Page 1

Product Bulletin

2500-249 Controllers and Transmitters

D200037X012

34.2:2500

July 2012

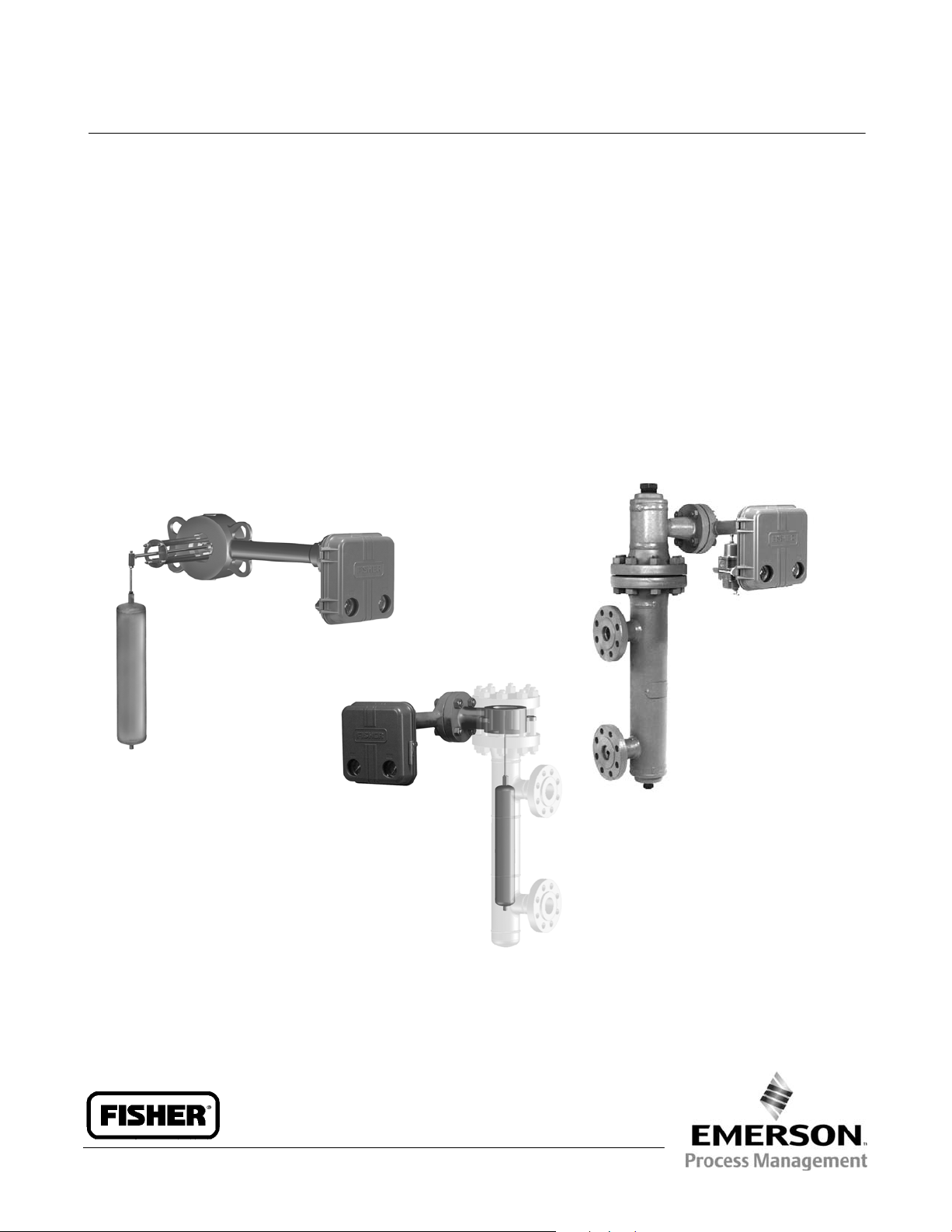

Fisherr 2500‐249 Pneumatic Controllers and

Transmitters

Typical caged and cageless sensor/instrument

configurations are shown below and in figure 1. Caged

sensors (figure 2) provide more stable operation than

do cageless sensors (figure 3) for vessels with internal

obstructions or considerable internal turbulence.

Cageless sensors are generally used on specific gravity

and interface control applications requiring large

displacers that are more easily accommodated by

flange connections up to NPS 8. The availability of

many different displacer stem lengths permits

lowering the displacer down to the most

advantageous depth in the vessel.

CAGELESS SENSORS CAN MOUNT

ON VESSEL SIDE OR TOP WITH

DISPLACER INSIDE VESSEL

Fisher pneumatic controllers and transmitters are used

wherever rugged, dependable, and simply constructed

displacer‐style pneumatic instrumentation is required

in liquid level, interface level, or density service. The

ruggedness of these products is demonstrated by their

use in many kinds of demanding applications,

including those in the power, chemical process, oil and

gas production, and petrochemical industries.

STANDARD CAGED SENSORS

MOUNT ON VESSEL SIDE WITH

DISPLACER INSIDE CAGE

W9354‐1

www.Fisher.com

W8334

FISHER L3 PNEUMATIC LEVEL CONTROLLER

(2500 CONTROLLER IN COMBINATION WITH A

249W SENSOR) CAN MOUNT ON VESSEL TOP OR

BE INSTALLED IN A CUSTOMER‐SUPPLIED CAGE

W8679

Page 2

Product Bulletin

34.2:2500

July 2012

Specifications

2500-249 Controllers and Transmitters

D200037X012

Available Configurations

See tables 1, 5, and 6

Input Signal

Fluid Level or Fluid‐to‐Fluid Interface Level: From 0 to

100 percent of displacer length—standard lengths for

all sensors are

J 356 mm (14 inches) or J 813 mm

(32 inches); other lengths available depending on

sensor construction

Fluid Density: From 0 to 100 percent of displacement

force change obtained with given displacer

volume—standard volumes are

J 980 cm

or

J 1640 cm

3

(60 inches3) for 249C and 249CP sensors

3

(100 inches3) for most other sensors;

other volumes available depending upon sensor

construction

Allowable Specific Gravity

Specific gravity with standard volume displacers and

standard wall torque tubes:

Fluid Level and Fluid‐to‐Fluid Interface

2500 Controllers, except 2503 and 2503R: Specific

gravity range, 0.20 to 1.10

2503 and 2503R: Specific gravity range, 0.25 to 1.10

Fluid Density

2500 Controllers, except 2503 and 2503R: Minimum

change in specific gravity, 0.20

2503 and 2503R: Minimum change in specific gravity,

0.25

Contact your Emerson Process Management sales

office for information on non‐standard applications

Output Signal

See table 1

Output Action

J Direct (increasing fluid or interface level or specific

gravity increases output pressure) or

J Reverse (increasing fluid or interface level or

specific gravity decreases output pressure)

Area Ratio of Relay Diaphragms

3:1

Supply Pressure

(1)

Normal Operation: See table 4.

