Emerson Fisher 299H Series, Fisher 299H, Fisher 299HR, Fisher 299HS, Fisher 299HSR Instruction Manual

Instruction Manual

Form 5497

January 2014

299H Series

299H Series Pressure Reducing Regulators

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or re causing property damage and

personal injury or death.

Fisher® regulators must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies, Inc.

(Regulator Technologies) instructions.

If the regulator vents gas or a leak

develops in the system, service to the unit

may be required. Failure to correct trouble

could result in a hazardous condition.

Call a gas service person to service the

unit. Only a qualied person must install

or service the regulator.

Introduction

Scope of the Manual

This Instruction Manual provides installation, adjustment

and maintenance instructions and parts ordering

information for the 299H Series regulators. Complete

instructions and parts list for the 67C Series ltered pilot

supply regulator and other Fisher equipment are found

in separate instruction manuals.

Description

The 299H Series pressure reducing regulators provide

a broad capacity of controlled pressure ranges and

capacities in a wide variety of distribution, industrial

and commercial applications. A 299H Series regulator

has a pilot integrally mounted to the actuator casing.

The 299H Series regulators can handle inlet pressures

up to 175 psi / 12.1 bar depending on orice size.

W7513

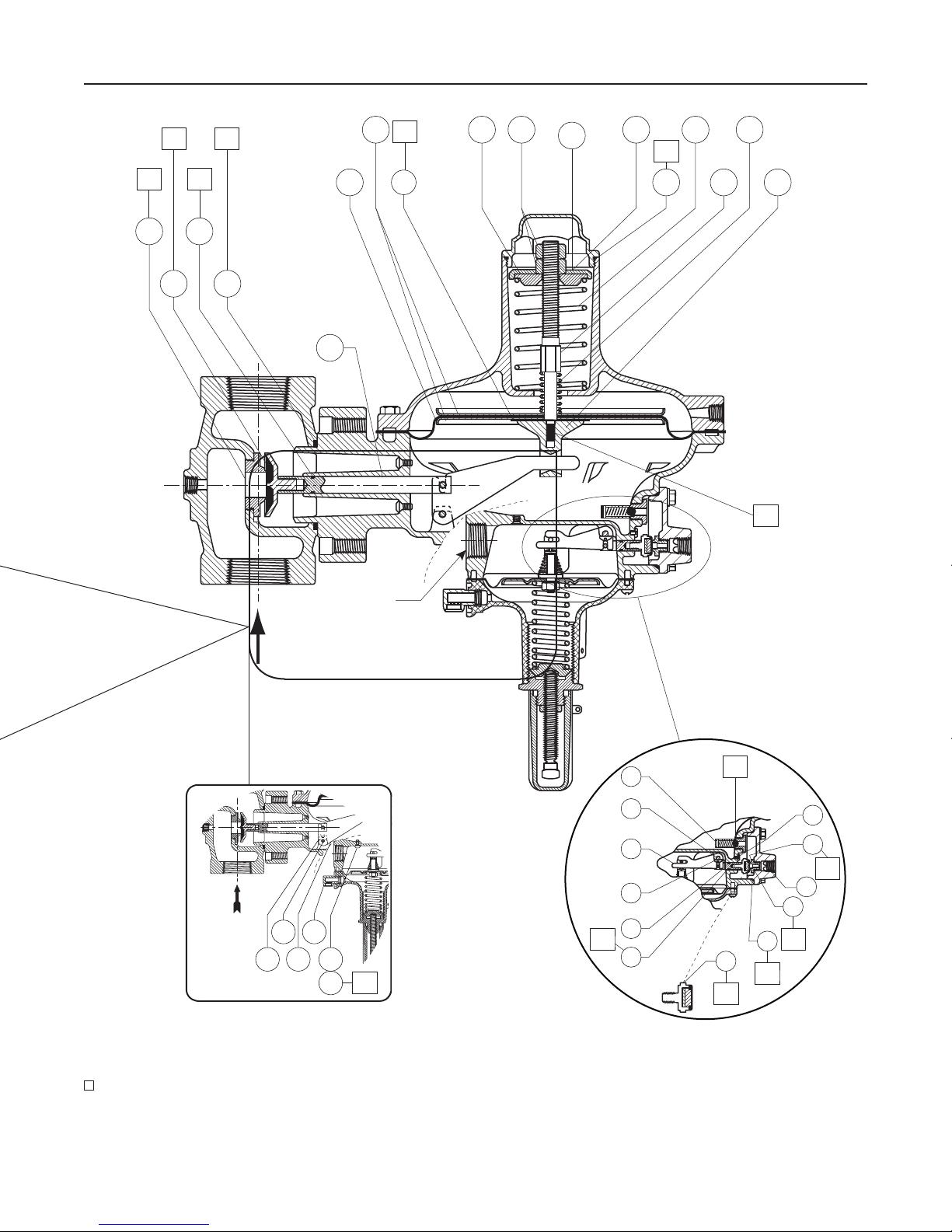

Figure 1. 299H Series Pressure Reducing Regulator

The integral token relief on the Types 299HR and

299HSR regulators is located in the pilot and opens

to relieve minor overpressure.

The Type 299HS provides overpressure or overpressure

and underpressure protection by completely shutting off

the ow of gas to the downstream system. It comes with

a Type VSX-2 slam-shut device which can be congured

for Ovepressure Shutoff (OPSO) or Overpressure and

Underpressure Shutoff (OPSO/UPSO). The slam-shut

device’s actions are independent of the main valve and

of variations to the inlet pressure. The Type VSX-2

slam-shut device has internal or external registration.

External registration requires a downstream sensing line.

D102684X012

www.sherregulators.com

299H Series

Specications

Specications for 299H Series constructions are given below. Some specications for a given regulator as it

originally comes from the factory are stamped on a nameplate located on the actuator upper casing.

Available Constructions

Type 299H: Pilot-operated pressure reducing

Minimum and Maximum Trip Pressure Ranges

See Table 3

regulator with a pilot integrally mounted to the

actuator casing.

Type 299HR: A Type 299H with a token internal

relief valve to relieve minor overpressure caused

by thermal expansion.

Type 299HS: Same as the Type 299H with a

Type VSX-2 slam-shut valve which provides

overpressure or overpressure and

Type VSX-2 Sensing Line Connection

1/4 NPT

Pressure Control Accuracy (Fixed Factor)(PFM)

(3)

±1%

of absolute control pressure

Minimum Differential Pressure For Full Stroke

1.5 psid / 0.10 bar d

underpressure protection.

Type 299HSR: Same as the Type 299HS with an

internal token relief valve.

