ESM-4410 48 x 48 1/16 DIN

Digital, On/Off Temperature Controller

igits display

- 3 D

- NTC Input or,

PTC Input or,

J type thermocouple or,

K type thermocouple or,

PT-100 2-wire or 3-wire temperature input

( It must be determined in order )

- ON/OFF control form

- Selectable heating and cooling function

- Operating type selection with hysteresis

- Adjustment of temperature offset value

- Minimum pulling time adjustment for control outputs

- Password protection for programming mode

ESM-4410 48 x 48 1/16 DIN Temperature Controller

Instruction Manual. ENG ESM-4410 02 V08 07/14

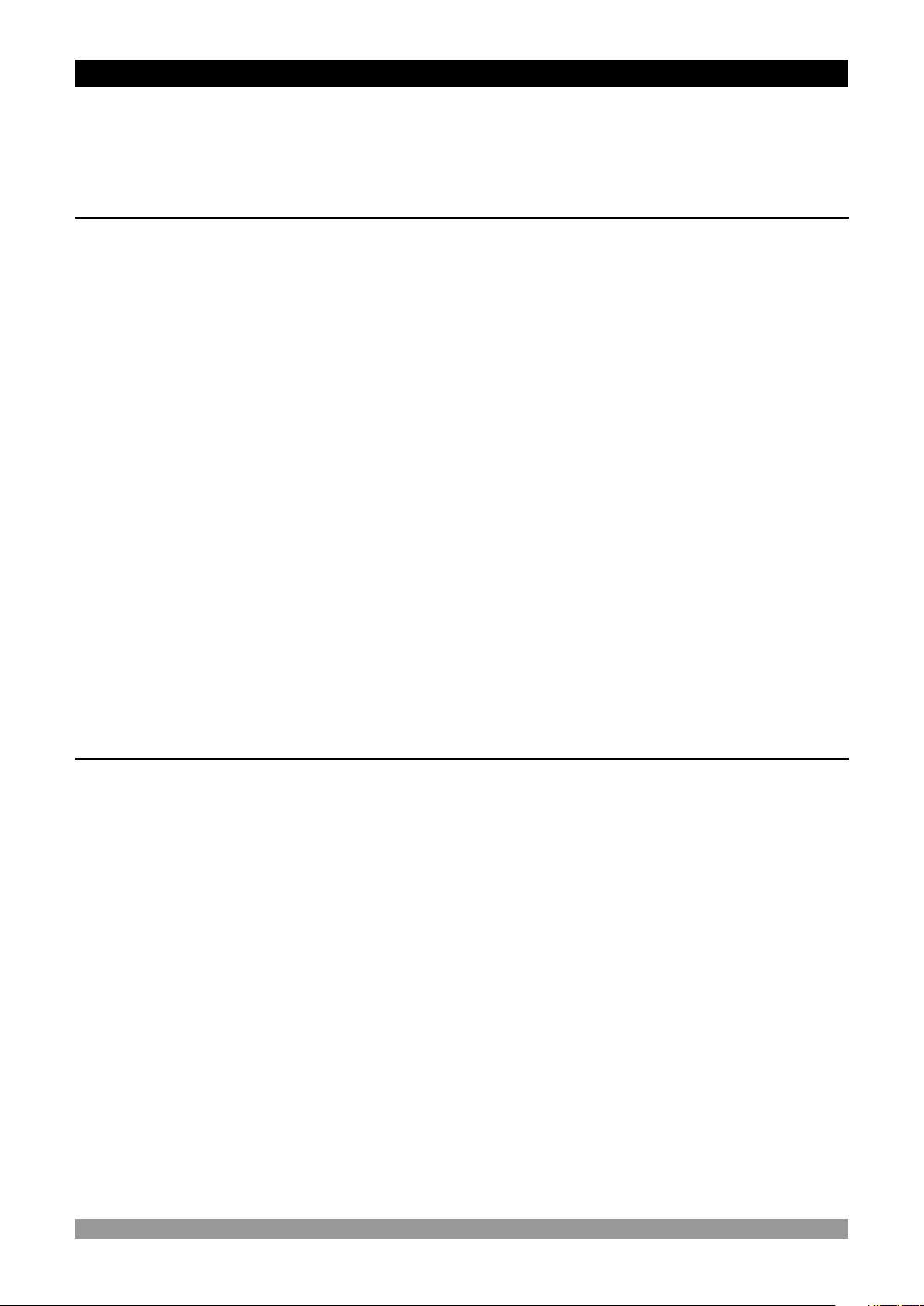

ABOUT INSTRUCTION MANUAL

Instruction manual of ESM-4410 Temperature Controller consists of three main sections.

Explanation of these sections are below. Also, there are other sections which include order

information and technical specifications of the device. All titles and page numbers in instruction

manual are in “CONTENTS” section. User can reach to any title with section number.

Installation:

In this section, physical dimensions of the device, panel mounting, electrical wiring are

explained.

Operation and Parameters:

In this section, user interface of the device, how to access to the parameters, description

of the parameters are explained.

Control Algorithm:

Configurable control function that is on the device is explained.

Also in these sections, there are warnings to prevent serious injury while doing the

physical and electrical mounting or using the device.

Explanation of the symbols which are used in these sections are given below.

This symbol is used for safety warnings. User must pay attention to these

warnings.

c

This symbol is used to determine the dangerous situations as a result of an electric

shock. User must pay attention to these warnings definitely.

a

This symbol is used to determine the important notes about functions and usage of

i

the device.

2

CONTENTS

1.PREFACE............................................................................................................................................

1.1 GENERAL SPECIFICATIONS

1.2 ORDERING INFORMATION

1.3 WARRANTY

1.4 MAINTENANCE

Page 5

2.INSTALLATION....................................................................................................................................

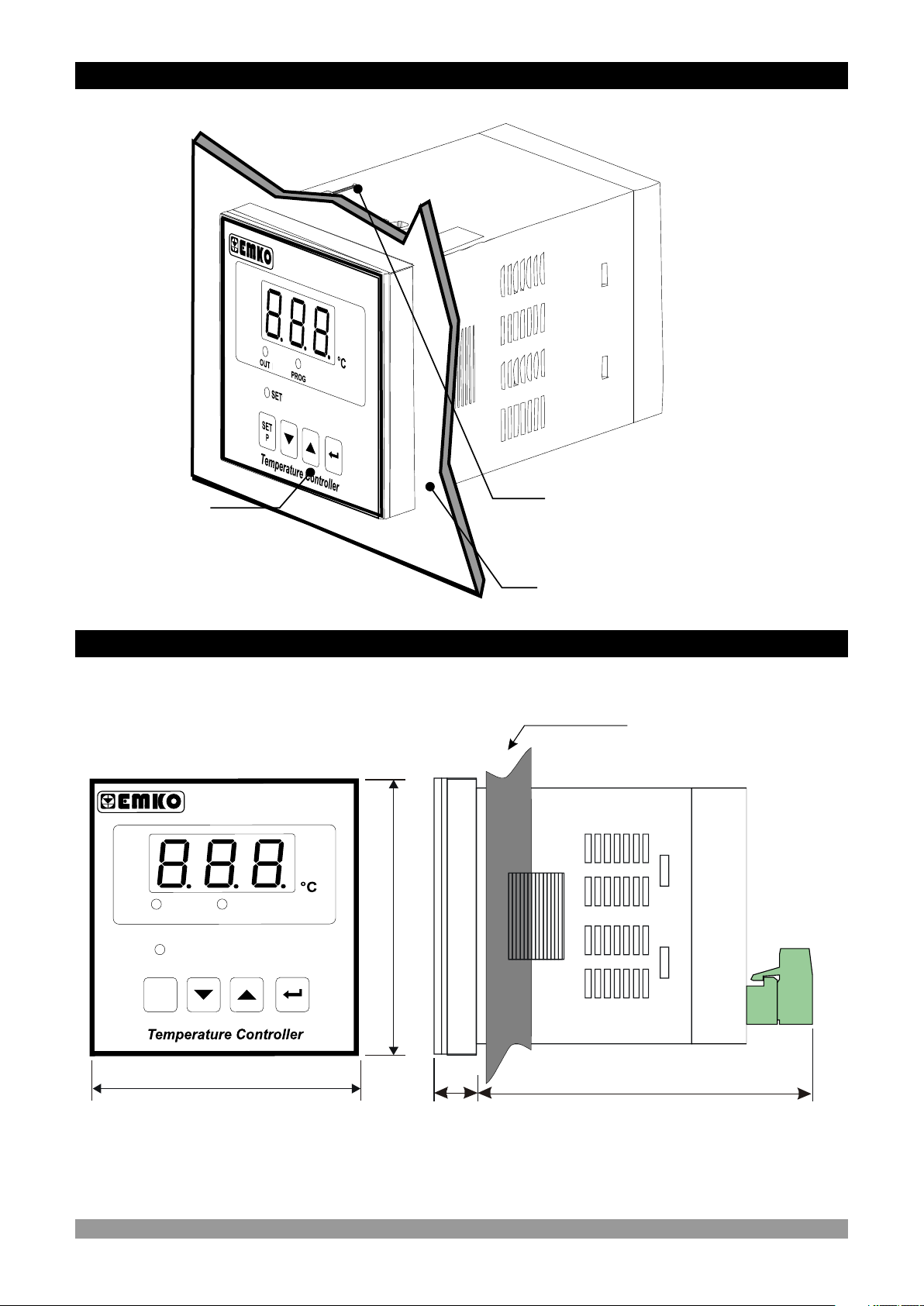

2.1 GENERAL DESCRIPTION

2.2 FRONT VIEW AND DIMENSIONS OF ESM-4410 TEMPERATURE CONTROLLER

2.3 PANEL CUT-OUT

2.4 ENVIRONMENTAL RATINGS

2.5 PANEL MOUNTING

2.6 INSTALLATION FIXING CLAMP

2.7 REMOVING FROM THE PANEL

3.ELECTRICAL WIRINGS......................................................................................................................

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTIONS

3.2 ELECTRICAL WIRING DIAGRAM

3.3 LABELS FOR ESM-4410 TEMPERATURE CONTROLLER

3.4 SUPPLY VOLTAGE INPUT CONNECTION OF THE DEVICE

3.5 TEMPERATURE INPUT CONNECTION

3.5.1 TC (THERMOCOUPLE) CONNECTION

3.5.2 RTD CONNECTIONS

3.5.3 PTC AND NTC CONNECTIONS

3.6 GALVANIC ISOLATION TEST VALUES OF ESM-4410 TEMPERATURE CONTROLLER

3.7 OUTPUT CONNECTION

3.7.1 RELAY OUTPUT CONNECTION

3.7.2 SSR DRIVER OUTPUT CONNECTION

4.FRONT PANEL DEFINITION AND ACCESSING TO THE MENUS....................................................

4.1 FRONT PANEL DEFINITION FOR ESM-4410

4.2 OBSERVATION OF ESM-4410 TEMPERATURE CONTROLLER SOFTWARE REVISION

4.3 CHANGING AND SAVING SET VALUE

4.4 ENTERING TO PROGRAMMING MODE, CHANGING AND SAVING PARAMETERS

Page 7

Page 12

Page 17

Page 18

5.PARAMETERS....................................................................................................................................

5.1 SET PARAMETER

5.2 PROGRAM PARAMETERS

6.FAILURE MESSAGE IN ESM-4410 TEMPERATURE CONTROLLERS............................................

7.CONTROL ALGORITHM.....................................................................................................................

7.1 ON/OFF CONTROL

7.1.1 ON/OFF CONTROL IN ESM-XX10 TEMPERATURE CONTROLLERS

8.SPECIFICATIONS................................................................................................................................

9.OTHER INFORMATIONS....................................................................................................................

