Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

MANUAL DE INSTRUCCIONES

DW7440RS

Heavy-Duty Rolling Table Saw Stand

Socle mobile robuste pour table de scie

Base rodante para sierra banco, para trabajo pesado

Page 2

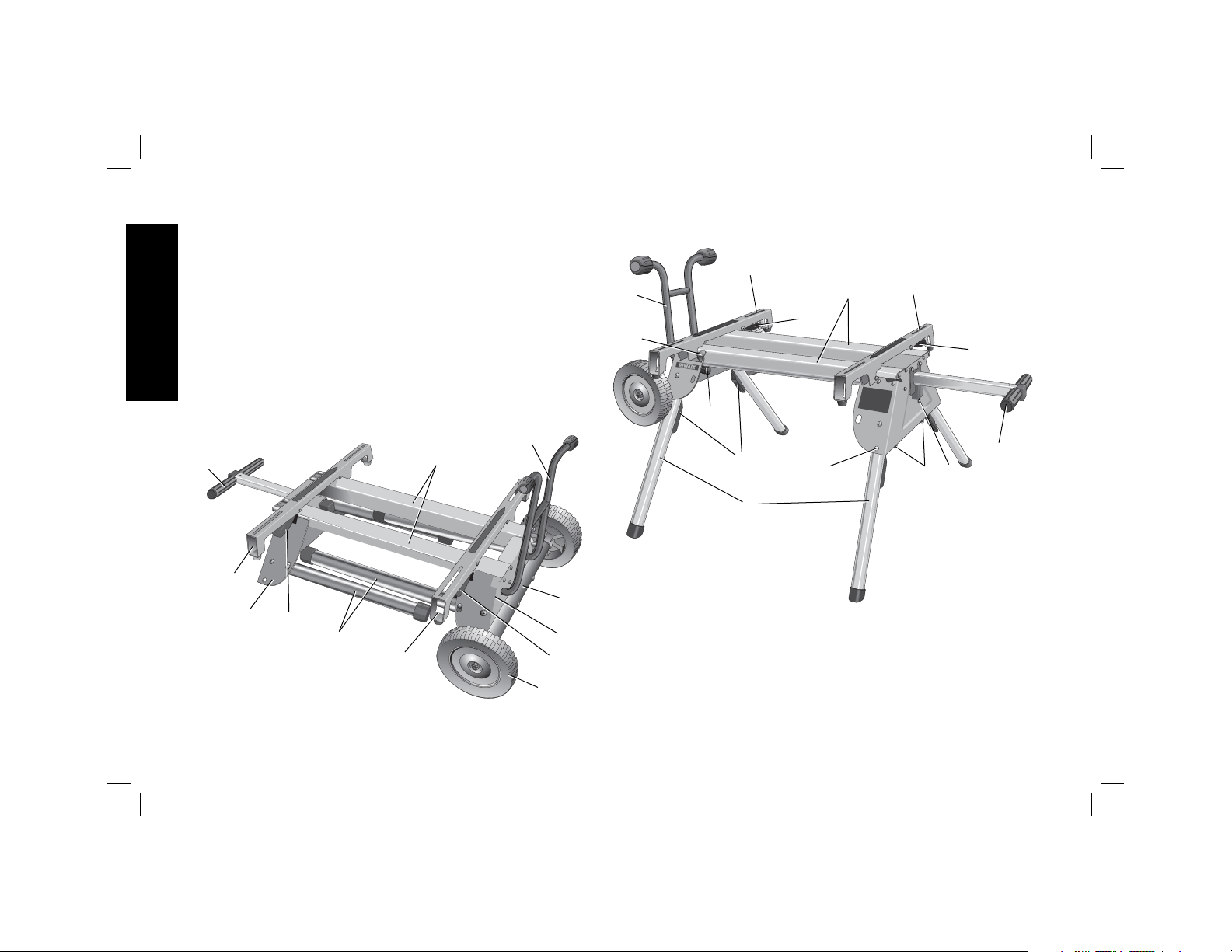

DW7440RS

Heavy-Duty Rolling Table Saw Stand

A. Axle

B. Leg supports

C. Wheels

D. Saw mounting bracket

English

E. Bracket release levers

F. Leg release levers

G. Locking pins

H. Legs

K

I. Beams

J. Locator clip

K. Handle

L. Handle lock

M. Rubber bumpers

N. Kickstand

O. Tube plugs

I

D

N

J

O

N

F

H

I

E

G

D

E

K

L

M

D

B

E

H

D

A

B

E

C

1

Page 3

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to

these symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

CAUTION: Used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided, may

result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

1-800-4-D

EWALT TOOL, CALL US TOLL FREE AT:

EWALT (1-800-433-9258)

DW7440RS Rolling Table Saw Stand

with Folding Legs

WARNING: For your own safety, read the table saw instruction

manual before using any accessory. Failure to heed these warnings

may result in personal injury and serious damage to the table saw

and the accessory. When servicing this tool, use only identical

replacement parts.

This stand is designed for use with table saws only. The DW7440RS

is approved for use with the DW744, DW744X and the DW745 table

saws. If you experience a problem with your D

please call 1-800-4-D

EWALT (1-800-433-9258).

EWALT purchase,

Tools Required

Phillips screwdriver

Socket or wrench set

Contents

Stand Carriage head bolts (2)

Mounting brackets (2) M8 lock nuts (4)

Wheels (2) Rear axle

Rubber bumpers (2) M4 screws (2)

Washers (4) M4 lock nuts (2)

Kickstand assembly M6 screws (4)

Tube plugs (2) M4 hex wrench

Saw mounting hardware: hex head bolts (4), washers (8),

nuts (4), lock washers (4)

General Safety Instructions for Table

Saw Accessories

WARNING: To reduce the risk of personal injury:

• ALWAYS use eye protection. All users and bystanders must

wear eye protection that conforms to ANSI Z87.1.

• Ensure all stand fasteners are securely fastened and that all

stand mechanisms are in proper working order before operating

the table saw.

• DO NOT exceed the weight this stand can hold. The DW7440RS

table saw stand is designed to support 150 lbs. (68 kgs.) safely

in a work environment. It is unsafe to climb, sit or stand on the

stand.

English

2

Page 4

• Follow the mounting instructions carefully. Fasten the tool to the

saw mounting brackets securely as instructed.

• DO NOT modify or use stand for operations for which it is

unintended.

• DO NOT use the stand on uneven surfaces. DO NOT use the

stand with the legs folded and stand sitting on the ground. The

stand is designed to be used on a flat, stable surface.

