Page 1

Art.-Nr.: 15.752.20 I.-Nr.: 11022

BT-FW

100

Original operating instructions

Flux Cored Welding Set

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 1

Page 2

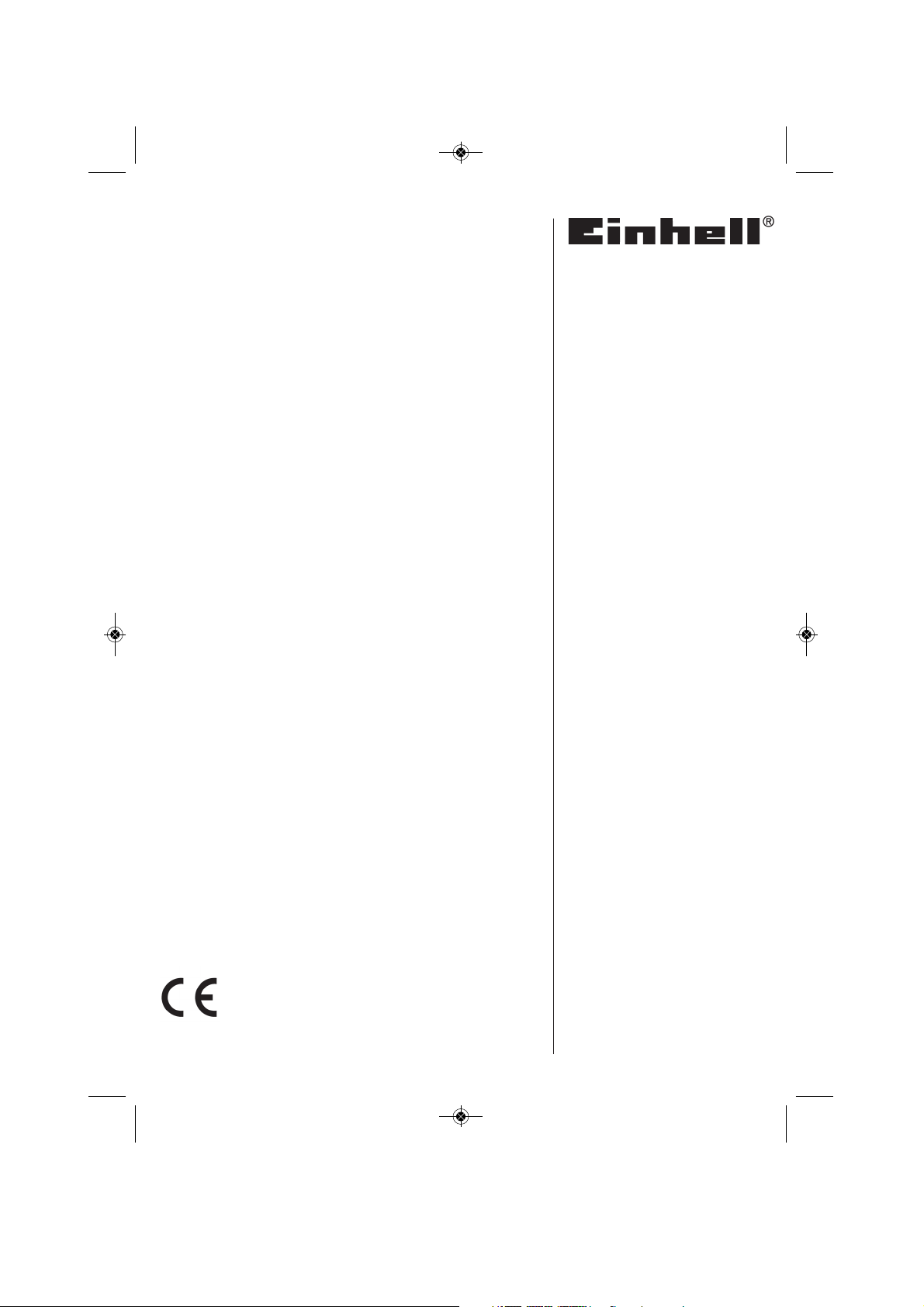

1

1

6

11

2

12

2

3

5

13

10

7

9

4

8

14

10

11

2

3

10

15

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 2

