Page 1

TI01045D/06/EN/08.17

71380240

Products Solutions Services

Technical Information

Proline Promag L 400

Electromagnetic flowmeter

Weight-optimized sensor with a state‐of‐the‐art transmitter for Water &

Wastewater

Application

• The bidirectional measuring principle is virtually

independent of pressure, density, temperature and viscosity

• Fully suitable for standard applications in the water and

wastewater industry

Device properties

• Up to 30 % less sensor weight

• Nominal diameter: DN 25 to 2400 (1 to 90")

• Maximum reduced installation length to DVGW/ISO

• Transmitter housing made of durable polycarbonate or

aluminum

• WLAN access

• Integrated data logger: measured values monitoring

Your benefits

• Reduced installation costs – flexible mounting by

one‐of‐a‐kind lap‐joint flange concept (DN < 350/14")

• Energy-saving flow measurement – no pressure loss due to

cross-section constriction

• Maintenance-free – no moving parts

• Safe operation – no need to open the device due to display

with touch control, background lighting

• Time‐saving local operation without additional software and

hardware – integrated web server

• Integrated verification – Heartbeat Technology

Page 2

Table of contents

Proline Promag L 400

About this document ........................ 4

Symbols used ................................ 4

Function and system design ................... 5

Measuring principle ............................ 5

Measuring system ............................. 6

Equipment architecture ......................... 7

Safety ..................................... 7

Input ..................................... 8

Measured variable ............................. 8

Measuring range .............................. 8

Operable flow range ........................... 11

Input signal ................................ 11

Output .................................. 11

Output signal ............................... 11

Signal on alarm .............................. 13

Low flow cut off ............................. 14

Galvanic isolation ............................ 14

Protocol-specific data .......................... 15

Power supply ............................. 19

Terminal assignment .......................... 19

Pin assignment, device plug ...................... 21

Supply voltage .............................. 22

Power consumption ........................... 22

Current consumption .......................... 22

Power supply failure .......................... 22

Electrical connection .......................... 23

Potential equalization ......................... 27

terminals .................................. 29

Cable entries ............................... 29

Cable specification ............................ 29

Performance characteristics .................. 32

Reference operating conditions ................... 32

Maximum measured error ....................... 32

Repeatability ............................... 32

Influence of ambient temperature ................. 32

Installation ............................... 33

Mounting location ............................ 33

Orientation ................................ 34

Inlet and outlet runs .......................... 35

Adapters .................................. 35

Length of connecting cable ...................... 36

Mounting the transmitter housing ................. 37

Special mounting instructions .................... 37

Environment .............................. 38

Ambient temperature range ..................... 38

Storage temperature .......................... 38

Atmosphere ................................ 39

Degree of protection .......................... 39

Vibration resistance ........................... 39

Shock resistance ............................. 39

Impact resistance ............................ 39

Mechanical load ............................. 39

Electromagnetic compatibility (EMC) ............... 39

Process .................................. 39

Medium temperature range ...................... 39

Conductivity ................................ 40

Pressure-temperature ratings .................... 40

Pressure tightness ............................ 41

Flow limit ................................. 42

Pressure loss ............................... 42

System pressure ............................. 43

Vibrations ................................. 43

Mechanical construction .................... 44

Dimensions in SI units ......................... 44

Dimensions in US units ......................... 55

Weight ................................... 64

Measuring tube specification ..................... 71

Materials .................................. 73

Fitted electrodes ............................. 76

Process connections ........................... 76

Surface roughness ............................ 76

Operability ............................... 76

Operating concept ............................ 76

Languages ................................. 77

Local display ................................ 77

Remote operation ............................ 77

Service interface ............................. 79

Supported operating tools ....................... 81

HistoROM data management ..................... 82

Certificates and approvals ................... 83

CE mark ................................... 83

C-Tick symbol ............................... 83

Ex approval ................................ 83

Drinking water approval ........................ 83

HART certification ............................ 83

Certification PROFIBUS ......................... 83

EtherNet/IP certification ........................ 84

Radio approval .............................. 84

Other standards and guidelines ................... 84

Ordering information ....................... 84

Product generation index ....................... 85

Application packages ....................... 85

Cleaning .................................. 85

Diagnostics functions .......................... 85

Heartbeat Technology ......................... 86

Accessories ............................... 86

Device-specific accessories ...................... 86

Communication-specific accessories ................ 86

Service-specific accessories ...................... 87

System components ........................... 88

2 Endress+Hauser

Page 3

Proline Promag L 400

Supplementary documentation ............... 88

Standard documentation ........................ 88

Supplementary device-dependent documentation ....... 89

Registered trademarks ...................... 89

Endress+Hauser 3

Page 4

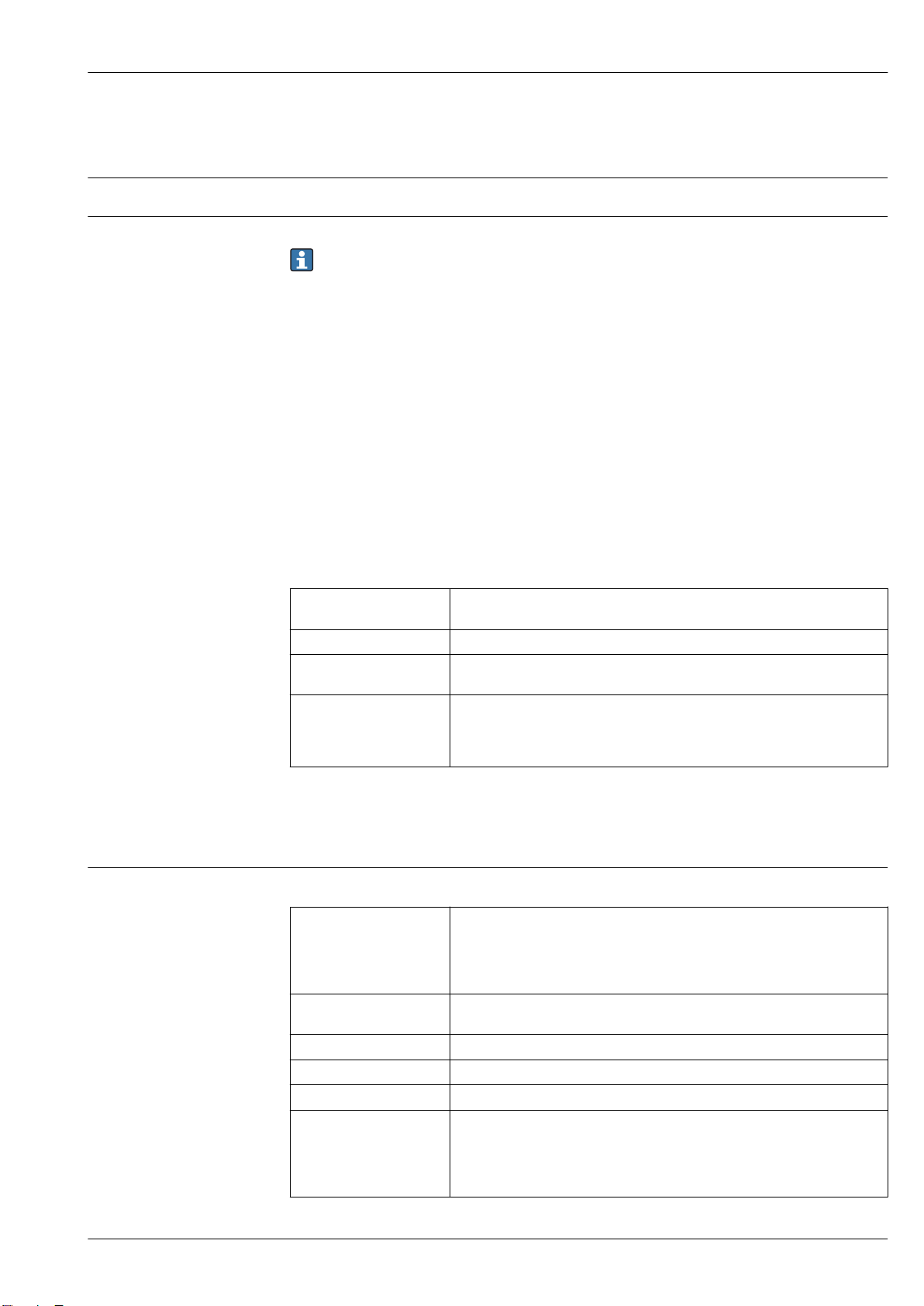

About this document

A

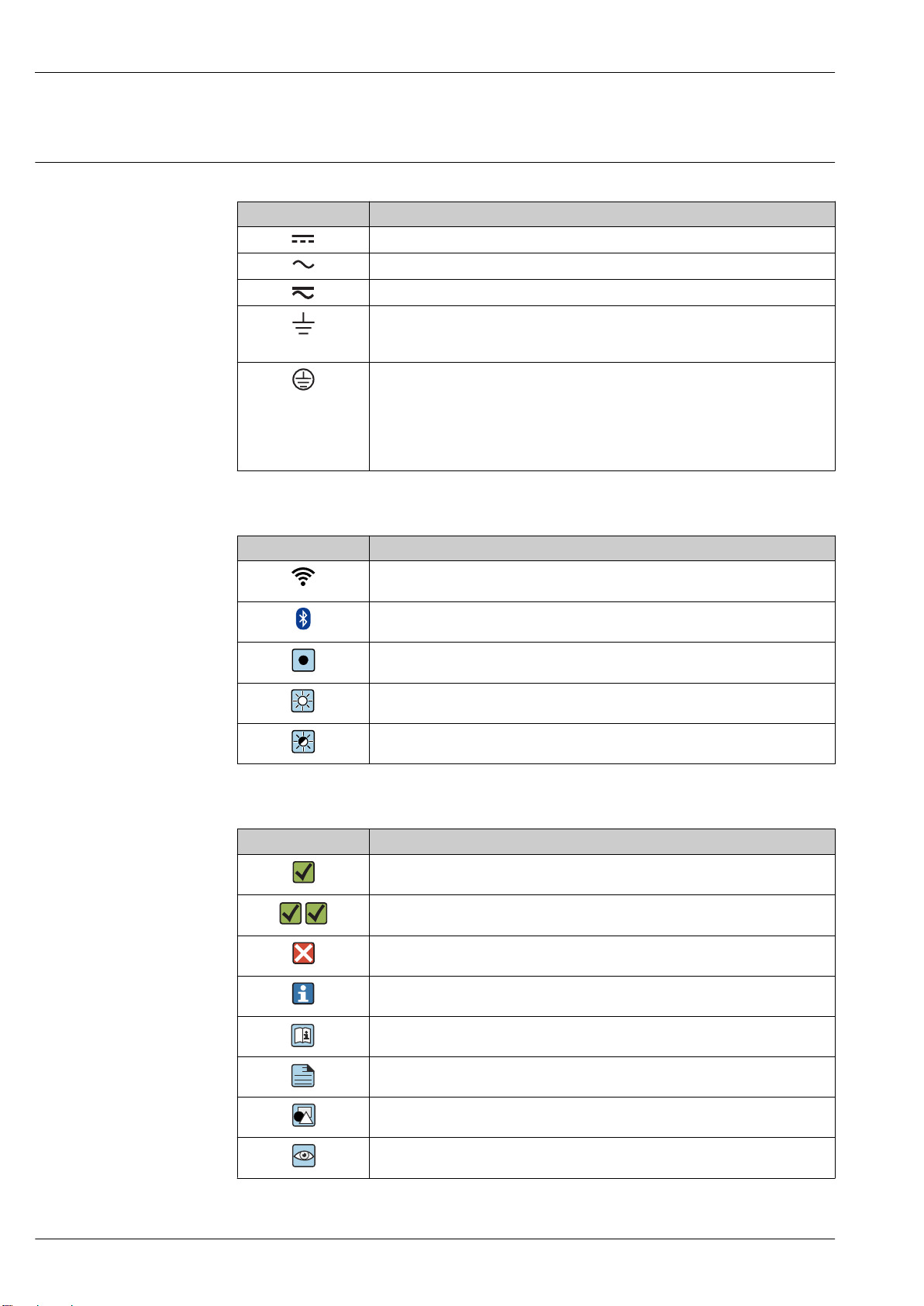

Symbols used Electrical symbols

Symbol Meaning

Proline Promag L 400

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

Communication symbols

Symbol Meaning

Wireless Local Area Network (WLAN)

Communication via a wireless, local network.

Bluetooth

Wireless data transmission between devices over a short distance.

LED

Light emitting diode is off.

LED

Light emitting diode is on.

LED

Light emitting diode is flashing.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation.

Reference to page.

Reference to graphic.

Visual inspection.

4 Endress+Hauser

Page 5

Proline Promag L 400

1.

-

.

U

e

L

B

I

I

v

Symbols in graphics

Symbol Meaning

1, 2, 3, ... Item numbers

, 2., 3., … Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Hazardous area

Safe area (non-hazardous area)

Flow direction

Function and system design

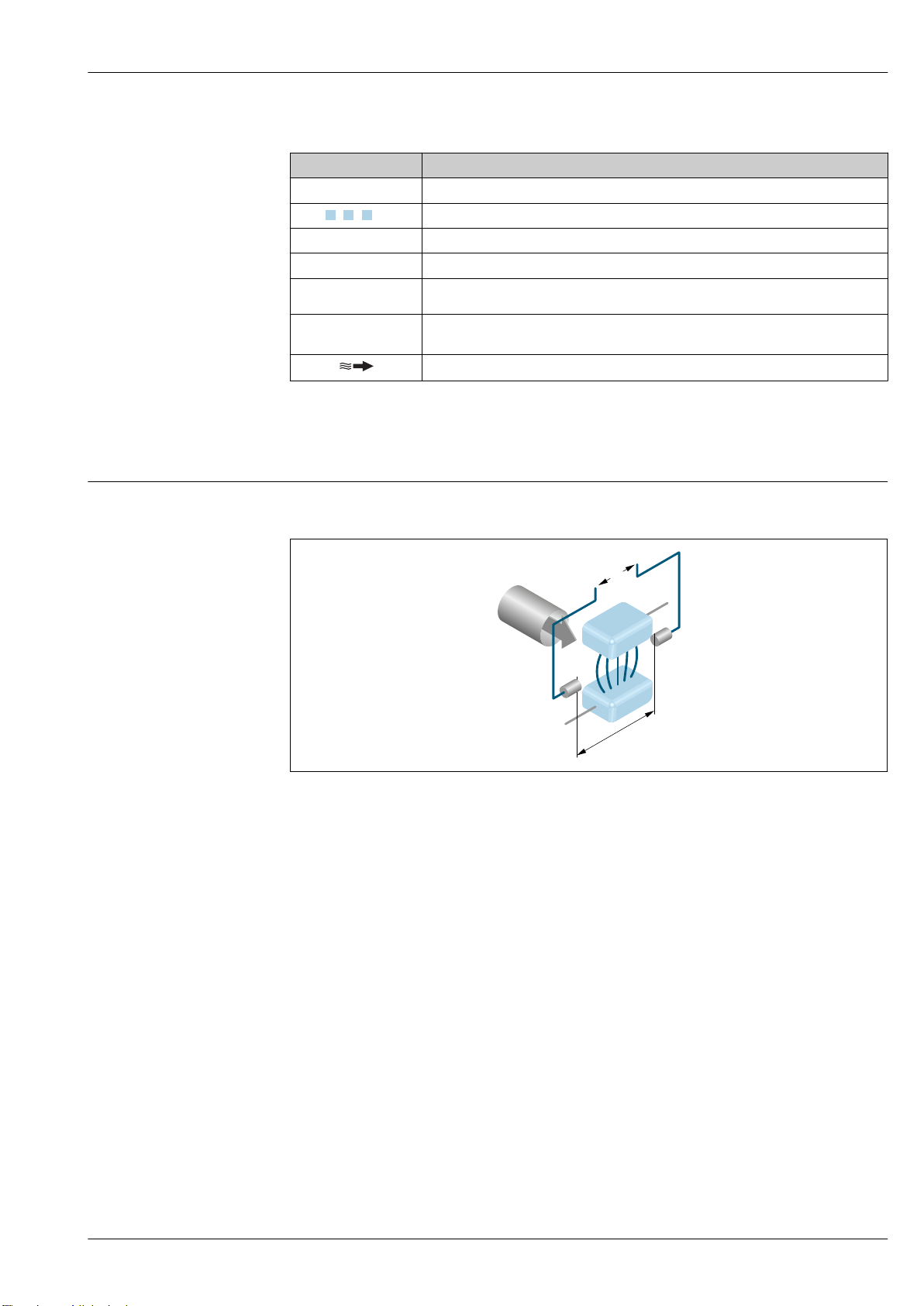

Measuring principle

Following Faraday's law of magnetic induction, a voltage is induced in a conductor moving through a

magnetic field.

A0028962

Ue Induced voltage

B Magnetic induction (magnetic field)

L Electrode spacing

I Current

v Flow velocity

In the electromagnetic measuring principle, the flowing medium is the moving conductor. The

voltage induced (Ue) is proportional to the flow velocity (v) and is supplied to the amplifier by means

of two measuring electrodes. The flow volume (Q) is calculated via the pipe cross-section (A). The DC

magnetic field is created through a switched direct current of alternating polarity.

Formulae for calculation

• Induced voltage Ue = B · L · v

• Volume flow Q = A · v

Endress+Hauser 5

Page 6

Proline Promag L 400

Measuring system

The device consists of a transmitter and a sensor.

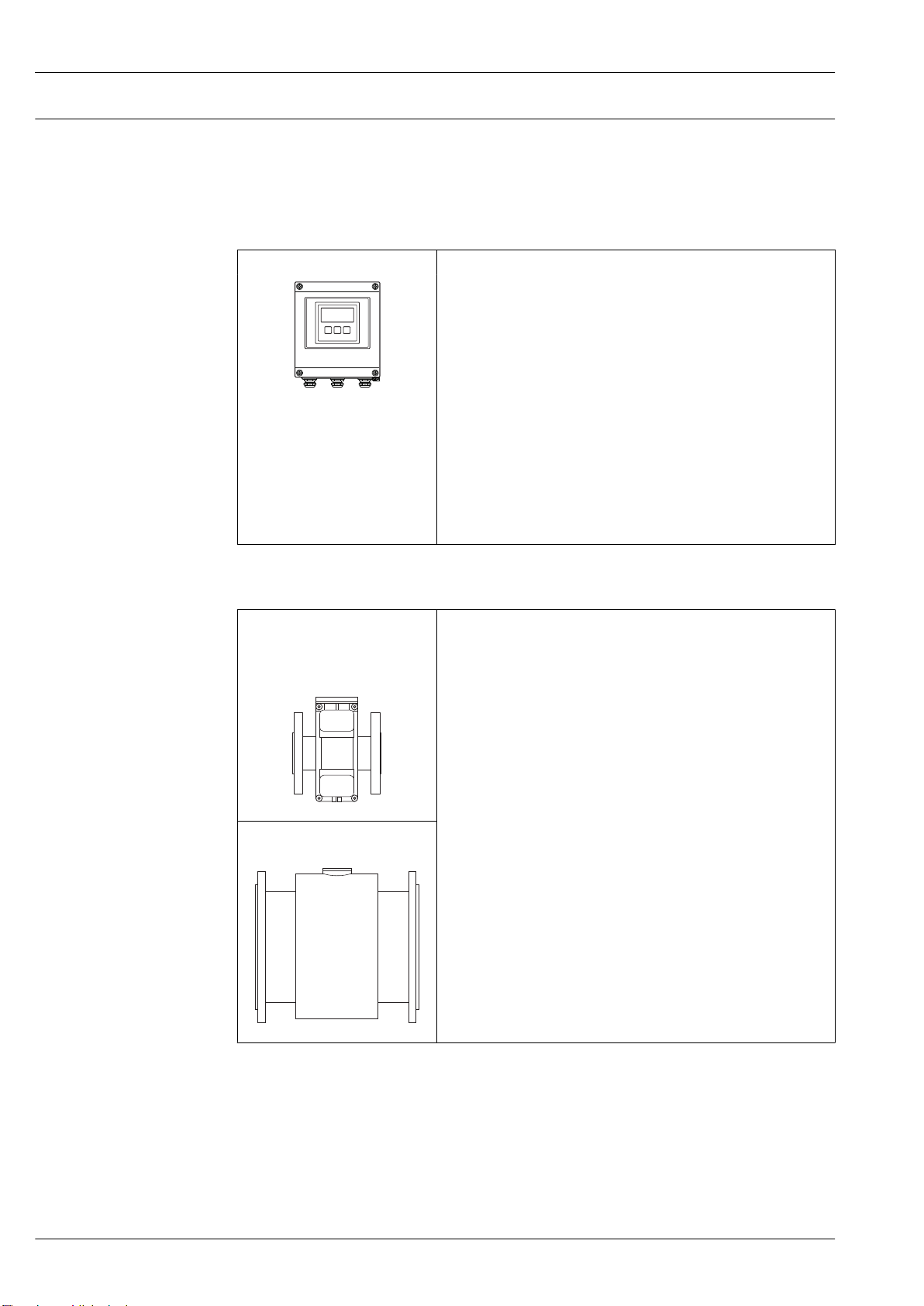

Two device versions are available:

• Compact version – transmitter and sensor form a mechanical unit.

