Page 1

Questions? See us on the World Wide Web at www.dewalt.com

INSTRUCTION MANUAL

DW744XP-XE

HEAVY-DUTY 254 MM (10") JOB SITE TABLE SAW

Page 2

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL US AT: 1800 654 155

(Aust) or 0800 339258 (NZ).

SAFETY INSTRUCTIONS

When using power tools, always observe the safety regulationsapplicable in your country to reduce the risk of fire,

electric shockand personal injury. Read the following safety instructions beforeattempting to operate this product.

KEEP THESE INSTRUCTIONS IN A SAFE PLACE!

General

1 . Keep work area clean .

Cluttered areas and benches can cause accidents.

2. Consider work area environment .

Do not expose power tools to humidity. Keep work area well lit. Do not use power tools in the presence of

flammable liquids or gases.

3. Guard against electric shock .

Prevent body contact with earthed surfaces (e.g., pipes, radiators, cookers and refrigerators). For use under

extreme conditions (e.g., high humidity, when metal swarf is being produced, etc.) electric safety can be

improved by inserting an isolating transformer or a (FI) earth-leakage circuit-breaker.

4. Keep children away .

Do not let children come into contact with the tool or extension cord. Supervision is required for inexperienced

operators.

5. Extension cords for outdoor use .

When the tool is used outdoors, always use extension cords intended for outdoor use and marked

accordingly.

6. Store idle tools .

When not in use, power tools must be stored in a dry place and locked up securely, out of reach of children.

7. Dress properly.

Do not wear loose clothing or jewellery. They can be caught in moving parts. Preferably wear rubber gloves

and non-slip footwear when working outdoors. Wear protective hair covering to keep long hair out of the way.

8. Wear safety goggles .

Also use a face or dust mask in case the operations produce dust or flying particles.

9. Beware of maximum sound pressure .

Take appropriate measures for the protection of hearing if the sound pressure of 85 dB(A) is exceeded.

10. Secure workpiece .

Keep proper footing and balance at all times .

11. Do not overreach .

Always check that adjusting keys and wrenches are removed from the tool before operating the tool.

12. Avoid unintentional starting .

Do not carry the plugged-in tool with a finger on the switch. Be sure that the switch is released when

plugging in.

13. Stay alert .

Watch what you are doing. Use common sense. Do not operate the tool when you are tired.

14. Disconnect tool .

Shut off power and wait for the tool to come to a complete standstill before leaving it unattended. Unplug the

tool when not in use, before servicing or changing accessories.

15. Remove adjusting keys and wrenches .

Always check that adjusting keys and wrenches are removed from the tool before operating the tool.

16. Use appropriate tool .

The intended use is described in this instruction manual. Do not force small tools or attachments to do the job

of a heavy-duty tool. The tool will do the job better and safer at the rate for which it was intended.

WARNING! The use of any accessory or attachment or performance of any operation with this tool, other than

those recommended in this instruction manual may present a risk of personal injury.

17. Do not abuse cord.

Never carry the tool by its cord or pull it to disconnect from the socket. Keep the cord away from heat, oil and

sharp edges.

18. Maintain tools with care.

Keep the tools in good condition and clean for better and safer performance. Follow the instructions for

maintenance and changing accessories. Inspect the tool cords at regular intervals and, if damaged, have them

repaired by an authorized D

damaged. Keep all controls dry, clean and free from oil and grease.

19. Check for damaged parts .

Before using the tool, carefully check it for damage to ensure that it will operate properly and perform its

intended function. Check for misalignment and seizure of moving parts, breakage of par ts and any other

conditions that may affect its operation. Have damaged guards or other defective parts repaired or replaced as

instructed. Do not use the tool if the switch is defective. Have the switch replaced by an authorized DEWALT

repair agent.

20. Have your tool repaired by an authorized DEWALT repair agent .

This power tool is in accordance with the relevant safety regulations. To avoid danger, electric appliances

must only be repaired by qualified technicians.

EWALT repair agent. Inspect the extension cords periodically and replace them if

Additional Safety Rules for Saw Benches

• Do - protect the electrical supply line with a suitable fuse or circuit breaker.

