 °C (38.3 °F) x 2 + 3.0 °C (37.4 °F) x 3 + 2.0 °C (35.6 °F) x 4) / (2 + 3 + 4) =

2.67 °C (36.8 °F)

In the diagram below, □ represents V (volume factor).

(3.5 °C (38.3 °F) x 2 + 3.0 °C (37.4 °F) x 3 + 2.0 °C (35.6 °F) x 4) / (2 + 3 + 4) =

2.67 °C (36.8 °F)

10 Advanced calculation method 2

1 Element No.5:4.5 °C (40.1 °F) (T5)

2 Element No.4: 4.0 °C (39.2 °F) (T4)

3 Element No.3: 2.0 °C (35.6 °F) (T3)

4 Element No.2: 3.0 °C (37.4 °F) (T2)

5 Element No.1: 3.5 °C (38.3 °F) (T1)

Code Display Details

VH27 Multi Spot Type

(Display array)

Item type Selection

Selection Spot

Displays individual temperature measurement elements.

The element array in a temperature probe is selected. This function is

particularly required if an average temperature probe other than

NMT539 is connected to the NMT539 converter-only version.

A0038547

Multi

The "Spot" element array must always be selected in the converter

+ temperature probe version. Selecting the parameter to "Multi"

will prevent accurate calculations. When several elements are

installed on each input cable in the probe, average temperature is

calculated based on the sum of temperature measurement

element values in the liquid phase and the sum of the number of

elements.

Endress+Hauser 31

Page 32

Operation Prothermo NMT539

3

4

5

6

8

9

1

2

a

b

c

7

VH27 Multi Spot Type: Spot temperature of the display array

The formula

(T1 + T2 + T3) /3 = 25.5 °C (77.9 °F)

calculates the average temperature.

A0038548

11 Spot temperature

a Gas (vapor phase)

b Level

c Liquid phase

1 NMT539

2 Converter

3 Pt100 element No.5: 2.45 °C (76.1 °F) (T5)

4 Pt100 element No.4: 24 °C (75.2 °F) (T4)

5 Pt100 element No.3: 26.0 °C (78.8 °F) (T3)

6 Pt100 element No.2: 25.5 °C (77.9 °F) (T2)

7 Pt100 element No.1: 25.0 °C (77.0 °F) (T1)

8 Input signal cable

9 Probe bottom

32 Endress+Hauser

Page 33

Prothermo NMT539 Operation

2

3

4

5

6

7

1

8

10

11

9

12

VH27 Multi Spot Type: Multi temperature of the display array

When elements with unequal lengths are installed on each input cable, out of the

elements that are submerged in the liquid phase, the temperature measurement element

in the liquid phase that is the closest to the liquid level is considered the average

temperature.

The average liquid temperature is the element temperature (Element No.3:

26.0 °C (78.8 °F) (T3)) of the liquid phase that is the closest to the liquid level.

A0038549

12 Multi temperature

1 NMT539 converter-only type + Other brand's average temperature probe

2 Pt100 element No.5: 2.45 °C (76.1 °F) (T5)

3 Pt100 element No.4: 24 °C (75.2 °F) (T4)

4 Pt100 element No.3: 26.0 °C (78.8 °F) (T3)

5 Pt100 element No.2: 25.5 °C (77.9 °F) (T2)

6 Pt100 element No.1: 25.0 °C (77.0 °F) (T1)

7 To converter

8 Input signal cable

9 Gas (vapor) phase

10 Level

11 Liquid phase

12 Probe bottom

5.3.4 Upper and lower limits of temperature measurement elements: VH28-VH29

Code Display Details

VH28 Lower Limit

VH29 Upper Limit

(Minimum

temperature

measurement

element value)

(Maximum

temperature

measurement

element value)

Item type Read / Write

Default –20.5 °C (–4.9 °F)

Range –999.9 to 999.9 °C (–1 767.82 to 1 831.82 °F)

The lower limit of a temperature measurement element is set and used

as a reference for determining an element short circuit.

