Page 1

CLIMATE

EN

DE

FR

ES

PTITNL

DA

SV

NOFIRUPLSK

CS

HU

AIR CONDITIONERS

Båtklimatanläggning

Monteringsanvisning . . . . . . . . . . . . . . .195

Klimaanlegg for båter

Monteringsanvisning . . . . . . . . . . . . . . .218

Veneilmastointilaite

Asennusohje . . . . . . . . . . . . . . . . . . . . . 240

Судовой кондиционер

Инструкция по монтажу . . . . . . . . . . . 263

System klimatyzacji dla łodzi

ijachtów

Instrukcja montażu . . . . . . . . . . . . . . . . 286

MCS T6, MCS T12, MCS T16

Marine Air Conditioner

Installation Manual . . . . . . . . . . . . . . . . . .10

Bootsklimaanlage

Montageanleitung . . . . . . . . . . . . . . . . . 33

Climatiseur pour bateau

Instructions de montage. . . . . . . . . . . . . 56

Equipo de aire acondicionado

para embarcaciones

Instrucciones de montaje . . . . . . . . . . . . 80

Sistema de ar condicionado de

barco

Instruções de montagem . . . . . . . . . . . 103

Impianto di condizionamento

Indicazioni di montaggio . . . . . . . . . . . 126

Bootairco

Montagehandleiding . . . . . . . . . . . . . . 149

Lodné klimatizačné zariadenie

Návod na montáž . . . . . . . . . . . . . . . . . .310

Lodní klimatizace

Návod k montáži. . . . . . . . . . . . . . . . . . 334

Hajó-klímaberendezés

Szerelési útmutató . . . . . . . . . . . . . . . . 357

Marineklimaanlæg

Monteringsvejledning . . . . . . . . . . . . . 172

Page 2

Page 3

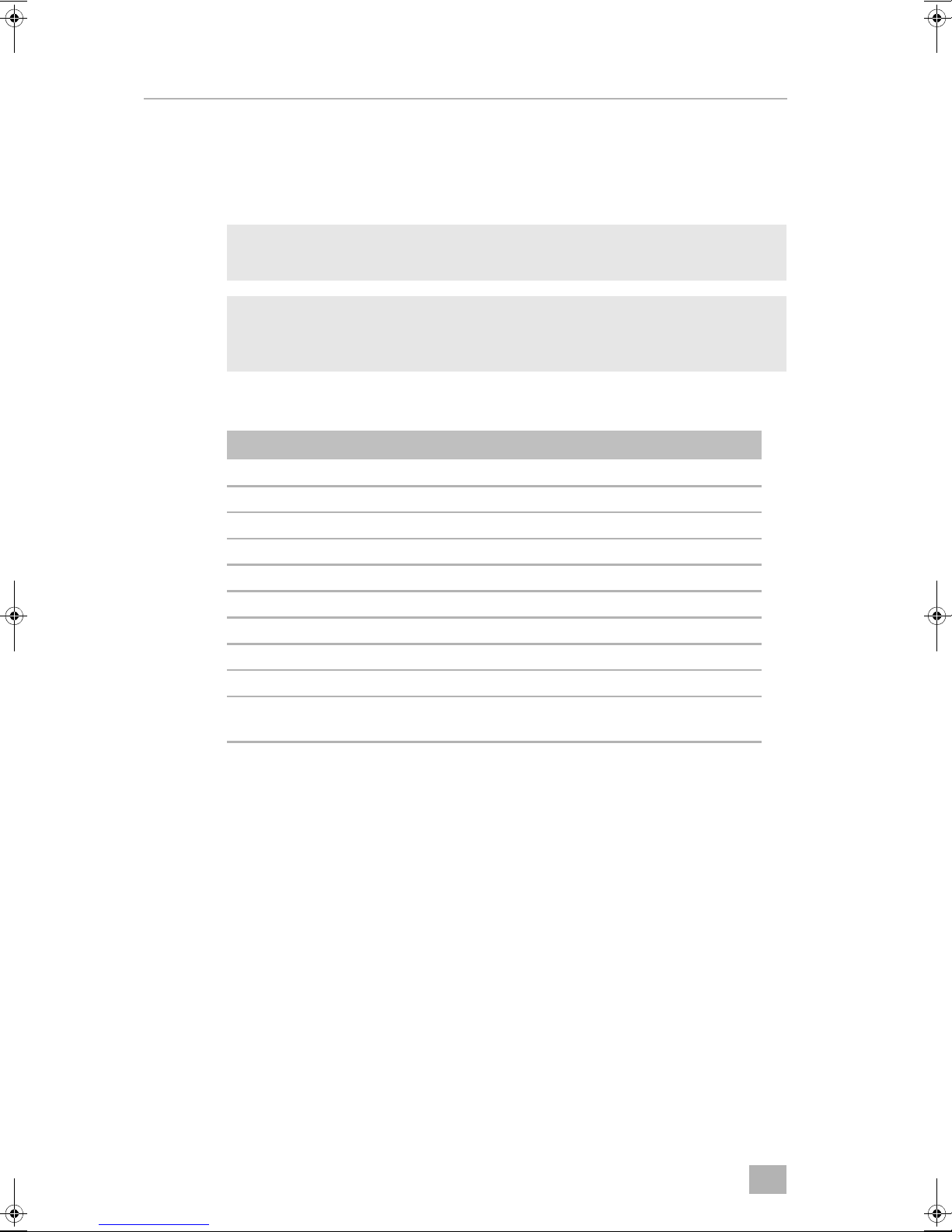

MCS T6, MCS T12, MCS T16

5 6

14

22 3

1

2

7“MR

4x

4.

2.

4x

1.

6“MR

3.

3

Page 4

MCS T6, MCS T12, MCS T16

B

A

3

4

1

2 3

4

5

6

1

2

5

4

Page 5

MCS T6, MCS T12, MCS T16

1

2

3

4

5

5

6

6

7

8

9

7

4

3

2

1

5

6

7

4

3

2

1

A

B

C

D

5

6

7

4

3

1

10

10

10

6

5

Page 6

MCS T6, MCS T12, MCS T16

7

8

1

16

15

14

13

12

11

2

3

4

5

6

7

8910

6

Page 7

MCS T6, MCS T12, MCS T16

9

A

3

2

9

1

9

11

10

8

7

6

5

4

12

13

14

15

16

17

18

19

20

7

Page 8

MCS T6, MCS T12, MCS T16

0

bl bu

og

bk

or

N/L2

GND

13

bu

L1

14

og

bk

JP5

og

J1 J3

1

2

bk

bk

wh

bn

C

HF

3

wh

gn/cy gn

wh/bk

bu

bkbkbn

bk

og

gn

rd

N/L2 L1

ge

wh/bk

GND

4

5

6

OPT

C

S

R

8

7

1112

10

9

8

Page 9

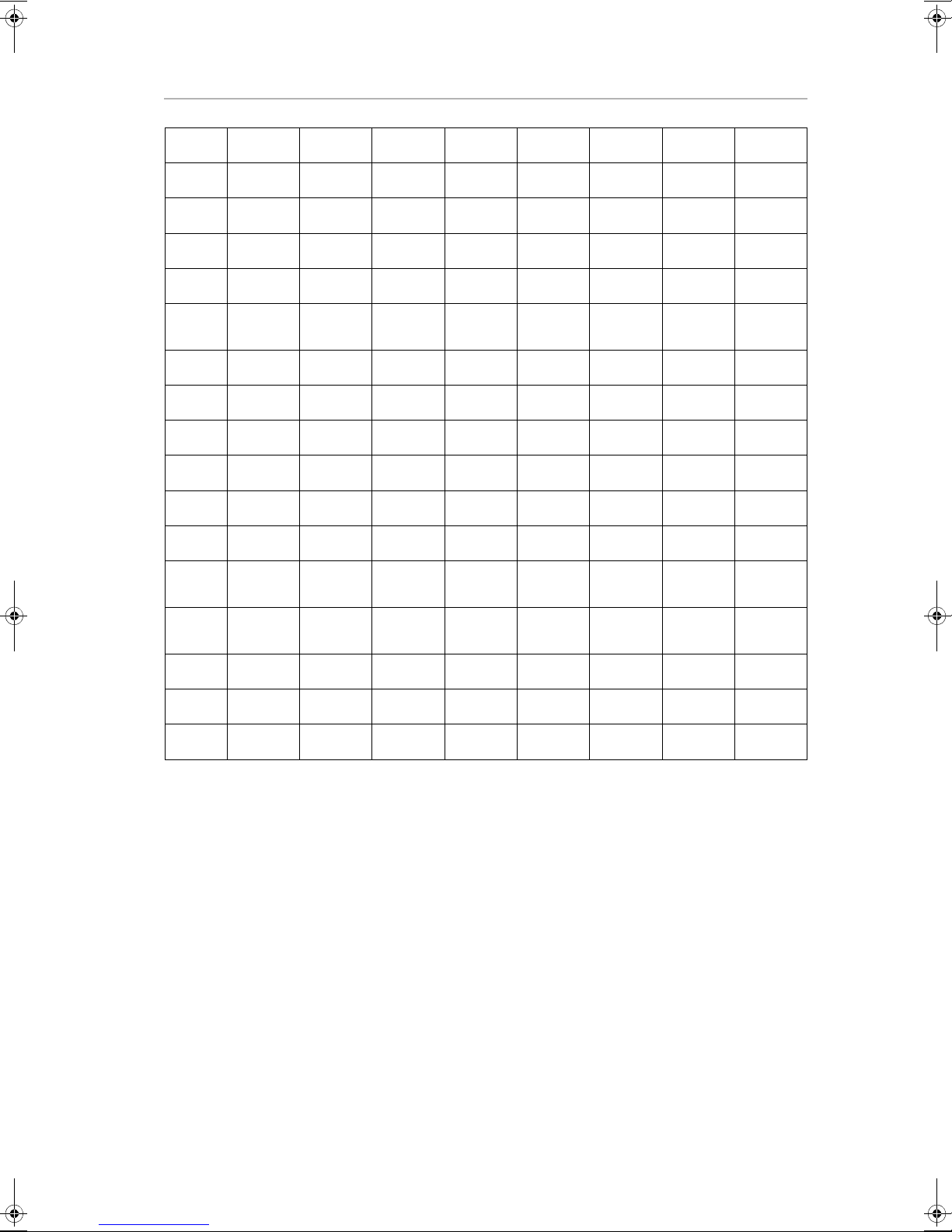

MCS T6, MCS T12, MCS T16

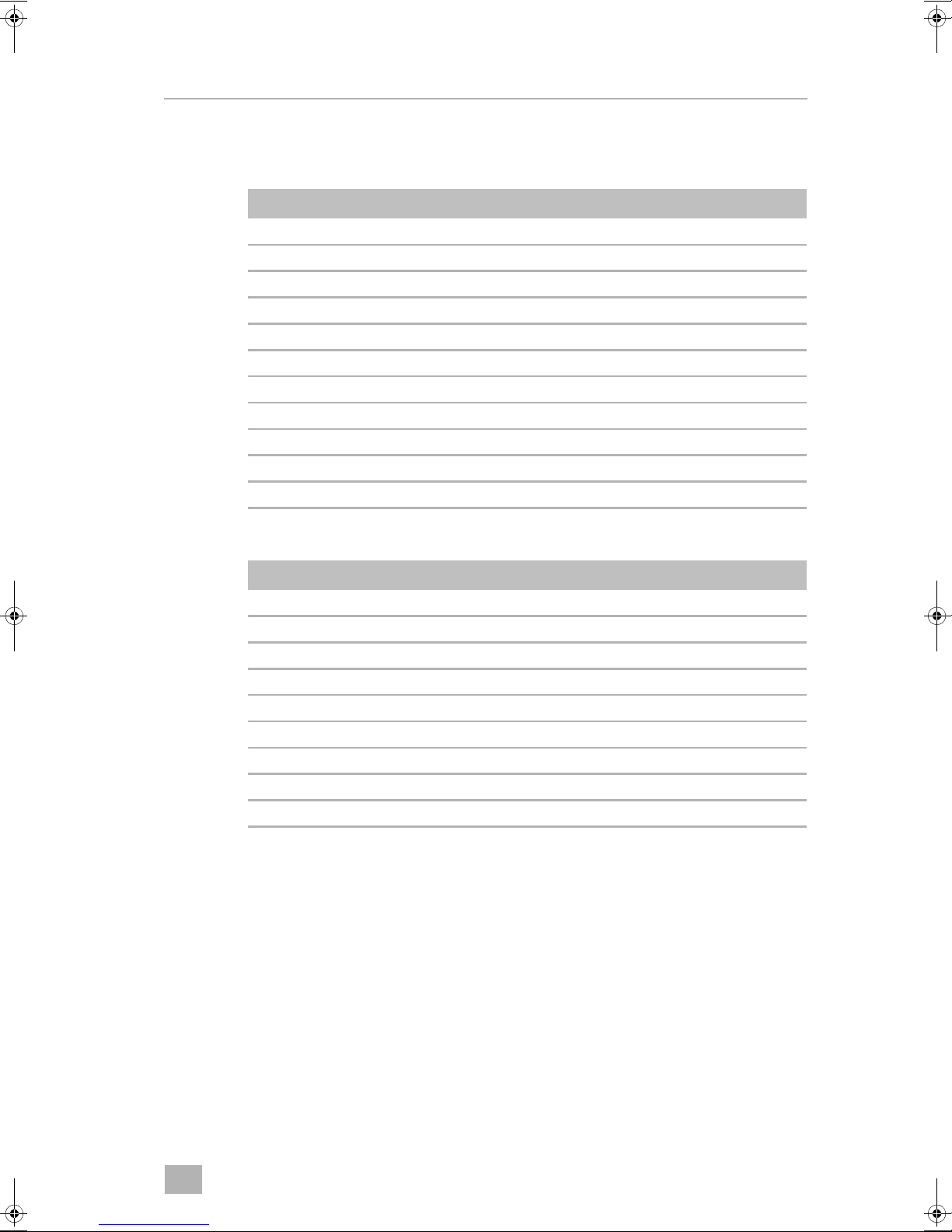

bu bn cy gn og rd bk wh

EN Blue Brown Yellow Green Orange Red Black White

DE Blau Braun Gelb Grün Orange Rot Schwarz Weiß

FR Bleu Marron Jaune Vert Orange Rouge Noir Blanc

ES Azul Marrón Amarillo Verde Naranja Rojo Negro Blanco

PT Azul Castanho Ciano Verde

IT Blu Marrone Giallo Verde Arancione Rosso Nero Bianco

NL Blauw Bruin Geel Groen Oranje Rood Zwart Wit

DA Blå Brun Gul Grøn Orange Rød Sort Hvid

SV Blå Brun Gul Grön Orange Röd Svart Vit

NO Blå Brun Gul Grønn Oransje Rød Svart Hvit

FI Sininen Ruskea Keltainen Vihreä Oranssi Punainen Musta Valkoinen

RU Синий

PL Niebieski Brązowy Żółty Zielony

SK Modrá Hnedá Žltá Zelená Oranžová Červená Čierna Biela

CS Modrá Hněda Žlutá Zelená Oranžová Červená Černá Bílá

HU Kék Barna Cián Zöld Narancs Piros Fekete Fehér

Коричне-

вый

Желтый Зеленый

Cor de

laranja

Оранже-

вый

Pomarań-

czowy

Vermelho Preto Branco

Красный Черный Белый

Czerwony Czarny Biały

9

Page 10

EN

Explanation of symbols MCS T6, MCS T12, MCS T16

Please read this instruction manual carefully before installation and

first use, and store it in a safe place. If you pass on the product to

another person, hand over this instruction manual along with it.

Contents

1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Unpacking and inspection of the scope of delivery . . . . . . . . . . 17

8 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 Connecting the Marine Climate System MCS T . . . . . . . . . . . . . .29

10 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11 Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

12 Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

13 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

14 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

15 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1 Explanation of symbols

WARNING!

Safety instruction: Failure to observe this instruction can cause fatal or

!

serious injury.

CAUTION!

Safety instruction: Failure to observe this instruction can lead to injury.

!

NOTICE!

Failure to observe this instruction can cause material damage and impair the

A

10

function of the product.

Page 11

EN

MCS T6, MCS T12, MCS T16 Safety Instructions

NOTE

Supplementary information for operating the product.

I

2 Safety Instructions

The manufacturer accepts no liability for damage in the following cases:

•

Faulty assembly or connection

•

Damage to the product resulting from mechanical influences and excess

voltage

•

Alterations to the product without express permission from the manufacturer

•

Use for purposes other than those described in the operating manual

2.1 General Safety

WARNING!

•

Danger of electrocution!

!

The units are AC voltage components, running on 230 V~.

•

Electrical shock hazard!

Disconnect voltage at main panel or power source before opening any

cover.

Failure to comply may result in injury or death.

•

To minimize the hazard of electrical shock and personal injury, this component must be effectively grounded.

•

This system does not meet requirements for ignition protection. Do not install

in spaces containing gasoline engines, tanks, LPG/CPG cylinders, regulators, valves or fuel line fittings.

Failure to comply may result in injury or death.

•

Do not terminate condensate drain line

– within 1 m of any outlet of engine or generator exhaust systems,

– in a compartment housing of an engine or generator,

– in a bilge, unless the drain is connected properly to a sealed condensate

or shower sump pump.

Failure to comply may allow bilge or engine room vapors to mix with the air

conditioners return-air and contaminate living areas which may result in

injury or death.

•

In order to prevent the ingress of carbon monoxide (CO) or other harmful

vapors, a trap should be installed in the condensate drain line(s).

•

Installation and servicing of this system can be hazardous due to system pressure and electrical components.

•

Never install your air conditioner in the bilge or engine room areas.

•

Place a fire extinguisher close to the work area.

11

Page 12

EN

Target Group MCS T6, MCS T12, MCS T16

CAUTION!

•

Wear safety glasses and work gloves.

!

NOTICE!

•

Attach the air conditioner unit to a solid level platform with the four mounting

A

2.2 Safety Handling Electrical Cables

!

A

brackets provided.

CAUTION!

•

Attach and lay the cables in such a manner that they cannot be tripped over

or damaged.

NOTICE!

•

Use cable ducts to run cables through walls and bulkheads with sharp edges.