• Remote version - transmitter and sensor are mounted in separate locations.

Transmitter

Promag 400 Device versions and materials

• Compact version: compact housing

– Polycarbonate plastic

– Aluminum, AlSi10Mg, coated

• Remote version: wall-mount housing

– Polycarbonate plastic

– Aluminum, AlSi10Mg, coated

Configuration:

• External operation via four-line, illuminated local display with touch

A0017117

control and guided menus ("Make-it-run" wizards) for applications

• Via operating tools (e.g. FieldCare)

• Via Web browser (e.g. Microsoft Internet Explorer)

• Also for device version with EtherNet/IP output:

– Via Add-on Profile Level 3 for automation system from Rockwell

Automation

– Via Electronic Data Sheet (EDS)

• Also for device version with PROFIBUS DP output:

Via PDM driver for Siemens automation system

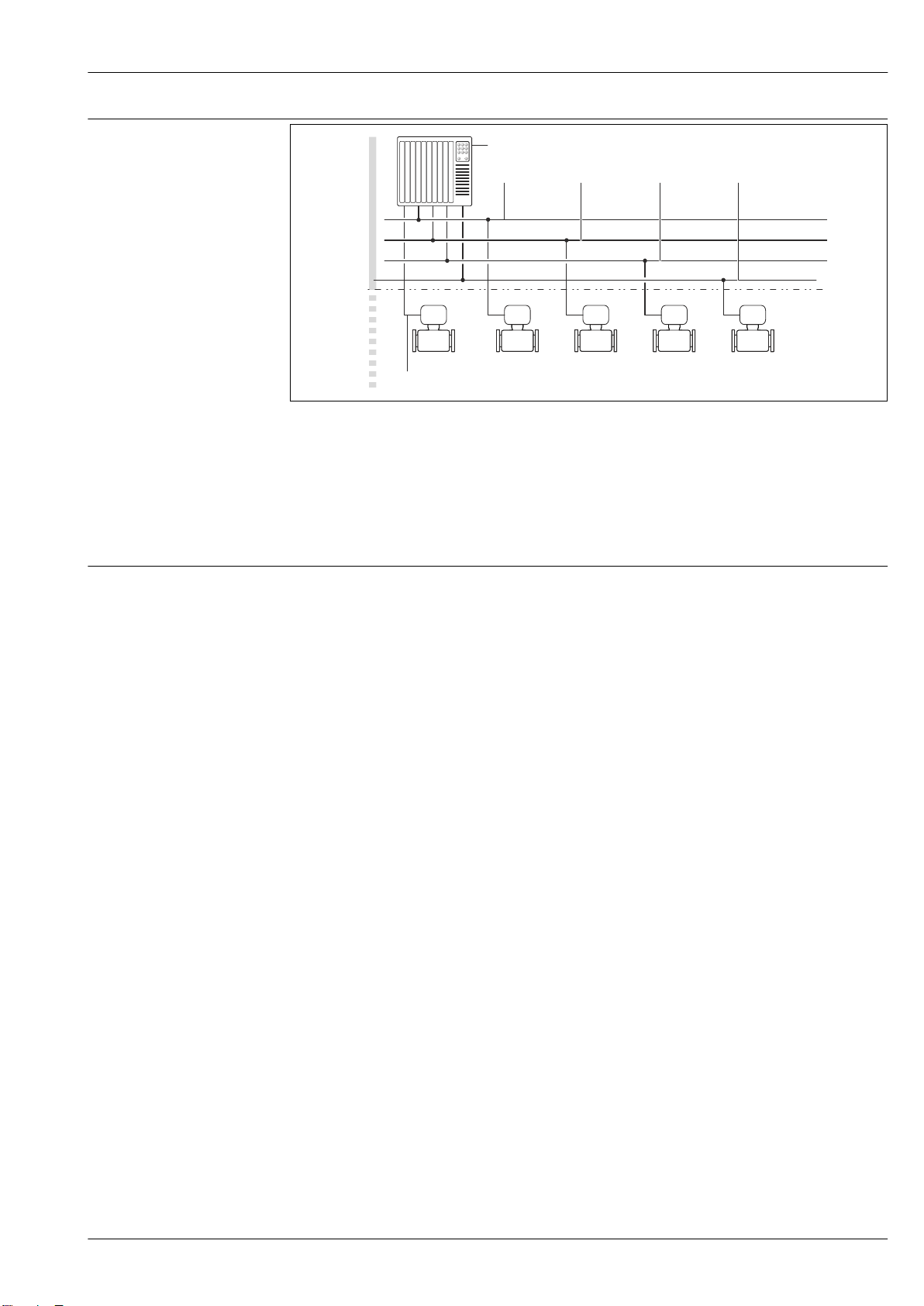

Sensor

Promag L • Nominal diameter range: DN 25 to 2400 (1 to 90")

A0017040

A0017041

• Materials:

– Sensor housing: aluminum, AlSi10Mg, coated; carbon steel with

protective varnish

– Sensor connection housing: aluminum, AlSi10Mg, coated

Sensor connection housing polycarbonate for

DN 350 to 2 400 mm (13.8 to 94.5 in) for IP68 option

– Measuring tubes:

DN 25 to 300 (1 to 12"): stainless steel, 1.4301/1.4306/304L

DN 350 to 1200 (14 to 48"): stainless steel, 1.4301/1.4307/304

DN 1350 to 2400 (54 to 90"): stainless steel, 1.4301/1.4307

– Liner: hard rubber, polyurethane, PTFE

– Electrodes: stainless steel, 1.4435 (316L); Alloy C22, 2.4602 (UNS

N06022)

– Process connections:

Stainless steel, 1.4301/1.4306/1.4404//1.4571/F316L

Carbon steel, A105/A181/A515(70)/FE410WB/P250GH/P235

GH/P265GH/S235JRG2/S235JR+N/S275JR

– Seals: as per DIN EN 1514-1 Form IBC

– Ground disks: stainless steel, 1.4435 (316L); Alloy C22, 2.4602

(UNS N06022)

Lap joint flange, lap joint flange,

stamped plate: DN 25 to 300 (1 to

12")

Fixed flange: DN 350 to 2400 (14

to 90")

6 Endress+Hauser

Page 7

Proline Promag L 400

2 3

6

7

8

4

1

5

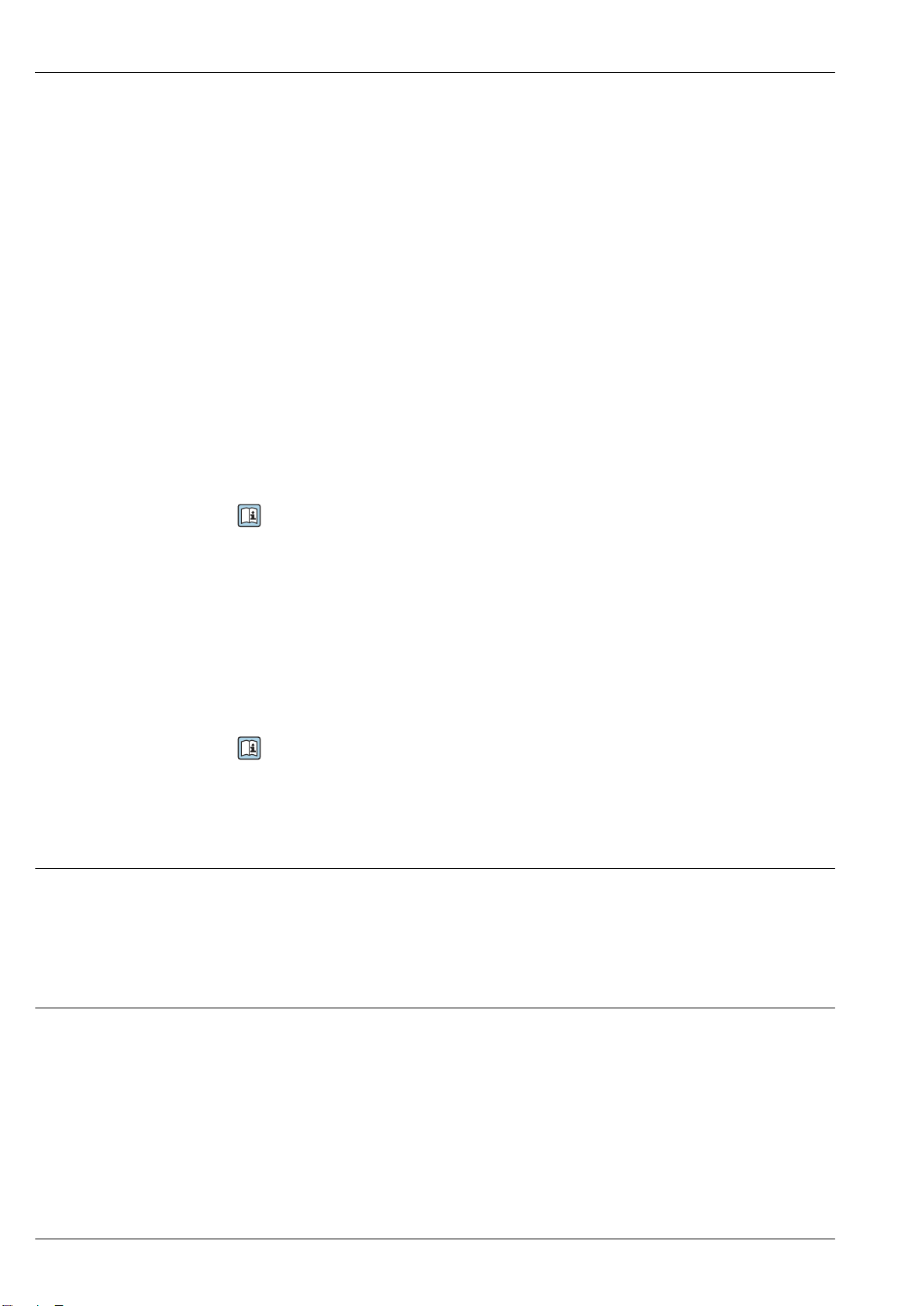

Equipment architecture

A0021560

1 Possibilities for integrating measuring devices into a system

1 Control system (e.g. PLC)

2 EtherNet/IP

3 PROFIBUS DP

4 Modbus RS485

5 4-20 mA HART, pulse/frequency/switch output

6 Non-hazardous area

7 Non-hazardous area and Zone 2/Div. 2

Safety IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any inadvertent

changes to the device settings.

IT security measures in line with operators' security standards and designed to provide additional

protection for the device and device data transfer must be implemented by the operators themselves.

Device-specific IT security

The device offers a range of specific functions to support protective measures on the operator's side.

These functions can be configured by the user and guarantee greater in-operation safety if used

correctly. An overview of the most important functions is provided in the following section.

Protecting access via hardware write protection

Write access to the device parameters via the local display or operating tool (e.g. FieldCare,

DeviceCare) can be disabled via a write protection switch (DIP switch on the motherboard). When

hardware write protection is enabled, only read access to the parameters is possible.

Hardware write protection is disabled when the device is delivered.

Protecting access via a password

Different passwords are available to protect write access to the device parameters or access to the

device via the WLAN interface.

• User-specific access code

Protect write access to the device parameters via the local display, Web browser or operating tool

(e.g. FieldCare, DeviceCare). Access authorization is clearly regulated through the use of a userspecific access code.

• WLAN passphrase

The network key protects a connection between an operating unit (e.g. notebook or tablet) and the

device via the WLAN interface which can be ordered as an option.

User-specific access code

Write access to the device parameters via the local display or operating tool (e.g. FieldCare,

DeviceCare) can be protected by the modifiable, user-specific access code.

Endress+Hauser 7

Page 8

Proline Promag L 400

WLAN passphrase

A connection between an operating unit (e.g. notebook or tablet) and the device via the WLAN

interface which can be ordered as an option is protected by the network key. The WLAN

authentication of the network key complies with the IEEE 802.11 standard.

When the device is delivered, the network key is pre-defined depending on the device. It can be

changed via the WLAN settings submenu in the WLAN passphrase parameter.

General notes on the use of passwords

• The access code and network key supplied with the device should be changed during

commissioning.

• Follow the general rules for generating a secure password when defining and managing the access

code or network key.

• The user is responsible for the management and careful handling of the access code and network

key.

Access via fieldbus

When communicating via fieldbus, access to the device parameters can be restricted to "Read only"

access. The option can be changed in the Fieldbus writing access parameter.

This does not affect cyclic measured value transmission to the higher-order system, which is always

guaranteed.

For detailed information, see the "Description of Device Parameters" document pertaining to the

device → 89

Access via Web server

The device can be operated and configured via a Web browser with the integrated Web server. The

connection is via the service interface (CDI-RJ45) or the WLAN interface. For device versions with

the EtherNet/IP and PROFINET communication protocols, the connection can also be established via

the terminal connection for signal transmission with EtherNet/IP or PROFINET (RJ45 connector).

The Web server is enabled when the device is delivered. The Web server can be disabled if necessary

(e.g. after commissioning) via the Web server functionality parameter.

The device and status information can be hidden on the login page. This prevents unauthorized

access to the information.

For detailed information, see the "Description of Device Parameters" document pertaining to the

device → 89

Input

Measured variable Direct measured variables

• Volume flow (proportional to induced voltage)