Body Size and End Connection Styles

See Table 1

Maximum Operating Inlet Pressure by Orice Size

1/4 x 3/8-inch / 6.4 x 9.5 mm .......... 175 psig / 12.1 bar

3/8 inch / 9.5 mm .......................... 175 psig / 12.1 bar

1/2 inch / 13 mm ........................... 175 psig / 12.1 bar

3/4 inch / 19 mm ........................... 150 psig / 10.3 bar

7/8 inch / 22 mm

1 inch / 25 mm

1-3/16 inches / 30 mm

(5)

........................... 125 psig / 8.6 bar

(5)

.................................100 psig / 6.9 bar

(5)

................... 80 psig / 5.5 bar

Maximum Casing and Emergency Outlet Pressure

66 psig / 4.5 bar

Outlet (Control) Pressure Ranges

(1)(2)

See Table 2

Maximum Set Pressure for Type 299HS

(1)

16 psig / 1.1 bar

Maximum Set Pressure for Slam-Shut Device

(1)

(1)

(1)

Control Line Connections

3/4 NPT

Temperature Capabilities

-20 to 150°F / -29 to 66°C

Approximate Weight

21 pounds / 10 kg

Pressure Registration

Internal, External or Dual Registration

See Figure 2

Fixed Restriction Sizes

0.044 inch / 1.1 mm, Red (standard gain)

0.071 inch / 1.8 mm, Green (low gain)

0.082 inch / 2.1 mm, Blue (lower gain)

Options

• Filter

(3)

: A P590 Series lter installed in the pilot

supply tubing between main body and pilot

• Filtered pilot supply regulator

supply regulator with integral 5 micron

Polyethylene lter

23 psig / 1.6 bar

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. For optimum performance, a pilot supply regulator may be installed in the pilot supply tubing between the main valve and pilot.

3. A pilot supply regulator or a P590 Series lter (only one may be used, not both) may be ordered with the Type 299H, but not both.

4. For inches w.c., use a pilot supply regulator if actual inlet pressure varies more than ±20 psi / ±1.4 bar and published accuracy is required.

5. This orice size is not available for Types 299HS and 299HSR.

(1)

(3)(4)

: A Type 67CF

BODY SIZE,

INCH / DN

1-1/4

1-1/2

2 / 50 NPT and CL125 FF

1. This ange is available with a face-to-face dimension of 7.5 inches / 190 mm or 10 inches / 254 mm.

2

Cast Iron (For Types 299H and 299HR only) Ductile Iron Steel (For Types 299H and 299HR only)

NPT

NPT

Table 1. Body Sizes and End Connection Styles

BODY MATERIAL AND END CONNECTION STYLE

- - - NPT

(1)

anged

NPT, CL125 FF and CL250 RF anged

and PN 10/16 anged

- - - NPT

NPT and CL150 RF anged

299H Series

Table 2. Outlet Pressure Ranges

TYPE PILOT CONTROL SPRING

OUTLET (CONTROL)

PRESSURE RANGE

299H

Inch w.c. mbar Inch mm Inch mm

(1)

3.5 to 6

(1)

5 to 9

(1)

7 to 20

(1)

16 to 40

1 to 3.25 psig

2.75 to 6 psig

5 to 16 psig

14 to 35 psig

30 to 60 psig

1. Use a pilot supply regulator if actual inlet pressure varies more than ±20 psi / ±1.4 bar and the published accuracy is required.

RANGE

69 mbar to 0.22 bar

0.19 to 0.41 bar

0.34 to 1.1 bar

0.97 to 2.4 bar

2.1 to 4.1 bar

SLAM-SHUT

REGISTRATION

9 to 15

12 to 22

17 to 50

40 to 99

(1)

(1)

(1)

(1)

FOR USE WITH MAIN VALVE

SPRING RANGE

Inch w.c. mbar Inch w.c. mbar Inch mm Inch mm

3.5 to 6 9 to 15

5 to 9 12 to 22

3.5 to 6 9 to 15

7 to 20 17 to 50

High

Pressure

Trip

Internal or

External

7 to 20 17 to 50

16 to 40 40 to 99

16 to 40 40 to 99

2.75 to 6 psig 0.19 to 0.41 bar

2.75 to 6 psig 0.19 to 0.41 bar

5 to 16 psig 0.35 to 1.1 bar

5 to 16 psig 0.35 to 1.1 bar 11.6 to 23 psig 800 to 1586 T14167T0012 3.15 80.0 0.17 4.32

5 to 9 12 to 22

7 to 20 17 to 50

7 to 20 17 to 50

External

16 to 40 40 to 99

1 to 3.25 psig 69 mbar to 0.22 bar

2.75 to 6 psig 0.19 to 0.41 bar

2.75 to 6 psig 0.19 to 0.41 bar

5 to 16 psig 0.35 to 1.1 bar

(1)

Low

Pressure

Trip

5 to 9

16 to 40

(1)

(1)

1 to 3.25 psig

Internal

2.75 to 6 psig

2.75 to 6 psig

5 to 16 psig

1. Low Pressure Trip cannot be used with this main valve spring range for an internally registered Type VSX-2 to provide underpressure shutoff under owing conditions. If protection

against loss of inlet pressure is the only required function for the Type VSX-2 then an internally registered Type VSX-2 may be used with the same minimum trip pressures as an

externally registered Type VSX-2.

2. 70% of regulator setpoint is the minimum allowable Low Pressure Trip setting for an internally registered Type VSX-2 used with this main valve spring range. If protection against

loss of inlet pressure is the only required function for the Type VSX-2 then an internally registered Type VSX-2 may be used with the same minimum trip pressures as an externally

registered Type VSX-2.

3. 75% of regulator setpoint is the minimum allowable Low Pressure Trip setting for an internally registered Type VSX-2 used with this main valve spring range. If protection against

loss of inlet pressure is the only required function for the Type VSX-2 then an internally registered Type VSX-2 may be used with the same minimum trip pressures as an externally

registered Type VSX-2.

Note: Other spring combinations are available, please contact your local Sales Ofce for additional information.

(3)

299HR,

299HS and

Part Number Color

Free Length Wire Diameter

299HSR

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

- - - -

- - - -

T13707T0012

T13589T0012

1N3112X0012

1B413727222

T13593T0012

T13671T0012

T13600T0012

19B0432X012

19B0432X022

Black

Yellow

Unpainted

Purple

Light blue

Orange

Red

Zinc

Green

1.86

2.05

2.18

2.12

2.12

2.40

2.10

2.15

2.75

Table 3. Type VSX-2 High and Low Trip Pressure Ranges

(2)

(2)

0.19 to 0.41 bar

(2)

0.19 to 0.41 bar

0.35 to 1.1 bar

(1)

12 to 22

(1)

17 to 50

(1)

40 to 99

69 mbar to

(2)

0.22 bar

MINIMUM TO MAXIMUM

TRIP PRESSURE

12 to 25 30 to 62 T14162T0012 3.15 80.0 0.07 1.70

20 to 52 50 to 129 T14163T0012 3.15 80.0 0.08 2.035 to 9 12 to 22

1.4 to 3.9 psig 97 to 269 T14164T0012 3.15 80.0 0.09 2.31

3.8 to 8.7 psig 262 to 600 T14165T0012 3.15 80.0 0.12 3.051 to 3.25 psig 69 mbar to 0.22 bar

5.8 to 16 psig 400 to 1103 T14166T0012 3.15 80.0 0.14 3.51

2 to 12 5 to 30 T14168T0012 3.15 80.0 0.04 1.09

4 to 30 10 to 75 T14169T0012 3.15 80.0 0.06 1.40

0.36 to 2.3 psig 25 to 159 T14170T0012 3.15 80.0 0.07 1.70

1.5 to 10.8 psig 103 to 745 T14171T0012 3.15 80.0 0.13 3.17

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7 to 20

70% of regulator

setpoint to

(2)