• Do - make certain the blade rotates in the correct direction and that the teeth are pointing to the front of the

saw bench.

• Do - be sure all clamp handles are tight before starting any operation.

• Do - be sure all blade and arbor collars are clean and the recessed sides of the collars are against the blade.

• Do - keep the saw blade sharp and properly set.

• Do - keep hands out of the path of the saw blade.

• Do - shut off the power and wait for the saw blade to stop before servicing or adjusting the tool.

• Do - disconnect the saw from the mains supply before changing the blade or carrying out maintenance.

• Don’t - attempt to operate on anything other than the designated voltage.

• Don’t - use blades larger or smaller than those which are recommended.

• Don’t - force the cutting action. (Stalling or partial stalling of the motor can cause major damage. Allow the

• Don’t - cut ferrous metals, non-ferrous metals or masonry.

• Don’t - use abrasive wheels.

• Don’t - apply lubricants to the blade when it is running.

• Don’t - place either hand in the blade area when the saw is connected to the power source.

• Don’t - use any blades other than those specified in this instruction manual.

• Don’t - operate the saw without the guards in place.

• Don’t - reach around behind the saw blade.

• Don’t - place hands closer than 150 mm from the saw blade while cutting.

• Don’t - use damaged or cracked saw blades.

motor to reach full speed before cutting.)

Residual Risks

The following risks are inherent to the use of saws:

– injuries caused by touching the rotating par ts

2

Page 3

In spite of the application of the relevant safety regulations and the implementation of safety devices, certain

residual risks cannot be avoided. These are:

– Impairment of hearing.

– Risk of accidents caused by the uncovered par ts of the rotating sawblade.

– Risk of injury when changing the blade.

– Risk of squeezing fingers when opening the guards.

– Health hazards caused by breathing dust developed when sawing wood, especially oak, beech and MDF.

Package Contents

The package contains:

1 Partly assembled machine

1 Rip fence

1 Mitre gauge

1 TCT saw blade

1 Upper blade guard assembly

1 Table insert

1 Blade wrench

1 Arbor wrench

1 Dust extraction adapter

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or accessories which may have occurred during transport.

• Take the time to thoroughly read and understand this manual prior to operation.

