Doosan DL06, D110S-5, D130S-5, D160S-5, DL06K Operation Manual

DL06 Diesel Engine

(interim Tier Ⅳ)

Specification

System Operation

Testing & Adjusting

Disassembly & Assembly

D110S-5, D130S-5, D160S-5

SB4391E00

Aug. 2012

DL06K Interim Tire-4 Diesel Engine Foreword

1

FOREWORD

This Operation & Maint enance Manual is des igned to provide the inf orm ation on engine operat ion and

maintenance manual to custom ers and service technicians of the DL06K industrial electronic cont rol

diesel engine provided by DO OSAN.

The DL06K industrial electronic control diesel engine is designed and manufactured to satisfy all

requirements, such as low noise, economical power consumption, high-speed, and durability by

applying DOOSAN's lates t technologies in or der to provide t he best engine to it s customers, and meet

interim Tier-4 em is s ion regulation.

It is important to use precise operation and maintenance procedur es to keep the engine in the best

possible condition and ensure the best possible long term performance. This Operation &

Maintenance Manual provides the specification, defined values, fault diagnosis, parts configuration

diagrams, and figures, that allow users to understand, manage, and take actions conveniently and

accurately.

Please read this Operation & Maintenance Manual c arefully befor e handling the engine, t o ensure that

the highest quality maintenance procedures can be applied and the technician's safety can be

protected through the use of proper work methods and operating procedures as recommended by

DOOSAN and compiled here within.

We are continually developing and investing in creating products with the best performance and

quality, as well as the improvement of maintenance procedures. We are not obliged to reflect all

design changes for product impr ovement in this Operation & Maintenance Manual, and this manual is

subject to change wit hout prior notice.

We are always working to satisfy customer requirements and provide more convenient and safe

maintenance procedures to its customers.

If you find any incorrec t inf ormation in this manual or have any inquiry , please c ontact our head offic e,

dealers or authorized ser v ic e s hops near by your loc ation for any services.

Doosan industrial vehicle Co. , Ltd.

* All contents in this O per ation & M aintenance Manual are the property of DOOSAN.

DL06K Interim Tire-4 Diesel Engine Foreword

2

DL06K Interim Tire-4 Diesel Engine Important Safety information

3

Important Safety Information

Most accidents involvi ng product operation, mai ntenance and repair are caused by failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these func tions properly.

Read and understand all safety precautions and warnings before operating or performing

lubrication, maintenance and repair on this product.

Basic safety precautions are listed in the “Safety” section of the Service or Technical Manual.

Additional safety precautions are listed in the: Safety” section of the owner/operation/maintenance

publication. Specific safety warnings for all these publications are provided in the description of

operations where hazards exist. WARNING labels have also been put on the product to provide

instructi ons and to identif y specific hazards. If these hazard warnings are n ot heeded, bodi ly i njury or

death could occur to you or other persons. Warnings in thi s public ation and on the product label s are

identified by the following symbol.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you

have read and understood the operation, lubricat ion, maintenance and repair information.

Operations that may cause product damage are identified by NOTICE labels on the product and i n this

publication.

DOOSAN cannot anticipate every possible circumstance that might involv e a potential hazard. The

warnings in this publication and on the product are therefore not all inclusive. If a tool, pr oc edur e, work

method or operating t echnique not specifically recommended by DOOSAN is used, you m ust satisfy

yourself that it is safe for you and others. You should also ensure that the produc t will not be damaged

or made unsafe by the operation, lubrication, maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information

available at the time it was written. The specifications, torques, pressures, measurements,

adjustments, illustrations, and other items can change at any time. These changes can affect the

service given to the product. Obtain the complete and most current informati on before starting any job.

DOOSAN dealers hav e the most curr ent information available.

WARNING

DL06K Interim Tire-4 Diesel Engine Important Safety information

4

DL06K Interim Tire-4 Diesel Engine Index

5

INDEX

1. Safety Regulations &

Specifications. ................................ 8

1.1. Safety Regulations ................................ 8

1.2. Engine Specifications .......................... 13

1.3. Engine Power ..................................... 14

1.4. Engine Performance Curve ................. 15

1.5. Engine As se mbly ................................ 17

2. Tech n ical In form ation ................... 20

2.1. Engine Model and Serial Num ber ........ 20

2.2. Diagnostic tool .................................... 21

2.3. Engine character ................................. 21

2.4. Diagnosis and Remedy ....................... 42

2.5. Engine Inspection ............................... 53

3. Disassembly and Reassembly of

Major Components ....................... 54

3.1. Engine Disassembl y ............................ 54

3.2. Inspection and Measurement on Major

Parts ................................................... 69

3.3. Engine Reassembly. ........................... 90

3.4. Fuel Injection System ........................ 114

3.5. Electrical System .............................. 126

3.6. Exhaust Gas Reducti on S y stem ........ 133

3.7. Engine Diagnostic ............................. 149

3.8. Operating Condition of the ECU ........ 161

4. Commissioning and Operation .... 163

4.1. Preparations ..................................... 163

4.2. Breaking-In ....................................... 163

4.3. Inspections after Starting ................... 165

4.4. Operation in Winter Time ................... 166

4.5. Engine Components Check after Long

Time Running ................................... 167

4.6. Maintenance and Car e ...................... 168

4.7. Cooling System ................................. 170

4.8. Adjustment of Valve Clearance .......... 171

5. Maintenance of Major Components

......................................................174

5.1. Cooling System ................................. 174

5.2. Lubric ation system ............................. 178

5.3. T u r b o Cha r g e r ................................... 181

5.4. Air cleaner ......................................... 193

5.5. Belt .................................................... 195

6. Special Tool List ..........................197

z Appendix

DL06K Interim Tire-4 Diesel Engine Index

6

DL06K Interim Tire-4 Diesel Engine General Instructions

7

0. General Instructions

This Operation & Maintenance Manual is a m anu al desi gne d for o fficially qual ified professi onal

service technicians. If maintenance procedures is performed by unqualified personnel, or without

the specified tools and facilities, workers or others may be injured or their life can be threatened,

or an error m ay oc cur that could fat al ly af fec t e ngi ne performance.

Regular checkups and management are required to keep the engine in optimal condition and

performing at i t s best. If any par t nee ds to be r epl ac ed, the genuine p ar t s up pli ed by DO O SAN

and specified in the Parts Book should be used. Use of uncertified, similar parts, or recycled

parts may cause serious damage to the engine. If such a part is used, DOOSAN will bear no

responsibility.

Please note that the work procedures described in this Operation & Maintenance Manual are

the safest and most efficient work procedures, and you may be required to use special tools

for some work items.

Please contact us for genuine parts and special tools.

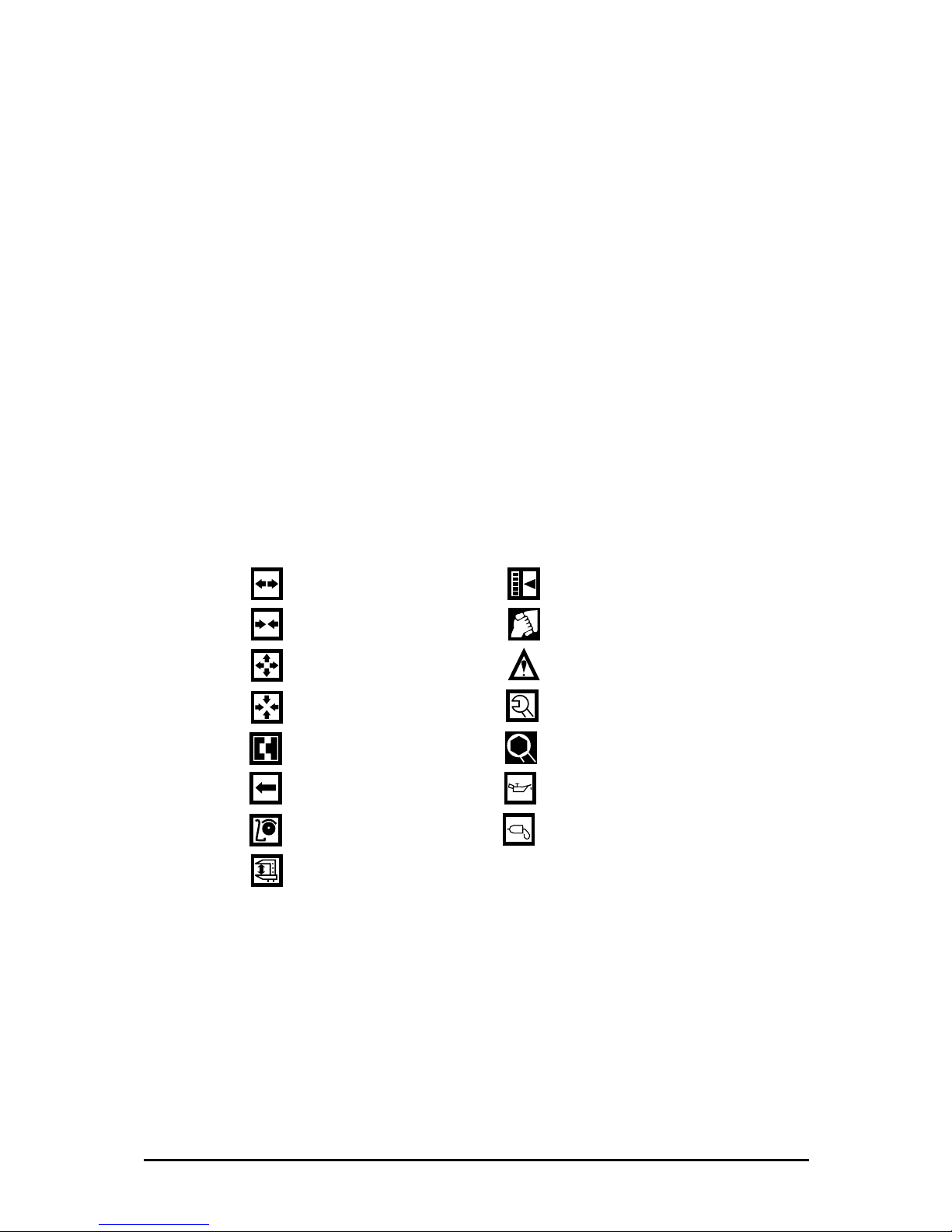

This Operation & Maintenance Manual uses the following symbols to explain maintenance

procedures, so that workers can make preparations and understand work items in advance.

Removal Adjustment

Installation Cleaning

Disassembly Pay close attention-Importants

Reassembly Tighten to specified torque

Algin the marks Use special tools of manuafacturer's

Directional Indication Lubricate with oil

Inspection Lubricate with grease

Measurement.

Please foll ow the instructions listed below to pr event environmental pol l u ti o n dur ing engine

maintenance.

z Take old oil to an old oil dis posal point onl y.

z Ensure without fail that oil and diesel fuel will not get into the sea or rive rs and canals

or the ground.

z Tr eat un di l ut ed an ti - cor r osi o n agents, antifreeze age nts, filter el em e nt an d cartr idges

as special waste.

z The regulations of the rel eva nt l oc al authoriti es ar e to be observed for the di sposal of

spent coolants and special waste.

