Page 1

A Technical Manual from the experts

in Business-Critical Continuity

™

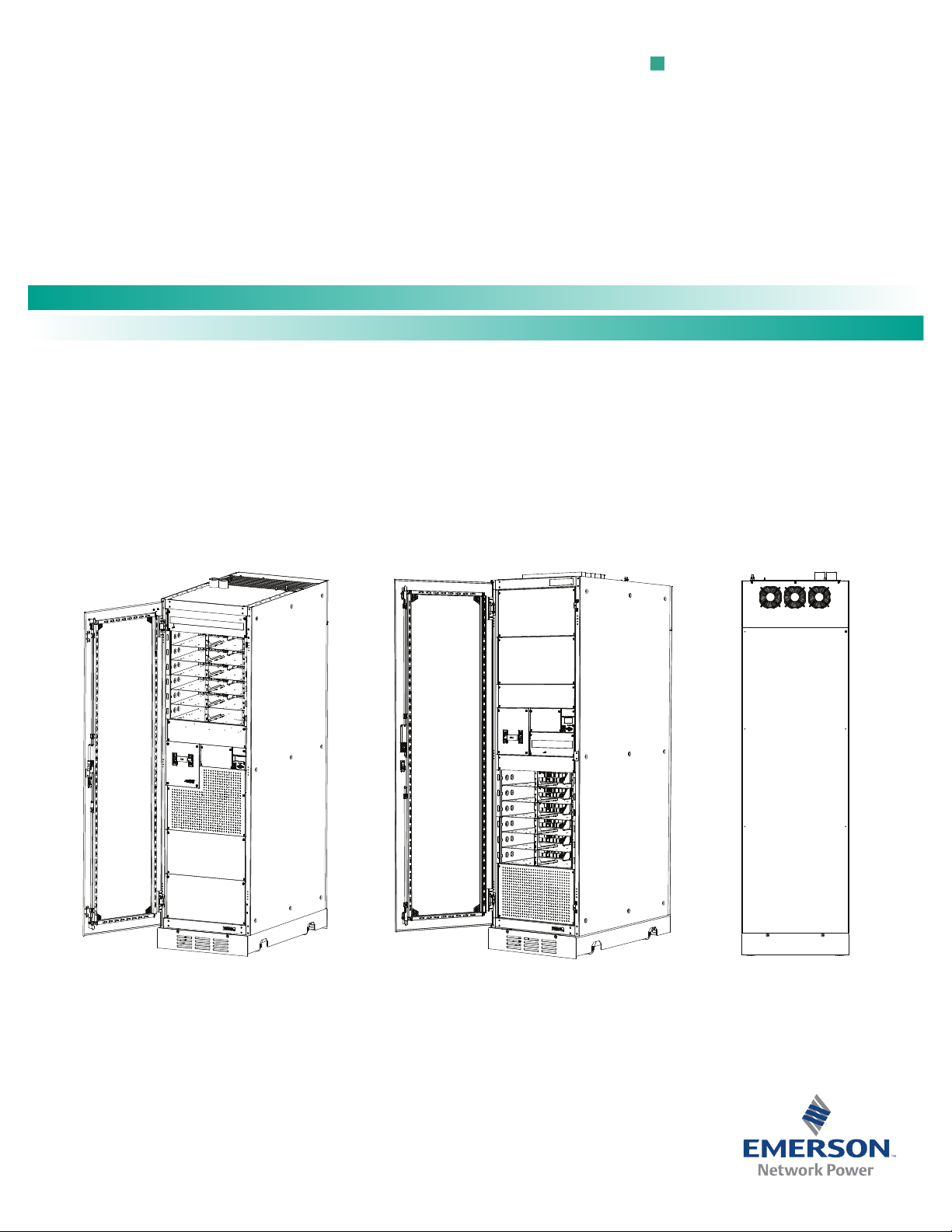

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Specification Number: 582145500

Model: NetSure™ ITM

Page 2

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

This page is intentionally blank.

Spec. No: 582145500 Section 6040

Model: NetSure™ ITM Issue AB, April 8, 2013

Page 3

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

TABLE OF CONTENTS

I

MPORTANT SAFETY INSTRUCTIONS

R

ELATED DOCUMENTATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 I

NSPECTING THE EQUIPMENT AND STORING FOR DELAYED INSTALLATIONS

. . . . . . . . . . . . .4

1.1 External Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Internal Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Storing for Delayed Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 I

NSTALLATION DRAWINGS AND RECOMMENDED TOOLS AND TEST EQUIPMENT

. . . . . . . . . . .6

2.1 Installation Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Row-Based Installation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Recommended Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.0 P

OSITIONING THE

DC UPS S

YSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 General Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 General Guidelines for Positioning the DC UPS Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Cable Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.3 Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Floor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Considerations in Moving the DC UPS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.1 Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.2 Moving a DC UPS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.3 Final Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Overhead Cable Tray Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.6 Front and Rear Bottom Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6.1 Bottom DC Distribution Feed (Bottom Cabled) Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6.2 Top DC Distribution Feed (Top Cabled) Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.0 E

LECTRICAL CONNECTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Wiring Information and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.1 Cable Lengths (Floor or Cabinet Top to Connection Point Inside DC UPS Module) . . . . . . . 19

4.1.2 Recommended Wire Sizes, Recommended Lugs, and Torque Requirements . . . . . . . . . . . . . 19

4.1.3 Wiring Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Protective Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Wiring Connections Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Making Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4.1 Cabinet Grounding Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4.2 DC Distribution Ground/Return Busbar Grounding Connection . . . . . . . . . . . . . . . . . . . . . . 23

4.4.3 DC Output Distribution Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.4 AC Input Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.5 Optional Alarm/Control Connections (to Primary Module only) . . . . . . . . . . . . . . . . . . . . . . . 27

4.4.6 ACU + Controller Ethernet Connection (to Primary Module only) . . . . . . . . . . . . . . . . . . . . . 30

4.4.7 Optional Emergency Power Off (EPO) Connection (to Primary Module only) . . . . . . . . . . . . 31

4.4.8 Battery Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

i

Section 6040

Page 4

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

4.5 Making Module-to-Module -48VDC and Ground/Return Interconnections

(if system consists of multiple DC UPS modules). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5.1 -48Vdc and Ground/Return Busbar Interconnects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.6 Making Alarm/Control Interconnections between Modules

(if system consists of multiple DC UPS modules). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.1 RS-485 Module-to-Module Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.2 CAN-Bus Module-to-Module Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.3 BLVD Module-to-Module Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.0 I

6.0 S

NSTALLING

TART-UP INSTRUCTIONS

PCUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2 Final Battery Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.3 Connecting Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3 Initially Starting and Verifying DC UPS System Operation. . . . . . . . . . . . . . . . . . . . . . . . . 54

6.3.1 Initially Starting the DC UPS System and Verifying System Operation . . . . . . . . . . . . . . . . 55

6.3.2 Setting Common Controller Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.3.3 Changing the Numbering Scheme of the PCUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.0 S

PECIFICATIONS AND TECHNICAL DATA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.1 Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.2 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3 Mechanical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4 Monitoring Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5 Electrical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5.1 Termination Type, Recommended Wire Size, Recommended Lugs. . . . . . . . . . . . . . . . . . . . . 59

7.5.2 Power Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.5.3 AC Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.5.4 DC Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.5.5 Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.5.6 Advanced Control Unit Plus (ACU+) Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.5.7 SM-DU+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.5.8 SM-DU (used in Expansion Modules only in place of Controller) . . . . . . . . . . . . . . . . . . . . . . 66

7.5.9 SM-AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.5.10 SM-BRC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.5.11 Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

ii

Section 6040

Page 5

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

FIGURES

Figure 1 Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2 Bottom DC Distribution Feed Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3 Top DC Distribution Feed Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4 NetSure™ ITM Row-Based DC UPS System Installation Example . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5 Emerson Floor Stands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 6 Mounting Locations for Overhead Cable Tray Rails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 7 Installing Front and Rear Bottom Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8 Installing Air Duct Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 9 Protective Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10 Wiring Connections Locations (DC UPS Module with Bottom Feed DC Distribution) . . . . . . . . 21

Figure 11 Wiring Connections Locations (DC UPS Module with Top Feed DC Distribution) . . . . . . . . . . . 22

Figure 12 Cabinet Grounding Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13 DC Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14 AC Input Power Connection Routing Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 15 Installing Conduit Fittings when AC is Fed from the Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 16 AC Input Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 17 Alarm and Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 18 ACU+ Controller RJ-45 Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 19 EPO Jumper Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 20 Module-Module Interconnect Busbars (DC UPS Module with Bottom Feed DC Distribution) . . 33

Figure 21 Module-Module Interconnect Busbars (DC UPS Module with Top Feed DC Distribution) . . . . . 34

Figure 22 SM-BRC RS-485 Jumper Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 23 Alarm/Control Cable Interconnects (cont’d on next page) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 24 System Configuration and Communications Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 25 Cabinet Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 26 Signal Cabling and Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 27 PCU Handle and Safety Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 28 Making Final Battery Shelf Battery Interconnect Link Connections . . . . . . . . . . . . . . . . . . . . . . 44

Figure 29 Field Battery Monitoring Lead Connections to the SM-BRC Unit . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 30 System Efficiency Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

iii

Section 6040

Page 6

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

TABLES

Table 1 DC UPS Module "Base Configuration Part Numbers"

and "Configured System Spec. Numbers" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2 Distance to Connection Points inside the DC UPS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 3 Programmable Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 4 Programmable Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 5 IB2 Board Communications Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 6 ACU+ Controller RJ-45 Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 7 DC UPS System Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 8 DC UPS System Mechanical Characteristics (per module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 9 Shipping Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 10 AC Input and AC Input Grounding (per DC UPS module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 11 Cabinet Frame Grounding (per DC UPS module). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 12 DC Distribution (Distribution Circuit Breaker Option - per circuit breaker position) . . . . . . . . . 60

Table 13 DC Distribution (Distribution Fuse Option - per fuse position) . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 14 Alarm/Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 15 Power Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 16 AC Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 17 DC Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 18 Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

iv

Section 6040

Page 7

NetSure™ ITM with eSure™ Technology

!

!

!

!

!

!

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

I

MPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during installation of your

NetSure™ ITM Row-Based DC UPS system.

Read this manual thoroughly before installing the DC UPS system. Retain this manual for use by

installing personnel.

WARNING

The DC UPS system should be installed by a qualified technician in accordance with the

information contained in this document.

WARNING

Special safety precautions are required for procedures involving handling and installation of

the DC UPS system. Observe all safety precautions in this manual before handling or

installing the DC UPS system.

WARNING

Exercise extreme care when handling DC UPS modules (cabinets) to avoid equipment damage

or injury to personnel. The DC UPS module weighs 3240 lb. (1470 kg), fully loaded.

Be aware of module weight and locate center of gravity symbols

before handling the DC UPS module. Test lift and balance the module

before transporting. Never tilt module more than 10 degrees from vertical.

WARNING

All power and control wiring should be installed by a qualified electrician. All power

and control wiring must comply with the National Electrical Code (NEC) and applicable local

codes.

Maximum load must not exceed that shown on the DC UPS module rating label.

Maximum output short circuit current is 7000 amperes.

WARNING

High Ground Leakage Current:

Ground connection is essential before connecting the input supply.

This equipment must be grounded in accordance with the NEC and applicable local codes.

CAUTION

Ground leakage current exceeds 3.5 mA and is less than 30 mA.

Transient and steady-state ground leakage currents, which may occur when starting the

equipment, should be taken into account when selecting instantaneous residual current

circuit breakers (RCCBs) or residual current devices (RCDs).

