Page 1

Installation Manual

308014EN, Edition 4

May 2013

Tank Gauging System

www.rosemount-tg.com

Page 2

Page 3

Installation manual

Fourth edition

Copyright

© May 2013

Rosemount Tank Radar AB

www.rosemount-tg.com

Page 4

Copyright © May 2013

Rosemount Tank Radar AB

The contents, descriptions and specifications within this manual is

subject to change without notice. Rosemount Tank Radar AB accepts no

responsibility for any errors that may appear in this manual.

Trademarks

Rosemount, and the Rosemount logotype are trademarks of

Rosemount Inc.

TankRadar is a trademark of Rosemount Tank Radar AB.

HART is a trademark of HART Communication Foundation

Modbus is a trademark of Modicon.

Pentium is a trademark of Intel Corporation.

Windows NT is a trademark of Microsoft Corporation.

Viton is a trademark of Du Pont Performance Elastomers.

Spare Parts

Any substitution of non-recognized spare parts may jeopardize safety.

Repair, e.g. substitution of components etc, may also jeopardize safety

and is under no circumstances allowed.

Rosemount Tank Radar AB will not take any responsibility for faults,

accidents, etc caused by non-recognized spare parts or any repair which

is not made by Rosemount Tank Radar AB.

EU Conformity

The EC declaration of conformity for all applicable European directives

for this product can be found on the Rosemount Tank Gauging website

at www.rosemount-tg.com. A hard copy may be obtained by contacting

our local sales representative.

Specific FCC Requirements (USA only)

Rosemount TankRadar REX generates and uses radio frequency

energy. If it is not installed and used properly, that is, in strict accordance

with the manufacturer´s instructions, it may violate FCC regulations on

radio frequency emission.

Rosemount TankRadar REX has been FCC certified under test

conditions which assume a metallic tank. Installation on a non-metallic

tank is not certified, and is not allowed.

The FCC certificate for Rosemount TankRadar REX requires that the

tank is closed as far as emitted radio energy is concerned. Tanks with

open manholes, external-floating-roof tanks without still pipes etc. are

not covered by the certificate.

www.rosemount-tg.com

Page 5

Installation Manual

308014EN, Edition 4

May 2013

Rosemount TankRadar REX

Table of Contents

Contents

Recovery of Packing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . TOC-6

Recovery of Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TOC-7

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 MANUAL OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2. SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 INTRINSIC SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 EXPLOSION PROOF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 EUROPEAN ATEX DIRECTIVE INFORMATION . . . . . . . . . . . . . . . . .2-3

2.3.1 Radar Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.2 Radar Tank Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3.3 Transmitter Interface Card (TIC) . . . . . . . . . . . . . . . . . . . . 2-5

2.3.4 Temperature Multiplexer Card (TMC) . . . . . . . . . . . . . . . .2-6

2.3.5 Data Acquisition Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.3.6 Remote Display Unit 40 (RDU 40) . . . . . . . . . . . . . . . . . .2-8

3. DESCRIPTION OF 3900 REX . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 TRANSMITTER HEAD RTG 3900 REX . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 Transmitter Head Electronics . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.2 Analog Processing Card - APC . . . . . . . . . . . . . . . . . . . .3-3

3.1.3 Transmitter Interface Card - TIC . . . . . . . . . . . . . . . . . . . .3-3

3.1.4 Temperature Multiplexer Card - TMC . . . . . . . . . . . . . . . .3-3

3.1.5 Relay Output Card - ROC . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.1.6 Field Communication Card - FCC . . . . . . . . . . . . . . . . . .3-3

3.1.7 Metrological Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.2 ANTENNA TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

4. THE DATA ACQUISITION UNIT . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 LOCAL READOUT DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 WRITE ENABLE/INHIBIT SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3 CONNECTING THE DATA ACQUISITION UNIT, DAU 2100 . . . . . . . .4-3

4.3.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.3.2 Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.3.3 Selecting the temperature range . . . . . . . . . . . . . . . . . . .4-4

TOC-1

Page 6

Installation Manual

Rosemount TankRadar REX

Table of Contents

308014EN, Edition 4

May 2013

5. THE REMOTE DISPLAY UNIT RDU40. . . . . . . . . . . . . . . . 5-1

5.1 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.2 TWO RDU 40 CONNECTED TO THE SAME REX . . . . . . . . . . . . . . .5-4

5.2.1 Data items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

6. THE FIELD COMMUNICATION UNIT . . . . . . . . . . . . . . . . . . 6-1

6.1 FCU ENCLOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 COMMUNICATION PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2.1 RS232 communication . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2.2 RS 485 communication . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3 WRITE INHIBIT/ENABLE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.4 CONNECTING THE FIELD COMMUNICATION UNIT, FCU 2160 . . .6-4

6.4.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.4.2 Connection to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.5 REDUNDANCY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

7. BUS MODEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 FIELD BUS MODEM 2180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.1 DIN Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.1.3 TRL/2 Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.1.4 RS 232 Communication . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.5 USB Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.6 USB Driver Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.1.7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.1.8 Communicating with TankMaster™ . . . . . . . . . . . . . . . . .7-7

7.1.9 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.1.10 RS 232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.1.11 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

7.2 ENRAF BUS MODEM, EBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

7.2.1 Connecting the Enraf Bus Modem . . . . . . . . . . . . . . . . . 7-11

7.2.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

8. JUNCTION BOXES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 INTEGRATED JUNCTION BOX, JBI . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.1.1 Explosion Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.2 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.1.3 Cable Inlets - RTG 3900 . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

TOC-2

Page 7

Installation Manual

308014EN, Edition 4

May 2013

8.2 JUNCTION BOXES FOR INTRINSICALLY SAFE AND

EEX E ENVIRONMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.2.1 JB 140-11 for EEx i environments . . . . . . . . . . . . . . . . . .8-3

8.2.2 JB 140-15 for EEx e environments . . . . . . . . . . . . . . . . . . 8-3

8.2.3 Junction Boxes with Conduit Outlets . . . . . . . . . . . . . . . .8-4

8.3 CONNECTION OF TEMPERATURE SENSORS . . . . . . . . . . . . . . . . .8-5

8.3.1 Junction Box JBT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

8.3.2 Junction Box JB 36/42 . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Rosemount TankRadar REX

Table of Contents

9. CONNECTION TO COMPUTER NETWORKS. . . . . . . . . . . . . 9-1

9.1 CONNECT TO THE FCU FOR QUICK UPDATES . . . . . . . . . . . . . . . .9-1

9.2 CONNECT TO TANKMASTER FOR INVENTORY DATA . . . . . . . . . .9-1

10. MECHANICAL INSTALLATION. . . . . . . . . . . . . . . . . . . . . 10-1

10.1 MOUNTING A HORN ANTENNA GAUGE . . . . . . . . . . . . . . . . . . . . .10-1

10.1.1 Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . .10-1

10.1.2 Free Space Requirements . . . . . . . . . . . . . . . . . . . . . . .10-2

10.1.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.4 Installation on the tank . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

10.2 MOUNTING THE PARABOLIC ANTENNA GAUGE . . . . . . . . . . . . .10-6

10.2.1 Inclination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

10.2.2 Free Space Requirements . . . . . . . . . . . . . . . . . . . . . . .10-9

10.2.3 Socket Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .10-10

10.2.4 Recommended Installation . . . . . . . . . . . . . . . . . . . . . .10-10

10.2.5 Mounting the Flange Ball model T30 . . . . . . . . . . . . . . 10-11

10.2.6 Mounting the Flange Ball model T38-W . . . . . . . . . . . .10-12

10.2.7 Mounting the Antenna . . . . . . . . . . . . . . . . . . . . . . . . .10-14

10.3 MOUNTING A STILL PIPE GAUGE . . . . . . . . . . . . . . . . . . . . . . . . .10-20

10.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

10.3.2 Still Pipe Requirements . . . . . . . . . . . . . . . . . . . . . . . .10-21

10.3.3 Flange Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

10.3.4 Recommended Installation . . . . . . . . . . . . . . . . . . . . . .10-22

10.3.5 Free space requirements - RTG 3950 Fixed Version . .10-23

10.3.6 Installation of the 3950 Fixed Version on the tank . . . .10-24

10.3.7 Free space requirements - RTG 3950 Inclined Version 10-28

10.3.8 Installation of the RTG 3950 Inclined Version . . . . . . .10-30

10.4 MOUNTING A LPG/LNG GAUGE . . . . . . . . . . . . . . . . . . . . . . . . . .10-38

10.4.1 Temperature and Pressure Measurement. . . . . . . . . . .10-38

10.4.2 Still Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-38

10.4.3 Reference Pin and Reflector . . . . . . . . . . . . . . . . . . . .10-40

10.4.4 Extension Pipe for Minimum Distance. . . . . . . . . . . . . .10-42

10.4.5 Installation on the tank. . . . . . . . . . . . . . . . . . . . . . . . . .10-43

TOC-3

Page 8

Installation Manual

Rosemount TankRadar REX

Table of Contents

308014EN, Edition 4

May 2013

11. ELECTRICAL INSTALLATION OF THE REX GAUGES. . . . . 11-1

11.1 CABLING FOR POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

11.2 CABLING FOR TRL/2 BUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

11.3 RECOMMENDED CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

11.4 GROUNDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

11.5 CONNECTING THE RADAR TANK GAUGE 3900 . . . . . . . . . . . . . .11-4

11.5.1 Cable Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

11.5.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-7

11.5.3 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.5.4 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

11.5.5 TRL/2 Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

11.5.6 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

11.5.7 Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-17

11.5.8 Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . .11-18

11.5.9 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-20

11.5.10 HART Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-21

11.5.11 DAU/RDU 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-22

12. SENSOR INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.1 TEMPERATURE SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

12.2 WATER LEVEL SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

12.2.1 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

12.2.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

13. LIST OF DRAWINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

13.1 MECHANICAL INSTALLATION DRAWINGS TANKRADAR REX . . .13-1

13.2 ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-2

13.3 FIELD BUS MODEM, FBM 2180 . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-2

13.4 FIELD COMMUNICATION UNIT, FCU 2160 . . . . . . . . . . . . . . . . . . .13-3

13.5 DATA ACQUISITION UNIT, SDAU 2100 . . . . . . . . . . . . . . . . . . . . . .13-3

13.6 REMOTE DISPLAY UNIT, RDU 40 . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

13.7 JUNCTION BOXES - JB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-4

13.8 TEMPERATURE / WLS SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . .13-4

TOC-4

Page 9

Installation Manual

308014EN, Edition 4

May 2013

Rosemount TankRadar REX

Table of Contents

14. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

14.1 RTG 3900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.1.1 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-2

14.1.2 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

14.1.3 Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

14.1.4 External Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

14.1.5 Temperature Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

14.2 RTG 3920 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-4

14.3 RTG 3930 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-5

14.4 RTG 3950 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-6

14.5 RTG 3960 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-7

14.6 DATA ACQUISITION UNIT, DAU 2100 . . . . . . . . . . . . . . . . . . . . . . .14-8

14.7 REMOTE DISPLAY UNIT, RDU 40 . . . . . . . . . . . . . . . . . . . . . . . . . .14-9

14.8 FIELD COMMUNICATION UNIT, FCU 2160 . . . . . . . . . . . . . . . . . .14-10

14.9 FIELD BUS MODEM, FBM 2180 . . . . . . . . . . . . . . . . . . . . . . . . . . .14-10

14.10 ENRAF BUS MODEM, EBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-10

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .INDEX-1

TOC-5

Page 10

Rosemount TankRadar REX

Table of Contents

Recovery of Packing Material

Rosemount Tank Radar AB is fully certified according to ISO 14000

environmental standards. By recycling the plywood boxes material used

for shipping our products you can contribute to take care of the

environment.

Reuse

Experience has shown that NEFAB ExPak packaging can be used 4-5

times.

Recycling

After careful disassembly the plywood sides may be reused. Metal waste

may be converted.

Energy recovery

Installation Manual

308014EN, Edition 4

May 2013

Products which have served their time may be divided into wood and

metal components and the wood can be used as fuel in sufficient ovens.

Due to its low moisture content (approximately 7%) this fuel has a higher

calorific value than ordinary wood fuel (moisture content approximately

20%).

When burning interior plywood the nitrogen in the adhesives may

increase emissions of nitrogen oxides to the air 3-4 times more than

when burning bark and splinter.

Note! Landfill is not a recycling option and should be avoided.

