Page 1

Intelligent Technologies

QCPort Starter Network Adapter Product

(QSNAP)

Installation and User Manual

Publication No. MN05001001E

February 2002

New

Page 2

Intelligent Technologies ( IT. ) QSNAP

Important Notice – Please Read

The product discussed in this literature is subject to terms and conditions outlined in

appropriate Eaton’s Cutler-Hammer selling policies. The sole source governing the

rights and remedies of any purchaser of this equipment is the relevant Eaton’s

Cutler-Hammer selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING

FROM COURSE OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE

INFORMATION, RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In

no event will Eaton’s Cutler-Hammer be responsible to the purchaser or user in

contract, in tort (including negligence), strict liability or otherwise for any special,

indirect, incidental or consequential damage or loss whatsoever, including but not

limited to damage or loss of use of equipment, plant or power system, cost of

capital, loss of power, additional expenses in the use of existing power facilities, or

claims against the purchaser or user by its customers resulting from the use of the

information, recommendations and descriptions contained herein.

February 2002

Cover Photo: QSNAP on

IT.

E101 Starter

Pub. No. MN05001001E

Page 3

February 2002

Table of Contents

PRODUCT OVERVIEW

PHYSICAL FEATURES

OPERATION

CONFIGURATION

INSTALLATION

TROUBLESHOOTING AND MAINTENANCE

APPENDIX A: QSNAP PARAMETERS

INTELLIGENT TECHNOLOGIES (

Intelligent Technologies ( IT. ) QSNAP

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Approvals/Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Catalog Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

“Out of Box” Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Typical Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Enhanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input/Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Input Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using CH Studio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Set the Group ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SW1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mount the

Wire the

IT.

QSNAP to the Starter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

IT.

QSNAP to the Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connect the QSNAP to QCPort. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

IT.

) PUBLICATIONS AND SUPPORT

. . . . . . . . . . . . . . 23

Pub. No. MN05001001E

i

Page 4

Intelligent Technologies ( IT. ) QSNAP

List of Figures

Figure 1: QSNAP Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2: QSNAP Dimensions, mm [in] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3: Starter Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4: Typical QSNAP Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5: Group ID Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6: QSNAP with 54 mm IT. Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 7: QSNAP Alignment and Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8: QSNAP Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9: Jumper and RJ-45 Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 10: Jumper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 11: QCPort Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 12: QCPort Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

List of Tables

Table 1: QSNAP Electromechanical Starter Connectivity Table . . . . . . . . . . . . . . . 1

Table 2: QSNAP S751 Connectivity Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 3: Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 4: Approvals/Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 5: Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 6: Default Input Data from QSNAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 7: Default Output Data to QSNAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 8: Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 9: Enhanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 10: Input Assembly Data Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 11: Default Input Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 12: Default Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 13: Output Assembly Data Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 14: Status LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 15: QSNAP Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 16: SW1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 17: Starter Size/Available Auxiliary Locations on Mounted QSNAP . . . . . . 16

Table 18: Terminal Block Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 19: QSNAP Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 20: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 21: Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 22: Data Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 23: IT. Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

February 2002

ii

Pub. No. MN05001001E

Page 5

February 2002

Product Overview

Description

Cutler-Hammer Intelligent Technologies ( IT. ) QSNAP (QCPort Starter Network Adapter

Product) by Eaton Corporation is the result of a substantive engineering and marketing effort,

involving extensive customer input. This product has greatly increased functionality of the

Eaton’s Cutler-Hammer Intelligent Technologies ( IT. ) Electromechanical Starter with the

addition of enhanced features, such as jam, stall and underload. This single front-mount

device is a single QCPort™ (Quick Connect Port) device providing control and monitoring of

Intelligent Technologies ( IT. ) Electromechanical Starter application.

The QSNAP product line provides communication capability to the following Intelligent

Technologies ( IT. ) Electromechanical Starters.