• Electrical conductivity

Calculated measured variables

Mass flow

Measuring range

Typically v = 0.01 to 10 m/s (0.03 to 33 ft/s) with the specified accuracy

Electrical conductivity: ≥ 5 μS/cm for liquids in general

8 Endress+Hauser

Page 9

Proline Promag L 400

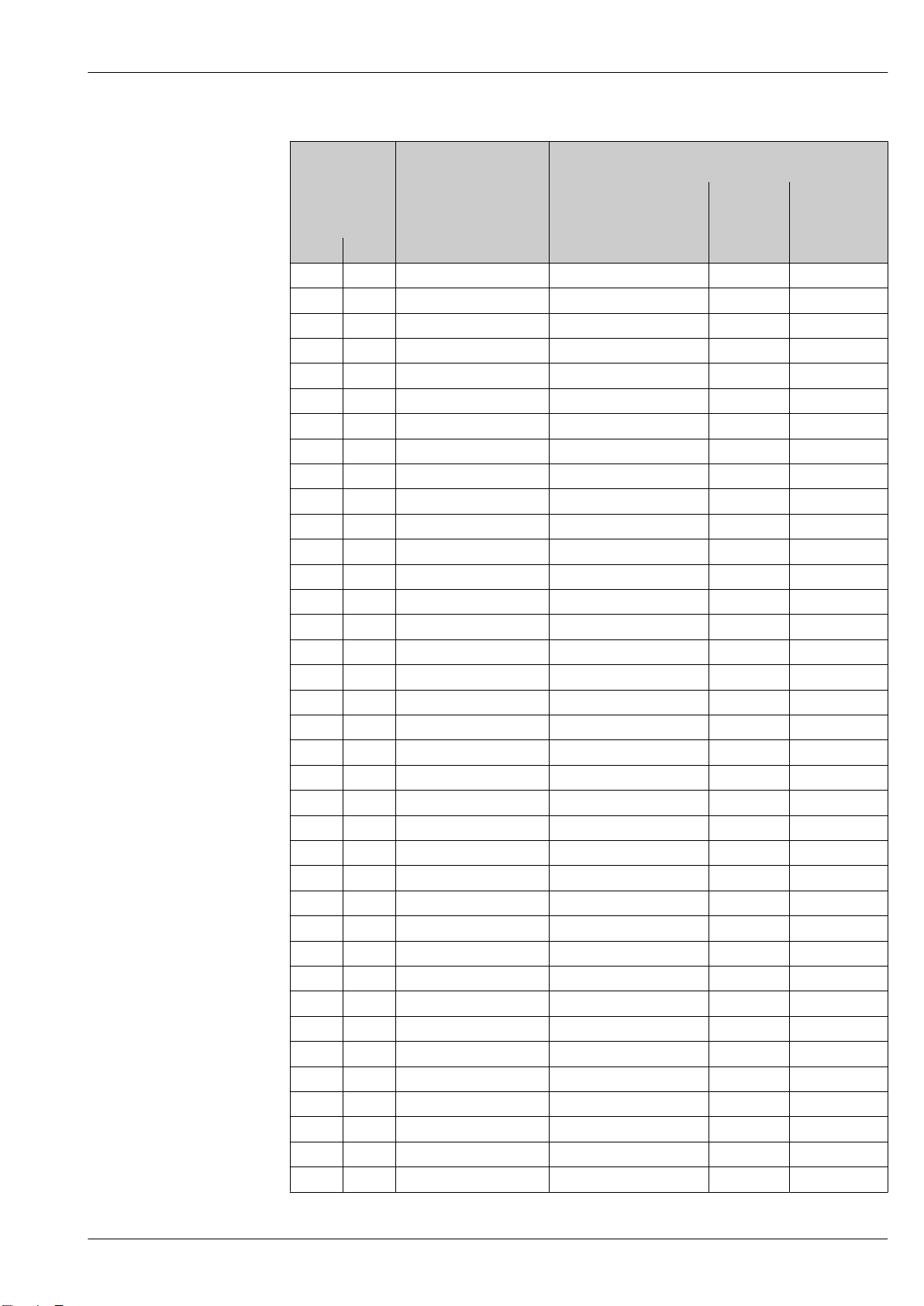

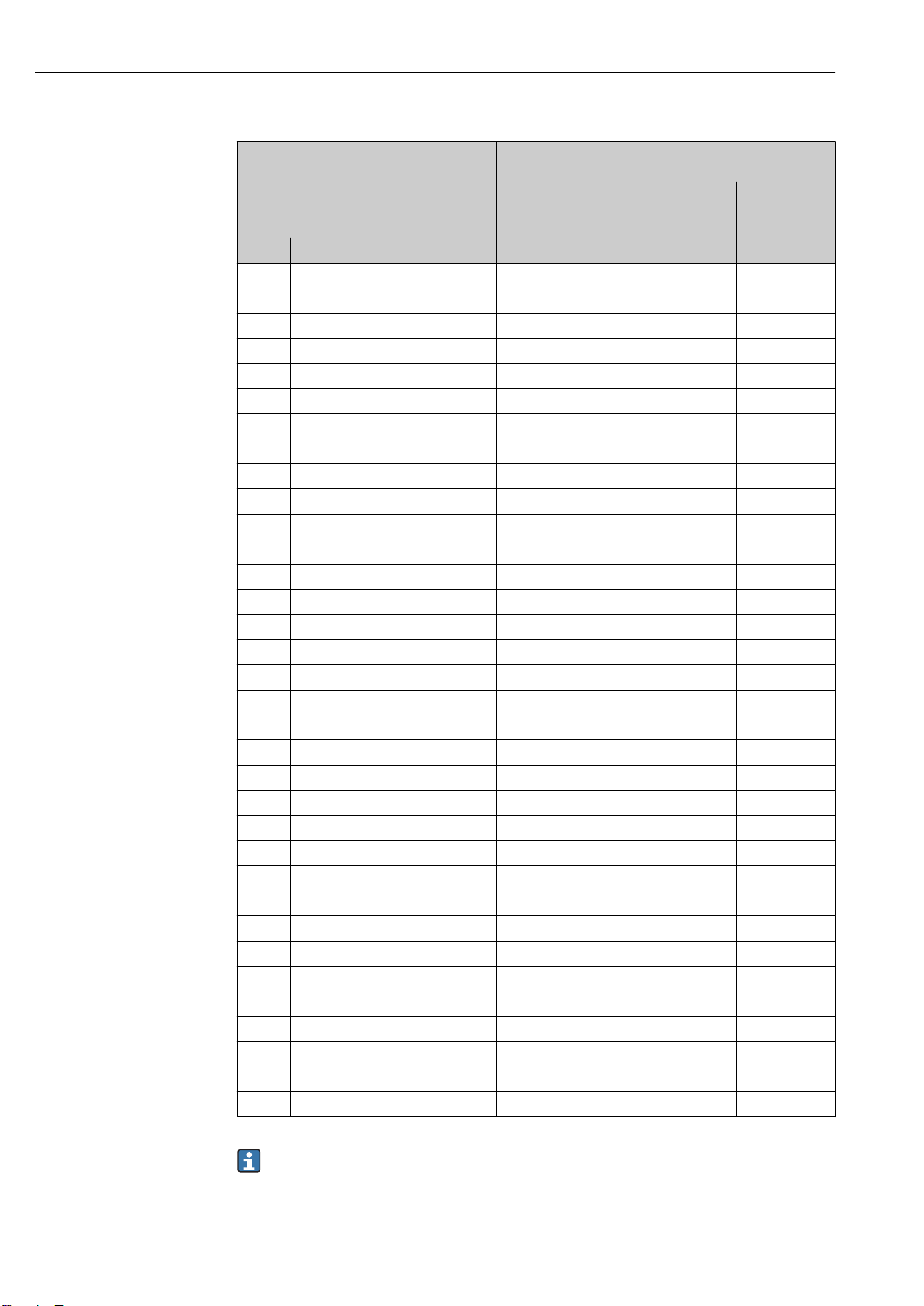

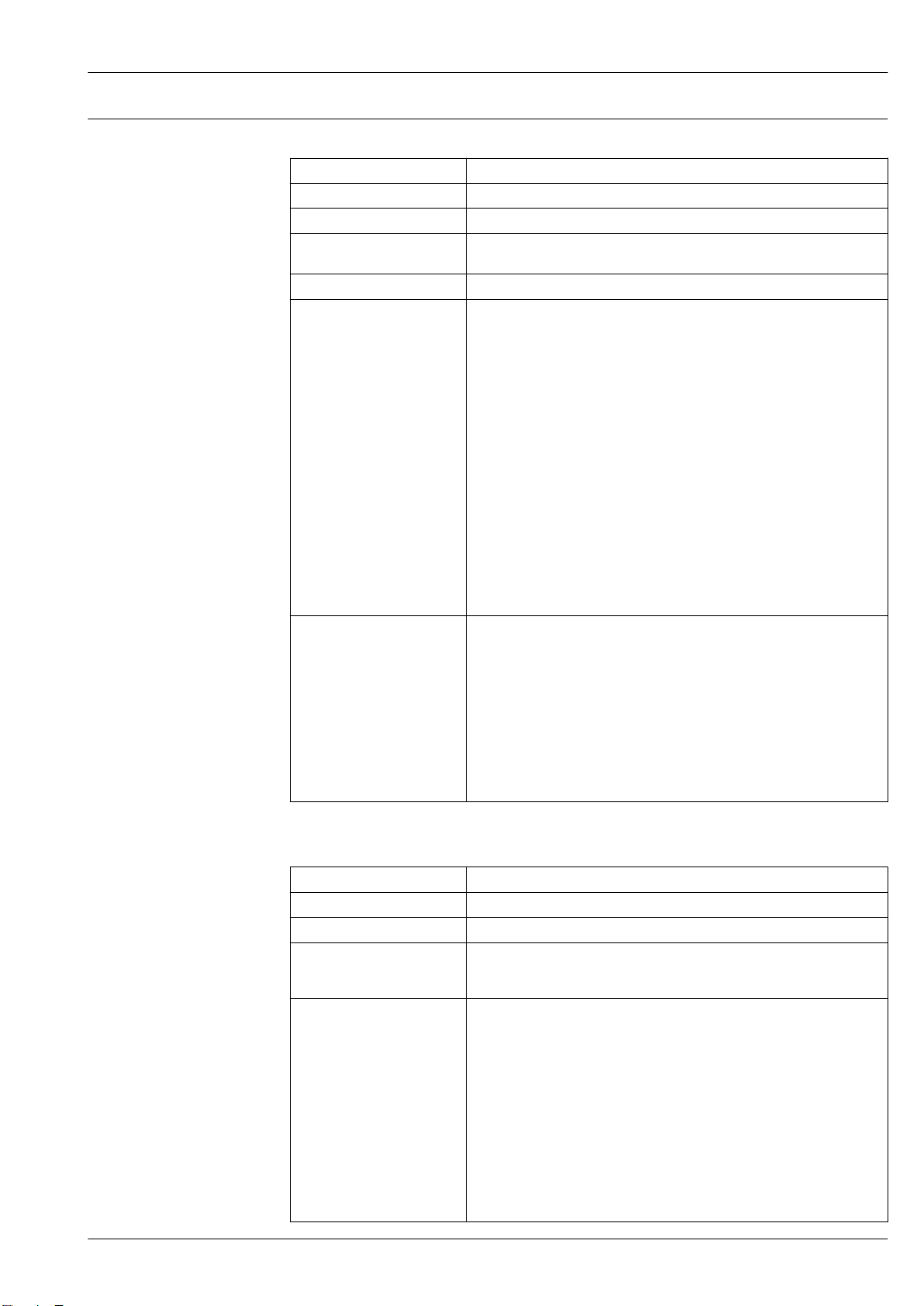

Flow characteristic values in SI units

Nominal

diameter

Recommended

flow

min./max. full scale value

(v ~ 0.3/10 m/s)

Factory settings

Full scale value current

output

(v ~ 2.5 m/s)

Pulse value

(~ 2 pulse/s)

Low flow cut off

(v ~ 0.04 m/s)

[mm] [in] [m3/h] [m3/h] [m3] [m3/h]

25 1 9 to 300 dm3/min 75 dm3/min 0.5 dm

32 – 15 to 500 dm3/min 125 dm3/min 1.0 dm

40 1 ½ 25 to 700 dm3/min 200 dm3/min 1.5 dm

50 2 35 to 1 100 dm3/min 300 dm3/min 2.5 dm

65 – 60 to 2 000 dm3/min 500 dm3/min 5 dm

80 3 90 to 3 000 dm3/min 750 dm3/min 5 dm

100 4 145 to 4 700 dm3/min 1 200 dm3/min 10 dm

125 – 220 to 7 500 dm3/min 1 850 dm3/min 15 dm

3

3

3

3

3

3

3

3

1 dm3/min

2 dm3/min

3 dm3/min

5 dm3/min

8 dm3/min

12 dm3/min

20 dm3/min

30 dm3/min

150 6 20 to 600 150 0.025 2.5

200 8 35 to 1 100 300 0.05 5

250 10 55 to 1 700 500 0.05 7.5

300 12 80 to 2 400 750 0.1 10

350 14 110 to 3 300 1 000 0.1 15

375 15 140 to 4 200 1 200 0.15 20

400 16 140 to 4 200 1 200 0.15 20

450 18 180 to 5 400 1 500 0.25 25

500 20 220 to 6 600 2 000 0.25 30

600 24 310 to 9 600 2 500 0.3 40

700 28 420 to 13 500 3 500 0.5 50

750 30 480 to 15 000 4 000 0.5 60

800 32 550 to 18 000 4 500 0.75 75

900 36 690 to 22 500 6 000 0.75 100

1 000 40 850 to 28 000 7 000 1 125

– 42 950 to 30 000 8 000 1 125

1 200 48 1 250 to 40 000 10 000 1.5 150

– 54 1 550 to 50 000 13 000 1.5 200

1 400 – 1 700 to 55 000 14 000 2 225

– 60 1 950 to 60 000 16 000 2 250

1 600 – 2 200 to 70 000 18 000 2.5 300

– 66 2 500 to 80 000 20 500 2.5 325

1 800 72 2 850 to 90 000 23 000 3 350

– 78 3 300 to 100 000 28 500 3.5 450

2 000 – 3 400 to 110 000 28 500 3.5 450

– 84 3 700 to 125 000 31 000 4.5 500

2 200 – 4 100 to 136 000 34 000 4.5 540

– 90 4 300 to 143 000 36 000 5 570

2 400 – 4 800 to 162 000 40 000 5.5 650

Endress+Hauser 9

Page 10

Flow characteristic values in US units

Proline Promag L 400

Nominal

diameter

[in] [mm] [gal/min] [gal/min] [gal] [gal/min]

1 25 2.5 to 80 18 0.2 0.25

1 ½ 40 7 to 190 50 0.5 0.75

2 50 10 to 300 75 0.5 1.25

– 65 16 to 500 130 1 2

3 80 24 to 800 200 2 2.5

4 100 40 to 1 250 300 2 4

8 200 155 to 4 850 1 200 10 15

10 250 250 to 7 500 1 500 15 30

12 300 350 to 10 600 2 400 25 45

14 350 500 to 15 000 3 600 30 60

15 375 600 to 19 000 4 800 50 60

16 400 600 to 19 000 4 800 50 60

18 450 800 to 24 000 6 000 50 90

20 500 1 000 to 30 000 7 500 75 120

24 600 1 400 to 44 000 10 500 100 180

28 700 1 900 to 60 000 13 500 125 210

30 750 2 150 to 67 000 16 500 150 270

32 800 2 450 to 80 000 19 500 200 300

36 900 3 100 to 100 000 24 000 225 360

40 1 000 3 800 to 125 000 30 000 250 480

42 – 4 200 to 135 000 33 000 250 600

48 1 200 5 500 to 175 000 42 000 400 600

54 – 9 to 300 Mgal/d 75 Mgal/d 0.0005 Mgal/d 1.3 Mgal/d

– 1 400 10 to 340 Mgal/d 85 Mgal/d 0.0005 Mgal/d 1.3 Mgal/d

60 – 12 to 380 Mgal/d 95 Mgal/d 0.0005 Mgal/d 1.3 Mgal/d

– 1 600 13 to 450 Mgal/d 110 Mgal/d 0.0008 Mgal/d 1.7 Mgal/d

66 – 14 to 500 Mgal/d 120 Mgal/d 0.0008 Mgal/d 2.2 Mgal/d

72 1 800 16 to 570 Mgal/d 140 Mgal/d 0.0008 Mgal/d 2.6 Mgal/d

78 – 18 to 650 Mgal/d 175 Mgal/d 0.0010 Mgal/d 3.0 Mgal/d

– 2 000 20 to 700 Mgal/d 175 Mgal/d 0.0010 Mgal/d 2.9 Mgal/d

84 – 24 to 800 Mgal/d 190 Mgal/d 0.0011 Mgal/d 3.2 Mgal/d

– 2 200 26 to 870 Mgal/d 210 Mgal/d 0.0012 Mgal/d 3.4 Mgal/d

90 – 27 to 910 Mgal/d 220 Mgal/d 0.0013 Mgal/d 3.6 Mgal/d

– 2 400 31 to 1 030 Mgal/d 245 Mgal/d 0.0014 Mgal/d 4.1 Mgal/d

Recommended

flow

min./max. full scale value

(v ~ 0.3/10 m/s)

Factory settings

Full scale value current

output

(v ~ 2.5 m/s)

Pulse value

(~ 2 pulse/s)

Low flow cut off

(v ~ 0.04 m/s)

To calculate the measuring range, use the Applicator sizing tool → 87

10 Endress+Hauser

Page 11

Proline Promag L 400

Recommended measuring range

"Flow limit" section → 42

Operable flow range

Over 1000 : 1

Input signal External measured values

Various pressure transmitters and temperature measuring devices can be ordered from Endress

+Hauser: see "Accessories" section → 88

It is recommended to read in external measured values to calculate the following measured variables:

Corrected volume flow

HART protocol

The measured values are written from the automation system to the measuring device via the HART

protocol. The pressure transmitter must support the following protocol-specific functions:

• HART protocol

• Burst mode

Digital communication

The measured values can be written from the automation system to the measuring via:

• PROFIBUS DP

• Modbus RS485

• EtherNet/IP

Status input

Maximum input values • DC 30 V

Response time Adjustable: 5 to 200 ms

Input signal level • Low signal: DC –3 to +5 V

Assignable functions • Off

• 6 mA

• High signal: DC 12 to 30 V

• Reset totalizers 1-3 separately

• Reset all totalizers

• Flow override

Output

Output signal Current output

Current output Can be set as:

• 4-20 mA NAMUR

• 4-20 mA US

• 4-20 mA HART

• 0-20 mA

Maximum output values • DC 24 V (no flow)

• 22.5 mA

Load 0 to 700 Ω

Resolution 0.5 µA

Damping Adjustable: 0.07 to 999 s

Assignable measured

variables

Endress+Hauser 11

• Volume flow

• Mass flow

• Flow velocity

• Conductivity

• Electronic temperature

Page 12

Proline Promag L 400

Pulse/frequency/switch output

Function • With the order code for "Output; Input", option H: output 2 can be set as a pulse

or frequency output

• With the order code for "Output; Input", option I: output 2 and 3 can be set as a

pulse, frequency or switch output

Version Passive, open collector

Maximum input values • DC 30 V

• 250 mA

Voltage drop For 25 mA: ≤ DC 2 V

Pulse output

Pulse width Adjustable: 0.05 to 2 000 ms

Maximum pulse rate 10 000 Impulse/s

Pulse value Adjustable

Assignable measured

variables

Frequency output

Output frequency Adjustable: 0 to 12 500 Hz

Damping Adjustable: 0 to 999 s

Pulse/pause ratio 1:1

Assignable measured

variables

Switch output

Switching behavior Binary, conductive or non-conductive

Switching delay Adjustable: 0 to 100 s

Number of switching

cycles

Assignable functions • Off

• Volume flow

• Mass flow

• Volume flow

• Mass flow

• Conductivity

• Flow velocity

• Electronic temperature

Unlimited

• On

• Diagnostic behavior

• Limit value:

– Off

– Volume flow

– Mass flow

– Conductivity

– Flow velocity

– Totalizer 1-3

– Electronic temperature

• Flow direction monitoring

• Status

– Empty pipe detection

– Low flow cut off

PROFIBUS DP

Signal encoding NRZ code

Data transfer 9.6 kBaud…12 MBaud

12 Endress+Hauser

Page 13

Proline Promag L 400

Modbus RS485

Physical interface In accordance with EIA/TIA-485-A standard

Terminating resistor Integrated, can be activated via DIP switch on the transmitter electronics module

EtherNet/IP

Standards In accordance with IEEE 802.3

Signal on alarm

Depending on the interface, failure information is displayed as follows:

Current output 4 to 20 mA

4 to 20 mA

Failure mode Choose from:

• 4 to 20 mA in accordance with NAMUR recommendation NE 43

• 4 to 20 mA in accordance with US

• Min. value: 3.59 mA

• Max. value: 22.5 mA

• Freely definable value between: 3.59 to 22.5 mA

• Actual value

• Last valid value

0 to 20 mA

Failure mode Choose from:

• Maximum alarm: 22 mA

• Freely definable value between: 0 to 22.5 mA

HART current output

Device diagnostics Device condition can be read out via HART Command 48

Pulse/frequency/switch output

Pulse output

Failure mode Choose from:

• Actual value

• No pulses

Frequency output

Failure mode Choose from:

• Actual value

• 0 Hz

• Defined value: 0 to 12 500 Hz

Switch output

Failure mode Choose from:

• Current status

• Open

• Closed

PROFIBUS DP

Status and alarm

messages

Diagnostics in accordance with PROFIBUS PA Profile 3.02

Endress+Hauser 13

Page 14

Modbus RS485

Failure mode Choose from:

• NaN value instead of current value

• Last valid value

EtherNet/IP

Device diagnostics Device condition can be read out in Input Assembly

Local display

Plain text display With information on cause and remedial measures

Backlight Red backlighting indicates a device error.

Status signal as per NAMUR recommendation NE 107

Interface/protocol

• Via digital communication:

– HART protocol

– PROFIBUS DP

– Modbus RS485

– EtherNet/IP

• Via service interface

– CDI-RJ45 service interface

– WLAN interface

Proline Promag L 400

Low flow cut off

Galvanic isolation

Plain text display With information on cause and remedial measures

Additional information on remote operation → 77

Web server

Plain text display With information on cause and remedial measures

Light emitting diodes (LED)

Status information Status indicated by various light emitting diodes

The following information is displayed depending on the device version:

• Supply voltage active

• Data transmission active

• Device alarm/error has occurred

• EtherNet/IP network available

• EtherNet/IP connection established

The switch points for low flow cut off are user-selectable.

The following connections are galvanically isolated from each other:

• Inputs

• Outputs

• Power supply

14 Endress+Hauser

Page 15

Proline Promag L 400

Protocol-specific data HART

Manufacturer ID 0x11

Device type ID 0x69

HART protocol revision 7

Device description files

(DTM, DD)

HART load Min. 250 Ω

Dynamic variables Read out the dynamic variables: HART command 3

Device variables Read out the device variables: HART command 9

Information and files under:

www.endress.com

The measured variables can be freely assigned to the dynamic variables.

Measured variables for PV (primary dynamic variable)

• Off

• Volume flow

• Mass flow

• Conductivity

• Flow velocity

• Electronic temperature

Measured variables for SV, TV, QV (secondary, tertiary and quaternary

dynamic variable)

• Volume flow

• Mass flow

• Conductivity

• Flow velocity

• Electronic temperature

• Totalizer 1

• Totalizer 2

• Totalizer 3

The device variables are permanently assigned.

