Instruction Manual

D102803X012

249W Sensor

December 2012

Fisherr 249W Cageless Wafer Style Displacer

Sensor

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Type Number Description 3.....................

Educational Services 3.........................

Installation 4..................................

Installation on Top of Vessel 5...................

Installation with Displacer Cage

on Side of Vessel 5..........................

Mounting the Sensor on the Process

Vessel or Displacer Cage 9....................

Maintenance 11................................

Removing the Displacer and Stem 12.............

Replacing the Displacer, Cotter Spring,

Stem End Piece, and Displacer Spud 13.........

Replacing the Displacer Rod/Driver

Assembly 13...............................

Replacing the Torque Tube 14...................

Changing the Mounting from Left‐Hand to

Right‐Hand, or Vice Versa 16.................

Simulation of Process Conditions for Calibration

of Fisher Level Controllers and Transmitters 16......

Related Documents 17..........................

Parts Ordering 17...............................

Determining Displacer Stem Length 17...........

Parts List 18...................................

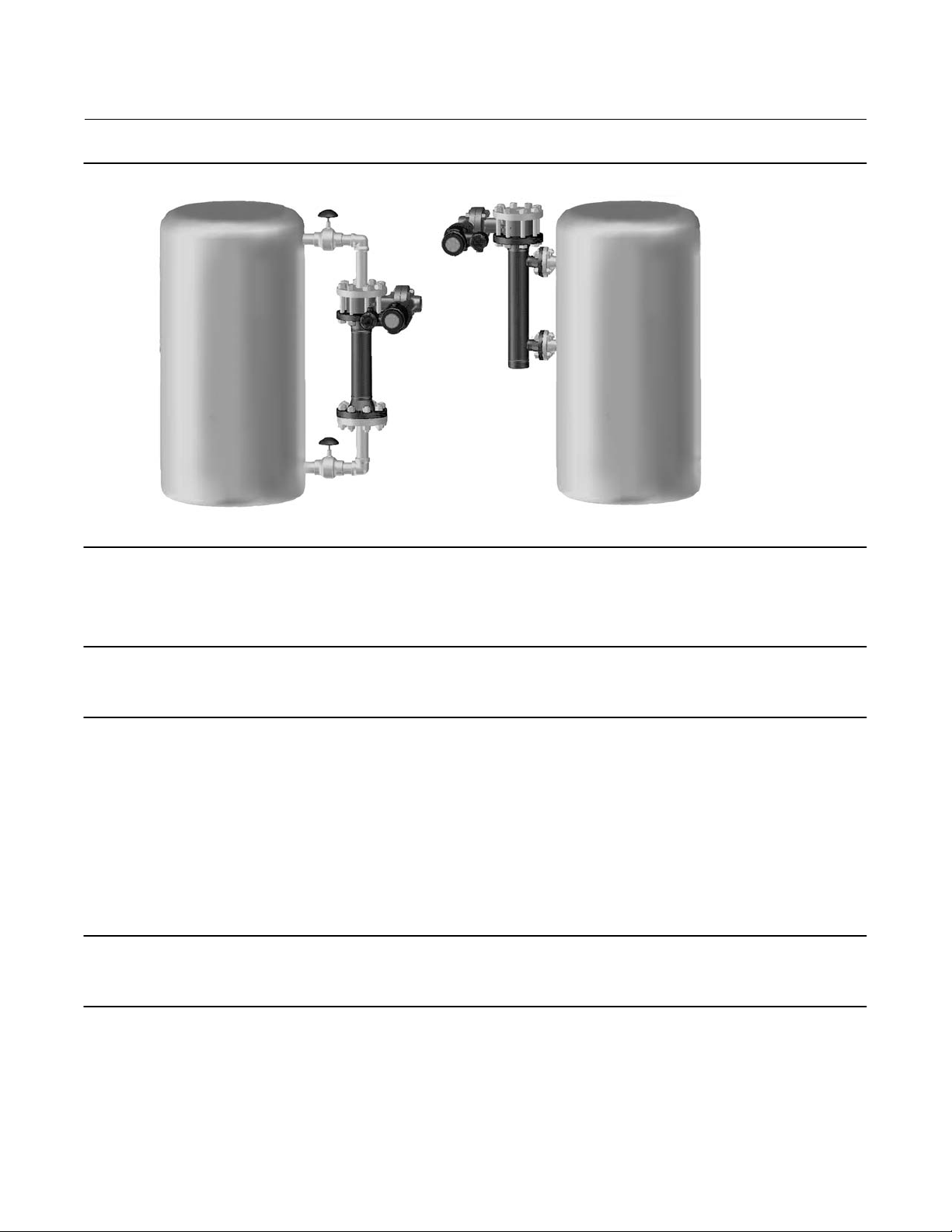

Figure 1. Fisher 249W Sensor with FIELDVUE™

DLC3010/DLC3020f Digital Level Controller

W8231

Introduction

Scope of Manual

This instruction manual includes maintenance, and parts ordering information for the 249W cageless wafer style

sensor.

Although the sensor is usually shipped with attached controller or transmitter, as shown in figure 1, this manual does

not include operation, installation, calibration, maintenance, or parts ordering information for the

controller/transmitter or for the complete unit. For this information, refer to the appropriate controller/ transmitter

instruction manual.

www.Fisher.com

249W Sensor

December 2012

Instruction Manual

D102803X012

Do not install, operate, or maintain a 249W sensor and the attached controller or transmitter without being fully

trained and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal

injury or property damage, it is important to carefully read, understand, and follow all of the contents of this manual,

including all safety cautions and warnings. If you have any questions about these instructions contact your Emerson

Process Management sales office before proceeding.

Description

The 249W sensor is designed to measure liquid level, interface level, or density/specific gravity inside a process vessel.

A torque tube assembly (figure 2) and displacer provide an indication of liquid level, interface level, or density/specific

gravity. The torque tube assembly consists of a hollow torque tube with a shaft welded inside it at one end and

protruding from it at the other end.