TOC-6

Page 11

Installation Manual

308014EN, Edition 4

May 2013

Recovery of Products

The label below is put on Rosemount Tank Gauging products as a

recommendation to customers if scrapping is considered.

Recycling or disposal should be done following instructions for correct

separation of materials when breaking up the units.

Rosemount TankRadar REX

Table of Contents

label_180.eps

TOC-7

Page 12

Rosemount TankRadar REX

Table of Contents

Installation Manual

308014EN, Edition 4

May 2013

TOC-8

Page 13

Installation

308014EN, Edition 4

May 2013

1. Introduction

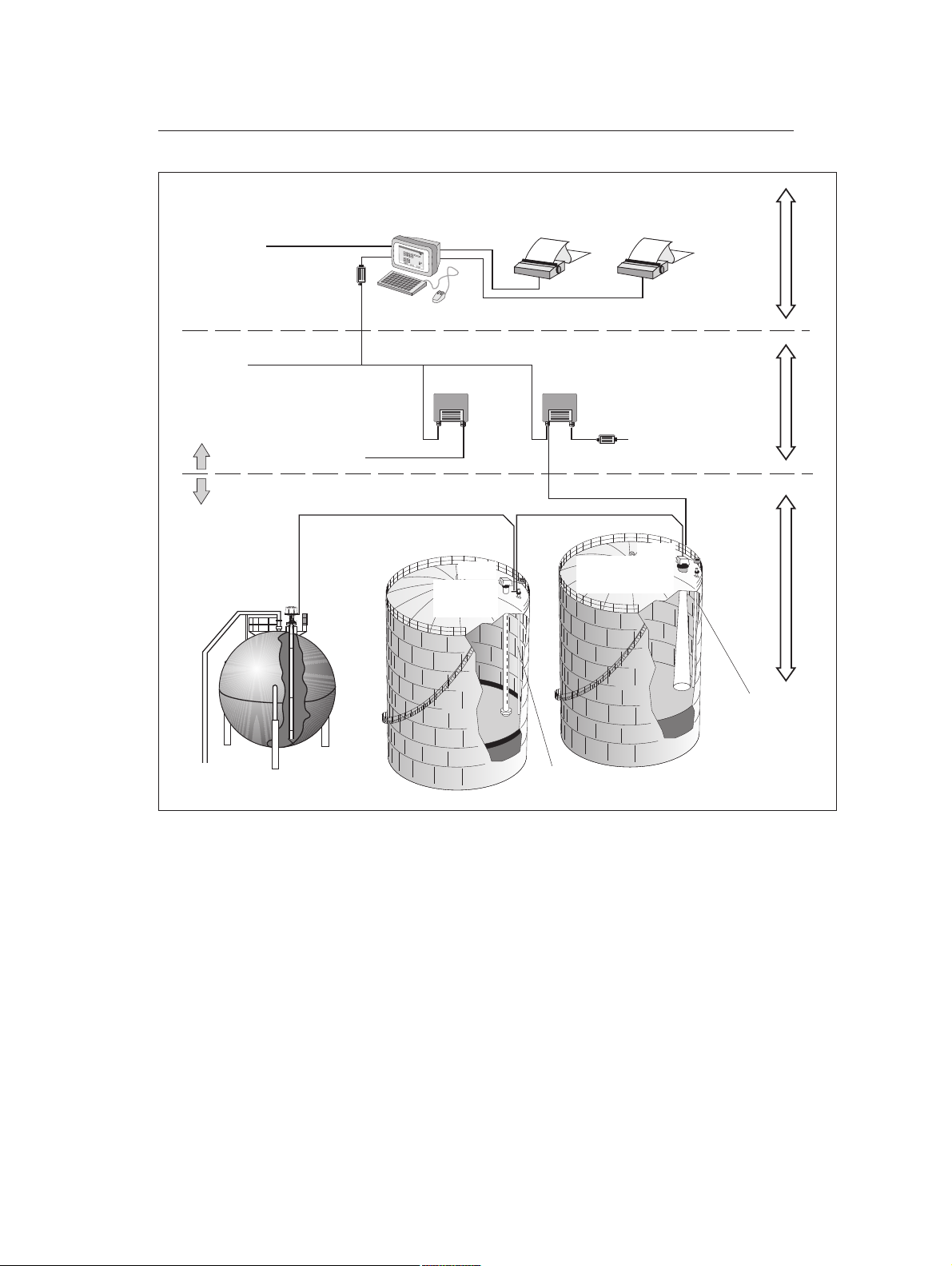

The Rosemount TankRadar REX System is a monitoring and control

system for tank level gauging. The system can interface various sensors,

such as temperature and pressure sensors, for complete inventory

control.

There is a distributed intelligence in the various units of the system. The

units continuously collect and process information. When a request for

information is received an immediate response is sent with updated

information. The units communicate with each other on a field bus, the

TRL/2 Bus.

No part of the equipment is in actual contact with the product in the tank

and the antenna is the only part of the gauge that is exposed to the tank

atmosphere. The Radar Tank Gauge sends microwaves towards the

surface of the product in the tank. The level is calculated based on the

echo from the surface.

Rosemount Tank Radar REX

Chapter 1 Introduction

TankRadar REX can measure the level of almost any product, including

bitumen, crude oil, refined products, aggressive chemicals, LPG and

LNG, etc. Using a suitable Tank Connection Unit, the TankRadar REX

System can gauge any type of tank.

1-1

Page 14

Rosemount Tank Radar REX

Chapter 1 Introduction

Installation Manual

308014EN, Edition 4

May 2013

Plant Host

Computer

To Other

FCUs

NonHazardous

Area

Hazardous

Area

LPG/LNG

Gauge

RTG

RS-232C

FBM

To Other

Tanks

DAU

TankMaster

WinOpi

V

a

l

u

e

E

n

t

ry

V

Le

al

Ta

ue

vel

nk1

H

i

Lim

Au

Te

to

mp

A

L

vg

o L

1

8.

im

0

A

00

u

Pre

t

o

H

ssu

H

Li

2

r

e

.

m

00

1

0

20.0

A

L

u

L L

t

o

20.0

i

m

0

8

0

0

.0

2

1

.0

.000

D

L

el

eve

ay

l

0

.0

Hy

st

Tem

0

p

A

v

g

0

.20

Pr

0

es

0

sur

e

5

.0

0

L

ea

k L

im

0

it

.5

0

.2

En

0

0

ter

Ena

Ca

b

l

e

nc

el

N

ew

Ta

nk

TRL/2 Group Bus

FCU

TRL/2 Field Bus

Still Pipe

Gauge

RTG

Report

Printer

FCU

TRL/2 Field Bus

DAU

Parabolic Antenna Gauge

FBM

Alarm Log

Printer

To Portable

Service PC

RTG

Control

Room

Level

Group

Level

DAU

Field

Level

Temperature

Sensors

Temperature

Sensors

Figure 1-1. General configuration of a TankRadar REX sys-

tem.

All the measured data is presented to the operator by the TankMaster

WinOpi, which in its complete version contains inventory functions. A

plant host computer can be connected for further processing of data.

All Rosemount Tank Gauging supplied parts for tank top mounting weigh

less than 25 kg (55 lb.) (except for pressure flange etc. for the LPG/LNG

Gauge). This makes it possible for one man to carry the various

TankRadar parts to the tank top for installation.

Please read the Technical Description for a more detailed description of

the Rosemount TankRadar REX system.

REX_System_General.eps

1-2

Page 15

Installation

308014EN, Edition 4

May 2013

The basic parts of the Rosemount TankRadar REX System are:

• The Radar Tank Gauge, RTG, is an intelligent explosion pro-

• The Data Acquisition Unit, DAU, is used for measuring tempera-

• The Field Communication Unit, FCU, acts as a gateway and

• The Field Bus Modem, FBM, is a converter between RS-232C

Rosemount Tank Radar REX

Chapter 1 Introduction

tected instrument for measuring the level of a product inside a

tank. Four different Tank Connection Units can be attached in

order to satisfy a variety of different applications.

The RTG 3900 is equipped with auxiliary inputs such as temperature sensor inputs and analog inputs. The RTG 3900 also features

two relay outputs.

ture and can, as an option, be equipped with a Local Readout Display (LCD) for presentation of measured values.

data concentrator between the Group Bus and the Field Bus. Each

FCU can have a total of 32 RTGs and 32 DAUs connected to it.

and the TRL/2 Bus. It is used for connecting a PC with TankMaster to the TRL/2 Bus.

• The TankMaster WinOpi is the operator´s interface for the REX

system. The WinOpi is used for setting up a REX system with

alarm handling, batch reports, automatic report handling, historical

data sampling and inventory calculations.

• The TankMaster WinSetup is a software for configuration, calibration and service of a REX System.

1-3

Page 16

Rosemount Tank Radar REX

Chapter 1 Introduction

1.1 Manual Overview

This manual provides information about mechanical and electrical

installation of Rosemount TankRadar REX equipment. It covers the

TankRadar REX 3900 series of transmitters, and also provides

instructions for TRL/2 Data Acquisition Units, Field Communication Units

and Field Bus Modems.

Chapter 1 provides an overview of the

Rosemount TankRadar REX radar gauging system.

Chapter 2 gives a brief description of safety concepts and

European ATEX Directive information.

Chapter 3 describes the 3900 transmitter head and the cor-

responding antennas.

Chapter 4 describes the Data Acquisition Unit in the

TankRadar REX system.

Installation Manual

308014EN, Edition 4

May 2013

Chapter 5 describes the Display Unit RDU 40.

Chapter 6 describes the Field Communication Unit (FCU).

Chapter 7 describes Bus Modems used for communication

between a workstation and a TankRadar REX level gauging

system.

Chapter 8 describes various types of Junction Boxes that

can be used to connect different system units.

Chapter 9 provides information on how to connect a

TankRadar REX system to a host computer system.

Chapter 10 describes how to assemble the various gauge

types and how to mount them on a tank.

Chapter 11 describes electrical installation of the

TankRadar REX gauge system.

Chapter 12 describes installation of sub-supplier equipment

used in the TankRadar REX system.

Chapter 13 provides a list of installation drawings.

Chapter 14 provides technical data for the different REX

units.

1-4

Page 17

Installation Manual

308014EN, Edition 4

May 2013

2. Safety

Rosemount TankRadar REX equipment is often used in areas where

flammable materials are handled and where an explosive atmosphere

may be present. To protect both the plant and the personnel, precautions

must be taken to ensure that this atmosphere cannot be ignited. These

areas are called hazardous areas and equipment within these areas

must be explosion protected.

A number of different explosion protection techniques have been

developed over the years. Intrinsic safety and explosion proof (or flame

proof) safety are two techniques.

2.1 Intrinsic Safety

Intrinsic safety, IS, is based on the principle of restricting electrical

energy available in hazardous-area circuits such that any sparks or hot

surfaces, that may occur as a result of electrical faults in components,

are unable to cause ignition. Intrinsic safety is the only technique

accepted for Zone 0 hazardous areas. It is also safe for personnel and

allows equipment to be maintained without the need for a gas-free

certificate.

Rosemount Tank Radar REX

Chapter 2 Safety

For example, temperature measurement with the DAU is intrinsically

safe.

The basic principles of intrinsic safety are:

• All flammable materials are grouped according to the energy

needed to ignite them.

• Equipment located in hazardous areas are classified according to

the maximum surface temperature that it can produce and this

must be safe with the flammable gases that may be present.

• Hazardous areas are classified according to the probability that an

explosive atmosphere is present, and this dictates whether or not

a particular explosion protection technique may be used.

Note! For trouble shooting and repair work of components in or in connection

to intrinsically safe equipment, strict observance of the following rules is

necessary:

- Disconnect the power supply to the Radar Tank Gauge.

- Use a certified battery operated instrument only.

- Use Rosemount TankRadar REX original spare parts only.

Replacement with non-original spare parts may jeopardize the intrinsic

safety.

2-1

Page 18

Installation Manual

Rosemount Tank Radar REX

Chapter 2 Safety

308014EN, Edition 4

2.2 Explosion Proof

Explosion proof enclosures can be used when an explosion can be

allowed inside the enclosure as long as it does not spread to the outside.

The enclosure must be strong enough to withstand the pressure and

must have narrow gaps to allow the pressure to escape without igniting

the atmosphere outside of the equipment.

Note! Any substitution to non-recognized parts may impair safety.

The explosion-proof (flame-proof) enclosure of the Transmitter Head

must not be opened while the unit is powered.