Page 3

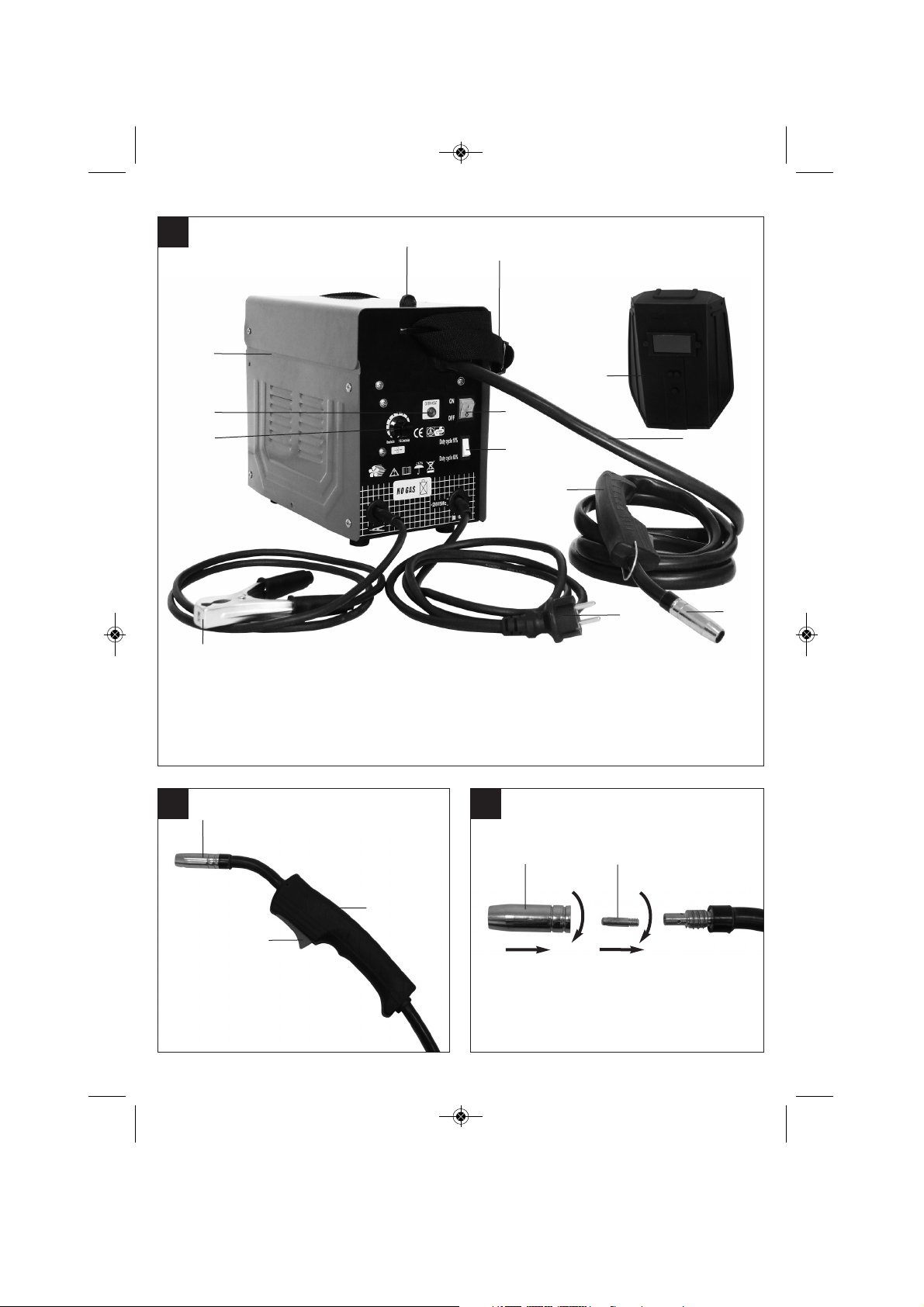

4

S

q

p

o

n

m

l

k

r

13

3

6

5

11

7

m

k

l

8

q

q

S

9

q

n

n

k, l, m

12

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 3

Page 4

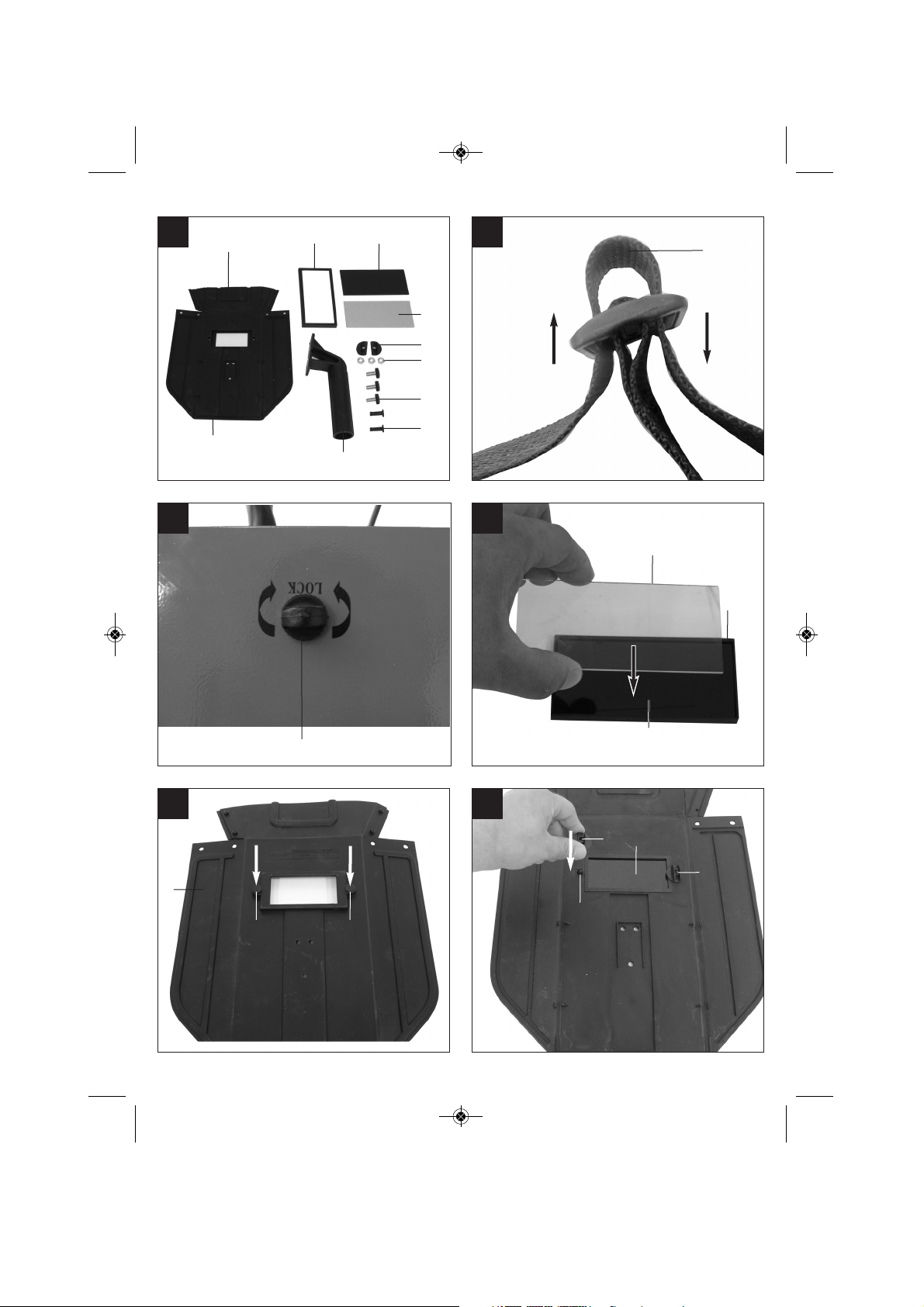

11

12

p

p

p

13

14 15

o

o

E

o

r

p

F

G

B

N

A

D

C

4

10

1.

