Page 1

DEWALTIndustrial Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead, MD 21074 Printed in U.S.A. (OCT98) Form No. 386171

DW730 Copyright © 1997, 1998

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW730

Heavy Duty Miter Saw Workstation

Poste de travail de service intensif pour scies à onglets

Estación de trabajo para sierra angular para trabajo pesado

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 3

Page 3

English

DW730 - 7’ Miter Saw Workstation with

Folding Legs

This workstation is designed for use with most miter saws. Certain

saws, including the DW708 sliding compound miter saw, may

require the tool mount to be reoriented 180˚ to properly secure the

saw. See mounting section for details. If you have any problem with

alignment or mounting, call 1-800-4-D

EWalt.

CAUTION: Read and understand all safety instructions before

using this or any other accessory with a miter saw.

Tools Required

1. 3’ level or straight edge

2. 12’ or 16’ long, 3/4” wide tape measure

3. Socket or wrench set.

4. Drill with 7/16” drill bit.(Not required for D

EWalt miter saws)

5. Phillips head screw driver

General Safety Instructions for Miter

Saw Accessories

• Open folding legs fully before placing tool on the stand.

• Safety glasses should be worn when using a miter saw.

• This workstation is designed to support 300 lbs. (136 kg.) safely

in a work environment. It is unsafe to climb, sit, or stand on the

workstation.

• Follow the mounting instructions carefully. Fasten the tool to the

base securely as instructed.

• Do not modify or use the workstation for an operation for which

it is not intended.

• This stand is designed to be used on a flat stable surface. To use

it on an uneven surface is dangerous.

1

PREPARATION

Lay the miter saw stand on the floor with the folded legs on top.

Push the brass locking pin and pull each leg up until the locking pin

clicks into its detent. Lift the stand by the center beam and place it

in an upright position. The stand should be stable and should not

rock. Check the legs to be sure that the locking pins have engaged

and the legs are firmly held in place.