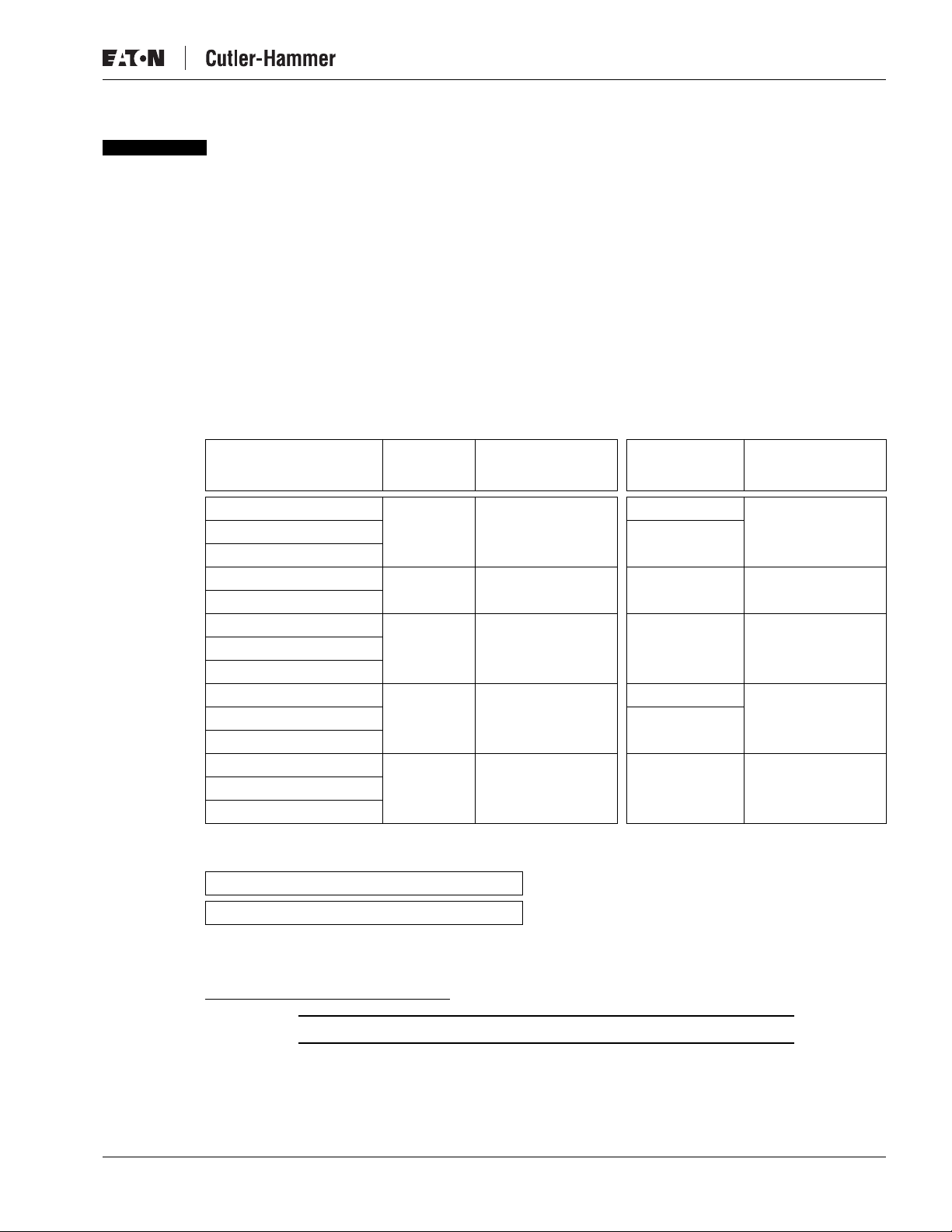

Table 1: QSNAP Electromechanical Starter Connectivity Table

Amperage

Rating

Intelligent Technologies ( IT. ) QSNAP

IEC

E101

E501

Frame

Size

NEMA

N101

N501

Frame

Size

18 Amp B 45 mm 00 45 mm

25 Amp 0

32 Amp

40 Amp C 54 mm 1 54 mm

50 Amp

65 Amp D 76 mm 2 76 mm

85 Amp

100 Amp

125 Amp E 105 mm 3 105 mm

160 Amp 4

200 Amp

250 Amp F 140 mm 5 140 mm

315 Amp

400 Amp

Table 2: QSNAP S751 Connectivity Table

S751

All

This manual specifically addresses the QCPort Starter Network Adapter Product (QSNAP).

Pub. No. MN05001001E

For further information on the IT. family of devices, visit our Web site at:

www.cutler-hammer.eaton.com/it

Notice

Because the IT. Starters use 24V DC for control and power, the

QSNAP can only be applied with the IT. family of starters.

1

Page 6

Intelligent Technologies ( IT. ) QSNAP

Features and Benefits

The IT. QSNAP includes the following significant features:

●

Communication to QCPort consuming a single QCPort ID

Control of non-reversing and reversing Eaton’s Cutler-Hammer Intelligent Technologies

●

( IT. ) Electromechanical Starters

Monitoring of non-reversing and reversing Eaton’s Cutler-Hammer Intelligent

●

Technologies ( IT. ) Electromechanical Starters

Direct mounting to the front of Eaton’s Cutler-Hammer Intelligent Technologies ( IT. )

●

Electromechanical Starter

●

Connection to an auxiliary ground fault detector

●

Sensing of the second contactor

Manually set Group ID; configuration using a software application is not required for

●

normal operation

February 2002

●

Enhanced features, such as jam and stall detection and nuisance trip avoidance

Warning levels that are user-settable

●

Settable current threshold alarm

●

2

Pub. No. MN05001001E

Page 7

February 2002

Safety

Intelligent Technologies ( IT. ) QSNAP

The following safety statements relate to the installation, setup and operation of Eaton’s

Cutler-Hammer IT. QSNAP and Starter.

Notice

Make sure you read and understand the installation procedures in

this manual before you attempt to operate or set up the equipment.

WARNING

This instruction manual should be used for proper installation,

setup and operation of the IT. QSNAP. Improperly installing and

maintaining this product can result in serious personal injury or

property damage. Before attempting installation, setup or

operation, read and understand this entire manual.

WARNING

Hazardous voltage can cause electric shock and burns. Always

disconnect power before proceeding with any work on this product.

CAUTION

Only apply 24V DC to the QSNAP power terminals. Use of any other

voltage may result in personal injury, property damage and

damage to the IT. QSNAP.

WARNING

To provide continued protection against fire or shock hazard, the

complete IT. QSNAP must be replaced if it becomes inoperative.

Pub. No. MN05001001E

3

Page 8

Intelligent Technologies ( IT. ) QSNAP

Environmental Ratings

The following environmental ratings apply to the QSNAP.