Page 28

Page 29

Page 30

Page 31

Page 32

3

EU DECLARATION OF CONFORMITY

Manufacturer’s Name : EMKO ELEKTRONIK A.S.

Manufacturer’s Address : DOSAB, Karanfil Sk., No:6,

16369 Bursa, TURKEY

The manufacturer hereby declares that the product:

Product Name : Temperature Controller Unit

Type Number : ESM-4410

Product Category : Electrical equipment for measurement, control and

laboratory use

Conforms to the following directives :

2006 / 95 / EC The Low Voltage Directive

2004 / 108 / EC The Electromagnetic Compatibility Directive

has been designed and manufactured to the following specifications:

EN 61000-6-4:2007 EMC Generic Emission Standard for Industrial Environments

EN 61000-6-2:2005 EMC Generic Immunity Standard for Industrial Environments

EN 61010-1:2001 Safety Requirements for electrical equipment for measurement, control

and laboratory use

When and Where Issued Authorized Signature

th

16 October 2009 Name : Serpil YAKIN

Bursa-TURKEY Position : Quality Manager

4

1.Preface

ESM series temperature controllers are designed for measuring and controlling

temperature. They can be used in many applications with On/Off control form and heating and

cooling selection. Some application fields which they are used are listed below:

Application Fields

Glass

Plastic

Petro-Chemistry

Textile

Automative

Machine Production Industries

1.1 General Specifications

Standard

ESM-4410

230 V V (±%15) , 50/60 Hz

Supply Voltage

Input

Temperature Input

Standard

Output (Relay

Output)

Optional Supply Voltage

Inputs

115 V V (±%15) , 50/60 Hz

24 V V (±%15) , 50/60 Hz

24 V W ( - %15, + %10 )

50/60 Hz

NTC

PTC

J or K Type TC

2 or 3 wire PT 100

Control Output

Alarm Output

Heating or Cooling

Function

ON/OFF Operation

5

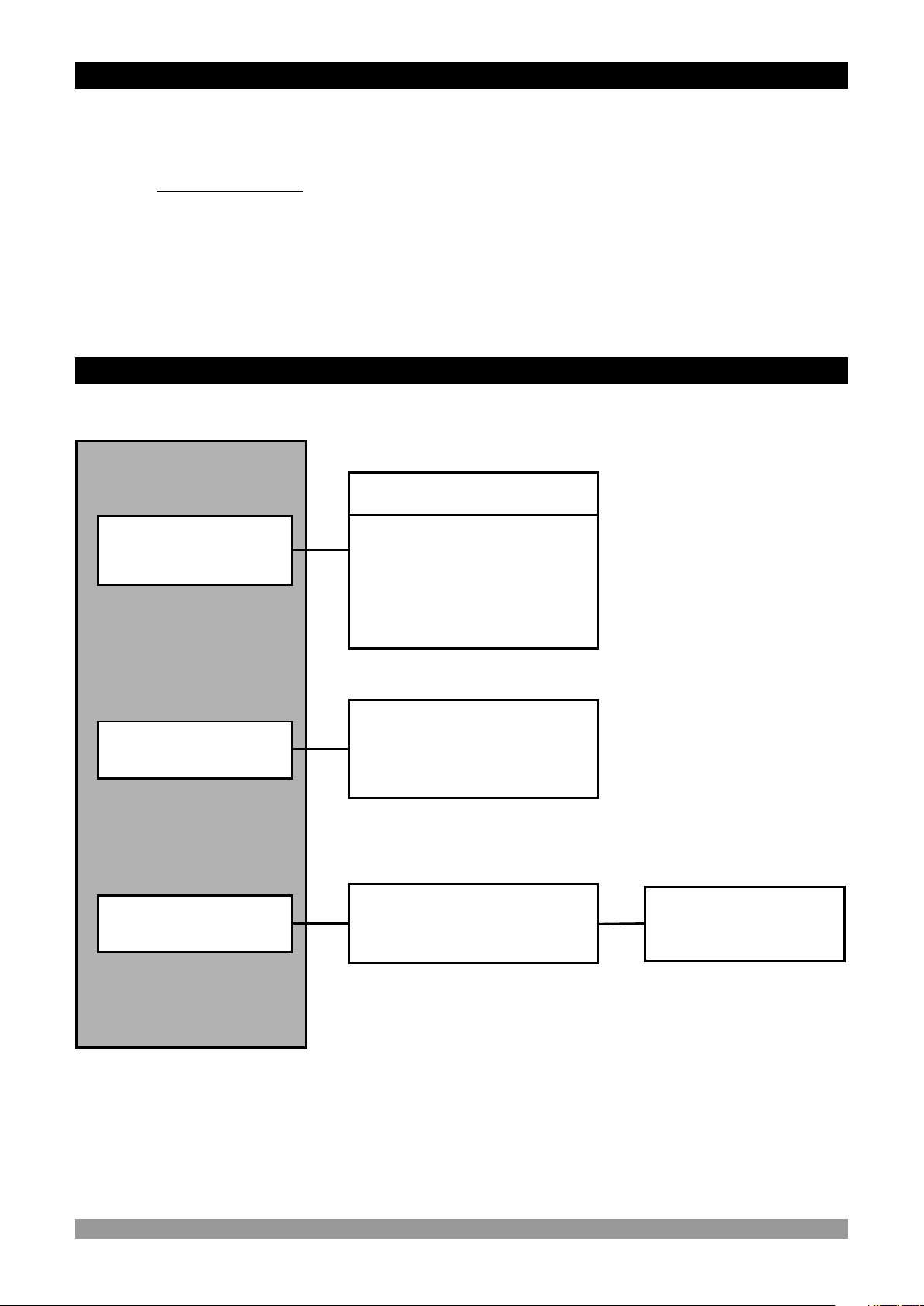

1.2 Ordering Information

A BC D E FG HI //U V W Z/

ESM-4410 (48x48 1/16 DIN)

/0 00 2 0 0

Supply Voltage

A

24 V W ( - %15, + %10 ) 50/60 Hz

2

24 V V (±15%) 50/60 Hz

3

115 V V (±15%) 50/60 Hz

4

230 V V (±15%) 50/60 Hz

5

Customer

9

Input Type

BC

PTC (Note-1)

12

PTC (Note-1)

15

09

PT 100 , IEC751(ITS90)

PT 100 , IEC751(ITS90)

03

05

J ,Fe CuNi IEC584.1(ITS90)

10

K ,NiCr Ni IEC584.1(ITS90)

NTC (Note-1)

18

19

NTC (Note-1)

Note-1 : If input type is selected PTC or NTC (BC = 12, 15, 18, 19 ),

Temperature sensor is given with the device. For this reason,

If input type is selected as PTC, sensor type (V = 0,1 or 2) or

If input type is selected as NTC, sensor type (V = 0,3 or 4) must be

declared in ordering information.

E

Output-1

1

Relay Output(7 A@250 V at resistive load, 1NO)

2

SSR Driver Output ( )Maksimum 23 mA, 15 V Z

Scale(°C)

-50°C

-19.9°C

-19.9°C

0°C

0°C

0°C

-50°C 100°C

-19.9°C 99.9°C

150°C

99.9°C

99.9°C

400°C

800°C

999°C

All order information of ESM-4410

Temperature Controller are given on the

table at left. User may form appropriate

device configuration from information and

codes that at the table and convert it to the

ordering codes.

Firstly, supply voltage then other

specifications must be determined. Please

fill the order code blanks according to your

needs.

Please contact us, if your needs are

out of the standards.

V Þ Vac,

Z Þ Vdc,

c

Þ VacdcW

Output-2 FG

None

00

Temp.Sensor which is given with ESM-4410

V

None

0

PTC-M6L40.K1.5(PTC Air probe with 1.5 m silicon cable)

1

PTCS-M6L30.K1.5.1/8”(PTC Liquid probe with 1.5 m silicon cable)

2

NTC-M5L20.K1.5 (NTC Probe, thermoplastic moulded with

3

1.5 m cable for cooling application)

NTC-M6L50.K1.5 (NTC Probe, stainless steel housing with

4

1.5 m cable for cooling application)

Customer

9

1.3 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts from

the delivery date. This warranty is in force if duty and responsibilities which are determined in

warranty document and instruction manual performs by the customer completely.

1.4 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the device

before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in ethyl

alcohol or water to clean the external plastic case.

6

2.Installation

Before beginning installation of this product, please read the instruction

manual and warnings below carefully.

c

In package ,

- One piece unit

- Two pieces mounting clamps

- One piece instruction manual

A visual inspection of this product for possible damage occured during shipment is

recommended before installation. It is your responsibility to ensure that qualified

mechanical and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power

off the system and separate the electrical connection of the device from the system.

The unit is normally supplied without a power switch or a fuse. Use power switch and fuse

as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to

prevent failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble

with the unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may

results in malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During the equipment is putted in hole on the metal panel while mechanical installation

some metal burrs can cause injury on hands, you must be careful.

Montage of the product on a system must be done with it’s own fixing clamps. Do not do

the montage of the device with inappropriate fixing clamps. Be sure that device will not fall

while doing the montage.

It is your responsibility if this equipment is used in a manner not specified in this

instruction manual.

7

2.1 General Description

Front Panel

IP65 protection

NEMA 4X

ESM

-44

10

Mounting Clamp

Panel surface

(maximum thickness 5 mm / 0.2 inch)

2.2 Front View and Dimensions of ESM-4410 Temperature Controller

Maximum 5 mm / 0.2 inch

0

4

4

- 1

SM

E

T

U

O

T

E

S

T

E

S

P

G

O

R

P

48 mm/ 1.89 inch

48 mm/ 1.89 inch

11 ± 1 mm /0.43 inch

84 mm / 3.31 inch

8

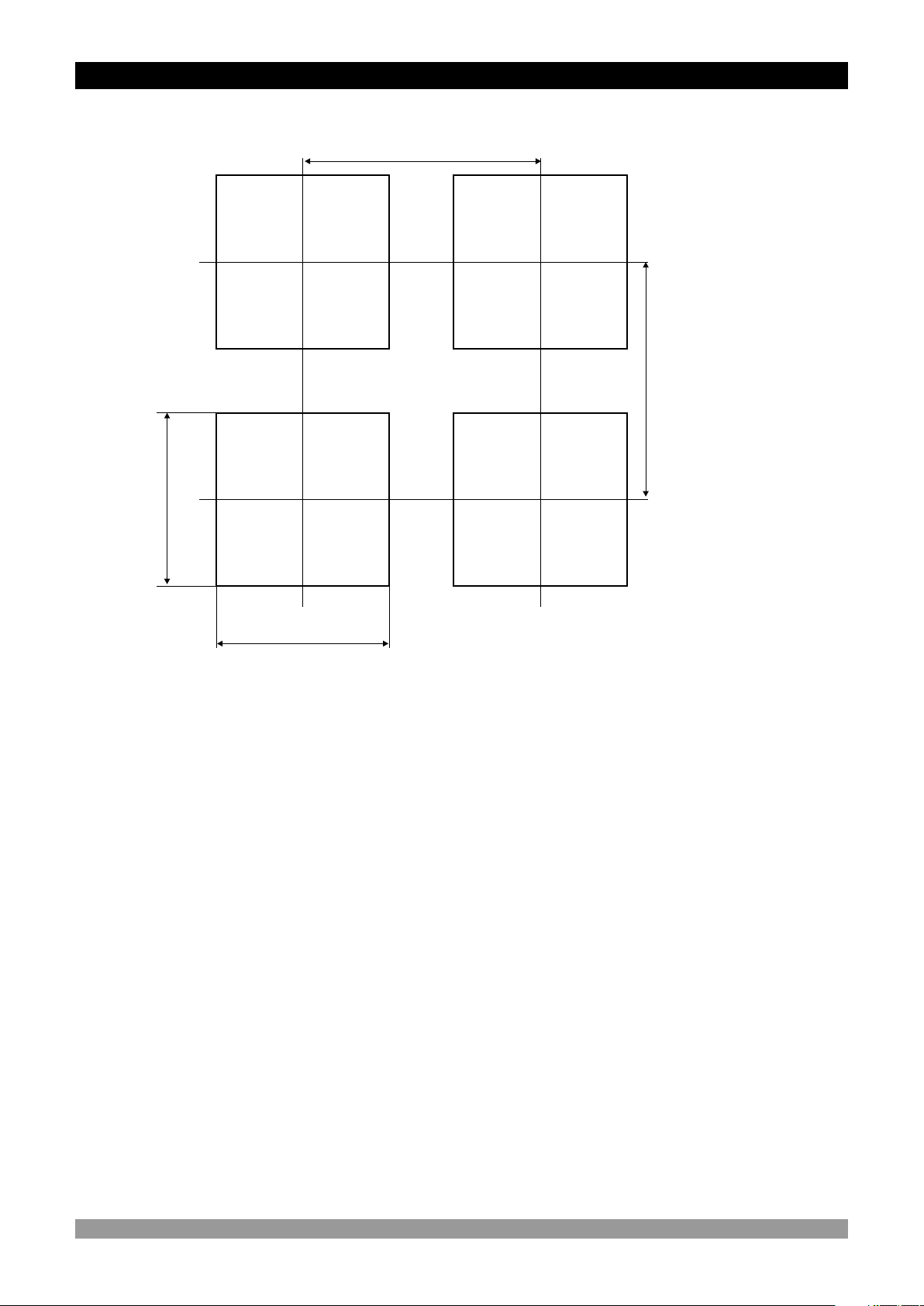

2.3 Panel Cut-Out

65 mm / 2.56 inch (min)