Assembly

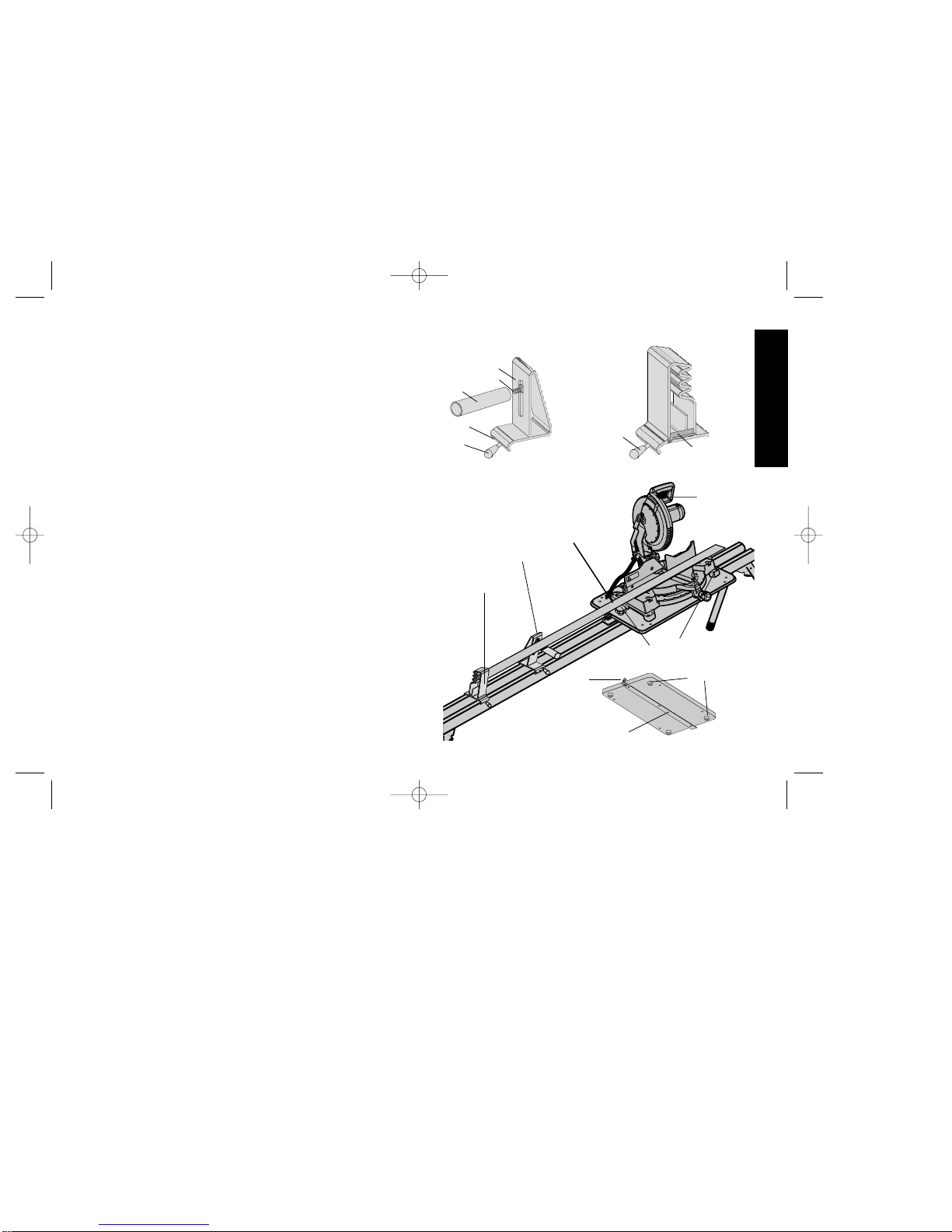

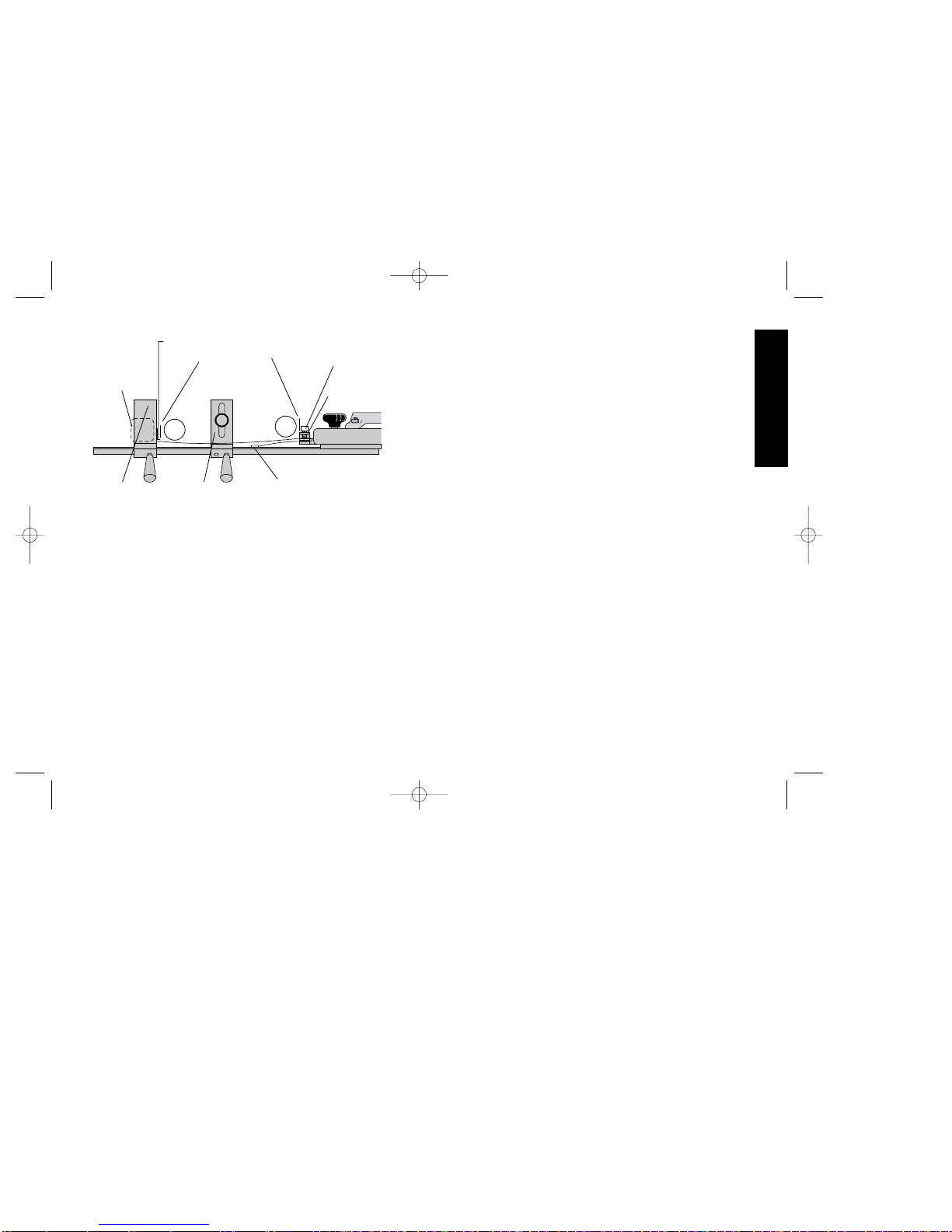

DW7301-Work Support (Fig.1)

a. The work support has a security screw (A) to capture the rail

and keep it from being knocked off the rails by your material.

b. Assemble the composite nylon work support horn (B) to the

adjustable work support (C) using the 1 1/2” carriage bolt (D)

supplied engaging the shoulder of the carriage bolt in the slot.

Rotate the work support horn clockwise to tighten.

c. Install knob (E).

d. Install the adjustable work support by sliding it onto the beam

from the left end with the knob (E) facing front.

e. After the saw is mounted to the beam, you can adjust the work

support horn until its height matches the height of the saw

table. Raise or lower the horn until it just contacts a straight

edge laid across the saw table. (Fig. 3) Rotate the horn clock-

wise to tighten in place.

DW7302-Work Stop (Fig.2)

a. Slide the work stop onto the rails from the left end.

b. Install the knob (A).

c. Position the work stop in the desired position and tighten knob (A)

to secure.

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 4

Page 4

English

Miter Saw Mounting (Fig.3)

NOTE: Four rubber feet have been provided with the tool mount.

(Fig. 3) Should you decide to leave your miter saw on the tool mount

and remove the assembly from the rails, these feet facilitate a stable

base that will not slide during use. Assemble the feet to the underside of the tool mount with the four #10 1”(25mm) self-tapping

screws in the holes provided.

NOTE: The miter saw must be able to be positioned on the tool

mount so that all four corners can be bolted to the mount. If this is

not possible or if the saw obstructs the tool mount locking knobs,

please call D

EWalt Industrial Tools at 1-800-4-DEWalt (433-9258) for

technical assistance.

Saw Mounting Instructions (DW704 and

DW705)Fig.5

The mount has been pre-drilled for the DW704 and DW705:

Slide the tool mount onto the beam by inserting the flat bar between

the T-tracks. Position the tool mount on the right end of the beam

with the tape measure clamp facing toward the left. Secure the tool

mount unit to the beam by turning the locking knobs until snug.

a. Place the saw on the tool mount and orient it so the enclosed 2 3/4”

hex head bolts and flat washers can be inserted through the miter

saw base and tool mount. Secure each bolt loosely with another

flat washer and self-locking nuts.

b. Re-check saw fence and work support alignment by placing a

straight-edge along the back of the saw fence and the back of the

work support.(Fig. 3)

c. Securely tighten the self-locking nuts.

d. Loosen the tool mount locking knobs, check movement of the tool

mount along the rail, and tighten the locking knobs.

2

FIG. 1

FIG. 2

FIG. 3

WORK SUPPORT

WORK STOP

A

B

C

D

E

A

TAPE CLIP

FEET

FLAT BAR

LOCKING KNOBS

STRAIGHT EDGE

WORK STOP

WORK SUPPORT

DW708

TAPE

CLAMP

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 5

Page 5

English

Slide the tool mount onto the beam by inserting the flat bar

between the T-tracks. Position the tool mount on the right end of

the beam with the tape measure clamp facing toward the left.

Secure the tool mount unit to the beam by turning the locking

knobs until snug.