Table 3: Environmental Ratings

Category Description Specification

Transportation Temperature -50°C to 80°C [-58°F to 176°F]

Storage Temperature -50°C to 80°C [-58°F to 176°F]

Operating Temperature -30°C to 55°C [-22°F to 131°F]

Humidity 95% non-condensing

Humidity 95% non-condensing

Humidity 95% non-condensing

Altitude Above 2000 meters [6600 feet] consult factory

Shock 15 g’s half-wave sinusoidal 11 msecs

Vibration 5 – 57.5 Hz (100 – 17 msecs) @ 0.3 mm SA

57.5 – 150 Hz (17 – 6.7 msecs) @ 0.35 mm SA

Enclosure IP20

February 2002

Approvals/Certifications

The following approvals and certifications apply to the QSNAP.

Table 4: Approvals/Certifications

Standard Approval/Certification

UL UL508

CE

CSA CSAC22.2 No. 14-95

Catalog Numbering System

There is only one catalog number for QCPort connection to Eaton’s Cutler-Hammer Intelligent

Technologies ( IT. ) Electromechanical Starters. These starters include those listed in Table 1

on Page 1 .

The catalog number is QSNAP.

This part number includes the QSNAP and the starter interface board that connects the

starter and the QSNAP.

Note: When ordering QSNAP for Full Voltage Reversing, consult factory for the QSNAP

Auxiliary contact and jumper catalog numbers.

Note: When ordering a ground fault detector, consult factory for catalog number.

4

Pub. No. MN05001001E

Page 9

February 2002

Physical Features

Physical Description

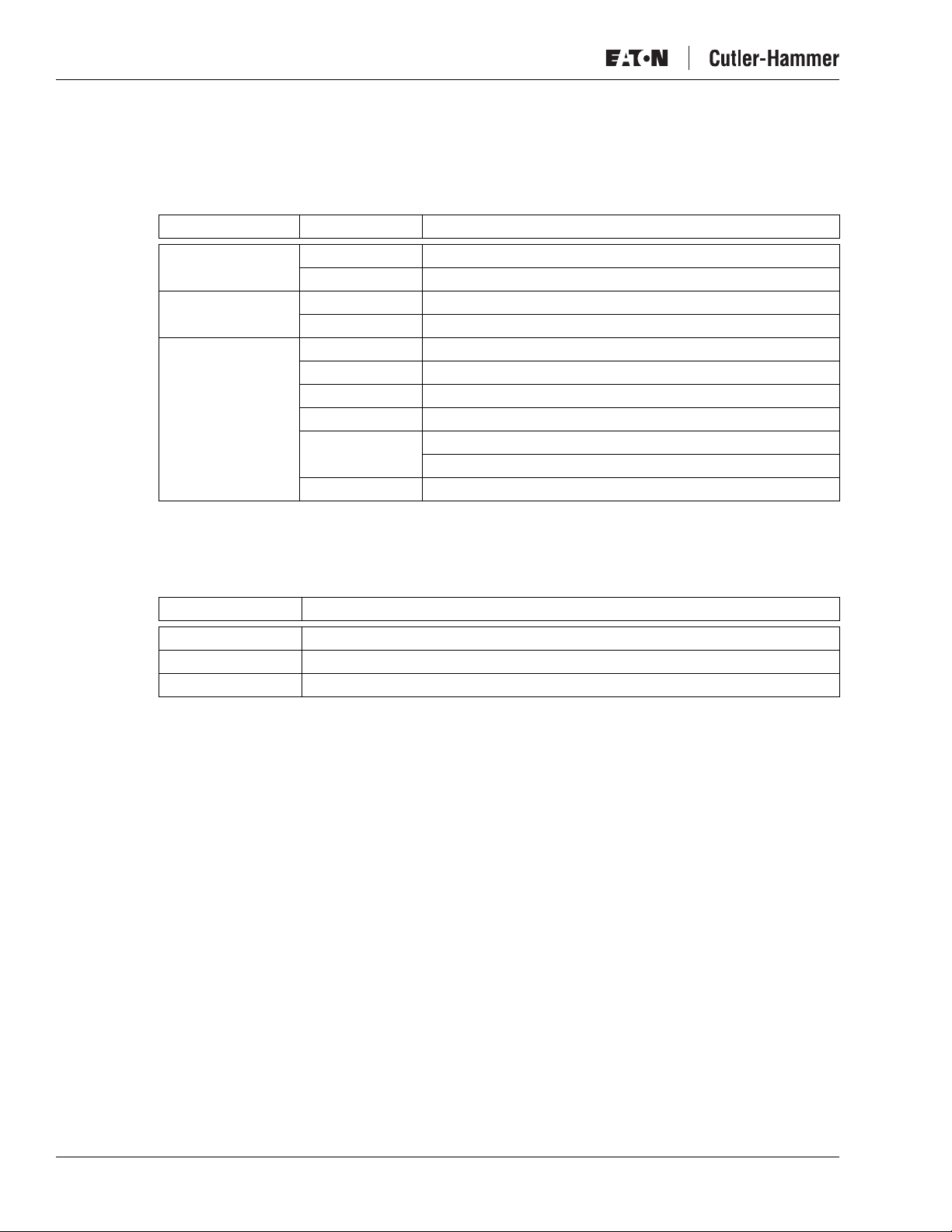

Figure 1 illustrates the front and back of the IT. QSNAP and its various features.

