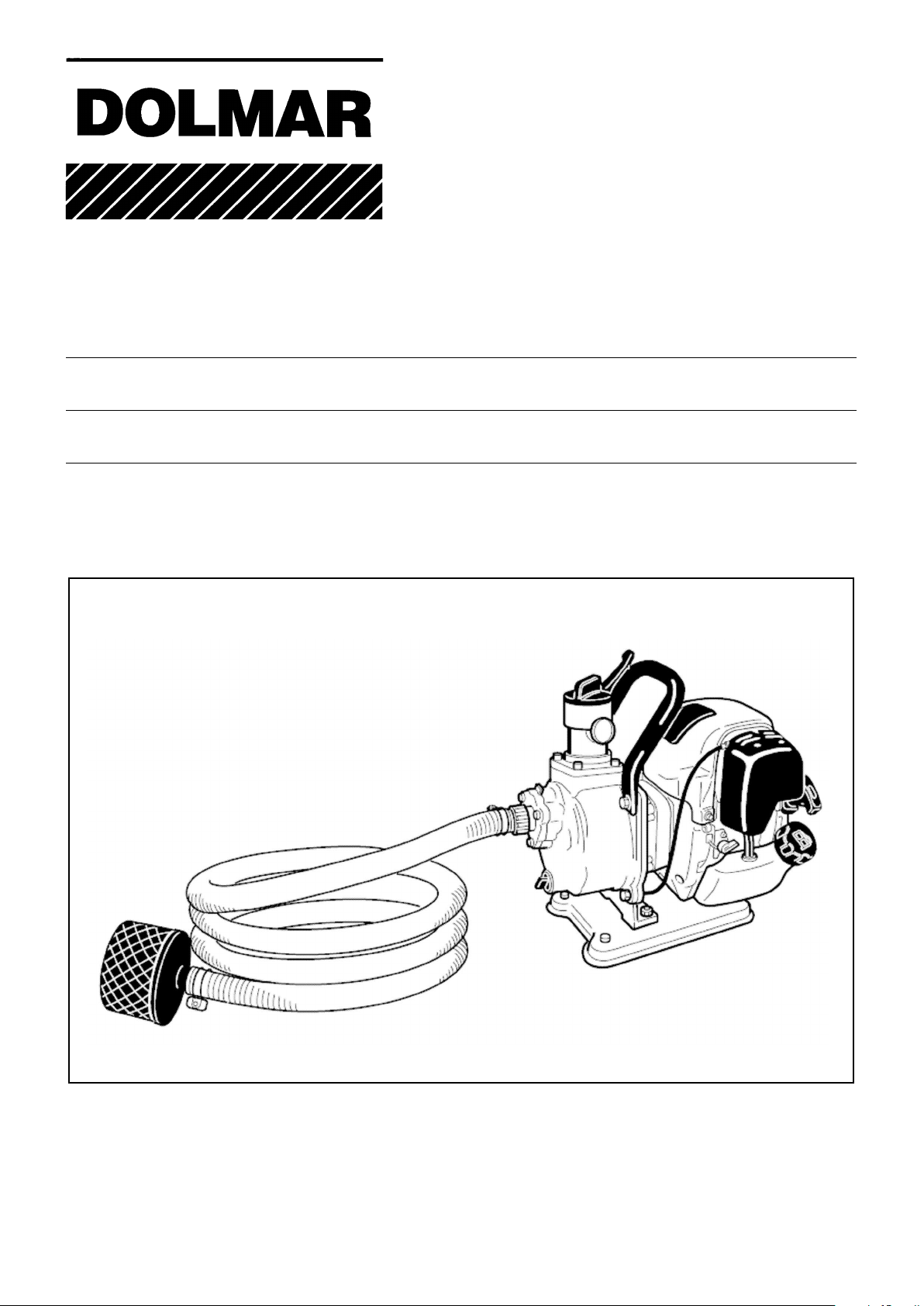

GB Gasoline Engine Pump Instruction manual

F Motopompe Manuel d’instructions

E Moto bomba Manual de instrucciones

MP-352.4

! WARNING

PLEASE READ AND UNDERSTAND

THIS MANUAL COMPLETELY BEFORE OPERATING THE MACHINE.

Particularly important information is distinguished in this manual by the following notations.

! ATTENTION

IL EST CONSEILLÉ DE LIRE CE MANUEL ATTENTIVEMENT ET INTÉGRALEMENT AVANT D’UTILISER LA MACHINE.

Dans ce manuel, les informations particulièrement importantes sont indiquées de la manière suivante.

! ADVERTENCIA

POR FAVOR LEA Y COMPRENDA ESTE MANUAL CON CUIDADO ANTES DE USAR LA MÁQUINA.

En este manual las informaciones muy importantes están remarcadas de la siguiente manera.

! WARNING

Failure to follow WARNING instructions could result in severe injury or death

person inspecting or repairing the machine.

! ATTENTION

Le non-respect des instructions ATTENTION peut entraîner des blessures sérieuses voire même mortelles pour la

personne utilisant la machine, un passant ou la personne vérifiant ou réparant la machine.

! ADVERTENCIA

La inobservancia de las instrucciones ADVERTENCIA puede ocasionar heridas graves o la muerte

persona de inspección o reparación de la máquina.

to the machine operator, a bystander, or a

del operador o de la

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the machine.

PRÉCAUTION:

PRÉCAUTION indique les précautions à prendre pour éviter d’endommager la machine

PRECAUCIÓN:

PRECUCIÓN muestra la indicación de las precauciones que se deben tener para evitar daños a la máquina.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

NOTA BENE:

NOTA BENE donne des informations nécessaires à une manipulation plus simple et plus claire de la machine.

NOTA:

Una NOTA provee la informatión necesaria para hacer el procedimiento fácil y claro.