Holes must be drilled in order to secure the saw to the tool mount.

When properly installed, the saw fence is aligned with the work

support so that the material you cut is square to the saw fence.

(Fig. 3) Before drilling any mounting holes, ensure that the saw

fence is aligned with the vertical face of the work support.

a. Place the saw on the tool mount, centering it left-to-right. Place

a straight edge against the saw fence and align the saw with the

vertical face of the work support. See Figure 3.

b. Mark the mounting holes on the tool mount.

c. Remove the saw and drill 7/16” holes at each location.

d. Place the miter saw on the tool mount.

e. Insert hex head bolts with flat washers through the saw base and

tool mount and loosely install flat washers and self-locking nuts

under the tool mount.

NOTE: The enclosed hardware is designed to secure D

EWalt miter

saws. Other miter saws may require a different length bolt for

proper fastening. The bolt must be long enough to allow 2 threads

to protrude through the self-locking nut.

f. Re-check saw fence and work support alignment by placing a

straight-edge along the face of the saw fence and the face of the

work support. See Figure 3.

g. Securely tighten the self-locking nuts.

h. Loosen the locking knobs, check movement of the tool mount

along the rail, and tighten the locking knobs.

3

Saw Mounting Instructions: (DW708)

NOTE:The DW730 has been pre-drilled for the DW708 sliding

compound miter saw. The tool mount must re-oriented 180˚

prior to mounting. When mounting the DW708 leave the rear

mounted stabilizer bars attached to the saw to ensure maximum stability.

1. Remove the two black knobs.

2. Remove the center bolt.

3. Remove the flat bar and rotate the tool mount 180 degrees.

4. Replace the center bolt and tighten it securely.

5. Replace the two black knobs.

Slide the tool mount onto the beam by inserting the flat bar between

the T-tracks. Position the tool mount on the right end of the beam

with the tape measure clamp facing toward the left. Secure the tool

mount unit to the beam by turning the locking knobs until snug.

a. Place the saw on the tool mount and orient it so the enclosed 2 3/4”

hex head bolts can be inserted through the miter saw base and tool

mount. Secure the bolts loosely with the flat washer and self-locking nuts.

b. Re-check saw fence and work support alignment by placing a

straight-edge along the back of the saw fence and the back of the

work support.

c. Securely tighten the self-locking nuts.

d. Loosen the locking knobs, check movement of the tool mount along

the rail, and tighten the locking knobs.

Mounting all other miter saws

T est fit your miter saw to the tool mount. If all four corners of the saw

are not on the tool mount after alignment of the saw fence and the

work support, the tool mount may need to be re-oriented 180˚.

Remove the saw and perform steps 1 through 5 above before proceeding.

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 6

Page 6

4

Measuring System Calibration (Fig.4)

The DW730 allows you to use a standard tape measure to easily

and accurately measure work to be cut. To ensure optimum accuracy, the unit must be calibrated prior to use.

a. Slide the work stop to approximately 3 feet from the miter saw

blade. Lock the work stop in place.

b. Position the miter saw blade at 90 degrees and lock the tool

mount in place by tightening the two black knobs.

c. Using a standard 3/4” wide, 12’ or 16’ tape measure, measure

the distance between the right edge of the work stop and the left

set of a saw blade tooth. For optimum accuracy, it is vital to

remember this measurement exactly.

d. Mount the tape measure in the work stop by sliding the belt clip

over the lip inside the work stop. Pull the end of the tape out and

flip the black tape clip down.

e. Pull the tape out, routing it under the black work support horn.

FIG. 4

SIGHT LINES

TAPE MEASURE

PLASTIC CLAMP

SCREW

WORK SUPPORT

WORK STOP

TAPE

MEASURE

(NOT

INCLUDED)

TAPE CLAMP

TAPE CLIP

English

A

B

Fold the tape back so the end is underneath and slide the top of

the tape into the tape clamp underneath the plastic clamp screw.

Route the end of the tape measure back through the tape clamp

so it rests on the rail between the two tracks. (Fig. 4)

f. Pull the tape measure out of the work stop until you read the mea-

surement obtained in step c. Line this measurement up exactly

at the right edge of the black tape clip(Fig. 4)(A). Since you have

not moved the saw or the work stop, you can calibrate the tape

measure to the edge of the tape clip and use that point as your

reference. This is where you will set the desired work length when

using the DW730. When you have positioned the tape at the

proper mark, tighten the plastic clamp screw. Your DW730

should now be calibrated.

g. If you choose to verify the calibration, loosen the work stop and

slide it to a specific measure; for example, 40.0”. Now, cut a piece

of scrap wood and measure. The length should be exactly the

same as the work stop reading. If it is not, re-calibrate the DW730

by starting at step “a” above.

h. After completion of work with the DW730, you may wish to

remove your saw and tape measure. Before doing so, record the

reading at the left edge of the tape clamp (Fig. 4)(B). You may

choose to make a mark on the tape measure, or use a pencil and

write the measurement down on the tool mount next to the tape

clamp. The next time you set up the DW730, simply mount the

tape measure in the work stop as before, and clamp the tape in

the tape clamp at the calibration setting. As long as the saw is still

mounted in the same location, the DW730 will again be calibrated.

Stowage

a. Remove the tape measure by loosening the plastic clamp screw

and sliding the tape from the work stop.

b. Loosen the black knobs on the tool mount and slide the saw off

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 7

Page 7

English

In addition to the warranty, DEWALT tools are covered by our:

30 DAYNO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the partici-

pating seller within 30 days for a full refund. Please return the

complete unit, transportation prepaid. Proof of purchase may be

required.

5

of the rail. It is not necessary to remove the saw from the tool

mount. There are four feet on the bottom of the mount that allow

the saw to be used on any flat surface while still fastened to the

tool mount.

c. The work stop and work support may be removed or left on at the

discretion of the user. Tip the DW730 on its side and fold all four

legs by sliding the brass locking pin out of its detent, fold the leg,

and ensure that the brass locking pin engages the detent in the

folded position.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

CAUTION: The use of any non-recommended accessory may

be hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be performed by authorized service

centers or other qualified service organizations, always using

identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year

from date of purchase. We will repair, without charge, any defects

due to faulty materials or workmanship. For warranty repair information, call 1-800-4-D

EWALT. This warranty does not apply to

accessories or damage caused where repairs have been made or

attempted by others. This warranty gives you specific legal rights

and you may have other rights which vary in certain states or

provinces.

