Page 1

Instruction Manual

D200100X012

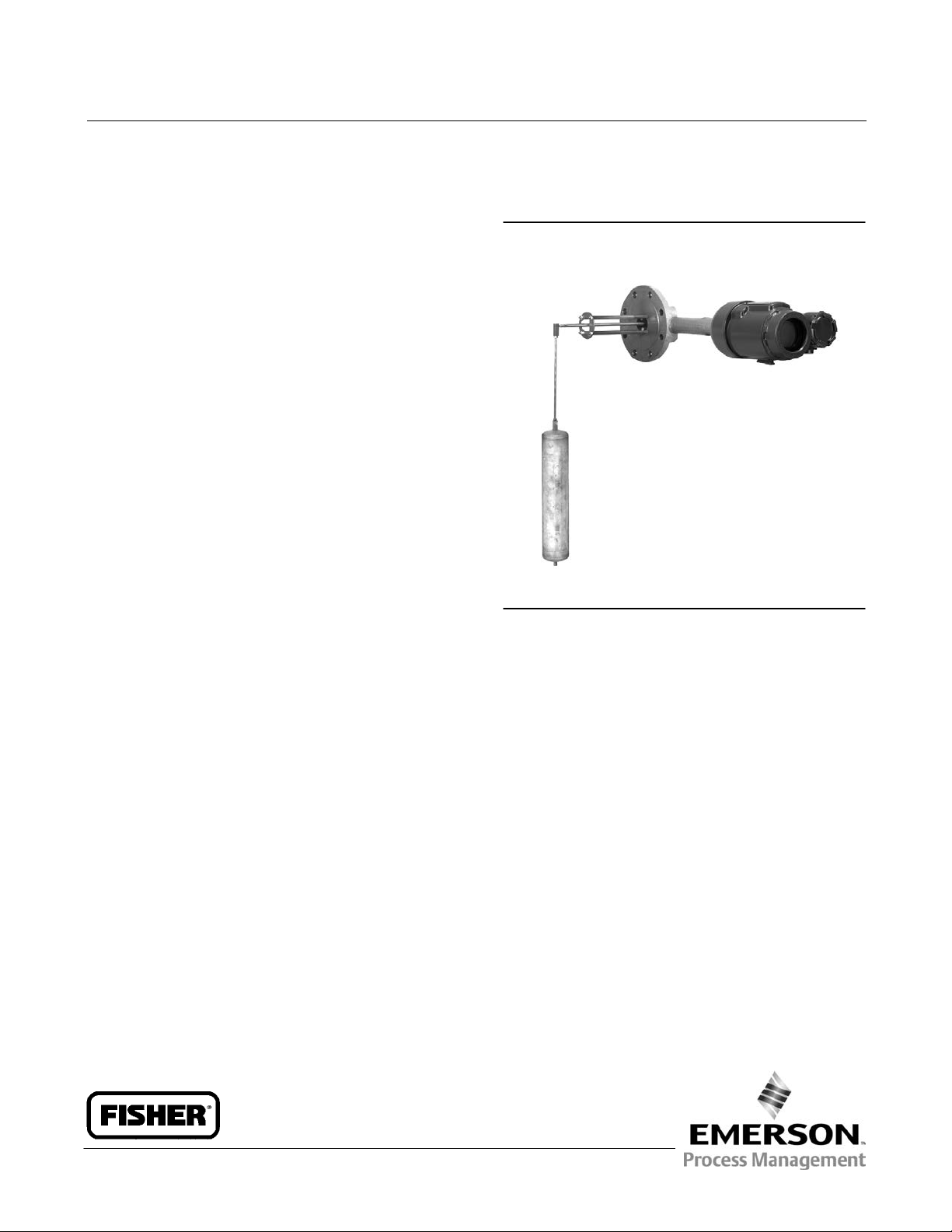

Fisherr 249 Cageless Displacer Sensors

249 Cageless Sensors

December 2012

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Type Number Description 2.....................

Educational Services 3.........................

Maintenance 3.................................

Removing the Displacer and Stem 4..............

Replacing the Displacer, Cotter Spring,

Stem End Piece, and Displacer Spud 6..........