A maximum of 8 device variables can be transmitted:

• 0 = volume flow

• 1 = mass flow

• 2 = conductivity

• 3 = flow velocity

• 4 = electronic temperature

• 5 = totalizer 1

• 6 = totalizer 2

• 7 = totalizer 3

PROFIBUS DP

Manufacturer ID 0x11

Ident number 0x1562

Profile version 3.02

Device description files (GSD,

DTM, DD)

Output values

(from measuring device to

automation system)

Information and files under:

• www.endress.com

• www.profibus.org

Analog input 1 to 4

• Mass flow

• Volume flow

• Flow velocity

• Conductivity

• Electronic temperature

Digital input 1 to 2

• Empty pipe detection

• Low flow cut off

• Verification status

Totalizer 1 to 3

• Mass flow

• Volume flow

Endress+Hauser 15

Page 16

Proline Promag L 400

Input values

(from automation system to

measuring device)

Supported functions • Identification & Maintenance

Configuration of the device

address

Analog output 1 (fixed assignment)

External density

Digital output 1 to 2 (fixed assignment)

• Digital output 1: switch positive zero return on/off

• Digital output 2: start verification

Totalizer 1 to 3

• Totalize

• Reset and hold

• Preset and hold

• Stop

• Operating mode configuration:

– Net flow total

– Forward flow total

– Reverse flow total

Simplest device identification on the part of the control system and

nameplate

• PROFIBUS upload/download

Reading and writing parameters is up to ten times faster with PROFIBUS

upload/download

• Condensed status

Simplest and self-explanatory diagnostic information by categorizing

diagnostic messages that occur

• DIP switches on the I/O electronics module

• Via operating tools (e.g. FieldCare)

Modbus RS485

Protocol Modbus Applications Protocol Specification V1.1

Device type Slave

Slave address range 1 to 247

Broadcast address range 0

Function codes • 03: Read holding register

• 04: Read input register

• 06: Write single registers

• 08: Diagnostics

• 16: Write multiple registers

• 23: Read/write multiple registers

Broadcast messages Supported by the following function codes:

• 06: Write single registers

• 16: Write multiple registers

• 23: Read/write multiple registers

Supported baud rate • 1 200 BAUD

• 2 400 BAUD

• 4 800 BAUD

• 9 600 BAUD

• 19 200 BAUD

• 38 400 BAUD

• 57 600 BAUD

• 115 200 BAUD

Data transfer mode • ASCII

• RTU

Data access Each device parameter can be accessed via Modbus RS485.

For Modbus register information

16 Endress+Hauser

Page 17

Proline Promag L 400

EtherNet/IP

Protocol • The CIP Networks Library Volume 1: Common Industrial Protocol

• The CIP Networks Library Volume 2: EtherNet/IP Adaptation of CIP

Communication type • 10Base-T

• 100Base-TX

Device profile Generic device (product type: 0x2B)

Manufacturer ID 0x49E

Device type ID 0x1067

Baud rates Automatic ¹⁰⁄₁₀₀ Mbit with half-duplex and full-duplex detection

Polarity Auto-polarity for automatic correction of crossed TxD and RxD pairs

Supported CIP connections Max. 3 connections

Explicit connections Max. 6 connections

I/O connections Max. 6 connections (scanner)

Configuration options for

measuring device

Configuration of the EtherNet

interface

Configuration of the device

address

Device Level Ring (DLR) No

Fix Input

RPI 5 ms to 10 s (factory setting: 20 ms)

Exclusive Owner Multicast Instance Size [byte]

Exclusive Owner Multicast Instance Size [byte]

Input only Multicast Instance Size [byte]

Input only Multicast Instance Size [byte]

• DIP switches on the electronics module for IP addressing

• Manufacturer-specific software (FieldCare)

• Custom Add-on Profile for Rockwell Automation control systems

• Web browser

• Electronic Data Sheet (EDS) integrated in the measuring device

• Speed: 10 MBit, 100 MBit, auto (factory setting)

• Duplex: half-duplex, full-duplex, auto (factory setting)

• DIP switches on the electronics module for IP addressing (last octet)

• DHCP

• Manufacturer-specific software (FieldCare)

• Custom Add-on Profile for Rockwell Automation control systems

• Web browser

• EtherNet/IP tools, e.g. RSLinx (Rockwell Automation)

Instance configuration: 0x68 398

O → T configuration: 0x66 56

T → O configuration: 0x64 32

Instance configuration: 0x69 -

O → T configuration: 0x66 56

T → O configuration: 0x64 32

Instance configuration: 0x68 398

O → T configuration: 0xC7 -

T → O configuration: 0x64 32

Instance configuration: 0x69 -

O → T configuration: 0xC7 -

T → O configuration: 0x64 32

Endress+Hauser 17

Page 18

Proline Promag L 400

Input Assembly • Current device diagnostics

• Volume flow

• Mass flow

• Conductivity

• Totalizer 1

• Totalizer 2

• Totalizer 3

Configurable Input

RPI 5 ms to 10 s (factory setting: 20 ms)

Exclusive Owner Multicast Instance Size [byte]

Instance configuration: 0x68 398

O → T configuration: 0x66 56

T → O configuration: 0x65 88

Exclusive Owner Multicast Instance Size [byte]

Instance configuration: 0x69 -

O → T configuration: 0x66 56

T → O configuration: 0x65 88

Input only Multicast Instance Size [byte]

Instance configuration: 0x68 398

O → T configuration: 0xC7 -

T → O configuration: 0x65 88

Input only Multicast Instance Size [byte]

Instance configuration: 0x69 -

O → T configuration: 0xC7 -

T → O configuration: 0x65 88

Configurable Input Assembly • Volume flow

• Mass flow

• Electronic temperature

• Conductivity

• Totalizer 1 to 3

• Flow velocity

• Volume flow unit

• Mass flow unit

• Temperature unit

• Conductivity unit

• Unit totalizer 1-3

• Flow velocity unit

• Verification result

• Verification status

The range of options increases if the measuring device has one or

more application packages.

Fix Output

Output Assembly • Activation of reset totalizers 1-3

• Activation of reference density compensation

• Reset totalizers 1-3

• External density

• Density unit

• Activation verification

• Start verification

18 Endress+Hauser

Page 19

Proline Promag L 400

Configuration

Configuration Assembly Only the most common configurations are listed below.

• Software write protection

• Mass flow unit

• Mass unit

• Volume flow unit

• Volume unit

• Density unit

• Conductivity

• Temperature unit

• Totalizer 1-3:

– Assignment

– Unit

– Operating mode

– Failure mode

• Alarm delay

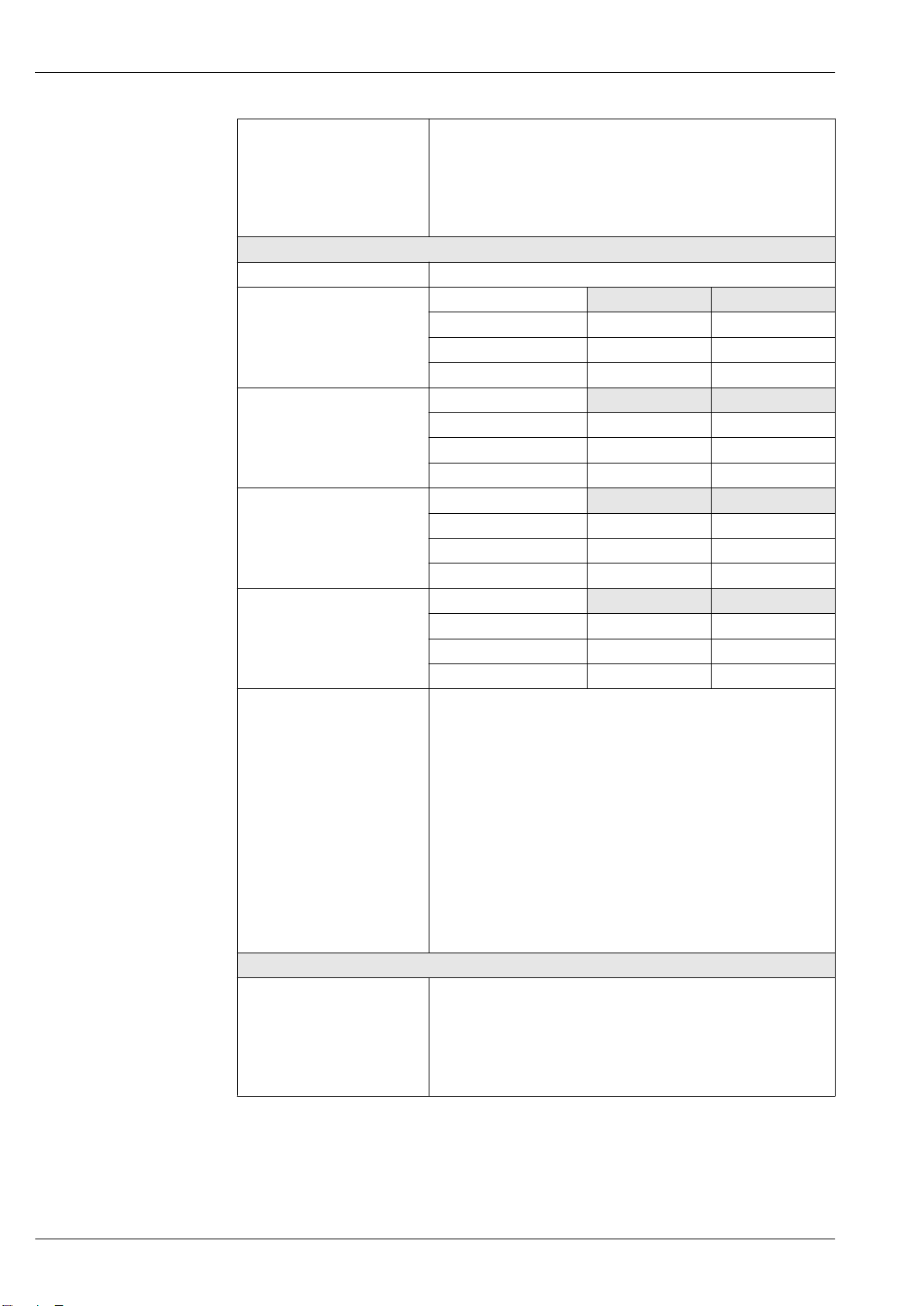

Power supply

Terminal assignment Transmitter: 0-20 mA/4-20 mA HART

The sensor can be ordered with terminals.

Connection methods available

Outputs

terminals terminals • Option A: coupling M20x1

Power

supply

Possible options for order code

"Electrical connection"

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

Supply voltage

Order code

"Power supply"

Option L

(wide range power unit)

Terminal numbers terminal voltage Frequency range

DC 24 V ±25% –

1 (L+/L), 2 (L-/N)

AC 24 V ±25% 50/60 Hz, ±4 Hz

AC 100 to 240 V –15 to +10% 50/60 Hz, ±4 Hz

Signal transmission 0-20 mA/4-20 mA HART and additional outputs and inputs

Order code for

"Output" and

"Input"

Option H • 4-20 mA HART

Option I • 4-20 mA HART

Output 1 Output 2 Output 3 Input

26 (+) 27 (-) 24 (+) 25 (-) 22 (+) 23 (-) 20 (+) 21 (-)

(active)

• 0-20 mA

(active)

(active)

• 0-20 mA

(active)

Pulse/frequency

Pulse/frequency/

Terminal numbers

output

(passive)

switch output

(passive)

Switch output

(passive)

Pulse/frequency/

switch output

(passive)

-

Status input

Endress+Hauser 19

Page 20

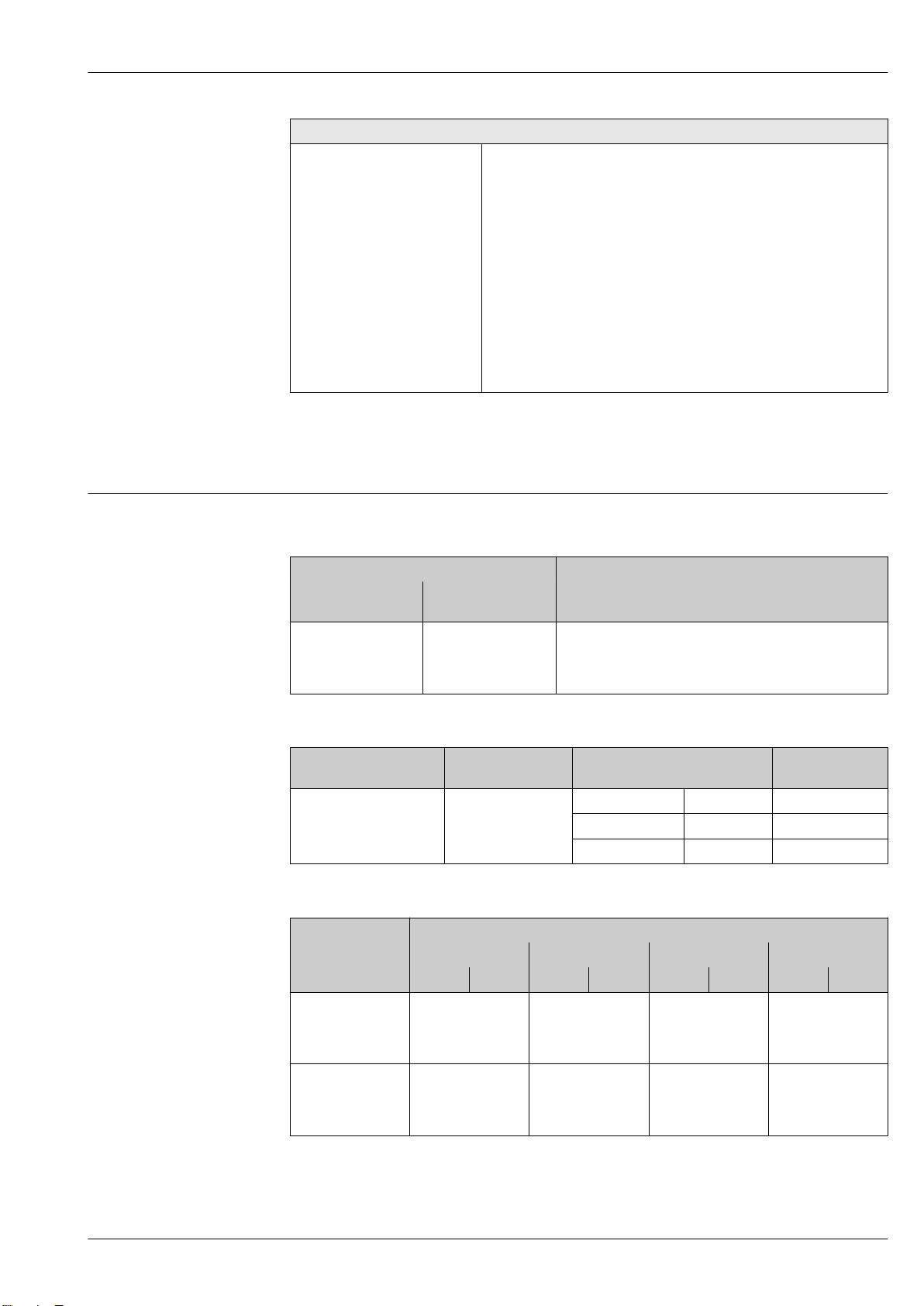

Transmitter: PROFIBUS DP

The sensor can be ordered with terminals.

Proline Promag L 400

Connection methods available

Outputs

terminals terminals • Option A: coupling M20x1

Power

supply

Possible options for order code

"Electrical connection"

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

Supply voltage

Order code

"Power supply"

Option L

(wide range power unit)

Terminal numbers terminal voltage Frequency range

DC 24 V ±25% –

1 (L+/L), 2 (L-/N)

AC 24 V ±25% 50/60 Hz, ±4 Hz

AC 100 to 240 V –15 to +10% 50/60 Hz, ±4 Hz

PROFIBUS DP signal transmission

Order code for "Output" and "Input" Terminal numbers

26 (RxD/TxD-P) 27 (RxD/TxD-N)

Option L B A

Order code for "Output":

Option L: PROFIBUS DP, for use in non-hazardous areas and Zone 2/div. 2

Transmitter: Modbus RS485

The sensor can be ordered with terminals.

Connection methods available

Outputs

terminals terminals • Option A: coupling M20x1

Power

supply

Possible options for order code

"Electrical connection"

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

Supply voltage

Order code

"Power supply"

Option L

(wide range power unit)

Terminal numbers terminal voltage Frequency range

DC 24 V ±25% –

1 (L+/L), 2 (L-/N)

AC 24 V ±25% 50/60 Hz, ±4 Hz

AC 100 to 240 V –15 to +10% 50/60 Hz, ±4 Hz

Signal transmission Modbus RS485

Order code for "Output" and "Input" Terminal numbers

26 (+) 27 (-)

Option M B A

20 Endress+Hauser

Page 21

Proline Promag L 400

E1

E2

S1

E1

E2

S2

GND

5

7

4

37

42 41

n.c. n.c.

21

1

2

42 41

A

B

6

5

7

8437 36

n.c.

E

E

S

Transmitter: EtherNet/IP

The sensor can be ordered with terminals or a device plug.

Connection methods available

Outputs

terminals terminals • Option A: coupling M20x1

Device plug terminals • Option L: plug M12x1 + thread NPT ½"

Power

supply

Possible options for order code

"Electrical connection"

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

• Option N: plug M12x1 + coupling M20

• Option P: plug M12x1 + thread G ½"

• Option U: plug M12x1 + thread M20

Supply voltage

Order code

"Power supply"

Option L

(wide range power unit)

Terminal numbers terminal voltage Frequency range

DC 24 V ±25% –

1 (L+/L), 2 (L-/N)

AC 24 V ±25% 50/60 Hz, ±4 Hz

AC 100 to 240 V –15 to +10% 50/60 Hz, ±4 Hz

EtherNet/IP signal transmission

Order code for "Output" Connection via

Option N EtherNet/IP connector

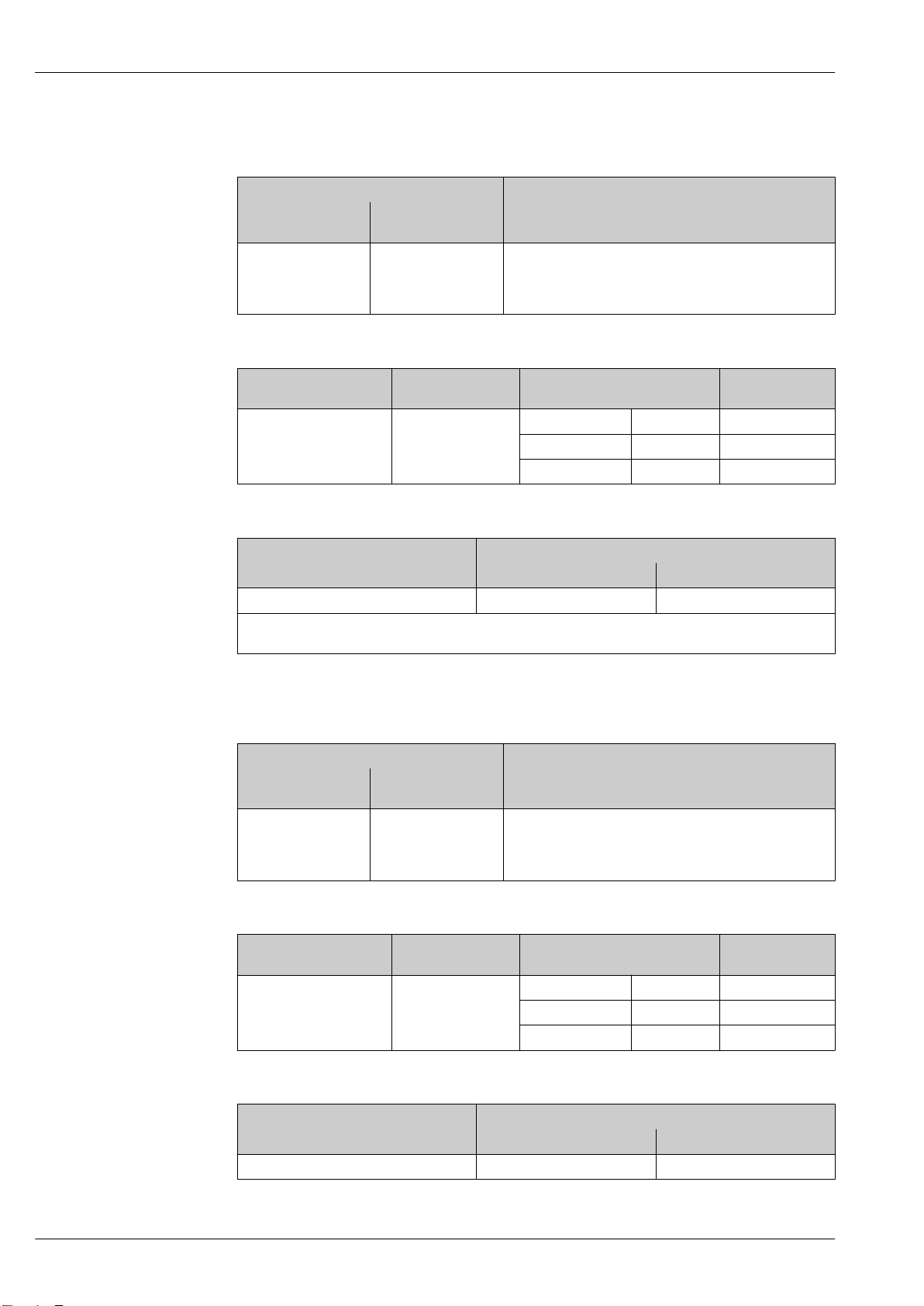

Remote version

A0032059

2 Remote version terminal assignment

A Transmitter wall-mount housing

B Sensor connection housing

1 Electrode cable

2 Coil current cable

n.c. Not connected, insulated cable shields

Terminal No. and cable colors: 6/5 = brown; 7/8 = white; 4 = green; 36/37 = yellow

