Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in U.S.A. (JAN98-CD-1) Form No. 385103

DW751 Copyright © 1998

DW751/385103 5/2/02 12:51 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW751

Drill Bit Sharpener

Affûte-foret

Afilador de brocas

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us on the World Wide Web at www.dewalt.com

DW751/385103 5/2/02 12:51 PM Page 3

Page 3

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

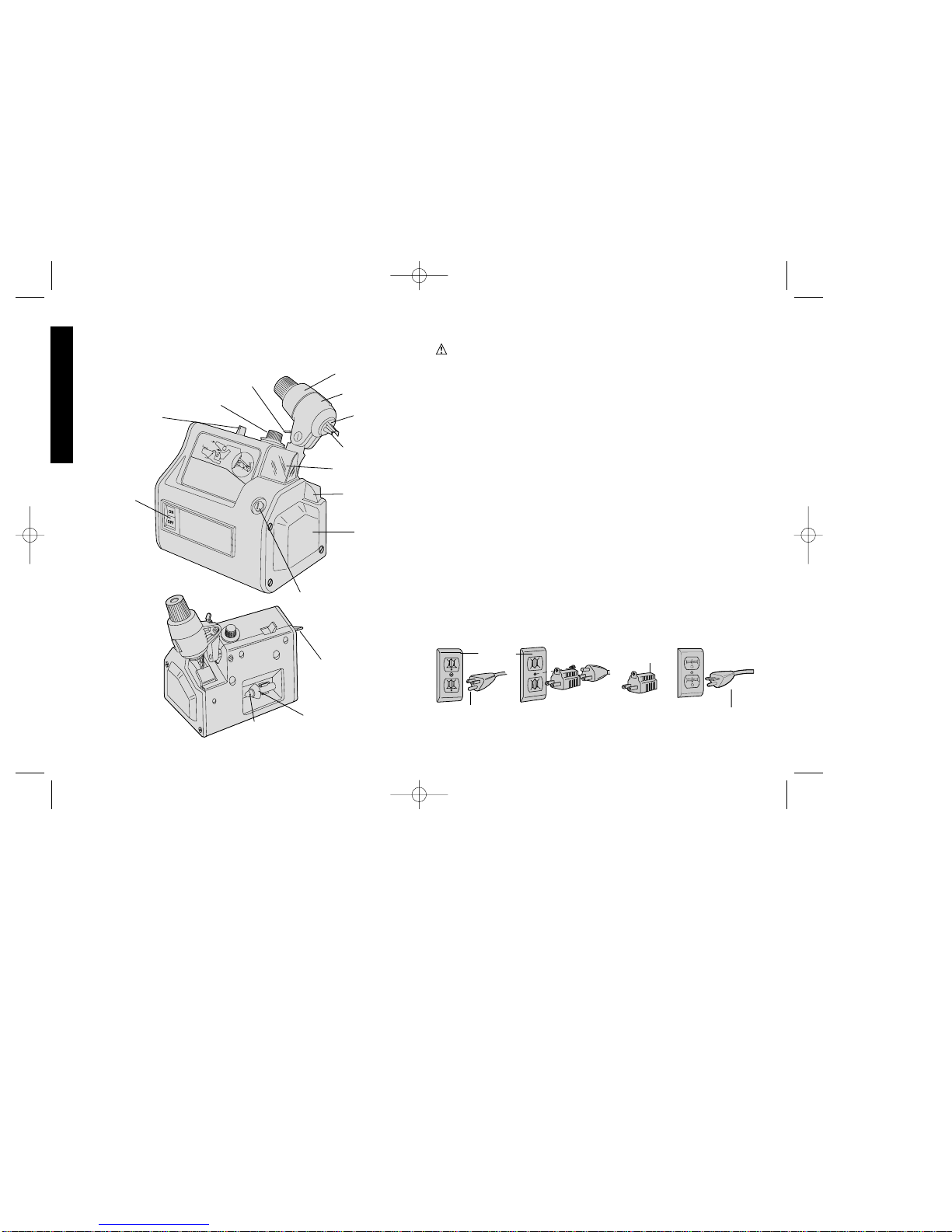

Grounding Instructions

This tool should be grounded while in use to protect the operator from

electric shock. The tool is equipped with a 3-conductor cord and 3prong grounding type plug to fit the proper grounding type receptacle.

The green (or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and yellow) wire

to a live terminal. If your unit is intended for use on less than 150 V,

it has a plug that looks like that shown in sketch A. If it is for use on

150 to 250 V, it has a plug that looks like that shown in sketch D. An

adapter, sketches B and C, is available for connecting sketch A type

plugs to 2-prong receptacles. The green-colored rigid ear, lug, or the

like, extending from the adapter must be connected to a permanent

ground, such as a properly grounded outlet box. No adapter is

available for a plug as shown in sketch D. ADAPTER SHOWN IN

FIGURES B and C IS NOT FOR USE IN CANADA.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

S

H

A

R

P

E

N

I

N

G

IN

S

T

R

U

C

T

I

O

N

S

S

W

IN

G

H

E

A

D

M

O

D

E

S

E

L

E

C

T

O

R

F

E

E

D

K

N

O

B

L

O

A

D

P

U

S

H

L

A

T

C

H

G

R

IN

D

T

O

1

/3

2"

ENTIRE

LOCATOR EDGE

TOUCHING

FLUTE

SHARPEN/DRESS

SELECTOR

FEED KNOB

INDEX SLEEVE

SWINGHEAD

CHUCK

LOCATOR

GRINDING

WHEEL

LATCH

EYE SHIELD

WHEEL

COVER

DRESS KNOB

DUST SHIELD

DIAMOND

DRESSER

GUARD BAND

ADJUSTMENT

SCREW

ON/OFF

MOTOR

SWITCH

AB CD

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

GROUNDING PIN

ADAPTER

DW751/385103 5/2/02 12:51 PM Page 4

Page 4

Safety Instructions For All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. All visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool for purpose not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dust mask if cutting

operation is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

handles dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger

on switch. Be sure switch is off when plugging in.

• EXTENSION CORDS. Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles that accept

the tool’s plug. Replace or repair damaged cords. Make sure your

extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The following table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage (AWG)

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

1

English

DW751/385103 5/2/02 12:51 PM Page 1

Page 5

2

• OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

• STAY ALERT. Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard

or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

Additional Safety Rules for Drill Bit

Sharpener

WARNING: This professional tool is designed for fast, accurate

sharpening of right-hand, 2-flute twist drill bits from 1/8" (3 mm) to

1/2" (13 mm) in diameter. DO NOT attempt to sharpen carbidetipped or cobalt bits. Since proper procedure is essential to

satisfactory results, read the operating instructions carefully, and,

for your own protection, pay close attention to the safety rules.

• Wear eye protection.

• Use grinding wheel suitable for speed of grinder.

• Replace cracked wheel immediately. Handle grinding wheels

carefully to avoid bumping or dropping. DO NOT use a grinding

wheel that has been dropped. Before using, inspect each grinding

wheel for cracks or flaws and if these are evident, discard the

wheel.

• Always use guards and eye shields. Keep the eye shield mounted

in proper positions.

• Do not overtighten wheel nut. Before mounting a new wheel, be

sure that it is marked with an R.P.M. that is the same as, or higher

than, the no-load speed of the tools as marked on the nameplate.

• Use only flanges furnished with the grinder.

• Bolt the drill bit sharpener to a bench to prevent movement.

• Adjust distance between wheel and guards to maintain 1/16" (1.6

mm) or less separation as the diameter of the wheel decreases

with use.

• Use accessories only in proper and intended manner.

SAVE THESE INSTRUCTIONS

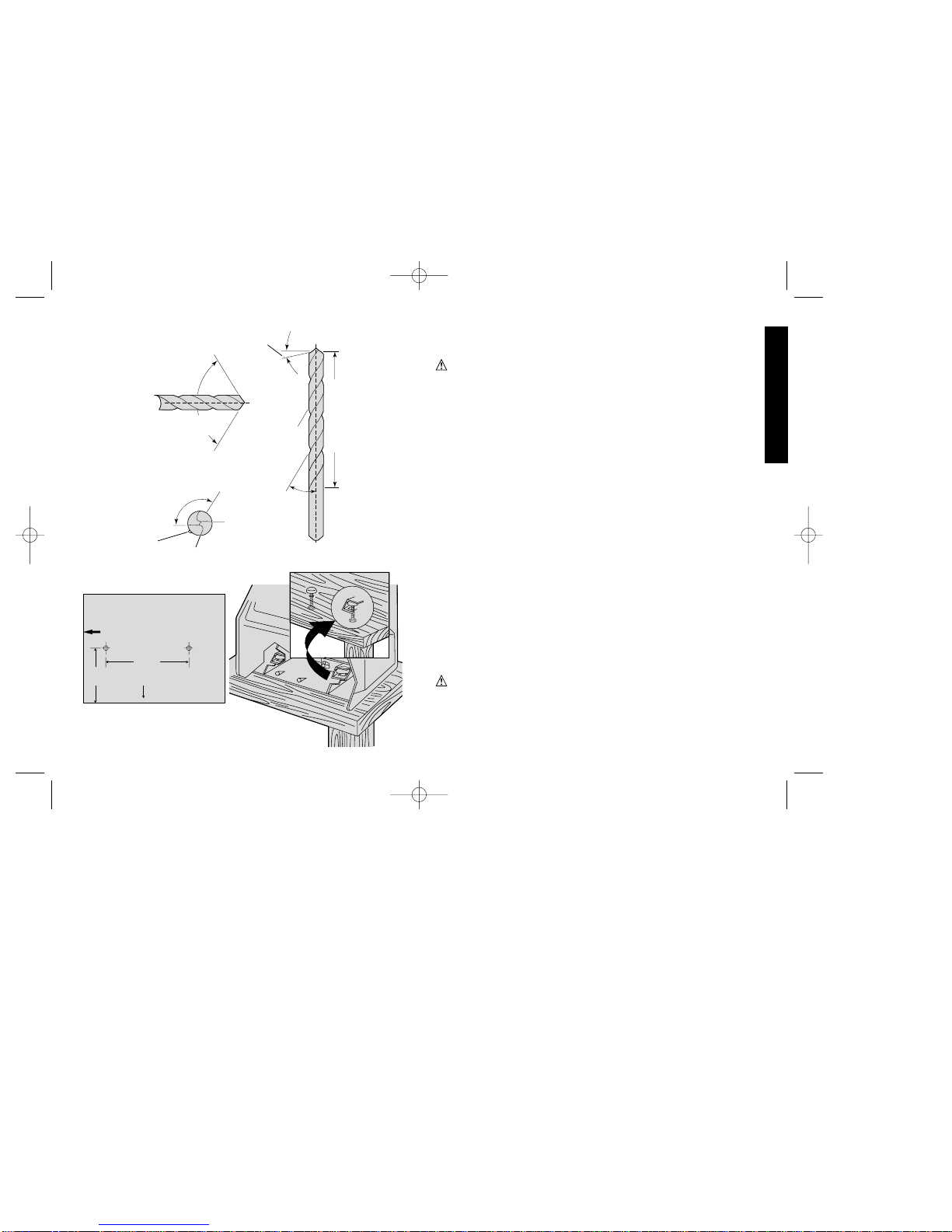

Drill Bit Terminology

A primary requirement for drilling accurately sized holes is that there

be minimal difference between the lip heights of the two flutes.

Variations in the two lip heights will alter the centrality of the point

which will produce eccentric drilling. (See Figures 1, 2, and 3.) See

paragraph 6 of the “Troubleshooting” section in this manual. Your

D

EWALT sharpener is engineered to produced equal lip heights and

a centrally located point.

