1030/1230 - SERVICE 1

SERIAL NUMBER RECORD

SERVICE

SERIAL NUMBER RECORD

Record serial numbers and date of purchase in spaces pr ovided.

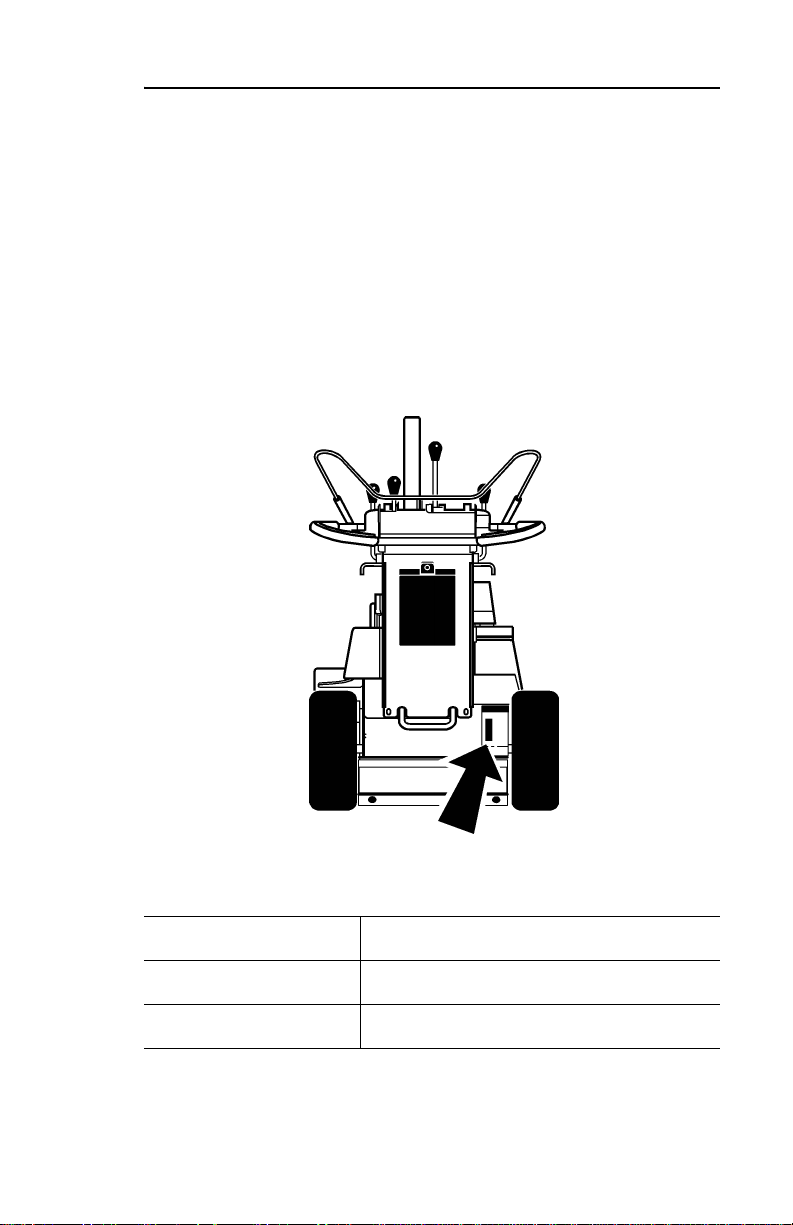

Serial number plate is mounted to frame behind right wheel.

Date of purchase

Serial number

Engine serial number

2 1030/1230 - SERVICE

SUPPORT PROCEDURE

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of

equipment purchase. This information should be recorded and

placed on file by owner at time of purchase.

Return damaged parts to dealer for inspection and warranty

consideration.

Order genuine Ditch Witch replacement parts from your

authorized Ditch Witch dealer. Use of another manufacturer’s

parts may void warranty.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications covering

operation, service, and repair of your equipment.

Ditch Witch Training

For information about on-site, individualized training, contact yo ur

Ditch Witch dealer.