Maximum to Prevent Internal Part Rupture

(2)

:

3 bar (45 psig)

‐continued‐

Steady‐State Air Consumption

See table 4

Proportional Band, Differential Gap, or Span

See table 1

Set Point (Controllers Only)

Continuously adjustable to position control point or

differential gap of less than 100 percent anywhere

within displacer length (fluid or interface level) or

displacement force change (density)

Zero Adjustment (Transmitters Only)

Continuously adjustable to position span of less than

100 percent anywhere within displacer length (fluid

or interface level) or displacement force change

(density)

Performance

Independent Linearity (Transmitters Only):

1 percent of output pressure change at span of 100

percent

Hysteresis: 0.6 percent of output pressure change at

100 percent of proportional band, differential gap, or

span

Repeatability: 0.2 percent of displacer length or

displacement force change

Deadband (Except Differential Gap Controllers

(3)

):

0.05 percent of proportional band or span

Typical Frequency Response: 4 Hz and 90‐degree

phase shift at 100 percent of proportional band,

differential gap, or span with output piped to typical

instrument bellows using 6.1 meters (20 feet) of 6.4

mm (1/4‐inch) tubing

Ambient Temperature Error: ±1.5 percent of output

pressure change per 28_C (50_F) of temperature

change at 100 percent of proportional band,

differential gap, or span when using sensor with

standard wall N05500 torque tube

Reset (Proportional‐Plus‐Reset Controllers Only):

Continuously adjustable from 0.005 to over 0.9

minutes per repeat (from 200 to under 1.1 repeats

per minute)

Anti‐Reset Differential Relief (2502F and 2502FR

Controllers Only): Continuously adjustable from 0.14

to 0.48 bar (2 to 7 psi) differential to relieve excessive

difference between proportional and reset pressures

2

Page 3

2500-249 Controllers and Transmitters

D200037X012

Specifications (Continued)

Standard Tubing Connections

1/4 NPT internal

Allowable Process Temperatures

See table 2

Product Bulletin

34.2:2500

July 2012

(1)

Sensor Connection Sizes

See tables 5 and 6

Maximum Working Pressures (Sensors Only)

(1)

Hazardous Area Classification

2500 controllers comply with the requirements of

ATEX Group II Category 2 Gas and Dust

Consistent with applicable ASME

pressure/temperature ratings for the specific sensor

constructions shown in tables 5 and 6

Operative Ambient Temperatures

(1)

Construction Materials

See tables 2, 3, and 7

Controller.

J Standard: -40 to 71_C (-40 to 160_F)

J High Temperature: -18 to 104_C (0 to 220_F)

Sensor.

Mounting Positions

See figure 9

See table 2

For ambient temperature ranges, guidelines, and use

of optional heat insulator, see figure 4

Caged Sensor Connection Styles

See figure 10

Standard Supply and Output Pressure Gauge

Indications

See table 4

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. The pressure/temperature limits in this document and any applicable code or standard should not be exceeded.

2. Also see Supply Pressure Overpressure Protection section.

3. For 2500S, 2500SC, and 2503 adjusting the differential gap is equivalent to adjusting the deadband.

Options

See Options section

Table of Contents

Specifications 2................................

Features 5.....................................

Supply Pressure Overpressure Protection 10........

Principle of Operation 10........................

Proportional Controller or Transmitter 11.........

Proportional-Plus-Reset Controller 11............

Anti-Resetup Windup 12.......................

On-Off Controller With Proportional Valve 12......

On-Off Controller Without Proportional Valve 12...

Options 12....................................

Installation 12.................................

Ordering Information 15.........................

Construction 15................................