65 mm / 2.56 inch (min)

46 mm / 1.81 inch (min)

46 mm / 1.81 inch (min)

9

2.4 Environmental Ratings

Operating Conditions

Operating Temperature : 0 to 50 °C

Max. Operating Humidity : 90% Rh (non-condensing)

Altitude : Up to 2000 m.

Forbidden Conditions:

Corrosive atmosphere

c

Explosive atmosphere

Home applications (The unit is only for industrial applications)

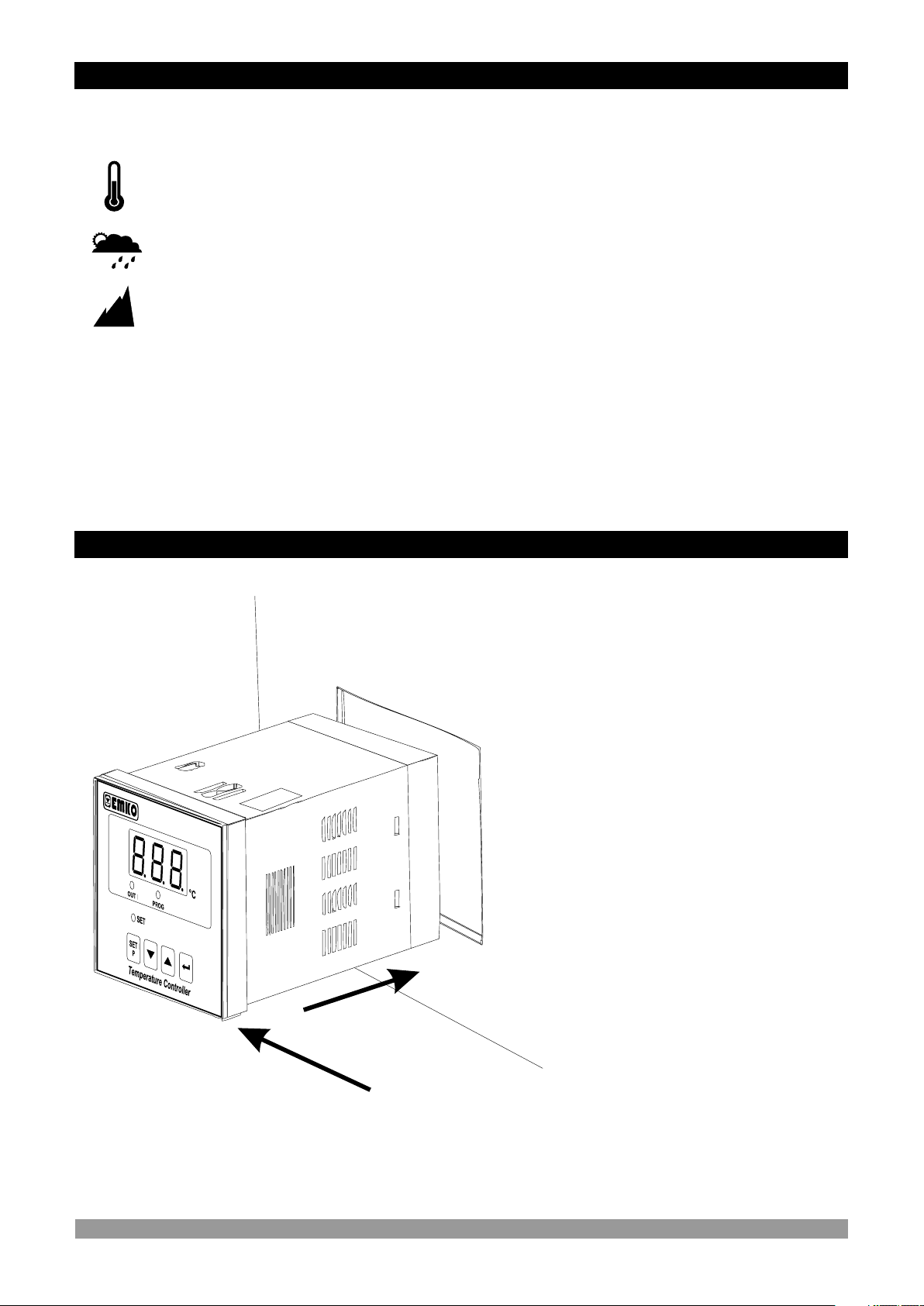

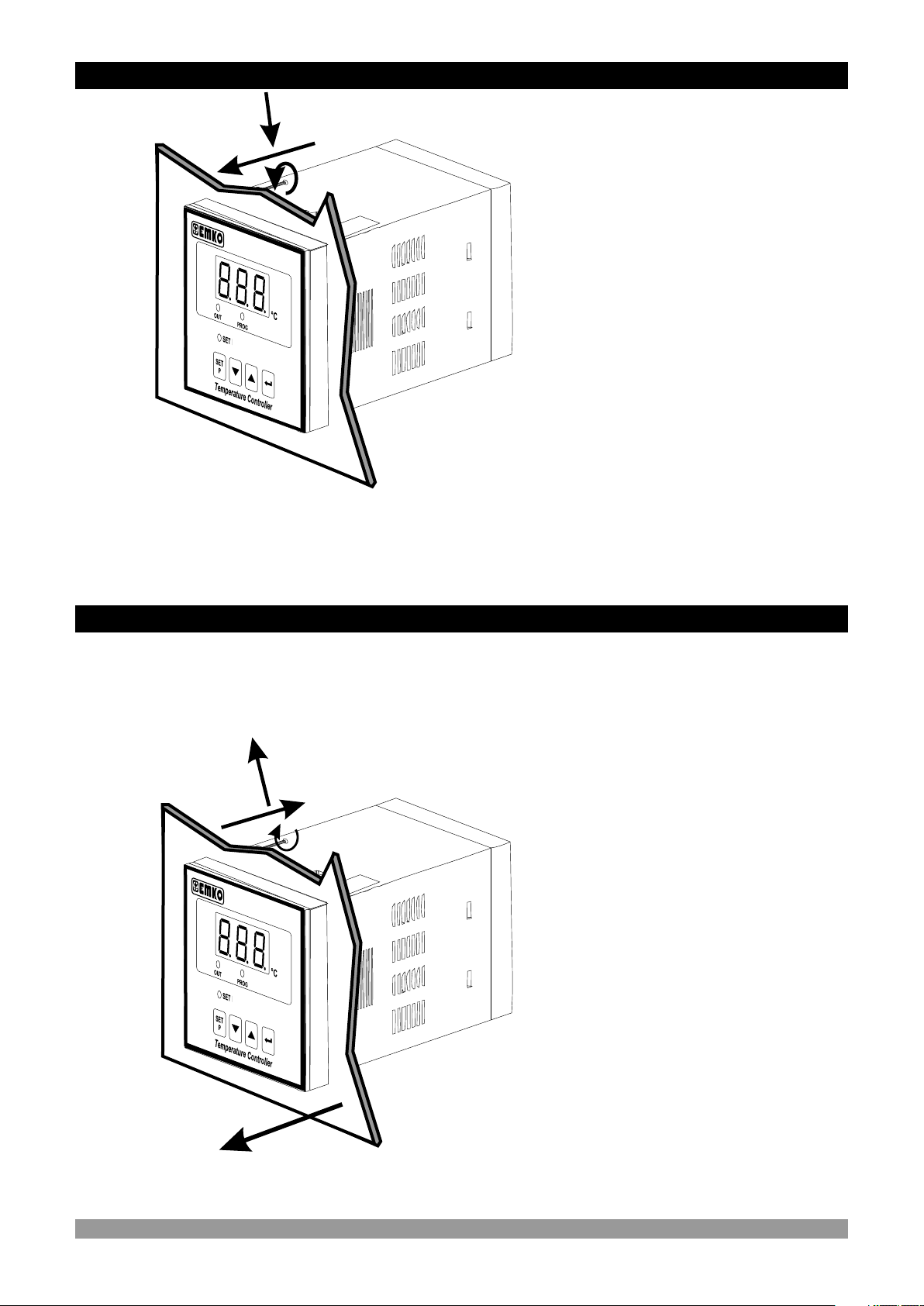

2.5 Panel Mounting

E

M

-4 0

4

1S

1

1-Before mounting the device in your

panel, make sure that the cut-out is of

the right size.

2-Check front panel gasket position

3-Insert the device through the cutout. If the mounting clamps are on the

unit, put out them before inserting the

unit to the panel.

c

3

2

During installation into a metal panel, care should be taken to avoid injury from

metal burrs which might be present. The equipment can loosen from vibration

and become dislodged if installation parts are not properly tightened. These

precautions for the safety of the person who does the panel mounting.

