Edwards IW100-3P575 User Manual

P R O D U C T C ATA L O G

TABLE OF CONTENTS |

|

IRONWORKERS |

|

CHOOSE YOUR IRONWORKER |

|

QUICK REFERENCE GUIDE.................................... |

4-5 |

25 TON..................................................................... |

6-7 |

40 TON................................................................... |

8-11 |

50 TON................................................................. |

12-15 |

55 TON.................................................................. |

16-19 |

60 TON............................................................... |

20-23 |

65 TON................................................................ |

24-27 |

75 TON................................................................. |

28-31 |

100 TON............................................................. |

32-35 |

100 TON DELUXE........................................... |

36-39 |

120 TON............................................................. |

40-43 |

ELITE 110 TON................................................. |

44-47 |

ELITE 110/65 TON............................................ |

48-51 |

IRONWORKER ATTACHMENT & ACCESSORY |

|

QUICK REFERENCE GUIDE............................... |

52-53 |

POWERLINKTM HYDRAULIC TOOLS |

|

PORTABLE POWER UNIT.................................. |

56 |

10 TON BENDER.................................................... |

57 |

20 TON RADIUS ROLLER.................................. |

58 |

20 TON HORIZONTAL PRESS......................... |

59 |

20 TON SHOP PRESSES.................................... |

60 |

40 TON SHOP PRESSES..................................... |

61 |

60 TON SHOP PRESSES............................. |

62-63 |

110 TON SHOP PRESSES............................. |

64-65 |

ALLIGATOR SHEARS................................................ |

66 |

HOLE SAW NOTCHER.............................................. |

67 |

PUNCH & DIE SETS.............................................. |

68-71 |

PIPE & TUBE BENDER DIES............................. |

72-74 |

2 |

EDWARDSIRONWORKERS.COM |

|

|

YOUR WORK IS YOUR REPUTATION.

That’s why each and every day, you put it all out there for the world to judge. Never stopping and always looking forward to your next challenge. You know what it means to work hard to move the industry ahead one build at a time.

AND SO DO WE.

That is why our focus is a new era of fabrication.

Not only do we have the largest line of Ironworkers but we’ve invented the PowerLinkTM System to revolutionize the industry.

BECAUSE WE ARE NEVER

CONTENT WITH THE STATUS QUO.

We push harder and dive deeper to provide our customers the products and resources they need to rise to their next build.

BECAUSE WE KNOW IT IS NOT ONLY ABOUT THE BUILD…

IT’S ABOUT BUILDING A REPUTATION.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

3 |

|||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IRONWORKERS

CHOOSE YOUR IRONWORKER

|

25 TON |

40 TON |

50 TON |

55 TON |

60 TON |

65 TON |

|

WORKSTATIONS |

2 |

4 |

4 |

4 |

4 |

5 |

|

COUNT |

|||||||

|

|

|

|

|

|

||

|

Standard (1) |

Standard (3) |

Standard (4) |

Standard (3) |

Standard (4) |

Standard (4) |

|

|

Punch |

Punch, Flat Bar |

Punch, Flat Bar |

Punch, Flat Bar |

Punch, Flat Bar |

Punch, Flat Bar |

|

|

|

Shear & Angle |

Shear, Angle |

Shear & Angle |

Shear, Angle |

Shear, Angle |

|

WORKSTATIONS |

|

Shear |

Shear & Coper |

Shear |

Shear & |

Shear & Coper |

|

DESCRIPTION |

|

|

Notcher |

|

Coper Notcher |

Notcher |

|

|

Open (1)* |

Open (1)* |

— |

Open (1)* |

— |

Open (1)* |

|

PUNCH |

25 |

40 |

50 |

55 |

60 |

65 |

|

RATINGS (TONS) |

|||||||

|

|

|

|

|

|

||

PUNCH MAX |

1 diam. |

1 diam. |

1 diam. |

1-1/16 diam. |

1 diam. |

1-1/16 diam. |

|

CAPACITY (IN.) |

in 5/16 mild steel |

in 1/2 mild steel |

in 5/8 mild steel |

in 5/8 mild steel |

in 3/4 mild steel |

in 3/4 mild steel |

|

|

|

3/8 x 10 |

1/2 x 10 |

3/8 x 14 |

3/8 x 14 |

3/8 x 24 |

|

FLAT BAR SHEAR MAX |

— |

1/2 x 12 |

1/2 x 12 |

1/2 x 14 |

|||

CAPACITY (IN.) |

1/2 x 6 |

3/4 x 4 |

|||||

|

3/4 x 4 |

3/4 x 4 |

1 x 4 |

||||

|

|

|

|

||||

ANGLE SHEAR MAX |

— |

3 x 3 x 1/4 |

3 x 3 x 3/8 |

3 x 3 x 3/8 |

3 x 3 x 1/2 |

5 x 5 x 3/8 |

|

CAPACITY (IN.) |

4 x 4 x 1/4 |

4 x 4 x 1/4 |

4 x 4 x 3/8 |

||||

|

|

|

|||||

COPER NOTCHER |

2 x 3 x 1/4 |

— |

2 x 3 x 5/16 |

— |

2-1/2 x 4 x 5/16 |

2-1/2 x 5 x 3/8 |

|

MAX CAPACITY (IN.) |

|||||||

|

|

|

|

|

|

||

OPTIONAL COPER |

|

|

|

|

|

|

|

NOTCHER MAX |

— |

2 x 3 x 5/16 |

— |

2-1/2 x 4 x 5/16 |

— |

— |

|

CAPACITY (IN.) |

|

|

|

|

|

|

|

MOTOR |

1 HP |

5 HP |

5 HP |

5 HP |

5 HP |

5 or 7.5 HP |

|

AVAILABLE |

No |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

||

ATTACHMENTS |

9 |

11 |

9 |

12 |

9 |

12 |

|

ACCESSORIES |

7 |

16 |

16 |

17 |

17 |

17 |

|

PAGE # |

6 - 7 |

8 - 11 |

12 - 15 |

16 - 19 |

20 - 23 |

24 - 27 |

ALL IRONWORKERS 40 TON & LARGER AVAILABLE IN THE FOLLOWING POWER CONFIGURATIONS:

1 PHASE, 230 VOLT | 3 PHASE, 208 VOLT | 3 PHASE, 230 VOLT | 3 PHASE, 380 VOLT, 50 HZ | 3 PHASE, 460 VOLT | 3 PHASE, 575 VOLT

* Open Workstation accepts optional Attachments to tailor the Ironworker to your needs

