ESM- 77 x 35 DIN Size3711HN

Digital , ON / OFF Temperature

Controller

- 4 Digits Display

- NTC Input or

PTC Input or

J Type thermocouple Input or,

K Type thermocouple Input or,

2-Wire PT-100 Input or,

2-Wire PT-1000 Input

- Adjustable temperature offset

ON/OFF temperature control

-

- Adjustable temperature offset

- Set value low limit and set value high limit boundaries

- Relay or SSR driver output

- Digital Input (Cooking Time Start/Stop Input)

- Adjustable cooking time from front panel

- Temperature control according to the cooking time (Timer)

- User can select to start cooking time (Timer) when temperature

reaches to the set value

- Temperature control with manual heating function

- Alarm parameters

- Adjustable internal buzzer according to cooking time, sensor

ESM-3711HN 77x35 DIN Size Heating Controller

defect and Alarm status.

- Button protection

- Password protection for programming section

- Installing parameters using Prokey

- Remote access, data collecting and controlling with Modbus RTU

- Having CE mark according to European Norms

(Must be determined in order.)

Instruction Manual. ENG ESM-3711HN 01 V00 11/14

ENGLISH

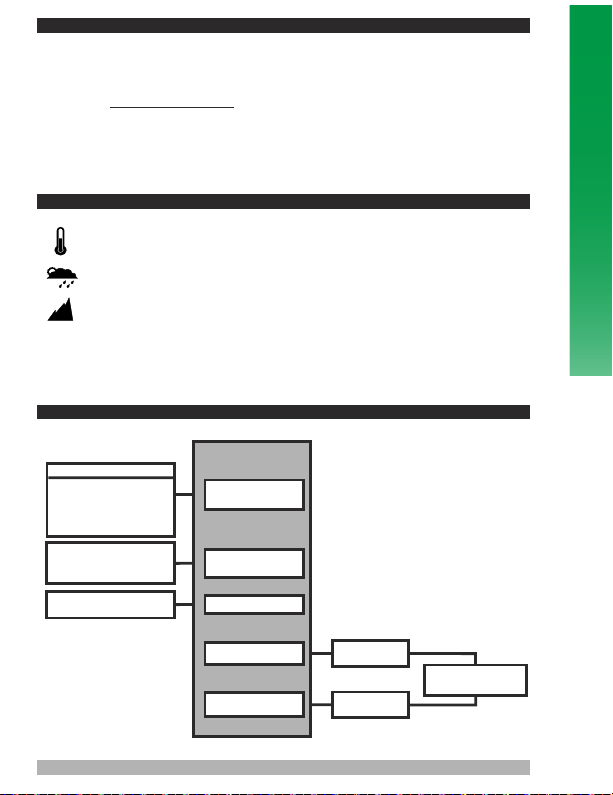

1.Preface

ESM-3711HN series heating controllers are designed for measuring and controlling

temperature. They can be used in many applications with their easy use, On/ Off control form

and cookingtime properties.Some applicationfields whichthey areused arebelow:

Application Fields Applications

Glass Heating

Food Baking Ovens

Plastic Incubators

Petro-Chemistry Storages

Textile, Automative Air Conditioning

Machine Production Industries Etc... Etc...

1.1 Environmental Ratings

Operating Temperature :

Max. Operating Humidity :

Altitude :

Forbidden Conditions:

Corrosive atmosphere

c

Explosive atmosphere

Home applications(The unitis onlyfor industrialapplications)

1.2 General Specifications

Standard

230V ( %15) 50/60HzV ±

Optional Supply Voltage

±

115 V ( %15) 50/60Hz,

V

±

24 V ( %15) 50/60Hz,

V

±

24 V ( %15) 50/60Hz,

W

10

- 30 V Z

NTC, PTC,

J or K Type TC

2-Wire PT-100

PT-10002-Wire

Cooking Time (Timer)

Start /Stop Input

0 to 50 °C

90% Rh (non-condensing)

Up to 2000 m.

ESM-3711HN

Power Supply

Input

Temperature Sensor

Input

Digital Input

Standard

Output-1

(Relay Output)

Optional

Output-1

(SSR Drive Output)

Control Output

Alarm Output

Control Output

Alarm Output

Heating Function

ON/OFF Operation

ENGLISH

2

1.3 Installation

A visual inspection of this product for possible damage occurred during shipment is

recommended before installation. It is your responsibility to ensure that qualified mechanical

and electricaltechnicians installthis product.

If there is danger of serious accident resulting from a failure or defect in this unit, power off the

system and separatethe electricalconnection ofthe devicefrom thesystem.

The unitis normally supplied withouta power supplyswitch or a fuse.Use powerswitch and fuse

as required.

Be sureto usethe rated power supply voltage to protect the unitagainst damage and to prevent

failure.

Keep the power off until all of the wiring iscompleted so that electric shock and troublewith the

unit canbe prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may results in

malfunction, electricshock orfire.

Do notuse theunit in combustibleor explosive gaseousatmospheres.

During putting equipment in hole on the metal panel while mechanical installation some metal

burrs cancause injuryon hands,you mustbe careful.

Montage ofthe producton a systemmust bedone withit’s fixingclamps. Do notdo themontage

of the device with inappropriate fixing clamp. Be sure that device will not fall while doing the

montage.

It is your responsibility if this equipment is used in a manner not specified in this instruction

manual.

1.4 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts

from thedelivery date. Thiswarranty is inforce if dutyand responsibilities whichare determined

in warrantydocument andinstruction manualperforms bythe customercompletely.

1.5 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the

device beforeaccessing internalparts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in

ethyl alcoholor waterto cleanthe externalplastic case.

1.6 Manufacturer Company

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and maintenance service information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA /TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

ENGLISH

3

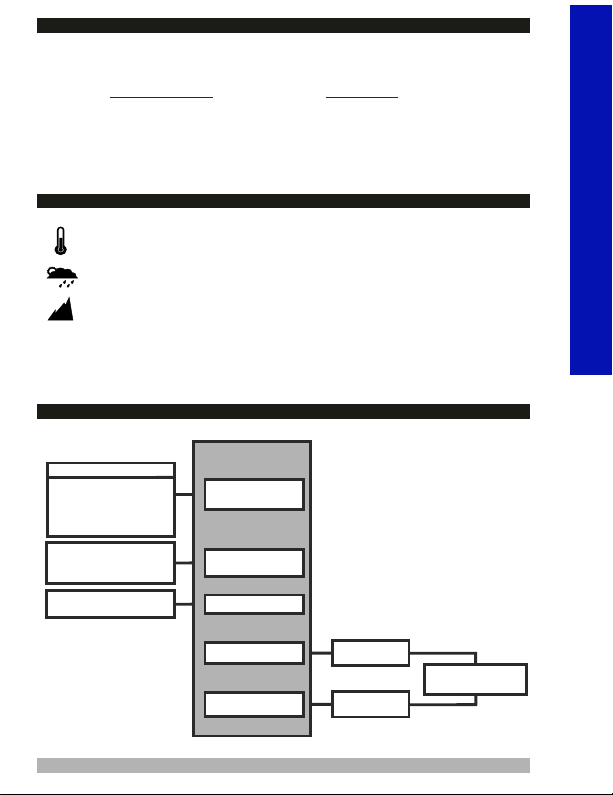

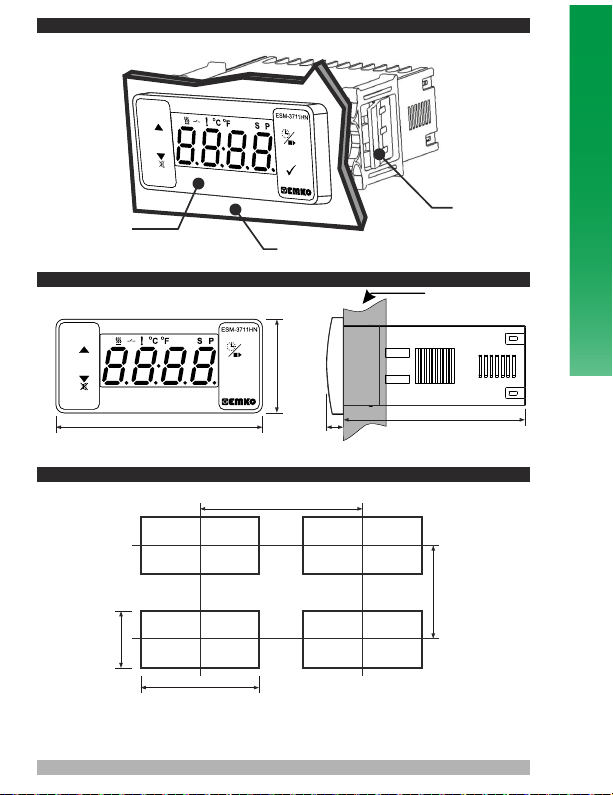

2. General Description

Front Panel

IP65 protection

Panel Surface

(maximum thickness 15 mm / 0.59 inch)

Mounting Clamp

2.1 Front View and Dimensions of ESM-3711HN Temperature Controller

Maximum 15 mm / 0.59 inch

ü

34,5 mm / 1.36 inch

76 mm / 3 inch

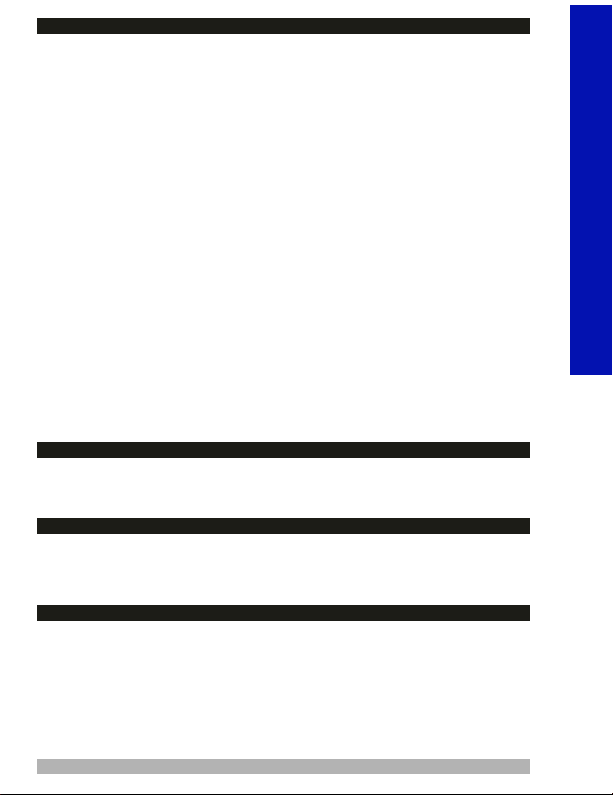

2.2 Panel Cut-Out

29 mm / 1.14 inch

6 mm / 0.24 inch

110 mm / 4.33 inch (min)

71 mm / 2.79 inch

65 mm / 2.56 inch

50 mm / 1.97 inch (min)

ENGLISH

4

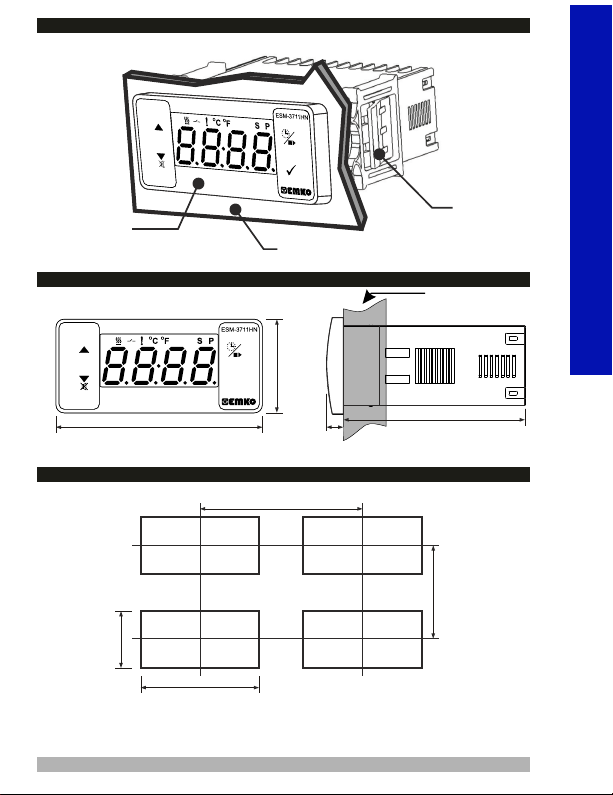

2.3 Panel Mounting

1

3

2

1-Before mounting the device in your panel,

make surethat thecut-out is ofthe rightsize.

2-Insert the device through the cut-out. If the

mounting clamps are on the unit, put out them

before insertingthe unitto the panel.

3- Insert the mounting clamps to the fixing sockets

that located left and rightsides of device and make

the unitcompletely immobilewithin the panel

2.4 Removing from the Panel

3

1-Pull mounting clamps from left and right fixing

sockets.