English

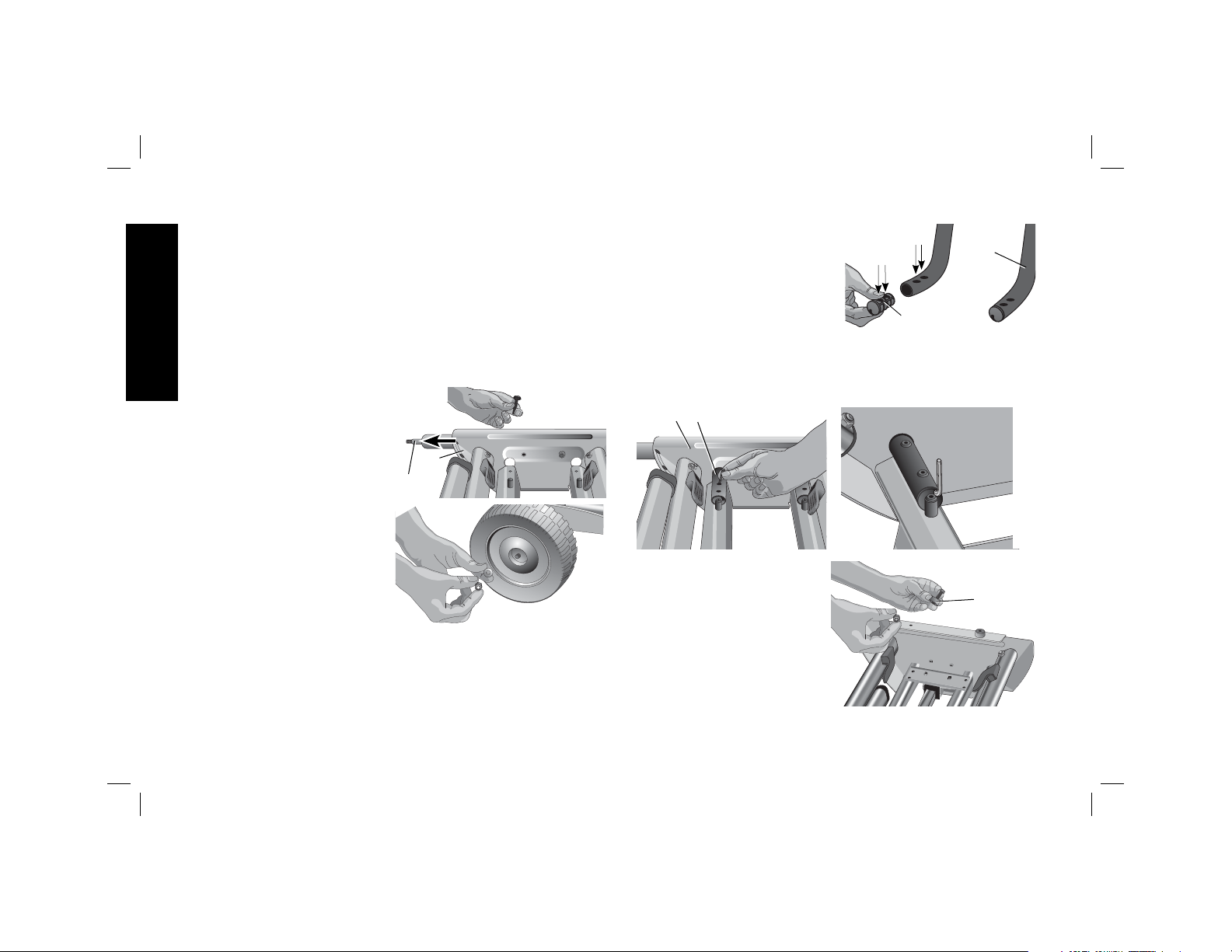

ASSEMBLY

Attaching the Wheels and Axle

1. Attach the axle (A) to

the leg support (B) by

aligning the pre-drilled

holes. Ensure the long end

of the axle is to the rear of

the stand as shown. Secure

axle to leg support using

two carriage bolts, washers

and lock nuts provided.

2. Place the wheels (C) on

the axle and secure with

washers and lock nuts as

shown. Tighten wheel and

axle nuts securely.

B

A

Attaching the

Kickstand

Insert the tube plugs (O) into the end of the kickstand tube (N). The

groove in the tube plug should be facing down as shown. Be sure

that the holes (P) in the tube plugs are in line with the holes (Q) in

the kickstand tube before inserting the tube plugs.

Insert the kickstand tube (N) through

the holes in the leg support (B) on

the wheel-axle side of the stand.

Be sure the kickstand is pointing

up when the stand is an upright

position. Secure the kickstand to

the beams (I) with the four M6

screws provided as shown (below,

left).

The hex wrench may be stored in the end of the tube plug as shown

for future use.

B

N

Q

P

O

N

Attaching the

Rubber Bumpers

Attach the two rubber

bumpers (M) to the

handle side leg support as

shown using the M4 screws

and lock nuts provided.

M

3

Page 5

Table Saw Bracket Mounting

WARNING: To reduce the risk of injury, turn unit off,

disconnect machine from power source before assembling

the table saw to the table saw stand. An accidental start-up can

cause injury.

WARNING: For your own safety, read and understand the table

saw instruction manual before using. Failure to heed these warnings

may result in personal injury and serious damage to the table saw

and the accessory.

WARNING: The saw mounting brackets provided with this stand

are equipped with lever locks. To reduce the risk of injury, DO NOT

modify the mounting bracket lever locks.

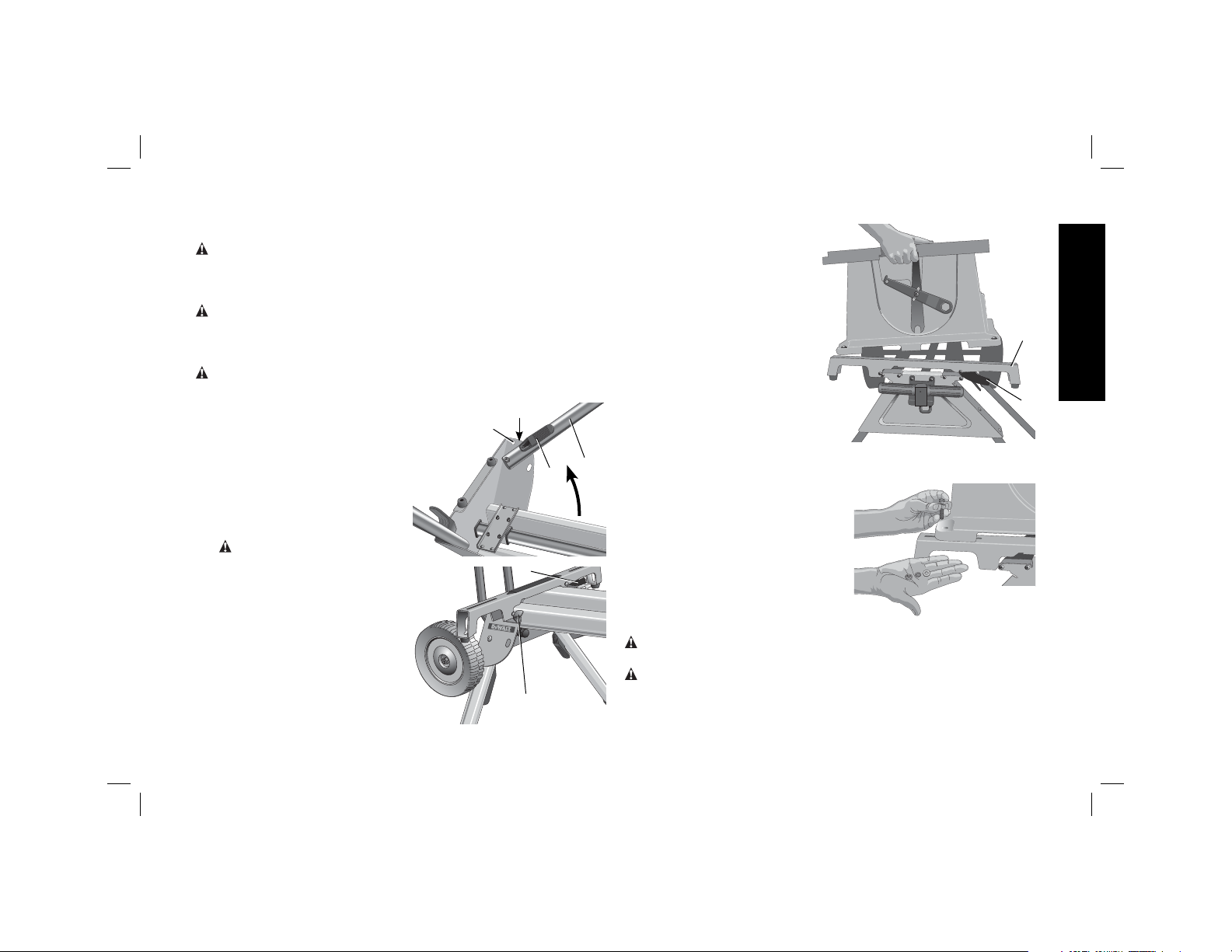

1. Unfold the legs by depressing

the leg release levers (F).

