Page 1

BA01462G/00/EN/04.18

71411070

2018-07-13

Valid as of version

01.03.zz (Device firmware)

Products Solutions Services

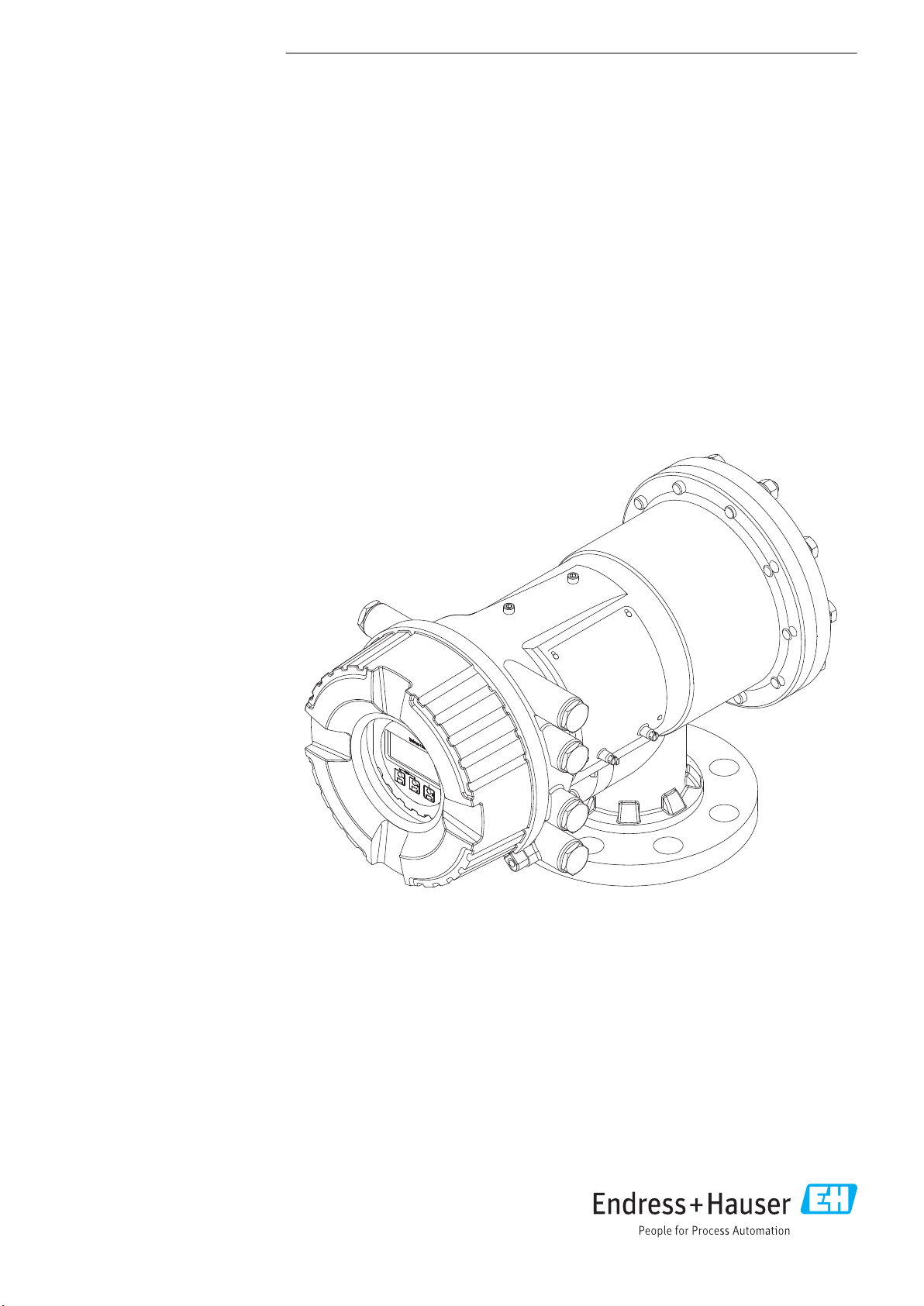

Operating Instructions

Proservo NMS83

Tank Gauging

Page 2

Proservo NMS83

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

2 Endress+Hauser

Page 3

Proservo NMS83 Table of contents

Table of contents

1 About this document ................ 4

1.1 Document function ..................... 4

1.2 Symbols .............................. 4

1.3 Documentation ........................ 7

1.4 Registered trademarks ................... 9

2 Basic safety instructions ........... 10

2.1 Requirements for the personnel ........... 10

2.2 Designated use ....................... 10

2.3 Workplace safety ...................... 11

2.4 Operational safety ..................... 11

2.5 Product safety ........................ 11

3 Product description ................ 12

3.1 Product design ........................ 12

4 Incoming acceptance and product

identification ..................... 13

4.1 Incoming acceptance ................... 13

4.2 Product identification .................. 13

4.3 Storage and transport .................. 15

5 Installation ....................... 17

5.1 Requirements ........................ 17

5.2 Mounting of the device ................. 30

5.3 Post-installation check .................. 36

6 Electrical connection .............. 38

6.1 Terminal assignment ................... 38

6.2 Connecting requirements ................ 53

6.3 Ensuring the degree of protection .......... 54

6.4 Post-connection check .................. 54

7 Operability ........................ 55

7.1 Overview of the operation options ......... 55

7.2 Structure and function of the operating

menu .............................. 56

7.3 Access to the operating menu via the local or

remote display and operating module. ...... 58

7.4 Access to the operating menu via the service

interface and FieldCare ................. 71

7.5 Access to the operating menu via Tankvision

Tank Scanner NXA820 and FieldCare ....... 72

8 System integration ................ 75

8.1 Overview of the Device Description files

(DTM) .............................. 75

9 Commissioning .................... 76

9.1 Terms related to tank measurement ........ 76

9.2 Initial settings ........................ 77

9.3 Calibration .......................... 79

9.4 Configuring the measuring device .......... 87

9.5 Configuring the tank gauging application .... 99

9.6 Advanced settings .................... 121

9.7 Simulation .......................... 121

9.8 Protecting settings from unauthorized

access ............................. 121

10 Operation ....................... 122

10.1 Reading off the device locking status ...... 122

10.2 Reading off measured values ............ 122

10.3 Gauge commands .................... 123

11 Diagnostics and troubleshooting .. 129

11.1 General trouble shooting ............... 129

11.2 Diagnostic information on local display ..... 130

11.3 Diagnostic information in FieldCare ....... 133

11.4 Overview of the diagnostic messages ...... 135

11.5 Diagnostic list ....................... 141

11.6 Reset measuring device ................ 142

11.7 Device information ................... 142

11.8 Firmware history ..................... 142

12 Maintenance .................... 143

12.1 Maintenance tasks .................... 143

12.2 Endress+Hauser services ............... 143

13 Repair ........................... 144

13.1 General information on repairs ........... 144

13.2 Spare parts ......................... 144

13.3 Endress+Hauser services ............... 145

13.4 Return ............................. 145

13.5 Disposal ........................... 145

14 Accessories ...................... 146

14.1 Device-specific accessories .............. 146

14.2 Communication-specific accessories ....... 149

14.3 Service-specific accessories .............. 149

14.4 System components ................... 149

15 Operating menu .................. 150

15.1 Overview of the operating menu .......... 150

15.2 "Operation" menu ..................... 161

15.3 "Setup" menu ........................ 177

15.4 "Diagnostics" menu .................... 308

Index ................................. 320

Endress+Hauser 3

Page 4

About this document Proservo NMS83

DANGER

WARNING

CAUTION

NOTICE

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

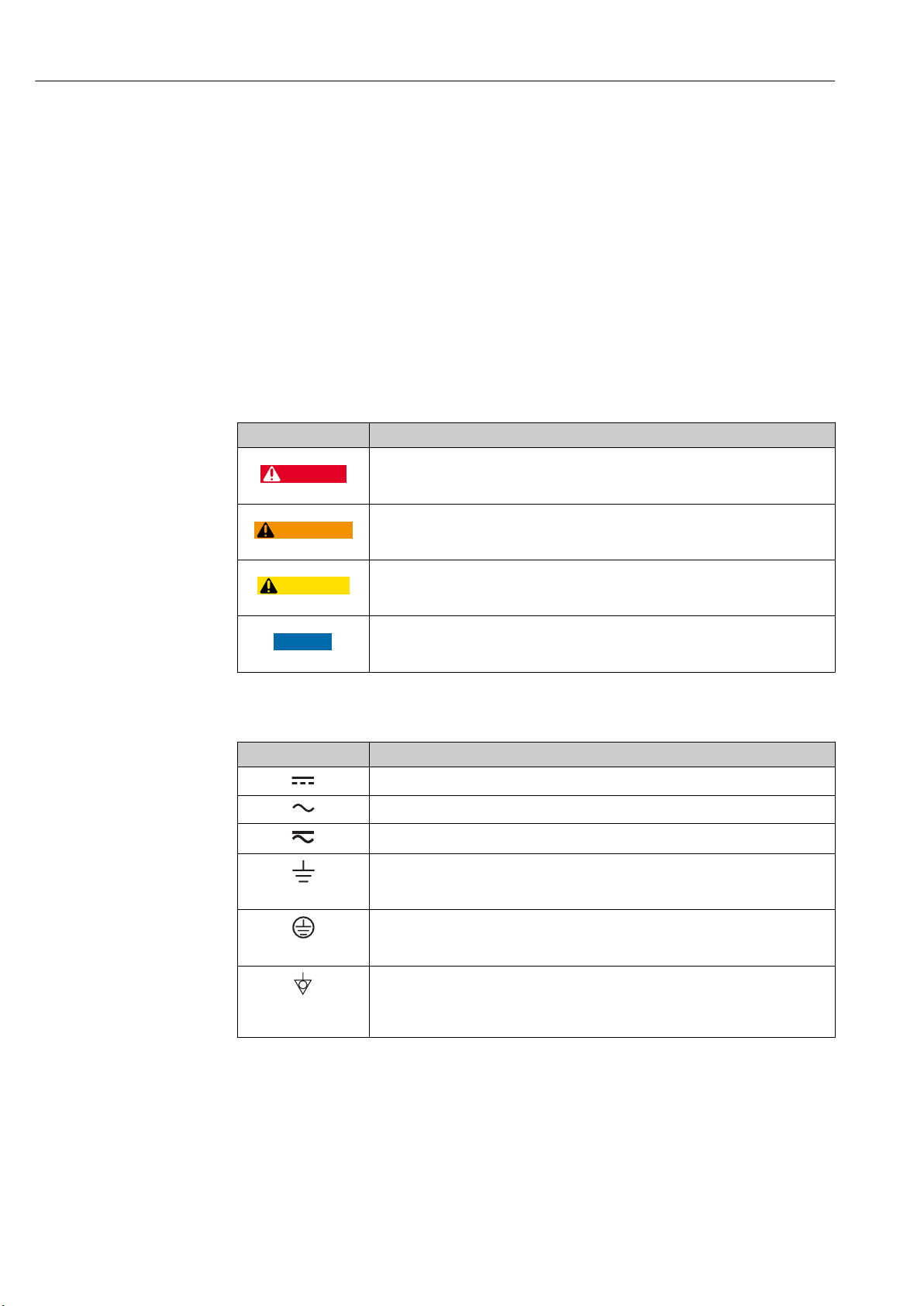

1.2 Symbols

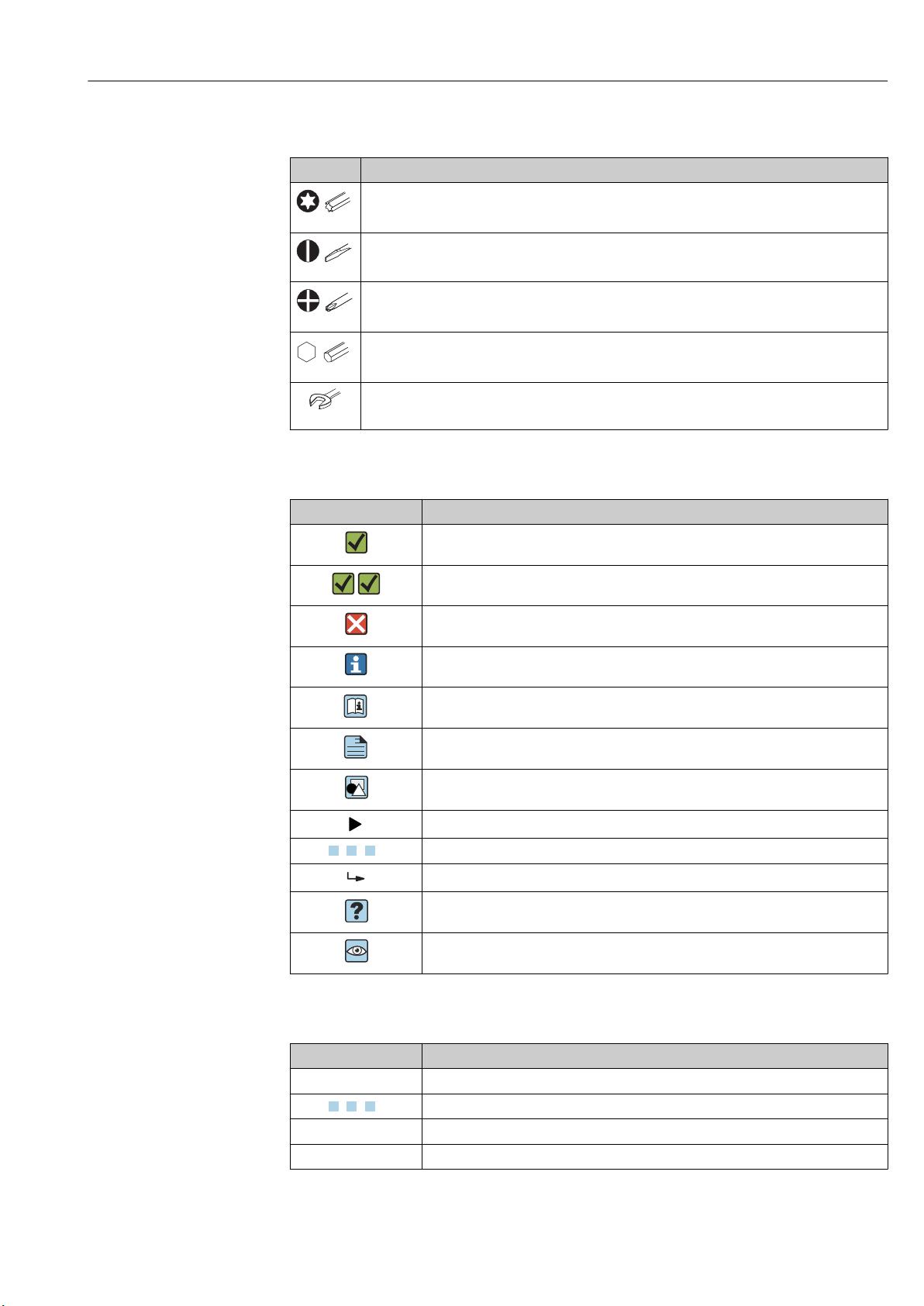

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or

company codes of practice.

4 Endress+Hauser

Page 5

Proservo NMS83 About this document

A

1.

1.

1.2.3 Tool symbols

Symbol Meaning

Torx screwdriver

A0013442

Flat blade screwdriver

A0011220

Cross-head screwdriver

A0011219

Allen key

A0011221

Hexagon wrench

A0011222

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Notice or individual step to be observed

, 2., 3.… Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Endress+Hauser 5

Page 6

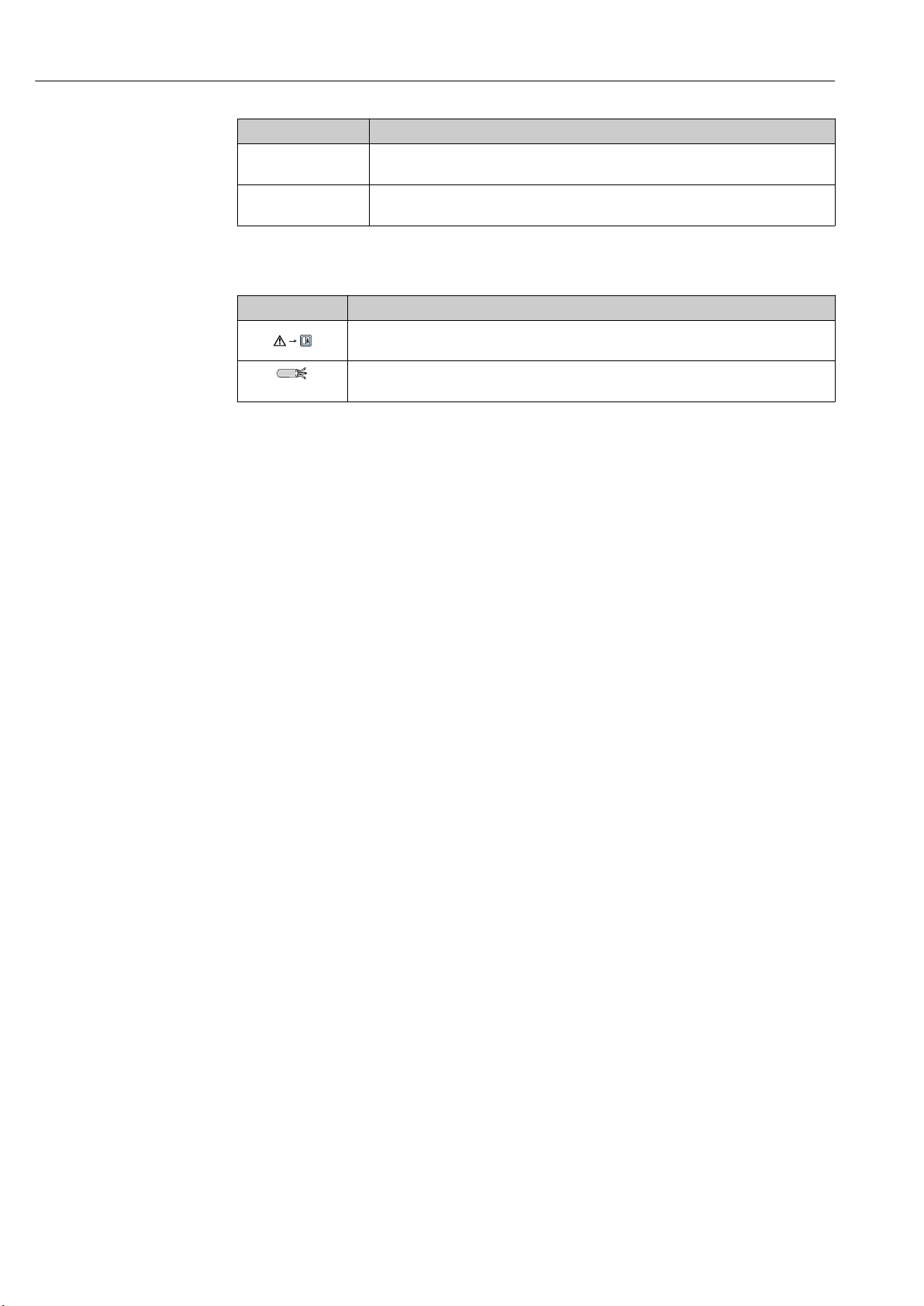

About this document Proservo NMS83

-

.

