Edwards iXH, iXL, pXH Instruction Manual

M561-00-880

Issue C Original

Instruction Manual

iXH, iXL and pXH Dry Pumping Systems

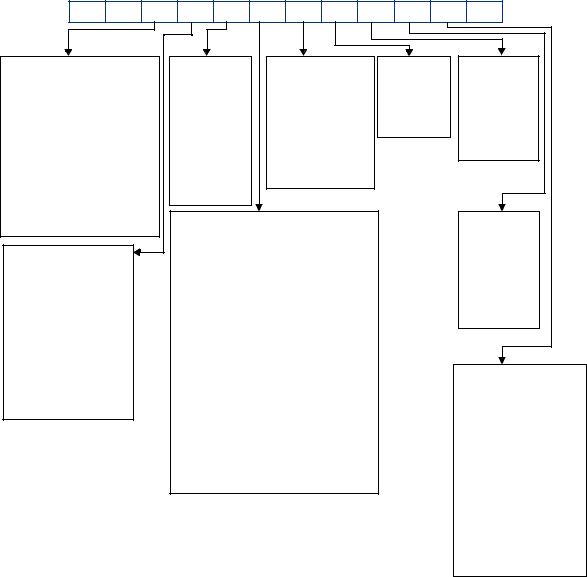

iXH and pXH Dry Pumping Systems

A |

C |

X |

|

X |

X |

X |

X |

X |

X |

X |

X |

0 |

|

Booster Size |

|

|

|

TMS System |

|

Exhaust |

|

|

Seals |

|

Pump |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor |

Low Voltage |

High Voltage |

|

0 |

= Standard |

|

0 = r |

|

|

0 = r |

|

0 = None |

||

0 = None |

A = None |

|

1 |

= T-Variant |

|

1 = Standard |

|

1 = r |

|

||||

|

2 |

= T-Variant |

|

without |

|

|

2 =Standard |

|

1 = 4.5 kW |

||||

1 = 600G |

B = 600G |

|

|

+ heated |

|

check valve. |

|

|

|

2 = 7.5 kW |

|||

2 = r |

C = r |

|

|

booster |

|

2 = r |

|

|

|

|

3 = 11 kW |

||

3 = 1200 |

D = 1200 |

|

3 |

= r |

|

|

3 = Standard with |

|

|

|

|

||

4 = 1800 |

E = 1800 |

|

4 |

= r |

|

|

check valve. |

|

|

|

|

||

5 = 3000 |

F = 3000 |

|

5 |

= r |

|

|

|

|

|

|

|

|

|

6 = 4500 |

G = 4500 |

|

Gas Module |

|

|

|

|

|

|

Booster |

|||

7 = 6000 |

H = 6000 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

Motor |

|||

|

|

|

|

0 |

= None (pXH) |

|

6 = Single Mode + |

|

|

|

|||

Dry Pump |

|

|

|

|

|

|

|

|

|||||

|

|

|

1 |

= Loadlock |

|

(44 slm flow) |

|

|

|

0 = None |

|||

|

|

|

|

|

|

|

|

||||||

Standard |

|

Harsh |

|

|

(4 slm flow) |

|

|

|

|

|

|

1 = 1.9 kW |

|

|

|

2 |

= Single Mode |

|

7 = Single Mode + |

|

|

|

2 = 4.5 kW |

||||

|

|

|

|

|

|

|

|

||||||

0 = None (pXH) |

|

A = 100 |

|

|

(44 slm flow) |

|

(96 slm flow) |

|

|

|

3 = 7.5 kW |

||

|

|

3 |

= Single Mode |

|

8 = Single Mode + |

|

|

|

4 = r |

||||

1 = 100 |

|

B = 200 |

|

|

|

|

|

||||||

|

|

|

(96 slm flow) |

|

(133 slm flow) |

|

|

|

|

||||

2 = 200 |

|

C = 300 |

|

|

|

|

|

|

|

||||

|

|

4 |

= Single Mode |

|

9 = Single Mode + |

|

|

|

|

||||

3 = 300 |

|

D = 450 |

|

|

|

|

|

|

|||||

|

|

|

(133 slm flow) |

(204 slm flow) |

|

|

|

|

|||||

4 = r |

|

E = 500 |

|

|

|

|

|

Special |

|||||

|

|

5 |

= Single Mode |

|

A = Multi Mode |

|

|

|

|||||

5 = r |

|

|

|

|

|

|

|

Features |

|||||

|

|

|

|

(204 slm flow) |

(44 slm flow) |

|

|

|

|||||

6 = r |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

B = Multi Mode |

|

|

|

|

||

7 = r |

|

|

|

|

|

|

|

|

|

|

0 = None |

||

|

|

|

|

|

|

|

(96 slm flow) |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

1 = Application Specific |

||

|

|

|

|

|

|

|

|

C = Multi Mode |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

2 = Application Specific |

||

|

|

|

|

|

|

|

|

(133 slm flow) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

3 = Application Specific |

||

|

|

|

|

|

|

|

|

D = Multi Mode |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

4 = Application Specific |

||

|

|

|

|

|

|

|

|

(204 slm flow) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

5 = Application Specific |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 = Application Specific |

|

|

|

|

|

|

|

|

|

|

|

|

|

7 = Application Specific |

|

|

|

|

|

|

|

|

|

|

|

|

|

8 = Application Specific |

Where r = reserved for future use |

|

|

|

|

|

|

|

|

9 = Application Specific |

||||

|

|

|

|

|

|

|

|

|

|||||

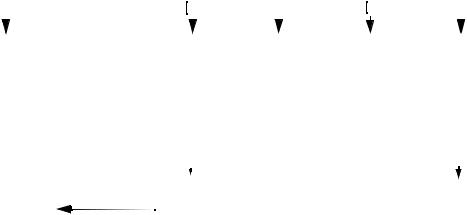

iXL Dry Pumping Systems

|

|

|

|

A |

|

S |

|

X |

|

X |

|

X |

|

X |

|

|

|

X |

|

|

X |

|

X |

|

X |

0 |

|

|

0 |

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Booster Size |

|

|

|

|

|

|

|

TMS System |

|

|

Exhaust |

|

|

|

|

Seals |

|

|

|

Pump |

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor |

|

|||||

Low Voltage |

High Voltage |

|

|

|

0 = Standard |

|

|

0 = r |

|

|

|

|

|

|

|

|

|

0 = r |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

1 = r |

|

|

|

|

1 = Standard |

|

|

|

1 = r |

|

|

|

|

0 = None |

|

||||||||||||||||||||||||

0 |

= None |

A = None |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

without |

|

|

|

|

|

2 = Standard |

|

1 = 4.5 kW |

|

|||||||||||||||||||||

1 |

= r |

B = r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

check valve. |

|

|

|

3 = EES |

|

|

2 = 7.5 kW |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

2 = r |

C = r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 = r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 = 11 kW |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