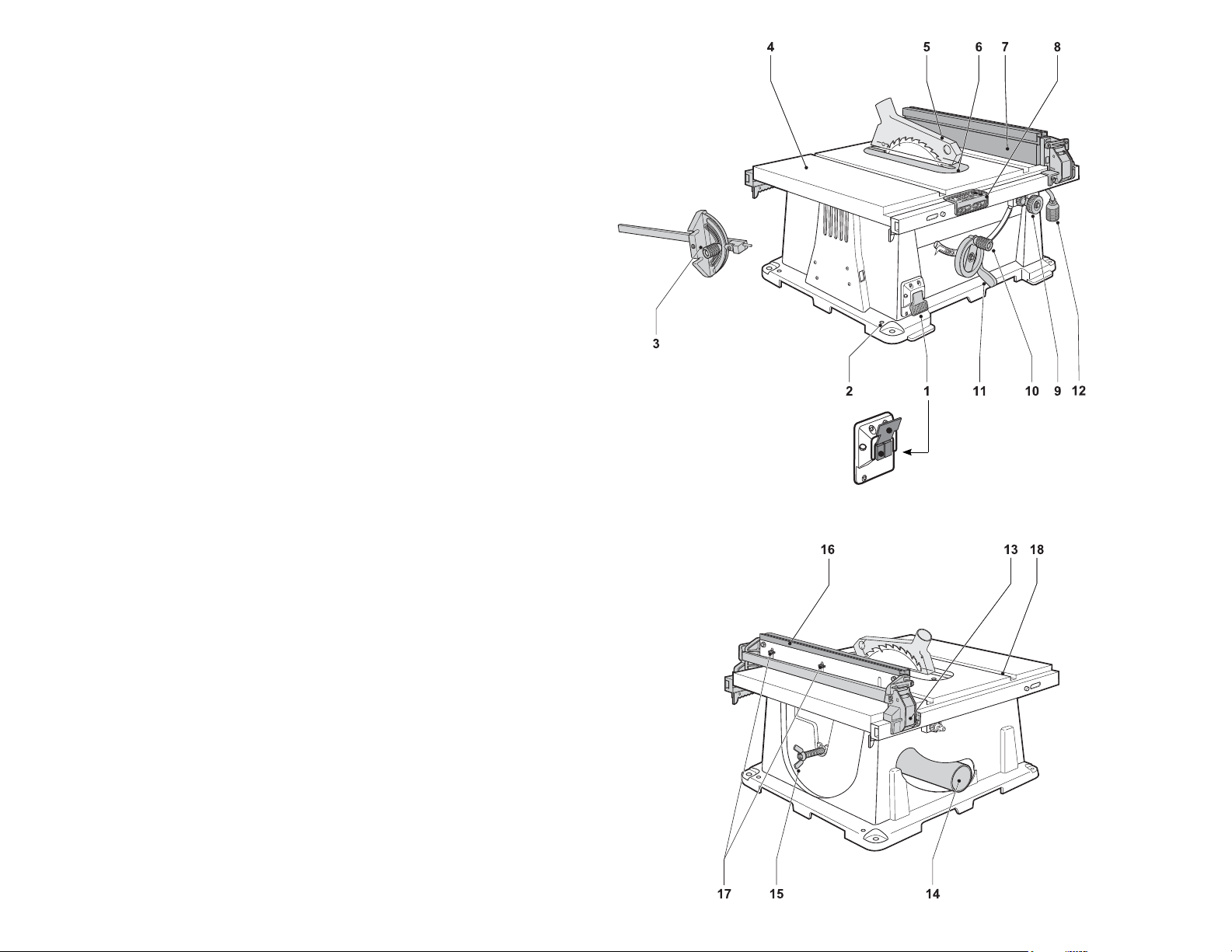

Description (fig. A1, A2)

Your DW744XP jobsite table saw has been designed to perform the four main sawing operations of ripping,

cross-cutting, bevelling and mitring easily, accurately and safely in wood, wood products and plastics. This unit is

designed for use with a 250 mm carbide-tipped blade.

A1 A2

1 On/off switch 13 Rip fence latch

2 Mounting holes 14 Dust extraction outlet (accepts dust

3 Mitre gauge extraction adaptor)

4 Table 15 Blade/wrench storage

5 Upper blade guard 16 Fence rail

6 Table insert 17 Locking knobs

7 Rip fence 18 Fence slot

8 Rip scale indicator

9 Fine adjustment knob

10 Combined elevating and bevel control wheel

11 Bevel lock lever

12 Ripping position lock lever

A1

A2

ELECTRICAL SAFETY

The electric motor has been designed for one voltage only. Always check that the power supply corresponds to the

voltage on the rating plate.

Mains Plug Replacement (U.K. & Ireland Only)

• Should your mains plug need replacing and you are competent to do this, proceed as instructed below. If you

are in doubt, contact an authorized D E WALT repair agent or a qualified electrician.

• Disconnect the plug from the supply.

• Cut off the plug and dispose of it safely; a plug with bared copper conductors is dangerous if engaged in a

live socket outlet.

• Only fit 13 Amperes BS1363A approved plugs fitted with the correctly rated fuse (1).

• The cable wire colours, or a letter, will be marked at the connection points of most good quality plugs. Attach

the wires to their respective points in the plug (see below). Brown is for Live (L) (2), blue is for Neutral (N)

(4) and green/yellow is for Earth (E).

3

Page 4

• Before replacing the top cover of the mains plug ensure that the cable restraint (3) is holding the outer sheath

of the cable firmly and that the leads are correctly fixed at the terminal screws.

1

B1

B2

4

3

WARNING: Never use a light socket. Never connect the live (L) or neutral (N) wires to the earth pin

marked E or .

For 115 V units with a power rating exceeding 1500 W, we recommend to fit a plug to BS4343 standard.

