Page 1

Product Bulletin

2625 Volume Booster

D200071X012

62.3:2625

January 2015

Fisherr 2625 and 2625NS Volume Boosters

A Fisher 2625 or 2625NS volume booster is used in

conjunction with a positioner on a throttling control

valve to increase stroking speed. The 2625NS is a

nuclear‐service version and uses elastomeric

components that better withstand high temperature

and radiation environments.

The booster incorporates fixed deadband, soft seat

construction, and an integral bypass restriction to

eliminate positioner saturation problems that can

occur with volume boosters that do not have these

features. Adjustment of the integral bypass restriction

is necessary for system stability. This adjustment does

not affect the deadband of the volume booster, but

does permit the control valve to respond to small input

signal changes without sacrificing steady‐state

accuracy. It also allows the booster to deliver

high‐volume output for fast stroking when large, rapid

input signal changes occur.

W4727-1

The volume booster is used to improve stroking speed.

If precision valve control is required, the use of a

positioner is recommended. If the volume booster is to

be used only with an actuator, for on‐off control, the

integral bypass restriction on the booster must be

closed (turned fully clockwise).

Connectors and piping can be installed with either

2625 or 2625NS volume booster for diagnostic

testing.

The 2625 is certified for use in Safety Instrumented

System (SIS) applications. Certification is by exida

Consulting LLC, a global provider of functional safety

and control system security. SIS certification is

identified on the product by the EXIDA logo on the

2625 nameplate.

Features

n Fast Response—Booster delivers the volume needed

for rapid actuator stroking when large input

changes suddenly occur.

n Adjustable Response—Integral bypass restriction

tunes the booster response so that smooth actuator

motion follows the slow signal changes.

n Efficient Operation—Soft seats provide tight shutoff

to reduce unnecessary air consumption and

eliminate saturation of positioner relays.

n Maintains Accuracy—Booster permits high actuator

stroking speeds upon demand without degrading

the positioner steady‐state accuracy.

n SIL 3 Capable - Certified for use in Safety

Instrumented System (SIS) applications.

www.Fisher.com

Page 2

Product Bulletin

62.3:2625

January 2015

Specifications

2625 Volume Booster

D200071X012

Supply Pressure Ranges

When used in conjunction with a positioner or other

pneumatic accessory, always pipe the positioner and

volume booster with one common supply through a

Fisher 67D, 67DR, or 95H regulator (see figure 2). A

high‐capacity filter, such as the Fisher 262K, should

be installed in the supply line to the regulator. Supply

pressure also must not exceed the maximum

pressure rating of the actuator. Constructions are

available in two maximum supply ranges.

When Normally Used With Diaphragm Actuators: Up

to 2.8 bar (40 psig)

When Normally Used With Piston Actuators: Up to

10.3 bar (150 psig)

Input Signal Pressure

Positioner output

Maximum Input Signal Pressure

10.3 bar (150 psig)

Fixed Input‐to‐Output Pressure Ratio

1 to 1

Nominal Deadband

Percent of Positioner Output Span

(1)

:

2.4 mm (0.094 inch) exhaust port: 2%

9.5 mm (0.375 inch) exhaust port: 3.5%

12.7 mm (0.5 inch) exhaust port: 5%

Upper and Lower Valves:

2625: Nitrile‐CSM rubber/aluminum/stainless steel

2625NS: EPDM/aluminum/stainless steel

O‐Rings:

2625: Nitrile

2625NS: EPDM

Connectors for Diagnostic Testing:

or

J brass

Operative Temperature Limits

J Stainless steel

(2)

2625: -40 to 71_C (-40 to 160_F)

2625NS: -40 to 93_C (-40 to 200_F)

Connections

Input Signal: 1/4 NPT

Supply and Output: 3/4 NPT

Port Diameters

(3)

Supply Port: J9.5 mm (0.375 inch) or

J 12.7 mm (0.5 inch)

Exhaust Port:

J9.5 mm (0.375 inch) or J12.7 mm (0.5 inch)

J2.4 mm (0.094 inch),

Maximum Flow Coefficients

See table 1

Hazardous Area Classification

Complies with the requirements of ATEX Group II

Category 2 Gas and Dust

Construction Materials

Body: Aluminum

Seat Ring: Brass

Diaphragms

2625: Nitrile/nylon

2625NS: EPDM/meta‐aramid

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. Zero to maximum supply.