•

Do not lay loose or bent cables next to electrically conductive materials

(metal).

•

Do not pull on the cables.

3Target Group

The instructions in this manual are intended for qualified personnel at workshops

who are familiar with the guidelines and safety precautions to be applied.

4 Scope of Delivery

NOTE

Each unit includes a condensate hose barb assembly and 4 mounting brackets.

I

12

Page 13

EN

MCS T6, MCS T12, MCS T16 Scope of Delivery

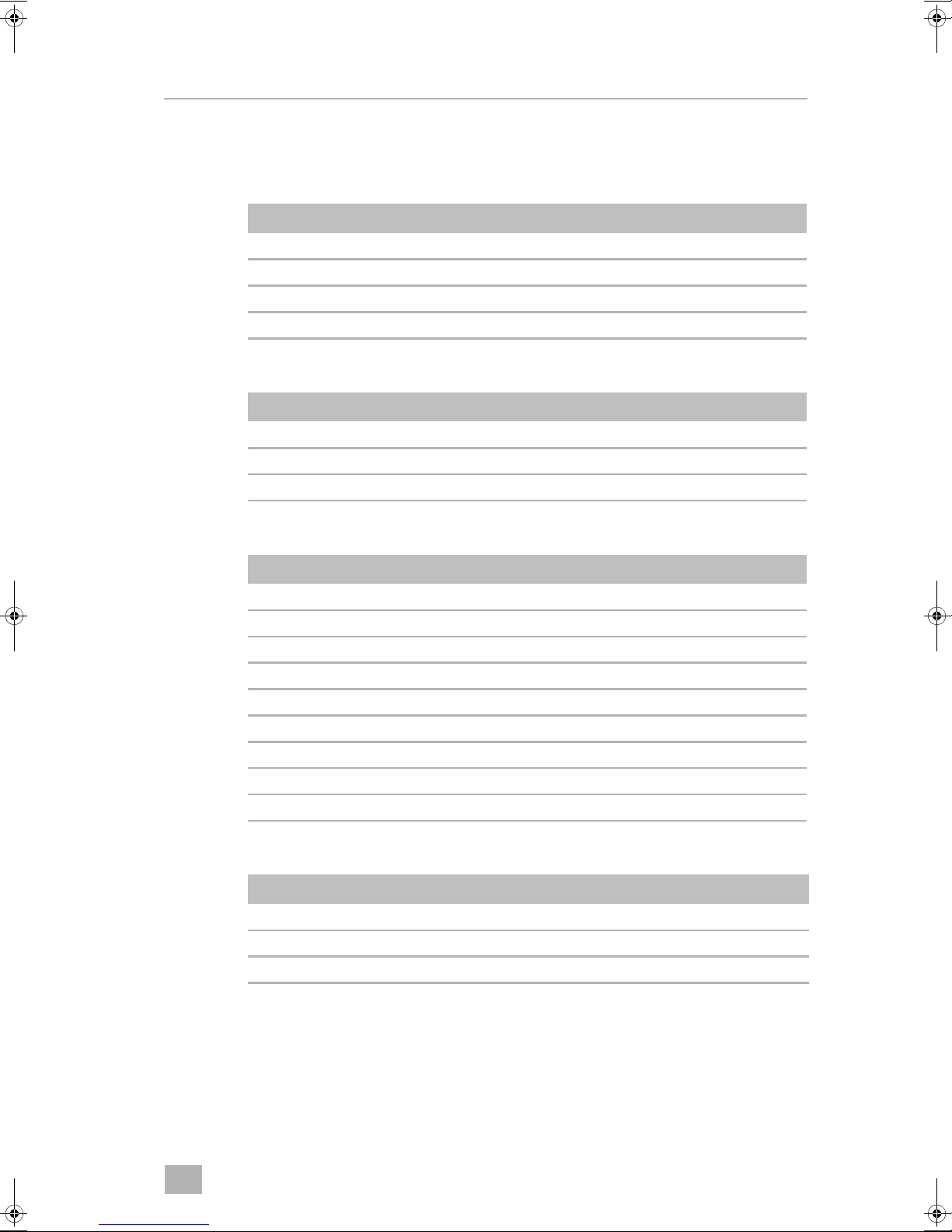

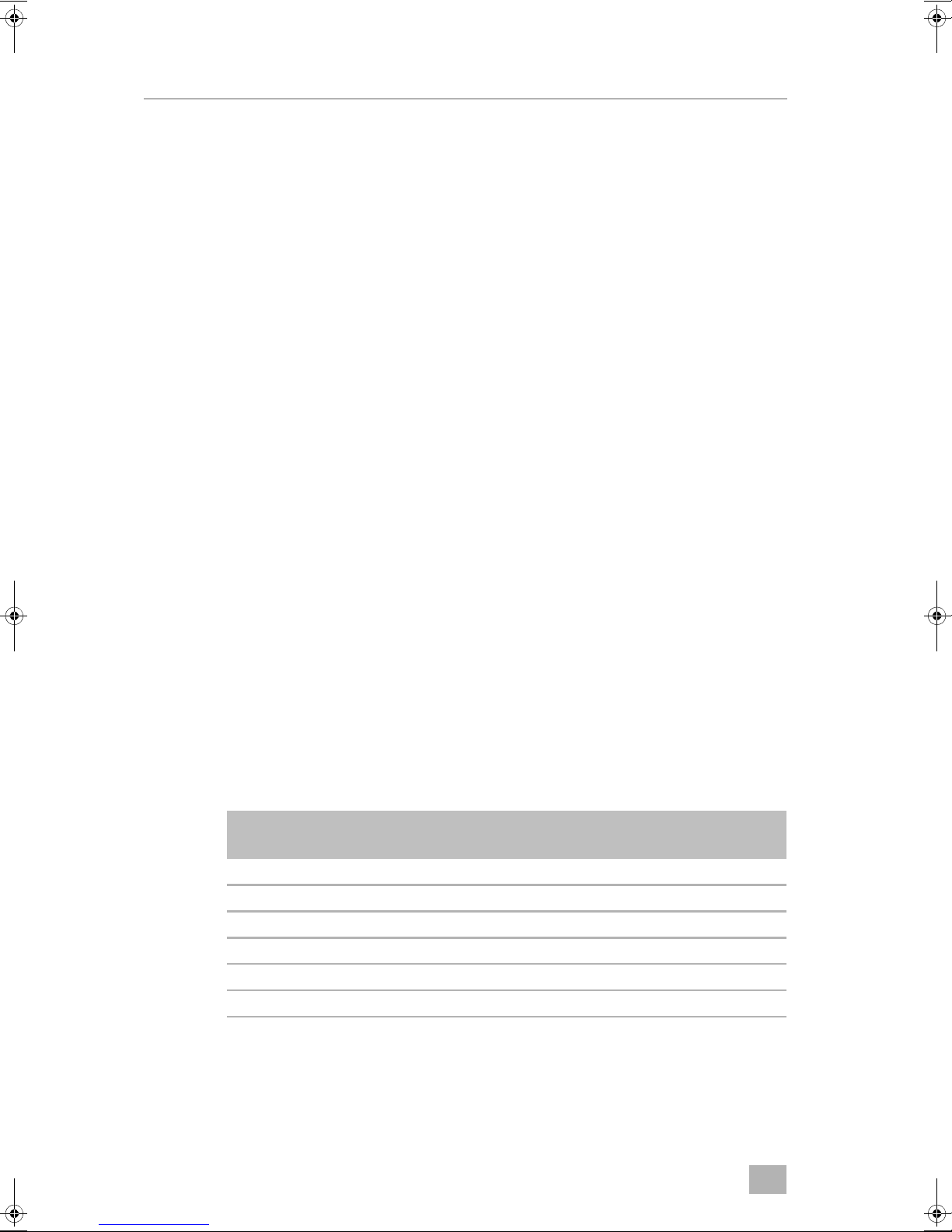

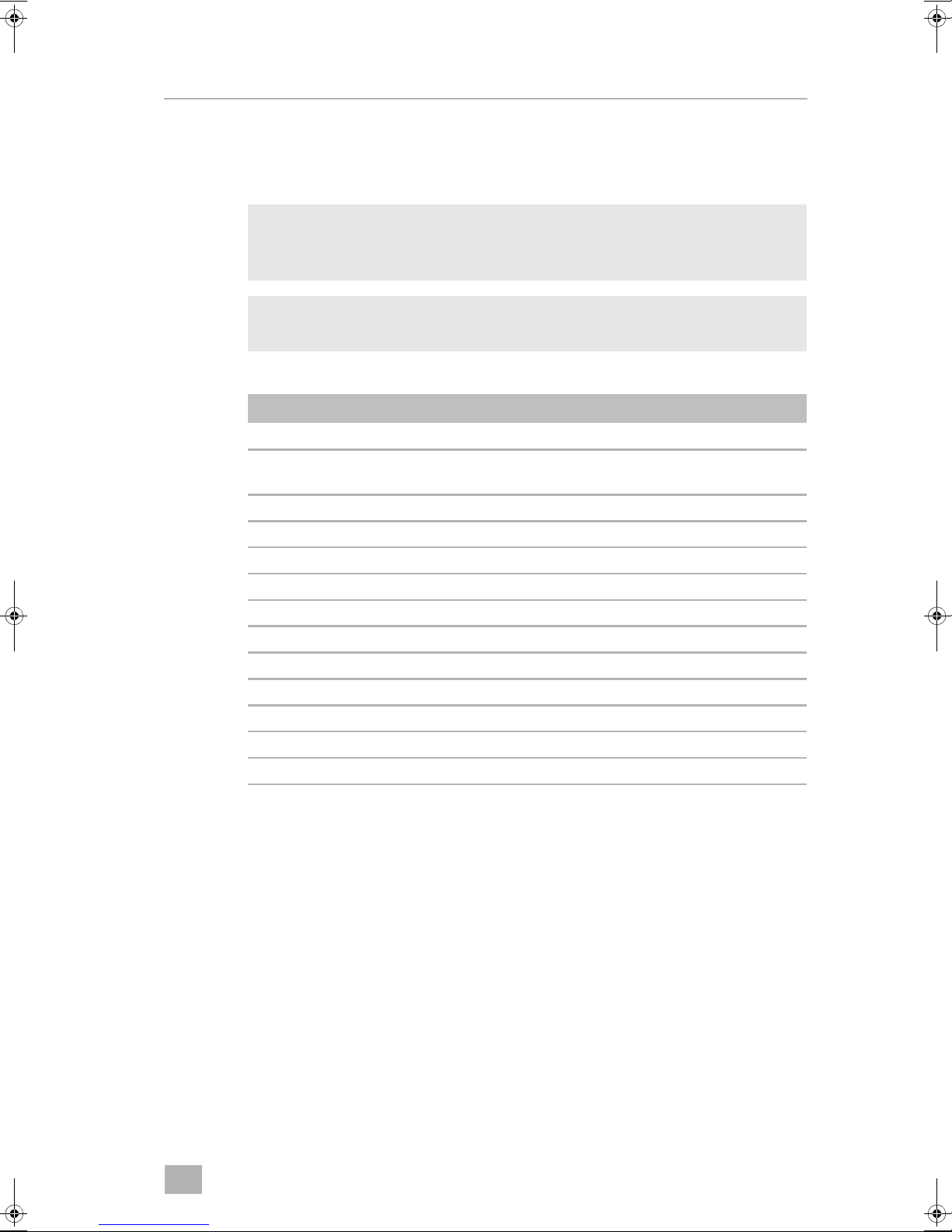

4.1 Marine Climate System MCS T6

MCS T6 – Complete Kit (part no. 9600000549)

Quantity Description

1 DTU6 unit only

1Control panel

1 Electrical box

1 Display cable

Duct Kit

Quantity Description

3.8 m Ducting, insulated, 100 mm/4" ID

1 Supply-air grille 4"x 4", 102 x 102 mm

1 Return-air grille 10"x 8", 254 x 203 mm, anodized

Seawater Kit

Quantity Description

1 Thru-hull, 5/8", plastic

7.6 m Seawater Hose, 5/8"

3 PVC adapter, 1/2" MPT x 1/2" HB

2 PVC adapter, 1/2" FPT x 1/2" HB

1 Strainer, 1/2", with bracket 1/2" FPT

1 Seawater pump PML250 (220 Vw, 50/60 Hz)

17 Hose clamps, thin

1 Ball valve, 1/2", bronze

1 Speed scoop, 1/2", bronze

Accessories

Quantity Description

1Hose barb assembly

4 Mounting brackets

1Return air filter

13

Page 14

EN

Scope of Delivery MCS T6, MCS T12, MCS T16

4.2 Marine Climate System MCS T12

MCS T12 – Complete Kit (part no. 9600000550)

Quantity Description

1 DTU12 unit only

1Control panel

1 Electrical box

1 Display cable

Duct Kit

Quantity Description

3.8 m Ducting, insulated, 150 mm/6" ID

1 Supply-air grille 10"x 6", 254 x 153 mm

1 Return-air grille 14"x 10", 356 x 254 mm, anodized

Seawater Kit

Quantity Description

1 Thru-hull, 5/8", plastic

7.6 m Seawater Hose, 5/8"

3 PVC adapter, 1/2" MPT x 1/2" HB

2 PVC adapter, 1/2" FPT x 1/2" HB

1 Strainer, 1/2", with bracket 1/2" FPT

1 Seawater pump PML250 (220 Vw,50/60 Hz)

17 Hose clamps, thin

1 Ball valve, 1/2", bronze

1 Speed scoop, 1/2", bronze

Spare Parts

Quantity Description

1Hose barb assembly

4Mounting brackets

1 Return air filter

14

Page 15

EN

MCS T6, MCS T12, MCS T16 Scope of Delivery

4.3 Marine Climate System MCS T16

MCS T16 – Complete Kit (part no. 9600000551)

Quantity Description

1 DTU16 unit only

1Control panel

1 Electrical box

1 Display cable

Duct Kit

Quantity Description

3.8 m Ducting, insulated, 150 mm/6" ID

1 Supply-air grille 10"x 8", 254 x 203 mm

1 Return-air grille 14"x 10", 356 x 254 mm

1 6" Duct Ring

4Push rivets

Seawater Kit

Quantity Description

1 Thru-hull, 5/8", plastic

7.6 m Seawater Hose, 5/8"

3 PVC adapter, 1/2" MPT x 1/2" HB

2 PVC adapter, 1/2" FPT x 1/2" HB

1 Strainer, 1/2", with bracket 1/2" FPT

1 Seawater pump PML500 (220– 240 Vw,

50/60 Hz)

17 Hose clamps, thin

1 Ball valve, 1/2", bronze

1 Speed scoop, 1/2", bronze

Spare Parts

Quantity Description

1 Hose barb assembly

4Mounting brackets

1 Return air filter

15

Page 16

EN

Intended Use MCS T6, MCS T12, MCS T16

5 Intended Use

The Marine Climate System MCS T is an air conditioning system designed for use

on boats or yachts. It can cool down or warm up the interior of the vessel.

6 Technical Description

The Marine Climate System MCS T marine air conditioner is designated to run on

230 Vw.

The Marine Climate System MCS T kit consists of the following components:

•

DTU self contained A/C unit

•

Control panel and display cable

•

Ducting

•

Supply-air grille

•

Return-air grille

•

Seawater pump

•

Strainer

•

Speed scoop thru-hull

•

Overboard discharge fitting

•

Seawater hose

•

Fittings for pump and strainer

The system is a seawater cooled air conditioning system.