RCCBs must be selected sensitive to DC unidirectional pulses (Class A) and insensitive to

transient current pulses.

Note also that the ground leakage currents of the load will be carried by this RCCB or RCD.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

1

Section 6040

Page 8

NetSure™ ITM with eSure™ Technology

!

!

!

!

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

CAUTION

This equipment is fitted with RFI suppression filters.

This unit complies with the limits for a Class A digital device, pursuant to Part 15 Subpart J

of the FCC rules. These limits provide reasonable protection against harmful interference in a

commercial environment. This unit generates, uses and radiates radio frequency energy and,

if not installed and used in accordance with this instruction manual, may cause harmful

interference to radio communications. This unit is not designed for use in a residential area.

Operation of this unit in a residential area may cause harmful interference that the User

must correct at his own expense.

WARNING

In case of fire involving electrical equipment, use only carbon dioxide fire extinguishers or

those approved for use in fighting electrical fires.

Battery Compartment Precautions

Batteries are factory installed in the DC UPS module. Final battery connections will be made by

Emerson after the DC UPS module is installed. DO NOT MAKE BATTERY CONNECTIONS. The

following precautions apply to the battery compartment that is part of the DC UPS module.

WARNING

Special safety precautions are required for procedures involving handling, installing, and

servicing batteries. Observe all battery safety precautions presented here and in the battery

instruction manual. These precautions should be followed implicitly at all times.

WARNING

A battery can present a risk of electrical shock and high short circuit current. Servicing of

batteries should be performed or supervised only by properly trained and qualified personnel

knowledgeable about batteries and the required precautions.

The following precautions should be observed when working on batteries:

• Remove watches, rings and other metal objects.

• Eye protection should be worn to prevent injury from accidental electrical arcs.

• Use certified and well maintained insulated tools.

• Do not lay tools or metal parts on top of batteries.

• Disconnect charging source prior to connecting or disconnecting battery terminals.

• Determine if battery is inadvertently grounded. If the battery is inadvertently grounded,

remove source from ground. Contact with any parts of a grounded battery can result in

electrical shock. The likelihood of such shock can be reduced if such grounds are removed

during installation and maintenance (applicable to equipment and remote battery supplies

not having a grounded supply circuit).

• Risk of explosion if battery is replaced with an incorrect type or if polarity is reversed.

When replacing batteries, replace with the same manufacturer and type, or equivalent. See

your local Emerson representative for a list of approved batteries.

• Dispose of used batteries according to the instructions provided with the batteries. Do not

dispose of batteries in a fire. They may explode.

In addition to the hazard of electric shock, gas produced by batteries can be explosive and

sulfuric acid can cause severe burns. Do not open or mutilate batteries. Released electrolyte is

harmful to the skin and eyes, and is toxic. If electrolyte comes into contact with skin, the

affected area should be washed immediately with large amounts of water.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

2

Section 6040

Page 9

NetSure™ ITM with eSure™ Technology

!

!

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

WARNING

The DC UPS module’s internal batteries are connected and energized even if the DC UPS

module is turned OFF. Battery disconnect fuses are provided inside the DC UPS module. To

minimize the risk of injury, remove the battery disconnect fuses before any off-line servicing

is performed on the unit.

WARNING

DO NOT REMOVE BATTERY STRAPS. If a battery cell is replaced, ensure the battery strap

is replaced and appropriately tighten.

• Battery compartments contain non-spillable batteries.

• Keep units upright.

• Do not stack.

• Do not tilt.

Failure to heed this warning could result in smoke, fire, or electric hazard.

Call Emerson before moving DC UPS modules (after initial installation).

R

ELATED DOCUMENTATION

• System Operation Document (Section 6047).

• Site Planning Data and System Drawings Document (Section 6037).

• Emerson Excellence Range VRLA Battery (31020591)

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

3

Section 6040

Page 10

NetSure™ ITM with eSure™ Technology

!

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

1.0 I

NSPECTING THE EQUIPMENT AND STORING FOR DELAYED INSTALLATIONS

1.1 External Inspections

1. While the DC UPS system is still on the truck, inspect the equipment and shipping container(s)

for any signs of damage or mishandling. Do not attempt to install the system if damage is

apparent. If any damage is noted, file a damage claim with the shipping agency within 24 hours

and contact Emerson Network Power (number located on last pages of this document) to inform

them of the damage claim and the condition of the equipment.

2. Compare the contents of the shipment with the bill of lading. Report any missing items to the

carrier and your local Emerson representative immediately.

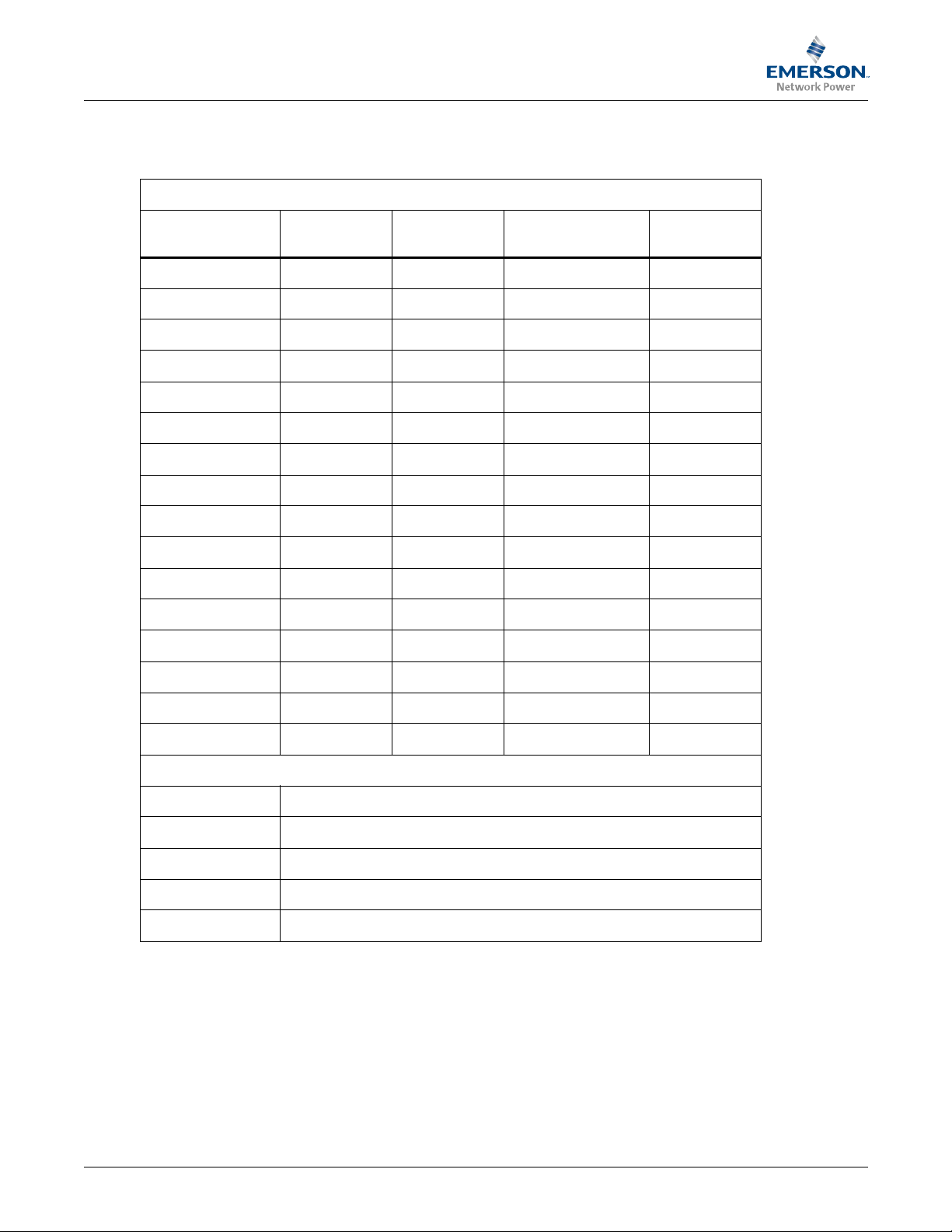

1.2 Internal Inspections

1. Remove any packaging material, then visually examine the DC UPS system for transit damage,

both internally and externally. Report any such damage to the shipper and to Emerson

immediately.

2. Check the nameplate inside the DC UPS module (located on the front top right side with front

door open) to verify that the "base configuration part number" and the "configured system spec.

number" correspond to the units ordered. Record the DC UPS module identification numbers and

serial number in the front of this manual. This information is necessary should service be

required. See Table 1.

NOTE

The "base configuration part number" determines how the DC UPS module is physically

configured and the "configured system spec. number" determines how the DC UPS module has

been set up.

3. Check for loose connections or unsecured components in the module.

4. Check for shipping damage to internal components.

1.3 Storing for Delayed Installation

If the equipment will not be installed immediately, it must be stored indoors where the humidity is no

higher than 95%. The storage area must protect the DC UPS system from excessive moisture.

For optimal battery life, store at a temperature between

Environmental).

CAUTION

If the batteries must remain disconnected from the DC UPS module for more than six (6)

months, the batteries must be recharged before use. To charge the batteries, the batteries

must be connected to the DC UPS module and the DC UPS module must be connected to

utility power and started up by qualified personnel.

-4°F to +77°F (-20°C to +25°C)

(see 7.2 -

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

4

Section 6040

Page 11

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Table 1 DC UPS Module "Base Configuration Part Numbers"

and "Configured System Spec. Numbers"

Base Configuration Part Numbers

Part Number Module

FAB8010542/2 Primary Top (22) Circuit Breaker 1

FAB8010542/1 Primary Top (22) Circuit Breaker 2

FAB8010542/4 Primary Top (6) Fuse 1

FAB8010542/3 Primary Top (6) Fuse 2

FAB8010540/2 Primary Bottom (22) Circuit Breaker 1

FAB8010540/1 Primary Bottom (22) Circuit Breaker 2

FAB8010540/4 Primary Bottom (6) Fuse 1

FAB8010540/3 Primary Bottom (6) Fuse 2

FAB8010543/2 Expansion Top (22) Circuit Breaker 1

FAB8010543/1 Expansion Top (22) Circuit Breaker 2

FAB8010543/4 Expansion Top (6) Fuse 1

FAB8010543/3 Expansion Top (6) Fuse 2

FAB8010541/2 Expansion Bottom (22) Circuit Breaker 1

Distribution

Feed

Distribution

No. of AC

Inputs

FAB8010541/1 Expansion Bottom (22) Circuit Breaker 2

FAB8010541/4 Expansion Bottom (6) Fuse 1

FAB8010541/3 Expansion Bottom (6) Fuse 2

Configured System Spec. Numbers

Spec. Number Description

582145500-M1 Primary Module

582145500-M2 1st Expansion Module

582145500-M3 2nd Expansion Module

582145500-M4 3rd Expansion Module

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

5

Section 6040

Page 12

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

2.0 I

NSTALLATION DRAWINGS AND RECOMMENDED TOOLS AND TEST EQUIPMENT

2.1 Installation Drawings

The diagrams in this section illustrate the key mechanical and electrical characteristics of the

NetSure ITM DC UPS system.

