Doosan DCT5JS Operation & Maintenance Manual

DCT5JS MODEL

OPERATION & MAINTENANCE MANUAL

Tool serial number

This manual contains

important safety information

and must be made available to

personnel who operate and

maintain this machine.

CPN: 85041903_en

DATE: AUGUST 2013

PORTABLE POWER PRODUCT WARRANTY

EN

WARRANTY TOOLS

DOOSAN BENELUX SA warrants to its authorized dealers, who

in turn warrant to the end-user/owner that each new tools will be

free from proven defects in material and workmanship for twelve

(12) months from the date of delivery to the end-user/owner.

Service schedules must be adhered to, documented and genuine

parts/lubricants must be used where applicable. The warranty

does not cover oils and lubricants and latch front head assembly,

springs, seals, dampeners.

During the warranty period, the authorized Doosan Infracore

dealer shall repair or replace, at DOOSAN BENELUX SA option,

without charge for parts and labor of mechanics, any part of the

product which fails because of defects in material or

workmanship. The end user/owner shall provide the authorized

Doosan Infracore dealer with prompt written notice of the defect

and allow reasonable time for replacement or repair. DOOSAN

BENELUX SA may, at its option, request failed parts to be

returned to the factory. Transportation of the product to the

authorized Doosan Infracore dealer for warranty work is the

responsibility of the end user/ owner.

The warranty does not apply to trade accessories not

manufactured by DOOSAN BENELUX SA. The owner shall rely

solely on the warranty, if any, of the respective manufacturers

thereof. The warranty does not cover replacement of scheduled

service items such as oil, filters, tune-up parts, and other high

wear items. The warranty does not cover damages resulting from

abuse, accidents, alterations, air flow obstructions, or failure to

maintain or use the product according to the instructions

applicable to it.

DOOSAN BENELUX SA EXCLUDES OTHER CONDITIONS,

WARRANTIES OR REPRESENTATIONS OF ALL KINDS,

EXPRESSED OR IMPLIED, STATUTORY OR OTHERWISE

(EXCEPT THAT OF TITLE) INCLUDING ALL IMPLIED

WARRANTIES AND CONDITIONS RELATING TO

MERCHANTABILITY, SATISFACTORY QUALITY AND FITNESS

FOR A PARTICULAR PURPOSE.

THE REMEDIES OF THE END-USER/OWNER SET FORTH

UNDER THE PROVISIONS OF THE WARRANTY OUTLINED

ABOVE ARE EXCLUSIVE AND THE TOTAL LIABILITY OF

DOOSAN BENELUX SA INCLUDING ANY HOLDING,

SUBSIDIARY, ASSOCIATED OR AFFILIATED COMPANY OR

DISTRIBUTOR WITH RESPECT TO THIS SALE OR THE

PRODUCT AND SERVICE FURNISHED HEREUNDER IN

CONNECTION WITH THE PERFORMANCE OR BREACH

THEREOF, OR FROM DELIVERY, INSTALLATION, REPAIR OR

TECHNICAL DIRECTION COVERED BY OR FURNISHED

UNDER THIS SALE, WHETHER BASED ON CONTRACT,

WARRANTY, TORT, NEGLIGENCE, INDEMNITY, STRICT

LIABILITY OR OTHERWISE SHALL NOT EXCEED THE

PURCHASE PRICE OF THE PRODUCT UPON WHICH SUCH

LIABILITY IS BASED.

