Page 1

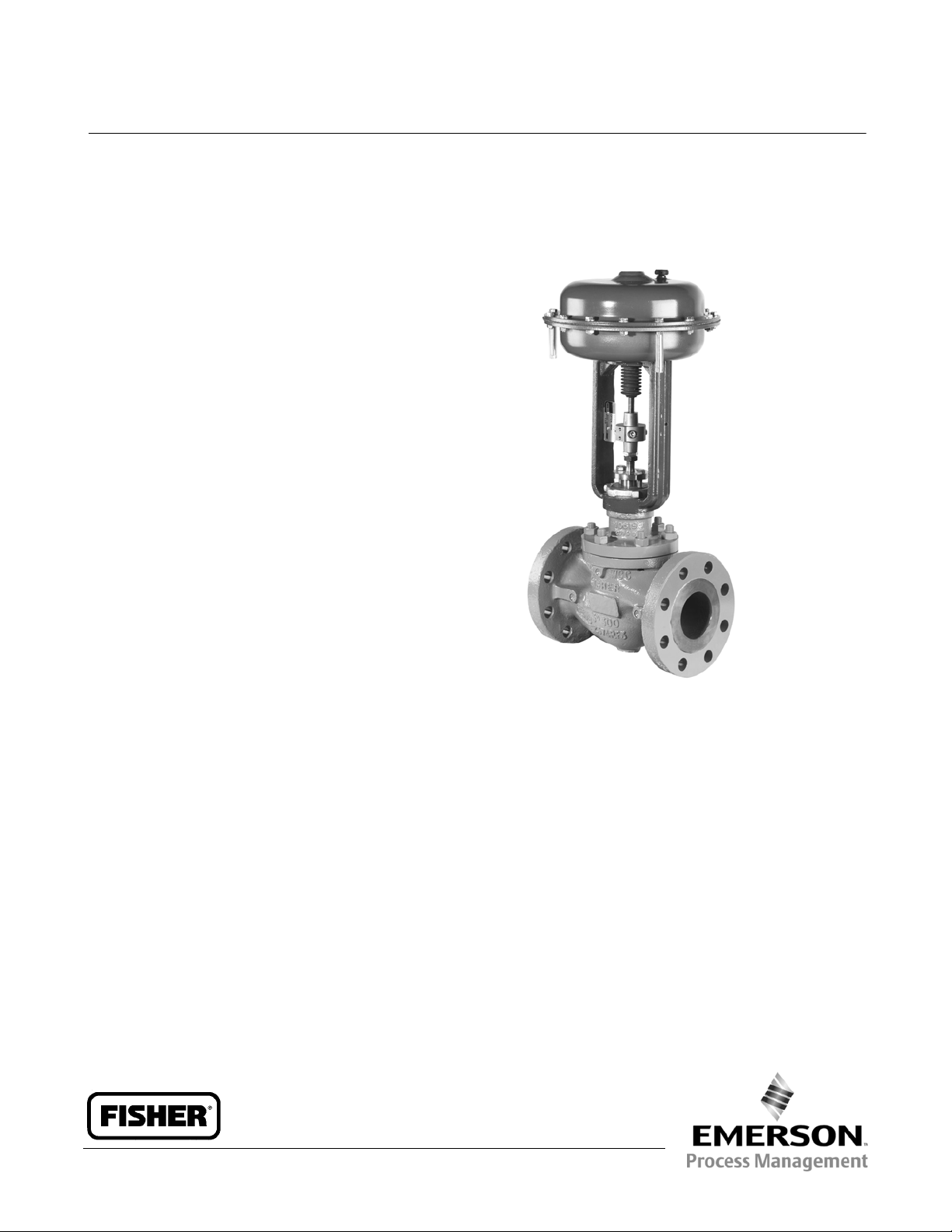

3024C Actuator

D103051X012

Fisherr 3024C Diaphragm Actuator

The 3024C actuator is a compact spring opposed

pneumatic diaphragm actuator incorporating a cast

yoke mounting and is suitable for general purpose

actuation of globe valves. It will position the valve plug

in response to varying controller or valve positioner

pneumatic output signals applied to the actuator

diaphragm. The 3024C actuator can be assembled as

either direct-acting or reverse-acting and provides

dependable and on-off or throttling operation of

automatic control valves.

Product Bulletin

61.1:3024C

March 2012

Features

Application Versatility–With eight different

configurations available, there is an actuator size to

meet your needs. Multi-spring combinations allow

for accurate selection of actuator thrust and valve

travel.

Reversible Action–The simple design allows the

change of action from direct to reverse acting

without the requirement for extra parts. Change of

action can be easily made in the field.

High Thrust Capability–The moulded diaphragm

and high strength casings allow for a maximum

casing pressure of 6 bar, enabling a high stem thrust

for a given size diaphragm.