2.3 psig

70% of regulator

(2)

setpoint to

10.8 psig

75% of regulator

(3)

setpoint to

10.8 psig

70% of regulator

setpoint to

159 mbar

70% of regulator

setpoint to

745 mbar

75% of regulator

setpoint to

745 mbar

TYPE VSX-2

SPRING PART

NUMBER

T14170T0012 3.15 80.0 0.07 1.70

T14171T0012 3.15 80.0 0.13 3.17

T14171T0012 3.15 80.0 0.13 3.17

47.2

52.1

55.4

53.8

53.8

61.0

53.3

54.6

69.8

SPRING FREE

LENGTH

0.055

0.051

0.075

0.092

0.105

0.120

0.142

0.207

0.225

1.40

1.30

1.90

2.34

2.67

3.05

3.61

5.26

5.71

SPRING WIRE

DIAMETER

3

299H Series

Type 299H

Type 299H with Dual Registration

November 2008

Type 299H Internal Registration

July 2008

Type 299H

OUTLET

INLET

K

G

C

A

B

E

H

F

J

3/4 NPT

CONTROL LINE

CONNECTION

PILOT SUPPLY

SCREEN

J

B

OUTLET

3/4 NPT

INLET

E0070

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

CONTROL LINE

CONNECTION

K

G

F

INTERNAL

REGISTRATION

E

A

H

PILOT SUPPLY

SCREEN

C

TYPE 299H

J

3/4 NPT

DOWNSTREAM

CONTROL LINE

CONNECTION

3/4 NPT

DOWNSTREAM

CONTROL LINE

CONNECTION

EXTERNAL REGISTRATION

J

DUAL REGISTRATION

G

G

A7272

TOKEN RELIEF CLOSED TOKEN RELIEF OPEN

TYPE 299HR (TOKEN RELIEF DETAIL)

Figure 2. 299H Series Operational Schematics

A7272

4

299H Series

Type 299HS

Type 299HS

Type 299HS

EXTERNAL REGISTRATION

Type 299H Internal Registration

July 2008

Type 299H

OUTLET

INLET

K

G

C

A

B

E

H

F

J

3/4 NPT

CONTROL LINE

CONNECTION

PILOT SUPPLY

SCREEN

E0069

EXTERNAL REGISTRATION

E0070

INTERNAL REGISTRATION

E0072

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

Principle of Operation

TYPE 299HS

Figure 2. 299H Series Operational Schematics (continued)

Internal registration—Outlet pressure is registered

WARNING

!

through the throat (J) to the main diaphragm chamber

and then through a small port (G) to the top of the

Since a pilot-operated regulator is

constructed of both a pilot and a main

valve, do not exceed the maximum inlet

pressure shown on the nameplate.

Letter keys in this section refer to Figure 2 unless

otherwise noted. Fast response and accuracy are

made possible by the amplifying effect of the pilot

and by the two-path control system. The function of

the pilot is to sense change in the controlled pressure

and amplify it into a larger change in the loading

pilot diaphragm.

External registration—The throat (J) is blocked and a

downstream control line is connected to the pilot upper

diaphragm chamber or the actuator lower diaphragm

chamber. A small port (G) connects the two chambers.

Dual registration—The lower main diaphragm chamber

registers outlet pressure through the throat (J) and the

upper pilot diaphragm chamber registers downstream

pressure by using a downstream control line. The port (G)

between the chambers is blocked.

pressure. Any changes in outlet pressure act quickly

on both the actuator diaphragm and the loading pilot,

thus providing the precise pressure control that is

characteristic of a two-path control system.

Upstream or inlet pressure is utilized as the operating

medium, which is reduced through pilot operation to load

the main diaphragm chamber. Tubing connects the inlet

pressure to the pilot. Downstream or outlet pressure

registers underneath the main diaphragm (E) and on top

of pilot diaphragm (F). There are three different versions

of pressure registration for the 299H Series.

Type 299H

In operation, assume the outlet pressure is less than

the setting of the pilot control spring (A). The top side

of pilot diaphragm assembly (F) will have a lower

pressure than the setting of the control spring (A).

The control spring (A) forces the diaphragm assembly

upward, opening the pilot orice (C). Additional loading

pressure is supplied from the pilot orice to the top side

of the main diaphragm (E).

5

299H Series

This creates a higher pressure on the top side of the

main diaphragm (E) than on the bottom side, forcing

the diaphragm downward. This motion is transmitted

through a lever, which pulls the valve disk (K) open,

allowing inlet pressure to ow through the valve.

When the demand in the downstream system has been

satised, the outlet pressure increases. The increased

pressure is transmitted through the downstream control

line (for external or dual registration) or through the

port (G) (for internal registration) and acts on top of the

pilot diaphragm (F). This pressure exceeds the pilot

spring setting and forces the diaphragm down, closing

the orice (C). The loading pressure acting on the

main diaphragm (E) bleeds to the downstream system

through a bleed restriction (H).

With a decrease in loading pressure on top of the

main diaphragm (E), the main closing spring (B)

exerts an upward force on the diaphragm post which

is connected to the main diaphragm (E), pulling it

upward. This moves the main valve disk (K) toward its

seat, decreasing ow to the downstream system.

Type 299HR

During normal operation the Type 299HR performance

is identical to the Type 299H. If an overpressure

condition occurs, the pilot diaphragm head will

separate from the pilot diaphragm post and travel until

it contacts the pilot spring case. The movement of the

diaphragm head creates a path and a token or small

amount of gas will be released.

When the overpressure condition ceases, the pilot

diaphragm head will return to the diaphragm post and

the regulator will return to normal operation.

Type 299HS

The Type VSX-2 slam-shut device on the Type 299HS

regulator is a fast acting slam-shut valve which provides

overpressure or overpressure and underpressure

protection by completely shutting off the ow of gas to

the downstream system. The slam-shut module’s actions

are independent of the Type 299HS main regulator and

of the variations to the inlet pressure. The Type VSX-2

has internal or external registration. External registration

requires a downstream sensing line.

The slam-shut disk is held in the open position (reset

position) by a small ball holding the disk stem. If

the pressure below the diaphragm increases (or

decreases) reaching the Type VSX-2 setpoint,

the diaphragm will travel upwards (or downwards)

operating a lever which in turn releases the ball.

Once the ball is released, the spring force on the stem

will push the stem and disk to the closed position

against the seat shutting off all gas ow. The pilot

supply pressure is also shut off when the Type VSX-2

is closed. The manual reset has an internal bypass to

equalize the reset pressure on either side on the

slam-shut disk.

In order for the Underpressure Shutoff (UPSO) of

any slam shut to be triggered, the downstream pipe

pressure must drop below the UPSO setpoint. In the

case of a downstream line break, numerous factors

can prevent the downstream pipe pressure from

decreasing below the slam-shut UPSO setpoint. These

factors include the distance of pipe to the break, the

diameter of the pipe, size of the break and the number

of restrictions, such as valves, elbows and bends,

downstream of the regulator and/or slam-shut device.

Due to these factors additional protections should be

installed to stop ow in the event of a line break.

