Page 1

Technical Information

Prothermo NMT539

Intrinsically safe multi-signal converter with precision average temperature

and water bottom sensor for inventory control and custody transfer applicatons

Applications

The Prothermo NMT 539 is based on API(American

Petroleum Institute) Manual of Petroleum

Measurement Standard, Chapter 7, and enables high

accuracy temperature measurement. At the same time, it

is an intelligent average temperature sensor for tank

gauging with an optional WB capacitance sensor at the

bottom of the temperature probe.

For average temperature measurement, it consists of

precision multi-spot Pt100 elements.

The NMT539 is a highly capable solution that provides

both constant average temperature data and water

interface data via local HART

For accurate inventory measurement, it is best suited

connected to Endress+Hauser’s Proservo NMS5/NMS7

or Tank Side Monitor NRF590 with Micropilot radar.

®

communication.

Features

• Intrinsically safe device allowing for the safest

electrical configuration possible.

• Available in four different versions based on customer

requirements:

– Converter Only

– Converter and Temperature probe

– Converter, temperature and water bottom (WB)

probe

• Converter is compatible with various element types

in third party manufacturer temperature probes.

• Variety of process connections and cable entries

available to meet worldwide classifications.

TI00042G/08/EN/14.11

71136671

Page 2

Prothermo NMT539

Table of Contents

Function and system design . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measurement system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ATEX, FM, CSA...Ex i combination with Proservo NMS5 . . . . . . 5

NMT 539 Converter + Temp. probe version . . . . . . . . . . . . . . . 5

ATEX, FM, CSA, TIIS ...

Ex i combination with Tank Side Monitor NRF 590 . . . . . . . . . . 6

NMT 539 Converter + Temp. + WB version . . . . . . . . . . . . . . . 6

TIIS...Ex d[ia] combination with Digital transmitter TMD1 . . . . . 7

TIIS...Ex d[ia] combination with Servo gauge TGM5 . . . . . . . . . . 8

TIIS...Ex i combination with Proservo NMS5/NMS7 (Ex d)

and Prothermo NMT539 (Ex i, high temp. specification) . . . . . . 8

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Measured variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Compatible element (Converter only version) . . . . . . . . . . . . . . 9

Number of elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Alarm signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Auxiliary energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Load HART

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 11

Temperature accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

WB accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . 11

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

New module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

All-in-one program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating condition : Installation . . . . . . . . . . . . . . . . . . . . . 12

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Process connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation height adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WB blocking distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Recommended installation height . . . . . . . . . . . . . . . . . . . . . . 13

Recommended still pipe installation . . . . . . . . . . . . . . . . . . . . . 14

Installation equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating condition : wiring . . . . . . . . . . . . . . . . . . . . . . . . 17

TIIS Ex d[ia] wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Example of Grounding cable construction (TIIS Ex d[ia]) . . . . . 17

Connecting diagram (TIIS Ex d[ia]) . . . . . . . . . . . . . . . . . . . . . . 18

Operating condition: terminal connection . . . . . . . . . . . . . . 19

Ex ia NMT539 terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ATEX, FM, CSA ... Ex d[ia] Proservo NMS5 terminal . . . . . . . . 19

TIIS Ex d[ia] Prothermo NMT539 terminal . . . . . . . . . . . . . . . . 20

®

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ex d NMS5 connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TGM5/TMD1 terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Terminal connection on the Tank Side Monitor NRF590 . . . . . . 21

Operating condition : Environment . . . . . . . . . . . . . . . . . . . 22

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Climate class. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operating condition : Process . . . . . . . . . . . . . . . . . . . . . . . 22

Process temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Process pressure limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Data transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Type 1: Converter only version . . . . . . . . . . . . . . . . . . . . . . . . . 23

Type 1: Measuring function . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Type 2: Converter only version . . . . . . . . . . . . . . . . . . . . . . . . . 24

Type 2: Measuring function . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Converter + average temperature probe version . . . . . . . . . . . . 25

Measuring function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

W&M function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Converter + average temperature probe

+ WB probe version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Measuring function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

WB probe design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operation using ToF Tool, FieldCare . . . . . . . . . . . . . . . . . . . . 27

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CE approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Ex approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

PTB W&M approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

External standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . 28

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Anchor weight (high profile, D120)

mounting attachment option: B . . . . . . . . . . . . . . . . . . . . . . . . 31

Anchor weight (low profile, hexagon H41)

mounting attachment option: C . . . . . . . . . . . . . . . . . . . . . . . . 31

Wire hook, Top anchor mounting attachment option: D,F . . . . . 32

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Stainless Steel conversion table . . . . . . . . . . . . . . . . . . . . . . . . . 34

Endress+Hauser 2

Page 3

Prothermo NMT539

Function and system design

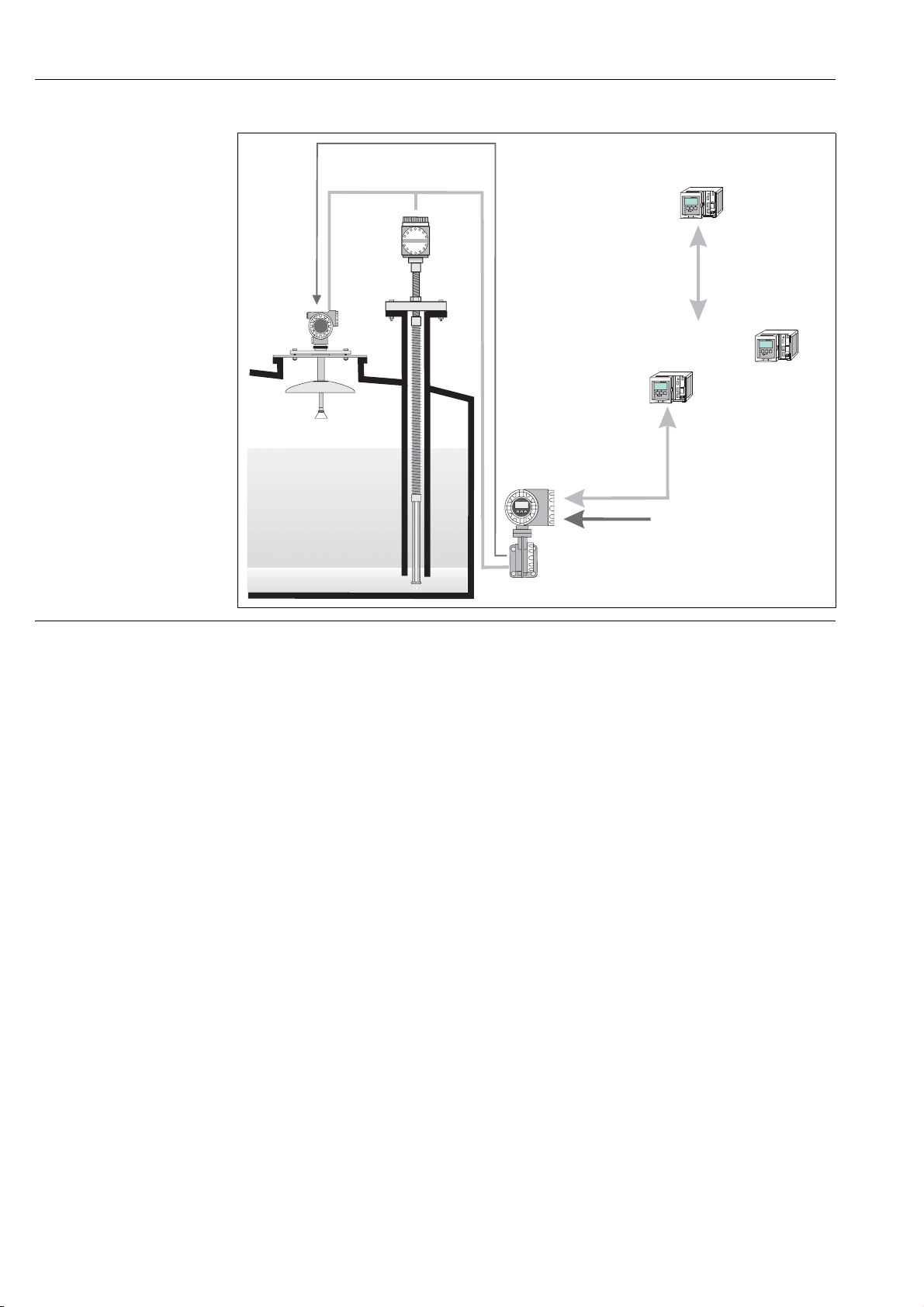

Measurement system The Prothermo NMT 539 is available in four different versions:

• Converter only

• Converter + Average temperature probe

• Converter + Average temp probe + Water bottom probe

The converter only version can be retrofitted without modifications onto existing third party average

temperature probes, such as Whessoe Varec 9909 and 1700 and Weed Beacon MW type probes. The average

temperature probe + converter inherits all the functionality of the former Prothermo NMT 535/536/537

series. The average temperature + WB + converter is the ultimate multi-function sensor, transmitting

temperature and water interface level data along only one pair of local HART

Proservo NMS5 ,TGM5, TMD1or NRF 590 Tank Side Monitor.

