Page 1

iF YOU SHOULD EXPERIENCE A PROBLEM WiTH YOUR

DEWALT PURCHASE,

call 1-800-4-DEWALT

iN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

iF YOU HAVE A SUGGESTION OR COMMENT, GiVE US A CALL.

YOUR FEEDBACK iS VITAL TO THE SUCCESS OF

DEWALT'S QUALITY iMPROVEMENT PROGRAM.

Questions? See us on the World Wide Web at www.dewait.corn

iNSTRUCTiON MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW745 Heavy-Duty 10" (254 ram) Job Site Table Saw

INSTRUCTIVO DE OPERACION, CENTROS DE SERVlCIO Y POLIZA

DE GARANTiA. ADVERTENCIA: Lt_ASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

®

Scie circulaire &table de chantier robuste avec lame de 254 mm (10 po), DW745

Sierra de banco para el lugar de trabajo de 254 mm (10") de alta resistencia DW745

Page 2

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay

attention to these symbols.

i_DANGER: Indicates an imminently hazardous

situation which, if not avoided, wifl result in death or

serious injury.

AWARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

_,CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury.

CAUTION: Used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

SAVE THESE INSTRUCTIONS

General Safety Rules

_ ARNING: Read all instructions before operating product. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

_WARNING: FOLLOW ALL WIRING CODES and recommended electrical connections

to prevent shock or electrocution.

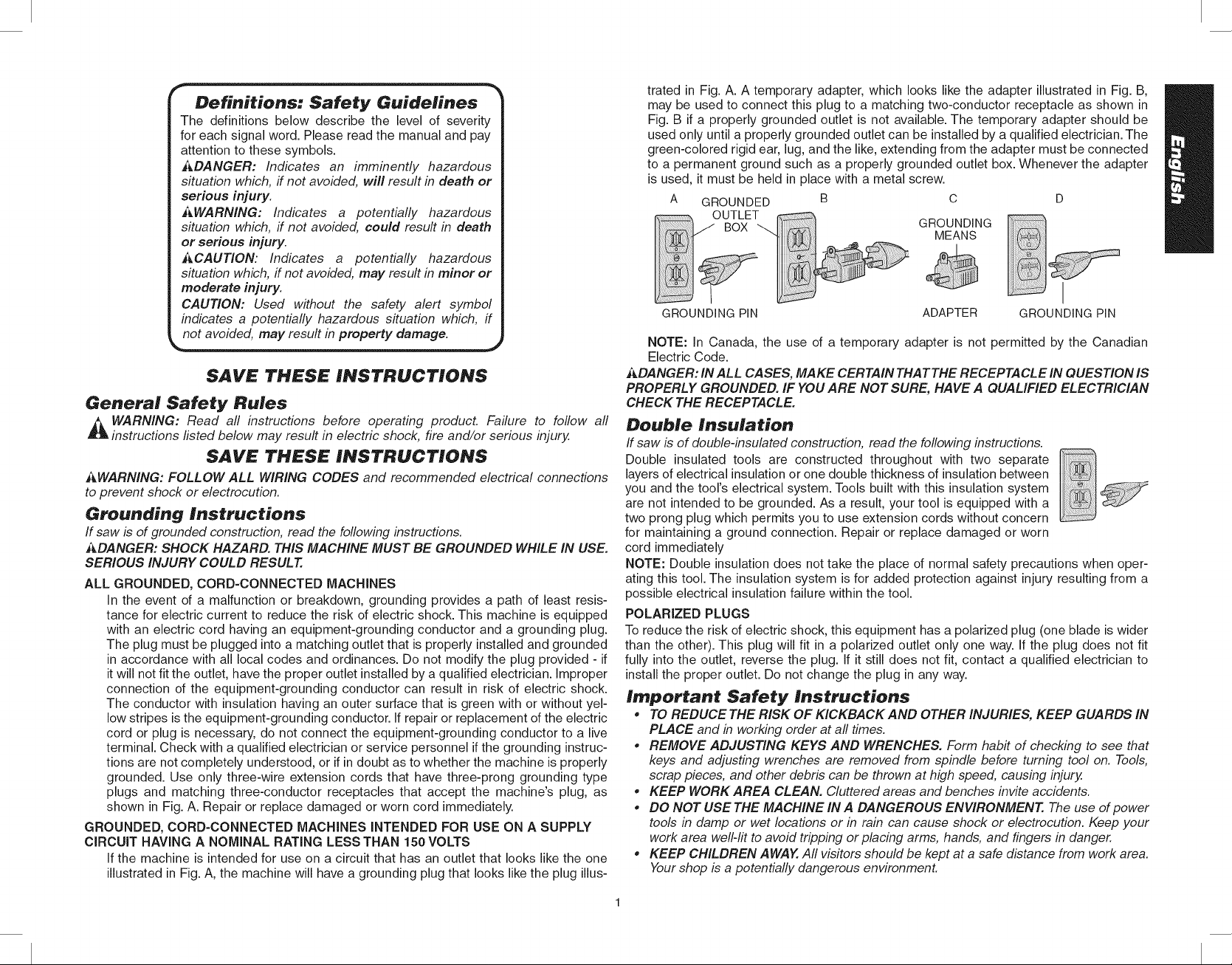

Grounding Instructions

If saw is of grounded construction, read the following instructions.

_DANGER: SHOCK HAZARD. THiS MACHINE MUST BE GROUNDED WHILE IN USE.

SERIOUS INJURY COULD RESULT.

ALL GROUNDED, CORD-CONNECTED MACHINES

In the event of a malfunction or breakdown, grounding provides a path of least resis-

tance for electric current to reduce the risk of electric shock. This machine is equipped

with an electric cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into a matching outlet that is properly installed and grounded

in accordance with all local codes and ordinances. Do not modify the plug provided - if

it will not fit the outlet, have the proper outlet installed by a qualified electrician. Improper

connection of the equipment-grounding conductor can result in risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yel-

low stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal. Check with a qualified electrician or service personnel if the grounding instruc-

tions are not completely understood, or if in doubt as to whether the machine is properly

grounded. Use only three-wire extension cords that have three-prong grounding type

plugs and matching three-conductor receptacles that accept the machine's plug, as

shown in Fig. A. Repair or replace damaged or worn cord immediately.

GROUNDED, CORD-CONNECTED MACHINES iNTENDED FOR USE ON A SUPPLY

CIRCUIT HAVING A NOMINAL RATING LESS THAN 150 VOLTS

If the machine is intended for use on a circuit that has an outlet that looks like the one

illustrated in Fig. A, the machine will have a grounding plug that looks like the plug illus-

trated in Fig. A. A temporary adapter, which looks like the adapter illustrated in Fig. B,

may be used to connect this plug to a matching two-conductor receptacle as shown in

Fig. B if a properly grounded outlet is not available. The temporary adapter should be

used only until a properly grounded outlet can be installed by a qualified electrician. The

green-colored rigid ear, lug, and the like, extending from the adapter must be connected

to a permanent ground such as a properly grounded outlet box. Whenever the adapter

is used, it must be held in place with a metal screw.

A GROUNDED B C D

GROUNDING

MEANS

GROUNDING PIN ADAPTER GROUNDING PIN

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian

Electric Code.

ADANGER: IN ALL CASES, MAKE CERTAIN THATTHE RECEPTACLE IN QUESTION IS

PROPERLY GROUNDED. IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN

CHECK THE RECEPTACLE.

Double Insulation

If saw is of double-insulated construction, read the following instructions.

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation between

you and the tool's electrical system. Tools built with this insulation system

are not intended to be grounded. As a result, your tool is equipped with a

two prong plug which permits you to use extension cords without concern

for maintaining a ground connection. Repair or replace damaged or worn

cord immediately

NOTE: Double insulation does not take the place of normal safety precautions when oper-

ating this tool. The insulation system is for added protection against injury resulting from a

possible electrical insulation failure within the tool.

POLARIZED PLUGS

To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider

than the other). This plug will fit in a polarized outlet only one way. If the plug does not fit

fully into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install the proper outlet. Do not change the plug in any way.

Important Safety Instructions

, TO REDUCE THE RISK OF KICKBACK AND OTHER INJURIES, KEEP GUARDS IN

PLACE and in working order at all times.

, REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from spindle before turning tool on. Tools,

scrap pieces, and other debris can be thrown at high speed, causing injury.

, KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

, DO NOT USE THE MACHINE INA DANGEROUS ENVIRONMENT. The use of power

tools in damp or wet locations or in rain can cause shock or electrocution. Keep your

work area well-lit to avoid tripping or placing arms, hands, and fingers in danger.

, KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

Your shop is a potentially dangerous environment.

Page 3

MAKEWORKSHOPCHILDPROOFwithpadlocks,masterswitches,orbyremoving

starterkeys.Theunauthorizedstart-upofamachinebyachildorvisitormayresultin

injury.

DO NOT FORCE TOOL. It will do the job better and be safer at the rate for which it was

designed.

USE RIGHT TOOL. Don't fome tool or attachment to do a job for which it was not

designed. Using the incorrect tool or attachment may result in personal injury.

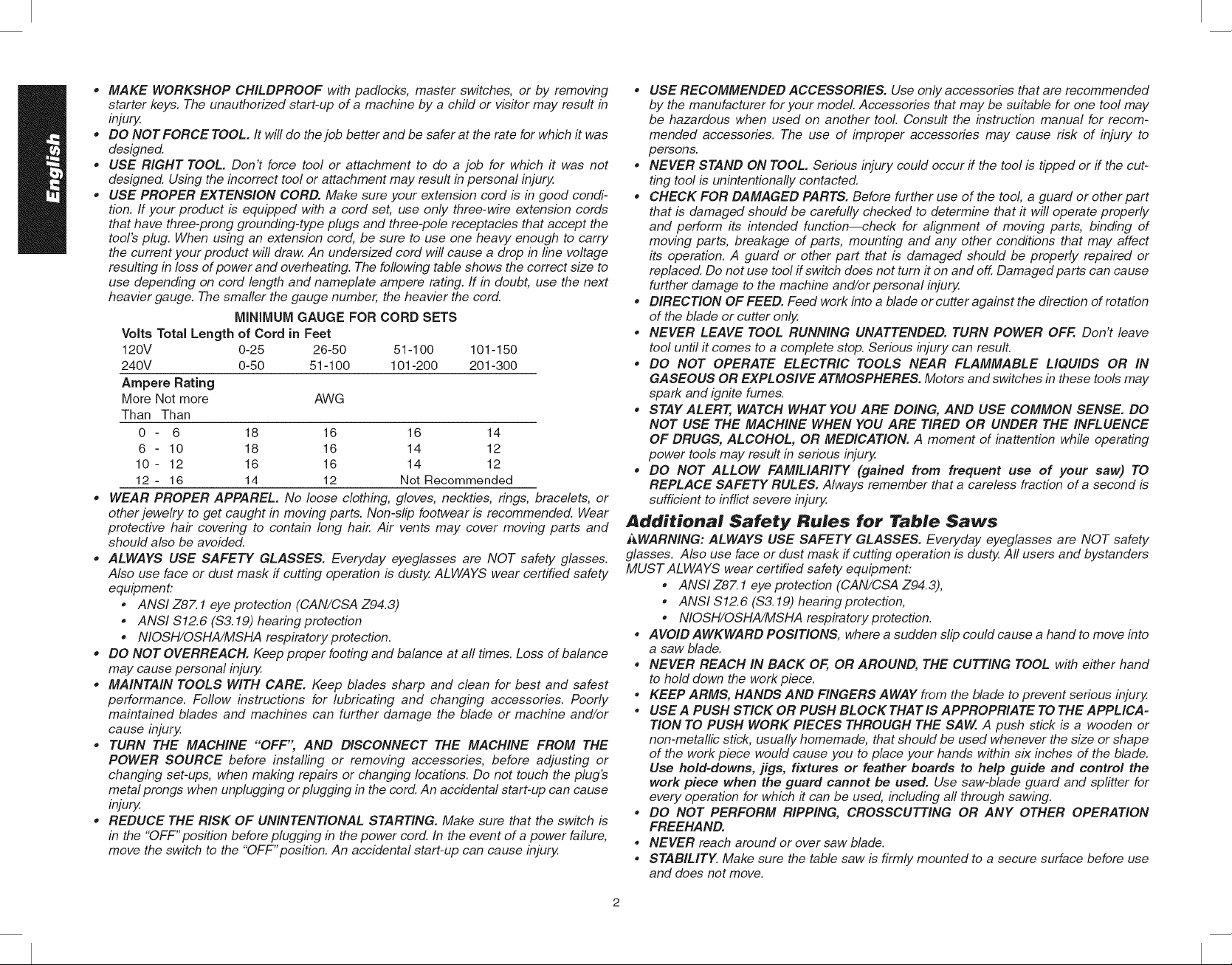

USE PROPER EXTENSION CORD. Make sure your extension cord is in good condi-

tion. If your product is equipped with a cord set, use only three-wire extension cords

that have three-prong grounding-type plugs and three-pole receptacles that accept the

tool's plug. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE FOR CORD SETS

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10- 12 16 16 14 12

12- 16 14 12 Not Recommended

, WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or

other jewelry to get caught in moving parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair. Air vents may cover moving parts and

should also be avoided.

, ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask ff cutting operation is dusty. ALWAYS wear certified safety

equipment:

* ANSI Z87.1 eye protection (CAN/CSA Z94.3)

* ANSI S12.6 ($3.19) hearing protection

* NIOSH/OSHA/MSHA respiratory protection.

, DO NOT OVERREACH. Keep proper footing and balance at aft times. Loss of balance

may cause personal injury.

, MAINTAIN TOOLS WITH CARE. Keep blades sharp and clean for best and safest

performance. Foflow instructions for lubricating and changing accessories. Poorly

maintained blades and machines can further damage the blade or machine and/or

cause injury.