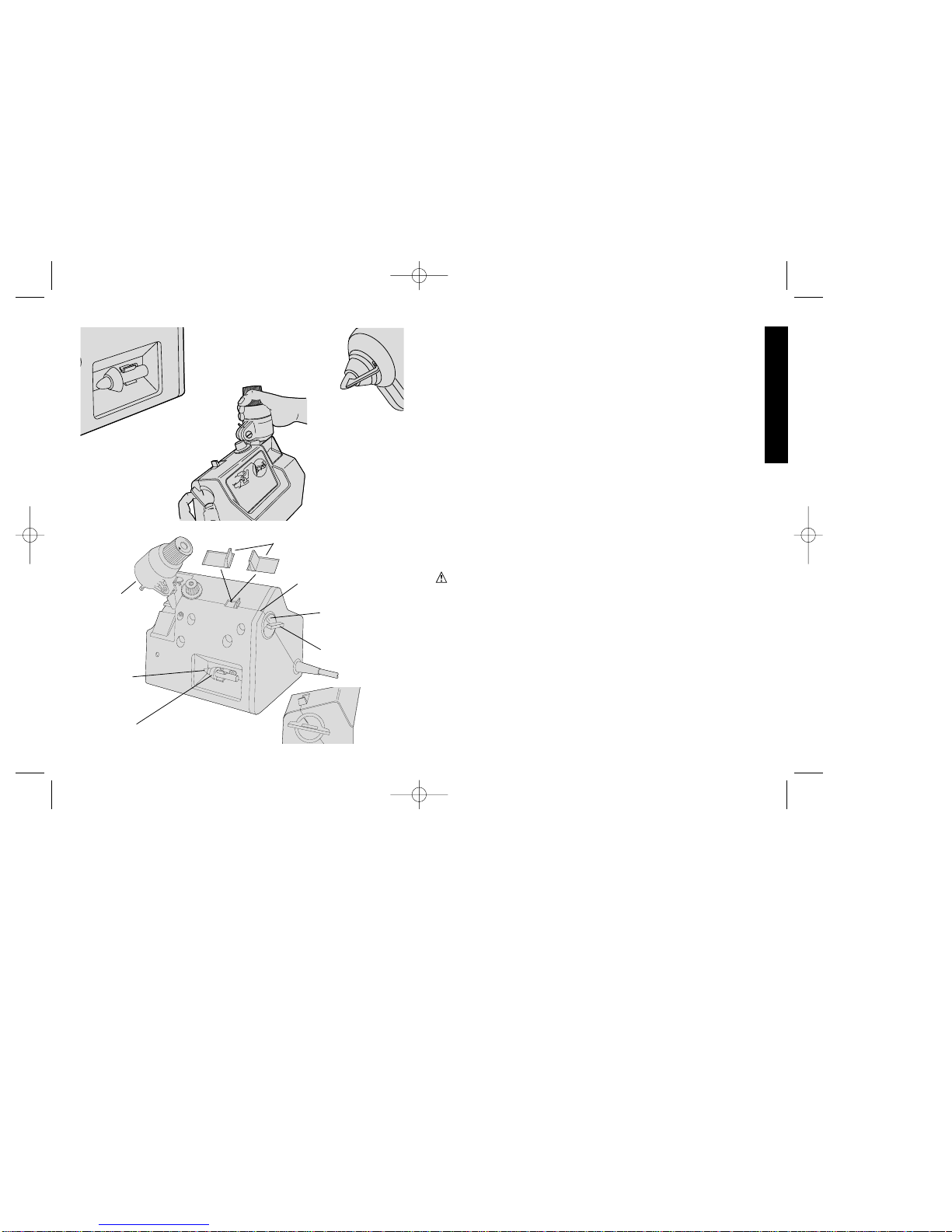

Mounting the Sharpener

FOR BEST RESULTS YOUR SHARPENER SHOULD BE

MOUNTED TO A FIRM WORK SURFACE. Drill two 5/16" (8 mm)

holes in work bench as shown in Fig. 4. Insert two 1/4" (6 mm)

diameter carriage bolts. Slide Sharpener over bolt heads and fit bolt

heads into openings provided in bottom of tool (Fig. 5.) Tighten nuts

on bolts evenly with moderate force. Do not overtighten!

English

DW751/385103 5/2/02 12:51 PM Page 2

Page 6

Main Functional Parts of Your Drill Bit

Sharpener

CAUTION:

• Play it safe—know all follow all SAFETY RULES.

• Be sure locator is clear of grinding wheel before starting motor.

• Use light pressure and an even motion in rocking the swinghead

when grinding.

• When shifting from BIT SHARPENING to WHEEL DRESSING—

and vice versa—follow instructions with extra care.

• Replace a cracked wheel immediately.

• Never disassemble the tool or try to do any rewiring in the electrical

system.

The Sharpen/Dress selector programs the tool for either bit

sharpening or wheel dressing. The Feed Knob provides precision

control of feed rate (material removal) during sharpening. The Index

Sleeve permits you to sharpen first one side of the drill bit tip, and

then the other side without removing the bit from the chuck. The

Swinghead lets you move the bit across the grinding wheel at the

correct angle repeatedly. The Chuck holds bit in position during

sharpening operation. The Locator guides positioning of drill bit so

that sharpening will be correct and accurate.

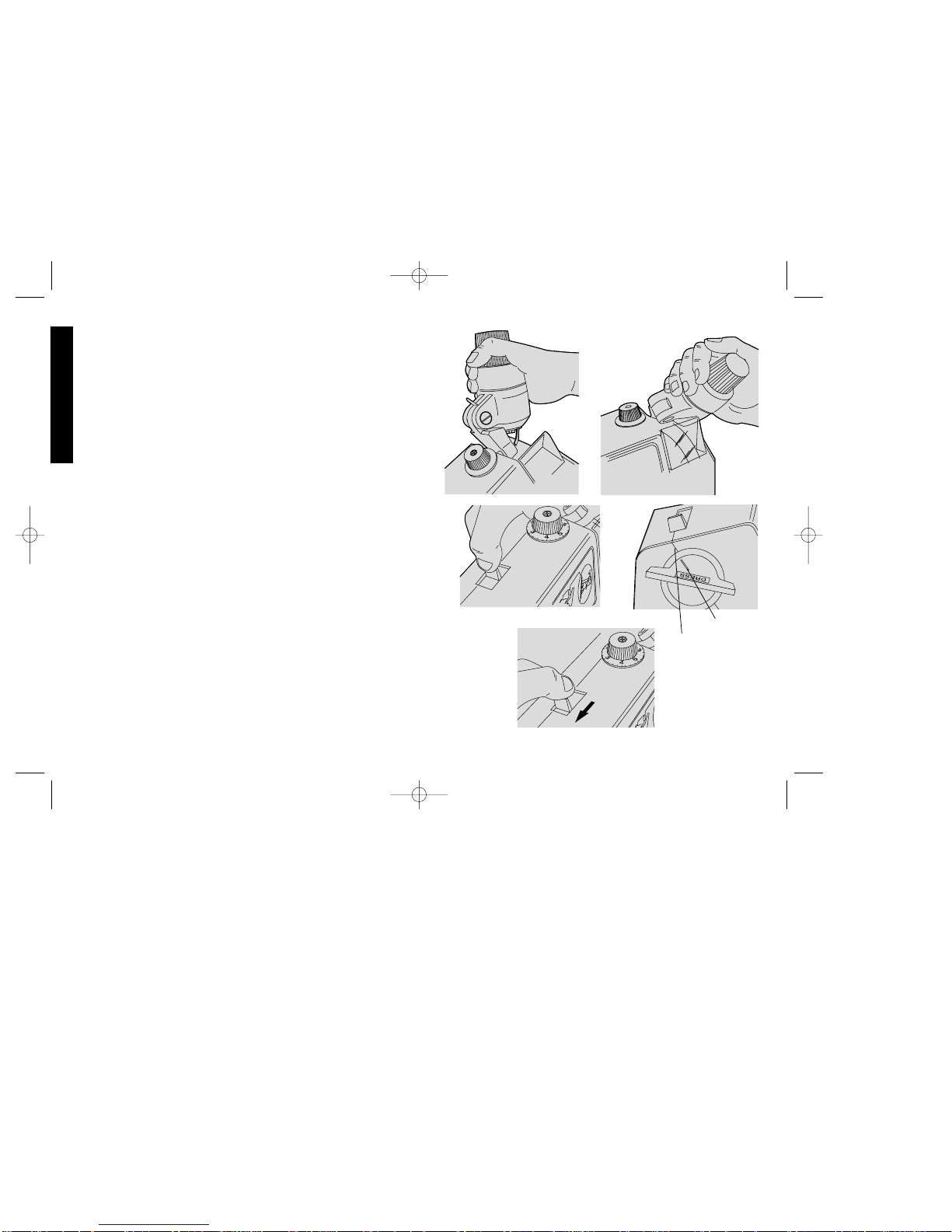

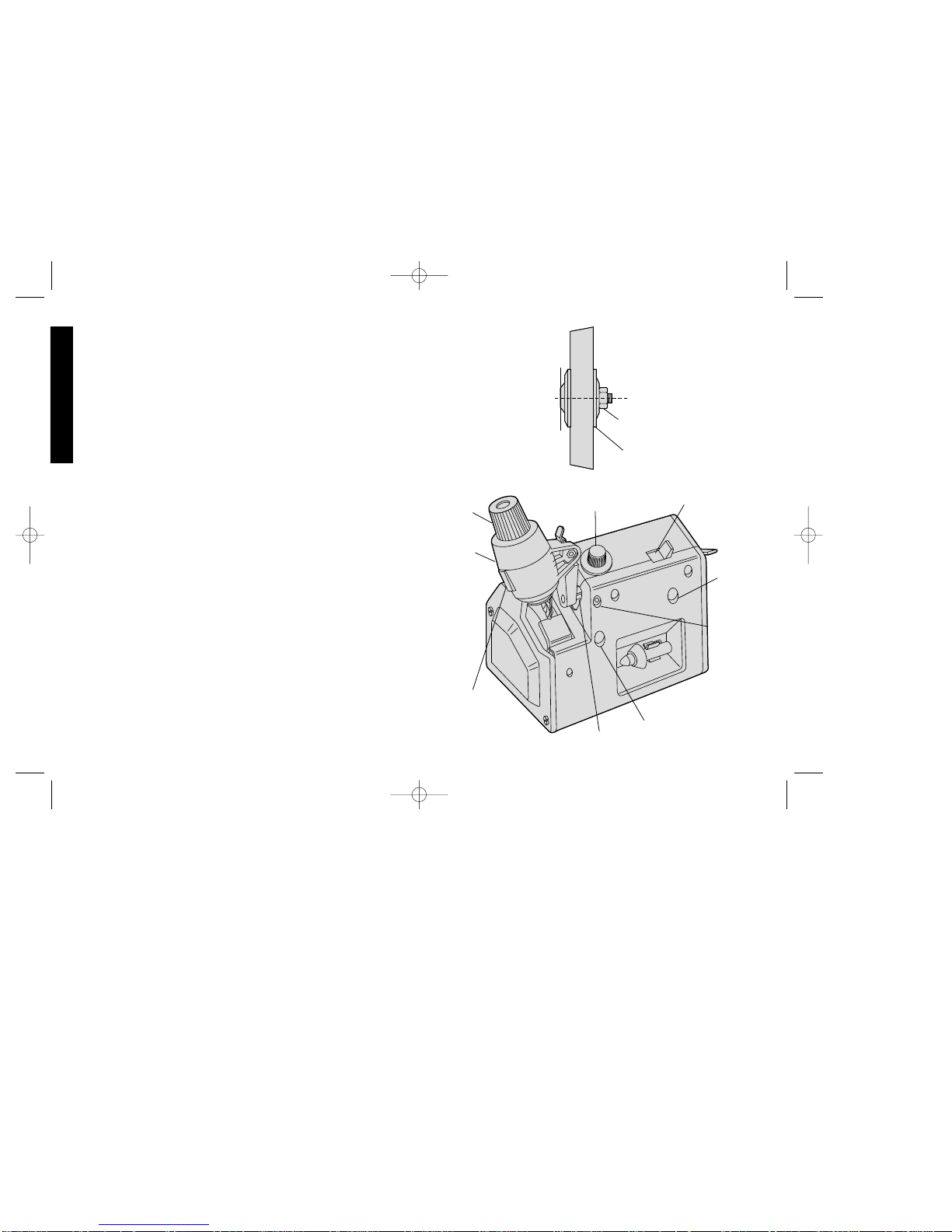

Shifting Selector Sharpen Bits or Dress

Wheel

(Figs. 6, 7, 8, 9, 10)

When you are ready to sharpen bits, the selector switch must be in

the “S” (sharpen) position. The “D” (dress) position is used when

dressing the grinding wheel.