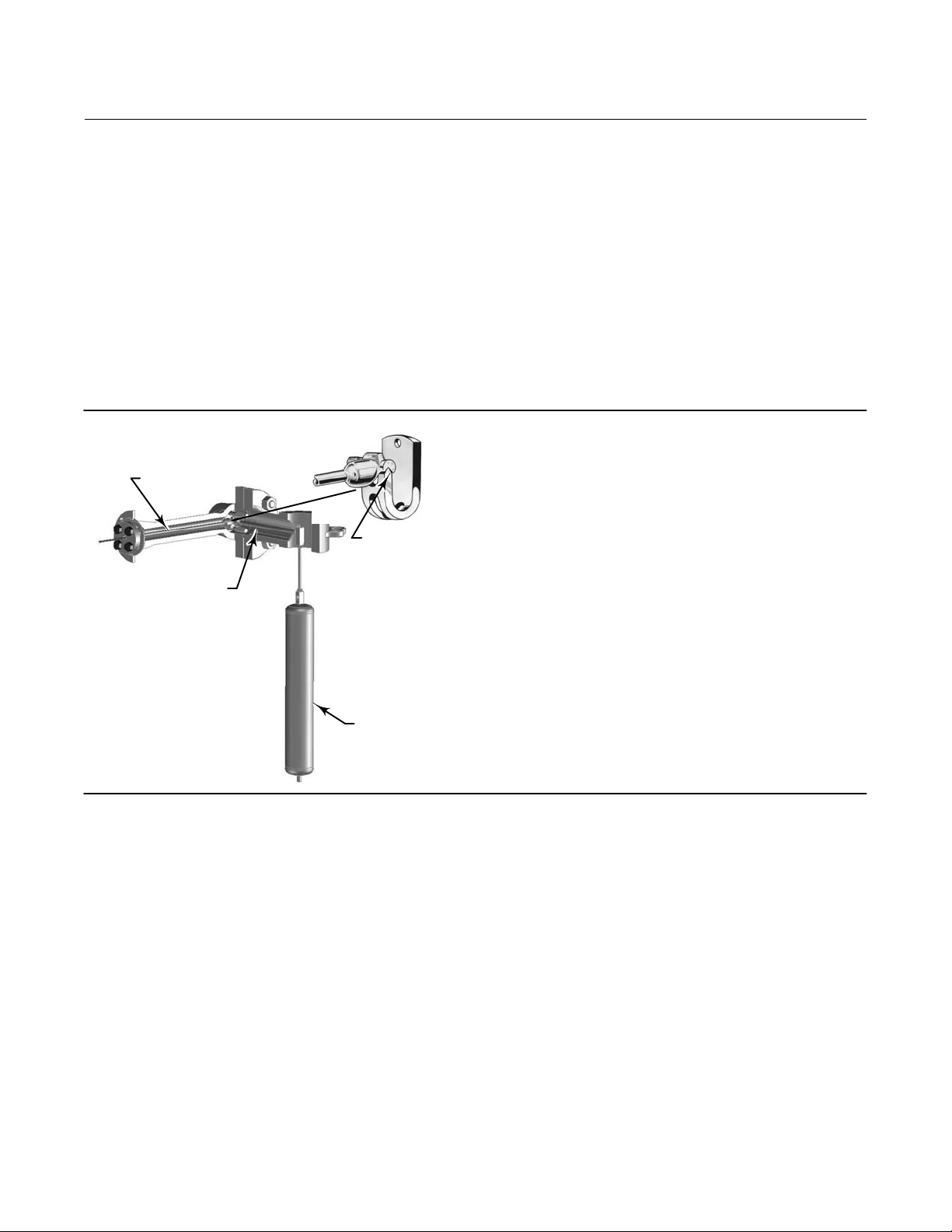

Figure 2. Typical Cageless Displacer

TORQUE TUBE

W1800‐1

KNIFE EDGE

BEARING

DISPLACER ROD

DISPLACER

W8325

The unconnected end of the tube is sealed by a gasket and clamped rigidly to the torque tube arm, permitting the

protruding end of the shaft to twist and therefore transmit rotary motion. This allows the interior of the torque tube to

remain at atmospheric pressure, thus eliminating packing and the disadvantages of packing friction.

The displacer always exerts a downward force on one end of the displacer rod. The other end of the displacer rod rests

on the knife‐edge of the driver bearing. A keyed shaft on the bearing end of the displacer fits into a socket on the

outside of the welded end of the torque tube assembly.

A change in liquid level, interface level, or density/specific gravity buoys up the displacer by a force equal to the weight

of the liquid displaced. Corresponding vertical movement of the displacer results in angular movement of the displacer

rod around the knife edge. Since the torque tube assembly is a torsional spring which supports the displacer and

determines the amount of movement of the displacer rod for a given displacement change, it will twist a specific

amount for each increment of buoyancy change. This rotation is brought through the torque tube arm by the

protruding rotary shaft. A controller or transmitter attached to the end of the rotary shaft converts the rotary motion

into varying pneumatic or electric signals. Figure 3 shows how the controller or transmitter mounts on the torque tube

arm.

Unless otherwise noted, all NACE references are to NACE MR0175-2002.

2

Instruction Manual

D102803X012

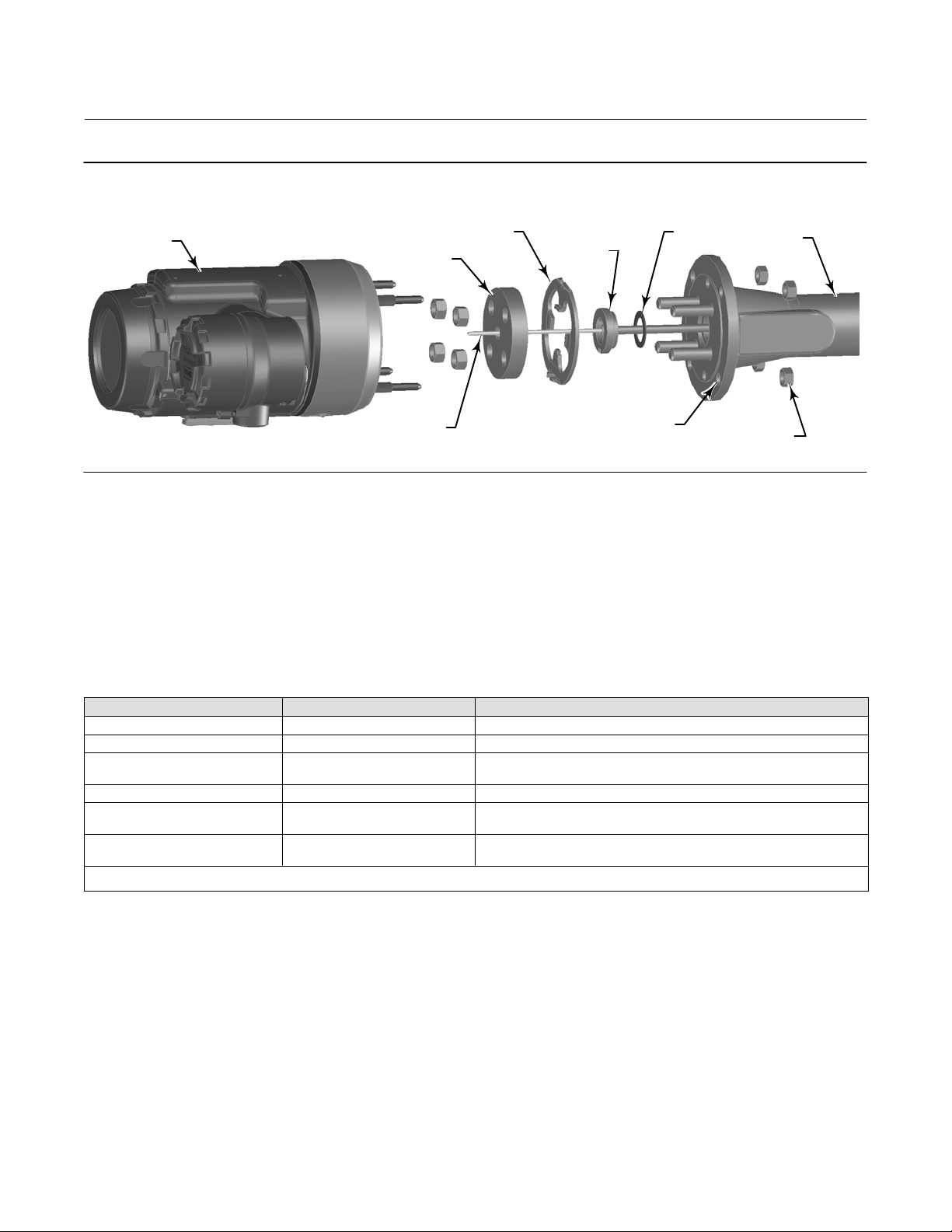

Figure 3. Torque Tube Arm Exploded View Showing Controller or Transmitter Mounting

249W Sensor

December 2012

CONTROLLER OR TRANSMITTER

(DLC3010/DLC3020f

SHOWN)

GE51212

RETAINING

FLANGE

ROTARY SHAFT

POSITIONING

PLATE

MOUNTING HOLES ACCEPT

FOUR STUDS OR CAP SCREWS

DEPENDING ON CONTROLLER OR

TRANSMITTER

OUTER

TUBE END

GASKET

HEX NUTS OR CAP

SCREWS DEPENDING ON

CONTROLLER OR TRANSMITTER

TORQUE

TUBE ARM

Type Number Description

D 249W—NPS 3 or 4, CL150, CL300, or CL600 steel cageless sensor.