Group ID

Switch

Connector

Breakout

Feet

Contactor

Detector

Intelligent Technologies ( IT. ) QSNAP

Dimensions

Starter

Connector

Lock

Status

LED

Lock Tab

Figure 1: QSNAP Features

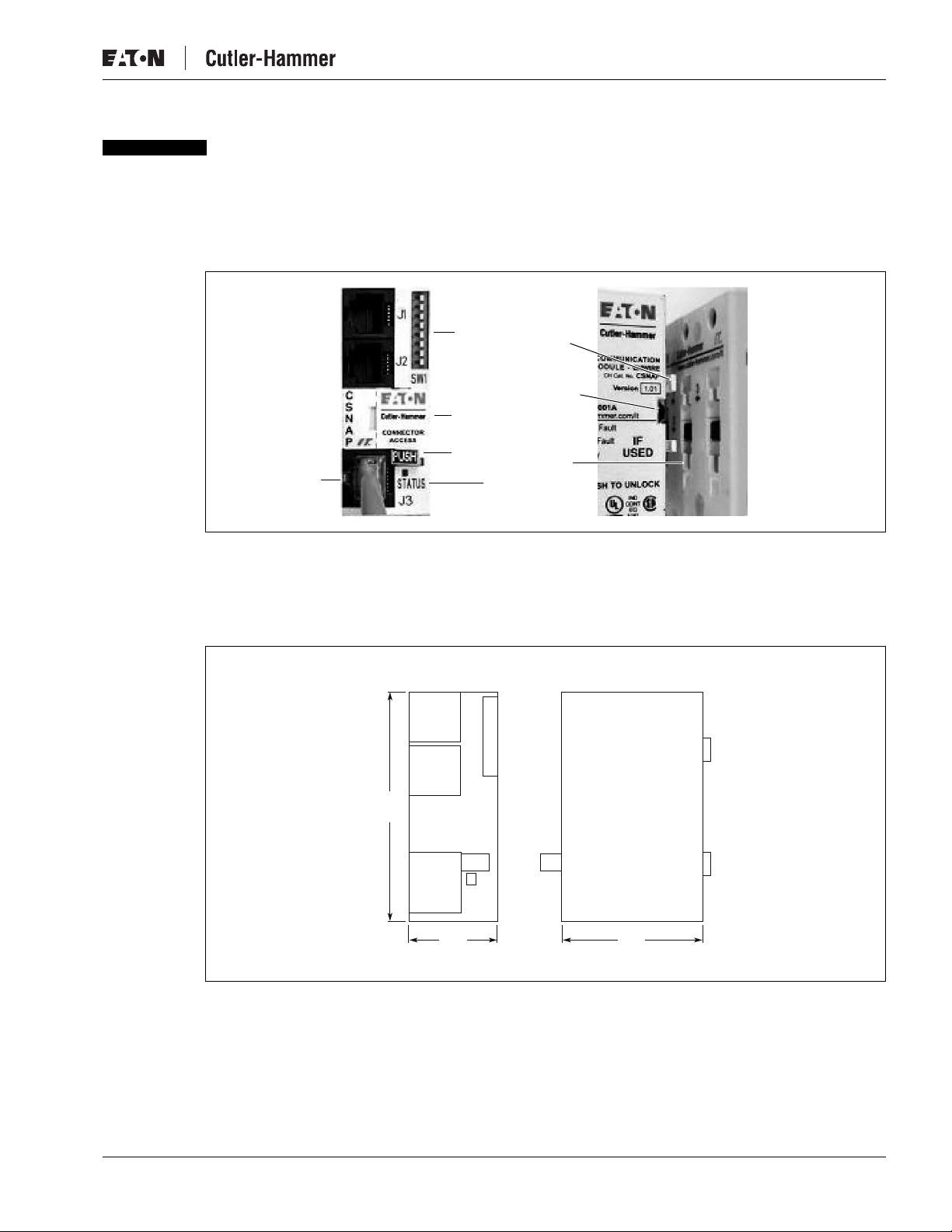

Figure 2 illustrates the dimensions of the IT. QSNAP.

Front

62

[2.4]

Side

Pub. No. MN05001001E

26

[1.0]

32

[1.3]

Figure 2: QSNAP Dimensions, mm [in]

5

Page 10

Intelligent Technologies ( IT. ) QSNAP

Power Source

The IT. QSNAP is designed for use with 24V DC power. The QSNAP uses power from two

sources when operating properly; these sources are the QCPort subnet and the Eaton’s

Cutler-Hammer Intelligent Technologies ( IT. ) Electromechanical Starter. This allows the

QSNAP to detect and communicate to the user that the IT. starter does not have 24V DC

power, signaling a fault or an E-Stop.

The main power that powers the communication is from QCPort, as illustrated in Table 5 .

Some power is required from the starter for communication to be present between the

Intelligent Technologies ( IT. ) Electromechanical Starter and the QSNAP.

The power for the IT. starter must be connected to the starter terminal.

Table 5: Power Requirements

Current Source Load

QCPort TBD

IT. Starter TBD

February 2002

When a power supply is chosen for QCPort, take into account the load on QCPort. When a

power supply is chosen for the starter(s), size it for the load of the starter(s) using the IT.