2

Using an extension cable

If an extension cable is required, use an approved extension cable suitable for the power input of this machine

(see technical data). The minimum conductor size is 1.5 mm

When using a cable reel, always unwind the cable completely.

Also refer to the table below.

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

2

.

C1

C2

ASSEMBLY AND ADJUSTMENT

WARNING: Prior to assembly and adjustment always unplug the tool.

The machine is fully assembled except for the blade, rip fence, upperblade guard and table insert.

Fitting the Rip Fence (fig. B1, B2)

The rip fence (7) can be installed on the left- or right-side of your table saw.

1. Locate the pin (19) with the slot (20) in the rip fence and align the opening (21) with the rip fence latch (22)

(fig. B1, B2).

2. Secure the rip fence by snapping both latches in place (fig. B2).

Mounting the Saw Blade (fig. A1, C1, C2)

WARNING: Ensure the machine is disconnected from the power source.

WARNING: The teeth of a new blade are very sharp and can be dangerous.

1. Raise the blade arbor to its maximum by rotating the control wheel (10) clockwise (fig. A1).

2. Place the saw blade onto the spindle in the order shown in figure C1. Make sure the teeth point down at the

front of the table.

3. Hold the spindle using the open-ended wrench and tighten the arbor nut by rotating clockwise using the arbor

wrench (fig. C2).

4. To remove the blade, proceed in reverse order.

WARNING: Always check the rip fence pointer and the riving knife after having changed the blade.

4

Page 5

Parallel Adjustment (fig. A2, D)

For optimum performance, the blade must be parallel to the mitre slots.

This adjustment has been made at the factory. To re-adjust:

1. Place the unit in upright position.

2. Using a 10 mm socket wrench, slacken the bracket fasteners (25)

slightly (fig. D).

3. Adjust the bracket (26) until the blade is parallel to the fence slot (18)

(fig. A2).

4. Tighten the bracket fasteners (25) to 11 Nm (fig. D).

BLADE HEIGHT ADJUSTMENT (FIG. A1)

The blade can be raised and lowered by turning the combined elevating

and bevel control wheel (10).

Make sure the top three teeth of the blade are just breaking through the

upper surface of the workpiece when sawing. This will ensure that the

maximum number of teeth are removing material at any given time, thus

giving optimum performance.

Adjusting the Rip Scale (fig. A1, E)

1. Remove the blade guard.

2. Unlock the lock lever (12) by pulling it up (fig. A1).

3. Unlock the bevel lock lever (11) and set the bevel angle to 0°.

4. Move the fence (7) until it touches the blade.

5. Lock the lock lever (12).

6. Loosen the rip scale pointer screws (27) and set the pointer (28) to

zero (fig. E).

7. Tighten the screws (27).

The rip scale reads correctly only when the fence is mounted to the right

of the blade.

Mounting the Riving Knife Assembly (fig. A1, F)

1. Raise the blade arbor to its maximum by rotating the blade height

adjustment wheel (10) clockwise (fig. A1).

2. Slacken the two bolts (29) (fig. F).

3. Align the slots (30) with the bolts (29) and insert the fence until the

tops of the slots rest on the bolts (fig. F).

NOTE: When properly aligned, the riving knife will be in line with

the blade at the table top and at the top of the blade. Check using a

straight edge in all bevel and blade height positions.

4. If adjustment is required, remove the blade guard and adjust the

shims (32).

5. Mount the blade guard on the bolts.

6. Retighten the bolts (29) securely.

WARNING: When properly aligned, the riving knife will be in

line with the blade at the table top and at the top of the blade.

Check using a straight edge in all bevel and blade height

positions.

WARNING: Correct mounting and alignment of the riving knife

and upper blade guard is essential to safe operation!

Mounting the Table Insert (fig. H)

1. Align the table insert (6) as shown and inser t the tabs of the back of

the table insert into the holes on the back of the table.

2. Press down the front of the table insert.

3. The front of the table insert must be flush or slightly below the table

top. The rear should be flush or slightly above the table top. Adjust

using the four adjustment screws (33).