1030/1230 - FOREWORD 3

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manu al are su bje c t to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improvements may have

taken place after this manual was published. For the latest

information on Ditch Witch equipment, see your Ditch Witch

dealer.

Thank you for buying and using Ditch Witch equipment.

4 1030/1230 - FOREWORD

Operator's Manual

Issue Number 4.2/OP-11/04

Part Number 054-515

Copyright 1997, 1999, 2001, 2003, 2004

by The Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, CMW, AutoCrowd,

Modularmatic, Jet Trac, Roto Witch, Subsite, Fluid Miser, PermaSoil, Power Pipe, Super Witch, Super Witch II, Pierce Airrow, The

Underground, and The Underground Authority Worldwide are

registered trademarks of The Charles Machine Works, Inc.

1030/1230 - CONTENTS 5

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Serial Number Record . . . . . . . . . . . . . . . . . . . . . . . . .1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Console Overview . . . . . . . . . . . . . . . . . . . . . .9

Control Console Descriptions . . . . . . . . . . . . . . . . . . . 10

Engine Controls Overview. . . . . . . . . . . . . . . . . . . . . .13

Engine Controls Descriptions . . . . . . . . . . . . . . . . . . . 14

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Underground Hazards . . . . . . . . . . . . . . . . . . . . . . . .16

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . . .17

Jobsite Classification . . . . . . . . . . . . . . . . . . . . . . . . .20

Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . .24

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6 1030/1230 - CONTENTS

TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tiedown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Freewheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Tow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Trenching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

LUBRICATION AND MAINTENANCE. . . . . . . . . . . . . . . 47

Lubrication Overview . . . . . . . . . . . . . . . . . . . . . . . . . 48

Lubrication Schedule . . . . . . . . . . . . . . . . . . . . . . . . . 49

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . 56

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1030 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1030/1230 - OVERVIEW 7

OVERVIEW

The Ditch Witch 1030 and 1230 pedestrian trenchers are

designed for easy, efficient use.

Color-coded controls are within easy reach of the operator.

These compact units fit through most standard yard gates, and

the machines are balanced for easy jobsite maneuvering. A

choice of a 24”, 30”, or 36” (610-, 760-, or 915-mm) digging

boom, along with several chain options, make these machines

flexible enough for most soil conditions. The axle lock feature

aids smooth, easy turns and straight trenching.

1. Trail wheel

2. Digging boom and chain

3. Engine

4. Operator station

8 1030/1230 - OVERVIEW

1030/1230 - CONTROLS 9

CONTROL CONSOLE OVERVIEW

CONTROLS

CONTROL CONSOLE OVERVIEW

1. Bail

2. Digging boom control (green)

3. Axle lock (blue)

4. Speed/direction control (orange)

5. Throttle (black)

6. Digging chain control (yellow)

7. Power switch

10 1030/1230 - CONTROLS

CONTROL CONSOLE DESCRIPTIONS

CONTROL CONSOLE DESCRIPTIONS

Bail

This start interlock control engages and disengages hydraulic

system.

• Move down into handlebar to engage.

• Release to disengage.