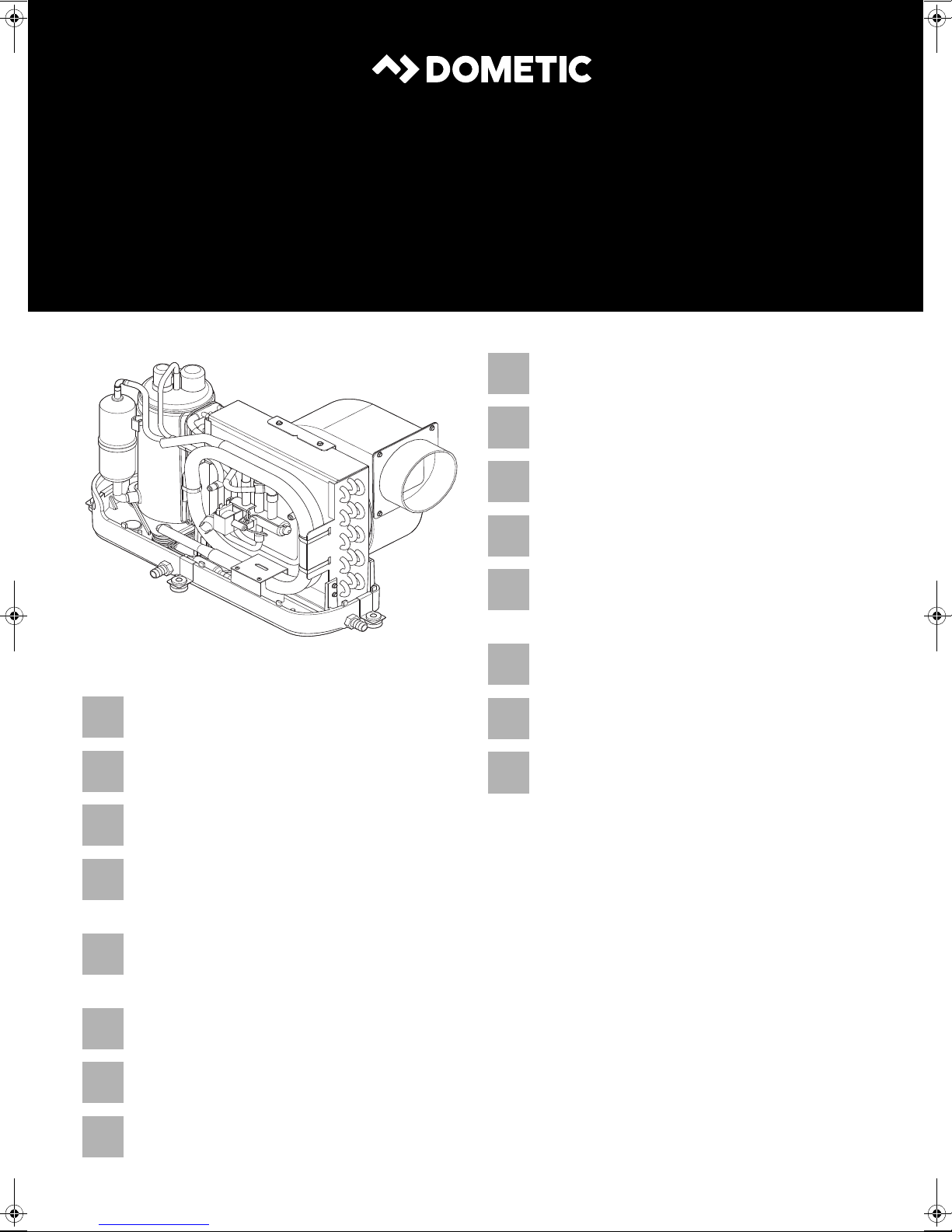

6.1 Components of the Marine Climate System MCS T

Item in

fig. 1, page 3

1Duct ring

2Mounting bracket

3 Condensate drain (two of three locations shown)

4 Composite base pan

5 Rotary compressor

6 Rotable blower assembly

Description

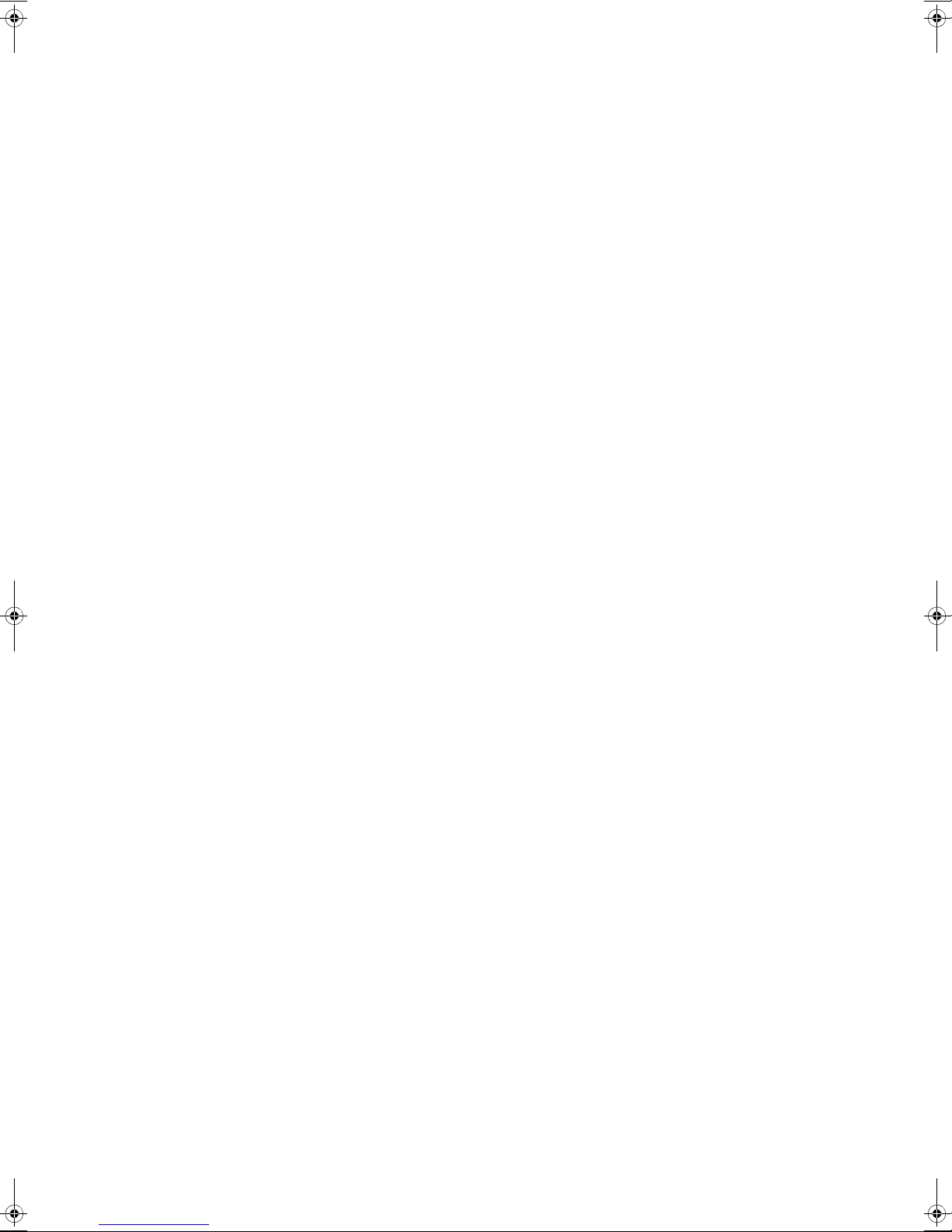

MCS T16 only:

The DTU unit T16 is supplied with a 7" duct ring.

➤ Replace the 7" duct ring with the 6" duct ring using the 4 rivets supplied

(fig. 2, page 3).

16

Page 17

EN

MCS T6, MCS T12, MCS T16 Unpacking and inspection of the scope of delivery

7 Unpacking and inspection of the scope of

delivery

➤ Check all items against the packing list to ensure all cartons have been

received.

➤ Move units in the normal “up” orientation as indicated by the arrows on each

carton.

➤ Examine cartons for shipping damage, removing the units from the cartons if

necessary.

➤ If the unit is damaged, the carrier should make the proper notation on the

delivery receipt acknowledging the damage.

8 Installation

CAUTION! Danger of injury

The system may only be installed by qualified personnel from a specialist com-

!

pany. The following information is intended for technicians who are familiar

with the guidelines and safety precautions to be applied.

I

•

Plan all connections which must be made including

– ducting,

– condensate drain,

– seawater in and out,

– electrical power connections,

– location of control,

– seawater pump placement,

to assure easy access for routing and servicing.

NOTE

Review the following notes prior to and after installation.

17

Page 18

EN

Installation MCS T6, MCS T12, MCS T16

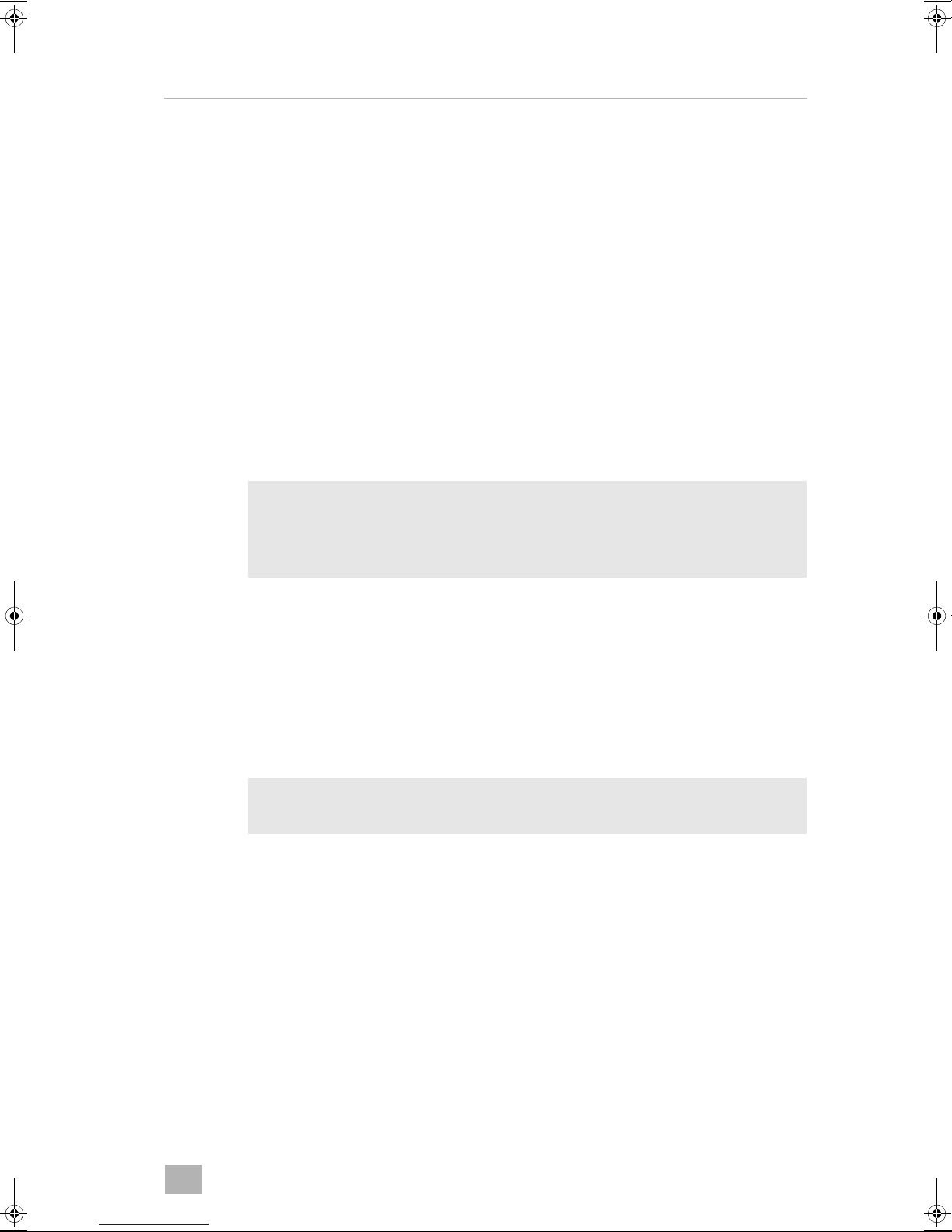

8.1 Spacing Allowances and Unit Dimensions

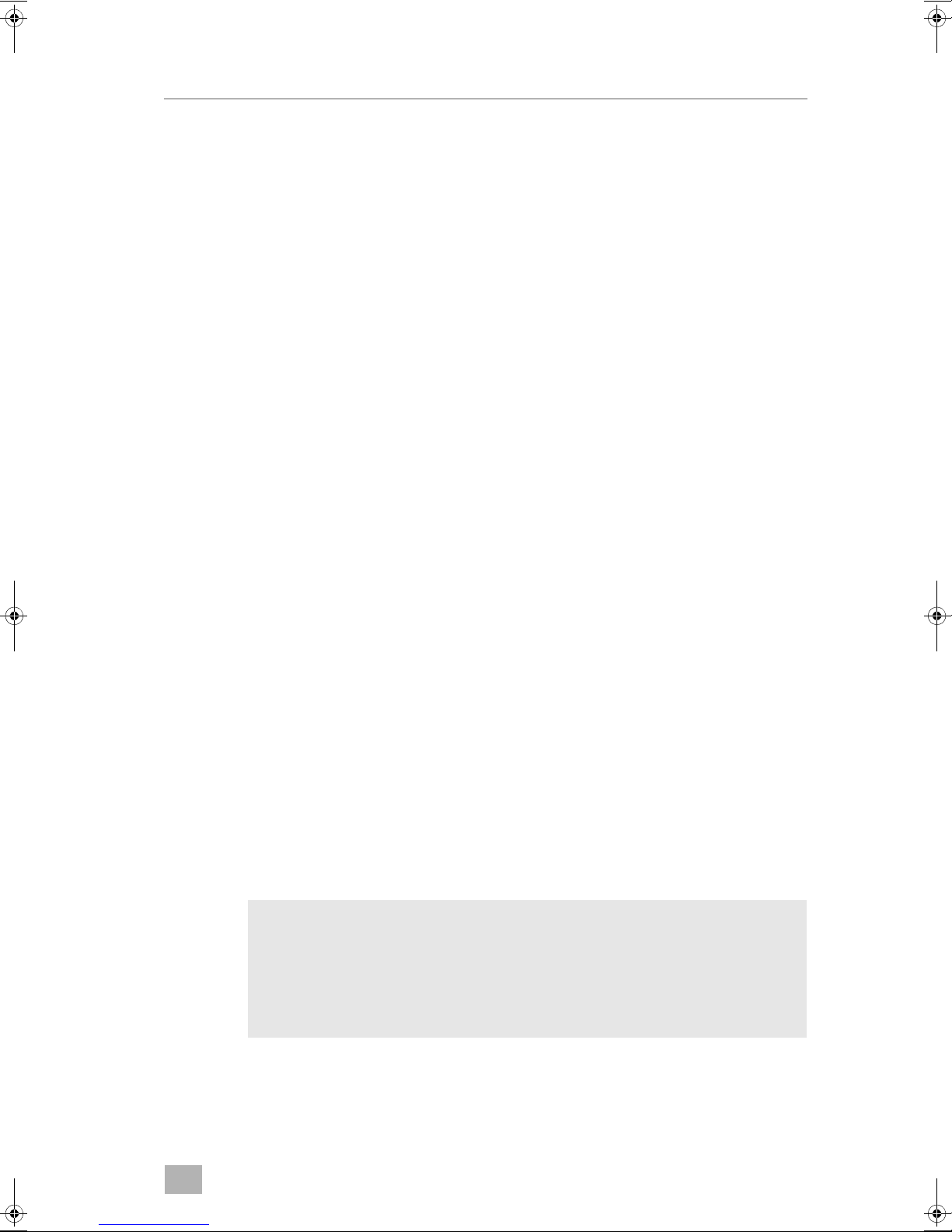

See fig. 3, page 4:

NOTE

The blower is rotatable by 270 degrees, to ease installation and improve air

I

flow.

Space allowances (fig. 3, page 4)

The following space allowances should be considered when mounting the unit:

•

Allow a minimum of 152 mm clearance around the unit in the area of the seawater and condensate drain piping.

•

Allow a minimum of 76 mm of air space in front of the evaporator coil for the

return-air intake if it is adjacent to a bulkhead.

•

For flexible ducting connection and for clearance needed behind the supplyair grille add the following values to get the total clearance distance:

– 51 mm for the duct ring

– 25 mm for the duct bend radius and

– diameter of the ducting.

•

Allocate enough space for installation and serviceability.

Unit dimensions

Unit Capacity 6 T 12 T 16 T

Minimum duct diameter (mm)

2

Minimum duct area (cm

Minimum distance return grill (cm

Minimum distance supply grill (cm

)

2

)

2

)

102 152 152

81 183 183

413 839 1032

206 452 516

18

Page 19

EN

MCS T6, MCS T12, MCS T16 Installation

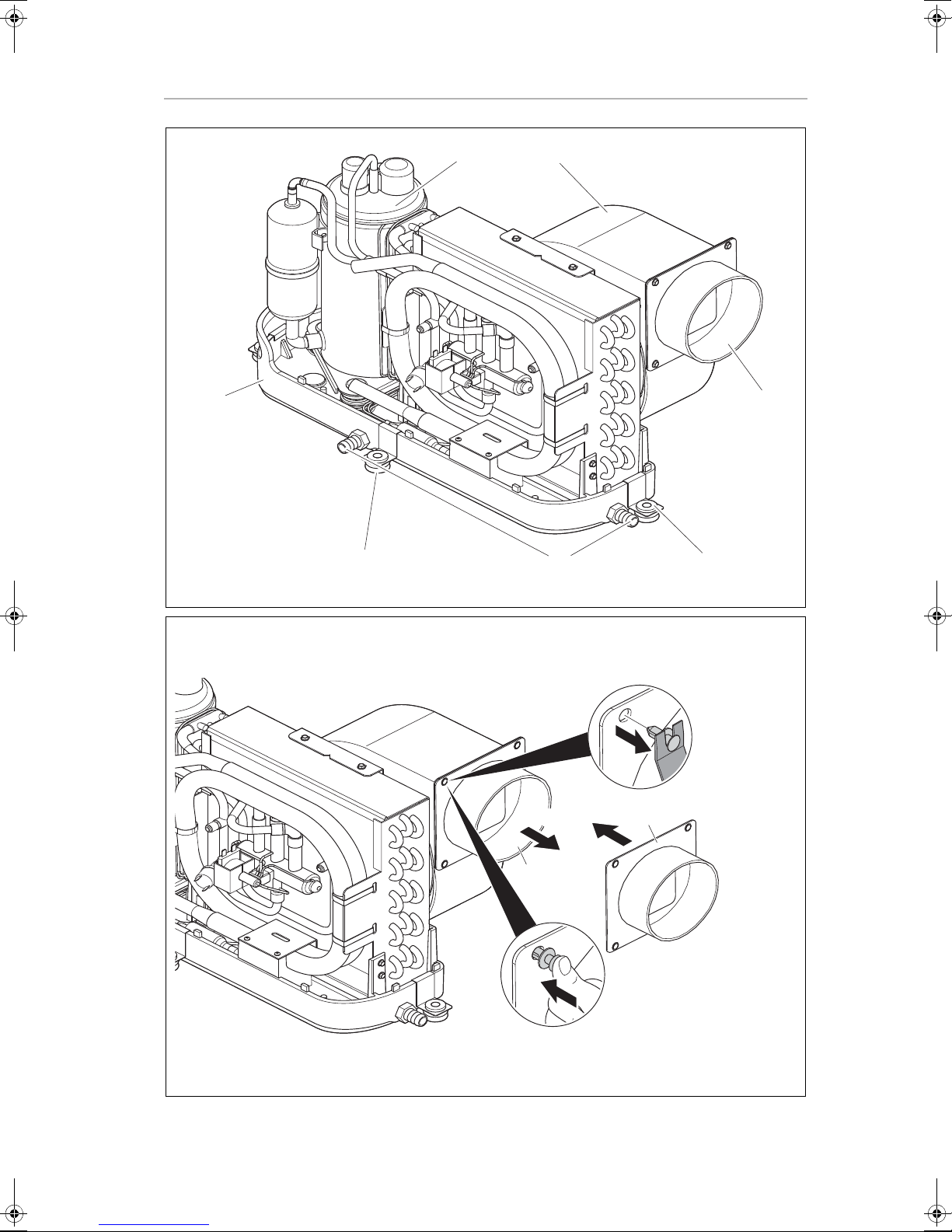

8.2 Condensate Drains

WARNING!

Do not terminate condensate drain line

!