Item type Read / Write

Default 245 °C (473 °F)

Endress+Hauser 33

Page 34

Operation Prothermo NMT539

Code Display Details

Range –999.9 to 999.9 °C (–1 767.82 to 1 831.82 °F)

The upper limit of a temperature measurement element is set and used

as a reference for determining an element short circuit.

5.3.5 Element position 1: VH30-VH39

Code Display Details

VH30-VH39 Position 1-10

(Element positions 1

to 10)

Item type Read / Write

Range 0 to 99 999 mm

Displays individual temperature measurement elements.

Sets the element position from the bottom of the tank.

Calculation is automatically performed if "Equal" was selected as the

element interval in VH85. If "Unequal" was selected, all element

positions must be entered manually.

5.3.6 Element position 2: VH40-VH49

Code Display Details

VH40-VH45 Position 11-16

(Element positions

11 to 16)

VH46 Hysteresis Width

(Hysteresis width)

VH47 Clear Memory

(Memory deletion)

VH48 Gas Offset

(Gas offset)

Item type Read / Write

Range 0 to 99 999 mm

Displays individual temperature measurement elements.

Sets the element position from the bottom of the tank.

Calculation is automatically performed if "Equal" was selected as the

element interval in VH85. If "Unequal" was selected, all element

positions must be entered manually.

Item type Read / Write

Default 10 mm (0.39 in)

Range 0 to 99 999 mm

Sets the hysteresis of an element switch position.

Hysteresis entered as an offset value can prevent hunting caused by

fluctuations of the level surface. This changes according to the range of

fluctuations.

Item type Selection

Default None (0)

Range 0 to 99 999 mm

Selection None, Clear

Resets the matrix parameter to the default setting.

Item type Read / Write

Default 300 mm (11.81 in)

Range 0 to 99 999 mm

When a temperature element in the gas (vapor) phase is within the

shown range below, it is not used for average gas temperature

calculations.

34 Endress+Hauser

Page 35

Prothermo NMT539 Operation

1

2

3

4

5

7

a

6

1

2

3

4

5

7

a

6

Code Display Details

A0038550

13 Gas offset

a VH48 gas offset 300 mm (11.81 in) (Default)

1 To NMT539 converter

2 Temperature element

3 Gas phase

4 Exclusion range (see Note)

5 Level

6 Liquid phase

7 To tank bottom

VH49 Liquid Offset

(Liquid offset)

Although temperature elements in this range are in the gas

phase, they are excluded from average gas temperature

calculations in order to avoid effects from the interface between

the liquid phase and the gas phase.

Item type Read / Write

Default 300 mm (11.81 in)

Range 0 to 99 999 mm

14 Liquid offset

a VH48 gas offset 300 mm (11.81 in) (Default)

1 To NMT539 converter

2 Temperature element

3 Gas phase

4 Exclusion range (see Note)

5 Level

6 Liquid phase

7 To tank bottom

A0038551

Although temperature elements in this range are in the liquid

phase, they are excluded from average liquid temperature

calculations in order to avoid effects from the interface between

the liquid phase and the gas phase.

Endress+Hauser 35

Page 36

Operation Prothermo NMT539

5.3.7 Advanced temperature: VH50-VH59

Code Display Details

VH53 Element Point

(Element point)

VH54 Element Position

(Element position)

VH55 Element Volume

(Element volume)

Item type Selection

Default 0

Selection 0-15 (Element No.1 = 0, Element No. 16 = 15)

Selects the number of elements for "Advanced" average temperature

calculations in VH26. The positions of the selected elements are

displayed in VH54 "Element Position," and additional volume factors

can be modified in VH55 "Element Volume."

Item type Read only

Range 0 to 99 999 mm

Displays the position of the element that was selected in VH53.

Item type Read only

Range 1 to 99 999.9

Sets the additional volume factor for the element that was selected in

VH53.

Additional volume can be added to individual elements for advanced

average temperature calculations (for details, see "VH26: Selec. Ave

Method").

