Page 1

Reference Manual

00809-0100-4860, Rev BC

January 2013

Rosemount 8600D Series Vortex Flowmeter

Page 2

Reference Manual

00809-0100-4860, Rev BC

January 2013

www.emersonprocess.com/rosemount

Page 3

Reference Manual

NOTICE

00809-0100-4860, Rev BC

Rosemount 8600D

Smart Vortex Flowmeter

Title Page

January 2013

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers:

Customer Central

Technical support, quoting, and order-related questions.

1-800-999-9307 (7:00 am to 7:00 pm CST)

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of the United States, contact your local Emerson Process Management

representative.

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management Sales Representative.

i

Page 4

Title Page

January 2013

Reference Manual

00809-0100-4860, Rev BC

ii

Page 5

Reference Manual

00809-0100-4860, Rev BC

Contents

1Section 1: Introduction

2Section 2: Installation

Table of Contents

January 2013

1.1 How to use this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 System description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2.1 General considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.2 Flowmeter sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.3 Flowmeter orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2.4 Wetted material selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2.5 Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Hazardous locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Hardware configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4.1 Failure mode vs. saturation output values . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.4.2 LCD indicator option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5 Meter body installation tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.1 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.2 Flow direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.3 Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.4 Flange bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5.5 Flanged-style flowmeter mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.5.6 Flowmeter grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.6 Electronics considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.6.1 High-Temperature installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.6.2 Conduit connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.6.3 High-Point installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.6.4 Cable gland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.6.5 Grounding the transmitter case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.6.6 Wiring procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.6.7 Remote electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.6.8 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Tab le of C ontents

2.7 Software configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.7.1 Installing the indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2.8 Transient protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

iii

Page 6

Table of Contents

January 2013

Reference Manual

00809-0100-4860, Rev BC

2.8.1 Installing the Transient Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3Section 3: Configuration

3.1 Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.2 Process variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.2.1 Primary Variable (PV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.2.2 PV% of range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.2.3 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.2.4 View other variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.2.5 Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.2.6 Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.2.7 Process config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.2.8 Reference K-factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.2.9 Flange type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.2.10Mating pipe ID (Inside Diameter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.2.11Variable mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.2.12PV units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.2.13Range values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.2.14PV damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3.2.15Auto adjust filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4Section 4: Operation

4.1 Diagnostics/service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.1.1 Test/status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.1.2 Loop test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

4.1.3 Pulse output test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.1.4 Flow simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.1.5 D/A trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4.1.6 Scaled D/A trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4.1.7 Shed freq at URV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.2 Advanced functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.3 Detailed set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.3.1 Characterize meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.3.2 Configure outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.3.3 Signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.3.4 Device information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

iv

Table of Contents

Page 7

Reference Manual

00809-0100-4860, Rev BC

5Section 5: Troubleshooting

Table of Contents

January 2013

5.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

5.2 Troubleshooting tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

5.3 Advanced troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

5.3.1 Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

5.3.2 Electronics test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

5.3.3 TP1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

5.4 Diagnostic messages on LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5.5 Testing procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.6 Hardware replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.6.1 Replacing the terminal block in the housing . . . . . . . . . . . . . . . . . . . . . . . . .76

5.6.2 Replacing the electronics boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

5.6.3 Replacing the electronics housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.6.4 Replacing the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

5.6.5 Remote electronics procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

5.6.6 Coaxial cable at the electronics housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

5.6.7 Changing the housing orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

5.6.8 Temperature sensor replacement

(MTA option only)88

5.7 Return of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

AAppendix A: Reference data

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

A.2 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

A.3 Typical flow ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

A.4 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

A.4.1 Flow accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

A.5 Physical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

A.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dimensional drawings107

BAppendix B: Approval information

B.1 Product certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

B.1.1 Approved manufacturing locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

B.1.2 International certifications (IECEx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Tab le of C ontents

B.1.3 Chinese certifications (NEPSI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

B.1.4 European certifications (ATEX). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

v

Page 8

Table of Contents

January 2013

Reference Manual

00809-0100-4860, Rev BC

CAppendix C: Electronics verification

C.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

C.2 Electronics verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

C.2.1 Electronics verification using flow simulation mode . . . . . . . . . . . . . . . . 120

C.2.2 Fixed flow rate simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

C.2.3 Varying flow rate simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

C.2.4 Electronics verification using an external frequency generator . . . . . . . 121

C.2.5 Calculating output variables with known

input frequency123

C.3 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

C.3.1 English units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

C.3.2 SI units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

vi

Table of Contents

Page 9

Reference Manual

00809-0100-4860, Rev BC

Section 1 Introduction

How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

1.1 How to use this manual

This manual provides installation, configuration, troubleshooting, and other procedures for the

use of the Rosemount 8600D Vortex Flowmeter. Specifications and other important

information are also included.

Section 2: Installation

Contains mechanical and electrical installation instructions.

Section 1: Introduction

January 2013

Section 3: Configuration

Contains information on entering and verifying basic configuration parameters.

Section 4: Operation

Contains information on advanced configuration parameters and functions that can aid in

maintaining the 8600D.

Section 5: Troubleshooting

Provides troubleshooting techniques, diagnostic information, and transmitter verification

procedures.

Appendix A: Reference data

Provides reference and specification data.

Appendix B: Approval Information

Provides specific information for approval codes.

Appendix C: Electronics verification

Introduction

Provides a short procedure for verification of electronic output to assist in meeting the quality

standards for ISO 9000 certified manufacturing processes.

Figure 1-1: Rosemount 8600D HART™ Menu Tree

Provides command tree, and Fast Key Sequence tables for the Field Communicator when used in

conjunction with the Rosemount 8600D.

1

Page 10

Section 1: Introduction

January 2013

1.2 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety

of the personnel performing the operations. Refer to the safety messages, listed at the

beginning of each section, before performing any operations.

1.3 System description

The Rosemount 8600D Vortex Flowmeter consists of a meter body and transmitter and

measures volumetric flow rate by detecting the vortices created by a fluid passing by the

shedder bar.

The meter body is installed in-line with process piping. A sensor is located at the end of the

shedder bar and creates an alternating sine wave due to the passing vortices. The transmitter

measures the frequency of the sine waves and converts it into a flowrate.

This manual is designed to assist in the installation and operation of the Rosemount 8600D

Vor tex Flowmeter.

Reference Manual

00809-0100-4860, Rev BC

This product is intended to be used as a flowmeter for liquid, gas, or

steam applications. Any use other than for which it was intended may

result in serious injury or death.

2

Introduction

Page 11

Reference Manual

00809-0100-4860, Rev BC

Section 2 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 5

Hazardous locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Hardware configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Meter body installation tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Electronics considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Software configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Transient protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

This section provides installation instructions for the Rosemount 8600D Vortex Flowmeter.

Dimensional drawings for each Rosemount 8600D variation and mounting configuration are

included in the Appendix on page 107.

The options available for the Rosemount 8600D flowmeter are also described in this section.

The numbers in parentheses refer to the codes used to order each option.

Section 2: Installation

January 2013

2.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Please refer to the following safety messages

before performing any operation in this section.

Explosions could result in death or serious injury:

Do not remove the transmitter cover in explosive atmospheres when the circuit is

alive.

Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Failure to follow these installation guidelines could result in death or serious injury:

Make sure only qualified personnel perform the installation.

Installation

3

Page 12

Section 2: Installation

Is

Configuration

OK?

Mount

Flowmeter

Wire

Flowmeter

Power

Flowmeter

DONE

Mount

Conduit

START HERE

FIELD

INSTALL

CONFIGURE

Tag

Process Config

• Transmitter Mode

•Process Fluid

•Fixed Process Temp.

•Dens/Dens Ratio

-Density Ratio

(Std. or Normal

Volumetric Flow Units

Only)

-Fixed Process Density

(Mass Flow Units Only)

No

Bench

Commissioning?

Review

Configuration

Yes

No

Yes

Did you

Configure on

Bench?

No

Yes

Configure if

Necessary

Go to

Review

Configuration

A

A

A

Go to

B

Go to

B

Reference

K-Factor

Mating Pipe ID

Variable Mapping

Flange Type

PV Unit

Range Values

PV Damping

Auto Adjust Filter

Using

LCD?

Yes

Configure

Local

Display

Using Pulse

Output

No

Using

Tot al iz er

Meter

Installed

Configure

Pulse

Output

Yes

No

Configure

Totalizer

Yes

No

Yes

No

DONE

January 2013

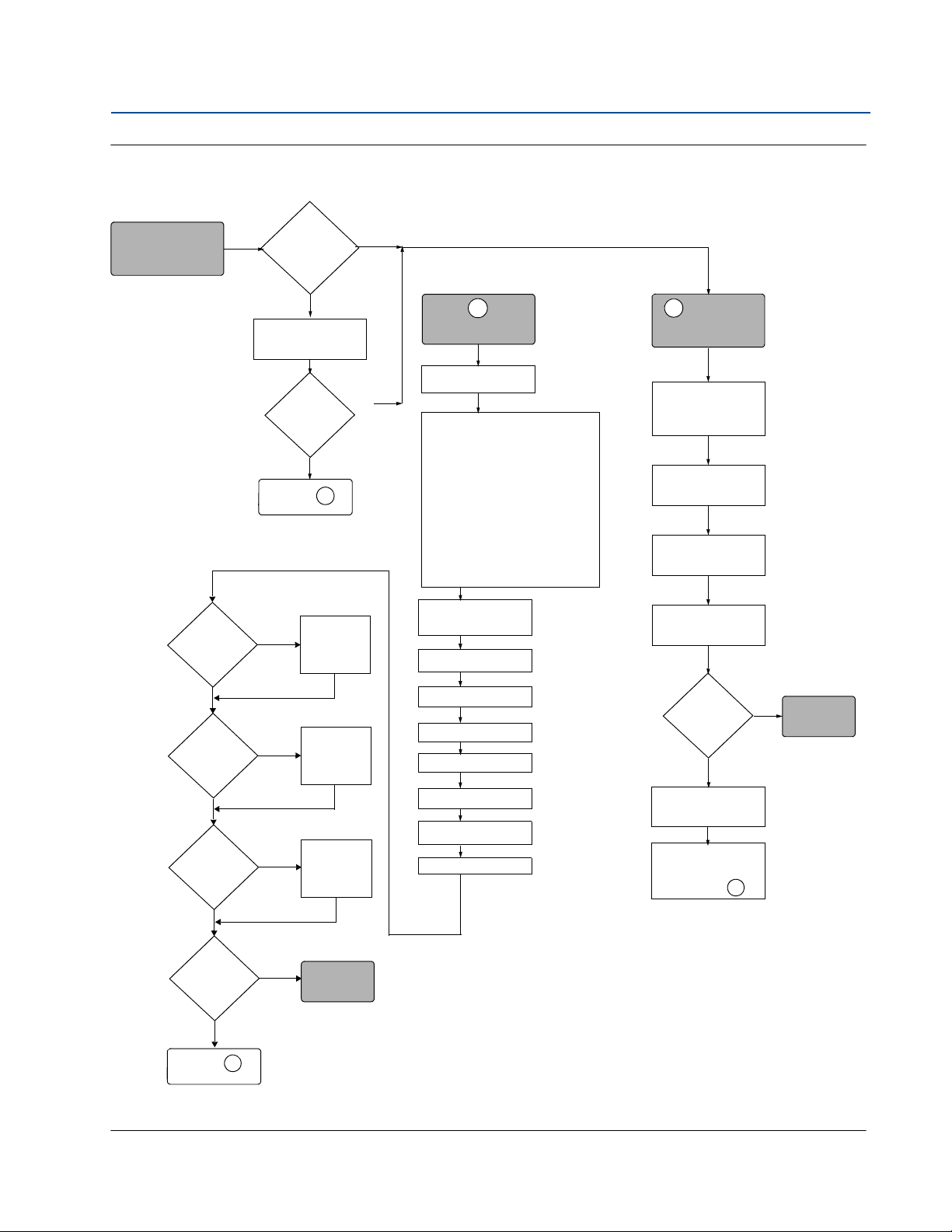

Figure 2-1. Installation Flowchart

Reference Manual

00809-0100-4860, Rev BC

4

Installation

Page 13

Reference Manual

00809-0100-4860, Rev BC

2.2 Commissioning

Commission the Rosemount 8600D before putting it into operation. This ensures proper

configuration and operation of the meter. It also enables you to check hardware settings, test

the flowmeter electronics, verify flowmeter configuration data, and check output variables. Any

problems can be corrected – or configuration settings changed – before going out into the

installation environment. To commission on the bench, connect the Field Communicator or

Asset Management Solutions

loop in accordance with the specifications for your communicator.

2.2.1 General considerations

Before you install a flowmeter in any application, you must consider flowmeter sizing (the line

size) and location. Choose the correct flowmeter size for an application to increase rangeability

and minimize pressure drop and cavitation. Proper location of the flowmeter can ensure a clean

and accurate signal. Follow the installation instructions carefully to reduce start-up delays, ease

maintenance, and ensure optimum performance.

2.2.2 Flowmeter sizing

™

(AMS) software (or other communications device) to the signal

Section 2: Installation

January 2013

Correct meter sizing is important for flowmeter performance. The Rosemount 8600D is capable

of processing signals from flow applications within the limitations described in Appendix A:

Reference data. Full scale is continuously adjustable within these ranges.

To determine the correct flowmeter size for an application, process conditions must be within

the stated requirements for Reynolds number and velocity. See Appendix A: Reference data for

sizing data.

Contact your local Rosemount Inc. sales representative to obtain a copy of Instrument Toolkit

which contains a sizing module for the Rosemount 8600D Vortex flowmeter. The vortex sizing

module will calculate valid flowmeter sizes based on user-supplied application information.

2.2.3 Flowmeter orientation

Design process piping so the meter body will remain full, with no entrapped air. Allow enough

straight pipe both upstream and downstream of the meter body to ensure a nonskewed,

symmetrical profile. Install valves downstream of the meter when possible.

