Page 1

Data Power Solutions

Installation Guide

Issue: IPN 997-00012-41D

Issue Date: December 2006

Eaton Corporation

Telecommunications Solutions Division

www.powerware.com

DCinfo@eaton.com

Page 2

Eaton Corporation disclaims any liability for direct, indirect, incidental, special or

consequential damages arising out of the application or use of any information contained

in this document. The foregoing disclaimer applies to damages or personal injury,

property damage, loss of operation, loss of profits, loss of product or loss of time, whether

incurred by the purchaser, the purchaser’s employees or third party.

Information in this document does not constitute a warranty, representation or guarantee

concerning the suitability or performance of Powerware products. No such warranty,

representation or guarantee is expressed or implied.

Information contained in this document is subject to change without further notice.

Powerware and DCTools are trade names, trademarks, and/or service marks of Eaton

Power Quality Corporation or its subsidiaries and affiliates. Unless otherwise noted,

brands, product names, trademarks or registered trademarks are the property of their

respective holders.

Subject to the right to use its equipment, Eaton Corporation does not convey any right,

title or interest in its intellectual property, including, without limitation, its patents,

copyrights and know-how.

No part of this document may be reproduced or transmitted in any form, by any means or

for any purpose other than the Purchaser’s personal use, without the express written

permission of Eaton Corporation.

Copyright © 2005-2006 Eaton Corporation

All Rights Reserved

Page 3

.

Purpose

This guide provides instructions to correctly install, commission and operate Data Power

Solutions.

Audience

This guide is intended for use by IT professionals who have a sound working knowledge of

safe working practices.

Scope

This guide covers installation, commissioning and operation of Data Power Solutions,

controlled by SM45 supervisory modules.

About This Guide

It does not cover:

• Installation and characterization of batteries.

• Changing the pre-configured configuration values. For full details on changing the pre-

configured configuration values, refer to the SM45 Front Panel Menu Structure (on the

inside back cover) or DCTools online help.

Related Information

DCTools Online Help

Application Note AN0080: Ventilation of VRLA Batteries

Reporting Problems with This Guide

Please use the fax or email addresses below to report any problems you find in this guide.

Powerware DC Marketing Services

FAX: ++64 3 343 5660

EMAIL: DCMarketingNZ@eaton.com

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

i

Page 4

About This Guide

For Further Information and Technical Assistance

Eaton recognizes the need to keep you informed about the availability of current product

information

For up-to-date product information and a complete listing of worldwide sales offices, visit

the Powerware website at: http://www.powerware.com

For comprehensive product data sheets and application notes please contact your local

Powerware DC product representative or email: DCinfo@eaton.com

For technical assistance, contact your local Powerware DC product representative in the first

instance, alternatively phone (++64) 3 343-7448 or email CustomerServiceNZ@eaton.com

.

ii

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 5

.

About This Guide

Purpose......................................................................................................................................i

Audience ...................................................................................................................................i

Scope..........................................................................................................................................i

Related Information.................................................................................................................i

Reporting Problems with This Guide....................................................................................i

For Further Information and Technical Assistance............................................................ii

Chapter 1 General Description

Overview...............................................................................................................................1-1

Data Power Solutions Product Range...............................................................................1-2

APS3-05X (Rack-Mounted Versions)........................................................................................1-3

APS3-06X (Desktop Versions)...................................................................................................1-4

APS6-05X (Rack-Mounted Versions)........................................................................................1-5

Access Power Rectifiers.......................................................................................................1-6

SM45 Supervisory Module.................................................................................................1-7

Low Voltage Disconnect (if applicable)............................................................................1-8

Chapter 2 Pre-Installation

Overview...............................................................................................................................2-1

Warnings...............................................................................................................................2-2

Inspecting the Equipment and Reporting Damage.........................................................2-6

Table of Contents

Chapter 3 Installation

Overview...............................................................................................................................3-1

Mounting the Power System..............................................................................................3-2

DC Installation Practices.....................................................................................................3-3

Connecting the DC Load Cables........................................................................................3-3

APS3-05X and APS6-05X (Rack-Mounted Versions)..............................................................3-4

APS3-06X (Desktop Versions)...................................................................................................3-5

Installing the External Batteries (if applicable)................................................................3-7

Connecting the Battery Cables (if applicable)..................................................................3-8

Installing the Battery Temperature Sensor (if batteries are fitted)..............................3-10

Connecting the Power System to the AC Supply..........................................................3-12

Chapter 4 Commissioning

Overview...............................................................................................................................4-1

Inserting the Access Power Rectifiers...............................................................................4-2

Pre-Power-Up Check...........................................................................................................4-3

Applying AC Power............................................................................................................4-4

Configuring the Power System for Operation.................................................................4-4

Using the Front Panel Keypad..................................................................................................4-4

Using DCTools............................................................................................................................4-5

Applying DC Power to the Load.......................................................................................4-8

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

iii

Page 6

Table of Contents

Chapter 5 Operations

Overview...............................................................................................................................5-1

About the SM45 Front Panel ..............................................................................................5-2

The Keypad and LED Indicators..............................................................................................5-2

The Display Indicators............................................................................................................... 5-2

The Audible Indicator................................................................................................................ 5-3

Display Time-out........................................................................................................................ 5-3

Changing the Display Contrast................................................................................................ 5-3

About Display Modes..........................................................................................................5-4

Changing Display Modes..........................................................................................................5-4

Scrolling within a Display Mode.............................................................................................. 5-4

Using Edit Mode......................................................................................................................... 5-4

Viewing System Values (Main Display Mode)................................................................5-5

Viewing Alarms and System Status Messages (Status View Mode)............................5-6

Viewing and Editing Configuration Parameters.............................................................5-7

Chapter 6 Communications

Overview...............................................................................................................................6-1

Communications Options...................................................................................................6-2

DCTools Setup......................................................................................................................6-3

SM45 Ethernet Setup...........................................................................................................6-3

Setting Up SNMP Traps......................................................................................................6-4

Entering the “sysObjectID” of a Power System...............................................................6-5

Synchronizing the SM45 Real-time Clock........................................................................6-6

Chapter 7 Maintenance

Overview...............................................................................................................................7-1

Troubleshooting...................................................................................................................7-2

Replacing a Rectifier............................................................................................................7-6

Removing a Rectifier.................................................................................................................. 7-6

Inserting a Rectifier.................................................................................................................... 7-8

Replacing AC Input Fuses..................................................................................................7-9

Replacing the SM45 Real-time Clock Battery.................................................................7-10

Appendix A Glossary of Alarms

Appendix B Control Function Glossary

Battery Current Limit (BCL).....................................................................................................B-1

Battery Test..................................................................................................................................B-1

Equalize.......................................................................................................................................B-1

Low Volts Disconnect................................................................................................................B-2

Temperature Compensation.....................................................................................................B-2

Appendix C Specifications

Equipment Incident Report

Worldwide Support

iv

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 7

Overview

Topic Page

Data Power Solutions Product Range 1-2

Access Power Rectifiers 1-6

SM45 Supervisory Module 1-7

Low Voltage Disconnect (if applicable) 1-8

Chapter 1

General Description

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

1-1

Page 8

General Description

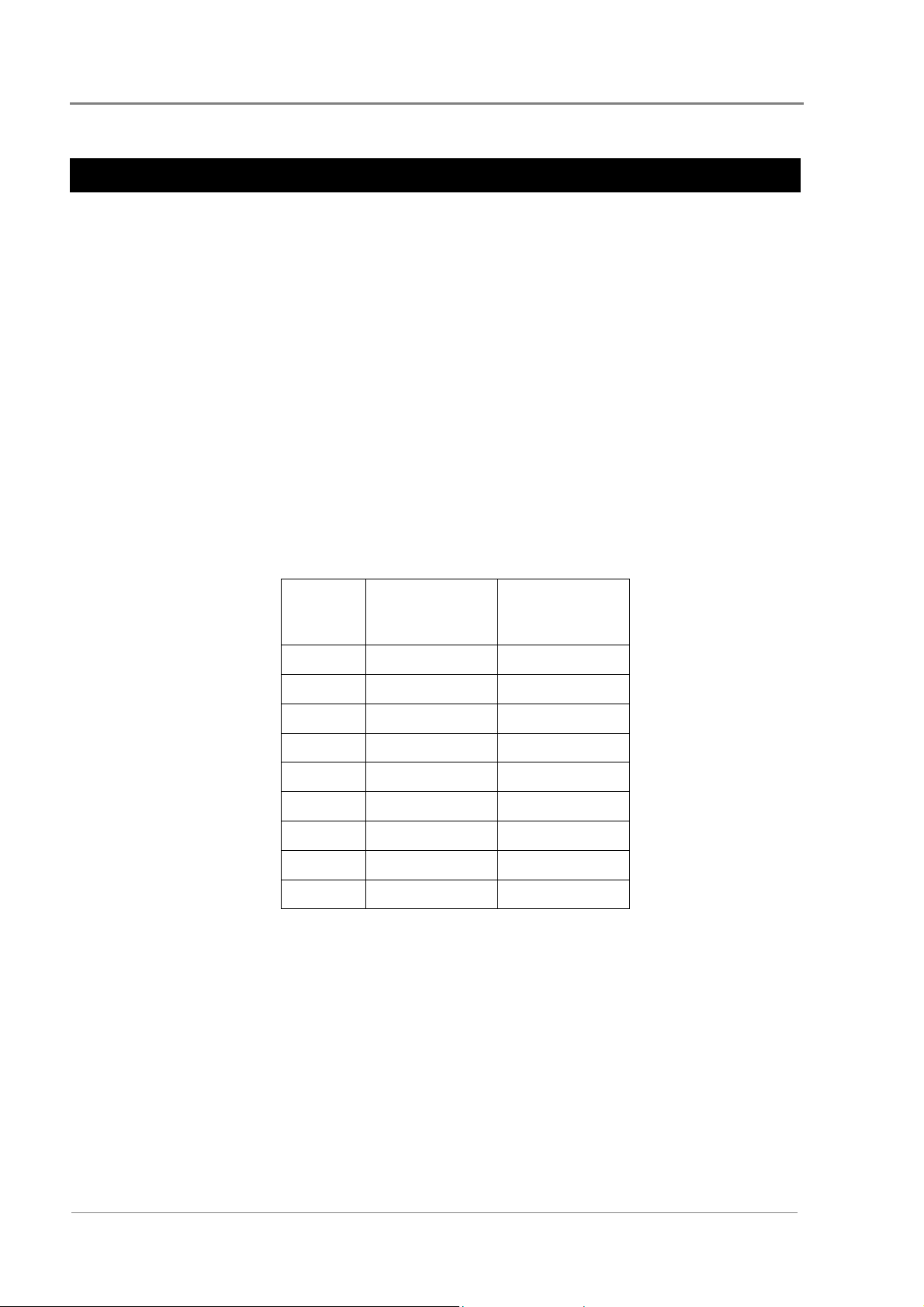

Data Power Solutions Product Range

Data Power Solutions provide high reliability 48 V DC power for Power over Ethernet,

network, data and telecommunications equipment.

Each power system includes AC/DC rectifier modules, a supervisory module to provide

control and communications functions, circuit breakers to protect the output cabling, and

output terminals to connect the cables to the DC powered equipment and optional batteries.

