Edwards E2M0.7, E2M1.5 Instruction Manual

A371–22–880

Issue R Original

Instruction Manual

E2M0.7 and E2M1.5 Rotary Vacuum Pumps

Description |

|

|

|

|

Item Number |

|

|

|

|||

E2M0.7 (0.7 m3 h-1, 0.4 ft3 min-1) |

220-240 V, 50/60 Hz |

A371-31-919 |

|||

E2M0.7 (0.7 m3 h-1, 0.4 ft3 min-1) |

100-120 V, 50/60 Hz |

A371-31-902 |

|||

E2M1.5 (1.5 m3 h-1, 0.8 ft3 |

min-1) |

220-240 |

V, 50/60 Hz |

A371-22-919 |

|

E2M1.5 (1.5 m3 |

h-1, 0.8 ft3 |

min-1) |

220-240 |

V, 50/60 Hz (Interstage) |

A371-03-919 |

E2M1.5 (1.5 m3 |

h-1, 0.8 ft3 |

min-1) |

100-120 |

V, 50/60 Hz |

A371-22-902 |

E2M1.5 (1.5 m3 |

h-1, 0.8 ft3 |

min-1) |

100-120 |

V, 50/60 Hz (Interstage) |

A371-03-902 |

Declaration of Conformity

We, Edwards Limited,

Crawley Business Quarter,

Manor Royal,

Crawley,

West Sussex, RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised to assemble the technical file, that the product(s)

E2M0.7 and E2M1.5 Rotary Vacuum Pumps without IEC connector

A371-31-919 |

A371-22-919 |

A371-13-930 |

A371-31-902 |

A371-13-988 |

A371-22-902 |

A371-03-919 |

|

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN61010-1:2010*

EN1012-2:1996+A1:2009

EN60034-1:2010

CAN/CSA-C22.2 No 77:2014#

CAN/CSA-C22.2 No 100:2014#

EN50581:2012

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use. General Requirements

Compressors and Vacuum Pumps. Safety Requirements. Vacuum Pumps

Rotating electrical machines. Rating and performance Motors with inherent overheating protection

Motors and Generators

Technical Documentation for the Assessment of Electrical and Electronic Products with respect to the Restriction of Hazardous Substances

* 1-phase pumps only. |

The pumps comply with EN 61010-1 when installed in |

|

accordance with the instruction manual supplied with the |

# 100/120V pumps only. |

pumps. |

Canadian Standards Association. |

|

and fulfils all the relevant provisions of |

|

2006/42/EC |

Machinery Directive |

2014/35/EU |

Low Voltage Directive |

2011/65/EU |

Restriction of Certain Hazardous Substances (RoHS) |

|

Directive |

Note: This declaration covers all product serial numbers from the date this Declaration was signed onwards.

|

|

10.08.2015, Burgess Hill |

|

|

|

Mr Peter Meares |

|

Date and Place |

Senior Technical Support Manager, General Vacuum |

|

|

This product has been manufactured under a quality management system certified to ISO 9001:2008

<![endif]>P200-00-560 Issue E

|

|

|

A371–22–880 Issue R |

|

|

|

|

||

|

Contents |

|

||

|

Section |

Page |

||

|

1 |

Introduction ....................................................................................... |

1 |

|

|

1.1 |

Scope and definitions ................................................................................................... |

1 |

|

|

1.2 |

ATEX directive implications ............................................................................................ |

2 |

|

|

1.3 |

Description ................................................................................................................ |

4 |

|

|

1.4 |

Gas-ballast ................................................................................................................ |

4 |

|

|

2 |

Technical data .................................................................................... |

5 |

|

|

2.1 |

Operating and storage conditions ..................................................................................... |

5 |

|

|

2.2 |

Performance .............................................................................................................. |

5 |

|

|

2.3 |

Mechanical data .......................................................................................................... |

6 |

|

|

2.4 |

Electrical data ............................................................................................................ |

6 |

|

|

2.5 |

Lubrication data ......................................................................................................... |

7 |

|

|

3 |

Installation ......................................................................................... |

9 |

|

|

3.1 |

Safety ...................................................................................................................... |