Replacing the Displacer Rod/Driver Assembly 7....

Replacing the Torque Tube 8....................

Replacing the Torque Tube Arm and

Changing the Mounting 9....................

Simulation of Process Conditions for

Calibration of Fisher Level Controllers

and Transmitters 10............................

Parts Ordering 10...............................

Parts Kits 11...................................

Parts List 11...................................

Sensor Common Parts 11.......................

Figure 1. Fisher 249V Sensor with FIELDVUE™

DLC3010/DLC3020f Digital Level Controller

W3120‐3

Introduction

Scope of Manual

This instruction manual includes maintenance and parts ordering information for Fisher 249 cageless displacer

sensors.

Although a 249 sensor is usually shipped with attached controller or transmitter, this manual does not include

operation, installation, calibration, maintenance, and parts ordering information for the controller/transmitter or for

the complete unit. For this information, refer to the appropriate controller/ transmitter instruction manual.

Do not install, operate, or maintain a 249 sensor without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all of the contents of this manual, including all safety cautions and warnings. If

you have any questions about these instructions, contact your Emerson Process Management sales office.

Description

249 sensors are designed to measure liquid level, interface level, or density/specific gravity inside a process vessel.

www.Fisher.com

Page 2

249 Cageless Sensors

December 2012

Instruction Manual

D200100X012

A torque tube assembly (figure 2) and displacer provide an indication of liquid level, interface level, or density/specific

gravity. The torque tube assembly consists of a hollow torque tube with a shaft welded inside it at one end and

protruding from it at the other end.

Figure 2. Typical Side‐Mounted Cageless Displacer

TRAVEL STOP ASSEMBLY

W1800‐1

DISPLACER ROD

DISPLACER

TORQUE TUBE

W0172‐1

KNIFE EDGE BEARING

The unconnected end of the tube is sealed by a gasket and clamped rigidly to the torque tube arm, permitting the

protruding end of the shaft to twist and therefore transmit rotary motion. This allows the interior of the torque tube to

remain at atmospheric pressure, thus eliminating packing and the disadvantages of packing friction.

The displacer always exerts a downward force on one end of the displacer rod. The other end of the displacer rod rests

on the knife‐edge of the driver bearing. A keyed shaft on the bearing end of the displacer fits into a socket on the

outside of the welded end of the of the torque tube assembly.

A change in liquid level, interface level, or density/specific gravity buoys up the displacer by a force equal to the weight

of the liquid displaced. Corresponding vertical movement of the displacer results in angular movement of the displacer

rod around the knife edge. Since the torque tube assembly is a torsional spring which supports the displacer and

determines the amount of movement of the displacer rod for a given displacement change, it will twist a specific

amount for each increment of buoyancy change. This rotation is brought through the torque tube arm by the

protruding rotary shaft. A controller or transmitter attached to the end of the rotary shaft converts the rotary motion

into varying pneumatic or electric signals.

Unless otherwise noted, all NACE references are to NACE MR0175-2002.

Type Number Description

D 249BP—CL150, 300, 600 steel top‐mounted sensor

D 249CP—CL150, 300, 600 stainless steel top‐mounted sensor

2

Page 3

Instruction Manual

D200100X012

249 Cageless Sensors

December 2012

D 249P—CL150, 300, 600, 900 or 1500 steel top‐mounted sensor

Note

249P CL150, 300, and 600 sensors are only available in Europe.

D 249V—CL125 or 250 cast iron or CL150, 300, 600, 900, or 1500 steel side‐mounted sensor

Note

249V sensors are only available in Europe.

All cageless 249 sensors have flanged connections.

The Parts List section shows some 249 sizes by construction, standard displacer lengths, and standard materials and

table 1 contains displacer and torque tube materials. However, 249 parts are available in a wide variety of materials of

construction, part dimensions, and other specifications. Contact your Emerson Process Management sales office for

assistance in selection of specific materials, dimensions, and specifications.