Contactor and Starter User Manual (Publication No. 49400). Refer to the IT. QCPort System

Install and Planning Guide (Publication No. MN05001002E) for more information on how to

size the power supply for the QCPort system.

The power for the Eaton’s Cutler-Hammer Intelligent Technologies (IT.) Electromechanical

Starter must be connected to the Intelligent Technologies (IT.) Electromechanical Starter

terminal, as illustrated in Figure 3.

To Starter

+ 24V DC

Optional

–

E-Stop

To QSNAP

Figure 3: Starter Interface Connection

6

Pub. No. MN05001001E

Page 11

February 2002

Intelligent Technologies (IT.) QSNAP

CAUTION

Only apply 24V DC to the QSNAP. Use of any other voltage may

result in personal injury, property damage and damage to the

QSNAP.

Pub. No. MN05001001E

7

Page 12

Intelligent Technologies (IT.) QSNAP

Operation

This section provides details about the following features and aspects of QSNAP operation:

● “Out of box” operation

● Typical application

● Enhanced features

● Input/output data

● Status LED

● Truth table

“Out of Box” Operation

When the QSNAP is properly installed and has a properly configured Group ID, as per the

“Installation” section, the following default data lists will be presented to the system for use

by a gateway.

For further information on the meaning of the terms in the assemblies, see the “Enhanced

Features” section on Page 10.

February 2002

Table 6: Default Input Data from QSNAP

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

3-Phase Average RMS Current LSB Byte 0

3-Phase Average RMS Current Byte 1

3-Phase Average RMS Current Byte 2

3-Phase Average RMS Current MSB Byte 3

% Thermal Capacity LSB Byte 4

% Thermal Capacity MSB Byte 5

Fault/Warning Codes LSB Byte 6

Fault/Warning Codes MSB Byte 7

Reserved Warning Faulted Local

Control

Resetting Permissive Running 2Running 1Byte 8

Table 7: Default Output Data to QSNAP

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Local

Control

Local/

Remote

Fault

Reset

Permissive Run 2 Run 1 Byte 8

8

Pub. No. MN05001001E

Page 13

February 2002

Typical Application

The following figure illustrates a typical QSNAP application, where a single QSNAP is

connected to one motor controller and where the motor controllers are distributed

throughout QCPort. The subnet is then being controlled by a PC or PLC, which scans the

D77D-DNA DeviceNet Adapter, retrieving the QSNAP’s control and monitoring information.

Intelligent Technologies (IT.) QSNAP

D77D-DNA D77A-IO D77A-IO

To Control

PC or PLC

IT. Starters with QSNAPs

24V DC IT.

Supply

QCPort

Figure 4: Typical QSNAP Application

Note: Such an application has more devices on QCPort than are shown in this illustration,

such as drives and user interface units.

Pub. No. MN05001001E

9

Page 14

Intelligent Technologies (IT.) QSNAP

Enhanced Features

The QSNAP offers a variety of enhanced features, including: settable warnings, current

threshold warning, underload warning and reset. To help diagnose an application, a fault

queue is provided to view the last five faults.

Refer to the following two tables for definitions of the QSNAP Enhanced Features and

Threshold Features.

Table 8: Standard Features

Fault Definition

February 2002

Phase Current

Unbalance/Phase Loss

Thermal Overload While the motor is running and depending on the FLA and trip class settings,

A phase current unbalance trip will occur if one or two of the line currents are

40 – 60% or less of the remaining line(s) for longer than 10 seconds.

A phase loss trip will occur with a load current of at least 75% of the minimum

FLA if one of the two input line voltages is lost, with the line current going to

zero for longer than 10 seconds.

when the FLA is exceeded for a period of time (depending on the trip class

setting), a thermal overload trip will occur. For more information on this

feature, see the IT. Contactor and Starter User Manual (Publication No. 49400).

Table 9: Enhanced Features

Fault Definition

Ground Fault With the addition of a Ground Fault module, the QSNAP will trip when the

Underload Warning While the motor is running, a warning will be activated when the current falls

Current Threshold

Warning

module detects a ground fault. To set the level of the trip, a setting is adjusted

on the Ground Fault Module. The Ground Fault Module is connected to the

QSNAP through the Auxiliary opening on the face of the QSNAP.

below a user settable % of FLA.

While the motor is running, a warning will be activated when the current rises

above a user settable % of FLA.

Note: The threshold values for Thermal Overload and Phase Current Unbalance can not be

modified.

10

Pub. No. MN05001001E

Page 15

February 2002

Input/Output Data

The QSNAP offers a standard data list (shown below) for default operation. The list is

configurable with data contained within Table 21 in Appendix A: QSNAP Parameters, using

the CH Studio application.

Input Data

Use Tables 10 and 11 when setting up the QSNAP input data.

