Page 1

DOMETIC

Dometic

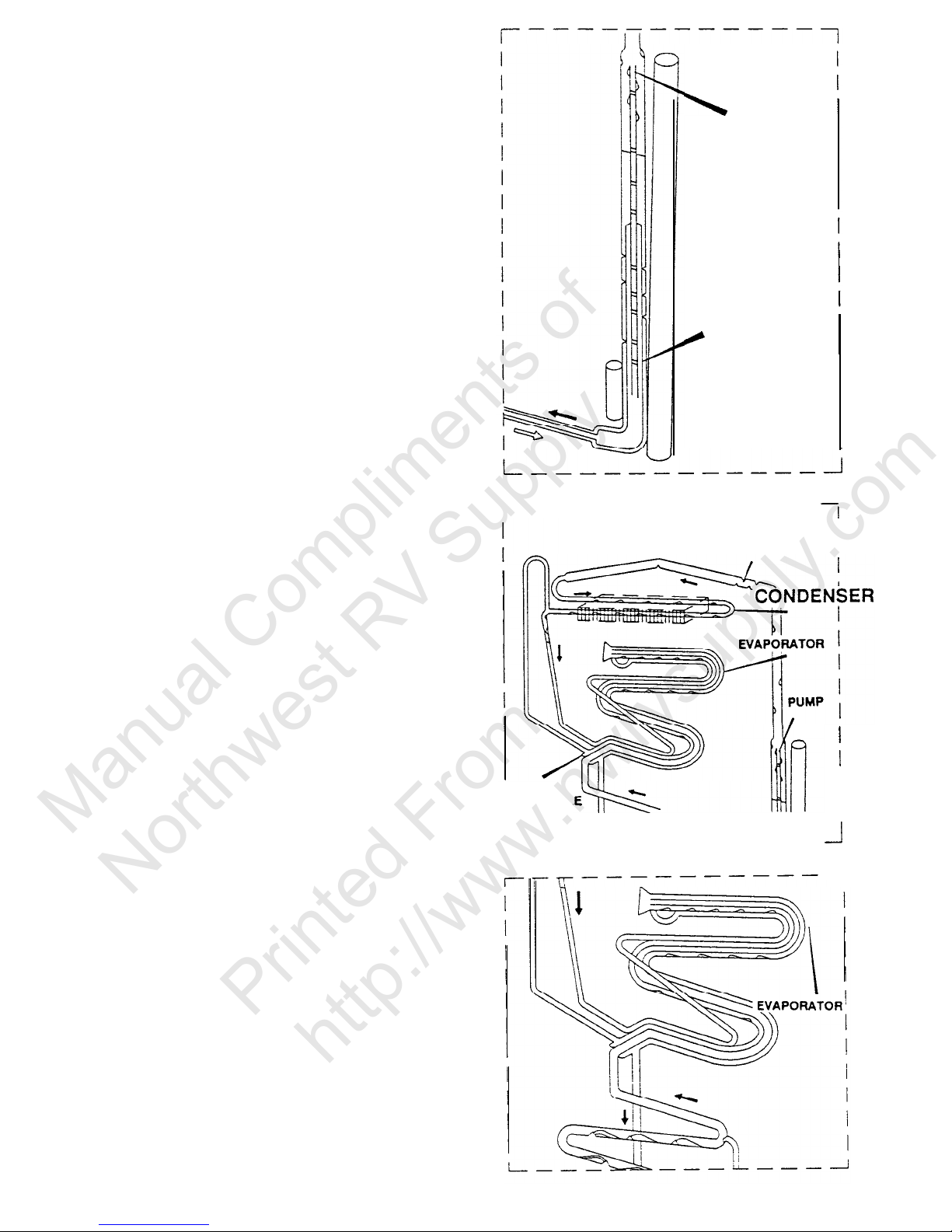

MANUAL REFRIGERATOR

DIAGNOSTIC SERVICE

MANUAL

The

Dometic

Corporation

Corporate Office

Warranty

Department

2320 Industrial Parkway

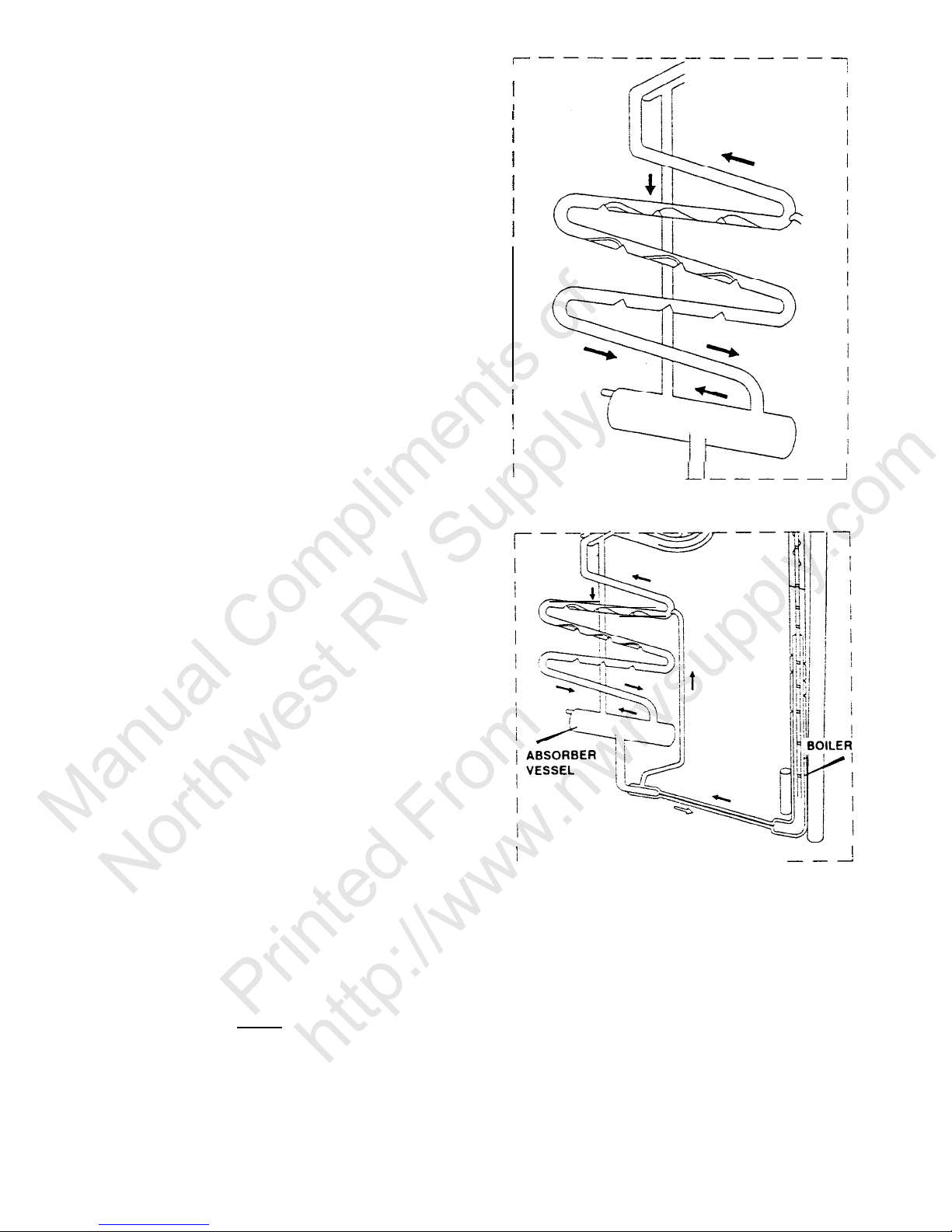

Elkhart, IN 46515

219-295-5228

205 E. Fenn St.

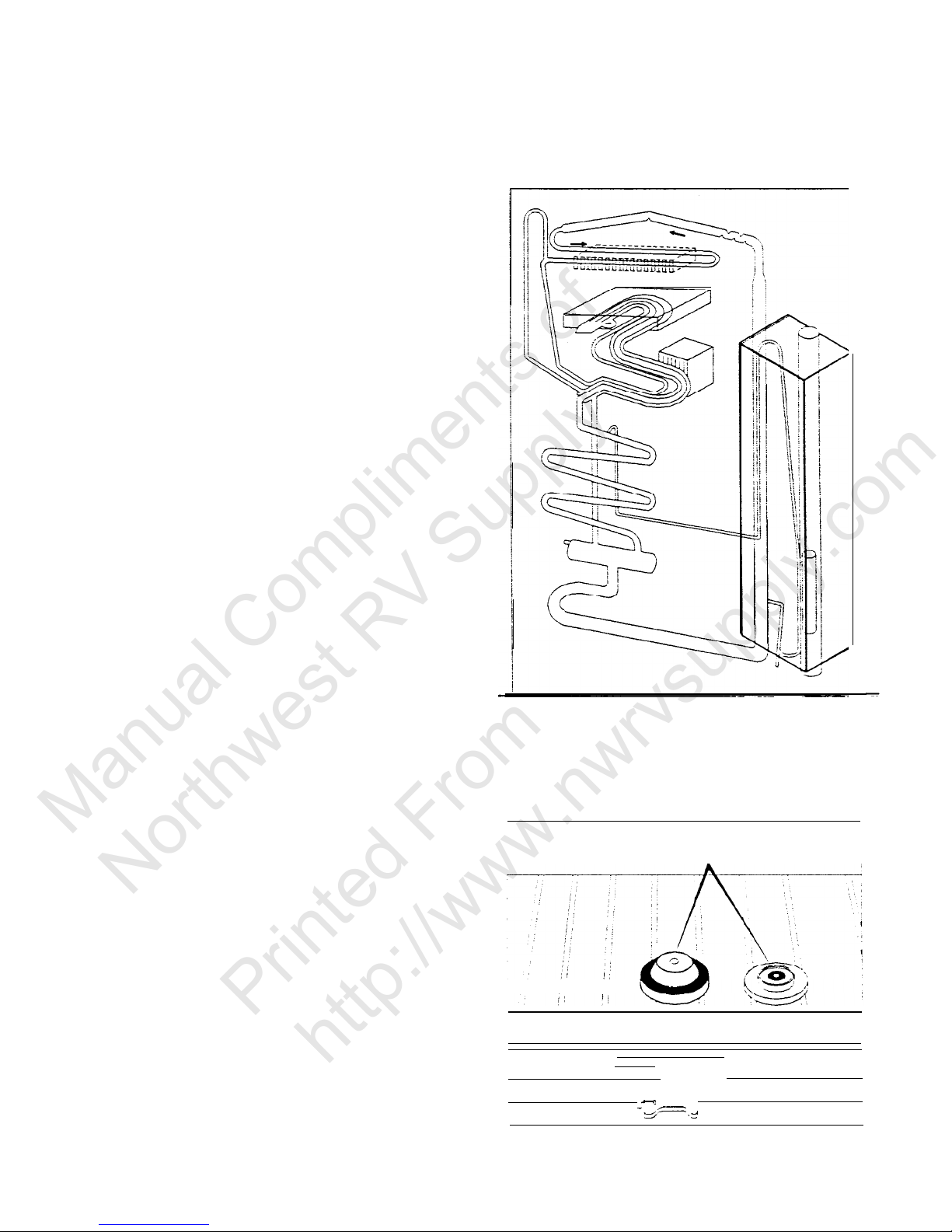

LaGrange, IN 46761

219-463-2191

Technical Services

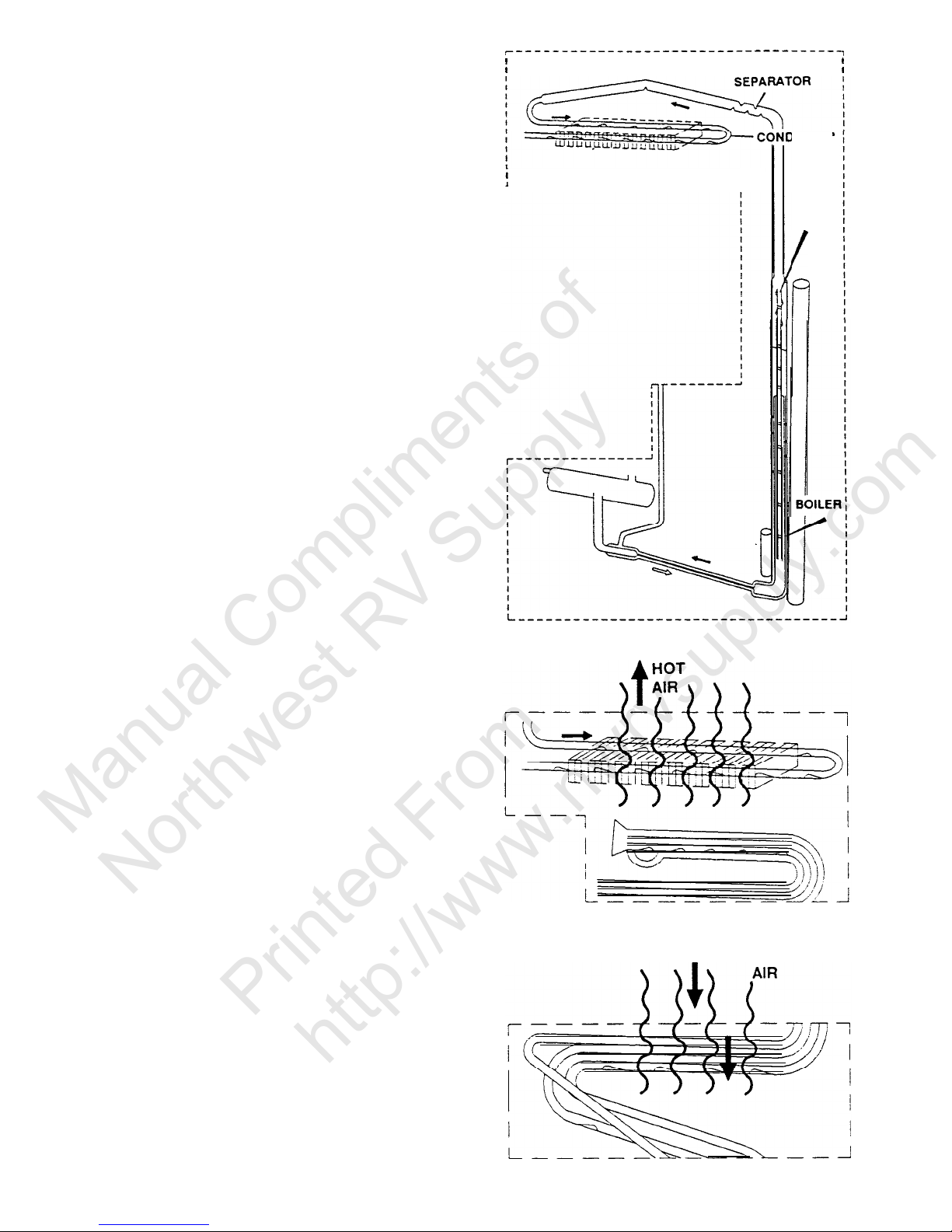

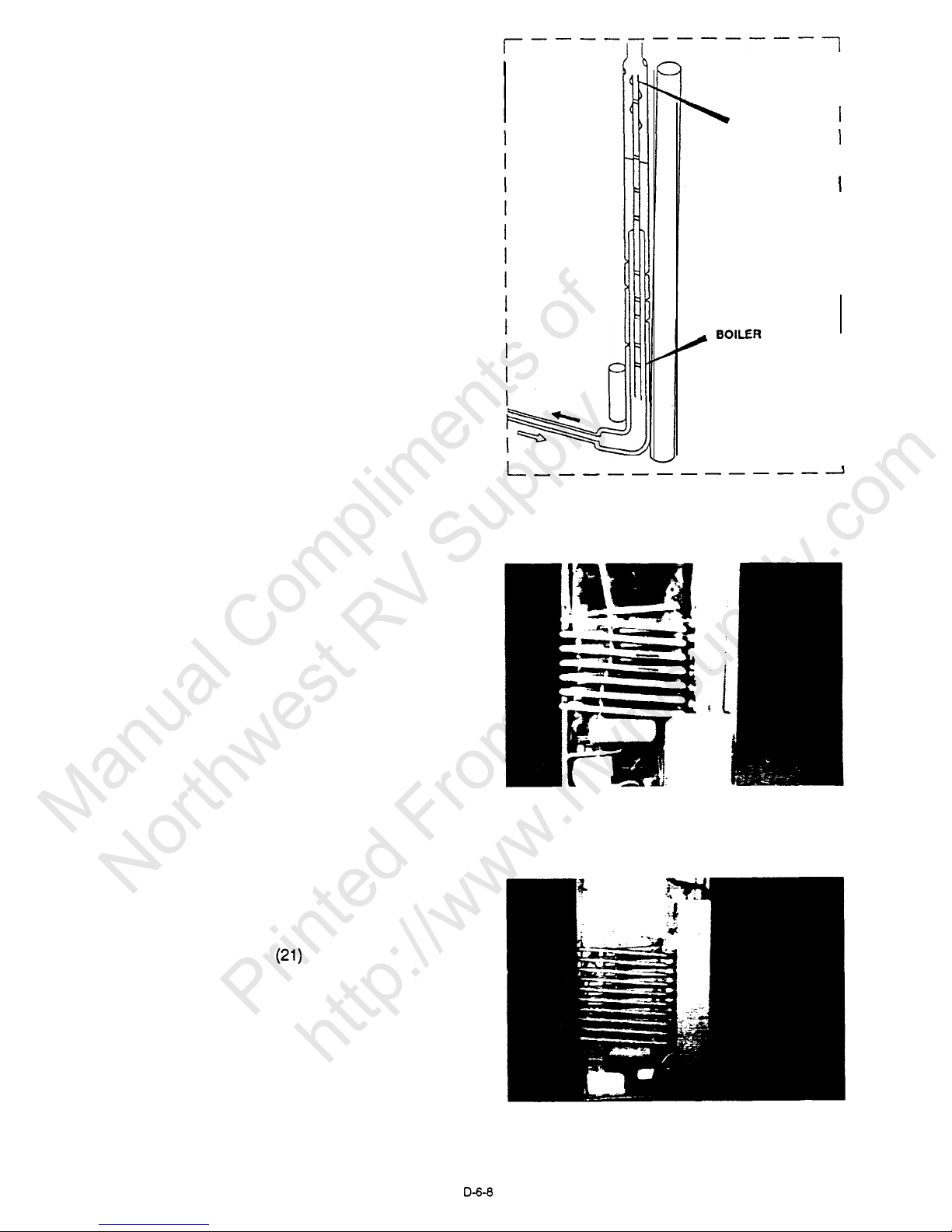

Department

509 S. Poplar St.

LaGrange, IN 46761

219-463-4858

OS1286

8/89

D-l

Diagnostic Service Manuals

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 2

NOTES:

D-2

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 3

MANUAL REFRIGERATOR

DIAGNOSTIC SERVICE ‘MANUAL

Table of Contents

Page

Diagnostic Flow Charts

No Operation . . . . . . . . . . . . .

No

12OV

AC Operation . . . . . . . . .

No Gas Operation (Piezo Igniter)

. . . .

No Gas Operation (Automatic Reigniter)

. .

Operation and Diagnosis

Dometic Manual Refrigerators.

. . . . . .

Glossary of Terms

. . . . . . . . . . . .

Service Bulletins

. . . . . . . . . . . .

