Page 1

NC Boring Maintenance

(DBC 130/

)

Manual (Alarm)

F30i Series

Machine Tools

Page 2

Page 3

DBC 130(F30i Series) DBC130ALE2A

Table of Contents

1. Emergency Alarm

1.1 2001 Emg. Button or Axes Emergency

1.2 2002 Spindle Alarm is Detected

........................................................................................... 4

.................................................................................... 4

.............................................................................................. 6

1.3 2003 Power Circuit Overcurrent Detected

1.4 2004 Hyd. Pump Motor Overload

1.5 2005 Hyd. Pressure Down Alarm

............................................................................................ 9

.......................................................................................... 12

1.6 2006 Spindle Gear Shift Check Switch Alarm

1.7 2008 PSM Contact Check Error

2. Cycle Alarm

................................................................................................. 21

2.1 2031 Return to Ref. Point in Manual

............................................................................................ 19

..................................................................................... 21

2.2 2032 Feed Ho l d Pu s h B utt o n i s Pr e ss e d

2.3 2033 Air Pressure down Alarm

2.4 2034 Coolant & Lub. Pump Overload

2.5 2035 Addition Coolant Unit Alarm

.............................................................................................. 26

.................................................................................... 28

.......................................................................................... 30

2.6 2037 Power Back Up Module Power Failure

2.7 2049 Spindle Speed Arrival Signal Error

............................................................................... 34

............................................................................... 7

....................................................................... 14

............................................................................... 24

......................................................................... 32

2.8 2051 Spind le Or ie nt at i on Ov e rti me

2.9 2052 Spindle Maximum rpm Setting Error

2.10 2054 Illegal Condition in Spindle Rotation

2.11 2056 Gear Shift Overtime Alarm

....................................................................................... 40

............................................................................. 44

........................................................................... 45

.......................................................................................... 47

2.12 2057 Spindle Tool Clamp/Unclamp Change Alarm

2.13 2058 Tool No. Select Keep Relay Not Set

2.14 2059 T-Code Command Initial Condition

2.16 2061 T-Code Over Command Error

2.17 2062 M06 Command Overtime Alarm

2.18 2080 Spindle Head Oil Overflow Alarm

2.19 2081 Y-Axis Clamp/Unclamp Alarm

2.20 2082 Spindle Stop in Cutting Alarm

2.21 2083 ATC Guide Rail Locate Sensor Error

2.22 2085 W-Axis Clamp/Unclamp Alarm

2.23 2133 Guide Rail Locating State Alarm

2.24 2139 Spindle Run Signal Alarm

........................................................................................... 86

........................................................................... 53

............................................................................. 57

.................................................................................... 65

................................................................................. 66

............................................................................... 74

..................................................................................... 76

..................................................................................... 78

.......................................................................... 79

................................................................................... 81

................................................................................. 83

............................................................. 51

3. Single Block Alarm

....................................................................................... 87

3.1 2160 Lubrication Oil Level Low X

.......................................................................................... 87

1

Page 4

DBC 130(F30i Series)

DBC130ALE2A

3.2 2161 Lubrication Oil Pressure Down ..................................................................................... 89

3.3 2162 Parts Count End Alarm ................................................................................................. 91

3.4 2164 Oil Cooling Unit Alarm .................................................................................................. 92

3.5 2165 Oil Cooling Flow Alarm ............................................................................................... 102

3.6 2166 Filter Changer of TSC. Alarm ..................................................................................... 104

3.7 2168 Coolant Pressure Down Alarm ................................................................................... 105

3.8 2170 Tool Life Count End Alarm .......................................................................................... 106

3.9 2171 RST Comman d Alarm On STL ................................................................................... 107

3.10 2183 Table Lubrication Oil Flow Alarm .............................................................................. 108

3.11 2185 Lubrication Oil Level Low Y, Z ................................................................................... 110

3.12 2186 Lubrication Oil Pressure Down .................................................................................. 111

4. Massage Alarm

........................................................................................... 113

4.1 2193 Safety Sw itc h Un l o c ke d ............................................................................................... 113

4.2 2195 OP- Door Close, Must Be D-Open .............................................................................. 115

4.3 2196 Coil Conveyor Overload Alarm .................................................................................... 117

4.4 2197 Chip Conveyor Alarm ................................................................................................... 119

4.5 2198 Auto Power Off Ready ................................................................................................ 121

4.6 2200 Warming Up Not Complete ......................................................................................... 123

4.7 2202 Machine Lock ............................................................................................................. 125

4.9 2205 Measurement Device Battery Low ............................................................................. 130

4.10 2206 Measurement Device Alarm ..................................................................................... 131

4.11 2207 Machine Interference Zone Error .............................................................................. 132

4.12 2208 Machine In Service Mode ......................................................................................... 137

4.13 2215 Tool Length Sensor Up/Down Alarm ........................................................................ 138

4.14 2216 Must Be Return to Ref. Poi n t X ................................................................................ 140

4.15 2217 Must Be Return to Ref. Point Y ................................................................................ 141

4.16 2218 Must Be Return to Ref. Point Z ................................................................................ 142

4.17 2219 Must Be Return to Ref. Point W ............................................................................... 143

4.18 2220 Must Be Re tu r n to Ref . Poi n t B ................................................................................ 144

4.19 2221 Must Be Return to Ref. Point 6 ................................................................................. 145

4.20 2223 Table (B-Axis) Locate/Unlocate ................................................................................ 146

4.21 2228 Operator Door Open Alarm....................................................................................... 150

4.22 2234 Spindle Gear Detection Switch ................................................................................. 152

4.23 2241 Wait. Pot or Spindle Tool data Zero .......................................................................... 156

4.24 2250 Manual Mode Selected On ATC Panel ..................................................................... 158

4.25 2254 ATC Carriage Overtime Alarm .................................................................................. 160

4.26 2255 Changer Arm In/Out Alarm ....................................................................................... 175

2

Page 5

DBC 130(F30i Series) DBC130ALE2A

4.27 2260 ATC Magazine Rotation Overtime ............................................................................ 177

4.28 2261 ATC Magazine Door Unlocking ................................................................................ 179

4.29 2262 ATC Magazine Guard Door Open ............................................................................ 181

4.30 2263 ATC Magazine Servo Unit Alarm .............................................................................. 183

4.31 2264 Tool Magazine Battery Alarm .................................................................................... 184

4.32 2265 Tool Magazine Servo Unit Off Signal Error ............................................................... 186

4.33 2266 Servo Tool Magazine Number Mismatched .............................................................. 188

4.34 2269 Tool Magazine Pot Detection Check Alarm .............................................................. 190

4.35 2270 Tool Pull Out Switch Alarm ....................................................................................... 192

4.36 2282 Carriage Servo Unit Alarm ........................................................................................ 194

4.37 2283 Carriage Battery Alarm ............................................................................................. 195

4.38 2284 Carriage Servo Unit Off Signal Error ........................................................................ 197

4.39 2323 B-Axis (Table) Clamp/Unclamp Alarm ...................................................................... 200

4.40 2341 ATC APC Interlock Alarm .......................................................................................... 203

4.41 2389 Angular Mismatch Alarm (M121 Must Be Released)................................................ 208

4.42 2392 Facing Head Interlock ............................................................................................... 210

3

Page 6

DBC 130(F30i Series)

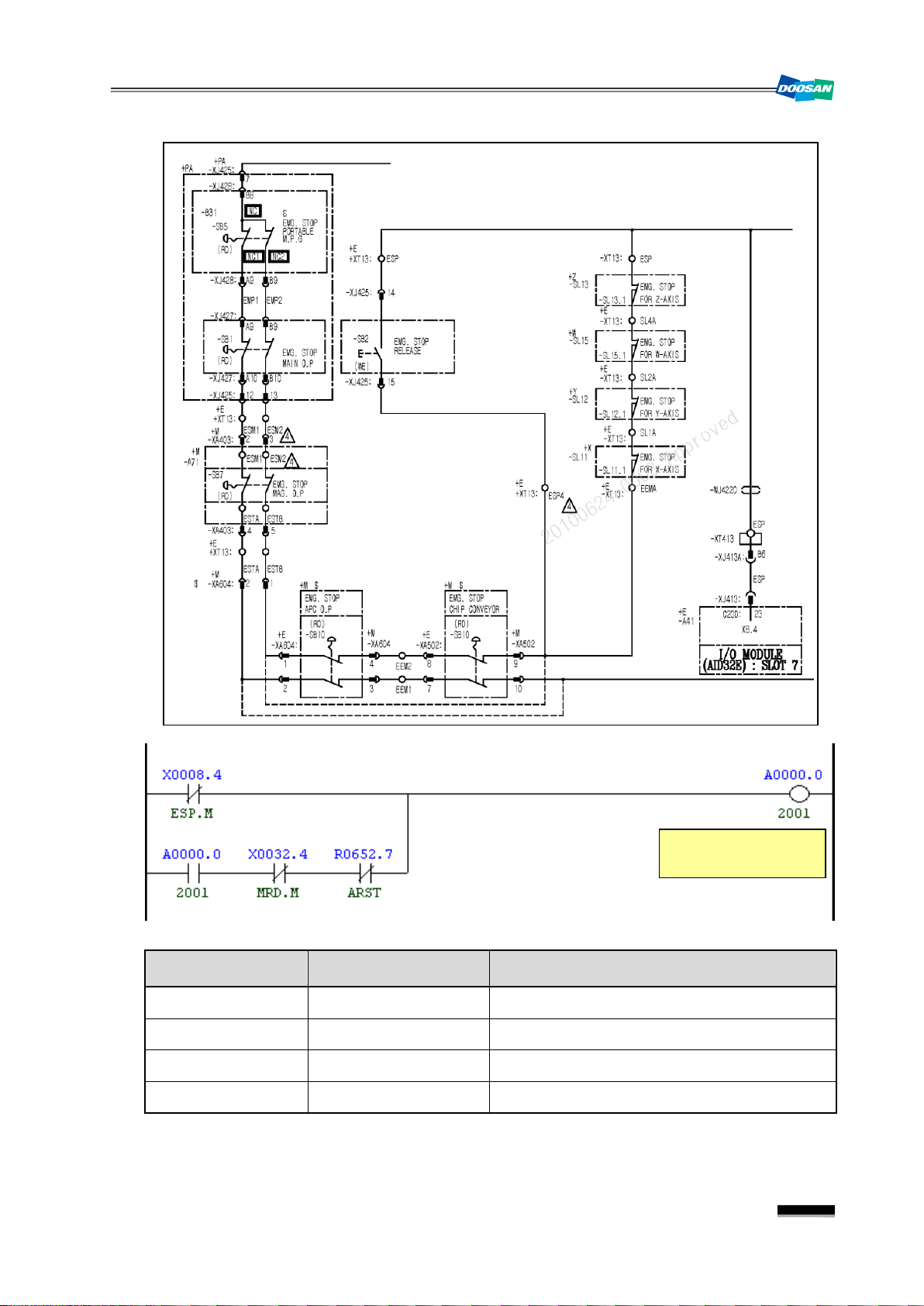

button switch on any of the main OP, the tool magazine OP, or

switch on the axis, and other related parts for any problem. Repair or replace the defective

find an error, repair or replace the defective part.

Symbol

(Pin)

ESP.M

1. Emergency Alarm

1.1

2001

1) Description

The Emergency Stop push-button switch on the operation panel is pressed down, or at least

one Emergency Stop limit switch for the axes is tripped.

2) Cause of problem

① The Emergency Stop push-

② The Limit switch for an emergency stop located for each axis (X, Y, Z, W) is pressed

③ An error in the Emergency Stop switch on the OP, or the Emergency Stop limit switch for

④ Disconnection of the wiring

Emg. Button or Axes Eme rgency

the chip conveyor is pressed down.

down.

each axis, or other related parts

DBC130ALE2A

3) Action

① Check if the red mushroom push-button switch on the main OP, the tool magazine OP, or

the chip conveyor is pressed down, and if so, turn the switch counter clockwise to release

it.

② If the Limit switch for any axis (X, Y, Z, or W) is tripped, press both the Machine Ready

switch and the Emergency Release switch simultaneously to enter the Machine Ready

state. (If you want to return to the emergency stop state, simply release the switch.)

Then, move the problem-making axis in jog or handle mode so as to remove it from the

emergency stop limit switch.

③ Check the Emergency Stop push-button switch on the main OP, the Emergency Stop limit

part if necessary.

④ Disconnection of the wiring

Refer to the circuit diagram and use the electric tester to check each terminal block. If you

Part Name Part No. Symbol Spec. Maker

Switch, Emergency P/B ESWPB0439 SB1,7,9,61

Switch, Limit ESWLM0111 SL11.1,12.1,13.1,15.1

Signal Address

Emergency Stop

4

X8.4

Device

-SB1,7,9,10 I/O Module Slot 7 XJ413 (23) ESP

I/O

B30-81L2B KACON

D4C-4332 OMRON

Connector

Numbering

Page 7

DBC 130(F30i Series) DBC130ALE2A

X8.4

ESP.M

X32.4

MRD.M

Emergency Button or

Axes Emergency

Adress Symbol Coil Comment

Emergency Stop

A0.0 2001 Emg. Button or Axes Emergency

Machine Ready

R652.7 ARST Alarm Reset

5

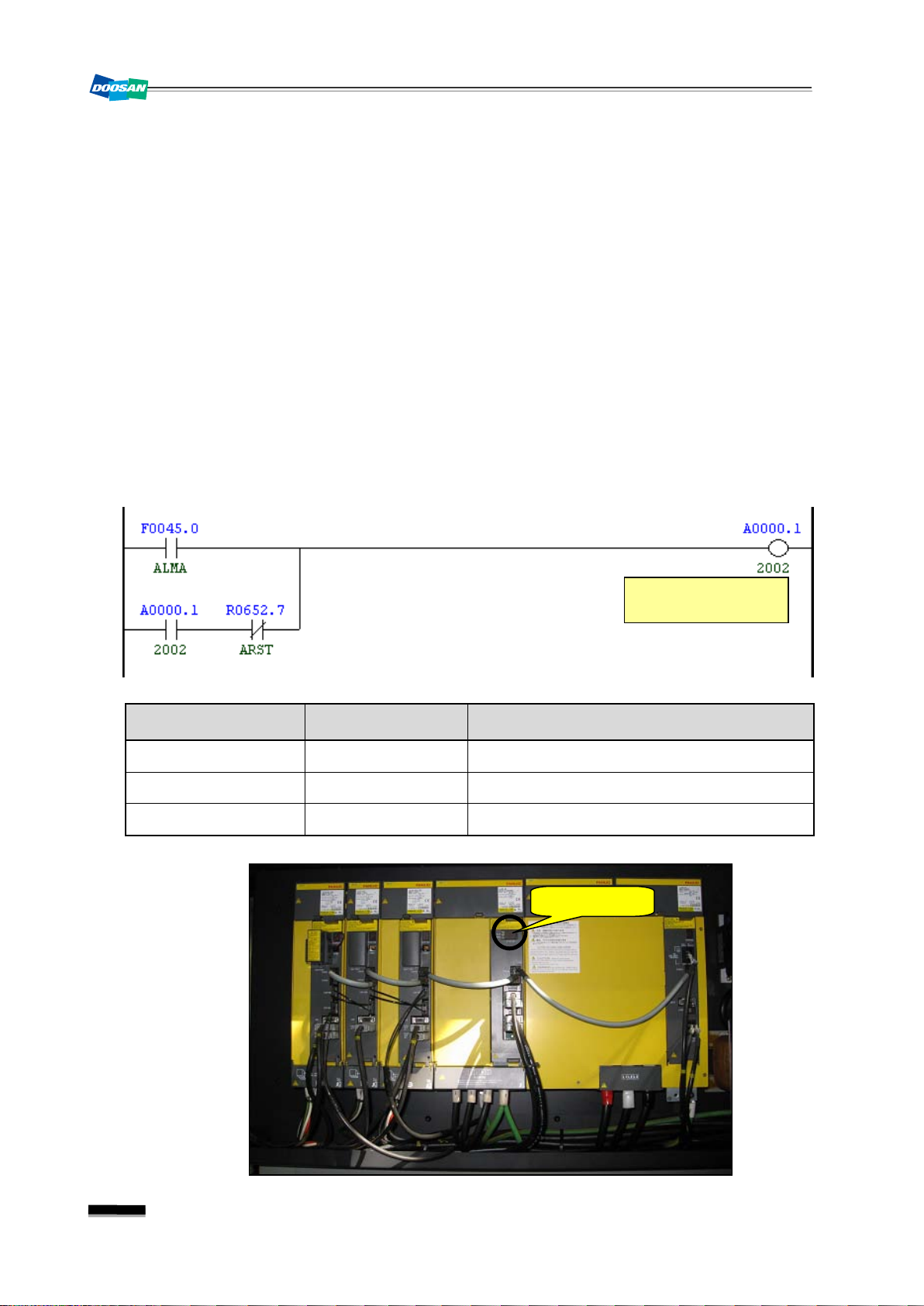

Page 8

DBC 130(F30i Series)

Main Spindle Servo

Alarm

Alarm Display

1.2

2002

Spindle Alarm is Detected

1) Description

There occurred an alarm from the main spindle drive unit.

2) Cause of problem

① An error found in the main spindle drive unit

② An error found in the spindle motor, power cable or signal cables

3) Action

① Check the alarm number that is displayed on the main spindle drive unit of the electric

cabinet. Take a necessary measure according to the alarm number.

☞ Refer to "Troubleshooting by the spindle amplifier alarm" in the appendix.

② Check the spindle motor for the 3-phase power source and the feedback cable if there is a

problem.

