Page 1

Instruction Manual

D100279X012

262K Filter

September 2019

Fisher™ 262K Filter

Introduction

Scope of Manual

This manual provides instructions for installation, maintenance and parts information for Fisher 262K filters.

Do not install, operate, or maintain a Fisher 262K filter without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office

Product Description

before proceeding.

The 262K filter is designed to remove dirt, scale, and other solid substances from the air supply to actuators and

instruments.

The 262K filter is available with a cast iron (Style B) or stainless steel body (Style SSB) with NPT screwed connections.

See table 1 for temperature capabilities.

The filter has a resin‐impregnated cellulose filter element capable of capturing particles as small as 40 microns.

Figure 1. Typical Fisher 262K Filter

W7910

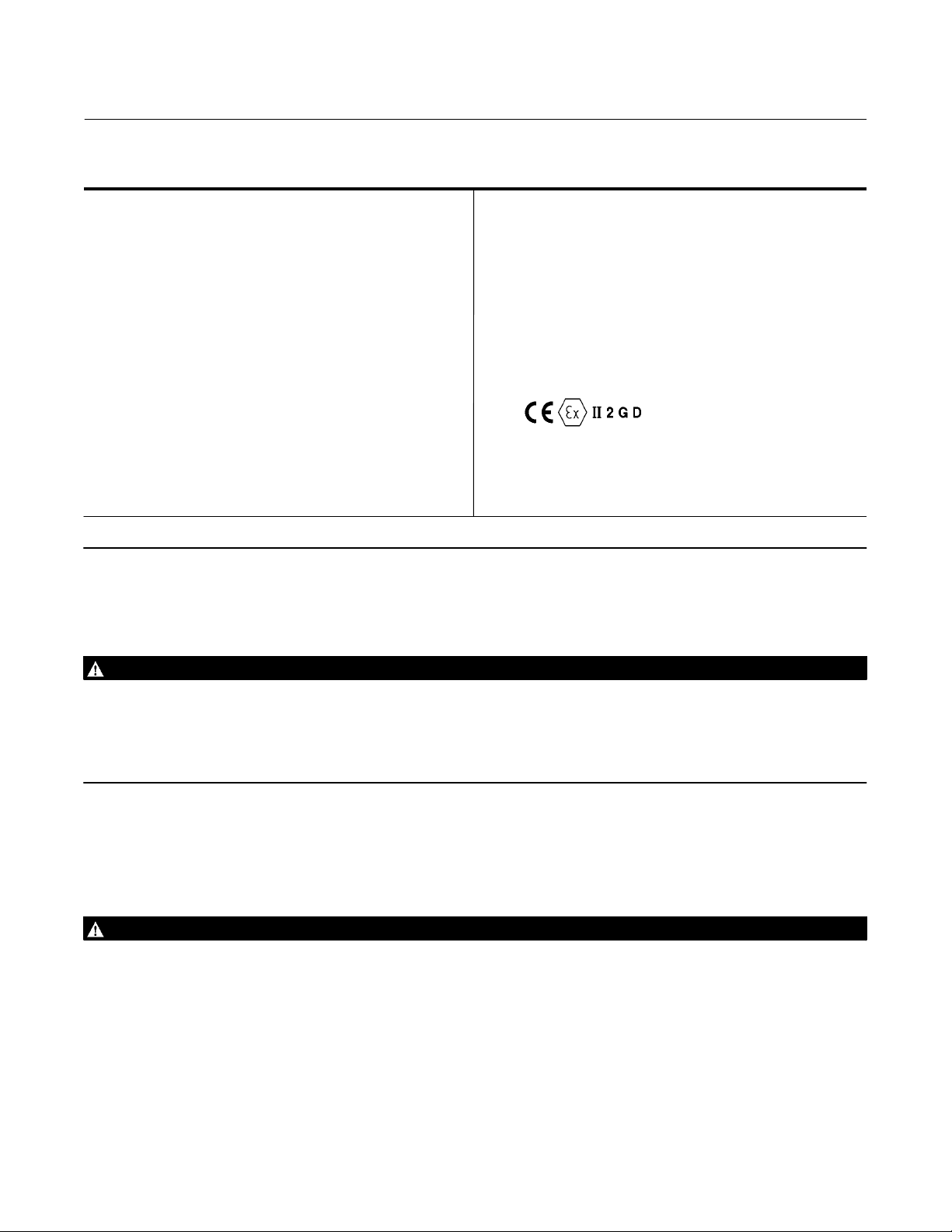

Figure 2. Construction Details

FILTER

ELEMENT

W0225‐1

PIPE PLUG

www.Fisher.com

Page 2

262K Filter

September 2019

Table 1. Specifications

Instruction Manual

D100279X012

Body Size

NPS 3/4

End Connection Styles

3/4 NPT screwed

Temperature Capabilities

Cast Iron: -28 to 208_C (-20 to 406_F)

Stainless Steel: -54 to 208_C (-65 to 406_F)

Clean Out Connection

Screwed

Hazardous Area Classification

Flow Coefficients

Complies with the requirements of ATEX Group II

Category 2 Gas and Dust

: 3.96

C

v

Maximum Inlet and Outlet Pressure

Capabilities

(1,2)

Cast Iron: 28 bar at 65_C (400 psig at 150_F)

Stainless Steel: 41 bar at 65_C (600 psig at 150_F)

1. The pressure/temperature limits in this instruction manual and any applicable standard or code should not be exceeded.

2. A pressure exceeding this value can cause failure of, or leakage from, pressure‐containing components.

Maximum surface temperature depends on operating

conditions

Gas: T6...T2

Dust: T85...T208

Specifications

Specifications for the 262K filter are in table 1.

(1)

Ex h IIC Tx Gb

Ex h IIIC Tx Db

WARNING

Installation, operation, and maintenance procedures performed by unqualified personnel may result in unsafe operation.

This condition may result in personal injury or equipment damage. Use qualified personnel when installing, operating, and

maintaining this filter.

If a leak develops in the system, the escaping gas may accumulate and become a fire or explosion hazard. Immediately call

qualified service personnel in case of trouble.

Installation

WARNING

Personal injury, equipment damage, or leakage due to escaping gas or bursting of pressure‐containing parts may result if