General Notes Applicable to All Illustrations

1. All dimensions are in inches (millimeters).

2. Minimum clearance above unit required for air exhaust is 8 in. (203mm).

3. Keep module within 10 degrees of vertical while handling.

4. Top and bottom cable entry options available.

5. Color - black.

6. Unit bottom is structurally adequate for forklift handling.

7. M12 mounting holes used for seismic anchoring or floor stand.

NOTE

If floor stand is used, the weight of the unit must be supported under all casters.

8. The Primary Module includes side panels. For installations consisting of Expansion Module(s),

one side panel on the Primary Module must be removed and be placed on the end Expansion

Module.

9. Leveling feet are not designed to carry the full weight of the module.

10. Finger-tighten leveler against the floor, then tighten with a wrench less than 2 turns for friction

fit against floor.

11. Control wiring, output cabling, and input cabling must be run separately.

12. Aluminum and copper-clad aluminum cables are not recommended.

13. All wiring is to be in accordance with the NEC and applicable local codes.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

6

Section 6040

Page 13

NetSure™ ITM with eSure™ Technology

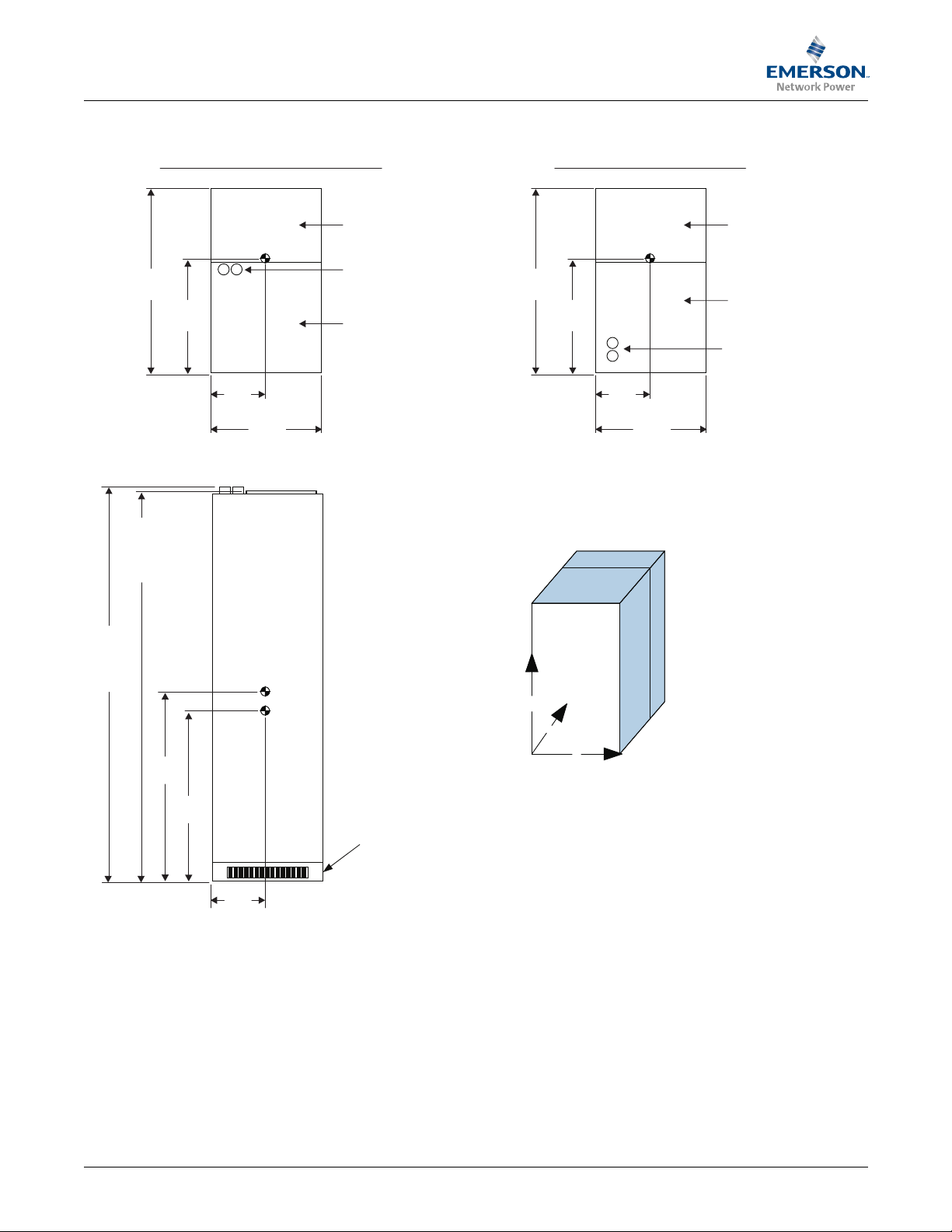

Notes:

1. Dimensions areininches (millimeters).

2. Weight (fully loaded): 3240 lbs/1470 kg.

3. Heat Rejection: 18096 BTU/hatfullload (per module).

4. May be installedon concreteslaborraised floor.

23.62

(600)

Battery Compartment

Conduits for

AC Inputs

41.34

(1050)

DC Power System

Compartment

Z

X

Y

To pCabledVersion

X=11.81 (300)

Y=26.38(670)

Z=36.61 (930)

Bottom CabledVersion

X=11.81 (300)

Y=26.38(670)

Z=40.55 (1030)

CENTER OF GRAVITY

26.38

(670)

CG

11.81

(300)

(Bottom

cabled)

CG

11.81

(300)

36.61

(930)

40.55

(1030)

CG

(top

cabled)

23.62

(600)

Battery Compartment

Conduits for

AC Inputs

41.34

(1050)

DC Power System

Compartment

26.38

(670)

CG

11.81

(300)

See Detail A

for Bott

om

DC UPS MODULE WITH

TOP FEED DC DISTRIBUTION

DC UPS MODULE WITH

BOTTOM FEED DC DISTRIBUTION

To p View

To p View

Front View

84.33

(2142)

top

cabled

84.72

(2152)

bottom

cabled

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Figure 1 Outline Drawing

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

7

Section 6040

Page 14

NetSure™ ITM with eSure™ Technology

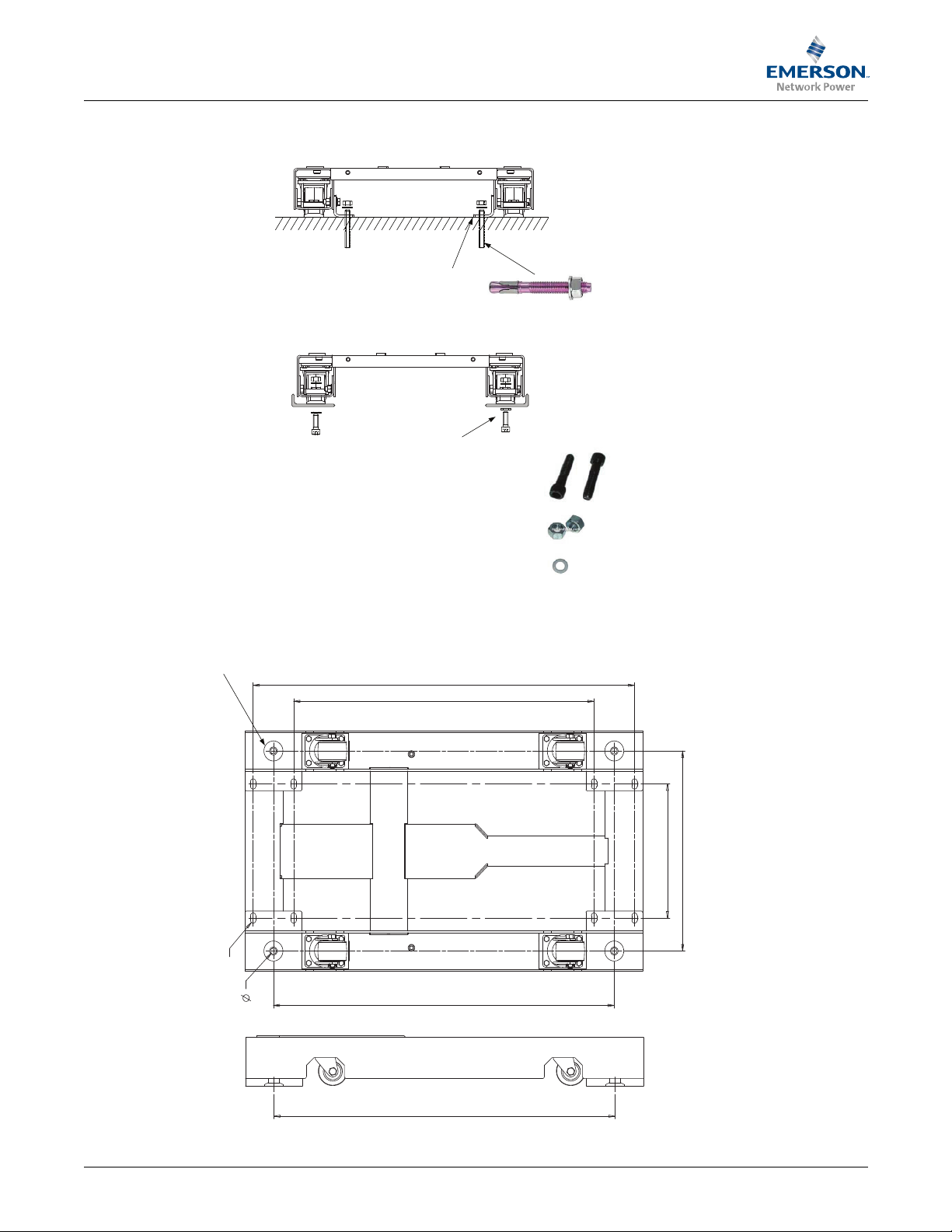

35.43 (900)

19.68 (500)

12.99 (330) - 13.39 (340)

39.65 (1007)

31.22 (793)

0.59 (15)

0.28 (7)R

35.43 (900)

Hole through foot (4x) for

anchoring on raised floo

r

Anchoring bracket (4x)

used on concrete floo

r

Anchoring bolts (4x)

used on raised

floor

ANCHORING

Hilti HSV 1/2X4 1/2:

Item No.: 00384687

M12 x 1.75 x 70 Metric Socket Head Cap Screw.

Plain Finish with Allen Drive (hex drive) / Coarse

thread. Grade 12.9

.

M12 X 1.75 Metric Hex Nuts - Grade 10.9 /

Coarse Thread / Zinc Plated

.

M12 Metric Flat Washer. Grade 10.9 /

Zinc. D=28mm or 11/8".

