Doosan DE08TS, D100, D120, D150, D130S-5 Disassembly/assembly

...

SB2088E02

Sep. 2011

DE08TS Diesel Engine

Disassembly & Assembly

D100, D120, D150

D110S-5, D130S-5, D160S-5

Important Safety Information

WARNING

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. Aperson must be alert to potential hazards. This person should also have the necessary training,

skills and tools to perform these functions properly.

Improper operation, Iubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any Iubrication, maintenance or repair on this product, until you have read and

understood the operation, Iubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not

heeded, bodily injury or death could occur to you or other persons.

The hazards are identified by the "Safety Alert Symbol" and followed by a "Signal Word" such as "WARNING" as

shown below.

The meaning of this safety alert symbol is as follows :

Attention! Become Alert! Your Safety is Involved.

The Message that appears under the warning, explaining the hazard, can be either written or pictorially presented.

Operations that may cause product damage are identified by NOTICE labels on the product and in this publication.

DOOSAN cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in this

publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating

technique not specifically recommended by DOOSAN is used, you must satisfy yourself that it is safe for you and

others. You should also ensure that the product will not be damaged or made unsafe by the operation, Iubrication,

maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product.

Obtain the complete and most current information before starting any job. DOOSAN dealers have the most current

information available.

1 of 76

Index

Air Cleaner Assembly ...........................................24

Air Cleaner Elements.............................................25

Air Compressor (if equipped).................................72

Alternator ...............................................................12

Camshaft And Camshaft Bearing ..........................61

Connecting Rod Bearings......................................48

Cooling Water Pipe................................................41

Crankshaft..............................................................69

Crankshaft Pulley...................................................63

Cylinder Head ........................................................49

Cylinder Head Cover..............................................34

Cylinder Liners.......................................................57

Electric Starting Motor............................................11

Engine And Transmission........................................5

Exhaust Manifold ...................................................33

Fan Assembly ........................................................26

Fan Belts................................................................26

Flywheel.................................................................64

Flywheel Housing...................................................68

Fuel Filter...............................................................18

Fuel Injection Lines................................................17

Fuel Injection Nozzle Assembly.............................20

Fuel Injection Pump ...............................................13

Fuel Pump..............................................................19

Fuel Strainer ..........................................................18

Intake Manifold.......................................................31

Muffler....................................................................22

OIl Cooler...............................................................39

Oil Filter..................................................................38

Oil Pan ...................................................................34

Oil Pump ................................................................42

Pistons ...................................................................53

Radiator .................................................................28

Rocker Shaft ..........................................................46

Rocker Shaft And Push Rods ................................45

Timing Gear Case..................................................60

Timing Gear Case Cover .......................................58

Timing Gears .........................................................58

Water Pump...........................................................35

Water Temperature Regulator ...............................27

Disconnect batteries before performance of any

service work

WARNING

Engine

2

5

4

7

6

3

8

1

Remove Engine And

Transmission

A10999 & D40999 - 02

Tools Needed A

Link Bracket 1

IEED002P

Start By :

a. Remove overhead guard.*

Remove floorplate.*

b.

Remove hood.*

c.

Remove air cleaner.

d.

e. Remove universal joint.*

This operation is in the Vehicle Systems,

*

Disassembly And Assembly Manual.

1. Drain the coolant from the radiator.

5. Remove bolts (4), washers and nuts that hold

coolant reservoir on the frame. Set coolant

reservoir (5) aside.

IEED003P

6. Disconnect two hoses (6) from the fuel tank.

7. Disconnect wiring harness (7) from fuel sender.

IEED001P

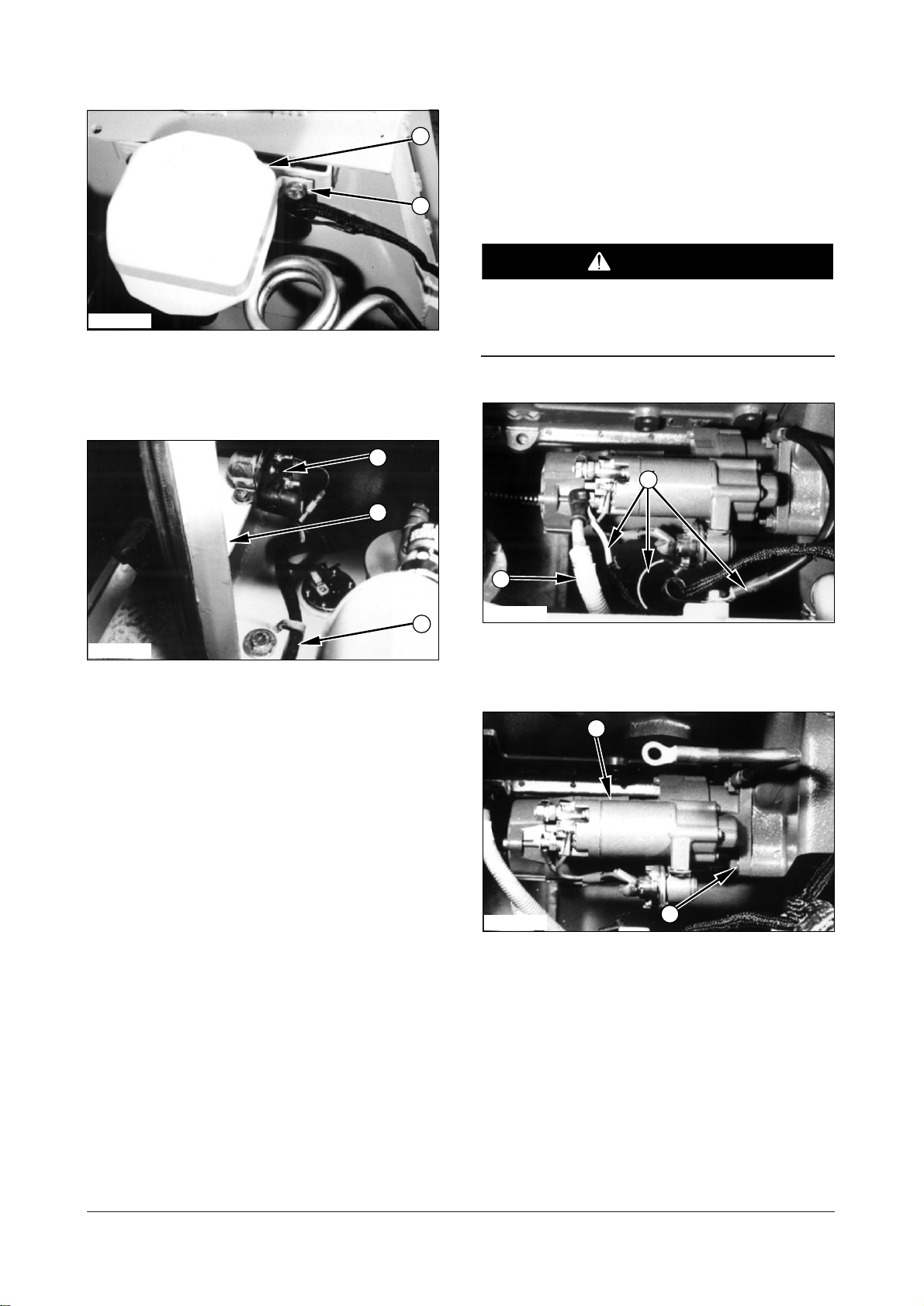

2. Remove engine harness assembly (1) from the

clips of bonnet assembly (3).

3. Remove screws, washers and circuit breaker (2)

from bonnet assembly (3).