3 |

= r |

D = r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 = r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

4 |

= 1800 |

E = 1800 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

5 |

= 3000 |

F = 3000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Gas Module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Booster |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

0 |

= None |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor |

|

|||||||||||

Dry Pump |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

0 |

= None |

|

|

|

|

|

|

|

1 |

= Loadlock (4 slm flow) |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 = None |

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

2 |

= r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 = r |

|

||||||||||||||||

1 |

= r |

|

|

|

|

|

|

|

3 |

= r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2= 4.5 kW |

|

||||||||||||||

2 |

= r |

|

|

|

|

|

|

|

4 |

= r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 = 7.5 kW |

|

||||||||||||||

3 |

= 250 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 = r |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

4 |

= r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

5 |

= 500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

6 |

= 750 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Where r = reserved for future use

Declaration of Conformity

We, Edwards Limited,

Crawley Business Quarter,

Manor Royal,

Crawley,

West Sussex RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised to assemble the technical file, that the product(s)

|

Low Volt Systems |

High Volt Systems |

|

(200 - 230V) |

(380 - 460V) |

iXH100 |

AC010xy21000 |

ACA10xy21000 |

iXH200H |

AC0B0xy22000 |

ACAB0xy22000 |

iXH610 |

AC110xy21100 |

ACB10xy21100 |

iXH1210 |

AC310xy21200 |

ACD10xy21200 |

iXH1210H |

AC3A0xy22200 |

ACDA0xy22200 |

iXH1210HT |

AC3A1xy22200 |

ACDA1xy22200 |

iXH1220H |

AC3B0xy22200 |

ACDB0xy22200 |

iXH1220HT |

AC3B1xy22200 |

ACDB1xy22200 |

iXH1220HTX |

AC3B2xy22200 |

ACDB2xy22200 |

iXH1820 |

AC420xy22200 |

ACE20xy22200 |

iXH1820H |

AC4B0xy22200 |

ACEB0xy22200 |

iXH1820T |

AC421xy22200 |

ACE21xy22200 |

Where x = 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C or D depending on gas module type

Where y=1 means 'no check valve' and y=3 means 'check valve supplied'

to which this declaration relates is in conformity with the following standard(s) or other normative document(s):

EN1012-2: 1997 Compressor and Vacuum Pumps Safety Requirements; Part 2 - Vacuum Pumps. EN61010-1: 2010 Safety Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use; Part 1 – General Requirements.

EN 61326-1: 2006 Electrical equipment for measurement, control and laboratory use - EMC requirements (Industrial Location Immunity – Class A Emissions)

EN50581:2012 Technical Documentation for the Assessment of Electrical and Electronic Products with respect to the Restriction of Hazardous Substances

ANSI/UL 61010-1 and CAN/CSA-C22.2 No. 61010-1, 2nd Edition July 12, 2004, including revision July 22, 2005 - Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use, Part 1: General Requirements

SEMI S2-0709 - Environmental, Health, and Safety Guideline for Semiconductor Manufacturing Equipment

when installed in accordance with the instruction manual supplied with the pump, following the provisions of:

2006/95/EC |

Low Voltage Directive. |

2004/108/EC |

Electromagnetic Compatibility Directive. |

2006/42/EC |

Machinery Safety Directive. |

2011/65/EU* |

Restriction of Certain Hazardous Substances (RoHS) Directive |

* i.e. The product(s) contain less than - 0.1wt% for hexavalent chromium, lead, mercury, PBB and PBDE; 0.01wt% for cadmium - in homogeneous materials (subject to the exemptions allowed by the Directive). The RoHS Directive does not legally apply to industrial vacuum equipment until July 2019 (July 2017 for instruments).

Note: This declaration covers all product serial numbers from the date this Declaration was signed onwards.

22.10.2013, Burgess Hill

Mr Mark Hope, Global Technical Support Manager |

Date and Place |

This product has been manufactured under a quality system certified to ISO9001:2008

P200-02-320 Issue J

Declaration of Conformity

We, |

Edwards Limited, |

|

Crawley Business Quarter |

|

Manor Royal, |

|

Crawley, |

|

West Sussex RH10 9LW, UK |

declare under our sole responsibility, as manufacturer and person within the EU authorised to assemble the technical file, that the product(s)

|

Low Volt Systems |

High Volt Systems |

|

(200-230V) |

(380-460V) |

iXH3030 |

AC530xy22300 |

ACF30xy22300 |

iXH3030T |

AC531xy22300 |

ACF31xy22300 |

iXH3030TX |

AC532xy22300 |

ACF32xy22300 |

iXH3045H |

AC5D0xy23310 |

ACFD0xy23310 |

iXH4545HT |

AC6D1xy23300 |

ACGD1xy23300 |

iXH4545HT |

- |

ACGD1B123390 |

iXH6045H |

AC7D0xy23300 |

ACHD0xy23300 |

iXH6045H |

AC7D02123310 |

ACHD02123310 |

iXH6045HT |

AC7D1xy23300 |

ACHD1xy23300 |

iXH450H |

AC0D0xy23000 |

ACAD0xy23000 |

pXH4500 |

AC6000120300 |

ACG000120300 |

pXH4500 |

- |

ACG000120310 |

pXH6000 |

AC7000120300 |

ACH000120300 |

iXL500Q |

AS450zy23300 |

ASE50zy23300 |

iXL500R |

AS550zy23300 |

ASF50zy23300 |

Where x = 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C or D depending on gas module type

Where y = 1 means 'no check valve' and y=3 means 'check valve supplied'

Where z = 1, 2, 3, 5, A or B depending on gas module type for iXL

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN1012-2: 1997 |

Compressor and Vacuum Pumps Safety Requirements. Part 2 - Vacuum Pumps |

EN61010-1: 2010 |

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory |

|

Use. Part 1 – General Requirements. |

EN 61326-1: 2006 |

Electrical equipment for measurement, control and laboratory use - EMC requirements |

|

(Industrial Location Immunity – Class A Emissions) |

EN50581:2012 |

Technical Documentation for the Assessment of Electrical and Electronic Products |

|

with respect to the Restriction of Hazardous Substances |

ANSI/UL 61010-1 and CAN/CSA-C22.2 No. 61010-1, 2nd Edition July 12, 2004, including revision July 22, 2005 - Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use, Part 1: General Requirements

SEMI S2-0709 - Environmental, Health, and Safety Guideline for Semiconductor Manufacturing Equipment

when installed in accordance with the instruction manual supplied with the pump, following the provisions of:

2006/95/EC |

Low Voltage Directive |

2004/108/EC |

Electromagnetic Compatibility Directive |

2006/42/EC |

Machinery Safety Directive |

2011/65/EU* |

Restriction of Certain Hazardous Substances (RoHS) Directive |

* i.e. The product(s) contain less than - 0.1wt% for hexavalent chromium, lead, mercury, PBB and PBDE; 0.01wt% for cadmium - in homogeneous materials (subject to the exemptions allowed by the Directive). The RoHS Directive does not legally apply to industrial vacuum equipment until July 2019 (July 2017 for instruments).