Symbol Meaning

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

1.2.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

6 Endress+Hauser

Page 7

Proservo NMS83 About this document

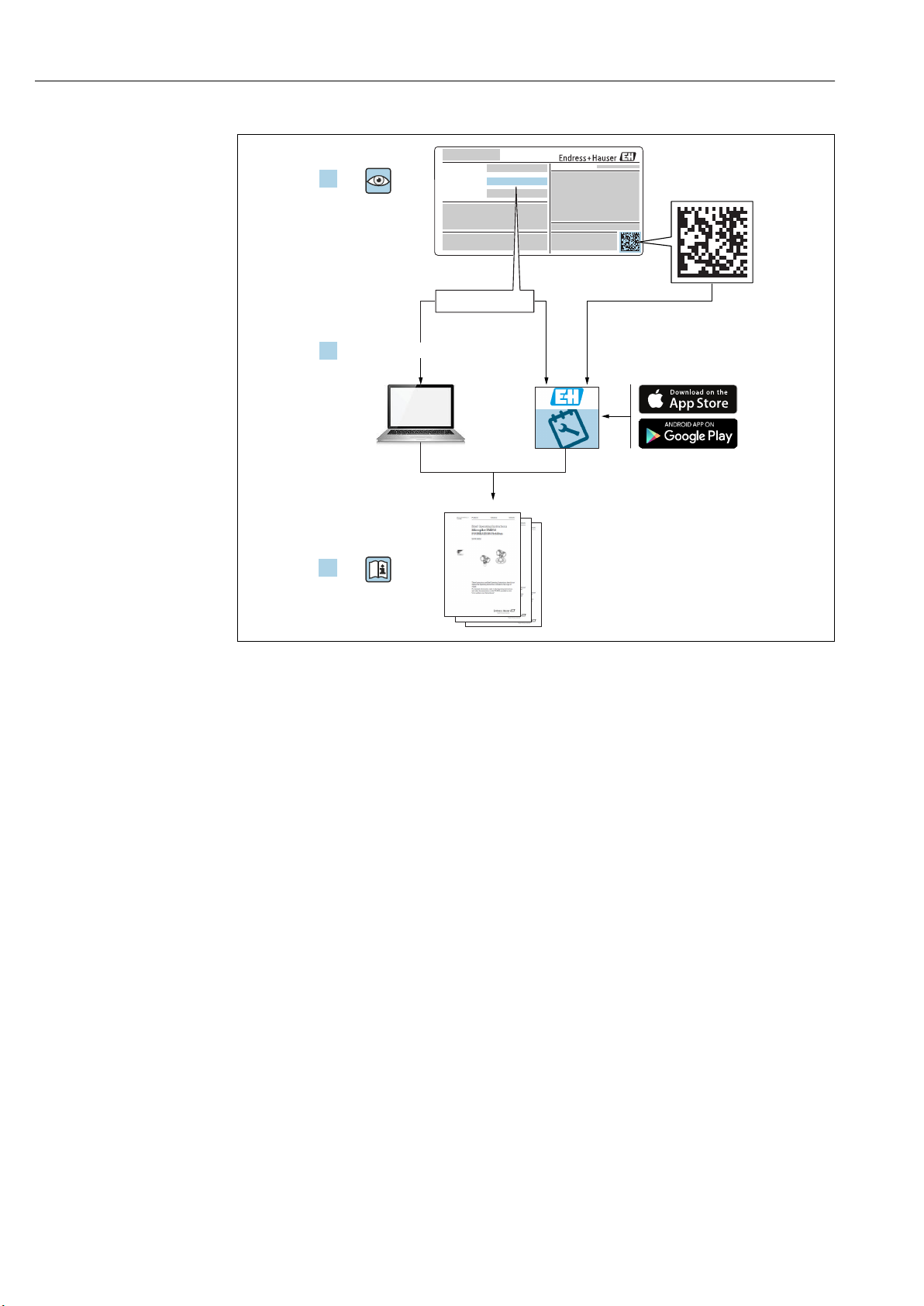

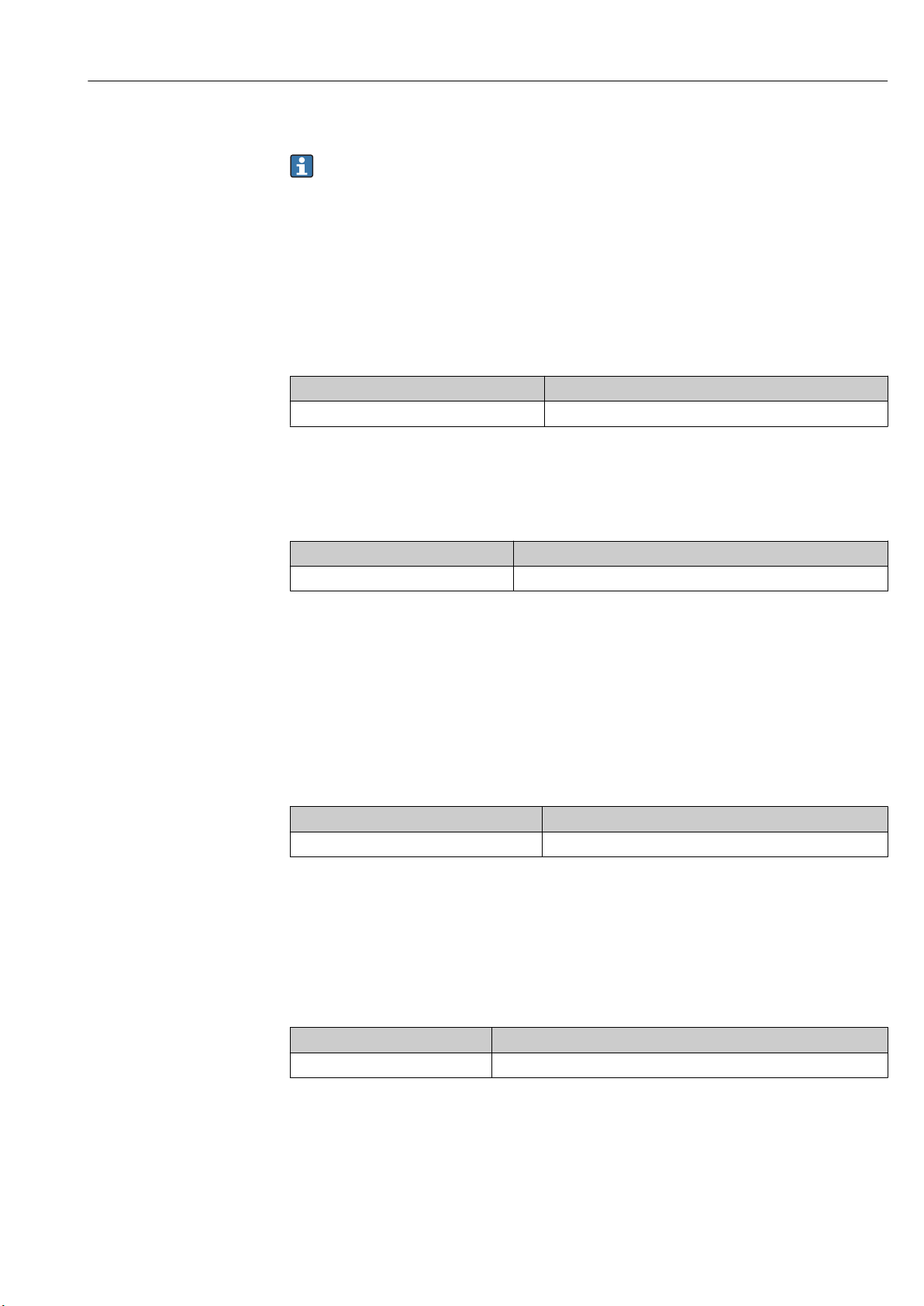

1.3 Documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The W@M Device Viewer : Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate

or scan the 2-D matrix code (QR code) on the nameplate.

1.3.1 Technical Information (TI)

The Technical Information contains all the technical data on the device and provides an

overview of the accessories and other products that can be ordered for the device.

Device Technical Information

Proservo NMS83 TI01250G

1.3.2 Brief Operating Instructions (KA)

The Brief Operating Instructions contain all the essential information from incoming

acceptance to initial commissioning.

Device Brief Operating Instructions

Proservo NMS83 KA01206G

1.3.3 Operating Instructions (BA)

The Operating Instructions contain all the information that is required in various phases of

the life cycle of the device: from product identification, incoming acceptance and storage,

to mounting, connection, operation and commissioning through to troubleshooting,

maintenance and disposal.

It also contains a detailed explanation of each individual parameter in the operating menu

(except the Expert menu). The description is aimed at those who work with the device

over the entire life cycle and perform specific configurations.

Device Operating Instructions

Proservo NMS83 BA01462G

1.3.4 Description of Device Parameters (GP)

The Description of Device Parameters provides a detailed explanation of each individual

parameter in the 2nd part of the operating menu: the Expert menu. It contains all the

device parameters and allows direct access to the parameters by entering a specific code.

The description is aimed at those who work with the device over the entire life cycle and

perform specific configurations.

Device Description of Device Parameters

Proservo NMS83 GP01080G

Endress+Hauser 7

Page 8

About this document Proservo NMS83

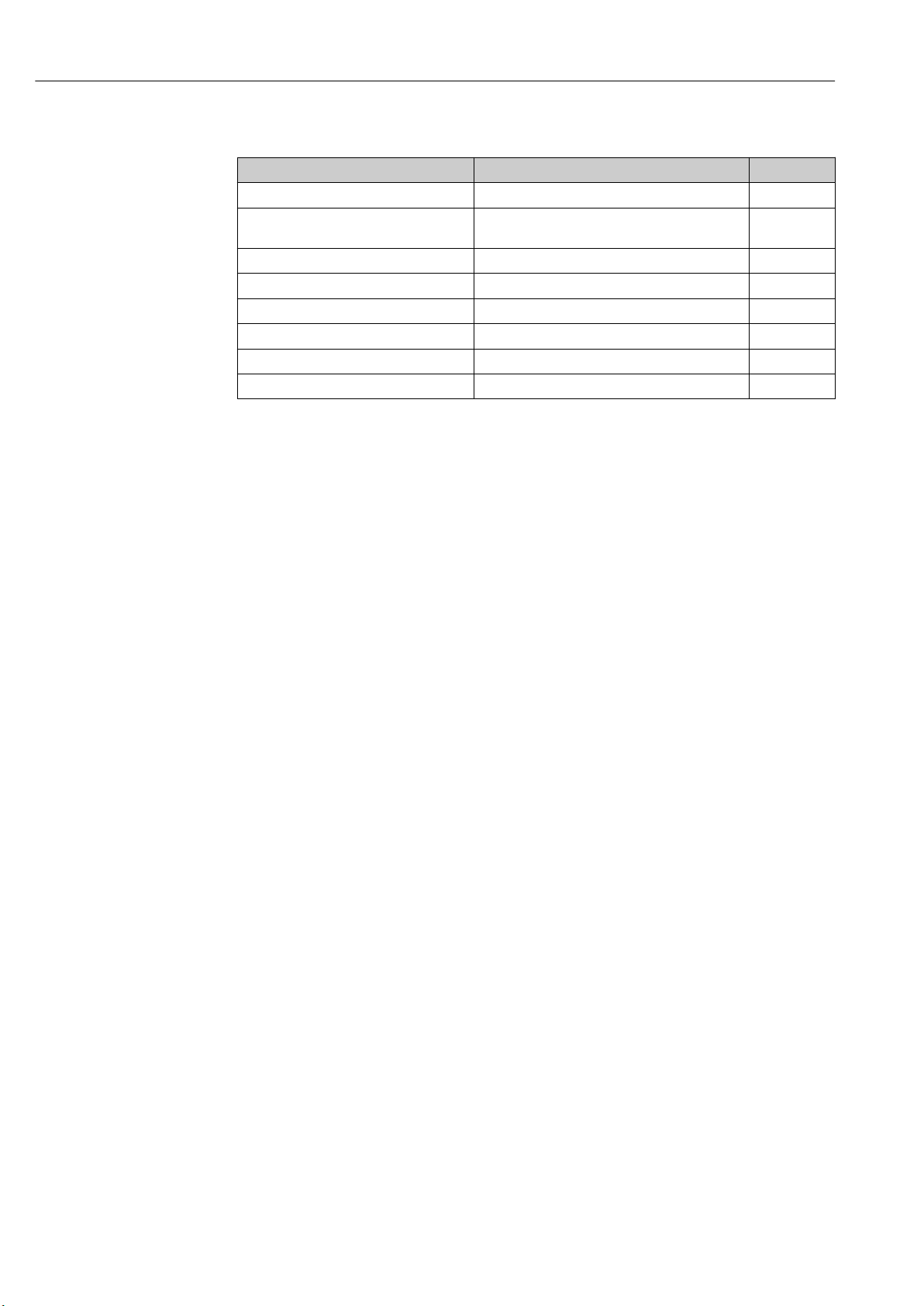

1.3.5 Safety instructions (XA)

Ordering feature 010 "Approval" Meaning XA

BC ATEX II 1/2G Ex db [ia Ga] IIC T6 Ga/Gb XA01495G

FD FM C/US XP-AIS Cl.I Div.1 Gr.BCD T6

AEx db [ia Ga] IIC T6 Ga/Gb

GC EAC Ga/Gb Ex db [ia Ga] IIC T6...T1 X XA01711G

IC IEC Ex db [ia Ga] IIC T6 Ga/Gb XA01495G

1)

KC

MC INMETRO Ex d[ia] IIC T6 Ga/Gb XA01705G

NC NEPSI Ex d[ia] IIC T6 Ga/Gb XA01704G

TC TIIS Ex d[ia] IIC T4 Ga/Gb XA01600G

1) KC approval is covered with IEC Ex approval.

KC Ex d[ia] IIC T6 Ga/Gb XA01495G

XA01496G

8 Endress+Hauser

Page 9

Proservo NMS83 About this document

1.4 Registered trademarks

FieldCare

Registered trademark of the Endress+Hauser Process Solutions AG, Reinach, Switzerland

MODBUS

Registered trademark of the MODBUS-IDA, Hopkinton, MA, USA

®

®

Endress+Hauser 9

Page 10

Basic safety instructions Proservo NMS83

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the

application).

Follow instructions and comply with basic conditions.

‣

The operating personnel must fulfill the following requirements:

Are instructed and authorized according to the requirements of the task by the facility's

‣

owner-operator.

Follow the instructions in this manual.

‣

2.2 Designated use

Application and measured materials

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or in applications

where there is an increased risk due to process pressure, are labeled accordingly on the

nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Only use the measuring device in full compliance with the data on the nameplate and

‣

the general conditions listed in the Operating Instructions and supplementary

documentation.

Check the nameplate to verify if the device ordered can be put to its intended use in the

‣

approval-related area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media against which the process-wetted materials

‣

are adequately resistant.

If the measuring device is not operated at atmospheric temperature, compliance with

‣

the relevant basic conditions specified in the associated device documentation is

absolutely essential.

Protect the measuring device permanently against corrosion from environmental

‣

influences.

Observe the limit values in the "Technical Information".

‣

The manufacturer is not liable for damage caused by improper or non-designated use.

Residual risk

During operation the sensor may assume a temperature near the temperature of the

measured material.

Danger of burns due to heated surfaces!

For high process temperatures: Install protection against contact in order to prevent

‣

burns.

10 Endress+Hauser

Page 11

Proservo NMS83 Basic safety instructions

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with the manufacturer.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from the manufacturer only.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the

hazardous area (e.g. explosion protection, pressure vessel safety):

Based on the nameplate, check whether the ordered device is permitted for the

‣

intended use in the hazardous area.

Observe the specifications in the separate supplementary documentation that is an

‣

integral part of these Instructions.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate. It meets general safety standards and legal requirements.

