Page 1

SmartWireless® CX

www.detcon.com

Sensor Station for SmartWireless®

Mobile Gas Detection System

Operator’s Installation and Instruction Manual

DETCON, Inc.

4055 Technology Forest Blvd.,

The Woodlands, Texas 77381

Ph.713.559.9200 / Fax 281.298.2868

May 30, 2014 • Document #4409 • Revision 1.4

Page 2

This page left intentionally blank

Sentinel CX

Shipping Address: 4055 Technology Forest Blvd., The Woodlands Texas77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Phone: 713.559.9200 • Fax: 281.292.2860 • www.detcon.com • sales@detcon.com

Sentinel CX Sensor Station IM Rev. 1.4 ii

Page 3

Sentinel CX

Table of Contents

1. Introduction............................................................................................................................................1

1.1 Features ..........................................................................................................................................................1

1.2 Optional Components.....................................................................................................................................2

1.3 Alarms and Fault Condition ........................................................................................................................... 2

1.4 Power Supply-Internal Rechargeable Battery and Charging Accessory ........................................................ 3

1.5 Radio Module................................................................................................................................................. 4

1.6 Sensor Inputs.................................................................................................................................................. 5

1.7 Alarm Outputs................................................................................................................................................ 6

1.8 Power Switch.................................................................................................................................................. 8

1.9 Power Connector............................................................................................................................................ 8

1.10 Remote I/O Cabling Accessory and Safe Use ................................................................................................ 8

2. Safety Guidelines for safe use.............................................................................................................10

3. Installation............................................................................................................................................12

3.1 Initial Setup .................................................................................................................................................. 12

4. Recharging the Internal Battery Pack...............................................................................................18

4.1 Non-Hazardous and Indoor Location ...........................................................................................................18

4.2 Connecting to Mains Supply........................................................................................................................ 18

5. Maintenance and Service Personnel Activities..................................................................................19

5.1 Replacement of Condensation Prevention Packet ........................................................................................ 19

5.2 Replacement of Lithium Ion Battery Pack ................................................................................................... 19

5.3 Proper Cleaning Procedure........................................................................................................................... 19

5.4 Servicing Risks and Verification of Safe State after Servicing .................................................................... 20

6. Troubleshooting Guide........................................................................................................................21

7. Customer Support and Service Policy...............................................................................................22

8. Warranty Notice ..................................................................................................................................23

9. Appendix...............................................................................................................................................24

9.1 Specifications ............................................................................................................................................... 24

9.2 Spare Parts and Wireless Accessories .......................................................................................................... 25

9.3 Revision Log ................................................................................................................................................ 26

Table of Figures

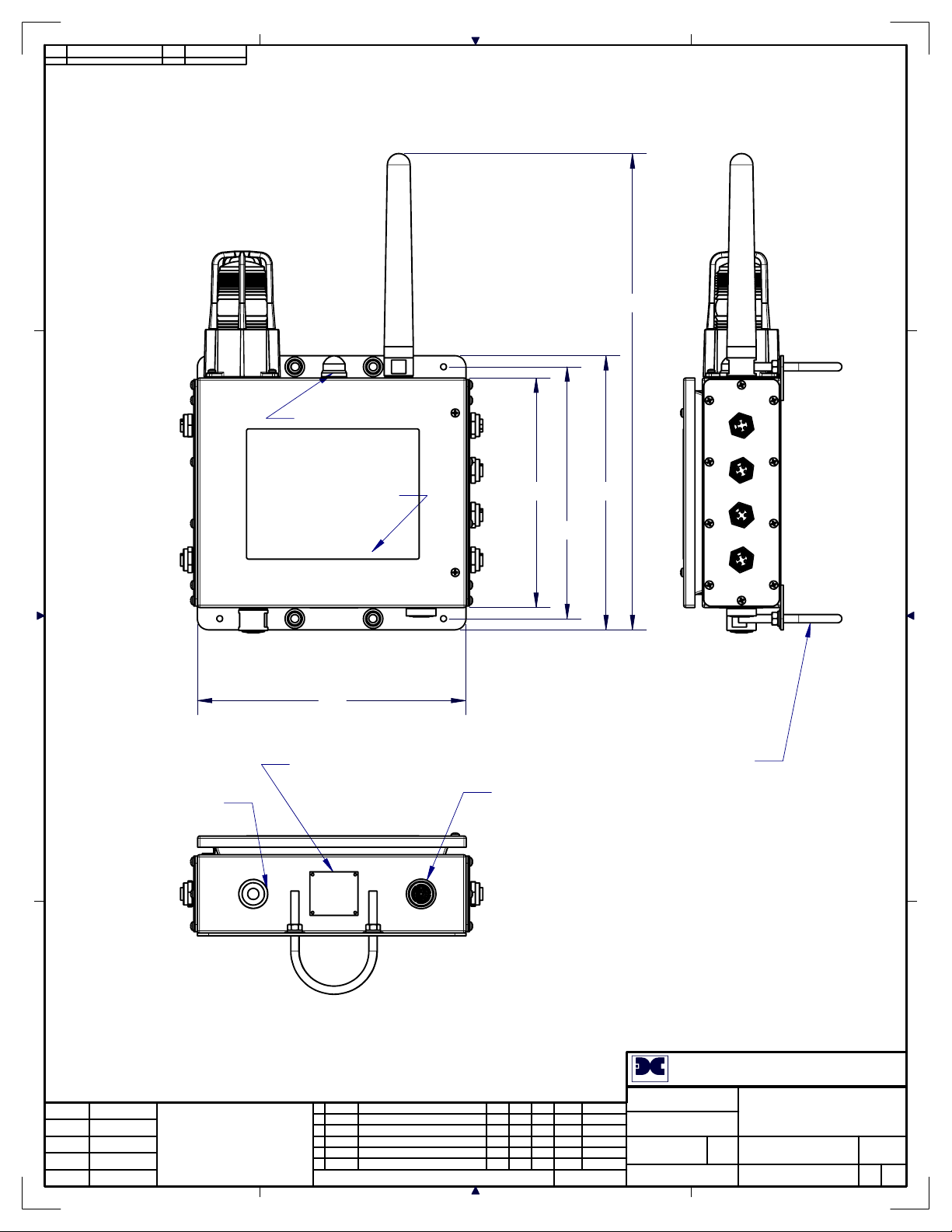

Figure 1 SmartWireless® CX Sensor Station..................................................................................................1

Figure 2 SmartWireless® CXT Radio Module ...............................................................................................4

Figure 3 Sensor Input PCA..............................................................................................................................5

Figure 4 Sensor Input Connector Pin-out........................................................................................................6

Figure 5 Relay PCA.........................................................................................................................................6

Figure 6 External Alarm Connector pin out for ‘Wet’ alarm contacts ............................................................7

Figure 7 External Alarm Connector Pin out for ‘Dry’ alarm contacts.............................................................7

