Page 1

Technical Manual

30985020_US, Rev. B

October 2007

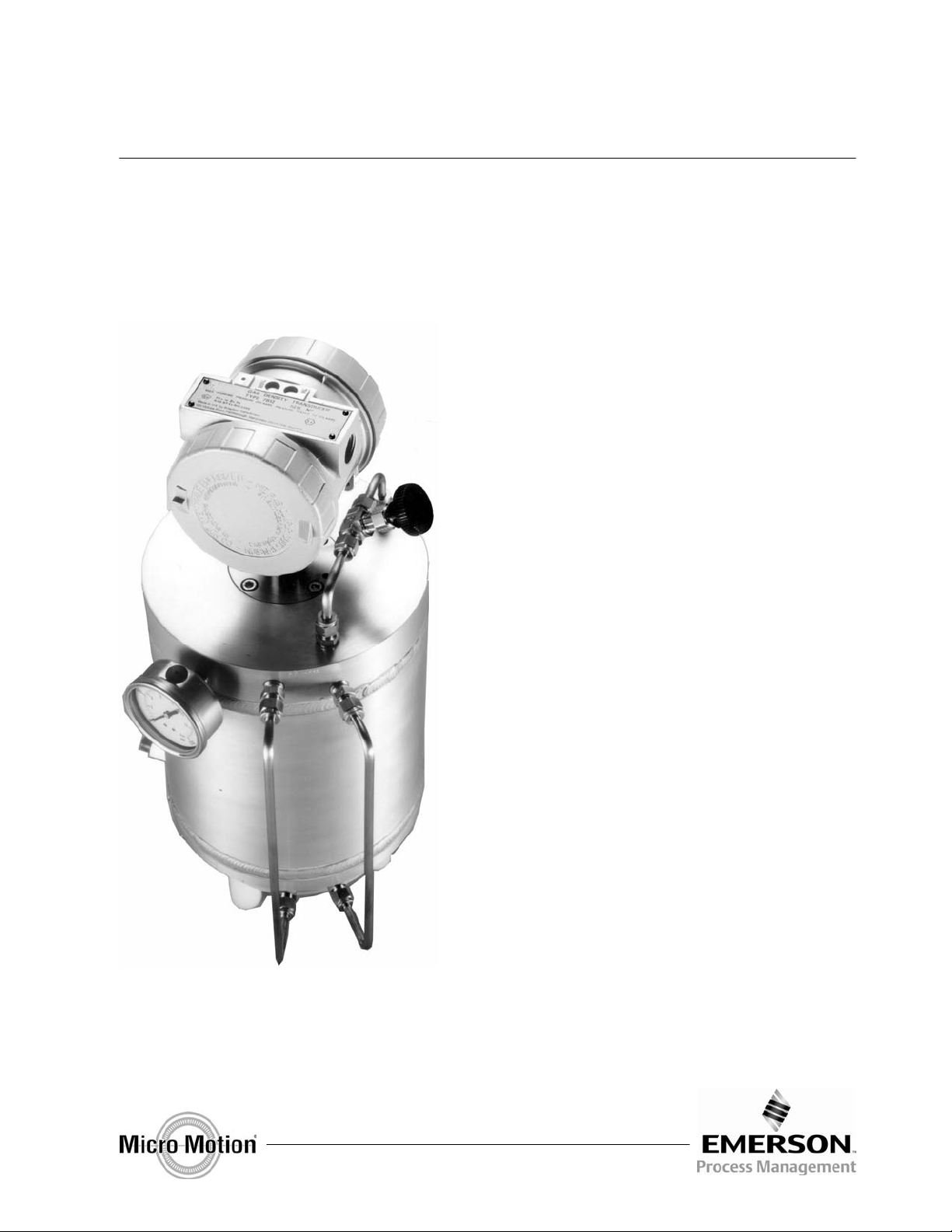

Micro Motion® 3098

3098 Gas Specific Gravity Meter

Page 2

Contents 3098 Technical Manual

Copyright © 2007

Micro Motion, Inc.

All Rights Reserved

Micro Motion pursues a policy of continuous development and product improvement. The specification in this document

may therefore be changed without notice.

To the best of our knowledge, the information contained in this document is accurate and Micro Motion cannot be held

responsible for any errors, omissions or other misinformation contained herein. No part of this document may be

photocopied or reproduced without prior written consent of Micro Motion.

Cont-2

Page 3

3098 Technical Manual Contents

IMPORTANT NOTICE

HANDLE THE 3098 WITH GREAT CARE

DO NOT drop the meter.

DO NOT use gases incompatible with MATERIALS OF CONSTRUCTION.

DO NOT operate the meter above its RATED PRESSURE.

DO NOT expose the meter to excessive vibration (>0.5g continuous).

ENSURE all ELECTRICAL SAFETY requirements are applied.

ENSURE good VENTILATION around the meter/cabinet to prevent gas build up in the unlikely

ENSURE meter is not TRANSPORTED when it contains hazardous substances. This includes

A Returns Form (see Appendix C) MUST be completed and returned together with

event of a leak.

fluids that may have leaked into, and are still contained, within the case.

the 3098 to the address given on the form.

Cont-3

Page 4

Contents 3098 Technical Manual

Cont-4

Page 5

3098 Technical Manual Contents

Contents

Chapter 1 Introduction

1.1 Specific gravity measurement ............................................................................................. 1-2

1.2 Functional description .........................................................................................................1-3

1.2.1 Meter sensing element .......................................................................................... 1-4

1.2.2 Installation............................................................................................................. 1-4

1.3 Definition of terms ............................................................................................................... 1-5

1.3.1 Specific gravity (G)................................................................................................ 1-5

1.3.2 Standard (base or normal) density (ρ

1.3.3 Relative density (ρ

1.4 Physical properties of gas compounds................................................................................ 1-7

1.5 Applications......................................................................................................................... 1-8

1.5.1 Supplementary gas supply .................................................................................... 1-8

1.5.2 Wobbe index measurement .................................................................................. 1-8

1.5.3 Consumer gas costing .......................................................................................... 1-8

Chapter 2 Installation procedure

2.1 Installation procedure .......................................................................................................... 2-1

2.2 Contents.............................................................................................................................. 2-1

2.3 Installing the 3098 enclosure...............................................................................................2-1

2.3.1 Important precautions ........................................................................................... 2-1

2.3.2 Connections .......................................................................................................... 2-2

2.4 Electrical connections and safety barriers / galvanic isolators............................................. 2-2

2.5 Reference chamber pressure determination ....................................................................... 2-2

2.6 Set-up procedure – purge cycling and calibration ............................................................... 2-4

2.7 Outline dimension drawings ................................................................................................2-7

)............................................................................................... 1-5

r

).................................................................. 1-5

s

Chapter 3 Electrical connections

3.1 Introduction .........................................................................................................................3-1

3.2 EMC cabling and earthing ................................................................................................... 3-2

3.3 Certificate conditions for hazardous areas ..........................................................................3-3

3.4 Use with Signal Converters and Flow Computers ............................................................... 3-4

3.5 System connections (7950/7951/7955) ............................................................................... 3-5

3.5.1 7950 2-wire configuration ...................................................................................... 3-5

3.5.2 7950 3-wire configuration ...................................................................................... 3-6

3.5.3 7951 2-wire configuration ...................................................................................... 3-7

3.5.4 7951 3-wire configuration ...................................................................................... 3-8

3.5.5 7955 2-wire configuration ...................................................................................... 3-9

3.5.6 7955 3-wire configuration .................................................................................... 3-10

3.6 System connections (customer’s own equipment) ............................................................ 3-11

3.6.1 Non-hazardous areas.......................................................................................... 3-11

3.6.2 Hazardous areas ................................................................................................. 3-11

3.6.3 Customer’s equipment, 2-wire configuration ....................................................... 3-12

3.6.4 Customer’s equipment, 3-wire configuration ....................................................... 3-13

3.7 Post-installation checks..................................................................................................... 3-14

Cont-5

Page 6

Contents 3098 Technical Manual

Chapter 4 Accuracy considerations

4.1 Accuracy considerations...................................................................................................... 4-1

4.2 Calibration (for non-natural gas applications) ......................................................................4-4

4.2.1 Operation at low reference pressure levels ...........................................................4-4

Chapter 5 Maintenance and faultfinding

5.1 Introduction..........................................................................................................................5-1

5.1.1 Calibration check ................................................................................................... 5-1

5.1.2 Faultfinding............................................................................................................5-1

5.2 Maintenance ........................................................................................................................5-4

5.2.1 Main meter (3098) removal ...................................................................................5-4

5.2.2 Density meter removal...........................................................................................5-6

5.2.3 Reference chamber diaphragm removal ...............................................................5-7

5.2.4 Re-assembly procedure ........................................................................................5-8

5.2.5 3098 filter change procedure.................................................................................5-8

5.2.6 Further servicing of the density meter ...................................................................5-9

5.2.7 Leak testing the 3098 ..........................................................................................5-10

5.2.8 Post maintenance tests .......................................................................................5-10

5.2.9 Worked example of calibration certificate ............................................................ 5-10

Chapter 6 Specification

6.1 3098 specification................................................................................................................6-1

6.1.1 Performance..........................................................................................................6-1

6.1.2 Electrical................................................................................................................6-1

6.1.3 Mechanical ............................................................................................................6-1

6.1.4 Safety ....................................................................................................................6-2

Appendix A Performance optimisation

A.1 Introduction......................................................................................................................... A-1

A.1.1 The density sensor ............................................................................................... A-1

A.1.2 The non-ideal behaviour of gases ........................................................................ A-1

A.1.3 Selection of reference chamber pressure ............................................................. A-1

A.1.4 Selection of calibration gases............................................................................... A-2

A.2 Recommended calibration methods ................................................................................... A-2

A.2.1 General calibration method .................................................................................. A-2

A.2.2 Specific calibration method................................................................................... A-2

Appendix B Principles of operation

B.1 Theory – specific gravity measurement .............................................................................. B-1

Appendix C Returns forms

Cont-6

Page 7

3098 Technical Manual Introduction

Chapter 1

Introduction

This chapter

This chapter contains an outline of how the 3098 works, defines some of the terms commonly used in the manual, and

also gives some practical applications for the 3098.

IMPORTANT NOTICE

The 3098 is normally installed in an IP rated enclosure prior to leaving the factory. In some instances however, the

3098 may be supplied without the enclosure, in which case the environmental and thermal performance of the meter

cannot be guaranteed. Warnings are given throughout this manual when the performance of the meter may be

affected by this.

Meters supplied complete have product labels attached to the outside of the enclosure, and none on the main

cylindrical body of the 3098. If the 3098 itself is labelled, this indicates that the product was supplied without the

enclosure.

For technical details, please refer to the system installer.

IMPORTANT NOTICE

The pressure relief valve has been factory set for the unit to conform to the Pressure Equipment Directive.

UNDER NO CIRCUMSTANCES SHOULD THIS SETTING BE CHANGED.

For further information, contact the factory using the details on the back page.

1-1

Page 8

Introduction 3098 Technical Manual

1.1 Specific Gravity Measurement

Most major gas flow metering systems require the metered quantity to be presented in Heat or standard volume units. To

achieve this requirement, it is often necessary to make continuous and accurate measurements of specific gravity.

Specific gravity can be evaluated by relating the molecular weight of the gas (or gas mixture) to that of the molecular

weight of air, or by evaluating the relative density of the gas (or gas mixture) and compensating the result for the Boyle’s

Law deviation on both the gas (or gas mixture) and the air.

The 3098 Specific Gravity Meter adopts a combination of these two methods, where, by measuring the density of the gas

under controlled conditions, the value of density obtained is directly related to the molecular weight of the gas, and thus to

its specific gravity.