Six models (with eight variants each) are available, as shown on the following three pages.

• APS3-058-x – rack-mounted version, without battery option

• APS3-059-x – rack-mounted version, with battery option

• APS3-060-x – desktop version, without battery option

• APS3-061-x – desktop version, with battery option

• APS6-058-x – rack-mounted version, without battery option

• APS6-059-x – rack-mounted version, with battery option

Where “–x” indicates the model variant with the following type and number of circuit

breakers:

x Number of 25A

Circuit

Breakers

Number of 6A

Circuit

Breakers

0 4 4

1 5 3

2 6 2

3 7 1

4 8 0

5 3 5

6 2 6

7 1 7

8 0 8

AC Input: Data Power Solutions can be powered by a wide range of AC power distribution

systems such as single-phase, two-phase, three-phase (L-N) and three-phase (L-L).

Depending on the nominal voltage of the AC supply (120 V or 240 V), the power systems are

equipped with either APU48 or APR48 rectifiers. Fused AC power sockets (one per rectifier)

are available for connecting the power system to the AC supply.

DC Output: Eight floating DC outlets are available for connecting equipment power cables.

Each DC outlet is protected by a corresponding 6 A or 25 A load circuit breaker. Any

combination of 6 A or 25 A rated load circuit breakers (up to a maximum of eight) can be

fitted, depending on customer requirements.

Battery Option: External VRLA 48 V batteries can be connected to APS3-059, APS3-061 and

APS6-059 models to provide backup power during AC outages. The battery float voltage is

temperature compensated.

1-2

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 9

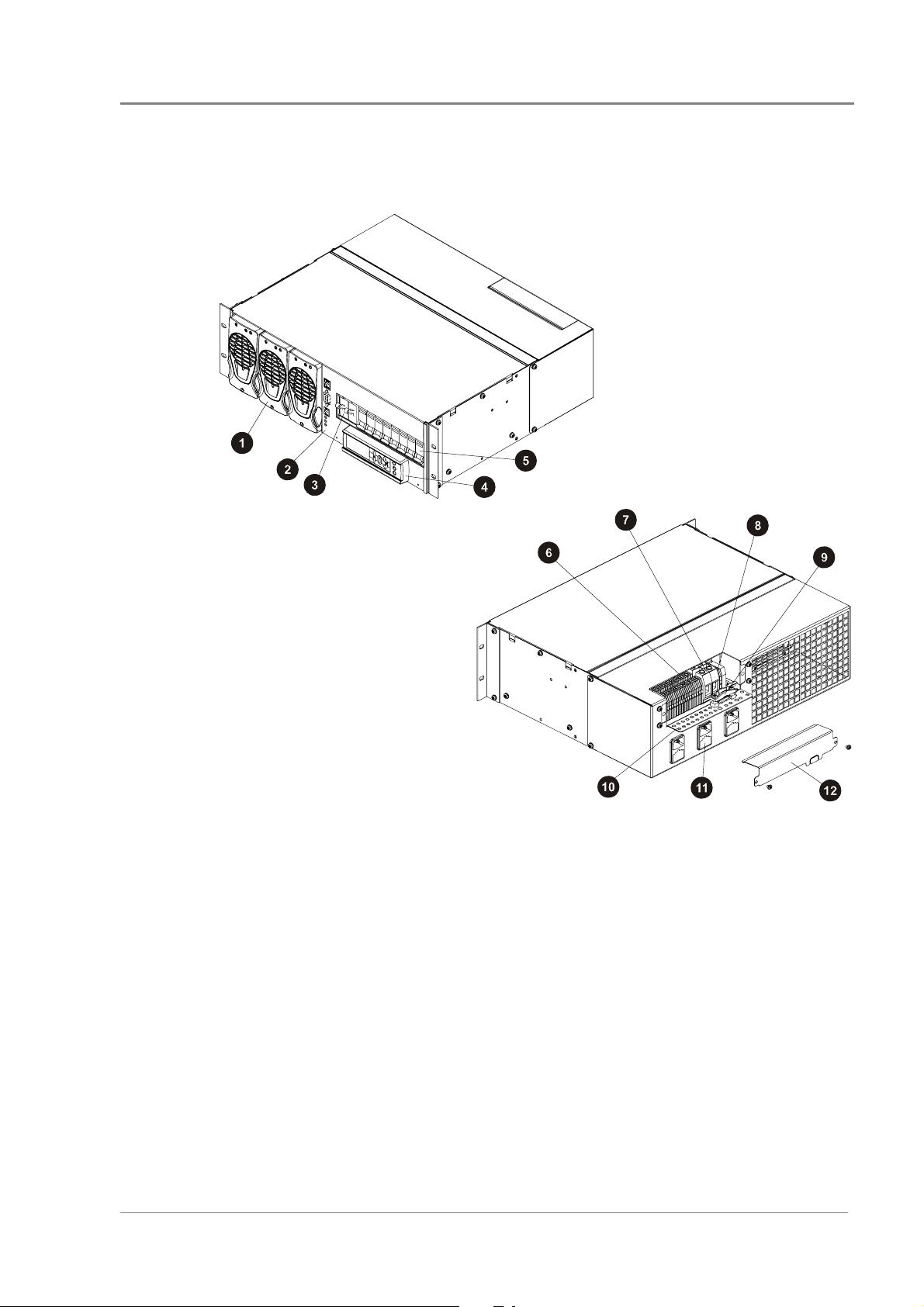

APS3-05X (Rack-Mounted Versions)

Data Power Solutions Product Range

Up to three Access Power Rectifiers, numbered 1

"

to 3 from left to right (see page 1-

SM45 Supervisory Module (see page 1-

#

One 2-pole Battery Circuit Breaker

$

(APS3-059 only)

SM45 Display Module with keypad and LED

%

indicators (see Chapter 5)

Load Circuit Breakers – any combination of 6 A

!

or 25 A rated circuit breakers up to a maximum of

eight, depending on customer requirements

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

6)

7)

16 DC Load Terminal Blocks (2 per DC Outlet)

&

Two Battery Terminal Blocks (APS3-059 only)

3

Two Battery Temperature Sensor Terminal

4

Blocks (APS3-059 only)

Battery Cable Clamp (APS3-059 only)

5

Cable Support Bracket

'

Three fused AC Power Sockets (one per rectifier)

(

and labeled K1 to K3. K1 powers Rectifier 1, etc.

DC Output Cover (remove to access DC Output

)

terminations)