D-4-l

D-4-2

D-4-3

D-4-4

D-6-

1

D-8-l

D-9-l

D-3

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 4

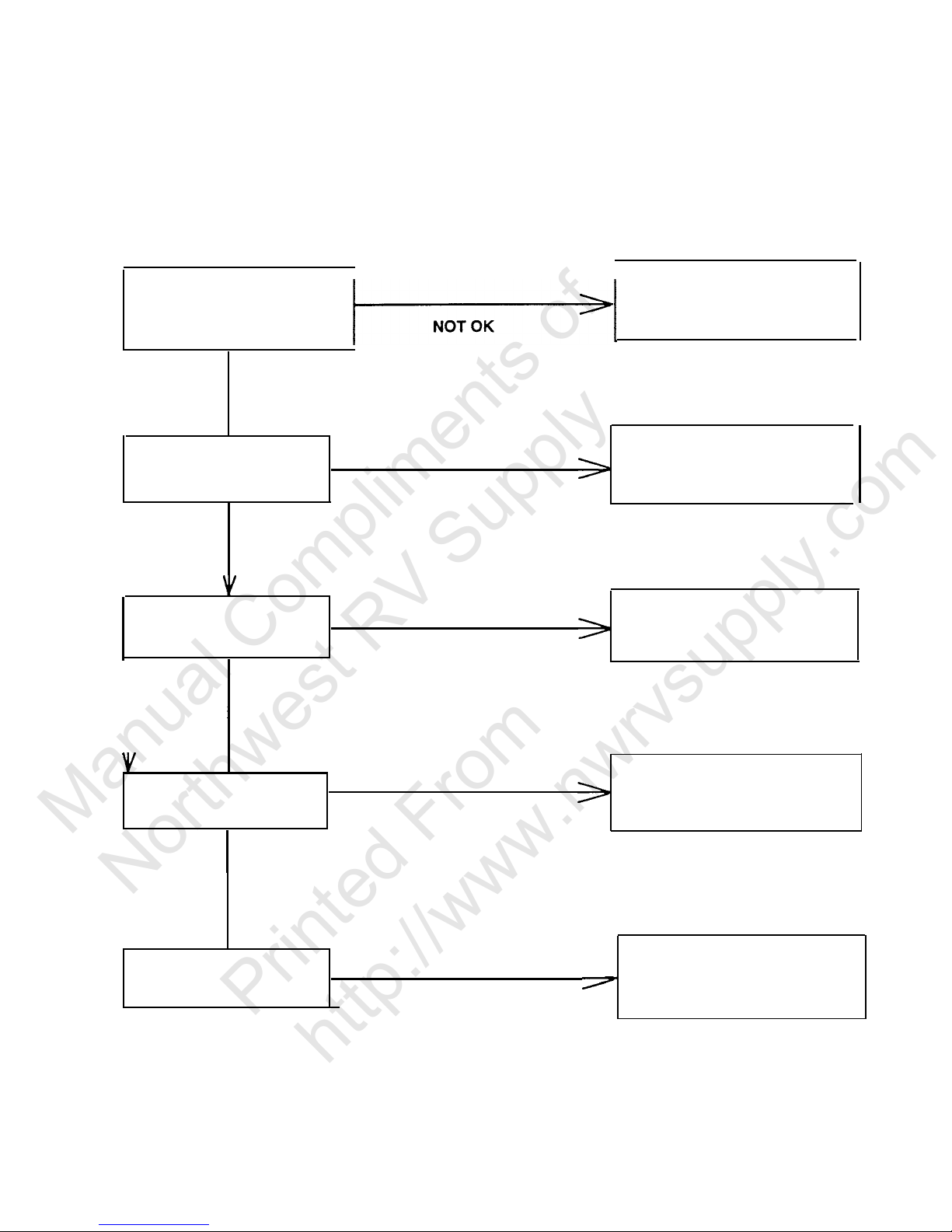

MANUAL REFRIGERATOR

DIAGNOSTIC FLOW CHART

NO OPERATION

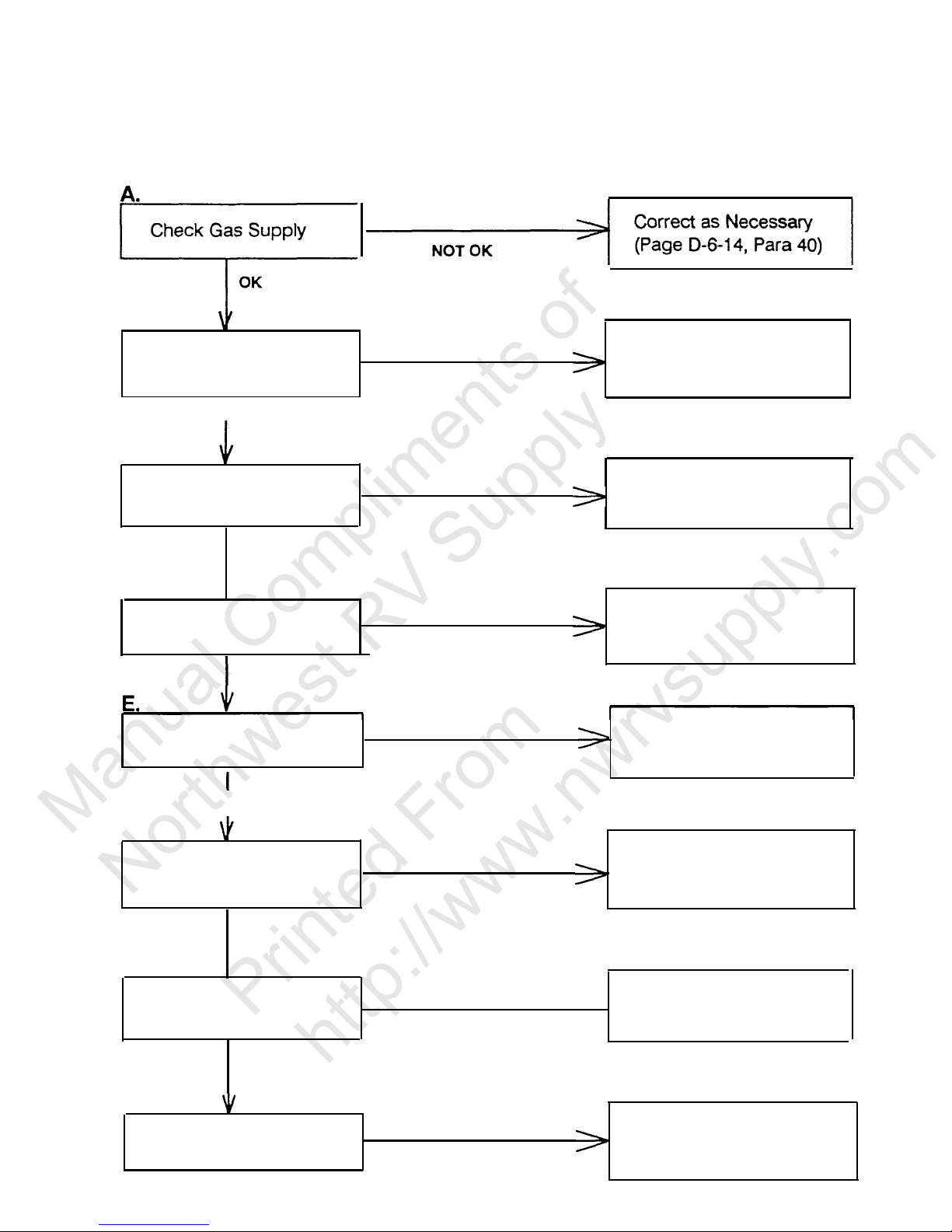

A.

1

Check Supply Voltage

1. 110 Volt Plug

2. Wire Size

Correct as Necessary

OK

B.

V

Check Fuse

Correct as Necessary

NOT OK

Replace if Defective

OK

.c.

Check wiring

Correct as Necessary

NOT OK

OK

D.

Check Switch

NOT OK

Correct as Necessary

(Page D-6-20,

Para.

66)

OK

E.

V

Check Thermostat

, Correct as Necessary

NOT OK

Continuity Check

D-4-l

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

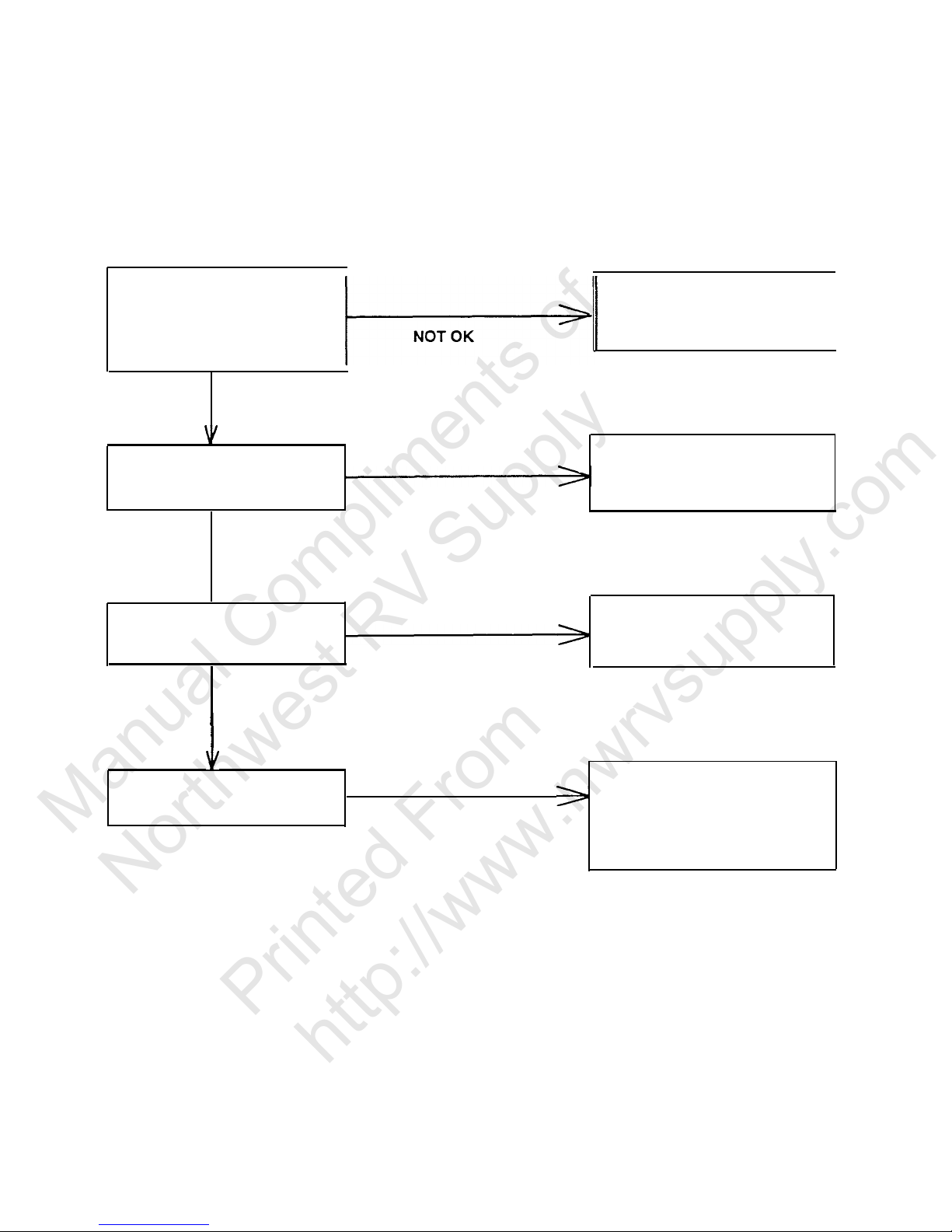

Page 5

MANUAL REFRIGERATOR

DIAGNOSTIC FLOW CHART

NO 120 VOLT AC OPERATION

A.

1. Check AC Power

2. Refrigerator Plugged in

3. Breaker

4. Coach

Plug

Correct as Necessary

OK

B.

Check Selector Switch

NOT OK

Correct as Necessary

(Page D-6-20,

Para.

66)

OK

c.

V

Check Thermostat

Correct as Necessary

Continuity Check

NOT OK

OK

D.

Check 120 Volt Heater

NOT OK

Correct as Necessary

Ohm’s Reading

Bulletin

#28

(Page D-9-l 4, D-9-l 5)

D-4-2

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 6

MANUAL REFRIGERATOR

DIAGNOSTIC FLOW CHART

NO GAS OPERATION - Models Equipped with Piezo igniter

.

Check Gas Supply

OK

B.

Check Switch

I

NOT OK

Correct as Necessary

(Page D-6-20,

Para

66)

OK

.C.

Check Thermostat

OK

D.

V

Check Gas Pressure

OK

NOT OK

NOT OK

Correct as Necessary

Continuity Check

Correct as Necessary

(Page D-6-13,

Para.

37)

Check Flue & Burner

NOT OK

Correct as Necessary

No Obstructions

OK

F.

Check Piezo Resistance

I

NOT OK

Correct as Necessary

(Page D-6-l 8,

Para.

58)

OK

G.

V

Check Piezo Electrode

I

r

Replace Electrod

(Page D-6-18, 58)

NOT OK

OK

Check Spark Gap

Correct as Necessary

of Electrode to Burner

NOT OK

(Page D-6-19,

Para.

62)

D-4-3

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

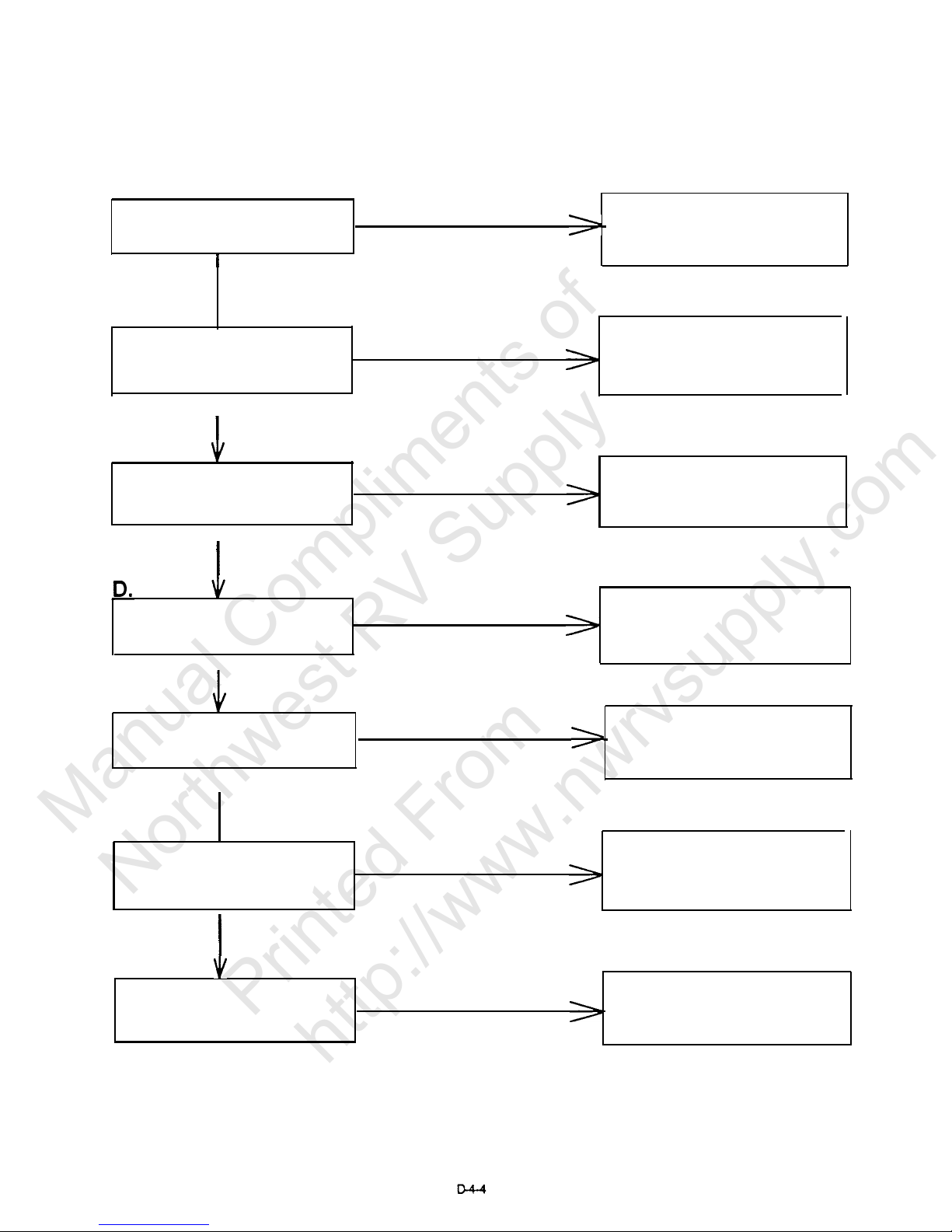

Page 7

MANUAL REFRIGERATOR

DIAGNOSTIC FLOW CHART

NO GAS OPERATION - Models Equipped with Automatic Reigniter

A.