1

2-Pull theunit throughthe front sideof thepanel

Before starting to remove the unit from

2

panel, power off the unit and the related

system.

c

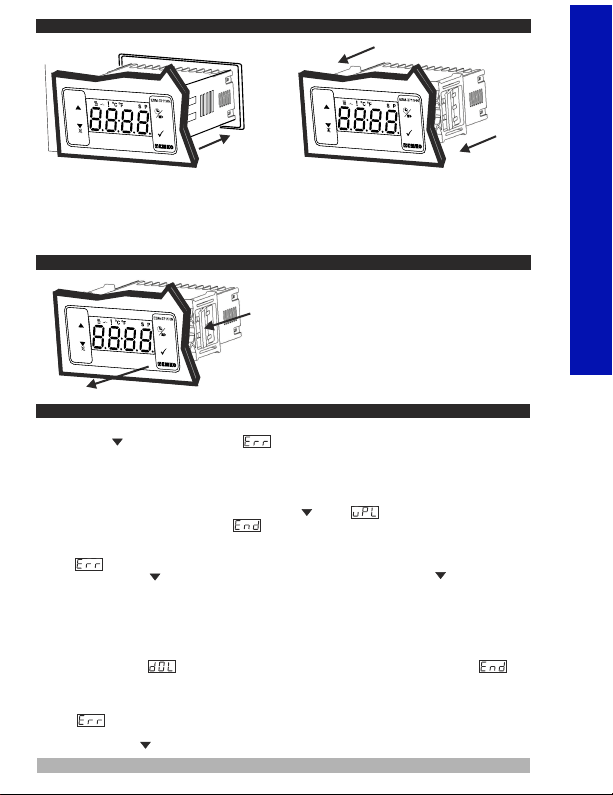

3. Using Prokey

TO USE PROKEY, VALUE OF THE PrC PARAMETER MUST BE ‘0’.

IF PrC=1 AND BUTTON IS PRESSED MESSAGE WILL BE SHOWN. 10s. LATER

DEVICE TURNS BACK TO THE MAIN OPERATION SCREEN OR YOU CAN PRESS SET

BUTTON TO TURN BACK TO MAIN OPERATION SCREEN.

DOWNLOADING FROM DEVICE TO PROKEY

1.The device is programmed by using the parameters.

2.Energize the device then put in PROKEY and press button. Message is shown on the

display. When the loading has finished, message is shown.

3.Press any button to turn back to main operation screen.

4.Remove the PROKEY.

NOTE: message is shown when an error occurs while programming. If you want to reload, put

in PROKEY and press button. If you want to quit, remove PROKEY and press button. The

device will turn back to main operation screen.

DOWNLOADING FROM PROKEY TO DEVICE

1.Switch off the device.

2.Put in PROKEY then energize the device.

3.When the device is energized, the parameter values in PROKEY, start downloading to the device

automatically. At first, message is shown on the display, when loading has finished,

message is shown.

4.After 10 seconds device starts to operate with new parameter values.

5.Remove the PROKEY.

NOTE: message is shown when an error occurs while programming. If you want to reload,

switch off the device and put in PROKEY then energize the device. If you want to quit remove

PROKEY and press button. The device will turn back to main operation screen.

ENGLISH

5

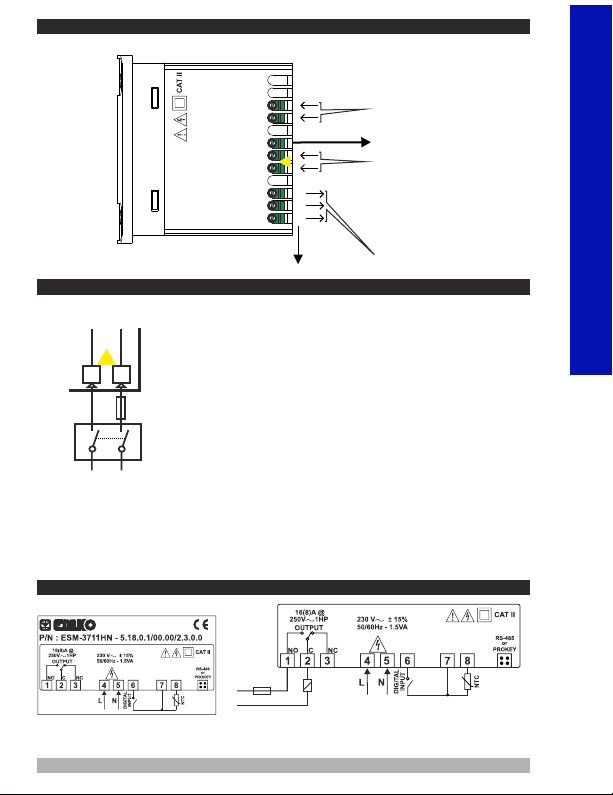

4. Electrical Wiring Diagram

8

7

6

5

N

a

4

L

3

2

(-)

1

P/N : ESM-3711HN

4.1 Supply Voltage Input Connection of the Device

Power Supply Connection

L

N

a

(+)(-)

4

5

EXTERNAL

FUSE

(1A T)

Note-1

Supply

Switch

c

Supply Voltage

±

V

230V ( %15) 50/60Hz ,

±

V

115V ( %15) 50/60Hz,

±

V

24V ( %15) 50/60Hz ,

±

W

24V ( %15) 50/60Hz ,

10..30 V - 1.5W

Z

Must be determined in order.

Note-1 : Externalfuse isrecommended.

Make sure that the power supply voltage is the same

indicated onthe instrument.

c

Switch on the power supply only after that all the electrical

connections havebeen completed.

Supply voltage range must be determined in order. While

installing the unit,supply voltage rangemust be controlled

and appropriatesupply voltagemust be appliedto theunit.

There is no power supply switch on the device. So a power

supply switchmust beadded to thesupply voltageinput.

c

Power switch must be two poled for seperating phase and

neutral, On/Off condition of power supply switch is very

important inelectrical connection.

External fuse that on power supply inputs must be on

phase connection.

External fusethat on power supplyinputs must beon (+)

connection.

(+)

For SSR Output

4.2 Device Label and Connection Diagram

230VV CONNECTION DIAGRAM

Temperature Sensor Input

TC,NTC,PTC,PT-100

or PT-1000

Cooking Time(Timer)

Start/Stop Input

Supply Voltage Input

230V ( %15) 50/60Hz

V

115V ( %15) 50/60Hz

V

24V ( %15) 50/60Hz

V

24V ( %15) 50/60Hz

W

10...30 V

Must bedetermined inorder.

Relay or SSR Output

V

Z

±

±

±

±

Z

ENGLISH

16A FUSE

L

N

LOAD

6

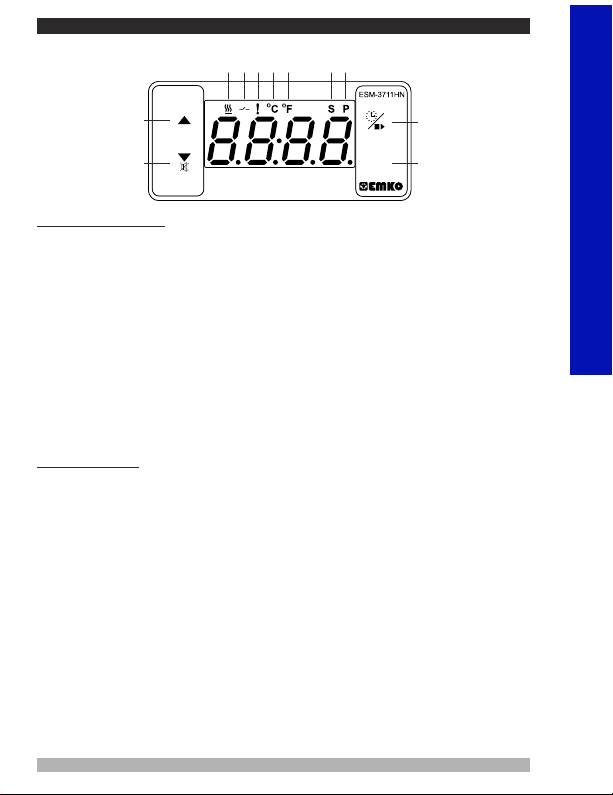

5.Front Panel Definition and Accessing to the Menus

5

6

7

9

10

8

11

1

2

BUTTON DEFINITIONS

1. IncrementButton :

** Itis usedto increase thevalue in the Setscreen and Programming mode.

2. Decrement,Silencing Buzzerand Downloading toProkey Button:

** Itis usedto decrease thevalue in the Setscreen and Programming mode.

** Itis usedto silence thebuzzer.

** IfPrc =0, it isused to download fromdevice to prokey.

3. SetButton :

** In themain operation screen; if this button pressed, set value willbe displayed. Value can be

changed using increment and decrement buttons. When Enter button pressed, value is saved

and returnsback tomain operatingscreen.

** To access the programming screen; in the main operation screen, press this button for 5

seconds.

** Itis usedto saving valuein the Set screenand programming screen.

4. Cooking Button :

** Inthe mainoperation screen;if thisbutton pressed, cookingtime value willbe displayed.

**In themain operationscreen; ifthis buttonpressed for3 seconds,cooking timestarts.

LED DEFINITIONS

5. CookingTime led:

** This ledindicates that cooking timeis active.

** Blinks(5 Hz)while enteringCooking time value.

6. Outputled :

** This led indicates that heating control is selected and process output relay is active.

7.Alarm led :

** Itis activewhen low alarmand high alarm statuses.

8.Celcius led:

** Indicatesthat deviceis in C mode.

9.Fahrenheit led:

** Indicatesthat deviceis in F mode.

10.Set led:

** Indicatesthat deviceis inSet valuechanging mode.

11.Programled :

**Blinks inprogramming mode.

o

o

ü

4

3

ENGLISH

7

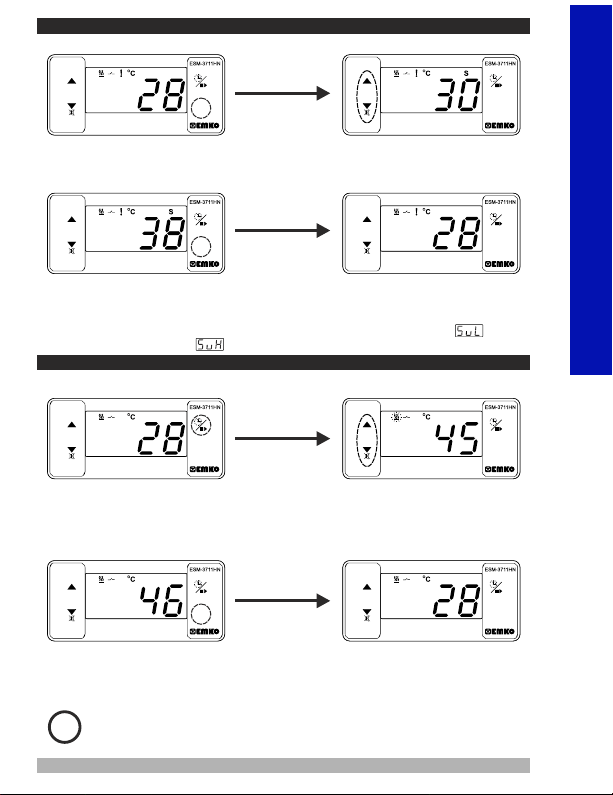

6. Changing and Saving Temperature Set Value

Main Operation Screen

SET Value Screen

ü

When SET button pressed ‘’S’’ led will

be active and temperature set value will

be displayed.

SET Value Screen

Temperature set value can

be changed with increment

and decrement buttons.

Main Operation Screen

ü

When ENTER button pressed

temperature set value can be saved.

Temperature set value parameter (Default = 10) MODBUS ADDRESS:40001

Temperature set value, can be programmed between minimum temperature set value and

maximum temperature set value .

6.1 Changing and Saving Cookıng Time (Timer) Parameter Value

Main Operating Screen

‘’S’’ will be inactive and goes back to

main operation screen.

Cooking Time (Timer) Value Screen

ü

When defrost button is pressed,

cooking time is shown and cooking time

led starts to fast blink (5 Hz).

Cooking Time (Timer) Value Screen

Change the cooking time with

increment and decrement

buttons.

Main Operating Screen

ü

Press set button for saving the

cooking time

Cooking time is saved, cooking time led

active led lights off, main operation screen

is shown.

ü

ü

ENGLISH

ü

ü

If no operation is performed in defrost time set value changing mode and temperature set

i

value changingmode for20 seconds, deviceturns tomain operation screenautomatically.