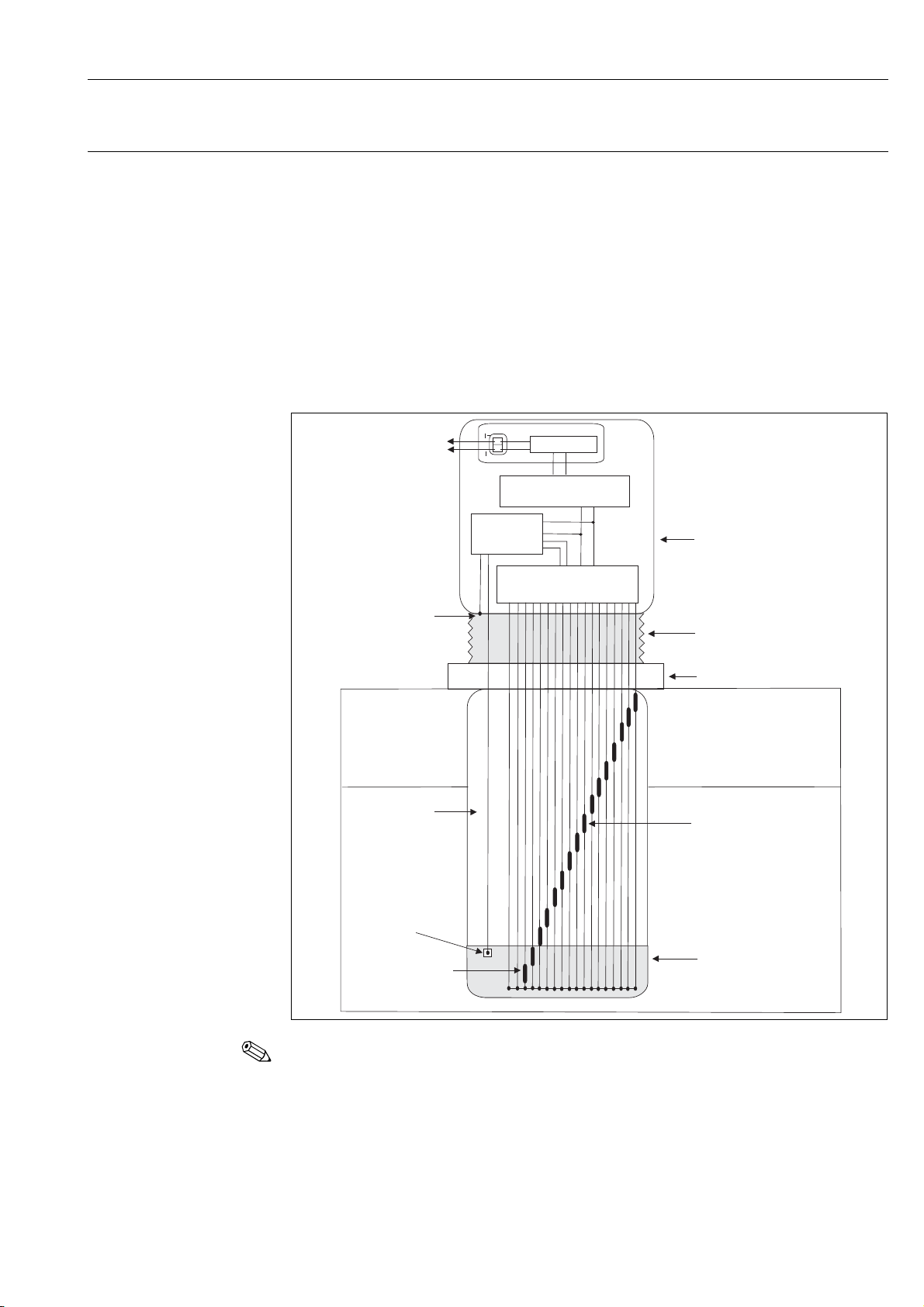

NMT 539 + WB operation principle (Converter + Temp + WB probe version)

®

signal cables to the host the

local HART®

communication

WB sensor signal FG

Isolated capacitance

signal data to

C/F module

Power Supply Module

C/F Module

Noise Filter

Converter housing

CPU Module

360mm adjustable

threaded connection

Flange

Gas

Pt100 multi-spot elements

up to 16 points

Liquid

WB sensor coaxial

signal cable

Max. 2 Pt100 elements

can be inserted in

WB sensor

Capacitance WB sensor

Note!

Different types of NMT 539, including "Converter only," "Coverter + average temperature" are simpler versions

of the "Converter + WB + temperature" probe.

