Page 1

DW752R

Page 2

English (original instructions) 3

Français (traduction de la notice d’instructions originale) 9

(ﺓﻲﻠﺻﻷا تﺎﻤﻴﻠﻌﺘﻟا ﻦﻋ ﻢﺟﺮﺘﻣ) :ﺔﻴﺑﺮﻌﻟﺍ 15

Copyright DEWALT

2

Page 3

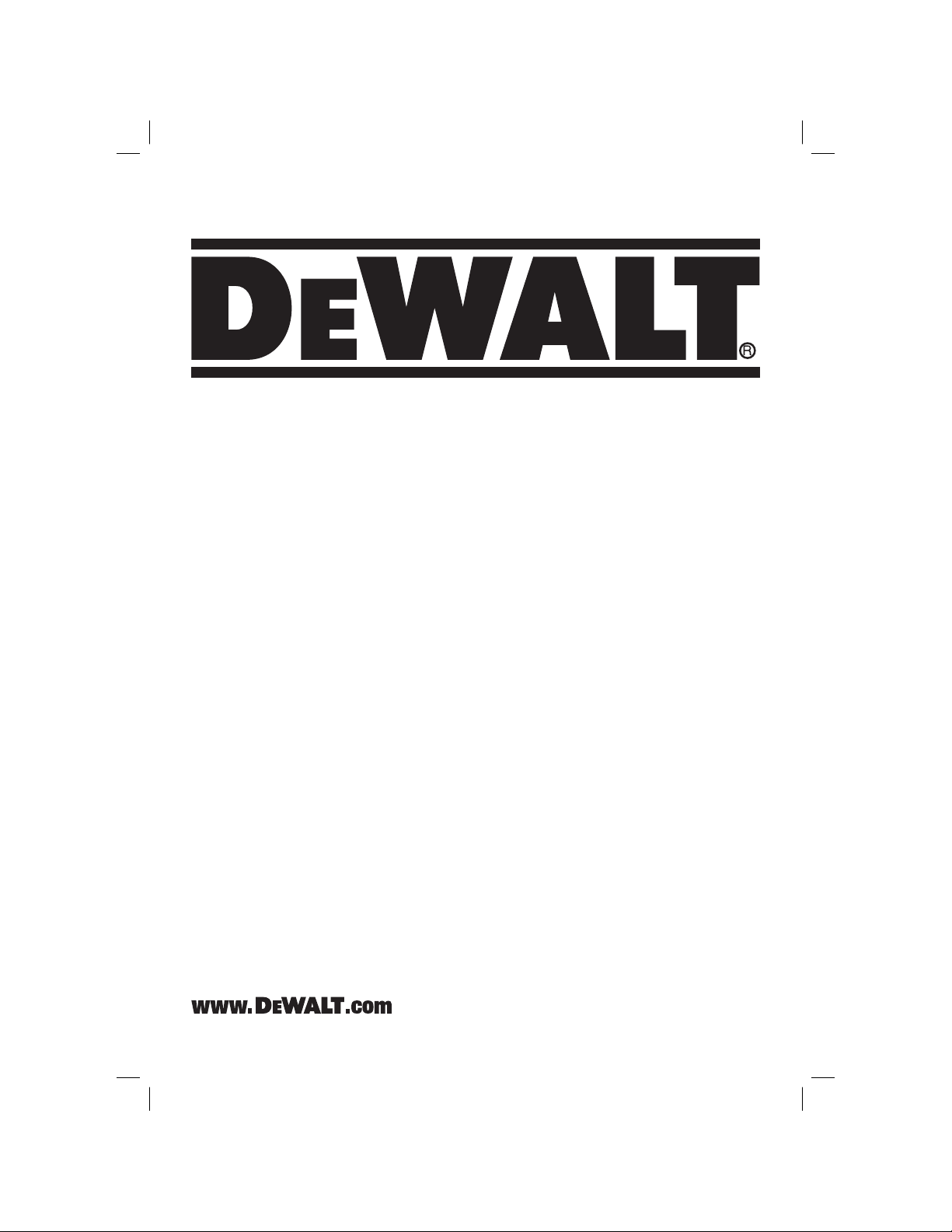

Figure 1

1 ﻞﻜﺷ

a

c

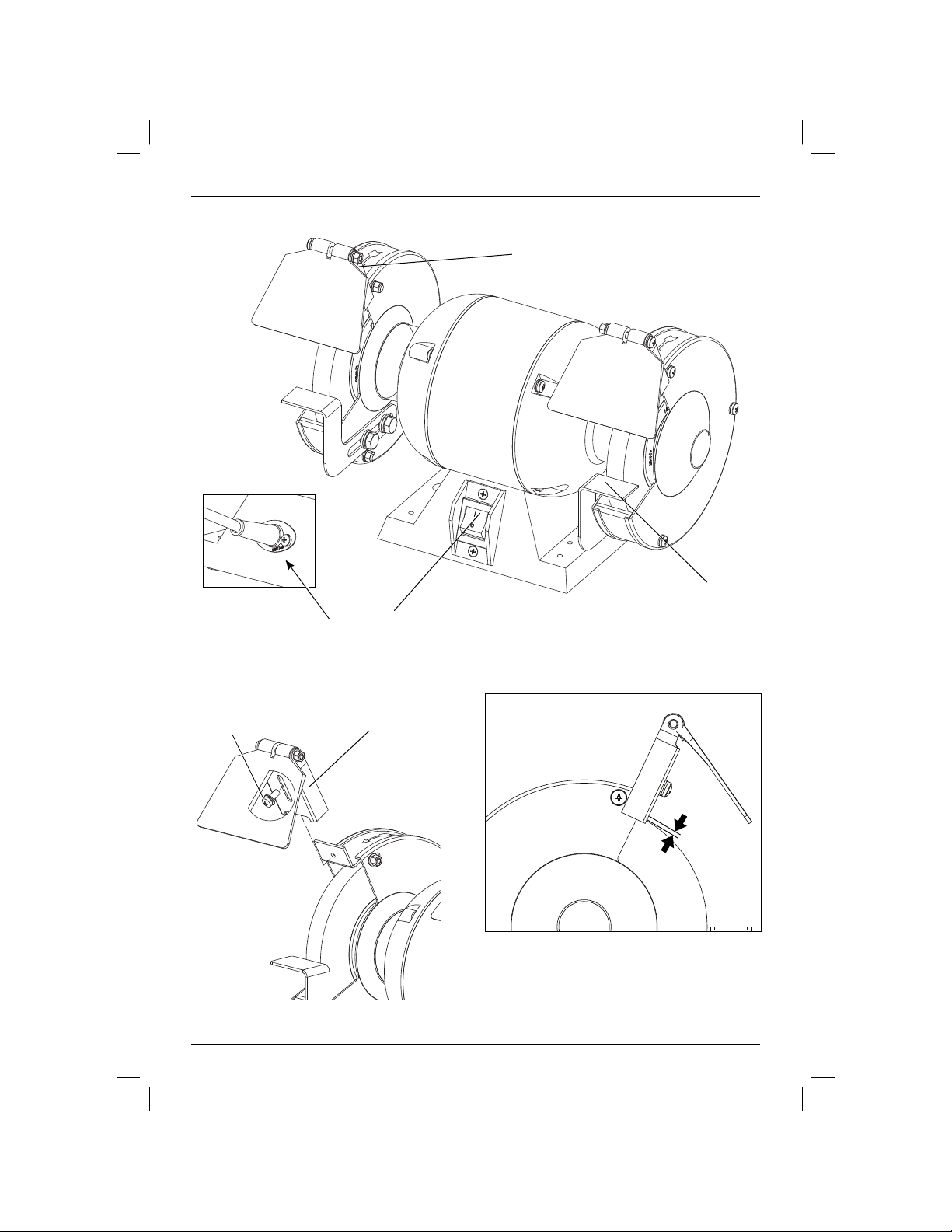

Figure 2

2 ﻞﻜﺷ

d a

i

b

Max 2mm

1

Page 4

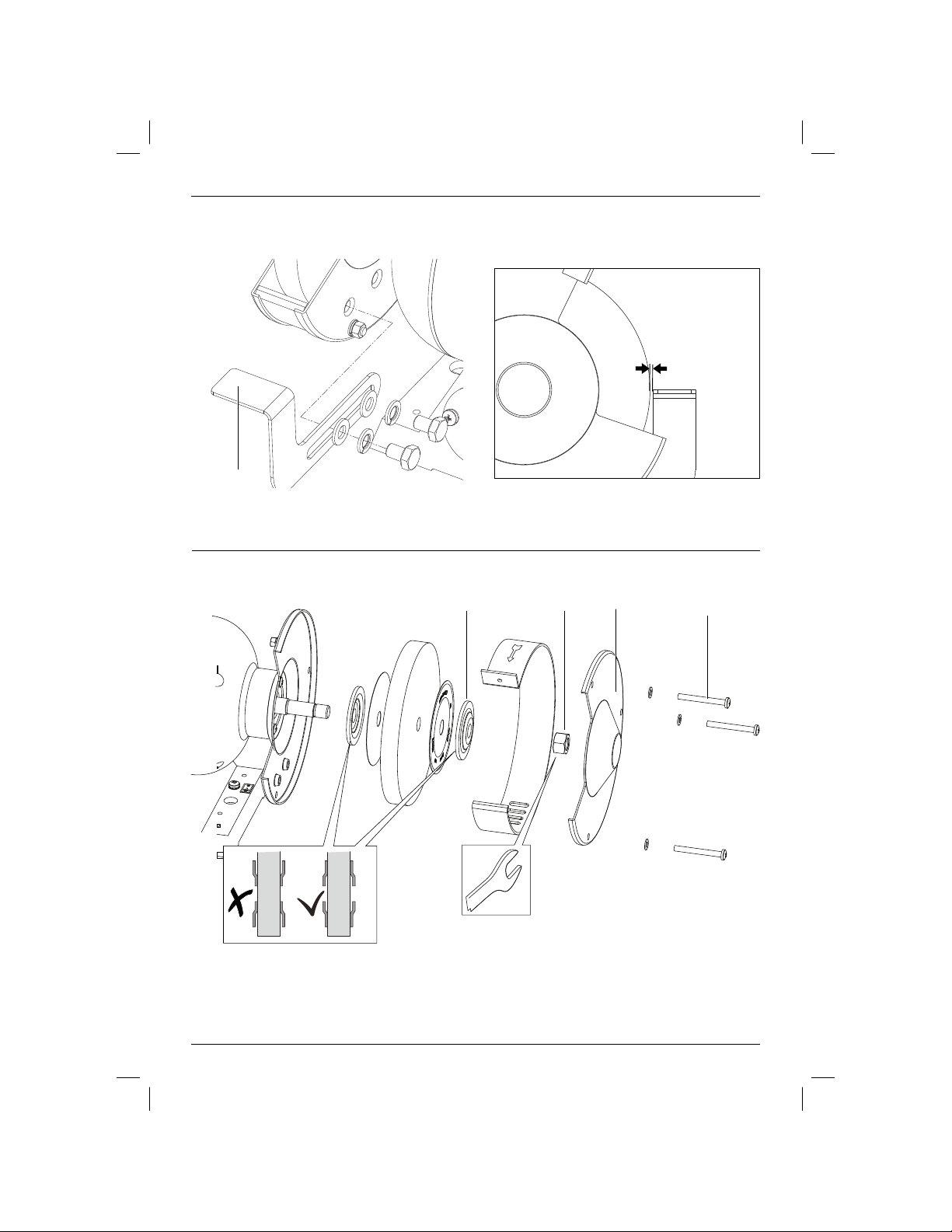

Figure 3

3 ﻞﻜﺷ

Figure 4

4 ﻞﻜﺷ

Max 2mm

c

gef

h

2

Page 5

BENCH GRINDER

DW752R

ENGLISH

Congratulations!

You have chosen a DEWALT tool. Years of

experience, thorough product development and

innovation make DEWALT one of the most reliable

partners for professional power tool users.

Technical Data

DW752R-B5 DW752R-ZA

Voltage V 220–240 230

Power input W 373 373

Frequency Hz 50/60 50

No-load speed /min 2950 2950

Wheel diameter mm 150 150

Wheel thickness mm 15–17 15–17

Bore diameter mm 12.7–12.9 12.7–12.9

Grinder wheel speed m/s 35 35

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

NOTICE: Indicates a practice not

related to personal injury which, if

not avoided, may result in property

damage.

Denotes risk of electric shock.

Denotes risk of fire.

WARNING: To reduce the risk of injury,

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

3

Page 6

ENGLISH

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

4

adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Additional Safety Instructions for

Bench Grinder

• Value of the thickness limit of wear of the

work rest is 1 mm.

• Always use proper guard with grinding

wheel. A guard protects operator from

broken wheel fragments.

• Accessories must be rated for at least the

speed recommended on the tool warning

label. Wheels and other accessories running

over the rated speed can fly apart and cause

injury.

• Do not use a grinding wheel that is

cracked or flawed in any way. Before using,

inspect recommended accessory for cracks or

flaws. If such a crack or flaw is evident, discard

the accessory.

• When starting the tool, let it run for one

minute. Never start the tool with a person

in line with the wheel. This includes the

operator.

Page 7

ENGLISH

• Do not grind on the sides of grinding

wheels unless they are specifically

designed for that purpose.

• Do not overtighten wheel clamp nut. This

may crack the grinding wheel.

• Clean the cavity around the grinding wheel

periodically.

• Wear protective glasses.

• Do not use damaged or misshapen wheels

or brushes.

• The adjustment of the spark arrestor shall

be made frequently, so as to compensate

the wear of the wheel, keeping the

distance between the guard and the wheel

as small as possible, but in any case not

greater than 2mm;

• The adjustment of the work rest shall be

done gradually so as to compensate the

wear of the wheel, keeping the distance

between the work rest and the wheel

as small as possible, but in any case not

greater than 2mm.

• Allow the tool to cool down after a

continuous use of 20 minutes (S2 20min).

Residual Risks

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

– Impairment of hearing.

– Risk of personal injury due to flying particles.

– Risk of burns due to accessories becoming hot

during operation.

– Risk of personal injury due to prolonged use.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

Wear eye protection.

Wear ear protection.

S2 20min The short-time duty is 20min.

DATE CODE POSITION (FIG. 1)

The date code (i), which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX XX

Year of Manufacture

Package Contents

The package contains:

1 Bench grinder

1 Wheel

2 Pairs of tool rests

2 Pairs of spark guards

2 Pairs of mounting brackets

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fi g. 1)

WARNING: Never modify the power

tool or any part of it. Damage or

personal injury could result.

a. Spark guard

b. Switch

c. Tool rest

INTENDED USE

This bench grinder is ideal for use in sharpening

chisels, axes and other wood-cutting tools. It is also

useful for repairing tips on screwdrivers and drill bits

or for removing excess metal burrs from pieces of

cut metal. With the proper accessories, this tool

can be used for cleaning metal surfaces using a

wire brush or for buffing and polishing using a cloth

wheel. Never use this bench grinder for cut-off

operations.

DO NOT use under wet conditions or in presence of

flammable liquids or gases.

This grinder is professional power tool. DO NOT let

children come into contact with the tool. Supervision

is required when inexperienced operators use this

tool.

• This product is not intended for use by persons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

5

Page 8

ENGLISH

Electrical Safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DEWALT tool is double insulated in

accordance with EN 60745; therefore no

earth wire is required.

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

D

EWALT service organisation.

Mains Plug Replacement

(Middle East and Africa)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal in

the plug.

• Connect the blue lead to the neutral terminal.

WARNING: No connection is to be

Follow the fitting instructions supplied with good

quality plugs. Recommended fuse: 13 A.

made to the earth terminal.

Using an Extension Cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see Technical Data). The minimum conductor

size is 1 mm2; the maximum length is 30 m.

When using a cable reel, always unwind the cable

completely.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing setups or when making repairs. Be sure

the trigger switch is in the OFF position.

An accidental start-up can cause injury.

Bench Mounting

1. Mark the position of the four mounting holes

provided in the base of the machine on the

workbench.

2. Drill appropriate sized hole at each of the

marked positions.

3. Place the machine on the workbench and insert

a 6mm hex head bolt with washer through

each mounting hole in the base and into each

of the holes drilled in the workbench.

4. Place a nut on each of the bolts and securely

tighten the nuts.

Mounting of Spark Guard (fi g. 2)

The spark guard offers additional protection from

sparks and must be used whenever possible.

NOTE: Spark guards are not designed to replace

safety glasses.

1. Loosen screw (d) (do not remove it).

2. Slide spark guard (a) onto bracket.

3. Position the spark guard at a distance of

approx. 2mm from the grinding wheel. Tighten

screw (d).

NOTE: Regularly check the distance between

spark guard and the grinding wheel and adjust,

if necessary. Replace the grinding wheel if spark

guard (a) can no longer be adjusted to the maximum

distance of 2mm.

Installing Tool Rest (fi g. 3)

WARNING: Use the washers and

screws supplied. Longer screws may

interfere with the movement of the

grinding wheel.

1. Use the supplied bolts, washers, spacers and

lock nuts to secure the tool rests (c) in place.

2. Position the tool rest at a distance of

approximately 2mm from the grinding wheel.

Regularly check the distance between tool

rest (c) and the grinding wheel and adjust, if

necessary.

OPERATION

Instructions for Use

WARNING: Always observe the safety

instructions and applicable regulations.

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing setups or when making repairs. Be sure

the trigger switch is in the OFF position.

An accidental start-up can cause injury.

WARNING: Never use a bench grinder

if it is not firmly fastened to a work

bench or rigid frame. Before turning the

grinder on, put on safety glasses.

6

Page 9

Turn on the grinder and allow it to reach full speed

(2950/min). Hold the workpiece firmly and against

the tool rest. Hold very small pieces with pliers or

other suitable clamps. Feed the work smoothly

and evenly into the grinding wheel. Move the work

slowly and avoid jamming the work against the

wheel. As the wheel tends to slow down you should

occasionally release the pressure to let the wheel

return to full speed. Grind only on the face of the

grinding wheel and never on the side. (Some wheels

are designed for side grinding and will say so on

their instruction sheets).

Switch

The switch is located on the front of the grinder, on

the base. To turn the tool on depress the side of the

rocker switch on the top side, marked “1”. To turn

off the grinder, depress the base side of the rocker

switch, marked “O”.

Changing Accessories (fi g. 4)

WARNING: Do not use a damaged

grinding wheel.