5.3.8 Temperature adjustment: VH70-VH79

Code Display Details

VH70 Element Select

(Element number

assignment)

VH71 Zero Adjust

(Zero adjustment of

temperature

measurement

element)

VH72 Adjust Span

(Adjustment of

temperature

measurement

element span)

VH73 Temperature X

(Temperature X)

Item type Selection

Range 0 to 19

The element number for performing temperature adjustments is

selected (Element 0-15 = Element 1-16, 19 = Reference 100 Ω

resistance).

Item type Read / Write

Default 0

Range –1 000.0 to 1 000.0

Performs zero adjustment for individual elements that were selected in

VH70. Unlike a standard temperature device, the reading value can be

adjusted when the measured temperature shows minor correction

values.

If element No.2 displays 25.4 °C (77.72 °F) and a standard

temperature device displays 25.2 °C (77.36 °F), the matrix is set

to -0.2.Once set, the correction value of element No.2 based on

the actual measured value will be –0.2 °C (31.6 °F).

Item type Read / Write

Default 1

Range 0.8 to 1.2

Span adjustment is applied to all installed temperature measurement

elements. This correction value is multiplied by the actual measured

values.

Item type Read only

Temperature of the elements that were selected in VH70. Also displays

each temperature measurement element that was displayed in VH10VH25. The value is calculated based on the following formula:

VH73: Temperature X = Unadjusted temperature x span (VH72) + Zero

offset (VH71)

36 Endress+Hauser

Page 37

Prothermo NMT539 Operation

Code Display Details

VH74 Position X

(Element position)

VH75 Resistance X

(Element resistance)

VH76 Resistance Adj.

(Element resistance

adjustment)

VH77 Element Type

(Element type)

Item type Read / Write

Range 0 to 99 999 mm

Position of the elements that were selected in VH70. If "Unequal" was

selected in VH85, the position of each element can be set here.

Item type Read only

Shows the measured resistance for elements that were selected in

VH70.

Item type Read / Write

Default 0

Range –1 000.0 to 1 000.0

Adjusts the resistance of elements selected in VH70. Minor resistance

adjustments can be applied on the reading value.

Under identical environmental conditions, if the selected element

No.5 displays 100.3 Ω and a standard high-precision resistor

displays 100 Ω, -0.3 is set in this matrix. Once set, the correction

value of element No.5 based on the actual measured value will be

–0.3 Ω. Be careful when configuring this setting in VH76, as it

will apply to all elements.

Item type Selection

Selection Pt100, Cu90, Cu100, PtCu100, JPt100

The element conversion formula is selected for when another brand's

average temperature probe is connected to the NMT539 converteronly version.

Element conversion

formula

VH78 Average Number

(Sampling number)

VH79 Protect Code

(Access code)

CAUTION

L

Changing the parameters:

NMT539 converter + temperature probe version is comprised of spot,

element array and PT100 element types.

Changing the parameters may cause erroneous calculations or

‣

unnecessary error displays.

Pt100 (formula above 0 °C):

R = -0.580195 x 10-4 x T2 + 0.390802 x T +100

Pt100 (formula below 0 °C): R = -4.2735 x 10-10 x T4 + 4.273 x 10- 8

x T³ - 0.58019 x 10- 4 x T² + 3.90802 x T + 100

Cu90: R = 0.3809 x T + 90.4778

Cu100: R = 0.38826 x T + 90.2935

PtCu100: R = 3.3367 x 10-7 x T3 - 2.25225 x 10-5 x T2 +0.38416 x T

+ 100.17

R: Resistance, T: Temperature

Item type Read / Write

Default 1

Range 1 to 10

The number of resistance samplings from all temperature

measurement elements can be changed, including that of the reference

resistance installed on the circuit of the main unit.