Positive Connections–Split block stem connection

provides a solid transfer of motion while allowing

easy mounting and no linkages that create lost

motion or inaccurate valve positioning.

W8488

Rugged Construction–The cast steel yoke and

Severe Temperature Applications–Through careful

Compact Design–The compact size minimizes

3024C Actuator Mounted on Fisher Valve

heavydutysteelcasingsprovidestability,

protection against corrosion, longevity, and

resistance against misuse.

selection of construction materials, this actuator

canbeusedforawiderangeofambient

temperature conditions from a minimum of -40_C

to a maximum of +82_C.

weight and space needed.

Available Configurations

Refer to figure 1.

www.Fisher.com

Page 2

Product Bulletin

61.1:3024C

March 2012

3024C Actuator

D103051X012

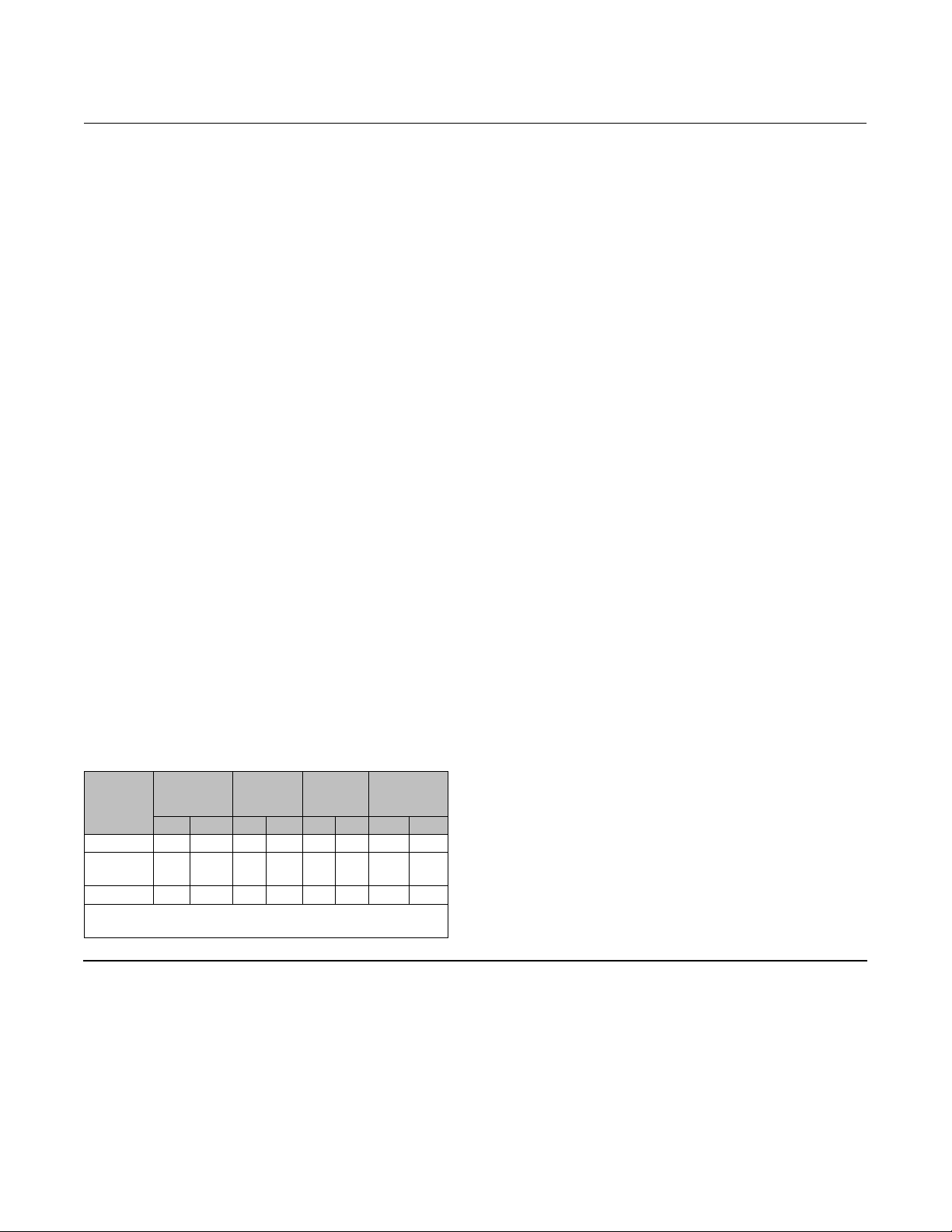

Direct Action

With the direct action mode on the 3024C actuator,

applying air pressure to the upper side of the

diaphragm forces the actuator stem downward while,

atthesametime,compressingthespringsonthe

underside of the diaphragm. Refer to figure 1. When

this pressure is reduced, the opposing spring force

moves the actuator stem upwards. Should the loading

pressure fail, the springs force the stem to the extreme

upward position, thereby providing fail-open action for

apush-down-to-closevalve.