Rotate the legs until the

locking pin (G) clicks into its

detent (R).

2. Turn the stand upright. The

stand should be stable and

should not rock.

WARNING: Be sure that

the locking pins have

engaged and the legs

are firmly held in place.

3. The locator clip (J)

keeps the saw from sliding

left or right during cutting

operations and during

transport. Install the mounting

brackets on to the beam as

shown by engaging the

concave front lip of the

G

R

H

F

E

J

mounting bracket with the

rounded front edge of the

beam. One of the brackets

must engage the locator

clip (J). The mounting

bracket release levers

(E) must be positioned to

the rear of the stand as

shown.

4. Measure the distance

between the mounting

holes of the table saw.

Position the second

mounting bracket onto

the beam at this distance

from the first mounting

bracket.

5. Align the holes in the table

saw base with the slots in the

saw mounting brackets (D).

6. Feed a hex head bolt with flat

washer installed through each

of the four holes in the table saw

base and mounting brackets.

Secure each location with a flat

washer, lock washer and nut

provided.

WARNING: To reduce the risk of personal injury, be sure the table

saw is fully anchored on the stand.

WARNING: The table saw must be positioned on the tool mount

so that all four corners can be bolted to the mounting brackets. If the

saw is mounted properly, the mounting brackets will be positioned

perpendicular to the stand rail when the saw is placed on the stand.

English

D

E

4

Page 6

Please call DEWALT customer support at 1-800-4-DEWALT if you

need assistance.

To Detach the Saw from the Stand

WARNING: To reduce the

risk of injury, turn unit off,

disconnect machine from

power source before detaching

English

the table saw from the table

saw stand. An accidental start-

up can cause injury.

The saw mounting brackets

included with the DW7440RS

stand are equipped with rubber

feet that can support the saw

when cutting on a work area

without a stand.

TO REMOVE THE SAW FOR

CARRYING OR FOR USE

WITHOUT THE STAND

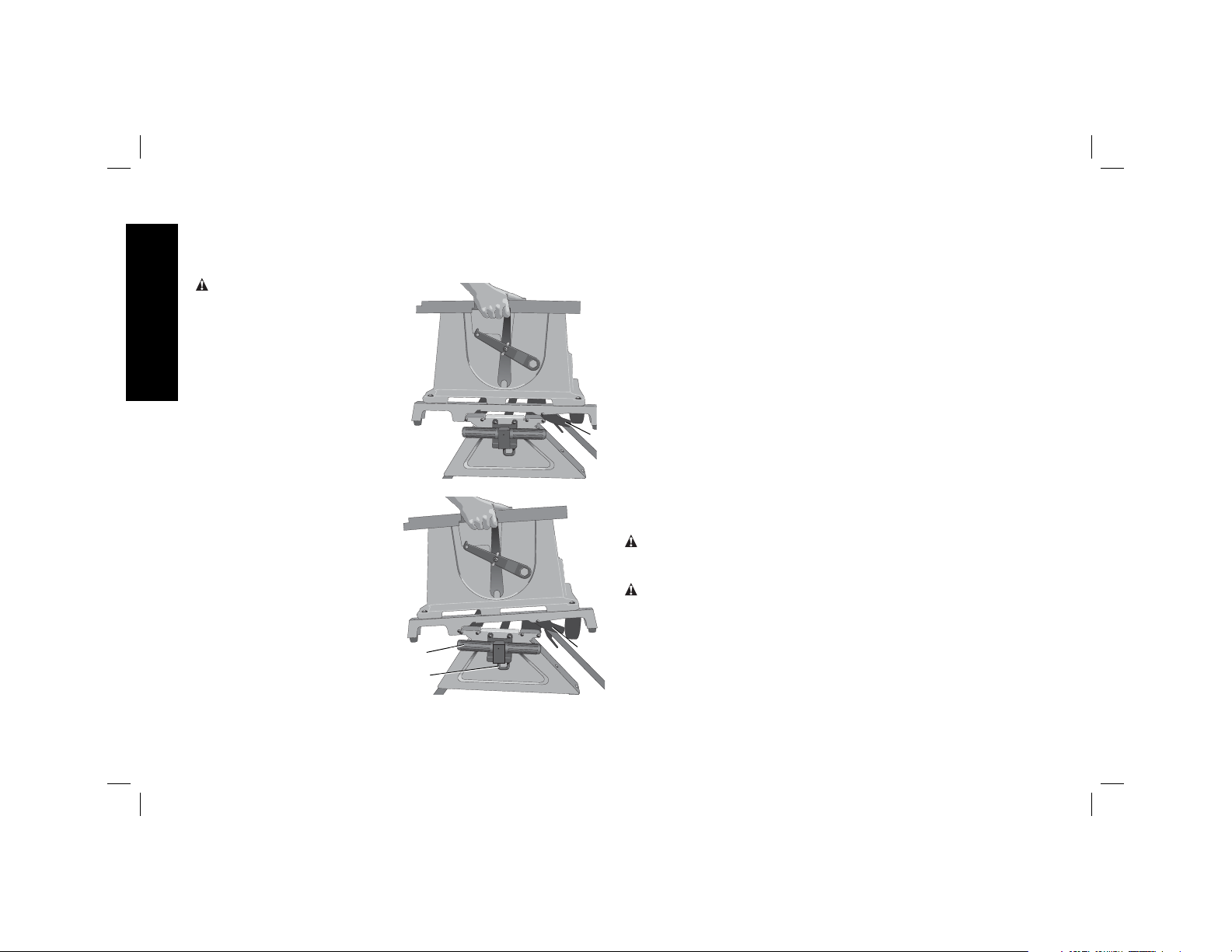

1. Reach around the sides

of the saw and grasp the

release levers (E).

2. Pull up slightly to clear

the beam and tilt the saw

toward you to carry.

TO REATTACH THE SAW

AND SAW MOUNTING

BRACKETS TO THE STAND

1. Grip the table saw table

as shown while facing the

front of the saw.

K

L

2. Position the left-hand side mounting bracket into the locator clip.

3. When the front concave lip of both mounting brackets are

engaged with the front round edge of the beam, pivot the

saw back and down allowing the release levers (E) to click

into place on the rear beam. Rock the saw gently to verify the

mounting brackets are locked onto the beams.

4. If the handle (K) has been extended, pull the handle lock (L)

down to release the handle and then slide the handle in for

storage or saw usage.