IMPORTANT: Improper shifting from “D” (wheel dressing) to “S”

(bit sharpening), and vice versa, can cause damage and make your

sharpener inoperative. The correct methods of shifting are

illustrated.

3

English

FIG. 4

FIG. 1

FIG. 2

(122.2 mm)

Tool Outline

Front

(82.5 mm)

3 1/4"

4 13/16"

FIG. 5

HELIX

ANGLE

FIG. 3

120° TO 135°

CHISEL EDGE

ANGLE

INCLUDED ANGLE

OF POINT 118°

LIP RELIEF

ANGLE

FLUTE

FLUTE LENGTH

WEB

CUTTING

LIP

DW751/385103 5/2/02 12:51 PM Page 3

Page 7

4

SHIFTING FROM “S” (SHARPEN) TO “D” (DRESS)

NOTE: Be sure to do Step 1 before Step 2. Otherwise, the

swinghead will not move up to the eye shield.

1. Pivot swinghead to normal sharpening position (Fig.6).

2. Rotate swinghead until it touches the eyeshield (Fig.7).

3. Move mode selector switch to “D” (Fig.8).

SHIFTING FROM “D” (DRESS) TO “S” (SHARPEN)

1. Line up mark on dress knob with parting line of housing. Position

swinghead close to the eyeshield (Fig. 9).

2. Shift mode selector to “S.” DO NOT FORCE. If selector switch

will not seat, rock dress knob back and forth while keeping slight

pressure on selector switch until it snaps into place (Fig. 10).

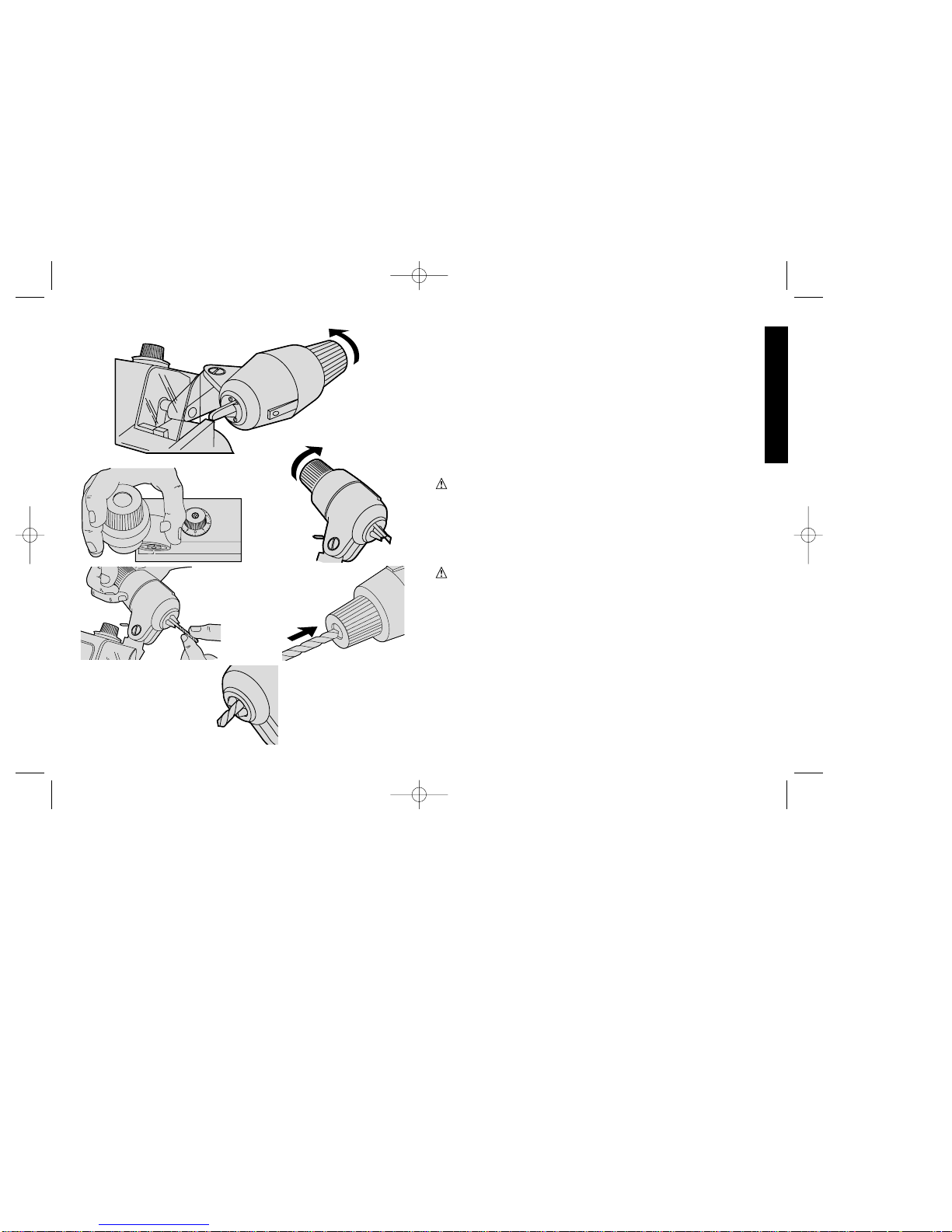

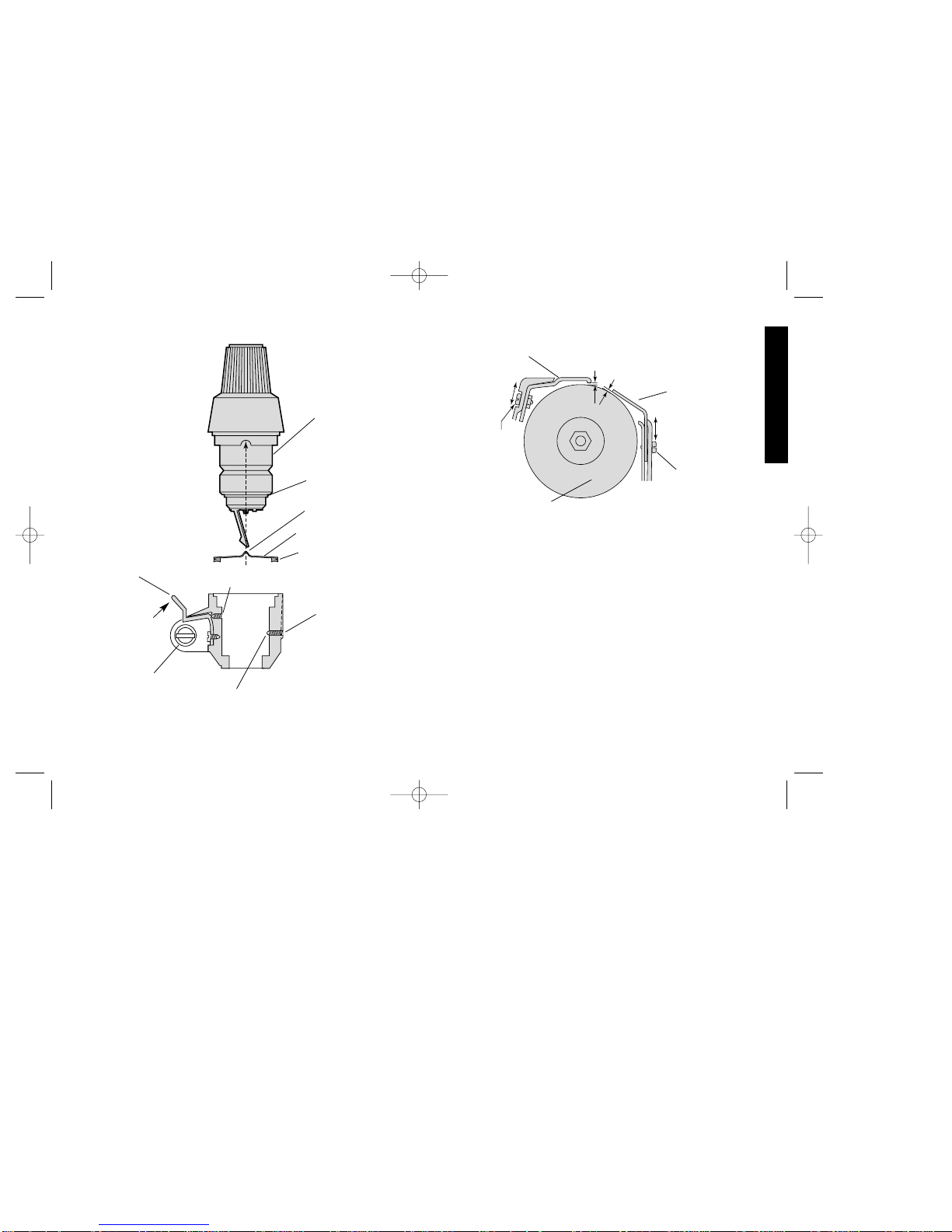

Sharpening of Drill Bits

(Figs. 11, 12, 13, 14, 15, 16)

PREPARING TO SHARPEN

NOTE: First, check the unit for the adjustments explained in the

“Adjustments” section of this manual.

1

. The swinghead has two indexing positions, 180° apart. Rotate sleeve

to make sure it is seated, with locator in top position. Make sure selector

switch on top of the tool is in the “S” (sharpen) position (Fig. 11).

2. Press latch toward swinghead and move swinghead toward

loading position (Fig. 12).

3. Open chuck jaws by turning chuck nut counter-clockwise (Fig.13).

4. Insert smaller diameter bits past the locator directly into the chuck

(Fig. 14).

5. Insert larger diameter bits through the opening in the chuck head

(Fig. 15).

6. Position bit so that tip is approximately 1/16" (1.6 mm) below end

of locator. Be sure straight edge at end of locator is flat against

flute. This positioning of the bit with the locator is the key to

satisfactory sharpening (Fig. 16).

English

FIG. 6 FIG. 7

FIG. 9

D

S

H

A

R

P

E

N

I

N

G

I

N

S

T

R

U

C

T

I

O

N

S

L

O

A

D

G

R

I

N

D

T

O

1

/

3

2

"

FIG. 8

S

S

H

A

R

P

E

N

I

N

G

I

N

S

T

R

U

C

T

I

L

O

A

D

FIG. 10

PARTING LINE

MARK

DW751/385103 5/2/02 12:51 PM Page 4

Page 8

SHARPENING FIRST CUTTING LIP (Figs. 17, 18, 19)

NOTE: Broken bits are more easily sharpened if they are first

roughed into shape by hand on a bench grinder. This will eliminate

unnecessary wear on the grinding wheel.

1.

With motor “OFF,” lower swinghead to sharpening position (Fig. 17).

2. Turn feed knob clockwise until bit is almost touching the wheel

when swinghead is rocked back and forth (Fig. 18).

NOTE: Turning feed knob clockwise feeds bit into wheel; turning

counterclockwise backs bit away from wheel.

3. Turn motor “ON,” Gently rock swinghead back and forth as you

turn the feed knob clockwise. DO NOT USE HEAVY HAND

PRESSURE WHEN ROCKING THE SWINGHEAD.

IMPORTANT: Advancing the feed knob one number (e.g., 2 to

3) moves the bit 5 thousandths of an inch closer to the wheel. Each

calibration (mark) between numbers moves the bit 1 1/4 thousandths.

