Page 1

Service Manual

SB4118E01

May. 2007

Diesel Engine 5.8 Liter (DB58S)

D35S-5, D40S-5, D45S-5, D50C-5, D55C-5

D50S-5, D60S-5, D70S-5, D80S-5, D90S-5

D50S-5, D60S-5, D70S-5

(2 speed)

(3 speed)

Page 2

Page 3

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. A person must be alert to potential hazards. This person should also have the necessary training,

skills and tools to perform these functions properly.

Read and understand all safety precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the “Safety” section of the Service or Technical Manual. Additional safety

precautions are listed in the “Safety” section of the owner/operation/maintenance publication.

Specific safety warnings for all these publications are provided in the description of operations where hazards exist.

WARNING labels have also been put on the product to provide instructions and to identify specific hazards. If

these hazard warnings are not heeded, bodily injury or death could occur to you or other persons. Warnings in this

publication and on the product labels are identified by the following symbol.

WARNING

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and

understood the operation, lubrication, maintenance and repair information.

Operations that may cause product damage are identified by NOTICE labels on the product and in this publication.

DOOSAN cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in

this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating

technique not specifically recommended by DOOSAN is used, you must satisfy yourself that it is safe for you and

others. You should also ensure that the product will not be damaged or made unsafe by the operation, lubrication,

maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product. Obtain the complete and

most current information before starting any job. DOOSAN dealers have the most current information available.

Page 4

Page 5

FOREWORD

This maintenance manual is designed to serve as a reference for DOOSAN Infracore Ltd's (here after DOOSAN’s)

customers and distributors who wish to gain basic product knowledge on DOOSAN's DB58S Diesel engine.

This economical and high-performance diesel engine (6 cylinders, 4 strokes, in-line, direct injection type) has been

so designed and manufactured to be used for the overland transport or industrial purpose. That meets all the

requirements such as low noise, fuel economy, high engine speed, and durability.

To maintain the engine in optimum condition and retain maximum performance for a long time, CORRECT

OPERATION and PROPER MAINTENANCE are essential.

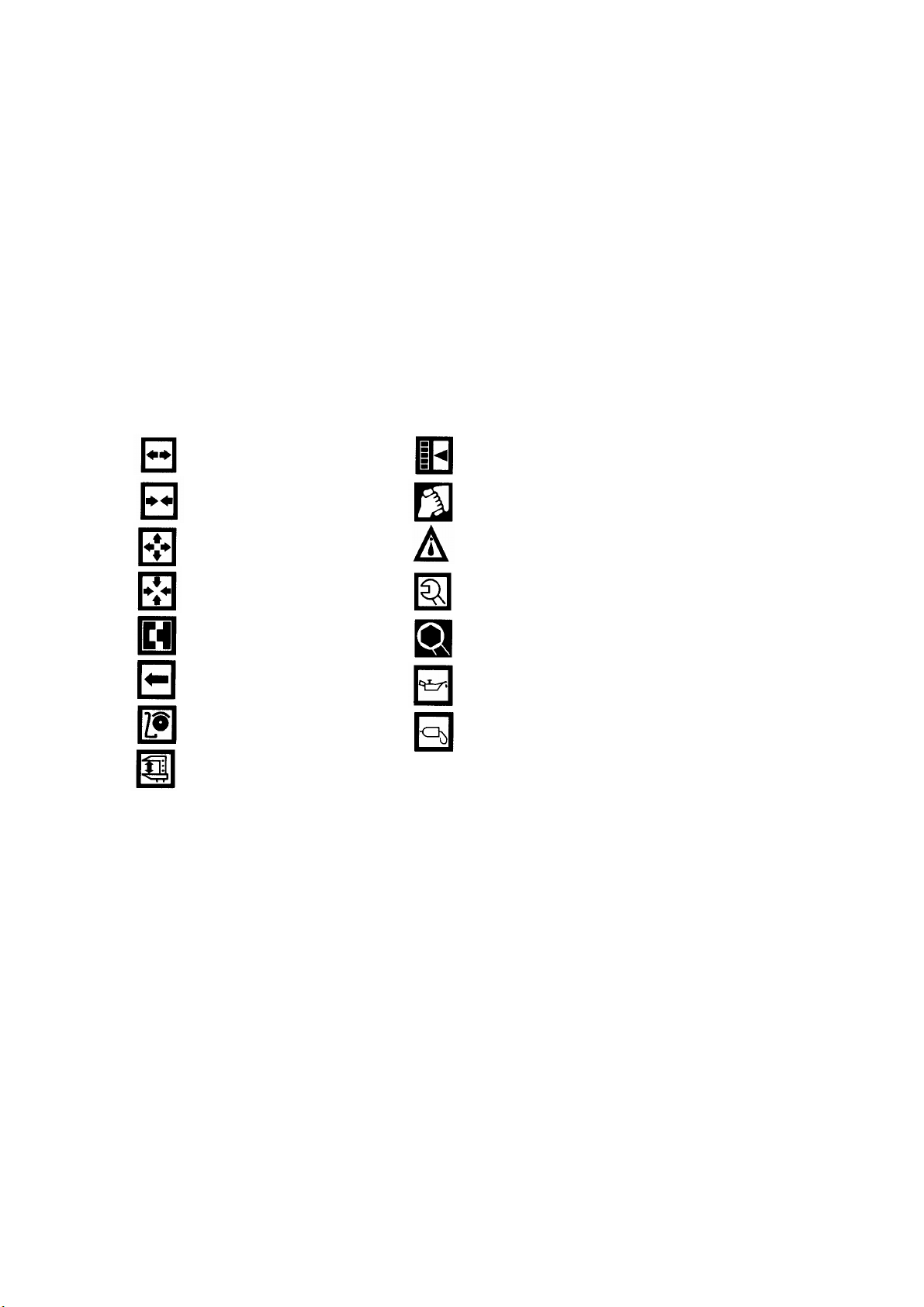

In this manual, the following symbols are used to indicate the type of service operations to be performed.

Removal Adjustment

Installation Cleaning 15

Disassembly Pay close attention-Important

Reassembly Tighten to specified torque

Align the marks Use special tools of manufacturer's

Directional Indication Lubricate with oil

Inspection Lubricate with grease

Measurement

During engine maintenance, please observe following instructions to prevent environmental damage;

z Take old oil to an old oil disposal point only.

z Ensure without fail that oil will not get into the sea or rivers and canals or the ground.

z Treat undiluted anti-corrosion agents, antifreeze agents, filter element and cartridges as special waste.

z The regulations of the relevant local authorities are to be observed for the disposal of spent coolants and

special waste.

If you have any question or recommendation in connection with this manual, please do not hesitate to contact our

head office, dealers or authorized service shops near by your location for any services.

For the last, the content of this maintenance instruction may be changed without notice for some quality

improvement. Thank you.