– within 1 m of any outlet of engine or generator exhaust systems,

– in a compartment housing of an engine or generator,

– in a bilge, unless the drain is connected properly to a sealed

condensate or shower sump pump.

Failure to comply may allow bilge or engine room vapors to mix with the air

conditioners return-air and contaminate living areas which may result in injury

or death.

Mind the following notes on the installation of the condensate drains:

•

Do not route condensate drains to the bilge.

•

Run the condensate drain line downward from the unit to a suitable drain

location.

•

The condensate drain line should have a trap.

I

For installation of the condensate drain (fig. 4, page 4):

➤ Remove the aft facing watertight plug (3) from the base pan (2) of the air

conditioning unit using the hose barb (1).

➤ Screw the hose barb into the drain hole and tighten it (4).

➤ Secure the drain hose with a stainless steel hose clamp (5).

➤ Install the condensate drain hose downhill from the unit and to a safe and

proper collection point (6).

The hose should have a trap.

NOTE

•

Two drain fittings may be used and the hoses teed together provided there

is a minimum 50 mm drop from the bottom of the base pan to the tee

connection.

•

Consideration should be given to installing a trap in the condensate drain

line(s) so that normal discharge of condensate can fill the trap and prevent

the ingress of carbon monoxide (CO) or other potentially harmful vapors.

➤ Test the installation by pouring one liter of water into the base pan and check-

ing for good flow.

19

Page 20

EN

Installation MCS T6, MCS T12, MCS T16

8.3 Blower Assembly

Rotate the blower to allow the most direct flow of air to the supply-air grille

(fig. 5, page 4).

➤ Loosen the adjustment screw (1).

➤ Rotate the blower (2).

➤ Tighten the adjustment screw (1).

8.4 Electrical Box

Mind the following notes on the installation of the electrical box (fig. 8 3,

page 6):

•

Mount the electrical box in a dry location.

•

Mount the electrical box to a flat, solid surface within 1 m of the unit.

•

Mount the electrical box within 4.5 m of the location where the digital control will be installed.

➤ Use the 4 mounting slots in the back of the electric box to attach it to a suita-

ble mounting surface.

➤ Use screws appropriate for mounting surface (not included).

8.5 Supply-Air Grille

Mind the following notes on the installation of the supply-air grille to ensure

direct uninterrupted airflow from the blower:

NOTICE!

In no instance should the supply-air grille discharge be directed towards the

A

return-air grille, as this will cause the system to short cycle.

•

Install the supply-air grille as high as possible.

•

A minimum clearance of 76 mm plus the duct diameter size is required

behind the supply-air grille for attaching the ducting.

➤ Create the cut outs for the supply-air grille according to the following table:

MCS T6 MCS T12 MCS T16

4.9" x 4.9"

125 x 125 mm

➤ Mount the supply-air grille.

20

9.9" x 5.9"

252 x 150 mm

9.9" x 7.9"

252 x 201 mm

Page 21

EN

MCS T6, MCS T12, MCS T16 Installation

8.6 Return-air Grille

Mind the following notes on the installation of the return-air grille to ensure direct

uninterrupted airflow to the evaporator:

•

Install the return-air grille as low and as close to the unit as possible.

•

Install the return-air grille away from exhaust and bilge vapors.

•

The return-air grille should have a minimum of 107 mm of clearance in front of

it in the cabin area (fig. 3, page 4).

➤ Create the cut out for the return-air grilles according to the following table:

MCS T6 MCS T12 MCS T16

9.9" x 7.9"

252 x 201 mm

➤ If your kit is supplied with a filtered return-air grille: Remove the filter attached

to the unit’s evaporator and discard it.

Two filters are not better than one, as the reduced air flow will decrease per-

formance and possibly freeze the evaporator coil.

➤ Mount the return-air grille.

8.7 Ducting

Mind the following notes on the installation of the ducting:

•

The ducting should be run as straight, smooth and taut as possible.

•

Avoid any unnecessary bends and loops. Rotate the blower instead.

•

Minimize the number of 90° bends (two tight 90° bends can reduce airflow

by 25 %).

•

Ensure the ducting is properly connected with no excess.

Proceed as follows to install the ducting:

13.9" x 9.9"

353 x 252 mm

13.9" x 9.9"

353 x 252 mm

➤ Start at either end (the air-discharge grille or the air conditioning unit).

➤ Pull back the fiberglass insulation exposing the inner mylar duct hose.

➤ Slide the inner mylar duct hose around the mount ring until it bottoms out.

➤ Screw 3 or 4 stainless steel sheet metal screws through the duct hose into the

transition ring.

Make sure to catch the wire in the duct hose with the heads of the screws.

Do not use band clamps, as the hose will slide off.

➤ Wrap duct tape around the ducting and ring joint to prevent any air leaks.

➤ Pull the insulation back up over the mylar to the ring and tape this joint.

21

Page 22

EN

Installation MCS T6, MCS T12, MCS T16

➤ Run the ducting to the other end, keeping it as straight, smooth, and taut as

possible.

➤ Remove excess ducting.

➤ Use the same connection method at the other end.

8.8 Control Panel Installation

Mind the following notes on the installation of the control panel (fig. 8 2,

page 6):

•

Mount the control panel (2) within 4.5 m of the electrical box (3).

•

Mount the control panel on an inside wall, slightly higher than mid-height of

the cabin, in a location with freely circulating air where it can best sense average temperature.

•

Do not mount the control panel

– in direct sunlight,

– near any heat producing appliances

– in a bulkhead where temperatures radiating from behind the panel may

affect performance

– in the supply-air stream

– above or below a supply or return-air grille

Before mounting the control panel, consider the location:

➤ Create a cut out size for the control panel:

64 mm (width) x 48 mm (height).

➤ Plug one end of the display cable (8-pin RJ-45 connector) into the display

socket J1 (fig. 0 4, page 8) of the electric box and the other end into the

back of the control panel.

➤ Remove jumper JP5 (fig. 0 14, page 8) of the electric box to activate

display.

➤ Prior to placement clean the mounting surface with isopropyl alcohol only

(test alcohol on hidden portion of surface first).

➤ Secure the control panel to a bulkhead with the adhesive strips provided.

22

Page 23

EN

MCS T6, MCS T12, MCS T16 Installation

8.9 Remote Air Sensor Installation (optional)

Install the optional remote air sensor if the display cannot be mounted in a proper

location for accurately sensing room temperature. Installing the remote sensor

overrides the display‘s built-in sensor. The standard cable length for the remote

air sensor is 5 ft (1.5 m).

➤ Mount the remote air sensor (fig. 8 4, page 6) in the plastic clip mounted

on the return air side of the evaporator.

➤ Plug the cable (6-pin connector) into the ALT AIR socket (J3)of the circuit

board (fig. 0 5, page 8).

23

Page 24

EN

Installation MCS T6, MCS T12, MCS T16

8.10 Unit and Seawater System Installation

8.10.1 Notes on Seawater System Installation

NOTICE!

If the sea water screen filter is not installed, the pump can be damaged.

A

NOTE

If the sea water screen filter is not installed, the warranty for the pump will be

I

void.