, TURN THE MACHINE "OFF'; AND DISCONNECT THE MACHINE FROM THE

POWER SOURCE before installing or removing accessories, before adjusting or

changing set-ups, when making repairs or changing locations. Do not touch the plug's

metal prongs when unplugging or plugging in the cord. An accidental start-up can cause

injury.

REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is

in the "OFF'position before plugging in the power cord. In the event of a power failure,

move the switch to the "OFF"position. An accidental start-up can cause injury.

, USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended

by the manufacturer for your model Accessories that may be suitable for one tool may

be hazardous when used on another tooL Consult the instruction manual for recom-

mended accessories. The use of improper accessories may cause risk of injury to

persons.

, NEVER STAND ON TOOL. Serious injury could occur ff the tool is tipped or ff the cut-

ting tool is unintentionally contacted.

, CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly

and perform its intended function--check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged should be properly repaired or

replaced. Do not use tool ff switch does not turn it on and off. Damaged parts can cause

further damage to the machine and/or personal injury.

, DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation

of the blade or cutter only.

, NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave

tool until it comes to a complete stop. Serious injury can result.

, DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN

GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors and switches in these tools may

spark and ignite fumes.

, STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE. DO

NOT USE THE MACHINE WHEN YOU ARE TIRED OR UNDER THE INFLUENCE

OF DRUGS, ALCOHOL, OR MEDICATION. A moment of inattention while operating

power tools may result in serious injury.

, DO NOT ALLOW FAMILIARITY (gained from frequent use of your saw) TO

REPLACE SAFETY RULES. Always remember that a careless fraction of a second is

sufficient to inflict severe injury.

.Additional Safety Ru#es for Tab#e Saws

_WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask ff cutting operation is dusty. Aft users and bystanders

MUST ALWAYS wear certified safety equipment:

* ANSI Z87.1 eye protection (CAN/CSA Z94.3),

* ANSI S12.6 ($3.19) hearing protection,

* NIOSH/OSHA/MSHA respiratory protection.

* AVOID AWKWARD POSITIONS, where a sudden slip could cause a hand to move into

a saw blade.

* NEVER REACH IN BACK OF, OR AROUND, THE CUTTING TOOL with either hand

to hold down the work piece.

* KEEP ARMS, HANDS AND FINGERS AWAY from the blade to prevent serious injury.

* USE A PUSH STICK OR PUSH BLOCKTHAT IS APPROPRIATE TO THE APPLICA-

TION TO PUSH WORK PIECES THROUGH THE SAW. A push stick is a wooden or

non-metallic stick, usually homemade, that should be used whenever the size or shape

of the work piece would cause you to place your hands within six inches of the blade.

Use hold-downs, jigs, fixtures or feather boards to help guide and control the

work piece when the guard cannot be used. Use saw-blade guard and spfitter for

every operation for which it can be used, including all through sawing.

* DO NOT PERFORM RIPPING, CROSSCUTTING OR ANY OTHER OPERATION

FREEHAND.

* NEVER reach around or over saw blade.

* STABILITY. Make sure the table saw is firmly mounted to a secure surface before use

and does not move.

Page 4

* NEVERCUTFERROUSMETALS(thosewithanyironorsteelcontent),CEMENT

BOARDORMASONRY.Certainman-madematerialshavespecialinstructionsfor

cuttingon tablesaws.Followthemanufacturer'srecommendationsat all times.

Damagetothesawandpersonalinjurymayresult.

* THEPROPERTHROATPLATEMUSTBEINPLACEATALLTIMEStoreducethe

riskofathrownworkpieceandpossibleinjury

* USETHECORRECTSAWBLADEFORTHEINTENDEDOPERATION.Theblade

mustrotatetowardthefrontofthesaw.Alwaystightenthebladearbornutsecurely

Beforeuse,inspectthebladeforcracksormissingteeth.Donotuseadamaged

blade.

* NEVERATTEMPTTOFREEASTALLEDSAWBLADEWITHOUTFIRSTTURNING

THEMACHINEOFFANDDISCONNECTINGTHESAWFROMTHEPOWER

SOURCE.ffaworkpieceorcut-offpiecebecomestrappedinsidetheguard,turnsaw

offandwaitforbladetostopbeforeliftingtheguardandremovingthepiece.

* NEVERSTARTTHEMACHINEwiththeworkpieceagainstthebladetoreducetherisk

ofathrownworkpieceandpersonalinjury

, NEVER run the work piece between the fence and a molding cutterhead to reduce the

risk of a thrown work piece and personal injury.

* NEVER have any part of your body in line with the path of the saw blade. Personal

injury will occur.

, NEVER PERFORM LAYOUT, ASSEMBLY OR SET-UP WORK on the table/work area

when the machine is running. A sudden slip could cause a hand to move into the blade.

Severe injury can result.

, CLEAN THE TABLE/WORK AREA BEFORE LEAVING THE MACHINE. Lock

the switch in the "OFF" position and disconnect from the power source to prevent

unauthorized use.

* DO NOT leave a long board (or other work piece) unsupported so the spring of

the board causes it to shift on the table resulting in loss of control and possible

injury. Provide proper support for the work piece, based on its size and the type of

operation to be performed. Hold the work firmly against the fence and down against the

table surface.

, DO NOT OPERATE THIS MACHINE until it is completely assembled and installed

according to the instructions. A machine incorrectly assembled can cause serious

injury.

* OBTAINADVICE from your supervisor, instructor, or another qualifiedperson if you are

not thoroughly familiar with the operation of this machine. Knowledge is safety.

ADDITIONAL INFORMATION regarding the safe and proper operation of power

tools (i.e., a safety video) is available from the Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851 (www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-

3201. Please refer to the American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the U.S. Department of Labor OSHA

1910.213 Regulations.

TERMS: THE FOLLOWING TERMS WILL BE USED THROUGHOUT THE MANUAL

ANDYOU SHOULD BECOME FAMILIAR WITH THEM.

Through-sawing refers to any cut that completely severs the work piece.

Push Stick refers to a wooden stick, usually homemade, that is used to push small

work piece through the saw and keeps the operator's hands clear of the blade.

Kickback occurs when the saw blade binds in the cut and violently thrusts the work

piece back toward the operator.

Freehand refers to cutting without the use of a miter gauge or rip fence or any other

means of guiding or holding the work piece other than the operator's hand.

SAW BLADE GUARD AND SPLITTER

Your table saw is equipped with a blade guard and spfitter assembly that covers the blade

and prevents accidental contact. The spfitter is a flat plate that fits into the cut made by the

saw blade and effectively fights kickback by lessening the tendency of the blade to bind

in the cut. The spfitter can only be used when making through cuts that sever the wood.

When making rabbets and other cuts that make less than through cuts, the blade guard

and spfitter assembly must be removed from the saw. Two anti-kickback pawls are located

on the sides of the spfitter that allow the wood to pass through the blade in the cutting

direction but lock it if it tries to move backwards toward the operator.

MAKING A PUSH STICK (Inside Back Cover)

* In order to operate your table saw safely you must use a push stick whenever the size

or shape of the work piece would cause your hands to be within 6" (152 mm) of the saw

blade or other cutter. A push stick is included with this saw.

* No special wood is needed to make additional push-sticks as long as it's sturdy and

long enough. A length of 12" (305 mm) is recommended with a notch that fits against

the edge of the work piece to prevent slipping. It's a good idea to have several push

sticks of the same length [12" (305 mm)] with different size notches for different work

piece thicknesses.

* See the inside back cover for a picture of a push stick. The shape can vary to suit your

own needs as long as it performs its intended function of keeping your hands away from

the blade.

KICKBACKS

How to Avoid Them and Protect Yourself from Possible Injury

a. Be certain that the rip fence is parallel to the saw blade.

b. Do not rip by applying the feed force to the section of the work piece that will become

the cut-off (free) piece. Feed force when ripping should always be applied between the

saw blade and the fence; use a push stick for short work, 6" (152 mm) wide or less. For

less than 2" (51 mm) wide, you must use a special fixture.

c. Keep saw blade guard, spfitter and anti-kickback teeth in place and operating properly.

Keep teeth sharp, ff teeth are not operational, return your unit to the nearest authorized

DEWALT service center for repair. The spfitter must be in alignment with the saw blade

and the teeth must stop a kickback once it has started. Check their action before ripping

by pushing the wood under the anti-kickback teeth. The teeth must prevent the wood

from being pulled toward the front of the saw.

d. Plastic and composition (like hardboard) materials may be cut on your saw. However,

since these are usually quite hard and slippery, the anti-kickback pawls may not stop

a kickback. Therefore, be especially attentive to following proper set up and cutting

procedures for ripping.

e. Use saw blade guard and spfitter for every operation for which it can be used, including

aft through-sawing.

f. Push the work piece past the saw blade prior to release.

g. NEVER rip a work piece that is twisted or warped, or does not have a straight edge to

guide along the fence.

h. Use featherboards when the anti-kickback device or the guard and spfitter cannot be

used.

L NEVER saw a large work piece that cannot be controlled.

j. NEVER use the fence as a guide or length stop when crosscutting.

k. NEVER saw a work piece with loose knots, flaws, nails or other foreign objects.

L NEVER rip a workpiece shorter than 10".

iI, WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

Page 5

* leadfromlead-basedpaints,

* crystallinesilicafrombricksandcementandothermasonryproducts,and

* arsenicandchromiumfromchemically-treatedlumber(CCA).

Yourriskfromtheseexposuresvaries,dependingonhowoftenyoudothistypeofwork.

Toreduceyourexposuretothesechemicals:workinawell-ventilatedarea,andworkwith

approvedsafetyequipment,suchasthosedustmasksthatarespeciallydesignedtofilter

outmicroscopicparticles.

, Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling, and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

_&WARNING: Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face

and body. Always operate tool in well-ventilated area and provide for proper dust removal

Use dust collection system wherever possible.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Specifications

15 AMP

Miter Angle

Bevel Angle

Blade Size

Max. Cut Depth

Max. Cut Depth

RPM, no load

FIG. 1

60° L and R

0° to 45° L

10" (254 mm)

0° Bevel 3-1/8" (79 mm)

45° Bevel 2-1/4" (57 ram)

3850

FIG.2

been damaged during shipping. If any parts are missing or damaged, contact your dealer to

replace them before attempting to assemble the tool.

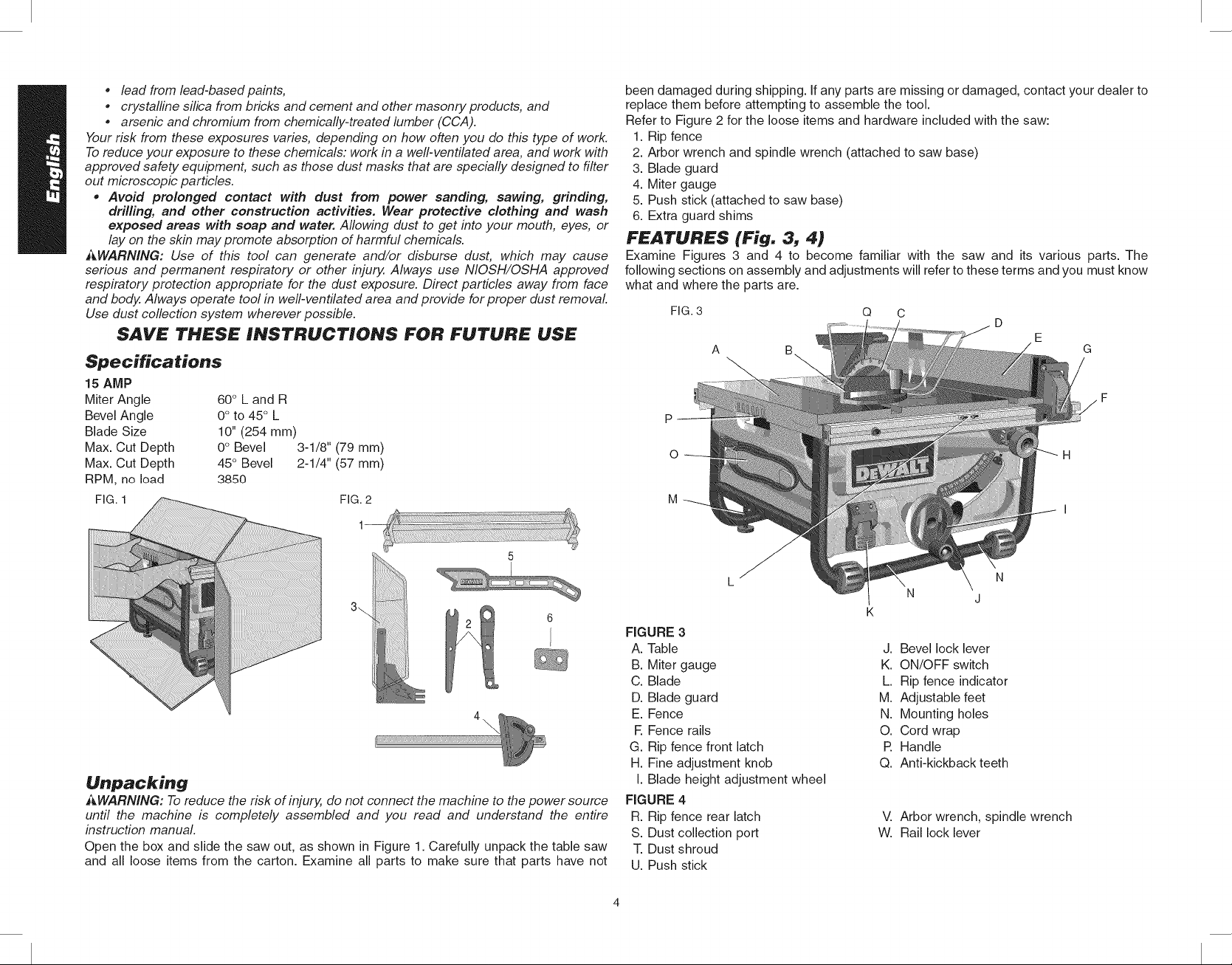

Refer to Figure 2 for the loose items and hardware included with the saw:

1. Rip fence

2. Arbor wrench and spindle wrench (attached to saw base)

3. Blade guard

4. Miter gauge

5. Push stick (attached to saw base)

6. Extra guard shims

FEATURES (Fig. 3, 4)

Examine Figures 3 and 4 to become familiar with the saw and its various parts. The

following sections on assembly and adjustments will refer to these terms and you must know

what and where the parts are.