2. The pressure/temperature limits in this document and any applicable code or standard should not be exceeded.

3. May be used in any combination.

2

Safety Instrumented System Classification

SIL3 capable - certified by exida Consulting LLC

Approximate Weight

2.3 kg (5 lb)

Page 3

2625 Volume Booster

D200071X012

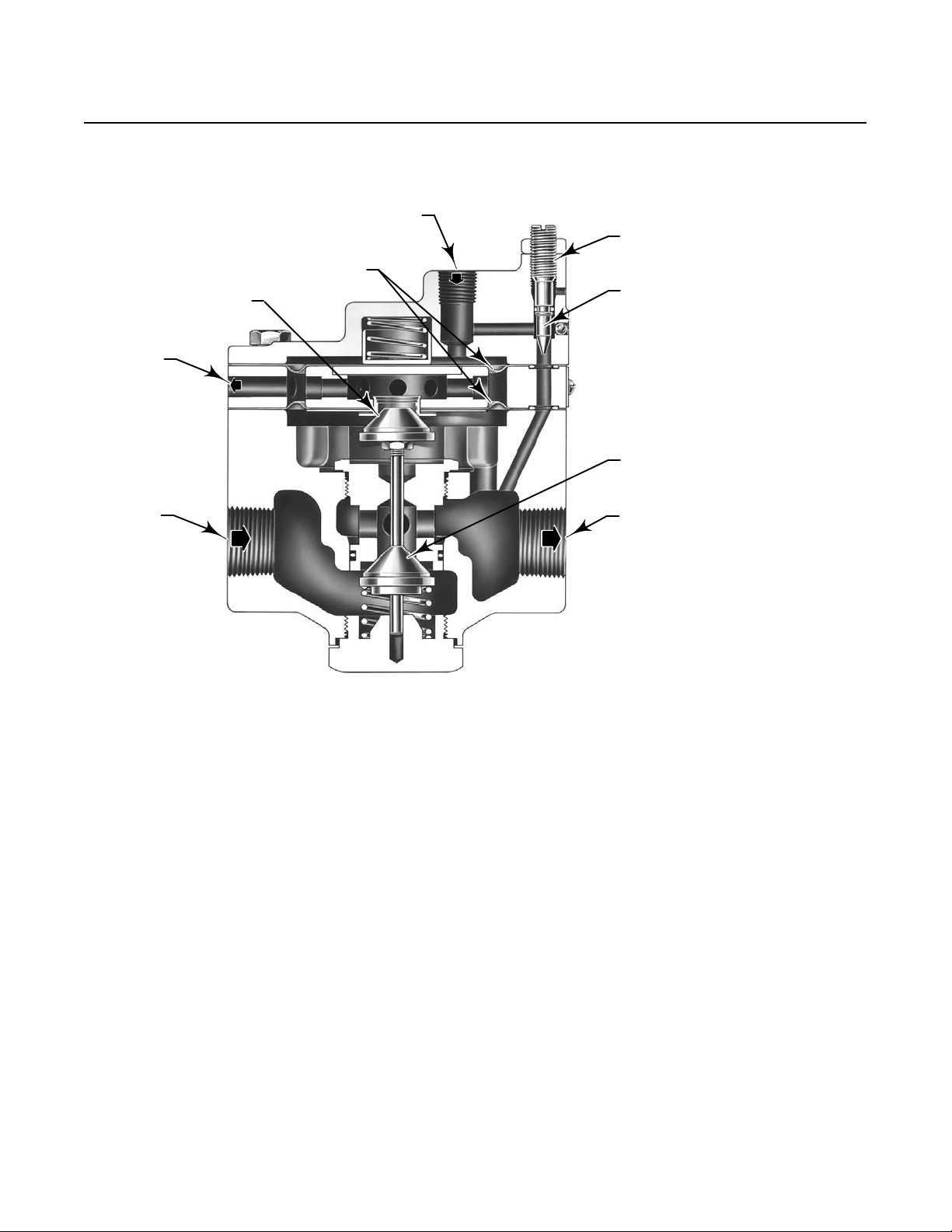

Figure 1. Sectional View of Fisher 2625 Volume Booster

INPUT SIGNAL

DIAPHRAGMS

EXHAUST

PORT

EXHAUST

Product Bulletin

62.3:2625

January 2015

BYPASS RESTRICTION

ADJUSTING SCREW

BYPASS

RESTRICTION

SUPPLY

PORT

SUPPLY

W0679‐1

Principle of Operation

Refer to figures 1 and 2. Because of the bypass

restriction, large input signal changes register on the

booster input diaphragm sooner than in the actuator.

A large, sudden change in input signal causes a

pressure differential to exist between the input signal

and the output of the booster. When this occurs, he

diaphragms move to open either the supply port or the

exhaust port, whichever action is required to reduce

OUTPUT TO

ACTUATOR

the differential. The port remains open until the

difference between the booster input and output

pressures returns to within the deadband limit of the

booster. With the bypass restriction adjusted for stable

operation, a signal with small magnitude and rate

changes passes through the bypass restriction and into

the actuator without initiating booster operation.

Both supply and exhaust ports remain closed,

preventing unnecessary air consumption and possible

saturation of positioner relays.