Vertical installation

Vertical installation allows upward process liquid flow and is generally preferred. Upward flow

ensures that the meter body always remains full and that any solids in the fluid are evenly

distributed.

®

Installation

The vortex meter can be mounted in the vertical down position when measuring gas or steam

flows. This type of application should be strongly discouraged for liquid flows, although it can

be done with proper piping design.

Note

To ensure that the meter body remains full, avoid downward vertical

liquid flows where back pressure is inadequate.

5

Page 14

Section 2: Installation

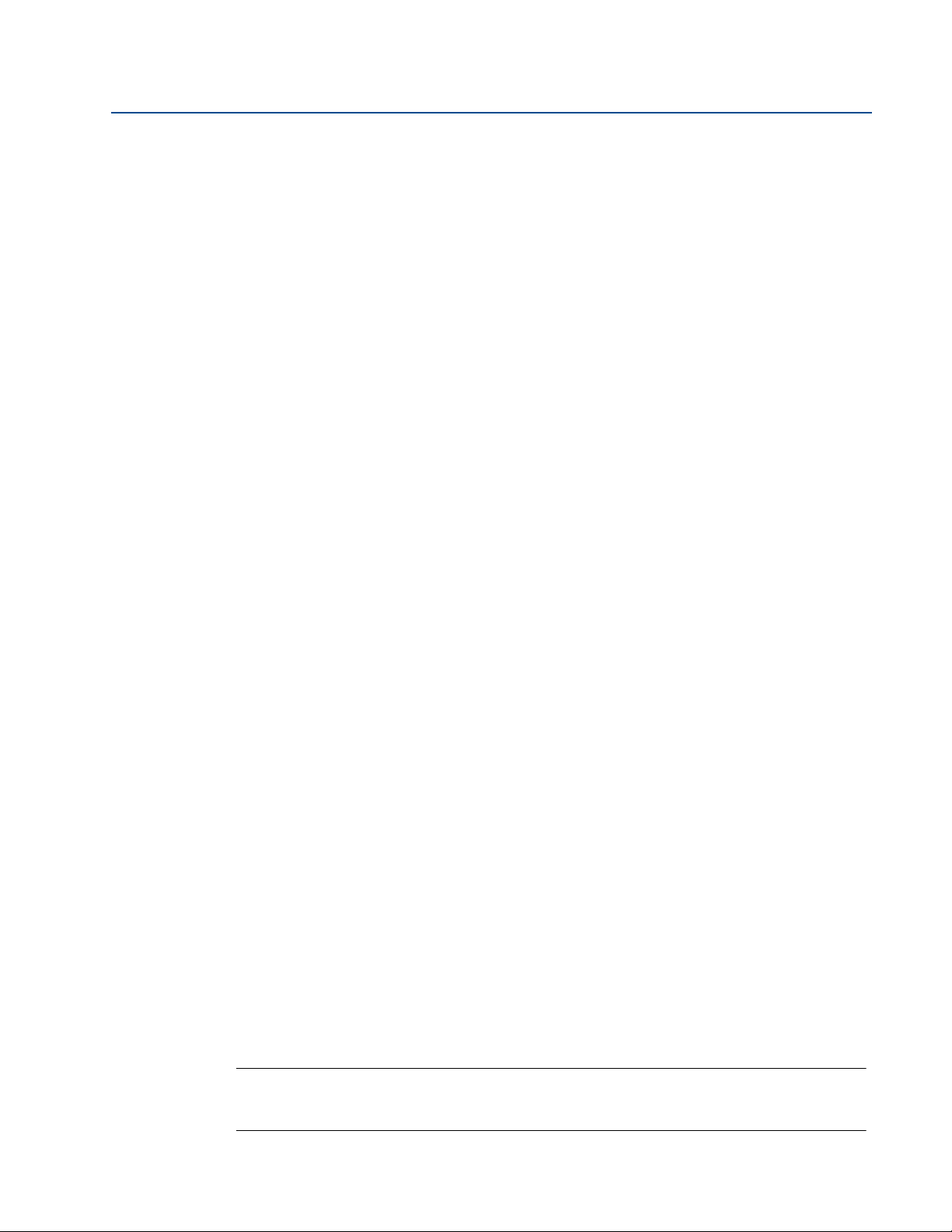

The meter body installed with the

electronics to the side of the pipe.

(PREFERRED ORIENTATION)

The meter body installed with the

electronics below the pipe.

(ACCEPTABLE ORIENTATION)

January 2013

Horizontal installation

For horizontal installation, the preferred orientation is to have the electronics installed to the

side of the pipe. In liquid applications, this ensures any entrapped air or solids do not strike the

shedding bar and disrupt the shedding frequency. In gas or steam applications, this ensures that

any entrained liquid (such as condensate) or solids do not strike the shedder bar and disrupt the

shedding frequency.

High-Temperature installations

Install the meter body so the electronics are positioned to the side of the pipe or below the pipe

as shown in Figure 2-2. Insulation may be required around the pipe to maintain an electronics

temperature below 185 °F (85 °C).

Figure 2-2. Examples of High-Temperature Installations

Reference Manual

00809-0100-4860, Rev BC

6

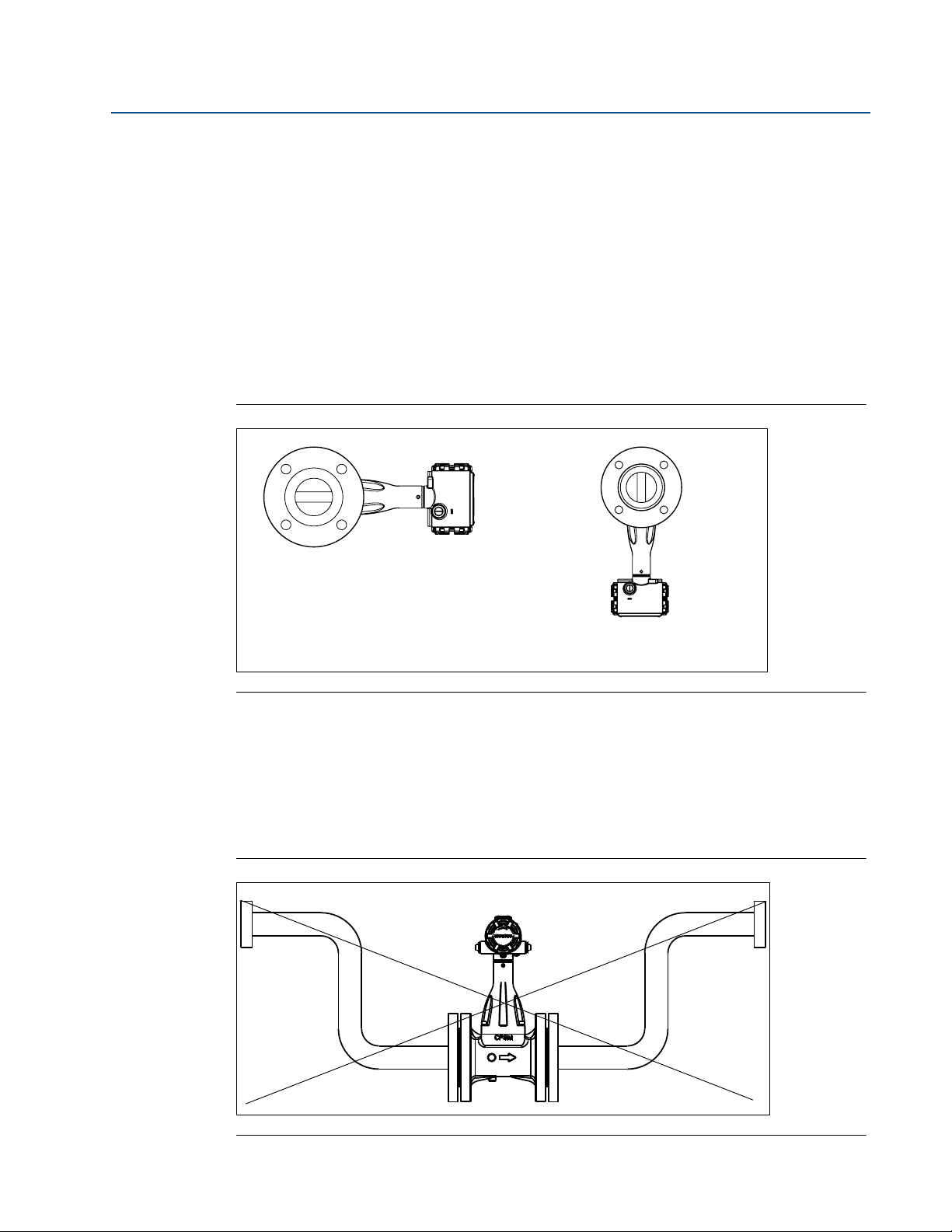

Steam installations

For steam applications, avoid installations such as the one shown in Figure 2-3. Such

installations may cause a water-hammer condition at start-up due to trapped condensate. The

high force from the water hammer can over stress the sensing mechanism and cause permanent

damage to the sensor.

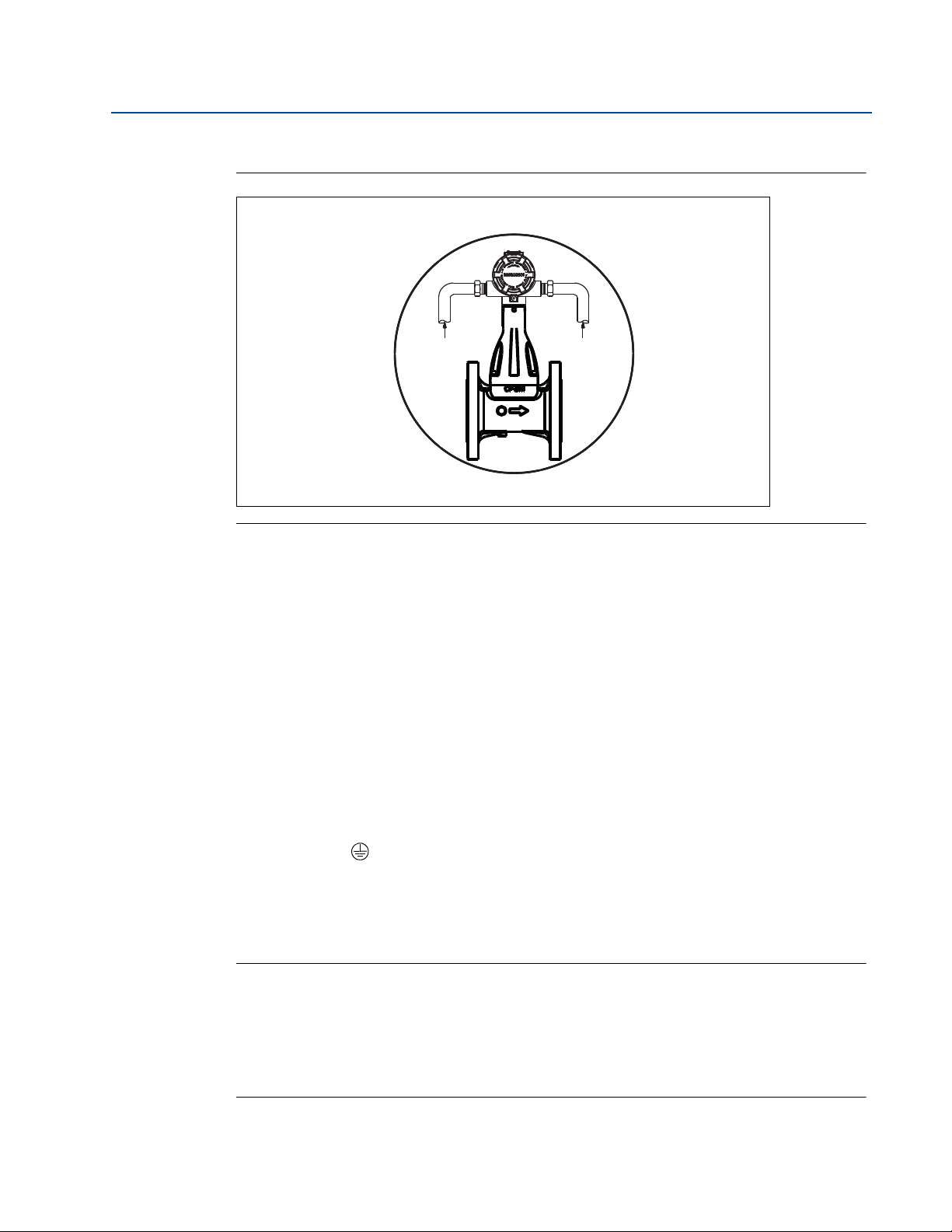

Figure 2-3. Avoid This Type of Installation for Steam Applications

Installation

Page 15

Reference Manual

NOTE: The MTA option can be purchased for an integral

temperature measurement and mass flow temperature

compensation for saturated steam only.

4 Downstream

6 Downstream

TP

00809-0100-4860, Rev BC

Section 2: Installation

January 2013

Upstream/Downstream piping

The vortex meter may be installed with a minimum of ten diameters (D) of straight pipe length

upstream and five diameters (D) of straight pipe length downstream.

Rated accuracy is based on the number of pipe diameter from an upstream disturbance. No

K-factor correction is required if the meter is installed with 35 D upstream and 5 D downstream.

The value of the K-factor may shift up to 0.5% when the upstream straight pipe length is

between 10D and 35D. Please see Technical Data Sheet (00816-0100-3250) on Installation

Effects for optional K-factor corrections. This effect can be corrected for using the Installation

Effect Correction Factor (See page 52).

Pressure and temperature transmitter location

When using pressure and temperature transmitters in conjunction with the Rosemount 8600D

for compensated mass flows, install the transmitter(s) downstream of the Vortex Flowmeter.

See Figure 2-4.

Figure 2-4. Pressure and Temperature Transmitter Location

2.2.4 Wetted material selection

2.2.5 Environmental considerations

Installation

Ensure that the process fluid is compatible with the meter body wetted materials when

specifying the Rosemount 8600D. Corrosion will shorten the life of the meter body. Consult

recognized sources of corrosion data or contact your Rosemount Sales Representative for more

information.