TO ATTACH D

MOUNTING BRACKETS

1. Remove the front feet bolts and the front rubber feet from the

E

E

DW745 table saw.

2. Remove the rear feet from the rear frame bar of the saw.

3. Retain these components for future use.

4. Feed a hex head bolt with flat washer installed through each of

the four holes in the frame bars where the removed front and

rear feet were previously installed. Secure each location with a

flat washer, lock washer and nut provided.

WARNING: To reduce the risk of personal injury, NEVER use the

table saw with the handle extended. An extended handle creates an

unsafe work area.

WARNING: To reduce the risk of personal injury, do not hang

objects from the handle. The stand may tip when downward force

is applied.

Transporting the Saw on the Stand

COLLAPSING THE STAND FOR TRANSPORT

1. Place one hand under the leg support and hold the legs slightly

off the ground.

EWALT DW745 TABLE SAW TO THE SAW

5

Page 7

2. Depress the leg release lever (F) with the other hand then push

the leg under the beam on the stand. Repeat the operation on

the second leg of the stand and rest the stand on wheels.

K

L

M

F

3. Repeat with the other end of the stand.

4. Pull the extendable handle (K) out of the side of the stand. The

spring-loaded handle lock (L) will lock the handle into position for

transporting the saw on the stand. Pull the handle lock down to

release the handle and then slide the handle in for storage.

WARNING: To reduce the risk of personal injury, DO NOT operate

the table saw mounted to the stand with the legs folded and the

stand sitting on the ground.

To Raise Stand from Collapsed Position

Roll the stand to the workspace. Be sure the area is flat and stable

before attempting to set up the saw and stand.

1. Tilt up the stand until the saw is at a 45 degree angle.

2. Depress the leg release levers one at a time to release the

locking pins and pull the front legs out until each locking pin

clicks into the detent.

WARNING: Be sure that the locking pins have engaged and

the legs are firmly held in place.

3. Rest the stand on the legs.

4. Depress the handle lock to release the handle. Slide the handle

into the leg support for storage as you work.

5. Go to the opposite side of the stand and grasp the saw under the

rear axle. Lift the saw and stand.

6. Reach under the stand and, one at a time, depress the leg

release levers to release the locking pins. Pull out the remaining

two legs. Be sure that the locking pins have engaged and the

legs are firmly held in place. Rest the stand on the ground.

Accessories

WARNING: Since accessories, other than those offered by

EWALT, have not been tested with this product, use of such

D

accessories with this tool could be hazardous. To reduce the risk of

serious injury, place stand on flat, stable surface. DO NOT create

unstable conditions.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact D

EWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

call 1-800-4-D

EWALT (1-800-433-9258) or visit our website www.

dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustments should be performed by a D

center, a D

EWALT authorized service center or other qualified

service personnel. Always use identical replacement parts.

EWALT factory service

English

6

Page 8

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of purchase.

This warranty does not cover part failure due to normal wear or

tool abuse. For further detail of warranty coverage and warranty

repair information, visit www.dewalt.com or call 1-800-4-D

(1-800-433-9258). This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

English

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT will maintain the tool and replace worn parts caused by

D

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

EWALT Power Tool, Laser, or Nailer for any reason, you can return

D

it within 90 days from the date of purchase with a receipt for a full

refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained either in the packaging, call

the local company or see website for warranty information.

EWALT tools are covered by our:

1 YEAR FREE SERVICE

EWALT

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

EWALT for a free

replacement.

7

Page 9

DW7440RS

Socle mobile robuste pour table de scie

A. Essieu

B. Supports de pattes

C. Roues

D. Rainures des supports

de fixation

E. Leviers de verrouillage

F. Leviers de dégagement

de la patte

G. Goupilles de blocage

H. Pattes

K

I. Travées

J. Attache de

positionnement

K. Poignée

L. Mécanisme de blocage

de la poignée

M. Amortisseurs en

caoutchouc

N. Béquille

O. Capuchons de tube

N

I

D

N

J

O

F

H

I

E

G

D

E

Français

K

L

M

D

B

E

H

D

A

B

E

C

8

Page 10

Définitions : lignes directrices

en matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur employé. Veuillez lire le

mode d’emploi et porter une attention particulière à ces

symboles.

DANGER : indique une situation dangereuse

imminente qui, si elle n’est pas évitée, causera la mort

ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait se

solder par un décès ou des blessures graves.

MISE EN GARDE : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée pourrait se

solder par des blessures mineures ou modérées.

MISE EN GARDE : utilisé sans le symbole d’alerte à la sécu-

Français

rité, indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée pourrait se solder par des dommages

à la propriété.

POUR TOUTES QUESTIONS OU COMMENTAIRES

RELATIFS À L’OUTIL OU À PROPOS DE TOUT AUTRE OUTIL

D

EWALT, COMPOSER SANS FRAIS LE : 1 (800) 4-DEWALT

(1 (800) 433-9258)

DW7440RS Socle mobile pour table de

scie à pattes pliantes

AVERTISSEMENT : pour votre propre sécurité, lire le mode

d’emploi de la scie de table avant d’utiliser tout accessoire. Négliger

de se conformer à ces avertissements pourrait se solder par des

blessures corporelles et des dommages importants à la scie de table

et à l’accessoire. Pour la réparation de cet outil, n’utiliser que des

pièces de rechange identiques.

Ce socle est conçu pour une utilisation uniquement avec des scies

de table. Le modèle DW7440RS est homologué pour une utilisation

avec les scies de table DW744, DW744X et DW745. Pour tout

problème avec votre achat D

(1-800-433-9258).

EWALT, composer le 1-800-4-DEWALT

Outils requis

Tournevis cruciforme

Jeu de clés ou de douilles

Contenu

Socle (2) boulons de carrosserie

(2) supports de fixation (4) contre-écrous M8

(2) roues Essieu arrière

(2) amortisseurs en caoutchouc (2) vis M4

(4) rondelles (2) contre-écrous M4

Béquille (4) vis M6

(2) capuchons de tube Clé hexagonale M4

Quincaillerie d’assemblage pour la scie : (4) boulons à tête

hexagonale, (8) rondelles, (4) écrous, (4) rondelles de blocage

Consignes de sécurité générales

relatives aux accessoires de la scie

de table

AVERTISSEMENT : pour réduire le risque de blessures :

• TOUJOURS porter une protection oculaire. Tous les utilisateurs

et toutes les personnes à proximité doivent porter une protection

oculaire conforme à la norme ANSI Z87.1.

9

Page 11

• Avant d’utiliser la scie de table, s’assurer que toute la quincaillerie

du socle soit bien serrée et que tous les mécanismes du socle

fonctionnent correctement.

• NE PAS dépasser la capacité (poids supporté) du socle. Le

socle DW7440RS de la scie de table supporte jusqu’à 68 kg

(150 lb) de façon sécuritaire dans un environnement de travail. Il

est imprudent de grimper, s’asseoir ou de se tenir sur le socle.

• Respecter attentivement les directives d’assemblage. Fixer

solidement l’outil aux supports de fixation comme indiqué.

• NE PAS modifier ou utiliser le socle pour des fonctions auxquelles

il n’est pas conçu.

• UTILISER le socle sur des surfaces régulières (égales). NE PAS

utiliser le socle avec les pattes repliées et le socle directement

posé sur le sol. Il est conçu pour une utilisation sur une surface

plane et stable.