4. Remove bolt and washer that hold bonnet

assembly. Remove bonnet assembly (3) from the

frame.

DE08TS Diesel Engine Disassembly and Assembly

5 of 76

IEED004P

8. Remove tube (8) from the tube of air compressor

(if equipped).

IEED005P IEED008P

9

11

14

15

12

10

13

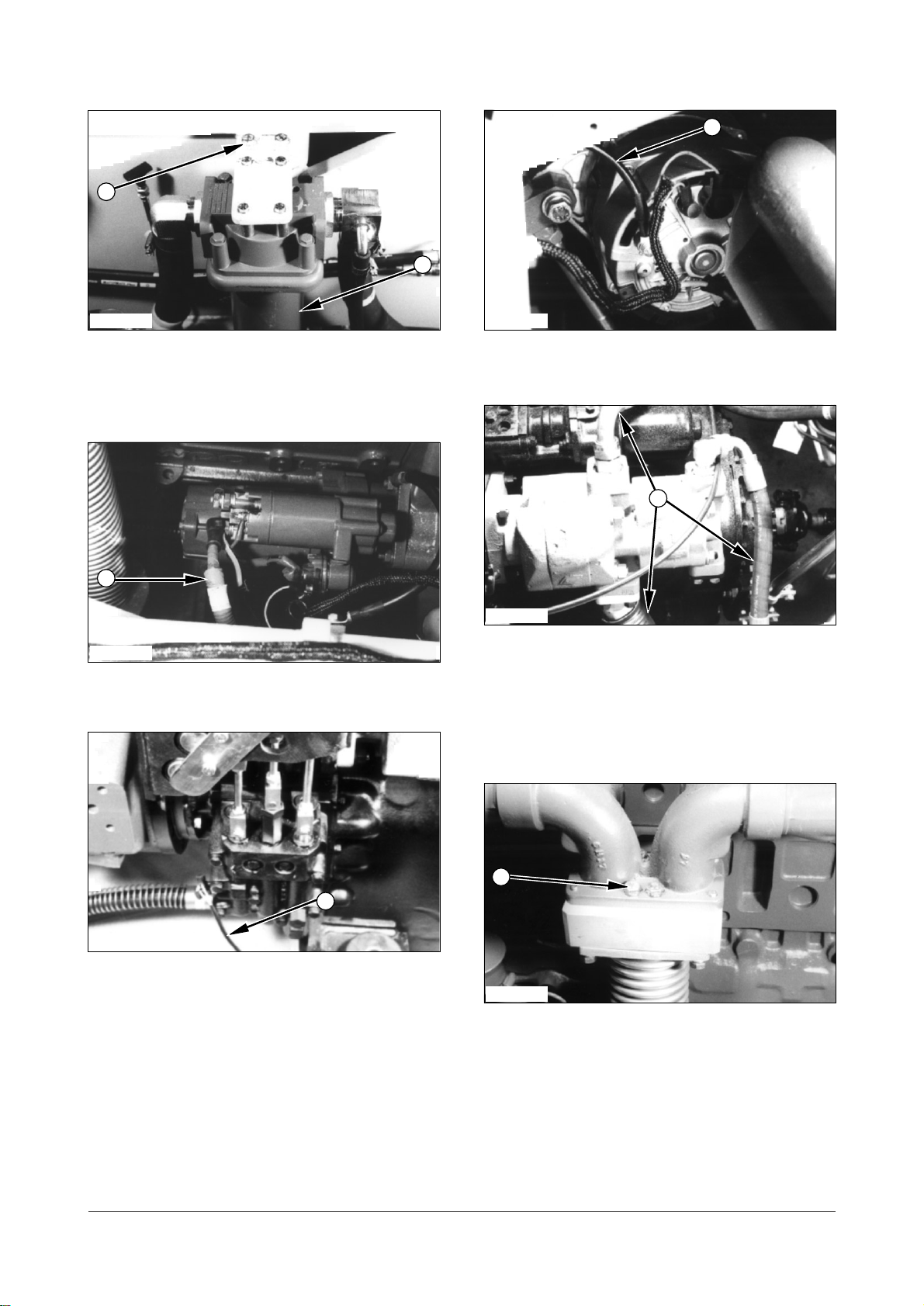

9. Remove two bolts washers (9) and hydraulic filter

assembly (10). Set hydraulic filter assembly (10)

aside.

IEED006P

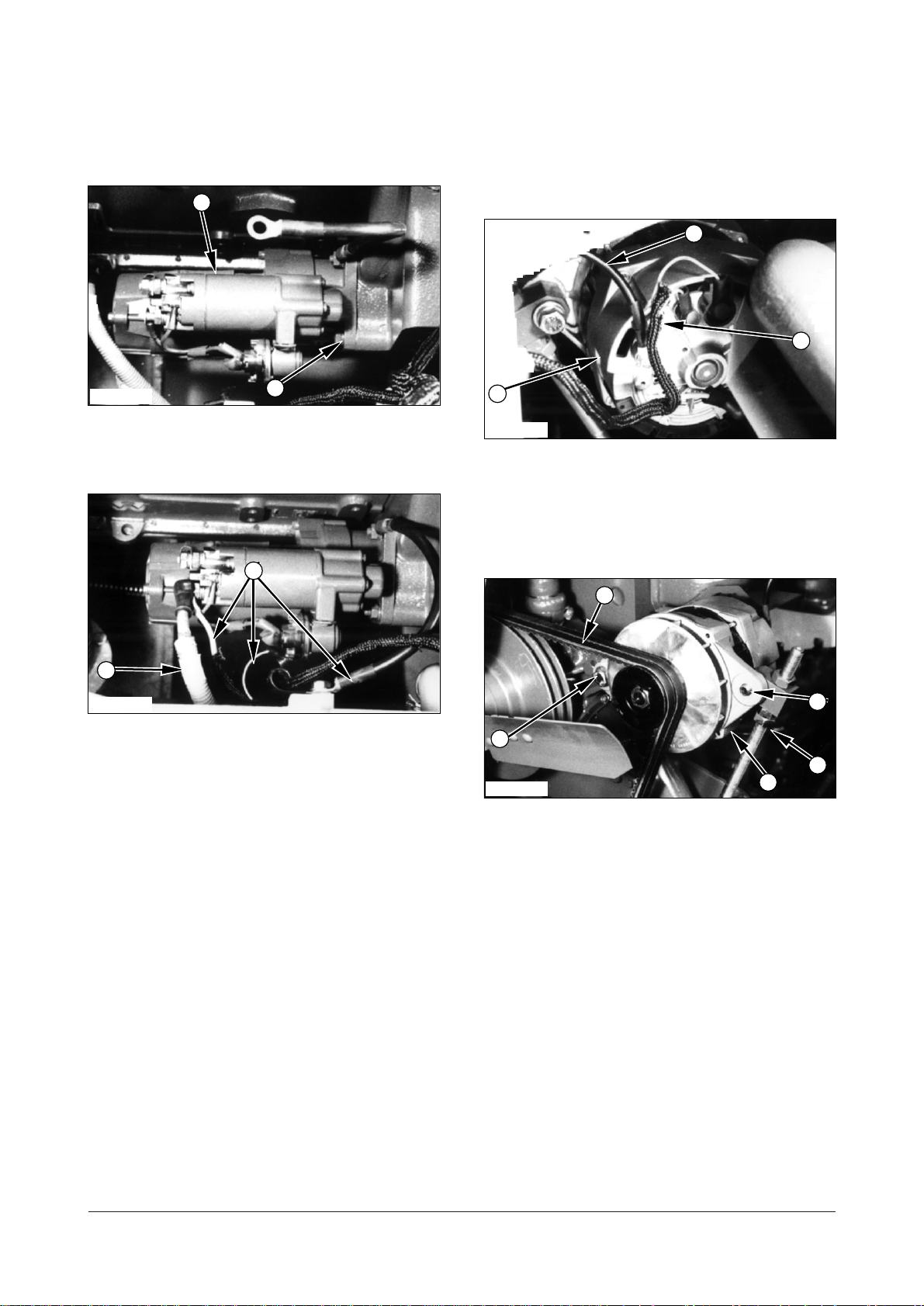

10. Disconnect battery cable (11) from the starting

motor.