1-3

Page 10

General Description

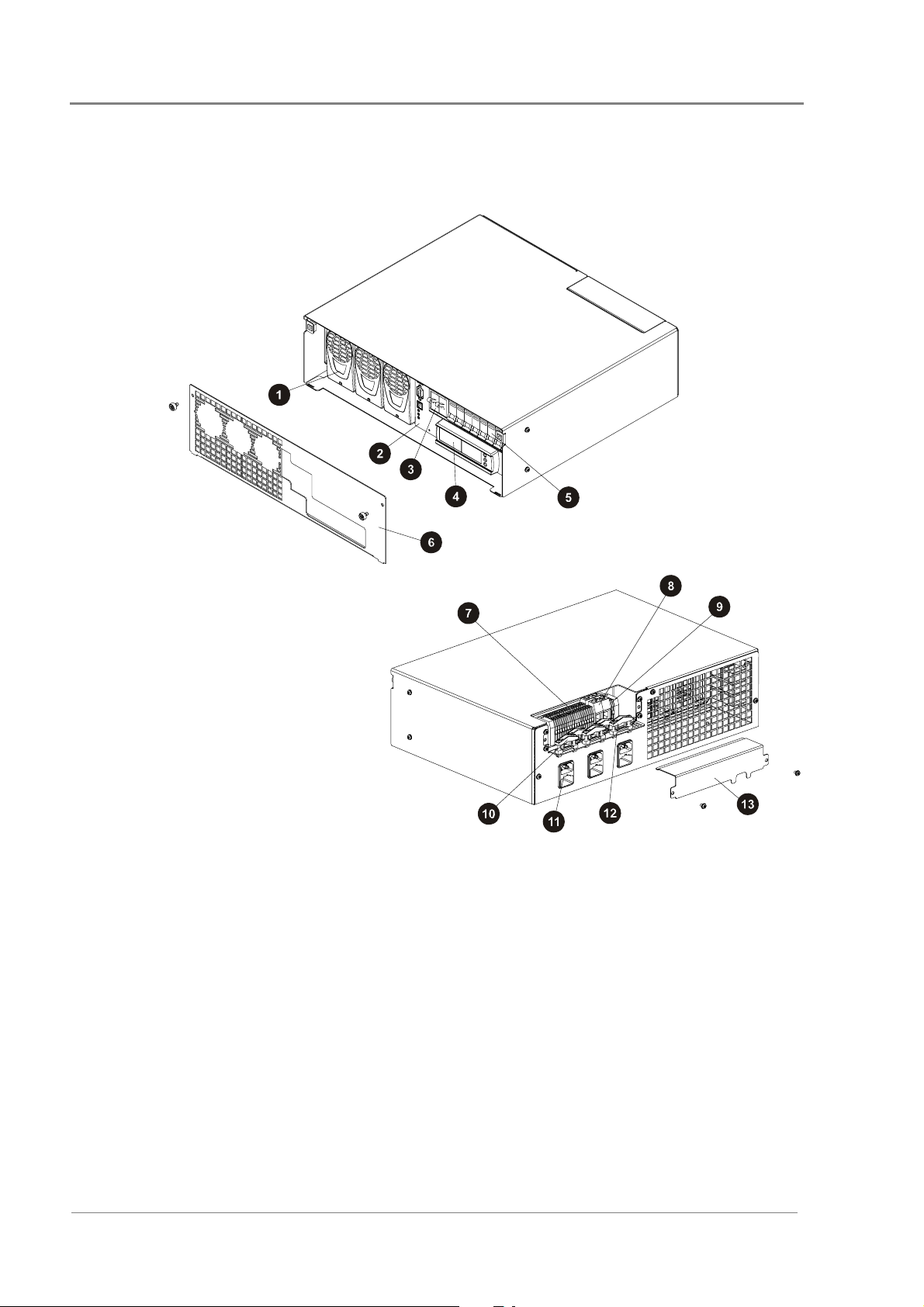

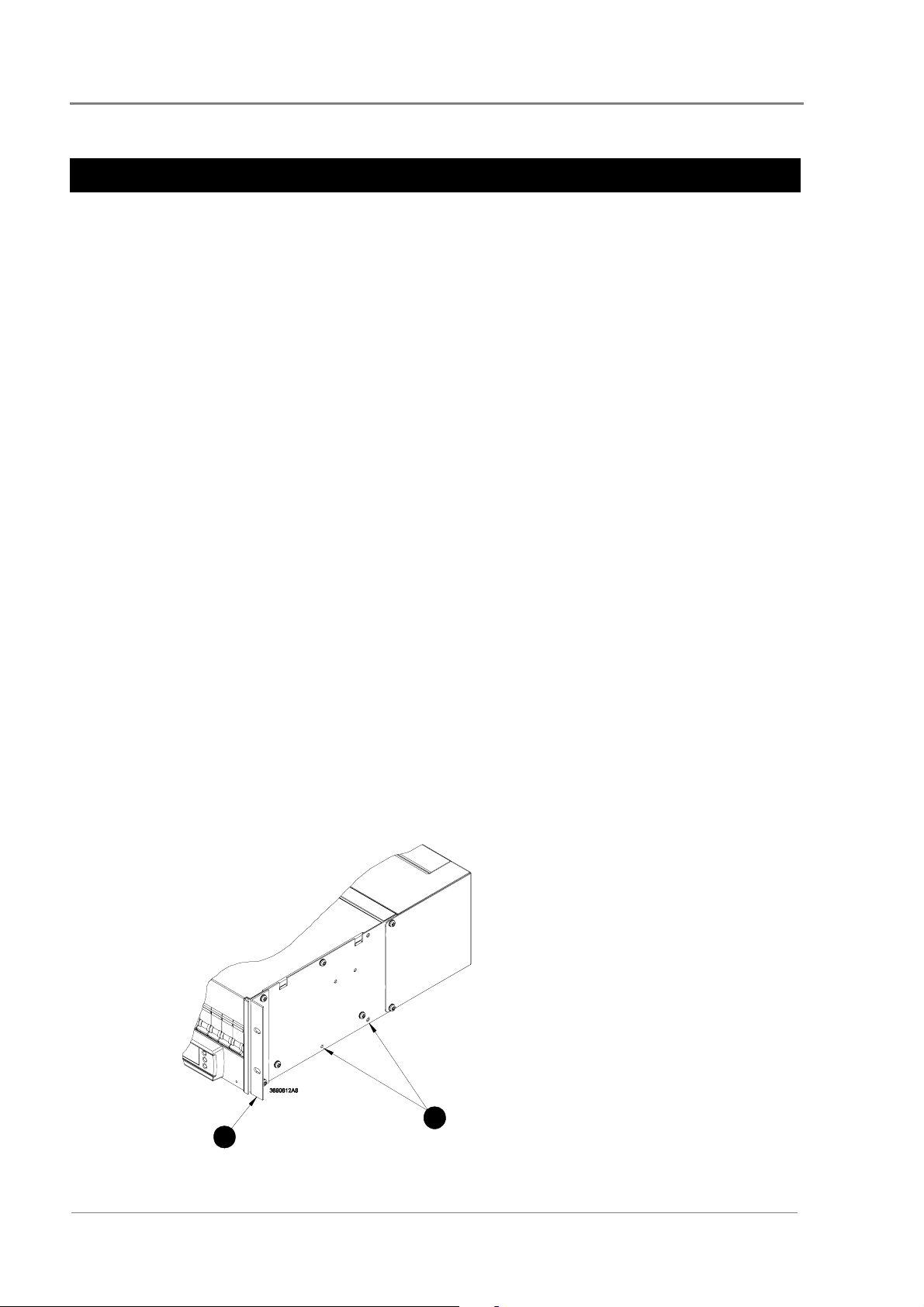

APS3-06X (Desktop Versions)

Up to three Access Power Rectifiers, numbered 1

"

to 3 from left to right (see page 1-

SM45 Supervisory Module (see page 1-

#

One 2-pole Battery Circuit Breaker

$

(APS3-061 only)

SM45 Display Module with keypad and LED

%

indicators (see Chapter 5

Load Circuit Breakers – any combination of 6 A

!

or 25 A rated circuit breakers up to a maximum of

eight, depending on customer requirements

Front Cover

&

)

)

6

16 DC Load Terminal Blocks (2 per DC Outlet)

3

Two Battery Terminal Blocks (APS3-061 only)

)

7

4

Two Battery Temperature Sensor Terminal

5

Blocks (APS3-061 only)

Four Nylon Strain Relief Clamps

'

Three fused AC Power Sockets (one per rectifier)

(

and labeled K1 to K3. K1 powers Rectifier 1, etc.

One Battery Cable Clamp (APS3-061 only)

)

DC Output Cover (remove to access DC output

*

terminations)

1-4

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 11

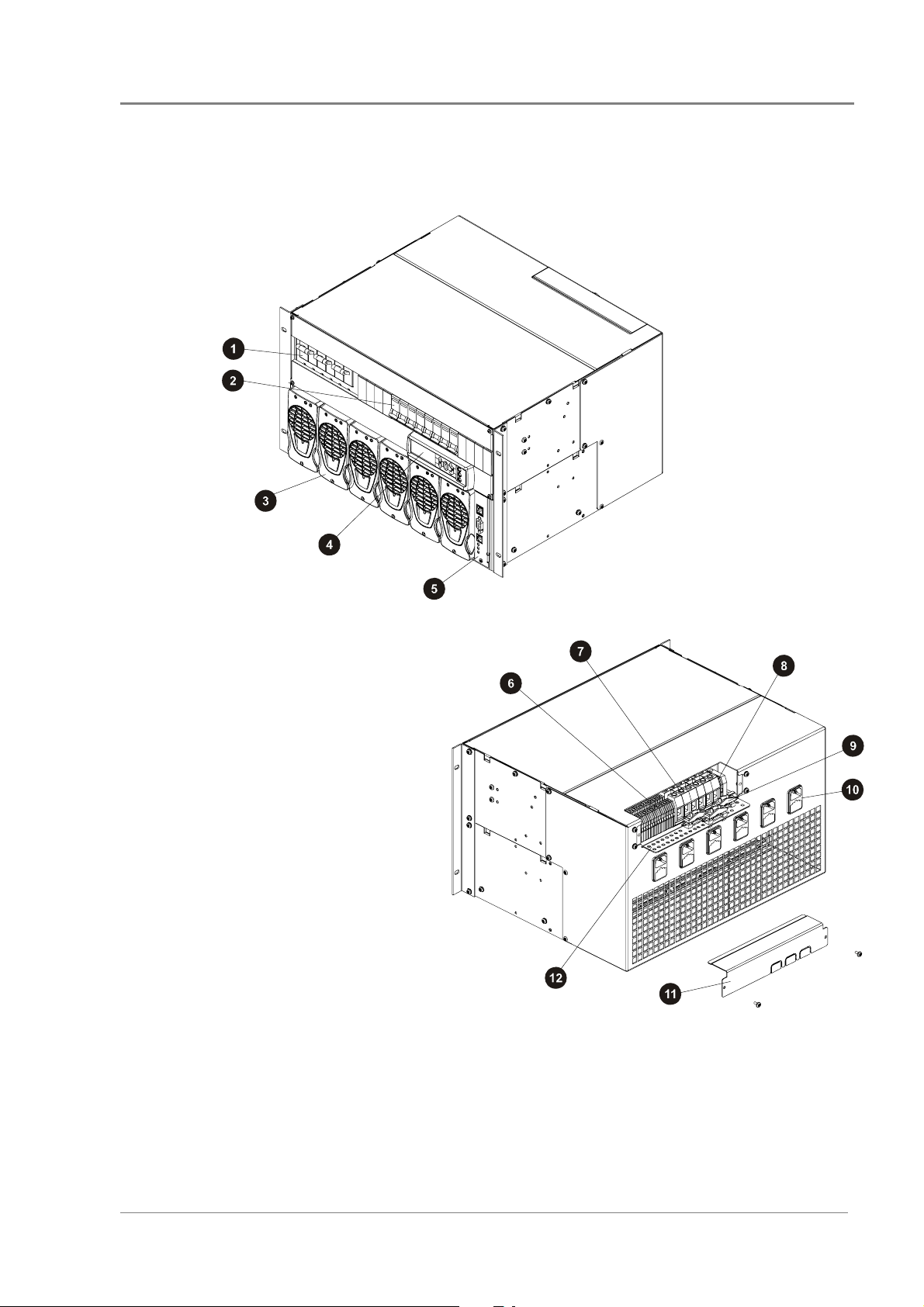

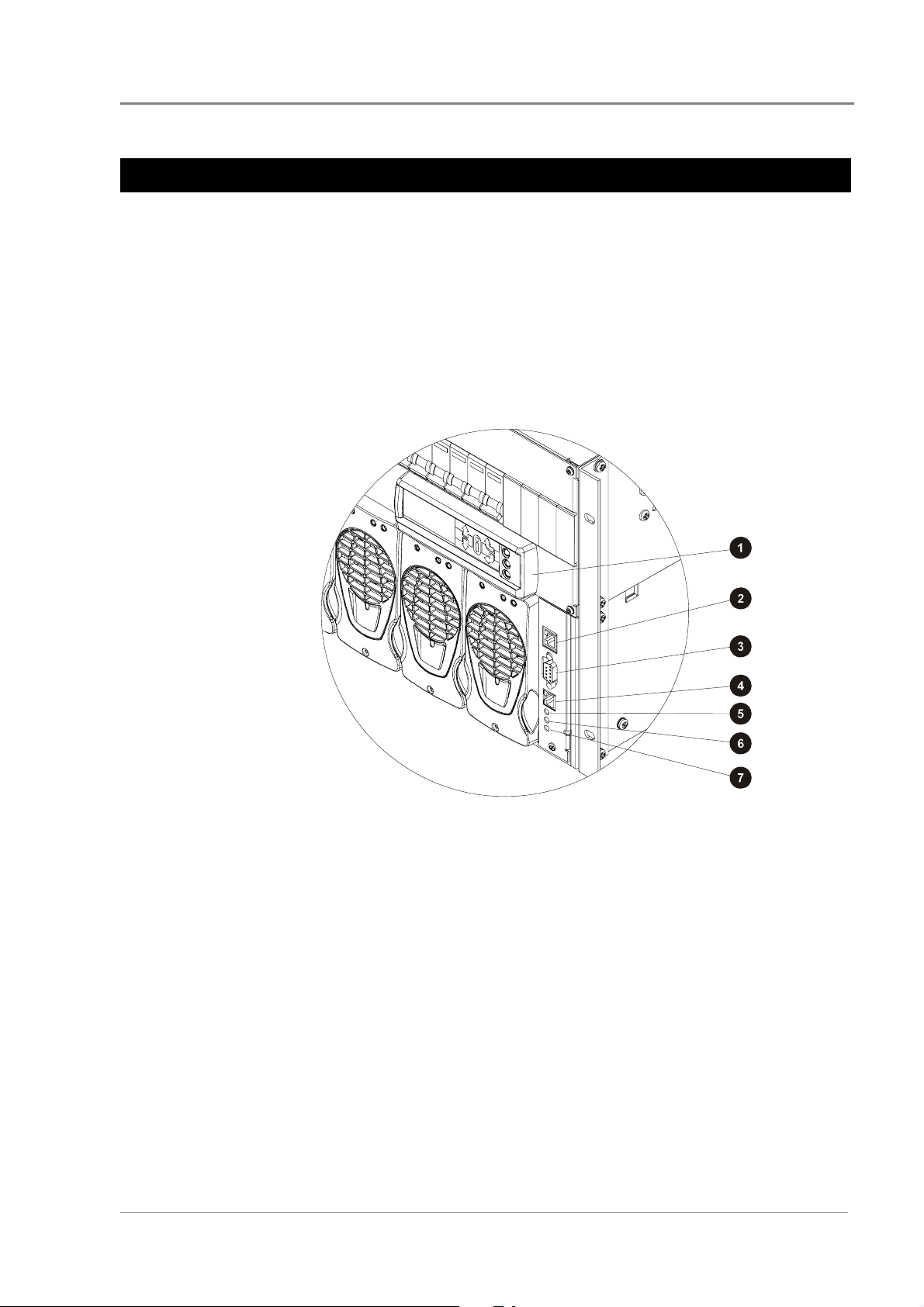

APS6-05X (Rack-Mounted Versions)

Data Power Solutions Product Range

Three 2-pole Battery Circuit

"

Breakers (APS6-059 only)

Load Circuit Breakers – any

#

combination of 6 A or 25 A

rated circuit breakers up to a

maximum of eight, depending

on customer requirements

Up to six Access Power Rectifiers,

$

numbered 1 to 6 from left to right

(see page 1-

SM45 Display Module with

%

keypad and LED indicators

(see Chapter 5)

SM45 Supervisory Module

!