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

8

1. Safety Regulations & Specifications.

1.1. Safety Regulations

1.1.1. General notes

z You should read this manual carefully and follow routine and regular check

methods to use the engine as safely as possible and minimize problems.

z Safety rules can be divided into three parts - injury to people, damage to property,

and pollution. In addition, users must comply with the regulations which apply to

each particular engine model, and the regulations regarding its place of use.

IMPORTANT:

If despite all precautions, an accident occurs, in particular through contact

with caustic acids, fuel penetrating the skin, scalding from oil, antifreeze being

splashed in the eyes etc, consult a doctor immediately.

1.1.2. To prevent accidents with injury to persons

(1) Engine starting and operation

z Please read "Caution" in the manual carefully before starting an engine. If you

don't understand anything, please contact Doosan.

z Please attach th e " Auth or i zed per s o nnel o nl y" w arni ng s ign on the engine for s a fety,

and remind the engine driver that the driver is responsible for safety in the engine

room.

z Only authorized per sonnel should start and run the engine. Un aut hor i z ed p er sonnel

should not start the engine.

z Do not access the engine parts when the engine is running.

z Do not touch the engine with bare hands while the engine is running, because

the engine is hot and dangerous.

z Exhaust fumes are toxic. Check ventilation w hen the engine is running i n an enclosed

space.

(2) Maintenance a n d care

z The engine must be stopped before performing maintenance procedures. If the

engine should be maintained during operation, please take additional caution as

to the danger of burns or accidents. Refrain from doing maintenance when the

engine is running as much as possible. Do not get too close to rotating parts, if

maintenance works are inevitable during operation.

z Replace engine oil when it is hot after operation, when the engine is stopped.

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

9

CAUTION:

Do not replace or disassemble pipes or hoses (engine fuel circuit, engine oil

circuit, coolant circuit, and compressed air circuit) while the engine is running.

Fluid spattering may cause injury.

z Check the amount of oil in the oil pa n, an d use a c ont ainer large eno ugh to hold

engine oil when replacing it.

z When replacing or rep lenishing engine coolant, cool down the engine and

disassemble the drain plug. The heated coolant may cause burns and safety

accident.

z Do not fasten or ope n pi p es or hoses (engine oi l ci r cui t, cool ant c ir c ui t, a nd

compressed air c i rc ui t) whi l e the engi n e is r unni ng. F l uid s p atter i ng m ay c aus e i nj ur y.

z Fuel is a highly combustible substance. Do not smoke or use fire around the

engine. Refuel the engine only when the engine is stopped.

z Do not mix engine maintenance materials (coolant, engine oil, fuel, battery fluid,

etc.) with drinking water containers.

z Follow the instructions of the manufacturer when checking or handling the battery.

CAUTION:

Battery fluid is toxic, corrosive, and explosive. Therefore, the battery should

be handled by a specialized technician only.

(3) When carrying out checking, setting and repair work

z Engine maintenance should be performed by authorized personnel only.

z Only tools suitable for the purpose should be used. If a wrench with a worn-out

edge is used, safety accidents may occur due to sliding.

z When an engine is lifted by a crane, nobody should stan d below it, or pass by it.

Please check the safety conditions of the crane first.

z For electric welding, turn off the engine, block the power supply, and remove the

vehicle side wire harness connector that is connected to the ECU (electronic

control unit).

z Never weld the electric device or ECU, or apply electric or mechanical shock.

z Disconnect the battery ground wire first when working with electric devices.

Connect the ground wire again when other work is completed, in order to prevent

a short circuit.

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

10

1.1.3. To prevent damage to engine and premature wear

(1) Do not use the en gi n e any purpose other than original d es i gn .

For more details, please refer to reference data from sales. Never calibrate the

ECU without the approval of DOOSAN.

(2) If any fault i s foun d i n th e e ngi ne, the cause s houl d be found and fixed i m medi atel y

to prevent ser ious damages to the en gi n e.

(3) Please use genuine spare and maintenance parts recommended by DOOSAN.

DOOSAN will bear no responsibility for damage due to the use of unauthorized

parts.

(4) Keep the following points in mind, in addition to the above instructions.

z Use normal and clean diesel fuel only. Do not use bio-diesel. Please refer to the

recommendations on fuel. Diesel fuel should not contain any moisture.

z Do not run the engine without lubricant and coolant. Use the service products

(engine oil, coolant, and anticorrosion agent) recommended by DOOSAN only.

z Keep the surroun di n gs o f the engine clean

z Refer to the recommendations about fuel in the handling manual.

z Maintain the engine at a regular interval, using the engine checklist.

z Do not stop the engine abruptly if the engine is hot. Instead, run the engine in the

idle state for 5 minutes without load to reduce engine temperature.

z Do not refill the coolant if the engine is overheated.

z Do not refill engine oil to a level higher than those marked on the level gauge.

Keep the maximum allowable slant of the engine during maintenance works.

z Check whether equipment gauges (battery, oil pressure, coolant temperature)

work properly (normally).

z Do not run the engine without coolant. If coolant freezing is expected in winter,

drain of f cool a nt.

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

11

1.1.4. To prevent pollution

(1) Engine oil filter elements, fuel filters

z Pour used oil into the oil collection drum.

z Pay special attention not to spill oil on the ground or into the ocean. Leaked oil

can pollute sources of drinking water.

z Separate oil and oil filter cartridge as wastes of environmental pollution, and

dispose th em acc ording to the presc r ibed regulations.

(2) Coolant

z Treat no n- di luted anticor r osi ve agents an d c oolants as da ng er o us was te.

z Comply with the relevant regulations of the related government office, when

disposing used coolant.

1.1.5. Notes on safety in handling used engine oil

If the skin is in contact with engine oil repetitively or for a long period of time, the skin

can contract or gets dry, and become inflamed.

As used engine oil contains hazardous substances, follow basic safety rules at the

work site when handling engine oil.

< Cautions for your health >

z Do not touch used engine oil rep etiti vely or for a long time.

z Apply skin pr ot ec tion cream or we ar gl oves.

z Clean the skin if contacted with engine oil.

z Use soap and water when washing your skin.

z Do not use gasoline, diesel fuel, thinner, or solvent as an abstergent.

z Apply an oily cream to your skin after washing your skin.

z Replace your clothes or shoes if they have been soaked with oil.

z Do not put oil-stained rags into your pocket.

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

12

CAUTION:

Plea s e check whethe r used e ngine oil is processed properly.

Wrongly processed engine oil can contaminate drinking water.

Therefore, do not pour out engine oil on the ground, waterway, drain, or sewer. You

may be punished if you don't ob ey th es e ha n dl i ng r egulations. Be careful when

disposing engine oil. Please contact the seller, supplier, or related agency,

regarding engine oil collection methods.

1.1.6. General repair instructions

1. Disconnect the battery ground wire first for maintenance, in order to prevent wire

damage due to a short circuit.

2. Use the cover not to damage or pollute disassembled parts.

3. Handle engine oil and coolant with care, as they can do damage to paintings.

4. It is recommended to use the proper tools and special tools for maintenance of the

specified parts, considering efficiency and reliability of the maintenance work.

5. Make sure to use the genuine Doosan replacement parts.

6. Use the new cotter pin, gasket, O-ring, sealing, oil seal, lock washer, and self lock

nut when maintaining these parts. If you use the existing parts without change,

normal function cannot be maintained.

7. Keep disassembled parts by group for smooth reassembly. In particular, bolts and

nuts with different strength and shape are used, depending on the assembly

position. Therefore, you should separate bolts and nuts clearly.

8. Clean all parts before inspection or re-assembly. In addition, clean the oil hole

using compressed air to prevent the presence of foreign objects.

9. Spray oil or grease on the rotation or sliding part thinly before assembly.

10. If necessary, apply adhesives to the gasket to prevent an oil or water leak.

11. Assemble parts, using pre-defined bolts and net fastening torque.

12. Please check the engine again, when maintenance is completed.

13. Check common rail pressures and engine temperature using the laptop diagnosis

device before working with fuel lines, and start work 5 minutes after the engine has

stopped.

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

13

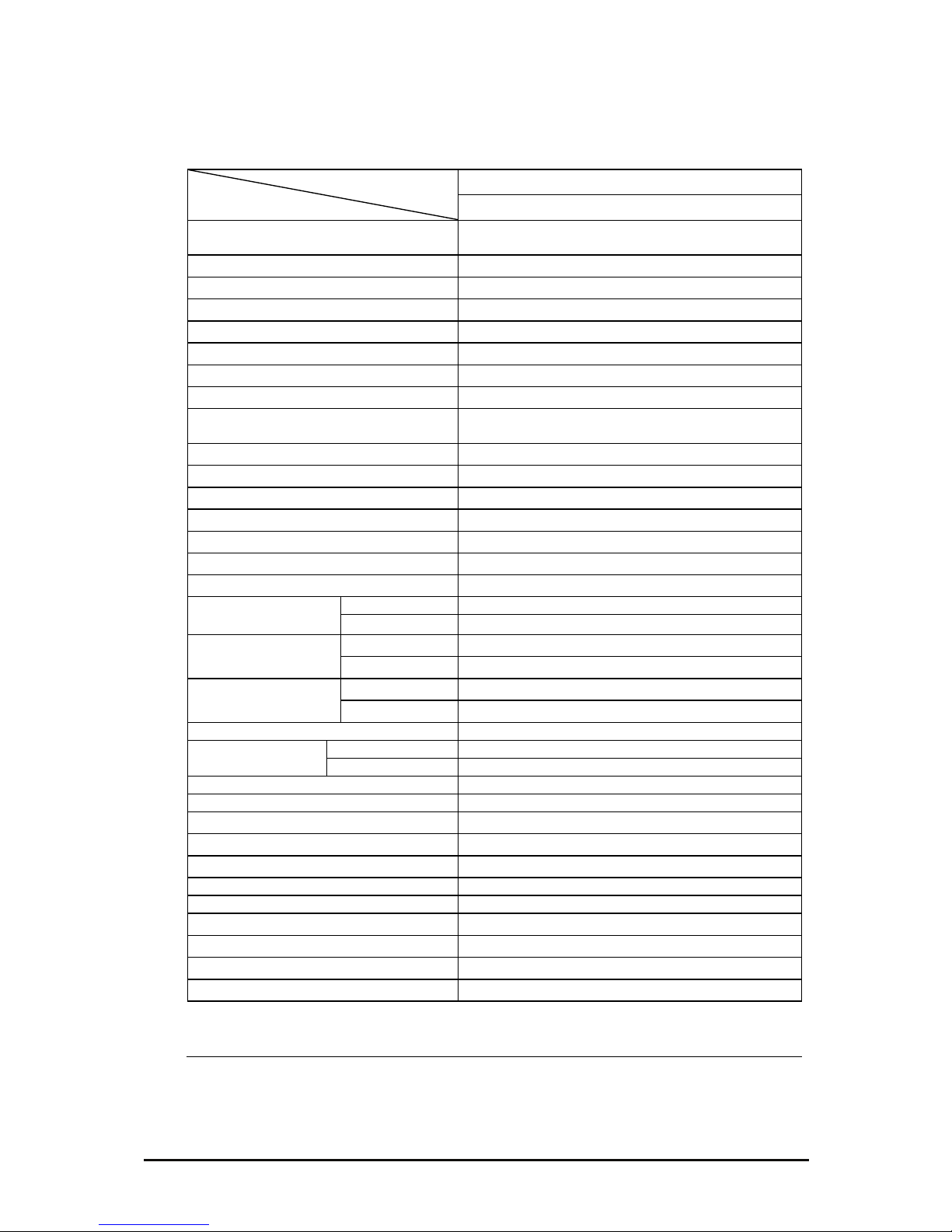

1.2. Engine Specifications

Engine model

Items

DL06K

LDF00/LDF01

Engine type

Water-cooled, 4 cycle, In-li ne,

Turbo charged & inter-cooled

Combustion cham ber ty pe Direct injection type

Cylinder liner type Replaceable dry liner

Timing gear system Gear driven type

No. of piston ring 2 compression ring, 1 oil ring

No. of cylinder-bore x stroke (mm)