FIG.3

P

0

M

D

H

4

\

i_i_i_ii{i_ii{i_ii{i_ii(iiiii(iiiii(iiiii(iiiii(iiiii(iiiii(ii

Unpacking

_WARNING: To reduce the risk of injury, do not connect the machine to the power source

until the machine is completely assembled and you read and understand the entire

instruction manual.

Open the box and slide the saw out, as shown in Figure 1. Carefully unpack the table saw

and all loose items from the carton. Examine all parts to make sure that parts have not

FIGURE 3

A. Table

B. Miter gauge

C. Blade

D. Blade guard

E. Fence

R Fence rails

G. Rip fence front latch

H. Fine adjustment knob

I. Blade height adjustment wheel

FIGURE 4

R. Rip fence rear latch

S. Dust collection port

T. Dust shroud

U. Push stick

N

N

J. Bevel lock lever

K. ON/OFF switch

L. Rip fence indicator

M. Adjustable feet

N. Mounting holes

O. Cord wrap

R Handle

Q. Anti-kickback teeth

V. Arbor wrench, spindle wrench

W. Rail lock lever

J

Page 6

FIG. 4 D

N

S

T

M

N

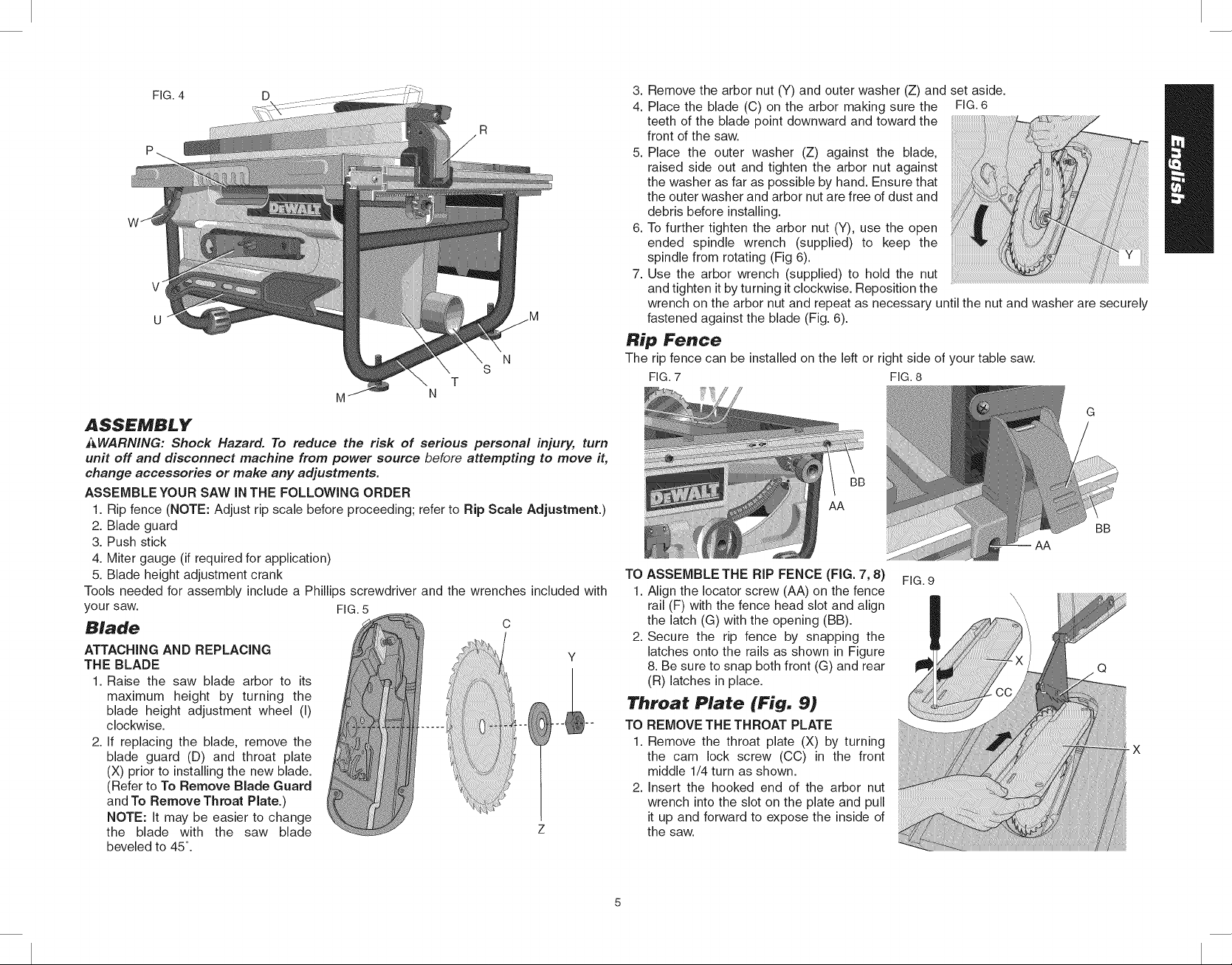

ASSEMBLY

JLWARNING: Shock Hazard. To reduce the risk of serious personal injury, turn

unit off and disconnect machine from power source before attempting to move it,

change accessories or make any adjustments.

ASSEMBLE YOUR SAW IN THE FOLLOWING ORDER

1. Rip fence (NOTE: Adjust rip scale before proceeding; refer to Rip Scale Adjustment.)

2. Blade guard

3. Push stick

4. Miter gauge (if required for application)

5. Blade height adjustment crank

Tools needed for assembly include a Phillips screwdriver and the wrenches included with

your saw. FIG.5

Blade c

ATTACHING AND REPLACING

THE BLADE

1. Raise the saw blade arbor to its

maximum height by turning the

blade height adjustment wheel (I)

clockwise.

2. If replacing the blade, remove the

blade guard (D) and throat plate

(X) prior to installing the new blade.

(Refer to To Remove Blade Guard

and To Remove Throat Plate.)

NOTE: It may be easier to change

the blade with the saw blade

beveled to 45°

3. Remove the arbor nut (Y) and outer washer (Z) and set aside.

4. Place the blade (C) on the arbor making sure the FIG. 6

teeth of the blade point downward and toward the

front of the saw.

5. Place the outer washer (Z) against the blade,

raised side out and tighten the arbor nut against

the washer as far as possible by hand. Ensure that

the outer washer and arbor nut are free of dust and

debris before installing.

6. To further tighten the arbor nut (Y), use the open

ended spindle wrench (supplied) to keep the

spindle from rotating (Fig 6).

7. Use the arbor wrench (supplied) to hold the nut

and tighten it by turning it clockwise. Reposition the

wrench on the arbor nut and repeat as necessary until the nut and washer are securely

fastened against the blade (Fig. 6).

Rip Fence

The rip fence can be installed on the left or right side of your table saw.

FIG.7 FIG.8

AA

AA

TO ASSEMBLE THE RIP FENCE (FIG. 7, 8)

FIG. 9

1. Align the Iocator screw (AA) on the fence

rail (F) with the fence head slot and align

the latch (G) with the opening (BB).

2. Secure the rip fence by snapping the

latches onto the rails as shown in Figure

8. Be sure to snap both front (G) and rear

(R) latches in place.

Throat Plate (Fig. 9)

TO REMOVE THE THROAT PLATE

1. Remove the throat plate (X) by turning

the cam lock screw (CC) in the front

middle 1/4 turn as shown.

2. Insert the hooked end of the arbor nut

wrench into the slot on the plate and pull

it up and forward to expose the inside of

the saw.

BB

-X

Page 7

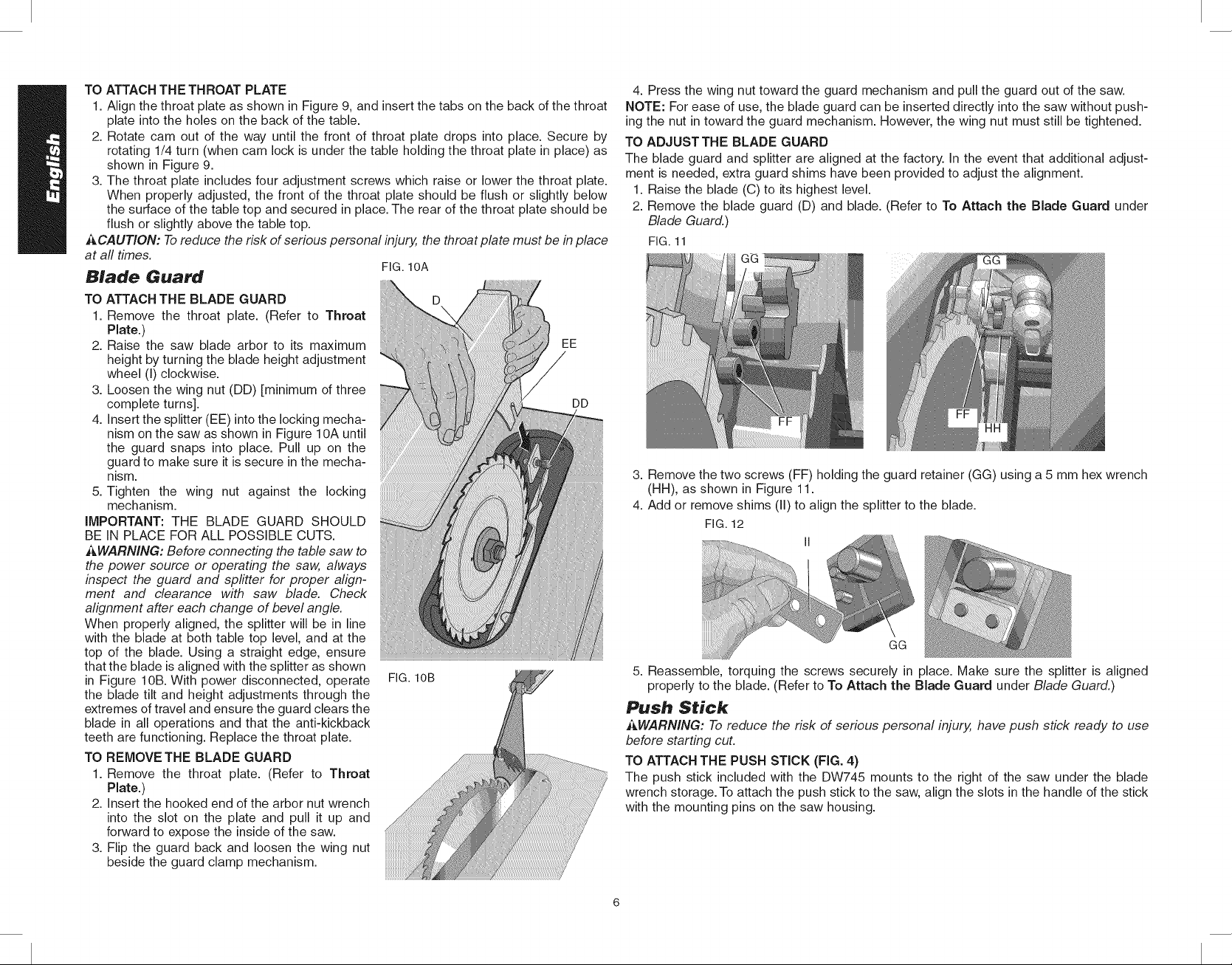

TO ATTACH THE THROAT PLATE

1. Align the throat plate as shown in Figure 9, and insert the tabs on the back of the throat

plate into the holes on the back of the table.

2. Rotate cam out of the way until the front of throat plate drops into place. Secure by

rotating 1/4 turn (when cam lock is under the table holding the throat plate in place) as

shown in Figure 9.

3. The throat plate includes four adjustment screws which raise or lower the throat plate.

When properly adjusted, the front of the throat plate should be flush or slightly below

the surface of the table top and secured in place. The rear of the throat plate should be

flush or slightly above the table top.

,_CAUTION: To reduce the risk of serious personal injury, the throat plate must be in place

at all times.

Blade Guard FiG.10A

TO ATTACH THE BLADE GUARD

1. Remove the throat plate. (Refer to Throat

Plate.)

2. Raise the saw blade arbor to its maximum

height by turning the blade height adjustment

wheel (I) clockwise.

3. Loosen the wing nut (DD) [minimum of three

complete turns].

4. Insert the splitter (EE) into the locking mecha-

nism on the saw as shown in Figure 10A until

the guard snaps into place. Pull up on the

guard to make sure it is secure in the mecha-

nism.

5. Tighten the wing nut against the locking

mechanism.

IMPORTANT: THE BLADE GUARD SHOULD

BE IN PLACE FOR ALL POSSIBLE CUTS.

,_,WARNING: Before connecting the table saw to

the power source or operating the saw, always

inspect the guard and spfitter for proper align-

ment and clearance with saw blade. Check

alignment after each change of bevel angle.

When properly aligned, the splitter will be in line

with the blade at both table top level, and at the

top of the blade. Using a straight edge, ensure

that the blade is aligned with the splitter as shown

in Figure 10B. With power disconnected, operate

the blade tilt and height adjustments through the

extremes of travel and ensure the guard clears the

blade in all operations and that the anti-kickback

teeth are functioning. Replace the throat plate.

TO REMOVE THE BLADE GUARD

1. Remove the throat plate. (Refer to Throat

Plate.)

2. Insert the hooked end of the arbor nut wrench

into the slot on the plate and pull it up and

forward to expose the inside of the saw.

3. Flip the guard back and loosen the wing nut

beside the guard clamp mechanism.