Note

For accurate results perform a Positive Material Identification (PMI) test on a machined surface.

Avoid excessive heat and vibration to ensure maximum flowmeter life. Typical problem areas

include high-vibration lines with integrally mounted electronics, warm-climate installations in

direct sunlight, and outdoor installations in cold climates.

7

Page 16

Section 2: Installation

January 2013

Although the signal conditioning functions reduce susceptibility to extraneous noise, some

environments are more suitable than others. Avoid placing the flowmeter or its wiring close to

devices that produce high intensity electromagnetic and electrostatic fields. Such devices include

electric welding equipment, large electric motors and transformers, and communication

transmitters.

2.3 Hazardous locations

The Rosemount 8600D has an explosion-proof housing and circuitry suitable for intrinsically

safe and non-incendive operation. Individual transmitters are clearly marked with a tag

indicating the certifications they carry.

2.4 Hardware configuration

The hardware jumpers on the Rosemount 8600D enable you to set the alarm and security. (See

Figure 2-5.) To access the jumpers, remove the electronics housing cover from the electronics

end of the Rosemount 8600D. If your Rosemount 8600D includes an LCD option, the alarm and

security jumpers are found on the face of the LCD indicator. (See Figure 2-6 on page 10.)

Reference Manual

00809-0100-4860, Rev BC

Note

If you will be changing configuration variables frequently, it may be

useful to leave the security lockout jumper in the OFF position to

avoid exposing the flowmeter electronics to the plant environment.

Set these jumpers during the commissioning stage to avoid exposing the electronics to the

plant environment.

Figure 2-5. Alarm and Security Jumpers

8

Installation

Page 17

Reference Manual

00809-0100-4860, Rev BC

Alarm

As part of normal operations, the Rosemount 8600D continuously runs a self-diagnostic

routine. If the routine detects an internal failure in the electronics, flowmeter output is driven to

a low or high alarm level, depending on the position of the failure mode jumper.

The failure mode jumper is labeled ALARM and is set at the factory per the CDS (Configuration

Data Sheet); the default setting is HI.

Security

You can protect the configuration data with the security lockout jumper. With the security

lockout jumper ON, any configuration changes attempted on the electronics are disallowed.

You can still access and review any of the operating parameters and scroll through the available

changes, but no actual changes will be permitted. The security lockout jumper is labeled

SECURITY and is set at the factory per the CDS; the default setting is OFF.

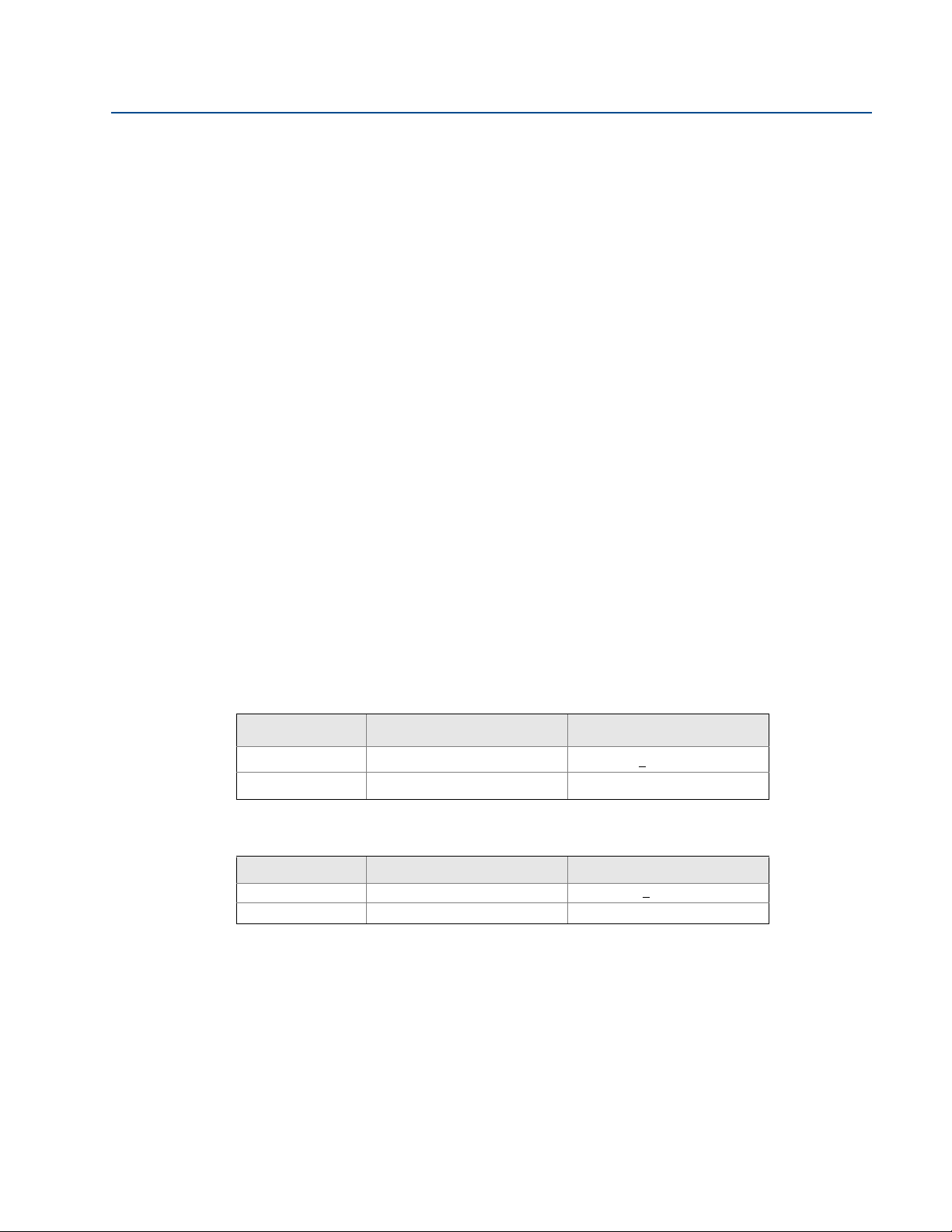

2.4.1 Failure mode vs. saturation output values

Section 2: Installation

January 2013

The failure mode alarm output levels differ from the output values that occur when the

operating flow is outside the range points. When the operating flow is outside the range points,

the analog output continues to track the operating flow until reaching the saturation value

listed below; the output does not exceed the listed saturation value regardless of the operating

flow. For example, with standard alarm and saturation levels and flows outside the 4—20 mA

range points, the output saturates at 3.9 mA or 20.8 mA. When the transmitter diagnostics

detect a failure, the analog output is set to a specific alarm value that differs from the saturation

value to allow for proper troubleshooting.

.

Table 2-1. Analog Output: Standard Alarm Values vs. Saturation Values

Level 4—20 mA Saturation Value 4—20 mA Alarm Value

Low 3.9 mA < 3.75 mA

High 20.8 mA 21.75 mA

.

Table 2-2. Analog Output: NAMUR-Compliant Alarm Values vs. Saturation Values

Level 4—20 mA Saturation Value 4—20 mA Alarm Value

Low 3.8 mA < 3.6 mA

High 20.5 mA 22.6 mA

Installation

9

Page 18

Section 2: Installation

ALARM

LO

HI

OFF

ON

SECURITY

January 2013

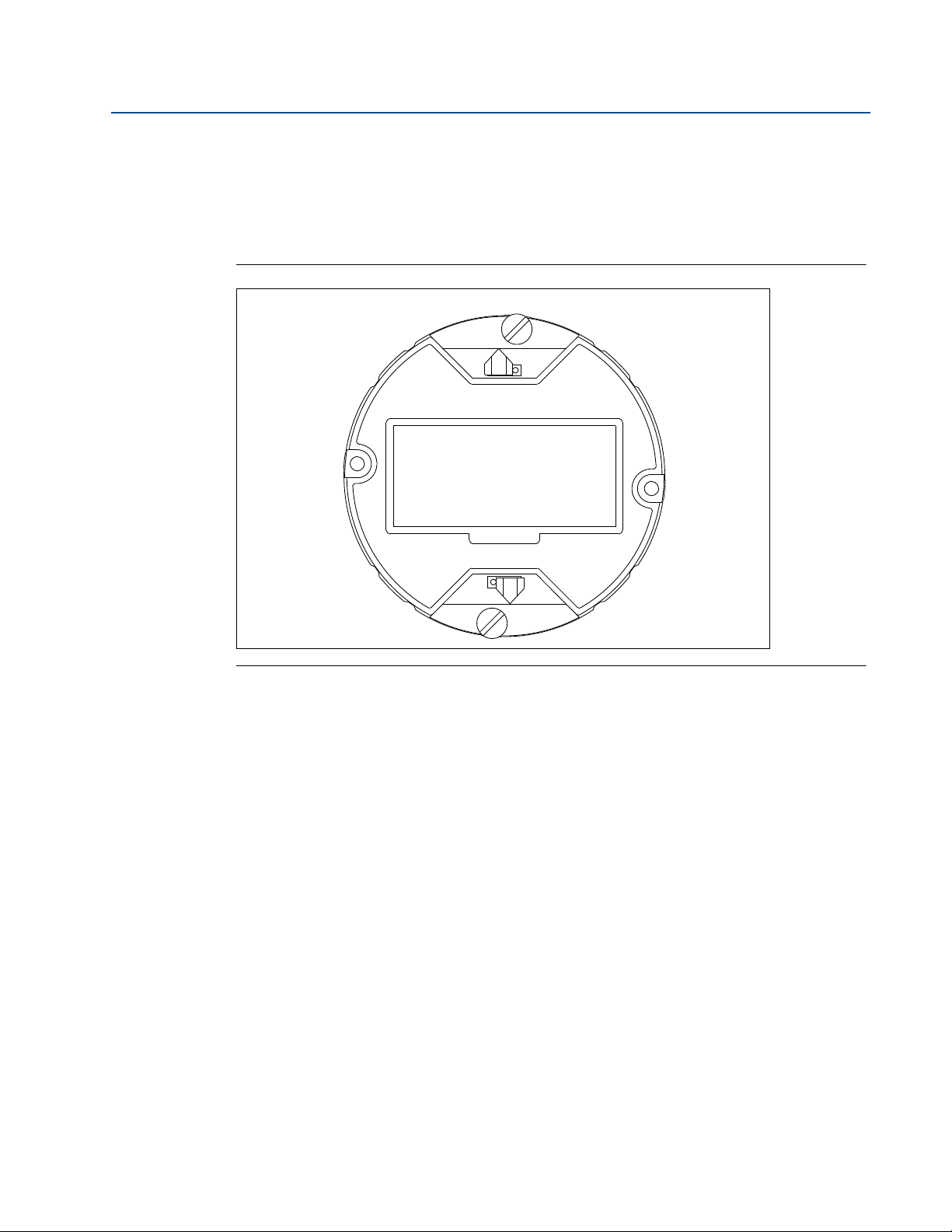

2.4.2 LCD indicator option

If your electronics are equipped with the LCD indicator (Option M5), the ALARM and SECURITY

jumpers are located on the face of the indicator as shown in Figure 2-6.

Figure 2-6. LCD Indicator Alarm and Security Jumpers

Reference Manual

00809-0100-4860, Rev BC

10

Installation

Page 19

Reference Manual

00809-0100-4860, Rev BC

2.5 Meter body installation tasks

The installation tasks include detailed mechanical and electrical

installation procedures.

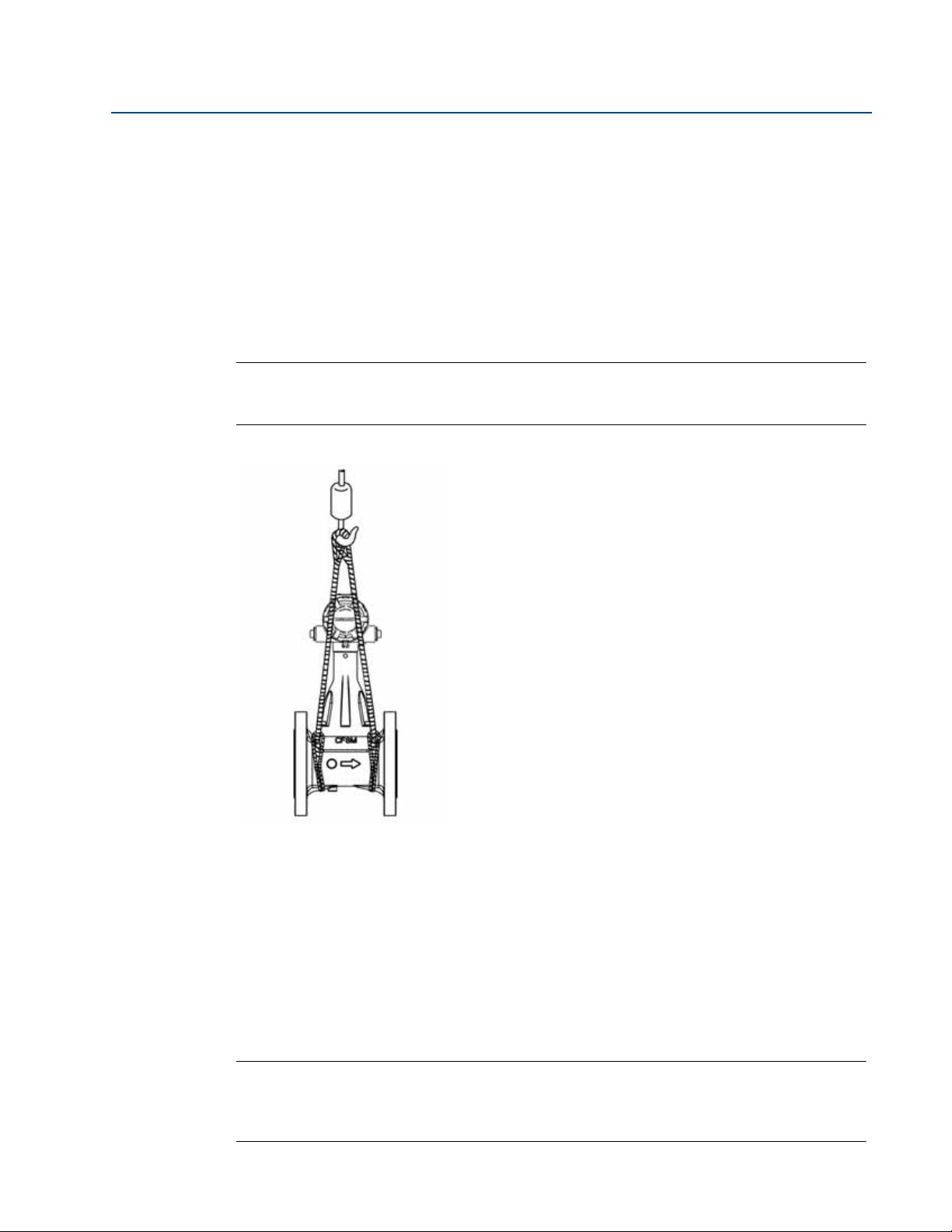

2.5.1 Handling

Handle all parts carefully to prevent damage. Whenever possible, transport the system to the

installation site in the original shipping containers. Keep the shipping plugs in the conduit

connections until you are ready to connect and seal them.