10

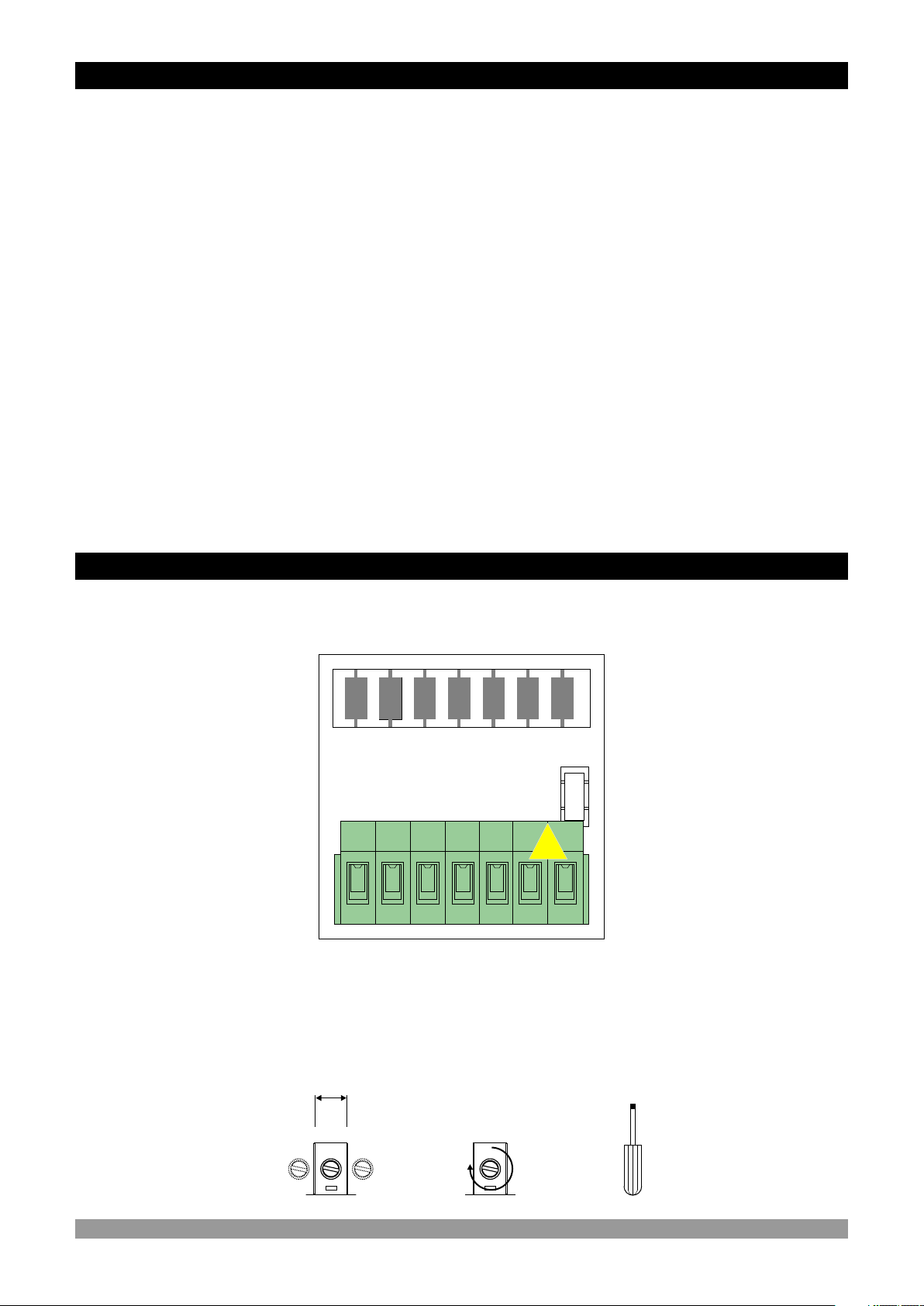

2.6 Installation Fixing Clamp

1

2

E

S -

M 441

0

Montage of the unit to a system must be done with it’s own fixing clamps. Do

not do the montage of the device with inappropriate fixing clamps. Be sure

c

2.7 Removing from the Panel

that device will not fall while doing the montage.

The unit is designed for panel

mounting.

1-Insert the unit in the panel cut-out

from the front side.

2- Insert the mounting clamps to the

holes that located top and screw up

the fixing screws until the unit

completely immobile within the panel

c

Before starting to remove the unit from panel, power off the unit and the

related system.

2

1

M 4

41ES - 0

1-Loosen the screws.

2-Pull mounting clamps from top and

bottom fixing sockets.

3-Pull the unit through the front side of

the panel

3

11

3.Electrical Wirings

You must ensure that the device is correctly configured for your application.

Incorrect configuration could result in damage to the temperature being

controlled, and/or personal injury. It is your responsibility, as the installer, to

c

c

ensure that the configuration is correct.

Device parameters has factory default values. These parameters must be set

according to the system’s needs.

Only qualified personnel and technicians should work on this equipment. This

equipment contains internal circuits with voltage dangerous to human life.

There is severe danger for human life in the case of unauthorized intervention.

Be sure to use the rated power supply voltage to protect the unit against

damage and to prevent failure.

c

Keep the power off until all of the wiring is completed so that electric shock and

trouble with the unit can be prevented.

c

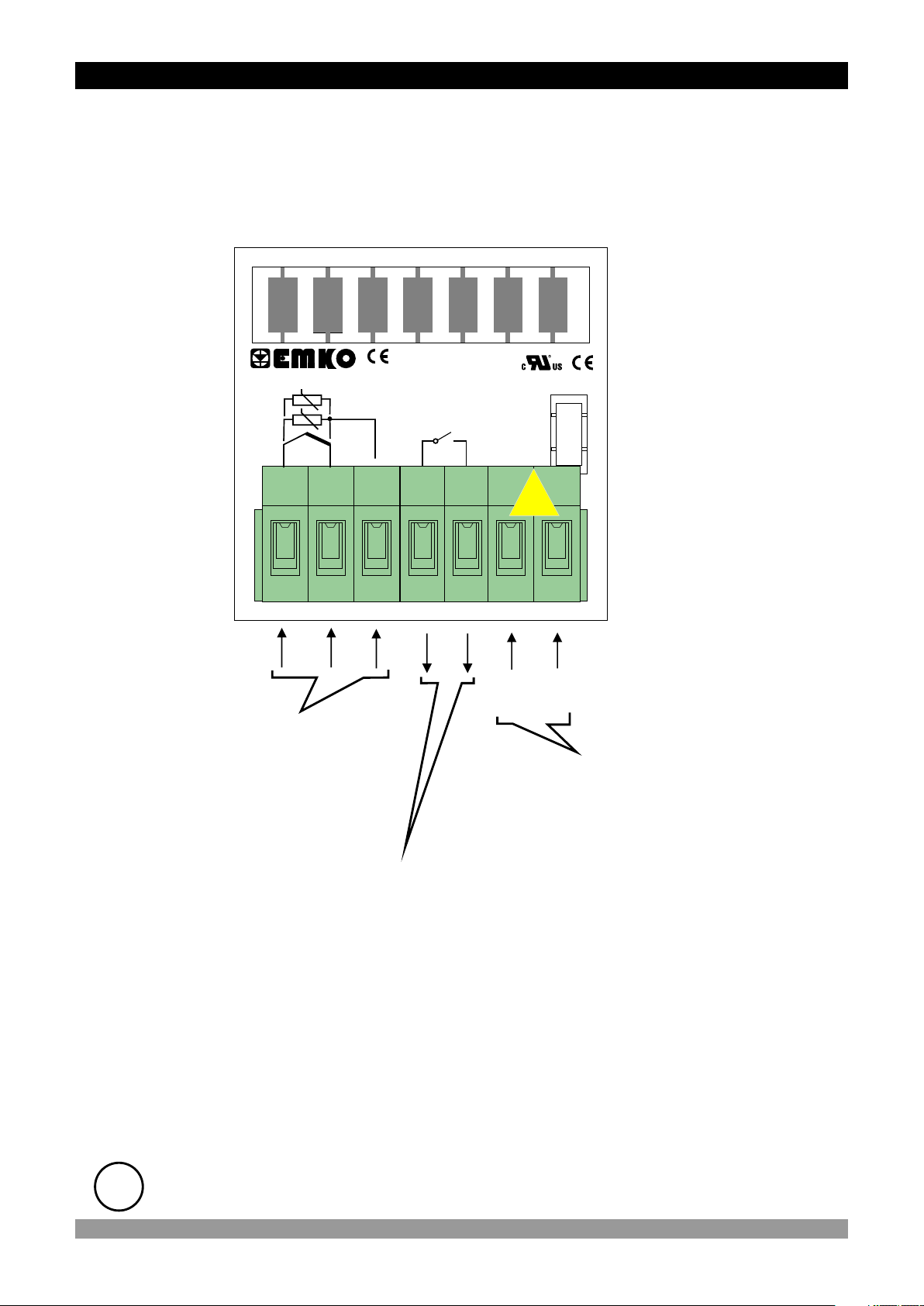

3.1 Terminal Layout and Connection Instructions

aa

Max. 2.5 mm / 0.098 inch

Wire Size:

14AWG/1 mm²

Solid /Stranded

Torque

0.5 Nm

Screw driver

0.8 x 3 mm

12

3.2 Electrical Wiring Diagram

Electrical wiring of the device must be the same as ‘Electrical Wiring Diagram’

below to prevent damage to the process being controlled and personnel

c

injury.

P/N : ESM-4410

+

TC

NTC, PTC

PT 100

ı

1 2 3 4 5 6 7

Temperature Input

(TC, PT-100, PTC or NTC)

Relay Output

Y

NOC

CAT II

c

OUTPUT

7A@250V V

aa

N

L

(+)

24 V W ( - %15, + %10 ) 50/60 Hz - 3 VA

(-)

Supply Voltage Input

230 V V (±15%) 50/60 Hz - 3 VA

115 V V (±15%) 50/60 Hz - 3 VA

24 V V (±15%) 50/60 Hz - 3 VA

(It must be determined in order)

ii

Temperature input is in CAT II class.

13

3.3 Labels for ESM-4410 Temperature Controller

Rear label appearance of the device

that have PT-100 (-19.9 C ; + 99.9 C) Scale

P/N : ESM - 4410 - 5.09.0.1/00.00/2.0.0.0

m

Pt-100

(-19.9 ; +99.9) Scale

2 31

Rear label appearance of the device

that have PTC (-19.9 ; + 99.9 ) Scale

P/N : ESM - 4410 - 5.15.0.1/00.00/2.0.0.0

m

PTC

(-19.9 ; +99.9) Scale

R W

2 31

o o

a

c

OUTPUT

7A@250VV

230 VV 15%±

50/60 Hz - 3VA

NOC

5

o o

C C

a

c

OUTPUT

7A@250VV

230 VV 15%±

50/60 Hz - 3VA

NOC

5

Y

L

64

Y

L

64

CAT II

N

7

CAT II

N

7

Rear label appearance of the device

that have PT-100 (0 C ; 400 C) Scale

P/N : ESM - 4410 - 5.03.0.1/00.00/2.0.0.0

m

Pt-100

(0 ; 400) Scale

2 31

Rear label appearance of the device

that have PTC (-50 ; 150 ) Scale

P/N : ESM - 4410 - 5.12.0.1/00.00/2.0.0.0

m

PTC

(-50 ; 150) Scale

WR

2 31

o o

a

c

OUTPUT

7A@250VV

NOC

5

o o

C C

a

c

OUTPUT

7A@250VV

NOC

5

CAT II

Y

230 VV 15%±

50/60 Hz - 3VA

L

N

7

64

CAT II

Y

230 VV 15%±

50/60 Hz - 3VA

L

N

7

64

Rear label appearance of the device

that have J Type Thermocouple

P/N : ESM - 4410 - 5.05.0.1/00.00/2.0.0.0

m

J TYPE TC

( 0 ; 800 ) Scale

o o

( 0 C ; 800 C ) Scale

a

230 VV 15%±

50/60 Hz - 3VA

NOC

5

64

Y

L

c

OUTPUT

7A@250VV

21

CAT II

N

7

Rear label appearance of the device

that have K Type Thermocouple

P/N : ESM - 4410 - 5.10.0.1/00.00/2.0.0.0

m

K TYPE TC

( 0 ; 999 ) Scale

o o

( 0 C ; 999 C ) Scale

a

230 VV 15%±

50/60 Hz - 3VA

NOC

5

64

Y

L

c

OUTPUT

7A@250VV

21

CAT II

N

7

14

3.4 Supply Voltage Input Connection of the Device

Connection of Supply Voltage Input

Y

Note-1

a

6 7

External

Fuse

(1 A T)

Power

Supply

Switch

NL

Note-2

Note-3

c

Supply Voltage

230 V V ( ± %15 ) 50/60 Hz

115 V V ( ± %15 ) 50/60 Hz

24 V V ( ± %15 ) 50/60 Hz

24 V W ( - %15, + %10 ) 50/60 Hz

Note-1 : There is an internal 33R W fusible flameproof resistor in

There is an internal 4R7 W fusible flameproof resistor in

Note-2 : “L” is (+),“N” is (-) for 24V Z Supply voltage

Note-3 : External fuse is recommended.