2.5.1 CE mark

The measuring system meets the legal requirements of the applicable EC guidelines. These

are listed in the corresponding EC Declaration of Conformity together with the standards

applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

Endress+Hauser 11

Page 12

Product description Proservo NMS83

2

1

3

4

5

6

7

8

2

3

4

9

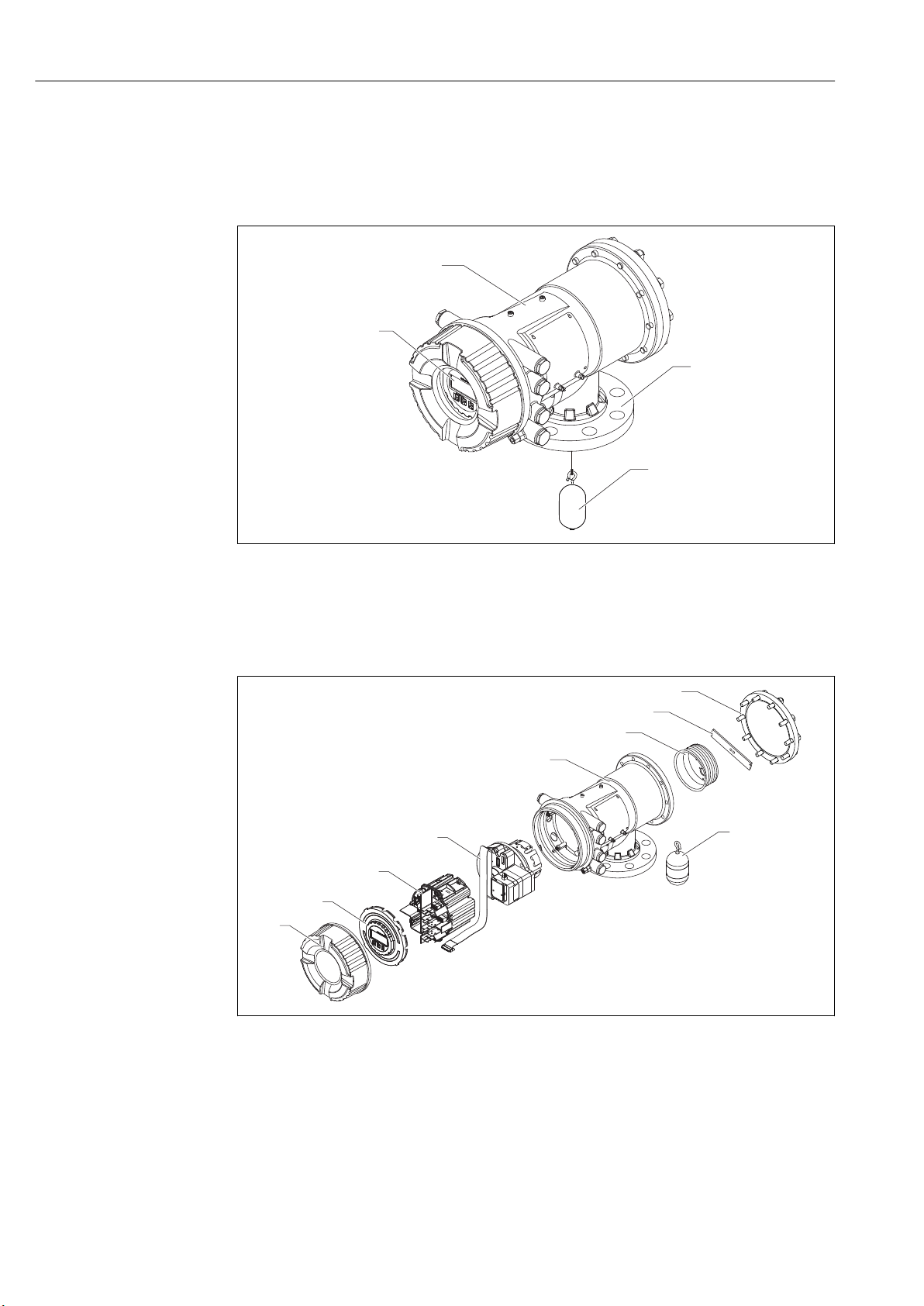

3 Product description

3.1 Product design

A0028699

1 Design of Proservo NMS83

1 Housing

2 Display and operating module (can be operated without opening the cover)

3 Process connection (Flange)

4 Displacer

2 Configuration of NMS83

1 Front cover

2 Display

3 Modules

4 Sensor unit

5 Housing

6 Wire drum

7 Bracket

8 Housing cover

9 Displacer

A0028873

12 Endress+Hauser

Page 13

Proservo NMS83 Incoming acceptance and product identification

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

Upon receipt of the goods check the following:

• Are the order codes on the delivery note and the product sticker identical?

• Are the goods undamaged?

• Do the nameplate data match the ordering information on the delivery note?

• If required (see nameplate): Are the Safety Instructions (XA) enclosed?

If one of these conditions is not satisfied, contact your Endress+Hauser Sales Center.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Extended order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

( www.endress.com/deviceviewer ): All information about the measuring device is

displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App

or scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser

Operations App: all the information for the measuring device is displayed.

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The W@M Device Viewer: Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate or

scan the 2-D matrix code (QR code) on the nameplate.

Endress+Hauser 13

Page 14

Incoming acceptance and product identification Proservo NMS83

1

3

21

22

23

6

7

8

9

14

16

15

19

20

11

18

12

13

24

25

26

28

27

4

5

Ext. ord. cd.:

Order code:

Ser. no.:

Tp max.:

Mat.:

Date:

FW:

Dev.Rev.:

ex works

DeviceID:

Ta

Ta:

if modification

see sep. label

X =

MWP:

Tank ID:

Tank ref.height:

2

Density range:

Kg/m³

17

10

4.2.1 Nameplate

A0027791

3 Nameplate

1 Manufacturer address

2 Device name

3 Order code

4 Serial number

5 Extended order code

6 Supply voltage

7 Maximum process pressure

8 Maximum process temperature

9 Permitted ambient temperature (Ta)

10 Temperature resistance of cable

11 Thread for cable entry

12 Material in contact with process

13 Device ID

14 Firmware version

15 Device revision

16 Metrology certification numbers

17 Customized parametrization data

18 Ambient temperature range

19 CE mark / C-tick mark

20 Additional information on the device version

21 Ingress protection

22 Certificate symbol

23 Data concerning the Ex approval

24 General certificate of approval

25 Associated Safety Instructions (XA)

26 Manufacturing date

27 RoHS mark

28 QR code for the Endress+Hauser Operations App

14 Endress+Hauser

Page 15

Proservo NMS83 Incoming acceptance and product identification

Proservo NMS

&'./0

1234:

-20°C + °C~ 60

67:

89:;;<=び?@のBC、E/0をGわないでください。

PQRはT9をUVしないでください。

XY34 Z[のケーブルを`aしてください。85℃

&'67cdefg

hi

+,-$%(2)

"#$%

j"#$%

Qk

+,-$%(3)

lm$%(4)

lm$%(5)

lm$%(6)

no,-$%(1)(2)

no+-$%(1)(2)

lm$%(1)

lm$%(2)

lm$%(3)

,-$%(1)

+,-$%( )1

+,-$%(4)

'p qr 2s がu vし ない こと をy zし てか らT 9を

Uけ てく ださ い。

&'():NMS

XA01600G

Ex d[ia] IIC T4 Ga/Gb

エンドレスハウザー)

い た で8 9の を らな いで くだ さい 。

:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Endress+Hauser 15

A0032435

4 Nameplate Proservo NMS8x for TIIS

1 Product type

2 Ex type

3 Input/Output circuit (1)

4 Input/Output circuit (2)

5 Signal circuit (1)

6 Signal circuit (2)

7 Signal circuit (3)

8 Output circuit (1)

9 Power supply

10 Input/output circuit (3)

11 Input/output circuit (4)

12 Signal circuit (4)

13 Signal circuit (5)

14 Signal circuit (6)

15 Contact output circuit (1) (2)

16 Contact input circuit (1) (2)

17 Drawing number

4.2.2 Manufacturer address

Endress+Hauser SE+Co. KG

Hauptstraße 1

79689 Maulburg, Germany

Address of the manufacturing plant: See nameplate.

4.3 Storage and transport

4.3.1 Storage conditions

• Storage temperature: –50 to +80 °C (–58 to +176 °F)

• Store the device in its original packaging.

Page 16

Incoming acceptance and product identification Proservo NMS83

4.3.2 Transport

NOTICE

Risk of injury

Transport the measuring device to the measuring point in its original packaging.

‣

Take into account the mass center of the device in order to avoid unintended tilting.

‣

Comply with the safety instructions, transport conditions for devices over 18kg

‣

(39.6lbs) (IEC61010).

16 Endress+Hauser

Page 17

Proservo NMS83 Installation

5 Installation

5.1 Requirements

5.1.1 Type of tanks

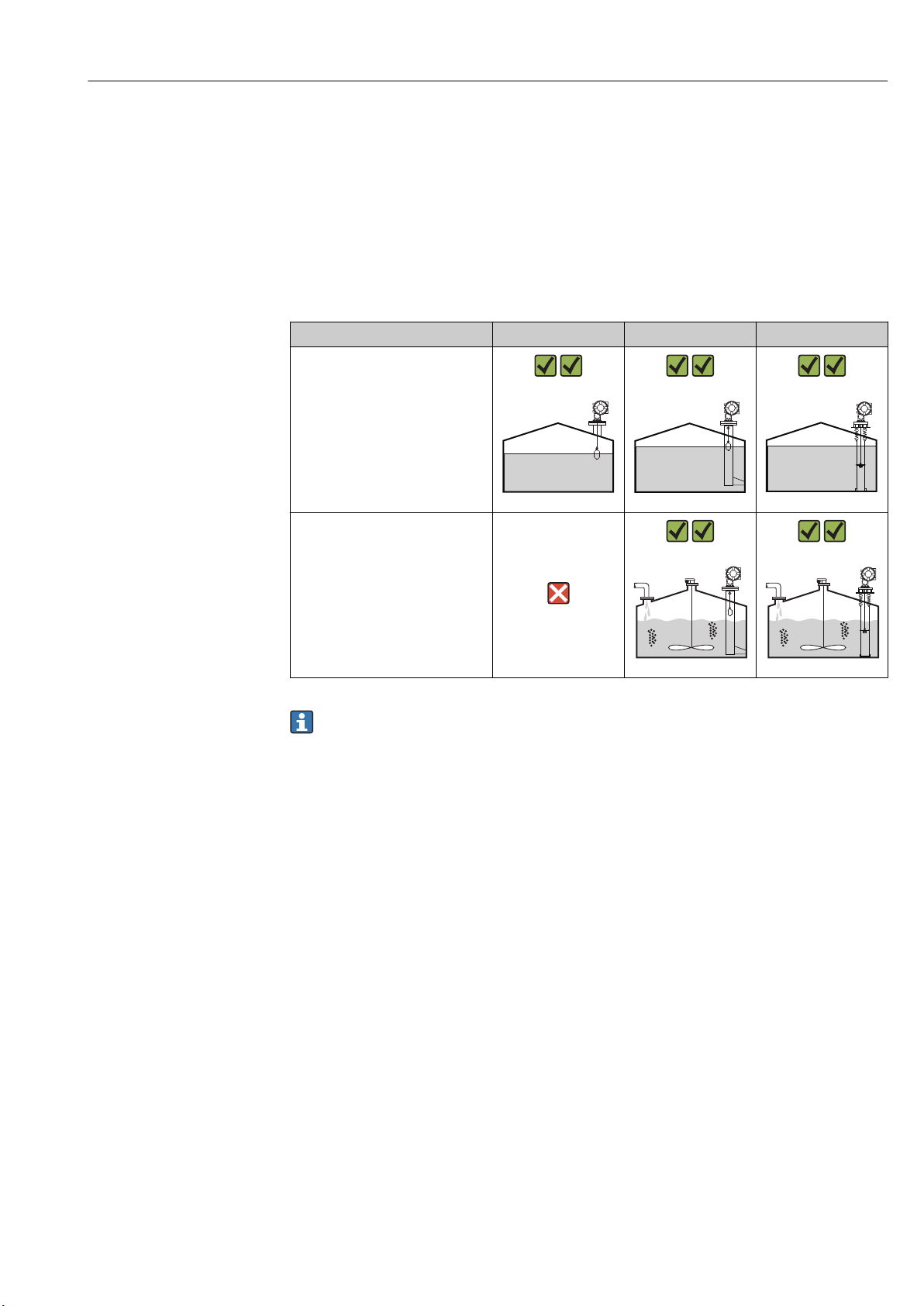

Depending on the type of tank and application, different installation procedures are

recommended for NMS8x.

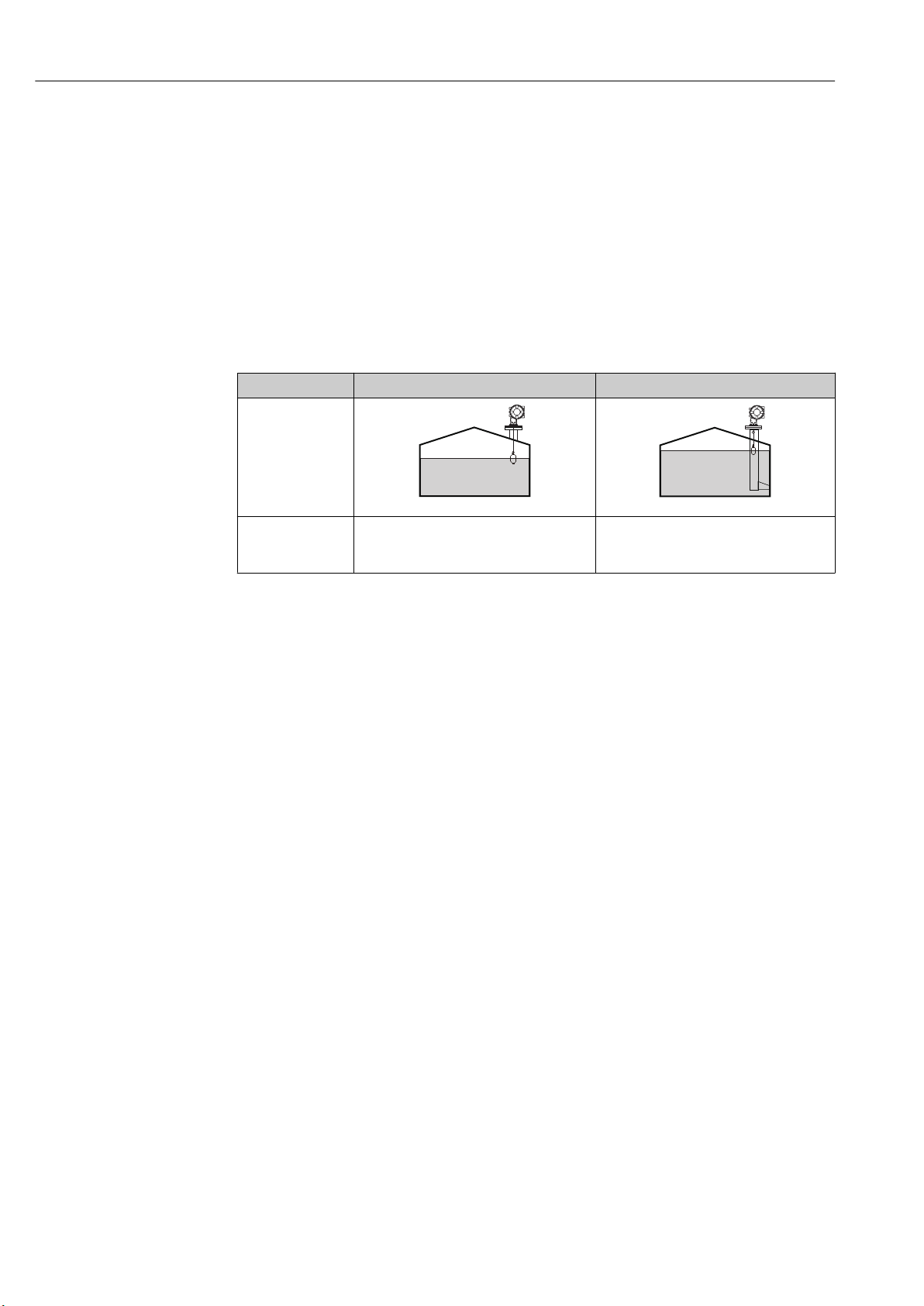

Type of tanks Without guide system With stilling well With guide wires

Fixed roof tank

A0032437 A0032438 A0032439

Tank with agitator or heavy

turbulence

A0032440 A0032441

• A stilling well is required in a floating roof tank and a covered floating roof tank.

• Guide wires cannot be installed in a floating roof tank. When the measuring wire is

exposed to free space, it may break due to an external shock.

• Installing guide wires is not allowed in pressurized tanks because the wires would

prevent closing the valve for replacing the wire, wire drum, or displacer. NMS8x

installation position is important for applications without the guide wire system in

order to prevent the measuring wire from being broken (refer to Operating

Instructions for details ).