May 2013

2-2

Page 19

Installation Manual

308014EN, Edition 4

May 2013

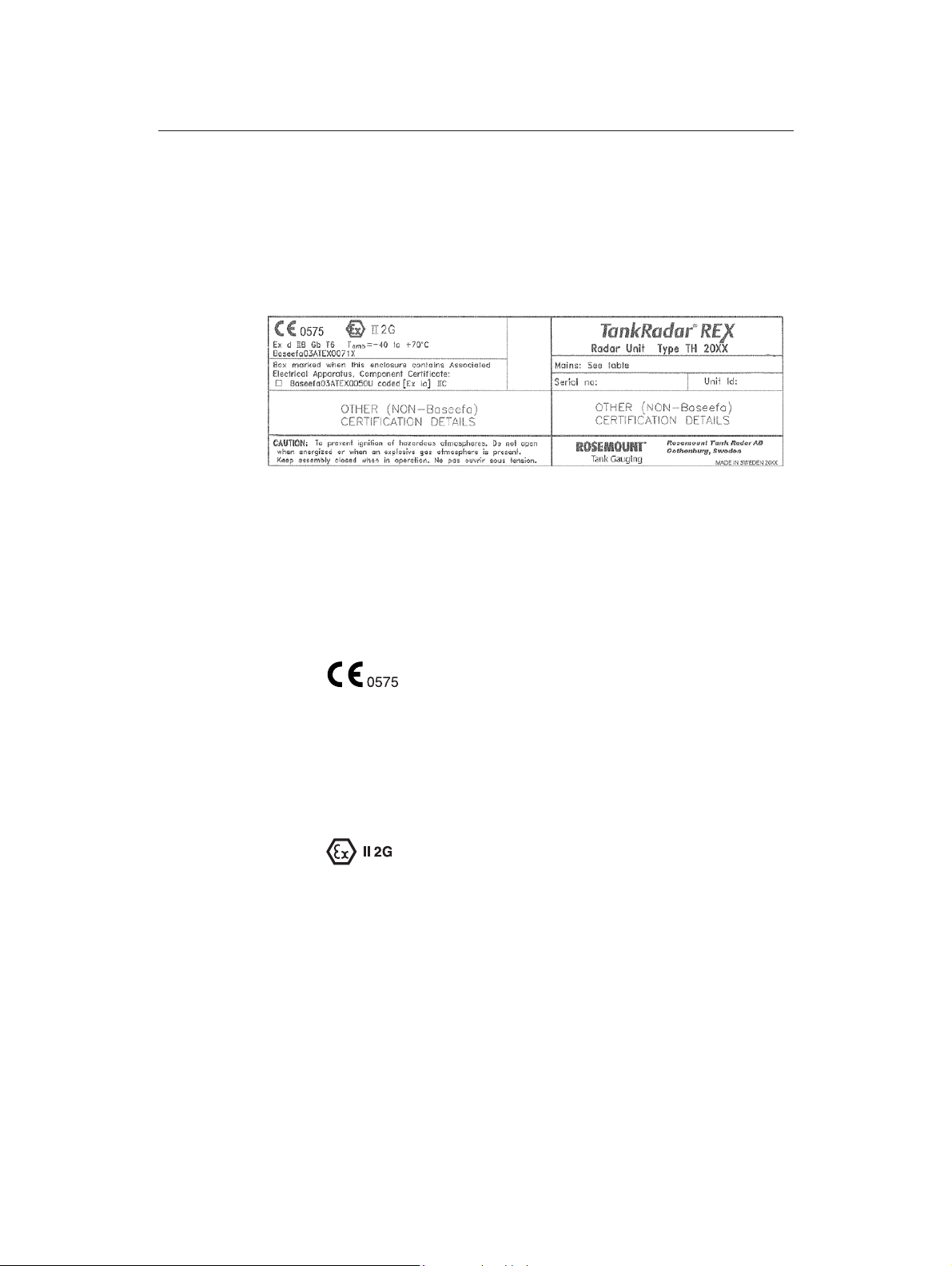

2.3 European ATEX Directive Information

2.3.1 Radar Unit

The REX Radar Unit has been certified to comply with Directive 94/9/EC

of the European Parliament and the Council as published in the Official

Journal of the European Communities No. L 100/1.

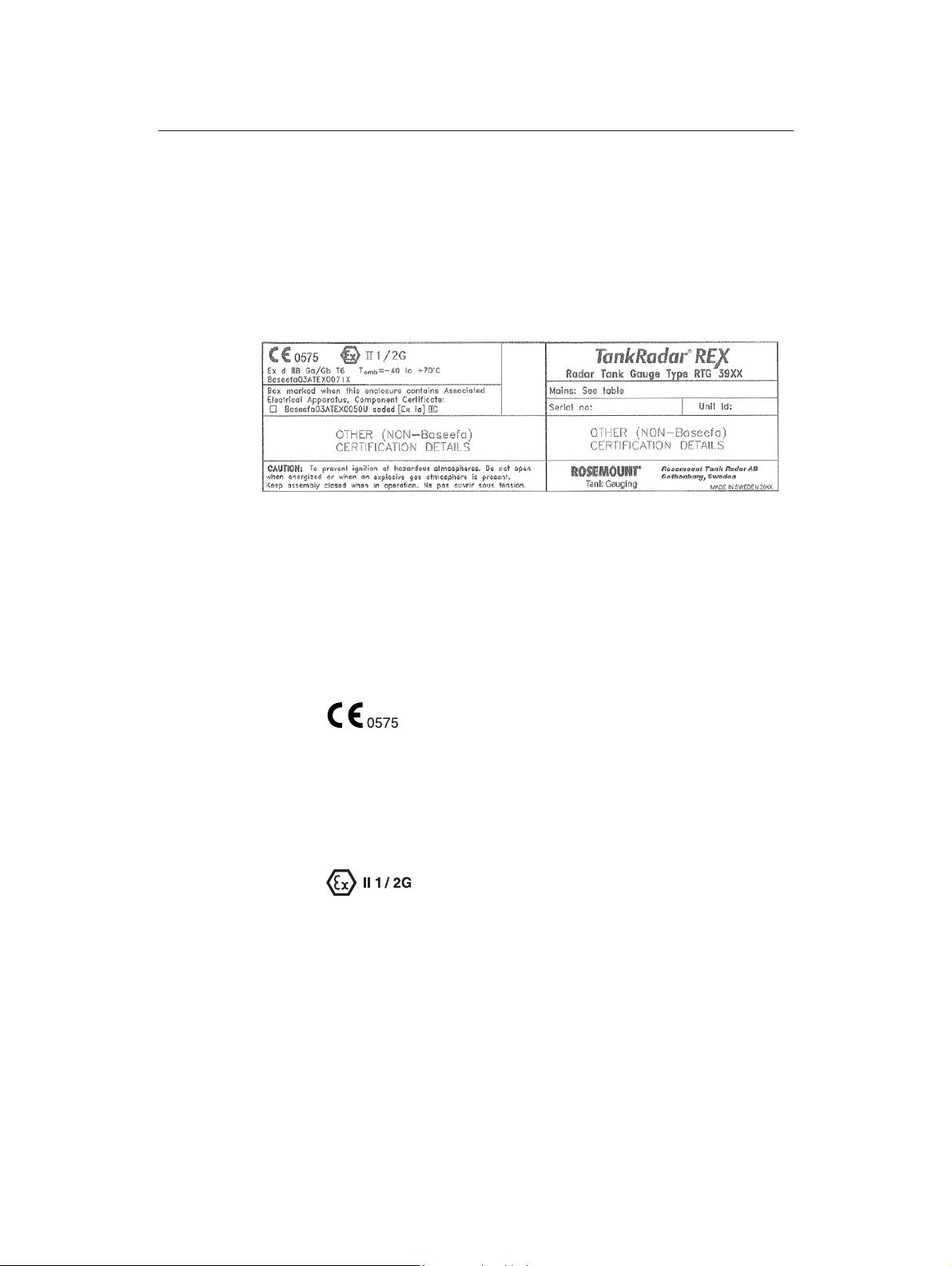

Figure 2-1. Certification label ATEX for the 2015 Radar Unit (used in

3900 series radar tank gauges).

Rosemount Tank Radar REX

Chapter 2 Safety

The following information is provided as part of the label of the radar unit:

• Name and address of the manufacturer

(Rosemount Tank Radar AB).

• CE Conformity Marking

• Complete model number

• The serial number of the device

• Year of construction

• Marking for explosion protection:

• Ex d IIB Gb T6 (-40 °C Ta +70 °C)

• Baseefa(2001) ATEX certificate number: Baseefa03ATEX0071X

Special Conditions for Safe Use (X):

• The Type TH2015-2019 Radar Units are not to be mounted

directly on to a tank.

• For replacement purposes the cover fastening screws are to be of

minimum grade A4-80 stainless steel.

• The permanently attached cables are to be suitably terminated

and protected against impact.

2-3

Page 20

Rosemount Tank Radar REX

Chapter 2 Safety

2.3.2 Radar Tank Gauge

The 3900 Radar Tank Gauge (type TH2015-2019 Radar Unit with

antenna certified for Zone 0) has been certified to comply with Directive

94/9/EC of the European Parliament and the Council as published in the

Official Journal of the European Communities No. L 100/1.

The 3900 series of Radar Tank Gauges is intended to be mounted

directly on tank.

Figure 2-2. Certification label ATEX for the 3900 Series Radar Tank

Installation Manual

308014EN, Edition 4

May 2013

Gauge.

The following information is provided as part of the label of the radar tank

gauge:

• Name and address of the manufacturer

(Rosemount Tank Radar AB).

• CE Conformity Marking

• Complete model number

• The serial number of the device

• Year of construction

• Marking for explosion protection:

• Ex d IIB Ga/Gb T6 (-40 °C Ta +70 °C)

• Baseefa(2001) ATEX certificate number: Baseefa03ATEX0071X

Special Conditions for Safe Use (X):

• For replacement purposes the cover fastening screws are to be of

minimum grade A4-80 stainless steel.

2-4

• The permanently attached cables are to be suitably terminated

and protected against impact.

Page 21

Installation Manual

308014EN, Edition 4

May 2013

2.3.3 Transmitter Interface Card (TIC)

Figure 2-3. Certification label for the Transmitter Interface Card (TIC).

The Transmitter Interface Card (TIC) is mounted within the flameproof

enclosure. It is required for intrinsically safe inputs such as 4-20 mA

current loops and local display unit.

The following information is provided as part of the label of the TIC:

Rosemount Tank Radar REX

Chapter 2 Safety

• Name and address of the manufacturer

(Rosemount Tank Radar AB)

• CE Conformity Marking:

• Year of construction

• Marking for explosion protection:

• [Ex ia] IIC (Ga) (-40 °C Ta +85 °C)

• Baseefa(2001) ATEX EC-Type Examination Certificate number:

Baseefa03ATEX0050U

Schedule of Limitations

• The Transmitter Interface Card must be housed within an enclosure which provides a degree of protection of at least IP20.

• The 0V connections must be interconnected and connected to an

I.S. earth point in accordance with EN60079-14 12.2.4., when the

component is installed within an assembly.

• The arrangements for the connections to non-hazardous area and

hazardous area external circuits must comply with the requirements of Clause 6.3 of EN 50020:2002.

Note! For electrical (I.S.) parameters refer to the appended EC-Type

Examination Certificate Baseefa03ATEX0050U.