Endress+Hauser 3

Page 4

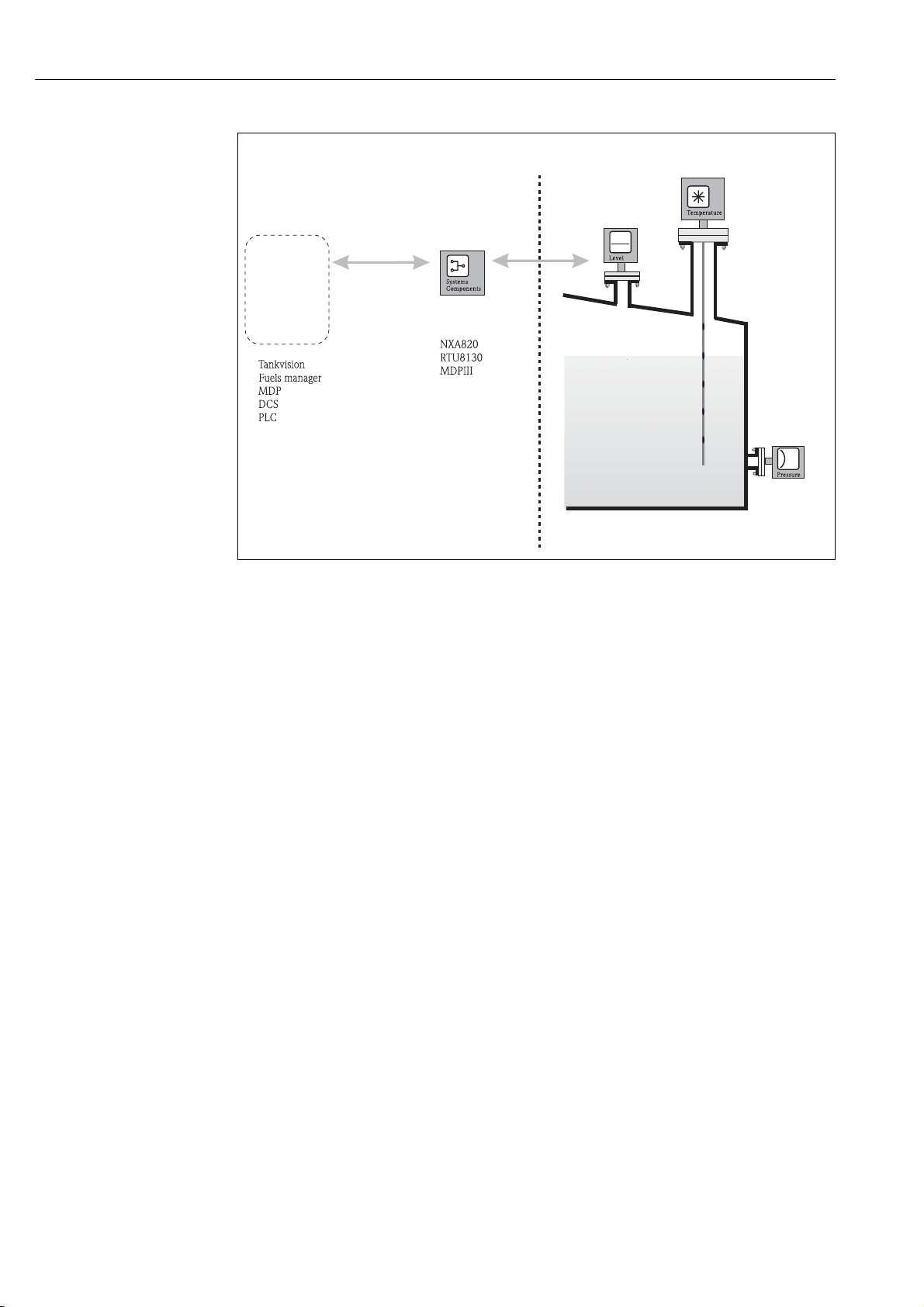

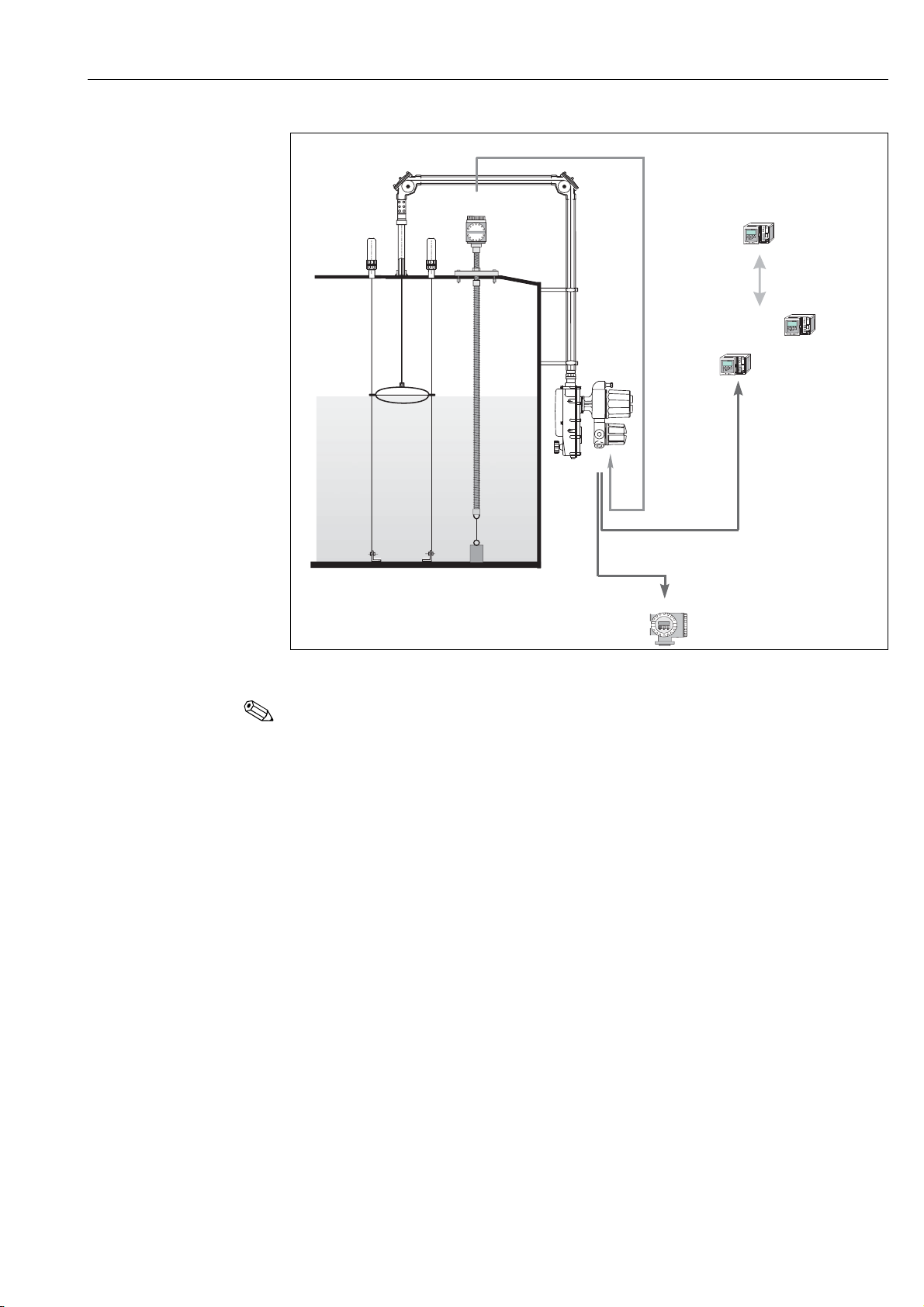

System design

Host application

Others

System

Data management

Field interface

Field process

Temperature

Level gauge

Pressure gauge

liquid /gas temperature

Level

Prothermo NMT539

Endress+Hauser offers a wide range of solutions to integrate field data into your process management

requirement.

The following diagrams describe some individual solutions according to various Ex concepts. For additional

application requirements, contact your local Endress+Hauser representative.

4 Endress+ Hauser

Page 5

Prothermo NMT539

Liquid Level

Power (AC/DC)

NMS5

NRF560

(Data transmission)

Liquid & Gas

Temperature

NMT 539

Fieldbus Protocol

Power (AC/DC)

Tankvision

Tank scanner

Ex d Local HART

®

Loop

(Data transmission

& Remote control

Tankvision

Host link

Tankvision

Data Concentrator

Communication to

Host system

local HART® (Ex i)Loop

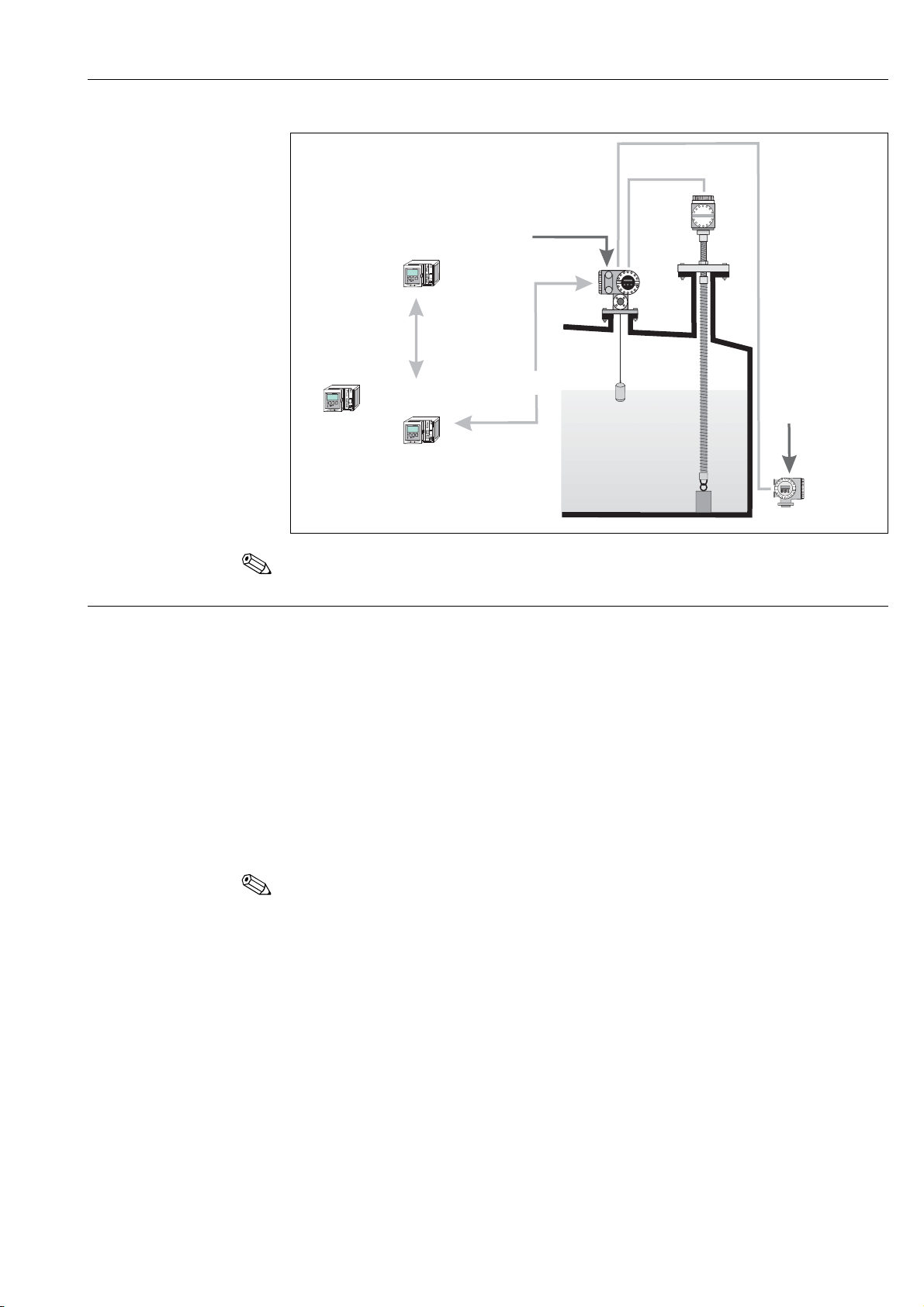

ATEX, FM, CSA...Ex i

combination with Proservo

NMS5

NMT 539 Converter + Temp.

probe version

Note!

NMT539 connection on the drawing is only available to connect with NMS Ex d[ia].

The Prothermo NMT 539 is the successor of the former NMT 535 Ex i version. For proper migration, the NMT

539 has inherited all the functionality and specifications of the NMT 535, including process connections, cable

entries and wiring method.

Since the Proservo NMS5 already provides water interface measurement, the NMT 539 Converter + Average

temperature may be the best version when used in combination with the Proservo. When the Converter + WB

+ Average temperature version is used in combination with the Proservo, the product in the tank will be

thoroughly managed with level, continuous average temperature and water interface measurement.

Most configuration and parameter settings for the NMT539 can be performed via the Proservo NMS5

programming matrix.

The NMT 539 receives liquid level data from the Proservo, then calculates liquid and gas phase average

temperature. Calculated data and basic information, including raw data for each temperature element and

device status, are transmitted to the Proservo.

Note!

Since the Proservo is a multi-functional device (measurement and data transmission), the Promonitor NRF 560

acts as a tank side remote data indicator and controller for Proservo.

All gathered data in the interface unit is sent to inventory management software, such as Endress+Hauser's

Tankvision, Fuelsmanager, Tank computer or directly sent to the customer's specific DCS or PLC.