2

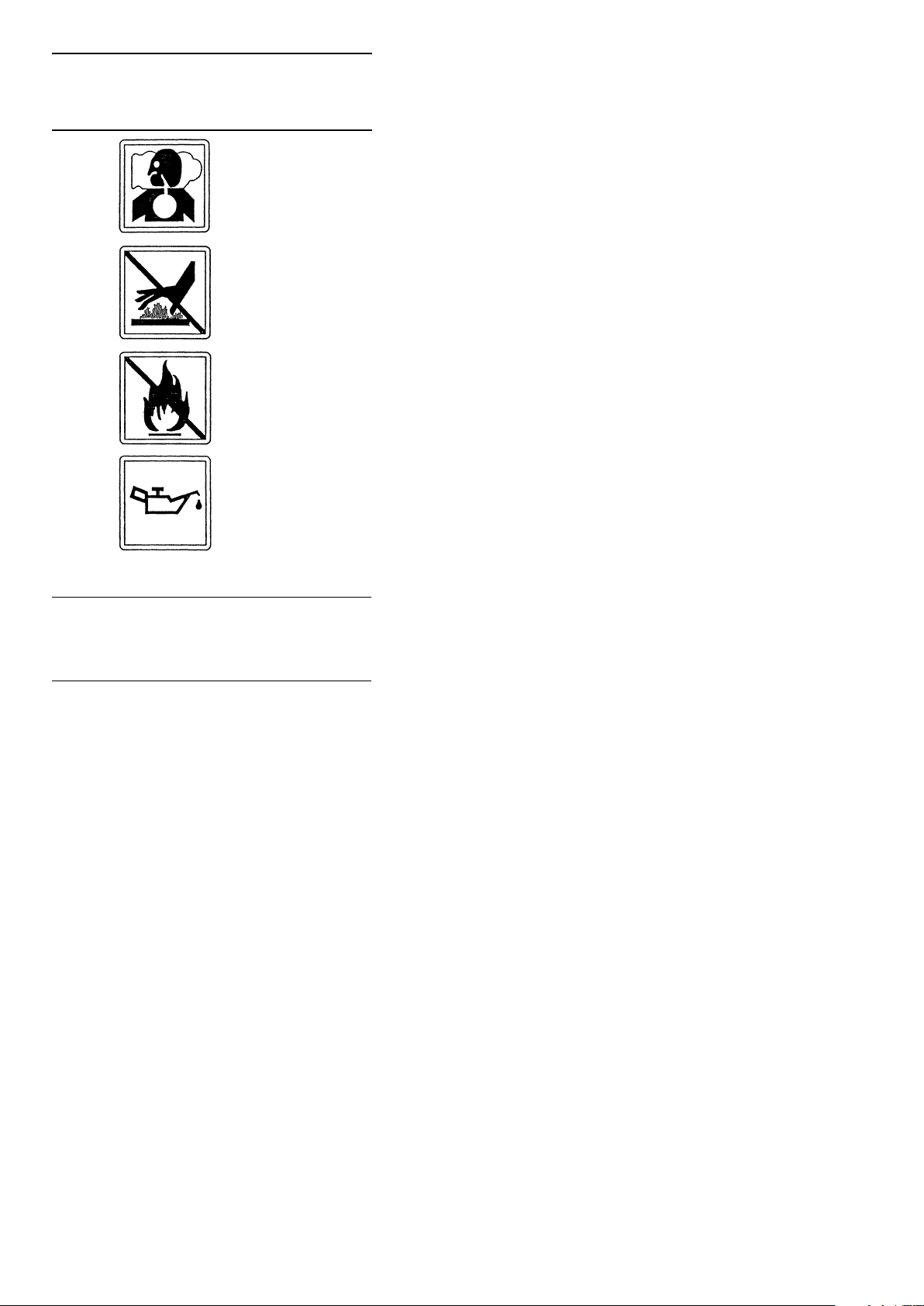

Explanation of warning signs

Signification des étiquettes

Explicación de la etiqueta de ADVERTENCIA

Never use the engine indoors.

Ne jamais utiliser le moteur à l’intérieur.

No usar nunca el motor en el interior de un ambiente.

Don’t touch the engine when it is hot.

Ne pas toucher les pières chaudes du moteur.

No tocar, son las partes calientes del motor.

Before refueling, be sure to stop the engine.

S’assurer que le moteur est arrêté avant de faire le plein.

Antes de repostar combustible, asegurarse de apagar el motor.

Check the oil level before starting.

Vérifier le niveau d’huile avant le démarrage.

Revisar el nivel de aceite antes de arrancar.

CONTENTS

TABLE DES MATIÈRES

ÍNDICE

NOMENCLATURE

TERMINOLOGIE

NOMENCLATURA

PRE-OPERATION CHECKS

VÉRIFICATION AVANT UTILISATION

INSPECCIONES ANTES DEL USO

OPERATION

MARCHE

FUNCIONAMIENTO

TROUBLE AND REMEDY

PROBLÈMES ET REMÈDES POUR LA PARTIE POMPE

AVERÍA Y REPARACIÓN

TROUBLESHOOTING PROCEDURES

PROBLÈMES ET REMÈDES POUR LA PARTIE MOTEUR

PROCEDIMIENTO PARA LOCALIZACIÓN DE AVERÍAS

SPECIFICATIONS

SPÉCIFICATIONS

ESPECIFICACIONES

SAFETY PRECAUTIONS

SÉCURITÉ

MEDIAS DE SEGURIPAD

......................................................................................................................................................

.............................................................................................................................

....................................................................................................................................................

...........................................................................................................................................

.................................................................................................................................................

...........................................................................................................................................

............................................................................................