(see page 1-

6)

7)

& 16 DC Load Terminal Blocks

(2 per DC Outlet)

Six Battery Terminal Blocks

3

(APS6-059 only)

Two Battery Temperature Sensor

4

Terminal Blocks (APS6-059 only)

Three Battery Cable Clamps

5

(APS6-059 only)

Six fused AC Power Sockets (one per rectifier) and labeled K1 to K6. K1 powers Rectifier 1, etc.

'

DC Output Cover (remove to access DC output terminations)

(

Cable Support Bracket

)

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

1-5

Page 12

General Description

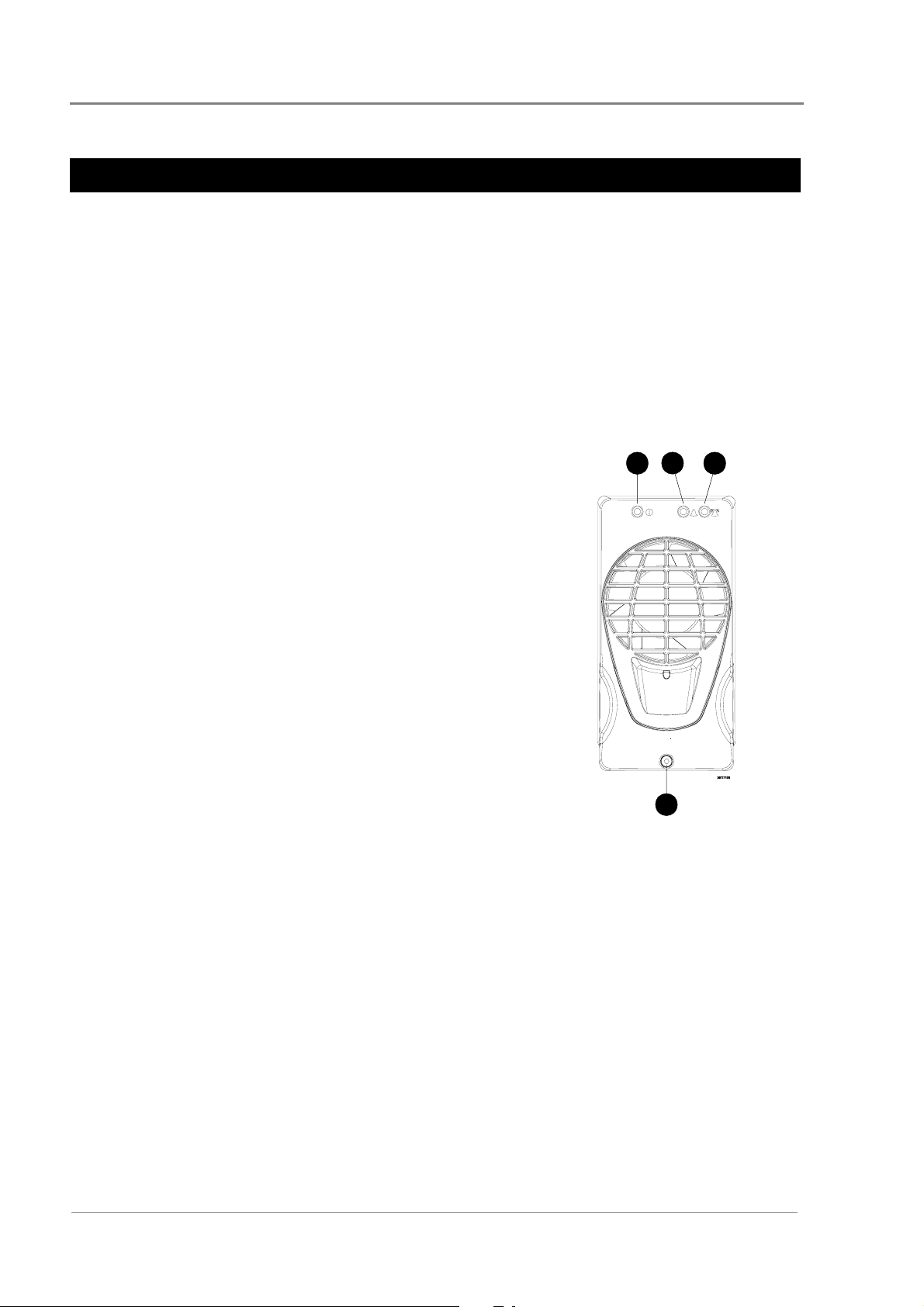

Access Power Rectifiers

Two types of fan-cooled, hot-pluggable Access Power Rectifiers are available.

• APU48 – 48 V, 720 W, (120 - 240 V AC)

• APR48 – 48 V, 1500 W, (208 - 240 V AC)

There are three status indicator LEDs on the Access Power Rectifier front panel (Power On,

Urgent Alarm and Non-Urgent Alarm).

Details about replacing a rectifier can be found in Chapter 7.

Power On LED (Green) – indicates that the rectifier is

"

powered.

Non-Urgent Alarm LED (Yellow) – indicates non-critical

#

conditions, such as:

• Rectifier in power/current limit mode

(This normally happens for a short period of time

when the batteries are recharging.)

• Rectifier operating in temperature turndown mode,

because of high ambient temperature or low AC

supply voltage

2

1

3

Urgent Alarm LED (Red) – indicates critical fault

$

conditions, that require urgent attention, such as:

• Rectifier failed

• Rectifier shut down

• AC supply failed (green LED off)

• Very high AC supply voltage

• DC overvoltage

% Retaining Screw (loosen to remove rectifier)

4

1-6

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 13

SM45 Supervisory Module

The SM45 supervisory module is an advanced control and monitoring solution for Data

Power Solutions.

It provides a full suite of advanced communications options, including built-in Ethernet

interface, Web server and SNMP agent. Details about the communications options can be

found in Chapter 6.

Alarm notifications may be by SNMP traps.

The SM45 has an onboard audible indicator and two alarm LEDs. Details about the SM45

front panel can be found in Chapter 5.

SM45 Supervisory Module

" Display Module with Keypad (see Chapter 5)

# Ethernet Interface

$ RS-232 Serial Interface

! Power On LED (green)

& Non-urgent Alarm LED (yellow)

3 Urgent Alarm LED (red)

% Not used

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

1-7

Page 14

General Description

Low Voltage Disconnect (if applicable)

APS3-059, APS3-061 and APS6-059 models are equipped with a Low Voltage Disconnect

(LVD) module.

The LVD disconnects the batteries at the LVD disconnect voltage to prevent damage to the

batteries due to excessive deep discharge. After the batteries are disconnected, they recover

to their open-circuit voltage. The LVD reconnects the batteries automatically after the AC

supply is restored. After the batteries are reconnected, the power system recharges the

batteries and powers the loads.

Both the LVD disconnect and reconnect voltages are configurable. The default LVD

disconnect voltage is set to 44 V and the reconnect voltage to 48 V. This hysteresis band

ensures that the open-circuit recovery of the discharged batteries does not rise above the

LVD reconnect voltage.

1-8

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 15

Overview

Topic Page

Warnings 2-2

Inspecting the Equipment and Reporting Damage 2-6

Chapter 2

Pre-Installation

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

2-1

Page 16

Pre-Installation

Warnings

This section contains important warnings relating to:

• AC Inputs

• Equipment Classification

• Batteries (if applicable)

• DC Outputs

• Rectifiers

• Location and Environment

• Servicing

• EMC Compliance

AC Inputs

• Desktop Versions:

Pluggable Type A: Except for 120V input, if APS3-06X power systems are fitted with

three rectifiers, then only two AC power cords may be connected to one building

branch circuit. The third AC power cord must be connected to a separate building

branch circuit. Failure to do so voids all safety approvals.

• The maximum earth leakage current of each Access Power Rectifier is 1.5 mA. Ensure

that any upstream Residual Current Devices (RCDs) are appropriately rated.

• The AC power cords (supplying the power system) must be suitably rated for the

environment and AC power distribution system. In addition, these AC power cords

must be approved and installed to comply with local wiring regulations.

• The earth conductor of each AC power cord must have a minimum cross sectional

area of 1 mm

• The maximum length of each AC power cord should not exceed 3m (10 feet), unless

local wiring regulations permit otherwise.

• Ensure that the AC supply is disconnected from those fused AC power sockets before

checking or replacing their respective fuses.

• Each socket, K1 to K3 (APS3), and K1 to K6 (APS6), contain two fuses, FS1 and FS2.

CAUTION: DOUBLE-POLE / NEUTRAL FUSING

• Use only 15 A, 250 VAC, 6.3 x 32 mm, fast-acting fuses of the same type (Bussman

ABC-15 or Littelfuse 314-015 Type 3AB) for continued protection against risk of fire.

2

(0.00155 in2).

Equipment Classification

• Data Power Solutions are classified as “Class 1” equipment that must be provided

with an earth connected to the “Protective Earthing Conductor” in the building

wiring. The earth conductor of each AC power cord must be connected to the

“Protective Earthing Conductor” in the building wiring.

2-2

• APS3-06X (desktop versions) are classed as “Pluggable equipment Type A” and

intended for use as “Desktop units”. All other units, APS3-05X and APS6-05X are

“Pluggable Equipment Type B” or for “Permanently connection” in host equipment.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 17

Warnings

Batteries (if applicable)

• Always install the batteries according to the relevant battery manufacturer’s

instructions.

• Batteries are powerful sources of energy and present a potential electrical shock and

energy hazard. The energy hazard is always present, even if the batteries are not

connected. Avoid short circuiting terminals of opposite polarity.

• Batteries are heavy, awkward to handle and can cause personal injury. To prevent

back injury, use correct lifting and bending techniques when moving batteries. If the

batteries are too heavy to move, request assistance. Always comply with the relevant

company rules or local regulations.

• Remove or cover rings, wristwatch and other metal jewelry that might be exposed to

battery terminals, before installing batteries.

• Do not wear synthetic clothing when installing batteries.

• Always use insulated tools.

• Only use a clean soft damp cloth for cleaning the batteries. Do not use cleaning

detergents or chemicals.

• When unpacking the batteries inspect them carefully for leaks, corrosion and possible

damage. Report any damage or other battery related problems immediately to your

battery supplier.

• Do not remove the factory-fitted transit insulation covers from the batteries until

access to the battery terminals is required.

• Do not place tools, loose cables or metal objects (such as interconnecting bars) on top

of batteries.

• Do not drop tools, loose cables or metal objects onto intercell connections or terminals

of opposite polarity.