ASSEMBLAGE

Fixation de l’essieu

et des roues

1. Fixer l’essieu (A) au

support des pattes (B) en

l’alignant avec les trous

prépercés. S’assurer que

l’extrémité la plus longue de

l’essieu est à l’arrière

du socle comme indiqué.

Utiliser les deux boulons de

carrosserie, les rondelles et

les contre-écrous fournis

pour fixer solidement

l’essieu au support des

pattes.

B

A

2. Enfiler les roues (C) sur l’essieu et les fixer solidement avec les

rondelles et les contre-écrous comme indiqué. Serrer solidement

tous les écrous des roues et de l’essieu.

Fixation de la béquille

Insérer les capuchons de tube (O) à l’extrémité du tube de la

béquille (N). La rainure pratiquée dans le capuchon du tube doit

faire face vers le bas comme montré. S’assurer que les trous (P) des

capuchons de tube sont alignés avec ceux (Q) du tube de la béquille

avant d’insérer les capuchons de tube.

Insérer le tube (N) de la béquille

dans les trous du support de patte

(B) de l’essieu du côté du socle.

S’assurer que la béquille pointe

vers le haut lorsque le socle est

en position verticale (sur ses

pattes). Fixer solidement la

béquille aux travées (I) au moyen

des quatre vis M6 fournies comme montré (ci-dessous, à gauche).

Il est possible de ranger la clé hexagonale dans l’extrémité du

capuchon de tube, comme montré, pour une utilisation ultérieure.

B

N

Q

P

O

N

Français

10

Page 12

Fixation des

amortisseurs

en caoutchouc

Avec les vis et les contreécrous fournis, assembler

les deux amortisseurs en

caoutchouc (M) sur le support

de patte du côté de la poignée

comme indiqué au moyen des

vis M4.

M

Fixation des supports destinés à

la scie de table

AVERTISSEMENT : pour réduire le risque de blessure,

éteindre l’outil et le débrancher avant de fixer la scie de table

sur son socle. Un démarrage accidentel peut provoquer des

blessures.

AVERTISSEMENT : pour votre propre sécurité, lire et assimiler le

Français

mode d’emploi de la scie de table avant de l’utiliser. Négliger de se

conformer à ces avertissements pourrait se solder par des blessures

et des dommages importants à la scie de table et à l’accessoire.

AVERTISSEMENT : les

supports de fixation de la scie

fournis avec ce socle sont dotés

de leviers de verrouillage. Pour

réduire le risque de blessure, NE

PAS modifier le levier de

verrouillage du support de

fixation.

1. Enfoncer les leviers de

dégagement (F) des pattes

pour les déployer. Faire

G

R

F

pivoter les pattes jusqu’à ce que la goupille de blocage (G)

s’enclenche dans son cran (R).

2. Remettre le socle sur ses pattes. Le socle devrait être stable

sans balancements. Vérifier les pattes.

AVERTISSEMENT: vérifier l’enclenchement correct des

goupilles de blocage des pattes et si celles-ci sont solidement

en position.

3. L’attache de positionnement

(J) empêche le glissement de

la scie vers la droite ou la

gauche lors de son utilisation

et de son transport. Installer

les supports de fixation sur la

travée comme indiqué en

engageant le bord concave

avant du support de fixation

avec le bord avant arrondi de

la travée. L’attache de positionnement (J) doit s’insérer dans l’un

des supports. Les leviers de verrouillage (E) du support de

fixation doivent être positionnés à l’arrière du socle comme

indiqué.

4. Mesurer la distance entre les trous de fixation de la scie de table.

Sur la travée, éloigner le second support de fixation du premier,

de la distance mesurée.

5. Aligner les trous de la base de la

H

scie de table avec les rainures

des supports de fixation (D) de

la scie.

6. Enfiler un boulon à tête

hexagonale et une rondelle plate

dans chacun des quatre trous

de la base de la scie de table et

E

J

11

Page 13

des supports de fixation. Fixer solidement chaque boulon avec

la rondelle plate, la rondelle de blocage et l’écrou fournis.

AVERTISSEMENT : pour réduire le risque de blessure, s’assurer

que la scie de table est bien ancrée au socle.

AVERTISSEMENT : positionner la scie de table sur le système de

fixation de sorte que les quatre coins de l’outil soient bien boulonnés

aux supports de fixation. Si la scie est bien installée, les supports

de fixation seront positionnés perpendiculaires au guide du socle

lorsque la scie est sur celui-ci.

Pour tout renseignement, communiquer avec le service à la clientèle

D

EWALT au 1-800-4-DEWALT.

Comment détacher la scie du socle

AVERTISSEMENT : pour réduire le risque de blessure,

éteindre l’outil et le débrancher avant de dégager la scie de

table de son socle. Un démarrage accidentel peut provoquer des

blessures.

Les supports de fixation de

la scie livrés avec le socle

DW7440RS sont dotés de pieds

en caoutchouc qui servent

d’appui à la scie lors de coupe

dans une zone de travail sans

le socle.

DÉGAGEMENT DE LA SCIE

POUR LE TRANSPORT OU

SON UTILISATION SANS

LE SOCLE

1. S’incliner pour atteindre les

cotés de la scie et saisir les leviers de dégagement (E).

2. Tirer légèrement vers le haut pour dégager la travée et incliner

la scie dans la direction de l’utilisateur pour le transport.

E

FIXATION DE LA SCIE ET DES SUPPORTS DE FIXATION

AU SOCLE

1. Saisir la table de la scie de table comme indiqué tout en faisant

face à la scie.

2. Insérer le support de fixation de gauche dans l’attache de

positionnement.

3. Lorsque le bord concave

avant des deux supports

de fixation est engagé

avec le bord avant arrondi

de la travée, faire pivoter

la scie en position et

vers le bas pour que les

leviers de dégagement (E)

s’enclenchent en position

sur la travée arrière.

Balancer délicatement la

scie pour vérifier la bonne

K

L

E

fixation des supports avec

les travées.

4. Si la poignée (K) était déployée, abaisser le mécanisme de

blocage de la poignée (L) pour dégager la poignée puis coulisser

la poignée pour le rangement ou l’utilisation de la scie.

FIXATION DE LA SCIE DE TABLE D

EWALT DW745 AUX

SUPPORTS DE FIXATION DE LA SCIE

1. Retirer les boulons des pieds avant et les pieds de caoutchouc

avant de la scie de table DW745.

2. Retirer les pieds arrière de la barre structurale arrière de la

scie.

3. Conserver ces composants pour une utilisation ultérieure.

4. Enfiler un boulon à tête hexagonale avec une rondelle plate dans

chacun des quatre trous des barres structurales (trous utilisés

Français

12

Page 14

pour la fixation des pieds avant et arrière). Fixer solidement

chaque boulon avec la rondelle plate, la rondelle de blocage et

l’écrou fournis.

AVERTISSEMENT : pour réduire le risque de blessure, ne

JAMAIS utiliser la scie de table avec la poignée déployée. Une

poignée déployée n’est pas sécuritaire dans un environnement de

travail.

AVERTISSEMENT : pour réduire le risque de blessure, ne pas

suspendre d’objets à la poignée. Le socle risquerait de basculer lors

de l’application d’une pression orientée vers le bas.