Page 6

Page 7

1. GENERAL INFORMATION

1.1. Engine specifications..................................1

1.2. Performance curve.....................................2

1.2.1. Performance curve (ECRFA),

D50/60/70/80/90S-5 (3 speed) .... 2

1.2.2. Performance curve (ECRFD),

D35/40/45S-5, D50/55C-5 ..........3

1.2.3. Performance curve (ECRFE),

D50/60/70S-5 (2 speed).............. 4

1.3. Engine assembly........................................5

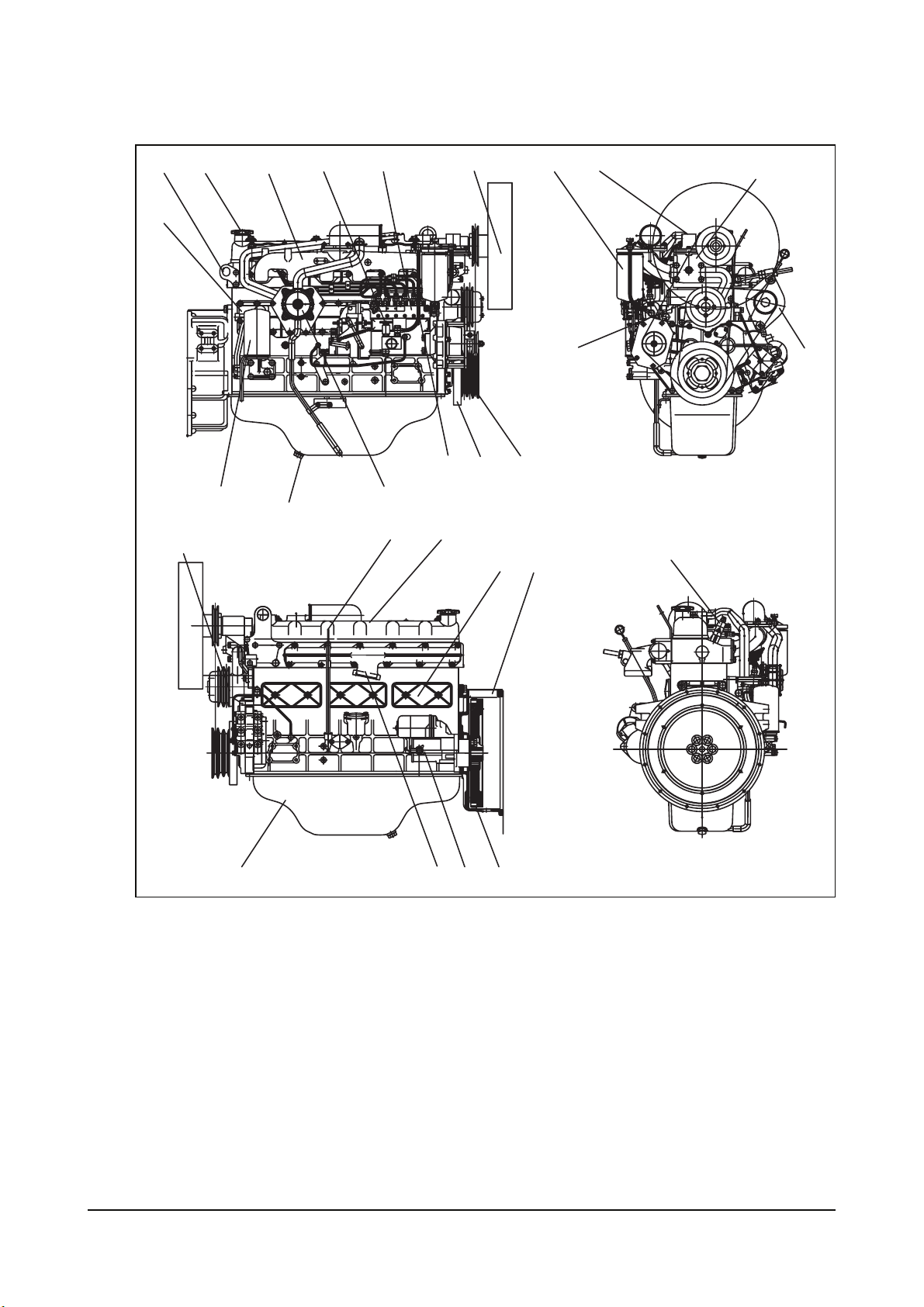

1.3.1. Engine assembly view (ECRFA),

D50/60/70/80/90S-5 (3 speed) .... 5

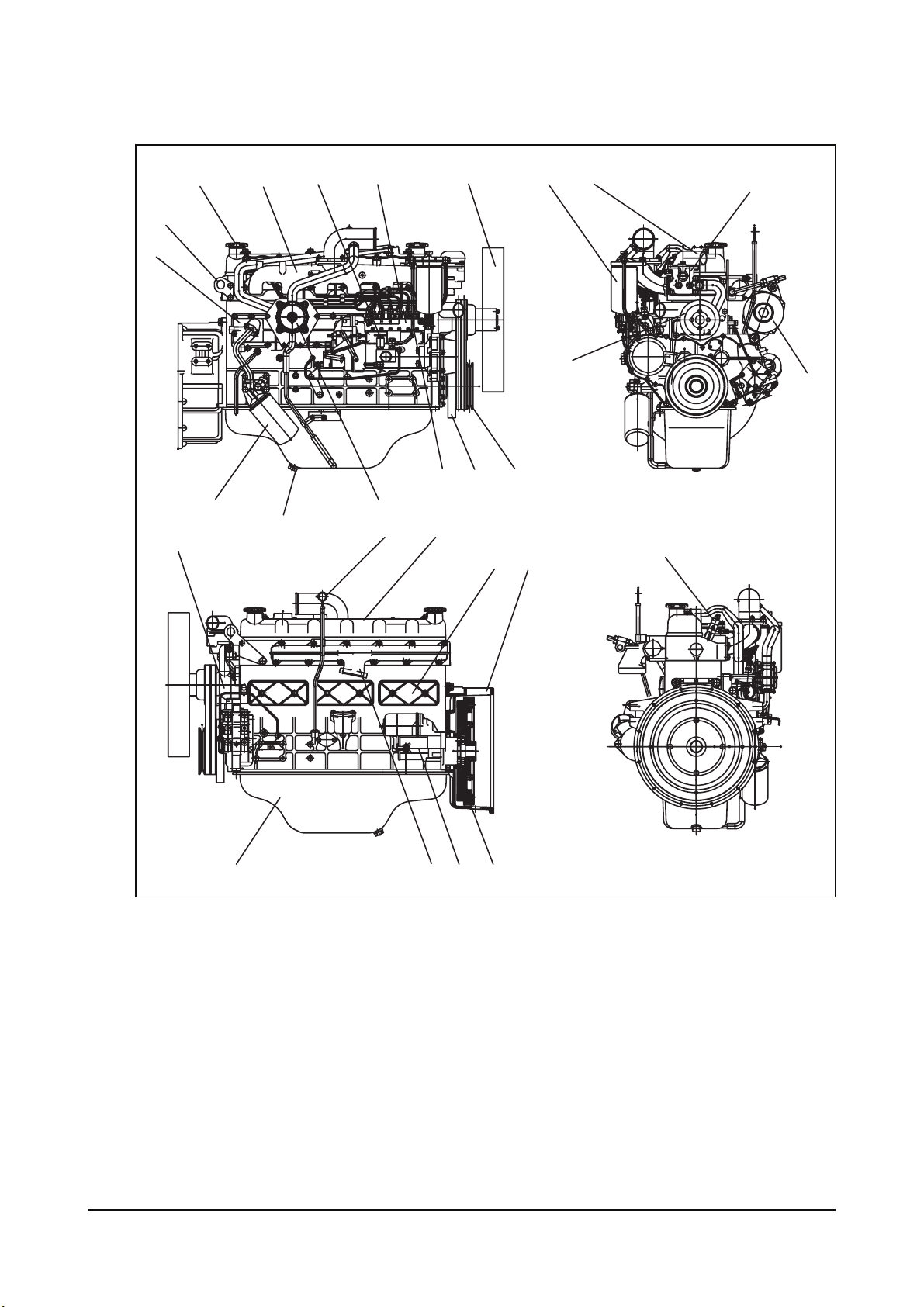

1.3.2. Engine assembly view (ECRFD),

D35/40/45S-5, D50/55C-5 ..........6

1.3.3. Engine assembly views (ECRFE),

D50/60/70S-5 (2 speed).............. 7

1.4. Safety regulations.......................................8

1.4.1. General notes ............................. 8

1.4.2. Regulations designed to prevent

accidents .................................... 8

1.4.3. Regulations designed to prevent

damage to engine and premature

wear........................................... 9

1.4.4. Regulations designed to prevent

pollution.................................... 10

1.4.5. General repair instructions ........ 11

2. TECHNICAL INFORMATION

2.1. Engine model and serial number..............12

2.2. Engine type ..............................................13

2.2.1. Cylinder block ........................... 13

2.2.2. Piston con-rod / crankshaft........ 13

2.3. Engine timing............................................13

2.4. Valves.......................................................14

2.5. Lubrication system ...................................14

2.5.1. Recommend of lubricating oil .... 15

2.5.2. Oil cooler .................................. 16

2.5.3. Oil filter..................................... 16

2.6. Air cleaner ................................................17

2.7. Fuel system..............................................17

2.7.1. Injection pump .......................... 18

2.7.2. Fuel filter................................... 18

2.7.3. Fuel requirements ..................... 18

2.7.4. How to select fuel oil................. 19

CONTENTS

2.8. Cooling system ........................................ 20

2.8.1. Anti-freeze.................................21

2.8.2. Cooling water............................21

2.9. V-belt tension check and adjust............... 23

2.10. Valve clearance and adjustment............ 24

2.11. Cylinder compression pressure ............. 25

2.12. Injection nozzle...................................... 26

2.13. Battery ................................................... 26

2.14. Starting motor ........................................ 26

2.15. Diagnosis and remedy........................... 27

2.16. Engine inspection .................................. 36

2.16.1. Stopping engine ......................36

2.16.2. General engine inspection cycle36

2.17. Use of original parts for repair and

replacement.................................................... 37

3. Maintenance

3.1. Engine Disassembly ................................ 38

3.1.1. Major part fixing nuts and bolts ..38

3.1.2. Main structure parts (1) .............49

3.1.3. Main structure parts (2) .............51

3.1.4. Rocker arm disassembly...........53

3.1.5. Cylinder head disassembly........54

3.1.6. Piston and connecting rod

disassembly.............................. 55

3.2. Engine Inspection .................................... 57

3.2.1. Cylinder block............................57

3.2.2. Cylinder head ............................57

3.2.3. Valve stem and valve guide

clearance..................................58

3.2.4. Valve spring .............................. 62

3.2.5. Tappet ......................................63

3.2.6. Push rod ...................................63

3.2.7. Rocker arm correction...............64

3.2.8. Idler gear and shaft ...................65

3.2.9. Camshaft ..................................65

3.2.10. Cylinder liner ...........................67

3.2.11. Cylinder block..........................68

3.2.12. Piston......................................71

3.2.13. Maintenance of cylinder block,

cylinder liner and piston ...........74

3.2.14. Connecting rod........................75

3.2.15. Crankshaft...............................77

3.2.16. Flywheel and flywheel housing 81

Page 8

3.3. Engine Reassembly .................................82

3.3.1. Piston and connecting rod assembly

................................................. 82

3.3.2. Cylinder head assembly parts ... 84

3.3.3. Rocker arm and shaft assembly 87

3.3.4. Main components ..................... 88

3.3.5. Major component assembly ...... 94

3.3.6. External parts ........................... 98

4. Commissioning and Operation

4.1. Preparation.............................................103

4.1.1. Starting................................... 103

4.2. Starting and operation ............................104

4.2.1. Operation of a new engine (Break-

In)........................................... 104

4.2.2. Check points for break-in ........ 104

4.3. Inspections after starting ........................106

4.4. Operation in winter time .........................106

4.4.1. Prevention against the freeze of

cooling water .......................... 106

4.4.2. Prevention against excessive

cooling.................................... 106

4.4.3. Lubricating oil ......................... 107

4.4.4. Starting of engine in winter...... 107

4.4.5. Tuning the engine ................... 107

4.5. Maintenance and care............................108

4.5.1. Periodical inspection and

maintenance........................... 108

4.5.2. Exchanging of lubrication oil.... 108

4.5.3. Oil level................................... 108

4.5.4. Oil exchange procedure .......... 108

4.5.5. Replacement of oil filter cartridge109

4.6. Cooling system.......................................110

4.6.1. Coolant draining...................... 110

4.6.2. Cleaning of the cooling inside

system circuit.......................... 111

4.7. Valve clearance and adjustment ............111

4.8. Injection timing .......................................113

4.9. Tightening the cylinder head bolts..........116

4.10. Fuel injection pump ..............................116

4.11. Feed pump strainer ..............................117

4.12. Separator (Add if necessary)................117

4.13. Air bleeding ..........................................117

4.14. Belts .....................................................118

5. Maintenance of Major Components

5.1. Lubrication system................................. 121

5.1.1. Oil pump .................................121

5.1.2. Oil cooler.................................123

5.2. Cooling system ...................................... 124

5.2.1. Water pump ............................124

5.2.2. Thermostat.............................. 128

5.3. Fuel system ........................................... 129

5.3.1. Fuel filter.................................129

5.3.2. Injection nozzle ....................... 130

5.3.3. Injection Pump Calibration.......134

5.3.4. Precautions for operation......... 137

5.3.5. Walk-around check and servicing

...............................................138

5.3.6. Diagnostics and troubleshooting139

6. Special Tool List ......................... 140

• Appendix ...............................................142

Page 9

1. GENERAL INFORMATION

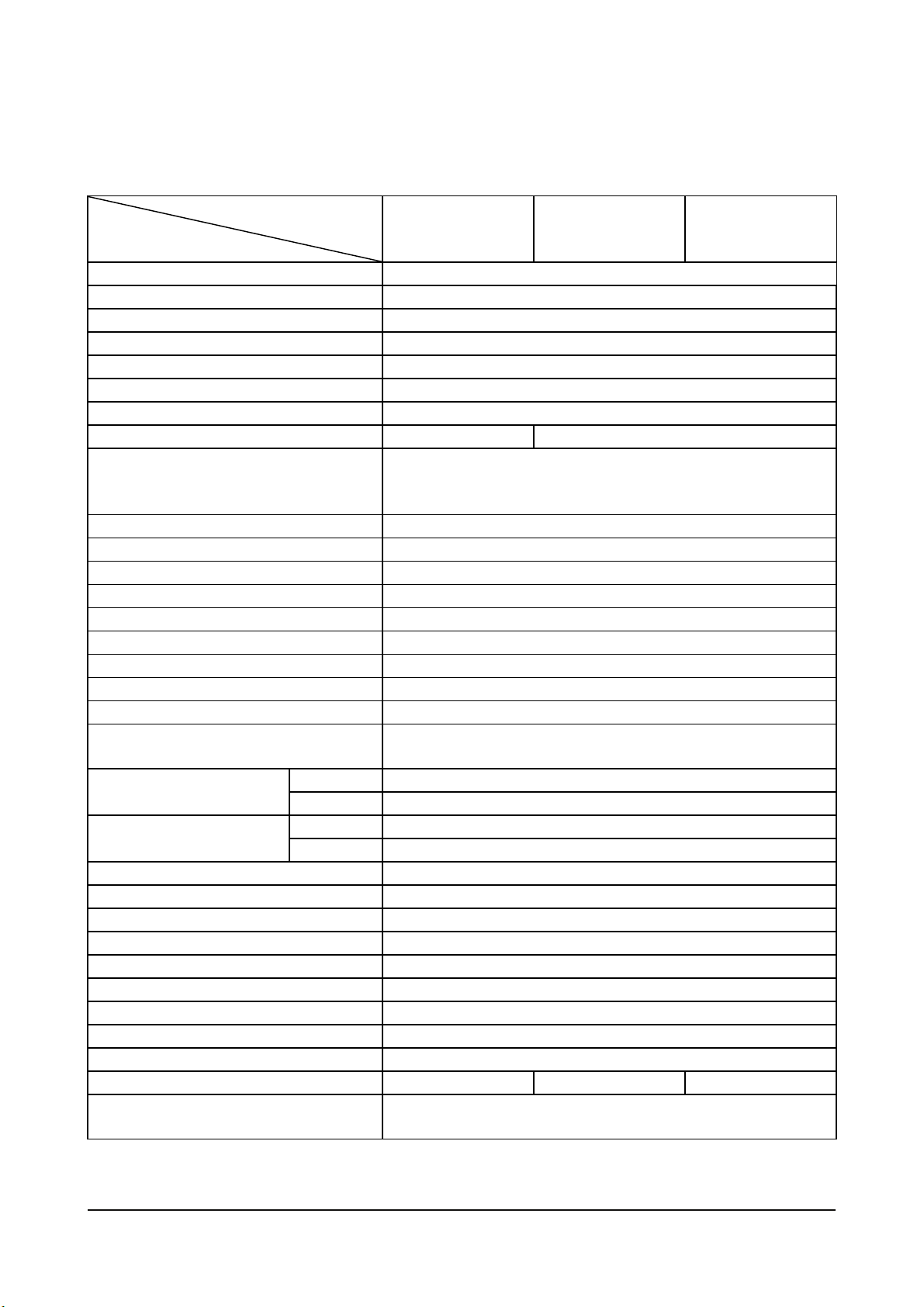

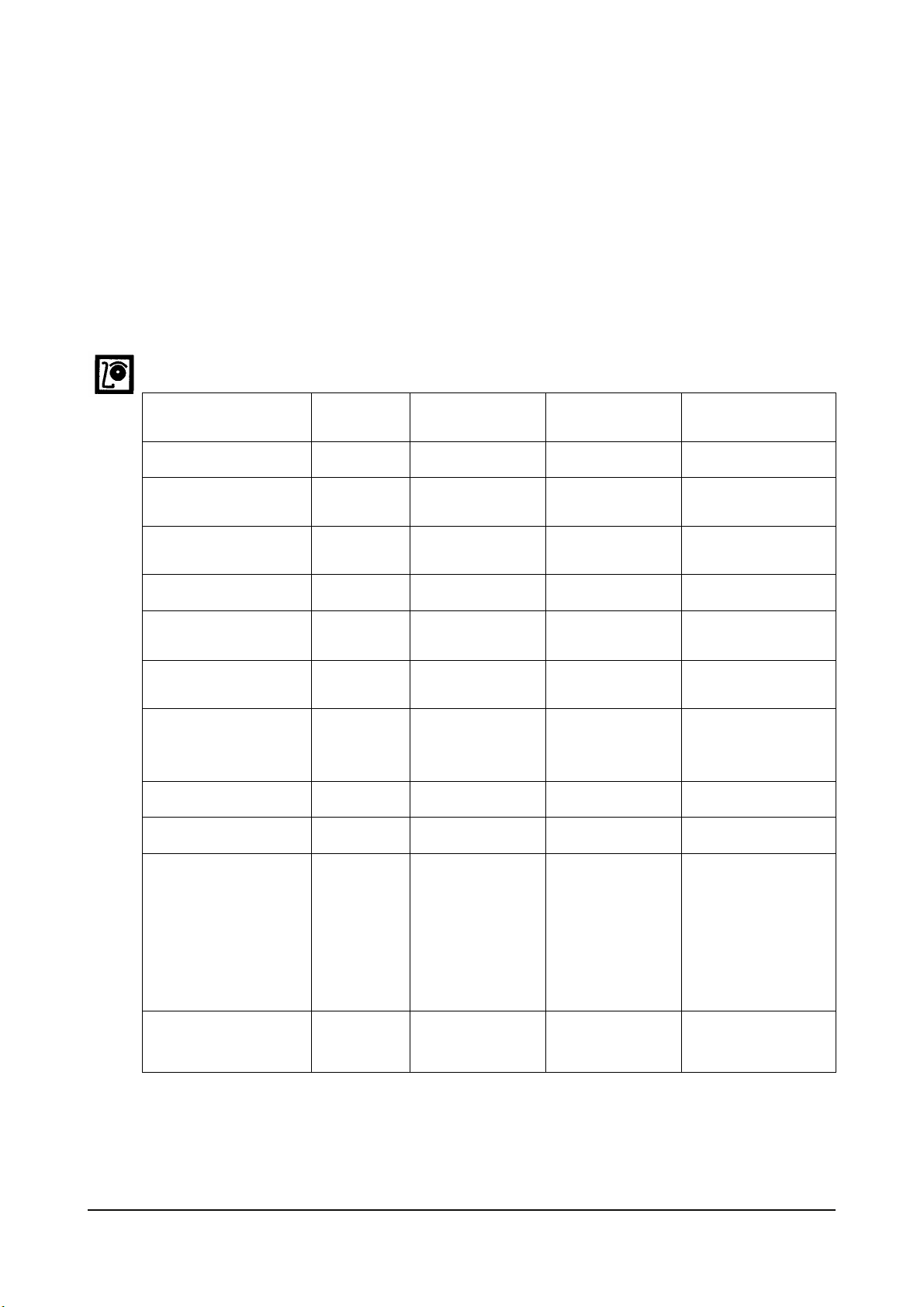

1.1. Engine specifications

Engine Model

Items

Engine type 4 cycle in-line Naturally aspirated

Combustion chamber type Direct injection type

Cylinder liner type Dry type

Timing gear system Gear driven type

No. of piston ring 2 Compression 1 ring, oil ring

No. of cylinder-bore x stroke (mm) 6 – 102 × 118

Total piston displacement (cc) 5,785

Compression ratio 17.5 : 1 18.5 : 1

Engine dimension

(length X width X height)

(mm)

Engine weight (kg) 450

Rotating direction (from fly wheel) counter clockwise

Fuel injection order 1 – 5 - 3 – 6 - 2 – 4

Fuel injection timing (B.T.D.C static) 15°

Injection pump type Bosch in-line A type

Governor type Mechanical governor RSV type

Injection nozzle type Multi-hole type (5 hole)

Fuel injection pressure (kg/cm²) 220

Compression pressure (kg/cm²) 28 (at 200 rpm)

Intake & exhaust valve clearance (mm)

(at cold)

Intake valve

Exhaust valve

Lubrication method Pressurized circulation

Oil pump type Gear type

Oil filter type Full-flow, cartridge type

Lubricating oil capacity (oil pan) (lit) 20.5(19)

Oil cooler type Water cooled

Water pump Belt driven impeller type

Cooling Method Pressurized circulation

Cooling water capacity(engine only) (lit) 12

Thermostat type Wax pallet type (82 ∼95°C)

Cooling fan 10- Ø 520.7 blower 7 – Ø 457 blower 10- Ø 520.7 blower

Starting Motor

(voltage – output) (V - kW)

Open at 17° B.T.D.C

Close at 51° A.B.D.C

Open at 60° B.B.D.C

Close at 18° A.T.D.C

DB58S ECRFA

D50/60/70/80/90S-5

(3 speed)

DB58S ECRFD

D35/40/45S-5,

D50/55C-5

1,173 x 666 x 793

0.4

24 – 4.5

DB58S ECRFE

D50/60/70S-5

(2 speed)

General information - 1 -

Page 10

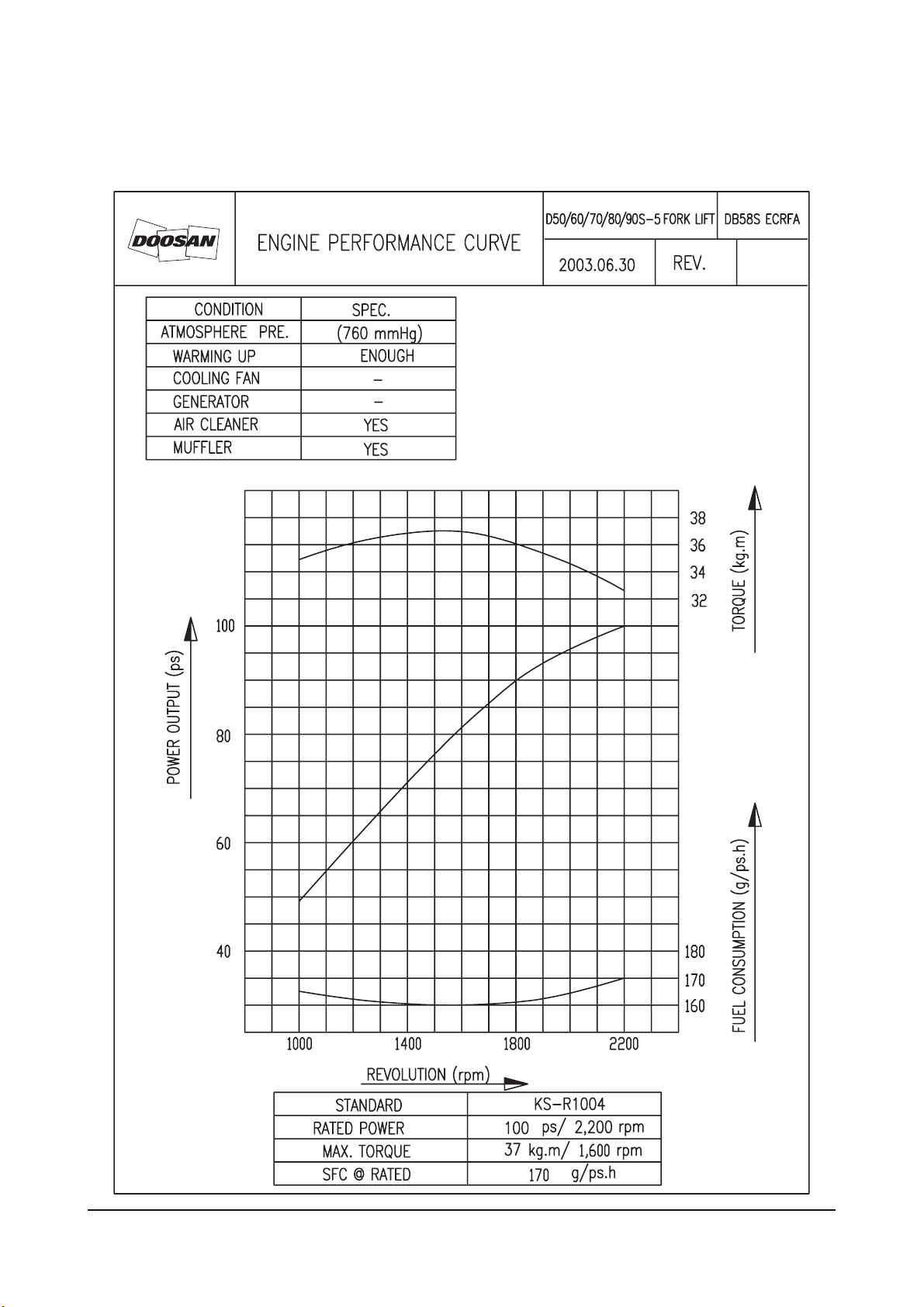

1. 2. Performance curve

1. 2.1. Performance curve (ECRFA), D50/60/70/80/90S-5 (3 speed)