Check Gas Pressure

NOT OK

Correct as Necessary

(Page D-6-13,

Para

37)

OK

B.

V

Check Gas Supply

I

OK

NOT OK

Correct as Necessary

(Page D-6-14,

Para.

40)

C.

Check 12 Volt D.C.

Supply

Correct as Necessary

NOT OK

I

OK

Check Switch

NOT OK

Correct as Necessary

(Page D-6-20,

Para.

66)

I

OK

_E.

Check Thermostat

NOT OK

Correct as Necessary

Check for Continuity

OK

F.

V

Clean Assembly

&

Check Flue & Burner

Orifice as Necessary

NOT OK

I

OK

,G.

Check Electrode

Replace Electrode

(Page D-6-19,

Para.

62)

NOT OK

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 8

NOTES:

D-5

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 9

OPERATION & DIAGNOSIS

OF

DOMETIC

MANUAL REFRIGERATORS

D-6-1

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 10

(1)

This is Dometic’s Manual Refrigeration Diagnosis and Troubleshooting program. In this program

we will discuss the way an absorption cooling unit operates, and the diagnostic procedures

used to troubleshoot the complete refrigerator system.

(2)

Before we begin extensive troubleshooting

procedures on the cooling unit, let’s take a few

minutes to see how it operates.

THE ABSORPTION SYSTEM

(3)

The sealed combustion unit contains a

mixture of ammonia, water and a rust

inhibiting agent. After this solution is

introduced into the coils, this unit is

pressurized with hydrogen gas. When

this system is in operation, the ammonia vaporizes in the hydrogen atmosphere and absorbs heat from inside

the refrigerator.

EVAPORATOR

GAS

TEMPERATURE

EXCHANGER

ABSORBER

VESSEL

BOILER

.

D-6-2

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 11

(4)

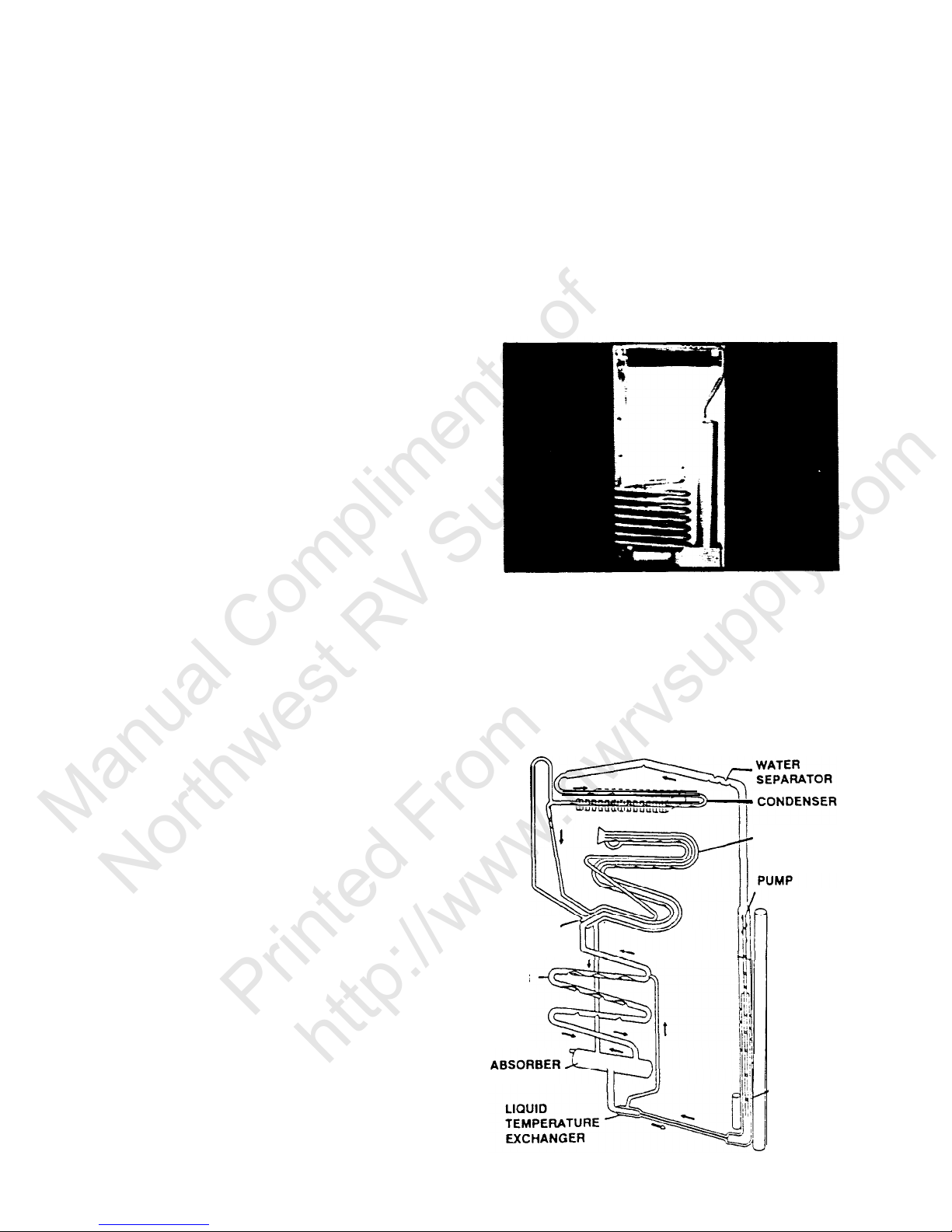

The cooling unit parts that accomplish this

‘cooling’ or heat extraction process, include the:

Boiler or Generator

(5)

Condenser

(6)

Evaporator

PUMP

BOILER

l-------------

WATER

SEPARATOR

I

GAS

TEMPERATUR

EXCHANGER

------------

I

I

1

D-6-3

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 12

(7)

Absorber

ABSORBER

THE ABSORPTION

SYSTEM

CONDENSER

EVAPORATOR

Because the self-contained cooling unit

does not utilize an electric compressor

or pump, the cooling coils can be operated from a variety of heat sources. LP

gas, 120 volts AC and 12 volts DC

heating elements are the most commonly used heat sources for recreational vehicle applications.

TEMPERATURE

EXCHANGER

TEMPERATURE

EXCHANGER

_

(9)

Before this cooling system can properly

extract heat from the cabinet of the

refrigerator, three requirements for proper refrigerator operation must be met.

These are precise heat, specified ventilation and proper leveling.

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2. Air Flow (Ventilation)

3. Heat

D-6-4

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 13

(10)

We will now take a closer look at how the

cooling unit functions in normal operation.

When proper heat is supplied to the boiler,

ammonia vapor is produced and rises in the

siphon pump, carrying with it a weak liquid

ammonia solution. As seen from this drawing,

the siphon pump, or pump tube, is an internal

arrangement within the boiler section. The boiler

section utilizes the ammonia-water liquid solution in the absorber and as it is heated, turns

the solution into a strong ammonia vapor, which

is needed to operate the system. This strong

ammonia vapor rises from the pump tube to the

condenser coil.

Any deviation from the listed amount of

heat to the absorption system will alter the

ammonia to water ratio, which, in turn, will

decrease the cooling unit’s overall efficiency.

The weak ammonia solution which remains

behind is diverted to the top of the absorber

coils to perform a function that we will discuss

in further detail later in the program.

(11)

The air that passes through the condenser fins,

from the venting system, removes heat from the

ammonia vapor, causing it to condense into a

strong liquid ammonia solution. As a liquid, it

then flows to the low temperature evaporator, or

freezer companment, where it comes into

contact with a hydrogen atmosphere. When this

occurs, the ammonia begins to evaporate which

draws heat from inside the freezer section, to

the rear of the cooling unit.

(12)

This heat is then dissipated out through the

upper vent, which allows the refrigerators

interior temperature to properly maintain food

storage requirements. Not all of the liquid

ammonia evaporates in the freezer. What is left

continues to evaporate as it flows to the high

temperature evaporator, or food storage com-

partment.

WATER

I------------------------~

ENSER

PUMP

COLD INTERIOR

D-6-5

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 14

U

3)

As this process continues, the ammonia and

hydrogen vapors become intermixed and flow

downward into the absorber vessel. As the

ammonia vapor comes in close contact to the

liquid ammonia solution in the absorber vessel,

the ammonia is absorbed into the liquid

solution, allowing the hydrogen vapor to rise up

through the absorber coils. After this absorption

process, the vapor consists of mostly hydrogen

with some traces of ammonia.

-------

(14)

To remove the remaining amounts of ammonia

vapor still present in the hydrogen, a

continuous flow of weak ammonia solution is

fed, by gravity, to the top of the absorber coil

from the boiler. As this weak ammonia solution

flows downward through the absorber, it

absorbs the ammonia vapor from the mixture,

allowing the hydrogen vapor to rise through the

absorber coil and return to the evaporator. With

the hydrogen returned to the evaporator and

the ammonia remixed into solution in the

absorber vessel, the cooling process can

continue.

(15)

Now that we have a basic understanding of

proper cooling unit flow and operation, let’s

take a step-by-step look at the three require-

ments for proper cooling unit operation. Please

note it is essential that these three requirements

be diagnosed before attempting to diagnose

the cooling unit. A problem with leveling, heat

input or ventilation may lead you to think that

the cooling unit is faulty, when actually it is not.

This

causes an

increased expense to you, the

customer, and valuable shop time is wasted

because of incorrect diagnosis, By following

and checking the three unit requirements, costly

diagnostic errors can be eliminated.

---

__------

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2.

Air Flow (Ventilation)

3. Heat

D-6-6

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 15

(16)

Since the absorption system utilizes no

mechanical pumps or compressors to circulate

the refrigerant within the system, proper leveling

is required to provide correct refrigerant flow in

the gravity-feed system. Without proper leveling,

refrigerant within the cooling coils will collect

and stagnate at certain areas. When this

happens the cooling process will stop.

(17)

On the older style cooling units equipped with

square boiler box covers, this condition can

cause permanent cooling unit failure. As we can

see from this drawing, square boiler box

cooling units utilize an exposed siphon pump

tube which will become excessively super-

heated in an out-of-level condition. This can

allow the rust inhibiting agent to chemically

break down and permanently block or restrict

the normal refrigerant flow through the pump.

Shaking, tipping or so called ‘burping the

refrigerator will not loosen or dislodge the

blockage. The only recommended service

procedure is to replace the cooling unit. To

prevent this occurrence, proper leveling is of

utmost importance when the RV is parked for

any length of time.

THREE REQUIREMENTS

FOR PROPER OPERATION

1.

Level

REFRIGERATOR IS TO BE LEVEL

(18)

To level these units, the spirit or bubble level

LEVELS

should be placed in the approximate front and

center of the floor of the freezer compartment.

The coach should then be positioned so that at

least 3/4 of the bubble is within the required

mark while the refrigerator is in operation.

REMEMBER: Failure to property

level

a square

boiler box can result in a lack of cooling or

permanent

damage to the coding unit. When

the vehicle is moving, leveling is not critical as

the rolling and pitching movement of the RV will

keep the solution in motion, preventing the

solution from accumulating in the piping.