1. Remove the guard cover (f) by loosening (not

removing) the three screws (h).

2. Remove the clamping nut (e) with a spanner.

3. Remove clamping flange (g) and grinding wheel.

4. Mounting new grinding wheel in reversed order.

5. Switch on the machine and let the wheel run

with no load for one minute to check for cracks.

MAINTENANCE

Your DEWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing setups or when making repairs. Be sure

the trigger switch is in the OFF position.

An accidental start-up can cause injury.

Lubrication

Your power tool requires no additional lubrication.

ENGLISH

Cleaning

WARNING: Blow dirt and dust out of

the main housing with dry air as often as

dirt is seen collecting in and around the

air vents. Wear approved eye protection

and approved dust mask when

performing this procedure.

WARNING: Never use solvents or

other harsh chemicals for cleaning the

non-metallic parts of the tool. These

chemicals may weaken the materials

used in these parts. Use a cloth

dampened only with water and mild

soap. Never let any liquid get inside the

tool; never immerse any part of the tool

into a liquid.

Optional Accessories

WARNING: Since accessories, other

Consult your dealer for further information on the

appropriate accessories.

than those offered by DEWALT, have

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only DEWALT recommended

accessories should be used with this

product.

Protecting the Environment

Separate collection. This product must

not be disposed of with normal

household waste.

Should you find one day that your DEWALT product

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products and

packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

Local regulations may provide for separate collection

of electrical products from the household, at

municipal waste sites or by the retailer when you

purchase a new product.

7

Page 10

ENGLISH

DEWALT provides a facility for the collection and

recycling of DEWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

D

EWALT office at the address indicated in this

manual. Alternatively, a list of authorised DEWALT

repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com.

8

Page 11

TOURET À MEULER

DW752R

FRANÇAIS

Félicitations!

Vous avez choisi un outil DEWALT. Des années

d’expertise dans le développement et l’innovation

de ses produits ont fait de D

privilégié des utilisateurs professionnels d’outils

électriques.

EWALT, le partenaire

Caractéristiques techniques

DW752R-B5 DW752R-ZA

Tension VAC 220–240 230

Puissance absorbée W 373 373

Fréquence Hz 50/60 50

Vitesse à vide /min 2950 2950

Diamètre de la meule mm 150 150

Épaisseur de la meule mm 15–17 15–17

Diamètre d’alésage mm 12,7–12,9 12,7–12,9

Vitesse de la meule m/s 35 35

Défi nitions: consignes de sécurité

Les définitions ci-après décrivent le degré de risques

associé à chaque balise. Lire soigneusement la

notice d’instructions et respecter ces symboles.

DANGER: indique une situation

AVERTISSEMENT: indique une

ATTENTION: indique une situation

AVIS: indique une pratique ne posant

Indique des risques de décharges

Indique des risques d’incendie.

de danger imminent qui, si rien

n’est fait pour l’éviter, aura comme

conséquences la mort ou des

dommages corporels graves.

situation de danger potentiel qui, si

rien n’est fait pour l’éviter, pourra avoir

comme conséquences la mort ou des

dommages corporels graves.

de danger potentiel qui, si rien n’est

fait pour l’éviter, pourrait avoir comme

conséquences des dommages

corporels mineurs ou moindres.

aucun risque de dommages

corporels, mais qui par contre, si rien

n’est fait pour l’éviter, pourrait poser

des risques de dommages matériels.

électriques.

AVERTISSEMENT: pour réduire tout

risque de dommages corporels, lire la

notice d’instructions

Consignes de sécurité générales

propres aux outils électriques

AVERTISSEMENT! lire toutes les

Le terme «outil électrique» mentionné dans les

avertissements ci-après se rapporte aux outils

alimentés sur secteur (avec fil) ou par piles (sans fil).

1) SÉCURITÉ – AIRE DE TRAVAIL

a) Maintenir l’aire de travail propre et bien

b) Ne pas utiliser un outil électrique dans un

c) Maintenir à l’écart les enfants, ou toute

2) SÉCURITÉ – ÉLECTRICITÉ

a) La fiche électrique de l’outil doit

b) Éviter tout contact corporel avec des

directives et consignes de sécurité.

Tout manquement aux directives et

consignes ci-incluses comporte des

risques de décharges électriques,

d’incendie et/ou de dommages

corporels graves.

CONSERVER TOUTES CES DIRECTIVES ET

CONSIGNES À TITRE DE RÉFÉRENCE

éclairée. Les lieux sombres ou encombrés

sont propices aux accidents.

milieu déflagrant, comme en présence de

liquides, gaz ou poussières inflammables.

Les outils électriques peuvent produire des

étincelles qui pourraient enflammer toute

émanation ou poussière ambiante.

autre personne, lors de l’utilisation d’un

outil électrique. Toute distraction pourrait

faire perdre la maîtrise de l’appareil.

correspondre à la prise murale. Ne

modifier la fiche en aucune façon. Ne

pas utiliser de fiche d’adaptation avec

un outil électrique mis à la terre (masse).

L’utilisation de fiches d’origine et de prises

appropriées réduira tout risque de décharges

électriques.

éléments mis à la terre comme: tuyaux,

radiateurs, cuisinières ou réfrigérateurs.

Les risques de décharges électriques

augmentent lorsque le corps est mis à la

terre.

9

Page 12

FRANÇAIS

c) Ne pas exposer les outils électriques à

la pluie ou à l’humidité. Tout contact d’un

outil électrique avec un liquide augmente les

risques de décharges électriques.

d) Ne pas utiliser le cordon de façon

abusive. Ne jamais utiliser le cordon

pour transporter, tirer ou débrancher un

outil électrique. Protéger le cordon de

toute source de chaleur, de l’huile, et

de tout bord tranchant ou pièce mobile.

Les cordons endommagés ou emmêlés

augmentent les risques de décharges

électriques.

e) En cas d’utilisation d’un outil électrique à

l’extérieur, utiliser systématiquement une

rallonge conçue à cet effet. Cela diminuera

tout risque de décharges électriques.

f) Si on ne peut éviter d’utiliser un outil

électrique en milieu humide, utiliser

un circuit protégé par un dispositif de

courant résiduel (RCD). Cela réduira tout

risque de décharges électriques.

3) SÉCURITÉ INDIVIDUELLE

a) Rester systématiquement vigilant et faire

preuve de jugement lorsqu’on utilise un

outil électrique. Ne pas utiliser d’outil

électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de

médicaments. Tout moment d’inattention

pendant l’utilisation d’un outil électrique

comporte des risques de dommages

corporels graves.

b) Porter un équipement de protection

individuel. Porter systématiquement un

dispositif de protection oculaire. Le fait

de porter un masque anti-poussières, des

chaussures antidérapantes, un casque

de sécurité ou un dispositif de protection

auditive, lorsque la situation le requiert,

réduira les risques de dommages corporels.

c) Prévenir tout démarrage accidentel.

S’assurer que l’interrupteur est en

position d’arrêt avant de brancher l’outil

sur le secteur et/ou à la batterie, ou de le

ramasser ou le transporter. Transporter un

outil le doigt sur l’interrupteur ou brancher un

outil électrique alors que l’interrupteur est en

position de marche invite les accidents.

d) Retirer toute clé de réglage avant de

démarrer l’outil. Une clé laissée sur une

pièce rotative d’un outil électrique comporte

des risques de dommages corporels.

e) Adopter une position stable. Maintenir les

pieds bien ancrés au sol et conserver son

équilibre en permanence. Cela permettra

de mieux maîtriser l’outil électrique en cas de

situations imprévues.

f) Porter des vêtements appropriés. Ne

porter aucun vêtement ample ou bijou.

Maintenir cheveux, vêtements et gants

à l’écart des pièces mobiles, car ils

pourraient s’y faire prendre.

g) Lorsqu’un dispositif de connexion

à un système de dépoussiérage ou

d’élimination est fourni, s’assurer qu’il est

branché et utilisé correctement. L’utilisation

de ces dispositifs peut réduire les risques

engendrés par les poussières.

4) UTILISATION ET ENTRETIEN DES OUTILS ÉLECTRIQUES

a) Ne pas forcer un outil électrique. Utiliser

l’outil approprié au travail en cours. L’outil

approprié effectuera un meilleur travail, de

façon plus sûre et à la vitesse pour laquelle il

a été conçu.

b) Ne pas utiliser un outil électrique dont

l’interrupteur est défectueux. Tout appareil

dont l’interrupteur est défectueux est

dangereux et doit être réparé.

c) Débrancher la fiche du secteur et/ou

la batterie de l’outil électrique avant

d’effectuer tout réglage, de changer tout

accessoire, ou avant de le ranger. Ces

mesures préventives réduiront tout risque de

démarrage accidentel de l’appareil.

d) Après utilisation, ranger les outils

électriques hors de portée des enfants

et ne permettre à aucune personne non

familière avec son fonctionnement (ou sa

notice d’instructions) de l’utiliser. Les outils

peuvent être dangereux entre des mains

inexpérimentées.

e) Entretenir les outils électriques. Vérifier

les pièces mobiles pour s’assurer qu’elles

sont bien alignées et tournent librement,

qu’elles sont en bon état et ne sont

affectées d’aucune condition susceptible

de nuire au bon fonctionnement de l’outil.

En cas de dommage, faire réparer l’outil

électrique avant toute nouvelle utilisation.

De nombreux accidents sont causés par des

outils mal entretenus.

f) Maintenir tout organe de coupe propre

et bien affûté. Les outils de coupe bien

entretenus et affûtés sont moins susceptibles

de se coincer et sont plus faciles à contrôler.

g) Utiliser un outil électrique, ses

accessoires, mèches, etc., conformément

aux présentes directives et suivant la

manière prévue pour ce type particulier

d’outil électrique, en tenant compte des

10

Page 13

FRANÇAIS

conditions de travail et de la tâche à

effectuer. L’utilisation d’un outil électrique

à des fins autres que celles prévues est

potentiellement dangereuse.

5) RÉPARATION

a) Faire entretenir les outils électriques par

un réparateur qualifié en n’utilisant que

des pièces de rechange identiques. Cela

permettra de préserver l’intégrité de l’outil

électrique et la sécurité de l’utilisateur.

Consignes de sécurité

supplémentaires pour le touret à

meuler

• La valeur de la limite d’usure en épaisseur

de la réglette porte-pièce est de 1 mm.

• Utilisez toujours la garde de protection

adéquate avec la meule. La garde protège

l’utilisateur des fragments de meule.

• Les accessoires doivent être classés au

minimum à la vitesse recommandée sur

l’étiquette d’avertissement se trouvant

sur l’outil. Les meules et autres accessoires

fonctionnant au dessus de la vitesse nominale

peuvent voler en éclats et provoquer des

blessures.

• N’utilisez pas une meule qui serait fissurée

ou biaisée de quelque manière que ce soit.

Avant utilisation, vérifiez l’absence de fissures ou

de défauts sur l’accessoire. En cas de fissures

ou défauts manifestes, débarrassez-vous de

l’accessoire.

• Lorsque vous démarrez l’outil, laissez-le

tourner à vide pendant une minute. Ne

démarrez jamais l’outil si quelqu’un se

trouve dans l’axe de la meule. Ceci inclut

également l’opérateur.

• N’utilisez pas les côtés de la meule

pour meuler à moins qu’elle ne soit

spécifiquement conçue pour.

• Ne serrez pas trop l’écrou de fixation de la

meule. Cela pourrait faire fissurer la meule.

• Nettoyez régulièrement la cavité autour de

la meule.

• Portez des lunettes de protection.

• N’utilisez jamais de meules ou de brosses

endommagées ou déformées.

• Le réglage du pare-étincelles doit être fait

régulièrement, en fonction de l’usure de

la meule, pour maintenir la distance entre

la protection et la meule aussi petite que

possible. Cette distance ne doit, dans tous

les cas, jamais excéder 2 mm.

• Le réglage de la réglette porte-pièce doit

être fait graduellement, en fonction de

l’usure de la meule, pour maintenir la

distance entre la réglette porte-pièces et

la meule aussi petite que possible. Cette

distance ne doit, dans tous les cas, jamais

excéder 2 mm.

• Laissez l’outil refroidir après une utilisation

continue de 20 minutes (S2 20min).

Risques résiduels

En dépit de l’application des normes de sécurité en

vigueur et de l’installation de dispositifs de sécurité,

certains risques résiduels sont inévitables. Il s’agit de:

– Diminution de l’acuité auditive;

– Risques de dommages corporels dus à des

projections de particules.

– Risques de brûlures provoquées par des

accessoires ayant surchauffé pendant leur

fonctionnement.

– Risques de dommages corporels dus à un

usage prolongé.

Étiquettes sur l’appareil

On trouve les diagrammes suivants sur l’outil:

Lire la notice d’instructions avant toute

utilisation.

Portez une protection oculaire.

Portez une protection auditive.

S2 20min La durée du service temporaire est de

20min

EMPLACEMENT DE LA DATE CODÉE DE FABRICATION

(FIG. 1)

La date codée de fabrication (i), qui comprend aussi

l’année de fabrication, est imprimée sur le boîtier.

Exemple:

2014 XX XX

Année de fabrication

Contenu de l’emballage

Ce carton comprend:

1 Touret à meuler

1 Meule

11

Page 14

FRANÇAIS

2 Paires de réglettes porte-pièce

2 Paires de pare-étincelles

2 Paires de supports de montage

1 Notice d’instructions

1 Dessin éclaté

• Vérifier que l’appareil et ses pièces ou

accessoires n’ont pas été endommagés lors du

transport.

• Prendre le temps de lire attentivement et

comprendre cette notice d’instructions avant

toute utilisation de l’appareil.

Description (fi g. 1)

AVERTISSEMENT: ne jamais modifier

l’outil ni aucun de ses composants, car

cela pose des risques de dommages

corporels ou matériels.

a. Pare-étincelles

b. Interrupteur

c. Réglette porte-pièce

USAGE PRÉVU

Le touret à meuler est idéal pour affûter les burins,

les ciseaux, les axes et tous les autres outils de

coupe. Il est également utile pour rectifi er les pointes

de tournevis ou de forêts ou pour supprimer l’excès

d’ébarbures des pièces métalliques découpées. A

l’aide des accessoires adéquats, cet outil peut être

utilisé pour nettoyer les surfaces métalliques avec

une brosse métallique ou pour les polir avec une

meule drap. N’utilisez jamais le touret à meuler pour

effectuer des découpes.

NE PAS utiliser ces outils en milieu ambiant humide

ou en présence de liquides ou de gaz inflammables.

Cette meuleuse est une machine-outil

professionnelle. NE PAS le laisser à la portée des

enfants. Une supervision est nécessaire auprès de

tout utilisateur non expérimenté.

• Ce produit n’est pas prévu pour être utilisé par

des personnes (y compris les enfants) dont les

capacité physiques, sensorielles ou mentales

sont réduites ou qui manquent d’expérience

ou d’aptitudes, sauf si ces personnes sont

surveillées par une autre personne responsable

de leur sécurité. Ne jamais laisser les enfants

seuls avec ce produit.

Sécurité électrique

Le moteur électrique a été conçu pour fonctionner

sur une tension unique. Vérifier systématiquement

que la tension du secteur correspond bien à la

tension indiquée sur la plaque signalétique.

Votre outil DEWALT à double isolation

est conforme à la norme EN60745; un

branchement à la terre n’est donc pas

nécessaire.

Si le cordon fourni est endommagé, le remplacer

par un cordon spécialement conçu à cet effet, et

disponible auprès du service après-vente D

EWALT.

Remplacement de la fi che

d’alimentation (Moyen-Orient et

Afrique)

Si une nouvelle fiche d’alimentation doit être

montée:

• Mettre soigneusement au rebut l’ancienne fiche.

• Raccorder le fil marron à la borne de phase

dans la fiche.

• Raccorder le fil bleu à la borne de neutre.

AVERTISSEMENT: aucun

Suivez les instructions de montage fournies avec

des fiches de bonne qualité. Fusible recommandé:

13 A.

branchement ne doit être fait à la borne

de terre.

Utilisation d’une rallonge

Si une rallonge s’avère nécessaire, utiliser une

rallonge homologuée et compatible avec la tension

nominale de cet outil (se reporter à la section

Caractéristiques techniques). La section

minimale du conducteur est de 1mm2 pour une

longueur maximale de 30m.

En cas d’utilisation d’un dévidoir, dérouler

systématiquement le câble sur toute sa longueur.

MONTAGE ET RÉGLAGES

AVERTISSEMENT: Afin de

réduire les risques de blessures,

arrêtez l’appareil et débranchezle de la source d’alimentation

avant d’installer ou de retirer des

accessoires, avant d’effectuer

des réglages ou de modifier la

configuration ou encore pendant

les réparations. Assurez-vous que

l’interrupteur est en position ARRÊT. Un

démarrage accidentel peut provoquer

des blessures.

Montage sur établi

1. Repérez sur l’établi, la position des quatre trous

de montage situés dans la base de la machine.

12

Page 15

FRANÇAIS

2. Percez des trous de taille adéquate au niveau

de chaque position repérée.

3. Placez la machine sur l’établi et insérez une vis

de boulon à tête hexagonale de 6 mm, avec

rondelle, traversant chaque trou de la base et

de l’établi.

4. Placez un écrou sur chaque vis et serrez-le

fermement.

Montage du pare-étincelles (fi g. 2)

Le pare-étincelles apporte une protection

supplémentaire contre les étincelles et il doit toujours

être utilisé le cas échéant.

REMARQUE: Les pare-étincelles ne remplacent

pas les lunettes de protection.

1. Dévissez la vis (d) (ne la retirez pas).

2. Glissez le pare-étincelles (a) sur le support.

3. Positionnez le pare-étincelles à une distance de

2 mm environ de la meule. Serrez la vis (d).

REMARQUE: Vérifiez régulièrement la distance

entre le pare-étincelles et la meule et réglez-la si

nécessaire. Remplacez la meule dès qu’il devient

impossible de régler le pare-étincelle (a) à une

distance maximum de 2 mm.

Installation de la réglette

porte-pièce (fig. 3)

AVERTISSEMENT: Utilisez les

rondelles et les vis fournies. Des vis plus

longues pourraient gêner le mouvement

de la meule.

1. Utilisez les boulons, rondelles, entretoises et

écrous de verrouillage fournis pour fixer la

réglette porte-pièce (c) en place.