the filter is installed where its capabilities can be exceeded or where conditions exceed any ratings of the adjacent piping or

piping connections. To avoid this, install a filter where:

D Service conditions are within unit capabilities.

D Service conditions are within applicable codes, regulations, or standards.

D Additionally, physical damage to the filter could result in breakage, causing personal injury and property damage due to

escaping gas. To avoid such injury or damage, install the unit in a safe location.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

2

Page 3

Instruction Manual

D100279X012

D If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

262K Filter

September 2019

Using good piping practices, install the filter in the line with the flow in the direction of the arrow cast on the body. As

shown in figure 2, when the 262K filter is mounted in a horizontal line, the filter element must be pointed down. When

mounted in a vertical line, the filter element must also point down, with the flow passing from top to bottom.

Figure 3. Fisher 262K Filter

19B0172-A

Maintenance

Filter parts are subject to normal wear and must be inspected periodically and replaced as necessary. The frequency of

inspection and replacement depends upon the severity of service conditions and upon applicable codes and

government regulations.

WARNING

Avoid personal injury or damage to property from sudden release of pressure or uncontrolled gas or other process fluid.

Before starting disassembly, carefully release all pressures. Use a gauge to monitor pressure while releasing it.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

3

Page 4

262K Filter

September 2019

Instruction Manual

D100279X012

Parts Ordering

When corresponding with your Emerson sales office about this filter, always reference the filter style (Cast iron, Style B;

Stainless steel, Style SSB).

When ordering the repair kit, specify the complete 11‐character part number from the following parts list.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson should not, under any

circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the performance

of the valve, and could cause personal injury and property damage.

Parts List

Note

Contact your Emerson sales office

for Part Ordering information.

262K Filter (figure 3)

Key Description Part Number

1 Body

2 Drain Plug

3 Filter Element

4 Cartridge Gasket

5 Cap Gasket

6 Pipe Plug

* Repair Kit 19B0173X012

*Recommended spare parts

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

4

E 1966, 2019 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...