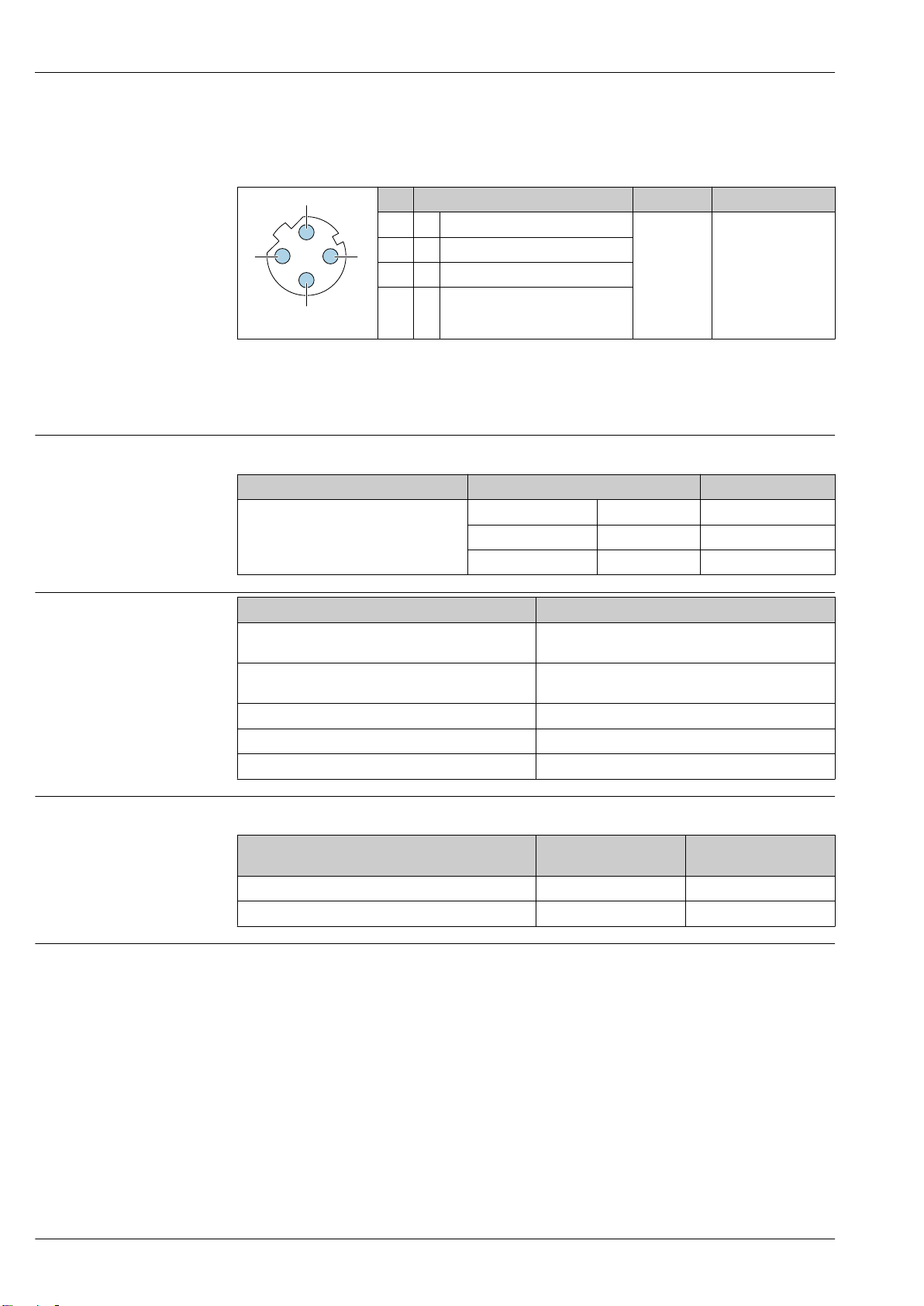

Pin assignment, device plug

Endress+Hauser 21

Order codes for the M12x1 connectors, see the "Order code for electrical connection" column:

EtherNet/IP → 21

Page 22

EtherNet/IP

3

2

4

Device plug for signal transmission (device side)

Recommended plug:

• Binder, series 763, part no. 99 3729 810 04

• Phoenix, part no. 1543223 SACC-M12MSD-4Q

• When using the device in a hazardous location, use a suitably certified plug.

Supply voltage Transmitter

Order code for "Power supply" terminal voltage Frequency range

Option L

Proline Promag L 400

Pin Assignment Coding Plug/socket

1 + Tx D Socket

2 + Rx

3 - Tx

4 - Rx

A0032047

DC 24 V ±25% –

AC 24 V ±25% 50/60 Hz, ±4 Hz

AC 100 to 240 V –15 to +10% 50/60 Hz, ±4 Hz

Power consumption

Option H: 4-20mA HART, pulse/frequency/switch

output, switch output

Option I: 4-20mA HART, 2 x pulse/frequency/switch

output, status input

Option L: PROFIBUS DP 30 VA/8 W

Option M: Modbus RS485 30 VA/8 W

Option N: EtherNet/IP 30 VA/8 W

Current consumption Transmitter

Order code for "Power supply" Maximum

Option L: AC 100 to 240 V 145 mA 25 A (< 5 ms)

Option L: AC/DC 24 V 350 mA 27 A (< 5 ms)

Power supply failure

• Totalizers stop at the last value measured.

• Configuration is retained in the plug-in memory (HistoROM DAT).

• Error messages (incl. total operated hours) are stored.

Order code for "Output" Maximum power consumption

30 VA/8 W

30 VA/8 W

Maximum

Current consumption

switch-on current

22 Endress+Hauser

Page 23

Proline Promag L 400

1

2

1 2 3 3

A B

1

2

A

2

1

B

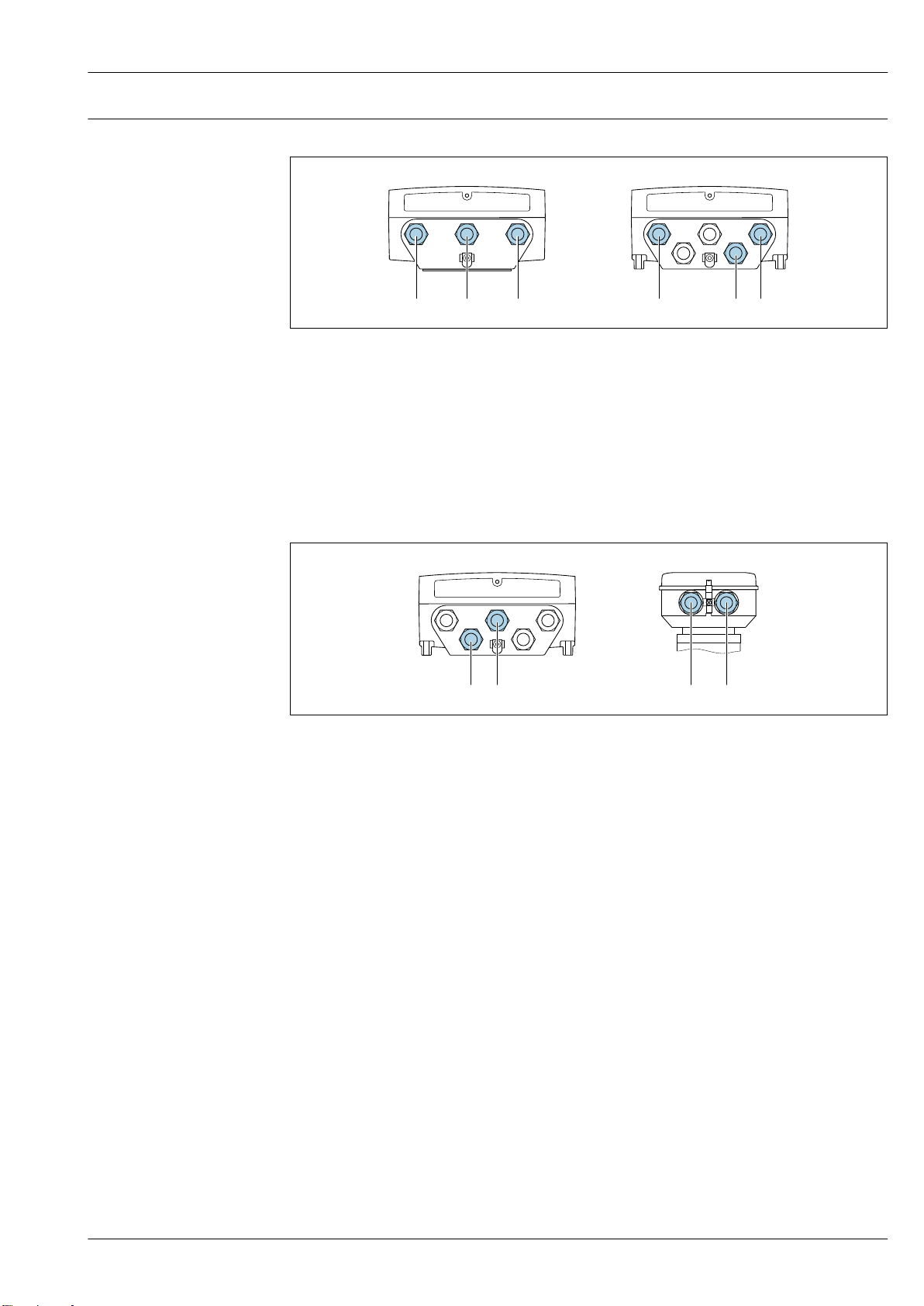

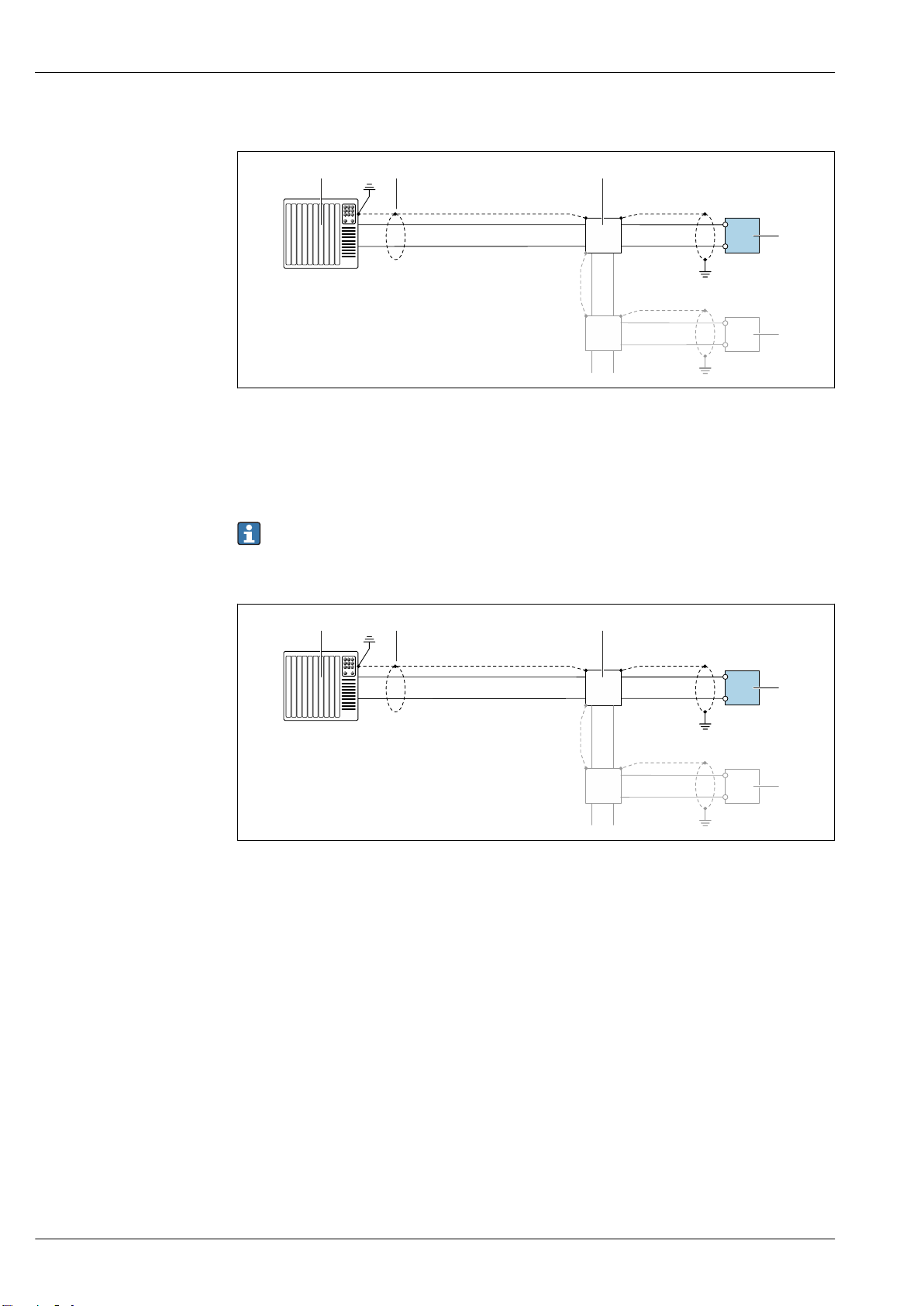

Electrical connection Connecting the transmitter

3 Supply voltage and signal transmission connection

A Compact version

B Remote version wall-mount housing

1 Cable entry for supply voltage

2 Cable entry for signal transmission

3 Cable entry for signal transmission

Remote version connection

A0032041

Connecting cable

4 Connecting cable connection: electrode and coil current cable

A Transmitter wall-mount housing

B Sensor connection housing

1 Electrode cable

2 Coil current cable

• Fix the cable run or route it in an armored conduit.

Cable movements can influence the measuring signal especially in the case of low fluid

conductivities.

• Route the cable well clear of electrical machines and switching elements.

• Ensure potential equalization between sensor and transmitter .