Reverse Action

With the reverse action mode, air is applied on the

underside of the diaphragm while opposing spring

force is on the top side. Increasing air pressure will

force the stem upwards. When the loading pressure is

reduced, the stem moves downwards. Should loading

pressure fail, the springs force the stem to the extreme

downward position, thereby providing fail-closed

action for a push-down-to-close valve.

Accessories

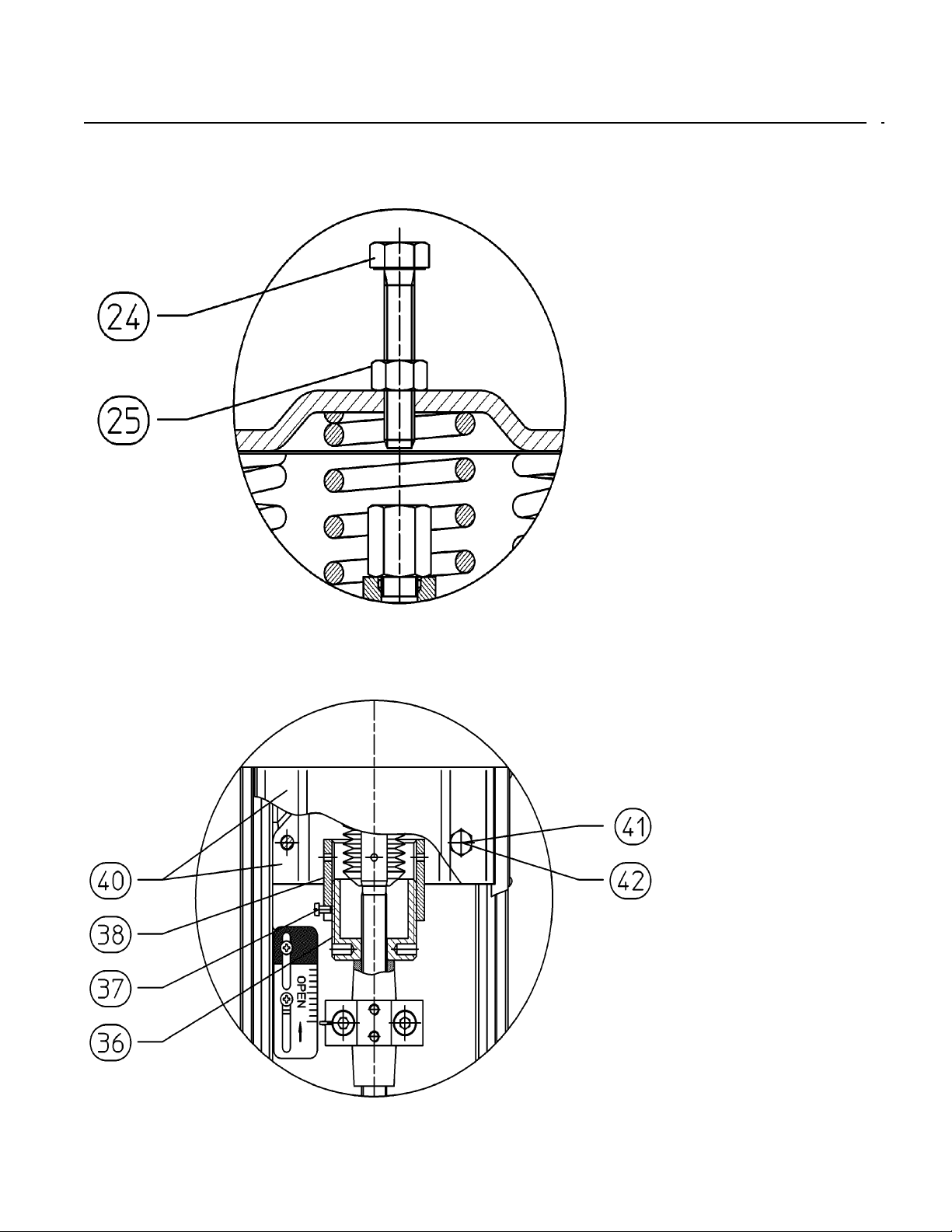

Handwheels

An optional side-mounted handwheel can be fitted to

all sizes of actuator with travel up to 32 mm (1.25 inch)

and where the maximum actuator thrust is less than

14,000 N (3150 lbf). These handwheels provide a

robust method of manually operating the valve in an

emergency o r when there is a loss of instrument air.

Refer to figures 2 and 3 and table 1 for details.

Note, a side-mounted handwheel cannot be fitted on

the sizes 45 and 45E actuator if an adjustable travel

stop is fitted as well.

When mounted on a direct action actuator, turning

the handwheel clockwise always moves the stem

downwards. When mounted on a reverse action

actuator, turning the handwheel clockwise moves the

stem upwards. Disengagement of the handwheel to

enable automatic operation is simply accomplished by

rewinding the handwheel.