Table 1. Displacer and Torque Tube Materials

Part Standard Material Other Materials

Displacer 304 Stainless Steel 316 Stainless Steel, N10276, N04400, Plastic, and Special Alloys

Displacer Stem, Driver Bearing,

Displacer Rod and Driver

Torque Tube N05500

1. N05500 is not recommended for spring applications above 232_C (450_F). Contact your Emerson Process Management sales office or application engineer if temperatures exceeding this

limit are required.

316 Stainless Steel N10276, N04400, other Austenitic Stainless Steels, and Special Alloys

(1)

316 Stainless Steel, N06600, N10276

Educational Services

For information on available courses for 249 displacer sensors, as well as a variety of other products, contact:

Emerson Process Management

Educational Services, Registration

P.O. Box 190; 301 S. 1st Ave.

Marshalltown, IA 50158-2823

Phone: 800-338-8158 or

Phone: 641-754-3771

FAX: 641-754-3431

e‐mail: education@emerson.com

Maintenance

Sensor parts are subject to normal wear and must be inspected regularly and replaced as necessary. The frequency of

inspection and replacement depends upon the severity of service conditions.

3

Page 4

249 Cageless Sensors

December 2012

Instruction Manual

D200100X012

WARNING

Always wear protective clothing, gloves, and eyewear when performing any maintenance operations to avoid personal

injury.

Avoid personal injury or property damage resulting from the sudden release of pressure. Before performing any

maintenance procedure:

D Relieve any process pressure in the process vessel where the 249 sensor is installed.

D Drain the process liquid from the process vessel.

D Shut off any electrical or pneumatic input to the controller or transmitter attached to the 249 sensor and vent any

pneumatic supply pressure.

D Use caution when loosening flange bolting or pipe plugs (key 26).

D Remove the controller or transmitter from the torque tube arm (key 3).

Before performing any maintenance procedure requiring the handling of the displacer, inspect the displacer (key 10) to

make sure process pressure or liquids have not penetrated the displacer.

The displacer in this unit is a sealed container. If penetrated by process pressure or liquid, the displacer may hold pressure

or hazardous liquid for an extended period. A displacer that has been penetrated by process pressure or liquid may contain:

D pressure as a result of being in a pressurized vessel.

D liquid that becomes pressurized due to a change in temperature.

D liquid that is flammable, hazardous, or corrosive.

Sudden release of pressure, contact with hazardous liquid, fire, or explosion, which might result in personal injury or

property damage, can occur if a displacer that is retaining pressure or process liquid is punctured, subjected to heat, or

repaired.

Handle the displacer with care. Consider the characteristics of the specific process liquid in use.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Note

Except for gaskets (keys 13, 14), trouble symptoms peculiar to specific parts are discussed in the following sections. Each section is

specific to these parts. Regardless of location, gasket failure is indicated by leakage in the gasket area. Every time a gasket is

removed, replace it with a new one upon reassembly.

The procedures below apply to all sensor types except where indicated. Key numbers used are shown in the following

illustrations:

D 249BP—figure 5

D 249CP—figure 6

D 249P—figure 7

D 249V—figure 8

Removing the Displacer and Stem

The displacer (key 10) is a sealed container. If the displacer has been penetrated by process pressure or liquid, it may

hold pressure or hazardous liquid for an extended period.

4

Page 5

Instruction Manual

D200100X012

249 Cageless Sensors

December 2012

Process residue buildup on the displacer and stem (key 24) may change displacer weight or displacement. A bent stem

or a dented or corroded displacer can impair performance.

If the displacer rests against the travel stop, appears to be overweight, or causes output drift or other output

inaccuracies, it may have been penetrated by process pressure or liquid. Such a displacer may contain pressure

because it was in a pressurized vessel, may contain process liquid that becomes pressurized due to a change in

temperature, and may contain process liquid that is flammable, hazardous, or corrosive.

WARNING

Sudden release of pressure, contact with hazardous liquid, fire, or explosion, which may result in personal injury or

property damage, can occur if a displacer that is retaining pressure or process liquid is punctured, subjected to heat, or

repaired.

Handle the displacer with care.

Note

On the 249V, 249P, and 249BP with travel stop, the displacer must come out with the sensor head (key 2) or torque tube arm

(key 3) before being completely disconnected from the displacer rod (key 7). If separating the displacer and displacer rod, remove

the cotter spring (key 11).