Note: This declaration covers all product serial numbers from the date this Declaration was signed onwards.

22.10.2013, Burgess Hill

Mr Mark Hope, Global Technical Support Manager |

Date and Place |

This product has been manufactured under a quality system certified to ISO9001:2008

P200-02-720 Issue K

Declaration of Conformity

We, |

Edwards Limited, |

|

Crawley Business Quarter, |

|

Manor Royal, |

|

Crawley, |

|

West Sussex, RH10 9LW, UK |

declare under our sole responsibility, as manufacturer and person within the EU authorised to assemble the technical file, that the product(s)

|

Low Volt Systems |

High Volt Systems |

|

(200-230V) |

(380-460V) |

iXH500H |

AC0E0xy23000 |

ACAE0xy23000 |

iXH3050H |

AC5E0xy23310 |

ACFE0xy23310 |

iXH3050HTX |

AC5E2xy23300 |

ACFE2xy23300 |

iXH4550HT |

AC6E1xy23300 |

ACGE1xy23300 |

iXH6050H |

AC7E0xy23300 |

ACHE0xy23300 |

iXH6050HT |

AC7E1xy23300 |

ACHE1xy23300 |

Where x = 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C or D depending on gas module type

Where y = 1 means ‘no check valve’ and y = 3 means ‘check valve supplied’

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN1012-2:1996, A1: 2009 |

Compressors and Vacuum Pumps. Safety Requirements. |

|

|

Part 2 - Vacuum Pumps. |

|

EN61010-1: 2010 |

Safety Requirements for Electrical Equipment for Measurement, |

|

|

Control and Laboratory Use. Part 1 - General Requirements. |

|

EN 61326-1: 2006 |

Electrical equipment for measurement, control and laboratory |

|

|

Use - EMC requirements. (Industrial Location Immunity |

|

|

- |

Class A Emissions) |

EN50581:2012 |

Technical Documentation for the Assessment of Electrical and Electronic Products |

|

|

with respect to the Restriction of Hazardous Substances |

|

ANSI/UL 61010-1 and CAN/CSA-C22.2 No. 61010-1, 2nd Edition July 12, 2004, including revision July 22, 2005 – Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use - Part 1: General Requirements

and fulfils all the relevant provisions of

2006/42/EC |

Machinery Directive |

2006/95/EC |

Low Voltage Directive |

2004/108/EC |

Electromagnetic Compatibility (EMC) Directive |

2011/65/EU* |

Restriction of Certain Hazardous Substances (RoHS) Directive |

* i.e. The product(s) contain less than - 0.1wt% for hexavalent chromium, lead, mercury, PBB and PBDE; 0.01wt% for cadmium - in homogeneous materials (subject to the exemptions allowed by the Directive). The RoHS Directive does not legally apply to industrial vacuum equipment until July 2019 (July 2017 for instruments).

Note: This declaration covers all product serial numbers from the date this Declaration was signed onwards.

22.10.2013, Burgess Hill

Mr Mark Hope, Global Technical Support Manager |

Date and Place |

This product has been manufactured under a quality system certified to ISO9001:2008

P200-06-000 Issue C

Declaration of Conformity

We, |

Edwards Limited, |

|

|

|

Crawley Business Quarter, |

|

|

|

Manor Royal, |

|

|

|

Crawley, |

|

|

|

West Sussex |

RH10 9LW, UK |

|

declare under our sole responsibility, as manufacturer and person within the EU authorised to assemble the |

|||

technical file, that the product(s) |

|

||

|

|

Low Volt Systems |

High Volt Systems |

|

|

(200-230V) |

(380-460V) |

|

iXL250Q |

AS43001x2300 |

ASE3001x2300 |

|

iXL750Q |

AS46001x4300 |

ASE6001x4300 |

|

iXL750R |

AS56001x4300 |

ASF6001x4300 |

Where x = 2 means 'standard booster oilbox evacuation' and x=3 means 'external booster oilbox evacuation'

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN1012-2: 1997 |

Compressor and Vacuum Pumps Safety Requirements. Part 2 - Vacuum Pumps |

EN61010-1: 2010 |

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory |

|

Use. Part 1 – General Requirements. |

EN 61326-1: 2006 |

Electrical equipment for measurement, control and laboratory use - EMC requirements |

|

(Industrial Location Immunity – Class A Emissions) |

ANSI/UL 61010-1 and CAN/CSA-C22.2 No. 61010-1, 2nd Edition July 12, 2004, including revision July 22, 2005 - Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use, Part 1: General Requirements

when installed in accordance with the instruction manual supplied with the pump, following the provisions of:

2006/95/EC |

Low Voltage Directive |

2004/108/EC |

Electromagnetic Compatibility Directive |

2006/42/EC |

Machinery Safety Directive |

Note: This declaration covers all product serial numbers from the date this Declaration was signed onwards.

|

|

22.10.2013, Burgess Hill |

Mr Mark Hope, Global Technical Support Manager |

|

Date and Place |

This product has been manufactured under a quality system certified to ISO9001:2008

P200-06-620 Issue B

P601-01-100

Issue C Original

The Chinese regulatory requirement on the Control of Pollution Caused by Electronic Information Products No. 39 (also known as ‘China RoHS’) mandates that manufacturers of certain categories of electronic products sold in China after 1st March 2007 –

Mark the product and packaging

Define the Product’s Environment Protection Use Period (EPUP)

Provide a Materials Content Declaration.

|

|

|

|

Product Labels |

|

|

|

|

|

|

|

Product |

Product Label |

|

Meaning |

||

|

|

|

|

|

|

All iXH, iXL500 and |

|

|

|

|

Indicates toxic or hazardous substance contained in at least |

pXH models |

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

one of the homogeneous materials used for this part is |

|

|

|

|

|

||

|

|

|

|

above the limit requirement in SJ/T11363-2006. |

|

|

|

|

|

|

Environmental Protection Use Period is 20 years. |

|

|

|

|

|

|

Packaging information

Pallet |

Overshipper |

Protection Pieces |

Support Braces |

|

|

|

|

NW |

|

|

|

|

|

|

|

Recyclable Natural Wood |

Recyclable Cardboard |

Recyclable Polypropylene |

Recyclable Mild Steel |

|

|

|

|

Environment Protection Use Period (EPUP)

This is the period in years during which the toxic or hazardous substances or elements contained in this product will not leak or mutate under normal operating conditions so that the use of such electronic information products will not result in any severe environmental pollution, any bodily injury or damage to any assets.