The Parts List section shows some 249W constructions, standard displacer lengths, and standard materials, and table 1

contains materials of construction. However, 249W parts are available in a wide variety of materials of construction,

part dimensions, and other specifications. Contact your Emerson Process Management sales office for assistance in

selection of specific materials, dimensions, and specifications.

Table 1. Materials of Construction

Part Standard Material Other Materials

Wafer Body and Torque Tube Arm WCC (NACE MR0175 compliant) 316 Stainless Steel

Displacer 304 Stainless Steel 316 Stainless Steel, N10276, N04400, Plastic, and Special Alloys

Displacer Stem, Driver Bearing,

Displacer Rod and Driver

Torque Tube N05500

Bolting

Torque Tube Arm Gasket and

Torque Tube End Gasket

1. N05500 is not recommended for spring applications above 232_C (450_F). Contact your Emerson Process Management sales office or application engineer if temperatures exceeding this

limit are required.

316 Stainless Steel N10276, N04400, other Austenitic Stainless Steels, and Special Alloys

(1)

NCF coated steel grade B7 studs or

cap screws and grade 2H nuts

Graphite/Stainless Steel N04400/PTFE

316 Stainless Steel, N06600, N10276

Steel Grade B7M or M8M studs and grade 2M nuts

Educational Services

For information on available courses for 249W level sensors, as well as a variety of other products, contact:

Emerson Process Management

Educational Services, Registration

P.O. Box 190; 301 S. 1st Ave.

Marshalltown, IA 50158-2823

Phone: 800-338-8158 or

Phone: 641-754-3771

FAX: 641-754-3431

e‐mail: education@emerson.com

3

249W Sensor

December 2012

Instruction Manual

D102803X012

Installation

WARNING

To avoid personal injury or property damage resulting from the sudden release of pressure:

D Always wear protective clothing, gloves, and eyewear when performing any installation operations to avoid personal

injury.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section of this

instruction manual.

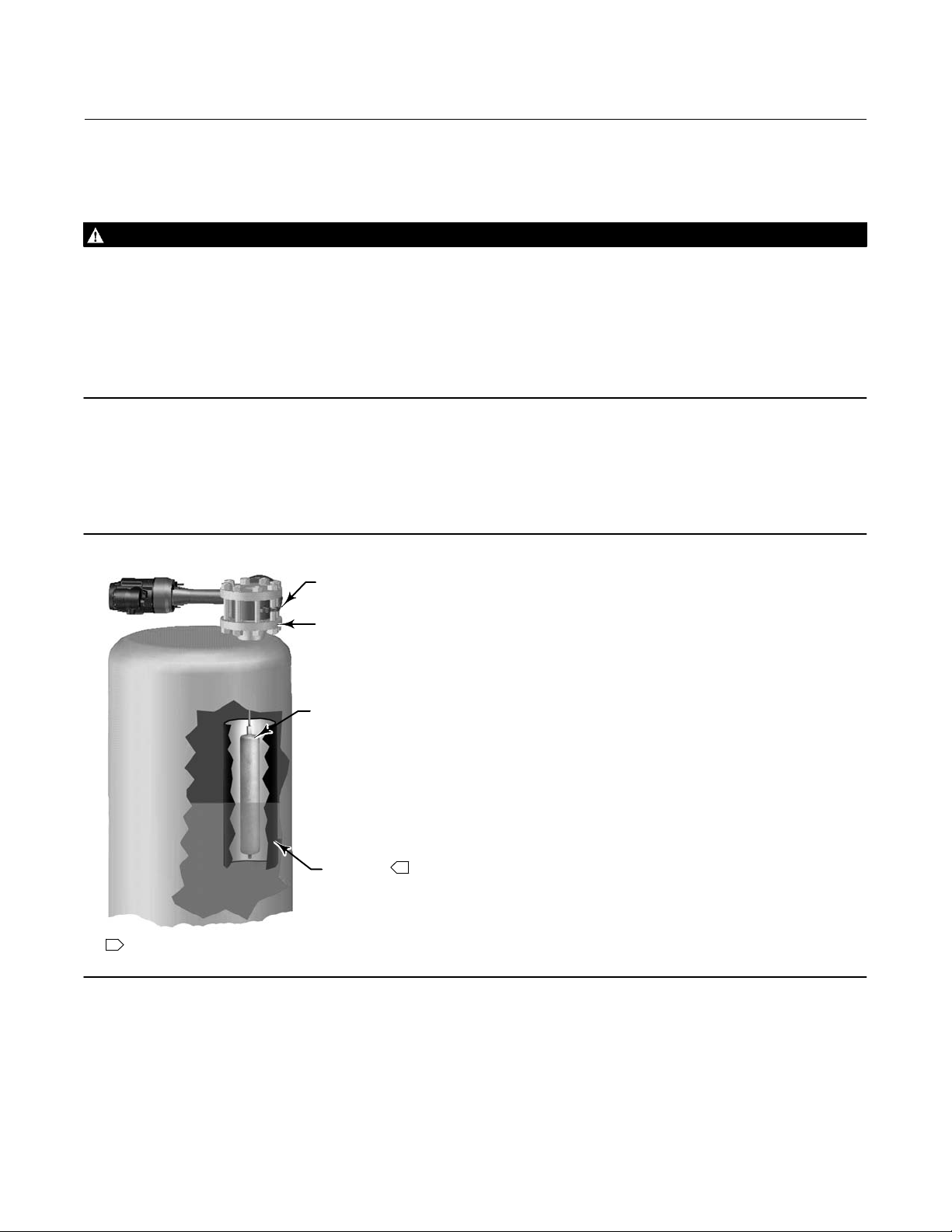

The 249W sensor can be installed directly on the vessel as shown in figure 4. It also can be installed in a user fabricated

cage mounted on the side of the vessel as shown in figure 5. The sensor mounts on the top of the vessel or in the

displacer cage using an NPS 3 raised face flange with the NPS 3 249W wafer body, or an NPS 4 raised‐face flange with

the NPS 4 249W wafer body.

Figure 4. Fisher 249W Sensor Top Mounted on Vessel

249W WAFER BODY

NPS 3 OR 4 RF FLANGE

DISPLACER

STILLWELL

NOTE:

1 STILLWELL REQUIRED AROUND DISPLACER IF THE FLUID IS IN A STATE

OF CONTINUOUS AGITATION

W8266

1

4

Instruction Manual

D102803X012

Figure 5. Fisher 249W Sensor Cage‐Mounted on Side of Vessel

249W Sensor

December 2012

W8267

CAGE WITH TOP AND BOTTOM CONNECTIONS

W8268

CAGE WITH SIDE CONNECTIONS

Installation on Top of Vessel

Note

If a stillwell is used, install it plumb so that the displacer does not touch the wall of the stillwell. If the displacer touches the wall,

the unit will transmit an erroneous output signal.

Because the displacer hangs inside the vessel, provide a stillwell around the displacer if the fluid is in a state of

continuous agitation to avoid excessive turbulence around the displacer.

To attach the sensor body to the vessel requires a flanged connection on the vessel as shown in figure 4. For interface

or fluid level applications, install a gauge glass on the vessel.