4 |

EDWARDSIRONWORKERS.COM |

|

|

IRONWORKERS

QUICK REFERENCE GUIDE

75 TON |

100 TON |

100 TON DELUXE |

120 TON |

ELITE 110 |

ELITE 110/65 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

4 |

5 |

5 |

4 |

5 |

|

|

|

|

|

|

|

|

Standard (4) |

Standard (3) |

Standard (5) |

Standard (4) |

Standard (3) |

Standard (4) |

|

Punch, Flat Bar |

Punch, Flat Bar |

Punch, Flat Bar |

Punch, Flat Bar |

Punch, Flat Bar |

Punch, Flat Bar |

|

Shear, Angle |

Shear & Angle |

Shear, Angle |

Shear, Angle |

Shear & Angle |

Shear, Angle |

|

Shear & Coper |

Shear |

Shear, Coper |

Shear & Coper |

Shear |

Shear & Coper |

|

Notcher |

|

Notcher, & Rod |

Notcher |

|

Notcher |

|

|

|

Shear |

|

|

|

|

|

|

|

|

|

|

|

— |

Open (1)* |

— |

Open (1)* |

Open (1)* |

Open (1)* |

|

|

|

|

|

|

|

|

75 |

100 |

100 |

120 |

110 |

110/65 |

|

|

|

|

|

|

|

|

1-1/16 diam. |

1-1/16 diam. |

1-1/16 diam. |

1-1/2 diam. |

1-3/8 diam. |

1-3/8 diam. |

|

in 7/8 mild steel |

in 1 mild steel |

in 1 mild steel |

in 1 mild steel |

in 1 mild steel |

in 1 mild steel |

|

|

|

|

|

|

|

|

1/2 x 14 |

3/4 x 14 |

1/2 x 18 |

1/2 x 24 |

3/4 x 14 |

3/8 x 24 |

|

3/4 x 14 |

1/2 x 14 |

|

||||

3/4 x 10 |

1 x 10 |

1 x 12 |

1 x 12 |

|

||

1 x 10 |

1 x 4 |

|

||||

|

|

|

|

|

||

|

|

|

|

|

|

|

5 x 5 x 1/2 |

6 x 6 x 1/2 |

6 x 6 x 1/2 |

6 x 6 x 1/2 |

6 x 6 x 1/2 |

5 x 5 x 3/8 |

|

|

|

|

|

|

|

|

2-1/2 x 5 x1/2 |

— |

3 x 6 x 1/2 |

3 x 6 x 1/2 |

— |

2-1/2 x 6 x 3/8 |

|

|

|

|

|

|

|

|

— |

2-1/2 x 6 x 1/2 |

— |

— |

2-1/2 x 6 x 1/2 |

— |

|

|

|

|

|

|

|

|

5 or 7.5 HP |

5 or 7.5 HP |

10 HP |

10 HP |

7.5 HP |

7.5 HP |

|

|

|

|

|

|

|

|

Yes |

Yes |

Yes |

Yes |

Standard |

Standard |

|

|

|

|

|

|

|

|

12 |

13 |

10 |

12 |

13 |

12 |

|

|

|

|

|

|

|

|

17 |

17 |

16 |

15 |

14 |

14 |

|

|

|

|

|

|

|

|

28 - 31 |

32 - 35 |

36 - 39 |

40 - 43 |

44 - 47 |

48 - 51 |

|

|

|

|

|

|

|

|

* Open Workstation accepts optional Attachments to tailor the Ironworker to your needs

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

5 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

25TON

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

|

Punch Rating (tons) |

25 |

|

|

|

|

|

|

|

|

Punch Max Capacity (In.) |

1 diam. in 5/16 mild steel |

|

|

|

|

|

|

|

|

Punch Work Height (In.) |

38-1/2 |

|

|

|

|

|

|

|

|

Punch Throat Depth (In.) |

5-1/2 |

|

|

|

|

|

|

|

|

Punch Stroke (In.) |

1 |

|

|

|

|

|

|

|

|

Open Workstation Work Height (In.) |

35-3/4 |

|

|

|

|

|

|

|

|

Open Workstation Throat Depth (In.) |

5 |

|

|

|

|

|

|

|

|

Motor |

1 HP |

|

|

|

|

|

|

|

|

Amps |

14 |

|

|

|

|

|

|

|

|

Hydraulics (GPM) |

11 |

|

|

|

|

|

|

|

|

Hydraulics (PSI) |

2750 |

|

|

|

|

|

|

|

|

Hydraulic Reservoir (gal.) |

3 |

|

|

|

|

|

|

|

|

Product Dimensions (In.) |

29 x 23 x 59 |

|

|

|

|

|

|

|

|

Shipping Dimensions (In.) |

45 x 51 x 65 |

|

|

|

|

|

|

|

|

Weight (lbs.) |

1200 |

|

|

|

|

|

|

|

|

FLEXIBILITY

• Two workstations: |

|

– Standard (1) – Punch |

|

– Open (1) – Customize your Ironworker |

WORK |

with optional Attachments |

STATIONS |

•9 interchangeable Attachments available to tailor the Ironworker to your needs

•7 optional Accessories available to increase precision and efficiency

PRODUCTIVITY

• Optimized workstation heights for improved efficiency

SAFETY

•ANSI B11.5-1988(02) Compliant Guarding

•Integrated Lock-out/Tag-out system with E-Stop for added safety

PERFORMANCE

•Durable, heavy-duty, Made In USA steel construction

•Vertical movement produces even pressure resulting in precise punching and shearing with minimal distortion that results in extended tooling life

•Punches are easily changeable, long-lasting and available from 1/8” to 4” diameters along with square, oblong, hex, metric, and custom shapes