6 – 100 ×125

Total piston displacement (cc) 5,890

Compression ratio 17.4 : 1

Engine dimensi on

(length x width x height) (mm)

1,264 x 848 x 1,124

weight (kg) 644

Rotating direction (fr om flywheel) Counter clock wise

Firing order 1 – 5 – 3 – 6 – 2 - 4

Fuel high pressure pump t ype Bosch CP3.3 fuel high pr essure pump type

Engine control type Electric cont r ol type ( E CU)

Injector ty pe Multiple hol e type

Fuel injection oper ating pressure (bar) 1,800

Valve clearance (cold)

(mm)

Intake valve 0.3

Exhaust valve 0.4

Intake valve

Open at

21° (B.T.D.C)

Close at

33° (A.B.D.C)

Exhaust valve

Open at

56.2° (B.B.D.C)

Close at

22.2° (A.T.D.C)

Fuel filter type Current type (cart ri dge type)

Oil pressure

(kg/cm

2

)

At idle speed 1.5 or more

At rated speed 3.0 ~ 6.0

Using lubrication oil SAE 15W40 (over API CJ-4 or ACEA-E9 class)

Lubrication method Full forced pressure feed type

Oil pump type Gear type driven by crank shaft

Oil filter type Cartridge type

Lubricating oil capacity (max./min.)

1

)

(lit) 27 / 17

Oil cooler type Water cooled

Oil pressure indi c ator Hydraulic indi c ator

Water pump Belt-driven centrifugal type

Cooling method Pressurized circulation

Oil separator OCV

Cooling water capac ity (eng ine on ly) (lit) 13

1)

With 2.0 liters in the engine

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

14

Engine model

Items

DL06K

LDF00/LDF01

Thermostat

Type Wax pallet type

Open at (°C)

75

Open wide at (°C)

90

Valve lift (mm) 9.5

Water temperature indicat or Water temperature sensor mounted

Turbo charger Exhaust gas driven type

Engine stop system Fuel feeding shut-off by ECU

Alternat or (voltage – capacity ) (V–A) 24 - 50

Starting motor(voltage–output) ( V –kW) 24 – 4.5

Air heater (V–A) 24 – 2.1

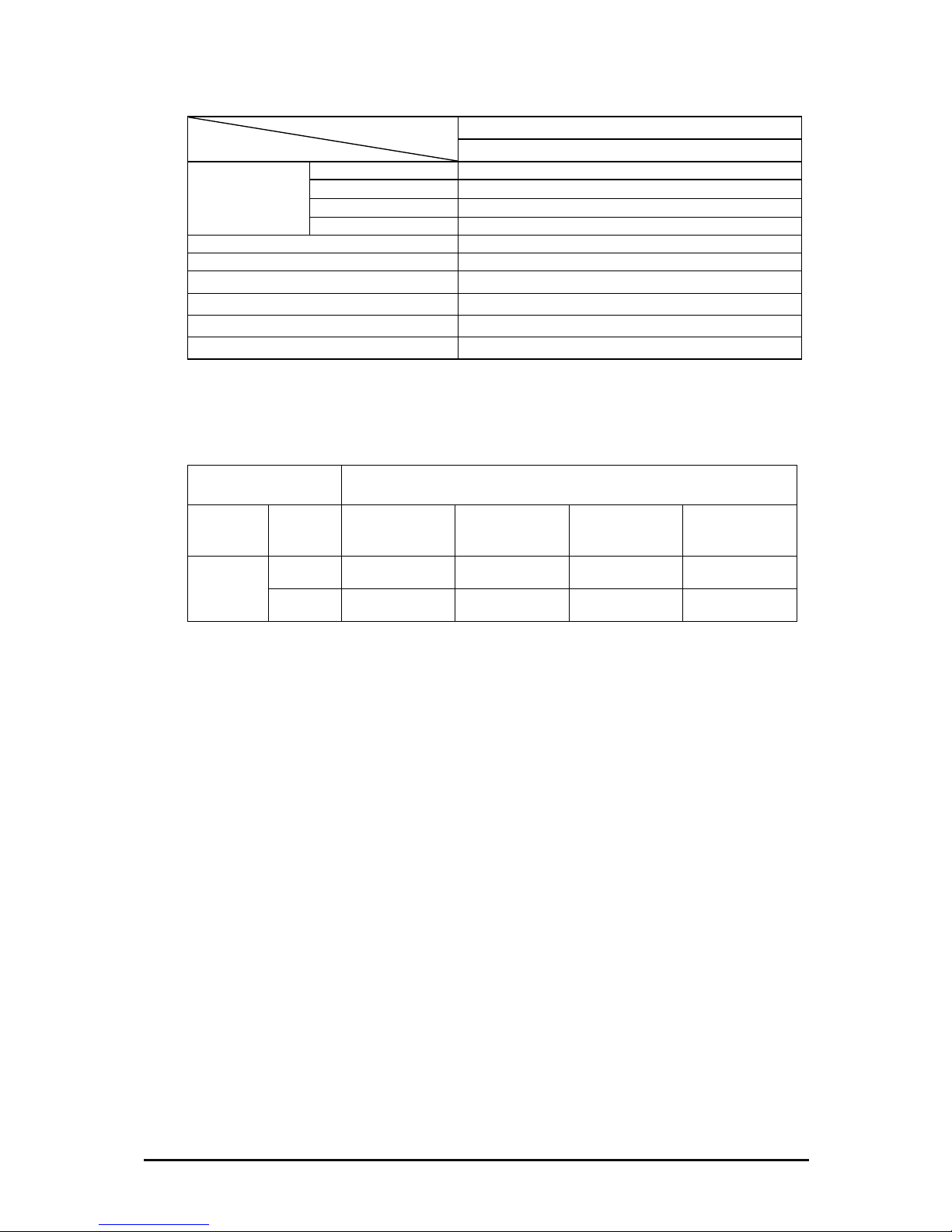

1.3. Engine Power

tolerance : ±5%

Engine model Performance1)

Model Suffix

Power

(PS / rpm)

Torque

(kg.m / rpm)

Low idle

(rpm)

High id le

(rpm)

DL06K

LDF00 140/2,100 65/1,400 850

±10 2,400±25

LDF01 160/2,100 74/1,400 850±10 2,400±25

* Note1) : All data are based on operation without cooling fan.

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

15

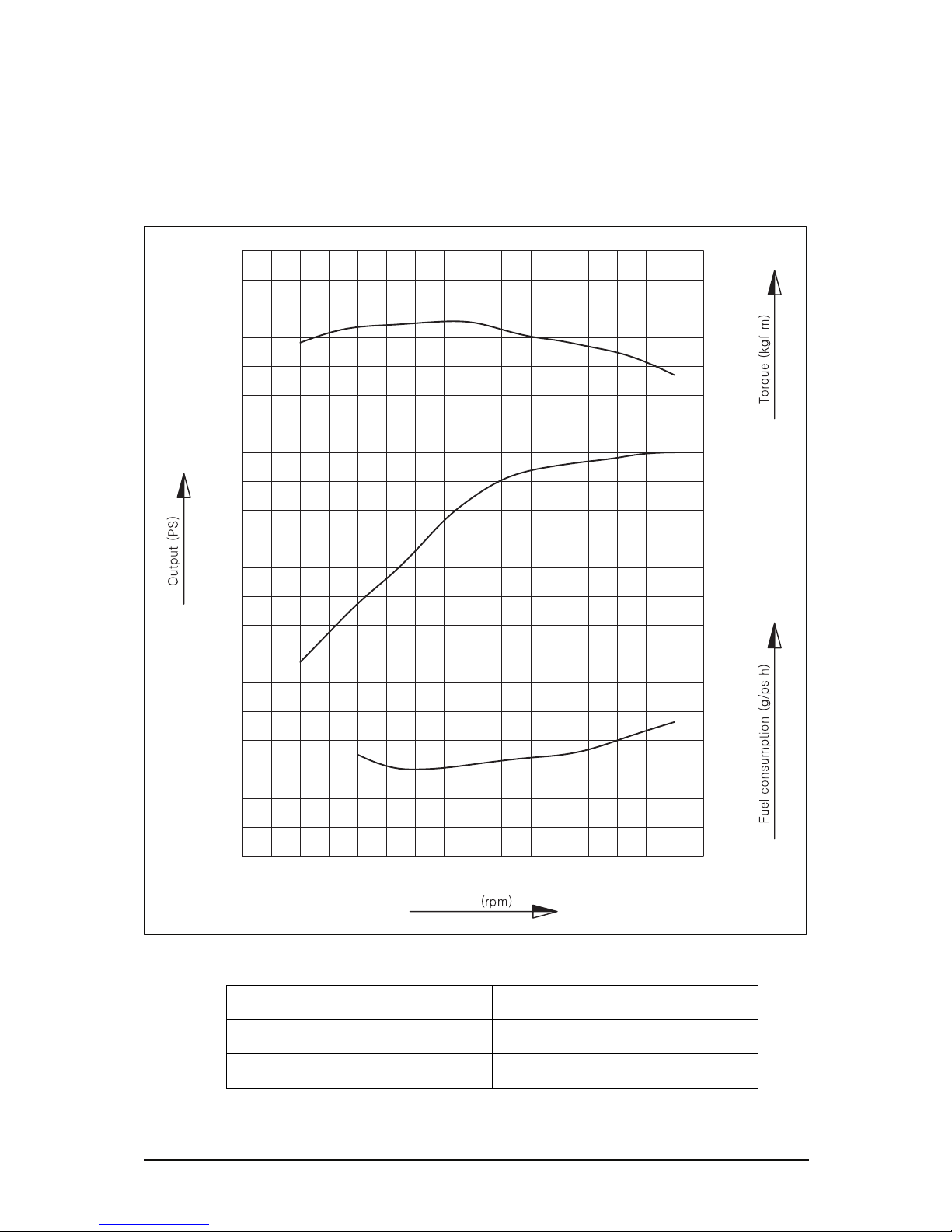

1.4. Engine Performance Curve

1.4.1. Performance curve

DL06 – LDF00

Performance KS-R 1004

Output (rating) 140 PS / 2,100 rpm

Torque (max)