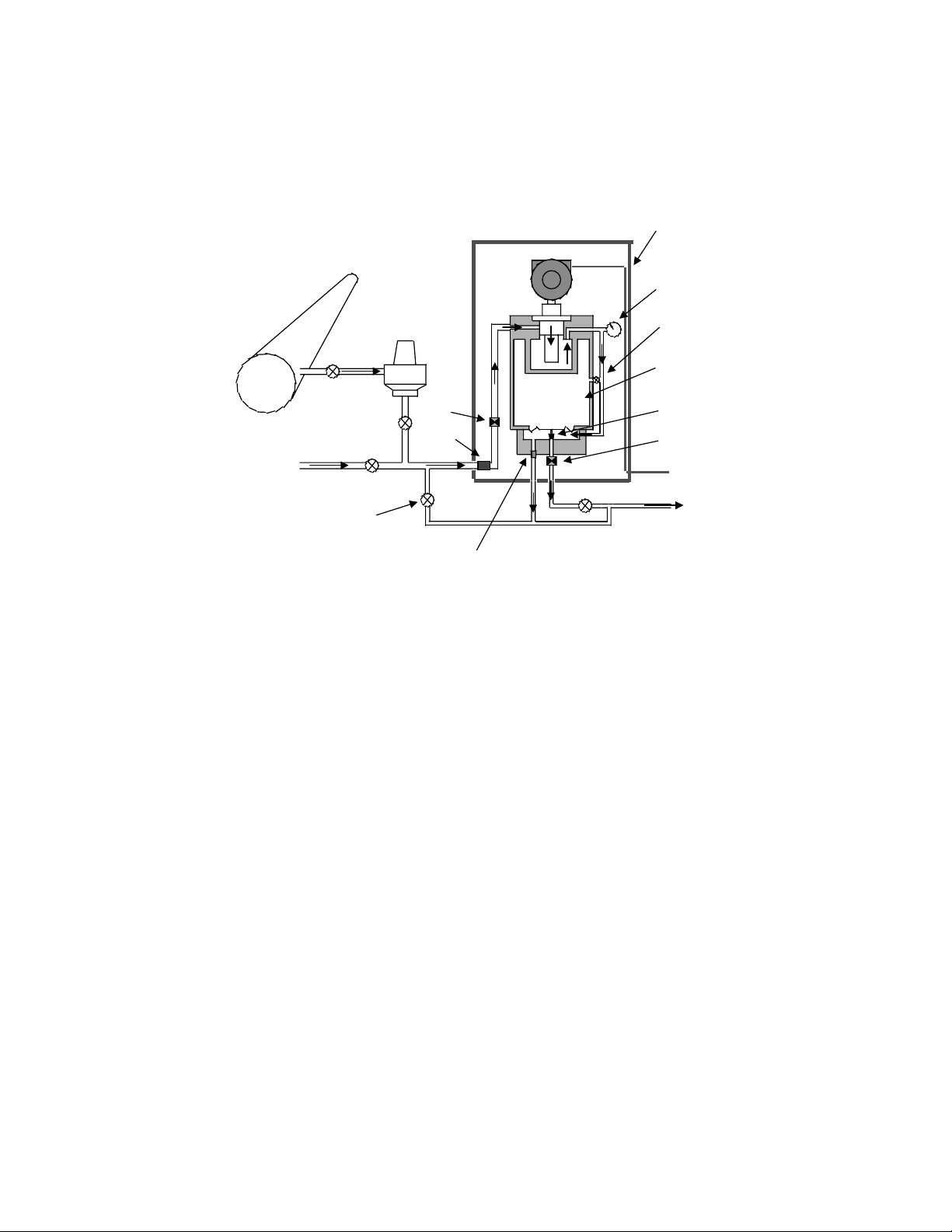

Figure 1-1: View of the 3098 Specific Gravity Meter

installed in a typical enclosure

1-2

Page 9

3098 Technical Manual Introduction

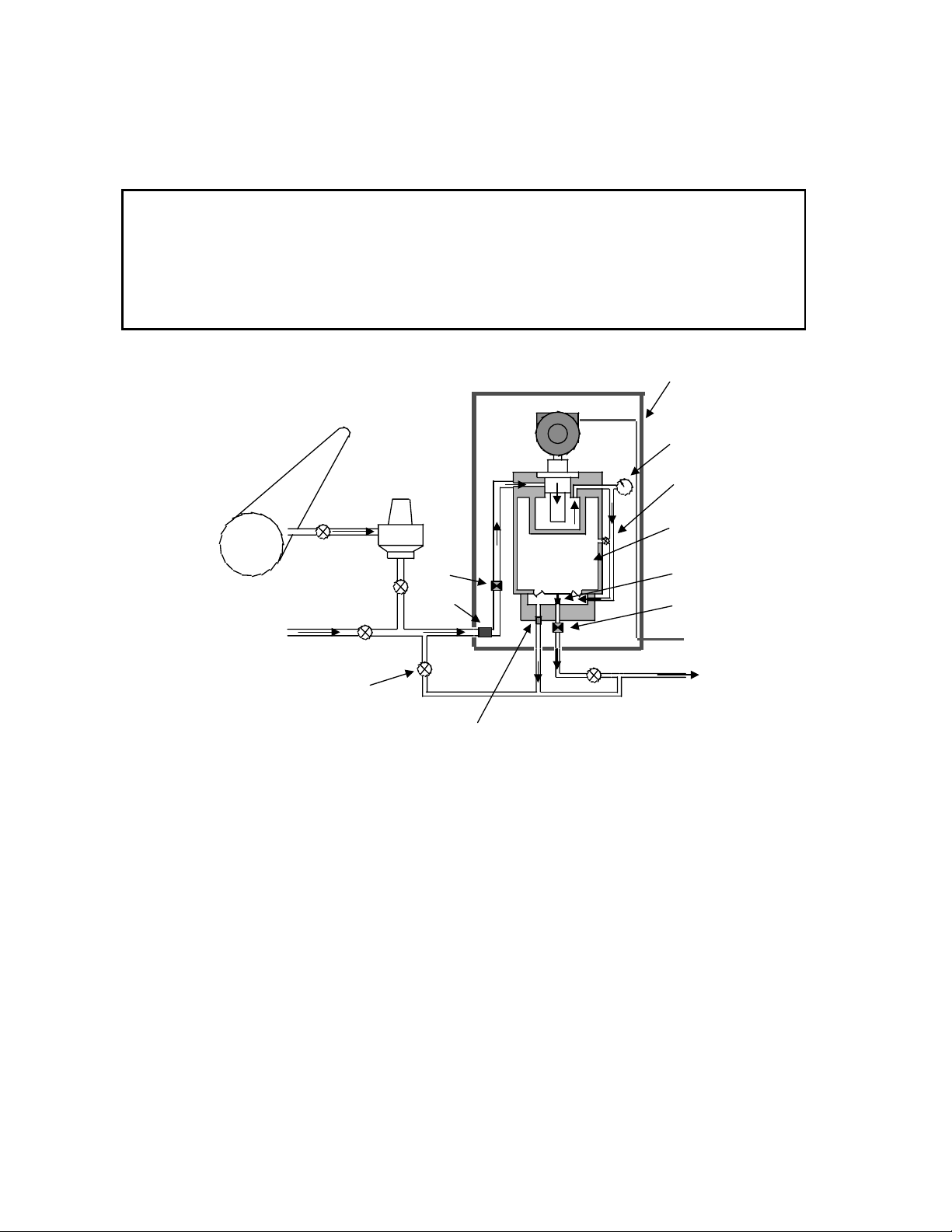

1.2 Functional Description

INSULATING

COVER

CONTROL

PRESSURE

INDICATOR

CHAMBER FILLING

VALVE, E

REFERENCE

CHAMBER

PRESSURE

CONTROL VALVE

OUTPUT

ORIFICE

TO SIGNAL

CONVERTER

TO VENT

Gas

Line

VENT AND INPUT

FOR CALIBRATION

GASES

ISOLATION

VALVE, D

VALVE A

VALVE B

VALVE F

(PURGING VALVE)

PRESSURE

REGULATOR

INPUT

ORIFICE

FILTER

PRESSURE

RELIEF VALVE

DENSITY

METER

3098

DIAPHRAGM

VALVE C

OUTLET

Figure 1-2: Schematic diagram of a typical 3098 Specific Gravity Measuring System

The 3098 Specific Gravity Meter consists of a vibrating cylinder gas density meter surrounded by a gas reference

chamber, which helps to achieve good thermal equilibrium. The gas reference chamber has a fixed volume that is initially

pressurised with the actual line gas. It is then sealed by closing the reference chamber filling valve, thus retaining a fixed

measure and quantity of gas, now known as the reference gas.

Note: Once the chamber has been filled, do not open this valve again.

The sample gas enters the instrument at the enclosure side and passes through a filter, followed by a pressure-reducing

orifice. The sample gas is then fed through input pipework so that it enters the gas density meter at the equilibrium

temperature of the unit. The gas then flows down to a pressure control valve chamber.

The pressure of the reference gas acts on the separator diaphragm and forces the line gas pressure to rise until the

pressures on both sides are equal, thus the gas pressures within the gas density meter and the reference chamber are

equal.

As the ambient temperature changes, the pressure of the fixed volume of reference gas will change as defined by the Gas

Laws. This change in pressure will affect the sample gas pressure within the gas density meter such that the temperature

and pressure changes are self-compensating.

If the sample gas pressure rises above that of the reference chamber pressure, the pressure control valve opens to vent

the excess gas via an outlet orifice in the enclosure side, so that the sample gas pressure is reduced to equal the

reference gas pressure. For gas to flow it is necessary that the supply pressure is greater than the reference pressure,

which in turn must be greater than the vent pressure. (Typically the line pressure must be between 15 and 25% above that

of the reference chamber pressure)

[The principles of operation that describe this operation are given in Appendix B]

A pressure gauge is fitted in order to monitor the pressure within the gas density meter. This is desirable when charging

the reference chamber and also for general maintenance.

Electrical connections to the 3098 are taken through the cable gland in the enclosure side and then into the density

meter’s electronics housing.

1-3

Page 10

Introduction 3098 Technical Manual

When the enclosure is sealed, the complete instrument is insulated so that rapid changes in ambient temperature will not

upset the temperature equilibrium of the unit and produce thermal shock errors.

Note that the 3098 may have been supplied without an enclosure - see Important Notice on page 1-1.

1.2.1 Meter Sensing Element

The gas density meter consists of a thin metal cylinder which is activated so that it vibrates in a hoop mode at its natural

frequency. The gas is passed over the inner and outer surfaces of the cylinder and is thus in contact with the vibrating

walls. The mass of gas which vibrates with the cylinder depends upon the gas density and, since increasing the vibrating

mass decreases the natural frequency of vibration, the gas density for any particular frequency of vibration can be

determined.

A solid state amplifier, magnetically coupled to the sensing element, maintains the conditions of vibration and also

provides the output signal.