DBC130ALE2A

Address Symbol Coil Comment

F45.0 ALMA Spindle Alarm

R820.1 2002 Spindle Alarm is Detected

R652.7 ARST Alarm Reset

6

Page 9

DBC 130(F30i Series) DBC130ALE2A

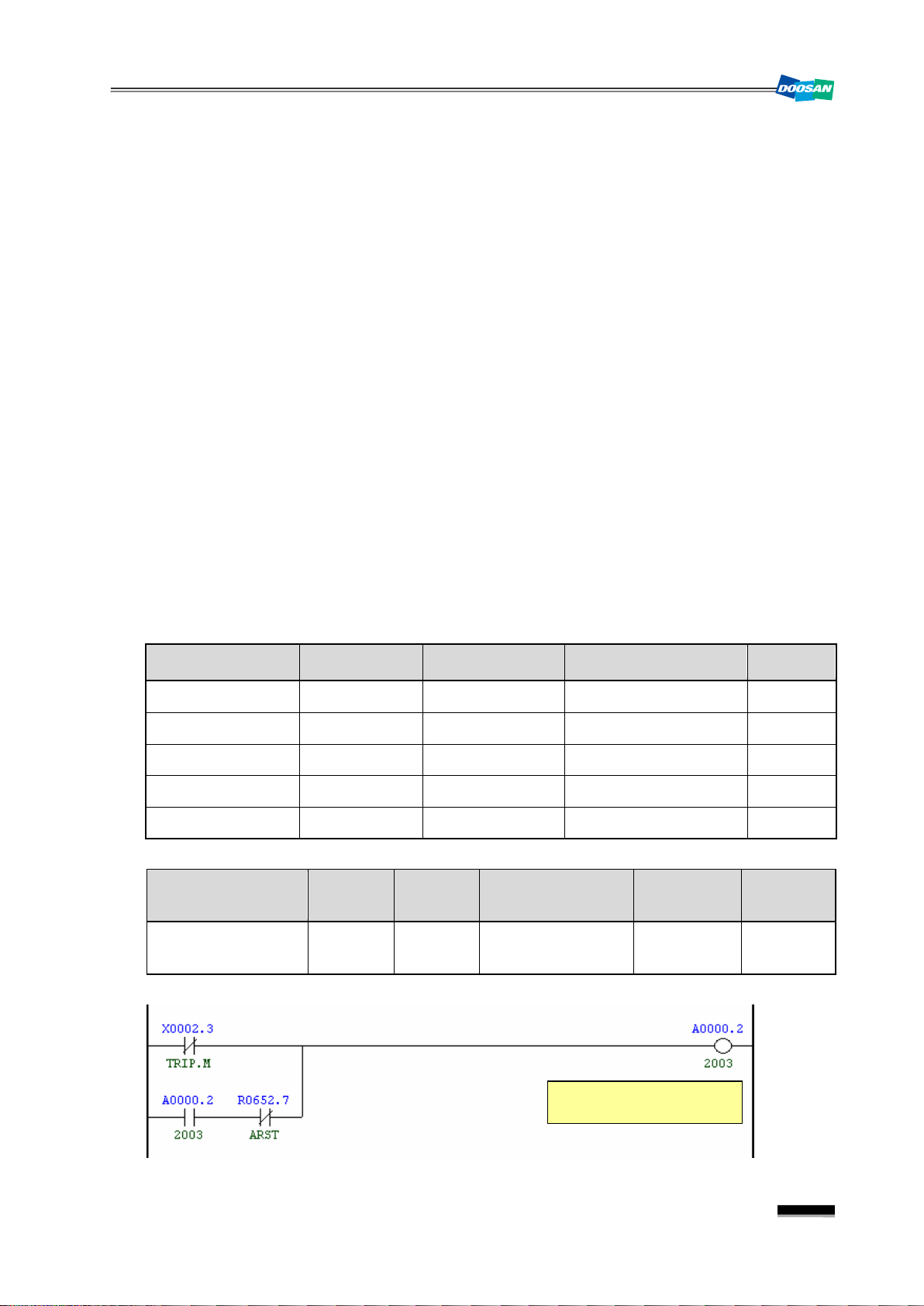

Symbol

(Pin)

TRIP.M

06

Power Circuit Overcurrent

Detected

1.3

2003

Power Circuit Overcurrent Detected

1) Description

The circuit protector that is installed in the electric cabinet is tripped.

2) Cause of problem

① The circuit protector is triggered. (Abnormal signal is detected)

② An error in power control

③ The circuit protector has an error itself.

3) Action

① Find out the cause that the circuit protector is tripped.

☞ (ex) If QF22 is tripped, check the secondary circuit (L+) of QF22 if it's short-circuited,

and take a necessary measure before turning the circuit protector back on.

② If the alarm occurs but no circuit protector is tripped, measure the resistance of each

contact point, and find out the defective circuit protector, and replace it with a new one.

☞ If you measure the resistance on the contact point of the circuit protector that is turned

on, you will get "0" ohm if it's normal.

③ If you have found nothing wrong in steps ① and ② above, that is thought to be caused by

the I/O circuit board. Check the I/O board and repair or replace it if necessary.

Part Name Part No. Symbol

Spec. Maker

Breaker, Auxiliary ENFBX0290K QF22,23,25,28,91 C60,26924,of Contact Schneider

Protector, Circuit ENFBX0268K QF22, 28 C60. 24430. 6A. 1P Schneider

Protector, Circuit ENFBX0272K QF23 C60. 24433. 13A. 1P Schneider

Protector, Circuit ENFBX0551K QF28 C60. 24436. 25A. 1P Schneider

Protector, Circuit ENFBX0266K QF91 C60. 24427. 3A. 1P Schneider

Signal Address

Circuit Protector Trip

X2.3

Device

-XT412

I/O

Input Module : Slot

Connector

Numbering

XJ412 (15) M214

7

Page 10

DBC 130(F30i Series)

a1

a2

M214D

-QF91

APC Motor Brake

X2.3

15

Input Module (AID32E) : Slot 6

XT412

M214

A5

Circuit Protector Trip

1L+

M

XJ412

21,36

40,41

C20C

23

24

M214C

-QF25

Work Light

a1

24

M214B

-QF23

AC 110V Source

a1

a2

M214A

-QF22

Servo Motor Brake

a1

a2

-QF28

Solenoid DC Power Source

Address Symbol Coil Comment

X2.3 TRIP.M Circuit Protector Trip Detection

R652.7 ARST Alarm Reset

A0.2 2003 Circuit Protector Trip

X2.3 TRIP.M Circuit Protector Trip Check

DBC130ALE2A

8

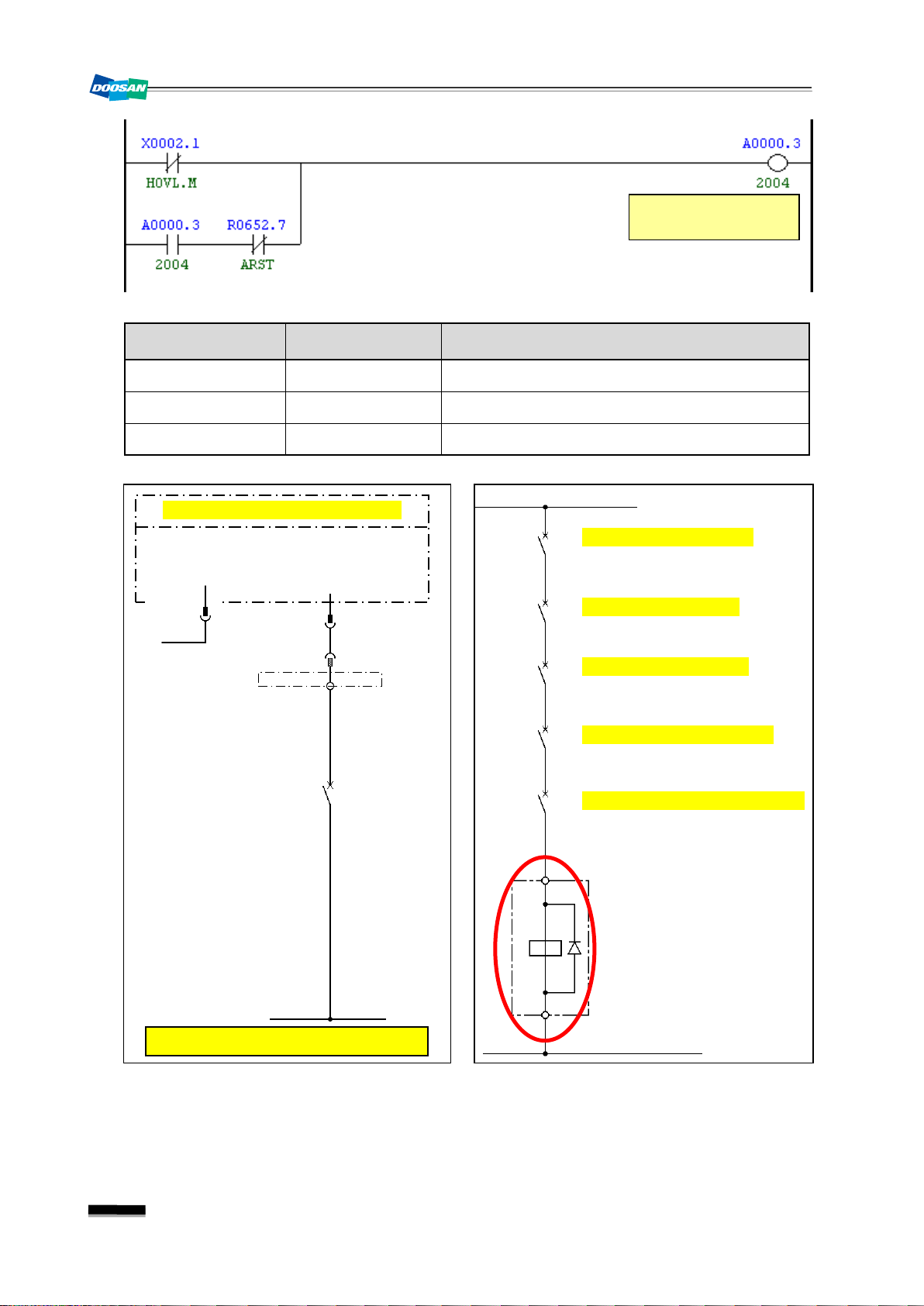

Page 11

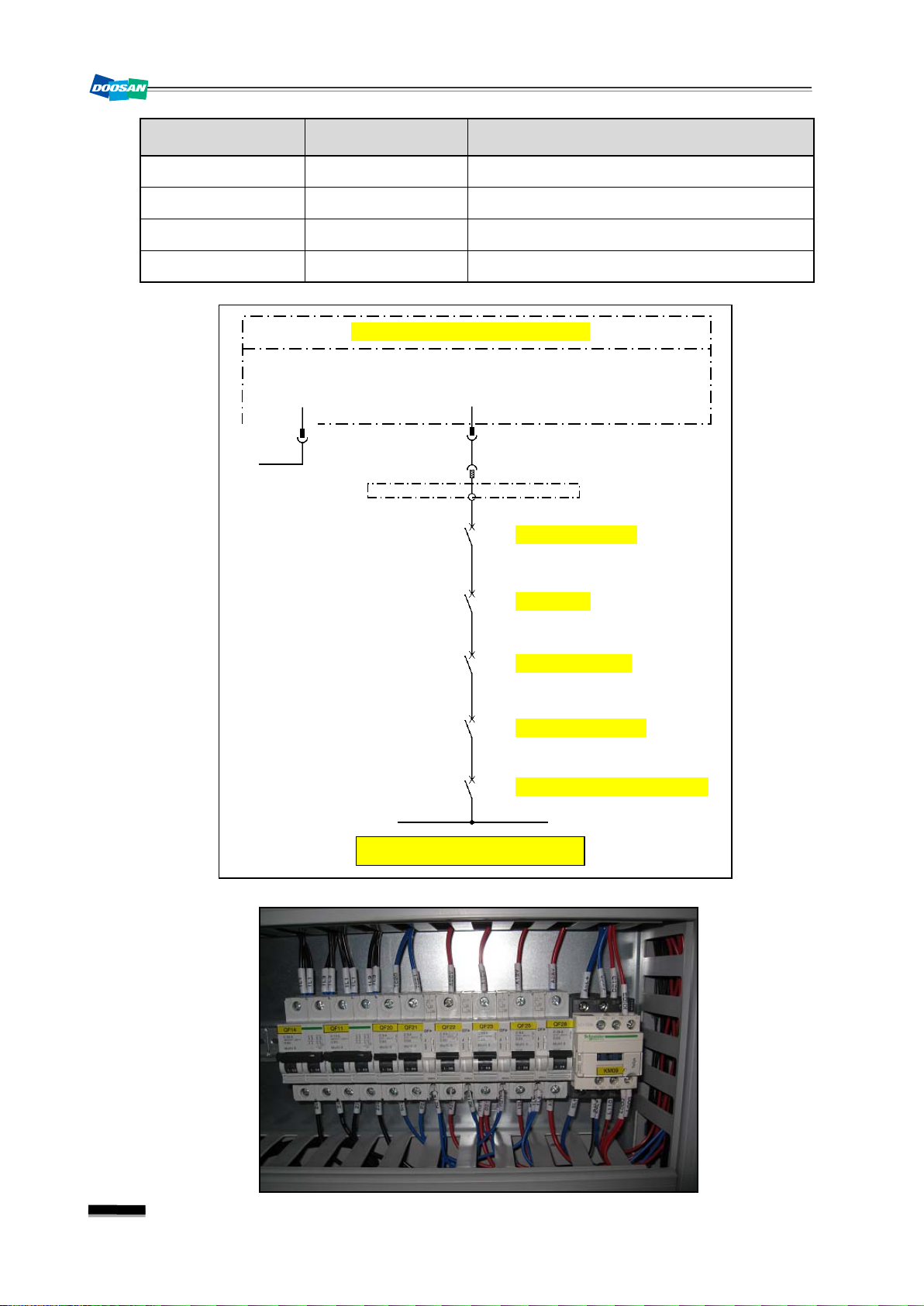

DBC 130(F30i Series) DBC130ALE2A

Circuit

Circuit

Symbol

(Pin)

1.4

2004

Hyd. Pump Motor Overload

1) Description

Hyd. An excessive electric current is detected in the hydraulic pump motor or the lubricant

pump motor of the spindle head.

2) Cause of problem

① The hydraulic pump motor, the lubricant pump motor of the spindle head, or the power

cable is burnt out.

② The circuit breaker that detects the excessive current is overloaded or defective itself.

3) Action

① Check the hydraulic pump motor, the lubricant pump motor of the spindle head, or the

power cable if there is a problem. Repair or replace the defective part if necessary.

② Check the circuit breaker for the load settings and make correction if necessary. If the

circuit breaker itself has an error, replace it with a new one.

(You can detect a defective circuit breaker by checking the resistance on either circuit of

M212 or 1L+)

▪ Overload settings

QM31 : 5.5 Kw : 24 A

QM33 : 3.7 Kw : 16.1 A

QM34 : 0.1 Kw : 0.7 A

QM73 : 1.5 Kw : 7 A

QM10 : 1.5 A

Part Name Part No. Symbol Spec. Maker

Breaker, Auxiliary ENFBX0290M QM33,34,73 TESYS. GVAE20. 2A Schneider

Breaker, Motor

Breaker, Motor

Circuit

Breaker, Motor

Circuit

Breaker, Motor

ENFBX0269M QM31 TESYS. GV3P32. 23-32A Schneider

ENFBX0261M QM33 TESYS. GV2ME21. 17-23A Schneider

ENFBX0254M QM34 TESYS. GV2ME05. 0.63-1A Schneider

ENFBX0259M QM73 TESYS. GV2ME14. 6-10A Schneider

Signal Address

Hydraulic Motor

Overload

X2.1

HOVL.M

Device

I/O

-KA11 Input Module Slot 06 XJ412 (32) M212

Connector

Numbering

9

Page 12

DBC 130(F30i Series)

Hyd. Pump Motor

Overload

9

5

-KA11

X2.1

32

Input Module (AID32E) : Slot 6

XT412

M212

A3

M

XJ412:

21,36

40,41

C20C:

Hydraulic Motor Overload

1L+

1L+

-QM73

a1

a2

KA11C

-QM34

a1

A2

KA11B

-QM33

a1

a2

KA11A

-QM31

a1

a2

KA11

14

13

Hydraulic 1 Pump Motor

Hydraulic Pump Motor

Table Lub. Pump Motor

Recovery Pump Motor/Spd

M

-QM10

a1

a2

Spindle Fan Motor & Motor Fan

KA11

DBC130ALE2A

Address Symbol Coil Comment

X2.1 HOVL.M Hydraulic Pump Motor Overload

A0.3 2004 Hydraulic Pump Motor Overload

R652.7 ARST Alarm Reset

10

Page 13

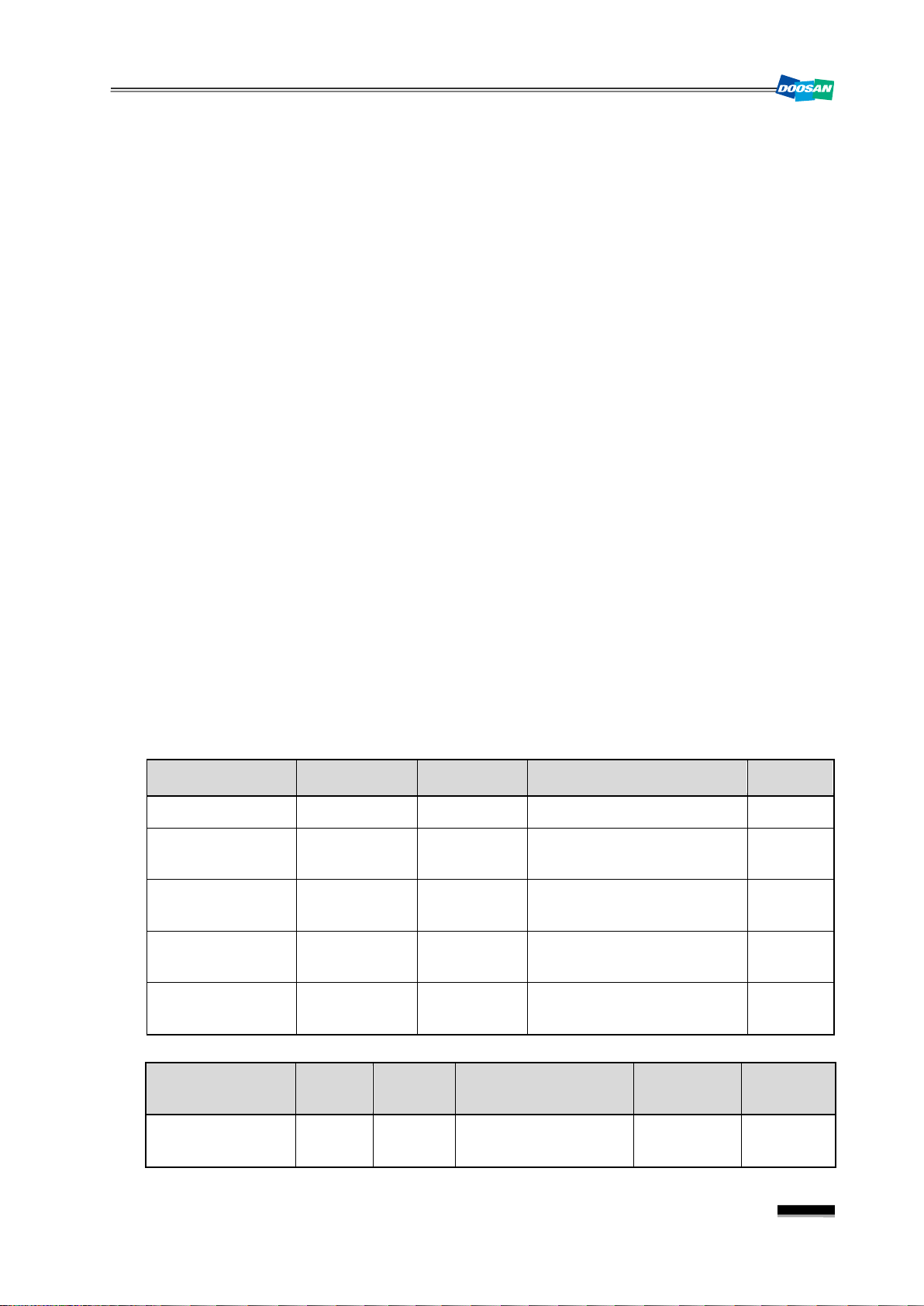

DBC 130(F30i Series) DBC130ALE2A

11

Page 14

DBC 130(F30i Series)