Figure 8 Power Connector...............................................................................................................................8

Figure 9 Mount CX on Tripod.......................................................................................................................13

Figure 10 Attach Sensor Brackets to Tripod .................................................................................................14

Figure 11 A1 C1D2 Alarm Connections .......................................................................................................14

Figure 12 Enclosure.......................................................................................................................................15

Figure 13 Connector to Transceiver ..............................................................................................................15

Figure 14 Battery Bracket in position............................................................................................................16

Sentinel CX Sensor Station IM Rev. 1.4 iii

Page 4

Sentinel CX

Figure 15 Battery and Battery Bracket ..........................................................................................................16

Figure 16 Battery Connections......................................................................................................................17

This page left intentionally blank

Shipping Address: 4055 Technology Forest Blvd., The Woodlands Texas77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Phone: 713.559.9200 • Fax: 281.292.2860 • www.detcon.com • sales@detcon.com

Sentinel CX Sensor Station IM Rev. 1.4 iv

Page 5

Sentinel CX

1. Introduction

1.1 Features

The SmartWireless® CX Sensor Station (Figure 1) is an accessory to the SmartWireless® CXT. The CX

wirelessly transmits the data from the sensors to the CXT and includes a battery that powers the radio,

alarm devices, and the attached sensors. The CX can sustain up to four 4-20mA wired sensors.

Remote mounted gas detection sensors include any analog 4-20maDC device such as;

toxic gas,

combustible gas, or

oxygen deficiency sensors.

Antenna

Strobe

Power

LED

4-20 Sensor Input PCA

& 4 Relay PCA

Optional

Ext Alarm

Connector

Power

Connector

RXT-320

Transceiver

Power

Switch

Sensor Ports

Battery Pack

Alarm Horn

Figure 1 SmartWireless® CX Sensor Station

The SmartWireless® CX Sensor Station package is a Division 2 assembly housed in a 316 stainless steel

enclosure that offers various connector options for multiple configurations.

System components of the SmartWireless® gas detection system include;

Smart Wireless CXT Controller

Smart Wireless CX Sensor Station,

alarm stations and

gas detection sensors.

Sentinel CX Sensor Station IM Rev. 1.4 Page 1 of 26

Page 6

Sentinel CX

SmartWireless® CXT Controller

The Detcon SmartWireless® CXT controller is a multi-channel mobile gas detection control system

mounted on a tripod or a suitable stand. The CXT can be utilized as a self-contained gas detection,

display/alarm system package or wirelessly connected to the main network. The CXT is equipped with an

auto configure system to automatically search for Detcon equipment associated with the controller.

SmartWireless® CX Sensor Station

The SmartWireless® CX Sensor Station is an accessory to the SmartWireless® CXT. The CX wirelessly

transmits the data from up to 4 wired sensors back to the CXT and includes a battery that powers the radio,

alarm devices, and the attached sensors.

Alarm Stations

Alarm stations can be used as part of the gas detection system. Class I Division 1 and Class I Division 2

alarm stations are available. The stations are battery powered and controlled wirelessly by the CXT. The

strobe and horn installed on the CX are activated by the CXT when the alarms levels are reached.

Alarm options are as follows:

1. Integral audio visual mounted on the CX (Class 1; Division 2 only)

2. Standalone audio visual alarm station (Class 1; Division 2)

3. Standalone audio visual alarm station (Class 1; Division 1)

Gas Detection Sensors

Gas sensors with a 4-20mA output can be connected directly to the CX. The Model CX sensors from

Detcon are designed specifically to work with the SmartWireless® CX.

Associated Accessories

The accessories associated for the CX Controller product are as follows:

Detcon Tripod

Detcon Battery Charging Accessory

Detcon Division 2 cables (various)

Detcon Operators Manual

1.2 Optional Components

Options for the SmartWireless® CX Sensor Station are as follows:

strobe

horn

external ‘Wet’ or ‘Dry’ alarm port

1.3 Alarms and Fault Condition

The CX Sensor Station includes an optional strobe and/or a piezoelectric horn and an external alarm

connector. The strobe is associated with Alarm 1, the horn is associated with Alarm2 and the external alarm

connector utilizes all alarm outputs (alarm 1, 2, 3 and fault) for connection to external alarm devices. The

external alarm outputs can be used to control annunciating devices or as signal inputs to other control

devices. The CX permits alarm and fault conditions to cause an assigned relay to fire, triggering external

alarm devices. When the alarm level is reached either the devices mounted to the box or attached to the

external alarm connector are activated, or both. The assigned relay outputs will return to normal state when

a gas alarm or a fault condition clears. The Alarm Relay Output can be either ‘Wet’ or ‘Dry’ determined

Sentinel CX Sensor Station IM Rev. 1.4 Page 2 of 26

Page 7

Sentinel CX

when the unit is ordered. The ‘Wet output connector provides 12V outputs for external alarms. The ‘Dry’

output connector provides dry contacts for external power to control external alarms.

All alarms can be configured as Energized/De-Energized, Latching/Non-Latching and Silenceable/NonSilenceable for the relays. This setup must be performed at the controller, refer to the controller manual for

more information.

1.4 Power Supply-Internal Rechargeable Battery and Charging

Accessory

SmartWireless® CX is powered by an internal rechargeable Smart Battery capable of delivering continuous

operation in a no alarm condition for two to eight weeks depending on the quantity and type of sensors tied

to the control panel. The internal re-chargeable battery pack shall only be charged in a non-hazardous area

where the required operating temperature limits are 0C to +45C. It may be used in the field and be

discharged in the temperature range of -20C to +60C.

The internal re-chargeable battery pack shall only be charged in a non-hazardous

area where the required operating temperature limits are 0C to +40C. Charging

CAUTION

outside this temperature range may degrade the life of the battery pack.

The Battery Pack Detcon PN 360-3S6PFP-290 contains an internal protection

circuit which maintains its safe operation against all potential hazard conditions.

CAUTION

No other Battery Pack except Detcon PN 360-3S6PFP-290 may be used in the

operation of this device.

CAUTION

The internal battery can only be recharged in a non-hazardous area and only using the Detcon supplied

Battery Charger Accessory that runs on AC power.

Detcon Approved Battery Charger Accessory Ratings:

AC Input Power

Voltage: 100-240 VAC, 50-60 Hz (requires correct PN version for optional 110 or 220 VAC use)

Current: 2.0 Amps maximum

DC Output Power

Voltage: 24+/- 1 VDC

Current: 3.1 Amps maximum

NOTE 1

Sentinel CX Sensor Station IM Rev. 1.4 Page 3 of 26

No other Battery Charger or VDC input power source may be used with this CX Controller

product.

Page 8

Sentinel CX

1.5 Radio Module

The SmartWireless® CX offers a wireless option to connect it to the SmartWireless CXT and other devices

wirelessly. The Radio Module includes a transceiver that operates at 2.4GHz and conforms to non-licensed

radio frequency usage worldwide. Spread spectrum technology supports integrity and security for the

wireless network.