8

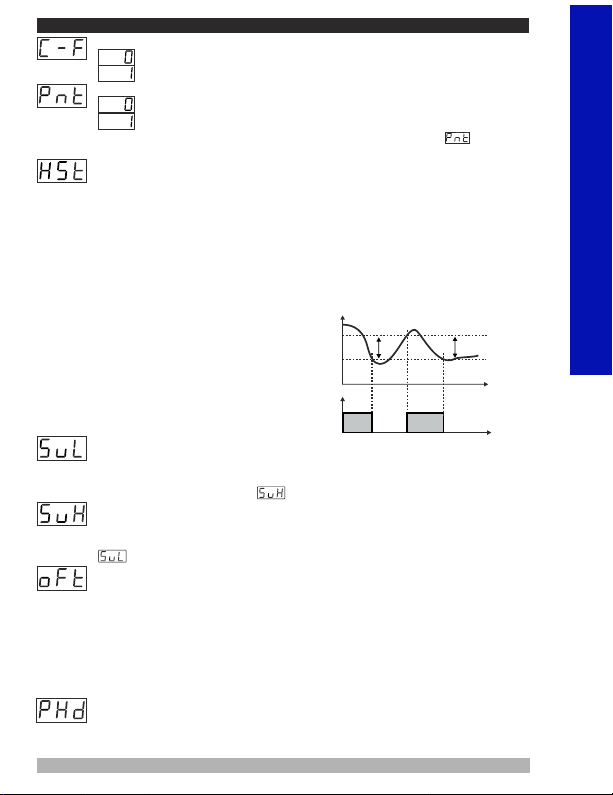

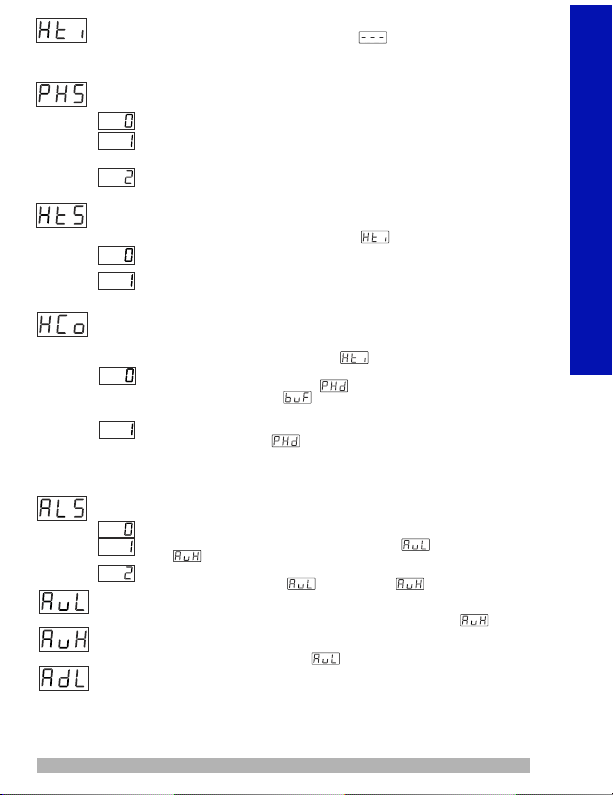

6.2 Programming Mode Parameter List

TemperatureUnit Selection Parameter (Default =0 )MODBUS ADDRESS:40002

°C selected.

°F selected.

Decimal SeperatorEnabling Parameter( Default =0 )MODBUS ADDRESS:40003

Disable.

Note: If sensor input type is selected J, K, PT-100 or PT-1000 (BC= 05,10,11 or14) parameter

becomes passiveand cannot be changed.

Enable.

Hysteresis Parameterfor CompressorOutput ( Default = 1)

MODBUSADDRESS:40004

from 1to 20°C forNTC (-50°C, 100°C)or PTC (-50°C, 150°C)or J Type TC (0°C, 800°C )or

K TypeTC ( 0°C,1000°C or PT-100Type (-50°C,400°C )or PT-1000Type( -50°C,400°C )

or PT-100Type( -20°C,100°C ),

from 1to 36°F for NTC (-58°F,212°F) orPTC (-58°F, 302°F)or J TypeTC (32°F,1472°F)or

K Type TC(32°F,1830°F) or PT-100 Type (-58°F,752°F) or PT-1000 Type (-58°F,752°F)

or PT-100Type (-4°F,212°F)

from 0.1to 10.0°Cfor NTC(-50.0°C,100.0°C) orPTC (-50.0°C,150.0°C)

or PT-100(-19.9°C,99.9°C),

from 0.1to 18.0°Ffor NTC (-58.0°F,212.0°F)or PTC(-58.0°F,302.0°F)or

PT-100(-4.0°F,212.0°F),

In ON/OFF control algorithm, temperature

value is tried to keep equal to set value by

opening or closing the last control element.

ON/OFF controlled system, temperature

value oscillates continuously. Temperature

value’s oscillation periodor amplitude around

set value changes according to controlled

system. For reducing oscillation period of

temperature value,a threshold zone isformed

below or around set value and this zone is

named hysteresis.

Minimum Temperature Set Value Parameter (Default = Minimum Value of Device

Scale ) MODBUS ADDRESS:40005

Temperatureset valuecan not belower thanthis value.

This parameter value can be adjusted from minimum value of device scale to maximum

temperature setvalue parameter

Maximum Temperature Set Value Parameter (Default = Maximum Value of Device

Scale )MODBUS ADDRESS:40006

Temperatureset valuecan not bebigger thanthis value.

This parametervalue canbe adjusted fromminimum temperatureset value parameter

to maximumvalue ofthe device scale

Sensor Offset Parameter ( Default = 0 ) MODBUS ADDRESS:40007

from -20 to 20 °C for NTC(-50°C, 100°C) or PTC(-50°C, 150°C) or J Type TC (0°C,800°C)

or J Type TC (0°C,1000°C) or PT-100(-50°C, 400°C)or PT-1000 (-50°C, 150°C) or

PT-100 (-20°C, 100°C),

from -36to 36°F for NTC(-58°F,212°F) orPTC(-58°F,302°F) orJ TypeTC (32°F,1472°F) or

or KTypeTC (32°F,1830°F)or PT-100(-58°F,752°F) or PT-1000(-58°F,752°F) or

PT-100(-4°F,212°F),

from -10.0to 10.0°Cfor NTC(-50.0°C,100.0°C) orPTC(-50.0°C,150.0°C) or

PT-100 (-19.9°C,99.9°C),

from -18.0to 18.0°Ffor NTC(-58.0°F,212.0°F)or PTC(-58.0°F,302.0°F)or

PT-100(-4.0°F,212.0°F),

Temperature Control Delay at PowerOn

It canbe adjustedfrom 0 to99 minutes.

Temperature

Set

Control

Output

ON

OFF

HSt

HSt

( Default= 0) MODBUSADRES :40008

Time

Time

ENGLISH

9

Cooking Time (Timer) Parameter

It can be adjusted from 1 to 999 minutes. When it is 1, can be observed by pressing

decrement buttonon the display.So ManualControl is selected.In Manualcontrol, usercan

start and stop temperature controlling with cooking ON/OFF button or

start/stop input

Selection of Temperature Control and Starting Cooking Time (Timer) Parameter

(Default =0 )MODBUS ADDRESS :40010

Cooking Time StartingConditions Parameter

MODBUS ADDRESS:40011

This parametercan beobserved if cookingtime (Timer) is 1.³

TemperatureControlling Continuity Selection Parameter

MODBUSADDRESS :40012

Temperature controlling can be continues or stopped according to the selection. This

parameter canbe observedif cooking time(Timer) is 1³

TemperatureAlarm FunctionSelection Parameter (Default =0 )

MODBUSADDRESS :40013

MinimumAlarm Parameter

MODBUSSADDRESS :40014

It canbe adjustedfrom minimum scaleof thedevice to maximumalarm value .

MaximumAlarm Parameter(Default =Input TypeMaximum Scale)

MODBUSADDRESS :40015

It canbe adjustedfrom minimum alarmvalue to maximumscale of the device.

Alarm DelayParameter (Default = 0) MODBUSADDRESS :40016

If analarm occurs,delay can bedefined withthis parameter.It can beadjusted from0

to 99minutes.

.

Temperaturecontrol andcooking time (Timer) starts atpower on.

Temperature control starts at power on. Cooking time (Timer) can be started by

pressing cooking ON/OFFbutton or when cooking time start/stop inputis getting

closed condition.

Temperaturecontrol and cooking time(Timer) canbe startedby pressing cooking

ON/OFF buttonor whencooking time start/stopinput isgetting closed condition.

Cooking time (Timer) is started with cooking ON/OFF button or when cooking

time start/stopinput isgetting closed condition.

Cooking time (Timer) is started when temperature reaches to the process set

value after pressing cooking ON/OFF button or when cooking time start/stop

input isgetting closedcondition.

Continuous Operation : Temperature control starts after the temperature

control starting delay at power on is expired and continues. If buzzer

function selectionparameter Is 1or 5,at theend ofthe cookingtime, (Timer)

internal buzzeroperates toindicate cooking timehas finished.

Interrupted Operation : Temperature control starts after temperature control

starting delayat poweron is expired. Temperature control can be stopped

at the end of the cooking time (Timer) or by pressing cooking ON/OFF button or

when Temperaturecontrol

cooking timestart/stop inputis gettingopen condition.

does not start till cooking ON/OFF buttonis pressed again or when

start/stop inputis gettingclosed condition again.

Alarm functionis inactive.

Absolute alarmis selected.If temperature lowerthan and higher

than , then alarm ison.

Relative alarmis selected.Alarm operatesaccording to theset value.

If temperatureis below(Set - ) orabove ( Set+ ), alarmoccurs.

( Default= 45) MODBUS ADDRESS: 40009

cooking time

( Default= 0)

( Default= 0)

cooking time

( Default= InputType MinimumScale )

ENGLISH

10

TemperatureAlarm DelayAfter PowerOn Parameter

MODBUSADDRESS:40017

When power is first applied to the device, this time delay must be expired for activation of

temperature alarm.It canbe adjusted from0 to99 minutes.

Buzer FonksiyonSeçimi Parametresi( Default =1 )MODBUS ADDRESS:40018

Buzzer isinactive.

Buzzer isactive atthe end ofthe cookingtime.

Buzzer isactive ifan alarm occurs.

Buzzer isactive duringsensor failures.

Buzzer isactive atthe end ofthe cookingtime, alarm orsensor failures.

Buzzer is active during this time

If buzzer function selection parameter value =0, this parameter can not be

observed. Buzzer stays active during this time. It can be adjusted from 1 to 99 minutes

When this parameter is 1, if decrement button is pressed, is observed. In this

condition buzzer is active till buzzer silence button is pressed.

Button ProtectionParameter 20( Default= 0) MODBUSADDRESS: 400

There isno protection

Cooking time(Timer) can not be changed. Cooking ON/OFF operation is not

performed.

SET value cannot bechanged.

Cooking time (Timer) and set value can not be changed. Cooking ON/OFF

operation isnot performed.

Cooking time (Timer) and set value can not be changed. Cooking ON/OFF

operation isperformed when button ispressed.

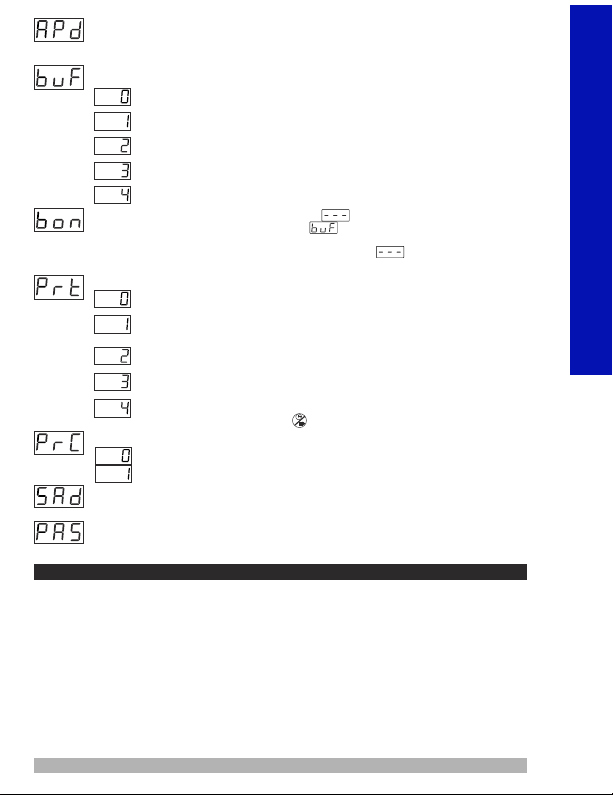

Communication ModeSelection Parameter 21( Default= 0) MODBUSADDRESS: 400

PROKEY communication selected.

RS-485 communicationselected.

Slave IDParameter 22( Default= 1) MODBUSADDRESS=400

Device communicationaddress parameter(1 to 247).

Programming SectionAccessing Password 23

It isused foraccessing tothe programming section. It can be adjusted from 0 to 9999. If it is

selected 0,password willnot be asked

( Default = ) MODBUS ADDRESS:40019

.