Symbol

(Pin)

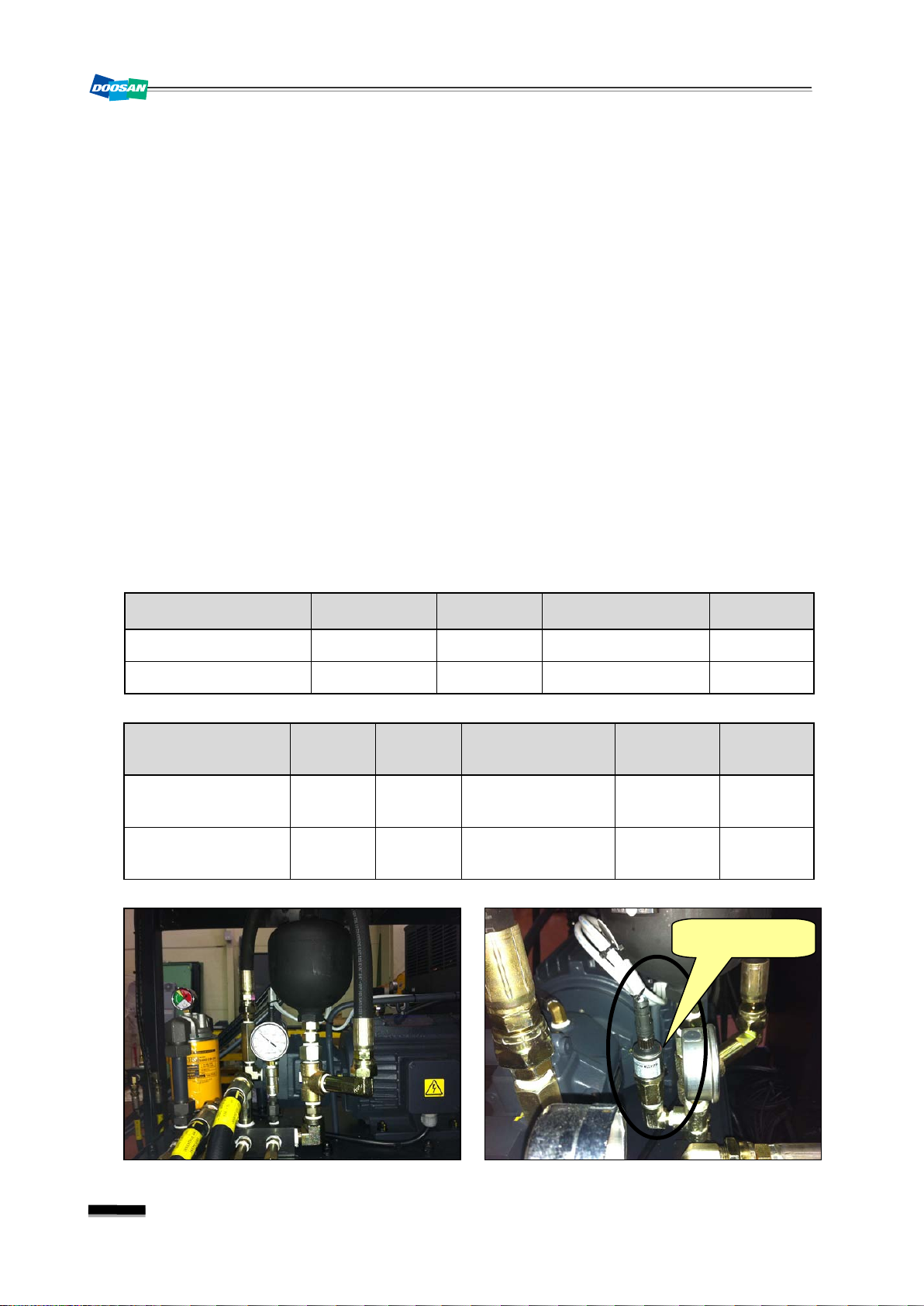

Main Hyd. Pump

Pressure Switch

1.5

2005

Hyd. Pressure Down Alarm

1) Description

The pressure of the hydraulic power unit falls below the setting value of the hydraulic

pressure switch, causing the hydraulic pressure switch to be tripped.

2) Cause of problem

① The hydraulic power unit has an error or its pressure falls below 20kg/㎠.

② The hydraulic pressure switch or any of its parts is defective.

3) Action

① Turn the pressure value of the hydraulic power unit clockwise to adjust the pressure to

50kg/㎠.

② The pressure switch of the hydraulic power unit has an error, or the wiring or related

component parts are defective.

Check the hydraulic power unit, the pressure switch, and the wiring from the switch to the

electric cabinet as well as the I/O board, and make repair or replacement if you find a

problem.

DBC130ALE2A

Part Name Part No. Symbol Spec. Maker

Cable, Pressure Switch ECBLS0167F -WK11 BKS B19-1-05 BALUFF

Switch Pressure R37983 -SP01

Signal Address

Hyd. Pressure Check

Hydraulic Motor Run

X8.3

HDPS.M

Y2.0

HYDM.R

Device

-SP31 Input Module Slot 7 XJ413(6) SP31

-KA31A

Output Module Slot

EDS810-060-0-024

I/O

Connector

2

(02) KA31A

HYDACS

Numbering

12

Page 15

DBC 130(F30i Series) DBC130ALE2A

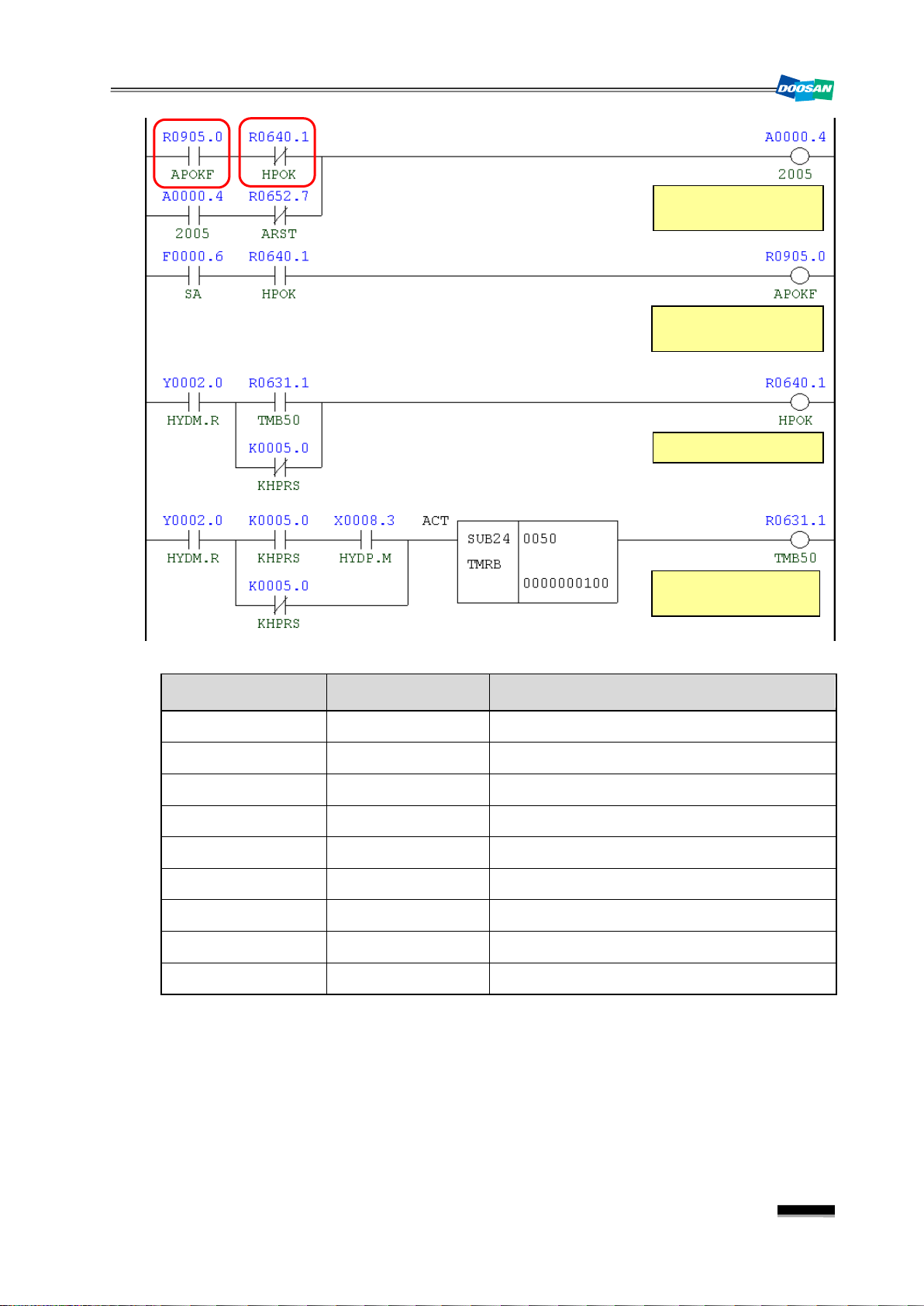

Hydraulic Pressure

Down

Aux. Hyd. Pressure

O.K Flag

Hyd. Pressure O.K

Hyd. Pressure Check

Delay Time

Address Symbol Coil Comment

R905.0 APOKF Aux. Hyd. Pressure OK Flag

R640.1 HPOK Hyd. Pressure OK

A0.4 2005 Hyd. Pressure Down Alarm

R652.7 ARST Alarm Reset

F0.6 SA Servo Ready

Y2.0 HYDM.R Hyd. Pump Motor Run

R631.1 TMB50 Hyd. Pressure Check Delay Time

K5.0 KHPRS Hyd. Pressure SW Used

X8.3 HYDP.M Hyd. Pressure Check

13

Page 16

DBC 130(F30i Series)

Symbol

(Pin)

Data of the data table---0002/0011(gear shift rpm)

Gear shift rpm in gear1 range

Gear shift rpm in gear2 range

Gear shift rpm in gear3 range

D0461 #

D0460 #

DATA

25

25

0000

D0462 #

ADDRESS

MEANING

25

0001

0002

NO.

1.6

2006

Spindle Gear Shift Check Switch Alarm

1) Description

3 or more of 4 check switches (Low, Middle, High, etc) on the spindle head gear range were

tripped, or none of them was tripped.

2) Cause of problem

The check switch for the main spindle gear range has short-circuited or any of its component

parts is defectiv e.

3) Action

Check the gear box switch of the main spindle if it works properly on the DGN screen, and

take a necessary measure.

Note 1) Spindle Gear Shifting I/O Settings

DBC130ALE2A

Signal Address

Device

I/O

Connector

Gear 1 Check X3.0 (SGA.M) -SL11 Input Module Slot 06 XJ412 (12) SL11

Gear 2 Check X3.2 (SGB.M) -SL13 Input Module Slot 06 XJ412 (44) SL13

Gear 3 Check X3.3 (S G C.M) -SL14 Input Module Slot 06 XJ412 (11) SL14

Gear 4 Check X3.4 (S G D.M) -SL15 Input Module Slot 06 XJ412 (27) SL15

Spindle Gear 1 Y4.0 (GR1.V) -KAR40 Output Module Slot 3 XJ400 (16) YV14

Spindle Gear 2 Y4.1 (GR2.V) -KAR41 Output Module Slot 3 XJ400 (32) YV15

Spindle Gear 3 Y4.2 (GR3.V) -KAR42 Output Module Slot 3 XJ400 (48) YV18

Spindle Gear 4 Y4.3 (GR4.V) -KAR43 Output Module Slot 3 XJ400 (15) YV19

Note 2) Spindle Gear Range Shifting RPM (D460~D462)

Numbering

14

Page 17

DBC 130(F30i Series) DBC130ALE2A

Activate the

vertical soft key

1

2

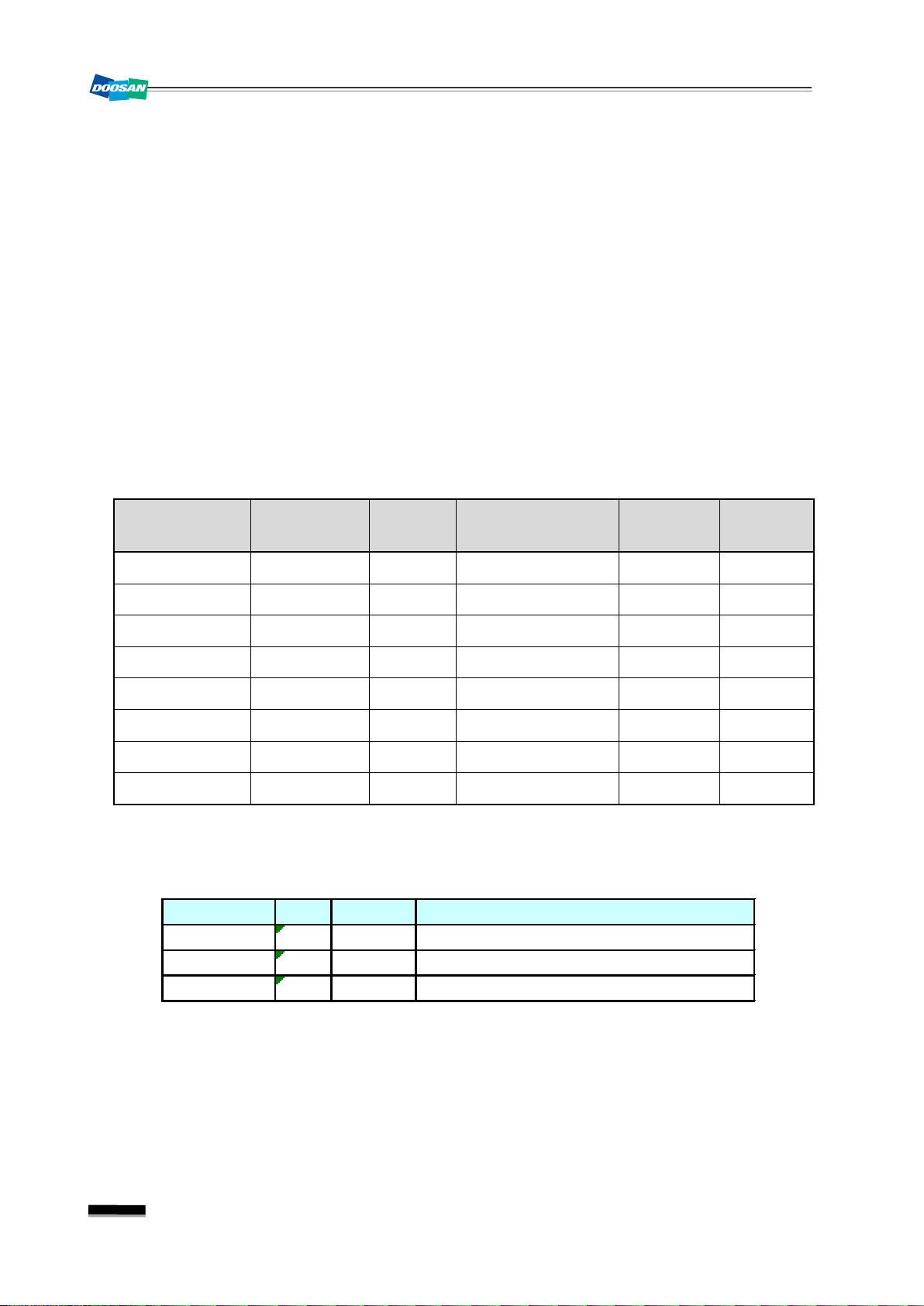

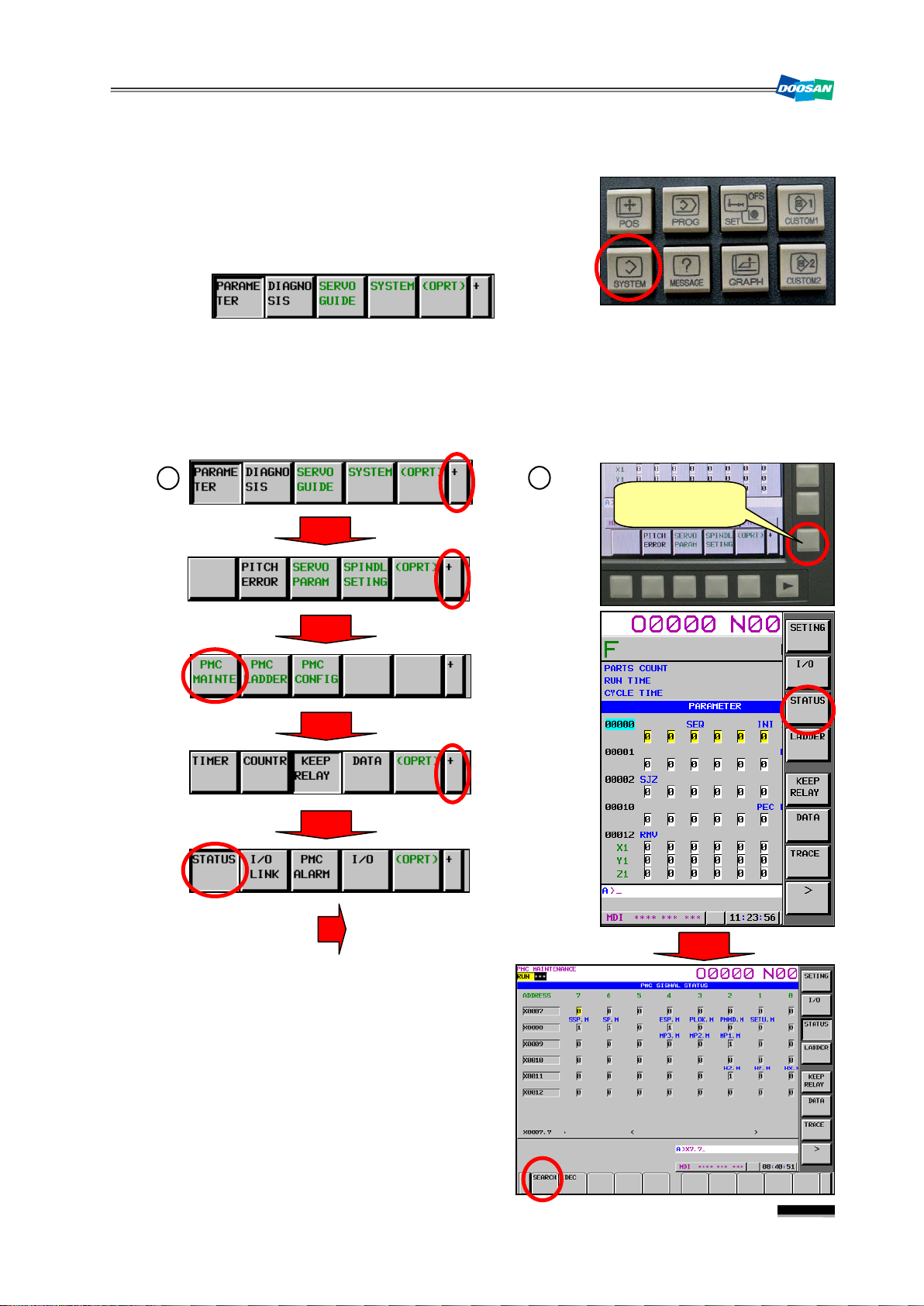

Note 3) How to move to DGN (Diagnostic)

(1) Press the “SYSTEM” button in the right side of the main

OP monitor.