12. Disconnect ground cable (13) from the alternator.

IEED009P

13. Disconnect three hoses (14) from the hydraulic

pump.

NOTE : Plug and cap all hydraulic connectors and hoses

to avoid debris and contamination from entering the

system.

IEED007P

11. Disconnect transmission neutral switch connector

IEED010P

(12).

14. Remove bolts (15) and washers that hold the

muffler expansion on exhanst manifold of the

engine.

DE08TS Diesel Engine Disassembly and Assembly

6 of 76

IEED011P IEED014P

17

16

21

18

22

A

20

19

15. Disconnect two transmission cooling hoses (16)

from the transmission.

16. Disconnect transmission oil temperature switch

wiring (17).

IEED012P

17. Disconnect two engine cooling hoses (18 ) from

the engine.

19. Remove bolts (21), washers and nuts from the

two transmission support.

NOTE : At this point, make a final check to be sure all

removals and disconnections have been made from

the engine and the transmission.

IEED015P

20. Install the tool (A) to the transmission. Fasten tool

(A) to the engine and transmission as shown.

21. Remove engine and transmission (22) from the

lift truck.

22. Put the engine and transmission on an

acceptable engine stand. Remove tool (A).

IEED013P

18. Remove bolts (19), washers, nuts from the two

engine support (20), one on both side of the

engine.

DE08TS Diesel Engine Disassembly and Assembly

7 of 76

IEED016P IEED017P

25

23

A

22

24

25

23

24

21

23. Support transmission (24) with fasten a strap and

remove twenty bolts(23) and washers. Remove

transmission (24) from engine (25).

Install Engine And Transmission

A10999 & C40999 - 03

Tools Needed A B

Link Bracket 1

Eye Bolt 1

3. Install the tool (A) to the transmission.

4. Fasten tool (A) to engine and transmission (22) as

shown.

IEED014P

5. Put the engine and transmission in position on the

lift truck. Make an alignment of supports with the

frame.

6. Install bolts (21), washers and nuts that hold the

transmission support to the frame.

Tightenbolts (21) to atorque of

(540

590 lbft).

730800 Nm

IEED016P

1. Put transmission (24) in position in engine (25).

2. Install bolts (23) and washers that hold

transmission to the engine. Tighten bolts (23) to

torque of

DE08TS Diesel Engine Disassembly and Assembly

55 10 Nm (40 7 lbft).

8 of 76

IEED013P

20

19

18

17

16

15

14

IEED011P

7. Install bolts (19), washers and nuts that hold

engine support (20) to the frame. Tighten bolts (19)

to a torque of

IEED012P

280 Nm (205 lbft).

8. Connect two engine cooling hoses (18) and tighten

the hose clamps.

9. Connect two transmission cooling hoses (16) to

transmission.

10. Connect transmission oil temperature switch

connector (17).

IEED010P

11. Install bolts (15) and washers that hold the muffler

expansion to exhaust manifold of the engine.

IEED009P

12. Connect three hydraulic hoses (14) to the

hydraulic pump.

DE08TS Diesel Engine Disassembly and Assembly

9 of 76

IEED008P

13

11

9

10

8

7

6

12

IEED005P

13. Connect ground cable (13) to the alternator.

IEED007P

14. Connect transmission neutral switch connector

(12).

16. Put hydraulic filter assembly (10) in position on

the frame. Install bolts (9) and washers.

IEED004P

17. Install tube (8) to the air compressor (if

equipped).

IEED006P

IEED003P

15. Connect battery cable(11) to the starting motor.

18. Connect wiring harness (7) to the fuel sender.

19. Connect two fuel hoses (6) and tighten the hose

clamp.

DE08TS Diesel Engine Disassembly and Assembly

10 of 76

Electric Starting Motor

1

2

4

3

5

4

2

3

1

WARNING

Remove Electric Starting Motor

A61564 - 02

IEED002P

20. Put the coolant reservoir with bracket (5) in

position on the frame. Install bolts (4) and

washers that hold coolant reservoir (5).

IEED001P

21. Put bonnet assembly (3) in position on the frame.

Install the bolts and washers. Tighten the bolts to

a torque of

200 N..m (150 lb..ft).

Disconnect the battery before the starting motor

is removed

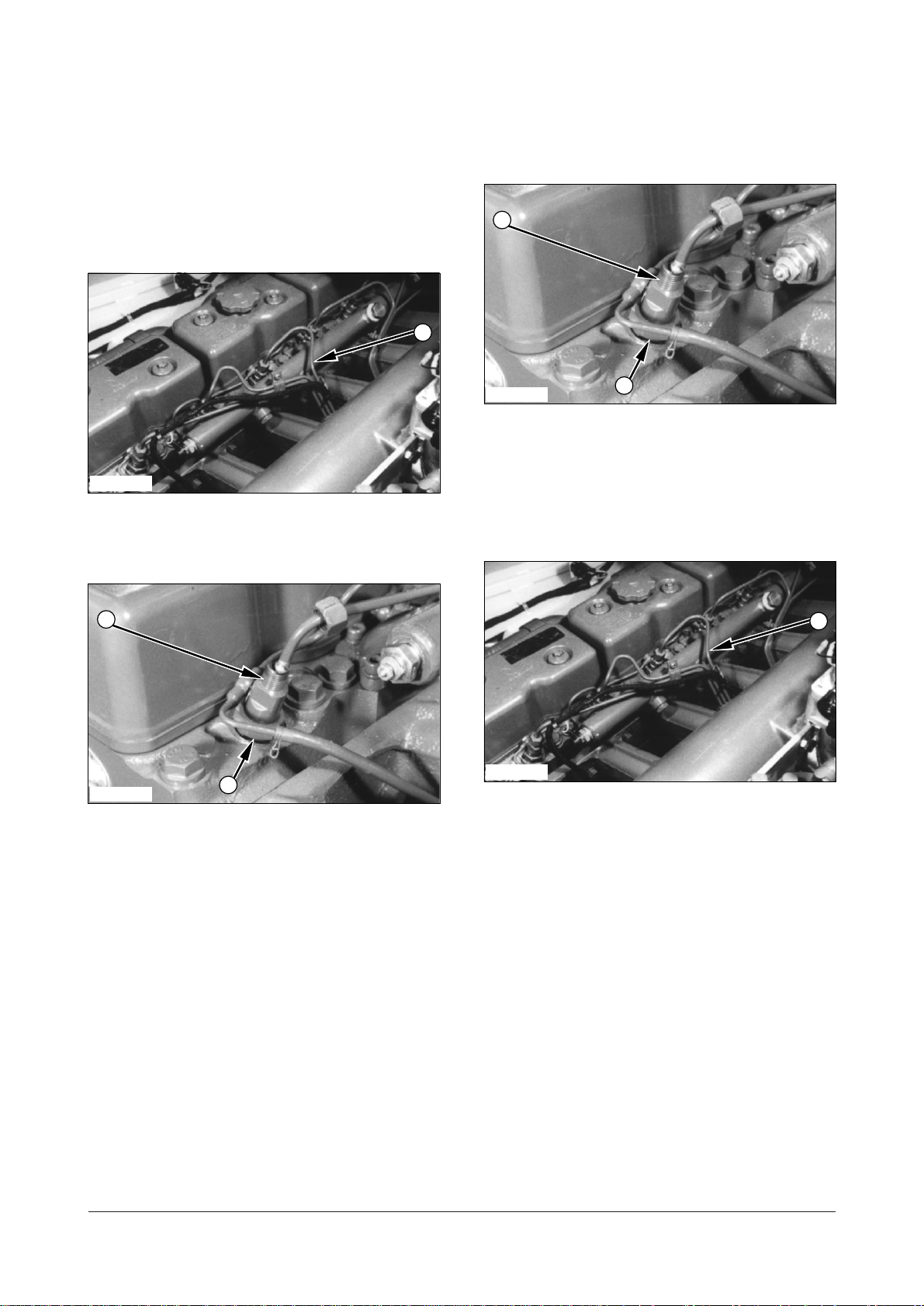

IEED018P

1.