( Default= 0)

( Default= 0) MODBUSADDRESS: 400

6.3 ModbusAdresses ofDevice Status Parameters (ReadInput Register)

MODBUS ADDRESS:30001 Temperature Value

MODBUS ADDRESS:30002 Led Status : 0.bit C Led,6.bit OutputLed, 7.bit Alarm Led,

A

MODBUS ADDRESS:30003 Device Status : 0.bit Alarm Status

MODBUS ADDRESS:30004 Output Status 0.Bit Output

MODBUS ADDRESS:30005 Device Type and Device Version

1.bit Buzzer Status 2.bit Sensor Break Status

o

13.bit Program Led, 14.bit Set Led

ENGLISH

11

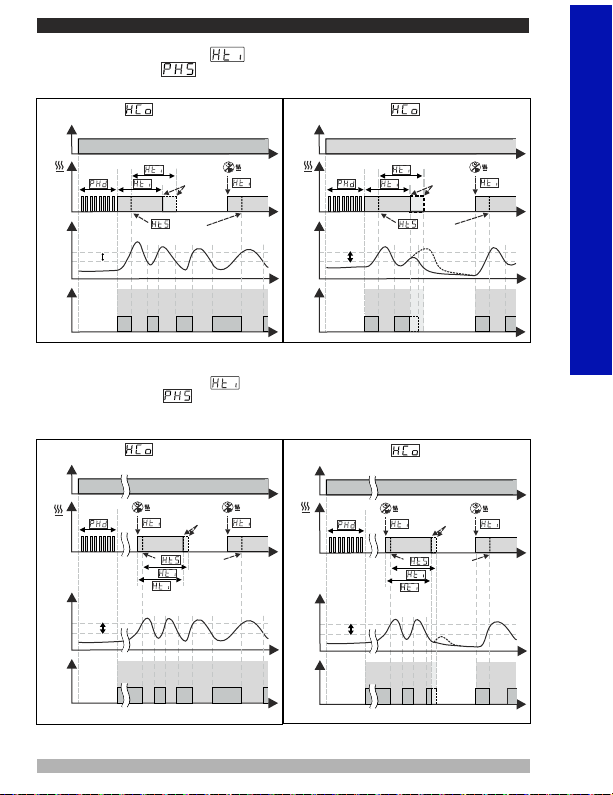

6.5 Operation Graphics of ESM3711HN Heating Controller

1- When cooking time parameter 1, if selection of temperature control andstarting the

cooking timeparameter = 0 ( Temperature controland cooking timestarts atpower on) is

selected;

01

( Continuous Operation )

Power

Cooking

Time

Active

Led

= =

Buzzer is

Active

°C

Process

Set

Hst

Process

Output

Temperature Control

is Active

³

Time

Cooking

Button starts

time

Time

Time

Time

Power

Cooking

Time

Active

Led

Process

Set

Process

Output

( Interrupted )Operation

°C

Hst

Temperature

Control

is Active

= 1= 1

Buzzer is

Active

Time

Cooking

Button starts

time

Time

Time

Temperature

Control

is Active

Time

ENGLISH

Buzzer is

Active

³

Time

Cooking

Button starts

time

Time

Time

Time

Power

Cooking

Time

Active

Led

Process

Set

Process

Output

cooking time start/stop input is

Button starts

°C

Hst

Temperature

Control

is Active

Cooking

1

=

Time

Cooking

Button starts

Buzzer is

time

= 1

Active

Time

Time

Temperature

Control

is Active

Time

time

2- When cooking time parameter 1, if selection of temperaturecontrol and starting the

cooking timeparameter = 1 (Temperature controlstarts at power on.Cooking time (Timer)

can be started by pressing cooking ON/OFF button or when

getting closedcondition)

( Continuous Operation ) ( Interrupted )Operation

Power

Cooking

Time

Active

Led

is selected;

0

=

Cooking

Button starts

time

= 1

°C

Process

Hst

Set

Temperature Control

Process

Output

is Active

12

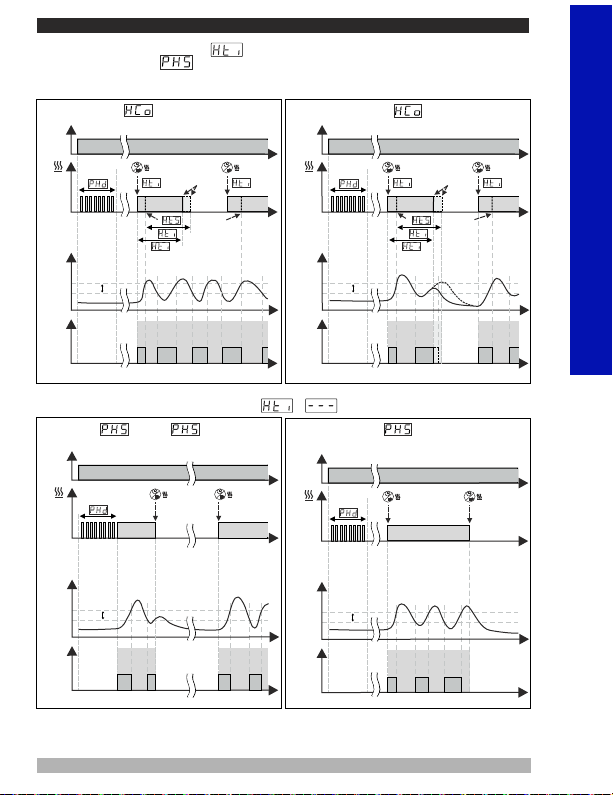

6.5 Operation Graphics of ESM3711HN Heating Controller

Buzzer is

Active

³

cooking time start/stop input is getting closed

( Interrupted )Operation

Cooking

Button starts

time

Time

Cooking

Button starts

time

Time

Power

Cooking

Time

Active

Led

°C

Process

Hst

Set

Time

Time

Process

Output

Temperature

Control

is Active

1

=

Time

Cooking

Button starts

Buzzer is

= 1

Active

Time

Time

Temperature

Control

is Active

Time

time

3- When cooking time parameter 1, if selection oftemperature control and starting the

cooking timeparameter = 2 ( Temperaturecontrol andcooking time(Timer) can be started

by pressing cooking ON/OFF button or when

condition)

is selected;

0

( Continuous Operation )

Power

Cooking

Time

Active

Led

=

Cooking

Button starts

time

= 1

°C

Process

Hst

Set

Process

Output

Temperature Control

is Active

ENGLISH

4- Manual Control : If cooking time (Timer)

0 or 1

=

( Temperature control starts at power on )

Power

Cooking

Time

Active

Led

Cooking

Button starts

the temperature

control

=

Cooking

Button stops

the temperature

control

°C

Process

Hst

Set

Process

Output

Temperature

Control

is Active

Temperature

Control

is Active

=

( Temperature control starts with cooking ON/OFF button or

when )cooking time start/stop input is getting closed condition

Power

Time

Cooking

Time

Active

Led

Time

°C

Process

Hst

Set

Time

Process

Output

Time

=

Cooking

Button starts

the temperature

control

Temperature Control

is Active

2

Time

Cooking

Button stops

the temperature

control

Time

Time

Time

13

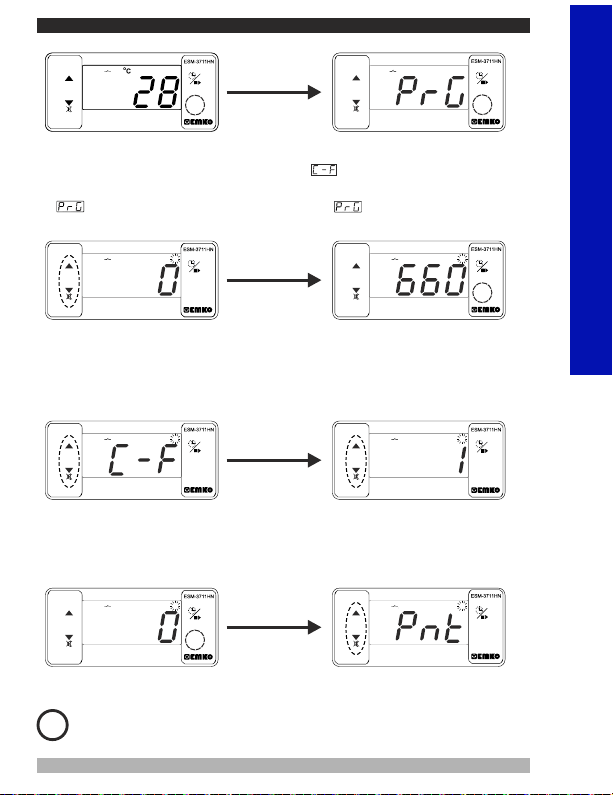

6.6 Entering To The Programming Mode, Changing and Saving Parameter

Main Operation Screen

O

O

S

C

F

P

ü

When SET button is pressed for 5

seconds, “P” led starts to blink. If

programming mode entering

password is different from 0,

programming mode entering screen

will be observed.

Password Entering Screen

O

O

S

P

C

F

Note1: If programming

mode accessing

password is 0,

Temperature Unit screen

is observed instead of

programming screen

Programming Mode

Entering Screen

Press OK button for

accessing to the

password entering

screen.

Password Entering Screen

O

C

ü

Enter programming mode accessing password

with increment and decrement buttons.

Note2: If programming mode accessing password is 0, only three parameters are accessible, and the

parameter valuescan bechanged.

Programming Screen

O

O

O

O

S

S

P

P

C

C

F

F

Press OK button for entering

the password.

Temperature Unit Selection

Parameter Value

O

O

C

C

ü

Press SET button for accessing to the parameter

value. Press increment button for accessing tothe

next parameter, press decrement button for

accessing tothe previousparameter.

Temperature Unit Selection

Parameter Value

O

O

O

O

S

S

P

P

C

C

F

F

Change the value with increment

and decrement buttons.

Decimal Seperator

Enabling Parameter

O

C

ü

Press OK button for saving the

parameter.

If no operation is performed in programming mode for 20 seconds, device turns to main

i

operation screenautomatically..

Press increment button for accessing to the

next parameter, press decrement button for

accessing tothe previousparameter

ü

O

S

P

F

ü

O

O

S

S

P

P

F

F

ü

O

S

P

F

ü

ENGLISH

14

7.Cooking Time (Timer) ON/OFF Operation

ü

In main operationscreen, If cookingbutton is pressedfor

3 seconds, then cooking time (Timer) is started and

cooking time active led becomes active. While cooking

3 sec.

time (Timer) continues if cooking button is pressed for 3

seconds, cooking time (Timer) is finished and cooking

time activeled lightsoff.

If button protection parameter = 4 cooking time

(Timer)ON/OFF operationis performedwhen

button ispressed.

7.1 Cooking Time (Timer) ON/OFF Operation with Cooking Time Start/Stop Input

DIGITAL INPUT

6

7

K

When K switch that is connected to the cooking time

start/stop input, getting closed condition, cooking time

(Timer) is started and cooking time active led becomes

active. While cooking time (Timer) continues if K switch

getting open condition, cooking time (Timer) is finished

and cookingtime activeled lights off.

8. Specifications

Device Type

Housing & Mounting

Protection Class

Weight

Environmental Ratings

Storage / Operating Temperature

Storage / Operating Humidity

Installation

Overvoltage Category

Pollution Degree

Operating Conditions

Supply Voltage and Power

Temperature Sensor Input

NTC input type

PTC input type

Thermocouple input type

Thermoresistance input type

Accuracy

Cold Junction Compensation

Sensor Break Protection

Sampling Cycle

Control Form

Relay Outputs

Optional SSR Drive Output

Display

LED

Internal Buzzer

Approvals

: Heating Controller

: 76mm x 34.5mm x 71mm plastic housing for panel

Mounting. Panel cut-out is 71x29mm.

: Ip65 at front, Ip20 at rear.

: Approximately 0.20 Kg.

: Standard, indoor at an altitude of less than 2000 meters

with none condensing humidity.

oooo

: -40 C to +80 C / -30 C to +80 C

: 90 % max. (None condensing)

: Fixed installation

: II.

: II, office or workplace, none conductive pollution

: Continuous

:

230V ( %15) 50/60Hz - 1.5VA

V

±

: 115

V ( %15) 50/60Hz - 1.5VA

V

±

: 24

V ( %15) 50/60Hz - 1.5VA

V

±

: 24

V ( %15) 50/60Hz - 1.5VA

W

±

:10 - 30

V 1.5WZ

: NTC, PTC, TC, RTD

: NTC (10 k @25 °C )

W

: PTC (1000 @25 °C )

: J, K (IEC584.1) (ITS 90)

: PT-100, PT-1000 (IEC751) (ITS 90)

: ± 1 % of full scale for thermoresistance

: Automatically ± 0.1°C / ± 1°C

: Upscale

: 3 samples per second

: ON / OFF

: A@250 V for Resistive load (Compressor output)

16(8) V

: Maximum 20mA, Maximum 17V

: 14 mm Red 4 digits LED Display

: S (Green), P (Green), C (Yellow), F(Yellow),

: 83dB

: ,

W

(Electrical life : 100.000 switching at full load)

Compressor Output (Red), Heating Output (Red)

³

Z

oo

ENGLISH

15

9. Failure Messages in ESM-3711HN Heating Controller

1- Screen Blinking

Sensor failure. Sensor connectionis wrong orthere is no sensorconnection. If buzzer function

selection parameter is 3or 4, internal buzzerstarts to operate.

2- MainScreen Value isBlinking.

Example : If alarm function selection parameter in programming section is 1 (Absolute Alarm)

and maximum alarm parameter is 50 When temperature is above 50 °C, value on the screen

starts to blink. Also buzzer function selection parameter is 2 or 4, then internal buzzer is on.