Valve Compatibility

With the availability of both metric and imperial

threaded stem connectors, the 3024C can be used

with a range of valve body assemblies such as the

Fisher metric 1018S construction or imperial easy-et

and RSS valve body constructions, along with others.

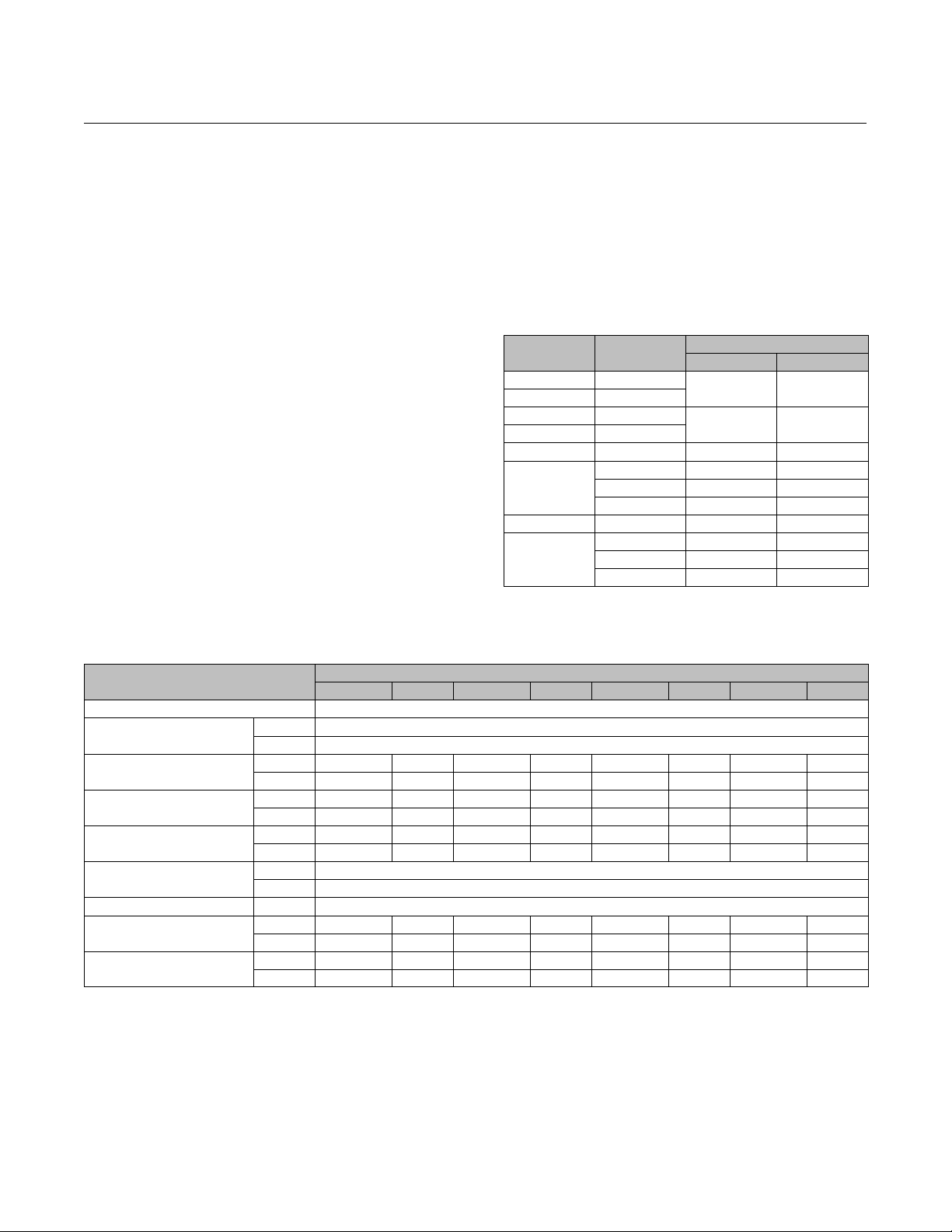

Table 1. Handwheel Specifications

ACTUATOR

SIZE

30 and 30E 200 7.87 0.24 6.1 179 40 5000 1125

34, 34E, 40,

and 40E

45 and 45E 250 9.84 0.21 5.5 400 90 14000 3150

1. Tangential handwheel force required to produce the handwheel output force

shown.

2. Brass operating nut and stainless steel screw.

HANDWHEEL

DIAMETER

mm Inch mm Inch N lbs N lbs

250 9.84 0.21 5.4 286 64 10000 2250

TURNS PER

mm/INCH

TRAVEL

RIM FORCE

(1, 2)

Contents

Features 1.....................................

Available Configurations 1.......................

Direct Action 2................................

Reverse Action 2..............................