Installation with Displacer Cage on Side of Vessel

Note

Install the cage so that it is plumb; the displacer must not touch the cage wall. If the displacer touches the cage wall, the unit will

transmit an erroneous output signal.

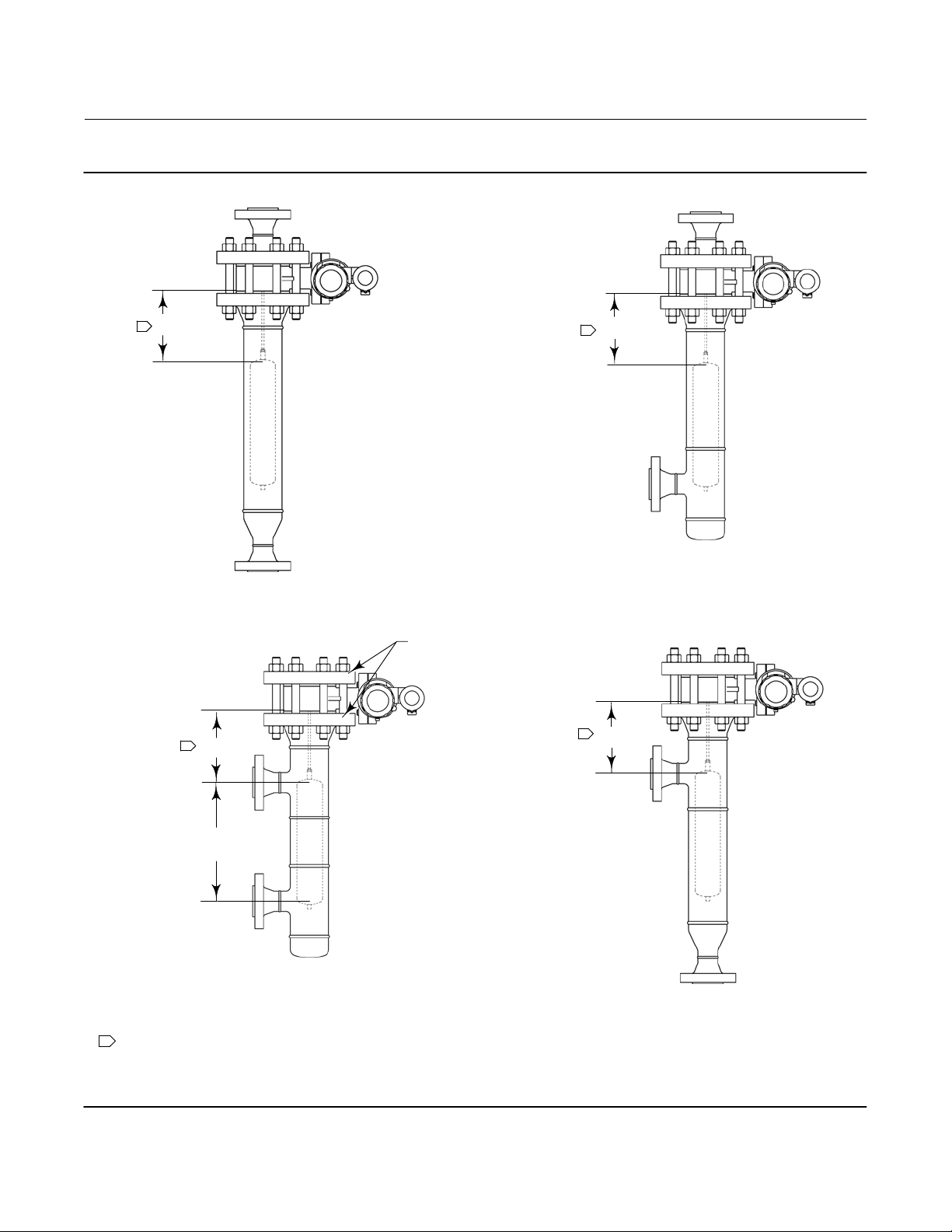

Figure 5 shows the 249W sensor mounted on the side of a vessel using a displacer cage. Figure 6 provides the 249W

dimensions required to fabricate a cage. Figure 7 provides overall envelope dimensions for a 249W sensor and

DLC3010/DLC3020f controller, and figure 8 provides overall envelope dimensions for a 249W and 2500 controller or

transmitter.

5

249W Sensor

December 2012

Figure 6. Typical Cage Connections

1

G

Instruction Manual

D102803X012

G

1

CAGE WITH TOP AND

STYLE 1

LOWER SIDE VESSEL CONNECTIONS

GE06686

CAGE WITH TOP AND

BOTTOM VESSEL CONNECTIONS

GE06685

NPS 3 OR 4 CL150, CL300, OR

CL600 FLANGE

1

1

G

G

356 mm

(14‐INCHES)

STYLE 3

CAGE WITH UPPER AND

LOWER SIDE VESSEL CONNECTIONS

NOTES:

GE06687

1 DIMENSION G IS CUSTOMER SPECIFIED

CAGE WITH UPPER SIDE AND

BOTTOM VESSEL CONNECTIONS

GE06688

2. VESSEL CONNECTIONS ARE EITHER NPS 1‐1/2 OR 2 CL150, CL300 OR CL600 FLANGES.

(VESSEL ENDS CAN BE ALSO SCREWED OR SOCKET WELDED CONNECTIONS)

3. DISPLACER LENGTH ILLUSTRATED IS 14‐INCHES

4. CONNECTIONS SHOWN ILLUSTRATE THE DLC3010/DLC3020f. CONNECTIONS ARE ALSO APPLICABLE TO THE 2500

STYLE 2

STYLE 4

6

Instruction Manual

D102803X012

Figure 7. Overall Envelope Dimensions for Fisher 249W / DLC3010 or DLC3020f for Mounting on

Customer Supplied Cage

249W Sensor

December 2012

507

(19.75)

66

(2.61)

LEFT HAND MOUNT

59

(2.34)

(5.49)

59

(2.34)

139

204

(8.04)

MATCHES NPS 3

RAISED‐FACE FLANGE

127

(5.00)

MATCHES NPS 4

RAISED‐FACE FLANGE

73

(2.87)

157

(6.19)

MATCHES NPS 3

RAISED‐FACE FLANGE

127

(5.00)

MATCHES NPS 4

RAISED‐FACE FLANGE

157

(6.19)

RIGHT HAND MOUNT

204

(8.04)

507

(19.75)

73

(2.87)

1/2 - 14 NPT

2 PLACES

D

j

NOTES:

1 DIMENSION G IS CUSTOMER SPECIFIED

2. DISPLACER LENGTH ILLUSTRATED IS 14‐INCHES

10C0786‐B

G

356

(14.00)

1

WAFER‐STYLE

SENSOR SIZE

NPS 3

NPS 4

mm

60

76

1

G

356

(14.00)

j

D

D

INCH

2.38

3.00

610

(24.00)

HEAT INSULATOR EXTENSION

mm

(INCH)

7

249W Sensor

Instruction Manual

December 2012

Figure 8. Overall Envelope dimensions for Fisher 249W / 2500 for Mounting on Customer Supplied Cage

LEFT-HAND MOUNT RIGHT-HAND MOUNT

D102803X012

98

(3.88)

417

(16.40)

239

(9.41)

MATCHES NPS 3

RAISED‐FACE FLANGE

203

(8.00)

328

(12.90)

127

(5.00)

MATCHES NPS 4

RAISED‐FACE FLANGE

157

(6.19)

WAFER‐STYLE

SENSOR SIZE

NPS 3

NPS 4

73

(2.87)

MATCHES NPS 4

RAISED‐FACE FLANGE

157

(6.19)

D

mm

60

76

INCH

2.38

3.00

MATCHES NPS 3

RAISED‐FACE FLANGE

127

(5.00)

73

(2.87)

98

(3.88)

417

(16.40)

203

(8.00)

318

(12.51)

232

(9.12)

D

NOTES:

1 DIMENSION G IS CUSTOMER SPECIFIED

2. DISPLACER LENGTH ILLUSTRATED IS 14‐INCHES

GE06028‐A

8

G

356

(14.00)

1

1

356

(14.00)

G

D

mm

(INCH)

Instruction Manual

D102803X012

When fabricating the cage, maintain a minimum clearance of 1/4‐inch between the displacer and the cage wall. Dirty

or viscous fluids may require a larger clearance. Provide sufficient cage length below the displacer to ensure that the

displacer does not hit the bottom of the cage. The A dimension should be sufficient to permit adequate clearance for

installation and to allow access to isolation valves, etc. When installing the cage, it must be vertically plumb so that the

displacer does not strike the side of the cage.