2. Positionnez la réglette porte-pièce à une

distance de 2 mm environ de la meule. Vérifiez

régulièrement la distance entre la réglette portepièce (c) et la meule et réglez-la si nécessaire.

FONCTIONNEMENT

Consignes d’utilisation

AVERTISSEMENT: respecter

systématiquement les consignes de

sécurité et les normes en vigueur.

AVERTISSEMENT: Afin de

réduire les risques de blessures,

arrêtez l’appareil et débranchezle de la source d’alimentation

avant d’installer ou de retirer des

accessoires, avant d’effectuer

des réglages ou de modifier la

configuration ou encore pendant

les réparations. Assurez-vous que

l’interrupteur est en position ARRÊT. Un

démarrage accidentel peut provoquer

des blessures..

AVERTISSEMENT: N’utilisez jamais

une meule qui ne soit pas fermement

fixée sur un établi ou un châssis fixe.

Mettez vos lunettes de protection, avant

de mettre la meuleuse en marche.

Allumez la meuleuse et laissez-la atteindre sa pleine

vitesse (2950/min). Maintenez la pièce à travailler

fermement contre la réglette porte-pièce. Maintenez

les très petites pièces à l’aide de pinces ou autres

dispositifs de fixation appropriés. Amenez la pièce à

travailler sans à coups et de façon régulière contre

la meule. Déplacez la pièce doucement en évitant

de bloquer la pièce contre la meule. La meule ayant

à tendance à ralentir, vous devez régulièrement

relâcher la pression pour lui laisser reprendre sa

pleine vitesse. Ne meulez qu’avec la partie avant de

la meule et jamais sur ses côtés. (Certaines meules

sont conçues pour meuler sur leurs côtés, cela est

précisé sur leurs notices).

Interrupteur

L’interrupteur se trouve à l’avant de la meuleuse, sur

la base. Pour mettre l’outil en marche, appuyez sur

l’interrupteur à bascule vers le haut, du côté marqué

d’un «1». Pour éteindre la meuleuse, appuyez sur

l’interrupteur à bascule vers le bas, du côté marqué

d’un «O».

Changer les accessoires (fi g. 4)

AVERTISSEMENT: N’utilisez jamais

une meule qui serait endommagée.

1. Retirez la garde de protection (f) en dévissant

(sans les retirer) les trois vis (h).

2. Retirez l’écrou de fixation (e) à l’aide d’une clé.

3. Retirez la bride de fixation (g) et la meule.

4. Remontez une nouvelle meule en procédant

dans l’ordre inverse.

5. Allumez la machine et laissez la meule tourner

à vide pendant une minute afin de contrôler

l’absence de fissures.

MAINTENANCE

Cet outil DEWALT a été conçu pour fonctionner

longtemps avec un minimum de maintenance. Le

fonctionnement continu et satisfaisant de l’outil

dépend d’un entretien adéquat et d’un nettoyage

régulier.

13

Page 16

FRANÇAIS

AVERTISSEMENT: Afin de réduire

les risques de blessures, arrêtez

l’appareil et débranchez-le de

la source d’alimentation avant

d’installer ou de retirer des

accessoires, avant d’effectuer

des réglages ou de modifi er la

confi guration ou encore pendant

les réparations. Assurez-vous que

l’interrupteur est en position ARRÊT. Un

démarrage accidentel peut provoquer

des blessures

Lubrifi cation

Votre outil électrique ne requiert aucune lubrification

additionnelle.

Entretien

AVERTISSEMENT: éliminer poussière

et saleté du boîtier principal à l’aide d’air

comprimé chaque fois que les orifices

d’aération semblent s’encrasser. Porter

systématiquement des lunettes de

protection et un masque anti-poussières

homologués au cours de cette

procédure.

AVERTISSEMENT: ne jamais utiliser

de solvants ou tout autre produit

chimique décapant pour nettoyer

les parties non métalliques de l’outil.

Ces produits chimiques pourraient en

attaquer les matériaux utilisés. Utiliser

un chiffon humidifié avec de l’eau et

un savon doux. Protéger l’outil de tout

liquide et n’immerger aucune de ses

pièces dans aucun liquide.

Protection de l’environnement

Collecte sélective. Ne pas jeter ce produit

avec les ordures ménagères.

En fin de durée de vie ou d’utilité de votre

produit D

ménagères, mais dans les conteneurs de collecte

sélective.

Selon les réglementations locales, il peut être offert:

service de collecte sélective individuel des produits

électriques, ou déchetterie municipale ou collecte

sur les lieux d’achat des produits neufs.

DEWALT dispose d’installations pour la collecte et

le recyclage des produits DEWALT en fin de vie.

Pour profiter de ce service, veuillez rapporter votre

produit auprès d’un centre de réparation agréé qui le

recyclera en notre nom.

Pour connaître l’adresse d’un centre de réparation

agréé près de chez vous, veuillez contacter votre

distributeur DEWALT local à l’adresse indiquée dans

cette notice d’instructions, ou consulter la liste des

centres de réparation agréés DEWALT, l’éventail de

notre SAV et tout renseignement complémentaire

sur Internet à l’adresse: www.2helpU.com.

EWALT, ne pas le jeter avec les ordures

La collecte sélective des produits et

emballages usagés permet de recycler et

réutiliser leurs matériaux. La réutilisation

de matériaux recyclés aide à protéger

l’environnement contre la pollution et à

réduire la demande en matière première.

Accessoires en option

AVERTISSEMENT: comme les

Veuillez consulter votre revendeur pour plus

d’informations sur les accessoires appropriés.

14

accessoires autres que ceux offerts par

DEWALT n’ont pas été testés avec ce

produit, leur utilisation avec cet appareil

pourrait être dangereuse. Pour réduire

tout risque de dommages corporels,

seuls des accessoires DEWALT

recommandés doivent être utilisés avec

cet appareil.

Page 17

ﺔﻴﺑﺮﻌﻟﺍ

ﺔﻳﺪﻀﻨﻟﺍ ﺔﺧﻼﺠﻟﺍ

DW752R

ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻰﻟإ تاﺮﻳﺬﺤﺘﻟا ﻲﻓ «ﺔﻴﺋﺎﺑﺮﻬﻛ ةادأ» ﺢﻠﻄﺼﻤﻟا ﺮﻴﺸﻳ

ةادﻷا وأ (ﻲﺋﺎﺑﺮﻬﻛ ﻚﻠﺴﺑ ةدوﺰﻣ) ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻗﺎﻄﻟﺎﺑ ﻞﻤﻌﺗ ﻲﺘﻟا

.(ﻲﺋﺎﺑﺮﻬﻛ ﻚﻠﺴﺑ ةدوﺰﻣ ﺮﻴﻏ) ﺔﻳرﺎﻄﺒﻟﺎﺑ ﻞﻤﻌﺗ ﻲﺘﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﺚﻴﺣ .ةﺪﻴﺟ ﺔﻘﻳﺮﻄﺑ ةءﺎﻀﻣو ﺔﻔﻴﻈﻧ ﻞﻤﻌﻟا ﺔﻘﻄﻨﻤﺑ ﻆﻔﺘﺣا (أ

عﻮﻗو ﻰﻟإ يدﺆﺗ ﺔﻤﻠﻈﻤﻟا وأ مﺎﻈﻧ ﺮﻴﻐﺑ ﺔﺳﺪﻜﺘﻤﻟا ﻖﻃﺎﻨﻤﻟا نأ

،ةﺮﺠﻔﺘﻤﻟا ءاﻮﺟﻷا ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ﻞﻴﻐﺸﺘﺑ ﻢﻘﺗ ﻻ (ب

.لﺎﻌﺘﺷﻼﻟ ﻞﺑﺎﻗ رﺎﺒﻏ وأ تازﺎ ﻏ وأ ﻞﺋاﻮﺳ نﺎﻜﻤﻟﺎﺑ ﺪﺟﻮﻳ نﺄﻛ

لﺎﻌﺘﺷا ﻲﻓ تاراﺮﺷ ثﺪﺤﺗ ﻲﺘﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا يدﺆﺗ ﺪﻗ

ً

ءﺎﻨﺛأ

اﺪﻴﻌﺑ ﻦﻳﺪﻫﺎﺸﻤﻟا صﺎﺨﺷﻷاو لﺎﻔﻃﻷا ﻰﻠﻋ ﻆﻓﺎﺣ

ناﺪﻘﻓ ﻰﻟإ هﺎﺒﺘﻧﻻا ﺖﺘﺸﺗ يدﺆﻳ ﺪﻘﻓ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ

رﺎﻴﺘﻟا رﺪﺼﻣ ﻊﻣ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﺲﺑﺎﻗ ﻖﺑﺎﻄﺘﻳ نأ ﺐﺠﻳ (أ

يﺄﺑ ﺲﺑﺎﻘﻟا ﻰﻠﻋ ﻞﻳﺪﻌﺗ ءاﺮﺟﺈ ﺑ ﺎ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ﻊﻣ لﻮﺤﻤﻟا ﺲﺑﺎﻗ مﺪﺨﺘﺴﺗ ﻻ .ﺔﻘﻳﺮﻃ

ﺔﻟﺪﻌﻤﻟا ﺮﻴﻏ ﺲﺑﺎﻘﻤﻟا ﻞﻠﻘﺘﺳ ﺚﻴﺣ .(ﺎﻬﻀﻳرﺄﺗ ﻢﺗ) ﺔﺿرﺆﻤﻟا

ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ﻦﻣ ﺔﻘﺑﺎﻄﺘﻤﻟا ﻲﺋﺎﺑﺮﻬﻜﻟا رﺎﻴﺘﻟا ردﺎﺼﻣو

ﺔﺿرﺆﻤﻟا وأ ﺔﻴﺿرﻷا ﺢﻄﺳﻷا ﻊﻣ ﺪﺴﺠﻟا ﺲﻣﻼﺗ ﺐﻨﺠﺗ (ب

ﺮﻄﺧ ﺪﺟﻮﻳ ﺚﻴﺣ .تﺎﺟﻼﺜﻟاو تﺎﻗﺎﻄﻨﻟاو عﺎﻌﺸﻤﻟا ،ﺐﻴﺑﺎﻧﻷﺎﻛ

وأ ﺎ

ﺿرﺆﻣ كﺪﺴﺟ نﺎﻛ اذإ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﻦﻣ ﺪﻳاﺰﺘﻣ

ً

ءﺎﻤﻟا يدﺆﻴﺳ ذإ .ﻞﻠﺒﻟا وأ ﺮﻄﻤﻠﻟ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ضﺮﻌﺗ ﻻ (ج

ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ةدﺎﻳز ﻰﻟإ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﺧﺪﻳ يﺬﻟا

ﺎًﻘﻠﻄﻣ مﺪﺨﺘﺴﺗ ﻻ .ﺔﺌﻃﺎﺧ ﺔﻘﻳﺮﻄﺑ ﻞﺑﺎﻜﻟا مﺪﺨﺘﺴﺗ ﻻ (د

ةادﻷا ﺲﺑﺎﻗ عﺰﻨﻟ وأ ﺎﻬﺒﺤﺳ وأ ءﺎﻴﺷﻷا ﻞﻤﺣ ﻞﺟأ ﻦﻣ ﻚﻠﺴﻟا

فاﻮﺤﻟا وأ تﻮﻳﺰﻟا وأ ةراﺮﺤﻟا ﻦﻋ ﻚﻠﺴﻟا ﺪﻌﺑأ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

وأ ﺔﻔﻟﺎﺘﻟا كﻼﺳﻷا ﺪﻳﺰﺗ ذإ .ﺔﻛﺮﺤﺘﻤﻟا ءاﺰﺟﻷا وأ ةدﺎﺤﻟا

.ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ﻦﻣ ﺔﻜﺑﺎﺸﺘﻤﻟا

ﻚﻠﺳ مﺪﺨﺘﺳا ،لﺰﻨﻤﻟا جرﺎﺧ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ ﺪﻨﻋ (ـﻫ

نإ ﺚﻴﺣ .ﺔﻴﺟرﺎﺨﻟا ﻦﻛﺎﻣﻷا ﻲﻓ ماﺪﺨﺘﺳﻼﻟ ﻢﺋﻼﻣ ﺔﻟﺎﻄﺘﺳا

ﺮﻄﺧ ﻦﻣ ﻞﻠﻘﻳ ﻲﺟرﺎﺨﻟا ماﺪﺨﺘﺳﻼﻟ ﻢﺋﻼﻤﻟا ﻚﻠﺴﻟا ماﺪﺨﺘﺳا

ﺪﺣأ ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ ﻦﻣ ﺮﻔﻣ كﺎﻨﻫ ﻦﻜﻳ ﻢﻟ اذإ (و

ﻊﻃﺎﻗ زﺎﻬﺠﺑ ﻲﻤﺤﻣ داﺪﻣإ رﺪﺼﻣ مﺪﺨﺘﺳﺎﻓ ،ﺔﺒﻃﺮﻟا ﻦﻛﺎﻣﻷا

ثوﺪﺣ ﻦﻣ ﻞﻠﻘﻳ ﻲﻘﺒﺘﻤﻟا رﺎﻴﺘﻟا زﺎﻬﺟ ماﺪﺨﺘﺳا .(RCD) ةروﺪﻟا

ﺔﻣﺎﻌﻟا ساﻮﺤﻟﺎﺑ ﻦﻌﺘﺳاو ﻪﻠﻌﻔﺑ مﻮﻘﺗ ﺎﻣ ﺐﻗارو

ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا مﺪﺨﺘﺴﺗ ﻻ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ ﺪﻨﻋ

وأ لﻮﺤﻜﻟا وأ تارﺪﺨﻤﻟا ﺮﻴﺛﺄﺗ ﺖﺤﺗ وأ ﺎ

تاودﻷا ﻞﻴﻐﺸﺗ ءﺎﻨﺛأ ﻮﻬﺴﻟا ﻦﻣ ﺔﻈﺤﻟ يأ يدﺆﺗ ﺪﻗ .ﺔﻳودﻷا

.ﺔﻤﻴﺴﺟ ﺔﻳﺪﺴﺟ ﺔﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﻲﻗاو ءاﺪﺗرﺎﺑ ﺎًﻣود ﻢﻗ .ﺔﻴﺼﺨﺸﻟا ﺔﻳﺎﻗﻮﻟا تاﺪﻌﻣ مﺪﺨﺘﺳا (ب

،ﺔﺑﺮﺗﻷا تﺎﻣﺎﻤﻛ ﻞﺜﻣ ﺔﻳﺎﻗﻮﻟا تاﺪﻌﻣ ماﺪﺨﺘﺳا نأ ذإ .ﻦﻴﻨﻴﻌﻟا

نذﻷا ﻲﻗاو وأ ،ﺔﺒﻠﺼﻟا ةذﻮﺨﻟاو ،قﻻﺰﻧﻼﻟ ﺔﻌﻧﺎﻤﻟا نﺎﻣﻷا ﺔﻳﺬﺣأو

.ﺔﻴﺼﺨﺸﻟا تﺎﺑﺎﺻﻹا ﻦﻣ ﻞﻠﻘﻴﺳ ﺔﻠﺼﻟا تاذ تﻻﺎﺤﻠﻟ

ﻞﻤﻌﻟﺍ ﺔﻘﻄﻨﻣ ﻥﺎﻣﺃ (1

.ثداﻮﺤﻟا

.ﺔﻨﺧدﻷا وأ ﺔﺑﺮﺗﻷا

.ﻚﺗﺮﻄﻴﺳ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺔﻣﻼﺴﻟﺍ (2

ً

ﻘﻠﻄﻣ ﻢﻘﺗ ﻻ .ﻲﺋﺎﺑﺮﻬﻜﻟا

.ﺔﻴﺋﺎﺑﺮﻬﻛ

.ضرﻷا ﻰﻠﻋ ﺎ

.ﺔﻴﺋﺎﺑﺮﻬﻛ

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻘﻌﺼﻟا ثوﺪﺣ

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻘﻌﺼﻟا

ﺔﻴﺼﺨﺸﻟﺍ ﺔﻣﻼﺴﻟﺍ (3

ً

ﺎﻈﻘﻴﺘﻣ ﻖﺑا (أ

ﺒﻌﺘﻣ نﻮﻜﺗ ﺎﻣﺪﻨﻋ

ً

!ﺎﻨﻴﻧﺎﻬﺗ

ﺕﺎﻴﻠﻤﻋ ﺎﻬﻟﻼﺧ ﺪﺘﻤﺗ ﻲﺘﻟﺍ ﺓﺮﺒﺨﻟﺍ ﺕﺍﻮﻨﺳ.DEWALT ﺓﺍﺩﺃ ﺕﺮﺘﺧﺍ ﺪﻘﻟ

ﻦﻳﺬﻟﺍ ءﺎﻛﺮﺸﻟﺍ ﺮﺜﻛﺃ ﻦﻣ DEWALT ﻞﻌﺠﺗ ﺎﻫﺭﺎﻜﺘﺑﺍﻭ ﺕﺎﺠﺘﻨﻤﻟﺍ ﺮﻳﻮﻄﺗ

.ﻦﻴﻓﺮﺘﺤﻤﻟﺍ ﺔﻴﻟﻵﺍ ﺕﺍﻭﺩﻷﺍ ﻲﻣﺪﺨﺘﺴﻤﻟ ﺔﺒﺴﻨﻟﺎﺑ ﻢﻬﻴﻠﻋ ﺩﺎﻤﺘﻋﻻﺍ ﻦﻜﻤﻳ

ﺔﻴﻨﻔﻟﺍ ﺕﺎﻧﺎﻴﺒﻟﺍ

DW752R-ZA DW752R-B5

230 220–240 ﺖﻟﻮﻓ ﻲﺋﺎﺑﺮﻬﻜﻟا ﺪﻬﺠﻟا

373 373 تاو ﺔﻗﺎﻄﻟا ﻞﺧد

(ج

50 50/60 ﺰﺗﺮﻫ ددﺮﺘﻟا

2950 2950 ﺔﻘﻴﻗد / ﻞﻤﺣ نوﺪﺑ ﺔﻋﺮﺴﻟا

150 150 ﻢﻣ ﺔﻧاﻮﻄﺳﻻا ﺮﻄﻗ

15–17 15–17 ﻢﻣ ﺔﻧاﻮﻄﺳﻻا ﻚﻤﺳ

12.7–12.9 12.7–12.9 ﻢﻣ ﺐﻘﺜﻟا ﺮﻄﻗ

35 35 ث/م ﺔﺧﻼﺠﻟا ﺔﻧاﻮﻄﺳا ﺔﻋﺮﺳ

ﻥﺎﻣﻷﺍ ﺕﺎﻤﻴﻠﻌﺗ :ﺕﺎﻔﻳﺮﻌﺘﻟﺍ

ﺓءﺍﺮﻗ ﻰﺟﺮﻳ .ﺔﻳﺮﻳﺬﺤﺗ ﺔﻤﻠﻛ ﻞﻛ ﺔﻴﻤﻫﺃ ﻯﻮﺘﺴﻣ ﺔﻴﻟﺎﺘﻟﺍ ﺕﺎﻔﻳﺮﻌﺘﻟﺍ ﻒﺼﺗ

اذإو ،ﺔﻳﺎﻐﻠﻟ عﻮﻗﻮﻟا ﺔﻜﻴﺷو ةﺮﻄﺧ ﺔﻟﺎﺣ ﻰﻟإ ﺮﻴﺸﺗ :ﺮﻄﺧ

ﺔﺑﺎﺻﻹا وأ ةﺎﻓﻮﻟا ثوﺪﺣ ﻰﻟإ يدﺆﺘﺳ ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ ﻢﻟ