FIG. lOB

EE

DD

4. Press the wing nut toward the guard mechanism and pull the guard out of the saw.

NOTE: For ease of use, the blade guard can be inserted directly into the saw without push-

ing the nut in toward the guard mechanism. However, the wing nut must still be tightened.

TO ADJUST THE BLADE GUARD

The blade guard and splitter are aligned at the factory. In the event that additional adjust-

ment is needed, extra guard shims have been provided to adjust the alignment.

1. Raise the blade (C) to its highest level.

2. Remove the blade guard (D) and blade. (Refer to To Attach the Blade Guard under

Blade Guard.)

FIG.11

3. Remove the two screws (FF) holding the guard retainer (GG) using a 5 mm hex wrench

(HH), as shown in Figure 11.

4. Add or remove shims (ll) to align the splitter to the blade.

FIG. 12

GG

5. Reassemble, torquing the screws securely in place. Make sure the splitter is aligned

properly to the blade. (Refer to To Attach the Blade Guard under Blade Guard.)

Push Stick

i_WARNING: To reduce the risk of serious personal injury, have push stick ready to use

before starting cut.

TO ATTACH THE PUSH STICK (FIG. 4)

The push stick included with the DW745 mounts to the right of the saw under the blade

wrench storage. To attach the push stick to the saw, align the slots in the handle of the stick

with the mounting pins on the saw housing.

Page 8

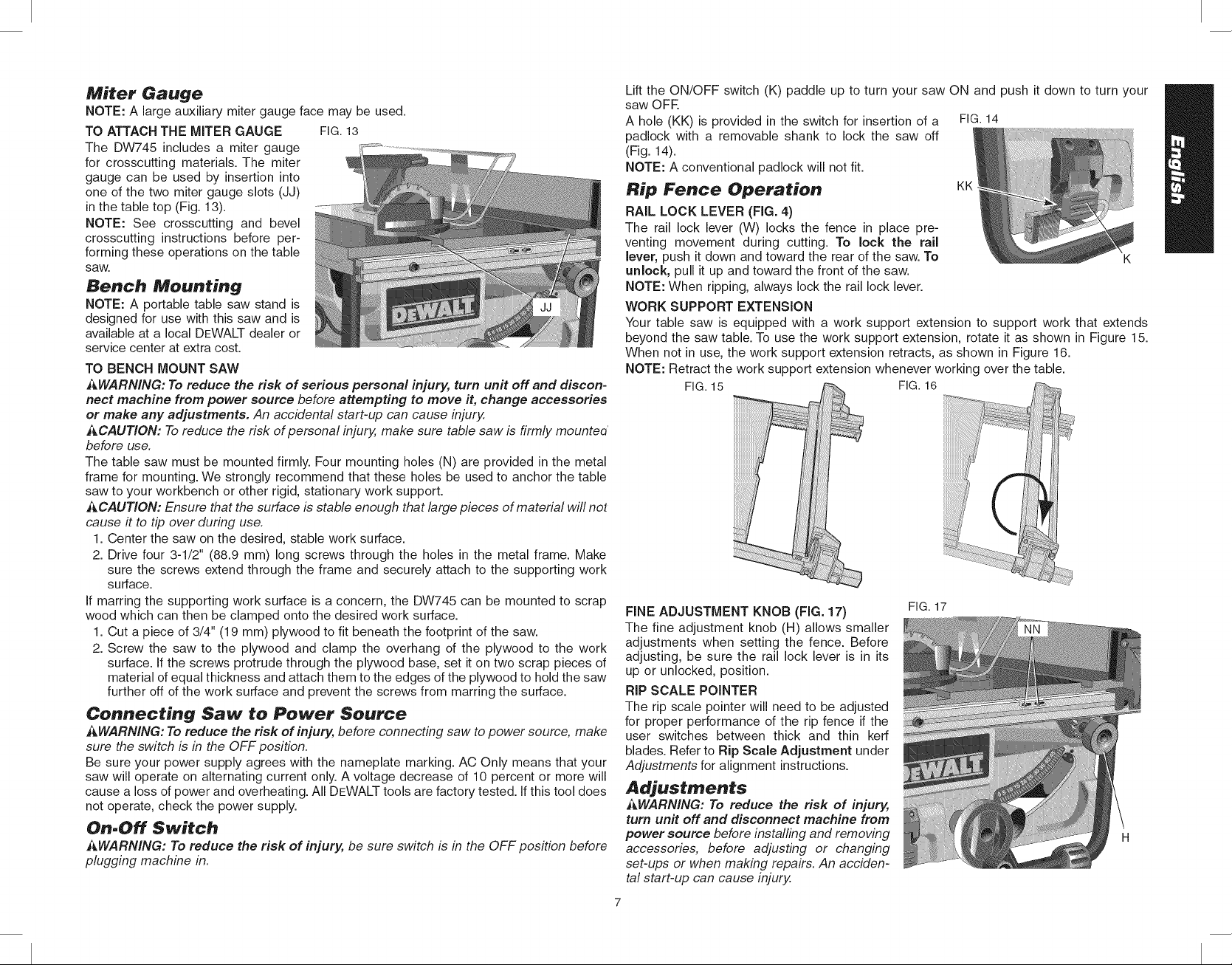

Miter Gauge

NOTE: A large auxiliary miter gauge face may be used.

TO ATTACH THE MITER GAUGE FIG. 13

The DW745 includes a miter gauge

for crosscutting materials. The miter

gauge can be used by insertion into

one of the two miter gauge slots (JJ)

in the table top (Fig. 13).

NOTE: See crosscutting and bevel

crosscutting instructions before per-

forming these operations on the table

saw.

Bench Mounting

NOTE: A portable table saw stand is

designed for use with this saw and is

available at a local DEWALT dealer or

service center at extra cost.

TO BENCH MOUNT SAW

i_WARNING: To reduce the risk of serious personal injury, turn unit off and discon-

nect machine from power source before attempting to move it, change accessories

or make any adjustments. An accidental start-up can cause injury.

,&CAUTION: To reduce the risk of personal injury, make sure table saw is firmly mounteQ

before use.

The table saw must be mounted firmly. Four mounting holes (N) are provided in the metal

frame for mounting. We strongly recommend that these holes be used to anchor the table

saw to your workbench or other rigid, stationary work support.

,&CAUTION: Ensure that the surface is stable enough that large pieces of material will nol

cause it to tip over during use.

1. Center the saw on the desired, stable work surface.

2. Drive four 3-1/2" (88.9 mm) long screws through the holes in the metal frame. Make

sure the screws extend through the frame and securely attach to the supporting work

surface.

If marring the supporting work surface is a concern, the DW745 can be mounted to scrap

wood which can then be clamped onto the desired work surface.

1. Cut a piece of 3/4" (19 mm) plywood to fit beneath the footprint of the saw.

2. Screw the saw to the plywood and clamp the overhang of the plywood to the work

surface. If the screws protrude through the plywood base, set it on two scrap pieces of

material of equal thickness and attach them to the edges of the plywood to hold the saw

further off of the work surface and prevent the screws from marring the surface.

Connecting Saw to Power Source

_,WARNING: To reduce the risk of injury, before connecting saw to power source, make

sure the switch is in the OFF position.

Be sure your power supply agrees with the nameplate marking. AC Only means that your

saw will operate on alternating current only. A voltage decrease of 10 percent or more will

cause a loss of power and overheating. All DEWALT tools are factory tested. If this tool does

not operate, check the power supply.

On-Off Switch

i_WARNING: To reduce the risk of injury, be sure switch is in the OFF position before

plugging machine in.

Lift the ON/OFF switch (K) paddle up to turn your saw ON and push it down to turn your

saw OFF.

A hole (KK) is provided in the switch for insertion of a FIG. 14

padlock with a removable shank to lock the saw off

(Fig. 14).

NOTE: A conventional padlock will not fit.

Rip Fence Operation KK

RAiL LOCK LEVER (FIG. 4)

The rail lock lever (W) locks the fence in place pre-

venting movement during cutting. To lock the rail

lever, push it down and toward the rear of the saw. To K

unlock, pull it up and toward the front of the saw.

NOTE: When ripping, always lock the rail lock lever.

WORK SUPPORT EXTENSION

Your table saw is equipped with a work support extension to support work that extends

beyond the saw table. To use the work support extension, rotate it as shown in Figure 15.

When not in use, the work support extension retracts, as shown in Figure 16.

NOTE: Retract the work support extension whenever working over the table.

FIG. 15 FIG. 16

FiNE ADJUSTMENT KNOB (FIG. 17)

The fine adjustment knob (H) allows smaller

adjustments when setting the fence. Before

adjusting, be sure the rail lock lever is in its

up or unlocked, position.

RiP SCALE POINTER

The rip scale pointer will need to be adjusted

for proper performance of the rip fence if the

user switches between thick and thin kerf

blades. Refer to Rip Scale Adjustment under

Adjustments for alignment instructions.

FIG. 17

Adjustments

,&WARNING: To reduce the risk of injury,

turn unit off and disconnect machine from

power source before installing and removing

accessories, before adjusting or changing

set-ups or when making repairs. An acciden-

tal start-up can cause injury.

Page 9

NOTE: Your saw is fully and accurately adjusted at the factory at the time of manufacture. If

readjustment due to shipping and handling or any other reason is required, follow the steps

below to adjust your saw.

Once made, these adjustments should remain accurate. Take a little time now to follow

these directions carefully to maintain the accuracy of which your saw is capable.

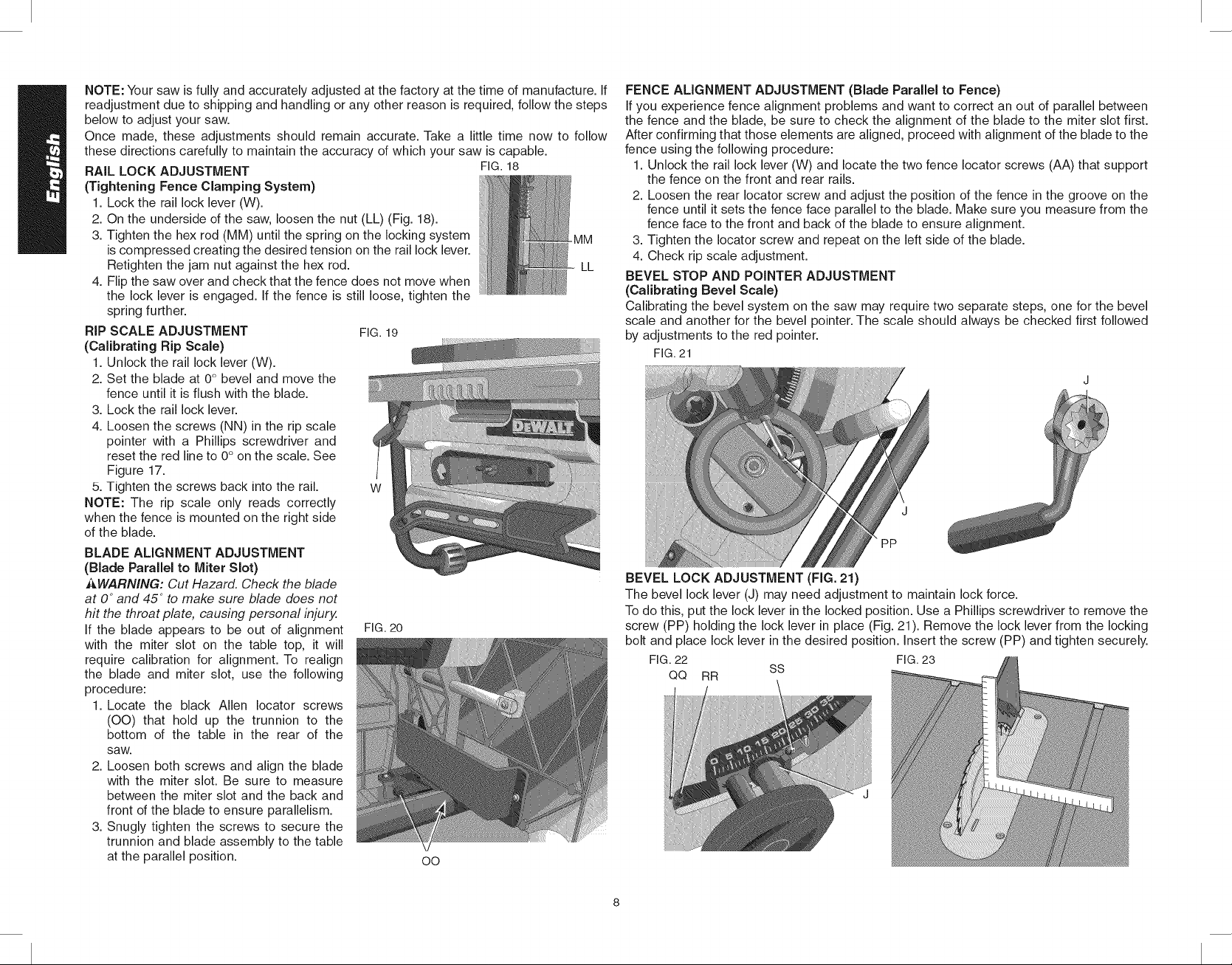

RAiL LOCK ADJUSTMENT FIG. 18

(Tightening Fence Clamping System)

1. Lock the rail lock lever (W).

2. On the underside of the saw, loosen the nut (LL) (Fig. 18).

3. Tighten the hex rod (MM) until the spring on the locking system MM

is compressed creating the desired tension on the rail lock lever.

Retighten the jam nut against the hex rod. LL

4. Flip the saw over and check that the fence does not move when

the lock lever is engaged. If the fence is still loose, tighten the

spring further.

RIP SCALE ADJUSTMENT

FiG. 19

(Calibrating Rip Scale)

1. Unlock the rail lock lever (W).

2. Set the blade at 0° bevel and move the

fence until it is flush with the blade.