Note

Do not lift the flowmeter by the transmitter. Lift the meter by the meter body. Lifting supports

can be tied around the meter body as illustrated below if necessary.

Section 2: Installation

January 2013

2.5.2 Flow direction

Mount the meter body so the FORWARD end of the flow arrow, shown on the meter body,

points in the direction of the flow in the pipe.

2.5.3 Gaskets

The Rosemount 8600D requires flange gaskets supplied by the user, and sensor gaskets

supplied with the meter. Be sure to select gasket material that is compatible with the process

fluid and pressure ratings of the specific installation.

Note

Ensure that the inside diameter of the flange gasket is larger than the inside

diameter of the flowmeter and adjacent piping. If gasket material extends into the flow stream,

it will disturb the flow and cause inaccurate measurements.

Installation

11

Page 20

Section 2: Installation

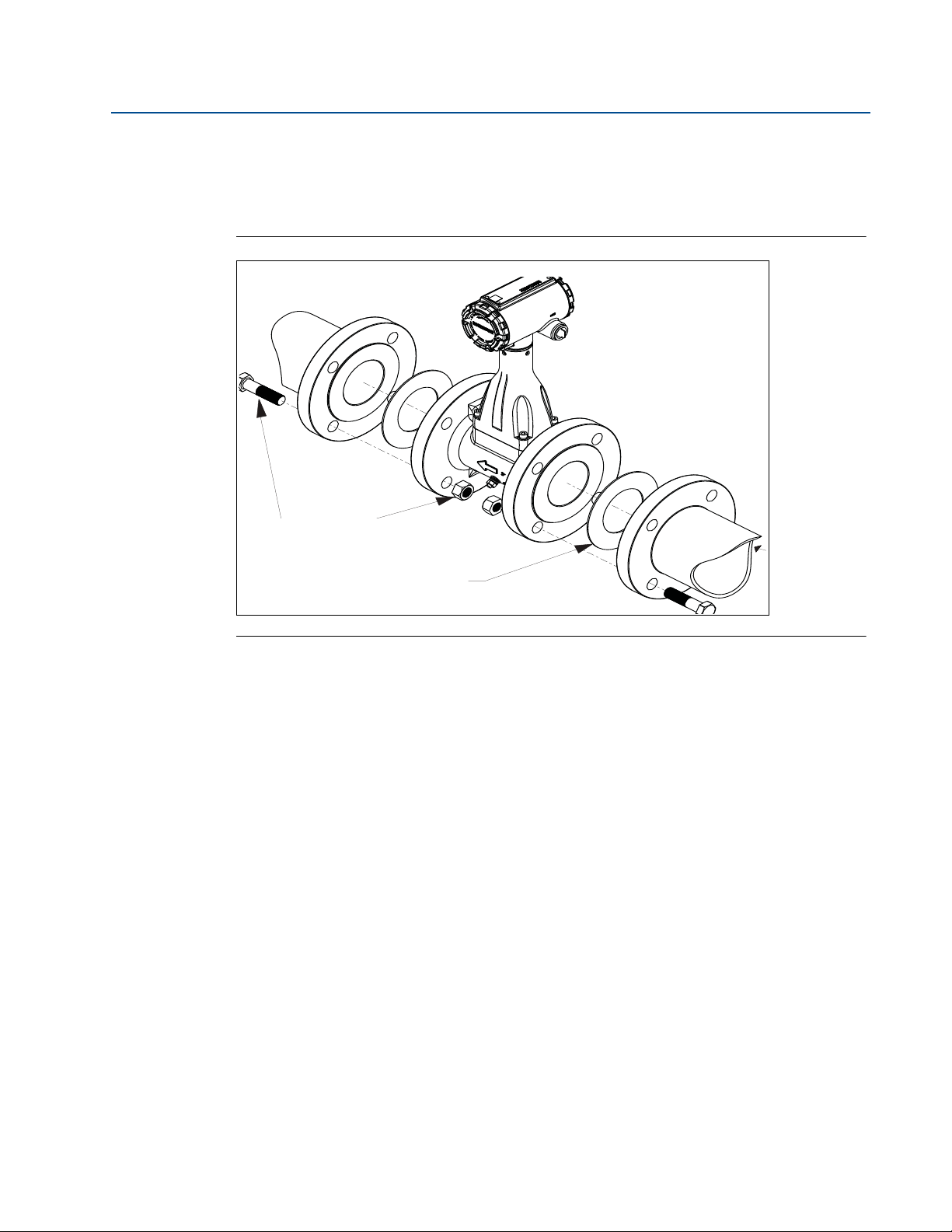

Gaskets

(Supplied by Customer)

Flow

Installation Bolts and Nuts

(Supplied by Customer)

January 2013

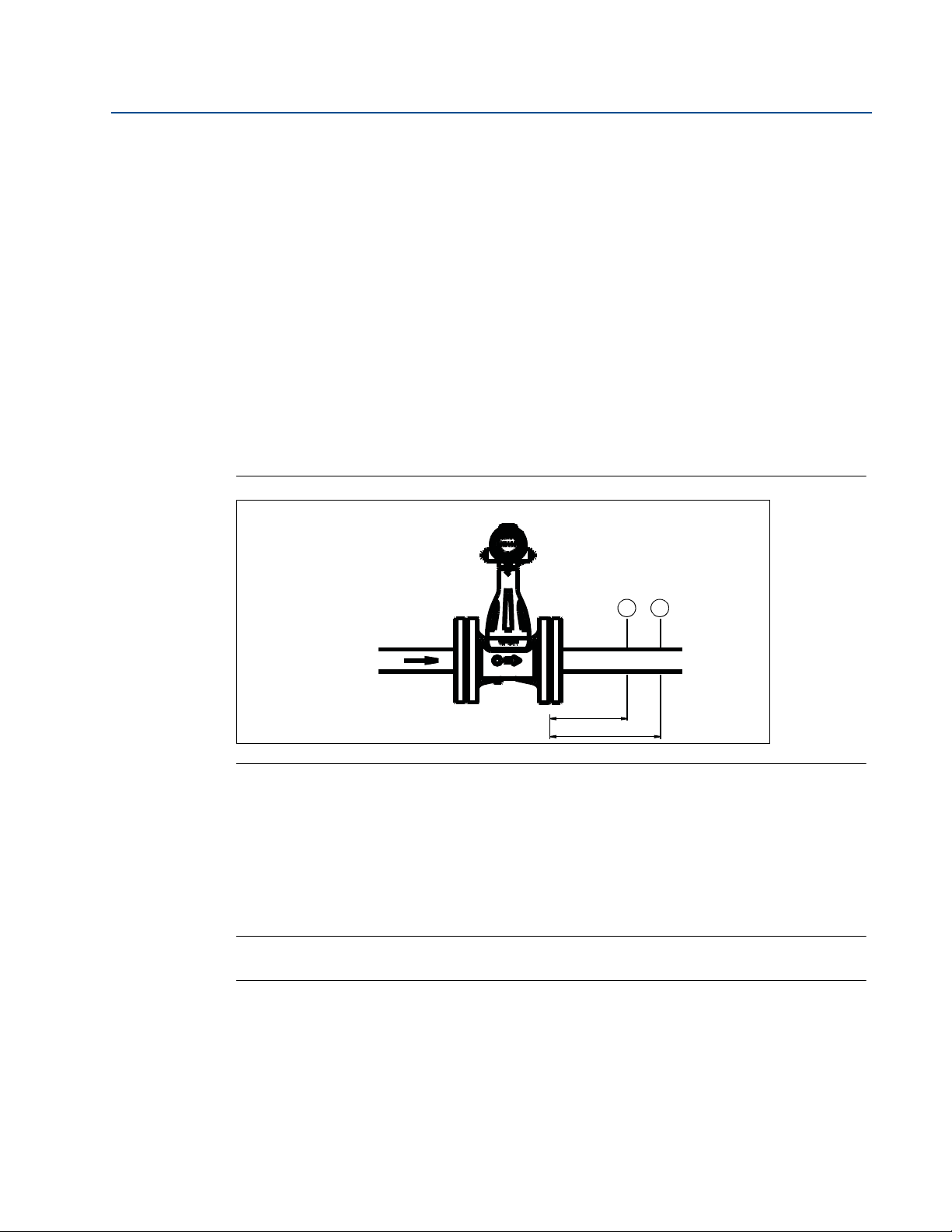

2.5.4 Flange bolts

Install the Rosemount 8600D Flowmeter between two conventional pipe flanges, as shown in

Figure 2-7 on page 12.

Figure 2-7. Flanged-Style Flowmeter Installation

Reference Manual

00809-0100-4860, Rev BC

12

Installation

Page 21

Reference Manual

1

3

4

2

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

10

11

12

00809-0100-4860, Rev BC

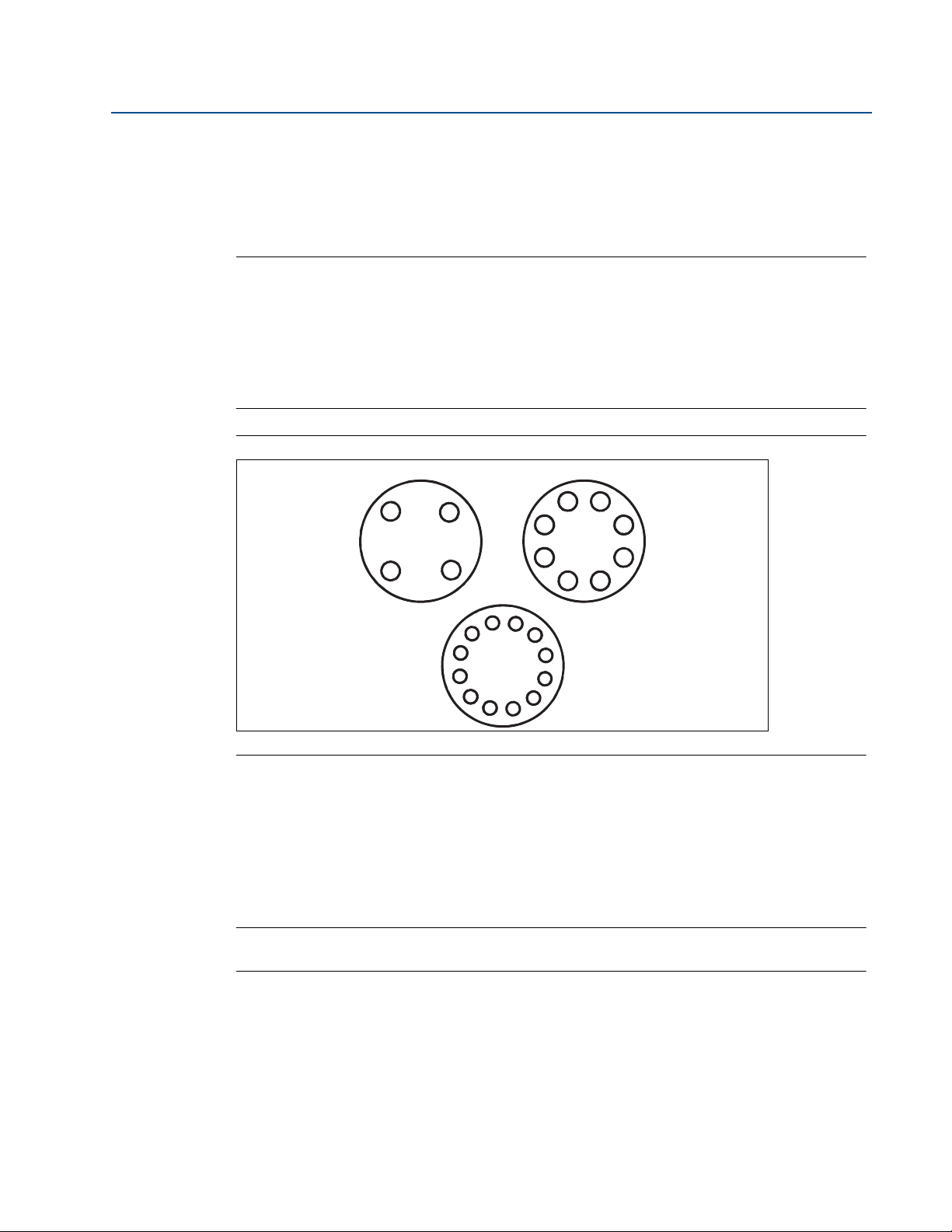

2.5.5 Flanged-style flowmeter mounting

Physical mounting of a flanged-style flowmeter is similar to installing a typical section of pipe.

Conventional tools, equipment, and accessories (such as bolts and gaskets) are required.

Tighten the nuts following the sequence shown in Figure 2-8.