The SmartWireless CXT and CX products use a wireless network with a mesh topology. If radio

communication directly between two devices is impossible due to distance or obstruction, each wireless

device is capable of locating an alternate route through an additional wireless device to communicate with

the designated device. This innovative technology is designed to create a robust network that automatically

routes around congestion and line-of-sight obstacles while improving throughput as subscriber device

density increases.

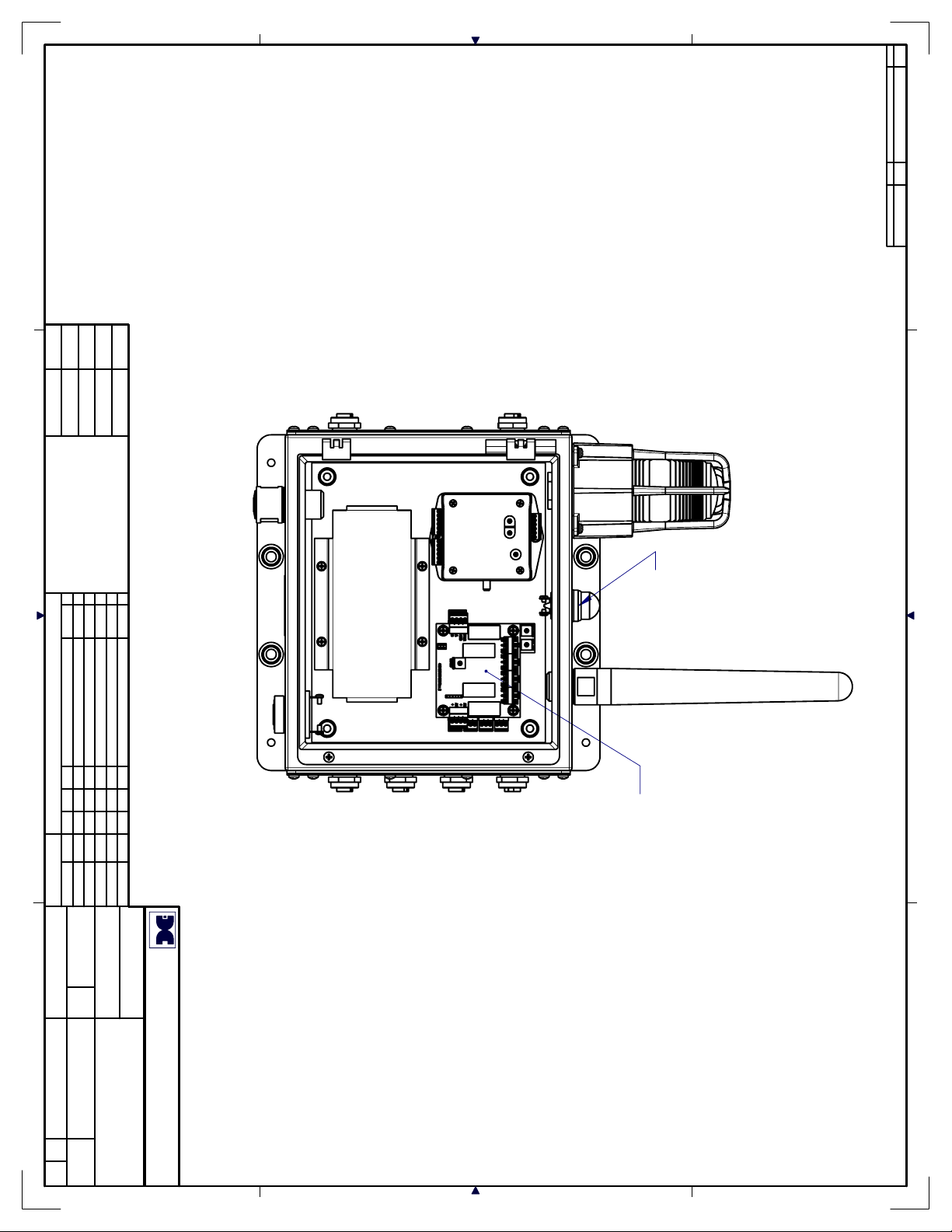

The radio module is housed in a black ABS box mounted inside of the CX stainless steel enclosure. The

standard package includes two PCAs mounted inside the black ABS box (radio PCA and Smart battery

charging PCA), 5 dB antenna, and a protective antenna cover. The battery PCA includes circuitry to safely

recharge the battery from a 24VDC input and a fuel gauge circuit to monitor the charge remaining in the

battery.

The radio PCA includes a 2.4Ghz radio and a rotary switch for setting the RF channel of the system (Figure

2). Use a small screwdriver to rotate the switch until the arrow points to the desired RF channel number (16

channels available, 0h-Fh).

NOTE

All devices within the network must be on the same RF channel to operate correctly.

Each radio module is required to have a unique address. These addresses typically start at 01h and continue

sequentially for each SmartWireless CX in the gas detection system. The radio PCA includes a pair of

rotary switches to set this address (Figure 2).

NOTE

The switch for the most significant digit (MSD) is on the right and the least significant digit

(LSD) is on the left.

Modbus

Address LSD

Switch

RF Channel

Selector Switch

Modbus

Address MSD

Switch

Figure 2 SmartWireless® CXT Radio Module

Sentinel CX Sensor Station IM Rev. 1.4 Page 4 of 26

Page 9

Sentinel CX

1.6 Sensor Inputs

The SmartWireless® CX Sensor Station includes a Sensor Input PCA that accepts 4-20mA inputs from up

to 4 attached sensors. The PCA includes two rotary switches to set its Modbus address (Figure 3). This

address is set to 01 for SmartWireless® systems using a CXT or Model X40 controller. If an MCX-32

controller is being used, this address needs to be unique for each CX Sensor Station in the system. For an

MCX-32 system, the addresses should start at 40h and continue sequentially for each CX in the system.

Sensor Connector Ratings

Voltage: 9-11.2 VDC

Current: 100 mA max through any single sensor connector

Modbus Address

LSD Switch

Modbus Address

MSD Switch

Figure 3 Sensor Input PCA

Four "quick connects" on the side of the CX are for sensor connection (Figure 4), supply power to the

sensor from the internal battery and accept the 4-20mA signal from the sensor.

NOTE

Power supplied to the sensors is 11VDC. Any attached sensor must be designed to work at

this voltage level.

The four sensor input lines are fused at the PC board level for safety purposes. These fuses are not

designed for field replacement and shall not under any circumstances be attempted to be changed out by

anyone but Detcon Factory trained Service personnel.

These PC board mounted fuses are not designed for field replacement and shall not

under any circumstances be attempted to be changed out by anyone but Detcon

CAUTION

Factory-Trained Service personnel.