STOCK # PRODUCT DESCRIPTION

IW25-1P120 25 Ton Ironworker 1 Phase, 120 Volt

IW25-1P230 25 Ton Ironworker 1 Phase, 230 Volt

6 |

EDWARDSIRONWORKERS.COM |

|

|

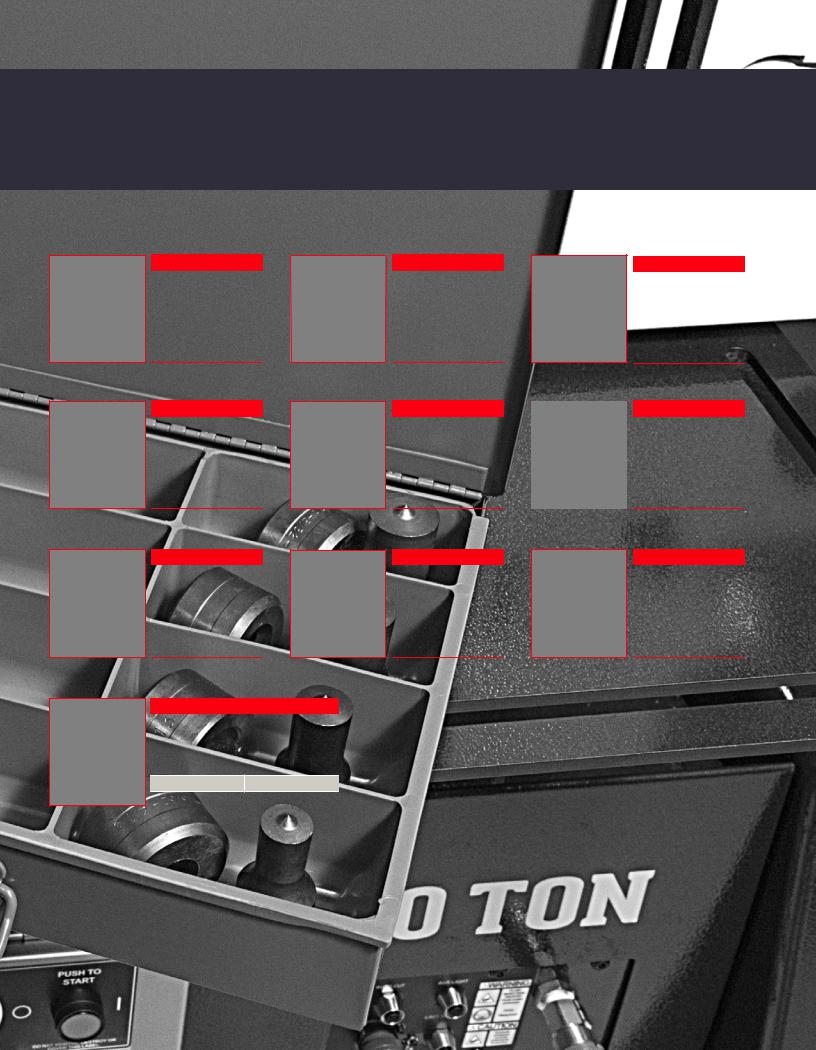

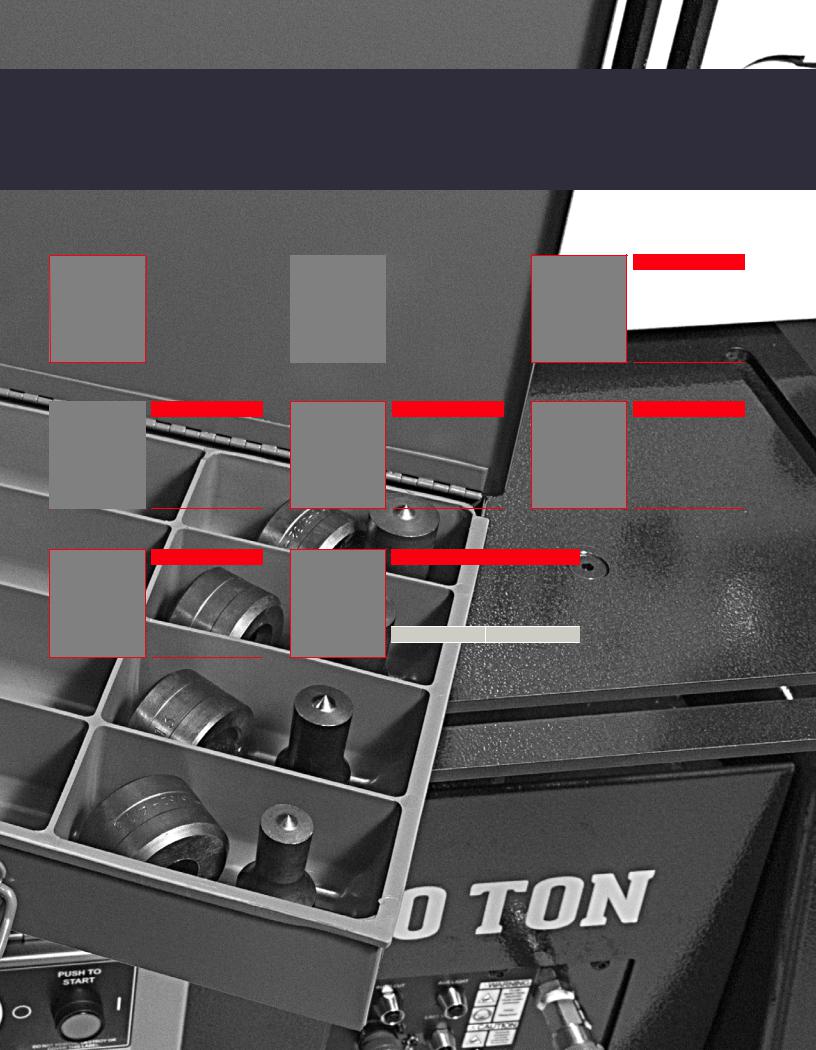

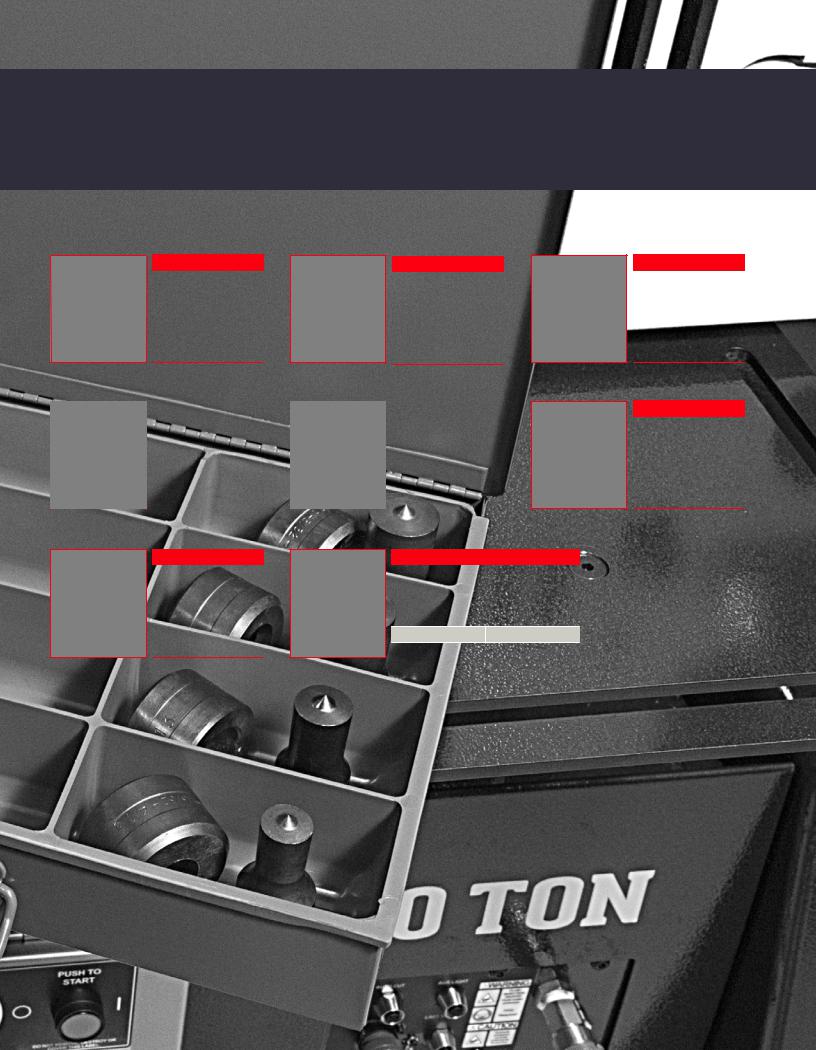

25TON ATTACHMENTS & ACCESSORIES

ATTACHMENTS

STANDARD PUNCH ASSEMBLY

• Accommodates punch & dies sets from 1/8” to 1-1/16” diameter

• Can be used as a secondary Punch Workstation on any Edwards Ironworker with an Open Workstation

AC1023-1*

OVERSIZE PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 1-9/16”

•Replaces Standard Punch Assembly or can be used as a secondary Punch Workstation

AC1027*

241 PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 4”

•Punch large holes and slots in anything from heavy sheet metal to steel beams

AC1055-1*

ANGLE NOTCHER

•Take precise 92° notch out of mild steel up to 3” x 3” x 1/4”

•Allows for an easy 90° to create a steel frame

AC0124*

COPER NOTCHER

•Versatile Attachment that removes anything from a small nibble to a large notch out of Flat Bar or Angle Iron

•Integrated alignment slots on the safety guarding easily allow for 45° shearing on Angle Iron to speed up your fabrication process

AC1012*

PIPE NOTCHER HOUSING

•Make clean 90° saddle joint connections quickly and easily

•Compatible with all Edwards Ironworkers

•Contact Edwards for custom dies to match your project

•Pipe Notcher Dies sold separately

AC0925*

MULTI SHEAR

•Designed to shear flat bar up to 1/4” x 6” and angle iron up to 2” x 2” x 1/4”

•Shears solid round bar 1/4”, 3/8”, 1/2”, 3/4” and 13/16” square bar

AC1075

ROD SHEAR

•Shear solid round rod easily with the Rod Shear

•Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid round bar

AC1074

7” BRAKE WITH 4-WAY DIE

•Fabricate brackets, frames, pans and tanks with this Brake with 4-Way Die

•Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4” material to be formed to a 90° angle

AC1033

ACCESSORIES

GAUGING TABLE KIT

• 3/8” thick, 12” x 16” table that adds precision to your Punch Workstation

• Compartible with both Standard and Oversized Pedestal Die Tables

• Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0902-1

QUICK CHANGE PUNCH ASSEMBLY

• Increase your efficiency by saving time and money with the Quick Change Punch Assembly.

• Accepts both Standard and Oversize Punch & Die Sets

AC1001

STRIPPER REDUCING PLATE

•Designed to minimize distortion on thinner gauge materials when using 1/2” punches & dies set or smaller

AC1914-1

PRESS BRAKE BACK GAUGE

•Speed up production on repeatable bends by

providing an adjustable stop for the various size Brake Attachments

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate bending

PR135

URETHANE STRIPPER

•Minimize material distortion when working with light gauge material

AC1099

PUNCH & DIE STARTER SET

•Includes 8 standard round punch & die sets selected to accommodate the most commonly used bolts

•Sized in 1/8” increments from 3/16” to 1-1/16” with 1/32” clearance

•See catalog page 68-71 for additional Punch & Die Sets

PD1000

*IMAGE NOTE: Guarding removed for clarity

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

|

|

|

7 |

|

|

|||

|

|

|

|

|

|

|

|

IRONWORKERS

40TON

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

Punch Rating (tons) |

40 |

|

|

|

|

|

|

Punch Max Capacity (in.) |

1 diam. in 1/2 mild steel |

|

|

|

|

|

|

Punch Work Height (in.) |

41-1/2 |

|

|

|

|

|

|

Punch Throat Depth (in.) |

7 |

|

|

|

|

|

|

Punch Stroke (in.) |

1-3/8 |

|

|

|

|

|

|

Flat Bar Shear Max Capacity (in.) |

3/8 x 10 |

|

|

1/2 x 6 |

|

||

|

|

|

|

|

|

|

|

Flat Bar Shear Work Height (in.) |

52-1/2 |

|

|

|

|

|

|

Flat Bar Shear Max Round Capacity (in.) |

1/2 diam. |

|

|

|

|

|

|

Flat Bar Shear Max Square Capacity (in.) |

1/2 |

|

|

|

|

|

|

Angle Shear Max Capacity (in.) |

3 x 3 x 1/4 |

|

|

|

|

|

|

Angle Shear Work Height (in.) |

52-1/2 |

|

|

|

|

|

|

Open Workstation Work Height (in.) |

35-3/4 |

|

|

|

|

|

|

Open Workstation Throat Depth (in.) |

7-3/4 |

|

|

|

|

|

|

Opt. Coper Notcher Max Capacity (in.) |

2 x 3 x 5/16 |

|

|

|

|

|

|

Opt. Coper Notcher Work Height (in.) |

35-3/4 |

|

|

|

|

|

|

Motor |

5 HP |

|

|

|

|

|

|

Amps |

23 |

|

|

|

|

|

|

Hydraulics (GPM) |

3-1/2 |

|

|

|

|

|

|

Hydraulics (PSI) |

2750 |

|

|

|

|

|

|

Hydraulic Reservoir (gal.) |

7 |

|

|

|

|

|

|

Product Dimensions (In.) |

32 x 23 x 60-1/2 |

|

|

|

|

|

|

Shipping Dimensions (In.) |

45 x 51 x 67 |

|

|

|

|

|

|

Weight (lbs.) |

1,900 |

|

|

|

|

|

|

FLEXIBILITY

• Four workstations:

– |

Standard (3) – Punch, Flat Bar Shear |

|

|

& Angle Shear |

WORK |

|

|

|

– |

Open (1) – Customize your Ironworker |

STATIONS |

|

with optional Attachments |

|

•11 interchangeable Attachments available to tailor the Ironworker to your needs

•16 optional Accessories available to increase precision and efficiency

PRODUCTIVITY

•Compact machine that allows for fast and easy transitions between fabrication operations: punch, shear, notch, bend and cope all in one machine.