7

6

9

11

13

15

16

3

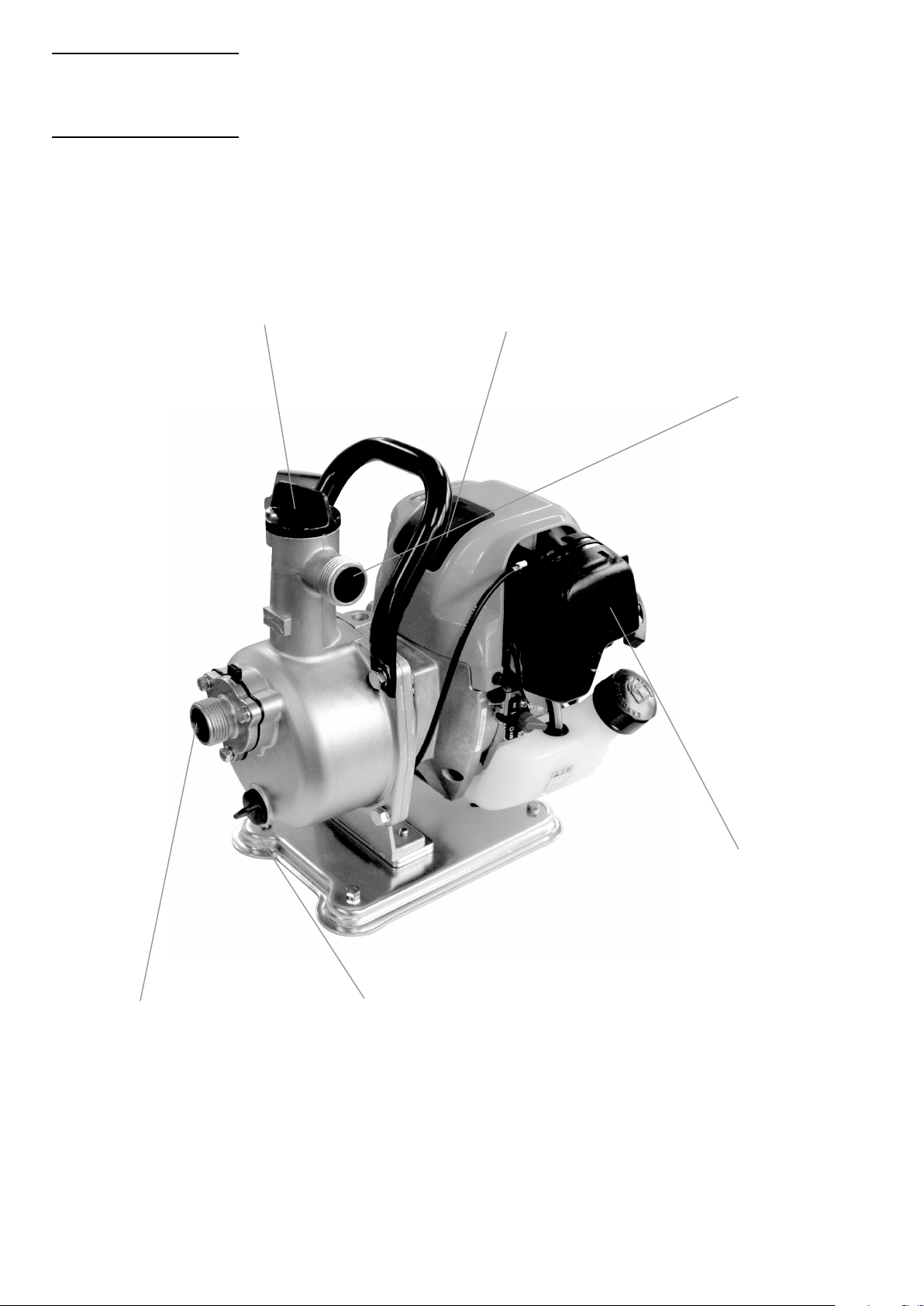

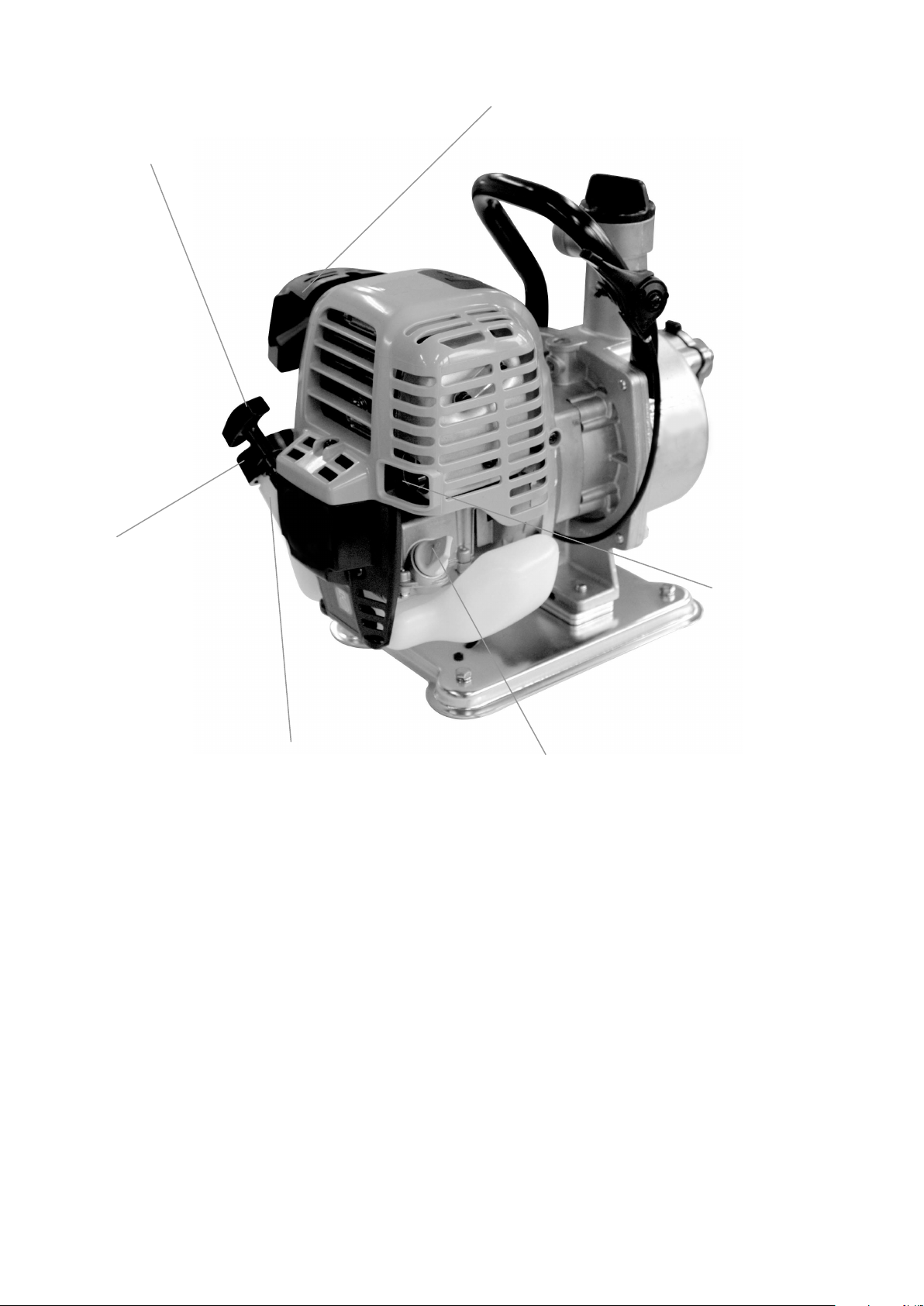

NOMENCLATURE

A

A

TERMINOLOGIE

NOMENCLATURA

Drain Cap

Bouchon d’amorçage

Tapa de inundación

Spark Plug

Bougie d’allumage

Bujía de encendido

Delivery

Refoulement

Descarga

ir cleaner

Filtre à air

Filtro de aire

Suction

spiration

Succión

Drain plug

Boulon de vidange

Tapón de drenaje

4

Recoil starter handle

Poignée du lanceur

Manija del arrancador de retroceso

Fuel tank cap

Bouchon réservoir à essence

Tap ón del tanque de combustible

Fuel tank

Réservoir du carburant

Depósito de gasolina

Standard accessories

Tool kit Engine)

Instruction manual

Strainer (1 PC)

Pipe joint ass’y (2 PCS)

Hose band (3 PCS)

Choke lever

Star te r

Palanca de estrangulación

Muffler

Pot d’échappement

Silenciador

Oil filter (with oil gauge)

Bouchon de remplissage d’huile ( avec jauge à huile)

Orificio de lubricación (con indicador del nivel de aceite)

Accessoires standard

Jeux d’outils (Moteur)

Manuel d’instructions

Crépine (1 pc)

Raccord pour tuyau (2 jeux)

Collier pour tuyau (3 pcs)

Accesorios normales

Juego de herramientas (Motor)

Manual de instrucciones

Colador (1 pieza)

Ensamblaje de unión de tubo (2 piezas)

Abrazadera para manguera (3 piezas)

5

PRE-OPERATION CHECKS

VÉRIFICATION AVANT UTILISATION

INSPECCIONES ANTES DEL USO

! WARNING Avoid touching the engine and muffler with any part of your body or clothing during inspection or repair, while

they are still hot.

! ATTENTION Lors de la vérification ou réparation, faire attention qu’une partie du corps ou un vêtement ne vienne

toucher le moteur ou le pot d’échappement si ces derniers sont encore chauds.

! ADVERTENCIA Evitar tocar el motor y silenciador mientras estén calientes con cualquier parte del cuerpo o ropa

durante la inspección o reparación.

Engine oil Recommended oil: 4-stroke engine oil

Huile moteur Huile recommandée : huile pour moteur à 4 temps

Aceite para motor Aceite recomendado: Aceite para motor de 4-tiempos

NOTE: API service Classification SE or SF, if not available, SD.

NOTA BENE: Classification du service API SE ou SF, si non disponible SD.

NOTA: Clasificación de servicio API SE o SF, si no se encuentra a disposición, utilice SD.

Engine oil quantity: 0.1 L

Quantité d’huile moteur: 0,1 L

Capacidad de aceite para motor: 0.1L

A NOTE FOR SAFE OPERATION

Take special care of ventilation. Beware of CO poisoning.

A NOTA POUR LA SÉCURITÉ

Veiller à une bonne aération. Attention aux gaz d’échappement.

A NOTA PARA UN FUNCIONAMIENTO SEGURO

Tenga cuidado especial con la ventilación. Cuidado de no tener intoxicación por monóxido de carbono (CO).

6

B Keep inflammables away from the exhaust outlet. Ԙ 1 m (3.94 in)

B Eloigner tout produit inflammable de la sortie d’échappement. Ԙ 1m (3,94 in)

B B Mantenga los productos inflamables a distancia de la válvula del escape. Ԙ 1m (3,94 in)

C Before refueling, be sure to stop the engine.

Never refuel while smoking or in the vicinity of an open flame.

After refueling, make sure the tank cap is tightened securely.

C Vérifier que le moteur soit bien arrêté avant de refaire le plein d’essence.

Ne jamais faire le plein d’essence en fumant ou à proximité d’une flamme.

Une fois le plein terminé, vérifier que le bouchon du réservoir à essence est bien resserré.

C Antes de repostar combustible, no olvidar de parar el motor.

No repostar nunca combustible cuando esté fumando o cerca de una flama.

Después de repostar combustible, asegurarse de que el tapón del tanque esté bien cerrado.