3. Lock the rail lock lever.

4. Loosen the screws (NN) in the rip scale

pointer with a Phillips screwdriver and

reset the red line to 0° on the scale. See

Figure 17.

5. Tighten the screws back into the rail.

W

NOTE: The rip scale only reads correctly

when the fence is mounted on the right side

of the blade.

BLADE ALIGNMENT ADJUSTMENT

(Blade Parallel to Miter Slot)

_WAFtNING: Cut Hazard. Check the blade

at 0 ° and 45 ° to make sure blade does not

hit the throat plate, causing personal injury.

If the blade appears to be out of alignment

FiG. 20

with the miter slot on the table top, it will

require calibration for alignment. To realign

the blade and miter slot, use the following

procedure:

1. Locate the black Allen Iocator screws

(OO) that hold up the trunnion to the

bottom of the table in the rear of the

saw.

2. Loosen both screws and align the blade

with the miter slot. Be sure to measure

between the miter slot and the back and

front of the blade to ensure parallelism.

3. Snugly tighten the screws to secure the

trunnion and blade assembly to the table

at the parallel position.

OO

FENCE ALIGNMENT ADJUSTMENT (Blade Parallel to Fence)

If you experience fence alignment problems and want to correct an out of parallel between

the fence and the blade, be sure to check the alignment of the blade to the miter slot first.

After confirming that those elements are aligned, proceed with alignment of the blade to the

fence using the following procedure:

1. Unlock the rail lock lever (W) and locate the two fence Iocator screws (AA) that support

the fence on the front and rear rails.

2. Loosen the rear Iocator screw and adjust the position of the fence in the groove on the

fence until it sets the fence face parallel to the blade. Make sure you measure from the

fence face to the front and back of the blade to ensure alignment.

3. Tighten the Iocator screw and repeat on the left side of the blade.

4. Check rip scale adjustment.

BEVEL STOP AND POINTER ADJUSTMENT

(Calibrating Bevel Scale)

Calibrating the bevel system on the saw may require two separate steps, one for the bevel

scale and another for the bevel pointer. The scale should always be checked first followed

by adjustments to the red pointer.

FIG.21

PP

BEVEL LOCK ADJUSTMENT (FIG. 21)

The bevel lock lever (J) may need adjustment to maintain lock force.

To do this, put the lock lever in the locked position. Use a Phillips screwdriver to remove the

screw (PP) holding the lock lever in place (Fig. 21). Remove the lock lever from the locking

bolt and place lock lever inthe desired position. Insert the screw (PP) and tighten securely.

FiG. 22 FIG.23

QQ RR

SS

Page 10

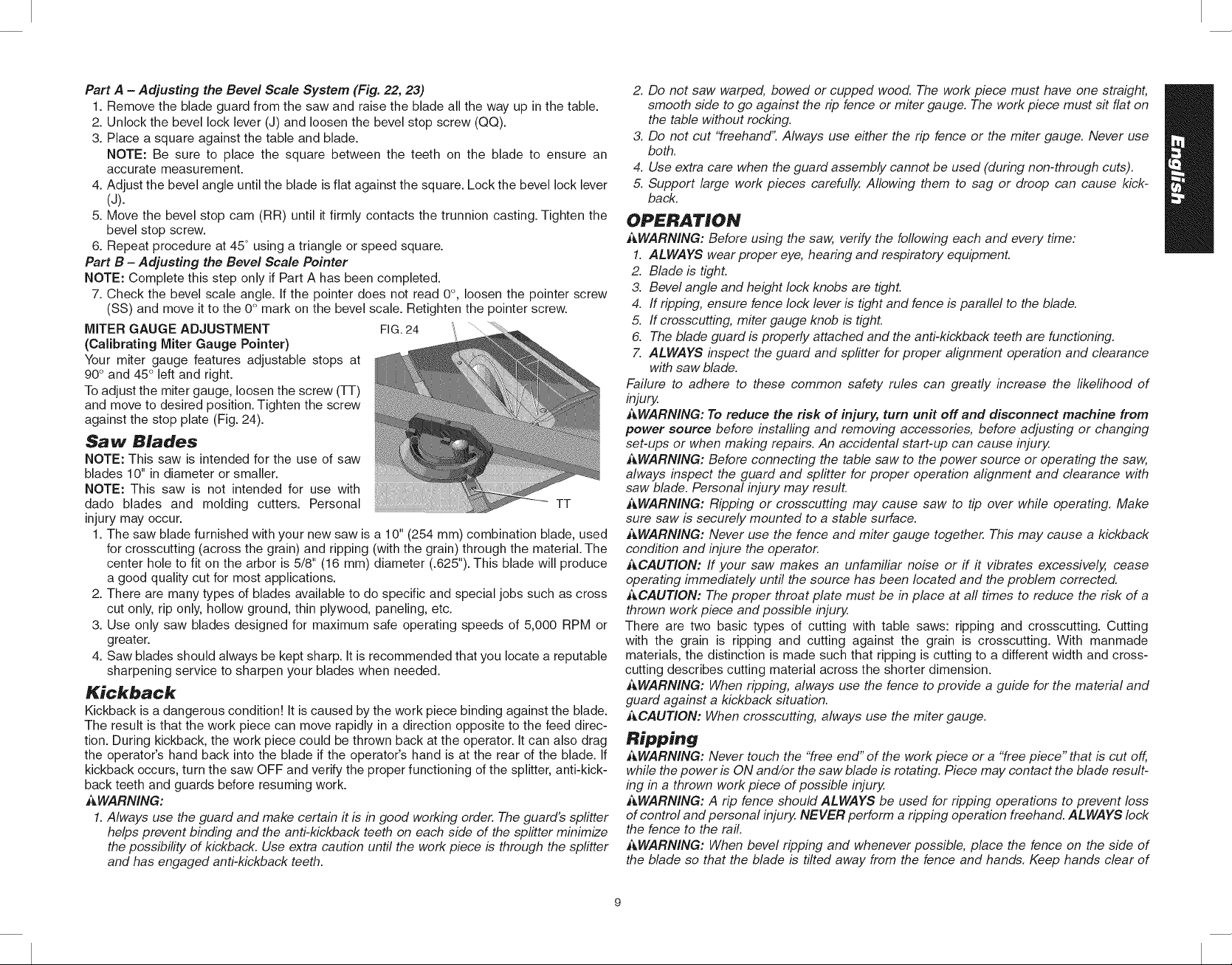

Part A - Adjusting the Bevel Scale System (Fig. 22, 23)

1. Remove the blade guard from the saw and raise the blade all the way up in the table.

2. Unlock the bevel lock lever (J) and loosen the bevel stop screw (QQ).

3. Place a square against the table and blade.

NOTE: Be sure to place the square between the teeth on the blade to ensure an

accurate measurement.

4. Adjust the bevel angle until the blade is flat against the square. Lock the bevel lock lever

(J).

5. Move the bevel stop cam (RR) until it firmly contacts the trunnion casting. Tighten the

bevel stop screw.

6. Repeat procedure at 45 ° using a triangle or speed square.

Part B - Adjusting the Bevel Scale Pointer

NOTE: Complete this step only if Part A has been completed.

7. Check the bevel scale angle. If the pointer does not read 0°, loosen the pointer screw

(SS) and move it to the 0° mark on the bevel scale. Retighten the pointer screw.

MITER GAUGE ADJUSTMENT FIG.24

(Calibrating Miter Gauge Pointer)

Your miter gauge features adjustable stops at

90° and 45 ° left and right.

Toadjust the miter gauge, loosen the screw (TT)

and move to desired position. Tighten the screw

against the stop plate (Fig. 24).

Saw Blades

NOTE: This saw is intended for the use of saw

blades 10" in diameter or smaller.

NOTE: This saw is not intended for use with

dado blades and molding cutters. Personal TT

injury may occur.

1. The saw blade furnished with your new saw is a 10" (254 mm) combination blade, used

for crosscutting (across the grain) and ripping (with the grain) through the material. The

center hole to fit on the arbor is 5/8" (16 mm) diameter (.625"). This blade will produce

a good quality cut for most applications.

2. There are many types of blades available to do specific and special jobs such as cross

cut only, rip only, hollow ground, thin plywood, paneling, etc.

3. Use only saw blades designed for maximum safe operating speeds of 5,000 RPM or

greater.

4. Saw blades should always be kept sharp. It is recommended that you locate a reputable

sharpening service to sharpen your blades when needed.

Kickback

Kickback is a dangerous condition! It is caused by the work piece binding against the blade.

The result is that the work piece can move rapidly in a direction opposite to the feed direc-

tion. During kickback, the work piece could be thrown back at the operator. It can also drag

the operator's hand back into the blade if the operator's hand is at the rear of the blade. If

kickback occurs, turn the saw OFF and verify the proper functioning of the splitter, anti-kick-

back teeth and guards before resuming work.

_WARNING:

1.Always use the guard and make certain it is in good working order. The guard's spfitter

helps prevent binding and the anti-kickback teeth on each side of the splitter minimize

the possibility of kickback. Use extra caution until the work piece is through the spfitter

and has engaged anti-kickback teeth.

2. Do not saw warped, bowed or cupped wood. The work piece must have one straight,

smooth side to go against the rip fence or miter gauge. The work piece must sit flat on

the table without rocking.

3. Do not cut "freehand': Always use either the rip fence or the miter gauge. Never use

both.

4. Use extra care when the guard assembly cannot be used (during non-through cuts).

5. Support large work pieces carefully. Allowing them to sag or droop can cause kick-

back.

OPERATION

AWARNING: Before using the saw, verify the following each and every time:

1. ALWAYS wear proper eye, hearing and respiratory equipment.

2. Blade is tight.

3. Bevel angle and height lock knobs are tight.

4. If ripping, ensure fence lock lever is tight and fence is parallel to the blade.

5. If crosscutting, miter gauge knob is tight.

6. The blade guard is properly attached and the anti-kickback teeth are functioning.

7. ALWAYS inspect the guard and spfitter for proper alignment operation and clearance

with saw blade.

Failure to adhere to these common safety rules can greatly increase the likelihood of

injury.

_WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing

set-ups or when making repairs. An accidental start-up can cause injury.

AWARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and spfitter for proper operation alignment and clearance with

saw blade. Personal injury may result.

,&WARNING: Ripping or crosscutting may cause saw to tip over while operating. Make

sure saw is securely mounted to a stable surface.

_&WARNING: Never use the fence and miter gauge together. This may cause a kickback

condition and injure the operator.

_&CAUTION: If your saw makes an unfamiliar noise or ff it vibrates excessively, cease

operating immediately until the source has been located and the problem corrected.

ACAUTION: The proper throat plate must be in place at aft times to reduce the risk of a

thrown work piece and possible injury,

There are two basic types of cutting with table saws: ripping and crosscutting. Cutting

with the grain is ripping and cutting against the grain is crosscutting. With manmade

materials, the distinction is made such that ripping is cutting to a different width and cross-

cutting describes cutting material across the shorter dimension.

AWARNING: When ripping, always use the fence to provide a guide for the material and

guard against a kickback situation.

ACAUTION: When crosscutting, always use the miter gauge.

Ripping

,&WARNING: Never touch the "free end" of the work piece or a "free piece" that is cut off,

while the power is ON and/or the saw blade is rotating. Piece may contact the blade result-

ing in a thrown work piece of possible injury.

_,WARNING: A rip fence should ALWAYS be used for ripping operations to prevent loss

of control and personal injury, NEVER perform a ripping operation freehand. ALWAYS lock

the fence to the rail.

,&WARNING: When bevel ripping and whenever possible, place the fence on the side of

the blade so that the blade is tilted away from the fence and hands. Keep hands clear of

Page 11

thebladeanduseapushsticktofeedtheworkpieceffthereis less than 6" (152 mm)

between the fence and the blade.

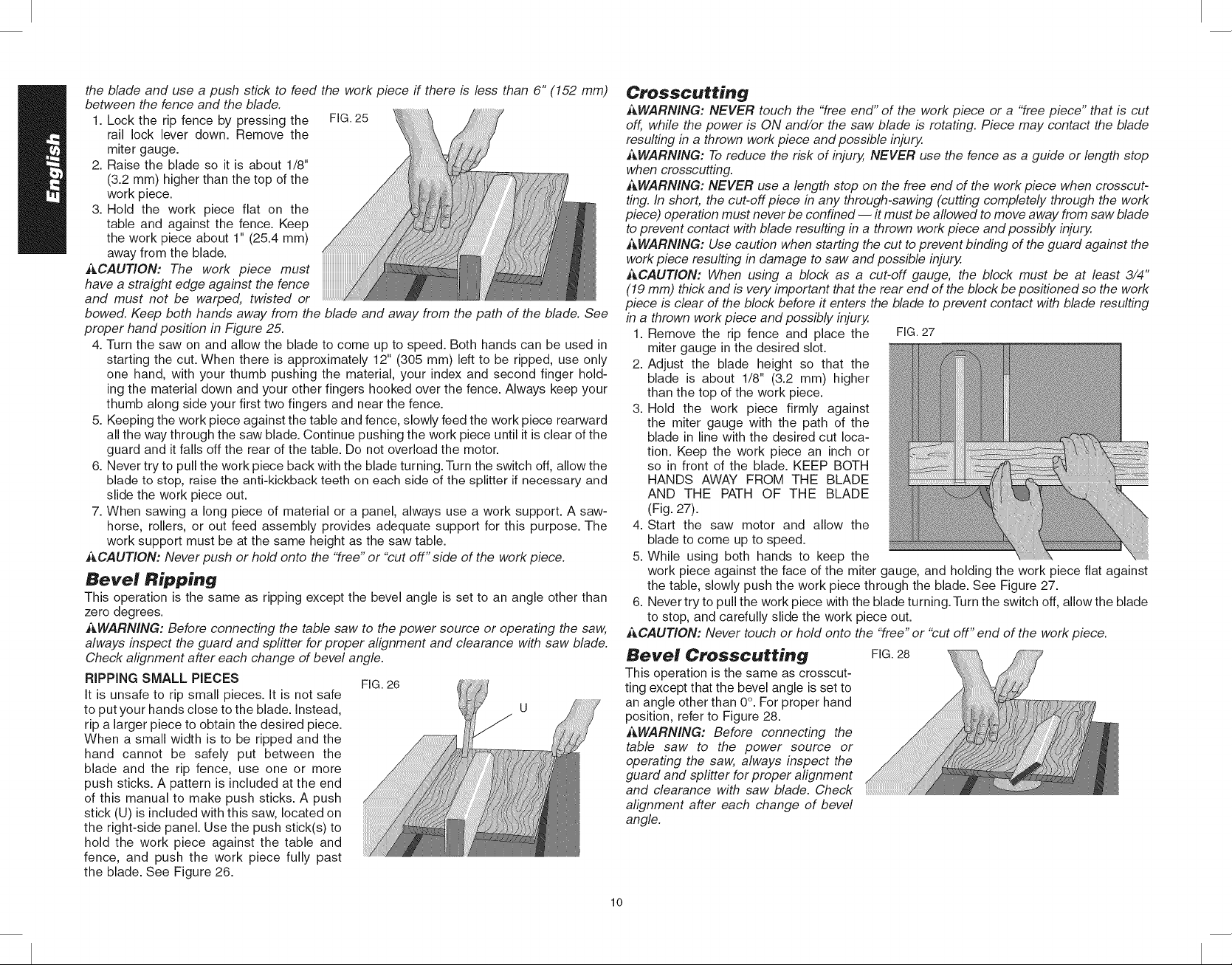

1. Lock the rip fence by pressing the FIG.25

rail lock lever down. Remove the

miter gauge.