•Optimized workstation heights for improved efficiency

•Electric foot pedal with integrated jog control

•Adjustable electric stoke control

SAFETY

•ANSI B11.5-1988(02) Compliant Guarding

•ETL Certified Controls

•Integrated Lock-out/Tag-out system with E-Stop for added safety

PERFORMANCE

•Durable, heavy-duty, Made In USA steel construction

•Vertical movement produces even pressure resulting in precise punching and shearing with minimal distortion that results in extended tooling life

•Punches are easily changeable, long-lasting and available from 1/8” to 4” diameters along with square, oblong, hex, metric, and custom shapes

•Flat Bar Shear blades are made of precision machined, high-quality tool steel with 4 cutting edges for extended life

•Angle Shear blades have 2 corner radii for both thin and thick material and are made of precision tool steel with 2 cutting edges for extended life

STOCK # |

PRODUCT DESCRIPTION |

||

IW40-1P230 |

40 |

Ton Ironworker 1 Phase, 230 Volt |

|

|

|

|

|

IW40-3P208 |

40 |

Ton Ironworker 3 Phase, 208 Volt |

|

|

|

|

|

IW40-3P230 |

40 |

Ton Ironworker 3 |

Phase, 230 Volt |

|

|

|

|

IW40-3P380 |

40 |

Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz |

|

|

|

|

|

IW40-3P460 |

40 |

Ton Ironworker 3 |

Phase, 460 Volt |

|

|

|

|

IW40-3P575 |

40 |

Ton Ironworker 3 |

Phase, 575 Volt |

|

|

PACKAGES |

|

40231010 |

40 |

Ton Ironworker 1 Phase, 230 Volt, Coper Notcher |

|

|

|

|

|

8 |

EDWARDSIRONWORKERS.COM |

|

|

IRONWORKERS

40TONWITH

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 55 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

•Simply PLUG IN & POWER UP any of our Hydraulic Tools and expand your fabrication capabilities

•Our factory installed PowerLink System includes quick connect couplings allowing easy transitions between Hydraulic Tools

•The Edwards Portable Power Unit is an additional power source with the PowerLink System

|

|

|

STOCK # |

PRODUCT DESCRIPTION |

|

IW40-1P230-AC400 |

40 Ton Ironworker 1 Phase, 230 Volt with PowerLink |

|

IW40-3P208-AC400 |

40 Ton Ironworker 3 Phase, 208 Volt with PowerLink |

|

IW40-3P230-AC400 |

40 Ton Ironworker 3 Phase, 230 Volt with PowerLink |

|

IW40-3P380-AC400 |

40 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink |

|

IW40-3P460-AC400 |

40 Ton Ironworker 3 Phase, 460 Volt with PowerLink |

|

IW40-3P575-AC400 |

40 Ton Ironworker 3 Phase, 575 Volt with PowerLink |

|

|

PACKAGES |

|

40231510 |

40 Ton Ironworker 1 Phase, 230 Volt, PowerLink, Coper |

|

Notcher |

||

|

10 TON |

20 TON |

20 TON |

20 TON |

40 TON |

60 TON |

60 TON |

110 TON |

110 TON |

BENDER |

RADIUS ROLLER |

HORIZONTAL PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS (PLC) |

SHOP PRESS |

SHOP PRESS (PLC) |

IRONWORKER TON 40 THE FOR ACCESSORIES & ATTACHMENTS OF LINE FULL OUR VIEW TO PAGE THE TURN

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

9 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

IRONWORKERS

40TON ATTACHMENTS

STANDARD PUNCH ASSEMBLY

•Accommodates punch & dies sets from 1/8” to 1-1/16” diameter

•Can be used as a secondary Punch Workstation on any Edwards Ironworker with an Open Workstation

AC1023-2*

OVERSIZE PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 1-9/16”

•Replaces Standard Punch Assembly or can be used as a secondary Punch Workstation

AC1024*

ANGLE NOTCHER

•Take precise 92° notch out of mild steel up to 3” x 3” x 1/4”

•Allows for an easy 90° to create a steel frame

AC0125-1*

COPER NOTCHER

•Versatile Attachment that removes anything from a small nibble to a large notch out of Flat Bar or Angle Iron

•Integrated alignment slots on the safety guarding easily allow for 45° shearing

AC1013*

241 PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 4”

•Punch large holes and slots in anything from heavy sheet metal to steel beams

AC1055*

PIPE NOTCHER HOUSING

•Make clean 90° saddle joint connections quickly and easily

•Compatible with all Edwards Ironworkers

•Contact Edwards for custom dies to match your project

•Pipe Notcher Dies sold separately

AC0925*

TURRET PIPE NOTCHER

•Make clean 90° saddle joint connections quickly and easily

•Compatible with all Edwards Ironworkers

•Contact Edwards for custom dies to match your project

•Pipe Notcher Dies sold separately

AC0925T*

MULTI SHEAR

•Designed to shear flat bar up to 1/4” x 6” and angle iron up to 2” x 2” x 1/4”

•Shears solid round bar 1/4”, 3/8”, 1/2”, 3/4” and 13/16” square bar

AC1075*

ROD SHEAR

•Shear solid round rod easily with the Rod Shear

•Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid round bar

AC1074*

BRAKE WITH 4-WAY DIE

•Choose from the sizes listed below to meet your specific needs

•Fabricate brackets, frames, pans and tanks with this Brake with 4-Way Die

•Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4” material to be formed to a 90° angle

7" |

8" |

AC1033* |

AC1034* |

|

|

*IMAGE NOTE: Guarding removed for clarity

10 |

EDWARDSIRONWORKERS.COM |

|

|

40TON ACCESSORIES

GAUGING TABLE KIT

•3/8” thick, 12” x 16” table that adds precision to your Punch Workstation

•Compatible with both Standard and Oversize Pedestal Die Tables

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0900

HEAVY DUTY GAUGING

TABLE KIT

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces Standard Pedestal Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0903

STRIPPER REDUCING PLATE

•Designed to minimize distortion on thinner gauge materials when using 1/2” punches & dies set or smaller

AC1914-3

AUTO CUT – 48”

•Optimize your productivity on both the Flat Bar Shear and Angle Shear Workstations on your Edwards Ironworker

•The adjustable proximity sensor automatically cycles your Ironworker as you feed in material

AC1010

URETHANE STRIPPER

•Minimize material distortion when working with light gauge material

AC1099

BACK GAUGE – 48”

•Speed up production on repeatable cuts by providing an adjustable stop for the Flat Bar Shear and Angle Shear

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate shearing

AC1009

IRONWORKERS

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces installed Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0905

QUICK CHANGE PUNCH ASSEMBLY

•Increase your efficiency by saving time and money with the Quick Change Punch Assembly.

•Accepts both Standard and Oversize Punch & Die Sets

AC1001

PRESS BRAKE BACK GAUGE

•Speed up production on repeatable bends by

providing an adjustable stop for the various size Brake Attachments

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate bending

PR135

PUNCH & DIE STARTER SET

•Includes 8 standard round punch & die sets selected to accommodate the most commonly used bolts

•Sized in 1/8” increments from 3/16” to 1-1/16” with 1/32” clearance

•See catalog page 68-71 for additional Punch & Die Sets

PD1000

12” & 18” FENCES GUIDES

•Easily adjustable to align your material, these 12” or 18” fence guides make precise, repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1913 18” Heavy Duty Handles

ACCESSORY LIGHT

•Super bright LED light with M12 connections plugs

•Powerful magnetic base allows users to attach the light to any Ironworker surface and move as needed

AC1000

FABRICATOR’S PROTRACTOR

•Includes 8 standard round punch & die sets selected to accommodate the most commonly used bolts

•Sized in 1/8” increments from 3/16” to 1-1/16” with 1/32” clearance

•See catalog page 66 for additional Punch & Die Sets

AC1017

PRODUCTIVITY PACK

Includes 5 Accessories designed to increase your accuracy and production speed.