9 |

|

|

3.2 |

System design ............................................................................................................ |

9 |

|

|

3.3 |

Unpack and inspect ..................................................................................................... |

10 |

|

|

3.4 |

Locate the pump ........................................................................................................ |

10 |

|

|

3.5 |

Fill the pump with oil .................................................................................................. |

10 |

|

|

3.6 |

Electrical installation .................................................................................................. |

11 |

|

|

3.6.1 |

Connect the pump to your electrical supply ....................................................................... |

11 |

|

|

3.6.2 |

Check the direction of rotation ...................................................................................... |

11 |

|

|

3.7 |

Connect the pump inlet ................................................................................................ |

12 |

|

|

3.7.1 |

General requirements .................................................................................................. |

12 |

|

|

3.7.2 |

Side inlet-port connection ............................................................................................. |

13 |

|

|

3.8 |

Connect the pump outlet .............................................................................................. |

13 |

|

|

3.9 |

Leak-test the system ................................................................................................... |

13 |

|

|

4 |

Operation ........................................................................................ |

15 |

|

|

4.1 |

ATEX directive implications ........................................................................................... |

15 |

|

|

4.1.1 |

Introduction ............................................................................................................. |

15 |

|

|

4.1.2 |

Flammable/pyrophoric materials .................................................................................... |

15 |

|

|

4.1.3 |

Gas purges ............................................................................................................... |

16 |

|

|

4.2 |

Gas-ballast control ..................................................................................................... |

16 |

|

|

4.3 |

Start-up procedure ..................................................................................................... |

17 |

|

|

4.4 |

To achieve ultimate vacuum .......................................................................................... |

17 |

|

|

4.5 |

To pump condensable vapours ........................................................................................ |

18 |

|

|

4.6 |

To decontaminate the oil .............................................................................................. |

18 |

|

|

4.7 |

Unattended operation .................................................................................................. |

18 |

|

|

4.8 |

Shut-down ................................................................................................................ |

18 |

|

|

5 |

Maintenance ..................................................................................... |

19 |

|

|

5.1 |

Safety information ...................................................................................................... |

19 |

|

|

5.2 |

Maintenance plan ....................................................................................................... |

19 |

|

|

5.3 |

Check the oil-level ..................................................................................................... |

20 |

|

|

5.4 |

Replace the oil .......................................................................................................... |

20 |

|

|

5.5 |

Inspect and clean the inlet-filter ..................................................................................... |

21 |

|

| <![if ! IE]> <![endif]>cg/8030/0813 |

5.6 |

Clean or replace the gas-ballast O-ring ............................................................................. |

21 |

|

5.7 |

Clean the motor fan-cover and enclosure |

22 |

||

|

||||

|

5.8 |

Clean and overhaul the pump ......................................................................................... |

22 |

|

|

|

|

||

|

© Edwards Limited 2013. All rights reserved. |

Page i |

||

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

||

<![endif]>Contents

A371–22–880 Issue R

<![endif]>Contents

5.9

5.10

5.11

6

6.1

6.2

Fit new blades ........................................................................................................... |

22 |

Replace the capacitor and test the motor .......................................................................... |

22 |

Fault finding ............................................................................................................. |

22 |

Storage and disposal ........................................................................... |

25 |

Storage ................................................................................................................... |

25 |

Disposal ................................................................................................................... |

25 |

7 |

Service, spares and accessories .............................................................. |

27 |

7.1 |

Introduction ............................................................................................................. |

27 |

7.2 |

Service .................................................................................................................... |

27 |

7.3 |

Spares ..................................................................................................................... |

27 |

7.4 |

Accessories ............................................................................................................... |

28 |

7.4.1 |

Introduction ............................................................................................................. |

28 |

7.4.2 |

Inlet catchpot ........................................................................................................... |

28 |

7.4.3 |

Inlet dust filter .......................................................................................................... |

28 |

7.4.4 |

Inlet desiccant trap ..................................................................................................... |

28 |

7.4.5 |

Inlet chemical trap ..................................................................................................... |

28 |

7.4.6 |

Foreline trap ............................................................................................................. |