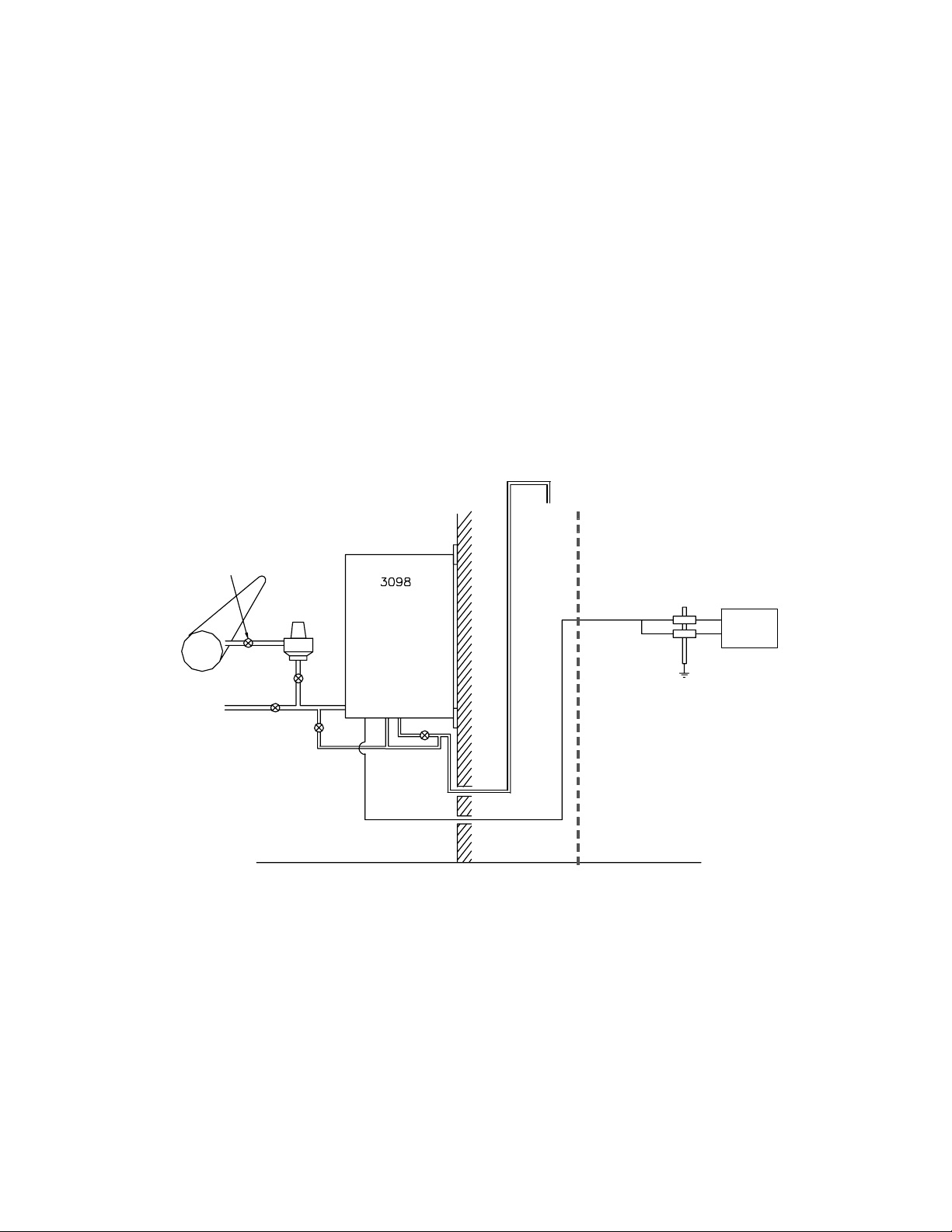

1.2.2 Installation

The 3098 has been designed to be installed wall mounted, a typical installation set-up being given in figure 1-3 below.

ISOLATION

VALVE

GAS

LINE

GAS FOR

CALIBRATION

HAZARDOUS AREA SAFE AREA

VENT TO

ATMOSPHERE

PRESSURE

REGULATOR

VALVE A

VALVE B

VALVE F

IN OUT

ELECTRICAL

CABLE

VALVE C

Figure 1-3: Typical 3098 Specific Gravity Measuring System

SAFETY

BARRIERS

SIGNAL

CONVERTER

1-4

Page 11

3098 Technical Manual Introduction

G

ρ

ρ

G

ρ

ρ

1.3 Definition of Terms

1.3.1 Specific Gravity (G)

This is the ratio of the molecular weight of a gas (or gas mixture) to that of the molecular weight of dry air; the molecular

weight of dry air is normally assumed to be 28.96469 (see Table 1).

M

i.e

=

G

M

A

where

and

1.3.2 Standard (Base or Normal) Density (

This is the absolute density of a gas at STANDARD (BASE or NORMAL) conditions of temperature and pressure and is

commonly used for STANDARD VOLUME flow determination from MASS flow measurement.

i.e

where P = Absolute pressure (bars)

1.3.3 Relative Density (

This is the ratio of the weight of a volume of gas (or gas mixture) to the weight of an equal volume of dry air (see Table 1),

where the weights of both gas (or gas mixture) and air are taken under identical conditions of temperature and pressure.

NOTE: Except for the effects of Boyle’s Law deviation upon both the gas (or gas mixture) and the air, G and

synonymous.

M

= Molecular weight of gas (or gas mixture)

G

M

= Molecular weight of dry air

A

ρ

T = Absolute temperature (degrees Kelvin)

M = Molecular weight

Z = Supercompressibility factor

R = Gas constant (taken as 0.0831434)

=

s

r)

PM

ZRT

s)

ρ

r are

M

i.e

=

where

=

=

ρ

= Density of the gas or gas mixture

G

= Density of air

A

Z

= Supercompressibility factor of the gas or gas mixture

G

Z

= Supercompressibility factor of air

A

M

GG

ρ

ρ

r

G

A

Z

Z

AA

Z

G

Z

A

1-5

Page 12

Introduction 3098 Technical Manual

ρ

The relative density of mixed hydrocarbon gases at 1 bar (14.735 lb/in2) absolute and 15.56°C (60°F) by empirical

equation is:

= 0.995899G + 0.010096G

r

2

1-6

Page 13

3098 Technical Manual Introduction

1.4 Physical Properties of Gas Compounds

Compound Formula Molecular Weight Specific Gravity

Hydrogen H2 2.01594 .069600

Helium He 4.00260 .138189

Water Vapour H2O 18.01534 .621976

Nitrogen N2 28.01340 .967157

Carbon Monoxide CO 28.01055 .967058

Oxygen O2 31.99880 1.104752

Argon Ar 39.94800 1.379197

Carbon Dioxide CO2 44.00995 1.519435

Air (3) - 28.96469 1.000000

Hydrogen Sulphide H2S 34.07994 1.176603

Methane CH4 16.04303 .553882

Ethane C2H6 30.07012 1.038165

Propane C3H8 44.09721 1.522447

i-Butane C4H10 58.12430 2.006730

n-Butane C4H10 58.12430 2.006730

i-Pentane C5H12 72.15139 2.491012

n-Pentane C5H12 72.15139 2.491012

Hexane C6H14 86.17848 2.975294

Heptane C7H16 100.20557 3.459577

Octane C8H18 114.23266 3.943859

Table 1

NOTES:

1. Based upon 1961 atomic weights, referred to Carbon-12 Isotope (12 AMU), recommended by the International

Commission of Atomic Weights and the International Union of Pure and Applied Chemistry.

2. Perfect gas specific gravity represents the ratio of molecular weight of compounds to the molecular weight of air.

3. Molecular weight of air based upon components of atmospheric air given in Handbook of Chemistry & Physics, 53rd

Edition (1972 - 1973). Value of 28.96469 differs from figure 28.966 provided by NBS Circular 564 due to minute

differences in component content and changes in atomic weights of the elements given in 1961 (NBS value based

upon 1959 atomic weights).

1-7

Page 14

Introduction 3098 Technical Manual

M

1.5 Applications

The following are typical applications where specific gravity measurement is an essential parameter.

1.5.1 Supplementary Gas Supply

This system is used to top up normal supplies during peak periods. Specific gravity monitoring of a propane/air mixture for

example, enables accurate control to be exercised over the ratio of the mixture, therefore ensuring that the correct burning

characteristic/calorific value is maintained.

1.5.2 Wobbe Index Measurement

The burning characteristic of a gas must be well established for efficient combustion and to ensure that no flame lift or

flame light-back occurs on a particular burner. Three criteria are used to establish this characteristic; calorific value,

specific gravity and flame speed. The calorific value and specific gravity are often combined to form the Wobbe Number

i.e:

Wobbe Number = C V

√G

where CV = Calorific value

G = Specific gravity

1.5.3 Consumer Gas Costing

This major application has already been described in the introduction, MASS to BASE VOLUME unit conversion, and may

be further illustrated by the following equations:

Base Unit Volume = Mass Flow

Base Density

i.e Vs = M

ρ

G

s

ρ

AA

Z

Z

G

=

1-8

Page 15

3098 Technical Manual Installation Procedure

Chapter 2

Installation Procedure

2.1 Installation Procedure

The procedure for installing the 3098 involves the following steps:

Check all components are present (Section 2.2)

Position and fix the 3098 enclosure (Section 2.3)

Connect the gas supply line (Section 2.3.2)

Make electrical connections (Section 2.4 and Chapter 3)

Select a reference pressure (Section 2.5)

Purge cycle and calibrate the 3098 (Section 2.6)

2.2 Contents

The following items should be enclosed with this 3098 unit:

3098 Specific Gravity Meter.

Labelled enclosure.

Enclosure mounting feet.

Enclosure mounting feet instructions.

This technical manual (30985020).

Safety Instructions (3095008/SI and 30988002/SI).

Accessories kit.

Temperature coefficient Calibration Certificate.

Check that all the above items are present; if not then contact your supplier immediately. (Note that the 3098 may have

been supplied without an enclosure.)

2.3 Installing the 3098 enclosure

The following installation instructions apply only to meters supplied with an enclosure (see Important Notice on page 1-1).

In all other cases, please refer to the system installer.

2.3.1 Important Precautions

Take care to observe the precautions listed at the front of this manual (page Cont-3).

The 3098 SG meter is contained inside an IP rated enclosure (which provides thermal insulation) and a mounting system

(consisting of a bracket and feet) to fix the unit in place. Whilst this structure is designed to minimise damage due to

shocks, the box and unit must not be dropped. Dropping of the 3098 either inside or outside its enclosure will damage

the meter.

Contained inside the enclosure are four box feet which, when attached to a vertical wall will hold the housing. A set of

instructions on how to attach these feet is included inside the box. Enclosure dimensions are in Section 2.7.

2-1

Page 16

Installation Procedure 3098 Technical Manual

2.3.2 Connections

There are four connections that need to be made to the 3098: three gas pipeline connections and one electrical

connection through an IP rated cable gland. The gas pipeline connections take the form of ¼” Swagelok bulkhead fittings,

and are used for the gas input, gas output and pressure relief lines.

Each connection is labelled.

Caution: Connecting the gas input line to the wrong bulkhead fitting might result in damage.

A 7812 gas density meter is used as the measuring instrument in the 3098 and needs to be connected inside the

enclosure. All wiring should be connected through the cable gland to maintain the enclosure’s overall protection to dust

and water ingress.

At all stages during calibration and operation, the 3098 is designed to function with the enclosure sealed. This allows the

unit to operate in the condition of thermal equilibrium, which is essential for accurate measurement.

2.4 Electrical Connections and Safety Barriers / Galvanic Isolators

When the 3098 is mounted in a hazardous area, the electrical connections to the meter must conform to stringent

conditions. For electrical connections between the meter and its associated flow computer/signal converter, reference

must be made to safety instruction booklet 30985018/SI.

Electrical cable connection to the 3098 is made to the terminal block inside the resonator electronics housing (i.e. inside

the enclosure). Poor connection to the terminals will prevent correct operation but will not damage the unit - provided that

safety barriers or galvanic isolators are included in the circuit for hazardous areas or the maximum power supply does not

exceed the 33V maximum limit (as described in chapter 3).

The power supplied to the meter terminals should be in the range of 15.5 to 33Vd.c with the average current drawn by the

unit being <20mA. If the current consumption exceeds this value, the polarity of the connections should be checked.

A full description of how to connect the 3098 to a signal converter/flow computer is given in Chapter 3.

2.5 Reference Chamber Pressure Determination

Once the 3098 has been placed in its fixture and all relevant pipework and electrical connections made, the reference

chamber pressure needs to be determined.

The gas type and reference chamber pressure define the ‘controlled condition’ at which the unit allows gas to flow and

establishes a direct relationship between density and the specific gravity of the sample gas.