Increasing the sampling number will allow for a more accurate

measurement, but it will slow down the device's overall scan

time. Element selection frequency: Approx. 2 seconds/element,

sampling maximum element number 21 (Number of elements:

16, Internal reference resistance: 5)

Item type Read / Write

Default 0

Endress+Hauser 37

Page 38

Operation Prothermo NMT539

Code Display Details

Range 0 to 999

Access code 530 enables selection and writing.

5.3.9 Device setting 1: VH80-VH89

Code Display Details

VH80 Present Error

(Error

information)

Item type Read only

Screen where error information is displayed. The following error codes will be

displayed. For details, refer to "Troubleshooting" in the separate BA1025G

operating instructions.

Error

code

0 No error presence

1 Common line open

3 #1 element open

4 #1 element short

5 #2 element open

6 #2 element short

7 #3 element open

8 #3 element short

9 #4 element open

10 #4 element short

11 #5 element open

12 #5 element short

13 #6 element open

14 #6 element short

15 #7 element open

16 #7 element short

17 #8 element open

18 #8 element short

19 #9 element open

21 #9 element short

21 #10 element open

22 #10 element short

23 #0 element over range

24 Memory defect (ROM)

25 #11 element open

26 #11 element short

27 #12 element open

28 #12 element short

29 Element exposed (liquid level below #1 element position)

32 Low power supply

33 #13 element open

34 #13 element short

35 #14 element open

36 #14 element short

38 Endress+Hauser

Page 39

Prothermo NMT539 Operation

Code Display Details

37 #15 element open

38 #15 element short

39 #16 element open

40 #16 element short

41 Memory defect (RAM)

42 Memory defect (EEROM)

43 WB line open

44 WB line short

Code Display Details

VH81 Temperature Unit

(Temperature unit)

VH82 Element Number

(Number of

temperature

measurement

elements)

Item type Selection

Default °C

Selection °C, °F, K

Screen used to select the temperature display unit.

Based on the HART configuration, °C (HART code: 32), °F (HART code:

33), and K (HART code: 35) are available.

Leave this parameter in °C if you are changing the default °C in

the host gauge (NMS8x, NMR8x, NRF81, NMS5, NMS7,

NRF590, TMD1) to another unit.

Item type Read / Write

Default 10 (NMT539 converter-only version)

Range 1 to 16

The number of available temperature measurement elements is

entered. This function is mainly used with the NMT539 converter-only

version.

Do not change the default parameter on the NMT539 converter

+ temperature probe version. The number of elements is

predetermined by the customer. Changing the default parameter

may cause erroneous calculations or unnecessary error displays.

VH83 No. of Preambles

(Number of

preambles)

VH84 Distance Unit

(Distance unit)

CAUTION

L

Changing the parameters:

Do not change the default parameter on the NMT539 converter +

temperature probe version. The number of elements is predetermined

by the customer.

Changing the default parameter may cause erroneous calculations

‣

or unnecessary error displays.

Item type Read / Write

Default 5

Range 2 to 20

Sets the number of preambles for HART communication.

CAUTION

L

Changing the value:

Do not change the default value.

This may cause erroneous calculations or unnecessary error

‣

displays.

Item type Selection

Default mm

Selection ft., m, inch, mm

Endress+Hauser 39

Page 40

Operation Prothermo NMT539

Code Display Details

• Selects the level display unit. This applies to the display of

VH02 "Liquid level" and VH50 "WB". Based on the configuration

of HART, the available level units are: ft. (HART code: 44), m

(HART code: 45), inch (HART code: 47) and mm (HART code:

49).

• Leave this parameter in mm if you are changing the default

mm in the host gauge (NMS8x, NMR8x, NRF81, NMS5,

NMS7, NRF590, TMD1) to another unit.

VH85 Kind of Interval

(Element interval

configuration)

VH86 Bottom Point

(Position of the

bottom-point

element)

VH87 Element Interval

(Element interval)

VH88 Short Error

(Output data from

element short circuit)

VH89 Open Error

(Output data when

element is open)

Item type Selection

Default Equal interval (NMT539 converter-only version)

Selection Equal interval, unequal interval

Screen that selects the element interval. This function is used in the

NMT539 converter-only version.