• Only terminate cables and interconnecting bars after confirming that the termination

will not create a short circuit.

• Always tighten the battery terminal bolts according to the battery manufacturer’s

specification. Failing to do so can cause erratic battery performance, possible damage

to the battery, and/or personal injury.

• Always ensure that any shrouding supplied with the batteries is correctly fitted to

cable connectors.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

2-3

Page 18

Pre-Installation

DC Outputs

• The DC outlets are floating to meet the isolation requirements for powering Power

• On APS3-06X (desktop versions), run the load cables through the supplied nylon

Rectifiers

• To reduce the risk of electric shock and maintain optimum system cooling, always

• To avoid electrical shock, do not place hands inside the rectifier shelf.

• Rectifier cases may exceed 100ºC (212ºF), especially after prolonged operation. Use

over Ethernet IEEE802.3af compatible devices.

In non-Power over Ethernet applications the positive or negative output of the DC

outlets can be referenced to earth, if required.

strain relief clamps. Failure to fit the strain relief clamps and using the incorrect

torque setting for tightening their captive screws voids all safety approvals.

cover empty rectifier slots with blanking panels (Part Number: IPN 621-05722-63A).

suitable gloves to remove the hot rectifier.

• Do not attempt to disassemble rectifiers. Return them, (in their original packaging)

along with the completed Equipment Incident Report, to your local Powerware DC

product representative for replacement or repair.

Location and Environment

• Data Power Solutions (rack-mounted and desktop versions) meet the safety and fire

enclosure requirements (as specified in AS/NZS 60950.1, EN 60950-1, IEC 60950-1

and UL 60950-1). Always mount APS3-05X and APS6-05X powers systems in 19-inch

wide host equipment racks (enclosed or open type) securely bolted to the floor and

position the desktop versions (APS3-06X) on a surface that supports the weight (12kg

/ 26lb) of the power system.

• To maintain optimum system cooling, keep the front and rear of the power system

clear from walls or other equipment. The minimum recommended clearance distance

at the front and rear of the power system is 50 mm (2”). No top and bottom clearance

is required.

• The location must provide adequate airflow around the unit, in an atmosphere free

from excessive dust, corrosive fumes or conductive contaminants.

• Dust build-up within the DC power system may cause premature failure. In dusty

environments filter the ventilation air entering the equipment room. Ensure regular

cleaning of the air filters.

2-4

• Do not allow water or any foreign object to enter the power system. Do not place

objects containing liquid on top of or near the unit.

• Flooded cell and VRLA lead acid batteries can emit explosive gases and must be

installed with adequate ventilation. Refer to the battery manufacturer or supplier for

advice on minimum ventilation levels, or refer to Application Note AN0080 available

from Eaton.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 19

Warnings

Servicing

• Data Power Solutions contain hazardous voltages. Do not attempt to disassemble or

service the unit if you are not qualified. Only service personnel of Eaton

Corporation’s Telecommunications Solutions Division or their authorized service

agents are permitted to service the unit.

• If the power system requires servicing other than external battery or rectifier

replacement, isolate the unit first, as follows:

1 Unplug the AC supply cords from the AC power outlets.

2 Disconnect the external batteries, by switching off the battery circuit breakers.

EMC Compliance

• Data Power Solutions may be used in close proximity to other electronic equipment

provided installation is carried out according to instructions in this manual.

However, proper installation and compliance with EMC standards does not

guarantee that the power system will not respond to electromagnetic disturbances, or

will not cause interference to other equipment in a particular installation.

• Data Power Solutions comply with part 15 of the FCC (Federal Communications

Commission) rules. Operation is subject to the following two conditions:

1 This device may not cause harmful interference, and

2 This device must accept any interference received, including interference that

may cause undesired operation.

• Changes or modifications to Data Power Solutions not approved by Eaton

Corporation could void FCC authority to operate that equipment.

• Data Power Solutions have been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that the

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different f rom that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

2-5

Page 20

Pre-Installation

Inspecting the Equipment and Reporting Damage

Unpack the power system and inspect it carefully for possible damage that may have

occurred while in transit.

Next, check the equipment against the packing list (supplied with the equipment) and

ensure that you have received the correct type of Access Power Rectifiers (either APR48 or

APU48).

Report any damage or incorrect shipment immediately, using a copy of the Equipment

Incident Report (at the back of this guide) to supply all relevant details. Fax the completed

form to your local Powerware DC product representative.

Keep the original packaging. You will need it if any equipment needs to be returned to your

local Powerware DC product representative.

2-6

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 21

Overview

Topic Page

Mounting the Power System 3-2

DC Installation Practices 3-3

Connecting the DC Load Cables 3-3

Installing the External Batteries (if applicable) 3-7

Connecting the Battery Cables (if applicable) 3-8

Installing the Battery Temperature Sensor (if batteries are fitted) 3-10

Connecting the Power System to the AC Supply 3-12

Chapter 3

Installation

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

3-1

Page 22

Installation

Mounting the Power System

Location and Environment

Data Power Solutions (rack-mounted and desktop versions) meet the safety and fire

enclosure requirements (as specified in AS/NZS 60950.1, EN 60950-1, IEC 60950-1 and

UL 60950-1).

• Rack-Mounted Versions: APS3-05X and APS6-05X series power systems may be

mounted in 19-inch wide host equipment racks (enclosed or open type) securely bolted

to the floor.

• Desktop Versions: APS3-06X series power systems may be positioned on any surface

that supports the weight of the power system.

The location must provide adequate airflow around the unit, (as per Clearance Requirements

below) in an atmosphere free from excessive dust, corrosive fumes, or conductive

contaminants.

Dust build-up within the DC power system may cause premature failure. In dusty

environments filter the ventilation air entering the equipment room. Ensure regular cleaning

of the air filters.

VRLA lead acid batteries can emit explosive gases and must be installed with adequate

ventilation. Refer to the battery manufacturer or supplier for advice on minimum ventilation

levels, or refer to Application Note AN0080 available from Eaton.

Clearance Requirements

All Data Power Solutions (rack-mounted and desktop versions) require the following

minimum clearances:

• Front and Rear Clearance – 50 mm (2”) from walls and other equipment, required for

optimum system cooling and access.

• Top and Bottom Clearance – None

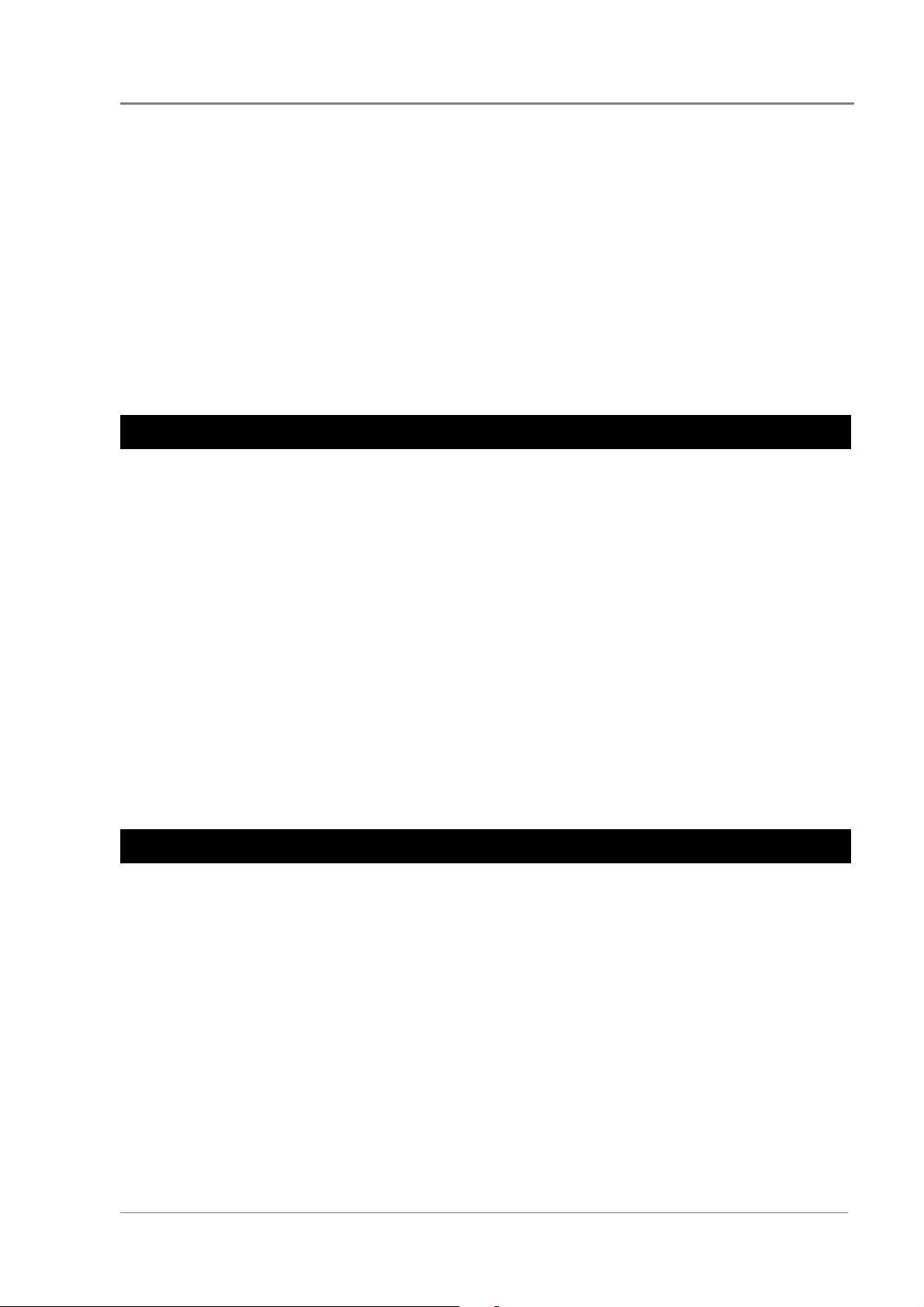

Rack Installation (rack-mounted versions only)

" APS3-05X and APS6-05X power systems come

pre-assembled with two 19-inch rack-mounting

brackets.

# The two rack-mounting brackets can be moved

backwards and lined up with alternative

bracket-mounting holes, to provide greater

mounting flexibility. Ensure the same screws are

used.

2

1

3-2

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 23

Important Notes for Rack Mounted Systems:

• If this DC power system is installed in a closed or multi-unit rack assembly ensure that

the ambient temperature is less than 40°C.

• Ensure that the air flow is not restricted.

• Ensure that the system’s weight is adequately and evenly supported.

• Take note of the maximum AC current stated on the nameplate. Ensure that the AC

supply is correctly rated.

• Ensure that reliable earthing is maintained. Carefully check earth continuity from the

branch circuit to the DC power system.

DC Installation Practices

Before you start connecting the DC load and battery cables (if applicable) to a power system,

please read the following DC Installation Practices:

• On APS3-06X (desktop versions), run the DC load cables through the supplied nylon

strain relief clamps at the rear. (See page 3clamps and using the incorrect torque setting for tightening their captive screws voids all

safety approvals.