--

-

D-6-7

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 16

(19)

In recent years

Dometic

has engineered a new

type of cooling unit that utilizes an improved

siphon pump tube design which drastically

reduces the possibility of permanent damage to

the coils if operated in an out-of-level condition,

or too much heat is generated at the boiler

section. As we can see from this drawing, the

siphon pump tube is enclosed in the design

and is surrounded by a weak ammonia solution,

which will protect the pump tube from abnormally over-heating. This type of unit; however,

does not eliminate the need for proper leveling.

The unit still requires gravitational flow to

provide the proper cooling process, and if

leveling is outside the necessary limits, cooling

will dramatically slow down or stop completely.

The cooling coils are not normally damaged in

this fashion and once proper leveling is maintained, the cooling process will resume.

(20)

Spirit or bubble levels are no longer being

supplied with the new style refrigerators as the

RV or vehicle only needs to be leveled so it is

comfortable to live in, with no noticeable sloping

of the floor or walls. For diagnosis, the new

style

cooling

units that incorporate the

protection boiler system, can be differentiated

from the older style coils by the shape and

design of the outer boiler box cover on the rear

of the cooling unit. These units will incorporate

a circular metal cover,

. . .

while the older style utilizes a square

shaped enclosure.

We will discuss diagnosis

and troubleshooting of these units in more

detail later in the program.

PUMP

I

I

I

I

I

I

I

I

I

I

I

I

I

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 17

(22)

The coach vent system must be able to provide

a way to direct the hot air, produced by the

action of the cooling unit, out away from the

installation of the refrigerator.

(23)

In a good installation there should be as little

open space as possible surrounding the sides

and top of the refrigerator to achieve proper air

flow. All potential dead air pockets should be

blocked or baffled to insure that heat from the

cooling unit won’t be trapped in these spaces

and reduce efficiency. In addition, the cooling

unit should be at least one inch from the

nearest surface made of combustible materials.

Please follow the installation manual for proper

dimensions and clearances.

RVIA

requires that the refrigerator be

installed in such a manner as to provide

complete separation of the combustion system

and the interior atmosphere of the recreational

vehicle. This regulation requires all seams and

joints in the enclosure be sealed. The under-

counter installation is different. The addition of

a metal chute the width of the enclosure, that

extends from the upper side vent, will help

eliminate the possibility of dead air pockets. It

helps direct the hot air out the exhaust vent.

The best method for venting the absorption

refrigerator is with a lower side vent and a roof

vent. Using proper Dometic vents will give you

sufficient intake and exhaust areas for ventila-

tion

(24)

Heat application to the boiler section of the

cooling unit must be within the designed

BTU’s.

Never oversize the heating element on AC or

DC power source. Always use the proper size

orifice for gas modes. As explained earlier, any

deviation will cause a potential cooling unit

failure.

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2. Air Flow (Ventilation)

--------

----1

I

I

0"

CLEARANCE

1"

FROM

AIR FLOW

I

I

I I

------------

J

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2. Air Flow (Ventilation)

3. Heat

D-6-9

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 18

(25)

Three things must be remembered

when diagnosing a cooling unit:

First, circulation within the cooling unit is totally gravitational. This

means proper leveling is important.

Second, heat - created to boil

the ammonia

-

now has to be dissipated into the surrounding air. Heat

from the absorber and condenser must

also be dissipated so as to cool the

ammonia sufficiently.

Third, proper heat application at

the boiler section.

THE ABSORPTION SYSTEM

(26)

When diagnosing a cooling unit, remember this

is the only part we cannot field check with test

equipment, yet it is the simplest and quickest

part to diagnose.

CONDENSER

EVAPORATOF

TEMPERATURE

EXCHANGER

BOILER

DIAGNOSING

THE

COOLING UNIT

(27)

After the unit has been operating for

approximately one hour, carefully touch the unit

at the boiler box and the absorber area. These

areas should be approximately the same

temperature, regardless

of the

ambient

temperature. Equal heat between the boiler and

the absorber indicates the fluid circulation within

the unit is good.

TEMPERATURE

GOOD CIRCULATION

D-6-10

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 19

(28)

One of the faults with a cooling unit is

a blockage. This can happen when the

unit is operated off-ievel, or if too much

heat has been applied to the boiler

area. To the touch, this unit will be

extremely hot at the boiler with little

warmth at the absorber. In other words,

no circulation.

(29)

This type of fault means a lost charge.

It is known as a ‘leaker’. To the touch,

this unit will be warm at the boiler and

extremely hot at the absorber. In this

condition we are still boiling ammonia

but have no hydrogen for evaporation.

(30)

The following section of the program

examines the Dometic manual refrigerator’s gas and

electrical systems.

Dometic refrigerators are designed for

both piezo and automatic ignition. Both

systems will be covered in this presentation.

T

BOILER

HOT GAS ONLY

WARM

BOILER

D-6-1 1

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 20

(31)

Let’s look at the current Dometic refrigerators

and see how the gas flows.

(32)

Gas flows from the gas line to the shut-off valve

and to the connection piece.

(33)

into the combination gas and electric thermostat

(34)

through the safety valve thermocouple

(35)

test housing

UNDERSTANDING

THE

GAS SYSTEM

SHUT-OFF

VALVE

I

GAS LINE

CONNECTION

PIECE

COMBINATION

GAS & ELECTRIC

THERMOSTAT

SAFETY VALVE/

PRESSURE

TEST

HOUSING

D-6-12

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 21

(36)

and onto the orifice and burner assembly.

Remember that except

for the connection

piece,

all fittings are O-ring sealed. Whenever the

system is separated the O-rings must be

replaced.

ORIFICE & BURNER

ASSEMBLY

(37)

To diagnose the gas system, connect a

manometer to the test point. With the

thermostat on maximum you must have 11

inches water column pressure at this point. If

you have 11 inches pressure, your problem

Is to the right of the test point. If you do not

have 11 inches water column pressure, the

problem Is to the left.

(38)

Let’s take a closer look at the gas thermostat.

In this drawing we will review how a thermostat

functions. When the thermostat is working

properly, the manometer will read line pressure

when set at maximum and the refrigerator is

trying to cool. From this drawing you can see

the gas flow when the refrigerator is trying to

cool. The gas flows through the thermostat at

line pressure without restriction. The valve is

(39)

The valve is now closed and the gas must flow

through the by-pass screw; the gas is now

diverted through the by-pass screw, which

regulates the size of the low flame. This

condition can only exist when the refrigerator is

cold or the thermostat is set to minimum or off.

If the sensing tube has lost its pressure, even

with the thermostat set on maximum, you will

have only low flame.

DIAL SHAFT

open at this time.

VALVE

DIAL SHAFT

SCREW

CLOSED VALVE

D-6-13

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 22

(40)

The most efficient way to diagnose the gas

system would be to first connect the gas

manometer to the pressure test point. With the

thermostat set at maximum you must have 11

to 12 inches water column pressure for the

refrigerator to operate properly. If your

manometer reads higher than 11 to 12 inches

water column pressure, the tank regulator is

adjusted to high, readjust it.

Make sure the

gas system has at least 50% of the coach’s LP

appliances on at the time the system is being

adjusted. If the manometer reads 11 inches, the

problem of no cooling lies in the burner

assembly, flue pipe or venting.

(41)

If you have less than 11 inches water column

pressure, the next step would be to remove the

by-pass screw.

NOTE:

The by-pass screw

reduces the pressure

and

volume of gas to the burner.

(42)

Shut off gas supply at the back of the refrigerator. Remove the by-pass screw from the top of

the thermostat,

Use a by-pass screw that does not have the

small O-ring at the bottom. Reinstall this by-

pass screw into the thermostat.

D-6-14

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 23

Turn on the main gas supply and take a

reading. If the manometer now reads 11 inches,

the thermostat is defective and must be

replaced.

(45)

If the by-pass screw test shows no change in

gas pressure, the problem lies with the gas

supply to the refrigerator. Shut off the gas

supply, remove the by-pass screw, replace it

with one that has an O-ring and turn on gas

supply. Remember to check for a gas leak. At

this time we will take a look at the rest of the

gas system.

(46)

The safety valve, or flame

consists of a brass alloy

failure

safety

device,

valve housing and

cap, an electro-magnet, and a thermocouple,

which generates 14 to 30 millivolts when heat is

applied to the tip. It is used to energize the

electro-magnet in the safety valve. The purpose

of this device is to insure that the flow of gas is

shut off in the event flame is lost at the burner.

If this should occur, the thermocouple cools,

the magnet loses it magnetic field and the

valve closes. Most failures of this device are

related to the magnet, not the thermocouple.

Should this happen, the complete safety valve

should be replaced.

D-6-15

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 24

(47)

Once the gas has been allowed to pass

through the safety valve, it flows to the gas jet

and burner. These have been specifically

designed to eliminate most of the normal maintenance required due to the corrosive contami-

nants in the gas, as well as soot and rust

which fall from the flue pipe. The jet has an

orifice made of an industrial ruby which has

been laser-beam drilled. Each model of

Dometic refrigerator uses a different size orifice

in order to maintain the required amount of

heat at the siphon pump. To clean the jet and

burner, soak them in an alcohol base solvent

and allow to air dry. DO NOT use a pin or

needle. This will distort or shatter the orifice.

(48)

If you determine that disassembly is required,

be aware there are two model designs for

manual refrigerators. The design pictured here

will be discussed first.

(49)

Shut off the main gas supply, then disconnect

at the back of the refrigerator. Remove the

cover over the thermostat and burner protection

cover at the right,

(50)

Now disconnect the 12 volts at the terminal

block and unplug the 120 volt cord. Remove

the two mounting screws on the left and pull

the metal locking arm out from under the

burner housing.

D-6-1

6

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 25

(51)

The control assembly will now drop down and

can be pulled outward for service.

(52)

Pictured here is the other model design. Make

sure the main gas supply has been shut off

and disconnect the gas supply line at the

refrigerator.

I

(53)

Remove 3 screws on the burner cover plate.

The sheet metal assembly should now slide out

from the back of the refrigerator.

Remove the 2 screws from the plastic cover.

Also the 2 screws on the left and 2 screws on

the right of the metal bracket.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 26

There are 3 screws in the burner area that

must also be removed. Please note - these are

machine screws, not sheet metal type. It is

important for them to be reinstalled in this area

only.

(56)

The control assernbly will now drop down and

can be pulled out..,.,

fnr

On the present line of manual refrigerators we

use one of two methods of igniting the burner

flame. Shown on the right is the piezo system;

on the left is the igniter reigniter.

(58)

The piezo lighter is a self-contained assembly

which generalty -does not need maintenance.

When the button is ‘pushed, a spring loaded

striker creates a spark. If

there is

no resistance

when pressing the button, the

piezo

igniter is

defective and must be replaced. If the

piezo

snaps or has resistance when the button is

pushed, but there is no spark, the problem lies

in the electrode or electrode wire.

D-6-16

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 27

The igniter reigniter, used on certain

Dometic

model refrigerators, operates on 12 volt current.

On gas operation the igniter senses the resistance through the flame between the electrode

and burner. When there is no flame at the

burner, the resistance is high and the igniter

begins sparking to light the burner. As soon as

the flame is lit, the resistance between the

electrode and burner drops and the igniter

stops sparking. The resistance is monitored by

the igniter, and, if for any reason the flame

goes out, the igniter begins sparking until the

burner is lit. This insures that the flame will

always be lit when desired. Each time the

igniter reigniter system sparks, a light will

illuminate on the lower left front corner of the

refrigerator.

If the electrode does not spark first, make sure

the igniter is receiving 12 volts. If the igniter is

receiving 12 volts and produces no spark, it

must be checked for operation.

(61)

Turn the refrigerator off and remove the wire

between the electrode and igniter. Now turn the

refrigerator to the gas mode. If no internal

clicking sound is heard the igniter is defective.

It is important to remove the high voltage wire

that goes to the electrode from the igniter when

you are checking the igniter for operation. The

high voltage wire and the electrode can be

shorted to ground causing the igniter reigniter

to think that the flame is lit, resulting in no

spark on gas operation.