CAUTION

L

Changing the parameters:

Do not change the default parameter on the NMT539 converter +

temperature probe version. The number of elements and the position

of each element is predetermined by the customer.

Changing the default parameter may cause erroneous calculations

‣

or unnecessary error displays. Do not change the parameters on

the NMT539 converter + temperature probe version other than for

repair purposes.

Item type Read / Write

Default 500 mm (19.69 in)

Selection 0 to 99 999 mm

The position of the bottom-point element from the tank bottom

(element No.1) is entered. If "Equal interval" has been selected in

VH85, the position of element No.1 is extremely important, as the rest

of the elements' positions will be determined by the position of the

bottom-point element.

Item type Read / Write

Default 1 000 mm (39.37 in)(NMT539 converter-only

version)

Range 0 to 99 999 mm

Changing the element interval and setting the element position are

only applied to reconfigure switching points for average temperature

calculations. The physical positions of elements will not change.

The default setting is 1 000 mm (39.37 in) in the NMT539

converter-only version, but other default settings will depend on

the ordered specifications.

Item type Read / Write

Default –49.5

Range –49.5 to 359.5

This data is output when the selected element short-circuits. The

display format can be configured in VH92 "Error Display Select."

Item type Read / Write

Default 359.0

Range –49.5 to 359.5

This data is output when the selected element is open. The display

format can be configured in VH92 "Error Display Select."

40 Endress+Hauser

Page 41

Prothermo NMT539 Operation

5.3.10 Device setting 2: VH90-VH99

Code Display Details

VH90 Device ID Number

(Device ID number)

VH91 Previous Error

(Previous error)

VH92 Error Dis. Sel.

(Error display

selection)

VH93 Custody Mode

(Custody mode)

VH94 Polling Address

(Polling address)

VH95 Manufacture ID

(Manufacturer ID)

VH96 Software Version

(Software version)

VH98 Below Bottom Item type Selection

Item type Read / Write

Default 0

Range 0 to 16 777 214

Screen used for distinguishing the device ID when the NMT539

connects to a HART communication loop.

NOTICE

Device ID and HART address:

When a device ID is changed, a communication error may occur due to

inappropriate device ID and HART address combination.

Ensure that the device ID and HART address are correct.

‣

Item type Read only

Displays the error history. The error messages are the same as those in

VH80.

Item type Selection

Default 0

Selection 0: OFF

1: ON

Selects the display of VH88 "Short Error Value" and VH89 "Open Error

Value."

OFF: VH88 and VH89 error messages are not sent to the host gauge.

This function automatically excludes defective elements in average

temperature calculations.

ON: Error messages are sent to the host gauge. As a result, the error

codes of VH88 and VH89 will appear on the host gauge's default

screen, and sent to the upper receiver as well.

Item type Read only

Default Configured at the factory according to

specifications.

The overwrite protection of hardware is located on the main CPU

board (CN3 connector).

Item type Read / Write

Default 2

Range 1 to 15

Polling address used in local HART communication.

Item type Read only

Default 17 (Endress+Hauser)

Screen showing the manufacturer ID.

Item type Read only

Screen showing the installed software version.

Default 0

Selection 0: OFF

1: ON

Displays an error when the liquid level drops below the bottom-point

element. If "ON" is selected, error code 29 will be displayed in VH80 and

VH91.

Endress+Hauser 41

Page 42

Operation Prothermo NMT539

V 50H = + VH58

( 52 - VG60) x VH59VH

VH63

Code Display Details

VH99 Device Type Code

(Device code)

Item type Read only

Screen displaying the device type.

• 184: Temperature measurement function

• 185: WB measurement function

• 186: Temperature + WB measurement function

5.4 WB measurement

HART device code 185 is exclusively for WB measurement function. Available parameters

and functions are as follows. The name of the HART device will be displayed in the default

header, and the selected HART device code will appear in VH99 "Device Type Code."