•Accessory light

•48” Auto Cut

•Fabricator’s Protractor

•3/8” x 12” x 16” Punch Station table

•Punch & Die Starter Kit

AC2000

*IMAGE NOTE: Guarding removed for clarity

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

11 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

IRONWORKERS

50TON

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|||

Punch Rating (tons) |

50 |

|

||

|

|

|||

Punch Max Capacity (In.) |

1 diam. in 5/8 mild steel |

|||

|

|

|

||

Punch Work Height (In.) |

39-9/16 |

|

||

|

|

|

||

Punch Throat Depth (In.) |

7 |

|

||

|

|

|

||

Punch Stroke (In.) |

1-7/8 |

|

||

|

|

|

||

Flat Bar Shear Max Capacity (In.) |

1/2 x 10 |

|||

3/4 x 4 |

||||

|

|

|||

|

|

|

||

Flat Bar Shear Work Height (In.) |

34-1/2 |

|

||

|

|

|||

Flat Bar Shear Max Round Capacity (In.) |

3/4 diam. |

|||

|

|

|

||

Flat Bar Shear Max Square Capacity (In.) |

3/4 |

|

||

|

|

|

||

Angle Shear Max Capacity (In.) |

3 x 3 x 3/8 |

|||

4 x 4 x 1/4 |

||||

|

|

|||

|

|

|

||

Angle Shear Work Height (In.) |

39-7/8 |

|

||

|

|

|||

Coper Notcher Max Capacity (In.) |

2 x 3 x 5/16 |

|||

|

|

|

||

Coper Notcher Work Height (In.) |

39-1/2 |

|

||

|

|

|||

Motor |

5 HP |

|||

|

|

|

||

Amps |

23 |

|

||

|

|

|

||

Hydraulics (GPM) |

3-1/2 |

|

||

|

|

|

||

Hydraulics (PSI) |

2500 |

|

||

|

|

|

||

Hydraulic Reservoir (gal.) |

7 |

|

||

|

|

|||

Product Dimensions (In.) |

36-3/4 x 36-1/8 x 54-1/2 |

|||

|

|

|||

Shipping Dimensions (In.) |

45 x 51 x 62 |

|||

|

|

|

||

Weight (lbs.) |

2,020 |

|

||

|

|

|

|

|

FLEXIBILITY

• Four workstations:

– Standard (4) – Punch, Flat Bar Shear,

Angle Shear & Coper Notcher |

WORK |

|

|

• 9 interchangeable Attachments available |

STATIONS |

|

|

to tailor the Ironworker to your needs |

|

•16 optional Accessories available to increase precision and efficiency

PRODUCTIVITY

•Compact machine that allows for fast and easy transitions between fabrication operations: punch, shear, notch, bend and cope all in one machine.

•Optimized workstation heights for improved efficiency

•Electric foot pedal with integrated jog control

•Adjustable electric stoke control

SAFETY

•Bright LED lights increase visibility

•ANSI B11.5-1988(02) Compliant Guarding

•ETL Certified Controls

•Integrated Lock-out/Tag-out system with E-Stop for added safety

PERFORMANCE

•Durable, heavy-duty, Made In USA steel construction

•Vertical movement produces even pressure resulting in precise punching and shearing with minimal distortion that results in extended tooling life

•Punches are easily changeable, long-lasting and available from 1/8” to 4” diameters along with square, oblong, hex, metric, and custom shapes

•Flat Bar Shear blades are made of precision machined, high-quality tool steel with 4 cutting edges for extended life

•Angle Shear blades have 2 corner radii for both thin and thick material and are made of precision tool steel with 2 cutting edges for extended life

STOCK # |

PRODUCT DESCRIPTION |

||

IW50-1P230 |

50 |

Ton Ironworker 1 Phase, 230 Volt |

|

|

|

|

|

IW50-3P208 |

50 |

Ton Ironworker 3 |

Phase, 208 Volt |

|

|

|

|

IW50-3P230 |

50 |

Ton Ironworker 3 |

Phase, 230 Volt |

|

|

|

|

IW50-3P380 |

50 |

Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz |

|

|

|

|

|

IW50-3P460 |

50 |

Ton Ironworker 3 |

Phase, 460 Volt |

|

|

|

|

IW50-3P575 |

50 |

Ton Ironworker 3 |

Phase, 575 Volt |

|

|

|

|

12 |

EDWARDSIRONWORKERS.COM |

|

|

IRONWORKERS

50TONWITH

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 50 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

•Simply PLUG IN & POWER UP any of our Hydraulic Tools and expand your fabrication capabilities

•Our factory installed PowerLink System includes quick connect couplings allowing easy transitions between Hydraulic Tools

•The Edwards Portable Power Unit is an additional power source with the PowerLink System

|

|

STOCK # |

PRODUCT DESCRIPTION |

IW50-1P230-AC500 |

50 Ton Ironworker 1 Phase, 230 Volt with PowerLink |

IW50-3P208-AC500 |

50 Ton Ironworker 3 Phase, 208 Volt with PowerLink |

IW50-3P230-AC500 |

50 Ton Ironworker 3 Phase, 230 Volt with PowerLink |

IW50-3P380-AC500 |

50 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink |

IW50-3P460-AC500 |

50 Ton Ironworker 3 Phase, 460 Volt with PowerLink |

IW50-3P575-AC500 |

50 Ton Ironworker 3 Phase, 575 Volt with PowerLink |

10 TON |

20 TON |

20 TON |

20 TON |

40 TON |

60 TON |

60 TON |

110 TON |

110 TON |

BENDER |

RADIUS ROLLER |

HORIZONTAL PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS (PLC) |

SHOP PRESS |

SHOP PRESS (PLC) |

IRONWORKER TON 50 THE FOR ACCESSORIES & ATTACHMENTS OF LINE FULL OUR VIEW TO PAGE THE TURN

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

13 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

IRONWORKERS

50TON ATTACHMENTS

OVERSIZE PUNCH ASSEMBLY |

|

|

|

241 PUNCH ASSEMBLY |

• Accommodates punch & die |

|

|

• Accommodates punch & die |

|

sets in various shapes and |

|

|

sets in various shapes and |

|

sizes from 1” up to 1-9/16” |

|

|

sizes from 1” up to 4” |

|

• Replaces Standard Punch |

|

|

• Punch large holes and slots |

|

Assembly or can be used |

|

|

in anything from heavy sheet |

|

as a secondary Punch |

|

|

metal to steel beams |

|

Workstation |

|

|

|

|

AC1024* |

|

|

AC1055* |

|

|

|

|

|

|

PIPE NOTCHER HOUSING

•Make clean 90° saddle joint connections quickly and easily

•Compatible with all Edwards Ironworkers

•Contact Edwards for custom dies to match your project

•Pipe Notcher Dies sold separately

AC0925*

TURRET PIPE NOTCHER

•Make clean 90° saddle joint connections quickly and easily

•Compatible with all Edwards Ironworkers

•Contact Edwards for custom dies to match your project

•Pipe Notcher Dies sold separately

AC0925T*

ANGLE NOTCHER

•Take precise 92° notch out of mild steel up to 3” x 3” x 1/4”

•Allows for an easy 90° to create a steel frame

AC0125-1*

MULTI SHEAR

•Designed to shear flat bar up to 1/4” x 6” and angle iron up to 2” x 2” x 1/4”

•Shears solid round bar 1/4”, 3/8”, 1/2”, 3/4” and 13/16” square bar

AC1075*

ROD SHEAR

•Shear solid round rod easily with the Rod Shear

•Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid round bar

AC1074*

BRAKE WITH 4-WAY DIE

•Choose from the sizes listed below to meet your specific needs

•Fabricate brackets, frames, pans and tanks with this Brake with 4-Way Die

•Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4” material to be formed to a 90° angle

7" |

8" |

AC1033* |

AC1034* |

|

|

*IMAGE NOTE: Guarding removed for clarity

14 |

EDWARDSIRONWORKERS.COM |

|

|

50TON ACCESSORIES

GAUGING TABLE KIT

•3/8” thick, 12” x 16” table that adds precision to your Punch Workstation

•Compatible with both Standard and Oversize Pedestal Die Tables

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0900

HEAVY DUTY GAUGING

TABLE KIT

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces Standard Pedestal Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0903

STRIPPER REDUCING PLATE

•Designed to minimize distortion on thinner gauge materials when using 1/2” punches & dies set or smaller

AC1914-3

AUTO CUT – 48”

•Optimize your productivity on both the Flat Bar Shear and Angle Shear Workstations on your Edwards Ironworker

•The adjustable proximity sensor automatically cycles your Ironworker as you feed in material

AC1010

URETHANE STRIPPER

•Minimize material distortion when working with light gauge material

AC1099

BACK GAUGE – 48”

•Speed up production on repeatable cuts by providing an adjustable stop for the Flat Bar Shear and Angle Shear

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate shearing

AC1011

IRONWORKERS

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces installed Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0905

QUICK CHANGE PUNCH ASSEMBLY

•Increase your efficiency by saving time and money with the Quick Change Punch Assembly.