The following soft key bar will be displayed at the

bottom.

(2) Move to the DGN screen.

① Press the soft keys one after another to move to the DGN screen.

② Press any soft key in the right corner to activate the vertical soft key bar, and press the

[STATUS] key.

(3) Enter a desired DGN address and press

[SEARCH] to display the DGN screen of

your choice.

15

Page 18

DBC 130(F30i Series)

SL11

SL13

SL14

SL15

YV19

YV18

YV15

YV14

Middle

1 2 3

4

SL11

SL13

SL14

SL15

SL12

YV15

YV14

YV19

YV18

YV11

Gear Shift

Tool Unclamp

P

T

DBC130ALE2A

Note 4) How to read DGN (Diagnostic)

Ex) X 0007 0 0 1 1 0 0 1 0

Bit 1, 4 and 5 in Address X7 turn ON while Bit 0, 2, 3, 6 and 7 turn OFF.

Symbol 0 0 1 1 0 0 1 0

Bit No Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

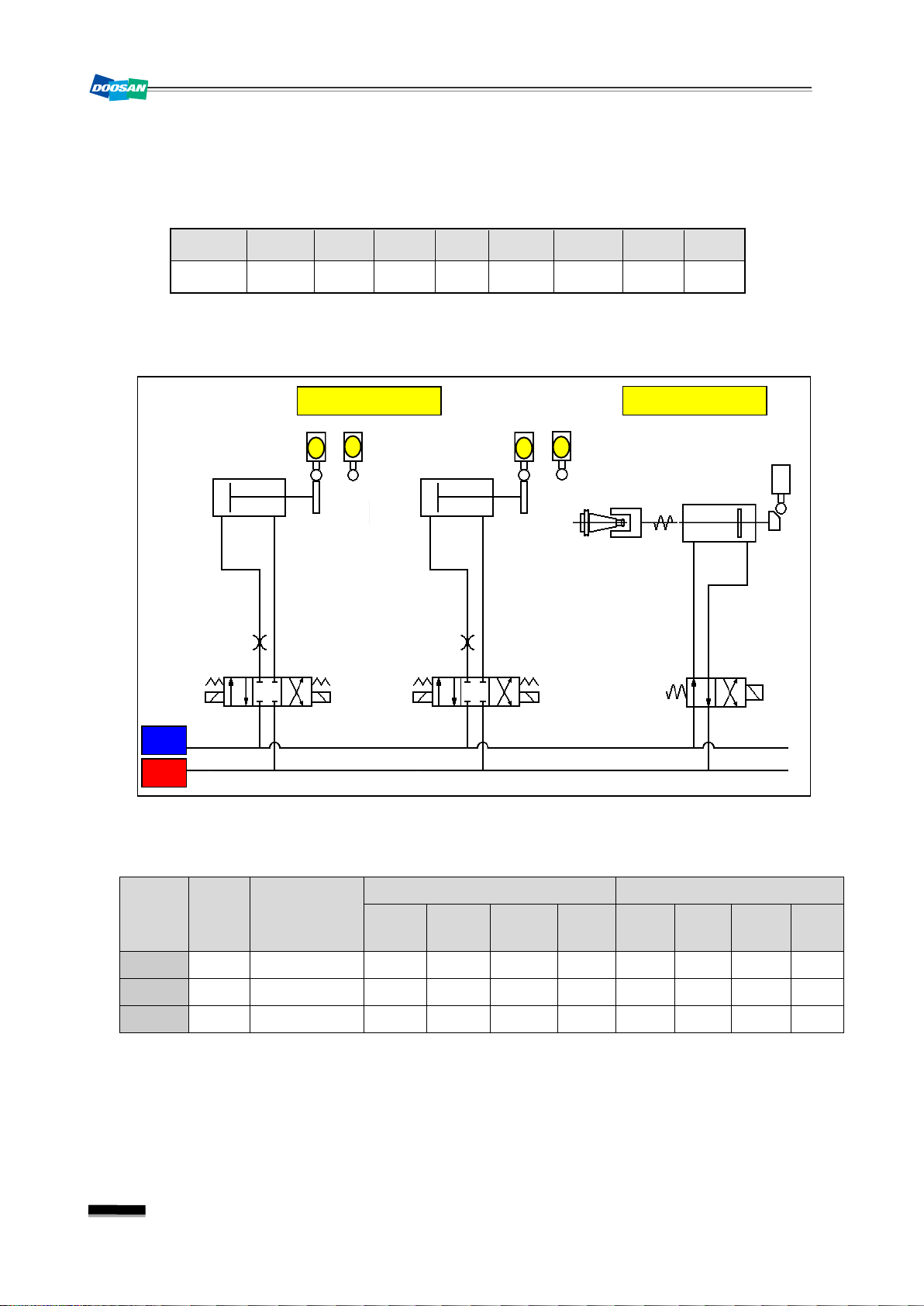

Note 5) Hydraulic circuit diagram of the spindle head

Note 6) Spindle Gear Selection Table

Gear

State

High

Keep

Relay

S-Code

K75.5 S0~S246 1 0 1 0 0 1 0 1

K75.6 S247~S806 1 0 0 1 1 0 0 1

Low

K75.7 S807~S2500 0 1 0 1 1 0 1 0

X3.0

Input Signal Output Signal

X3.2

X3.3

X3.4

Y4.3

Y4.2

Y4.1

Y4.0

16

Page 19

DBC 130(F30i Series) DBC130ALE2A

SL11

SL13

SL14

SL15

Spindle Gear Shift

Check Switch Alarm

Gear Shift End Flag

17

Page 20

DBC 130(F30i Series)

Gear Shift O.K

Gear Shift Range

Low

Gear Shift Range

Middle

Gear Shift Range

High

DBC130ALE2A

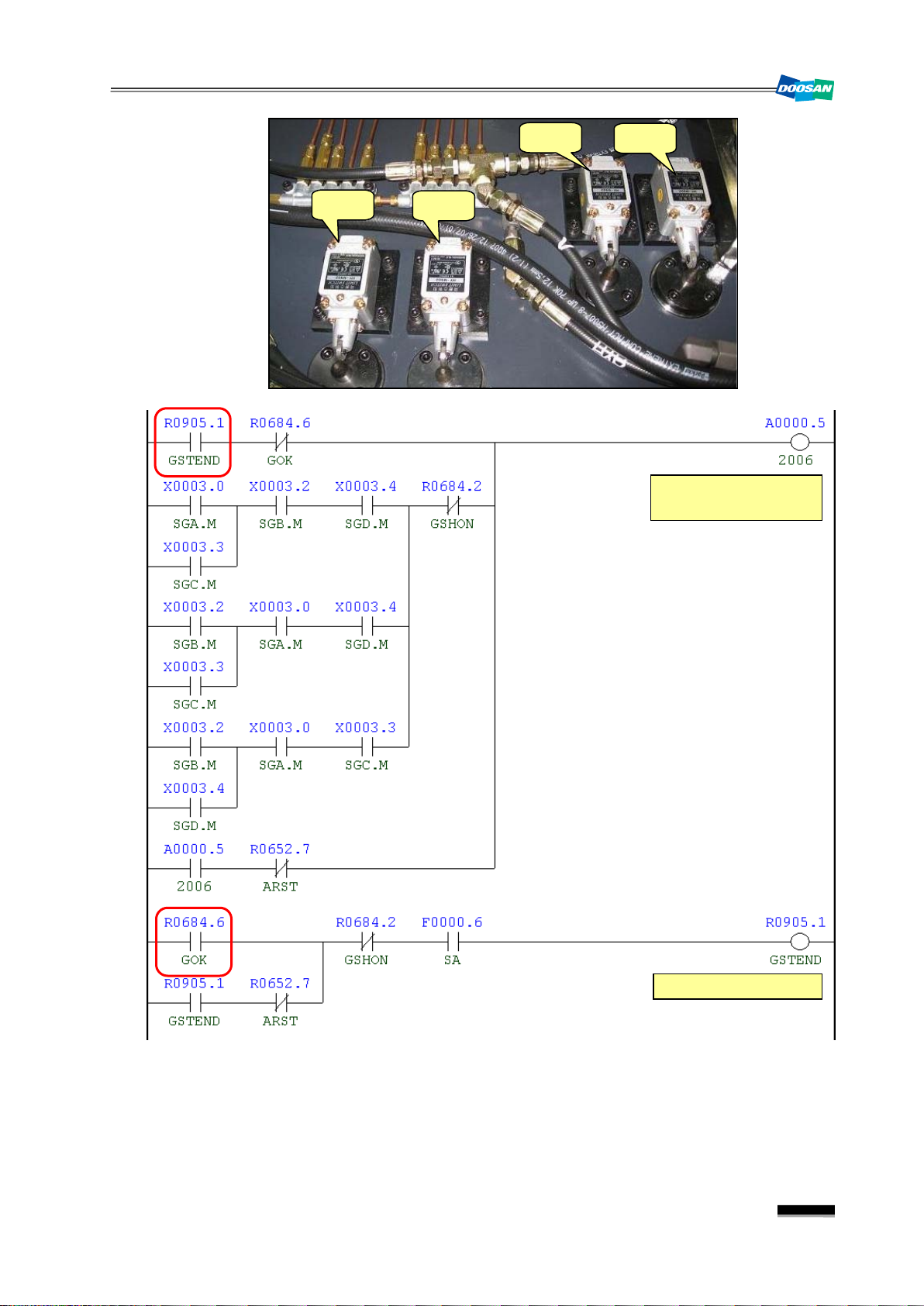

Address Symbol Coil Comment

R905.1 GSTEND Gear Shift End Flag

R684.6 GOK Gear Shift O.K

X3.0 SGA.M Spindle Gear A/S-Unclamp Built

X3.2 SGB.M Spindle Gear Shift Status B

X3.3 SGC.M Spindle Gear Shift Status C

X3.4 SGD.M Spindle Gear Shift Status D

R684.2 GSHON Gear Shift On

A0.5 2006 Gear Shift Check Switch Alarm

R652.7 ARST Alarm Reset

R905.1 GSTEND Gear Shift End Flag

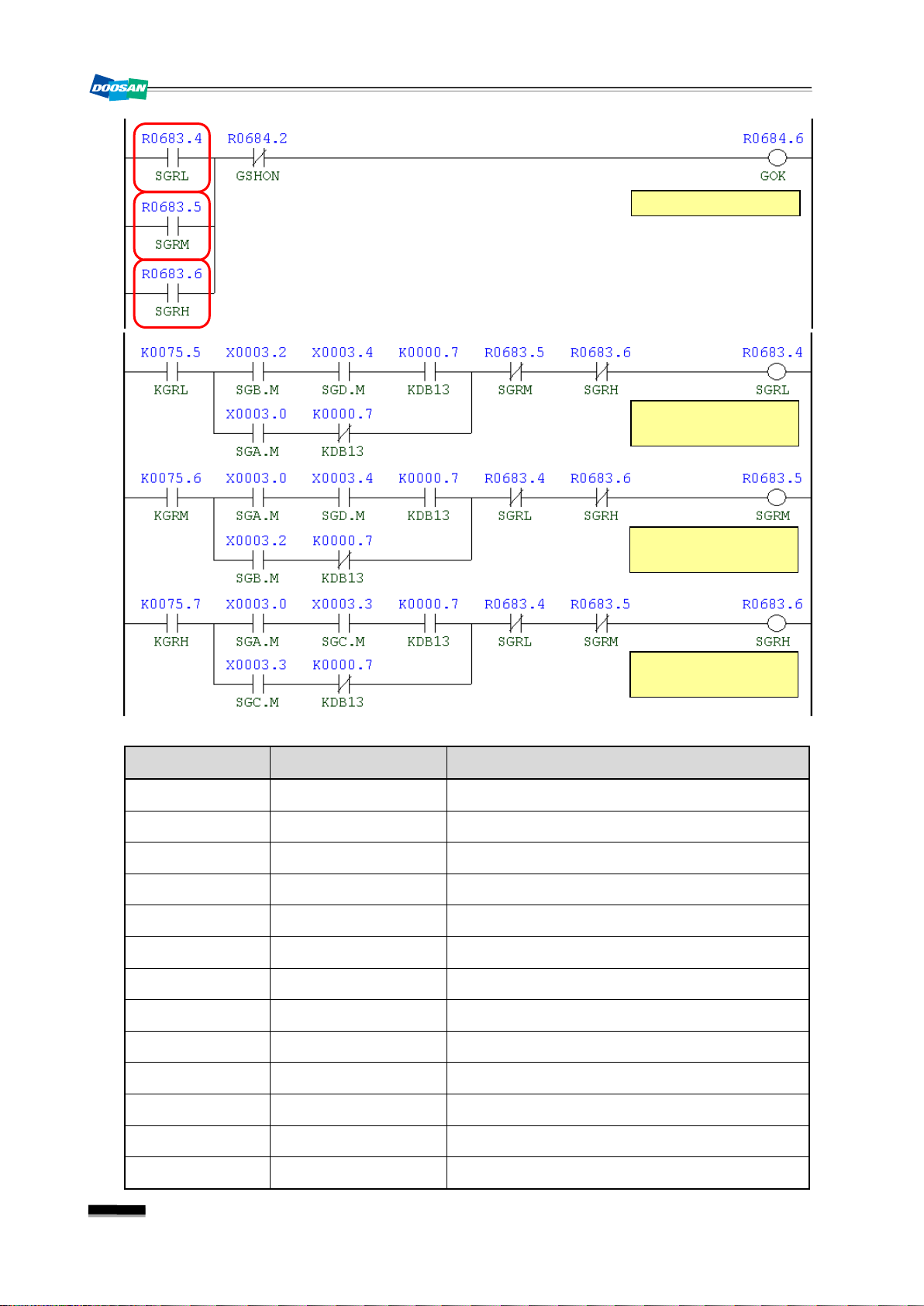

R683.4 SGRL Spindle Gear Shift Low

R683.5 SGRM Spindle Gear Range Middle

R683.6 SGRH Spindle Gear Range High

18

Page 21

DBC 130(F30i Series) DBC130ALE2A

Symbol

(Pin)

On State

PMON.M

Interlock

SDIC.M

KM10 (Magnet)

Auxiliary “a” contact

KM10

(Magnet)

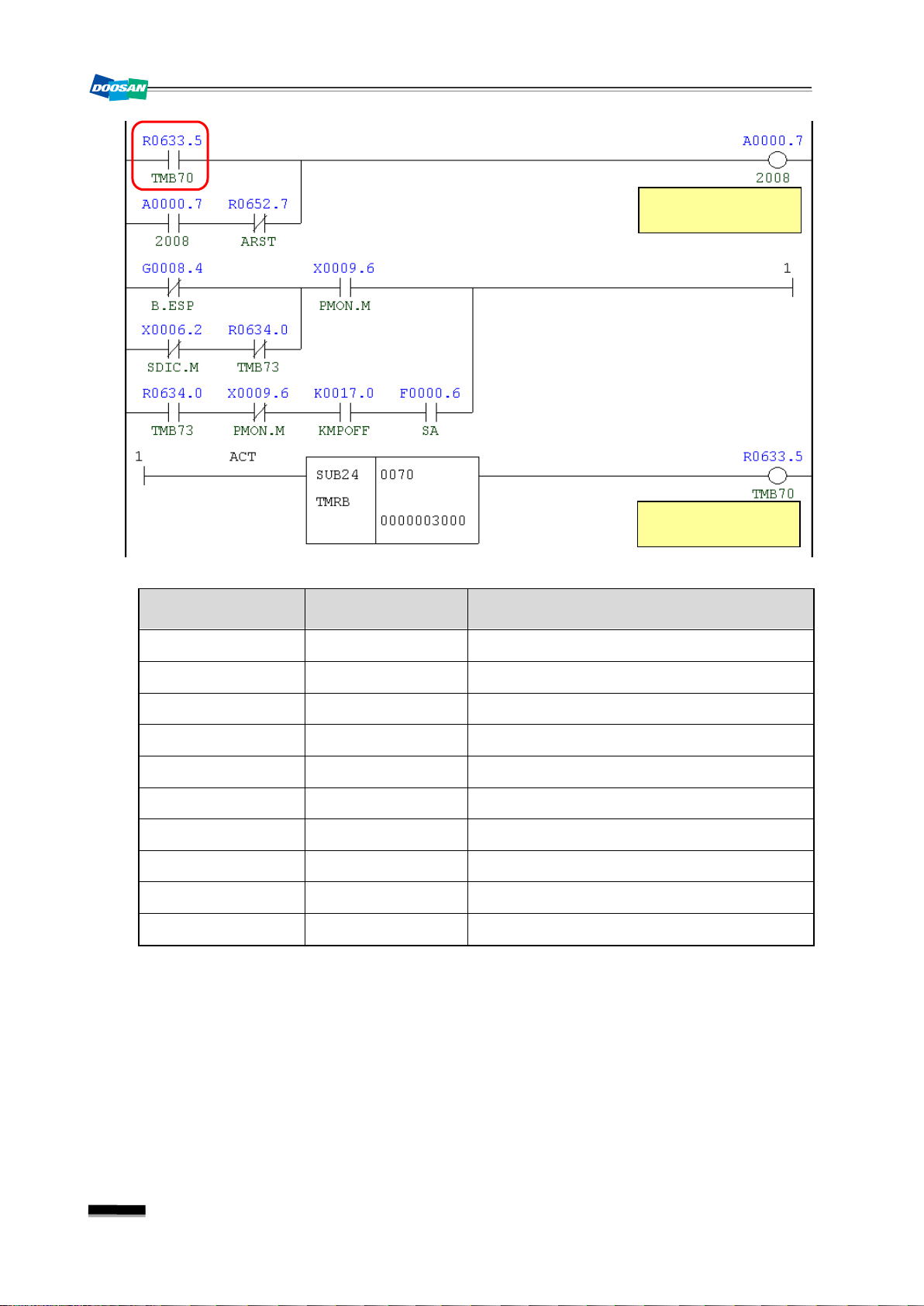

1.7

2008

PSM Contact Check Error

1) Description

There occurred an error while KM10 magnetic contactor was operating.