As shown in figure 5, mount the cage by running equalizing lines between the cage connections and the vessel. A

shutoff or hand valve with a 1‐1/2 inch diameter or larger port should be installed in each of the equalizing lines. Also

install a drain between the cage and shutoff or hand valve whenever the bottom cage line has a fluid‐trapping low

point. On fluid or interface level applications, position the displacer cage so that the cage center is as close as possible

to the center of the fluid level or interface level range being measured. Also consider installing a gauge glass on the

vessel, or on the displacer cage.

249W Sensor

December 2012

Mounting the Sensor on the Process Vessel or Displacer Cage

CAUTION

If inserting the displacer into the vessel or displacer cage before attaching to the displacer rod, provide a means of

supporting the displacer to prevent it from dropping into the vessel or cage and suffering damage.

Install the sensor wafer body on the vessel or displacer cage using the following procedure.

You may attach the displacer to the displacer rod before installing the sensor on the cage or vessel. If so, attach the

displacer to the displacer rod as described in step 1. If the displacer diameter is small enough, you may install a long or

sectionalized displacer through the wafer body after it is positioned on the connecting flange. In this case, install the

displacer in step 4.

1. Place the seal on the connecting flange. To install the displacer, insert the displacer in the vessel or cage. Hold the

wafer body above the connecting flange. Connect the displacer as shown in figure 9, locking the assembly with the

cotter springs provided. If a stem extension is used between the displacer spud and the stem end piece, make sure

the nuts are tight at each end of the stem.

2. To position the wafer body on the connecting flange, insert a stud, with nut, through the connecting flange and one

of the eyelets on the wafer body, as shown in figure 10. Screw a second nut onto the top of the stud to hold the

wafer body in place. This second nut may be removed after the top flange is installed.

3. If you installed the displacer in step 1, go to step 5, otherwise continue with step 4.

4. If installing a long or sectionalized displacer:

a. Remove the torque tube arm assembly and displacer rod from the wafer body.

b. Insert the displacer through the wafer body into the vessel or cage.

c. Reassemble the torque tube arm assembly and displacer rod to the wafer body.

d. Connect the displacer as shown in figure 9, locking the assembly with the cotter springs provided. If a stem

extension is used between the displacer spud and the stem end piece, make sure the nuts are tight at each end of

the stem.

9

249W Sensor

December 2012

Instruction Manual

D102803X012

Figure 9. Displacer and Displacer Rod Connections

Figure 10. Positioning Fisher 249W Wafer Body on

the Connecting Flange

DISPLACER

STEM END

PIECE

DISPLACER

STEM

EXTENSION

Note

In the next step, if mounting the wafer body on a displacer cage and a flange adaptor is required, install the flange adaptor instead

of the blind flange.

COTTER SPRING

DISPLACER ROD

LOCKING NUTS

DISPLACER SPUD

W8224

5. Refer to figure 11. Place a second seal on top of the wafer body. Place a blind flange on the wafer body so that the

holes in the blind flange align with the holes in the connecting flange.

6. Refer to figure 12. Secure the wafer body between the blind flange and connecting flange by inserting the

remaining studs and nuts. Tighten the nuts just enough to hold the wafer body in place.

7. Remove the nut from the stud that was used in step 2. Reinsert the stud so it passes through the holes in the blind

flange and connecting flange. Thread the nut back onto the stud.

8. Tighten all nuts in a crisscross fashion to the torque recommended in tables 2 or 3.

Figure 11. Blind Flange Installation

W8225

Figure 12. Fisher 249W Installation Complete

W8227

10

Instruction Manual

D102803X012

Table 2. Recommended Bolt Torque for Typical Lubricants (NPS 3 Flanges)

Coating

(1)

MolykoteR 321R LubriplateR Mag‐1

667±98 (150±22)

667±98 (150±22)

689±71 (155±16)

689±71 (155 ±16)

689±102 (155±23)

689±102 (155±23)

(1)

Molykote 321R Lubriplate Mag‐1

431±62 (97±14)

667±98 (150±22)

1022±102 (230±23)

431±44 (97±10)

689±71 (155±16)

1022±102 (230±23)

418±62 (94±14)

689±102 (155±23)

956±96 (255±96)

431±62 (97±14)

431±44 (97±10)

418±62 (94±14)

Bolt and Nut

Material

SA193‐B7

SA193‐B7M

SA193‐B8M CL2

1. Torque values for NCF2 without additional lubricant are equal to Molykote 321R

Bolt Size

5/8 ‐ 11

3/4 ‐ 10

3/4 ‐ 10

5/8 ‐ 11

3/4 ‐ 10

3/4 ‐ 10

5/8 ‐ 11

3/4 ‐ 10

3/4 ‐ 10

Mating Flange

Pressure Rating

CL150

CL300

CL600

CL150

CL300

CL600

CL150

CL300

CL600

Fisher NCF2

431±62 (97±14)

667±98 (150±22)

667±98 (150±22)

431±44 (97±10)

689±71 (155±16)

689±71 (155±16)

Not applicable

Table 3. Recommended Bolt Torque for Typical Lubricants (NPS 4 Flanges)

Bolt and Nut

Material

SA193‐B7

SA193‐B7M

SA193‐B8M CL2

1. Torque values for NCF2 without additional lubricant are equal to Molykote 321R

Bolt Size

5/8 ‐ 11

3/4 ‐ 10

7/8 ‐ 9

5/8 ‐ 11

3/4 ‐ 10

7/8 ‐ 9

5/8 ‐ 11

3/4 ‐ 10

7/8 ‐ 9

Mating Flange

Pressure Rating

CL150

CL300

CL600

CL150

CL300

CL600

CL150

CL300

CL600

Fisher NCF2

Coating

431±62 (97±14)

667±98 (150±22)

1022±102 (230±23)

431±44 (97±10)

689±71 (155±16)

1022±102 (230±23)

Not applicable

Lubricant

Torque, NSm (lbfSft)

556±84 (125±19)

845±124 (190 ±28)

845±124 (190±28)

556±58 (125±13)

890±89 (200±20)

890±89 (200±20)

534±80 (120±18)

890±133 (200±30)

890±133 (200±30)

Lubricant

Torque, NSm (lbfSft)

556±84 (125±19)

845±124 (190 ±28)

1289±129 (290±29)

556±58 (125±13)

890±89 (200±20)

1289±129 (290±29)

534±80 (120±18)

890±133 (200±30)

1133±114 (255±26)

249W Sensor

December 2012

Never‐Seez

Nickel Special

534±80 (120±18)

801±133 (180±30)

801±133 (180±30)

534±53 (120±12

845±84 (190±19)

845±84 (190±19)

511±67 (115±15)

845±124 (190±28)

845±124 (190±28)

Never‐Seez

Nickel Special

534±80 (120±18)

801±133 (180±30)

1222±122 (275±28)

534±53 (120±12

845±84 (190±19)

1222±122 (275±28)

511±67 (115±15)

845±124 (190±28)

1111±111 (250±25)

R

Maintenance

Sensor parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection

and replacement depends upon the severity of service conditions.