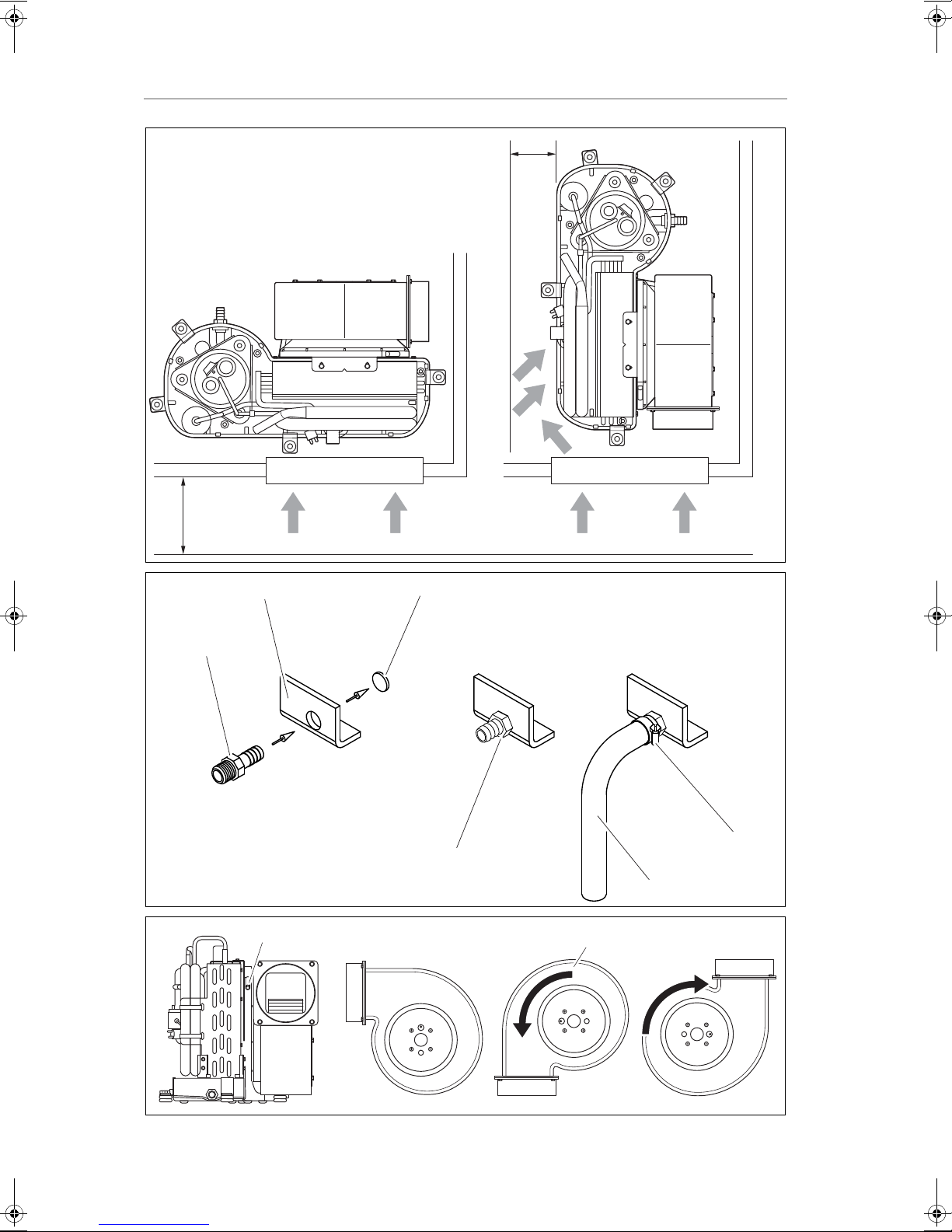

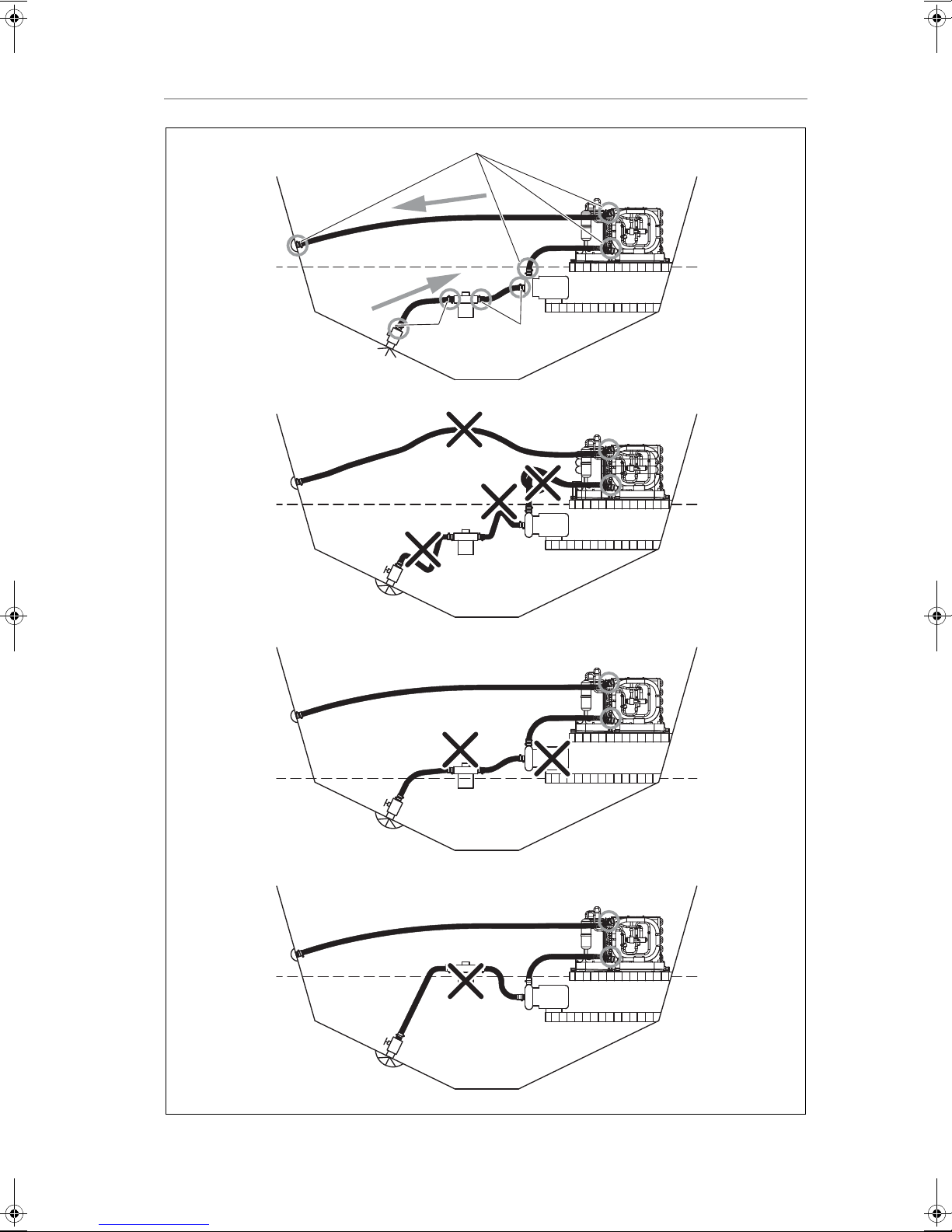

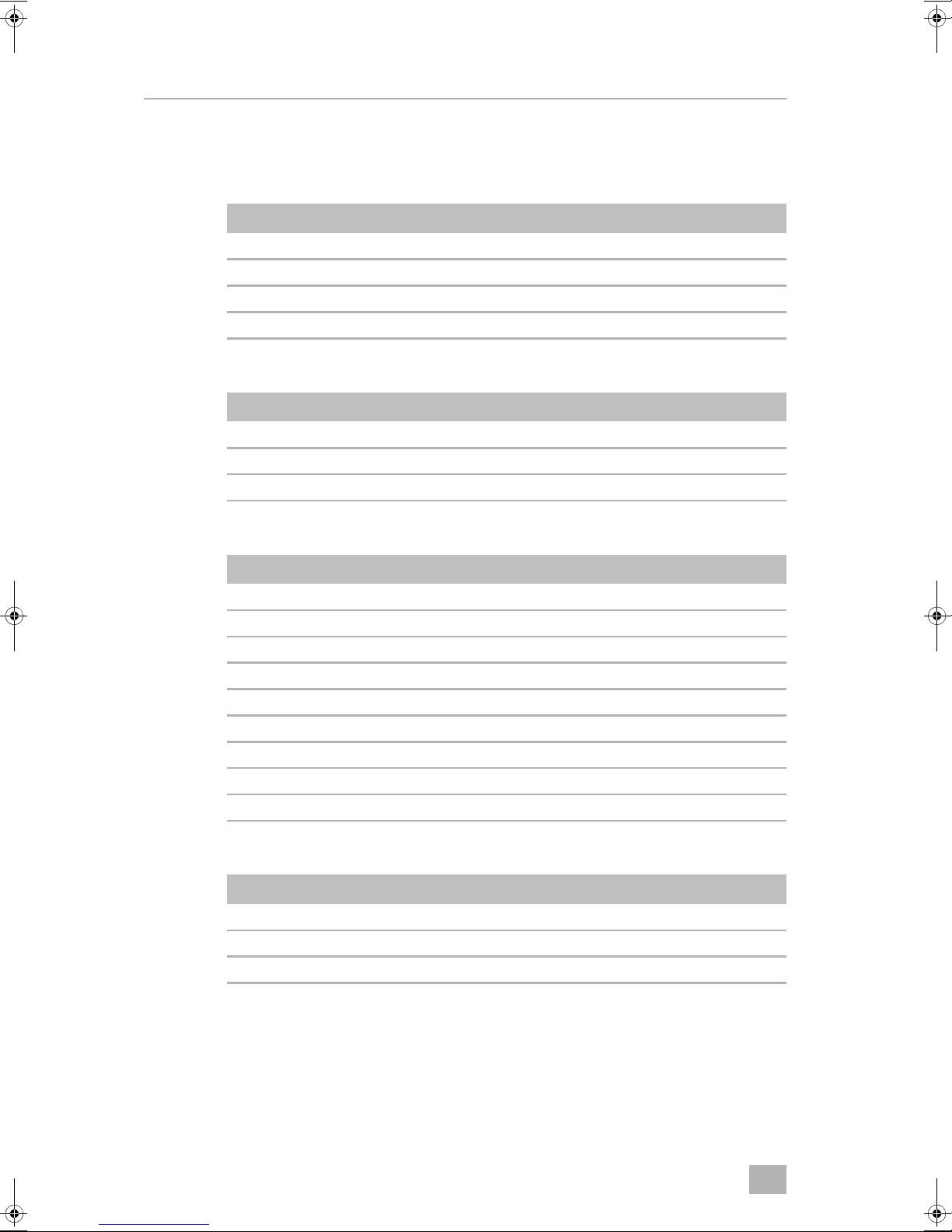

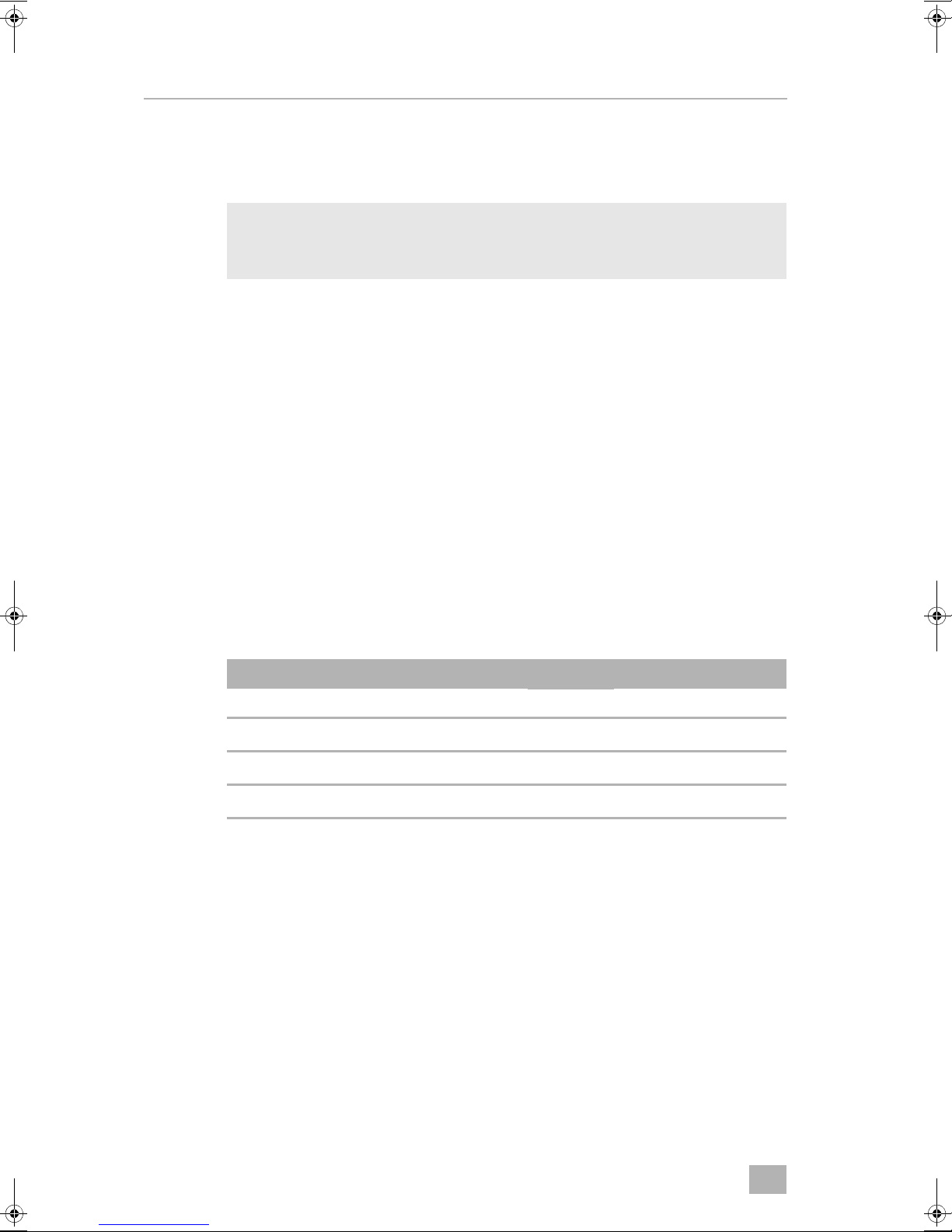

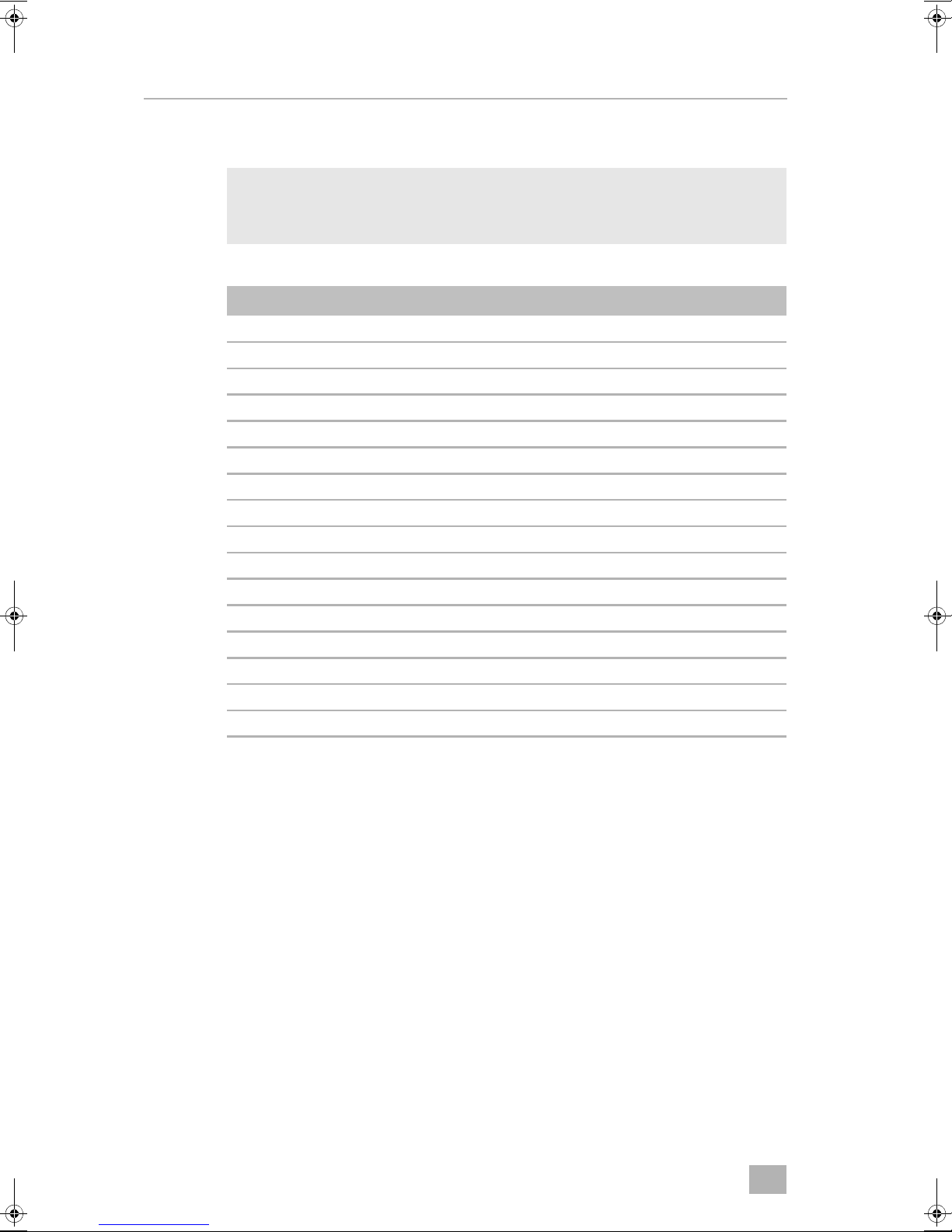

Key to fig. 6, page 5

Item Description

1 Scoop type thru-hull inlet

2 Ball valve

3Strainer

4Seawater pump

5DTU unit

6 Overboard discharge

7 Water line

8Inlet flow

9Outlet flow

10 Hose clamps, installed in pairs with adjustment ends on opposite

sides

– A: Correct

Steady upward flow from inlet to unit (8), then downward to outlet (9),

hoses double clamped (10).

– B: Incorrect

Hoses must not have kinks, loops or high spots where air can be trapped.

– C: Incorrect

Pump (4) and strainer (3) must be below water line (7).

– D: Incorrect

Strainer (3) must be below pump (4) and below waterline (7).

Mind the following notes on the installation of the seawater system:

•

The seawater pump must be mounted so that it is always at least 300 mm

below the water line.

•

The seawater pump may be mounted horizontally or vertically, however the

discharge must always be above the inlet (fig. 7, page 6).

•

Ensure the water is flowing freely from overboard discharge while the pump

is running.

24

Page 25

EN

MCS T6, MCS T12, MCS T16 Installation

•

The speed scoop intake must face forward and not be shared with any other

pump.

•

The speed scoop and the shut off valve must be tight and properly sealed.

•

A seawater strainer (3) is mandatory between the shut off valve (seacock) (1)

and the pump (4) to protect the pump from any foreign matter.

•

Ensure access to the filter of the strainer (3).

•

The seawater system should be installed

– with an upward incline from the speed scoop and seacock (1),

– through the strainer (3),

– to the inlet of the pump (4) and

– then up to the inlet of the air conditioning unit’s condenser coil (5).

•

The discharge from the air conditioning unit (5) should run to the seawater

outlet thru-hull fitting (6) which should be located where it can be visually

checked for water flow and as close as practicable to the waterline to reduce

noise.

•

Ensure the hose runs uphill from speed scoop to strainer (3), pump (4) and air

conditioning unit (5).

!

•

Avoid loops, high spots or the use of 90° elbows with seawater hose.

•

The air conditioning unit (5) should be installed as low as possible, but never

in the bilge or engine room areas (such as under a V-berth, dinette seat or

bottom of a locker).

•

Ensure proper spacing around unit.

•

Ensure that the selected location is sealed from direct access to bilge and/or

engine room vapors.

•

Mount the unit (5) on a firm, level, horizontal surface.

•

Double clamp all hose connections with stainless steel clamps, reversing the

clamps.

•

Secure all threaded connections with threaded-sealing tape. Wrap it only

2 to 3 times around it.

•

Tighten one and a half turns beyond hand tight.

WARNING!

•

Do not tighten the threaded connections too firmly. Otherwise cracks may

form within hours or days.

•

Before you start up the boat, check for any leaks. If you are unsure of how to

proceed, contact a qualified ship's mechanic. Otherwise there is a danger

of the boat sinking. This can result in injury or death.

25

Page 26

EN

Installation MCS T6, MCS T12, MCS T16

8.10.2 Duct Kit Installation

NOTE

•

Unit shown with blower rotated to vertical position.

I

•

Dimensions and part numbers see chapter “Scope of Delivery” on page 12.

Key to fig. 8, page 6

Item Description

1 Supply air grille and transition box

2 Digital display

3Electric box

4 Remote air sensor (optional)

5Seawater outlet hose

6 Overboard discharge

7Seawater inlet hose

8 Seawater scoop thru-hull inlet

9 Seacock shut-off valve

10 Seawater strainer

11 Seawater pump

12 Condensate drain

13 Mounting bracket

14 A/C unit

15 Return air grille and filter

16 Insulated flexible ducting

26

Page 27

EN

MCS T6, MCS T12, MCS T16 Installation

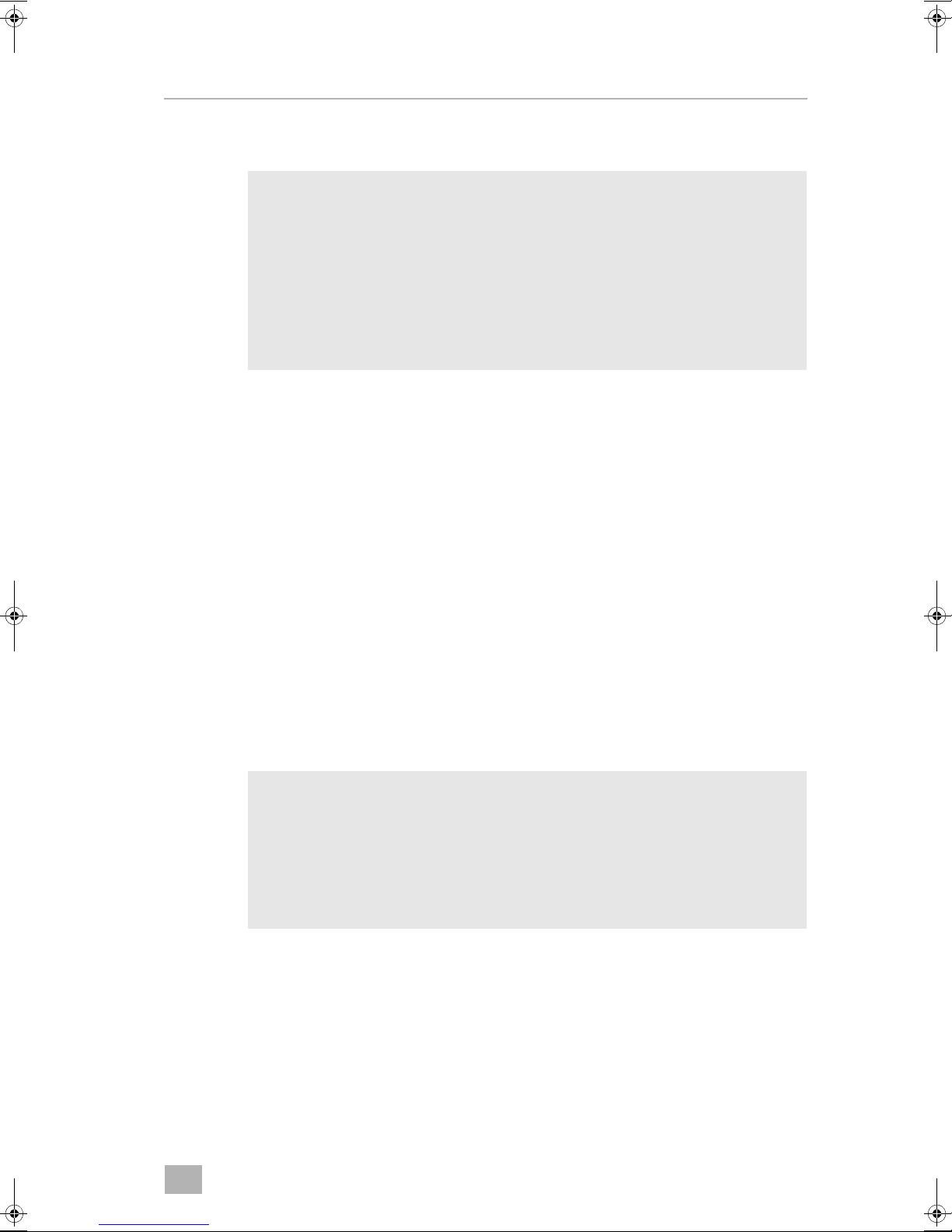

8.10.3 Seawater Kit Installation

Key to fig. 9, page 7

Item Description

1Water line

2 Overboard discharge thru-hull

3Seawater hose

4DTU unit

5 Electrical box

6 Seawater pump electrical cable

7Seawater pump

8 PVC adapter, 1/2" FPT x 1/2" HB

9 PVC adapter, 1/2" MPT x 1/2" HB

10 Strainer

11 Seawater intake (see Detail A)

Seawater Intake (Detail A)

Item in A Description

12 Seawater house

13 Hose clamps, reversed

14 PVC adapter, 1/2" MPT x 1/2" HB

15 Ball valve

16 Nut

17 Backing plate (not included in kit)

18 Bedding compound (not included in kit)

19 Hull

20 Speed scoop

27

Page 28

EN

Installation MCS T6, MCS T12, MCS T16

8.10.4 Installation of the Seawater System

➤ Install the seawater speed scoop intake as far below the water line and as

close to the keel as possible and with intake facing forward.

This keeps the intake in the water when the boat heels over so that air does

not get into the system.

➤ Bed the scoop with a marine sealant designed for underwater use.

➤ Apply the bedding compound liberally to both sides and throughout the

hole.

➤ Install the bronze, full flow seacock on the speed scoop thru-hull inlet.

➤ Install the seawater strainer below the level of the pump with access to filter.

➤ Connect the seacock and strainer with an uphill run using the 5/8" (16 mm)

reinforced marine grade hose.

➤ Mount the seawater pump securely above the strainer, at least 300 mm

below the water line.

➤ Mount the air conditioning unit by securing the base pan onto a flat, horizon-

tal surface with the mounting clip brackets and the 4 screws.

The base pan also serves as a condensate pan.

➤ Connect the discharge from the pump uphill to the bottom inlet of the air

conditioning unit’s condenser coil with 5/8 (16 mm) reinforced marine grade

hose.

➤ Install the overboard discharge thru-hull fitting.

➤ Connect the discharge from the condenser coil to the overboard discharge

thru-hull fitting with 5/8" (16 mm) reinforced marine grade hose.

➤ Connect all metallic parts in contact with seawater to the vessel’s bonding

system including

– the speed scoop inlet,

– pump (the harness ground wire),

– the air conditioner.

28

Page 29

EN

MCS T6, MCS T12, MCS T16 Connecting the Marine Climate System MCS T

9 Connecting the Marine Climate System

MCS T

WARNING!

Turn off AC power supply circuit breaker before opening electrical box and

!

accessing the terminal strip.

NOTE

Failure to properly ground and bond the system will void the warranty!