Note

The required bolt load for sealing the gasket joint is affected by several factors, including operating

pressure and gasket material, width, and condition. A number of factors also affect the actual bolt

load resulting from a measured torque, including condition of bolt threads, friction between the nut

head and the flange, and parallelism of the flanges. Due to these application-dependent factors, the

required torque for each application may be different. Follow the guidelines outlined in the ASME

Pressure Vessel Code (Section VIII, Division 2) for proper bolt tightening. Make sure the flowmeter is

centered between flanges of the same nominal size as the flowmeter.

Figure 2-8. Flange Bolt Torquing Sequence

Section 2: Installation

January 2013

2.5.6 Flowmeter grounding

Grounding is not required in typical vortex applications; however, a proper ground will eliminate

possible noise pickup by the electronics. Grounding straps may be used to ensure that the

meter is grounded to the process piping. If you are using the transient protection option (T1),

grounding straps are required to provide a proper low impedance ground.

Note

Properly ground flow meter body and transmitter per the local code.

Installation

To use grounding straps, secure one end of the grounding strap to the bolt extending from the

side of the meter body and attach the other end of each grounding strap to a suitable ground.

13

Page 22

Section 2: Installation

January 2013

2.6 Electronics considerations

Both integral and remote mounted electronics require input power at the electronics. For

remote mount installations, mount the electronics

against a flat surface or on a pipe that is up to two inches (50 mm) in diameter.

Remote mounting hardware includes an L bracket that is stainless steel and one stainless steel

u-bolt. See Appendix A: Reference data, “Dimensional drawings” on page 107 for dimensional

information.

2.6.1 High-Temperature installations

Install the meter body so the electronics are positioned to the side of or

below the pipe as shown in Figure 2-2 on page 6. Insulation may be required around the pipe to

maintain an ambient transmitter temperature below 185 °F (85 °C) or the more restrictive

temperature ratings marked on hazardous locations tags.

2.6.2 Conduit connections

Reference Manual

00809-0100-4860, Rev BC

The electronics housing has two ports for 1/2–14 NPT or M201.5 conduit connections. Unless

marked otherwise conduit entries in the housing are

conventional manner in accordance with local or plant electrical codes. Be sure to properly seal

unused ports to prevent moisture or other contamination from entering the terminal block

compartment of the electronics housing. Additional conduit entry types are available via

adapters.

Note

In some applications it may be necessary to install conduit seals and arrange for conduits to

drain to prevent moisture from entering the wiring compartment.

2.6.3 High-Point installation

Prevent condensation in any conduit from flowing into the housing by mounting the flowmeter

at a high point in the conduit run. If the flowmeter is mounted at a low point in the conduit run,

the terminal compartment could fill with fluid.

If the conduit originates above the flowmeter, route conduit below the flowmeter before entry.

In some cases a drain seal may need to be installed.

1

/2 NPT. These connections are made in a

14

Installation

Page 23

Reference Manual

Conduit Line

Conduit Line

00809-0100-4860, Rev BC

Section 2: Installation

January 2013

Figure 2-9. Proper Conduit Installation with Rosemount 8600D

2.6.4 Cable gland

If you are using cable glands instead of conduit, follow the cable gland manufacturer’s instructions

for preparation and make the connections in a conventional manner in accordance with local or plant

electrical codes. Be sure to properly seal unused ports to prevent moisture or other contamination

from entering the terminal block compartment of the electronics housing.

2.6.5 Grounding the transmitter case

The transmitter case should always be grounded in accordance with national and local electrical

codes. The most effective transmitter case grounding method is direct connection to earth

ground with minimal impedance. Methods for grounding the transmitter case include:

Internal Ground Connection: The Internal Ground Connection screw is inside the

FIELD TERMINALS side of the electronics housing. This screw is identified by a ground

symbol ( ), and is standard on all Rosemount 8600D transmitters.

External Ground Assembly: This assembly is included with the optional transient

protection terminal block (Option Code T1). The External Ground Assembly can also be

ordered with the transmitter (Option Code V5) and is automatically included with

certain hazardous area approvals.

Note

Grounding the transmitter case using the threaded conduit connection may not provide a

sufficient ground. The transient protection terminal block (Option Code T1) does not provide

transient protection unless the transmitter case is properly grounded. See “Transient Terminal

Block” on page 27 for transient terminal block grounding. Use the above guidelines to ground

the transmitter case. Do not run the transient protection ground wire with signal wiring as the

ground wire may carry excessive current if a lightning strike occurs.

Installation

15

Page 24

Section 2: Installation

8600

V

ps

R

loop

V

terminals

January 2013

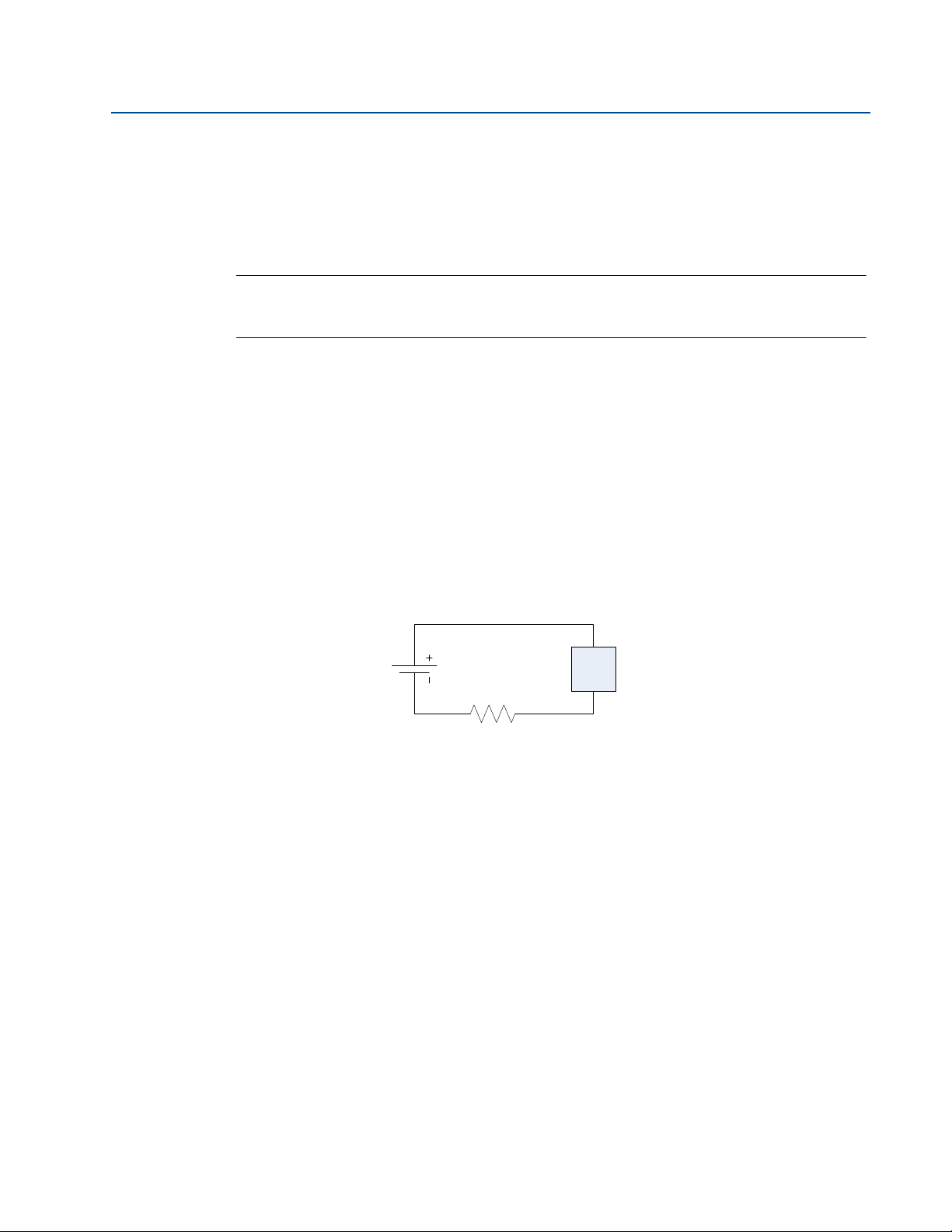

2.6.6 Wiring procedure

The signal terminals are located in a compartment of the electronics housing separate from the

flowmeter electronics. Connections for a HART-based communicator and a current test

connection are above the signal terminals. Figure 2-10 illustrates the power supply load

limitations for the flowmeter.

Note

A power disconnect is required to remove power from the transmitter for maintenance,

removal, and replacement.

Power supply

Power Supply Specifications:

Typical installations use a 22 Vdc – 28 Vdc power supply. The dc power supply should provide

clean power with less than 2% ripple. Refer to Figure 2-10 as a quick reference.

Loop resistance specification:

Reference Manual

00809-0100-4860, Rev BC

If HART communication is required, a minimum resistance of 250 dc is required between the

power supply and the transmitter. *Note: See the loop load calculation section to determine the

maximum allowable loop resistance as a function of power supply voltage.

Typical single loop wiring diagram:

*Loop Load Calculation: R

loop(max)

= (Vps – 10.8) / 0.024

Where:

R

R

V

10.8 = minimum terminal voltage “V

0.024 = maximum transmitter current in Adc

loop(min)

loop(max)

ps

= 250 . Required for HART communication.

= The maximum value the loop load resistor can be.

= Power Supply Voltage

terminals

” in Vdc.

16

Installation

Page 25

Reference Manual

00809-0100-4860, Rev BC

Section 2: Installation

January 2013

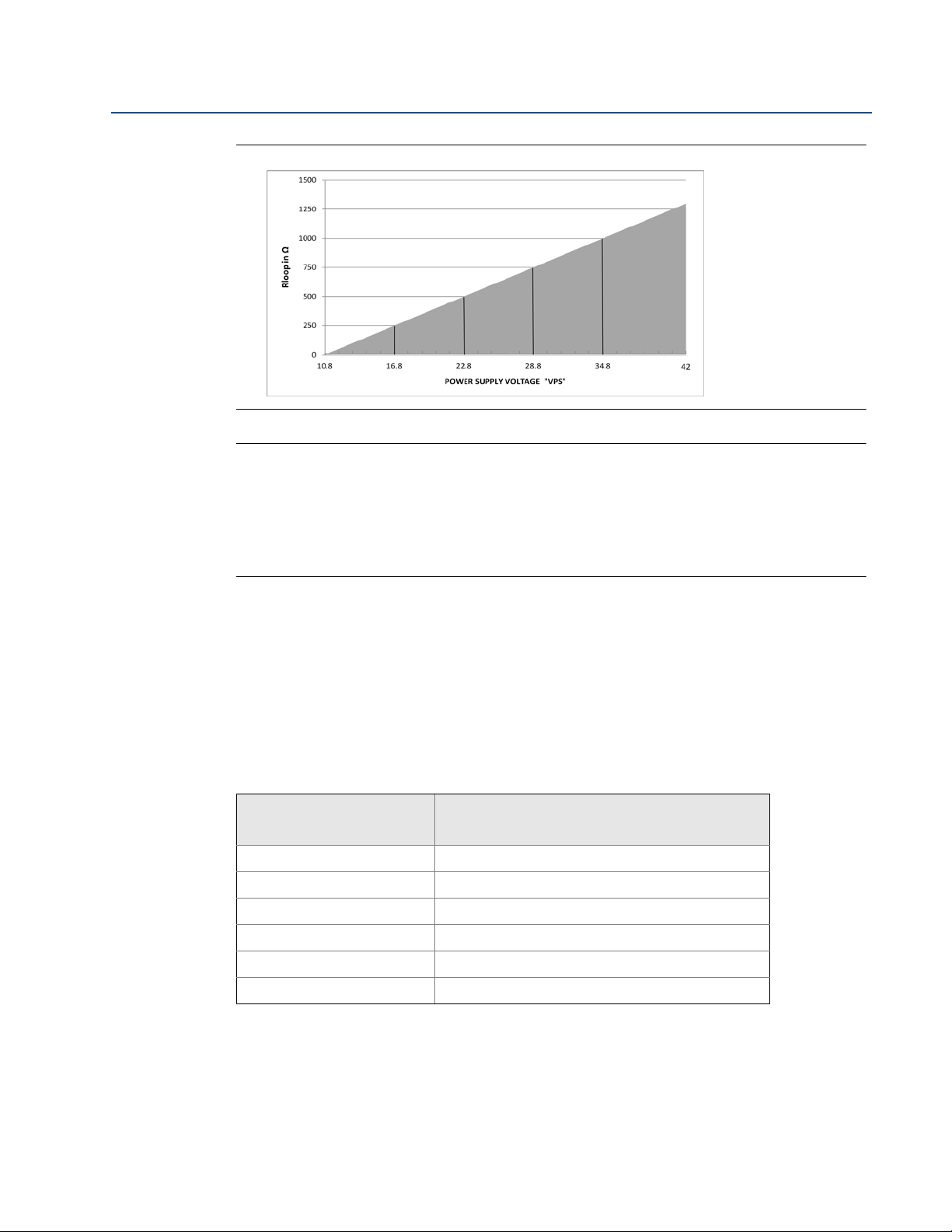

Figure 2-10. Power Supply Load Limitations

Note

R

loop(max)

in the equation above refers to the total loop load resistance. Technically, the total

loop load resistance is the sum of the loop load resistor, signal wiring resistance, and if

applicable, any intrinsic safety barriers. In a typical installation, the loop load resistor will largely

determine the total loop resistance. In some installations, depending on signal wire gauge and

signal wire length, and/or any IS barriers, the additional resistance may need to be accounted

for.

To minimize noise pickup on the 4-20 mA signal and any digital communications signal:

Twisted pair wiring is recommended.

Shielded signal wire is preferred.

For high EMI/RFI environments, shielded signal wire is required.

To ensure proper operation, wiring should be:

24 AWG or larger.

Less than 5000 ft. (1500 m) in length.

Ohms per 1,000 ft (305 m) at 68 °F (20 °C)

Gage Number A.W.G.

