Doosan D110S-5 with OCDB, D130S-5 with OCDB, D160S-5 with OCDB Disassembly/assembly

Vehicle System

SB4376E01

Aug.2012

Disassembly & Assembly

D110S-5 with OCDB

D130S-5 with OCDB

D160S-5 with OCDB

Important Safety Information

Most accidents involving pr oduct operation, maintenance and repair ar e caused by failure to observe basic

safety rules or precautions. An ac cident can often be avoided by recogniz ing potent ially hazardous sit uations

before an accident occurs. A person must be alert to potential hazards. This person should also have the

necessary training, skills and tools to perf orm these functions properly.

Read and understand all safety precau tions and warni ngs before operati ng or perfo rming lubrication ,

maintenance and repair on this product.

Basic safety pr ec autions are listed in the “Safety” section of the Ser v ic e or Technic al M anual. Additional safet y

precautions are list ed in the “Safety” section of t he owner/oper ation/maintenance publication.

Specific safet y warnings for all these public ations ar e provided in t he descript ion of oper ations wher e hazard s

exist. WARNING labels have also been put on the product to provide instructions and to identify specific

hazards. If these hazard warnings ar e not heeded, bodily injury or death could occur to you or other persons.

Warnings in this publication and on the product labels are ident ified by the following sym bol.

WARNING

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could

result in in jury or death.

Do not operate or perfo rm any lubrication, maint enance or repair on this produ ct, until you have read

and understood the operation, lubrication, maintenance and repair information.

Operations that may cause product damage are identified by NOTICE labels on the product and in this

publication.

DOOSAN cannot anticipate ev ery possible circumstance that might involve a potential hazard. The warnings

in this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or

operating technique not s pecifically recommended by DO OSAN is used, you must satisfy yourself t hat it is

safe for you and others. You should also ens ure that the product will not be damaged or made unsafe by the

operation, lubricat ion, maintenance or repair pr oc edur es y ou c hoos e.

The information, specifications , and illustrat ions in this publication are on t he basis of inf ormation available at

the time it was written. T he specifications, tor ques, pressures, measurement s, adjustments, illustrat ions, and

other items can c hange at any time. These changes can aff ect the service given to the produc t. Obtain the

complete and most current information before starting any job. DOOSAN dealers have the most current

information available.

Vehicle System Index 1

INDEX

Forks ........................................................ 5

Remove & Install Forks ..................................... 5

Carriage ................................................... 6

Remove & Install Carriage ................................. 6

Carriage Rollers ...................................... 7

Remove & Install Carriage Rollers ..................... 7

Disassemble & Assem ble Car r iage Roller s ........ 7

Disassemble & Assem ble Car r iage .................... 8

Mast ......................................................... 9

Remove Mast .................................................... 9

Install Mast ...................................................... 10

STD Mast ........................................................ 11

Disass embly ................................................ 11

Assembl y ........................................................ 1 4

FFT Mast......................................................... 18

Lift Cylinder ........................................... 20

Removal & Installation ..................................... 20

Disassembly .................................................... 22

Assembl y ........................................................ 2 4

Tilt Cylinder ........................................... 25

Removal & Installation ..................................... 25

Disassembly & Assembly ................................ 26

Brake Assembly .................................... 29

Removal & Installation ..................................... 29

Remote Control Valve .......................... 31

Replacing the parts ......................................... 31

Attachment Carriage ............................ 33

Lift Cylinder and Mast .......................... 33

Hydraulic Pump .................................... 35

Removal & Installation ..................................... 35

Start-up Inst ructions & Recommendations ....... 36

Rotation & Ports Indication ........................... 36

Start-up : ...................................................... 36

Removal of Air in Pump – Motor line ................ 36

Pump & Cartridge Breakdown Dr awing ............ 37

Disassembly .................................................... 38

Reasse mbly .................................................... 43

Seal Driver ...................................................... 48

Dimension of Protective Cone ......................... 48

Hydraulic Oil Filter ................................ 49

Removal & Installation ..................................... 49

Disassembly & Assembly ................................ 49

Universal Joint ......................................50

Removal & Installation .....................................50

Disassembly & Assembly .................................51

Steering Wheel & Gear .........................52

Steering Wheel ................................................52

Removed & Disassembly of Steering Gear.......52

Assembly of Steering Gear ..............................54

Steer Axle ..............................................58

Removal & Installation .....................................58

Steering Cylinder ..................................60

Removal & Installation .....................................60

Disassembly & Assembly .................................62

Steering Knuckle, Kingpin And Bearings

................................................................64

Removal & Installation .....................................64

Steer Tire And Rim ................................67

Removal & Installation .....................................67

Removal of Wheel Bear ing ..............................67

Installation of Wheel Bearing ............................68

Drive Tire And Rim ................................69

Removal & Installation .....................................69

Counterweight .......................................70

Removal of Air.......................................71

Pump – Motor line ............................................71

After changing main pump ...............................71

Air in Brake system ..........................................72

Removal of the High Pres sure in accumulator ..72

Emergency Lowering .......................................73

Removal and installation of Engine and

Transmi ssion ...................................................74

Vehicle System Index 3

Forks

Remove & Install Forks

1. Pull out pin assembly ( 1) from the fork.

2. Rem ov e two bolts, washers (2) and plate ( 3) .

3. Support the fork with strap and hoist. Remove

shaft (4). Remov e str ap and hois t from the fork.

The weight of the fork is 217 to 465 kg (477 to

1025 lb).

4. Tilt the mast at full forward direction. Lower the

carriage until for k is s epar ated from the carriage.

Drive the truck at backwar d dir ec tion.

5. Repeat steps 1 through 4 f or the ot her fork.

6. Install the fork s in the rev erse order of removal.

Vehicle System Disassembly & Assembly 5

Carriage

Remove & Install Carriage

Start By :

a. Remove forks.

1. Com pletely lower carriage and inner m as t.

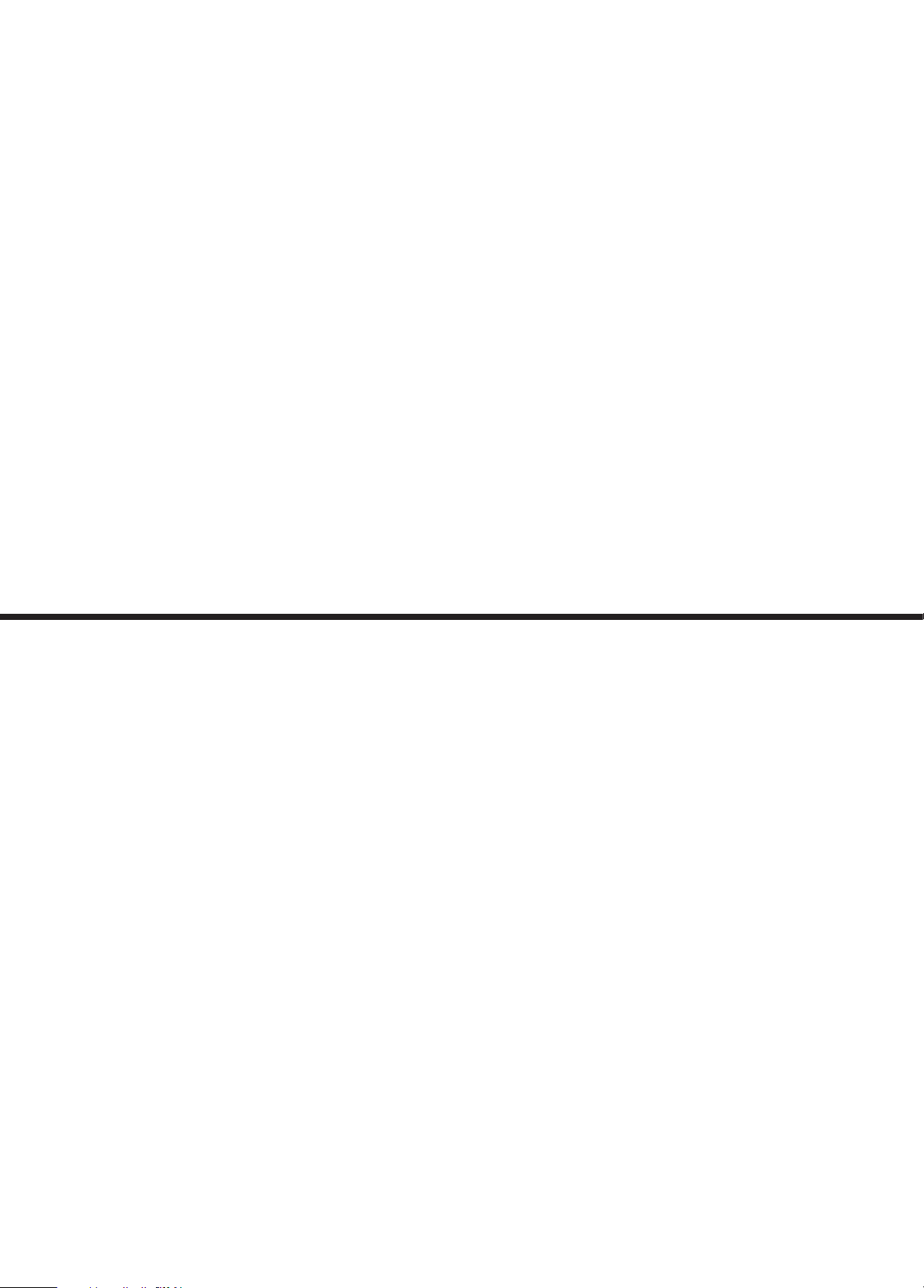

2. Attach a hoist t o the car r iage as shown.

3. Lift the car riage wit h the hoist unt il the chains and

hoses hang loosely.

4. Put identification marks on sideshift cylinder

hoses if equipped. Disconnec t two hoses.