2. Raise the blade so it is about 1/8"

(3.2 ram) higher than the top of the

work piece.

3. Hold the work piece flat on the

table and against the fence. Keep

the work piece about 1" (25.4 ram)

away from the blade.

_,CAUTION: The work piece must

have a straight edge against the fence

and must not be warped, twisted or

bowed. Keep both hands away from the blade and away from the path of the blade. See

proper hand position in Figure 25.

4. Turn the saw on and allow the blade to come up to speed. Both hands can be used in

starting the cut. When there is approximately 12" (305 mm) left to be ripped, use only

one hand, with your thumb pushing the material, your index and second finger hold-

ing the material down and your other fingers hooked over the fence. Always keep your

thumb along side your first two fingers and near the fence.

5. Keeping the work piece against the table and fence, slowly feed the work piece rearward

all the way through the saw blade. Continue pushing the work piece until it is clear of the

guard and it falls off the rear of the table. Do not overload the motor.

6. Never try to pull the work piece back with the blade turning. Turn the switch off, allow the

blade to stop, raise the anti-kickback teeth on each side of the splitter if necessary and

slide the work piece out.

7. When sawing a long piece of material or a panel, always use a work support. A saw-

horse, rollers, or out feed assembly provides adequate support for this purpose. The

work support must be at the same height as the saw table.

ACAUTION: Never push or hold onto the "free" or "cut off" side of the work piece.

Bevel Ripping

This operation is the same as ripping except the bevel angle is set to an angle other than

zero degrees.

_&WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and spfitter for proper alignment and clearance with saw blade.

Check alignment after each change of bevel angle.

RIPPING SMALL PIECES

It is unsafe to rip small pieces. It is not safe

to put your hands close to the blade. Instead,

rip a larger piece to obtain the desired piece.

When a small width is to be ripped and the

hand cannot be safely put between the

blade and the rip fence, use one or more

push sticks. A pattern is included at the end

of this manual to make push sticks. A push

stick (U) is included with this saw, located on

the right-side panel. Use the push stick(s) to

hold the work piece against the table and

fence, and push the work piece fully past

the blade. See Figure 26.

FIG. 26

Crosscutting

_WARNING: NEVER touch the "free end" of the work piece or a "free piece" that is cut

off, while the power is ON and/or the saw blade is rotating. Piece may contact the blade

resulting in a thrown work piece and possible injury.

,_,WARNING: To reduce the risk of injury, NEVER use the fence as a guide or length stop

when crosscutting.

ZCWARN/NG: NEVER use a length stop on the free end of the work piece when crosscut-

ting. In short, the cut-off piece in any through-sawing (cutting completely through the work

piece) operation must never be confined -- it must be allowed to move away from saw blade

to prevent contact with blade resulting in a thrown work piece and possibly injury.

i_WARNING: Use caution when starting the cut to prevent binding of the guard against the

work piece resulting in damage to saw and possible injury,

_I,CAUTION: When using a block as a cut-off gauge, the block must be at least 3/4"

(19 mm) thick and is very important that the rear end of the block be positioned so the work

piece is clear of the block before it enters the blade to prevent contact with blade resulting

in a thrown work piece and possibly injury,

1. Remove the rip fence and place the FIG.27

miter gauge in the desired slot.

2. Adjust the blade height so that the

blade is about 1/8" (3.2 mm) higher

than the top of the work piece.

3. Hold the work piece firmly against

the miter gauge with the path of the

blade in line with the desired cut loca-

tion. Keep the work piece an inch or

so in front of the blade. KEEP BOTH

HANDS AWAY FROM THE BLADE

AND THE PATH OF THE BLADE

(Fig. 27).

4. Start the saw motor and allow the

blade to come up to speed.

5. While using both hands to keep the

work piece against the face of the miter gauge, and holding the work piece flat against

the table, slowly push the work piece through the blade. See Figure 27.

6. Never try to pull the work piece with the blade turning. Turn the switch off, allow the blade

to stop, and carefully slide the work piece out.

ACAUTION: Never touch or hold onto the "free" or "cut off" end of the work piece.

Bevel Crosscutting FIG.28

This operation is the same as crosscut-

ting except that the bevel angle is set to

an angle other than 0°. For proper hand

position, refer to Figure 28.

_iWARNING: Before connecting the

table saw to the power source or

operating the saw, always inspect the

guard and splitter for proper alignment

and clearance with saw blade. Check

alignment after each change of bevel

angle.

lO

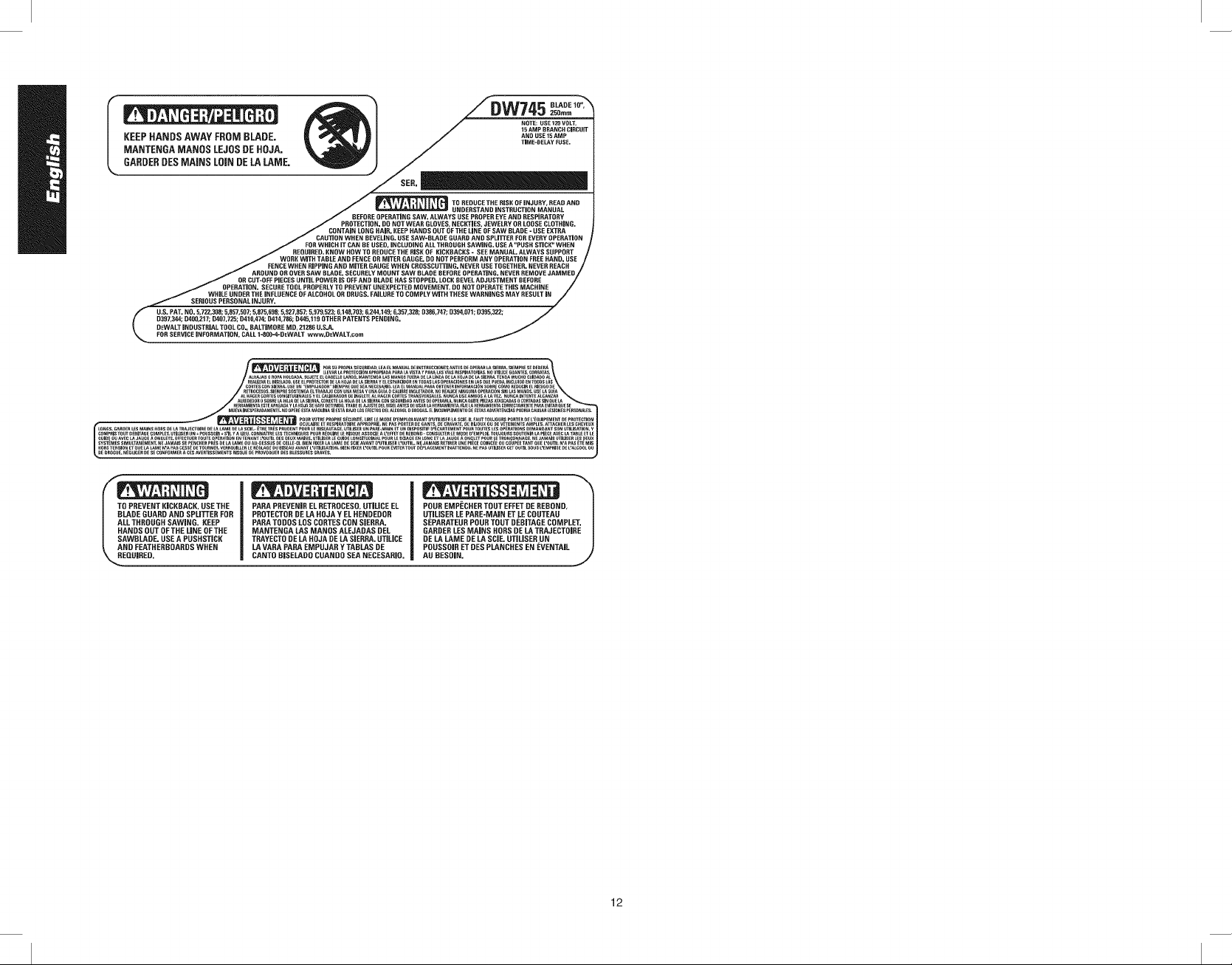

Page 12

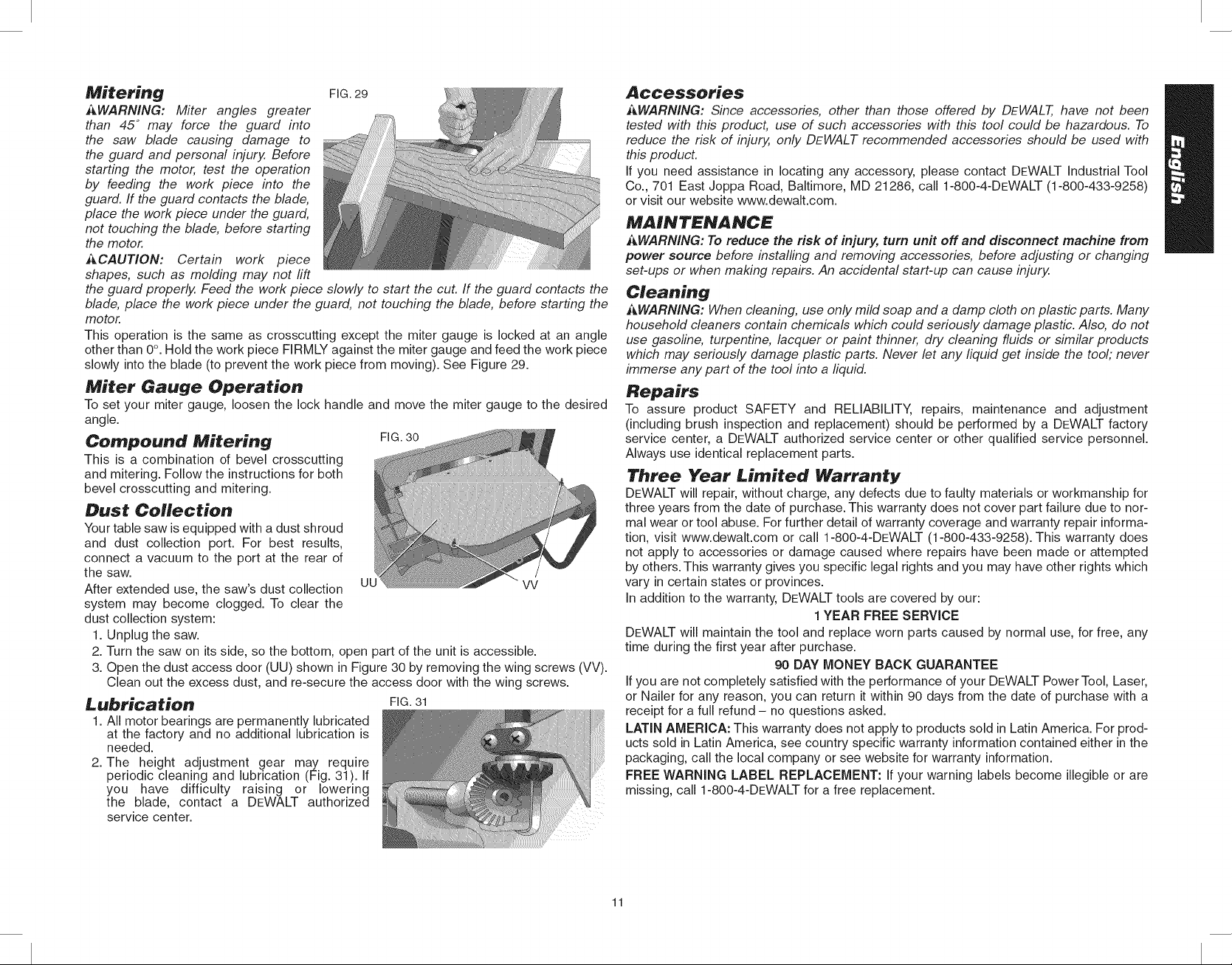

Mitering

_WARN/NG: Miter angles greater

than 45 ° may force the guard into

the saw blade causing damage to

the guard and personal injury. Before

starting the motor, test the operation

by feeding the work piece into the

guard, ff the guard contacts the blade,

place the work piece under the guard,

not touching the blade, before starting

the motor.