28 |

7.4.7 |

Outlet mist filter ........................................................................................................ |

30 |

7.4.8 |

Oil drain extension ..................................................................................................... |

30 |

7.4.9 |

Vibration isolators ...................................................................................................... |

30 |

7.4.10 |

Pump inlet or outlet NW25 adaptor .................................................................................. |

30 |

7.4.11 |

Solenoid operated gas-ballast control valve ........................................................................ |

30 |

7.4.12 |

Solenoid operated pipeline valve .................................................................................... |

30 |

|

For return of equipment, complete the HS Forms at the end of this manual. |

|

Illustrations

Figure |

|

Page |

1 |

The E2M0.7 and E2M1.5 pump ......................................................................................... |

3 |

2 |

Dimensions: mm (inches) ............................................................................................... |

7 |

3 |

Electrical supply connection .......................................................................................... |

12 |

4 |

Inlet-filter removal and replacement ............................................................................... |

21 |

5 |

Gas-ballast O-ring removal and replacement ...................................................................... |

22 |

6 |

Accessories ............................................................................................................... |

29 |

Page ii |

© Edwards Limited 2013. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

|

A371–22–880 Issue R |

Tables |

|

|

Table |

|

Page |

1 |

Operating and storage conditions |

..................................................................................... 5 |

2 |

Performance data ........................................................................................................ |

5 |

3 |

Mechanical data .......................................................................................................... |

6 |

4 |

Electrical data ............................................................................................................ |

6 |

5 |

Lubrication data ......................................................................................................... |

7 |

6 |

Checklist of items ....................................................................................................... |

10 |

7 |

Maintenance plan ....................................................................................................... |

20 |

8 |

Fault finding ............................................................................................................. |

23 |

9 |

Spares Item Numbers ................................................................................................... |

27 |

10 |

Accessories Item Numbers ............................................................................................. |

28 |

Associated publications

Publication title |

Publication number |

Vacuum Pump and Vacuum System Safety |

P400-40-100 |

<![endif]>Contents

© Edwards Limited 2013. All rights reserved. |

Page iii |

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

A371–22–880 Issue R

This page has been intentionally left blank.

Page iv |

© Edwards Limited 2013. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

A371–22–880 Issue R

1 Introduction

1.1Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards E2M0.7, and E2M1.5 rotary vacuum pumps. You must use the pump as specified in this manual. Read this manual before you install and operate the pump.

Important safety information is highlighted as WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is defined below.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to people.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated equipment and process.

The units used throughout this manual conform to the SI international system of units of measurement. Equivalent values using imperial units of measurement are also included.

The following warning symbols are on the pump:

Warning - refer to accompanying documentation.

Warning - risk of electric shock.

Warning - hot surfaces.

<![endif]>Introduction

© Edwards Limited 2013. All rights reserved. |

Page 1 |

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

A371–22–880 Issue R

<![endif]>Introduction

1.2

ATEX directive implications

This equipment is designed to meet the requirements of Group II Category 3 equipment in accordance with Directive 94/9/EC of the European Parliament and the Council of 23rd March 1994 on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres. (The ATEX Directive)

The ATEX Category 3 applies in respect of potential ignition sources internal to the equipment. An ATEX Category has not been assigned in respect of potential ignition sources on the outside of the equipment as the equipment has not been designed for use where there is an external potentially explosive atmosphere.

There is no potential source of ignition within the pump during normal operation but there may be potential sources of ignition under conditions of predictable and rare malfunction as defined in the Directive. Accordingly, although the pump is designed to pump flammable materials and mixtures, operating procedures should ensure that under all normal and reasonably predictable conditions, these materials and mixtures are not within explosive limits. Category 3 is considered appropriate for the avoidance of ignition in the case of a rare malfunction which allows flammable materials or mixtures to pass through the pump while within their explosive limits.

When flammable or pyrophoric materials are present within the equipment you must:

Not allow air to enter the equipment.

Ensure that the system is leak tight.

For further information, please contact Edwards: refer to the Addresses page at the end of this manual for details.