Table 10: Input Assembly Data Definitions

Data Description

Faulted/Trip The motor controller is faulted or tripped

Warning The motor controller has a warning of an impending trip

Running 1 The first motor controller is running

Running 2 The second motor controller is running

Permissive The motor controller run/stop permissive

Resetting Motor controller is in the process of resetting a fault

Thermal Capacity % thermal capacity of the motor from 0 to 100%

RMS Average

Current

Fault Codes and

Warning Codes

Intelligent Technologies (IT.) QSNAP

Average RMS current of the motor (0.000A)

Valid fault and warning codes are:

0 No Fault

1 General Fault

2 Firmware Fault

3 Interdevice Communication Fault

4 Control Voltage Low Fault

5 Control Device Overtemperature Fault

6 Motor Phase Loss Fault

7 Motor Phase Imbalance Fault

8 Motor Ground Fault

9 Motor Underload Fault

10 Motor Overcurrent Fault

13 Motor Bypass Failure Fault

14 Motor Thermal Pile Fault

15 Control Device Test Fault

40000 Current Threshold Warning

40001 Underload Warning

40002 Control Device Overtemperature Warning

40003 Overload Warning

Pub. No. MN05001001E

11

Page 16

Intelligent Technologies (IT.) QSNAP

Table 11: Default Input Data

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Warning Faulted Local

Output Data

Use Tables 12 and 13 when setting up the QSNAP output data.

Table 12: Default Output Data

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

February 2002

3-Phase Average RMS Current LSB Byte 0

3-Phase Average RMS Current Byte 1

3-Phase Average RMS Current Byte 2

3-Phase Average RMS Current MSB Byte 3

% Thermal Capacity LSB Byte 4

% Thermal Capacity MSB Byte 5

Fault/Warning Codes LSB Byte 6

Fault/Warning Codes MSB Byte 7

Resetting Permissive Running 2 Running 1 Byte 8

Control

Reserved Reserved Local

Control

Local /

Remote

Fault

Reset

Permissive Run 2 Run 1 Byte 8

Table 13: Output Assembly Data Definitions

Data Description

Run 1 Energize the first starter when Permissive is 1

Run 2 Energize the second starter when Permissive is 1

Fault Reset Reset the fault

Permissive Starter Permissive, O – Stops the starter, I – Enables to run the starter

12

Pub. No. MN05001001E

Page 17

February 2002

Status LED

Intelligent Technologies (IT.) QSNAP

The status LED is located on the lower right of the QSNAP as pictured in Figure 1: QSNAP

Features. The LED’s status changes depending on the state of the QSNAP.

The following table lists the IT. QSNAP LED statuses and describes the meaning of each state.

Table 14: Status LED

State LED Behavior

No Power OFF

Power-Up Routine OFF – CRC corrupt

Waiting for a member ID,

power-up OK (mostly off)

Received a member ID,

off-line (slow blink)

On-line (mostly on)

Faulted (fast blink)

Identify device (burst)

Truth Table

Table 15: QSNAP Truth Table

Fieldbus Inputs

Old State

FAULTED ––1 RESET OFF FAULT = 0 READY = 1

OFF 0 0 – NONE OFF NONE

OFF 1 0 – RUN 1 RUNNING 1 RUNNING 1 = 0

OFF 0 1 – RUN 2 RUNNING 2 RUNNING 2 = 0

RUNNING 1 1 1 – RUN 2 RUNNING 1 NONE

RUNNING 2 1 1 – RUN 1 RUNNING 2 NONE

RUNNING 1 1 1 – RUN 1 removed RUNNING 2 RUNNING 1 = 0, RUNNING 2 = 1

RUNNING 2 1 1 – RUN 2 removed RUNNING 1 RUNNING 1 = 1, RUNNING 2 = 0

RUNNING 1 1 0 – FAULT OFF RUNNING 1 = 0 READY = 0

RUNNING 2 0 1 – FAULT OFF RUNNING 2 = 0 READY = 0

RUNNING 1 1 0 – WARNING RUNNING 1 RUNNING 1 = 1 WARNING = 1

RUNNING 2 0 1 – WARNING RUNNING 2 RUNNING 2 = 1 WARNING = 1

Event New State ActionRun 1 Run 2 Reset

– = state not important RUNNING 1 = Run/FWD/SLOW

1 = state true (energized) RUNNING 2 = REV/FAST

0 = state false (de-energized) FAULT = GND FLT and/or OL TRIP

WARNING = Running Current > FLA but not tripped

Pub. No. MN05001001E

13

Page 18

Intelligent Technologies (IT.) QSNAP

Configuration

The only configuration that is necessary for normal operation of the QSNAP is setting the

Group ID and SW1 positions A and B, as described in the “Installation” section. However, the

QSNAP offers a variety of enhanced features. When these features are required, use the CH

Studio application or a tool that can read an EDS file to perform the configuration.

Using CH Studio

The CH Studio software application is designed for programming and configuring industrial

automation systems. The application simplifies the monitoring and configuration of entire

networks as well as the enhanced features of individual IT. communicating devices within

those networks.

CH Studio takes advantage of the Windows graphical interface to present a suite of tools that

is easy to learn and efficient to use, while meeting the requirements for developing complex

network configurations.

CH Studio performs the following configuration functions for DeviceNet and QCPort

networks:

February 2002

● Discover network devices

● Display device properties

● Monitor and configure network devices

● Save existing network configurations

● Configure networks off-line

● Configure devices off-line

14

Pub. No. MN05001001E

Page 19

February 2002

Installation

Set the Group ID

The Group ID refers to the logical QCPort group to which the QSNAP belongs. For further

information on the explanation of Group ID and the system configuration, see the IT. QCPort

System Install and Planning Guide (Publication No. MN05001002E).