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 8

Page 8

Modèle DW730 - Poste de travail de 2.2 m

(7 pi) à pattes pliantes pour scies à

onglets

Le poste de travail est conçu pour servir avec la plupart des scies à

onglets. On peut également l'utiliser avec la scie coulissante à

onglets mixtes, modèle DW708, après y avoir apporté quelques

modifications. Voir la rubrique relative au montage pour obtenir de

plus amples renseignements. En cas de problème de centrage ou

de montage, composer le 1 (800 4-DeWalt (433-9258).

MISE EN GARDE : Lire et comprendre toutes les mesures de

sécurité avant d'utiliser le présent accessoire ou tout autre accessoire avec une scie à onglets.

Outils requis

1. Un niveau ou une règle de précision de 1,1 m (3 pi)

2. Un ruban à mesurer de 19 mm (3/4 po) de largeur sur 4,0 m (12

pi) ou 4,9 m (16 pi) de longueur

3. Un jeu de douilles ou de clés

4. Une perceuse avec un foret de 11 mm (7/16 po)

5. Un tournevis à lame Phillips

Mesures de sécurité relatives aux accessoires de scies à onglets

• Ouvrir complètement les pattes pliantes avant de placer l'outil sur

le support.

• Porter des lunettes de sécurité lorsqu'on utilise une scie à

onglets.

• Le poste de travail est conçu pour soutenir 136 kg (300 lb) en

toute sécurité dans une zone de travail. Il est toutefois déconseillé d'y monter ou de s'y asseoir.

• Bien respecter les consignes de montage. Bien fixer l'outil au sup-

port de la façon indiquée. Ne jamais utiliser des brides temporaires lorsqu'on se sert d'une scie à onglets.

• Ne pas modifier le poste de travail ni s'en servir pour une utilisation non recommandée.

• Le poste de travail est conçu pour servir sur une surface plane et

stable. Il est dangereux de s'en servir sur une surface inégale.

PRÉPARATIFS

Placer le support de la scie à onglets sur le sol avec les pattes

pliées sur le dessus. Enfoncer la tige de verrouillage en laiton et

déplier chaque patte jusqu'à ce que la tige de verrouillage s'enclenche. Soulever le support par la poutre centrale et le placer à

l'endroit. Le support doit être stable et il ne devrait pas bercer.

Vérifier si les tiges de verrouillage des pattes sont bien enclenchées

et si les pattes sont bien retenues en place.

Assemblage

Modèle DW7301 - Soutien (Fig. 1)

a. Le soutien comporte une vis de fixation permettant de fixer le rail

et d'empêcher le soutien d'être expulsé des rails par le matériau.

b. Fixer le rebord en nylon composite (A) au soutien réglable (B) à

l'aide du boulon de carrosserie (C) de38 mm (1 1/2 po) fourni en

insérant l'épaule du boulon de carrosserie dans la fente. Faire

tourner le rebord du soutien dans le sens horaire pour le serrer.

c. Installer le bouton (D).

d. Installer le soutien réglable en le faisant glisser sur la poutre à par-

tir de la gauche en plaçant le bouton (E) vers l'avant.

e. Lorsque la scie est installée sur la poutre, on peut régler le rebord

du soutien jusqu'à ce que sa hauteur corresponde à celle de la

table. Soulever ou abaisser le rebord jusqu'à ce qu'il entre en contact avec une règle de précision déposée sur la table de la scie.

Faire tourner le rebord dans le sens horaire afin de fixer le tout.

Français

6

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 9

Page 9

7

Modèle DW7302 - Butée (Fig. 2)

a. Faire glisser la butée sur les rails à partir de la gauche.

b. Installer le bouton (A).

c. Placer la butée dans la position voulue et serrer le bouton (A) pour

la fixer en place.

Montage de la scie à onglets (Fig. 3)

NOTE : Le dispositif de fixation de l'outil comporte quatre pattes de

caoutchouc (fig. 3). Lorsqu'on décide de laisser la scie à onglets

sur le dispositif de fixation et de retirer l'assemblage des rails, ces

pattes procurent une base stable et empêchent le glissement pendant l'utilisation. Installer les pattes dans les trous prévus à cet effet

sur la face inférieure du dispositif de fixation de l'outil à l'aide de

quatre vis autotaraudeuses n° 10 de 25 mm (1 po).

NOTE : La scie à onglets doit pouvoir être placée sur le dispositif

de fixation de sorte qu'on puisse en boulonner les quatre coins au

dispositif. Lorsque ce n'est pas le cas ou lorsque la scie nuit au

fonctionnement des boutons de verrouillage du dispositif de fixation,

prière de communiquer avec le soutien technique de DeWalt

Industrial Tools en composant le 1 (800) 4-DeWalt (433-9258).

Instructions relatives au montage de la

scie (Modèles DW704 et DW705) (Fig. 5)

Le dispositif de fixation est déjà percé pour l'installation d'une scie

de modèle DW704 ou DW705.

Faire glisser le dispositif de fixation de l'outil sur la poutre en insérant

la barre de fer entre les voies en T. Placer le dispositif de fixation à

l'extrémité droite de la poutre avec la bride du ruban à mesurer vers

la gauche. Fixer le dispositif à la poutre en faisant tourner les boutons de verrouillage jusqu'à ce qu'ils soient bien serrés.

a. Placer la scie sur le dispositif de fixation et l'orienter de façon à

pouvoir passer les boulons à tête hexagonale de 69 mm (2 3/4

po) et les rondelles plates à travers le socle de la scie et le dis-

Français

FIG. 1

FIG. 2

FIG. 3

SOUTIEN

BUTÉE

A

B

C

D

E

A

PINCE À

RUBAN

PATTES

BARRE DE FER

BOUTONS DE VER-

ROUILLAGE

LIGNES FINES

BUTÉE

SOUTIEN

DW708

RUBAN À

MESURER

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 10

Page 10

ofreinés.

b. Revérifier le centrage du guide de la scie et du soutien en plaçant

une règle de précision le long de l'arrière du guide de la scie et de

l'arrière du soutien.

c. Bien serrer les écrous autofreinés.

d. Relâcher les boutons de verrouillage, vérifier le déplacement de

l'outil le long du rail et serrer les boutons de verrouillage.