Put identification on the starting motor and

solenoid wires. Disconnect wirings (1) and battery

cable (2).

22. Install the screws and washers that hold circuit

breaker (2).

23. Clear engine harness assembly (1).

24. Fill the cooling system. See the Maintenance

Guide for the correct level.

End By :

a. Install universal joint.

b. Install air cleaner.

c. Install hood.

d. Install floorplate.

e. Install overhead guard.

IEED019P

2. Remove mounting nuts (3) and then remove

starting motor (4) from the lift truck.

DE08TS Diesel Engine Disassembly and Assembly

11 of 76

Install Electric Starting Motor

1

54653

2

6

4

3

1

2

A61564 - 03

IEED019P

Alternator

Remove Alternator B31018 - 02

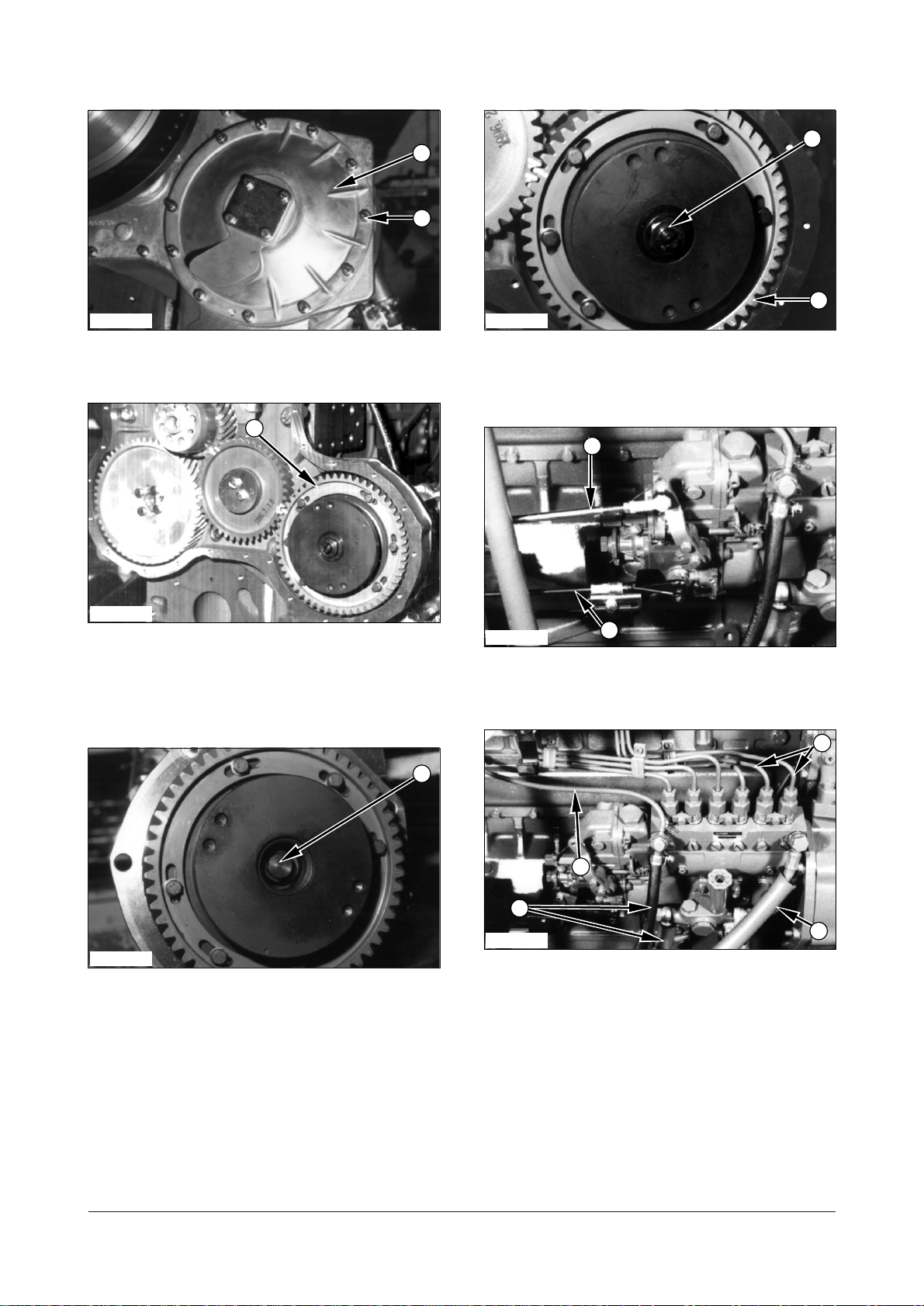

1. Put starting motor (4) in position on the flywheel

housing and install nuts (3) that hold it.

IEED018P

2. Connect wirings (2) to the starting motor and

solenoid. Connect battery positive cable (1).