D

F

4. Turn the locking screw (see insert in fig. H) clockwise 90° to lock the

table insert in place.

WARNING: Never use the machine without the table inser t.

Immediately replace the table insert when worn or damaged.

Bench Mounting (fig. A1)

• Holes (2) are provided in all four feet to facilitate bench mounting.

Two different sized holes are provided to accommodate different

sizes of bolts. Use either hole; it is not necessary to use both.

Always mount your saw firmly to prevent movement. To enhance the

portability, the tool can be mounted to a piece of 12.5 mm or thicker

plywood which can then be clamped to your work support or moved

to other job sites and reclamped.

• When mounting your saw to a piece of plywood, make sure that the

mounting screws do not protrude from the bottom of the wood. The

plywood must sit flush on the work support. When clamping the saw

to any work surface, clamp only on the clamping bosses where the

mounting screw holes are located. Clamping at any other point will

interfere with the proper operation of the saw.

• To prevent binding and inaccuracy, be sure the mounting sur face is

not warped or otherwise uneven. If the saw rocks on the surface,

place a thin piece of material under one saw foot until the saw is firm

on the mounting surface.

E

G

H

5

Page 6

WARNING: The mounting surface must have a 350 x 500 mm

opening to allow dust to escape.

Rail lock adjustment (fig. A1, J)

The rail lock has been factory-set. If you need to re-adjust, proceed as

follows:

1. Lock the lock lever (12) by pushing it down (fig. A1).

2. Adjust the nut (34) on the underside of your saw until the gap between

the Belleville washers (35) closes (fig. J).

3. Once the Belleville washers are almost touching, loosen the nut (34)

half a turn.

Bevel Stop and Pointer Adjustment (fig. K1, K2)

1. Raise the blade to its maximum by rotating the blade height

adjustment wheel (10) clockwise (fig. K1).

2. Unlock the bevel lock lever (11) by pushing it up and to the right.

3. Loosen the bevel stop screw (36).

4. Place a set square (37) on the table and up against the blade (38)

(fig. K2).

5. Adjust the bevel angle using the bevel lock lever (11) until the blade is

flat against the square.

6. Tighten the bevel lock lever (11).

7. Turn the bevel stop cam (39) until it firmly contacts the bearing block

(fig. K1).

8. Check the bevel angle scale. If adjustment is required, loosen the

pointer screw (40) and set the pointer to 0°.

9. Tighten the pointer screw (40).

10. Repeat the procedure at 45° for the 45° bevel stop, but do not adjust

the pointer.

Mitre Gauge Adjustment (fig. A3, L)

Your mitre gauge (3) is equipped with adjustable stops at 90° and 45°.

To adjust these stops, loosen the lock nuts (41) and set the adjusting

screws (42) as required.

Adjusting the Fence Parallel to the Blade (fig. A1, D)

The fence has been factory-set. If you need to re-adjust, proceed as

follows:

1. Unlock the rail lock lever (12).

2. Remove the upper blade guard (5).

3. Locate the rear pinion bearing and loosen the two hex bolts (25A) just

enough to allow side-to-side movement.

4. Move the fence over until it touches the side of the blade.

5. Adjust the fence parallel to the blade.

6. Tighten the hex bolts.

7. Lock the rail lock lever and check that the fence is parallel to the blade.

WARNING: If there is not enough travel in the pinion bearing

assembly, take the unit to an authorized D E WALT repair agent.

Fine Adjustment Knob (fig. D)

The fine adjustment knob is factory adjusted.

If adjustment is required, proceed as follows:

1. Turn the saw upside down and locate the front pinion bearing.

2. Using a narrow blade screwdriver, access the screw through the slot

(26A).

3. Loosen the screw by turning counterclockwise until the head touches

the inside of the bearing box.

J K1

K2

4. Tighten the screw 1/2 of a turn.

5. Repeat this procedure for the rear pinion bearing.

INSTRUCTIONS FOR USE

WARNING:

• Always observe the safety instructions and applicable

regulations.

• Install the appropriate saw blade. Do not use excessively

worn blades. The maximum rotation speed of the tool must

not exceed that of the saw blade.