3

Page 4

Product Bulletin

34.2:2500

July 2012

2500-249 Controllers and Transmitters

D200037X012

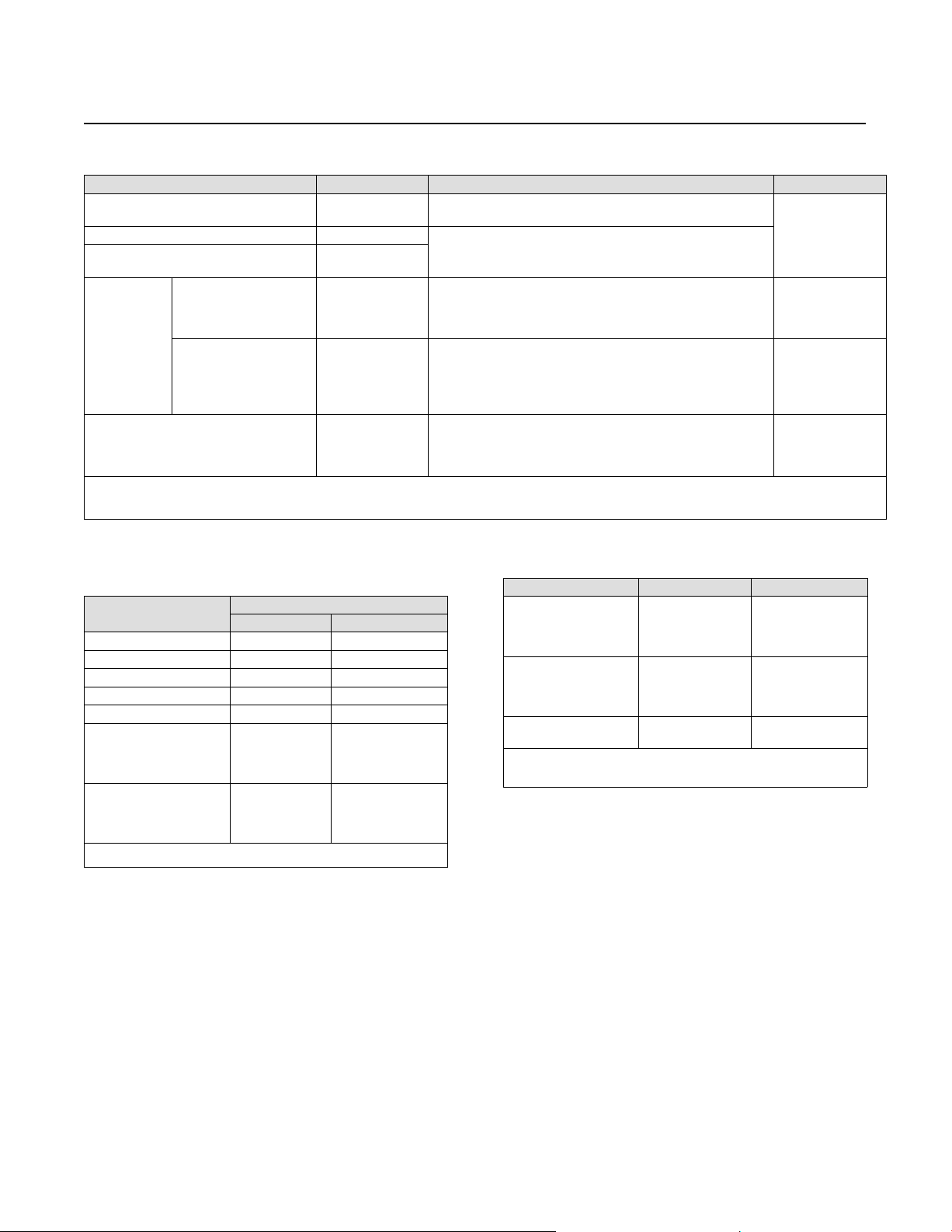

Table 1. Additional Specifications for Selected Fisher 2500 Controller Configurations

Control or Transmission Mode Controller

Proportional control 2500, 2500C

Proportional‐plus‐reset control 2502, 2502C

Proportional‐plus‐reset control with

anti‐reset windup

With proportional valve

and full differential

Differential

Gap (On‐off)

Control

Proportional transmission 2500T, 2500TC

1. The suffix R is added to the type number for reverse action, and all types have a 67CFR supply regulator mounted as standard.

2. The suffix C is added to the type number for indicator assembly.

3. Other displacer lengths and volumes, or service conditions, will result in other differential gaps.

4. 1.4 bar (20 psig) and 2.4 bar (35 psig) are the standard factory‐set supply regulator pressures, but these values will vary whenever the supply pressure is changed to adjust the differential gap.

gap adjustment

Without proportional

valve - has limited

differential gap

adjustment

2502F

2500S, 2500SC

2503

Table 2. Allowable Process Temperatures for

Common Fisher 249 Sensor Component Materials

MATERIAL

(1)

Cast Iron

Steel -29_C (-20_F) 427_C (800_F)

Stainless Steel -198_C (-325_F) 427_C (800_F)

N04400 -198_C (-325_F) 427_C (800_F)

Aluminum -195_C (-320_F) 99_C (210_F)

Gaskets

Graphite Laminate/SST

N04400/PTFE

Soft Iron Gasket

Bolting

B7 steel

B7M steel

B8M stainless steel

1. Cast iron may be used to -73_C (-100_F) provided a heat insulator is used below

-18_C (0_F) and stainless steel studs and nuts are used below -46_C (-50_F).

PROCESS TEMPERATURE

Minimum Maximum

-29_C (-20_F) 232_C (450_F)

-198_C (-325_F)

-73_C (-100_F)

-29_C (-20_F)

-46_C (-50_F)

-29_C (-20_F)

-198_C (-325_F)

(1)

(2)

(2)

(2)

(2)

427_C (800_F)

204_C (400_F)

427_C (800_F)

427_C (800_F)

427_C (800_F)

427_C (800_F)

Full Output Signal Change Obtainable Over Input Of: Output Signal

Proportional band of 0 to 100 percent of displacer length or

displacement force change (10 to 100 percent recommended)

Proportional band of 0 to 200 percent of displacer length or

displacement force change (20 to 200 percent recommended)

Differential gap of 0 to 100 percent of displacer length

Differential gap of approximately 25 to 40 percent of displacer

length, when a 356 millimeter (14-inch) ideal‐volume displacer is

used on 1.0 specific gravity liquid level service and a standard 1.4

bar (20 psig) supply regulator setting is varied between 1.0 and 1.7

bar (15 and 25 psig)

Span of 0 to 100 percent of displacer length or displacement force

change (20 to 100 percent recommended)

(3)

0.2 to 1.0 bar

(3 to 15 psig) or

0.4 to 2.0 bar

(6 to 30 psig)

0 and 1.4 bar

(0 and 20 psig) or

0 and 2.4 bar

(0 and 35 psig)

0 and full supply

pressure

0.2 and 1.0 bar

(3 to 15 psig) or

0.4 to 2.0 bar

(6 to 30 psig)

Table 3. Displacer and Torque Tube Materials

Part Standard Material Other Material

316 Stainless Steel,

Displacer 304 Stainless Steel

Displacer Stem,

Driver Bearing,

Displacer Rod and Driver

Torque Tube N05500

1. N05500 is not recommended for spring applications above 232_C

(450_F). Contact your Emerson Process Management sales office or

application engineer if temperatures exceeding this limit are required.

316 Stainless Steel

(1)

N10276, N04400,

Plastic, and Special

Alloys

N10276, N04400,

other Austenitic

Stainless Steels, and

Special Alloys

316 Stainless Steel,

N06600, N10276

(4)

4

Page 5

2500-249 Controllers and Transmitters

D200037X012

Table 4. Supply Pressure Data

OUTPUT SIGNAL

0.2 to 1.0 bar (3 to 15 psig),

except 0 and 1.4 bar (0 and 20

(2)

psig)

for on‐off controllers

0.4 to 2.0 bar (6 to 30 psig),

except 0 and 2.4 bar (0 and 35

(2)

psig)

for on‐off controllers

1. Consult your Emerson Process Management sales office about gauges in other units.

2. Control and stability may be impaired if this pressure is exceeded (except 2503 or 2503R controller without proportional valve).