DOOSAN BENELUX SA INCLUDING ANY HOLDING,

SUBSIDIARY, ASSOCIATED OR AFFILIATED COMPANY AND

DISTRIBUTOR SHALL IN NO EVENT BE LIABLE TO THE END

USER/OWNER, ANY SUCCESSORS IN INTEREST OR ANY

BENEFICIARY OR ASSIGNEE RELATING TO THIS SALE FOR

ANY CONSEQUENTIAL, INCIDENTAL, INDIRECT, SPECIAL OR

PUNITIVE DAMAGES ARISING OUT OF THIS SALE OR BY

ANY BREACH THEREOF, OR ANY DEFECT IN, OR FAILURE

OF, OR MALFUNCTION OF THE PRODUCT UNDER THIS

SALE, WHETHER BASED UPON LOSS OF USE, LOST

PROFITS OR REVENUE, INTEREST, LOST GOODWILL, WORK

STOPPAGE, IMPAIRMENT OF OTHER GOODS, LOSS BY

REASON OF SHUTDOWN OR NON-OPERATION, INCREASED

EXPENSES OF OPERATION OR CLAIMS OF USER OR

CUSTOMERS OF THE USER FOR SERVICE INTERRUPTION

WHETHER OR NOT SUCH LOSS OR DAMAGE IS BASED ON

CONTRACT, WARRANTY, TORT, NEGLIGENCE, INDEMNITY,

STRICT LIABILITY OR OTHERWISE

CORRECTIONS BY DOOSAN BENELUX SA OF

NONCONFORMITIES WHETHER PATENT OR LATENT, IN THE

MANNER AND FOR THE TIME PERIOD PROVIDED ABOVE,

SHALL CONSTITUTE FULFILMENT OF ALL LIABILITIES OF

DOOSAN TRADING LTD FOR SUCH NONCONFORMITIES,

WHETHER BASED ON CONTRACT, WARRANTY, TORT,

NEGLIGENCE, INDEMNITY, STRICT LIABILITY OR

OTHERWISE WITH RESPECT TO OR ARISING OUT OF SUCH

PRODUCT.

2

Machine models represented in this manual may be used in various locations world-wide. Machines sold

and shipped into European common market countries requires that the machine display the EC Mark and

conform to various directives. In such cases, the design specification of this machine has been certified as

complying with EC directives. Any modification to any part is absolutely prohibited and would result in the

CE certification and marking being rendered invalid. A declaration of that conformity follows:

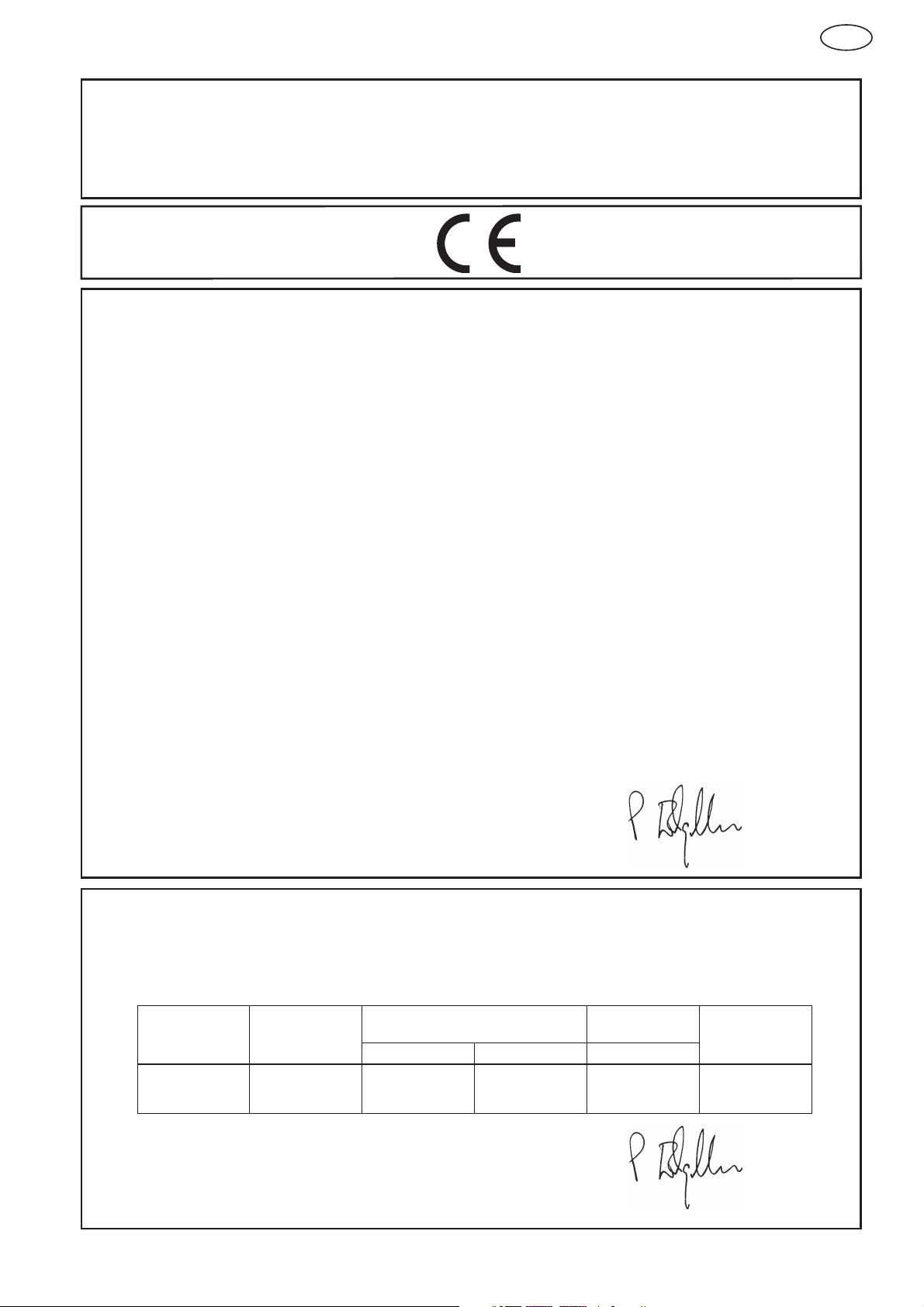

DECLARATION OF CONFORMITY WITH EC DIRECTIVES

We

Doosan Benelux SA

Drève Richelle 167

B-1410 Waterloo

Belgium

Declare that under our sole responsibility for manufacture and supply, the product(s)

To which this declaration relates, is (are) in conformity with the provisions of the above directives using the

following principal standards

EN ISO 12100-1, EN ISO 12100-2, EN ISO 5349-2, ISO 8662-3, EN 792

Issued at Waterloo in 1-2010

CONFORMITY TO NOISE DIRECTIVE

2000/14/EC

Doosan Benelux SA declare that the following Hammer Drill has been

manufactured in conformity with the directive as shown.

P. Edgeller

Technical Manager

P. Edgeller

Technical Manager

Directive Model

Sound Level dB (A)

Pressure Power

Vibrations Level

m/s

2

2000/14/EC

Annex VI Part 1

DCT5JS 109.795.7 9.3

TÜV SÜD

Czech

Nr. 1017

Issued at Waterloo,

5th Declaration 01/2010

Hammer Drill Type DCT5JS

2006/42/CE - 2000/14/CE

EN

3

SAFETY

EN

DANGER

WARNING

CAUTION

NOTICE

NOTICE

DANGER

NOTICE

Look for these signs on machines shipped to markets in North America, which point out potential hazards to the safety of you

and others. Read and understand thoroughly. Heed warnings and follow instructions. If you do not understand, Inform your

supervisor.

Red Background

Indicates the presence of a hazard which WILL cause serious

injury, death or property damage, if ignored.

Orange Background

Indicate the presence of a hazard which CAN cause serious

injury, death or property damage. if ignored.

Yellow Background

Indicates the presence of a hazard which WILL or can cause

injury or property damage. if ignored.

Blue Background

Indicates important set-up, operating or maintenance information.

DCT5JS Hammer Drills are designed for drilling concrete and other demolition work in construction applications.

Doosan Benelux SA is not responsible for customer modifications of tools for applications on which Doosan Benelux SA was not

consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION IN THIS

MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

• Always operate. inspect and maintain this tool in accordance

with all regulations (local, state, federal and country), that may

apply to hand held / hand operated pneumatic tools.

• For safety, top performance, and maximum durability of parts,

operate this tool at 90 psig (6.2 bar / 620 kPa) maximum air

pressure at the inlet with 1/2" (13 mm) inside diameter air

supply hose.

• Always turn off the air supply and disconnect the air supply

hose before installing, removing or adjusting any accessory on

this tool, or before performing any maintenance on this tool.

• Do not use damaged. frayed or deteriorated air hoses and

fittings.