2) Cause of problem

The operation of KM10 did not comply with the intended signal.

3) Action

① The check signal (X9.6) of the magnetic contactor should turn on only while KM10 is

operating.

② Set "Keep Relay K17.0" to 1 if you want to enable the option of Motor Power On/Off.

☞ If you set "K17.0=(1)" to enable the option of Motor Power ON/OFF, KM10 magnetic

contactor turns off if the door is open, and turns on if the door is close.

Signal Address

Power Supply Contact

Splash Guard Door

X9.6

X6.2

Device

I/O

Connector

Numbering

-KM10 Input Module Slot 07 XJ413 (01) PMON

-S61 Input Module Slot 07 XJ413(48) SS61B

19

Page 22

DBC 130(F30i Series)

PSM Contact Check

Error

Power Module Alarm

Check Time

DBC130ALE2A

Address Symbol Coil Comment

R633.5 TMB70 Power Module Alarm Check Time

A0.7 2008 PSM Contact Check Error

R652.7 ARST Alarm Reset

G8.4 B.ESP Emergency Stop

X6.2 SDIC.M Splash Guard Door Interlock

R634.0 TMB73 Connect Delay Time Again

X9.6 PMON.M Power Supply Magnet On State

K17.0 KMPOFF Module Elec. Off D-Open

F0.6 SA Servo Ready

X17.7 MENB.M Machine Enable Switch On

20

Page 23

DBC 130(F30i Series) DBC130ALE2A

to operate the machine regardless of whether the axes return to their reference

Return to Ref. Point

Manually

Ref. Point Return

Interlock. Alarm

2. Cycle Alarm

2.1

2031

1) Description

A message prompting you to manually return the axis to the reference point

2) Cause of problem

① The machine was instructed to operate before all axes had returned to their respective

② In the Machine Lock state, AUTO mode (EDIT, MEMORY, TAPE, MDI) was selected. (X,

③ In the Machine Lock state, EDIT or MEMORY mode was selected. (B, 6 axes)

3) Action

① Return to the reference point manu al l y

② If you want

③ In the Machine Lock st at e, the ma chi n e c a n b e in st r u ct e d to ope r at e i n AU TO mo d e o nl y

Return to Ref. Point in Manual

reference point.

Y, Z, W)

point, set "Keep Relay K1.6" to 1.

after the axes have returned to their respective reference point.

21

Page 24

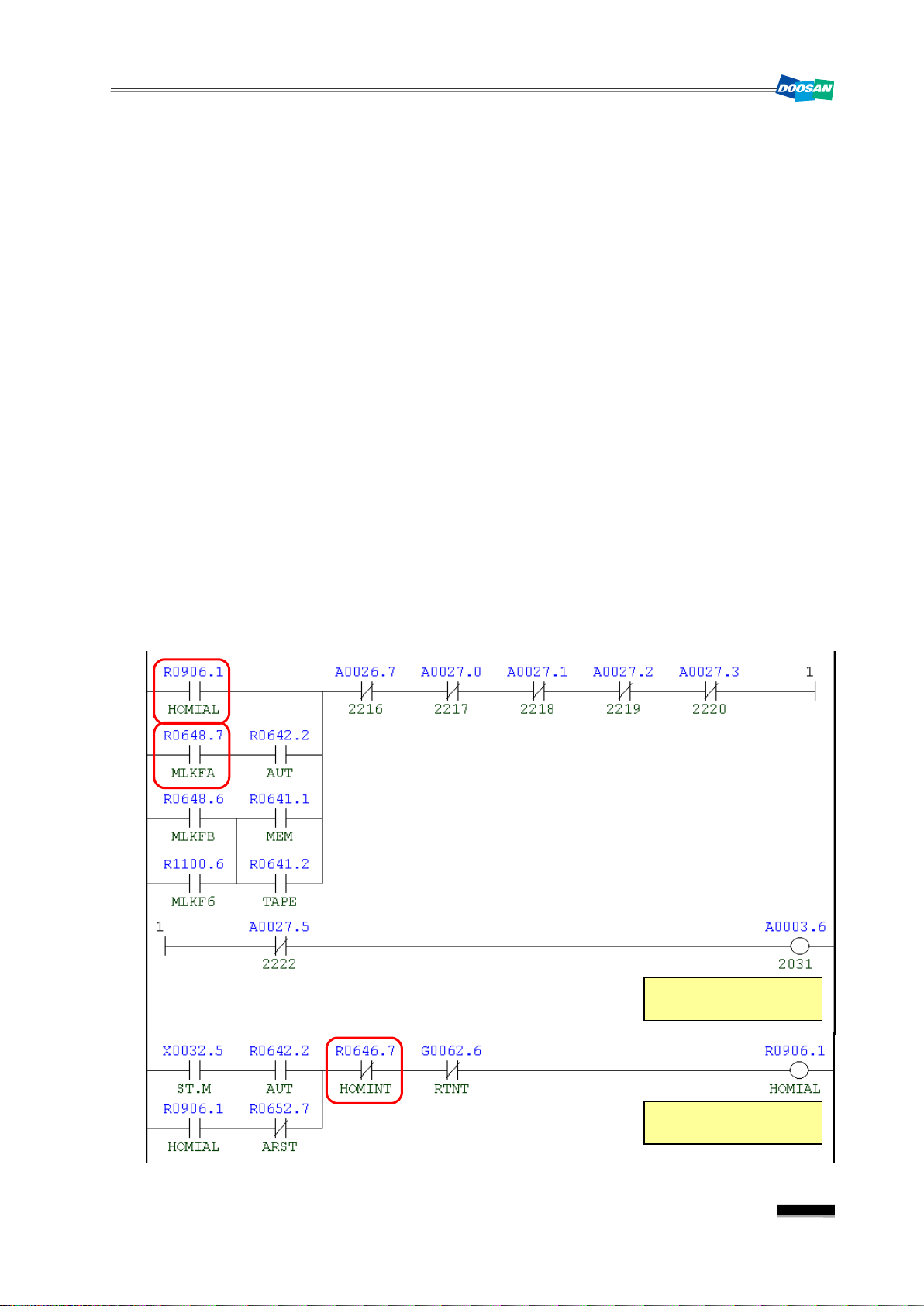

Home Position

Interlock

Machine Lock on

Flag X, Y, Z, W

DBC 130(F30i Series)

DBC130ALE2A

Address Symbol Coil Comment

R906.1 HOMIAL Ref. Point Return Interlock Alarm

R648.7 MLKFA Machine Lock On Flag X, Y, Z, W

R642.2 AUT Auto Mode

R648.6 MLKFB Machine Lock On Flag B-Axis

R1100.6 MLKF6 Machine Lock On Flag 6-Axis

R641.1 MEM Memory Mode

R641.2 TAPE Tape Mode

A26.7 2216 Must Be Return to Ref. Point X

A27.0 2217 Must Be Return to Ref. Point Y

A27.1 2218 Must Be Return to Ref. Point Z

A27.2 2219 Must Be Return to Ref. Point W

A27.3 2220 Must Be Return to Ref. Point B

A27.5 2222 6th Axis Clamp/Unclamp Alarm

22

Page 25

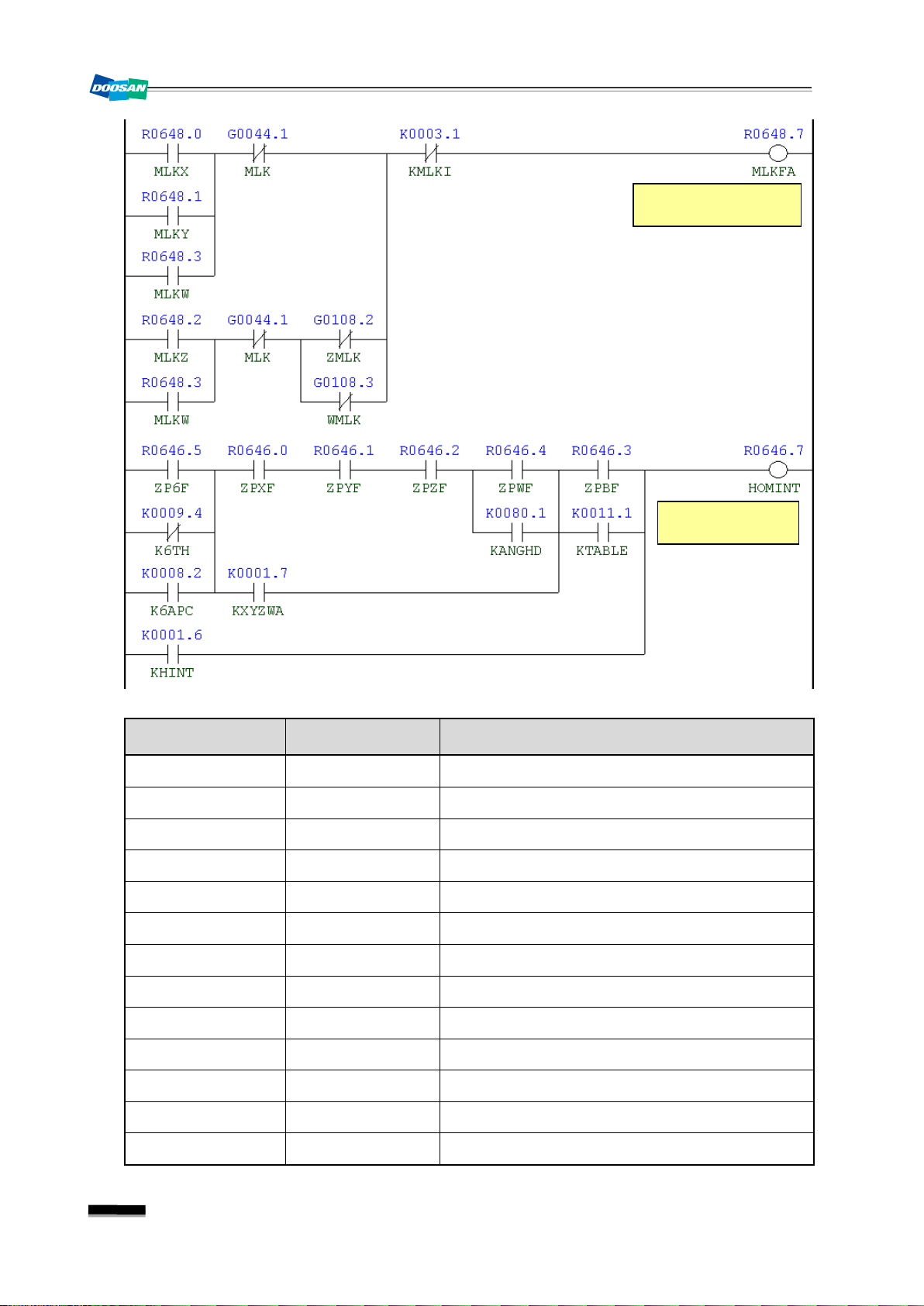

DBC 130(F30i Series) DBC130ALE2A

Address Symbol Coil Comment

A3.6 2031 Return to Ref. Point in Manual

X32.5 ST.M Cycle Start

R652.7 ARST Alarm Reset

R646.7 HOMINT Home Position Interlock

G62.6 RTNT Rigid Tapping Retraction Start

R648.0 MLKX Machine Lock X-Axis

R648.1 MLKY Machine Lock Y-Axis

R648.3 MLKW Machine Lock W-Axis

G44.1 MLK Machine Lock

R648.2 MLKZ Machine Lock Z-Axis

G108.2 ZMLK Z-Axis Machine Lock

G108.3 WMLK W-Axis Machine Lock

K3.1 KMLKI Machine Lock Ref. Point Invalid

23

Page 26

DBC 130(F30i Series)

Symbol

(Pin)

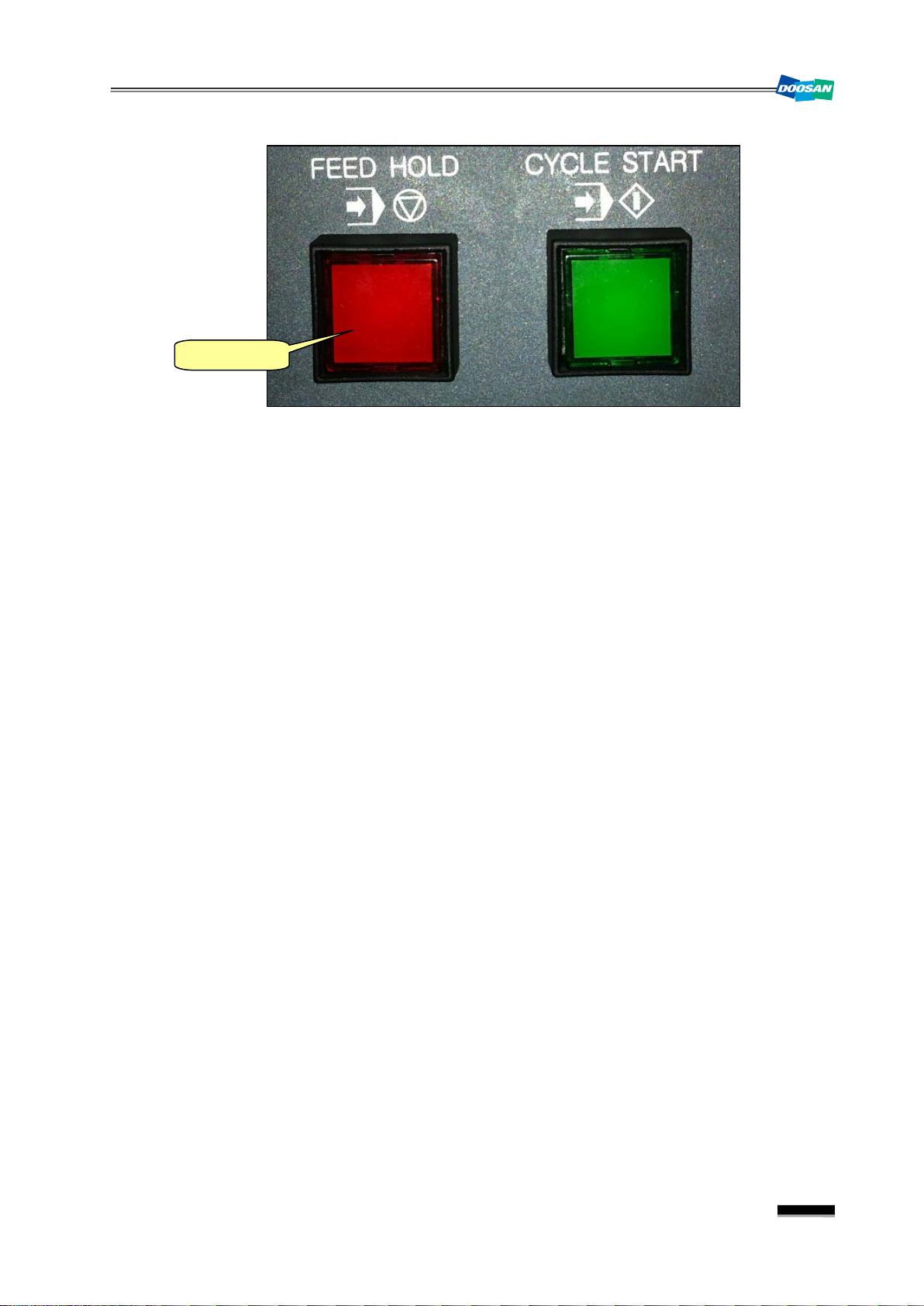

Feed Hold Push

Button is Pressed

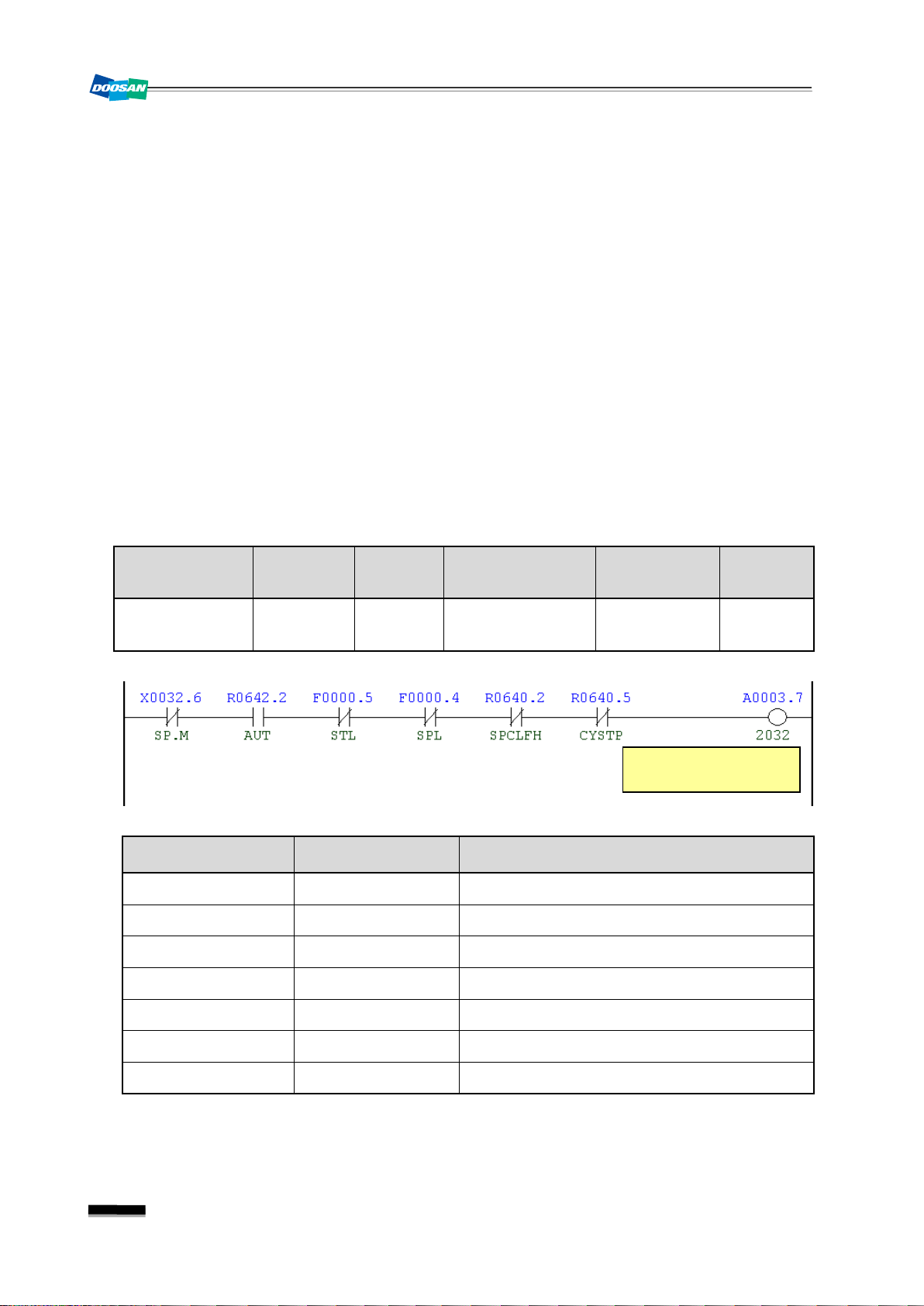

2.2

2032

Feed Hold Push Button is Pressed

1) Description

An error in the signal of the feed hold switch while the program is running (in AUTO mode)

2) Cause of problem

① The feed hold switch on the main OP is tripped.