3. Except 2503 or 2503R controller, which bleeds only when relay is open at exhaust position.

4. At zero or maximum proportional band or span setting.

5. At setting in middle of proportional band or span range.

6. Normal m

3

/hr=normal cubic meters per hour at 0_C and 1.01325 bar. Scfh=standard cubic foot per hour at 60_F and 14.7 psia.

STANDARD SUPPLY AND OUTPUT

PRESSURE GAUGE INDICATIONS

0 to 30 psig 1.4 20 0.11 0.72 4.2 27

0 to 60 psig 2.4 35 0.19 1.1 7 42

NORMAL OPERATING

(1)

SUPPLY PRESSURE

(2)

Bar Psig Min

Product Bulletin

AIR CONSUMPTION AT NORMAL

OPERATING SUPPLY PRESSURE

Normal m3/h

(4)

Max

(6)

(5)

Min

(4)

34.2:2500

July 2012

(3)

(6)

Scfh

Max

(5)

Features

n Easy Adjustment—Set point, proportional valve

opening, and reset changes are made with simple

dial‐knob controls.

n Simple, Durable Construction—Few moving parts

are used. Knife‐edged driver bearing in sensor and

plated brass instrument case ball bearing for torque

tube rotary shaft help provide low‐friction

operation. Sensors are available in ratings up to

CL2500.

n Mounting Versatility—Caged sensors are available in

a variety of orientations and connection styles, and

all sensors can be either right‐ or left‐hand

mounted.

n Sensitive to Small Changes—Displacer reaction to

small specific gravity changes allows these

instruments to be used for density applications and

in other applications where a response to low levels

of input signal change is required.

n Easy Reversibility—Action is field reversible from

direct to reverse or vice versa without additional

parts.

n Reduced Maintenance Costs—Spring‐out wire

provides for in‐service cleaning of relay orifice

(figure 1). Torque tube can be replaced without

removing torque tube arm.

n Reduced Operating Costs—Supply pressure

conservation is enhanced in all constructions

because relay exhaust opens only when output

pressure is being reduced.

n Smaller Vessel Sizes Required for Stable

Control—Caged 249 sensors come standard with a

liquid damping orifice in the lower equalizing

connection that helps stability where vessel

capacitance is small and permits narrower

proportional valve settings.

5

Page 6

Product Bulletin

34.2:2500

July 2012

Figure 1. Typical Fisher 2500 Controller Constructions with Right‐Hand Mounting Shown

RESET ADJUSTMENT

W5637

DETAIL OF DIRECT ACTING 2502

PROPORTIONAL‐PLUS RESET CONTROLLER

2500-249 Controllers and Transmitters

3‐WAY BOURDON TUBE VALVE HAS LARGE

PORTS WHICH GREATLY REDUCE CLOGGING

PIPE PLUG INSTEAD OF PROPORTIONAL

VALVE MEANS INTERMITTENT BLEED THAT

MINIMIZES FREEZE UP

W0671‐1

DETAIL OF REVERSE‐ACTING 2503R

ON‐OFF CONTROLLER

SPRING‐OUT

CLEANING WIRE

PROPORTIONAL BAND

ADJUSTMENT

D200037X012

W0648‐1

INDICATOR ASSEMBLY DETAIL

POINTER

INDICATOR AND

BASE PLATES

W0656‐1

DIRECT‐ACTING 2500 CONTROLLER

6

Page 7

2500-249 Controllers and Transmitters

D200037X012

Product Bulletin

34.2:2500

July 2012

Figure 2. Fisher 249B Caged Sensor (Typical

of all Rotatable‐Head Caged Sensors)

W1800‐1

KNIFE EDGE

BEARING

ROTATABLE

HEAD

TORQUE TUBE

DISPLACER ROD

Figure 3. Typical Cageless Sensors

DISPLACER

STEM END

CONNECTOR

OPTIONAL

TRAVEL

STOP PIN

AND PLATE

DISPLACER

STEM

W0660‐1

249BP MOUNTS ON

TOP OF VESSEL

DISPLACER ROD

DISPLACER

STUD

W2141‐1

DAMPING ORIFICE

(REMOVABLE IF

CLOGGING WILL OCCUR)

W0144-1

DISPLACER

CAGE

STANDARD TRAVEL

STOP ASSEMBLY

249W WAFER BODY

NPS 3 OR 4

RF FLANGE

W9353

249VS MOUNTS ON

SIDE OF VESSEL

CENTER OF DISPLACER

SHOULD BE LOCATION

OF LIQUID OR INTERFACE

LEVEL DURING NORMAL

OPERATION

STILLWELL

W8252

249W MOUNTS ON TOP OF VESSEL AS SHOWN OR CAN

MOUNT IN CUSTOMER FABRICATED CAGE

Note:

1 Stillwell required around displacer if the fluid is in

a state of continuous agitation

`

1

7

Page 8

Product Bulletin

(

)

34.2:2500

July 2012

2500-249 Controllers and Transmitters

D200037X012

Table 5. Caged Displacer Sensors

SENSOR

(3)

249

(1)

EQUALIZING CONNECTION

Style Size (NPS)

Screwed 1‐1/2 or 2

Flanged 2

PRESSURE RATING

CL125 or 250

Screwed or optional socket weld 1‐1/2 or 2 CL600

Torque tube

arm rotatable

with respect

to equalizing

connections

249B or 249BF

249C

(4)

Raised face or optional ring‐type joint flanged

1‐1/2 CL150, 300, or 600

2 CL150, 300, or 600

Screwed 1‐1/2 or 2 CL600

(2)

Raised face

1‐1/2 CL150, 300, or 600

2 CL150, 300, or 600

249K Raised face or optional ring‐type joint flanged 1‐1/2 or 2 CL1500

249L Ring‐type joint flanged 2

1. Standard displacer lengths for all styles (except 249) are 14, 32, 48, 60, 72, 84, 96, 108, and 120 inches. The 249 uses a displacer with a length of either 14 or 32 inches.

2. PN flange connections available in EMA (Europe, Middle East, and Africa).

3. Not available in EMA.

4. 249BF available in EMA only. Also available in EN size DN 40 with PN 10 to PN 100 flanges and size DN 50 with PN 10 to PN 63 flanges.