Valve Compatibility 2..........................

Accessories 2..................................

Handwheels 2................................

HANDWHEEL

OUTPUT

FORCE

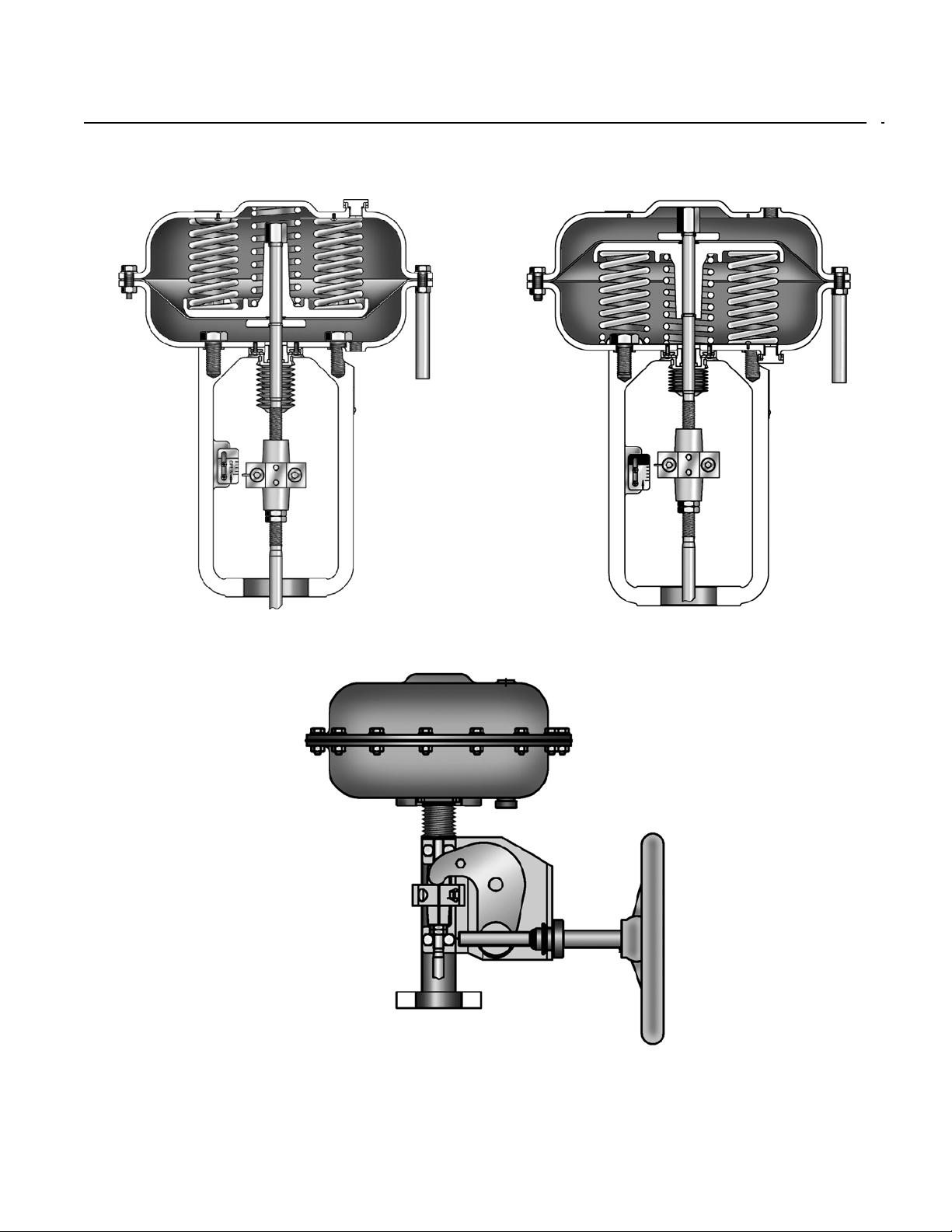

Adjustable Travel Stops

Top mounted adjustable up travel stops are available

for all actuators from size 30 to 40E. For the larger sizes

45 and 45E, an adjustable stop can be fitted to the

actuator stem below the diaphragm casings. Both

constructions give total variable adjustment of the

travel of the actuator by limiting movement in the

upward direction. Refer to figures 4 and 5.

Others

Accessories such as transducers, positioners, position

transmitters, air relays, volume boosters, switching

valves, lockup valves, limit switches, and solenoid

valves are also available for actuator mounting. They

are described in separate publications. Contact your

Emerson Process Management sales office for details.

Adjustable Travel Stops 2.......................

Others 2.....................................

Construction Materials 6.........................

General S pecifications 6.........................

Actuator Dimensions 9..........................

Ordering Information 9..........................