_CAUTION: Certain work piece

shapes, such as molding may not rift

the guard properly. Feed the work piece slowly to start the cut. If the guard contacts the

blade, place the work piece under the guard, not touching the blade, before starting the

motor.

This operation is the same as crosscutting except the miter gauge is locked at an angle

other than 0°. Hold the work piece FIRMLY against the miter gauge and feed the work piece

slowly into the blade (to prevent the work piece from moving). See Figure 29.

FIG. 29

Miter Gauge Operatien

To set your miter gauge, loosen the lock handle and move the miter gauge to the desired

angle.

Compound Mitering FIG.30

This is a combination of bevel crosscutting

and mitering. Follow the instructions for both

bevel crosscutting and mitering.

Dust Collection

Your table saw is equipped with a dust shroud

and dust collection port. For best results,

connect a vacuum to the port at the rear of

the saw.

After extended use, the saw's dust collection Ut VV

system may become clogged. To clear the

dust collection system:

1. Unplug the saw.

2. Turn the saw on its side, so the bottom, open part of the unit is accessible.

3. Open the dust access door (UU) shown in Figure 30 by removing the wing screws (VV).

Clean out the excess dust, and re-secure the access door with the wing screws.

Lubrication FIG.31

1. All motor bearings are permanently lubricated

at the factory and no additional lubrication is

needed.

2. The height adjustment gear may require

periodic cleaning and lubrication (Fig. 31). If

you have difficulty raising or lowering

the blade, contact a DEWALT authorized

service center.

Accessories

iCWARNING: Since accessories, other than those offered by DEWALT, have not been

tested with this product, use of such accessories with this tool could be hazardous. To

reduce the risk of injury, only DEWALT recommended accessories should be used with

this product.

If you need assistance in locating any accessory, please contact DEWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-9258)

or visit our website www.dewalt.com.

MAINTENANCE

•_,WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing

set-ups or when making repairs. An accidental start-up can cause injury.

Cleaning

,_WARNING: When cleaning, use only mild soap and a damp cloth on plastic parts. Many

household cleaners contain chemicals which could seriously damage plastic. Also, do not

use gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products

which may seriously damage plastic parts. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement) should be performed by a DEWALT factory

service center, a DEWALT authorized service center or other qualified service personnel.

Always use identical replacement parts.

Three Year £irnited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to nor-

mal wear or tool abuse. For further detail of warranty coverage and warranty repair informa-

tion, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does

not apply to accessories or damage caused where repairs have been made or attempted

by others. This warranty gives you specific legal rights and you may have other rights which

vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any

time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser,

or Nailer for any reason, you can return it within 90 days from the date of purchase with a

receipt for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For prod-

ucts sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT for a free replacement.

11

Page 13

° " " = _ NOTE,USE120VOLT

/ KEEPHANDS AWAY FROM BLADE" _J / TI......... RE.

i MANTENGAMANOR LEJOSDEHOJA. VJ

k o,,oE,DE==,,,=Lo,,LA ; /

TO=DUCETREMRKDF=JURY.=ARA=

BEFOREOPERATING SAW. ALWAYS USE PROPEREYEAND RESPIRATORY

PROTECTION.DONOT WEAR GLOVES.NECKTIES.JEWELRYDR LOOSECLOTHING.

CONTAIN LONGHAIR. KEEPBANDS OUT OFTHE LINE OF SAW BLARE-USE EXTRA

CAUTIONWHEN BEVELING. USE RAW-BLADEGUARDAND SPLITTERFOREVERYOPERATION

FORWHICH iT CAN REUSED, iNCLUDiNG ALLTHROUGH SAWING. USE A *'PUSH STICK'*WHEN

REQUIRED.KNOW HOW TO REDUCETHERISK OF KICKBACKS- SEE MANUAL. ALWAYSSUPPORT

WORK WiTH TABLE AND FENCEORMITER GAUGE.DO NOT PERFORMANY OPERATIONFREEHAND. USE

FENCEWHEN RiPPiNG AND MITERGAUGEWHEN CROSSCUTTING.NEVERUSE TOGETHER.NEVERREACH

AROUND OROVER SAW BLADE.SECURELYMOUNT SAW BLADEBEFORE OPERATING.NEVERREMOVEJAMMED

ORCUT-OFFPIECESUNTIL POWER iS OFFAND BLADE HASSTOPPED. LOCKBEVEL ADJUSTMENT BEFORE

OPERATION. SECURETOOLPROPERLYTO PREVENTUNEXPECTED MOVEMENT. DONOT OPERATETHiS MACHINE

WHILE UNDERTHE INFLUENCEOFALCOHOLORDRUGS.FAILURETO COMPLY WiTH THESEWARNINGS MAY RESULTIN

f U.S.PAT. NO.5,722,308;5,857,507;5,875,698;5,827,557;5,978,523;6,148,703;6,244,149;6,357,328;D386,747;D39_1,071;9355,322; /

( D397,3_4;D400,3t7; R407,725; DRI0,R74;D414,756;0445,119 OTHER PATENTSPENDING. /

FORSERVICEINFORMATION, CALLI'800-@DEWALT www.OEWALT.com

D_WALTINDUSTRIAL TOOL CO. BALTIMOREMR, 21ZBI U,S.A.

L_EVARL_PROTEICl0NAPRONAO/__ARALAVIST_Y_AP_L_SVIASRES_II_T0_IAS._0U_klC_GU_NTES,_01_ATAS,'_

CORTESCO_SlEII_._SlU_"E_PIJ_OOI+SlE_PI__UESE__RCES_IO.t_ it _I_L PaR_OeTE_E_I_FOIMglIONSO_I_COCORE_U_IrEkIIE_O _g

Mg_A INE_P_AOAME_TE. NO OPE_E ES_A N_,OUINA $1 _ST/_ BAJO LOS EFECTOS O_L A_CO!O_ 0 ItOGAS. E_ INCU*_pL_I£NTO O_ EST_*S AOYErTE_CIAS PO_RN _AUSAR [E_IO_ES PERSONALE$.

r '

COMPRiSTO_T_EBiTAGE_NPt_. Ull_ISER_N. POUS_OI__S_ YAUEU.CONNA_TRELES_HNi_ES POU_Ri_UlRELE_IS(ZUEASSOCiEAL'E_ET_ERE6ON_CONSULTERL_M_OEI'Er_PLOi.TIU_IU_SSOIT_Ni_LAPIE

! 6Ull_OUAVECLAJAUGEAONGLETS.EFFECTUERTOUT£OpE!AT]ONE_TENANT_'OU_OESOEUXNAJ_S.UTJ_JS_RLEGUIOEL_iTUDINALPODR_ES_IAGE£_LO_ETLAJAUGEAON,LETP_UILETRON_CtO_A_E._EJAMAiSA/$UTItJSERLES_EU×UTIL_SERL_S_EU×

J ................ _............... P_ ....... _................ S ..... C ................ S......... 'UTiLIS_R L'...... _ ............................. _IPE ......... 'Olff_.'ApAIITFMIS J

_ORS T_NSJG_ ET Q_ _ _ N'A pAR C_SSEOE TOU_NE_ VERRO_J_LER L_ R_G_GE IU BIS_U AV_T L'UTI_SA_O_. BIER _E_ L'OU_L POUR EV_E_ TOUT DEP_CEM_ J_A_ENDU. _ PAR _TI_SE_ C_ OUTJL SO_S L'EMPRISE D_ L'ALCOOL OU

POUR VOTR_ _ROPRE S Ecutrt_, _IRE kE MOlE _'EM_'LOI AVANT O'UTILISER kA S_l£. IL FAUT TOIJO URS PORTER _)_ L'E(_UIp_M ENT 1£ PROTECTION

. OCILAIIE ET RESPI_ATOI_E APPROPfllE. NE PAR ORTER IE GANTS, DE CRAVATE, OE BIJOUX OU OE VETENENT$ AMPLER. AT_ACHER LE_ CH£VEUX

UNDERSTAND INSTRUCTIONMANUAL

_RISE II L'IOOL

u

I/lllliXII%ll= l PARAPREVENIREL.E=OOESG,O.L=EELIIlllIIi 'llI!=OI/lllllllI"O's- G

ALL THIGIGI SAWING. KEEP PAIA TOIGS LOS CGITES CON SIEIRA.

J HANGS GUT OF THE LiNE GFTHE MANTENGA LAS MANOR ALEJAGAS DEL GAtGEI LES MAINS HORS DE LATIAJECTGIRE J

J SAWBLADE. USE A PUSHSTiCK TtAYECTO DE LA HOJA BE LA SIERRA. UTILICE DE LA LAME DE LA SCiE. UTILISER UN |

AND FEATHERBOARGS WHEN LA VARA PARA EMPU3AR Y TABLAS DE POUSSO|R ET DES PLANCHES EN EVENTAIL }

_% REQUIRED.

PIITEITII DE LA IIJA Y EL IENDEIII SIiPAIATEII Pill TOUT IilITAIE CIMPLE |T. J

CANTO BISELAGO CUANDO SEA NECESARIG. AU HEROIN.

12

Page 14

D_finitions : lignes directrices en

rnati_re de s_curit_

Les d6finitions ci-dessous d6crivent le niveau de danger pour chaque mot-indicateur

employ6. Veuillez lire le mode d'emploi et porter une attention particuli_re & ces

symboles.

i_DANGER : indique une situation dangereuse imminente quL si elle n'est pas

6vit6e, causera la mort ou des blessures graves.

i_AVERTISSEMENT : indique une situation potentiellement dangereuse quL si elle

n'est pas 6vit6e, pourrait se solder par un d#c_s ou des blessures graves. |

AMISE EN GARDE : indique une situation potentiellement dangereuse |

quL si efle n'est pas 6vit6e pourrait se solder par des blessures mineures ou |

mod_r#es. |

MISE EN GARDE : utilise sans le symbole d'alerte a la s4curit6, indique une situation |

potentieflement dangereuse quL si elle n'est pas dvit4e pourrait se solder par des |

dommages b la proprietY.

CONSERVER CES DIRECTIVES

R_gles de s_.curit_, g_n_rales

AVERTISSEMENT : /ire toutes les directives avant d'utiliser le produit. Tout manque-

ment aux directives suivantes pose des risques de choc 61ectrique, d'incendie et/ou

de blessure grave.

CONSERVER CES DIRECTIVES

,_AVERTISSEMENT : SUIVRE TOUS LES CODES DE C,4BLAGE et /es branchements

dlectriques recommandds afin d'dviter tout choc dlectrique ou dlectrocution.

Directives relatives _ ia rnise _ la terre

Si la scie est mise a la terre (int#gr#), lire les directives suivantes.

_\DANGER : RISQUE D'E.LECTROCUTION. LE PRE=SENT APPAREIL DOlT C=TRE

MIS Ji LA TERRE LORS DE SON UTILISATION. DE GRAVES BLESSURES PEUVENT

SURVENIR.

POUR TOUS LES APPAREILS MIS ._ LATERRE, BRANCHES ._ UN CORDON

D'AMMENTATION :

En cas de d6faillance ou de panne, la mise & la terre permet un cheminement de moin-

dre r6sistance pour le courant 61ectrique afin de r6duire le risque de choc 61ectrique.

Cet appareil est muni d'un cordon d'alimentation dot6 d'un conducteur de mise & la terre

d'6quipement et d'une fiche de mise b,la terre. La fiche doit 6tre branch6e sur une prise

de courant correspondante qui est install6e et mise b,la terre conform6ment & tous les

codes et &toutes les ordonnances & 1'6chelle locale. Ne pas modifier la fiche fournie; si

elle ne s'ins_re pas dans la prise de courant, faire installer une prise appropri6e par un

61ectricien professionnel. Si le conducteur de mise a la terre d'6quipement n'est pas cor-

rectement connect6, ceci peut provoquer un choc 61ectrique. Le conducteur de mise

la terre d'6quipement est le conducteur avec isolation qui a une surface ext6rieure verte

avec ou sans rayures jaunes. S'il est n6cessaire de faire r6parer ou remplacer le cordon

61ectrique ou lafiche, ne pas connecter le conducteur de mise & la terre d'6quipement b,

une borne sous tension. V6rifier aupr_s d'un 61ectricien ou d'un personnel de r6paration

professionnel si les directives de mise a la terre ne sont pas parfaitement comprises ou

en cas de doute sur le fait que I'appareil soit correctement mis & la terre ou non. Utiliser

uniquement une rallonge &3 ills pourvue d'une fiche de mise &la terre &3 lames et une

prise & 3 conducteurs correspondant a la fiche de I'appareil comme le montre la fig. A.

R6parer ou remplacer imm6diatement le cordon s'il est endommag6 ou us6.

POUR LES APPARE_LS MIS ._,LATERRE ET BRANCHE_S ._ UN CORDON

D'AMMENTATION UTILISE SUR UN CIRCUIT D'ALIMENTATION DE R#GJME

NOMINAL INFERJEUR ._ 150V :

Si I'appareil est utilis6 sur un circuit dont la prise de courant ressemble & celle de lafig.

A, il aura alors une fiche de mise & la terre semblable & celle de la fig. A. Un adaptateur

temporaire, qui ressemble & celui de la fig. B, peut 6tre utilis6 pour connecter cette

fiche & une prise & 2 conducteurs, comme le montre la fig. B, s'il n'existe aucune prise

de courant correctement mise a la terre. L:adaptateur temporaire ne doit 6tre utilis6

que jusqu'b, ce qu'un 61ectricien qualifi6 puisse installer une prise 61ectrique correcte-

ment mise & la terre. La patte rigide verte, la cosse et tout 616ment semblable sortant

de I'adaptateur doivent 6tre correctement branch6s b,une masse permanente comme

une boite de sortie mise a la terre. Chaque fois que I'adaptateur est utilis6, il dolt 6tre

maintenu en place par une vis m6tallique.