ﺘﺑﺎﺛ

ً

ﻢﻟ اذإو ،عﻮﻗﻮﻟا ﺔﻠﻤﺘﺤﻣ ةﺮﻄﺧ ﺔﻟﺎﺣ ﻰﻟإ ﺮﻴﺸﺗ :ﺮﻳﺬﺤﺗ

ﺔﺑﺎﺻﻹا وأ ةﺎﻓﻮﻟا ثوﺪﺣ ﻰﻟإ يدﺆﺗ ﺪﻘﻓ ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ

ﻢﻟ اذإو ،عﻮﻗﻮﻟا ﺔﻠﻤﺘﺤﻣ ةﺮﻄﺧ ﺔﻟﺎﺣ ﻰﻟإ ﺮﻴﺸﺗ :ﻪﻴﺒﻨﺗ

وأ ﺔﻄﻴﺴﺑ ﺔﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ يدﺆﺗ ﺪﻗو ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ

ﺔﺑﺎﺻﺈﺑ ﺔﻘﻠﻌﺘﻣ ﺮﻴﻏ ﺔﺳرﺎﻤﻣ ﻰﻟإ ﺮﻴﺸﺗ :ﺔﻈﺣﻼﻣ

رﺮﺿ ﻰﻟإ يدﺆﺗ ﺪﻘﻓ ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ ﻢﻟ اذإ ،ﺔﻴﺼﺨﺷ

.ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ﻰﻟإ ﺮﻴﺸﺗ

.ﻖﻳﺮﺣ بﻮﺸﻧ ﺮﻄﺧ ﻰﻟإ ﺮﻴﺸﺗ

ﻞﻴﻟد ةءاﺮﻗ ﻰﺟﺮﻳ ،تﺎﺑﺎﺻﻹا ثوﺪﺣ ﺮﻄﺧ ﻞﻴﻠﻘﺘﻟ :ﺮﻳﺬﺤﺗ

.ﺯﻮﻣﺮﻟﺍ ﻚﻠﺘﻟ ﻩﺎﺒﺘﻧﻻﺍﻭ ﻞﻴﻟﺪﻟﺍ

.ﺔﻤﻴﺴﺠﻟا

.ﺔﻤﻴﺴﺠﻟا

.ﺔﻄﺳﻮﺘﻣ

.تﺎﻜﻠﺘﻤﻤﻟا

.تﺎﻤﻴﻠﻌﺘﻟا

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺕﺍﻭﺩﻸﻟ ﺔﻣﺎﻌﻟﺍ ﻥﺎﻣﻷﺍ ﺕﺍﺮﻳﺬﺤﺗ

ﻊﻴﻤﺟو نﺎﻣﻷا تاﺮﻳﺬﺤﺗ ﻊﻴﻤﺟ ةءاﺮﻗ ﻰﺟﺮﻳ :ﺮﻳﺬﺤﺗ

تاﺮﻳﺬﺤﺘﻟا هﺬﻫ عﺎﺒﺗﺎﺑ ماﺰﺘﻟﻻا مﺪﻋ .تﺎﻤﻴﻠﻌﺘﻟا

وأ/و ،ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﻰﻟإ يدﺆﻳ ﺪﻗ تﺎﻤﻴﻠﻌﺘﻟاو

ﻲﻓ ﺎﻬﻴﻟﺇ ﻉﻮﺟﺮﻟﺍ ﻞﺟﺃ ﻦﻣ ﺕﺎﻤﻴﻠﻌﺘﻟﺍﻭ ﺕﺍﺮﻳﺬﺤﺘﻟﺍ ﻊﻴﻤﺠﺑ ﻆﻔﺘﺣﺍ

.ﺔﻤﻴﺴﺟ ﺔﺑﺎﺻإ وأ/و ،ﻖﻳﺮﺣ بﻮﺸﻧ

ﻞﺒﻘﺘﺴﻤﻟﺍ

15

Page 18

ﺔﻴﺑﺮﻌﻟﺍ

حﻼﺻإ ﻲﻨﻓ ﺪﻳ ﻰﻠﻋ ﻚﺑ ﺔﺻﺎﺨﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﺔﻧﺎﻴﺼﺑ ﻢﻗ (أ

.ﻂﻘﻓ ﺔﻘﺑﺎﻄﺘﻣ ﺔﻠﻳﺪﺑ ءاﺰﺟأ ماﺪﺨﺘﺳا لﻼﺧ ﻦﻣ ﻚﻟذو ﻞﻫﺆﻣ

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا نﺎﻣأ ﻰﻠﻋ ظﺎﻔﺤﻟا ﻚﻟذ ﻦﻤﻀﻴﺳ ﺚﻴﺣ

ﺔﻣﺪﺨﻟﺍ (5

ﺔﻳﺪﻀﻨﻟﺍ ﺔﺧﻼﺠﻠﻟ ﺔﻴﻓﺎﺿﻹﺍ ﺔﻣﻼﺴﻟﺍ ﺕﺎﻤﻴﻠﻌﺗ

.ﻢﻣ 1 ﻞﻤﻌﻟا ﺪﻨﺴﻣ ﻰﻠﺑ ﺪﺣ ﺔﻤﻴﻗ •

ﻲﻤﺤﻳو .ﺦﻴﻠﺠﺘﻟا ﺔﻧاﻮﻄﺳا ﻊﻣ ﺎ

.ﺔﻧاﻮﻄﺳﻻا ﻦﻣ ةرﻮﺴﻜﻤﻟا ءاﺰﺟﻷا ﻦﻣ ﻞﻐﺸﻤﻟا ﻲﻗاﻮﻟا

ﺔﻋﺮﺴﻟا ﺔﻴﺣﺎﻧ ﻦﻣ ﻞﻗﻷا ﻰﻠﻋ تﺎﻘﺤﻠﻤﻟا ﻢﻴﻴﻘﺗ ﻢﺘﻳ نأ ﺐﺠﻳ •

ﻞﺼﻔﻨﺗ نأ ﻦﻜﻤﻳ .ةادﻷﺎﺑ صﺎﺨﻟا ﺮﻳﺬﺤﺘﻟا ﻖﺼﻠﻣ ﻲﻓ ﺎﻬﺑ ﻰﺻﻮﻤﻟا

ﺔﻋﺮﺴﻟا ﻦﻣ ﻰﻠﻋأ ﺔﻋﺮﺴﺑ ﻞﻤﻌﺗ ﻲﺘﻟا ىﺮﺧﻷا تﺎﻘﺤﻠﻤﻟاو تﻼﺠﻌﻟا

.عﻮﻧ يأ ﻦﻣ ﺐﻴﻋ ﺎﻬﺑ وأ ﺔﻘﻘﺸﻣ ﺦﻴﻠﺠﺗ ﺔﻧاﻮﻄﺳا مﺪﺨﺘﺴﺗ ﻻ •

عوﺪﺻ يأ ﻦﻋ ﺎًﺜﺤﺑ ﻪﺑ ﻰﺻﻮﻤﻟا ﻖﺤﻠﻤﻟا ﺺﺤﻔﺑ ﻢﻗ ،ماﺪﺨﺘﺳﻻا ﻞﺒﻗ

اﺬﻫ ﻦﻣ ﺺﻠﺨﺘﻓ ،ﺢﺿاو ﺐﻴﻌﻟا وأ عﺪﺼﺘﻟا اﺬﻫ نﺎﻛ اذإ .بﻮﻴﻋ وأ

ﻢﻘﺗ ﻻ .ﺔﻘﻴﻗد ةﺪﻤﻟ ﻞﻤﻌﺗ ﺎﻬﻛﺮﺗا ،ةادﻷا ﻞﻴﻐﺸﺗ ءﺪﺑ ﺪﻨﻋ •

اﺬﻫو .ﺔﻧاﻮﻄﺳﻸﻟ

ﺖﻧﺎﻛ اذإ ﻻإ ﺦﻴﻠﺠﺘﻟا تﺎﻧاﻮﻄﺳا ﻲﺒﻧﺎﺟ ﻰﻠﻋ ﺦﻴﻠﺠﺘﻟﺎﺑ ﻢﻘﺗ ﻻ •

ﻚﻟذ يدﺆﻳ نأ ﻦﻜﻤﻳ ﺚﻴﺣ .ﺔﻧاﻮﻄﺳﻻا ﻚﺒﺸﻣ ﺔﻟﻮﻣﺎﺻ ﻂﺑر ﻲﻓ طﺮﻔﺗ ﻻ •

ﻞﻜﺸﺑ ﺦﻴﻠﺠﺘﻟا ﺔﻧاﻮﻄﺳا لﻮﺣ دﻮﺟﻮﻤﻟا ﻒﻳﻮﺠﺘﻟا ﻒﻴﻈﻨﺘﺑ ﻢﻗ •

ﺾﻳﻮﻌﺘﻟا ﻞﺟأ ﻦﻣ ،رﺮﻜﺘﻣ ﻞﻜﺸﺑ رﺮﺸﻟا ﺰﺟﺎﺣ ﻂﺒﺿ ءاﺮﺟإ ﻢﺘﻳ •

ﻦﻴﺑ ﺔﻓﺎﺴﻤﻟا ﻰﻠﻋ ظﺎﻔﺤﻟا ﻰﻠﻋ ﺪﻋﺎﺴﻳ ﺎﻤﺑ ،ﺔﻧاﻮﻄﺳﻻا ﻰﻠﺑ ﻦﻋ

ﻲﻓ ﻢﻣ 2 زوﺎﺠﺘﻳ ﻻ ﺎﻤﺑ ﻦﻜﻟو ،ﺎﻬﻟ رﺪﻗ ﺮﻐﺻﺄﺑ ﺔﻧاﻮﻄﺳﻻاو ﻲﻗاﻮﻟا

ﻦﻜﻟو ،ﺎﻬﻟ رﺪﻗ ﺮﻐﺻﺄﺑ ﺔﻧاﻮﻄﺳﻻاو ﻞﻤﻌﻟا ﺪﻨﺴﻣ ﻦﻴﺑ ﺔﻓﺎﺴﻤﻟا

ﺔﻘﻴﻗد 20 ةﺪﻤﻟ ﺮﻤﺘﺴﻣ ﻞﻜﺸﺑ ﺎﻬﻣاﺪﺨﺘﺳا ﺪﻌﺑ دﺮﺒﺗ ةادﻷا كﺮﺗا •

ٍ

ذﺎﺤﻣ ﺺﺨﺷ دﻮﺟو ﻊﻣ ﺎًﻘﻠﻄﻣ ةادﻷا ﻞﻴﻐﺸﺘﺑ

.ﺦﻴﻠﺠﺘﻟا ﺔﻧاﻮﻄﺳا ﻲﻓ قﻮﻘﺷ ثوﺪﺣ ﻰﻟإ

.ﺔﻫﻮﺸﻤﻟا وأ ﺔﻔﻟﺎﺘﻟا شﺮ

ﻞﺟأ ﻦﻣ ،ﻲﺠﻳرﺪﺗ ﻞﻜﺸﺑ ﻞﻤﻌﻟا ﺪﻨﺴﻣ ﻂﺒﺿ ءاﺮﺟإ ﻢﺘﻳ •

ﻰﻠﻋ ظﺎﻔﺤﻟا ﻰﻠﻋ ﺪﻋﺎﺴﻳ ﺎﻤﺑ ،ﺔﻧاﻮﻄﺳﻻا ﻰﻠﺑ ﻦﻋ ﺾﻳﻮﻌﺘﻟا

ﺒﺳﺎﻨﻣ ﺎًﻴﻗاو مﺪﺨﺘﺳا ﺎًﻤﺋاد •

ً

.تﺎﺑﺎﺻإ ﺐﺒﺴﺗو تﺎﻘﺤﻠﻤﻠﻟ ﺔﻔﻨﺼﻤﻟا

.ﻖﺤﻠﻤﻟا

.ﻞﻐﺸﻤﻟا ﻞﻤﺸﻳ

.ضﺮﻐﻟا اﺬﻬﻟ ﺎ

ﺼﻴﺼﺧ ﺔﻤﻤﺼﻣ

ً

.يرود

.ﺔﻴﻗاﻮﻟا تارﺎﻈﻨﻟا ﺪﺗرا •

ُ

ﻔﻟا وأ تﺎﻧاﻮﻄﺳﻷا مﺪﺨﺘﺴﺗ ﻻ •

؛ﺔﻟﺎﺣ يأ

.ﺔﻟﺎﺣ يأ ﻲﻓ ﻢﻣ 2 زوﺎﺠﺘﻳ ﻻ ﺎﻤﺑ

.(ﺔﻘﻴﻗد 20 ةﺮﻴﺼﻘﻟا مﺎﻬﻤﻟا ﺖﻗو)

ﺔﻴﻘﺒﺘﻤﻟﺍ ﺮﻃﺎﺨﻤﻟﺍ

ﺓﺰﻬﺟﺄﺑ ﺩﻭﺰﺘﻟﺍﻭ ﺔﻠﺼﻟﺍ ﺕﺍﺫ ﺔﻣﻼﺴﻟﺍ ﺕﺎﻤﻴﻠﻌﺗ ﻖﻴﺒﻄﺗ ﻦﻣ ﻢﻏﺮﻟﺍ ﻰﻠﻋ

.ﺓﺩﺪﺤﻤﻟﺍ ﺔﻴﻘﺒﺘﻤﻟﺍ ﺮﻃﺎﺨﻤﻟﺍ ﺾﻌﺑ ﻱﺩﺎﻔﺗ ﻦﻜﻤﻳ ﻻ ﻪﻧﺃ ﻻﺇ ،ﻥﺎﻣﻷﺍ

:ﻲﻠﻳ ﺎﻣ ﺮﻃﺎﺨﻤﻟﺍ ﻩﺬﻫ ﻞﻤﺸﺗﻭ

.ﻊﻤﺴﻟا ﻒﻌﺿ –

.ةﺮﻳﺎﻄﺘﻤﻟا تﺎﻤﻴﺴﺠﻟا ﺐﺒﺴﺑ ﺔﻴﺼﺨﺸﻟا ﺔﺑﺎﺻﻺﻟ ضﺮﻌﺘﻟا ﺮﻄﺧ –

.ﻞﻴﻐﺸﺘﻟا ءﺎﻨﺛأ تﺎﻘﺤﻠﻤﻟا ﺔﻧﻮﺨﺳ ﺐﺒﺴﺑ قوﺮﺤﻠﻟ ضﺮﻌﺘﻟا ﺮﻄﺧ –

.لﻮﻄﻤﻟا ماﺪﺨﺘﺳﻻا ﺐﺒﺴﺑ ﺔﻴﺼﺨﺸﻟا ﺔﺑﺎﺻﻺﻟ ضﺮﻌﺘﻟا ﺮﻄﺧ –

ﻊﺿو ﻲﻓ حﺎﺘﻔﻤﻟا نأ ﻦﻣ ﺪﻛﺄﺗ .ﻲﺿﺮﻌﻟا ﻞﻴﻐﺸﺘﻟا ﺐﻨﺠﺗ (ج

ﺔﻋﻮﻤﺠﻣ وأ /و ،ﺔﻗﺎﻄﻟا رﺪﺼﻤﺑ ﻞﻴﺻﻮﺘﻟا ﻞﺒﻗ ﻞﻴﻐﺸﺘﻟا فﺎﻘﻳإ

تاودﻷا ﻞﻤﺣ يدﺆﻳ ﺪﻗ ﺚﻴﺣ .ةادﻷا ﻞﻤﺣ وأ طﺎﻘﺘﻟا وأ ،ﺔﻳرﺎﻄﺒﻟا

تاودﻷا داﺪﻣإ وأ حﺎﺘﻔﻤﻟا ﻰﻠﻋ ﻚﻌﺒﺻإ دﻮﺟو ءﺎﻨﺛأ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﻰﻟإ ءﺎﺑﺮﻬﻜﻟﺎﺑ ﻞﻴﻐﺸﺘﻟا ﻊﺿﻮﺑ ﺎﻬﺣﺎﺘﻔﻣ نﻮﻜﻳ ﻲﺘﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ةادﻷا ﻞﻴﻐﺸﺗ ﻞﺒﻗ ﻂﺑر حﺎﺘﻔﻣ وأ ﻂﺒﺿ حﺎﺘﻔﻣ يأ جاﺮﺧﺈﺑ ﻢﻗ (د

ءﺰﺠﻟﺎﺑ حﺎﺘﻔﻤﻟا وأ ﻂﺑﺮﻟا حﺎﺘﻔﻣ كﺮﺗ يدﺆﻳ ﺪﻘﻓ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