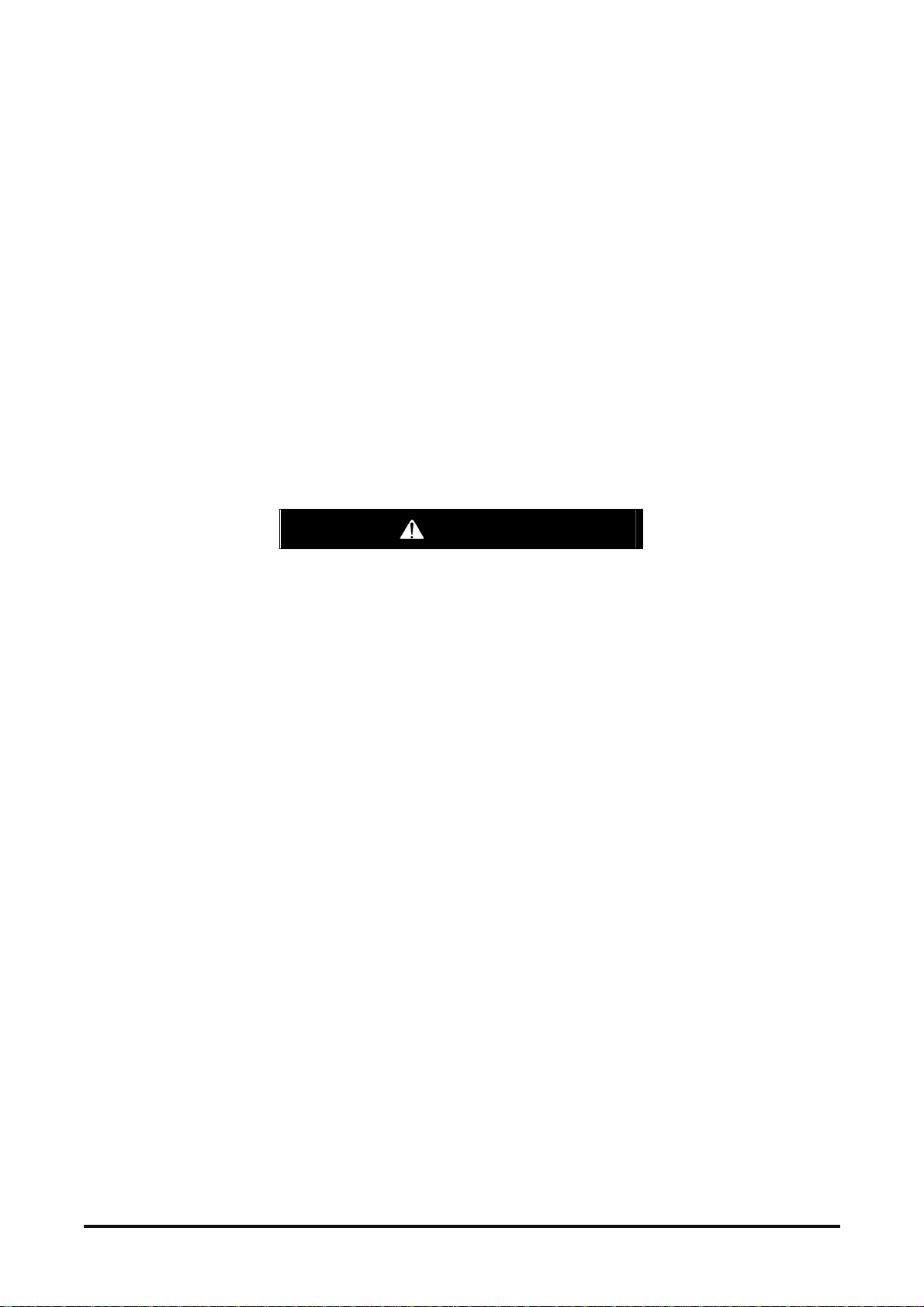

5. Rem ov e the cotter pin and pin (2) f r om both of t he

lift chains.

6. Start the engine. Raise the mast until the inner

mast clears the car r iage.

7. Remove the carriage. The weight of the carriage

is 936 kg (2063 lb).

NOTE : The following steps are for installation of the

carriage. See the topic ent itled Carriage Adjustment

in the Testing and Adjusting Manual bef ore inst alling

the carriage on the m ast.

8. Attach a hoist t o the car r iage as shown.

9. Start the engine. Rais e the mast until t he carriage

will go under the inner mast .

10. Move the carriage in position under the mast.

11. Completely lower the mast over the carriage

making sure the roller s ar e pr oper ly aligned

inside the inner mast.

12. Connect two hoses. If necessary, rais e the

carriage slightly wit h the hoist.

13. Pull the chains into position on the carr iage.

Install pin (2) and t he cotter pin in both of the lift

chains.

14. Make an adjust m ent to the lift chains. See the

topic entitled Chain Adjus tments in the Testing

and Adjusting Manual.

End By :

a. Install forks.

Vehicle System Disassembly & Assembly 6

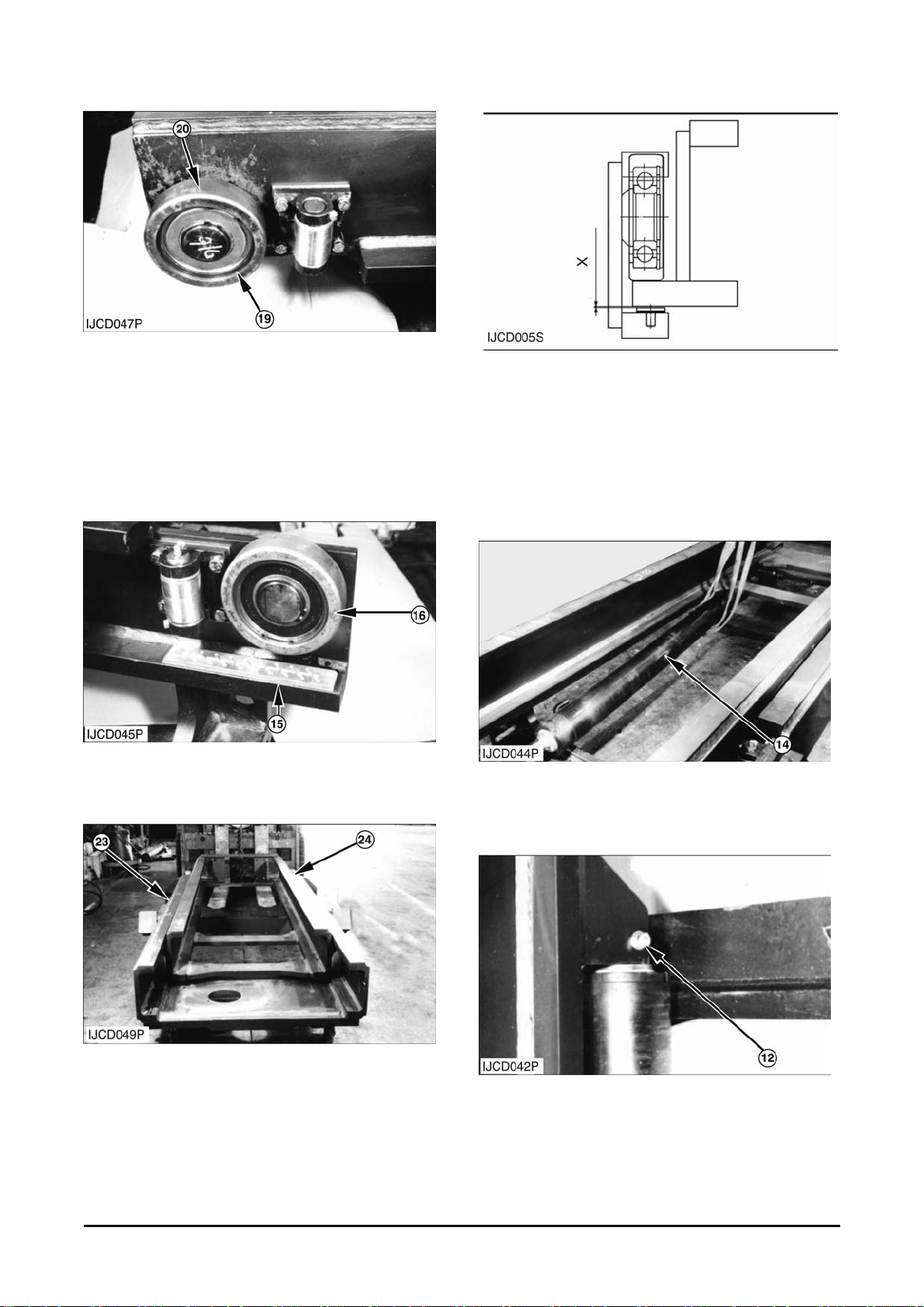

Carriage Rollers

Remove & Install Carriage Rollers

Start By :

a. Remove car r iage.