14 2.525

16 4.016

18 6.385

20 10.15

22 16.14

24 25.67

Equivalent

Installation

17

Page 26

Section 2: Installation

January 2013

Note

If a Smart Wireless THUM™ Adapter is being used with the Rosemount 8600 flowmeter to

exchange information via the WirelessHART protocol, an additional 2.5 Vdc is dropped in the

connected loop. This is because the THUM is wired in series with the transmitter. Please use the

following formula to calculate the maximum loop load resistor.

Reference Manual

00809-0100-4860, Rev BC

Loop Load Calculation: R

loop(max)

= (Vps – 10.8 – 2.5) / 0.024

Where:

R

V

10.8 = minimum terminal voltage “V

2.5 = Maximum voltage drop across the THUM wireless adapter.

0.024 = maximum transmitter current in Adc.

loop(max)

ps

= The maximum value the loop load resistor can be.

= Power Supply Voltage.

terminals

” in Vdc.

Analog output

The flowmeter provides a 4–20 mA dc isolated current output, linear

with the flow rate.

To make connections, remove the FIELD TERMINALS side cover of the electronics housing. All

power to the electronics is supplied over the 4–20 mA signal wiring. Connect the wires as shown

in Figure 2-13 on page 21.

18

Installation

Page 27

Reference Manual

50% Duty Cycle

00809-0100-4860, Rev BC

Section 2: Installation

Pulse output

Note

Remember when using the pulse output, all power to the electronics

is still supplied over the 4–20 mA signal wiring.

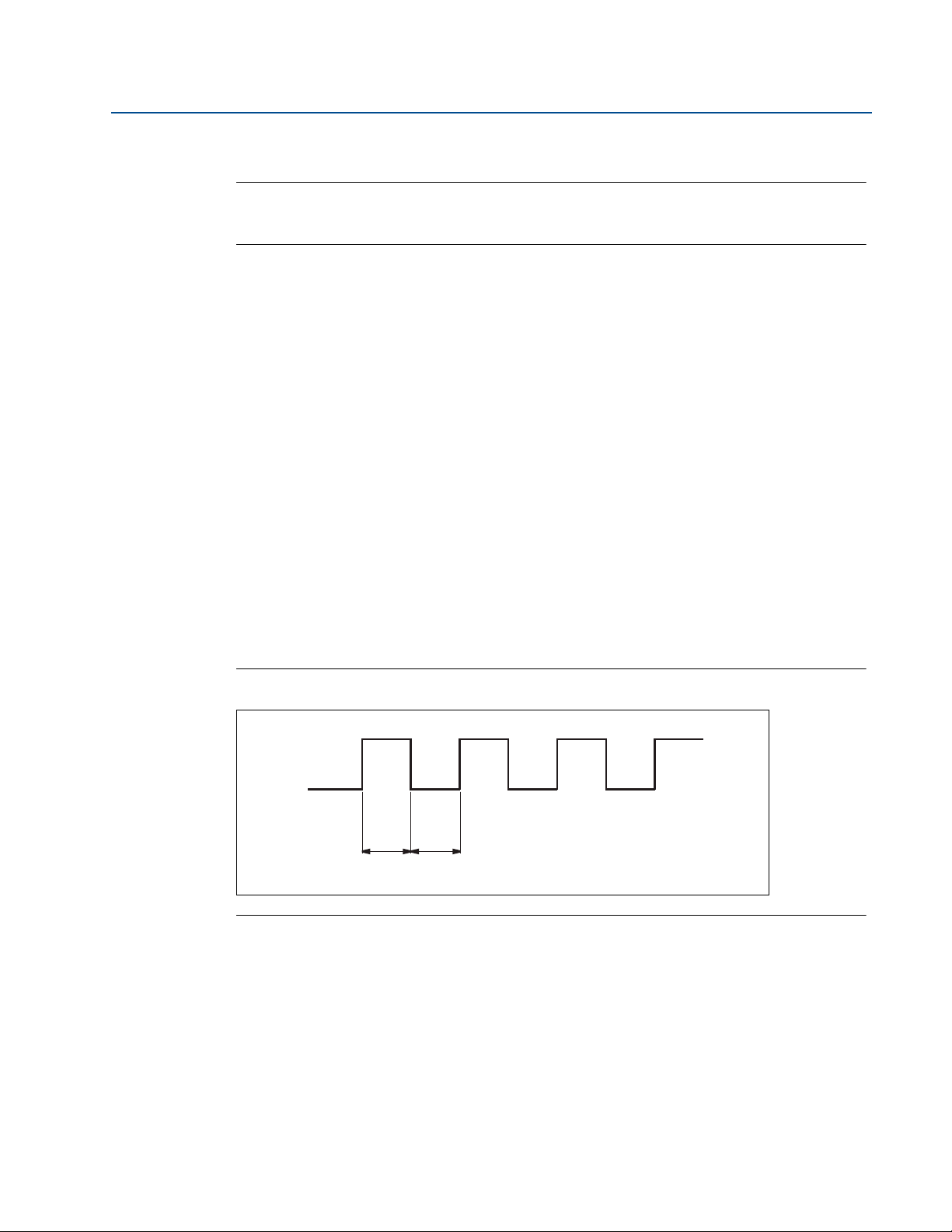

The flowmeter provides an isolated transistor switch-closure frequency output signal

proportional to flow, as shown in Figure 2-11. The

frequency limits are as follows:

Maximum Frequency = 10000 Hz

Minimum Frequency = 0.0000035 Hz (1 pulse/79 hours)

Duty Cycle = 50%

External Supply Voltage (V

Load Resistance (R

Max Switching Current = 75 mA >= V

Switch Closure: Transistor, open collector

Open contact < 50

Close contact < 20

): 100 to 100 k

L

A leakage

): 5 to 30 Vdc

s

S/RL

January 2013

The output may drive an externally powered electromechanical or electronic totalizer, or may

serve as a direct input to a control element.

To connect the wires, remove the FIELD TERMINALS side cover

of the electronics housing. Connect the wires as shown in Figure 2-14 on page 21.

Figure 2-11. Example: The pulse output will maintain a 50 percent duty cycle for all

frequencies.

Installation

19

Page 28

Section 2: Installation

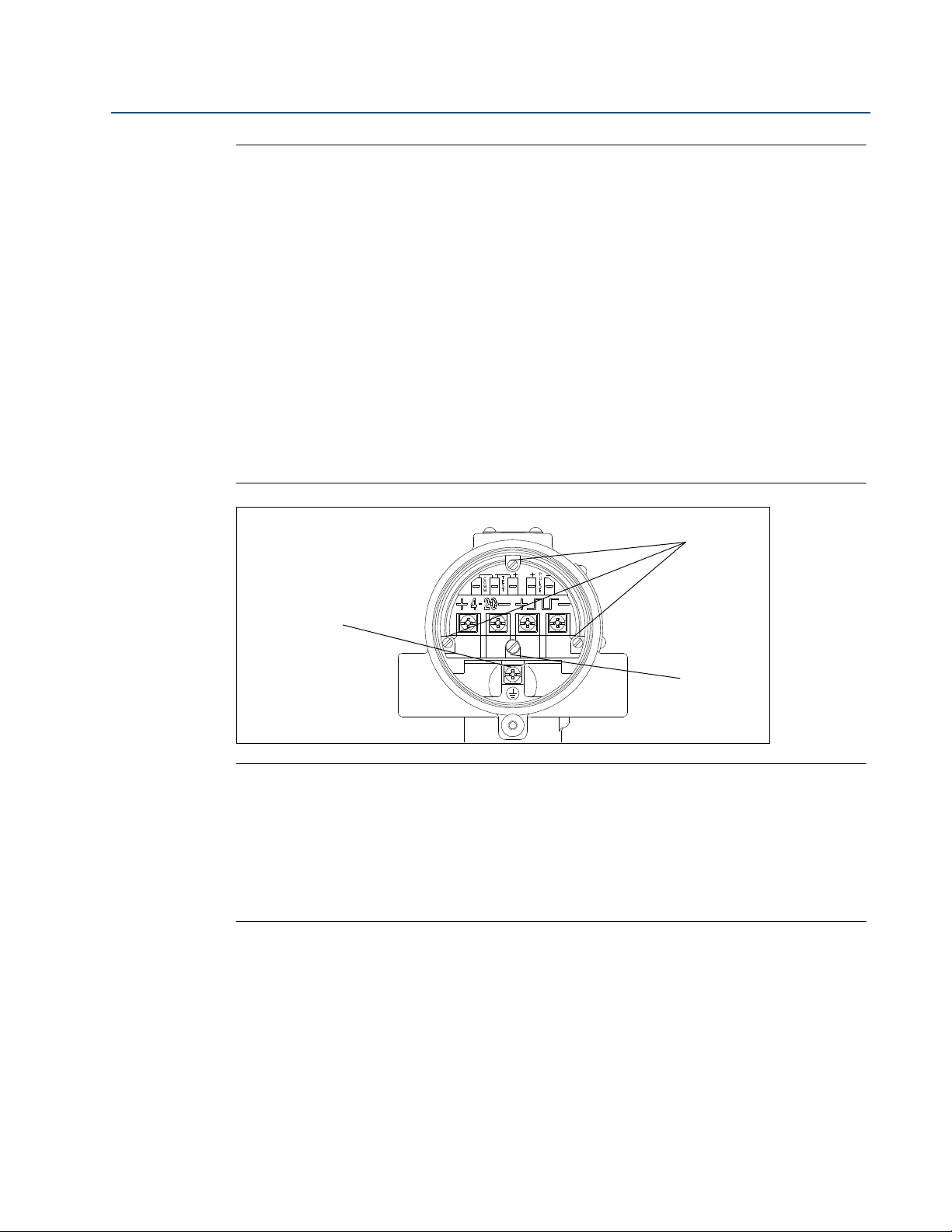

Housing

Ground

Screw

Captive

Screws

Transient Terminal

Block Ground Tab

January 2013

Note

When using pulse output, be sure to follow these precautions:

Shielded twisted pair is required when the pulse output and 4–20 mA output are run in

Do not connect the powered signal wiring to the test terminals. Power could damage

Do not run signal wiring in conduit or open trays with power wiring or near heavy

If the flowmeter is protected by the optional transient protector, you must provide a

Figure 2-12. The Transient Terminal Block

Reference Manual

00809-0100-4860, Rev BC

the same conduit or cable trays. Shielded wire will also reduce false triggering caused

by noise pickup. Wiring should be 24 AWG or larger and not exceed 5,000 ft. (1500 m).

the test diode in the test connection.

electrical equipment. If needed, ground signal wiring at any one point on the signal

loop, such as the negative terminal of the power supply. The electronics housing is

grounded to the meter body.

high-current ground connection from the electronics housing to earth ground. Also,

tighten the ground screw in the bottom center of the terminal block to provide a good

ground connection.

20

Plug and seal all unused conduit connections on the electronics housing to avoid

moisture accumulation in the terminal side

of the housing.

If the connections are not sealed, mount the flowmeter with the conduit entry

positioned downward for drainage. Install wiring with a drip loop, making sure the

bottom of the drip loop is lower than the conduit connections or the electronics

housing.