5. Top connection is NPS 1 ring‐type joint flanged for connection styles F1 and F2.

Table 6. Cageless Displacer Sensors

(1)

(5)

CL2500

Mounting Sensor Flange Connection (Size) Pressure Rating

NPS 4 raised face or optional ring‐type joint CL150, 300, or 600

NPS 6 or 8 raised face CL150 or 300

Mounts on top of vessel

249BP

(3)

249CP NPS 3 raised face CL150, 300, or 600

CL900 or 1500

(EN PN 10 to DIN PN 250)

Mounts on top of vessel 249P

(4)

NPS 4 raised face or optional ring‐type joint

NPS 6 or 8 raised face CL150, 300, 600, 900, 1500, or 2500

CL125, 150, 250, 300, 600, 900, or 1500

(EN PN 10 to DIN PN 160)

Mounts on side of vessel 249VS

For NPS 4 raised face or flat face

For NPS 4 butt weld end, XXS CL2500

Mounts on top of vessel or on

customer supplied cage

1. Standard displacer lengths are 14, 32, 48, 60, 72, 84, 96, 108, and 120 inches.

2. PN flange connections available in EMA (Europe, Middle East, and Africa).

3. Not available in EMA.

4. 249P with NPS 6 and 8 flanges and PN flanges are available in EMA only.

249W For NPS 3 or 4 raised face CL150, 300, or 600

(2)

(2)

Figure 4. Guidelines for Use of Optional Heat Insulator Assembly

-40

800

_

400

AMBIENT TEMPERATURE (_C)

01020-20 -10 30 40 50 60-30

HEAT INSULATOR REQUIRED

NO INSULATOR NECESSARY

0

1

TOO

COLD

PROCESS TEMPERATURE ( F)

-325

-40 -20

0 20 40 60 80 100 120 140 160

HEAT INSULATOR REQUIRED

AMBIENT TEMPERATURE (_F)

STANDARD CONTROLLER

Note:

If ambient dewpoint is above process temperature, ice formation might cause instrument

malfunction and reduce insulator effectiveness.

1 For process temperatures below -29_C (-20_F) and above 204_C (400_F) sensor

materials must be appropriate for the process - see table 2.

B1413-1A

8

TOO

HOT

71

70

400

300

200

100

0

-100

-200

-240

-18 -10

800

___

400

0

1

PROCESS TEMPERATURE ( C)

PROCESS TEMPERATURE ( F)

-325

0 20 40 60 80 100 120 140 200

AMBIENT TEMPERATURE (_C)

01020

HEAT INSULATOR REQUIRED

NO INSULATOR NECESSARY

TOO

COLD

AMBIENT TEMPERATURE (_F)

HIGH‐TEMPERATURE CONTROLLER

30 40 50 60 70

HEAT INSULATOR REQUIRED

80 90

TOO

HOT

180160

93

400

C

300

200

100

0

-100

-200

PROCESS TEMPERATURE

-240

Page 9

2500-249 Controllers and Transmitters

D200037X012

Table 7. Construction Materials

Part Sensor Material

In contact

with process

In contact with

supply pressure

Other

1. Available only in EMA.

2. Trim parts include displacer rod, driver bearing; displacer stem parts, and stem connection parts.

Cage, head,

torque tube arm

Wafer body,

torque tube arm

Torque tube

Displacer

Standard trim

Bolting All Steel grade B7 studs or cap screws and grade 2H nuts (standard),

Standard torque

tube end gasket

Standard torque

tube arm and

cage gasket, if used

Optional trim

and gasketing

Bourdon tube or bellows

Tubing

Relay diaphragms

Relay O‐ring

Gasketing

Seal ring O‐rings (and reset relief

valve O‐rings if used)

Case

Cover

Retaining flange

(2)

249 Cast iron

249B, 249BF

249C and 249CP CF8M (316 stainless steel) standard,

249K Steel standard, CF8, CF8M, CF3M, LCC, C5,

249L Steel standard, CF8M, C5, WC1, LCC

249BP Carbon Steel

249P Carbon Steel

249VS LCC, WCC (steel), CF8M

249W NPS 3

249, 249B, 249BF

249K, 249L,

249P, 249VS, 249W

249C, 249CP,

stainless steel 249VS,

249W

All S30403 (304L stainless steel), S31603 (316L stainless steel),

249, 249B, 249BF

249K, 249VS, 249W

249C, 249CP, 249W S31600 (316 stainless steel) standard

249L A91100F (solid aluminum) standard

All Solid PTFE, N04400 or other special materials

All S31600

All 316 stainless steel/graphite laminate, except 304 stainless steel/graphite

All Composition, except soft iron for the 249L sensor

All 316 stainless steel trim with 316L stainless steel gasketing

(1)

NPS 4

Carbon steel

CF3M (316L stainless steel),

CF8 (304 stainless steel), CF3 (304L stainless steel),

LCC (steel), C5 (steel),

LC3 (3.5 percent nickel steel), M35‐1,

CN7M (Alloy 20)

LC3, WC1 (chrome moly steel), M35‐1, CN7M optional

WCC, CF8M

LCC, CF8M

(1)

,

N05500 standard

S31600 (316 stainless steel) standard

N06600, N08020 (Alloy 20) optional

(1)

,

S30400 (304 stainless steel) standard

steel grade B7M studs and grade 2M nuts optional on 249B and

WCC 249W sensor

laminate for 249K sensor

or soft iron gasketing; 317 stainless steel or N06600 trim with composition

gasketing; 304, 304L or 316L stainless steel, N04400 or

N08020 trim and gasketing

Brass, plus SST 3‐way valve for 2503 or 2503R controller

Stainless steel

Nitrile (standard) or polyacrylate (high‐temperature)

Nitrile

Chloroprene (standard) or rubber (high‐temperature)

Nitrile (standard) or fluorocarbon (high‐temperature)

Aluminum

Aluminum with glass gauge windows and nitrile cover gasket

Steel

Product Bulletin

34.2:2500

July 2012

9

Page 10

Product Bulletin

34.2:2500

July 2012

Figure 5. Schematic of Direct‐Acting Fisher 2500‐249 Proportional Controller (or Transmitter) Shown with