General information - 2 -

Page 11

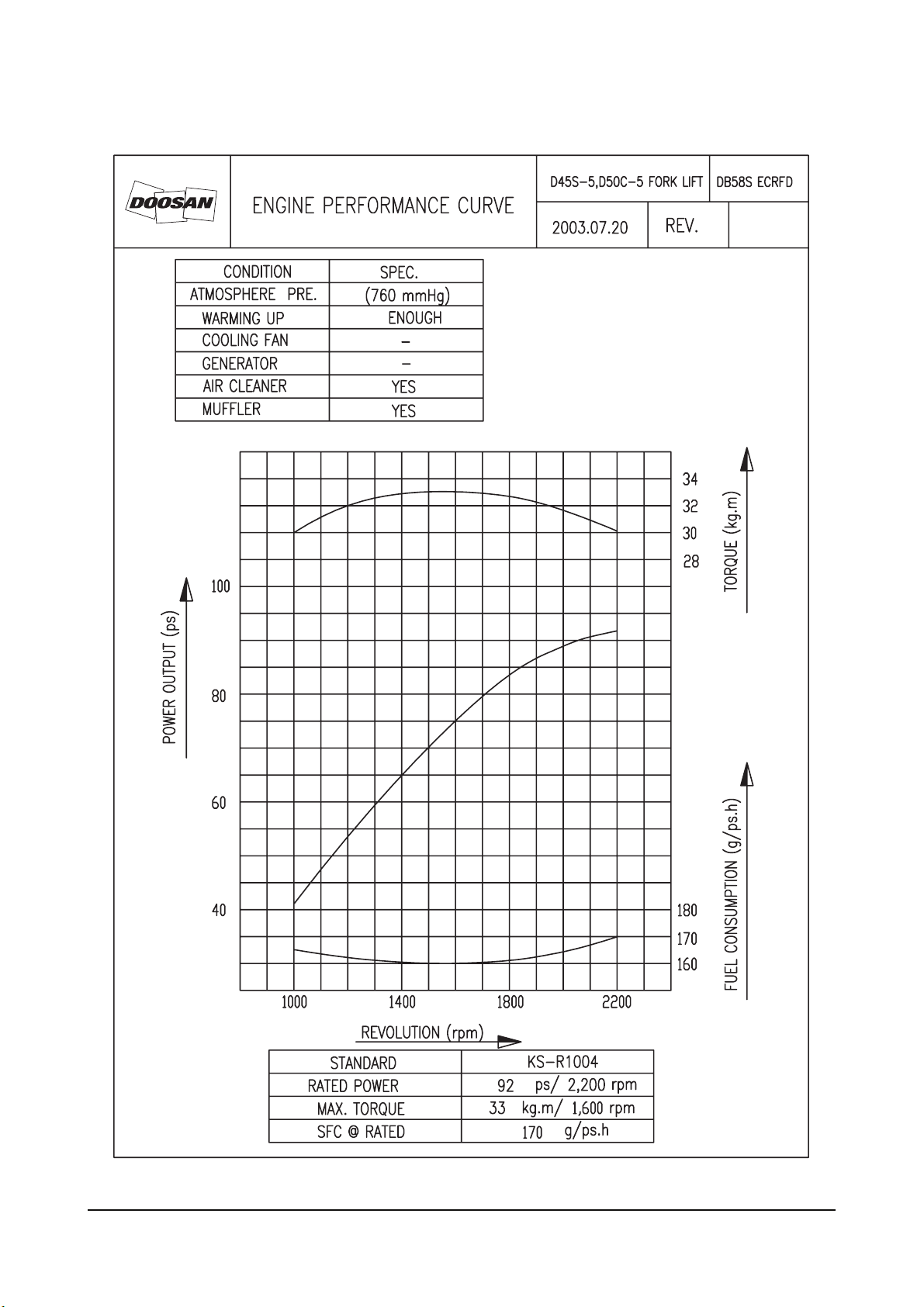

1. 2.2. Performance curve (ECRFD), D35/40/45S-5, D50/55C-5

General information - 3 -

Page 12

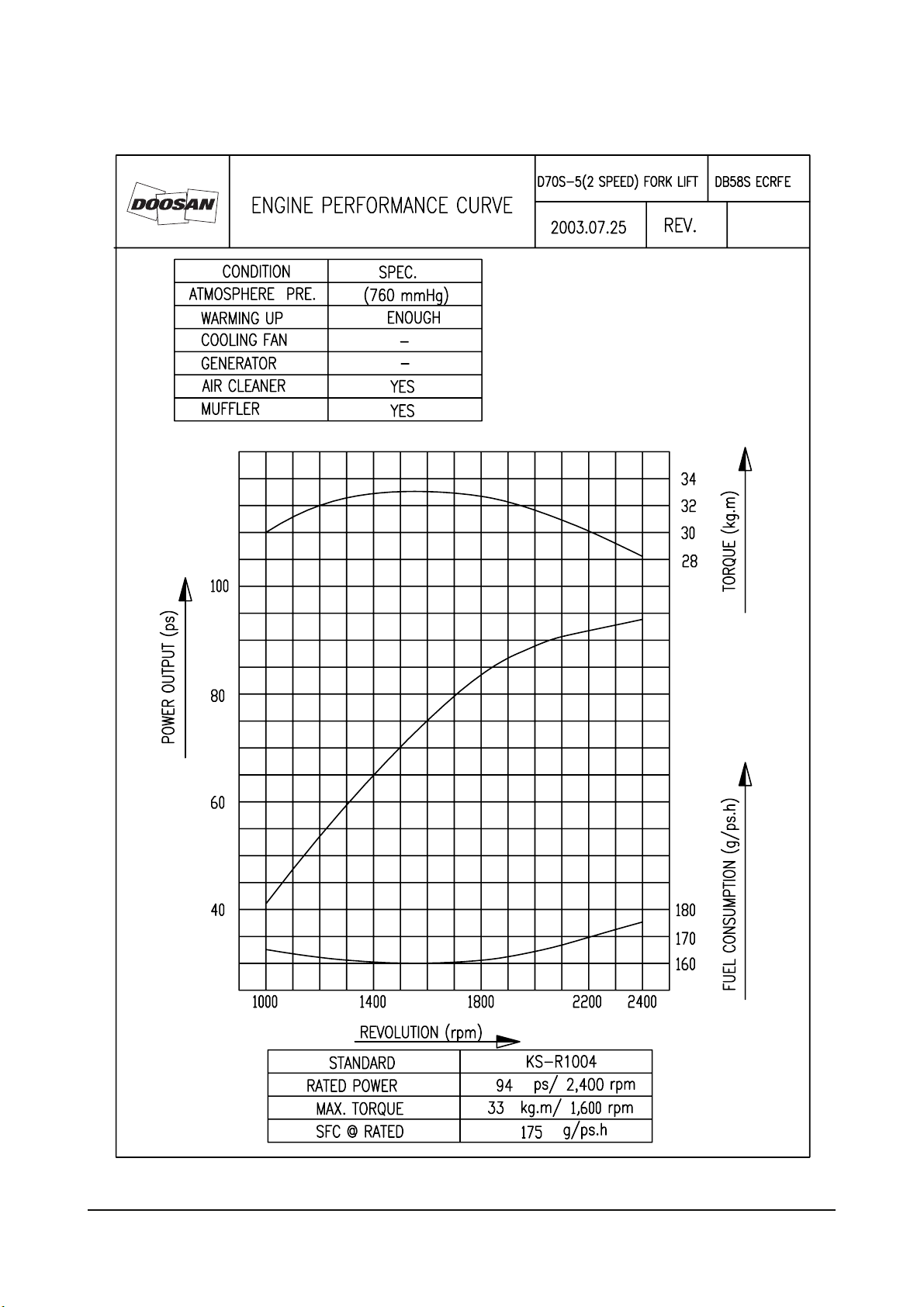

1. 2.3. Performance curve (ECRFE), D50/60/70S-5 (2 speed)