ü

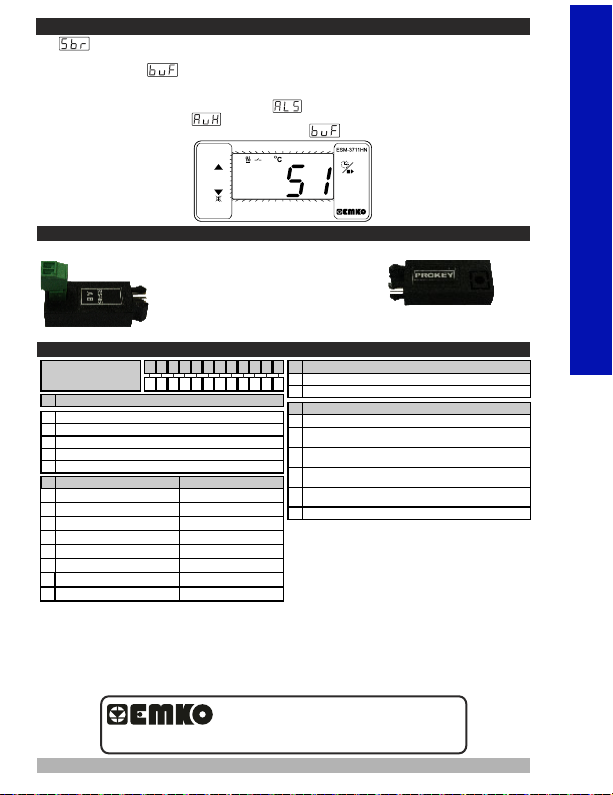

10.Optional Accessories

1.RS-485 Module

RS-485 Communication Interface

11.Ordering Information

ESM-3711HN

(77x35 DIN Sizes)

Supply VoltageA

2

24V ( %15) 50/60Hz - 1.5VAW ±

3

24V ( %15) 50/60Hz - 1.5VAV ±

4

115V ( %15) 50/60Hz - 1.5VAV ±

5

230V ( %15) 50/60Hz - 1.5VAV ±

8

10 - 30 V Z

Input Type

BC

J ,Fe CuNi IEC584.1(ITS90)

05

K ,NiCr Ni IEC584.1(ITS90)

10

PT 100, IEC751(ITS90)

11

PT 100, IEC751(ITS90

09

PT 1000, IEC751(ITS90)

14

PT 1000, IEC751(ITS90

13

PTC (Not-1)

12

NTC (Not-1)

18

All order information of ESM-3711HN Heating Controller are given on the table at above. User may

form appropriate device configuration from information and codes that at the table and convert it to the

ordering codes.Firstly, supply voltage thenother specificationsmust be determined. Please fillthe order

code blanksaccording toyour needs. Pleasecontact us,if your needsare outof the standards.

Note-1:If input type is selected PTC or NTC (BC= 12, 18), Temperature sensor is given with the

device.For thisreason, ifinput type is selectedas PTC,sensor type(V =0,1 or2) orif input type is

selected asNTC, sensortype (V =0,3 or4) must bedeclared inordering information.

ABCD E FGHI /

0100

Your Technology Partner

U

VWZ/

00 00

/

/

Scale(°C)

0°C/32°F ; 800°C/1472°F

0°C/32°F ; 999°C/1830°F

-50°C/-58°F ; 400°C/752°F

-19.9°C/-4°F ; 99.9°C/212°F

-50°C/-58°F ; 400°C/752°F

-19.9°C/-4°F ; 99.9°C/212°F

-50°C/-58°F ; 150°C/302°F

-50°C/-58°F ; 100°C/212°F

Thank you very much for your preference to

use Emko Elektronik products, please visit our

web page to download detailed user manual.

2.PROKEY Programming Module

The device is programmed(Upload or

Download) by using the parameters.

Output-1

E

Relay Output (16(8) A@250 V ,at resistive Load, 1 NO )V

1

SSR Driver Maximum 20m, Maximum 17VOutput ( )Z

2

Temp. Sensor which is given withESM-3711HN

V

0

None

PTC-M6L40.K1.5 (PTC Air Probe 1.5 mt Silicon Cable)

1

PTCS-M6L30.K1.5.1/8” (PTC Liquid Probe 1.5 mt Silicon Cable)

2

NTC-M5L20.K1.5 (NTC Sensor, thermoplastic moulded with 1.5 m cable

3

4

9

for cooling application)

NTC-M6L50.K1.5 (NTC Sensor, stainless steel housing with 1.5 m cable

for cooling application)

Customer

VZVac,

Þ

Vdc

c

Þ

Vdc or Vac

ÞW

can beapplied

www.emkoelektronik.com.tr

16

ENGLISH

ESM-3711HN 77 x 35 DIN-Größe

Digital, EIN/AUS Temperaturregler

- 4-stellige Anzeige

- NTC Eingang oder

PTC Eingang oder

J Typ Thermoelement-Eingang oder,

K Typ Thermoelement-Eingang oder,

PT-100 Zweileitereingang oder,

PT-1000 Zweileitereingang (Muss der Reihenfolge

nach bestimmt werden.)

- EIN/AUS Temperaturregelung

- Einstellbares Temperaturoffset

- Obere und untere Sollwertbegrenzung

- Relais oder SSR-Treiberausgang

- Digitaleingabe (Kochzeit Start/Stopp-Eingabe)

- Einstellbare Kochzeit über Bedienfeld

- Temperaturregelung gemäß Kochzeit (Timer)

- Benutzer kann das Starten der Kochzeit (Timer)

bei Erreichen des Temperatursollwerts wählen

- Temperaturregelung mit manueller Heizfunktion

- Alarmparameter

ESM-3711HN 77 x 35 DIN-Größe Heizungsregler

- Einstellbarer interner Summer für Kochzeit,

Sensordefekt und Alarmstatus.

- Tastenschutz

- Passwortschutz für Programmierbereich

- Installationsparameter über Prokey

- Fernzugriff, Datenerfassung und Steuerung mit Modbus RTU

- CE-Kennzeichnung gemäß Europäischen Normen

Bedienungsanleitung. DE ESM-3711HN 01 V00 11/14

DEUTCH

1. Einleitung

Die Heizungsregler der Serie ESM-3711HN dienen zur Messung und Steuerung der

Temperatur. Dank ihrer einfachen Handhabung, Ein/Aus-Steuerungsform und

Kochzeiteigenschaften sindsie invielenAnwendungen einsetzbar:

Anwendungsbereiche Anwendungen

Glas Heizen

Lebensmittel Backöfen

Kunststoff Brutschränke

Petrochemie Speicher

Textil Automatisierte Klimaanlagen

Maschinenfertigungsindustrie usw... usw...

1.1 Umgebungsbedingte Leistungsfähigkeit

Betriebstemperatur

Max. Luftfeuchtigkeit bei Betrieb

Höhe

VerboteneBedingungen:

KorrosiveAtmosphäre

c

ExplosionsfähigeAtmosphäre

Heimbereich (DasGerät istnur fürindustrielle Anwendungen)

1.2 Allgemeine Spezifikationen

Standard

230V ( %15) 50/60HzV ±

Optionale Versorgungsspannung

±

115 V ( %15) 50/60 Hz,

V

±

24 V ( %15) 50/60 Hz,

V

±

24 V ( %15) 50/60 Hz,

W

10

- 30 V Z

NTC, PTC,

J oder K Typ TC

PT-100

2-Leiter

PT-1000

2-Leiter

Kochzeit (Timer)

Start/Stopp-Eingang

ESM-3711HN

Stromversorgungseingang

Temperatursensoreingang

Digitale Eingabe

Standard

Ausgang-1

()Relaisausgang

Optional

Ausgang-1

()SSR-Treiber-Ausgang

:

0 bis 50 °C

:

90% Rh (nicht kondensierend)

:

Bis zu 2000 m.

Steuerausgang

Alarmausgang

Steuerausgang

Alarmausgang

Heizfunktion

EIN/AUS-Betrieb

DEUTCH

2

1.3 Installation

Eine Sichtprüfung dieses Produkts auf mögliche Transportschäden wird vor der Installation

empfohlen. Es liegt in Ihrer Verantwortung dafür zu sorgen, dass qualifizierte Maschinenbauund Elektrotechnikerdieses Produktinstallieren.

Bei Gefahr eines schweren Unfalls durch Ausfall oder Defekt dieser Einheit, schalten Sie das

System ausund trennenSie dieelektrische Verbindungdes Gerätsvom System.

Die Einheit wird normalerweise ohne Stromschalter oder Sicherung geliefert. Verwenden Sie

Netzschalter undSicherung nachBedarf.

Stellen Sie sicher, dass Sie die Nennversorgungsspannung verwenden, um die Einheit vor

Schäden zuschützen undeinenAusfall zu verhindern.

Lassen Sie den Strom abgeschaltet, bis die gesamte Verkabelung abgeschlossen ist, damit

Stromschläge undProbleme mitdem Gerätverhindert werdenkönnen.

VersuchenSie niemals dieEinheit zu zerlegen, zuverändern oder zureparieren.

Die Manipulierungdes Gerätskann zuFehlfunktion, Stromschlagoder Brandführen.

Verwenden Sie die Einheit nicht in brennbaren oder explosionsgefährdeten gashaltigen

Atmosphären.

Beim Einsetzen des Geräts in die Öffnung der Metallplatte während der mechanischen

Installation, können Metallgrate Verletzungen an den Händen verursachen. Seien Sie

vorsichtig.

Die Montage des Produkts ineinem System muss mitdessen Befestigungsklammern erfolgen.

Führen Sie die Montage des Geräts nicht mit ungeeigneten Befestigungsklammern durch.

Achten Siedarauf, dassdas Gerätwährend derMontage nichtherunterfällt.

Es liegt in Ihrer Verantwortung, wenn das Gerät auf eine nicht in dieser Bedienungsanleitung

vorgeschriebenenArt undWeise benutztwird.

1.4 Garantie

EMKO Elektronik garantiert, dass das gelieferte Gerät keinerlei Material- oder Verarbeitungsmängel

aufweist. Diese Garantie beschränkt sich auf einen Zeitraum von zwei Jahren. Die Garantiezeitbeginnt

mit dem Lieferdatum. Diese Garantie ist gültig, wenn die im Garantieschein und in der

Bedienungsanleitung festgelegten Pflichten und Verantwortlichkeiten vollständig durch den Kunden

erfüllt werden.

1.5 Wartung

Reparaturen dürfen nur von geschultem Fachpersonal durchgeführt werden. Trennen Sie das Gerät

von der Stromversorgung, bevor Sie Innenteile manipulieren. Reinigen Sie das Gehäuse nicht mit

Kohlenwasserstoff-Lösemitteln (Benzin, Trichloräthylen usw.). Die Verwendung dieser

Lösemittelkann die mechanische Zuverlässigkeit des Geräts beeinträchtigen. Verwenden Sie einmit

Ethylalkohol oderWasser angefeuchtetesTuch, umdas externeKunststoffgehäuse zu reinigen.

1.6 Herstellerfirma

Herstellerangaben:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

: +90 224 261 1900

Tel e fo n

Fax : +90 224 261 1912

Reparatur und Wartungsservice:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA /TURKEY

: +90 224 261 1900

Tel e fo n

Fax : +90 224 261 1912

DEUTCH

3

2. Allgemeine Beschreibung

Bedienfeld

IP 65 Schutz

Tafeloberfläche

(maximale Dicke 15 mm / 0,59 Zoll)

Befestigungsklammer

2.1 Frontansicht und Abmessungen des ESM-3711HN Temperaturreglers

Maximum 15 mm / 0 59, Zoll

ü

34,5 mm / 1 36, Zoll

76 mm / 3 Zoll

2.2 Tafelausschnitt

Zoll

29 mm / 1 14,

6 mm / 0 24, Zoll

110 mm / 4 33 (min), Zoll

71 mm / 2 79, Zoll

65 mm / 2 56, Zoll

Zoll

50 mm / 1 97 (min),

DEUTCH

4

2.3 Tafeleinbau

1

3

2

1-Bevor Sie das Gerät in Ihre Tafel einbauen,

stellen Sie sicher, dassder Ausschnitt dierichtige

Größe hat.

2-Setzen Sie das Gerät durch denAusschnitt ein.

Wenn die Befestigungsklammern an der Einheit

sind, ziehen Sie sieheraus, bevor Sie die Einheit

in dieTafeleinführen.

2.4 Ausbauen aus der Tafel

2

3-Stecken Sie die Befestigungsklammern in die

Befestigungsbuchsen an der linken und rechten

Seite des Geräts und fixieren Sie das Gerät

vollständig ander Tafel,bis es einrastet.

1-Ziehen Sie Befestigungsklammern aus der linken

und rechtenBefestigungsbuchse heraus.

1

2-Ziehen Sie die Einheit durch die Vorderseite des

Panels heraus.

Bevor Sie die Einheit aus der Tafel

entnehmen, schalten Sie die Einheit und

das verbundeneSystem aus.

c

3. Über Prokey

UM PROKEY ZU VERWENDEN, MUSS DER WERT DES PrC-PARAMETERS „0“ SEIN. WENN

PrC=1 UND DIE TASTE GEDRÜCKT WIRD, WIRD DIE MELDUNG ANGEZEIGT. 10

SEKUNDEN SPÄTER SCHALTET DAS GERÄT ZUM HAUPTBETRIEBSBILDSCHIRM ZURÜCK.