4.

2.

3.

S

H

J

K L

I

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 4

Page 5

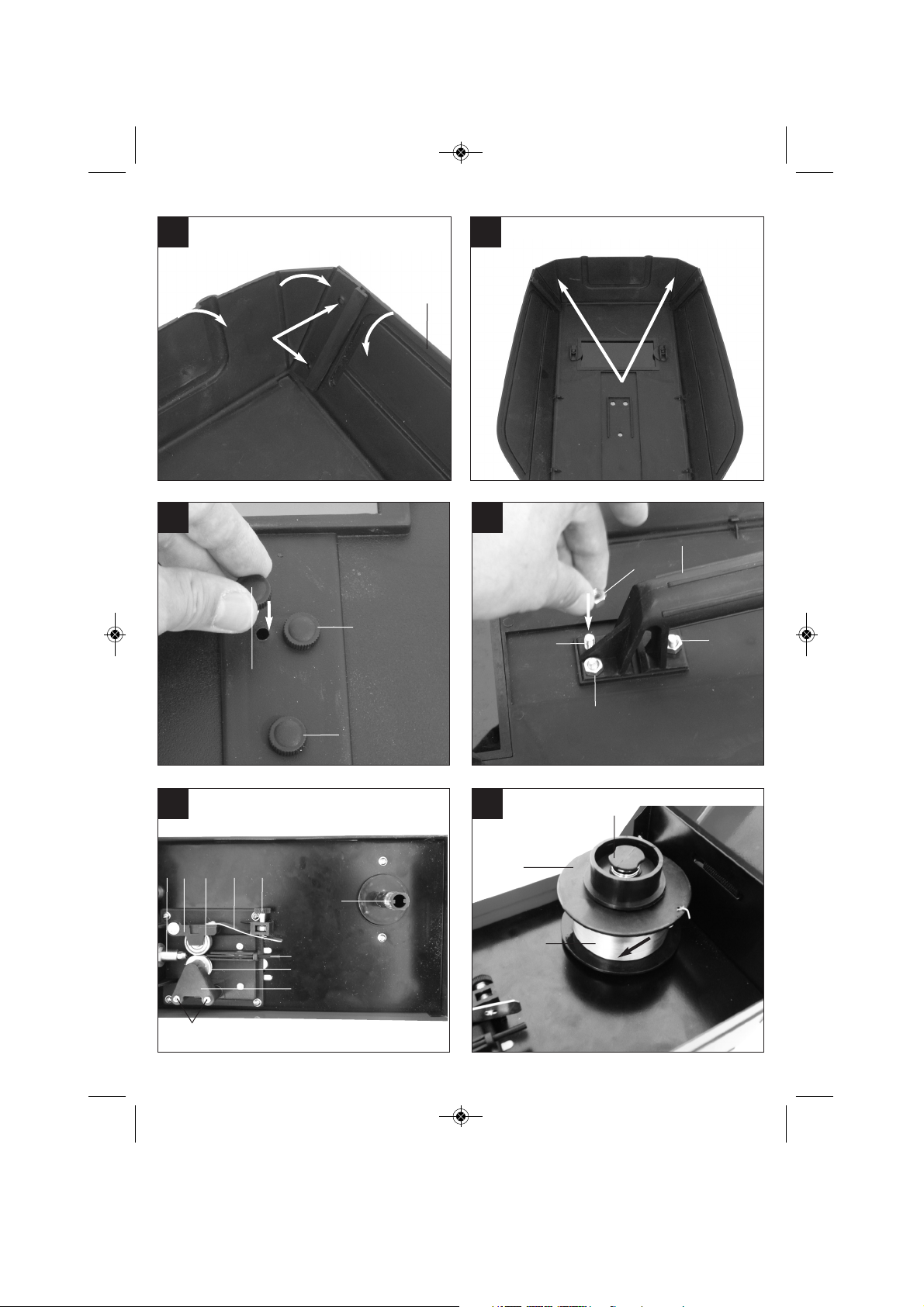

5

17

I

K

J

18

E

E

F

16

K

19

G

20

C

H

21

K

J

I

L

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 5

Page 6

6

22

L

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 6

Page 7

GB

7

Table of contents: Page

1. Safety regulations 8

2. Layout and items supplied 10

3. Intended use 10

4. Technical data 10

5. Before starting the equipment 11

6. Operation 12

7. Cleaning, maintenance and ordering of spare parts 13

8. Disposal and recycling 13

9. Troubleshooting 14

10. Key to symbols 15

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 7

Page 8

Important!

When using the equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating instructions and

safety regulations with due care. Keep this manual in

a safe place so that the information is available at all

times. If you give the equipment to any other person,

hand over these operating instructions and safety

regulations as well. We cannot accept any liability for

damage or accidents which arise due to a failure to

follow these instructions and the safety instructions.

1. Safety regulations

Safety information

Please note

Handling this system incorrectly may be hazardous

for persons, animals and property. The user of this

system is responsible for his/her own safety and for

the safety of others.

Read these operating instructions and follow all the

regulations.

앬 Repairs and/or maintenance work may only be

carried out by qualified personnel.

앬 Use only the welding cables supplied.

앬 Ensure that the appliance is looked after properly.

앬 To ensure that sufficient air can be drawn in

through the ventilation slits, the appliance should

not be constricted or placed next to a wall while it

is operating. Make sure that the appliance is

correctly connected to the mains supply.

Do not subject the mains lead to any tensile

stress. Unplug the appliance before you change

its position.

앬 Check the condition of the welding cables, the

burner and the earth terminals; wear on the

insulation and the live parts may result in

dangerous conditions and reduce the quality of

the welding work.