General information - 4 -

Page 13

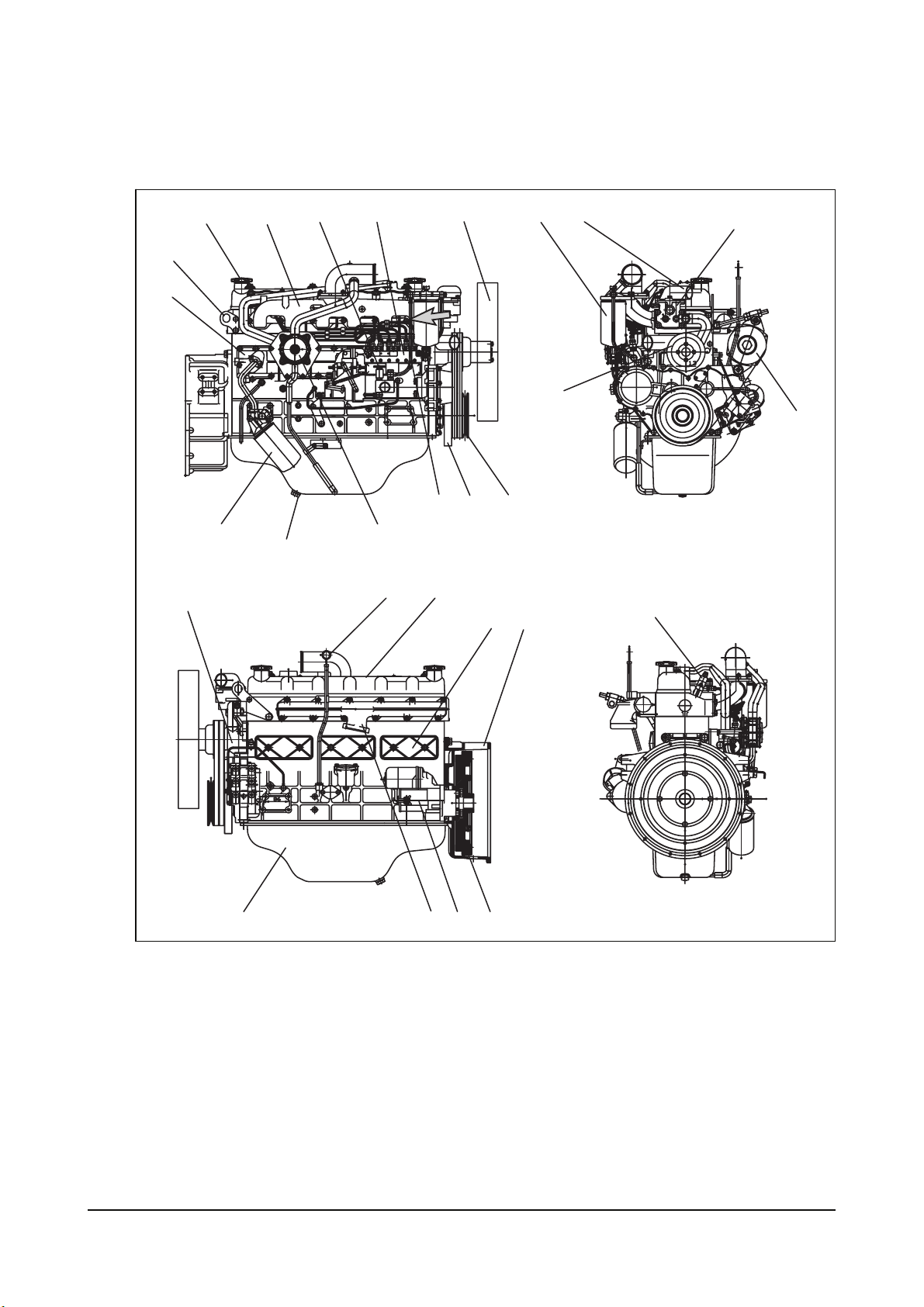

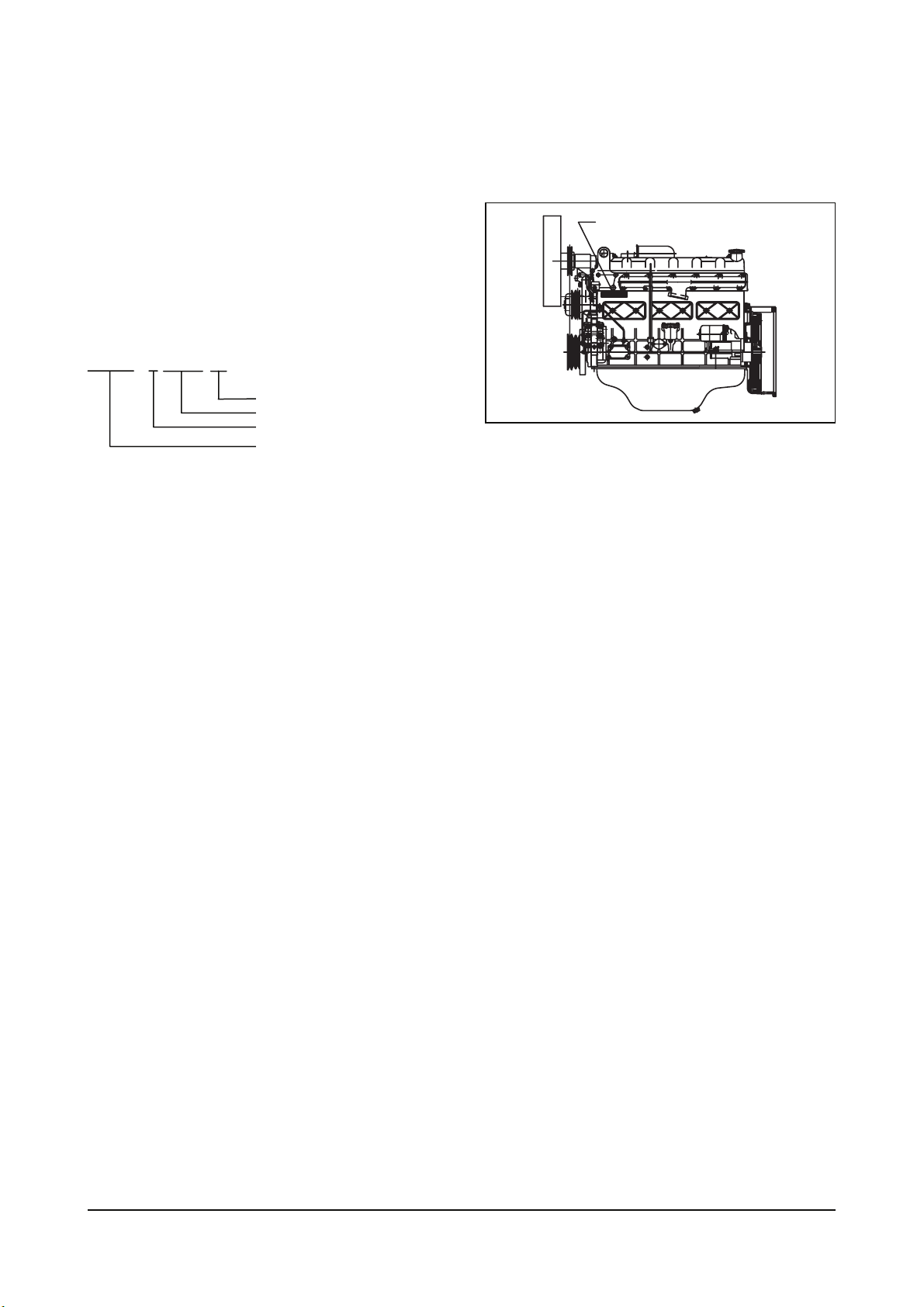

1.3. Engine assembly

1.3.1. Engine assembly view (ECRFA), D50/60/70/80/90S-5 (3 speed)

10

4

5

2

3

1

14

15

24

1 Oil filter 11 C.C.V 21 Push rod chamber cover

2 Lifting hook 12 Crank shaft pulley 22 Flywheel housing

3 Oil cooler 13 Vibration damper 23 Fly wheel

4 Intake manifold 14 Oil drain plug 24 Oil pan

5 Priming pump 15 water pump 25 Starter

6 Fuel injection pump 16 Alternator 26 Cylinder head cover

7 Fuel injection pipe 17 Oil level gauge 27 Fuel injection nozzle

8 Water outlet 18 Exhaust manifold 28 Fuel filter

9 Cooling fan 19 Water pump pulley

10 Oil filler cap 20 Thermostat housing

6

11

17 26

18

12

22

28

8

19

9

13

7

21

23

25

20

16

27

General information - 5 -

Page 14

1.3.2. Engine assembly view (ECRFD), D35/40/45S-5, D50/55C-5

10

2

4

5

6

9

28

8

3

19

1

14

15

11

17 26

7

13

21

12

22

24

18

1 Oil filter 11 C.C.V 21 Push rod chamber cover

2 Lifting hook 12 Crank shaft pulley 22 Flywheel housing

3 Oil cooler 13 Vibration damper 23 Fly wheel

4 Intake manifold 14 Oil drain plug 24 Oil pan

5 Priming pump 15 water pump 25 Starter

6 Fuel injection pump 16 Alternator 26 Cylinder head cover

7 Fuel injection pipe 17 Oil level gauge 27 Fuel injection nozzle

8 Water outlet 18 Exhaust manifold 28 Fuel filter

9 Cooling fan 19 Water pump pulley

10 Oil filler cap 20 Thermostat housing

25

23

20

16

27

General information - 6 -

Page 15

1.3.3. Engine assembly views (ECRFE), D50/60/70S-5 (2 speed)

10

4

5

6

9

28

8

2

3

19

15

1

14

11

17

7

26

13

21

12

22

24

18

25

23

1 Oil filter 11 C.C.V 21 Push rod chamber cover

2 Lifting hook 12 Crank shaft pulley 22 Flywheel housing

3 Oil cooler 13 Vibration damper 23 Fly wheel

4 Intake manifold 14 Oil drain plug 24 Oil pan

5 Priming pump 15 water pump 25 Starter

6 Fuel injection pump 16 Alternator 26 Cylinder head cover

7 Fuel injection pipe 17 Oil level gauge 27 Fuel injection nozzle

8 Water outlet 18 Exhaust manifold 28 Fuel filter

9 Cooling fan 19 Water pump pulley

10 Oil filler cap 20 Thermostat housing

20

16

27

General information - 7 -

Page 16

1.4. Safety regulations

1.4.1. General notes

Day-to-day use of power engines and the service products necessary for running them presents no

problems if the persons occupied with their operation, maintenance and care are given suitable training

and think as they work.

This summary is a compilation of the most important regulations. These are broken down into main

sections which contain the information necessary for preventing injury to persons, damage to property and

pollution. In addition to these regulations those dictated by the type of engine and its site are to be

observed also.

IMPORTANT.

If, despite all precautions, an accident occurs, in particular through contact with caustic acids, fuel

penetrating the skin, scalding from oil, antifreeze being splashed in the eyes etc., consult a doctor

immediately.

1.4.2. Regulations designed to prevent accidents

a) During commissioning, starting and operation

Before putting the engine into operation for the first time, read the operating instructions carefully and

familiarize yourself with the "critical" points. If you are unsure, ask your DOOSAN representative.

z For reasons of safety we recommend you attach a notice to the door of the engine room prohibiting

the access of unauthorized persons and that you draw the attention of the operating personal to

the fact that they are responsible for the safety of persons who enter the engine room.

z The engine must be started and operated only by authorized personnel. Ensure that the engine

cannot be started by unauthorized persons.

z When the engine is running, do not get too close to the rotating parts. Wear close-fitting clothing.

z Do not touch the engine with bare hands when it is warm from operation risk of burns.

z Exhaust gases are toxic. Comply with the installation instructions for the installation of DOOSAN

diesel engines which are to be operated in enclosed spaces. Ensure that there is adequate

ventilation and air extraction.

z Keep vicinity of engine, ladders and stairways free of oil and grease.

Accidents caused by slipping can have serious consequences.

b) During maintenance and care

z Always carry out maintenance work when the engine is switched off. If the engine has to be

maintained while it is running, e.g. changing the elements of change-over filters, remember that

there is a risk of scalding. Do not get too close to rotating parts.

z Change the oil when the engine is warm from operation.

CAUTION

There is a risk of burns and scalding. Do not touch oil drain valve or oil filters with bare hands.

Safety regulations - 8 -

Page 17

z Take into account the amount of oil in the sump. Use a vessel of sufficient size to ensure that the

oil will not overflow.

z Open the coolant circuit only when the engine has cooled down. If opening while the engine is still

warm is unavoidable, comply with the instructions In the chapter entitled "Cooling".

z Neither tighten up nor open pipes and hoses (lube oil circuit, coolant circuit and any additional

hydraulic oil circuit) during the operation. The fluid which flow out can cause injury.

z Fuel is inflammable. Do not smoke or use naked lights in its vicinity. The tank must be filled only

when the engine is switched off.

z Keep service products (anti-freeze) only in containers which can not be confused with drinks

containers.

z Comply with the manufacturer's instructions when handling batteries.

CAUTION

Accumulator acid is toxic and caustic. Battery gases are explosive.

c) When carrying out checking, setting and repair work

z Checking, setting and repair work must be carried out by authorized personnel only.

z Use only tools which are in satisfactory condition. Slip caused by the worn open-end wrench could

lead to Injury.

z When the engine is hanging on a crane, no-one must be allowed to stand or pass under it. Keep

lifting gear in good condition.

z When checking injectors, do not put your hands under the jet of fuel.

z Do not inhale at atomized fuel.

z When working on the electrical system disconnect the battery earth cable first. Connect it up again

last in prevent short circuits.

1.4.3. Regulations designed to prevent damage to engine and premature wear

(1) Never demand more of the engine than it was designed to yield for its intended purpose.

Detailed information on this can be found in the sales literature. The injection pump must not be

adjusted without prior written permission of DOOSAN.

(2) If faults occur, find the cause immediately and have it eliminate in order to prevent more serious of

damage.

(3) Use only genuine DOOSAN spare parts. DOOSAN will accept no responsibility for damage resulting

from the installation of other parts which are supposedly "just as good".

(4) In addition to the above, note the following points.

z Never let the engine run when dry, i.e. without lube oil or coolant. Use only DOOSAN-approved

service products. (engine oil, anti-freeze and anticorrosion agent)

z Pay attention to cleanliness. The Diesel fuel must be free of water. See "Maintenance and care".

z Have the engine maintained at the specified intervals.

z Do not switch off the engine immediately when it is warm, but let it run without load for about 5

minutes so that temperature equalization can take place.

z Never put cold coolant into an overheated engine. See "Maintenance and care".

Safety regulations - 9 -

Page 18

z Do not add so much engine oil that the oil level rises above the max. marking on the dipstick. Do

not exceed the maximum permissible tilt of the engine. Serious damage to the engine may result if

these instructions are not adhered to.

z Always ensure that the testing and monitoring equipment (for battery charge, oil pressure, and

coolant temperature) function satisfactorily.

z Comply with instructions for operation of the alternator. See "Commissioning and operation".

z Do not let the water pump run dry. If there is a risk of frost, drain the water when the engine

switched off.

1.4.4. Regulations designed to prevent pollution

a) Engine oil, filter element, fuel filter

z Take old oil only to an oil collection point. Take strict precautions to ensure that oil does not get into

the drains or into the ground.

z The drinking water supply may be contaminated.

z Oil and fuel filter elements are classed as dangerous waste and must be treated as such.

b) Coolant

z Treat undiluted anti-corrosion agent and / or antifreeze as dangerous waste.

z When disposing of spent coolant comply with the regulations of the relevant local authorities.

1.4.5. Notes on safety in handling used engine oil

Prolonged or repeated contact between the skin and any kind of engine oil decreases the skin.

Drying, irritation or inflammation of the skin may therefore occur. Used engine oil also contains dangerous

substances which have caused skin cancer in animal experiments. If the basic rules of hygiene and health

and safety at work are observed, health risks are not to the expected as a result of handling used engine oil.

<Health precautions>

z Avoid prolonged or repeated skin contact with used engine oil.

z Protect your skin by means of suitable agents (creams etc.) or wear protective gloves.

z Clean skin which has been in contact with engine oil.

z Wash thoroughly with soap and water, A nailbrush is an effective aid.

z Certain products make it easier to clean your hands.

z Do not use petrol, Diesel fuel, gas oil, thinners or solvents as washing agents.

z After washing apply a fatty skin cream to the skin.

z Change oil-soaked clothing and shoes.

z Do not put oily rags into your pockets.

Ensure that used engine oil is disposed of properly.

- Engine oil can endanger the water supply -

For this reason do not let engine oil get into the ground, waterways, the drains or the sewers. Violations

are punishable. Collect and dispose of used engine oil carefully.

For information on collection points please contact the seller, the supplier or the local authorities.

Safety regulations - 10 -

Page 19

1.4.5. General repair instructions

1. Before performing service operation, disconnect the grounding cable from the battery for reducing the

chance of cable damage and burning due to short-circuiting.

2. Use covers for preventing the components from damage or pollution.

3. Engine oil and anti-freeze solution must be handled with reasonable care as they cause paint damage.

4. The use of proper tools and special tools where specified is important to efficient and reliable service

operation.

5. Use genuine DOOSAN parts necessarily.

6. Used cotter pins, gaskets, O-rings, oil seals, lock washer and self-lock nuts should be discarded and

new ones should be prepared for installation as normal function of the parts can not be maintained if

these parts are reused.

7. To facilitate proper and smooth reassemble operation, keep disassembled parts neatly in groups.

Keeping fixing bolts and nut separately is very important as they vary in hardness and design depending

on position of installation.

8. Clean the parts before inspection or reassembly. Also clean oil ports, etc. using compressed air to make

certain they are free from restrictions.

9. Lubricate rotating and sliding faces of parts with oil or grease before installation.

10. When necessary, use sealer on gaskets to prevent leakage.

11. Carefully observe all torque specifications for bolts and nuts.

12. When service operation is completed, make a final check to be sure service has been done properly.

Safety regulations - 11 -

Page 20

2. TECHNICAL INFORMATION

2.1. Engine model and serial number

The engine model and serial number is located on the

engine as illustrated. These numbers are required

when requesting warranty and ordering parts. They

are also referred to as engine model and serial

number because of their location.

Engine serial No. (example : DB58)

DB58S 3 00001 FA

Engine suffix (ECRFA)

Serial no.

Production year (2003)

Engine model

ENGINE SERIAL NO.

EC90M011

Technical information - 12 -

Page 21

2.2. Engine type

The Engines DB58S are in-line vertical, water-cooled, 6-cylinder four stroke diesel engines with direct

injection. DB58S is natural aspiration.

2.2.1. Cylinder block

The cylinder block is a single piece of alloy cast iron. To increase its stiffness, it is extended to a level

below the crankshaft center line. The engine has replaceable dry cylinder liners and common cylinder

heads with struck-in valve seat rings and replaceable valve guides,

2.2.2. Piston con-rod / crankshaft

The forged crankshaft is a integrate type (Counterweight is integrated with crank shaft body). Radial oil

seal on crankshaft and flywheel are provided to seal the flywheel housing inside penetrations.

The con-rods (connecting rods) are die-forged and can be removed through the top of the cylinders

together with the pistons. Crankshaft and connecting rods run in steel-backed lead bronze ready-to fit type

bearings.

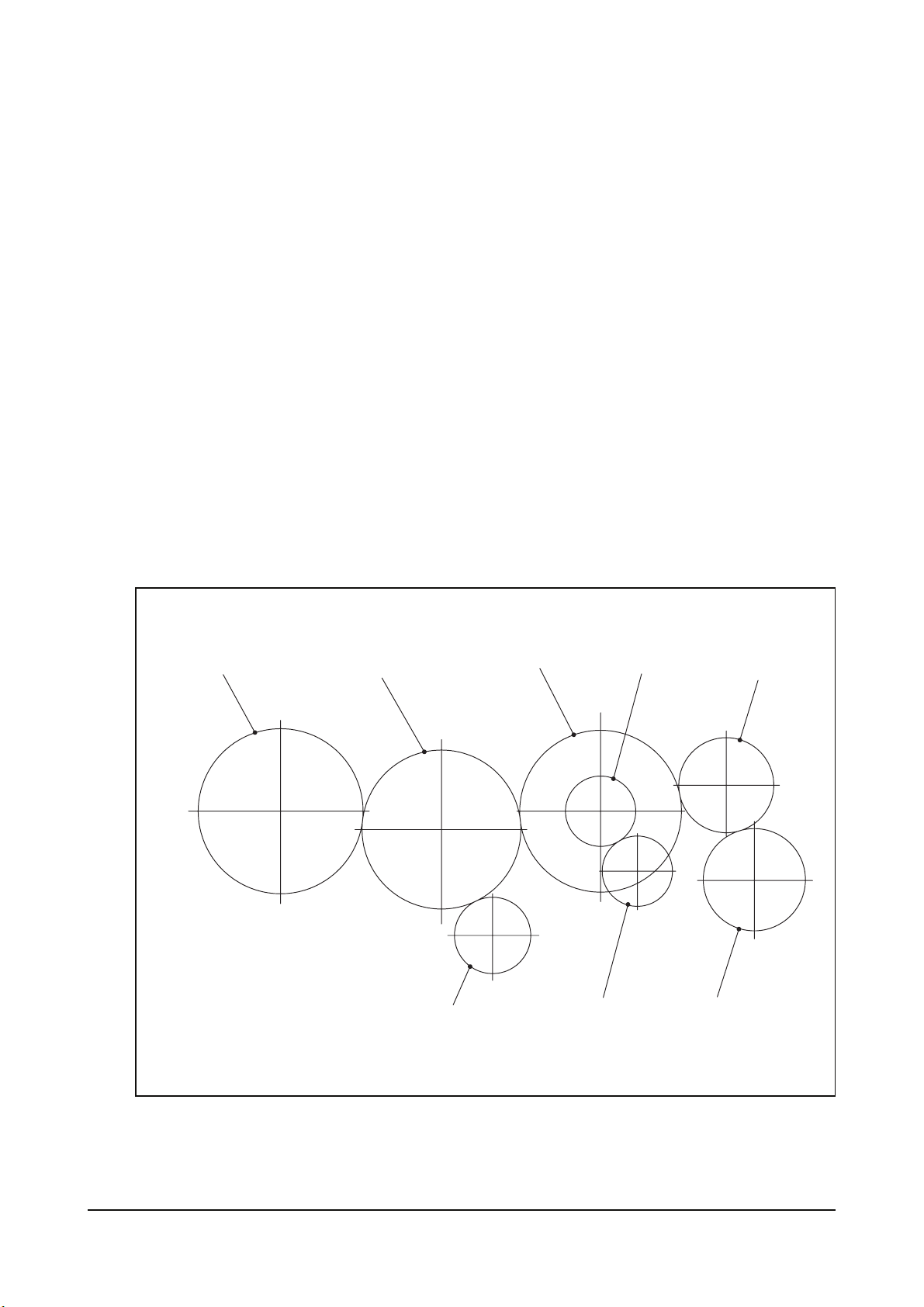

2.3. Engine timing

Camshaft, oil pump, PTO (power take off) pump and injection pump are driven by a gear train arranged at

the front end.