2-5

Page 22

Rosemount Tank Radar REX

Chapter 2 Safety

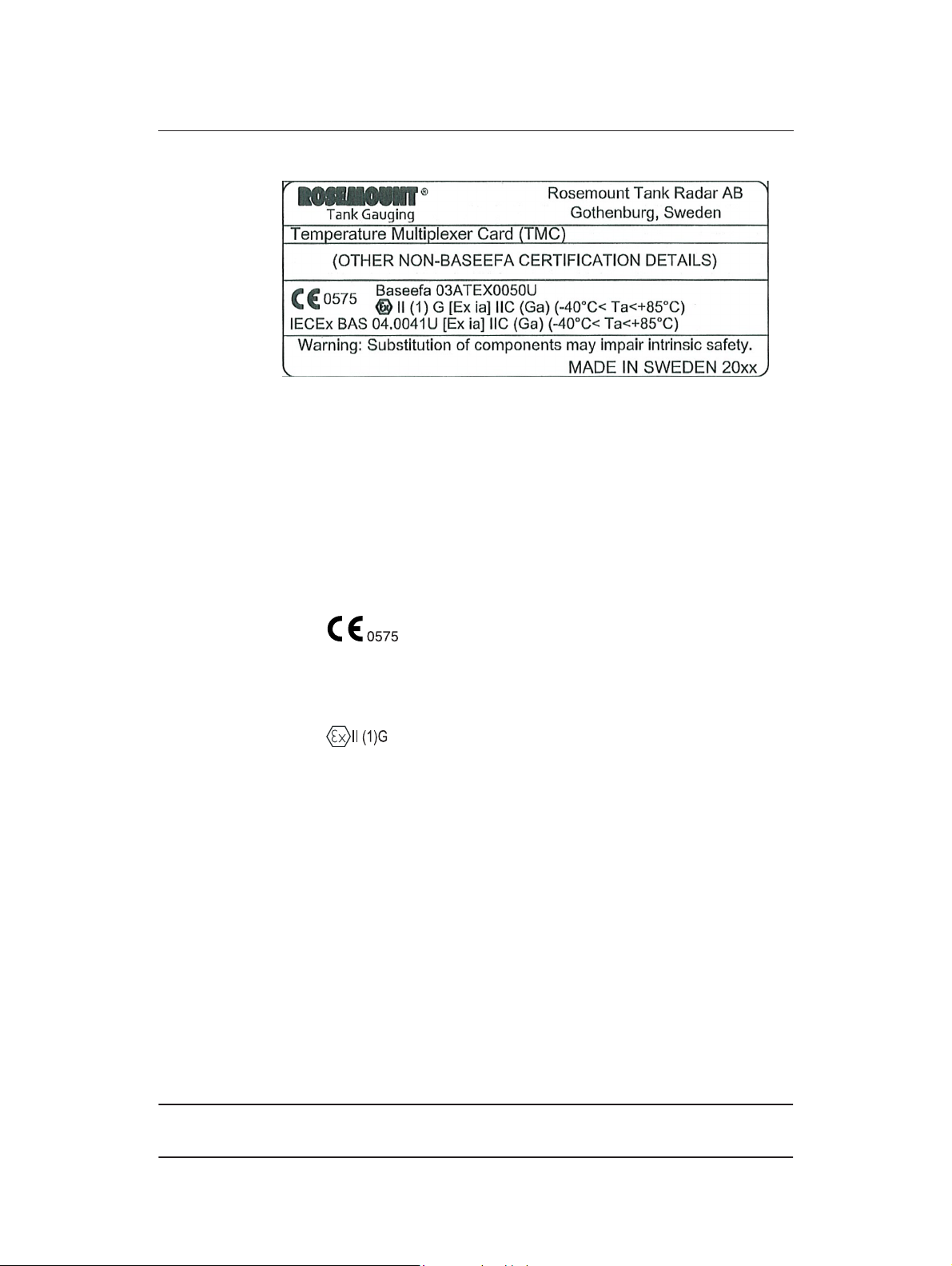

2.3.4 Temperature Multiplexer Card (TMC)

Figure 2-4. Certification label for the Temperature Multiplexer Card

The Temperature Multiplexer Card (TMC) is mounted within the

flameproof enclosure. It is used for connecting up to 6 temperature

sensors to the REX 3900 gauge.

The following information is provided as part of the label of the TMC:

Installation Manual

308014EN, Edition 4

May 2013

(TMC).

• Name and address of the manufacturer

(Rosemount Tank Radar AB)

• CE Conformity Marking:

• Year of construction

• Marking for explosion protection:

• [Ex ia] IIC (Ga) (-40 °C Ta +85 °C)

• Baseefa(2001) ATEX EC-Type Examination number:

Baseefa03ATEX0050U

Schedule of Limitations

• The Temperature Multiplexer Card must be housed within an

enclosure which provides a degree of protection of at least IP20.

• The 0V connections must be interconnected and connected to an

I.S. earth point in accordance with EN60079-14 12.2.4., when the

component is installed within an assembly.

• The arrangements for the connections to non-hazardous area and

hazardous area external circuits must comply with the requirements of Clause 6.3 of EN 50020:2002.

Note! For electrical (I.S.) parameters refer to the appended EC-Type

Examination Certificate Baseefa03ATEX0050U.

2-6

Page 23

Installation Manual

308014EN, Edition 4

May 2013

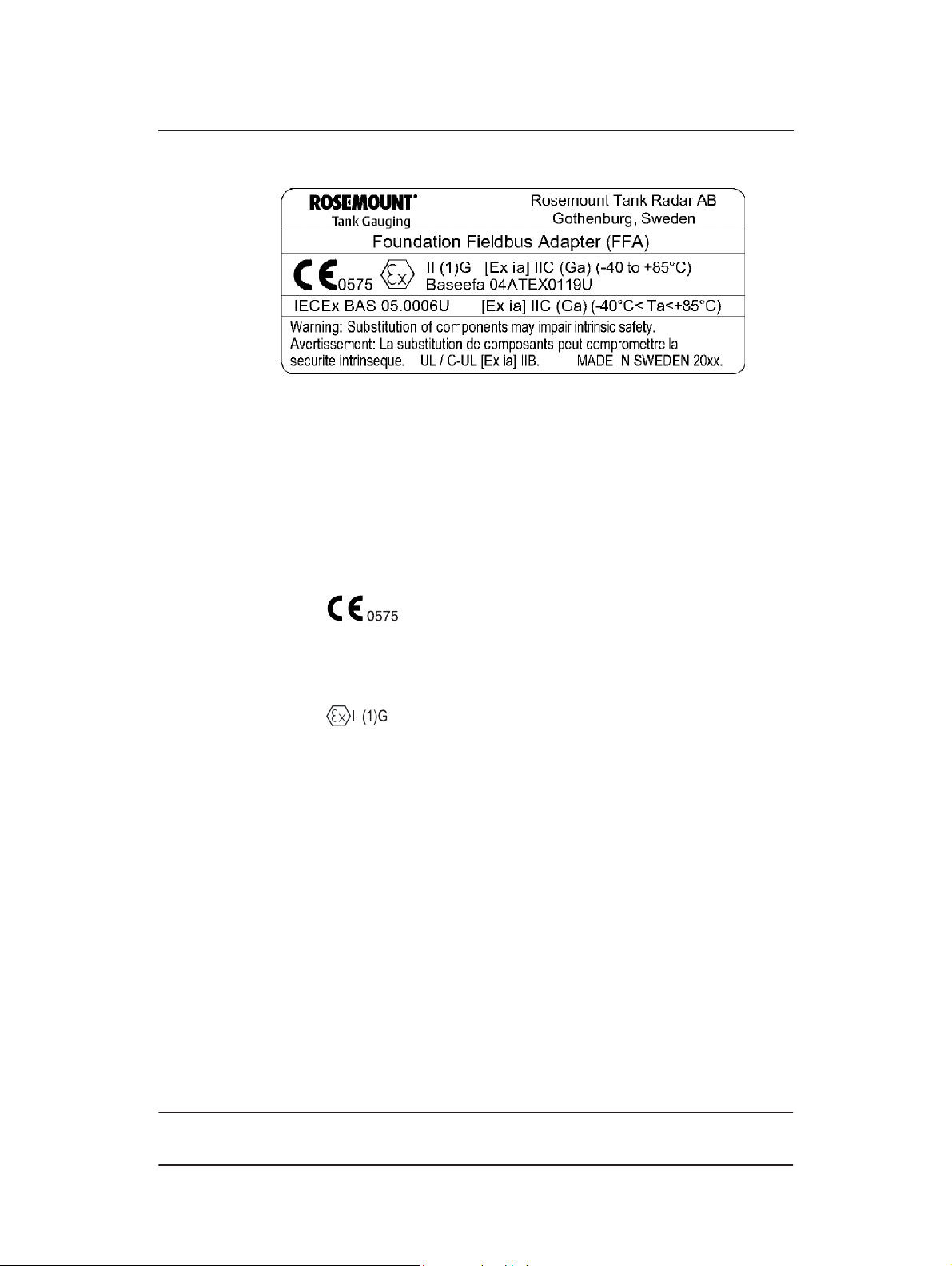

2.3.5 FF Adaptor Card (FFA)

Figure 2-5. Certification label for the FF Adaptor Card (FFA).

The FF Adaptor card (FFA) is mounted within the flameproof enclosure.

It is, in conjunction with a Fieldbus Communication Board

(BAS01ATEX1385U), used to interface to an intrinsically safe Fieldbus.

The following information is provided as part of the label of the FFA:

• Name and address of the manufacturer

Rosemount Tank Radar REX

Chapter 2 Safety

(Rosemount Tank Radar AB)

• CE Conformity Marking:

• Year of construction

• Marking for explosion protection:

• [Ex ia] IIC (Ga) (-40 °C Ta +85 °C)

• Baseefa(2001) ATEX EC-Type Examination Certificate number:

Baseefa04ATEX0119U

Schedule of Limitations

• The FF Adaptor Card must be housed within an enclosure which

provides a degree of protection of at least IP20. If the FF Adaptor

Card is mounted within a hazardous area it must be installed

within an appropriately certified flameproof enclosure.

• The arrangements for the connections to non-hazardous area and

hazardous area external circuits must comply with the requirements of Clause 6.3 of EN 50020:2002.

• The FF Adaptor Card is considered to be suitable for use within

EEx d apparatus with an Ambient Temperature range of

(-40 °C Ta +85 °C).

Note! For electrical (I.S.) parameters refer to the appended EC-Type

Examination Certificate Baseefa04ATEX0119U.

2-7

Page 24

Rosemount Tank Radar REX

Chapter 2 Safety

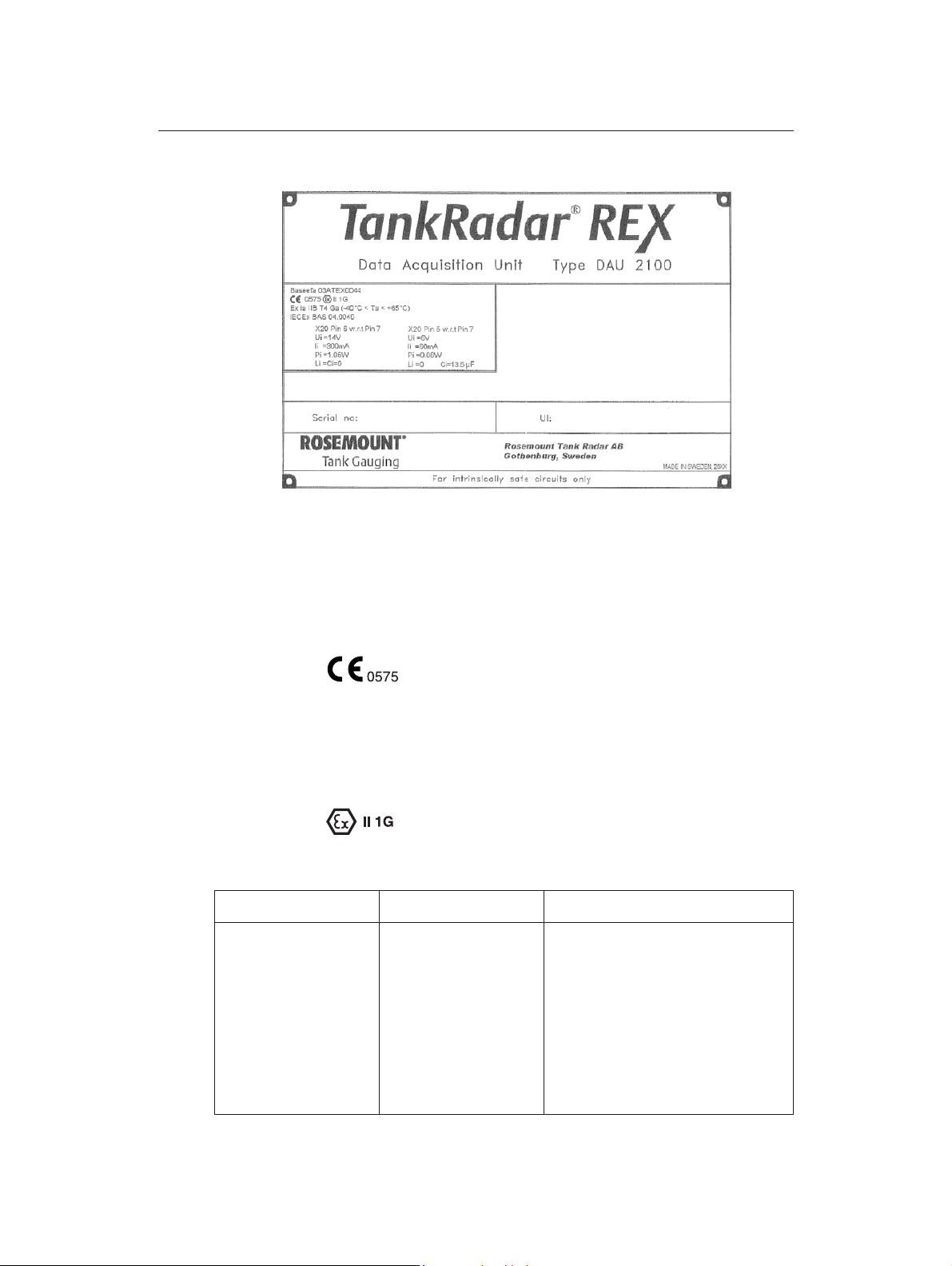

2.3.6 Data Acquisition Unit (DAU)

Figure 2-6. Certification label ATEX for the Data Acquisition Unit.