.ﺔﻴﺼﺨﺷ ﺔﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷﺎﺑ راوﺪﻟا

ﻊﺿﻮﻣ تﺎﺒﺛ ﻰﻠﻋ ﻆﻓﺎﺣ .زﺎﻬﺠﻟﺎﺑ ا

ﻢﻜﺤﺘﻟا ﻰﻠﻋ ﻚﻟذ كﺪﻋﺎﺴﻳ ذإ .ﺖﻗﻮﻟا ﺔﻠﻴﻃ نزاﻮﺘﻟاو ﻚﻣﺪﻗ

.ﺔﻴﺋﺎﺠﻔﻟا ﻒﻗاﻮﻤﻟا ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻲﻓ ﻞﻀﻓأ

تاﺮﻫﻮﺠﻣ وأ ﺲﺑﻼﻣ ءاﺪﺗرﺎﺑ ﻢﻘﺗ ﻻ .ﺔﺒﺳﺎﻨﻣ ﺲﺑﻼﻣ ﺪﺗرا (و

ءاﺰﺟﻷا ﻦﻋ تازﺎﻔﻘﻟاو ﺲﺑﻼﻤﻟاو ﺮﻌﺸﻟا ﺪﻌﺑأ .ﺔﺿﺎﻔﻀﻓ

وأ ﺔﺿﺎﻔﻀﻔﻟا تاﺮﻫﻮﺠﻤﻟا وأ ﺲﺑﻼﻤﻟا ﺮﺸﺤﻨﺗ ﺪﻘﻓ .ﺔﻛﺮﺤﺘﻤﻟا

ﻊﻴﻤﺠﺗو صﻼﺨﺘﺳا ﻞﺋﺎﺳﻮﺑ ﻞﻴﺻﻮﺘﻠﻟ ةﺰﻬﺟﻷا ﺮﻴﻓﻮﺗ لﺎﺣ ﻲﻓ (ز

.ﺔﺤﻴﺤﺻ ﺔﻘﻳﺮﻄﺑ ﺎﻬﻣاﺪﺨﺘﺳاو ﺎﻬﻠﻴﺻﻮﺗ ﻦﻣ ﺪﻛﺄﺘﻓ ،ﺔﺑﺮﺗﻷا

ﺔﻘﻠﻌﺘﻤﻟا ﺮﻃﺎﺨﻤﻟا ﻞﻴﻠﻘﺗ ﻰﻟإ يدﺆﻳ ﺪﻗ ﺔﺑﺮﺗﻷا ﻊﻴﻤﺠﺗ نأ ﺚﻴﺣ

ةادﻷا مﺪﺨﺘﺳا .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻊﻣ ةﻮﻘﻟﺎﺑ ﻞﻣﺎﻌﺘﺗ ﻻ (أ

ﺚﻴﺣ .ﻚﺑ صﺎﺨﻟا ماﺪﺨﺘﺳﻻا ضﺮﻐﻟ ﺔﻤﺋﻼﻤﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﺮﺜﻛأو ﻞﻀﻓأ

ﻰﻟإ يدﺆﻳ ﻻ حﺎﺘﻔﻤﻟا نﺎﻛ اذإ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا مﺪﺨﺘﺴﺗ ﻻ (ب

ﻻ ﺔﻴﺋﺎﺑﺮﻬﻛ ةادأ يأ ﻞﻜﺸﺗ ﺚﻴﺣ .ﻞﻴﻐﺸﺘﻟا فﺎﻘﻳإو ﻞﻴﻐﺸﺘﻟا

.ﺎﻬﺣﻼﺻإ ﺐﺠﻳو ةرﻮﻄﺧ حﺎﺘﻔﻤﻟا ﺔﻄﺳاﻮﺑ ﺎﻬﻴﻓ ﻢﻜﺤﺘﻟا ﻦﻜﻤﻳ

ﺔﻳرﺎﻄﺒﻟا ﺔﻋﻮﻤﺠﻣ وأ /و ﺔﻗﺎﻄﻟا رﺪﺼﻣ ﻦﻣ ﺲﺑﺎﻘﻟا ﻞﺼﻔﺑ ﻢﻗ (ج

ﺮﻴﻴﻐﺗ وأ ﻂﺒﺿ تﺎﻴﻠﻤﻋ يأ ءاﺮﺟإ ﻞﺒﻗ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻦﻣ

تاءاﺮﺟإ ﻞﺜﻣ ﻞﻠﻘﺗ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ﻦﻳﺰﺨﺗ وأ تﺎﻘﺤﻠﻣ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ ﺮﻄﺧ ﻦﻣ هﺬﻫ ﺔﻴﺋﺎﻗﻮﻟا ﺔﻣﻼﺴﻟا

ﻦﻋ اًﺪﻴﻌﺑ ﻞﻤﻌﻟا ﻦﻋ ﺔﻔﻗﻮﺘﻤﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ﻦﻳﺰﺨﺘﺑ ﻢﻗ (د

ةادﻷﺎﺑ ﻦﻴﻤﻠﻤﻟا ﺮﻴﻏ صﺎﺨﺷﻷا عﺪﺗ ﻻو لﺎﻔﻃﻷا لوﺎﻨﺘﻣ

ةادﻷا ﻞﻴﻐﺸﺘﺑ نﻮﻣﻮﻘﻳ تﺎﻤﻴﻠﻌﺘﻟا هﺬﻬﺑ وأ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

يﺪﻳأ ﻲﻓ ةﺮﻴﻄﺧ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ﺪﻌﺗ ذإ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

يأ ﻦﻋ يﺮﺤﺘﻠﻟ ﺺﺤﻓا .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﺮﺴﻛ وأ ،ﺔﻛﺮﺤﺘﻤﻟا ءاﺰﺟﻸﻟ قﺎﺼﺘﻟا وأ ﺔﺤﻴﺤﺻ ﺮﻴﻏ ةاذﺎﺤﻣ

ةادﻷا ﻞﻴﻐﺸﺗ ﻰﻠﻋ ﺮﺛﺆﺗ ﺪﻗ ىﺮﺧأ تﻻﺎﺣ يأو ءاﺰﺟﻷﺎﺑ

ةادﻷا حﻼﺻﺈﺑ ﻢﻗ ،ﻒﻠﺗ دﻮﺟو لﺎﺣ ﻲﻓو .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﻦﻣ ﺪﻳﺪﻌﻟا عﻮﻗو ﺐﺒﺳ ﻊﺟﺮﻳ ﺚﻴﺣ .ماﺪﺨﺘﺳﻻا ﻞﺒﻗ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

نأ ﺚﻴﺣ .ﺔﻔﻴﻈﻧو ةدﺎﺣ ﺔﻟﺎﺣ ﻲﻓ ﻊﻄﻘﻟا تاودأ ﻰﻠﻋ ﻆﻓﺎﺣ (و

فاﻮﺤﺑ ةدوﺰﻣو ﺔﺤﻴﺤﺻ ﺔﻘﻳﺮﻄﺑ ﺎﻬﺘﻧﺎﻴﺻ ﻢﺘﺗ ﻲﺘﻟا ﻊﻄﻘﻟا تاودأ

ﺎﻬﺑ ﻢﻜﺤﺘﻟا ﻞﻬﺴﻳو قﺎﺼﺘﻟﻼﻟ ﻞﻗأ

ﻪﺑﺎﺷ ﺎﻣو ةادﻷا ﻢﻘﻟو تﺎﻘﺤﻠﻤﻟاو ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا مﺪﺨﺘﺳا (ز

فوﺮﻇ رﺎﺒﺘﻋﻻا ﻲﻓ ﺬﺧﻷا ﻊﻣ تﺎﻤﻴﻠﻌﺘﻟا هﺬﻬﻟ ﺎ

ةادﻷا ماﺪﺨﺘﺳا نأ ذإ .هﺬﻴﻔﻨﺗ داﺮﻤﻟا ﻞﻤﻌﻟاو ﻞﻴﻐﺸﺘﻟا

ﺔﺼﺼﺨﻤﻟا تﺎﻴﻠﻤﻌﻟا ﻚﻠﺗ ﻦﻋ ﺔﻔﻠﺘﺨﻣ تﺎﻴﻠﻤﻌﻟ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

.ﺔﻛﺮﺤﺘﻤﻟا ءاﺰﺟﻷا ﻲﻓ ﻞﻳﻮﻄﻟا ﺮﻌﺸﻟا

ﺎﻬﺑ ﺔﻳﺎﻨﻌﻟﺍﻭ

ٍ

ﻞﻜﺸﺑ ﺔﻤﻬﻤﻟا ﺔﻤﺋﻼﻤﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﺰﺠﻨﺘﺳ

.ﻪﻠﺟأ ﻦﻣ ﺖﻤﻤﺻ يﺬﻟا لﺪﻌﻤﻟا ﺪﻨﻋ ﺎ

.ﺎﻬﻣاﺪﺨﺘﺳا ﻰﻠﻋ ﻦﻴﺑرﺪﻤﻟا ﺮﻴﻏ ﻦﻴﻣﺪﺨﺘﺴﻤﻟا

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻸﻟ ﺔﺌﻴﺴﻟا ﺔﻧﺎﻴﺼﻟا ﻰﻟإ ثداﻮﺤﻟا

.ثداﻮﺤﻟا عﻮﻗو

ﺪﻴﻌﺑ كﺪﻳ ﺪﻣ ﺐﻨﺠﺗ (ـﻫ

ً

ٍ

ﻞﻜﺸﺑ

.ﺔﺑﺮﺗﻷﺎﺑ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺓﺍﺩﻷﺍ ﻡﺍﺪﺨﺘﺳﺍ (4

ٍ

.ﻲﺋﺎﺠﻓ

ﻞﻜﺸﺑ

تاودﻷا ﻰﻠﻋ ﻆﻓﺎﺣ (ـﻫ

ٍ

ﻞﻜﺸﺑ ضﺮﻌﺘﺗ ةدﺎﺣ ﻊﻄﻗ

.ةﺮﻄﺧ ﺔﻟﺎﺣ ﻰﻟإ يدﺆﻳ ﺪﻗ ﺎﻬﻟ

.ﺮﺒﻛأ

ٍ

ﻮﺤﻧ ﻰﻠﻋ

ً

ﻘﻓو ﻚﻟذ

ﻧﺎﻣأ

ً

16

Page 19

ﺔﻴﺑﺮﻌﻟﺍ

ﺔﻠﺑﺎﻗ ﺕﺍﺯﺎﻏ ﻭﺃ ﻞﺋﺍﻮﺳ ﺩﻮﺟﻭ ﻲﻓ ﻭﺃ ﻞﻠﺒﻟﺍ ﻑﻭﺮﻇ ﻲﻓ ﺎﻬﻣﺪﺨﺘﺴﺗ ﻻ

ﻥﻮﺴﻤﻠﻳ ﻝﺎﻔﻃﻷﺍ ﻉﺪﺗ ﻻ .ﺔﻗﺎﻄﻟﺎﺑ ﻞﻤﻌﺗ ﺔﻴﻓﺍﺮﺘﺣﺍ ﺓﺍﺩﺃ ﻲﻫ ﺔﺧﻼﺠﻟﺍ ﻩﺬﻫ

ﻩﺬﻬﻟ ﺓﺮﺒﺨﻟﺍ ﻞﻴﻠﻗ ﻞﻐﺸﻣ ﻡﺍﺪﺨﺘﺳﺍ ﺪﻨﻋ ﺎًﻳﺭﻭﺮﺿ ﺍًﺮﻣﺃ ﻑﺍﺮﺷﻹﺍ ﻥﻮﻜﻳ .ﺓﺍﺩﻷﺍ

ﻚﻟﺫ ﻲﻓ ﺎﻤﺑ) ﺩﺍﺮﻓﻷﺍ ﻞﺒﻗ ﻦﻣ ﻡﺍﺪﺨﺘﺳﻼﻟ ﺺﺼﺨﻣ ﺮﻴﻏ ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ •

ﺔﻴﺴﺤﻟﺍ ﻭﺃ ﺔﻳﺪﺴﺠﻟﺍ ﺕﺍﺭﺪﻘﻟﺍ ﻲﻓ ﺭﻮﺼﻗ ﻦﻣ ﻥﻮﻧﺎﻌﻳ ﻦﻳﺬﻟﺍ (ﻝﺎﻔﻃﻷﺍ

ﺖﺤﺗ ﺍﻮﻧﻮﻜﻳ

ﻝﺎﻔﻃﻷﺍ ﻙﺮﺘُﻳ ﻥﺃ ﻲﻐﺒﻨﻳ ﻻ .ﻢﻬﺘﻣﻼﺳ ﺔﻴﻟﻭﺆﺴﻣ ﻞﻤﺤﺘﻳ ﻦﻣ ﻑﺍﺮﺷﺇ

ﻢﻟ ﺎﻣ ﺕﺍﺭﺎﻬﻤﻟﺍ ﻭﺃ ﺔﻓﺮﻌﻤﻟﺍ ﻭﺃ ﺓﺮﺒﺨﻟﺍ ﺔﻠﻗﻭ ،ﺔﻴﻠﻘﻌﻟﺍ ﻭﺃ

.ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﻊﻣ ﻢﻫﺪﺣﻭ

.ﻝﺎﻌﺘﺷﻼﻟ

.ﺓﺍﺩﻷﺍ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺔﻣﻼﺴﻟﺍ

ﺎًﻣﻭﺩ ﺪﻛﺄﺗ .ﻂﻘﻓ ﺪﺣﺍﻭ ﻲﺋﺎﺑﺮﻬﻛ ﺪﻬﺟ ﻞﻤﺤﺘﻟ ﻲﺋﺎﺑﺮﻬﻜﻟﺍ ﻙﺮﺤﻤﻟﺍ ﻢﻴﻤﺼﺗ ﻢﺗ

ﺔﺣﻮﻟ ﻰﻠﻋ ﻦﻴﺒﻤﻟﺍ ﻲﺋﺎﺑﺮﻬﻜﻟﺍ ﺪﻬﺠﻠﻟ ﻖﺑﺎﻄﻣ ﺔﻗﺎﻄﻟﺍ ﺩﺍﺪﻣﺇ ﺭﺪﺼﻣ ﻥﺃ ﻦﻣ

ﻝﺯﺎﻌﺑ DEWALT ﻦﻣ ﻚﺑ ﺔﺻﺎﺨﻟﺍ ﺓﺍﺩﻷﺍ ﺪﻳﻭﺰﺗ ﻢﺗ

ﻚﻠﺴﻠﻟ ﺔﺟﺎﺣ ﻻ ﺍﺬﻟ ، 0 4 ﺭﺎﻴﻌﻤﻟ ﺎًﻘﺒﻃ ﺝﻭﺩﺰﻣ

ﺼﻴﺼﺧ ﺪﻌﻣ ﺮﺧ ﻚﻠﺴﺑ ﻟﺍﺪﺒﺘﺳﺍ ﺐﺠﻴﻓ ،ﺎًﻔﻟﺎﺗ ﺔﻗﺎﻄﻟﺍ ﺩﺍﺪﻣﺇ ﻚﻠﺳ ﻥﺎﻛ ﺫﺇ

ﺎ

ً

.D

.ﻲﺿﺭﻷﺍ

EWALT ﺔﻣﺪﺧ ﺰﻛﺍﺮﻣ ﺪﻟ ﺮﻓﻮﺘﻣﻭ

.ﻒﻴﻨﺼﺘﻟﺍ

ﻂﺳﻭﻷﺍ ﻕﺮﺸﻟﺍ) ﻲﺴﻴﺋﺮﻟﺍ ﺭﺎﻴﺘﻟﺍ ﺲﺑﺎﻗ ﻝﺍﺪﺒﺘﺳﺍ

(ﺎﻴﻘﻳﺮﻓﺇﻭ

:ﻲﻟﺎﺘﻟﺎﺑ ﻢﻘﻓ ،ﻲﺴﻴﺋر رﺎﻴﺗ ﺲﺑﺎﻗ ﺐﻴﻛﺮﺗ ةروﺮﻀﻟا ﺖﻋﺪﺘﺳا اذإ

.ﻢﻳﺪﻘﻟا ﺲﺑﺎﻘﻟا ﻦﻣ نﺎﻣﺄﺑ ﺺﻠﺨﺗ •

.ﺲﺑﺎﻘﻟا ﻲﻓ ﻂﺸﻨﻟا ﻞﻴﺻﻮﺘﻟا فﺮﻄﺑ ﻲﻨﺒﻟا ﻚﻠﺴﻟا ﻞ

.ﺪﻳﺎﺤﻤﻟا ﻞﻴﺻﻮﺘﻟا فﺮﻄﺑ قرزﻷا ﻚﻠﺴﻟا ﻞ

.ﻲﺿرﻷا ﻞﻴﺻﻮﺘﻟا فﺮﻄﺑ ﻞﻴ ﺻﻮﺗ يأ ءاﺮﺟإ ﻢﺘﻳ ﻻ :ﺮﻳﺬﺤﺗ

ﺮﻬﺼﻨﻤﻟا .ﺔﻴﻟﺎﻌﻟا ةدﻮﺠﻟا تاذ ﺲﺑاﻮﻘﻟا ﻊﻣ ةدراﻮﻟا تﺎﻤﻴﻠﻌﺘﻟا عﺎﺒﺗﺎﺑ ﻢﻗ

ﺮﻴﺒﻣأ 13 :ﻪﻣاﺪﺨﺘﺳﺎﺑ ﻰﺻﻮﻤﻟا

ﺻو

ﱢ

ﺻو

ﱢ

•

•

ﺔﻟﺎﻄﺘﺳﻻﺍ ﻞﺑﺎﻛ ﻡﺍﺪﺨﺘﺳﺍ

ﺔﻟﺎﻄﺘﺳﺍ ﻞﺑﺎﻛ ﻡﺪﺨﺘﺳﺎﻓ ،ﺔﻟﺎﻄﺘﺳﺍ ﻞﺑﺎﻛ ﻡﺍﺪﺨﺘﺳﺍ ﺓﺭﻭﺮﻀﻟﺍ ﺖﻋﺪﺘﺳﺍ ﺍﺫﺇ

ﻢﺠﺣ .(ﺔﻴﻨﻔﻟا تﺎﻧﺎﻴﺒﻟا ﺮﻈﻧﺍ) ،ﺓﺍﺩﻷﺍ ﻩﺬﻫ ﺔﻗﺎﻃ ﻞﺧﺪﻟ ﻢﺋﻼﻣ ﺪﻤﺘﻌﻣ

.ﻡ 0 ﻮﻫ ﻝﻮﻃ ﻰﺼﻗﺃ ،ﻢﻣ 1 ﻮﻫ ﻰﻧﺩﻷﺍ ﻞﺻﻮﻤﻟﺍ

.ﺎًﻣﺎﻤﺗ ﻞﺑﺎﻜﻟﺍ ﻚﻔﺑ ﺎًﻣﻭﺩ ﻢﻗ ،ﻞﺑﺎﻜﻟﺍ ﺓﺮﻜﺑ ﻡﺍﺪﺨﺘﺳﺍ ﺪﻨﻋ

ﻂﺒﻀﻟﺍﻭ ﻊﻴﻤﺠﺘﻟﺍ ﺕﺎﻴﻠﻤﻋ

فﺎﻘﻳﺈﺑ ﻢﻗ ،ﺔﺑﺎﺻﻺﻟ ضﺮﻌﺘﻟا ﺮﻄﺧ ﺾﻔﺨﻟ :ﺮﻳﺬﺤﺗ

ﺔﻗﺎﻄﻟا رﺪﺼﻣ ﻦﻣ ﺔﻨﻴﻛﺎﻤﻟا ﻞﺼﻓو ،ةﺪﺣﻮﻟا ﻞﻴﻐﺸﺗ

ﺮﻴﻴﻐﺗ وأ ﻂﺒﺿ ﻞﺒﻗو ،ﺎﻬﻜﻓو تﺎﻘﻠﺤﻤﻟا ﺐﻴﻛﺮﺗ ﻞﺒﻗ

حﺎﺘﻔﻣ نأ ﻦﻣ ﺪﻛﺄﺗ .تﺎ ﺣﻼﺻﻹا ءاﺮﺟإ ﺪﻨﻋ وأ ،تاداﺪﻋﻹا

يدﺆﻳ ﺪﻗ .(ﻞﻴﻐﺸﺘﻟا فﺎﻘﻳإ) OFF ﻊﺿو ﻲﻓ ﻞﻴﻐﺸﺘﻟا

.ﺔﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ دﻮﺼﻘﻤﻟا ﺮﻴﻏ ﻞﻴﻐﺸﺘﻟا ءﺪﺑ

ﺔﺧﻼﺠﻟﺍ ﺐﻴﻛﺮﺗ

ﺓﺪﻋﺎﻗ ﻲﻓ ﺔﺣﺎﺘﻤﻟﺍ ﺔﻌﺑﺭﻷﺍ ﺐﻴﻛﺮﺘﻟﺍ ﺕﺎﺤﺘﻓ ﻊﺿﺍﻮﻣ ﻢﻴﻠﻌﺘﺑ ﻢﻗ .1

ﻚﻠﺗ ﻦﻣ ﻊﺿﻮﻣ ﻞﻛ ﻲﻓ ﺐﺳﺎﻨﻣ ﺱﺎﻘﻣ ﺕﺍﺫ ﺕﺎﺤﺘﻓ ﺐﻘﺜﺑ ﻢﻗ .2

.ﻞﻤﻌﻟﺍ ﺢﻄﺳ ﻰﻠﻋ ﺓﺍﺩﻷﺍ

.ﺔﻤﻠﻌﻤﻟﺍ ﻊﺿﺍﻮﻤﻟﺍ

ﺓﺍﺩﻷﺍ ﻰﻠﻋ ﺕﺎﻣﻼﻌﻟﺍ

:ﺓﺍﺩﻷﺍ ﻰﻠﻋ ﺔﺤﺿﻮﻣ ﺔﻴﻟﺎﺘﻟﺍ ﺭﻮﺼﻟﺍ

.ﻡﺍﺪﺨﺘﺳﻻﺍ ﻞﺒﻗ ﺕﺎﻤﻴﻠﻌﺘﻟﺍ ﻞﻴﻟﺩ ﺃﺮﻗﺍ

.ﻦﻴﻌﻟﺍ ﺕﺎﻴﻗﺍﻭ ءﺍﺪﺗﺭﺎﺑ ﻢﻗ

.ﻥﺫﻷﺍ ﺕﺎﻴﻗﺍﻭ ءﺍﺪﺗﺭﺎﺑ ﻢﻗ

.(ﺔﻘﻴﻗﺩ 20) ﺓﺮﻴﺼﻘﻟﺍ ﻡﺎﻬﻤﻟﺍ ﺖﻗﻭ S2 20min

(1 ﻞﻜﺸﻟﺍ) ﺦﻳﺭﺎﺘﻟﺍ ﺩﻮﻛ ﻊﺿﻮﻣ

.ﻒﻳﻮﺠﺘﻟﺍ ﻲﻓ ﻉﻮﺒﻄﻣ ،ﻊﻴﻨﺼﺘﻟﺍ ﻡﺎﻋ ﺎًﻀﻳﺃ ﻦﻤﻀﺘﻳ ﻱﺬﻟﺍ ،(ﻁ) ﺦﻳﺭﺎﺘﻟﺍ ﺩﻮﻛ

2014 XX XX

ﻊﻴﻨﺼﺘﻟﺍ ﻡﺎﻋ

ﺓﻮﺒﻌﻟﺍ ﺕﺎﻳﻮﺘﺤﻣ

:ﻲﻠﻳ ﺎﻣ ﻰﻠﻋ ﺓﻮﺒﻌﻟﺍ ﻱﻮﺘﺤﺗ

ﺔﻳﺪﻀﻧ ﺔﺧﻼﺟ 1

ﺔﻧﺍﻮﻄﺳﺍ 1

ﺓﺍﺩﻷﺍ ﺪﻧﺎﺴﻣ ﻦﻣ ﺝﻭﺯ 2

ﺭﺮﺸﻟﺍ ﺪﺿ ﺕﺎﻴﻗﺍﻮﻟﺍ ﻦﻣ ﺝﻭﺯ 2

ﺐﻴﻛﺮﺘﻟﺍ ﺕﺎﻣﺎﻋﺩ ﻦﻣ ﺝﻭﺯ 2

نأ ﻦﻜﻤﻳ تﺎﻘﺤﻠﻤﻟا وأ ءاﺰﺟﻷا وأ ةادﻷﺎﺑ ﻖﺤﻟ ﻒﻠﺗ يأ ﻦﻋ ﺎًﺜﺤﺑ ﺺﺤﻓا •

.ﻞﻴﻐﺸﺘﻟا ﻞﺒﻗ اًﺪﻴﺟ ﻪﻤﻬﻓو ﻞﻴﻟﺪﻟا اﺬﻫ ةءاﺮﻘﻟ مزﻼﻟا ﺖﻗﻮﻟا قﺮﻐﺘﺳا •

ﺕﺎﻤﻴﻠﻌﺗ ﻞﻴﻟﺩ 1

ﺪﺘﻤﻣ ﻢﺳﺭ 1

.ﻞﻘﻨﻟا ءﺎﻨﺛأ ثﺪﺣ ﺪﻗ نﻮﻜﻳ

(1 ﻞﻜﺸﻟﺍ) ﻒﺻﻮﻟﺍ

ءﺰﺟ يأ وأ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻳﺪﻌﺘﺑ ًﺎﻘﻠﻄﻣ ﻢﻘﺗ ﻻ :ﺮﻳﺬﺤﺗ

.ﺔﻴﺼﺨﺸﻟا ﺔﺑﺎﺻﻹا وأ ﻒﻠﺘﻟا ﻚﻟذ ﻦﻋ ﻢﺠﻨﻳ ﺪﻘﻓ .ﺎﻬﻨﻣ

ﺭﺮﺸﻟﺍ ﺪﺿ ﻲﻗﺍﻮﻟﺍ .ﺃ

ﺡﺎﺘﻔﻣ .ﺏ

ﺓﺍﺩﻷﺍ ﺪﻨﺴﻣ .ﺝ

ﺩﻮﺼﻘﻤﻟﺍ ﻡﺍﺪﺨﺘﺳﻻﺍ

ﺱﻭﺆﻔﻟﺍﻭ ﻞﻴﻣﺍﺯﻷﺍ ءﺎﻀﻣﺇ ﻲﻓ ﻡﺍﺪﺨﺘﺳﻼﻟ ﺔﻴﻟﺎﺜﻣ ﺔﻳﺪﻀﻨﻟﺍ ﺔﺧﻼﺠﻟﺍ ﺪﻌﺗ

ﺓﺪﻴﻔﻣ ﻥﻮﻜﺗ ﺎﻬﻧﺃ ﺎﻤﻛ .ﺏﺎﺸﺧﻷﺍ ﻊﻄﻘﻟ ﻡﺪﺨﺘﺴﺗ ﻲﺘﻟﺍ ﺕﺍﻭﺩﻷﺍ ﻦﻣ ﻚﻟﺫ ﺮﻴﻏﻭ

ﺔﻨﺸﺨﻟﺍ ﻑﺍﻮﺤﻟﺍ ﺔﻟﺍﺯﻹ ﻭﺃ ﺐﻘﺜﻟﺍ ﻢﻘﻟﻭ ﺕﺎﻜﻔﻤﻟﺍ ﻑﺍﺮﻃﺃ ﺡﻼﺻﻹ ﻚﻟﺬﻛ

ﻡﺍﺪﺨﺘﺳﺍ ﻝﻼﺧ ﻦﻣﻭ .ﺎﻬﺼﻗ ﻢﺘﻳ

ﻒﻴﻈﻨﺗ ﻞﺟﺃ ﻦﻣ ﺓﺍﺩﻷﺍ ﻩﺬﻫ ﻡﺍﺪﺨﺘﺳﺍ ﻢﺘﻳ ﻥﺃ ﻦﻜﻤﻳ ،ﺔﺒﺳﺎﻨﻤﻟﺍ ﺕﺍﺭﺍﻮﺴﺴﻛﻹﺍ

ﻡﺍﺪﺨﺘﺳﺎﺑ ﻊﻴﻤﻠﺘﻟﺍﻭ ﻞﻘﺼﻟﺍ ﻭﺃ ﺔﻴﻜﻠﺴﻟﺍ ﺓﺎﺷﺮﻔﻟﺍ ﻡﺍﺪﺨﺘﺳﺎﺑ ﻥﺩﺎﻌﻤﻟﺍ ﺢﻄﺳﺃ

ﺺﻘﻟﺍ ﺕﺎﻴﻠﻤﻌﻟ ﻩﺬﻫ ﺔﻳﺪﻀﻨﻟﺍ ﺔﺧﻼﺠﻟﺍ ﻡﺪﺨﺘﺴﺗ ﻻ .ﺔﻴﺷﺎﻤﻘﻟﺍ ﺔﻧﺍﻮﻄﺳﻻﺍ

ﻲﺘﻟﺍ ﻥﺩﺎﻌﻤﻟﺍ ﻊﻄﻗ ﻦﻣ ﺪﺤﻟﺍ ﻦﻋ ﺓﺪﺋﺍﺰﻟﺍ

ﻡﺎﻬﻤﻟﺍ ﺖﻗﻭ

:ﻝﺎﺜﻣ

.ﺎًﻘﻠﻄﻣ

17

Page 20

ﺔﻴﺑﺮﻌﻟﺍ

ﺡﺎﺘﻔﻤﻟﺍ

ﻂﻐﺿﺍ ،ﺓﺍﺩﻷﺍ ﻞﻴﻐﺸﺘﻟ .ﺓﺪﻋﺎﻘﻟﺍ ﻲﻓ ،ﺔﺧﻼﺠﻟﺍ ﺔﻣﺪﻘﻣ ﻰﻠﻋ ﺩﻮﺟﻮﻣ ﺡﺎﺘﻔﻤﻟﺍ

.«1» ﻢﻗﺮﻟﺎﺑ ﺰﻴﻤﻣ ﻮﻫﻭ ،ﻱﻮﻠﻌﻟﺍ ﺐﻧﺎﺠﻟﺍ ﻲﻓ ﻞﻳﺪﺒﺘﻟﺍ ﺡﺎﺘﻔﻣ ﺐﻧﺎﺟ ﻰﻠﻋ

ﺰﻴﻤﻤﻟﺍ ،ﻞﻳﺪﺒﺘﻟﺍ ﺡﺎﺘﻔﻣ ﻦﻣ ﻲﻠﻔﺴﻟﺍ ﺐﻧﺎﺠﻟﺍ ﺭﺮﺣ ،ﺔﺧﻼﺠﻟﺍ ﻞﻴﻐﺸﺗ ﻑﺎﻘﻳﻹ

.«0» ﻢﻗﺮﻟﺎﺑ

(4 ﻞﻜﺷ) ﺕﺎﻘﺤﻠﻤﻟﺍ ﺮﻴﻴﻐﺗ

.ﺔﻔﻟﺎﺗ ﺦﻴﻠﺠﺗ تﺎﻧاﻮﻄﺳأ يأ مﺪﺨﺘﺴﺗ ﻻ :ﺮﻳﺬﺤﺗ

(ﺔﻟﺍﺯﺇ ﺲﻴﻟﻭ) ﻚﻓ ﻝﻼﺧ ﻦﻣ (ﻭ) ﻲﻗﺍﻮﻟﺍ ءﺎﻄﻏ ﺔﻟﺍﺯﺈﺑ ﻢﻗ .1

.(ﺡ) ﺔﺛﻼﺜﻟﺍ ﻲﻏﺍﺮﺒﻟﺍ

.ﺓﺪﻋﺎﺒﻣ ﺡﺎﺘﻔﻣ ﻡﺍﺪﺨﺘﺳﺎﺑ (ـﻫ) ﻂﺑﺮﻟﺍ ﺔﻟﻮﻣﺎﺻ ﺔﻟﺍﺯﺈﺑ ﻢﻗ .2

.ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍﻭ (ﺯ) ﻂﺑﺮﻟﺍ ﺔﻔﺷ ﺔﻟﺍﺯﺈﺑ ﻢﻗ .3

.ﻲﺴﻜﻋ ﺐﻴﺗﺮﺘﺑ ﺓﺪﻳﺪﺠﻟﺍ ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍ ﺐﻴﻛﺮﺗ ﻢﺘﻳ .4

ﻞﺟﺃ ﻦﻣ ﺔﻘﻴﻗﺩ ﺓﺪﻤﻟ ﺔﻟﻮﻤﺣ ﻥﻭﺪﺑ ﻞﻤﻌﺗ ﺎﻬﻋﺩﻭ ﺓﺍﺩﻷﺍ ﻞﻴﻐﺸﺘﺑ ﻢﻗ .5

.ﺎﻬﺑ ﻕﻮﻘﺷ ﺩﻮﺟﻭ ﻡﺪﻋ ﻦﻣ ﻖﻘﺤﺘﻟﺍﻭ ﺓﺍﺩﻷﺍ ﺺﺤﻓ

ﺔﻧﺎﻴﺼﻟﺍ

ﺓﺮﺘﻓ ﻝﻼﺧ ﻞﻤﻌﻠﻟ ﻚﺑ ﺔﺻﺎﺨﻟﺍ DEWALT ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺓﺍﺩﻷﺍ ﻢﻴﻤﺼﺗ ﻢﺗ

ﻞﺻﺍﻮﺘﻤﻟﺍ ﻲﺿﺮﻤﻟﺍ ﻞﻴﻐﺸﺘﻟﺍ ﺪﻤﺘﻌﻳ.ﺔﻧﺎﻴﺼﻟﺍ ﻦﻣ ﺪﺣ ﻰﻧﺩﺃ ﻊﻣ ﺔﻠﻳﻮﻃ ﺔﻴﻨﻣﺯ

.ﻢﻈﺘﻨﻣ ٍﻞﻜﺸﺑ ﺎﻬﻔﻴﻈﻨﺗﻭ ﺓﺍﺩﻷﺎﺑ ﺔﻤﺋﻼﻤﻟﺍ ﺔﻳﺎﻨﻌﻟﺍ ﻰﻠﻋ

فﺎﻘﻳﺈﺑ ﻢﻗ ،ﺔﺑﺎﺻﻺﻟ ضﺮﻌﺘﻟا ﺮﻄﺧ ﺾﻔﺨﻟ :ﺮﻳﺬﺤﺗ

ﺔﻗﺎﻄﻟا رﺪﺼﻣ ﻦﻣ ﺔﻨﻴﻛﺎﻤﻟا ﻞﺼﻓو ،ةﺪﺣﻮﻟا ﻞﻴﻐﺸﺗ

ﺮﻴﻴﻐﺗ وأ ﻂﺒﺿ ﻞﺒﻗو ،ﺎﻬﻜﻓو تﺎﻘﻠﺤﻤﻟا ﺐﻴﻛﺮﺗ ﻞﺒﻗ

حﺎﺘﻔﻣ نأ ﻦﻣ ﺪﻛﺄﺗ .تﺎ ﺣﻼﺻﻹا ءاﺮﺟإ ﺪﻨﻋ وأ ،تاداﺪﻋﻹا

يدﺆﻳ ﺪﻗ .(ﻞﻴﻐﺸﺘﻟا فﺎﻘﻳإ) OFF ﻊﺿو ﻲﻓ ﻞﻴﻐﺸﺘﻟا

.ﺔﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ دﻮﺼﻘﻤﻟا ﺮﻴﻏ ﻞﻴﻐﺸﺘﻟا ءﺪﺑ

6 ﺱﺃﺮﻟﺍ ﻲﺳﺍﺪﺳ ﺭﺎﻤﺴﻣ ﻞﺧﺩﺃﻭ ﻞﻤﻌﻟﺍ ﺢﻄﺳ ﻰﻠﻋ ﺓﺍﺩﻷﺍ ﻊﺿ .3

ﺔﺤﺘﻓ ﻞﻛ ﻲﻓﻭ ﺓﺪﻋﺎﻘﻟﺍ ﻲﻓ ﺐﻴﻛﺮﺗ ﺔﺤﺘﻓ ﻞﻛ ﺮﺒﻋ ﺔﻘﻠﺣ ﻊﻣ ﻢﻣ

.ﻞﻤﻌﻟﺍ ﺢﻄﺳ ﻲﻓ ﺎﻬﺒﻘﺛ ﻢﺗ ﻲﺘﻟﺍ ﺕﺎﺤﺘﻔﻟﺍ ﻦﻣ ﺐﻘﺛ

.ﻡﺎﻜﺣﺈﺑ ﻞﻴﻣﺍﻮﺼﻟﺍ ﻂﺑﺭ ﻢﻗﻭ ،ﺭﺎﻤﺴﻣ ﻞﻛ ﻕﻮﻓ ﺔﻟﻮﻣﺎﺻ ﻊﺿ .4

(2 ﻞﻜﺸﻟﺍ) ﺭﺮﺸﻟﺍ ﺪﺿ ﻲﻗﺍﻮﻟﺍ ﺐﻴﻛﺮﺗ

ﻢﺘﻳ ﻥﺃ ﺐﺠﻳﻭ ﺭﺮﺸﻟﺍ ﺪﺿ ﺔﻴﻓﺎﺿﺇ ﺔﻳﺎﻤﺣ ﺭﺮﺸﻟﺍ ﺪﺿ ﻲﻗﺍﻮﻟﺍ ﺮﻓﻮﻳ

.ﺔﻣﻼﺴﻟﺍ ﺕﺍﺭﺎﻈﻧ ﻞﺤﻣ ﻞﺤﻴﻟ ﺭﺮﺸﻟﺍ ﺪﺿ ﻲﻗﺍﻮﻟﺍ ﻢﻴﻤﺼﺗ ﻢﺘﻳ ﻢﻟ :ﺔﻈﺣﻼﻣ

.(ﻪﺘﻟﺍﺯﺈﺑ ﻢﻘﺗ ﻻ) ًﻼﻴﻠﻗ (ﺩ) ﻲﻏﺮﺒﻟﺍ ﻚﻓ .1

.ﺔﻣﺎﻋﺪﻟﺍ ﻰﻠﻋ (ﺃ) ﺭﺮﺸﻟﺍ ﺪﺿ ﻲﻗﺍﻮﻟﺍ ﻕﻻﺯﺈﺑ ﻢﻗ .2

ﺔﻧﺍﻮﻄﺳﺍ ﻦﻣ ﻢﻣ 2 ﻲﻟﺍﻮﺣ ﺔﻓﺎﺴﻣ ﻰﻠﻋ ﺭﺮﺸﻟﺍ ﺪﺿ ﻲﻗﺍﻮﻟﺍ ﻊﺿ .3

ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍﻭ ﺭﺮﺸﻟﺍ ﻲﻗﺍﻭ ﻦﻴﺑ ﺔﻓﺎﺴﻤﻟﺍ ﺺﺤﻔﺑ ﺎًﻤﺋﺍﺩ ﻢﻗ :ﺔﻈﺣﻼﻣ