Sentinel CX Sensor Station IM Rev. 1.4 Page 5 of 26

Page 10

Sentinel CX

Enclosure

PCB

3

4

Shld (Green) 4

PWR (Red) 3

4-20mA (White) 2

GND (Black) 1

Sensor Connector

2

1

1

1

(White) 4-20mA

(Red) PWR

(Black) GND

(Green) Shld

Sensor

Cable to Sensor 1

Figure 4 Sensor Input Connector Pin-out

1.7 Alarm Outputs

The SmartWireless® CX can optionally include an internal Relay PCA for activating alarm annunciators.

The Relay PCA includes four Class I Division 2 Groups A,B,C,D relays. If the SmartWireless® CX

includes an attached strobe and/or horn, these devices are also activated by the Relay PCA.

Each Relay PCA must have a unique Modbus address. The Relay PCA includes a single rotary switch to set

its Modbus address (Figure 5). The most significant digit of the address is hard-wired to “8”. The least

significant digit (LSD) is controlled by the rotary switch. The Relay PCA addresses should start at 80h and

continue sequentially for each SmartWireless® CX in the system.

Alarm Relay Connections

Modbus™

LSD Address

Modbus™

Connections

Internal Alarm

Connections

Figure 5 Relay PCA

If the SmartWireless® CX is ordered with the Relay PCA option, the Relay PCA can be configured to

provide either ‘Wet’ or ‘Dry’ contacts for external annunciator activation. The ‘Wet’ contact option

provides 11V Battery Power to external annunciators when an alarm is initiated. The ‘Wet’ relay contacts

are rated for 9-11.1 VDC, 2A max total (A1, A2, A3, and FLT outputs combined). The “wet” contacts are

available on a 5 pin Alarm Connector (Figure 6). These outputs are specifically meant for external 12V

annunciators such as the external A1 C1D2 Horn, which is designed to operate on the unit’s 12V Battery.

Sentinel CX Sensor Station IM Rev. 1.4 Page 6 of 26

Page 11

12V Battery Power

Figure 6 External Alarm Connector pin out for ‘Wet’ alarm contacts

Sensor Connector Ratings

Voltage: 9-11.2 VDC

Current: 2 Amps max through single relay connector (2 Amps max total across 4 connectors.

12V Return

FAULT

ALARM 3

ALARM 2

ALARM 1

Relay PCA

Enclosure

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

3

4

5

FAULT (BLUE) 5

ALARM 3 (Brown) 4

ALARM 2 (Gray) 3

ALARM 1 (White) 2

GND (Black) 1

1

Alarm Connector

Sentinel CX

2

1

When utilizing ‘Wet’ contacts, the maximum power that can be drawn by the

CAUTION

annunciators is 2A.

The SmartWireless® CX is also available with ‘Dry’ relay contacts (Figure 7). Dry relay Contacts allow

the user to control annunciators that operate off an exterior power source that relies on the controller to

provide only contact closure to apply voltage to the annunciator. The relays are rated for 120-220 VAC/24

VDC, 2 A max. It is important to note that the ‘Dry’ contact feature utilizes a common return for all

annunciators.

3

FAULT

ALARM 3

ALARM 2

ALARM 1

Enclosure

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

4

1

5

6

FAULT (Blue) 6

ALARM 3 (Orange) 4

ALARM 2 (Green) 3

ALARM 1 (White) 1

COM (Black) 5

Alarm Connector

(Pin 2 is not used)

2

1

Relay PCA

Figure 7 External Alarm Connector Pin out for ‘Dry’ alarm contacts

Sentinel CX Sensor Station IM Rev. 1.4 Page 7 of 26

Page 12

Sentinel CX

1.8 Power Switch

Power to the SmartWireless® CX is controlled by a power switch located on the bottom of the enclosure

(Figure 1). Pressing this switch while the power is off will turn the CX on. Pressing the switch while the

power is on will turn the power off. When the power to the CX is on, the green LED indicator on top of the

enclosure will be illuminated.

1.9 Power Connector

The internal battery inside the SmartWireless® CX Sensor Station can be recharged by connecting 24VDC

to the power connector on the side of the enclosure (Figure 1). A VAC/24VDC battery charging adapter is

included with every CX.

Detcon Approved Battery Charger Accessory Ratings:

AC Input Power

Voltage: 100-240 VAC, 50-60 Hz (requires correctly selected 110 VAC or 220 VAC Charger)

Current: 2.0 Amps maximum

DC Output Power

Voltage: 24+/- 1 VDC

Current: 3.1 Amps maximum

The SmartWireless® CX Sensor Station must be charged with the Detcon supplied

Battery Charger. (Detcon P/N: 976-0003BC-00T for 110VAC and P/N 976-

CAUTION

0003BC-220 for 220VAC ). Use of any other charger may damage the controller.

Pin 2

Pin 1

+24VDC (White) 3

GND (Black) 2

Chassis GND (Green) 1

Figure 8 Power Connector

Pin 3

1.10Remote I/O Cabling Accessory and Safe Use

The I/O cabling option designed for the CX Sensor Station and its safe use is described in the cabling

Speciation section in Section 9.1. A specific list of Detcon approved cabling option lengths are given in the

Spare Parts List.

Security clips, which require a tool for removal, are provided and are required for all I/O Turck connector

based cables. All Turck connectors should have the security clip engaged at all times except for when

disconnecting them in the safe area.

Sentinel CX Sensor Station IM Rev. 1.4 Page 8 of 26

Page 13

CAUTION

CAUTION

Sentinel CX

Use only Detcon specified cable accessories described in this Manual to maintain

the Division 2 rating and safe use of this product.

Security clips, which require a tool for removal, are provided and are required for

all I/O Turck connector based cables. Turck connectors should have the security

clip engaged at all times except for when disconnecting in the safe area.

Sentinel CX Sensor Station IM Rev. 1.4 Page 9 of 26

Page 14

Sentinel CX

2. Safety Guidelines for safe use

If equipment is used in a manner not specified by Detcon, the protection provided by the equipment may be

impaired. It is mandatory to read and follow all of the Safety Warnings and Cautions listed below.

ThisapparatusissuitableforuseinClassI,Division2,GroupsA,B,C,D,orunclassifiedlocations.

Warning

Explosion Hazard. Do not make any disconnections while the circuit is live or

Warning

Warning

unless the area is known to be free of ignitable concentrations.

Charging of the internal Battery Pack shall never be done while equipment is

located in the Division 2 hazardous area. The equipment must be moved to a nonhazardous are for the battery charging to take place. The temperature during the

indoorbatterychargingshall be between 0 - 40C.

Warning

Warning

Warning

Warning

Explosion Hazard. Do not remove or replace the Lithium Ion Battery Pack unless

power has been disconnected or unless the area is known to be free of ignitable

concentrations.

Substitution of any component may impair suitability for Division 2 use.