CAUTION

Be careful not to let the displacer slip and drop into the bottom of the process vessel, as displacer damage could result.

1. Before starting any maintenance procedure, be sure the following safety actions are completed.

D Relieve process pressure in the process vessel where the 249 sensor is installed.

D Drain the process liquid from the process vessel.

D Shut off any electrical or pneumatic input to the controller or transmitter attached to the 249 sensor and vent

any pneumatic supply pressure. Remove the controller or transmitter from the torque tube arm.

D Use caution when loosening flange bolting or pipe plugs.

D Be sure process pressure or liquids have not penetrated the displacer.

2. Support the sensor head (key 2) and the torque tube arm (key 3). Remove the bolting that holds the sensor head to

the process vessel.

CAUTION

When removing a sensor from a process vessel, the displacer may remain attached to the displacer rod and be lifted out

with the sensor head (key 2) when the sensor head is removed. If separating the displacer and displacer rod before

removing the sensor head, remove the cotter spring (key 11). If the displacer comes out with the head or torque tube arm,

be careful not to damage the displacer or bend the stem when setting the head or arm down.

5

Page 6

249 Cageless Sensors

December 2012

Be careful not to let the displacer slip and drop into the bottom of the process vessel, as displacer damage could result.

Instruction Manual

D200100X012

3. Carefully remove the sensor head or torque tube arm.

4. On the 249V, the travel stop plate can be located in one of four positions as shown in figure 3.

For proper operation in the target application, the displacer rod must not touch either plate over the expected

range of process conditions.

D When the displacer is completely submerged in the upper fluid, the net load of weight minus buoyancy must be

low enough to allow the displacer rod to be above the lower plate.

D When the displacer is completely submerged in the lower fluid, the net load of weight minus buoyance must be

high enough to keep the displacer rod from hitting the upper plate.

If necessary, remove the place and choose a position where the rod will not touch the plate.

Figure 3. Fisher 249V Travel Stop Plate Positions

4

LOW

BJ8646‐A

1

HIGH

2

INTERMEDIATE

3

INTERMEDIATE

5. Follow the procedure for replacing the displacer, displacer rod assembly, cotter spring, stem end piece, and

displacer spud as necessary.

Replacing the Displacer, Cotter Spring, Stem End Piece, and Displacer

Spud

The cotter spring (key 11), the ball on the displacer rod/driver assembly (key 7), and the stem end piece or displacer

stem connector (key 23) may be either too worn for a secure connection or so clogged or corroded that the displacer

does not pivot properly. Replace these parts, as necessary.

CAUTION

If the displacer is to be disconnected from the displacer rod before being removed from the process vessel, provide a

suitable means of supporting the displacer to prevent it from dropping into the process vessel and being damaged.

6

Page 7

Instruction Manual

D200100X012

1. After following the proper procedure to remove the sensor head and the displacer from the process vessel, move

the sensor assembly to a suitable maintenance area. Support the assembly to avoid damage to the displacer,

displacer stem, displacer rod/driver assembly, and associated parts.

2. To help support the displacer on a unit without travel stop (249BP, 249P, 249CP), install the stem and stem end

piece (or a threaded rod) into the 1/4 inch‐28 UNF threaded hole in the displacer spud or stem connector. On the

249BP with travel stop, the groove pin (key 42) will secure the displacer as long as the travel stop plate (key 41) is

installed and the sensor head (key 2) is in position.

3. Reach the cotter spring, displacer spud, ball end of the displacer rod/driver assembly, stem end piece, or displacer

stem connector as follows:

D Top‐Mounted 249BP, 249CP, and 249P Sensors—By removing the pipe plug (key 26).

D Side‐Mounted 249V Sensor—By removing the process vessel bolting and pulling out the torque tube arm (key 3).

The inside of the process vessel wall will cause the displacer to swing up so it can be pulled out through the vessel

opening.

4. Remove the cotter spring to free the displacer or stem end piece from the ball end of the displacer rod/driver

assembly. Lift the displacer or stem end piece from the ball.

5. Replace worn or damaged parts as necessary. Return the displacer or stem end piece to the displacer rod/driver

assembly. Install the cotter spring.