24VV 50/60Hz and 24VW 50/60Hz

100-240 V V 50/60Hz

c

c

c

Make sure that the power supply voltage is the same indicated on the

instrument.

Switch on the power supply only after that all the electrical connections have

been completed.

Supply voltage range must be determined in order. While installing the unit,

supply voltage range must be controlled and appropriate supply voltage must

be applied to the unit. Controlling prevents damages in unit and system and

possible accidents as a result of incorrect supply voltage.

There is no power supply switch on the device. So a power supply switch must

be added to the supply voltage input. In accordance with the safety regulations,

the power supply switch shall bring the identification of the relevant

instrument.Power supply switch shall be easily accessible by the user.

Power switch must be two poled for seperating phase and neutral. On/Off

condition of power switch is very important in electrical connection. On/Off

condition of power switch must be signed for preventing the wrong connection.

If an external fuse is used, it must be on phase connection in Vsupply input.

If an external fuse is used, it must be on (+) line connection in Zsupply input.

The instrument is protected with an internal fuse (Please refer to Note-1 for

information). In case of failure it is suggested to return the instrument to the

manufacturer for repair.

15

3.5 Temperature Input Connection

3.5.1 TC (Thermocouple) Connection

TC

1 2

3.5.2 RTD Connections

PT-100

3

Connect the wires with the polarity as shown in the figure at left.

Always use compensation wire corresponding to

the thermocouple used. If present, the shield must

ii

be connected to a proper ground.

Input resistance is greater than 10 M W.

ii

PT-100

Note 1

Note 2

1 12 23 3

3-wire PT-100 connection

(with line compensation)

(Max. Line impedance is 10 W)

Note 1 : In 3-wire system, use always cables of the same diameter (min 1mm²)

Its necessary to use cable in the same gauge and type for doing the line compensation

properly.

Note 2 : Install a jumper between terminals 2 and 3 when using a 2-wire RTD.

Note 3 : If the distance is longer than 10 meters, use 3-wire system.

Input resistance is greater than 10 M W.

ii

3.5.3 PTC and NTC Connections

PTC

RED

WHITE

2-wire PT-100 connection

(without line compensation)

NTC

1 2

ii

ii

Input resistance is greater than 10 M W.r.

While doing the PTC Probe connection, pay attention to the PTC Probe cable

colour.

1 2

16

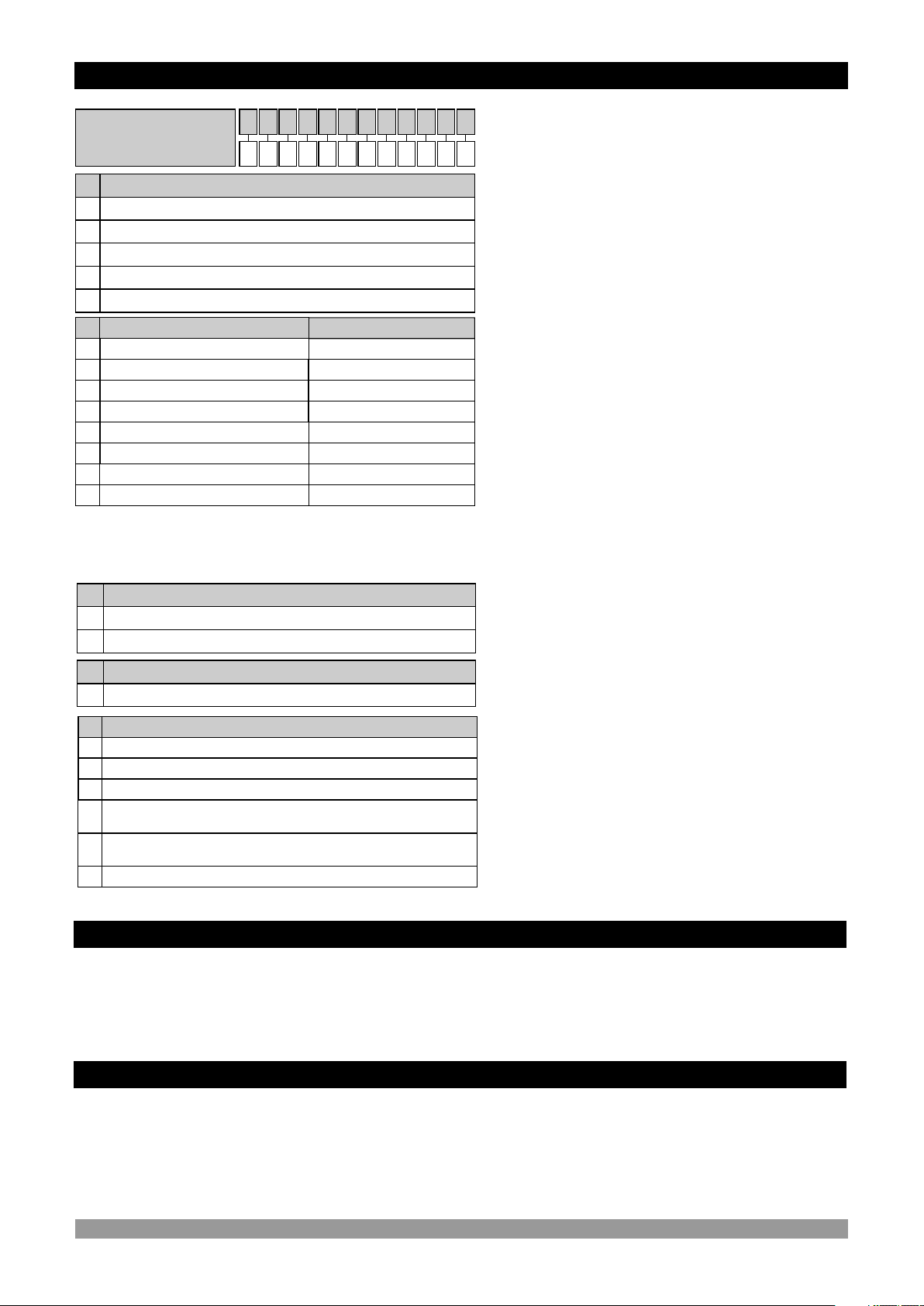

3.6 Galvanic Isolation Test Values of ESM-4410 Temperature Controller

2000V V ( For ESM-4410.5.....,ESM-4410.4..... )

500V V ( For ESM-4410.3.....,ESM-4410.2.....)

Supply Input

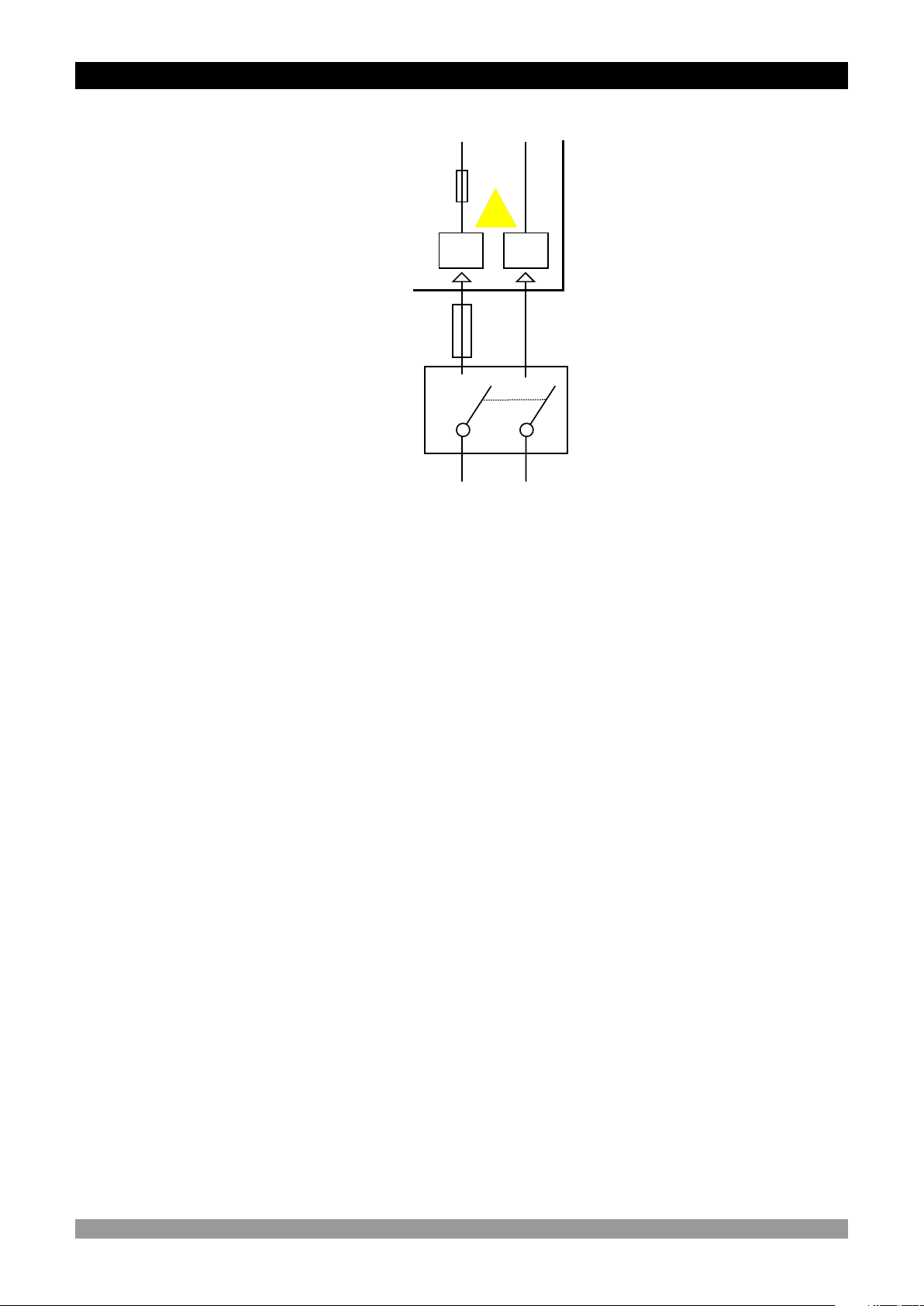

3.7 Output Connections

3.7.1 Relay Output Connection

6

7

2000V V

2000V V

Device

4

Relay Output

5

1

3

Analogue

Inputs

4

5

1

3

L N

Ground

2000V V

2

c

C

7A V T Fuse

4

Last Control Element

(Contactor)

NO

5

c

Fuse

Load

Fuses must be selected according to the application

17

3.7.2 SSR Driver Output Connection

c

Device

Last Control Element

(SSR)

L N

4

5

Max.15 V Z

Max. 23mA

Fuses must be selected according to the application.