(62)

The distance between the tip of the electrode

and the burner, known as the spark gap,

should be 3/16 of an inch. A greater distance

will create a slow spark causing the light to

blink. A lesser distance will create a fast spark

that may not light the burner.

Burner

SPARK GAP

D-6-19

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 28

(67)

Before an appliance can be sold to a recrea-

tional vehicle manufacturer it must be tested

and approved by a nationally recognized

testing laboratory for the specific end use

intended.

All Dometic refrigerators used in

recreational vehicles have received this certifica-

tion.

If you require additional service assistance on

the basic requirements for the cooling unit

operation or the manual refrigeration, please

refer to the diagnostic manual. For additional

technical service assistance, contact the

Technical Service Department at (219)

463-

4858.

(69)

You are an essential part of a team that contributes greatly to the successful future of the

RV industry, your dealership and

Dometic.

Thank you for participating in the training

program.

D-6-21

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 29

NOTES:

D-7

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 30

Glossary of Terms

MANUAL REFRIGERATION

1.

ABSORBER: Section of the cooling unit where the hydrogen and ammonia vapor are intermixed

in the absorber. Ammonia vapor returns to solution and the hydrogen returns to the

evaporator.

2.

BOILER:

Section of the cooling unit where heat is applied. This is where the ammonia is

partially separated from the water.

3.

BY-PASS SCREW: Small brass screw located on any

Dometic

gas thermostat that regulates gas

flow in the low flame mode. There are three common sizes of this screw: S-17-350 BTU, S-

14-325 BTU, S-l l-300 BTU.

4.

Found on current

Dometic

manual GAS/ELECTRIC THERMOSTAT:

refrigerators, this device is held in place with "0"" ring seals in the gas line and replaces

separate electric and LP gas thermostat controls. On the LP gas mode, full line pressure is

directed through the thermostat to the burner until the thermostat senses that the

refrigerator cabinet has reached proper cooling temperature. At that rime an internal valve

closes and redirects the gas flow through the by-pass screw. This reduces the amount of LP

gas going to the burner assembly. The gas flow remains in this “by-pass” mode until the

thermostat senses that the refrigerator cabinet needs more cooling. Again, the thermostat

directs the LP gas flow through the thermostat at full line pressure until the cabinet

temperature is sufficient. On the electric mode the internal mechanism breaks contact

(continuity) when adequate cabinet temperature has been reached.

5.

CONDENSER:

Section of the cooling unit that cools the ammonia vapor into ammonia liquid.

6.

COOLING UNIT: Self-contained, hermetically sealed set of steel coils where the refrigeration

process takes place. The chemicals involved in the cooling process include hydrogen,

ammonia, water and a rust inhibiting agent.

7.

CUT-OFF VALVE (Shut-Off Valve): Valve where the incoming propane supply is attached.

This valve is direct-coupled to the selector switch by means of a steel clip. When the selector

switch is turned to the electric mode, the cut-off valve is automatically closed. When this

same switch is turned to the LP gas mode, the electric circuit is also automatically

interrupted.

8.

EVAPORATION:

A process that causes a liquid to turn into a vapor. Whenever evaporation

takes place, heat is removed.

9.

EVAPORATOR:

Section of the cooling unit where the cooling effect is produced. Liquid

ammonia evaporating in a hydrogen atmosphere takes place in the evaporator.

10.

HEATING ELEMENTS:

Elements that operate off either AC or DC voltage that create heat to

the cooling unit.

11.

IGNITER-REIGNITER:

The igniter-reigniter, used on certain

Dometic

model refrigerators,

operates on 12 volt current. On gas operation the igniter senses the resistance through the

flame between the electrode and burner. When there is no flame at the burner, the resistance

is high and the igniter begins sparking to light the burner. As soon as the flame is lit, the

resistance between the electrode and burner drops and the igniter stops sparking. The

resistance is monitored by the igniter, and if for any reason the flame goes out, the igniter

begins sparking until the burner is lit. This insures that the flame will always be lit when

desired. Each time the igniter-reigniter system sparks, a light will illuminate on the lower

left front corner of the refrigerator.

12.

L.P. GAS PRESSURE: For the refrigerator to operate properly on LP gas, the gas pressure

should be set at 11” water column pressure.

NOTE: use the test port at the rear of the

refrigerator to take this reading.

D-8-1

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 31

(Glossary of Terms . . continued)

13.

14.

15.

16.

17.

18.

ORIFICE

(JET):

A small brass fitting that is mounted on the gas line just prior to the burner.

This device incorporates a very small opening to greatly reduce gas flow to the burner. The

orifice is cleaned by using an alcohol based solvent and allowing to air dry.

PIEZO LIGHTER: Self-contained lighter assembly that is used to generate a spark to light the

refrigerator on LP gas. This unit contains a quantity of quartz crystals that when pushed or

snapped, produce a spark. There are no serviceable parts on this device.

SAFETY DEVICE: An assembly of parts (safety valve, magnet and thermocouple) that shuts off

the supply of LP gas to the burner assembly if the flame goes out for any reason. This is to

ensure that a concentration of unburned gas does not accumulate in the refrigerator vent

area.

SELECTOR SWITCH: This is also a circuit interrupter on the 12 volt DC, 120 volt AC and gas

sides of operation on the refrigerator. When the customer selects either DC, AC or GAS

operation, the selector switch directs electricity first to the thermostat and on to the heating

element, or igniter-reigniter. When this switch is turned off, the AC or DC circuit is

interrupted.

SPIRAL BAFFLE: Spiral metal device that is hung in the flue tube assembly of the cooling unit.

The baffle causes the heat supplied by the gas burner to stay at the boiler assembly a longer

period of time. This allows the absorption system to work as efficiently on LP gas as other

heat sources.

WATER COLUMN: The pressure rating given to LP gas line pressure. Usually this pressure can

be varied by adjusting the regulator on the LP supply tank. A manometer is the device used

to test LP gas pressure.

D-8-2

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 32

TYPES OF BLOCKAGE

To understand the absorption principle we have set up several refrigerators to inspect and diagnose.

Carefully touch the absorber and boiler sections of each unit and record your findings. Proceed with

caution as some of these units could be extremely

HOT.

Listed below are three types of units you will be testing:

q

GOOD COOLING UNIT

Carefully touch the unit at the boiler box and the absorber area. These areas

should be approximately the same temperature, regardless of the ambient

temperature. The equal heat between the boiler and the absorber indicates the

fluid circulation within the unit is good.

BLOCKAGE

One of the faults with a cooling unit is blockage. This can happen when the unit

is operated off-level, or if too much heat has been applied to the boiler area. To

the touch this unit will be extremely hot at the boiler with little warmth at the

absorber. In other words, NO CIRCULATION.

LEAKER

This type of fault means the unit has lost its charge - it’s known as a “leaker”. To

the touch this unit will be warm at the boiler and extremely hot at the absorber.

In this condition we are still boiling ammonia but have no hydrogen for

evaporation.

D-9-l

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 33

CHANGING THE

HINGE POSITION

q

Refrigerator

Bulletin R54/7A

March 1987

R54/7A

MODELS:

2600,2602,2800,2802,

3600,3601,3800

& 3801

I

WHEN

CHANGING

THE HINGE POSITION:

Insure that the door latch assembly operates

properly after changing the hinge position from

left to right, or vice-versa, with the following

checks:

A. The refrigerator door(s) opens and closes

easily.

B.

The door gasket seals smoothly and completely

on all sides.

C. Slide the latch left to the locked position

and try to open the door(s).

The latch

assembly should keep the door(s) from opening.

NOTE: A

hard

pull will release the door

latch assembly and the door(s) will

open.

This is not a fault.

(If

an

adjustment

is

required,

repeat the

above

procedure to determine the

effectiveness of the repair.)

SMOOTH FIT,

PROPER SEAL

SMOOTH FIT,

FIG. 1

P

ROPER SEAL

If the door(s) open when the latch assembly

is in the locked position, adjust the hinge/door

assembly. Follow the outlined steps to complete

this procedure:

1.

Open the door and remove the two (2)

front decoration screws located underneath

the upper hinge assemblies.

2.

Remove the front decoration by lifting

the decoration upward.

D-9-2

FIG. 2

3.

4.

FlG.

3

Loosen the screws that hold the upper

hinge in place.

Reorient the door so the catch retainer

on the door will engage with the latch

assembly. (Usually lowering the door

will accomplish this.)

MOVABLE

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 34

(Bulletin R54/7A continued)

5.

Hold the door in its new position and

carefully

retighten

the hinge screws,

being careful not to change the hinge

position.

6.

Close the door and again determine if

the latch is now operational.

7.

If more adjustment of the door position

is

necessary,

the center hinge screws

may be loosened to reorient the door in

the proper position.

8.

Again retighten the hinge screws to

allow the latch to operate properly.

SPECIAL

HINTS TO ADJUST DOOR

1.

If there is a large distance between the lower door

catch retainer

and the latch,

adjusting

the hinge

position still may not allow the latch to operate properly.

LATCH

FIG. 5

EXCESSIVE

GAP

2.

Remove the upper, and if necessary, the center hinge

pin(s).

This allows you to remove the refrigerator

door(s).

3.

Place a metal,

1/4"

flat washer (available at any

hardware store) over the lower hinge pin and reinstall

the

door(s).

This will raise the door to engage the

latch assembly. (On very rare occasions two

[2]

washers

may be required.)

If the latch assembly still will not engage, the base can

be repositioned to reorient the door as follows:

1.

Turn the refrigerator on its side to gain access to the

four (4) base screws. Loosen all four (4) screws slightly.

2.

Reposition the base so that the door catch retainer

engages with the latch.

3.

Retighten the base screws

while

holding

the base in

its new position.

By following the above listed procedures you will be able

to correct any door latching problems incurred when

reversing the hinge position on your

Dometic

refrigerator.

If you have any questions concerning

contact our Technical Services Department at:

DOMETIC

SALES CORPORATION

509 South Poplar St.

LaGrange,

IN 46761

this procedure,

FIG. 7

BASE SCREWS

D-9-3

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 35

PROCEDURE FOR

CHANGING COOLING UNIT

The following categories have been established

predicated on similarity of design and procedure

for replacement of cooling units. Most

Dometic

refrigerators are covered in one (1) of these

categories.

SPECIAL NOTE: After the cooling unit has been

installed, the initial

start-up

time can be

shortened by tilting the refrigerator from side

to side and then from front to back before the

refrigerator is turned on.

TILT SIDE-TO-SIDE

Run the refrigerator on a bench for 12 hours

after the cooling unit has been installed (all

food should be removed for testing).

Refrigerator

Bulletin

R55/7A

April 1987

6

WOOD BLOCK

FIG. Al

2

FIG. A2

\I

FC140

Cooling

Unit cannot be replaced

A. Category

#l

RM46

RM46 1

RM663

RM2500

RM360

RM660

RM2300 RM3500

RM460

RM661

RM2400

REMOVAL OF COOLING UNIT

1.

2.

3.

4.

5.

6.

Remove heater(s) from boiler case (FIG. Al).

Disconnect burner from chimney (FIG. A2).

Remove evaporator screws inside refrigerator

and remove cooling flange (FIG. A3).

Remove screws holding clamp for capillary

tube.

Pull capillary gently out of plug (FIG.

A3).

Remove screws

Al).

Apply leverage

Al).

holding unit from rear (FIG.

as shown and pull out (FIG.

FIG. A3

D-9-4

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 36

(Bulletin

R55/7A

continued)

INSTALL REPLACEMENT COOLING UNIT:

1.

2.

3.

4.

5.

6.

7.

Trim the Styrofoam portion of the cooling

unit if

it does not go freely into the

refrigerator.

Apply sealing permagum (sealing tape) on

mounting plate (A; FIG. A4).

Apply thermal mastic on the evaporator coil

(B; FIG. A4).

Tighten screws securely to obtain proper

contact between the evaporator coil and

evaporator flange; otherwise improper cabinet

performance may result.