• Do not attempt to cut excessively small pieces.

• Allow the blade to cut freely. Do not force.

• Allow the motor to reach full speed before cutting.

• Make sure all locking knobs and clamp handles are tight.

• Never place either hand in the blade area when the saw is

connected to the electrical power source.

• Never use your saw for freehand cuts!

L

• Do not saw warped, bowed or cupped workpieces. There

must be at least one straight, smooth side to go against the

rip fence or mitre fence.

• Always support long workpieces to prevent kickback.

• Do not remove any off-cuts from the blade area while the

blade is running.

The attention of UK users is drawn to the "woodworking machines

regulations 1974" and any subsequent amendments.

Switching on and off (fig. A1)

The on/off switch of your saw bench offers multiple advantages:

– No-volt Release Function: should the power be shut off for any

reason, the switch has to be deliberately reactivated.

– Extra Safety: the hinged safety enclosure plate can be locked by

passing a padlock through the centre hasp. The plate also serves as

an "easy to locate" emergency stop button as pressure on the front of

the plate will depress the stop button.

To switch the machine on, press the green start button.

To switch the machine off, press the red stop button.

6

Page 7

BASIC SAW CUTS

Ripping (fig. A1, A2, M1, M2)

WARNING: Sharp edges.

1. Set the blade to 0°.

2. Lock the rip fence (7) (fig. A1).

3. Raise the blade until it is about 3.2 mm higher than the top of the

workpiece.

4. Hold the workpiece flat on the table and against the fence. Keep the

workpiece approx. 25 mm away from the blade.

5. Press the green button to switch ON and allow the blade to reach full

6. Slowly feed the workpiece underneath the guard, keeping it firmly

7. Always use a push stick (43) when close to the blade (fig. M1).

8. After completing the cut, switch the saw OFF, allow the blade to

WARNING:

• Never push or hold the "free" or cut-off-side of the

• Do not cut excessively small workpieces.

• Always use a push stick when ripping small workpieces.

WARNING: Keep both hands away from the path of the blade

(fig. M2).

speed.

pressed against the rip fence. Allow the teeth to cut, and do not force

the workpiece through the blade. The blade speed should be kept

constant.

stopand remove the workpiece.

workpiece.

Bevel Cuts

1. Set the required bevel angle (refer to the section "Adjusting the rip

scale").

2. Proceed as for ripping.

Cross-cutting and Bevel Cross-cutting

1. Remove the rip fence and install the mitre gauge in the desired slot.

2. Lock the mitre gauge at 0°.

3. Proceed as for ripping.

Mitre Cuts (fig. A1)

1. Set the mitre gauge to the required angle.

2. Always hold the workpiece tightly against the face of the mitre gauge.

3. Proceed as for ripping.

Compound Mitre

This cut is a combination of a mitre and a bevel cut.

1. Set the bevel to the angle required.

2. Proceed as for a cross-cut mitre.

Support for Long Pieces

Always suppor t long pieces.

Suppor t long workpieces using any convenient means such as saw-

horses or similar devices to keep the ends from dropping.

Dust Extraction (fig. A2)

The machine is provided with dust extraction outlets (5, 14). An adaptor is

provided for outlet (14) .

M1

M2

N

O

• Connect a suitable dust extraction device during all sawing

• Whenever possible, connect a dust extraction device

WARNING:

operations.

designed in accordance with the relevant regulations

regarding dust emission.

Transporting (fig. A1)

• Always carry the machine at the hand indentations.

WARNING: Always transport the machine with the upper blade

guard fitted.

MAINTENANCE

Your D E WALT machine has been designed to operate over a long period of

time with a minimum of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

Lubrication (fig. N)

The motor and bearings require no additional lubrication. If raising

and lowering the blade becomes difficult, clean and grease the height

adjustment screws:

1. Turn the saw on its side.

2. Clean and grease the height adjustment threads as shown in figure N.

Use general purpose grease.

Cleaning

WARNING: To reduce the risk of serious personal injury, turn unit

off and disconnect machine from power source before cleaning. An

accidental start-up can cause injury.