(4X)

(4X)

(8X)

(8X

)

Corresponding ½” Imperial Fasteners Can Also be Used

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Figure 1, Detail A

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

8

Section 6040

Page 15

NetSure™ ITM with eSure™ Technology

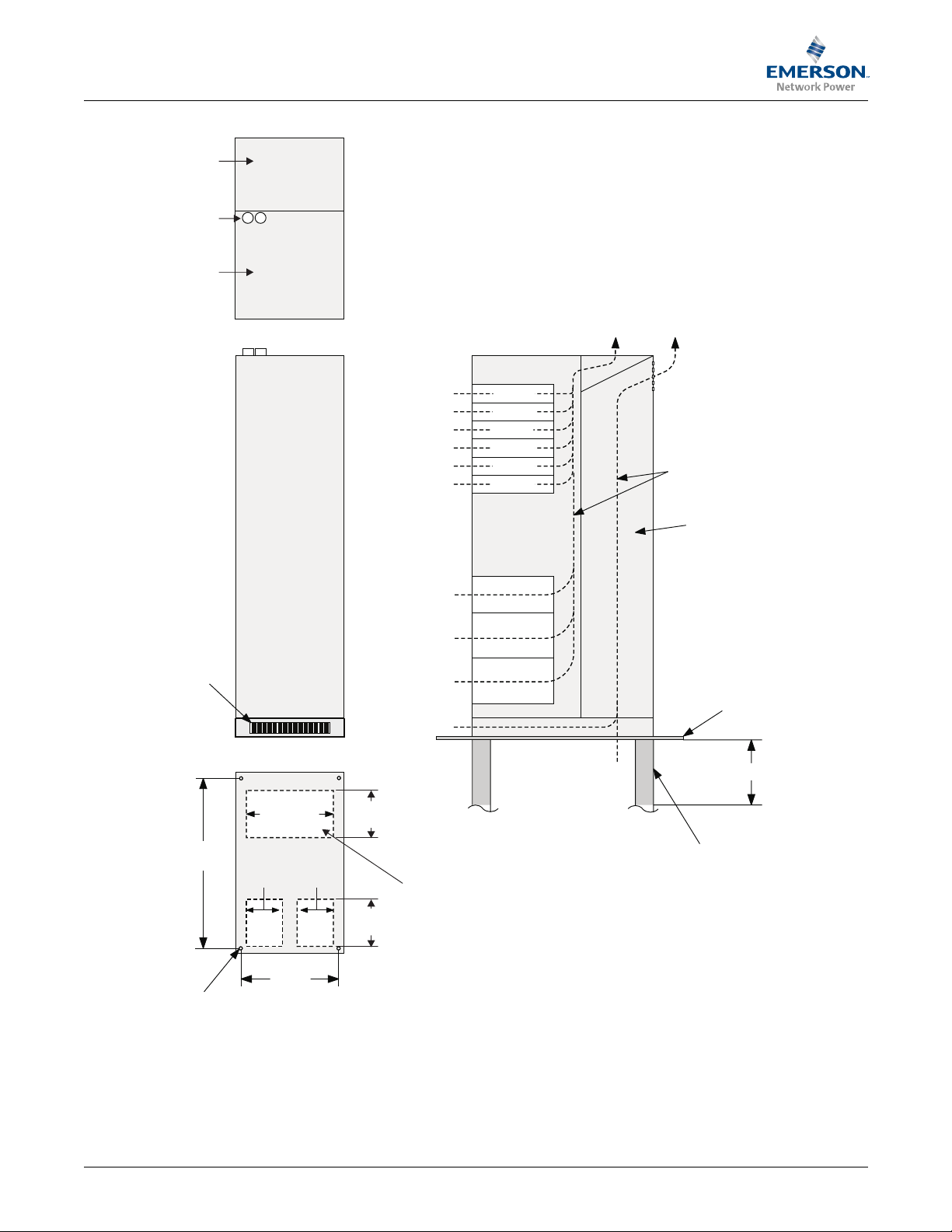

Battery

Compartment

BFU

Distr.

Distr.

Raised Floor

HotAisle

Cold Aisle

A

AirFlow

Note2

Side View

Support

Stand

½” (12mm) Floor

Anchoring Bolts

(4 places)

To p

Front

Notes:

1. Dimensions areininches (millimeters).

2. Do not block airintake openings.

3. Minimum under floor space for underfloor

output cable runs: A=1f (300mm).

4. Run cables not to block air openings for battery

cooling.

Battery

Compartment

Conduits for

AC Inputs

DC Power System

Compartment

35.43

(900)

17.72 (450)

8.86

(225)

9.84

(250)

19.68

(500)

9.84

(250)

8.86

(225)

Optional Floor

Opening for

Battery Cooling

PCUs

PCUs

PCUs

PCUs

PCUs

PCUs

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Figure 2 Bottom DC Distribution Feed Modules

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

9

Section 6040

Page 16

NetSure™ ITM with eSure™ Technology

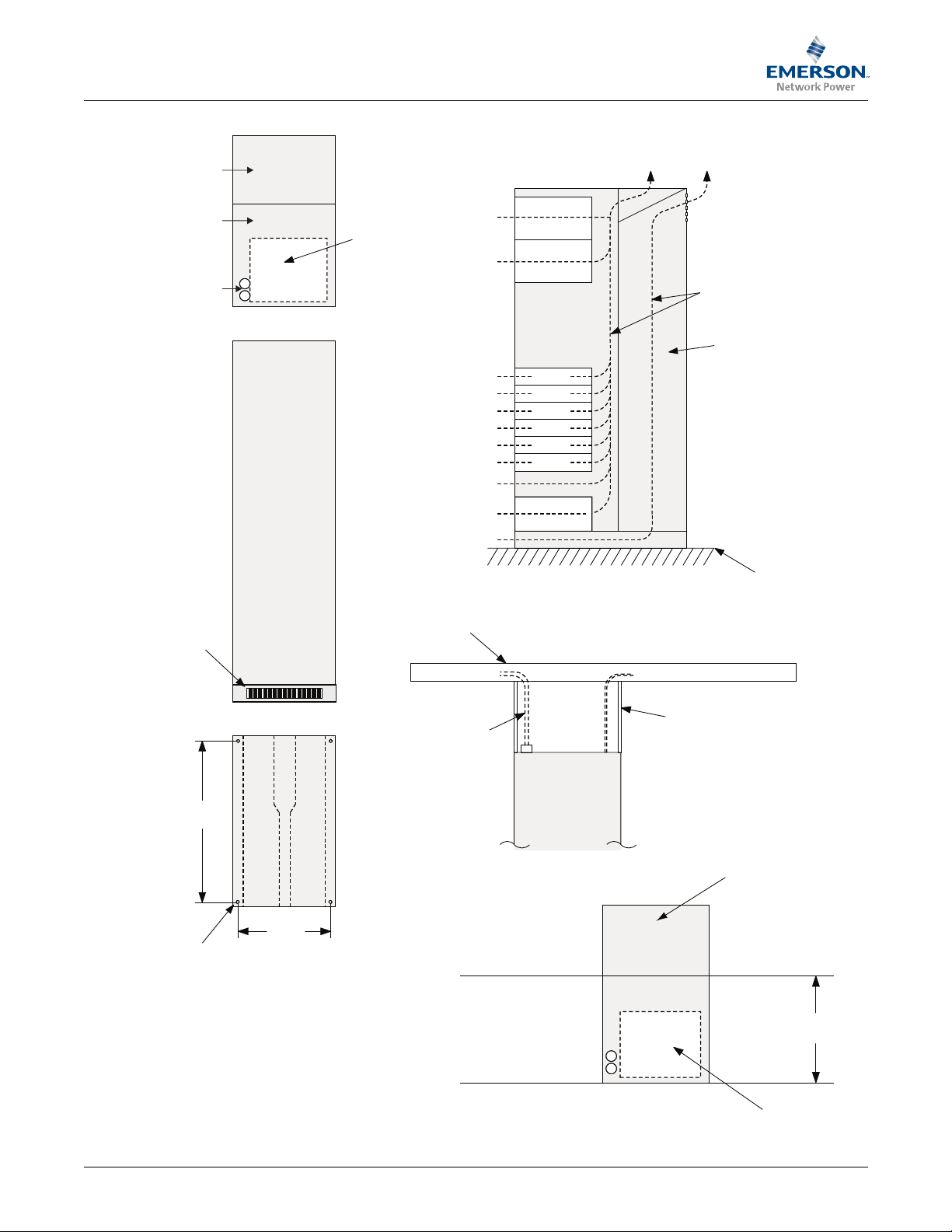

Note2

Distr.

Distr.

HotAisle

Cold Aisle

AirFlow

Concrete

Floor (slab)

Side View

Notes:

1. Dimensions areininches (millimeters).

2. Do not block airintake openings.

To p

Battery

Compartment

DC Power

System

Compartment

Openings for

Output Cables

Front

CableTraySupports

if Mounted on To pof

Module

Front View

CableTray

CableRun

Battery

Compartment

PCUs

PCUs

PCUs

PCUs

PCUs

PCUs

To pView

Battery

Compartment

Openings for

Output Cables

CableTray

23.62

(600)

BFU

½” (12mm) Floor

Anchoring Bolts

(4 places)

35.43

(900)

19.68

(500)

Air Exchange

(keep clear)

AC Input

Conduit Openings

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Figure 3 Top DC Distribution Feed Modules

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

10

Section 6040

Page 17

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

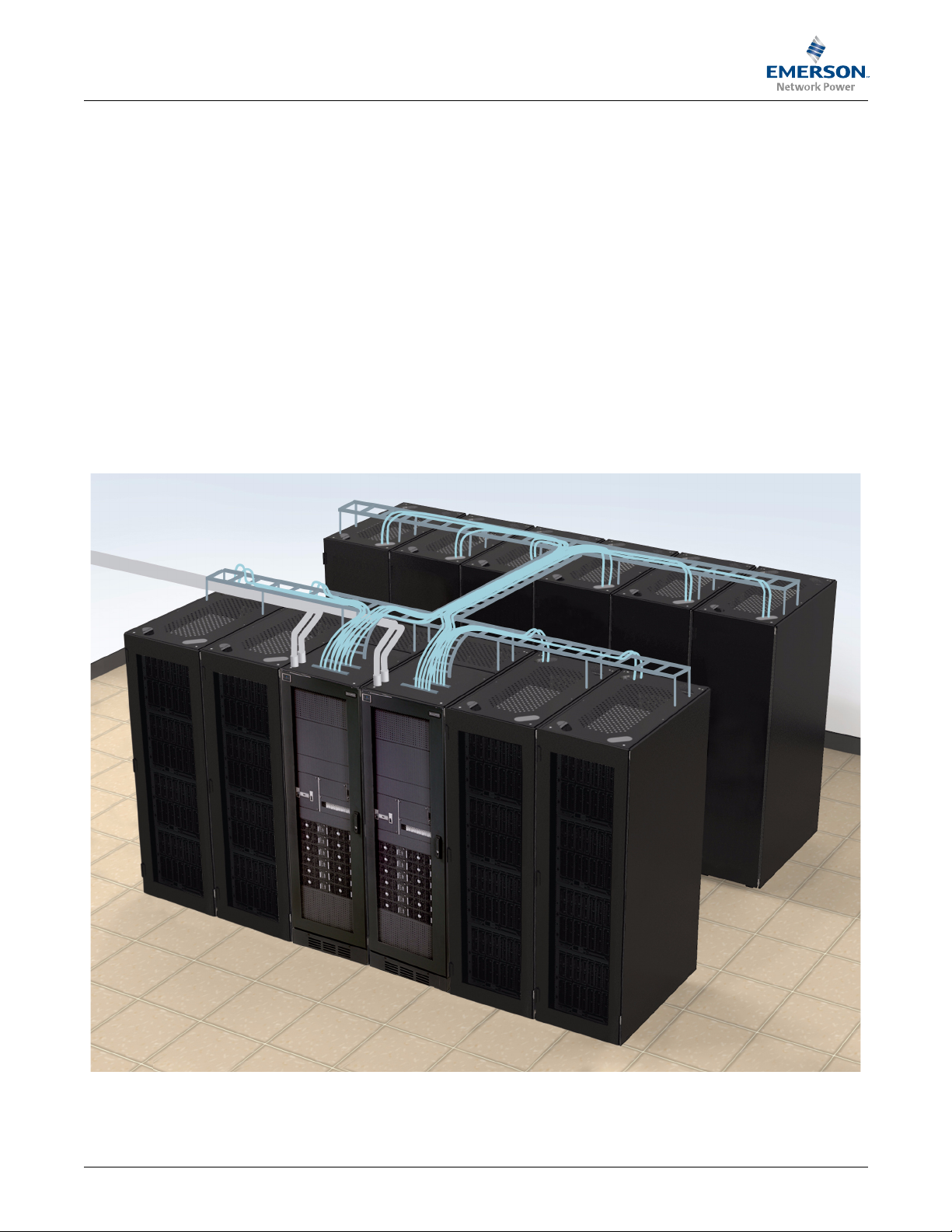

2.2 Row-Based Installation Example

The NetSure ITM DC UPS system provides the flexibility to meet the needs of any data center.