• Be sure all hoses and fittings are the correct size and are

tightly secured.

• Always use clean, dry lubricated air at 90 psig

(6.2 bar / 620 kPa) maximum air pressure. Dust, corrosive

fumes and/or excessive moisture can ruin the motor of an air

tool.

• Do not lubricate tools with flammable or volatile liquids such as

kerosene, diesel or jet fuel.

• Do not remove any labels. Replace any damaged labels.

USING THE TOOL

• Always wear eye protection when operating or performing

maintenance on this tool.

• Always wear hearing protection when operating this tool.

• Keep hands, loose clothing and long hair away from rotating

end of tool.

• Anticipate and be alert for sudden changes in motion during

start up and operation of any power tool.

• Keep body stance balanced and firm. Do not overreach when

operating this tool.

• Tool accessories may continue to impact briefly after throttle is

released.

• Air powered tools can vibrate in use. Vibration, repetitive

motions or uncomfortable positions may be harmful to your

hands and arms. Stop using any tool if discomfort, tingling

feeling or pain occurs. Seek medical advice before resuming

use.

• Use accessories recommended by Doosan Benelux SA.

• This tool is not designed for working in explosive atmospheres.

• This tool is not insulated against electric shock.

The use of other than genuine Doosan Benelux SA replacement parts may result in safety hazards, decreased tool performance,

and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorised trained personnel. Consult your nearest Doosan Benelux SA Authorised Service

Centre.