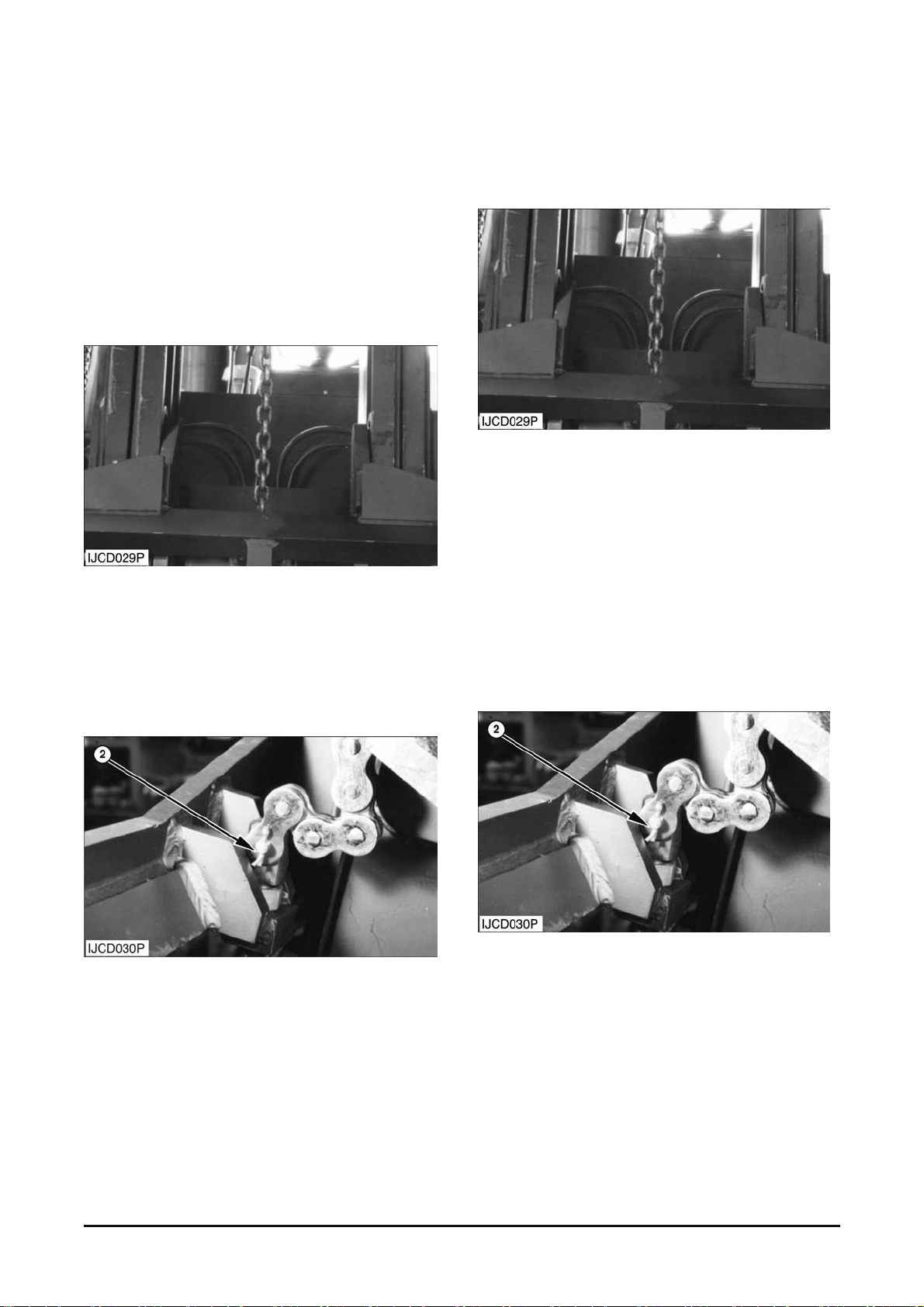

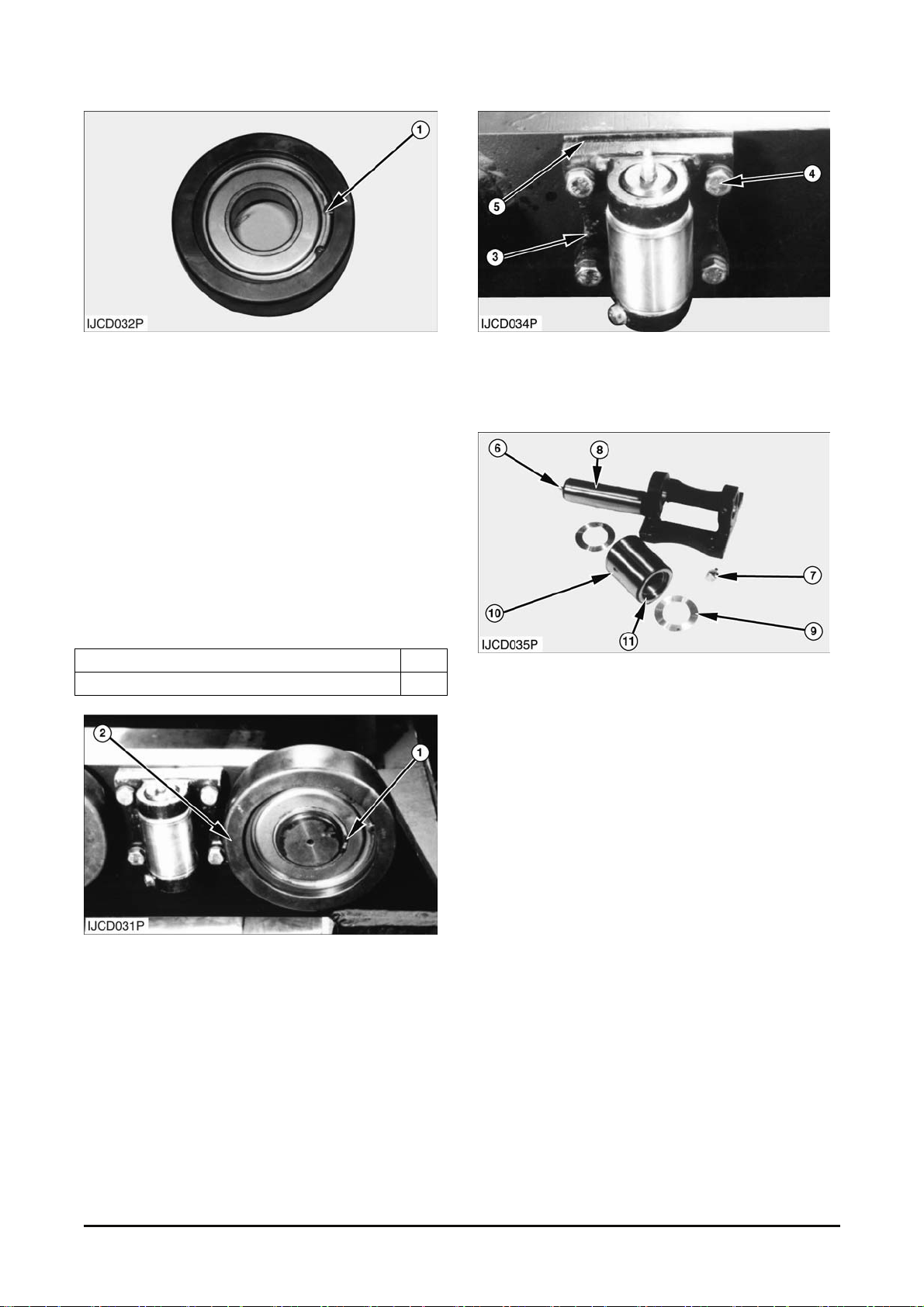

1. Remove the snap ring (1) that holds the roller in

place.

2. Remove load roller (2) from the carriage.

NOTE : The following steps are for installation of the

carriage rollers.

3. P ut the load roller in position on the carriage.

4. Install the snap ring that holds the roller in place.

End By :

a. Install carriage.

Disassemble & Assemble Carriage

Rollers

Tools Needed A B

Bearing Cup Puller Att achment

Puller Assembly

Ratchet Box Wrench

Bearing Installer

Start By :

a. Remove car r iage r oller s ( load) .

1

1

1

1

1. Rem ov e s nap ring (1) from the roller.

2. Remove bearing (2) from the roller using the tool

group (A).

NOTE : The following steps are for the as sembly of

the carriage rollers .

3. Put (pack) clean grease in the bearings for the

load roller.

4. Install bearing (2) in the roller using tool ( B ).

Vehicle System Disassembly & Assembly 7

5. Install snap ring ( 1) in the roller.

End By :

a. Install carriage r oller s ( load)

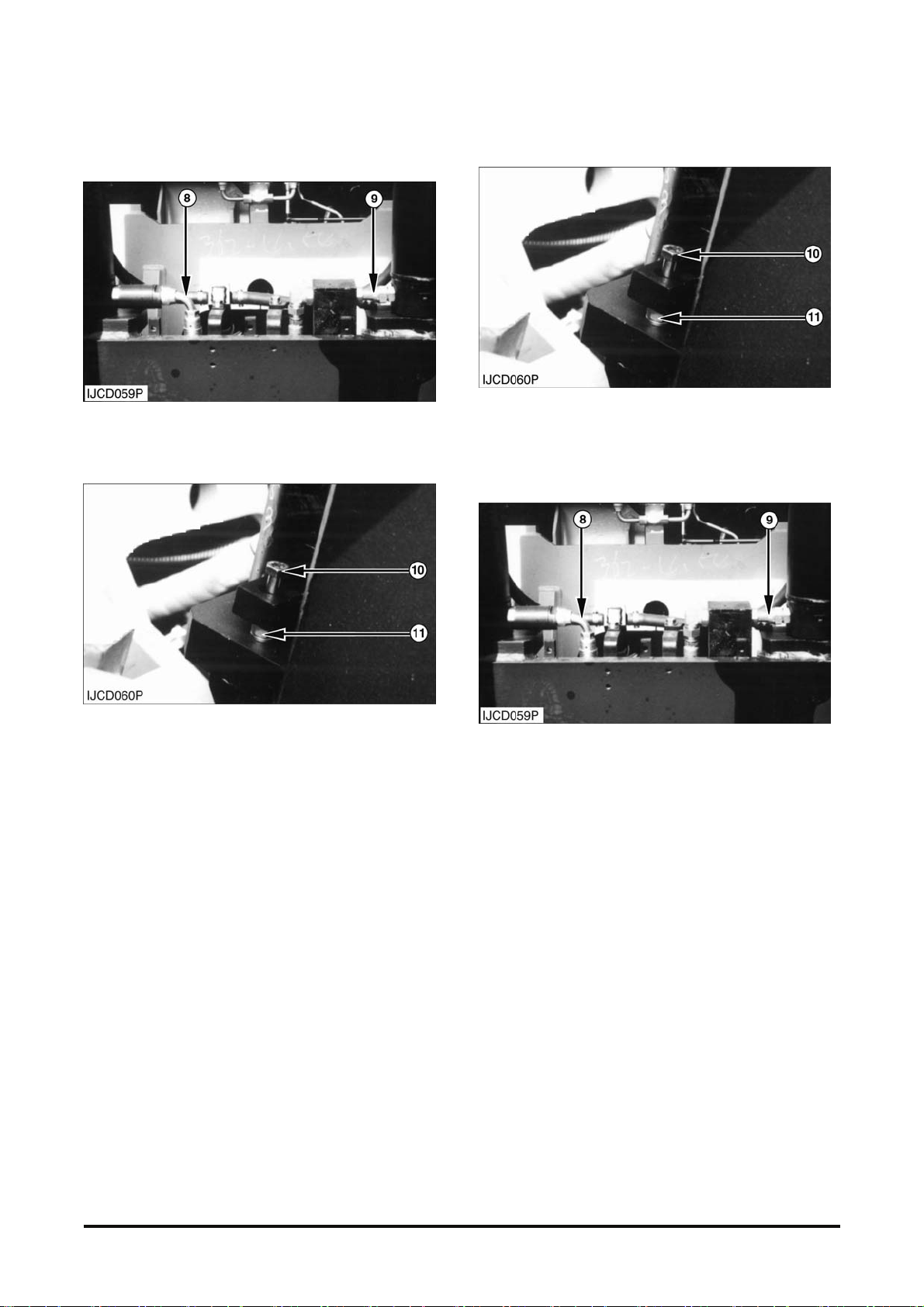

Disassemble & Assemble Carriage

Start By :

a. Remove car r iage

Tools Needed A

Bearing Cup Puller Att achment 1

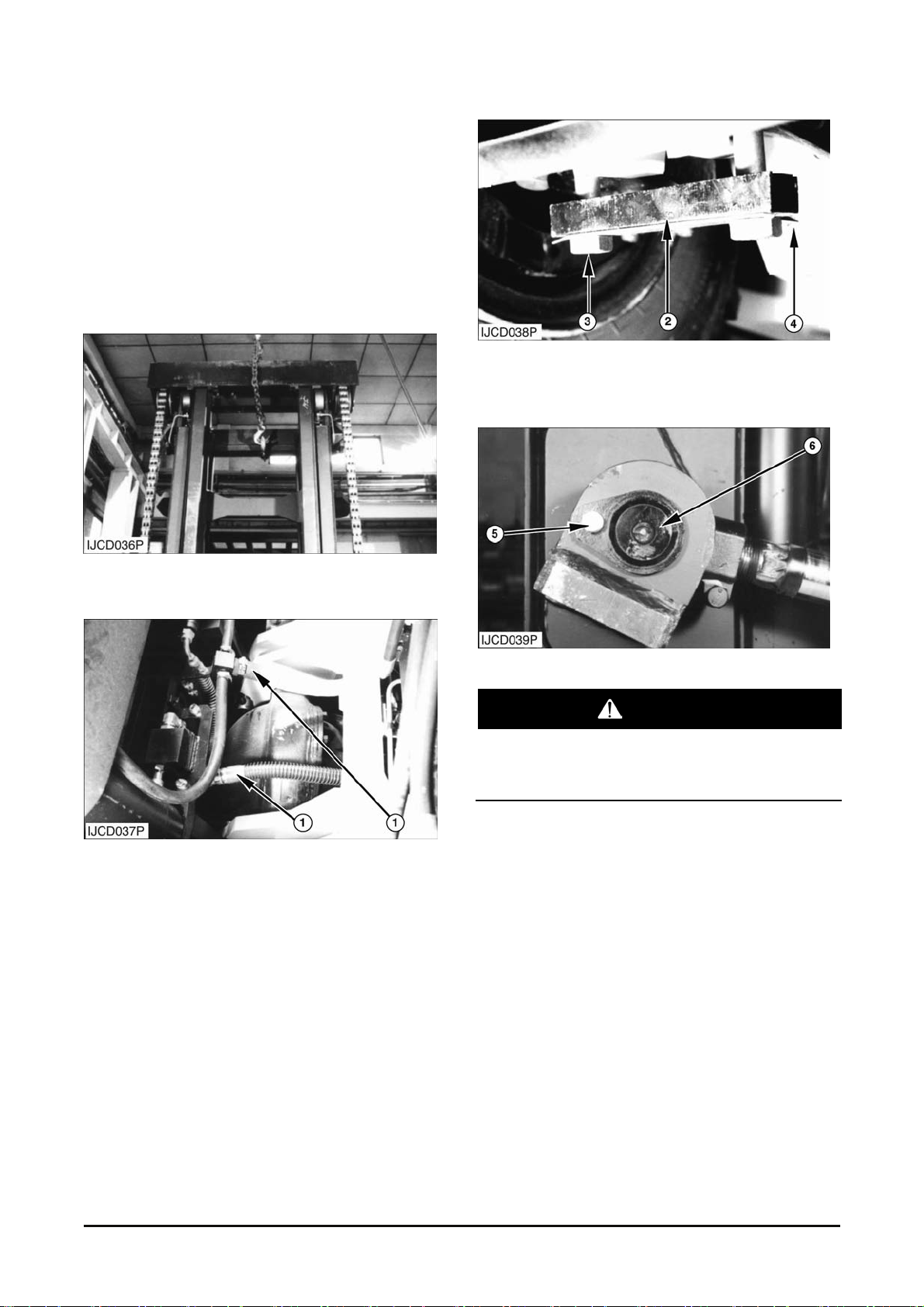

1. Remove snap ring (1) with tool (A).

2. Rem ov e roller (2) from the pin of the c arriage.

3. Remove bolts (4), washers, roller and bracket

assembly (3) and shims (5) from carriage

assembly.