Installation

Page 29

Reference Manual

+

-

R

L

250

Tes t Am mete r

RL 250

+

Tes t

Ammeter

+

–

-

Pulse

Counter

00809-0100-4860, Rev BC

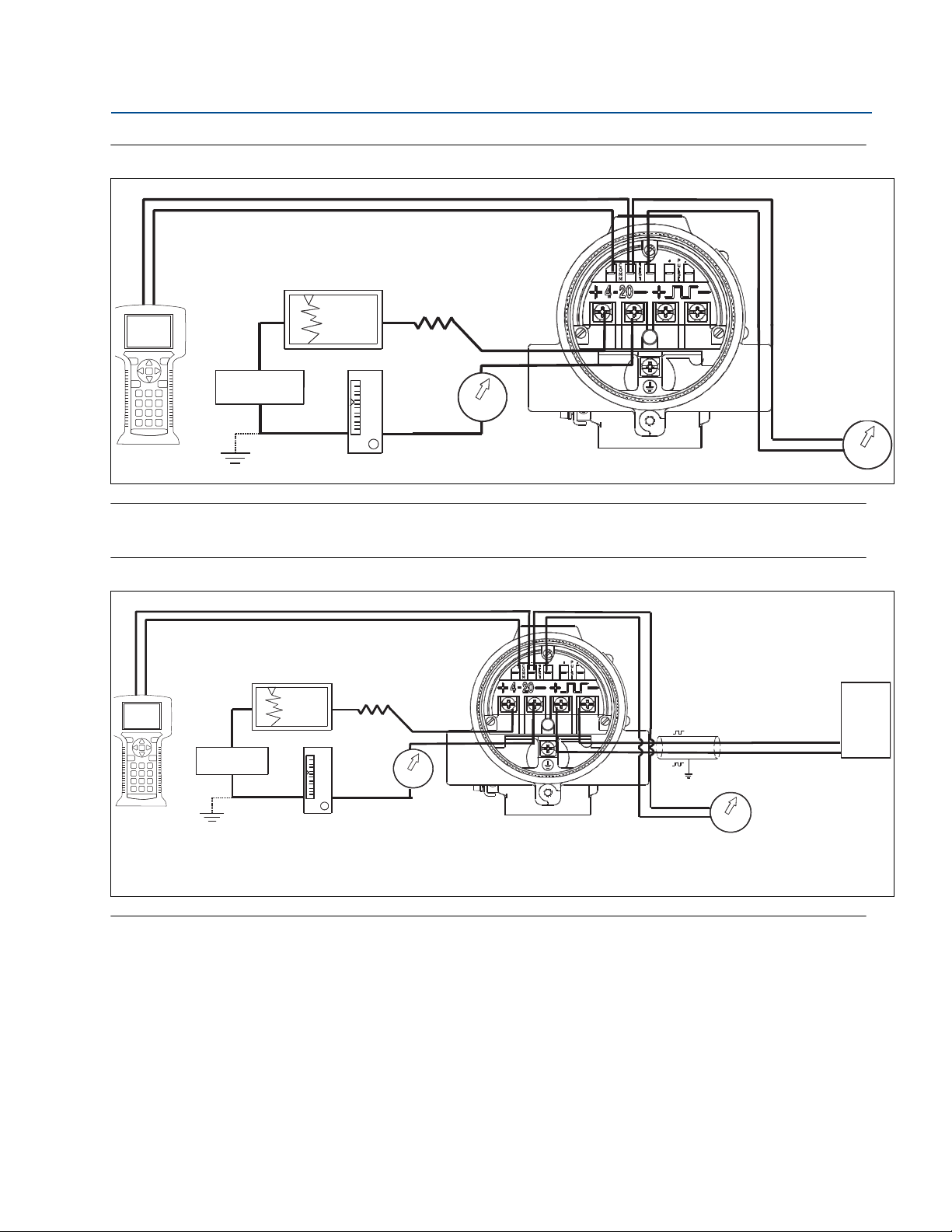

Figure 2-13. 4-20 mA Wiring

Section 2: Installation

January 2013

Figure 2-14. 4–20 mA and Pulse Wiring with Electronic Totalizer/ Counter

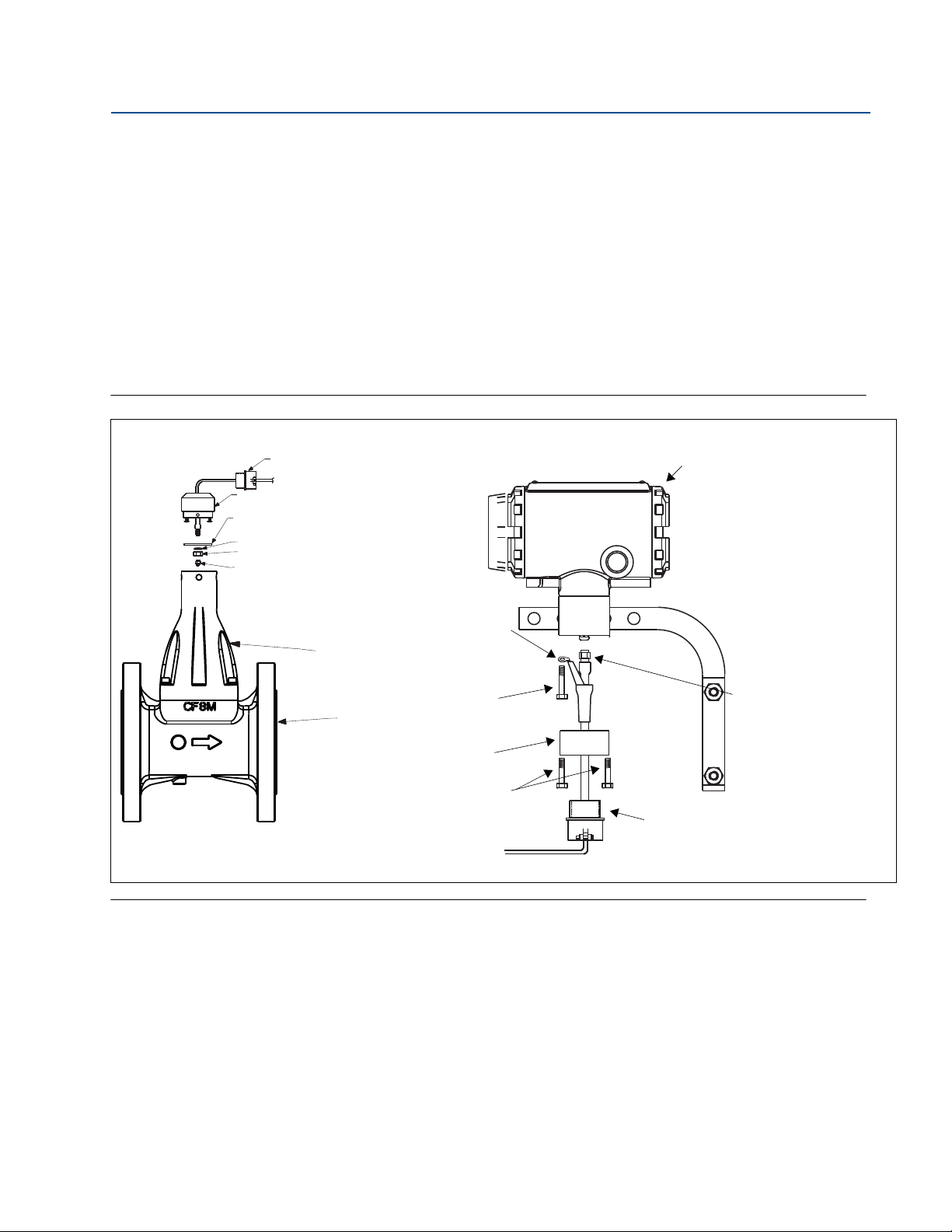

2.6.7 Remote electronics

If you order one of the remote electronics options (options R10, R20, R30, R33, R50, or RXX),

the flowmeter assembly will be shipped in two parts:

Installation

1. The meter body with an adapter installed in the bracket and an interconnecting coaxial

cable attached to it.

2. The electronics housing installed on a mounting bracket.

21

Page 30

Section 2: Installation

NOTE

Consult factory for SST installation

Ground

Connection

Housing Adapter

Housing Adapter Screws

Electronics Housing

Coaxial

Cable Nut

Housing

Base Screw

1

/2 NPT Conduit Adapter or Cable Gland

(Supplied by Customer)

Coaxial Cable

Meter Adapter

Union

Wash er

Sensor Cable Nut

Meter Body

Nut

Bracket

½ NPT Conduit Adapter or Cable

Gland (Supplied by Customer)

January 2013

Mounting

Mount the meter body in the process flow line as described earlier in this section. Mount the

bracket and electronics housing in the desired location. The housing can be repositioned on the

bracket to facilitate field wiring and conduit routing.

Cable connections

Refer to Figure 2-15 and the following instructions to connect the loose end of the coaxial cable

to the electronics housing. (See “Remote electronics procedure” on page 83 if connecting/dis-

connecting the meter adapter to the meter body.)

Figure 2-15. Remote Electronics Installation

Reference Manual

00809-0100-4860, Rev BC

22

Installation

Page 31

Reference Manual

00809-0100-4860, Rev BC

Section 2: Installation

January 2013

1. If you plan to run the coaxial cable in conduit, carefully cut the conduit to the desired

length to provide for proper assembly

at the housing. A junction box may be placed in the conduit run to provide a space for

extra coaxial cable length.

2. Slide the conduit adapter or cable gland over the loose end of the coaxial cable and

fasten it to the adapter on the meter body bracket.

3. If using conduit, route the coaxial cable through the conduit.

4. Place a conduit adapter or cable gland over the end of the

coaxial cable.

5. Remove the housing adapter from the electronics housing.

6. Slide the housing adapter over the coaxial cable.

7. Remove one of the four housing base screws.

8. Attach the coaxial cable ground wire to the housing via the housing base ground screw.

9. Attach and securely tighten the coaxial cable nut to the connection on the electronics

housing.

10. Align the housing adapter with the housing and attach

with two screws.

11. Tighten the conduit adapter or cable gland to the

housing adapter.

Caution

To prevent moisture from entering the coaxial cable connections, install the interconnecting

coaxial cable in a single dedicated conduit run or use sealed cable glands at both ends of the

cable.

2.6.8 Calibration

Rosemount 8600D Flowmeters are wet-calibrated at the factory and need no further calibration

during installation. The calibration factor (K-factor) is indicated on each meter body and is

entered into the electronics. Verification can be accomplished with a Field Communicator

or AMS.

2.7 Software configuration

Installation

To complete the installation of the Rosemount 8600D Vortex Flowmeter, configure the

software to meet the requirements of your application. If the flowmeter was pre-configured at

the factory, it may be ready to install. If not, refer to Section 3: Configuration.

LCD indicator

The LCD indicator (option M5) provides local indication of the output and abbreviated

diagnostic messages governing operation of the flowmeter. The indicator is located on the

electronics side of the flowmeter electronics. An extended cover is required to accommodate

23

Page 32

Section 2: Installation

Electronics Board

January 2013

the indicator. Figure 2-16 shows the flowmeter fitted with the LCD indicator and extended

cover.

Figure 2-16. Rosemount 8600D with Optional Indicator

Reference Manual

00809-0100-4860, Rev BC

The indicator features an eight-character (and five alphanumeric) liquid crystal display that

gives a direct reading of the digital signal from the microprocessor. During normal operation,

the display can be configured to alternate between the following readings:

1. Primary variable in engineering units

2. Percent of range

3. Totalized flow

4. 4–20 mA electrical current output

5. Shedding Frequency

6. Electronics Temperature

7. Pulse Output Frequency

8. Process Temperature

(MTA Option Only)

9. Mass Flow

10. Volume Flow

11. Velocity Flow

24

12. Calculated Process Density

(MTA Option Only)

Installation

Page 33

Reference Manual

00809-0100-4860, Rev BC

Section 2: Installation

January 2013

Figure 2-17 shows the indicator display with all segments lit.

Figure 2-17. Optional Liquid Crystal Display

A HART-based communicator can be used to change the engineering units of the parameters

displayed on the indicator. (SeeSection 4: Operation for more information).

2.7.1 Installing the indicator

For flowmeters ordered with the LCD indicator, the indicator is shipped installed. When

purchased separately from the Rosemount 8600D, you must install the indicator using a small

instrument screwdriver and the indicator kit (part number 8600-5640). The indicator kit

includes:

One LCD indicator assembly

One extended cover with o-ring installed

One connector

Two mounting screws

Two jum per s

Referring to Figure 2-16, use the following steps to install the

LCD indicator:

1. If the flowmeter is installed in a loop, secure the loop and disconnect the power.

2. Remove the flowmeter cover on the electronics side.

Installation

25

Page 34

Section 2: Installation

January 2013

Note

The circuit board is electrostatically sensitive. Be sure to observe handling precautions for

static-sensitive components.

3. Insert the mounting screws into the LCD indicator.

4. Remove the two jumpers on the circuit board that coincide with the Alarm and the

5. Insert the connector into the Alarm / Security junction.

6. Gently slide the LCD indicator onto the connector and tighten

7. Insert jumpers into ALARM and SECURITY positions on the face of the LCD indicator.

8. Attach the extended cover and tighten at least one-third turn past o-ring contact.

Note

The indicator may be installed in 90-degree increments for easy viewing. Mounting screws may

need to be installed in the alternative holes based on LCD orientation. One of the four

connectors on the back of the indicator assembly must be positioned to fit into the ten-pin

connector on the electronic board stack.

Reference Manual

00809-0100-4860, Rev BC

Security settings.

the screws into place.

Note the following LCD temperature limits:

Operating: –4 to 185 °F (–20 to 85 °C)

Storage: –50 to 185 °F (–46 to 85 °C)

2.8 Transient protection

The optional transient terminal block prevents damage to the flowmeter from transients

induced by lightning, welding, heavy electrical equipment, or switch gears. The transient

protection electronics are located in the terminal block.

The transient terminal block meets the following specifications:

IEEE C62.41 - 2002 Category B.

3 kA crest (8 X 20

6 kV crest (1.2 X 50

6 kV/0.5 kA (0.5

Note

The ground screw inside the terminal housing must be tightened for the proper operation of the

transient protection. Also, a high-current ground connection to earth is required.

s)

s)

s, 100 kHz, ring wave)

26

Installation

Page 35

Reference Manual

Transient Terminal

Block Ground Tab

Captive Screws

Housing Ground

Screw

00809-0100-4860, Rev BC

2.8.1 Installing the Transient Protector

For flowmeters ordered with the transient protector option (T1), the protector is shipped

installed. When purchased separately from the Rosemount 8600D, you must install the

protector on a Rosemount 8600D flowmeter using a small instrument screwdriver, a pliers, and

the transient protection kit.

The transient protection kit includes the following:

One transient protection terminal block assembly

Three captive screws

Use the following steps to install the transient protector:

1. If the flowmeter is installed in a loop, secure the loop and disconnect power.

2. Remove the field terminal side flowmeter cover.

3. Remove the captive screws.

4. Remove the housing ground screw.

Section 2: Installation

January 2013

5. Use pliers to pull the terminal block out of the housing.

6. Inspect the connector pins for straightness.

7. Place the new terminal block in position and carefully press it into place. The terminal

block may have to be moved back and forth to get the connector pins started into the

sockets.

8. Tighten the captive screws.

9. Install and tighten the ground screw.

10. Replace the cover.

Figure 2-18. Transient Terminal Block

Installation

27

Page 36

Section 2: Installation

January 2013

Reference Manual

00809-0100-4860, Rev BC

28

Installation

Page 37

Reference Manual

00809-0100-4860, Rev BC

Section 3 Configuration

Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Process variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 37

3.1 Review

Field Comm. 1, 5

Review the flowmeter configuration parameters set at the factory to ensure accuracy and

compatibility with your particular application of the flowmeter. Once you have activated the

Review function, scroll through the data list to check each variable in the configuration data list.

The last step of start-up and commissioning is to check the flowmeter output to ensure that the

flowmeter is operating properly. Rosemount 8600D digital process variables include: primary

variable, primary variable as a percent of range, analog output, vortex shedding rate, pulse

frequency, mass flow, volumetric flow, velocity flow, totalizer, electronics temperature,

calculated process density, cold junction temperature, and process temperature.

Section 3: Configuration

January 2013

3.2 Process variables

Field Comm. 1, 1

The process variables for the Rosemount 8600D provide the flowmeter output. When

commissioning a flowmeter, review each process variable, its function and output, and take

corrective action if necessary before using the flowmeter in a process application.

3.2.1 Primary Variable (PV)

Field Comm. 1, 1, 1

PV – The measured value of the variable mapped to the primary variable. This can be either

Process Temperature (MTA option only) or Flow. Flow variables are available as mass, volume, or

velocity. When bench commissioning, the flow values for each variable should be zero and the

temperature value should be the ambient temperature.

If the units for the flow or temperature variables are not correct, refer to “View other variables”

on page 30. Use the Process Variable Units function to select the units for your application.