The Group ID and SW1 A and B DIP switches are located at the upper right of the QSNAP, as

illustrated in Figure 5: Group ID Setting. CH Studio can view the settings for the Group ID, but

cannot be used to modify them.

Move the DIP switches to ON/OFF positions to create the Group ID. Moving a DIP switch to

the right is ON and moving the switch to the left is OFF. The Group ID is in binary with the

major units numbered to the right of the switch on the side label. Adding up the major units

set to ON determines the Group ID of the QSNAP.

Example: To set the Group ID to 25, start from the top (or 32) and set the switches to OFF, ON,

Intelligent Technologies (IT.) QSNAP

ON, OFF, OFF, ON (16+8+1=25).

32

16

8

Group

ID

4

2

1

A

SWI

B

OFF (0)

Figure 5: Group ID Setting

When a gateway is present and presenting the QSNAP as remote IO, each device on the

QCPort must have a unique Group ID. If any two like QCPort devices have the same Group ID,

those devices will go off-line. Refer to the appropriate gateway install manual for information

on the data packet construction for that fieldbus (IT. DeviceNet Adapter Installation and User

Manual, Publication No. MN05004002E).

Once the Group ID is set, a power cycle is not required; after five seconds of inactivity of the

switches, the change takes effect. The Status LED indicates if the QSNAP is properly

configured; the LED is located on the lower right of the QSNAP, as illustrated in Figure 6:

QSNAP with 54 mm IT. Starter. For more information on the LED, see “Operation.”

Pub. No. MN05001001E

15

Page 20

Intelligent Technologies (IT.) QSNAP

SW1 Settings

SW1 is used to set the existence of the second Aux contact and the external ground fault.

Table 16: SW1 Settings

SW1 Position Event

A 0 = no second Aux installed, 1 = second Aux installed

B 0 = no ground fault installed, 1 = ground fault installed

Mount the IT. QSNAP to the Starter

The IT. QSNAP is designed to be installed in the auxiliary contact locations of the IT. family of

starters as illustrated in Figure 6. On all starters, one or more auxiliaries can be used along

with the QSNAP. Table 17 lists starters and indicates the number of available auxiliary

locations for each.

Table 17: Starter Size/Available Auxiliary Locations on Mounted QSNAP

Starter Frame Size (mm)

45 1 single

54 1 single or 1 dual

76 2 single or 2 dual

105 2 single or 2 dual

140 2 single or 2 dual

February 2002

Number of Available Auxiliary Locations

when Center Mounted

16

Figure 6: QSNAP with

54 mm IT. Starter

Pub. No. MN05001001E

Page 21

February 2002

Intelligent Technologies (IT.) QSNAP

Use the following steps and the illustration in Figure 7 to mount the QSNAP.

1. Align both the QSNAP feet with the auxiliary contact mounting slots on the starter, as

illustrated in the figure.

Recommendation: Use the middle mounting auxiliary contact on the contact block when

mounting the QSNAP.

2. When the QSNAP is aligned, insert the feet into the detents and slide the QSNAP

towards the overload until a “click” is heard. This ensures that the QSNAP is mounted

securely to the starter.

1. Align and

Insert

2. Slide

Figure 7: QSNAP Alignment and Mounting

Note: To remove the QSNAP, press the “PUSH” tab protruding from the QSNAP while sliding

the QSNAP up and pulling away from the contactor block, as illustrated in Figure 8.

1. Slide

2. Pull

Away

Figure 8: QSNAP Removal

Pub. No. MN05001001E

17

Page 22

Intelligent Technologies (IT.) QSNAP

Wire the IT. QSNAP to the Starter

The QSNAP is connected to the IT. starter using a factory-provided jumper with an RJ-45 plug

on one end and a pigtail on the other. The pigtail is color coded to facilitate accurate

connection to the overload terminal block. Refer to the following figure and table when

wiring the terminal block.

1

Table 18: Terminal Block Wiring

Starter RJ-45

February 2002

RJ-45 Plug

1

1

Figure 9: Jumper and RJ-45 Plug

GND 1

+24 2

P3

F4

R5

16

27

38

Use the following steps and illustrations to install the jumper.

1. Once the jumper is wired, insert the terminal block into the overload and the RJ-45

connector into J3 on the QSNAP as illustrated in Figure 10: Jumper Installation.

QSNAP

Jumper

18

IT. Starter Terminal Block

Figure 10: Jumper Installation

Pub. No. MN05001001E

Page 23

February 2002

2. To lock the starter interface to the overload, rotate the orange locking tabs until the tab

is locked into the slots in the overload. Use Figure 11 for information on which way to

rotate the locking tabs.

Note: Refer to the IT. Contactor and Starter User Manual (Publication No. 49400) for more

information on locking and unlocking the terminal block to the starter.

Connect the QSNAP to QCPort

The connection to QCPort consists of using the QCPort interconnect jumper from the second

port of the upstream device and connecting it to J1 on the QSNAP. The downstream QCPort

device then connects to J2 on the QSNAP as in Figure 11: QCPort Connection. Use the

following wiring diagram and illustration to connect the QSNAP to QCPort.