Montage de tous les autres modèles de

scies à onglets

Placer la scie à onglets contre le dispositif de fixation de l'outil pour

en vérifier la compatibilité. Lorsque les quatre coins de la scie ne

sont pas sur le dispositif de fixation de l'outil après avoir aligné le

guide de la scie sur le soutien, il peut être nécessaire de déplacer le

dispositif de fixation de l'outil sur 180°. Enlever la scie et répéter les

étapes 1 à 5 précédentes.

Faire glisser le dispositif de fixation de l'outil sur la poutre en insérant

la barre de fer entre les voies en T. Placer le dispositif de fixation à

l'extrémité droite de la poutre avec la bride du ruban à mesurer vers

la gauche. Fixer le dispositif à la poutre en faisant tourner les boutons de verrouillage jusqu'à ce qu'ils soient bien serrés.

Il faut percer des trous afin de fixer la scie au dispositif de fixation de

l'outil. Lorsque la scie est bien installée, son guide est centré sur le

soutien de sorte que le matériau coupé est perpendiculaire au guide

(fig. 3). Avant de percer des trous, s'assurer que le guide est aligner sur la face verticale du soutien.

a. Installer la scie sur le dispositif de fixation de l'outil, en la centrant

de gauche à droite. Placer une règle de précision contre le guide

de la scie et aligner la scie sur la face verticale du soutien (fig. 3).

b. Marquer l'emplacement des trous de montage sur le dispositif de

fixation de l'outil.

c. Enlever la scie et percer des trous de 12 mm (7/16 po) à chaque

emplacement.

8

Français

positif de fixation. Installer chaque boulon lâchement avec une

autre rondelle plate et les écrous autofreinés.

b. Revérifier le centrage du guide de la scie et du soutien en plaçant

une règle de précision le long de l'arrière du guide de la scie et de

l'arrière du soutien (fig. 3).

c. Bien serrer les écrous autofreinés.

d. Relâcher les boutons de verrouillage du dispositif de fixation de

l'outil, vérifier le déplacement de l'outil le long du rail et serrer les

boutons de verrouillage.

Instructions relatives au montage de la

scie (Modèle DW708)

NOTE : Le poste de travail est déjà percé pour l'installation d'une

scie coulissante à onglets mixtes de modèle DW708. Il faut

déplacer sur 180° le dispositif de fixation de l'outil avant de procéder

au montage. Lorsqu'on installe une scie (modèle DW708), laisser

les stabilisateurs fixés à l'arrière en place afin d'en maximiser la stabilité.

1. Retirer les deux boutons noirs.

2. Retirer le boulon du centre.

3. Retirer la barre de fer et faire tourner la planche sur 180 degrés.

4. Remettre le boulon du centre en place et bien le serrer.

5. Remettre en place les deux boutons noirs.

Faire glisser le dispositif de fixation de l'outil sur la poutre en insérant

la barre de fer entre les voies en T. Placer le dispositif de fixation à

l'extrémité droite de la poutre avec la bride du ruban à mesurer vers

la gauche. Fixer le dispositif à la poutre en faisant tourner les boutons de verrouillage jusqu'à ce qu'ils soient bien serrés.

a. Placer la scie sur le dispositif de fixation et l'orienter de façon à

pouvoir passer les boulons à tête hexagonale de 69 mm (2 3/4

po) à travers le socle de la scie et le dispositif de fixation. Installer

les boulons lâchement avec la rondelle plate et les écrous aut-

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 11

Page 11

9

ruban pour le faire sortir et abaisser la pince noire à ruban.

e. Faire sortir le ruban en le dirigeant sous le rebord noir du soutien.

Plier le ruban vers l'arrière pour en fixer l'extrémité au rebord et

faire glisser le haut du ruban dans la pince à ruban sous la vis de

serrage en plastique. Diriger l'extrémité du ruban de nouveau par

la pince à ruban de sorte que le ruban repose sur le rail entre les

deux voies (fig. 4).

f. Faire sortir le ruban à mesurer de la butée jusqu'à l'obtention de la

mesure obtenue à l'étape c. Aligner cette mesure exactement à

l'extrémité droite de la pince à ruban noire (fig. 4) (A). Puisque la

scie ni la butée n'ont été déplacées, le ruban à mesurer peut être

étalonné au rebord de la pince à ruban et on peut se servir de ce

point comme référence. C'est à cet endroit qu'il faut régler la

longueur du matériau lorsqu'on utilise le poste de travail, modèle

DW730. Lorsque le ruban est placé au bon endroit, serrer la vis de

serrage en plastique. Le poste de travail, modèle DW730, est

alors étalonné.

g. Lorsqu'on veut vérifier l'étalonnage, desserrer la butée et la faire

glisser à une mesure spécifique (40,0 po, par exemple). Couper

Français

d. Installer la scie à onglets sur le dispositif de fixation de l'outil.

e. Passer les boulons à tête hexagonale à travers le socle de la scie

et le dispositif de fixation et installer lâchement les rondelles plates

et les écrous autofreinés sous le dispositif de fixation de l'outil.

NOTE : Les ferrures fournies servent à installer des scies à onglets

DeWalt. Il peut être nécessaire d'utiliser des boulons de longueur différente pour installer convenablement d'autres modèles de scies à

onglets. Le boulon doit être suffisamment long pour laisser dépasser deux filets de l'écrou autofreiné.

f.Revérifier le centrage du guide de la scie et du soutien en plaçant une

règle de précision le long de l'arrière du guide de la scie et de l'ar-

rière du soutien (fig. 3).

g. Bien serrer les écrous autofreinés.

h. Relâcher les boutons de verrouillage, vérifier le déplacement de

l'outil le long du rail et serrer les boutons de verrouillage.