SIE KÖNNEN ABER AUCH DIE EINSTELL-TASTE DRÜCKEN, UM ZUM

HAUPTBETRIEBSBILDSCHIRM ZURÜCKZUSCHALTEN.

HERUNTERLADEN VOM GERÄT AUF PROKEY

1. Das Gerät wird mit Hilfe der Parameter programmiert.

2. Schalten Sie das Gerät ein, stecken Sie PROKEY ein und drücken Sie die -Taste. Die

Meldung wird angezeigt. Wenn der Ladevorgang abgeschlossen ist, wird die Meldung angezeigt.

3. Drücken sie eine beliebige Taste, um zum Hauptbetriebsbildschirm zurückzukehren.

4. Entfernen Sie den PROKEY.

HINWEIS: Die Meldung wird angezeigt, wenn ein Fehler während der Programmierung auftritt.

Wenn Sie neu laden möchten, stecken Sie PROKEY ein und drücken Sie die -Taste. Wenn Sie

beenden wollen, entfernen Sie PROKEY und drücken Sie die -Taste. Das Gerät schaltet zum

Hauptbetriebsbildschirm zurück.

HERUNTERLADEN VON PROKEY AUF DAS GERÄT

1. Schalten Sie das Gerät aus.

2. Stecken Sie PROKEY ein und schalten Sie dann das Gerät ein.

3. Sobald das Gerät eingeschaltet ist, werden die Parameterwerte in PROKEY automatisch auf das

Gerät heruntergeladen. Zunächst wird die Meldung angezeigt, und sobald der Ladevorgang

abgeschlossen ist, wird die Meldung angezeigt.

4. Nach 10 Sekunden beginnt das Gerät mit neuen Parameterwerten zu arbeiten.

5. Entfernen Sie den PROKEY.

HINWEIS: Die Meldung wird angezeigt, wenn ein Fehler während der Programmierung

auftritt. Wenn Sie neu laden wollen, schalten Sie das Gerät aus, stecken Sie PROKEY ein und

schalten Sie das Gerät wieder ein. Wenn Sie beenden wollen, entfernen Sie PROKEY und drücken

3

Sie die -Taste. Das Gerät schaltet zum Hauptbetriebsbildschirm zurück.

5

DEUTCH

4. Elektrisches Anschlussschema

8

7

6

5

N

a

4

L

3

2

(-)

1

P/N : ESM-3711HN

4.1 Versorgungsspannungseingangsanschluss des Geräts

Stromversorgungsanschluss

L

N

a

(+)(-)

4

5

EXTERNE

SICHERUNG

(1A T)

Strom-

versorgungs

schalter

Hinweis-1

c

Versorgungsspannung

±

V

230 V ( %15) 50/60 Hz,

±

V

115V ( %15) 50/60Hz,

±

V

24 V ( %15) 50/60 Hz,

W ±

24 V ( %15) 50/60 Hz,

10..30 V - 1 5W,

Z

Muss der Reihenfolge nach bestimmt werden.

Hinweis-1: ExterneSicherung wirdempfohlen.

Stellen Sie sicher, dass die Versorgungsspannung der auf

dem Gerät angezeigten entspricht. Schalten Sie die

c

Stromversorgung erst ein, nachdem alle elektrischen

Anschlüsse vorgenommenwurden.

Der Versorgungsspannungsbereich muss der Reihenfolge

nach bestimmt werden. Während der Installation des

Geräts muss die Versorgungsspannung kontrolliert

werden; es muss die geeignete Versorgungsspannung am

Gerät angelegtwerden.

Es gibt keinen Stromversorgungsschalter am Gerät. Ein

c

Stromversorgungsschalter mussdem

Versorgungsspannungseingang hinzugefügt werden. Der

Stromschalter muss zweipolig sein, um Phase und

Neutralleiter zu trennen. Der Ein/Aus-Zustand des

Stromversorgungsschalters ist bei elektrischen

Verbindungensehr wichtig.

Externe Sicherung, die bei Stromversorgungseingang

auf Phasenverbindungsein muss.

Externe Sicherung, die bei Stromversorgungseingang

auf (+)Verbindung seinmuss.

(+)

Für SSR-Ausgang

4.2 Gerätelabel und Verbindungsschema

230 V VERBINDUNGSSCHEMAV

16(8)

250 V 1 HP

V

AUSGANG

@

230,V ± 15%

V

50/60 Hz - 1 5 VA

DIGITAL-

EINGANG

oder

16 A SICHERUNG

L

N

16(8)

250 V 1 HP

V

AUSGANG

@

230,V ± 15%

50/60 Hz - 1 5 VA

LAST

Temperatursensoreingang

TC, NTC, PTC, PT-100

o PT-1000der

Kochzeit (Timer)

Start/Stopp-Eingang

Versorgungsspannungseingang

VV±

230 V ( %15) 50/60Hz

±

115V ( %15) 50/60Hz

VW±

24 V ( %15) 50/60Hz

±

24 V ( %15) 50/60Hz

10...30 V

Z

Muss der Reihenfolge nach bestimmt

werden.

Relais oder SSR-Ausgang

V

Z

V

oder

DIGITAL-

EINGANG

DEUTCH

6

5. Bedienfelddefinition und Menü-Zugriff

5

6

7

8

9

10

11

1

2

TASTENDEFINITIONEN

1. :Aufwärtstaste

** Wirdverwendet, umden Wert im Einstellbildschirmund im Programmiermodus zuerhöhen.

2.Abwärtstaste, Stummschaltendes Summers und Taste zum Herunterladenauf Prokey:

** Wirdverwendet, umden Wert im Einstellbildschirmund im Programmiermodus zuverringern.

** Wirdverwendet, umden Summerstummzuschalten.

** Wenn Prc =0, wird zum Herunterladenvom Gerät auf Prokeyverwendet.

3. Einstelltaste:

** Im Hauptbetriebsbildschirm; bei Betätigung dieser Taste wird der Sollwert angezeigt. Der

Wert kann mit den Aufwärts- und Abwärtstasten geändert werden. Beim Drücken der EnterTastewird derWert gespeichert undman gelangt zurück zumHauptbetriebsbildschirm.

** Für den Zugriff auf den Programmierbildschirm; im Hauptbetriebsbildschirm, drücken Sie

diese Tastefür 5 Sekunden.

** Wird verwendet, um den Wert im Einstellbildschirm und im Programmierbildschirm zu

speichern.

4. Kochtaste:

** ImHauptbildschirm; beiBetätigung dieserTastewird der Kochzeitwert angezeigt.

** ImHauptbildschirm; wenndiese Tastefür 3 Sekunden gedrücktwird, beginnt die Kochzeit.

LED-DEFINITIONEN

5. Kochzeit-LED:

** DieseLed zeigtan, dass dieKochzeit aktiv ist.

** Blinkt(5 Hz),während derKochzeitwert eingestelltwird.

6.Ausgangs-LED:

** Diese LED zeigt an, dass die Heizungsregelung ausgewählt und das

Prozessausgangsrelais aktiv ist.

7.Alarm-LED:

** Istbei niedrigemund hohemAlarmzustand aktiv.

8. Celsius-LED:

** Zeigtan, dassdas Gerät imºC-Modus ist.

9. Fahrenheit-LED:

** Zeigtan, dassdas Gerät imF-Modus ist.

10. Einstell-LED:

** Zeigtan, dassdas Gerät imSollwert-Änderungsmodus ist.

11.Programm-LED:

** Blinktim Programmiermodus.

ü

4

3

DEUTCH

7

6. Ändern und Speichern des Temperatursollwerts

Hauptbetriebsbildschirm

Sollwert-Bildschirm

ü

Beim Betätigen der EINSTELL-Taste

wird die „S“-LED aktiv sein und der

Temperatursollwert angezeigt.

Sollwert-Bildschirm

Temperatursollwert kann mit

Aufwärts- und Abwärtstasten

geändert werden.

Hauptbetriebsbildschirm

ü

Wenn die ENTER-Taste gedrückt wird, kann

der Temperatursollwert gespeichert werden.

Temperatursollwert-Parameter (Standard = 10) MODBUS-ADRESSE: 40001

Temperatursollwert kann zwischen dem minimalen Temperatursollwert und dem maximalen

Temperatursollwert programmiert werden.

„S“ wird inaktiv sein und man gelangt

zurück zum Hauptbildschirm.

ü

ü

6.1 Ändern und Speichern des Parameterwerts Kochzeit (Timer)

Hauptbetriebsbildschirm

ü

Beim Betätigen der Taste mit dem

Abtausymbol wird die Kochzeit

angezeigt, und die Kochzeit-LED beginnt

schnell zu blinken (5Hz).

Kochzeitwert (Timer) Bildschirm

ü

Drücken Sie die Einstell-Taste zum

Speichern der Kochzeit.

Wenn im Abtauzeit-Sollwert-Änderungsmodus und Temperatursollwert-Änderungsmodus

für 20 Sekunden kein Vorgang durchgeführt wird, schaltet das Gerät automatisch zum

i

Hauptbetriebsbildschirm zurück.

Kochzeitwert (Timer) Bildschirm

ü

Ändern Sie die Kochzeit mit

den Aufwärts- und

Abwärtstasten.

Hauptbetriebsbildschirm

ü

Kochzeit wird gespeichert,

Kochzeit-Aktiv-LED erlischt,

Hauptbetriebsbildschirm

wird angezeigt.

DEUTCH

8

6.2 Programmiermodus-Parameterliste

Parameter zurTemperatureinheitsauswahl (Standard =0) MODBUS-ADRESSE:40002

°C ausgewählt.

°F ausgewählt.

Dezimaltrennzeichen-Aktivierungsparameter (Standard= 0)MODBUS-ADRESSE: 40003

Deaktivieren.

Hinweis: Wennder Sensoreingangstyp J,K, PT-100 oder PT-1000 ausgewähltist (BC =05, 10,11 oder

14), wirdder Parameter passivund kann nicht geändertwerden.

Aktivieren.

Hystereseparameter fürKompressorleistung (Standard= 1)

MODBUS-ADRESSE: 40004

von 1 bis 20°C für NTC (-50°C, 100°C) oder PTC (-50°C, 150°C) oder J Typ TC (0°C,

800°C) oderK Typ TC (0°C,1000°C oder PT-100Typ (-50°C,400°C)oder PT-1000Typ

(-50°C, 400°C)oder PT-100 Typ (-20°C,100°C);

von 1 bis 36°F für NTC (-58°F, 212°F) oder PTC (-58°F, 302°F) oder J Typ TC (32°F,

1472°F) oderK Typ TC (32°F,1830°F) oder PT-100Typ (-58°F,752°F) oderPT-1000 Typ

(-58°F,752°F) oderPT-100 Typ (-4°F,212°F);

von 0,1bis 10,0°Cfür NTC (-50,0°C,100,0°C) oderPTC (-50,0°C, 150,0°C)oder PT-100

(-19,9°C, 99,9°C);

von 0,1bis 18,0°Ffür NTC (-58,0°F,212,0°F) oderPTC (-58,0°F,302,0°F) oderPT-100

(-4,0°F,212,0°F).

Im EIN/AUS-Regelalgorithmus wird versucht,

den Temperaturwert auf dem Sollwert zu halten,

indem das letzte Kontrollelement geöffnet oder

geschlossen wird. EIN/AUS-Regelstrecke,

Temperaturwert schwingt kontinuierlich. Die

Schwingungsdauer des Temperaturwerts oder

Amplitude um den Sollwert ändert sich je nach

Regelstrecke. Zur Verringerung der

Schwingungsdauer des Temperaturwerts wird

um oder unter dem Sollwert ein

Schwellenbereich gebildet und dieser Bereich

wird Hysteresegenannt.

Minimaler Temperatursollwert-Parameter(Standard = Minimalwertder Geräteskala)

MODBUS-ADRESSE: 40005

Der Temperatursollwert kann nicht unter diesem Wert liegen. Dieser Parameterwert kann

vom Minimalwertder Geräteskalabis zum maximalenTemperatursollwert-Parameter

eingestellt werden.

Maximaler Temperatursollwert-Parameter(Standard = Maximalwertder Geräteskala)

MODBUS-ADRESSE: 40006

Der Temperatursollwert kann nicht über diesem Wert liegen. Dieser Parameterwert kann

vom minimalenTemperatursollwert-Parameter bis zummaximalen Wert

der Geräteskalaeingestellt werden.