앬 Arc welding generates sparks, molten metal

particles and smoke, so the following is required:

Remove all inflammable substances and/or

materials from the working area.

앬 Ensure that there is adequate ventilation.

앬 Do not weld on tanks, vessels or pipes that have

contained inflammable liquids or gases. Avoid all

direct contact with the welding circuit; the idling

voltage between the burner and the earth terminal

may be dangerous.

앬 Do not store or use the appliance in wet or damp

conditions or in the rain.

앬 Protect your eyes with specially designed goggles

(DIN level 9-10), which you can attach to the

supplied safety shield. Wear gloves and dry safety

clothing that are not contaminated by any oil or

grease to ensure that your skin is not exposed to

ultraviolet radiation from the arc.

앬 Do not use this welder to defrost pipes.

앬 Make sure that the equipment is set up so it stands

firmly. If the equipment is set up on an angled

surface, it may need to be secured by tying or

blocking the wheels.

Remember.

앬 The radiation from the arc can damage your eyes

and cause burns on skin.

앬 Arc welding generates sparks and droplets of

molten metal; the welded workpiece may start to

glow and will remain very hot for a relatively long

period of time.

앬 Arc welding releases vapors that may be harmful.

Every electric shock is potentially fatal.

앬 Do not approach the arc within a radius of 15 m

unprotected.

앬 Protect yourself (and others around you) against

the possible hazardous effects of the arc.

앬 Warning: Depending on the mains connection

conditions at the connection point of the welding

set, other consumers connected to the mains may

suffer faults.

Important!

If the supply mains and circuits are overloaded, other

consumers may suffer interference during the

welding work. If you have any doubts, contact your

electricity supply company.

Sources of danger during arc welding

Arc welding results in a number of sources of

danger. It is therefore particularly important for the

welder to comply with the following rules so as not to

place himself or others in danger and to avoid

endangering people and equipment.

1. Have all work on the mains voltage system, for

example on cables, plugs, sockets, etc.,

performed only by trained electricians. This

particularly applies to configuring intermediate

cables.

2. If an accident occurs, disconnect the welding

power source from the mains immediately.

3. If electric touch voltages occur, switch off the

welding set immediately and have it checked by

an expert.

4. Always check for good electrical contacts on the

welding current side.

5. Wear insulating gloves on both hands for

8

GB

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 8

Page 9

9

GB

welding. These offer protection from electric

shocks (idling voltage in the welding circuit),

harmful radiation (Heat and UV radiation) and

from glowing metal and slag spatter.

6. Wear firm, insulated footwear. Your shoes

should also protect you in wet conditions. Opentoed footwear is not suitable since falling droplets

of glowing metal will cause burns.

7. Wear suitable clothing, do not wear synthetic

clothes.

8. Do not look into the arc with unprotected eyes,

use only a welding safety shield with the proper

safety glass in compliance with DIN standards. In

addition to light and heat, which may cause

dazzling and burns, the arc also gives off

UV radiation. Without proper protection, this

invisible ultraviolet radiation causes very painful

conjunctivitis, which will only be noticeable

several hours later. In addition, UV radiation will

cause sunburn-type symptoms on unprotected

parts of the body.

9. Personnel or assistants in the vicinity of the arc

must also be notified of the dangers and

provided with the required protection; if

necessary install safety walls.

10. Ensure adequate ventilation for welding,

particularly in small rooms since the process

causes smoke and harmful gases.

11. Do not carry out any welding work on tanks that

have been used to store gases, fuels, mineral oil

or the like, even if they have been empty for a

lengthy period of time, since any residue will

result in a danger of explosion.

12. Special regulations apply in areas where there is

a potential risk of fire and/or explosion.

13. Welds that are exposed to large stresses and

must comply with safety requirements may only

be completed by specially trained and approved

welders. Examples of such welds include

pressure vessels, rails, trailer hitches, etc.

14. Note: It must be noted that the protective

conductor in electrical systems of appliances

may be destroyed by the welding current in the

event of negligence, for example if the earth

terminal is placed on the welding set casing to

which the protective conductor of the electrical

system is connected. The welding work is

completed on a machine with a protective

conductor connection. It is therefore possible to

weld on the machine without having connected

the earth terminal to it. In this case the welding

current will flow from the earth terminal through

the protective conductor to the machine. The

high welding current may cause the protective

conductor to melt.

15. The fuses on the supply cables to the mains

sockets must comply with the relevant

regulations (VDE 0100). To comply with these

regulations, only fuses or circuit breakers

suitable for the cross-section of the cables may

be used (for earthing contact sockets max. 16 A

fuses or 16 A circuit breakers). The use of too

high a fuse may result in the cable burning and

fire damage to the building.

Constricted and wet areas

When working in constricted, wet or hot areas, use

insulating supports and intermediate layers as well

as slip-on gloves made of leather or other nonconductive materials to insulate your body against

the floor, walls, conductive parts of the machine and

the like.

If you use small welding transformers for welding in

places with an increase electrical risk, for example in

constricted areas with conductive walls, (tanks,

pipes, etc.), in wet areas (which make work clothes

wet) and in hot areas (perspiration on work clothes),

the output voltage of the welding set when idling

must not exceed 48 V (effective value). Therefore,

the appliance may not be used for these purposes

because its output voltage is higher than this.

Safety clothing

1. While working, the welder must protect his entire

body from radiation and burns by wearing

suitable clothing and a face guard.

2. Slip-on gloves made of a suitable material

(leather) must be worn on both hands. They

must be in perfect condition.

3. Suitable aprons must be worn to protect clothing

from sparks and burns. A safety suit and, if

necessary, head protection must be worn if

required by the type of work in question, e.g.

overhead welding.

4. The safety clothing used as well as all

accessories must comply with the „Personal

Safety Equipment“ directive.

Protection from radiation and burns

1. Provide information about the risk to eyes at the

working site in the form of a poster with the

wording “Caution – do not look at the flames”.

Workplaces are to be screened off wherever

possible so that personnel in the vicinity are

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 9

Page 10

protected. Unauthorized persons are to be kept

away from the welding work.