Injection pump gear

(Z = 50)

Idle gear

(Z = 51)

Camshaft gear

(Z = 50)

Oil pump drive gear

(Z = 12)

P.T.O Drive gear

(Z=24)

Crankshaft gear

(Z = 25)

Oil pump gear

(Z = 9)

P.T.O gear (Option)

(Z = 25)

EC90M013

Technical information - 13 -

Page 22

2.4. Valves

The overhead valves are actuated via chilled cast iron tappets, push rods and rocker arms from the

camshaft.

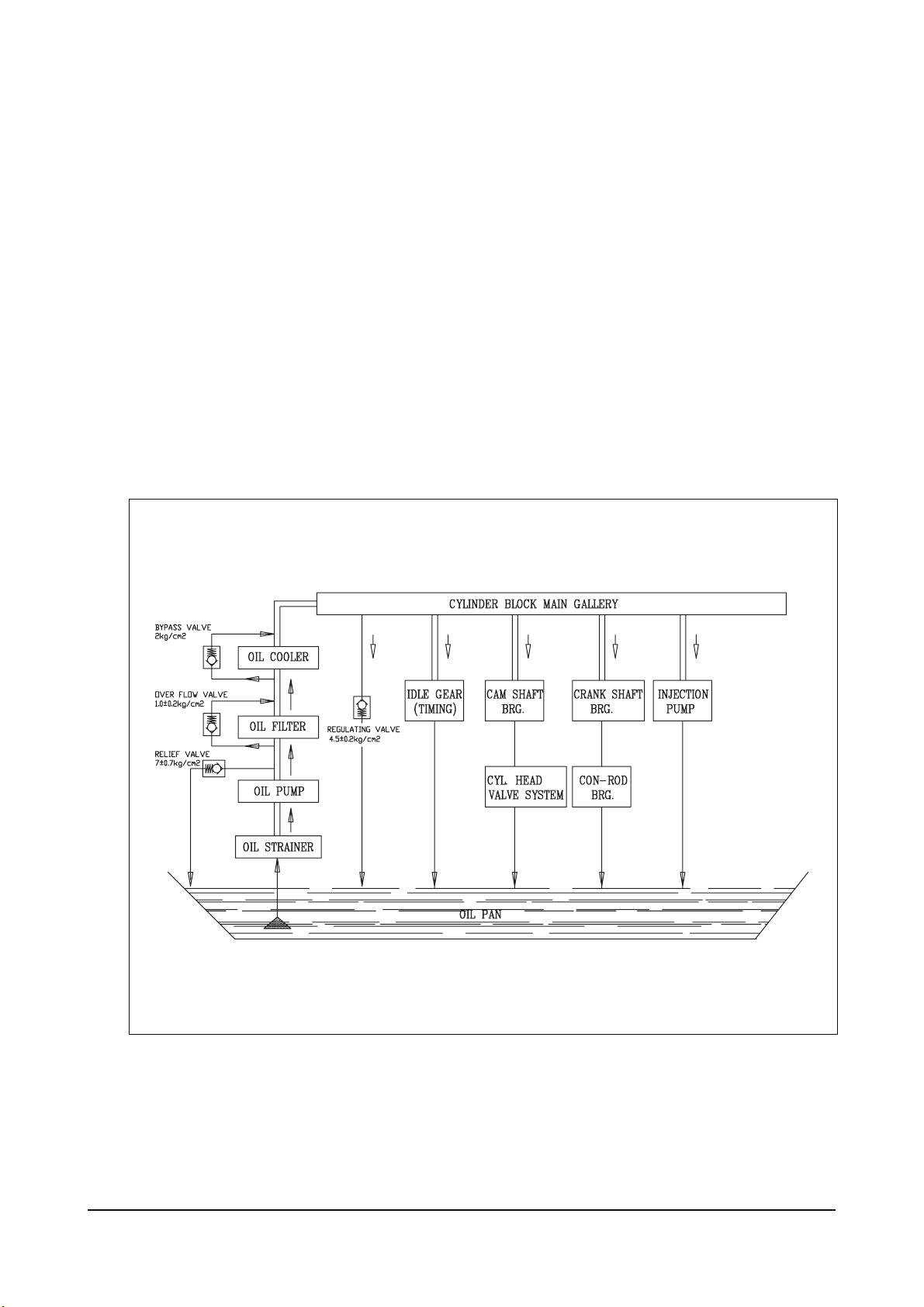

2.5. Lubrication system

The engine is equipped with force-feed lubrication.

The pressure is produced by a gear pump whose drive gear is in direct mesh with the camshaft gear at the

middle of cylinder block.

The oil pump draws the oil from the oil sump and delivers it through the oil cooler and oil filter to the main

distributor gallery and from there to the main bearings, big-end bearings and camshaft bearings as well as

to the small-end bearings and the rocker arms.

The injection pump are also connected to the engine lubricating system.

The cylinder block walls and timing gears are splash-lubricated.

The lube oil is cleaned in a full-flow oil filter.

EC90M014

Technical information - 14 -

Page 23

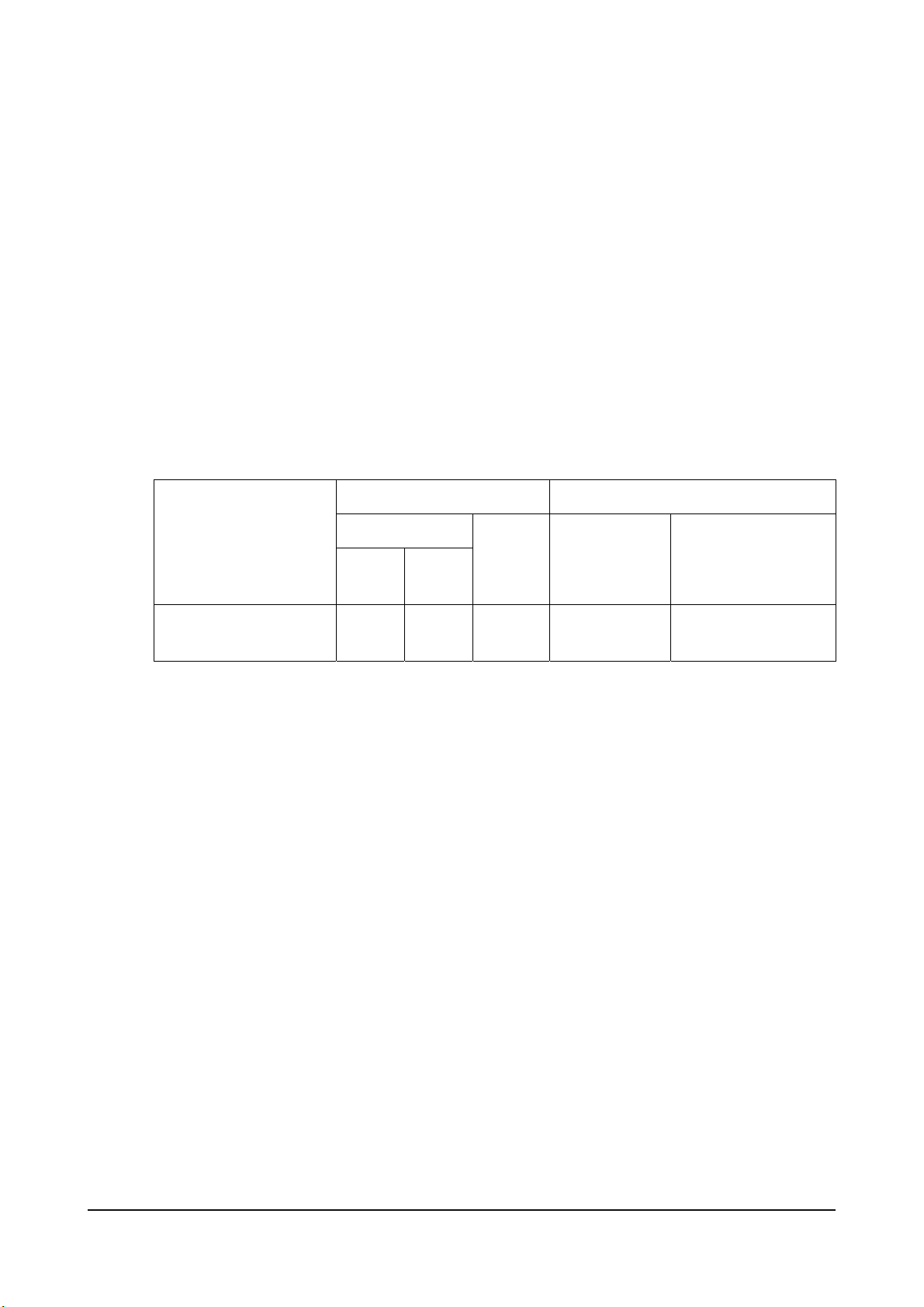

2.5.1. Recommend of lubricating oil

Initial factory fill is high quality break-in oil for API Service. During the break-in period (50 hours),

frequently check the oil level. Somewhat higher oil consumption is normal until piston rings are seated.

The oil level should be maintained in the safe range between the Min. and Max. marks on the dipstick. The

safe range between the marks represents approximately 3 liters. To obtain the best engine performance

and engine life, grade of engine oil is recommended. Engine oils are specified by API Service, letter

designations and SAE viscosity numbers. If the specified motor oil is not available, use a reputable brand

of engine oil labeled for API Service CH-4 and SAE viscosity 30 or 15W40. Refer to oil identification

symbol on the container.

z Engine oil should be changed at the specified intervals.

Oil filter cartridge should be changed simultaneously.

- First oil change : 50 hr operating

- After 50hr operation ; 250

z The following oils are also recommended

Engine oil capacity Recommend oil

Max.

(liter)

Oil pan

(liter)

Min.

Total

(liter)

SAE No. API No.

SAE10W40

SAE15W40

ACEA-E2 or ACEA-E3

(API CH-4)

Engine model

DB58S 19 14 20.5

Technical information - 15 -

Page 24

* If long oil change intervals are to be used, ACEA-E3 oil must be used.

2.5.2. Oil cooler

An oil cooler is provided between the oil filter and the cylinder block. This cooler is a flat tube type with

turbulence inserts and operated by the coolant.

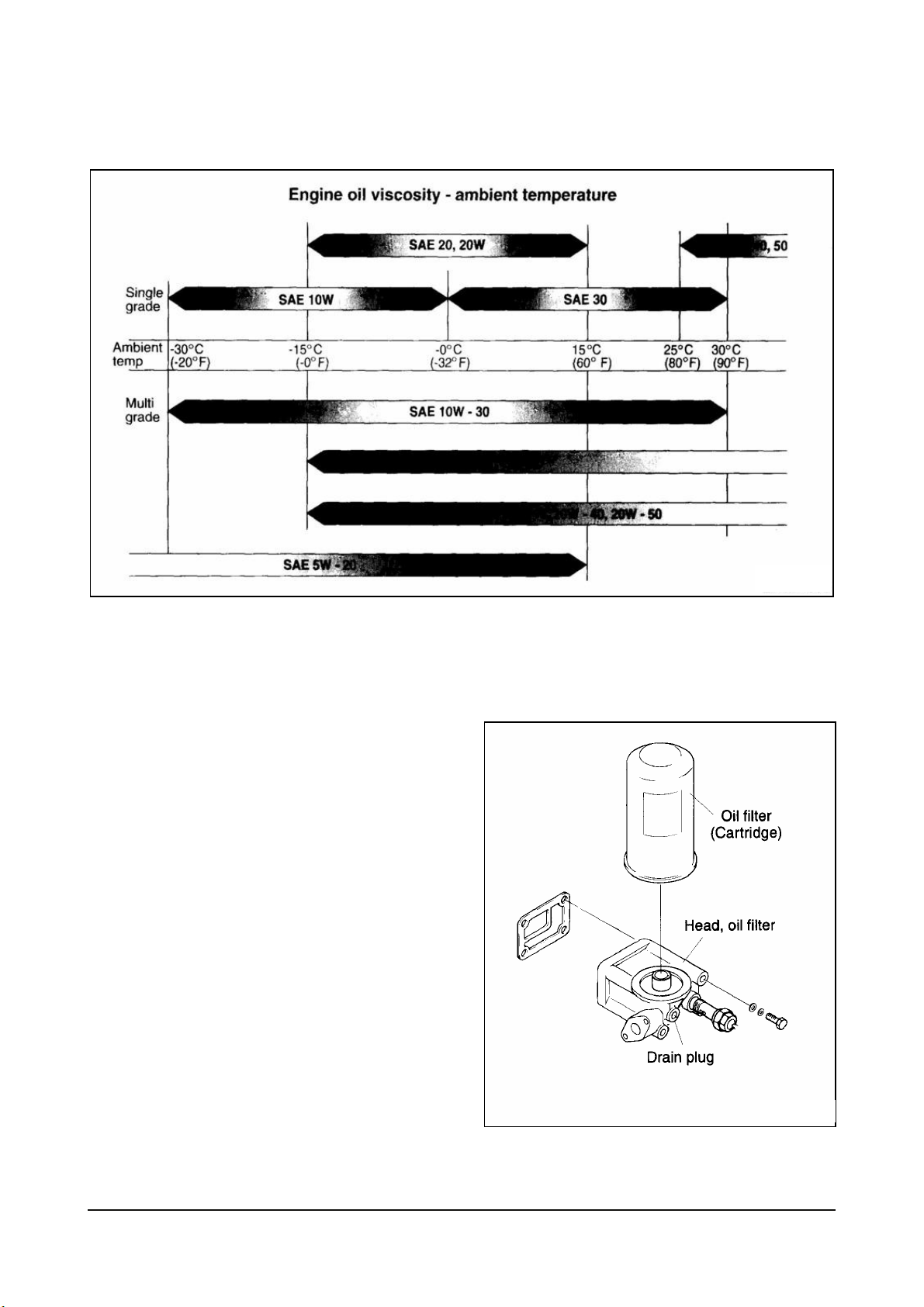

2.5.3. Oil filter

• Check for oil pressure and oil leaks, and

repair or replace the oil filter if necessary.

• Change the oil filter cartridge

simultaneously at every replacement of

engine oil.

EA4M1008

Technical information - 16 -

EDM3001I

<ECRFD>

Page 25

Cartridge,

Oil filter

<ECRFA, ECRFE>

Head, oil filter

2.6. Air cleaner

In case that elements are deformed, damaged

or if the air cleaner has a crack, replace it.

By the definite interval, the elements must be

cleaned and replaced.