2

Page 3

3024C Actuator

D103051X012

Figure 1. Typical Applications

Product Bulletin

61.1:3024C

March 2012

W8466-1 W8495-1

3024C (AIR RETRACTS STEM)

W8496-1

3024C (AIR EXTENDS STEM)

3024C FITTED WITH A SIDE-MOUNTED HANDWHEEL

3

Page 4

Product Bulletin

61.1:3024C

March 2012

Figure 2. Side-Mounted Handwheel with Air-Extends-Stem Actuator

3024C Actuator

D103051X012

1Q57490

Figure 3. Side-Mounted Handwheel with Air-Retracts-Stem Actuator

1Q57490

4

Page 5

3024C Actuator

D103051X012

Figure 4. Up Stop for Actuator Sizes up to 40 and 40E

Product Bulletin

61.1:3024C

March 2012

3Q57478

Figure 5. Up Stop for Actuator Sizes 45 and 45E

3Q57478

5

Page 6

Product Bulletin

61.1:3024C

March 2012

3024C Actuator

D103051X012

Construction Materials

Refer to figure 1.

Diaphragm Casings: Steel

Diaphragm: Nitrile

Diaphragm Plate: Aluminium

Springs: Steel

Spring locator: Steel

Actuator Stem: Stainless steel

O-Rings: Nitrile

Yoke: Cast steel

Stem Connector: Steel

Nameplate: Stainless steel

Travel Indicator Scale: Stainless steel

General Specifications

The sizes 30, 34, 40 and 45 are typically used with the

1018S valve bodies. The sizes 30E, 34E, 40E and 45E

are used with such valves as the easy-e or RSS.

Table 2. Volumetric Data

(Air-to-Open and Air-to-Close)

ACTUATOR

SIZE

30 16 mm

30E 0.75 inch

34 16 mm

34E 0.75 inch

40 32 mm 1.5 2.8

40E

45 32 mm 3.0 5.7

45E

ACTUATOR

TRAVEL

1.125 inch 1.5 2.8

1.5 inch 1.8 3.3

2inch 1.5 3.5

1.125 inch 3.0 5.7

1.5 inch 3.8 7.0

2inch 3.0 7.4

VOLUME (L)

0% Travel 100% Travel

0.6 0.9

1.9 2.6

Table 3. Specifications

Specification

Nominal Effective Area See tables 4 and 5

Maximum Operating Pressure

to Diaphragm

Maximum Travel

Yoke Boss Diameter

Valve Stem Connector Thread

TemperatureRange

Pressure Connections Inch 1/4 — 18 NPT

Maximum Approximate

Weight (without handwheel)

Maximum Approximate

Weight (with handwheel)

Bar 6

psig 87

mm 16 --- 16 --- 32 --- 32 --Inch --- 0.75 --- 0.75 --- 2 --- 2

mm 54 mm 54 mm 54 mm 54 mm 71 mm 71 mm 71 mm 71mm

Inch 2-1/8 2-1/8 2-1/8 2-1/8 2-13/16 2-13/16 2-13/16 2-13/16

mm M12 x 1.75 --- M12 x 1.75 --- M16 x 2 --- M16 x 2 --Inch --- 3/8-24 --- 3/8-24 --- 1/2-20 --- 1/2-20

_C Nitrile diaphragm and steel studs and nuts: -40 to +82

_F Nitrile diaphragm and steel studs and nuts: -40 to + 180

kg 9.5 9.5 18.0 18.0 19.5 21.5 33.5 35.5

lb 20.9 20.9 39.7 39.7 43.0 47.4 73.9 78.3

kg 16.5 16.5 25.0 25.0 26.5 28.5 40.5 42.5

lb 36.4 36.4 55.1 55.1 58.4 62.8 89.3 93.7

30 30E 34 34E 40 40E 45 45E

Actuator Size

6

Page 7

Product Bulletin

3024C Actuator

D103051X012

Table 4. Additional Specifications (Action - Air Extends Stem)

SIZE

30

30E

34

34E

40

40E

45

45E

1. Effective diaphragm area at 0% valve travel from seat.

2. Based upon 6 bar operating pressure to the diaphragm and valve travel at 0% from seat. This does not consider limitation to the valve such as stem buckling load. Consult your Emerson

Process Management sales office for details.