Right‐Hand Mounting

2500-249 Controllers and Transmitters

D200037X012

OUTER

BOURDON

TUBE

CHANNEL

NOZZLE

FIXED

ORIFICE

INNER BOURDON

TUBE CHANNEL

FLAPPER

LARGE

DIAPHRAGM

EXHAUST END

OF RELAY VALVE

SUPPLY

PRESSURE

SETPOINT OR

ZERO ADJUSTMENT

TORQUE TUBE SHAFT

EXHAUST

SMALL

DIAPHRAGM

EXHAUST

PROPORTIONAL VALVE

TO OTHER

PNEUMATIC INSTRUMENT

IF TRANSMITTER

CONSTRUCTION OR

APPLICATION

SUPPLY END OF

RELAY VALVE

SUPPLY PRESSURE

NOZZLE PRESSURE

CD2114‐E

B2296

Supply Pressure

Overpressure Protection

Applying excessive pressure to any portion of a

controller, transmitter or connected equipment may

cause leakage, part damage, or personal injury due to

bursting of pressure‐containing parts. Although the

standard 67CFR supply regulator for 2500 instruments

has internal relief to provide very limited overpressure

protection, complete overpressure protection

between the supply regulator outlet and the

instrument case is needed if a malfunctioning supply

regulator can deliver a supply pressure that exceeds

3.4 bar (50 psig).

10

OUTPUT PRESSURE

PROPORTIONAL PRESSURE

Principle of Operation

All 2500 controllers and transmitters use the same

basic pressure‐balanced relay with a yoked

double‐diaphragm assembly. Supply pressure either

passes through the fixed orifice and bleeds out the

nozzle (figure 5 or 6) or directly enters the Bourdon

tube valve (figure 7). Nozzle pressure registers on the

large relay diaphragm, and output pressure on the

small relay diaphragm.

The following descriptions show how the various

controller and transmitter constructions work in

conjunction with displacer action.

Page 11

2500-249 Controllers and Transmitters

D200037X012

Figure 6. Schematic of Direct‐Acting Proportional‐Plus‐Reset Controller

PROPORTIONAL

BELLOWS

TORQUE TUBE SHAFT

SET POINT

ADJUSTMENT

Product Bulletin

34.2:2500

July 2012

WITH ARROW DOWN‐

RELIEVES ON

DECREASING OUTPUT

(OUTPUT AT SUPPLY

DURING SHUTDOWN)

RESET

VALVE

EXHAUST

SUPPLY PRESSURE

OUTPUT PRESSURE

NOZZLE PRESSURE

PROPORTIONAL

PRESSURE

RESET PRESSURE

CJ4081‐A

B2347‐2

E0792

Proportional Controller or

Transmitter

As long as the process remains constant, the displacer

will hold the torque tube shaft and attached flapper

steady in relation to the nozzle. The nozzle‐flapper

opening will be such as to permit pressure to bleed

from the nozzle as fast as it enters through the fixed

orifice of the relay, keeping the pressure loading on

the large relay diaphragm at the amount necessary to

balance the output pressure loading on the small relay

diaphragm.

A process variable change (such as a variation in

downstream demand that affects liquid outflow and

thus the level of the tank shown in figure 5) changes

the buoyant force acting on the displacer and moves

the flapper with respect to the nozzle. An increasing

buoyant force with direct action, or decreasing

buoyant force with reverse action, produces a

nozzle‐flapper restriction that increases nozzle

pressure on the large relay diaphragm. This opens the

supply end of the relay valve and increases relay

output pressure. But a decreasing buoyant force with

direct action, or increasing buoyant force with reverse

DIFFERENTIAL

RELIEF VALVE

PROPORTIONAL

VALVE

TO PROPORTIONAL

BELLOWS

TO RESET BELLOWS

FROM

RELAY

PROPORTIONAL‐PLUS‐RESET CONTROL

WITH ANTI‐RESET WINDUP

RESET

ADJUSTMENT

PROPORTION

BAND ADJUSTMENT

action, produces a nozzle‐flapper opening that bleeds

off nozzle pressure on the large relay diaphragm and

opens the exhaust end of the relay valve to let output

pressure (and thus actuator loading pressure) bleed

away. The relay diaphragm pressure differential

equalizes and a new output pressure is maintained

according to the change in displacer position.

Proportional‐Plus‐Reset Controller

All 2502 controllers (figure 6) have a two‐way reset

restriction valve that channels proportional pressure

into a reset bellows to oppose proportional bellows

action. This automatically slows the canceling effect of

any proportional action by a set amount per time

interval, as long as there is a deviation from the control

point. Action of this reset pressure occurs on a delayed

basis, and the reset valve can be adjusted to vary the

time of delay.

If a prolonged difference exists between the set point

and the process variable, output pressure with a

proportional‐plus‐reset controller will either drop to

zero or rise to the maximum delivered by the supply

regulator. This condition is called reset windup.

11

Page 12

Product Bulletin

34.2:2500

July 2012

2500-249 Controllers and Transmitters

D200037X012

Anti‐Reset Windup

2502F and 2502FR controllers additionally have

anti‐reset windup to minimize the delay in returning

the controlled variable to the set point. This capability

is provided by a reversible differential relief valve with

adjustable spring. As shown in figure 6, proportional

pressure registers rapidly on the spring side of the

relief valve diaphragm as well as in the proportional

bellows. Reset pressure registers slowly on the

opposite side of the diaphragm. As long as the output

pressure changes are slow enough for normal

proportional and reset action, the relief valve spring

prevents opening of the relief valve diaphragm.

A large or rapid decrease in controller output pressure

decreases the pressure in the proportional system, and

on the spring side of the relief diaphragm. If the

decrease on the spring side of the diaphragm is greater

than the relief valve spring setting, the diaphragm

moves off the relief valve orifice and permits reset

pressure on the opposite side of the relief valve

diaphragm to bleed rapidly into the proportional

system. The differential relief valve can also be

reversed to relieve with an increasing output pressure.

On‐Off Controller With Proportional

Valve

This construction has the same flapper, relay, and

proportional valve responses to a level or density

change as does a proportional 2500 controller.

However, the Bourdon tube is constructed (figure 1) so

that output pressure change feedback moves the

nozzle in the opposite direction from the way the

flapper is moving. This reinforcement completely

opens the relay valve either to full supply pressure or

to full exhaust of output pressure, allowing no

in‐between throttling.

When level or density sufficiently decreases with direct

action or increases with reverse action, the flapper

pushes the Bourdon tube valve in enough to seal the

inner Bourdon tube channel (figure 7). This opens the

exhaust port of the valve and permits exhaust of

pressure from the actuator, initiating the appropriate

control action. This control action continues until the

level or density change again moves the flapper away

enough to permit closing of the Bourdon tube valve

exhaust port and the full application of output

pressure to the actuator.