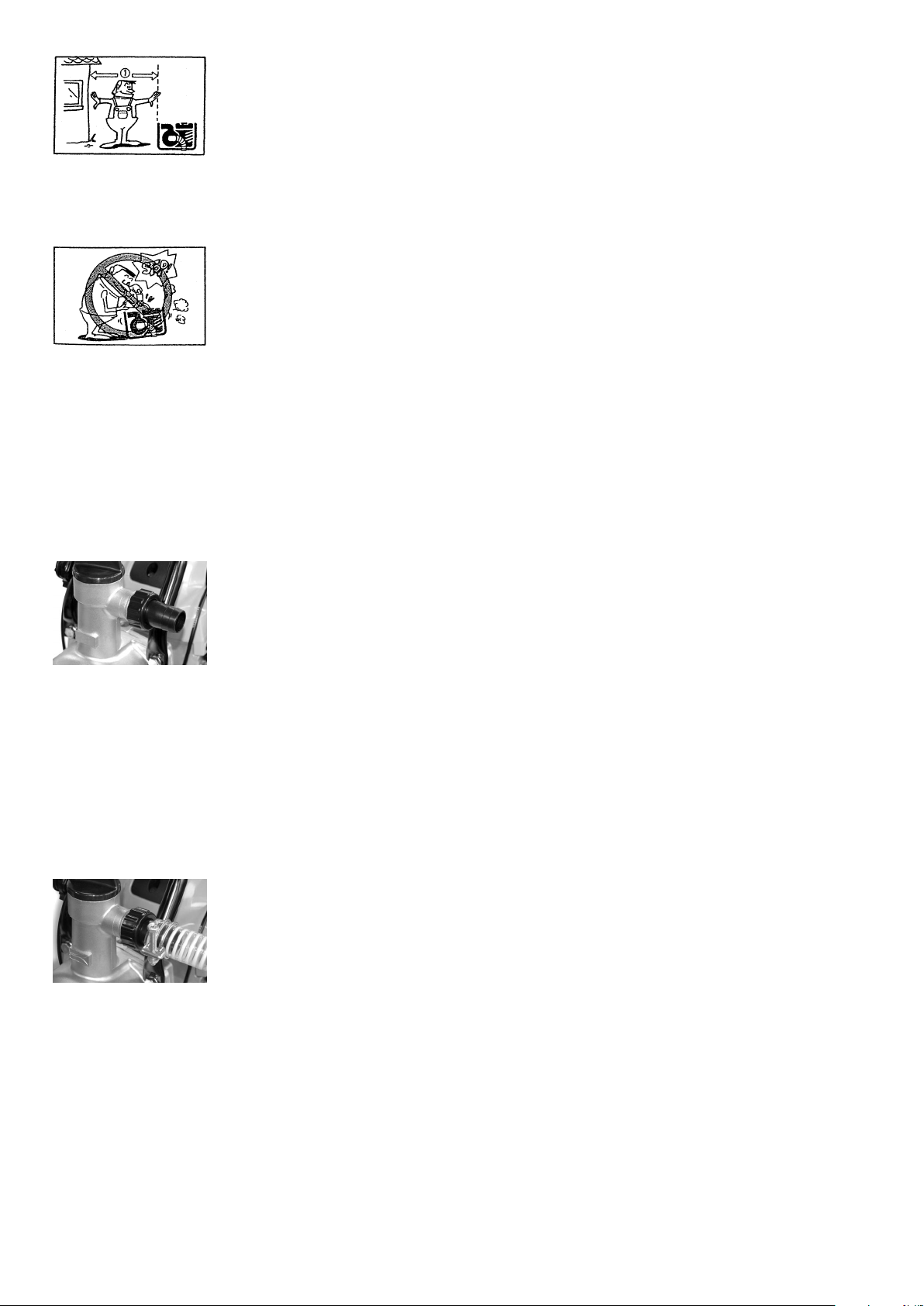

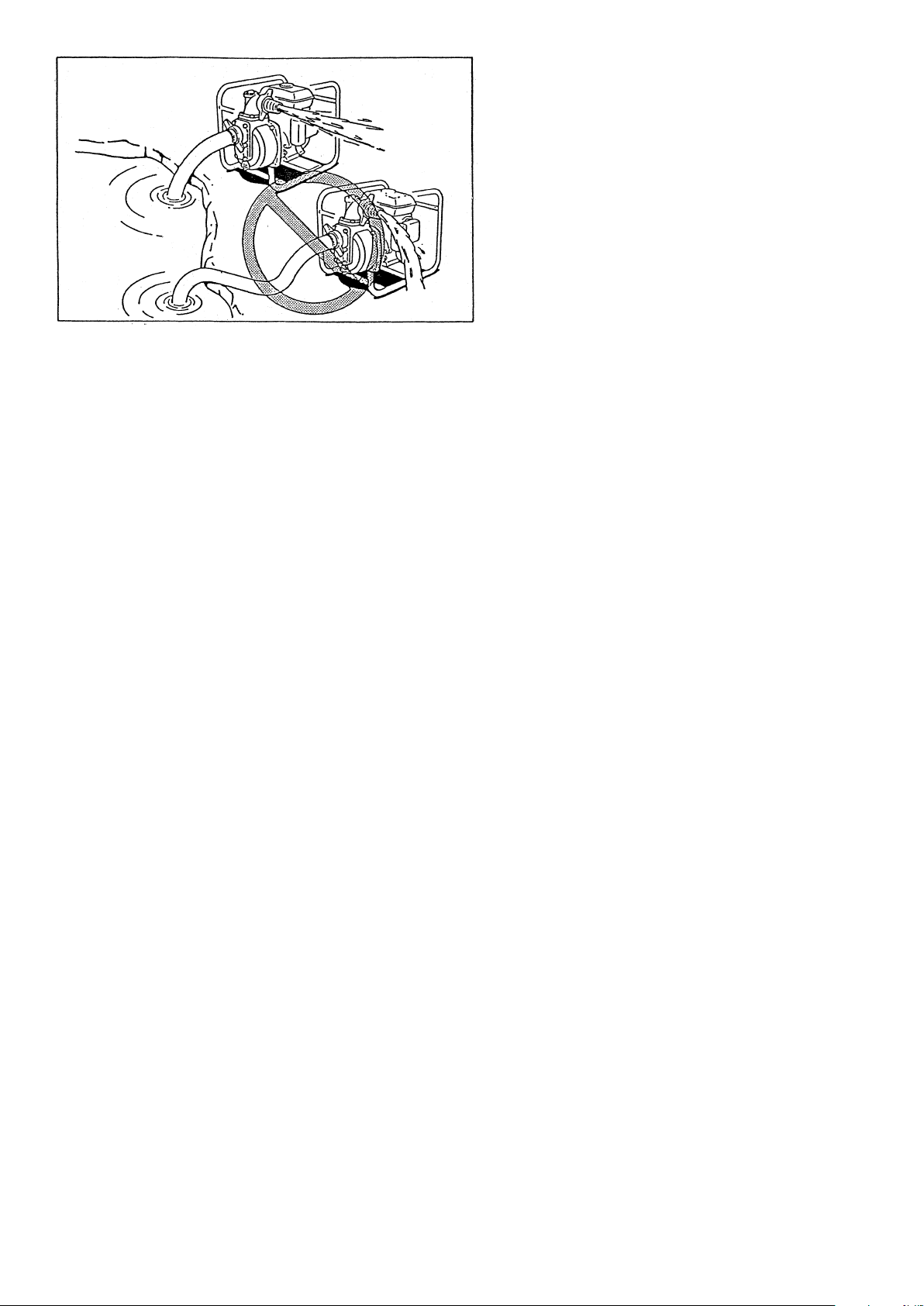

A HOSE INSTALLATION

1. Install the hose joints on the pump.

CAUTION: When installing the joint to the pump, be sure the gasket is in place.

A INSTALLATION DES FLEXIBLES

1. Monter les raccords de flexible sur la pompe

PRÉCAUTION: Lors du montage de raccord à la pompe, vérifier que le joint d’étanchéité soit bien en place.

A INSTALACIÓN DE LA MANGA

1. Instalar la unión de manga en la bomba.

PRECAUCIÓN: Al instalar la unión en la bomba, asegurarse de que la junta esté en su lugar.

B 2. Connect the hoses on the joints with band.

3. Connect the strainer on the inlet hose end.

NOTE: Should air leak, water could not be drawn up.

B 2. Fixer les flexibles sur les raccords avec un collier.

3. Fixer, de même, la crépine à l’autre extrémité du flexible d’aspiration.

NOTA BENE: Si les fixations ne sont pas correctes, l’air entrera dans les flexibles et l’eau ne pourra pas être aspirée.

B 2. Juntar la manguera en la unión con un fleje.

3. Juntar el tensor a la toma de la manguera.

NOTA: En caso de fuga de aire, el agua no se puede succionar.

7

C CAUTION: Do not remove strainer or pump damage may occur by foreign material.

C PRECAUTION: Ne pas retirer la crépine car la pompe risquerait d’être endommagé par les corps étrangers alors

aspirés.

C PRECAUCIÓN: No quitar el tensor, dado que materiales extraños pueden dañar la bomba.

Fuel

Recommended fuel: Regular Gasoline

Fuel tank capacity: 0.65L

! WARNING Fuel is highly flammable and poisonous. Check “NOTE FOR SAFE OPERATION” carefully before refueling.

Carburant

Carburant recommandé: essence normale

Capacité du réservoir: 0,65L

! ATTENTION: L’essence est un produit hautement inflammable et toxique. Toujours se conformer au “NOTA POUR LA

SÉCURITÉ” avant de faire le plein du réservoir.

Combustible

Combustible recomendado: Gasolina Regular.

Capacidad del tanque de combustible 0.65L.

! ADVERTENCIA: La gasolina es una sustancia muy inflamable y tóxica. Revisar “NOTA PARA UN FUNCIONAMIENTO

SEGURO” antes de repostar el combustible.