4. Moving the feed knob clockwise one calibration (mark) at a time,

continue to rock the swinghead across the wheel until the edge of

the bit is about 1/32” (.8 mm) from the end of the locator. BE

CAREFUL NOT TO GRIND LOCATOR.

IMPORTANT: Make a note of the final feed knob setting because

you’ll need it when you sharpen the second lip.

5. Now turn feed knob counterclockwise several turns to back bit

away from grinding wheel.

6. Move swinghead down and back to rest position illustrated. Rotate

sleeve 180° clockwise until it snaps into the second index position.

(The locator will now be on the underside of the chuck.)(Fig. 19)

SHARPENING SECOND CUTTING LIP

1. Repeat steps 3 and 4 under “Sharpening first cutting lip.”

2. STOP SHARPENING WHEN THE FEED KNOB REACHES THE

CALIBRATION YOU NOTED.

5

English

FIG. 11

FIG. 12

FIG. 14

FIG. 13

FIG. 15

FIG. 16

DW751/385103 5/2/02 12:51 PM Page 5

Page 9

6

For finest finish, turn feed knob one more calibration and grind

bit. Without touching feed knob, turn sleeve 180° clockwise (step

6 on page 5) and grind first lip until sparking stops.

3. Turn motor “OFF.” Raise swinghead to loading position and

remove bit.

CAUTION: Tip of bit may be hot.

Wheel Dressing (Figs. 20, 21, 22)

The special grinding wheel included with your DEWALT drill bit

sharpener is ready to sharpen your bits. When the sharpening

surface becomes worn and uneven, it’s time to dress the wheel.

Follow these steps:

IMPORTANT: See instructions for shifting from “S” (sharpen) to

“D” (dress) under “Shifting selector to sharpen bits or dress wheel.”

After you have taken the necessary steps, proceed to:

1. Press latch and move swinghead to loading position.

2. Take diamond dressing tool which is kept in the spring-clip in back

of the sharpener. Remove protective sleeve. Position the dust

shield as shown below. Position diamond dresser in chuck, with

diamond tip 1/16" (1.6 mm) beyond locator as illustrated. Tighten

chuck jaws by turning chuck nut clock-wise. Slide dust shield up

against face of chuck to prevent grit and dust from fouling chuck.

(Fig. 20 & 21)

3. Move swinghead downward until latch engages. Adjust feed knob

clockwise until diamond tip almost touches sharpening surface of

the grinding wheel.

4. With SLIGHT PRESSURE, push swinghead back and away from

eyeshield until it stops.

5. Turn motor “ON.” Maintain light pressure, away from the

eyeshield, on the swinghead. Move the diamond back and forth

across the wheel by turning the dress knob clockwise and

counterclockwise. Feed the diamond into the wheel by turning

English

FIG. 17

FIG. 18

FIG. 19

SLEEVE

TURN SLEEVE 180°

DW751/385103 5/2/02 12:51 PM Page 6

Page 10

the feed knob, clockwise, one calibration at a time. Smooth,

continuous motion completely across the face of the wheel will

provide a smoother finish. Stopping the diamond on the wheel

will score it. Removing wheel material during the outside-to-inside

motion of the diamond will assure a finer finish (Fig. 22).

6. Turn motor “OFF.” Back off feed knob (turn counterclockwise)

enough so that diamond clears sharpening surface of wheel.

Return swinghead to loading position. Remove diamond dresser

and dust shield.

TO CHANGE FROM “D” (DRESSING) TO “S”

(SHARPENING)(Fig. 23)

1. Line dress knob mark up with parting line of housing.

2. Move swinghead close to eyeshield.

3 . Shift mode selector to “S.” DO NOT FORCE. If selector will not

seat, check position of dress knob mark.

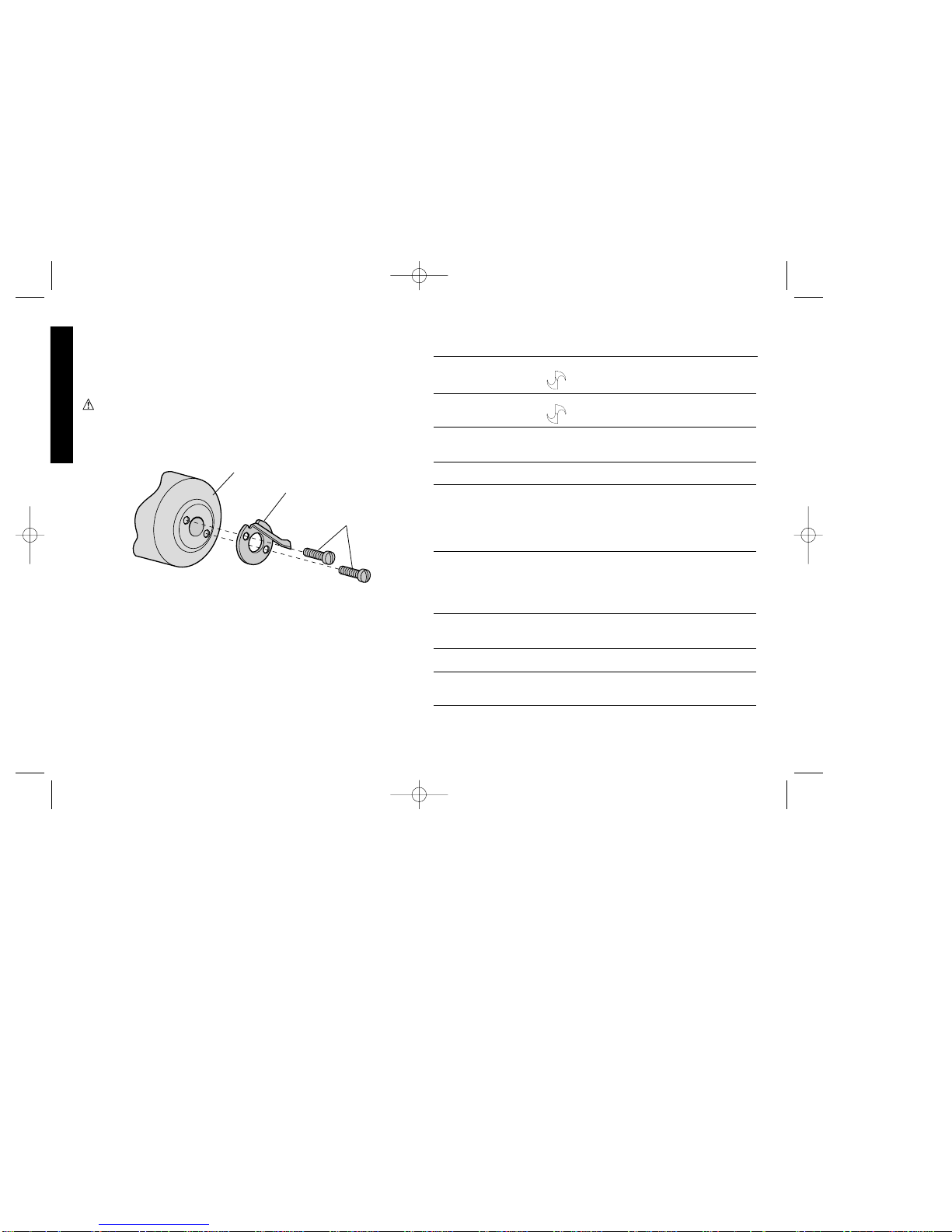

Wheel Replacement

Replace the grinding wheel when it has been worn down from the

original 5" (127 mm) to 4" (102 mm) diameter.

CAUTION: REPLACE A CRACKED WHEEL IMMEDIATELY!

For replacement, use only a D

EWALT 5" (127 mm) x 3/4" (19 mm)

wheel (DW7510). This wheel is designed specifically for this tool.

To replace the grinding wheel:

1. UNPLUG TOOL.

2. Remove 3 screws holding wheel cover and remove cover.

3. Hold wheel with a rag to keep it from turning and remove spindle

nut and clamp washer (LEFT HAND THREAD—TURN NUT

CLOCKWISE). Remove wheel.

4. Move guard band and finger guard to uppermost position (Fig.

27.).

7

English

SH

AR

P

EN

ING

IN

ST

RU

CT

IO

N

S

S

W

I

N

G

H

E

A

D

M

O

D

E

S

E

L

E

C

T

O

R

F

E

E

D

K

N

O

B

L

O

A

D

P

U

S

H

L

A

T

C

H

G

R

I

N

D

T

O

1

/

3

2

"

E

N

T

I

R

E

L

O

C

A

T

O

R

E

D

G

E

T

O

U

C

H

I

N

G

F

L

U

T

E

S

S

D

T

I

G

H

T

E

N

D

R

E

S

S

FIG. 20

FIG. 22

FIG. 23

FIG. 21

SWINGHEAD

SHARPEN/DRESS

SELECTOR

PARTING LINE

MARK

DRESS

KNOB

DIAMOND

DRESSER

DUST

SHIELD

DW751/385103 5/2/02 12:51 PM Page 7

Page 11

8

5. Attach new wheel (Fig. 24) (Note that the wheel is marked to show

which side faces out.) with clamp washer and spindle nut. Hold

wheel with a rag and tighten nut counterclockwise. Do not

overtighten.

6. Adjust guard band and finger guard to about 1/16" (1.6 mm) from

wheel (Fig. 27) and tighten adjusting screws.

7. Replace wheel cover.

8. For best results dress the new wheel with the diamond dresser.

Adjustments

FROM TIME TO TIME ADJUSTMENTS MAY BE NECESSAR Y DUE

TO WEAR OR SEVERE HANDLING OF THE UNIT DURING

SHIPMENT OR MOVEMENT FROM PLACE TO PLACE. SHOULD

ADJUSTMENTS BECOME NECESSARY, THE FOLLOWING

PROCEDURES SHOULD BE FOLLOWED CAREFULLY TO

INSURE PROPER AND SAFE OPERATION OF YOUR

SHARPENER.

UNPLUG TOOL BEFORE MAKING ANY ADJUSTMENTS.

1. Looseness in Pivot Rod Bearing System (Fig. 25.)

A. Set selector lever to “S” (Sharpen).

B. Position swinghead with locator approximately 1/8” (3 mm)

above wheel.

C. Loosen both front bearing gib screws until slight side play in

pivot is evident.

D. While rocking swinghead, adjust back bearing gib screw until

very slight pivoting resistance is felt. Back off screw 1/8 to 1/4

turn.

E. Adjust front bearing top and bottom gib screws evenly, while

rocking swinghead, until slight pivoting resistance is felt.

2. Latch Adjustment (Fig. 26)

A. Move swinghead to sharpening position.

English

FIG. 24

SPINDLE

NUT

CLAMP

WASHER

CHUCK

KNOB

SHARPEN/DRESS

SELECTOR

BACK

BEARING

GIB

SCREW

FRONT

BEARING

GIB

SCREW

(TOP)

FRONT BEARING GIB

SCREW (BOTTOM)

PIVOT ROD

CHUCK

RETAINING

SCREW

SWING-

HEAD

FIG. 25

FEED KNOB

RETAINING SCREW

DW751/385103 5/2/02 12:51 PM Page 8

Page 12

B. Loosen chuck retaining set screw with 1/8" (3 mm) allen wrench

until chuck and detent spring can be removed from swinghead.

C. Adjust latch set screw with 1/16" (1.6 mm) allen wrench so that

swinghead locks firmly into sharpening position.

D. Replace detent spring (note orientation of “U” and “V” shaped

projections) and chuck.

E. Tighten set screw so that chuck is snug in swinghead but can

be easily rotated.

3. Finger Guard and Guard Band (Fig. 27)

Adjust opening between guards and wheel to 1/16" (1.6 mm) by

means of adjusting screws as shown. Maintain clearance as wheel

wears.

NOTE: This sharpener is completely adjusted at the factory.

However, due to rough handling that might occur during shipment,

slight readjustments may be necessary. Please take a few minutes to

check the adjustments of your unit.