Endress+Hauser 17

Page 18

Installation Proservo NMS83

3

4

1

2

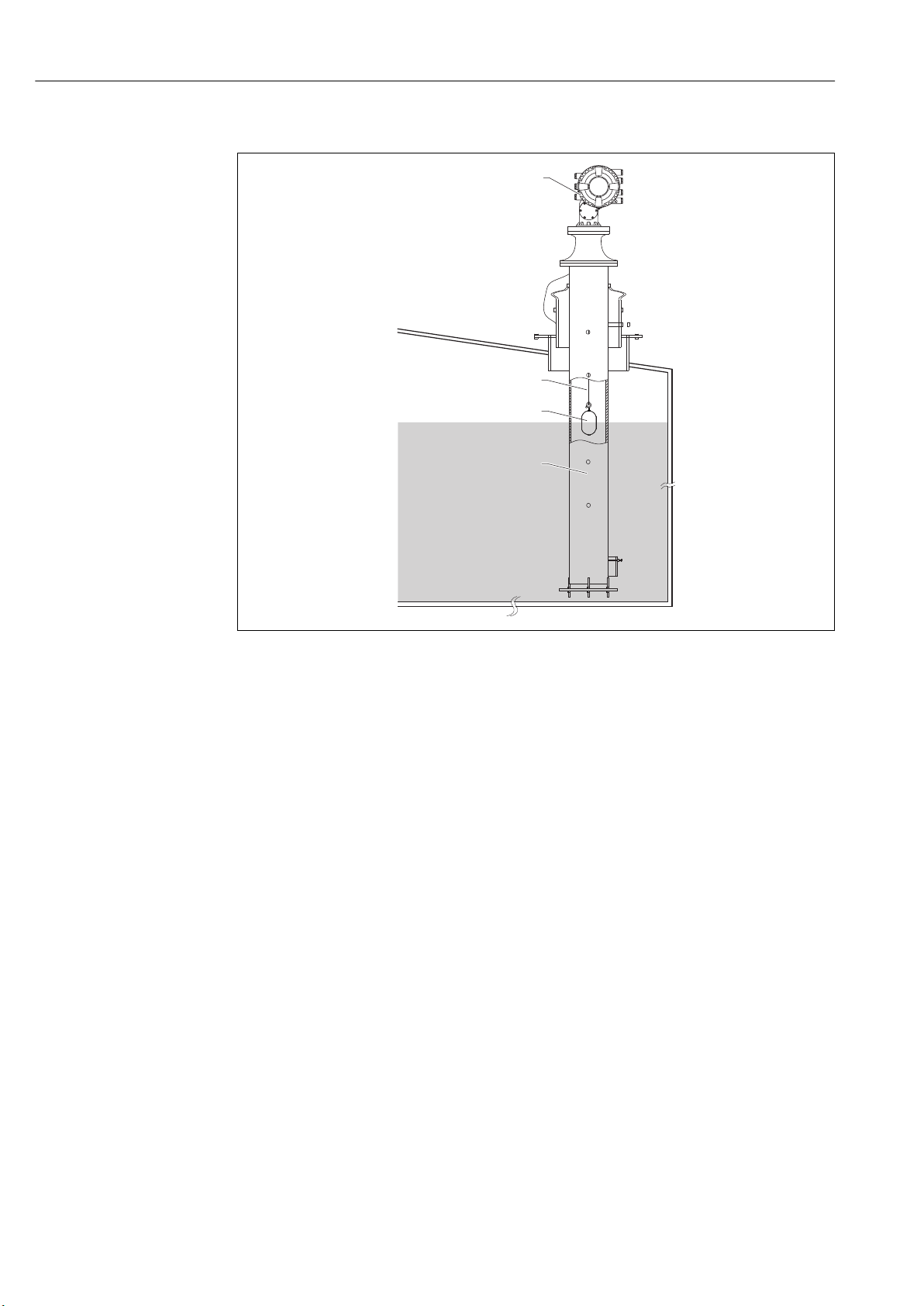

Typical tank installation

A0026904

5 Typical tank installation 1

1 NMS8x

2 Measuring wire

3 Displacer

4 Stilling well

18 Endress+Hauser

Page 19

Proservo NMS83 Installation

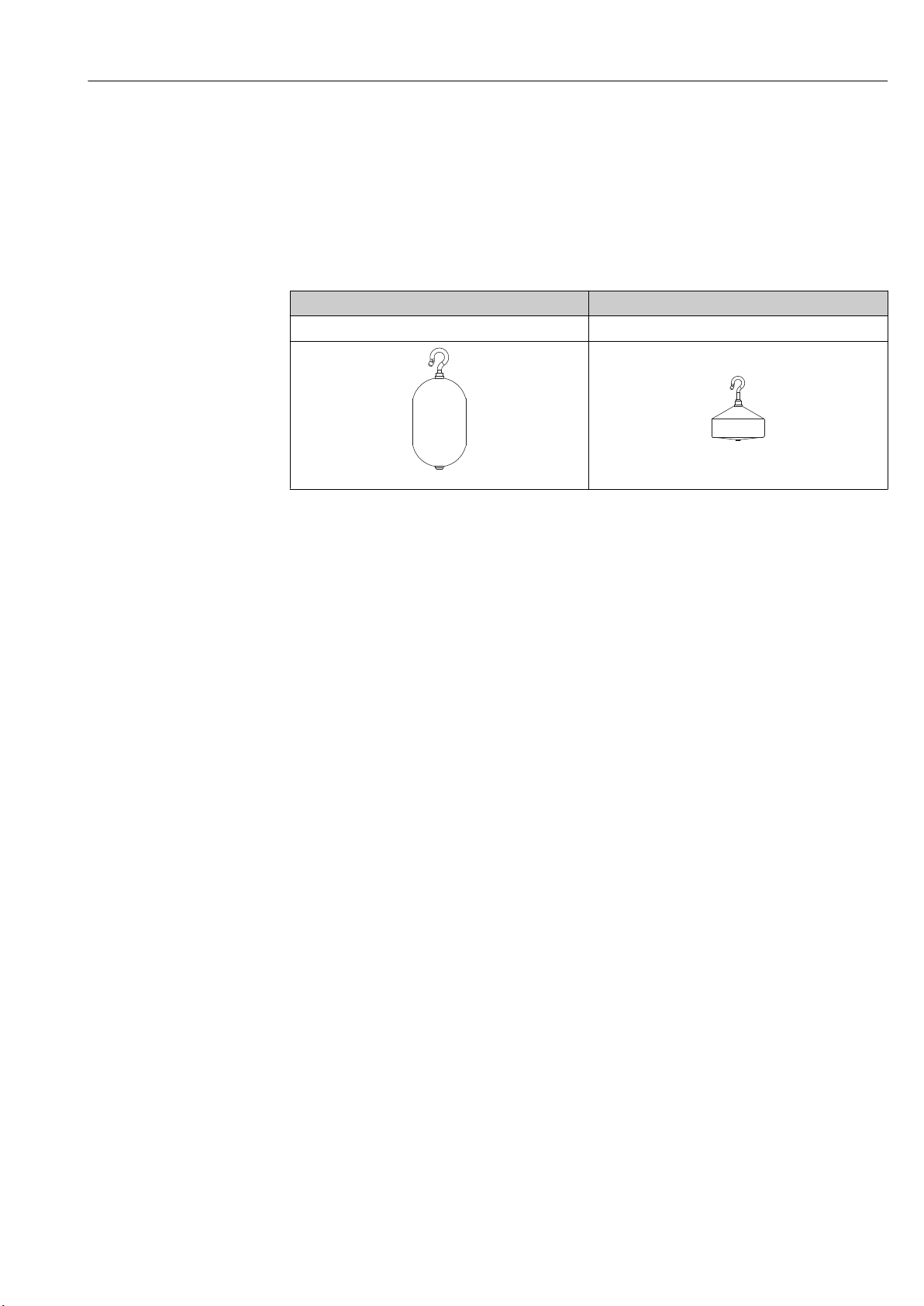

5.1.2 Displacer selection guide

A wide variety of displacers are available to suit different application. Proper displacer

selection ensures optimal performance and longevity. The following guidelines will assist

you in selecting the most suitable displacer for your application.

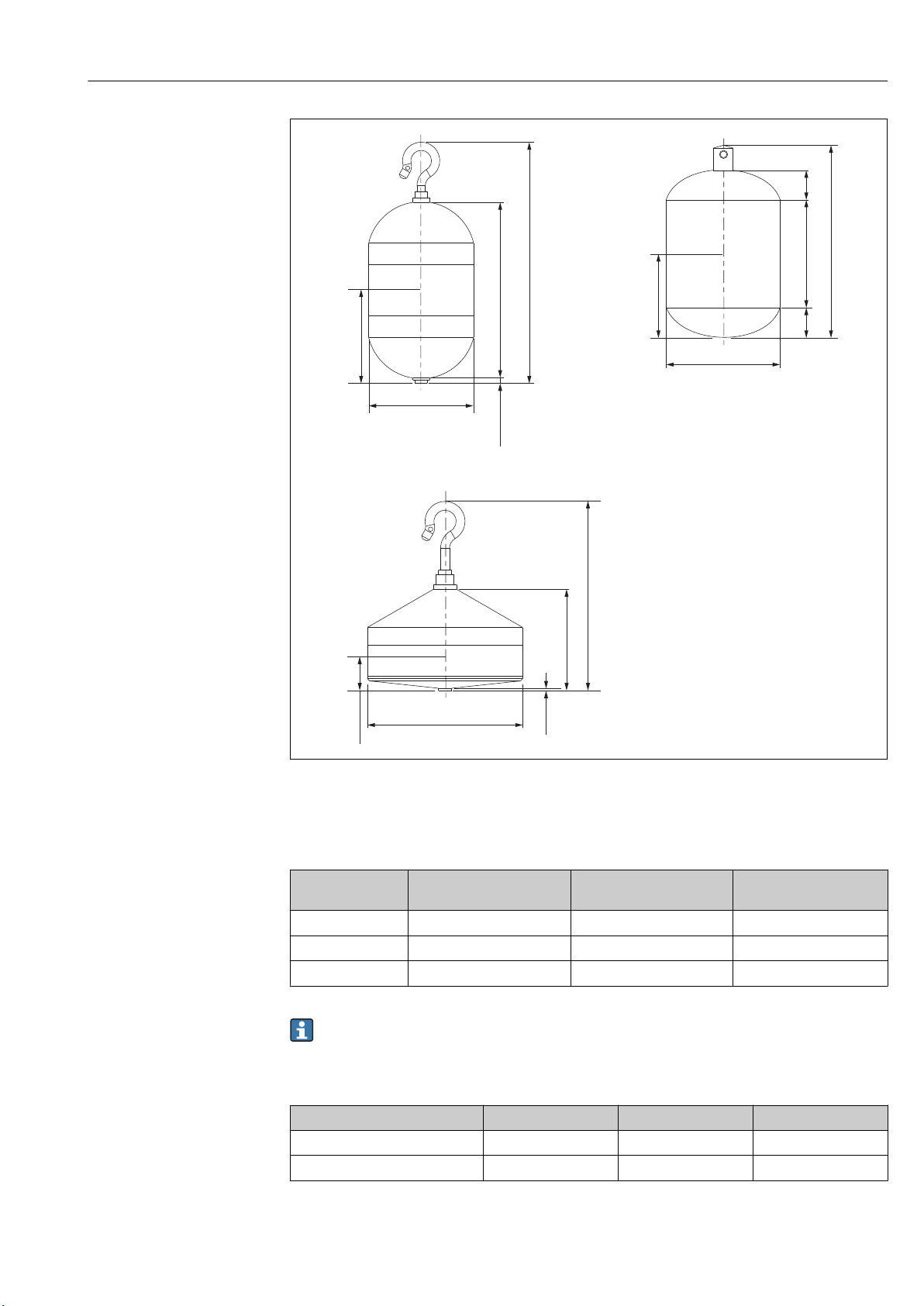

Displacer types

The following NMS8x displacers are available.

50 mm (1.97 in) 70 mm (2.76 in)

316L/PTFE 316L

A0032430

A0032429

Endress+Hauser 19

Page 20

Installation Proservo NMS83

A

Ø50.8 (2)

a

45 (1.77)

85 (3.35)

116.6 (4.59)

2.5 (0.09)

B

Ø50 (1.97)

a

35 (1.38)

82.7 (3.26)

46.7 (1.84)

11.5

(0.45)

11.5

(0.45)

C

17 (0.67)

46.6 (1.83)

1 (0.03)

90 (3.54)

Ø70(2.76)

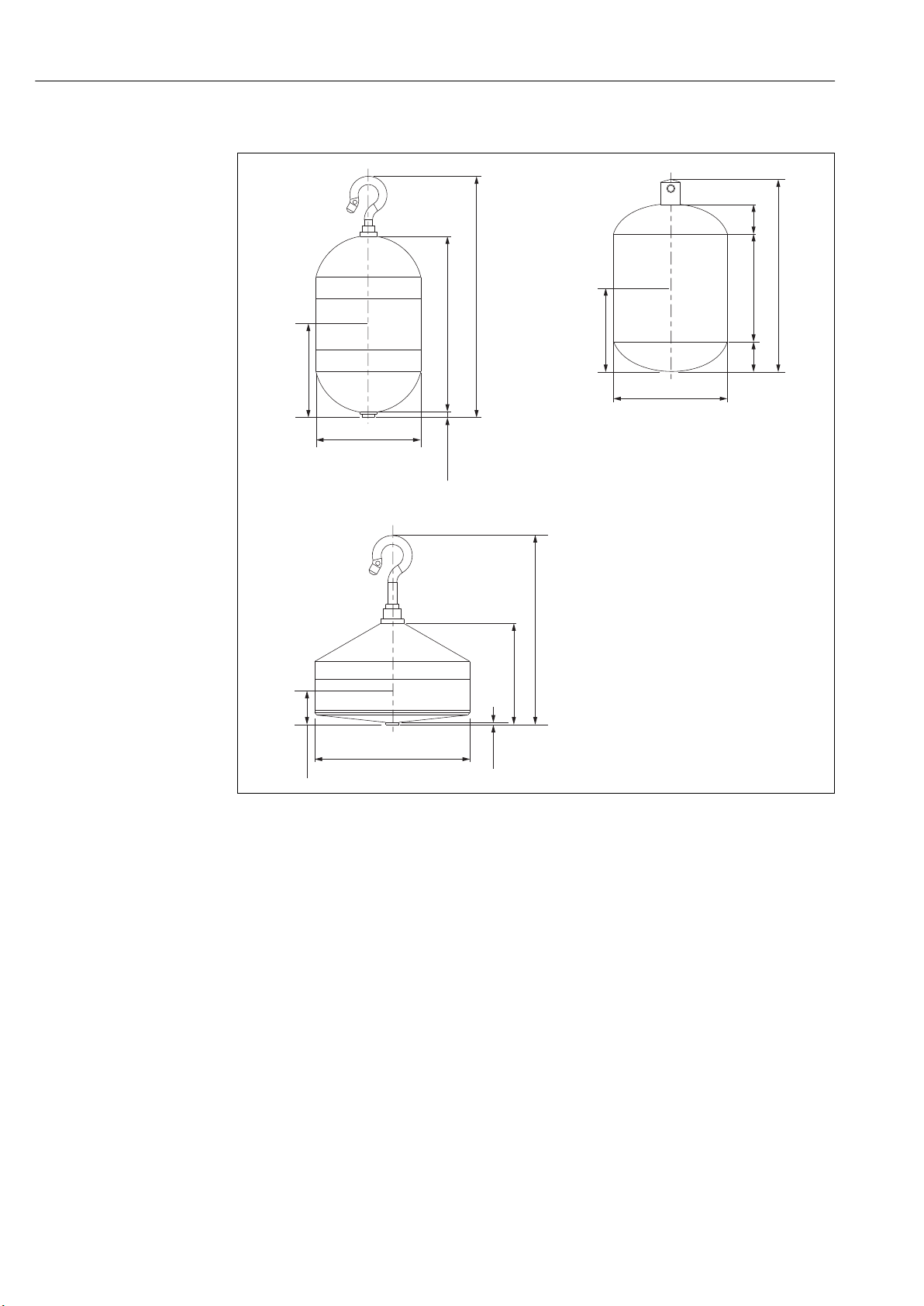

a

Displacer dimensions

A ⌀50 mm (1.97 in) 316L cylindrical displacer

B ⌀50 mm (1.97 in) PTFE cylindrical displacer

C ⌀70 mm (2.76 in) 316L conical displacer

a Immersion point

A0029581

20 Endress+Hauser

Page 21

Proservo NMS83 Installation

A

Ø50.8 (2)

a

45 (1.77)

85 (3.35)

116.6 (4.59)

2.5 (0.09)

B

Ø50 (1.97)

a

35 (1.38)

82.7 (3.26)

46.7 (1.84)

11.5

(0.45)

11.5

(0.45)

C

17 (0.67)

46.6 (1.83)

1 (0.03)

90 (3.54)

Ø70(2.76)

a

A ⌀50 mm (1.97 in) 316L cylindrical displacer

B ⌀50 mm (1.97 in) PTFE cylindrical displacer

C ⌀70 mm (2.76 in) 316L conical displacer

a Immersion point

Item

Weight (g) 253 250 245

Volume (ml) 143 118 124

Balance volume (ml) 70.7 59 52.8

⌀50 mm (1.97 in) 316L

cylindrical displacer

The weight, volume, and balance volume are individually determined by each

displacer and also might vary depending on the values stated above.

Recommended displacer by application

Application Product level Interface level Density

Viscous liquid 50 mm (1.97 in) PTFE Not Recommended Not Recommended

Not viscous liquid (e.g. alcohol) 50 mm (1.97 in) 316L 50 mm (1.97 in) 316L 50 mm (1.97 in) 316L

⌀50 mm (1.97 in) PTFE

cylindrical displacer

A0029581

⌀70 mm (2.76 in) 316L

conical displacer

Endress+Hauser 21

Page 22

Installation Proservo NMS83

1

d

D

1

5.1.3 Mounting without a guide system

NMS8x is mounted on a nozzle of the tank roof without a guide system. Sufficient

clearance inside the nozzle is necessary to allow the displacer to move without hitting the

inner walls (for details of D, → 23).