Installation Manual

308014EN, Edition 4

May 2013

The following information is provided as part of the label of the Data

Acquisition Unit (DAU):

• Name and address of the manufacturer

(Rosemount Tank Radar AB)

• CE Conformity Marking

• Complete model number

• The serial number of the device

• Year of construction

• Marking for explosion protection:

• Ex ia IIB T4 Ga (-40 °C Ta +65 °C)

X20 Pin 6 w.r.t Pin 7 X20 Pin 5 w.r.t Pin 7 X21 (For connection of up to 14 RTDs)

Ui=14 V

Ii=334 mA

Pi=1.17 W

Li=Ci=0

Ui=6 V

Ii=60 mA

Pi=0.08 W

Li=Ci=0

U0=6 V

I0=394 mA

P0=1.25 W

Ui=1.2 V

Ii=10 mA

Pi=0.02 W

Li=0

Ci=13.5 F

2-8

• Baseefa(2001) ATEX EC-Type Examination Certificate number:

Baseefa03ATEX0044

Page 25

Installation Manual

308014EN, Edition 4

May 2013

2.3.7 Remote Display Unit 40 (RDU 40)

Figure 2-7. Approval label for the Remote Display Unit RDU40.

The following information is provided as part of the label of the Remote

Display Unit 40 (RDU 40):

• Name and address of the manufacturer

• CE Conformity Marking:

Rosemount Tank Radar REX

Chapter 2 Safety

(Rosemount Tank Radar AB).

• Year of construction

• Marking for explosion protection:

• Ex ib IIC T4 Gb (-40 °C Ta +70 °C)

• Sira ATEX certificate number: Sira 00 ATEX 2062

The following instructions apply to equipment covered by certificate

number Sira 00ATEX2062:

1 The equipment may be used with flammable gases and vapours

with apparatus groups IIC, IIB and IIA and with temperature

classes T1, T2, T3 and T4.

2 The equipment is only certified for use in ambient temperatures in

the range -40 °C to +70 °C and should not be used outside this

range.

3 Installation shall be carried out in accordance with the applicable

code of practice.

4 Repair of this equipment shall be carried out in accordance with

the applicable code of practice.

5 Certification marking as detailed in drawing number 9150 074-

980.

2-9

Page 26

Rosemount Tank Radar REX

Chapter 2 Safety

Installation Manual

308014EN, Edition 4

May 2013

2-10

Page 27

Installation Manual

308014EN, Edition 4

May 2013

3. Description of 3900 REX

3.1 Transmitter Head RTG 3900 REX

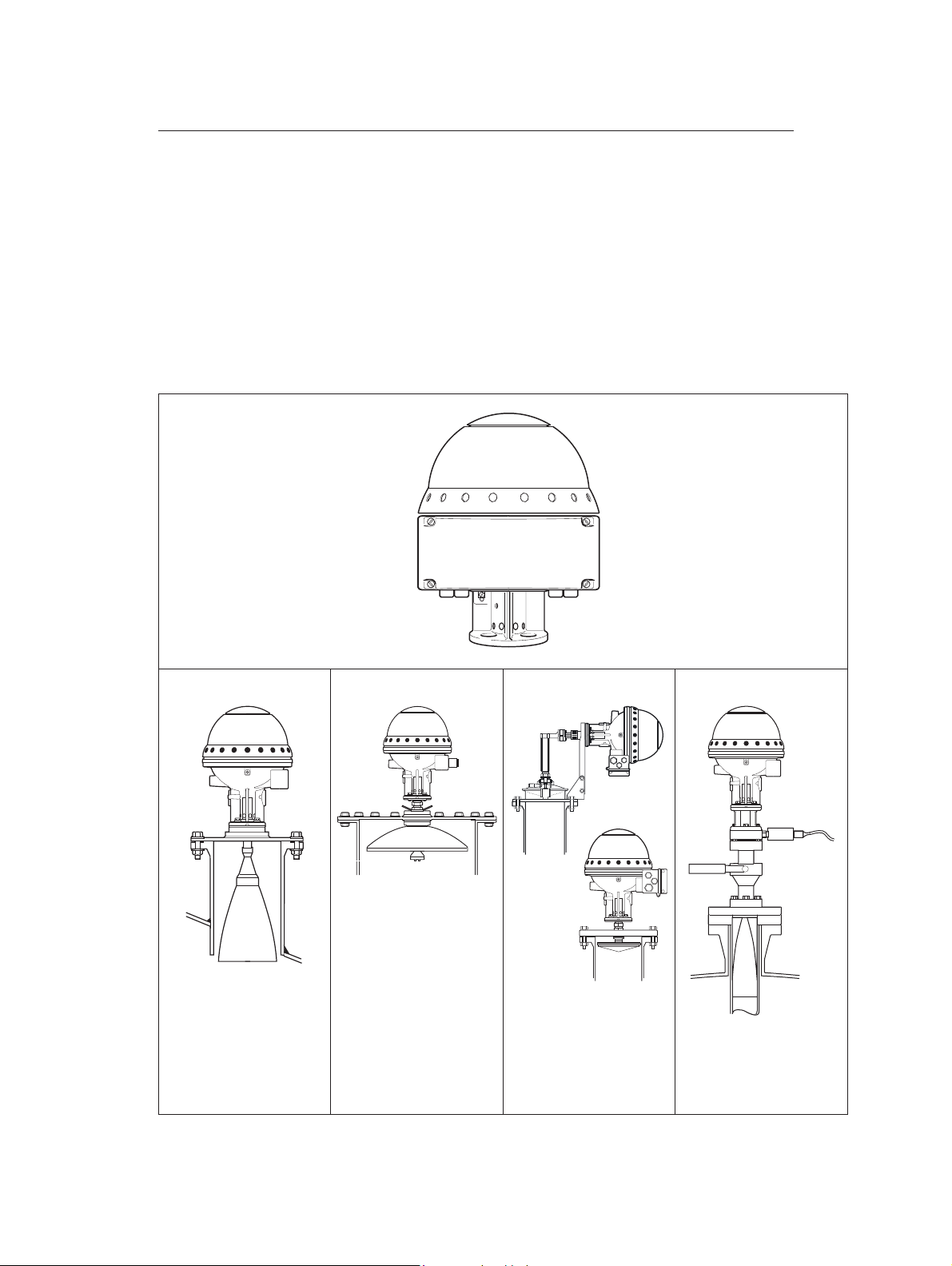

Depending on the type of tank connection unit that the transmitter head

is mounted on, there are four types of Radar Tank Gauges. The

transmitter head contains all the electronics for signal processing,

communication and connection of external sensors. The RTG 3900

transmitter head is used on all the gauge types 3920 - 3960.

Rosemount Tank Radar REX

Chapter 3 Description of 3900 REX

RTG 3920 RTG 3930 RTG 3950 RTG 3960

The Horn Antenna

Gauge for fixed roof

installation without still

pipe.

The Parabolic

Antenna Gauge for

demanding environments without still pipe.

The Still Pipe Gauge

for measuring in still

pipes.

The LPG/LNG Gauge

for liquid gas, LPG and

LNG.

3900_TH.eps

Figure 3-1. The RTG 3900 gauge can use different antennas.

3-1

Page 28

Rosemount Tank Radar REX

Chapter 3 Description of 3900 REX

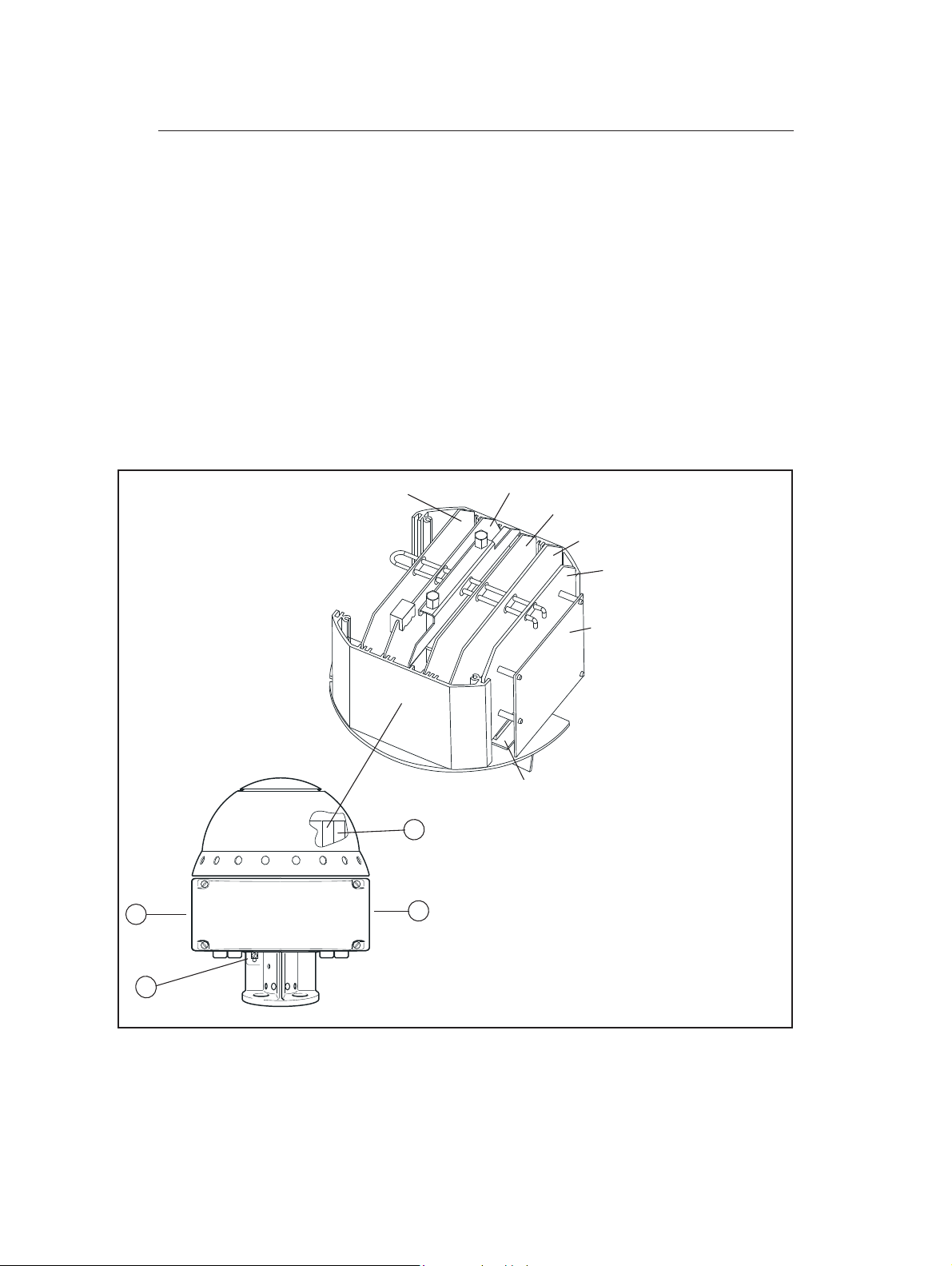

3.1.1 Transmitter Head Electronics

The electronics is mounted in an exchangable unit in the explosion proof

Transmitter Head. A high measurement accuracy is achieved by using

digital reference circuitry, and by controlling the internal temperature by

an internal heater.

The 3900 transmitter head can be used on all types of TRL/2 antennas.

A metrological seal is available to prevent unauthorized changes of

database settings.

Some of the electronic cards shown below are optional and may not be

installed in your transmitter.