I

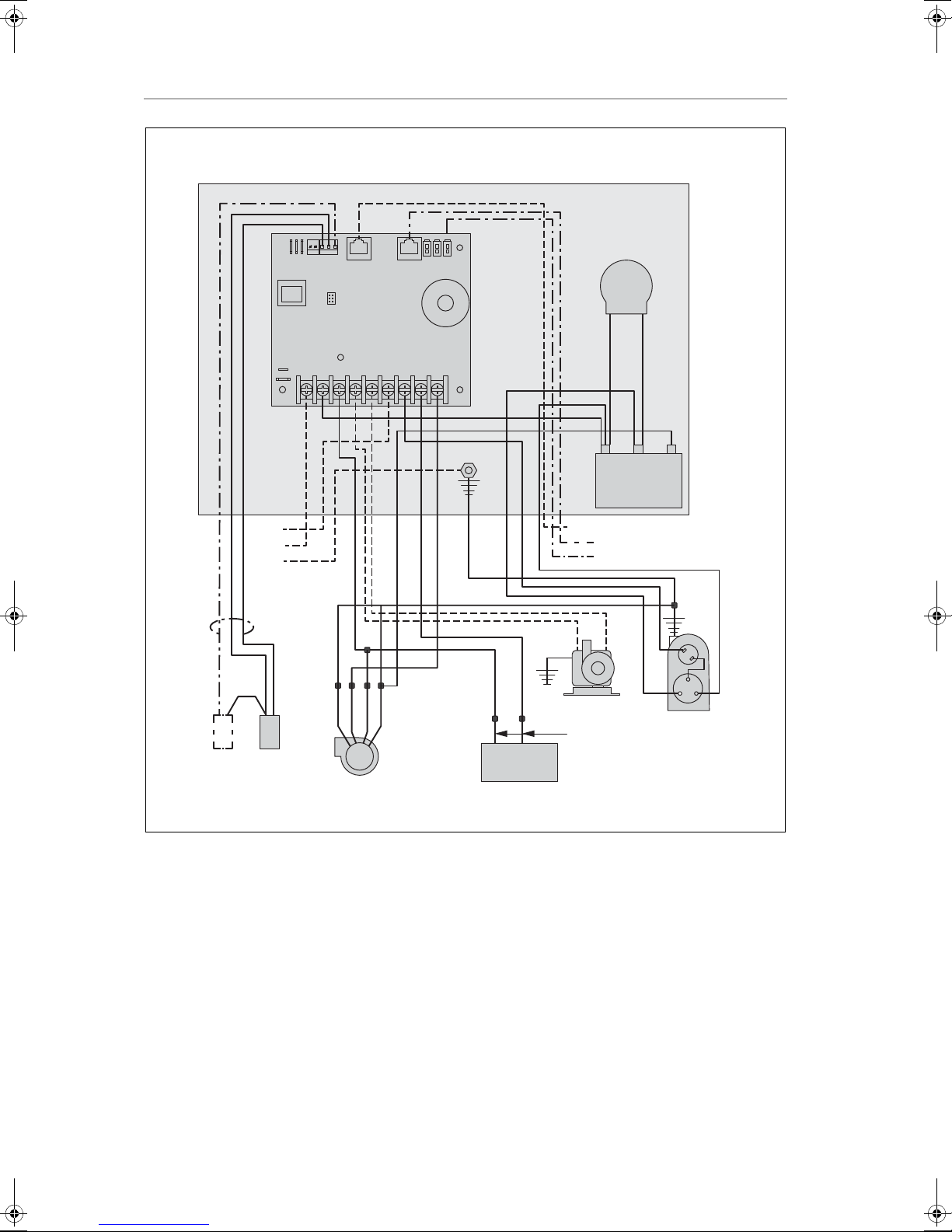

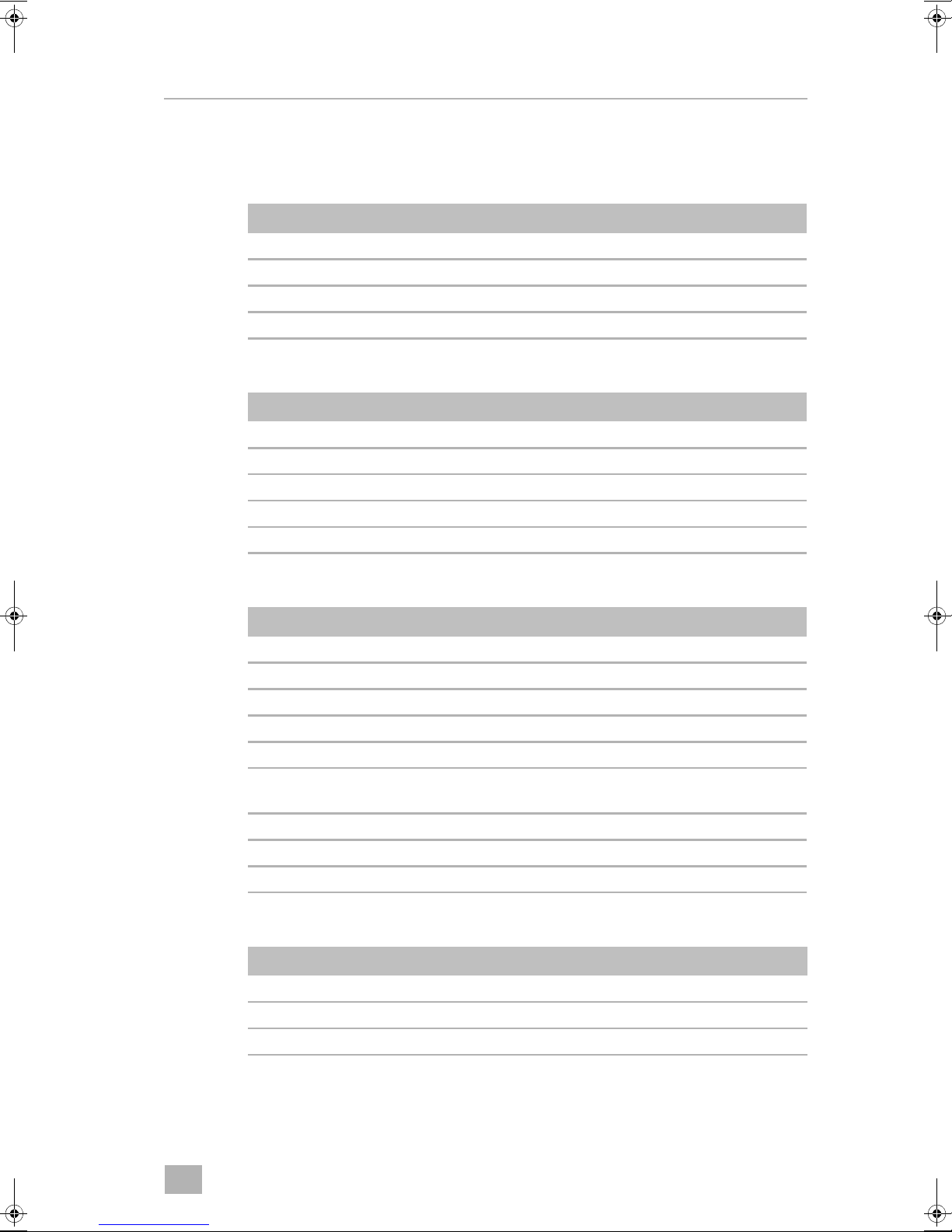

Key to the wiring diagram (fig. 0, page 8):

Item Description

1 Electrical box

2 Positive Temperature Coefficient Resistor (PTCR) start assistant

(MSC T16 only)

3 Run capacitor

4 8-Pin display cable

5 Alternative air sensor (optional)

6 Outside air sensor (not used)

7Compressor

8 Pump or pump relay panel

9 Reversing valve

10 Fan

11 High pressure switch

12 Low pressure switch (not used)

13 Power supply

The following guidelines should be followed during the connection of the

Marine Climate System:

•

The correct size circuit breaker should be used to protect the system as specified on the air conditioning unit’s data plate label.

•

Install and ground/bond AC power source in accordance with marine electrical standards.

•

Use a minimum of 3.5 mm² boat cable

– to supply power to the air conditioning unit

– to supply power to the seawater pump

– to extend the wires on the pump

•

Any electrical connections in the bilge below the waterline should use sealing heat shrink type butt splices.

29

Page 30

EN

Operation MCS T6, MCS T12, MCS T16

•

All connections to the terminal strip shall be made with appropriately sized

ring terminals (not supplied).

•

Each air conditioning unit installed requires its own dedicated circuit breaker.

– If there is only one air conditioning unit installed, the seawater pump

does not require a circuit breaker; the wiring from the seawater pump is

connected to the terminal strip on the unit (see wiring diagram, fig. 0,

page 8)

➤ Connect the air conditioning unit to the boat's bonding system to prevent

corrosion due to stray electrical current.

➤ Ensure that the AC ground of the air conditioning unit is properly connected

to the AC ground of the boat.

➤ Within the boat itself, ensure that the AC ground bus is connected to the DC

ground bus at exactly one place.

➤ Bond individually all pumps, metallic valves and fittings in the seawater circuit

that are insulated from the air conditioning unit by PVC or rubber hoses to the

boat's bonding system.

This will help eliminate any possibility of corrosion due to stray current.

10 Operation

NOTE

For operation see the Operating Manual.

I

11 Programming

NOTE

For programming and defining the parameters see the Operating Manual.

I

12 Troubleshooting Guidelines

NOTE

For troubleshooting see the Operating Manual.

I

30

Page 31

EN

MCS T6, MCS T12, MCS T16 Warranty

13 Warranty

The statutory warranty period applies. If the product is defective, please contact

the service partner in your country (addresses on the back on the instruction manual).

Our experts will be happy to help you and will discuss the warranty process with

you in more detail.

14 Disposal

➤ Place the packaging material in the appropriate recycling waste bins

wherever possible.

If you wish to finally dispose of the product, ask your local recycling centre or

specialist dealer for details about how to do this in accordance with the appli-

M

cable disposal regulations.

31

Page 32

EN

Technical Data MCS T6, MCS T12, MCS T16

15 Technical Data

15.1 Unit Data

Marine Climate

System

MCS T6

Cooling capacity: 6000 BTU/h

1758 W

Input Voltage: 230 V 230 V 230 V

Current consumption

Cooling:

Heating: 4.7 A 5.3 A 6.9 A

Refrigerant: R-410A R-410A R-410A

Refrigerant quantity: 8.5 oz/241 g 10.5 oz/298 g 12.5 oz/354 g

CO

equivalent: 0.503 t 0.622 t 0.739 t

2

Global warming potential

(GWP):

Dimensions (WxHxD):

Unit:

Control panel: 81 x 64 x 24 mm 81 x 64 x 24 mm 81 x 64 x 24 mm

Panel cutout: 64 x 48 mm 64 x 48 mm 64 x 48 mm

Weight (unit only): 19.3 kg 23.6 kg 26.5 kg

3.7 A 4.3 A 5.5 A

2088 2088 2088

448 x 282 x

272 mm

Marine Climate

System

MCS T12

12000 BTU/h

3517 W

519 x 318 x

315 mm

Marine Climate

System

MCS T16

16000 BTU/h

4689 W

544 x 341 x

338 mm

Contains fluorinated greenhouse gases

Hermetically sealed equipment

15.2 Cable Lengths

Display Cable: 4.5 m Standard

Alternate Air Sensor: 2.0 m Standard

All custom cable lengths supplied in

standard 1.5 m increments:

NOTE

Maximum length of display and sensor cables is 22.9 m.

I

32

22.5 m Maximum

Page 33

DE

MCS T6, MCS T12, MCS T16 Erklärung der Symbole

Bitte lesen Sie diese Anleitung vor der Inbetriebnahme sorgfältig

durch und bewahren Sie sie auf. Geben Sie sie im Falle einer Weitergabe der Anlage an den Nutzer weiter.

Inhalt

1 Erklärung der Symbole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2 Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3 Zielgruppe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4 Lieferumfang. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 Bestimmungsgemäßer Gebrauch . . . . . . . . . . . . . . . . . . . . . . . . 39

6 Technische Beschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 Lieferumfang entpacken und prüfen . . . . . . . . . . . . . . . . . . . . . . 40

8 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 Anschluss der Bootsklimaanlage MCS T . . . . . . . . . . . . . . . . . . . 52

10 Betrieb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11 Programmieren. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12 Richtlinien zur Fehlerbeseitigung. . . . . . . . . . . . . . . . . . . . . . . . . 53

13 Garantie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

14 Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

15 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1 Erklärung der Symbole

WARNUNG!

Sicherheitshinweis: Nichtbeachtung kann zu Tod oder schwerer Verletzung

!

führen.

VORSICHT!

Sicherheitshinweis: Nichtbeachtung kann zu Verletzungen führen.

!

ACHTUNG!

Nichtbeachtung kann zu Materialschäden führen und die Funktion des

A

Produktes beeinträchtigen.

33

Page 34

DE

Sicherheitshinweise MCS T6, MCS T12, MCS T16

HINWEIS

Ergänzende Informationen zur Bedienung des Produktes.

I

2 Sicherheitshinweise

Der Hersteller übernimmt in folgenden Fällen keine Haftung für Schäden:

•

Montage- oder Anschlussfehler

•

Beschädigungen am Produkt durch mechanische Einflüsse und Überspannungen

•

Veränderungen am Produkt ohne ausdrückliche Genehmigung vom

Hersteller

•

Verwendung für andere als die in der Anleitung beschriebenen Zwecke

2.1 Grundlegende Sicherheit

WARNUNG!

•

Achtung Lebensgefahr!

!

In der Anlage befinden sich Bauteile, an denen eine Wechselspannung von

230 V~ anliegt.

•

Es besteht die Gefahr von elektrischen Schlägen!

Bevor Sie eine der Abdeckungen öffnen, trennen Sie die Spannung an der

Hauptschalttafel oder an der Stromquelle.

Andernfalls besteht die Gefahr von Personenschäden oder Verletzungen mit

Todesfolge.

•

Um die Gefahr von elektrischen Schlägen und Personenschäden auf ein Minimum zu beschränken, muss diese Komponente effektiv geerdet werden.

•

Diese Anlage erfüllt nicht die Anforderungen an den Explosionsschutz. Installieren Sie die Anlage nicht in Räumen für mit Benzin angetriebenen Motoren,

Tanks, LPG/CPG-Zylindern, Reglern, Ventilen oder Anschlüssen für Kraftstoffleitungen.

Andernfalls besteht die Gefahr von Personenschäden oder Verletzungen mit

Todesfolge.

•

Schließen Sie die Kondensatablaufleitung nicht

– innerhalb von 1 m im Umkreis von Motorausgängen oder Generator-

Auspuffanlagen,

– in einem Fach eines Motors oder Generators,

– in einer Bilge ab, es sei denn, der Ablauf ist ordnungsgemäß mit einer

abgedichteten Kondensatpumpe oder Pumpenanlage für den Sammel-

brunnen der Dusche verbunden.

34

Page 35

DE

MCS T6, MCS T12, MCS T16 Zielgruppe

Andernfalls können sich Dämpfe aus der Bilge oder dem Maschinenraum

mit der Abluft der Klimaanlage vermischen und die Wohnbereiche kontaminieren. Es besteht die Gefahr von Personenschäden oder Verletzungen mit

Todesfolge.

•

Um das Eindringen von Kohlenmonoxyd (CO) oder anderen schädlichen

Gasen zu verhindern, sollte ein Abscheider in der oder den Kondensatablaufleitungen installiert werden.

•

Installation und Wartung dieser Anlage kann wegen des Systemdrucks und

der elektrischen Bauteile gefährlich sein.

•

Installieren Sie die Klimaanlage nicht in der Bilge oder im Maschinenraum.

•

Sorgen Sie dafür, dass sich ein Feuerlöscher in der Nähe des Arbeitsbereichs

befindet.

VORSICHT!

•

Tragen Sie eine Schutzbrille und Arbeitshandschuhe.

!

ACHTUNG!

•

Befestigen Sie das Klimagerät an einer festen ebenen Plattform mit den vier

A

Montagebügeln aus dem Lieferumfang.

2.2 Sicherer Umgang mit elektrischen Leitungen

VORSICHT!

•

Befestigen und verlegen Sie Leitungen so, dass keine Stolpergefahr entsteht

!

A

und eine Beschädigung des Kabels ausgeschlossen ist.

ACHTUNG!

•

Müssen Leitungen durch scharfkantige Wände oder Schotte geführt werden,

so verwenden Sie Leerrohre bzw. Leitungsdurchführungen!

•

Verlegen Sie keine losen oder scharf abgeknickten Leitungen an elektrisch

leitenden Materialien (Metall)!

•

Ziehen Sie nicht an den Leitungen.

3 Zielgruppe

Diese Anleitung richtet sich an Facharbeiter in Werkstätten, die mit den anzuwendenden Richtlinien und Sicherheitsvorkehrungen vertraut sind.

35

Page 36

DE

Lieferumfang MCS T6, MCS T12, MCS T16

4 Lieferumfang

HINWEIS

Zum Lieferumfang jeder Klimaanlage gehört eine Hakenbaugruppe für den

I

4.1 Bootsklimaanlage MCS T6

Kondensatschlauch und vier Montagebügeln.

MCST6 – Komplettes Kit (Teile-Nr. 9600000549)

Menge Beschreibung

1 DTU6, nur Einheit

1 Bedienfeld

1 Schaltkasten

1 Elektrischer Kabelbaum

Rohrleitungs-Kit

Menge Beschreibung

3,8 m Rohrleitung, isoliert, 100 mm/4" ID

1 Zuluft-Schutzgitter 4"x 4", 102 x 102 mm

1 Abluft-Schutzgitter 10"x 8", 254 x 203 mm, eloxiert

Meerwasser-Kit

Menge Beschreibung

1 Rumpf, 5/8", Kunststoff

7,6 m Meerwasserschlauch, 5/8"

3 PVC-Adapter, 1/2" MPT x 1/2" HB

2 PVC-Adapter, 1/2" FPT x 1/2" HB

1 Siebfilter, 1/2", mit Klammer 1/2" FPT

1 Meerwasserpumpe PML250 (220 Vw, 50/60 Hz)

17 Schlauchklemmen, dünn

1 Kugelventil, 1/2", Bronze

1 Speed-Scoop, 1/2", Bronze

36

Page 37

DE

MCS T6, MCS T12, MCS T16 Lieferumfang

Zubehör

Menge Beschreibung

1 Schlauchhakenbaugruppe

4 Befestigungswinkel

1 Rückluftfilter

4.2 Bootsklimaanlage MCS T12

MCS T12 – Komplettes Kit (Teile-Nr. 9600000550)

Menge Beschreibung

1 DTU12, nur Einheit

1Bedienfeld

1 Schaltkasten

1 Elektrischer Kabelbaum

Rohrleitungs-Kit

Menge Beschreibung

3,8 m Rohrleitung, isoliert, 150 mm/6" ID

1 Zuluft-Schutzgitter 10"x 6", 254 x 153 mm

1 Abluft-Schutzgitter 14"x 10", 356 x 254 mm, eloxiert

Meerwasser-Kit

Menge Beschreibung

1 Rumpf, 5/8", Kunststoff

7,6 m Me er wa ss er sc hl au ch , 5/8 "

3 PVC-Adapter, 1/2" MPT x 1/2" HB

2 PVC-Adapter, 1/2" FPT x 1/2" HB

1 Siebfilter, 1/2", mit Klammer 1/2" FPT

1 Meerwasserpumpe PML250 (220 Vw, 50/60 Hz)

17 Schlauchklemmen, dünn

1 Kugelventil, 1/2", Bronze

1 Speed-Scoop, 1/2", Bronze

37

Page 38

DE

Lieferumfang MCS T6, MCS T12, MCS T16

Ersatzteile

Menge Beschreibung

1 Schlauchhakenbaugruppe

4 Befestigungswinkel

1Rückluftfilter

4.3 Bootsklimaanlage MCS T16

MCS T16 – Komplettes Kit (Teile-Nr. 9600000551)

Menge Beschreibung

1 DTU16, nur Einheit

1 Bedienfeld

1 Schaltkasten

1 Elektrischer Kabelbaum

Rohrleitungs-Kit

Menge Beschreibung

3,8 m Rohrleitung, isoliert, 150 mm/6" ID

1 Zuluft-Schutzgitter 10"x 8", 254 x 203 mm

1 Abluft-Schutzgitter 14"x 10", 356 x 254 mm

1 Befestigungsring 6"

4Kunststoffniete

Meerwasser-Kit

Menge Beschreibung

1 Rumpf, 5/8", Kunststoff

7,6 m Meerwasserschlauch, 5/8"

3 PVC-Adapter, 1/2" MPT x 1/2" HB

2 PVC-Adapter, 1/2" FPT x 1/2" HB

1 Siebfilter, 1/2", mit Klammer 1/2" FPT

1 Meerwasserpumpe PML500 (220–240 Vw,

50/60 Hz)

17 Schlauchklemmen, dünn

1 Kugelventil, 1/2", Bronze

1 Speed-Scoop, 1/2", Bronze

38

Page 39

DE

MCS T6, MCS T12, MCS T16 Bestimmungsgemäßer Gebrauch

Ersatzteile

Menge Beschreibung

1 Schlauchhakenbaugruppe

4 Befestigungswinkel

1 Rückluftfilter

5 Bestimmungsgemäßer Gebrauch

Die Bootsklimaanlage MCS T wurde für den Einsatz auf Booten und Yachten

entwickelt. Sie kann die inneren Bereiche des Boots oder der Yacht abkühlen

oder erwärmen.