Overpressure Protection

Like most regulators, the Type 299H has outlet

pressure ratings lower than the inlet pressure ratings.

Complete downstream overpressure protection is

needed if the actual inlet pressure exceeds the outlet

pressure rating.

Overpressure protection for internal parts is built

into the main and pilot diaphragms by means of a

small spring on each post. The springs will allow

the diaphragm heads to move farther on the posts

avoiding damage to or bending of the valve trim.

Overpressuring any portion of a regulator or

associated equipment may cause leakage, parts

damage or personal injury due to bursting of

pressure-containing parts or explosion of accumulated

gas. Regulator operation within ratings does not

preclude the possibility of damage from external

sources or from debris in the pipeline. A regulator

should be inspected for damage periodically and after

any overpressure condition.

The pilot vent is provided with a 1/4 NPT tapped

connection in the spring case.

Installation

!

WARNING

Personal injury, equipment damage or

leakage due to escaping gas or bursting

of pressure-containing parts might result

6

299H Series

if this regulator is overpressured or is

installed where service conditions could

exceed the limits for which the regulator

was designed or where conditions exceed

any ratings of the adjacent piping or

piping connections. To avoid such injury

or damage, provide pressure-relieving

or pressure-limiting devices (as required

by the appropriate code, regulation or

standard) to prevent service conditions

from exceeding those limits.

A regulator may vent some gas to the

atmosphere in hazardous or ammable

gas service. Vented gas might accumulate

and cause personal injury, death or

property damage due to re or explosion.

Vent a regulator in hazardous gas service

to a remote, safe location away from air

intakes or any hazardous location. Protect

the vent line or stack opening against

condensation or clogging.

If the regulator is exposed to an

overpressure condition, it should be

inspected for any damage that may have

occurred. Operation below these limits

does not preclude the possibility of

damage from external sources or from

debris in the pipeline.

If the Type VSX-2 is exposed to an

overpressure condition, it should be

inspected for any damage that may have

occurred. Operation below these limits

does not preclude the possibility of

damage from external sources or from

debris in the pipeline.

In the case of a downstream line break,

numerous factors affect the capability

to evacuate gas from the pipeline.

These factors include the distance of

pipe to the break, the diameter of the

pipe, size of the break and the number

of restrictions, such as valves, elbows

and bends, downstream of the regulator

and/or slam-shut device. Due to these

factors additional protections should be

installed to stop ow in the event of a

line break.

Like most regulators, the 299H Series regulators have

an outlet pressure rating lower than its inlet pressure

rating. Complete downstream overpressure protection

is needed if the actual inlet pressure can exceed the

regulator outlet pressure rating or the pressure ratings

of any downstream equipment. Regulator operation

within ratings does not preclude the possibility of

damage from external sources or from debris in the

lines. A regulator should be inspected for damage

periodically and after any overpressure condition.

Clean out all pipelines before installation. Check for

damage which might have occurred during shipment.

Also, check for and remove any dirt or foreign material

which may have accumulated in the regulator body.

Apply pipe compound to the external pipe threads of

threaded bodies or use suitable line gaskets and good

bolting practices with a anged body. This regulator

may be installed in any position desired as long as the

ow through the body is in the direction indicated by the

arrow on the body. Install a three-valve bypass around

the regulator if continuous operation is necessary during

maintenance or inspection.

Although the standard orientation of the actuator and

pilot to the main valve body is as shown in Figure 1,

this orientation may be changed in 90° intervals by

rotating the actuator lower casing (key 1, Figure 6) and

the elbow tting (key 19) by 90° and then reinstalling

the cap screws.

To keep the pilot spring case from being plugged or the

spring case from collecting moisture, corrosive chemicals

or other foreign material, the vent must be pointed down

oriented to the lowest possible point on the spring case

or otherwise protected. Vent orientation may be changed

by rotating the pilot spring case with respect to the

pilot body.

To remotely vent the pilot, remove the screwed-in vent

assembly (key 27, Figure 5) from the pilot spring case

and install obstruction-free tubing or piping into the

1/4 NPT vent tapping. Provide protection on a remote

vent by installing a screened vent cap into the remote

end of the vent pipe.

An upstream pilot supply line is not required

because of the integral pilot supply tubing (key 21,

Figure 6). However, as long as the 1/4 NPT tapping

in the main valve body is plugged, this tubing may

be disconnected from the main valve (key 17) in

order to install a pilot supply line from a desired

remote location into the pilot.

If using a control line, attach the control line from the

pilot tap 2 to 3 feet / 0.61 to 0.91 meters downstream

of the regulator in a straight run of pipe. If impossible

to comply with this recommendation due to the pipe

arrangement, it may be better to make the control line

tap nearer the regulator outlet rather than downstream

of a block valve. Do not make the tap near any elbow,

swage or nipple which might cause turbulence. For

optimal performance, use as large of a control line

as practical.

7

299H Series

In many instances, it will be necessary to enlarge the

downstream piping to keep ow velocities within good

engineering practices. Expand the piping as close to

the regulator outlet as possible.

!

WARNING

Adjustment of the pilot control spring to

produce an outlet pressure higher than

the upper limit of the outlet pressure

range for that particular spring can cause

personal injury or equipment damage due

to bursting of pressure-containing parts

or the dangerous accumulation of gases

if the maximum actuator emergency

casing pressure is exceeded. If the

desired outlet pressure is not within the

range of the pilot control spring, install a

spring of the proper range according to

the Maintenance section.

Each regulator is factory-set for the pressure setting

specied on the order. If no setting was specied,

the outlet pressure is set midrange of the pilot control

spring. In all cases, check the control spring setting to

make sure it is correct for the application.

Registration Conversion

To convert the 299H Series regulators from one type of

registration to another, all that is required is adding or

removing screws and O-rings.

To change an internal registration regulator to an

external registration regulator with a downstream

control line, block the two ports in the throat with

screws and O-rings (J in Figure 2). Remove either the

3/4 NPT pipe plug in the pilot casing or the 3/4 NPT

pipe plug in the lower casing and add a downstream

control line.

To convert an external registration regulator to a dual

registration regulator, remove the two screws and

O-rings (J in Figure 2) from the throat and use a screw

and an O-ring to block the port (G in Figure 2) between

the lower diaphragm chamber and pilot diaphragm

chamber. Remove the 3/4 NPT pipe plug in the pilot

lower casing and add a downstream control line.

control line, block the body pitot tube with a screw

and gasket (keys 10 and 11, Figure 7). Remove the

pipe plug in the Type VSX-2 and add a downstream

control line.

Type VSX-2 Installation

Note

The Type VSX-2 slam-shut module

should be mounted so that the spring

case vent points towards the ground.

Keys are referenced in Figure 7. Place new O-rings

(keys 2 and 3) on the Type VSX-2 and slide the

module into the Type 299HS body (key 17). Secure

the Type VSX-2 to the Type 299HS body with the four

set screws (key 4). The Type VSX-2 device may be

oriented in any direction with respect to the sensor

line connection.

Startup

With proper installation completed and downstream

equipment properly adjusted, perform the following

procedure while monitoring the pressure with gauges.