☞ The feed hold switch enables you to stop running the program instantly without

instructing the emergency stop.

② A short-circuit or defective part in the feed hold switch

3) Action

① If you have pressed the feed hold switch by necessity, release the switch to set off the

alarm. Then, you can press the Cycle Start switch to resume running the program.

② Turn the feed hold switch manually to check the input signal on the DGN screen of PMC.

Take necessary measures (reconnect the wiring, etc) to restore normal conditions.

DBC130ALE2A

Signal Address

X32.6

Feed Hold

SP.M

Device

-SB17

I/O

Distribute I/O

Module(A)

Connector

Numbering

XCE56A(A05) SB17

Address Symbol Coil Comment

X32.6 SP.M Cycle S t op

R642.2 AUT Auto Mode

F0.5 STL Cycle Start

24

F0.4 SPL Feed Hold

R640.2 SPCLFH Spindle & Coolant At Feed Hold

R640.5 CYSTP Cycle Stop

A3.7 2032 Feed Hold Push Button is Pressed

Page 27

DBC 130(F30i Series) DBC130ALE2A

Feed Hold

25

Page 28

DBC 130(F30i Series)

if

Symbol

(Pin)

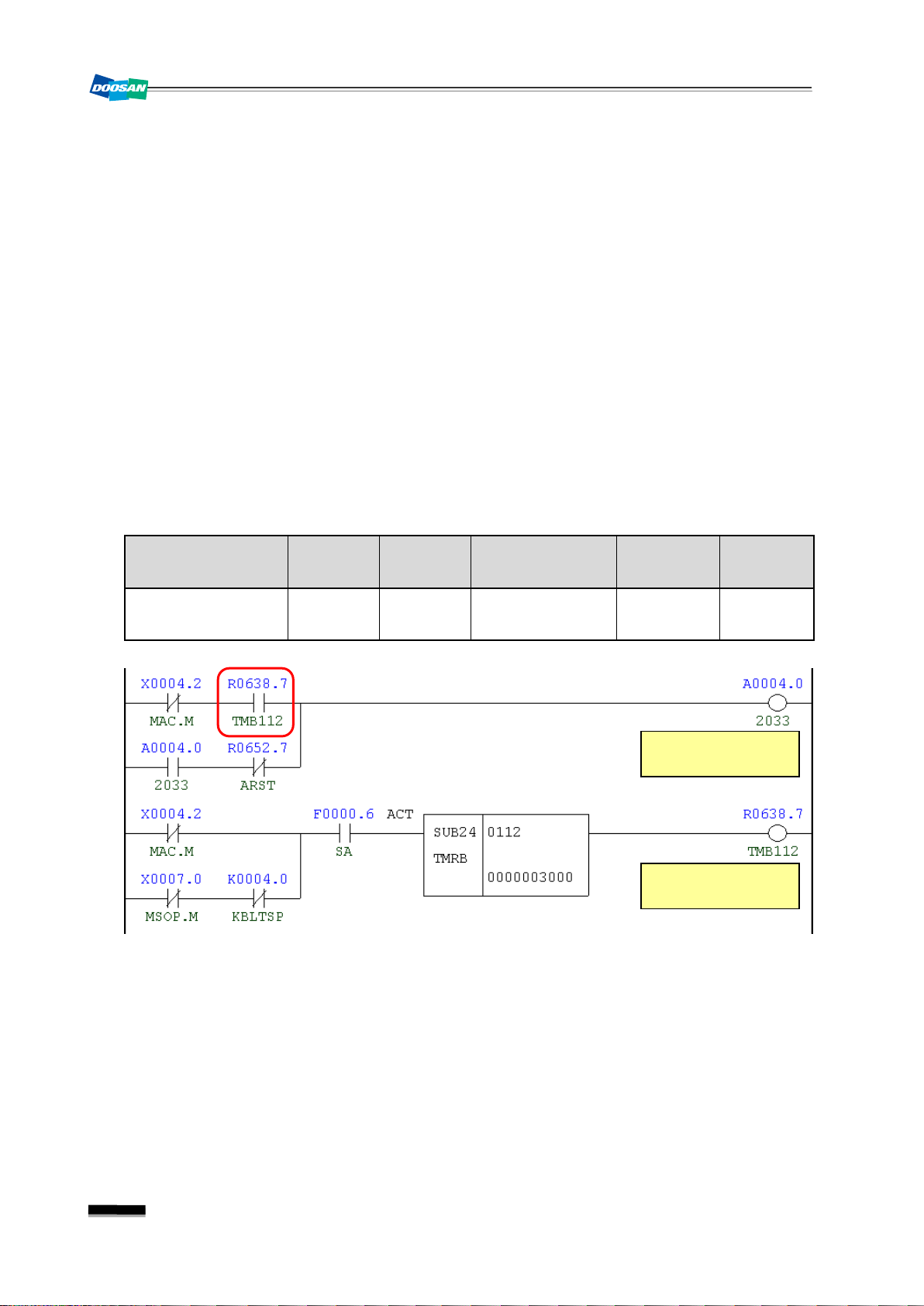

Air Pressure Down

Alarm

Main Air Check

D-Time

2.3

2033

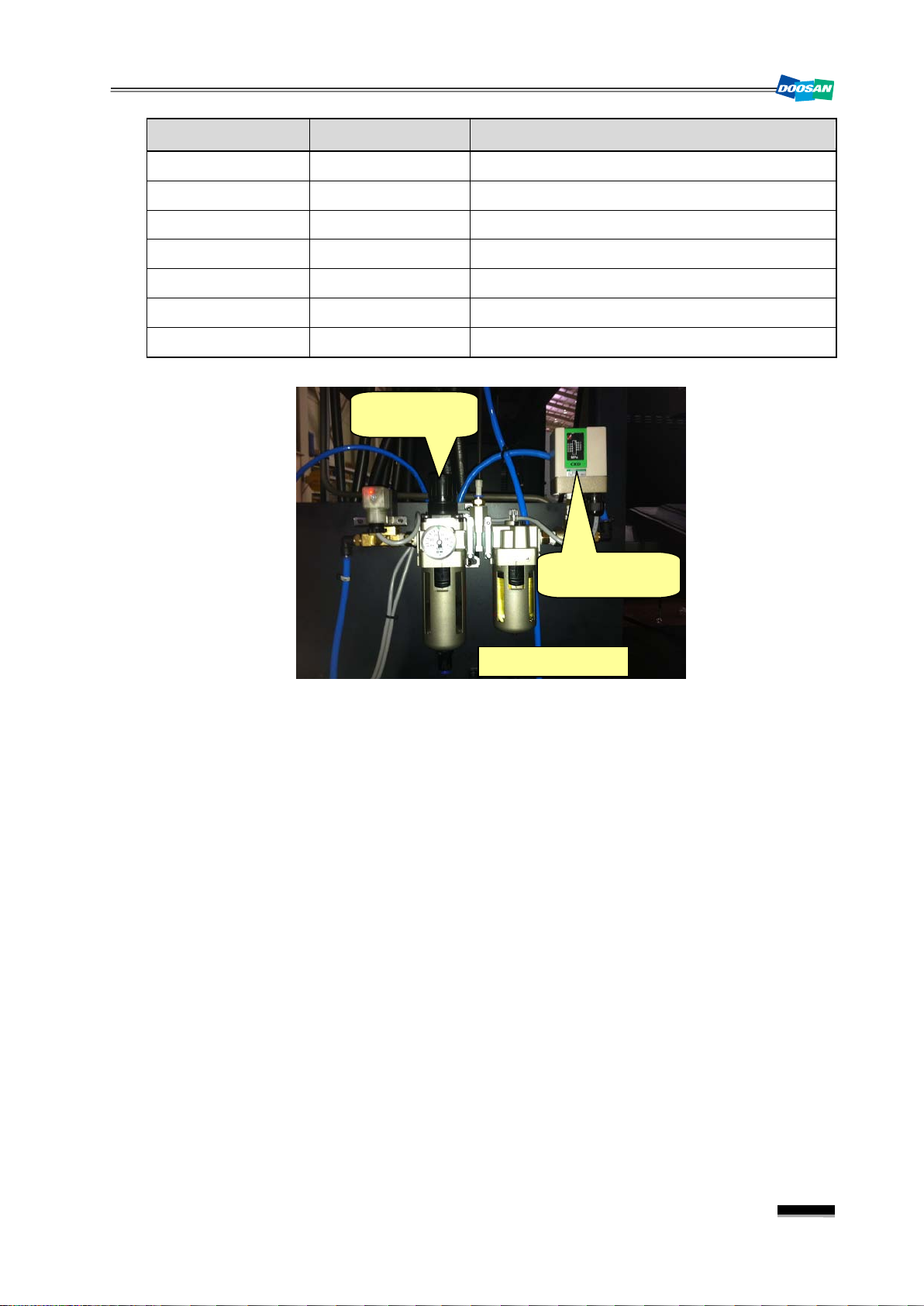

Air Pressure down Alarm

1) Description

The air pressure switch is tripped because the air pressure falls below the specified value.

2) Cause of problem

①

The factory-supplied air pressure falls below the standard (4kg).

②

The air pressure switch or any of its parts is defective.

3) Action

① Increase the factory-supplied air pressure to more than 5kg/㎠.

▪ Check the air pressure measurement displayed on the gauge of the air service unit, and

it's below 4kg/㎠, turn the air pressure handle to the right. If the gauge does not increase

any further, this indicates the current air pressure is not appropriate.

② Check the air pressure switch, wiring and I/O module if there is no error. And make repair

or replacement if necessary.

DBC130ALE2A

Signal Address

Main Air Pressure

Check

X4.2

MAC.M

Device

-SP8C

I/O

Input Module :

Slot 06

Connector

Numbering

XJ412 (39) SP8C

26

Page 29

DBC 130(F30i Series) DBC130ALE2A

R638.7

TMB112

Main Air Check D-Time

A4.0

2033

Air Pressure Down Alarm

R652.7

ARST

Alarm Reset

Air Supply Unit

Air Pressure

Adjustable Valve

Air Pressure

Switch (SP8C)

Address Symbol Coil Comment

X4.2 MAC.M Main Air Pressure Check

X7.0 MSOP.M Mist Oil Operating Pressure

K4.0 KBLTSP Built In Spindle Used

F0.6 SA Servo Ready

27

Page 30

DBC 130(F30i Series)

Symbol

(Pin)

Motor Overload

MOVL.M

Slot 06

Coolant Motor

Overload Alarm

2.4

2034

Coolant & Lub. Pump Overload

1) Description

An excessive electric current is detected in the coolant or lubricant pump motor.

2) Cause of problem

① The coolant or lubricant pump motor, or the power cable is burnt out.

② The circuit breaker that detects the excessive current is overloaded or defective itself.

3) Action

① Check the coolant or lubricant pump motor, or the power cable, and repair or replace a

defective one if found.

② Check the circuit breaker for the load settings and make correction if necessary. If the

circuit breaker itself has an error, replace it with a new one.

☞ Overload settings

QM41 (Flood Coolant Pump Motor) : 1.5 Kw : 7 A / 2.2 Kw : 11 A

DBC130ALE2A

QM42 (T-T-S Coolant Pump Motor) : 1.5 Kw : 7 A / 3.7 Kw : 17 A

QM43 (Cool Jet T-S-C Unit) : 5.5 Kw : 23.9 A / 3.7Kw : 17A

QM422 (Recovery Pump Motor/C-J) : 0.9 Kw : 5.2 A

Part Name Part No. Symbol Spec. Maker

Breaker, Auxiliary ENFBX0290M QM41,42,43,422 TESYS. GV2ME22. 20-25A Schneider

Breaker, Motor Circuit ENFBX0259M QM41,QM42 TESYS. GV2ME14. 6 -10A Schneider

Breaker, Motor Circuit ENFBX0285M QM41 TESYS. GV2 ME16. 9-14A Schneider

Breaker, Motor Circuit ENFBX0261M QM42, QM43 TESYS. GV2ME21. 17-23A Schneider

Breaker, Motor Circuit ENFBX0262M QM43 TESYS. GV2ME22. 20-25A Schneider

Breaker, Motor Circuit ENFBX0258M QM422 TESYS. GV2ME10. 4-6.3A Schneider

Signal Address

Coolant & Lub.

X2.2

Device

-M213

I/O

Input Module :

Connector

Numbering

XJ411 (48) M213

28

Page 31

DBC 130(F30i Series) DBC130ALE2A

A4.1

2034

Coolant Motor Overload Alarm

R652.7

ARST

Alarm Reset

9

5

-KA12

X2.2

48

Input Module (AID32E) : Slot 6

XT412

M213

A4

M

XJ412

21,36

40,41

C20C

Coolant & Lub. Motor Overload

1L+

1L+

-QM422

23

24

KA11C

-QM43

23

24

KA11B

-QM42

23

24

KA11A

-QM41

23

24

KA12

KA12

14

13

Flood Coolant Pump Motor

T-T-S Coolant Pump Motor

Cool Jet T-S-C Unit

Recovery Pump Motor/C-J

Address Symbol Coil Comment

X2.2 MOVL.M Lub. & Coolant Motor Overload

29

Page 32

DBC 130(F30i Series)

Symbol

(Pin)

TSCA.M

Slot 07

Additional Coolant

Unit Alarm

2.5

2035

Addition Coolant Unit Alarm

1) Description

An error occurred in an external coolant unit.

2) Cause of problem

① The coolant pressure of the TSC unit has decreased, or the filter of the TSC filter unit is

clogged.

② The pressure switch has an error or the wiring has a problem.

3) Action

① Take necessary measures to solve the problems of both the TSC unit and the filter.

② Check the pressure switch and the wiring, and repair or replace a defective one if

necessary.

DBC130ALE2A

Signal Address

T-S-C Unit Alarm

X7.6

Device

-SP15

I/O

Input Module :

Address Symbol Coil Comment

X7.6 TSCA.M T.S.C Un it Al a r m

F0.6 SA Servo Ready

A4.2 2035 Addition Coolant Unit Alarm

R652.7 ARST Alarm Reset

Connector

XJ413 (10)

30

Page 33

DBC 130(F30i Series) DBC130ALE2A

31

Page 34

DBC 130(F30i Series)

Symbol

(Pin)

TSCA.M

Slot 07

Power Back Up Module

Power Failure

2.6

2037

1) Description

An error in the power backup module

2) Cause of problem

In pre-operation stages, no power is applied to the power backup module. (An error in the

power supply line to PFM.M)

3) Action

Check the power supply line to PFM.M, and take a necessary measure if an error is found.

DBC130ALE2A

Power Back Up Module Power Failure

Signal Address

X9.7

Power Failure Detection

Device

PFL

I/O

Input Module :

Connector

XJ413 (33)

Address Symbol Coil Comment

X9.7 PFM.M Power Failure Detection

F1.7 MA NC Ready

F0.6 SA Servo Ready

K4.1 KPFM Power Failure Detection Use

32

A4.4 2037 Power Back Up Module Power Failure

Page 35

DBC 130(F30i Series) DBC130ALE2A

33

Page 36

DBC 130(F30i Series)

R628.0

TMB25

Spindle Speed Arrival Check Time

Spindle Speed

Arrival Signal Error

Spindle Speed

Arrival Check Time

2.7

2049

Spindle Speed Arrival Signal Error

1) Description

The spindle failed to reach the instructed revolutions within 20 seconds after the rotation

instruction (M03, M04).

2) Cause of problem

① An error found in parameter settings related to the spindle

② An error found in the signal from the main spindle drive unit

③ An error found in the signal from the position coder

3) Action

① Refer to the parameter sheet that comes with the product and check the spindle-related

parameters (N3700∼N4175). Take a necessary measure if an error is found.

② Check the alarm number that is displayed on the main spindle drive unit of the electric

cabinet, and take a necessary measure according to the alarm number.

☞ Refer to "Troubleshooting by the spindle amplifier alarm" in the appendix.

③ Set the parameter to ignore the position coder settings, and rotate the spindle to check if

DBC130ALE2A

the position coder is set properly. If not, take an appropriate action.

☞ For the parameter to ignore the position coder settings, change all bit numbers of

N4001/N4002 to "0" and rotate the spindle after restarting the machine.

Address Symbol Coil Comment

A6.0 2049 Spindle Speed Arrival Signal Error

R652.7 ARST Alarm Reset

G70.5 SFRA Spindle Forward

G70.4 SRVA Spindle Reverse

R656.0 SARINT Spindle Speed Arrival Interlock

R684.2 SGHON Gear Shift On

34

Page 37

DBC 130(F30i Series) DBC130ALE2A

◈

Note) Spindle-related NC Parameter Table

35

Page 38

DBC 130(F30i Series)

DBC130ALE2A

36

Page 39

DBC 130(F30i Series) DBC130ALE2A

37

Page 40

DBC 130(F30i Series)

alarm

(Note) To change the parameter setting s

(1) Set the mode switch in the main OP to "MDI".