Endress+Hauser 5

Page 6

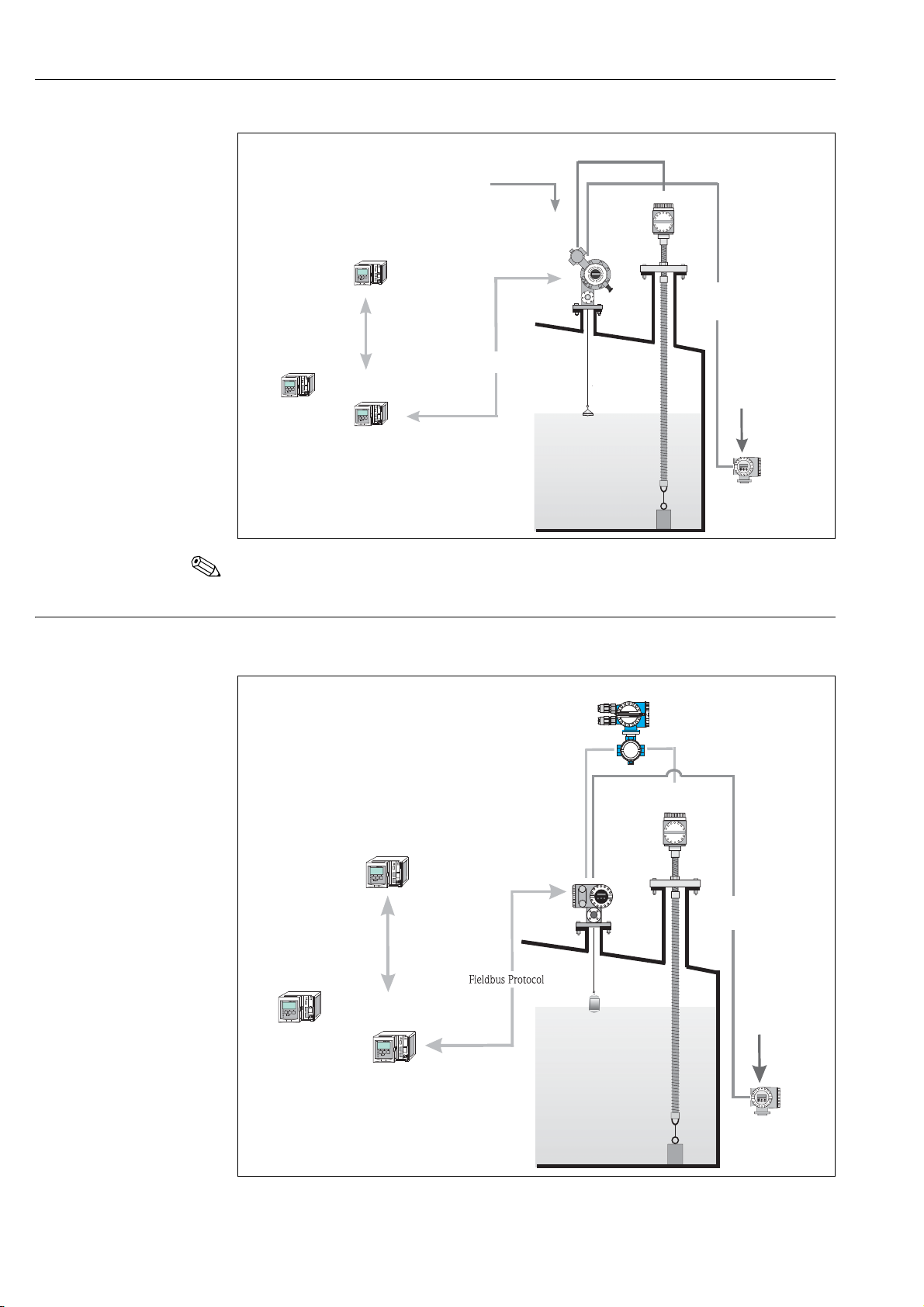

ATEX, FM, CSA, TIIS ... Ex i

Liquid Level

Power (AC/DC)

FMR 533

NRF590

NMT 539

(Data transmission)

Liquid & Gas

Temperature

Water interface

(WB)

FMR Power

(DC,Ex i)

Fieldbus Protocol

Tankvision

Tank scanner

Tankvision

Host link

Tankvision

Data Concentrator

Communication to

Host system

Ex i local HART

®

Loop

combination with Tank Side

Monitor NRF 590

Prothermo NMT539

NMT 539 Converter + Temp.

+ WB version

The NMT 539 Converter + Temp. + WB is utilised effectively in combination with radar level gauging. Water

interface, temperature and level measurement, with data collection and calculations via the NRF 590, allow

for optimal inventory control. Basic functionality of the NMT 539 is displayed and configured on the NRF 590.

Detailed NMT 539 functionality and data access can be performed by the ToF tool or FieldCare.

The NMT 539 receives radar level data from the NRF 590 and then calculates liquid and gas phase average

temperature. Calculated and standard data, including temperature element raw data and device status, are

transmitted to the NRF 590.

All gathered data in the interface unit is sent to inventory management software, such as Endress+Hauser's

Tankvision, Fuelsmanager, tank computer or directly sent to the customer's specific DCS or PLC.

6 Endress+ Hauser

Page 7

Prothermo NMT539

TIIS...Ex d[ia]

combination with Digital

transmitter TMD1

local HART® (Ex d ) Loop

Average temperature

Prothermo NMT539

Digital

transmitter

TMD1

Float gauge

LT11

Field Protocol

Local HART

®

Promonitor NRF560

Tankvision

Host link

Communication to

Host system

Tankvision

Tank scanner

(Ex d ) Loop

Tankvision

Data Concentrator

®

Average temperature data is transmitted to transmitter TMD1 via local HART

communication.

Note!

If NMT539 WB probe and NRF560 are used together, confirm supply voltage to TMD1 is stable 100 VAC or

more.

Endress+Hauser 7

Page 8

TIIS...Ex d[ia]

Power (AC/DC)

Servo gauge TGM5

Ex d local HART

®

loop

Ptothermo NMT539

Ex d Local HART

®

loop

(Data transmission)

Power (AC/DC)

Promonitor NRF560

Level

liquid/gas

temp.

Fieldbus Protocol

Tankvision

Tank scanner

Tankvision

Host link

Tankvision

Data Concentrator

Communication to

Host system

Proservo NMS5

Prothermo NMT539

(high temp. sepc.)

Ex d local HART

®

loop

Ex d local HART

®

loop

(data transmission)

Power(AC/DC)

Promonitor NRF560

Level

Liquid /gas

temperature

Ex i local HART® loop

Ex i/Ex d barrier NAB560

Tankvision

Tank scanner

Tankvision

Host link

Tankvision

Data Concentrator

Communication to

Host system

combination with Servo gauge

TGM5

Prothermo NMT539

TIIS...Ex i

combination with Proservo

NMS5/NMS7 (Ex d) and

Prothermo NMT539 (Ex i,

high temp. specification)

Note!

If NMT539 WB probe and NRF560 are used together, confirm supply voltage to servo gauge is stable 100VAC

or more.

Prothermo NMT539 high temperature specification is Ex i output. When using with Proservo NMS5/NMS7,

Barrier Box NAB560 is required.

8 Endress+ Hauser

Page 9

Prothermo NMT539

Input

Measured variables Temperature measuring range:

Temperature conversion : -200 ...+235 °C (-328 ...+455 °F), (-170...+235°C TIIS)

Standard : -40...+100°C (-20...+100°C TIIS)

Wide range : -55...+235°C (-20...+235°C TIIS)

Cryogenic : -170...+60°C

Probe length : 40m or less

Water interface level (water bottom) range

Standard : 1m ...2m (3.3 ...6.6 ft)

Compatible element

(Converter only version)

Number of elements 2 to16 can be connected

Pt100

Cu90

Cu100

PtCu100

JPt100

In case of TIIS, it is only Pt100 and JPt100.

Note!

NMT 539 Converter + Temp. version has only Pt100 elements installed. The element types above can be

utilised in third party temperature probes, such as the Endress+Hauser 9909, 1700 or Weed Beacon MWR.

Other manufacturer multi-resistant and multi-spot average temperature probes may be compatible.

Output

Communication 2 wire, Endress + Hauser local HART® protocol to host commanding gauge

• Proservo NMS5/NMS7

• Tank Side Monitor NRF 590

• Digital Transmitter TMD1

• Servo Gauge TGM5

Alarm signal Error information via the following interface and transmission digital protocol. Please refer to Operating

Instructions of each device.

• Proservo NMS5/NMS7 ... BA1001N(BA01001G)

• Tank Side Monitor NRF590 ... BA256F(BA00256F), BA257F(BA00257F)

®

Output signal •local HART

Connection • Proservo NMS5/NMS7

• Tank Side Monitor NRF590

• Digital Transmitter TMD1

• Servo Gauge TGM5

protocol

Endress+Hauser 9

Page 10

Auxiliary energy

Load HART® Minimum loading for local HART® circuit : 250Ω

Cable entry Wiring of the NMT 539 must meet explosion proof or intrinsically safe requirements.

The following cable entries are available:

• Thread G 1/2

• Thread NPT 1/2

• Thread M 20

Only G1/2 is selectable on TIIS Ex d[ia] and 2 cable glands SXC-16B are attached.

Supply voltage DC16 ... 30V : Ex ia

DC20 ... 24V : TIIS Ex d[ia] connectable only TGM5, TMD, NMS...Ex d

Power consumption Ex ia:

6mA (Temperature measurement)

12mA (WB measurement)

TIIS, Ex d[ia]:

8mA (Temperature measurement)

14mA (WB measurement)

Prothermo NMT539

10 Endress+ Hauser

Page 11

Prothermo NMT539

Performance characteristics

Temperature accuracy ±0.1°C or better (under the reference condition)*1

Reference condition*1:

Accuracy of RTD - Temperature conversion. Accuracy measurement shall be conditioned with precisely cali-

brated dial resistor or IEC class A Pt100 ohm temperature element.

WB accuracy ±2mm or less (under the reference condition)*2

Reference condition*2:

Measurement condition is based on 80% span of 1m probe in water / air interface at 25°C.