4. Disassemble the roller and bracket assembly (3)

as follows:

a. Remove grease fitting (6).

b. Remove bolt (7) and washer that hold shaft (8)

in bracket.

NOTE : When assembly, apply Loctite No.242 to

bolt thread.

c. Tap the shaft ( 8) and r emove shaft from

bracket.

d. Remove spacers (9) and roller (10).

e. Remove bushings (11) from r oller ( 10) .

Replace the bushings with new ones if worn or

damaged.

NOTE : Assemble carriage in the reverse order of

disassembly.

End By :

a. Install carriage.

b. Make an adjustment to the carriage (see Carriage

Adjustment in Test ing and Adjusting).

Vehicle System Disassembly & Assembly 8

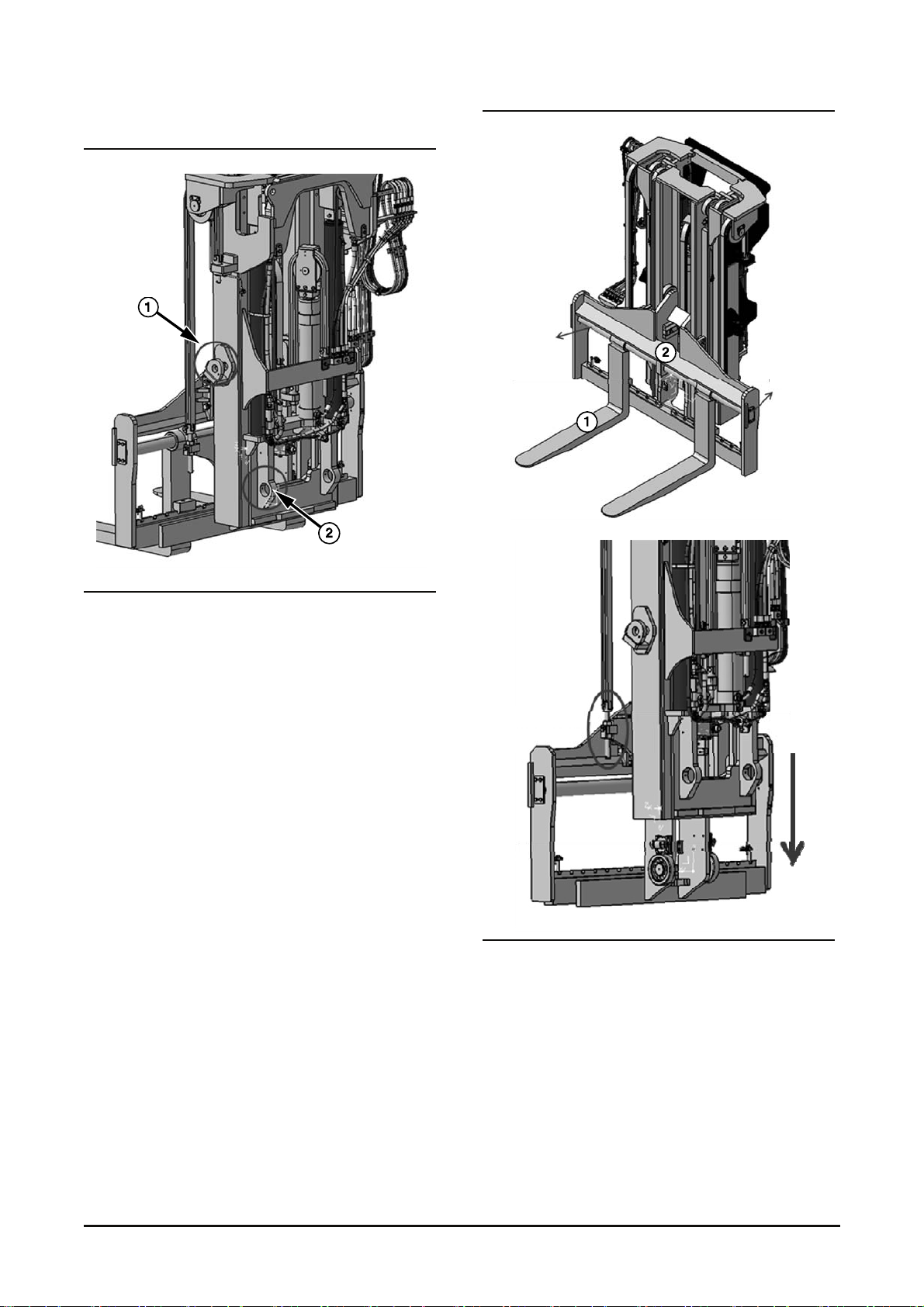

Mast

Remove Mast

Start By :

a. Remove carriage.

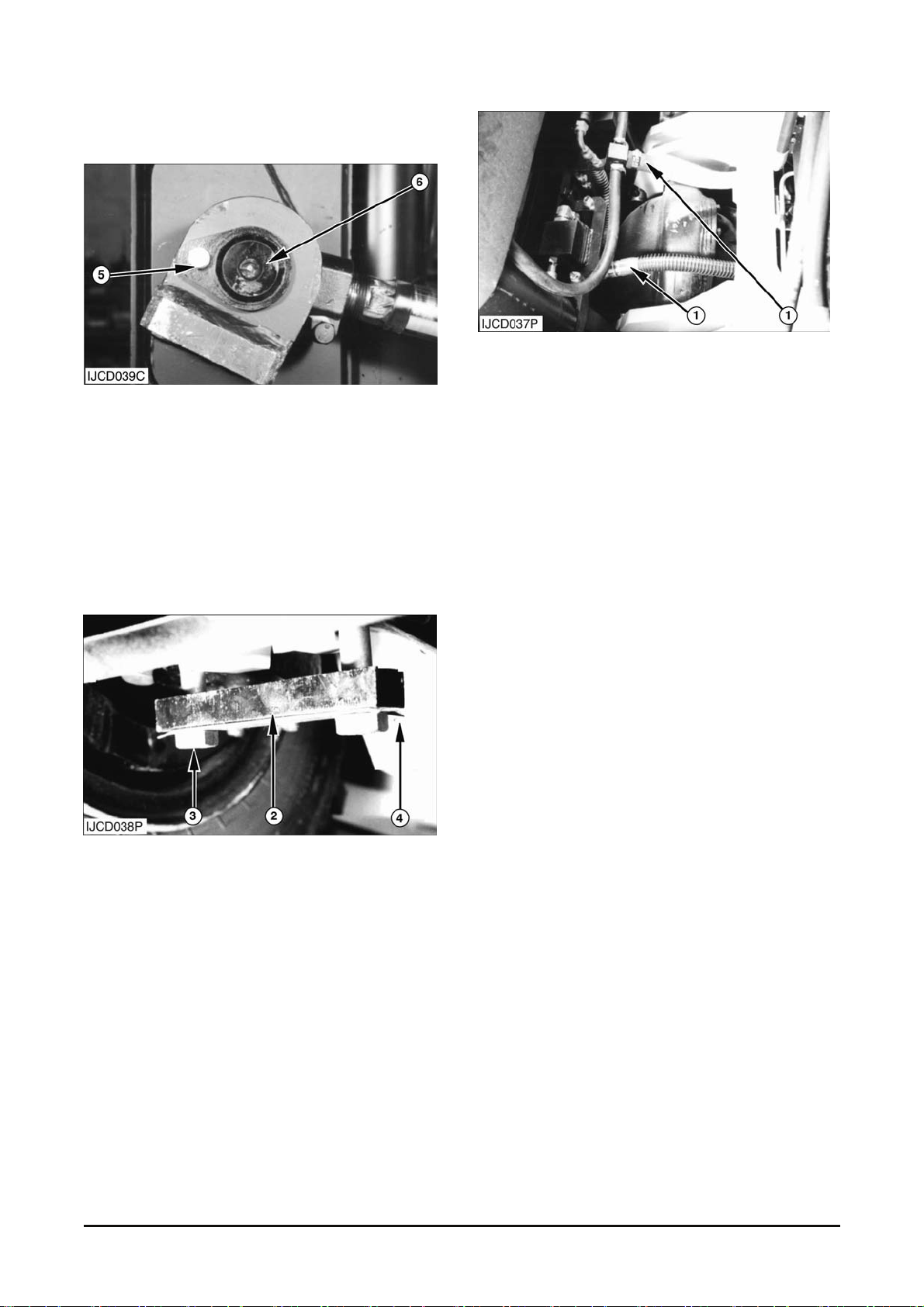

1. Fully lower mast.

2. Fasten a hoist to the mast as shown.

3. Tilt the mast forward. Disconnect hydraulic lines

(1).

4. B end bac k the tab on clip (4).

5. Remove bolt (3), clip (4) and block (2).

WARNING

Tilt cylinders can drop when pin (6) is removed.

To avoid component damage or personal injury,

support tilt cylinder while removing pin (6).

6. Remove retaining bolts (5). Remove pin (6).

7. Repeat Steps 4, 5 and 6 for the other side of t he

mast.

8. Start the engine. O perate the contr ol lever for the

tilt cylinders until the rods are fully retrac ted.

9. Remove the mast from the frame of the vehicle.

The weight of the mast is approximately 2600 to

4400 kg (5732 to 9700 lb).

Vehicle System Disassembly & Assembly 9

Install Mast

1. Install the mast on the frame of the vehicle. The

weight of the mast is appr oximately 2600 t o 4400

kg (5732 to 9700 lb).

2. Start the engine. O perate the contr ol lever for the

tilt cylinders until the holes in the cylinder rods are

aligned with the holes in the mas t.

3. Install two pins (6). Inst all bolts (5) and retainers

to hold both pins in place.

4. Inst all bolts (3), clip (4) and bloc k ( 2) on eac h s ide.

Torque bolts (3) to 800 ± 100 N•m (590 ± 74 lb•ft).

5. Bend back the tabs on clips (4) against the bolt

heads.

6. Connect hydr anlic lines ( 1) .

NOTE : If lift c ylinders wer e remov ed from the mas t,

adjust both lift chains to equal tension. Run the mast

to full lift. If mast does not kick to either side no

shims are required. If mast does kick to one side

disconnect cylinder from support assembly on that

side. Add shims, reassemble and repeat. Repeat

process until “kic king” is corr ected. Do not exceed 3

mm (.12 in) of shims.

End By :

a. Install brack et assembly carriage.