DC Installation Practices

5 for details.) Failure to fit the strain relief

• To easily distinguish between positive and negative load cables, we recommend using

cables with different colors (as specified by local wiring regulations). The same applies

to battery cables (if applicable).

• To reduce inductive coupling, separate DC load, battery and communications cabling

from AC supply cables. If the cables have to cross, run them at right angles to the AC

supply cables.

• In order to minimize parasitic cable inductance and reduce electromagnetic interference

(EMI), all DC load cables should be routed in close proximity to one another, and large

current loops should be avoided. The same applies to battery cables (if applicable).

Connecting the DC Load Cables

Eight DC outlets (labeled 1 to 8) are available for connecting your equipment power cables.

Each DC outlet is protected by a corresponding 6 A or 25 A circuit breaker (accessible from

the DC distribution at the front). The current rating of the corresponding circuit breaker

determines the current rating of a DC outlet.

The DC outlets are floating to meet the isolation requirements for powering

Power over Ethernet IEEE802.3af compatible devices. In non-Power over Ethernet applications

the positive or negative output of the DC outlets can be referenced to earth, if required.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

3-3

Page 24

Installation

DC Load Cable Specifications

No DC load cables are supplied.

DC load cables are sized differently, depending on whether you connect to 6A or 25A

DC outlets. All DC load cables must meet the following specifications and no other cable

sizes must be used.

6 A DC Outlets:

25 A DC Outlets:

UL 1015*, 18 AWG (1mm

UL 1015*, 12 AWG (4mm

2

), multi-strand cable

2

), multi-strand cable

Cable Length:

*Required to maintain approval compliance.

3m (10 feet) maximum

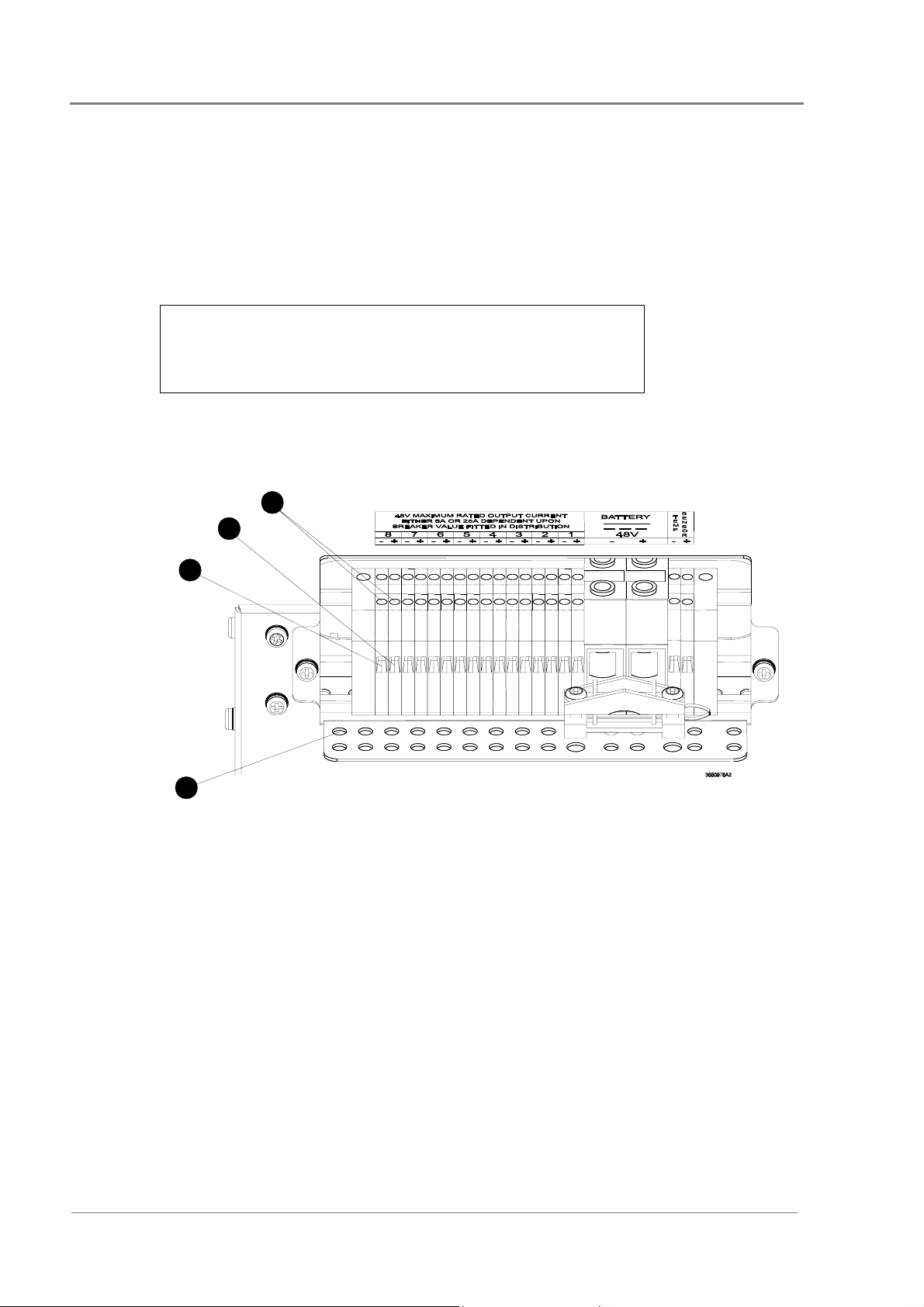

APS3-05X and APS6-05X (Rack-Mounted Versions)

3

2

1

4

" Terminate the negative load cable(s) at the (-) terminal block(s) of the DC outlet(s).

# Terminate the positive load cable(s) at the (+) terminal block(s) of the DC outlet(s).

Ensure that the polarity at the DC outlet(s) matches the power input polarity of your

equipment. Connecting reverse polarity equipment power cables to the DC outlets of a

power system might cause damage to your equipment. Such damage is not covered by

our warranty.

Ensure that the correct cable sizes have bee used (18 AWG for 6 A outlets and 12 AWG

for 25 A outlets).

$ To ensure reliable connections at the terminal blocks of the DC outlets, torque the clamp-screws

0.4 – 0.6 Nm (3.5 – 5.3 lb-in).

% Use cable-ties (not supplied) and the provided cable-tie holes on the cable support bracket to tie

down the load cables.

3-4

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 25

APS3-06X (Desktop Versions)

Before proceeding check you have:

• 4 x load cable clamps

• 8 x 25mm blunt ended screws

• 8 x 5mm and 4 x 10mm cable sleeves (50mm long)

Depending on the cables sizes, not all sleeves will be required.

Connecting the DC Load Cables

• 1mm

• 4mm

2

(18 AWG) cable for connection to 6A outlets

2

(12 AWG) cable for connection to 25A outlets

Step 1 - Fit load cable clamps

Insert the square ends of the load cable clamps into the holes in the back of the

system.

Engage two turns of each retaining screw. This will ensure that the clamp does

not move when the wires and sleeves are inserted.

Fit all clamps even if you do not use them all. Tighten unused clamps to prevent

access to the DC outputs.

Step 2 - Strip cable ends

Strip approximately 10mm (3/8”) from the cable ends. We recommend fitting cable ferrules

over the cable ends.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

3-5

Page 26

Installation

Step 3 – Fit cables and sleeves

To maintain safety approvals insert only the following numbers of cables per clamp,

with sleeves where applicable. This will ensure that cables are retained correctly in

their clamps.

Feed the cables through the clamps as follows, depending on cable size:

2

(18 AWG) – 2 cable pairs* per clamp:

1mm

2

4mm

(12 AWG) – 1 or 2 cable pairs per clamp

Do not tighten the clamps at this stage.

Step 4 – Terminate cables

" 2 x 5mm sleeves

# 10mm sleeve

* If only one cable pair is required

then use a dummy pair with

sleeves to make up the space.

Terminate the negative load cable(s) at the (-) terminal block(s) of the DC

outlet(s).

Terminate the positive load cable(s) at the (+) terminal block(s) of the DC

outlet(s).

Tighten the terminal screws. Required torque: 0.4 – 0.6 Nm (3.5 – 5.3 lb-in).

Ensure that the polarity at the DC outlet(s) matches the power input polarity of your

equipment. Connecting reverse polarity equipment power cables to the DC outlets of

a power system might cause damage to your equipment. Such damage is not covered

by our warranty.

Ensure that the correct cable sizes have been used (1mm

2

and 4mm

/12 AWG for 25 A outlets).

2

/18 AWG for 6 A outlets

Step 5 – Arrange sleeves and tighten clamp screws

Arrange the sleeves so that they are all within 10mm (3/8”) of the terminals.

Tighten all cable clamp screws. Required torque: 1.5 – 2 Nm (13.2 – 17.7 lb-in).

Tighten the screws of any unused clamps to prevent access to the DC output

terminations.

Procedure complete

3-6

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 27

Installing the External Batteries (if applicable)

Installing the External Batteries (if applicable)

This section applies to APS3-059, APS3-061 and APS6-059 power systems only.

One 48 V battery string can be connected to APS3-059 and APS3-061 and up to three 48 V

battery strings to APS6-059 power systems.

A 48 V battery string consists of either:

• 24 Valve Regulated Lead Acid (VRLA) 2 V cells or

• Four VRLA 12 V monoblocs

Because of the wide range of battery types and sizes available, we do not supply batteries

with the above mentioned power systems and therefore do not cover battery installation in

this guide. Always install batteries according to the relevant battery manufacturer’s

instructions.

Battery Sizing

Battery manufacturers provide various types of information for sizing batteries such as

constant current discharge and constant power discharge data. Your battery supplier will be

able to assist you with sizing the battery for your application.

Before a battery can be sized, the following information is required.

• Required backup time

• Minimum cell voltage (typically 1.83 V per Cell)

• Load profile

• Operating temperature

In telecommunications and data applications most loads are constant power for a specified

backup time. Therefore, for sizing a battery for the required backup time, constant power

discharge data should be used.

For charging the battery, constant current discharge data should be used. When charging

the battery, battery current limit should be used to set the battery charge to no more than the

maximum recharge specified by the battery manufacturer.

Batteries for use in North America must be a UL recognized type, category BAZR2.

Battery Location

Valve Regulated Lead Acid (VRLA) batteries emit very small amounts of hydrogen gas into

the surrounding atmosphere under normal float charging conditions. For that reason

batteries should never be installed in a sealed enclosure or cabinet.

Install the batteries in a well-ventilated location to prevent accumulation of hydrogen gas to

flammable or explosive levels.

Building air conditioning and ventilation systems already in place for optimum equipment

operation and comfort of personnel usually meet or exceed VRLA battery ventilation

requirements. For specific battery ventilation requirements, always refer to the battery

manufacturer’s installation instructions.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

3-7

Page 28

Installation

Avoid:

• Installing the batteries next to any heating source or under air ducts.

• Exposing part of a battery string to direct sunlight.

• Any other locations that would cause temperature variations within the batteries.

Battery Fault Protection

A fault protection device (such as a circuit breaker or fuse) must be fitted in series with one

of the battery cables of each battery string.

The fault protection device must be:

• Located as close as practical to the corresponding battery string output terminal and

• Capable of disconnecting the potential fault current of the battery string.