A0032042

Endress+Hauser 23

Page 24

Proline Promag L 400

4

4...20 mA

5

2

1

3

6

2

3

4...20 mA

41

5

0/4...20 mA

+

–

2

1

3

+

_

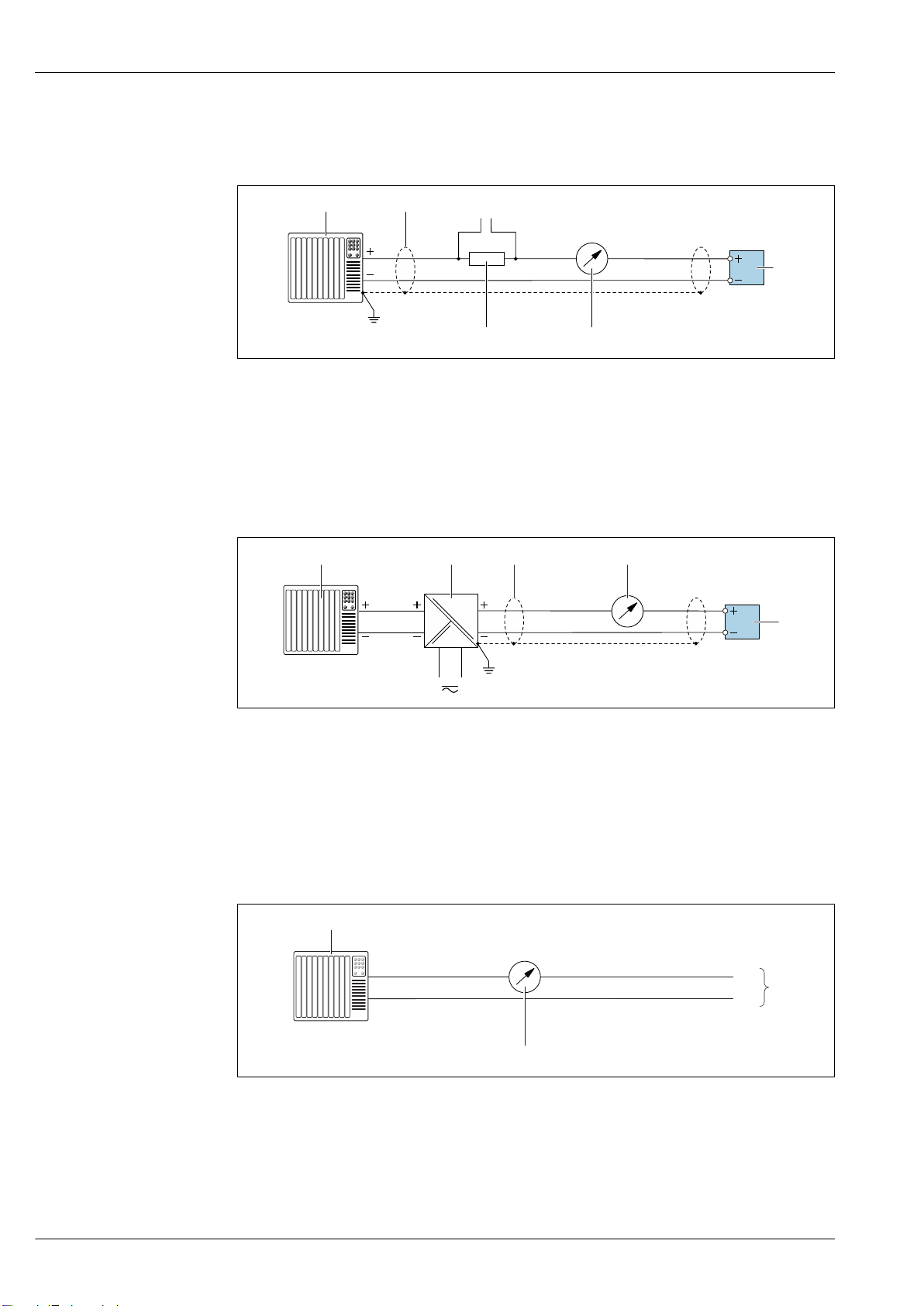

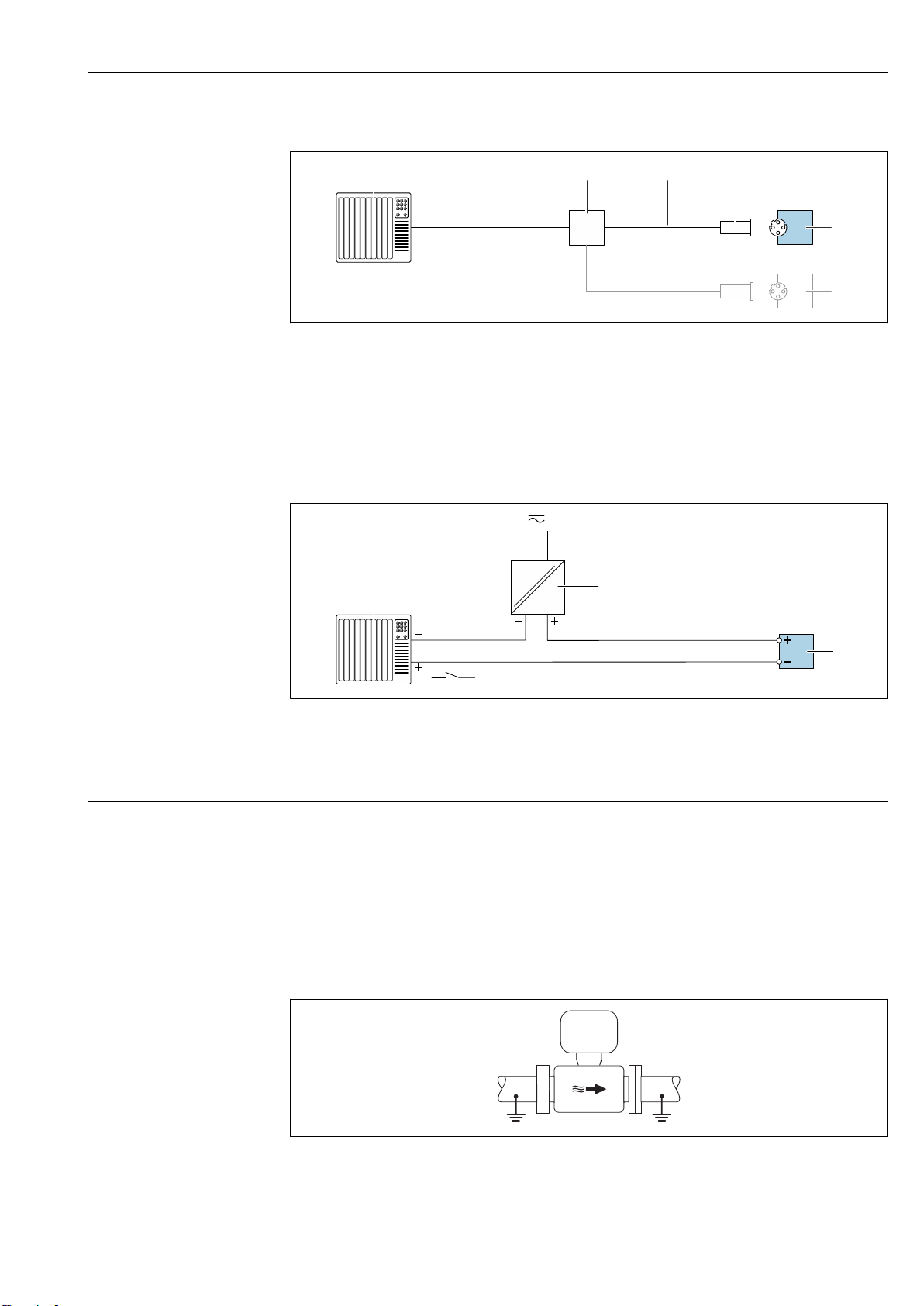

Connection examples

Current output 4 to 20 mA HART

A0029055

5 Connection example for 4 to 20 mA HART current output (active)

1 Automation system with current input (e.g. PLC)

2 Cable shield: the cable shield must be grounded at both ends to comply with EMC requirements; observe cable

specifications → 29

3 Connection for HART operating devices → 77

4 Resistor for HART communication (≥ 250 Ω): observe maximum load → 11

5 Analog display unit: observe maximum load → 11

6 Transmitter

A0028762

6 Connection example for 4 to 20 mA HART current output (passive)

1 Automation system with current input (e.g. PLC)

2 Power supply

3 Cable shield: the cable shield must be grounded at both ends to comply with EMC requirements; observe cable

specifications → 29

4 Analog display unit: observe maximum load → 11

5 Transmitter

Current output 4-20 mA

A0017162

7 Connection example for 0-20 mA current output (active) and 4-20 mA current output (active)

1 Automation system with current input (e.g. PLC)

2 Analog display unit: observe maximum load

3 Transmitter

24 Endress+Hauser

Page 25

Proline Promag L 400

1

2

3

12345

1

2

3

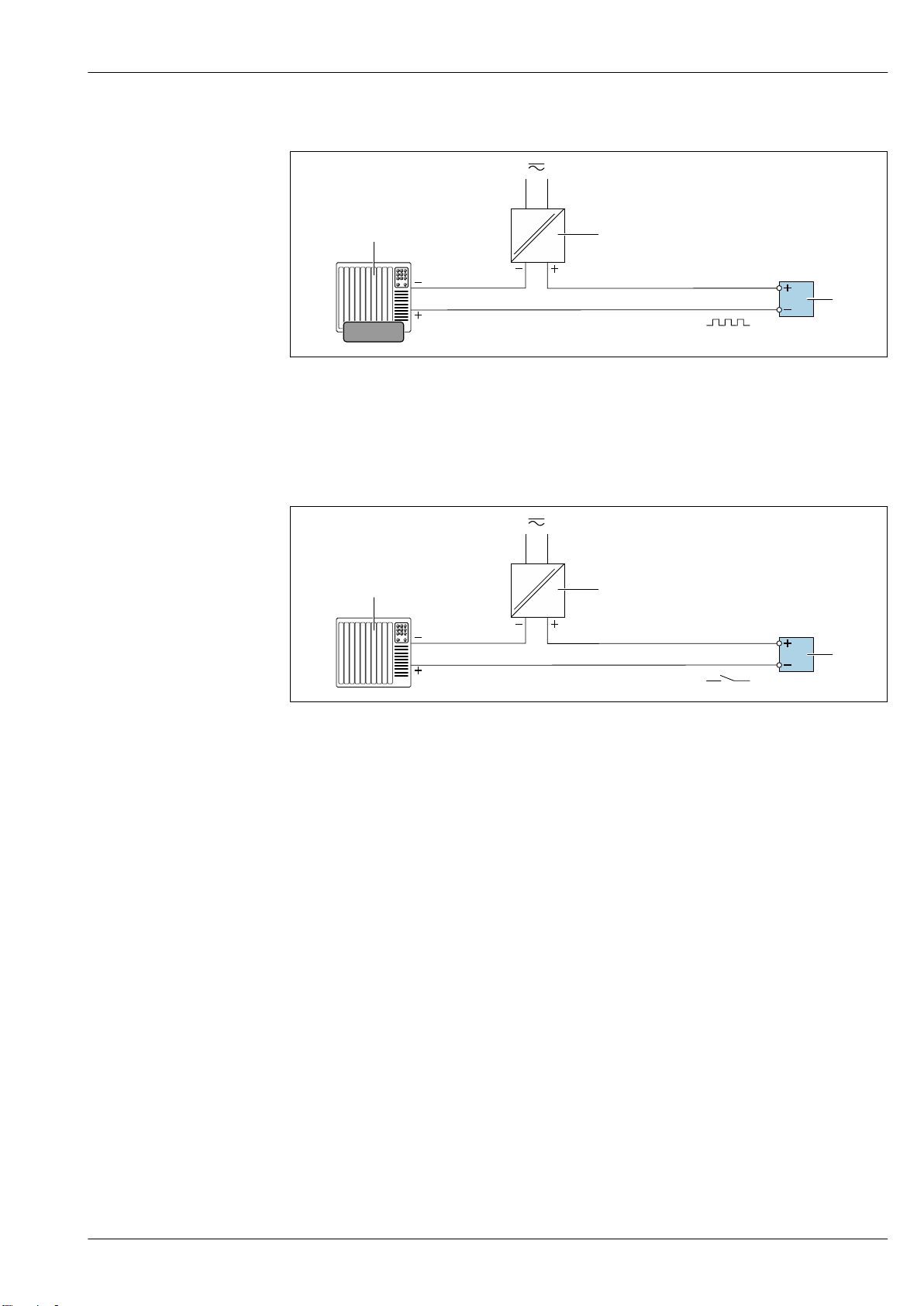

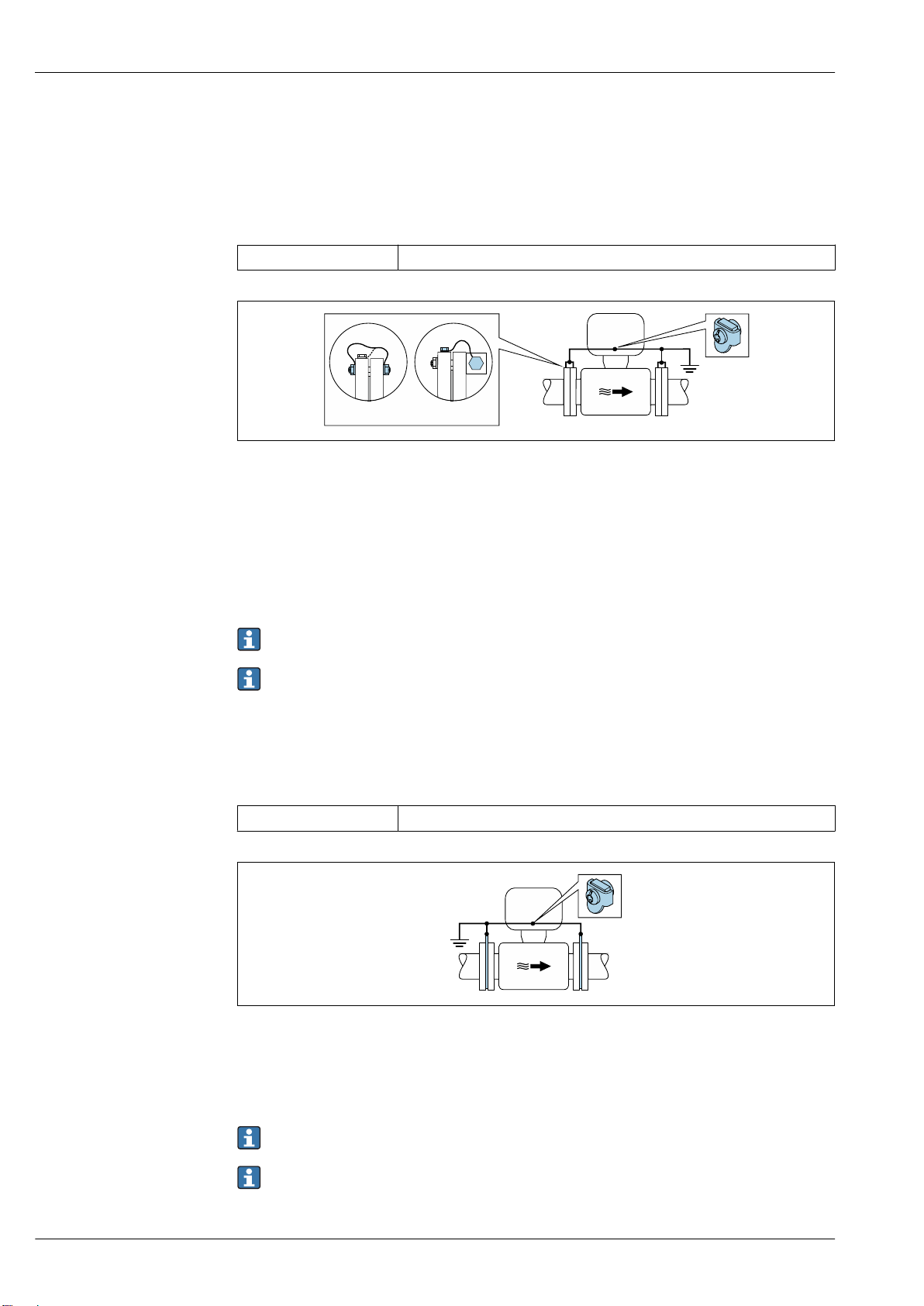

Pulse/frequency output

A0028761

8 Connection example for pulse/frequency output (passive)

1 Automation system with pulse/frequency input (e.g. PLC)

2 Power supply

3 Transmitter: Observe input values → 12

Switch output

9 Connection example for switch output (passive)

1 Automation system with switch input (e.g. PLC)

2 Power supply

3 Transmitter: Observe input values → 12

A0028760

Endress+Hauser 25

Page 26

Proline Promag L 400

2

1

A

B

3

4

4

A

B

A

B

2

1

A

B

3

4

4

A

B

A

B

PROFIBUS DP

A0028765

10 Connection example for PROFIBUS DP, non-hazardous area and Zone 2/Div. 2

1 Control system (e.g. PLC)

2 Cable shield: the cable shield must be grounded at both ends to comply with EMC requirements; observe cable

specifications

3 Transmitter

If baud rates > 1.5 MBaud an EMC cable entry must be used and the cable shield must continue

as far as the terminal wherever possible.

Modbus RS485

A0028765

11 Connection example for Modbus RS485, non-hazardous area and Zone 2/Div. 2

1 Control system (e.g. PLC)

2 Cable shield: the cable shield must be grounded at both ends to comply with EMC requirements; observe cable

specifications

3 Distribution box

4 Transmitter

26 Endress+Hauser

Page 27

Proline Promag L 400

1

2

4

3

5

5

1

2

3

EtherNet/IP

A0028767

12 Connection example for EtherNet/IP

1 Control system (e.g. PLC)

2 Ethernet switch

3 Observe cable specifications

4 Device plug

5 Transmitter

Status input

A0028764

13 Connection example for status input

1 Automation system with status output (e.g. PLC)

2 Power supply

3 Transmitter: Observe input values

Potential equalization Requirements

Please consider the following to ensure correct measurement:

• Same electrical potential for the medium and sensor

• Remote version: same electrical potential for the sensor and transmitter

• Company-internal grounding concepts

• Pipe material and grounding

Connection example, standard scenario

Metal, grounded pipe

A0016315

14 Potential equalization via measuring tube

Endress+Hauser 27

Page 28

Connection example in special situations

DN 300≤ DN 350≥

Unlined and ungrounded metal pipe

This connection method also applies in situations where:

• The customary potential equalization is not used

• Equalizing currents are present

Ground cable Copper wire, at least 6 mm2 (0.0093 in2)

15 Potential equalization via ground terminal and pipe flanges

Proline Promag L 400

A0029338

Note the following when installing:

• Connect both sensor flanges to the pipe flange via a ground cable and ground them.

• Connect the connection housing of the transmitter or sensor to ground potential by means of the

ground terminal provided for the purpose. To mount the ground cable:

– If DN ≤ 300 (12"): Mount the ground cable directly on the conductive flange coating of the

sensor with the flange screws.

– If DN ≥ 350 (14"): Mount the ground cable directly on the metal transport bracket.

For remote device versions, the ground terminal in the example always refers to the sensor and

not to the transmitter.

You can order the necessary ground cable from Endress+Hauser: → 86.

Plastic pipe or pipe with insulating liner

This connection method also applies in situations where:

• The customary potential equalization is not used

• Equalizing currents are present

Ground cable Copper wire, at least 6 mm2 (0.0093 in2)

16 Potential equalization via ground terminal and ground disks

Note the following when installing:

The ground disks must be connected to the ground terminal via the ground cable and be connected

to ground potential.

For remote device versions, the ground terminal in the example always refers to the sensor and

not to the transmitter.

The ground cable and ground disks can be ordered from Endress+Hauser → 86.

28 Endress+Hauser

A0029339

Page 29

Proline Promag L 400

+

–

Pipe with a cathodic protection unit

This connection method is only used if the following two conditions are met:

• Metal pipe without liner or pipe with electrically conductive liner

• Cathodic protection is integrated in the personal protection equipment

Ground cable Copper wire, at least 6 mm2 (0.0093 in2)

A0030377

1 Connection of the two flanges of the pipe via a ground cable

2 Signal line shielding via a capacitor

3 Measuring device connected to power supply such that it is floating in relation to the protective ground

(isolation transformer)

terminals

Cable entries

Note the following when installing:

The sensor is installed in the pipe in a way that provides electrical insulation.

For remote device versions, the ground terminal in the example always refers to the sensor and

not to the transmitter.

You can order the necessary ground cable from Endress+Hauser: → 86.

Transmitter

• Supply voltage cable: plug-in spring terminals for wire cross-sections

0.5 to 2.5 mm2 (20 to 14 AWG)

• Signal cable: plug-in spring terminals for wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• Electrode cable: spring terminals for wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• Coil current cable: spring terminals for wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

Sensor connection housing

Spring terminals for wire cross-sections0.5 to 2.5 mm2 (20 to 14 AWG)

Cable entry thread

• M20 x 1.5

• Via adapter:

– NPT ½"

– G ½"

Cable gland

• For standard cable: M20 × 1.5 with cable 6 to 12 mm (0.24 to 0.47 in)

• For reinforced cable: M20 × 1.5 with cable 9.5 to 16 mm (0.37 to 0.63 in)

If metal cable entries are used, use a grounding plate.

Cable specification Permitted temperature range

• The installation guidelines that apply in the country of installation must be observed.

• The cables must be suitable for the minimum and maximum temperatures to be expected.

Power supply cable

Standard installation cable is sufficient.

Signal cable

Current output 0/4 to 20 mA

Standard installation cable is sufficient.

Endress+Hauser 29

Page 30

Proline Promag L 400

Current output 4 to 20 mA HART

A shielded cable is recommended. Observe grounding concept of the plant.

Pulse/frequency/switch output

Standard installation cable is sufficient.

Status input

Standard installation cable is sufficient.

PROFIBUS DP

The IEC 61158 standard specifies two types of cable (A and B) for the bus line which can be used for

every transmission rate. Cable type A is recommended.

Cable type A

Characteristic impedance 135 to 165 Ω at a measuring frequency of 3 to 20 MHz

Cable capacitance < 30 pF/m

Wire cross-section

Cable type Twisted pairs

Loop resistance ≤110 Ω/km

Signal damping Max. 9 dB over the entire length of the cable cross-section

Shield Copper braided shielding or braided shielding with foil shield. When grounding

> 0.34 mm2 (22 AWG)

the cable shield, observe the grounding concept of the plant.

Modbus RS485

The EIA/TIA-485 standard specifies two types of cable (A and B) for the bus line which can be used

for every transmission rate. Cable type A is recommended.

Cable type A

Characteristic impedance 135 to 165 Ω at a measuring frequency of 3 to 20 MHz

Cable capacitance < 30 pF/m

Wire cross-section

Cable type Twisted pairs

Loop resistance ≤110 Ω/km

Signal damping Max. 9 dB over the entire length of the cable cross-section

Shield Copper braided shielding or braided shielding with foil shield. When grounding

> 0.34 mm2 (22 AWG)

the cable shield, observe the grounding concept of the plant.

EtherNet/IP

The standard ANSI/TIA/EIA-568-B.2 Annex specifies CAT 5 as the minimum category for a cable

used for EtherNet/IP. CAT 5e and CAT 6 are recommended.