65 kgf·m / 1,400 rpm

EL4OM001

80

100

120

140

150

160

170

70

60

50

1000 1500 2000

Revolution

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

16

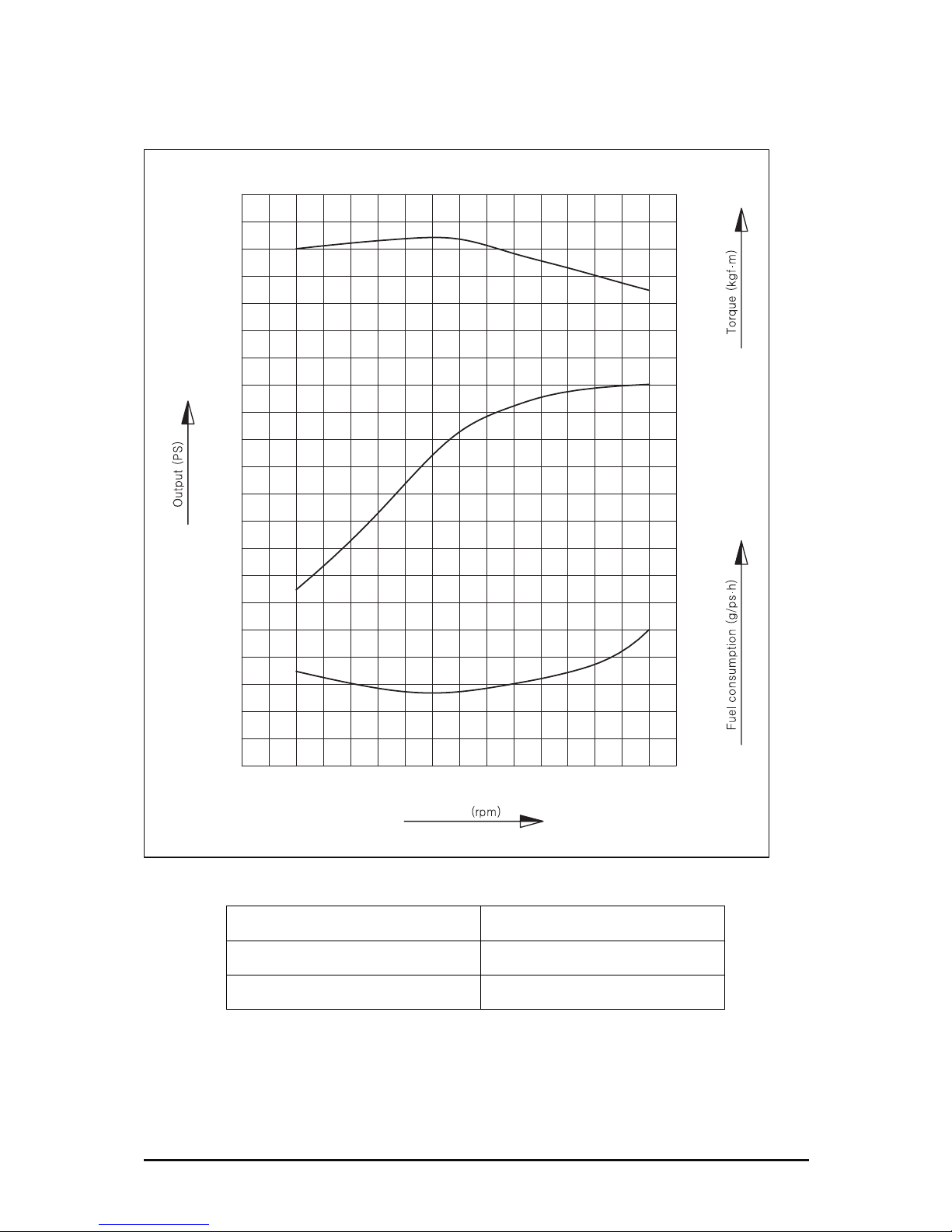

DL06 – LDF01

Performance KS-R 1004

Output (rating) 160PS / 2,100 rpm

Torque (max)