εr)=2.1

Reference operating

conditions

The Factory default is adjusted based on DC (

• Temperature = +25°C(77°F) ±5 (9°F)

• Pressure = 1013 hPa (mbar) abs.(14.7 psi)±20 hPa (mbar) (0.3 psi)

• Relative humidity (air) = 65% ±20%

Maximum measured error Typical statements for reference conditions, include linearity, repeatability, and hysteresis:

• Linearity:

– Temperature: ±0.15°C (0.27°F) + element deviation (based on IEC class A standard)

– WB: ±2mm *2

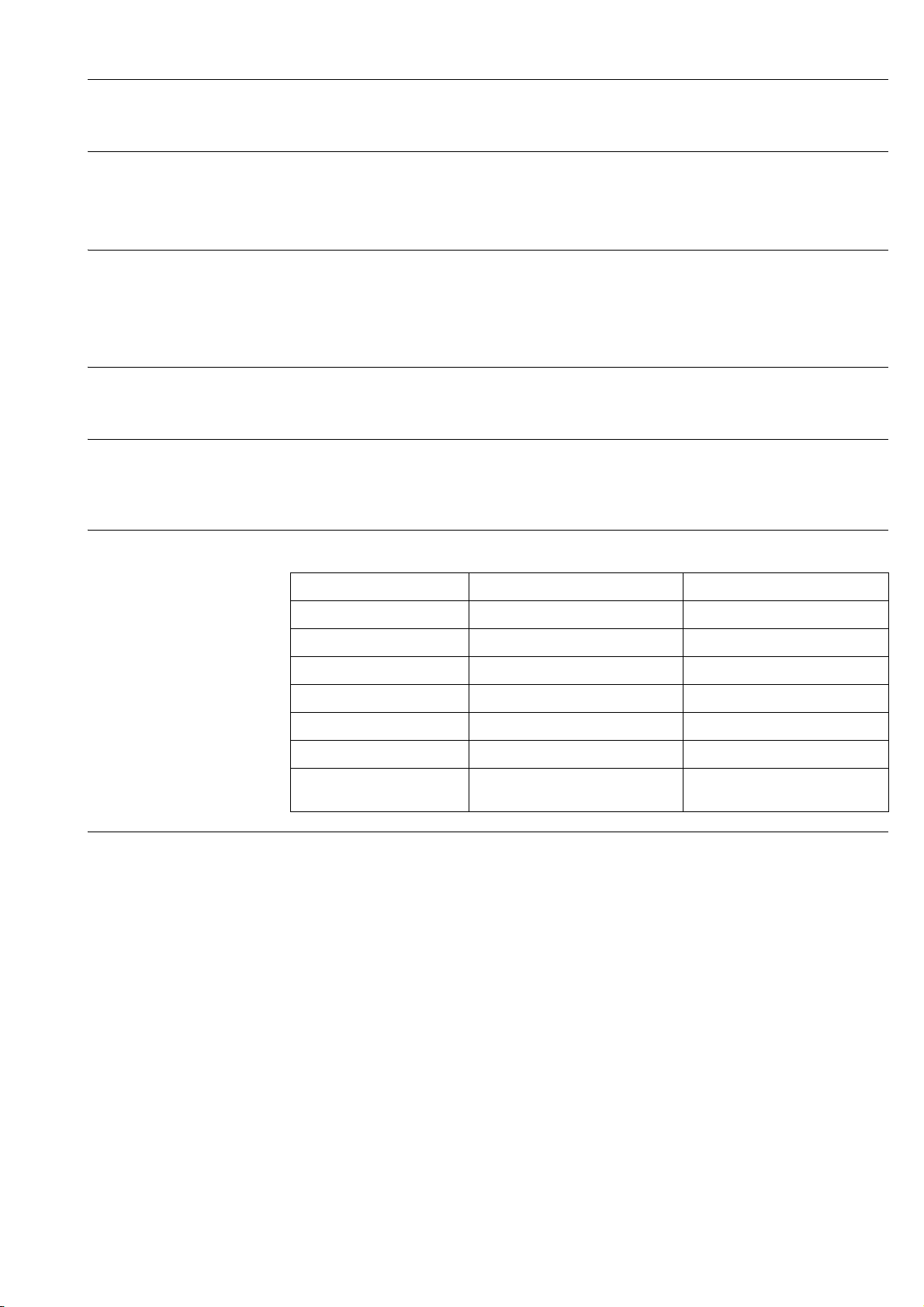

New module The Prothermo NMT 539 employs a completely new electronic module compared to the previous NMT 535.

NMT 539 NMT 535

CPU Performance 16 bit 8 bit

Clock speed 2.7648 MHz 0.9216 MHz

Memory capacity (RAM) 20K bytes 176 bytes

EEPROM 2K bytes 256 bytes

Flash memory 256K bytes 16K bytes

Total # of print boards 4 (5 with Capacitance board) 5

Current consumption

(Converter + temp. probe)

6mA@16VDCEx ia

8mA@16VDCEx d[ia]

10mA@16VDC

All-in-one program The powerful processor enables multi-function calculations under a single program. This means that there is

no need for a variety of spare parts.

RTD Temperature calculation

The main CPU board now has all the required data processing functionality, including RTD - local HART

®

conversion. With the NMT 538, various programs were required depending on temperature element

characteristics, such as Pt100, Cu90, Cu100 and PtCu100. The new NMT 539 has all the programs in one

powerful processor.

®

Capacitance - local HART

signal conversion

A separate CF (Capacitance - Frequency) board can be connected directly to the CPU board when NMT 539

is equipped with WB sensor.

Endress+Hauser 11

Page 12

Operating condition : Installation

Wiring Wiring of the NMT 539 must meet explosion proof or intrinsically safe requirements.

The following cable entries are available:

• Thread G 1/2"

• Thread NPT 1/2"

• Thread M20

Only G1/2 is selectable for TIIS Ex d[ia] and 2 cable glands SXC-16B, are attached.

Caution!

In case of Ex d, please prepare a metal cable gland (not a plastic one) that has shield cable grounding functionality to meet the condition of EMC certification.

Except as noted above, cable gland is not provided with the NMT 539.

Size and condition of the communication cable must meet the requirements of intrinsically safe local HART

communication.

Prothermo NMT539

®

Process connection Converter only version

NMT 539's local HART

mechanical connection size and type:

®

converter can fit onto third party average temperature probes with the following

• G 3/4" (equivalent to NPS 3/4") universal coupling.... Housing type 1

• M20 threaded.... housing type 2, specific design to fit to Varec 1700 terminal housing

Note!

Use seal tape to secure the connection between converter and temperature probe.

Please refer to the NMT 539 instruction manual for the detailed installation procedure.

Converter + Temp. , Converter + Temp. + WB version

All three versions have the same installation method to fit onto the tank nozzle.

The following flange sizes are available:

• JIS 10K 50A RF, SUS316

• ANSI 150lb 2" RF, SUS316

• JPI 150lb 2" RF, SUS316

• DIN DN50 PN 10RF, SUS316

Installation height adjuster An additional feature of the NMT 539, the height adjuster, can be used to adjust installation height of the NMT

539 within approximately ±180 mm (7") from original height.

Note!

The height adjuster is not included in "Converter only" version.

Caution!

Please tighten the lock nut with seal tape to secure rigidity of the NMT 539 at the end of physical installation

and/or if the height adjuster will be used during operation. A loose lock nut can lead to improper tank sealing

or unexpected leakage into the tank.

WB blocking distance The Water Bottom sensor can be set as low as zero clearance from the tank floor by using height adjuster. Due

to mechanical design of WB sensor, bottom plate has approximately 10mm thickness. This will become a

blocking distance (ineffective measuring range).

Caution!

Calculate vertical movement of NMT 539 installation height prior to setting the WB sensor bottom clearance.

Typical tank shell deformation causes vertical movement at a minimum 20 ~ 30mm (1"). Excessive weight

load of entire NMT 539 on WB sensor by contacting tank floor may cause critical damage that disables accurate

& stable WB level measurement.

12 Endress+ Hauser

Page 13

Prothermo NMT539

NMT539

Ordered installation height:

Below flange to end of

Temp probe or WB probe

Adjusting range approx. ±180mm

(total approx. 360mm)

Recommended bottom clearance:

with mounting attachment B, D, F: 400mm from the tank floor

with mounting attachment A,C: 200mm from the tank floor

Ø45mm

Recommended installation

height

Note!

The required bottom clearance of both the temperature probe and WB sensor depends on the anchoring

method. Consider the required bottom clearance when ordering the NMT 539. Please see the recommended

bottom clearance in the above illustration and/or consult your Endress+Hauser representative for further

information.

When ordering the NMT 539 with special element position and bottom clearance, please refer to "Ordering

Information," section 80, Element Spacing. Select 4, Equally spaced, defined by length.

The standard location of the lowest temperature element should be set at 500 mm (20") from the tank bottom

regardless of probe type.

Endress+Hauser 13

Page 14

Prothermo NMT539

A

Slotted Still

Pipe

more than 300mm

Slotted Still

Pipe

Datum plate A

Datum plate B

max. 150mm

max. 150mm

Slot-hole

Ø25mm

Datum plate

Slotted Still Pipe

more than 300mm

Ø45mm

Recommended still pipe

installation

Note!

Datum plate should be mounted on tank bottom below the slotted still pipe or located at least 300

B

(11.8 inches) below the slotted still pipe (as shown below drawing).

If anchor weight is not used with still pipe method, the water bottom should extend out from the end of the

still pipe, enough to allow liquid to enter/exit the pipe.

When using still pipe, it is available from 50A(2")(JIS, ANSI) pipe

when using anchor weight, use more than 100A(4")(JIS, ANSI) pipe.

Caution!

Do not allow turbulence to carry/shake the water bottom sensor laterally, such movement may damage the

sensor.

Installation equipment The bottom anchor hook on the WB sensor is not available when "A: no installation material" is selected. The

Converter + Temp. probe version includes the bottom anchor hook as standard, although, "A: no installation

material" is selected.

Contents of anchoring hardware: Based on the choice of "100: Mounting attachment"

F:

Tension wire +

wire hook +

R1 top anchor

bottom hook

base plate

wire hook

R1 top anchor

tension wire

0:

Converter only

1:

Temp. + Converter

3:

Temp. + WB + Converter

No installation

A:

Material

B:

Anchor weight

(High profile, D120)

C:

Anchor weight

(Low profile,

hexagon H41)

D:

Tension wire +

wire hook +

NPT1 top anchor

none none none none none

bottom hook bottom hook

anchor weight

sling wire

bottom hook

anchor weight

sling wire

bottom hook

base plate

wire hook

NPT1 top anchor

tension wire

none same as above same as above same as above same as above

14 Endress+ Hauser

Page 15

Prothermo NMT539

Element position #1

(Bottom element )

Tank oor

500mm

400mm

Clearance below

bo tto m ho o k

200mm

500mm

Clearance below

WB or Temp sensor

Element position #1

(Bottom element )

Mounting attachment B : "High profile anchor, D120" , D : "Tension wire + Wire hook +NPT1 Top

anchor" or "F : "Tension wire + Wire hook + R1 Top anchor"

"High profile anchor weight" is the anchor method designed for converter + temperature probe

Both temperature probe and WB sensor with "High profile anchor weight" and "Tension wire anchor" methods

have a recommended clearance below the bottom of the anchor hook of approximately 400 mm (16"). This

clearance can be easily changed by turning the height adjuster at the tank top.