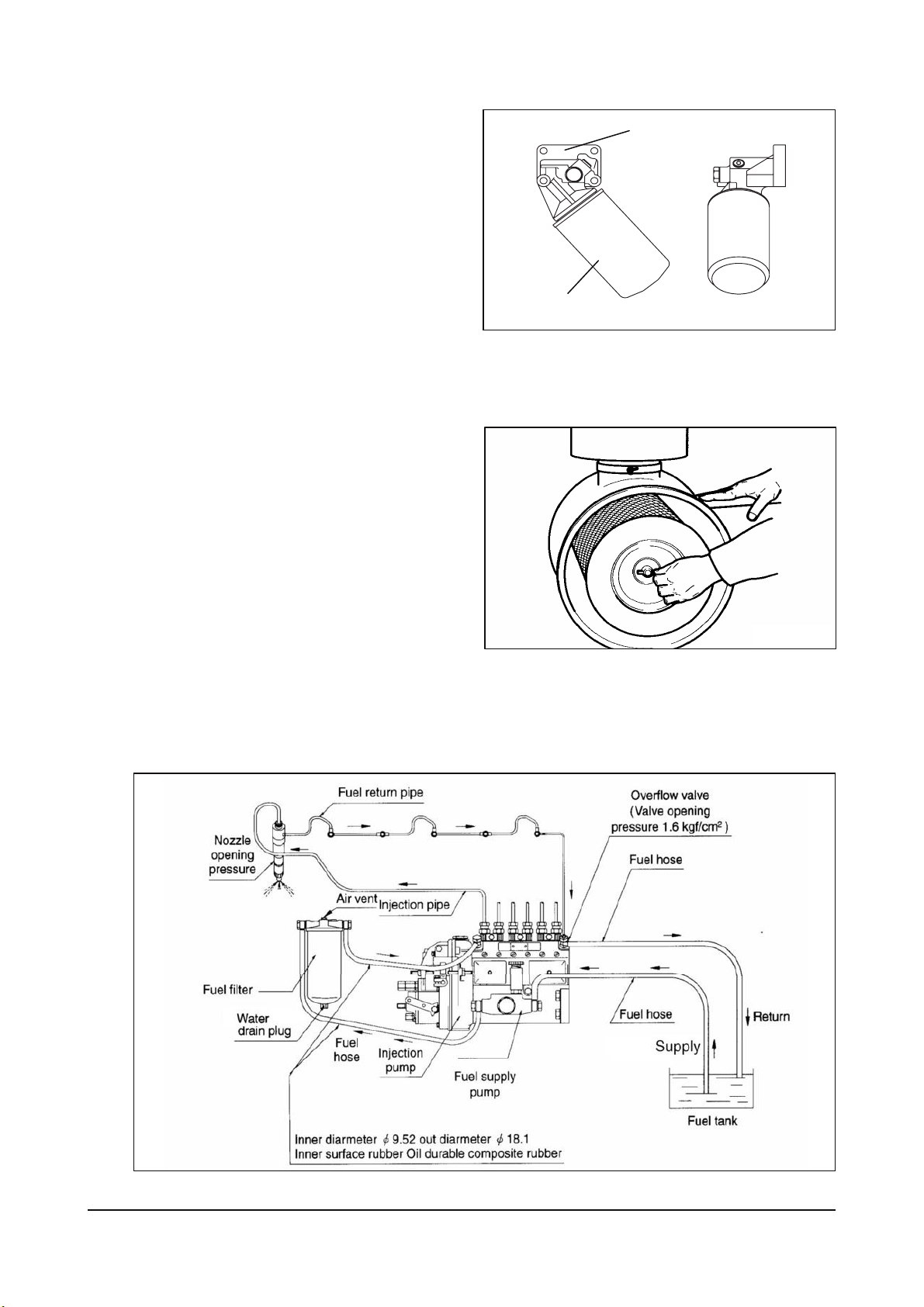

2.7. Fuel system

The fuel is delivered by the fuel feed pump via the fuel filter to the injection pump and from there to the

injection nozzles.

EC9OM015

EFM1002I

EC9OM065

Technical information - 17 -

Page 26

The fuel is sprayed into the cylinders through nozzles fitted in screw-fit injection nozzle holders in the

cylinder heads.

Excessively delivered fuel and leak fuel from the nozzle flow through the return pipe back to the tank.

A strainer is arranged ahead of the fuel feed pump.

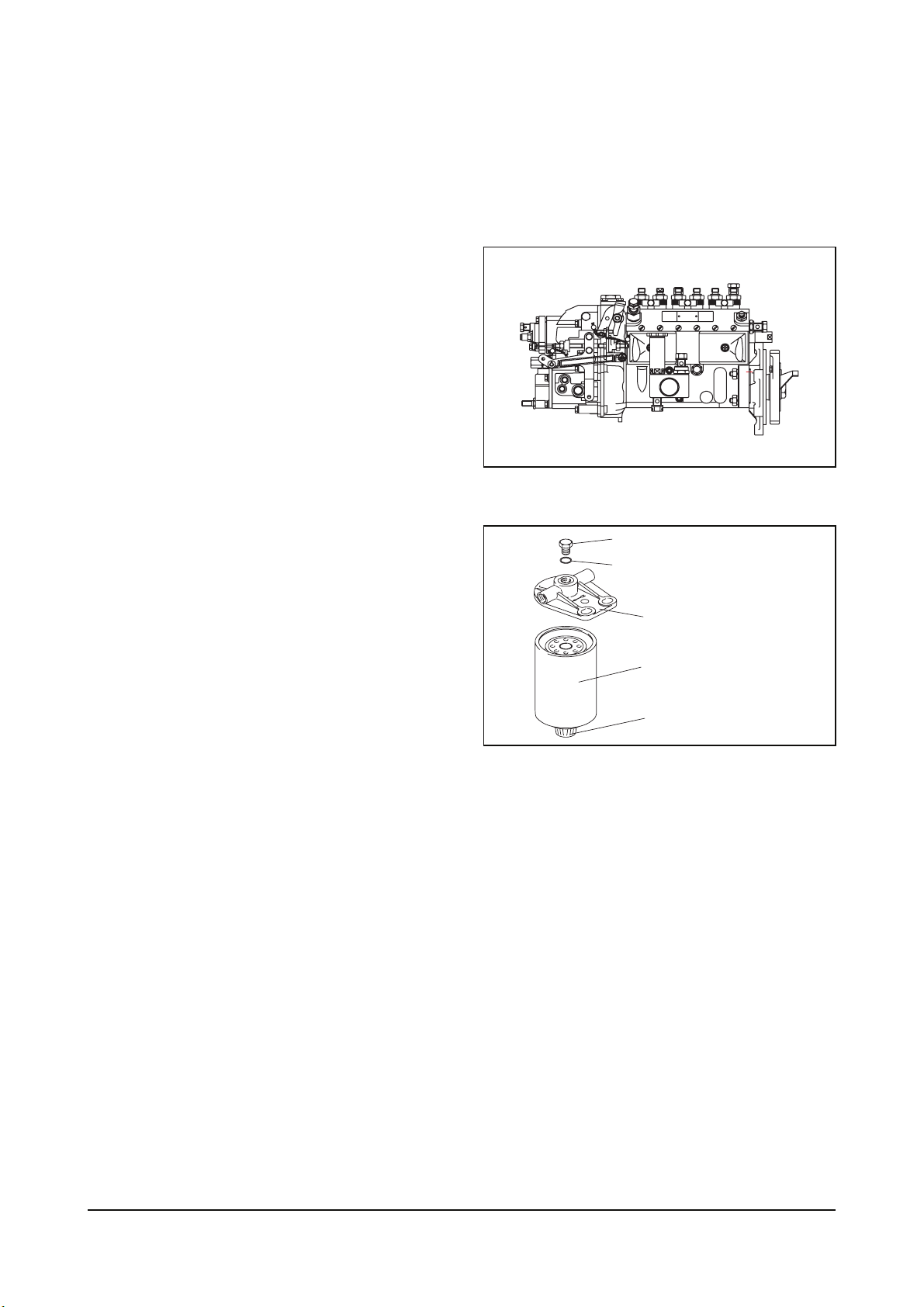

2.7.1. Injection pump

The in-line injection pump is driven via gears

from the crankshaft. It is connected to the

force feed lubricating system of the engine

and consequently maintenance-free. The

governor flange-mounted on the pump casing

is a variable range governor designed to

keep the speed set of varying load.

2.7.2. Fuel filter

This fuel filter has two functions not only oil

filtering but

also water separating

Before entering the suction chamber of the

injection pump, the fuel is cleaned in a

strainer of fuel feed pump and a fuel filter.

Drain water in filter with loosening the drain

plug under filter manually from time to time.

The fuel filter element should be replaced at

every 200 hours.

Air bleeding plug

Seal ring

Head, fuel filter

Cartridge, fuel filter

Water drain plug

2.7.3. Fuel requirements

DOOSAN diesel engines was designed to use Number 2-D diesel fuel or equivalent that meets

specification DIN 51601-DK. For maximum fuel economy, Number 2-D fuel whenever possible. When

temperatures are below -7 °C (20 °F), use Number 1-D fuel. If Number 1-D fuel is not available, the

mixture of one kerosene to two gallons of Number 2-D fuel can be used. Once kerosene has been added,

the engine should be run for several minutes to mix the fuel.

EC9OM016

EC9OM017

Technical information - 18 -

Page 27

2.7.4. How to select fuel oil

Fuel quality is an important factor in obtaining satisfactory engine performance, long engine life, and

acceptable exhaust emission levels. DOOSAN engines are designed to operate on most diesel fuels

marketed today. In general, fuels meeting the properties of ASTM Designation D975 (grades 1-D and 2-D)

have provided satisfactory performance.

The ASTM 975 specification, however, does not in itself adequately define the fuel characteristics needed

for assurance of fuel quality.

The properties listed in the fuel oil selection chart below have provided optimum engine performance.

Grade 2-D fuel is normally available for generator service. Grade 1-D fuel should not be used in pleasure

craft engines, except in an emergency.

Fuel Oil Selection Chart

General Fuel

Classification

Gravity, °API #) D 287 40 ~ 44 33 ~ 37 0.815 ~ 0.855

ASTM

Test

No. 1

ASTM 1-D

No. 2

ASTM 2-D

DIN 51601

Flash Point

Min. °F (°C)

Viscosity, Kinematic

CST 100 °F (40 °C )

Cloud Point °F #) D 2500 See Note 1) See Note 1) See Note 1)

Sulfur Content

wt%, Max.

Carbon Residue

on 10%, wt%, Max.

Accelerated Stability

Total Insolubles

mg/100 ml, Max. #)

Ash, wt%, Max. D 482 0.01 0.01

Cetane Number, Min. +) D 613 45 45 > 45

Distillation

Temperature, ℉(℃)

IMP, Typican #)

10% Typical #)

50% Typical #)

90% +)

End Point #)

D 93 100 (38) 125 (52) 131 (55)

D 445 1.3 ~ 2.4 1.9 ~ 4.1 1.8 ~ 10

D 129 0.5 0.5 0.15

D 524 0.15 0.35 0.1

D 2274 1.5 1.5

D 86

350(177)

385(196)

45(218)

500 (260) Max.

550(288) Max.

625(329) Max.

675(357) Max.

375(191)

430(221)

510(256)

680(360)

Water & Sediment

%, Max.

#) Not specified In ASTM D 975

+) Differs from ASTM D 975

NOTE

1) The cloud point should be 6 °C (10 °F) below the lowest expected fuel temperature to prevent clogging

of fuel fitters by crystals.

D 1796 0.05 0.05 0.05

Technical information - 19 -

Page 28

2.8. Cooling system

The engine has a liquid-cooling system. The fresh water pump is a maintenance-free by V-belt from the

crankshaft pulley.

Depending on the agreed extent of delivery and the design of the engine, the coolant circuit can be

equipped with temperature monitors which, in the event of loss of coolant, shut the engine down.

z Check the coolant level of the expansion tank by removing the expansion tank filler cap, and add coolant

if necessary.

z When injecting antifreeze solution, first drain out the old coolant from the cylinder block and radiator, and

then clean them with cleaning solution.

z Be sure to mix soft water with antifreeze solution.

Technical information - 20 -

Page 29

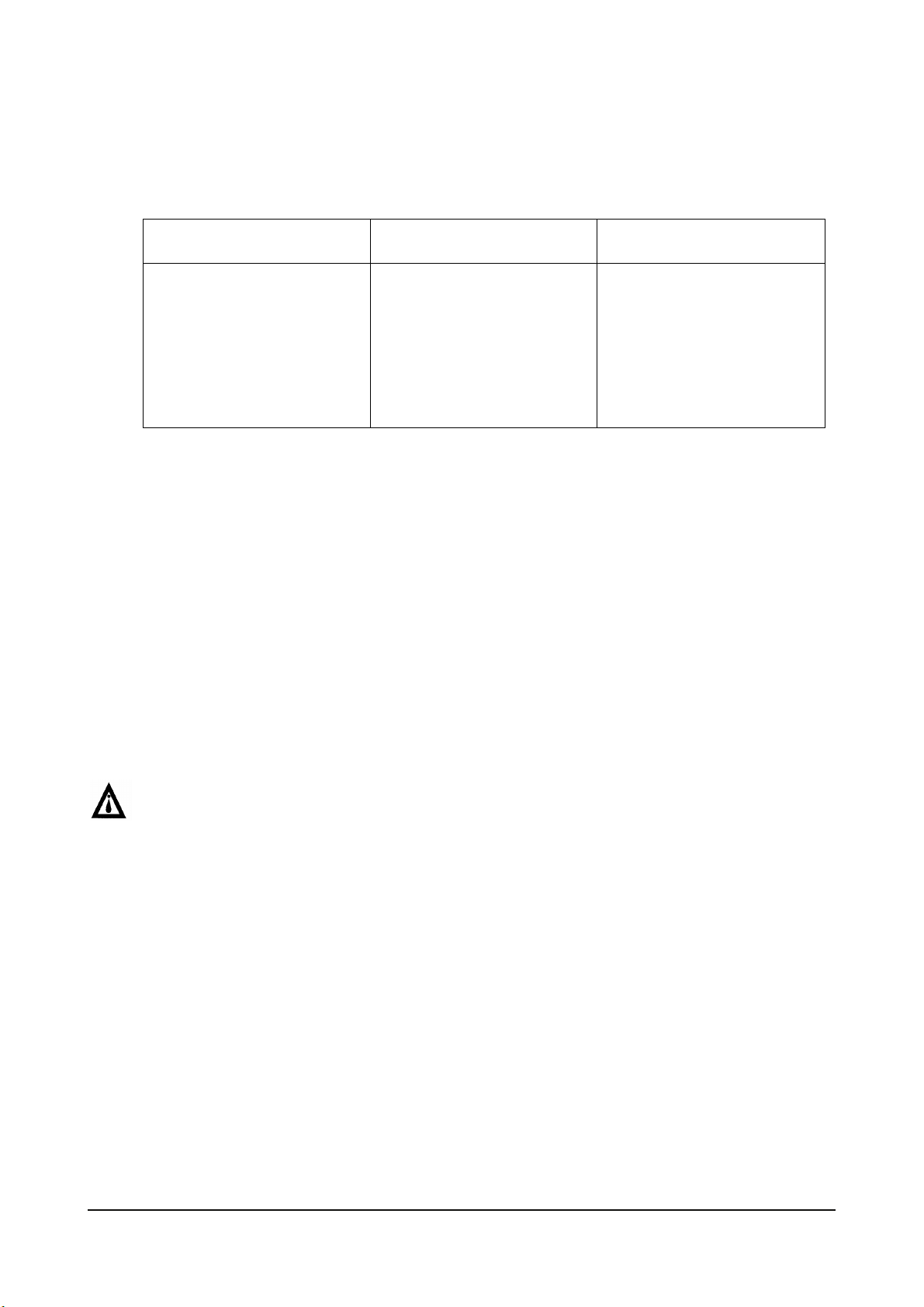

2.8.1. Anti-freeze

The anti-freeze, 50% of the whole coolant, is always to be used to prevent the cooling system from the

corrosion. And in winter the amount of anti-freeze shown in the following table should be used in

accordance with the ambient temperature.

Temperature (°C)

Ambient

Cooling water (%) Anti-freeze (%)

Over -10

-10

-15

-20

-25

-30

-40

85

80

73

67

60

56

50

15

20

27

33

40

44

50

As the individual freezing points corresponding to the proportions of antifreeze in the table are subject to

change slightly according to the kind of antifreeze, you must follow the specifications provided by the

antifreeze manufacturer.

As the ratio of antifreeze in the mixture decrease each time new coolant is added to make up for the loss

coolant resulting from engine operation, Check the mix ratio with every replenishment of coolant, and top

up as necessary.

2.8.2. Cooling water

z Regarding the engine cooling water, the hard water must be used (Do not use the soft water).

z The engine cooling water can be used diluting it with antifreezing solution 40% and the additive for rust

prevention (DCA4) 3 ∼ 5 %.

z The density of above solution and additive must be inspected every 500 hours to maintain it properly.