74 kgf·m / 1,400 rpm

EL4OM002

Revolution

100

120

140

160

150

160

170

70

60

50

1000 1500 2000

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

17

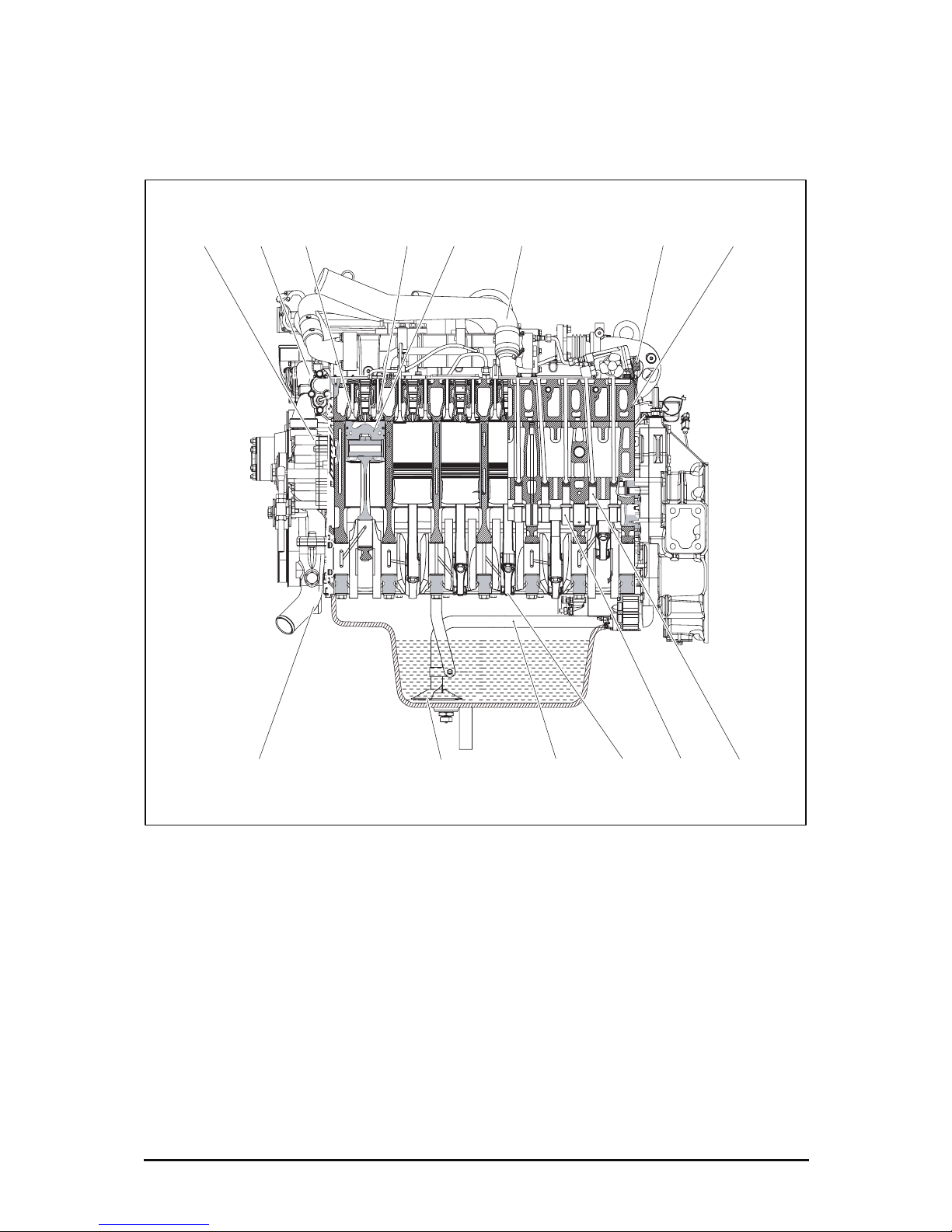

1.5. Engine Assembly

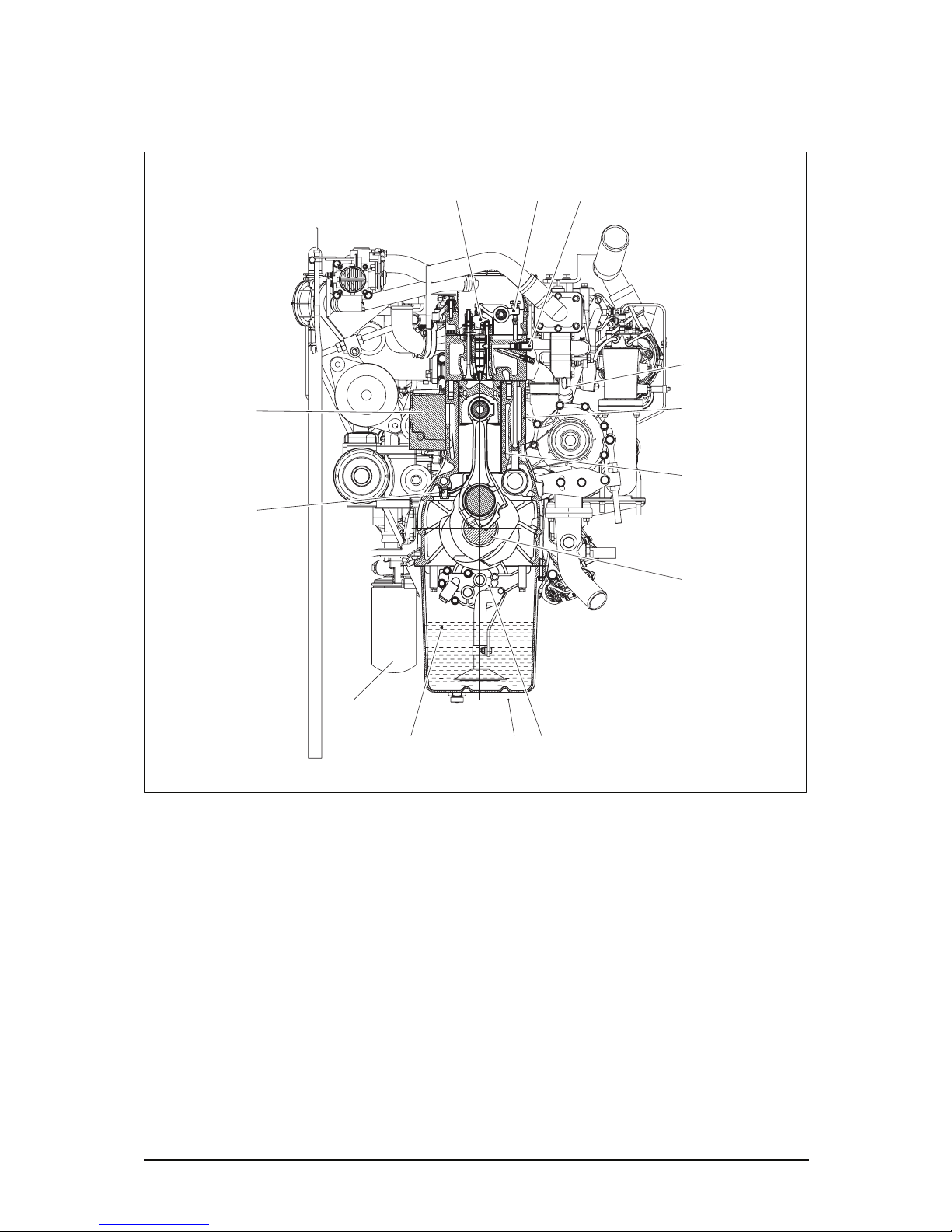

1.5.1. Sectional drawing

1 Cooling water pump 8 Cylinder head

2 Thermostat 9 Vibration damper

3 Exhaust valve 10 Oil pan

4 Intake valve 11 Oil suction pipe

5 Piston 12 Connecting rod

6 Cy linder head cover 13 Camshaft

7 Intermediate cover 14 Tappet

9 10 11 121314

123 45 6 7 8

EL4OM003

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

18

1.5.2. Sectional drawing

1 Fuel filter 8 Cylinder block

2 Oil spray nozz le 9 Cylinder liner

3 Oil cooler 10 Crankshaft

4 Caliper 11 Oil lev el gauge

5 Rocker arm 12 Oil drain valve

6 Fuel high pressure connector 13 Oil pump

7 Fuel high pressure pipe

EL4OM004

7

8

9

10

131211

4

5

6

2

3

1

DL06K Interim Tire-4 Diesel Engine Safety Regulations & Specifications

19

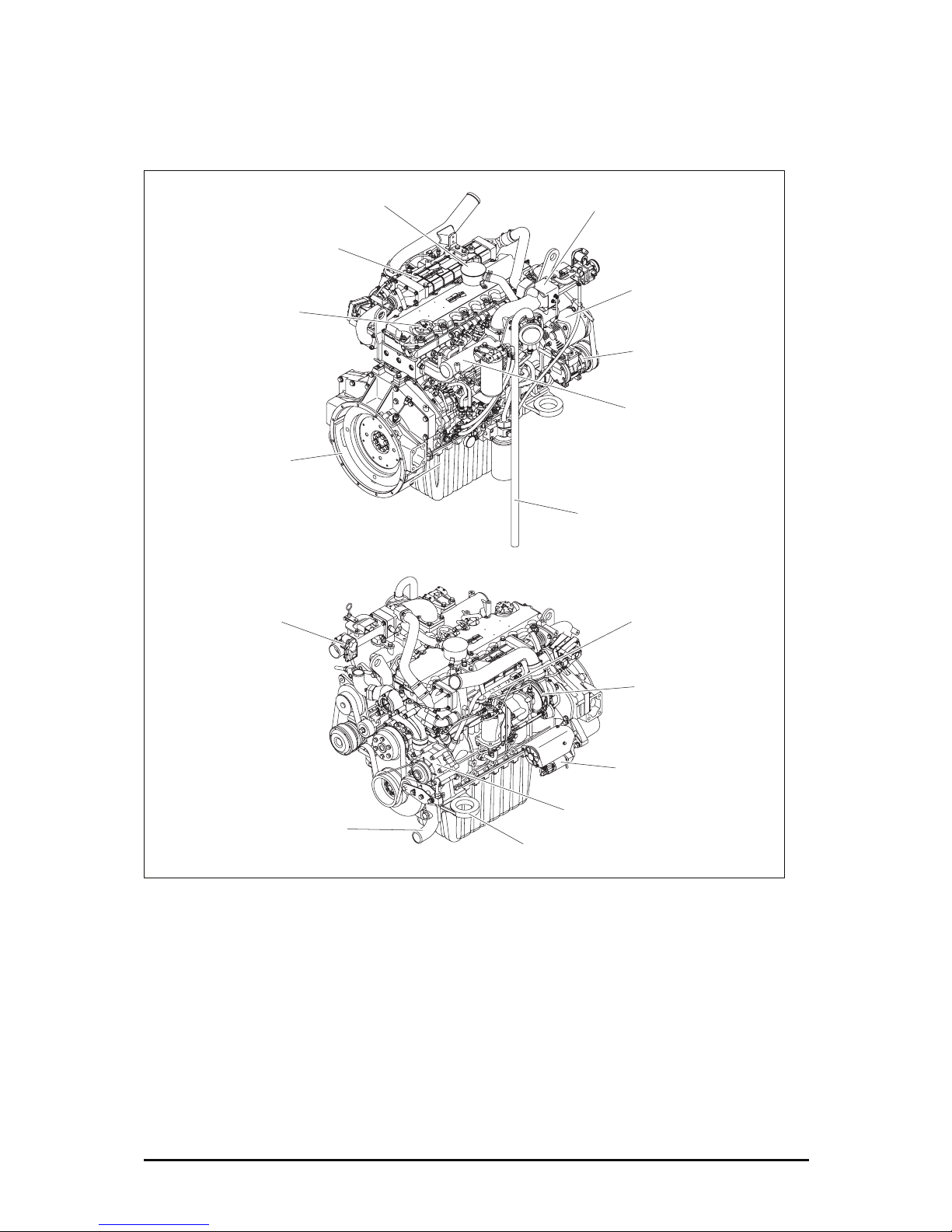

1.5.3. Engine assembly

(1) DL06K

1 Flywheel housing 9 Mounting bracket

2 B r eather 10 Cool ing water pump

3 B r eather pipe 11 Water outlet pipe

4 Exhaust manifold 12 Intake manifold

5 Oil filter cap 13 Air heater

6 EGR cooler 14 Throttle valve

7 Turbo charger 15 Starting motor

8 Alternator 16 Air compressor

EL4OM006

14

4

11

9

10

12

1

2

5

6

13

8

16

12

3

7

15

DL06K Interim Tire-4 Diesel Engine Technical Information

20

2. Technical Information

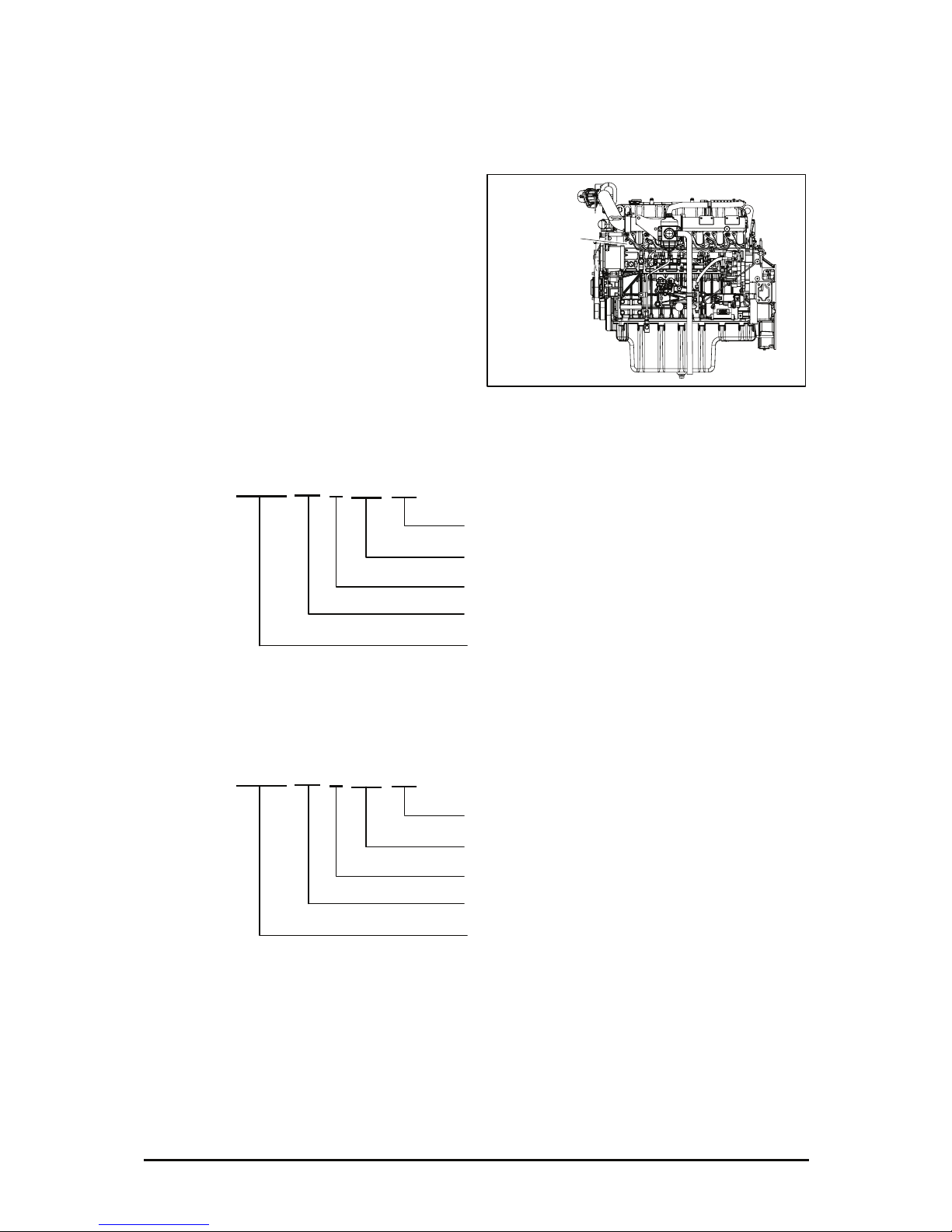

2.1. Engine Model and Serial Number

z You can find the engine model and

serial number at the market position

in the figure.