Transport de la scie sur le socle

DÉMONTAGE DU SOCLE POUR LE TRANSPORT

1. Positionner une main sous le support de patte. Soulever pour

dégager un peu les pattes du sol.

2. De l’autre main, enfoncer le levier de dégagement (F) de la patte

puis replier la patte sous la travée du socle. Répéter la procédure

pour la deuxième patte du socle et déposer le socle sur les

Français

roues.

K

L

M

F

3. Répéter la séquence pour l’autre extrémité du socle.

4. Déployer la poignée extensible (K) sur le côté du socle. Le

mécanisme de blocage à ressort (L) bloquera la poignée en

position pour le transport de la scie sur le socle. Abaisser le

mécanisme de blocage pour dégager la poignée et la coulisser

pour la ranger.

AVERTISSEMENT : pour réduire le risque de blessure, NE PAS

faire fonctionner la scie de table, assemblée sur le socle, avec les

pattes repliées et le socle posé sur le sol.

Déploiement des pattes du socle

Au moyen des roues, déplacer le socle à l’espace de travail prévu.

S’assurer que l’aire choisie est plane et stable avant d’installer la

scie et le socle.

1. Incliner le socle jusqu’à ce que la scie soit à 45 degrés.

2. Enfoncer, un à un, les leviers de dégagement des pattes pour

dégager les goupilles de blocage. Déployer chaque patte jusqu’à

ce que les goupilles s’enclenchent dans les crans.

AVERTISSEMENT : vérifier l’enclenchement correct des

goupilles de blocage des pattes et si celles-ci sont solidement en

position.

3. Remettre le socle sur ses pattes.

4. Enfoncer le mécanisme de blocage de la poignée pour la

dégager. Pour ranger la poignée lors de l’utilisation de la scie, la

coulisser dans le support de patte.

5. Se déplacer au côté opposé du socle et saisir la scie sous

l’essieu arrière. Soulever la scie et le socle.

6. S’incliner pour atteindre l’espace sous le socle puis enfoncer l’un

après l’autre les leviers de dégagement des pattes pour dégager

les goupilles de blocage. Déployer les deux autres pattes. Vérifier

l’enclenchement correct des goupilles de blocage des pattes et

si celles-ci sont solidement en position. Remettre le socle sur le

sol.

13

Page 15

Accessoires

AVERTISSEMENT : puisque les accessoires autres que ceux

offerts par D

de ceux-ci avec l’outil pourrait s’avérer dangereuse. Pour réduire le

risque de blessure, placer le socle sur une surface plane et stable.

ÉVITER toutes conditions instables.

Les accessoires recommandés pour utilisation avec l’outil sont offerts,

à un coût supplémentaire, auprès du distributeur ou du centre de

réparation autorisé de votre région. Pour toute demande d’assistance

pour trouver un accessoire, communiquer avec D

Tool Co., 701 East Joppa Road, Baltimore, MD 21286, É.-U.,

composer le 1-800-4-D

Web www.dewalt.com.

EWALT n’ont pas été testés avec ce produit, l’utilisation

EWALT Industrial

EWALT (1-800-433-9258) ou visiter notre site

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, confier les

réparations, l’entretien et les réglages à un centre de réparation en

usine D

EWALT, à un centre de réparation autorisé DEWALT ou à

du personnel de réparation qualifié. Toujours utiliser des pièces de

rechange identiques.

Garantie limitée trois ans

DEWALT réparera gratuitement tous les problèmes dus à des

défauts de matériau ou de fabrication pendant trois ans à compter

de la date d'achat. Cette garantie ne couvre pas des défaillances de

pièce dues à une usure normale ou à une mauvaise utilisation de

l'outil. Pour plus de détails relatifs à la couverture de la garantie et

aux réparations sous garantie, visiter le site Web www.dewalt.com

ou composer le 1-800-4-D

ne s'applique pas aux accessoires ni aux dommages causés par

des réparations réalisées ou tentées par des tiers. Cette garantie

vous accorde des droits légaux spécifiques et il est possible que

vous ayez d'autres droits qui varient d'un État ou d'une province à

l'autre.

EWALT (1-800-433-9258). Cette garantie

En plus de la garantie, les outils D

EWALT sont couverts par notre :

SERVICE D'ENTRETIEN GRATUIT DE 1 AN

EWALT entretiendra l'outil et remplacera les pièces usées par une

D

utilisation normale et ce, gratuitement, à tout instant pendant la

première année à compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n'êtes pas entièrement satisfait des performances de votre

outil électrique, laser ou de votre marteau-cloueur D

EWALT pour

quelque raison que ce soit, vous pouvez le retourner accompagné

d'un reçu dans les 90 jours suivant la date d'achat et nous vous

rembourserons entièrement - sans poser de questions.

AMÉRIQUE LATINE : cette garantie ne s'applique pas aux produits

vendus en Amérique latine. Pour ceux-ci, veuillez consulter les

informations relatives à la garantie spécifique présente dans

l'emballage, appeler l'entreprise locale ou consulter le site Web pour

les informations relatives à cette garantie.

REMPLACEMENT GRATUIT DES ÉTIQUETTES

D'AVERTISSEMENT : si les étiquettes d'avertissement deviennent

illisibles ou sont manquantes, composer le 1-800-4-D

EWALT pour

en obtenir le remplacement gratuit.

Français

14

Page 16

DW7440RS

Base rodante para sierra de banco para trabajo pesado

A. Eje

B. Soporte para patas

C. Ruedas

D. Soportes de montaje

de la sierra

E. Palancas de liberación de

los soportes de montaje

F. Palancas de liberación

de las patas

K

G. Clavija de bloqueo

H. Patas

I. Vigas

J. Pinza del localizador

K. Mango

L. Traba del mango

M. Protectores de goma

N. Soporte

O. Tapones para tubos

N

I

N

J

O

F

D

I

E

G

H

D

E

K

L

M

D

Español

A

B

E

H

D

B

E

C

15

Page 17

Definiciones: Normas de

seguridad

Las siguientes definiciones describen el nivel de gravedad

de cada palabra de señal. Lea el manual y preste atención

a estos símbolos.

PELIGRO: indica una situación de peligro inminente que,

si no se evita, provocará la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial

que, si no se evita, podría provocar la muerte o lesiones

graves.

PRECAUCIÓN: indica una situación de peligro potencial

que, si no se evita, posiblemente provocaría lesiones leves

o moderadas.

PRECAUCIÓN: cuando se utiliza sin el símbolo de alerta de

seguridad indica una situación de peligro potencial que, si no

se evita, puede provocar daños en la propiedad.

SI TIENE ALGUNA DUDA O COMENTARIO ACERCA DE ÉSTA

U OTRA HERRAMIENTA D

GRATUITO: 1-800-4-D

EWALT (1-800-433-9258)

EWALT, LLÁMENOS AL NÚMERO

DW7440RS Base rodante con patas

plegables para sierra de banco

ADVERTENCIA: Por su propia seguridad, lea el manual de

instrucciones de la sierra de banco antes de usar cualquier

accesorio. El incumplimiento de estas advertencias podría ocasionar

daños graves en la sierra de banco y el accesorio Al reparar esta

herramienta, sólo utilice piezas de repuesto idénticas.

Esta base está diseñada para ser utilizada únicamente con sierras

de banco. Los modelos de sierras de banco aprobados para ser

utilizados con esta base son: el DW7440RS, el DW744, el DW744X

y el DW745. En caso de que tenga algún problema con su producto

D

EWALT, llame al 1-800-4-DEWALT (1-800-433-9258).