NOTE

The proper density control of antifreezing solution and rust preventing additive will be able to

prevent the rusting effectively and maintain the stable quality of engine.

For the improper control might give the fatal damage to the cooling water pump and cylinder liners,

detail care is needed.

z Since DB58 cylinder liner is dry type, particularly the cooling water control should be applied thoroughly.

z The density of antifreezing solution and additive for rust prevention is able to be confirmed by the

cooling water test kit. (Fleetguard CC2602M)

z How to use the cooling water test kit

(1) When the cooling water temp. of engine is in the range of 10 ∼ 55 °C, loosen the plug for cooling

water discharge and fill the plastic cup about a half.

Technical information - 21 -

Page 30

NOTE:

In taking the cooling water sample, if the water in auxiliary tank were taken, it is hard to measure

the accurate density. Take the cooling water sample necessarily loosening the cooling water

discharge plug.

(2) At the state of a test paper soaked in the sampled water, after taking the paper out through water

agitation, shake off the water.

(3) Wait for about 45 sec. till the color change of test paper.

NOTE:

However, it should not elapse longer than 75 sec, and if it did, the hue would change.

(4) Make the numerical value by comparing the test paper which hue has changed with the color list of

label on storage bottle.

(5) By comparing the hue changed into yellowish green or so with the green color indication of test paper

storage bottle, confirm the density. (Then, the density indication must be in the hue range of 33% to

50%).

(6) The brown at the middle of test paper and the lower pink color indication represent the additive state

for rust prevention, and the proper range is that the meeting numerical value of brown (vertical) and

pink color (horizontal) (7) locates in the range of 0.3 to 0.8 at the color list of label on the test paper

storage bottle.

(8) In case of less than 0.3, replenish the additive for rust prevention (DCA4), and in case of more than

0.8, pour out the cooling water about 50% and then readjust the density after refilling with clean fresh

water.

Technical information - 22 -

Page 31

2.9. V-belt tension check and adjust

z V-Belt

By the finger-pressure the belt is pressed by

10mm ∼ 15mm between the fan pulley and

the alternator pulley in normal condition. For

the adjustment of the tension, loosen the

adjusting bolts which support the alternator,

adjust the tension and tighten the bolts

again.

z Poly belt

Poly belt will be properly tensioned if the

deflection force “F” is applied midway

between the belt`s tangent points with the

pulley.

T = 0.015 x S (about 1.5mm per 100mm)

EA9O2006

EB5O6003

Technical information - 23 -

Page 32

2.10. Valve clearance and

adjustment

NOTE:

The cylinder head bolts were previously

tightened with the torque wrench.

Therefore it is not necessary to retighten

the cylinder head bolts before adjusting

the valve clearance.

Rocker arm screw

lock nut torque

z After letting the #1 cylinder's piston come

at the compression top dead center by

turning the crankshaft, adjust the valve

clearances.

z Loosen the lock nuts of rocker arm

adjusting screws and push the feeler

gauge of specified value between a rocker

arm and a valve stem and adjust the

clearance with adjusting screw

respectively and then tighten with the lock

nut.

z As for the valve clearance, adjust it when

in cold, as follows.

2.6 ±0.5kg.m

EAOO4014

EJM1035S

Model Intake Valve Exhaust Valve

DB58S 0.4 mm 0.4 mm

1) Rotate the crankshaft to overlap the intake and the exhaust valves of #6, then #1 cylinder become the

compression state of top dead center.

2) Therefore adjust the valve clearance corresponding to “ ” of lower figure. At this time there are

no force on the push rods of #1 cylinder.

3) Rotating the crankshaft by one revolution, #6 cylinder become the compression state of top dead center.

4) Thereafter adjust the valve clearances corresponding to “ ” of lower figure.

5) After reinsuring the valve clearances, retighten if necessary.

Technical information - 24 -

Page 33

• No. 1 cylinder is located at the side where flywheel was installed.

Cooling fan Cylinder no.

2.11. Cylinder compression

pressure

z Stop the engine after warming up, and

take out preheating plug and injection pipe.

z Install the special tool (compression gauge

adapter) at the preheating plug hole, and

connect the compression pressure gauge

there.

z Check the compression pressure at gauge

several times until highest compression

reading is reached.

Standard value 28kg/cm² over

Limit value 24kg/cm²

Difference

between each

cylinder

z Condition : Water temperature 75°C.

Within ± 10 %

Exhaust valve Intake valve Fly wheel

EC9OM020

EJM1046S

EJM1047I

Technical information - 25 -

Page 34

2.12. Injection nozzle

z Install a nozzle on the nozzle tester.

z If the inspected injection pressure is less than the specified value, adjust using the adjusting shims.

Engine model Injection nozzle pressure

DB58S 220 kg/cm²

z Check the atomizing state and replace it if abnormal.

2.13. Battery

z Inspect for any leakage of electrolytic solution owing to battery crack, and replace the battery in case of

poor condition.

z Inspect for amount of electrolytic solution, and replenish if insufficient.

z Measure the gravity of electrolytic solution, if less than specified value (1.12 ∼ 1.28), replenish.

2.14. Starting motor

z In case of engine maintenance, clean pinion and ring gear thoroughly putting in the fuel, and coat them

with grease.

Also, in case of washing engine room and so forth, inspect the wiring state being careful for water not to

get in.

EFM1006I

EFM1007I

Technical information - 26 -

Page 35

2.15. Diagnosis and remedy

r

z The following description summarizes the probable cause of and remedy for general failure by item.

z Immediate countermeasures should be taken before a failure is inflamed if any symptom is detected.

1. Engine Starting Impossible

Starting motor does not turn

Inspection of battery electrolytic

Iiquid amount & gravity

Normal Too Iow

Adjustment,

Recharging

Inspection of Ioose electric

Wiring & short

Normal

Inspection of starter switch

Inspection of starter relay

Normal Replace

Inspection of starter switch

Normal

Starting motor

disassembly

Retighten.

Replace

Retighten.

Replace

Retighten.

Replace

Starting motor turns but

engine does not revolution

Engine

Inspect air cleaner

Normal Polluted

Replace or

Clean element

Check compression

pressure

Normal Too low

Repai

Replace

Inspect of

other parts

Check valve

clearance

Normal

Check

clinder

head gasket

Normal

Adjust

Replace

Fule

Inspect amount of fule

Normal No fule

Replenish

Inspect fule injection

Normal No fule injection

Inspect

injection

timing

Normal

Inspect injust

nozzle (injection

pressure, injection

state ect.)

Normal

Disassemble and

Inspect injection pump

Air bleeding

and re-start

Adiust

Repair

Replace

Engine disassembly

(valve assembly, piston,

cylinder liner ect.

Inspect fule feed pump for function

Normal

Disassemble and

Inspect injection pump

Inspect feed pump valne and

Normal

Inspect fule filter

Dirty element ald/or

overflow valve faulty

Replace

Clean

Replace

Air mixture in fule

Retighten connection

Parts. Replace gasket

Air bleeding

Continuous entry of air

In fuel system

Disassemble and

Check fuel feed pump

Technical information - 27 -

Page 36

2. Engine Overheated

Operating state

1. Overload

2. Radiator core clogged

Cooling system

Fule system

3. Continuous over-run

Check coolant level

Normal Too low

Check fan belt

tension, wear

or damage etc.

Normal

Repair.

Replenish

Replace

Check fresh

radiator tank cap

Normal Repair

Check thermostat

Normal Repair

Inspect radiator Damage

Inspect fule quality

Poor

Clean and replace

with specified fule

Inspect cooling

water leakage

Extemal

Repair

Replace

Intemal

Engine

disassembly

Fuel excessive supply

Check injection nozzle

Normal Abnormal

Adjust or

repair

Repair

Replace

Injection

pump

Normal

Check cooling

water passage

Repair.

Replace

Check cooling

water pump

Normal

Repair.

Replace

Engine

disassembly

Technical information - 28 -

Page 37

3. Output insufficient

Engine Chassis

Check for clutch silp

Check for air maxing

In fule

Inspect fule supply pump

Normal

Clean.

Replace

Inspect fule filter

and over flow valve

Normal Replace

Inspect injection pipes

Normal

Repair

Replace

Inspect injection nozzle

(injection pressure,

atomizing state ect.)

Normal

Adjust.

Replace

Others Fule system

Inspect air cleaner

Normal

Clean.

Replace

Inspect engine control

rod, link, cable, ect

Normal

Repair

Replace

Check valve clearance

Normal Adjust

Inspect cylinser head

gasket for damage

Normal

Replace

Engine disassembly

(valve assembly)

Adjust or replace clutch

Inspect air leakage

of air piping line

Normal

Retighten.

Replace

Inspect air leakage

of intercooler

Check injection timing

Normal Adjust.

Disassemble engine

or injection pump

Check turbocharger

Normal

Repair

Replace

Disassemble injection

pump or engine

Technical information - 29 -

Page 38

4. Oil Pressure Iowered

Check oil amount

Check if pressure

gauge indicates wrongly

Normal

Check cooling

temperature

Normal

Inspect oil quality

Normal

Check oil

relief valve

Normal

Refer to engine overheat

Reyighten.

Replace

Too high

Disassemble engine

or injection pump

Water and fule

mixed in oil

To Iow

Use recommened oil

(replenish)

Improper

Replace with

recommended oil

Disassemble

engine

Technical information - 30 -

Page 39

5. Fule Consumption Excessive

Cause according to use conditions

1. Overlow

2. Frequent use of low gear position

3. Frequent use of high gear position

Inspect fule Ieakage

at low speed

4. Clutch slip

5. Too low tire inflation pressure

Normal Fule leakage

Inspect injection nozzle

(injection pressure

atomizing state, ect.)

Normal

Adjust

Replace

Inspect injection timing

Normal

Adjust

Inspect compressed

pressure

Normal

Adjust

Disassemble

injection pump

Check valve

clearance

Retighten

Replace

Pepair, Replace

(cylinder liner,

piston ring, piston)

Normal

Adjust

Inspect head gasket

Normal

Replace

Disassemble engine

(valve assembly, pistion,

cylinder er, ect.)

Technical information - 31 -

Page 40

6. Oil Consumption Excessive

Cause according to use conditions

1. Excessive oil infusing

2. Continuous operation in low speed

or extremely cold state

Inspect oil leakage

Normal Oil leakage

Check oil quality

Extermal Internal

Replace with

specified oil

Retighten.

Replace

7. Engine Knocking

Inspection combustion of fule & oil

(carbon residue of exhaust gas)

Check compressed

pressure

Engine disassembly

(piston, cylinder liner)

Inspect air cleaner

Clean Replace

Normal

Disassemble

cylinder head

(valve stem seal)

Unconfirmed Confirm

Inspect compressed

pressure

Normal Too Low

Inspect injection

timing

Normal Adjust

Check fule quality

Check valve clearance and

cylinder head gasket crush

Normal

Disassemble

engine

Use specified fule

Technical information - 32 -

Disassemble

engine

Replace

Adjust

Page 41

8. Battery Discharge

Battery Wiring, Switch Altemator

Check electrolytic

liquid amount

Normal

Electrolytic

liquid’s standard

Replenish

Inspect cut wire

shorts and loose

connections, etc.

Repair. Replace

Damaged

battery case

Replace Charging

Normal Abnormal

Check charged stated

Battery self

dischage

Check fan belt

tension & damage

Battery over

charging

Inspect altemator

and voltage regulator

Adjust

Replace

Discharging

Disassemble altemator

and voltage regulator

Technical information - 33 -

Page 42

Condition Causes Remedies

1) Starting difficult

(1) Compression pressure

2) Idle operation abnormal

3) Engine output insufficient

(1) Continuous output

z Valve's poor shut, stem distortion

z Valve spring damage

z Cylinder head gasket's leak

z Wear of piston, piston ring or liner

z Injection timing incorrect

z Air mixing at injection pump

z Valve clearance incorrect

Insufficient

(2) Output insufficient

z Valve tightness poor

z Cylinder head gasket's leak

z Wear, stick, damage of piston ring

z Injection timing incorrect

z Fuel injection amount insufficient

z Nozzle injection pressure improper or stuck

z Supply pump's function lowered

z Fuel pipe system clogged

z Air suction amount insufficient

z Turbocharger poor

z Compression pressure insufficient

when in acceleration

4) Overheating

z Injection timing incorrect

z Fuel injection amount insufficient

z Injection pump timer's function insufficient

z Nozzle injection pressure, injection angle

improper

z Supply pump's function lowered

z Air intake amount insufficient

z Engine oil insufficient or poor

z Cooling water insufficient

z Fan belt loosened, worn, damaged

z Cooling water pump's function lowered

z Water temperature regulator's operation poor

z Valve clearance incorrect

z Exhaust system's resistance increased

Repair or replace

Replace valve spring

Replace gasket

Adjust

Adjust

Remove air

Adjust

Repair

Replace gasket

Replace piston ring

Adjust

Adjust injection pump

Adjust or replace

Repair or replace

Repair

Clean or replace air cleaner

Repair or replace

Disassemble engine

Adjust

Adjust injection pump

Repair or replace

Repair, replace

Repair or replace

Clean or replace air cleaner

Replenish or replace

Replenish or replace

Adjust or replace

Repair or replace

Replace

Adjust

Clean or replace

Technical information - 34 -

Page 43

Condition Causes Remedies

5) Engine noisy For noises arise compositely such as

rotating parts, lapping parts etc., there is

necessity to search the cause of noises

accurately.

(1) Crankshaft

z As the wear of bearing or crankshaft

progress, the oil clearances increase.

z Lopsided wear of crankshaft

z Oil supply insufficient due to oil passage

clogging

(2) Connecting rod and

z Stuck bearing

z Lopsided wear of connecting rod bearing

Connecting rod bearing

z Lopsided wear of crank pin

z Connecting rod distortion

z Stuck bearing

z Oil supply insufficiency as clogging at oil

passage progresses

(3) Piston, piston pin &

piston ring

(4) Others

6) Fuel Consumption excessive

7) Oil consumption excessive

z Piston clearance increase as the wear of

piston and piston ring progresses

z Wear of piston or piston pin

z Piston stuck

z Piston insertion poor

z Piston ring damaged

z Wear of crankshaft, thrust bearing

z Camshaft end play increased

z Idle gear end play increased

z Timing gear backlash excessive

z Valve clearance excessive

z Abnormal wear of tappet, cam

z Injection timing incorrect

z Fuel injection amount excessive

excessive

(1) Oil level elevated

z Clearance between cylinder liner &

piston

z Wear of piston ring, ring groove

z Piston ring's damage, stick, wear

z Piston ring opening's disposition

improper

z Piston skirt part damaged or abnormal

wear

(2) Oil level lowered

(3) Oil leak

z Oil ring's oil return hole clogged

z Oil ring's contact poor

z Looseness of valve stem & guide

z Wear of valve stem seal

z Cylinder head gasket’s leak

z Looseness of connection parts

z Various parts' packing poor

z Oil seal poor

Replace bearing & grind

crankshaft

Grind or replace

Clean oil passage

Replace bearing & grind

Replace bearing

Grind crankshaft

Repair or replace

Replace & grind crankshaft

Clean oil passage

Replace piston &

piston ring

Replace

Replace piston

Replace piston

Replace piston

Replace thrust bearing

Replace thrust plate

Replace thrust washer

Repair or replace

Adjust valve clearance

Replace tappet, cam

Adjust

Adjust injection pump

Replace

Replace piston, piston ring

Replace piston ring

Correct position

Replace piston

Replace piston ring

Replace piston ring

Replace in set

Replace seal

Replace gasket

Replace gasket, repair

Replace packing

Replace oil seal

Technical information - 35 -

Page 44

2.16. Engine inspection

2.16.1. Stopping engine

After checking the engine for any unusual condition at the idling speed, then turn the key switch to the stop

the engine.

2.16.2. General engine inspection cycle

In order to insure maximum, trouble-free engine performance at all times, regular inspection, adjustment

and maintenance are vital.

z Daily inspections in below figure should be checked every day.

z The following maintenance details should be executed thoroughly at regular internals.