6. Install the sensor head and controller/transmitter. Calibrate the controller/transmitter following the procedures

given in the controller/transmitter instruction manual.

249 Cageless Sensors

December 2012

Replacing the Displacer Rod/Driver Assembly

The ball on the displacer rod/driver assembly (key 7) may be either too worn for a secure connection or so corroded

that the displacer does not pivot properly. Replace the displacer rod/driver assembly, if necessary.

CAUTION

If the displacer is to be disconnected from the displacer rod/driver assembly before being removed from the process vessel,

provide a suitable means of supporting the displacer to prevent it from dropping into the process vessel and being

damaged.

1. After following the proper procedure to remove the sensor head and the displacer from the process vessel, move

the sensor assembly to a suitable maintenance area. Support the assembly to avoid damage to the displacer,

displacer stem, displacer rod assembly, and associated parts.

2. Remove the controller/transmitter and displacer (key 10). Then, remove the hex nuts (key 20) that hold the torque

tube arm (key 3) to the sensor head (key 2). Separate the torque tube arm from the sensor head.

3. Remove the nuts (key 18) and retaining flange (key 6) at the end of the torque tube arm.

4. Remove the positioning plate (key 8) by freeing its two lugs.

The vertical lug fits into a hole in the flange of the torque tube arm (top of figure 4, left). The horizontal lug (hidden

behind the screwdriver at the bottom of figure 4, left) fits into a slot in the outer tube end of the torque tube

assembly (figure 4 exploded view shows this lug to the right of the outer tube end).

Place a screwdriver blade in the slots of the positioning plate and outer tube ends as shown in figure 4. Slowly turn

the positioning plate to release its lug from the torque tube arm. Then carefully turn the plate back to allow the

displacer to come to rest, and slip the other lug of the plate from its slot in the outer tube end.

5. Pull the torque tube assembly out of the torque tube arm. Remove the tube end gasket (key 14) and discard (a new

gasket will be installed in step 9). Clean and inspect the gasket mating surfaces.

7

Page 8

249 Cageless Sensors

December 2012

Figure 4. Torque Tube and Displacer Rod Assemblies

W0145‐2

DISPLACER ROD

ASSEMBLY

GASKET

TORQUE TUBE

OUTER TUBE END

POSITIONING PLATE

DRIVER BEARING

Instruction Manual

D200100X012

ROTARY

SHAFT

W0654‐1

REMOVAL OR INSTALLATION OF POSITIONING PLATE

EXPLODED VIEW OF TORQUE TUBE AND DISPLACER ROD ASSEMBLY

6. Using the proper tool, loosen and then remove the upper bearing driver bolt (key 5). Lift the displacer rod/driver

assembly from the knife edge of the driver bearing (key 4).

7. Visually inspect the bearing driver for corrosion or wear. If replacement is necessary, remove the bearing driver by

removing the lower bearing driver bolt. Install a new bearing driver and the lower bearing driver bolt.

8. Install the new displacer rod/driver assembly on the knife edge of the bearing driver. Install the upper bearing driver

bolt (key 5), but do not tighten.

9. Insert new tube end gasket into recess in torque tube arm.

10. Insert the torque tube assembly and rotate until its socket mates with the displacer rod assembly and so that the

outer tube flange rests against the gasket.

11. With a thumb on the upper portion of the positioning plate and a screwdriver in the slots as shown in figure 4,

rotate the plate and press the lug on the plate into the hole in the torque tube arm (this will preload the torque

tube).

12. Install the retaining flange and secure it with four nuts (key 18), being sure to tighten all nuts evenly.

13. Tighten the upper bearing driver bolt (key 5). It will be necessary to put slight pressure on the displacer rod/driver

assembly to access the upper bearing driver bolt.

14. Install the sensor head and controller/transmitter. Calibrate the controller/transmitter following the procedures

given in the controller/transmitter instruction manual.

Replacing the Torque Tube

Corrosion or leakage through the outer end of the torque tube is evidence of deterioration in the torque tube

assembly (key 9) or torque tube end gasket (key 14). Erratic or nonexistent rotary shaft output may occur if the socket

on the inner end of the torque tube assembly does not engage the bearing end of the displacer rod assembly (key 7).