The NetSure ITM DC UPS system is delivered fully configured for quick and easy field installation.

Multiple DC UPS modules can easily be connected on site in order to increase capacity. Each module

takes only 24" (w) x 41" (d) of floor space, including batteries and primary distribution. The NetSure

ITM DC UPS system is typically installed in the middle or at the end of a row of server racks. This

makes the system uniquely flexible and scalable. Deploy only the capacity that is initially needed;

modules can be added at any time to existing units on the data center floor.

Figure 4 depicts a top distribution feed installation powering IT racks. Depending on your site and

budget requirements, the NetSure ITM DC UPS solution can either be installed as a single

deployment, or incrementally by row. In either scenario, DC distribution cabling to each rack is

reduced by placing the NetSure ITM DC UPS in-the-row.

Whatever the physical layout of your data center, the NetSure ITM DC UPS allows for maximum

space for IT equipment. With DC UPS building block modules, you can mix and match configurations

and standard layouts to fit your available space.

Figure 4 NetSure™ ITM Row-Based DC UPS System Installation Example

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

11

Section 6040

Page 18

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

2.3 Recommended Tools and Test Equipment

The following tools and test equipment are recommended to install the DC UPS modules.

• Non-Contact Voltage Detector

• Digital Multimeter (DMM), 0 to 60 V dc, 0 to 600 V ac

• NO-OX-ID-A or Approved Equivalent

• Lineman's Scissors

• Lineman's Strippers

• Lineman's Cutters

• Electrician's Insulated Screwdrivers, Phillips, No. 1 and 2

• Electrician's Insulated Screwdrivers, Flat-Blade, Small and Large

• Adjustable Torque Wrench, 1/2" Drive, 0 in-lb to 800 in-lb

• Ratchet, 1/2" Drive

• Insulated Nut Driver Set

• Crimping Tool with Dies from 350 kcmil to 2 AWG

• Torx Screwdrivers or Bits: TX10 and TX20

• 17 mm Wrench or Socket for M10 Bolts and Nuts (for circuit breaker distribution)

• 19 mm Wrench or Socket for M12 Bolts and Nuts (for fuse distribution)

• 24 mm Wrench for Pallet.

• Hexagonal mm Bit for the Air Duct.

• Hexagonal Bit for the AC Input Breaker.

Contact Emerson for full turn key installation quote.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

12

Section 6040

Page 19

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

3.0 P

OSITIONING THE

This section describes the environmental and mechanical considerations that must be taken into

account when planning the positioning and cabling of the DC UPS system. This section also provides

procedures for physical installation of the DC UPS cabinet.

Because every site is unique, some subsections present a guide to general procedures and practices

that should be observed by the installing engineer, rather than step-by-step installation instructions.

DC UPS S

YSTEM

3.1 General Requirements

• The installer should be familiar with the installation requirements and techniques to be used in

securing the DC UPS module (cabinet) to the floor. It is up to the customer to determine the

requirements for anchoring the cabinet to the specific type of floor at the site, select proper

anchors, and to investigate the proper use of the anchor.

• This product is intended only for installation in a Restricted Access Location on or above a noncombustible surface.

• Front and rear access is required for installation and operation (see Clearances in this section).

3.2 General Guidelines for Positioning the DC UPS Modules

Choose a location for the DC UPS system that offers:

• Easy connection to inputs, outputs, and alarms.

• Air circulation sufficient to expel heat produced by the DC UPS system.

• Protection against moisture and excessive humidity.

• Protection against dust and other particulate matter.

• Enough space to service the DC UPS system (see Clearances in this section).

• Compliance with fire prevention regulations and practices.

3.2.1 Cable Entry

DC distribution and alarm cables enter the DC UPS module from the top or bottom, depending on

module configuration (top distribution feed or bottom distribution feed).

AC input cables can enter either at the top or bottom. Conduit openings are provided in both

locations.

3.2.2 Environmental Considerations

Before installing the DC UPS system, verify that the room satisfies the environmental conditions

stipulated in 7.2 - Environmental, paying particular attention to the ambient temperature and air

exchange system. Also refer to 7.2 - Environmental for details on heat dissipation.

The DC UPS system should be installed in a cool, dry, clean-air environment with adequate

ventilation to keep the ambient temperature within the specified operating range +23°F to +95°F

(-5°C to +35°C).

• Batteries are installed in the DC UPS module’s battery compartment. Temperature is a major

factor in determining battery life and capacity. Battery manufacturers recommend an operating

temperature of 77°F (25°C). Ambient temperatures higher than this reduce battery life;

temperatures lower than this reduce battery capacity. For optimal battery performance and

service life, inlet air temperature to the battery compartment (from the front of the system)

should be maintained between +68°F to +77°F (+20°C to +25°C).

The DC UPS module is cooled by internal fans. Cooling air enters the system through the front of the

unit and is exhausted out the top. To permit proper air flow and prevent overheating, do NOT block or

cover the ventilation openings or blow air down onto the unit. Ventilation clearance above the unit

must be a minimum of 8 in. (203mm).

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

13

Section 6040

Page 20

NetSure™ ITM with eSure™ Technology

P/N 547823

36” Tall Floor Stand

P/N 547822

24” Tall Floor Stand

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

3.2.3 Mechanical Considerations

The DC UPS system can be comprised of up to four (4) modules (cabinets), depending upon your

power requirements. All modules used are the same size and are designed to be positioned side-byside to form an aesthetically appealing equipment suite. The system always contains one (1) Primary

Module. For increased power demands, up to three (3) Expansion Modules may be added. Locate the

Primary Module at the far left or far right of the row. Remove the side panel from the Primary Module

from the side that will face adjacent Expansion Modules. Place the first Expansion Module next to the

Primary Module. Place additional Expansion Modules (if required) next to each other. Install the side

panel removed from the Primary Module to the open side of the last Expansion Module in the row.

NOTE

When the DC UPS system consists of multiple modules, the switches inside the modules are

pre-set at the factory to identify the module as the Primary Module, 1st Expansion Module, 2nd

Expansion Module, or 3rd Expansion Module. When placing modules, refer to the nameplate

identification number (see Table 1) to ensure the Primary Module is placed on the end, and

Expansion Modules are place in sequential order.

Clearances

There are no ventilation grilles on the sides of the DC UPS module. The DC UPS modules may be

placed with the sides touching or against a wall.

To enable routine tightening of power terminations within the DC UPS module, make sure there is

sufficient clearance in front and rear of the DC UPS module to permit free passage of personnel and

that the front door can be fully opened.

Leave a minimum of 8 in. (203mm) between the top of the DC UPS module and the ceiling to permit

adequate air circulation above the unit. Emerson recommends against using air conditioning or other

systems that blow air onto the top of the unit.

Leave a minimum of 36 in. (914 mm) between the back of the DC UPS module and a wall to permit

adequate air circulation for the battery compartment fans and facilitate maintenance access.

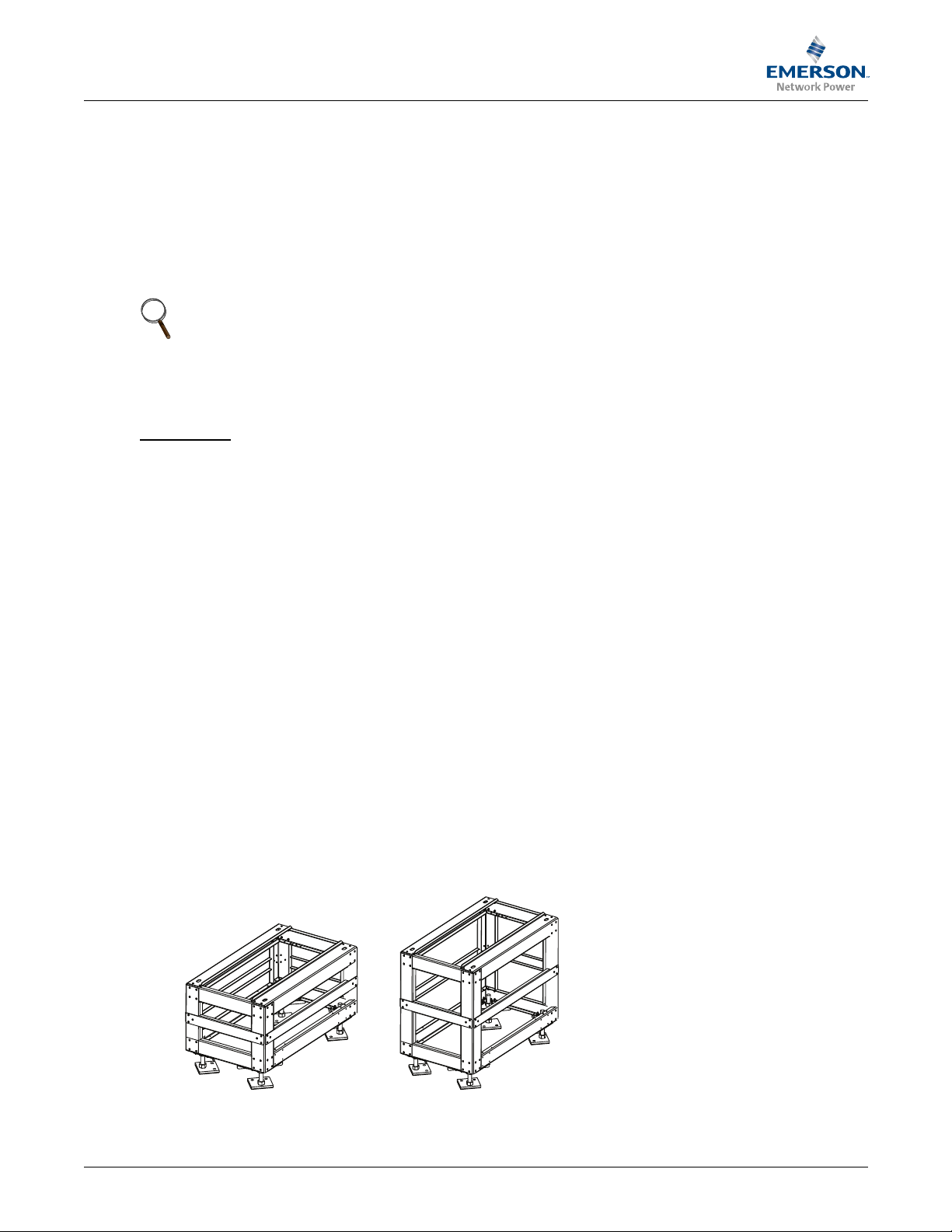

3.3 Floor Installation

Refer also to 3.1 - General Requirements.