Exposure to some chemicals may degrade the sealing properties of materials used

in the following devices used in this equipment; namely the Div2 Strobe, relay

contacts,andmagneticprogrammingswitches

All Turck connectors have dust/water sealing caps that are mandatory to be

installed on any connector that is not actively connected to a cable. This is

required to maintain the safety rating of this device. These caps are tethered

adjacent to each of the connector fittings for convenient connection.

The user must consult this manual for more information about any location marked

CAUTION

DANGER

Sentinel CX Sensor Station IM Rev. 1.4 Page 10 of 26

with this symbol.

Danger of electrical shock. User must ensure that power has been disconnected

prior to installation or servicing of the equipment.

Page 15

Warning

which requires suitable securement that holds four times the weight of the unit.

Assembly, 2 people are required to work together to avoid possible lifting risk.

Sentinel CX

When moving the base CX Sensor Station handle it with 2 hands securely around

the body of the unit so as to prevent a possible dropping or lifting hazard.

When wall mounting the CX Sensor Station, make sure to have 2 people working

together and follow the recommended wall mounting instruction in Section 3.1.9,

Warning

Warning

Warning

Warning

This will prevent chances of a dropping hazard during the installation or prevent

the risk of the unit falling off from the wall mount.

When moving or manipulating the CX Sensor Station mounted to the Tripod

Do not place your fingers in the areas of the sliding tripod legs as there is risk of

hand injury. Personnel should wear safety gloves while moving and setting up the

tripod assembly.

To avoid accidental tip-over risk of injury, press and anchor the 3 pointed legs of

the tripod deep and firmly into the soft ground. If the ground is too hard for use

of the point, use an independent anchored pin and a short chain connecting to each

leg to secure the unit.

To avoid a tripping hazard, hang a brightly colored flag type marker half down

each tripod leg to provide visual warning of the location of the tripod legs.

To avoid any possible ergonomic risk in interfacing with the CX Sensor Station,

make sure it is installed at a height of 4-5 feet. Place the unit in place where it is

Warning

Sentinel CX Sensor Station IM Rev. 1.4 Page 11 of 26

easy to access the front of the unit and as possible avoid placing it where there is

constant direct sunlight.

Page 16

Sentinel CX

3. Installation

3.1 Initial Setup

The Detcon tripod (P/N 975-TRIPOD-100) provides a stable and mobile base for the SmartWireless® CX

Sensor Station. A maximum of two sensors can be secured to the tripod using Detcon brackets (P/N 943004413-000) installed on the tripod.

1. Unpack the tripod, open the legs and place on a level surface. The tripod must have the 3 legs

extended to widest position possible and be locked in place. The tripod must be firmly located on

level terrain or this is an extreme safety risk of the unit tipping over and causing personnel harm or

equipment damage. As is possible, the points of the tripod legs should be equally plunged into the

ground to make the tripod most firmly stabilized.

The tripod must have the 3 legs extended to widest position possible and be locked

in place. It then shall be firmly located on level terrain or there is an extreme safety

CAUTION

2. Mount the CX Sensor Station to the center pipe using the supplied U-bolts in accordance with

Figure 9. The height position should be about 4-5 feet maximum to minimize tip-over potential.

The U-bolts should be thoroughly tightened such that there is no vertical slide of the controller up

or down the tripod center pipe. If it slides it may be a safety issue related to personnel injury.

CAUTION

NOTE

3. Install the 8" antenna on the antenna connector on the top right of the CX Sensor Station (Figure 1).

4. Secure the antenna cover over the antenna.

Position the CX controller on the tripod and position the tripod such that all disconnecting

devices are readily accessible.

risk of the unit tipping over and causing personnel harm and/or equipment damage.

The installed height position should be 4-5 feet maximum to minimize tip-over

potential. The U-bolts should be thoroughly tightened so there is no chance for

vertical slide of the controller up or down the tripod center pipe. If it slides

unexpectedly it is a safety issue related to personnel injury and/or tipping over.

5. If sensors are being mounted on the tripod legs, attach the sensor mounting brackets to the tripod

legs using the supplied 1/4" bolts, nuts and lock washers in accordance with Figure 10.

Sentinel CX Sensor Station IM Rev. 1.4 Page 12 of 26

Page 17

Tripod Center Pipe

11.25"

10.25"

12.25"

Sentinel CX

21.3"

3.5"

12"

4.5"

Pipe Mounting U-Bolts

and hardware

Figure 9 Mount CX on Tripod

Tripod Leg

Mounting

Hardware

Sensor with

Mini Condulet

Mounting Plate

Mounting

Support

Sentinel CX Sensor Station IM Rev. 1.4 Page 13 of 26

Page 18

Sentinel CX

Figure 10 Attach Sensor Brackets to Tripod

6. Hang the sensors on the brackets using the hook and pin supplied with the bracket.

7. Connect sensor cables to the sensor ports on the CX (Figure 1).

8. If the unit is ordered with the optional external A1 C1D2 Horn, the horn should be mounted either

on the tripod, or on a separate tripod. . The optional A1 C1D2 Horn requires the cable for the

External ‘Wet’ Alarms.

a. The horn should be wired to the ‘Wet’ Alarm Output cable per Figure 11.

b. The alarm Cable should be connected to the External Alarm Connector on the controller.

Turck Alarm Cable

from Sentinel

Gray

White

Black

Green/Yellow

Red

Black

To

Horn

C1D1 Cable Assembly

12-24 Alarm

Terminal PCA

Figure 11 A1 C1D2 Alarm Connections

Battery Installation

9. Loosen the screws holding the door panel in place, and swing the front door of the enclosure open

to gain access to the battery bracket.

Sentinel CX Sensor Station IM Rev. 1.4 Page 14 of 26

Page 19

Sentinel CX

Figure 12 Enclosure

10. Unplug the connector from the transceiver, and move it out of the way to gain access to the screws

holding the battery bracket in place. There should be enough of a service loop to safely move this

connector out of the way for removal/installation of the battery bracket.

Figure 13 Connector to Transceiver

11. Remove the 6-32 screws and washers holding the battery bracket is place, and remove the bracket

from the enclosure. Retain the screws and washers for installation of the bracket with the battery

pack.

Sentinel CX Sensor Station IM Rev. 1.4 Page 15 of 26

Page 20

Figure 14 Battery Bracket in position

Sentinel CX

12. Install the battery pack in the bracket. The battery will fit snugly into the holder, being somewhat

held in place by the foam padding in the bracket.

Figure 15 Battery and Battery Bracket

13. Position the battery bracket (and battery) with the connector on the left side, and install the battery

and bracket in the enclosure using the 6-32 screws removed is step 11. Some wiring may need to

be moved out of the way during this process to ensure that the wiring is not caught under the

bracket.