WARNING

Avoid personal injury or property damage resulting from the sudden release of pressure. Before performing any

maintenance procedure:

D Always wear protective clothing, gloves, and eyewear.

D Relieve any process pressure in the process vessel where the 249W sensor is installed.

D Drain the process liquid from the process vessel.

D Shut off any electrical or pneumatic input to the controller or transmitter attached to the 249W sensor and vent any

pneumatic supply pressure.

D Use caution when loosening flange bolting or pipe plugs.

D Remove the controller or transmitter from the torque tube arm (key 2).

Before performing any maintenance procedure requiring the handling of the displacer, inspect the displacer (key 4) to

make sure process pressure or liquids have not penetrated the displacer.

11

249W Sensor

December 2012

The displacer in this unit is a sealed container. If penetrated by process pressure or liquid, the displacer may hold pressure

or hazardous liquid for an extended period. A displacer that has been penetrated by process pressure or liquid may contain:

D pressure as a result of being in a pressurized vessel.

D liquid that becomes pressurized due to a change in temperature.

D liquid that is flammable, hazardous, or corrosive.

Sudden release of pressure, contact with hazardous liquid, fire, or explosion, which might result in personal injury or

property damage, can occur if a displacer that is retaining pressure or process liquid is punctured, subjected to heat, or

repaired.

Handle the displacer with care. Consider the characteristics of the specific process liquid in use.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Note

Except for gaskets (keys 12, 13), trouble symptoms peculiar to specific parts are discussed in the following sections. Each section is

specific to these parts. Regardless of location, gasket failure is indicated by leakage in the gasket area. Every time a gasket is

removed, replace it with a new one upon reassembly.

Instruction Manual

D102803X012

The procedures below apply to the 249W assembly as shown in figure 14. Refer to figure 14 for key number locations.

Removing the Displacer and Stem

WARNING

Refer to the Maintenance WARNING at the beginning of this section.

The displacer (key 4) is a sealed container. If the displacer has been penetrated by process pressure or liquid, it may

hold pressure or hazardous liquid for an extended period.

Process residue buildup on the displacer and stem (key 11) may change displacer weight or displacement. A bent stem

or a dented or corroded displacer can impair performance.

If the displacer rests against the travel stop, appears to be overweight, or causes output drift or other output

inaccuracies, it may have been penetrated by process pressure or liquid. Such a displacer may contain pressure

because it was in a pressurized vessel, may contain process liquid that becomes pressurized due to a change in

temperature, and may contain process liquid that is flammable or hazardous.

WARNING

Sudden release of pressure, contact with hazardous liquid, fire, or explosion, which may result in personal injury or

property damage, can occur if a displacer that is retaining pressure or process liquid is punctured, subjected to heat, or

repaired.

Handle the displacer with care.

1. Support the sensor body (key 1) and the torque tube arm (key 2). Remove the bolting that holds the wafer body to

the process vessel or displacer cage.

12

Instruction Manual

D102803X012

249W Sensor

December 2012

CAUTION

When removing the sensor from a process vessel or displacer cage, the displacer may remain attached to the displacer rod

and be lifted out with the wafer body (key 1) when the wafer body is removed. If separating the displacer and displacer rod

before removing the wafer body, remove the cotter spring (key 10).

Be careful not to let the displacer slip and drop into the bottom of the process vessel or displacer cage, as displacer damage

could result.

2. Carefully remove the sensor. If the displacer comes out with the sensor, be careful not to damage the displacer or

bend the stem when setting the sensor down.

3. Follow the procedure for replacing the displacer, displacer rod assembly, cotter spring, stem end piece, and

displacer spud as necessary.

Replacing the Displacer, Cotter Spring, Stem End Piece, and Displacer

Spud

The cotter spring (key 10), the ball on the displacer rod/driver assembly (key 5), and the stem end piece or displacer

stem connector (key 6) may be either too worn for a secure connection or so clogged or corroded that the displacer

does not pivot properly. Replace these parts, as necessary.

CAUTION

If the displacer is to be disconnected from the displacer rod before being removed from the process vessel or displacer

cage, provide a suitable means of supporting the displacer to prevent it from dropping into the vessel or cage and being

damaged.

1. After following the proper procedure to remove the sensor and the displacer from the process vessel or displacer

cage, move the sensor assembly to a suitable maintenance area. Support the assembly to avoid damage to the

displacer, displacer stem, displacer rod/driver assembly, and associated parts.

2. To help support the displacer, install the stem and stem end piece (or a threaded rod) into the 1/4 inch‐28 UNF

threaded hole in the displacer spud or stem connector.

3. Reach the cotter spring, displacer spud, ball end of the displacer rod/driver assembly, stem end piece, or displacer

stem connector as follows:

Remove the cotter spring to free the displacer or stem end piece from the ball end of the displacer rod/driver

assembly. Lift the displacer or stem end piece from the ball.

4. Replace worn or damaged parts as necessary. Return the displacer or stem end piece to the displacer rod/driver

assembly. Install the cotter spring.

5. Install the sensor and controller/transmitter. Calibrate the controller/transmitter following the procedures given in

the controller/transmitter instruction manual.

Replacing the Displacer Rod/Driver Assembly

The ball on the displacer rod/driver assembly (key 5) may be either too worn for a secure connection or so corroded

that the displacer does not pivot properly. Replace the displacer rod/driver assembly, if necessary.

13

249W Sensor

December 2012

Instruction Manual

D102803X012

CAUTION

If the displacer is to be disconnected from the displacer rod/driver assembly before being removed from the process vessel

or displacer cage, provide a suitable means of supporting the displacer to prevent it from dropping into the vessel or cage

and being damaged.

1. After following the proper procedure to remove the sensor and the displacer from the process vessel or displacer

cage, move the sensor assembly to a suitable maintenance area. Support the assembly to avoid damage to the

displacer, displacer stem, displacer rod assembly, and associated parts.

2. Remove the controller/transmitter and displacer (key 4). Then, remove the hex nuts (key 20) that hold the torque

tube arm (key 2) to the wafer body (key 1). Separate the torque tube arm from the wafer body.

3. Remove the nuts (key 18) and retaining flange (key 14) at the end of the torque tube arm.

4. Remove the positioning plate (key 15) by freeing its two lugs.

The vertical lug fits into a hole in the flange of the torque tube arm (top of figure 13, left). The horizontal lug (hidden

behind the screwdriver at the bottom of figure 13, left) fits into a slot in the outer tube end of the torque tube

assembly (the figure 13 exploded view shows this lug to the right of the outer tube end).

Place a screwdriver blade in the slots of the positioning plate and outer tube end as shown in figure 13. Slowly turn

the positioning plate to release its lug from the torque tube arm. Then carefully turn the plate back to allow the

displacer to come to rest, and slip the other lug of the plate from its slot in the outer tube end.

5. Pull the torque tube assembly out of the torque tube arm. Remove the tube end gasket (key 13) and discard (a new

gasket will be installed in step 9). Clean and inspect the gasket mating surfaces.