Inspection Daily

Check for leakage(hoses,

clamp)

Cooling

System

Lubrication

System

Intake & Exhaust

System

Fuel

System

Engine

Adjust

Check the water level O

Change the coolant water ●

Adjust the V-belt tension O

Clean the radiator O

Check for leakage O

Check the oil level gauge O

Change the lubricating oil

Replace the oil filter

cartridge

Check the leakage for

intercooler (hoses, clamp)

Clean and change

the air cleaner element

Check the leakage fuel

line

Clean the fuel strainer

of fuel feed pump

Remove sediment from

fuel tank

Drain the water in

separator

Replace the fuel filter

element

Check fuel injection timing O

Check the injection

nozzles

Check the state of

exhaust gas

Check the battery

charging

Check the compression

pressure

Adjust Intake/Exhaust

valve clearance

O : Check & adjust ● : Replace

Every

50hrs

O

●

1st

O

O

O

O

O

●

O

O

O

O

●

1st

O

1st

Every

200hrs

O

clean

Every

500hrs

●

●

Every

600hrs

●

Every

1200hrs

Remark

Every

2,000hrs

When

necessary

When

necessary

When

necessary

When

necessary

Technical information - 36 -

Page 45

2.17. Use of original parts for repair and replacement

For engine is being mechanically harmonized with many parts, only when the original parts that the

manufacture recommends to use is used, the engine trouble would be preventively maintained and

capable to keep up the maximum performances.

For the analogous parts not the original parts are poor in qualities and gives ill performance, it may rather

bring early engine failure.

Technical information - 37 -

Page 46

3. Maintenance

3.1. Engine Disassembly

3.1.1. Major part fixing nuts and bolts

1) Cylinder head cover

(Unit : kg.m)

Engine disassembly - 38 -

EJM1001S

Page 47

2) Cylinder block

(Unit : kg.m)

EJM1002S

Engine disassembly - 39 -

Page 48

3) Oil pan and level gauge

(Unit : kg.m)

Engine disassembly - 40 -

EJM1003S

Page 49

4) Camshaft and rocker arm

(Unit : kg.m)

EJM1004S

Engine disassembly - 41 -

Page 50

5) Crankshaft, piston and flywheel

(Unit : kg.m)

Engine disassembly - 42 -

EJM1005S

Page 51

6) Thermostat and housing

(Unit : kg.m)

EJM1006S

Engine disassembly - 43 -

Page 52

7) Intake and exhaust manifold

(Unit : kg.m)

Engine disassembly - 44 -

EJM1009S

Page 53

8) Timing gear case and flywheel housing

(Unit : kg.m)

EFM1010S

Engine disassembly - 45 -

Page 54

9) Oil cooler, oil filter and oil pump

(Unit : kg.m)

Engine disassembly - 46 -

EFM1011S

Page 55

10) Fuel system

(Unit : kg.m)

EFM1012S

Engine disassembly - 47 -

Page 56

11) Engine repair parts

1

6

11

16

1. Cover to timing gear case gasket 12. Oil filter cover gasket

2. Gear case to cylinder block gasket 13. Oil cooler gasket

17

12

2

3

5

4

8

9

10

7

18

13

14

20

19

21

15

22

EC9OM064

3. Timing gear case oil seal 14. Intake manifold gasket

4. Flywheel housing gasket 15. Oil pan gasket

5. Crank shaft rear oil seal 16. Turbocharger gasket

6. Cylinder head gasket 17. Turbocharger outlet gasket

7. Cylinder head cover gasket 18. Water pump gasket

8. Valve guide oil seal 19. Water pump housing gasket

9. Tappet chamber cover gasket 20. Exhaust manifold gasket

10. Air heater gasket 21. Thermostat gasket

11. Thermostat housing gasket 22. Oil pump hole cover gasket

Engine disassembly - 48 -

Page 57

3.1.2. Main structure parts (1)

1. Rubber hose (Coolant by-pass) 9. Oil pump driving pinion

▲ 2. Rocker arm shaft assembly 10. Nut

3. Push rod ▲ 11. Crankshaft pulley and dust cover

4. Cylinder head bolt ▲ 12. Taper bushing

▲ 5. Cylinder head assembly 13. Timing gear cover

6. Cylinder head gasket 14. Oil thrower

7. Coolant pump assembly ▲ 15. Fly wheel

8. Tappet chamber cover

2) Rocker arm shaft

Loosen the rocker arm shaft fixing bolts a

little in numerical sequence as specified.

EJM2010S

EJM2013S

Engine disassembly - 49 -

Page 58

5) Cylinder head

Loosen the cylinder head bolts a little in the

numerical order shown in the figure.

11) Crankshaft pulley

Use an appropriate wrench (54 mm) to

remove the crankshaft pulley nut.

12) Taper bushing

Use the taper bushing remover to remove

the crankshaft end taper bushing.

15) Flywheel

Loosen the flywheel bolts a little in the

numerical order as specified.

EJM2014S

EJM2015S

EDM1010I

Engine disassembly - 50 -

EJM2017S

Page 59

3.1.3. Main structure parts (2)

1. Oil cooler 9. Timing gear case

2. Oil pan 10. Idler gear shaft

3. Oil pump and coupling ▲ 11. Crank shaft bearing cap

4. Flywheel housing 12. Crank shaft bearing (lower part)

5. Piston and connecting rod 13. Thrust bearing

▲ 6. Idler gear 14. Crank shaft

▲ 7. Cam shaft 15. Crank shaft bearing (upper part)

8. Tappet

EJM2018S

Engine disassembly - 51 -

Page 60

6) Idler gear

Measure the following points before

disassembly.

<Idler gear end play>

Standard Limit

0.058 ∼ 0.115 mm 0.2 mm

<Timing gear back lash>

Standard Limit

0.10 ∼ 0.17 mm 0.3 mm

Includes the crankshaft gear, the camshaft

gear and the idler gear

7) Camshaft

Measure the following points before

disassembly.

<Cam Gear End Play>

Standard Limit

EJM2022S

EJM2019S

0.050 ∼ 0.114 mm 0.2 mm

11) Crankshaft bearing cap

Measure the crankshaft endplay at the thrust

bearing (center main bearing) before

disassembly.

<Crankshaft End Play>

Standard Limit

0.15 ∼ 0.33 mm 0.4 mm

Engine disassembly - 52 -

EJM2020S

EJM2021S

Page 61

3.1.4. Rocker arm disassembly

1. Bracket 3. Spring

EJM2023S

2. Rocker arm

4. Rocker arm shaft

Engine disassembly - 53 -

Page 62

3.1.5. Cylinder head disassembly

1. Exhaust manifold and gasket 7. Spring seat (upper)

2. Intake manifold and gasket 8. Valve spring

3. Coolant outlet pipe 9. Spring seat (lower)

4.Thmostat 10.Valve

5. Thermostat housing and gasket 11. Valve stem oil seal

▲ 6. Valve cotter

EJM2024S

Engine disassembly - 54 -

Page 63

Importance

6) Valve cotter

Use the valve spring compressor to remove

the valve cotter.

3.1.6. Piston and connecting rod disassembly

▲ 1. Piston rings

▲ 2. Snap ring 5. Connecting rod bearing

▲ 3. Piston pin and connecting rod

EJM2027S

EJM2028I

4. Piston

Engine disassembly - 55 -

Page 64

IMPORTANT:

Remove any carbon deposits from the

upper part of the cylinder bore.

This will prevent damage to the piston and

the piston rings when they are removed

from the cylinder bore.

1) Piston rings

Use a piston ring remover to remove the piston

rings.

Do not attempt to use other tools. Stretching

piston ring will result in reduced piston ring

tension.

2) Snap ring

Use a pair of snap ring pliers to remove the

snap ring.

3) Piston pin

Tap the piston pin out with a hammer and

brass bar.

EDM1011I

EJM2030I

EJM2031S

Engine disassembly - 56 -

EJM2032S

Page 65

3.2. Engine Inspection

3.2.1. Cylinder block

z Clean the cylinder block thoroughly and make a visual inspection for cracks or damage.

z Replace if cracked or severely damaged, and correct if slightly damaged.

z Check oil and water flow lines for restriction or corrosion.

z Make a hydraulic test to check for any cracks or air leaks.

(Hydraulic test) :

Stop up each outlet port of water/oil passages in the cylinder block, apply air pressure of about

5kg/cm2 against the inlet ports, then immerse the cylinder block in water for about 3 minute to check

any leaks. (Water temperature : 70 °C)

3.2.2. Cylinder head

1) Inspection

z Carefully remove carbon from the lower lace of the cylinder head using nonmetallic material to

prevent scratching of the valve seat faces.

z Check the entire cylinder head for very fine cracks or damage invisible to ordinary sight using a

hydraulic tester or a magnetic flaw detector.

2) Distortion at the lower face

z Measure the amount of distortion using a

straight edge and a feeler gauge at six

positions (A ∼ F) as shown in the right

figure.

z If the measured value exceeds the

standard value, retrace the head with

grinding paper of fine grain size to correct

such defect.

z If the measured value exceeds the

maximum allowable limit, replace the

cylinder head.

<Lower face warpage and height>

Standard Limit

EA3M2031

Warpage

Thickness : t

0.2 mm or

less

89.95 ∼ 90.05

mm

0.3 mm

89.65 mm

EJM2034S

Engine inspection - 57 -

Page 66

3) Flatness

Measure flatness of the intake/exhaust

manifolds fitting surfaces on the cylinder

head using a straight edge and a feeler

gauge.

Standard Limit

0.05 mm 0.2 mm

4) Hydraulic test

Hydraulic test method for the cylinder head

is same as that for cylinder block.

3.2.3. Valve stem and valve guide

clearance

1) Measuring method - I

z After install dial gauge needle on the

inserted valve stem, set up calibrator to

“0”. (as shown in figure)

z Move valve head from side to side.

z Record total dial indicator reading.

z This valve is the clearance between the

valve stem and valve guide.

z Valve and guide set must be replaced if

measured value exceed the specified

limit

<Valve stem clearance (T.I.R)>

EJM2036S

EJM2037S

Standard Limit

Intake side

Exhaust side

0.039 ∼

0.071mm

0.064 ∼

0.096mm

0.20mm

0.25mm

Engine inspection - 58 -

Page 67

2) Measuring method – II

z Measure valve stem outside diameter.

z Measure valve guide inside diameter by

using of caliper calibrator of telescoping

gauge.

z The difference between the valve stem

outside diameter and the valve guide

inside diameter is the valve stem

clearance.

3) Valve guide replacement

z Removal of valve guide

z Pull out the valve guide, by using

hammer and valve guide remover, from

bottom of cylinder head.

z Install of valve guide

z The height from the bottom of the

cylinder head to the edge of valve guide

top should be 14.1mm.

4) Valve depression

z Install the valve① to the cylinder head②.

z Measure valve depression by using the

depth gauge or calibrator from the bottom

of cylinder head.

z Seat insert and valve must be replaced if

the measured value exceed the specified

limit.

z If the valve is replaced, the valve guide

must be also replaced.

EJM2038S

EJM2039S

EJM2040S

EJM2041I

Engine inspection - 59 -

Page 68

Standard Limit

Intake and exhaust

valve depression

1.0 mm 2.5mm

5) Valve contact width

z Inspect the valve contact faces for the

roughness and unevenness.

z Make valve contact surfaces smooth.

z Measure the width of valve contact.

Standard

Valve contact width, Intake 2.4mm

Valve contact width, Exhaust 1.6mm

6) Valve seat replacement

z Arc weld entire inside circumference① of

the valve seat②. (see figure)

z Cool valve seat for a few minutes. This

will make removal of the valve seat

easier.

z Pull out the valve seat by using the inner

extractor.

z Carefully remove the carbon and other

foreign material from the cylinder head

insert bore.

7) Valve seat installation

z Carefully place Jig①.

CAUTION:

The smooth face of jig must contact the

valve seat.

z Assemble valve insert by slowly pressing

it against the jig with the bench press.

(The amount of needed pressure is more

than 2,500kg.)

IMPORTANT:

Do not press the valve seat excessively with the bench press.

It may damage the valve seat.

EJM2042I

EJM2043S

EJM2044I

Engine inspection - 60 -

Page 69

8) Valve seat correction

z Remove the carbon deposits from the

valve seat surface.

z Remove the rough areas by using valve

cutter. (30°, 90° or 150°)

Do not cut the valve seat too much.

Angle Location Standard

Intake valve seat 90°

Exhaust valve seat

IMPORTANT:

Use an adjustable valve cutter pilot.

Do not allow the cutter pilot to wobble

inside the valve guide.

z Spread compound on the surface of

valve seat.

z Insert valve into valve guide.

z Lap the valve and valve seat with the

lapping tool.

z Check that valve contact width is correct.

z Check that the entire surface of valve

seat is in contact with the valve.

90°

EJM2046S

EJM2047I

EJM2048S

Engine inspection - 61 -

Page 70

3.2.4. Valve spring

1) Valve spring free length

z Measure the valve spring with the vernier

caliper.

z Replace the spring if the measured value

is less than the specified limit.

Standard Limit

Exhaust and intake

valve spring free

length

2) Valve spring inclination

z Measure the valve spring inclination by

the using of square.

z Replace the valve spring if the measured

value exceed the specified limit.

Standard Limit

Valve spring

Inclination

3) Valve spring tension

z Measure the valve tension by using

spring tester.

z Replace the valve spring if the measured

value exceed the specified limit.

Standard Limit

Valve spring tension

at 44mm set length

53.65 mm

52 mm

2.5 mm 3.5 mm

22.5 kg 20.0 kg

EJM2049I

EJM2050I

EA0M4056

Engine inspection - 62 -

Page 71

3.2.5. Tappet

z Check the valve tappets for excessive

wear, damage or abnormalities.

z Measure the outside diameter of tappet

with the micrometer.

Standard Limit

Tappet

outside

diameter

z Measure the clearance between tappets

and cylinder motion parts by the using

dial indicator.

Standard Limit

Tappet and tappet

bore clearance

3.2.6. Push rod

z Measure the run out of push rod with the

feeler gauge.

z Roll the push rod along a smooth flat

surface as shown in the figure.

Limit

∅27.96 ∼

∅27.98mm

0.020 ∼

0.054mm

EA0M4070

∅27.92

mm

EJM2052S

0.1mm

EJM2053S

Push rod of run-out 0.2mm

EA0M4073

Engine inspection - 63 -

Page 72

3.2.7. Rocker arm correction

z Check the valve stem contact part of

rocker arm.

z Grind contact surface with an oil stone if it

is irregularly contacted.

z Replace the rocker arm if it is extremely

damaged.

1) Rocker arm and shaft

z Check the disassembled parts for wear,

damage and abnormalities.

2) Rocker arm shaft outside diameter

z Measure the outside diameter of rocker

arm with the micrometer.

z Replace shaft if measured value exceed

the specified limit.

Standard Limit

diameter of

rocker arm

shaft

∅18.98-∅19.00

mm

3) Rocker arm and shaft clearance

z Measure the inside diameter of rocker

arm bushing with the vernier caliper.

the out side diameter of rocker arm

shaft.

z Replace the rocker arm or rocker arm

shaft if measured value exceed the

specified limit.

Standard Limit

Diameter of rocker

Arm bushing

∅19.02 ∼

∅19.05mm

Engine inspection - 64 -

∅18.85

mm

∅19.07

mm

EJM2055S

EC9OM054

EJM2057S

EJM2058S

Page 73

Standard

Rocker arm

bushing and

rocker arm shaft

0.02 ∼ 0.07

mm

clearance

z Check the rocker arm oil port whether

alien substance is in it or not.

z Clean the rocker arm oil port with

compressed air if necessary.

3.2.8. Idler gear and shaft

z Replace the idler gear shaft if the

measured value exceeds the specified

limit.

Standard Limit

Diameter of

idler gear

shaft

∅44.945 ∼

∅44.975 mm

z Measure the inside diameter of idler gear

with the dial indicator,

Standard Limit

Clearance of idle

gear and shaft

0.045 ∼

0.105 mm

3.2.9. Camshaft

z Use the jig to install or overhaul camshaft

bearing in cylinder block.