IEED020P

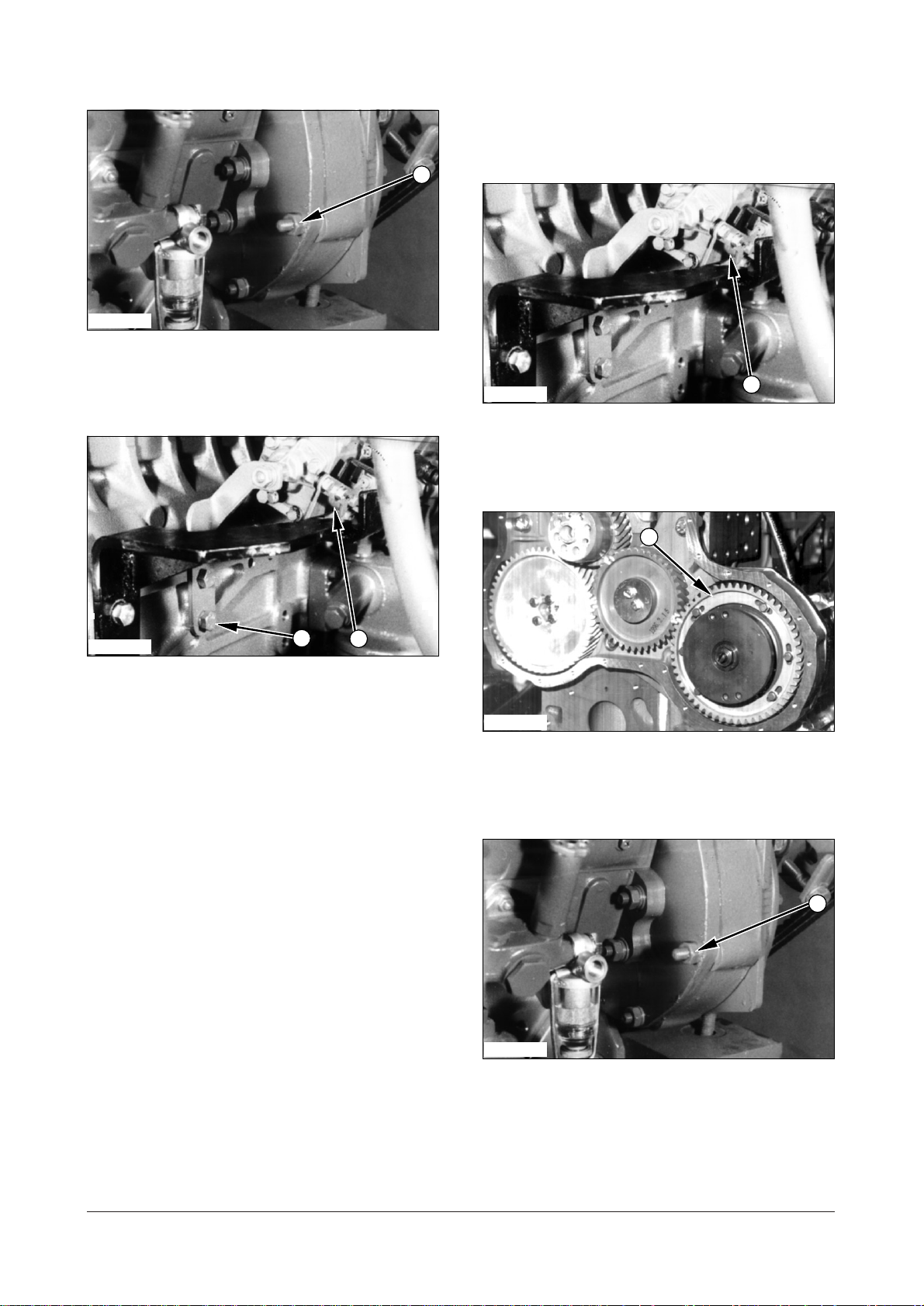

1. Put identification on all wires (1) and the

disconnect them from alternator (6).

2. Disconnect ground cable (2) from alternator (6).

IEED021P

3. Loosen nuts (4) and then remove belt (3) from the

alternator.

4. Remove bolts (5) from the alternator’s bracket to

remove alternator (6).

DE08TS Diesel Engine Disassembly and Assembly

12 of 76

Install Alternator B31018 - 03

1

6

5

3

4

1

2

6

2

546

5

3

IEED021P

1. Put alternator (6) in position on its bracket and

install bolts (5) that hold it.

2. Install fan belt (3) on the alternator and tighten nuts

(4).

Fuel Injection Pump

Remove Fuel Injection Pump

A25663 - 02

Start By :

a. Remove air compressor (if equipped).

b. Remove intake manifold.

IEED020P

3. Connect all wires (1) to their respective positions.

4. Connect ground cable (2) to alternator (6).

IEED022P

1. Remove two bolts (1) and washers.

2. Remove bolt (2), washers, spacer (3) and lifting

bracket (4).

IEED166P

3. Remove bolts (5) and washers that hold the

tension adjusting bracket on the timing gear case.

4. Remove the idle pulley and V-belt tension

adjusting bracket assembly (6) and gasket.

Discard the gasket.

DE08TS Diesel Engine Disassembly and Assembly

13 of 76

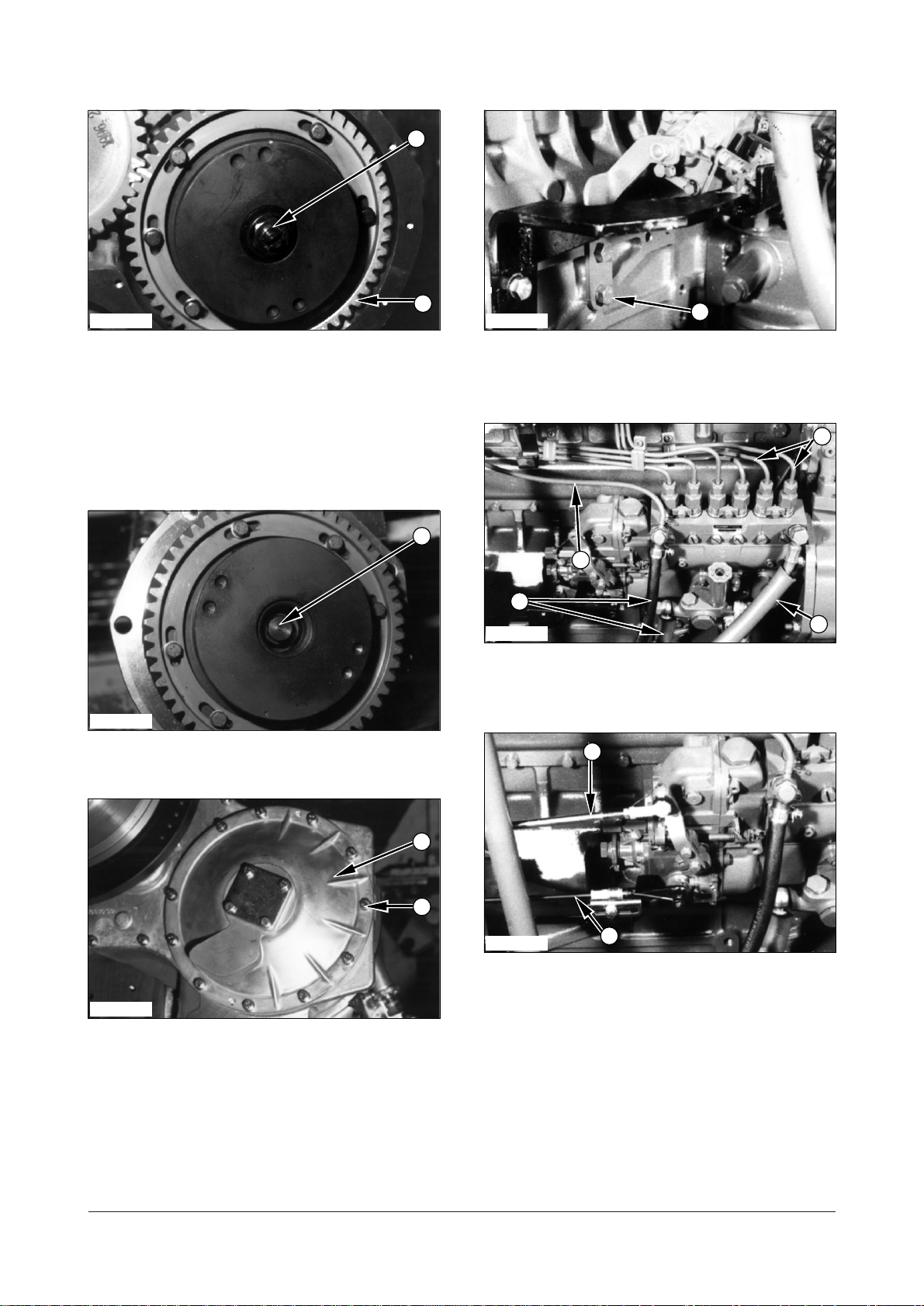

IEED023P

12

8

7

9

1414141513

10

11

9

IEED118P

5. Remove bolts (7), washers and cover (8).

IEED024P

6. Make an alignment of the timing marks on fuel

injection pump gear (9) and the idle gear or put a

mark of identification on the gears for correct

installation.