Note!

When ordering the NMT 539, please refer to "Ordering Information," section 80, Element Spacing. Select 4,

Equally spaced, defined by length. This allows you to choose the desired element position and intervals.

Mounting attachment A : "No installation material" and C : "Low profile anchor, hexagon H41"

Element position #1

(Bottom element )

Clearance below

WB sensor

200mm

file type Anchor Weight

Low pro

500mm

"Low profile anchor weight" is provided to anchor WB probe and to measure accurately water bottom range.

When installing NMT539 on small tank nozzle [max.50A (2")] in operating tank, it is available as mounting

attachment for converter + temperature probe version. Both the temperature probe and WB sensor with "Low

profile anchor weight" at 100: Mounting attachment option (see Ordering Information) should have 200 mm

(8") of bottom clearance from the edge of probes.

Note!

The lowest possible WB measuring point can be approx. 10 mm from the tank floor with "No installation

material" selected (see Ordering Information). If necessary, use the height adjuster to set at the desired

installation height. No bottom anchor hook is available with the WB sensor and 100: Mounting attachment

Endress+Hauser 15

"A : No installation material".

Page 16

Prothermo NMT539 #1 Element position

Electrical compartment

Flange

Uppermost

element

Flexible tube

Element position #1

Ø36mm(1.42”)

Clearance tank bottom

to bottom hook

500mm

400mm

Anchor weight

(low profile)

Element position #1

Clearance tank bottom

to bottom hook

400mm

500mm

200mm

Ø45mm(1.77”)

Anchor weight

(high profile)

Anchor weight

(low profile)

Anchor weight

(high profile)

Prothermo NMT539

244

NMT5 39-++++++++A+ (le ngth belo w flan ge )

1st element

400 mm

Tank Bottom

NMT539

NMT539-+1,4++++++A A

NMT 539-+1,4++++++AC

NMT53 9-+1,4++++++AD/F

NMT539-+1,4+++ +++ A B

NMT539-+2,3,5++++++AA

NMT5 39-++++++++A+ (le ngth b elo w flang e)

300 mm

500 mm

222 typ.

200 mm

NMT539 W B

NMT539-+2,3,5++++++AC

NMT 539-+2,3,5++++ ++A D/F

NMT53 9-+2,3,5++++++A B

NMT5 39-++++++++A+ (le ngth b elo w flang e)

400 mm

Mounting and element position of Prothermo NMT539 anchor weight method

16 Endress+ Hauser

Page 17

Prothermo NMT539

Local HART® (Ex d )

Proservo NMS5

Prothermo NMT539

Under ground

Non-hazardous area

Class A grounding

Grounding cable

The grounding cable for safety barrier grounds on a tank.

Use cable with more than Ø8mm with finished dimension

Operating condition : wiring

TIIS Ex d[ia] wiring When the Prothermo NMT539 TIIS, Ex d [ia] available only in Japan, Class A grounding directly from NMT539

is required.

Note!

The grounding cable for safety barrier in Prothermo NMT539should be connected independent of any other

Example of Grounding cable

construction (TIIS Ex d[ia])

devices or purpose, according to “Class A grounding” standards.

Use a conductive grounding wire with cross-sectional dimensions 2~2.6mm

In an instrumentation room, a field device with Class A ground may be connected in common with the

communication cable shield.

"Class A ground" general description

Ground resistance value 10Ωor less

Grounding cable

Tensile strength : more 1.04kN Metallic wire

Cross-sectional dimensions : more than 2~2.6mm

Cable finished external diameter : more than Ø8mm

2

.

2

copper wire

Endress+Hauser 17

Page 18

Prothermo NMT539

Hazardous area

Non-hazardous area

Measuring device in a tank

Ex ia compartment

Ex d compartment

(terminal box)

Ex ia circuit

(+) General machinery

*Measuring part

Measuring temp. tube

Water bottom sensor

External grounding terminal

Note!

when grounding the barrier, connect wi th tank or

use the shielded wire for remote cable.

When using the shielded wi re for remote cable,

refer to “Electrical connection”.

Class A grounding

Hazardous area Non-hazardous area

*Measuring part

Measuring temp. tube

Water bottom sensor

External grounding terminal

Measuring device in a tank

Ex ia compartment

Ex d compartment

(terminal box)

Ex ia circuit

Ex d compartment

(+) General machinery

Note!

when grounding the barrier, connect wi th tank or

use the shielded wire for remote cable

When using the shielded wi re for remote cable,

refer to “Electrical connection”.

Class A grounding

*Measuring parts: In case of average temperature measuring, there is no water bottom probe.

DC20~26.4V

(-)

CN2-1

CN2-4

CN2-1

CN2-4

PE

H1+

H1+

H1-

H1-

CN2-1

CN2-4

CN2-1

CN2-4

PE

DC20~26.4V

(-)

Connecting diagram

(TIIS Ex d[ia])

Note!

Install wiring in a manner to prevent currect or voltage from causing electro magnetic interference on the i.s.

circuit.

18 Endress+ Hauser

Page 19

Prothermo NMT539

Z1Z1

H2-H2 -

H2+

H2+

H1-

H1-

H1+

H1+

Z2

Z2

Z3Z3

AR1AR1

H2-H2-

H2+H2+

H1-H1-

H1+H1+

Blind plug

Temp. (and / or WB) data

+: H1+ terminal

- : H1 - terminal

Screened twisted pair

or steel armored wire

to NRF 590

+ terminal 24, 26 or 28

- terminal 25, 27 or 29

to NMS5

+ terminal 24

- terminal 25

Note!

Metal cable gland only:

Shield of HART communication

line must be grounded

Intrinsically safe HART on NMT539

+: H2 + terminal

- : H2 - terminal

4 ... 20 mA

4 ... 20 mA

Channel 1

Channel 2

HART

+

+

_

_

22

23

24

25

26

+

_

COM

HOIST

STOP

Operation

contact

input

20

21

16

19

18

17

Alarm contact

Alarm contact

Alarm contact

+

_

+

_

+

_

10

15

14

13

12

11

Alarm contact

+

_

Non IS HART

to NRF or others

+

_

9

8

7

6

5

4

Power supply

AC 85 ... 264V 50/60Hz

or

DC 20 ... 62V AC20 ... 55V

2

3

1

G

N

L

L

G

N

ARS

ARS

ARS

+

_

Digital output

Rack bus RS485,

Serial pulse,

or

HART

from NMT539

Ex i HAR

Operating condition: terminal connection

Ex ia

NMT539 terminal

Note!

The NMT539 (Ex ia) allows an intrinsically safe local HART

establishing wiring and field device layout.

®

connection. Please refer to the i.s. regulation for

ATEX, FM, CSA ... Ex d[ia]

Proservo NMS5 terminal

Since the Prothermo NMT539 is an intrinsically safe instrument, the terminal connection to the Ex i side on

local HART® connection is allowed on the NMS5 terminal housing.

Note!

Endress+Hauser 19

Do not connect the NMT539 local HART

terminals are designed to connect Ex d local HART

®

communication on terminals 4 and 5 on the Proservo NMS5. These

®

communication.

Page 20

Prothermo NMT539

NMT+

NMT-

TIIS Ex d[ia]

Prothermo NMT539

terminal

Note!

The NMT539 Ex d[ia] allows a local HART® connection available in Japan. Please refer to the i.s. regulation for

establishing wiring and field device layout.

local HART

®

multi drop connection depends on approval type.

Cable gland

(SXC-16B)

Non-hazardous area

Class A grounding (1 to 1.5mm

Note!

when grounding the barrier, connect with tank or

use the shielded wi re fo r remote cable

When using the shielded w ire for remo te cable,

refer to “Electrical connection”.

2

x 2)

Screened twisted pair

or steel armored wire

Note!

Metal cable gland only:

Shield of HART communication

line must be grounded

Temp. (and / or WB) data

Ex frame HART on NMT 539

+: H1+ terminal

- : H1- terminal

to NRF 590

+ terminal 24, 26 or 28

- terminal 25, 27 or 29

to NMS5/7

+ terminal 24

- terminal 25

Ex d

NMS5 connection

Connect Prothermo NMT539 Ex d[ia] to Proservo Ex d terminals.

L

1

2

N

G

3

Power supply

AC 85 ... 264V 50/60Hz

or

DC 20 ... 62V AC20 ... 55V

L

ARS

G

ARS

N

ARS

4

5

6

7

8

9

+

Non IS HART

to NRF or others

_

Digital output

+

Rack bus RS485,

Serial pulse,

_

or

HART

+

Alarm contact

_

10

11

12

13

14

15

+

Alarm contact

_

+

Alarm contact

_

+

Alarm contact

_

16

17

18

19

20

21

COM

HOIST

STOP

+

_

Operation

contact

input

4 ... 20 mA

Channel 1

+

22

4 ... 20 mA

Channel 2

_

23

+

24

HART

_

25

26

from NMT539

Ex d HART

20 Endress+ Hauser

Page 21

Prothermo NMT539

24V

mA

TGM5/TMD1 terminal When TGM5 except Sakura code (collector common), BCD (emitter common), BCD (collector common) is

equipped with local HART® communication, it is possible to connect Ex d[ia] equipment, but terminal number

depends on the specification. Please see terminal figure for TGM5.