Options

n Stainless Steel Heat Insulator Assembly—Refer to

figure 8. Available for mounting between the torque

tube arm of any 249 sensor and the instrument.

Recommended for applications where combination

of process and environmental temperatures would

result in controller temperatures in excess of safe

limits (figure 4).

n Jerguson™ Gages—Permit direct observation of

process level and other relevant characteristics.

These gages are described in the Jerguson Gages

supplement. The 249 sensor cage comes standard

with suitable bosses that can be tapped for gage

installation. All other sensors require the gages to

be installed at the factory. When specified, the

bosses will be tapped 1/2 NPT on the CL125 249

sensor, and 3/4 NPT on the CL250 249.

Installation

On‐Off Controller Without

Proportional Valve

As long as vessel level or density remains above the

lower snapping point on a direct‐acting controller (or

below the upper snapping point on a reverse‐acting

controller), the flapper remains far enough away to

keep the exhaust port of the Bourdon tube valve

closed and prevent any pressure escape from the

Bourdon tube. The relay valve remains closed at the

exhaust end and open at the supply end, allowing full

output pressure into the control valve actuator.

12

Although it can be shipped alone for separate

installation, a 249 sensor usually is shipped with a

controller or transmitter installed. During shipment,

displacers are detached from cageless sensors and

optional tubular gauge glasses are detached from

caged sensors.

Equalizing piping, stillwells, or other equipment may

be required for installation. Emerson Process

Management does not provide this equipment.

Complete dimensions and case connection

information for all 249 constructions can be found in

Fisher product bulletin 34.2:249 (D200039X012).

Page 13

2500-249 Controllers and Transmitters

D200037X012

Figure 7. Schematic of Reverse‐Acting Fisher 2503R Controller

INNER BOURDON

OUTER BOURDON

TUBE CHANNEL

SUPPLY PORT OF THREE‐WAY

BOURDON TUBE VALVE

EXHAUST PORT OF

BOURDON TUBE VALVE

(OPEN FOR RELEASE

OF LOADING PRESSURE)

FLAPPER

TUBE CHANNEL

SWITCHING POINT

ADJUSTMENT

Product Bulletin

34.2:2500

July 2012

EXHAUST END

OF RELAY VALVE

SUPPLY END OF

RELAY VALVE

B04466‐E

A2546‐1

Figure 8. Optional Heat Insulator Assembly

TORQUE TUBE

ARM

LARGE

DIAPHRAGM

SMALL

DIAPHRAGM

TORQUE TUBE

SHAFT

SUPPLY PRESSURE

OUTPUT PRESSURE

NOZZLE PRESSURE

W0630‐2

TORQUE TUBE

SHAFT

EXTENSION

SHAFT

COUPLING

13

Page 14

Product Bulletin

34.2:2500

July 2012

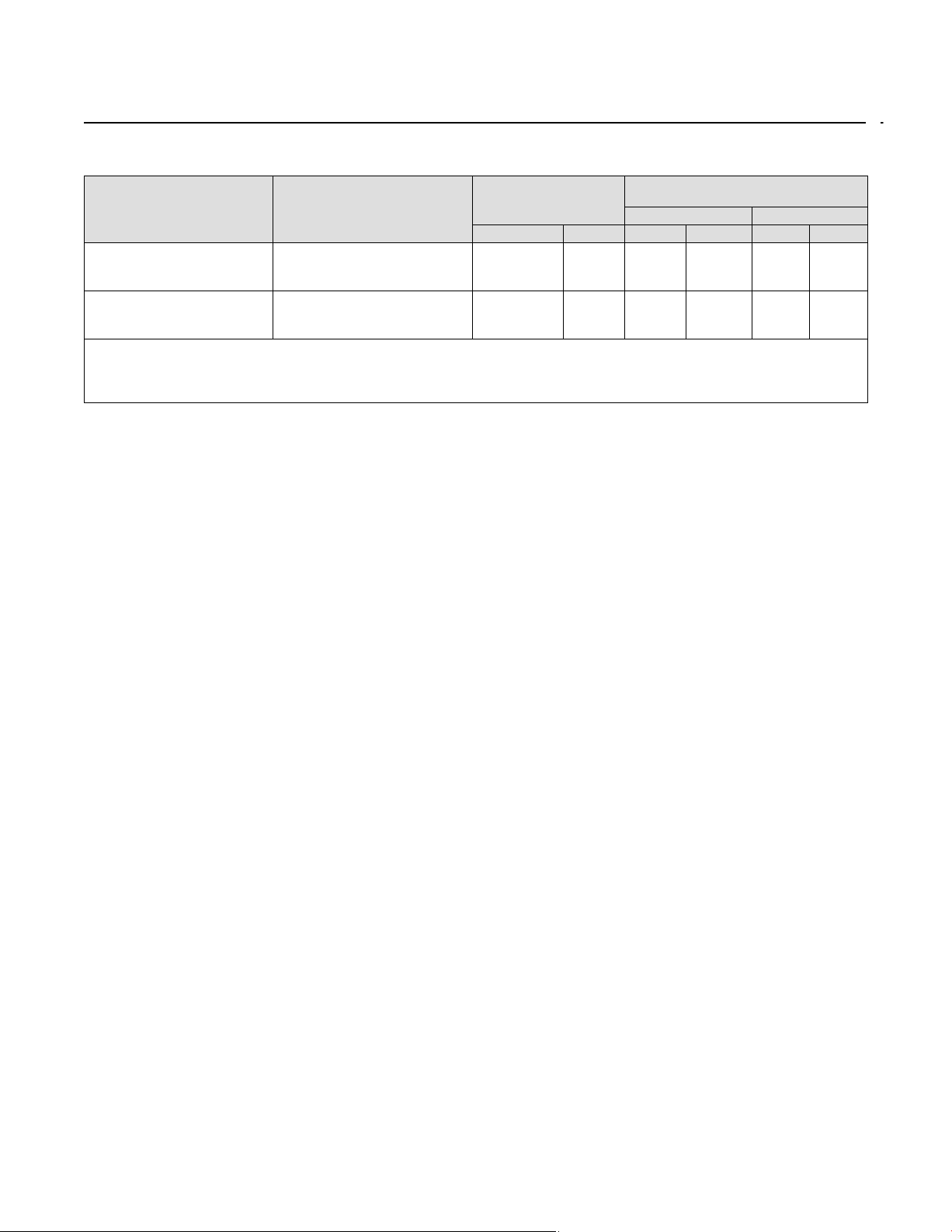

Figure 9. Torque Tube Arm Mounting Positions

2500-249 Controllers and Transmitters

D200037X012

SENSOR

CAGED

CAGELESS

Not availalable for NPS 2 CL300 and 600 249C.