A0026908

6 No guide system

D1Inner diameter of the tank nozzle

d Diameter of the displacer

1 Displacer

22 Endress+Hauser

Page 23

Proservo NMS83 Installation

L

1

L

2

L

1

L

2

A

B

L

3

L

3

D

2

D

1

d

r

D

1

d

D

2

p(L )x

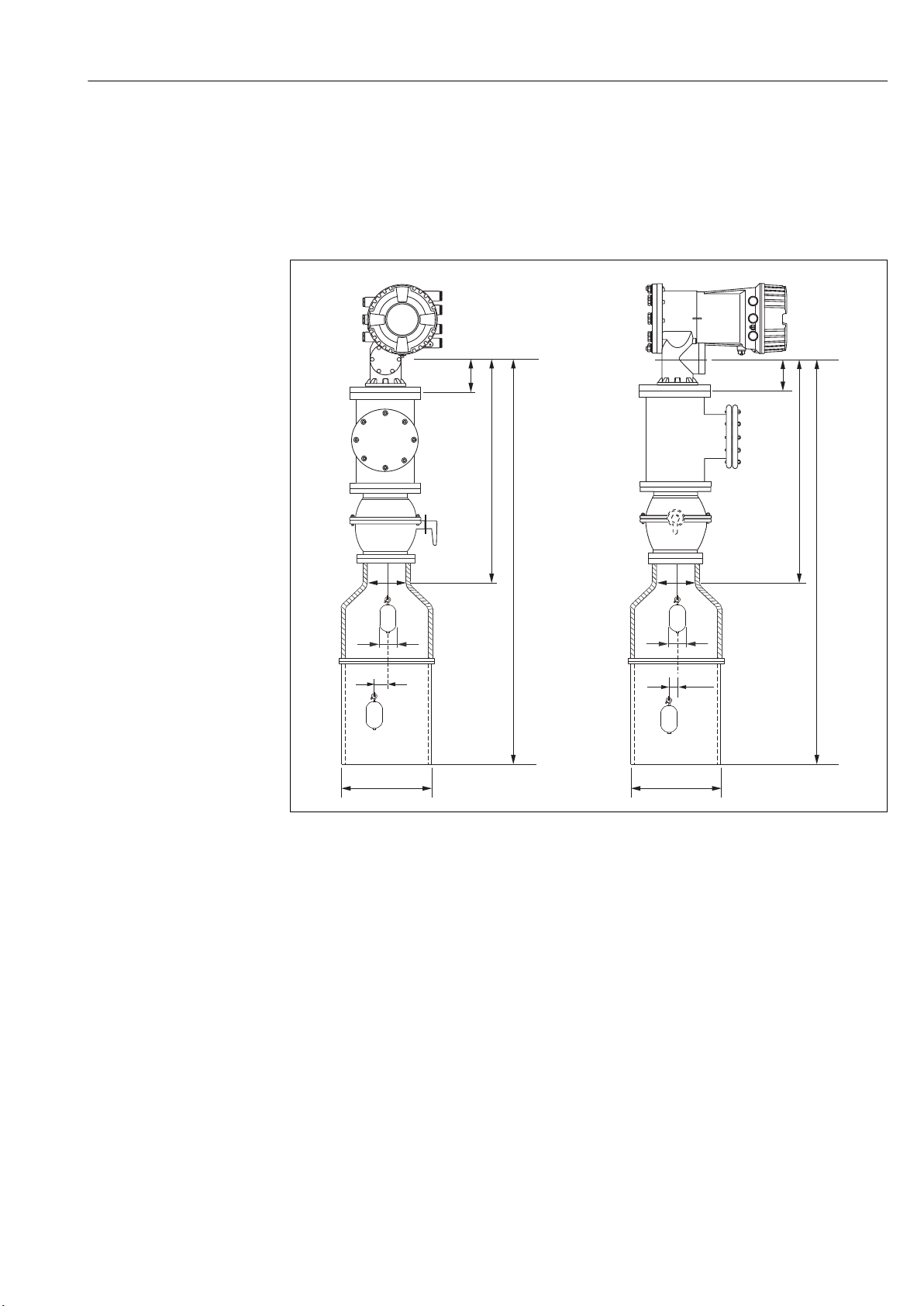

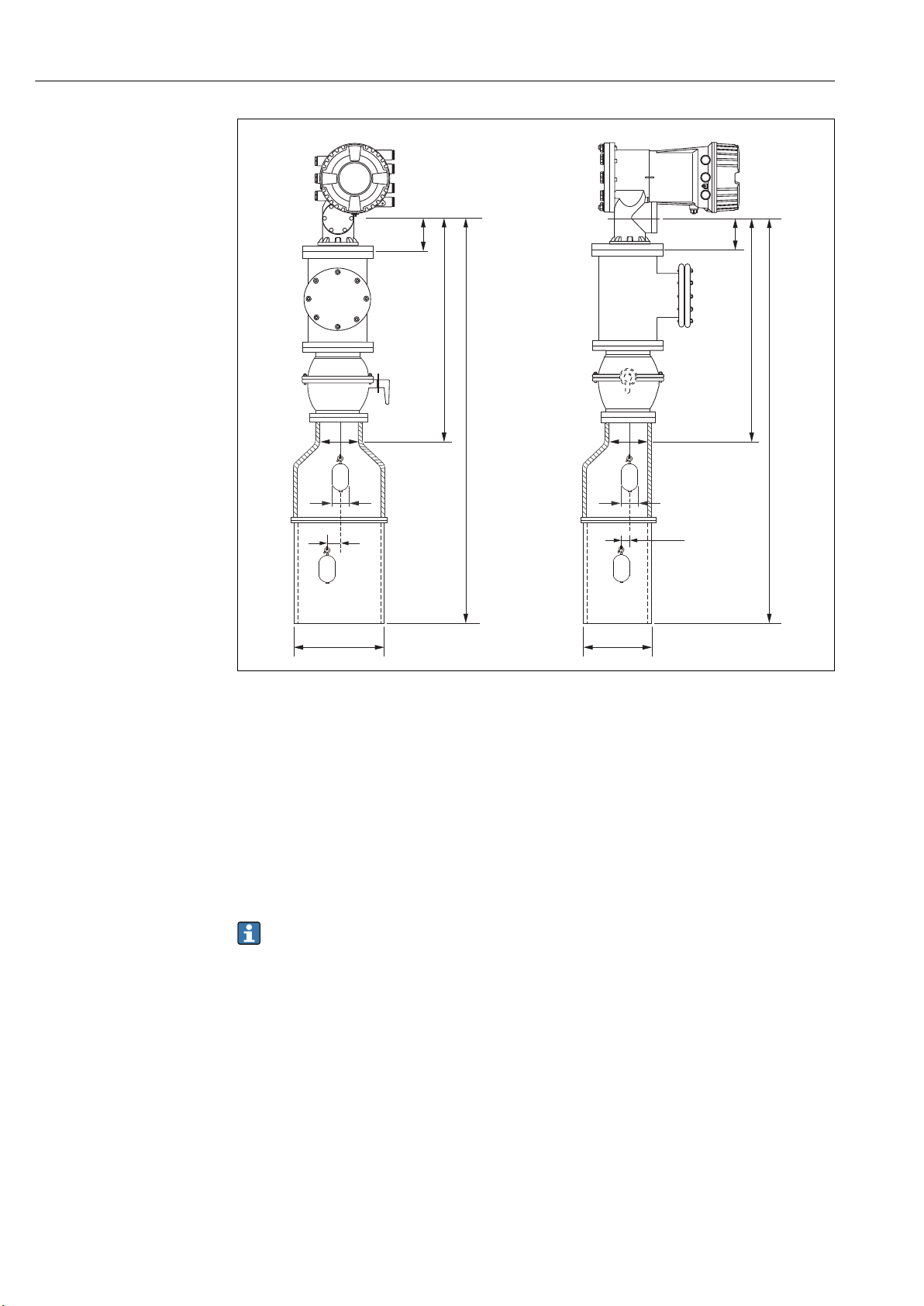

5.1.4 Mounting with a stilling well

The stilling well diameter that is required to protect the measuring wire without disturbing

its operation varies depending on the tank height. The stilling well could either be of

constant diameter, or narrower at its upper part and wider at its lower part. The following

figure shows two examples of the latter case, namely a concentric stilling well and an

asymmetric stilling well.

A0029574

7 Mounting with concentric stilling well

A Front view

B Side view

L1Length from the center of the calibration window to the upper part of the stilling well

L2Length from the center of the calibration window to the bottom of the stilling well

L3Length from the center of the calibration window to the bottom of the flange

D1Diameter of upper part of stilling well

D2Diameter of stilling well

d Diameter of displacer

p

Longitudinal wire position from the center of the flange

(Lx)

r Radial direction offset

Endress+Hauser 23

Page 24

Installation Proservo NMS83

L

1

L

2

L

1

L

2

A

B

L

3

L

3

D

2

D

1

d

r

D

1

d

D

2

p (L )x

A0026909

8 Mounting with asymmetric stilling well

A Front view

B Side view

L1Length from the center of the calibration window to the upper part of the stilling well

L2Length from the center of the calibration window to the bottom of the stilling well

L3Length from the center of the calibration window to the bottom of the flange

D1Diameter of upper part of stilling well

D2Diameter of stilling well

d Diameter of displacer

p

Longitudinal wire position from the center of the flange

(Lx)

r Radial direction offset

• L3: length from center of the calibration window to the bottom of the flange

(77 mm (3.03 in) + flange thickness).

For JIS 10K 150A RF, the flange thickness is 22 mm (0.87 in).

• When using an asymmetric stilling well, take into account the lateral shift of the

displacer and follow the NMS8x mounting direction as shown in the figure.

• To calculate the required stilling well diameters, the formula below should be used.

The following tables contain the necessary parameters in order to calculate the

dimensions of the stilling well. Be sure to have appropriate dimensions of the

stilling well according to each dimension in the table.

• The radial direction offset (r) is required for only the 47 m (154.20 ft) and

55 m (180.45 ft) wire drum. For all other drums, the offset is 0 mm/in.

24 Endress+Hauser

Page 25

Proservo NMS83 Installation

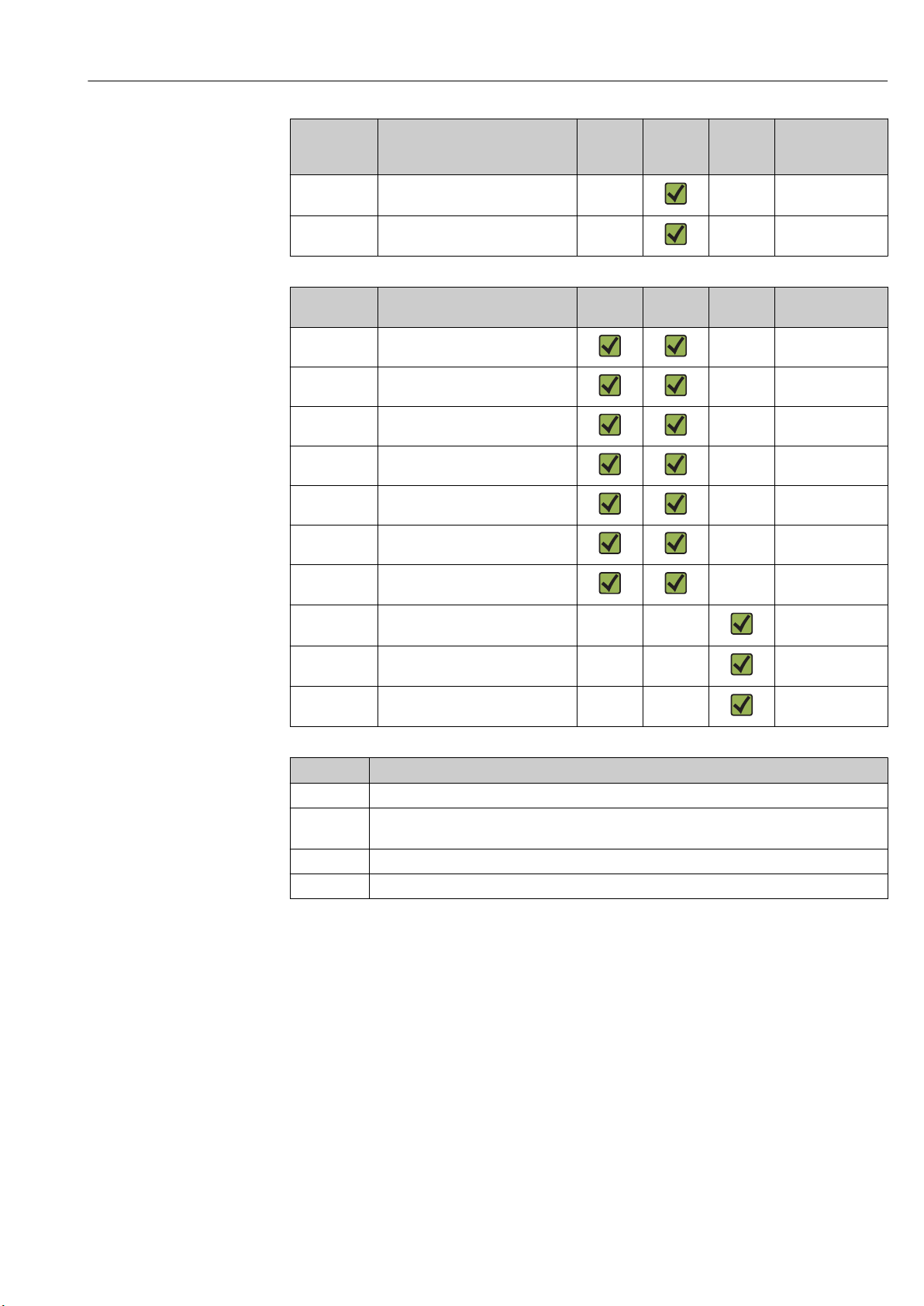

Feature: 110 Description

(Measuring range; Wire;

Diameter)

G1

H1

Feature: 120 Description

1AA 316L; 30 mm (1.18 in) cylindrical 30 mm (1.18 in)

1AC 316L; 50 mm (1.97 in) cylindrical 50 mm (1.97 in)

1BE 316L; 70 mm (2.76 in) conical 70 mm (2.76 in)

1BJ 316L;110 mm (4.33 in) conical 110 mm (4.33 in)

2AA PTFE; 30 mm (1.18 in) cylindrical 30 mm (1.18 in)

2AC PTFE; 50 mm (1.97 in) cylindrical 50 mm (1.97 in)

3AC AlloyC276; 50 mm (1.97 in)

4AC 316L polished; 50 mm (1.97 in)

4AE 316L polished; 70 mm (2.76 in)

5AC PTFE; 50 mm (1.97 in) cylindrical,

47 m (154.20 ft); 316L;

0.15 mm (0.00591 in)

55 m (180.45 ft); 316L

0.15 mm (0.00591 in)

(Displacer material; Type)

cylindrical

cylindrical

conical

hygienic white

NMS80 NMS81 NMS83 r

6 mm (0.24 in)

6 mm (0.24 in)

NMS80 NMS81 NMS83 d

50 mm (1.97 in)

50 mm (1.97 in)

70 mm (2.76 in)

50 mm (1.97 in)

Parameter Description

d Diameter of displacer

p(Lx) Longitudinal wire position from the center of the flange

The value can be determined by using following graph.

r Radial direction offset

s Safety factor recommended: 5 mm (0.197 in)

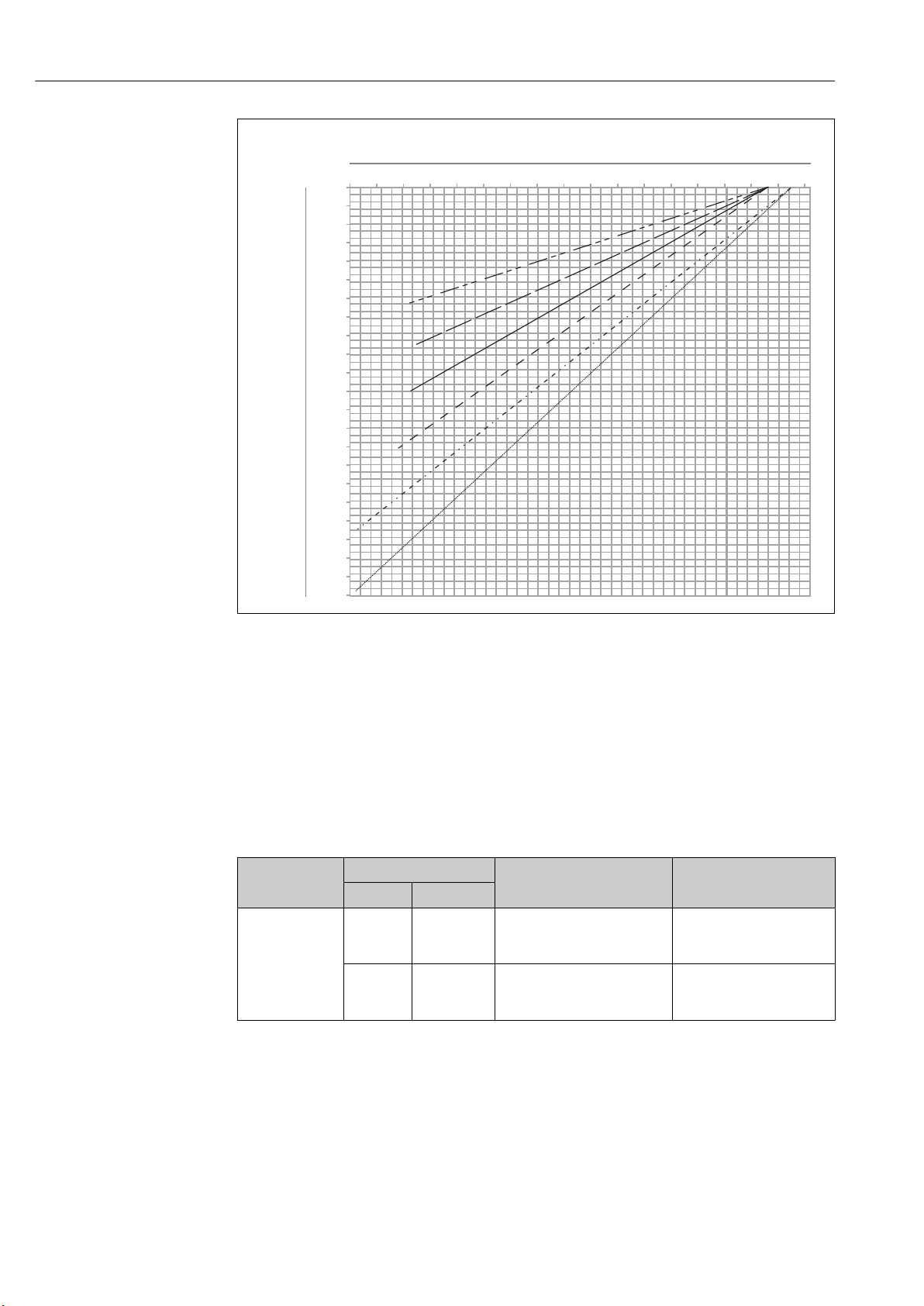

The following graph shows the lateral shift of the displacer depending on the measured

distance for the different wire drums.