SPRING

SET/QTY

217/3

218/5

218/7

217/3

218/5

218/7

219/3

212/5

212/7

219/3

212/5

212/7

212/3

213/6

214/7

212/3

213/6

214/7

213/4

214/5

214/7

213/4

214/5

214/7

221/8

221/12

223/12

221/8

221/12

223/12

221/8

221/12

223/12

221/8

221/12

223/12

TRAVEL SPRING RANGE

mm Inch Bar Psig cm

0.3 - 1.1 4-16 160 24.8 7840 1760

16 ---

--- 0.75

16 ---

--- 0.75

32

--- 1.125

--- 1.5

--- 2

32 ---

--- 1.125

--- 1.5

--- 2

---

1.3 - 2.0 19 - 29 160 24.8 6400 1440

1.8 - 2.9 26 - 42 160 24.8 4960 1120

0.3 - 1.3 4-19 160 24.8 7520 1690

1.3 - 2.2 19 - 32 160 24.8 6080 1360

1.8 - 3.0 26 - 44 160 24.8 4800 1070

0.3 - 1.1 4-16 400 62.0 19,600 4400

0.9 - 1.7 13 - 25 400 62.0 17,200 3840

1.3 - 2.3 19 - 33 400 62.0 14,800 3350

0.3 - 1.3 4-19 400 62.0 18,800 4220

0.9 - 1.8 13 - 26 400 62.0 16,800 3780

1.3 - 2.5 19 - 36 400 62.0 14,000 3160

0.4 - 1.3 6-19 390 60.5 18,300 4110

0.8 - 1.8 12 - 26 390 60.5 16,400 3690

1.2 - 2.4 17 - 35 390 60.5 14,000 3150

0.4 - 1.2 6-17 390 60.5 18,700 4230

0.8 - 1.7 12 - 25 390 60.5 16,800 3750

1.2 - 2.3 17 - 33 390 60.5 14,400 3270

0.3 - 1.0 4-15 380 58.9 19,000 4240

0.6 - 1.5 9-22 380 58.9 17,100 3830

0.9 - 2.1 13 - 30 380 58.9 14,800 3360

0.2 - 1.2 3-17 370 57.4 17,800 4220

0.5 - 1.7 7-25 370 57.4 15,900 3560

0.7 - 2.4 10 - 35 370 57.4 13,300 2980

0.8 - 1.6 12 - 23 790 122 34,800 7810

1.2 - 2.5 17 - 36 790 122 27,600 6220

1.5 - 3.1 22 - 45 790 122 22,900 5120

0.8 - 1.6 12 - 23 790 122 34,800 7810

1.2 - 2.3 17 - 33 790 122 29,200 6590

1.5 - 3.0 22 - 44 790 122 23,700 5250

0.5 - 1.4 7-20 780 121 35,900 8110

0.8 - 2.2 12 - 32 780 121 29,600 6650

1.0 - 2.7 15 - 39 780 121 25,700 5810

0.5 - 1.7 7-25 770 119 33,100 7380

0.7 - 2.5 10 - 36 770 119 26,900 6070

0.9 - 3.1 12 - 45 770 119 22,300 5000

EFFECTIVE DIAPHRAGM

2

AREA

(1)

Inches

THRUST (MAXIMUM

ACTUATOR STEM FORCE)

2

61.1:3024C

March 2012

MAXIMUM OUTPUT

N Lb

(2)

7

Page 8

Product Bulletin

61.1:3024C

March 2012

Table 5. Additional Specifications (Action - Air Retracts Stem)

SIZE

30

30E

34

34E

40

40E

45

45E

1. Effective diaphragm area at 0% valve travel from seat.

2. Based on zero operating pressure to the diaphragm and valve travel at 0% from valve seat. This does not consider limitations such as stem buckling load. Consult your Emerson Process

Management sales office for details.