The Environmental Protection Use Period is 20 years for this product.

For the purposes of EPUP, normal operating conditions are considered to be use in accordance with the product’s instruction manual.

Materials Content Declaration for all iXH, iXL & pXH models

|

|

|

Toxic or Hazardous Substances and Elements |

|

|||

Part name |

|

|

|

|

|

|

|

Lead (Pb) |

Mercury (Hg) |

Cadmium (Cd) |

Hexavalent |

Poly brominated |

Poly brominated |

||

|

|||||||

|

Chromium (Cr (VI)) |

biphenyls (PBB) |

diphenyl ethers (PBDE) |

||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

Motor (Mechanical |

O |

O |

O |

O |

O |

O |

|

Booster) |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Motor (pump) |

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

Pump & Booster |

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

Electronics and Controls |

O |

O |

X |

O |

O |

O |

|

|

|

|

|

|

|

|

|

Cooling System |

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

Purge System |

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is below the limit requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials used for this part is above the limit requirement in SJ/T11363-2006.

DJD 24/03/10

|

|

|

|

M561-00-880 Issue C |

|

|

|

|

|

||

|

|

Contents |

|

||

|

|

Section |

Page |

||

|

1 |

Introduction ....................................................................................... |

1 |

||

|

1.1 |

Scope and definitions ................................................................................................... |

1 |

||

|

1.2 |

Applications ............................................................................................................... |

2 |

||

|

1.3 |

Description ................................................................................................................ |

2 |

||

|

1.4 |

Priority of control ........................................................................................................ |

2 |

||

|

1.5 |

Active utility control .................................................................................................... |

3 |

||

|

2 |

Technical data .................................................................................... |

5 |

||

|

2.1 |

General technical data .................................................................................................. |

5 |

||

|

2.2 |

Performance data ........................................................................................................ |

7 |

||

|

2.3 |

Loading data .............................................................................................................. |

8 |

||

|

2.4 |

Nitrogen purge data ..................................................................................................... |

9 |

||

|

2.5 |

Electrical data ........................................................................................................... |

11 |

||

|

2.6 |

Cooling-water data ..................................................................................................... |

17 |

||

|

2.7 |

T variants ................................................................................................................ |

20 |

||

|

2.8 |

Tracer gas analysis ..................................................................................................... |

20 |

||

|

3 |

Installation ....................................................................................... |

23 |

||

|

3.1 |

Locate the dry pumping system ...................................................................................... |

24 |

||

|

3.2 |

Lubrication ............................................................................................................... |

25 |

||

|

3.3 |

Connect the dry pumping system to your vacuum/exhaust system ............................................. |

25 |

||

|

3.4 |

Connect to your factory extraction system (optional) ............................................................ |

27 |

||

|

3.5 |

Connect the nitrogen supply .......................................................................................... |

28 |

||

|

3.5.1 |

Flammable/pyrophoric materials .................................................................................... |

28 |

||

|

3.5.2 |

Gas purges ............................................................................................................... |

29 |

||

|

3.6 |

Leak-test the system ................................................................................................... |

29 |

||

|

3.7 |

Electrical supply ........................................................................................................ |

29 |

||

|

3.7.1 |

Mains supply cable connection ....................................................................................... |

31 |

||

|

3.8 |

Connect an additional RF earth (ground) (optional) .............................................................. |

35 |

||

|

3.9 |

Connect to your emergency stop circuit ............................................................................ |

35 |

||

|

3.10 |

Connect and set up the cooling-water .............................................................................. |

36 |

||

|

3.11 |

Accessories ............................................................................................................... |

37 |

||

|

3.12 |

Commission the system ................................................................................................ |

37 |

||

|

3.13 |

Install additional safety equipment .................................................................................. |

38 |

||

|

4 |

Operation ........................................................................................ |

39 |

||

|

4.1 |

Start-up .................................................................................................................. |

39 |

||

|

4.1.1 |

MicroTIM operation ..................................................................................................... |

40 |

||

|

4.1.2 |

PDT operation ........................................................................................................... |

40 |

||

|

4.1.3 |

Front panel control operation ........................................................................................ |

40 |

||

|

4.2 |

Status indicators ........................................................................................................ |

40 |

||

|

4.3 |

Manual shut-down ...................................................................................................... |

41 |

||

|

4.3.1 |

Shut-down modes ....................................................................................................... |

41 |

||

|

4.3.2 |

MicroTIM operation ..................................................................................................... |

41 |

||

|

4.3.3 |

PDT operation ........................................................................................................... |

41 |

||

|

4.3.4 |

Front panel control operation ........................................................................................ |

41 |

||

|

4.4 |

Automatic shut-down .................................................................................................. |

42 |

||

gea/0179/01/12 |

4.5 |

Unplanned shut-down and alarms .................................................................................... |

43 |

||

4.6 |

Emergency stop |

44 |

|||

|

|||||

|

4.7 |

Restart the pump after an emergency stop or automatic shut-down .......................................... |

44 |

||

|

4.8 |

Advanced control and monitoring .................................................................................... |

44 |

||

|

|

|

|

||

|

|

© Edwards Limited 2012. All rights reserved. |

Page i |

||

|

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

||

Contents

M561-00-880 Issue C

Contents

5

5.1

5.2

5.3

5.4

5.5

5.6

5.6.1

5.6.2

5.6.3

5.7

Maintenance ..................................................................................... |

45 |

Safety and maintenance frequency .................................................................................. |

45 |

Relocate the system for maintenance ............................................................................... |

46 |

Draining the cooling water ............................................................................................ |

47 |

General maintenance .................................................................................................. |

48 |

Inspect the connections, pipelines, cables and fittings .......................................................... |

48 |

Gas module configuration ............................................................................................. |

49 |

iXH single mode and single mode+ ................................................................................... |

49 |

Multi mode ............................................................................................................... |

49 |

iXL variants .............................................................................................................. |

50 |

System operating temperature configuration ...................................................................... |