2. The walls in the immediate vicinity of stationary

workplaces should not have a light color or a

sheen. Windows up to head height are to be

protected against radiation passing through them

or reflecting off them, for example by coating

them with a suitable paint.

Do not store or use the equipment in wet

conditions or in the rain. Use the

equipment only indoors.

2. Layout and items supplied (Fig. 1-8)

1. Carrying strap

2. Thermostat control lamp

3. Housing cover

4. ON/OFF switch

5. Welding wire speed controller

6. Switch for welding current adjustment

7. Mains plug

8. Earth terminal

9. Hose package

10. Welding nozzle

11. Burner

12. Fastening screw for housing cover

13. Welding screen

14. Burner switch

2.1 Assembly material

k. 1 x Safety glass frame

l. 1 x Welding glass

m. 1 x Transparent safety glass

n. 2 x Safety glass retaining bushes

o. 3 x Nut for handle

p. 3 x Screws for handle

q. 2 x Safety glass retaining pin

r. 1 x Handle

s. 1 x Welding screen frame

3. Intended use

The flux cored welding set is designed for selfshielding flux cored welding using suitable wire. The

additional application of gas is not required.

The equipment is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse. The user / operator and not the

manufacturer will be liable for any damage or injuries

of any kind caused as a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

equipment is used in commercial, trade or industrial

businesses or for equivalent purposes.

4. Technical data

Mains connection: 230 V ~ 50 Hz

Welding current: 45-90 A

Duty cycle X% 10 60

Welding current I2(A): 90 45

Idling voltage: 31 V

Max. welding wire drum: 0.4 kg

Welding wire diameter 0.9 mm

Fuse: 16 A

Weight: 14 kg

10

GB

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 10

Page 11

11

GB

5. Before starting the equipment

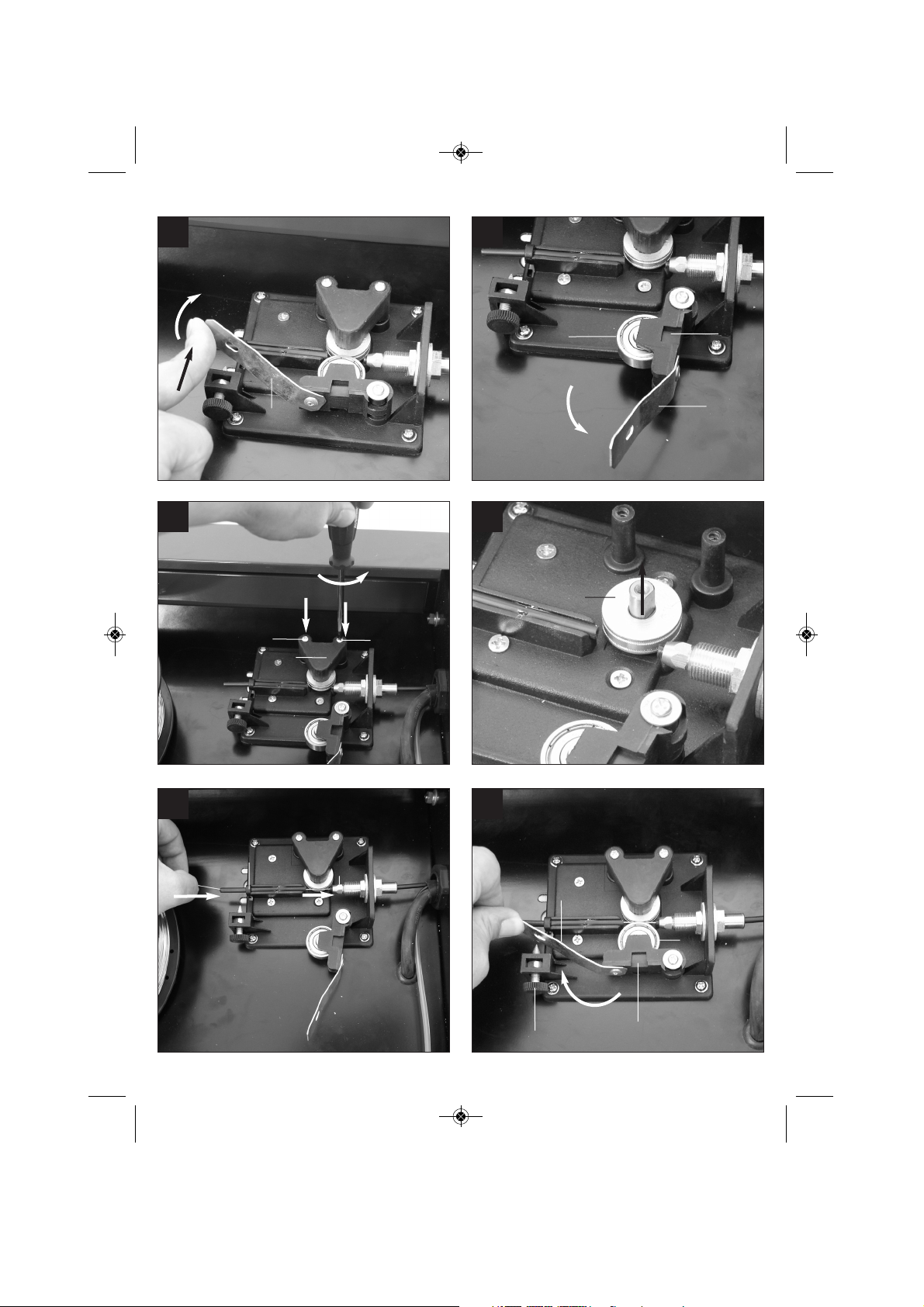

5.1 Assembly (Fig. 7-13)

5.1.1 Fitting the carrying strap (1)

n Guide the carrying strap (1) through the slit on

the rear of the equipment, over the housing

cover (3) and through the slit on the front of

equipment. Connect the ends of the carrying

strap as shown in Figure 5 and adjust the strap

to the required length.