Étalonnage du système de mesure (Fig.4)

Le poste de travail, modèle DW730, permet de se servir d'un ruban

à mesurer standard et de mesurer avec précision le matériau à

couper. Afin d'en optimiser la précision, le poste doit être étalonné

avant de servir.

a. Faire glisser la butée à environ 276 cm (3 pi) de la lame de la scie

à onglets. Verrouiller la butée en place.

b. Fixer la lame de la scie à 90° et verrouiller le dispositif de fixation de

l'outil en place en serrant les deux boutons noirs.

c. À l'aide d'un ruban à mesurer standard de 19 mm (3/4 po) de

largeur sur 3,6 m ou 4,9 m (12 pi ou 16 pi) de longueur, mesurer

la distance entre le rebord droit de la butée et le jeu gauche de dent

de lame. Afin d'optimiser la précision de la lecture, il est essentiel

de s'en rappeler exactement.

d. Installer le ruban dans la butée en faisant glisser la pince pour la

ceinture sur la lèvre à l'intérieur de la butée. Tirer sur l'extrémité du

FIG. 4

LIGNES FINES

RUBAN À MESURER

VIS DE SERRAGE

EN PLASTIQUE

SOUTIEN

BUTÉE

RUBAN À

MESURER

BRIDE À

RUBAN

PINCE À RUBAN

A

B

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 12

Page 12

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil,

n’en confier la réparation, l’entretien et les rajustements qu’au personnel d'un centre de service ou d'un atelier d’entretien autorisé n’utilisant que des pièces de rechange identiques.

Garantie complète

Les outils industriels de service intensif DeWALT sont garantis pendant un an à partir de la date d’achat. Toute pièce d’un outil

DeWAL Tqui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Pour obtenir

de plus amples renseignements sur les réparations couvertes par la

garantie, composer le 1 (800) 4-DeWALT (1 (800) 433-9258). La

présente garantie ne couvre pas les accessoires ni les dommages

causés par des réparations tentées ou effectuées par des tiers. Les

modalités de la présente garantie donnent des droits légaux spécifiques. L'utilisateur peut également se prévaloir d'autres droits selon

l'état ou la province qu'il habite.

En outre, la garantie suivante couvre les outils DeWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT

REMIS

Si, pour quelque raison que ce soit, l'outil industriel de service intensif DeWalt ne donne pas entière satisfaction, il suffit de le retourner

chez le marchand participant dans les 30 jours suivant la date

d'achat afin d'obtenir un remboursement complet. Il faut retourner,

port payé, l'outil complet. On peut exiger une preuve d'achat.

10

Français

ensuite un bout de bois inutile et le mesurer. Il devrait avoir exactement la même longueur que la mesure choisie. Lorsque ce n'est

pas le cas, il faut étalonner de nouveau le poste de travail, modèle

DW730, en recommençant à l'étape «a» précédente.

h. Après avoir terminé une tâche sur le poste de travail, on peut

vouloir en retirer la scie et le ruban à mesurer. Il faut au préalable

consigner la lecture prélevée au rebord gauche de la pince à

ruban (fig. 4) (B). On peut alors faire une marque sur le ruban ou

inscrire la mesure à l'aide d'un crayon sur le dispositif de fixation de

l'outil près de la pince à ruban. Ainsi, lors de la prochaine utilisation du poste de travail, il suffit d'installer le ruban à mesurer dans

la butée de la façon décrite précédemment et de le fixer dans la

pince à ruban au réglage étalonné. Tant que la scie est installée

au même endroit, le poste de travail reste étalonné.

Rangement

a. Retirer le ruban à mesurer en desserrant la vis de serrage en plas-

tique et en faisant glisser le ruban hors de la butée.

b. Desserrer les boutons noirs du dispositif de fixation de l'outil et faire

glisser la scie hors des rails. Il n'est pas nécessaire de retirer la

scie du dispositif de fixation de l'outil. Les quatre pattes du dispositif permettent d'utiliser la scie sur toute surface plane.

c. L'utilisateur peut décider de retirer ou non la butée et le soutien.

Renverser le poste de travail sur le côté et en plier les quatre pattes

en faisant glisser la tige de dégagement de laiton hors de son dispositif de retenue, en pliant la patte et en s'assurant que la tige de

dégagement de laiton s'enclenche dans le dispositif de retenue de

la position pliée.

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément

chez les détaillants et au centre de service de la région.

MISE EN GARDE : L’utilisation de tout accessoire non recom-

mandé peut être dangereuse.

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 13

Page 13

11

DW730 - Estación de trabajo para sierra

angular de 2,13 m (7’) con patas plegables

Esta estación de trabajo está diseñada para emplearse con la mayoría de las sierras angulares. Puede utilizarse también con la sierra

de inglete compuesto DW708 con algunas modificaciones. Consulte

la sección de montaje para conocer los detalles. Si tiene cualquier

problema con la alineación o con el montaje por favor llame al 326-

7100.

PRECAUCIÓN: Lea y comprenda todas las instrucciones de

seguridad antes de utilizar este o cualquier otro accesorio con la

sierra angular.

Herramientas requeridas

1. Nivel de 90 cm (3’) o una regla.

2. Flexómetro de 3,6 m (12 ft.) o 5 m (16 ft.) por 19 mm (3/4”).

3. Juego de llaves o de dados.

4. Taladro con broca de 7/16” (11 mm).

5. Destornillador Phillips.

Instrucciones generales de seguridad

para accesorios de sierra angular

• Abra completamente las patas plegables antes de colocar la her-

ramienta en la base.

• Debe utilizar gafas de seguridad cuando utilice una sierra angu-

lar.

• Esta estación de trabajo está diseñada para soportar hasta 136

kg (300 lbs.) de manera segura en el espacio de trabajo. No es

seguro pararse, sentarse y trepar en la estación de trabajo.

• Siga cuidadosamente las instrucciones de montaje. Fije la her-

ramienta a la base de manera segura como se le indica. Nunca

debe utilizar prensas temporales cuando trabaje con una sierra

angular.

• No modifique ni utilice la estación de trabajo para una operación

para la que no está destinada.

• La base está diseñada para usarse en una superficie plana y

estable. Utilizarla en una superficie irregular es peligroso.

PREPARACIÓN

Coloque la base para sierra angular en el suelo con la patas plegadas hacia arriba. Empuje el perno de seguridad de latón y tire de

cada pata hasta que el perno de seguridad haga clic en el retén.