The serial number is required for

the warranty or parts ordering.

z Engine serial No. (Example 1 : DL06-LDF00)

z Engine serial No. (Example 2 : DL06-LDF01)

EK3OM010

Engine model

and serial number

(Cylinder block)

F00

DL06K 140

2

0001

Main type specification

Serial no

Production year ( 2012)

Power

Engine model

F00

DL06K 160

2

0001

Main type specification

Serial no

Production year ( 2012)

Power

Engine model

DL06K Interim Tire-4 Diesel Engine Technical Information

21

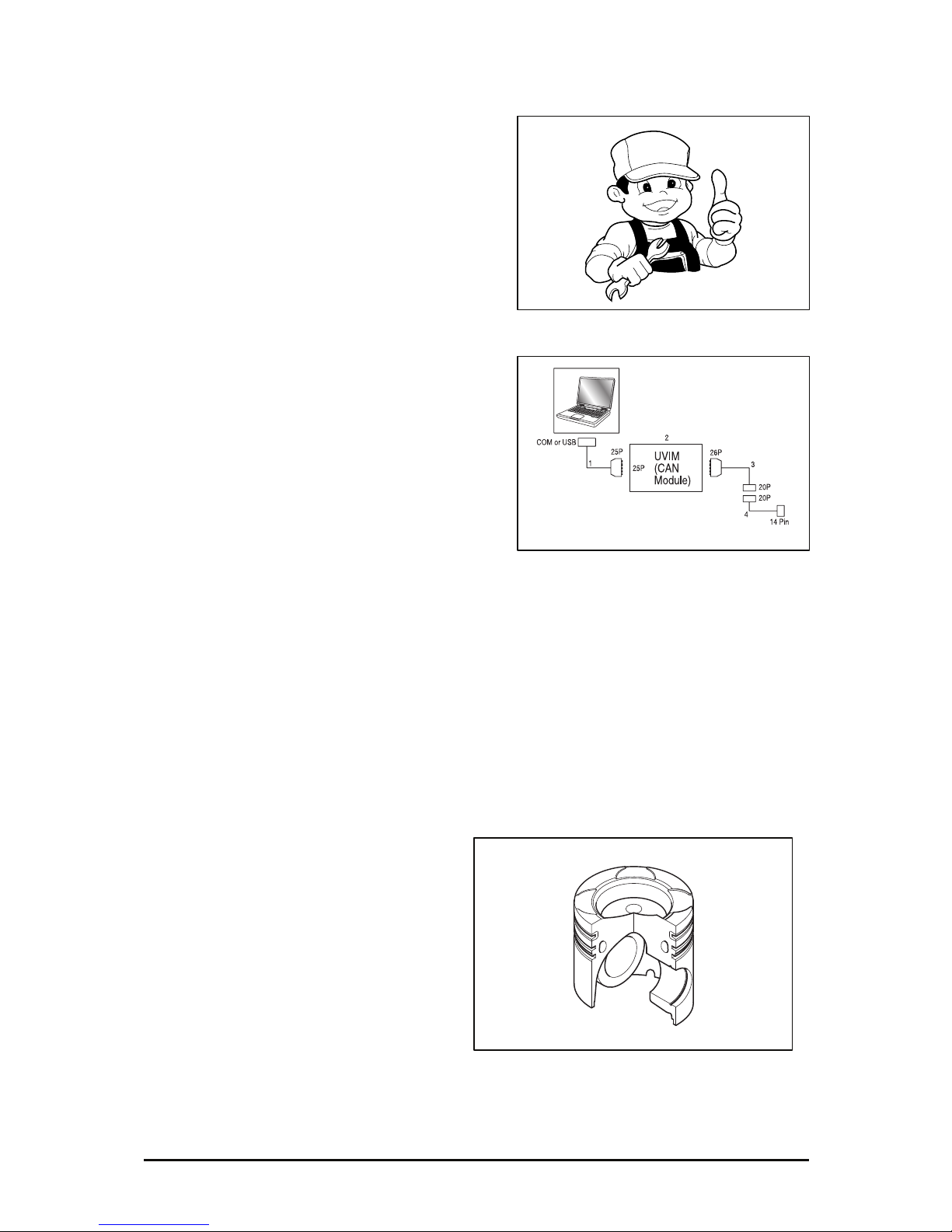

2.2. Diagnostic tool

z Electrical problems in vehicles

mounted with the DL06K engine can

be checked conveniently, using a

laptop comp uter.

1) Diagnostic by laptop computer

z Please see the Fault Diagnosis Device

Manual for more details on how to use

a fault diagn osi s dev i c e.

2.3. Engine character

z DL06K diesel engine adopts the overhead valve and turbo charger. DL06K is an

air cooling ECU engine.

z High pressure fuel pr oc es sed by the high pres sure fuel pump is saved in the

common rail. When the driver operates the vehicle, the optimal fuel amount and

fuel spray timings are determined, based on the data set in the ECU, according to

the vehicle speed and operating conditions. Then, the solenoid valve of the

injector, which is installed for each engine cylinder, is activated and fuel is

sprayed into the cylinder

z The oil gallery cooling metho d is

used to cool down the engine

piston. For piston gallery cooling,

the gallery shape, nozzle shape,

and nozzle position and oil flow

amount are important in reducing

the temperature. The sectional

shape of the pi sto n gal l er y is

designed to obtain maximum coolin g efficie ncy by m ak ing the oil flow ef fec ti ve.

EL4OM007

EH4OM008

IB3O302I

DL06K Interim Tire-4 Diesel Engine Technical Information

22

2.3.1. Cylinder block

z The cylinder block is made of single alloy cast iron, and put under the crankshaft

axis line to increase strength. In addition, the cylinder liner can be replaced with a

dry one. The cylinder head is built-in.

2.3.2. Piston, connecting rod, crankshaft

z The cylinder block is made of single alloy cast iron, and put under the crankshaft

axis line to increase strength. In addition, the cylinder liner can be replaced with a

dry one. The cylinder head is built-in.

z The connecting rod is a forging product, and the big end is separated diagonally,

and can be disassembled through the upper side of the cylinder like a piston. The

assembly type al l oy bearing is use d for the operating p ar t o f the crankshaft an d

connecting rod.

DL06K Interim Tire-4 Diesel Engine Technical Information

23

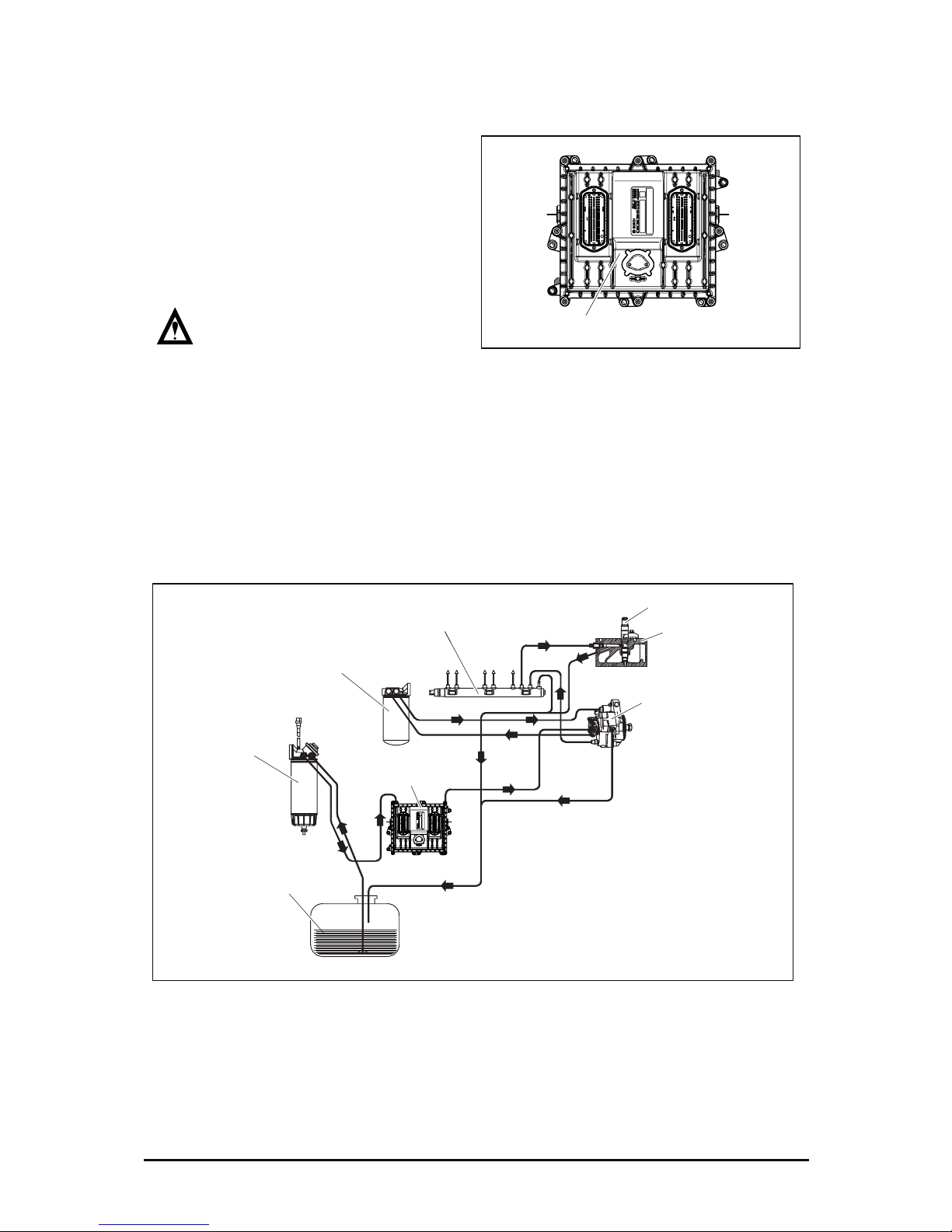

2.3.3. Electric control unit : ECU

z The ECU is used to supply fuel.

z The ECU is connected to various

types of sensors, and controls the

engine with the value set in these

sensors for opti m al operation.

CAUTION:

Make sure to disconnect the

ground wire of the battery cable before removing the connector of the ECU.

Never disassemble the ECU.

2.3.4. Fuel injection system

z High pressure fuel pr ocessed by the hi gh pr essure fuel pump is saved in the

common rail, and spraying and fuel amount are calculated, based on the data

programmed in the ECU. At this time, the ECU activates the solenoid valve of the

injector, which is installed for each engine cylinder, to spray fuel into the cylinder.

2.3.5. Bleeding the fuel system

z To expel air from the fuel line, loosen the fuel supply pipe from the secondary fuel

filter to the fu el high pr es sure pump, an d acti v a te t he pr i m i ng pump manuall y of

the primary fuel fi l ter unti l no bubble is foun d.