c

Fuse

Load

18

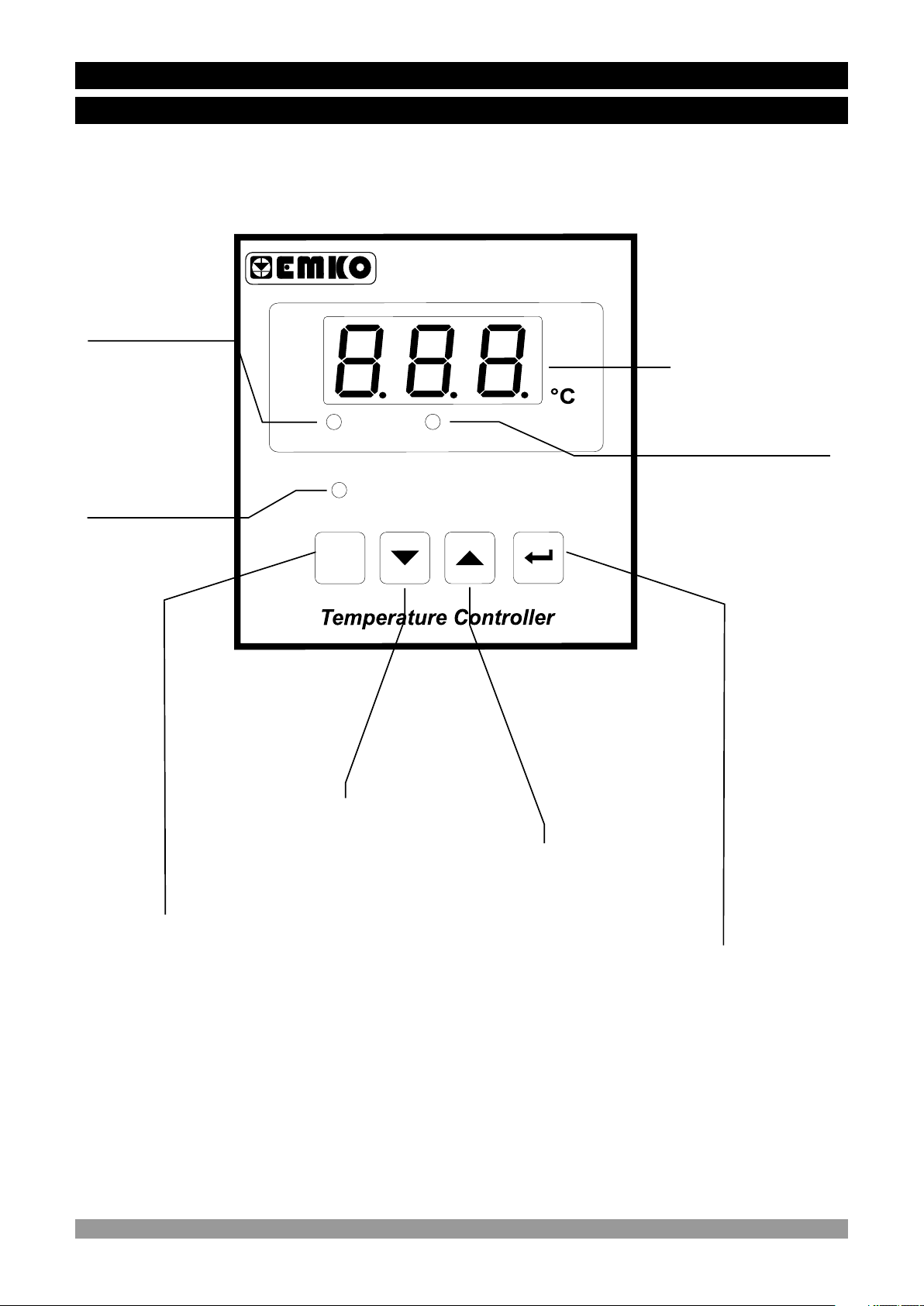

4. Front Panel Definition and Accessing to the Menus

4.1 Front Panel Definition for ESM-4410

S - 1

E

M

0

4

4

Led indication of

Output is active

Led indication of

Output Set value

OU

Displays

Temperature

Value,

Temperature Set

Value

and Parameters

T

TS

E

TS

E

P

OG

R

P

Led indication of

Programming Mode

is active

Note-1

It is used to decrease the

value

It is used to increase the

value and access to the

parameter in programming

It is used to change the Set

value, enter to and exit from

the programming mode

Note-1: In Set value or programming mode while changing the parameter, if increment or

decrement button is pressed for 5 seconds continuously, increment and decrement number

become 10, if increment or decrement button is pressed for 10 seconds continuously, increment

and decrement number become 100.

Note-1

mode

It is used to change the Set

value and confirm the

parameter in programming

mode

19

4.2 Observation of ESM-4410 Temperature Controller Software Revision

When the power is applied to the device, software revision number is momentarily shown on the

display.

0

1

4

-4

M

ES

“ r”Þ Revision

T

U

O

PR

G

O

Software

T

E

S

Revision

number

ET

S

P

1

4

4 0

-

SM

E

T

U

O

T

E

S

G

O

R

P

c

ET

S

P

Main operation screen is

shown

If there is an unexpected situation while opening the device, power off the

device and inform a qualified personnel.

20

4.3 Changing and Saving Set Value

Main Operation Screen

SET Value Screen

OUT

SET

OUT

SET

When SET button is

pressed, SET led lights on

and SET value is observed

on display.

PROG

SET

PROG

SET

SET value can be

changed with increment

and decrement buttons.

SET Value Screen

Press SET button again to

exit without saving SET

value.

Main Operation Screen

OUT

SET

OUT

SET

PROG

SET

Press Enter button for

saving SET value.

For both conditions, SET

led lights off and it turns to

main operation screen.

PROG

SET

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns back to main operation screen automatically.

21

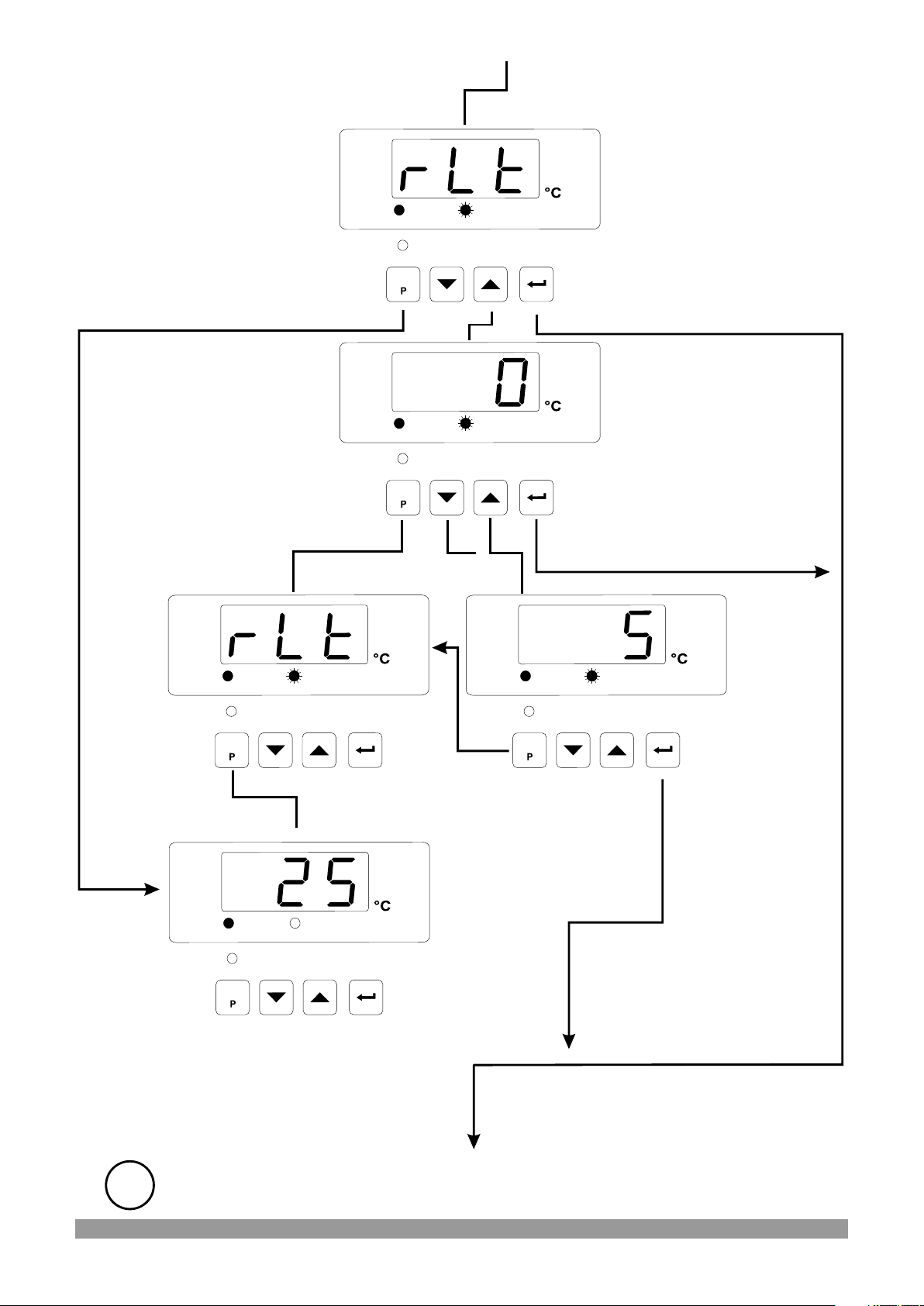

4.4 Entering to Programming Mode, Changing and Saving Parameters

Main Operation Screen

When SET button is pressed

for 10 seconds, “PROG” led

starts to blink. If programming

mode entering password is

different from 0, programming

mode entering screen

will be observed

Programming Mode

Entering Screen

In programming mode

entering screen, press SET

button to exit from

programming mode and turn

to the main operation screen.

Password Entering Screen

In password entering screen,

press SET button to return

the programming mode

entering screen

Programming Mode

Entering Screen

OUT

SET

OUT

SET

OUT

SET

SET

SET

SET

PROG

PROG

PROG

Note: If programming mode

accessing password is 0,

hysteresis screen

is observed instead of

programming screen

accessing password

Press increment button for

accessing to the password

entering screen

Parameters can be

observed by pressing Enter

button, but parameters can

not be changed.

Enter programming mode

accessing password with

increment and decrement

buttons

Parameters can be

observed by pressing Enter

button, but parameters can

not be changed.

Press SET

button to exit

programming

mode.

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns to main operation screen automatically.

OUT

SET

OUT

SET

PROG

SET

PROG

SET

Main Operation Screen

OUT

SET

PROG

SET

In password entering

screen, press SET

button to return the

programming mode

entering screen

Password

Entering

Screen

Press Enter

button for

accessing to the

parameters

22

Programming Screen

In programming screen,

Press SET button to exit from

programming mode and turn

to the main operation screen.

In programming screen,

Press SET button to exit from

programming mode and turn

to the main operation screen.

Programming Screen

OUT

SET

OUT

SET

SET

SET

PROG

PROG

Hysteresis

Parameter

Parameter value can

be observed by

pressing increment

button.

If Enter button is

pressed next

parameter is shown.

Hysteresis Value

If Enter button is

pressed next

parameter is shown.

Parameter can be

changed with increment

and decrement buttons.

Press SET

button to exit

from

programming

mode.

OUT

SET

OUT

SET

PROG

SET

PROG

SET

Main Operation Screen

OUT

SET

PROG

SET

Press SET button

to turn to the

programming

screen without

saving the

parameter.

Hysteresis

Value

Press Enter

button for saving

parameter

value.

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns to main operation screen automatically.

23

Programming Screen

In programming screen,

Press SET button to exit from

programming mode and turn

to the main operation screen.

In programming screen,

Press SET button to exit from

programming mode and turn

to the main operation screen.

Programming Screen

OUT

SET

OUT

SET

SET

SET

PROG

PROG

Operation Type

Selection for Output

Parameter value can

be observed by

pressing increment

button.

If Enter button is

pressed next

parameter is shown.

Value of Operation

Type Selection for

Output

Heating is selected

If Enter button is

pressed next

parameter is shown.

Parameter can be

changed with increment

and decrement buttons.

Press SET

button to exit

from

programming

mode.

OUT

SET

OUT

SET

PROG

SET

PROG

SET

Main Operation Screen

OUT

SET

PROG

SET

Press SET button

to turn to the

programming

screen without

saving the

parameter.

Value of

Operation

Type

Selection

for Output

It is changed as

cooling

Press Enter

button for saving

parameter

value.

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns to main operation screen automatically.