6 Technische Beschreibung

Die Bootsklimaanlage Marine Climate System MCS T ist für eine Spannungsversorgung mit 230 Vw vorgesehen.

Der Bausatz der Bootsklimaanlage MCS T besteht aus folgenden Bauteilen:

•

DTU-Einheit

•

Bedienfeld

•

Rohrleitungen

•

Zuluft-Schutzgitter

•

Abluft-Schutzgitter

•

Meerwasserpumpe

•

Siebfilter

•

Rumpf-Speed-Scoop

•

Außenbordanschluss

•

Meerwasserschlauch

•

Armaturen für Pumpe und Filtersieb

Es handelt sich um eine meerwassergekühlte Klimaanlage.

39

Page 40

DE

Lieferumfang entpacken und prüfen MCS T6, MCS T12, MCS T16

6.1 Bauteile der Bootsklimaanlage MCS T

Position in

Abb. 1,

Seite 3

1Rohrleitungsring

2 Befestigungswinkel

3 Kondensatablauf (angezeigt werden zwei von drei Positionen)

4 Zusammengesetzte Basiswanne

5 Rotationskompressor

6 Drehbare Gebläsebaugruppe

Nur MCS T16:

Die Einheit T16 wird mit einem 7" Rohrleitungsring geliefert.

➤ Ersetzen Sie den 7" Rohrleitungsring durch den mitgelieferten

6" Rohrleitungsring und verwenden Sie die 4 mitgelieferten Kunststoffnieten

(Abb. 2, Seite 3).

Beschreibung

7 Lieferumfang entpacken und prüfen

➤ Überprüfen Sie alle Teile anhand der Verpackungsliste, um sicherzustellen,

dass alle Kartons in der Lieferung enthalten sind.

➤ Stellen Sie die Teile in der normalen aufrechten Position hin, die durch die

Pfeile auf jedem Karton angegeben wird.

➤ Untersuchen Sie, ob die Kartons Versandschäden aufweisen und entnehmen

Sie die Teile ggf. aus den Kartons.

➤ Wenn ein Teil Beschädigungen aufweist, sollte die Spedition die Beschädi-

gung durch einen entsprechenden Vermerk auf dem Lieferschein quittieren.

40

Page 41

DE

MCS T6, MCS T12, MCS T16 Installation

8 Installation

VORSICHT! Verletzungsgefahr!

Die Installation der Anlage darf ausschließlich nur von entsprechend geschul-

!

ten Fachbetrieben durchgeführt werden. Die nachfolgenden Informationen

richten sich an Fachkräfte, die mit den anzuwendenden Richtlinien und

Sicherheitsvorkehrungen vertraut sind.

•

Planen Sie alle durchzuführenden Verbindungen, inkl.:

– Rohrleitungen,

– Kondensatablauf,

– Meerwasserein- und -ausgänge,

– Stromanschlüsse,

– Lage der Steuerung,

– Platzierung der Meerwasserpumpe,

um den einfachen Zugang für die Verlegung der Leitungen und Wartung

sicherzustellen.

HINWEIS

Lesen Sie die folgenden Hinweise vor und nach der Installation.

I

8.1 Erforderlicher Platzbedarf und Geräteabmessungen

Siehe Abb. 3, Seite 4

HINWEIS

Das Gebläse ist um 270 Grad drehbar, um die Installation zu vereinfachen und

I

einen besseren Luftstrom zu ermöglichen.

Erforderlicher Platz (Abb. 3, Seite 4)

Bei der Gerätemontage sollten die folgenden Platzanforderungen berücksichtigt werden:

•

Berücksichtigen Sie um die Anlage im Bereich der Ablaufrohre für Meerwasser und Kondensat einen Freiraum von 152 mm.

•

Berücksichtigen Sie bei einer Montage in der Nähe des Schotts für den

Ablufteinlass vor der Verdampferspule einen Mindestabstand von 76 mm.

•

Um flexible Rohranschlüsse und den erforderlichen Abstand hinter dem

Zuluft-Schutzgitter zu gewährleisten, addieren Sie die folgenden Werte, um

den erforderlichen Gesamtabstand zu ermitteln:

– 51 mm für den Rohrleitungsring,

– 25 mm für den Biegeradius der Rohrleitungen und

– Durchmesser der Rohrleitungen.

•

Achten Sie darauf, dass der Platz für Montage- und Wartungsarbeiten ausreicht.

41

Page 42

DE

Installation MCS T6, MCS T12, MCS T16

Geräteabmessungen

Geräteabmessung 6 T 12 T 16 T

Mindestmaß Leitungsdurchmesser (mm)

Mindestmaß Leitungsquerschnitt (cm

Mindestabstand Abluft-Schutzgitter (cm

Mindestabstand Zuluft-Schutzgitter (cm

8.2 Kondensatabläufe

WARNUNG!

Lassen Sie die Kondensatablaufleitung nicht enden:

!

– innerhalb von 1 m im Umkreis von Motorausgängen oder Generator-

Auspuffanlagen,

– in einem Gehäuse eines Motors oder Generators,

– in einer Bilge, es sei denn, der Ablauf ist ordnungsgemäß mit einer

abgedichteten Kondensatpumpe oder Pumpenanlage für den Sammel-

brunnen der Dusche verbunden.

Andernfalls können Dämpfe aus der Bilge oder dem Maschinenraum sich mit

der Abluft der Klimaanlage vermischen und die Wohnbereiche kontaminieren.

Es besteht die Gefahr von Tod oder schwerer Verletzung.

102 152 152

2

)

2

)

2

)

81 183 183

413 839 1032

206 452 516

Beachten Sie folgende Hinweise bei der Installation der Kondensatabläufe:

•

Führen Sie die Kondensatabläufe nicht zur Bilge.

•

Führen Sie die Kondensatablaufleitung nach unten von der Anlage zu einer

geeigneten Position für den Ablauf.

•

Die Kondensatablaufleitung sollte mit einem Abscheider versehen sein.

Installation des Kondensatablaufs (Abb. 4, Seite 4):

➤ Entfernen Sie mit Hilfe der Schlauchtülle (1) den nach Achtern weisenden

wasserdichten Stopfen (3) von der Basiswanne (2) des Klimageräts.

➤ Drehen Sie die Schlauchtülle in das Loch und ziehen Sie sie fest (4).

➤ Sichern Sie den Kondensatablaufschlauch mit einer Schlauchklemme (5).

➤ Führen Sie den Kondensatablaufschlauch von der Anlage nach unten und an

einen richtlinienkonformen Ort (6).

Der Schlauch sollte mit einem Abscheider versehen sein.

42

Page 43

DE

MCS T6, MCS T12, MCS T16 Installation

HINWEIS

•

Es ist möglich, zwei Ablaufanschlüsse zu verwenden und die Schläuche mit

I

einem T-Anschluss zusammenzuführen, vorausgesetzt, der Abfall von der

Unterkante der Basiswanne zur T-Verbindung beträgt mindestens 50 mm.

•

Ziehen Sie die Installation eines Abscheiders in den Kondensatablaufleitungen in Betracht, so dass der Abscheider durch den normalen

Kondensatabfluss gefüllt wird und Kohlenmonoxyd und andere schädliche

Gase nicht eindringen können.

➤ Testen Sie die Installation, indem Sie einen Liter Wasser in die Basiswanne

gießen und den guten Abfluss überprüfen.

8.3 Gebläsemontage

Drehen Sie das Gebläse, um einen möglichst direkten Luftfluss zum ZuluftSchutzgitter zu gewährleisten (Abb. 5, Seite 4).

➤ Lösen Sie die Einstellschraube (1).

➤ Drehen Sie das Gebläse (2).

➤ Ziehen Sie die Einstellschraube fest (1).

8.4 Schaltkasten

Beachten Sie folgende Hinweise bei der Installation des Schaltkastens

(Abb. 8 3, Seite 6):

•

Montieren Sie den Schaltkasten an eine trockene Position.

•

Montieren Sie den Schaltkasten auf einer ebenen, festen Oberfläche im

Umkreis von 1 m von der Anlage.

•

Montieren Sie den Schaltkasten im Umkreis von 4,5 m von der Position, an

der die digitale Steuerung installiert wird.

➤ Befestigen Sie den Schaltkasten an den 4 Montageöffnungen an der Rück-

seite des Schaltkastens an einer geeigneten Einbaufläche.

➤ Verwenden Sie dabei Schrauben, die für die Einbaufläche geeignet sind

(nicht im Lieferumfang enthalten).

43

Page 44

DE

Installation MCS T6, MCS T12, MCS T16

8.5 Zuluft-Schutzgitter

Beachten Sie folgende Hinweise bei der Installation des Zuluft-Schutzgitters, um

einen direkten, ununterbrochenen Luftfluss zum Gebläse zu gewährleisten:

ACHTUNG!

Unter keinen Umständen darf der Auslass des Zuluft-Schutzgitters zum Abluft-

A

Schutzgitter gerichtet werden, da sonst die Anlage in kurzen Abständen einund ausgeschaltet wird.

•

Installieren Sie das Zuluft-Schutzgitter an einer möglichst hohen Position.

•

Hinter dem Zuluft-Schutzgitter ist ein Mindestabstand von 76 mm plus dem

Rohrdurchmesser erforderlich, um die Rohrleitungen anzuschließen.

➤ Fertigen Sie die Bohrlöcher für das Zuluft-Schutzgitter gemäß der folgenden

Tabelle:

MCS T6 MCS T12 MCS T16

4,9" x 4,9"

125 x 125 mm

➤ Montieren Sie das Zuluft-Schutzgitter.

8.6 Abluft-Schutzgitter

Beachten Sie folgende Hinweise bei der Installation des Abluft-Schutzgitters, um

einen direkten, ununterbrochenen Luftfluss zum Verdampfer zu gewährleisten:

•

Installieren Sie das Abluft-Schutzgitter so tief und so nahe wie möglich an der

Anlage.

•

Installieren Sie das Abluft-Schutzgitter an eine Position, an der es nicht mit

Abgas- und Bilgedämpfen in Kontakt kommen kann.

•

Im Kabinenbereich sollte der Mindestabstand für das Abluft-Schutzgitter

107 mm betragen (Abb. 3, Seite 4).

➤ Fertigen Sie die Bohrlöcher für das Abluft-Schutzgitter gemäß der folgenden

Tabelle:

MCS T6 MCS T12 MCS T16

9,9" x 5,9"

252 x 150 mm

9,9" x 7,9"

252 x 201 mm

9,9" x 7,9"

252 x 201 mm

44

13,9" x 9,9"

353 x 252 mm

13,9" x 9,9"

353 x 252 mm

Page 45

DE

MCS T6, MCS T12, MCS T16 Installation

➤ Wenn zum Lieferumfang des Kits ein Abluft-Schutzgitter mit Filter gehört: Ent-

fernen Sie den Filter, der am Verdampfer der Anlage befestigt ist, und entsorgen Sie diesen.

Zwei Filter sind nicht besser als einer, da der reduzierte Luftfluss die Leistung

vermindert und möglicherweise die Verdampferspule einfriert.

➤ Montieren Sie das Abluft-Schutzgitter.

8.7 Rohrleitungen

Beachten Sie folgende Hinweise bei der Installation der Rohrleitungen:

•

Die Rohrleitungen sollten so gerade, eben und straff wie möglich verlegt

werden.

•

Vermeiden Sie unnötige Biegungen und Schleifen. Drehen Sie stattdessen

das Gebläse.

•

Beschränken Sie die Anzahl der 90°-Biegungen auf ein Minimum (zwei enge

90°-Biegungen können den Luftfluss um 25 % reduzieren).

•

Vergewissern Sie sich, dass die Rohrleitungen ordnungsgemäß ohne Überschuss angeschlossen sind.

Gehen Sie wie folgt vor, um die Rohrleitungsverbindungen herzustellen:

➤ Beginnen Sie an einem Ende (Schutzgitter für den Luftauslass oder Klima-

gerät).

➤ Ziehen Sie die Glasfaserisolierung zurück, um das innere Schlauchrohr aus

Mylar freizulegen.

➤ Schieben Sie das innere Schlauchrohr aus Mylar um den Montagering, bis

der Montagering den Boden berührt.

➤ Schrauben Sie 3 oder 4 Blechschrauben aus Edelstahl durch das

Schlauchrohr in den Übergangsring.

Sorgen Sie dafür, dass der Draht im Schlauchrohr an den Schraubköpfen

befestigt wird.

Verwenden Sie keine Bandverschlüsse, da der Schlauch sonst abrutscht.

➤ Wickeln Sie Klebeband um die Verbindung zwischen Rohrleitung und Ring,

um Luftlecks zu verhindern.

➤ Ziehen Sie die Isolierung wieder über den Mylar-Schlauch zum Ring und

dichten Sie diese Verbindung mit Klebeband ab.

➤ Führen Sie die Rohrleitung zum anderen Ende, achten Sie dabei darauf, dass

diese so gerade, eben und straff wie möglich verlegt wird.

➤ Entfernen Sie überschüssige Rohrleitung.

➤ Verwenden Sie dieselbe Anschlussmethode wie am anderen Ende.

45

Page 46

DE

Installation MCS T6, MCS T12, MCS T16

8.8 Installation des Bedienfelds

Beachten Sie folgende Hinweise bei der bei der Installation des Bedienfelds

(Abb. 8 2, Seite 6):

•

Montieren Sie das Bedienfeld (2) in einem Umkreis von 4,5 m des

Schaltkastens (3).

•

Montieren Sie das Bedienfeld an einer Innenwand, etwas höher als die Mitte

der Kabine an einer Position, an der die Luft frei zirkulieren kann.

•

Montieren Sie das Bedienfeld nicht an Positionen

– mit direkter Sonneneinstrahlung,

– in der Nähe von Wärmequellen,

– in einem Schott, wo hinter dem Bedienfeld Temperaturen abgestrahlt

werden, die die Leistung beeinträchtigen könnten,

– im Zuluftstrom,

– über oder unter einem Zuluft- oder Abluft-Schutzgitter.

Bereiten Sie vor der Montage des Bedienfelds die Einbauposition wie folgt vor:

➤ Fertigen Sie eine Aussparung für die Montage des Bedienfelds:

64 mm (Breite) x 48 mm (Höhe).

➤ Verbinden Sie das eine Ende des Displaykabels (8-poliger RJ-45-Anschluss)

mit der Displaybuchse J1 (Abb. 0 4, Seite 8) im Schaltkasten und das

andere Ende mit der Rückseite des Bedienfelds.

➤ Entfernen Sie den Jumper JP5 im Schaltkasten, um das Display zu aktivieren

(Abb. 0 14, Seite 8).

➤ Reinigen Sie vor der Platzierung die Einbaufläche nur mit Isopropanol (testen

Sie die Lösung vorher an einer unauffälligen Stelle der Oberfläche).

➤ Befestigen Sie das Bedienfeld an einem Schott mit den Klebestreifen aus

dem Lieferumfang.

8.9 Installation des Rückluftsensors (optional)

Wenn am Montageort des Bedienfeld die Raumtemperatur nicht richtig gemessen werden kann, kann ein zusätzlicher Rückluftsensor montiert werden. Der

Rückluftsensor überstimmt die Messwerte des eingebauten Sensors. Das Sensorkabel hat eine Länge von 5 ft (1,5 m).

➤ Befestigen Sie den Rückluftsensor (Abb. 8 4, Seite 6) im Kunstoffclip an der

Rückluftseite des Verdampfers.

➤ Verbinden Sie das Kabel (6-poliger Anschluss) mit der Buchse ALT AIR (J3)

(Abb. 0 5, Seite 8) im Schaltkasten.

46

Page 47

DE

MCS T6, MCS T12, MCS T16 Installation

8.10 Installation der Einheit und der Meerwasseranlage

8.10.1 Hinweise zur Installation der Meerwasseranlage

ACHTUNG!

Wenn der Meerwassersiebfilter nicht installiert wird, kann die Pumpe beschä-

A

I

digt werden!

HINWEIS

Wenn der Meerwassersiebfilter nicht installiert wird, erlischt die Garantie der

Pumpe.