Page 2 |

© Edwards Limited 2013. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

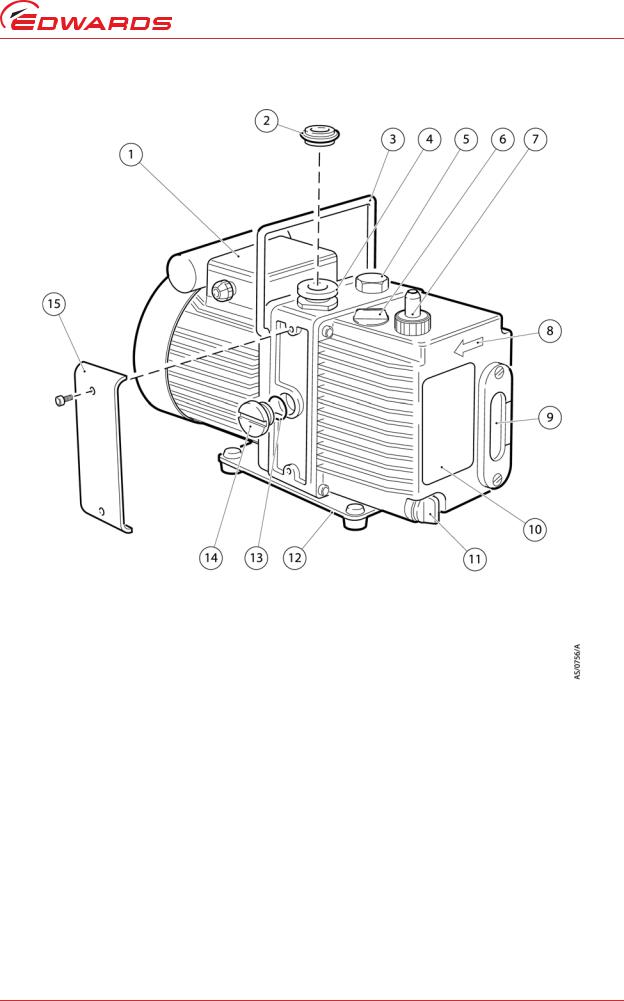

Figure 1 - The E2M0.7 and E2M1.5 pump

A371–22–880 Issue R

<![if ! IE]><![endif]>Introduction

1. |

Motor terminal box |

9. Oil sight-glass and bezel |

2. |

NW10 centring ring and O-ring (supplied) |

10. Pump identification label |

3. |

Handle (removable: refer to Section 3.4) |

11. Oil drain-plug |

4. |

NW10 inlet port (adaptor flange) |

12. Baseplate |

5. |

Gas-ballast control |

13. O-ring |

6. |

Oil filler-plug |

14. Blanking plug (side inlet-port) |

7. |

Outlet nozzle |

15. Removable side panel |

8. |

Pump/motor shaft rotation direction arrow |

|

© Edwards Limited 2013. All rights reserved. |

Page 3 |

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

A371–22–880 Issue R

<![endif]>Introduction

1.3Description

The Edwards E2M0.7 and E2M1.5 pump is shown in Figure 1. Refer to Figure 1 for item numbers in brackets in the following descriptions.

The E2M0.7 and E2M1.5 pumps are two-stage, direct drive, sliding vane pumps. The pump is oil-sealed and designed for reliable, long-term operation. The pump is a free-standing unit. The drive is provided through a coupling by a single-phase motor.

The motor is totally enclosed and is cooled by the motor-cooling fan which directs air along the motor fins. The motors are fitted with a thermal overload device. When the motor is too hot, the thermal overload device switches off the pump. The thermal overload device has an automatic reset; when the motor cools down, the device resets and the motor will restart.

An oil pressure system lubricates the pump shaft bearing surfaces and rotor sealing faces. The pump has an oil distribution valve which prevents discharge of oil to the pump interior (suckback) after the pump stops. The pumping chambers are air-tight, so this arrangement prevents oil suckback unless the gas-ballast valve is open. For protection in this case, refer to Section 1.4.

The level and condition of the oil in the oil box reservoir can be inspected through the sight-glass (9). An oil fillerplug (6) is fitted to the top of the oil box. An oil drain-plug (11) is fitted at the bottom of the oil box.