DBC130ALE2A

(2) Press the “OFS/SET” key in the right side of the main

OP monitor.

The following soft key bar will be displayed at the

bottom.

(3) Press the [SETTING] button.

▪ The Setting screen appears where the cursor is

positioned at the “PARAMETER WRITE” item on the

top.

※ If the screen is not displayed as shown in the right

picture, move to the first page of the Setting

Parameter menu (“0”

“NO.SRH”) and press the

Page Up button three times. Then, you will see the

right screen properly.

(4) Enter the number of 1, and keep pressing the INPUT

and EXEC keys.

★

The “SW0100 Parameter Enable Switch ON”

will occur.

38

Page 41

DBC 130(F30i Series) DBC130ALE2A

screen with the cursor positioned at the number.

(addition or subtraction).

necessary.

(5) Press the “SYSTEM” button in the right side of the main

OP monitor.

The following soft key bar will be displayed at the

bottom.

(6) Press the 〔PARAMETER〕 key in the soft key bar.

▪ You will see the Parameter setting screen.

☞

About the soft key bar

Find a desired parameter number.

Ex) If calling parameter no.4175: Enter the number of "4175" and press

the[NO.SRH]soft key in the key bar to move to the Parameter N4175

Used to turn ON (1) the BIT-format parameter.

Ex) Press this to turn ON (1) only the highlighted BIT-format parameters.

Used to turn OFF (0) the BIT-format parameter.

Ex) Press this to turn OFF (0) only the highlighted BIT-format parameters.

Used to increase or decrease a word-format parameter by adding or subtracting

data.

Ex) If you want to add to or subtract from the existing data included in the

parameter, enter a data value to add or subtract (In subtraction, add "-" in

front of the data value.) and press this key to perform the operation

Used to enter a parameter value in the word format.

Ex) Regardless of the existing data, enter a data value and press this button.

The data value will be entered immediately and properly.

(7) Select a navigation button that is suitable to your needs, and use it to adjust the value as

(8) When done, move back to

press the

“RESET” key to release the alarm.

“SETTING”

and turn off

“PARAMETER WRITE”

(“1”

‘0”). Then,

39

Page 42

DBC 130(F30i Series)

cable that is connected from the sensor to the spindle drive unit of the

Spindle Orientation

Overtime Alarm

Orientation

Check Time

2.8

2051

Spindle Orientation Overtime

1) Description

Since the spindle orientation command was instructed in manual or auto mode, no

completion signal is output within 15 seconds.

2) Cause of problem

① An error in parameter settings related to the spindle orientation

② An error in the position coder or defect in feedback cable

3) Action

① Check the parameters (N4042 ~ N4080) related to spindle orientation if they are set

properly. If not, change the settings as appropriate.

② Check the feedback

electric cabinet, and make repair or replacement if you encounter a problem.

DBC130ALE2A

40

Address Symbol Coil Comment

R627.5 TMB22 Orientation Check Time

A6.2 2051 Spindle Orientation Overtime Alarm

R652.7 ARST Alarm Reset

R602.3 M19 Spindle Orientation

R653.0 MEND M-Function End

G70.6 ORCMA Orientation Command

R726.0 MORC Man Orientation Command

F45.7 ORARA Spindle Orientation Complete

Page 43

DBC 130(F30i Series) DBC130ALE2A

SPINDLE AMPLIFIER MODULE 1

TB2

POSITION CODER

41

Page 44

DBC 130(F30i Series)

◈

Note) Spindle Orientation-Related NC Parameter Table (N4042∼N4080)

DBC130ALE2A

42

Page 45

DBC 130(F30i Series) DBC130ALE2A

43

Page 46

DBC 130(F30i Series)

Spindle Maximum

RPM Setting Error

2.9

2052

Spindle Maximum rpm Setting Error

1) Description

A rotation command exceeding the max limit was instructed.

2) Cause of problem

① A rotation command exceeding the max limit (2,500 rpm) was instructed.

② No max rpm has ever been set for the angular head.

3) Action

① Check the current rpm value of the spindle and adjust it to below 2,500 rpm.

② Check the max rpm settings of the angular head (the max rpm setting value: D600)

DBC130ALE2A

Address Symbol Coil Comment

R2910.1 SPDMAX Spindle Max rpm Check

F0.6 SA Servo Ready

R688.2 ANSPMAX Angular Head rpm Max.

K0.1 KANGU Angular Head Used

A6.3 2052 Spindle Maximum rpm Setti n g Err o r

R652.7 ARST Alarm Reset

44

Page 47

DBC 130(F30i Series) DBC130ALE2A

Illegal Condition

Spindle Rotation

Spindle Rotation

Overtime

2.10

2054

Illegal Condition in Spindle Rotation

1) Description

The spindle rotation command is instructed under the condition where the spindle is

prohibited from rotating.

2) Cause of problem

① After the machine starts initially, the rotation command is instructed with no revolution (S-

code command) specified.

② The gear shifting is not complete within 40 seconds after the spindle rotation command

(M03 or M04) was instructed.

3) Action

① Instruct the spindle rotation command after instructing S-Code.

② Check the status of gear shifting.

45

Page 48

DBC 130(F30i Series)

Gear Shift On

DBC130ALE2A

Address Symbol Coil Comment

X38.5 SCW.M Spindle CW

X38.7 SCCW.M Spindle CCW

R680.2 SBY Spindle Stand-By

R642.1 MAN Manual Mode

F0.6 SA Servo Ready

R1600.3 M03 Spindle Forward (CW) Rotation

R1600.4 M04 Spindle Reverse (CCW) Rotation

R685.1 SFON Initial S-Function On

R628.1 TMB26 Spindle Rotation Overtime

R653.0 MEND M-Function End

R684.2 GSHON Gear Shift On

A6.5 2054 Illegal Condition Spindle Rotation

R652.7 ARST Alarm Reset

R683.0 SGL Spindle Gear Change Low

R683.4 SGRL Spindle Gear Change Low

R683.1 SGM Spindle Gear Change Middle

R683.5 SGRM Spindle Gear Change Middle

R683.2 SGH Spindle Gear Change High

R683.6 SRRH Spindle Gear Change High

46

Page 49

DBC 130(F30i Series) DBC130ALE2A

Turn off the machine and loosen the tube connector that is connected to the cylinder. Move

Symbol

(Pin)

ering

SGA.M

SGC.M

SGD.M

GR3.V

GR4.V)

2.11

2056

Gear Shift Overtime Alarm

1) Description

The gear shifting is not complete within 40 seconds after the command was instructed.

2) Cause of problem

① An error found in the solenoid valve for shifting the main spindle gear, or short-circuit of or

error in the gear-shift switch

② An error found in the hydraulic cylinder for gear shifting, or defective in the shift gear itself

3) Action

① Check the solenoid valve, limit switch, wiring cables and I/O module, and make repair or

replacement if you encounter a problem.

②

the cylinder piston up or down to check if it works normally. If you feel it's clamped

somewhere, repair it as necessary.

Signal Address

Gear 1 Check

Gear 2 Check

Gear 3 Check

Gear 4 Check

Gear 1

Gear 2

Gear 3

Gear 4

X3.0

X3.2

SGB.M

X3.3

X3.4

Y4.0

GR1.V

Y4.1

GR2.V

Y4.2

Y4.3

Device

I/O

Connector

Numb

-SL11 Input Module : Slot 06 XJ412 (12) SL11

-SL13 Input Module : Slot 06 XJ412 (44) SL13

-SL14 Input Module : Slot 06 XJ412 (11) SL14

-SL15 Input Module : Slot 06 XJ412 (27) SL15

-KAR40 Output Module : Slot 03 XJ400 (16) YV14

-KAR41 Output Module : Slot 03 XJ400 (32) YV15

-KAR42 Output Module : Slot 03 XJ400 (48) YV18

-KAR43 Output Module : Slot 03 XJ400 (15) YV19

47

Page 50

DBC 130(F30i Series)

Gear Shift

Overtime Alarm

Gear Shift Overtime

Gear Shift On

Spindle Gear

Change Low

SL11

SL13

SL15

SL14

DBC130ALE2A

48

Page 51

DBC 130(F30i Series) DBC130ALE2A

Spindle Gear

Range Low

Spindle Gear

Change Middle

Spindle Gear

Range Middle

Spindle Gear

Change High

Spindle Gear

Range High

Address Symbol Coil Comment

R625.7 TMB24 Gear Shift Overtime

A6.7 2056 Gear Shift Overtime Alarm

R652.7 ARST Alarm Reset

R684.2 GSHON Gear Shift On

49

Page 52

DBC 130(F30i Series)

DBC130ALE2A

Address Symbol Coil Comment

R683.0 SGL Spindle Gear Low

R683.4 SGRL Spindle Ge ar R ange Low

R683.1 SGM Spindle Gear Middle

R683.5 SGRM Spin dle G e ar R ange Mid dl e

R683.2 SGH Spindle Gear High

R683.6 SGRH Spindle Gear Range High

R685.0 IGSL Initial Gear Shift Low

R2700.5 SWAPI Wait for Spindle Warm Up

R1612 M102 Spindle Warm Up Start

F34.0 GR10 Spindle Gear Change Low

K11.3 KG96 G96 Function Used

R2862.5 GEARLOW Gear Low Speed

R684.0 GSTST Gear Shift Start

R682.3 RTAPGH Rigid Tap Only Gear High

F34.1 GR20 Spindle Gear Change Middle

R2862.6 GEARMID Gear Middle Speed

F34.2 GR30 Spindle Gear Change High

R2862.7 GEARHIG Gear High Speed

K75.5 KGRL Gear Shift Low Keep

X3.2 SGA.M Spindle Gear Shift Status B

X3.4 SGD.M Spindle Gear Shift Status D

K0.7 KDB13 DBC130 Type Machine

K75.6 KGRM Gear Shift Middle Keep

K75.7 KGRH Gear Shift High Keep

50

Page 53

DBC 130(F30i Series) DBC130ALE2A

Symbol

(Pin)

SL12

2.12

2057

Spindle Tool Clamp/Unclamp Change Alarm

1) Description

① The tool unclamp command was instructed while not in spindle orientation mode.

② It has passed 10 seconds since the position sensor switch of the spindle tool unclamp

cylinder did not match with the applicable instruction.

2) Cause of problem

① An error in adjusting the position sensor switch

② An error in wiring or component parts

3) Action

① An error in adjusting the position sensor switch

Check the sensor indicator displayed on the proximity switch (located in the rear of the

spindle tool unclamping cylinder) and correct it according to the indicator.

② An error in wiring or component parts

Check the proximity switch, the wiring from the proximity switch to the electric cabinet as

well as the I/O module if there is a problem. Repair or replace the defective part if

necessary.

Signal Address

Spindle Tool Clamp

Spindle Tool Unclamp

X3.1

THLP.M

Y4.6

STUN.V

Device

-SL12

-KAR46

Output Module :

I/O

Input Module :

Slot 6

Slot 3

Connector

Numbering

XJ412 (28) SX12

XA107 (10) YV11

51

Page 54

DBC 130(F30i Series)

Y4.6

STUN.V

Spindle Tool Unclamp

R628.5

TMB30

Spindle Clamp / Unclamp Check Ti me

A7.0

2057

Spindle Tool CL / UNCL Check Alarm

Spindle Tool Clamp/

Unclamp Check Alarm

Spindle Tool Clamp/

Unclamp Check Time

DBC130ALE2A

Address Symbol Coil Comment

R730.5 MSUNCD Manual Spindle Unclamp Command

X3.1 TCLP.M Spindle Tool Clamp

R687.6 ORARAC Spindle Orientation Complete Aux.

R687.5 ORAKEP Orientation Keep Aux.

K4.0 KBLTSP Built-In Spindle Used

R652.7 ARST Alarm Reset

Y4.6 STUN.V Spindle Tool Unclamp

X3.1 TCLP.M Spindle Tool Clamp

X3.0 SGA.M Spindle Gear A/S-Unclamp Built

K4.0 KBLTSP Built-In Spindle Used

F0.6 SA Servo Ready

52

Page 55

DBC 130(F30i Series) DBC130ALE2A

R700.0

TOLSOK

Tool No. Select Keep Relay Set O.K

F0.6

SA

Servo Ready

A7.1

2058

Tool Magazine Selection Keep Relay Not Set

K6.1

K32TS

Tool Magazine 32Tools Used

K6.3

K40TS

Tool Magazine 40Tools Used

K6.6

K120TS

Tool Magazine 120Tools Used

Tool No. Select Keep

Relay Not Set

Tool No. Select Keep

Relay Set O.K

2.13

2058

Tool No. Select Ke ep Relay Not Set

1) Description

An error in the Keep Relay setting that specifies the maximum number of tool pots.

2) Cause of problem

The Keep Relay setting that enables you to select the maximum number of tool pots is not

specified, or more than one setting is found.

3) Action

Check the Keep Relay settings and select a value appropriate to the machine.

Address Symbol Coil Comment

R652.7 ARST Alarm Reset

K6.4 K60TS Tool Magazine 60Tools Used

K6.5 K90TS Tool Magazine 90Tools Used

53

Page 56

DBC 130(F30i Series)

right screen properly.

alarm

DBC130ALE2A

(Note) To change the Keep Relay settings

(1) Set the mode switch in the main OP to "MDI".

(2) Press the “OFS/SET” key in the right side of the main

OP monitor.

The following soft key bar will be displayed at the

bottom.

(3) Press the [SETTING] button.

▪ The Setting screen appears where the cursor is

positioned at the “PARAMETER WRITE” item on the

top.

※ If the screen is not displayed as shown in the right

picture, move to the first page of the Setting

Parameter menu (“0”

“NO.SRH”) and press the

Page Up button three times. Then, you will see the

(4) Enter the number of 1, and keep pressing the INPUT

and EXEC keys.

★

The “SW0100 Parameter Enable Switch ON”

will occur.

54

Page 57

DBC 130(F30i Series) DBC130ALE2A

Activate the

vertical soft key

1

2

(5) Press the “SYSTEM” button in the right side of the main

OP monitor.

The following soft key bar will be displayed at the

bottom.

(6) Move to the Keep Relay screen.

① Press the soft keys one after another to move to the Keep Relay screen.

② Press to activate the vertical soft key in the lower right corner and press the

[KEEP RELAY] key.

55

Page 58

DBC 130(F30i Series)

Tool

DBC130ALE2A

(7) Enter a desired Keep Relay number and press [SEARCH], or move the cursor to the Keep

Relay item and enter 1 or 0. Then, press the INPUT button.

(8) When done, move back to

press the

“RESET” key to release the alarm.

“SETTING”

and turn off

“PARAMETER WRITE”

(“1”

K-Relay K6.6 K6.5 K6.4 K6.3 K6.2 K6.1 K6.0

‘0”). Then,

Tool Count

120

60 Tool 40 Tool 90 Tool Matrix

56

Page 59

DBC 130(F30i Series) DBC130ALE2A

Symbol

(Pin)

MTIO.M

Slot 08

TCAI.M

Slot 08

TCAO.M

Slot 08

Unlocate

TRUC.M

Slot 08

2.14

2059

T-Code Command Initial Condition

1) Description

When the tool magazine or ATC waiting pot had not been initialized, a tool was called (T_:).

2) Cause of problem

① A positioning error in switches that check the home position of ATC or tool magazine

② Defective component part in the switch

3) Action

① Check if the switch works properly on the DGN screen, and adjust the distance from the

dog as appropriate.

② Check the Limit Switch, wiring cables and I/O module, and make repair or replacement if

you encounter a problem.

Signal Address

Device

I/O

Connector

Tool Mag. Tool Out Interlock

Tool Changer Arm 180° CW

Tool Changer Arm 180°

CCW

Tool Changer Arm In

Tool Changer Arm Out

Tool Chg. Guide Rail Locate

Tool Chg. Guide Rail

※

T-Code Initial Position

X12.7

X13.0

T8CW.M

X13.1

T8CC.M

X13.2

X13.3

X13.4

TRLC.M

X13.5

-SL75

-SX78

-SX79

-SX7A

-SX7B

-SX7G

-SX7H

Input Module :

Input Module :

Slot 08

Input Module :

Slot 08

Input Module :

Input Module :

Input Module :

Slot 08

Input Module :

XJ414(37)

XJ414(3)

XJ414(20)

XJ414(35)

XJ414(2)

XJ414(19)

XJ414(34)

Address X12.7 X13.0 X13.1 X13.2 X13.3 X13.4 X13.5

Status 1 1 or 0 0 or 1 1 0 0 1

57

Page 60

DBC 130(F30i Series)

Activate the

vertical soft key

1

2

DBC130ALE2A

(Note) How to move to DGN (Diagnostic)

(1) Press the “SYSTEM” button in the right side of the

main OP monitor.

▪ The following soft key bar will be displayed at the

bottom.

(2) Move to the DGN screen.

① Press the soft keys one after another to move to the DGN screen.

② Press any soft key in the right corner to activate the vertical soft key bar, and press the

[STATUS] key.

(3) Enter a desired DGN address and press

[SEARCH] to display the DGN screen of

your choice.

58

Page 61

DBC 130(F30i Series) DBC130ALE2A

표시

T-Code Command

Initial Condition

M06 Initial Position

T-Code Initial Position

(Note) How to read DGN (Diagnostic)

Ex ) X 00 0 7 0 0 1 1 0 0 1 0

Bit 1, 4 and 5 in Address X7 turn ON while Bit 0, 2, 3, 6 and 7 turn OFF.

0 0 1 1 0 0 1 0

Bit No Bit 7 Bit 6 Bit 5 Bit 4 B it 3 Bit 2 Bit 1 Bit 0

Address Symbol Coil Comment

R709.2 M06INP M06 Initial Position

F7.3 TF T Function Strobe

59

Page 62

DBC 130(F30i Series)

DBC130ALE2A

Address Symbol Coil Comment

R709.3 M06CD M06 Command

R702.1 TCCMD T-Code Command

R702.2 RTCCMD Re-Charge T-Code Command

R708.2 STSECH Spindle Tool Search

R1605.5 M45 Spindle Tool No. Set

R700.2 WPTNCM Wait. Pot Tool No. Command

R701.6 TFINP T-Code Initial Position

R910.0 ATCALM ATC Alarm

K40.7 SUMA_ Sub. OP Manual Mode

A7.2 2059 T-Code Command Initial Condition

R652.7 ARST Alarm Reset

R649.7 TMADOP Tool Magazine Door Open Aux.