•Accepts both Standard and Oversize Punch & Die Sets

AC1001

PRESS BRAKE BACK GAUGE

•Speed up production on repeatable bends by

providing an adjustable stop for the various size Brake Attachments

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate bending

PR135

PUNCH & DIE STARTER SET

•Includes 8 standard round punch & die sets selected to accommodate the most commonly used bolts

•Sized in 1/8” increments from 3/16” to 1-1/16” with 1/32” clearance

•See catalog page 68-71 for additional Punch & Die Sets

PD1000

12” & 18” FENCES GUIDES

•Easily adjustable to align your material, these 12” or 18” fence guides make precise, repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1913 18” Heavy Duty Handles

ACCESSORY LIGHT

•Super bright LED light with M12 connections plugs

•Powerful magnetic base allows users to attach the light to any Ironworker surface and move as needed

AC1000

FABRICATOR’S PROTRACTOR

•Increase user accuracy on the Punch and Flat Bar Shear Workstations

•Designed to guide your workpiece and gauged at 15° increments through 180°

AC1017

PRODUCTIVITY PACK

Includes 5 Accessories designed to increase your accuracy and production speed.

•Accessory light

•48” Auto Cut

•Fabricator’s Protractor

•3/8” x 12” x 16” Punch Station table

•Punch & Die Starter Kit

AC2000

*IMAGE NOTE: Guarding removed for clarity

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

15 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

IRONWORKERS

55TON

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|||

Punch Rating (tons) |

55 |

|

||

|

|

|||

Punch Max Capacity (In.) |

1-1/16 diam. in 5/8 mild steel |

|||

|

|

|

||

Punch Work Height (In.) |

36-9/16 |

|

||

|

|

|

||

Punch Throat Depth (In.) |

7-1/2 |

|

||

|

|

|

||

Punch Stroke (In.) |

1-1/4 |

|

||

|

|

|

||

|

|

3/8 x 14 |

||

Flat Bar Shear Max Capacity (In.) |

1/2 x 12 |

|||

|

|

3/4 x 4 |

||

|

|

|

||

Flat Bar Shear Work Height (In.) |

34-1/2 |

|

||

|

|

|||

Flat Bar Shear Max Round Capacity (In.) |

7/8 diam. |

|||

|

|

|

||

Flat Bar Shear Max Square Capacity (In.) |

7/8 |

|

||

|

|

|

||

Angle Shear Max Capacity (In.) |

3 x 3 x 3/8 |

|||

4 x 4 x 1/4 |

||||

|

|

|||

|

|

|

||

Angle Shear Work Height (In.) |

39-7/8 |

|

||

|

|

|

||

Open Workstation Work Height (In.) |

34-1/2 |

|

||

|

|

|

||

Open Workstation Throat Depth (In.) |

11-3/16 |

|

||

|

|

|||

Opt. Coper Notcher Max Capacity (in.) |

2-1/2 x 4 x 5/16 |

|||

|

|

|

||

Opt. Coper Notcher Work Height (in.) |

39-1/2 |

|

||

|

|

|||

Motor |

5 HP |

|||

|

|

|

||

Amps |

23 |

|

||

|

|

|

||

Hydraulics (GPM) |

3-1/2 |

|

||

|

|

|

||

Hydraulics (PSI) |

2500 |

|

||

|

|

|

||

Hydraulic Reservoir (gal.) |

7 |

|

||

|

|

|||

Product Dimensions (In.) |

36-1/8 x 44-3/8 x 55-1/4 |

|||

|

|

|||

Shipping Dimensions (In.) |

45 x 51 x 62 |

|||

|

|

|

||

Weight (lbs.) |

2,480 |

|

||

|

|

|

|

|

FLEXIBILITY

• Four workstations:

– |

Standard (3) – Punch, Flat Bar Shear |

|

|

& Angle Shear |

WORK |

|

|

|

– |

Open (1) – Customize your Ironworker |

STATIONS |

|

with optional Attachments |

|

•12 interchangeable Attachments available to tailor the Ironworker to your needs

•17 optional Accessories available to increase precision and efficiency

PRODUCTIVITY

•Compact machine that allows for fast and easy transitions between fabrication operations: punch, shear, notch, bend or cope all in one machine.

•Optimized workstation heights for improved efficiency

•Electric foot pedal with integrated jog control

•Adjustable electric stoke control

SAFETY

•Bright LED lights increase visibility

•ANSI B11.5-1988(02) Compliant Guarding

•ETL Certified Controls

•Integrated Lock-out/Tag-out system with E-Stop for added safety

PERFORMANCE

•Durable, heavy-duty Made In USA steel construction

•Vertical movement produces even pressure resulting in precise punching and shearing with minimal distortion that results in extended tooling life

•Punches are easily changeable, long-lasting and available from 1/8” to 4” diameters along with square, oblong, hex, metric, and custom shapes

STOCK # |

PRODUCT DESCRIPTION |

|

||

IW55-1P230 |

55 |

Ton Ironworker 1 Phase, 230 Volt |

||

|

|

|

|

|

IW55-3P208 |

55 |

Ton Ironworker 3 Phase, 208 |

Volt |

|

|

|

|

|

|

IW55-3P230 |

55 |

Ton Ironworker 3 Phase, 230 |

Volt |

|

|

|

|

||

IW55-3P380 |

55 |

Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz |

||

|

|

|

||

IW55-3P460 |

55 |

Ton Ironworker 3 Phase, 460 Volt |

||

|

|

|

||

IW55-3P575 |

55 |

Ton Ironworker 3 Phase, 575 Volt |

||

|

|

PACKAGES |

|

|

55231012 |

55 |

Ton Ironworker 1 Phase, 230 Volt, Coper Notcher |

||

|

|

|

|

|

55203512 |

55 |

Ton Ironworker 3 Phase, 208 |

Volt, Coper Notcher |

|

|

|

|

|

|

55233012 |

55 |

Ton Ironworker 3 |

Phase, 230 |

Volt, Coper Notcher |

|

|

|

||

55231022 |

55 |

Ton Ironworker 1 Phase, 230 Volt, 10" Brake |

||

|

|

|

|

|

55203022 |

55 |

Ton Ironworker 3 |

Phase, 208 |

Volt, 10" Brake |

|

|

|

|

|

55233022 |

55 |

Ton Ironworker 3 |

Phase, 230 |

Volt, 10" Brake |

|

|

|

|

|

16 |

EDWARDSIRONWORKERS.COM |

|

|

IRONWORKERS

55TON WITH

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 55 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

•Simply PLUG IN & POWER UP any of our Hydraulic Tools and expand your fabrication capabilities

•Our factory installed PowerLink System includes quick connect couplings allowing easy transitions between Hydraulic Tools

•The Edwards Portable Power Unit is an additional power source with the PowerLink System