Vehicle System Disassembly & Assembly 10

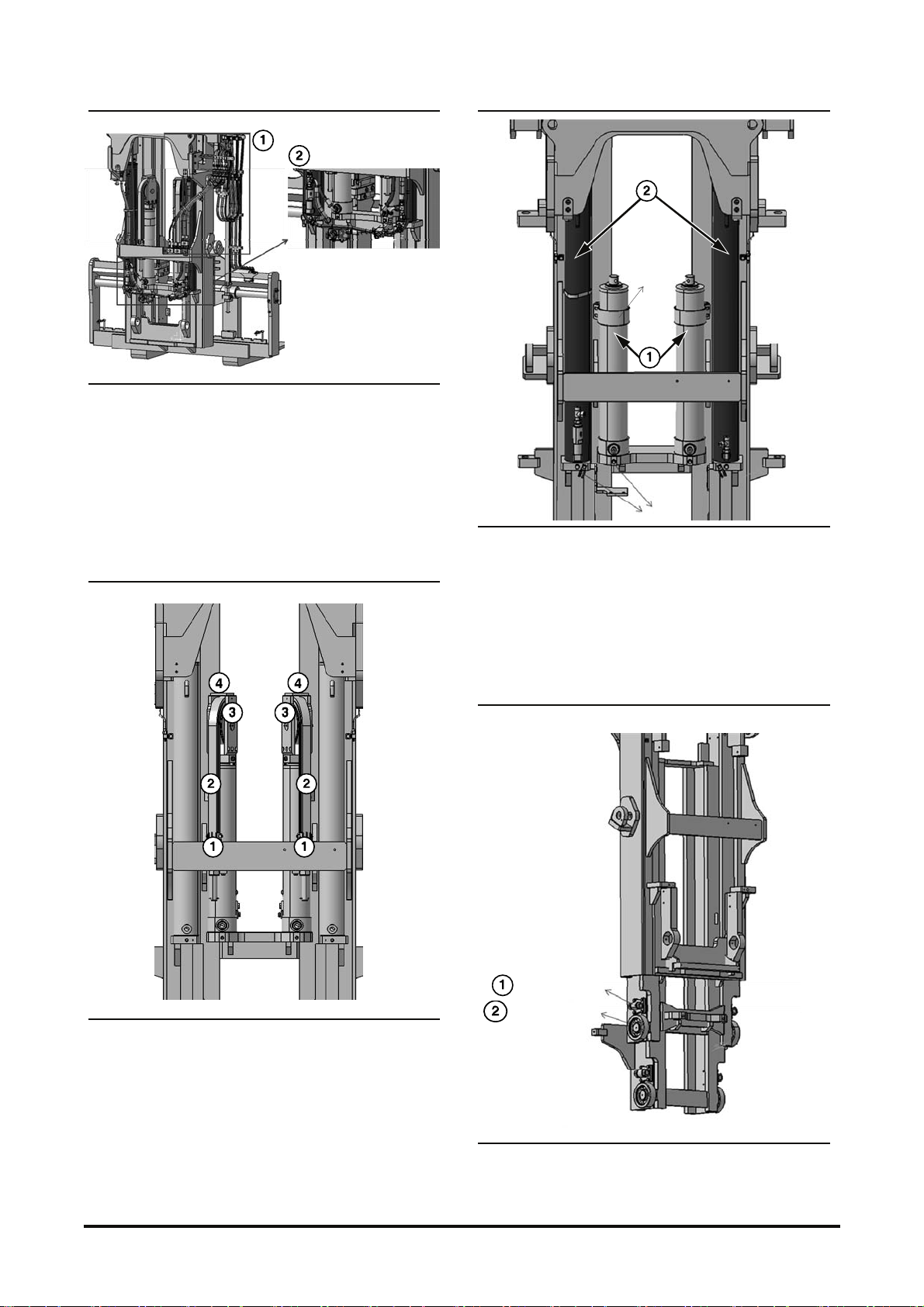

STD Mast

Disassembly

Start By :

a. Remove mast.

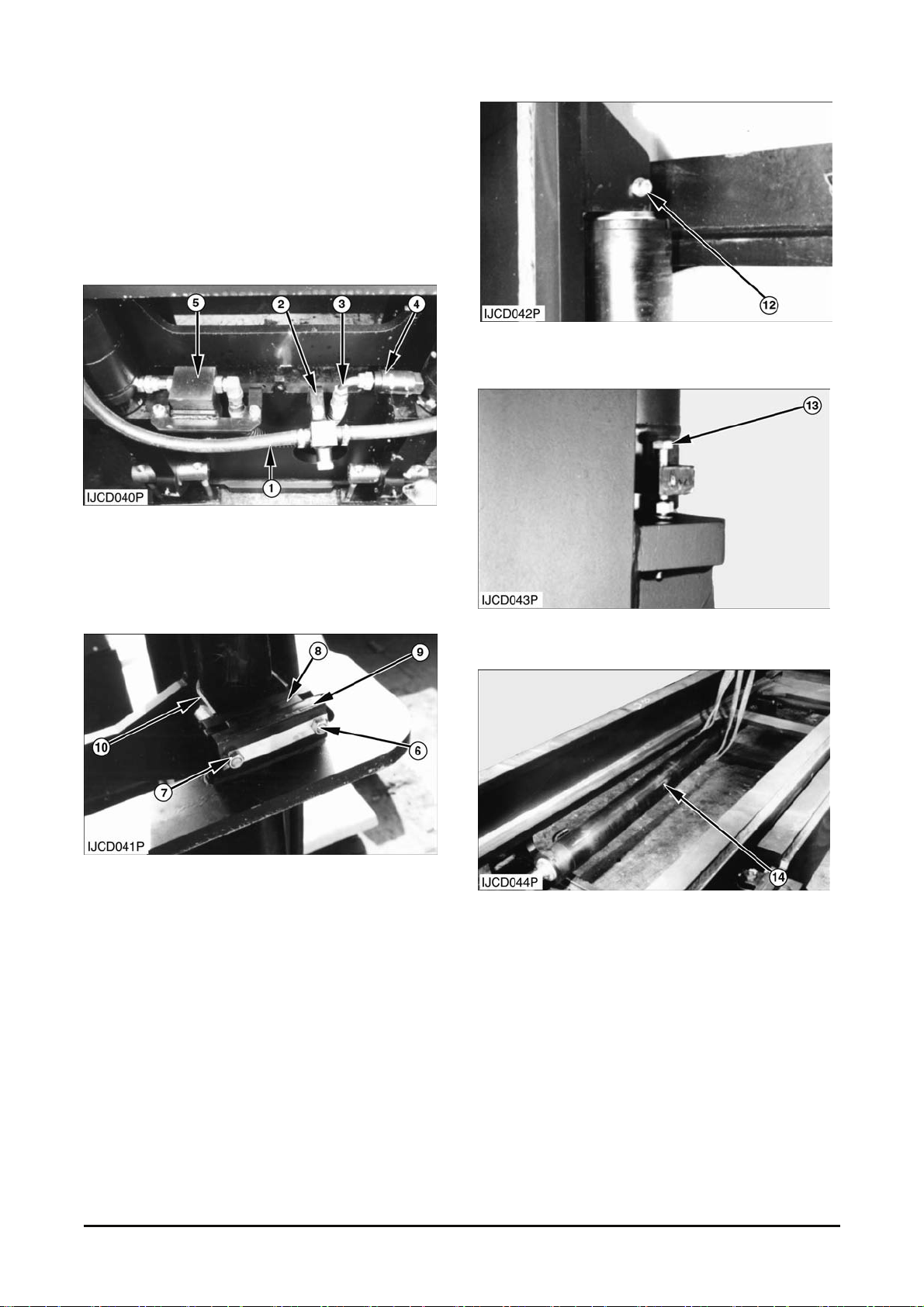

1. Rem ov e hos e (1) and bracket (2).

2. Remove hose (3), flow protector (4) and flow

regulating and bracket assembly (5) from outer

mast channel.

3. Bend back the plate (7) support ing nut (6) not to

be loosened. Remove nut (6), plate (7), spacers

(8), pad-rubber (9) and clamp assembly(10) if

they were installed.

4. Remove grease pipe if it was inst alled.

5. Rem ov e bolt (12) and washers.

6. Remove bolts (13) , washers and nuts.

7. A ttach hoist to lift cylinder (14).

8. Remove lift cy linder (14). The weight of the

cylinder is 171 to 400 kg (377 to 881 lb) . Mark for

identification and rem ove the shims at top of

cylinder (14).

NOTE : At inst allation, adjust both lift chains with t he

same tension. Run the mast to full lift. If mas t does

not kick to either side, no shimming is required. If

mast does kick to one side, disc onnect cylinder from

support assembly on that side. Add shims to

reassemble Repeat this process until “kicking” is

corrected.

Vehicle System Disassembly & Assembly 11

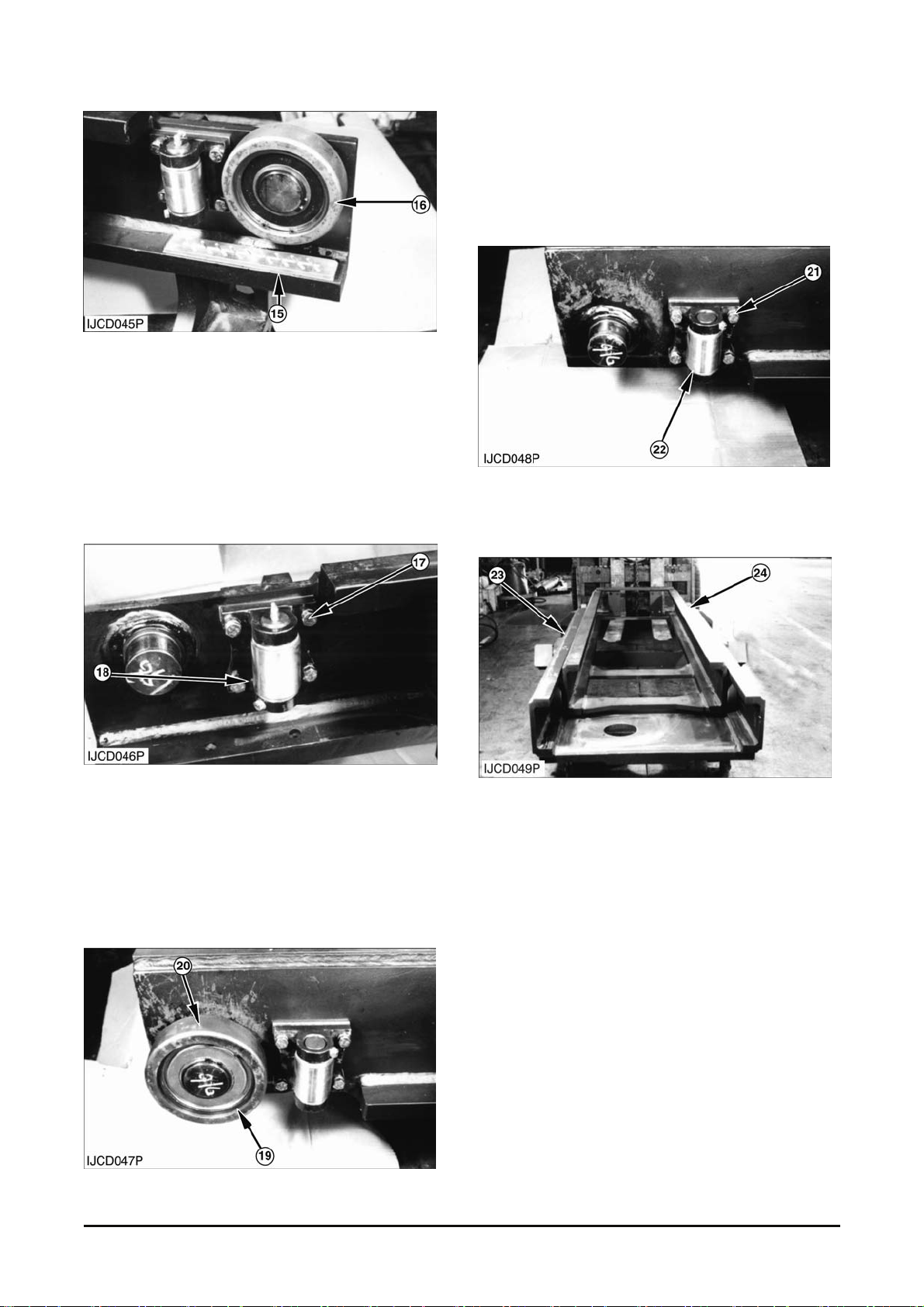

9. Remove pads (15) and shims from the outer mast

channel.