6. Using the proper tool, loosen and then remove the upper bearing driver bolt (key 8). Lift the displacer rod/driver

assembly from the knife edge of the driver bearing (key 7).

7. Visually inspect the bearing driver for corrosion or wear. If replacement is necessary, remove the bearing driver by

removing the lower bearing driver bolt. Install a new bearing driver and the lower bearing driver bolt.

8. Install the new displacer rod/driver assembly on the knife edge of the bearing driver. Install the upper bearing driver

bolt (key 8), but do not tighten.

9. Insert new tube end gasket into the recess in torque tube arm.

10. Insert the torque tube arm assembly and rotate until its socket mates with the displacer rod assembly and so that

the outer tube flange rests against the gasket.

11. With a thumb on the upper portion of the positioning plate and screwdriver in the slots as shown in figure 13,

rotate the plate and press the lug on the plate into the hole in the torque tube arm (this will preload the torque

tube).

12. Install the retaining flange and secure it with four nuts (key 18), being sure to tighten all nuts evenly.

13. Tighten the upper bearing driver bolt (key 8). It will be necessary to put slight pressure on the displacer rod/driver

assembly to access the upper bearing driver bolt.

14. Install the torque tube arm on the wafer body and secure it with the proper bolting (keys 19 and 20).

15. Install the sensor and controller/transmitter. Calibrate the controller/transmitter following the procedures given in

the controller/transmitter instruction manual.

Replacing the Torque Tube

Corrosion or leakage through the outer end of the torque tube is evidence of deterioration in the torque tube

assembly (key 3) or torque tube end gasket (key 13). Erratic or nonexistent rotary shaft output may occur if the socket

on the inner end of the torque tube assembly does not engage the bearing end of the displacer rod/driver assembly

(key 5).

14

Instruction Manual

D102803X012

Figure 13. Torque Tube and Displacer Rod Assemblies

W0145‐2

DISPLACER ROD

ASSEMBLY

GASKET

TORQUE TUBE

OUTER TUBE END

POSITIONING PLATE

DRIVER BEARING

249W Sensor

December 2012

ROTARY

SHAFT

W0654‐1

REMOVAL OR INSTALLATION OF POSITIONING PLATE

EXPLODED VIEW OF TORQUE TUBE AND DISPLACER ROD ASSEMBLY

1. After following the proper procedure to remove the sensor and the displacer from the process vessel or displacer

cage, move the sensor assembly to a suitable maintenance area. Support the assembly to avoid damage to the

displacer, displacer stem, displacer rod assembly, and associated parts.

2. Remove the controller/transmitter and displacer (key 4). Then, remove the hex nuts (key 20) that hold the torque

tube arm (key 2) to the wafer body (key 1). Separate the torque tube arm from the wafer body.

3. Remove the nuts (key 18) and retaining flange (key 14) holding the positioning plate (key 15) at the end of the

torque tube arm.

CAUTION

If the displacer is still attached to the displacer rod at this point, be careful not to let the torque tube assembly slip when

using the screwdriver leverage procedure in steps 4 and 6. Sudden release of the displacer could cause damage to the

displacer or torque tube assembly.

4. Remove the positioning plate (key 15) by freeing its two lugs.

The vertical lug fits into a hole in the flange of the torque tube arm (figure 13). The horizontal lug (hidden behind

the screwdriver in figure 13) fits into a slot in the outer tube end of the torque tube assembly (the figure 13

exploded view shows this lug to the right of the outer tube end).

The positioning plate may be pried away from the torque tube arm and outer tube end if the displacer already has

been disconnected from the displacer rod. However, if the displacer is still connected to the displacer rod, place a

screwdriver blade in the slots of the positioning plate and outer tube end as shown in figure 13. Slowly turn the

positioning plate to release its lug from the torque tube arm. Then, carefully turn the plate back to allow the

displacer to come to rest and slip the other lug of the plate from its slot in the outer tube end.

5. Pull the torque tube assembly and tube end gasket out of the torque tube arm. Remove the tube end gasket

(key 13) and discard (a new gasket will be installed in step 6). Clean and inspect the gasket mating surfaces.

6. Install a new tube end gasket into recess in torque tube arm.

7. Insert the torque tube assembly into the torque tube arm as shown in figure 13. Rotate the torque tube assembly

until its socket mates with the driver member on the displacer rod assembly and so the outer tube flange rests

15

249W Sensor

December 2012

against the gasket. With a thumb on the upper portion of the positioning plate and a screwdriver in the slots as

shown in figure 13, rotate the plate and press the lug on the plate into the hole in the torque tube arm (this will

preload the torque tube).

8. Install the retaining flange and secure it with four nuts (key 18), being sure to tighten all nuts evenly.

9. Install the torque tube arm on the wafer body and secure it with the proper bolting (keys 19 and 20).

10. Install the sensor and controller/transmitter. Calibrate the controller/transmitter following the procedures given in

the controller/transmitter instruction manual.

Instruction Manual

D102803X012

Changing the Mounting from Left‐Hand to Right‐Hand or Vice Versa.

Looseness of the driver bearing (key 7), wear on its knife‐edged surface, or a bent, worn, or corroded displacer

rod/driver assembly (key 5) may impair performance. Be especially sure to check the ball on the displacer rod.

CAUTION

Support the sensor assembly to avoid damage to the displacer, displacer stem, displacer rod assembly, and associated

parts.

1. After following the proper procedure to remove the sensor and the displacer from the process vessel or displacer

cage, move the sensor assembly to a suitable maintenance area.

2. Remove the controller/transmitter and displacer (key 4). Then, remove the hex nuts (key 20) that hold the torque

tube arm (key 2) to the wafer body (key 1). Separate the torque tube arm from the wafer body.

3. Follow the proper procedure to remove the torque tube assembly (key 3).

4. Remove the driver bearing bolts (key 8), displacer rod/driver assembly (key 5), and driver bearing (key 7).

Note

Be sure to install the driver bearing so its knife edge is pointing up when the torque tube arm is mounted in the desired orientation.

Since changing the mounting position of the torque tube arm by 180_ will change controller or transmitter action from direct to

reverse or vice versa, controller/transmitter action must be reversed from what it was before the mounting method was changed.

5. Install the driver bearing (key 7), displacer rod/driver assembly (key 5), and bearing bolts (key 8) into the torque

tube arm (key 2). Install a new arm gasket (key 12). Install the torque tube arm on the wafer body and secure it with

the proper bolting (keys 19 and 20).

6. Install the sensor and controller/transmitter. Calibrate the controller/transmitter following the procedures given in

the controller/transmitter instruction manual.

Simulation of Process Conditions for Calibration of Fisher Level

Controllers and Transmitters

Contact your Emerson Process Management sales office for information on obtaining the Supplement to 249 Sensor

Instruction Manuals: Simulation of Process Conditions for Calibration of Fisher Level Controllers and Transmitter

(D103066X012).

16

Instruction Manual

D102803X012

249W Sensor

December 2012

Related Documents

This section lists other documents containing information related to the 249W level sensor. These documents include:

D 2500‐249 Pneumatic Controllers and Transmitters (Bulletin 34.2:2500)

D Fisher Level Controller and Transmitter Dimensions (Bulletin 34.2:249)

D Fisher L3 Pneumatic Level Controller (Bulletin 34.2:L3)

D Simulation of Process Conditions for Calibration of Fisher Level Controllers and Transmitters— Supplement to 249

Sensor Instruction Manuals (D103066X012)

D Bolt Torque Information— Supplement to 249 Sensor Instruction Manuals (D103220X012)

D Torque Tube Identification— Supplement to 249 Sensor Instruction Manuals (D103283X012)

All documents are available from your Emerson Process Management sales office. Also visit our website at

www.Fisher.com.