8. Remove nut (11) and injection pump coupling and

gear (9) from the injection pump.

IEED025P

9. Disconnect accel rod (12) and engine stop cable

(13).

IEED026P

IEED117P

10. Disconnect five hoses (14) and tubes (15) from

7. Remove nut (10) from the injection pump coupling.

DE08TS Diesel Engine Disassembly and Assembly

14 of 76

the injection pump.

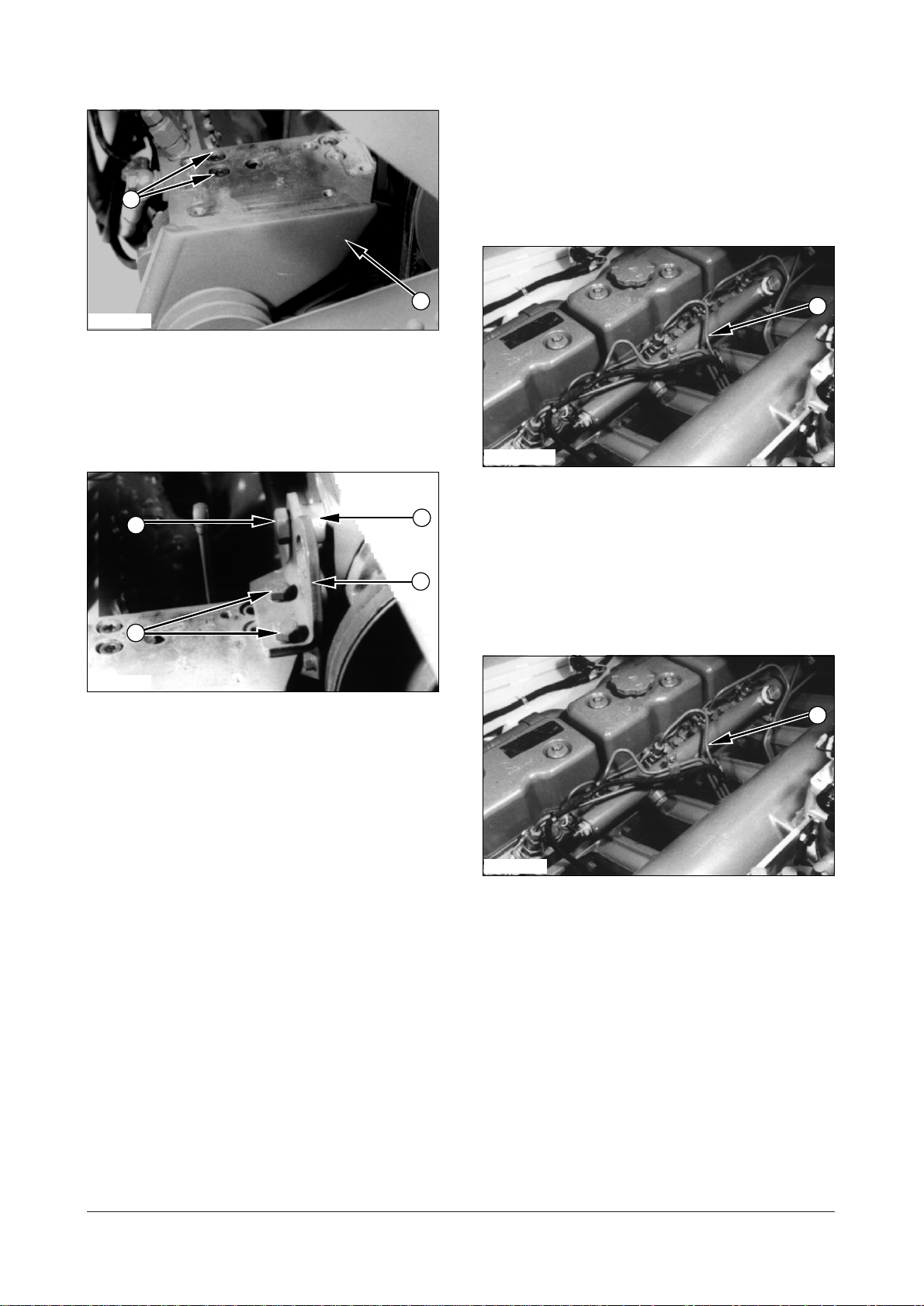

17

IEED027P

16

16

18

17

9

11. Remove four nuts (16) and washers that hold the

injection pump in place. Remove the gasket and

discard it.

Install Fuel Injection Pump

A25663 - 03

IEED028P

1. Install the new gasket in position on the timing

gear case. Put fuel injection pump (17) in position

on the timing gear case.

IEED028P

12. Support injection pump (17). Remove two bolts

(18) and washers that hold injection pump (17) on

the block. Remove injection pump (17).

IEED024P

2. Make sure the timing marks or the marks that were

put on the fuel injection pump gear (9) and the idle

gear are in alignment.

IEED027P

3. Install four nuts (16) and washers that hold the fuel

injection pump on the timing gear case.

DE08TS Diesel Engine Disassembly and Assembly

15 of 76

141414

15

12

13

18

8

7

10

IEED118P

11

9

IEED028P

4. Put the fuel injection pump drive coupling and gear

(9) in position. Make an alignment of the key and

the groove (slot) in the coupling.

5. Install nut (11) that hold the injection pump drive

coupling and gear (9) in place. Tighten nut (11) to

a torque of

IEED117P

130 Nm (96 lbft).

6. Install nut (10) into the injection pump coupling.

8. Install bolts (18) and washers that hold the

injection pump on the block.

IEED026P

9. Connect three hoses (14) and tube (15) to the

injection pump.

IEED025P

10. Connect accel cable (12) and engine stop cable

IEED023P

(13) to the injection pump.

7. Install cover (8), bolts (7) and washers.

DE08TS Diesel Engine Disassembly and Assembly

16 of 76

1

1

IEED166P

5

6

3

4

1

2

11. Install the new gasket on the timing gear case.

12. Put the idle pulley and V-belt tension adjusting

bracket assembly (6) on the timing gear case and

install bolts (5) and washers.

Fuel Injection Lines

Remove Fuel Injection Lines

A23525 - 02

IEED029P

1. Disconnect fuel injection lines (1) from the fuel

injection nozzle assemblies and the fuel injection

pump.

IEED022P

13. Install lifting bracket (4), spacer (3), washers and

bolts (2) on the block.

14. Install two bolts (1) and washers.

End By :

a. Install air compressor (if equipped).

b. Install intake manifold.

Install Fuel Injection Lines

A23525 - 03

IEED029P

2. Connect fuel injection lines (1) to the fuel injection

pump and the fuel injection nozzle assemblies.

Tighten the fuel line nuts toa torque of

16 to20 Nm (12 to 15 lbft).