Fitting the welding screen (13)

n Place the welding glass (l) and the transparent

safety glass (m) over it in the frame for the safety

glass (k) (Fig. 7).

n Press the safety glass retaining pins (q) into the

holes in welding screen frame (s) from the

outside. (Fig. 8).

n Place the frame for the safety glass (k) with the

welding glass (l) and transparent safety glass (m)

from the inside into the recess in the welding

frame (s), press the safety glass retaining

bushes (n) on to the safety glass retaining pins

(q) until they engage to secure the frame for the

safety glass (k). The transparent safety glass (m)

must be on the outside. (Fig. 9).

n Bend the top of the welding screen frame (s)

inwards (Fig. 10/1) and fold down the top corners

(Fig. 10/2) Now bend the outer sides of the

welding screen frame (l) inwards (Fig. 10/3) and

connect them by pressing the top corners and

outer sides together. When the retaining pins

engage, you should be able to hear 2 clear clicks

on each side (Fig. 10/4).

n When the top corners of the welding screen are

connected as shown in Figure 11, place the

screws for the handle (p) from the outside

through the three holes in the welding screen.

(Fig. 12).

n Turn over the welding screen and place the

handle (r) over the threads on the three screws

for the handle (p). Secure the handle (r) to the

welding screen using the three nuts for the

handle (o). (Fig. 13).

5.2 Mains connection

n Before you connect the equipment to the mains

supply make sure that the data on the rating

plate are identical to the mains data.

n The equipment may only be operated from

properly earthed and fused shock-proof sockets.

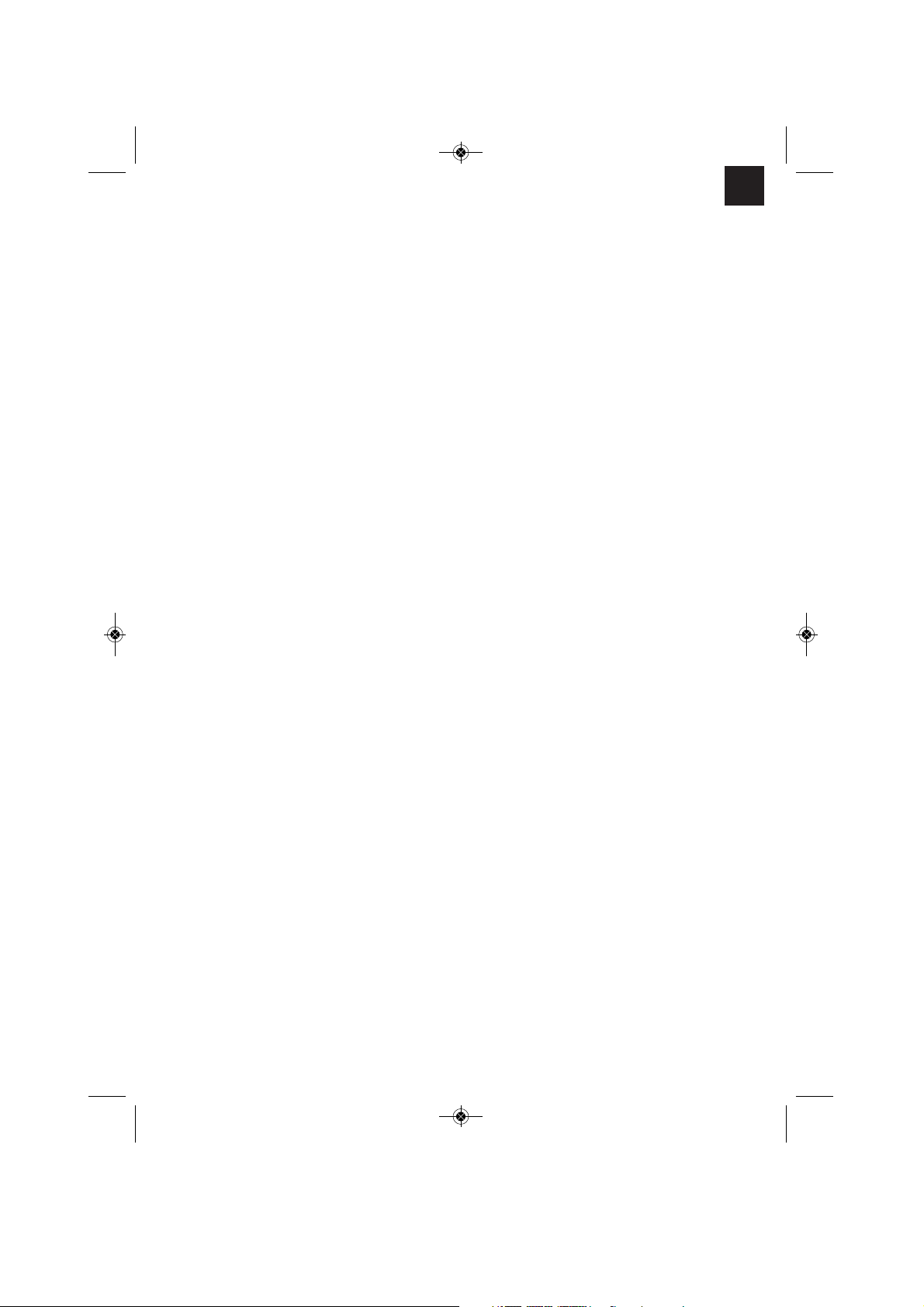

5.3 Fitting the wire spool (Fig. 1, 2, 3, 14 – 22)

The wire spool is not supplied.

5.3.1 Wire types

Various welding wires are required for different

applications. The welding set can be used with

welding wires with a diameter of 0.9 mm. The

appropriate feed rollers and contact tubes are

supplied with the set. The feed roller, contact tube

and wire cross-section must always match each

other.

5.3.2 Wire spool capacity

Wire spools with a maximum weight of 0.4 kg can be

fitted in the welding set.