9

English

FIG. 26

CHUCK

FELT SEAL

“V” SHAPE UP

DETENT SPRING

“U” SHAPE DOWN

CHUCK

RETAINING

SET SCREW

PLUG

LATCH SET SCREW

SWINGHEAD

CLAMP SCREW

PRESS

FIG. 27

GUARD

BAND

ADJUSTING

SCREW

GRINDING

WHEEL

FINGER GUARD

ADJUSTING

SCREW

FINGER

GUARD

GUARD

BAND

LATCH

1/16”

(1.6 MM)

1/16”

(1.6 MM)

DW751/385103 5/2/02 12:51 PM Page 9

Page 13

10

PROBLEM

1. Chisel angle too great—

greater than 135°

2. Chisel angle too small—

less than 120°

3. Bit will not drill

4. Discoloration (burning)

near cutting lips

5. Flats or chatter marks

on ground surfaces

6. Large variation in lip height

(point off center)

7. Swinghead will not stay

locked in sharpening or

dressing position

8. Hard to pivot swinghead

back and forth

9. Bent locator

10.Unit getting unusually hot

English

Troubleshooting

REMEDY

Bit was not ground close enough to

locator or was positioned incorrectly, See

Step 6 under “Preparing to sharpen.”

Edge of locator was not flat against flute.

See step 6 under “Preparing to sharpen.”

Or bit was ground too close to locator.

Insufficient relief angle. See Step 6

under “Preparing to sharpen,” for proper

positioning of bit.

Material is being removed too fast. Slow

down feed rate.

A. Looseness in pivot rod bearing

system—see adjustments

B. Wheel needs dressing

C. Feed at slower rate

D. Slow down speed of rocking motion

A. Bent bit

B. Looseness in pivot rod bearings—

follow adjustments

C. Unequal hand pressure on

swinghead while sharpening

Latch set screw needs adjustment.

Gib screws adjusted too tight.

Place a 1/8" (3 mm) bit in chuck and

bend locator until the tip is directly over

bit center or replace locator.

Check motor air intake and exhaust

openings on bottom of tool for blockage.

4. The Locator (Fig. 28)

The locator on the chuck of your drill bit sharpener has been

inspected at the factory for proper positioning and assembly. Should

the locator edge become damaged for any reason while grinding

during the initial learning operation of the tool, it is easily replaced

with the extra locator provided.

CAUTION: Tighten screws just enough to seat locator against

chuck. DO NOT OVERTIGHTEN

FIG. 28

CHUCK

LOCATOR

SCREWS

DW751/385103 5/2/02 12:51 PM Page 10

Page 14

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALTheavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

11

English

Maintenance

Self lubricating bearings are used in the tool and periodic

relubrication is not required. However, it is recommended that, once

a year, you take or send the tool to a D

EWALT Service Center for

thorough cleaning and inspection.

STANDARD EQUIPMENT

1. Special grinding wheel with 3° bevel on sharpening surface.

2. Diamond wheel dresser.

3. Extra locator.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or authorized service center.

• Replacement 5" (127 mm) x 3/4" (19 mm) Grinding Wheel

(DW7510)

• Replacement Diamond Dresser (DW 7511).

• Bit Locator (DW 7512).

CAUTION: The use of any non-recommended accessory may be

hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWAL T. This warranty does not apply to accessories or

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

DW751/385103 5/2/02 12:51 PM Page 11

Page 15

12

Importantes mesures de sécurité

AVERTISSEMENT : Afin de réduire les risques d’incendie, de

secousses électriques ou de blessures lorsqu’on utilise des outils

électriques, il faut toujours respecter les mesures de sécurité

suivantes.

LIRE TOUTES LES DIRECTIVES.

Mise à la terre

L’outil devrait être mis à la terre lors de son utilisation afin de protéger

l’utilisateur contre les risques de secousses électriques. L’outil est

doté d’un cordon trifilaire et d’une fiche à trois broches de type mis à

la terre qui s’insère dans une prise mise à la terre. Le conducteur

vert (ou vert et jaune) du cordon est le fil de mise à la terre. Ne

jamais raccorder le fil vert (ou vert et jaune) à une borne sous

tension. Lorsque l’outil est conçu pour recevoir une alimentation de

moins de 150 volts, il est doté d’une fiche semblable à celle illustrée

à la figure A. Lorsque l’outil est conçu pour recevoir une alimentation

variant entre 150 et 250 volts, il est doté d’une fiche semblable à celle

illustrée à la figure D. On peut se procurer un adaptateur (fig. B et

C) pour brancher une fiche semblable à celle de la figure A dans

des prises à deux orifices. Il faut alors relier la tige, la cosse ou le

dispositif similaire de couleur verte à une mise à la terre permanente

(comme une prise bien mise à la terre). Il n’y a pas d’adaptateur pour

Français

S

H

A

R

P

E

N

IN

G

I

N

S

T

R

U

C

T

I

O

N

S

S

W

IN

G

H

E

A

D

M

O

D

E

S

E

L

E

C

T

O

R

F

E

E

D

K

N

O

B

L

O

A

D

P

U

S

H

L

A

T

C

H

G

R

I

N

D

T

O

1

/3

2

"

ENTIRE

LOCATOR EDGE

TOUCHING

FLUTE

SÉLECTEUR -

AFFÛTE-FORET OU

DÉCRASSE-MEULE

BOUTON

D’ALIMENTATION

TÊTE PIVOTANTE

MANCHON-REVOLVER

MANDRIN

POSITIONNEUR

MEULE

LOQUET

ÉCRAN

PROTECTEUR

COUVERCLE

DE LA MEULE

BOUTON

DU DÉCRASSE-

MEULE

ÉCRAN

ANTIPOUSSIÈRE

DÉCRASSE-

MEULE DIAMANT

VIS DE RÉGLAGE

DE LA BANDE

DE PROTECTION

INTERRUPTEUR

DU MOTEUR

AB CD

BROCHE DE PRISE

MISE À LA TERRE

BROCHE DE MISE À

LA TERRE

PRISE MISE

À LA TERRE

DISPOSITIF DE

MISE À LA TERRE

ADAPTATEUR

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO :

1 800 4-DEWALT (1 800 433-9258).

DW751/385103 5/2/02 12:51 PM Page 12

Page 16

la fiche illustrée à la figure D. L’ADAPTATEUR ILLUSTRÉ AUX

FIGURES B ET C NE PEUT PAS ETRE UTILISÉ AU CANADA.

Mesures de sécurité pour tous les outils

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail. Ne pas se

servir de l’outil en présence de liquides ou de vapeurs

inflammables.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à

l’outil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr

et efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste. Se servir de l’outil selon l’usage prévu.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue.

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne

pas transporter l’outil par le cordon ni tirer sur ce dernier pour le

débrancher de la prise. Éloigner le cordon des sources de chaleur,

des flaques d’huile et des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides

ou d’un étau. On peut alors se servir des deux mains pour faire

fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et

affûtés pour qu’ils donnent un rendement supérieur et sûr. Suivre

les directives concernant la lubrification et le remplacement des

accessoires. Inspecter régulièrement le cordon de l’outil et le faire

réparer au besoin à un atelier d’entretien autorisé. Inspecter

régulièrement les cordons de rallonge et les remplacer lorsqu’ils

sont endommagés. S’assurer que les poignées sont toujours

propres, sèches et libres de toute tache d’huile ou de graisse.

• DÉBRANCHER OU VERROUILLER EN POSITION HORS

TENSION LES OUTILS NON UTILISÉS. Respecter cette mesure

lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer ou en

changer un accessoire (comme une lame, un foret ou un couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de

vérifier si les clés de réglage ont été retirées avant de faire

démarrer l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

• CORDONS DE RALLONGE. Utiliser seulement des cordons de

rallonge trifilaires ayant une fiche à 3 broches ainsi qu’une prise à

3 trous acceptant la fiche de l’outil. Remplacer ou réparer les

cordons de rallonge endommagés. S’assurer que le cordon de

rallonge est en bon état. Lorsqu’on se sert d’un cordon de

rallonge, s’assurer qu’il est de calibre approprié pour la tension

nécessaire au fonctionnement de l’outil. L’utilisation d’un cordon

13

Français

DW751/385103 5/2/02 12:51 PM Page 13

Page 17

14

de calibre inférieur occasionne une baisse de tension entraînant

une perte de puissance et la surchauffe. Le tableau suivant

indique le calibre approprié selon la longueur du cordon et les

mentions de la plaque signalétique de l’outil. En cas de doute,

utiliser un cordon de calibre supérieur. Le chiffre indiquant le

calibre est inversement proportionnel au calibre du cordon.

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Faire

réparer ou remplacer tout protecteur ou toute autre pièce

endommagée dans un centre de service autorisé, sauf si le

présent guide fait mention d’un avis contraire. Confier le

remplacement de tout interrupteur défectueux à un centre de

service autorisé. Ne jamais se servir d’un outil dont l’interrupteur

est défectueux.

Mesures de sécurité additionnelles

relatives aux affûte-forets

AVERTISSEMENT: Cet outil professionnel est conçu pour affûter

rapidement et précisément des forets hélicoïdaux à 2 goujures et

à filet à droite de 3 mm (1/8 po) à 13 mm (1/2 po) de diamètre. NE

PAS tenter d’affûter des forets au carbure ou au cobalt. Puisqu ’il faut

respecter les consignes afin d’obtenir des résultats satisfaisants, lire

attentivement les directives relatives au fonctionnement et, par un

surcroît de protection, accorder une attention particulière aux

mesures de sécurité.

• Porter des lunettes de sécurité.

• Utiliser la meule appropriée au régime de l’outil.

• Remplacer immédiatement une meule craquée. Manipuler les

meules avec soin en évitant de les frapper ou de les échapper. NE

PAS se servir d’une meule qui est tombée. Avant de s’en servir,

vérifier chaque meule afin de s’assurer qu’elle ne comporte aucun

craque ni défaut. Le cas échéant, jeter la meule.

• Toujours utiliser des protecteurs et des écrans protecteurs.

S’assurer que les écrans protecteurs sont bien installés.

• Éviter de trop serrer l’écrou de la meule. Avant d’installer une

nouvelle meule, s’assurer que la vitesse nominale de la meule est

égale ou supérieure à la vitesse sous vide indiquée sur la plaque

signalétique de l’outil.

• Utiliser seulement les brides fournies avec l’outil.

• Boulonner l’affûte-foret à un établi afin d’en empêcher le

déplacement.

• Régler la distance entre la meule et les protecteurs de sorte qu’il y

ait un jeu maximal de 1,6 mm (1/16 po) puisque le diamètre de la

meule décroît à l’usage.

• Utiliser les accessoires seulement de manière appropriée.

CONSERVER CES MESURES.

Français

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

DW751/385103 5/2/02 12:51 PM Page 14

Page 18

Précisions sur les forets

Une exigence primordiale pour l’obtention de trous percés avec

précision consiste à ce qu’il y ait une différence minimale entre les

hauteurs des arêtes de coupe des deux goujures. Une variation

entre les hauteurs des arêtes de coupe nuit au centrage du point qui

procure le perçage excentrique (fig. 1, 2 et 3). Consulter le

paragraphe 6 du guide de dépannage du présent guide. L’affûte-

foret D

EWALT est conçu pour procurer des hauteurs d’arêtes de

coupe égales et un point central.

Montage de l’affûte-foret

AFIN D’OPTIMISER LES RÉSULTATS, INSTALLER L’AFFÛTEFORET SUR UNE SURFACE DE TRAVAIL SOLIDE. Percer deux

trous de 8 mm (5/16 po) dans l’établi (fig. 4). Y insérer deux boulons

à tête bombée de 6 mm (1/4 po) de diamètre. Faire glisser les têtes

des boulons dans les trous qui se trouvent sur la face inférieure de

l’affûte-foret (fig. 5). Serrer les écrous sur les boulons uniformément

en exerçant une force modérée. Éviter de trop serrer!