1. After following the proper procedure to remove the sensor head and the displacer from the process vessel, move

the sensor assembly to a suitable maintenance area.

CAUTION

Support the sensor assembly to avoid damage to the displacer, displacer stem, displacer rod assembly, and associated

parts.

8

Page 9

Instruction Manual

D200100X012

2. Remove the controller/transmitter and displacer (key 10). Then, remove the hex nuts (key 20) that hold the torque

tube arm (key 3) to the sensor head (key 2). Separate the torque tube arm from the sensor head.

3. Remove the nuts (key 18) and retaining flange (key 6) holding the positioning plate (key 8) at the end of the torque

tube arm.

249 Cageless Sensors

December 2012

CAUTION

If the displacer is still attached to the displacer rod at this point, be careful not to let the torque tube assembly slip when

using the screwdriver leverage procedure in steps 4 and 6. Sudden release of the displacer could cause damage.

4. Remove the positioning plate (key 8) by freeing its two lugs.

The vertical lug fits into a hole in the flange of the torque tube arm (top of figure 4). The horizontal lug (hidden

behind the screwdriver at the bottom of figure 4) fits into a slot in the outer tube end of the torque tube assembly

(the figure 4 exploded view shows this lug to the right of the outer tube end).

The positioning plate may be pried away from the torque tube arm and outer tube end if the displacer already has

been disconnected from the displacer rod. However, if the displacer is still connected to the displacer rod, place a

screwdriver blade in the slots of the positioning plate and outer tube end as shown in figure 4. Slowly turn the

positioning plate to release its lug from the torque tube arm. Then, carefully turn the plate back to allow the

displacer to come to rest and slip the other lug of the plate from its slot in the outer tube end.

5. Pull the torque tube assembly and tube end gasket out of the torque tube arm. Remove the tube end gasket

(key 14) and discard (a new gasket will be installed in step 6). Clean and inspect the gasket mating surfaces.

6. Insert new tube end gasket into recess in torque tube arm.

7. Insert the torque tube assembly into the torque tube arm as shown in figure 4. Rotate the torque tube assembly

until its socket mates with the driver member on the displacer rod assembly and so the outer tube flange rests

against the gasket. With a thumb on the upper portion of the positioning plate and a screwdriver in the slots as

shown in figure 4, rotate the plate and press the lug on the plate into the hole in the torque tube arm (this will

preload the torque tube).

8. Install the retaining flange and secure it with four nuts (key 18), being sure to tighten all nuts evenly.

9. Install the sensor head and controller/transmitter. Calibrate the controller/transmitter following the procedures

given in the controller/transmitter instruction manual.

Replacing the Torque Tube Arm and Changing the Mounting

Looseness of the driver bearing (key 4), wear on its knife‐edged surface, or a bent, worn, or corroded displacer rod

assembly (key 7) may impair performance. Be especially sure to check the ball on the displacer rod.

1. After following the proper procedure to remove the sensor head and the displacer from the process vessel, move

the sensor assembly to a suitable maintenance area.

CAUTION

Support the sensor assembly to avoid damage to the displacer, displacer stem, displacer rod assembly, and associated

parts.

2. Remove the controller/transmitter and displacer (key 10). Then, remove the hex nuts (key 20) that hold the torque

tube arm (key 3) to the sensor head (key 2). Separate the torque tube arm from the sensor head.

9

Page 10

249 Cageless Sensors

December 2012

3. Follow the proper procedure to remove the torque tube assembly (key 9).

4. Remove the bearing bolts (key 5), displacer rod assembly, and driver bearing.

Note

Be sure to install the driver bearing so its knife edge is pointing up when the torque tube arm is mounted in the desired orientation.

Since changing the mounting position of the torque tube arm by 180_ will change controller or transmitter action from direct to

reverse or vice versa, controller/transmitter action must be reversed from what it was before the mounting method was changed.

5. Install the driver bearing, displacer rod assembly, and bearing bolts (key 5) into the torque tube arm. Install a new

arm gasket. Install the torque tube arm on the sensor head or process vessel and secure it with the proper bolting

(keys 19 and 20).