The choice of reference chamber gas pressure is dependent upon 3 factors:

1. The span of specific gravity to be measured.

2. The expected change in sample gas supercompressibility, Z.

3. The accuracy required.

2-2

Page 17

3098 Technical Manual Installation Procedure

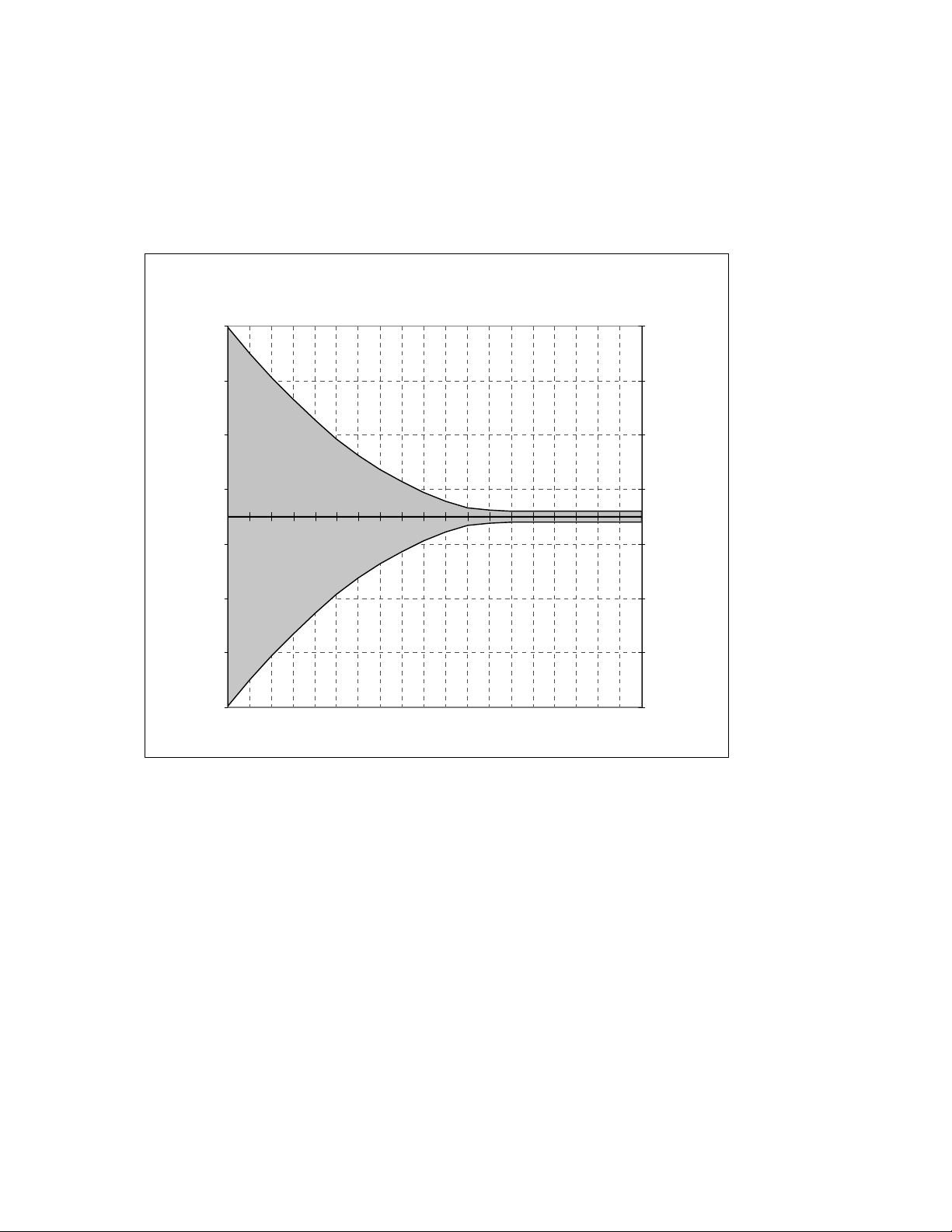

The graph below gives an indication of the typical errors associated with using different reference chamber pressures for

natural gas with a reasonably constant specific gravity (in the range of 0.55-0.8). This is typical for natural gas metering

market, where the gas is available at a line pressure of 7 Bar abs.

As can be seen, below 7 Bar abs, the total error begins to increase; using a higher reference pressure will not improve

accuracy, but may encourage gas leakage. Therefore, for the conditions specified, 7 Bar is the recommended pressure.

Typical Total Error/ °C vs Referenc e Chamber Pressure

For NATURAL GAS APPLICATIONS ONLY.

0.035

0.035

0.025

0.015

0.005

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10

-0.005

-0.015

Typ % of FS Specific Gravity /°C

-0.025

-0.035

Reference Chamber Pressure (Bar A)

0.025

0.015

0.005

-0.005

-0.015

-0.025

-0.035

Typ % of FS Specific Gravity /°C

This graph should only be used for natural gas applications, and.gives typical errors seen on the 3098 if it is not used at

the recommended reference chamber pressure.

If the span of specific gravity or change in supercompressibility, Z, is large, and the gas is not a methane/nitrogen mix,

then the best reference chamber pressure can still be determined. The calculation for doing this is explained in Chapter 4,

‘Accuracy Considerations’.

Once the desired reference pressure has been found, the 3098 can now be purge cycled and then calibrated.

2-3

Page 18

Installation Procedure 3098 Technical Manual

2.6 Set-up procedure - Purge Cycling and Calibration

IMPORTANT NOTICE

The pressure relief valve has been factory set for the unit to conform to the Pressure Equipment Directive.

UNDER NO CIRCUMSTANCES SHOULD THIS SETTING BE CHANGED.

For further information, contact the factory using the details on the back page.

INSULATING

COVER

CONTROL

PRESSURE

INDICATOR

CHAMBER FILLING

VALVE, E

REFERENCE

CHAMBER

PRESSURE

CONTROL VALVE

OUTPUT

ORIFICE

Gas

Line

VENT AND INPUT

FOR CALIBRATION

GASES

ISOLATION

VALVE, D

VALVE A

VALVE B

VALVE F

(PURGING VALVE)

PRESSURE

REGULATOR

INPUT

ORIFICE

FILTER

PRESSURE

RELIEF VALVE

DENSITY

METER

3098

DIAPHRAGM

VALVE C

OUTLET

Figure 2-1: Schematic diagram of a typical 3098 Specific Gravity Measuring System

TO SIGNAL

CONVERTER

TO VENT

The procedure for purging and calibrating the 3098 is given below:

1. Ensure isolation valve (D) is closed.

2. Ensure valve (A) is closed.

3. Ensure valve (B) is closed.

4. Ensure valve (F) is closed.

5. Open valve (C).

6. Open chamber filling valve (E).

7. Set the pressure regulator to the required value - i.e. the actual working pressure of the system.

8. Open isolation valve (D).

9. Open valve (A) and allow gas to flow for 3 minutes.

2-4

Page 19

3098 Technical Manual Installation Procedure

Purge Cycling

10. Close valve (C).

11. When Control Pressure Indicator is at the desired value, shut valve (A) and open valve (F). Allow the gas to vent to

atmospheric pressure.

12. Close valve (F) and open valve (A).

13. When Control Pressure Indicator is at the desired value, shut valve (A) and open valve (F). Allow the gas to vent to

atmospheric pressure.

Actions 12 and 13 define the purging cycle required for setting up the reference chamber gas in the 3098.

The number of times that this procedure should be repeated depends upon the gas regulator pressure used and is defined by:

ª

=cyclespurgeofNumber

«

¬

14. Once the required number of cycles has been performed, close valve (F) and open valve (A).

15. When the desired gas pressure inside the chamber has been reached (as shown by the Control Pressure Indicator)

shut the chamber valve.

7 x 3

pressureregulatormax

º

»

¼

DO NOT open the chamber valve again.

The gas now inside the 3098 chamber is the line reference gas.

3098 Calibration using two known gases

16. Close valve (A).

17. Connect the first calibration gas bottle to the pipework and set the pressure to be typically 25% above that inside the

reference chamber.

18. Open valve (B).

19. Ensure valve (C) is open and allow gas to flow until the time period as measured by the signal converter/flow

computer is stable to ±1ns or better (the typical stability will be better than this). [For the required electrical

connections see Chapter 3]

20. Note this time period (τ

21. Shut valve (B).

22. Replace the first calibration gas bottle with the second calibration gas bottle.

23. Set pressure to typically 25% above that inside the reference chamber and open valve B.

24. Allow gas to flow until the time period shown by the meter is stable to ±1ns or better.

25. Note this time period (τ

26. Apply these noted numbers into equations (1) and (2) below:

) together with the certified SG from the bottle of gas (SG1).

1

) and the certified SG from the bottle of gas (SG2).

2

ª

K

=

«

2

2

() ()

1

¬

−=

Alternatives to this are to use the calibration certificate shown in table 4 (found in Chapter 4), or to use the Excel

program ‘Calcert.xls’ that is supplied on the attached floppy disk.

28. Shut valve (B) and disconnect the second calibration gas bottle from pipework.

29. Open the isolation valve (D).

30. Open valve (A).

SGSG

−

ττ

−

KSGK

º

21

»

2

2

¼

2

()

τ

1210

(1)

(2)

2-5

Page 20

Installation Procedure 3098 Technical Manual

IMPORTANT NOTE

If the application is running with a reference pressure less than 45.5 psi (3 BarA), the maximum flow rate that can be used

for correct operation is 50cm

The unit should now give a live reading of the measured gas SG. If the unit does not output a sensible reading, certain

checks can be made. These checks are summarised in Chapter 5, ‘Maintenance & Fault finding’.

If optimum SG accuracy is required, the optimisation method described in Appendix A - which compensates for errors due

to gas velocity of sound, compressibility and temperature coefficient - should be used.

For optimum accuracy, the time period (τ) must be resolved to ±0.1ns. This can be achieved using 7950/7951/7955 signal

converters and flow computers set to a cycle time of 10s.

3

/s. A full explanation of this effect is given in Accuracy Considerations, Chapter 4.

2-6

Page 21

3098 Technical Manual Installation Procedure

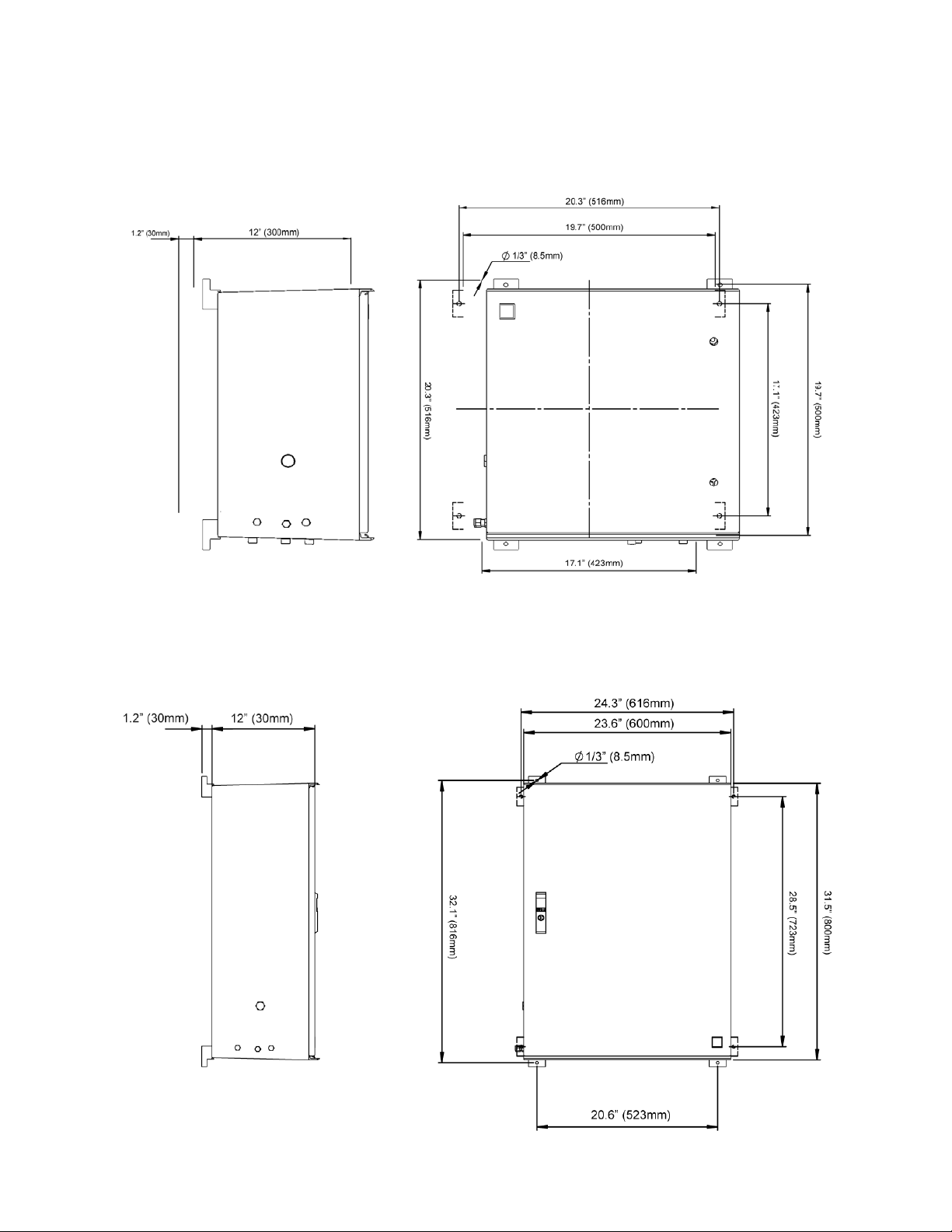

2.7 Outline dimensional drawings

The drawings below show a 3098 without an enclosure. For dimensions of small and large enclosures, see the following

two pages.