A BO/TE DE B

GOUPILLE DE MISE GOUPILLE DE MISE

,_,LA TERRE ,_,LA TERRE

C D

MOYENS DE

MISE ,&,LA

TERRE

ADAPTATEUR

REMARQUE : Au Canada, I'utilisation d'un adaptateur temporaire n'est pas autoris6e

par le Code 61ectrique canadien.

i_,DANGER: DANS TOUS LES CAS, S'ASSURER QUE LA PRISE DE COURANT

EN QUESTION EST CORRECTEMENT MISE ,4 LA TERRE. EN CAS DE DOUTE,

DEMANDER ,4 UN E:LECTRICIEN PROFESSIONNEL DE VE:RIFIER LA PRISE.

Double isolation

Si la scie est a double isolation, lire les directives suivantes.

Les outils & double isolation comportent partout deux couches d'isolant

61ectrique s6par6es ou une double 6paisseur de mat6riau isolant entre

rop6rateur et le syst_me 61ectrique de I'outil. Les outils comportant ce

syst_me d'isolation ne sont pas con£us pour 6tre mis & la terre. Votre outil

est donc dot6 d'une prise & deux broches qui vous permet d'utiliser des

cordons d'alimentation sans vous soucier de maintenir une connexion &

la terre. R6parer ou remplacer imm6diatement le cordon s'il est endommag6 ou us6.

REMARQUE : la double isolation ne remplace pas les pr6cautions normales de s6curit6

lots de I'utilisation de cet outil. Le syst_me d'isolation sert b,apporter une protection accrue

contre toute blessure r6sultant d'une d6faillance d'isolation 61ectrique au sein de I'outil.

FICHES POLARISE_ES

Pour r6duire le risque de chocs 61ectriques, le pr6sent appareil comporte une fiche polari-

s6e (une broche est plus large que I'autre). Cette fiche ne se branche que d'une seule fa(_on

dans une prise de courant polaris6e. Si la fiche ne s'ins_re pas totalement dans la prise de

courant, I'inverser. Si elle ne s'ins_re toujours pas dans la prise, demander & un 61ectricien

comp6tent d'installer une fiche polaris6e. Ne pas remplacer la fiche.

Directives de s_curit_ irnportantes

* POUR RE:DUIRE LE RISQUE D'EFFET DE REBOND, CONSERVER LES

DISPOSITIFS DE PROTECTION EN PLACE et en bon dtat de fonctionnement.

13

Page 15

, RETIRER LES CLE:S,4 MOLETTE ET LES CLF=SDE RE:GLAGE. S'habituer a v@rifier

si les cl@sa molette et les cl@sde r@glagesont retir@es de la broche avant de mettre

I'outil sous tension. Des outils, chutes, et autres d@brispeuvent @treprojet@s a grande

vitesse, provoquant des blessures.

, GARDER LA ZONE DE TRAVAIL PROPRE. Les zones et @tablis encombr@s sont

souvent des causes d'accidents.

, NE PAS UTILISER LE PRE:SENT APPAREIL DANS UN ENVIRONNEMENT

DANGEREUX. L'utilisation d'outils @lectriques clans un endroit humide ou mouill@ ou

sous la pluie peut provoquer un choc @lectrique ou une @lectrocution. Tenir la zone de

travail bien @clair@epour @viterde tr@bucher ou de mettre vos bras, mains et doigts en

danger.

, TENIR LES ENFANTS,4 L'E:CART. Tousles visiteurs doivent se trouver a une distance

s_re de la zone de travail. L'atelier repr@sente un environnement potentiellement dan-

gereux.

, S'ASSURER QUE L'ATELIER NE PRF=SENTE PAS DE DANGER POUR LES

ENFANTS en utilisant des cadenas, des interrupteurs principaux ou en retirant les cl@s

de d@marrage. Le d@marrage non autoris@ d'un appareil par un enfant ou un visiteur

pourrait se solder par des blessures.

, NE PAS FORCER L'OUTIL. Le travail sera mieux accompfi et sera moins dangereux

au rythme pr@vupour I'appareiL

, UTILISER L'OUTIL APPROPRIF=. Ne pas forcer un outil ou un accessoire a accomplir

un travail pour lequel il n'a pas @t@con_u. L'utilisation de I'outil ou de I'accessoire de

fa_on incorrecte pourrait se solder par des blessures corporelles.

, UTILISER LA RALLONGEAPPROPRIE:E. S'assurer que la rallonge est en bon @tat.Si

le produit est dot@d'un cordon d'alimentation, utiliser uniquement une rallonge a 3 ills

pourvue d'une fiche de mise a la terre a 3 lames et une prise a 3 fentes correspondant

la fiche de I'outil. Lorsque qu'une rallonge @lectrique est utilis@e, s'assurer d'en utiliser

une de calibre suffisamment 61ev@pour assurer le transport du courant n@cessaire

au fonctionnement de I'appareiL Un cordon de calibre inf@rieur causera une chute de

tension de ligne et donc une perte de puissance et une surchauffe. Le tableau suivant

indique le calibre appropri@ a utiliser selon la Iongueur du cordon et I'intensit@nominale

de la plaque signal@tique. En cas de doute, utiliser le calibre suivant le plus gros. Plus

le num@rode calibre est petit, plus le cordon est Iourd.

CALIBRE MINIMUM POUR RALLONGE

Volts Longueur totale de la rallonge en pieds

120V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensit_ norninale

Plus Pas plus AWG

de de

0 - 6 18 16 16 14

6- 10 18 16 14 12

10- 12 16 16 14 12

12 - 16 14 12 Non recommand@

PORTER LES VETEMENTS APPROPRIE:S. Ne pas porter ni v@tementample, ni gant,

ni cravate, ni bague, ni bracelet, ni autre bijou, car ces derniers pourraient s'enchev@trer

clans des pi@ces mobiles. Des souliers antid@rapants sont recommand@s. Se couvrir

les cheveux s'ils sont longs. Se tenir @loign@des @vents, car ces derniers pourraient

camoufler des pi@ces mobiles.

TOUJOURS PORTER DES LUNETTES DE SE:CURITF=. Les lunettes de vue ne

constituent PAS des lunettes de s@curit@.Utiliser @galement un masque facial ou anti-

poussi@re si Fop@rationde d@coupe g@n@rede la poussi@re. TOUJOURS porter un

@quipement de protection homologu@ :

* protection oculaire conforme a la norme ANSI 787.1 (CAN/CSA Z94.3);

protection auditive ANSI S12.6 ($3.19) et;

protection des voles respiratoires conformes aux normes NIOSH/OSHA/MSHA.

, NE PAS TROP TENDRE LES BRAS. Conserver son @quilibreen tout temps. Une perte

d'@quilibre risquerait d'entraTner une blessure corporelle.

PRENDRE SOIN DES OUTILS. S'assurer que les lames sont aiguis6es et propres

afin d'optimiser s@curit@et performance. Suivre les consignes de graissage et de

changement d'accessoires. Les lames et les appareils mal entretenus peuvent

s'endommager davantage et/ou provoquer des blessures.

, E:TEINDRE L'APPAREIL ET COUPER LE COURANT avant d'installer ou de retirer des

accessoires, avant tout r@glages ou modifications de celles-cL /ors de r@paration ou de

d@placements de I'appareiL Lots du branchement/d@branchement de la fiche, prendre

garde de ne pas toucher a ses lames m@talliques. Un d@marrage accidentel peut provo-

quer des blessures.

, RE:DUIRE LE RISQUE DE DE:MARRAGE ACCIDENTEL. S'assurer que I'interrupteur

se trouve sur la position d'arr@t avant de brancher le cordon d'alimentation. En cas de

panne de courant, mettre I'interrupteur sur la position d'arr@t. Un d@marrage accidentel

peut provoquer des blessures.

, UTILISATION DES ACCESSOIRES RECOMMANDE:S. N'utiliser que les accessoires

conseill@s par le fabricant pour le mod@le de votre outiL Des accessoires qui convien-

nent a un outil pourraient @tredangereux Iorsqu'ils sont utilis6s avec un autre outiL

Une liste des accessoires recommandes se trouve clans le mode d'emploL L'utilisation

d'accessoires inappropri@s peut entrMner un risque de blessure corporelle.

, NE JAMAIS SE TENIR SUR L'OUTIL. Une blessure grave pourrait se produire en cas

de basculement de I'outil ou de demarrage accidentel de I'outil de decoupe.

, VE.RIFIER QUE LES PIECES NE SONT PAS ENDOMMAGE:ES. Avant toute utilisation

ult@rieure de I'outil, un prot@ge-lame (ou une autre pi@ce) endommag@ doit @tresoi-

gneusement examine afin de d@terminer s'il fonctionnera correctement et s'il remplira

sa fonction pr@vue - v@rifierI'alignement des pi@ces mobiles, la pr@sence de grippage

des pi@ces mobiles, la rupture de pi@ces, la fixation et tout probl@me pouvant nuire au

fonctionnement de I'outiL Un prot@ge-lame (ou toute autre pi@ce) endommag6 dolt @tre

r@par@et remplac@ ad@quatement. Ne pas utiliser I'outil si I'interrupteur ne fonctionne

pas. Les pi@cesendommag@es peuvent contribuer a endommager davantage I'appareil

et/ou provoquer des blessures corporelles.

, DIRECTION DE L'AVANCEMENT DE LA PIt=CE. Acheminer la pi@ceclans une lame

ou un couteau uniquement a contre-courant de la rotation de la lame ou du couteau.

, NE JAMAIS LAISSER L'OUTIL FONCTIONNER SANS SURVEILLANCE. E:TEINDRE

L'APPAREIL. Ne pas laisser I'outil tant qu'il n'est pas compl@tement art@t@.De graves

blessures pourraient survenir.

, NE PAS UTILISER D'OUTILS =LLECTRIQUES ,4 PROXIMITCL DE LIQUIDES

INFLAMMABLES OU DANS UNE ATMOSPHERE GAZEUSE OU EXPLOSIVE. Les

moteurs et interrupteurs des outils pourraient provoquer des @tincelles et enflammer

des vapeurs.

, F=TRE VIGILANT, SURVEILLER LE TRAVAIL EFFECTUE:, ET FAIRE PREUVE DE

JUGEMENT. NE PAS UTILISER L'APPAREIL EN CAS DE FATIGUE OU SOUS

L'INFLUENCE DE DROGUES, D'ALCOOL, OU DE ME:DICAMENTS. Un moment

d'inattention, durant I'utilisation d'un outil @lectrique, peut se solder par des blessures

corporelles graves.

, NE PAS LAISSER UNE BONNE CONNAISSANCE DE L'OUTIL (ACQUISE PAR

L'UTILISATION FRF=QUENTE DE LA SCIE) PRENDRE PRF=CE:DENCE SUR LES

14

Page 16

RE.GLES DE SE:CURITr:. Toujours se souvenir qu'une fraction de seconde d'imprudence

est suffisante pour infliger de graves blessures.

R_gles de s_curit_ suppl_rnentaires pour les scies

circulaires _ table

i_AVERTISSEMENT : TOUJOURS PORTER DES LUNETTES DE SE:CURITE:. Les

lunettes de vue ne constituent PAS des lunettes de s@curit@. Utiliser @galement un

masque facial ou anti-poussi@re si I'op@rationde d@coupe g@n@rede la poussi@re. Tous

les utilisateurs et les personnes a proximit@ DOIVENT TOUJOURS utiliser un @quipement

de s@curit@homologu@ :

* protection oculaire conforme a la norme ANSI Z87.1 (CAN/CSA Z94.3),

* protection auditive conforme a la norme ANSI $12.6 ($3.19) et

* protection des voles respiratoires conformes aux normes NIOSH/OSHA/MSHA.

* E:VITER de placer les mains a un endroit ob un glissement soudain pourrait amener la

main sur la lame de la scie.

* NE JAMAIS PASSER LES MAINS .4 L'ARRIERE OU AUTOUR DE L'OUTIL DE

COUPE pour tenir lapi@ce.

* GARDER LES BRAS, LES MAINS, ET LES DOIGTS E:LOIGNE:S de la lame afin

d'@viter des blessures graves.

* UTILISER UN POUSSOIR OU UN BLOC-POUSSOIR ADE:QUAT POUR

L'APPLICATION EN COURS, QUI PERMET D'AVANCER LES PIECES SUR LA

LAME. Un poussoir est un petit b_ton de bois ou d'une mati@re non m@tallique,

normalement fait maison, qui s'utilise pour @viter d'approcher vos mains a pr@s de

15,2 cm (6 po) de la lame a chaque fois que la taille ou la forme de la pi@ce I'exige.

Utiliser des dispositifs d'ancrage, serre-joints, fixations ou planches en #ventail

pour mieux guider et contr61er la pi@ce en I'absence du guide longitudinal. Utiliser

un prot@ge-lame et un couteau s#parateur pour toutes les operations demandant son

utilisation, y compris tout d@bitagecomplet.

* NE PAS SCIER EN LONG,. EXE:CUTER DES TRON_ONNAGES OU TOUTE AUTRE

OPE:RATION DE COUPE A MAINS LIBRES.

* NE JAMAIS s'incliner pr@sou au-dessus de la lame de scie.

* STABILITF=. S'assurer que le banc de scie soit fermement fix@a une surface solide et

qu'il ne bouge pas avant de I'utiliser.

* NE JAMAIS COUPER DE ME:TAUX FERREUX (m@taux contenant du fer ou de

I'acier), PANNEAU DE CIMENT OU MA_.ONNERIE. Certaines mati@res artificielles

comportent des directives sp@cifiques pour la coupe sur des bancs de scie. Suivre les

recommandations du fabricant en tout temps. II sera ainsi possible de pr@venir des

dommages a la scie ou des blessures corporelles.

* TOUJOURS INSF=RER LE PASSE-LAME APPROPRIE: pour r@duire le risque de pro-

jection d'une pi@ce et de blessures @ventuelles.

* UTILISER LA LAME DE SCIE APPROPRIF=E POUR L'UTILISATION PRE:VUE. La

lame dolt tourner vers I'avant de la scie. Toujours serrer solidement I'@crou d'axe de la