Herramientas requeridas

Destornillador Phillips

Juego de tubos adaptadores o llaves

Contenido

Base Pernos de cabeza de hongo (2)

Soportes de montaje (2) Tuercas de seguridad M8 (4)

Ruedas (2) Eje trasero

Protectores de goma (2) Tornillos M4 (2)

Arandelas (4) Tuercas de seguridad M4 (2)

Conjunto del soporte Tornillos M6 (4)

Tapones para tubos (2) Llave hexagonal M4

Tornillería de montaje de la sierra: pernos de cabeza

hexagonal (4), arandelas (8), tuercas (4), arandelas

de seguridad (4)

Instrucciones de seguridad

generales para los accesorios

de la sierra de banco

ADVERTENCIA: Para reducir el riesgo de lesiones:

• SIEMPRE utilice protección para los ojos. Todos los usuarios

y espectadores deben utilizar protección para los ojos conforme

con las normas ANSI Z87.1.

• Asegúrese de que todos los sujetadores de la base estén bien

ajustados y que todos los mecanismos de la base funcionen

adecuadamente antes de operar la sierra de banco.

Español

16

Page 18

• NO supere el peso que la base puede soportar. La base para

sierra de banco DW7440RS está diseñada para soportar 68 kg

(150 lb) de manera segura en el lugar de trabajo. No es seguro

subirse a la base ni sentarse o pararse sobre ésta.

• Siga cuidadosamente todas las instrucciones de montaje. Sujete

bien la herramienta a los soportes de montaje de la sierra, según

lo indicado.

• NO modifique la base ni la utilice para otras tareas que no sean

aquéllas para la que fue diseñada.

• NO utilice la base sobre superficies desniveladas. NO utilice la

base con las patas plegadas y la base apoyada en el suelo. La

base fue diseñada para utilizarse sobre una superficie plana y

estable.

ENSAMBLAJE

Colocación de las

ruedas y el eje

1. Alinee los orificios

pretaladrados y fije el eje

(A) al soporte para patas

(B). Asegúrese de que el

extremo largo del eje esté

en la parte trasera de la

base, como se muestra.

Sujete el eje al soporte

para patas con los dos

pernos de cabeza de

Español

hongo, las arandelas y

las tuercas de seguridad

incluidos.

B

A

2. Coloque las ruedas (C) en el eje y sujételas con las arandelas

y las tuercas de seguridad, como se muestra. Ajuste bien las

tueras de las ruedas y del eje.

Fijación del soporte

Inserte los tapones para tubos (O) en el extremo del tubo del

soporte (N). La ranura de los tapones para tubos debe apuntar hacia

abajo como se muestra. Antes de insertar los tapones para tubos,

asegúrese de que los orificios (P) de los tapones para tubos estén

alineados con los orificios (Q) del tubo del soporte.

Inserte el tubo del soporte (N) a

través de los orificios del soporte

para las patas (B) en el lado del

eje de la rueda del soporte.

Asegúrese de que el soporte

quede hacia arriba cuando la

base esté en posición vertical.

Asegure el soporte a las barras (I) con los cuatro tornillos M6

suministrados, como se muestra (abajo, a la izquierda).

La llave hexagonal puede guardarse en el extremo del tapón para

tubo, como se muestra, para su uso posterior.

B

N

Q

P

O

N

17

Page 19

Colocación de

los protectores

M

de goma

Con los tornillos M4 y las

tuercas de seguridad

suministradas, fije los dos

protectores de goma (M) al

soporte para patas del lado

del mango, como se muestra.

Montaje de los soportes de la sierra

de banco

ADVERTENCIA: Para reducir el riesgo de lesiones, apague

la unidad y desconéctela de la fuente de alimentación antes

de montar la sierra de banco a la base para sierra de banco.

Un arranque accidental podría causar lesiones.

ADVERTENCIA: Por su propia seguridad, lea el manual

de instrucciones de la sierra de banco antes de utilizarla. El

incumplimiento de estas advertencias podría ocasionar lesiones

personales y daños graves en la sierra de banco y el accesorio.

ADVERTENCIA: Los soportes

de montaje de la sierra incluidos

con esta base vienen equipados

con bloqueos de palanca. Para

reducir el riesgo de lesiones, NO

modifique los bloqueos de

palanca de los soportes de

montaje.

1. Para desplegar las patas,

presione las palancas de

liberación de las patas (F).

G

R

H

F

Gire las patas hasta que la clavija de bloqueo (G) emita un

chasquido y se ajuste en el retén (R).

2. Coloque la base en posición vertical. La base debe estar estable

y no debe mecerse.

ADVERTENCIA: Asegúrese de que las clavijas de bloqueo

estén trabadas y que las patas estén firmemente sujetadas en

su lugar.

3. La pinza del localizador (J)

evita que la sierra se deslice

hacia la izquierda o hacia la

derecha durante las

operaciones de corte o el

transporte. Para instalar los

soportes de montaje en la viga

como se muestra, fije el borde

cóncavo delantero del soporte

de montaje al borde convexo

delantero de la viga. Uno

de los soportes debe

fijarse en la pinza del

localizador (J). Las

palancas de liberación de

los soportes de montaje

(E) deben ubicarse en la

parte trasera de la base,

como se muestra.

4. Mida la distancia entre los

orificios de montaje de la

sierra de banco. Coloque

el segundo soporte de

montaje en la viga, a

esta distancia del primer

soporte de montaje.

E

J

D

E

Español

18

Page 20

5. Alinee los orificios de la base de la sierra de banco con las

ranuras de los soportes de montaje de la sierra (D).

6. Coloque un perno de cabeza

hexagonal y una arandela plana

en cada uno de los cuatro

orificios de la base de la

sierra de banco y de los

soportes de montaje. Asegure

cada ubicación con las

arandelas planas, las arandelas

de seguridad y las tuercas

incluidas.

ADVERTENCIA: Para reducir el riesgo de lesiones personales,

asegúrese de que la sierra de banco esté bien sujeta a la base.

ADVERTENCIA: La sierra de banco debe colocarse sobre la

superficie de montaje de manera tal que las cuatro esquinas puedan

atornillarse a los soportes de montaje. Si la sierra está montada

adecuadamente, los soportes de montaje quedarán posicionados

de forma perpendicular al riel de la base cuando se coloque la sierra

sobre la base.

Llame al servicio al cliente

EWALT al 1-800-4-DEWALT si

D

necesita asistencia.

Cómo desmontar la

sierra de la base

ADVERTENCIA: Para

reducir el riesgo de

lesiones, apague la unidad

Español

y desconéctela de la fuente

de alimentación antes de

desmontar la sierra de banco de la base para sierra de banco.

Un arranque accidental podría causar lesiones.

Los soportes de montaje de la sierra incluidos en la base DW7440RS

vienen equipados con patas de goma, que pueden sostener la sierra

al cortar sobre una superficie de trabajo sin base.

CÓMO DESMONTAR LA SIERRA PARA TRANSPORTARLA O

PARA UTILIZARLA SIN LA BASE

1. Sujete las palancas de liberación (E) que se encuentran en

ambos costados de la sierra.

2. Levante levemente hasta quitar del paso la viga e incline la

sierra hacia su lado, para transportarla.