10. Remove the s nap- r ing from the outer mast pin.

Remove roller assemblies ( 16) from the outer

mast channel.

NOTE : Place identification marks on all roller

assemblies (16) t o as s ur e pr oper installation.

11. Remove bolts (17), washers, roller and bracket

assembly (18) and shims from the outer mast

channel.

NOTE : Mark and separate the shims and roller and

bracket assemblies (18) r emoved f rom each s ide for

identification at as s em bly .

12. Remove s nap-ring (19) from the inner m ast pin.

Remove roller assemblies (20) from the inner

mast channel.

NOTE : Place identification marks on all roller

assemblies (20) t o as s ur e pr oper installation.

13. Remove bolts (21), washers, roller and bracket

assembly (22) and shims from the inner mast

channel.

14. Remove c hains from the outer mast.

15. Repeat st eps 10 through 13 for the other side.

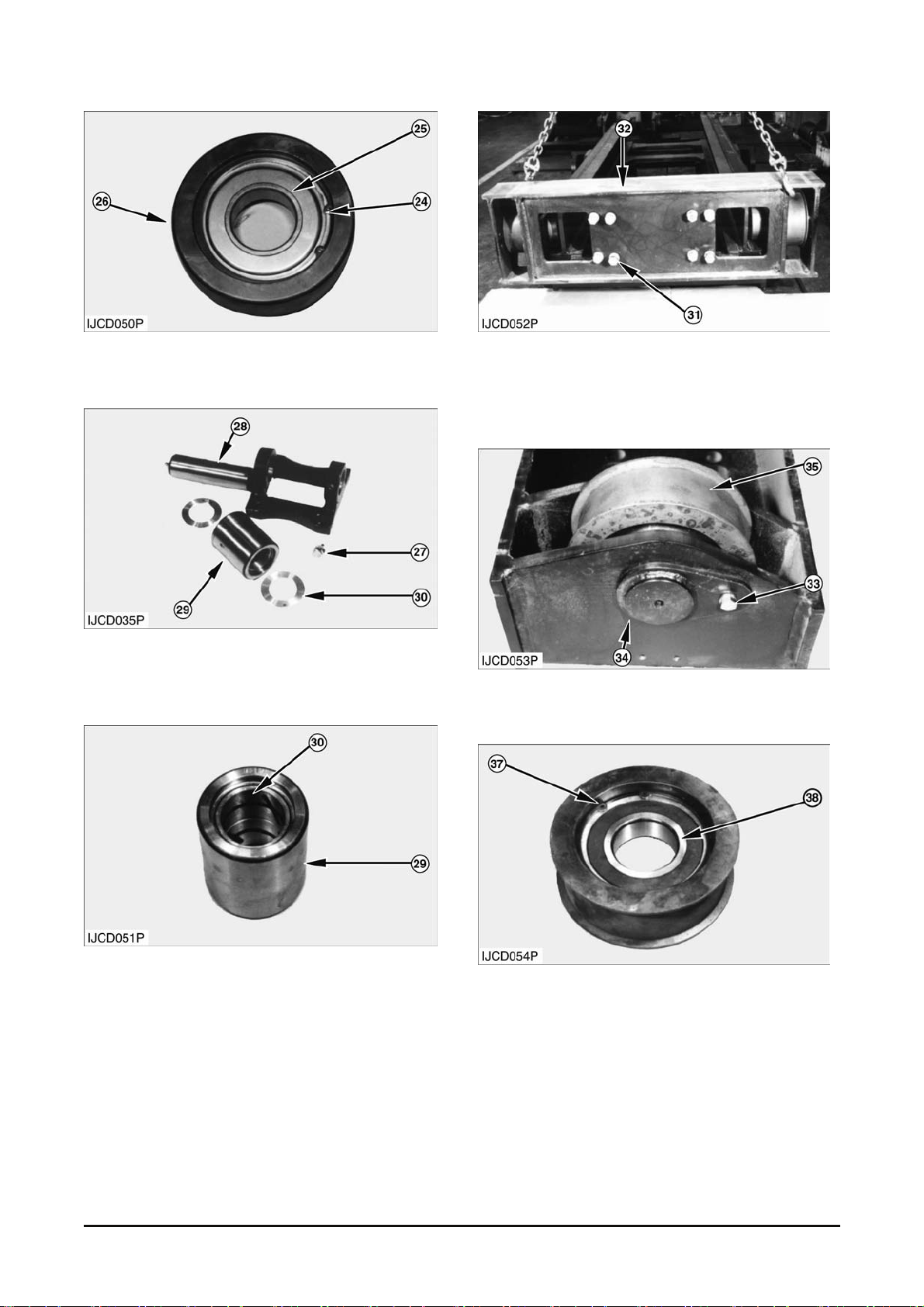

16. Fas ten a hoist to outer mast (23). Use a lift truck

to separate inner m as t (24) from outer mast (23).

The weight of outer mast (23) is about 1230kg

(2771lb) and The weight of inner mast (24) is

about 910kg (2006lb).