14. Locate the connector mate for the battery connector, and plug the two connectors together.

Sentinel CX Sensor Station IM Rev. 1.4 Page 16 of 26

Page 21

Figure 16 Battery Connections

15. Re-install the connector to the transceiver (removed in step 10).

Sentinel CX

16. Cycle power to ensure that the unit powers up. The LED on the top of the unit should illuminate to

indicate power is applied. Close the front door panel and screw the front cover down. The screws

should be tightened down to a ‘snug’ fit. These screws do not need to be tightened down

completely, but need to be tightened down enough to give the front door a water tight seal.

17. Turn power on to the unit. The LED on the top of the unit should illuminate to indicate power is

applied.

Sentinel CX Sensor Station IM Rev. 1.4 Page 17 of 26

Page 22

Sentinel CX

4. Recharging the Internal Battery Pack

4.1 Non-Hazardous and Indoor Location

At a safe time interval prior to full discharge of the internal battery pack, relocate the CX Sensor Station to

a non-hazardous indoor location area that has suitable 110 VAC or 220 VAC AC power receptacles

available.

4.2 Connecting to Mains Supply

Using the appropriate Battery Charging Accessory product (PN 976-0003BC-00T for 110 VAC or PN 976-

0003BC-220 for 220 VAC), find the corresponding Mains Supply receptacle in an indoor non-hazardous

area and plug-in the pronged end of the cable. Connect the Turck connector to the external port labeled

external power. Turn on the power switch and begin charging. Operate the charger for the necessary time

it takes to accomplish a full charge.

Only the Mains supply cord that is supplied with the Detcon-approved Battery

Charger Accessory product shall be used. Use of any other Mains supply cords will

CAUTION

Warning

impair the safety of this device.

Charging of the internal Battery Pack shall never be done while equipment is

located in the Division 2 hazardous area. The equipment must be moved to a nonhazardous indoor location area for the battery charging to take place. The

temperature during the indoor battery charging shall be between 0-40C.

Warning

The charging power supply is only safely rated for indoor use, so use of the Detcon

charging accessory is limited to indoor non-hazardous areas.

Sentinel CX Sensor Station IM Rev. 1.4 Page 18 of 26

Page 23

Sentinel CX

5. Maintenance and Service PersonnelActivities

Only service or maintenance related activities as described below in Sections 5.1- 5.4 are

NOTE

The following is a list of items that are supplied standard with the CX Sensor Station. They can also be

purchased for service or maintenance needs. These components are only to be supplied by Detcon as part of

this product configuration. No substitutions are allowed.

Rechargeable Battery Pack (Detcon PN 360-3S6PFP-290)

Condensation Prevention Packet (Detcon PN 960-798434-000)

Battery Charging Accessory (Detcon PN 976-0003BC-00T or PN 976-0003BC-220)

allowed to be performed by the on-site un-certified service personnel. Any other required

service or maintenance related activity shall only be performed by a Factory-Certified

Detcon technician.

Any maintenance or servicing performed outside the allowable scope of this section

CAUTION

may impair the safe operation of this device.

5.1 Replacement of Condensation Prevention Packet

On an annual or bi-annual basis, the Condensation Prevention packet should be exchanged with a new

packet. Remove the CX Sensor Station to a non-hazardous area and turn power OFF. Open hinged door

and locate packet. Remove packet and replace with a new packet in the same physical position. Close

hinged door and turn power ON.

5.2 Replacement of Lithium Ion Battery Pack

Explosion Hazard. Do not remove or replace the Lithium Ion Battery Pack unless

power has been disconnected or unless the area is known to be free of ignitable

Warning

If there are any warnings or fault indicators that suggest there is a problem with the lithium ion battery pack

(ie. not charging when expected), it should be removed and replaced. Relocate the CX Sensor Station to a

non-hazardous area and remove power from the CX Sensor Station by turning the power switch to OFF.

Open the hinged door to gain access to interior. Locate the four screws that attach the metal bracket that

secures the battery pack. Undo the four screws and set them aside carefully. Lift metal bracket and expose

battery pack. Disconnect the two wire male/female connector to free the pack. Replace the old pack with a

new pack and reverse the directions given above, making sure the wire connections are made correctly.

concentrations.

5.3 Proper Cleaning Procedure

If the unit requires cleaning, take a clean water-damped wet cloth and wipe off the exterior surfaces of the

unit as required. Allow for air dry. It is not necessary to relocate the unit to a non-hazardous area to

perform cleaning.

Sentinel CX Sensor Station IM Rev. 1.4 Page 19 of 26

Page 24

Sentinel CX

5.4 Servicing Risks and Verification of Safe State after Servicing

While performing any of the above-mention user-authorized service activities, proper caution shall be used

to avoid safety risks.

The first protective measure and mandatory requirement is that the CX Sensor Station must be relocated to

a non-hazardous area while performing these functions.

The second protective measure is to make sure the power switch is turned OFF while opening the enclosure

and addressing internal components.

The third protective measure is to use static protection while touching any internal components within the

controller enclosure.

The fourth protective measure is to follow these instructions properly and secure the hinged enclosure

cover fully closed before returning unit to the hazardous area.

Once all servicing has been completed turn power ON and verify that all configured gas sensors are reading

the correct value and also verify that the battery charge level is correct. Once verified, it is safe to return

the unit to active usage.

Sentinel CX Sensor Station IM Rev. 1.4 Page 20 of 26

Page 25

6. Troubleshooting Guide

Sensor COMM Error

Verify all SmartWireless® CXT devices have a unique Modbus ID number.

Verify the Sensor Input PCA and Relay PCA Modbus address are set correctly

Verify the Radio Module Modbus address is set correctly

Sensor Fault

Verify if sensor displays any fault. If so, follow sensor trouble shooting notes.

Verify if sensor cell needs replacement.

Low Battery

Attach external battery charger

Verify solar panel (if used) is oriented correctly

Poor Link Quality

Verify antenna is securely attached to all devices.

Verify obstructions are eliminated or minimized between SmartWireless® CXT devices and

controller or other CXT devices.

Sentinel CX

Slow Gas Response

Some delay in gas response is normal if the network update rate is greater than zero. To increase

response time, reduce the update rate. Reducing the update rate will reduce the battery life for

devices.

SmartWireless® CXT not found during controller Auto Configure

Verify CXT device set to correct RF Channel

Verify Radio Module has correct Modbus address

Verify the Sensor Input PCA and Relay PCA Modbus address are set correctly

Verify a proper mA load is present on sensor input. Sensor inputs are not detected unless the mA

input is greater than 1.9mA.

Contact the Detcon Service Department for further troubleshooting assistance at 713-559-9200

Sentinel CX Sensor Station IM Rev. 1.4 Page 21 of 26

Page 26

Sentinel CX

7. Customer Support and Service Policy

Detcon Headquarters

Shipping Address: 4055 Technology Forest Blvd, The Woodlands, Texas 77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Phone: 713.559.9200

Fax: 281.298.2868

• www.detcon.com

• service@detcon.com

• sales@detcon.com

All Technical Service and Repair activities should be handled by the Detcon Service Department via

phone, fax or email (contact information given above). RMA numbers should be obtained from the Detcon

Service Department prior to equipment being returned. For on-line technical service, have the model

number, part number, and serial number of product(s) in question available.