The pump has a carrying handle (3), inlet-port (4), outlet nozzle (7) and gas-ballast control (5). The pump is mounted on a steel baseplate (12) on rubber pads. Details of suitable vibration isolators and other recommended accessories are given in Section 7.4.

1.4Gas-ballast

To pump high vapour loads, gas-ballast is delivered into the pump to prevent condensation of the vapour carried by the pumped gases.

Air (or another gas) can be introduced into the low vacuum stage through the gas-ballast control. The gas-ballast control is a multi-turn valve that can be adjusted, as required, between closed and fully open.

Page 4 |

© Edwards Limited 2013. All rights reserved. |

|

Edwards and the Edwards logo are trademarks of Edwards Limited. |

A371–22–880 Issue R

2 Technical data

Note: To comply with EN61010 and CSA standards, the pump must be installed and used indoors, and within the operating conditions specified in Table 1.

2.1Operating and storage conditions

Table 1 - Operating and storage conditions

Ambient temperature range (operation) |

12 to 40°C (53.6 to 104°F) |

Ambient temperature range (storage) |

-30 to 70°C (-22 to 158°F) |

Normal surface temperature of the pump-body* |

50 to 70°C (122 to 158°F) |

Maximum humidity (operation) |

90% RH |

Maximum altitude (operation) |

2000 m (6561 ft) |

Pollution degree |

2 |

Installation category |

II |

|

|

*At ultimate vacuum, with ambient temperature of 20°C (68°F).

2.2Performance

Note: Where total pressures are shown below, the measurements were taken using an untrapped total pressure capacitance diaphragm gauge on a header, as specified by Pneurop 6602.

Table 2 - Performance data

Maximum displacement |

E2M0.7 |

E2M1.5 |

50 Hz electrical supply |

0.9 m3 h-1 (0.53 ft3 min-1) |

1.8 m3 h-1 (1.06 ft3 min-1) |

60 Hz electrical supply |

1.1 m3 h-1 (0.65 ft3 min-1) |

2.2 m3 h-1 (1.30 ft3 min-1) |

Maximum pumping speed – Pneurop |

|

|

50 Hz electrical supply |

0.75 m3 h-1 (0.44 ft3 min-1) |

1.6 m3 h-1 (0.94 ft3 min-1) |

60 Hz electrical supply |

0.95 m3 h-1 (0.56 ft3 min-1) |

2.0 m3 h-1 (1.18 ft3 min-1) |

Motor rotational speed |

|

|

50 Hz electrical supply |

1400 r min-1 |

2800 r min-1 |

60 Hz electrical supply |

1700 r min-1 |

3400 r min-1 |

Ultimate vacuum |

|

|

without gas-ballast (partial pressure) |

7 x 10-4 mbar, 7 x 10-2 Pa |

5 x 10-4 mbar, 5 x 10-2 Pa |

|

(5.2 x 10-4 Torr) |

(3.7 x 10-4 Torr) |

without gas-ballast (total pressure) |

3 x 10-3 mbar, 3 x 10-1 Pa |

1.5 x 10-3 mbar, 1.5 x 10-1 Pa |

|

(2.2 x 10-3 Torr) |

(1.1 x 10-3 Torr) |

with full gas-ballast (partial pressure) |

2 x 10-1 mbar, 2 x 10-1 Pa |

2.5 x 10-2 mbar, 2.5 Pa |

|

(1.5 x 10-1 Torr) |

(1.9 x 10-2 Torr) |

Maximum water vapour inlet pressure |

15 mbar (11.2 Torr) |

15 mbar (11.2 Torr) |

Maximum water vapour pumping rate |

8 g h-1 |

16 g h-1 |

Maximum permitted outlet pressure |

0.5 bar gauge |

0.5 bar gauge |

(at full pump throughout) |

1.5 bar absolute |

1.5 bar absolute |

|

1.5 x 105 Pa (21.75 psi) |

1.5 x 105 Pa (21.75 psi) |

<![endif]>data Technical

© Edwards Limited 2013. All rights reserved. |

Page 5 |

Edwards and the Edwards logo are trademarks of Edwards Limited. |

|

Loading...

Loading...