1. Very slowly open the upstream block valve.

2. On a Type 299HS, the Type VSX-2 is shipped in

the tripped position and will need to be reset. If the

Type VSX-2 is a high trip only, it can be reset before

starting the regulator. If the Type VSX-2 is a high

and low trip, the regulator will need to be started

and the downstream system pressurized before the

Type VSX-2 can be reset. See the section for

Type VSX-2 reset.

3. Slowly open the hand valve (if used) in the

control line. The regulator will control downstream

pressure at the pilot control spring setting. See

the Adjustment section following these numbered

steps if changes in the setting are necessary

during the start-up procedure.

4. Slowly open the downstream block valve.

5. Slowly close the bypass valve, if used.

6. Check all connections for leaks.

Type VSX-2 Slam-Shut Device

To convert the Type VSX-2 from one type of

registration to another, all that is required is adding or

removing a screw and gasket.

To change an internal registration Type VSX-2 to an

external registration Type VSX-2 with downstream

8

Adjustment

Keys are referenced in Figure 4. The only adjustment

on a 299H Series regulator is the reduced pressure

setting of the pilot control spring (key 32). Remove

the closing cap (key 29) and turn the adjusting screw

299H Series

(key 36). Turning the adjusting screw clockwise into

the spring case increases the controlled or reduced

pressure setting. Turning the screw counterclockwise

decreases the reduced pressure setting. Always

tighten the locknut (key 35) and replace the closing

cap after making adjustments.

Type VSX-2 Reset

Note

The overpressure and underpressure

trip points can only be reset if the

Type 299HS outlet pressure is between

the overpressure and underpressure

trip points.

Use the following procedure to reset the Type VSX-2:

1. Unscrew the brass resetting knob to open the

equalizing bypass.

2. Pull out the knob until it stops. This resets the

tripping mechanism.

3. Push in and tighten the knob.

Type VSX-2 Trip Adjustment

Note

An adjustment tool is included with the

Type VSX-2 (see Figure 8). Use only

this tool to make adjustments to the

Type VSX-2. To make adjustments, the

overpressure trip spring (key 7, Figure 7)

is found under the outer adjusting screw

and the underpressure trip spring (key 8)

is found under the inner adjusting screw.

Use the following procedure to adjust the Underpressure

Trip Spring:

1. Use the Type VSX adjusting tool to

adjust the underpressure trip spring to its

minimum compression.

2. Backpressure the unit with the desired

underpressure trip pressure.

3. Increase the underpressure trip spring

compression (using the Type VSX adjusting tool)

until the Type VSX-2 trips.

Shutdown

Installation arrangements may vary, but in any installation

it is important to open and close valves slowly and the

outlet pressure be vented before venting inlet pressure to

prevent damage caused by reverse pressurization of the

regulator. Isolate the regulator from the system. Vent the

downstream pressure; then vent inlet pressure to release

any remaining pressure in the regulator.

Maintenance

Regulator parts are subject to normal wear and must

be inspected periodically and replaced as necessary.

The frequency of inspection and replacement depends

upon the severity of service conditions and upon

applicable codes and government regulations.

Due to the care Regulator Technologies takes in

meeting all manufacturing requirements (heat treating,

dimensional tolerances, etc.), use only replacement parts

manufactured or furnished by Regulator Technologies.

!

WARNING

Use the following procedure to adjust the Overpressure

Trip Spring:

1. Use the Type VSX adjusting tool to adjust

the overpressure trip spring to its maximum

compression (see Figure 8).

2. If present, adjust the underpressure spring

(using the Type VSX adjusting tool) to its

minimum compression.

3. Backpressure the unit with the desired

overpressure trip pressure.

4. Reduce the overpressure trip spring compression

until the Type VSX-2 trips.

Avoid personal injury or damage

to property from sudden release

of pressure or uncontrolled gas or

other process uid. Before starting

to disassemble, carefully release all

pressures according to the Shutdown

procedure. Use gauges to monitor inlet,

loading and outlet pressures while

releasing these pressures.

On reassembly of the regulator, it is recommended

that a good quality pipe thread sealant be applied to

pressure connections and ttings and a good quality

lubricant be applied to all O-rings. Also apply an anti-

seize compound to the adjusting screw threads and

other areas as needed.

9

299H Series

Note

The regulator body may remain in the

pipeline during maintenance procedures.

Main Actuator Diaphragm

Follow this procedure to change the actuator

diaphragm or to inspect, clean or replace any other

parts in the main actuator. Part key numbers are

referenced in Figures 5 and 6.

1. Cut the wire seal (key 68) (being careful not to

lose the warning tag) and remove the closing cap

(key 3). Inspect the O-ring (key 9) and replace

if necessary.

2. Carefully loosen and remove the double nuts

(key 5) on the actuator diaphragm post (key 10).

When removing the adjusting nuts, do not twist

or unscrew the diaphragm post, as this action will

loosen the joint between the diaphragm post and

the pusher post (keys 10 and 11).

3. Remove the spring seat (key 4) and closing spring

(key 6).

4. Remove the eight hex head cap screws (key 23)

and lift off the upper casing (key 2).

5. Remove the diaphragm assembly (key 8) by

tipping it so that the lever (key 26) slips out of the

pusher post (key 11).

6. Separate the diaphragm assembly by unscrewing

the diaphragm post (key 10) from the pusher

post (key 11) and remove the diaphragm post,

pressure equalization spring (key 7), diaphragm

head (key 81), diaphragm (key 8), the second

diaphragm head (key 81) and diaphragm pad

(key 80). Inspect the diaphragm parts for damage

and replace if necessary.

7. Inspect the lever (key 26) and replace if necessary.

To replace the valve stem (key 16), also perform

Main Body Valve Disk and Orice maintenance

procedure steps 1, 2 and 3, remove disk (key 13)

and pull the stem out of the lower casing assembly

(key 1). Lightly lubricate the replacement stem

O-ring (key 14) and install it on the valve stem.

Reinstall the valve stem into the lower casing

assembly. Reinstall the body (key 17) or continue

with the reassembly of the diaphragm.

Note

8. Loosely reassemble the diaphragm and diaphragm

post parts so that the bolt holes in the diaphragm

align with the corresponding holes in the lower

casing (key 1) when the lever (key 26) is tted

properly into the pusher post. When this orientation

is made, tighten the diaphragm post into the pusher

post (keys 10 and 11).

9. Reinstall the diaphragm assembly using the

reverse order of step 5.

10. Install the upper casing (key 2) and secure it to the

lower casing (key 1) with the eight hex head screws

(key 23). Tighten the hex head screws evenly using

a crisscross pattern to avoid placing an uneven

strain on the regulator. Tighten the screws to a nal

bolt torque of 10 to 13 foot-pounds / 13 to 17 N•m

to avoid crushing the diaphragm.

CAUTION

In step 11, the spring seat (key 4) is

under spring pressure. Use constant

hand pressure to hold the spring down

when installing the hex nuts (key 5), see

Figure 5.

11. Install the closing spring (key 6) and the spring seat

(key 4). Push and hold down on the spring seat,

cocking it to one side until the seat catches onto the

threads of the diaphragm post (key 10). Then, pull

up on the diaphragm post allowing access to the

post threads so that the two adjusting hex nuts

(key 5) can be installed. Install the adjusting hex

nuts as shown in Figure 5. The closing spring must

be adjusted down to a depth of 1/2-inch / 13 mm

from the top of the upper case opening to the top

of the spring seat. When tightening the two hex

nuts, use care not to rotate the diaphragm post,

which may damage the post.