Install the heating element completely back

into the pocket and plug in.

Reconnect burner assembly to chimney.

Reinstall capillary tube into proper position

(FIG. A3).

FIG.

A4

B. Category #2

RM100

RM763

RM1303

RM760

RM1300

RM2600

RM3600

RM76

1

RM1301

RM2800

RM3800

REMOVAL OF COOLING UNIT:

1.

2.

3.

Remove screw holding clamp for capillary

tube.

Pull capillary tube out gently and

place aside (FIG.

Bl).

a.

RM3600, RM3800 (FIG. B4)

Remove heater(s) from boiler case (FIG.

Bl).

Disconnect burner from chimney (FIG. B2

and B3).

a.

RM2600,

RM2800,

RM3600,

RM3800

(FIG. B3).

D-9-5

4.

Remove

evaporator screws (FIG.

B4).

5.

Remove screws holding unit from rear (FIG.

Bl).

6. Cut tape holding plate (FIG.

B1).

7. Apply leverage as shown and pull unit out

(FIG. B

).

5

6

WOOD BLOCK

FIG.

B3

FIG. 84

INSTALL REPLACEMENT COOLING UNIT:

1. Trim the Styrofoam portion of the cooling

unit if

it does not go freely into the

refrigerator.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 37

(Bulletin R55/7A) continued)

2.

3.

4.

5.

6.

7.

Apply sealing permagum (sealing tape) on

mounting plate (A; FIG.

B5).

Apply thermal mastic on the evaporator coil

(B; FIG.

B5).

Tighten screws securely to obtain proper

contact between the evaporator coil and

evaporator flange;

otherwise improper cabinet

performance may result.

Install the heater element completely back

into pocket and plug in.

Reinstall capillary tube into proper position.

a.

RMl00,

RM2600 & RM2800 will clamp to

cooling flange. (FIG. B4)

b.

RM760, RM761 & RM763 will extend into

retainer tube approximately 31” (FIG .

Bl)

C.

RM1300, RM1301 ` RM1303 will extend

into retainer tube approximately 36”

(FIG.

Bl)

d.

RM3600

&

RM3800 have internal thermostat

with capillary tube clamped to cooling

flange (FIG. B4)

Reconnect the burner assembly to chimney.

SEALING PERMAGUM

FIG.

B5

C. Category

#3

RC150

RC160

REMOVAL OF COOLING UNIT:

1. Remove screw and disconnect burner

chimney (FIG. Cl).

2. Disconnect heater wires from terminal

(FIG. Cl).

from

block

a.

Remove heaters from boiler case (FIG. Cl).

D-9-6

3.

4.

5.

6.

7.

Remove screws holding unit from rear (FIG.

Cl).

Disconnect green grounding wire (FIG. Cl).

Pull out on cooling flange to remove

fr

evaporator coil (FIG. Cl).

Pull thermostat capillary tube out gently and

move so that cooling unit will clear (FIG. Cl).

Remove cooling unit by hinging out on right

side (FIG. Cl).

INSTALL REPLACEMENT COOLING UNIT:

1.

2.

3.

4.

5.

6.

7.

Trim the Styrofoam portion of the cooling

unit if it does not go freely into the

refrigerator.

Apply sealing permagum (sealing tape) on

window insulation (A; FIG. C2).

Apply thermal mastic on the evaporator coil

(B; FIG. C2).

Tighten screws securely to obtain proper

seal; otherwise improper cabinet performance

may result.

Install the heat elements completely back

into the pocket and attach to terminal block

(FIG. Cl).

Reconnect burner assembly to chimney (FIG.

Cl).

Reinstall capillary tube into proper position

(FIG. Cl).

SEALING PE

(Sealing

(A)

FIG. C2

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 38

(Bulletin

R55/7A

continued)

D. Category

#4

RM190

RM2190

RM2 192

REMOVAL OF COOLING UNIT:

1.

2.

3.

4.

5.

Remove cover and flue tube, then disconnect

burner from chimney (FIG.

D1).

Remove heater(s) from boiler case (FIG.

Dl).

Remove screws and take out evaporator fins

and shelf (FIG. D2).

Release holding clamp for thermostat capillary

tube and pull tube out gently (FIG. D2).

Remove one (1) screw and bend two (2) tabs

and then pull cooling unit out (FIG.

Dl).

FIG.

D1

INSTALL REPLACEMENT COOLING UNIT:

1.

Trim the Styrofoam portion of the cooling

unit if it does not go freely into the

refrigerator.

2. Apply thermal mastic on the evaporator coil

(B; FIG. D3).

D-9-7

3.

4.

5.

6.

7.

Apply sealing permagum (sealing tape) on

window

insulation

(A; FIG. D3).

Tighten screws securely to obtain proper seal.

Install the heating elements completely back

into the pocket.

Reinstall capillary tube into proper position.

Reconnect burner assembly to chimney and

replace cover.

FIG. D3

E. Category

#5

REMOVAL

OF COOLING UNIT:

1.

2.

3.

4.

Remove

chimney

Remove

Remove

rear (FIG. E 1).

cover and disconnect burner

from

(FIG. El).

heater from boiler case (FIG. El).

three (3) screws holding unit from

Pull cooling unit part way out and then

disconnect thermostat capillary tube and pull

out

(1;

FIG. E2).

5.

Complete removal of cooling unit.

6.

Remove evaporator fins and shelf (2; FIG. E2).

A)

SEALING

PERMAGUM

(Sealing

Tape)

RM211

INSTALL REPLACEMENT COOLING UNIT:

1.

2.

3.

4.

5.

6.

7.

Apply thermal mastic on the evaporator coil

(B; FIG. E2).

Install evaporator fins and shelf (FIG. E2).

Apply sealing permagum (sealing tape) on

window insulation (A; FIG. E2).

Reinstall capillary tube into proper position

(FIG. E2).

Tighten screws securely to obtain proper

sealing.

Reconnect burner assembly to chimney and

replace cover (FIG. El).

Install the heating elements completely back

into the pocket (FIG. El).

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 39

(Bulletin

R55/7A

continued)

3

FIG. El

(A)

SEALING

PERMAGUM

(Sealing Tape)

FIG. E2

F.

Category

#6

3

RM75

RM76

RM77

REMOVAL OF COOLING UNIT:

1.

2.

3.

3.

5.

Remove burner protection cover and remove

burner from chimney (FIG.

Fl).

Remove heaters from boiler case (FIG.

Fl).

Remove evaporator screws (FIG. F2).

Remove two (2) screws holding clamp for

thermostat

capillary

tube.

Pull capillary

tube out gently (FIG. F2).

Remove ten (10) screws holding unit from

rear (FIG.

Fl).

6.

Pull out on cooling unit and remove.

5

2

5

INSTALL REPLACEMENT COOLING UNIT:

1.

3

_.

3.

Trim the Styrofoam portion of the cooling

unit

if it does not go freely into the

refrigerator.

Thermal mastic is not used on these units.

Apply sealing permagum (sealing tape) on

mounting plate (FIG. F3).

FIG.

F1

D-9-8

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 40

(Bulletin

R55/7A

continued

4. Tighten screws securely to obtain proper seal.

5.

Install heating elements completely back into

the pocket and plug in (FIG.

Fl).

6. Reconnect burner assembly to chimney (FIG.

Fl

).

7. Reinstall capillary tube into proper position

(FIG. F2).

FIG. F3

REMOVAL OF COOLING UNIT:

1.

2.

3.

4.

5.

6.

Remove six (6) screws from burner cover

(FIG.

Gl).

Disconnect burner from chimney (4 screws)

(FIG.

Gl).

Remove heaters from boiler case (FIG.

G1).

Carefully pull out thermostat capillary tube

(FIG.

G1).

Remove two

(2)

evaporator screws and take

out ice tray support (FIG. G2).

Remove eight (8) screws holding unit from

rear (FIG.

G1).

Remove

two (2) screws holding gas line

gasket (FIG.

Gl).

6

/

l THERMAL MASTIC IS NOT USED

G.

Category

#7

RM182

5.

6.

7.

Tighten screws securely to obtain proper seal.

Install the heating elements completely back

into the pocket.

Reconnect burner assembly to chimney and

replace cover.

FIG.

G1

FIG.

G2

INSTALL REPLACEMENT COOLING UNIT:

1.

2.

3.

4.

Trim the Styrofoam portion of the cooling

unit if

it does not go freely into the

refrigerator.

Apply thermal mastic on the evaporator coil

(B; FIG. G3).

Apply sealing permagum (sealing tape) (A;

FIG. G3).

Reinstall thermostat capillary tube.

D-9-9

(A

SEALING PERMAGUM

(Sealing

Tape)

FIG. G3

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 41

Before You Change

That

Cooling Unit

PART I. PROPER DIAGNOSIS

Cooling units are sometimes diagnosed as being

defective when the actual problem is something

else.

Cooling units are expensive to replace, so

it is important to make the correct diagnosis. By

using the proper test procedures, you can eliminate

all other possibilities before condemning the

cooling unit.

Any time the cooling unit is a possible suspect,

use the following step-by-step procedure before

replacing it.

A.

1.

2.

3.

4.

PRELIMINARY

CHECKS

Check for an ammonia smell around the

cooling

unit and

inside

the refrigerator.

This could indicate a possible refrigerant

leak.

Check for any deposits of yellow

powder on the tubing which will sometimes

form around the area of a leak. NOTE: A

yellow deposit in the area of the fill valve

could be due to splashing of refrigerant

during manufacture,

and would not indicate

a leak.

Determine if the refrigerator works on one

heat source but not another by testing it in

the alternate modes. Also, ask the customer

if he gets better cooling results from one

energy source than another. If this is true,

it indicates the problem is

NOT

in the cooling

unit.

Make sure the refrigerator is level. Sometimes

the vehicle is level but the refrigerator is

not, due to improper installation.

Place a

level on the bottom of the freezer compartment and check side-to-side and front-to-back

levels (see FIG. Al).

Use a mirror, if

necessary to read the level.

Carefully check door gaskets for proper

seal.

A leaking gasket can allow enough

warm air inside the refrigerator to overcome

most of the cooling being produced.

D-9-l

0

REFRlGERATOR

BULLETIN

R61/7A

DEC.

1987

For a simple method to check gaskets, close

the door on a dollar bill, then pull the dollar

bill out.

If no resistance is felt, the gasket

is not sealing properly.

This should be done

on all four sides of the door.

FIG. Al

CHECK

LEVEL

BOTH

WAY.

5.

Check the venting system to insure that

ample air flow is provided at the back of

the refrigerator.

A. Check for, and remove, any restrictions

in the vents, such as filters installed by

the customer, bird nests in the roof

vent,

or smashed louvers in the wall

vents (see FIG. A2).

B.

Make sure the correct roof vent has

been installed.

Larger models such as

RM100, 760, 761, 1300, 1303, 2600, 2800,

2802, 3600, 3800, 3802 and 4801, require

a 5” X 24” opening for the roof vent

Smaller models will also use the

5”

24” roof opening. To check this, measure

the actual opening in the roof - DO

NOT measure the roof vent itself.

See

FIG. A2.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 42

(Bulletin continued)

FIG.

A2

Also,

make sure the distance from

the bottom of the refrigerator to the

roof

vent is

at least the minimum

dimension

given

in

the Installation

Instructions for each model.

See FIG.

A2.

FOR MINIMUM

DIMENSION.

SEE INSTALLATION

INSTRUCTIONS

MIN. 5

C.

MAXIMUM OPEN

SPACE 1

1/2

IN.

(See 5D)

CHECK FOR RESTRICTIONS

IN AIR DUCTS OR VENTS

(See

5A)

Some smaller models may be installed

with two side wall vents instead of

using a roof vent.

For this type of

installation make sure the top of the

upper vent is the correct distance above

the refrigerator.

See FIG. A3.

The

minimum dimension for this measurement

is listed in the Installation Instructions

for each model.