All Sales activities (including spare parts purchase) should be handled by the Detcon Sales Department via

phone, fax or email (contact information given above).

NOTE

NOTE

All additional parts must be supplied by Detcon. Use of parts from a third party will void

warranty and safety approvals.

The CX Sensor Station should only be repaired by Detcon personnel or a Detcon trained

representative.

Sentinel CX Sensor Station IM Rev. 1.4 Page 22 of 26

Page 27

Sentinel CX

8. Warranty Notice

Detcon Inc. warrants the SmartWireless® CX Sensor Station to be free from defects in workmanship of

material under normal use and service for one year from the date of shipment.

Detcon Inc. will repair or replace without charge any such equipment found to be defective during the

warranty period. Full determination of the nature of, and responsibility for, defective or damaged

equipment will be made by Detcon Inc. personnel.

Defective or damaged equipment must be shipped to the Detcon Inc. factory or representative from which

the original shipment was made. In all cases, this warranty is limited to the cost of the equipment supplied

by Detcon Inc. The customer will assume all liability for the misuse of this equipment by its employees or

other contracted personnel.

All warranties are contingent upon the proper use in the application for which the product was intended and

does not cover products which have been modified or repaired without Detcon Inc. approval, or which have

been subjected to neglect, accident, improper installation or application, or on which the original

identification marks have been removed or altered.

Except for the express warranty stated above, Detcon Inc. disclaims all warranties with regard to the

products sold. Including all implied warranties of merchantability and fitness and the express warranties

stated herein are in lieu of all obligations or liabilities on the part of Detcon Inc. for damages including, but

not limited to, consequential damages arising out of, or in connection with, the performance of the product.

Sentinel CX Sensor Station IM Rev. 1.4 Page 23 of 26

Page 28

Sentinel CX

9. Appendix

9.1 Specifications

System Specifications

Capacity: Up to 4 Analog 4-20mA inputs

Sensor Inputs: Up to 4 Analog 4-20mA

Outputs: 4 switched alarm outputs, (11VDC)

Warranty: One year

Environmental Specifications

1) Operating Temperature: -20C to +60C (for field use where battery pack is only discharging)

2) Operating Temperature: 0C to +40C (for non-hazardous area where battery is only charging)

Storage Temperature: -40C to +85C

Humidity: 0-99%RH, non-condensing

Altitude: 0 – 2000m

Electrical Specifications

Battery Charger Input: 100-240 VAC, 50-60 Hz, Max Current 2 Amps

Battery Charger Output: 24 +/- 0.1 VDC nominal, Max Current 3.25 Amps

Internal Battery Pack: Rechargeable Lithium–Ion, 9-11.2 VDC, 17.4Ah capacity

External Alarm Connectors: ‘Wet’: 9-11.1 VDC, 2A max total (A1, A2, A3, and FLT outputs

combined)

‘Dry’: Dry Contact 120-220VAC/24VDC, 2A Max

Sensor Input Connectors: 9-11.1 VDC, 100mA max per connector

RFI/EMI Protection: Complies with EN61326

Electrical Classification: NEMA 4X, Class I Division 2 Groups A,B,C,D

Cabling Specifications

External Alarms Cables: Use only Detcon cables, termination insulation resistance > 10K ohms.

‘Wet’: Connector style is 5 pin Turck connector with security clip.

‘Dry’: Connector style is 6 pin Turck connector with security clip.

Sensor Input Cables: Use only Detcon cables, termination insulation resistance > 10K ohms

Connector style is 4 pin Turck connector with security clip.

Power Input Cable: Use only Detcon Battery Charging Accessory product

Connector style is 3 pin Turck connector with security clip.

Mechanical Specifications

Dimensions: 12" W x 21.3" H x 4.73" D (including antenna and strobe)

12" W x 12.25" H x 4.73 D (without antenna and strobe)

Wireless Specifications

Frequency: ISM 2.4GHz

Range: Indoor/No Line of Sight – 1,000ft

Outdoor RF Line of Sight – 1.5 Miles

Spread Spectrum: Digital-Sequence Spread Spectrum (DSSS)

Modulation: 0-QPSK

Sensitivity: -102dBm (1% PER)

Sentinel CX Sensor Station IM Rev. 1.4 Page 24 of 26

Page 29

9.2 Spare Parts and Wireless Accessories

Part Number Spare Parts

976-0003BC-00T CXT Battery Charger Accessory for 110 VAC

976-0003BC-220 CXT Battery Charger Accessory for 220 VAC

976-0003A4-200 Antenna Assembly

960-798434-000 Condensation Prevention Packet (replace annually)

894-7845K6-400 Hole Plug

500-005199-000 Relay Board

500-005194-000 Sensor Input Board

360-3S6PFP-ASM Battery Pack

320-N45161-000 Power Switch

302-RSFCC0-05M Connector Dust Cap

302-RFK40D-05M Sensor Connector

302-RFK380-05M Power Connector

302-RFK520-05M External Alarm Connector for ‘Wet’ Relay Contacts

302-PRSF63-M20 External Alarm Connector for ‘Dry’ Relay Contacts

275-556160-432 Power LED Indicator

976-001320-CHR Radio Module (320 Network)

Part Number Accessories

975-TRIPOD-100 Detcon tripod

943-004413-000 Detcon Tripod sensor brackets

975-TRIPOD-MNI Mini Sensor Tripod

980-PRSM40-02M 2m Sensor Cable (with security clip)

980-PRSM40-10M 10m Sensor Cable (with security clip)

980-PRSM40-30M 30m Sensor Cable (with security clip)

980-PRSM40-45M 45m Sensor Cable (with security clip)

980-PRSM52-02M 2m External Alarm Cable for ‘Wet’ Alarms (with security clip)

980-PRSM52-30M 30m External Alarm Cable for ‘Wet’ Alarms (with security clip)

980-PRSM52-45M 45m External Alarm Cable for ‘Wet’ Alarms (with security clip)

980-PRKM63-30M 30m External Alarm Cable for ‘Dry’ Alarms (with security clip)

980-PRKM63-45M 45m External Alarm Cable for ‘Dry’ Alarms (with security clip)

Sentinel CX

Sentinel CX Sensor Station IM Rev. 1.4 Page 25 of 26

Page 30

Sentinel CX

9.3 Revision Log

Revision Date Changes made Approval

1.0 03/27/2013 Release LBU

1.1 10/30/13 Update for removable battery pack LBU

1.2 11/20/13 Updates for Approval Agency BM

1.3 04/04/14 Updates to sensor wiring, and battery charging BM

1.4 05/30/14 Various corrections, clarifications and addition of final Warnings BM

Shipping Address: 4055 Technology Forest Blvd., The Woodlands Texas77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Phone: 713.559.9200 • Fax: 281.292.2860 • www.detcon.com • sales@detcon.com

Sentinel CX Sensor Station IM Rev. 1.4 Page 26 of 26

Page 31

3

REV

4409-1

DRAWING NO.