Endress+Hauser 25

Page 26

Installation Proservo NMS83

L , L (mm) ( )

1 2

in

p (Lx) (mm) ( )in

-1.4 -1.3 -1.2 -1.1 -1.0 -0.9 -0.8 -0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1 0.0 0.1 0.2 0.3

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

0

2000

4000

6000

8000

10000

12000

14000

16000

18000

20000

22000

24000

26000

28000

30000

32000

34000

36000

38000

40000

42000

44000

46000

48000

50000

52000

54000

56000

-36 -32 -28 -24 -20 -16 -12 -8 -4 0 4 8

a

d

e

c

b

f

9 Lateral shift of displacer according to measurement range

a 16 m (A3) (NMS80/NMS81/NMS83)

b 22 m (C2) (NMS80/NMS81/NMS83)

c 28 m (D1) (NMS80/NMS81)

d 36 m (F1) (NMS80/NMS81)

e 47 m (G1) (NMS81)

f 55 m(H1) (NMS81)

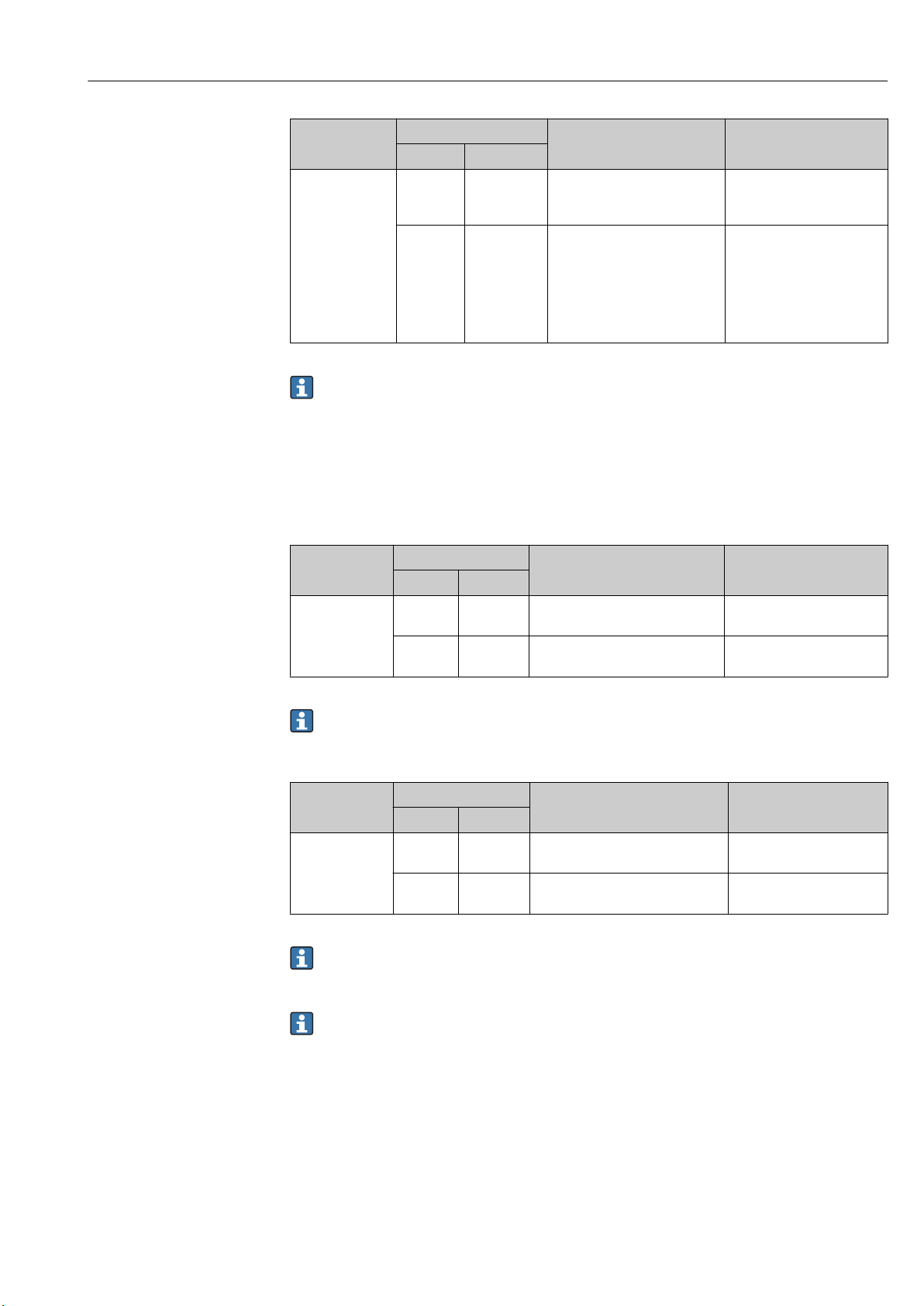

Upper diameter of stilling well

The dimension of D1 has to be the largest value of the dimensions D1a, D1b , D1c, and D

according to the following formula.

26 Endress+Hauser

D1 Dimension

(Example)

>68.1 mm

(2.68 in)

D

Dimension

1x

Example Parameter

68.1 mm

(2.68 in)

65.6 mm

(2.58 in)

D

1a

D

1b

Description Formula

D1 dimension when the

displacer is at the center of the

calibration window

D1 dimension when the

displacer is at the upper part of

the stilling well

= 2 x ( |p (0)|+ d/2 + s)

= 2 x (|p (L1)|+ d/2 + s)

A0027997

1d

Page 27

Proservo NMS83 Installation

D1 Dimension

(Example)

D

Dimension

1x

Example Parameter

50.9 mm

(2.00 in)

D

1c

D

1d

Description Formula

D1 dimension when the

displacer is at the bottom of the

stilling well

D1 dimension when the radial

direction offset is considered.

This calculation is used only

with the 47 m (154.20 ft) wire

drum (G1 in Feature110) and

55 m (180.45 ft) (H1 in feature

110)

= 2 x ( |p (L2)|+ s)

= 2 x (d/2 + r + s)

Example: L1 = 1 000 mm, L2 = 20 000 mm, d = 50 mm, s = 5.0, 28 m drum

Lower diameter of stilling well

The dimension of D2 has to be the larger value of the dimensions D1 and D2b .

See the table below.

Concentric pipe

D2 Dimension

(Example)

>100.9 mm

(3.97 in)

D2x Dimension

Example Parameter

68.1 mm

(2.68 in)

100.9 mm

(3.97 in)

D

1

D

2b

Description Formula

Calculated D1 value

D2 dimension when the displacer is

in L2 length

= 2 x (|p (L2)| + d/2 + s)

Example: L2 = 20 000 mm, d = 50 mm, s = 5.0, 28 m drum

Asymmetric pipe

D2 Dimension

(Example)

>84.5 mm

(3.33 in)

D2x Dimension

Example Parameter

68.1 mm

(2.68 in)

84.5 mm

(3.33 in)

D

1

D

2b

Description Formula

Calculated D1 value

D2 dimension that the displacer can

pass through (nth groove)

= |p (L2)| + d/2 + s + D1/2

Example: L2 = 20 000 mm, d = 50 mm, s = 5.0, 28 m drum

Recommendations for NMS8x mounting with a stilling well

Follow the recommendations for mounting NMS8x with a stilling well.

• Keep the pipe connection welds smooth.

• When drilling holes into the pipe, keep the interior surface of the holes clear of

metal chips and burrs.

• Keep the pipe as vertical as possible. Check using a plumb bob.

• Install the asymmetric pipe under the valve and align the centers of the NMS8x and

the valve.

• Set the center of the lower part of the asymmetric pipe in the direction of the lateral

motion.

• Observe the recommendations as per API MPMS chapter 3.1B.

• Confirm grounding between NMS8x and the tank nozzle.

Endress+Hauser 27

Page 28

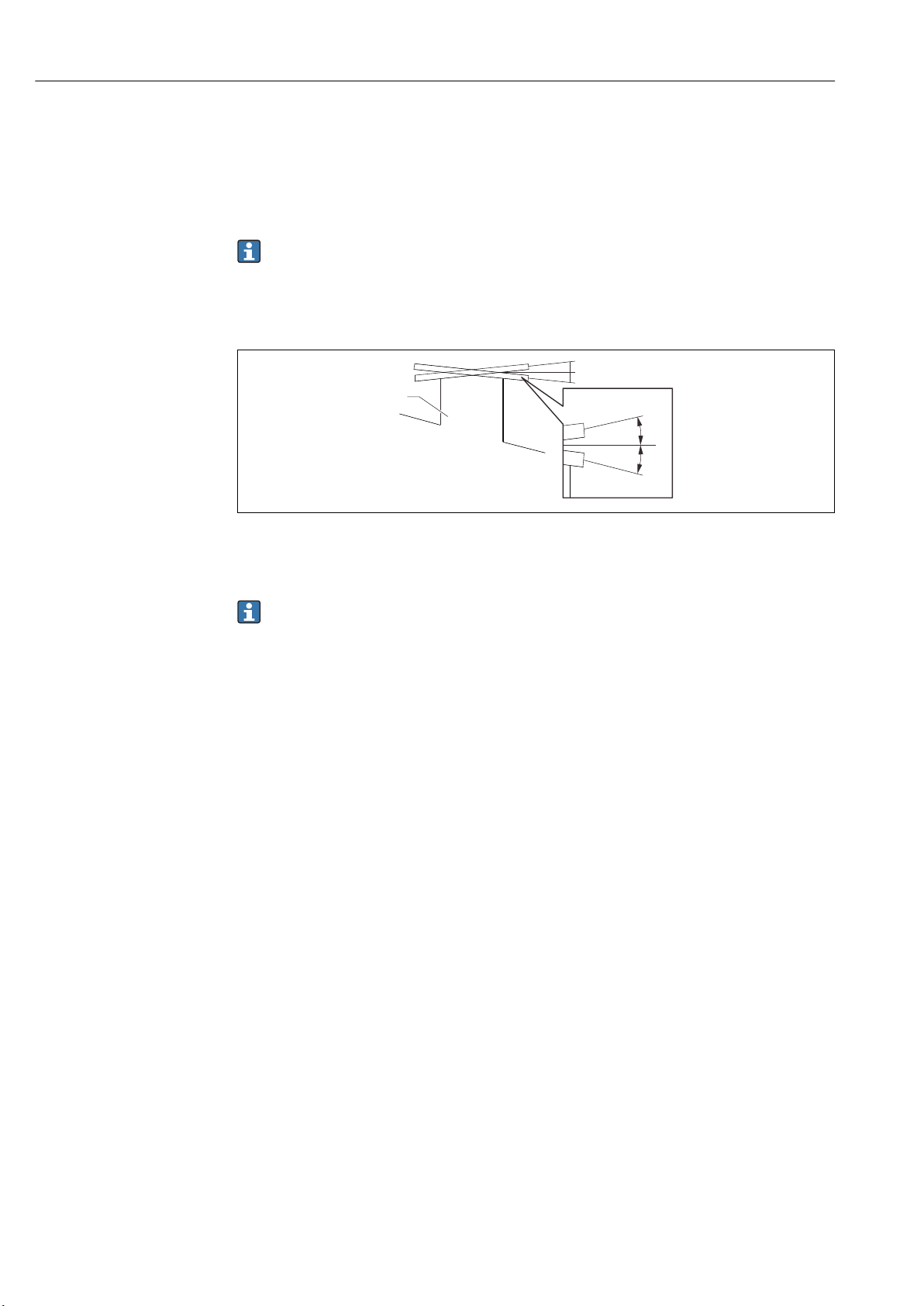

Installation Proservo NMS83

+1°

-1°

1

5.1.5 Alignment of NMS8x

Flange

Confirm that the size of the nozzle and the flange is matched prior to mounting NMS8x on

the tank. The flange size and the rating of NMS8x vary depending on the customer’s

specifications.

• Check the flange size of NMS8x.

• Mount the flange on the top of the tank. The deviation of the flange from the

horizontal plane should not exceed +/- 1 degree.

• When mounting NMS8x on a long nozzle, make sure that the displacer does not

touch the inner wall of the nozzle.

10 Allowable inclination of mounting flange

1 Nozzle

When NMS8x is installed without a guide system, follow the recommendations below:

• Confirm the mounting nozzle is in the sector between 45 and 90 degrees (or -45

and -90 degrees)away from the inlet pipe of the tank. This prevents heavy swinging

of the displacer caused by waves or turbulence from the inlet liquid.

• Confirm the mounting nozzle is 500 mm (19.69 in) or more away from the tank

wall.

• Confirm the minimum measuring level is at 500 mm (19.69 in) or more above the

top of the inlet pipe by setting the low stop (for details of low stop setting,

→ 89). This protects the displacer from direct flow of the inlet liquid.

• If a stilling well cannot be mounted in the tank due to the shape or condition of the

tank, attaching a guide system is recommended. Consult E+H services for further

information.

A0026889

28 Endress+Hauser

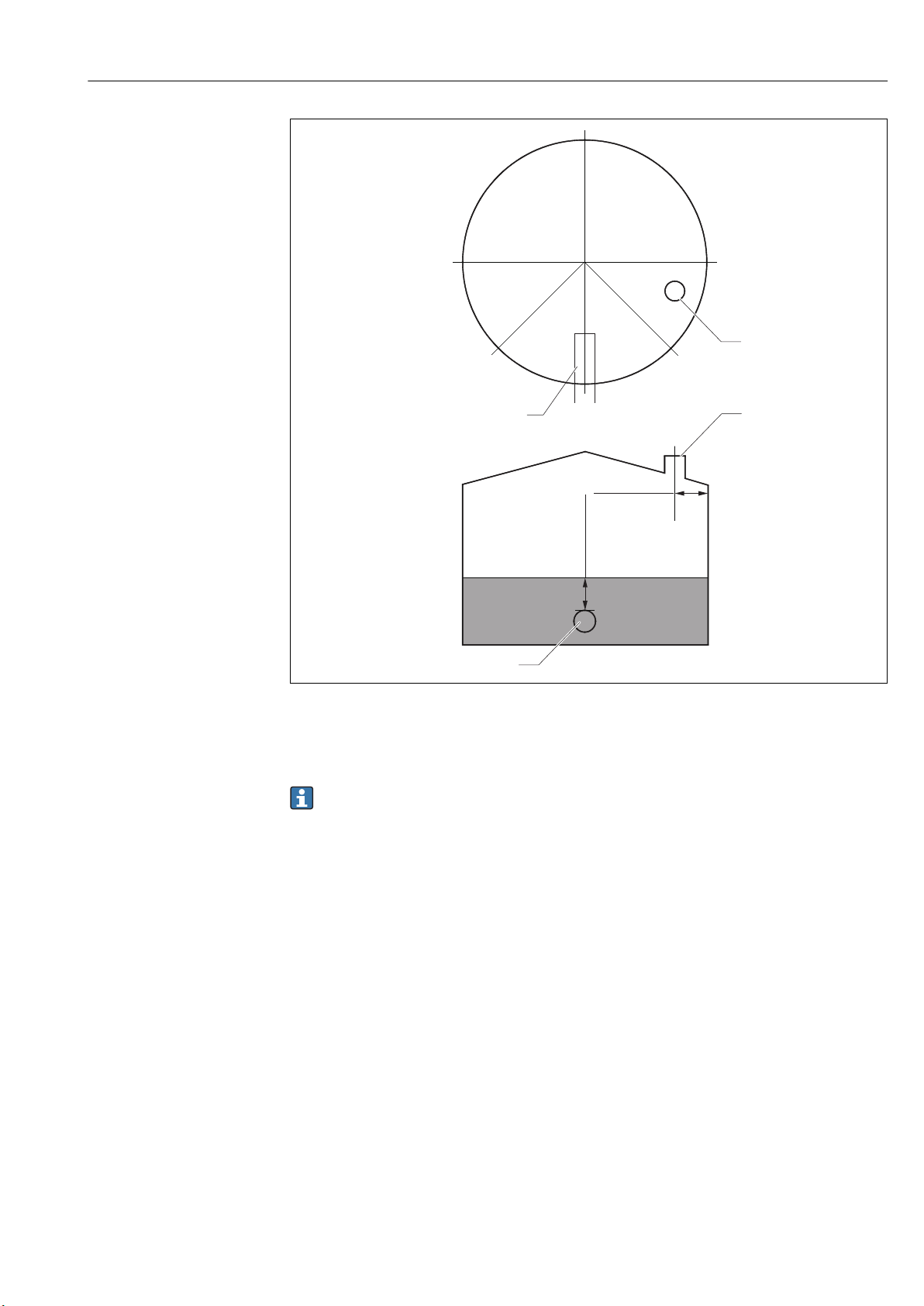

Page 29

Proservo NMS83 Installation

≥500 (19.69)

90°-90°

0°

45°-45°

1

1

≥500 (19.69)

2

2

A0026890

11 Recommended position for mounting NMS8x and minimum measuring level; dimensions mm (in)

1 Inlet pipe

2 Tank nozzle

• Before pouring liquid into the tank, confirm that liquid flowing through the inlet of

the pipe will not contact the displacer directly.

• When discharging liquid out of the tank, ensure that the displacer will not get

caught in the liquid current and sucked into the outlet pipe.

5.1.6 Electrostatic charge

When liquid measured by NMS8x has a conductivity of 1 uS/m or less, it is quasinonconductive. In this case, using a stilling well or guide wire is recommended. This

releases the electrostatic charge on the liquid surface.

Endress+Hauser 29

Page 30

Installation Proservo NMS83

5.2 Mounting of the device

When NMS8x is delivered, the displacer is always shipped separately and there are two

methods to install displacer as follows.

• Installation for displacer shipped separately method

• Installation through the calibration window

5.2.1 Available installations

The following installation procedures are available for NMS8x.

• Mounting without guide system

• Mounting with stilling well

Mounting options Free-space mounting With stilling well

Type of tanks

A0032437 A0032438

Type of installations • Displacer shipped separately

• Displacer installation through calibration

window

• Displacer shipped separately

• Displacer installation through calibration

window

30 Endress+Hauser

Page 31

Proservo NMS83 Installation

316L

50

ml

70.8

ml

141.6

g

256.6

Ø

B

V

D

V

D

m

NMS8

Displacer

12345678901

Ser.no.:

712xxxxx

Spare part-no.:

HNBR

O-Ring

28m

Range

NMS8

98765432109

Ser. no.:

3

1.

2.

12345678901

712xxxxx

m 256.6g

D

V 141.6mL

D

V 70.8mL

B

!50 316L

Spare part-no.: 712xxxxx

mm

302.xxx

Cir.

NMS8

Wiredrum

98765432109

Ser.no.:

1.35g/10m

HNBR

28 m

WireWgt.

O-Ring

Range

Spare part-no.: 712xxxxx

5.2.2 Verification of displacer and wire drum

Prior to installation of NMS8x, confirm that the serial numbers of displacer and the wire

drum match with those printed to the label attached on the housing.

Endress+Hauser 31

12 Verification of displacer and wire drum

A0029470

Page 32

Installation Proservo NMS83

A

5.2.3 Tools to be required for installation

The following tools are required when installing NMS8x.