6. Install the torque tube assembly. Install the displacer.

7. Install the sensor head and controller/transmitter. Calibrate the controller/transmitter following the procedures

given in the controller/transmitter instruction manual.

Instruction Manual

D200100X012

Simulation of Process Conditions for Calibration of Fisher Level

Controllers and Transmitters

Contact your Emerson Process Management sales office for information on obtaining the Supplement to 249 Sensor

Instruction Manuals—Simulation of Process Conditions for Calibration of Fisher Level Controllers and Transmitters

(D103066X012), or visit our website at www.Fisher.com.

Parts Ordering

When corresponding with your Emerson Process Management sales office about this equipment, always refer to the

sensor serial number. Each sensor is assigned a serial number which is stamped on a nameplate (key 54, not shown)

attached to the torque tube arm. This same number also appears on the controller/ transmitter nameplate when a

complete controller/ transmitter‐sensor unit is shipped from the factory. When ordering a replacement part, be sure

to include the 11‐character part number from the following parts list.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher instrument. Use of components not supplied by Emerson Process

Management may void your warranty, might adversely affect the performance of the instrument, and could cause personal

injury or property damage.

10

Page 11

Instruction Manual

D200100X012

249 Cageless Sensors

December 2012

Parts Kits

Description Part Number

Sensor Part Kit

Kit contains keys 9, 11, 13, 14

For 249BP R249X000012

Parts List

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson Process Management sales

office.

Sensor Common Parts

Key Description

2 Sensor Head

For 249BP, 249CP, 249P

(If a part number is required, contact your Emerson Process

Management sales office.) Not req'd for 249V

3 Torque Tube Arm

For 249V

(If a part number is required, contact

your Emerson Process Management sales office.)

4 Driver Bearing, S31600

5 Driver Bearing Bolt, S31600 (2 req'd)

6 Retaining Flange

(If a part number is required, contact

your Emerson Process Management sales office.)

7 Rod/Driver Assy, S31600

8 Positioning Plate, S31600

*Recommended spare parts

1. This part is available in a wide variety of materials of construction, part dimensions, or other

specifications. Listed here are standard or typical materials, dimensions, or specifications.

Contact your Emerson Process Management sales office for assistance in selection of specific

materials, dimensions, or specifications.

Key Description Part Number

9* Torque Tube Assy

For 249BP

N05500

Std wall 1K4493X0012

Heavy wall 1K4497X0012

Thin wall 1K4495X0012

For 249CP

S31600

Std wall 1K4505000A2

Heavy wall 1K4503000A2

For 249P

N05500

Std wall 1K4499X0012

Thin wall 1K4501X0012

For 249V

N05500

Std wall 1K4499X0012

Thin wall 1K4501X0012

10 Displacer

For 249BP, 249CP

3 inch X 14 inches (1600 psi), S30400 or S31600

2 inch x 32 inches (1500 psi), S30400 or S31600

1.5 inch x 60 inches (1800 psi), S30400

1.375 inch x 72 inches (1400 psi), S30400

For 249P

2.75 inch x 14 inches (6000 psi), S30400 or S31600

2.875 inch x 14 inches (4000 psi), S30400

1.75 inch x 32 inches (4200 psi), S30400 or S31600

1.9062 inch x 32 inches (3400 psi), S30400 or S31600

For 249V

3 inch x 10 inches (1600 psi), S30400 or S31603 (NACE)

3 inch x 14 inches (1600 psi), S31600 or S31603 (NACE)

2 inch x 32 inches (1500 psi), S30400 or S31600

2 inch x 32 inches (1500 psi), S31603 (NACE)

1.375 inch x 48 inches (1800 psi), S30400

1.5 inch x 60 inches (1800 psi), S30400

11* Cotter Spring

13* Arm Gasket

For 249BP, 249CP

thru CL600, graphite/SST 1E5629X0072

For 249P

CL900 & 1500 graphite/SST 1A1297X0022

14* Tube End Gasket

For 249BP, 249CP, or 249V

thru CL600, graphite/SST 0Y0876X0052

For 249P

CL900 & 1500 graphite/SST 0Y0876X0052

15 Stud Bolt

For 249BP, 249CP, 249V

(249V thru CL600)