CÓMO VOLVER A MONTAR LA SIERRA Y LOS SOPORTES DE

MONTAJE DE LA SIERRA EN LA BASE

1. Sujete el banco de la sierra como se muestra, con el frente de

la sierra hacia su lado.

2. Coloque el soporte de montaje del lado izquierdo en la pinza del

localizador.

3. Una vez que los bordes

cóncavos delanteros de

ambos soportes de

montaje se hayan fijado al

borde convexo delantero

de la viga, gire la sierra

hacia atrás y hacia abajo,

hasta que las palancas de

liberación (E) emitan un

chasquido y se ajusten en

la viga trasera. Sacuda

E

suavemente la sierra, para

verificar que los soportes

de montaje se hayan

trabado en las vigas.

K

L

E

19

Page 21

4. Si el mango (K) está extendido, presione la traba del mango

(L) para liberarlo y luego deslice el mango hacia adentro, a la

posición de almacenamiento o uso de la sierra.

PARA MONTAR LA SIERRA DE BANCO D

LOS SOPORTES DE MONTAJE PARA SIERRA

1. Retire los pernos de las patas delanteras y las patas delanteras

de goma de la sierra de banco DW745.

2. Retire las patas traseras de la barra del marco trasero de la

sierra.

3. Guarde estos componentes para utilizarlos en un futuro.

4. Coloque un perno de cabeza hexagonal y una arandela plana

en cada uno de los cuatro orificios de las barras del marco,

donde estaban instaladas las patas delanteras y traseras que

se retiraron. Asegure cada ubicación con las arandelas planas,

las arandelas de seguridad y las tuercas incluidas.

ADVERTENCIA: Para reducir el riesgo de lesiones personales,

NUNCA utilice la sierra de banco con el mango extendido. El mango

extendido genera situaciones de inseguridad en el área de trabajo.

ADVERTENCIA: Para reducir el riesgo de lesiones personales,

no cuelgue objetos del mango. La base puede inclinarse si se aplica

fuerza descendente.

EWALT DW745 A

Transporte de la sierra en la base

PLIEGUE DE LA BASE PARA TRANSPORTE

1. Coloque una mano debajo del soporte para patas y sostenga las

patas levemente separadas del suelo.

2. Baje la palanca de liberación de la patas (F) con la otra mano y

empuje la pata debajo de la viga de la base. Repita el proceso

con la segunda pata de la base y apoye la base sobre las

ruedas.

K

L

M

F

3. Repita el proceso una vez más en el otro extremo de la

base.

4. Extraiga el mango extendido (K) del costado de la base. La

traba con resorte del mango (L) trabará el mango en la posición

de transporte de la sierra sobre la base. Presione la traba del

mango para liberarlo y luego deslice el mango hacia adentro, a

la posición de almacenamiento.

ADVERTENCIA: Para reducir el riesgo de lesiones personales,

NO opere la sierra de banco montada en la base con las patas

plegadas y la base apoyada en el suelo.

Cómo desplegar la base

Desplace la base al lugar de trabajo. Asegúrese de que la superficie

sea plana y estable antes de comenzar a instalar la sierra y la

base.

1. Incline la base hacia arriba, hasta que la sierra esté en un

ángulo de 45 grados.

2. Presione las palancas de liberación de las patas una por vez,

para liberar las clavijas de bloqueo, y tire de las patas delanteras

hasta que cada una de las clavijas de bloqueo emita un

chasquido y se ajuste en el retén.

Español

20

Page 22

ADVERTENCIA: Asegúrese de que las clavijas de bloqueo

estén trabadas y que las patas estén firmemente sujetadas en

su lugar.

3. Apoye la base sobre las patas.

4. Presione la traba del mango para liberarlo. Deslice el mango en

el soporte para patas para almacenarlo durante la tarea.

5. Vaya al lado opuesto de la base y sujete la sierra por debajo del

eje trasero. Levante la sierra y la base.

6. Presione las palancas de liberación de las patas una por vez

que se encuentran debajo de la base, para liberar las clavijas

de bloqueo. Retire las dos patas restantes. Asegúrese de que

las clavijas de bloqueo estén trabadas y que las patas estén

firmemente sujetadas en su lugar. Apoye la base en el suelo.

Accesorios

ADVERTENCIA: Debido a que no se han probado con este

producto otros accesorios que no sean los que ofrece D

uso de dichos accesorios con esta herramienta podría ser peligroso.

Para reducir el riesgo de lesiones graves, coloque la base en una

superficie plana y estable. EVITE las condiciones inseguras.

Los accesorios que se recomiendan para utilizar con la herramienta

están disponibles a un costo adicional en su distribuidor local o

en un centro de mantenimiento autorizado. Si necesita ayuda

para localizar algún accesorio, comuníquese con D

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

llame al 1-800-4-D

EWALT (1-800-433-9258) o visite nuestro sitio

web www.dewalt.com.

Reparaciones

Español

Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto,

las reparaciones, el mantenimiento y los ajustes deben realizarse

EWALT, el

EWALT

en un centro de mantenimiento de fábrica DEWALT, un centro de

mantenimiento autorizado D

EWALT u otro personal de mantenimiento

calificado. Utilice siempre piezas de repuesto idénticas.

Garantía limitada de tres años

DEWALT reparará sin cargo cualquier defecto ocasionado por

materiales defectuosos o mano de obra, durante tres años a partir de

la fecha de compra. Esta garantía no cubre fallas en las piezas que

resulten del desgaste normal de la herramienta o de su utilización

inadecuada. Para obtener información detallada sobre la cobertura

de la garantía y sobre reparaciones, visite nuestra página Web www.

dewalt.com o llame al 1-800-4-D

garantía no se extiende a los accesorios o a los daños causados

por terceros al intentar realizar reparaciones. Esta garantía le

concede derechos legales específicos; usted goza también de otros

derechos que varían según el estado o provincia.

Además de la garantía, las herramientas D

por nuestro:

SERVICIO GRATUITO DE 1 AÑO

EWALT realizará el mantenimiento de la herramienta y reemplazará

D

las piezas gastadas tras el uso normal, sin costo alguno, en cualquier

momento durante el primer año después de la compra.

GARANTÍA DE REEMBOLSO DE DINERO DE 90 DÍAS

Si por alguna razón no estuviera plenamente satisfecho con el

rendimiento de la herramienta eléctrica, el láser o la clavadora

D

EWALT, puede devolver el producto dentro de los 90 días

siguientes a la fecha de compra acompañado del recibo de compra.

De esta manera, se le reintegrará el importe total del producto sin

formularle pregunta alguna.

EWALT (1-800-433-9258). Esta

EWALT están cubiertas

21

Page 23

AMÉRICA LATINA: Esta garantía no se aplica a los productos que

se venden en América Latina. Para los productos que se venden

en América Latina, debe consultar la información de la garantía

específica del país que viene en el empaque, llamar a la compañía

local o visitar el sitio Web a fin de obtener esa información.

REEMPLAZO GRATUITO DE LAS ETIQUETAS DE ADVERTENCIA:

si sus etiquetas de advertencia se tornan ilegibles o faltan, llame al

1-800-4-D

EWALT para que se las reemplacen gratuitamente.

Español

22

Page 24

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (FEB08) Part No. 648674-00 DW7440RS

The following are trademarks for one or more D

Copyright © 2007, 2008 D

EWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the

EWALT

array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Loading...

Loading...