12. Lightly lubricate the O-ring (key 9) on the closing

cap and reinstall the closing cap (key 3).

!

WARNING

The wire seal and warning tag (keys 68

and 69) contain important safety

information, make sure they are attached

when maintenance is completed.

When assembling the diaphragm assembly

(keys 8, 80 and 81), lubricate the actuator

diaphragm post (key 10) threads.

10

13. Install the wire seal and warning tag (keys 68

and 69).

299H Series

Main Body Valve Disk and Orice

Follow this procedure to inspect, clean or replace

the main body valve disk or to inspect or replace the

orice. Part key numbers are referenced in Figures 5

and 6.

Note

The regulator body may remain in the

pipeline during maintenance procedures.

1. Disconnect the pilot supply tubing (key 21) from

the main body (key 17).

2. Remove the two hex head cap screws (key 18)

which hold the lower casing (key 1) to the body.

Separate the lower casing from the body. Inspect

the body O-ring (key 15) and replace if worn

or damaged.

3. Examine the valve disk (key 13) and orice (key 12)

for nicks, cuts and other damage. Unscrew the disk

holder assembly from the valve stem assembly

(key 16) and replace it with a new part if necessary.

For the Type 299HS, also examine the insert and

O-ring (keys 82 and 83, Figure 7) for any damage.

Replace if needed.

If the orice is being replaced with a new or

differently sized orice, change the nameplate

(key 63) to state the new size and maximum

inlet pressure. Lubricate the threads and at

face of the orice with a good grade of anti-seize

lubricant. Install the orice using 100 to

120 foot-pounds / 136 to 163 N•m of torque.

4. After replacing all damaged parts, slide the entire

assembly into the valve body (key 17) and secure

with the two hex head cap screws (key 18).

5. Connect the pilot supply tubing (key 21), then refer

to the Startup section for putting the regulator

into operation.

Integral Pilot Valve Disk and Orice

6

7

A7008

KEY 72 - OPTIONAL P590 SERIES FILTER

Figure 3. Optional P590 Series Filter

5 2 5

1 4 3

4. If the seating edge of the orice (key 50) is nicked

or rough, use a thin-walled socket to remove the

orice from the inlet tting (key 47). Install a new

orice and a lightly lubricated O-ring (key 49) when

reassembling the regulator.

5. Inspect the check valve assembly (key 45) and

the bleed restriction (key 70) for damage and

replace if necessary.

6. The Type 299H has a wire inlet screen (key 51)

in the pilot supply inlet tting (key 47). If clogging

is suspected in the pilot supply, remove the elbow

tting (key 19) and clean the wire screen.

7. Lightly lubricate the O-ring (key 54) on the inlet

tting (key 47) and reinstall using the four machine

screws (key 46). Torque the machine screws to

30 to 40 inch-pounds / 3.4 to 4.5 N•m. Then install

and tighten the pilot supply tubing.

Follow this procedure to inspect, clean or replace the

integral pilot valve disk or orice. Part key numbers are

referenced in Figures 5 and 6.

1. Remove or loosen the pilot supply tubing (key 21).

2. Remove the inlet tting (key 47) and the four

machine screws (key 46).

3. Examine the valve disk (key 52) for nicks, cuts and

other damage. Unscrew the disk holder assembly

from the valve stem (key 48) and replace

if necessary.

Integral Pilot Control Spring and Diaphragm

Follow this procedure to change the pilot control spring

or to inspect, clean or replace the diaphragm. Part key

numbers are referenced in Figures 4, 5 and 6.

1. Remove the pilot closing cap (key 29) and

loosen the hex lock nut (key 35). Turn the

adjusting screw (key 36) counterclockwise to

ease spring compression.

2. Unscrew the bonnet (key 34).

11

299H Series

3. Remove the bonnet (key 34), spring seat (key 33)

and control spring (key 32).

4. If only replacing the control spring (key 32),

sparingly apply lubricant to the control spring seat

(key 33) and reassemble in the reverse order.

Note

When replacing the control spring with

a different spring range, be sure to

delete the spring range appearing on the

nameplate and indicate the new range.

5. Remove the machine screws (key 30) and spring

case (key 31) from the lower casing (key 1).

6. Remove the diaphragm assembly (key 28) by tilting

them so that the pusher post (key 40) slips off the

lever (key 57). To separate the diaphragm from the

attached parts, unscrew the hex nut (key 37) and

separate the parts: washer (key 38), diaphragm

post (key 39), pusher post (key 40), overtravel

spring (key 41), machine screw (key 42), spring

seat (key 88) (Types 299HR and 299HSR), rivet

(key 43) and retaining ring (key 44).

7. To replace the lever assembly (key 57), remove the

lever pin (key 25). To replace the valve stem

(key 48), also perform Integral Pilot Valve Disk and

Orice maintenance procedure steps 1, 2 and 3

and pull the stem (key 48) out of the lower casing

assembly (key 1). Lightly lubricate the replacement

stem O-ring (key 53) and install it on the valve stem.

8. Install the valve stem (key 48) into the lower

casing assembly (key 1). Be careful not to cut the

O-ring (key 53) when sliding the valve stem into

the lower casing.

9. Reinstall the diaphragm (key 28) assembly using

the reverse order of step 6.

10. Place the spring case (key 31) on the lower casing

(key 1) with the vent (key 27) oriented downwards

to prevent clogging or entrance or moisture. Install

the machine screws (key 30) and tighten in a

crisscross pattern using 12 to 18 inch-pounds /

1.4 to 2.0 N•m of torque.

11. When all maintenance is complete, refer to the

Startup section to put the regulator back into

operation and adjust the pressure setting. Tighten

the locknut (key 35) and install the closing cap

(key 29).

Type VSX-2 Maintenance

Parts numbers are referenced in Figure 7. The

Type VSX-2 device (key 1) is designed to be

removed as a unit from the Type 299HS body

(key 17) and be replaced as a complete unit. The

only replaceable parts in the Type VSX-2 module

are the O-rings (keys 2 and 3) and the high and

low pressure springs (keys 7 and 8). The high and

low pressure springs may be adjusted or replaced

without removing the slam-shut device from the

Type 299HS body.

Optional P590 Series Filter

Keys are referenced in Figures 3 and 6. If clogging

is suspected in the upstream regulator passages,

disconnect the pilot supply tubing (key 21, Figure 6),

remove the lter assembly (key 72) and check for lter

clogging. If necessary, to clean or replace lter parts,

remove the following: lter body (key 1), machine

screw (key 4), spring washer (key 6), gasket

(key 7), washer (key 5) and lter element (key 2).

Upon reassembly, place one at washer (key 5)

between the lter element and lter head (key 3) and

the other between the lter element and gasket.

Optional Type 67CF Pilot Supply

Regulator

For complete installation, maintenance and parts list

refer to the 67C Series Instruction Manual.