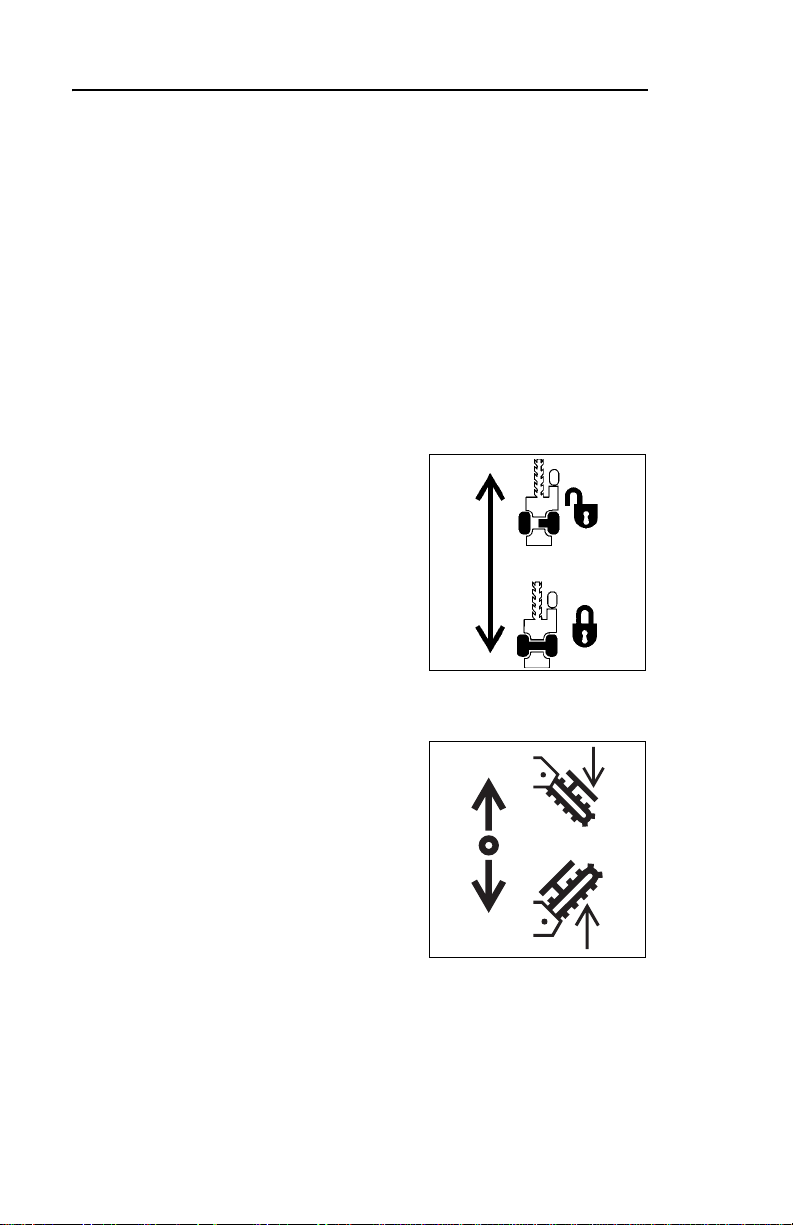

Axle Lock (Blue)

This lever locks or unlocks axle.

• Push to unlock. Use unlocked

axle to manuever trencher.

• Pull to lock. Use locked axle

for straight trenching and

driving over rough terrain.

ic1034.tif

Digging Boom Control (Green)

This lever raises or lowers digging

boom when bail is engaged.

• Push to lower boom.

• Pull to raise boom.

ic0127h.eps

1030/1230 - CONTROLS 11

CONTROL CONSOLE DESCRIPTIONS

Digging Chain Control (Yellow)

This lever starts digging chain

when bail is engaged.

• Push to start digging chain.

• Returns to neutral and digging

chain stops when bail is

released.

ic0014c.tif

Speed/Direction Control

(Orange)

This lever controls unit speed and

direction when bail is engaged.

• Ensure control is in BAIL

RELEASE (neutral) position,

and engage bail.

• Push to move forward.

ic0013c.tif

• Pull to move backward.

• Move farther from center to go faster in either direction.

• Return to BAIL RELEASE (neutral) to stop.

12 1030/1230 - CONTROLS

CONTROL CONSOLE DESCRIPTIONS

Throttle (Black)

This lever controls engine speed.

Increasing engine speed also

increases digging chain speed.

• Push down to speed engine.

• Pull up to slow engine.

ic0128h.eps

Power Switch

This two-position switch controls power to the ma ch in e.

• Turn clockwise to turn power on. In this position, engine will

start when rope start is pulled.

• Turn counterclockwise to stop engine.