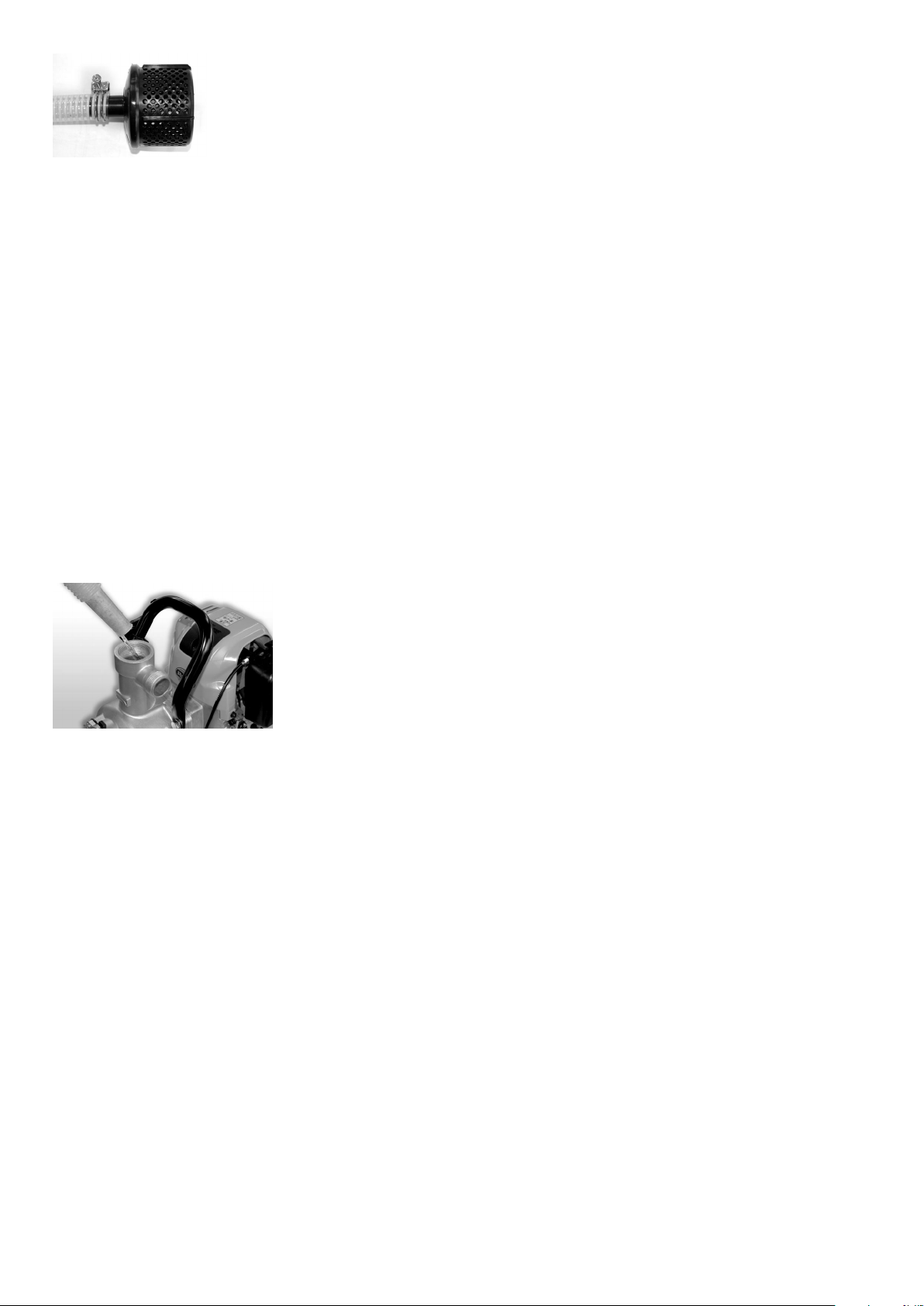

Water

1. Remove priming plug and add water until pump casing is filled up with water

CAUTION: Should the pump be started without water in the casing, mechanical seal could be damaged.

Eau

1. Retirer le bouchon d’amorçage remplir d’eau le corps de la pompe.

PRÉCAUTION: Ne jamais faire fonctionner la pompe si elle n’est pas pleine. Le joint mécanique risquerait d’être

endommagé.

Agua

1. Quitar el tapón de cebador y añadir agua hasta que caja de la bomba esté completamente llena.

PRECAUCIÓN: Si la bomba se pone en marcha sin agua en la caja, puede dañarse el sello mecánico.

8

NOTE:

Be sure the pump is placed on the firm place and as near to available water source as possible.

The higher the suction head is the more time will be required for priming with a less discharge.

NOTA BENE:

S’assurer que la pompe est installée sur un sol ferme et aussi près que possible d’une source d’eau.

Plus la tête d’aspiration est élevée et plus le temps d’amorçage sera long et le débit sera faible.

NOTA:

Asegurarse de que la bomba esté puesta en un lugar firme y lo más cerca posible de una fuente de agua.

Cuanto más alta esté la carga de aspiración, más tiempo necesitará para la succión con una descarga menor.

OPERATION

CAUTION: This water pump has been shipped without engine oil. Unless you fill with oil, water pump damage will occur.

UTILISATION

PRÉCAUTION: Cette pompe à l’eau est expédiée sans huile moteur. Donc ne pas oublier de mettre de l’huile dans le

moteur, faute de quoi la pompe serait endommagée.

FUNCIONAMIENTO

PRECAUCIÓN: Esta bomba de agua se envió sin incluir aceite para motor. A menos que Ud. La llene de aceite, puede

causar daños en la bomba de agua.

Beware of water-hammering

Do not allow the wheel of a vehicle to run over the delivery hose. Do not close the delivery valve abruptly, because a

water-hammer will occur which may result in heavy damage to the pump.

Attention au coup de bélier

Ne pas laisser le véhicule stationner sur le tuyau de refoulement ou ne pas fermer brusquement la vanne de refoulement,

ce qui engendrerait un coup de bélier pouvant endommager grandement la pompe.

Tener cuidado con el ariete hidráulico

No deje que las ruedas de un vehículo pisen la manguera de descarga, o no cierre la válvula de descarga de una manera

brusca. Si no, ocurrirá un ariete hidráulico que puede ocasionar daños graves a la bomba.

Do not put your hands or foreign objects in the release or valves when the pump is in use.

Ne pas laisser de corps étrangers du côté aspiration et refoulement pendant le fonctionnement de la pompe

No meter la mano o cuerpos extraños en la salida de descarga o la toma de aspiración durante el funcionamiento.

9

CAUTION: Running over the delivery hose.

PRÉCAUTION: Écrasement du tuyau de refoulement

PRECAUCIÓN: Cuidado con pisar la manguera de descarga.

CAUTION: Abrupt closing of delivery valve.

PRÉCAUTION: Fermeture brusque de la vanne de refoulement

PRECAUCIÓN: Cuidado con cerrar la válvula de descarga en forma brusca.

Drain of water after use.

Water inside casing freezes at below 0°C (32°F) in winter and there by pump may possibly break. After use, drain water

from drain port at bottom to store.

Vidange de l’eau après utilisation

En hiver, l’eau restant dans la pompe gèle à 0°C (32 °F) et peut provoquer une cassure du corps de la pompe. Il est donc

nécessaire de purger la pompe après son utilisation et avant son stockage.

Drenaje de agua después del uso

El agua dentro de la caja se congela a 0 °C (32°F) en invierno y como consecuencia de ello la bomba puede estropearse.

Después de usarla, drene el agua por el orificia de drenaje antes de almacenarla.

10

TROUBLE AND REMEDY

Pump does not revolve.

Pumping volume is small.

Pump does not self-prime.