Tools Figures Notes

Box end wrench Use the following size

• 24 mm (0.94 in)

• 26 mm (1 in)

• 30 mm (1.2 in)

• 32 mm (1.3 in)

Crescent wrench Use the size of 350 mm (13.78 in)

Allen key Use the size of 3 mm (0.12 in)or 5 mm (0.17 in)

Screw driver

• Cross-head screwdriver

• Flat-blade screwdriver

Wire cutters or terminal

pliers

Crimp terminal

Water pump pliers

Density calibration test

weight

A:

Signal and power supply:

0.2 to 2.5 mm2 (24 to 13 AWG)

• Ground terminal in the terminal

compartment: max. 2.5 mm2 (13 AWG)

• Ground terminal at the housing: max.

4 mm2 (11 AWG)

This tool is used especially for density

measurement application (optional).

32 Endress+Hauser

Page 33

Proservo NMS83 Installation

1.

200 (7.87)

200 (7.87)

130 (5.12) 130 (5.12)

2.

3.

3

1

2

6

4

4.

5.

6.

7.

8.

9.

5.2.4 Installation for displacer shipped separately method

It is necessary to remove the wire drum from NMS8x, remove the tape on the wire drum,

mount the wire drum in the drum housing, and install the displacer on the measuring

wire.

Use blocks or a pedestal to secure NMS8x and provide an environment where electrical

power can be supplied to NMS8x.

The following procedure uses NMS81 figures for an example.

Displacer is shipped separately according to the following specifications.

• 47 m (154.2 ft) measuring range

• 55 m (180.5 ft) measuring range

• 110 mm (4.33 in) measuring range

• 8 in flange

• Cleaned from oil+grease option

Procedures Figures

Secure NMS8x on the blocks or pedestal.

Confirm that there is enough space under NMS8x.

Be careful not to drop NMS8x.

Remove screws and M6 bolts [6] (M10 bolts for stainless

steel housing).

Remove the wire drum cover [5], wire drum stopper [4],

and the bracket [2].

Remove the wire drum [1] from the drum housing.

Remove the tape [3] on the wire drum.

Unwind the measuring wire approximately

250 mm (9.84 in) so that the wire ring is positioned

under the flange.

Mount the wire drum on NMS8x.

Mount the bracket.

• Take special care to not hit the wire drum against the

housing due to strong magnet force.

• Handle the measuring wire with care. It may kink.

• Be sure that the wire is wound correctly in the grooves.

A0032442

Dimensions mm (in)

A0028876

Endress+Hauser 33

Page 34

Installation Proservo NMS83

10.

1

3

2

11.

2

3

4

1

12.

13.

14.

15.

16.

17.

1

18.

19.

20.

Procedures Figures

Hook the displacer [3] on the ring [2].

• Be sure that the wire is wound correctly in the grooves.

• If not, remove the displacer and the wire drum, and

repeat step 7.

A0029116

Turn on the power of NMS8x.

Perform sensor calibration

Secure the displacer [2] to the measuring wire [1] using

the securing wire [3].

Perform reference calibration.

Turn off the power.

Mount the wire drum cover [4].

• For sensor calibration, → 82

• For reference calibration, → 84.

Mount NMS8x on the tank nozzle [1].

Confirm that the displacer does not touch the inner wall

of the nozzle.

Turn on the power.

Perform drum calibration.

For drum calibration, → 85

A0027017

A0028877

34 Endress+Hauser

Page 35

Proservo NMS83 Installation

1.

1

2.

2

1

3

4

6

3.

4.

5.

6.

3

4

2

1

7.

8.

9.

10.

1

2

3

11.

12.

5.2.5 Installation through the calibration window

In the case of a 50 mm (1.97 in) diameter displacer, the displacer can be installed through

the calibration window.

It is only possible to install the following displacers through the calibration window:

50 mm SUS, 50 mm alloy C, 50 mm PTFE

The following procedure uses NMS81 figures for an example.

Procedures Figures

Remove the calibration window cover [1].

A0032443

Remove M6 bolts and screws [6] (M10 bolts for stainless

steel housing).

Remove the cover [5], wire drum stopper [4], and the

bracket [3].

Remove the wire drum [1] from the drum housing.

Remove the tape [2] that is securing the wire.

Handle the measuring wire with care. It may kink.

Holding the wire drum [1] with one hand, unwind the

measuring wire [3] approximately 500 mm (19.69 in).

Secure the wire [3] temporarily with the tape [2].

Insert the wire ring [4] into the drum housing.

Pull the wire ring out through the calibration window.

• Take special care to not hit the wire drum against the

housing due to strong magnet force.

• Handle the measuring wire with care.

Insert the wire drum [3] temporarily into the drum

housing.

Hook the displacer [2] on the wire ring.

Secure the displacer to the measuring wire using the

securing wire [1].

Handle the measuring wire with care. It may kink.

A0029118

A0028879

A0027984

Endress+Hauser 35

Page 36

Installation Proservo NMS83

13.

2

1

14.

15.

16.

17.

3

4

5

2

1

18.

19.

20.

21.

22.

23.

24.

25.

Procedures Figures

Remove the wire drum from the drum housing and

unwind the measuring wire down approximately

500 mm (19.69 in).

Hold the wire drum [1] up and place the displacer [2] into

the calibration window.

Hold the displacer at the center of the calibration window.

Hold the other hand (wire drum) up to add tension to the

measuring wire in order not to drop the displacer rapidly.

A0027986

Let go of the displacer [2].

Remove the tape from the wire drum [5].

Insert the wire drum into the drum housing.

Mount the bracket [4].

Be sure that the wire is wrapped correctly in grooves.

Turn on the power of NMS8x and move the displacer up

using the Move displacer wizard→ 80 until the wire

ring can be seen in the calibration window.

• Confirm that there are no kinks or other defects in the

measuring wire.

• Confirm that the displacer does not touch the inner wall

of the nozzle.

Perform sensor calibration.

For sensor calibration, → 82

Perform reference calibration.

For reference calibration, → 84.

Mount the drum housing cover [5] and the calibration

window cover [1].

Perform drum calibration.

For drum calibration, → 85

A0032444

5.3 Post-installation check

Is the device undamaged (visual inspection)?

m

Does the device conform to the measuring point specifications?

For example:

36 Endress+Hauser

• Process temperature

m

• Process pressure (refer to the chapter on "Material load curves" of the "Technical Information"

document)

• Ambient temperature range

• Measuring range

Page 37

Proservo NMS83 Installation

Are the measuring point identification and labeling correct (visual inspection)?

m

Is the device adequately protected from precipitation and direct sunlight?

m

Connection check for wire ring of displacer

To keep it clean, the NMS83 displacer does not have any washers or nuts. When using

the NMS83 in a hazardous area, make sure that the wire ring is connected to the wire

hook of the displacer without any foreign matter interfering in order to prevent static

electricity.

Endress+Hauser 37

Page 38

Electrical connection Proservo NMS83

D

E

G

F

C

B

A

1

1

1

1

1 3

2

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

POWER

i

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

G1 N

G3 L

AC 85...264 V

6 Electrical connection

6.1 Terminal assignment

13 Terminal compartment (typical example) and ground terminals

Terminal area Module

Up to four I/O modules, depending on the order code

A/B/C/D

(slots for I/O

modules)

• Modules with four terminals can be in any of these slots.

• Modules with eight terminals can be in slot B or C.

The exact assignment of the modules to the slots is dependent on the device version

→ 41.

E HART Ex i/IS interface

• E1: H+

• E2: H-

F Remote display

• F1: VCC (connect to terminal 81 of the remote display)

• F2: Signal B (connect to terminal 84 of the remote display)

• F3: Signal A (connec t to terminal 83 of the remote display)

• F4: Gnd (connect to terminal 82 of the remote display)

Power consumption: 28.8 VA

Power supply: 85 to 264 V

G

• G1: N

1)

AC

• G2: not connected

• G3: L

Protective ground connection (M4 screw)

A0018339

A0032445

1) Maximum power varies depending on the configuration of the modules. As the value of 28.8 VA shows

12 w.

maximum apparent power, select the applicable cables accordingly. The actual consumed effective power is

38 Endress+Hauser

Page 39

Proservo NMS83 Electrical connection

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

4

F

1

1 3

2

2 4

HR

CDI

WP

SIM

G

1

3

2

POWER

1

3

Vcc

Gnd

A B

2

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

F

1 3

2 4

HR

WP

Vcc

Gnd

A

B

81 82 83 84

F1 F2 F3 F4

6.1.1 Power supply

A0033413

G1 N

G2 not connected

G3 L

4 Green LED: indicates power supply

Supply voltage

85 to 264 VAC, 50/60 Hz, 28.8 VA

1)

The supply voltage is also indicated on the nameplate.

6.1.2 Remote display and operating module DKX001

14 Connection of the remote display and operating module DKX001 to the Tank Gauging device (NMR8x,

NMS8x or NRF8x)

1 Remote display and operating module

2 Connecting cable

3 Tank Gauging device (NMR8x, NMS8x or NRF8x)

A0037025

The remote display and operating module DKX001 is available as an accessory. For

details refer to SD01763D.

• The measured value is indicated on the DKX001 and on the local display and

operating module simulataneously.

• The operating menu cannot be accessed on both modules at the same time. If the

1) maximum value; actual value depending on modules installed. 28.8 VA includes the nominal power, and the cabling specification has to meet

Endress+Hauser 39

this value. On the other hand, the effective power consumption is 12 W.

operating menu is entered in one of these modules, the other module is

automatically locked. This locking remains active until the menu is closed in the

first module (back to measured value display).

Page 40

Electrical connection Proservo NMS83

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

E

1

1

2

CDI

i

G

1

3

2

POWER

3

6.1.3 HART Ex i/IS interface

A0033414

E1 H+

E2 H3 Orange LED: indicates data communication

This interface always operates as the main HART master for connected HART slave

transmitters. The Analog I/O modules, on the other hand, can be configured as a

HART master or slave → 48 → 50.

40 Endress+Hauser

Page 41

Proservo NMS83 Electrical connection

Spare parts for: Proservo NMS81

Ser.-no.:

8A21AC098AF4

Spare part

Spare no./structure

Displacer

Wire Drum

Additional information:

XPF0002-AABICR+

AAEAEBEFLALC76

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

71273689

7122xxxx

XPF0002-AABEFEG+

AAAAACDEFEG+

XPF0002-AAACABADJ+

AAHAHCHRIJJAJBKP

71023451

71023451

71023451

Cover

IOM-V1

IOM-A/RTD

IOM-D

SlotA

Slot B

Slot C

Slot D

IO Mod FF

Display

Display asm.

Detector

Main electr.

SMS electr.

6

7

8

9

10

11

12

5

4

3

2

1

www.endress.com/deviceviewer

D

C

B

A

6.1.4 Slots for I/O modules

The terminal compartment contains four slots (A, B, C and D) for I/O modules. Depending

on the device version (ordering features 040, 050 and 060) these slots contain different

I/O modules. The table below shows which module is located in which slot for a specific

device version.

The slot assignment for the device is also indicated on a label attached to the back

cover of the display module.

A0030121

1 Label showing (among other things) the modules in the slots A to D.

A Cable entry for slot A

B Cable entry for slot B

C Cable entry for slot C

D Cable entry for slot D

Endress+Hauser 41

Page 42

Electrical connection Proservo NMS83

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

"Primary Output" (040) = "Modbus" (A1)

Ordering feature

040

Primary

Output

A1 X0 X0 Modbus - - -

A1 X0 A1 Modbus - - Digital

A1 X0 A2 Modbus - Digital Digital

A1 X0 A3 Modbus Digital Digital Digital

A1 X0 B1 Modbus Modbus - -

A1 X0 B2 Modbus Modbus - Digital

A1 X0 B3 Modbus Modbus Digital Digital

A1 A1 X0 Modbus Analog Ex d/XP - -

A1 A1 A1 Modbus Analog Ex d/XP - Digital

A1 A1 A2 Modbus Analog Ex d/XP Digital Digital

A1 A1 B1 Modbus Modbus Analog Ex d/XP -

A1 A1 B2 Modbus Modbus Analog Ex d/XP Digital

A1 A2 X0 Modbus Analog Ex d/XP Analog Ex d/XP -

A1 A2 A1 Modbus Analog Ex d/XP Analog Ex d/XP Digital

A1 A2 B1 Modbus Analog Ex d/XP Analog Ex d/XP Modbus

A1 B1 X0 Modbus Analog Ex i/IS - -

A1 B1 A1 Modbus Analog Ex i/IS - Digital

A1 B1 A2 Modbus Analog Ex i/IS Digital Digital

A1 B1 B1 Modbus Modbus Analog Ex i/IS -

A1 B1 B2 Modbus Modbus Analog Ex i/IS Digital

A1 B2 X0 Modbus Analog Ex i/IS Analog Ex i/IS -

A1 B2 A1 Modbus Analog Ex i/IS Analog Ex i/IS Digital

A1 B2 B1 Modbus Analog Ex i/IS Analog Ex i/IS Modbus

A1 C2 X0 Modbus Analog Ex i/IS Analog Ex d/XP -

A1 C2 A1 Modbus Analog Ex i/IS Analog Ex d/XP Digital

A1 C2 B1 Modbus Analog Ex i/IS Analog Ex d/XP Modbus

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

42 Endress+Hauser

Page 43

Proservo NMS83 Electrical connection

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

"Primary Output" (040) = "V1" (B1)

Ordering feature

040

Primary

Output

B1 X0 X0 V1 - - -

B1 X0 A1 V1 - - Digital

B1 X0 A2 V1 - Digital Digital

B1 X0 A3 V1 Digital Digital Digital

B1 X0 B1 V1 Modbus - -

B1 X0 B2 V1 Modbus - Digital

B1 X0 B3 V1 Modbus Digital Digital

B1 A1 X0 V1 Analog Ex d/XP - -

B1 A1 A1 V1 Analog Ex d/XP - Digital

B1 A1 A2 V1 Analog Ex d/XP Digital Digital

B1 A1 B1 V1 Modbus Analog Ex d/XP -

B1 A1 B2 V1 Modbus Analog Ex d/XP Digital

B1 A2 X0 V1 Analog Ex d/XP Analog Ex d/XP -

B1 A2 A1 V1 Analog Ex d/XP Analog Ex d/XP Digital

B1 A2 B1 V1 Analog Ex d/XP Analog Ex d/XP Modbus

B1 B1 X0 V1 Analog Ex i/IS - -

B1 B1 A1 V1 Analog Ex i/IS - Digital

B1 B1 A2 V1 Analog Ex i/IS Digital Digital

B1 B1 B1 V1 Modbus Analog Ex i/IS -

B1 B1 B2 V1 Modbus Analog Ex i/IS Digital

B1 B2 X0 V1 Analog Ex i/IS Analog Ex i/IS -

B1 B2 A1 V1 Analog Ex i/IS Analog Ex i/IS Digital

B1 B2 B1 V1 Analog Ex i/IS Analog Ex i/IS Modbus

B1 C2 X0 V1 Analog Ex i/IS Analog Ex d/XP -

B1 C2 A1 V1 Analog Ex i/IS Analog Ex d/XP Digital

B1 C2 B1 V1 Analog Ex i/IS Analog Ex d/XP Modbus

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

Endress+Hauser 43

Page 44

Electrical connection Proservo NMS83

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

"Primary Output" (040) = "4-20mA HART Ex d" (E1)

Ordering feature

040

Primary

Output

E1 X0 X0 - Analog Ex d/XP - -

E1 X0 A1 - Analog Ex d/XP - Digital

E1 X0 A2 - Analog Ex d/XP Digital Digital

E1 X0 A3 Digital Analog Ex d/XP Digital Digital

E1 X0 B1 Modbus Analog Ex d/XP - -

E1 X0 B2 Modbus Analog Ex d/XP - Digital

E1 X0 B3 Modbus Analog Ex d/XP Digital Digital

E1 A1 X0 - Analog Ex d/XP Analog Ex d/XP -

E1 A1 A1 - Analog Ex d/XP Analog Ex d/XP Digital

E1 A1 A2 Digital Analog Ex d/XP Analog Ex d/XP Digital

E1 A1 B1 Modbus Analog Ex d/XP Analog Ex d/XP -

E1 A1 B2 Modbus Analog Ex d/XP Analog Ex d/XP Digital

E1 B1 X0 - Analog Ex d/XP Analog Ex i/IS -

E1 B1 A1 - Analog Ex d/XP Analog Ex i/IS Digital

E1 B1 A2 Digital Analog Ex d/XP Analog Ex i/IS Digital

E1 B1 B1 Modbus Analog Ex d/XP Analog Ex i/IS -

E1 B1 B2 Modbus Analog Ex d/XP Analog Ex i/IS Digital

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

44 Endress+Hauser

Page 45

Proservo NMS83 Electrical connection

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

"Primary Output" (040) = "4-20mA HART Ex i" (H1)

Ordering feature

040

Primary

Output

H1 X0 X0 - Analog Ex i/IS - -

H1 X0 A1 - Analog Ex i/IS - Digital

H1 X0 A2 - Analog Ex i/IS Digital Digital

H1 X0 A3 Digital Analog Ex i/IS Digital Digital

H1 X0 B1 Modbus Analog Ex i/IS - -

H1 X0 B2 Modbus Analog Ex i/IS - Digital

H1 X0 B3 Modbus Analog Ex i/IS Digital Digital

H1 A1 X0 - Analog Ex i/IS Analog Ex d/XP -

H1 A1 A1 - Analog Ex i/IS Analog Ex d/XP Digital

H1 A1 A2 Digital Analog Ex i/IS Analog Ex d/XP Digital

H1 A1 B1 Modbus Analog Ex i/IS Analog Ex d/XP -

H1 A1 B2 Modbus Analog Ex i/IS Analog Ex d/XP Digital

H1 B1 X0 - Analog Ex i/IS Analog Ex i/IS -

H1 B1 A1 - Analog Ex i/IS Analog Ex i/IS Digital

H1 B1 A2 Digital Analog Ex i/IS Analog Ex i/IS Digital

H1 B1 B1 Modbus Analog Ex i/IS Analog Ex i/IS -

H1 B1 B2 Modbus Analog Ex i/IS Analog Ex i/IS Digital

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

Endress+Hauser 45

Page 46

Electrical connection Proservo NMS83

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

WP

on

SIM

2

23344

112233445566778

8

A

1 2 3 4

A1-4

i

D

1

2 3 4

D1-4

6.1.5 Terminals of the "Modbus" or "V1" module

A0031200

15 Designation of the "Modbus" or "V1" modules (examples); depending on the device version these modules

may also be in slot B or C.