”

4

2.

1

m)

m

4

1

(3

4.4” (112mm)

)

”

4

.

6

8

2

(

”

5

.

0

1

2-7

Page 22

Installation Procedure 3098 Technical Manual

Small Enclosure Dimensions

Large Enclosure Dimensions

2-8

Page 23

3098 Technical Manual Electrical Connections

Chapter 3

Electrical Connections

This chapter

This chapter contains details and wiring diagrams for connecting the 3098 to 7950/51/55 Signal Converters and Flow

Computers, and more generally to other equipment in both hazardous and non-hazardous situations.

3.1 Introduction

The electrical connections to the 3098 are made to the 7812 gas density meter held inside the enclosure. When installed

in hazardous areas, connections between the meter and the power supply/readout equipment must be completed through

ZENER SAFETY BARRIERS [or galvanic isolators]. The electrical cable enters the enclosure (if supplied - see Important

Notice on page 1-1) through a cable gland assembly and then passes into the amplifier housing.

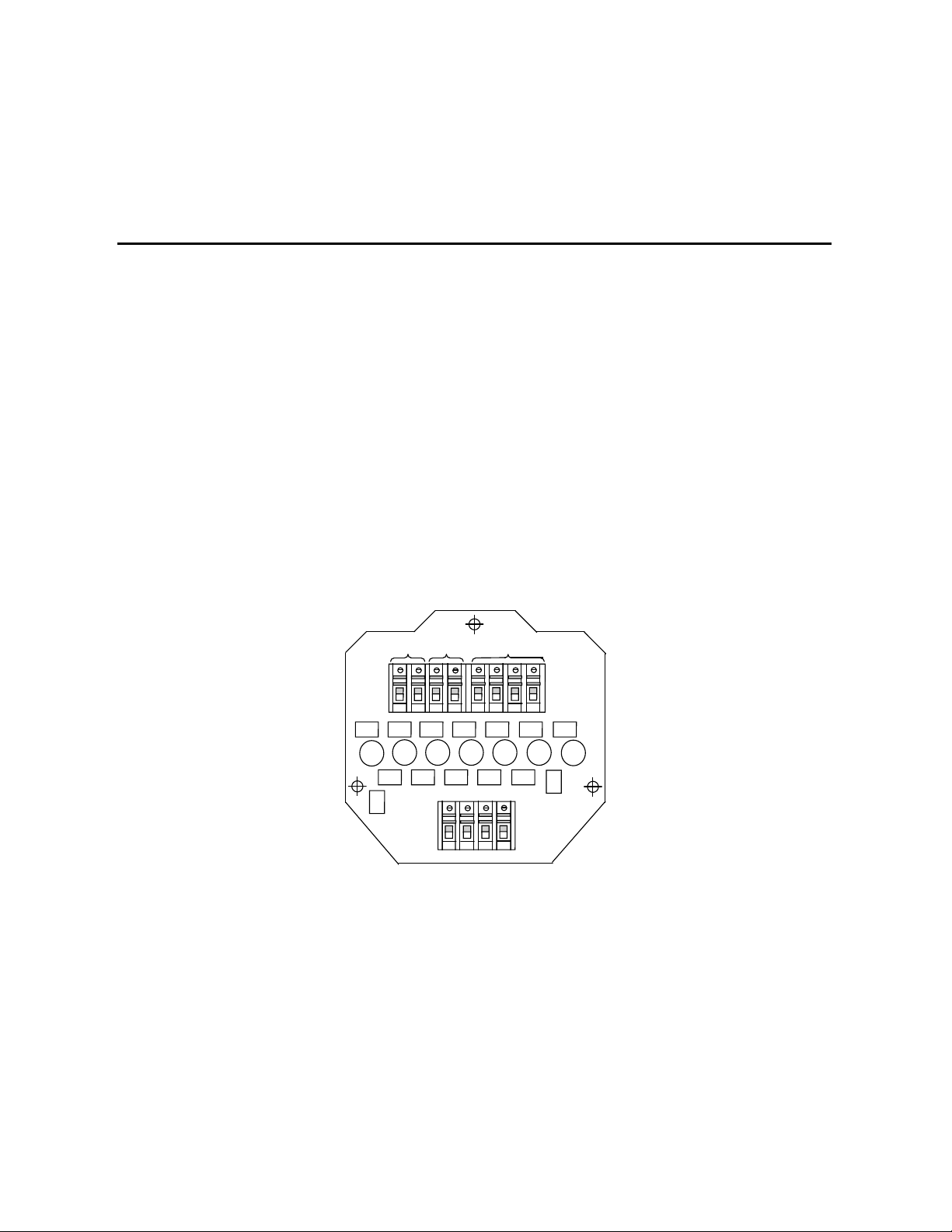

The meter terminal layout is shown in Figure 3-1.

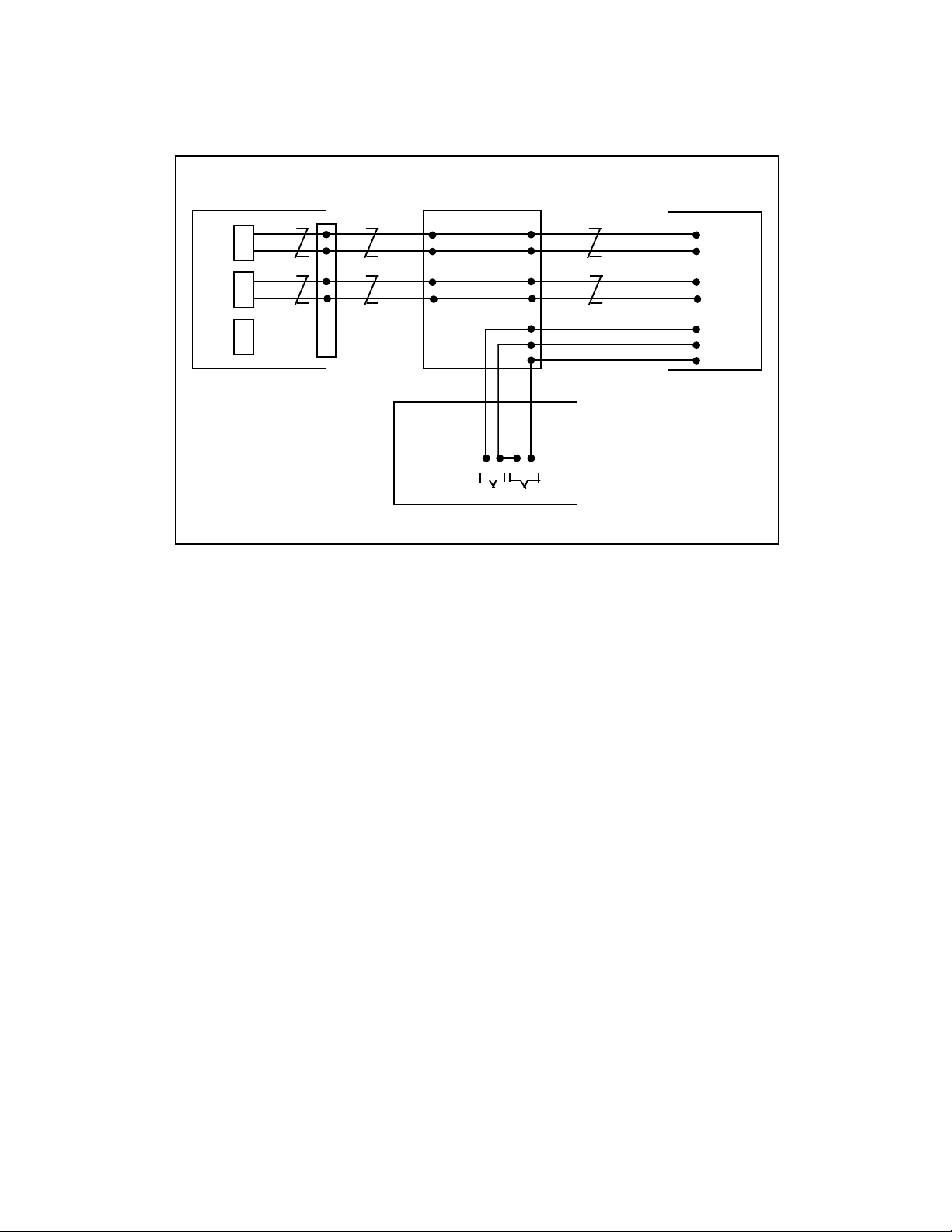

The amplifier housing has two chambers. The one nearest the cable gland axis contains the terminals for connection to

the meter/signal processing instrument. The other chamber contains the maintaining amplifier unit. The amplifier board is

encapsulated in a circular plastic container, with the complete module secured by a keyway and a centrally positioned

clamping screw. Behind the amplifier there is an interconnect terminal board which links the sensor to the maintaining

amplifier, and the amplifier to the user connect board (see Figure 3-2).

SIG A

SIG B

123

Figure 3-1: Main Terminal Board Connections

4567

9110 11 12

PRT

8

3-1

Page 24

Electrical Connections 3098 Technical Manual

INTERCONNECT PCB

78121503

PICK UP

COIL

DRIVE

COIL

BN

O

R

B

SPOOLBODY

78121201

2

3

4

5

BN

13 20

R

14 19

O

16 18

Y

15 17

12 4 3

TERMINAL PCB

78121502

BN PL1

R PL2

O PL5

Y PL6

22

21

23

- B+ -

SIG BSIG A

R PL3

G PL4

O PL7

I/P +

I/P -

O/P +

O/P -

V +

V -

FREQ. OUT

AMPLIFIER PC B

78121501

Figure 3-2: Interconnection diagram

3.2 EMC Cabling and Earthing

To meet the EC Directive for EMC (Electromagnetic Compatibility), it is recommended that the meter be connected using

a suitable instrumentation cable and earthed through the meter body and pipework. The instrumentation cable should

have an individual screen, foil or braid over each twisted pair and an overall screen to cover all cores. Where permissible,

the screen should be connected to earth at both ends. Note that for intrinsic safety, termination of the screen to earth in

the hazardous area is NOT generally permitted.

Typical cables that are suitable are those that meet BS5308 Multi-pair Instrumentation Types 1 and 2, such as Belden

types 9500, 9873, 9874, 9773, 9774 etc.

3-2

Page 25

3098 Technical Manual Electrical Connections

3.3 Certificate conditions for hazardous areas

For details of hazardous area installations, please refer to safety instructions (30985018/SI).

The 3098 can be electrically connected in either a 2-wire or 3-wire configuration. A schematic block diagram of these two

types is given in figures 3-3 and 3-4 below:

SENSING ELEMENT AMPLIFIER UNIT

CYLINDER

VIBRATING

CYLINDER

PART OF

SPOOLBODY

ACTIVATING

COIL

PICK OFF

COIL

PICK OFF CURRENT

CYLINDER DRIVE CURRENT

A

D

B

C

SIGNAL

OUTPUT

330R

POSITIVE

SUPPLY

VOLTAGE (+V)

NEGATIVE

SUPPLY

VOLTAGE (0V)

Figure 3-3: Schematic Block Diagram of Meter Circuit (2-wire System)

SENSING ELEMENT AMPLIFIER UNIT

CYLINDER

ACTIVATING

VIBRATING

CYLINDER

PART OF

SPOOLBODY

COIL

PICK OFF

COIL

PICK OFF CURRENT

CYLINDER DRIVE CURR ENT

A

D

B

C

USER CONNECT BOARD

USER CONNECT BOARD

POSITIVE

SUPPLY

VOLTAGE (+V)

SIGNAL

OUTPUT

NEGATIVE

SUPPLY

VOLTAGE (0V)

Figure 3-4: Schematic Block Diagram of Meter Circuit (3-wire System)

3-3

Page 26

Electrical Connections 3098 Technical Manual

3.4 Use with Signal Converters and Flow Computers

The meter can be operated in two general environments, either in SAFE AREAS or in HAZARDOUS AREAS. When

used in hazardous areas, safety barriers or galvanic isolators MUST be placed between the meter and the signal

converter/flow computer.