Sensor-Offset-Parameter (Standard = 0) MODBUS-ADRESSE: 40007

von -20 bis 20 °C für NTC (-50°C, 100°C) oder PTC (-50°C, 150°C) oder J Typ TC (0°C,

800°C) oder J Typ TC (0°C, 1000°C) oder PT-100(-50°C, 400°C) oder PT-1000

(-50°C, 150°C) oder PT-100 (-20°C, 100°C);

von -36 bis 36 °F für NTC (-58°F, 212°F) oder PTC (-58°F, 302°F) oder J Typ TC (32°F,

1472°F) oder oder K Typ TC (32°F, 1830°F) oder PT-100 (-58°F, 752°F) oder PT-1000 (58°F, 752°F) oder PT-100 (-4°F, 212°F);

von -10,0 bis 10,0°C für NTC (-50,0°C, 100,0°C) oder PTC (-50,0°C, 150,0°C) oder PT100 (-19,9°C, 99,9°C);

von -18,0 bis 18,0°F für NTC (-58,0°F, 212,0°F) oder PTC (-58,0°F, 302,0°F) oder PT100 (-4,0°F, 212,0°F).

Temperaturregelungsverzögerungbeim Einschalten (Standard =0)

MODBUS-ADRESSE: 40008

Kann von0 bis99 Minuten eingestelltwerden.

Temperatur

Einstellung

Steuer-

ausgang

EIN

AUS

HSt

HSt

Zeit

Zeit

DEUTCH

9

Kochzeit (Timer) Parameter(Standard =45) MODBUS-ADRESSE: 40009

Kann von 1 bis 999 Minuten eingestellt werden. Wenn es 1 ist, kann überwacht

werden, indem die Abwärtstaste auf der Anzeige gedrückt wird. So ist die manuelle

Steuerung ausgewählt. Bei der manuellen Steuerung kann der Benutzer die

Temperaturregelung mit der Taste Kochen EIN/AUS oder über die Kochzeit Start/Stopp-

Auswahl des Parameters zur Temperaturregelung und zum Starten der Kochzeit

(Timer), (Standard =0) MODBUS-ADRESSE:40010

Temperaturregelungund Kochzeit(Timer) startetbeim Einschalten.

Temperaturregelung startet beim Einschalten. Kochzeit (Timer) kann durch

Drücken der Taste Kochen EIN/AUS gestartet werden oder wenn Kochzeit

Start/Stopp-Eingang einengeschlossenen Zustanderhält.

Temperaturregelungund Kochzeit (Timer) kann durchDrücken der TasteKochen

EIN/AUS gestartet werden oder wenn Kochzeit Start/Stopp-Eingang einen

geschlossenen Zustanderhält.

Parameter fürdie Kochzeit-Startbedingungen(Standard = 0)MODBUS-ADRESSE: 40011

Dieser Parameterkann überwachtwerden, wenn Kochzeit(Timer) ist1.³

Kochzeit (Timer) wird durch Drücken der Taste Kochen EIN/AUS gestartet oder

wenn KochzeitStart/Stopp-Eingang einengeschlossenen Zustand erhält.

Kochzeit (Timer) wird gestartet, wenn die Temperatur den Prozesssollwert

erreicht, nachdemdie TasteKochen EIN/AUSgedrückt wirdoder wennKochzeit

Start/Stopp-Eingang einengeschlossenen Zustanderhält.

Auswahlparameter fürdie Temperaturregelungskontinuität (Standard= 0)

MODBUS-ADRESSE: 40012

Temperaturregelung kann je nach Auswahl fortgesetzt oder gestoppt werden. Dieser

Parameter kannüberwacht werden,wenn Kochzeit (Timer) ist.1³

Dauerbetrieb: Die Temperaturregelung startet nachdem die Startverzögerung der

Temperaturregelung beim Einschalten abgelaufen ist und bleibt aktiviert.

Wenn der Auswahlparameterfür die Summerfunktion 1 oder 5 ist, aktiviert

sich der interne Summer am Ende der Kochzeit (Timer), um zu signalisieren, dass

die Kochzeitabgelaufen ist.

Unterbrochener Betrieb: Die Temperaturregelung startet, nachdem die

Startverzögerung derTemperaturregelungbeim Einschalten abgelaufen ist.

Die Temperaturregelung kann am Ende der Kochzeit (Timer) angehalten werden,

oder auch durch Drücken der Taste Kochen EIN/AUS oder wenn Kochzeit

Start/Stopp-Eingang einen offenen Zustand erhält. Die Temperaturregelung startet

nicht, bis die Taste Kochen EIN/AUS erneut gedrückt wird oder wenn Kochzeit

Start/Stopp-Eingang wiedereinen geschlossenenZustand erhält.

Auswahlparameter fürdie Temperatur-Alarmfunktion (Standard= 0)

MODBUS-ADRESSE: 40013

Alarmfunktion istinaktiv.

AbsoluterAlarm ist ausgewählt.Wenn dieTemperaturniedriger als

und höherals ist, dannist derAlarm aktiviert.

Relativer Messwertalarm ist ausgewählt. Der Alarm arbeitet gemäß dem Sollwert.

Wenn dieTemperatur unter (Set- ) oder über(Set + )liegt, wird einAlarm

ausgelöst.

Mindestalarmparameter (Standard= MinimalerSkalenwert des Eingangstyps)

MODBUS-ADRESSE: 40014 - Kann vom minimalen Skalenwert des Geräts bis zum

maximalenAlarmwert eingestellt werden.

Höchstalarmparameter (Standard= MaximalerSkalenwert des Eingangstyps)

MODBUS-ADRESSE: 40015 -

Skalenwert desGeräts eingestelltwerden.

Alarmverzögerungsparameter (Standard= 0)MODBUS-ADRESSE: 40016

TritteinAlarm auf, kanndie Verzögerungmit diesemParameter definiert werden.

Kann von0 bis99 Minuten eingestelltwerden.

Kann vom Mindestalarmwert bis zum maximalen

DEUTCH

10

Parameter zur Temperatur-Alarmverzögerung nach dem Einschalten (Standard = 0)

MODBUS-ADRESSE: 40017

Beim ersten Einschalten des Geräts muss zur Aktivierung des Temperaturalarms diese

Zeitverzögerung abgelaufensein. Kannvon 0 bis99 Minuteneingestellt werden.

Summerfunktion-Auswahlparameter (Standard= 1)MODBUS-ADRESSE: 40018

Summer istinaktiv.

Summer istam Endeder Kochzeit aktiv.

Summer istaktiv, wenn einAlarm auftritt.

Summer istwährend Sensorausfällenaktiv.

Summer istam Endeder Kochzeit, beiAlarm oderSensorausfällen aktiv.

Summer ist während dieser Zeit aktiv (Standard = ) 40019MODBUS-ADRESSE:

Wenn der Auswahlparameter für die Summerfunktion = 0, ist, kann dieser Parameter

nicht überwacht werden. Der Summer bleibt während dieser Zeit aktiv. Kann von 1 bis 99

Minuten eingestellt werden. Wenn dieser Parameter 1 ist wird beim Betätigen der

Abwärtstaste angezeigt. In diesem Zustand ist der Summer aktiv, bis die SummerStummschalttaste gedrückt wird.

Tastenschutzparameter(Standard = 0) MODBUS-ADRESSE:40020

Kein Schutz.

Kochzeit (Timer) kann nicht geändert werden. Kochen EIN/AUS kann nicht

ausgeführt werden.

Sollwert kannnicht geändertwerden.

Kochzeit (Timer) undSollwert können nichtgeändert werden.Kochen EIN/AUS

kann nichtausgeführt werden.

Kochzeit (Timer) undSollwert können nichtgeändert werden. KochenEIN/AUS

wird beimBetätigen derTaste ausgeführt.

Auswahlparameter fürden Kommunikationsmodus(Standard=0)MODBUS-ADRESSE: 40021

PROKEY-Kommunikationausgewählt.

RS-485-Kommunikation ausgewählt.

Slave-ID-Parameter (Standard= 1)MODBUS-ADRESSE: 40022

Parameter derGerätekommunikationsadresse (1bis 247).

Zugangspasswort fürden Programmierbereich(Standard =0) MODBUS-ADRESSE: 40023

Es wird für den Zugriff auf den Programmierbereich verwendet. Es kann von 0 bis 9999

eingestellt werden.Wenn 0ausgewählt ist, wird nichtnach einemPasswort gefragt.

6.3 Modbus-Adessesedes Gerätestatusparameters(Eingangsregister lesen)

MODBUS-ADRESSE Temperaturwert

MODBUS-ADRESSE LED-Status : 0.bit ºC-LED, 6.bit Ausgangs-LED, 7.bit Alarm-LED,

MODBUS-ADRESSE Gerätestatus: 0.bit Alarmstatus, 1.bit Summerstatus,

MODBUS-ADRESSE Ausgangsstatus 0.Bit Ausgang

MODBUS-ADRESSE Gerätetyp und Geräteversion

: 30001

: 30002

13.bit Programm-LED, 14.bit Einstell-LED

: 30003

2.bit Sensorbruchstatus

: 30004

: 30005

DEUTCH

11

6.5 Betriebsgrafiken des ESM3711HN Heizungsreglers

1-Wenn Kochzeitparameter 1, wenn Auswahl der Temperaturregelung und Starten des

Kochzeitparameters = 0 (Temperaturregelung und Kochzeit startet beim Einschalten)

ausgewählt ist;

Leistung

Kochzeit-

Aktiv-

Led

= =

()Dauerbetrieb

°C

Prozess-

einstellung

Hst

Prozess-

leistung

Temperaturregelung ist aktiv.

³

01

Summer

ist aktiv

Zeit

Kochtaste

startet

Zeit

Zeit

Zeit

Zeit

Leistung

Kochzeit-

Aktiv-

Led

Prozess-

einstellung

Prozess-

leistung

()Unterbrochener Betrieb

°C

Hst

Temperatur-

regelung

ist aktiv.

Zeit

Kochtaste

Summer

ist aktiv

= 1= 1

startet

Zeit

Zeit

Temperatur-

regelung

ist aktiv.

Zeit

Zeit

DEUTCH

startet

³

0

Leistung

Zeit

Kochtaste

startet

Summer

Zeit

ist aktiv

= 1

Kochzeit-

Zeit

Aktiv-

Led

Zeit

Kochtaste

startet

Zeit

1

=

Zeit

Kochtaste

startet

Summer

Zeit

ist aktiv

= 1

Zeit

°C

Prozess-

einstellung

Hst

Zeit

Prozessleistung

Zeit

Temperatur-

regelung ist aktiv.

Zeit

Temperatur-

regelung

ist aktiv.

Zeit

2-Wenn Kochzeitparameter 1, wenn Auswahl der Temperaturregelung und Starten des

Kochzeitparameters = 1 (Temperaturregelung startet beim Einschalten. Kochzeit (Timer)

kann durch Drücken der Taste Kochen EIN/AUS gestartet werden oder wenn Kochzeit

Start/Stopp-Eingang einengeschlossenen Zustanderhält) ausgewählt ist;

=

Leistung

Kochzeit-

Aktiv-

Led

()Dauerbetrieb ( )Unterbrochener Betrieb

Kochtaste

°C

Prozess-

Hst

einstellung

Prozessleistung

Temperaturregelung ist aktiv.

12

6.5 Betriebsgrafiken des ESM3711HN Heizungsreglers

3-Wenn Kochzeitparameter 1, wenn Auswahl derTemperaturregelung undStarten des

Kochzeitparameters = 2 (Temperaturregelung und Kochzeit (Timer) kann durchDrücken

der Taste Kochen EIN/AUS gestartet werden oder wenn Kochzeit Start/Stopp-Eingang einen

geschlossenen Zustanderhält) ausgewähltist;

=

Leistung

Kochzeit-

Aktiv-

Led

()Dauerbetrieb

Kochtaste

startet

°C

Prozess-

Hst

einstellung

Prozess-

leistung

Temperaturregelung ist aktiv.

³

0

Summer

Zeit

ist aktiv

= 1

Zeit

Kochtaste

startet

Zeit

Leistung

Zeit

Kochzeit-

Aktiv-

Led

()Unterbrochener Betrieb

Kochtaste

startet

Zeit

1

=

Zeit

Kochtaste

startet

Summer

ist aktiv

= 1

Zeit

Zeit

°C

Prozess-

Hst

einstellung

Zeit

Prozess-

leistung

Zeit

Temperatur-

regelung

ist aktiv.

Zeit

Temperatur-

regelung

ist aktiv.

Zeit

DEUTCH

4-Manuelle Steuerung: Wenn Kochzeit (Timer)

0 o r 1de

=

()Temperaturregelung startet beim Einschalten

Leistung

Kochzeit-

Aktiv-

Led

Kochtaste

startet die

Temperatur-

regelung

=

Zeit

Kochtaste

stoppt die

Temperatur-

regelung

Zeit

°C

Prozess-

Hst

einstellung

Prozessleistung

Temperatur-

regelung

ist aktiv.

Zeit

Temperatur-

regelung

ist aktiv.

Zeit

=

2

(Temperaturregelung startet mit der Taste Kochen EIN/AUS

oder wenn Kochzeit Start/Stopp-Eingabe

Leistung

einen geschlossenen Zustand erhält)

Kochzeit-

Aktiv-

Led

°C

Prozess-

Hst

einstellung

Prozess-

leistung

=

Kochtaste

startet die

Temperatur-

regelung

Temperaturregelung

ist aktiv.