Depending on the device version, the "Modbus" and/or "V1" module may be in different

slots of the terminal compartment. In the operating menu the "Modbus" and "V1" interfaces

are designated by the respective slot and the terminals within this slot: A1-4, B1-4, C1-4,

D1-4.

Terminals of the "Modbus" module

Terminal

X1 S Cable shielding connected via a capacitor to EARTH

X2 0V Common reference

X3 B- Non-inverting signal line

X4 A+ Inverting signal line

Designation of the module in the operating menu: Modbus X1-4; (X = A, B, C or D)

1) In this column, "X" stands for one of the slots "A", "B", "C", or "D".

1)

Name Description

Terminals of the "V1" module

Terminal

X1 S Cable shielding connected via capacitor to EARTH

X2 not connected

X3 B- Protocol loop signal -

X4 A+ Protocol loop signal +

Designation of the module in the operating menu: V1 X1-4; (X = A, B, C or D)

1)

Name Description

46 Endress+Hauser

1) In this column, "X" stands for one of the slots "A", "B", "C", or "D".

Page 47

Proservo NMS83 Electrical connection

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

WP

on

SIM

22334

4

112233445566778

8

i

B

1 2 3 4 5 6 7 8

B1-3 B4-8

C

1 2 3 4 5 6 7 8

C1-3 C4-8

6.1.6 Terminals of the "Analog I/O" module (Ex d /XP or Ex i/IS)

A0031168

Terminals Function Connection diagrams Designation in the operating menu

B1-3 Analog input or output

C1-3 Analog I/O C1-3 (→ 205)

B4-8 Analog input RTD: → 51 Analog IP B4-8 (→ 199)

C4-8 Analog IP C4-8 (→ 199)

(configurable)

• Passive usage: → 48

• Active usage: → 50

Analog I/O B1-3 (→ 205)

Endress+Hauser 47

Page 48

Electrical connection Proservo NMS83

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

ca

b

-

+

!

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

a

+

–

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

b

6.1.7 Connection of the "Analog I/O" module for passive usage

• In the passive usage the supply voltage for the communication line must be supplied

by an external source.

• The wiring must be in accordance with the intended operating mode of the Analog

I/O module; see the drawings below.

"Operating mode" = "4..20mA output" or "HART slave +4..20mA output"

16 Passive usage of the Analog I/O module in the output mode

a Power supply

b HART signal output

c Analog signal evaluation

"Operating mode" = "4..20mA input" or "HART master+4..20mA input"

A0027931

48 Endress+Hauser

17 Passive usage of the Analog I/O module in the input mode

a Power supply

b External device with 4...20mA and/or HART signal output

A0027933

Page 49

Proservo NMS83 Electrical connection

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

a

+

–

!

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

b

"Operating mode" = "HART master"

A0027934

18 Passive usage of the Analog I/O module in the HART master mode

a Power supply

b Up to 6 external devices with HART signal output

Endress+Hauser 49

Page 50

Electrical connection Proservo NMS83

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

b

a

-

+

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

-

+

a

6.1.8 Connection of the "Analog I/O" module for active usage

• In the active usage the supply voltage for the communication line is supplied by the

device itself. There is no need of an external power supply.

• The wiring must be in accordance with the intended operating mode of the Analog

I/O module; see the drawings below.

• Maximum current consumption of the connected HART devices: 24 mA

(i.e. 4 mA per device if 6 devices are connected).

• Output voltage of the Ex-d module: 17.0 V@4 mA to 10.5 V@22 mA

• Output voltage of the Ex-ia module: 18.5 V@4 mA to 12.5 V@22 mA

"Operating mode" = "4..20mA output" or "HART slave +4..20mA output"

A0027932

19 Active usage of the Analog I/O module in the output mode

a HART signal output

b Analog signal evaluation

"Operating mode" = "4..20mA input" or "HART master+4..20mA input"

50 Endress+Hauser

20 Active usage of the Analog I/O module in the input mode

a External device with 4...20mA and/or HART signal output

A0027935

Page 51

Proservo NMS83 Electrical connection

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

a

-

+

A

C

B

1 112 22

3 33

4 445 556 667 778 88

"Operating mode" = "HART master"

A0027936

21 Active usage of the Analog I/O module in the HART master mode

a Up to 6 external devices with HART signal output

The maximum current consumption for the connected HART devices is 24 mA (i.e.

4 mA per device if 6 devices are connected).

6.1.9 Connection of a RTD

A0026371

A 4-wire RTD connection

B 3-wire RTD connection

C 2-wire RTD connection

Endress+Hauser 51

Page 52

Electrical connection Proservo NMS83

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

WP

on

SIM

22334

4

1

122334455667788

A

1 2 3 4

A1-2 A3-4

i

C

1

2 3 4 5 6 7

C1-2 C3-4

6.1.10 Terminals of the "Digital I/O" module

A0026424

22 Designation of the digital inputs or outputs (examples)

• Each Digital IO Module provides two digital inputs or outputs.

• In the operating menu each input or output is designated by the respective slot and two

terminals within this slot. A1-2, for example, denotes terminals 1 and 2 of slot A. The

same is valid for slots B, C and D if they contain a Digital IO module.

• For each of these pairs of terminals, one of the following operating modes can be

selected in the operating menu:

– Disable

– Passive Output

– Passive Input

– Active Input

52 Endress+Hauser

Page 53

Proservo NMS83 Electrical connection

6.2 Connecting requirements

6.2.1 Cable specification

Terminals

Terminal Wire cross section

Signal and power supply

• Spring terminals (NMx8x-xx1...)

• Screw terminals (NMx8x-xx2...)

Ground terminal in the terminal compartment max. 2.5 mm2 (13 AWG)

Ground terminal at the housing max. 4 mm2 (11 AWG)

Power supply line

Standard device cable is sufficient for the power line.

HART communication line

• Standard device cable is sufficient if only the analog signal is used.

• Shielded cable is recommended if using the HART protocol. Observe the grounding

concept of the plant.

0.2 to 2.5 mm2 (24 to 13 AWG)

Modbus communication line

• Observe the cable conditions from the TIA-485-A, Telecommunications Industry

Association.

• Additional conditions: Use shielded cable.

V1 communication line

• Two wire (twisted pair) screened or un-screened cable

• Resistance in one cable: ≤ 120 Ω

• Capacitance between lines: ≤ 0.3 µF

Endress+Hauser 53

Page 54

Electrical connection Proservo NMS83

6.3 Ensuring the degree of protection

To guarantee the specified degree of protection, carry out the following steps after the

electrical connection:

1. Check that the housing seals are clean and fitted correctly. Dry, clean or replace the

seals if necessary.

2. Tighten all housing screws and screw covers.

3. Firmly tighten the cable glands.

4. To ensure that moisture does not enter the cable entry, route the cable so that it

loops down before the cable entry ("water trap").

A0013960

5. Insert blind plugs appropriate for the safety rating of the device (e.g. Ex d/XP).

6.4 Post-connection check

Are cables or the device undamaged (visual inspection)?

m

Do the cables comply with the requirements?

m

Do the cables have adequate strain relief?

m

Are all cable glands installed, firmly tightened and correctly sealed?

m

Does the supply voltage match the specifications on the transmitter nameplate?

m

Is the terminal assignment correct → 38?

m

If required: Is the protective earth connected correctly ?

m

If supply voltage is present: Is the device ready for operation and do values appear on the display

m

module?

Are all housing covers installed and firmly tightened?

m

Is the securing clamp tightened correctly?

m

54 Endress+Hauser

Page 55

Proservo NMS83 Operability

7 Operability

7.1 Overview of the operation options

The device is operated via an operating menu → 56. This menu can be accessed by

the following interfaces:

• The display and operating module at the device or the remote display and operating

module DKX001 (→ 58).

• FieldCare connected through the service interface in the terminal compartment of the

device (→ 71).

• FieldCare connected through Tankvision Tank Scanner NXA820 (remote operation;

→ 72).

• FieldCare connected through Commubox FXA195 (→ 149) to a HART interface of

the device.

Confirm that the servo motor stops before changing parameters for safety use.

Endress+Hauser 55

Page 56

Operability Proservo NMS83

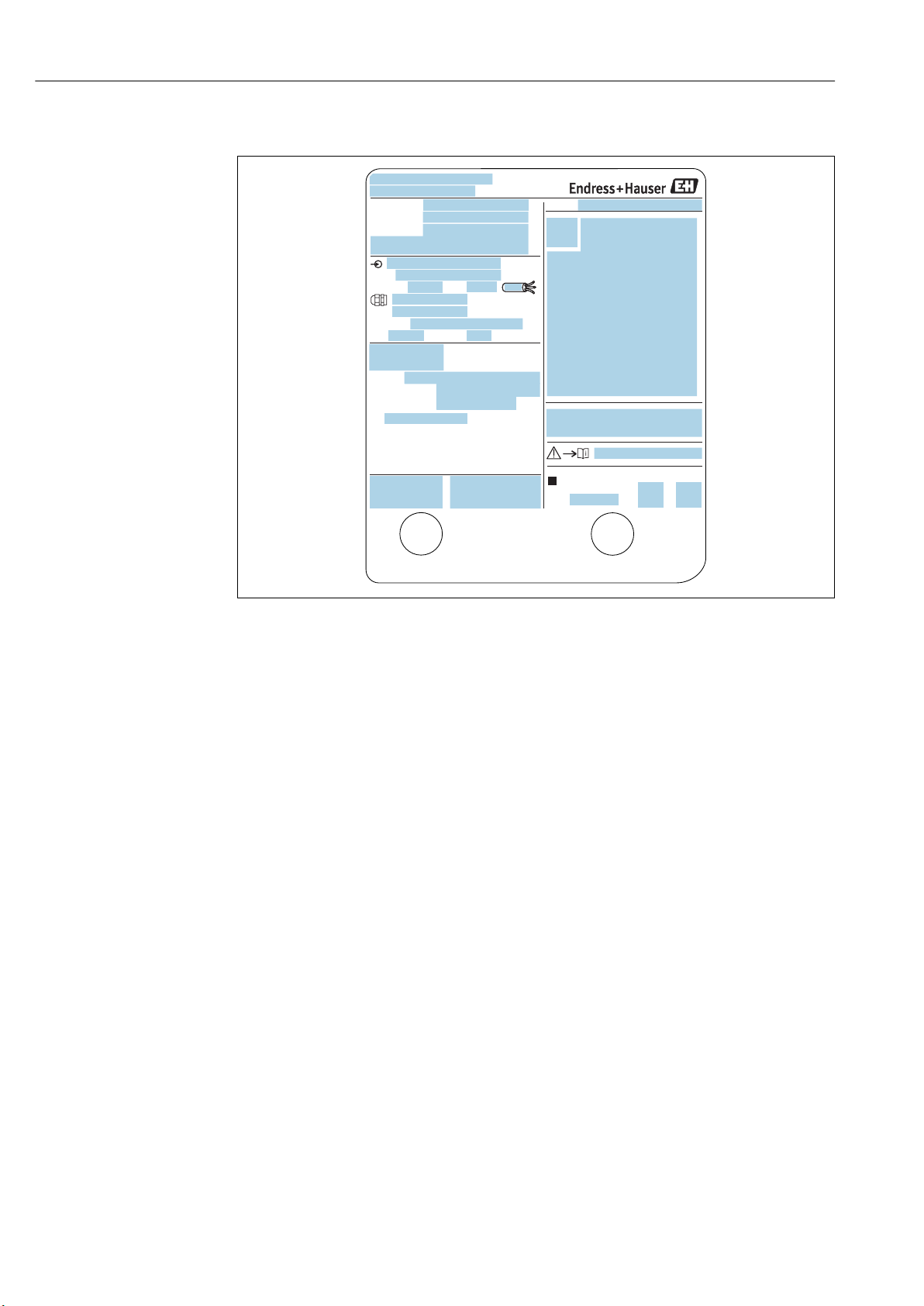

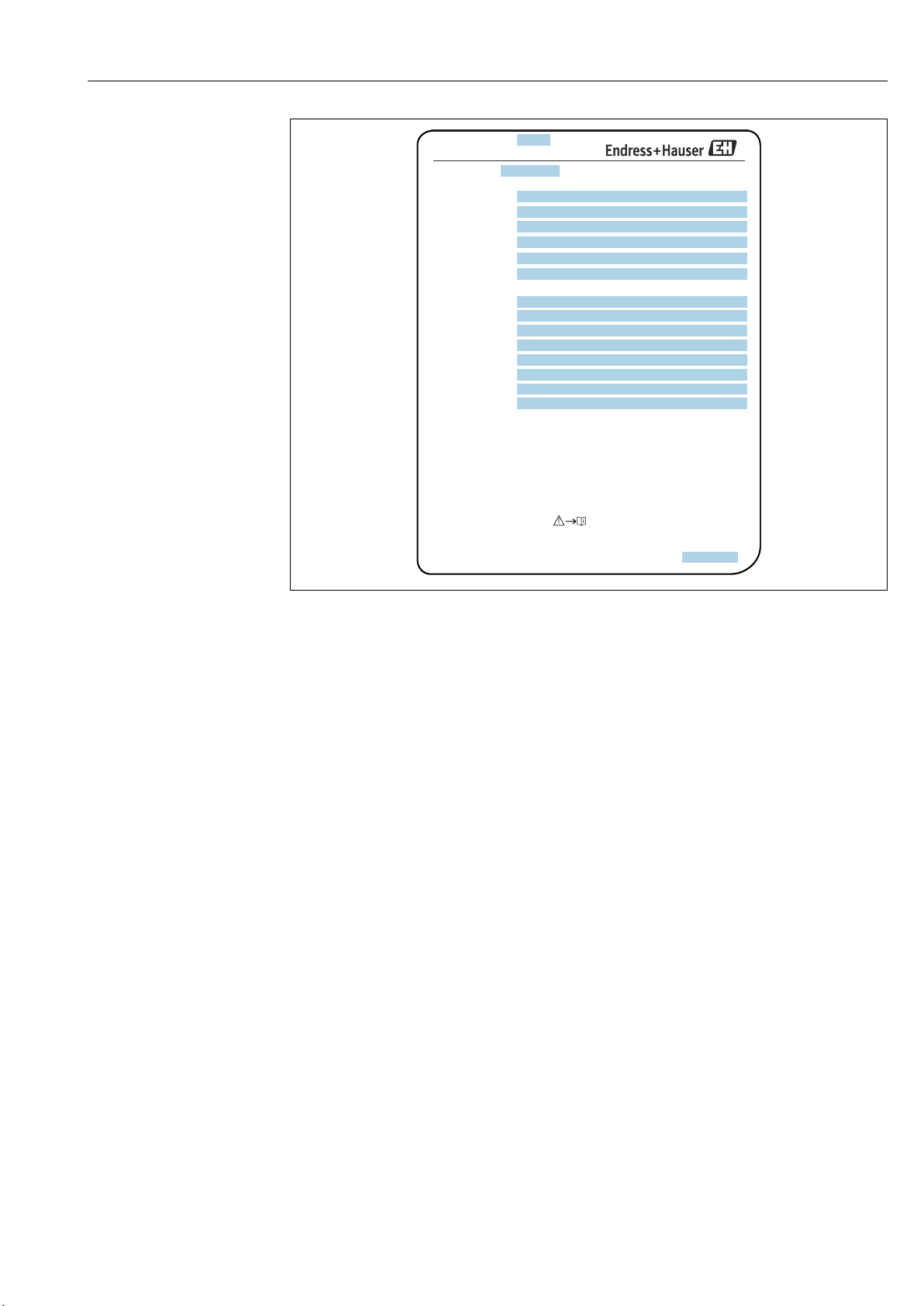

7.2 Structure and function of the operating menu

Menu Submenu /

parameter

Operation Proservo

parameters

Level Shows the measured and calculated

Temperature Shows the measured and calculated

Density Shows the measured and calculated

Pressure Shows the measured and calculated

GP values Shows the general purpose values.

Setup Standard

parameters

Calibration Calibration of the measurement

Advanced setup Contains further parameters and

Diagnostics Diagnostic

parameters

Diagnostic list Contains up to 5 currently active error

Device information Contains information needed to

Simulation Used to simulate measured values or

Device check Contains all parameters needed to

1)

Expert

Contains all parameters of the device (including

those which are already contained in one of the

other menus). This menu is organized

according to the function blocks of the device.

The parameter of the Expert menu are

described in:

GP01080G (NMS83)

System Contains all general device parameters

Sensor Contains all parameters needed to

Input/output Contains submenus to configure the

Communication Contains all parameters needed to

Application Contains submenus to configure

Meaning

Contains parameters to operate

Proservo (e.g. Gauge command).

level values.

temperature values.

density values.

pressure values.

Standard commissioning parameters

submenus:

• to adapt the device to special

measuring conditions.

• to process the measured value.

• to configure the signal output.

Indicates:

• The latest diagnostic messages and

their timestamps.

• The operating time (overall time and

time since last restart).

• The time according to the real-time

clock.

messages.

identify the device.

output values.

check the measurement capability of

the device.

which do not affect the measurement

or the communication interface.

configure the measurement.

analog and discrete I/O modules and

connected HART devices.

configure the digital communication

interface.

• the tank gauging application

• the tank calculations

• the alarms.

56 Endress+Hauser

Page 57

Proservo NMS83 Operability

Menu Submenu /

parameter

Tank values Shows measured and calculated tank

Diagnostics Contains all parameters needed to

1) On entering the "Expert" menu, an access code is always requested. If a customer specific access code has

not been defined, "0000" has to be entered.

Meaning

values

detect and analyze operational errors.

Endress+Hauser 57

Page 58

Operability Proservo NMS83

XX XX XX XX X

mm

1

2

7.3 Access to the operating menu via the local or remote display and operating module.