Parts Ordering

The type number, orice size, spring range and date of

manufacture are stamped on the nameplate. Provide

this information along with the eleven-character part

number to your local Sales Ofce when ordering parts.

If construction changes are made in the eld, be sure

that the nameplate is also changed to reect the most

recent construction.

12

299H Series

40

43

42

38

28

32

34

36

35

33

88

29

37

41

44

39

L2

A

40

39

L2

29

T80391-6

TYPE 299H PILOT WITHOUT RELIEF VALVE

APPLY ANTI-SEIZE COMPOUND (L2) / ADHESIVE (A)

43

42

38

28

32

34

36

44

41

37

33

35

40

43

44

39

37

38

A

88

28

A

41

L2

32

42

33

29

34

35

36

T80391-6

TYPE 299HR PILOT WITH TOKEN RELIEF VALVE

Parts List

299H Series Regulator (Figures 4, 5 and 6)

Key Description Part Number

Parts Kit (Includes keys 8, 9, 13, 14, 15, 28,

49, 52, 53, 54, 60, 61 and 80) R299X000012

1 Lower Casing, Aluminum T80447T0012

2 Upper Casing, Aluminum T40577T0012

3 Closing Cap, Aluminum 1L928308012

4 Spring Seat, Steel T13831T0012

5 Adjustment Nut, Steel (2 required) 1A341224122

6 Closing Spring, Steel T13918T0012

7 Pressure Equalization Spring, Steel T13463T0012

8* Diaphragm, Nitrile (NBR) T20986T0012

9* O-ring, Nitrile (NBR) 1F914106992

10 Diaphragm Post, Steel T13814T0012

11 Pusher Post, Aluminum 1L143311992

12 Orice, Aluminum

1/4 x 3/8 inch / 6.4 x 9.5 mm T13833T0012

3/8 inch / 9.5 mm 1H979309022

1/2 inch / 13 mm 1H979409022

3/4 inch / 19 mm 1H979509022

7/8 inch / 22 mm

(for Types 299H and 299HR only) T14098T0012

1 inch / 25 mm

(for Types 299H and 299HR only) 1H979609022

1-3/16 inches / 30 mm

(for Types 299H and 299HR only) 1H979709022

13* Disk, Nitrile (NBR) 1P7349000A2

14* O-ring, Nitrile (NBR) 1E216306992

* Recommended spare part

Figure 4. 299H Series Pilot Assemblies

Key Description Part Number

15* O-ring, Nitrile (NBR) T12587T0012

16 Valve Stem Assembly 1L1426000A2

17 Valve Body

Cast Iron, For Types 299H and 299HR only

1-1/4 NPT T40578T0012

1-1/2 NPT 1J190419012

2 NPT 1H968919012

NPS 2 / DN 50

CL125 FF anged

7.5-inch / 90 mm face-to-face dimension T80445T0012

10-inch / 254 mm face-to-face dimension 2L425119012

Ductile Iron, For all 299H Series

1-1/2 NPT T40561T0012

2 NPT T40562T0012

NPS 2 / DN 50

CL125 FF anged T80424T0012

CL250 RF anged T80425T0012

PN 10/16 anged T80426T0012

Steel, For Types 299H and 299HR only

1-1/2 NPT 1J1904T0022

2 NPT 1H9689T0022

NPS 2 / DN 50

CL150 RF anged T80415T0012

18 Cap Screw, Steel (2 required)

Types 299H and 299HR T14034T0012

Types 299HS and 299HSR T14082T0012

19 Elbow (3 required for Cast Iron or Steel bodies;

2 required for Ductile Iron Bodies) - - - - - - - - - - -

20 Connector

21 Pilot Supply Tubing, Without lter - - - - - - - - - - -

22 Loading Tubing - - - - - - - - - - 23 Cap Screw, Steel (8 required) 1C379124052

(1)

- - - - - - - - - - -

13

299H Series

HEX NUTS

APPLY CONSTANT

HAND PRESSURE

SPRING SEAT

UPPER

SPRING CASE

CLOSING SPRING

DIAPHRAGM POST

LOCKING DOWN THE SPRING SEAT TO

FACILITATE INSTALLING THE HEX NUTS

T80391-2

T80391-3

61

25

27

56 24 26

L1

EXTERNAL REGISTRATION

25

26

2724 59

APPLY MULTI-PURPOSE LUBRICANT (L1) / MULTI-PURPOSE POLYTETRAFLUOROETHYLENE (PTFE) THREAD SEALANT (S1)

14

S1

INTERNAL REGISTRATION

Figure 5. 299H Series Interior Assembly

L2 L1

299H Series

81 4 5 93 6 7

A

93

L1

L2

12 14

13 15

L1

8 80

16

3/4 NPT

DOWNSTREAM

CONTROL LINE

CONNECTION

11109

S2

T80391

27

25

24

T80391-4

DUAL REGISTRATION

APPLY MULTI-PURPOSE LUBRICANT (L1) / ANTI-SEIZE COMPOUND (L2) / THREAD LOCK SEALANT (S1) / ADHESIVE (A)

26

56

61

L1

T80391-7

L1

Figure 5. 299H Series Interior Assembly (continued)

45

25

57

56

48

53

52

L2

299H SERIES PILOT TRIM

L2

54

L1

70

50

L2

51

49

L1

15

299H Series

79

20762078

S1

TYPE 67CF PILOT

SUPPLY REGULATOR

T80391-1

S1

84

85

86

87

20

21

S1

19

18

17

68

69

2231

21

29

299H SERIES EXTERIOR VIEW

89

L2

3

63

62

19

S1

22

46

S1

20

S1

58

47

30

19

S1

31

78 20 72 20

S1

T80391-5 T80391-5

TUBING AND FITTINGS WITH

OPTIONAL TYPE P590 FILTER

APPLY ANTI-SEIZE COMPOUND (L2) / MULTI-PURPOSE PTFE THREAD SEALANT (S1).

16

79

TYPE 67CF PILOT

SUPPLY REGULATOR

TUBING AND FITTINGS WITH OPTIONAL

TYPE 67CF PILOT SUPPLY REGULATOR

Figure 6. 299H Series Exterior Assembly

20762078

79

S1

299H Series

Parts List (continued)

299H Series Regulator (Figures 4, 5

and 6) (continued)