DE08TS Diesel Engine Disassembly and Assembly

17 of 76

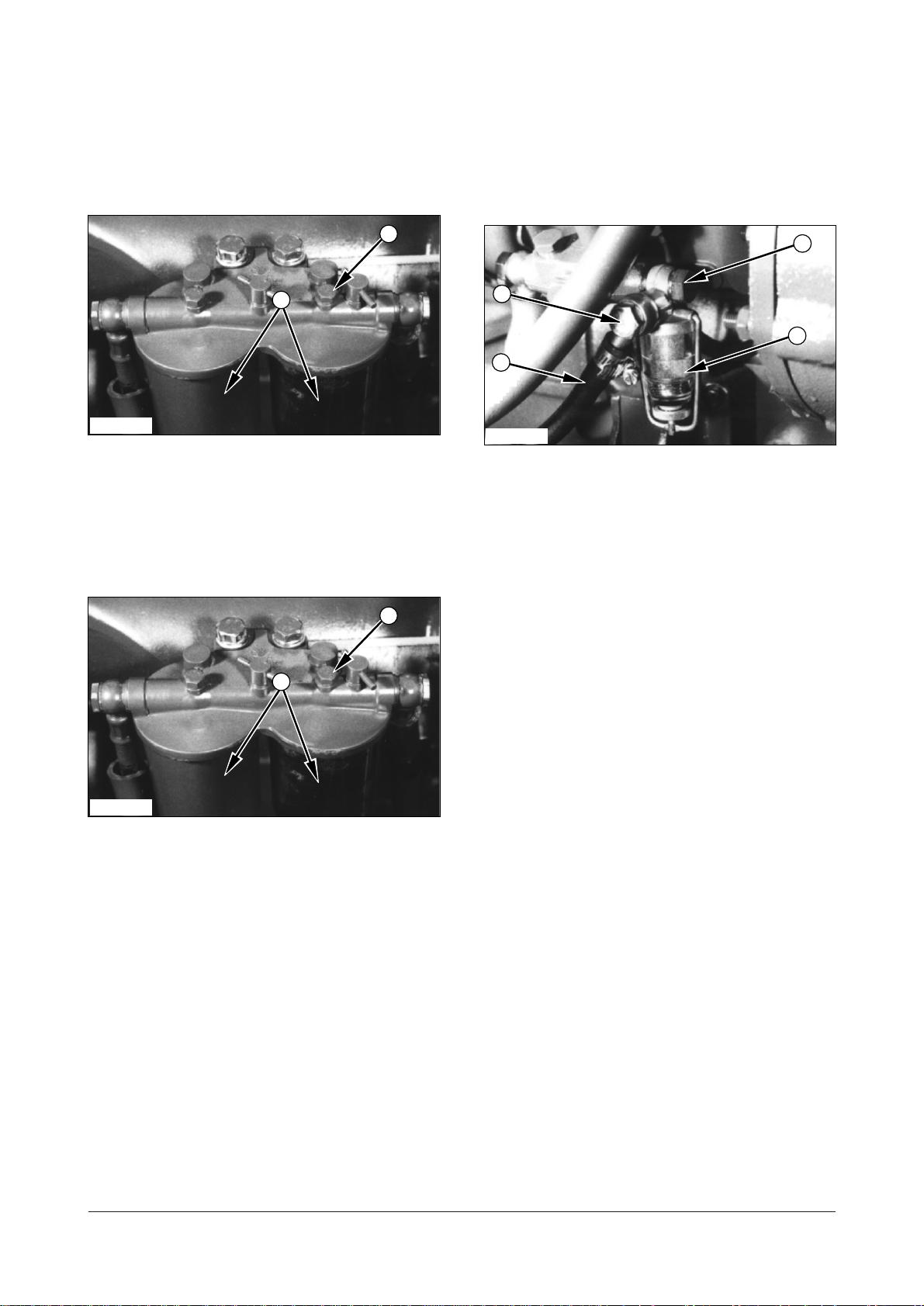

Fuel Filter

2

1

3

4

1

2

2

1

Remove Fuel Filter A21357SE - 02

Fuel Strainer

Remove & Install Fuel Strainer

A21357PR - 01

IEED030P

1. Loosen bolt (1). Remove bowl (2).

2. Remove fuel filter.

Install Fuel Filter A21357SE - 03

IEED030P

1. Install a new gasket in the filter bowl.

IEED031P

1. Remove bolt (1) and washers and disconnect fuel

line (2) that connected the fuel tank.

2. Remove bolt (3), washers and fuel strainer (4) from

the injection pump.

3. Install fuel strainer (4) in reverse order of removal.

2. Put a new fuel filter element in position.

3. Put filter bowl (2) in position and tighten bolt (1)

that holds the bowl in position.

DE08TS Diesel Engine Disassembly and Assembly

18 of 76

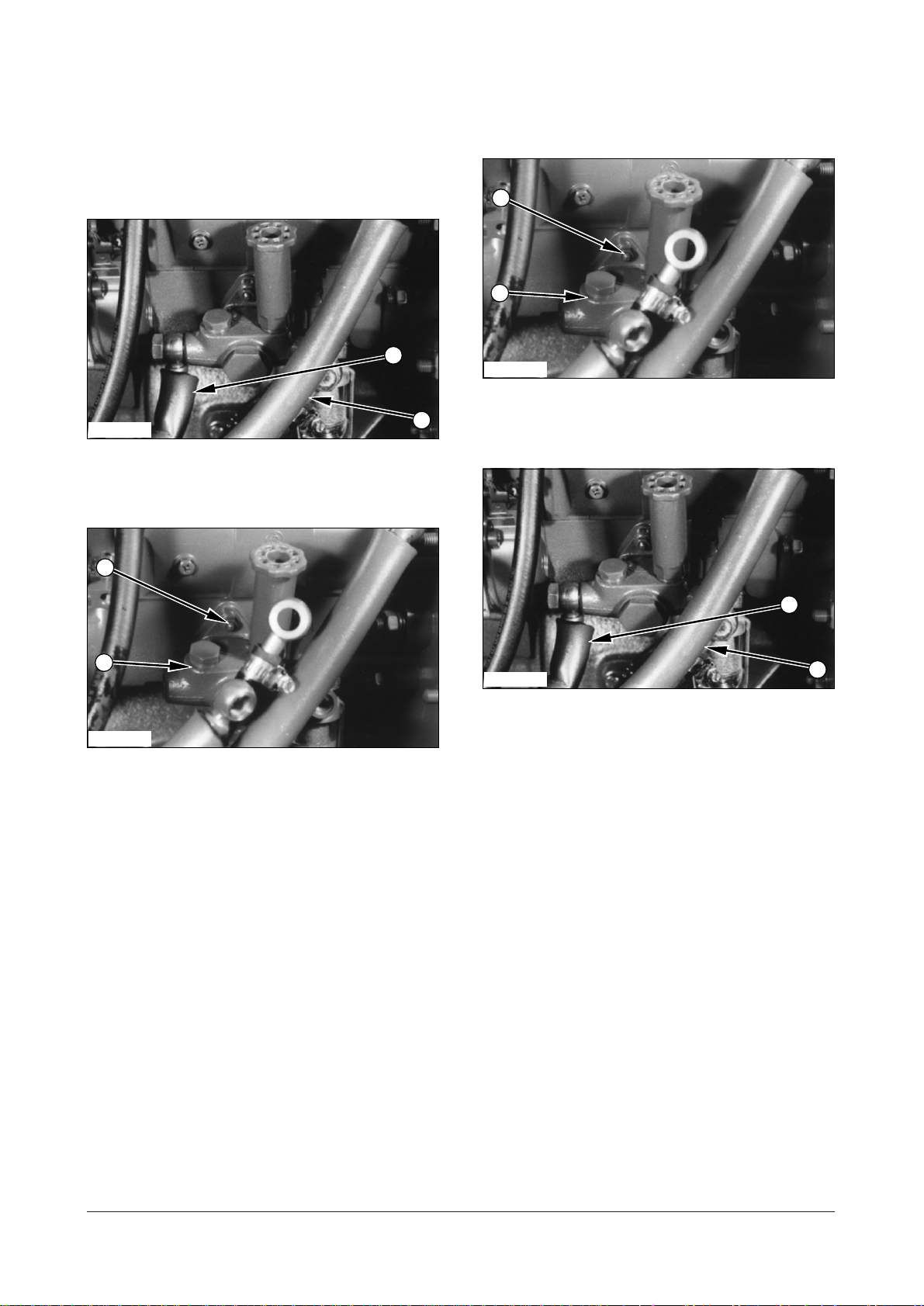

Fuel Pump

2

1

2

1

3

4

3

4

Remove Fuel Pump A21663 - 02

IEED032P

1. Disconnect fuel inlet line (1) and fuel outlet line (2)

from the fuel pump.