When operating in a safe area with a 3-wire system, the line resistance between meter and signal converter must be

greater than 40 ohms. This can be achieved by placing a suitable resistor in the line or by using the inherent resistance of

the cable used (if the resistance per km and length of cable used is sufficient).

Given these conditions, we recommend that the maximum cable length between the 3098 and signal converter - assuming

a BS5308 standard cable - is 2km.

For details of hazardous area installations, please refer to safety instructions (30985018/SI).

For the purposes of clarity, all wiring diagrams describing a ‘Safe Area’ setup using the 3-wire system have had a

40 ohm resistor placed into the +24V power supply line.

3-4

Page 27

3098 Technical Manual Electrical Connections

3.5 System Connections (7951/7950/7955)

The density and power connections to the 3098 in safe and hazardous areas are shown in the following diagrams:

3.5.1 7950 2-wire configuration

3098 7950 Signal Converter

Ch.1

PL9/2

PL9/4

PL9/3

SIG A

SIG B

1

+

2

-

3

+

4

-

330R

Figure 3-5.9: 7950 Signal Converter and Gas Specific Gravity 2-Wire System (Safe Area)

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

Density power +PL9/1

Density input +

Density power -

Density input -

3098 7950 Signal Converter

Ch.1

PL9/2

PL9/4

PL9/3

+

SIG A

-

+

SIG B

-

Hazardous Area

1

2

3

4

3

MTL 787 (+ve)

4

1

2

Safe Area

Figure 3-5.10: 7950 Signal Converter and Gas Specific Gravity 2-Wire System

with Shunt-Diode Safety Barrier (Hazardous Area)

3098 7950 Signal Converter

Ch.1

PL9/4

PL9/2

PL9/3

SIG A

SIG B

1

+

2

-

3

+

4

-

200R

4

14

2kR

5

13

1

12

MTL 5032

11

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

Ch.2

PL9/5

PL9/8

PL9/6 Density input +

PL9/7

Density power +PL9/1

Density input +

Density power -

Density input -

Density power +PL9/1

Density power -

Density input -

Hazardous Area Safe Area

Note: Switches on MTL5032 should be set to give a threshold voltage of 3 volts.

Figure 3-5.11: 7950 Signal Converter and Gas Specific Gravity 2-Wire System

with Galvanic Isolator (Hazardous Area)

3-5

Page 28

Electrical Connections 3098 Technical Manual

3.5.2 7950 3-wire configuration

3098 7950 Signal Converter

Ch.1

PL9/2

PL9/4

PL9/3

SIG A

SIG B

1

+

2

-

3

+

4

-

Figure 3-5.12: 7950 Signal Converter and Gas Specific Gravity 3-Wire System (Safe Area)

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

Density power +PL9/1

Density input +

Density power -

Density input -

3098 7950 Signal Converter

Ch.2

PL9/5

PL9/6

PL9/8

PL9/7

Density power +PL9/1

Density input +

Density power -

Density input -

SIG A

SIG B

1

+

2

-

3

+

4

-

3

MTL 787 (+ve)

4

1

2

Ch.1

PL9/2

PL9/4

PL9/3

Hazardous Area Safe Area

Figure 3-5.13: 7950 Signal Converter and Gas Specific Gravity 3-Wire System

with Shunt-Diode Safety Barrier (Hazardous Area)

3098 7950 Signal Converter

Ch.1

PL9/4

PL9/2

PL9/3

SIG A

SIG B

1

+

2

-

3

+

4

-

4

1

5 12

MTL 5032

14

2kR

13

11

Hazardous Area Safe Area

Note: Switches on MTL5032 should be set to give a threshold voltage of 3 volts

Figure 3-5.14: 7950 Signal Converter and Gas Specific Gravity 3-Wire System

with Galvanic Isolator (Hazardous Area)

Ch.2

PL9/5

PL9/8

PL9/6 Density input +

PL9/7

Density power +PL9/1

Density power -

Density input -

3-6

Page 29

3098 Technical Manual Electrical Connections

3.5.3 7951 2-wire configuration

3098 7951 Signal Converter/Flow Computer

SIG A

SIG B

1

+

2

-

3

+

4

-

330R

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

Figure 3-5.15: 7951 Flow Computer/7951 Signal Converter

Gas Specific Gravity 2-Wire System (Safe Area)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

3098 7951 Signal Converter/Flow Computer

SIG A

SIG B

1

+

2

-

3

+

4

-

3

MTL 787 (+ve)

4

1

2

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

Hazardous Area

Safe Area

Figure 3-5.16: 7951 Flow Computer/7951 Signal Converter

Gas Specific Gravity 2-Wire System with Shunt-Diode Safety Barrier (Hazardous Area)

3098 7951 Signal Converter/Flow Computer

SIG A

SIG B

1

+

2

-

3

+

4

-

200R

4

14

2kR

13

5

1

12

MTL 5032

11

Ch.1

PL5/9 (SK6/22)

PL5/10 (SK6/24)

PL5/1 (SK6/14)

PL5/2 (SK6/15)

Ch.2

PL5/9 (SK6/22)

PL5/10 (SK6/24)

PL5/3 (SK6/16)

PL5/4 (SK6/17)

Hazardous Area Safe Area

Note: Switches on MTL5032 should be set to give a threshold voltage of 3 volts

Figure 3-5.17: 7951 Flow Computer/7951 Signal Converter

Gas Specific Gravity 2-Wire System with Galvanic Isolator (Hazardous Area)

24V pwr +

(+24V dc)

24V pwr -

(0V dc)

Den ip +

(Den +)

Den ip -

(Den -)

3-7

Page 30

Electrical Connections 3098 Technical Manual

3.5.4 7951 3-wire configuration

3098 7951 Signal Converter/Flow Computer

SIG A

SIG B

1

+

2

-

3

+

4

-

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

Figure 3-5.18 : 7951 Flow Computer/7951 Signal Converter

Gas Specific Gravity 3-Wire System (Safe Area)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

3098 7951 Signal Converter/Flow Computer

SIG A

SIG B

1

+

2

-

3

+

4

-

3

MTL 787 (+ve)

4

1

2

Ch.1

PL5/9 (SK6/22)

PL5/1 (SK6/14)

PL5/10 (SK6/24)

PL5/2 (SK6/15)

Ch.2

PL5/9 (SK6/22)

PL5/3 (SK6/16)

PL5/10 (SK6/24)

PL5/4 (SK6/17)

24V pwr +

(+24V dc)

Den ip +

(Den +)

24V pwr -

(0V dc)

Den ip -

(Den -)

Hazardous Area

Safe Area

Figure 3-5.19 : 7951 Flow Computer/7951 Signal Converter

Gas Specific Gravity 3-Wire System with Shunt-Diode Safety Barrier (Hazardous Area)

3098 7951 Signal Converter/Flow Computer

Ch.1

PL5/9 (SK6/22)

PL5/10 (SK6/24)

PL5/1 (SK6/14)

PL5/2 (SK6/15)

SIG A

SIG B

1

+

2

-

3

+

4

-

Hazardous Area Safe Area

Note: Switches on MTL5032 should be set to give a threshold voltage of 3 volts

Figure 3-5.20 : 7951 Flow Computer/7951 Signal Converter

Gas Specific Gravity 3-Wire System with Galvanic Isolator (Hazardous Area)

4

1

5 12

MTL 5032

14

2kR

13

11

Ch.2

PL5/9 (SK6/22)

PL5/10 (SK6/24)

PL5/3 (SK6/16)

PL5/4 (SK6/17)

24V pwr +

(+24V dc)

24V pwr -

(0V dc)

Den ip +

(Den +)

Den ip -

(Den -)

3-8

Page 31

3098 Technical Manual Electrical Connections

3.5.5 7955 2-wire configuration

3098 7955 Flow Computer

SIG A

SIG B

1

+

2

-

3

+

4

-

330R

Ch.1

SK1/31

SK3/19

SK1/32

Figure 3-5.21 : 7955 Flow Computer

Gas Specific Gravity 2-Wire System (Safe Area)

3098 7955 Flow Computer

+

SIG A

-

+

SIG B

-

Hazardous Area

1

2

3

4

3

MTL 787 (+ve)

4

1

2

Safe Area

Ch.1

SK1/31

SK3/19

SK1/32

Ch.2

SK3/35

SK1/48

SK3/19

SK1/49

Ch.2

SK3/35

SK1/48

SK3/19

SK1/49

+24V DensitySK3/35

Density Sig +

0V Density

Density Sig -

+24V DensitySK3/35

Density Sig +

0V Density

Density Sig -

Figure 3-5.22: 7955 Flow Computer

Gas Specific Gravity 2-Wire System with Shunt-Diode Safety Barrier (Hazardous Area)

3098 7955 Flow Computer

Ch.2

SK3/35

SK3/19

SK1/48

SK1/49

SIG A

SIG B

1

+

2

-

3

+

4

-

200R

4

14

2kR

5

13

1

12

MTL 5032

11

Ch.1

SK3/19

SK1/31

SK1/32

Hazardous Area Safe Area

Note: Switches on MTL5032 should be set to give a threshold voltage of 3 volts

Figure 3-5.23 : 7955 Flow Computer

Gas Specific Gravity 2-Wire System with Galvanic Isolator (Hazardous Area)

+24V DensitySK3/35

0V Density

Density Sig +

Density Sig -

3-9

Page 32

Electrical Connections 3098 Technical Manual

3.5.6 7955 3-wire configuration

3098 7955 Flow Computer

Ch.1

SK1/31

SK3/19

SK1/32

SIG A

SIG B

1

+

2

-

3

+

4

-

Figure 3-5.24 : 7955 Flow Computer

Gas Specific Gravity 3-Wire System (Safe Area)

3098 7955 Flow Computer

Ch.1

SK1/31

SK3/19

SK1/32

SIG A

SIG B

1

+

2

-

3

+

4

-

3

MTL 787 (+ve)

4

1

2

Ch.2

SK3/35

SK1/48

SK3/19

SK1/49

Ch.2

SK3/35

SK1/48

SK3/19

SK1/49

+24V DensitySK3/35

Density Sig +

0V Density

Density Sig -

+24V DensitySK3/35

Density Sig +

0V Density

Density Sig -

3-10

Hazardous Area Safe Area

Figure 3-5.25: 7955 Flow Computer

Gas Specific Gravity 3-Wire System with Shunt-Diode Safety Barrier (Hazardous Area)

3098 7955 Flow Computer

Ch.2

SK3/35

SK3/19

SK1/48

SK1/49

SIG A

SIG B

1

+

2

-

3

+

4

-

4

1

5 12

MTL 5032

14

2kR

13

11

Ch.1

SK3/19

SK1/31

SK1/32

Hazardous Area Safe Area

Note: Switches on MTL5032 should be set to give a threshold voltage of 3 volts

Figure 3-5.26: 7955 Flow Computer

Gas Specific Gravity 3-Wire System with Galvanic Isolator (Hazardous Area)

+24V DensitySK3/35

0V Density

Density Sig +

Density Sig -

Page 33

3098 Technical Manual Electrical Connections

3.6 System Connections (customer’s own equipment)

3.6.1 Non-hazardous areas

Power supply to Density Meter: 15.5V to 33Vdc, <20mA.

Power supply to PRT: 5mA max.

The frequency at which the meter is operating can be detected in one of two ways:

a. For the two-wire option, a 330Ω series resistor should be used in the +ve power line. The electrical connections to

be made are shown in Figure 3-6.1. The signal across the 330Ω resistor is greater than 2V peak to peak. The

minimum impedance of the signal measuring equipment should be 500kΩ. Where necessary, the 1nF capacitors will

block the power supply dc voltage to the measuring equipment.

b. For the three-wire option, the frequency can be measured directly. The electrical connections to be made are shown

in Figure 3-6.3.

3.6.2 Hazardous Areas

For details of hazardous area installations, please refer to safety instructions (30985018/SI).