50 |

6 |

Transportation, storage and disposal ........................................................ |

51 |

6.1 |

Transportation .......................................................................................................... |

51 |

6.2 |

Storage ................................................................................................................... |

51 |

6.3 |

Disposal ................................................................................................................... |

51 |

7 |

Service, spares and accessories .............................................................. |

53 |

7.1 |

Introduction ............................................................................................................. |

53 |

7.2 |

Service .................................................................................................................... |

53 |

7.3 |

Ordering accessories ................................................................................................... |

54 |

Appendix A1 Pump display terminal .................................................................. |

57 |

|

A1.1 |

LEDs ....................................................................................................................... |

57 |

A1.2 |

Pump start / stop and control ........................................................................................ |

57 |

A1.3 |

Warning / Alarm display and acknowledgement ................................................................... |

58 |

A1.4 |

Menus ..................................................................................................................... |

58 |

A1.4.1 |

Normal menu ............................................................................................................ |

58 |

A1.4.2 |

Status menu ............................................................................................................. |

59 |

A1.4.3 |

SETUP menu ............................................................................................................. |

60 |

A1.4.4 |

COMMANDS menu ....................................................................................................... |

61 |

A1.4.5 |

INV FAULT HIST (Display Inverter Fault History) menu ........................................................... |

61 |

A1.4.6 |

SOFTWARE VERSION Display menu ................................................................................... |

62 |

A1.4.7 |

FIT ACCESSORY menu .................................................................................................. |

62 |

A1.4.8 |

IP Configuration menu ................................................................................................. |

62 |

A1.4.9 |

Display attributes menu ............................................................................................... |

63 |

Appendix A2 Troubleshooting .......................................................................... |

65 |

|

A2.1 |

Warnings ................................................................................................................. |

65 |

A2.1.1 |

LED warning indicators ................................................................................................. |

65 |

A2.1.2 |

PDT warnings ............................................................................................................ |

65 |

A2.2 |

Alarms .................................................................................................................... |

68 |

A2.2.1 |

LED alarm indicators ................................................................................................... |

68 |

A2.2.2 |

PDT alarms ............................................................................................................... |

68 |

A2.3 |

Inverter warnings and alarms ......................................................................................... |

70 |

A2.4 |

Other problems ......................................................................................................... |

75 |

A2.4.1 |

Pump controller communications .................................................................................... |

75 |

|

For return of equipment, complete the HS Forms at the end of this manual. |

|

Page ii |

© Edwards Limited 2012. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

|

M561-00-880 Issue C |

Illustrations |

|

|

Figure |

|

Page |

1 |

Applications ............................................................................................................... |

2 |

2 |

The front panel controls ................................................................................................ |

3 |

3 |

Front view of pumping system ......................................................................................... |

3 |

4 |

The controls/connectors on the rear of the pump ................................................................. |

4 |

5 |

Centre of gravity and levelling foot loads ........................................................................... |

9 |

6 |

Reduce the effective system footprint .............................................................................. |

25 |

7 |

Connecting the pump inlet ............................................................................................ |

27 |

8 |

The Harting Han® K 4/4 cable-mounted connector ............................................................... |

32 |

9 |

The Harting 100A axial screw module cable-mounted connector ............................................... |

33 |

10 |

Customer connection kit - combination low volts iXL750 ........................................................ |

34 |

11 |

Electrical connector locking mechanism ............................................................................ |

35 |

A1 |

Pump display terminal ................................................................................................. |

57 |

Tables |

|

|

Table |

|

Page |

1 |

General technical data .................................................................................................. |

5 |

2 |

General technical data .................................................................................................. |

6 |

3 |

Performance data ........................................................................................................ |

7 |

4 |

Loading data (refer to Figure 5) ....................................................................................... |

8 |

5 |

Nitrogen purge data for iXH and iXL systems ........................................................................ |

9 |

6 |

Gas module types and flows .......................................................................................... |

10 |

7 |

Electrical data iXH100 to iXH1820/H/T ............................................................................. |

11 |

8 |

General electrical data ................................................................................................ |

14 |

9 |

Electrical connections .................................................................................................. |

15 |

10 |

Wire assembly according to VDE 0295 ............................................................................... |

16 |

11 |

Water cooling system data ............................................................................................ |

17 |

12 |

Cooling water supply temperature ................................................................................... |

18 |

13 |

Water consumption data ............................................................................................... |

19 |

14 |

Heater data .............................................................................................................. |

20 |

15 |

Tracer gas test parameters ........................................................................................... |

20 |

16 |

Tracer gas test system parameters .................................................................................. |

20 |

17 |

Worst case test results ................................................................................................. |

21 |

18 |

Extraction rates required by system variant ....................................................................... |

22 |

19 |

Alarm actions ............................................................................................................ |

42 |

20 |

Pump protection sensors .............................................................................................. |

43 |

21 |

Dry pump and booster temperature settings ....................................................................... |

50 |

22 |

Accessories ............................................................................................................... |

54 |

23 |

Seismic bracket kits .................................................................................................... |

55 |

24 |

Exhaust check valve kits ............................................................................................... |

55 |

A1 |

Pump start control ...................................................................................................... |

57 |

A2 |

Pump stop and control ................................................................................................. |

58 |

A3 |

Normal menu ............................................................................................................ |

58 |

A4 |

Normal menu ............................................................................................................ |

59 |

A5 |

Status menu ............................................................................................................. |

59 |

A6 |

SETUP menu ............................................................................................................. |

60 |

A7 |

COMMANDS menu ....................................................................................................... |

61 |

A8 |

GAS VALVES menu ...................................................................................................... |

61 |

A9 |

INV FAULT HIST (Display Inverter Fault History) menu ........................................................... |

61 |

A10 |

FIT ACCESSORY menu .................................................................................................. |

62 |

Contents

© Edwards Limited 2012. All rights reserved. |

Page iii |

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

M561-00-880 Issue C

Contents

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

IP Configuration menu ................................................................................................. |

62 |

Display attributes menu ............................................................................................... |

63 |

SELECT LINE (Normal display selection menu) ..................................................................... |

63 |

UNITS (Units to display) ................................................................................................ |

63 |

Warnings ................................................................................................................. |

65 |

Alarms .................................................................................................................... |

68 |

Hexadecimal to digital conversion ................................................................................... |

70 |

Inverter alarm codes ................................................................................................... |

71 |

Inverter warnings codes ............................................................................................... |

72 |

Inverter diagnostic display text ...................................................................................... |

73 |

Associated publications

Publication title |

Publication number |

Vacuum Pump and Vacuum System Safety |

P400-40-100 |

Semiconductor Pumping Application Guide |

P411-00-090 |

Trademark Credits

Han® is a registered trademark of Harting Electric GmbH

EtherCon® is a registered trademark of Neutrik® AG

Fomblin® is a registered trademark of Solvay Solexis SpA

Page iv |

© Edwards Limited 2012. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

M561-00-880 Issue C

1 Introduction

1.1Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards iXH, iXL and pXH dry pumping systems. You must use your pumping system as specified in this manual otherwise the protection provided by the equipment may be impaired.