24

Programming Screen

In programming screen,

Press SET button to exit from

programming mode and turn

to the main operation screen.

Press SET button to turn

to the programming

screen without saving

the parameter.

Programming Screen

OUT

SET

OUT

SET

SET

SET

PROG

PROG

Process Offset

Parameter

Parameter value can be

observed by pressing

increment button.

If Enter button is

pressed, next

parameter is shown.

Process Offset Value

If Enter button is

pressed, next parameter

is shown.

Parameter can be

changed with increment

and decrement buttons.

Press SET

button to exit

from

programming

mode.

OUT

SET

OUT

SET

PROG

SET

PROG

SET

Main Operation Screen

OUT

SET

PROG

SET

Press SET button

to turn to the

programming

screen without

saving the

parameter.

Process

Offset

Value

Press Enter

button for saving

parameter

value.

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns to main operation screen automatically.

25

Programming Screen

In programming screen,

Press SET button to exit from

programming mode and turn

to the main operation screen.

Press SET button to

turn to the

programming screen

without saving the

parameter.

Programming Screen

OUT

SET

OUT

SET

SET

SET

PROG

PROG

Minimum Pulling Time

for Output Parameter

Parameter value can be

observed by pressing

increment button.

If Enter button is

pressed, next

parameter is shown.

Value of Minimum

Pulling Time for Output

If Enter button is

pressed, next parameter

is shown.

Parameter can be

changed with increment

and decrement buttons.

Press SET

button to exit

from

programming

mode.

OUT

SET

OUT

SET

PROG

SET

PROG

SET

Main Operation Screen

OUT

SET

PROG

SET

Press SET button

to turn to the

programming

screen without

saving the

parameter.

Value of

Minimum

Pulling

Time for

Output

Press Enter

button for saving

parameter

value.

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns to main operation screen automatically.

26

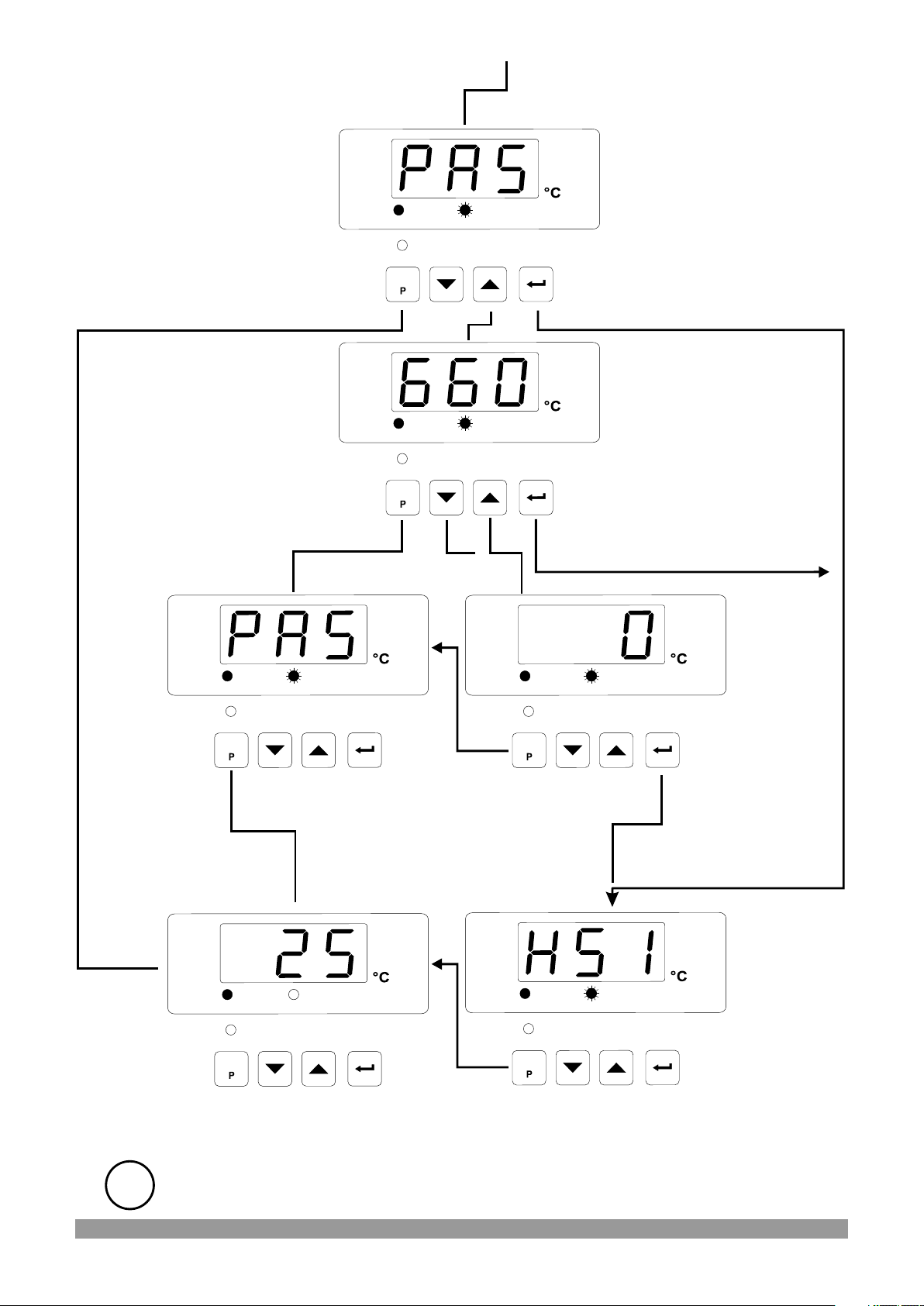

Programming Screen

In programming screen,

Press SET button to exit from

programming mode and turn

to the main operation screen.

OUT

SET

SET

PROG

Programming Mode

Accessing Password

Parameter value can be

observed by pressing

increment button.

If Enter button is

pressed, next

parameter is shown.

Programming Mode

Accessing Password

Value

Press SET button to

turn to the

programming screen

without saving the

parameter.

Programming Screen

OUT

SET

SET

Press SET

button to exit

from

programming

mode.

PROG

OUT

SET

SET

PROG

OUT

SET

PROG

SET

Press SET button to turn to

the programming screen

without saving the

parameter.

Programming Screen

If Enter button is

pressed, next parameter

is shown.

Parameter can be

changed with increment

and decrement buttons.

Programming

Mode

Accessing

Password

Value

Press Enter

button for

saving

parameter

value.

Hysteresis

Parameter

It turns to

beginning of

OUT

SET

PROG

SET

Main Operation Screen

OUT

SET

Press SET button to

exit from programming

section

SET

PROG

the

programming

mode

Continue to press SET2/Enter

button for accessing to the

parameters.

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns to main operation screen automatically.

27

5. Parameters

Parameters are divided into two groups as SET and PROGRAM parameters.

5.1 Set Parameter

SET value for Output. Control of output relay is done according to this value.

SET1

5.2 Program Parameters

This value can be adjusted according to input type, minimum and maximum

of scale.

Hysteresis Parameter for Output ( Default = 3 )

1 to 100 °C for TC Type Devices,

1 to 100 °C for PT-100 (0°C , 400°C),

0.1 to 10.0 °C for PT-100 (-19.9°C, 99.9°C),

1 to 100 °C for PTC (-50°C, 150°C),

0.1 to 10.0 °C for PTC (-19.9°C, 99.9°C) and NTC (-19.9°C, 99.9°C)

1 to 20 °C for NTC (-50°C, 100°C)

Operation Type Selection parameter for output

Operation type of output relay can be adjusted as

“HEATING”. Normally energised.

Operation type of output relay can be adjusted

“COOLING”. Normally de-energised.

Process Offset Parameter (Default = 0).

This parameter is offset for the process value. This defined value is added to

the process value.

-10 to 10 °C for TC Type Devices,

-10 to 10 °C for PT-100 (0°C , 400°C),

-10.0 to 10.0 °C for PT-100 (-19.9°C, 99.9°C),

-10 to 10 °C for PTC (-50°C, 150°C),

-10.0 to 10.0 °C for PTC (-19.9°C, 99.9°C) and NTC (-19.9°C, 99.9°C)

-10 to 10 °C for NTC (-50°C, 100°C)

Minimum Pulling Time Parameter for Output (Minimum Off Time)

(Default = 0)

When Output is inactive this time must be expired for Output to become active

again. It can be adjusted from 0 to 100 seconds

Programming Mode Accessing Password ( Default =0 )

It is used for accessing to the programming mode. It can be adjusted from 0 to

999. If it is selected 0, password is not entered for accessing to the

parameters.

If no operation is done in programming or Set value mode for 20 seconds, device

i

turns to main operation screen automatically.

28

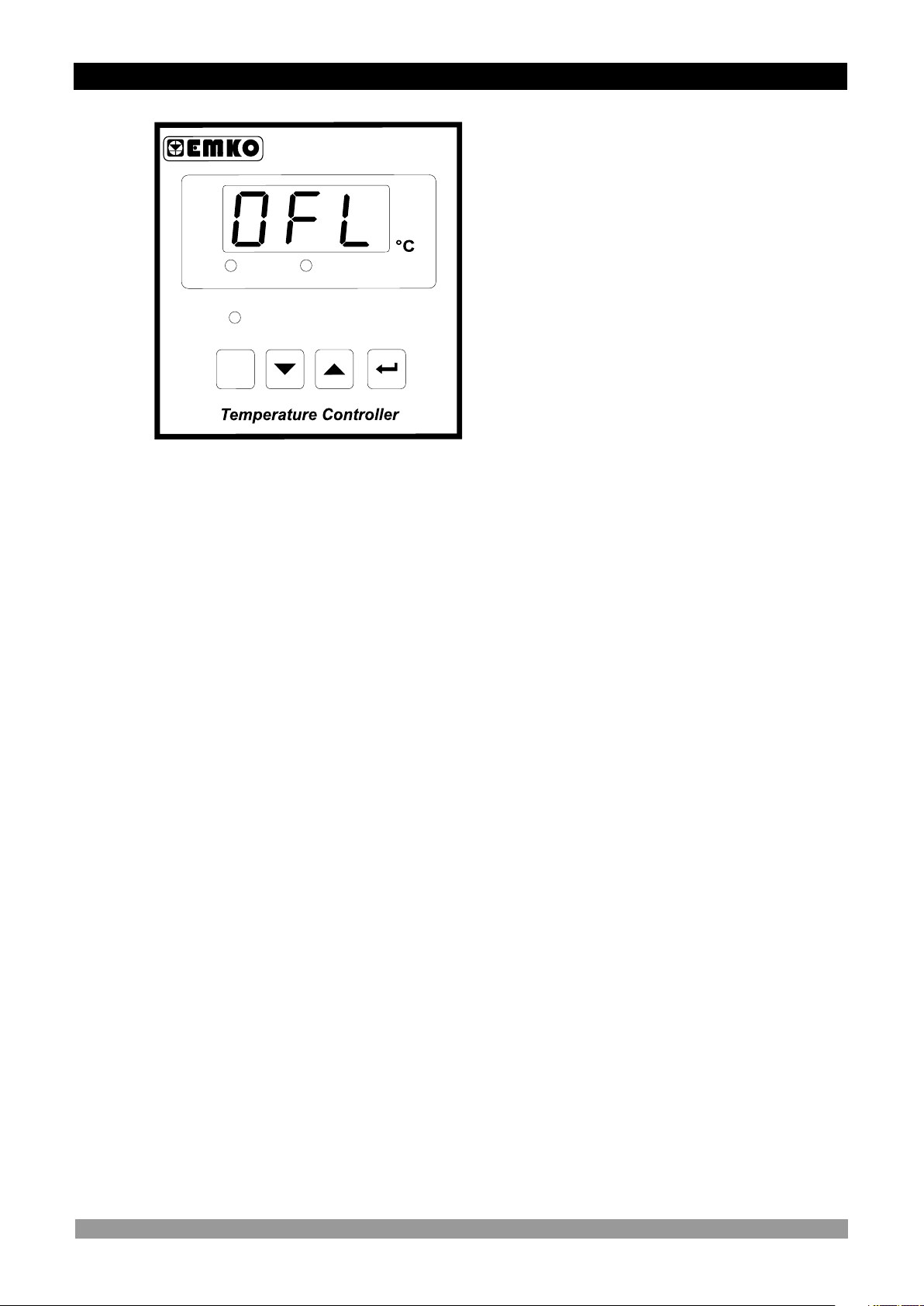

6. Failure Message in ESM-4410 Temperature Controllers

0

1

44

-

M

S

E

Sensor failure in analogue inputs. It means

sensor connection is wrong or there is no

sensor.