Configuration

29

Page 38

Section 3: Configuration

January 2013

3.2.2 PV% of range

Field Comm. 1, 1, 2

Percent of Range — The primary variable as a percentage of range provides a gauge as to where

the current measurement of the meter is within the configured range of the meter. For example,

the range may be defined as 0 gal/min to 20 gal/min. If the current flow is 10 gal/min, the

percent of range is 50 percent.

3.2.3 Analog output

Field Comm. 1, 1, 3

Analog Output — The analog output variable provides the analog value for the primary variable.

The analog output refers to the industry standard output in the 4–20 mA range. Check the

analog output value against the actual loop reading given by a multi-meter. If it does not match,

a 4–20 mA trim is required. See D/A Trim (Digital-to-Analog Trim).

3.2.4 View other variables

Reference Manual

00809-0100-4860, Rev BC

Field Comm. 1, 1, 4

View Other Variables — Allows for the viewing and configuration of other variables such as flow

units, totalizer operation, and pulse output.

Volume flow

Field Comm. 1, 1, 4, 1, 1

Allows the user to view the current volumetric flow value.

Volume flow units

Field Comm. 1, 1, 4, 1, 2

Allows the user to select the volumetric flow units from the available list.

Volumetric Unit LCD Display Field Communicator

U.S. Gallons per second GAL/S gal/s

U.S. Gallons per minute GAL/M gal/m

U.S. Gallons per hour GAL/H gal/h

U.S. Gallons per day GAL/D gal/d

Actual Cubic Feet per second ACFS ACFS

Actual Cubic Feet per minute ACFM ACFM

Actual Cubic Feet per hour ACFH ACFH

Actual Cubic Feet per day ACFD ACFD

Standard Cubic Feet per

minute

Standard Cubic Feet per hour SCFH

Barrels per second BBL/S bbl/s

Barrels per minute BBL/M bbl/min

Barrels per hour BBL/H bbl/h

SCFM

30

Configuration

Page 39

Reference Manual

00809-0100-4860, Rev BC

Barrels per day BBL/D bbl/d

Imperial Gallons per second IGAL/S Impgal/s

Imperial Gallons per minute IGAL/M Impgal/min

Imperial Gallons per hour IGAL/H Impgal/h

Imperial Gallons per day IGAL/D Impgal/d

Liters per second L/S L/s

Liters per minute L/MIN L/min

Liters per hour L/H L/h

Liters per day L/D L/D

Actual Cubic Meters per

second

Actual Cubic Meters per

minute

Actual Cubic Meters per hour ACMH ACMH

Actual Cubic Meters per day ACMD ACMD

Million Actual Cubic Meters per

day

Normal Cubic Meters per

minute

Normal Cubic Meters per hour NCMH

Normal Cubic Meters per day NCMD

ACMS ACMS

ACMM ACMM

MACMD MACMD

NCMM

Section 3: Configuration

January 2013

Standard/Normal flow units

StdCuft/min

SCFH

NCMM

NmlCum/h

NCMD

Note

When configuring Standard or Normal Flow units to the volumetric flow, a density ratio must be

provided. See the Density/Density Ratio on page 39.

Special units

Field Comm. 1, 1, 4, 1, 3

Special Units allows you to create flow rate units that are not among the standard options. They

can be volumetric only. Configuration of a special unit involves entry of these values: base

volume unit, base time unit, user defined unit and conversion number. Suppose you want the

Configuration

31

Page 40

Section 3: Configuration

January 2013

Rosemount 8600D to display flow in barrels per minute instead of gallons per minute, and one

barrel is equal to 31.0 gallons.

Base volume unit: gal

Base time unit: min

User defined unit: br

Conversion number:

See the specific variables listed below for more information on setting special units.

Base volume unit

Field Comm. 1, 1, 4, 1, 3, 1

Base Volume Unit is the unit from which the conversion is made. You must select one of the Field

Communicator defined unit options:

Gallons (gal)

Liters (L)

Imperial gallons (Impgal)

Cubic meters (Cum)

Barrels (bbl) where 1 bbl=42 gal

1

/31.0

Reference Manual

00809-0100-4860, Rev BC

Cubic Feet (Cuft)

Base time unit

Field Comm. 1, 1, 4, 1, 3, 2

Base Time Unit provides the time unit from which to calculate the special units. For example, if

your special units is a volume per minute, select minutes. Choose from the following units:

Seconds (s)

Minutes (min)

Hours (h)

Days (d)

User defined unit

Field Comm. 1, 1, 4, 1, 3, 3

User Defined Unit is a format variable that provides a record of the flow units to which you are

converting. The LCD on the Rosemount 8600D will display the actual units you define. The Field

Communicator will simply display “SPCL.” There are four characters available to store the new

units designation.

Conversion number

Field Comm. 1, 1, 4, 1, 3, 4

32

Conversion Number is used to relate base units to special units. For a straight conversion of

volume units from one to another, the conversion number is the number of base units in the

new unit.

Configuration

Page 41

Reference Manual

00809-0100-4860, Rev BC

For example, if you are converting from gallons to barrels and there are 31 gallons in a barrel,

the conversion factor is 31. The conversion equation is as follows (where barrels is the new

volume unit):

1 gallon = 0.032258 bbl.

Mass flow

Allows the user to view the current mass flow value and units. Also allows the user to configure

the mass flow units.

Mass flow

Displays the current mass flow value and units.

Mass units

Section 3: Configuration

January 2013

Field Comm. 1, 1, 4, 2

Field Comm. 1, 1, 4, 2, 1

Field Comm. 1, 1, 4, 2, 2

Allows the user to select the mass flow units from the available list. (1 STon = 2000 lb; 1 MetTon

= 1000 kg)

Mass Flow Units

lb/s STon/min

lb/min STon/h

lb/h STon/d

lb/d MetTon/min

kg/s MetTon/h

kg/min MetTon/d

kg/h g/s

kg/d g/min

g/h

Note

If you select a Mass Units option, you must enter process density in your configuration. See the

Density/Density Ratio section on page 39.

Velocity flow

Field Comm. 1, 1, 4, 3

Allows the user to view the current velocity flow value and units. Also allows the user to

configure the velocity flow units.

Configuration

33

Page 42

Section 3: Configuration

January 2013

Velocity flow

Field Comm. 1, 1, 4, 3, 1

Displays the current velocity flow value and units.

Velocity units

Field Comm. 1, 1, 4, 3, 2

Allows the user to select the velocity units from the available list.

ft/s

m/s

Velocity measured base

Field Comm. 1, 1, 4, 3, 3

Velocity Measured Base will determine if the velocity measurement is based on the mating pipe

ID or the meter body ID.

Reference Manual

00809-0100-4860, Rev BC

Tota li ze r

Field Comm. 1, 1, 4, 4

To ta li ze r — Totalizer tallies the total amount of liquid or gas that has passed through the

flowmeter since the totalizer was last reset.

It enables you to change the settings of the totalizer.

Total

Field Comm. 1, 1, 4, 4, 1

To ta l — Provides the output reading of the totalizer. Its value is the amount of liquid or gas that

has passed through the flowmeter since the totalizer was last reset.

Start

Field Comm. 1, 1, 4, 4, 2

Start — Starts the totalizer counting from its current value.

Stop

Field Comm. 1, 1, 4, 4, 3

Stop — Interrupts the totalizer count until it is restarted again. This feature is often used during

pipe cleaning or other maintenance operations.

34

Reset

Field Comm. 1, 1, 4, 4, 4

Reset — Returns the totalizer value to zero. If the totalizer was running, it will continue to run

starting at zero.

Configuration

Page 43

Reference Manual

00809-0100-4860, Rev BC

Totalizer config

Totalizer Conf ig — Used to configure the flow parameter (volume, mass, velocity) that will be

totalled.

Note

The totalizer value is saved in the non-volatile memory of the electronics every three seconds.

Should power to the transmitter be interrupted, the totalizer value will start at the last saved

value when the power is re-applied.

Note

Changes that affect the density, density ratio, or compensated K-Factor will affect the totalizer

value being calculated. These changes will not cause the existing totalizer value to be

recalculated.

Pulse frequency

Section 3: Configuration

January 2013

Field Comm. 1, 1, 4, 4, 5

Field Comm. 1, 1, 4, 5

Allows users to view the pulse output frequency value. To configure the pulse output, refer to

the section on pulse output found on page 54.

Vortex frequency

Field Comm. 1, 1, 4, 6

Allows users to view the shedding frequency directly off of the sensor.

Electronics temperature

Field Comm. 1, 1, 4, 7

Allows users to view the electronics temperature value and units. Also allows the user to

configure the units for the electronics temperature.

Electronics temperature

Field Comm. 1, 1, 4, 7, 1

Displays the current electronics temperature value and units.

Electronics temperature unit

Configuration

Field Comm. 1, 1, 4, 7, 2

Allows the user to select the units for electronics temperature from the available list.

deg C

deg F

deg R

Kelvin

35

Page 44

Section 3: Configuration

January 2013

Calculated process density

Field Comm. 1, 1, 4, 8

Allows users to view the calculated process density value when the vortex is configured for

temperature compensated steam applications. Also allows the user to configure the calculated

density units.

Process density

Field Comm. 1, 1, 4, 8, 1

Displays the current calculated process density value.

Density units

Field Comm. 1, 1, 4, 8, 2

Allows the user to configure the units for the calculated process density from the available list.

g/Cucm (cm3)

Reference Manual

00809-0100-4860, Rev BC

g/L

kg/Cum (m3)

lb/Cuft (ft3)

lb/Cuin (in3)

Process temperature

Field Comm. 1, 1, 4, 9

Allows users to view the process temperature value when the vortex transmitter has the

temperature sensor option. Also allows the user to configure the process temperature units.

Process temperature

Field Comm. 1, 1, 4, 9, 1

Displays the current process temperature value.

Process temperature units

Field Comm. 1, 1, 4, 9, 2

Allows the user to configure the units for the process temperature from the available list.

36

deg C

deg F

deg R

Kelvin

Configuration

Page 45

Reference Manual

00809-0100-4860, Rev BC

T/C failure mode

Allows the user to configure the temperature sensor failure mode. In the event that the

thermocouple sensor fails, the vortex can go either into an alarm output mode, or continue to

operate normally using the Fixed Process Temperature value. See Fixed Process Temperature

page 38. This mode is only relevant with the MTA option.

Note

If the Primary Variable is set to Process Temperature and there is an error, the output will always

go to alarm and this setting will be ignored.

Cold Junction (CJ) temperature

Allows users to view the thermocouple cold junction temperature value when the vortex has the

temperature sensor option. Also allows the user to configure the CJ temperature units.

Section 3: Configuration

January 2013

Field Comm. 1, 1, 4, 9, 3

Field Comm. 1, 1, 4, Scroll to bottom of list

CJ temperature

Field Comm. 1, 1, 4, -, 1

Displays the current thermocouple cold junction temperature value.

CJ temperature units

Field Comm. 1, 1, 4, -, 2

Allows the user to configure the units for the thermocouple cold junction temperature from the

available list.

deg C

deg F

deg R

Kelvin

3.2.5 Basic setup

Field Comm. 1, 3

The Rosemount 8600D must be configured for certain basic variables in order to be operational. In

most cases, all of these variables are pre-configured at the factory. Configuration may be required if

your Rosemount 8600D is not configured or if the configuration variables need revision.

Configuration

37

Page 46

Section 3: Configuration

January 2013

3.2.6 Tag

Field Comm. 1, 3, 1

Tag is the quickest way to identify and distinguish between flowmeters. Flowmeters can be

tagged according to the requirements of your application. The tag may be up to eight

characters long.

3.2.7 Process config

Field Comm. 1, 3, 2

The flowmeter can be used for liquid or gas/steam applications, but it must be configured

specifically for the application. If the flowmeter is not configured for the proper process,

readings will be inaccurate. Select the appropriate Process configuration parameters for your

application:

Transmitter mode

Field Comm. 1, 3, 2, 1

Reference Manual

00809-0100-4860, Rev BC

For units with an integral temperature sensor, the temperature sensor can be activated here.

Without Temperature

Sensor

With Temperature Sensor

Process fluid

Field Comm. 1, 3, 2, 2

Select the fluid type: either Liquid, Gas/Steam, Tcomp Sat Steam. Tcomp Sat Steam requires the

MTA Option and provides a temperature compensated mass flow output for saturated steam.

Fixed process temperature

Field Comm. 1, 3, 2, 3

Process Temperature is needed for the electronics to compensate for thermal expansion of the

flowmeter as the process temperature differs from the reference temperature. Process

temperature is the temperature of the liquid or gas in the line during flowmeter operation.

Fixed process temperature may also be used as a back-up temperature value in the event of a

temperature sensor failure if the MTA option is installed.

Note

The Fixed Process Temperature may also be changed under Calculate Density Ratio.

38

Configuration

Page 47

Reference Manual

DensityRatio

density at actual (flowing) conditions

density at s dard (base)tan conditions

--------------------------------------------------------------------------------------------------------=

DensityRatio

TbxPfxZ

b

TfxPbxZ

f

---------------------------=

00809-0100-4860, Rev BC

Density/Density ratio

When configuring a meter for mass flow units, a density value needs to be entered. When

configuring a meter for Standard and Normal Volumetric flow units a density ratio will be

required.

Density ratio

Configure the Density Ratio in one of two ways:

1. Enter Density Ratio to convert from actual flow rate to standard flow rate.

2. Enter the process and base conditions. (The Rosemount 8600D electronics will then

Note

Be careful to calculate and enter the correct conversion factor. Standard flow is calculated with

the conversion factor you enter. Any error in the factor entered will result in an error in the

standard flow measurement. If pressure and temperature changes over time, use actual

volumetric flow units. The Rosemount 8600D does not compensate for changing temperature

and pressure.

Section 3: Configuration

January 2013

Field Comm. 1, 3, 2, 4

Field Comm. 1, 3, 2, 4, 1

calculate the density ratio for you).

Note

Changing the base process conditions will modify the density ratio. Likewise a change to the