3-11

Page 34

Electrical Connections 3098 Technical Manual

3.6.3 Customer's equipment, 2-wire configuration

3098

SIG A

SIG B

SIG A

SIG B

+

+

+

+

+

-

+

-

1

2

3

4

3098

330R

Power +

1nF

1nF

Signal +

Power -

Signal -

2.3V pk to pk

Figure 3-6.1: Electrical connections for meter 2-wire option

used with customers’ own equipment (Safe Area)

1

2

3

4

3

MTL 787 (+ve)

4

1

2

10kΩ

1nF

Power + (24.25 to 27V DC, 30mA)

Signal +

Power -

1nF

Signal -

3-12

Hazardous Area Safe Area

Figure 3-6.2: Electrical connections for meter 2-wire option

used with customers’ own equipment and Shunt-Diode Safety Barrier (Hazardous Area)

Page 35

3098 Technical Manual Electrical Connections

3.6.4 Customer's equipment, 3-wire configuration

3098

SIG A

SIG B

SIG A

SIG B

+

-

+

-

+

-

+

-

3098

1

2

3

4

1

2

3

4

Figure 3-6.3: Electrical connections for meter 3-wire option

used with customers’ own equipment (Safe Area)

3

MTL 787 (+ve)

4

1

2

1nF

Power +

Signal +

Power -

Signal -

Power + (24.25 to 27V DC, 30mA)

Signal +

Power -

Signal -

6V pk to pk

Hazardous Area Safe Area

Figure 3-6.4: Electrical connections for meter 3-wire option

used with customers’ own equipment and Shunt-Diode Safety Barrier (Hazardous Area)

3-13

Page 36

Electrical Connections 3098 Technical Manual

3.7 Post-installation checks

After installation, the following procedure will indicate to a high degree of confidence that the meter is operating correctly.

a. Electrical Check

Measure the current consumption and the supply voltage at the meter amplifier. This should be within the following

limits:

15.5V to 33V dc (Safe Areas)

15.5V to 21.5 dc (Hazardous Areas)

17mA ±1mA (Safe and Hazardous Areas)

b. Stability Check

Check the stability of the frequency output signal using a period meter on a 1000 cycle count. The measurement

scatter should be within ±2ns. If this value is exceeded, it is likely that dirt is present on the sensing element. This test

may be performed at any gas density, provided that the latter is not changing.

3-14

Page 37

3098 Technical Manual Accuracy Considerations

Chapter 4

Accuracy Considerations

This chapter

This chapter provides a method for estimating the accuracy of 3098 measurements under various conditions.

4.1 Accuracy Considerations

The ‘controlled condition’ which establishes a direct relationship between density and the specific gravity of the sample

gas is mainly determined by the pressure and the type of gas used in the reference chamber. The choice of reference

chamber gas pressure is dependent upon:

1. The span of specific gravity to be measured.

2. The expected change in sample gas supercompressibility, Z.

3. The accuracy required.

The exact choice in reference gas pressure is made after considering all the error sources for that application. To simplify

the selection, Table 1 is provided which can be reproduced by the user. In general, unless a pump is used to boost the

pipeline pressure, the reference gas pressure at 20°C must be at least 10% less than the minimum line pressure, to

ensure gas flow over the operating temperature range.

Example 1

When a gas has a relatively low and reasonably constant specific gravity, and is available at a line pressure greater than 7

Barg (100psig) such as natural gas measurement in the range 0.55-0.8, a very high accuracy is possible using a reference

pressure of 7 Barg. (See Example 1 table below for a worked example).

Example 2

If large range specific gravity measurements are to be made, or where changes in the supercompressibility factor of the

sample gases become significant, (such as in flare gases or air/CO

required. (See Example 2 table below for N

/CO2 mix).

2

mixes), a much lower reference gas pressure is

2

4-1

Page 38

Accuracy Considerations 3098 Technical Manual

ρ

ρ

ρ

3098 SPECIFIC GRAVITY METER

CONTROL PRESSURE SELECTION

Date: ................................. Type of Gas: ................................... Specific Gravity Range: ............. to ............

3

3098 Serial No. ................... Temperature Coefficient of Density Meter: ............................................. kg/m

/°C

CONTROL PRESSURE AT 20°C (lb/in2 abs.)

(bars abs.)

DENSITY RANGE AT 20°C (kg/ m

Measurement Errors (% of FS Specific Gravity/°C)

due to:

Density Meter Temp. Coefficient

Gas Compressibility of Sample Gas

Velocity of Sound in Sample Gas

Reference Chamber/Relief Valve +0.007 +0.007 +0.007 +0.007

Total Error

3) 0.79 - .15 1.32 - 2.0 2.66 - 3.8 4.58 - 6.72

Table 1

18

1.2

30

60

2

4

100

7

Calculating the parameters

Density Range at 20°C

Calculated using equation:

Density range = to PG PG

where P = Absolute pressure in bars.

= Density of dry clean air (1.2kgm-3 approximately)

air

GG

& = Specific Gravity minimum and maximum values.

min max

air air

min max

Density Meter Temperature Coefficient Error

Inversely proportional to density (therefore pressure) and is calculated as follows:

Temperature coefficient from calibration certificate = x kgm

-3

At maximum density value of y kgm

:

-3

/°C

x

Sensor equivalent temperature coefficient =

Gas Compressibility Error

This describes the deviation in gas compressibility of the sample gas compared with that of the reference chamber gas.

The error is taken as 2/3 of the deviation caused by temperature change on the two gases at the reference pressure and

is typically proportional to this pressure.

For information on the gas characteristics see the Gas Tables.

Velocity of Sound Error

This error is taken as - 0.0034 G %/°C with G taken at maximum specific gravity

4-2

/

x 100%/°C

y

G

max

.

Page 39

3098 Technical Manual Accuracy Considerations

Example 1

3098 SPECIFIC GRAVITY METER

CONTROL PRESSURE SELECTION

Date: 24th June 1997 Type of Gas: Natural Gas Specific Gravity Range: 0.55 to 0.8

3

3098 Serial No.: 000124 Temperature Coefficient of Density Meter: -0.0003 kg/m

/°C

CONTROL PRESSURE AT 20°C (lb/in2 abs.)

(bars abs.)

DENSITY RANGE AT 20°C (kg/ m

Measurement Errors (% of FS Specific Gravity/°C)

due to:

Density Meter Temp. Coefficient

Gas Compressibility of Sample Gas

Velocity of Sound in Sample Gas

Reference Chamber/Relief Valve

Total Error

3) 0.79 - 1.15 1.32 - 2.0 2.66 - 3.8 4.58 - 6.72

18

1.2

-0.026 -0.016 -0.008 -0.004

+

0.0003 +0.0003 +0.001 +0.002

-0.003 -0.003 -0.003 -0.003

+0.007 +0.007 +0.007 +0.007

-0.022 -0.012 -0.003 to

30

60

2

4

-0.000 to

-0.005

Example 2

3098 SPECIFIC GRAVITY METER

CONTROL PRESSURE SELECTION

Date: 28th July 1997 Type of Gas: N2/CO2 mix Specific Gravity Range: 1.0 to 1.5

100

7

-0.002

3098 Serial No.: Temperature Coefficient of Density Meter: -0.0003 kg/m

CONTROL PRESSURE AT 20°C (lb/in2 abs.)

(bars abs.)

DENSITY RANGE AT 20°C (kg/ m

Measurement Errors (% of FS Specific Gravity/°C)

due to:

Density Meter Temp. Coefficient

Gas Compressibility of Sample Gas

Velocity of Sound in Sample Gas

Reference Chamber/Relief Valve

Total Error

3) 0.4 - 2.16 2.4 - 3.6 4.8 - 7.2 8.4 - 12.6

18

1.2

-0.014 -0.008 -0.004 -0.002

+

0.0002 +0.0004 +0.008 +0.015

-0.005 -0.005 -0.005 -0.005

+0.007 +0.007 +0.007 +0.007

-0.014 -0.006 +0.006 to

30

2

3

/°C

60

4

-0.010

100

7

+0.015 to

-0.015

4-3

Page 40

Accuracy Considerations 3098 Technical Manual

4.2 Calibration (for non-natural gas applications)

The instrument is supplied with its reference chamber empty and thus in an un-calibrated condition. After installation on

site it is necessary to decide what reference chamber pressure to use, and then to charge and calibrate the instrument as

described in the Installation Procedure (Chapter 2).

Some examples of how to calculate these reference chamber pressures are given in Examples 1 and 2, which show the

best pressures for a natural gas and a N2/CO2 mix application.

Once this has been done, the gases to be used for calibration need to be defined. The calibration gases to be used must

be of known specific gravities and substantially represent the properties of the line gas to be measured (i.e compressibility,

viscosity etc.) For example, if measuring a natural gas which is substantially methane and carbon dioxide, then these two

gases in their pure forms or at defined specific gravities should be used in the calibration.

With this decided, the 3098 can be calibrated by following the calibration procedure described in Chapter 2, the Installation

Procedure.

Note

In the case where only one calibration gas is available, the time period of the density meter at zero density/specific gravity

(i.e., vacuum conditions), which is included on the meter temperature coefficient calibration certificate, can be used as

time period τ

effect on supercompressibility compensation. An example of the meter temperature coefficient calibration certificate is

given below.

. Under this condition, calibration is less accurate due to the non-homogenic condition of a vacuum and its

y

Once the calibration has been performed, the coefficients can be calculated using equations (1) and (2) in the Installation

procedure or by using the calibration certificate shown below. (An Excel program, calcert.xls, to perform these

calculations is contained on the 3½” disk which came with this manual).

For more specific details on calibration see Appendix A.

4.2.1 Operation at Low Reference Pressure levels

One of the design features of the 3098 is that two orifice plates are used to control and regulate the flow of sample gas

through the unit, one of which is placed at the output port and is used to reduce the stresses placed on the unit’s

diaphragm. It is important to note that in order to increase the sample gas flow rate, the pressure at the input port must be

increased. As this pressure is increased, the pressure across the output orifice increases. If this pressure exceeds that of

the gas inside the reference chamber, the diaphragm will not regulate the input gas pressure and hence not allow an SG

measurement.

For reference pressures greater than 3 bar absolute (3 bar A), this situation will not occur in the unit flow range of (0.2 -

3

60cm

/s). However, it may occur if the reference pressure is less than 3 bar A and the flow rate > 50cm3/s.

It is recommended that in order to achieve the optimum accuracy when performing SG measurement, the corrections for

VOS and compressibility are taken into consideration. This can be done by following the procedure described in Appendix A.

4-4

Page 41

3098 Technical Manual Accuracy Considerations

μ

3098 CALIBRATION

Ref. No.: A1 Date: 24/07/97

3098 Ser. No.: xxxxx Signal Amplifier Ser. No.: YYYYY Vibrating Cylinder Ser. No.: ZZZZZZ

INPUTS

Sample Gas Type: Natural Gas Required Specific Gravity Span: 0.5 to 0.7

Selected Reference Pressure at 20°C: 7 bars

Calibration Gas X Type: Methane Calibration Gas Y Type: Nitrogen

Specific Gravity (Gx): 0.5549 Specific Gravity (Gy): 0.96715

3098 Output (Tx): 514.798

NOTE: Where the output is required in Relative or Standard Density units, simple substitute these values for

the Specific Gravity values.

s 3098 Output (Ty): 523.213μs

CALCULATIONS

Since the Specific Gravity, G = Ko + K2T2 1.

x - Gy

G

where K

2 =

T

2.

2

x2- Ty

= 4.719593X10-5

y - K2Ty

G

K

o =

2

3.

= -11.952

4-5

Page 42

Accuracy Considerations 3098 Technical Manual

T E M P E R A T U R E C O E F F I C I E N T

C A L I B R A T I O N C E R T I F I C A T E

3098 SPECIFIC GRAVITY METER

Serial Numbers:

Instrument 000001

Amplifier 000001

Cyclinder 000001

Pressure Test

Units pressure tested to 300 p.s.i.g.