Installation Manual

308014EN, Edition 4

May 2013

Transmitter Rectifier Card

3

1

2

4

1. X12. Intrinsically safe connec-

2. X11. Non-intrinsically safe con-

3. Electronic unit.

4. Ground connection.

Field Communication Card

Signal Processing Card

Analog Processing Card

Transmitter Interface Card

Temperature Multiplexing

Motherboard

tion for auxiliary inputs such as

Slave DAU/RDU, temperature

sensors and analog inputs.

nection for power, communication and relays.

REX3900_TH_Electronics.eps

3-2

Figure 3-2. RTG 3900 transmitter head electronics.

Page 29

Installation Manual

308014EN, Edition 4

May 2013

3.1.2 Analog Processing Card - APC

The APC is used for filtering and multiplexing of analog input signals. By

keeping the analog circuitry on a separate card a high Signal to Noise

Ratio is achieved.

3.1.3 Transmitter Interface Card - TIC

The Transmitter Interface Card (TIC) is required for intrinsically safe

auxiliary inputs. The TIC includes:

• Two supply zener barriers and two return zener barriers for 4-20

• One supply zener barrier for a Slave Data Acquisition Unit or a

• Signal/supply connection for optional Temperature Multiplexer

Rosemount Tank Radar REX

Chapter 3 Description of 3900 REX

mA current loops.

Remote Display Unit.

Card (TMC).

3.1.4 Temperature Multiplexer Card - TMC

The Temperature Multiplexer Card (TMC) is used to connect up to 6

temperature sensors. Both spot and average sensors are supported.

3.1.5 Relay Output Card - ROC

The Relay Output Card (ROC) contains two relays. It allows controlling

external devices such as valves, pumps, heating coils, overfill protection

according to TÜV etc.

3.1.6 Field Communication Card - FCC

The Field Communication Card (FCC) handles communication with

external devices. There are different versions of the FCC card allowing

you to use various types of communication protocols and even emulate

other types of gauges.

3-3

Page 30

Rosemount Tank Radar REX

Chapter 3 Description of 3900 REX

3.1.7 Metrological Seal

A switch on the FCC board can be used to prevent unauthorized

changes in the RTG database. The switch can be sealed in the writeinhibit position by using a special plastic cover.

Internal switch

Metrological Seal

Installation Manual

308014EN, Edition 4

May 2013

TH_Top.eps

Figure 3-3. RTG 3900 transmitter head with metrological seal.

External switch

REX can also be equipped with an external metrological seal. It consists

of a rod which is connected to a write protection switch inside the

transmitter head. The rod can be sealed.

Write enable

Write inhibit

WriteProtect.eps

3-4

Figure 3-4. RTG 3900 transmitter head with metrological seal.

Page 31

Installation Manual

308014EN, Edition 4

May 2013

3.2 Antenna Types

Rosemount Tank Radar REX

Chapter 3 Description of 3900 REX

Weather

Protection

Hood

Transmitter

Head

Tank Nozzle

Min. 8"

Horn

Antenna

Figure 3-5. The RTG 3920 Horn Antenna Gauge

Weather

Protection

Hood

Transmitter

Head

0.75 m

Parabolic

Reflector

Figure 3-6. The RTG 3930 Parabolic

Antenna Gauge

0.44 m

Antenna Feeder

The Horn Antenna Gauge,

RTG 3920

The Horn Antenna Gauge is

designed for an 8” antenna to be

used in small size openings on tanks

with fixed roofs.

The RTG 3920 is designed for measurement of a variety of oil products

and chemicals. However, for bitumen/asphalt and similar products the

Parabolic antenna is recommended.

The Parabolic Antenna Gauge,

RTG 3930

The Parabolic Antenna Gauge measures level of all types of liquids, from

light products to bitumen/asphalt.

The gauge is designed for mounting

on tanks with fixed roofs and has

custody transfer accuracy.

The design of the parabolic antenna

provides extreme tolerance against

sticky and condensing products. The

narrow beam of this antenna makes

it very suitable in narrow tanks with

internal structures.

3-5

Page 32

Rosemount Tank Radar REX

Chapter 3 Description of 3900 REX

Waveguide

Unit

0.5 m

Figure 3-7. The RTG 3950 Still Pipe Gauge

0.59 m

Antenna

Weather

Protection

Hood

Installation Manual

308014EN, Edition 4

May 2013

The Still Pipe Gauge, RTG 3950

The Still Pipe Gauge is used on tanks

with still pipes and with all products

suited for still pipes.

The gauge uses a low-loss radar

propagation mode which virtually

eliminates the influence of the still

pipe condition. Measurement is

made with highest accuracy even

when the pipe is old, rusty and covered with deposits.

0.7 m

The Still Pipe Gauge fits 5”, 6", 8",

10" and 12" pipes. It can be mounted

on an existing still pipe and there is

no need to take the tank out of operation during installation.

There are two versions of RTG 3950:

fixed and inclined. The inclined version has a hinged hatch, enabling full

pipe size product sampling or verification hand-dips.

0.3 m

Transmitter

Head

Housing

1.0 m

Lower Flange

6" Existing

pressure vessel

flange

Figure 3-8. The RTG 3960 LPG/LNG

Antenna Gauge

Weather

Protection

Hood

Pressure

Transducer

Valve

Pipe Cone

4" or Ø 100 mm

Still Pipe

The LPG/LNG Gauge, RTG 3960

The RTG 3960 is designed for level

measurements in LPG and LNG

tanks. A 4” still pipe is used as a

wave guide for the measurement and

prevents a wavy or boiling surface

from disturbing the measurement.

Radar signals are transmitted inside

the pipe towards the surface.

The pressure sealing is a quarts window approved for use in pressure

vessels. As standard the gauge is

also equipped with a fire-proof block

valve and a vapor space pressure

sensor.

The LPG/LNG Gauge is available in

two versions, a 150 PSI version and

a 300 PSI version.

The reference pin function enables

verification of measurement without

opening the tank. By setting the

gauge into “test mode” the measured

distances are compared with the

actual distances.

3-6

Page 33

Installation Manual

308014EN, Edition 4

May 2013

Chapter 4 The Data Acquisition Unit

4. The Data Acquisition Unit

The Data Acquisition Unit (DAU) is a complement to the Radar Tank

Gauge (RTG) to interface various sensors for temperature

measurement.

The DAU is intrinsically safe and is connected to the RTG on the same

tank. It receives its power supply from and communicates via the

Transmitter Interface Card (TIC) in the RTG.

LCD display for

local readout

0.28 m (11”)

Rosemount Tank Radar REX

0.23 m (9”)

Figure 4-1. The Slave Data Acquisition Unit.

4.1 Local Readout Display

The DAU can as an option be equipped with a Local Readout Display

showing the product level as well as the parameters measured by the

DAU itself.

Cable glands (not for US market)

SDAU_2100.eps

4-1

Page 34

Rosemount Tank Radar REX

Chapter 4 The Data Acquisition Unit

4.2 Write Enable/Inhibit Switch

The DAU is equipped with a switch that can be used to prevent

unauthorized changes in the database (EEPROM).

In order to enable programming of the EEPROM, the S1 switch must be

set in the position, towards the block terminals. The switch can be locked

and sealed in the write inhibit position using a wire through the clevis

pins.

WRITE INHIBIT SWITCH S1

Installation Manual

308014EN, Edition 4

May 2013

DAU

Figure 4-2. The write enable/inhibit switch.

DAU_WriteInhibit.eps

4-2

Page 35

Installation Manual

308014EN, Edition 4

May 2013

Rosemount Tank Radar REX

Chapter 4 The Data Acquisition Unit

4.3 Connecting the Data Acquisition Unit, DAU 2100

Instructions for connection of the Data Acquisition Unit is given on the

inside of its cover.

4.3.1 Power Supply

The Data Acquisition Unit receives its power via the local line from the

associated Radar Tank Gauge. If the distance between the Transmitter

Head and the Data Acquisition Unit is longer than 2.0 m, a junction box

must be used to connect an extension cable. This extension cable must

not be longer than 50 m. For safety reasons the ends of the unused

wires must be properly insulated and terminated. The junction box can

either be customer supplied or supplied by Rosemount Tank Gauging as

an option, see chapter 8.

4.3.2 Temperature Sensors

Under the lid of the Data Acquisition Unit there are instructions printed as

to how to connect the sensors and transducers.

Connect

temperature

sensors.

DAU_Tempsens_Connect.eps

Connect Reference

Resistor to terminals

43, 44 and 45.

Figure 4-3. The X21 terminal for temperature sensor connec-

tions.

Either Pt 100 (spot element) or Cu 100 (averaging sensor) temperature

sensors can be used. If the sensors are connected with common return

wires then jumpers must be connected in the Data Acquisition Unit

terminals.

Intrinsically safe connection of the temperature sensors, the RTDs, is

made with n + 2 wires for an n-element spot or averaging sensor. There

are spot elements with three wires for each element. The DAUs can

connect up to 14 RTDs (Resistance Temperature Detectors) on the X21

terminal on the motherboard.

4-3

Page 36

Rosemount Tank Radar REX

Chapter 4 The Data Acquisition Unit

4.3.3 Selecting the temperature range

A DAU can be configured for one of three different temperature ranges

by means of a multiplexer. The multiplexer for the RTDs has two different

amplification factors which are jumper selected. It is also possible to

provide an offset to the measured signal by adding a current to it.

Installation Manual

308014EN, Edition 4

May 2013

X1 - OPEN

X2 - OPEN

X3 - CLOSED

Figure 4-4. Selecting the temperature range.

The amplification is selected on the X1 and X2 sockets and the offset is

selected on the X3 according to table 11.3. The standard setting is from 50°C to +125°C. The database setting of the temperature range in the

TankMaster WinSetup must correspond to the setting of the jumpers.

Temperature Range

Pt 100

-50 to +125 °C OPEN OPEN CLOSED

-50 to +300 °C CLOSED CLOSED CLOSED

-200 to +150 °C CLOSED CLOSED OPEN

X1 X2 X3

Table 4-1. Temperature range settings.

A high precision reference resistor must be connected to the X21

terminal to positions 43, 44 and 45. Depending on the temperature range

stated in the Required System Information form, one out of three

different reference resistors is chosen and connected. See Figure 4-3

and the spare parts list in Rosemount TankRadar REX Service Manual.

DAU_TempRange.eps

4-4

Page 37

Installation Manual

308014EN, Edition 4

May 2013

Rosemount Tank Radar REX

Chapter 5 The Remote Display Unit

5. The Remote Display Unit RDU40

The Remote Display Unit 40 (RDU 40) is a robust display unit for outdoor

use in hazardous areas. If there are less than six temperature elements

per tank, the RDU 40 is the most cost-effective solution for field display.

In this case the temperature elements can be connected directly to the

TankRadar gauge (RTG). The display functions are software controlled

by the connected TankRadar gauge.

The RDU 40 is connected by a 3-wire cable up to 100 m (330 ft) from the

RTG. Up to two units can be connected to one TankRadar Rex gauge. It

displays calculated data, such as level, average temperature, volume,

signal strength, etc. The data can be displayed in lists or as single

values. The operator can set up a user-defined window where the most

useful information is presented. This window will be shown as the default

view. The RDU 40 can view up to six spot temperature elements

connected to a TankRadar Rex gauge.

See chapter 11.5.11 for more information on how to connect the RDU40

to the REX transmitter. See also the Display Unit RDU40 User´s Guide

for instructions on how to use the RDU40.

Level

.

2 x M20 M25

RDU40.eps, RDU40_REX.eps

LCD display 128 x 64 pixels

Level

.

Figure 5-1. RDU 40 connected to the REX gauge.

5-1

Page 38

Rosemount Tank Radar REX

Chapter 5 The Remote Display Unit

5.1 Installation

Unscrew and remove all six screws on the RDU40 cover. Remove the

cover and take care of the locking device for the weather protection

hatch.

The RDU 40 shall be connected to the TankRadar REX junction box for

cable connections.

Installation Manual

308014EN, Edition 4

May 2013

RDU40_install_master_slave.eps

Figure 5-2. Installation of RDU 40 master and slave

Any of the three cable glands may be used to take the cable into the

RDU40:

2xM20 - Cable diameter: 7 mm - 14 mm

1xM25 - Cable diameter: 9 mm - 18 mm.

External adapters 1/2 NPT and 3/4 NPT are optional.

Connect the RDU 40 to the X12 terminal in the REX junction box as

illustrated in Figure 5-2.