K7.6 KATC ATC Use

R720.1 WTZERO Waiting Pot Tool Number Zero

R712.2 T0END T-Code Zero Command End

R717.0 TM06 Tool Zero M06 Command

X13.0 T8CW.M Tool Changer Arm 180° CW

X13.1 T8CC.M Tool Changer Arm 180° CCW

R731.3 AM.MWT ATC Changer Mag. Wait Position

X13.2 TCAI.M Tool Changer Arm In

X13.3 TCAO.M Tool Changer Arm Out

X13.4 TRLC.M Tool Changer Guide Rail Locate

X13.5 TRUC.M Tool Changer Guide Rail Unlocate

X12.7 MTOI.M Tool Mag. Tool Out Interlock

K36.7 ANHD_ Angle Head

K80.1 KANGHD Angular Mismatch Alarm(M121)

K80.7 KFACKEP

60

Page 63

DBC 130(F30i Series) DBC130ALE2A

Symbol

(Pin)

Interlock

MTIO.M

Slot 08

CW

T8CW.M

Slot 08

TCAI.M

Slot 08

TCAO.M

Slot 08

Unlocate

TRUC.M

Slot 08

2.15

2060

M06 Command Illegal Position

1) Description

A tool change was instructed (by M06 or manually) in other than the home position.

2) Cause of problem

① The tool had not been called before the instruction.

② An error in the switch that detects the home position of tool magazine, waiting tool pot, or

ATC.(The interval between switch and dog is set improperly, or the switch itself has a

defective part.)

3) Action

① You should call a tool before instructing to change it.

T_ _ ; M06 ; or T_ _ M06 ;

② Check if the switch works properly on the DGN screen, and adjust the distance from the

dog as appropriate. Check the Limit Switch, wiring cables and I/O module, and make

repair or replacement if you encounter a problem.

Signal Address

Tool Mag. Tool Out

Tool Changer Arm 180°

Tool Changer Arm 180°

CCW

Tool Changer Arm In

Tool Changer Arm Out

Tool Chg. Guide Rail

Locate

Tool Chg. Guide Rail

X12.7

X13.0

X13.1

T8CC.M

X13.2

X13.3

X13.4

TRLC.M

X13.5

Device

-SL75

-SX78

-SX79

-SX7A

-SX7B

-SX7G

-SX7H

I/O

Input Module :

Input Module :

Input Module :

Slot 08

Input Module :

Input Module :

Input Module :

Slot 08

Input Module :

Connector

XJ414(37)

XJ414(3)

XJ414(20)

XJ414(35)

XJ414(2)

XJ414(19)

XJ414(34)

※

T-Code Initial Position

Address X12.7 X13.0 X13.1 X13.2 X13.3 X13.4 X13.5

Status 1 1 or 0 0 or 1 1 0 0 1

61

Page 64

DBC 130(F30i Series)

Activate the

vertical soft key

1

2

DBC130ALE2A

(Note) How to move to DGN (Diagnostic)

(1) Press the “SYSTEM” button in the right side of the main

OP monitor.

▪ The following soft key bar will be displayed at the

bottom.

(2) Move to the DGN screen.

① Press the soft keys one after another to move to the DGN screen.

② Press any soft key in the right corner to activate the vertical soft key bar, and press the

[STATUS] key.

(3) Enter a desired DGN address and press

[SEARCH] to display the DGN screen of

your choice.

62

Page 65

DBC 130(F30i Series) DBC130ALE2A

표시

M06 Command

Illegal Position

M06 Initial Position

(Note) How to read DGN (Diagnostic)

Ex ) X 00 0 7 0 0 1 1 0 0 1 0

Bit 1, 4 and 5 in Address X7 turn ON while Bit 0, 2, 3, 6 and 7 turn OFF.

0 0 1 1 0 0 1 0

Bit No Bit 7 Bit 6 Bit 5 Bit 4 B it 3 Bit 2 Bit 1 Bit 0

Address Symbol Coil Comment

R709.2 M06INP M06 Initial Position

F7.3 TF T Function Strobe

R709.3 M06CD M06 Command

R702.1 TCCMD T-Code Command

R702.2 RTCCMD Re-Charge T-Code Command

R708.2 STSECH Spindle Tool Search

63

Page 66

DBC 130(F30i Series)

DBC130ALE2A

Address Symbol Coil Comment

R1605.5 M45 Spindle Tool No. Set

R700.2 WPTNCM Wait. Pot Tool No. Command

R701.6 TFINP T-Code Initial Position

R910.0 ATCALM ATC Alarm

K40.7 SUMA_ Sub. OP Manual Mode

A7.2 2059 T-Code Command Initial Condition

R652.7 ARST Alarm Reset

R649.7 TMADOP Tool Magazine Door Open Aux.

K7.6 KATC ATC Use

R720.1 WTZERO Waiting Pot Tool Number Zero

R712.2 T0END T-Code Zero Command End

R717.0 TM06 Tool Zero M06 Command

X13.0 T8CW.M Tool Changer Arm 180° CW

X13.1 T8CC.M Tool Changer Arm 180° CCW

R731.3 AM.MWT ATC Changer Mag. Wait Position

X13.2 TCAI.M Tool Changer Arm In

X13.3 TCAO.M Tool Changer Arm Out

X13.4 TRLC.M Tool Changer Guide Rail Locate

X13.5 TRUC.M Tool Changer Guide Rail Unlocate

X12.7 MTOI.M Tool Mag. Tool Out Interlock

K36.7 ANHD_ Angle Head

K80.1 KANGHD Angular Mismatch Alarm(M121)

K80.7 KFACKEP

64

Page 67

DBC 130(F30i Series) DBC130ALE2A

T-Code Over

Command Error

2.16

2061

T-Code Over Command Error

1) Description

A T code that is not appropriate to the machine is instructed.

2) Cause of problem

A larger POT number than the pot count available in the machine is called.

3) Action

Check the number of the spindle tool data and waiting tool data in "PMC" > "D-Data" and

correct it appropriately and try again.

Address Symbol Coil Comment

R710.0 TNOVER Tool No. Over Command Error

R710.3 TN=SN T-Code=Spindle Tool Command

R1605.5 M45 Spindle Tool No. Set

K8.3 KTC=SP Spindle Tool Command Error Used

R700.1 TFSTB TF Strobe

A7.4 2061 T-Code Command Error

R652.7 ARST Alarm Reset

K7.6 KATC ATC Not Use

65

Page 68

DBC 130(F30i Series)

M06 Command

Overtime Alarm

M06 Command

Overtime

DBC130ALE2A

2.17

2062

M06 Command Overtime Alarm

1) Description

The mode switch of the ATC manual OP is set to Auto with the door being open. A tool

change command (M06) was instructed but not complete within 6 seconds.

2) Cause of problem

In most cases, this happens if a tool is stuck in the changer arm while it is changed.

3) Action

Move the changer arm to the home position manually and find and resolve the cause of

trouble.

Address Symbol Coil Comment

R625.6 TMB23 M06 Command Overtime

A7.5 2062 M06 Command Overtime Alarm

R652.7 ARST Alarm Reset

K7.6 KATC ATC Not Use

R1600.6 M06 ATC Change Macro Call

R640.5 CYSTP Cyc le S t op

R650.1 DCL Operator Door Close Confirm

R1120.2 M250A Door Interlock Bypass On Aux.

A31.1 2250 Manual Mode Selected On ATC PA

R649.7 TMADOP Tool Mag. Door Open Aux.

66

Page 69

DBC 130(F30i Series) DBC130ALE2A

Address Symbol Coil Comment

R702.1 TCCMD T-Code Command

Y10.4 MSON.R TMG Servo On

F0.5 STL Cycle Start

67

Page 70

DBC 130(F30i Series)

Tool Search Start (T _ _;)

No

Yes

★ AL 2250 “ATC OP Manual Mode” occurs

Searched tool No

No

Searched tool No

No

No

TMG & ATC Initial

Yes

Yes

Yes

Yes

No

★ Tool Search Complete

★ 1st Tool to Tool Magazine, And 2nd Tool In Valid

★ AL 2059 “T-Code Command Illegal Position”

occurs

On/Off

On

Off

1

Carriage Magazine Pot Position

On

Carriage Mag. Pot

No

On

Off/On

Off

On

On

On

Yes

Off

Off

Off

On

Off

Off

Off

Note) Tool Search (T _ _ ;) Sequence Chart

ATC Manual O.P

Auto Mode?

=Spd. Tool No?

=Wait. Tool No?

DBC130ALE2A

▪ Turn the mode switch in the manual OP to Auto.

Double Tool

Search?

Position?

▪ Check: X13.0(T8CW.M) –SX78 Chan. Arm 180 CCW

X13.1(T8CC.M) –SX79 Chan. Arm 180 CW

X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

X13.2(TCAI.M) –SX7A Tool Changer Arm In

X13.3(TCAO.M) –SX7B Tool Changer Arm Out

X13.4(TRLC.M) –SX7G Guide Rail Location

X13.5(TRUC.M) –SX7H Guide Rail Unlocation

X12.7(MTOI.M) –SL75 Tool Outer Unpush

▪ Output: Y9.0(CPSO1.R) –CPSO1 ATC Carriage Pos. 1

▪ Completed:X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

68

Position?

▪ c

heck: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

Page 71

DBC 130(F30i Series) DBC130ALE2A

Tool Changer Arm

No

★ AL 2255 “Changer Arm In/Out Alarm”

On

Yes

3

Carriage Magazine Wait Position

No

On

Yes

4

Tool Changer Arm In

On

On

Tool Changer Arm

No

★ AL 2255 “Changer Arm In/Out Alarm”

occurs

On

Yes

Off

Off

2

Tool Changer Arm Out

On

On

On

On

Off

Off

Off

Tool Search End

▪

Output: 6.4(TCAO.V) –YV79 Tool Changer Arm Out

▪

Completed:X13.3(TCAO.M) –SX7B Tool Changer Arm Ou

occurs

Out O.K?

Carriage Mag.

Wait. Position?

In O.K?

▪

Check: X13.3(TCAO.M) –SX7B Tool Changer Arm Out

X13.2(TCAI.M) –SX7A Tool Changer Arm In

▪ Output: Y9.1(CPSO2.R) –CPSO2 ATC Carriage Pos. 2

▪ Completed: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

▪

Check: X16.1(TPSI1.M) ATC Servo Carriage Pos.1

▪

Output: Y6.3(TCAI.V) –YV78 Tool Changer Arm In

▪

Completed: X10.1(SCAO.M) –SL31 Sub Changer Arm In

▪

Check: X13.3(TCAO.M) –SX7B Tool Changer Arm Out

X13.2(TCAI.M) –SX7A Tool Changer Arm In

69

Page 72

DBC 130(F30i Series)

1

ATC Change Position & M19

No

Yes

Tool Change Start (M06)

★ AL 2060 “M06 Command Illegal Position” occurs

On/Off

On

Off

Off/On

Off

On

On

On

Off

Off

Off

ATC Manual O.P

Yes

★ AL 2262 “ATC magazine Guard Door Open” occurs

No

No

No

No

Off

2

Guide Rail Locate

On

On

★ AL 2083 “ATC Guide Rail Locate Sensor Error” occurs

No

Off

On

Yes

Yes

Yes

Yes

Note) Tool Changing (M06;) Sequence Chart

DBC130ALE2A

Spindle

Orientation?

Spindle

Orientation?

M06 Initial

Position?

Auto Mode?

▪

Return Y, Z, W to 2nd ref. points & Spindle Orientation

▪

Program : G91 G30 Y0. Z0. W0. M19 ;

▪ Check: X13.0(T8CW.M) –SX78 Chan. Arm 180 CCW

X13.1(T8CC.M) –SX79 Chan. Arm 180 CW

X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

X13.2(TCAI.M) –SX7A Tool Changer Arm In

X13.3(TCAO.M) –SX7B Tool Changer Arm Out

X13.4(TRLC.M) –SX7G Guide Rail Location

X13.5(TRUC.M) –SX7H Guide Rail Unlocation

X12.7(MTOI.M) –SL75 Tool Outer Unpush

▪ Turn the mode switch in the manual OP to Auto.

Magazine Guard

Door Close

Guide Rail

Location O.K?

?

70

▪

Check: X13.6(MGOP.M) Mag. Side Door Open

▪

Output: Y6.2(TRLC.V) –YV7G Guide Rail Locate

▪ Completed: X13.4(TRLC.M) –SX7B Chan.Guide Rail

Locate

▪ Check: X13.4(TRLC.M) –SX7G Chan.Guide Rail Locate

X13.5(TRUC.M) –SX7H Guide Rail Unlocate

Page 73

DBC 130(F30i Series) DBC130ALE2A

3

Carriage Spindle Wait Pos.(Pos.6)

No

On

On

Off

Off

On

On

4

Carriage Spindle Side(Pos.7)

On

On

Off

On

No

On

On

On

On

On

On

5

Spindle Tool Unclamp

Off

★ AL 2057 “Spindle Tool Clamp Switch Alarm” 발생

No

Off

On

6

Tool Changer Arm Out

On

On

Tool Changer Arm

No

★ AL 2255 “Changer Arm In/Out Alarm”

occurs

On

Off

On

7

Changer Arm 180CW Rotation

On

No

★ AL 2256 “Changer 180CW/180CCW Alarm”

occurs

On

Off

Yes

Yes

Yes

Yes

Yes

On

On

Carriage Spindle

Wait Position?

▪

Output: Y9.1(CPSO2.R) –CPSO2 ATC Carriage Pos. 2

Y9.2(CPSO3.R) –CPSO3 ATC Carriage Pos. 3

▪

Completed: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

▪

Check: X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

▪ Output: Y9.0(CPSO1.R) –CPSO1 ATC Carriage Pos. 1

Y9.1(CPSO2.R) –CPSO2 ATC Carriage Pos. 2

Y9.2(CPSO3.R) –CPSO3 ATC Carriage Pos. 3

▪ Completed: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

Carriage Spindle

Wait Position?

Spindle Tool

Unclamp O.K?

Out O.K?

▪

Check: X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

▪

Output: Y4.6(STUN.V) –YV22 Spindle Tool Unclamp

▪

Completed: X3.1(TCLP.M) –SL12 Spindle Tool Clamp

▪

Check: X3.1(TCLP.M) –SL12 Spindle Tool Clamp

▪

Output: Y6.4(TCAO.V) –YV79 Tool Changer Arm Out

▪

Completed: X13.3(TCAO.M) –SX7B Tool Changer Arm Out

▪

Check: X13.3(TCAO.M) –SX7B Tool Changer Arm Out

X13.2(TCAI.M) –SX7A Tool Changer Arm In

▪

Output: Y6.0(TC8F.V) –YV7A Tool Changer 180CW

▪ Completed: X13.0(T8CW.M)–SX78 Tool Changer 180CW

Changer Arm CW

Rotation O.K?

▪

Check: X13.0(T8CW.M)–SX78 Tool Changer 180CW

X13.1(T8CC.M) –SX79 Tool Changer 180CCW

71

Page 74

DBC 130(F30i Series)

Yes

8

Tool Changer Arm In

On

Tool Changer Arm

No

★ AL 2255 “Changer Arm In/Out Alarm”

occurs

On

Off

On

9

Spindle Tool Clamp

On

★ AL 2057 “Spindle Tool Clamp Switch Alarm” 발생

No

On

Off

Carriage Spindle Wait Pos.(Pos.6)

On

Off

Off

On

No

On

On

11

Carriage Magazine Wait Position

On

On

Off

Off

Off

No

On

Yes

Guide Rail Unlocate

On

★ AL 2083 “ATC Guide Rail Locate Sensor Error” occurs

No

On

Off

Off

12

Yes

Yes

Yes

10

Tool Change (M06)End

In O.K?

Spindle Tool

Clamp O.K?

▪

Output: Y6.3(TCAI.V) –YV78 Tool Changer Arm In

▪

Completed: X10.1(SCAO.M) –SL31 Sub Changer Arm In

▪

Check: X13.3(TCAO.M) –SX7B Tool Changer Arm Out

X13.2(TCAI.M) –SX7A Tool Changer Arm In

▪

Output: Y4.6(STUN.V) –YV22 Spindle Tool Unclamp

▪

Completed: X3.1(TCLP.M) –SL12 Spindle Tool Clamp

▪

Check: X3.1(TCLP.M) –SL12 Spindle Tool Clamp

DBC130ALE2A

Carriage Spindle

Wait Position?

Carriage Mag.

Wait. Position?

Guide Rail

Unlocation O.K?

▪

Completed: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

▪

Check: X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

▪ Output: Y9.1(CPSO2.R) –CPSO2 ATC Carriage Pos. 2

▪

Completed: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

▪

Check: X16.1(TPSI1.M) ATC Servo Carriage Pos.1

▪

Output: Y6.2(TRLC.V) –YV7G Guide Rail Locate

▪

Completed: X13.4(TRLC.M) –SX7B Chan. Guide Rail

Locate

▪

Check: X13.4(TRLC.M) –SX7G Chan. Guide Rail Locate

X13.5(TRUC.M) –SX7H Guide Rail Unlocate

72

Page 75

DBC 130(F30i Series) DBC130ALE2A

M06 End

Carriage Magazine Pot Position

On

On

Off

Off

Off

Pot

No

On

Yes

Tool Changer Arm Out

On

Tool Changer Arm

No

★ AL 2255 “Changer Arm In/Out Alarm”

occurs

On

Off

Tool Changer Arm In

On

Tool Changer Arm

No

★ AL 2255 “Changer Arm In/Out Alarm”

On

Off

On

Carriage Magazine Wait Position

On

On

Off

Off

Off

No

On

Yes

Tool Re-Charge End

Yes

Yes

1

2

3

3

Note) Tool Re-Charging Sequ ence Chart

Out O.K?

Carriage Mag.

Position?

▪

Completed: X13.3(TCAO.M) –SX7B Tool Changer Arm Out

▪

Check: X13.3(TCAO.M) –SX7B Tool Changer Arm Out

X13.2(TCAI.M) –SX7A Tool Changer Arm In

▪ Output: Y9.0(CPSO1.R) –CPSO1 ATC Carriage Pos. 1

▪

Completed: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

X16.1(TPSI1.M) ATC Servo Carriage Pos.1

X16.2(TPSI2.M) ATC Servo Carriage Pos.2

X16.3(TPSI3.M) ATC Servo Carriage Pos.3

▪

Check: X16.0(TPSI0.M) ATC Servo Carriage Pos.0

In O.K?

Carriage Mag.

Wait. Position?

▪

Output: Y6.3(TCAI.V) –YV78 Tool Changer Arm In

▪

Completed: X10.1(SCAO.M) –SL31 Sub Changer Arm In

occurs

▪

Check: X13.3(TCAO.M) –SX7B Tool Changer Arm Out