Principales composantes

de l’affûte-foret

MISE EN GARDE :

• Prendre garde - connaître et respecter toutes les MESURES DE

SÉCURITÉ.

• S’assurer que le positionneur est loin de la meule avant de

démarrer l’outil.

• Exercer une pression légère et imprimer un mouvement uniforme

lorsqu’on balance la tête pivotante pour l’affûtage.

• Lorsqu’on passe du mode d’AFFÛTE-FORET à celui de DÉCRASSE-

MEULE, et vice versa, respecter les consignes avec soin.

• Remplacer immédiatement une meule craquée.

• Ne jamais démonter l’outil ni en refaire le filage du système

électrique.

15

Français

FIG. 4

FIG. 1

FIG. 2

(122,2 mm)

Contour de l'outil

Devant

42,5 mm

3 1/4 po

4 13/16 po

FIG. 5

ANGLE

D’HÉLICE

FIG. 3

ANGLE DE L’ARÊTE

CENTRALE DE 120°

À 135°

ANGLE DE LA POINTE

COMPRIS 118°

ANGLE

DE DÉPOUILLE

GOUJURE

LONGUEUR TAILLÉE

ÂME

ARÊTE

DE COUPE

FRONTALE

DW751/385103 5/2/02 12:51 PM Page 15

Page 19

16

Le sélecteur du mode de fonctionnement programme l’outil pour

affûter les forets ou pour décrasser les meules. Le bouton

d’alimentation procure la précision du taux d’alimentation

(enlèvement du matériau) lors de l’affûtage. Le manchon-revolver

permet d’affûter d’abord un côté d’un foret, puis l’autre sans retirer

le foret du mandrin. La tête pivotante permet de déplacer le foret le

long de la meule continuellement à l’angle approprié. Le mandrin

retient le foret en place pendant l’affûtage. Le positionneur guide

l’emplacement du foret de façon à assurer un affûtage correct et

précis.

Sélecteur pour l’affûte-foret

ou le décrasse-meule

(Fig. 6, 7, 8, 9 et 10)

Pour affûter un foret, le sélecteur doit se trouver à la position “S”

(pour affûter). La position “D” (pour décrasser) sert pour décrasser

les meules.

IMPORTANT : Lorsque le changement de mode de

fonctionnement est mal fait, cela présente des risques de

dommage à l’outil, et cela peut même le rendre inopérant. Les

méthodes de changement appropriées sont illustrées.

PASSAGE DU MODE “S” (AFFÛTE-FORET) AU MODE “D”

(DÉCRASSE-MEULE)

NOTE : Exécuter l’étape1 avant de passer à l’étape 2. Sinon, la tête

pivotante ne se déplace pas vers le haut jusqu’à l’écran protecteur.

1. Faire tourner la tête en position d’affûtage normale (fig. 6).

2. Faire tourner la tête jusqu’à ce qu’elle touche à l’écran protecteur

(fig. 7).

3. Déplacer le sélecteur à la position “D” (fig. 8).

PASSAGE DU MODE “D” (DÉCRASSE-MEULE) AU MODE “S”

(AFFÛTE-FORET)

Français

FIG. 6 FIG. 7

FIG. 9

D

S

H

A

R

P

E

N

I

N

G

I

N

S

T

R

U

C

T

I

O

N

S

L

O

A

D

G

R

I

N

D

T

O

1

/

3

2

"

FIG. 8

S

S

H

A

R

P

E

N

I

N

G

I

N

S

T

R

U

C

T

I

L

O

A

D

FIG. 10

PLAN DE JOINT

DU MOULE

MARQUE

DW751/385103 5/2/02 12:51 PM Page 16

Page 20

1. Aligner la marque du bouton du décrasse-meule sur le plan de

joint du moule. Placer la tête pivotante près de l’écran protecteur

(fig. 9).

2. Déplacer le sélecteur à la position “S”. NE PAS FORCER.

Lorsque le sélecteur ne s’enfonce pas en place, faire basculer le

bouton du décrasse-meule de l’avant vers l’arrière tout en

exerçant une légère pression sur le sélecteur jusqu’à ce qu’il

s’enclenche en place (fig. 10).

Affûtage de forets

(Fig. 11, 12, 13, 14, 15 et 16)

PRÉPARATIFS EN VUE DE L’AFFÛTAGE

NOTE : D’abord, il faut vérifier les réglages de l’outil mentionnés à

la rubrique “Réglage” du présent guide.

1. La tête pivotante comporte deux positions, à 180° l’une de l’autre.

Faire tourner le manchon pour s’assurer qu’il est bien enclenché, avec

le positionneur dans l’emplacement supérieur. S’assurer que le

sélecteur du dessus de l’outil se trouve à la position “S” (affûtage)

(fig. 11).

2. Enfoncer le loquet vers la tête pivotante et déplacer la tête vers

la position de chargement (fig. 12).

3. Ouvrir les mâchoires du mandrin en faisant tourner l’écrou du

mandrin dans le sens antihoraire (fig. 13).

4. Insérer les forets de petits diamètres au-delà du positionneur,

directement dans le mandrin (fig. 14).

5. Insérer les forets de grands diamètres dans l’ouverture du

mandrin (fig. 15).

6. Placer le foret de sorte que la pointe se trouve à environ 1,6 mm

(1/16 po) sous l’extrémité du positionneur. S’assurer que le

rebord droit à l’extrémité du positionneur repose à plat contre la

goujure. On obtient des résultats satisfaisants lorsqu’on place

bien le foret dans le positionneur (fig. 16).

17

Français

FIG. 11

FIG. 12

FIG. 14

FIG. 13

FIG. 15

FIG. 16

DW751/385103 5/2/02 12:51 PM Page 17

Page 21

18

AFFÛTAGE DE LA PREMIÈRE ARÊTE DE COUPE

FRONTALE (FIG. 17, 18 ET 19)

NOTE : Il est plus aisé d’affûter un foret brisé lorsqu’on le façonne

d’abord à la main à l’aide d’une meuleuse d’établi. On élimine de la

sorte l’usure inutile de la meule.

1. Lorsque le moteur se trouve en position d’arrêt (OFF), abaisser

la tête pivotante à la position d’affûtage (fig. 17).

2. Faire tourner le bouton d’alimentation dans le sens horaire jusqu’à

ce que le foret touche presque à la meule lorsqu’on bascule la tête

de l’avant vers l’arrière (fig. 18).

NOTE : Lorsqu’on fait tourner le bouton d’alimentation dans le sens

horaire, le foret avance sur la meule; dans le sens antihoraire, on

éloigne le foret de la meule.

3. Pour mettre le moteur en marche (ON), faire basculer doucement la

tête pivotante tout en faisant tourner le bouton d’alimentation dans le

sens horaire. NE PAS EXERCER UNE FORTE PRESSION

MANUELLE SUR LA TÊTE LORSQU’ON LA FAIT BASCULER.

IMPORTANT : Lorsqu’on avance le bouton d’alimentation d’un

cran (de 2 à 3, par exemple), le foret se déplace de 5 millièmes de

pouce vers la meule. Chaque degré (marque) entre les chiffres

correspond à un déplacement de 1 1/4 millième du foret

4. Tout en déplaçant le bouton d’alimentation d’un cran (marque) à

la fois, continuer de faire basculer la tête pivotante le long de la

meule jusqu’à ce que l’arête du foret se trouve à environ 0,8 mm

(1/32 po) de l’extrémité du positionneur. PRENDRE GARDE DE

NE PAS AFFÛTER LE POSITIONNEUR.

IMPORTANT : Prendre note du dernier réglage du bouton

d’alimentation car on en a besoin pour affûter la deuxième arête.

5. Puis faire tourner le bouton d’alimentation dans le sens antihoraire

de plusieurs tours afin d’éloigner le foret de la meule.

6. Abaisser la tête pivotante vers l’arrière en position de repos

illustrée. Faire tourner le manchon sur 180° dans le sens horaire

jusqu’à ce qu’il s’enclenche dans la deuxième position. (Le

positionneur se trouve alors sous le mandrin (fig. 19).)

Français

FIG. 17

FIG. 18

FIG. 19

MANCHON

FAIRE TOURNER LE MANCHON SUR 180°.

DW751/385103 5/2/02 12:51 PM Page 18

Page 22

AFFÛTAGE DE LA DEUXIÈME ARÊTE DE COUPE FRONTALE

1. Répéter les étapes 3 et 4 de la rubrique “Affûtage de la première

arête de coupe frontale”.

2. CESSER D’AFFÛTER LORSQUE LE BOUTON

D’ALIMENTATION ATTEINT LE DEGRÉ NOTÉ

PRÉCÉDEMMENT.

Afin d’obtenir un fini satiné, faire tourner le bouton d’alimentation

d’un autre degré et affûter le foret. Sans toucher au bouton

d’alimentation, faire tourner le manchon sur 180° dans le sens

horaire (étape 6 à la page 18) et affûter la première arête jusqu’à

ce qu’il n’y ait plus de production d’étincelles.

3. Arrêter le moteur (OFF). Soulever la tête pivotante à la position

de chargement et retirer le foret.

MISE EN GARDE : Le bout du foret peut être brûlant.

Décrasse-meule (Fig. 20, 21 et 22)

La meule spéciale fournie avec l’affûte-foret DEWALT est prête à

servir. Lorsque ses surfaces d’affûtage deviennent usées et

inégales, il faut décrasser la meule. Faire ce qui suit.

IMPORTANT: Voir les directives pour passer du mode“S” (affûte-

foret) au mode “D” (décrasse-meule) sous la rubrique relative au

sélecteur. Après avoir respecté les consignes appropriées, faire ce

qui suit.

1. Enfoncer le loquet et déplacer la tête à la position de chargement.

2. Prendre le décrasse-meule diamant qui se trouve dans une pince

à ressort à l’arrière de l’affûte-foret. En retirer le manchon

protecteur. Placer l’écran antipoussière de la façon illustrée plus

bas. Placer le décrasse-meule diamant dans le mandrin en

plaçant la pointe diamant à 1,6 mm (1/16 po) au-dessus du

positionneur comme le montre la figure. Serrer les mâchoires du

mandrin en faisant tourner l’écrou du mandrin dans le sens

horaire. Faire glisser l’écran antipoussière vers le haut contre la

19

Français

S

H

A

RP

E

N

IN

G

IN

S

TR

U

C

TION

S

S

W

I

N

G

H

E

A

D

M

O

D

E

S

E

L

E

C

T

O

R

F

E

E

D

K

N

O

B

L

O

A

D

P

U

S

H

L

A

T

C

H

G

R

I

N

D

T

O

1

/

3

2

"

E

N

T

I

R

E

L

O

C

A

T

O

R

E

D

G

E

T

O

U

C

H

I

N

G

F

L

U

T

E

S

S

D

T

I

G

H

T

E

N

D

R

E

S

S

FIG. 22

FIG. 23

TÊTE

PIVOTANTE

SÉLECTEUR - AFFÛTE-FORET

OU DÉCRASSE-MEULE

PLAN DE JOINT

DU MOULE

MARQUE

BOUTON

DU DÉCRASSE-

MEULE

MEULE

DIAMANT

ÉCRAN

ANTIPOUSSIÈRE

DW751/385103 5/2/02 12:51 PM Page 19

Page 23

20

face du mandrin afin d’empêcher les saletés et la poussière

d’encrasser le mandrin (fig. 20 et 21).

3. Déplacer la tête pivotante vers le bas jusqu’à ce que le loquet

s’enclenche. Régler le bouton d’alimentation dans le sens horaire

jusqu’à ce que la pointe diamant touche presque la surface

d’affûtage de la meule.

4. En exerçant une LÉGÈRE PRESSION, pousser la tête pivotante

vers l’arrière et loin de l’écran protecteur jusqu’à ce qu’elle

s’arrête.