The diagrams in 2.0 - Installation Drawings and Recommended Tools and Test Equipment

show the location of holes in the base plate for bolting the DC UPS module to the floor.

If the module is to be placed on a raised floor, it should be mounted on a floor stand that will support

the equipment point loading. Refer to the cabinet-bottom views in 2.0 - Installation Drawings and

Recommended Tools and Test Equipment to design this pedestal. Contact your Emerson Sales

Representative for a floor stand designed for this system (see Figure 5).

Figure 5 Emerson Floor Stands

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

14

Section 6040

Page 21

NetSure™ ITM with eSure™ Technology

!

!

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

3.4 Considerations in Moving the DC UPS Module

3.4.1 Transporting

Ensure that the DC UPS module weight is within the designated surface weight loading (lb./ft2 or kg/

cm2) of any handling equipment. The DC UPS module weighs 3240 lb. (1470 kg), fully loaded.

WARNING

Ensure that any equipment that will be used to move the DC UPS module has sufficient

lifting capacity. Ensure adequate personnel and lifting equipment are available when taking

the module off its shipping pallet. The module presents a tipping hazard. Do not tilt the

module further than 10 degrees from vertical.

The DC UPS module is fitted with casters. Take care to prevent movement when unbolting

the module from its shipping pallet. The casters are strong enough for movement across even

surfaces only. Casters may fail if they are subjected to shock loading, such as being dropped or

rolled over holes in the floor or obstructions. Such failure may cause the unit to tip over,

injuring personnel and damaging the equipment.

WARNING

Batteries are factory installed in the DC UPS module’s battery compartment. Care must be

taken when maneuvering modules with batteries. Keep such moves to a minimum. See

Battery Compartment Precautions on page 2.

3.4.2 Moving a DC UPS Module

Cabinet Preparation

1. Inspect the cabinet as described in 1.1 - External Inspections and 1.2 - Internal Inspections.

2. Remove the front and rear bottom panels to gain access to the bolts securing the cabinet to the

pallet.

Moving DC UPS Module from Shipping Pallet

Use lifting equipment, such as a forklift or similar equipment, appropriately rated for the weight of

the load to move the DC UPS cabinet from its shipping pallet.

When moving a DC UPS cabinet with a forklift or similar equipment, make sure that the fork is of

sufficient length for the pallet size and capable of lifting the cabinet. Also use a forklift with

adjustable forks or a narrow type.

1. Close the front door.

2. Slide the forklift into place.

3. Unbolt the cabinet from the pallet.

4. Lift the cabinet. The pallet should drop off from its own weight.

5. Carefully move the DC UPS module to its installation location or set the DC UPS module down on

its casters if it is to be rolled into position.

Moving DC UPS Module to Installation Location

The DC UPS module may be rolled on its casters when moving the unit a short distance. For longer

distances, move the DC UPS module with a forklift or similar equipment to ease the relocation and to

reduce vibration.

3.4.3 Final Positioning

Note that the DC UPS modules sit on four casters. When the DC UPS module has been finally

positioned, ensure that the adjustable stops are set so that the DC UPS module will remain

stationary and stable.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

15

Section 6040

Page 22

NetSure™ ITM with eSure™ Technology

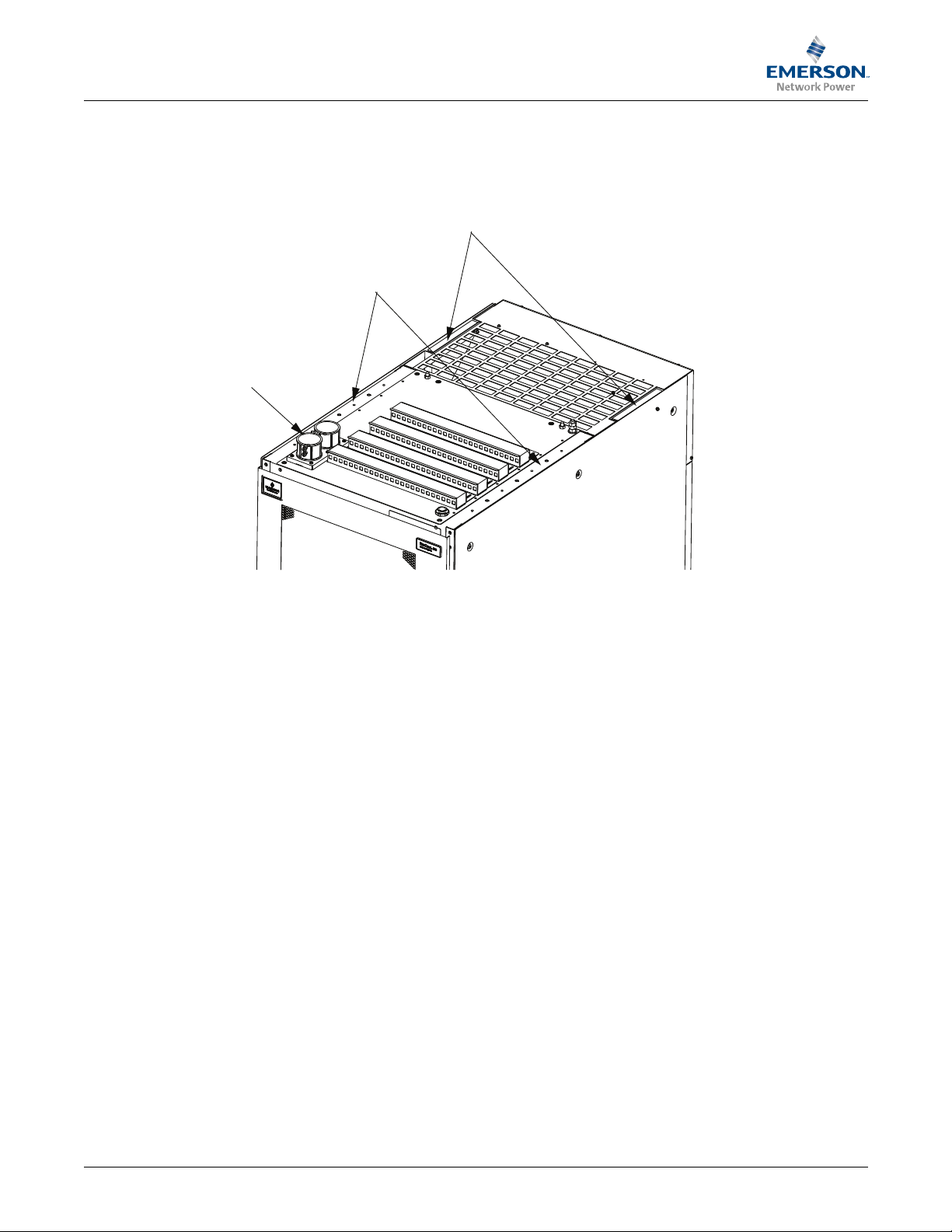

Holes for 1/4” thread-forming

screws to secure rails for

overhead cable trays.

Customer supplied

conduit fittings

Brackets can be used to secure

rails for overhead cable trays, drill

as required.

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

3.5 Overhead Cable Tray Rails

Refer to Figure 6 for mounting locations for overhead cable tray rails.

Figure 6 Mounting Locations for Overhead Cable Tray Rails

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

16

Section 6040

Page 23

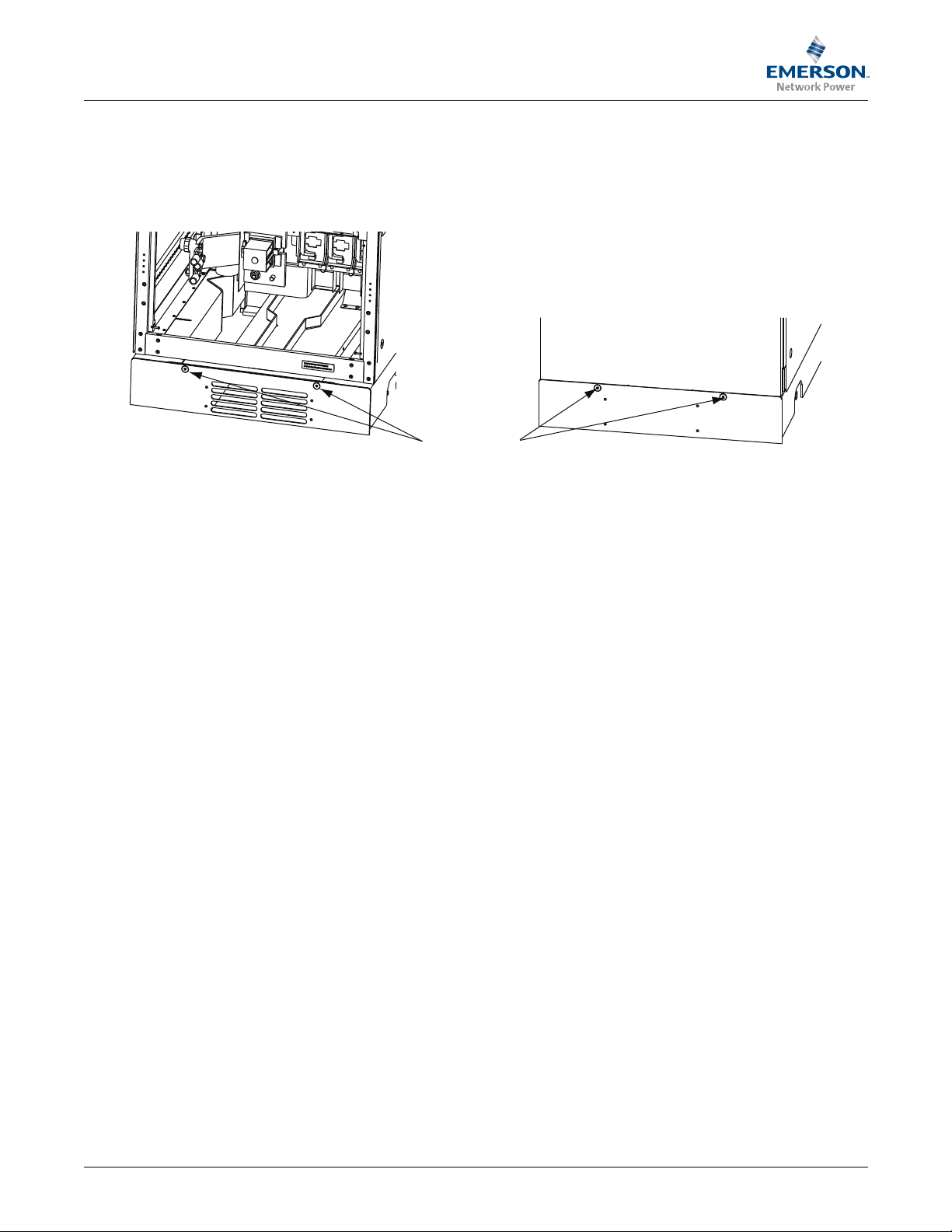

NetSure™ ITM with eSure™ Technology

Battery Compartment Half

Power Compartment Half

Secure with

Supplied Screws

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

3.6 Front and Rear Bottom Panel Installation

3.6.1 Bottom DC Distribution Feed (Bottom Cabled) Modules

Refer to Figure 7 and install the front and rear bottom panels.