5-2

Page 39

Installation Manual

308014EN, Edition 4

May 2013

In order to allow proper operation and to fulfil EMC requirements, the

cable between the RDU 40 and the REX junction box should meet the

following requirements:

• Shielded cable. Minimum 3 wires. The shield shall be circular connected inside the cable gland of the RDU 40 and connected to

ground in the REX junction box.

• All wires must have at least 0.25 mm individual insulation.

• Maximum total length of 100 m, both master and slave included.

• Minimum AWG 20 or 0.5 mm² for each wire.

The RDU 40-chassi shall be grounded locally to the tank. Use minimum

4 mm² or AWG 11 wire. Additional protective ground connection to the

power distribution central or the REX junction box is not recommended

except where required according to national code of practice. A ground

loop with circulating current may occur.

Note! It is not possible to use an RDU40 and a SDAU simultaneously.

Rosemount Tank Radar REX

Chapter 5 The Remote Display Unit

If a cable with two shields is used, one shield shall be connected to

ground in the REX junction box and the other shall be circular connected

inside the cable gland of the RDU 40.

Figure 5-3. Back of RDU40.

Check the gasket and put the locking device for the weather protection

hatch in position when remounting the RDU-cover. Tighten all six screws

firmly.

Mount the RDU 40 with the four M4 screws. Distances between the

screws are 60 mm and 68 mm according to the drawing on the back of

the RDU 40.

See the RDU 40 User´s Guide, Ref. no. 308010E, for further

information on RDU 40 installation.

5-3

Page 40

Rosemount Tank Radar REX

Chapter 5 The Remote Display Unit

5.2 Two RDU 40 connected to the same REX

If two RDU 40 are connected to the same REX, one of them has to be

configured as “slave” while the other is “master”. The slave cannot be

configured or controlled individually but follows the master. Only the

LCD-contrast can be individually controlled on the slave RDU 40.

To make an RDU 40 work as a slave it is necessary to move the jumper

at the RDU 40 cover to position 2 (see Figure 5-2).

5.2.1 Data items

24 items are available, dependent of how the REX gauge is equipped:

• Level

• Ullage

• Level rate

Installation Manual

308014EN, Edition 4

May 2013

• Signal strength

• Volume

• Average temperature

• Temperature spot 1-6

• Analog input 1-2

• Vapour pressure

• Observed density

• Free water level

• Hart slave 1-3

• Relay 1-2

5-4

Page 41

Installation Manual

308014EN, Edition 4

May 2013

Rosemount Tank Radar REX

Chapter 6 The Field Communication

6. The Field Communication Unit

The Field Communication Unit (FCU) continuously polls data from the

Radar Tank Gauges and the Data Acquisition Units and stores it in a

buffer memory. The Field Communication Unit is the master on the Field

Bus but acts as a slave on the Group Bus.

Note! No explosion protection is provided, so the Field Communication Unit

must be installed in a non-hazardous area.

FCU_2160.eps

Ground

connection

Figure 6-1. The Field Communication Unit.

6.1 FCU Enclosure

As standard the Field Communication Unit is shipped in a weather

protected, wall-mounted box of the same type as the Data Acquisition

Unit. The Field Communication Unit is built on a Printed Circuit Board

and may be delivered as such for mounting within a customer supplied

enclosure.

Cable

outputs

6-1

Page 42

Rosemount Tank Radar REX

Chapter 6 The Field Communication Unit

6.2 Communication Ports

The Field Communication Unit has six connections for communication

interface boards, X1 to X6. The connections can be individually

configured as either Group Bus or Field Bus ports. There can be

maximum four Group Buses or four Field Buses at the same time.

Maximum configuration can be 2+4, 3+3 or 4+2 buses of each kind.

However, connections X5 and X6 are never configured as Field Bus

ports, while the X1 and X2 connections are never configured as Group

Bus ports.

As standard the Field Communication Unit is delivered with six FCM

interface boards for four Field Bus ports and two Group Bus ports.

The table below shows the maximum configurations of an extended

FCU:

Ports X1 X2 X3 X4 X5 X6

Installation Manual

308014EN, Edition 4

May 2013

Alternative 4+2

Alternative 3+3

Alternative 2+4

Table 6-1. Communication ports.

6.2.1 RS232 communication

There are two jumper connectors delivered with each unit. These can be

connected to the X5 and/or X6 for RS-232C Group Bus communication.

See Figure 6-2.

X4

X5

X6

FB FB FB FB GB GB

FB FB FB GB GB GB

FB FB GB GB GB GB

TRL/2 Bus

Interface boards,

FCM boards

X3

X2

X1

6-2

Jumper for

RS232C

FCU_BusPorts.eps

Figure 6-2. FCU Bus Ports

Page 43

Installation Manual

308014EN, Edition 4

May 2013

6.2.2 RS 485 communication

Each FCM interface board can be replaced with FCI interface boards for

RS-485 communication.

Note! The wire terminals 1 and 3 respectively 2 and 4 on FCM board connector

are parallel connected. See installation drawing.

Rosemount Tank Radar REX

Chapter 6 The Field Communication

6.3 Write Inhibit/Enable Switch

There is a write inhibit switch in the FCU that can be used to prevent

unauthorized changes in the FCU database. It can be locked in the write

inhibit position by securing a locking plate with a wire through the clevis

pins.

Write

enable

FCU_WriteEnableInhibit.eps

Write inhibit

Figure 6-3. Write inhibit/enable switch.

Reset switch

115 V

230 V

6-3

Page 44

Installation Manual

Rosemount Tank Radar REX

Chapter 6 The Field Communication Unit

308014EN, Edition 4

6.4 Connecting the Field Communication Unit, FCU 2160

6.4.1 Power Supply

There is a switch to select the supply voltage to either 115 V or 230 V.

Check that the switch is set in the right position before power is

connected. The switch is set to 230 V as standard.

If the switch is set to 115 V, mark the check-box on the nameplate: “Mark

box if re-wired for 115 VAC”:

May 2013

FCU_2160_Label.eps

Figure 6-4. FCU marking for 115 VAC.

Note! Do not turn the switch all the way around as it may damage the switch.

30

11

FCU_Power.eps

Figure 6-5. Selecting the FCU power supply voltage.

6.4.2 Connection to a PC

The FCU can be connected to the PC either directly via RS-232C or via a

Field Bus Modem (FBM) on the TRL/2 Group Bus.

6-4

The TRL/2 Bus requires a twisted and shielded pair with an area of min

0.50 mm2 (AWG 20 or similar). See chapter 11.2.

The RS-232C connection can be made with 3 wires from the PC to the

Field Communication Unit. The area must be at least 0.25 mm2 (AWG 24

or similar). The maximum length of the RS-232C connection is 30 m.

Page 45

Installation Manual

308014EN, Edition 4

May 2013

6.5 Redundancy

In order to reduce the risk of communication failure between the

TankMaster and the units connected to the TRL/2 fieldbus, two FCUs

can be connected to run in parallel to provide automatic redundancy. The

FCUs are connected with an extra cable allowing them to communicate.

The inactive FCU constantly checks if the connected FCU is active. If the

active FCU fails, it signals to the backup FCU to take over. Then the

backup FCU immediately switches to an active state. It is also possible

to use up to four TankMaster PC:s connected via different Group Buses.

FCU_redundant.eps

Rosemount Tank Radar REX

Chapter 6 The Field Communication

Redundant FCU:s.

Two FCU:s can be connected

in parallel. One of them is configured as the primary FCU and

the other as backup. The primary FCU is active. The

backup FCU listens to the communication on the Field Bus

and automatically takes over

the communication without any

action from the operator if the

primary FCU fails.

FCU_redundant_workstation.eps

Double FCU:s and

workstations.

With two FCU:s and two TankMaster workstations a complete redundancy from control

room to RTG is achieved.

6-5

Page 46

Rosemount Tank Radar REX

Chapter 6 The Field Communication Unit

Installation Manual

308014EN, Edition 4

May 2013

Local Area Network

FCU_redundant_FBM.eps

Redundant FCU:s, FBM:s and

workstations.

With two FBM:s safe communication between the TankMaster

workstation and the FCU is

achieved.

Several Group Buses.

An FCU can connect up to four

group buses. The buses can

have different masters like

TankMaster PC:s and DCS

units.

FCU_redundant_groupbus.eps

6-6

Page 47

Installation Manual

308014EN, Edition 4

May 2013

7. Bus Modems

Emerson Process Management/Rosemount Tank Gauging supplies two

types of modems (for technical details, please see chapter 14):

Field Bus Modem 2180: converts between USB or RS 232C and the

TRL/2 Bus. The TRL/2 protocol is used for communication with

Rosemount Tank Gauging equipment.

Rosemount Tank Radar REX

Chapter 7 Bus Modems

Figure 7-1. Field Bus Modem 2180

Enraf Bus Modem: converts between RS 232C and TRL/2 Bus or

RS 232C and Enraf GPU communication protocol.

Figure 7-2. Enraf Bus Modem

FBM2180_USB_Top_RosemounTG.eps

Modemb.eps

7-1

Page 48

Rosemount Tank Radar REX

Chapter 7 Bus Modems

7.1 Field Bus Modem 2180

7.1.1 DIN Rail Mounting

The FBM 2180 can be mounted on a DIN-rail 35 EN 50022. The

following is delivered with the FBM2180 kit:

• FBM 2180 TRL/2 Bus Modem

• Four screws

• Two DIN mounting clips

4 x

Installation Manual

308014EN, Edition 4

May 2013

1 Attach the two DIN rail

mounting clips to the back of

the FBM2180 by using the

four screws. There are four

holes drilled on the modem

housing to be used for the

clips.

20 mm

FBM2180_DIN_Rail.eps

FBM2180_DIN_Rail_Top.eps

15 mm 15 mm

2 Mount the FBM2180 on the

DIN rail and make sure that

the FBM2180 is securely

fastened.

7-2

Page 49

Installation Manual

308014EN, Edition 4

May 2013

7.1.2 Power Supply

Use adapter 90-264 V ac/9 V dc 1.5 A for RS232 communication.

DO NOT use external power supply when the modem is connected to

the USB port. The USB interface itself supports power to the FBM2180

modem.

Rosemount Tank Radar REX

Chapter 7 Bus Modems

FBM2180_Back.eps

7.1.3 TRL/2 Bus

Power supply (polarity independent)

(RS 232 communication only)

Figure 7-3. Power supply for RS232

Use single twisted preferably shielded pair cable. Individual shielding is

mandatory if parallel buses run in the same cable. Polarity independent.

Recommended wiring length:

Cable dimension Maximum Length

AWG 20 (0.50 mm2)

AWG 18 (0.75 mm2)

3000 m

4000 m

FBM2180_Back.eps

TRL/2 Bus

Figure 7-4. TRL/2 Bus terminal

7-3

Page 50

Rosemount Tank Radar REX

Chapter 7 Bus Modems

7.1.4 RS 232 Communication

The serial port on the FBM2180 fits to a standard M 9P Dsub connector.

Connect the modem to the COM port on the PC with a standard RS232

DTE-DCE cable (“straight” cable).

Installation Manual

308014EN, Edition 4

May 2013

RS 232 connector

FBM2180_Back / FBM2180_RS232_Top

RS 232 port

Figure 7-5. RS232 connection

7.1.5 USB Communication

For the USB port use cable type A>B. Do not use external power supply

when using the USB port. The USB interface itself supports power to the

FBM2180 modem.

USB connector

FBM2180_Back / FBM2180_USB_Top

7-4

USB port

Figure 7-6. USB connection

Page 51

Installation Manual

308014EN, Edition 4

May 2013

7.1.6 USB Driver Installation

The USB interface requires a Virtual COM Port driver. Rosemount

TankMaster version 4.F1 and higher fully supports Virtual COM Ports.

The driver is included on the Rosemount TankMaster CD version 4.F1

and higher.

To install the USB driver do the following:

1 Plug the USB cable into the FBM 2180 and to the USB port on the com-

puter. The Found New Hardware Wizard dialog for the FBM 2180 Serial

Converter will appear:

Rosemount Tank Radar REX

Chapter 7 Bus Modems

2 Follow the instructions on the screen for the FBM 2180 driver. The FBM

2180 drivers can be found on the installation CD for the Rosemount

TankMaster software. If you have the drivers on another location, choose

“Install from a list or specific location (Advanced)” and browse to the

folder where the drivers are located.