Intelligent Technologies (IT.) QSNAP

Figure 11: QCPort Connection

1

1

1 – +24

2 – G

3 – B

4 – A

5 – +24

6 – G

Figure 12: QCPort Wiring Diagram

Use one of the pre-manufactured cables for connecting between QCPort devices. If a custom

cable is to be made, follow the guidelines for cable specifications and connector types listed

in IT. QCPort System Install and Planning Guide (Publication No. MN05001002E).

Pub. No. MN05001001E

19

Page 24

Intelligent Technologies (IT.) QSNAP

Troubleshooting and Maintenance

Renewal Parts

The renewal parts for the QSNAP are shown in the following table.

Table 19: QSNAP Renewal Parts

Description Part Number

J3 Jumper Consult Factory

Starter Interface Consult Factory

Auxiliary Contact Consult Factory

Ground Fault Detector Consult Factory

Auxiliary Plug Consult Factory

Troubleshooting

Table 20: Troubleshooting

Observation Possible Cause/Corrective Action

February 2002

IT. starter attempts to

energize when RUN is

commanded but will not

stay in

IT. starter will not energize Control terminal block is not seated or connected properly on overload or

Reversing starter will not

energize

Reversing starter will not

energize but forward does

IT. starter automatically

energizes on power-up

Check 24V DC coil power supply.

customer wiring.

Check 24V DC control power supply.

Verify that the permissive bit is = 1.

Check J3 wiring.

Make sure there is not a trip.

Unit already running in forward. The units are electrically and

mechanically interlocked.

Check J3 wiring.

Check J3 wiring.

Reversing interlock is jammed.

Check J3 wiring.

20

Pub. No. MN05001001E

Page 25

Intelligent Technologies (IT.) QSNAP

February 2002

Appendix A: QSNAP Parameters

Refer to the following table when configuring the QSNAP.

Table 21: Configuration Parameters

Number Parameter Length Units

1 Config Data 14

2 Configuration CRC check 2

3 Node ID 2

4 QCPort mode 1

5 Baud Rate 1

6 Slave Address 1

7 Production Dest 2

8 Device ID Tag 16

9 Prod Int 2

10 Cons Int 2

11 Parameter List 0

12 Production List 0

13 Consumption List 0

32 Overload Trip FLA Value 4 Amps

33 Overload Trip Class Value 1 Class

34 Percent Initial Torque 1 %

37 Motor Start Ramp Time 2 mS

38 Motor Stop Ramp Time 2 mS

43 Current Threshold Warning Threshold 1 En/Dis

44 Current Threshold Warning Threshold 1 %

46 Current Threshold Warning Debounce 2 mS

51 Motor Underload Warning Level 1 En/Dis

52 Motor Underload Warning Level 1 %

54 Motor Underload Warning Debounce 2 mS

55 Motor Ground Fault Enable 1 En/Dis

56 Motor Ground Fault Debounce Time 2 mS

57 Motor Ground Fault Inhibit From Start Delay Enable 1 En/Dis

58 Motor Ground Fault Inhibit From Start Delay 1 S

Pub. No. MN05001001E

21

Page 26

Intelligent Technologies (IT.) QSNAP

Table 22: Data Parameters

Number Parameter Units Length

11 Motor Control 1

12 Motor Control Status 1

13 Motor Control Faults 2

14 Button State 1

15 LED State 1

16 ASCII Text 1

18 RMS AC Current Amps 4

22 Control DC Voltage Amps 2

23 Thermal Pile Percentage Volts 2

24 Temperature Deg C % 2

26 Fault Quene Hz 2

February 2002

22

Pub. No. MN05001001E

Page 27

Intelligent Technologies (IT.) QSNAP

February 2002

Intelligent Technologies (IT.) Publications and Support

Table 23: IT. Publications

Publication Description

MN05002001E IT. D77A- IO Module Products Installation and Users Manual

MN05001002E IT. QCPort System Install and Planning Guide

MN05001001E IT. QCPort Starter Network Adapter Product (QSNAP) Installation

Pub 4960 IT. Overload Relay Setup and Troubleshooting Guide

Pub 49601 IT. Overload Relay Quick Setup Guide

MN05004001E IT. DeviceNet Starter Network Adapter Product (DSNAP) Installation

MN05004002E IT. DeviceNet Adapter Installation and User Manual

Pub 49907 Intelligent Technologies S751 Soft Starter User Manual

For copies of these and other publications contact the Literature Fulfillment Center at

1-800-957-7050.

and Users Manual

and Users Manual

Pub. No. MN05001001E

23

Page 28

Intelligent Technologies (IT.) QSNAP

February 2002

24

Pub. No. MN05001001E

Page 29

Page 30

Eaton’s Cutler-Hammer Aftermarket Services

• Technical/telephone support

• Resident service engineers in major trading centers

• Factory repair services

• Warranty administration

• Equipment modification and upgrading services

• Training seminars

For additional information on this

product, please call our Customer

Support Center at:

1-800-356-1243

For service or start-up assistance

24 hours/day, 7 days/week,

please call:

1-800-498-2678

A response network that gives new meaning to customer service

• Personalized

• Comprehensive

• Professional

Eaton Corporation

Cutler-Hammer business unit

1000 Cherrington Parkway

Moon Township, PA 15108-4312

USA

tel: 1-800-525-2000

www.cutler-hammer.eaton.com

© 2002 Eaton Corporation

All Rights Reserved

Publication No. MN05001001E

February 2002

Printed in USA

Loading...

Loading...