Devices with a temperature measurement function as specified by product order codes are

as follows.

Measurement function 2: Converter + WB probe

5.4.1 Element position: VH40-VH49

Code Display Details

VH47 Clear Memory

(Memory deletion)

Item type Selection

Default None (0)

Range 0 to 99 999 mm

Selection None, Clear

Resets the matrix parameter to the default setting.

5.4.2 WB primary and advanced temperature: VH50-VH59

Code Display Details

VH50 Water Level

(WB)

VH51 Capacitance

(Capacitance)

VH52 WB Frequency

(WB frequency)

VH57 Sel. Water Span

(WB probe length)

VH58 Offset Water

(WB offset)

Item type Read only

Displays the measured "Water level."

These are measured values that were calculated using the following

formula:

Item type Read only

Range • 1 000 mm probe: 10 to 10 000 pF

• 2 000 mm probe: 10 to 2 200 pF

Screen displaying the WB probe capacitance based on the frequency.

Item type Read only

Range 1 200 to 4 500 Hz

Screen displaying the WB probe measurement frequency.

Item type Selection

Selection 1 000 mm, 2 000 mm

Screen for selecting the WB probe length.

Item type Read / Write

Default Approx. 100 to 110

Set individually at the factory.

A0038555

42 Endress+Hauser

Page 43

Prothermo NMT539 Operation

Code Display Details

Range –200 to 2 000

Screen for WB offset of the measured values. There are two methods:

Use the scale

For measured WB value 530 mm (20.87 in) and manual dipping

‣

value 730 mm (28.74 in):

By entering VH58's default value + 200, offset + 200 mm (7.87 in)

can be corrected. (For default 110 mm (4.33 in), at +

200 mm (7.87 in) set 310 mm (12.2 in)).

Adding a WB probe position according to specification code

By default 110 mm (4.33 in), the distance between the bottom of

‣

a WB probe and the tank floor (or the datum plate) is

200 mm (7.87 in):

Set to 110 mm (4.33 in) + 200 mm (7.87 in) = 310 mm (12.2 in).

VH59 Water Span

(Water span

adjustment)

VH60 Empty Frequency

(Empty frequency

(Frequency of

VH58))

VH63 Water Factor

(Frequency per unit

liquid level)

Item type Read / Write

Default 1

Range 0.1 to 99.9

Adjusts the linearity of WB probe capacitance. The adjustment is used

to correct WB properties with slight linear slope.

Item type Read / Write

Default Approx. 1 800 to 2 200

Set individually at the factory.

Range 0 to 9 999 Hz

If a WB probe is in the liquid (oil) phase (NMT539 WB probe is not

touching the water phase), the measured frequency (VH52 value) is

entered.

Item type Read only

Displays the liquid's vertical motion per 1 mm in Hz (frequency) as WB

probe linearity. Calculation is performed based on the following

formula:

(VH61 Full Frequency - VH60 Empty Frequency) / VH62 Probe Length

= VH63 Water Factor

5.4.3 WB adjustment and operation power: VH60-VH69

Code Display Details

VH60 Empty Frequency

(Empty frequency

(Frequency of

VH58))

If a WB probe is in the liquid (oil) phase (NMT539 WB probe is not touching the water

phase), the measured frequency (VH52 value) is entered.

Endress+Hauser 43

Item type Read / Write

Default Approx. 1 800 to 2 200

Set individually at the factory.

Range 0 to 9 999 Hz

Page 44

Operation Prothermo NMT539

a

1

2

3

4

a

1

2

3

A0038552

15 Measurement frequency input 1

a Measurement range: 1000 or 2000

1 WB probe

2 Liquid phase (oil)

3 Interface (oil and water)

4 Water phase

Code Display Details

VH61 Full Frequency

(Frequency at full

tank)

16 Measurement frequency input 2

a Measurement range: 1000 or 2000

1 Liquid phase (oil)

2 Interface (oil and water)

3 Water phase

Item type Read / Write

Default Approx. 3 600 to 4 400