PROBLEMES ET REMÈDES POUR LA PARTIE POMPE

La pompe ne tourne pas

Le volume pompe est faible

Défaut de l’auto-amorçage

Engine does not start. (Refer to instruction manual of engine)

Sticking of impeller (Disassemble & clean)

Entrance of air at suction side (Check piping at suction side)

Drop of engine output (Repair)

Breakage of mechanical seal (Replace mechanical seal)

High suction lift (Lower)

Thin or long or kink of hose (Thicken or shorten or straighten)

Leak of water from water passage (Stop leak)

Clogging of foreign substance in impeller (Disassemble & clean)

Wear of impeller (Replace impeller)

Suction of air at suction side (Check piping at suction side)

Insufficient priming water inside pump casing (Prime fully)

Imperfect tightening of drain cock (Tighten the 2 plugs completely)

Imperfect revolution of engine (Repair engine)

Entrance of air from mechanical seal (Replace mechanical seal)

Le moteur ne démarre pas ( Se référer au Manuel d’instructions du moteur)

Encrassage du rotor (Démonter et nettoyer)

Entrée d’air du côté aspiration (Vérifier la conduite du côté aspiration)

Baisse de puissance du moteur (Réparer)

Rupturé du joint mécanique (Remplacer ledit joint)

Côté aspiration surélévé ( Le baisser)

Tuyau fin ou long ou faux-pli ( Épaissir, raccourcir ou retendre)

Fuite d’eau dans les conduites (Arrêter la fuite)

Encrassage du rotor ( Démonter et nettoyer)

Usure du rotor ( Remplacer le rotor)

Entrée d’air du côté aspiration (Vérifier la conduite du côté aspiration)

Eau d’amorçage insuffisante dans le corps de la pompe

(Remplir correctement)

Mauvais serrage du boulon de vidange ( Bien resserrer les 2 boulons)

Mauvaise rotation du moteur (Réparer le moteur)

Entrée d’air à partir du joint mécanique (Remplacer ledit joint)

11

AVERÍA Y REPARACIÓN

La bomba no gira.

Capacidad de bombeo es

pequeña

La bomba no se autoceba.

El motor no funciona. (Referirse al manual de instrucciones del motor)

Se pega el impulsor. (Desmontar y limpiar)

Entrada del aire en el lado de succión (Comprobar la tubería de la succión)

Caída del rendimiento de motor (Reparar)

Rotura del sello mecánico (Reemplazar el sello mecánico)

Levantamiento prolongado de la altura de aspiración (Bajar)

La manguera es delgada, larga o retorcida (Engrosar, cortar o enderezar)

Fuga de agua desde el paso de agua (Eliminar la fuga)

Atasco de sustancias extrañas en el impulsor (Desmontar y limpiar)

Desgaste del impulsor (Reemplazar el impulsor)

Succión de aire en el lado de succión. (Comprobar la tubería en la succión)

Insuficiente agua de cebadura dentro de la caja de bomba (Cebar por completo)

Cierre insuficiente del tapón de drenaje (Cerrar bien los dos tapones)

Revolución de motor imperfecta (Reparar el motor)

Entrada del aire desde el sello mecánico (Reemplazar el sello mecánico)

12

g

g

g

y

y

g

TROUBLESHOOTING PROCEDURES

Do sparks fly in

spark plug?

Starting failure

PROBLEMES ET REMEDES POUR LA PARTIE MOTEUR

Défaut de

démarrage

Is compression

sufficient?

Is fuel sucked into

the cylinder?

Étincelles à la

bougie d’allumage?

Compression suffisante?

Alimentation du

carburant au

cylindre?

1. Remove spark plu

build sparks in the spark plug.

2. If nospark flies between the electrodes of the sparkplug, replace it.

3. If still no spark flies, have a qualified service shop check the engine.

1. Check the compression by pulling starter handle slowly.

If compression is low, check the tightness of the spark plugs and other

members, and tighten all loose members.

2. If compression is still low, have a qualified service shop check the en

1. Set combination control lever to “CHOKE”, pull the starter handle several

times and remove spark plu

fuel suction is in order.

2. If fuel is not sucked properl

entry for possible blockage.

3. When fuel is properl

new fuel.

1. Retirer la bougie et vérifier si une étincelle se produit au niveau des

électrodes.

2. S’il n’y a pas d’étincelle, remplacer ladite bougie.

3. S’il y a une étincelle, faire vérifier le moteur par le service après-vente du

revendeur.

1. Vérifier la compression en tirant doucement la poignée du lanceur. Si la

compression est faible, vérifier le serrage de la bougie d’alluma

éléments connexes. Resserrer toutes les pièces qui seraient desserrées.

2. Si la compression reste faible, faire vérifier le moteur par le service après-

vente du revendeur.

1. Mettre le levier d’accélérateur sur la position starter "CHOKE", tirer plusieurs

fois la poignée du lanceur. Puis retirer la bougie d’allumage. Si son

extrémité est mouillée, cela signifie que l’arrivée d’essence est correcte.

2. Si l’arrivée d’essence est incorrecte, vérifier l’entrée du carburateur et

l’entrée du filtre a essence où il peut y avoir blocage.

3. Si l’arrivée d’essence est correcte mais que le moteur ne démarre toujours

pas, essayer un nouveau carburant.

, and with its metal part touching the cylinderhead, try to

ine.

. If the end of the spark plug is wet with fuel,

, check the carburetor entry and fuel strainer

sucked and still the engine can not be started, try with

e et autres

13

j

j

j

Ó

j

j

PROCEDIMIENTO PARA LOCALIZACIÓN DE AVERÍAS

Fallas en el

arranque

Saltan chispas en

la bujíad?

Hay suficiente

compresión?

Es succionado el

combustible dentro

de cilindro?

1. Quite la bu

de hacer chispas en la bujía de encendido.

2. Si no saltan chispas entre los electrodos de la bujía de encendido, reemplácela.

3. Si aún no saltan chispas, llame a la tienda de servicio especializada para

que revise el motor.

1. Comprobar la compresión

Si la compresión está ba

y ajustar todos las partes flojas.

2. Si la compresión todavía está baja, llame a la tienda de servicio especializada

para que revise el motor.

1. Poner la palanca del control de combinación a “ESTRANGULACI

(CHOQUE), tirar de la mani

de encendido.

Si la punta de la bu

succión de combustible está en orden.

2. Si no está succionando bien el combustible, compruebe las entradas del

carburador y del colador de combustible para verificar si existe un posible

bloqueo.

3. Cuando el combustible está siendo correctamente succionado pero el

motor no se puede poner en funcionamiento, pruebe con combustible

nuevo.

ía, y con su parte, metálica que toca la culata del cilindro, trate

alando de la manija del arrancador lentamente.

a, comprobar la tensión de la bujía y otras partes,

N

a del arrancador varias veces y retirar la bujía

ía de encendido está mojada con combustible, la

14

)

A

A

y

g sy

SPECIFICATIONS

Model MP-352.4

Weight 7.5㫂㪾

Pump

Engine

The specifications are subject to change without notice for the purpose of product improvement.

SPECIFICATIONS

Modèle MP-352.4

Poids 7.5㫂㪾

POMPE

MOTEUR

En vue d’amélioration du produit, ces spécifications peuvent être modifiées sans préavis.

SPECIFICATIONS

Modelo MP-352.4

Peso 7.5㫂㪾

BOMBA

MOTOR

Con el objeto una mejora del producto, las especificaciones están sujetas a cambios sin previo aviso.

The specifications are subject to change without notice for the purpose of product improvement.

En vue d’amélioration du produit, ces spécifications peuvent être modifiées sans préavis.

Con el objeto de una mejora del producto, las especificaciones están sujetas a cambios sin previo aviso.

Type Self-priming CENTRIFUGAL PUMP

Diameters (suction-discharge

Total head 45m 148Ft

Maximum delivery volume 130Ͱ/min

Maximum suction lift 26Ft(8m)

xle seal Mechanical seal

Type 4-stroke, single cylinder

Model EH035P

Displacement cylinder 33.5cm3

Fuel combustible

Fuel tank capacit

Startin

Diamètres (aspiration-refoulement) 11in

Chute totale 45m 148Ft

Débit maximum 130Ͱ/min

Hauteur maximum d’aspiration 26Ft(8m)

Joint d’axe Joint Mécanique

Cylindrée 33.5cm3

Carburant Essence ordinaire

Capacitè du réservoir a essence 0.65Ͱ

Système de démarrage Lanceur à retour

Diámetros (succión-descarga) 11in

Altura de elevación total 45m 148Ft

Volumen máximo de descarga 130Ͱ/min

Altura máxima de aspiración 26Ft(8m)

Sello del eje Sello mecánico

Desplazamiento del cilindro 33.5cm3

Combustible Gasolina para automóvil

Capacidad del depósito de combustible 0.65Ͱ

Sistema de arranque Arrancador de retroceso

stem Recoil starter

Type Pompe centrifuge à auto-amorçage

Type Monocylindre à 4 temps

Modèle EH035P

Tipo BOMBA CENTRIFUGA autocebable

Tipo 4-tiempos, mono cilíndrico

Modelo EH035P

11in

utomobile gasoline

0.65Ͱ

15

SAFETY PRECAUTIONS

Please make sure you review each precaution carefully.