To maintain correct operation of your saw, clean the table insert area

regularly. Remove saw dust, chips and any other debris. If using

compressed air, always wear approved eye protection.

Regularly clean the dust collection system:

1. Turn the saw on its side.

2. Remove the screws (44) (fig. O).

3. Remove all dust and resecure the access door (45) using the screws

(fig. O).

IMPORTANT: The guard and throat plate must be placed in position before

operating the saw.

Accessories

WARNING: Since accessories, other than those offered by

Recommended accessories for use with your tool are available at extra

cost from your local service center. If you need any assistance in locating

any accessory, please contact DEWALT Industrial Tool Co., 20 Fletcher

Road, Mooroolbark, VIC 3138 Australia or call 1800 654 155 or (NZ)

0800 339258.

The following attachments are available:

– legstand DE7440

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the

risk of injury, only DEWALT, recommended accessories should

be used with this product.

WARNING: Sharp edges.

7

Page 8

Unwanted Tools and the Environment

Take your tool to an authorized DEWALT repair agent where it will

bedisposed of in an environmentally safe way.

Service Information

Please have the following information available for all service calls:

Model Number _____________ Serial Number _________________

Date and Place of Purchase __________________________________

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustments should be performed by a DEWALT factory service center,

a DEWALT authorized service center or other qualified service personnel.

Always use identical replacement parts.

Guarantee

Applicable to hand held Power Tools, Lasers and Nailers.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. Please return the

complete unit, transportation prepaid, to any DEWALT Service Centre, or

any authorised service station.

For warranty repair information, call (AUS) 1800 654 155 or (NZ) 0800

339258.

This warranty does not apply to

• Accessories

• Damage caused where repairs have been made or attempted by

others.

• Damage due to misuse, neglect, wear and tear, alteration or

modification.

This warranty gives you specific legal rights and you may have other rights

under the provisions of the Consumer Guarantee Act 1993 (New Zealand

only), Trade Practices Act 1974 and State Legislation (Australia only).

In addition to the warranty, D

FREE ONE YEAR SERVICE CONTRACT

DEWALT will also maintain the tool for free at any time during the first year

of purchase. This includes labour, parts and lubrication required to restore

the product to sound mechanical and/or electrical condition. Normal wear

parts are not covered in this service. Carbon brushes worn more then

50% will be replaced.

NOTE: Three Year Warranty is not applicable to items deemed as

consumables. Radial arm saws are covered by a one (1) year warranty

only. DEWALT reserves the right to review its warranty policy prior to

launch of any new business development products.

30 DAY NO SATISFACTION GUARANTEE

If you are dissatisfied with any DEWALT power tool, laser or nailer, for any

reason, simply return it to the point of purchase with your sales receipt

within 30 days for a replacement unit or a full refund.

FREE WARNING LABEL REPLACEMENT: If your warning labels become

illegible or are missing, call (AUS) 1800 654 155 or (NZ) 0800 339258

for a free replacement.

EWALT tools are covered by our:

Specifications

DW744XP-XE

Voltage V 220-240

Motor power (input) W 2000

Motor power (output) W 1300

No load speed min-1 3000

Blade diameter mm 250

Blade bore mm 15.88 (5/8")

Depth of cut at 90˚ mm 77

Depth of cut at 45˚ mm 56

Ripping capacity mm 610

Overall dimensions mm 570 x 700 x 410

Weight kg 29

L

(sound pressure) db(A)• 91

pa

Lwa (acoustic pressure) db(A)• 104

• at operator's ear

8910

Page 9

Page 10

Page 11

11

Page 12

The following are trademarks for one or more D

on the surface of the tool.

DEWALT Industrial Tool Co.,

20 Fletcher Road, Mooroolbark, VIC 3138 Australia (03 8720 5100) • 5 Te Apunga Place, Mt Wellington, New Zealand (0800 339258)

(AUG08) Part No. 662700-00 DW744XP-XE Copyright © 2008 D

EWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps

EWALT

Loading...

Loading...