Legende zu Abb. 5, Seite 5:

Pos. Beschreibung

1Scoop-Rumpfeinlass

2Kugelventil

3 Siebfilter

4Meerwasserpumpe

5 DTU-Einheit

6 Überbord-Auslass

7 Wasserlinie

8Einlassfluss

9 Auslassfluss

10 Schlauchklemmen, die paarweise mit den Einstellungsenden an

gegenüberliegenden Seiten installiert werden

– A: Richtig

Stetiger Fluss nach oben vom Einlass zum Gerät (8), dann nach unten zum

Auslass (9), Schläuche zweifach mit Klemmen gesichert (10).

– B: Falsch

Die Schläuche dürfen keine Knicke, Schleifen oder hohe Bereiche aufweisen, in denen sich Luft ansammeln kann.

– C: Falsch

Pumpe (4) und Siebfilter (3) müssen sich unterhalb der Wasserlinie befinden (7).

– D: Falsch

Der Siebfilter (3) muss sich unterhalb der Pumpe (4) und unterhalb der

Wasserlinie (7) befinden.

47

Page 48

DE

Installation MCS T6, MCS T12, MCS T16

Beachten Sie folgende Hinweise bei der bei der Installation der Meerwasseranlage:

•

Die Meerwasserpumpe muss so montiert werden, dass sie sich immer

wenigstens 300 mm unterhalb der Wasserlinie befindet.

•

Die Meerwasserpumpe kann horizontal oder vertikal montiert werden, aber

der Auslass muss sich immer über dem Einlass befinden (Abb. 7, Seite 6).

•

Vergewissern Sie sich, dass das Wasser frei aus dem Außenbord-Auslass

fließt, während die Pumpe läuft.

•

Der Speed-Scoop-Einlass muss nach vorn weisen und darf nicht von einer

anderen Pumpe mitbenutzt werden.

•

Speed-Scoop und Absperrventil müssen dicht und ordnungsgemäß abgedichtet werden.

•

Ein Meerwassersiebfilter (3) muss zwischen dem Absperrventil (Seeventil)

(1) und der Pumpe (4) zum Schutz der Pumpe vor Fremdstoffen installiert werden.

•

Sorgen Sie dafür, dass der Zugang zum Filter im Sieb (3) gewährleistet ist.

•

Die Meerwasseranlage sollte wie folgt installiert werden:

– mit einer nach oben gerichteten Schräge vom Speed-Scoop und See-

ventil (1),

– durch den Siebfilter (3),

– zum Einlass der Pumpe (4) und

– dann hoch zum Einlass der Kondensatorspule des Klimageräts (5).

•

Der Auslass vom Klimagerät (5) sollte zum Rumpfanschluss des MeerwasserAuslasses (6) verlaufen, der sich an einer Position befinden sollte, an der eine

Sichtprüfung des Wasserflusses durchgeführt werden kann und die sich so

nah wie möglich an der Wasserlinie befindet, um die Geräuschentwicklung

zu vermindern.

•

Vergewissern Sie sich, dass der Schlauch vom Speed-Scoop zum Siebfilter

(3), zur Pumpe (4) und zum Klimagerät (5) nach oben verläuft.

•

Vermeiden Sie beim Meerwasserschlauch Schleifen, Erhebungen und die

Verwendung von 90°-Bogenstücken.

•

Das Klimagerät (5) sollte an einer möglichst tiefen Position installiert werden.

Dabei darf es aber unter keinen Umständen in der Bilge oder in Bereichen

des Maschinenraums (wie z. B. unter einer V-förmigen Koje, unter einem Sitz

im Ess- oder Sitzraum oder am Boden eines Schranks) installiert werden.

•

Vergewissern Sie sich, dass der Platz um das Gerät ausreicht.

•

Vergewissern Sie sich, dass der gewählte Standort ausreichend abgedichtet

ist, so dass Dämpfe und Abgase aus der Bilge und dem Maschinenraum nicht

ungehindert eindringen können.

•

Montieren Sie das Gerät (5) auf einer festen, ebenen und horizontalen Oberfläche.

48

Page 49

DE

MCS T6, MCS T12, MCS T16 Installation

•

Sichern Sie alle Schlauchverbindungen mit doppelten Klemmen aus Edelstahl, ordnen Sie dabei die Klemmen in umgekehrter Richtung an.

•

Sichern Sie alle Gewindeverbindungen mit Gewindedichtband. Umwickeln

Sie diese nur 2 bis 3 mal.

•

Ziehen Sie Gewindeverbindungen um 1 1/2 Drehungen weiter an, als mit

Handanzug möglich ist.

WARNUNG!

•

Ziehen Sie Gewindeverbindungen nicht zu fest an. Andernfalls können sich

!

innerhalb von Stunden oder Tagen Risse bilden.

•

Bevor Sie das Boot in Betrieb nehmen, führen Sie eine Überprüfung nach

Lecks durch. Wenn Sie nicht wissen, wie Sie das Verfahren durchführen,

wenden Sie sich an einen qualifizierten Schiffsmechaniker. Sonst besteht

die Gefahr, dass das Schiff sinkt. Dies kann zu Tod oder schwerer Verletzung führen.

8.10.2 Installation des Rohrleitungs-Kits

I

HINWEIS

•

Bei der dargestellten Anlage wurde das Gebläse in die vertikale Position

gedreht.

•

Abmessungen und Teilenummern finden Sie in Kapitel „Lieferumfang“ auf

Seite 36.

Legende für Abb. 8, Seite 6

Pos. Beschreibung

1 Zuluft-Schutzgitter

2 Bedienfeld

3 Schaltkasten

4 Rückluftsensor (optional)

5 Meerwasser-Auslass

6 Überbord-Auslass

7 Meerwasser-Einlass

8 Meerwasser-Einlassventil

9 Meerwasser-Absperrventil

10 Meerwassersiebfilter

11 Meerwasserpumpe

12 Kondensatablauf zum Auffangbehälter

13 Befestigungswinkel

14 Klimagerät

49

Page 50

DE

Installation MCS T6, MCS T12, MCS T16

Pos. Beschreibung

15 Abluft-Schutzgitter

16 Rohrleitungen

8.10.3 Installation des Meerwasser-Kits

Legende für Abb. 9, Seite 7

Pos. Beschreibung

1 Wasserlinie

2 Außenbord-Auslasss

3Meerwasserschlauch

4 DTU-Einheit

5 Schaltkasten

6 Stromkabelbaum für die Pumpe

7Meerwasserpumpe

8 PVC-Adapter, 1/2" FPT x 1/2" HB

9 PVC-Adapter, 1/2" MPT x 1/2" HB

10 Siebfilter

11 Meerwasser-Einlass (siehe Detail A)

Meerwasser-Einlass (Detail A)

Position in A Beschreibung

12 Meerwasserschlauch

13 Schlauchklemmen

14 PVC-Adapter, 1/2" MPT x 1/2" HB

15 Kugelventil

16 Mutter

17 Grundplatte (nicht im Kit enthalten)

18 Auflageverbindung (nicht im Kit enthalten)

19 Rumpf

20 Speed-Scoop

50

Page 51

DE

MCS T6, MCS T12, MCS T16 Installation

8.10.4 Installation der Meerwasseranlage

➤ Installieren Sie den Meerwasser-Speed-Scoop-Einlass so weit unter der

Wasserlinie und so nah am Kiel wie möglich. Der Einlass sollte dabei

nach vorn weisen.

Auf diese Weise bleibt der Einlass im Wasser, wenn das Boot sich auf die

Seite legt, so dass keine Luft in das System gelangt.

➤ Betten Sie den Scoop-Einlass mit einem für den Einsatz auf Booten geeigne-

tes Dichtmittel, das für den Unterwassereinsatz entwickelt wurde.

➤ Tragen Sie die Bettungsverbindung großzügig an beiden Seiten und durch

das Loch auf.

➤ Installieren Sie das Vollstromseeventil aus Bronze auf dem Speed-Scoop-

Rumpfeinlass.

➤ Installieren Sie den Meerwassersiebfilter unterhalb der Pumpenebene mit

Zugang zum Filter.

➤ Verbinden Sie das Seeventil und den Siebfilter aufwärts verlaufend mit einem

verstärkten 5/8" (16 mm) Schlauch, der für den Einsatz auf Booten ausgelegt

ist.

➤ Montieren Sie die Meerwasserpumpe sicher über dem Siebfilter, wenigstens

300 mm unterhalb der Wasserlinie.

➤ Montieren Sie das Klimagerät, indem Sie die Basiswanne an einer flachen,

horizontalen Oberfläche mit den Montageklammern und 4 Schrauben befestigen.

Die Basiswanne dient auch als Kondensatwanne.

➤ Schließen Sie den Auslass von der Pumpe (oben) an den Einlass der Konden-

satorspule des Klimageräts (unten) mit einem verstärkten 5/8" (16 mm)

Schlauch an, der für den Einsatz auf Booten geeignet ist.

➤ Installieren Sie den Rumpfanschluss für den Außenbord-Auslass.

➤ Verbinden Sie den Auslass von der Kondensatorspule mit dem Rumpfan-

schluss des Außenbord-Auslasses mit einem verstärkten 5/8" (16 mm)

Schlauch, der für den Einsatz auf Booten geeignet ist.

➤ Schließen Sie alle Metallteile, die mit Meerwasser in Kontakt kommen an das

Anschlusssystem des Schiffs an. Dazu gehören:

– der Speed-Scoop-Einlass,

– Pumpe (Erdleiter des Kabelbaums),

– die Klimaanlage.

51

Page 52

DE

Anschluss der Bootsklimaanlage MCS T MCS T6, MCS T12, MCS T16

9 Anschluss der Bootsklimaanlage MCS T

WARNUNG!

Schalten Sie die Stromversorgung am Leistungsschalter aus, bevor Sie den

!

I

Schaltkasten öffnen und auf die Klemmleiste zugreifen.

HINWEIS

Wenn Sie die Anlage nicht ordnungsgemäß erden und anschließen, verfällt

der Garantieanspruch.

Legende zum Schaltbild (Abb. 0, Seite 8):

Pos. Beschreibung

1 Schaltkasten

2 PTC-Widerstand für die Starthilfe (nur MCS T16)

3Motorkondensator

48-Pin Displaykabel

5 Alternativer Luftsensor (optional)

6 Außenluftsensor (nicht genutzt)

7Kompressor

8 Pumpen- oder Pumpenrelais Schalttafel

9Umkehrventil

10 Lüfter

11 Hochdruckschalter

12 Niederdruckschalter (nicht genutzt)

13 Stromversorgung

Die folgenden Richtlinien müssen beim Anschluss der Bootsklimaanlage berücksichtigt werden:

•

Der Leistungsschalter sollte die richtige Größe aufweisen, um die Anlage entsprechend den Angaben auf dem Typenschild des Klimageräts zu schützen.

•

Installieren Sie eine Wechselstromquelle und erden/verbinden Sie diese

gemäß den Vorgaben für elektrische Anlagen auf Schiffen.

•

Verwenden Sie ein Bootskabel mit einem Mindestdurchmesser von

3,5 mm²,

– um das Klimagerät mit Strom zu versorgen

– um die Meerwasserpumpe mit Strom zu versorgen

– um die Kabel auf der Pumpe zu verlängern

•

Bei allen elektrischen Anschlüssen in der Bilge unterhalb der Wasserlinie sollten abdichtende wärmeschrumpfende Kabelverbinder verwendet werden.

52

Page 53

DE

MCS T6, MCS T12, MCS T16 Betrieb

•

Alle Verbindungen zur Klemmleiste sollten mit entsprechend bemessenen

Ringösen vorgenommen werden (nicht im Lieferumfang).

•

Jedes installierte Klimagerät benötigt einen eigenen Leistungsschalter.

–Wenn nur ein Klimagerät installiert wird, muss kein Leistungsschalter für

die Meerwasserpumpe installiert werden. Die Kabel von der

Meerwasserpumpe werden an die Klemmleiste auf dem Gerät (siehe

Schaltbild, Abb. 0, Seite 8) angeschlossen.

➤ Schließen Sie das Klimagerät an das Anschlusssystem des Boots an, um Kor-

rosion aufgrund von elektrischen Streuströmen zu vermeiden.

➤ Vergewissern Sie sich, dass der AC-Erdleiter des Klimageräts ordnungsge-

mäß am AC-Erdleiter des Boots angeschlossen ist.

➤ Vergewissern Sie sich innerhalb des Boots, dass die AC-Erdschiene mit der

DC-Erdschiene an genau einer Stelle verbunden ist.

➤ Binden Sie individuell alle Pumpen, metallischen Ventile und Anschlüsse im

Meerwasserkreislauf, die vom Klimagerät isoliert sind, mit PVC- oder Gummischläuchen an das Anschlusssystem des Boots.

Auf diese Weise wird Korrosion aufgrund von Streuströmen verhindert.

10 Betrieb

HINWEIS

Die Betriebsanweisungen finden Sie in der Bedienungsanleitung.

I

11 Programmieren

HINWEIS

Hinweise zur Programmierung und Parameterdefinition finden Sie in der

I

Bedienungsanleitung.

12 Richtlinien zur Fehlerbeseitigung

HINWEIS

Angaben zur Fehlerbeseitigung finden Sie in der Bedienungsanleitung.

I

53

Page 54

DE

Garantie MCS T6, MCS T12, MCS T16

13 Garantie

Es gilt die gesetzliche Gewährleistungsfrist. Sollte das Produkt defekt sein, wenden Sie sich bitte an einen Service-Partner in Ihrem Land (Adressen siehe Rückseite der Anleitung).

Unsere Spezialisten helfen Ihnen gerne weiter und besprechen mit Ihnen den

weiteren Verlauf der Gewährleistung.

14 Entsorgung

➤ Geben Sie das Verpackungsmaterial möglichst in den entsprechenden

Recycling-Müll.

Wenn Sie das Produkt endgültig außer Betrieb nehmen, informieren Sie sich

bitte beim nächsten Recyclingcenter oder bei Ihrem Fachhändler über die

M

zutreffenden Entsorgungsvorschriften.

54

Page 55

DE

MCS T6, MCS T12, MCS T16 Technische Daten

15 Technische Daten

15.1 Anlagendaten

Bootsklima-

anlage MCS T6

Kühlleistung: 6000 BTU/h

1758 W

Eingangsspannung: 230 V 230 V 230 V

Stromverbrauch

Kühlung:

Heizen: 4,7 A 5,3 A 6,9 A

Kühlmittel: R-410A R-410A R-410A

Kühlmittelmenge: 8,5 oz/241 g 10,5 oz/298 g 12,5 oz/354 g

CO

-Äquivalent: 0,503 t 0,622 t 0,739 t

2

Treibhauspotential (GWP): 2088 2088 2088

Abmessungen (BxHxT):

Anlage:

Bedienfeld: 81 x 64 x 24 mm 81 x 64 x 24 mm 81 x 64 x 24 mm

Tafelausschnitt: 64 x 48 mm 64 x 48 mm 64 x 48 mm

Gewicht (nur DTU-Einheit): 19,3 kg 23,6 kg 26,5 kg

3,7 A 4,3 A 5,5 A

448 x 282 x

272 mm

Bootsklima-

anlage MCS T12

12000 BTU/h

3517 W

519 x 318 x

315 mm

Bootsklima anl

age MCS T16

16000 BTU/h

4689 W

544 x 341 x

338 mm

Enthält fluorierte Treibhausgase

Hermetisch geschlossene Einrichtung

15.2 Kabellängen

Displaykabel: 4,5 m (Standard)

Alternativer Luftsensor: 2,0 m (Standard)

Alle anwenderspezifischen Kabellängen

werden in Standardstufen von 1,5 m

bereitgestellt:

HINWEIS

Die maximale Länge der Display- und Sensorkabel beträgt 22,9 m.

I

22,5 m (Maximal)

55

Page 56

FR

Explication des symboles MCS T6, MCS T12, MCS T16

Veuillez lire ce manuel avec attention avant la mise en service, puis le

conserver. En cas de revente de l'unité, veuillez le transmettre au nouvel acquéreur.

Sommaire

1 Explication des symboles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2 Consignes de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3 Groupe cible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4 Contenu de la livraison. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5 Usage conforme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6 Description technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7 Déballage et vérification du contenu de la livraison. . . . . . . . . . 63

8 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9 Raccordement du climatiseur pour bateau MCS T . . . . . . . . . . . 75

10 Exploitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

11 Programmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12 Directives permettant de remédier aux erreurs . . . . . . . . . . . . .76

13 Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14 Mise au rebut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

15 Caractéristiques techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1 Explication des symboles

AVERTISSEMENT !

Consigne de sécurité : le non-respect de ces consignes peut entraîner la

!

!

mort ou de graves blessures.

ATTENTION !

Consigne de sécurité : le non-respect de ces consignes peut entraîner des

blessures.

AVIS !

Le non-respect de ces consignes peut entraîner des dommages matériels et

A

56

des dysfonctionnements du produit.

Page 57

FR

MCS T6, MCS T12, MCS T16 Consignes de sécurité

REMARQUE

Informations complémentaires sur l'utilisation du produit.

I

2 Consignes de sécurité

Le fabricant décline toute responsabilité pour des dommages dans les cas

suivants :

•

des défauts de montage ou de raccordement

•

des influences mécaniques et des surtensions ayant endommagé le matériel

•

des modifications apportées au produit sans autorisation explicite de la part

du fabricant

•

une utilisation différente de celle décrite dans la notice

2.1 Consignes générales de sécurité

AVERTISSEMENT !

•

Attention, danger de mort !

!

Des composants sous tension alternative de 230 V~ se trouvent dans l’unité.

•

Il existe un danger d’électrocution !

Avant d’ouvrir l’un des capots, déconnectez la tension sur le commutateur

principal ou sur la source d’électricité.

Dans le cas contraire, vous vous exposez à des risques de dommages corporels ou de blessures pouvant entraîner la mort.

•

Afin de limiter autant que possible le risque d’électrocution et de dommages

corporels, les composants doivent être correctement mis à la terre.

•

Cette unité ne répond pas aux exigences de la protection ignifuge. N’installez pas l’unité dans des pièces où se trouvent des moteurs fonctionnant à