Vehicle System Disassembly & Assembly 12

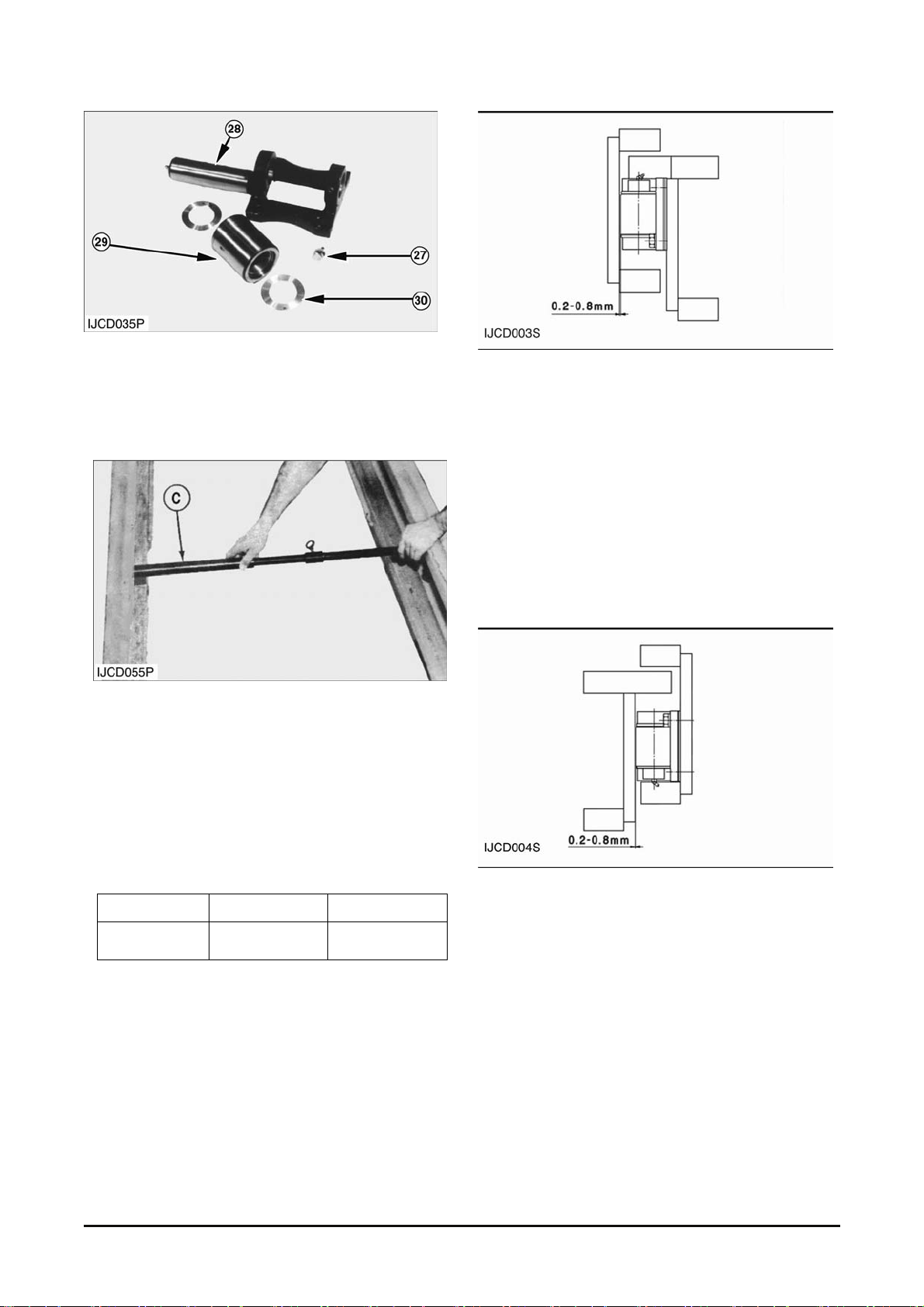

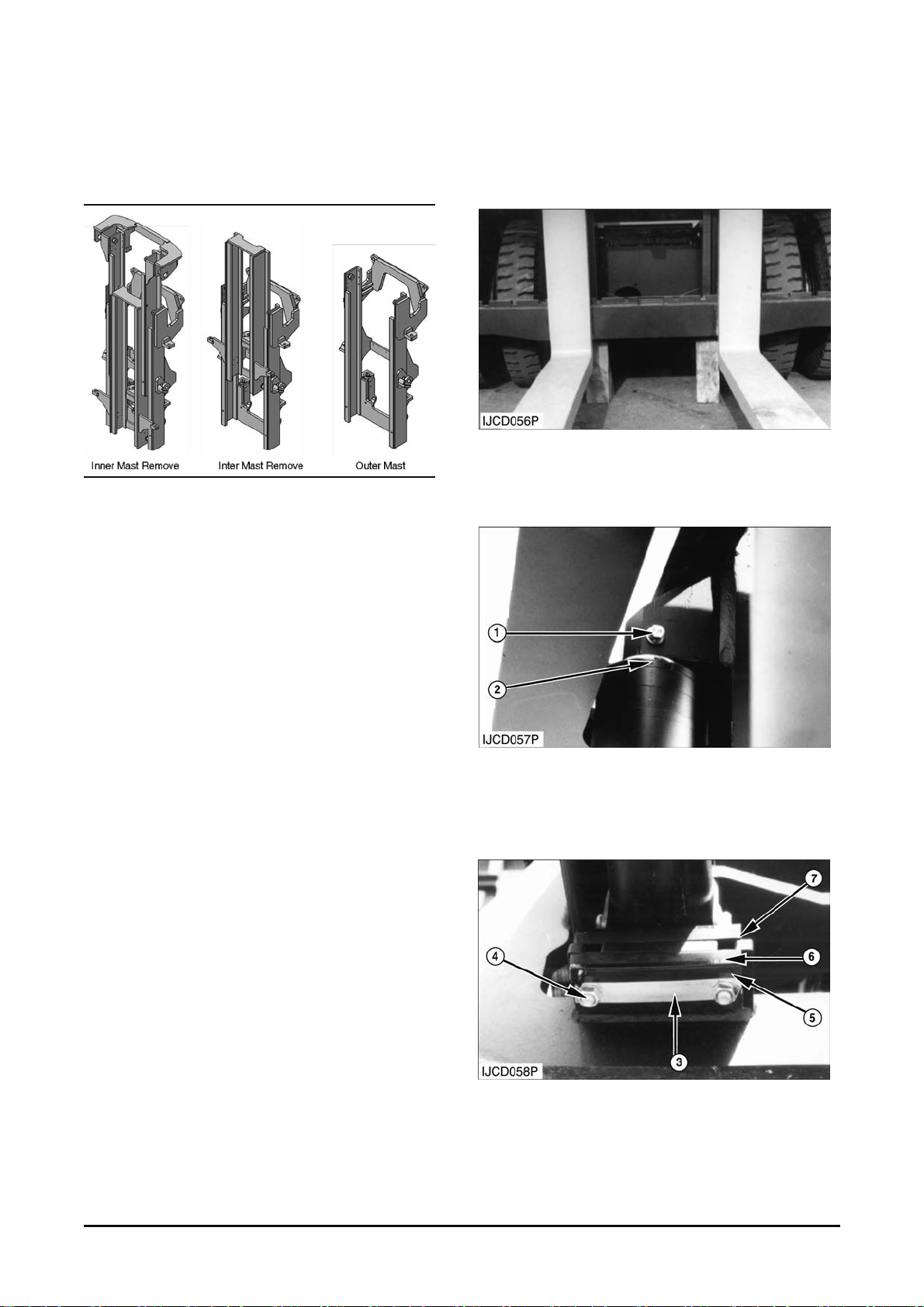

17. Remove s nap- r ing ( 24) , bearing (25) from roller

(26) if needed.

18. Remove bolt ( 27) , washer and grease fitting. T ap

the shaft and remove s haft ( 28) , spac er s (30),

and roller (29) from the brac k et if needed.

19. Check the c ondition of bushing (30) in the roller

(29). Replace the bushing (30) with new one if

worn or damaged.

20. Support crosshead assembly ( 32) with a hois t

and remove eight bolts, washers (31) and

crosshead assembly (32) from the inner mast

channel.

21. Remove r etaining bolts, washers ( 33) and pins

(34) and then remove c hain s heav es ( 35).

22. Remove snap-r ing ( 37) and bear ing (38) from

the wheel if needed.

Vehicle System Disassembly & Assembly 13

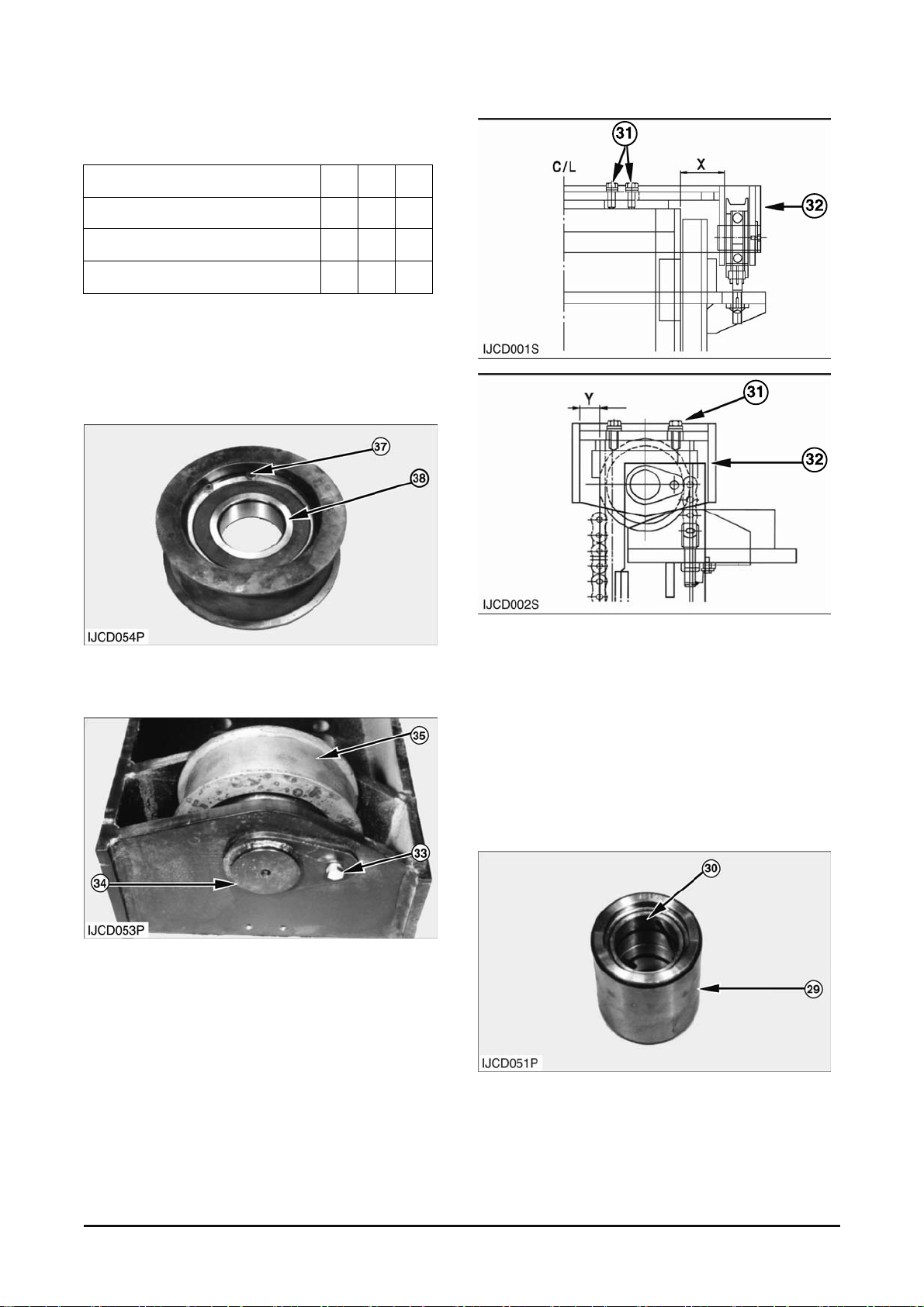

Assembly

Tools Needed A B C

Vernier Calipers 1

Inside Vernier Calipers 1

Mast Gauge 1

1. Make sure all parts are clean and free of dirt and

foreign material.

2. Check all parts for damage. If damaged, use new

parts for replacement.

3. Install bearing (38) and snap ring (37) into the

wheel if they were rem ov ed.

4. Inst all chain sheav es (35), pins (34), washer s and

retaining bolts (33) that hold pins (34) to the

crosshead assembly.

5. Put crosshead assembly (32) in position and

install washers and bolts (31). Adjust crosshead

assembly (32) of which distance difference (X)

between left hand and right hand should be within

1.5mm(.06 in) from side of the inner beam.

Tighten bolts.

6. When crosshead assembly (32) is assembled,

distance difference (Y) between left hand and

right hand should be wit hin 1.5 mm (.06 in) f rom

front of the inner beam .

7. Install new bushes (30) into the roller.

Vehicle System Disassembly & Assembly 14

8. Install the shaft, spacers and roller (29) to the

bracket.

Install bolt (27) and washer using Loctit e No.242.

Install grease fitting (28) to the shaft. Be careful

for assembling direc tion.

Typical Example

9. To shim the inner m ast (lower) side roller, move

gauge (C) up and down inside outer mas t channel

(8) to find the narrowest point across the outer

mast channels in track wher e the side roller t ravel.

Measure the channel lap which is the distance

between the outer rail upper face and inner rail

lower face. Record this measurement. The

channel lap is to be shown in the below t able.

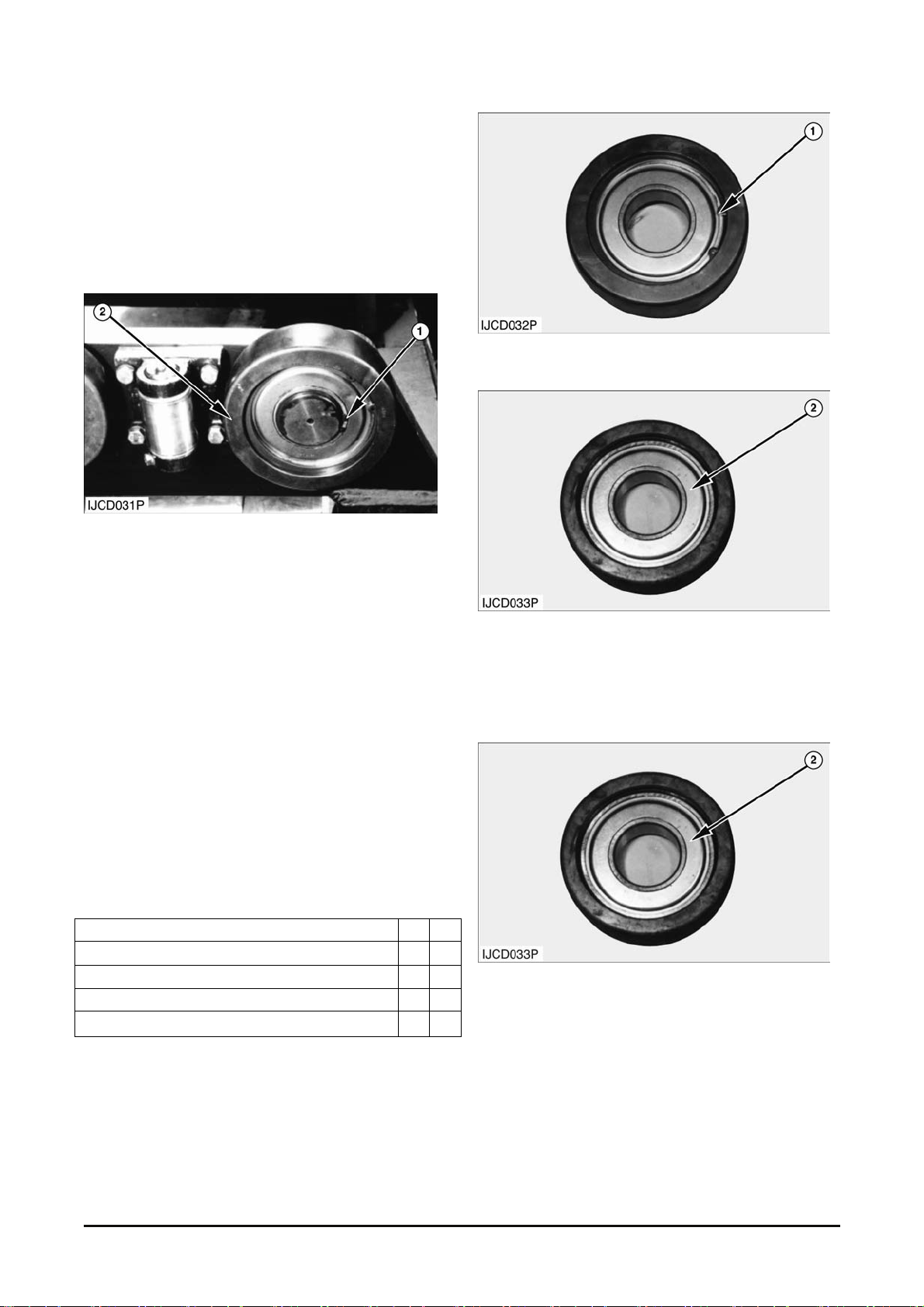

MFH 3.0~4.5 M 5.0~6.0 M

CHANNEL

LAP

1115 mm 1315 mm

10. Inst all the inner mast channel side roller and

bracket assemblies (22) without shims on the

inner mast.