Key Description Part Number

24 Machine Screw, Steel (2 required) 1B420428982

25 Lever Pin, Stainless steel (2 required) 1H972935032

26 Lever, Steel T13813T0012

27 Vent Hood (Type Y602-12 Vent Assembly) 27A5516X012

28 Diaphragm Assembly, Nitrile (NBR) diaphragm

and steel diaphragm head T14259T0012

29 Closing Cap, Plastic 24B1301X012

30 Machine Screw, Steel (8 required) T14069T0012

31 Spring Case, Aluminum T14097T0012

32 Control Spring See Table 2

33 Spring Seat, Steel T13917T0012

34 Bonnet, Steel T14135T0012

35 Locknut, Steel 1A352224122

36 Adjusting Screw, Steel T14133T0012

37 Hex Nut, Steel 1E985324142

38 Washer, Steel 1F230328992

39 Diaphragm Post, Stainless steel

Types 299H and 299HS T13915T0012

Types 299HR and 299HSR T14033T0012

40 Pusher Post, Steel T13914T0012

41 Overtravel Spring, Stainless steel

Types 299H and 299HS T14136T0012

Types 299HR and 299HSR T14031T0012

42 Machine Screw, Steel 1A954828992

43 Rivet, Flat head, Stainless steel T13916T0012

44 Retaining Ring, Steel 16A6977X012

45 Check Valve Assembly T14258T0012

46 Machine Screw, Steel (4 required) T13920T0012

47 Inlet Fitting, Aluminum T13824T0012

48 Stem Assembly, Aluminum 1H9666T0012

49* O-ring, Nitrile (NBR) T13939T0012

50 Pilot Orice, Aluminum T13825T0012

51 Inlet Screen, Stainless steel T13791T0012

52* Pilot Disk Assembly, Hydrogenated Nitrile (NBR)

and Aluminum disk holder T13955T0012

53* O-ring, Nitrile (NBR) 1D682506992

54* O-ring, Nitrile (NBR) 13A2331X022

56 Screw, Steel (External Registration - 2 required

or Dual Registration - 1 required) 1E175828982

57 Lever, Steel T14134T0012

58 Pipe Plug, Steel 1A7715T0012

59 Pipe Plug, Internal Registration only, Steel

3/4 NPT 1A7715T0012

1/4 NPT 1A767524662

61 O-ring, Nitrile (NBR) (External Registration - 2 required

or Dual Registration - 1 required) 17A0960X012

62 Drive Screw, Steel (2 required) 1E501728982

63 Nameplate, Aluminum - - - - - - - - - - 68* Wire Seal T14088T0012

69 Warning Tag, Aluminum - - - - - - - - - - 70 Bleed Restriction, Steel

0.044 inch / 1.1 mm, Red (standard) 17A2029X012

0.071 inch / 1.8 mm, Green 17A2030X012

0.082 inch / 2.1 mm, Blue 17A7277X012

72 Filter Assembly, See P590 Series

Type P593-1 AJ5004T0012

Type P594-1 AJ5004000A2

78 Pilot Supply Tubing, Long (for constructions with

lter or pilot supply option) - - - - - - - - - - 79 Pilot Supply Tubing, Short (for constructions with

lter or pilot supply option) - - - - - - - - - - 80 Pad, Nitrile (NBR) T13830T0012

* Recommended spare part

1. Cast iron or steel bodies without lter and pilot supply regulator require 1 connector; all other combinations of lter and/or pilot supply regulator require 3 connectors. Ductile iron

bodies without lter and pilot supply regulator require 2 connectors; all other combinations of lter and/or pilot supply regulator require 4 connectors.

2. Ductile iron bodies only.

Delrin® is a mark owned by E.I. du Pont de Nemours and Co.

Key Description Part Number

81 Diaphragm Head, Steel (2 required) T13812T0012

82 Insert (for Types 299HS and 299HSR only,

see Figure 7) Aluminum

83 O-ring (for Types 299HS and 299HSR only,

see Figure 7) Nitrile (NBR)

84 Plate (for Types 299H and 299HR only), Steel

85 O-ring (for Types 299H and 299HR only),

Nitrile (NBR)

86 O-ring (for Types 299H and 299HR only),

Nitrile (NBR)

87 Set Screw (for Types 299H and 299HR only)

(4 required)

88 Spring Seat, Types 299HR and 299HSR T14030T0012

89 Label, (not shown)

Types 299H and 299HS T1215806032

Types 299HR and 299HSR T1215906032

92 Tee, Stainless steel - - - - - - - - - - 93 Spring Seat Washer, Delrin

94 Plastic Plugs (not shown) T13543T0042

(2)

T13769T0012

(2)

T13772T0012

(2)

1C629828992

(2)

T14013T0012

(2)

T1072606562

®

(2)

T14039T0012

19B0553X012

Optional P590 Series Filter

(Key 72, Figure 3)

Key Description Part Number

1 Filter Body

Type P594-1, Brass 1E312414012

Type P593-1, Aluminum 1E3125X0022

2* Filter Element, Cellulose 1E312606992

3 Filter Head

Type P594-1, Brass 1E312514012

Type P593-1, Aluminum 1E3125X0022

4 Machine Screw

Type P594-1, Brass 1J500218992

Type P593-1, Aluminum 1J500209012

5 Washer (2 required)

Type P594-1, Brass 1J500018992

Type P593-1, Aluminum 1J500010062

6 Spring Washer, Plated carbon steel 1H885128982

7* Gasket, Composition 1F826804022

Type VSX-2 Slam-Shut Device (Figure 7)

Key Description Part Number

1 Type VSX-2 Module FA196247X12

2* Upper O-ring, Nitrile (NBR) T13769T0012

3* Lower O-ring, Nitrile (NBR) T13772T0012

4 Set Screw (4 required), Stainless steel 1C629828992

6 Type Y602-12 Vent Assembly 27A5516X012

7 High pressure Control Spring, Zinc-plated steel

12 to 25 inches w.c. / 30 to 62 mbar, Black T14162T0012

20 to 52 inches w.c. / 50 to 129 mbar, Brown T14163T0012

1.4 to 3.9 psig / 97 to 269 mbar, Red T14164T0012

3.8 to 8.7 psig / 262 to 600 mbar, Orange T14165T0012

5.8 to 16 psig / 400 to 1103 mbar, Pink T14166T0012

11.6 to 23 psig / 800 to 1586 mbar, Green T14167T0012

8 Low pressure Control Spring, Zinc-plated steel

2 to 12 inches w.c. / 5 to 30 mbar, White T14168T0012

4 to 30 inches w.c. / 10 to 75 mbar, Blue T14169T0012

0.36 to 2.3 psig / 25 to 159 mbar, Unpainted T14170T0012

1.5 to 10.8 psig / 103 to 745 mbar, Olive T14171T0012

10 Machine Screw (for external control line), Steel 1H8162X0012

11* Gasket (for external control line), Nitrile (NBR) T14191T0012

12 Adjustment Tool (see Figure 8) FA142932X12

13 Pipe Plug (for internal registration),

Steel, (not shown) 1A767524662

17

299H Series

3 2

VIEW A

1

7

6

8

4

17

82

83

10 11

VIEW A

T80423

NOTE: FOR KEYS 12, 13, 17, 82 AND 83, REFER TO 299H SERIES REGULATORS PARTS LIST.

Figure 7. Type VSX-2 Assembly (for Types 299HS and 299HSR)

18

12

13

USE THIS END FOR UNDERPRESSURE

TRIP ADJUSTMENT

TYPE VSX ADJUSTING TOOL

299H Series

USE THIS END FOR OVERPRESSURE

TRIP ADJUSTMENT

TYPE VSX TOOL BEING USED TO ADJUST A TYPE VSX-2

Figure 8. Type VSX Adjusting Tool

19

299H Series

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +011 971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Emerson Process Management Regulator Technologies, Inc. product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Chartres 28008, France

Tel: +33 2 37 33 47 00

Middle East and Africa

Dubai, United Arab Emirates

Tel: +011 971 4811 8100

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9499

©Emerson Process Management Regulator Technologies, Inc., 1999, 2014; All Rights Reserved

Loading...

Loading...