5. Faire démarrer le moteur. Exercer une légère pression, en

éloignant la tête de l’écran protecteur. Déplacer le diamant vers

l’avant et l’arrière sur la meule en faisant tourner le bouton du

décrasse-meule dans les sens horaire et antihoraire. Faire

avancer le diamant sur la meule en faisant tourner le bouton

d’alimentation, dans le sens horaire, d’un cran à la fois. On

obtient un fini satiné en imprimant un mouvement uniforme et

continu sur toute la face de la meule. On risque de marquer la

meule en y arrêtant le diamant. Le fini sera encore plus satiné si

on enlève le matériau de la meule lors du mouvement extérieurintérieur du diamant (fig. 22).

6. Arrêter le moteur. Éloigner le bouton d’alimentation (dans le sens

antihoraire) suffisamment pour éloigner le diamant de la surface

d’affûtage de la meule. Remettre la tête pivotante en position de

chargement. Enlever le décrasse-meule diamant et l’écran

antipoussière.

PASSAGE DU MODE “D” (DÉCRASSE-MEULE) AU MODE “S”

(AFFÛTE-FORET)(FIG. 23)

1. Aligner le bouton du décrasse-meule sur le plan de joint du moule.

2. Déplacer la tête pivotante près de l’écran protecteur.

3. Déplacer le sélecteur à la position “S”. NE PAS FORCER.

Lorsque le sélecteur ne s’enfonce pas en place, vérifier la position

de la marque du bouton du décrasse-meule.

Remplacement de la meule

Il faut remplacer la meule lorsqu’elle passe de son diamètre original

de 127 mm (5 po) à un diamètre de 102 mm (4 po).

MISE EN GARDE : REMPLACER IMMÉDIATEMENT UNE

MEULE CRAQUÉE!

Utiliser seulement une meule de rechange D

EWALT de 127 mm

(5 po) sur 19 mm (3/4 po) (modèle DW7510). Cette meule a été

spécialement conçue pour l’outil.

Faire ce qui suit pour remplacer la meule.

1. DÉBRANCHER L’OUTIL.

2. Retirer les trois vis retenant le couvercle de la meule et enlever ce

dernier.

3. Retenir la meule à l’aide d’un chiffon afin de l’empêcher de bouger

et retirer l’écrou de l’arbre ainsi que la rondelle de serrage (FILET

À GAUCHE - FAIRE TOURNER L’ÉCROU DANS LE SENS

HORAIRE). Enlever la meule.

4. Déplacer la bande de protection et le protège-doigts dans la

position supérieure (fig. 27).

5. Fixer la nouvelle meule (fig. 24) (prendre note que la meule porte

une mention indiquant quelle face va vers l’extérieur) à l’aide de la

rondelle de serrage et de l’écrou de l’arbre. Retenir la meule à

l’aide d’un chiffon et serrer l’écrou dans le sens antihoraire. Éviter

de trop serrer.

6. Régler la bande de protection et le protège-doigts à environ

1,6 mm (1/16 po) de la meule (fig. 27) et serrer les vis de réglage.

7. Remettre le couvercle de la meule en place.

8. Afin d’optimiser les résultats, se servir du décrasse-meule

diamant pour décrasser la nouvelle meule.

Réglages

DE TEMPS À AUTRE, IL FAUT RÉGLER L’OUTIL EN RAISON DE

L’USURE OU DU MAUVAIS TRAITEMENT INFLIGÉ À L’OUTIL

Français

DW751/385103 5/2/02 12:51 PM Page 20

Page 24

PENDANT LE TRANSPORT OU LE DÉPLACEMENT D’UN

ENDROIT À UN AUTRE. LE CAS ÉCHÉANT, FAIRE CE QUI SUIT

AVEC SOIN AFIN DE S’ASSURER DU FONCTIONNEMENT SÛR

ET APPROPRIÉ DE L’OUTIL.

DÉBRANCHER L’OUTIL AVANT DE LE RÉGLER.

1. Jeu dans le système de support de la tige de rotation (fig. 25)

A. Régler le levier du sélecteur à la position “S” (affûter).

B. Placer la tête pivotante avec le positionneur à environ 3 mm

(1/8 po) au-dessus de la meule.

C. Desserrer les deux vis à talon du roulement avant jusqu’à ce

qu’on obtienne un très léger jeu latéral de la tige.

D. Tout en basculant la tête pivotante, régler la vis à talon du

roulement arrière jusqu’à ce qu’on obtienne une très légère

résistance à la rotation. Reculer la vis de 1/8 à 1/4 tour.

E. Régler uniformément les vis supérieure et inférieure du

roulement avant tout en basculant la tête pivotante, jusqu’à ce

qu’on ressente une légère résistance à la rotation.

2. Réglage du loquet (fig. 26)

A. Déplacer la tête pivotante à la position d’affûtage.

B. Desserrer la vis de pression du mandrin à l’aide d’une clé

hexagonale de 3 mm (1/8 po) jusqu’à ce que le mandrin et le

ressort de détente puissent être enlevés de la tête pivotante.

C. Régler la vis de pression du loquet avec une clé hexagonale de

1,6 mm (1/16 po) de sorte à verrouiller fermement la tête

pivotante en position d’affûtage.

D. Remettre le ressort de détente (remarquer le sens des formes

en “U” et en “V”) et le mandrin en place.

E. Serrer la vis de pression de sorte que le mandrin soit tout

contre la tête pivotante mais qu’on puisse facilement le faire

tourner.

3. Protège-doigts et bande de protection (fig. 27)

21

Français

FIG. 24

ÉCROU

DE L’ARBRE

RONDELLE

DE SERRAGE

BOUTON

DU MANDRIN

SÉLECTEUR AFFÛTE-FORET OU

DÉCRASSE-MEULE

VIS À TALON

DU ROULEMENT

ARRIÊRE

VIS À TALON

DU ROULEMENT

AVANT

(SUPÉRIEURE)

VIS À TALON DU ROULEMENT

AVANT (INFÉRIEURE)

TIGE DE ROTATION

VIS

DE RETENUE

DU MANDRIN

TÊTE

PIVOTANTE

FIG. 25

VIS DE RETENUE

DU BOUTON

D’ALIMENTATION

DW751/385103 5/2/02 12:51 PM Page 21

Page 25

22

Français

MANDRIN

RONDELLE

DE FEUTRE

FORME EN “V”

VERS LE HAUT

RESSORT

DE DÉTENTE

FORME EN “U”

VERS LE BAS

VIS

DE PRESSION

DU MANDRIN

FICHE

VIS DE PRESSION

DU LOQUET

VIS DE SERRAGE

DE LA TÊTE

PIVOTANTE

ENFONCER

LOQUET

FIG. 27

FIG. 26

VIS DE RÉGLAGE

DE LA BANDE

DE PROTECTION

MEULE

VIS DE RÉGLAGE

DU PROTÈGE-DOIGTS

PROTÈGE-

DOIGTS

BANDE

DE PROTECTION

1,6 mm (1/16 po )

1,6 mm (1/16 po )

DW751/385103 5/2/02 12:51 PM Page 22

Page 26

Régler l’ouverture entre les protecteurs et la meule à 1,6 mm

(1/16 po) à l’aide des vis de réglage de la façon illustrée. Maintenir

un jeu à mesure que la meule s’use.

NOTE : L’affûte-foret est complètement réglé en usine. T outefois, en

raison d’une rude manipulation qui peut se produire pendant le

transport, il peut être nécessaire de le régler légèrement de nouveau.

Prendre quelques minutes afin de vérifier les réglages de l’outil.

4. Le positionneur (fig. 28)

Le positionneur du mandrin de l’affûte-foret a été inspecté en usine

afin de s’assurer de sa bonne position et de son montage correct. En

cas de dommage à l’arête du positionneur pendant l’affûtage lors de

l’apprentissage du fonctionnement de l’outil, on peut facilement le

remplacer avec le positionneur supplémentaire fourni.

MISE EN GARDE : Serrer les vis suffisamment pour faire reposer

le positionneur contre le mandrin. ÉVITER DE TROP SERRER.

PROBLÈME

1. Angle de l’arête centrale trop

grand — supérieur à 135°

2. Angle de l’arête centrale trop petit

—inférieur à 120°

3. Foret ne perçant pas

4.

Décoloration (brûlures)

près des arêtes de coupe frontales

5.

Côtés plats ou facettes de rectification

sur les surfaces affûtées

6. Grande différence de la hauteur

des arêtes (point décentré)

7.

Tête pivotante ne restant pas

verrouillée en position d’affûte-foret

ou de décrasse-meule

8. Tête pivotante difficile à faire

basculer

9. Positionneur plié

10.Outil inhabituellement chaud

SOLUTION

Le foret n’a pas été affûté suf fisamment près

du positionneur ou il était mal placé. Voir

l’étape 6 des préparatifs en vue de l’affûtage.

L’arête du positionneur ne reposait pas

à plat contre la goujure. Voir l’étape6 des

préparatifs en vue de l’affûtage. Ou, le

foret était trop près du positionneur.

Angle de dépouille insuffisant. Voir

l’étape 6 des préparatifs en vue de

l’affûtage afin de bien placer le foret.

Matériau enlevé trop rapidement.

Diminuer le taux d’alimentation.

A. Jeu dans le système de support de la

tige de rotation - voir la rubrique

“réglages”.

B. Il faut décrasser la meule.

C. Ralentir le taux d’alimentation.

D. Ralentir le mouvement de rotation.

A. Foret plié.

B. Jeu dans le système de support de la

tige de rotation - respecter les

consignes de réglage.

C. Pression manuelle inégale sur la

tête pivotante pendant l’affûtage.

Réglage nécessaire de la vis de

pression du loquet.

Vis à talon trop serrées.

Placer un foret de 3 mm (1/8 po) dans le

mandrin et plier le positionneur jusqu’à ce que

l’extrémité se trouve directement au-dessus du

centre du foret ou remplacer le positionneur.

Vérifier si l’admission d’air du moteur et

les évents sous l’outil sont obstrués.

23

Français

MANDRIN

POSITIONNEUR

VIS

FIG. 28

Guide de dépannage

DW751/385103 5/2/02 12:51 PM Page 23

Page 27

24

Entretien

L’outil comporte des roulements autolubrifiés qui ne nécessitent

aucune lubrification périodique. Toutefois, il est conseillé de confier

l’outil, une fois l’an, au personnel d’un centre de service D

EWALT

pour qu’il y soit complètement nettoyé et inspecté.

ÉQUIPEMENT STANDARD

1. Meule spéciale avec un biseau de 3° sur la surface d’affûtage.

2. Décrasse-meule diamant.

3. Positionneur supplémentaire.

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément

chez les détaillants et au centre de service de la région.

• Meule de rechange de 127 mm (5 po) sur 19 mm (3/4 po)

(modèle DW7510)

• Décrasse-meule diamant de rechange (modèle DW7511).

• Positionneur de foret (modèle DW7512).

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’au personnel d’un

centre de service D

EWALT ou d’un atelier d’entretien autorisé

n’utilisant que des pièces de rechange identiques.

Garantie complète

Les outils industriels de service intensif DEWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Pour obtenir de

plus amples renseignements sur les réparations couvertes par la

garantie, composer le 1 (800) 4-D

EWALT (! (800) 433-9258). La ga

rantie ne couvre pas les accessories ni les réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L’utilisateur peut également

se prévaloir d’autres droits selon l’état ou la province qu’il habite.

En outre, la garantie suivante couvre les outils D

EWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

D

EWALT ne donne pas entière satisfaction, il suffit de le retourner

chez le marchand participant dans les 30 jours suivant la date

d’achat afin d’obtenir un remboursement complet. Il faut retourner,

port payé, l’outil complet. On peut exiger une preuve d’achat.