1030/1230 - CONTROLS 13

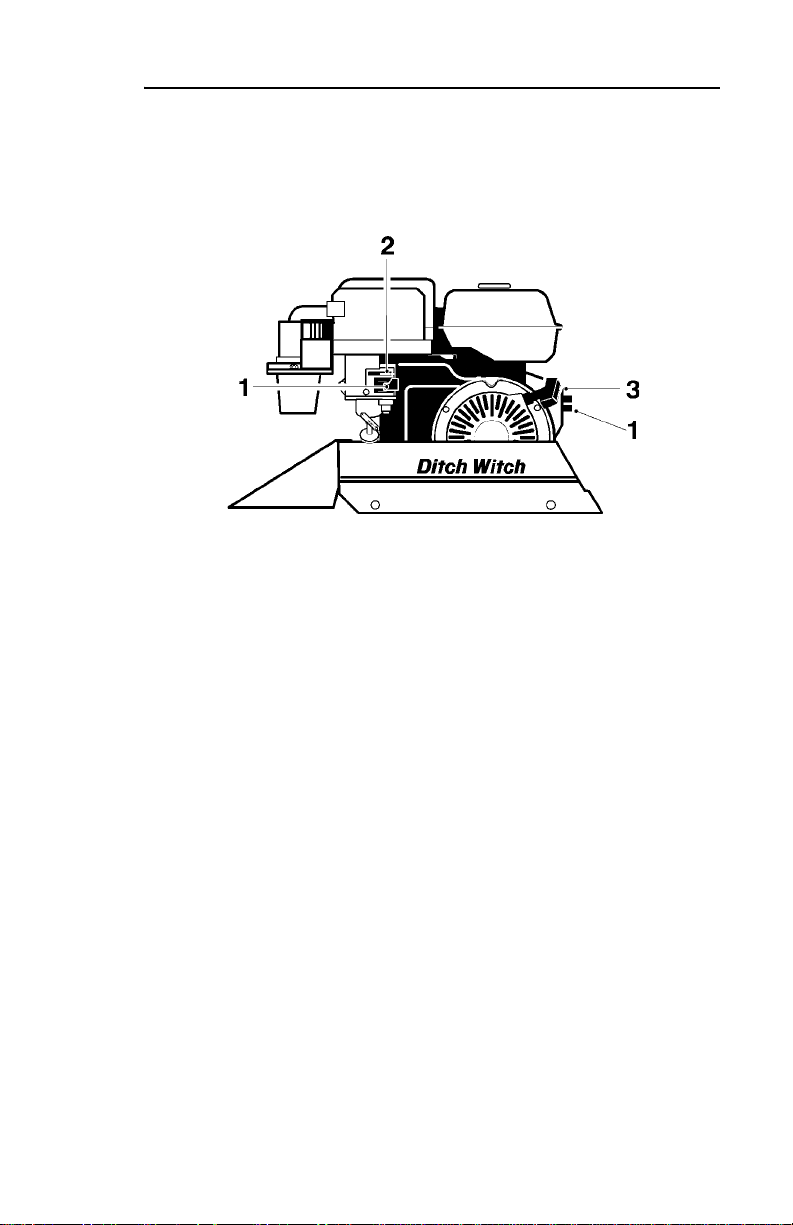

ENGINE CONTROLS OVERVIEW

ENGINE CONTROLS OVERVIEW

1. Fuel shut-off valves

2. Choke

3. Pull start

14 1030/1230 - CONTROLS

ENGINE CONTROLS DESCRIPTIONS

ENGINE CONTROLS DESCRIPTIONS

Fuel Shut-off Valves

Two valves separate fuel reservoir from engine.

• Close when transporting unit to or from jobsite.

• Open before starting engine.

Choke

This valve regulates air/fuel mixture. Close valve to help start cold

engine.

Pull Start

Cranks engine for starting.

• Ensure that power switch is on and fuel shut-off valves are

open.

• Pull to start engine.

If engine does not start after three pulls, turn power switch off and

check for fuel blockage or electrical system problems.

1030/1230 - SAFETY 15

SAFETY

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before

using equipment.

• Contact One-Call (888-258-0808) and any utility companies

which do not subscribe to One-Call. Have all underground

pipes and cables located and marked before operating

equipment. If you damage a utility, contact utility company.

• Classify jobsite based on its hazards and use correct tools

and machinery, safety equipment, and work methods for

jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures,

and individual responsibilities with all personnel before work

begins. Safety videos are available from your Ditch Witch

dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop oper ation and investigate

anything that does not look or feel right.