Parts Ordering

Whenever corresponding with your Emerson Process Management sales office about this equipment, always mention

the sensor serial number. Each sensor is assigned a serial number which is stamped on a nameplate (key 21) attached

to the torque tube arm. This same number also appears on the controller/transmitter nameplate when a complete

controller/transmitter/ sensor unit is shipped from the factory. When ordering a replacement part, be sure to include

the 11‐character part number from the following parts list.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher instrument. Use of components not supplied by Emerson Process

Management may void your warranty, might adversely affect the performance of the instrument, and could cause personal

injury or property damage.

Determining Displacer Stem Length

When ordering a displacer stem, determine the displacer stem length from the G dimension in figure 6 for cage styles

3 and 4. For cage styles 1 and 2, the G dimension is typically 0, because the displacer is generally suspended from the

rod and driver assembly with no displacer stem required.

The stem length will be the G dimension rounded to the nearest 1/2‐inch increment. For example, if dimension G is

12.63 inches, round it to 12.5 inches. Specify a stem length of 12.5 inches. If dimension G is 9.44 inches, round it to 9.5

inches. Specify a stem length of 9.5 inches.

Stem lengths can be adjusted approximately ±0.25 inches for a more exact dimension. Stems are available in 1/2‐inch

increments from 2 to 54 inches.

17

249W Sensor

December 2012

Figure 14. Fisher 249W Sensor Construction

Instruction Manual

D102803X012

PARTS NOT SHOWN: 23

19B3127

Parts List

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson Process Management sales

office.

Key Description

1 Wafer Body

NPS 3

WCC steel

CF8M (316 SST)

NPS 4

LCC steel

CF8M (316 SST)

2 Torque Tube Arm

WCC steel

LCC

CF8M (316 SST)

18

Instruction Manual

D102803X012

249W Sensor

December 2012

Key Description Part Number

3* Torque Tube Assy

(1)

Std wall

N05500 (std w/WCC steel) 1K4493X0012

316 SST (std w/CF8M) 1K4503000A2

N06600 1K4515000A2

N10276 1K4527000A2

Thin wall

N05500 (std w/WCC steel) 1K4495X0012

316 SST (std w/CF8M) 1K4505000A2

N06600 1K4517000A2

N10276 1K4529000A2

Heavy wall

N05500 (std w/WCC steel) 1K4497X0012

316 SST (std w/CF8M) 1K4541000A2

N06600 1P8662X0012

N10276 1K453140152

4 Displacer

(1)

2‐3/8 x 14 inches (62 cubic inches)

3.75 pounds (1400 psi)

S30400

S31600

4.75 pounds (1400 psi)

S30400

S31600

3 x 14 inches (99 cubic inches)

4.75 pounds (1600 psi)

S30400

S31600

2 x 24 inches (75 cubic inches)

3.75 pounds (1480 psi)

S31600

4.75 pounds (1450 psi)

S30400

2‐3/8 x 24 inches (106 cubic inches)

4.75 pounds (1400 psi)

S30400

S31600

1‐1/2 x 32 inches (57 cubic inches)

3.75 pounds

S30400 (1800 psi)

S31600 (1300 psi)

4.75 pounds

S31600 (1300 psi)

2 x 32 inches (100 cubic inches)

S30400 (1500 psi) 4.75 pounds

1‐1/4 inch x 48 inches (59 cubic inches)

S30400 (1800 psi) 3.75 pounds

1‐1/2 x 48 inches (85 cubic inches)

3.75 pounds (1300 psi)

S31600

4.75 pounds (1300 psi)

S31600

1‐5/8 x 48 inches (99 cubic inches)

S31600 (1800 psi) 3.75 pounds

1‐1/8 x 60 inches (60 cubic inches)

3.75 pounds

S30400 (1600 psi)

S31600 (2100 psi)

Key Description Part Number

4 Displacer

(1)

(cont'd)

1‐1/2 x 60 inches (106 cubic inches)

4.75 pounds

S30400 (1800 psi)

S31600 (1300 psi)

1‐1/8 x 72 inches (72 cubic inches)

3.75 pounds (1600 psi)

S30400

S31600

1‐3/8 x 72 inches (107 cubic inches)

4.75 pounds (1400 psi)

S30400

S31600

1 x 84 inches (66 cubic inches)

3.75 pounds (1400 psi)

S30400

S31600

1‐1/4 x 84 inches (103 cubic inches)

4.75 pounds (1800 psi)

S30400

S31600

1‐1/8 x 96 inches (95 cubic inches)

4.75 pounds

S30400 (1570 psi)

S31600 (2100 psi)

1‐1/8 x 108 inches (107 cubic inches)

4.75 pounds (1600 psi)

S30400

S31600

1 x 120 inches (94 cubic inches)

4.75 pounds (1400 psi)

S30400

S31600

5 Rod/Driver Assy

S31600

N05500

N10276

6 Displacer Stem End Piece

S31600

N05500

N10276

7 Driver Bearing

S31600

N05500

N10276

8 Driver Bearing Bolt (2 req'd)

S31600

N05500

N10276

9 Hex Nut (2 req'd)

S31600

N05500

N10276

10* Cotter Spring (2 req'd)

N04400 1A517942022

N10276 1A517940152

11 Displacer Stem

When ordering a replacement displacer stem,

specify length and desired material.

*Recommended spare parts

1. This part is available in a wide variety of materials of construction, part dimensions, or other

specifications. Listed here are standard or typical materials, dimensions, or specifications.

Contact your Emerson Process Management sales office for assistance in selection of specific

materials, dimensions, or specifications.

19

249W Sensor

December 2012

Instruction Manual

D102803X012

Key Description Part Number

12* Arm Gasket

Graphite/SST 1E5629X0072

N04400/PTFE 10B6639X012

13* Tube End Gasket

(1)

Graphite/SST 0Y0876X0052

N04400/PTFE 13B8741X012

14 Retaining Flange

For SA‐193 B7 and B7M bolting

For SA‐193 B8M bolting

15 Positioning Plate, zn pl steel

16 Groove Pin, plated steel

17 Stud Bolt

(1)

(4 req'd)

For SA‐193 B7 bolting

For SA‐193 B7M bolting

For SA‐193 B8M bolting

18 Hex Nut

(1)

(4 req'd)

For SA‐193 B7 bolting

For SA‐193 B7M bolting

For SA‐193 B8M bolting

Key Description

19 Bolt Stud

(1)

(4 req'd)

NPS 3 Wafer Body

For SA‐193 B7 bolting

For SA‐193 B7M bolting

For SA‐193 B8M bolting

NPS 4 Wafer Body

For SA‐193 B7 bolting

For SA‐193 B7M bolting

For SA‐193 B8M bolting

20 Hex Nut

(1)

NPS 3 Wafer Body (8 req'd)

NPS 4 Wafer Body (4 req'd)

For SA‐193 B7 bolting

For SA‐193 B7M bolting

For SA‐193 B8M bolting

21 Nameplate

22 Drive Screw

23 B31‐3 Nameplate (not shown)

24 NACE Tag (not shown)

25 Wire (not shown)

*Recommended spare parts

1. This part is available in a wide variety of materials of construction, part dimensions,

or other specifications. Listed here are standard or typical materials, dimensions, or

specifications. Contact your Emerson Process Management sales office for assistance

in selection of specific materials, dimensions, or specifications.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and FIELDVUE are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

20

E 2001, 2012 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...