For 249P

CL900 & 1500

16 Groove Pin, S31600

For 249BP, 249CP, 249P

18 Hex Nut

(1)

For 249BP, 249CP, and 249V

thru CL600

For 249P

CL900 & 1500

(1)

(1)

(1)

, N04400 (2 req'd) 1A517942022

(1)

(1)

(1)

, steel B7 (4 req'd)

, steel B7 (4 req'd)

11

Page 12

249 Cageless Sensors

December 2012

Figure 5. Fisher 249BP Sensor Construction

SECTION A‐A

Instruction Manual

D200100X012

20A7432‐B

20A7433‐B

Key Description

19 Bolt Stud

(1)

, steel B7 (4 req'd)

For 249B, 249CP

thru CL600

For 249P

CL900 & 1500

20 Hex Nut

(1)

, steel (8 req'd)

For 249BP, 249CP

thru CL600

For 249P

CL900 & 1500

23 Displacer Stem End Piece

For 249BP, 249CP w/out travel stop

For 249BP w/travel stop

For 249P w/out travel stop

For 249V

Stem End Piece

Rod Connector

(1)

, S31600

DETAIL OF TRAVEL STOP VERSION

Key Description

24 Displacer Stem

When ordering a replacement displacer stem,

specify length and desired material.

25 Hex Nut

26 Pipe Plug

For 249BP

For 249CP

For 249P

35 Heat Insulator Ass'y (use only when specified)

36 Shaft Coupling (for heat insulator ass'y)

Use only when specified

37 Shaft Extension (for heat insulator ass'y)

Use only when specified

38 Set Screw (for heat insulator ass'y) (2 req'd)

Use only when specified

39 Cap Screw (for heat insulator ass'y) (4 req'd)

Use only when specified

(1)

(1)

, B8M (2 req'd)

(1)

, steel

12

1. This part is available in a wide variety of materials of construction, part dimensions,

or other specifications. Listed here are standard or typical materials, dimensions, or

specifications. Contact your Emerson Process Management sales office for assistance

in selection of specific materials, dimensions, or specifications.

Page 13

Instruction Manual

D200100X012

Figure 6. Fisher 249CP Sensor Construction

249 Cageless Sensors

December 2012

SECTION A‐A

30A7434‐B

Key Description Part Number

40 Cap Screw (for heat insulator ass'y) (4 req'd)

Use only when specified

41 Travel Stop Plate, steel

For 249V

For 249BP

42* Groove Pin (travel stop pin), SST

For 249BP 1A524635032

not req'd for 249V

43 Cap Screw, hex head, steel (2 req'd)

For 249BP

44 Stud Bolt

(1)

, steel B7

For 249BP

w/ NPS 2 top flange, CL150 (4 req'd)

w/ NPS 2 top flange, CL300 (8 req'd)

Key Description

45 Hex Nut

(1)

, steel

For 249BP w/ NPS 2 top flange,

CL150 (8 req'd)

CL300, 600 (16 req'd)

46 Hex Nut, steel (4 req'd)

For 249V

52 Travel Stop Post, S31600 (4 req'd)

For 249V

53 Washer (for heat insulator ass'y) (4 req'd)

Use only when specified

54 Nameplate

55 Drive Screw

56 NACE Tag

57 Wire

*Recommended spare parts

1. This part is available in a wide variety of materials of construction, part dimensions,

or other specifications. Listed here are standard or typical materials, dimensions, or

specifications. Contact your Emerson Process Management sales office for assistance

in selection of specific materials, dimensions, or specifications.

13

Page 14

249 Cageless Sensors

December 2012

Figure 7. Fisher 249P Sensor Construction

SECTION A‐A

Instruction Manual

D200100X012

A

20A2094‐C

A

14

Page 15

Instruction Manual

D200100X012

Figure 8. Fisher 249V Sensor Construction

249 Cageless Sensors

December 2012

30A7435‐C

15

Page 16

249 Cageless Sensors

December 2012

Instruction Manual

D200100X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and FIELDVUE are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

16

E 1997, 2012 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...