Levante la base por la viga central y colóquela en la posición de trabajo. La base deberá ser estable y no deberá balancearse. Revise

las patas para asegurarse que los pernos de seguridad engancharon y que las patas estén firmes en su posición.

Ensamblaje

Soporte de trabajo DW7301 (Fig. 1)

a. La estación de trabajo tiene un tornillo de seguridad para capturar

el riel y evitar que salga de su sitio con el material.

b. Ensamble el cuerno de nylon (A) al soporte ajustable (B) con el

tornillo de carro de 1 1/2” que se suministra enganchando el hombro del tornillo de carro en la ranura. Gire el cuerno del soporte de

trabajo en el sentido de las manecillas del reloj para apretarlo.

c. Instale la perilla.

d. Instale el soporte de trabajo ajustable deslizándolo en la viga

desde el extremo izquierdo con la perilla (E) hacia el frente.

e. Después de montar la sierra en la viga, puede ajustar el cuerno del

soporte de trabajo hasta que su altura concuerde con la altura de

la mesa de la sierra. Suba o baje el cuerno hasta que apenas haga

contacto con una regla que se coloque en la mesa de la sierra.

Gire el cuerno en el sentido de las manecillas del reloj para apretarlo en posición.

Español

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 14

Page 14

Tope de trabajo DW7302 (Fig. 2)

a. Deslice el tope sobre los rieles desde el extremo izquierdo.

b. Instale la perilla (A).

c. Coloque el tope en la posición deseada y apriete la perilla (A) para

asegurarlo.

Montaje de la sierra angular (Fig. 3)

NOTA: Se han provisto cuatro regatones de goma con la base de

la herramienta (Fig. 3). Si usted decide dejar la sierra angular en

base y quitar el montaje de los rieles, estos regatones facilitan estabilizar la base mientras no se utilice de manera deslizable.

Ensamble los regatones a la parte inferior de la base con los cuatro

tornillos auto roscantes # 10 de 25 mm (1”) que se le proporcionan.

NOTA:La sierra angular debe poder colocarse en la base de la herramienta de manera que puedan atornillarse las cuatro esquinas. Si

esto no es posible o si la sierra obstruye las perillas de montaje de

la herramienta, por favor llame al 326-7100 para recibir asistencia

técnica.

Instrucciones de montaje de la sierra

(DW704 y DW705)

El montaje se ha pre barrenado para los modelos DW704 y DW705

Deslice la base de la herramienta en la viga insertando la barra

plana entre los rieles. Coloque la base en el extremo derecho de la

viga con la pinza para la cinta métrica apuntando hacia la izquierda. Asegure la unidad de la base de la herramienta a la viga girando las perillas hasta apretarlas.

a. Coloque la sierra sobre la base y oriéntela de manera que los

tornillos de 44 mm (2-3/4”) con cabeza hexagonal se puedan insertar a través de la base de la sierra angular y la base de la estación

de trabajo. Asegure los tornillos sin apretarlos con la roldana plana

y las tuercas auto asegurables.

12

Español

FIG. 1

FIG. 2

FIG. 3

SOPORTE DE TRABAJO

A

B

C

D

E

A

SUJETADOR

PARA CINTA

MÉTRICA

REGATONES

BARRA

PLANA

PERILLAS DE

SEGURIDAD

REGLA

DW708

PINZA PARA

CINTA

TOPE DE TRABAJO

TOPE DE

TRABAJO

SOPORTE DE

TRABAJO

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 15

Page 15

13

c. Retire la sierra y perfore orificios de 7/16” (11 mm) en cada lugar .

d. Coloque la sierra angular sobre la base.

e. Inserte tornillos con cabeza hexagonal con roldanas planas a

través de la base de la sierra y la base para la herramienta y

coloque las roldanas y las tuercas auto asegurables sin apretar

bajo la base para la herramienta.

NOTA: La herramienta proporcionada está diseñada para fijar las

sierras angulares DeWALT. Otras sierra pueden requerir tornillos

de diferente longitud para sujetarse de manera apropiada. El

tornillo debe ser suficientemente largo para permitir que sobresalgan dos vueltas de cuerda de la tuerca auto asegurable.

f. Verifique la alineación de la guía de la sierra y el soporte de tra-

bajo colocando una regla a lo largo de la cara de la guía de la

sierra y la cara del soporte de trabajo.

g. Apriete con firmeza las tuercas auto asegurables.

h. Afloje las perillas de seguridad, verifique el movimiento de la

base de la herramienta a lo largo del riel y apriete de nuevo las

perillas de seguridad.

Español

b. Revise la alineación de la guía y el soporte de trabajo colocando

una regla a lo largo de la guía de la sierra y en la parte posterior

del soporte de trabajo.

c. Apriete con firmeza las tuercas auto asegurables.

d. Afloje las perillas de seguridad, verifique el movimiento del monta-

je de la herramienta a lo largo del riel y apriete las perillas.

Instrucciones de montaje de la sierra:

(DW708 y otras sierras)

NOTA: Cuando monte la sierra DW708, deje las barras estabilizadoras posteriores instaladas en la sierra para asegurar la

máxima estabilidad.

1. Quite las dos perillas negras.

2. Quite el tornillo central.

3. Quite la barra plana y gírela 180 grados.

4. Coloque de nuevo la barra central y apriétela y asegúrela.

5. Coloque de nuevo las dos perillas negras.

PARAMONTAR OTRAS SIERRAS ANGULARES

NOTA: Deslice la base de la herramienta en la viga insertando la

barra plana entre los rieles T. Coloque la base en el extremo derecho de la viga con la pinza para la cinta métrica apuntando hacia la

izquierda. Asegure la base a la viga girando las perillas de seguridad hasta quedar apretadas.

Deben perforarse los orificios para poder asegurar la sierra a la

estación de trabajo. Cuando está instalada correctamente, la guía

de la sierra debe quedar alineada con la base de manera que el

material de trabajo esté a escuadra con respecto a la guía. Antes de

perforar los orificios de montaje, asegúrese que la guía esté alineada con la cara vertical del soporte de trabajo.

a. Coloque la sierra sobre la base, centrándola de izquierda a

derecha. Coloque una regla contra la guía de la sierra y alinee la

sierra con la cara vertical del soporte de trabajo.

b. Marque los orificios de montaje en la base de la herramienta.