Figure 7 Installing Front and Rear Bottom Panels

3.6.2 Top DC Distribution Feed (Top Cabled) Modules

Installing the Supplied Air Duct Assembly: The Air Duct Assembly must be installed in DC UPS

modules configured for top DC distribution feed (top cabled). The Air Duct Assembly allows air to be

drawn from the bottom front of the DC UPS module and up into the battery compartment for cooling.

Refer to Figure 8 and install the supplied Air Duct Assembly.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

17

Section 6040

Page 24

NetSure™ ITM with eSure™ Technology

Air Duct Assembly

Power Compartment Half

Battery Compartment Half

Installed View

Battery Compartment Half

Power Compartment Half

4) Slide the remaining half of the air duct assembly into the

rear bottom compartment of the DC UPS module (battery compartment bottom).

5) Secure the air duct half just installed with the supplied screws.

Secure with supplied screws.

Note: If AC power cables are fed from the bottom, install AC power cables before installing air duct.

Note: The rubber parts of the air duct assembly may be lubricated with water before sliding the air duct halves into place.

Procedure:

1) Partially slide the half of the air duct assembly with vents into the

front bottom compartment of the DC UPS module (power compartment bottom).

2) Install and secure the supplied bracket with the supplied screws.

3) Slide the half of the air duct assembly with vents completely into the DC UPS module,

and secure with the supplied screws.

Secure with supplied screws.

Install supplied bracket after

partially sliding assembly in.

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Figure 8 Installing Air Duct Assembly

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

18

Section 6040

Page 25

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

4.0 E

LECTRICAL CONNECTIONS

The DC UPS system requires grounding, DC output distribution, AC input power, alarm/control, and

battery wiring once it has been mechanically installed.

If the system consists of multiple DC UPS modules, battery and ground/return busbars must be

interconnected and alarm/control interconnect wiring between modules must be made.

4.1 Wiring Information and Guidelines

4.1.1 Cable Lengths (Floor or Cabinet Top to Connection Point Inside DC UPS Module)

To help calculate the total cable length required, refer to Table 2 for the distance from the floor or

cabinet top to selected connection points inside the DC UPS module. Determine the cable length

required to reach the DC UPS module, then add the appropriate length from the table and adequate

slack for repair and maintenance.

Table 2 Distance to Connection Points inside the DC UPS Module

Connection Point

inside DC UPS

Module

AC Input 79 (2000) 138 (3500) 157 (4000) 59 (1500)

DC Output 28 (700) N/A N/A 28 (700)

From Floor

in. (mm)

Distance - Bottom

DC Distribution Feed Module

From Top of Module

in. (mm)

DC Distribution Feed Module

From Floor

in. (mm)

Distance - Top

From Top of Module

in. (mm)

Grounding 79 (2000) 138 (3500) 157 (4000) 59 (1500)

Alarm/Control 59 (1500) N/A N/A 47 (1200)

4.1.2 Recommended Wire Sizes, Recommended Lugs, and Torque Requirements

The main factors affecting the choice and size of wires are voltage, current (also taking into account

overcurrent), room temperature, and installation conditions.

The power cables of the system must be sized with respect to the following:

• AC Input Cables - The AC input cables must be sized for the module’s maximum input current.

• DC Output Distribution Cables - The DC output distribution cables must be sized for the

module’s output breakers or fuses.

• Battery Cables - The DC UPS module contains a battery compartment. Battery cables are

factory supplied and sized accordingly.

Refer to Termination Type, Recommended Wire Size, Recommended Lugs on page 59 for

recommended wire sizes and recommended lugs. Refer to the illustrations in this section for torque

requirements.

NOTE

The above referenced section gives nominal currents for determining the size of DC UPS

module power cables. Other important factors to consider include cable route length and

coordination with protective devices.

4.1.3 Wiring Guidelines

The following are guidelines only and are superseded by the NEC and applicable local codes where

applicable.

• The grounding cable connecting the DC UPS module to the main ground system must follow the

most direct route possible.

• Consider using paralleled smaller cables for heavy currents—this can ease installation.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

19

Section 6040

Page 26

NetSure™ ITM with eSure™ Technology

Front View

(Top Cabled Configuration)

Rear View

Protective Cover

Protective Cover

Protective Cover

Protective Cover

Protective Cover

Protective Cover

Protective Cover

Protective Cover

Front View

(Bottom Cabled Configuration)

SUITABLE FOR MOUNTING ON CONCRETE

OR OTHER NON-COMBUSTIBLE SURFACE ONLY.

SUITABLE FOR MO UN T IN G O N CO N CR ET E

OR OTHER NO N-C OM BU ST IB LE SU RF AC E ON LY.

Protective Cover

Protective Cover

Dual AC Input

Circuit Breaker Option

Protective Cover View

(Top cabled configuration shown,

bottom cabled configuration similar.)

AC Input

Protective Cover

AC Input Protective

Cover Removed

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

• When laying power cables, do not form coils; this will help avoid increasing formation of

electromagnetic interference. Positive and negative cables should be run together.

• Alarm/control wiring and power wiring must be run separately.

Output and input cables must be run separately.

4.2 Protective Covers

Wiring connection access requires removing protective covers from the DC UPS module. When

making electrical connections, remove the appropriate protective cover, as shown in Figure 9.

Replace all protective covers after all electrical connections have been made and checked.

Figure 9 Protective Covers

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

20

Section 6040

Page 27

NetSure™ ITM with eSure™ Technology

Module Cabinet

Grounding

AC Input

(to circuit breakers)

DC Output

Circuit Breaker (Fuse)

Busbars (-48VDC)

Ground/Return

Busbars

AC Input

Circuit Breaker(s)

Battery Fuses (3)

(Battery leads factory

connected and routed to

Battery Compartment.)

Alarm/Control Connections

(to ACU+ IB2 Interface Board)

(Primary Module only)

Load Distribution Devices

DCCB01 - DCCB11 (Top Row)

DCCB12 - DCCB22 (Bottom Row)

(DC distribution breakers shown,

large fuses available.)

Battery Return and Load Return

(Battery return leads factory

connected and routed to

Battery Compartment.)

AC Input Channel

AC Input

Conduit Openings

(AC input cables

may also enter at

bottom of cabinet.)

Alarm/Control

Cabling Channel

AC Input Circuit

Breaker Cover

PCU AC Input

Circuit Breakers

Note: Three extra positions are provided

on the ground/return busbar for customer

connection to site ground.

ACU+ Controller

(Primary Module only)

Front View

(door removed)

ISO View

(panels removed)

ISO View

(panels removed)

Battery Compartment and Base

Removed in Illustrations for Clarity

2"

AC Input Conduit Opening

Recommended Coupling:

Raco Type 2628 (Grainger 3LV08)

or Thomas Betts Type TK126US

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

4.3 Wiring Connections Locations

The DC UPS module input and output cable connections are easily accessible from the front of the

unit for installation. Refer to Figure 10, Figure 11, Figure 12, Figure 13, Figure 14, Figure 16,

Figure 17, Figure 18, and Figure 19 for connection locations. The DC UPS module contains a

battery compartment. Battery cables are factory supplied and connected to the DC UPS module. Final

connections to the batteries are made in the procedure in 6.2 - Final Battery Connections. Battery

connections are done from the rear of the DC UPS module.

Figure 10 Wiring Connections Locations (DC UPS Module with Bottom Feed DC Distribution)

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

21

Section 6040

Page 28

NetSure™ ITM with eSure™ Technology

DC Output

Cable Openings

AC Input Conduit

Openings (AC input

cables may also enter

at bottom of cabinet,

conduit supplied

routed to bottom

of cabinet.)

AC Input

Circuit Breaker(s)

AC Input Channel

Battery Fuses (3)

(Battery leads factory

connected and routed to

Battery Compartment.)

Battery Return and Load Return

(Battery return leads factory

connected and routed to

Battery Compartment.)

Module Cabinet

Grounding

Alarm/Control

Cabling Channel

AC Input

(to circuit breakers)

DC Output

Circuit Breaker (Fuse)

Busbars (-48VDC)

Ground/Return

Busbars

Front View

(door removed)

SUITABLE FOR MO UNT ING O N CO NCRET E

OR OTHER NON-COM BUST IBLE SUR FACE O NLY.

Battery Compartment and Base

Removed in Illustrations for Clarity

ISO View

(panels removed)

ISO View

(panels removed)

AC Input Circuit

Breaker Cover

2"

AC Input Conduit Opening

Recommended Coupling:

Raco Type 2628 (Grainger 3LV08)

or Thomas Betts Type TK126US

Alarm/Control Connections

(to ACU+ IB2 Interface Board)

(Primary Module only)

ACU+ Controller

(Primary Module only)

Load Distribution Devices

DCCB01 - DCCB11 (Top Row)

DCCB12 - DCCB22 (Bottom Row)

(DC distribution breakers shown,

large fuses available.)

PCU AC Input

Circuit Breakers

Note: Three extra positions are provided

on the ground/return busbar for customer

connection to site ground.

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Figure 11 Wiring Connections Locations (DC UPS Module with Top Feed DC Distribution)

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

22

Section 6040

Page 29

NetSure™ ITM with eSure™ Technology

!

!

Module Cabinet

Grounding Stud

Studs for Connecting

Grounding Strap

between Modules

3/8” (M10) Stud.

Recommended Torque is

407-434 in-lbs (46-49 Nm).

5/16” (M8) Studs.

Recommended Torque is

204-221 in-lbs (23-25 Nm).

Module Top View

Customer supplied

conduit fittings

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

4.4 Making Electrical Connections

CAUTION

The electrical connections described in this section must be performed by authorized

electricians or qualified technical personnel. Follow the NEC and applicable local codes. If you

have any difficulties, contact your local Emerson representative or Emerson Services.

Before making electrical connections, do the following for each DC UPS module (see Figure 10 and

Figure 11 for circuit breaker and fuse locations).

• Open the front door. For bottom cable installations, remove the lower front panel. For all

installations, remove protective panels as required (see 4.2 - Protective Covers).

• Ensure the main AC input circuit breaker(s) is in the OFF position.

• Ensure all PCU AC input circuit breakers are in the OFF position.

• Ensure the three (3) battery disconnect fuses are removed.

• Ensure all distribution circuit breakers are in the OFF position or distribution fuses are removed.

4.4.1 Cabinet Grounding Connection

The cabinet grounding connection is made to a stud located on the top of the DC UPS module, as

shown in Figure 12. A cabinet grounding cable must be connected to this stud, per site requirements.

Tighten the connection to the torque indicated in Figure 12.

Each module also contains a separate stud located on each side to connect the supplied grounding

strap between DC UPS modules, if desired.

All modules and cable conduit should be grounded in accordance with the NEC and all applicable

local codes.

WARNING

Failure to follow proper grounding procedures can result in electric shock hazard to personnel

or the risk of fire, should a ground fault occur.

NOTE

Proper grounding significantly reduces electromagnetic interference problems in systems.

Figure 12 Cabinet Grounding Connection

4.4.2 DC Distribution Ground/Return Busbar Grounding Connection

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

The DC distribution ground/return busbar must be connected via a solidly grounded lead to the main

building ground. Three extra positions are provided on the ground/return busbar for customer

connection to site ground. Refer to Figure 10 and Figure 11 for location of the DC distribution

ground/return busbar. Refer to Table 250-122 in the American National Standards Institute (ANSI)

approved National Fire Protection Association's (NFPA) National Electrical Code (NEC) for

grounding conductor size. Typically use equivalent or minimum of 1/0 AWG.

23

Section 6040

Page 30

NetSure™ ITM with eSure™ Technology

!