ﻥﺎﻜﻣﻹﺎﺑ ﺪﻌﻳ ﻢﻟ ﺍﺫﺇ ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍ ﻝﺪﺒﺘﺳﺍ .ﺮﻣﻷﺍ ﻡﺰﻟ ﺍﺫﺇ ،ﺎﻬﻄﺒﺿﺍﻭ

.ﻢﻣ 2 ﻮﻫﻭ ﺔﻓﺎﺴﻤﻠﻟ ﻰﺼﻗﻷﺍ ﺪﺤﻟﺍ ﻰﻠﻋ (ﺃ) ﺭﺮﺸﻟﺍ ﺪﺿ ﻲﻗﺍﻮﻟﺍ ﻂﺒﺿ

.ﻚﻟﺫ ﻦﻜﻣﺃ ﻰﺘﻣ ﻪﻣﺍﺪﺨﺘﺳﺍ

.(ﺩ) ﻲﻏﺮﺒﻟﺍ ﻂﺑﺭﺍ .ﺦﻴﻠﺠﺘﻟﺍ

(3 ﻞﻜﺸﻟﺍ) ﺓﺍﺩﻷﺍ ﺪﻨﺴﻣ ﺐﻴﻛﺮﺗ

ﻲﻏاﺮﺒﻟا يدﺆﺗ نأ ﻦﻜﻤﻳ .ﺔﻘﻓﺮﻤﻟا ﻲﻏاﺮﺒﻟاو تﺎﻘﻠﺤﻟا مﺪﺨﺘﺳا :ﺮﻳﺬﺤﺗ

ﺔﻘﻓﺮﻤﻟﺍ ﻂﺑﺮﻟﺍ ﻞﻴﻣﺍﻮﺻﻭ ﺕﺍﺪﻋﺎﺒﻤﻟﺍﻭ ﺕﺎﻘﻠﺤﻟﺍﻭ ﻲﻏﺍﺮﺒﻟﺍ ﻡﺪﺨﺘﺳﺍ .1

.ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍ ﻦﻣ ﻢﻣ 2 ﻲﻟﺍﻮﺣ ﺔﻓﺎﺴﻣ ﻰﻠﻋ ﺓﺍﺩﻷﺍ ﺪﻨﺴﻣ ﻊﺿ .2

ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍﻭ (ﺝ) ﺓﺍﺩﻷﺍ ﺪﻨﺴﻣ ﻦﻴﺑ ﺔﻓﺎﺴﻤﻟﺍ ﺺﺤﻔﺑ ﺎ

.ﺦﻴﻠﺠﺘﻟا ﺔﻧاﻮﻄﺳا ﺔﻛﺮﺣ ﺔﻗﺎﻋإ ﻰﻟإ لﻮﻃﻷا

.ﻪﻧﺎﻜﻣ ﻲﻓ (ﺝ) ﺓﺍﺩﻷﺍ ﺪﻨﺴﻣ ﺖﻴﺒﺜﺘﻟ

.ﺮﻣﻷﺍ ﻡﺰﻟ ﺍﺫﺇ ،ﺎﻬﻄﺒﺿﺍﻭ

ﻤﺋﺍﺩ ﻢﻗ

ً

ﻞﻴﻐﺸﺘﻟﺍ

.ﻲﻓﺎﺿﺇ ﻢﻴﺤﺸﺗ ﻱﺃ ﻰﻟﺇ ﻚﺑ ﺔﺻﺎﺨﻟﺍ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺓﺍﺩﻷﺍ ﺝﺎﺘﺤﺗ ﻻ

ﻲﺴﻴﺋﺮﻟا ﻒﻳﻮﺠﺘﻟا جرﺎﺧ رﺎﺒﻐﻟاو ﺔﺑﺮﺗﻷا ﺦﻔﻨﺑ ﻢﻗ :ﺮﻳﺬﺤﺗ

لﺎﺣ ﻲﻓ تاﺮﻤﻟا ﻦﻣ ﺮﺒﻛأ دﺪﻋ فﺎﺠﻟا ءاﻮﻬﻟا ﺔﻄﺳاﻮﺑ

.ﺎﻬﻟﻮﺣو ﺔﻴﺋاﻮﻬﻟا ﺬﻓﺎﻨﻤﻟا ﻞﺧاﺪﺑ ﺔﺑﺮﺗﻷا ﻊﻤﺠﺗ ةﺪﻫﺎﺸﻣ

ةﺪﻤﺘﻌﻤﻟا ﺔﺑﺮﺗﻷا ﺔﻣﺎﻤﻛو ﺪﻤﺘﻌﻤﻟا ﻦﻴﻌﻟا ﻲﻗاو ءاﺪﺗرﺎﺑ ﻢﻗ

.ءاﺮﺟﻹا اﺬﻫ ﺬﻴﻔﻨﺗ ﺪﻨﻋ

داﻮﻣ يأ وأ تﺎﺒﻳﺬﻣ ماﺪﺨﺘﺳﺎﺑ ﺎًﻘﻠﻄﻣ ﻢﻘﺗ ﻻ :ﺮﻳﺬﺤﺗ

ﺔﻴﻧﺪﻌﻤﻟا ﺮﻴﻏ ءاﺰﺟﻷا ﻒﻴﻈﻨﺘﻟ ىﺮﺧأ ﺔﻴﺳﺎﻗ ﺔﻴﺋﺎﻴﻤﻴﻛ

داﻮﻤﻟا ﻦﻣ ﺔﻴﺋﺎﻴﻤﻴﻜﻟا داﻮﻤﻟا هﺬﻫ ﻒﻌﻀﺗ ﺪﻗ ذإ .ةادﻷﺎﺑ

شﺎﻤﻗ ﺔﻌﻄﻗ مﺪﺨﺘﺳا .ءاﺰﺟﻷا هﺬﻫ ﻲﻓ ﺔﻣﺪﺨﺘﺴﻤﻟا

ﻂﻗ ﺢﻤﺴﺗ ﻻ .ﻂﻘﻓ ﻒﻴﻔﺨﻟا نﻮﺑﺎﺼﻟاو ءﺎﻤﻟﺎﺑ ﺔﻠﻠﺒﻣ

ءﺰﺟ يأ ﺮﻤﻐﺑ ﺎًﻘﻠﻄﻣ ﻢﻘﺗ ﻻو ،ةادﻷا ﻰﻟإ ﻞﺋﺎﺳ يأ لﻮﺧﺪﺑ

.ﻞﺋﺎﺴﻟا ﻲﻓ ةادﻷا ﻦﻣ

18

ﻢﻴﺤﺸﺘﻟﺍ

ﻒﻴﻈﻨﺘﻟﺍ

ﻡﺍﺪﺨﺘﺳﻻﺍ ﺕﺎﻤﻴﻠﻌﺗ

.ﺎﻬﺑ لﻮﻤﻌﻤﻟا ﺢﺋاﻮﻠﻟاو نﺎﻣﻷا تﺎﻤﻴﻠﻌﺘﺑ ﺎ

،ةﺪﺣﻮﻟا ﻞﻴﻐﺸﺗ فﺎﻘﻳﺈﺑ ﻢﻗ ،ﺔﺑﺎﺻﻺﻟ ضﺮﻌﺘﻟا ﺮﻄﺧ ﺾﻔﺨﻟ :ﺮﻳﺬﺤﺗ

ﻞﺒﻗو ،ﺎﻬﻜﻓو تﺎﻘﻠﺤﻤﻟا ﺐﻴﻛﺮﺗ ﻞﺒﻗ ﺔﻗﺎﻄﻟا رﺪﺼﻣ ﻦﻣ ﺔﻨﻴﻛﺎﻤﻟا ﻞﺼﻓو

نأ ﻦﻣ ﺪﻛﺄﺗ .تﺎﺣﻼﺻﻹا ءاﺮﺟإ ﺪﻨﻋ وأ ،تاداﺪﻋﻹا ﺮﻴﻴﻐﺗ وأ ﻂﺒﺿ

ءﺪﺑ يدﺆﻳ ﺪﻗ .(ﻞﻴﻐﺸﺘﻟا فﺎﻘﻳإ) OFF ﻊﺿو ﻲﻓ ﻞﻴﻐﺸﺘﻟا حﺎﺘﻔﻣ

.ﺔﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ دﻮﺼﻘﻤﻟا ﺮﻴﻏ ﻞﻴﻐﺸﺘﻟا

مﺎﻜﺣﺈﺑ ﺎﻬﺘﻴﺒﺜﺗ ﻢﺗ ﺪﻗ ﻦﻜﻳ ﻢﻟ اذإ ﺪﻀﻨﻟا ﺔﺧﻼﺟ مﺪﺨﺘﺴﺗ ﻻ :ﺮﻳﺬﺤﺗ

ﺪﺗرا ،ﺔﺧﻼﺠﻟا ﻞﻴﻐﺸﺗ ﻞﺒﻗ .ﺐﻠﺻ ﺢﻄﺳ ﻰﻠﻋ وأ ﻞﻤﻌﻟا ﺢﻄﺳ ﻰﻠﻋ

ﺓﺭﻭﺩ 2950) ﻯﻮﺼﻘﻟﺍ ﺔﻋﺮﺴﻟﺍ ﻰﻟﺇ ﻞﺼﺗ ﺎﻬﻛﺮﺗﺍﻭ ﺔﺧﻼﺠﻟﺍ ﻞﻴﻐﺸﺘﺑ ﻢﻗ

.ﺓﺍﺩﻷﺍ ﺪﻨﺴﻣ ﻡﺎﻣﺃ ﻡﺎﻜﺣﺈﺑ ﺎﻬﻴﻠﻋ ﻞﻤﻌﻟﺍ ﺏﻮﻠﻄﻤﻟﺍ ﺔﻌﻄﻘﻟﺍ ﻚﺴﻣﺍ .(ﺔﻘﻴﻗﺩ ﻞﻜﻟ

ﻢﻗ .ﺔﺒﺳﺎﻨﻣ ﻯﺮﺧﺃ ﺕﺎﻄﻣﺎﻗ ﻱﺄﺑ ﻭﺃ ﺔﺷﺎﻤﻜﻟﺎﺑ ﺔﻳﺎﻐﻠﻟ ﺓﺮﻴﻐﺼﻟﺍ ﻊﻄﻘﻟﺍ ﻚﺴﻣﺍ

ﻊﻄﻘﻟﺍ ﻙﺮﺣ .ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍ ﻰﻠﻋ ﻖﺴﺘﻣﻭ ﻞﺴﻠﺳ ﻞﻜﺸﺑ ﻊﻄﻘﻟﺍ ﺮﻳﺮﻤﺘﺑ

ﺐﺠﻳ ،ﺔﻧﺍﻮﻄﺳﻻﺍ ﺆﻃﺎﺒﺗ ءﺎﻨﺛﺃ .ﺔﻧﺍﻮﻄﺳﻻﺍ

ﻰﻟﺇ ﺓﺩﻮﻌﻠﻟ ﺔﻧﺍﻮﻄﺳﻼﻟ ﺔﺻﺮﻔﻟﺍ ﺔﺣﺎﺗﻹ ﻲﺠﻳﺭﺪﺗ ﻞﻜﺸﺑ ﻂﻐﻀﻟﺍ ﺭﺮﺤﺗ ﻥﺃ

ﻢﻘﺗ ﻻﻭ ﺦﻴﻠﺠﺘﻟﺍ ﺔﻧﺍﻮﻄﺳﺍ ﻪﺟﻭ ﻰﻠﻋ ﻻﺇ ﺦﻴﻠﺠﺘﻟﺎﺑ ﻢﻘﺗ ﻻ .ﻯﻮﺼﻘﻟﺍ ﺔﻋﺮﺴﻟﺍ

ﻰﻠﻋ ﺦﻴﻠﺠﺘﻠﻟ ﺔﻤﻤﺼﻣ ﺕﺎﻧﺍﻮﻄﺳﻻﺍ ﺾﻌﺑ) .ﺎ

.(ﺎﻬﺑ ﺔﺻﺎﺨﻟﺍ ﺕﺎﻤﻴﻠﻌﺘﻟﺍ ﻕﺍﺭﻭﺃ ﻲﻓ ﻚﻟﺫ ﺮﻬﻈﻳﻭ ﺐﻧﺎﺠﻟﺍ

ﻣود مﺰﺘﻟا

:ﺮﻳﺬﺤﺗ

ً

.ﺔﻣﻼﺴﻟا تارﺎﻈﻧ

ﻲﻓ ﺔﻌﻄﻘﻟﺍ ﺭﺎﺸﺤﻧﺍ ﺐﻨﺠﺗﻭ ءﻂﺒﺑ

ً

ﻘﻠﻄﻣ ﺎﻬﺒﻧﺎﺟ ﻰﻠﻋ ﺦﻴﻠﺠﺘﻟﺎﺑ

Page 21

ﺔﻴﺑﺮﻌﻟﺍ

ﺔﻳﺭﺎﻴﺘﺧﻻﺍ ﺕﺎﻘﺤﻠﻤﻟﺍ

ﺎﻬﺗﺪﻤﺘﻋﺍ ﻲﺘﻟﺍ ﻚﻠﺗ ﻑﻼﺨﺑ ،ﺕﺎﻘﺤﻠﻤﻟﺍ ﻥﻷ ﺍًﺮﻈﻧ :ﺮﻳﺬﺤﺗ

ﻥﺈﻓ ،ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﻊﻣ ﺭﺎﺒﺘﺧﻼﻟ ﻊﻀﺨﺗ ﻢﻟ ،DEWALT

.ﺓﺭﻮﻄﺧ ﻞﻜﺸﻳ ﺪﻗ ﺓﺍﺩﻷﺍ ﻊﻣ ﺕﺎﻘﺤﻠﻤﻟﺍ ﻩﺬﻫ ﻞﺜﻣ ﻡﺍﺪﺨﺘﺳﺍ

ﺕﺎﻘﺤﻠﻣ ﻡﺍﺪﺨﺘﺳﺍ ﺐﺠﻳ ،ﺔﺑﺎﺻﺇ ﻉﻮﻗﻭ ﺮﻄﺧ ﻞﻴﻠﻘﺘﻟ

.ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﻊﻣ ﻂﻘﻓ ﺎﻬﺑ ﻰﺻﻮﻤﻟﺍ DEWAL T

.ﺔﻤﺋﻼﻤﻟﺍ ﺕﺎﻘﺤﻠﻤﻟﺍ ﻝﻮﺣ ﺕﺎﻣﻮﻠﻌﻤﻟﺍ ﻦﻣ ﺪﻳﺰﻤﻟﺍ ﺔﻓﺮﻌﻤﻟ ﻚﻠﻴﻛﻭ ﺮﺸﺘﺳﺍ

ﺔﺌﻴﺒﻟﺍ ﺔﻳﺎﻤﺣ

ﻲﻓ ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﻦﻣ ﺺﻠﺨﺘﻟﺍ ﻡﺪﻋ ﺐﺠﻳ .ﻞﺼﻔﻨﻣ ﻊﻴﻤﺠﺗ

ﻭﺃ ،ﻚﺑ ﺹﺎﺨﻟﺍ DEWALT ﺞﺘﻨﻣ ﻝﺍﺪﺒﺘﺳﺍ ﻰﻟﺇ ﻡﺎﻳﻷﺍ ﺪﺣﺃ ﻲﻓ ﺖﺠﺘﺣﺍ ﺍﺫﺇ

.ﺔﻴﻟﺰﻨﻤﻟﺍ ﺕﺎﻳﺎﻔﻨﻟﺍ ﻲﻓ ﻪﻨﻣ ﺺﻠﺨﺘﺗ ﻼﻓ ،ﻪﻣﺍﺪﺨﺘﺳﻻ ﺔﺟﺎﺣ ﻚﻟﺎﻨﻫ ﺪﻌﺗ ﻢﻟ

ﺓﺩﺎﻋﺇ ﺢﻴﺘﻳ ﺔﻜﻠﻬﺘﺴﻤﻟﺍ ﺕﺍﻮﺒﻌﻟﺍﻭ ﺕﺎﺠﺘﻨﻤﻠﻟ ﻞﺼﻔﻨﻤﻟﺍ ﻊﻴﻤﺠﺘﻟﺍ

ﺩﺍﻮﻤﻟﺍ ﻡﺍﺪﺨﺘﺳﺍ ﺓﺩﺎﻋﺇ .ﺮﺧﺃ ﺓﺮﻣ ﺎﻬﻣﺍﺪﺨﺘﺳﺍﻭ ﺩﺍﻮﻤﻟﺍ ﺮﻳﻭﺪﺗ

ﺐﻠﻄﻟﺍ ﻞﻴﻠﻘﺗﻭ ﻲﻴﺒﻟﺍ ﻮﻠﺘﻟﺍ ﻊﻨﻣ ﻰﻠﻋ ﺪﻋﺎﺴﻳ ﺎﻫﺮﻳﻭﺪﺗ ﺩﺎﻌﻤﻟﺍ

ﻦﻋ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺕﺎﺠﺘﻨﻤﻠﻟ ﺔﻠﺼﻔﻨﻣ ﻊﻴﻤﺠﺗ ﻦﻛﺎﻣﺃ ﺔﻴﻠﺤﻤﻟﺍ ﻦﻴﻧﺍﻮﻘﻟﺍ ﺮﻓﻮﺗ ﺪﻗ