Français

Imported by / Importé par

DeWalt Industrial Tools of Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

DW751/385103 5/2/02 12:51 PM Page 24

Page 28

25

Español

S

H

A

R

P

E

N

I

N

G

I

N

S

T

R

U

C

T

I

O

N

S

S

W

IN

G

H

E

A

D

M

O

D

E

S

E

L

E

C

T

O

R

F

E

E

D

K

N

O

B

L

O

A

D

P

U

S

H

L

A

T

C

H

G

R

IN

D

T

O

1

/3

2

"

ENTIRE

LOCATOR EDGE

TOUCHING

FLUTE

SELECTOR

DE MODO

PERILLA

DE ALIMENTACION

INDICE

CABEZA MOVIL

PORTABROCA

BUSCADOR

PIEDRA

DE ESMERIL

SEGURO

PROTECTOR

OCULAR

CUBIERTA

DE LA PIEDRA

PERILLA

DE DESBASTE

PROTECTOR

DE POLVO

DESBASTADOR

DE DIAMANTE

TORNILLO DE AJUSTE

DE LA BANDA

DE LA GUARDA

INTERRUPTOR

DE ENCENDIDO

Y APAGADO

DEL MOTOR

ESPECIFICACIONES

2,2 A

120V AC ˜60 Hz

3600 RPM

AB CD

PATA DE

CONEXION A

TIERRA

PATA DE

CONEXION A

TIERRA

TOMA DE

CORRIENTE

ATERRIZADA

MEDIO DE

ATERRIZAJE

ADAPTADOR

Instrucciones importantes de seguridad

ADVERTENCIA: Es indispensable sujetarse a las precauciones

básicas de seguridad, con la finalidad de reducir el peligro de

incendio, choque eléctrico y lesiones personales, en todas las

ocasiones en que se utilicen herramientas eléctricas. entre estas

precauciones se incluyen las siguientes.

LEA TODAS LAS INSTRUCCIONES

Instrucciones de aterrizaje

Esta herramienta debe conectarse a tierra para proteger al operador

de choques eléctricos. Esta unidad está equipada con un cordón

eléctrico de tres hilos y una clavija para aterrizaje de tres patas para

conectarse a la toma de corriente adecuada. El conductor verde (o

verde y amarillo) es el cable de tierra. Nunca conecte el cable verde

(o verde y amarillo) a una terminal viva. Si su unidad está hecha para

funcionar con menos de 150 volts, tiene una clavija similar a la que se

muestra en la figura A. Si es para usarse con corriente de 150 a 250

volts, tiene una clavija como la que se muestra en la figura D. Hay

adaptadores, figuras B y C, para conectar clavijas del tipo de la figura

A a tomas de corriente para dos patas. La oreja de color verde deberá

conectarse a tierra permanente, tal como una toma de corriente

aterrizada adecuadamente. No hay adaptadores para clavijas como la

de la figura D. EL ADAPTADOR MOSTRADO EN LAS FIGURAS B Y

C NO ESTA HECHO PARA USARSE EN CANADA.

SI TIENE CUALQUIER PREGUNTA O COMENTARIO ACERCA DE

ESTA O CUALQUIER OTRA HERRAMIENTA D

EWAL T, POR F AVOR

LLÁMENOS AL: 326-7100

DW751/385103 5/2/02 12:51 PM Page 25

Page 29

26

• NO MALTRATE EL CABLE. Nunca levante la herramienta por el

cordón ni tire de éste para desconectarlo del enchufe. Apártelo de

calor, aceite y bordes cortantes.

• SUJETE FIRMEMENTE LOS OBJETOS SOBRE LOS QUE

TRABAJE. Utilice prensas o tornillos de banco para sujetar bien

los objetos sobre los que va a trabajar. Esto ofrece mayor

seguridad que sujetar los objetos con la mano, y además deja

libres ambas manos para operar la herramienta.

• NO SE SOBREEXTIENDA. Conserve en todo momento bien

apoyados los pies, lo mismo que el equilibrio.

• CUIDE BIEN SUS HERRAMIENTAS.Conserve sus herramientas

bien afiladas y limpias para que funcionen mejor y con mayor

seguridad. Obedezca las instrucciones de lubricación y cambio

de accesorios. Inspeccione los cordones eléctricos con frecuencia

y, si los encuentra dañados, hágalos cambiar o reparar en un

centro de servicio autorizado. Revise también con frecuencia las

extensiones eléctricas y reemplácelas si están dañadas. Conserve

los mangos secos, limpios y libres de aceites y grasas.

• DESCONECTE O APAGUE LAS HERRAMIENTAS. Hágalo

cuando no las emplee, antes de darles servicio y cuando vaya a

cambiarles accesorios como seguetas, discos, brocas y otros

dispositivos de corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera

el hábito de asegurarse de que se han retirado las llaves de ajuste

de la herramienta antes de accionarla.

• EVITE QUE LA HERRAMIENTA SE ACCIONE

ACCIDENTALMENTE. Nunca sostenga una herramienta con el

dedo en el interruptor si se encuentra conectada a la corriente

eléctrica. Asegúrese que el interruptor está en la posición de

"apagado" antes de conectarla.

• CABLES DE EXTENSION. Asegúrese que su extensión esté en

buenas condiciones. Cuando utilice una extensión, asegúrese de

que tenga el calibre suficiente para soportar la corriente necesaria

para su producto. Una extensión con calibre menor al necesario

Español

Instrucciones de seguridad

para todas las herramientas

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

• OTORGUE PRIORIDAD AL AMBIENTE DE TRABAJO. No deje

las herramientas eléctricas expuestas a la lluvia. No las utilice en

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el

contacto corporal con superficies aterrizadas, por ejemplo,

tuberías, radiadores, antenas y gabinetes de refrigeración.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que los

visitantes toquen las herramientas o los cables de extensión. Los

visitantes deben estar alejados del área de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las

herramientas que no se están utilizando deben guardarse en un

lugar seco y elevado o bajo llave, fuera del alcance de los niños.

• NO FUERCE LA HERRAMIENTA.Esta cumplirá su función mejor

y con más seguridad a la velocidad y la presión para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta pequeña o a sus dispositivos de montaje en un

trabajo de tipo pesado. No emplee la herramienta en una tarea

para la que no se diseñó; por ejemplo, no recurra a una sierra

circular para cortar ramas o troncos de árbol.

•

VISTASE DE LA MANERA ADECUADA. No tenga puestas ropas o

artículos de joyería flojos, pues podrían quedar atrapados por las

partes móviles de las herramientas. Se recomienda el empleo de

guantes de caucho y calzado antiderrapante cuando se trabaja al aire

libre. Cúbrase bien la cabeza para sujetarse el pelo si lo tiene largo.

• COLOQUESE ANTEOJOS DE SEGURIDAD. Póngase también

una mascarilla contra el polvo si lo produce la operación de corte

que va a efectuar.

DW751/385103 5/2/02 12:51 PM Page 26

Page 30

causará una caída en el voltaje de la línea, resultando en pérdida

de potencia y sobrecalentamiento. El cuadro siguiente muestra los

calibres correctos para usarse de acuerdo con la longitud de la

extensión y el amperaje especificado. Si tiene dudas, utilice el

calibre siguiente, más pesado. Cuanto más pequeño el número de

calibre del alambre, mayor la capacidad del cable.

• CABLES DE EXTENSION PARA INTEMPERIE. Cuando trabaje

a la intemperie, utilice siempre cordones de extensión diseñados

exclusivamente para esta finalidad y marcados así.

• NO SE DISTRAIGA. Concéntrese en lo que está haciendo.

Recurra al sentido común. No opere ninguna herramienta si se

encuentra fatigado.

• VERIFIQUE LAS PARTES DAÑADAS. Antes de seguir

empleando cualquier herramienta, es indispensable verificar con

mucho cuidado que las guardas u otras partes dañadas puedan

operar de la manera adecuada para cumplir con su función.

Verifique la alineación de las partes móviles, la firmeza con que

deben encontrarse sujetas en sus montaduras, las partes rotas,

las propias montaduras y cualesquiera otros detalles que pudieran

afectar a la operación de la herramienta. Las guardas y las otras

partes que se encuentren dañadas deberán repararse bien o

cambiarse en un centro de servicio autorizado, a menos que se

27

Español

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7.62 7.63-15.24 15.25-30.48 30.49-45.72

240V 0-15.24 15.25-30.48 30.49-60.96 60.97-91.44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

diga otra cosa en el manual del usuario. Haga que se cambien los

interruptores dañados en un centro de servicio autorizado. No

emplee ninguna herramienta que tenga inutilizado o estropeado

el interruptor.

Reglas adicionales de seguridad

para el afilador de brocas

ADVERTENCIA: Esta herramienta profesional está diseñada

para afilar de manera rápida y precisa brocas derechas de doble

estría, desde 1/8” (3 mm) hasta 1/2” (13 mm) de diámetro. NO

intente afilar brocas de carburo ni de cobalto. Ya que es esencial

llevar el procedimiento adecuado para obtener resultados

satisfactorios, lea cuidadosamente las instrucciones de operación, y,

por su propia protección, ponga especial atención a las reglas de

seguridad.

• Utilice protección en los ojos.

• Utilice una piedra de esmeril adecuada para la velocidad de la

unidad.

• Reemplace una piedra cuarteada inmediatamente. Maneje con

cuidado las piedras de esmeril para evitar dejarlas caer o

golpearlas. NO emplee una piedra de esmeril que se haya caído.

Antes de usarlas, revíselas en busca de cuarteaduras o fallas, y si

son evidentes, descarte las piedras de inmediato.

• Utilice siempre las guardas y las cubiertas oculares. Conserve la

cubierta ocular montada en las posiciones apropiadas.

• No apriete de más la tuerca de la piedra. Antes de montar una

piedra nueva, asegúrese que su velocidad de trabajo sea igual o

mayor a la velocidad sin carga de las herramientas indicada en la

placa de identificación.

• Utilice únicamente las arandelas que vienen con la esmeriladora.

• Fije el afilador de brocas a un banco para evitar movimientos.

• Ajuste la distancia entre el disco y las guardas para conservar

una separación de 1,6 mm (1/16”) o menor, ya que el diámetro de

la piedra disminuye con el uso.

DW751/385103 5/2/02 12:51 PM Page 27

Page 31

28

• Solamente utilice los accesorios en la manera debida.

CONSERVE ESTAS INSTRUCCIONES

Terminología de las brocas

Un requerimiento primario para perforar orificios con tamaño preciso

es que debe haber una diferencia mínima entre las alturas de los dos

filos de una broca. Las variaciones de estas alturas altera el punto

central, lo que producirá orificios excéntricos. (Observe las figuras

1, 2 y 3.) Consulte el párrafo 6 de la sección de “Solución a

problemas frecuentes” de este manual. Su afilador D

EWALT está

diseñado para producir alturas iguales en los filos y un punto

localizado en l centro.

Montaje del afilador

PARA OBTENER MEJORES RESULTADOS, DEBE MONTAR SU

AFILADOR EN UNA SUPERFICIE DE TRABAJO FIRME. Perfore

dos orificios de 5/16” (8 mm) en el banco de trabajo, como se

muestra en la figura 4. Inserte dos tornillos de carro de 1/4” (6 mm)

de diámetro. deslice el afilador sobre las cabezas de los tornillos y

acomode las cabezas en las aberturas que se han provisto para este

efecto en la parte inferior de la herramienta (Fig. 5). Apriete las

tuercas en los tornillos de manera uniforme con fuerza moderada.

¡No se exceda al apretar!

Partes funcionales principales

de su afilador de brocas

PRECAUCION:

• Trabaje seguro—conozca y siga todas las REGLAS DE

SEGURIDAD.

• Asegúrese que el buscador no haga contacto con la piedra de

esmeril antes de encender el motor.

Español

(122.2 mm)

Tool Outline

Front

(82.5 mm)

3 1/4"

4 13/16"

FIG. 5

ANGULO DE LA

HELICOIDAL

FIG. 1

FIG. 2

FIG. 4

FIG. 3

120° A 135°

ANGULO DEL

BORDE DE CORTE

ANGULO DE

PUNTA 118°

ANGULO DE

AVANCE DEL FILO

ESTRIA

LONGITUD DE ESTRIA

CURVA

BORDE