Kochtaste

stoppt die

Temperatur-

regelung

Zeit

Zeit

Zeit

Zeit

13

6.6 Aufrufen des Programmiermodus, Ändern und Speichern von Parametern

Hauptbetriebsbildschirm

O

O

S

P

C

F

ü

Wenn die EINSTELL-Taste für 5

Sekunden gedrückt wird, beginnt die

„P“-LED zu blinken. Wenn das

Passwort zum Aufrufen des

Programmiermodus ungleich 0 ist,

erscheint der Bildschirm zum Aufrufen

des Programmiermodus .

Passwort-Eingabebildschirm

O

O

S

C

F

Hinweis 1: Wenn das

Zugangspasswort für den

Programmiermodus 0 ist,

wird der Temperatureinheitsbildschirm anstelle des

Programmierbildschirms

angezeigt.

P

Programmiermodus

Aufrufbildschirm

OK-Taste drücken,

um auf den Passwort-

Eingabebildschirm

zuzugreifen.

Passwort-Eingabebildschirm

O

C

ü

Programmiermodus-Zugangspasswort mit

Aufwärts- und Abwärtstasten eingeben.

Hinweis 2: Wenn das Zugangspasswort für den Programmiermodus 0 ist, sind nur drei Parameter

zugänglich unddie Parameterwertekönnen geändert werden.

Programmierbildschirm

O

O

O

O

S

S

P

P

C

C

F

F

OK-Taste zur Eingabe des

Passworts drücken.

Parameterwert

Temperatureinheitsauswahl

O

O

C

C

ü

EINSTELL-Taste drücken, um auf den Parameterwert

zuzugreifen. Aufwärtstaste für den Zugriff auf den

nächsten Parameter drücken, Abwärtstaste für den

Zugriff auf denvorherigen Parameterdrücken.

Parameterwert

Temperatureinheitsauswahl

O

O

O

O

S

S

P

P

C

C

F

F

Wert mit Aufwärts- und

Abwärtstaste ändern.

Dezimaltrennzeichen-

Aktivierungsparameter

O

C

ü

OK-Taste zur Speicherung des

Parameters drücken.

Wenn im Programmiermodusfür 20Sekunden keinVorgang durchgeführtwird,

schaltet dasGerät automatischzum Hauptbildschirm zurück.

i

Aufwärtstaste für den Zugriff auf den nächsten

Parameter drücken,Abwärtstaste fürden Zugriff

auf denvorherigen Parameterdrücken.

ü

O

S

P

F

ü

O

O

S

S

P

P

F

F

ü

O

S

P

F

ü

DEUTCH

14

7. Kochzeit (Timer) EIN/AUS-Funktion

ü

Im Hauptbetriebsbildschirm, wennman die Kochtastefür

3 Sekunden drückt, startet die Kochzeit (Timer) und die

Kochzeit–Aktiv-Led leuchtetauf. Wennman während der

3 sec.

Kochzeit (Timer) die Kochtaste für 3 Sekunden drückt,

wird dieKochzeit (Timer) beendet unddie Kochzeit-AktivLED erlischt.

Wenn Tastenschutzparameter = 4, wird die

EIN/AUS-Funktion für die Kochzeit (Timer) durch

Drücken derTasteausgeführt.

7.1 Kochzeit (Timer) EIN/AUS-Funktion mit Kochzeit-Start/Stopp-Eingabe

DIGITALER

EINGANG

6

7

8. Spezifikationen

Gerätetyp

Gehäuse und Montage

Schutzklasse

Gewicht

Umgebungsbedingte Leistungsfähigkeit

Lagerungs- / Betriebstemperatur

Luftfeuchtigkeit bei Lagerung /

Betrieb

Installation

Überspannungskategorie

Verschmutzungsgrad

Betriebsbedingungen

Versorgungsspannung und Stromversorgung

Temperatursensoreingang

NTC-Eingangstyp

PTC-Eingangstyp

Thermoelement-Eingangstyp

Temperaturwiderstand-Eingangstyp

Genauigkeit

Kaltstellenkompensation

Sensorbruchschutz

Abfragezyklus

Steuerungsform

Relaisausgänge

Optionaler SSR-Treiberausgang

Anzeige

LED

Interner Summer

Zulassungen

K

Wenn der K-Schalter, der mit dem Kochzeit-Start/StoppEingang verbunden ist, einen geschlossenen Zustand

erhält, wird die Kochzeit (Timer) gestartet und die

Kochzeit-Aktiv-Led leuchtetauf.

Wenn derK-Schalter während derKochzeit (Timer)einen

offenen Zustand erhält, ist die Kochzeit (Timer) beendet

und dieKochzeit-Aktiv-Led erlischt.

:

Heizungsregler

:

76mm x 34,5mm x 71mm Kunststoffgehäuse für Tafeleinbau.

Tafelausschnitt ist 71x29mm.

:

IP65 frontseitig, IP20 rückseitig.

:

Ca. 0,20 Kg.

:

Standard, in Innenräumen unterhalb einer Meereshöhe

von 2000 Metern bei nicht-kondensierender Luftfeuchtigkeit.

ooo o

: -40 C +80 C / -30 C +80 C

bis bis

: 90 % max. ( )

:

: II.

: II,

:

: 115

: 24

: 24

: 10 - 30

: NTC, PTC, TC, RTD

: NTC (10 k @ 25 °C )

: PTC (1000 @ 25 °C )

: J, K (IEC584.1) (ITS 90)

: PT-100, PT-1000 (IEC751) (ITS 90)

:

:

:

:

: ON / OFF ( )

: A@ 250V

: Maximum 20mA, Maximum 17V

:

: S ( ), P ( ), C ( ), F( ),

: 83 dB

: ,

nicht kondensierend

Festeinbau

Büro oder Arbeitsplatz, nicht leitfähige Verschmutzung

Dauerbetrieb

V

V ( %15) 50/60Hz - 1 5 VA

V

V ( %15) 50/60 Hz - 1 5 VA

W

V ( %15) 50/60 Hz - 1 5 VA

V1 5 W

± 1 % vom Endwert für Temperaturwiderstand

Automatisch ± 0,1°C/± 1°C.

Gehoben

3 Abtastwerte pro Sekunde

16(8) für ohmsche Last (Kompressorleistung)

(Elektrische Lebensdauer: 100 000 Umschalten bei Volllast)

14 mm Rot 4-stellige LED-Anzeige

Grün Grün Gelb Gelb

Kompressorleistung (Rot), Wärmeleistung (Rot)

³

±

V

230V ( %15) 50/60 Hz - 1,5 VA

:

±

±

±

W

W

EIN/AUS

,Z

V

,

,

,

Z

oo

DEUTCH

15

9. Fehlermeldungen im ESM-3711HN Heizungsregler

1- BildschirmflackernSensorausfall. Sensoranschluss ist falsch oder es gibt keinen

Sensoranschluss. Wenn der Auswahlparameter für die Summerfunktion 3 oder 4 ist,

beginnt derinterne Summerzu funktionieren.

2- Hauptbildschirmwertblinkt.

Beispiel: Wenn der Auswahlparameter für die Alarmfunktion im Programmierbereich 1 ist

(Absoluter Alarm) und der maximale Alarmparameter 50 ist, beginnt der Wert auf dem

Bildschirm zu blinken, sobald die Temperatur über 50°C liegt. Wenn auch der Auswahlparameter für

die Summerfunktion 2 oder 4 ist, dann ist der interne Summer eingeschaltet.

ü

10. Optionales Zubehör

1. RS-485 Modul

RS-485 Kommunikationsschnittstelle

11. Bestellinformationen

ESM-3711HN

()77 x 35 DIN Größen

Versorgungsspannung

A

2

24 V ( %15) 50/60 Hz - 1 5 VA,W ±

3

24 V ( %15) 50/60 Hz - 1 5 VA,V ±

4

115 V ( %15) 50/60 Hz - 1 5 VA,V ±

5

230 V ( %15) 50/60 Hz - 1 5 VA,V ±

8

10 - 30 V Z

Eingangstyp

BC

J, Fe CuNi IEC584.1(ITS90)

05

K, NiCr Ni IEC584.1(ITS90)

10

PT 100, IEC751(ITS90)

11

PT 100, IEC751(ITS90

09

PT 1000, IEC751(ITS90)

14

PT 1000, IEC751(ITS90

13

PTC (Not-1)

12

NTC (Not-1)

18

Alle Bestellinformationen des ESM-3711HN Heizungsreglers sind auf der obigen Tabelle angegeben. Der Benutzer kann die

geeignete Gerätekonfiguration anhand der Informationen und Codes aus der Tabelle zusammenstellen und sie in

Bestellnummernkonvertieren. Zuerst muss man die Versorgungsspannung bestimmen, und anschließend die anderen

Spezifikationen. Bitte füllen Sie die Felderfür die Bestellnummern gemäß Ihren Bedürfnissen aus. Bitte kontaktieren Sie uns,

falls IhreBedürfnisse vomStandard abweichen.

Hinweis-1: WennEingangstyp PTC oder NTCausgewählt wird (BC=12,18), wird der Temperatursensor mit

dem Gerät geliefert. Aus diesem Grund muss bei Auswahl des Eingangstyps PTC der Sensortyp (V = 0,1

oder 2) oder bei Auswahl des Eingangstyps NTC der Sensortyp (V = 0, 0,3 oder 4) in den

Bestellinformationen angegebenwerden.

ABCD E FGHI /

0100

Ihr Technologiepartner

U

VWZ/

00 00

/

/

Skala (°C)

0°C/32°F ; 800°C/1472°F

0°C/32°F ; 999°C/1830°F

-50°C/-58°F ; 400°C/752°F

-19.9°C/-4°F ; 99 9°C/212°F,

-50°C/-58°F ; 400°C/752°F

-19.9°C/-4°F ; 99 9°C/212°F,

-50°C/-58°F ; 150°C/302°F

-50°C/-58°F ; 100°C/212°F

Vielen Dank, dass Sie sich für Emko Elektronik Produkte

entschieden haben. Bitte besuchen Sie unsere Webseite,

um die detaillierte Bedienungsanleitung herunterzuladen.

2. PROKEY Programmiermodul

Das Gerät wird anhand der Parameter

programmiert (Upload oder Download).

Ausgang-1

E

Relaisausgang (16(8) A 250 V, ohmscher Last, 1 NO)@@

1

SSR-Treiberausgang (Maximum 20 m, Maximum 17 V Z)

2

Im ESM-3711HN enthaltener Temperatursensor

V

0

Keiner

PTC-M6L40.K1.5 (PTC Luftsonde mit 1,5 m Silikonkabel)

1

PTCS-M6L30.K1.5.1/8” (PTC Flüssigkeitssonde mit 1,5 m Silikonkabel)

2

NTC-M5L20.K1.5 (NTC Sensor, geformter Thermoplast

3

4

9

mit 1,5 m Kabel für Kühlungsanwendungen)

NTC-M6L50.K1.5 (NTC Sensor Edelstahlgehäuse mit 1,5 m Kabel

für Kühlungsanwendungen)

Kunde

VZVac,

c

VdcÞÞ

Þ Vdc oderVac kann

W

angewendet werden

www.emkoelektronik.com.tr

16

DEUTCH

ESM-3711HN Taille DIN 77x35 Régulateur de chauffage

ESM-3711HN Taille DIN 77 x 35

Régulateur de chauffage

--Affichage à 4 chiffres

Entrée NTC ou

Entrée PTC ou

Entrée de thermocouple de type J ou,

Entrée de thermocouple de type K ou entrée PT-100 à 2 fils ou,

Entrée PT-1000 à 2 fils (doit être déterminé dans l'ordre).

- Écart de température réglable

- Contrôle de température ON/OFF

- Écart de température réglable

- Valeur de consigne minimale et valeur de consigne maximale

- Sortie relais ou à entraîneur SSR

- Entrée numérique (Entrée Démarrer/Arrêter le temps de cuisson)

- Temps de cuisson réglable à partir du panneau avant

- Régulat. de températ. en fonction du temps de cuisson (minuterie)

- L'utilisateur peut choisir de démarrer le temps de cuisson

(minuterie) lorsque la température atteint la valeur de consigne

- Régulation de température avec la fonction manuelle de chauffage

- Paramètres d'alarme

- Avertisseur interne réglable en fonction du temps de cuisson,

de la défaillance de la sonde et de l'état d'alarme.

- Menu Protection

- Protection par mot de passe pour la section de programmation

- Installation de paramètres à l'aide de la ProKey

- Accès à distance, collecte et contrôle de données grâce

à Modbus RTU

- Possède le marquage CE selon les normes européennes

Manuel d'utilisation. FRA ESM-3711HN 01 V00 11/14

FRANCE

1. Préface

Les régulateurs de chauffage série ESM-3711HN sont conçus pour mesurer et contrôler la

température. Ils peuvent être utilisés dans de nombreuses applications grâce à leur facilité

d'utilisation, forme de contrôle ON/OFF et propriétés du temps de cuisson. Voici quelques

domaines d'applicationutilisés :

Domaines d'application Applications

Verre Chauffage

Alimentation Fours

Plastique Incubateurs

Pétrochimie Stockages

Textile, Climatisation automatique

Industries de la production des machines, etc... Etc.

1.1 Évaluations environnementales

Température de fonctionnement :

Humidité max. de fonctionnement :

0 à 50°C

90% Hr (sans condensation)