In case of TMD1-xBxxxxxxxxx (with local HART

®

input), it is possible to connect Ex d[ia] equipment, but

terminal number depends on the specification. Please see terminal figure for TMD1.

Terminal connection on the

Tank Side Monitor NRF590

Ex ia terminal

Note!

The Tank Side Monitor NRF590 has three sets of i.s. local HART

®

terminals.

Caution!

Do not connect signal local HART

®

lines from the NMT539 to terminals 30 and 31. They are designed to

supply drive power for the FMR 53x series only.

TIIS Ex d terminal

Power supply

Digital I/O A

Digital I/O B

Cable screened

Field

Protocol and

analog I/O

Endress+Hauser 21

Page 22

Operating condition : Environment

Ambient temperature range -40 C°... +85C°(-40°F...+185°F)

-20 C°... +60C°(-4°F...+140°F)...TIIS

Storage temperature -40 C°... +85C°(-40°F...+185°F)

Climate class DIN EN 60068-2-38 (test Z/AD)

Degree of protection Housing : IP65, (Converter only, open housing: IP20)

Probe : IP68

Electromagnetic compatibility When installing the probes in metal and concrete tanks and when using a coax probe:

• Interference Emission to EN 61326, Electrical Equipment Class B

• Interference Immunity to EN 61326, Annex A (Industrial)

Operating condition : Process

Process temperature range Temperature probe : -170 ...+235 °C (-274 ...+455°F)

WB probe : 0 ...+100 °C (+32 ...+212°F)

Prothermo NMT539

Process pressure limits 100kPa

Data transmission 2.5mm coaxial cable & common ground

22 Endress+ Hauser

Page 23

Prothermo NMT539

Mechanical construction

Type 1: Converter only

version

Type 1: Measuring function The Converter only version is the direct replacement of the previous NMT 538 series. Connection and

Standard PF(NPS) 3/4" universal coupling connection

Approx. 319mm

189mm

48mm

compatibility are provided to third party temperature probes with various element types. Unlike the NMT 538,

the powerful processor of the NMT 539 calculates and converts the following element types without altering

the program (EPROM installed software):

• Pt100

• Cu100

• Cu90

• PtCu100

The type 1 converter also enables connection to a dual function average temperature and capacitance WB

probe, such as the Weed Beacon MWR. Wiring, however, requires the isolation of the RTD temperature signal

from the capacitance WB signal on coaxial cable. The wiring of the temperature signal is exactly the same as

Endress+Hauser's 1700, 9909 and other RTD probes. The coaxial (WB) cable must be routed from the existing

auxiliary capacitance to the local HART

Caution!

NMT 539 is only compatible with MRTs (Multi-Resistance Thermometers) and/or MSTs (Multi-Spot

Thermometers). It is not designed to work with "Thermocouple" type thermometers.

The physical connection between probe to NMT 539 is completed by Zinc plated carbon steel PF 3/4" (NPS

3/4") universal threaded coupling. In case a different thread size is required, Endress+Hauser can provide the

simplest and most efficient solution by adapting a variety of coupling sizes and materials based on existing

temperature probe specifications.

The power supply and data transmission lines are both fed to the host gauge, Proservo NMS5 or Tank Side

Monitor NRF 590, by one pair of local HART

NMT 539 can also be configured and operated via the ToF (Time-of-Flight) tool or FieldCare.

®

(or 4 - 20 mA) converter via NMT 539's terminal compartment.

®

loop connections. In addition to the user-friendly display, the

Endress+Hauser 23

Page 24

Prothermo NMT539

Type 2: Converter only

version

For the Varec 1700, M20 threaded connection

Terminal Box of 1700 series RTD probe

168mm

32mm

Lock nut

Type 2: Measuring function Basic functionality remains the same, but the special M20 threaded connection allows the NMT 539 converter

to fit directly onto the existing terminal housing of the 1700.

Actual wiring of the RTD signal from the probe to the NMT 539 must be executed in the terminal box of the

1700, not the NMT 539. Therefore, the type 2 converter only has a primary housing that contains NMT 539

electronics and no secondary housing is included.

Caution!

Secure the threaded connection with seal tape and tighten the lock nut at the actual installation. A loose connection of the NMT 539 & Varec 1700 terminal housing can cause serious electrical damage depending on

environmental conditions.

24 Endress+ Hauser

Page 25

Prothermo NMT539

A

Converter + average

temperature probe version

Adjustable installation height:

approx.

180mm(7”)

djustable installation height:

approx.

180mm(7”)

194mm

Ø32mm

104mm

15mm (0.6”)

*Depend on flange spec.

Flexible tube depends

on the tank height

Margin of error for

temp. probe length : ± 50mm

Ø36mm

Measuring function The W&M approved high accuracy temperature device is well suited for both custody transfer and inventory

control applications. Based on the product temperature range and specific application, the NMT 539 has several

different temperature ranges to meet your application requirements:

Temp. range Approval Application

-20 ...+100°C

TIIS Most standard temperature range for inventory control applications

(-4 ...+212 °F)

-20 ...+235°C

(-4 ...+455 °F)

-40...+100°C

(-40 ...+212 °F)

-55...+235°C

(-67 ...+455 °F)

-170 ...+60°C

TIIS Capability of high and / or low temperature product applications like

sulfur & asphalt and moderate liquid / gas application.

ATEX/FM/CSA/

IECEx

ATEX/FM /CSA/

IECEx

Most standard temperature range for inventory control

applications

Capability of high and / or low temperature product applications like sulfur &

asphalt and moderate liquid / gas application

TIIS Cryogenic, e.g. LNG, ethylene...

(-274 ...140 °F)

-20 ...+120°C

PTB [PTB (Germany)] : W&M certified applications.

(-4 ...248 °F)

The NMT 539 converter and average temperature probe consists of up to 16 IEC class A Pt100 elements in

the protection tube. The very sensitive sensor elements change resistance values depending on the surrounding

temperature. Therefore, applied voltage through this sensor deviates based on resistance change at the element.

As a specific design to meet intrinsically safe standards, the NMT 539 converter and temperature version is

built with a very efficient power management concept.

In order to achieve the highest degree of measurement accuracy and mechanical & electrical durability,

NMT539 employs a powerful processor, large storage capacity, and simple module structure.

To achieve the user-friendly concept, the newly adopted height adjuster allows the adjustment of the

installation height up to approximately 360mm (14") at the process connection (flange) depending on the tank

shape and condition.

W&M function The NMT 539 converter and temperature probe is custody transfer approved. Once the NMT 539 is

configured to "W&M mode", all the changeable parameters are frozen by software and mechanical switch

protection.

Endress+Hauser 25

Page 26

Converter + average

Adjustable installation height:

approx.180mm(7”)

Adjustable installation height:

approx.180mm(7”)

15mm (0.6”)

Flexible tube depends

on the tank height

1000, 2000mm (39.37",78.74")

capacitance WB probe

(when there is Anchor weight)

194mm

104mm

Ø45mm

Ø45mm

10mm

Margin of error for

temp. probe length : ± 50mm

*Depend on flange spec.

temperature probe + WB

probe version

Prothermo NMT539

Measuring function The Prothermo NMT 539 is available in the ultimate all-in-one "Converter + Temp. + WB" version. Both

temperature and WB data are fully accessible on one pair of local HART

®

communication lines.

Parameters can be configured via Proservo NMS5/NMS7, Tank Side Monitor NRF 590, ToF tool, FieldCare.

The integrated WB sensor (capacitance water interface measurement) is set at the bottom of the average

temperature probe. The standard WB measurement ranges are 1m (3.3 ft) and 2m (6.6 ft). The tube structured

WB sensor is made of SUS304 pipe and exterior is protected by an additional 1mm thick PFA tube. Pt 100

elements are set inside of this tube structure, meaning that temperature measurement is not disturbed due to

the WB functionality.

Caution!

Due to the characteristic of capacitance measurement, precise initial calibration must be performed in order to

achieve the maximum measurement accuracy.

The condition of tank contents (both oil & water), liquid temperature and individual probe characteristic can

greatly effect the measurement performance.

Specific accuracy & repeatability measurement must be taken within the same environment in order to perform

data comparison.

Note!

If water in the tank freeses, it is not possible to measure the water interface. Protect the water in the tank from

freezing.

26 Endress+ Hauser

Page 27

Prothermo NMT539

WB probe design

Weight Approx. 13kg

Condition:

16 elements

Temp. probe : 10m

WB probe: 1m

Flange : 2" 150lbs RF, SUS316

PFA protection tube

(1mm (0.04") thickness)

Up to 2 Pt100 element

can be inserted

Solid structured

side rods

(SUS 316)

Center rod

(SUS304 tube)

Pt100 element

base plate &

Material Elements : Class A Pt100, IEC PUB 751 1995, JIS 1604 1997

Housing : Aluminum diecast

Temp. probe : SUS316 flexible tube

WB sensor : SUS316 (center rod SUS 304 & PFA protected)

Human interface

Operation using ToF Tool,

FieldCare

The Prothermo NMT539 can also be operated via the ToF Tool or FieldCare Package. These programs support

commissioning, securing of data, signal analysis and documentation of the instruments. They are compatible

with the following operating systems: WinNT4.0, Win 2000 and Win XP.

The ToF Tool and FieldCare Packages support the following functions:

• Online configuration of transmitters

• Loading and saving of instrument data (Upload/Download)

• Documentation of measuring points

Endress+Hauser 27

Page 28

Prothermo NMT539

Certificates and approvals

CE approvals By attaching the CE mark, Endress+Hauser confirms that the instruments pass the required tests.