11. Measure t he dis tance between inner mast side

rollers with tool ( A ) . Add s him s between one of

side rollers to be 0.2~0.8 mm (.008~.031 in)

clearance.

12. Divide t he s him s into two groups to have the

same thickness and ins tall them on each side of

the inner channel behind side roll er and bracket

assemblies (22).

13. To shim outer mast (upper) side roller(18) ,

measure outside of the inner m as t channel ( 24)

to find the widest point ac r os s t he inner m ast

channels in the track where side roller (18) travel

using tool (A). Rec ord this measurement.

14. Ins tall the outer mast channel side roller and

bracket assemblies (18) without shims on the

outer mast.

15. Measure t he dis tance between outer mast side

rollers (18) with tool (B). Add shims between one

of side rollers t o be 0.2~ 0.8 mm (.008~.031 in)

clearance.

Vehicle System Disassembly & Assembly 15

NOTE : Assemble after spray to anti-seizing

lubricant, Molybdenum disulfide type between

bearing and roller.

16. Ass em ble the bearings and snap rings into the

rollers if they were removed. Install roller

assemblies (20) on t he inner m as t pin. Install

snap rings (19).

17. Ins tall roller assemblies (16) on the outer mast

pin. Install t he snap rings.

18. Use a hoist and nylon strap to install inner m ast

(24) into outer m ast c hannel ( 23) .

The weight of outer mast ( 23) is about 1230k g

(2771lb) and The weight of inner m as t (24) is

about 910kg (2006lb).

19. Place the shims between wear pads ( 15) and the

inner mast. Clearance (X) between outer roller

(16) and inner mast flange is to be 0.0 to 1.0 mm

(.0 to .04 in).

20. Slide the mas t completely together.

21. Inst all the chains on each side of the outer mast.

22. Fas ten a hoist and nylon str ap to lift cylinder ( 14)

and put lift cylinder (14) and shims in position.

Install bolts ( 13), washers and nut.

23. Ins tall bolts (12) and washers on the inner m ast.

Apply the Loctit e No.242 t o thread of bolts (12).

Vehicle System Disassembly & Assembly 16

24. Ins tall clamp assembly (10), pad- r ubber (9),

spacers (8), plate (7) and nut (6). Bend plate (7)

supporting nut (6) not to be loosened.

NOTICE

Make lift cylinders vertical by adjusting pad-rubber

(9) and U-clamp assem bly ( 10).

25. Ins tall grease pipe if it was removed.

26. Install t he flow regulating and bracket assembly

(5), flow protector (4) and hose (3).

27. Ins tall bracket (2) and hose (1).

End By :

a. Install mast.

Vehicle System Disassembly & Assembly 17

FFT Mast

NOTE: Since many things f or FFT are same for STD,

please also refer to the instruction for STD.

1. Remove the mast chassis

a) Remove tilt pin from the (1) & tilt cy linder

b) Remove hinge pin (2)

c) Remove mast from chassis

Tilt

Shaft

Cover

Chain anchor

2. Rem ov e fork & carriage

( How to same the STD mast)

a) Remove fork(1) - Remove cover & shaf t

b) Remove carriage(2) - Rem ov e c ar riage chain

anchor

Vehicle System Disassembly & Assembly

18

3. Rem ov e hy draulic line.

a) Remove attachment line(1)

- Remove bolt & fitting

- Close the port with plug

b) Remove lift line( 2)

- Remove clamp & fitting

- Close the port with plug

4. Rem ov e c hain & c rosshead.

a) Remove chain anchor bolt ( 1) - Rem ov e pin

b) Remove chain(2)

c) Remove chain sheave - Remove pin(3)

d) Remove crosshead( 4) - Remove bolt

clamp

Bolt(pin)

5. Remove cylinder

a) Remove primary cylinder

- Remove clamp(1)

- Remove cylinder f itt ing bolt

b) Remove secondary c y linder ( 2)

- Remove cylinder f itt ing bolt

Side Roller As

Mast Roller As

Vehicle System Index 19

6. Rem ov e bearing & mast as

a) Remove side roller bearing ( 1)

b) Remove mast roller bearing ( 2)

End by:

a. Install car r iage, raise the inner mast and ins er t t he

carriage from bott om of inner mast.

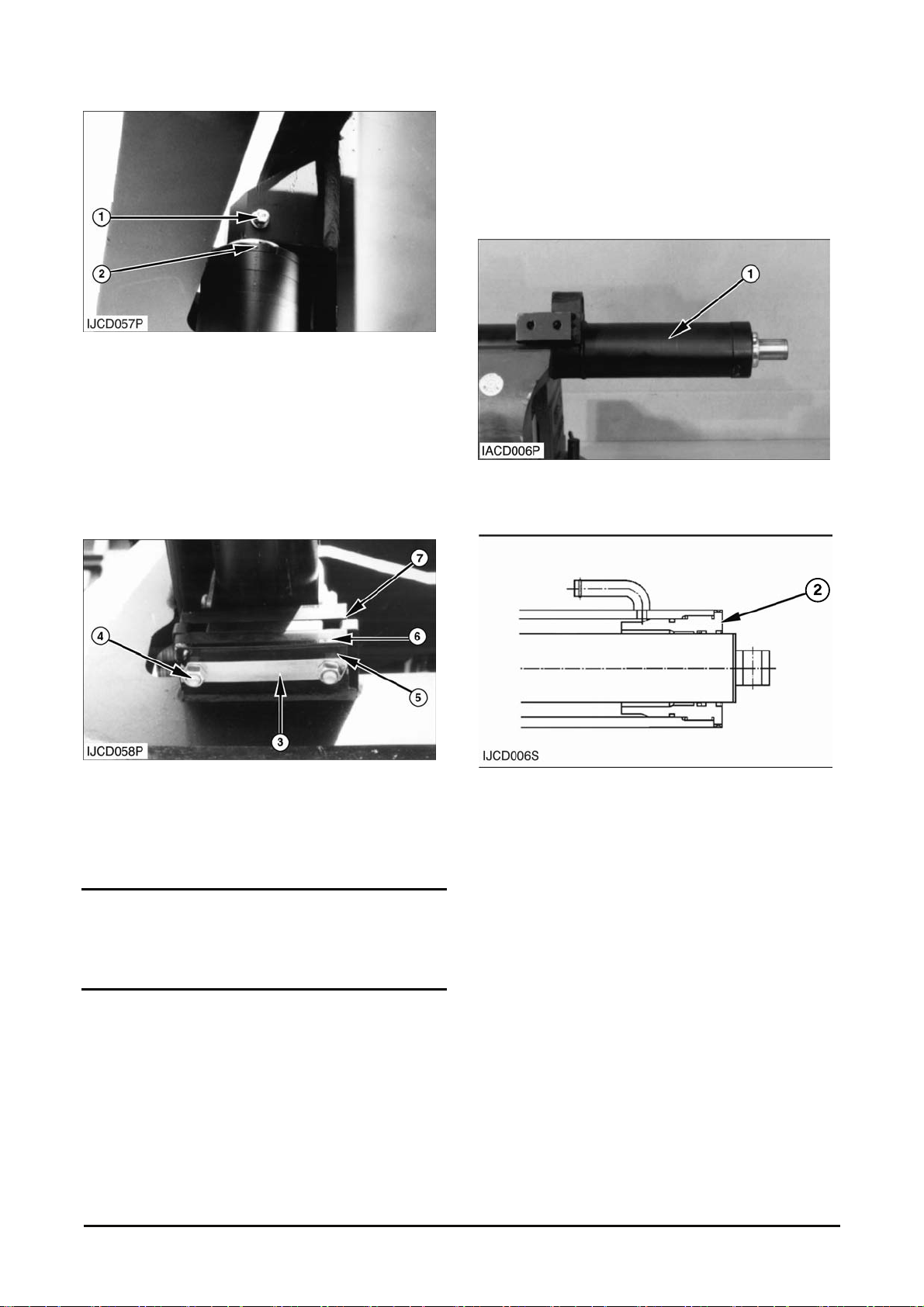

Lift Cylinder

Removal & Installation

1. Start the engine and l ift the inner mast. Put blocks

under the inner mast as shown and lower the

weight on the blocks. Tilt the mast forward fulling.

2. Fasten a hoist to the lif t cy linder .

3. Remove bolt (1) and was hers that hold rod (2) to

the inner mast.

4. Bend back plate (3) s upporting nut (4) not to be

loosened. Remove nut (4) , plate (3), s pacers (5),

rubber pad (6) and clamp assembly (7) if they

were installed.

Vehicle System Disassembly & Assembly

20

5. Move the lift control lev er to the "DOWN" position

and push rod (2) into t he cylinder to get enough

clearance for rem ov al.

6. Disconnect hydr aulic lines (8) and (9) from the lift

cylinder.

7. Remove bolt (10) , washers and nut (11) t hat hold

the bottom of the cylinder to the mast.

8. Remove the lift cylinder from the machine. The

weight of the cylinder is 171 to 319 kg (377 to 703

lb).

NOTE : The following steps are for the installation of

the lift cylinder.

9. Fasten a hoist to the lift cylinder and put it in

position on the mast. Install t he washers, nut (11)

and bolt (10). Tighten nut (11) to a torque of

55~80 N∙m (40~60 lb∙ft).

10. Connect hy dr aulic lines ( 8) and ( 9) to the lift

cylinder.

Vehicle System Index 21

11. Make s ur e the bolt holes in the end of rod (2) are

in alignment with the bolt holes in the inner mast

plate. Start t he engine. Move rod (2) out of the

cylinder until it is in c or r ec t alignment with the

inner mast plate.

12. Ins tall bolt (1) and washer that hold r od ( 2) to the

inner mast. Tight en bolt (1) to a torque of 55~80

N∙m (40~60 lb∙ft) with Loctite No.242.

13. Inst all c lam p as s em bly ( 7), r ubber pad (6),

spacers (5), plates (4) and nut (4). Bend plates

(4) that nut (4) does not loos e.

Disassembly

Start By :

a. Remove lift cy linder .

Typical Example

1. P ut lift cylinder (1) in position as shown.

2. Remove head assembly ( 2) with tool.

NOTICE

Make lift cylinder ver tical by adjusting r ubber pad (6)

and U-clamp assembly ( 7) .

14. Lift the mast and remove the blocks from under

the inner mast. Lower the mast and stop the

engine.

Vehicle System Disassembly & Assembly 22

Loading...

Loading...