EXHAUST PRECAUTIONS

ع Never inhale exhaust gasses.

They contain carbon monoxide, a colorless, odorless and extremely dangerous gas which can cause unconsciousness

or death.

ع Never operate the engine indoors or in a poorly venblated area, such as tunnel, cave, etc.

ع Exercise extreme care when operating the engine near people or animals.

ع Keep the exhaust pipe free of foreign objects.

REFUELING PRECAUTIONS

ع Be sure to stop the engine prior to refueling.

ع Do not overfill the fuel tank.

ع If fuel is spilt, wipe it away carefully and wait until the fuel has dried before starting the engine.

ع After refueling, make sure that the fuel cap is secured to prevent spillage.

FIRE PREVENTION

ع Do not operate while smoking or near an open flame.

ع Do not use around dry brush, twigs, cloth rags, or other flammable materials.

ع Keep the engine at least 3 feet (1 meter) away from buildings or other structures.

ع Keep the engine away from flammables and other hazardous materials (trash, rags, lubricants, explosiver).

SECURITE

Veuillez suivre ces conseils pour une utilisation correcte et sure de votre moteur.

ÉCHAPPEMENT

ع Ne jamais respirer les gaz d’échappement. Ils contiennent du monoxyde de carbone, un gaz inodore, incolore et très

dangereux, qui peut causer de graves accidents pour l'homme.

ع Ne jamais utiliser le moteur dans un endroit comine ni un endroit insuffisament ventile tel que cave, tunnel etc.

ع Être très prudent lors de l’utilisation du moteur près des enfants ou des animaux ou de quelques êtres vivants.

ع Eviter le pot d’échappement.

PLEIN DE CARBURANT

ع Arreter le moteur avant de faire le plein.

ع Ne pas faire déborder le carburant lors du plein.

ع Essayer soigneusement toute trace de carburant sur le moteuret et attendre que tout soit evaporation avant le

demarrage

ع Après avoir fait le plein, vérifier que le bouchon du réservoir est bien en place pour éviter toute fuite.

PRÉVENTION DES INCENDIES

ع Ne pas appracher du moteur avec une cigarette ou toute autre flamme.

ع Ne pas utiliser le moteur près d’un stockage de materieres inflammables.

ع Utiliser le moteur a un mètre de tout obstacle, mur meuble, porle,.....

16

MEDIDAS DE SEGURIDAD

Por favor, asegúrese de reviser detenidamente cada uno de estos apartados.

PRECAUCIONS CON LOS GASES DEL ESCAPE

ع No inhale gases del escape.

ع Contienen monóxido de carbono, un gas incolaro e incdora. Sumamente peligroso que puede causar pérdida del

conocimiento e incluso la muerte.

ع No haga funcionar nunca el motor en recintos cerrados o en sitios con venilbodegas, etc.

ع Tenga sumo cuidado cuando trabaje con el motor cerca de personas o animales.

ع Mantenga el tubo de escape libre de cuerpos.

PRECAUCIONES DE LLENADO

ع Asegúrese de parar el motor antas del Nenado.

ع No llene a rebosar el depósito de combustible.

ع Si el combustible se derrama, límpialo con cuidado y espere hasta secado completamente antes de encender el

motor.

ع Cuando cambie el aceite, asegúrese de que el tapón del combustible está bien cerado para prevenir cualquier derrame.

PREVENCION DE INCENDIO

ع No tenga el motor en funcionamiento mientras fuma, o cerca de una llama.

ع No opere el motor cerca de arbustos secos, palos, hilachas u otros materiales inflamables.

ع Mantenga el motor a una distancia mínima de un metro de edificios u otras instalaciones.

ع Mantenga el motor lejos de materiales inflamables y de alto riesgo (basura, hilachas, lubricantes, explosivos).

17

EMISSION COMPLIANCE PERIOD

For handheld engine : The Emissions

Compliance Period referred to on the Emissions

Compliance label indicates the number of operating hours for which the engine

has been shown to meet Federal emission requirements.

Category C=50 hours, B=125 hours, and A=300 hours.

AIR INDEX

An Air Index Information hang tag was supplied to this engine in accordance with the

emission regulations of the California Air Resources Board.

The bar graph on the hang tag shows the emissions performance of this engine.

The bar graph can be used to compare the emissions performance with other available

engine. The lower the Air Index, the less pollution.

The following durability description is to provide you with information relating to the

emission durability period of the engine.

Descriptive Term Applicable to Emissions Durability Period

Moderate − 50hours (0-65 cc)

Intermediate − 125hours (0-65cc)

Extended − 300hours (0-65cc)

Notice : The Air Index Information hang tag must remain on the engine or on the

equipment until it is sold to the ultimate purchaser. Remove the hang tag

before operating the engine.

18

CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and DOLMAR GmbH North American Division. (Dolmar) are pleased to

explain the emissions control system’s warranty on your 2007 and later small off-road engine. In California, new

equipment that use small off-engines must be designed, built, and equipped to meet the State’s stringent anti-smog

standards. Dolmar must warrant the emissions control system on your small off-road engine for the period listed

below provided there has been no abuse, neglect or improper maintenance of your equipment.

Your emissions control system may include parts such as: carburetors or fuel injection system, ignition system,

catalytic converters, fuel tanks, valves, lters, clamps, connectors, and other associated components. Also,

included may be hoses, belts, connectors, sensors, and other emission-related assemblies.

Where a warrantable condition exists, Dolmar will repair your small off-road engine at no cost to you including

diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emissions-related part on your equipment is

defective, the part will be repaired or replaced by Dolmar.

OWNER’S WARRANTY RESPONSIBILITIES:

• As the small off-road engine owner, you are responsible for performance of the required maintenance listed

in your owner’s manual. Dolmar recommends that you retain all receipts covering maintenance on your small

off-road engine, but Dolmar cannot deny warranty solely for the lack of receipts or your failure to ensure the

performance of all scheduled maintenance.

• As the small off-road engine owner, you should however be aware that Dolmar may deny you warranty coverage

if your small off-road engine or a part has failed due to abuse, neglect, or improper maintenance or unapproved

modications.

• You are responsible for presenting your small off-road engine to a Dolmar Service Center as soon as the

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed

30 days. If you have a question regarding your warranty coverage, you should contact Dolmar Warranty Service

Department at 1-888-OPE-PART for the information.

DEFECTS WARRANTY REQUIREMENTS:

(a) The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

(b) General Emissions Warranty Coverage. Dolmar must warrant to the ultimate purchaser and each subsequent

owner that the engine or equipment is:

(1) Designed, built, and equipped so as to conform with all applicable regulations adopted by the Air

Resources Board; and

(2) Free from defects in materials and workmanship that causes the failure of a warranted part for a period of

two years.

(c) The warranty on emissions-related parts will be interpreted as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in the written

instructions required by subsection (d) must be warranted for the warranty period dened in Subsection

(b) (2). If any such part fails during the period of warranty coverage, it must be repaired or replaced by the

manufacturer according to Subsection (4) below. Any such part repaired or replaced under the warranty

must be warranted for the remaining warranty period.

19

(2) Any warranted part that is scheduled only for regular inspection in the written instructions required by

subsection (d) must be warranted for the warranty period dened in Subsection (b) (2). A statement

in such written instructions to the ef

of warranty coverage. Any such part repaired or replaced under warranty must be warranted for the

remaining warranty period.

(3)

Any warranted part that is scheduled for replacement as required maintenance in the written instructions

required by subsection (d) must be warranted for the period of time prior to the rst scheduled

replacement point for that part. If the part fails prior to the rst scheduled replacement, the part must

be repaired or replaced by the engine manufacturer according to Subsection (4) below. Any such part

repaired or replaced under warranty must be warranted for the remainder of the period prior to the rst

scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty must be performed at no charge to the

owner at a warranty station.