5.3.3 Inserting the wire spool

n Unlock the housing cover (Fig. 1/3) by turning

the fastening screw (Fig. 6/12) through 90° and

flip open the cover.

n Check that the windings on the spool do not

overlap so as to ensure that the wire can be

unwound evenly.

Description of the wire guide unit (Fig. 14-22)

A Wire spool

B Spool holder

C Guide tube

D Adjusting screw for roller brake

E Screws for feed roller holder

F Fee roller holder

G Feed roller

H Hose package mounting

I Pressure roller

J Pressure roller holder

K Pressure roller spring

L Adjusting screw for counter-pressure

Inserting the wire spool (Fig. 14, 15)

Place the wire spool (A) on the spool holder (B).

Ensure that the end of the welding wire is unwound

on the side of the wire guide, see arrow.

Inserting the welding wire and adjusting the wire

guide (Fig. 16-22)

n Push the pressure roller spring (K) upwards and

swing it forwards (Fig. 16).

n Pull the pressure roller holder (J) with the

pressure roller (I) and pressure roller spring (K)

downwards (Fig. 17).

n Undo the screws for the feed roller holder (E)

and pull off the feed roller holder (F) upwards

(Fig. 18).

n Check the feed roller (G). The appropriate wire

thickness must be specified on the top of the

feed roller (G). The feed roller (G) is fitted with

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 11

Page 12

12

GB

two guide grooves. Turn the feed roller (G) over

if necessary or replace it. (Fig. 19).

n Position the feed roller holder (F) again and

secure it.

n Remove the gas nozzle (Fig. 2/10) from the

burner (Fig. 2/11) by turning it clockwise,

unscrew the contact tube (Fig. 3/15). (Fig. 2 – 3).

Place the hose package (Fig. 1/9) on the floor as

straight as possible pointing away from the

welding set.

n Cut off the first 10 cm of the welding wire to

produce a straight cut with no shoulders, warping

or dirt. Deburr the end of the welding wire.

n Push the welding wire through the guide tube (C)

between the pressure and feed rollers (G/I) into

the hose package mounting (H). (Fig. 20)

Carefully push the welding wire by hand into the

hose package until it projects out of the hose

package by approx. 1 cm at the burner (Fig.

2/11).

n Undo the adjusting screw for counter-pressure

(L) a few turns. (Fig. 22).

n Push the pressure roller holder (J) with pressure

roller (I) and pressure roller spring (K) upwards

again and attach the pressure roller spring (K) to

the adjusting screw for counter-pressure (L)

again (Fig. 21).

n Now set the adjusting screw for counter-pressure

(L) so that the welding wire is positioned firmly

between the pressure roller (I) and feed roller (G)

without being crushed. (Fig. 22).

n Screw the appropriate contact tube (Fig. 3/15) for

the welding wire diameter on to the burner (Fig.

2/11) and fit the gas nozzle(Fig. 2/10), turning it

clockwise.

n Set the adjusting screw for the roller brake (D) so

that the wire can still be moved and the roller

stops automatically after the wire guide has been

braked.

6. Operation

6.1 Setting

Since the welding set must be set to suit the specific

application, we recommend that the settings be

made on the basis of a test weld.

6.1.1 Setting the welding current

The welding current can be set to 2 different levels

using the welding current adjustment switch (Fig.

1/6). The required welding current depends on the

material thickness, the required penetration depth

and the welding wire diameter.

6.1.2 Setting the wire feed speed

The wire feed speed is automatically adjusted to the

current setting. The final wire feed speed setting can

be made on the welding wire speed controller (Fig.

1/5). It is advisable to start with the medium setting

and to re-adjust the speed as necessary. The

required quantity of wire depends on the material

thickness, the penetration depth, the welding wire

diameter and also the size of the gap to be bridged

between the workpieces you wish to weld.

6.2 Electrical connection

6.2.1 Mains connection

See point 5.2

6.2.2 Connecting the earth terminal (Fig. 1/8)

Connect the welding set’s earth terminal (8) in the

immediate vicinity of the welding position if possible.

Ensure that the contact point is bare metal.

6.3 Welding

When all the electrical connections for the power

supply and welding current circuit have been made,

you can proceed as follows:

The workpieces for welding must be clear of paint,

metallic coatings, dirt, rust, grease and moisture in

the area where they are to be welded.

Set the welding current and wire feed (see 6.1.1 –

6.1.3) as required.

Hold the welding screen (Fig. 4/13) in front of your

face and move the welding nozzle to the point on the

workpiece where you wish to complete the weld.

Now press the burner switch (Fig. 2/14).

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 12

Page 13

When the arc is burning, the welding set will feed

wire into the weld pool. When the weld nugget is

large enough, move the burner slowly along the

required edge. Move it to and fro if necessary to

enlarge the weld pool a little.

Find the ideal setting of the welding current and wire

feed speed by carrying out a test weld. Ideally an

even welding noise will be audible. The penetration

depth should be as deep as possible, but the weld

pool must not be allowed to fall through the

workpiece.

Do not remove the slag until the weld has cooled. If

you want to continue a welding job on an interrupted

weld seam, the slag from your initial attempt must

first be removed.

6.4 Safety equipment

6.4.1 Thermostat

The welding set is fitted with an overheating guard

that protects the welding transformer from

overheating. If the overheating guard trips, the

control lamp (2) on your set will be lit. Allow the

welding set to cool for a time.

7. Cleaning, maintenance and ordering

of spare parts

Always pull out the mains power plug before starting

any cleaning work.

7.1 Cleaning

n Keep all safety devices, air vents and the motor

housing free of dirt and dust as far as possible.

Wipe the equipment with a clean cloth or blow it

down with compressed air at low pressure.

n We recommend that you clean the equipment

immediately after you use it.

n Clean the equipment regularly with a damp cloth

and some soft soap. Do not use cleaning agents

or solvents; these may be aggressive to the

plastic parts in the equipment. Ensure that no

water can get into the interior of the equipment.

7.2 Servicing

There are no parts inside the equipment which

require additional maintenance.