Datum Periodic Time

Time period with vacuum at 20°C (μs) 504.398

(zero specific gravity)

Temperature Coefficients

Cylinder coefficient at 20°C (μs/°C) 0.0013

Density equivalent at 20°C (Kg/m

3

/°C) 0.0006

#### ## ## ## #### ## ######

#### ## ## ## #### ## ######

## ## ## #### #### ## ## ## ##

## ## ## #### #### ## ## ## ## ------------- ## ###### ## ## ## #### ## #### | FINAL TEST |

## ###### ## ## ## #### ## #### | |

## ## ## ## ## ## ## ## | |

## ## ## ## ## ## ## ## | |

#### ## ## ## ## ## ###### ###### | |

#### ## ## ## ## ## ###### ###### | |

--------------

3098CERTGEN V1.0 DATE: xx-xxx-xx

4-6

Page 43

3098 Technical Manual Maintenance & Fault Finding

Chapter 5

Maintenance & Fault Finding

5.1 Introduction

This chapter deals with the recommended servicing and maintenance that can be carried out under field conditions,

including calibration checks, faultfinding procedures and simple maintenance. If a fault is traced to a reference chamber

malfunction, it is strongly recommended that the repair of the faulty unit be restricted to a qualified engineer or that the

faulty unit be returned to the factory (see Appendix C for Returns Forms).

If a calibration check reveals a significant error, the cause of this error (e.g. reference chamber leak, deposition on the

vibrating cylinder) should be thoroughly investigated before any re-calibration attempt is made.

5.1.1 Calibration Check

It is normally good practice to carry out periodic checks on the system accuracy. This is simply achieved by passing a gas

of known specific gravity through the instrument as previously detailed under the Calibration section of the Installation

Procedure (Chapter 2). It is preferable that the specific gravity of this calibration gas lies within the specific gravity range

of the system under test since this will simplify the system check procedure. However, a gas whose specific gravity is

outside this range can be used if its characteristics are similar to those of the system line gas.

5.1.2 Fault Finding

If any adverse or suspect readings occur upon checking the calibration, the possible causes for this can be summarised

into 4 groups:

• Instrument Over-reads;

• Instrument Under-reads;

• Erratic Instrument readings;

• Meter Faults.

a) Instrument Over-reads

This is generally due to deposition, condensation or corrosion on the vibrating cylinder walls.

The effects of deposition and condensation can be removed from the cylinder by carefully cleaning the cylinder walls

(once the density meter has been removed from the 3098) although corrosion cannot be dealt with this way.

If the cylinder is corroded or damaged in any way (i.e. dents, scratches etc.) then it must be replaced with a new unit.

b) Instrument Under-reads

This is most probably due to a gas leak from the reference chamber. Before dismantling the instrument it is desirable

to locate the leak, the cause of which may be one of the following:

5-1

Page 44

Maintenance & Fault Finding 3098 Technical Manual

(i) Reference Chamber to sample gas path

Parts affected are:

• Diaphragm;

• Reference Chamber Valve;

• Reference Chamber metalwork.

This type of leak can be identified by using the following test.

Charge the reference chamber to a high pressure (up to 7 BarA maximum) and then isolate by closing the reference

chamber valve. Vent the sample gas path at the instrument’s inlet and outlet to atmosphere then seal by closing the

inlet and outlet line valves.

If gas is leaking into the sample gas flow path, this will be indicated by the change in output signal from the

density meter.

Alternatively, if the leak rate is influenced by whether the sample gas path is at atmospheric pressure or at the line

operating pressure, then this is indicative of a leak into the sample gas flow path.

(ii) Reference Chamber to Atmosphere

Parts affected are:

• Diaphragm;

• Sealing gasket (meter);

• Reference Chamber valve pipework;

• Reference Chamber metalwork.

This type of leak can often be traced by the application of a soap solution, or 'Snoop', and bubble observation. Unlike

the previous type of leak this will not be influenced by sample gas path pressure.

If the leak is due to a faulty gasket seal, diaphragm or reference chamber valve then a serviceable replacement should

be fitted.

If in doubt, advice should be sought from the factory – contact details are on the back page.

(iii) Erratic Instrument Readings

These can be caused by:

a) Electronic Fault

This can exist in either the meter or its associated electronics.

If an independent frequency generator is available, this can be used to check the performance of the flow

computer/signal converter.

If the fault is in the meter amplifier, this can be changed with no degradation in performance.

b) Vibrating Cylinder

If the sample gas flow is stopped by closing the inlet valve, the time period signal should drop slightly to a steady value

or, if there is a small leak, continue to drop slowly. Should the reading remain erratic, it is likely that there is deposition

on the vibrating cylinder which needs to be stripped, cleaned and re-assembled.

c) Pressure Control Valve

If the erratic signal is only present while there is a flow of sample gas through the unit, then the fault is likely to be due

to a malfunction of the pressure control valve, brought about by the presence of dirt. In this case the diaphragm (and

hence valve mechanism) should be stripped down, cleaned and re-assembled. Any poor seals or damaged parts

should be replaced. Alternatively, the gas pressure may be falling below that of the designed input condition.

5-2

Page 45

3098 Technical Manual Maintenance & Fault Finding

d) Meter Faults

These faults can be found by a few simple tests:

I. Spoolbody Assembly: The magnetic drive and pick-up assembly (spoolbody) can be checked visually for problems

and also electrically for continuity, by measuring the resistance of the drive and pick-up coils. The resistance of each

coil should be (72±10)Ω at 20°C.

II. Meter Amplifier: If careful examination of the sensing element and spoolbody assembly does not reveal the cause

of the problem, the amplifier should be replaced. This will show whether the problem is with the amplifier.

Note: A check of the amplifier current consumption is a good indicator of the amplifier’s health.

A further test to check the amplifier is to change the supply voltage across its operating range and check that the time

period does not change.

5-3

Page 46

Maintenance & Fault Finding 3098 Technical Manual

5.2 Maintenance

Apart from scheduled calibration checks and filter replacements (these being dependent upon the condition of the sample

gas) no other routine maintenance should be required.

When a fault is suspected, the 3098 can be easily dismantled to expose the section that needs inspection. A full

dismantling procedure to major component level is described below.

1. Main meter (3098) removal: removal of the complete unit from its installation, allowing all other servicing to

be performed.

2. Density meter removal: removal of the sensing element to a clean environment where further dismantling can

take place.

3. Reference Chamber Diaphragm removal: (performed after stage 1).

General Notes

• All gaskets, O-rings and the diaphragm are to be lightly greased with silicone grease MS4 before re-assembly.

Gas connection threads to be sealed using PTFE tape or Loctite 572.

• Loctite 221 is to be applied to all screws during re-assembly.

• New gaskets should be fitted on re-assembly.

• Any re-assembly must be followed by a leak test, procedure 5.2.7.

WARNING: BEFORE ANY SERVICING IS ATTEMPTED THE 3098 MUST

AND ELECTRICAL SUPPLIES

BE ISOLATED FROM BOTH THE GAS

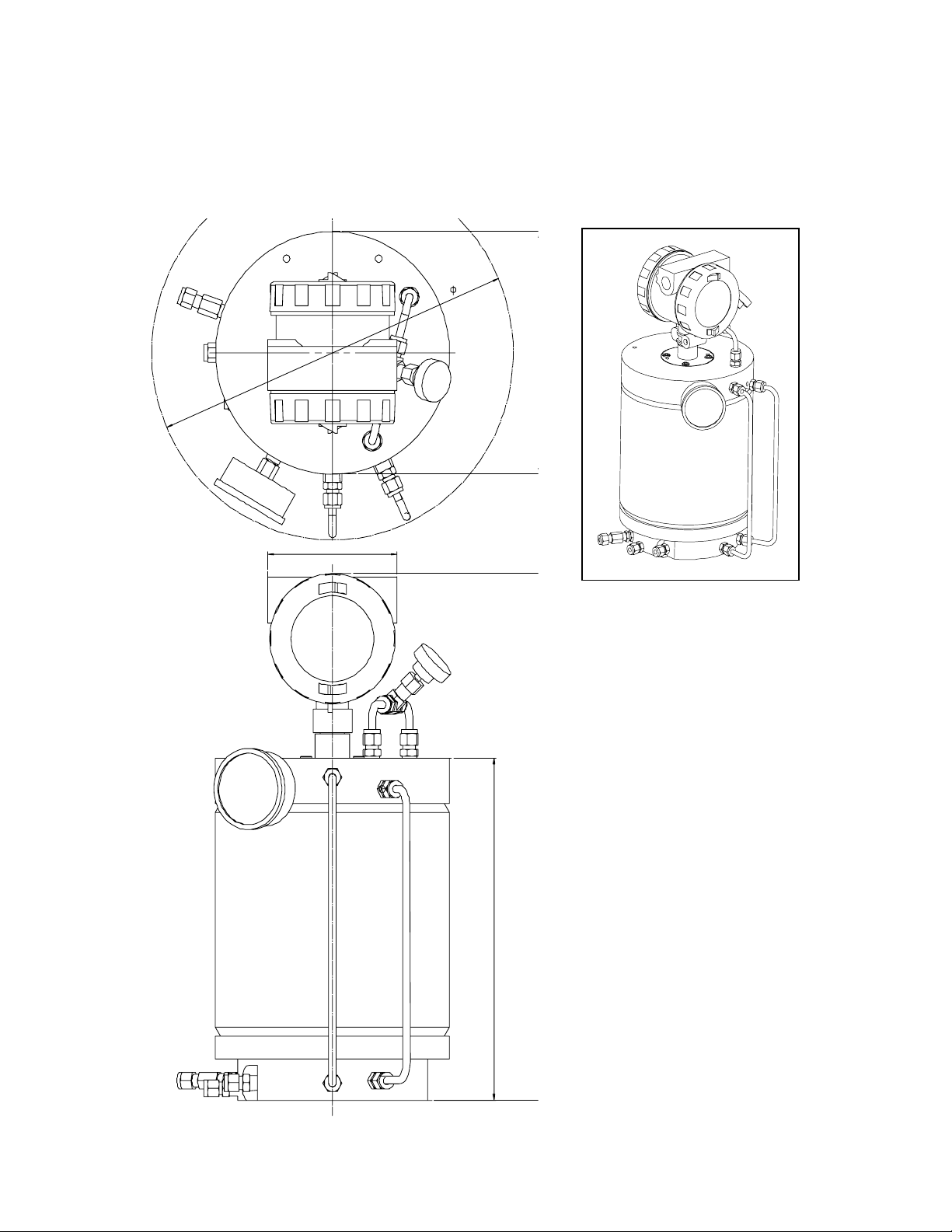

5.2.1 Main meter (3098) removal (Figure 5-1)

The instructions in this section apply only to 3098 meters supplied with an enclosure (see Important Notice on page 1-1). In

all other cases, please refer to the system installer.

1. Ensure that the 3098 has been isolated from the gas and electrical supplies. Vent the instrument to atmospheric

pressure.

Note: The reference chamber may remain charged with gas unless a reference chamber diaphragm requires servicing.

WARNING: FOR SOME GASES, E.G. METHANE, IT IS

TO ATMOSPHERIC PRESSURE WHENEVER THE 3098 HAS TO BE TAKEN OFF-LINE

2. Disconnect the 3098 externally from the system pipework at the side of the enclosure having vented the reference

chamber (if required). Cover all exposed gas connections.

3. The 3098 may be removed from its installation whilst still inside its enclosure, or it can be separated at this stage,

leaving the box in situ. If the latter is required then continue from 5.

4. The enclosure can now be removed from its installation by unscrewing the four mounting feet fixings.

5. Once the electrical wiring has been disconnected from the meter and the cable removed from the gland, the instrument

can be further dismantled. The 3098 metalwork can be removed from the enclosure as described in points 6 - 8 and

transported to a clean area for further servicing.

IMPERATIVE TO VENT THE REFERENCE CHAMBER

6. Remove the enclosure door by pulling out the two retaining pins. Undo the three Swagelok pipe fittings that connect

the gas lines to the unit at the enclosure wall (item a). When this is done, remove the two recess headed screws that

hold the unit’s mounting bracket to the rear of the enclosure (item b).

5-4

Page 47

3098 Technical Manual Maintenance & Fault Finding

7. Loosen and remove the three bolts at the base of the box that hold the unit’s feet (item c).

8. Carefully remove the unit from the enclosure by moving it to the right to disengage the pipes from their fittings. Take

the metalwork to a clean area.

9. The 3098 is installed using this procedure in reverse order. All gas pipe connections will require leak testing.

b

a

Figure 5-1: 3098 general assembly schematic (typical enclosure)

c

5-5

Page 48

Maintenance & Fault Finding 3098 Technical Manual

5.2.2 Density meter removal (Figure 5-2)