ﺪﻨﻋ ﺔﺋﺰﺠﺘﻟﺍ ﻊﺋﺎﺑ ﺔﻄﺳﺍﻮﺑ ﻭﺃ ﺔﻳﺪﻠﺒﻟﺍ ﺕﺎﻳﺎﻔﻨﻟﺍ ﻊﻗﺍﻮﻣ ﻲﻓﻭ ،ﺔﻴﻟﺰﻨﻤﻟﺍ ﺕﺎﻳﺎﻔﻨﻟﺍ

ﺕﺎﺠﺘﻨﻣ ﺮﻳﻭﺪﺗ ﺓﺩﺎﻋﺇﻭ ﻊﻴﻤﺠﺘﻟ ﺎ

،ﺔﻣﺪﺨﻟﺍ ﻩﺬﻫ ﻦﻣ ﺓﺩﺎﻔﺘﺳﻼﻟ.ﻞﻴﺸﺘﻟﺍ ﺮﻤﻋ ﺔﻳﺎﻬﻧ ﺎﻬﻮﻠﺑ ﺭﻮﻓ DEWALT

ﻡﻮﻘﻴﺳ ﺬﻟﺍﻭ ﺪﻤﺘﻌﻣ ﻼﺻﺇ ﻞﻴﻛﻭ ﻰﻟﺇ ﻚﺑ ﺹﺎﺨﻟﺍ ﺞﺘﻨﻤﻟﺍ ﺓﺩﺎﻋﺇ ﺎﺟﺮﻟﺍ

ﻦﻣ ﻚﺘﻘﻄﻨﻣ ﻲﻓ ﺪﻤﺘﻌﻣ ﻼﺻﺇ ﻞﻴﻛﻭ ﺮﻗﺃ ﻊﻗﻮﻣ ﻰﻠﻋ ﻑﺮﻌﺘﻟﺍ ﻚﻧﺎﻜﻣﺈﺑ

ﺍﺬﻫ ﻲﻓ ﺩﺪﺤﻤﻟﺍ ﻥﺍﻮﻨﻌﻟﺍ ﻰﻠﻋ ﻲﻠﺤﻤﻟﺍ D

ﻟ ﻦﻴﻌﺑﺎﺗ ﻦﻳﺪﻤﺘﻌﻣ ﻼﺻﺇ ﻼﻛﻭ ﻦﻣ ﺔﻤﺋﺎﻗ ﺮﻓﻮﺘﺗ ،ﻚﻟﺫ ﻦﻣ ًﻻﺪﺑ.ﻞﻴﻟﺪﻟﺍ

ﺕﺎﻬﺟﻭ ﻊﻴﺒﻟﺍ ﺪﻌﺑ ﺎﻣ ﺔﻣﺪﺨﻟ ﺔﻠﻣﺎﻜﻟﺍ ﺔﻴﻠﻴﺼﻔﺘﻟﺍ ﻢﻬﺗﺎﻧﺎﻴﺑ ﻊﻣ DEWALT

ﻲﻧﻭﺮﺘﻜﻟﺍ ﻊﻗﻮﻤﻟﺍ ﺮﺒﻋ ﺖﻧﺮﺘﻧﺍ ﻰﻠﻋ ﺓﺮﻓﻮﺘﻤﻟﺍ ﻝﺎﺼﺗﻻﺍ

.ﺔﻳﺩﺎﻌﻟﺍ ﺔﻴﻟﺰﻨﻤﻟﺍ ﺕﺎﻳﺎﻔﻨﻟﺍ

.ﻞﺼﻔﻨﻤﻟﺍ ﻊﻴﻤﺠﺘﻠﻟ ﺍًﺮﻓﻮﺘﻣ ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﻞﻌﺟﺍ

.ﻡﺎﺨﻟﺍ ﺩﺍﻮﻤﻟﺍ ﻰﻠﻋ

.ﺪﻳﺪﺟ ﺞﺘﻨﻤﻟ ﻚﺋﺍﺮ

ﺼﺼﺨﻣ ﺎًﻧﺎﻜﻣ DEWALT ﺔﻛﺮ ﻡﺪﻘﺗ

ً

.ﻚﻨﻋ ﺔﺑﺎﻴﻧ ﻪﻌﻴﻤﺠﺘﺑ

EWALT ﺐﺘﻜﻤﺑ ﻝﺎﺼﺗﻻﺍ ﻝﻼﺧ

.www.2helpU.com

19

Page 22

20

Page 23

Afghanistan Ariana Hafiz Zabi Co. Ltd. info@arianahafiz.com Tel: 93-0-799331079

Dahan Bagh Squire Karte Ariana, Kabul, Afghanistan Fax: 93-0-700007576 / 93-0-799331079

Algeria Sarl Outillage Corporation hakim.merdjadi@outillage-dz.com Tel: 213-0-21375130

08, Rue Med Boudiaf (ex TELLA Achen) lyes@outillage-dz.com 213-0-21375131

Cheraga, Alger Mali.faiza@outillage-dz.com; Fax: 213-0-21369667

sidahmed@outillage-dz.com

Angola Angoferraria, Lda. angoferraria@gmail.com Tel: 244-222-395837 / 244-222-395034

Rua Robert Shields, nº 61, Luanda, Angola sequeira.angoferraria@gmail.com Fax: 244-222-394790

Azerbaijan Royalton Holdings Ltd. jai@royaltonholdings.com Tel: 994-12-4935544

41 Khagani St. Apt. 47 AZ1001 Baku- Azerbaijan office@royaltonholdings.com Fax: 994-12-5980378

Egypt ElFarab S.A.E. elfarab@elfarab.com Tel: 202-37603946

15-Nabil El Wakkad Street, Dokki, adel.ezzat@elfarab.com Fax: 202-33352796

Giza, Egypt mahmoud.elhosseiny@elfarab.com

Ethiopia Seif Tewfik Sherif seif@ethionet.et Tel: 251-11-1563968

Arada Sub City, Kebele 01/02, Global Insurance Bldg., nawanag@ethionet.et 251-11-1563969

2nd Flr., Room 43, P.O. Box 2525, Addis Ababa Fax: 251-11-1558009

Iraq Al-Sard Co. for General Trading Ltd dewalt.service@yahoo.com Tel: 964-18184102

Jbara Bldg. 3Flr. Al Rasheed St., Baghdad, Iraq

Jordan Amman West Stores-Bashiti ali@bashitistores.com Tel: 962-6-5350009

210 Garden St. Tla’a Ali, P.O. Box 1564 yousef@bashitistores.com Fax: 962-6-5350012

Tla Ali Amman 11953, Jordan

Kenya Dextron Tools Ltd. info@alibhaishariff.co.ke Tel: 254-20-6905000

P.O. Box 20121-00200, Shariff House, dextron@alibhaishariff.co.ke 254-20-2358021

Kimathi Street, Nairobi Fax: 254-20-6905111 / 254-20-6905112

Lebanon Est. Shaya & Azar S.A.R.L. shayazar@dm.net.lb Tel: 961 1 872305

Boulvard Jdeideh - Mar Takla - Bouchrieh . 961 1 872306

P.O. Box 90545, Jdeideh. Beirut – Lebanon Fax: 961 1 872303

Libya North Africa Trading ( El Ghoul Brothers) maryam_farooq2003@yahoo.com Tel: 218-061-3383994

P.O. Box 348, 7 October Street 11 nagte@eim.ae Fax: 218-092-7640688

Benghazi dewalt_libya@yahoo.com

North Africa Trading ( El Ghoul Brothers) dewalt_libya@yahoo.com Tel: 218-021-3606430

AlBarniq D

Mokhazin-elsukar St. ElFallah, Tripoli

North Africa Trading ( El Ghoul Brothers) Tel: 218-091-3221408

AlHilal Service Center Tawergha St., Misurata

Mauritius Robert Le Marie Limited a.blackburn.rlm@rlmgroup.mu Tel: 230-212 1865

Old Moka Road, Bell Village, P.O. Box 161, jm.pierrelouis.rlm@rlmgroup.mu 230-212 2847

Port Louis Fax: 230-2080843

Morocco Ets Louis Guillaud & Cie boumadiane.azedine@elg.ma Tel: 522-301446 / 305971 / 317815 /

31, Rue Pierre Parent, doukkali.marouane@elg.ma 315576

Casablanca – 21000 Fax: 522-444518 / 317888

Nigeria Meridian Power Tools Ltd. braj@meridian-nigeria.com Tel: 234-1-7740431

Gr. Floor, #1 Alhaji Masha Rd, Next toTeslim Balogun 234-1-7740410

Stadium, Near National Stadium Surulere, Lagos, Nigeria Fax: 234-1-7913798

Pakistan Northern Toolings (Pvt) Ltd.-Lahore zhayee@norther n.pk Tel: 92-423-7651220

86- Railway Road, Lahore – 7 import@northern.pk 92-423-7641675

Pakistan sales@northern.pk Fax: 92-423-7641674

Northern Toolings (Pvt) Ltd.-Karachi karachibr@northern.pk Tel: 92-213-2465305

224-231 Industrial Town Plaza, Shahrah-e-Liaqat, 92-213-2465307

Karachi, Pakistan Fax: 92-213-2465301

Northern Toolings (Pvt) Ltd.-Taxila taxilabr@northern.pk Tel: 92-51-4545811

Al-Rehman Plaza, Opposite Tehsil Court, Fax: 92-51-4544194

Faisal Shaheed Road, Taxila

South Benray Tool Wholesalers C.C. dewaltservice@benray.co.za Tel: 27-11-6838350

Africa 91 Turffontein Road, Stafford, Johannesburg, 2001 P.O. zain@benray.co.za Fax: 27-11-6837456

Box 260037 EXCOM 2023, South Africa shafiq@benray.co.za

Tanzania General Motors Investment Ltd. ezra@gmi-tz.com Tel: 255-22-2865022 /

14 Vingunguti-Nyerere Road, P.O.Box 16541, info@gmi-tz.com 2862661 / 2862671 / 2862659

Dar es Salaam, Tanzania chiwelesa@yahoo.com Fax: 255-22-2862667

Tunisia Ets. Mohamed Ghorbel slim.ghorbel@gnet.tn Tel: 216-71794248

03 Rue 8603 Charguia I Tunis. moh.ghorbel@gnet.tn 216-71793848

Postal Code 2035 mourad.ghorbel@gnet.tn Fax: 216-71770759

Uganda The Building Center (u) Ltd. tbc@africaonline.co.ug Tel: 256-041-4234567

52 Station Road, Kitgum House, chris@tbcu.co.ug 256-041-4259754

P.O. Box 7436 Kampala, Uganda Fax: 256-041-4236413

Yemen Middle East Trading Co. (METCO) tamer.metco@gmail.com Tel: 967-4-213455

5th Flr.Hayel Saeed Anam Bldg. tamer@metcotrading.com Fax: 967-4-219869

Al-Mugamma St. Taiz, metco@metcotrading.com

Yemen sami@metcotrading.com

Middle East Trading Co. (METCO) tamer.metco@gmail.com Tel: 967-2-222670

Mualla Dakka, tamer@metcotrading.com Fax: 967-2-222670

Aden metco@metcotrading.com

Middle East Trading Co. (METCO) tamer.metco@gmail.com Tel: 967-1-204201

Hayel st., Sana'a, tamer@metcotrading.com Fax: 967-1-204204

Yemen metco@metcotrading.com

EWALT Center, Fax: 218-092-6514813

Page 24

UAE Black & Decker (Overseas) GmbH service.mea@blackdecker.com Tel: 971-4 8127400 / 8127406

P.O. Box 5420, Dubai Fax: 971-4 2822765

Ideal Star Workshop Eqpt. Trading LLC idealeq@emirates.net.ae Tel: 971-4 3474160

P.O. Box 37116, Al Quoz, Dubai Fax: 971-4 3474157

Alebrah Engineering Service alebrah@eim.ae Tel: 971-4 2850044

P.O. Box 78954, Al Qusais, Dubai Fax: 971-4 2844802

Burj Al Madeena dewaltuae@hotmail.com Tel: 971-6 5337747

Industrial Area No. 1, opp. Pakistani Masjid Fax: 971-6 5337719

P.O. Box 37635, Sharjah

McCoy Middle East LLC mccoy@emirates.net.ae Tel: 971-6 5395931

P.O. Box 25793, Sharjah Fax: 971-6 5395932

McCoy Middle East LLC mccoyrak@gmail.com Tel: 971-7 2277095

P.O. Box 10584, Ras Al Khaimah Fax: 971-7 2277096

Al Sukoon Gen. Trdg. Co. LLC sukoon@eim.ae Tel: 971-6 7435725 / 7438317

P.O. Box 2975, Ajman Fax: 971-6 7437350

Zillion Equipment and Spare Parts Trading LLC zilliontrdg@gmail.com Tel: 971-3 7216690

P.O. Box 19740, opp. Bin Sadal / Trimix Redymix Sanaiya, Al Ain Fax: 971-3 7216103

Light House Electrical, Abu Dhabi Branch dewalt_lhe@hotmail.com Tel: 971-2 6726131

P.O. Box 120, Abu Dhabi Fax: 971-2 6720667

Light House Electrical, Musaffah Branch dewalt_lhe@hotmail.com Tel: 971-2 5548315

P.O. Box 120, Abu Dhabi Fax: 971-2 5540461

Bahrain Alfouz Services Co. WLL alfouz@batelco.com.bh Tel: 973 17783562 / 17879987

P.O. Box 26562, Tubli, Manama Fax: 973 17783479

Kavalani & Sons W.L.L. info@kavalani.com Tel: 973 17732888

P.O. Box 71, Sitra, Manama pradeep@kavalani.com Fax: 973 17737379

Kuwait Al Omar Technical Co. alexotc@usa.net Tel: 965 24848595 / 24840039

P.O. Box 4062, Safat 13041, Kuwait Fax: 965 24845652

Fawaz Al Zayani Establishment dewaltkuwait@hotmail.com Tel: 965 24828710

P.O. Box 42426, Shop No.18, Fax: 965 24828716

Al Humaizi Commercial Complex, Khalifa Al Jassim, Shuwaikh

Fawaz Al Zayani Establishment dewaltkuwait@hotmail.com Tel: 965 23925830

Fahaheel Industrial Area, Main St., Sanaya Fax: 965 24828716

Oman Al Jizzi Company LLC aljizied@omantel.net.om Tel: 968 24832618 / 24835153

P.O. Box 1704, P.C. 112, Ruwi jizzi10@omantel.net.om Fax: 968 24831334 / 24836460

Al Hassan Technical & Construction Supplies Co. LLC hamriya.sr@al-hassan.com Tel: 968 24810575 / 24837054

P.O. Box 1948, P.C. 112, Ruwi abrar.h@al-hassan.com Fax: 968 24810287 / 24833080

Oman Hardware Co. LLC omanhard@omantel.net.om Tel: 968 24815131

P.O. Box 635, Ruwi Postal Code 112 Fax: 968 24816491

Khimji Ramdas bilal.m@khimjiramdas.com Tel: 968 24595906/ 907

P.O. Box 19, Post Code 100, Ghala, Muscat Fax: 968 24852752

Qatar Teyseer Industrial Supplies & Services Co. WLL manish@tissco-qatar.com Tel: 974 4581536

55, Al Wakalat St. (Between St. 18 & 19) tool.service@tissco-qatar.com Fax: 974 4682024

Salwa Industrial Area, P.O. Box 40523 Doha

Shaheen Electrical Works & Trading Co. WLL shaheenelc@gmail.com Tel: 974 460 02 30 / 460 05 25

Gate 34, St. 44 Industrial Area P.O. Box 9756, Doha Fax: 974 460 13 38

KSA Industrial Material Organization (IMO) service@imo.com.sa Tel: 966-1 4028010 Ext. 26

P.O. Box 623, Rail Street, Riyadh Tel: 966-1 8001245757

Fax: 966-1 4037970

Fawaz Ebrahim Al Zayani Trading Est. dewaltdammam@hotmail.com Tel: 966-3 8140914

P.O. Box 76026, Al Raka : 31952 Fax: 966-3 8140824

MSS (Al-Mojil Supply & Services) mssjubail@almojilservices.com Tel: 966-3 3612850 / 3624487

P.O. Box 450, Jubail 31951 alex.chang@almojilservices.com Tel: 966-3 3621729

Opp-Gulf Bridge Library & Riyadh House Fax: 966-3 3623589 / 3620783

EAC (Al Yousef Contg. & Trdg. Est.) golamkibria77@yahoo.com Tel: 966-2 6519912

P.O. Box 30377, Jeddah -21477 Fax: 966-2 6511153

Mohamed Ahmed Bin Afif Est. binafifyanbu@hotmail.com Tel: 966-4 3222626 / 3228867

P.O. Box 530, Yanbu, Al Bahr Fax: 966-4 3222210

Garziz Trading for Bldg Mat & Decoration agarziz@yahoo.com Tel: 966-4 826 14 90 / 822 76 36

P.O. Box 3364, Madina Fax: 966-4 826 57 41

Sultan Garment Factory (RSC) rscservice@digi.net.sa Tel: 966-1 4055148 / 4042889

P.O. Box 29912, Riyadh 11467 Fax: 966-1 4055148

Al Bawardi Tools & Hardware asattar@albawardi.com Tel: 966-3 8330780 Ext. 24

P.O. Box 112, Dammam 31411 nibanez@albawardi.com Tel: 966-3 8348585 Ext. 24

Fax: 966-3 8336303

Al Bawardi Tools & Hardware rbaltao@albawardi.com Tel: 966-1 4484999

P.O. Box 68, Riyadh 11411 asamad@albawardi.com Fax: 966-3 4487877

Al Bawardi Tools & Hardware sharadji@albawardi.com Tel: 966-2 6444547 / 6439035

P.O. Box 16905, Jeddah 21474 fgaber@albawardi.com Tel: 966-2 6456095

Fax: 966-2 6439024

90602458 04/14

Loading...

Loading...