3 When the FBM 2180 driver installation is finished the Found New Hard-

ware Wizard dialog for the FBM 2180 Serial Port driver will appear:

Wizard_Welcome.TIF

Wizard_USB.TIF

7-5

Page 52

Rosemount Tank Radar REX

Chapter 7 Bus Modems

4 Follow the instructions on the screen for the FBM 2180 Serial Port driver.

5 If you are using Windows XP operating system, you will see the warnings

below appear during the USB driver installations:

Installation Manual

308014EN, Edition 4

May 2013

Wizard_Windows_XP / Wizard_Windows_XP_USB

6 Please click the Continue Anyway button. Our drivers are Microsoft

WHQL certified and work with the operating system.

7 Once the USB drivers are installed you are ready to use the FBM 2180.

7-6

Page 53

Installation Manual

308014EN, Edition 4

May 2013

7.1.7 Operation

Front Panel

The FBM 2180 front LEDs show information on power supply,

communication status and communication interface.

Rosemount Tank Radar REX

Chapter 7 Bus Modems

LEDs for external power

and communication

External power

RS232

USB

Gain

switch

Receive

Transmit

Termination

switch

Figure 7-7. FBM 2180 front panel

The Termination switch is used if there are extremely short cables

between the transmitter and the modem.

The Gain switch is set to Lo by default. This setting is sufficient in most

cases. The Hi Gain setting may be used if cable dimensions are

insufficient resulting in a heavily damped communication signal.

FBM2180_Front.eps

7.1.8 Communicating with TankMaster™

TankMaster WinSetup allows you to setup the communication between a

PC, Field Communication Unit (FCU) and field instruments in a

Rosemount Tank Gauging system. For each communication port that is

used on the PC a protocol channel has to be configured (see the

TankMaster WinSetup Reference Manual for more information on

communication protocol setup).

7-7

Page 54

Rosemount Tank Radar REX

Chapter 7 Bus Modems

7.1.9 USB Interface

The USB interface requires a Virtual COM Port driver. Virtual COM Ports

are supported by Rosemount TankMaster version 4.F1 or higher. See

“USB Driver Installation” on page 5. for more information.

In TankMaster™ WinSetup each FBM 2180 connected via a USB port is

displayed as a virtual COM port designated FBM 2180 Serial Port. For

each FBM 2180 a new Virtual COM Port is installed on the TankMaster

PC.

Virtual COM Port

for USB

communication

Installation Manual

308014EN, Edition 4

May 2013

Figure 7-8. Virtual COM port for USB interface

7.1.10 RS 232 Interface

For RS 232 communication simply connect to one of the COM ports on

the PC and select the corresponding port in the Master Protocol Channel

Configuration window:

COM Port

Figure 7-9. COM port configuration for RS232

TM_ProtocolConfig_FBM2180_b.TIF

MBMaster_ChannelConfig_COM1.TIF

7-8

Page 55

Installation Manual

308014EN, Edition 4

May 2013

7.1.11 Specifications

Rosemount Tank Radar REX

Chapter 7 Bus Modems

Explosion protection

Power supply (for RS-232)

Cable to Host PC

Field bus over voltage

protection

Field interface

Computer/Host interface

LED indicators

None

DC 7-12 V, max. 50 mA

RS-232: 3 m (10 ft)

USB: 3 m (10 ft)

Galvanic insulation, transient suppressors

TRL/2

RS-232 or USB

External power. Host connection TRL/2

transmit and receive

7-9

Page 56

Rosemount Tank Radar REX

Chapter 7 Bus Modems

7.2 Enraf Bus Modem, EBM

An Enraf Bus Modem (EBM) is used when configuring a Rex gauge for

Enraf emulation.

Entis / TankMaster

Installation Manual

308014EN, Edition 4

May 2013

Network

PLC

Enraf_Fieldbus_REX.eps

PC with WinSetup

software for

EBM

CIU

configuration of Rex

Rex gauge

Figure 7-10. A system where Enraf gauges have been replaced

by TankRadar Rex.

7-10

Page 57

Installation Manual

308014EN, Edition 4

May 2013

7.2.1 Connecting the Enraf Bus Modem

Rosemount Tank Radar REX

Chapter 7 Bus Modems

Field bus

connector

Modemb.eps

Modbus/Normal (Enraf) Switch

Modbus, left position

Enraf, right position

Figure 7-11. Connecting an Enraf Bus Modem (EBM).

7.2.2 Configuration

When an Enraf gauge is replaced with TankRadar Rex it is necessary to

configure the Rex gauge for emulation. Configuration is made with the

WinSetup software and requires an Enraf Bus Modem (EBM). How the

procedure is done depends on system type

System Type

Required Steps

(described below)

PC

connector

Baud rate Switch

2400, left position;

1200, right position most commonly used.

Optional Steps

(described below)

Standard System Step 1-2, 6-7 Step 3

Hybrid Step 1-4, 6-7

LPG Step 1-4, 6-7

Installation with

Step 1-2, 5-7 Step 3

Water Level Sensor

(WLS)

Table 7-2. Configuration procedure

7-11

Page 58

Installation Manual

Rosemount Tank Radar REX

Chapter 7 Bus Modems

Below follows a short configuration description. Details are described in

the Enraf Emulation Guideline (reference number 308013EN) and in

TankMaster WinSetup Reference Manual (reference number

303027EN).

Step 1 Connect the EBM.

Step 2 Configure the gauge in WinSetup.

Step 3 Install a tank in Winsetup: Required only for Hybrid / LPG systems

for which the analog inputs are used. However it is a good idea to

install a tank and associate a gauge to it, because then it is possible to benefit from the Open Tank View function.

Step 4 Configure the gauge by using the Hybrid Calculation window

(Hybrid

system) or LPG Setup window (LPG system) in Winsetup.

308014EN, Edition 4

May 2013

Step 5 Set holding registers for free water level measurements.

Step 6 Enter information into the Enraf Emulation window in WinSetup.

Set Enraf mode and move EBM switch from Modbus to Normal

(Enraf).

Step 7 Close Enraf Emulation window. The gauge now acts like an Enraf

instrument and the EBM can be disconnected. Connect the fieldbus to the CIU.

7-12

Page 59

Installation Manual

308014EN, Edition 4

May 2013

8. Junction Boxes

As optional equipment, a series of junction boxes can be delivered with

the TankRadar Rex system. They are used to connect the various

system units.

FCU

Rosemount Tank Radar REX

Chapter 8 Junction Boxes

Alternative connections

to DCS

system_JB

RTG with JBi

(section 8.1)

Temp.

Sensor

JB 36/42

(section 8.3)

JB

JB

Temp.

Sensor

DAU

RTG

JB

EEx e

(section 8.2)

Field

Bus

Modem

TankMaster PC

workstations in

network

Figure 8-1. Overview of the different junction boxes in a

TankRadar Rex system.

8.1 Integrated Junction Box, JBi

8.1.1 Explosion Approval

The integrated junction box is designed for increased safety classified

according to EEx e [ia] IIC T6. There is one EExe side for mains, bus

cables and relay outputs. The EExi side is for intrinsically safe

connections.

8-1

Page 60

Rosemount Tank Radar REX

Chapter 8 Junction Boxes

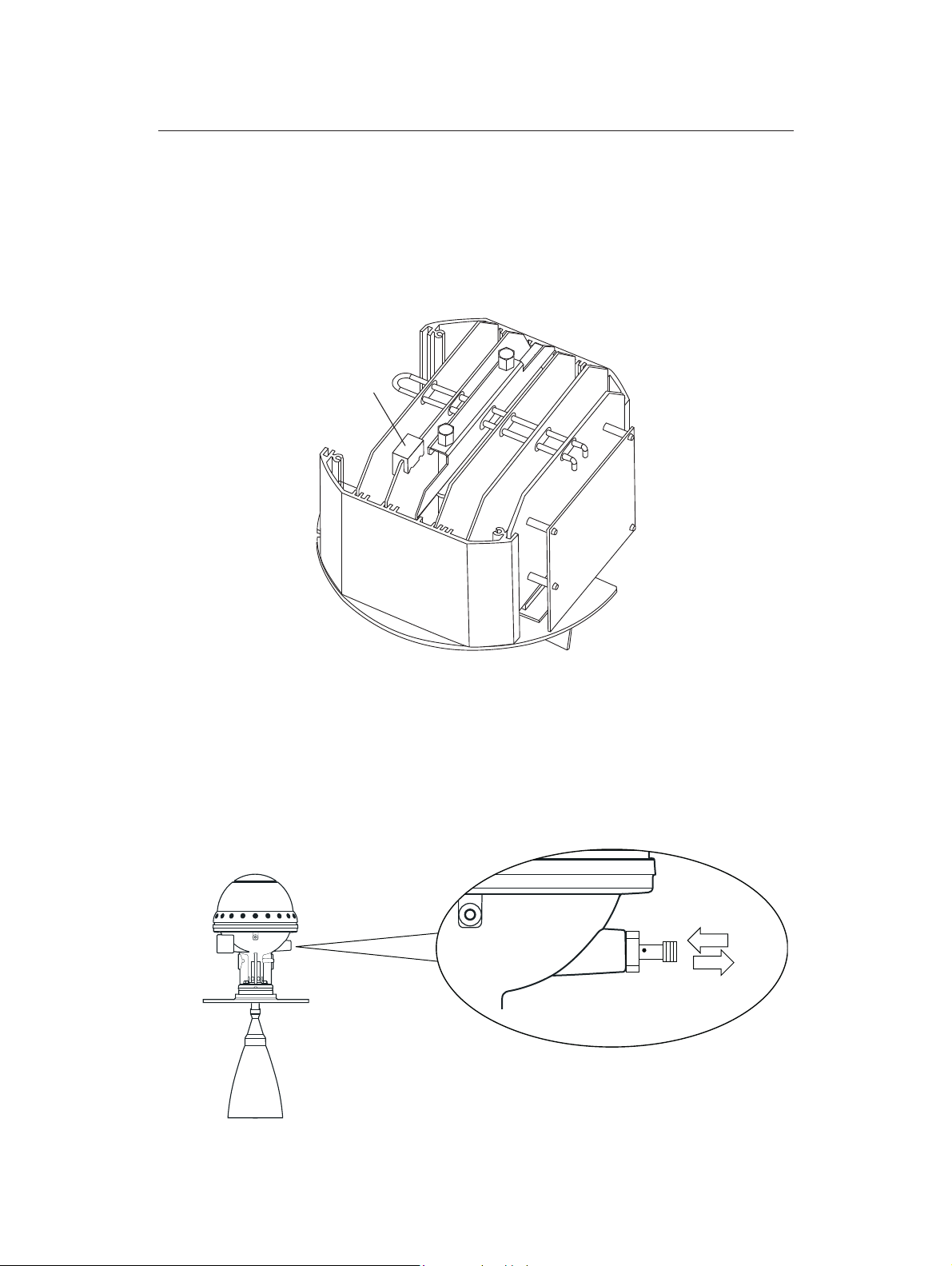

8.1.2 Design

• The box is sealed according to IP65.

• Temperature range is -40°C to +70°C (-40°F to +158°F).

8.1.3 Cable Inlets - RTG 3900

On the left-hand side (X12) there are two 1/2 in. and one 3/4 in. inlets.

There are 15 terminals for intrinsically safe cables to analog inputs, DAU

or Display Panel and up to 6 temperature sensors.

On the right-hand side (X11) there are two 3/4 in. and one 1/2 in. inlets.

The box has 8 terminals for power, communication signals and relay

outputs.

Installation Manual

308014EN, Edition 4

May 2013

JB_integrated

EEX i

Intrinsically safe side

Analog inputs

Temperature

sensors

DAU / RDU

Figure 8-2. RTG 3900 with Integrated Junction Box.

EEX e

Non-Intrinsically safe side

TRL/2 Bus

Analog outputs

Relay output

Power 230/115 VAC

8-2

Page 61

Installation Manual

308014EN, Edition 4

May 2013

Rosemount Tank Radar REX

Chapter 8 Junction Boxes

8.2 Junction Boxes for Intrinsically Safe and EEX e environments

JB 140-15

(EEX i)

JB_general_ed3

DAU / RDU

Cable

~ 2 m cable with

protective hose

~ 2 m cable

with

protective

hose

Figure 8-3. Intrinsically Safe and Explosion Proof Junction

Boxes.

JB 140-11

(EEX e)

5 x M25

TRL/2 Bus,

Analog

outputs,

Relay

output,

Power 230/

115 VAC

8.2.1 JB 140-15 for EEx i environments