FIG. A3

CHECK MINIMUM

HEIGHT (See

Installation

Instructions)

D. Check the open space above the refrigera-

tor. If this space is 1

1/2

inches or

more it must be blocked off to prevent

hot air from being trapped above the

refrigerator. See FIG. A2.

If venting is suspected as a problem, run the

performance test described below with

the refrig-

erator installed, then run the same test with

the refrigerator removed. If there is a definite

improvement in performance, a venting problem

is indicated.

Also, see Section B. PERFORMANCE

TEST, Item 9.

L

D-9-1 1

SPECIAL VENTING FOR DIRECT-VENT MODELS

RM

182, 215, 2192

These models are designed to be installed in

small vans and are usually placed in a cabinet

that is not open to the outside of the vehicle.

This means that air from within the vehicle

must be used to cool the condenser.

Customers with this type of installation must be

made aware that the vehicle interior must be

kept from getting too hot.

If the vehicle is

left parked in the sun, with all doors and windows

closed, the inside temperature can quickly exceed

100 degrees,

and the cooling process will slow

down or stop completely.

REAR VIEW OF REFRIGERATOR

Arrows indicate direction

Alternative positions

SIDE VIEW OF

upper

ventilator

Arrows indicate

direction

of air flow over Cooling

Unit

Lower

Ventilator

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 43

[Bulletin

R61/7A

continued)

B.

1.

3

3.

4.

PERFORMANCE

TEST

First perform

all the preliminary

checks

described previously.

Remove all food from the refrigerator and

place all controls in the OFF position.

Place an accurate thermometer in an ice

cube tray, half filled with water, and place

the tray in the center of the lower food

storage compartment. NOTE: If a

remote-

reading thermometer

is

used (allowing

temperature readings without opening the

door) the tray of water is not required.

Make sure the AC heating element is the

correct wattage for the model being tested,

and that the resistance reading is correct.

(See

“Checking Resistance of a Heating

Element” below.)

Connect 120 volt AC power directly to

the heating element leads (make sure the

leads are not connected to the refrigerator

circuit),

then check

the voltage at the

element with a volt meter.

Reading must

show at least 115 volts.

CHECKING RESISTANCE OF A HEATING

ELEMENT

A simple test to check a heating element is to

measure

the resistance through

the element

with an ohmmeter.

The correct resistance, in

ohms,

can be calculated if the wattage and

voltage ratings are known.

(These ratings are

stamped on all

Dometic

heating elements.)

Use this Formula:

Volts (Watts Volts) = Ohms

Example:

Heating element rated 135 Watts at 110 Volts.

110 (13.5 110) or,

110

1.23 = 89.4 ohms

The ohm reading should be within 10% of this

figure, or between 80.46 and 98.34 ohms.

Use

the lowest setting on the ohmmeter which will

give an accurate reading.

When testing a 12 volt heating element, a

very accurate ohmmeter must be used because

of the very low readings that will be found.

For example, a 200 watt element will have a

reading of

.72

ohms (less than 1 ohm).

5.

After two hours of operation, check

temperature on the back of the cooling

with your hand, at the locations shown.

FIG.

Bl

(TEMPERATURE

TEST AREA)

the

unit

CONDENSER

ENCLOSURE

(TEMPERATURE

TEST AREA)

Under normal operation the temperature at

the absorber coils (A) and the boiler (B)

should be approximately the same.

If the

temperature at the absorber coils (A) is

much hotter it indicates loss of refrigerant

and the cooling unit must be replaced.

If

the temperature at the boiler (B) is very hot

and the absorber coils (A) are cool it indicates

that the refrigerant is not circulating properly.

This could indicate:

A. Liquid trapped in the evaporator sections,

caused by out-of-level operation for a

period of time.

Resetting the refrigerator

to a level position will not necessarily

correct the problem as liquid can remain

trapped even after level is corrected.

Shut off the heat source and let the

system cool down,

then re-start it and

observe the temperatures at A and B

again after several hours.

If the same

condition exists it could indicate:

B.

A permanent blockage within the boiler

pump tube,

caused by too much heat

applied to the burner (oversized orifice

or heating element) or prolonged operation

of the unit when out-of-level or with

restricted ventilation.

This type of

blockage consists of hard deposits inside

the boiler pump tube. This condition is

not repairable and the cooling unit must

be replaced.

D-9-12

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 44

(Bulletin

R61/7A

continued)

NOTE:

The cooling units currently being used

are specially designed to prevent overheating of

the boiler tube even when operated out-of-level.

This special design can be identified by the

round insulation box around the boiler, rather

than the square-cornered box used on older units.

FIG. B2

Older Style

Current Style

Boiler Enclosure Boiler Enclosure

Blockage symptoms on the newer cooling units

almost always, indicate

trapped liquid in the

evaporator, which can be corrected by proper

leveling and allowing the cooling unit to cool

off before restarting.

6.

If the temperatures are satisfactory in Step

5, continue operating the unit, with power

directly to the heating element, for a total

of

10-12

hours.

The doors must be kept

closed for this entire period.

7.

If the temperature is within the previously

mentioned guidelines the problem is not in

the cooling unit. See Section II. OTHER

CAUSES for additional items that could be

causing a loss of cooling.

8.

If the temperature in the food compartment

is higher than the acceptable limit, the

cooling unit is probably defective.

If you

are still in question as to the performance

of the cooling unit, please contact our Technical Service Department (219) 463-4858.

See

the next paragraph before changing the

cooling unit.

9. The importance of adequate air flow across

the cooling unit cannot be emphasized too

much. A minor restriction in the venting

system will not create a problem on cooler

days

-

the available air flow

will

still provide

adequate cooling due to the lower temperature.

However, on a hot day (90” or more) even

a minor restriction will cause overheating of

the cooling unit and the cooling process will

slow down or stop.

ONE LASTCHECK

If the previously mentioned test was performed

in air

temperatures above and the

temperature in the refrigerator is above the

acceptable ranges, it may indicate a restricted

air flow. To make sure there is no problem

with the venting system repeat the performance test with the refrigerator removed

from its installed location and placed on

the floor, or in your service shop. If the

second test indicates satisfactory performance,

re-check the venting and installation.

PART II.

OTHER CAUSES FOR

LOSS OF COOLING

If the previously

mentioned performance test

shows that the refrigerator is working satisfac-

torily, and the customer still experiences loss of

cooling, the following items need to be considered:

1.

Make sure the customer is using the refrigerator properly.

The cooling capacity of the

absorption refrigerator is usually much lower

than the refrigerator the customer has in his

home, so the customer should be advised to

follow the instructions for proper use in his

Owner’s Manual.

A.

B.

C.

D.

Start the refrigerator the day before it

is to be filled with food.

When the refrigerator is being filled

when preparing for a trip, the food

should be pre-cooled, and frozen foods

should be pre-frozen,

before placing

them in the refrigerator.

Ice making

should be avoided until the refrigerator

has cooled the lower compartment to the

desired temperature.

Air circulation within the food compartment is important for proper cooling.

DO NOT place paper on the shelves or

over-fill the compartment

with large

cartons, etc.

Do not put hot food in the refrigerator.

Allow it to cool in room air first.

D-9-13

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 45

REFRIGERATOR TECHNICAL DATA

RAK1 00

RAK1302

l

RC15

RC65G

RC65K

l

RC150

l

RC150A

RC1 50TEG

RC 150TEG

l RC152

RC160E

RC 160E

RC1

60TEG

RC 1

60TEG

l M52

l

M70

9286111001 Kerosene

9286179008 Kerosene

2922000000

- - - - - - - -

N/A

50 (0061667002)

N/A Kerosene

2922302001

- - - - - - - -

2922471020 - - - - - - - 2942312022 (2928787031)

2922441015 -------2942312022 (2928787031)

2942312121 (2928787031)

N/A

________

N/A

________

l

RM45,46,47

9283171008 51 (2002660179)

l

RM45,46,47

RM46E

9283191006 43 (2002660161)

RM46E

l

RM60,66

9283521004 52 (2002660187)

l

RM60,66

RM66E

9283571009 52 (2002660187)

RM66E

RM66F

9283599000 51 (2002660179)

RM66F

*

RM67 928352 1004 52 (2002660187)

l RM67

RM67D

9283521004 52 (2002660187)

l

RM67D

9283521004 52 (2002660187)

l

RM75,76,77,76D

9285134004 53 (2002660195)

l

RM100

9286109005 58 (2002660211)

l

RM100

RM182 2929302004 24 (2928787049)

RM182B

2929302053 24 (2928787506)

RM182B

I I

RM190 9281

152000 F (2902540059)

l

RM211

9282740010

4 (2901860010)

l

RM2llB

19282743005

1

4 (2901860010)

RM215 19282761000 J (2902540075)

l Models that use brass heating elements approximately in diameter.

D-9-14

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 46

(Bulletin continued)

RM3601 0173757022

17.9

RM3604 2934803996

53

(2007419191)

0173754045

2.5

48 ___

0173757022

17.9

RM3800 2934901097

58 (2007419217)

0173742081

2.7

44 ___

l Models that use brass heating elements in diameter.

D-9-15

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 47

(Bulletin continued)

l Models that use brass heating elements approximately in diameter.

NOTE: The

formula for calculating amps

Watts Volts = AMPS

Volts (120) Amps =

D-9-16

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 48

BULLETIN 4

MAY 1983

Replacement of cooling units in RM760.

Cooling unit will replace 530A in production and service.

When installing as replacement for 530A three new holes should be drilled in the cooling

flange.

New holes

1 (29 mm)

down.

0

Furthermore the hole for the air channel (no longer necessary) in the burner box should be covered

by a piece of aluminium tape (No combustible material must be used).

Cover this hole

D-9-17

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 49

CROSS REFERENCE OF

REFRIGERATORS MANUFACTURED BY

A.B. ELECTROLUX AND

PROCEDURE CHANGES

REFRIGERATOR BULLETIN

REVISED AUGUST, 1984

SUBJECT: Dometicare Procedure

An out of warranty cooling unit purchased from for installation on

an Instamatic, Magic Chef, Hadco or GE refrigerator does not qualify for our

three year Dometicare cooling unit coverage.

We will warrant cooling units purchased from for installation on

other than refrigerators for two (2) years providing the installation is

within our established installation specifications.

We will offer our three year Dometicare coverage on the following cooling

units purchased from for out of warranty refrigerators only,

for $35.00.

150

RM 215 RM

361

RM 66 RM

663

RM 763

100

RM

182

RM 235 RM 46

RM

66E

RM

76 RM

100

1302

RM

RM 36C

RM 46E RM 66F RM 77

RM 13C0 1300

RM

211

RM

36E

RM

460

RM

660

RM

760

RM 1303

1302

RM

RM 360 RM

461

RM

661

RM

761

RA

100

RC 65

All cooling units for refrigerators manufactured prior to

these models will no longer qualify for our coverage.

CROSS REFERENCE OF REFRIGERATORS MANUFACTURED BY

A.B. ELECTROLUX

HADCO

HR-2 same as RM 24

HR-3 same as RM 36C

same as RM

HR-6 same as RM

HR-7 same as RM 760

GE

same as RM 36

same as RM

same as RM 60

MAGIC CHEF

MKM

DOM

same as M-28

INSTAMATIC

IM-2

same as 211

MKM-110

MKM-150

R-82, 83,

R-87

same as M-40

same as M-52

same as RM 75

same as RM 77

same as RM 760

IM-3

same as Rhl 36E

IM-4

same as

Rhl

IM-6

same as

same as 77

IM-10 same as 100

D-9-1

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Page 50

HEATING ELEMENTS 360-460-660-760

Previous literature covering the following models, lists the wattage of 110 volt

heading elements as follows:

RM

360

120

watts

RM

460

135

watts

RM

660 175

watts

RM

760 250

watts

The ratings that are actually stamped on the replacement heating elements are

as follows:

RM

360

135

watts

RM

460 150

watts

RM

660

190

watts

RM

760 275

watts

These elements are identical and are covered under the same part numbers.

The difference being that the newer elements have been rated at 115 volt input

rather than 110 volt input.

The American Gas Association now requires that every refrigerator be