The battery circuit breaker(s) of the power system can not be considered as the fault

protection device for the battery string(s) and associated wiring.

The interrupt rating of the battery circuit breaker(s) fitted within the power systems is 10 kA.

Therefore, the maximum potential short-circuit current of a 48 V battery string must be

limited to less than 10 kA or the total internal impedance of the battery string should be

greater than 5.7 mΩ.

If a smaller rated external fault protection device is used, then batteries with appropriate

internal impedance need to be selected.

Connecting the Battery Cables (if applicable)

This section applies to APS3-059, APS3-061 and APS6-059 power systems only.

Before You Start

Ensure that all the circuit breakers at the front of the power system and the external battery

circuit breaker (close to the battery output terminals) are switched OFF.

Before proceeding check you have:

• Battery cable clamp(s) (one for APS3 models, three for APS6-059)

• 2 x 25mm blunt ended screws per clamp

• 1 x 16mm cable sleeve (50mm long) per clamp

• Battery cable (see specifications below).

Battery Cable Specifications

No battery cables are supplied with APS3-059, APS3-061 and APS6-059 power systems. All

battery cables must meet the following specifications and no other cable sizes must be used.

Cable Style and Size:

UL 1283*, 4 AWG (25mm

2

), multi-strand cable

Cable Length:

*Required to maintain approval compliance.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

3-8

3m (10 feet) maximum

IPN 997-00012-41D December 2006

Page 29

Connecting the Battery Cables (if applicable)

Step 1 - Prepare cable clamp

Cut off the two inside posts of the battery cable clamp to enable the battery

cables and sleeve to fit.

Step 2 – Strip cable and fit sleeve

Strip approximately 17mm (3/4”) of the insulation from the cable ends. We

recommend fitting cable ferrules over the cable ends.

Feed both battery cables through the 16mm sleeve.

Step 3 – Terminate cable

Terminate the positive battery cable at the Battery (+) terminal block.

Terminate the negative battery cable at the Battery (-) terminal block.

Tighten the terminal screws. Required torque: 2.5 - 3 Nm (22.1 – 26.5 lb-in).

Ensure that the polarity at the battery terminal blocks matches the polarity of the

external battery. Connecting a reverse polarity battery to a power system will cause

damage to the rectifier modules. Such damage may not be covered by the warranty.

" 16mm battery cable sleeve.

# Battery cable clamp with posts removed.

Step 4 – Arrange sleeve and clamp the battery cables

Arrange the cable sleeve so that it is within 10mm (3/8”) of the terminals.

Tighten the cable clamp screws. Required torque: 1.5 – 2 Nm (13.2 – 17.7 lb-in).

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

3-9

Page 30

Installation

Step 5 – Repeat for other battery cables (if required)

Repeat the above procedure to connect up to three battery strings to an APS6-

059 power system.

Step 6 – Remove knockout and fit cover

Remove the battery cable knockout(s) on the DC output cover.

" Battery cable knockout.

Remove any sharp edges, in particular the remaining knock-out webs.

Fit the DC output cover.

Procedure complete

Installing the Battery Temperature Sensor (if batteries are fitted)

This section applies to APS3-059, APS3-061 and APS6-059 power systems only.

Each APS3-059, APS3-061 and APS6-059 power system is supplied with a battery

temperature sensor and standard 2 m (6.5 feet) long cable (factory-fitted to the sensor).

Longer cables are available from your local Powerware DC product representative or you

can make up your own. We strongly recommend limiting the maximum cable length of the

battery temperature sensor to 20 m (65 feet) because of noise considerations.

Connecting the Battery Temperature Sensor Cable

There are two screw-clamp terminal blocks at the rear of APS3-059, APS3-061 and APS6-059

power systems for terminating the battery temperature sensor cable, as shown below.

The two terminal blocks are labeled TEMP SENSOR (+) and TEMP SENSOR (-).

3-10

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 31

Installing the Battery Temperature Sensor (if batteries are fitted)

" Terminate the Black/White wire at TEMP SENSOR (+) and the Black wire at

TEMP SENSOR (-), as shown.

# To ensure reliable connections at the battery temperature sensor terminal blocks, torque the

clamp-screws 0.4 – 0.6 Nm (3.5 – 5.3 lb-in).

$ Use cable-ties (not supplied) and the provided cable-tie holes on the cable support bracket to tie

down the battery temperature sensor cable.

On APS3-061 power systems, there is a cable-tie hole on the bracket behind the battery

cable clamp, to tie down the battery temperature sensor cable.

Mounting the Battery Temperature Sensor

The battery temperature sensor is designed to measure the average ambient temperature

around the batteries. It is important to mount the battery temperature sensor at a location

that truly reflects the average ambient temperature of the batteries.

Attaching the battery temperature sensor to the battery stand (centered and above the

batteries) may provide the most reliable temperature reading.

If possible, avoid:

• Placing the battery temperature sensor on top of battery cases.

• Attaching the battery temperature sensor to battery cables, terminals or interconnecting

bars.

• Exposing the battery temperature sensor to direct sunlight and drafts from the airconditioning system or open windows.

• Running the battery temperature sensor cable along power or earth cables.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

3-11

Page 32

Installation

Connecting the Power System to the AC Supply

Data Power Solutions can be connected to single-phase (L-N), two-phase (L-L), three-phase

(L-N) and three-phase (L-L) AC power distribution systems.

Fused AC power sockets (one per rectifier) are available for connecting the power system to

the AC supply. These fused AC power sockets are labeled K1 to K3 on APS3 and K1 to K6

on APS6 power systems. AC power socket K1 powers Rectifier 1, etc. (See Chapter 1 for

location of Rectifier 1.)

No AC power cords are supplied with the power systems.

AC Supply Requirements

• AC Power Cords – The AC power cords (supplying the power system) must be suitably

rated for the environment and AC distribution system. In addition, these AC power

cords must be approved and installed to comply with local wiring regulations. (See

Appendix C for maximum AC input current specifications.)

The earth conductor of each AC power cord must have a minimum cross sectional area

of 1 mm

The maximum length of each AC power cord should not exceed 3m (10 feet), unless local

wiring regulations permit otherwise.

• Desktop Versions – If APS3-06X power systems are fitted with three rectifiers, then only

two AC power cords may be connected to one building branch circuit. The third AC

power cord must be connected to a separate building branch circuit. Failure to do so

voids all safety approvals.

• Earthing – Data Power Solutions are classified as “Class 1” equipment that must be

provided with an earth connected to the “Protective Earthing Conductor” in the building

wiring. The earth conductor of each AC power cord must be connected to the

“Protective Earthing Conductor” in the building wiring.

• Earth Leakage Current – The maximum earth leakage current of each Access Power

Rectifier is 1.5 mA. Ensure that any upstream Residual Current Devices (RCDs) are

appropriately rated.

AC Installation

Install all AC cabling between the AC power source and the power system according to the

AC Supply Requirements above, but do NOT switch on the AC supply at this stage.

2

(0.00155 in2).

3-12

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 33

Overview

Topic Page

Inserting the Access Power Rectifiers 4-2

Pre-Power-Up Check 4-3

Applying AC Power 4-4

Configuring the Power System for Operation 4-4

Applying DC Power to the Load 4-8

Chapter 4

Commissioning

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

4-1

Page 34

Commissioning

Inserting the Access Power Rectifiers

Do NOT switch on the AC supply at this stage.

Step 1 – Unpack the rectifiers

Unpack the rectifiers and inspect them carefully for possible damage that may

have occurred in transit. Report any damage immediately, using a copy of the

Equipment Incident Report (located at the back of this guide) to supply all

relevant details. Fax the completed form to your local Powerware DC product

representative.

Keep the original packaging. You will need this if any equipment needs to be

returned to your nearest authorized service agent for replacement or repair.

Step 2 – Align the rectifier with the burst-out guides in the shelf

Step 3 – Push in the rectifier

1 Slowly push in the rectifier, sliding it along the burst-out guides, as shown

To avoid injury to your hands, keep your fingers clear, as shown in

the diagram below.

below, until it plugs firmly into the backplane connector.

4-2

2 Tighten the rectifier retaining screw with a Pozidriv® screwdriver.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 35

Pre-Power-Up Check

Use the checklist below to complete initial checks before progressing further.

Checklist

Pre-Power-Up Check

All AC and DC cabling is installed

All cabling is neat and correctly insulated

DC battery and load cabling has the correct polarity

All panels are in place and all empty rectifier slots are covered

with blanking panels

The AC supply to the power system is switched OFF

All circuit breakers at the front of the power system are

switched OFF

Batteries (if fitted) are isolated from the power system

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

4-3

Page 36

Commissioning

Applying AC Power

1 Switch on the AC supply.

2 Check that each rectifier starts up and that the green

the red urgent

troubleshooting section in Chapter 7).

3 Check that the SM45 supervisory module has powered up and that the green

Power On LED on both the SM45 and the display module is on.

and yellow non-urgent alarm LEDs are off. (If not consult the

Depending on your configuration settings, the urgent and/or non-urgent alarm LED(s)

may also be on.

4 Check that all installed rectifiers are communicating and that the SM45 supervisory

module has correctly registered all rectifiers, by viewing the individual rectifier currents

in Main Display Mode. (See front panel menu structure on inside front cover or

Viewing System Values in Chapter 5 for details.)

If no load is connected each rectifier will show 0 A.

Configuring the Power System for Operation

Each power system is supplied with a pre-loaded configuration file.

It is important that the settings of this configuration file are checked/verified and changed as

required for site-specific conditions. In particular settings that may affect the performance

and life expectancy of the battery must be checked and set according to the battery

manufacturer’s recommendations.

Power On LED is on and both

Only those configuration parameters that are most likely to be changed on-site can be

configured from the front panel. For entering and editing of all other configuration

parameters (such as mapping of alarms to relays and setting up communications) a laptop

computer and the latest version of DCTools is required. The latest version of DCTools can be

downloaded from http://www.powerware.com/downloads

We recommend using DCTools for configuring your power system for operation.

Using the Front Panel Keypad

Scroll through the SM45’s Configuration Mode and change the configuration settings as

required.

A list of all the configuration settings that can be changed from the front panel can be f ound

on the inside back cover.

For details about changing configuration settings from the front panel, see

Viewing and Editing Configuration Parameters in Chapter 5.

4-4

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 37

Using DCTools

Before you start, you need

• A PC (preferably a laptop) with the latest version of DCTools installed.

• A null modem cable

Step 1 – Connect a PC to the RS-232 port of the APS DC power system

1 Connect the null modem cable between the RS-232 port of the power system

Configuring the Power System for Operation

and the serial port of your laptop or PC.

2 Start DCTools by double clicking on the DCTools icon

Step 2 – Check that your PC port is specified correctly

1 Double-click on the DCTools icon

the DCTools Connection List. The default connection is COM1.

2 If the port properties are correct, enable the connection by selecting the

Active check box

The correct port properties are, (Protocol: S3P and S3P Address: 0).

If the port properties are incorrect, select the relevant connection from the

Connection List and click the

dialog, edit the properties as necessary and click OK.

If the connection is successful, the DCTools System Summary (Home) screen

is displayed as shown.

of that connection.

in the Windows™ task bar to display

toolbar button. In the Comms Properties

on the desktop.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

4-5

Page 38

Commissioning

Step 3 – Check through the loaded configuration and make changes as required

Check through the loaded configuration in DCTools by clicking on the hotlinks

at the top of the DCTools System Summary (Home) screen and make changes as

required.