Read this manual before you install and operate your pump. Important safety information is highlighted as WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is defined below.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to people.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated equipment and/or process.

The units throughout this manual conform to the SI international system of units of measurement.

The following warning labels are on the pump:

Warning - Refer to accompanying documentation.  Warning - Maximum angle between paired slings

Warning - Maximum angle between paired slings

Warning - Risk of electric shock. |

Warning - Heavy object. |

Warning - Hot surfaces. |

Protective earth (ground). |

Warning - Moving parts present.

Warning - use protective equipment. |

RF earth (ground). |

Introduction

© Edwards Limited 2012. All rights reserved. |

Page 1 |

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

M561-00-880 Issue C

Introduction

The following warnings only appear in this manual:

Warning - Risk of explosion. |

Warning - pressurised. |

Material Safety Data Sheets for chemicals supplied by Edwards can be obtained by contacting Edwards, or on www.edwardsvacuum.com.

1.2Applications

iXH, iXL and pXH pumping systems are intended for use on the Semiconductor, Solar and FPD processes shown in Figure 1.

Figure 1 - Applications

iXH, iXL and pXH applications

ALD |

Metal Etch |

RTP |

HDP-CVD |

Metrology |

SACVD |

Implant Source |

Oxide etch |

Silicon Etch |

Lithography |

PECVD |

Strip/Ashing |

Load lock |

PVD Pre-Clean |

Transfer |

LPCVD |

PVD Process |

|

MOCVD |

RTA |

|

|

|

|

The iXL systems are intended for use on clean duty applications.

If you use the system on an application for which it is not suitable, you may invalidate your warranties. If in doubt, contact Edwards who will advise you as to the suitability of the system for any particular application.

1.3Description

The iXH dry pump range has been developed to meet the demanding requirements for process pumping solutions in the Semiconductor, Flat Panel and Solar industries. The range sets new standards for harsh process capability, reliability and reduced cost of ownership in low footprint packages.

The iXL pump range has been developed to meet cyclic loadlock duty applications used in the flat panel and solar industries.

The pXH booster systems are not intended for use as stand-alone units. Each system must be backed using a suitable Edwards dry pump selected to match process and performance specifications.

1.4Priority of control

The pumping system can be controlled by a number of modules: the front control panel (refer to Figure 2), a Pump Display Terminal (PDT), the Edwards System Controller or by the tool through the MicroTIM or one of the serial interfaces. Only one of these can have control of the system at any one time. That is, once one of these has control of the system, control requests from the others are denied.

In addition to the control modules listed above, the pXH proximity booster can control or be controlled by the Edwards backing pump. Contact Edwards for more information on how to control a pXH using an iXH or other Edwards pumping system.

The PDT indicates who is in control. LEDs are also provided on the rear panel, front panel or PDT, which illuminate to indicate 'in control'.

Page 2 |

© Edwards Limited 2012. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

M561-00-880 Issue C

1.5Active utility control

The Active Utility Control (Green Mode) function reduces utility consumption of the system while on stand-by. The Green Mode functionality is controlled by the on/off process signal from the Tool Interface Module. Contact Edwards for advice on application and activation.

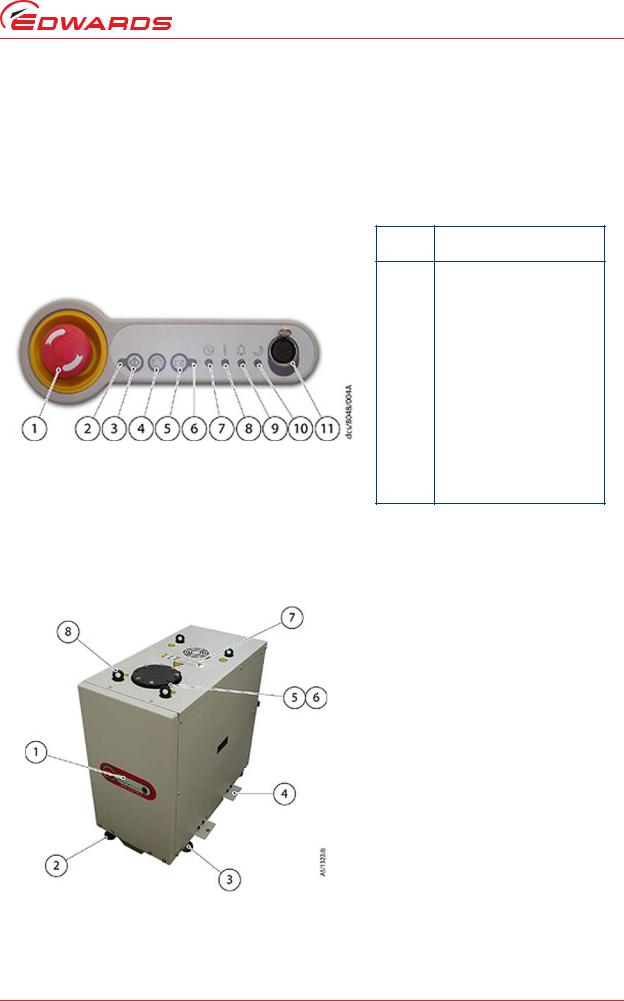

Figure 2 - The front panel controls

Item Control/connector

identification

1 EMS button

2 Running LED (green)

3 Start button

4 Stop button

5 Local control button

6 Local control LED (green)

7 Power LED (green)

8 Warning LED (amber)

9 Alarm LED (red)

10 Green Mode LED (green)

11 PDT (Pump Display Terminal) connection

Figure 3 - Front view of pumping system

Introduction

Item |

Control/connector |

|

identification |

||

|

||

|

|

|

1 |

Front panel control |

|

2 |

Levelling feet (4 off) |

|

3 |

Castors (4 off) |

|

4 |

Seismic bracket (4 off if |

|

|

fitted) |

|

5 |

Pumped gas inlet connection |

|

6 |

RF Earth (ground) cable |

|

7 |

Extraction port |

|

8 |

Lifting eyebolts (4 off) |

|

|

|

Note: iXH 100, iXH 200H and iXH 610 variants have only two eyebolts provided for lifting.