7.3 Ordering replacement parts:

Please provide the following information on all orders

for spare parts:

n Model/type of the equipment

n Article number of the equipment

n ID number of the equipment

n Spare part number of the required spare part

For our latest prices and information please go to

www.isc-gmbh.info

8. Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in

this packaging can be reused or recycled. The

equipment and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

13

GB

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 13

Page 14

14

GB

Fault Cause Remedy

Feed roller does not turn Power supply not connected

Wire feed controller set to 0

Check connection

Check setting

Feed roller turns, but does not feed

any wire

Incorrect roller pressure (see 5.3.3)

Roller brake set too firmly (see

5.3.3)

Dirty / damaged feed roller (see

5.3.3)

Damaged hose package

Contact tube wrong size / dirty /

worn (see 5.3.3)

Welding wire welded to the gas

nozzle / contact tube

Check setting

Check setting

Clean or replace

Check the wire guide jacket

Clean or replace

Release

After a lengthy period of use the

welding set does not work any

longer, the thermostat (2) control

light is lit

The welding set has overheated

due to being used for too long and

a failure to observe the reset time

Leave the set to cool down for at

least 20 – 30 minutes

Very poor weld Incorrect current / feed setting (see

6.1.1/6.1.2)

Check setting

9. Troubleshooting

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 14

Page 15

15

GB

10. Key to symbols

EN 60974-1 European standard for

arc welding sets and

welding power supplies

with limited on time

Do not store or use the

equipment in wet or

damp conditions or in

the rain.

U

s

Standardized operating

voltage

Single-phase mains

connection

U

1

Mains voltage ~ 50 Hz Mains frequency

I1max Rated maximum mains

current

Symbol for falling

characteristic curve

Read the operating

instructions carefully

before using the welding

set and follow them

Self-shielding flux cored

welding

U

0

Rated idling voltage IP 21 S Protection type

I

2

Welding current X On-load factor

Ø mm Welding wire diameter I1eff Effective value of the

highest line current

Single-phase

transformer

1쓒

1쓒

1 ~

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 15

Page 16

t For EU countries only

Never place any electric tools in your household refuse.

To comply with European Directive 2002/96/EC concerning old electric and electronic equipment and its

implementation in national laws, old electric tools have to be separated from other waste and disposed of

in an environment-friendly fashion, e.g. by taking to a recycling depot.

Recycling alternative to the demand to return electrical devices:

As an alternative to returning the electrical device, the owner is obliged to cooperate in ensuring that the

device is properly recycled if ownership is relinquished. This can also be done by handing over the used

device to a returns center, which will dispose of it in accordance with national commercial and industrial

waste management legislation. This does not apply to the accessories and auxiliary equipment without

any electrical components which are included with the used device.

16

t

Given unfavorable conditions in the power supply the equipment may cause the voltage to drop temporarily. If the supply

impedance “Z” at the connection point to the public power supply exceeds 0,448 Ω it may be necessary to take further measures

before the equipment can be used as intended from this power supply. If necessary, you can ask your local electricity supply

company for the impedance value.

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 16

Page 17

17

The reprinting or reproduction by any other means, in whole or in part,

of documentation and papers accompanying products is permitted only

with the express consent of ISC GmbH.

Technical changes subject to change

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 17

Page 18

18

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 18

Page 19

19

t

GUARANTEE CERTIFICATE

Dear Customer,

All of our products undergo strict quality checks to ensure that they reach you in perfect condition. In the unlikely

event that your device develops a fault, please contact our service department at the address shown on this

guarantee card. Of course, if you would prefer to call us then we are also happy to offer our assistance under the

service number printed below. Please note the following terms under which guarantee claims can be made:

1. These guarantee terms cover additional guarantee rights and do not affect your statutory warranty rights.

We do not charge you for this guarantee.

2. Our guarantee only covers problems caused by material or manufacturing defects, and it is restricted to the

rectification of these defects or replacement of the device. Please note that our devices have not been

designed for use in commercial, trade or industrial applications. Consequently, the guarantee is invalidated

if the equipment is used in commercial, trade or industrial applications or for other equivalent activities. The

following are also excluded from our guarantee: compensation for transport damage, damage caused by

failure to comply with the installation/assembly instructions or damage caused by unprofessional

installation, failure to comply with the operating instructions (e.g. connection to the wrong mains voltage or

current type), misuse or inappropriate use (such as overloading of the device or use of non-approved tools

or accessories), failure to comply with the maintenance and safety regulations, ingress of foreign bodies into

the device (e.g. sand, stones or dust), effects of force or external influences (e.g. damage caused by the

device being dropped) and normal wear resulting from proper operation of the device.

This applies in

particular to rechargeable batteries for which we nevertheless issue a guarantee period of 12 months.

The guarantee is rendered null and void if any attempt is made to tamper with the device.

3. The guarantee is valid for a period of 2 years starting from the purchase date of the device. Guarantee

claims should be submitted before the end of the guarantee period within two weeks of the defect being

noticed. No guarantee claims will be accepted after the end of the guarantee period. The original guarantee

period remains applicable to the device even if repairs are carried out or parts are replaced. In such cases,

the work performed or parts fitted will not result in an extension of the guarantee period, and no new

guarantee will become active for the work performed or parts fitted. This also applies when an on-site

service is used.

4. In order to assert your guarantee claim, please send your defective device postage-free to the address

shown below. Please enclose either the original or a copy of your sales receipt or another dated proof of

purchase. Please keep your sales receipt in a safe place, as it is your proof of purchase. It would help us if

you could describe the nature of the problem in as much detail as possible. If the defect is covered by our

guarantee then your device will either be repaired immediately and returned to you, or we will send you a

new device.

Of course, we are also happy offer a chargeable repair service for any defects which are not covered by the

scope of this guarantee or for units which are no longer covered. To take advantage of this service, please send

the device to our service address.

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 19

Page 20

EH 03/2013 (01)

Anleitung_BT_FW_100_GB_SPK7__ 13.03.13 13:12 Seite 20

Loading...

Loading...