T

U

O

T

E

S

T

E

S

P

G

O

R

P

29

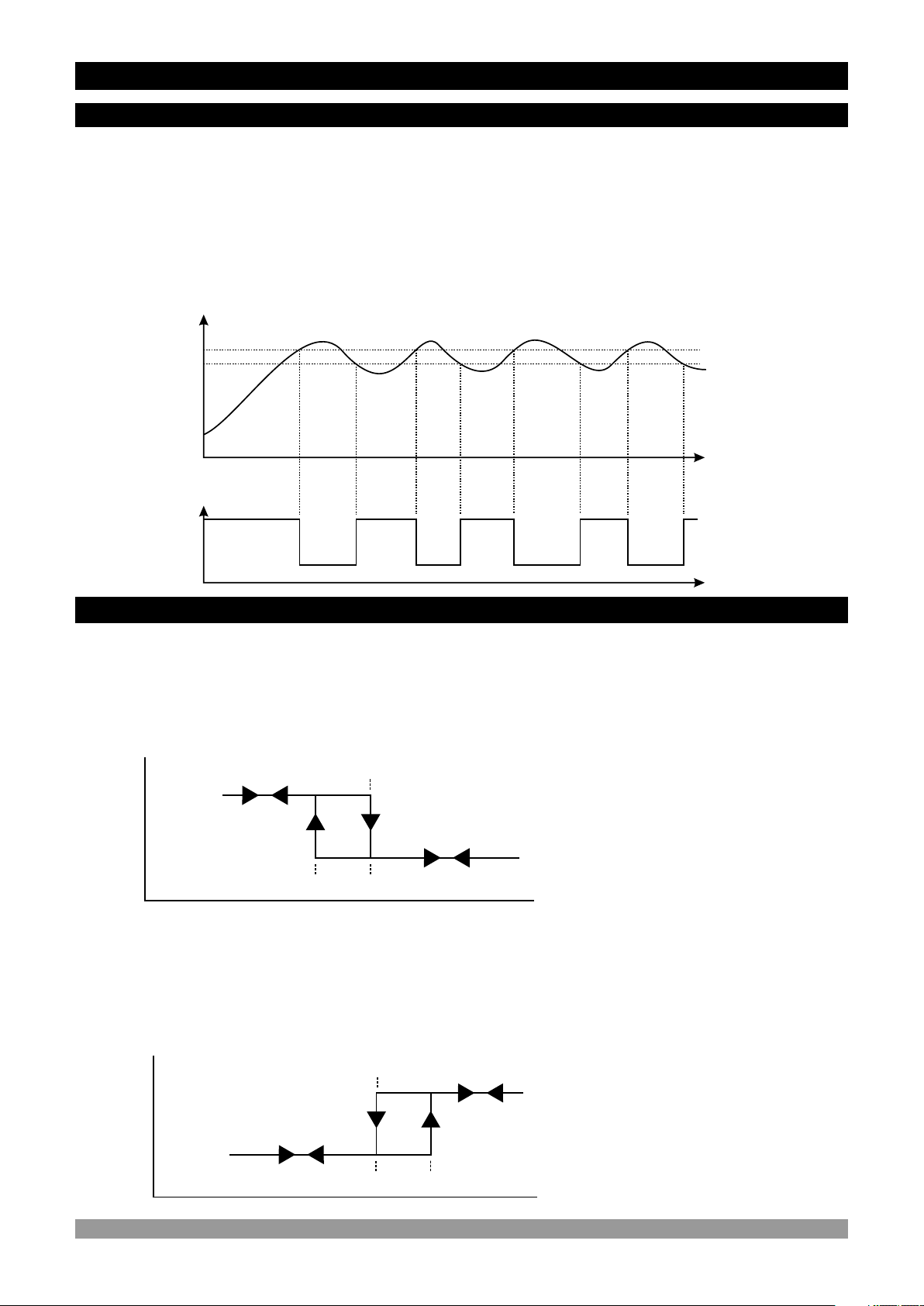

7. Control Algorithm

7.1 ON/OFF Control

In ON/OFF control algorithm, temperature value is tried to keep equal to set value by

opening or closing the last control element. ON/OFF controlled system, temperature value

oscillates continuously. Temperature value’s oscillation period or amplitude around set value

changes according to controlled system. For reducing oscillation period of temperature value,

a threshold zone is formed below or around set value and this zone is named hysteresis. Action

of control output is described with figures below.

Temperature

Temperature

Set Value

Hysteresis

Time

Temperature

Control Output

ON

OFF

Time

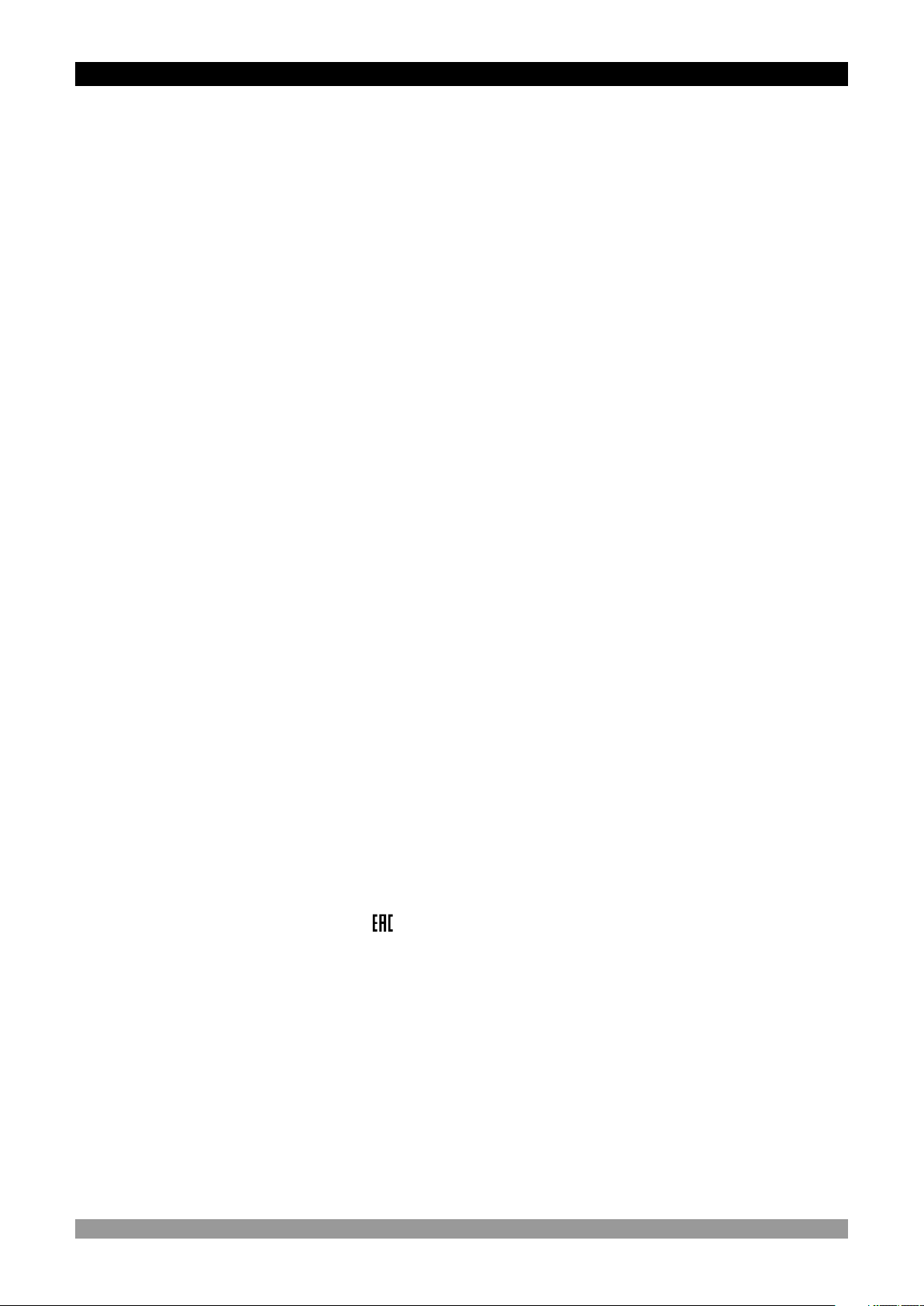

7.1.1 ON/OFF Control in ESM-XX10 Temperature Controller

ON/OFF control algorithm in temperature control output which has heating function

Temperature

Control

Output

Temperature

Set

ON

OFF

HYS

Temperature

ON/OFF control algorithm in temperature control output which has cooling function

Temperature

Control

Output

Temperature

Set

ON

OFF

HYS

Temperature

30

8. Specifications

Device Type : Temperature Controller

Housing&Mounting : 48 mm x 48 mm x 95 mm 1/16 DIN 43700 plastic housing

for panel mounting. Panel cut-out is 46 x 46 mm

Type-1 Enclosure Mounting

Protection Class : NEMA 4X (IP65 at front, IP20 at rear)

Weight : Approximately 0.16 Kg.

Environmental Ratings : Standard, indoor at an altitude of less then 2000 meters

with non-condensing humidity

Storage/Operating Temperature : -40 C to +85 C / 0 C to +50 C

o o o o

Storage/Operating Humidity : 90 % max. (Non-condensing)

Installation : Fixed installation

Over Voltage Category : II

Pollution Degree : II, office or workplace, none conductive pollution

Operating Conditions : Continuous

Supply Voltage and Power : 230 V V (±15%) 50/60 Hz. 3 VA

115 V V (±15%) 50/60 Hz. 3 VA

24 V V (±15%) 50/60 Hz. 3 VA

24 V (-%15, +%10) 50/60 Hz. 3 VA

W

Temperature Inputs : NTC, PTC, TC, RTD

NTC Input Types : N

TC (10 kW @.25 °C )

PTC Input Type : PTC (1000 W @.25 °C )

Thermocouple Input Types : J,

Thermoresistance Input Type :

K (IEC584.1)(ITS90)

PT 100 (IEC751(ITS90)

Accuracy : ± 1% of FS for Thermocouple, Thermoresistance

Cold Junction Compensation : Automatically ± 0.1°C/1°C

Line Compensation : Maximum 10 W

Sensor Break Protection : Upscale

Sampling Cycle : 3 samples per second

Control Forms : ON / OFF

Relay Outputs : 7 A@250 V V at resistive load

(Electrical Life : 100.000 Operation (Full Load))

Opsiyonel SSR Driver : Maximum 23 mA, Maximum 15 V Z

Output

Display : 10 mm Red 3 digits LED display

Led Indicators : SET (Green), OUT (Red), PROG (Red) 3 mm

Approvals : UL Recognized Component (File No : E 254103),

,

CECE

31

9. Other Informations

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and Maintenance Service Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Your Technology Partner

Thank you very much for your preference to use Emko Elektronik

Products.

www.emkoelektronik.com.tr

32

Loading...

Loading...