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STOCK # |

PRODUCT DESCRIPTION |

||||

|

|

|

|

|

IW55-1P230-AC500 |

55 Ton Ironworker 1 Phase, 230 Volt with PowerLink |

||||

|

|

|

|

|

IW55-3P208-AC500 |

55 Ton Ironworker 3 Phase, 208 Volt with PowerLink |

||||

|

|

|

|

|

IW55-3P230-AC500 |

55 Ton Ironworker 3 Phase, 230 Volt with PowerLink |

||||

|

|

|

|

|

IW55-3P380-AC500 |

55 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink |

||||

|

|

|

|

|

IW55-3P460-AC500 |

55 Ton Ironworker 3 Phase, 460 Volt with PowerLink |

||||

|

|

|

|

|

IW55-3P575-AC500 |

55 Ton Ironworker 3 Phase, 575 Volt with PowerLink |

||||

|

|

|

|

|

|

|

PACKAGES |

|||

|

|

55231512 |

55 Ton Ironworker 1 Ph, 230 V, PowerLink, Coper Notcher |

|||||||

|

|

55203512 |

55 Ton Ironworker 3 Ph, 208 V, PowerLink, Coper Notcher |

|||||||

|

|

55233512 |

55 Ton Ironworker 3 Ph, 230 V, PowerLink, Coper Notcher |

|||||||

|

|

55231522 |

55 Ton Ironworker 1 Ph, 230 V, PowerLink, 10" Brake |

|||||||

|

|

55203522 |

55 Ton Ironworker 3 Ph, 208 V, PowerLink, 10" Brake |

|||||||

|

|

55233522 |

55 Ton Ironworker 3 Ph, 230 V, PowerLink, 10" Brake |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 TON |

20 TON |

20 TON |

20 TON |

40 TON |

60 TON |

60 TON |

110 TON |

110 TON |

BENDER |

RADIUS ROLLER |

HORIZONTAL PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS (PLC) |

SHOP PRESS |

SHOP PRESS (PLC) |

IRONWORKER TON 55 THE FOR ACCESSORIES & ATTACHMENTS OF LINE FULL OUR VIEW TO PAGE THE TURN

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

|

|

|

17 |

|

|

|||

|

|

|

|

|

|

|

|

IRONWORKERS

55TON ATTACHMENTS

STANDARD PUNCH ASSEMBLY

•Accommodates punch & dies sets from 1/8” to 1-1/16” diameter

•Can be used as a secondary Punch Workstation on any Edwards Ironworker with an Open Workstation

AC1023-2*

OVERSIZE PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 1-9/16”

•Replaces Standard Punch Assembly or can be used as a secondary Punch Workstation

AC1024*

ANGLE NOTCHER

•Take precise 92° notch out of mild steel up to 3” x 3” x 1/4”

•Allows for an easy 90° to create a steel frame

AC0125-1*

COPER NOTCHER

•Versatile Attachment that removes anything from a small nibble to a large notch out of Flat Bar or Angle Iron

•Integrated alignment slots on the safety guarding easily allow for 45° shearing

AC1014*

TURRET PIPE NOTCHER

•Make clean 90° saddle joint connections quickly and easily

•Compatible with all Edwards Ironworkers

•Contact Edwards for custom dies to match your project

•Pipe Notcher Dies sold separately

AC0925T*

MULTI SHEAR

•Designed to shear flat bar up to 1/4” x 6” and angle iron up to 2” x 2” x 1/4”

•Shears solid round bar 1/4”, 3/8”, 1/2”, 3/4” and 13/16” square bar

AC1075*

241 PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 4”

•Punch large holes and slots in anything from heavy sheet metal to steel beams

AC1055*

PIPE NOTCHER HOUSING

•Make clean 90° saddle joint connections quickly and easily

•Compatible with all Edwards Ironworkers

•Contact Edwards for custom dies to match your project

•Pipe Notcher Dies sold separately

AC0925*

ROD SHEAR

•Shear solid round rod easily with the Rod Shear

•Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid round bar

AC1074*

BRAKE WITH 4-WAY DIE

•Choose from the sizes listed below to meet your specific needs

•Fabricate brackets, frames, pans and tanks with this Brake with 4-Way Die

•Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4” material to be formed to a 90° angle

7" |

8" |

10" |

AC1033* |

AC1034* |

AC1051* |

|

|

|

*IMAGE NOTE: Guarding removed for clarity

18 |

EDWARDSIRONWORKERS.COM |

|

|

55TON ACCESSORIES

GAUGING TABLE KIT

•3/8” thick, 12” x 16” table that adds precision to your Punch Workstation

•Compatible with both Standard and Oversize Pedestal Die Tables

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0900

HEAVY DUTY GAUGING

TABLE KIT

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces Standard Pedestal Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0903

COPER NOTCHER

GAUGING TABLE KIT

•Provides a larger 3/8” x 12- 1/2” x 15-5/8” size table and two fences to better align your material

AC0800

QUICK CHANGE PUNCH ASSEMBLY

•Increase your efficiency by saving time and money with the Quick Change Punch Assembly.

•Accepts both Standard and Oversize Punch & Die Sets

AC1001

STRIPPER REDUCING PLATE

•Designed to minimize distortion on thinner gauge materials when using 1/2” punches & dies set or smaller

AC1914-3

AUTO CUT – 48”

•Optimize your productivity on both the Flat Bar Shear and Angle Shear Workstations on your Edwards Ironworker

•The adjustable proximity sensor automatically cycles your Ironworker as you feed in material

AC1010

IRONWORKERS

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces installed Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0905

URETHANE STRIPPER

•Minimize material distortion when working with light gauge material

AC1099

BACK GAUGE – 48”

•Speed up production on repeatable cuts by providing an adjustable stop for the Flat Bar Shear and Angle Shear

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate shearing

AC1011

PRESS BRAKE BACK GAUGE

•Speed up production on repeatable bends by

providing an adjustable stop for the various size Brake Attachments

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate bending

PR135

FABRICATOR’S PROTRACTOR

•Increase user accuracy on the Punch and Flat Bar Shear Workstations

•Designed to guide your workpiece and gauged at 15° increments through 180°

AC1017

PUNCH & DIE STARTER SET

•Includes 8 standard round punch & die sets selected to accommodate the most commonly used bolts

•Sized in 1/8” increments from 3/16” to 1-1/16” with 1/32” clearance

•See catalog page 68-71 for additional Punch & Die Sets

PD1000

12” & 18” FENCES GUIDES

•Easily adjustable to align your material, these 12” or 18” fence guides make precise, repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1913 18” Heavy Duty Handles

ACCESSORY LIGHT

•Super bright LED light with M12 connections plugs

•Powerful magnetic base allows users to attach the light to any Ironworker surface and move as needed

AC1000

PRODUCTIVITY PACK

Includes 5 Accessories designed to increase your accuracy and production speed.

•Accessory light

•48” Auto Cut

•Fabricator’s Protractor

•3/8” x 12” x 16” Punch Station table

•Punch & Die Starter Kit

AC2000

*IMAGE NOTE: Guarding removed for clarity

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

19 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

IRONWORKERS

60TON

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

Punch Rating (tons) |

60 |

|

|

|

|

|

|

Punch Max Capacity (In.) |

1 diam. In 3/4 mild steel |

|

|

|

|

|

|

Punch Work Height (In.) |

36-9/16 |

|

|

|

|

|

|

Punch Throat Depth (In.) |

8-7/8 |

|

|

|

|

|

|

Punch Stroke (In.) |

1-1/4 |

|

|

|

|

|

|

|

|

3/8 x 14 |

|

Flat Bar Shear Max Capacity (In.) |

1/2 x 12 |

|

|

|

|

3/4 x 4 |

|

|

|

|

|

Flat Bar Shear Work Height (In.) |

34-1/2 |

|

|

|

|

|

|

Flat Bar Shear Max Round Capacity (In.) |

7/8 diam. |

|

|

|

|

|

|

Flat Bar Shear Max Square Capacity (In.) |

7/8 |

|

|

|

|

|

|

Angle Shear Max Capacity (In.) |

3 x 3 x 1/2 |

|

|

4 x 4 x 3/8 |

|

||

|

|

|

|

|

|

|

|

Angle Shear Work Height (In.) |

39-7/8 |

|

|

|

|

|

|

Coper Notcher Max Capacity (In.) |

2-1/2 x 4 x 5/16 |

|

|

|

|

|

|

Coper Notcher Work Height (In.) |

39-1/2 |

|

|

|

|

|

|

Motor |

5 HP |

|

|

|

|

|

|

Amps |

23 |

|

|

|

|

|

|

Hydraulics (GPM) |

3-1/2 |

|

|

|

|

|

|

Hydraulics (PSI) |

2500 |

|

|

|

|

|

|

Hydraulic Reservoir (gal.) |

7 |

|

|

|

|

|

|

Product Dimensions (In.) |

36-1/8 x 46-1/8 x 56-1/8 |

|

|

|

|

|

|

Shipping Dimensions (In.) |

45 x 51 x 63 |

|

|

|

|

|

|

Weight (lbs.) |

2,550 |

|

|

|

|

|

|

FLEXIBILITY

• Four workstations:

– Standard (4) – Punch, Flat Bar Shear,

Angle Shear & Coper Notcher |

WORK |

|

|

• 9 interchangeable Attachments available |

STATIONS |

|

|

to tailor the Ironworker to your needs |

|

•17 optional Accessories available to increase precision and efficiency

PRODUCTIVITY

•Compact machine that allows for fast and easy transitions between fabrication operations: punch, shear, notch, bend and cope all in one machine.