For more information on planning and installing EtherNet/IP networks, please refer to the

"Media Planning and Installation Manual. EtherNet/IP" of ODVA Organization

Connecting cable for remote version

Electrode cable

Standard cable

Cable for empty pipe

detection (EPD)

3 ×0.38 mm2 (20 AWG) with common, braided copper shield

( ~9.5 mm (0.37 in)) and individual shielded cores

4 ×0.38 mm2 (20 AWG) with common, braided copper shield

( ~9.5 mm (0.37 in)) and individual shielded cores

30 Endress+Hauser

Page 31

Proline Promag L 400

1

2

3

4

5

6

7

a

b

Conductor resistance ≤50 Ω/km (0.015 Ω/ft)

Capacitance: core/shield ≤420 pF/m (128 pF/ft)

Operating temperature –20 to +80 °C (–68 to +176 °F)

Coil current cable

Standard cable

Conductor resistance ≤37 Ω/km (0.011 Ω/ft)

Capacitance: core/core,

shield grounded

Operating temperature –20 to +80 °C (–68 to +176 °F)

Test voltage for cable

insulation

17 Cable cross-section

a Electrode cable

b Coil current cable

1 Core

2 Core insulation

3 Core shield

4 Core jacket

5 Core reinforcement

6 Cable shield

7 Outer jacket

3 ×0.75 mm2 (18 AWG) with common, braided copper shield

( ~9 mm (0.35 in))

≤120 pF/m (37 pF/ft)

≤ AC 1433 V r.m.s. 50/60 Hz or ≥ DC 2026 V

A0029151

Reinforced connecting cables

Reinforced connecting cables with an additional, reinforcing metal braid should be used for:

• When laying the cable directly in the ground

• Where there is a risk of damage from rodents

Reinforced connecting cables with an additional, reinforcing metal braid can be ordered from

Endress+Hauser .

Operation in zones of severe electrical interference

The measuring system meets the general safety requirements → 84 and EMC specifications

→ 39.

Grounding is by means of the ground terminal provided for the purpose inside the connection

housing. The stripped and twisted lengths of cable shield to the ground terminal must be as short as

possible.

Endress+Hauser 31

Page 32

Performance characteristics

2.5

[%]

2.0

1.5

1.0

0.5

0

0.2 %

0.5 %

0

1

2 4 6 8 10 [m/s]

v

5 10 15 20 25 30 32 [ft/s]0

Proline Promag L 400

Reference operating conditions

• Error limits following DIN EN 29104, in future ISO 20456

• Water, typically +15 to +45 °C (+59 to +113 °F); 0.5 to 7 bar (73 to 101 psi)

• Data as indicated in the calibration protocol

• Accuracy based on accredited calibration rigs according to ISO 17025

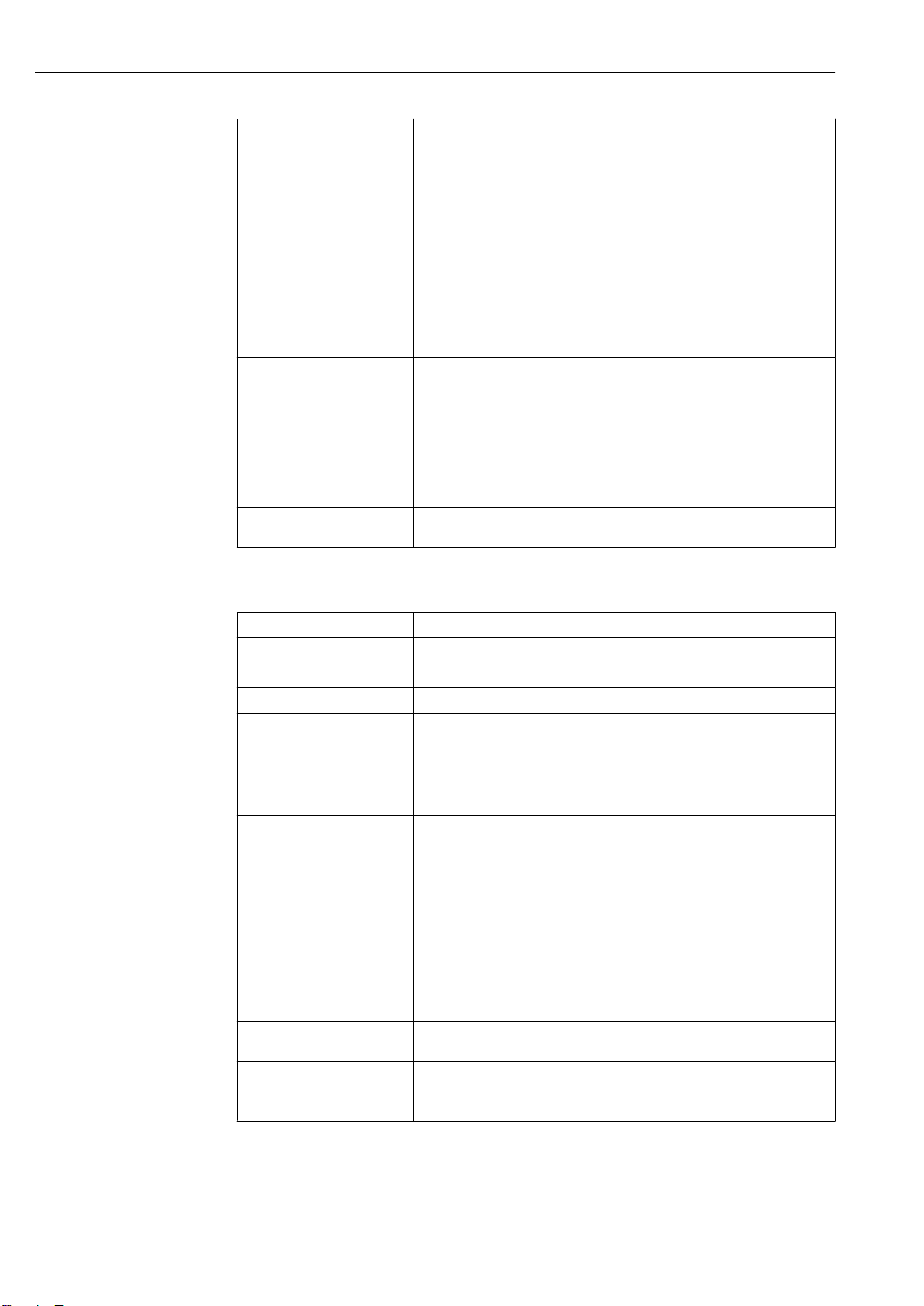

Maximum measured error Error limits under reference operating conditions

o.r. = of reading

Volume flow

• ±0.5 % o.r. ± 1 mm/s (0.04 in/s)

• Optional: ±0.2 % o.r. ± 2 mm/s (0.08 in/s)

Fluctuations in the supply voltage do not have any effect within the specified range.

18 Maximum measured error in % o.r.

Electrical conductivity

Max. measured error not specified.

Accuracy of outputs

The outputs have the following base accuracy specifications.

Current output

Accuracy Max. ±5 µA

Pulse/frequency output

o.r. = of reading

Accuracy Max. ±50 ppm o.r. (over the entire ambient temperature range)

Repeatability

o.r. = of reading

Volume flow

max. ±0.1 % o.r. ± 0.5 mm/s (0.02 in/s)

Influence of ambient temperature

32 Endress+Hauser

Electrical conductivity

Max. ±5 % o.r.

Current output

o.r. = of reading

A0032069

Page 33

Proline Promag L 400

h

h

2

1

Mounting location

Temperature coefficient Max. ±0.005 % o.r./°C

Pulse/frequency output

Temperature coefficient No additional effect. Included in accuracy.

Installation

No special measures such as supports etc. are necessary. External forces are absorbed by the

construction of the device.

A0029343

Preferably install the sensor in an ascending pipe, and ensure a sufficient distance to the next pipe

elbow: h ≥ 2 × DN

Installation in down pipes

Install a siphon with a vent valve downstream of the sensor in down pipes whose length h ≥

5 m (16.4 ft). This precaution is to avoid low pressure and the consequent risk of damage to the

measuring tube. This measure also prevents the system losing prime.

A0028981

19 Installation in a down pipe

1 Vent valve

2 Pipe siphon

h Length of down pipe

Installation in partially filled pipes

A partially filled pipe with a gradient necessitates a drain-type configuration.

Endress+Hauser 33

Page 34

2 x DN³

5 x DN³

For heavy sensors DN ≥ 350 (14")

Proline Promag L 400

A0029257

Orientation

A0016276

The direction of the arrow on the sensor nameplate helps you to install the sensor according to the

flow direction (direction of medium flow through the piping).

Orientation Recommendation

A Vertical orientation

A0015591

B Horizontal orientation, transmitter at

top

A0015589

C Horizontal orientation, transmitter at

bottom

A0015590

D Horizontal orientation, transmitter at

side

A0015592

1) Applications with low process temperatures may decrease the ambient temperature. To maintain the

minimum ambient temperature for the transmitter, this orientation is recommended.

2) Applications with high process temperatures may increase the ambient temperature. To maintain the

maximum ambient temperature for the transmitter, this orientation is recommended.

3) To prevent the electronics module from overheating in the case of a sharp rise in temperature (e.g. CIP- or

SIP processes), install the device with the transmitter component pointing downwards.

1)

2) 3)

Horizontal

• Ideally, the measuring electrode plane should be horizontal. This prevents brief insulation of the

two measuring electrodes by entrained air bubbles.

• Empty pipe detection only works if the transmitter housing is pointing upwards as otherwise there

is no guarantee that the empty pipe detection function will actually respond to a partially filled or

empty measuring tube.

34 Endress+Hauser

Page 35

Proline Promag L 400

1

2

3

≥ 5 × DN

≥ 2 × DN

≥ 0 × DN

A0029344

1 EPD electrode for empty pipe detection

2 Measuring electrodes for signal detection

3 Reference electrode for potential equalization

Inlet and outlet runs

If possible, install the sensor upstream from fittings such as valves, T-pieces or elbows.

Observe the following inlet and outlet runs to comply with accuracy specifications:

A0028997

20 Order code for "Design", option A "Insertion length short, ISO/DVGW until DN400, DN450-2000 1:1" and

order code for "Design", option B "Insertion length long, ISO/DVGW until DN400, DN450-2000 1:1.3"

A0032859

21 Order code for "Design", option C "Insertion length short ISO/DVGW until DN300, w/o inlet and outlet

runs, constricted meas.tube"

Adapters

Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor in largerdiameter pipes. The resultant increase in the rate of flow improves measuring accuracy with very

slow-moving fluids.

The nomogram shown here can be used to calculate the pressure loss caused by reducers and

expanders:

• Calculate the ratio of the diameters d/D.

• From the nomogram read off the pressure loss as a function of flow velocity (downstream from

the reduction) and the d/D ratio.

The nomogram only applies to liquids with a viscosity similar to that of water.

Endress+Hauser 35

Page 36

Proline Promag L 400

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

200

100

5

10 100 200

[m]

[ S/cm]µ

L

max

[ ]ft

200 6000 400

L

max

A0029002

Length of connecting cable

To ensure correct measuring results when using the remote version,

observe the maximum permitted length of the connecting cable L

max

the conductivity of the fluid.

If measuring liquids in general: 5 µS/cm

22 Permitted length of connecting cable for remote version

Colored area = permitted range

L

=

length of connecting cable in [m] ([ft])

max

[µS/cm] = fluid conductivity

. This length is determined by

A0016539

36 Endress+Hauser

Page 37

Proline Promag L 400

149 (5.85)

210.5 (8.29)

=

5.8 (0.23)

17 (0.67) =

14 (0.55)

5.8 (0.23)

ø 20…70

( 0.79…2.75)ø

~102 (~ 4.0)

4 x

SW 10

3 x

TX 25

Mounting the transmitter housing

Wall mounting

A0020523

23 Engineering unit mm (in)

Post mounting

24 Engineering unit mm (in)

Special mounting instructions

Display protection

To ensure that the optional display protection can be easily opened, maintain the following

minimum head clearance: 350 mm (13.8 in)

Temporary immersion in water

A remote version with IP67 protection, Type 6 is optionally available for temporary immersion in

water for up to 168 hours at ≤ 3 m (10 ft) or in exceptional cases for use for up to 48 hours at ≤

10 m (30 ft).

Compared with the standard degree of protection IP67, Type 4X enclosure, the version IP67, Type 6

enclosure has been designed to withstand short-term or temporary flooding.

Endress+Hauser 37

A0029051

Page 38

≤ ≤

3 ( 10)

25 Engineering unit in m(ft)

Replacement of cable gland on connection housing

Environment

Proline Promag L 400

A0029320

Ambient temperature range

Transmitter –40 to +60 °C (–40 to +140 °F)

Local display –20 to +60 °C (–4 to +140 °F), the readability of the display may be

impaired at temperatures outside the temperature range.

Sensor • Process connection material, carbon steel:

–10 to +60 °C (+14 to +140 °F)

• Process connection material, stainless steel:

–40 to +60 °C (–40 to +140 °F)

Mount the transmitter separately from the sensor if both the ambient

and fluid temperatures are high.

Liner Do not exceed or fall below the permitted temperature range of the liner .

If operating outdoors:

• Install the measuring device in a shady location.

• Avoid direct sunlight, particularly in warm climatic regions.

• Avoid direct exposure to weather conditions.

• If the compact version of the device is insulated at low temperatures, the insulation must also

include the device neck.

• Protect the display against impact.

• Protect the display from abrasion by sand in desert areas.

You can order a display guard from Endress+Hauser : → 86

Temperature tables

Observe the interdependencies between the permitted ambient and fluid temperatures when

operating the device in hazardous areas.

For detailed information on the temperature tables, see the separate document entitled "Safety

Instructions" (XA) for the device.

Storage temperature

The storage temperature corresponds to the operating temperature range of the measuring

transmitter and the appropriate measuring sensors.→ 38

• Protect the measuring device against direct sunlight during storage in order to avoid unacceptably

high surface temperatures.

• Select a storage location where moisture cannot collect in the measuring device as fungus or

bacteria infestation can damage the liner.

• If protection caps or protective covers are mounted these should never be removed before

installing the measuring device.

38 Endress+Hauser

Page 39

Proline Promag L 400

Atmosphere

Degree of protection

Vibration resistance

If a plastic transmitter housing is permanently exposed to certain steam and air mixtures, this can

damage the housing.

If you are unsure, please contact your Endress+Hauser Sales Center for clarification.

Transmitter

• As standard: IP66/67, type 4X enclosure

• When housing is open: IP20, type 1 enclosure

Sensor

• As standard: IP66/67, type 4X enclosure

• Optionally available for remote version:

– IP67, type 4X enclosure. Suitable for temporary immersion in water for up to 168 hours at

depths ≤ 3 m (10 ft) or up to 48 hours at depths ≤ 10 m (30 ft).

– IP68, type 6P enclosure (for DN ≤ 300 (12") only possible in conjunction with stainless steel

flanges)

Not suitable for use in corrosive atmospheres/liquids or in buried applications if special

precautions are not taken.

Compact version

• Vibration, sinusoidal according to IEC 60068-2-6

– 2 to 8.4 Hz, 3.5 mm peak

– 8.4 to 2 000 Hz, 1 g peak

• Vibration broad-band random, according to IEC 60068-2-64

– 10 to 200 Hz, 0.003 g2/Hz

– 200 to 2 000 Hz, 0.001 g2/Hz

– Total: 1.54 g rms

Remote version

• Vibration, sinusoidal according to IEC 60068-2-6

– 2 to 8.4 Hz, 7.5 mm peak

– 8.4 to 2 000 Hz, 2 g peak

• Vibration broad-band random, according to IEC 60068-2-64

– 10 to 200 Hz, 0.01 g2/Hz

– 200 to 2 000 Hz, 0.003 g2/Hz

– Total: 2.70 g rms

Shock resistance

Impact resistance

Mechanical load

Electromagnetic compatibility (EMC)

Medium temperature range

Shock, half-sine according to IEC 60068-2-27

6 ms 50 g

Rough handling shocks according to IEC 60068-2-31

• Protect the transmitter housing against mechanical effects, such as shock or impact; the use of the

remote version is sometimes preferable.

• Never use the transmitter housing as a ladder or climbing aid.

• As per IEC/EN 61326 and NAMUR Recommendation 21 (NE 21)

• Complies with emission limits for industry as per EN 55011 (Class A)

• Device version with PROFIBUS DP: Complies with emission limits for industry as per EN 50170

Volume 2, IEC 61784

The following applies for PROFIBUS DP: If baud rates > 1.5 MBaud, an EMC cable entry must be

used and the cable shield must continue as far as the terminal wherever possible.

Details are provided in the Declaration of Conformity.

Process

• 0 to +80 °C (+32 to +176 °F) for hard rubber, DN 350 to 2400 (14 to 90")

• –20 to +50 °C (–4 to +122 °F) for polyurethane, DN 25 to 1200 (1 to 48")

• –20 to +90 °C (–4 to +194 °F) for PTFE, DN 25 to 300 (1 to 12")

Endress+Hauser 39

Page 40

Proline Promag L 400

1 2

0

5

10

15

20

[bar][psi]

-60

-40

-20

0 20

40 60 80 100120140

[°C]

[°F]

0-40 100 200 300

200

100

300

0

0

5

10

15

20

[bar][psi]

-40

-20

0

20 40

60 80 100120140

[°C]

0-40 100 200 300

200

100

300

0

[°F]

PN10

PN6

0

10

20

30

40

[bar][psi]

-40

-20

0 20

40 60 80 100120140

[°C]

[°F]

0-40 100 200 300

200

100

400

300

500

0

Class150

Conductivity

Pressure-temperature ratings

≥ 5 μS/cm for liquids in general. Stronger filter damping is required for very low conductivity values.

Note that in the case of the remote version, the requisite minimum conductivity also depends

on the cable length → 36.