4

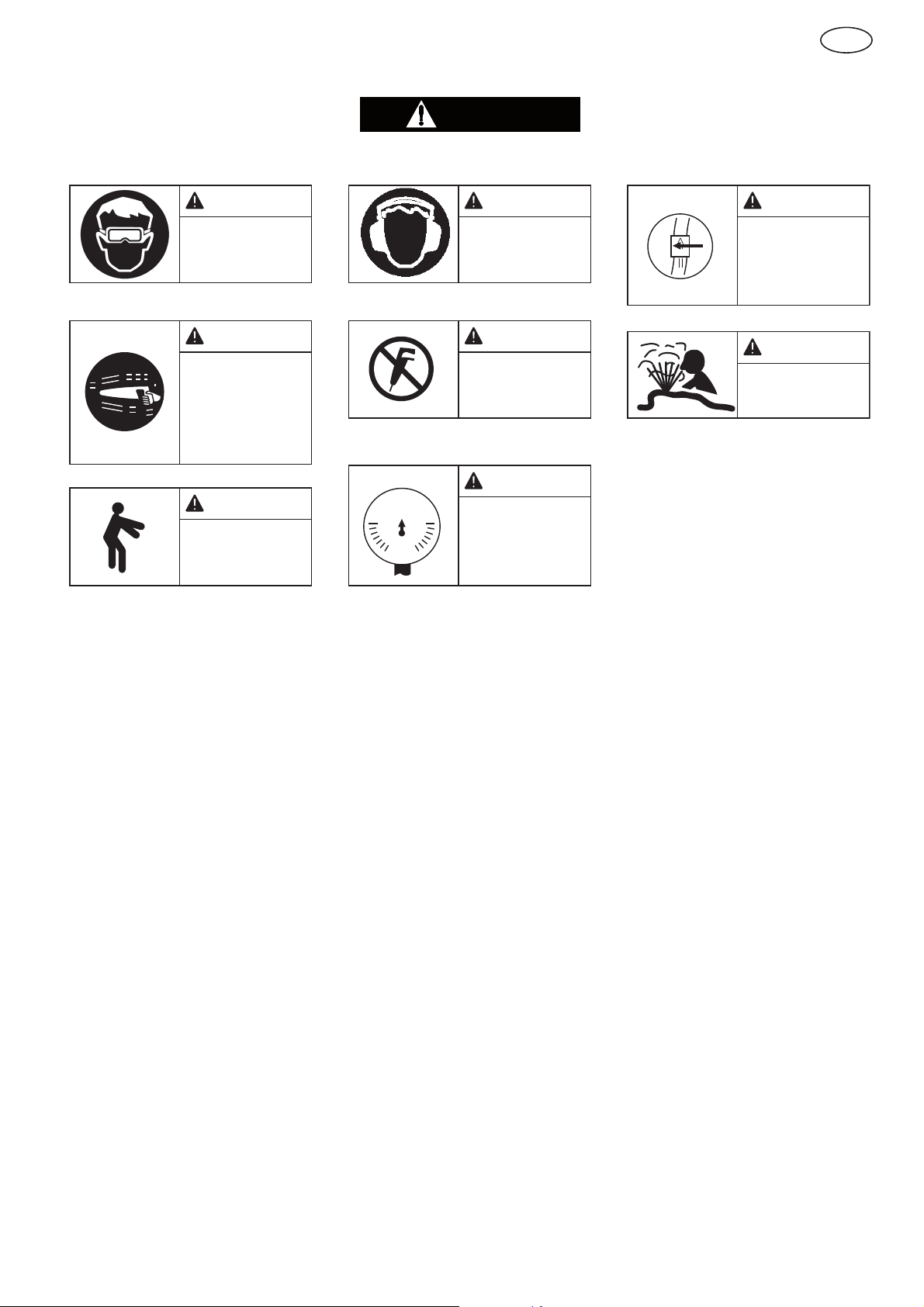

SAFETY

EN

WARNING

Always wear eye protection

when operating or performing

maintenance on this tool.

WARNING

WARNING

Always wear hearing

protection when operating

this tool.

WARNING

WARNING

WARNING

WARNING

WARNING

Always turn off the air supply

and disconnect the air supply

hose before installing,

removing or adjusting any

accessory on this tool, or

before performing any

maintenance on this tool.

OFF

ON

Air powered tools can vibrate

in use. Vibration, repetative

motions or uncomfortable

positions may be harmful to

your hands and arms. Stop

using any tool if discomfort,

tingling feeling or pain occurs.

Seek medical advice before

resuming use.

WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

WARNING

WARNING

WARNING

Do not carry the tool by the

hose.

WARNING

WARNING

Do not use damaged, frayed

or deteriorated air hoses and

fittings.

WARNING

WARNING

Operate at 90 psig

(6.2 bar / 620 kPa)

Maximum air pressure.

90 psig

(6.2 bar / 620 kPa)

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

SPECIFIC WARNINGS

• When wearing gloves and operating models with inside trigger,

always be sure that the gloves will not prevent the trigger from

being released.

• Wear safety shoes, hard hat, safety goggles, gloves, dust

mask and any other appropriate protective clothing while

operating the tool.

• Do not indulge in horseplay. Distraction can cause accidents.

• Keep hands and fingers away from the throttle lever until it is

time to operate the tool.

• Never rest the tool or chisel on your foot.

• Never point the tool at anyone.

• Compressed air is dangerous. Never point an air hose at

yourself or co-workers.

• Never blow clothes free of dust with compressed air.

• Be sure all hose connections are tight. A loose hose not only

leaks but can come completely off the tool and while whipping

under pressure, can injure the operator and others in the area.

Attach safety cables to all hoses to prevent injury in case a

hose is accidentally broken.

• Never disconnect a pressurised air hose. Always turn off the

air supply and bleed the tool before disconnecting a hose.

• The operator must keep limbs and body clear of the chisel. If a

chisel breaks, the tool with the broken chisel projecting from

the tool will suddenly surge forward.

• Do not ride the tool with one leg over the handle. Injury can

result if the chisel breaks while riding the tool.

• Know what is underneath the material being worked. Be alert

for hidden water, gas, sewer, telephone or electric lines.

• Use only proper cleaning solvents to clean parts. Use only

cleaning solvents which meet current safety and health

standards. Use cleaning solvents in a well ventilated area.

• Do not flush the tool or clean any parts with diesel fuel. Diesel

fuel residue will ignite in the tool when the tool is operated.,

causing damage to internal parts. When using models with

outside triggers or throttle levers, take care when setting the

tool down to prevent accidental operation.

• Do not operate the tool with broken or damaged parts.

• Never start the tool when it is lying on the ground.

• This tool is not designed for working in explosive atmospheres.

• This tool is not insulated against electric shock.

5

Loading...

Loading...