Emerson Fisher FIELDVUEDVC2000, Fisher FIELDVUEDVC6200 SIS, Fisher FIELDVUEDVC6200f, Fisher FIELDVUE Brochure

®

Fisher

FIELDVUE™ Instrumentation

Easy Integration with FDT Technology

A process control plant, regardless of

industry, makes money based on its ability to

minimize variability and maximize availability.

Performance and reliability are the foundation

for the Fisher

controllers. Their role is to maintain control

valve position, diagnose the assembly, and

enable predictive maintenance.

Emerson’s FIELDVUE digital valve controllers,

with HART® or Foundation™ fieldbus

communications, can be integrated into

process control systems that support FDT

technology.

Integrating with FDT Technology

• Communicate with any FIELDVUE instrument.

Emerson’s ValveLink™ DTM communicates with FIELDVUE instruments, including DVC6200, DVC6200f, DVC6000,

DVC6000f, DVC6000 SIS, DVC2000, DVC5000, and DVC5000f.

®

FIELDVUE™ family of digital valve

• Certifications for non-host systems.

Emerson’s ValveLink DTM has been certied by The FDT Group.

For more information, visit www.FDTGroup.org.

• Tested and approved by host systems.

Emerson’s ValveLink DTM has been tested and approved by most control system manufacturers, including ABB,

Invensys, Honeywell, and Yokogawa.

• Full diagnostic capability offering.

In addition to providing setup, conguration, and

calibration of all FIELDVUE instruments, Emerson’s

ValveLink DTM is capable of providing the following

diagnostics when available from the instrument:

• Valve Signature and Analysis

• Step Response and Analysis

• Graph Overlay

• Performance Diagnostics

• Triggered Prole

• Partial Stroke Tests

• Share information easily.

Import and review data from other ValveLink

software users, including ValveLink Mobile software.

• Document the performance of your control valve.

It’s easy to create and print specication sheet data and reports that document control valve

assembly performance.

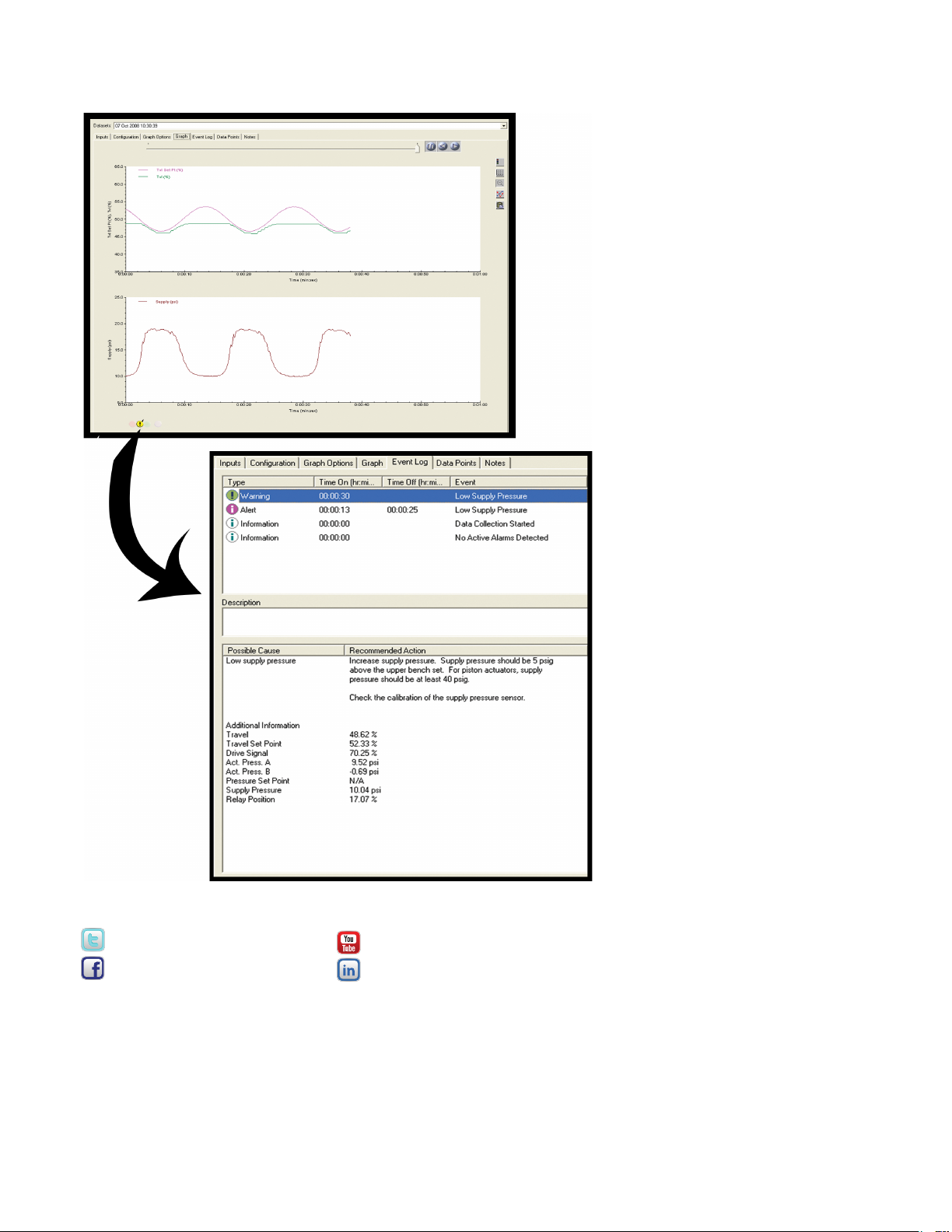

FIELDVUE Performance Diagnostics support the users ability to troubleshoot their valve assembly with on-line / inservice predictive diagnostics which help to identify faults, list possible causes, and recommended corrective actions

for each. Green, yellow, red indicators provide visual indication of control valve assembly performance.

Performance Diagnostics monitor the health of

the valve assembly while it is at work, without

introducing intrusive test signals that could disrupt

the process.

A Green, Yellow, or Red light indicates

the level of urgency of the fault.

• Green light - OK

• Yellow light - maintenance soon

• Red light - maintenance required

http://www.twitter.com/FisherValves

http://www.facebook.com/FisherValves

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore, 128461 Singapore

www.EmersonProcess.com/Fisher

D351977X012 / MX70 (H:) / Dec11

Corrective action can be more rapidly

determined with the support of the

Possible Cause and a Recommended

Action to the fault.

http://www.YouTube.com/user/FisherControlValve

http://www.linkedin.com/groups/Fisher-3941826

© 2011, Fisher Controls International LLC. All Rights Reserved.

Fisher, FIELDVUE, and ValveLink are marks owned by one of the companies in the Emerson Process Management

business section of Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are

trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has

been made to ensure their accuracy they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify

or improve the designs or specifications of such products at any time without notice. Neither Emerson,

Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection,

use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any

product remains solely with the purchaser and end-user.

Loading...

Loading...