• Do not operate unit where flammable gas is present.

• Contact your Ditch Witch dealer if you have any question

about operation, maintenance, or equipment use.

16 1030/1230 - SAFETY

ACCESSORIES

ACCESSORIES

Fire Extinguisher

If required, a fire extinguisher should be mounted near the power

unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric

fires. It should meet legal and regulatory requirements.

Lighting Kit

If you need additional light, plug lighting kit into provided outlet.

Contact your Ditch Witch dealer for further information.

UNDERGROUND HAZARDS

Striking underground hazards can cause explosion, electrocution,

fire, and exposure to hazardous materials.

Hazards include:

• Electric lines

• Natural gas lines

• Fiber optic cables

• Water lines

• Sewer lines

• Pipes carrying other chemicals, liquids, or ga se s

• Storage tanks

1030/1230 - SAFETY 17

EMERGENCY PROCEDURES

EMERGENCY PROCEDURES

Before operating any equipment, review emergency procedures

and check that all safety precautions have been taken.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position

or push remote engine stop button.

Electric Strike Description

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least

resistance.

• Pipes, hoses, and cables will conduct electricity back to all

equipment.

• Low voltage current can injure or kill. Almost one-third of

work-related electrocutions result from contact with less than

440 volts.

Most electric strikes are not noticeable, but indications of a strike

include:

• power outage

•smoke

•explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occ urred.

18 1030/1230 - SAFETY

EMERGENCY PROCEDURES

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on

tractor, DO NOT MOVE. Remain on tractor and take the

following actions. The order and degree of action will depend

upon the situation.

• Warn people nearby that an electric strike has occurred.

Instruct them to leave the area and contact utility.

• Raise attachments and drive from immediate area.

• Contact utility company to shut off power.

• Do not return to jobsite or allow anyone into area until given

permission by utility company.

If you suspect an electric line has been damaged and you are off

tractor, DO NOT TOUCH TRACTOR. Take the following actions.

The order and degree of action will depend upon the situation.

• LEAVE AREA.

• Contact utility company to shut off power.

• Do not return to jobsite or allow anyone into area until given

permission by utility company.

1030/1230 - SAFETY 19

EMERGENCY PROCEDURES

If a Gas Line is Damaged

If you suspect a gas line has been damaged, take the following

actions. The order and degree of action will depend on the

situation.

• Immediately shut off engine(s), if this can be done safely and

quickly.

• Remove any ignition source(s), if this can be done safely and

quickly.

• Warn others that a gas line has been cut and that they should

leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and

utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency

personnel and utility company.

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable.

Vision damage can occur.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the

following actions. The order and degree of action will depend on

the situation.

• Immediately move battery disconnect switch (if equipped) to

disconnect position.

• If fire is small and fire extinguisher is available, attempt to

extinguish fire.

• If fire cannot be extinguished, leave area as quickly as

possible and contact emergency personnel.

20 1030/1230 - SAFETY

JOBSITE CLASSIFICATION

JOBSITE CLASSIFICATION

Inspecting Jobsite

• Follow U.S. Department of Labor regulations on excavating

and trenching (Part 1926, Subpart P) and other similar

regulations.

• Contact One-Call (888-258-0808) and any utility companies

which do not subscribe to One-Call.

• Inspect jobsite and perimeter for evidence of underground

hazards, such as:

– “Buried utility” notices

– Utility facilities without overhead lines

– Gas or water meters

– Junction boxes

– Drop boxes

– Light poles

– Manhole covers

– Sunken ground

• Have an experienced locating equipment operator sweep

area within 20’ (6 m) to each side of trench path. Verify

previously marked line and cable locations.

• Mark location of all buried utilities and obstructions.

• Classify jobsite.