EK1OM012

Electronic Control Unit (ECU)

Primary fuel filter

Electronic Control Unit

(ECU)

Fuel tank

Common rail

Injector

Cylinder head

High pressure fuel pump

(CP 3.3 NH fuel pump)

EK1OM013

Secondary fuel filter

DL06K Interim Tire-4 Diesel Engine Technical Information

24

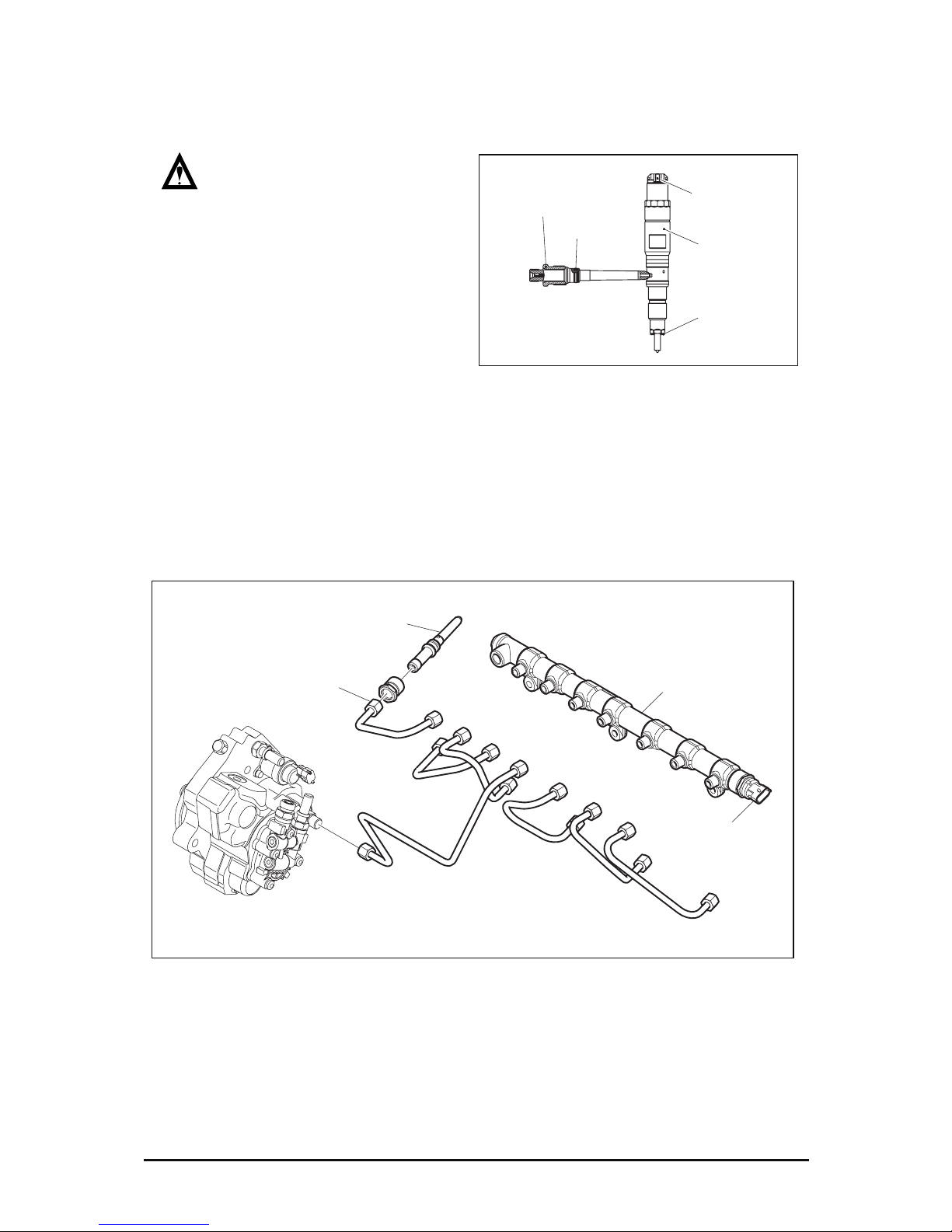

2.3.6. Injector and high pressure connector

z Be careful not to put any foreign

objects inside the injector and

high pressure connector when

perform i ng dis as s em bl y

maintenance.

z O-rings and cooper washers

should be replaced with new one,

when reassembling the engine.

z Spray oil before assembling O-

Ring parts.

z Check the model num ber o f th e repl ac ing part first before assem bly.

2.3.7. Common rail system

z Pressure generation and fuel injection are completely decoupled from each other

in the “Common Rail” fuel injection system. The injection pressure is generated

independent of engine speed and injected fuel quantity stored in the ECU.

EH6OM056

High pressure fuel

connector nut

Injector harness

connector

O-ring

Injector

Seal ring

Fuel high pressure pump

Common rail

High fuel pressure connector

Common rail pressure

sensor

High pressure pipe

EK4OM007

DL06K Interim Tire-4 Diesel Engine Technical Information

25

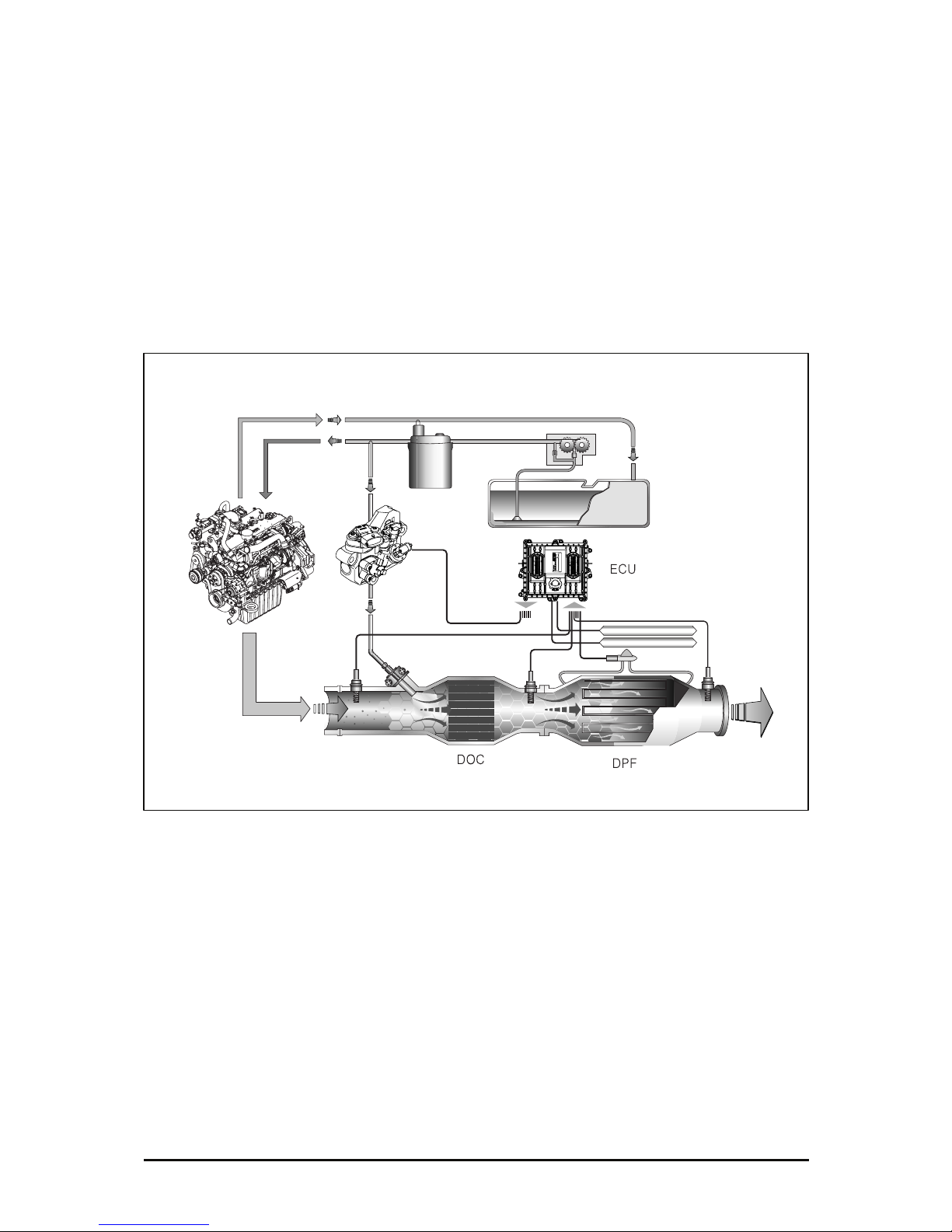

2.3.8. Emission reduction system

z Tier4 Interim DL06K engine has both oxidation catalyst system and exhaust

reduction system as an emission reduction system.

z Operating principle : The oxidation catalyst system reduces HC and CO in

exhaust gas and induces DBF temperature increase during HC injection to

regenerate exhaust par ti cl es i n D PF and r ed uc e exhaust. DPF ( D ies el Par ti c ulate

Filter) collects harmful particles in diesel exhaust to prevent emission to the air,

and regenerate the collected particles by burning them to reuse the filter.

EL4OM008

Fuel return

Fuel entry

Temperature

sensor

Fuel tank

Injection

pump

Engine

exhaust

gas

Exhaust

manifold

(from engine)

Sensor

Temperature

sensor

Temperature

sensor

Actuator

Injection unit

(IU)

Engine CAN communication

Diagnosis CAN communication

Fuel filter

Metering unit (MU)

Differential

pressure sensor

DL06K Interim Tire-4 Diesel Engine Technical Information

26

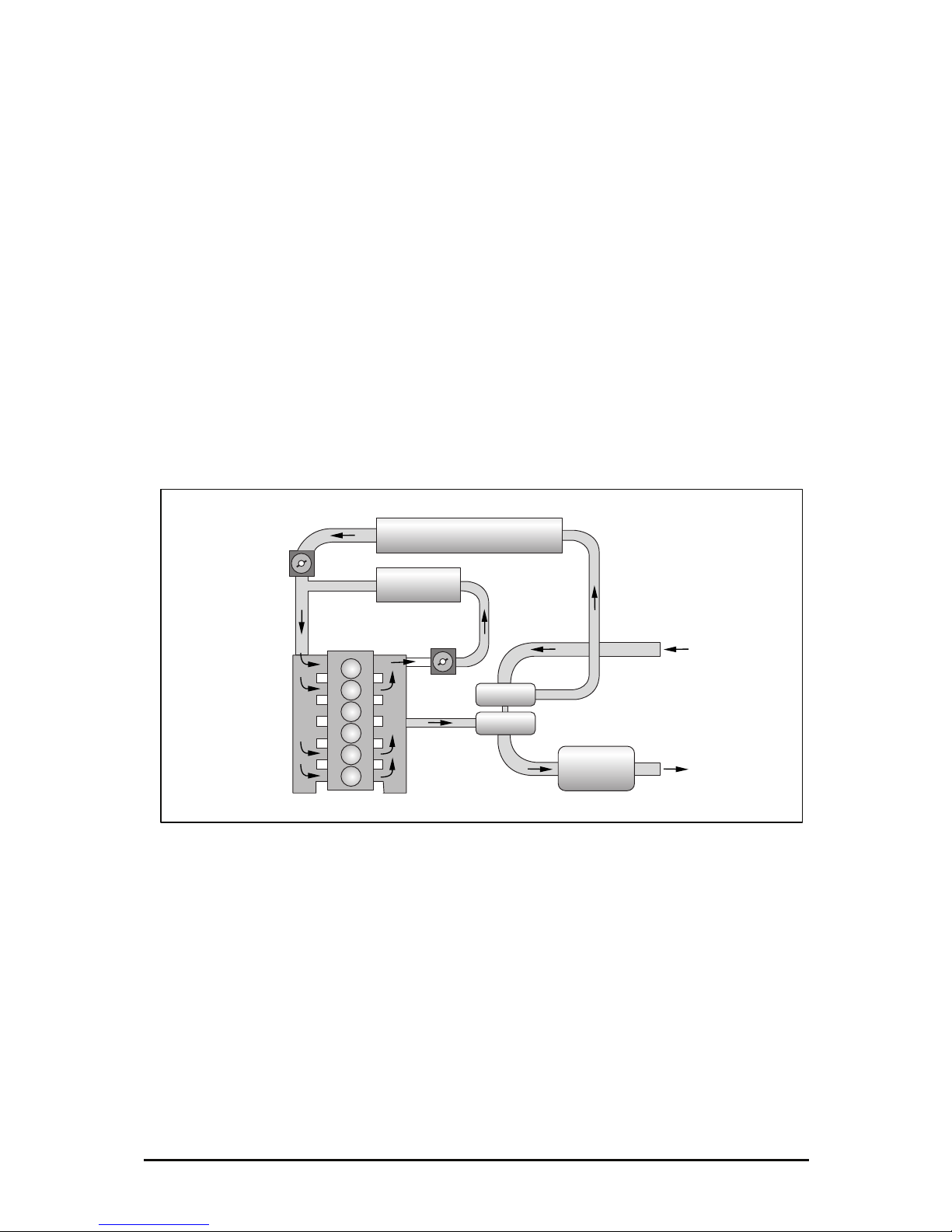

2.3.9. Exhaust gas recirculation (EGR)

z To reduce exhaust gas, the EGR (Exhaust Gas Recirculation) circulates some of

exhaust gas combusted in the engine to the intake side, and supplies it to the

engine after cooling for re-combustion to reduce NOx emission amount.

z Operating principle : To reduce NOx exhaust gas amount emitted from the engine,

the exhaust gas that contains almost no oxygen is circulated to the intake side,

so that concentration of oxygen supplied to the engine can be reduced for the

reduction of NOx emission by inducing low-temperature combustion.