3

Page 4

Product Bulletin

62.3:2625

January 2015

Figure 2. Typical Installations

SIGNAL

OUTPUT A

OUTPUT B

2625

VOLUME

BOOSTER

DIGITAL VALVE CONTROLLER

ACTUATOR

2625

VOLUME

BOOSTER

67D, 67DR

OR 95H

SUPPLY

2625 Volume Booster

D200071X012

2625

VOLUME

BOOSTER

POSITIONER

OUTPUT

E1407

WITH A PISTON ACTUATOR

POSITIONER

ACTUATOR

A0794‐3

67D, 67DR

OR 95H

WITH A DIAPHRAGM ACTUATOR

Note:

1 Connection location for diagnostic testing

Table 1. Maximum Flow Coefficients

PORT SIZE COMBINATIONS COEFFICIENTS

Supply Port Exhaust Port Supply Port Exhaust Port

mm Inch mm Inch C

9.5 3/8

12.7 1/2

FIELDVUEt DVC6200, DVC6200 SIS, DVC6200f, DVC6200p, DVC6000, DVC6000 SIS, DVC6000f

digital valve controllers

FIELDVUE DVC2000 digital valve controller

Low Pressure Relay

High Pressure Relay

Fisher 3570 valve positioner 0.25 0.25

Fisher 3582 valve positioner 0.17 0.19

Fisher 3610J, 3610JP, 3611JP, 3620J, 3620JP, 3621JP valve positioners 0.37 0.30

1. Consult your Emerson Process Management sales office for special stroking speed requirements.

(1)

2.4

9.5

12.7

2.4

9.5

12.7

3/32

3/8

1/2

3/32

3/8

1/2

v

3.74

3.74

3.74

4.98

4.98

4.98

0.37 0.31

0.13

0.19

C

0.23

2.29

3.40

0.24

2.30

3.40

0.15

0.20

SIGNAL

SUPPLY

v

4

Page 5

2625 Volume Booster

D200071X012

Figure 3. Dimensions

1/4‐18 NPT INPUT CONN

9 EXHAUST

HOLES 7 (0.28) DIA

Product Bulletin

62.3:2625

January 2015

21

(0.84)

111

(4.38)

3/4‐14 NPT

SUPPLY CONN

60

(2.38)

A0807‐3

(4.75)

2625NS for Nuclear

Service Applications

The 2625NS volume booster uses EPDM

(ethylene‐propylene) elastomeric parts. These parts

have superior resistance to degradation at elevated

temperature and radiation levels. This version is

designed for nuclear service applications where oil‐free

supply air is available.

48

(1.88)

3/4‐14 NPT

OUTPUT TO ACTUATOR

121

mm

(INCH)

Both the 2625 and 2625NS are available as

safety‐related items when processed using the

commercial grade dedication section of the 10CFR50,

Appendix B, quality assurance program. 10CFR21

reporting is also part of the safety related processing

program. Seismic operability testing has been done to

qualify both versions as rigid items at levels up to 9g's

uniaxial (in each axis). Further nuclear service

qualification data is available on request.

5

Page 6

Product Bulletin

62.3:2625

January 2015

2625 Volume Booster

D200071X012

Installation

Figure 2 shows typical installations for the 2625 or

2625NS volume booster on piston and diaphragm

actuators. A single regulator that supplies both the

positioner and booster (or boosters) is recommended.

The supply medium must be clean, dry, oil‐free air or

non‐corrosive gas.

Note

Use a clean, dry, oil‐free air supply with instruments

containing EPDM components. EPDM is subject to

degradation when exposed to petroleum‐base lubricants.

Keep in mind that many actuators require larger casing

or cylinder connections to take full advantage of the

booster's ability to deliver its high‐volume output.

Dimensions are shown in figure 3. Ensure that the

supply pressure is connected to correspond with the

flow arrow on the booster.

Ordering Information

When ordering, specify:

1. Supply and exhaust port sizes. See table 1 for Cv

values.

2. Supply pressure range of up to 2.8 bar (40 psig) or

up to 10.3 bar (150 psig).

3. Stroking speed information when being mounted at

the factory, for proper tuning of the instruments.

Specify either critical or non‐critical stroke speed

time.

Note

Critical stroke speed time example: Valve to stroke in both

directions in 4 seconds or less.

Non‐critical stroke speed time example: Valve to stroke in

approximately 4 seconds in both directions.

4. Nuclear service, if applicable. Consult your Emerson

Process Management sales office for ordering

assistance.

6

Page 7

2625 Volume Booster

D200071X012

Product Bulletin

62.3:2625

January 2015

7

Page 8

Product Bulletin

62.3:2625

January 2015

2625 Volume Booster

D200071X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and FIELDVUE are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1986, 2015 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...