1030/1230 - SAFETY 21

JOBSITE CLASSIFICATION

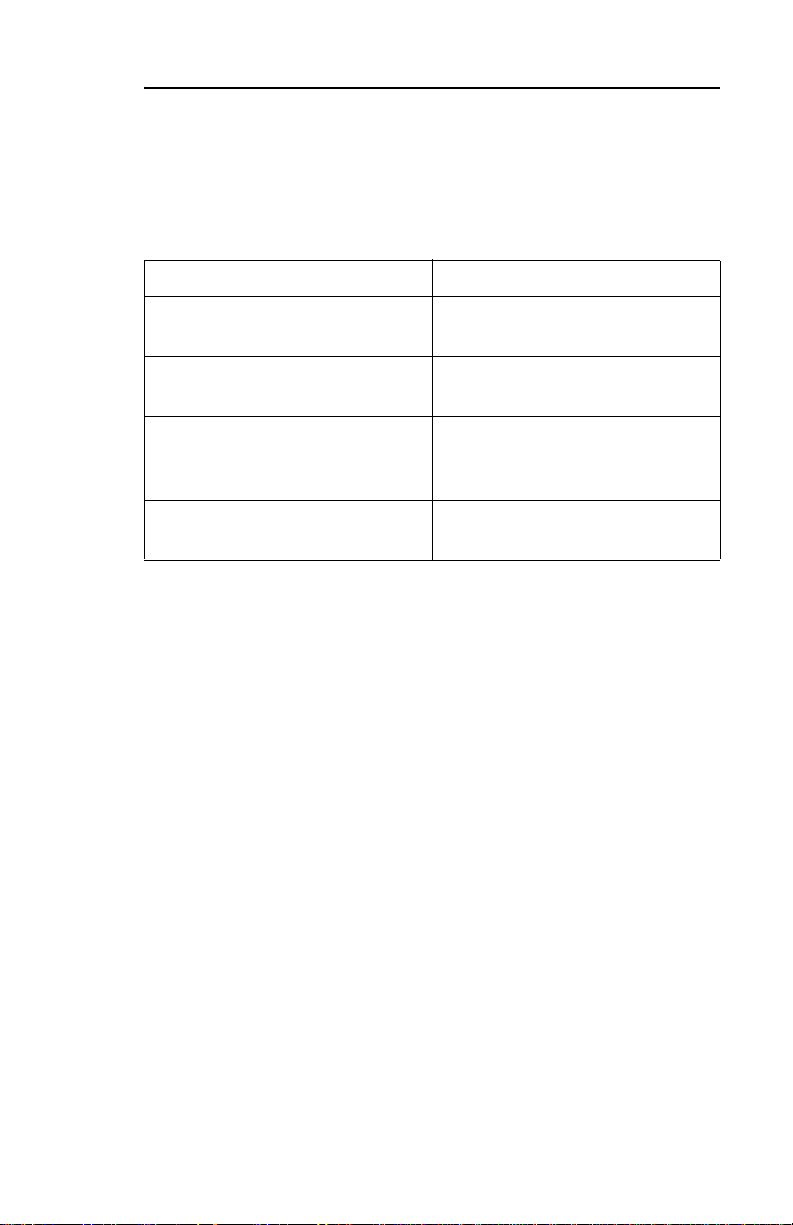

Selecting a Classification

Jobsites are classified according to underground hazards

present.

If working . . . then classify jobsite as . . .

within 10’ (3 m) of a buried

electric

electric line

within 10’ (3 m) of a natural

natural gas

gas line

in sand, granite, or concrete

crystalline silica (quartz) dust

which is capable of producing

crystalline silica (quartz) dust

within 10’ (3 m) of any other

other

hazard

NOTICE: If you have any doubt about jobsite classification, or if

jobsite might contain unmarked hazards, take steps outlined

previously to identify hazards and classify jobsite before working.

22 1030/1230 - SAFETY

JOBSITE CLASSIFICATION

Applying Precautions

Once classified, precautions appropriate for jobsite must be

taken.

Electric Jobsite Precautions

Use one or both of these methods.

• Expose line by careful hand digging or soft excavation.

• Have service shut down while work is in progress. Have

electric company test lines before returning them to service.

Natural Gas Jobsite Precautions

In addition to positioning equipment upwind from gas lines, use

one or both of these methods.

• Expose lines by careful hand digging or soft excavation.

• Have gas shut off while work is in progress. Have gas

company test lines before returning them to service.

Loading...

Loading...