© Edwards Limited 2012. All rights reserved. |

Page 3 |

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

M561-00-880 Issue C

Introduction

Figure 4 - The controls/connectors on the rear of the pump

Item |

Control/connector identification |

|

|

1 |

Ethernet LAN LED (green) |

2 |

Ethernet link LED (yellow) |

3 |

Ethernet connection |

4 |

Power LED (green) |

5 |

System interface |

6 |

Warning LED (yellow) |

7 |

Running and Alarm LEDs (2 colours, |

|

either green or red) |

8 |

Accessory interface |

9 |

MicroTIM in control LED (green) |

10 |

EMS interface |

|

|

Item |

Control/connector identification |

|

|

11 |

Micro TIM connection (if fitted) |

12 |

Electrical supply connection |

13 |

Electrical connector locking |

|

mechanism |

14 |

Nitrogen purge connection |

15 |

Cooling water supply connection |

16 |

Protective earth (ground) stud |

17 |

Exhaust gas outlet connection |

18 |

Cooling water return connection |

19 |

RF earth (ground) stud |

|

|

Page 4 |

© Edwards Limited 2012. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

Edwards the and Edwards |

.2012 Limited Edwards © |

are logo |

rights All |

trademarks |

.reserved |

.Limited Edwards of |

|

5 Page

2 Technical data

2.1General technical data

Table 1 - General technical data

|

|

|

|

Characteristics |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Body dimensions |

|

|

|

|

|

|

|

|

|

Pump |

Length x Width x |

Mass |

Noise level |

Typical |

Initial force |

Sustained |

Pump inlet |

Exhaust gas |

Extraction |

|

Height |

(excluding |

vibration |

to push the |

force to push |

flange |

port |

||||

|

(at ultimate) |

outlet |

||||||||

|

(excludes exhaust |

packaging) |

level at inlet |

pump† |

the pump† |

(bolted) |

diameter |

|||

|

enclosure)* |

|

|

|

|

|

|

|

|

|

Units |

mm |

kg |

dB(A) |

mm/s |

kg force |

kg force |

|

|

mm |

|

|

|

|

|

|

|

|

|

|

|

|

iXH100 |

784 x 390 x 526 |

260 |

< 70 |

< 1.5 |

< 20 |

< 4 |

ISO63 |

NW40 |

105 |

|

iXH200H |

901 x 390 x 526 |

287 |

< 70 |

< 1.5 |

< 20 |

< 4 |

ISO63 |

NW40 |

105 |

|

iXH450H |

1000 x 517 x 650 |

455 |

< 70 |

< 1.5 |

< 20 |

< 10 |

ISO63 |

NW40 |

105 |

|

iXH500H |

1000 x 517 x 650 |

490 |

< 70 |

< 1.5 |

< 20 |

< 10 |

ISO63 |

NW40 |

105 |

|

iXH610 |

784 x 390 x 780 |

355 |

< 70 |

< 1.5 |

< 20 |

< 4 |

ISO100 |

NW40 |

105 |

|

iXH1210/H |

784 x 390 x 780 |

413 - 430 |

< 70 |

< 1.5 |

< 20 |

< 4 |

ISO100 |

NW40 |

105 |

|

iXH1220H/T |

901 x 390 x 780 |

455 - 460 |

< 70 |

< 1.5 |

< 20 |

< 4 |

ISO100 |

NW40 |

105 |

|

iXH1820/H/T |

901 x 390 x 780 |

471 - 487 |

< 70 |

< 1.5 |

< 20 |

< 4 |

ISO160 |

NW40 |

105 |

|

iXH3030/T |

915 x 517 x 966 |

619 - 624 |

< 70 |

< 1.5 |

< 20 |

< 10 |

ISO160 |

NW40 |

105 |

|

iXH3045H |

1000 x 517 x 966 |

776 |

70 |

< 1.5 |

< 20 |

< 10 |

ISO160 |

NW40 |

105 |

|

iXH3050H |

1000 x 517 x 966 |

811 |

70 |

< 1.5 |

< 20 |

< 10 |

ISO160 |

NW40 |

105 |

|

iXH4545HT |

1000 x 517 x 966 |

814 |

70 |

< 1.5 |

< 20 |

< 10 |

ISO200 |

NW40 |

105 |

|

iXH4550HT |

1000 x 517 x 966 |

849 |

70 |

< 1.5 |

< 20 |

< 10 |

ISO200 |

NW40 |

105 |

|

iXH6045H/T |

1080 x 517 x 966 |

860 - 865 |

74 |

< 1.5 |

< 20 |

< 10 |

ISO250 |

NW40 |

105 |

|

iXH6050H/T |

1080 x 517 x 966 |

899 |

70 |

< 1.5 |

< 20 |

< 10 |

ISO250 |

NW40 |

105 |

|

pXH4500 |

1086 x 517 x 531 |

400 |

< 70 |

< 1.5 |

< 20 |

< 10 |

ISO200 |

ISO160 |

- |

|

pXH6000 |

1086 x 517 x 531 |

435 |

< 70 |

< 1.5 |

< 20 |

< 10 |

ISO250 |

ISO160 |

- |

|

iXL250Q |

1092 x 390 x 830 |

515 |

<64 |

<1.5 |

<20 |

<10 |

ISO160 |

NW40 |

105 |

|

iXL500Q |

1186 x 517 x 966 |

860 |

< 70 |

< 1.5 |

< 20 |

< 10 |

ISO160 |

NW50 |

105 |

|

iXL500R |

1186 x 517 x 966 |

874 |

< 70 |

< 1.5 |

< 20 |

< 10 |

ISO160 |

NW50 |

105 |

|

|

|

|

|

|

|

|

|

|

|

|

C Issue 880-00-M561

Technicaldata

6 Page

.reserved rights All .2012 Limited Edwards © .Limited Edwards of trademarks are logo Edwards the and Edwards

|

|

|

Table 1 - General technical data (continued) |

|

Technicaldata |

||||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Characteristics |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Body dimensions |