SPRING

SET/QTY

217/3

218/5

218/7

217/3

218/5

218/7

219/3

212/5

212/7

219/3

212/5

212/7

212/3

213/6

214/7

212/3

213/6

214/7

213/4

214/5

214/7

213/4

214/5

214/7

221/8

221/12

223/12

221/8

221/12

223/12

221/8

221/12

223/12

221/8

221/12

223/12

TRAVEL SPRING RANGE

mm Inch Bar Psig cm

0.5 - 1.3 7-19 170 26.4 780 170

16 ---

--- 0.75

16 ---

--- 0.75

32 ---

--- 1.125

--- 1.5

--- 2

32 ---

--- 1.125

--- 1.5

--- 2

1.4 - 2.2 20 - 32 170 26.4 2360 530

2.0 - 3.1 29 - 45 170 26.4 3360 760

0.3 - 1.3 4-19 175 27.1 550 120

1.2 - 2.2 17 - 32 175 27.1 2180 490

1.8 - 3.1 26 - 45 175 27.1 3110 700

0.6 - 1.4 9-20 410 63.6 2450 550

1.1 - 1.9 16 - 28 410 63.6 4610 1040

1.6 - 2.7 23 - 39 410 63.6 6560 1480

0.4 - 1.4 6-20 420 65.1 1880 420

1.0 - 1.9 15 - 28 420 65.1 4120 930

1.4 - 2.7 20 - 39 420 65.1 5870 1320

0.4 - 1.3 6-19 450 69.8 1880 420

0.8 - 1.8 12 - 26 450 69.8 3640 820

1.2 - 2.4 17 - 35 450 69.8 5530 1240

0.5 - 1.3 7-19 440 68.2 2200 500

0.9 - 1.8 13 - 26 440 68.2 3970 890

1.3 - 2.4 19 - 35 440 68.2 5920 1330

0.4 - 1.1 6-16 410 63.6 1560 350

0.7 - 1.6 10 - 23 410 63.6 3010 680

1.0 - 2.3 15 - 33 410 63.6 4270 960

0.2 - 1.2 3-17 440 68.2 1060 240

0.5 - 1.8 7-26 440 68.2 2390 540

0.8 - 2.5 12 - 36 440 68.2 3400 760

0.8 - 1.7 12 - 25 940 146 7790 1750

1.2 - 2.5 17 - 36 940 146 11,700 2630

1.6 - 3.2 23 - 46 940 146 14,700 3300

0.9 - 1.7 13 - 25 910 141 8350 1880

1.4 - 2.5 20 - 36 910 141 12,500 2810

1.7 - 3.2 25 - 46 910 141 15,700 3530

0.7 - 1.6 10 - 23 870 135 6150 1380

1.1 - 2.4 16 - 35 870 135 9230 2080

1.3 - 3.1 19 - 45 870 135 11,500 2590

0.5 - 1.7 7-25 940 146 4740 1070

0.8 - 2.6 12 - 38 940 146 7110 1600

0.9 - 3.2 13 - 46 940 146 8800 1980

EFFECTIVE DIAPHRAGM

2

AREA

(1)

Inches

3024C Actuator

D103051X012

MAXIMU M OUTPUT

THRUST (MAXIMUM

ACTUATOR STEM FORCE)

2

N Lb

(2)

8

Page 9

3024C Actuator

D103051X012

Actuator Dimensions

See table 6.

Product Bulletin

61.1:3024C

March 2012

VALVE

(1)

YOKE BOSS, INCHES

C E F

Inches

7. Stroking time requirements, if critical

8. Ambient temperature range

(2)

AR Js Hs M(ARS)

Millimeters

Table 6. Dimensions

ACTUATOR

SIZE

30 16 mm 2-1/8 (54 mm) 215 370 140 105 205 280 185 80

34 16 mm 2-1/8 (54 mm) 315 400 140 105 250 280 185 80

40 32 mm 2-13/16 (71 mm) 315 420 170 133 250 280 210 100

45 32 mm 2-13/16 (71 mm) 420 450 170 133 250 280 210 100

30E 0.75 2-1/8 8.5 14.6 5.6 4.7 8.1 11.0 7.3 3.1

34E 0.75 2-1/8 12.4 15.8 5.6 4.7 9.8 11.0 7.3 3.1

40E 1.125 2-13/16 12.4 17.9 8.1 6.6 9.8 11.0 9.6 5.5

40E 1.5 2-13/16 12.4 18.9 8.3 6.6 9.8 --- --- --40E 2 2-13/16 12.4 18.9 8.5 6.2 9.8 --- --- --45E 1.125 2-13/16 16.5 19.3 8.1 6.6 9.8 11.0 9.6 5.5

45E 1.5 2-13/16 16.5 20.1 8.3 6.6 9.8 --- --- --45E 2 2-13/16 16.5 20.1 8.5 6.2 9.8 --- --- ---

1. See figures 6 and 7.

2. This is the centre of the stem connector at the fully-up postion. This ensures the positioner feedback arm, if fitted, is horizontal at mid-travel.

3. ARS - air retracts stem.

4. AES - air extends stem.

TRAVEL

Ordering Information

When ordering please specify the following

information:

Actuator and Positioner

Application Details:

1. On-off or throttling service

2. Input signal range

3. Maximum supply pressure

4. Valvebodytypeandsizewithwhichtheactuator

will be used

Be sure to specify the actuator type number required,

whether a positioner is needed, whether a handwheel

is required and whether an adjustable travel stop is

required. Refer to the Specifications section in this

bulletin. Review the information under each

specification a nd in the referenced tables and figures.

Specify the desired choice wherever there is a selection

to be made.

(3)

M(AES)

(4)

5. Valve plug travel

6. Actuator thrust required with the actuator stem

both fully retracted and fully extended

Valve Body and Accessories

Refer to the separate valve body bulletin and bulletins

covering accessories for ordering information.

9

Page 10

Product Bulletin

61.1:3024C

March 2012

Figure 6. Actuator Dimensions with Handwheel (see table 6)

M

3024C Actuator

D103051X012

J

S

1Q57490

REVERSE-ACTING

H

S

J

S

M

H

S

DIRECT-ACTING

10

Page 11

3024C Actuator

D103051X012

Figure 7. Actuator Dimensions (see table 6)

Product Bulletin

61.1:3024C

March 2012

AR (ACTUATOR

REMOVAL)

E

C

1Q57491

F

D

11

Page 12

Product Bulletin

61.1:3024C

March 2012

3024C Actuator

D103051X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and easy-e are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2003, 2012 Fisher Controls International LLC. All rights reserved.

12

Loading...

Loading...