(5) Notwithstanding the provisions of Subsection (4) above, warranty services or repairs must be provided at

all manufacturer distribution centers that are franchised to service the subject engines.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part

is in fact defective, provided that such diagnostic work is performed at a warranty station.

(7) The manufacturer is liable for damages to other engine components proximately caused by a failure under

warranty of any warranted part.

(8) Throughout the emissions warranty period dened in Subsection (b) (2), the manufacturer must maintain a

supply of warranted parts sufcient to meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and

must be provided without charge to the owner. Such use will not reduce the warranty obligations of the

manufacturer.

(10) Add-on or modied parts that are not exempted by the Air Resources Board may not be used. The use

of any non-exempted add-on or modied parts will be grounds for disallowing a warranty claim. The

manufacturer will not be liable to warrant failures of warranted parts caused by the use of a non-exempted

add-on or modied part.

(11) The manufacturer issuing the warranty shall provide any documents that describe that manufacturer’s

warranty procedures or policies within ve working days of request by the Air Resources Board.

(d) Emission Warranty Parts List.

(1) Fuel Metering System

(i) Carburetor and internal parts

(ii) Fuel Filter

(iii) Fuel Tank.

(2) Air Induction System

(i) Air cleaner plate (including choke system)

(ii) Air cleaner cover

(iii) Air cleaner element

(3) Ignition System

(i) Spark Plugs.

(ii) Magneto or electronic ignition system.

(iii) Spark advance/retard system.

(4) Miscellaneous Items Used in Above Systems

(i) Hoses, Sealing gaskets, belts, connectors, and assemblies.

Dolmar will furnish with each new engine written instructions for the maintenance and use of the engine by the

owner.

fect of “repair or replace as necessary” will not reduce the period

20

(e) MAINTENANCE STATEMENTS

It is your responsibility to have all scheduled inspection and maintenance services performed at the times

recommended in the 2007 and later Owner’s Manual and to retain proof that inspection and maintenance

services are performed at the times when recommended. Dolmar will not deny a warranty claim solely because

you have no record of maintenance; however, Dolmar may deny a warranty claim if your failure to perform

required maintenance resulted in the failure of warranted part. The proof, which you maintain, should be given

to each subsequent owner of the engine. You are responsible for performing the scheduled maintenance

described below based on the procedures specied in the 2007 and later Owner’s Manual.

maintenance below is based on the normal engine-operating schedule.

PROCEDURE INTERVAL

1) Clean engine and check bolts and nuts. Retighten if

necessary.

2) Check and rell engine oil (4 stroke engine only) : Every 8 hours (rell daily up to upper limit)

3) Change engine oil (4 stroke engine only) : Initial 20 hours and every 50 hours afterward

4) Check clogging of cooling air passage and cylinder

ns. Remove and clean if necessary.

5) Clean air cleaner. : Every 8 hours (daily)

6) Check spark plug. Clean and adjust if necessary. : Every 8 hours (daily)

7) Check mufer exhaust outlet (or port). Clean if

necessary.

8) Check fuel lter. If clogged, replace with new one. : Every 50 hours (monthly)

9) Adjust valve clearance, if applicable (4 stroke

engine only).

10) Replace fuel lines. : Every 200 hours (yearly)

11) Clean and inspect the complete engine. Replace

any damaged or worn out parts.

12) Replace packings and gaskets with new ones. : Every reassembling

: Every 8 hours (daily)

: Every 8 hours (daily)

: Every 50 hours (monthly)

: Every 200 hours (yearly)

: Every 200 hours

The scheduled

21

FEDERAL EMISSION COMPONENT DEFECT WARRANTY

EMISSION COMPONENT DEFECT WARRANTY COVERAGE - This emission warranty is applicable in all States,

except the State of California

DOLMAR GmbH North American Division, (herein “Dolmar”) warrant to the initial retail purchaser and each

subsequent owner, that this utility equipment engine (herein “engine”) was designed, built, and equipped to conform

at the time of initial sale to all applicable regulations of the U.S. Environmental Protection Agency (EPA), and that

the engine is free of defects in materials and workmanship which would cause this engine to fall to conform with

EPA regulations during its warranty period.

For the components listed under PARTS COVERED, the dealer or service center authorized by Dolmar will, at no

cost to you, make the necessary diagnosis, repair, or replacement necessary to ensure that the engine complies

with applicable U.S. EPA regulations.

EMISSION COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to the initial purchaser and continues for a period of

2 years.

PARTS COVERED

Listed below are the parts covered by the Emission Component Defect Warranty. Some of the parts listed below

may require scheduled maintenance and are warranted up to the rst scheduled replacement point for that part.

Fuel Metering System

1)

(i)

Carburetor and internal parts

(ii) Fuel lter, if applicable

(iii) Throttle stopper, if applicable

(iv) Choke System, if applicable

2) Air Induction System

(i) Air cleaner plate

(ii) Air cleaner case

(iii) Air cleaner element

3) Ignition System

(i) Spark plug

(ii) Flywheel Magneto

(iii) Ignition Coil

4) Miscellaneous Items Used in Above Systems

(i) Fuel hoses, clamps and sealing gaskets

22

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest Service Center authorized by Dolmar. Bring your

sales receipts indicating date of purchase for this engine. The dealer or service center authorized by Dolmar will

perform the necessary repairs or adjustments within a reasonable amount of time and furnish you with a copy of

the repair order. All parts and accessories replaced under this warranty become the property of Dolmar.

WHAT IS NOT COVERED

* Conditions resulting from tampering, misuse, improper adjustment (unless they were made by the dealer

or service center authorized by Dolmar

recommended fuel and oil, or not performing required maintenance services.

* The replacement parts used for required maintenance services.

Consequential damages such as loss of time, inconvenience, loss of use of the engine of equipment, etc.

*

* Diagnosis and inspection charges that do not result in warranty-eligible service being performed.

* Any non-authorized replacement part, or malfunction of authorized parts due to use of non-authorized parts.

OWNER'S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the required maintenance listed in your owner’s

manual, Dolmar recommends that you retain all receipts covering maintenance on your engine, but Dolmar can

not deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled

maintenance.

during a warranty repair), alteration, accident, failure to use the

As the engine owner, you should however be aware that the Dolmar may deny your warranty coverage if your

engine or a part has failed due to abuse, neglect, improper maintenance or unapproved modications.

You are responsible for presenting your engine to the nearest dealer or service center authorized by Dolmar when

a problem exists.

If you have any questions regarding your warranty rights and responsibilities, you should contact the Dolmar

Warranty Service Department at 1-888-OPE-PART for the information.

23

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROL SYSTEM WARRANTY

MAINTENANCE AND REPAIRS

You are responsible for the proper use and maintenance of the engine. You should keep all receipts and

maintenance records covering the performance of regular maintenance in the event questions arise. These receipts

and maintenance records should be transferred to each subsequent owner of the engine. Dolmar reserves the

rights to deny warranty coverage if the engine has not been properly maintained. Warranty claims will not be

denied, however, solely because of the lack of required maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND

SYSTEMS MAY BE PERFORMED BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL;

HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A DEALER OR SERVICE

CENTER AUTHORIZED BY Dolmar. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN

PERFORMANCE AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS

OF THE EMISSION CONTROL SYSTEM AND MAY HAVE A BEARING ON THE OUTCOME OF A

WARRANTY CLAIM.

If other than the parts authorized by Dolmar are used for maintenance replacements or for the repair of

components affecting emission control, you should assure yourself that such parts are warranted by their

manufacturer to be equivalent to the parts authorized by Dolmar in their performance and durability.

HOW TO MAKE A CLAIM

All repairs qualifying under this limited warranty must be performed by a service dealer authorized by Dolmar. In

the event that any emission-related part is found to be defective during the warranty period, you shall notify Dolmar

Warranty Service Department at 1-888-OPE-PART. Dolmar and you will be advised of the appropriate

warranty service dealer or service providers where the warranty repair can be performed.

24

MEMO

MEMO

MEMO

DOLMAR POWER PRODUCTS

PO Box 5007

Alpharetta

GA 30005-5007

5939504801 10.08

Loading...

Loading...