RIGHT-HAND LEFT-HAND

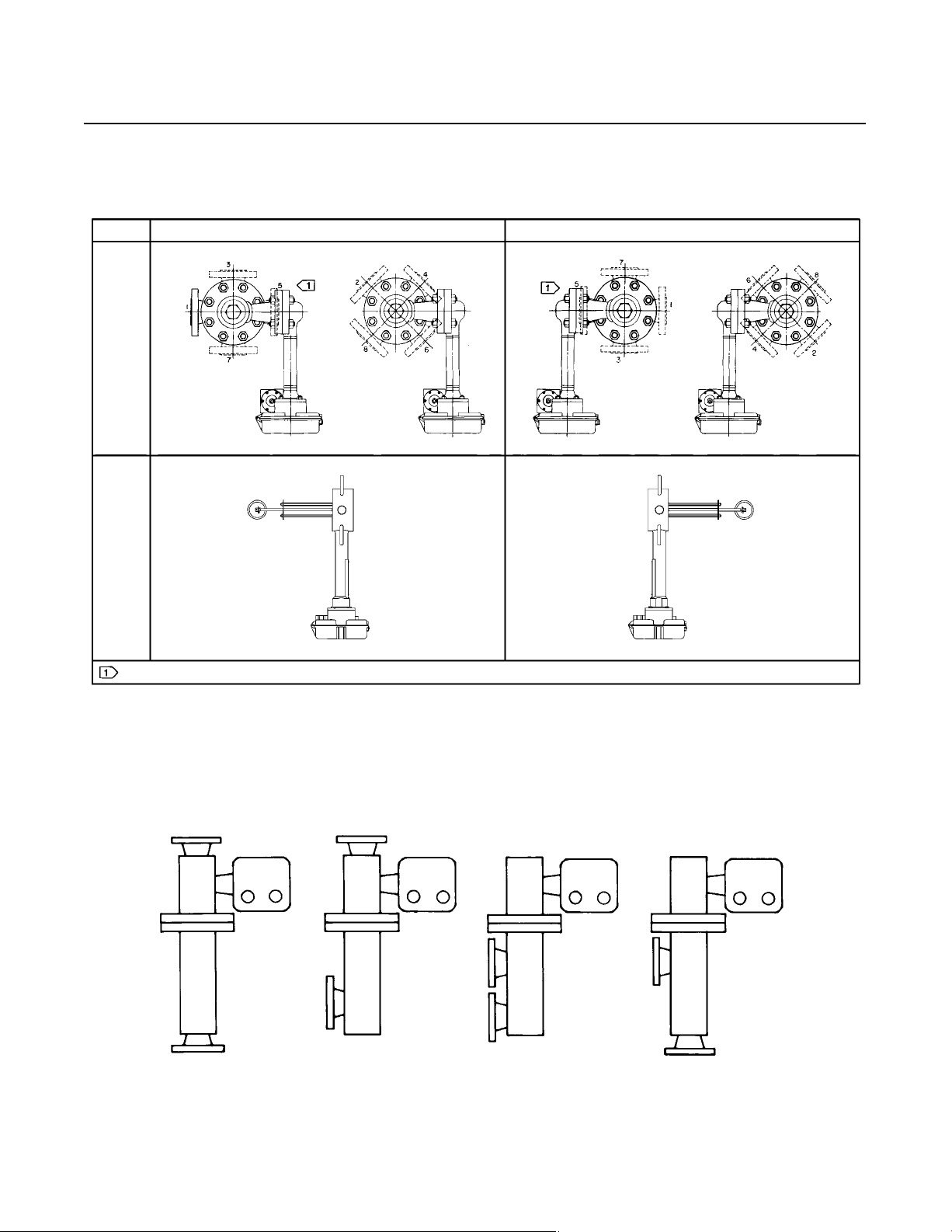

Figure 10. Cage Connection Styles

STYLE 1: TOP

AND BOTTOM

SCREWED: S1

FLANGED: F1

SOCKET WELD: SW1

A1271‐3

14

STYLE 2: TOP

AND LOWER SIDE

SCREWED: S2

FLANGED: F2

SOCKET WELD: SW2

STYLE 3: UPPER

AND LOWER SIDE

SCREWED: S3

FLANGED: F3

SOCKET WELD: SW3

STYLE 3: UPPER

SIDE AND BOTTOM

SCREWED: S4

FLANGED: F4

SOCKET WELD: SW4

Page 15

2500-249 Controllers and Transmitters

D200037X012

Product Bulletin

34.2:2500

July 2012

Ordering Information

Application

When ordering, specify:

n Control (proportional, proportional‐plus‐reset, or

on‐off), or transmission mode

n Liquid level service (give type, pressure,

temperature and specific gravity)

n Interface level service (give specific gravity of both

liquids and minimum proportional band, differential

gap, or span required)

n Density service (give minimum and maximum

specific gravity required)

Construction

Refer to the specifications and the Options section.

Review the descriptions for each specification, under

each option, and in the referenced tables and figures;

specify the desired selection whenever there is a

choice to be made. Right‐hand mounting (with

position 1 if appropriate) will be supplied automatically

unless some other mounting method is specified.

Unless another length is specified, 305 millimeters

(12 inches) will be used as the standard cageless

sensor length from flange face—or displacer rod—to

displacer top.

Always specify the complete type number (including

the R suffix for reverse action) of the controller or

transmitter, sensor, supply pressure regulator, and

other desired equipment. On differential relief

controllers, specify whether relief is to occur with

excessive proportional or with excessive reset

pressure.

15

Page 16

Product Bulletin

34.2:2500

July 2012

2500-249 Controllers and Transmitters

D200037X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1990, 2012 Fisher Controls International LLC. All rights reserved.

16

Loading...

Loading...