When E GR is app lied, co mbustio n is normal because of its characteristics.

Therefore, the NOx and PM generation amount increases during combustion. To

resolve this problem, both DPF and EGR are applied, and the EGR cooler is

used to reduce NOx generation (by reducing the temperature of high-pressure

exhaust gas) and improve engine combustion efficiency.

EJ9OM055

Throttle

Valve

Intake

Intake

Exhaust

Exhaust

Turbine

Compressor

EGR

Valve

Charge Air Cooler

EGR Cooler

DPF

DL06K Interim Tire-4 Diesel Engine Technical Information

27

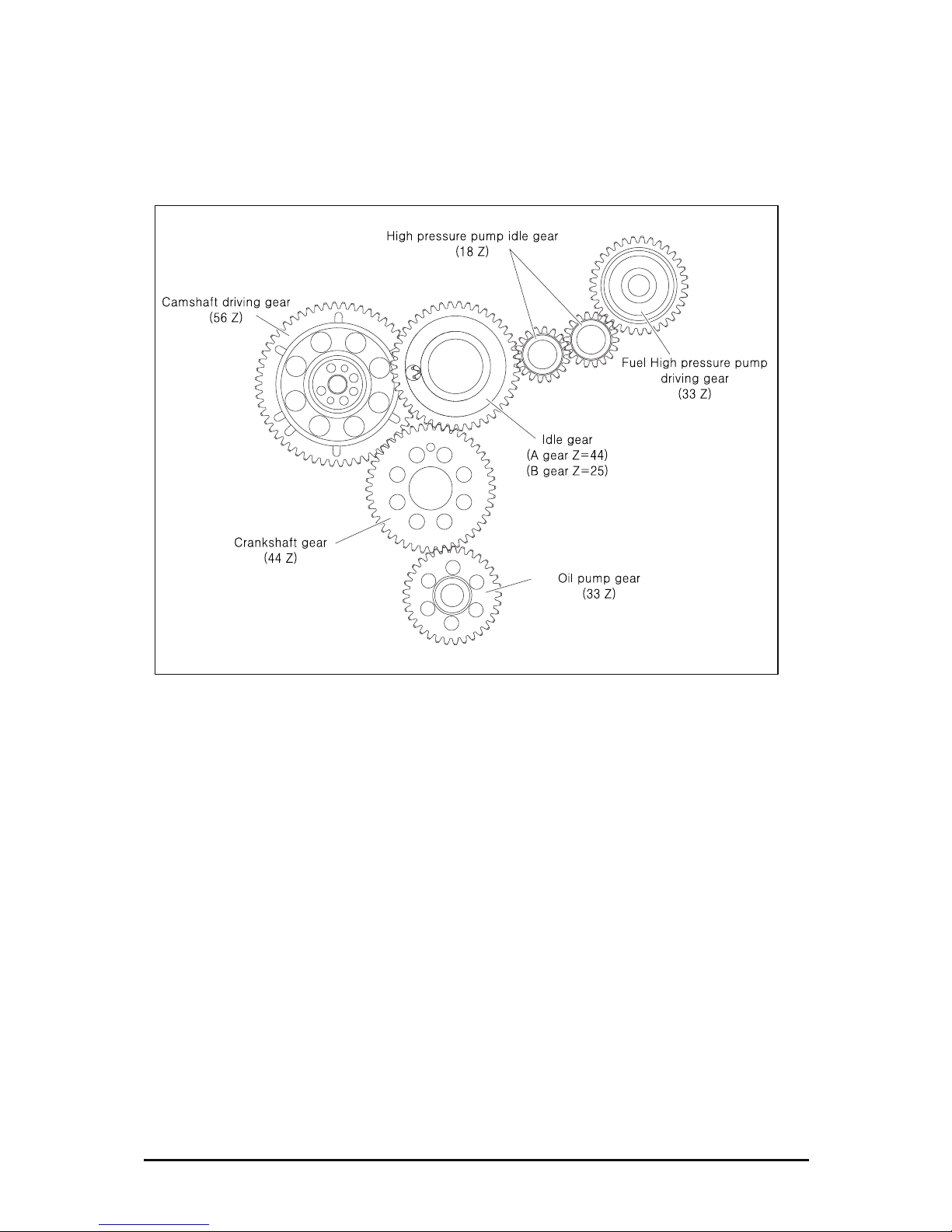

2.3.10. Engine timing

z Camsha ft, oil pump, fuel hi gh pr essure pump ar e dr i ven by ge ar con nec tion

inside the en gi n e flyw h eel housing.

2.3.11. Valve

z The overhead valve is operated by the valve tappet, push rod, and rocker arm on

the camshaft.

EK4OM009

DL06K Interim Tire-4 Diesel Engine Technical Information

28

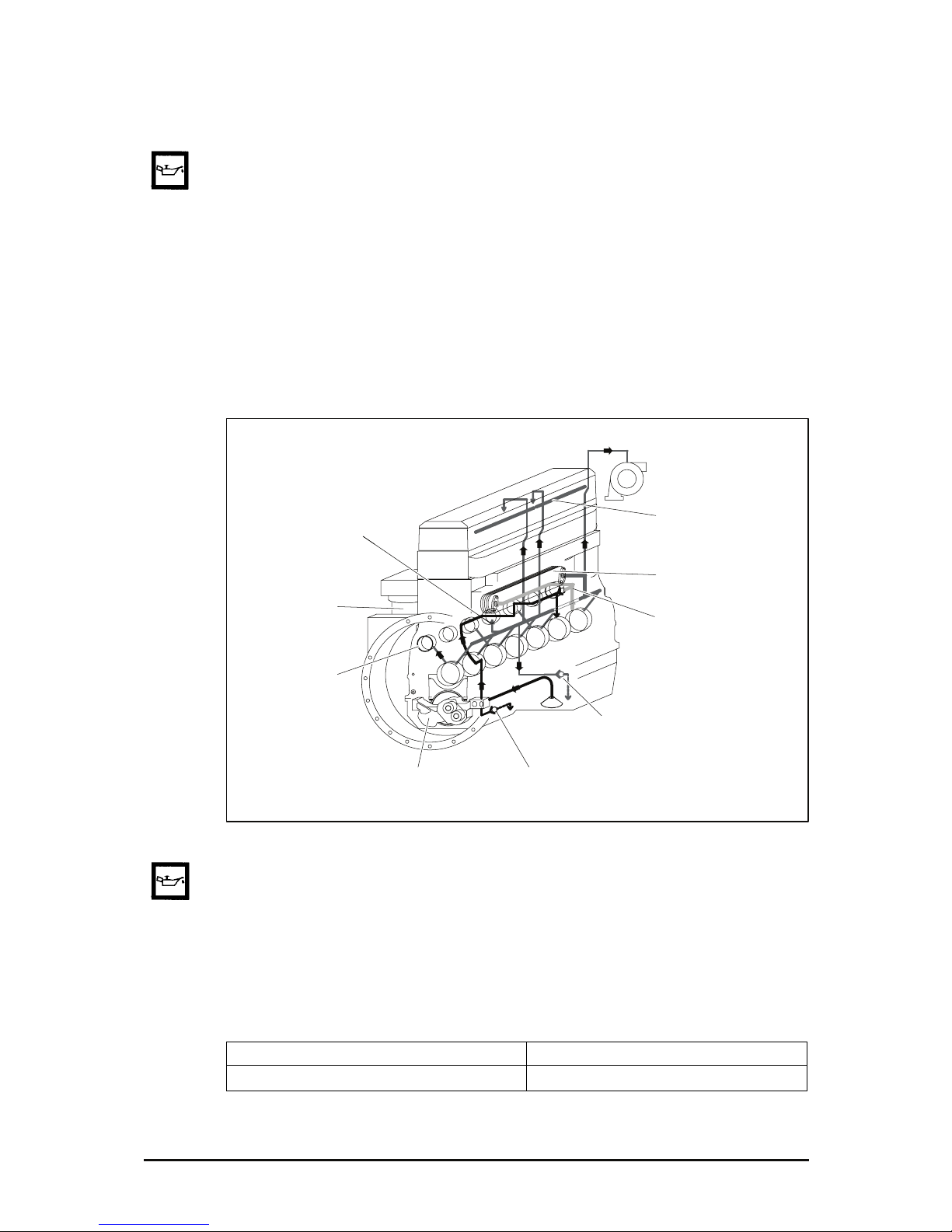

2.3.12. Lubrication system

z The engine runs with the forced lubrication system. Oil pressure is generated and

supplied by gear revolution of the oil pump, which is meshed directly with the

crankshaft located at the rear side of the cylinder block.

z The oil pump sends oil sucked by the oil pan with the intake pipe via the oil filter

and oil cooler. Then, oil is supplied to the crankshaft bearing, camshaft bearing,

and rocker arm for lubrication. In addition, the turbo charger is also connected to

the engine lubricant circuit, and supplies oil for engine break operation.

z Lubricant is sprayed around cylinder blocks and timing gears. Each cylinder has

the oil injection nozzle to cool down the inside of the piston. Engine oil is cleaned

by passing through the oil filter.

2.3.13. Engine oil

z Check the oil amount with an oil level gauge, and refill oil, if necessary. Check the

oil level after stopping the engine. If the engine was running, measure the oil level

after 5 ~ 10 minutes, so that oil is returned to the crank case. The oil level should

be between upper and lower limit of the gauge.

z Engine oil should be replaced regularly, and the oil filter cartridge should be

replaced at the same time.

- First oil change

First oil change After 50 Hr operating

Excavator, fork lift Every 500Hours

Oil pump relief valve

(10bar)

Oil spray nozzle

(for piston cooling)

Air compressor

Camshaft bush

Oil pump

Oil pressure adjustment valve

(5bar)

Oil filter

(bypass valve 2.1 bar)

Oil cooler

Rocker arm shaft

Turbo charger

EK1OM015

Loading...

Loading...