•Optimized workstation heights for improved efficiency

•Electric foot pedal with integrated jog control

•Adjustable electric stoke control

SAFETY

•Bright LED lights increase visibility

•ANSI B11.5-1988(02) Compliant Guarding

•ETL Certified Controls

•Integrated Lock-out/Tag-out system with E-Stop for added safety

PERFORMANCE

•Durable, heavy-duty, Made In USA steel construction

•Vertical movement produces even pressure resulting in precise punching and shearing with minimal distortion that results in extended tooling life

•Punches are easily changeable, long-lasting and available from 1/8” to 4” diameters along with square, oblong, hex, metric, and custom shapes

•Flat Bar Shear blades are made of precision machined, high-quality tool steel with 4 cutting edges for extended life

•Angle Shear blades have 2 corner radii for both thin and thick material and are made of precision tool steel with 2 cutting edges for extended life

STOCK # |

PRODUCT DESCRIPTION |

||

IW60-1P230 |

60 |

Ton Ironworker 1 Phase, 230 Volt |

|

|

|

|

|

IW60-3P208 |

60 |

Ton Ironworker 3 |

Phase, 208 Volt |

|

|

|

|

IW60-3P230 |

60 |

Ton Ironworker 3 |

Phase, 230 Volt |

|

|

|

|

IW60-3P380 |

60 |

Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz |

|

|

|

|

|

IW60-3P460 |

60 |

Ton Ironworker 3 |

Phase, 460 Volt |

|

|

|

|

IW60-3P575 |

60 |

Ton Ironworker 3 |

Phase, 575 Volt |

|

|

|

|

20 |

EDWARDSIRONWORKERS.COM |

|

|

IRONWORKERS

60TONWITH

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 60 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

•Simply PLUG IN & POWER UP any of our Hydraulic Tools and expand your fabrication capabilities

•Our factory installed PowerLink System includes quick connect couplings allowing easy transitions between Hydraulic Tools

•The Edwards Portable Power Unit is an additional power source with the PowerLink System

|

|

STOCK # |

PRODUCT DESCRIPTION |

IW60-1P230-AC500 |

60 Ton Ironworker 1 Phase, 230 Volt with PowerLink |

IW60-3P208-AC500 |

60 Ton Ironworker 3 Phase, 208 Volt with PowerLink |

IW60-3P230-AC500 |

60 Ton Ironworker 3 Phase, 230 Volt with PowerLink |

IW60-3P380-AC500 |

60 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink |

IW60-3P460-AC500 |

60 Ton Ironworker 3 Phase, 460 Volt with PowerLink |

IW60-3P575-AC500 |

60 Ton Ironworker 3 Phase, 575 Volt with PowerLink |

10 TON |

20 TON |

20 TON |

20 TON |

40 TON |

60 TON |

60 TON |

110 TON |

110 TON |

BENDER |

RADIUS ROLLER |

HORIZONTAL PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS |

SHOP PRESS (PLC) |

SHOP PRESS |

SHOP PRESS (PLC) |

IRONWORKER TON 60 THE FOR ACCESSORIES & ATTACHMENTS OF LINE FULL OUR VIEW TO PAGE THE TURN

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

21 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

IRONWORKERS

60TON ATTACHMENTS

OVERSIZE PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 1-9/16”

•Replaces Standard Punch Assembly or can be used as a secondary Punch Workstation

AC1024*

241 PUNCH ASSEMBLY

•Accommodates punch & die sets in various shapes and sizes from 1” up to 4”

•Punch large holes and slots in anything from heavy sheet metal to steel beams

AC1055*

PIPE NOTCHER HOUSING |

|

|

|

TURRET PIPE NOTCHER |

• Make clean 90° saddle joint |

|

|

|

• Make clean 90° saddle joint |

connections quickly and easily |

|

|

|

connections quickly and easily |

• Compatible with all Edwards |

|

|

|

• Compatible with all Edwards |

Ironworkers |

|

|

|

Ironworkers |

• Contact Edwards for custom |

|

|

|

• Contact Edwards for custom |

dies to match your project |

|

|

|

dies to match your project |

• Pipe Notcher Dies sold |

|

|

|

• Pipe Notcher Dies sold |

separately |

|

|

|

separately |

AC0925* |

|

|

|

AC0925T* |

|

|

|

|

|

ANGLE NOTCHER

•Take precise 92° notch out of mild steel up to 3” x 3” x 1/4”

•Allows for an easy 90° to create a steel frame

AC0125-1*

MULTI SHEAR

•Designed to shear flat bar up to 1/4” x 6” and angle iron up to 2” x 2” x 1/4”

•Shears solid round bar 1/4”, 3/8”, 1/2”, 3/4” and 13/16” square bar

AC1075*

ROD SHEAR

•Shear solid round rod easily with the Rod Shear

•Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid round bar

AC1074*

BRAKE WITH 4-WAY DIE

•Choose from the sizes listed below to meet your specific needs

•Fabricate brackets, frames, pans and tanks with this Brake with 4-Way Die

•Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4” material to be formed to a 90° angle

7" |

8" |

AC1033* |

AC1034* |

|

|

*IMAGE NOTE: Guarding removed for clarity

22 |

EDWARDSIRONWORKERS.COM |

|

|

60TON ACCESSORIES

GAUGING TABLE KIT

•3/8” thick, 12” x 16” table that adds precision to your Punch Workstation

•Compatible with both Standard and Oversize Pedestal Die Tables

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0900

HEAVY DUTY GAUGING

TABLE KIT

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces Standard Pedestal Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0903

COPER NOTCHER

GAUGING TABLE KIT

•Provides a larger 3/8” x 12- 1/2” x 15-5/8” size table and two fences to better align your material

AC0800

STRIPPER REDUCING PLATE

•Designed to minimize distortion on thinner gauge materials when using 1/2” punches & dies set or smaller

AC1914-3

QUICK CHANGE PUNCH ASSEMBLY

•Accommodates punch and Increase your efficiency by saving time and money with the Quick Change Punch Assembly.

•Accepts both Standard and Oversize Punch & Die Sets

AC1001

AUTO CUT – 48”

•Optimize your productivity on both the Flat Bar Shear and Angle Shear Workstations on your Edwards Ironworker

•The adjustable proximity sensor automatically cycles your Ironworker as you feed in material

AC1010

IRONWORKERS

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

•1” x 12” x 16” table adds speed and precision to your Punch Workstation

•Replaces installed Die Table

•Adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

AC0905

URETHANE STRIPPER

•Minimize material distortion when working with light gauge material

AC1099

BACK GAUGE – 48”

•Speed up production on repeatable cuts by providing an adjustable stop for the Flat Bar Shear and Angle Shear

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate shearing

AC1011

PRESS BRAKE BACK GAUGE

•Speed up production on repeatable bends by

providing an adjustable stop for the various size Brake Attachments

•A positive stop attachment that is fitted to the back of the Ironworker ensures accurate bending

PR135

FABRICATOR’S PROTRACTOR

•Increase user accuracy on the Punch and Flat Bar Shear Workstations

•Designed to guide your workpiece and gauged at 15° increments through 180°

AC1017

PUNCH & DIE STARTER SET

•Includes 8 standard round punch & die sets selected to accommodate the most commonly used bolts

•Sized in 1/8” increments from 3/16” to 1-1/16” with 1/32” clearance

•See catalog page 68-71 for additional Punch & Die Sets

PD1000

12” & 18” FENCES GUIDES

•Easily adjustable to align your material, these 12” or 18” fence guides make precise, repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1913 18” Heavy Duty Handles

ACCESSORY LIGHT

•Super bright LED light with M12 connections plugs

•Powerful magnetic base allows users to attach the light to any Ironworker surface and move as needed

AC1000

PRODUCTIVITY PACK

Includes 5 Accessories designed to increase your accuracy and production speed.

•Accessory light

•48” Auto Cut

•Fabricator’s Protractor

•3/8” x 12” x 16” Punch Station table

•Punch & Die Starter Kit

AC2000

*IMAGE NOTE: Guarding removed for clarity

EDWARDS–MADE IN THE USA SINCE 1875 |

|

|

23 |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

Loading...

Loading...