Mass |

|

|

|

Sustained |

Pump inlet |

|

|

|

|

Pump |

Length x Width x |

Noise level |

Typical |

Initial force |

|

Exhaust gas |

Extraction |

|

|||

Height |

(excluding |

vibration |

to push the |

force to push |

flange |

|

port |

|

|||

|

(at ultimate) |

|

outlet |

|

|||||||

|

(excludes exhaust |

packaging) |

level at inlet |

pump† |

the pump† |

(bolted) |

|

diameter |

|

||

|

enclosure)* |

|

|

|

|

|

|

|

|

|

|

Units |

mm |

kg |

dB(A) |

mm/s |

kg force |

kg force |

|

|

|

mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

iXL750Q |

1622 x 517 x 1031 |

918 |

<70 |

<1.5 |

22 |

<10 |

ISO160 |

|

NW50 |

105 |

|

iXL750R |

1622 x 517 x 1031 |

976 |

<70 |

<1.5 |

22 |

<10 |

ISO160 |

|

NW50 |

105 |

|

|

|

|

|

|

|

|

|

|

|

|

|

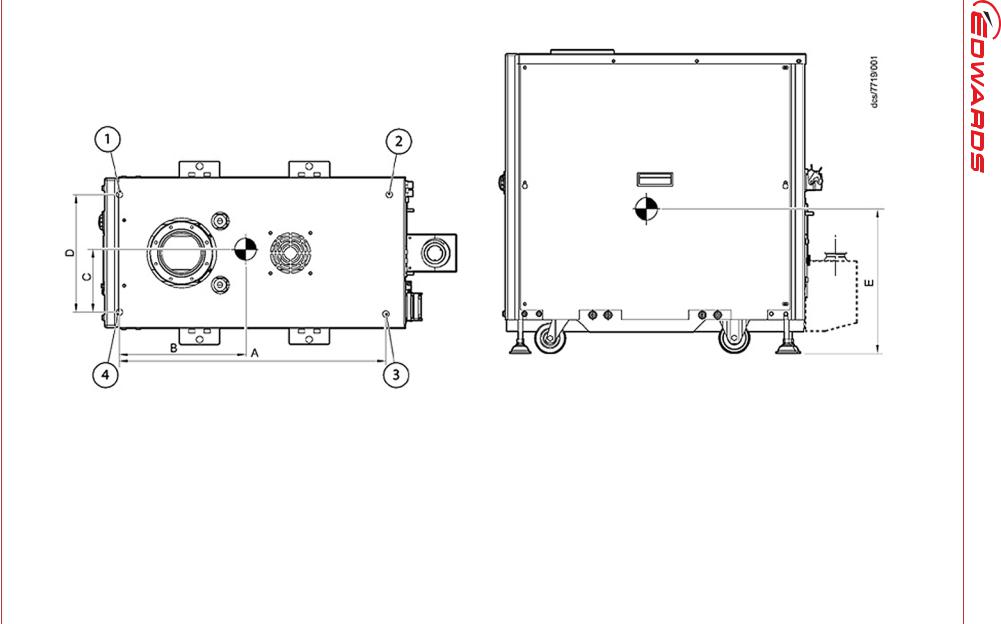

*Contact Edwards for installation drawings

†Measured in laboratory on level concrete surface

Table 2 - General technical data

Item |

Description |

Rating |

Units |

|

|

|

|

|

Intended use |

Indoor |

|

|

|

|

|

|

Ambient temperature range: |

|

|

|

Operating |

5 to 40 |

°C |

Operating conditions |

Storage |

-45 to 55 |

°C |

|

|

|

|

|

Maximum relative humidity: |

80% for temperatures up to 31 °C decreasing linearly to 50% relative |

|

|

|

humidity at 40 °C |

|

|

|

|

|

|

Maximum operating altitude |

2000 |

m |

|

|

|

|

|

Pollution degree |

2 (IEC 61010) |

|

|

|

|

|

|

Pump, shaft and rotors |

Cast Iron, Steel |

|

|

|

|

|

Materials in contact with process gas |

Seals |

PTFE and fluoroelastomer |

|

|

|

|

|

|

Gas system |

Stainless steel, aluminium, brass, PTFE and fluoroelastomer |

|

|

|

|

|

Degree of protection provided by |

Enclosure protection when installed |

IP21D (IEC60529) |

|

enclosure |

|

|

|

|

|

|

|

C Issue 880-00-M561

Edwards the and Edwards |

.2012 Limited Edwards © |

are logo |

rights All |

trademarks |

.reserved |

.Limited Edwards of |

|

7 Page

2.2Performance data

Table 3 - Performance data

|

|

Characteristics |

|

Pump |

|

|

|

Typical peak pumping speed |

Ultimate |

Maximum continuous inlet pressure |

|

|

(shaft seal purge only) |

||

|

|

|

|

|

|

|

|

Units |

m3/h |

mbar |

mbar |

iXH100 |

100 |

< 3 x 10-2 |

1000 |

iXH200H |

215 |

< 3 x 10-2 |

1000 |

iXH450H |

500 |

< 3 x 10-2 |

1000* |

iXH500H |

500 |

< 3 x 10-2 |

1000* |

iXH610 |

665 |

< 5 x 10-3 |

1000 |

iXH1210/H |

1025 - 1065 |

< 5 x 10-3 |

1000 |

iXH1220H/T |

1200 - 1250 |

< 5 x 10-3 |

1000 |

iXH1820/H/T |

1700 - 1900 |

< 5 x 10-3 |

1000 |

iXH3030/T |

2750 - 2900 |

< 5 x 10-3 |

1000* |

iXH3045H |

3225 |

< 5 x 10-3 |

1000* |

iXH3050H |

3200 |

< 5 x 10-3 |

1000* |

iXH4545HT |

4450 |

< 5 x 10-3 |

1000* |

iXH4550HT |

4220 |

< 5 x 10-3 |

1000* |

iXH6045H/T |

5000 - 5200 |

< 5 x 10-3 |

1000* |

iXH6050H/T |

5000 - 5200 |

< 5 x 10-3 |

1000* |

pXH4500 |

N/A |

< 5 x 10-3† |

1000* |

pXH6000 |

N/A |

< 5 x 10-3† |

1000* |

iXL250Q |

1900 |

< 1 x 10-3 |

1000* |

iXL500Q |

2150 |

< 5 x 10-3 |

1000* |

iXL500R |

3100 |

< 5 x 10-3 |

1000* |

iXL750Q |

2300 |

< 1 x 10-3 |

1000* |

iXL750R |

3450 |

< 1 x 10-3 |

1000* |

*Speed may be limited

†Ultimate achieved when pXH used in conjunction with an appropriate backing pump. Please contact Edwards to discuss your application. The pXH does not have a shaft seal purge.

C Issue 880-00-M561

Technicaldata

8 Page

.reserved rights All .2012 Limited Edwards © .Limited Edwards of trademarks are logo Edwards the and Edwards

2.3 |

Loading data |

|

|

|

|

|

|

|

Technicaldata |

||||

|

Table 4 - Loading data (refer to Figure 5) |

|

|

|

|

|

|||||||

|

|

|