A

SIZENAJOB NO.

Antenna

Alarm Port

Power-In

Port

Power Switch

Power

Switch

Strobe

Power LED

Enclosure Label

12

Serial Number

Name Plate

Sonalert

10.25

11.25

Sonalert

21.275

12.25

2~3" Pole Mounting

Hardware

Sensor

Ports

P.O. NO.

REQ. NO.

PROJECT NO.

SERIAL NO.

PLANT:

The information and technical data disclosed by

NA

this document may be used and disseminated

only for the purposes and to the extent

NA

specifically authorized by Detcon Incorporated

in writing. Such information and technical data

are proprietary to Detcon Incorporated and may

NA

not be used or disseminated except as provided

in the foregoing sentence.

NA

NA

NOTE:

Unit shown has the max options:

Power Input Port

4 sensor ports

Alarm Output connector

Strobe and Sonalert Horn

All dimensions are in inches

detcon, inc.

CLIENT:

ECO-1830

ECO-1808

ECO-1753

RELEASE

SUBJECT

PROJECT:

NA

DRAWN BY:

R HUTSKO

FIRST ISSUE:

3

2

1

0

Rev

ADD EPOXY TO HORN THREADS

04/01/14

10/08/13

MAKE BATTERY PACK REMOVABLE

07/26/13

01/21/13

DATE

CHANGE ENCLOSURE

ISSUED FOR APPROVAL

REVISION HISTORY

DESCRIPTION

RH

DRN

RH

RH

RH

CHKD

4409

LU

BM

4409

BM

LU

4409

LU

BM

4409

LU

BM

APPD

DWG #

REF. DWGS

DETCON INC.

4055 Technology Forest Bvd. Suite 100 * The Woodlands Texas 77381 * www.detcon.com

NA

01/21/13

_

Sentinel w Solid Cover

Dimensional

P/N 954-CX04y4-200

SCALE

SALES ORDER NO.

NTS

NA

DETCON PRPOSAL #

NA

DRAWING NO.

4409-1

REV

SIZE

A

3

Page 32

External Alarm

3

REV

4409-2

DRAWING NO.

A

SIZE

JOB NO.

NA

PLANT:

NANANA

REVISION HISTORY

REF. DWGS

REQ. NO.

SERIAL NO.

in the foregoing sentence.

Rev

DATE

DESCRIPTION

DRN

CHKD

APPD

DWG #

P.O. NO.

PROJECT NO.

NA

NA

The information and technical data disclosed by

this document may be used and disseminated

only for the purposes and to the extent

specifically authorized by Detcon Incorporated

in writing. Such information and technical data

are proprietary to Detcon Incorporated and may

not be used or disseminated except as provided

1

0

2

3

07/26/13

01/21/13

10/08/13

04/01/14

MAKE BATTERY PACK REMOVABLE

ADD EPOXY TO HORN THREADS

ISSUED FOR APPROVAL

CHANGE ENCLOSURE

RH

RH

RH

RH

LU

LU

LU

LU

BM

BM

BM

BM

4409

4409

4409

4409

Switch

Power

Sonalert

Connector

Charger

Battery Pack

Connector

RXT-320

Xcvr

Sensor Ports

(Optional)

Strobe

Power LED

Antenna

Sentinel Relay PCA

and 4-20mA PCA

RELEASE

SUBJECT

FIRST ISSUE:

R HUTSKO

01/21/13

NTS

DETCON PRPOSAL #

NA

NA

4409-2

SIZE

A

REV

3

ECO-1753

ECO-1808

ECO-1830

DRAWN BY:

PROJECT:

CLIENT:

NA

SCALE

SALES ORDER NO.

P/N 954-CX04y4-200

detcon, inc.

4055 Technology Forest Bvd. Suite 100 * The Woodlands Texas 77381 * www.detcon.com

NA

_

DETCON INC.

Sentinel w Solid Cover

Overview

DRAWING NO.

NOTE:

Unit shown has the max options:

Power Input Port

4 sensor ports

Alarm Output connector

Strobe and Sonalert Horn

All dimensions are in inches

Cover removed for clarity

Page 33

4409-3

DRAWING NO.

REV

SIZE

3

A

White

Gray

Brown

Blue

Red

Black

White

Red

Sensor 1

Red

Black

Black

White

Black

Sensor 2

Red

Red

Relay PCA

Black

White

Sensor 3

Red

4-20mA PCA

Sensor 4

Red

Black

White

NOTE:

Green wire from sensor

connectors to be tied to

base plate (Ground).

Black

Red

+ -

(Mounted under the Relay PCA)

Wiring

NA

SALES ORDER NO.

DETCON PRPOSAL #

SCALE

NTS

R HUTSKO

DRAWN BY:

FIRST ISSUE:

ECO-1753

SUBJECT

RELEASE

4409

DWG #

4409

BM

BM

APPD

LU

LU

CHKD

RH

DRN

RH

NA

01/21/13

REF. DWGS

P/N 954-CX04y4-200

Sentinel w Solid Cover

DETCON INC.

_

NA

4055 Technology Forest Bvd. Suite 100 * The Woodlands Texas 77381 * www.detcon.com

CLIENT:

NA

PROJECT:

ECO-1808

ECO-1830

4409

4409

BM

BM

LU

LU

RH

RH

detcon, inc.

Sonalert Horn

DESCRIPTION

CHANGE ENCLOSURE

ISSUED FOR APPROVAL

ADD EPOXY TO HORN THREADS

MAKE BATTERY PACK REMOVABLE

REVISION HISTORY

NA

JOB NO.

SIZE

A

DRAWING NO.

4409-3

REV

3

LED

+

Strobe

Red

Black

Red

Black

White

Brown

Gray

+

To

Red

Color

1502B Cable Wiring

Black

Blue

(Optional)

External Alarm

Black

-

A

B

Blue

Black

White

shown)

Connector

("Wet' alarm wiring

NOTE:

1502B Cable

Red

To

Antenna

RXT-320

Green wire from Power

Input connector to be tied

to base plate (Ground).

Black

Black

White

Power Port

Red

Red

Black

White

Red

Black

Black

Flat Battery Pack

Assembly

Red

Power

Switch

10/08/13

DATE

07/26/13

04/01/14

01/21/13

2

1

3

0

Rev

The information and technical data disclosed by

this document may be used and disseminated

only for the purposes and to the extent

specifically authorized by Detcon Incorporated

in writing. Such information and technical data

are proprietary to Detcon Incorporated and may

not be used or disseminated except as provided

in the foregoing sentence.

NA

NA

NANANA

PROJECT NO.

REQ. NO.

SERIAL NO.

PLANT:

P.O. NO.

Loading...

Loading...