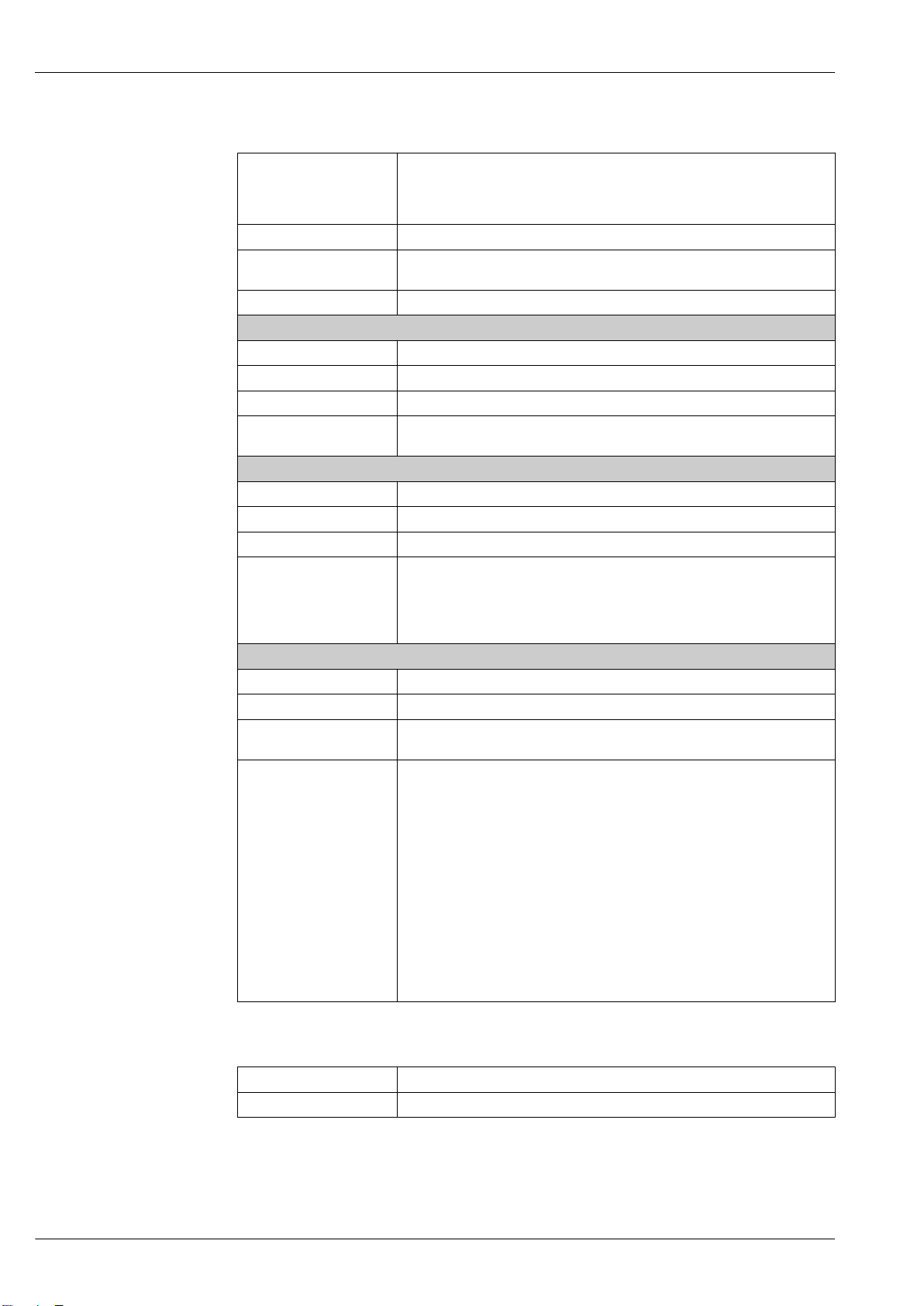

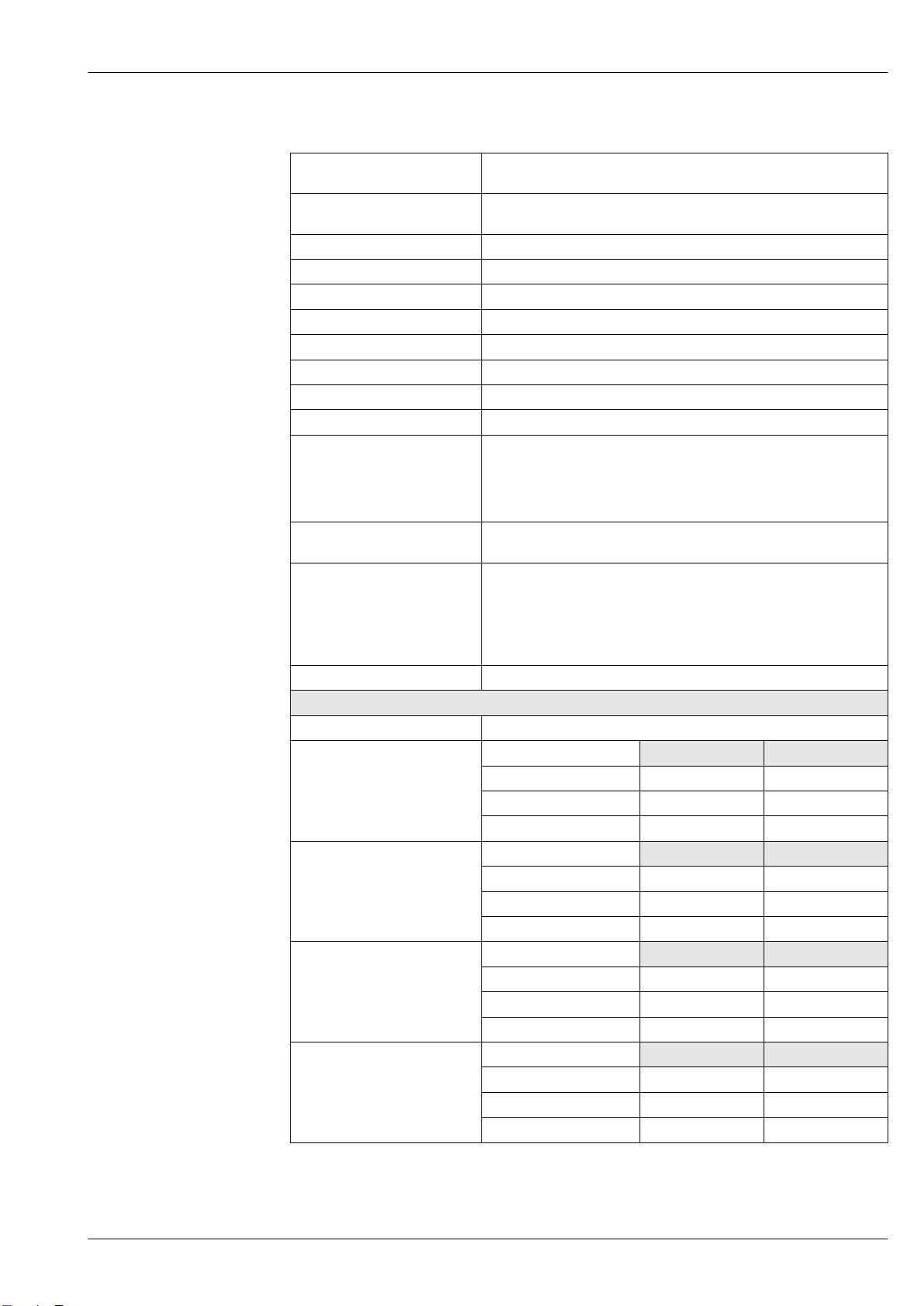

The following pressure/temperature diagrams apply to all pressure-bearing parts of the device and

not just the process connection. The diagrams show the maximum permissible medium pressure

depending on the specific medium temperature.

Process connection: lap joint flange/lap joint flange, stamped plate according to EN 1092-1

(DIN 2501) and ASME B16.5; DN 25 to 300 (1 to 12")

A0032067-EN

26 Process connection material: stainless steel (min. -40 °C (-40 °F)), carbon steel (min. -10 °C (+14 °F))

1 Lap joint flange PN16/ Class150

2 Lap joint flange, stamped plate PN10, lap joint flange PN10

Process connection: fixed flange according to EN 1092-1 (DIN 2501)

27 Process connection material: stainless steel, 1.4306/1.4404/1.4571/F316L; carbon steel, A105/

FE410WB/S235JRG2

Process connection: fixed flange according to ASME B16.5

A0032068-EN

40 Endress+Hauser

28 Process connection material: stainless steel, F316L similar to 1.4404; carbon steel, A105/A515(70)

A0032070-EN

Page 41

Proline Promag L 400

0

8

9

10

11

[bar][psi]

-40

-20020 40

60 80 100120140

[°C]

0-40 100 200 300

0

[°F]

ClassD

-40

-20

0 20

40 60 80 100 120140

[°C]

0

10

5

20

15

[bar]

0-40 100 200

300

[psi]

200

100

300

0

[°F]

PN16

Process connection: fixed flange according to AWWA C207

A0032071-EN

29 Process connection material: carbon steel, A105/A181/P265GH/S275JR

Process connection: fixed flange according to AS 2129

30 Process connection material: A105/FE410WB/P235GH/P265GH/S235JRG2

Process connection: fixed flange according to AS 4087

31 Process connection material: A105/P265GH/S275JR

Pressure tightness

Liner: hard rubber, polyurethane

Nominal diameter Liner Limit values for absolute pressure in [mbar] ([psi]) for fluid

temperatures:

[mm] [in] +25 °C (+77 °F) +50 °C (+122 °F) +80 °C (+176 °F)

350…2400 14…90 Hard rubber 0 (0) 0 (0) 0 (0)

25…1200 1…48 Polyurethane 0 (0) 0 (0) –

Endress+Hauser 41

A0032072-EN

A0032073-EN

Page 42

Proline Promag L 400

DN80

(3")

DN65

(2½")

DN50

(2")

500

450

400

350

300

250

200

150

100

50

0

0 10 20 30 40 50 60 70 80 90 100 110 120

[mbar]

[m /h]³

0 100 200 300 400 50050 150 250 350 450

[gal/min]

7

0

1

2

3

4

5

6

Liner: PTFE

Nominal diameter Limit values for absolute pressure in [mbar] ([psi]) for fluid temperatures:

[mm] [in] +25 °C (+77 °F) +90 °C (+194 °F)

25 1 0 (0) 0 (0)

40 2 0 (0) 0 (0)

50 2 0 (0) 0 (0)

65 2 ½ 0 (0) 40 (0.58)

80 3 0 (0) 40 (0.58)

100 4 0 (0) 135 (2.0)

125 5 135 (2.0) 240 (3.5)

150 6 135 (2.0) 240 (3.5)

200 8 200 (2.9) 290 (4.2)

250 10 330 (4.8) 400 (5.8)

300 12 400 (5.8) 500 (7.3)

Flow limit

Pressure loss

The diameter of the pipe and the flow rate determine the nominal diameter of the sensor. The

optimum velocity of flow is between 2 to 3 m/s (6.56 to 9.84 ft/s). Also match the velocity of flow

(v) to the physical properties of the fluid:

• v < 2 m/s (6.56 ft/s): for abrasive fluids (e.g. potter's clay, lime milk, ore slurry)

• v > 2 m/s (6.56 ft/s): for fluids producing buildup (e.g. wastewater sludge)

A necessary increase in the flow velocity can be achieved by reducing the sensor nominal

diameter.

For an overview of the full scale values for the measuring range, see the "Measuring range"

section → 8

• No pressure loss occurs if the sensor is installed in a pipe with the same nominal diameter.

• Pressure losses for configurations incorporating adapters according to DIN EN 545 → 35

32 Pressure loss DN 50 to 80 (2 to 3") in the case of order code for "Design", option C "Insertion length short

ISO/DVGW to DN300, without inlet/outlet runs, constricted meas.tube"

42 Endress+Hauser

A0032667-EN

Page 43

Proline Promag L 400

DN300

(12")

DN100

(4")

DN250

(10")

DN200

(8")

DN150

(6")

DN125

(5")

[mbar]

900

800

700

600

500

400

300

200

100

0

0 200 400 600 800 1000 1200 1400 1600 1800

[m /h]³

0

13

12

11

10

9

8

7

6

5

4

3

2

1

0 1000 2000 3000 4000 5000 6000 7000 8000

[gal/min]

L

A0032668-EN

33 Pressure loss DN 100 to 300 (4 to 12") in the case of order code for "Design", option C "Insertion length

short ISO/DVGW to DN300, without inlet/outlet runs, constricted meas.tube"

System pressure

A0028777

Never install the sensor on the pump suction side in order to avoid the risk of low pressure, and thus

damage to the liner.

Furthermore, install pulse dampers if reciprocating, diaphragm or peristaltic pumps are used.

• Information on the liner's resistance to partial vacuum → 41

• Information on the shock resistance of the measuring system → 39

• Information on the vibration resistance of the measuring system → 39

Vibrations

Endress+Hauser 43

34 Measures to avoid device vibrations (L > 10 m (33 ft))

In the event of very strong vibrations, the pipe and sensor must be supported and fixed.

It is also advisable to mount the sensor and transmitter separately.

• Information on the shock resistance of the measuring system → 39

• Information on the vibration resistance of the measuring system → 39

A0029004

Page 44

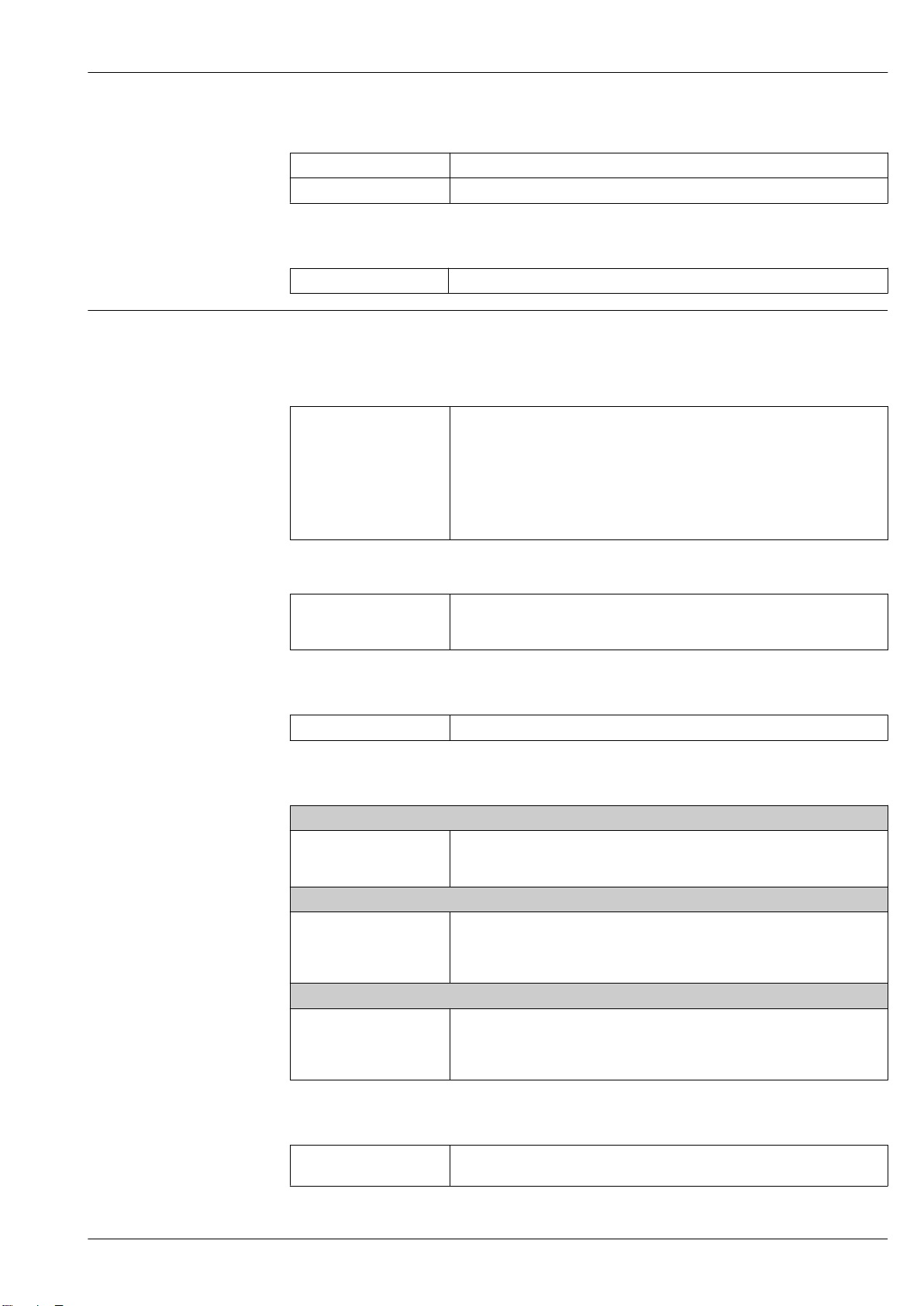

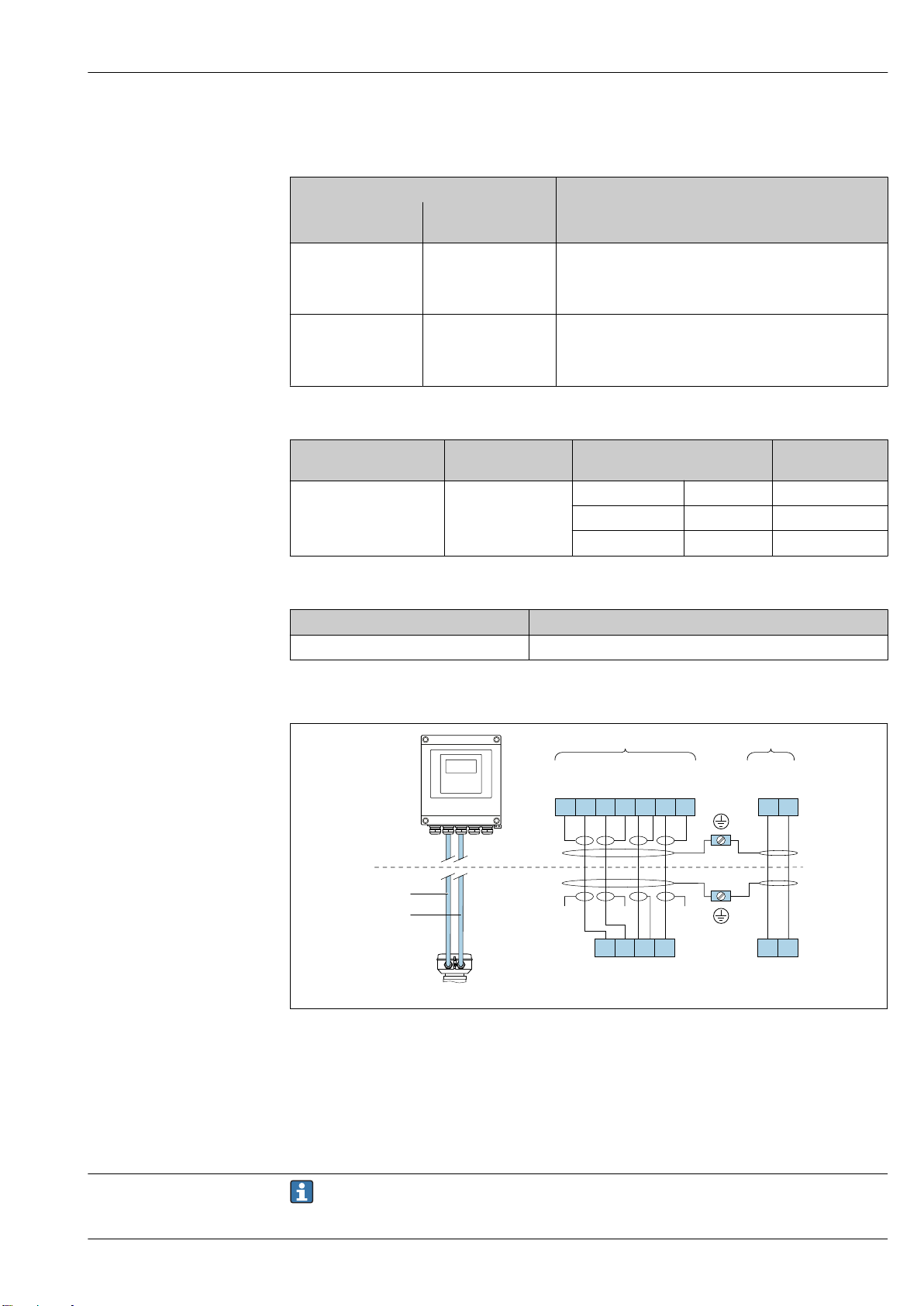

Mechanical construction

A

H

B

C

E

G

D

F

J

K

Dimensions in SI units Compact version

Order code for "Housing", option M "Compact, polycarbonate" or option A "Compact, aluminum, coated"

Proline Promag L 400

DN A B C D E F G H J K

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

25 193 103 90 167 222 84 306 120 94 200

32 193 103 90 167 222 84 306 120 94 200

40 193 103 90 167 222 84 306 120 94 200

50 193 103 90 167 222 84 306 120 94 200

65 193 103 90 167 247 109 356 180 94 200

80 193 103 90 167 247 109 356 180 94 200

100 193 103 90 167 247 109 356 180 94 250

125 193 103 90 167 287 150 437 260 140 250

150 193 103 90 167 287 150 437 260 140 300

200 193 103 90 167 312 180 492 324 156 350

250 193 103 90 167 337 205 542 400 166 450

300 193 103 90 167 362 230 592 460 166 500

1) The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

A0020352

1)

44 Endress+Hauser

Page 45

Proline Promag L 400

G

J

H

E

F

A

B

D

C

A0017153

DN A B C D E H J

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

350 193 103 90 167 386 290 550

375 193 103 90 167 412 290 600

400 193 103 90 167 412 290 600

450 193 103 90 167 440 290 600

500 193 103 90 167 465 290 600

600 193 103 90 167 506 290 600

700 193 103 90 167 571 424 700

750 193 103 90 167 608 454 750

800 193 103 90 167 627 500 800

900 193 103 90 167 677 580 900

1000 193 103 90 167 727 664 1000