Install Fuel Pump A21663 - 03

IEED033P

1. Put fuel pump (4) in position on the engine block

with nuts (3) that hold it.

IEED033P

2. Remove three nuts (3) that hold fuel pump (4) to

the injection pump. Remove fuel pump (4).

IEED032P

2. Connect fuel outlet line (2) and fuel inlet line (1) to

the fuel pump.

DE08TS Diesel Engine Disassembly and Assembly

19 of 76

Fuel Injection Nozzle

1

1

2

3

2

3

Assembly

Remove Fuel Injection Nozzle

Assembly A28999 - 02

IECD029P

1. Disconnect fuel lines (1) from the fuel injection

nozzles.

Install Fuel Injection Nozzle

Assembly A28999 - 03

IEED034P

1. Install the new seal rings in the nozzle hole of the

cylinder head.

2.Put fuel injection nozzles (2) in position. Install nuts

(3) and tighten them to a torque of

(52

7 lbft).

7010 Nm

IEED034P

2. Remove nuts (3) and then remove fuel injection

nozzles (2).

3. Remove the seals from the nozzle holders of the

cylinder head and discard it.

IEED029P

3. Connect fuel lines (1) to the injection nozzles and

then tighten the nuts to a torque of

30 Nm (22 lbft).

DE08TS Diesel Engine Disassembly and Assembly

20 of 76

Disassemble & Assemble Fuel

1

1

6

4

2

3

5

7

6

4

2

3

5

7

Injection Nozzle Assembly

A28999 - 06

Start By :

a. Remove fuel injection nozzle assembly

IEED035P

1. Remove union nut (1) from the nozzle assembly.

IEED036P

4. Install shims (7), spring (6), guide (5) and

intermediate washer (4) to the nozzle holder.

5. Install needle valve (3) into fuel nozzle (2) and

install the fuel nozzle.

IEED036P

2. Remove fuel nozzle (2), needle valve (3),

intermediate washer (4), guide (5), spring (6) and

shims (7) from the nozzle holder.

3. Check all parts for damage. If damaged, use new

parts for replacement.

NOTE : The following steps are for assembling the

fuel injection nozzle assembly.

IEED035P

6. Install union nut (1) and tighten to a torque of

7010 Nm (527 lbft).

End By :

a. Install fuel injection nozzle assembly.

DE08TS Diesel Engine Disassembly and Assembly

21 of 76

Muffler

2

8

15

12

11

14

13

5

9

10

4

5

6

7

3

1

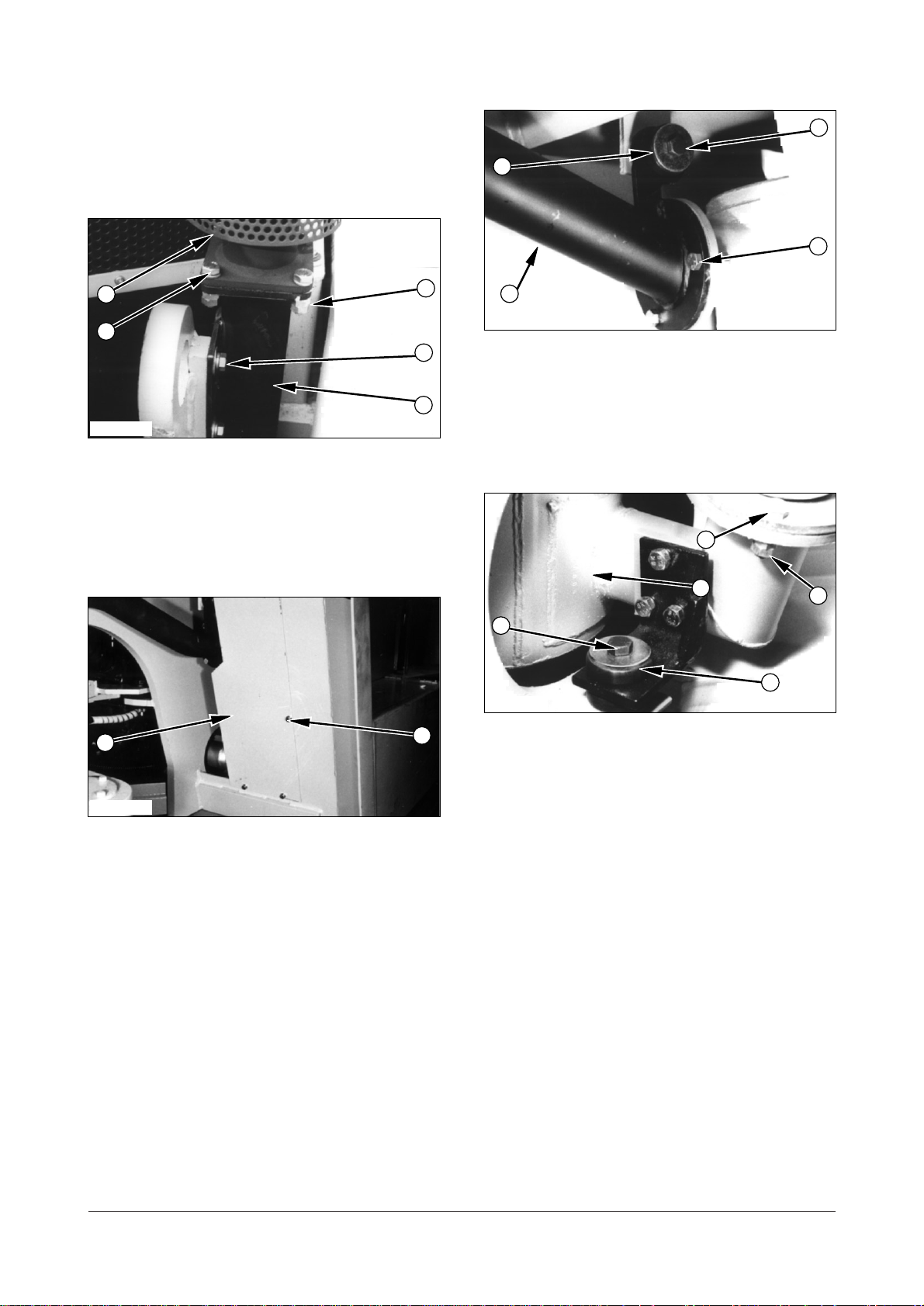

Remove Muffler A32570 - 02

IEED037P

1. Remove four bolts (1), washers and nuts (2) that

hold muffler tube assembly (3) on tube assembly

(5).

2. Remove two bolts (4) and washers that hold tube

assembly (5) on the frame.

IEED039P

4. Remove three bolts (8), washers and nuts.

5. Support tube assembly (5) and remove bolt (9),

washers, rubber mounts (10), shims and nuts that

hold tube assembly (5) on the frame. Remove tube

assembly (5).

IEED038P

3. Remove five bolts (6), washers and cover (7) from

the frame.

IEED040P

6. Remove three bolts (11), washers and nuts (12).

7. Remove bolt (13), washers, rubber mounts (14),

shims and nuts that hold mount bracket of muffler

assembly (15) on the frame. Remove muffler

assembly (15).

DE08TS Diesel Engine Disassembly and Assembly

22 of 76

Loading...

Loading...