Ex approvals

Ex approval Class

ATEX II 1/2 G Ex ia IIB T2...T6

IECEx Ex ia IIB T2 - T6 Ga/Gb

FM IS Class 1, Div. 1, Gp. C, D, T6, T4, T3, T2

Class 1, Zone 0, AEx ia IIB, T6, T4, T3, T2

CSA Ex ia Class 1, Div.1, Gp. C, D, T6...T2

Ex ia IIB T6...T2

Ex ia IIB T4

TIIS

PTB W&M approval PTB 14.70 08.01 (Germany)

Ex ia IIB T2

Ex d[ia] IIB T4

External standards and

guidelines

IEC 61326 Appendix :A, Immunity according to table A-1

EN 60529

Protection class of housing (IP-code)

EN 61326

Emissions (equipment class B), compatibility (appendix A - industrial area) EN61000-4-2

Immunity to electrostatic discharge

IEC 61508

Functional safety of electrical/electronic/programmable electronic safety-related systems

28 Endress+ Hauser

Page 29

Prothermo NMT539

Ordering information

010 Protection class:

0 Weather proof, IP65 NEMA4X

7 FM IS Cl.I Div.1 Gr.C-D

8 CSA IS Cl.I Div.1 Gr.C-D

B ATEX Ex (ia) IIB T2-T6

C TIIS Ex ia IIB T2

A TIIS Ex ia IIB T4

E TIIS Ex d (ia) IIB T4

F IEC Ex ia IIB T2-T6 Ga

9 Special version, TSP-no. to be spec.

020 Measuring function:

0Converter

1 Temperature, Converter

3 Temperature, Water Bottom, Converter

4 Temperature, Converter (PTB type approval)

5 Temperature, Converter, Water Bottom (PTB type approval)

9 Special version, TSP-no. to be spec.

030 Temperature Measuring Range:

0 Not selected

5 -20 ...+100 °C

1 -40 ...+100 °C

6 -20 ...+235 °C

2 -55 ...+235 °C

3 -170 ...+60 °C

4 -20 ...+120 °C (PTB type approval only)

9 Special version, TSP-no. to be spec.

040 Water Bottom Measuring range:

0 Not selected

1 1m/3.3 ft.

2 2m/6.6 ft.

9 Special version, TSP-no. to be spec.

050 Cable entry:

AThread G1/2

BThread NPT1/2

D Thread M20

9 Special version, TSP-no. to be spec.

060 Process connection :

0 10K 50A RF, SUS316, flange JIS B2220

1 2" 150lbs RF, SUS316, flange ANSI B16.5

2 DN50 PN10 B1, SUS316, flange EN1092-1 (DIN2527 B)

3 50A 150lbs RF, SUS316, flange JPI 7S-15

4 Universal coupling, G3/4, (converter only)

5 Thread M20 (converter only)

9 Special version, TSP-no. to be spec.

NMT539- Product designation (part1)

Endress+Hauser 29

Page 30

070 Temperature Element:

A 2 x Pt100

B 3 x Pt100

C 4 x Pt100

D 5 x Pt100

E 6 x Pt100

F 7 x Pt100

G 8 x Pt100

H 9 x Pt100

J 10 x Pt100

K 11 x Pt100

L 12 x Pt100

M 13 x Pt100

N 14 x Pt100

O 15 x Pt100

P 16 x Pt100

Q Not selected

Y Special version, TSP-no. to be spec.

080 Temperature Element Spacing:

7 UK standard (converter only)

31m / 39"

21.5m / 59"

12m / 79"

5 3m / 118"

4 Equally spaced, defined by length

6 Not selected

9 Special version, TSP-no. to be spec.

090 Probe Length:

A .....mm

B Not selected

C ..... , Gas-tight feed through

Y Special version, TSP-no. to be spec.

100 Mounting Attachment:

A Not selected

B Anchor weight, high profile (D120)

C Anchor weight, low profile (hexagon H41)

D Tension wire, wire hook, NPT1 top anchor

F Tension wire, wire hook, R1 top anchor

G *Bottom hook

Y Special version, TSP-no. to be spec.

Prothermo NMT539

NMT539- Complete product designation

Note!

030 Temperature Measuring Range:

5 : -20...+100°C (TIIS only)

6 : -20...+235°C (TIIS only)

090 Probe Length:

A : .....mm (TIIS : 1000

C : ..... , Gas-tight feed through (TIIS : 1000 ≤ L ≤ 40000)

Y : .....mm (TIIS

30 Endress+ Hauser

≤ L ≤ 30000)

: 30000< L ≤ 40000)

Page 31

Prothermo NMT539

120mm (4.72")

180mm (7.09")

222mm (8.74")

42mm (1.65")

Weight

approx. 16kg

Material:

Weight : JIS SS400 mild carbon steel)

Ring: JIS SS400 mild carbon steel)

Accessories

Anchor weight (high profile,

D120) mounting attachment

option: B

This high profile anchor type is designed for Converter + temperature probe versions.

Caution!

Installation of the anchor weight will cause the lowest temperature measurement position to be raised

approximately 400mm (16") from the tank floor.

Anchor weight (low profile,

hexagon H41) mounting

attachment option: C

Different dimensions, weight and material for the anchor weight are also available.

The low profile anchor weight is mainly designed to stabilize the WB sensor, securing it straight up without

shortening the WB measuring range. It is also suitable for an existing tank installation with a small nozzle

opening for converter and temperature version.

Material

Weight : JIS SS400 mild carbon steel)

Ring : JIS SS400 mild carbon steel)

Weight

approx. 12kg

1040mm (40.94")

41mm (1.61")

Endress+Hauser 31

Page 32

Wire hook, Top anchor

9mm(0.35")

21mm(0.83")

70mm

(2.76")

200

mm(7.87")

150

mm(5.91")

Weight : approx 1.5kg

Material

Weight : JIS SS400 mild carbon steel)

Ring : JIS SS400 mild carbon steel)

Wire hook

Material

Exterior: ADC(aluminium)

Internal parts : SUS316, Carbon steel

Weight: Approx. 1.2kg

52mm (2.05”)

190mm (7.48”)

R1 or NPT1( specified by order code)

Top anchor

mounting attachment

option: D,F

Prothermo NMT539

Actual tensioning can be completed with SUS316 stranded 3mm diameter tension wire between wire hook

and top anchor.

Note!

The standard process connection of the top anchor is R1 or NPT1 threaded connection.

32 Endress+ Hauser

Page 33

Prothermo NMT539

Documentation

Technical Information TI00452G

Proservo NMS5

TI008N

Promonitor NRF560

TI024N

Digital Transmitter TMD1

Operating Instructions BA01025G

Prothermo NMT539 (Installation Instructions)

BA01026G

Prothermo NMT539 (Operating Instructions and Description of Instrument Function)

Certificates

Prothermo NMT539

Temp. converter Ex496-826XJ

Average temp.and/or

WB sensor

Average temp.

(high temp.)

Average temp.

(low temp.)

Average temp.and/or

WB sensor

TIIS

(Ex ia)

Ex463-820XJ

(Ex ia)

Ex495-823XJ

(Ex ia)

Ex1061-986XJ

(Ex ia)

Ex1016-983XJ

(Ex d[ia])

ATEX IEC FM CSA

Ex461-851-1 Ex462-712-2

XA00585G-A XA00583G-A

Ex461-850-1 Ex462-711-2

Endress+Hauser 33

Page 34

Appendix

Prothermo NMT539

Stainless Steel conversion

table

The stainless steel material used in products of Endress + Hauser Yamanashi normally have expressions

according to Japanese industrial standards, such as JIS. Each country or region may have different expressions.

The following conversion table contains the expression of equivalent stainless steel material based on chemical

composition and mechanical properties.

Country Standard Expressions

Japan JIS SUS304 SUS304L SUS316 SUS316L

Germany DIN 17006 X5 CrNi 18 10

W.N. 17007 1.4301 1.4303 1.4306 1.4401 / 1.4436 1.4404

France AFNOR Z 6 CN 18-09 Z 2CN 18-10 Z 6 CND 17-11 / 17 12 Z2 CND 17-12

Italy UNI X5 CrNi 1810 X2 CrNi 1911 X5 CrNiMo 1712 /

U.K. BSI 304S15 / 304S16 304S11 316S31 / 316S33 316S11

U.S.A. AISI 304 304 L 316 316L

U.E. EURONORM X6 CrNi 1810 X3 CrNi 1810 X6 CrNiMo 17 12 2 /

Spain UNE X6 CrNi 19-10 X2 CrNi 19-10 X6 CrNiMo 17-12-03 X2 CrNiMo 17-12-

Russia GOST 08KH18N10

- ISO 11 10 20 19

- ASME S30400 S30403 S31600 S31603

X5 CrNi 18 12

06KH18N11

X2 CrNi 18 11 X5 CrNiMo 17 12 2 /

1713 3

1713

17 13 3

03KH18N11 _ 03KH17N14M2

X2 CrNiMo 17 13 2

X2 CrNiMo 1712

X3 CrNiMo 17 12 2

03

Note!

Standards may be not necessarily correspond exactly to the Japanese Industrial Standard, because they are

defined by mechanical and chemical criteria.

34 Endress+ Hauser

Page 35

Endress + Hauser Yamanashi Co., Ltd.

862-1 Mitsukunugi Sakaigawa-cho

Fuefuki-shi Yamanashi,

406-0846 Japan

Phone: ++81 55 266 4964

Fax: ++81 55 266 4969

http://www.endress.com

Prothermo MT530

TI00042G/08/EN/14.11

71136671

FM+SGML 6.0

Loading...

Loading...