The DCTools System Summary (Home) screen below shows the main

configuration hotlinks, followed by a list of what can be configured under each

hotlink.

Hotlink Click to …

Configuration

Alarms Configure system alarms (see Example 1)

Analogs

Digitals

Relays

Toggle relay states when performing a Relay Test and

Control

LVD

Enable/disable LVD(s) and to configure the LVD settings

Rectifiers

Enter site specific information and synchronize the SM45

real-time clock with the internal UTC time of your PC under

Identity

Set up Ethernet communications and SNMP traps under

Communications

Configure analog inputs, current inputs and external analog

inputs

Set-up user alarms

configure external digital inputs

Configure the settings of control functions such as Manual

Equalize, Temperature Compensation, Battery Test, Fast

Charge, Battery Current Limit and Active Voltage Control.

Configure rectifier settings

, and sysObjectID under SNMP

4-6

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 39

Configuring the Power System for Operation

Example 1 Reconfiguring System Alarms

In general reconfiguring system alarms requires the following:

• Changing the urgency (Disabled, Relay Only, Urgent or

Non Urgent)

• Setting the alarm thresholds and recognition times

For example, to reconfigure an alarm, follow the steps below.

1 From the DCTools System Summary (Home) screen, click

the Alarms

hotlink. The Alarm Table screen is then

displayed.

2 To change the urgency of an alarm, double-click on the

Urgency for that alarm, then click the

the new urgency from the popup list.

3 To change alarm thresholds and recognition times, click

the

button to the left of Alarm Configuration at the

bottom of the Alarm Table screen and change the settings

as required.

button and select

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

4-7

Page 40

Commissioning

Applying DC Power to the Load

1 Check the DC output voltage and polarity of the power system and battery string(s).

2 Switch on the Battery MCB(s) (if fitted) and check that the Battery Fuse Fail alarm clears.

When connecting multiple battery strings in parallel to the system DC bus, ensure that

the individual strings are of similar voltage.

3 Check the Battery Current reading, if batteries are fitted. (The actual value depends on

the state of charge of the batteries.)

4 Switch on the Load MCB(s). Check that the load (the equipment) powers up and that the

Load Fuse Fail alarm clears.

5 Check the rectifier currents and verify that the load current is representative of what the

load draws and also that the power system has sufficient capacity.

6 Charge the batteries (if fitted) according to the battery manufacturer’s recommendations.

Manual Equalize can be started from DCTools or the front panel.

Manual Equalize increases the system voltage to the pre-configured equalize voltage for

the pre-configured equalize duration. After the pre-configured equalize duration has

expired, the power system voltage reverts back to normal battery float voltage

automatically.

7 Fit the DC output cover.

4-8

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 41

Overview

Topic Page

About the SM45 Front Panel 5-2

About Display Modes 5-4

Viewing System Values (Main Display Mode) 5-5

Viewing Alarms and System Status Messages (Status View Mode) 5-6

Viewing and Editing Configuration Parameters 5-7

Chapter 5

SM45 Operations

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

5-1

Page 42

SM45 Operations

About the SM45 Front Panel

The Keypad and LED Indicators

Backlit LCD Display

"

Keypad

#

Power On LED (green) – indicates that the SM45 is powered

$

21

3

4

5

Non-urgent Alarm LED (yellow) – indicates one or more active non-urgent alarms

%

Urgent Alarm LED (red) – indicates one or more active urgent alarms

!

Scroll Keys: Press these keys to scroll through lists and menus and to increase or decrease

configuration values.

Information Key: Press this key to view status messages and a list of active alarms in Status

View Mode.

Enter Key: Press this key to go to Configuration Mode and Edit Mode, save configuration

changes, clear alarms or toggle relay states.

Escape Key: Press this key to go to Main Display Mode or cancel configuration changes.

The Display Indicators

The following display indicators may appear on the screen from time to time.

Indicates an urgent alarm.

Indicates a non-urgent alarm.

???

5-2

disconnected or unconfigured sensor.

Indicates which scroll key to press, to view further display items.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Indicates that the system value cannot be displayed, because of a failed,

Page 43

The Audible Indicator

The SM45 has an onboard audible indicator.

The audible indicator informs you about pressing invalid keys and active alarms as follows:

• One beep every 2 seconds - indicates that a non-urgent alarm is active

• A continuous sound - indicates that an urgent alarm is active

An urgent alarm always overrides a non-urgent alarm.

► To disable the audible indicator (when an alarm is active)

• Press any key

At the next active alarm, the audible indicator is automatically enabled again.

Display Time-out

About the SM45 Front Panel

The SM45 has a display time-out function – that is, if no keys are pressed for a

predetermined time interval, the SM45 reverts back to the default display (total rectifier

current).

The predetermined time interval varies (according to the display mode you are in) as

follows:

• Edit Mode – no time-out

• All other display modes – 2 minutes

Changing the Display Contrast

The display contrast can be adjusted from 0 (lowest contrast) to 63 (highest contrast).

► To change the display contrast

1 Press the

2 Press the

3 Press the

4 Press either the

changes are immediately visible.)

key to enter Configuration Mode.

key to scroll down to Display Contrast.

key to enter Edit Mode.

or key to change the display contrast as appropriate. (Contrast

5 Press the

6 Press the

key to save the new value.

key to return to Main Display Mode.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

5-3

Page 44

SM45 Operations

About Display Modes

The SM45 front panel menu structure consists of four display modes:

• Main Display Mode – for viewing system values

• Status View Mode – for viewing system statuses as well as viewing and clearing alarms

• Configuration Mode – for viewing settings of configurable parameters

• Edit Mode – for editing the configurable parameters in Configuration Mode

For quick and easy reference, graphical representations of the menu structure are printed on

the inside front and back covers.

Changing Display Modes

► To enter a display mode

• From Main Display Mode, press the key to enter Status View Mode and Alarm Mode.

• From Main Display Mode, press the key to enter Configuration Mode and Edit Mode.

► To exit a display mode

• Press the key to return from any mode to Main Display Mode.

Scrolling within a Display Mode

► To scroll within a display mode

• Press the key to scroll up within a display mode.

• Press the key to scroll down within a display mode.

To scroll through a display mode faster, hold down the or key.

Using Edit Mode

For details about viewing and editing configuration parameters, see page 2-7.

5-4

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 45

Viewing System Values (Main Display Mode)

Viewing System Values (Main Display Mode)

Nine system values (as at right) can

be viewed in Main Display Mode.

If a system value is not available (for

example, because of an incorrectly

configured or disconnected battery

temperature sensor), the following is

displayed.

Details about the other display

indicators can be found on page 2-

Total Rectifier

Current

(Default Display)

2.

Main Display Mode

► To view system values

1 Press the

through the system values in

Main Display Mode.

2 Only six individual rectifier

currents are displayed at once.

If more than six rectifiers are

installed, press the

to scroll through the list.

3 Press the

the top of the list – total rectifier

current.

or key to scroll

key to return to

or key

Total output

power delivered

by the rectifiers

as a percentage of

available power

Individual

Rectifier

Currents

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

5-5

Page 46

SM45 Operations

Viewing Alarms and System Status Messages (Status View Mode)

Status View Mode displays alarm and status messages.

The appearance of one of the following display indicators in Main Display Mode indicates

the presence of an alarm message.

indicates an urgent alarm

indicates a non-urgent alarm

Details about the other display indicators can be found on page 2-

Rules for displaying alarms and system status

• Active alarms are always displayed before status messages.

• Urgent alarms are always displayed before non-urgent alarms.

• Alarms with their urgency set to Disabled are not displayed.

2.

Important note about Rect Comms Lost alarm

If a rectifier is removed, a Rectifier Comms Lost alarm is displayed after 10 seconds. The

operator or installer then has the opportunity to clear the alarm immediately to prevent

triggering an external alarm device. The alarm must be cleared within the configurable

Alarm Recognition Time (default is 10 seconds), otherwise an external alarm is generated.

Rects Comms Lost is remotely displayed as Multiple Rectifier Comms Lost.

► To view and clear alarms

1 From Main Display Mode, press the

2 Press the

3 Press the

Lost, Rects Comms Lost and Battery Test Fail.)

4 Press the

key to scroll through the list of alarms.

key to clear the alarms. (Only three alarms can be cleared – Rect Comms

key to return to Main Display Mode.

key to enter Status View Mode.

For a comprehensive list of alarms (that can be displayed in Status View Mode) see

Appendix A.

► To view system status messages

1 Press the

If there are active alarms, press the

control status list is displayed after the last alarm.

2 Press the

3 Press the

5-6

key to enter Status View Mode.

key to scroll to the bottom of the alarm list. The

or key to scroll through the list of status messages.

key to return to Main Display Mode.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 47

Viewing and Editing Configuration Parameters

Viewing and Editing Configuration Parameters

Configuration Mode displays only those configuration parameters that are most likely to be

changed on-site. Configuration parameters configurable from the front panel are changed in

Edit Mode.

For viewing and editing all other configuration parameters a laptop computer or remote

access is required. See Chapter 3 for details about the standard communications options.

► To view and edit a configuration parameter

1 From Main Display Mode, press the

2 Press the

3 Press the

4 Press either the

5 Press the

6 Press the

7 Press the

key to scroll down to the required parameter.

key to enter Edit Mode.

or key to change the value as appropriate.

key to save the new value and return to Configuration Mode, or

key to cancel the change and return to Configuration Mode.

key to return to Main Display Mode.

key to enter Configuration Mode.

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

5-7

Page 48

SM45 Operations

5-8

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 49

Overview

Topic Page

Communications Options 6-2

DCTools Setup 6-3

SM45 Ethernet Setup 6-3

Setting Up SNMP Traps 6-4

Entering the “sysObjectID” of a Power System 6-5

Synchronizing the SM45 Real-time Clock 6-6

Chapter 6

Communications

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

6-1

Page 50

Communications

Communications Options

The SM45 supervisory module communicates to a designated PC (running the DCTools

software) via a:

• Standard RS-232 serial interface, or

• Ethernet 10BaseT interface, both accessible from the front panel

Shown below are the two standard communications options.

Direct Connection

Ethernet

6-2

Copyright © 2005-2006 Eaton Corporation. All Rights Reserved.

IPN 997-00012-41D December 2006

Page 51

DCTools Setup

For your chosen communications option, configure the communications settings, in DCTools

according to the table below.

Then check that DCTools communicates correctly.

Properties Direct Connection Ethernet

Comms Enabled True True

Protocol S3P S3P

Connect Using COM1 Local Network

S3P Address 0 0

Server IP Address – 10.64.129.1 (See Note 1)

Server Port – 14000

DCTools Setup

Telnet – Cleared

Note 1:

Allocated by network administrator

SM45 Ethernet Setup

Before an SM45 supervisory module can communicate over an IP network with DCTools, the

SM45 must be set up for Ethernet communications.

Use the front panel or DCTools for configuring the SM45 supervisory module for Ethernet

communications.

Setup of Ethernet communications requires the following:

• The network administrator assigning a unique IP address to each SM45 supervisory

module to be connected to the IP network