FIG. 4

LÍNEAS DE

VISIÓN

CINTAMÉTRICA

TORNILLO DE SUJE-

CIÓN DE PLÁSTICO

SOPORTE DE TRABAJO

TOPE DE TRABAJO

CINTAMÉTRICA

PINZA PARA

LA CINTA

SUJETADOR DE LACINTA

A

B

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 16

Page 16

una medida específica; por ejemplo 1,0 m (40”). Ahora corte una

pieza de material de desperdicio y mídalo. La longitud deberá ser

exactamente la misma que la lectura del tope de trabajo. Si no es

así, repita la calibración comenzando por el paso “a”.

h. después de haber terminado un trabajo con la estación DW730,

usted puede desear retirar su sierra y la cinta métrica. Antes de

hacerlo, apunte la lectura en el borde izquierdo de la pinza sujetadora de la cinta (Fig. 4) Puede hacer una marca en la cinta métrica, o utilizar un lápiz y escribir la medida en la base de la herramienta, junto a la pinza sujetadora de la cinta. La siguiente vez

que utilice la estación DW730, simplemente monte la cinta métrica

en el tope como lo hizo anteriormente, y fije la cinta en la pinza en

el sitio de calibración. Mientras la sierra permanezca montada en

el mismo sitio, la estación DW730 permanecerá calibrada.

Almacenaje

a. Retire la cinta métrica aflojando el tornillo de sujeción de plástico y

deslizando la cinta del tope de trabajo.

b. Afloje las perillas negras de la base de la herramienta y deslice la

sierra hacia fuera del riel. No es necesario quitar la sierra de la

base. Esta cuenta con cuatro patitas en la parte inferior para poder

colocar la sierra en cualquier superficie plana mientras esté unida

a la base.

c. El tope de trabajo y el soporte de trabajo puede quitarse o dejarse

a discreción del usuario. Coloque la estación de trabajo de lado y

pliegue las cuatro patas deslizando el perno de seguridad de latón

hacia fuera del retén. Pliegue la pata y asegúrese que el perno de

latón enganche con el retén en la posición plegada.

Accesorios

Los accesorios recomendados para usarse con su herramienta

están a su disposición con costo adicional con su distribuidor o centro de servicio locales.

14

Español

Calibración del sistema de medición (Fig.4)

La estación de trabajo DW730 le permite utilizar una cinta métrica

estándar para medir sus cortes de manera sencilla y precisa. Para

asegurar la máxima precisión, debe calibrar la unidad antes de usarla.

a. Deslice el tope de trabajo a aproximadamente 90 cm del disco de la

sierra angular. Asegure el tope en esta posición.

b. Coloque el disco de la sierra angular a 90 grados y asegure la base

en esa posición apretando las dos perillas negras.

c. Con una cinta métrica estándar de 3,6 o 5 metros por 19 mm (3/4”),

m ida la distancia entre el borde derecho del tope de trabajo y la

punta de un diente del disco de la sierra que esté inclinado hacia la

izquierda. Para obtener la mayor precisión, es vital recordar esta

medida con exactitud.

d. Monte la cinta métrica en el tope de trabajo deslizando el sujetador

sobre el borde interior del tope de trabajo. Empuje el extremo de la

cinta hacia afuera y pliegue el sujetador negro hacia abajo.

e. Tire de la cinta hacia afuera, guiándola bajo el cuerno negro del

soporte de trabajo. Doble la cinta hacia atrás de manera que el

extremo quede debajo y deslice la parte superior de la cinta dentro

de la pinza que se encuentra debajo del tornillo de sujeción de plástico. Guíe el extremo de la cinta hacia atrás, a través de la pinza de

manera que se apoye en el riel entre las dos guías (Fig. 4).

f. Tire de la cinta métrica hacia fuera del tope de trabajo hasta leer la

medida obtenida en el paso c. Haga coincidir exactamente esta

medida en el borde derecho del sujetador negro. Ya que no ha movido la sierra ni el tope de trabajo, puede calibrar la medida de la cinta

al borde del sujetador y utilizar ese punto como referencia. En este

momento usted ajusta el espacio de trabajo que desee cuando utiliza la estación de trabajo DW730. Una vez que haya posicionado la

cinta en la marca apropiada, apriete el tornillos de sujeción de plástico. Su estación DW730 está calibrada ahora.

g. Si desea verificar la calibración, afloje el tope de trabajo y deslícelo a

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 17

Page 17

15

En adición a la garantía, las herramientas DeWALT están amparadas por nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de su herramienta industrial DeWALT, sencillamente devuélvala a los vendedores participantes durante los primeros 30 días

después de la fecha de compra para que le efectúen un reembolso

completo. Por favor regrese la unidad completa, con el transporte

pagado. Se puede requerir prueba de compra.

Español

PRECAUCIÓN: El uso de cualquier accesorio no recomendado

para emplearse con su herramienta puede ser peligroso.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto,

las reparaciones, el mantenimiento y los ajustes deberán realizarse

en los centros de servicio autorizado Black & Decker u otras organizaciones de servicio calificado. Estas organizaciones prestan servicio a las herramientas DeWALT Y utilizan siempre refacciones

DeWALT. Los centros de servicio para herramientas industriales de

Black & Decker están certificados para dar servicio a las herramientas industriales DeWALT.

Garantía Completa

Las herramientas industriales DeWALT están garantizadas durante

un año a partir de la fecha de compra. Repararemos, sin cargos,

cualquier falla debida a material o mano de obra defectuosos.

Hemos hecho arreglos con la División de Herramientas Industriales

de Black & Decker para que hagan las reparaciones en garantía a

las herramientas DeWALT. Por favor regrese la unidad completa,

con el transporte pagado, a cualquier Centro de Servicio para

Herramientas Industriales de Black & Decker o a las estaciones de

servicio autorizado enlistadas bajo "Herramientas Eléctricas" en la

Sección Amarilla. Esta garantía no se aplica a los accesorios ni a

daños causados por reparaciones efectuadas por terceras personas. Esta garantía le otorga derechos legales específicos, y usted

puede tener otros derechos que pueden variar de estado a estado.

DW730/MiterSawWkStn 5/2/02 10:48 AM Page 18

Loading...

Loading...