1.75”

(44.45mm)

1.75”

(44.45mm)

11

1.75”

(44.45mm)

1.75”

(44.45mm)

1.5”

(38.1mm)

1.75”

(44.45mm)

1.5”

(38.1mm)

1.75”

(44.45mm)

1”

(25.4mm)

1”

(25.4mm)

1”

(25.4mm)

1”

(25.4mm)

Terminals are 1/2” (M12) studs.

Recommended Torque is 690-743 in-lbs (78-84 Nm).

Terminals are 3/8” (M10) studs.

Recommended Torque is 407-434 in-lbs (46-49 Nm).

DC UPS MODULE WITH

TOP FEED DC DISTRIBUTION

DC UPS MODULE WITH

BOTTOM FEED DC DISTRIBUTION

DC UPS MODULE WITH

TOP FEED DC DISTRIBUTION

DC UPS MODULE WITH

BOTTOM FEED DC DISTRIBUTION

DISTRIBUTION CIRCUIT BREAKERS

DISTRIBUTION FUSES

(optional)

DC Output (-48Vdc)

(per distribution position)

to distribution device busbar

DC Output Return

(per distribution position)

to ground/return busbars

DC Output (-48Vdc)

(per distribution position)

to distribution device busbar

DC Output Return

(per distribution position)

to ground/return busbars

Note: Three extra positions are provided

on the ground/return busbar for customer

connection to site ground.

Note: Three extra positions are provided

on the ground/return busbar for customer

connection to site ground.

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

4.4.3 DC Output Distribution Connections

Connect the DC output distribution cables between the DC UPS module and the loads as required.

These connections are made to the output circuit breaker or fuse busbars and the ground/return

busbar, as shown in Figure 10 or Figure 11. Refer to Figure 13 for a view of the busbar

terminations. Tighten the connections to the torque indicated in Figure 13.

WARNING

If the load equipment will not be ready to accept power on the arrival of the commissioning

engineer, then ensure that the system output cables are safely isolated.

Figure 13 DC Output Connections

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

24

Section 6040

Page 31

NetSure™ ITM with eSure™ Technology

!

!

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

4.4.4 AC Input Power Connections

WARNING

AC input power connections must be performed by a qualified electrician.

Before connecting AC input cables to the DC UPS module, ensure that you are aware of the

location and operation of the overcurrent protection devices that connect these cables to the

power distribution panel. Before connecting AC input cables, de-energize and lockout or

tagout these overcurrent protection devices.

Do not apply AC input power to the DC UPS module before the arrival of the commissioning

engineer.

AC Input Overcurrent Protective Device

CAUTION

To reduce the risk of fire, connect AC input only to a circuit provided with correct amperes

maximum branch circuit overcurrent protection in accordance with the NEC, ANSI/NFPA 70.

External overcurrent protection for the AC input circuit is to be provided by the customer. Refer to

AC Input Specifications on page 61 for maximum input current ratings. Each DC UPS module is

provided with one or two internal 150A AC input circuit breaker.

AC Input Connections

AC input leads can enter the DC UPS module from the top or from the bottom. Refer to Figure 14 for

an AC input routing diagram. Figure 15 provides a diagram for installing conduit fittings when AC

is fed from the top.

One or two AC input breakers are provided (depending on module configuration). Refer to Figure 16

for an AC input connections diagram. Tighten the connections to the torque indicated in Figure 16.

Note that a cover needs to be removed to access the circuit breakers as shown in Figure 9.

• Connect Feed A AC input supply cables between the power distribution panel and the DC UPS

module’s internal Feed A input circuit breaker (Feed A: L1, L2, L3 terminals).

• If the DC UPS module is configured for two AC input feeds, connect the optional Feed B AC input

supply cables between the power distribution panel and the DC UPS module’s internal Feed B

input circuit breaker (Feed B: L1, L2, L3 terminals).

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

25

Section 6040

Page 32

NetSure™ ITM with eSure™ Technology

Battery Compartment

Battery Compartment

AC enters at top.

AC enters at bottom.

AC enters at bottom.

AC enters at top.

65kAic

Circuit

Breaker

65kAic

Circuit

Breaker

DC UPS MODULE WITH

TOP FEED DC DISTRIBUTION

DC UPS MODULE WITH

BOTTOM FEED DC DISTRIBUTION

Run AC Cables

from Top OR Bottom

Run AC Cables

from Top OR Bottom

1) Remove cover plate.

Note: Cut cover plate in half if

only one conduit being installed.

3) Secure conduit plate with conduit

fittings installed to top of cabinet.

Note: If only one conduit being installed,

re-install plate that was cut in half.

2) Install one or two customer provided

conduit fittings to supplied conduit plate.

Customer provided

conduit fittings.

One or two AC input circuit breakers are provided (depending on module configuration).

Two ground studs (5/16” [M8]) are provided attached to the sides of the enclosure surrounding the AC input circuit breaker(s).

Recommended torque is 124 in-lbs (14 Nm) for AC input circuit breaker connection.

Recommended torque is 204-221 in-lbs (23-25 Nm) to grounding studs.

A

FeedBFeed

A

FeedBFeed

(optional)

(optional)

AC INPUT

380/480VAC, 3 Phase, 50/60Hz

AC INPUT

380/480VAC, 3 Phase, 50/60Hz

factory wiring

AC IN A

L1 L2 L3

AC IN B

L1 L2 L

3

factory wiring

L1 L2 L3

AC IN A

L1 L2 L3

AC

IN B

DC UPS MODULE WITH

BOTTOM FEED DC DISTRIBUTION

DC UPS MODULE WITH

TOP FEED DC DISTRIBUTION

GND

Stud

GND

Stud

GND

Stud

GND

Stud

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Figure 14 AC Input Power Connection Routing Options

Figure 15 Installing Conduit Fittings when AC is Fed from the Top

Figure 16 AC Input Power Connections

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

26

Section 6040

Page 33

NetSure™ ITM with eSure™ Technology

Te rminals are M2 screws.

Recommended Torque is 1.92-2.16 in-lbs (0.22-0.25 Nm).

Wire size range is 26 AWG to 16 AWG (0.14 mm^2 to 1.0 mm^2).

Customer Input/Output (I/O) Connections

N C = N orm ally C losed

C O M = C o m mo n

N O = N o rm a lly O p e n

A ll re la y contact s a r e sh ow n

w it h t h e re lay d e e n e r g ized.

To p View

ACU+ IB2 Interface Board

Tem p.

P robe # 1

Tem p.

P robe # 2

+

J6

D ig ital Inputs

R e la y Ou tputs

N O C N C

5 3 1

to ACU+

J12

J11

S W 1

5 3 1 5 3 1 5 3 1

6 4 2 6 4 2 6 4 2 6 4 2

N O C N C N O C NC N O C N C

N O C N C N O C N C N O C N C NO C N C

J7J8J9

1357

2468

-

5 3 1 5 3 1 5 3 1

6 4 2 6 4 2 6 4 2

J3J 4J5

8 7 6 5 4 3 2 1

ON

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

4.4.5 Optional Alarm/Control Connections (to Primary Module only)

Alarm/control connections are made to the ACU+ Controller Customer Interface Board (IB2). The IB2

board provides connection points for digital inputs and relay outputs. System required connections

are factory wired to the IB2 board. The customer may wire to un-used digital input and relay outputs,

if desired. The IB2 board is located in an enclosure above the ACU+ Controller (see Figure 10 or

Figure 11). To access these connections, loosen the captive fastener on the front of the enclosure and

slide the IB2 board partially out of the shelf. Note that a wireway is provided to route the wires to the

IB2 board, as shown in Figure 10 or Figure 11. Connect external alarm/control wiring to terminal

blocks J3-J9 of the IB2 board, as required. Refer to Figure 17.

Figure 17 Alarm and Control Connections

Digital Input Connections

Up to eight (8) digital inputs may be connected to the IB2 board. Digital inputs that have factory

connections are listed in Table 3. A blank column in Table 3 is also provided if you want to document

custom connections to un-used digital inputs.

• Observe proper polarity per Table 3. Note that you must supply both paths for the digital input

(either a positive or negative signal and the opposite polarity return path).

• The digital inputs can be configured to provide an alarm when the signal is applied (HIGH) or

removed (LOW) (Local menu "Settings / System Dashboard / General"). Refer to Appendix A in

the NetSure ITM Operation Manual (Section 6047).

Connecting a NetSure RDB Rack PDU (Power Distribution Unit) to the NetSure ITM: The following

applies to all PDUs listed in the NetSure RDB Installation and Operation Manual (Section 6041).

Perform the following after installing and making the DC input and output connections to the PDU

per Section 6041.

• Connect a 22 AWG lead from the circuit breaker alarm connector located on the last PDU to the

(-) input of one of the unused digital inputs on the IB2 board. Connect a second 22 AWG lead from

the NetSure ITM System Ground/Return (+) to the (+) input of the same digital input on the IB2

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

27

Section 6040

Page 34

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

board. Assign a unique signal name to this digital input (Web interface "Signal Information

Modification Submenu"). Refer to Appendix A in the NetSure ITM Operation Manual (Section

6047).

Table 3 Programmable Digital Inputs

Programmable

Digital Input

1

2

3

4

5

6

7

Pin No. Dedicated to...

J3-1 –

J3-2 +

J3-3 –

J3-4 +

J3-5 –

J3-6 +

J4-1 –

J4-2 +

J4-3 –

J4-4 +

J4-5 –

J4-6 +

J5-1 –

J5-2 +

Available for Customer

Custom Digital Input

Available for Customer

Custom Digital Input

Available for Customer

Custom Digital Input

PCU EPO factory wired

Fan Supply Alarm factory wired

Fan Alarm factory wired

Available for Customer

Custom Digital Input

Customer

Custom Digital Input

8

J5-3 –

J5-4 +

J5-5

-J5-6

Available for Customer

Custom Digital Input

internal connections

Relay Output Connections

The IB2 board provides eight (8) programmable alarm relays with Form-C contacts. Default relay

assignments are documented in Table 4. A blank column in Table 4 is also provided if you want to

document a custom configuration. Alarm relay contacts are rated for 2A @ 30VDC and 0.5A @

125VAC (60W maximum power consumption).

• Each relay can be individually configured to activate for any system alarm condition.

• Refer to the NetSure ITM Operation Manual (Section 6047) for programming instructions.

Spec. No: 582145500

Model: NetSure™ ITM Issue AB, April 8, 2013

28

Section 6040

Page 35

NetSure™ ITM with eSure™ Technology

Installation Manual, Section 6040 (Issue AB, April 8, 2013)

Table 4 Programmable Relay Outputs

Programmable

Relay Output

1

2

3

4

Pin No.

J6-5 NO All alarms programmed

J6-3 COM

J6-1 NC

J6-6 NO All alarms programmed

J6-4 COM

J6-2 NC

J7-5 NO All alarms programmed

J7-3 COM

J7-1 NC

J7-6 NO

J7-4 COM

J7-2 NC

Alarms Assigned

to this Relay (Default)

with alarm severity of

"critical alarm".

Relay de-energizes

during an alarm condition.

(See Note 1.)

with alarm severity of

"warning alarm".

Relay energizes

during an alarm condition.

(See Note 1.)

with alarm severity of

"information alarm".

Relay energizes

during an alarm condition.

(See Note 1.)

Available for Customer

Custom Setting

Alarms Assigned

to this Relay (Custom)

J8-5 NO

5

6

7

8

J8-3 COM